Patents

Literature

359 results about "Engineering production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production engineering is a combination of manufacturing technology, engineering sciences with management science. A production engineer typically has a wide knowledge of engineering practices and is aware of the management challenges related to production.

Self-Assembling Cell Aggregates and Methods of Making Engineered Tissue Using the Same

Owner:MUSC FOUND FOR RES DEV +1

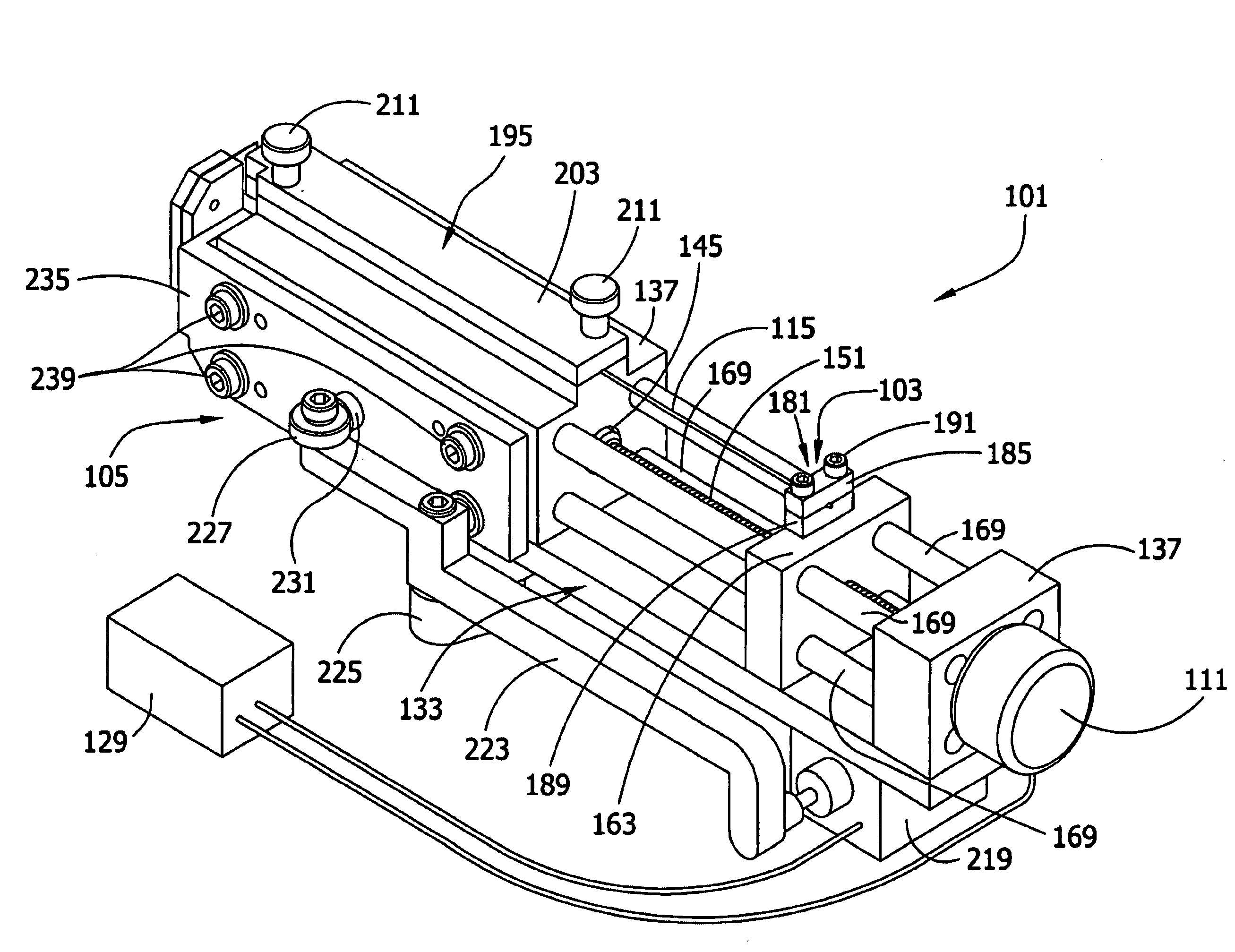

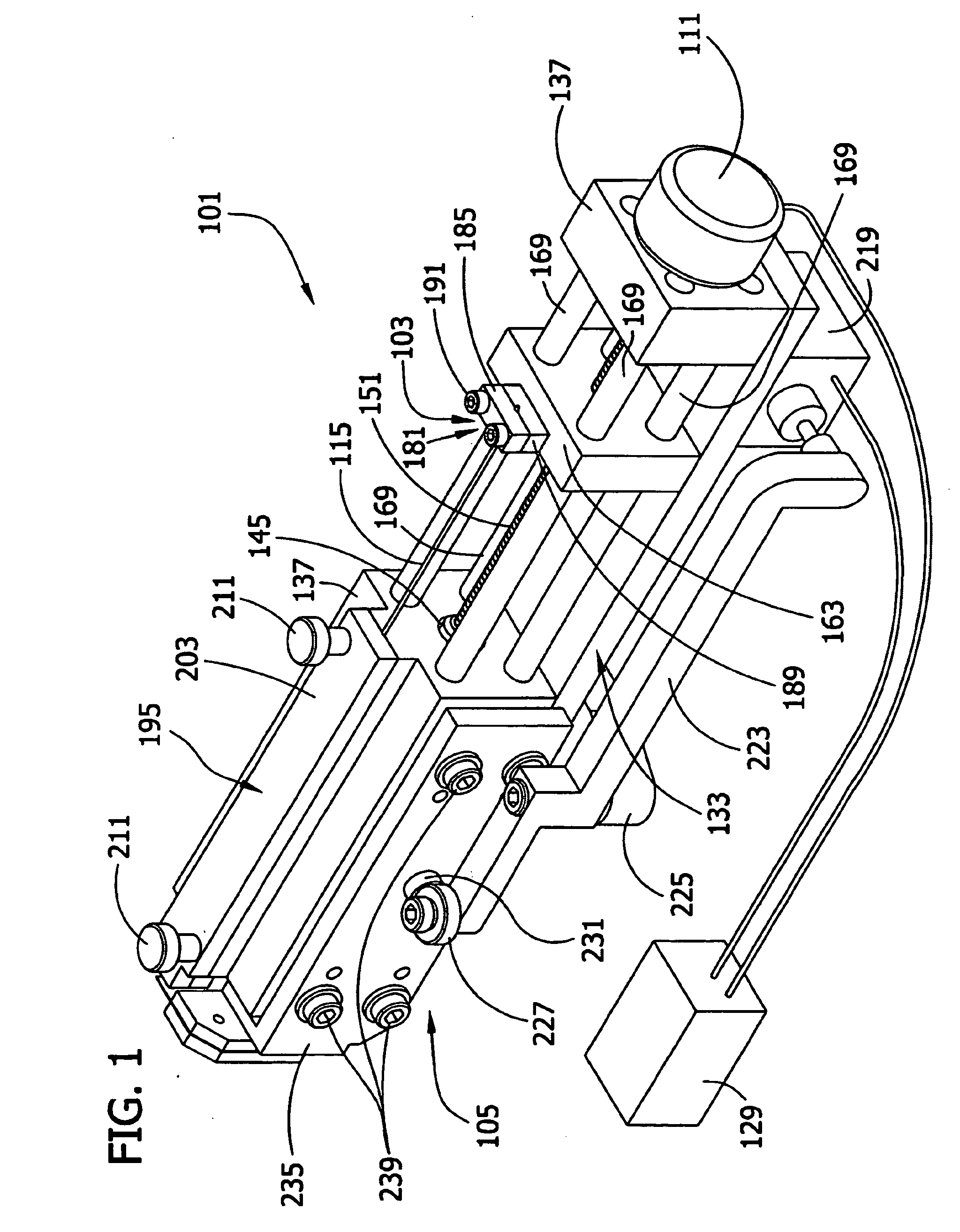

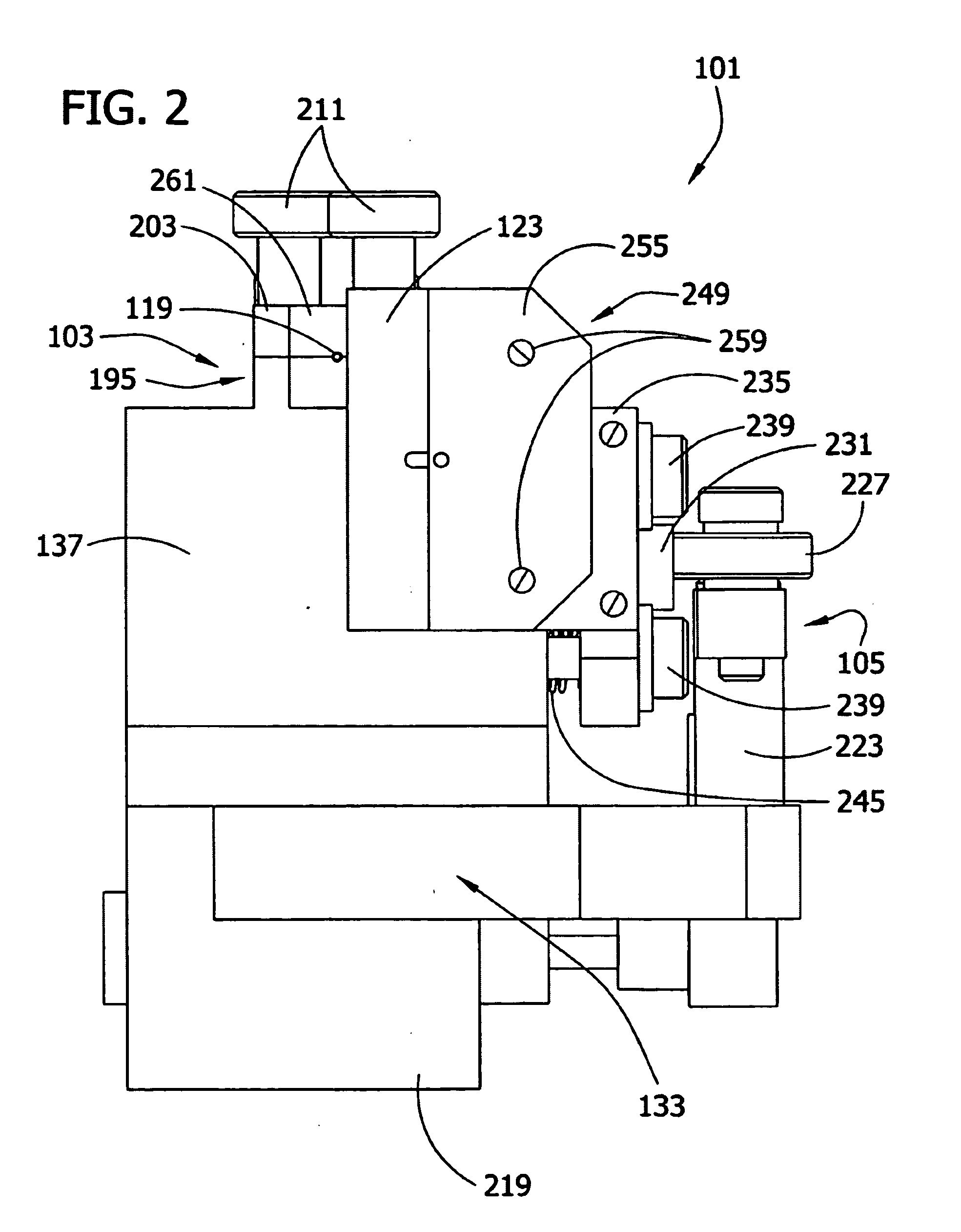

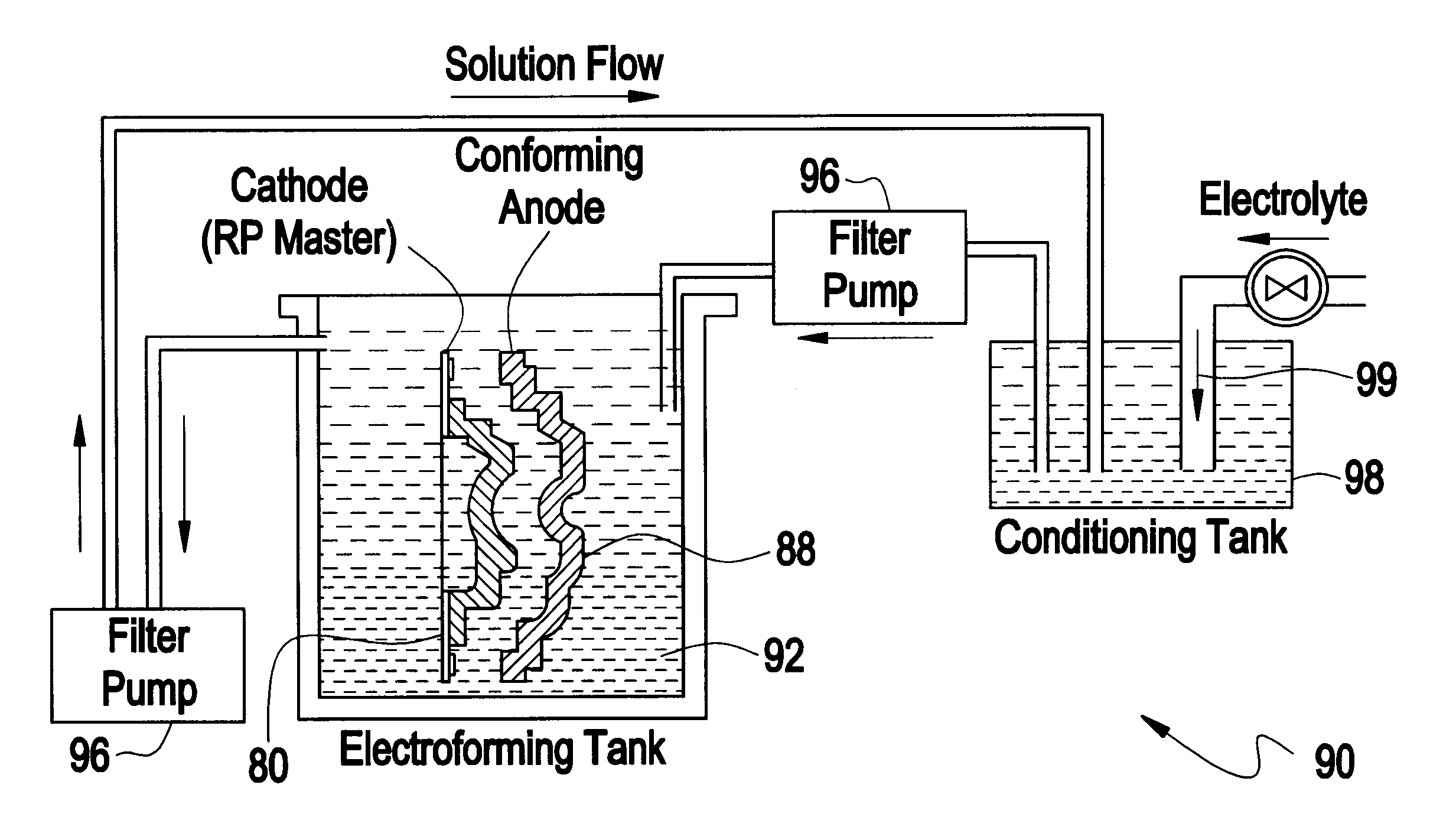

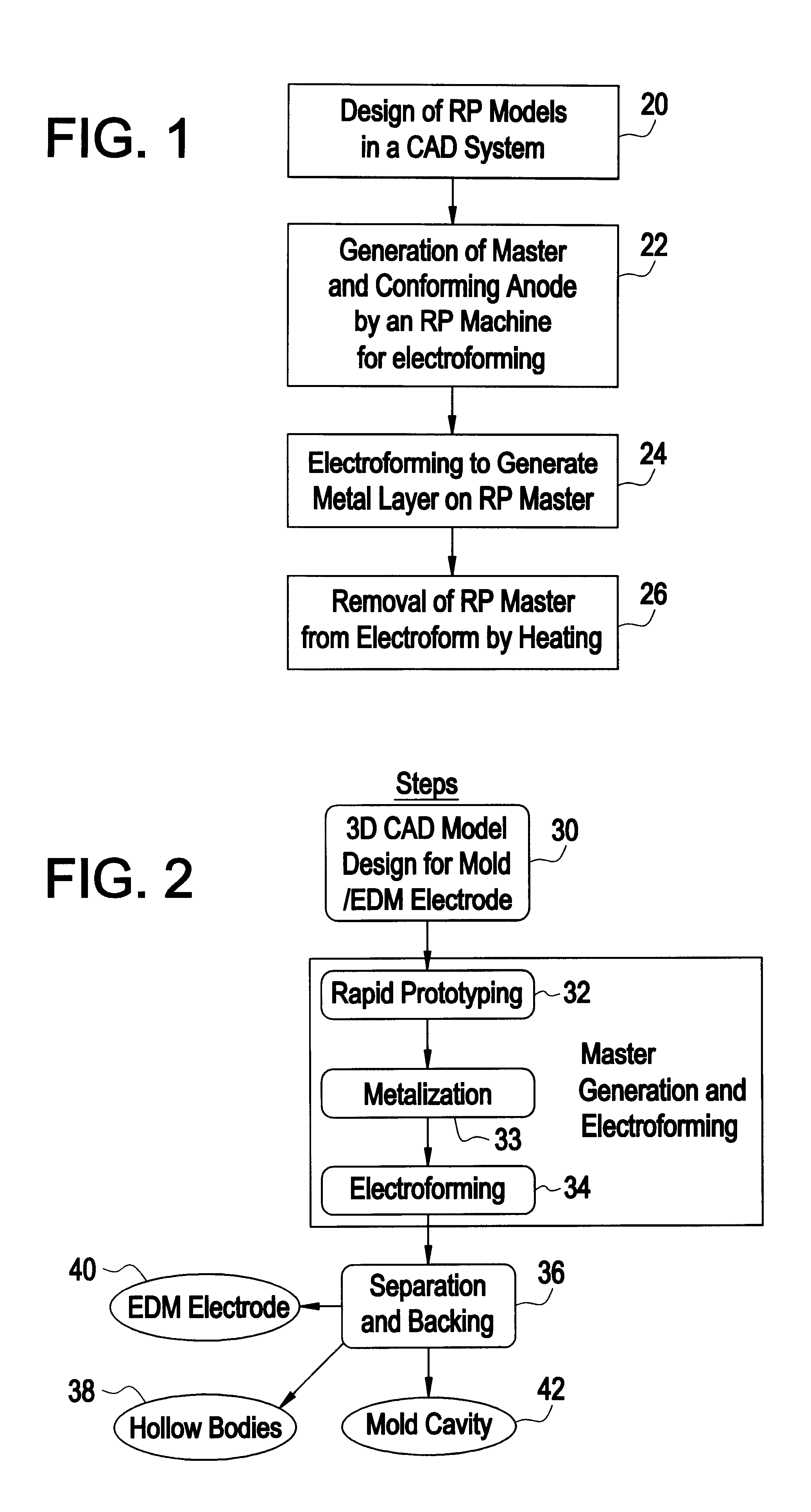

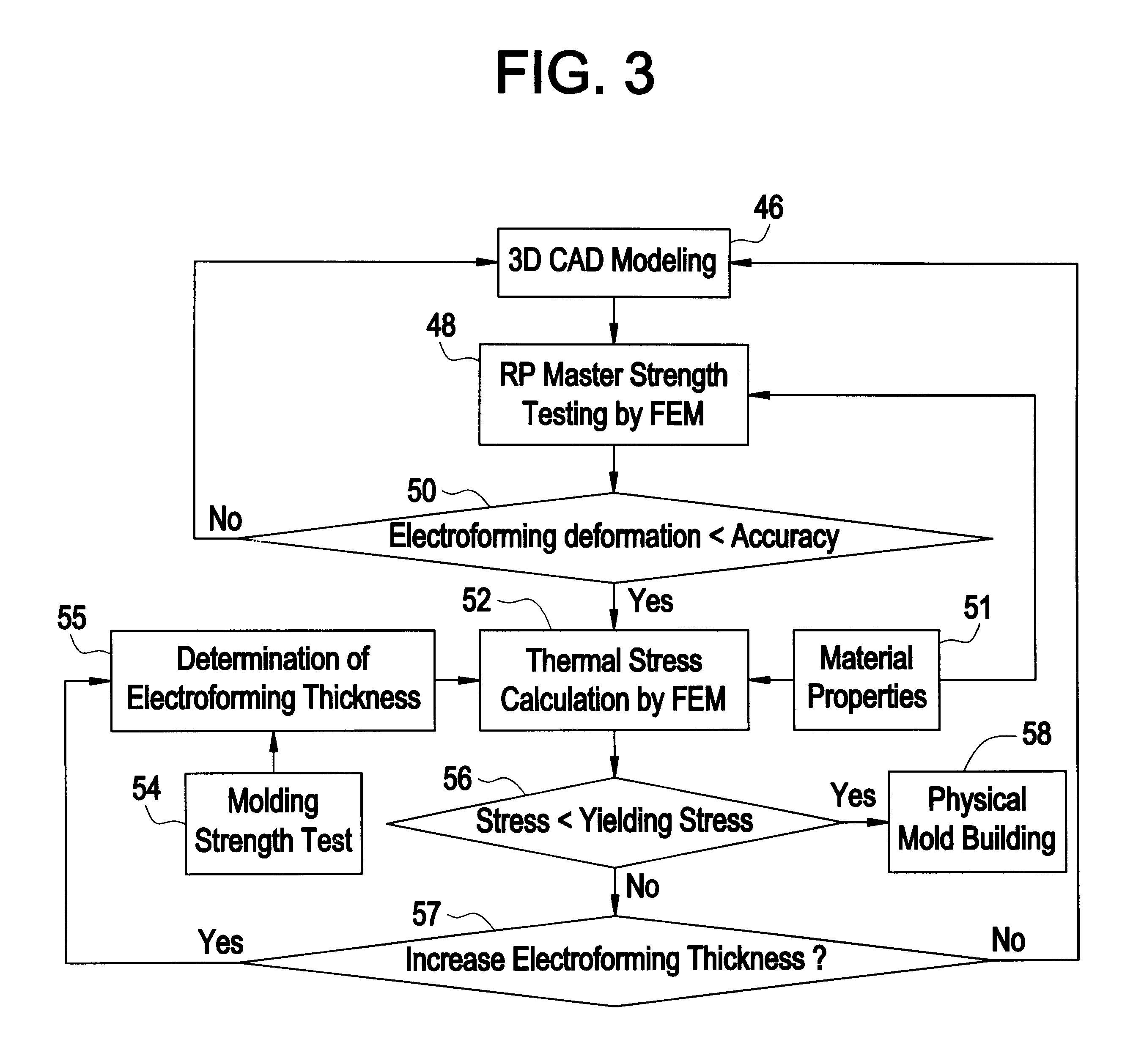

Rapid production of engineering tools and hollow bodies by integration of electroforming and solid freeform fabrication

InactiveUS6409902B1Stay in shapeAvoid insufficient thicknessAdditive manufacturing apparatusFoundry mouldsElectrolysisElement analysis

