Production process for preparing calcium oxide and sulfur dioxide by decomposing ardealite

A sulfur dioxide, production process technology, applied in the fields of calcium/strontium/barium oxide/hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of low comprehensive utilization of phosphogypsum waste residue, and achieve the reduction of production equipment specifications , save engineering investment, and improve the effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

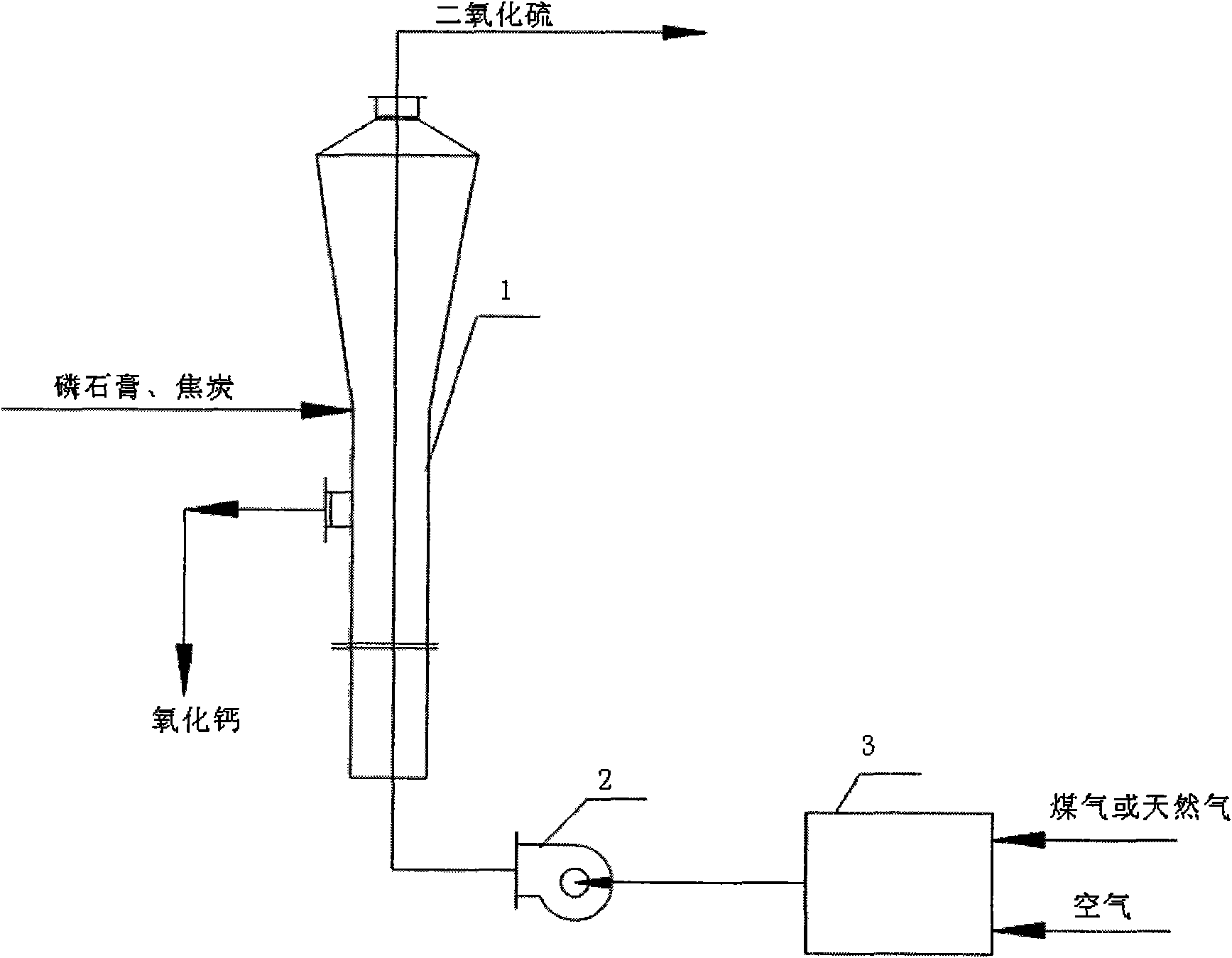

[0025] A 20,000-ton / year phosphogypsum decomposition device (calculated on the basis of decomposed dry phosphogypsum), which consists of a production line, and its process is as follows figure 1 As shown, the main equipment is as follows:

[0026] (1) Granulator (Q=2700kg / h, carbon steel casing)

[0027] (2) Drum dryer D=1200mm L=8000mm carbon steel

[0028] (3) Gas combustion furnace Q=260×10 4 kcal / h

[0029] (4) Fluidized bed decomposition furnace 2700kg / h, D=1560mm

[0030] (5) The hearth diameter of the gas generator is 1.4 meters, and the coal consumption is 800 kg / hour.

[0031] After the phosphogypsum and coke powder with a particle size of about 0.2mm are accurately measured by the weight loss scale, they are added to the mixer by the bucket elevator according to the weight ratio of 20:1 after drying and mixed evenly, and then flowed into the double-screw granulator to make Granules, forming granular materials with a size of about 2mm, enter the drum dryer for dr...

Embodiment 2

[0034] Equipment is the same as embodiment 1, and other conditions are as follows:

[0035]After the phosphogypsum and coke with a particle size of about 0.6mm are accurately measured by the weight loss scale, they are added to the mixer by the bucket elevator according to the weight ratio of 16:1 after drying and mixed evenly, and then flow into the double-screw granulator for granulation , to form granular materials with a size of about 1mm, and enter the rotary drum dryer for drying and dehydration. The moisture content of the dried mixed materials is controlled below 3%, and the dried materials are continuously, uniformly and quantitatively added to the decomposition furnace (phosphogypsum dosage: 2.8 tons / hour, coke charging amount: 0.175 tons / hour), make it directly contact with the high-temperature furnace gas whose airflow velocity is 2m / s, maintain the reaction temperature in the furnace at 1150°C for 20 minutes, the generated sulfur dioxide gas (volume The percentage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com