Patents

Literature

321results about How to "Increase production intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for converting alcohols and ethers into aromatic hydrocarbons as well as preparation method and use method thereof

ActiveCN103007985ASmall particle sizeEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenAlcohol

The invention discloses a catalyst for converting alcohols and ethers into aromatic hydrocarbons, as well as a preparation method and a use method of the catalyst, and belongs to the technical field of chemical engineering. The preparation method comprises the steps as follows: at first, taking a template agent, kaolin, sodium hydroxide and water as raw materials for preparing a hydrogen type nanoscale ZSM-5 molecular sieve, and then directly preparing the catalyst; or based on the hydrogen type nanoscale ZSM-5 molecular sieve, preparing the two-component, three-component or four-component catalyst with metal and / or a structure enhancer and / or a stabilizing additive. The catalyst comprises the following components in percentage by mass: 30-100% of the needle-like nanoscale ZSM-5 molecular sieve, 0-10% of the metal, 0-50% of the structure enhancer and 0-10% of the stabilizing additive. The invention further provides a method for enabling the catalyst to be used for converting alcohols and ethers into aromatic hydrocarbons. The catalyst is small in particle size, high in catalytic efficiency and low in use cost; the preparation method is simple and efficient; and the use method is reasonable and efficient.

Owner:TSINGHUA UNIV

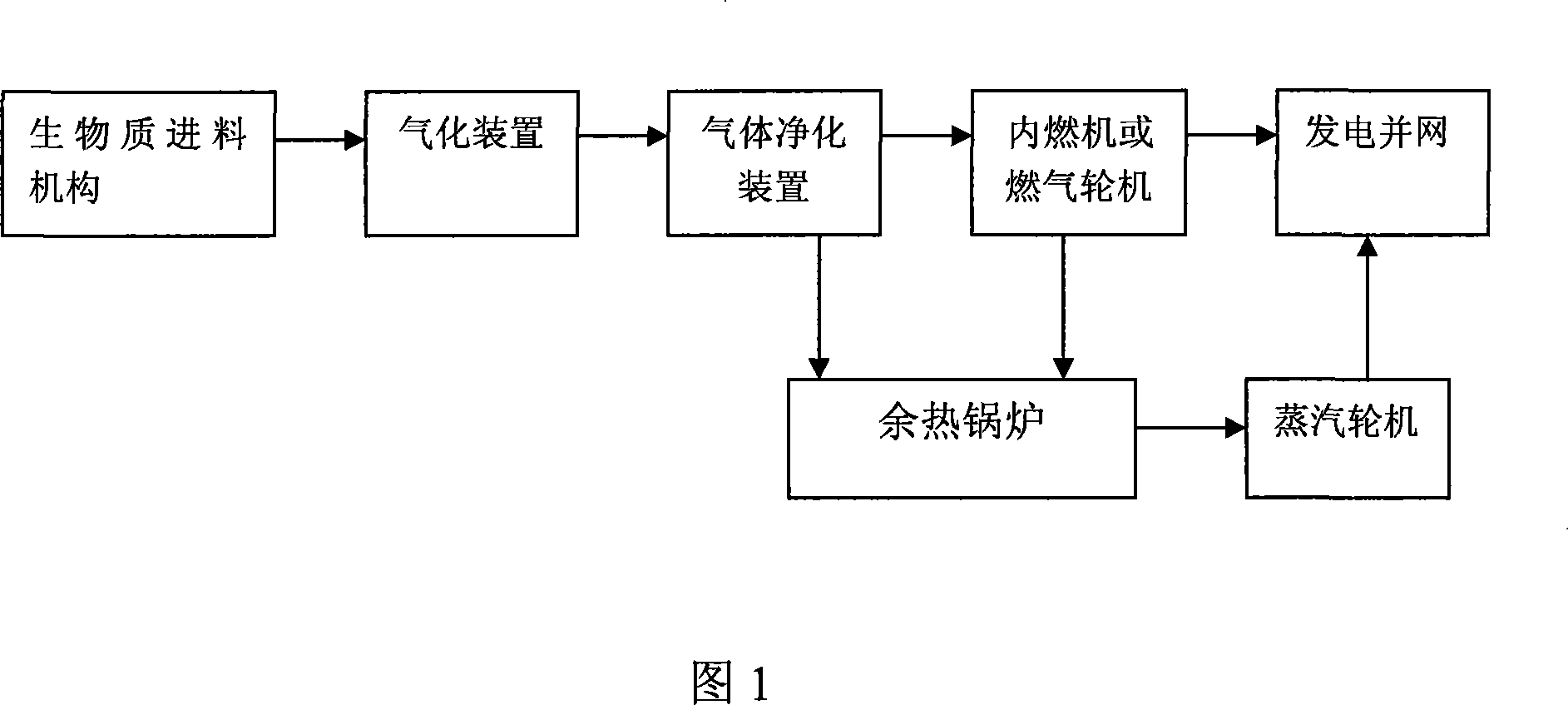

Power generation method using biomass

InactiveCN101158312AAdaptableStrong production intensityProductsInternal combustion piston enginesAgricultural residueInternal combustion engine

The invention relates to a method for generation by a biomass. The method utilizes the gasification technology, which converts the forestry and agricultural residues comprising wasted straws, sawdust, haulms, rice husks, bagasse, etc. into the flammable gas approaching the coal gas; after the dust and the tar of the flammable gas is removed by a purifier, the flammable gas is conveyed in a gas internal combustion engine or a gas turbine for generation. The invention has strong raw material adaptability, can dispose the biomass raw material of different types, and has the advantages of large production intensity, high gas heat value, little tar content, high gasification efficiency, strong load adaptability, easy start and stop, large adjustable range, stable operation, extremely high flexibility in scale. Furthermore, the generation scale depends on the quantity of the raw material and the requirement of the power, and can be designed and matched according to the requirement of the user.

Owner:WUHAN LIREN INVESTMENT

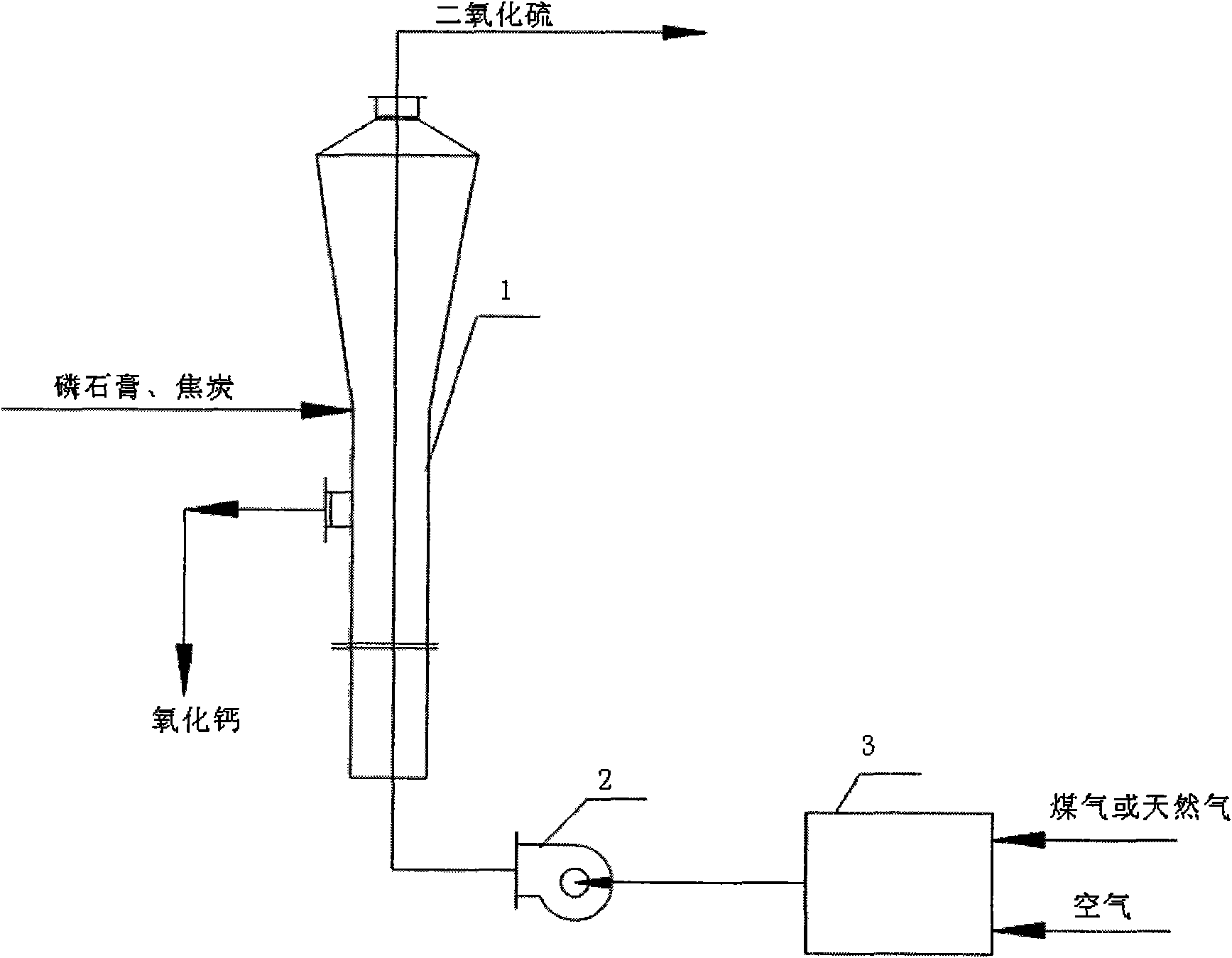

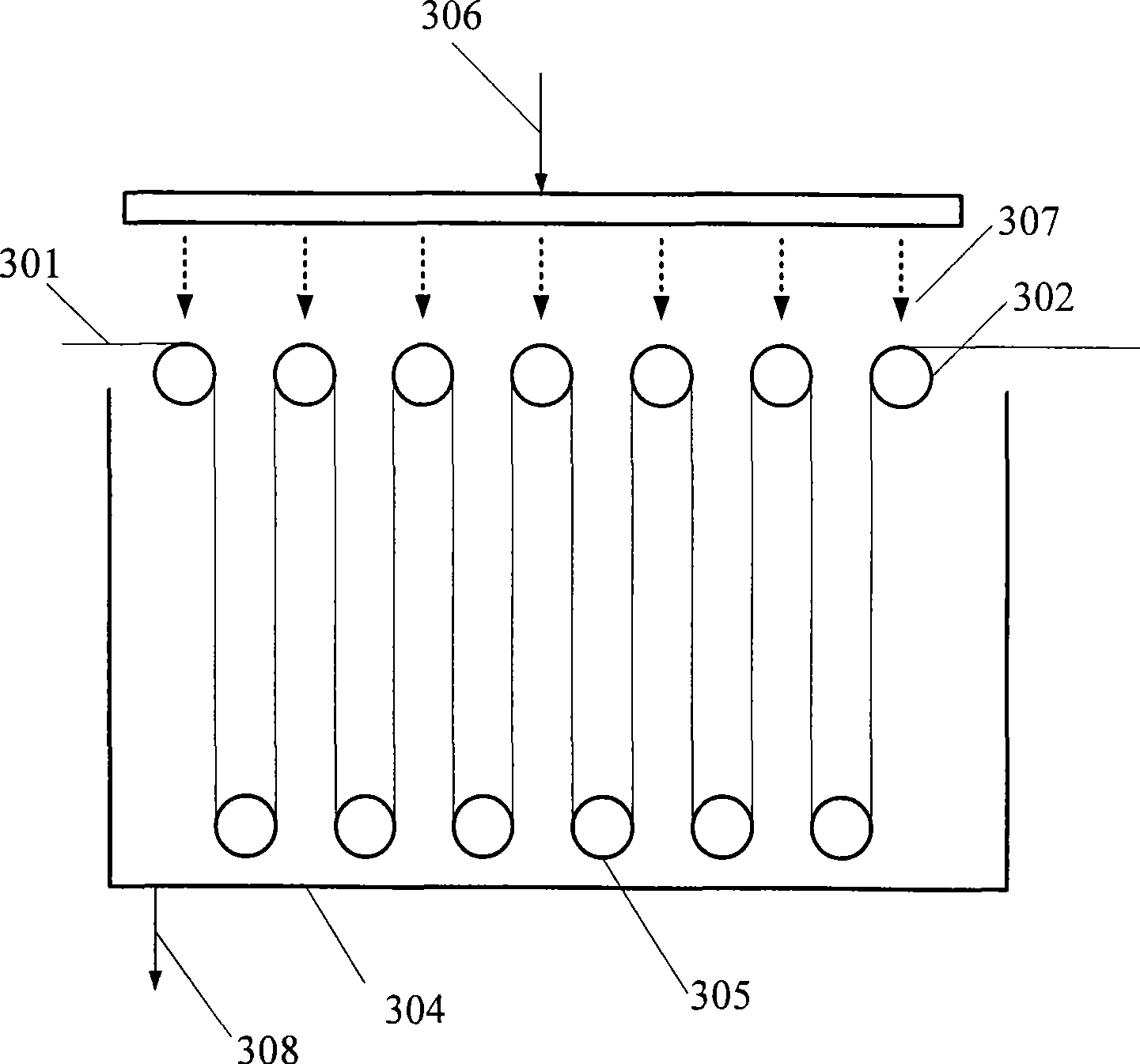

Production process for preparing calcium oxide and sulfur dioxide by decomposing ardealite

InactiveCN101602518ASolve the use problemReduce ecological damageSolid waste disposalSulfur compoundsDry weightReaction temperature

The invention belongs to the technical field of environmental protection treatment and chemical engineering production, and relates to a production process for preparing calcium oxide and sulfur dioxide by decomposing ardealite. The process comprises the following steps of: mixing the ardealite and charcoal according to a dry weight ratio of 10-20:1, granulating the mixture to obtain particles of which the particle size is between 1 and 4mm, drying and dewatering the particles, putting the particles in a fluidized bed decomposing furnace to be directly contacted with high-temperature furnace gas for reaction for 15 to 50 minutes at a temperature of between 1,000 and 1,300 DEG C, and generating the sulfur dioxide gas and the calcium oxide. The process can solve the problem of comprehensively utilizing waste residues of ardealite, the content of SO2 in the discharged tail gas is high enough to be used for producing sulfuric acid, and the calcium oxide which is a byproduct can be used in various industries such as construction, road, aquaculture and the like, so that the process meets the requirements on the scientific outlook on development; moreover, compared with the process for co-production of cement by sulfuric acid prepared by the ardealite, the process greatly saves investment and electric consumption.

Owner:SINOPEC NANJING ENG & CONSTR

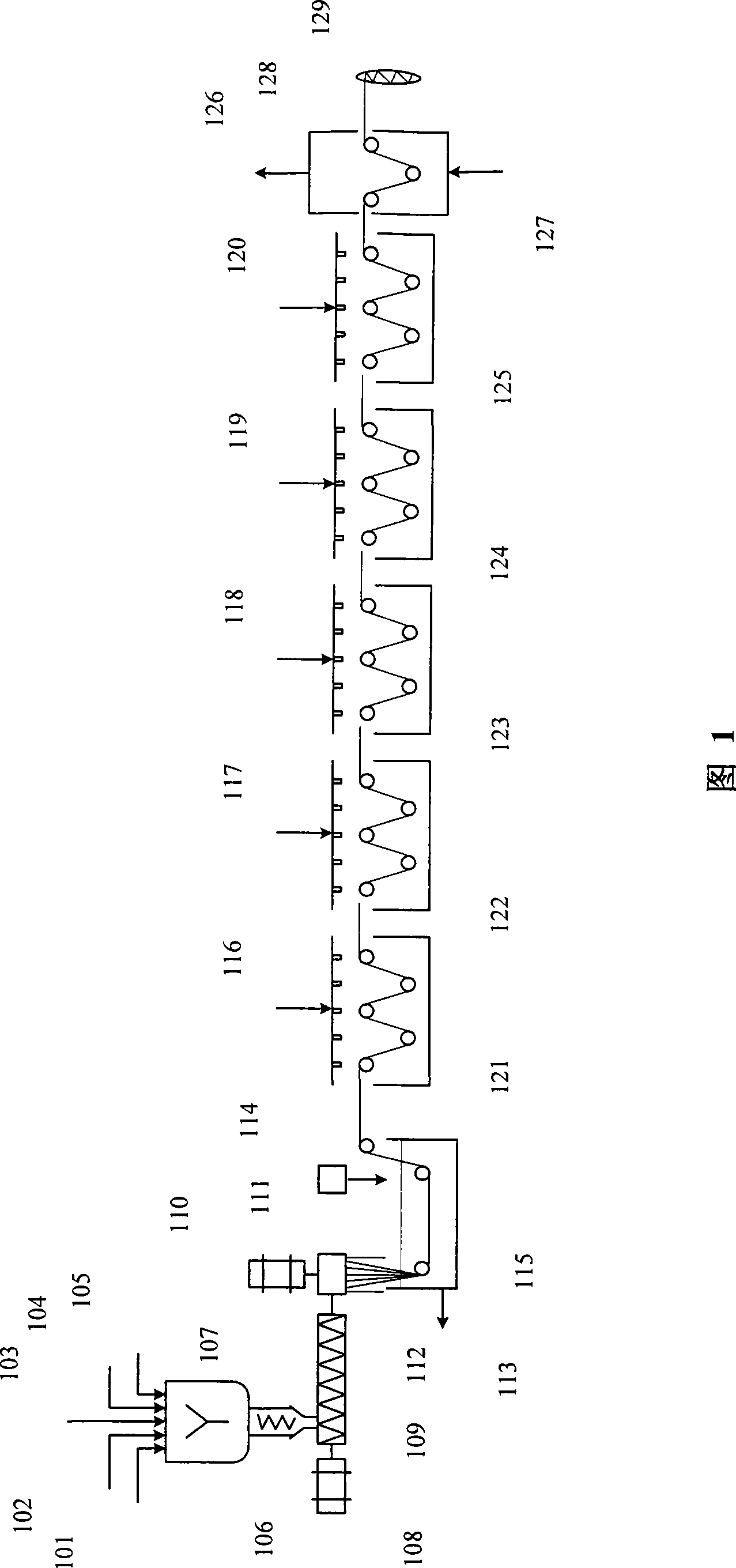

Method for preparing polybenzazole fiber

InactiveCN101423986AEliminate oxidationHelp to closeArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a method for preparing poly (p-phenylene) bis (benzoxazolyl) fibers, which belongs to the technical field of preparation of polymer materials. The method comprises the following steps: firstly, composite salt is prepared by diamino hydroxyphenol hydrochloride and a terephthalic acid, and phosphorus pentoxide, a polyphosphoric acid and an auxiliary agent are added into the composite salt, and subjected to prepolymerization under the condition of stirring and heating; secondly, a polymer reaction mixture after prepolymerization is over enters a screw extruder for further polymerization under the pressure of high-pressure inert gas or under the actuation of mechanical propulsion; thirdly, the polymer reaction mixture is extruded by the screw extruder, filtered, accurately measured, ejected, and solidified and formed in a solidification liquid after passing through a section of spinning shaft of inert gas; and fourthly, the polymer reaction mixture is subjected to five procedures of a diluted phosphoric acid aqueous solution, water, hot water, an alkaline solution and purified water for cleaning and removal of a phosphoric acid, and dried, rolled and formed. The method completely removes the phosphoric acid; the process is tempered; drying under the condition of exertion of a tensile force helps to close fiber holes; and the products produced have high strength and modulus.