This invention describes a rapid tooling process that integrates solid freeform fabrication (SFF) with electroforming to produce metal tools including molds, dies, and electrical discharge machining (EDM) electrodes. An SFF part is metalized by electroless plating and then placed in an electroplating solution, where metal is deposited upon the part by electrolysis. When the desired thickness of metal has been reached, the SFF part is removed from the metal shell. The shell is then optionally backed with other materials to form a mold cavity, and EDM electrode, or other desired parts for tooling. Thermomechanical modeling and numerical simulation with finite element analysis (FEA) is used to determine the geometry of the SFF part and the electroform thickness for minimizing the manufacturing time and cost while satisfy the tooling requirement.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

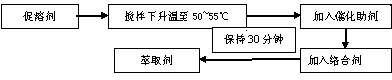

Method for producing acerbity-removing persimmon wine

ActiveCN101215498AReduce astringencyTypical styleAlcoholic beverage preparationMicroorganism based processesYeastAlcohol

The invention discloses a production method for persimmon wine to remove acerbity, which comprises the following procedures: (1) selecting fruits, cleaning and beating; (2) protecting the color; (3) enzymolysising; (4) removing acerbity and clarifying; (5) adjusting ingredient; (6) fermenting; (7) ageing; (8) filtering, filling in bottles and sterilizing; (9) stocking, wherein removing acerbity and clarifying is completed via charging 0.3-0.6g gelatin into one kilogram persimmon juice, standing for 30-40 minutes, clarifying and filtering. The invention protects the color of persimmon juice and reduces oxidation by adding ascorbic acid and citrate, applies gelatin to remove acerbity and clarify, which can effectively remove acerbity and suspended granules in persimmon juice and enable persimmon wine without acerbity and to be easily clarified,) and employs brewing dry yeast to ferment at higher temperature, which has short ferment period. The persimmon wine is clear, transparent, lucidus and free of sediment, which has typical style, good taste, pure flavour, coordinated alcohol and acerbity, full wine body, tasty, good aftertaste, no objectionable odour, fresh persimmon flavour and wine flavour.

