High-pressure grouting process of water-rich weathering fracture rock formation below thick unconsolidated formation for coal mine

A high-pressure grouting, thick and loose technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of inability to realize grouting in weathered and fractured rock formations, insufficient solid pipe material thickness, and slurry leakage to the ground and other problems, to achieve the effect of large effective diffusion radius, long grouting time, and avoid waste of grout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

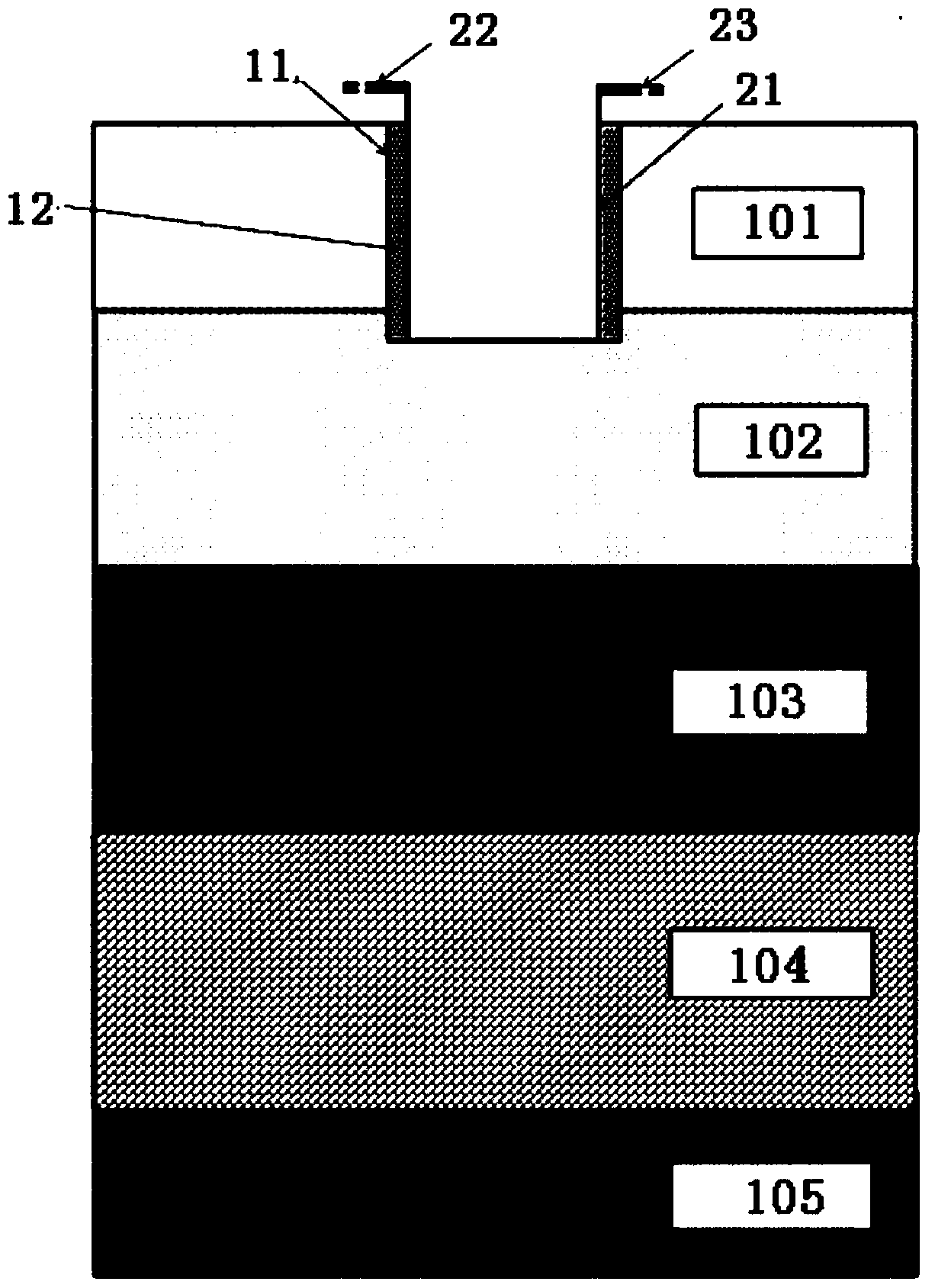

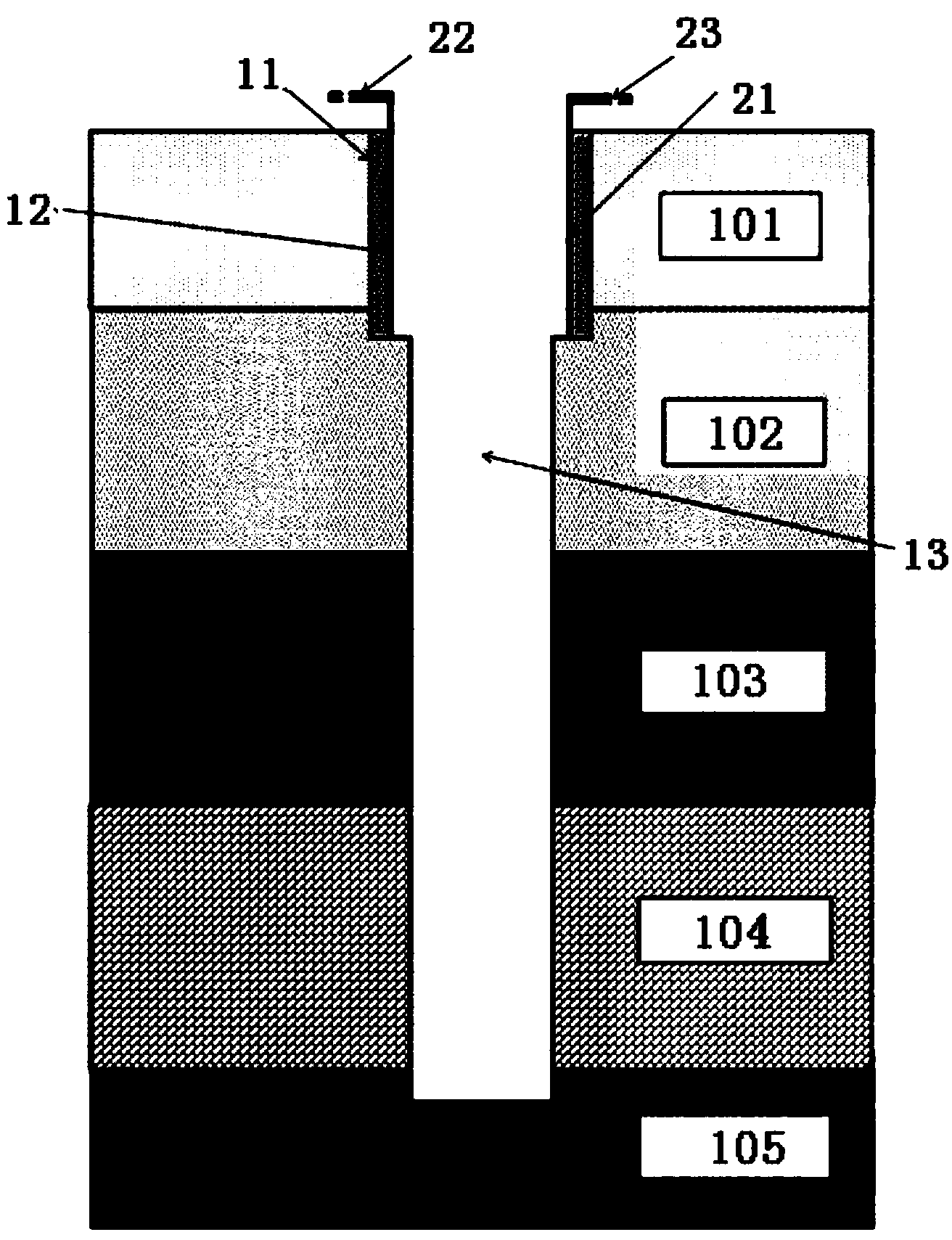

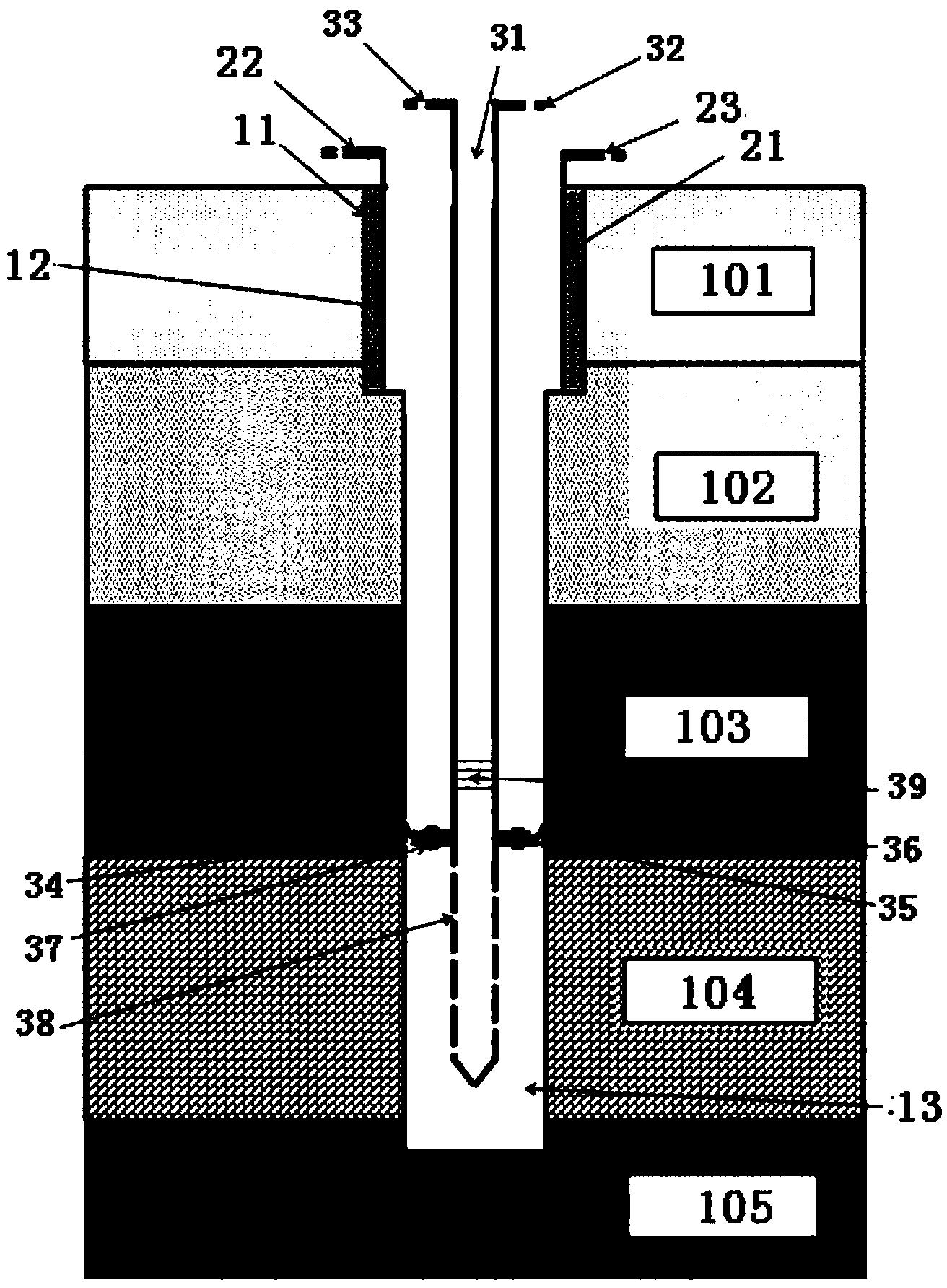

[0028] see Figure 1-5 , shows the high-pressure grouting process of the water-rich weathered cracked rock formation under the thick loose layer for coal mines of the present invention.

[0029] The high-pressure grouting process of the water-rich weathered cracked rock formation under the thick loose layer for coal mines at least includes the following steps:

[0030] A) Solid pipe grouting: drill for the first time on the hole position of the grouting hole, and the drilling depth is preferably to a certain depth in the clay layer 102 under the loose layer 101, so as to complete the work of the primary drilling 11, and then carry out The lower pipe operation of the orifice pipe 21, the outer diameter of the orifice pipe 21 is smaller than the diameter of the primary borehole 11, and the length is greater than the depth of the primary borehole 11, preferably, the orifice pipe 21 The outer diameter of the orifice pipe 21 is 30mm smaller than the diameter of the primary borehol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com