Owner:BEIJING TEX STRONG NEW MATERIAL DEV +1

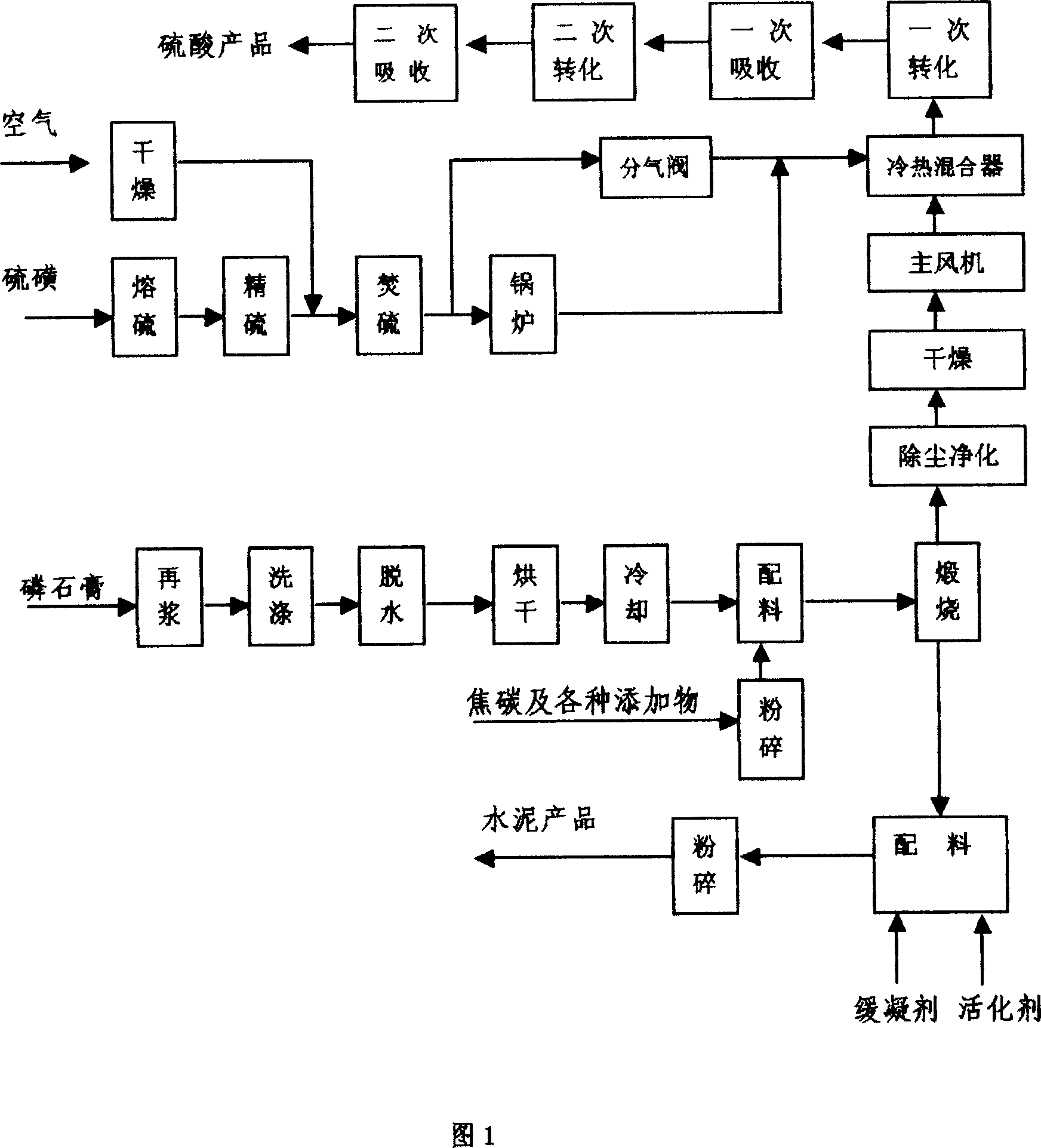

Coproducing cement technological method of producing acid using phosphogypsum and sulfur

ActiveCN1948131AIncrease production intensitySimplify the heat transfer processSulfur-trioxide/sulfuric-acidExhaust gasSlag

The present invention relates to a process capable of simultaneously preparing acid and producing cement by combining phosphogypsum with sulfur. It is characterized by utilizing waste slag phosphogypsum obtained by wet process phosphoric acid production to prepare acid and produce cement. In the concrete, the invented process includes the following steps: utilizing low-concentration SO2 gas discharged out from rotary kiln of phosphogypsum acid-making system and making said kiln gas undergo the processes of washing, cleaning and drying, then be mixed with high-concentration SO2 gas discharged from sulfur acid-making system to obtain the SO2 gas whose concentration is 8-9%; and adopting an advanced two-stage two-absorption acid-making process to prepare sulfuric acid; at the same time firing the phosphogypsum in the rotary kiln to obtain cement clinker, grinding and blending so as to obtain cement.

Owner:GUIZHOU CHANHEN CHEM CO LTD

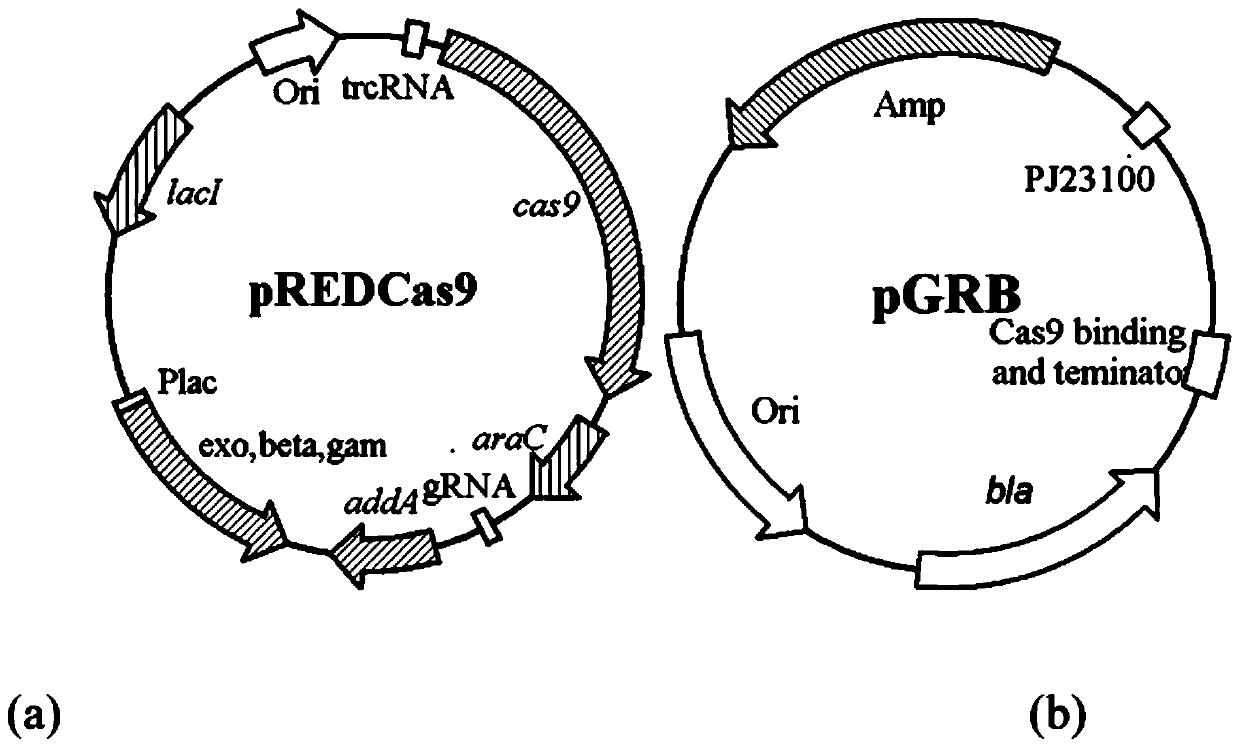

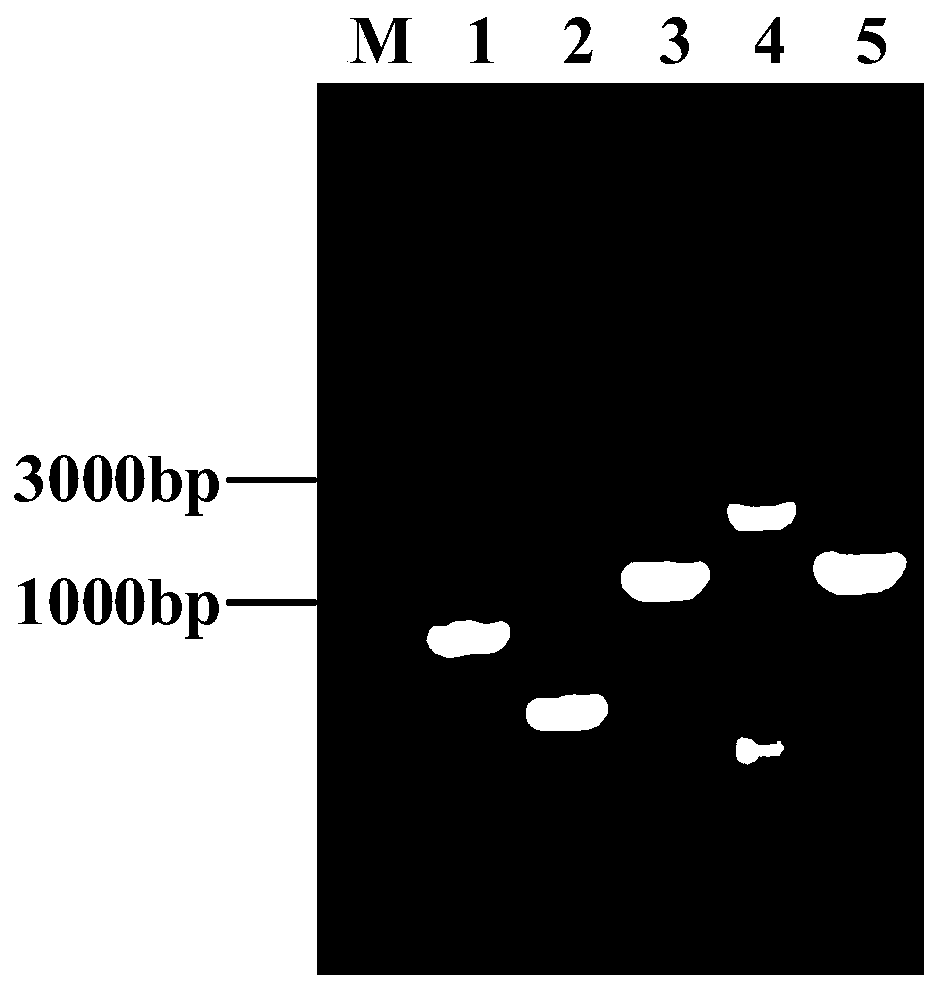

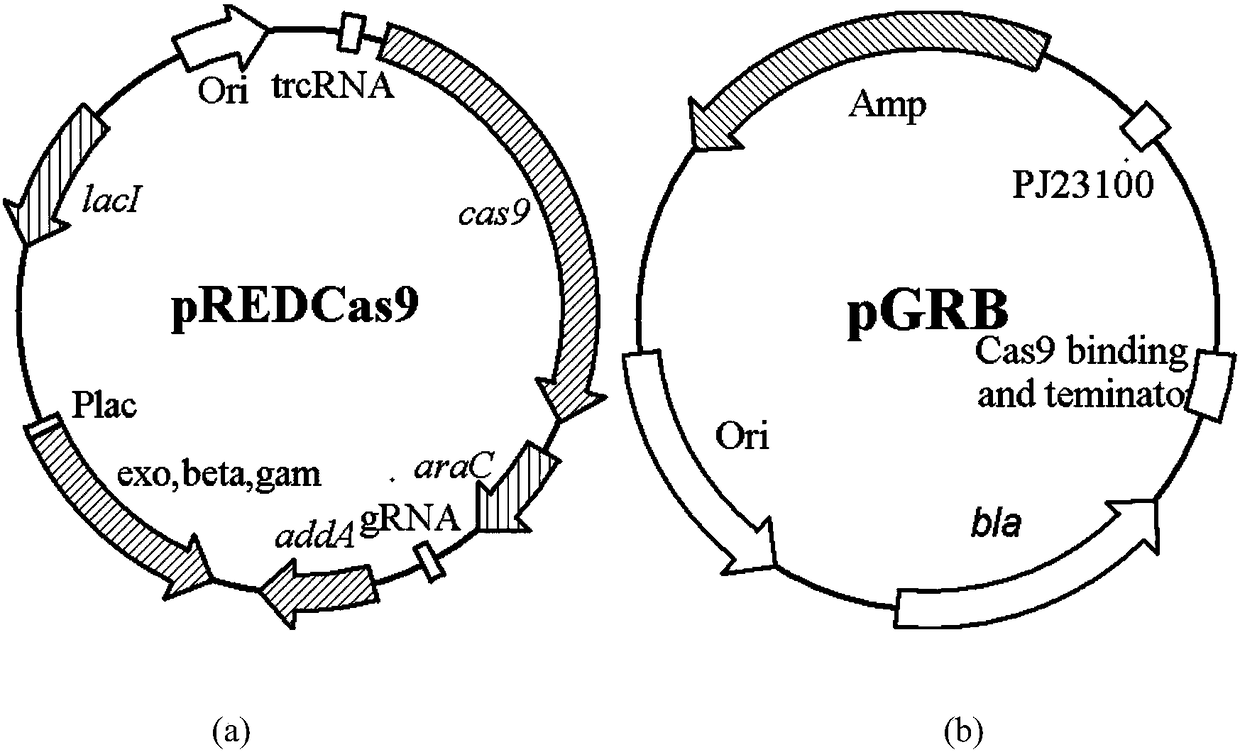

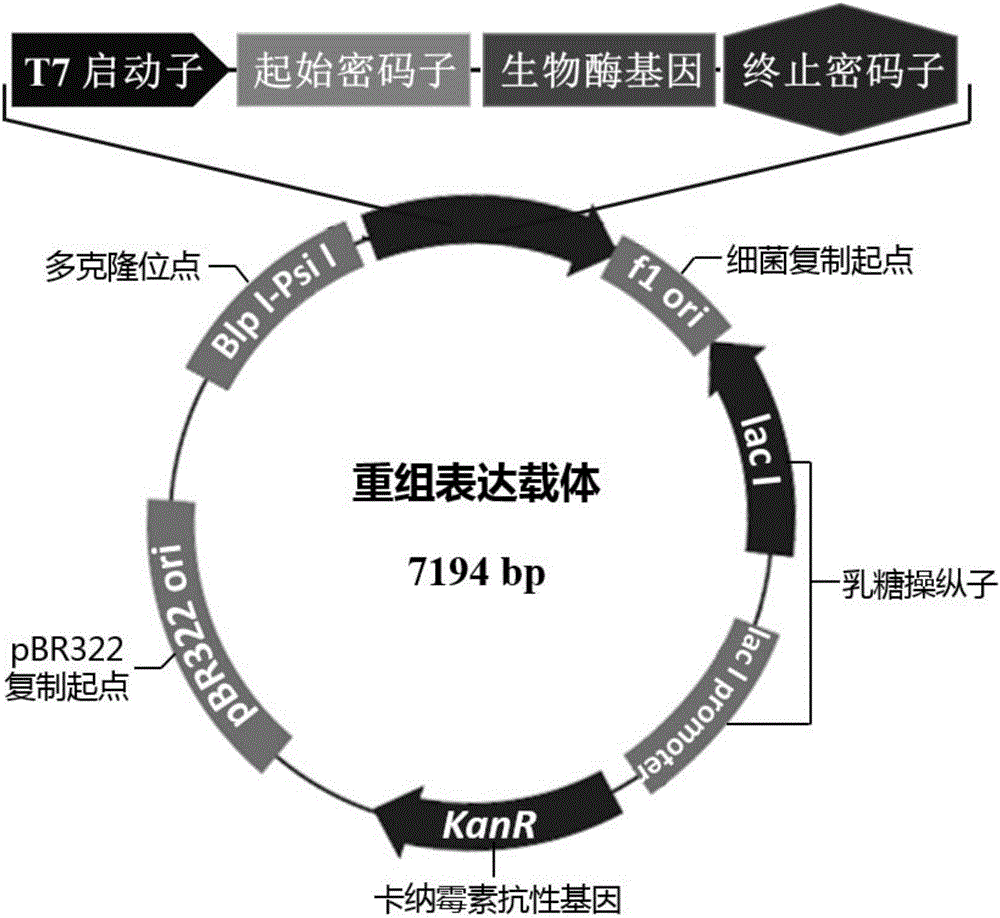

A high-yielding glucosamine engineering bacterium and its construction method through homologous recombination knockout nage

ActiveCN102268399AShort fermentation timeNo allergic reactionBacteriaMicroorganism based processesEscherichia coliHypersensitive response

The invention discloses a high-yield glucosamine gene engineering bacterium and an application thereof; the gene engineering bacterium E. coli-glmS-gnal-delta nagE is obtained by introducing a glucosamine synthase gene (glmS) and a glucosamine acetylase gene (gnal) into escherichia coli E. coli K-12, and knocking out an encoding gene nagE of an acetyl-glucosamine phosphate transport system; the bacterial strain is applicable to the fermentation production of glucosamine, has the advantages of high production intensity, low production cost, less environmental pollution, no allergic reaction, and the like; and the obtained glucosamine is widely applicable to fields such as medicin, food, etc.

Owner:衢州益康园生物科技有限公司

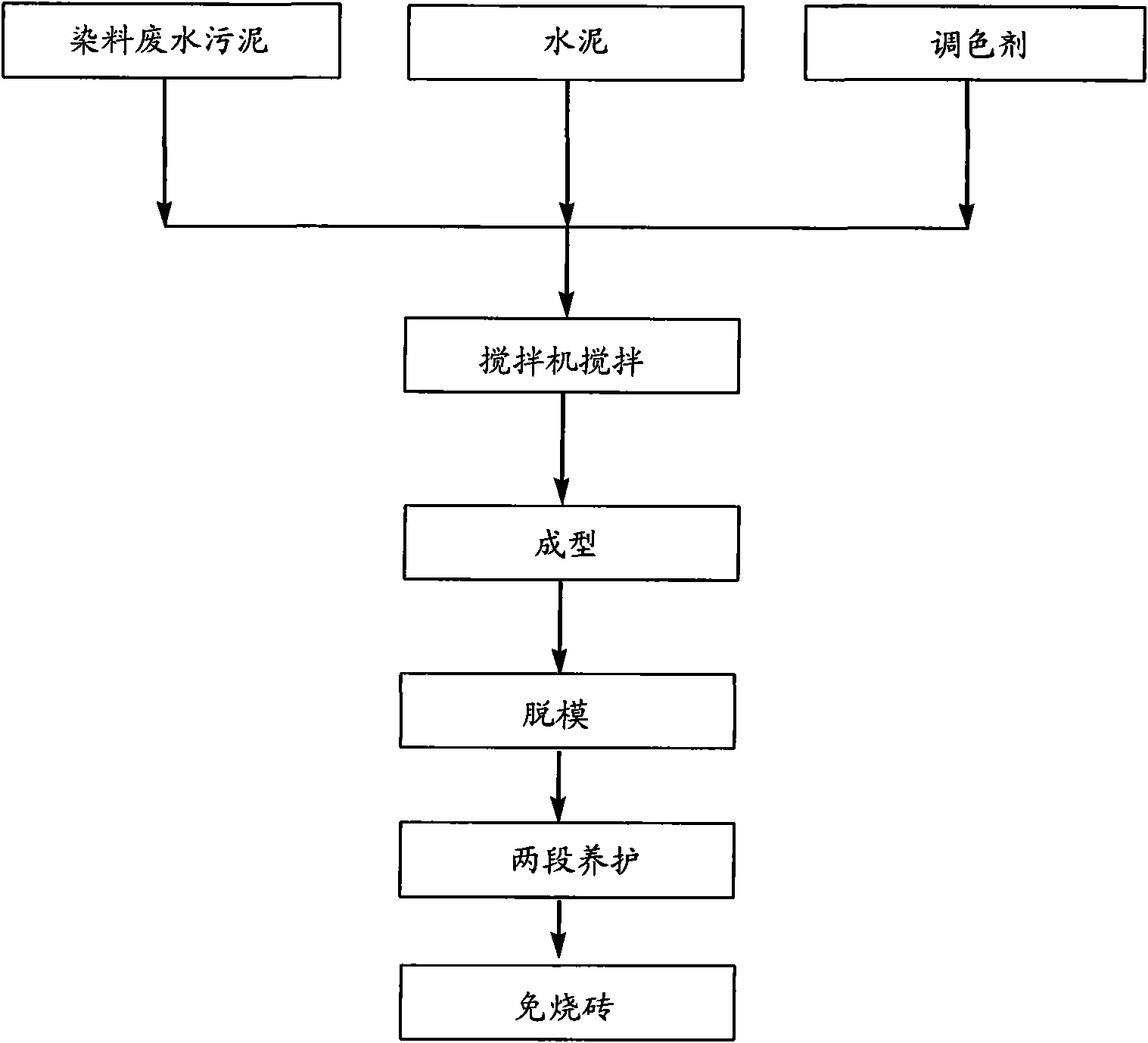

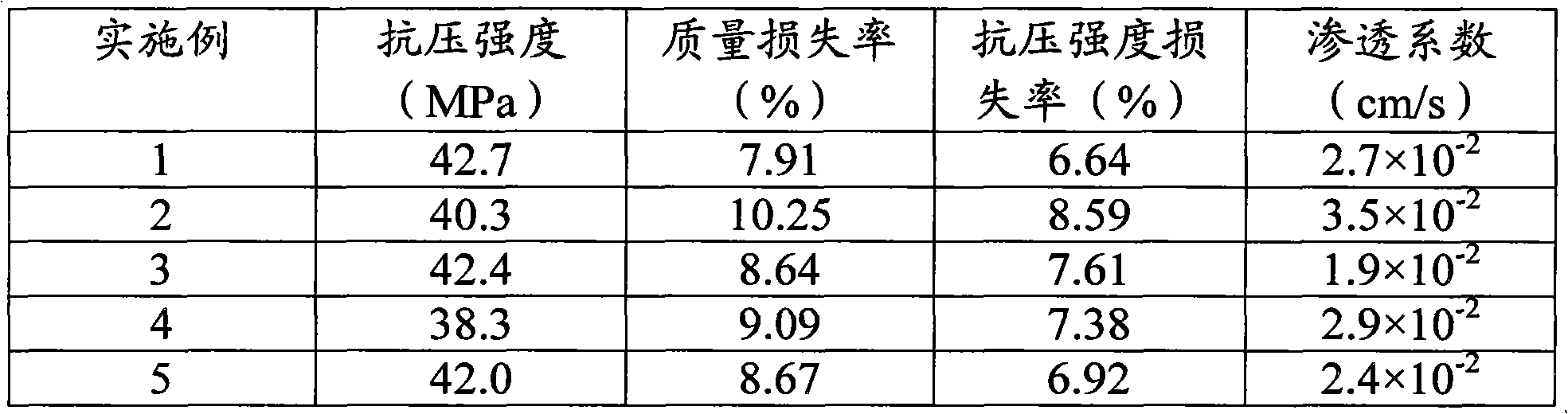

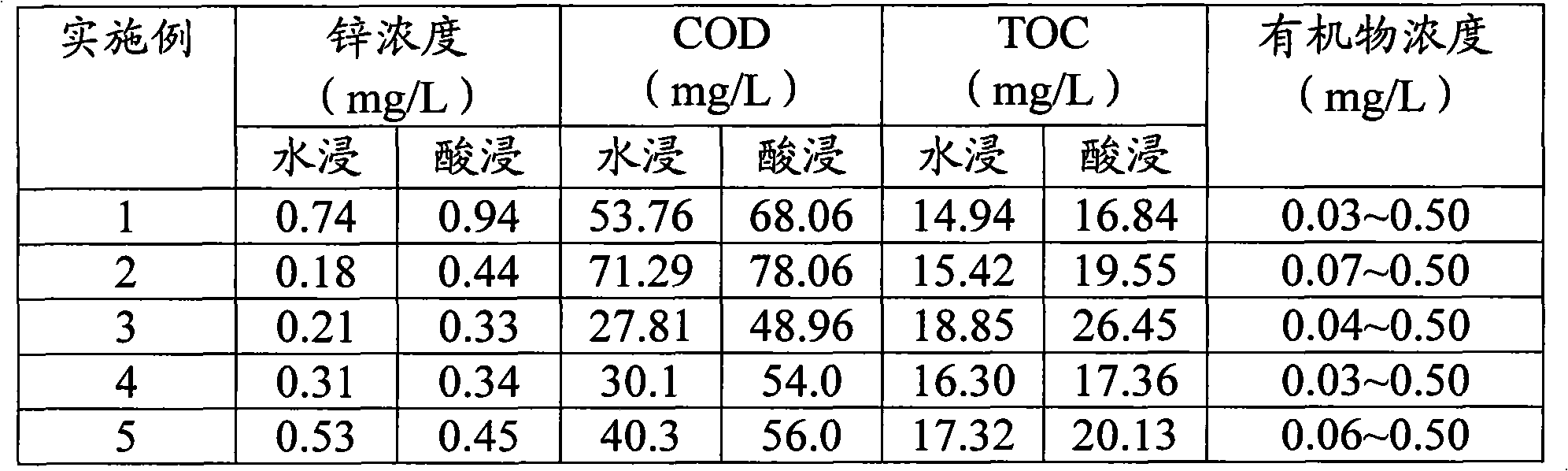

Method for making baking-free bricks by using dye waste water coagulated sludge and baking-free bricks

