Production technology of ethylene propylene rubber

A production process and technology for ethylene-propylene rubber, applied in the rubber field, can solve the problems of poor catalytic effect, low productivity, low steam efficiency and solvent recycling rate, and achieve high recycling rate, high production flexibility and high production strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Polymerization: pre-cool the reaction ethylene and propylene to -50°C in two stages, use hexane as the solvent, and then add VOCl 3 -1 / 2Al 2 EtCl 3 Catalyst, dicyclohexyl peroxydicarbonate monomer, aminophenyl diethylaluminum amino complex activator, and pass into hydrogen, then put into the liquid-liquid filled reactor system to carry out polymerization reaction, the reaction temperature is 45°C, reaction pressure 2.0MPa, polymerization time 2min;

[0017] (2) Catalyst removal: By adding alkaline vanadium-removing agent sodium hydroxide and washing with hot water, the vanadium catalyst remaining in the polymer glue enters the water phase, and after two washings, the reactant The vanadium catalyst remaining in the medium is completely removed;

[0018] (3) Recovery of monomers and solvents: the unreacted polymer glue in step (2) is decompressed and flashed twice to complete the recovery of monomers and solvents;

[0019] (4) Agglomeration: Add additives such as ...

Embodiment 2

[0021] Example 2: The rest is the same as Example 1, except that in the step (1), the reaction temperature is 48°C, the reaction pressure is 2.2MPa, and the polymerization time is 3min; in the step (4), the polymer The glue concentration is taken as 8.0%.

Embodiment 3

[0022] Example 3: The rest is the same as Example 1, except that in the step (1), the reaction temperature is 53°C, the reaction pressure is 2.5MPa, and the polymerization time is 4min; in the step (4), the polymerization The glue solution concentration is 8.5%.

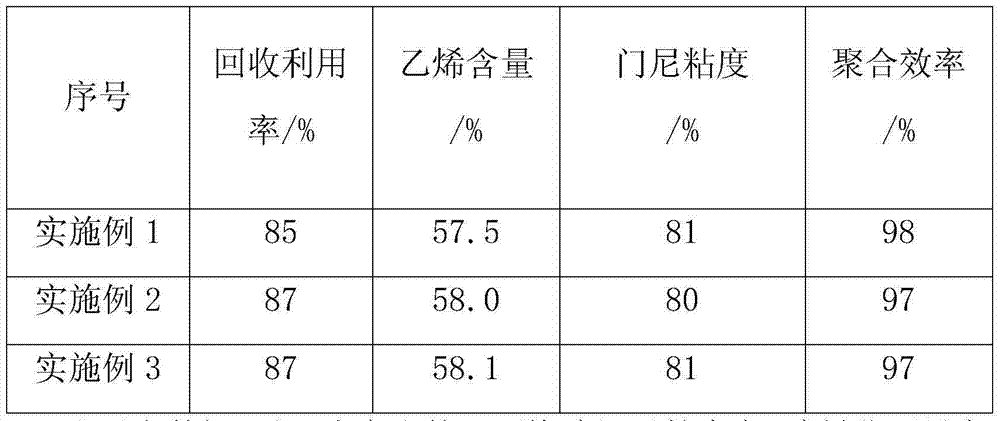

[0023] After the above process steps, the ethylene-propylene rubber sample is taken out to be tested:

[0024]

[0025] It can be seen from the above data that the produced ethylene-propylene rubber has high Mooney viscosity, high molecular weight, wide distribution range, moderate ethylene content, high recovery rate of monomer and solvent, polymerization efficiency above 96%, and high production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com