Method for recovering toluene, butanone and dimethyl formamide from waste gas in wet synthetic leather production

A technology of dimethylformamide and a recovery method is applied in the field of recovery of toluene, butanone and dimethylformamide in waste gas produced by wet-process synthetic leather, which can solve the difficulty of enterprises, fail to meet environmental protection standards, and high operating costs Not inferior to other problems, to achieve obvious social benefits, low operating costs, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The main absorption equipment of the small laboratory test device adopts a packed tower. The technical design parameters of the packed tower are as follows: the tower height is 1000mm, the tower inner diameter is 75mm, the tower wall thickness is 5mm. Part of the airflow with a certain temperature before entering the tower takes out the solute (toluene, methyl ethyl ketone) through the gas cylinder and enters the main air pipe, thereby artificially creating air containing a certain concentration of solute, and using a self-priming pump to pump the absorbent dimethyl formaldehyde into the main air pipe. The amide is pumped into the tower, the absorbent flows from the top of the tower to the bottom of the tower under the action of gravity, and the air and absorbent are mass-transferred on the surface of the packing. The concentration of organic matter in gas samples was determined by gas chromatography. Absorption liquid dimethyl formamide flow rate 25L / h. The relevant t...

Embodiment 2

[0022] Engineering application On the basis of the above experimental small test device, we applied the above recovery method to the waste gas treatment of wet synthetic leather production in a synthetic leather Co., Ltd. in Wenzhou, Zhejiang, and achieved success. Toluene, methyl ethyl ketone and dimethylformamide in the waste gas (DMF) is efficiently recovered.

[0023] parameters

Quantity

capacity

45000m 3 / h

temperature

70~80℃

pressure

DMF Concentration

2000mg / m 3

Toluene concentration

900mg / m 3

butanone concentration

300mg / m 3

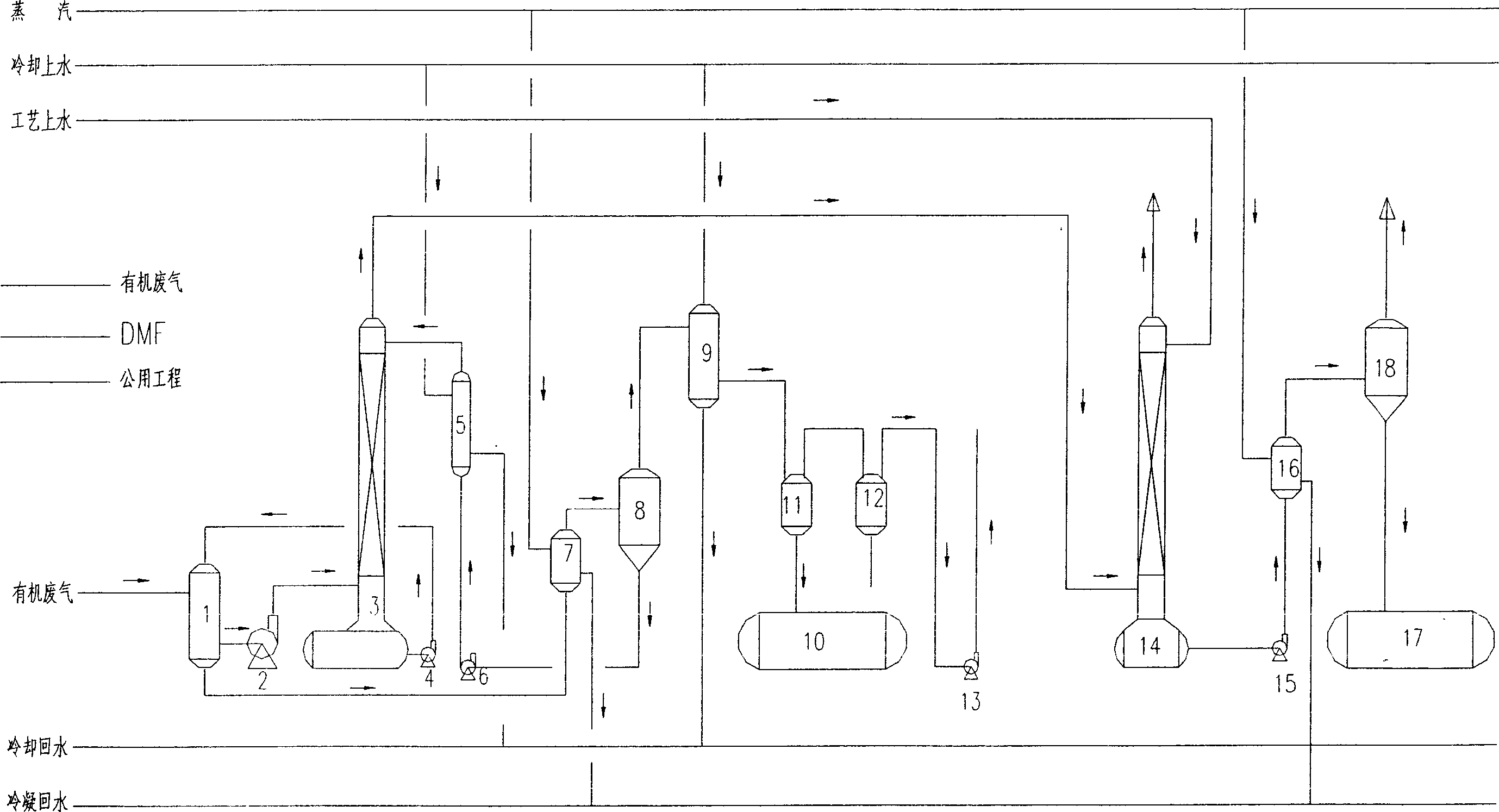

[0024] According to the above design parameters and combined with the actual situation of the factory, we design the recovery device as shown in the attached figure.

[0025] 1. The main structures and equipment in the device are as follows:

[0026] (1) DMF-tolylbutanone absorption tower

[0027] Basic size: Φ3.0×20.0m

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com