InactiveCN101941820AIncrease production intensityIncreased durabilitySolid waste managementChemical industryMoisture

The invention discloses a method for making baking-free bricks by using dye waste water coagulated sludge, which comprises the following steps of: uniformly blending cement and the dye waste water coagulated sludge of which the moisture content is 40 to 60 weight percent, molding and maintaining to obtain the baking-free bricks, wherein the raw material comprises the following components in percentage by weight: 20 to 60 percent of cement, 40 to 80 percent of dye waste water coagulated sludge and the balance of water. The baking-free bricks prepared by the preparation method have the advantages of avoiding secondary pollution, along with high compression strength, high durability and high water permeability speed. The method has the advantages that: a production process is simple; less equipment is needed; investment is small; industrial production and production operation are easily carried out; a large amount of dye waste water coagulated sludge can be consumed; considerable environmental benefit and economical benefit are generated; and conditions for sustainable development of dye chemical industry are created.

Owner:ZHEJIANG DIBANG CHEM +1

Genetically engineered bacterium for producing L-arginine and construction method and application thereof

ActiveCN110964683AShorten the growth cycleClear genetic backgroundBacteriaHydrolasesEscherichia coliCarbamyl Phosphate

The invention discloses a genetically engineered bacterium for producing L-arginine and a construction method and application thereof. According to the invention, a gene for encoding carbamyl phosphate synthetase and a gene for encoding L-arginine biosynthetic pathway enzyme are integrated in escherichia coli; a synthetic route of arginine in escherichia coli and metabolic flux related to argininein a whole amino acid metabolic network are analyzed and reconstructed to obtain genetically engineered bacteria which are clear in genetic background, do not carry plasmids, are not mutated and canstably and efficiently produce L-arginine; and the genetically engineered bacteria have good L-arginine production capacity.

Owner:NINGXIA EPPEN BIOTECH

Genetic engineering bacterium capable of producing uridine at high yield as well as building method and application thereof

ActiveCN108130306AImprove growth traitsIncrease productivityBacteriaEnzymesEscherichia coliNucleotide

The invention provides a genetic engineering bacterium capable of producing uridine at high yield as well as a building method and application thereof. The genetic engineering bacterium is characterized in that pyrimidine nucleoside operons pyrBCAKDFE with the nucleotide sequence shown as SEQ ID NO:1 is integrated on a genome of colon bacillus; the starting is realized by a strong promoter P[trc];a uridine synthesis path is reconstituted; the self PRPP synthetase coding gene prsA on the genome is subjected to dual copying, and the starting is realized by the strong promoter P[trc]; meanwhile,the activity of udk, udp, and rihA, rihB and rihC is lacked; the thrA activity is lacked; the argF activity is lacked. The genetic engineering bacterium is applied to fermentation production of uridine; 40 to 67g / L of uridine can be produced after the fermentation is performed for 40 to 70h in a 5L fermentation tank; the maximum production intensity can reach 1.5g / (L*h); the glucoside conversionrate is 15 to 25 percent; the genetic engineering bacterium belongs to the highest level for producing the uridine by the fermentation method reported in the prior art.

Owner:TIANJIN UNIV OF SCI & TECH

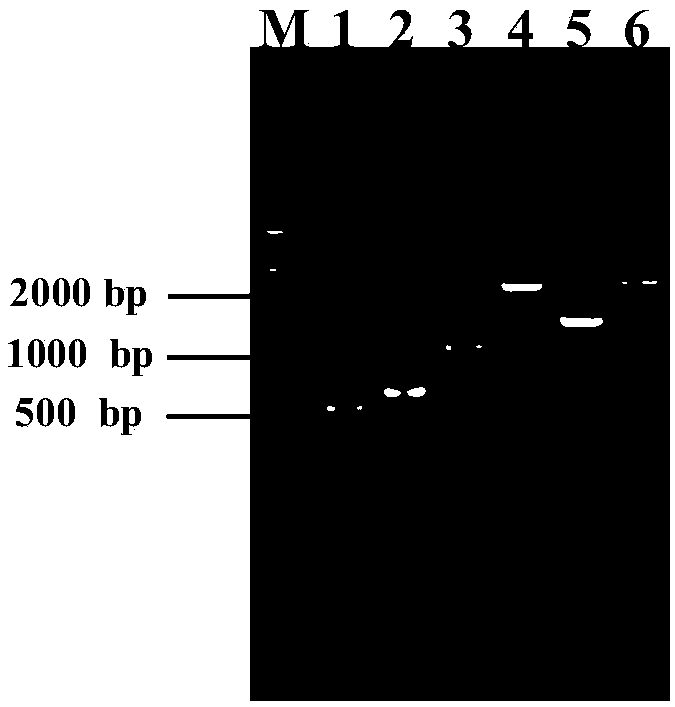

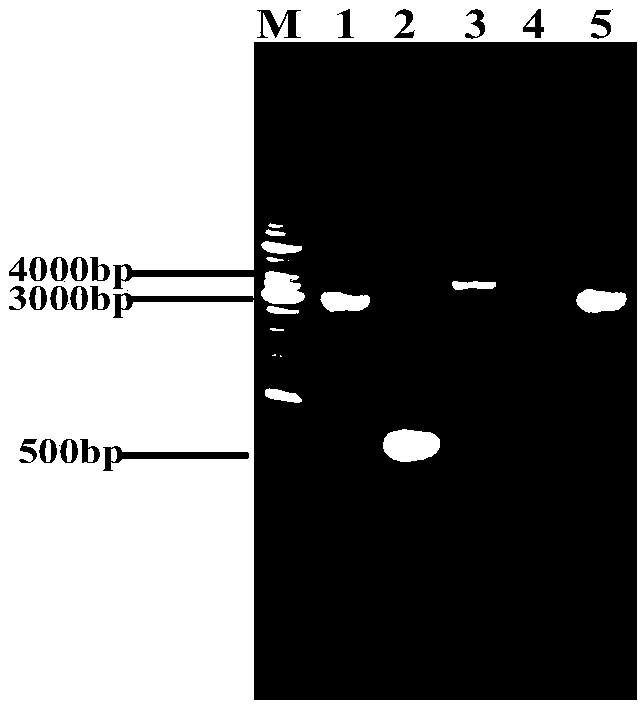

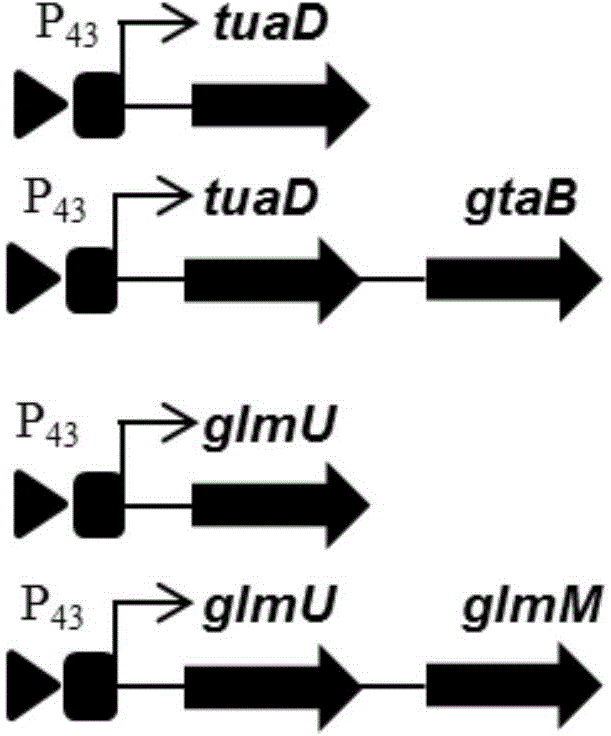

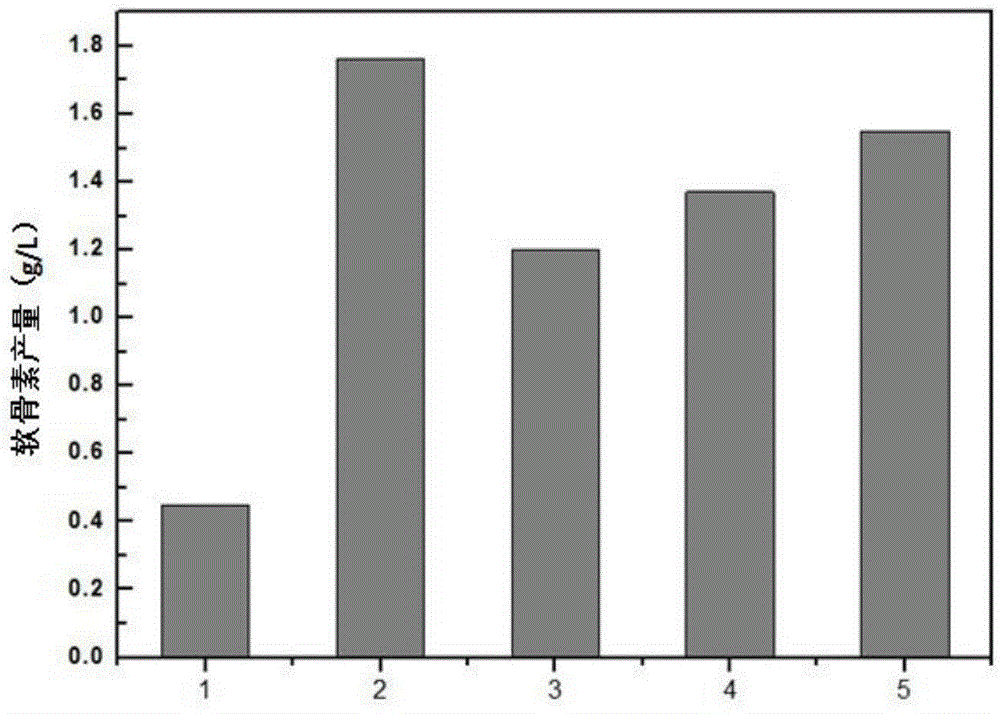

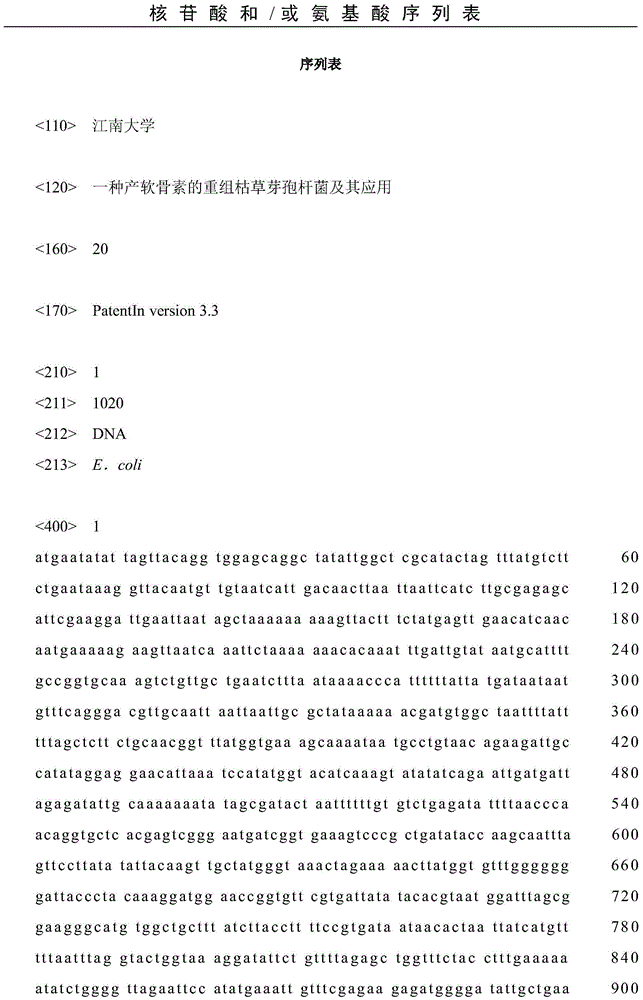

Recombinant bacillus subtilis for producing chondroitin and application of recombinant bacillus subtilis

ActiveCN104388372AReduce the cost of trainingIncrease production intensityBacteriaMicroorganism based processesMicroorganismBacillus aryabhattai

The invention discloses recombinant bacillus subtilis for producing chondroitin and application of the recombinant bacillus subtilis, belonging to the technical field of biological engineering. According to the recombinant bacillus subtilis, UDP-GlcNAc C4 isomerase KfoA and chondroitin synthetase KfoC encoding genes are integrated into a bacillus subtilis genome, the way for anabolic synthesis of chondroitin is completed, the genes of the synthesis way of UDP-GlcA and UDP-GlcNAc in the bacillus subtilis are subjected to modulation assembling expression analysis, the different concentrations of UDP-GlcA and UDP-GlcNAc are controlled, and key genes and nodes of the synthesis way for producing chondroitin from bacillus subtilis are analyzed. Certain basis is provided for efficiently producing and preparing chondroitin from food-order microorganisms, and the recombinant bacillus subtilis is applicable to industrial production and application.