Owner:ZHONGKAI UNIV OF AGRI & ENG

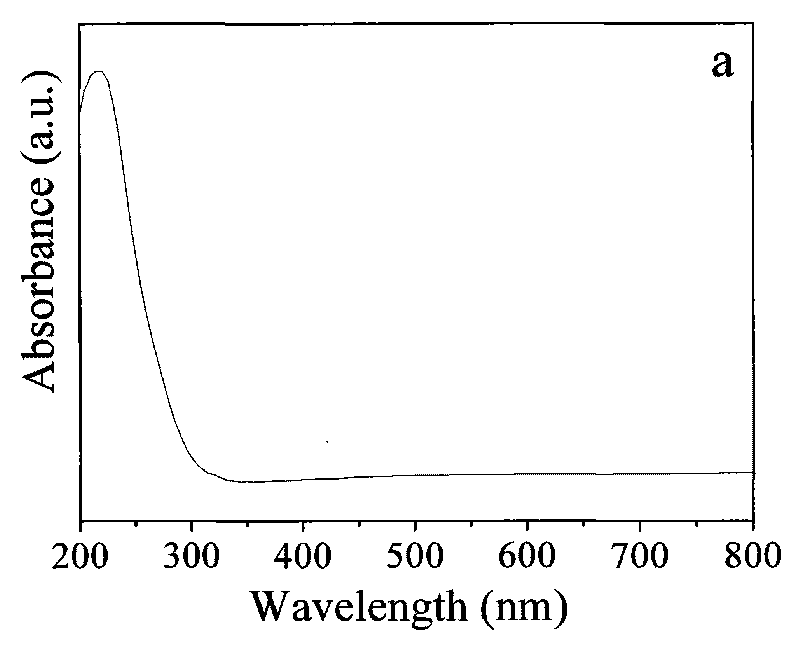

Preparation method for graphene conductive slurry

The invention discloses a preparation method for graphene conductive slurry. The preparation method comprises the steps of dissolving a dispersing agent into a solvent firstly, and performing ultrasonic oscillation to form a uniform solution; then adding graphene and a conductive carbon material into the solution to be mixed and stirred; next, performing full dispersion through a way of ultrasonic oscillation; and finally transferring the well-dispersed slurry to a high-speed shearing emulsification homogenizing machine to be sheared and dispersed to obtain the uniform and consistent and fully-dispersed graphene conductive slurry. The preparation method is simple and easy to implement and applicable to engineering production.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Precise forming method for titanium-aluminum intermetallic compounds

The invention relates to a precise forming method for titanium-aluminum intermetallic compounds. According to the method, yttrium oxide powdery sand is selected as a surface-layer refractory to prepare a ceramic shell for investment casting, and in combination with processes such as a vacuum consumable skull furnace or a vacuum induction water-cooling copper crucible furnace and centrifugal casting, a titanium-aluminum intermetallic compound casting is prepared. The ceramic shell prepared according to the forming method is high in inertia, and good in matching between strength and deformability and collapsibility, and is suitable for investment casting of the titanium-aluminum intermetallic compounds; a prepared casting is complete in forming, the smallest wall thickness can reach 1mm, the dimension precision reaches lower than CT7, a surface pollution layer is thin, surface roughness is less than or equal to 6.3 micrometers, and more importantly, cracks cannot be formed, and therefore, the problems that titanium-aluminum alloy is low in room-temperature plasticity and easy to crack during forming are solved. The forming method is applicable to development and engineering production of various structural parts of the titanium-aluminum intermetallic compounds.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

