Belt conveyer key component automatic identification method based on infrared thermography

A belt conveyor and belt conveying technology, applied to computer parts, character and pattern recognition, instruments, etc., to achieve high engineering application value and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following descriptions are only illustrative, not intended to limit the scope of the present invention and its application.

[0030] The key components of the belt conveyor are motors, idlers and pulleys.

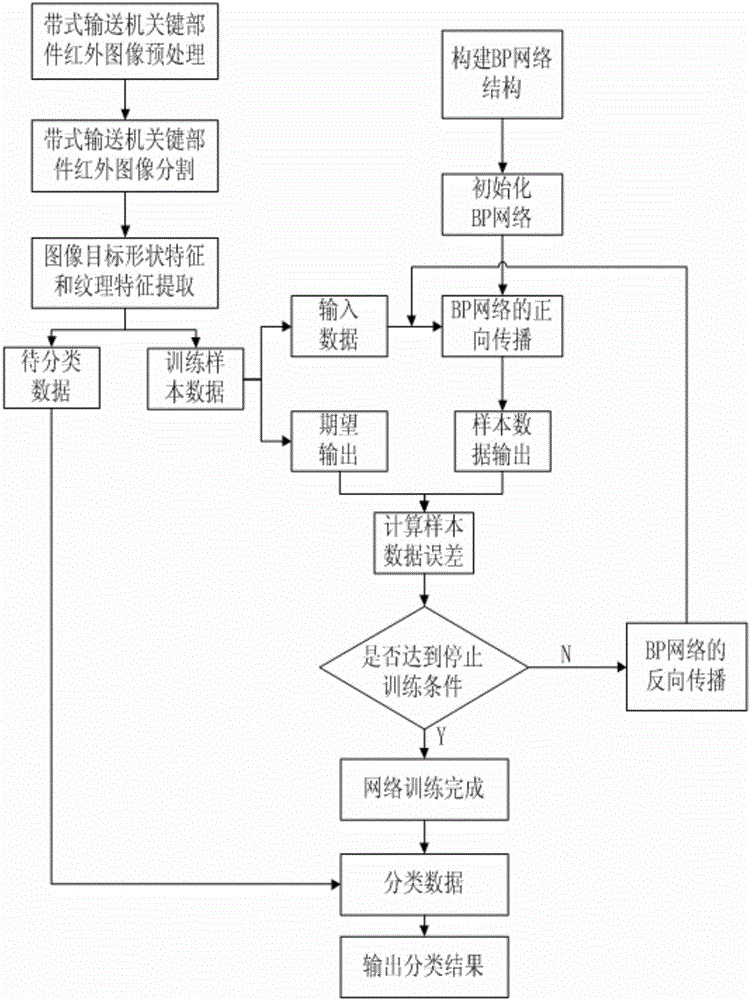

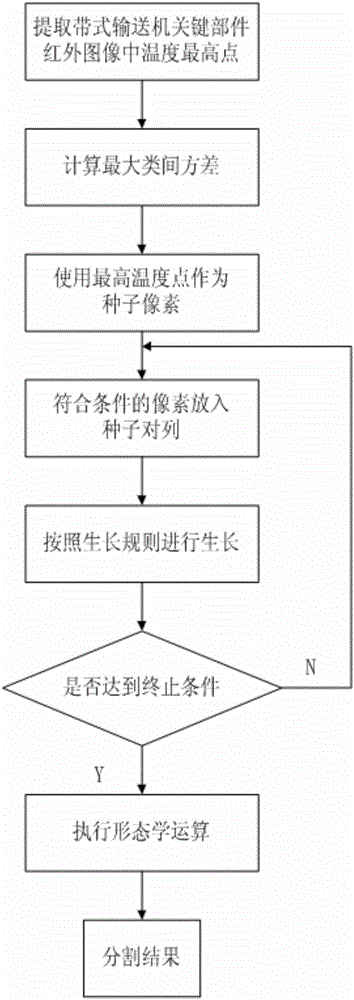

[0031] Such as figure 1 As shown, an automatic identification method for key components of a belt conveyor based on infrared thermal images includes the following steps:

[0032] Step (1) denoises the infrared image of the belt conveyor collected, and adopts the bilateral filtering of the preprocessing algorithm applicable to the infrared image of the belt conveyor, which can effectively eliminate the streak noise in the infrared image of the belt conveyor;

[0033] Step (2) Carry out piecewise linear transformation to the belt conveyor infrared image after denoising, enhance the contrast of key parts and background;

[0034] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com