Owner:JIANGNAN UNIV

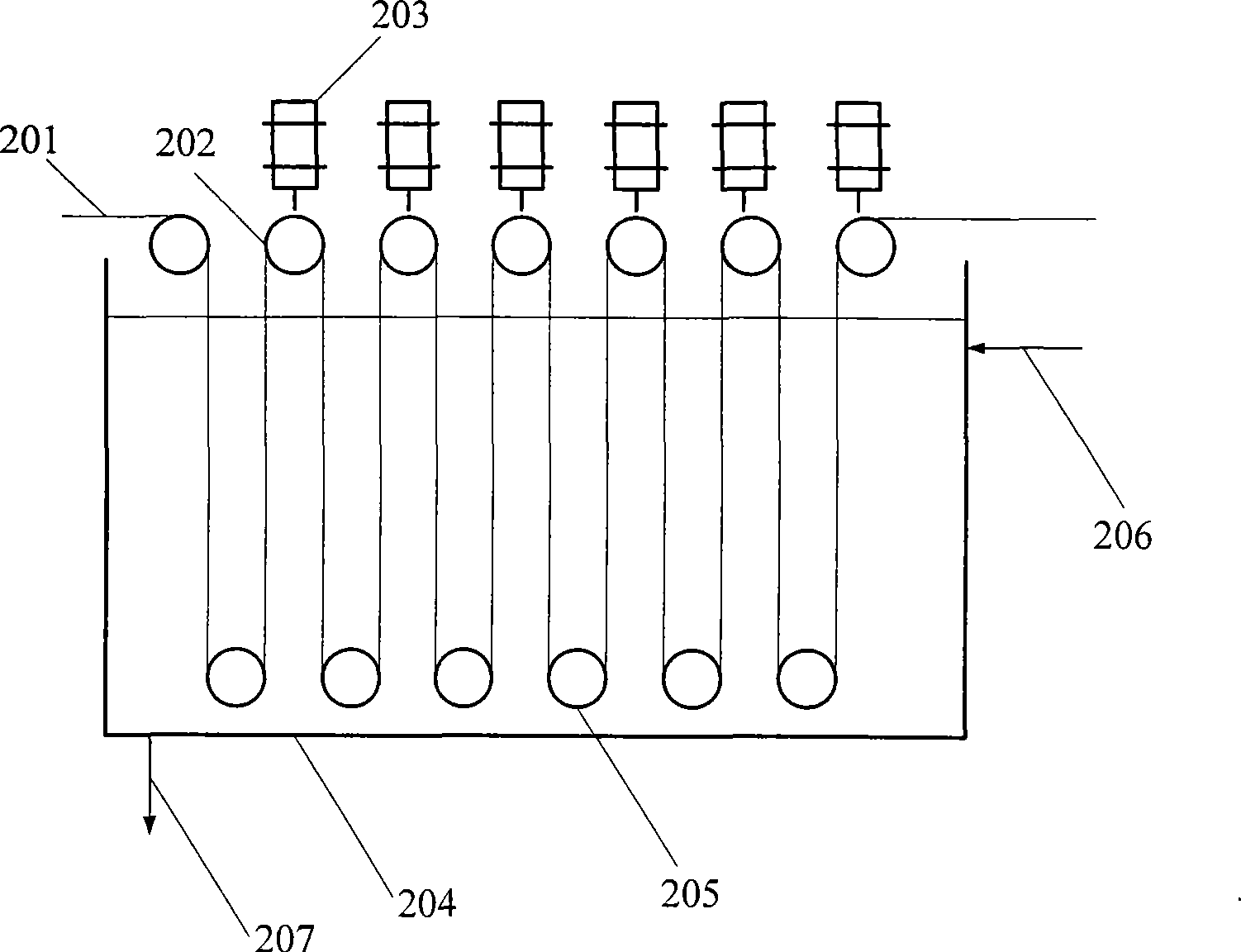

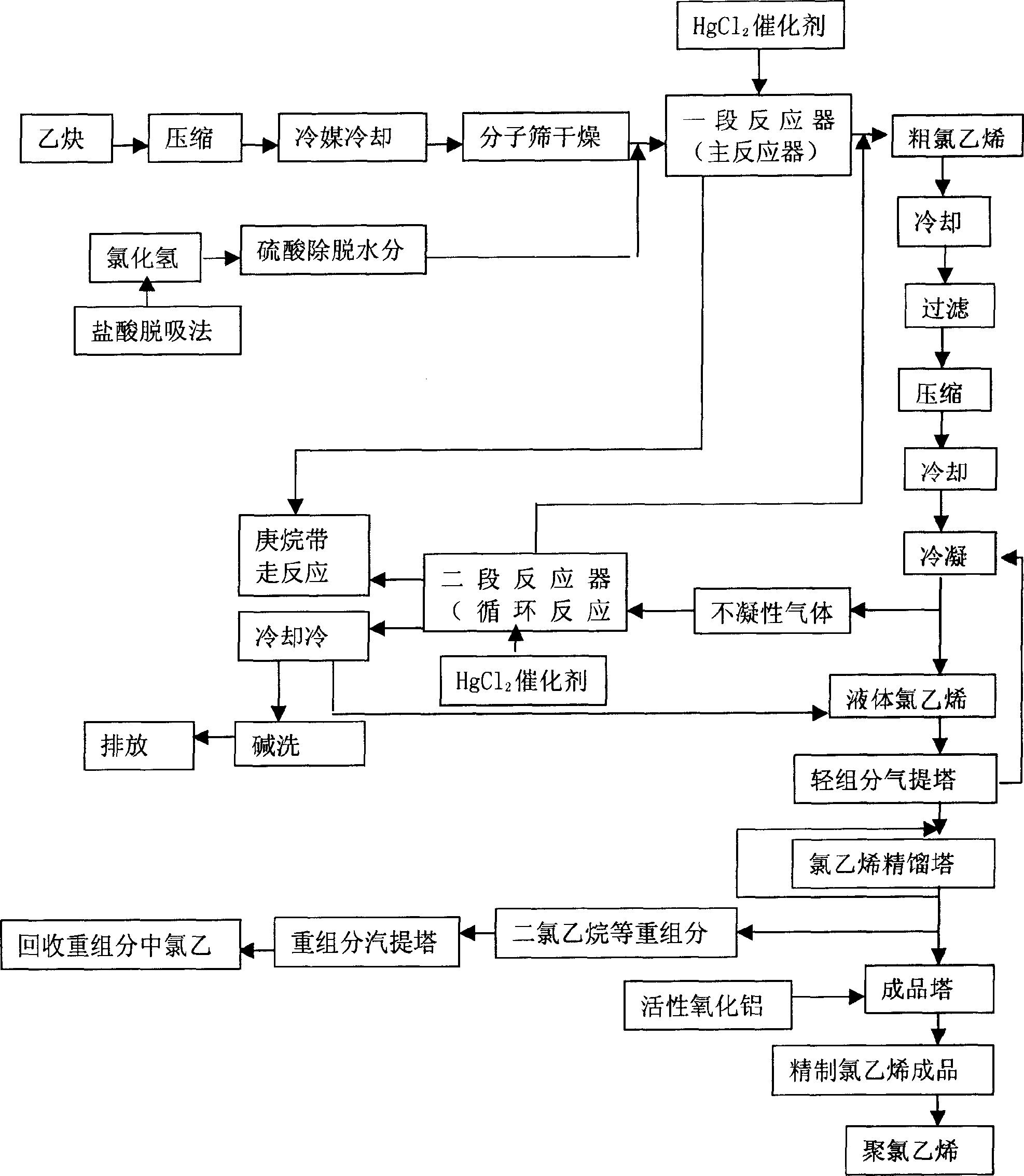

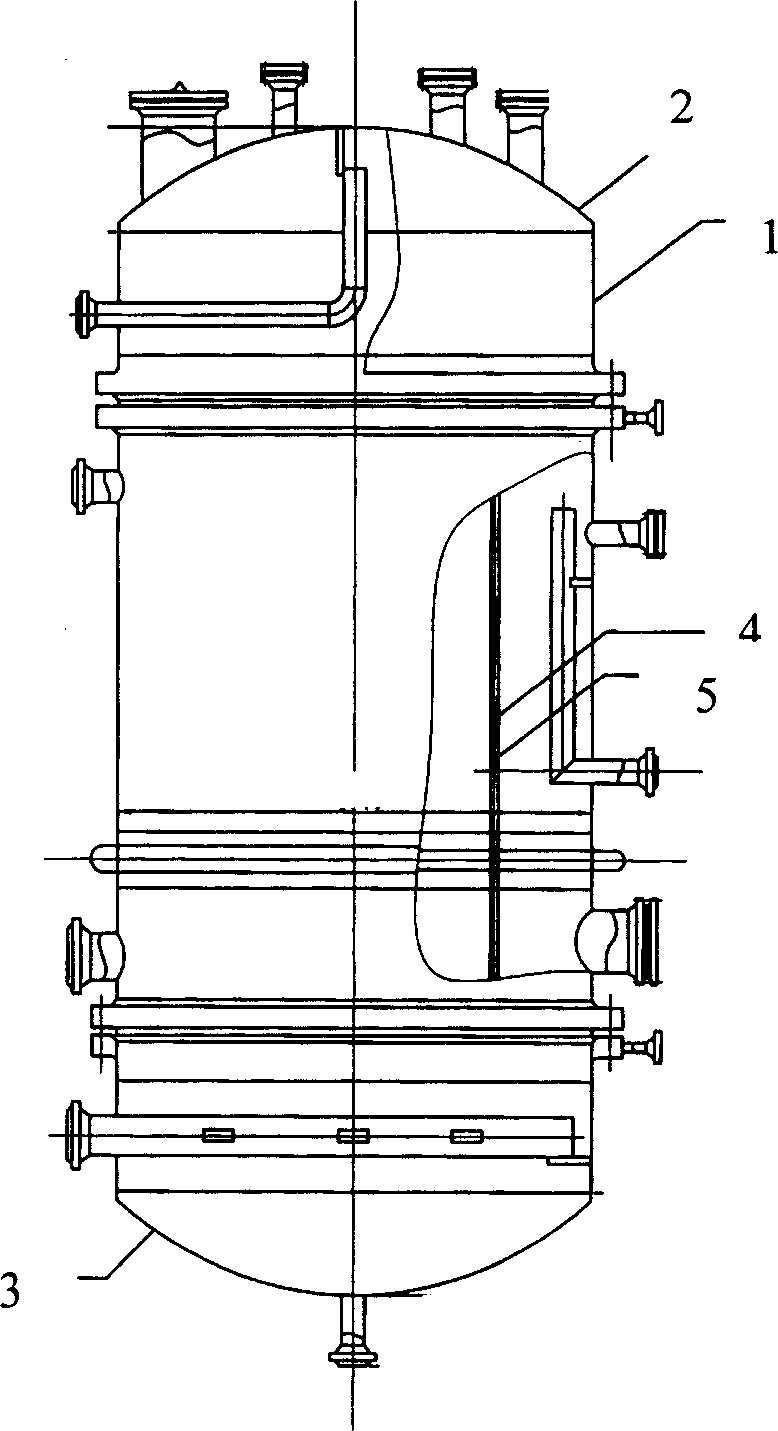

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

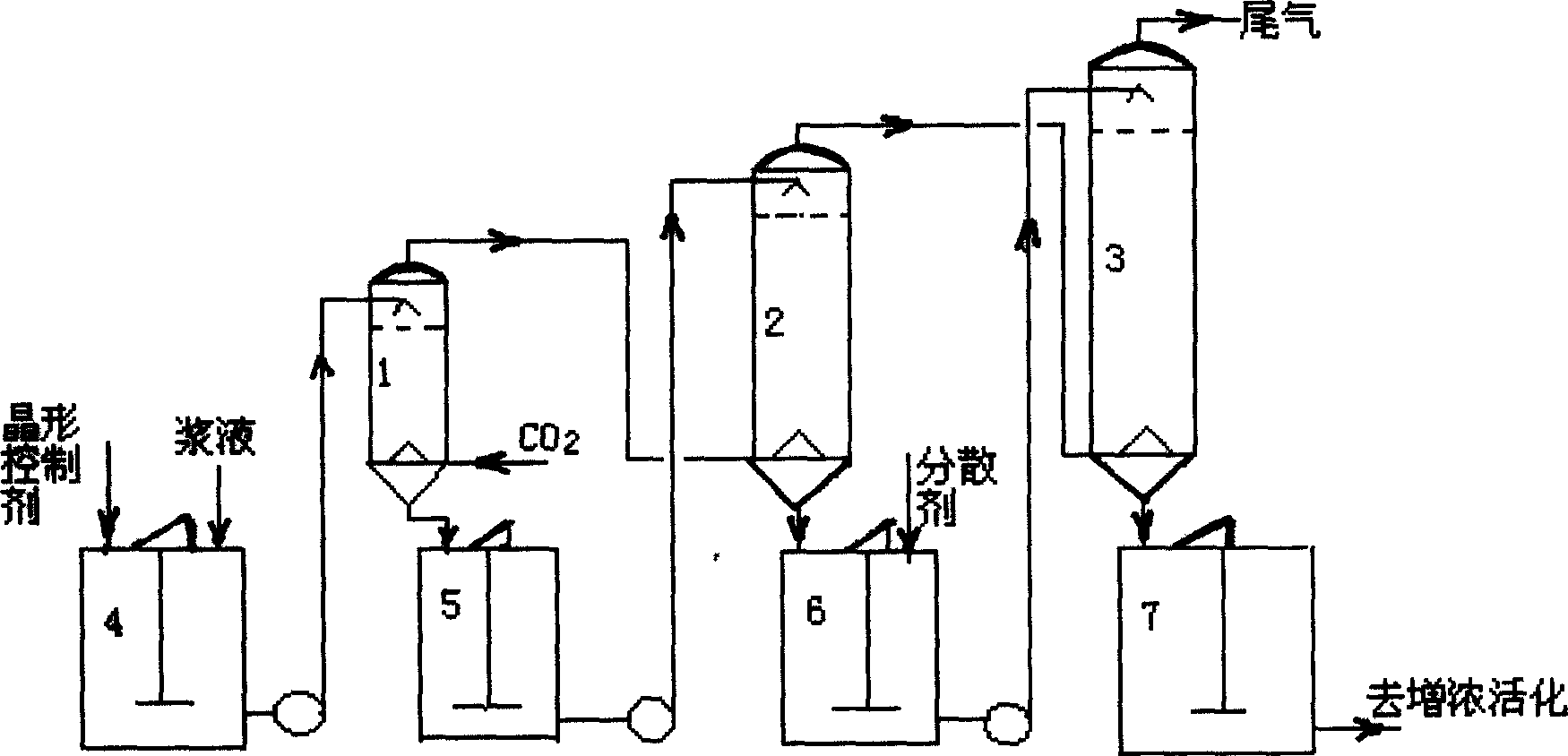

Continuous bubbling carbonizing new process for producing super fine active calcium carbonate

InactiveCN1749168AIncrease the nucleation rateIncrease production intensityCalcium/strontium/barium carbonatesHigh concentrationCO2 content

The present invention discloses continuous bubbling carbonizing process for producing superfine active calcium carbonate in the installation with pre-carbonizing tower with high concentration carbonizing gas with CO2 content of 50-99 %, No. 1 carbonizing tower and No. 2 carbonizing tower connected serially. Calcium other slurry passes successively through fine slurry trough, pre-carbonizing tower, No. 1 slurry trough, No. 1 carbonizing tower, No. 2 slurry trough, No. 2 carbonizing tower and chamotte trough; while carbonizing gas passes successively through pre-carbonizing tower, No. 1 carbonizing tower and No. 2 carbonizing tower before being exhausted to air. There are crystal form controlling agent added into the fine slurry trough and dispersant added into the No. 2 slurry trough, and the calcium carbonate slurry in the chamotte trough is prepared into the superfine active calcium carbonate through thickening, activating, dewatering, drying and crushing.

Owner:颜鑫

Process for producing 1,3-propylene glycol by microorganism aerobic fermentation

The present invention provides microbial aerobic fermentation process of producing 1, 3-propylene glycol, and belongs to the field of biochemical technology. Seed liquid is first added into industrial glycerin or initial fermentation culture medium of glycerin fermenting liquid with glycerin concentration of 20-50 g / L, and under fermentation condition of 30-40 deg.c, the culture medium is fermented with PDO producing Klebsiella pneumoniae or acid producing Klebsiella pneumoniae to produce PDO. During fermentation, air in 0.2-1.0 vvm is led in, the fermented matter is stirred in 50-250 rpm, glycerin and sodium hydroxide in certain amount are added to maintain certain glycerin concentration. The present invention has the advantages of lowered investment and power consumption, raised final PDO concentration, raised production strength and increased bacteria biomass.

Owner:TSINGHUA UNIV

A method for producing succinic acid by fermenting distiller's grain raw materials

InactiveCN102260715ALow costReduce inhibitionMicroorganism based processesFermentationChemical synthesisButanedioic acid

The invention discloses a method for producing succinic acid by fermenting a vinasse raw material, and belongs to the technical field of bioengineering. The method comprises the following steps of: dehydrating fresh vinasse and crushing, pretreating to form a fermentation culture medium, pre-hydrolyzing by using enzymes, and saccharifying with fermenting by using enzyme and actinobacillus succinogenes to obtain the succinic acid at the concentration of 25-40g / L, wherein 0.033 to 0.050g of the succinic acid can be produced by using one gram of dry vinasse. The method has the advantages that: the succinic acid is produced by fermenting industrial waste vinasse which is used as a raw material, the vinasse is used as a carbon source instead of glucose, and a nitrogen source is not required tobe externally added in the fermentation culture medium, so that the problem that the petrochemical resource for chemically synthesizing the succinic acid is tense is solved, the environment pollutioncaused by the vinasse is also prevented, and the using value of the vinasse is enhanced.

Owner:JIANGNAN UNIV

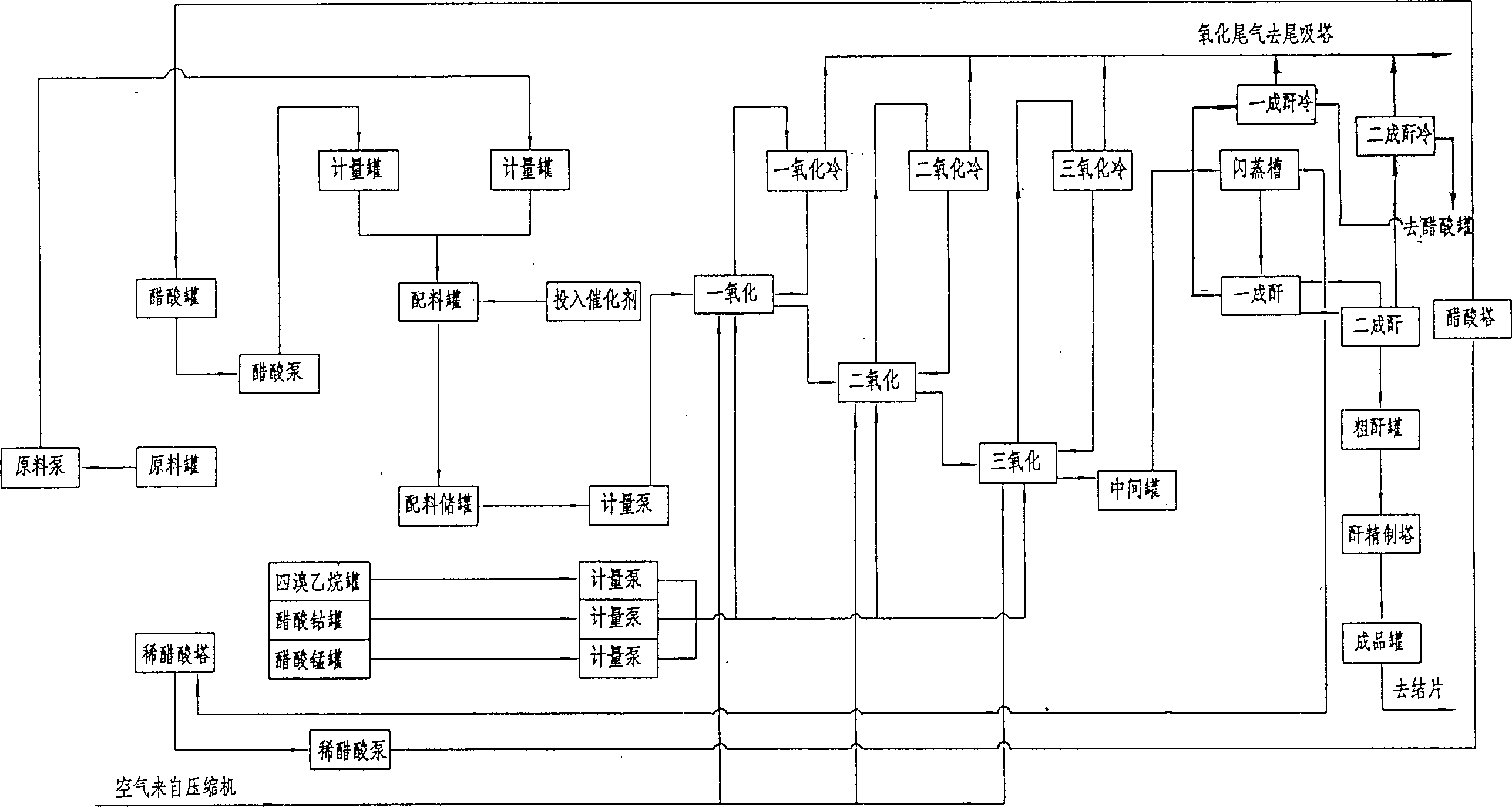

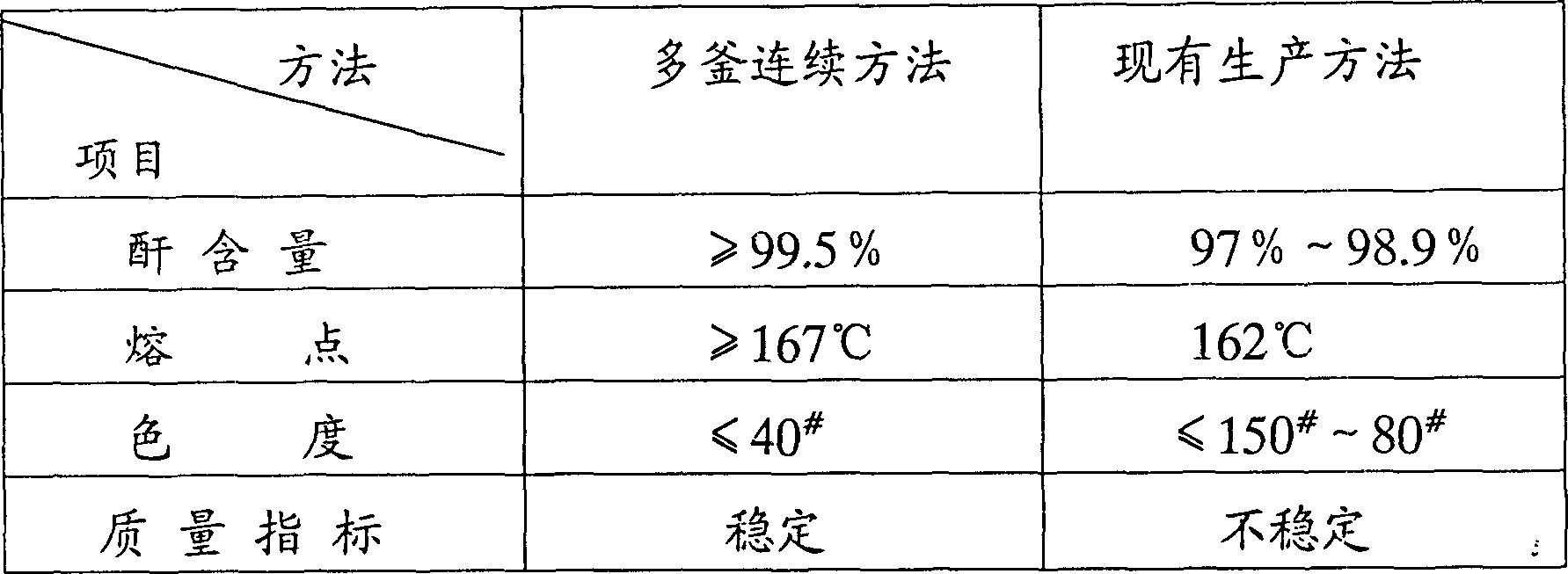

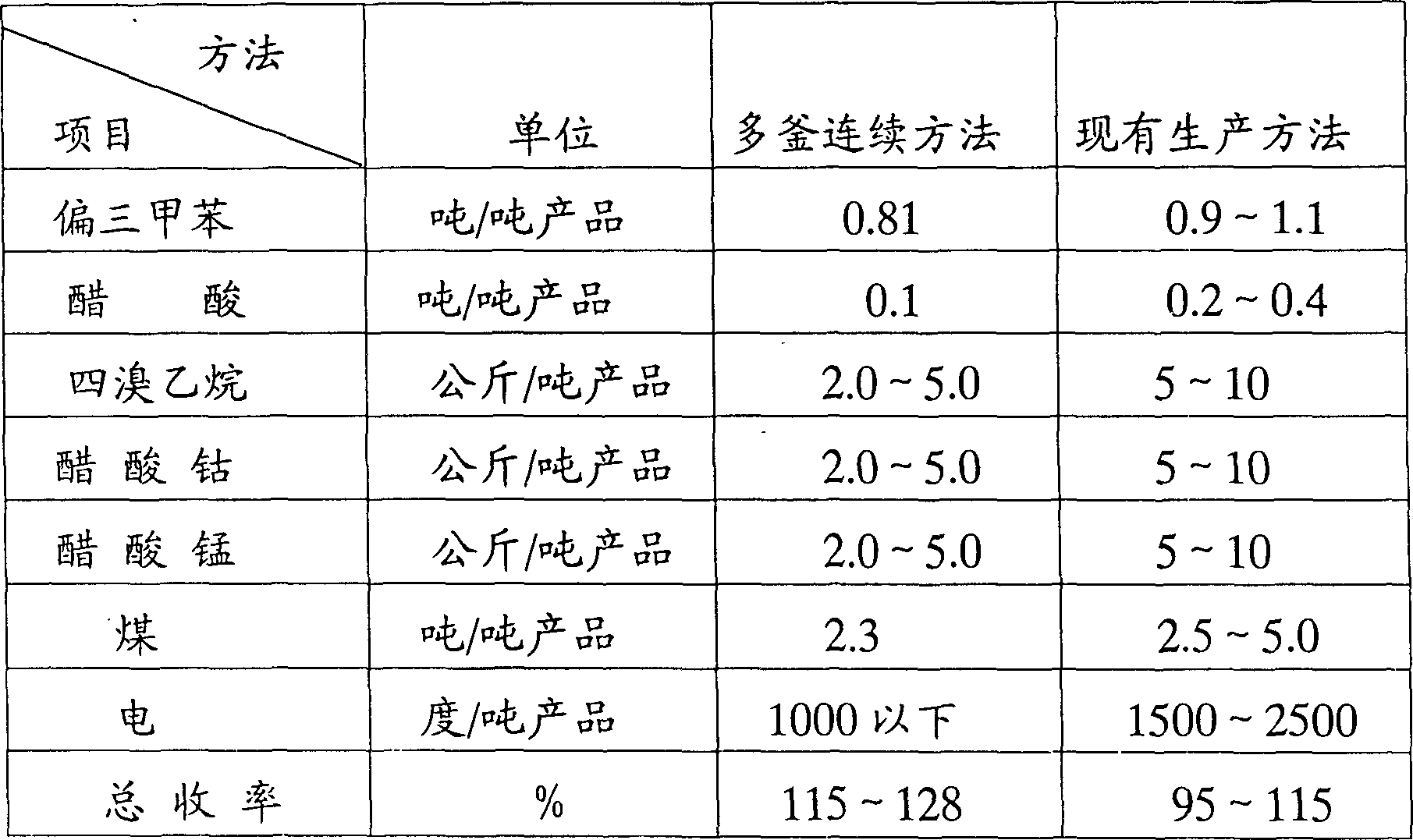

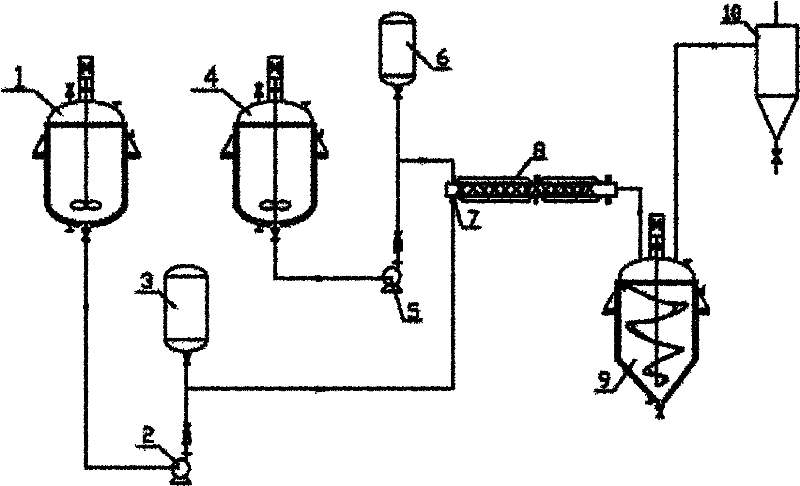

Process for stirring type multi-kettle continuous oxidation preparation of trimellitic anhydride

The invention relates to a process for stirring type multi-kettle continuous oxidation preparation of trimellitic anhydride with 1,2,3-trimethylbenzene as raw materials, acetic acid as solvent, tetrabromoethane as promoter, and cobalt acetate and manganese acetate as catalyst. Three and four stage cascade oxidation reaction kettles with stirring device are employed, the temperature of kettle is 160C.í½250C. with step type temperature rise among kettles, and pressure is 1.8í½3.2MPa (absolute pressure); Two and three stage cascade anhydride-forming reaction kettles with stirring device are employed with the temperature of kettle of 160C.í½250C. and pressure of 0.08MPaí½0.12Mpa (absolute pressure). Said materials are added separately in proportion in oxidation reaction kettle, and fed into multi-stage cascade reaction kettle with stirring device through pipeline connection by pump power, liquid phase continuous oxidation, anhydride-forming, purification are carried out with stirring to produce trimellitic anhydride. Miulti-kettle continuous production can prevent frequent operation of temperature and pressure control.