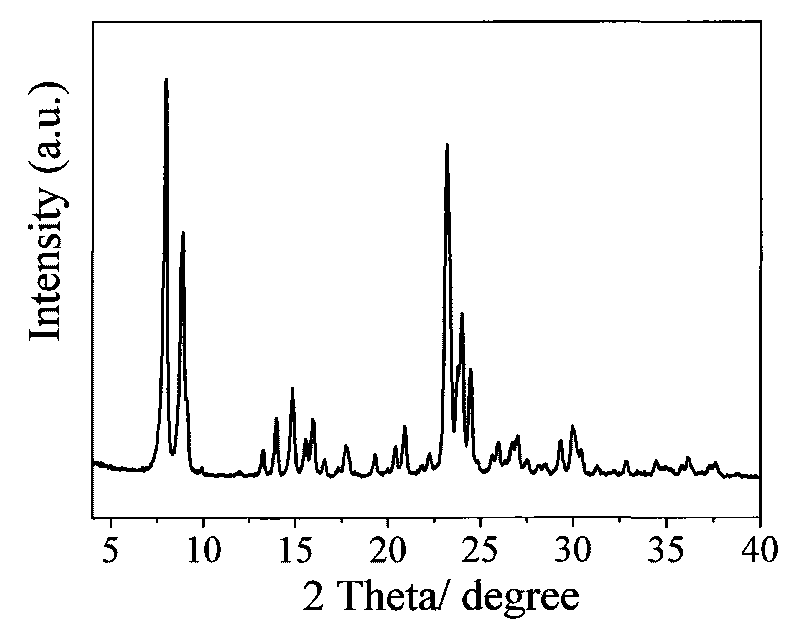

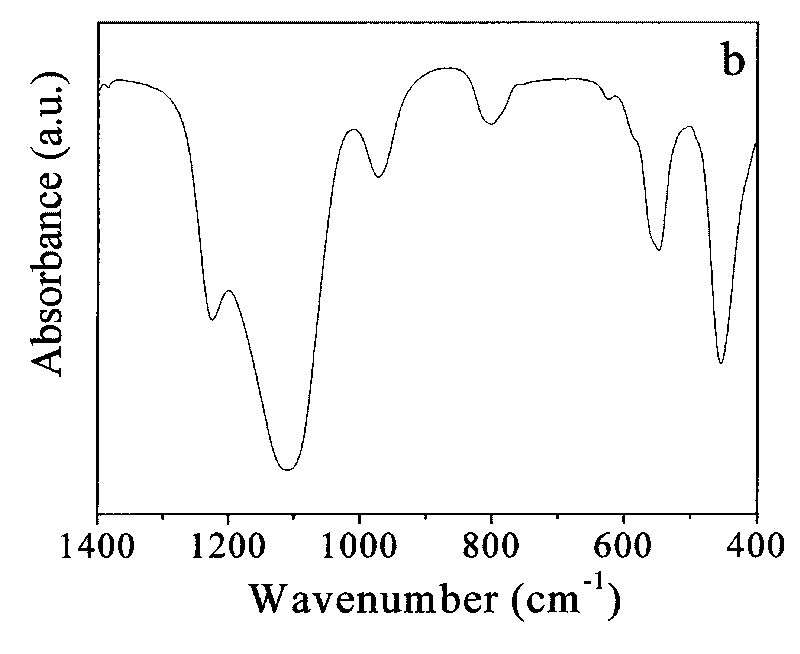

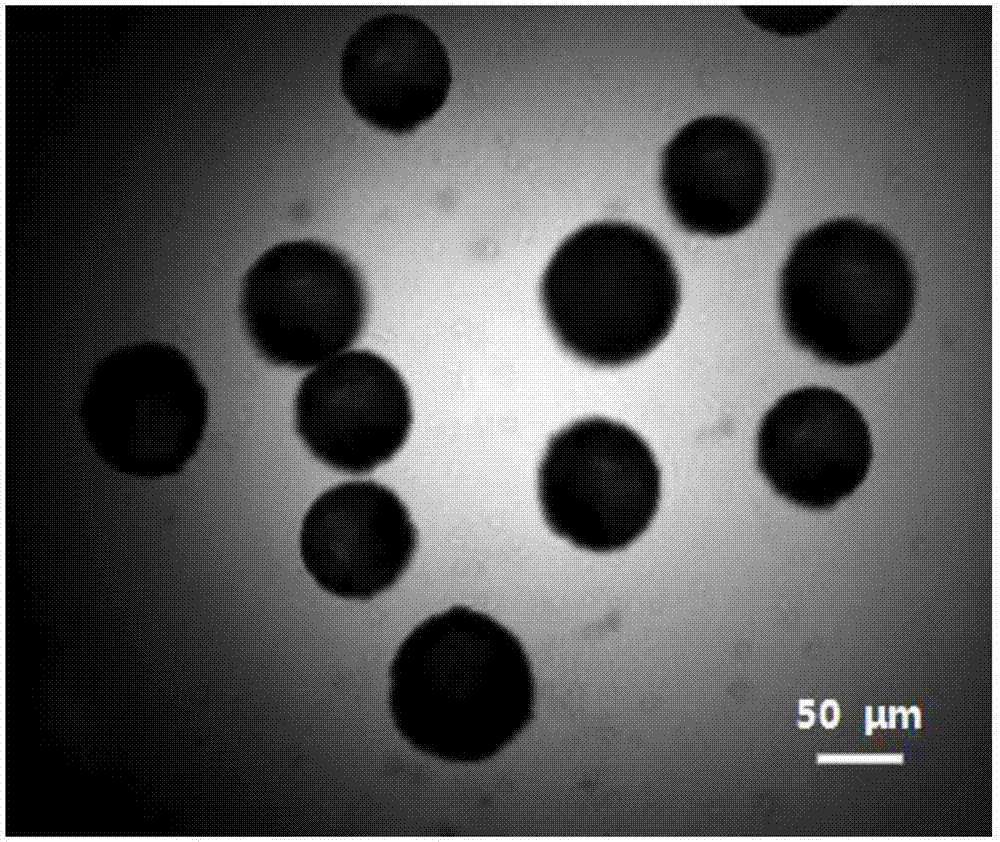

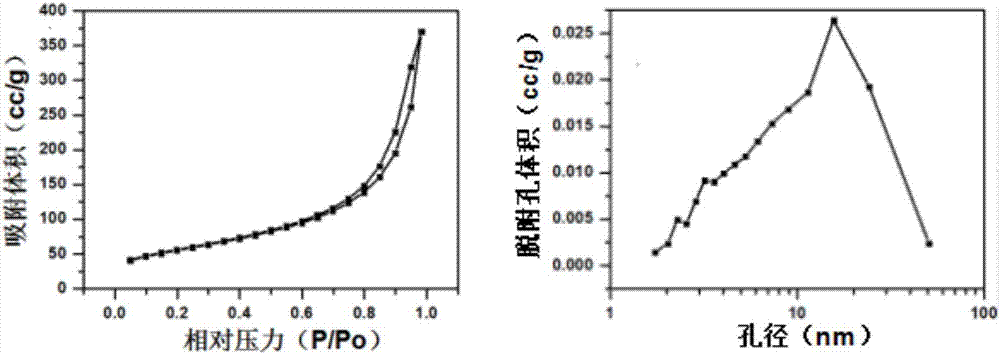

Large blocked TS-1 molecular sieve with high catalytic activity and synthetic method thereof

InactiveCN101696019AHigh catalytic activityReduce lossMolecular sieve catalystsCrystalline aluminosilicate zeolitesSynthesis methodsSingle crystal

The invention relates to a large blocked TS-1 molecular sieve with high catalytic activity and a synthetic method thereof, belonging to the technical fields of catalytic chemistry and chemical engineering. The large blocked TS-1 molecular sieve is a titanium-silicalite molecular sieve which has an MFI structure and formed by mutually piling nano-level TS-1 crystal grains with the blocked size of 20-100 micrometers and the mesoporous volume of 0.55cm<3> / g. The large blocked TS-1 molecular sieve is formed by evenly mixing tetraethoxysilane as a silicon source, tetrabutyl titanate as a titanium source, tetrapropylammonium hydroxide as a template agent, water and isopropanol as a solvent and H2O2 as an inorganic additive and carrying out hydrothermal crystallization on the mixture at a temperature between 160 DEG C and 180 DEG C for 6-96 hours. The large blocked TS-1 molecular sieve maintains a single crystal grain nano-size structure, has favorable catalytic reaction activity and can realize the separation on the entire device by filtering operation; and the adopted inorganic addictive H2O2 is friendly to the environment and has low price, thus the invention has important significance in the practical chemical engineering production.

Owner:JILIN UNIV

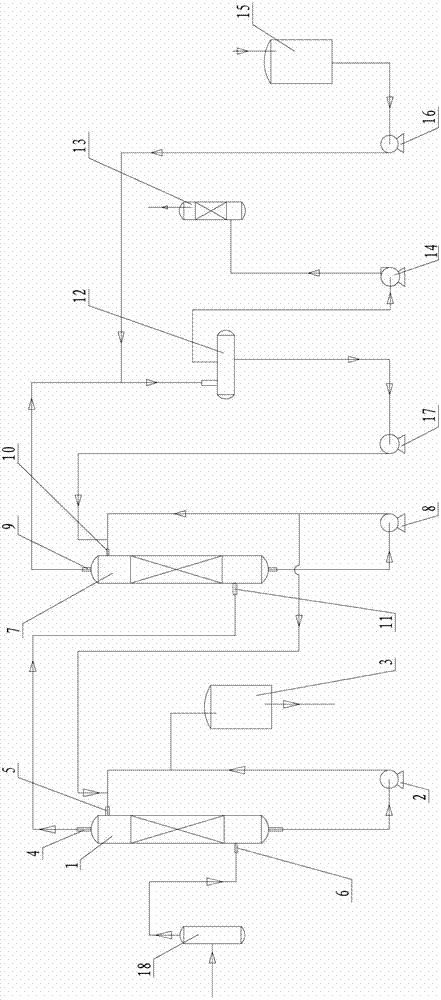

Technique method for producing sodium bisulfide

InactiveCN102765700AReduce power consumptionProduction costSulfur compoundsSodium bisulfideSodium hydrosulfide

The invention discloses a technique method for producing sodium bisulfide and belongs to the technical field of the chemical engineering production technology. The technique method for producing sodium bisulfide is low in production cost and can control product quality easily during production. The technique method includes: feeding buffered hydrogen sulfide and process absorption liquid with sodium sulphide as the main ingredient into an absorption tower respectively from the lower portion and the upper portion of the absorption tower, absorbing the hydrogen sulfide and the process absorption liquid on the surface of packing in the absorption tower to generate solution with the sodium bisulfide as the main ingredient, enabling the solution to flow to the bottom of the absorption tower, and discharging the unabsorbed hydrogen sulfide tail gas from the top of the absorption tower; pumping the solution at the bottom of the absorption tower out, returning most of the solution back to the absorption tower for recycling, feeding the small amount of solution to a sodium bisulfide production solution storing tank, and simultaneously adding the process absorption liquid in the absorption tower from the upper portion of the absorption tower during the absorption circulating process; and finally performing evaporation, concentration and dehydration on the solution, cooling the solution for molding, packaging and finishing the production of the sodium bisulfide.

