Electromagnetic inching forming method and its device for plate moving coil

A progressive forming and electromagnetic forming technology, applied in the direction of program control, instrument, computer control, etc., can solve the problems of easy wrinkling and tearing, poor dimensional accuracy of formed parts, large resistance, etc., and achieve good repeatability and easy energy control and the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

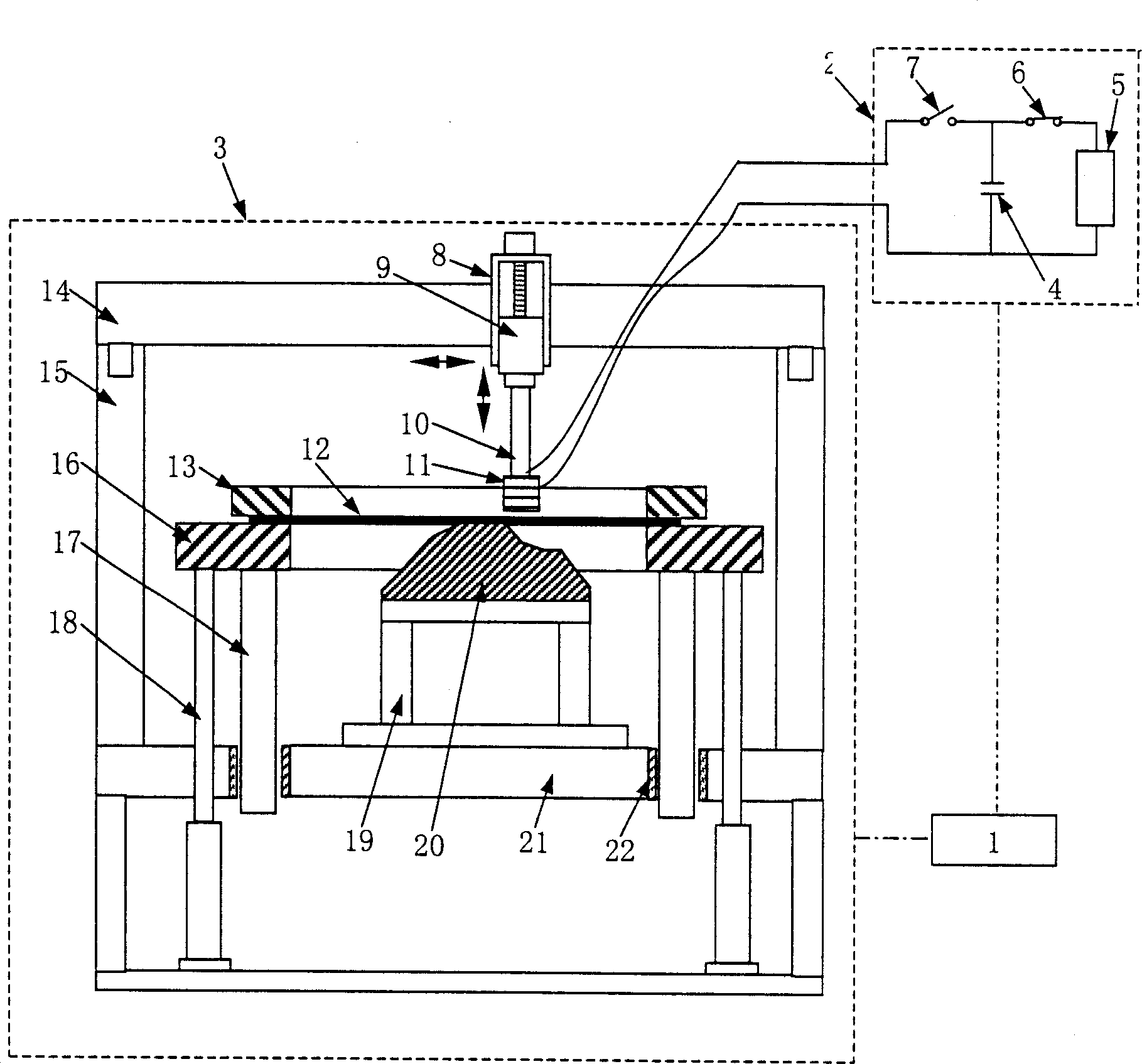

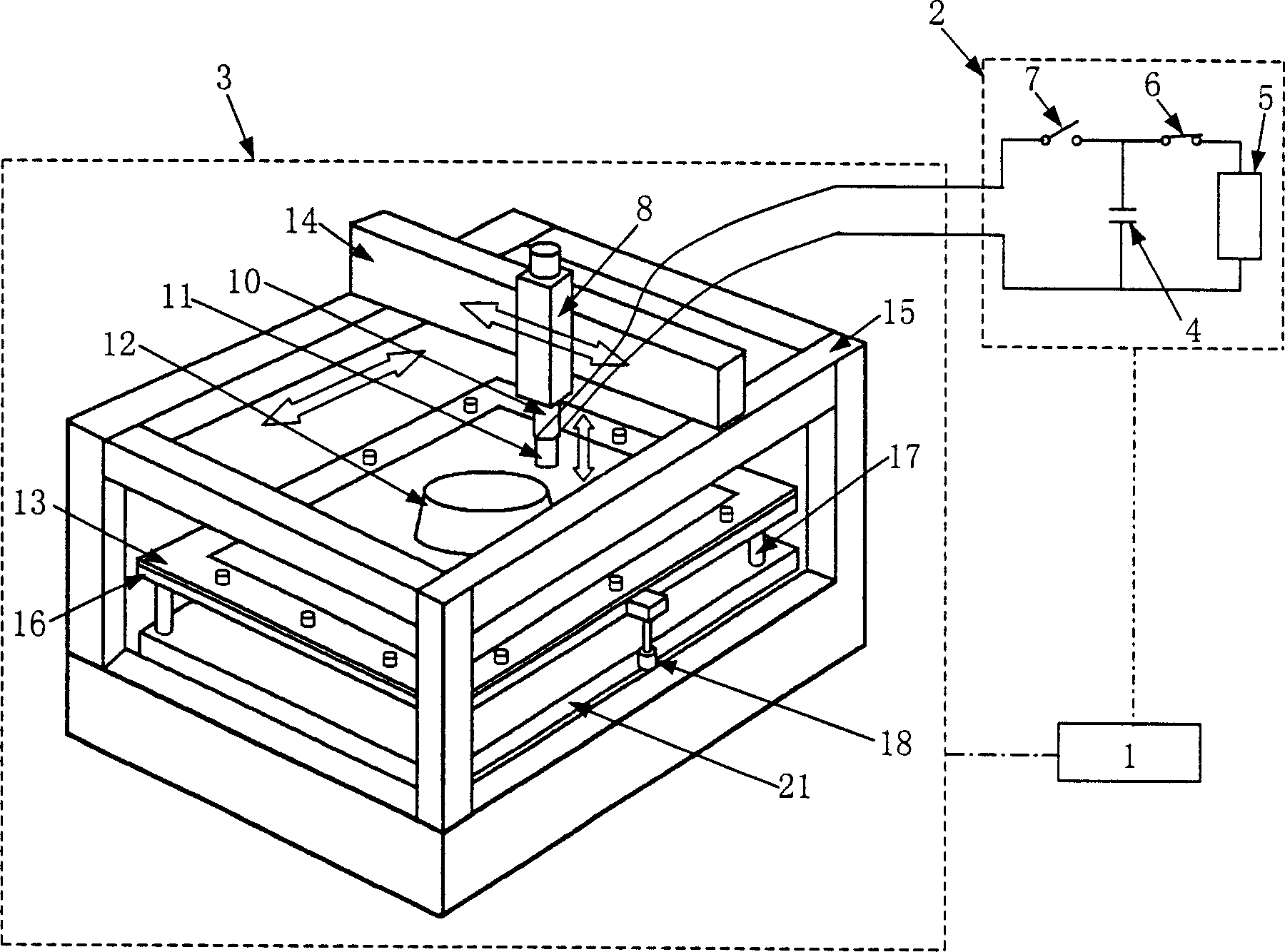

Embodiment 1

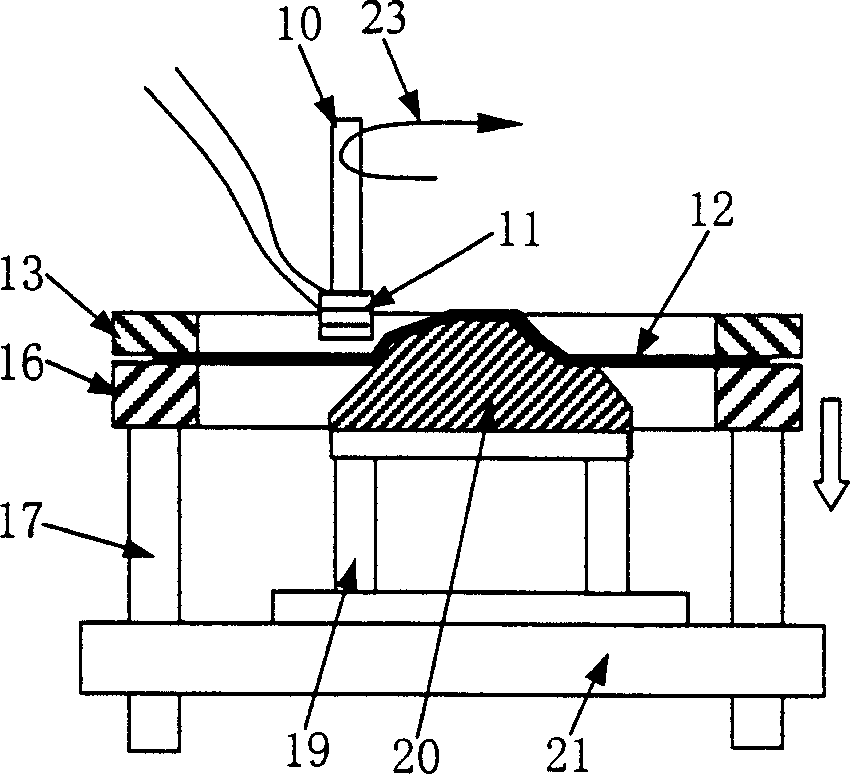

[0035] In the forming device, the pulse energy storage capacitor is 56000μF, and the working voltage is 400V. The electromagnetic forming coil is wound from a copper electromagnetic wire with a specification of 2.5mm×5mm to form a circular densely wound wire plate coil with a diameter of Φ70mm. The space is insulated with epoxy resin and glass cloth, the total resistance of the discharge circuit is 0.167Ω, the total inductance is 3.7μH, the charging time is 4 seconds, the plate is made of AA6061-T6 aluminum alloy, the thickness is 1mm, and the initial size is 410mm×410mm. A circular platform with a side diameter