Owner:天津大学北方化工新技术开发公司 +1

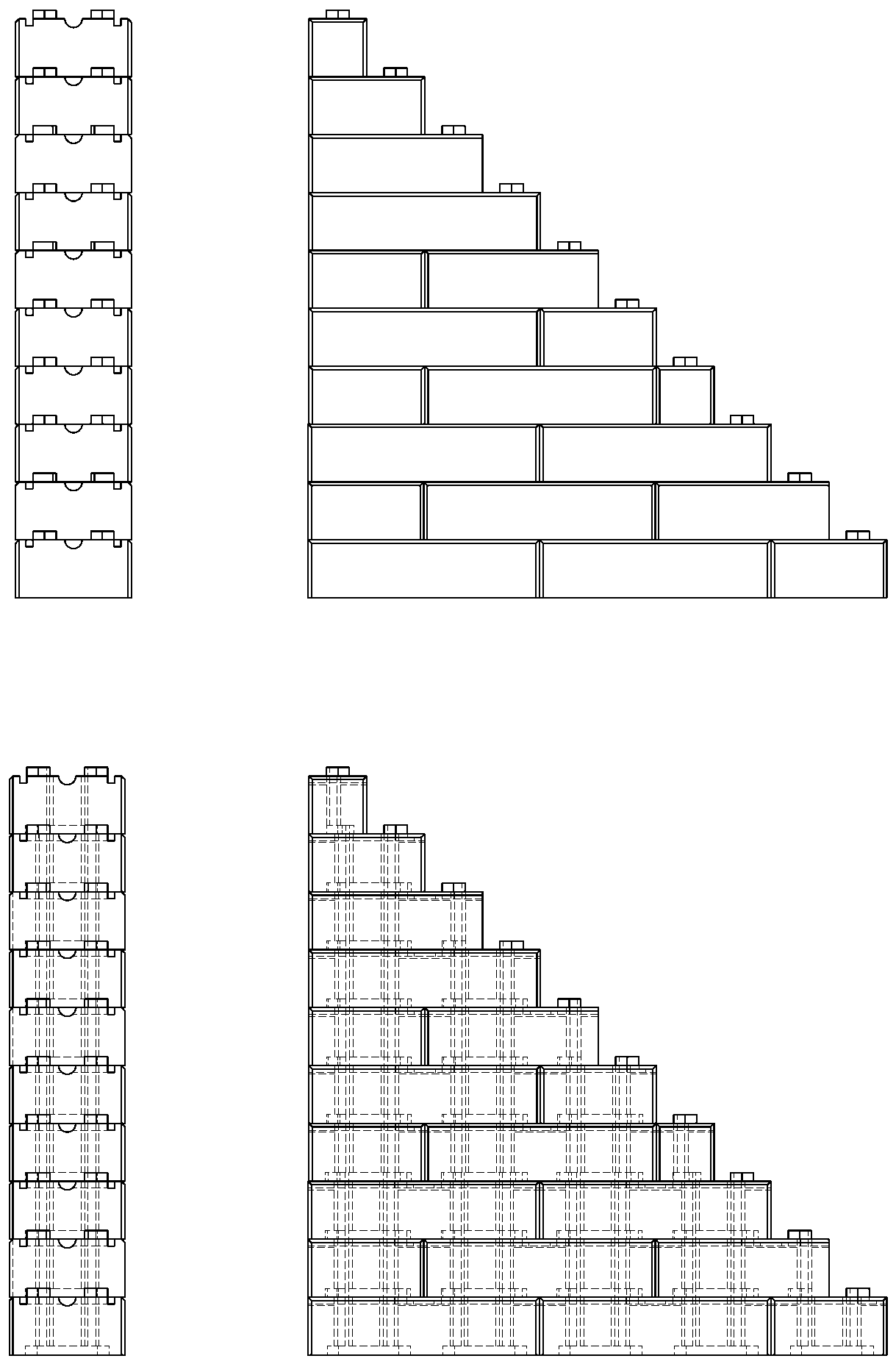

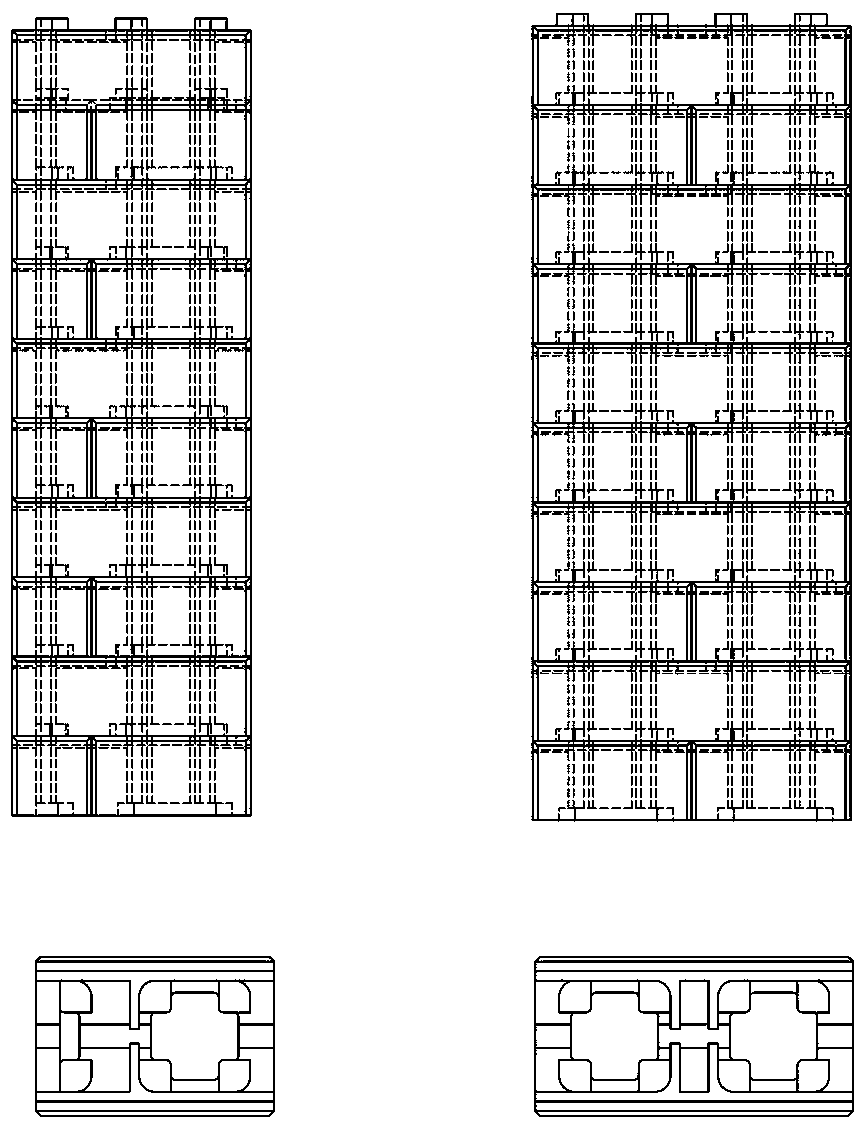

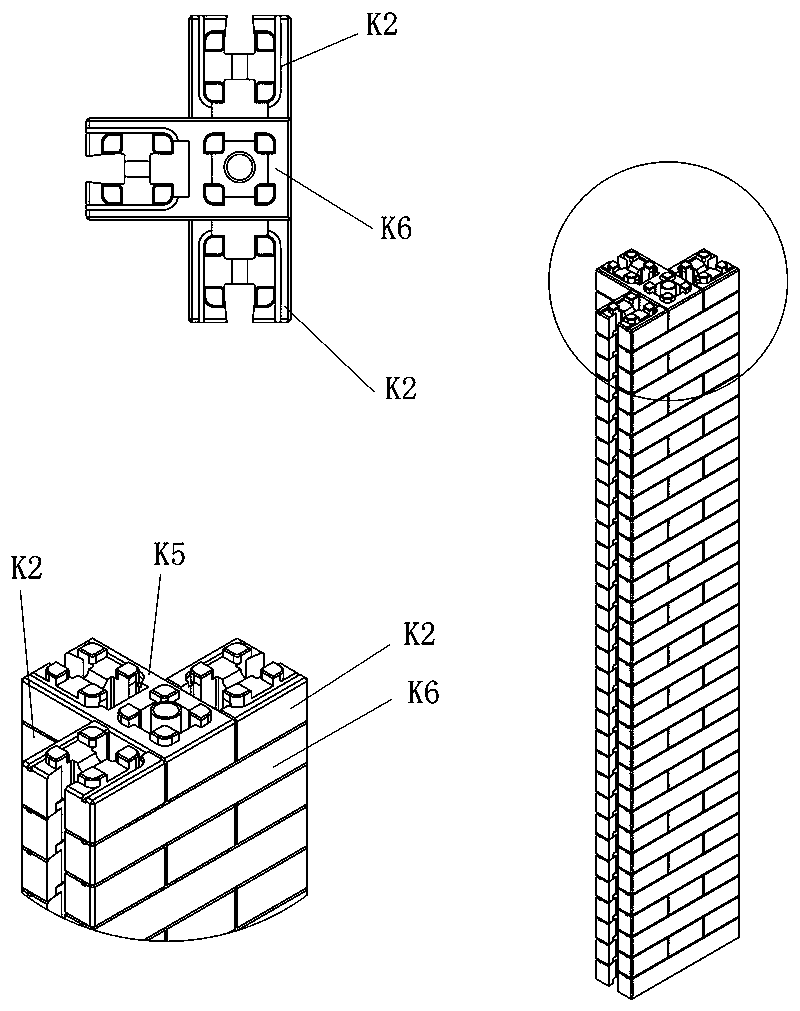

Unified-modulus combined interlocking building block combination and method for building energy-saving and anti-seismic house

PendingCN108487538AMeet the basic requirements of wide and narrowRealize interlockingWallsProtective buildings/sheltersBrickBuilding energy

The invention discloses a method for building an energy-saving and anti-seismic house through unified-modulus combined interlocking building blocks, and an adopted main and auxiliary building block combination. The length, width and height of the building blocks are an integral multiple of 100 mm, so that no matter how long, wide and high a masonry, formed by the building blocks, is, and no matterwhether a convex lock tenon is in a square shape, a circular arc shape, a circular shape or a triangular shape, reciprocal interlocking is achieved always through a matched concave lock table hole, under the premise of interlocking layer by layer, a penetrating cross-shaped through hole or a square through hole or a combination of the cross-shaped through hole and the square through hole which are used for pouring of a core column is arranged between the upper portion and the lower portion, and the space between through holes is 100 mm. According to the method, the building blocks can be built through manpower or a robot on a construction site and can be also suitable for being assembled by a robot in a factory, and the components of an interlock door frame, inner and outer wall bodies ofthe interlock door frame, a structural column, a ring beam, a floor and the like. The method has the comprehensive characteristics that production is simple, the input is saved, building is convenient, and the energy-saving and anti-seismic effects of the house are excellent. A traditional multi-layer brick-concrete house building can be replaced, and the method is also applied to a modern high-rise building.

Owner:段志祥

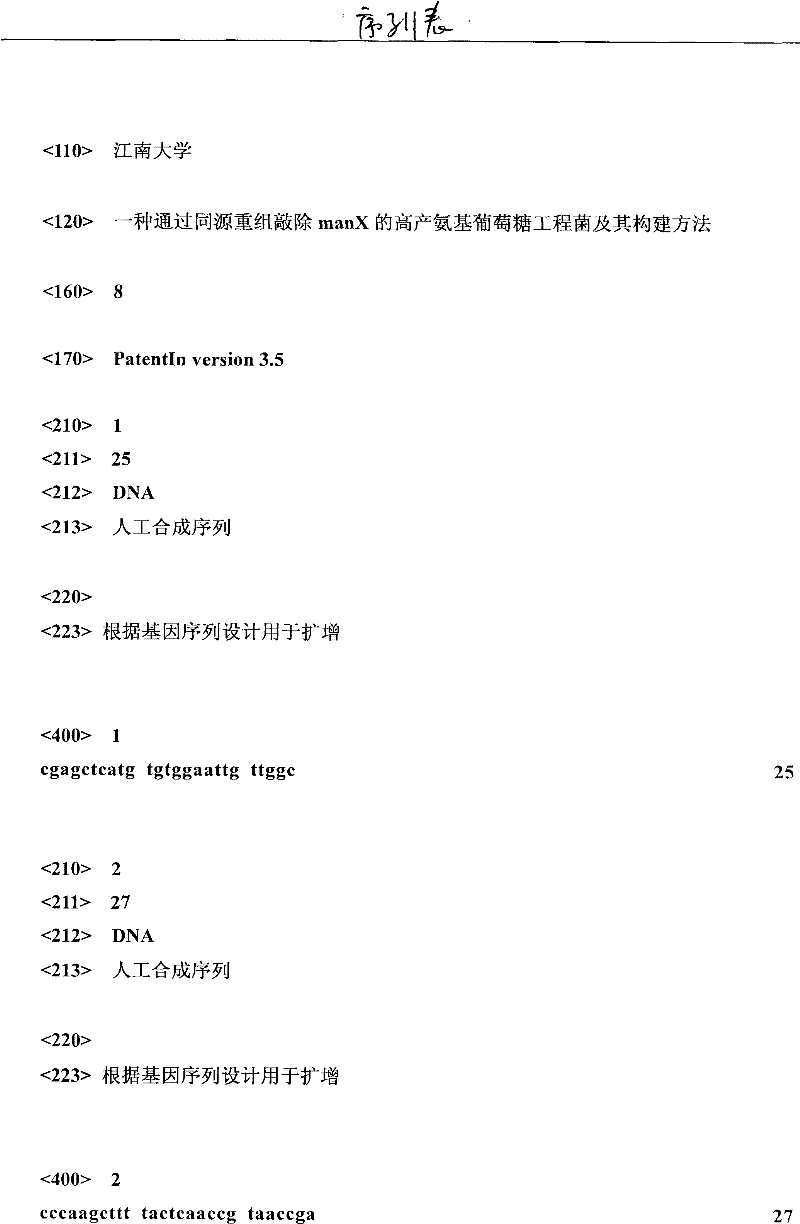

A high-yielding glucosamine engineering bacterium and its construction method through homologous recombination knockout of manx

ActiveCN102286420AShort fermentation timeNo allergic reactionBacteriaMicroorganism based processesBiotechnologyEscherichia coli

The invention discloses a high-glucosamine-yield engineering bacterium and use thereof. In the invention, the gene engineering bacterium E.coli-glmS-gnal-deltanagE-deltamanX is obtained by transferring a glucosamine synthase gene (glmS) and a glucosamine acetyltransferase (gnal) into E.coli K-12 and knocking out an acetylglucosamine phosphoric acid transfer system nagE gene and a mannose phosphoric acid transfer system manX gene; the strain is used for fermenting to produce glucosamine, and has the advantages of short fermentation time, high production strength, low production cost, small environment pollution, no allergic reaction and the like; and the produced glucosamine can be widely used in fields of medicines, foods and the like.

Owner:JIANGNAN UNIV

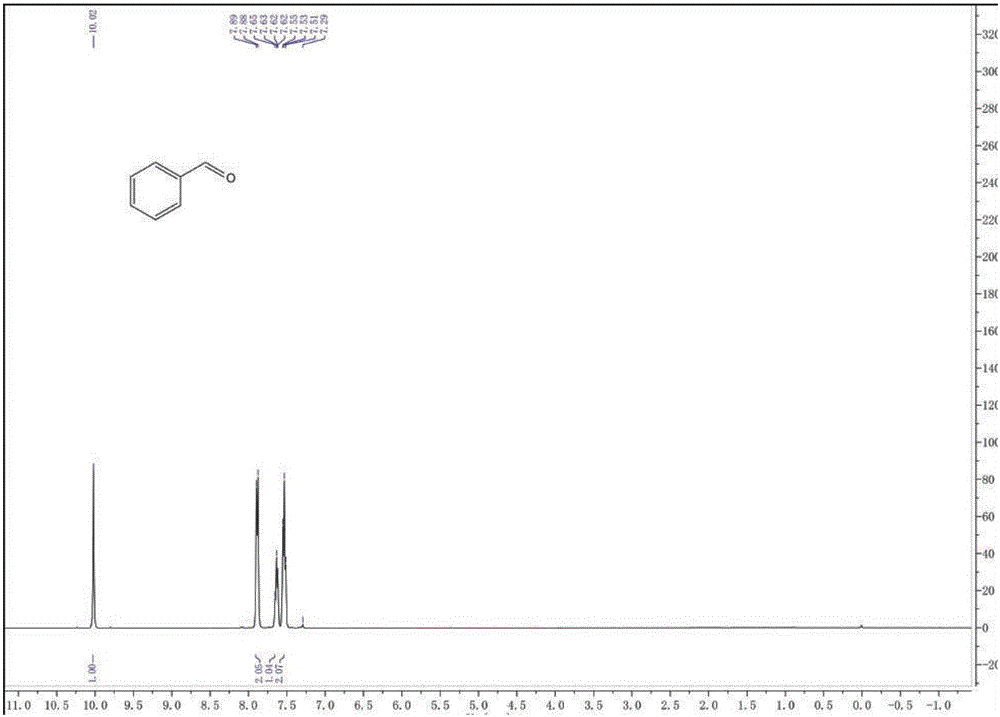

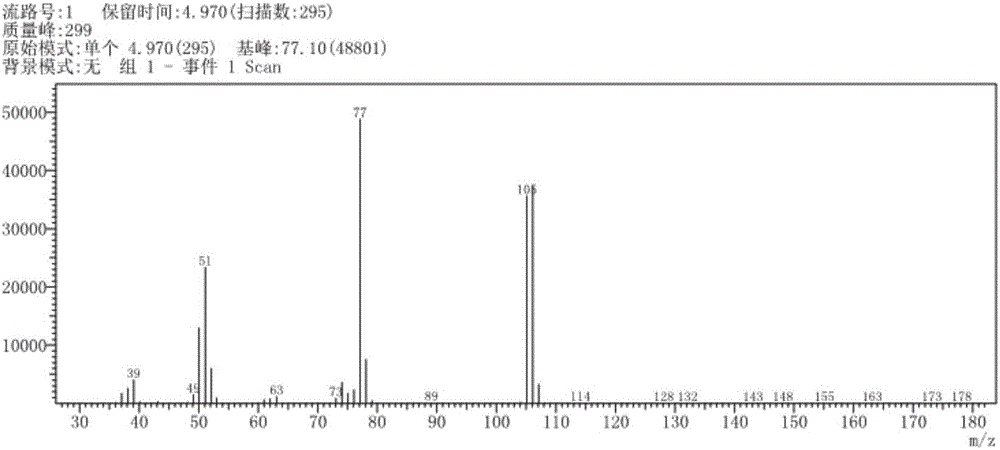

Preparation method of benzaldehyde and its derivatives

InactiveCN106748688ALow priceWide variety of sourcesOrganic compound preparationCarbonyl compound preparationBenzaldehydeMetal catalyst

The invention provides a preparation method of benzaldehyde and its derivatives. The preparation method comprises adding a catalyst and toluene or toluene homolog into a reaction system in the presence of an oxidizing agent, and carrying out a one-step reaction process to produce benzaldehyde or its derivatives, wherein the catalyst comprises a metal catalyst, an auxiliary catalyst I and an auxiliary catalyst II, the metal catalyst is a transition metal catalyst, the auxiliary catalyst I is a basic nitrogen-containing ligand, and the auxiliary catalyst II is a basic compound. The preparation method can prepare benzaldehyde and its derivatives through one-step direct oxidation of toluene, utilizes cheap raw materials having wide sources, has a fast reaction speed and high production intensity, is suitable for automatic and continuous production, does not use chlorine, is suitable for industrial production and has a good application prospect.

