Mold for pressing hemispherical grain

A spherical explosive and semicircular technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problem that the explosive column cannot be used directly, and achieve the effect of precise control of the shape and quality of the explosive column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

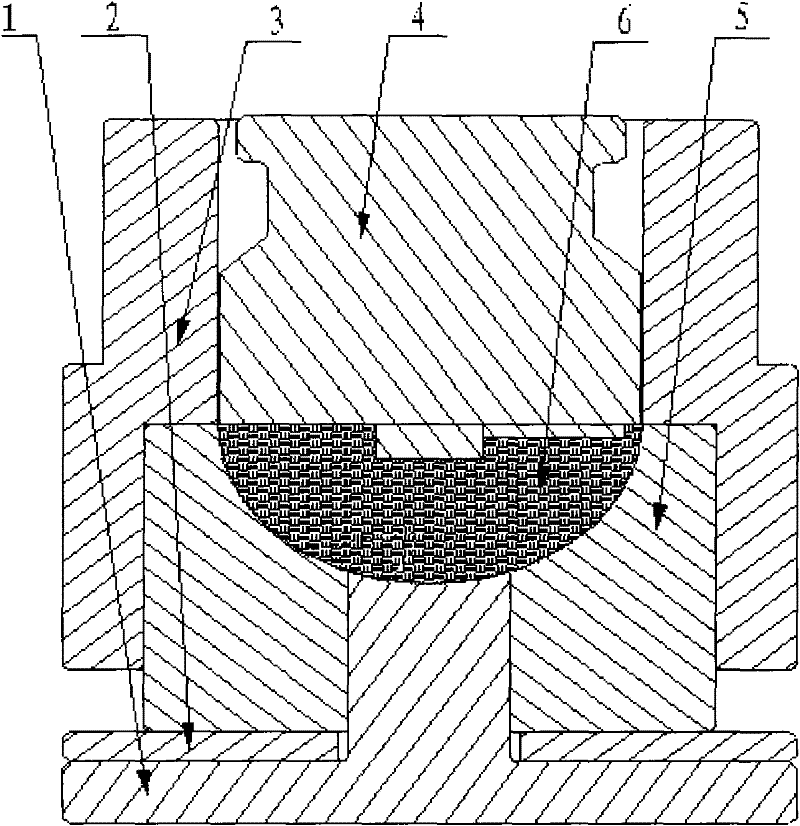

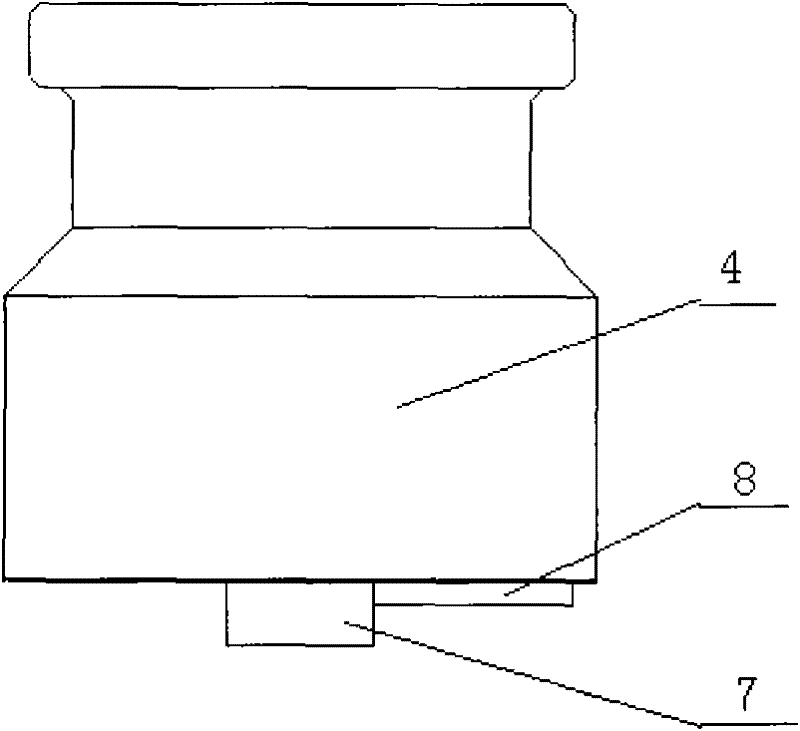

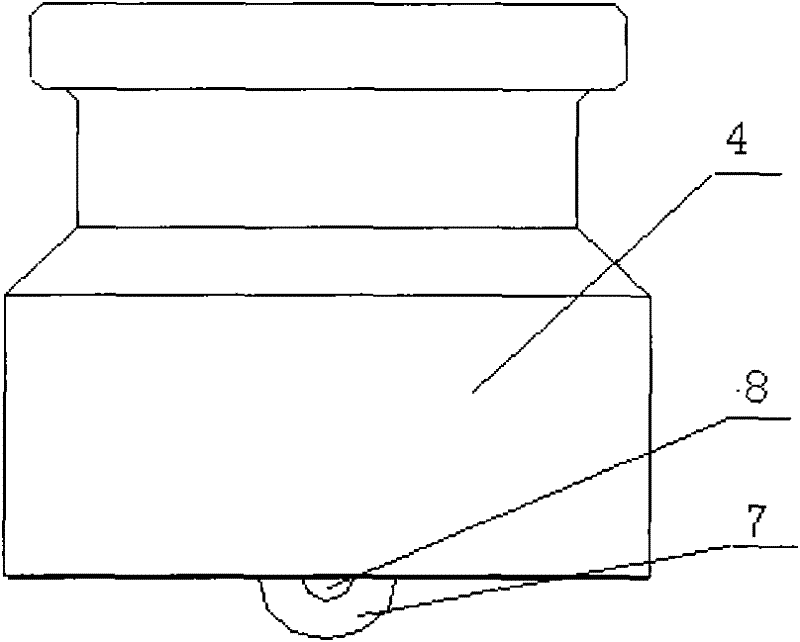

[0016] Such as figure 1 Shown is the assembly drawing of the press-packed explosive mold of the present invention when in use. The ejector module 1 is placed at the bottom of the entire mold, the gasket 2 is placed on the ejector module 1, the base 5 is placed on the ejector pin of the ejector module 1, and the ejector pin of the ejector module 1 and the base 5 together form a complete semicircular spherical shape Inner cavity; the larger end of the guide sleeve 3 inner diameter is placed on the base 5, and the required amount of explosive molding powder is calculated according to the density of the semi-spherical powder column to be pressed and the volume of the semi-spherical inner cavity, and the weighed explosive molding powder is poured into the "U"-shaped cavity formed by the hemispherical inner cavity and the guide sleeve 3, put the punch 4 into the end with the smaller inner diameter of the guide sleeve 3, the diameter of the pressing surface of the press is larger tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com