of Φ350mm, a height of 150mm, and a cone angle of 76°. Such as Figure 4A As shown, the forward electromagnetic progressive stretching method is adopted, the electromagnetic forming coil 11 gradually forms the plate 12 along the outer surface of the model 20 by means of electromagnetic force, and the edge of the plate 12 descends as the electromagnetic forming coil 11 ...

Embodiment 2

[0038] In the forming device, the pulse energy storage capacitor is 60μF, and the working voltage is 26.9KV. The electromagnetic forming coil is wound by a copper electromagnetic wire with a specification of 2mm×6mm to form a circular densely wound wire plate coil with a diameter of Φ90mm. The space is insulated with epoxy resin and glass cloth, the total resistance of the discharge circuit is 0.159Ω, the total inductance is 3.4μH., the charging time is 5 seconds, the plate is SUS304 stainless steel, the thickness is 0.2mm, the initial size is 410mm×410mm, and it is shaped as the bottom edge A square cone with a side length of 350mm, a height of 150mm, and a cone angle of 60°. Such as Figure 5A As shown, the method of reverse electromagnetic progressive stretching is adopted, the electromagnetic forming coil 11 is formed along the inner surface of the model 20, the edge of the plate 12 is fixed by the fixed support 25 and does not fall, and the electromagnetic forming coil 11...

Embodiment 3

[0041] In the forming device, the pulse energy storage capacitor is 1000μF, and the working voltage is 2500V. The electromagnetic forming coil is wound from a copper electromagnetic wire with a specification of 2.2mm×5mm to form a circular densely wound wire plate coil with a diameter of Φ100mm. The space is insulated with epoxy resin and glass cloth, the total resistance of the discharge circuit is 0.115Ω, the total inductance is 2.7μH, the charging time is 5 seconds, the plate is made of OHFC copper, and the thickness is 1.6mm. This example is a shell made into a ship shape. Such as Image 6 As shown, the opposite sides of the housing have an angle of 15° relative to the vertical direction, a length of 800 mm, a width of 400 mm, and a height of 300 mm. As in Example 1, the positive electromagnetic progressive stretching method is adopted.

[0042] The specific implementation process is: under the control of the computer, the electromagnetic forming coil 11 first walks to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com