Owner:SUZHOU RES INST LANZHOU INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

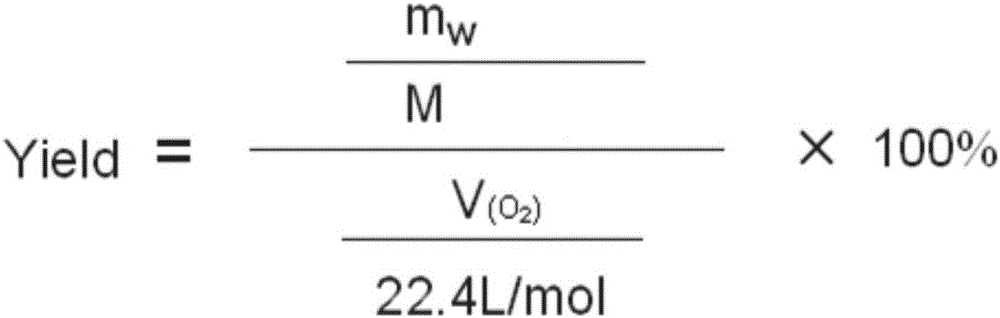

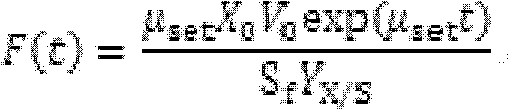

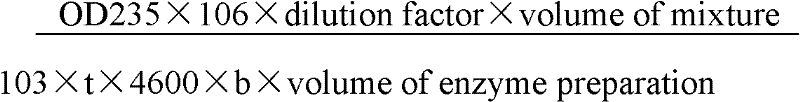

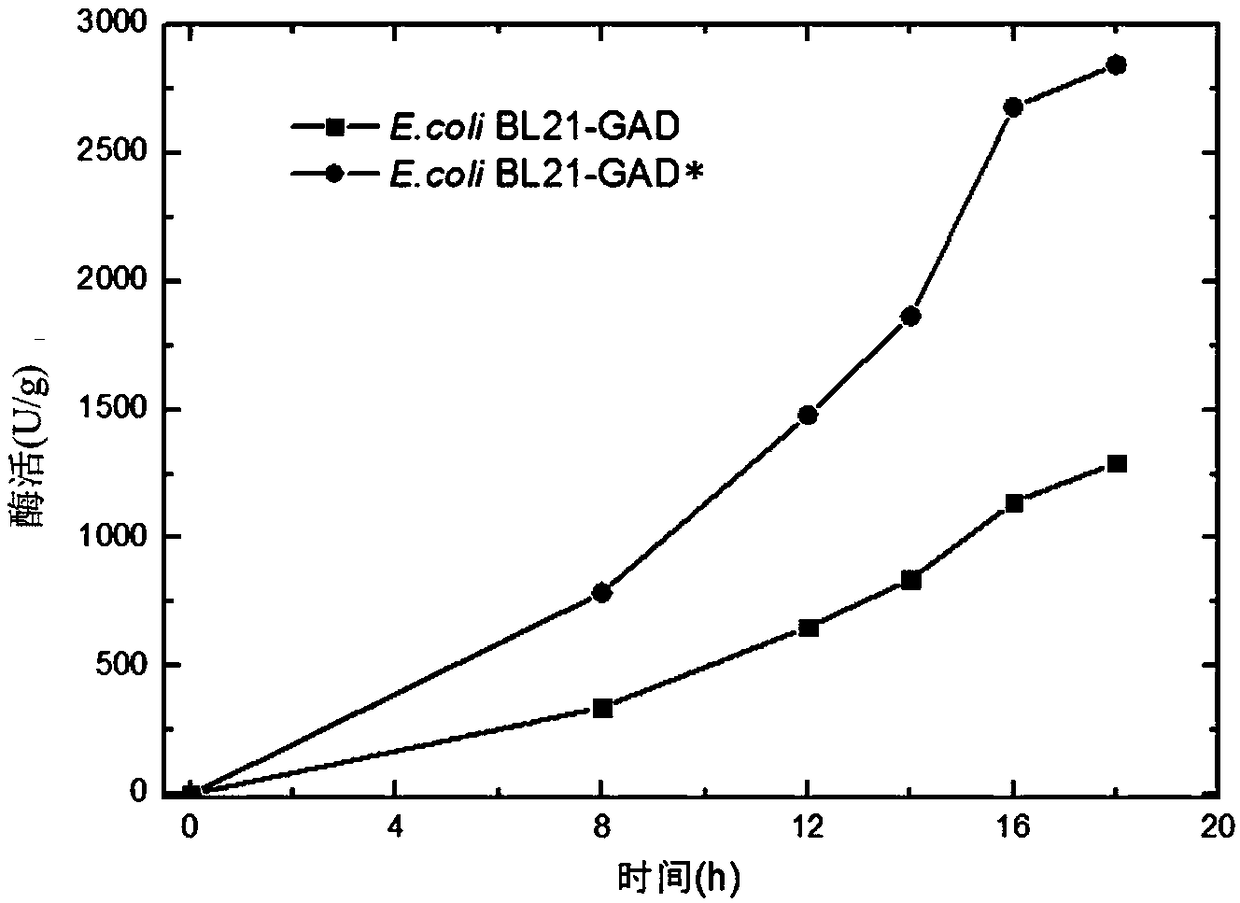

Method for producing pectinase by fermentation of recombinant Escherichia coli

InactiveCN102367437AIncrease productionIncrease production intensityMicroorganism based processesEnzymesPectinaseForeign protein

The invention provides a method for producing pectinase by fermentation of recombinant Escherichia coli, which belongs to the technical field of fermentation engineering. According to the invention, Escherichia coli BL21DE3 is used as an original strain, and a glycerin medium is fed in batches according to a certain specific growth rate. The method provided in the invention is simple and practicable, substantially improves output, production intensity and secretory expression efficiency of pectinase, is favorable for large scale industrial production, and has important significance in guiding secretory expression level of foreign proteins in other Escherichia coli expression systems.

Owner:JIANGNAN UNIV

Gene for coding glutamine dipeptide biosynthetic enzyme and application thereof

ActiveCN106754985AImprove conversion efficiencyResolve separabilityBacteriaMicroorganism based processesEscherichia coliDipeptide

The invention discloses a gene for coding a glutamine dipeptide biosynthetic enzyme and application thereof. The nucleotide sequence of the gene is shown as SEQ ID NO.1. The invention further discloses an amino acid sequence coded by the gene, and provides a recombinant vector containing the gene, recombinant escherichia coli, and a method for performing biotransformation to synthesize the glutamine dipeptide by using the gene. The gene and the application of a recombinant bacterial strain of the gene have the advantages of high mol conversion rate, high reaction speed, easy separation, low cost and the like. In the synthesis method, the maximum mol conversion rate of the glutamine dipeptide can reach 83.3 percent; meanwhile, the thalli can be applied to the catalytic synthesis of the glutamine dipeptide again after the circulation recovery; in addition, the catalytic activity is stable. Therefore high market competitive power and application values are realized; a foundation is laid for the industrial production of the glutamine dipeptide.

Owner:INNOBIO CORP LTD

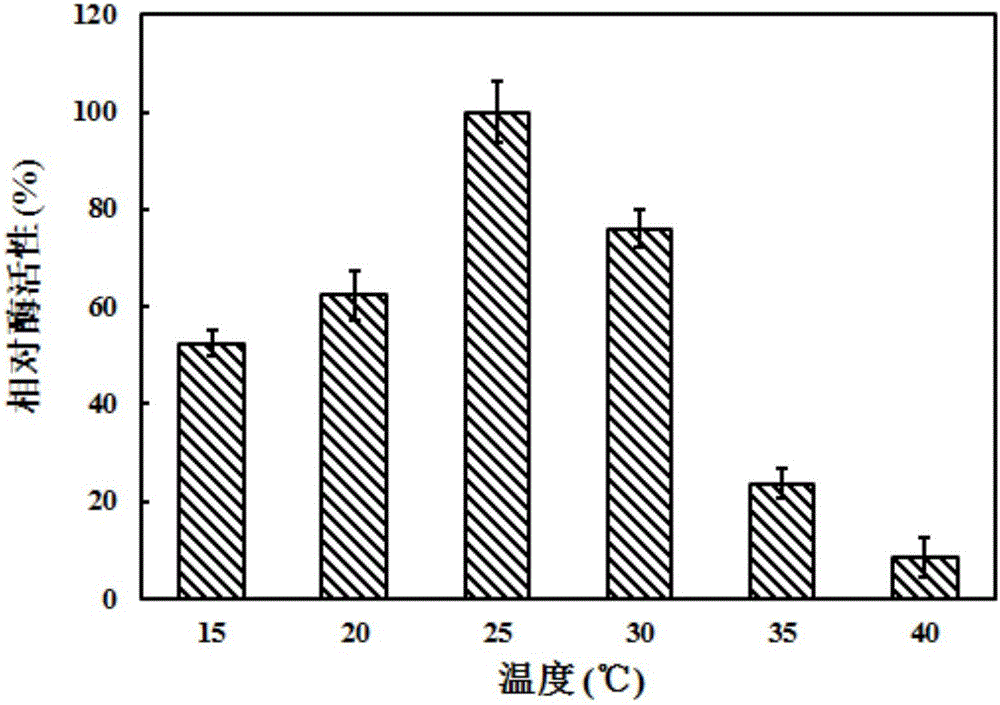

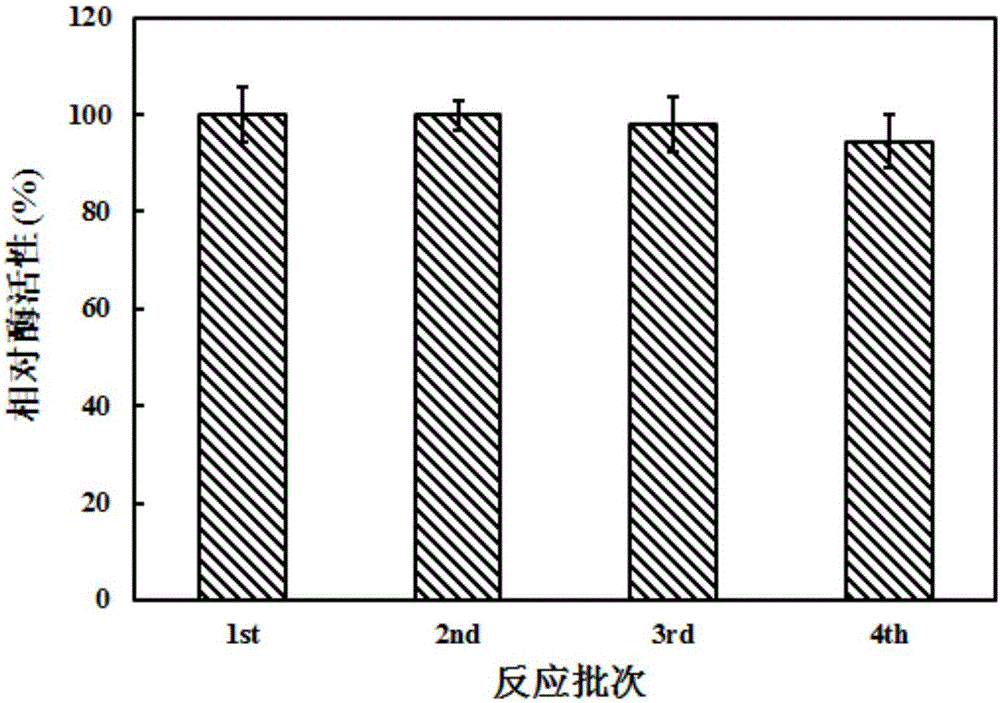

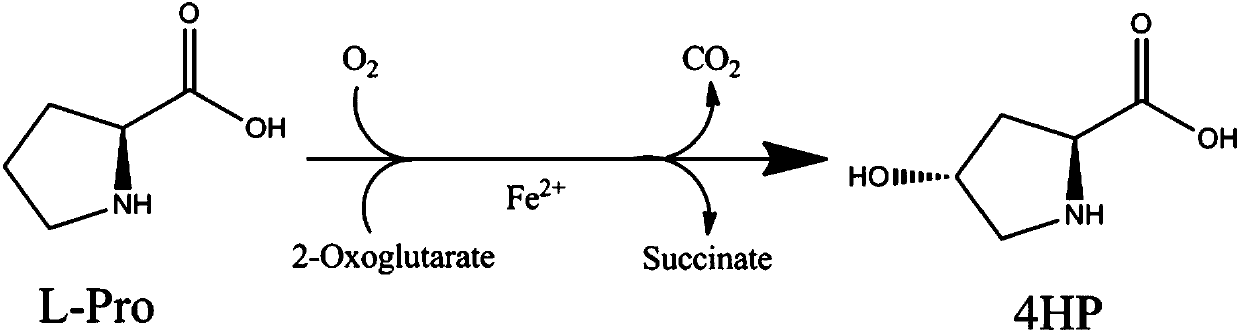

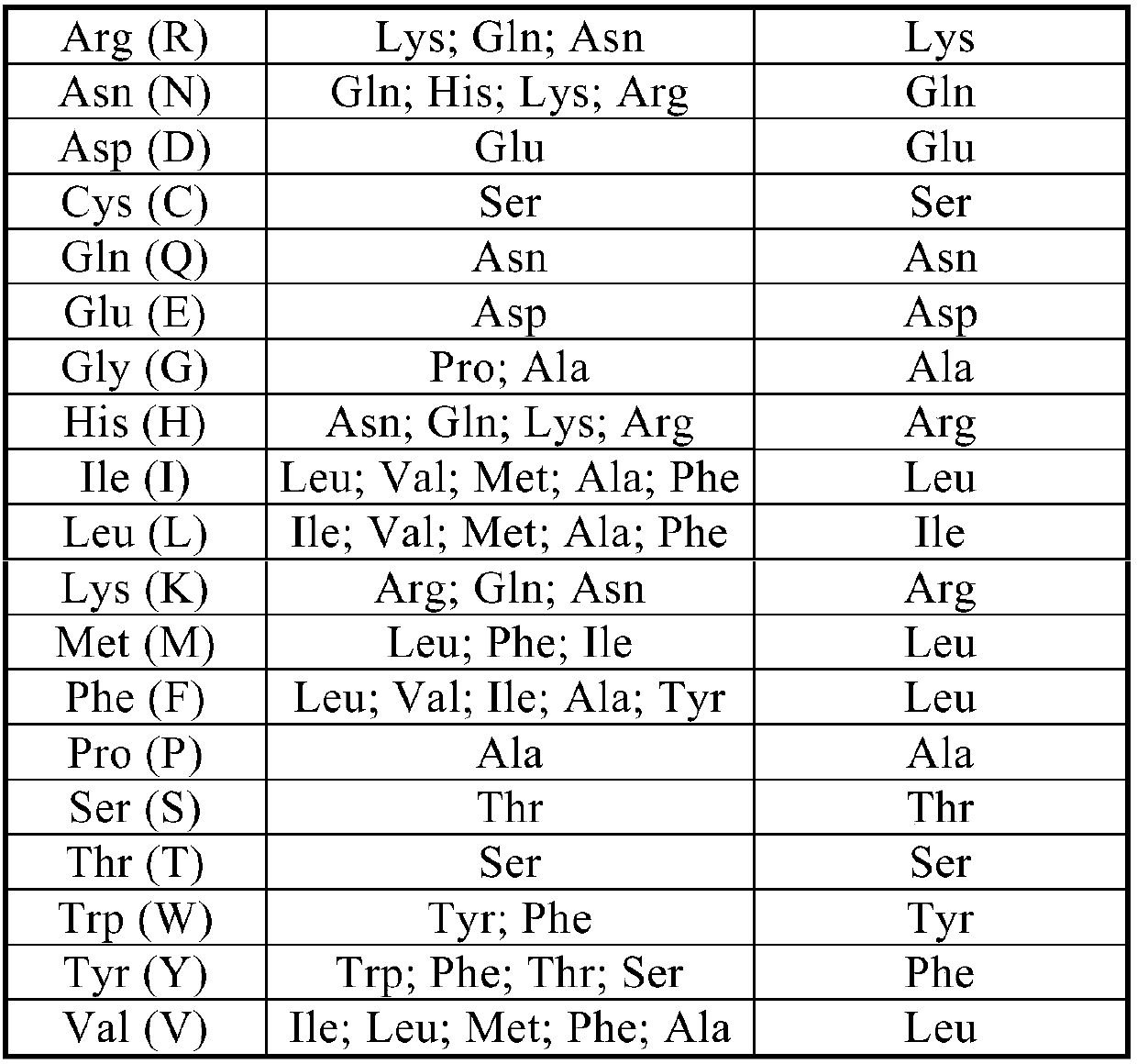

Method for producing trans-4-hydroxy-L-proline

ActiveCN107674863AActiveIncreased specific enzyme activityBacteriaMicroorganism based processesBiotechnologyTrans-4-Hydroxy-L-proline

The invention provides a method for producing trans-4-hydroxy-L-proline. Specifically, the invention provides an application of polypeptide in producing the trans-4-hydroxy-L-proline or a downstream product taking the trans-4-hydroxy-L-proline as a precursor. The invention also provides the method for producing the trans-4-hydroxy-L-proline, wherein the method comprises a step of cultivating and expressing a strain of polypeptide, so that the trans-4-hydroxy-L-proline is obtained. The invention also provides a trans-4-hydroxy-L-proline producing strain and a construction method of the trans-4-hydroxy-L-proline producing strain. With the application of the method provided by the invention, the efficient production of the trans-4-hydroxy-L-proline with low cost is achieved.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method adding trehalose to strengthen production strength of 2-keto-L-Gulonic acid

InactiveCN101654695ASpeed up consumptionIncrease production intensityMicroorganism based processesFermentationGluconic acidTrehalose

The invention discloses a method adding trehalose to strengthen production strength of 2-keto-L-Gulonic acid, belonging to the technical filed of ferment preparation of vitamin C. The invention takesthe mixing strain of Ketogulonigenium vulgare and Bacillus megaterium as a production strain, and 10mmol.L<-1> of trehalose is exogenously added into fermentation culture medium to be used as protective agent, therefore, the cell growth and production of 2-keto-L-Gulonic acid (2-KLG) are promoted, and the efficient production of 2-KLG is realized. When 10mmol.L<-1> of trehalose is added under a hyperosmotic condition (1067.5mOsmol.kg<-1>), the content of 2-KLG is 56.83g.L<-1> at 72h, which is 1.94 times of the content of 2-KLG of a matched group that adds no trehalose under the hyperosmotic condition, wherein the content of 2-KLG of the matched group is 29.24g.L<-1>. When 10mmol.L<-1> of trehalose is added under a normal fermentation condition adding no NaCl, the fermentation period is shortened to 52h, the end point acid production is up to 69.38g.L<-1>, and the consumption speed of L-sorbose and the production intensity of 2-KLG are respectively increased by 43.1% and 45.5%.