Owner:CHENGDU DEMEI ENG TECH

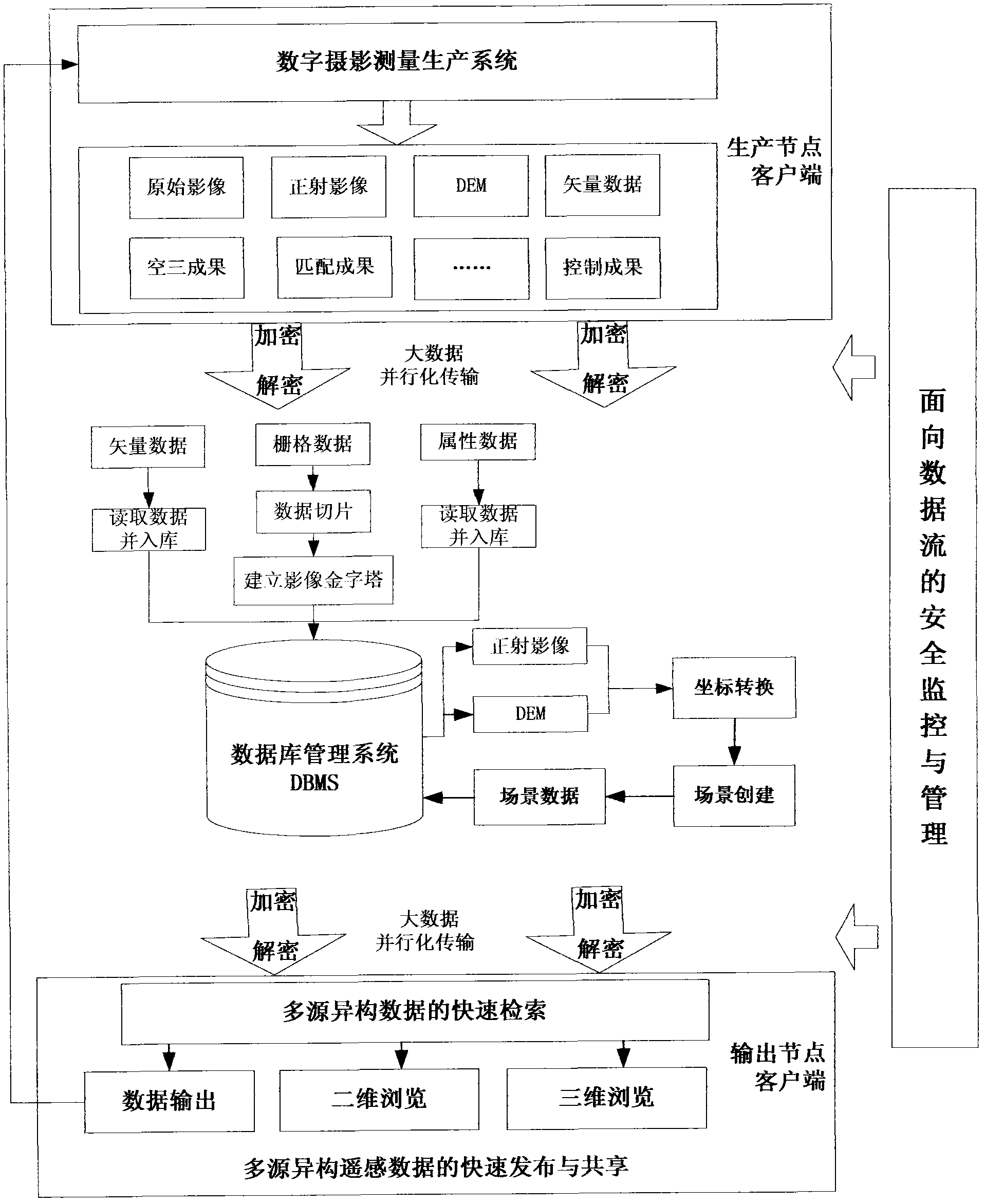

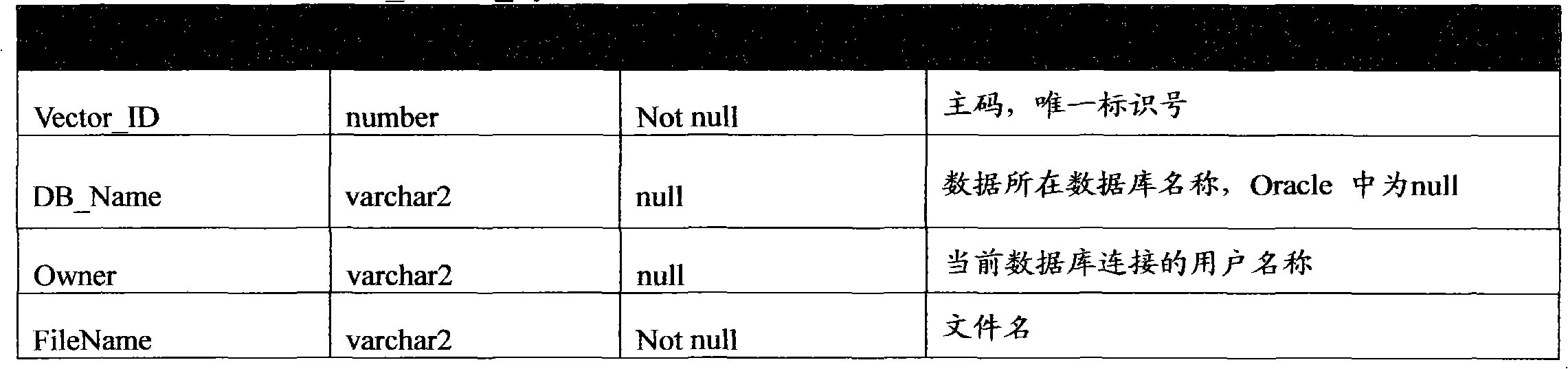

Method for managing multisource-isomerism aviation remote sensing data

InactiveCN102663057AQuick storageQuick searchSpecial data processing applicationsSensing dataAviation

The invention discloses a method for managing multisource-isomerism aviation remote sensing data, which comprises the following steps: (1) using geographic regions and production engineering as units so as to realize aviation remote sensing data storage and management; and realizing high-efficient data storage and management served for aviation remote sensing data products by technologies such as tiles and the like; and (2) using a method for dynamically generating a continuous detail level model, establishing a corresponding high-efficient mechanism, and realizing three-dimensional visual issuing and sharing of the aviation remote sensing data products automatically and high-efficiently. According to the invention, the method effectively solves integrated storage and management problems of multisource, multi-time-phase, isomerism aviation remote sensing data in a digital aviation photography measurement producing system.

Owner:苏州大地影像科技有限公司

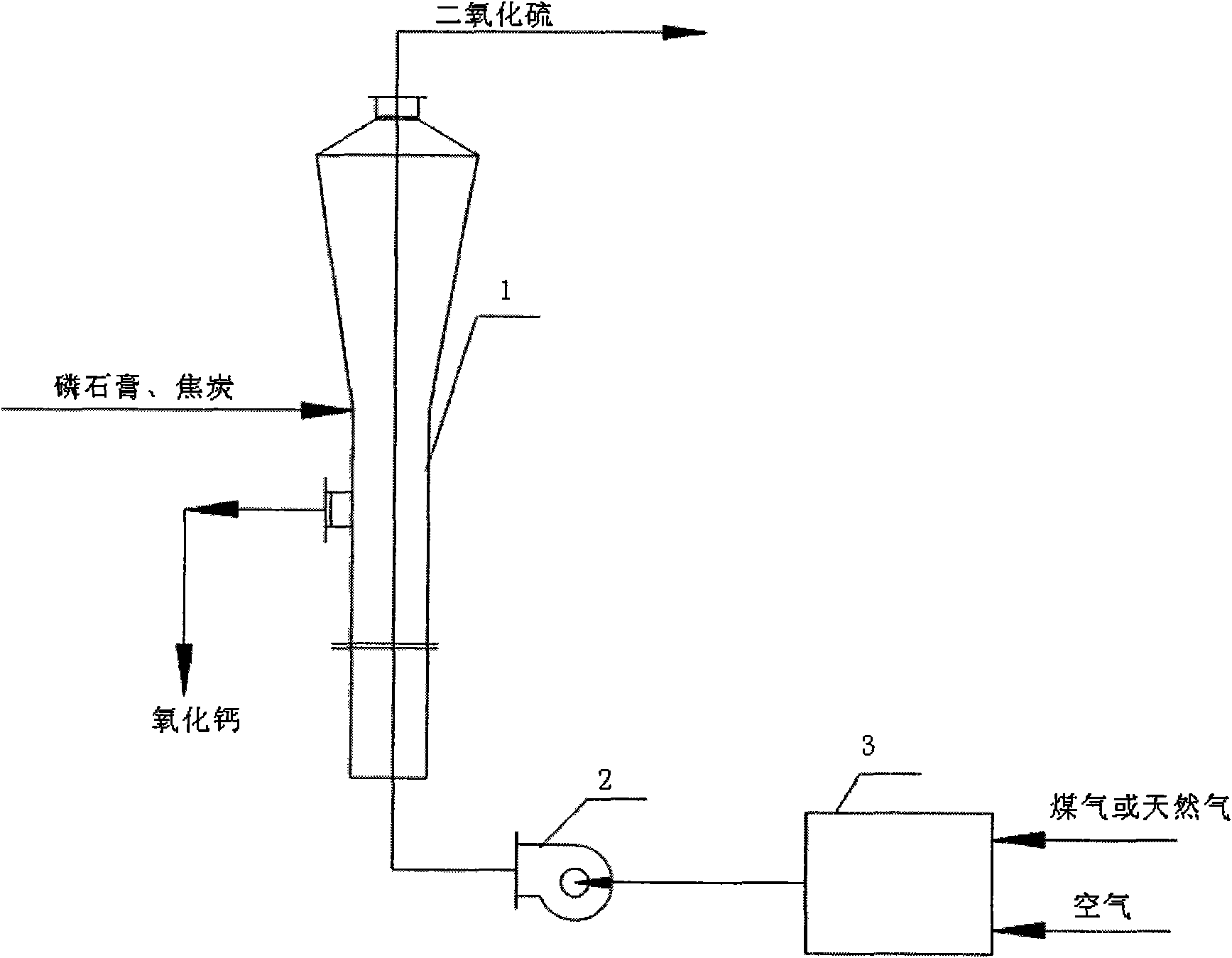

Production process for preparing calcium oxide and sulfur dioxide by decomposing ardealite

