Unified-modulus combined interlocking building block combination and method for building energy-saving and anti-seismic house

A block and interlocking technology, applied in earthquake-proof, construction, building components, etc., can solve the problem of ignoring the unified modular opening and interlocking method of blocks, failing to reflect, and failing to truly reflect the vertical seismic principle of interlocking blocks, etc. problems, to achieve the effect of automatic management and operation of the machine, energy saving and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

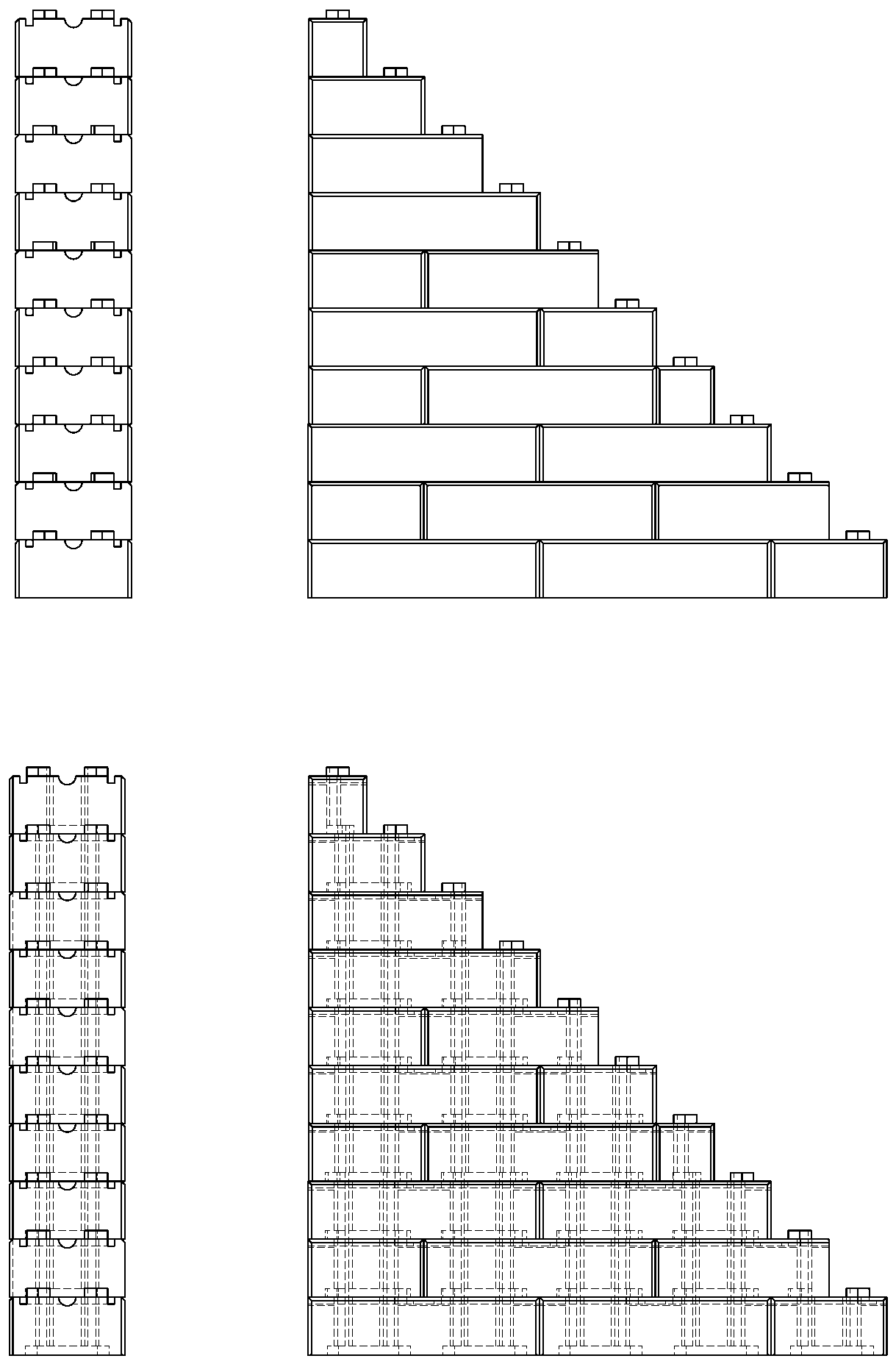

[0075] Such as image 3 , 4 As shown, a combination of interlocking blocks with uniform modulus, including the following blocks:

[0076] The main block K1 is 400mm, 200mm, and 100mm in length, width, and height, respectively, and includes two rows of eight male locking tenons 1, two recessed locking table holes 2 at the bottom, and openings extending between the nearest pairs of convex locking tenons on both sides. The dovetail groove 3, the cross-shaped through-hole 4 is set between the four convex lock tenons in the middle, the convex lock tenons on the surface of the block and the outer wall are provided with tension rib grooves 10, the block chamfers 11, the block chamfers 12, and the center Threading hole 17;

[0077]The main block K2 is 1 / 2 the length of the main block K1, and the block shape is half of the disconnected length of the main block K1;

[0078] The main block K3 is 3 / 4 of the length of the main block K1, including six convex locking tenons, among which f...

Embodiment 2

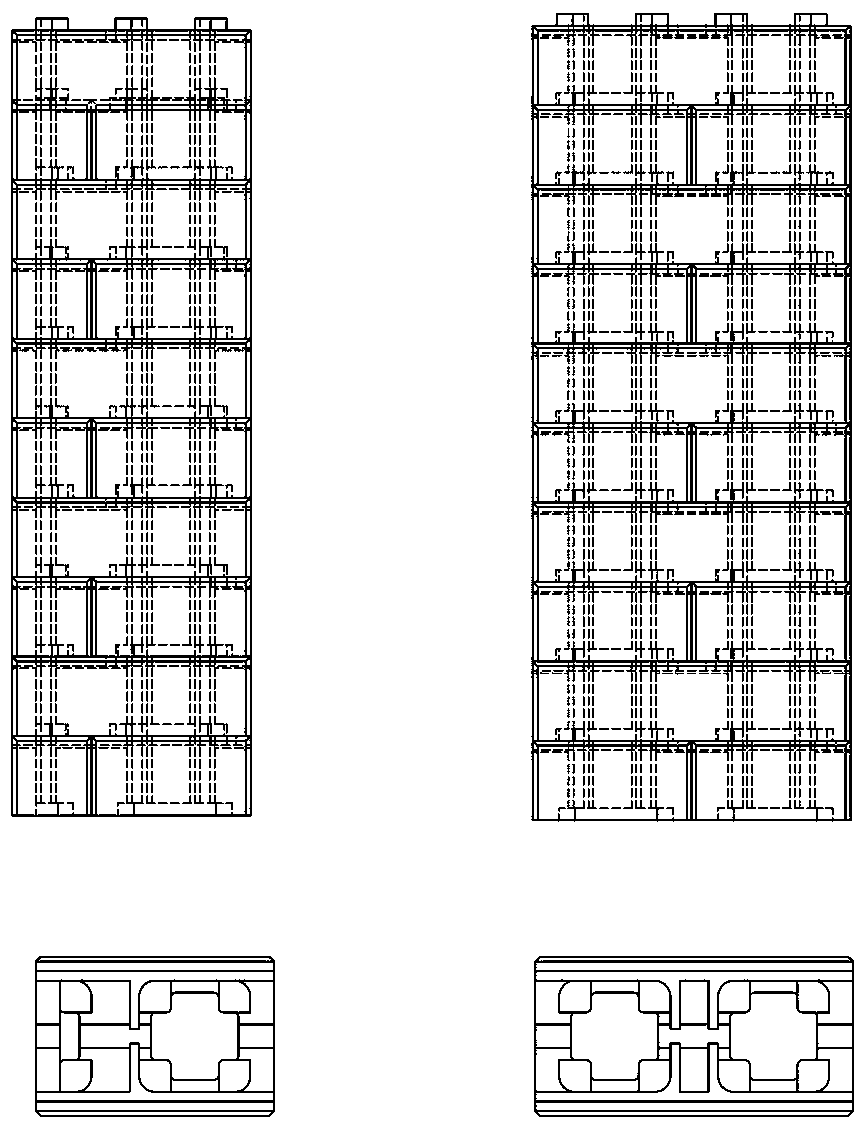

[0090] Such as Figure 5 , 6 As shown, compared with Embodiment 1, the main block K1 described in this embodiment is provided with a cross hole 4 between every four convex lock tenons, a total of two cross holes; the main block K3A will be the main block K1 3 / 4 after a cross hole is disconnected along the center; there is no main block K5; the main block K6 is a combination of the main block K1 and the main block K2 along the length direction.