Owner:JIANGNAN UNIV

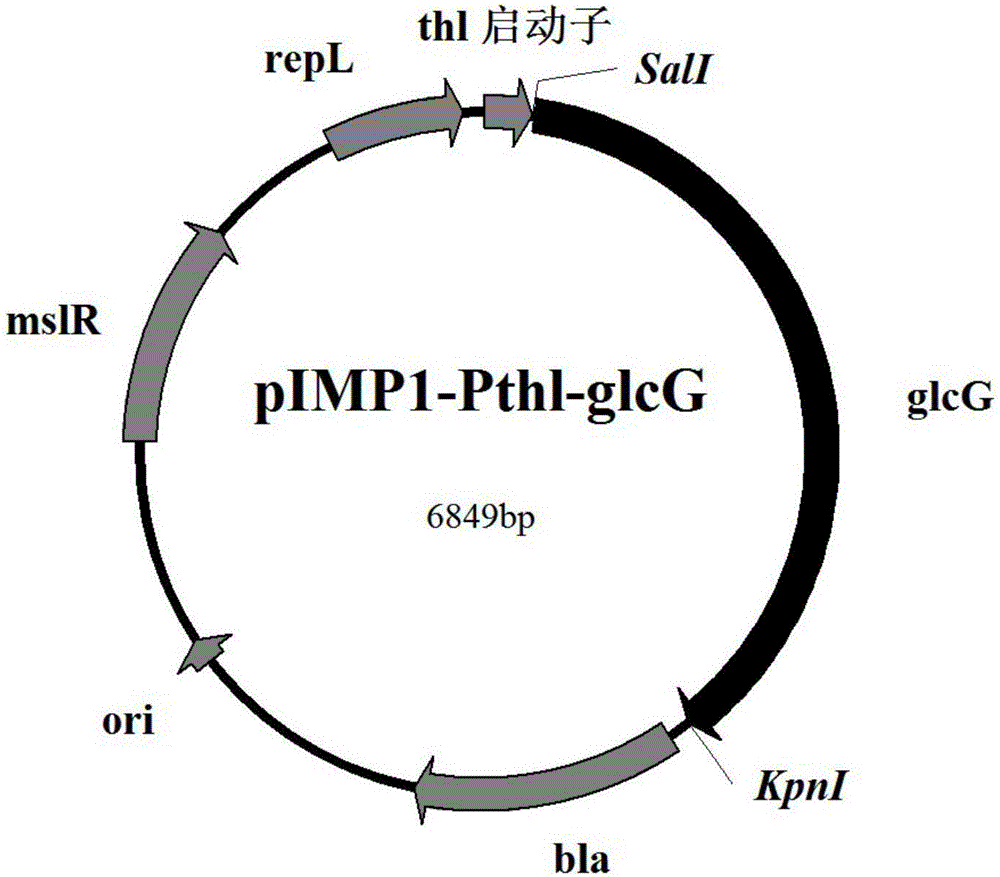

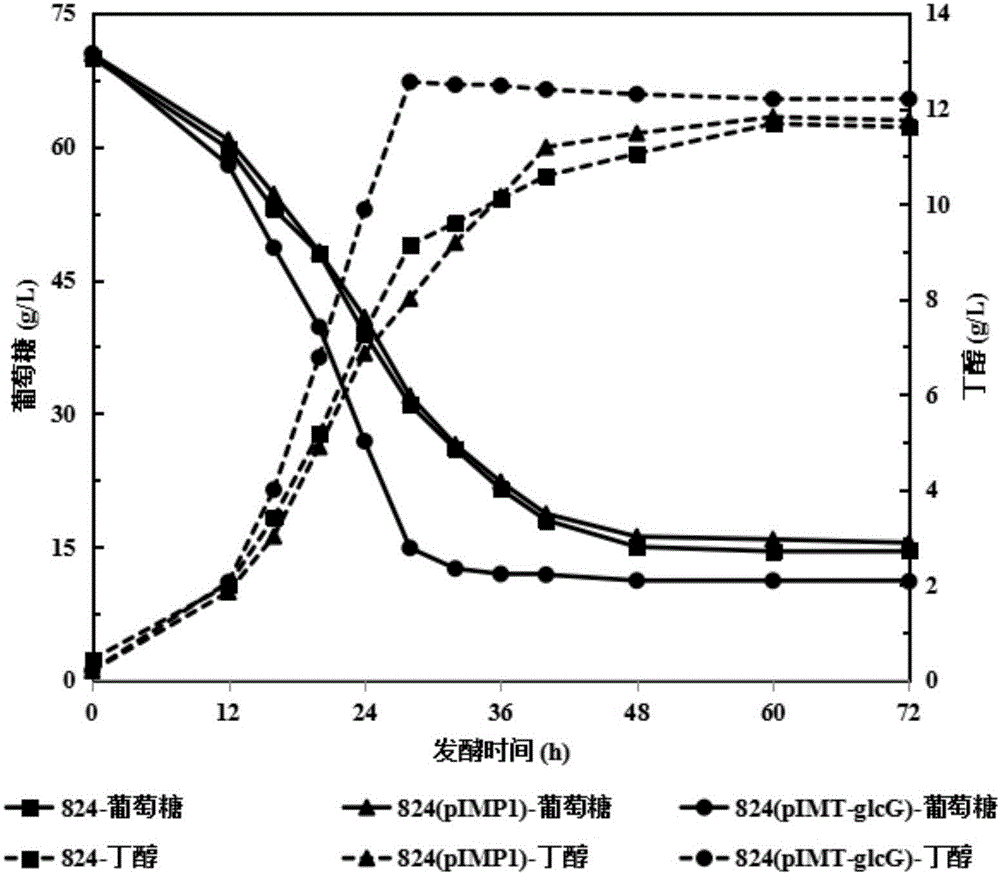

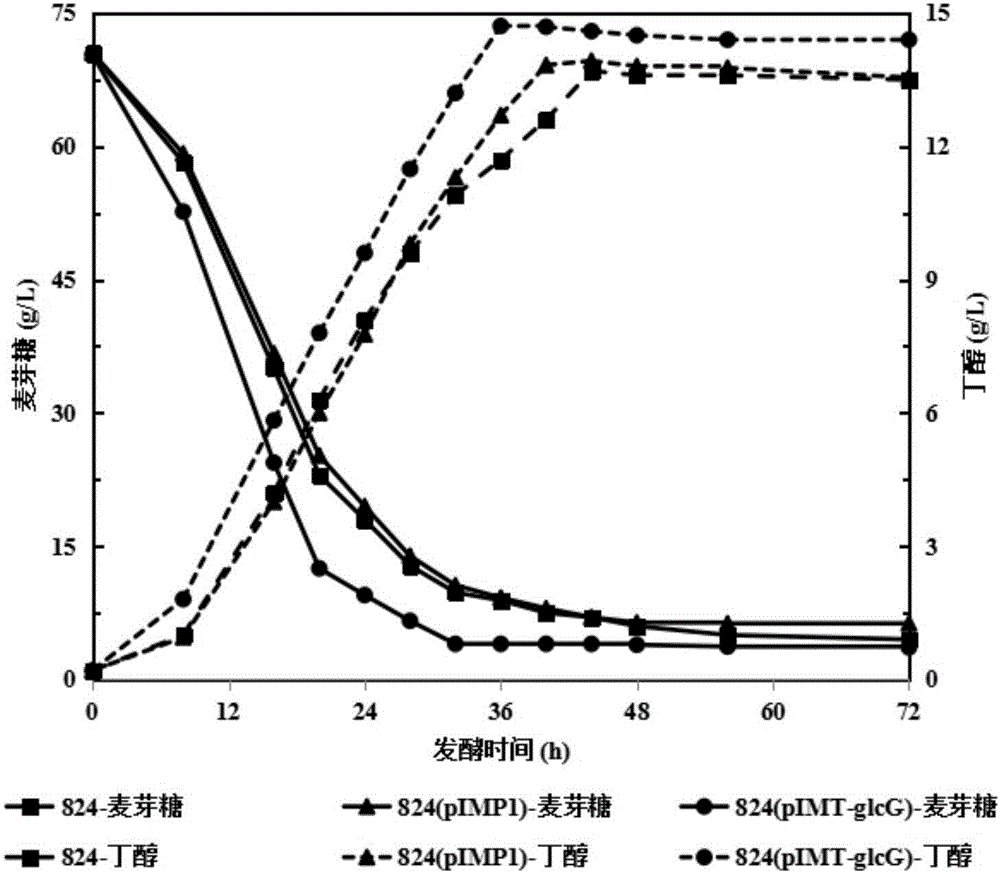

Recombinant clostridium for efficiently producing butanol, and construction method and application of recombinant clostridium

ActiveCN106399215AImprove utilization efficiencyIncrease production intensityBacteriaBiofuelsGlucose polymersD-Glucose

The invention discloses clostridium capable of improving the utilization efficiency and the production intensity of butanol fermentation glucose maltose, and a construction method and application of the lostridium, and belongs to the technical field of biochemical industry. The clostridium comprises a glcG gene with the sequence being SEQ ID NO.1; the amino acid sequence of protein GlcG encoded by the glcG gene is SEQ ID NO.2. The construction method of the clostridium comprises the following steps: (1) constructing a glcG gene overexpression recombinant plasmid; (2) constructing a glcG gene overexpression recombinant bacterial strain; and (3) detecting the fermentation performance of the recombinant bacterial strain butanol. The invention also provides application of the clostridium capable of improving the utilization efficiency and the production intensity of butanol fermentation glucose maltose to production of butanol. The glcG gene is overexpressed in C.acetobutylicum ATCC 824, so that the utilization efficiency of the glucose maltose and the production intensity of the butanol can be obviously improved.

Owner:DALIAN UNIV OF TECH

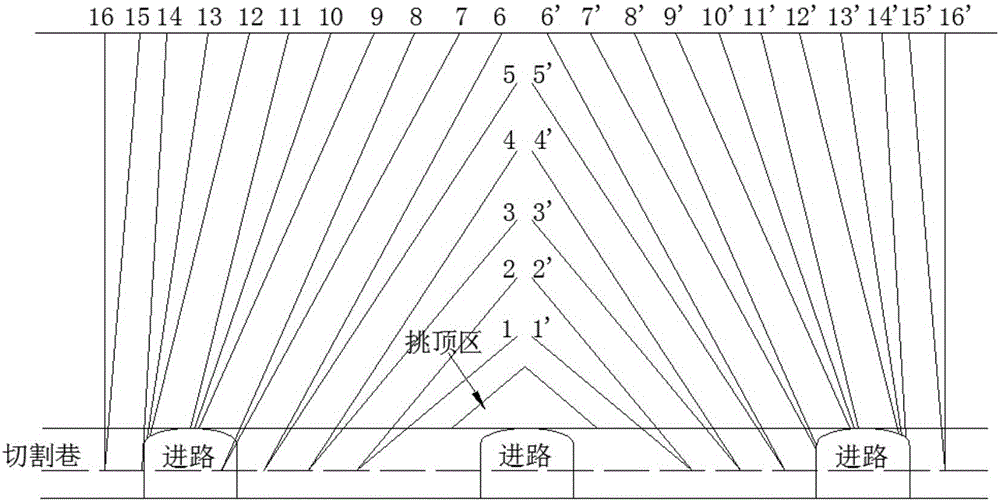

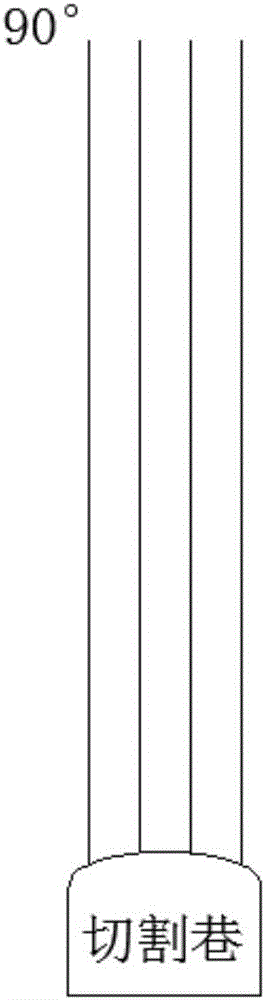

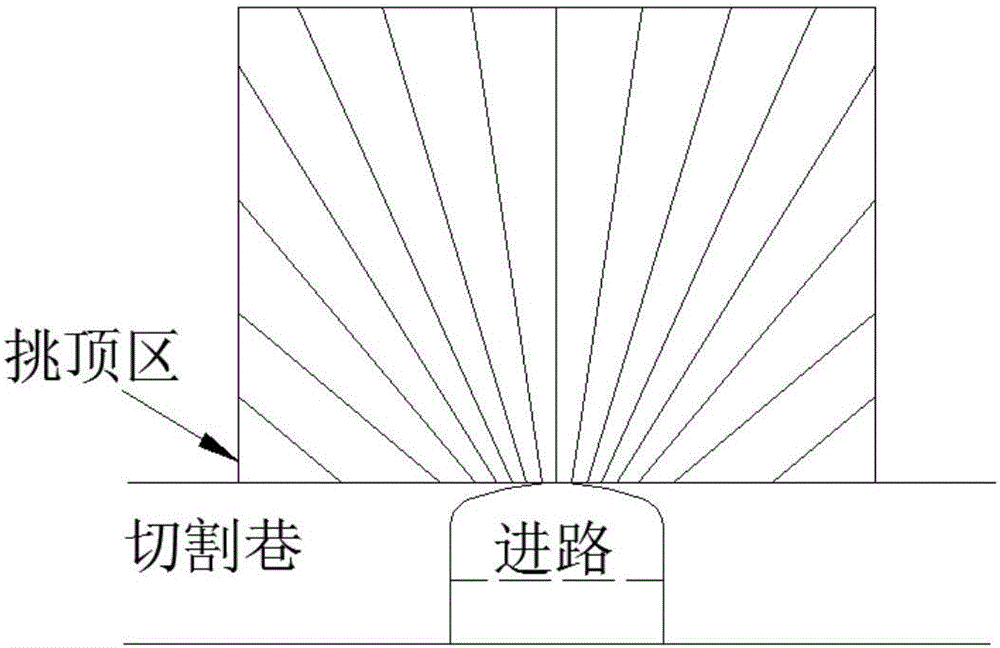

Super-high diagonal symmetric forced grooving method without grooving well

ActiveCN106247877AIncrease production intensityReduce cutting ratioBlastingEngineeringBilateral symmetry

The invention discloses a super-high diagonal symmetric forced grooving method without a grooving well, and belongs to the field of underground mining. The method includes the steps of 1, according to stope conditions, carrying out construction and completing construction of an extracted ore drift, a cutting roadway, a linked roadway and a gathering trench to form a stope; 2, carrying construction on the middle of the cutting roadway to form a roof cutting area, wherein the roof cutting area is a triangular area; 3, determining drilling construction sites at the bilateral symmetry positions of the roof cutting area of the cutting roadway through a drilling trolley, wherein drilling is carried out in the drilling construction sites according to forward inclination angles of blast hole row surfaces, the forward inclination angles are 40-88 degrees relative to the horizontal plane, and horizontal dip angles of the blast hole row surfaces from the middle to the two sides are gradually increased; and 4, after drilling is completed, carrying out filling to form a blast hole filling area, carrying out blasting sequentially according to the blast hole row surfaces, blasting the blasting holes in two symmetric hole sites each time, then carrying out blasting continuously and withdrawing ore through blasting. The method has the advantages that the sub-section height of the stope is large, the cost is low and the safety risk is low.

Owner:安徽马钢罗河矿业有限责任公司

Gene engineering bacterium for producing glucosamine and application thereof

ActiveCN102071164AShort fermentation timeNo allergic reactionBacteriaMicroorganism based processesGlucosamine SynthetaseBacterial strain

The invention discloses a gene engineering bacterium for producing glucosamine and application thereof. The gene engineering bacterium is the gene engineering bacterium E.coloK-12-glms which is obtained by introducing the gene (glms) of glucosamine synthetase into Escherichia coli E.coliK-12. The bacterial strain is used for producing the glucosamine by fermentation, and has the advantages of short fermentation time, high productivity, low production cost, environmental friendliness, no anaphylactic reaction and the like; and the produced glucosamine can be widely applied to the fields of medicine, food and the like.

Owner:JIANGNAN UNIV

Reaction apparatus for resorcinol neutralization reaction section and reaction technology thereof

ActiveCN102329253ASimple structureLow costOrganic compound preparationFlow mixersBenzenePhysical chemistry

The invention which discloses a reaction apparatus for the resorcinol neutralization reaction and a reaction technology thereof relates to a continuous application of a mixer in a resorcinol neutralization reaction section, and concretely relates to a continuous application of a static mixer in the resorcinol neutralization reaction section, so problems of high energy consumption, a large amount of solid wastes and the like existing in present production processes of m-benzene sodium disulfonate can be solved. The reaction technology comprises the following steps: conveying m-benzene disulfonic acid and a liquid alkali to the static mixer through a metering pump; carrying out the neutralization reaction; and carrying out heating and water evaporation on a generated material with heat generated in neutralization to directly form m-benzene sodium disulfonate which has a powder form at a high temperature and is used for an m-benzene sodium disulfonate alkali fusion section. According to the invention, the acid-base neutralization and drying are synchronously carried out, the drying speed is fast, and drying is complete, so a purpose of the continuous production is realized, and simultaneously the energy utilization rate is improved and the generation of the solid wastes is reduced.

Owner:JIANGSU ZHONGDAN CHEM TECH

Marsh gas engineering inoculum and preparation method thereof

ActiveCN104805125AIncrease productionHigh yieldBacteriaGas production bioreactorsMicroorganismMixed culture

The invention discloses a marsh gas engineering inoculum and a preparation method thereof, and aims to solve the problems of low anaerobic fermentation speed, long fermentation period and poor marsh gas engineering gas productivity and engineering running efficiency in the conventional marsh gas engineering. Organic waste sludge or biogas slurry is taken as a raw material, and a special marsh gas engineering inoculum is prepared through mixed culture and a fixed anaerobic fermentation microbial flora according to an anaerobic fermentation principle and a microbial ecology principle. Compared with the prior art in which an inoculum is prepared by culturing single strains respectively and mixing proportionally, the preparation method has the advantages that the inoculum is prepared through mixed culture of sludge or biogas slurry is stable in micro-ecology; moreover, the marsh gas engineering fermentation period can be remarkably shortened, the marsh gas yield is increased, and the marsh gas engineering economical benefit is increased.

Owner:马力通

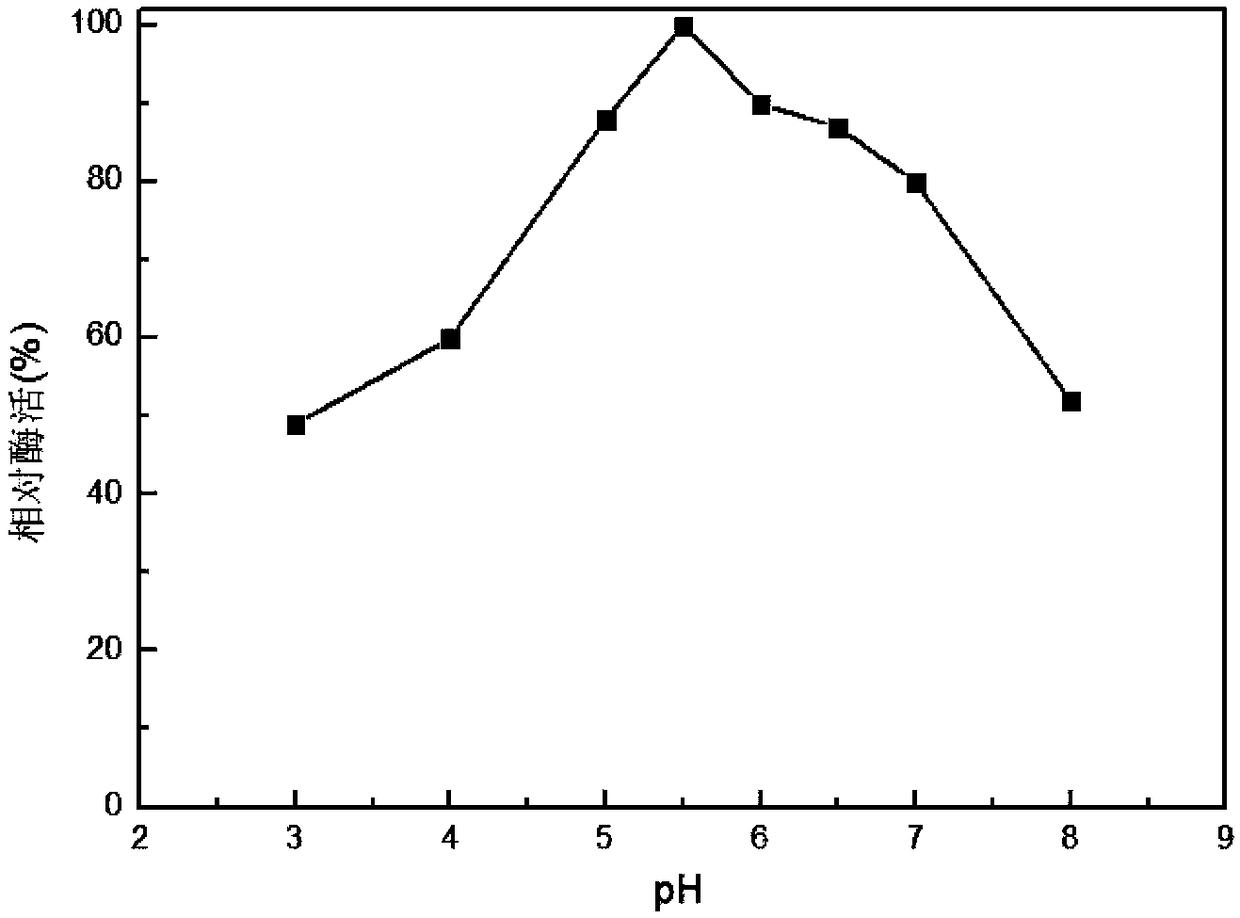

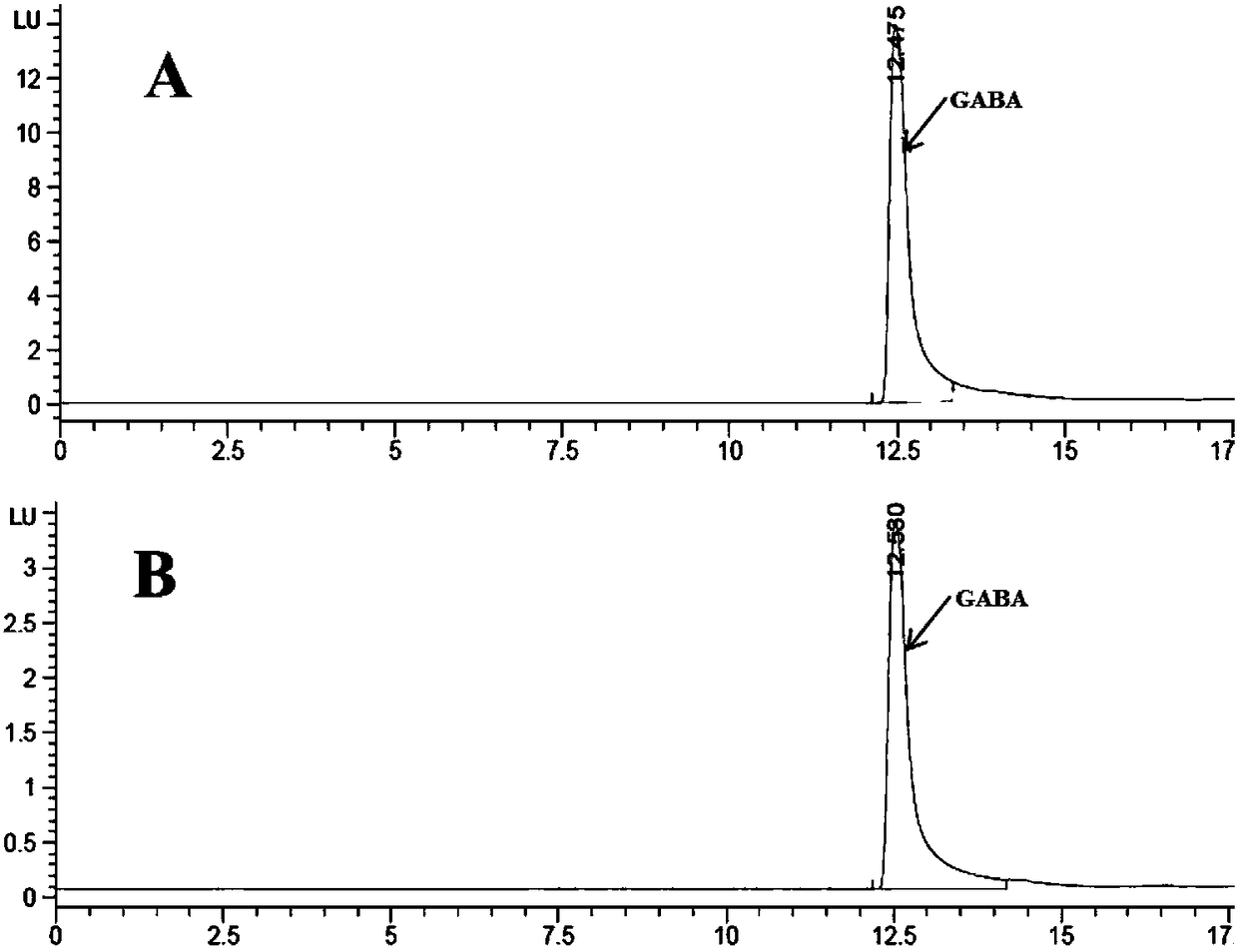

Method for producing gamma-aminobutyric acid with high yield

ActiveCN108467860AIncreased enzyme activityImprove stabilityBacteriaMicroorganism based processesBacillus megateriumGlutamate decarboxylase