InactiveCN101602518ASolve the use problemReduce ecological damageSolid waste disposalSulfur compoundsDry weightReaction temperature

The invention belongs to the technical field of environmental protection treatment and chemical engineering production, and relates to a production process for preparing calcium oxide and sulfur dioxide by decomposing ardealite. The process comprises the following steps of: mixing the ardealite and charcoal according to a dry weight ratio of 10-20:1, granulating the mixture to obtain particles of which the particle size is between 1 and 4mm, drying and dewatering the particles, putting the particles in a fluidized bed decomposing furnace to be directly contacted with high-temperature furnace gas for reaction for 15 to 50 minutes at a temperature of between 1,000 and 1,300 DEG C, and generating the sulfur dioxide gas and the calcium oxide. The process can solve the problem of comprehensively utilizing waste residues of ardealite, the content of SO2 in the discharged tail gas is high enough to be used for producing sulfuric acid, and the calcium oxide which is a byproduct can be used in various industries such as construction, road, aquaculture and the like, so that the process meets the requirements on the scientific outlook on development; moreover, compared with the process for co-production of cement by sulfuric acid prepared by the ardealite, the process greatly saves investment and electric consumption.

Owner:SINOPEC NANJING ENG & CONSTR

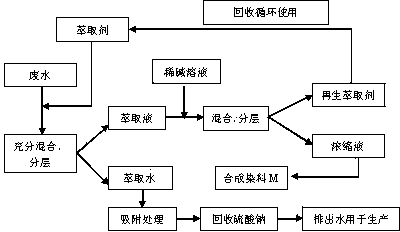

Treatment method for production wastewater of sulfonic acid group dye and dye intermediate of sulfonic acid group dye

ActiveCN103408092ANot affected by treatment effectsImprove practicalityNature of treatment waterWater/sewage treatment by extractionInorganic saltsWastewater

The invention belongs to the technical field of treatment of dye chemical engineering production wastewater and provides a treatment method for production wastewater of sulfonic acid group dye and dye intermediate of the sulfonic acid group dye to solve the problem of treatment of production wastewater of the sulfonic acid group dye and the dye intermediate of the sulfonic acid group dye. The treatment method comprises the steps as follows: (1), extracting the production wastewater; (2), performing absorption treatment on an aqueous layer after extraction; (3), recovering and reusing inorganic salt; (4), regenerating an extractant, recovering and reusing organisms, recovering the inorganic salt sodium sulfate contained in the production wastewater, and taking the sodium sulfate as a commercialized thinner and a dyeing accelerant used in the process of dyeing to enable the sodium sulfate to be applied to practical production of active dyes so as to realize wastewater treatment and recovery comprehensive utilization.

Owner:ZHEJIANG JIHUA GROUP +1

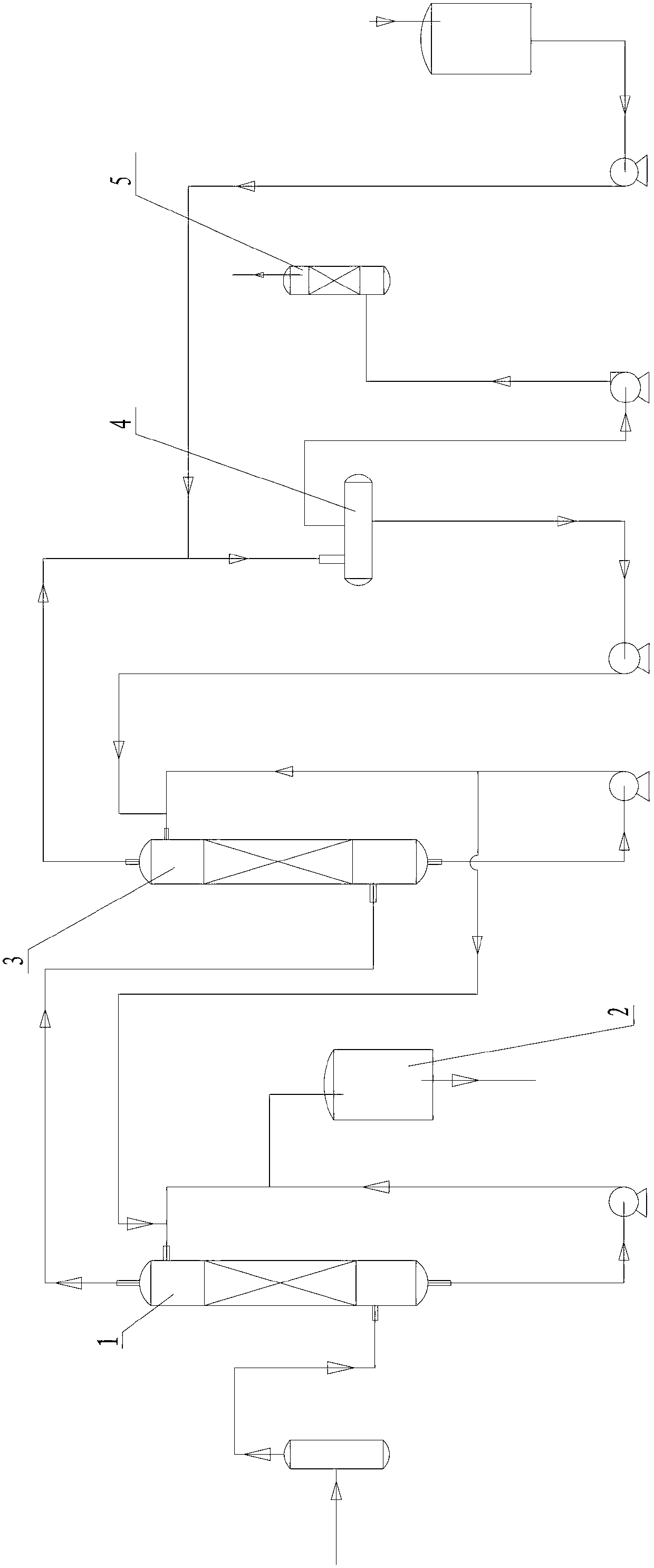

Production device for sodium bisulfide continuous absorption reaction

InactiveCN102807193AReduce power consumptionProduction costDispersed particle separationSulfur compoundsSodium bisulfideAbsorption column

The invention discloses a production device, particularly a production device for sodium bisulfide continuous absorption reaction, and belongs to the technical field of chemical engineering production equipment. The invention provides the production device for the sodium bisulfide continuous absorption reaction, which is low in power consumption and production cost and easy in control of product quality. The production device comprises an absorption tower, an absorption column bottoms pump and a sodium bisulfide production solution storage tank, a process tail gas output interface is arranged at the top of the absorption tower, a process absorption liquid input interface is arranged at the upper part of the absorption tower, a hydrogen sulfide gas input interface is arranged at the lower part of the absorption tower, an input end of the absorption column bottoms pump is connected with the bottom of the absorption tower, and an output end of the absorption column bottoms pup is connected with the process absorption liquid input interface and the sodium hydrosulfide production solution storage tank respectively.