Embodiment 3

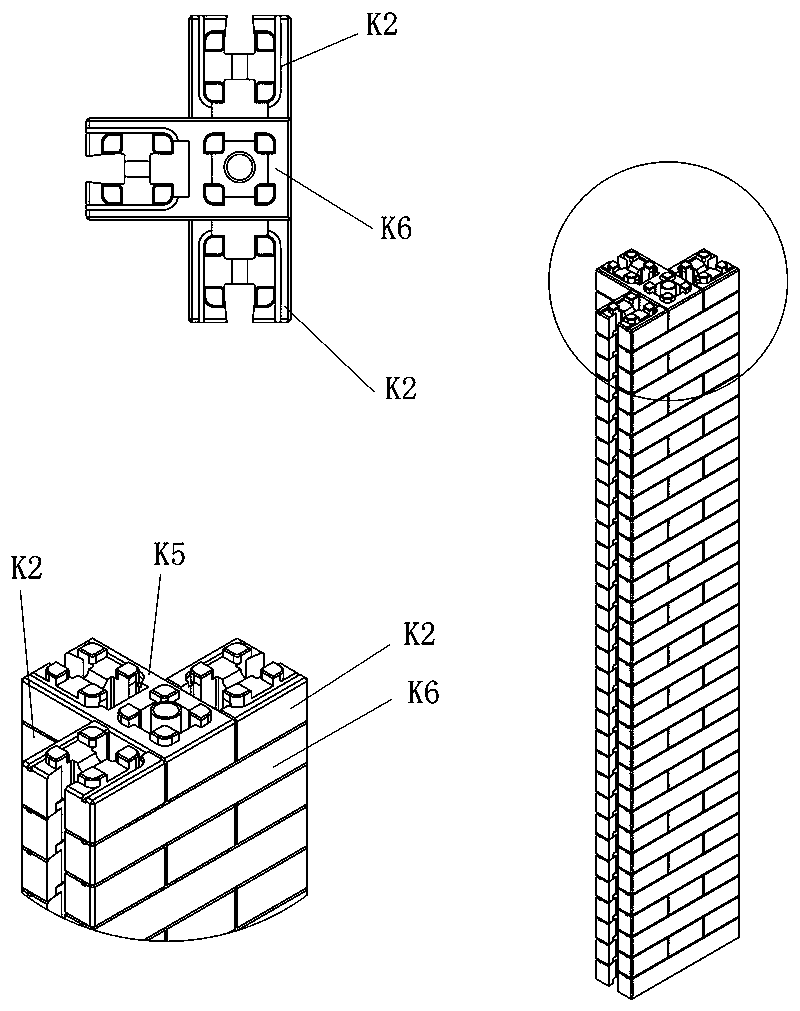

[0092] Such as Figure 7 , 8 As shown, the main block K1 has a length, width, and height of 400 mm, 200 mm, and 100 mm, respectively, and two circular protruding lock tenons 8 are arranged on the top, and node tension rib grooves 10 are arranged on the surface of the block around the protruding lock tenons. Two recessed lock table holes 2 are arranged at the bottom, and each circular protruding lock tenon corresponds to a recessed lock table hole, and a circular through hole penetrating up and down is provided; the length of the main block K2 is half that of the main block K1, including four There are two convex lock tenons, a corresponding concave lock table hole is set at the bottom, and a cross-shaped through hole is set between the four convex lock tenons; the length of the main block K3 is 3 / 2 of the main block K2, and the block shape is half of K2 and K2 The main block K3A is the same size as the main block K3, including six convex lock tenons, among which four convex l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com