The invention discloses a method for producing gamma-aminobutyric acid with a high yield, and belongs to the technical field of bioengineering. Glutamic acid decarboxylase derived from Bacillus megaterium is modified by protein engineering, and a modified glutamic acid decarboxylase gene is linked to a pET24a vector, and is epressed in E. coli BL21 (DE3). A recombinant strain is cultured in a fermenter for transforming glutamic acid to produce the gamma-aminobutyric acid, the wet cell addition amount is 7.0g / L, the transformation period is 8h, the yield can reach 425.0g / L, and the glutamic acid molar conversion rate is up to 99%, the space time yield of the gamma-aminobutyric acid is 53.1 g / L / h.

Owner:JIANGNAN UNIV +1

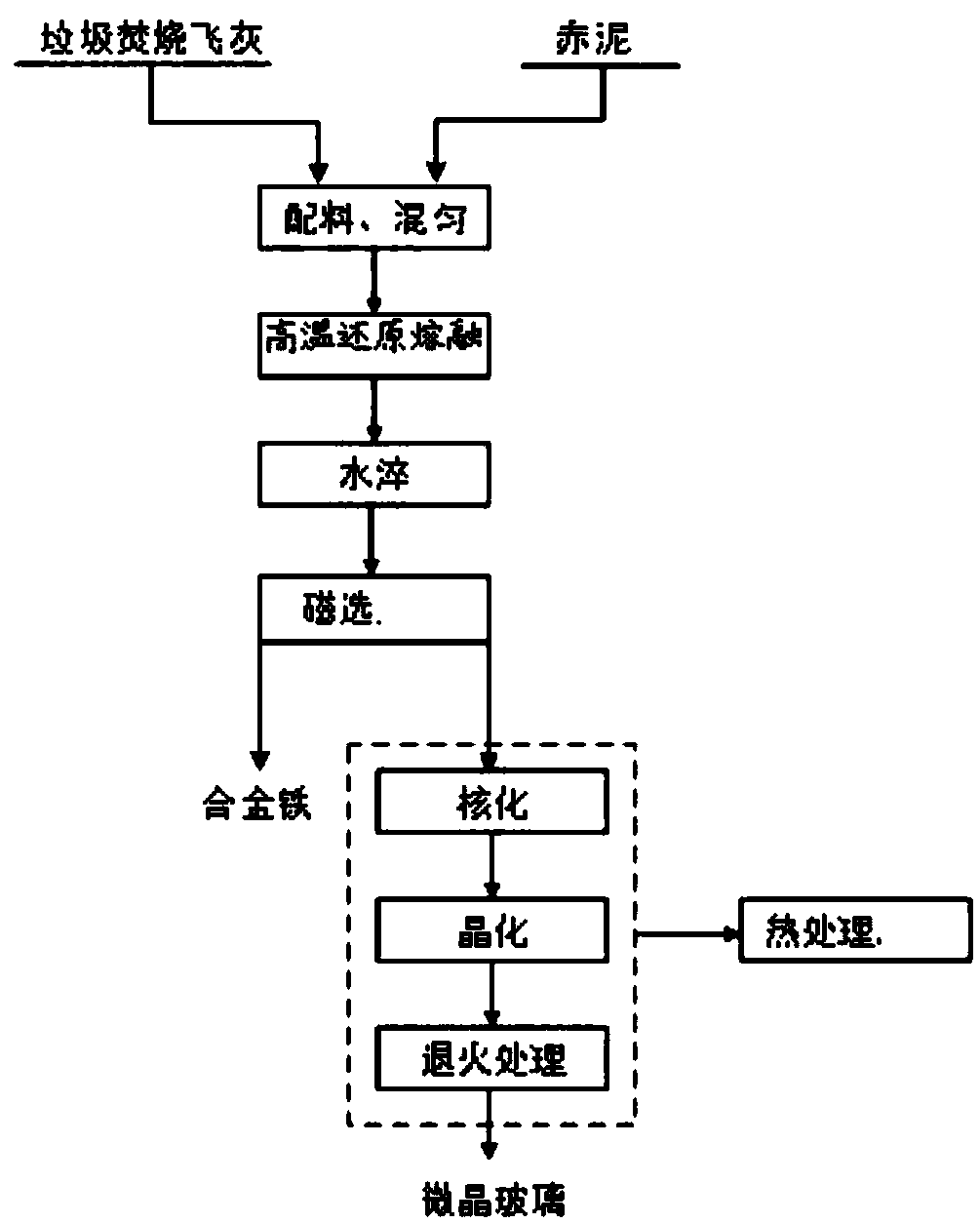

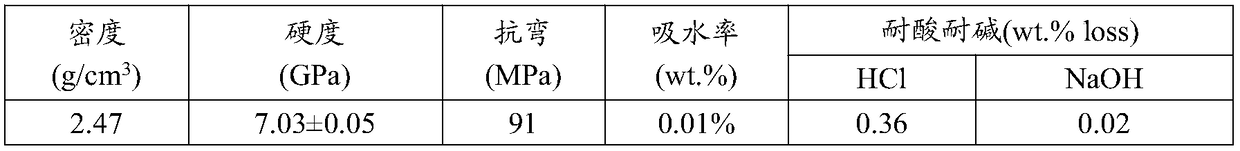

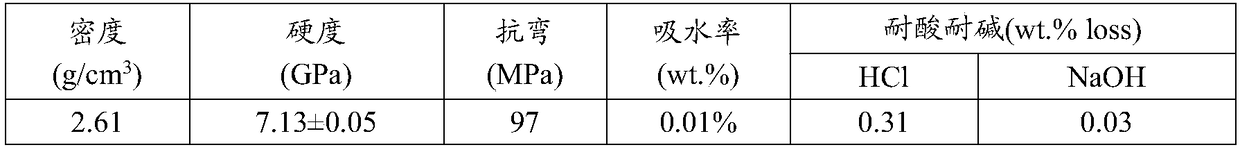

Method for preparing alloy iron and glass ceramics

The invention provides a method for preparing alloy iron and glass ceramics, and belongs to the field of solid waste recycling. The method is characterized in that a syneryistic effect between carbon,calcium and heavy metal components in waste incineration fly ash, and iron, aluminum, silicon and titanium main components in red mud is efficiently utilized, so that alloy iron and glass ceramics can be finally obtained, and therefore, waste is treated with waste, to-be-treated important hazardous wastes of waste incineration fly ash and red mud, and bulk industrial solid waste are recycled andcomprehensively utilized, a resource comprehensive utilization rate is increased, resource-saving type society is favorably established, a higher economic value can be realized, an alloy iron productis obtained through high-temperature reductive smelting and thermal treatment, and the alloy iron product is higher than iron concentrate in price; the alloy iron product contains trace elements suchas Ni and Cu, and has a higher value than that of a directly reduced iron product; and the obtained glass ceramic is better and more excellent in comprehensive performance as a small amount of titanium oxide and heavy metal is contained.

Owner:TSINGHUA UNIV

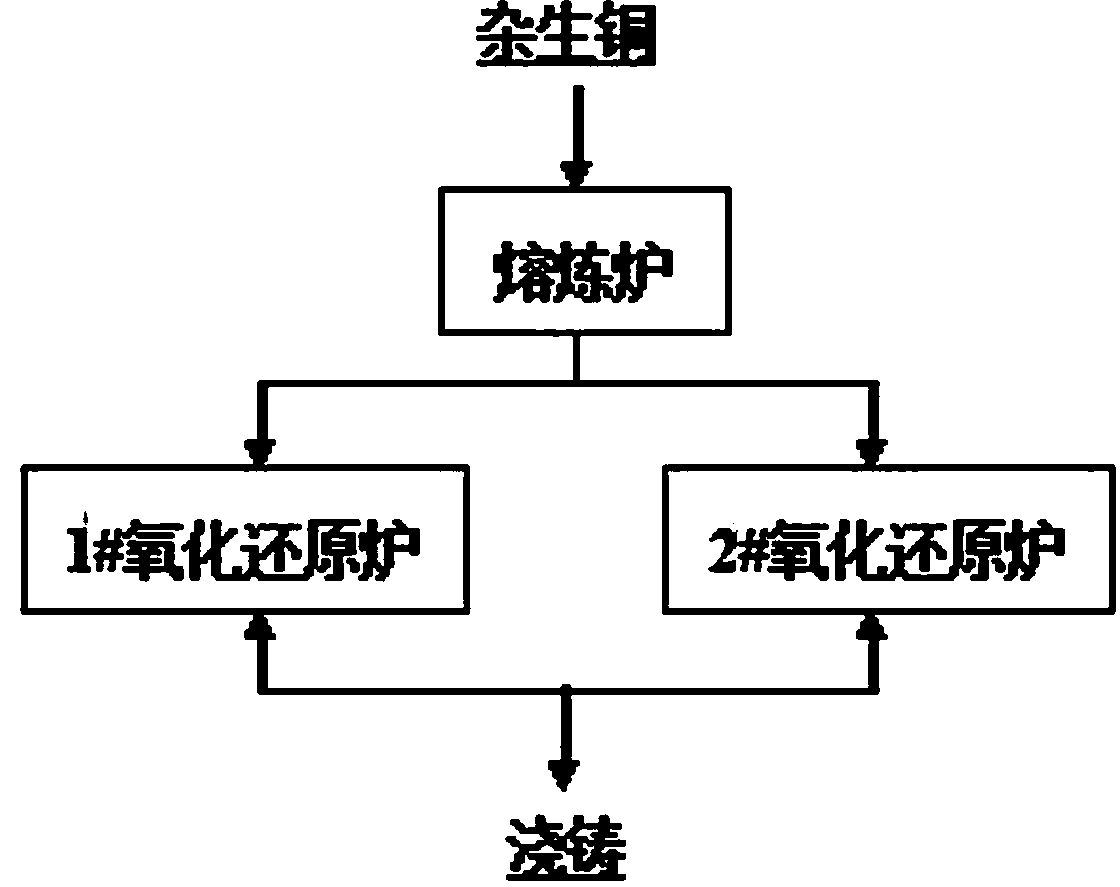

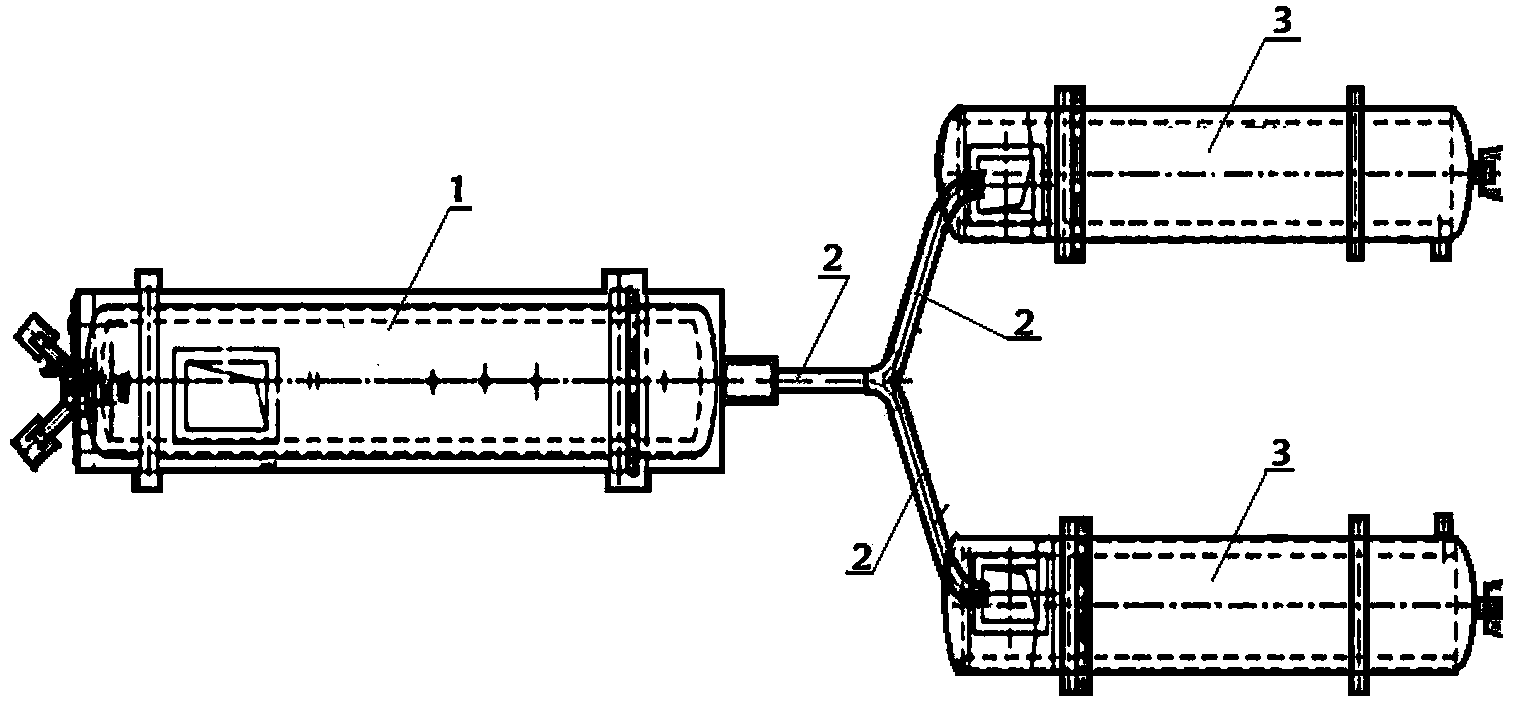

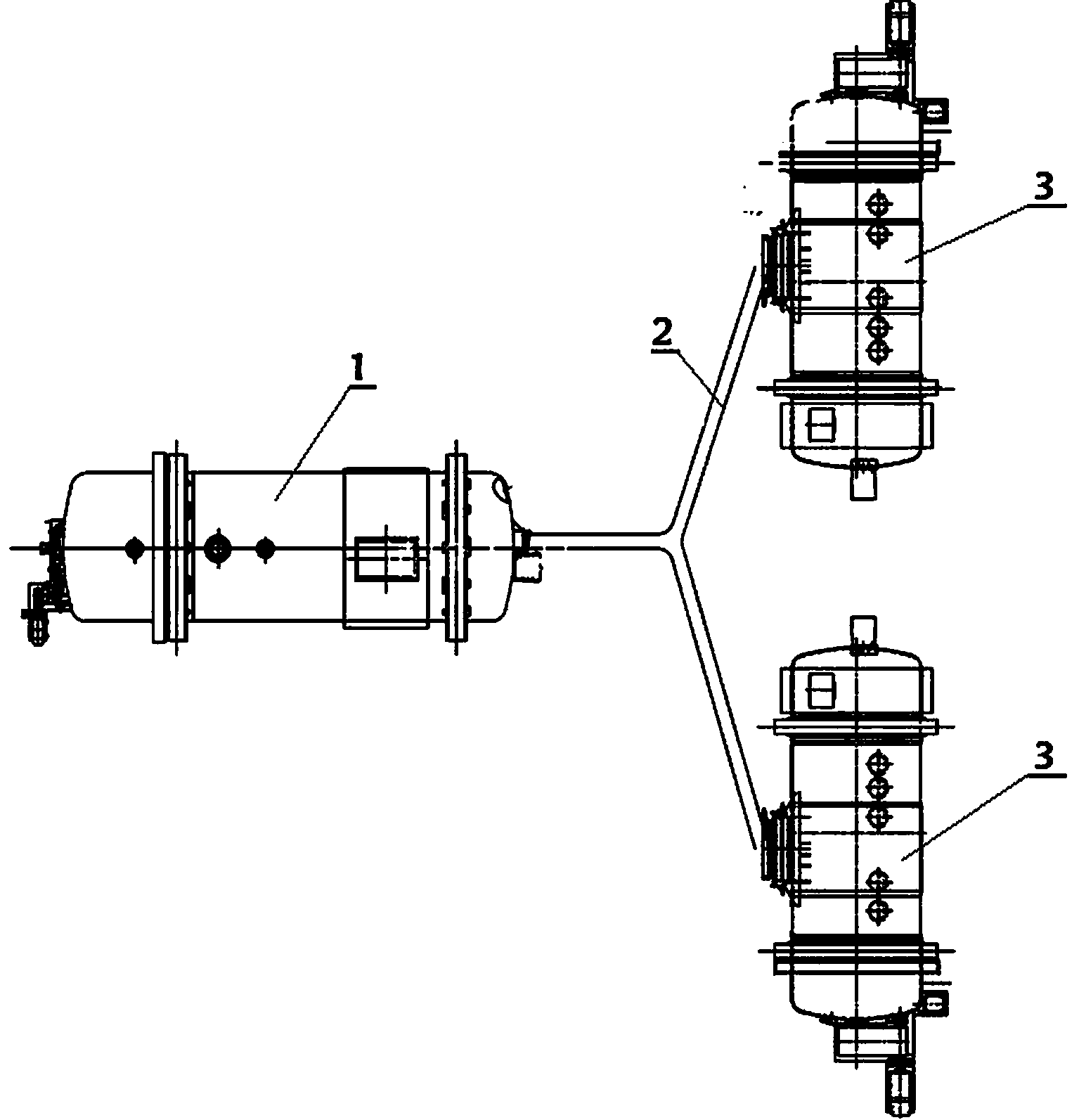

Reclaimed copper smelting process and device

ActiveCN103382529AIncrease production intensityImprove efficiencyProcess efficiency improvementShort cycleSmelting process

The invention provides a reclaimed copper smelting process and a device. The process device is composed of a smelting furnace and two parallelly arranged redox furnaces, which are in connection with two branch chutes through a main chute. The three furnaces are arranged in the shape of the Chinese character ''pin''. A furnace body consists of a feed inlet, a flue gas outlet, a copper matte outlet, a slag notch, a side wall jack on a furnace body lateral part and a spray gun jack at the furnace body bottom. The slag notch is located at the furnace body end face, the copper outlet is located on the furnace body end face at the slag notch end or the lower part of the furnace body. The furnace body is cylindrical and rotatable. The furnace body has a round cross section and its radial dimension is consistent in the axial direction of the furnace body. The spray gun is in a casing pipe form, and is inserted into the spray gun jack so as to spray oxygen and natural gas into the furnace at the same time. The included angle alpha between the opening direction of the spray gun and the vertical direction is greater than or equal to -65 degrees and smaller than or equal to +65 degrees. The process and the device involved in the invention have the advantages of high production intensity, high efficiency, short cycle, energy saving and environmental protection, and good economic benefits.

Owner:DONGYING FANGYUAN NONFERROUS METALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com