Owner:CHENGDU DEMEI ENG TECH

Preparation method of nitrogen/ sulphur co-doping three-dimensional graphene sponge

InactiveCN106517162AImprove electrochemical performanceImprove conductivityCell electrodesGraphenePorosityThiourea

The invention relates to a preparation method of a nitrogen / sulphur co-doping three-dimensional graphene sponge. The preparation method of the nitrogen / sulphur co-doping three-dimensional graphene sponge comprises the steps of firstly, fully dispersing a graphene oxide and thiourea mixture through an ultrasonic oscillating way, then filling the mixture into a hydrothermal reaction kettle, reducing the graphene oxide into graphene through high temperature and high pressure, meanwhile, self-assembling the graphene into a three-dimensional graphene macroscopic body, and doping a nitrogen element and a sulphur element into a graphene substrate; and finally, repetitively cleaning the three-dimensional graphene macroscopic body, and freeze drying to obtain the nitrogen / sulphur co-doping three-dimensional graphene sponge. The three-dimensional graphene sponge synthesized through hydrothermal reaction has the advantages of light weight and porosity, and is applied in a lithium-sulfur battery so as to be capable of improving the electrical conductivity of an anode material and solving the problem of big volume change during an electrode reaction process. The preparation method of the nitrogen / sulphur co-doping three-dimensional graphene sponge provided by the invention is simple and easy to implement, and is very applicable to engineering production.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Full-automatic commercial pure titanium smelting method adopting electron beam cold hearth furnace

The invention relates to a full-automatic TA1 smelting method adopting an electron beam cold hearth furnace and belongs to the technical field of production engineering application. The production method comprises the following steps: drying and putting titanium sponge into an Archimedean screw tube which is mounted into a feeding system of an electron beam cold hearth melting furnace (EB furnace for short), wherein different rotary speeds are set; when the degree of vacuum of the feeding system reaches 0.4-0.8 Pa and the degree of vacuum of a main smelting cold hearth reaches 0.05-0.8 Pa, starting the feeding system to feed the titanium sponge into the smelting cold hearth of a main smelting chamber; triggering an electron gun to melt the titanium sponge into liquid titanium which flows through a primary refining cold hearth and a main refining cold hearth and then into a rectangular withdrawing crucible; controlling the rotary speed of the Archimedean screw tube to control the feeding speed and scanning patterns so as to control the melting speed, and the ingot pulling rate thereby realizing full-automatic control. The method has the advantages of good ingoting quality, high one-step yield, low manufacturing cost, controllable production period, simplicity in operation, energy conservation, environmental protection and high repeatability.

Owner:YUNNAN TITANIUM IND

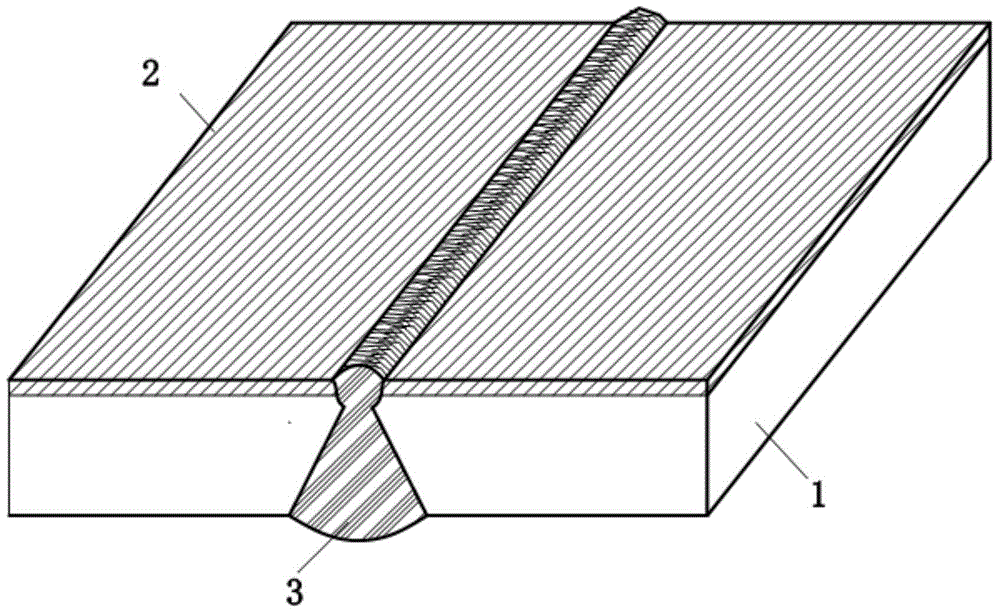

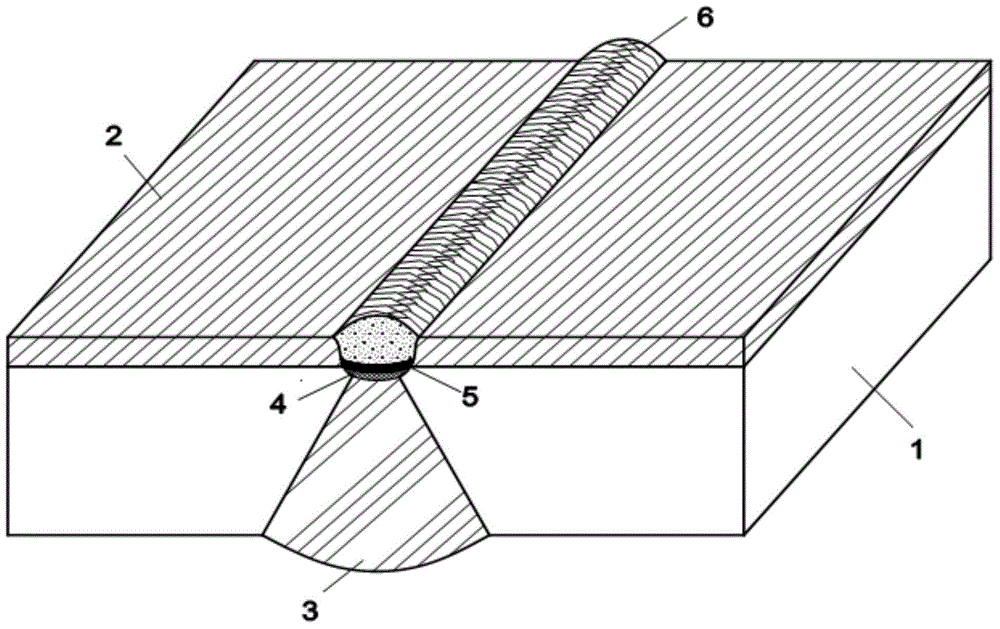

Vanadium/copper solid solution transition connection-based welding process for titanium-containing metal layer/pipeline steel layer composite board

ActiveCN105014207AEffective Butt Weld LinksImprove barrier propertiesArc welding apparatusWelding/soldering/cutting articlesButt weldingTitanium

The invention discloses a vanadium / copper solid solution transition connection-based welding process for a titanium-containing metal layer / pipeline steel layer composite board. The titanium-containing metal layer / pipeline steel layer composite board is formed in the way that an industrial pure titanium and titanium alloy board and a pipeline steel board are connected together by the explosive welding process and the connected boards are rolled by use of the controlled rolling and controlled cooling technology, so that an industrial pure titanium and titanium alloy layer is arranged on one side of the titanium-containing metal layer / pipeline steel layer composite board, and a pipeline steel layer is arranged on the other side. The welding process provided by the invention is simple in process implementation, can realize metallurgical butt-welding engineering production of the titanium-containing metal layer / pipeline steel layer composite board, enables a metallurgically connected seam to be relatively good in appearance and favorable in mechanical property index, and achieves reliable connection of the titanium-containing metal layer / pipeline steel layer composite board while guaranteeing the decay resistance of the titanium-containing metal layer / pipeline steel layer composite board.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

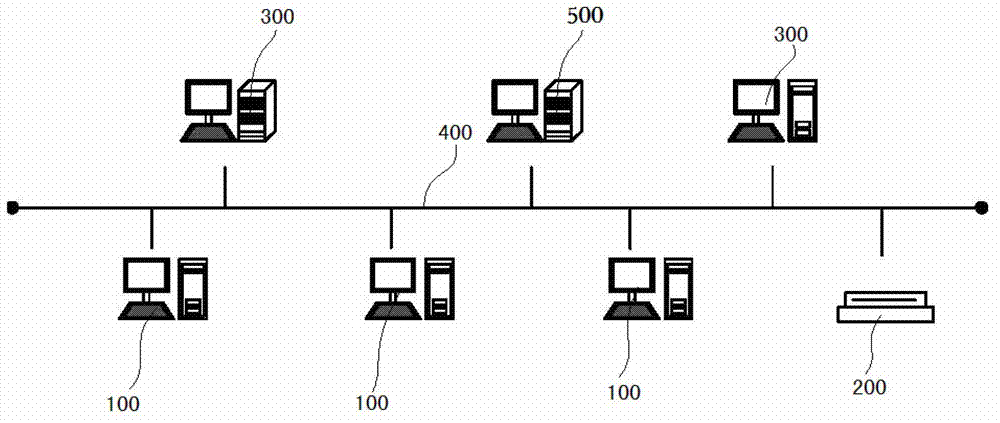

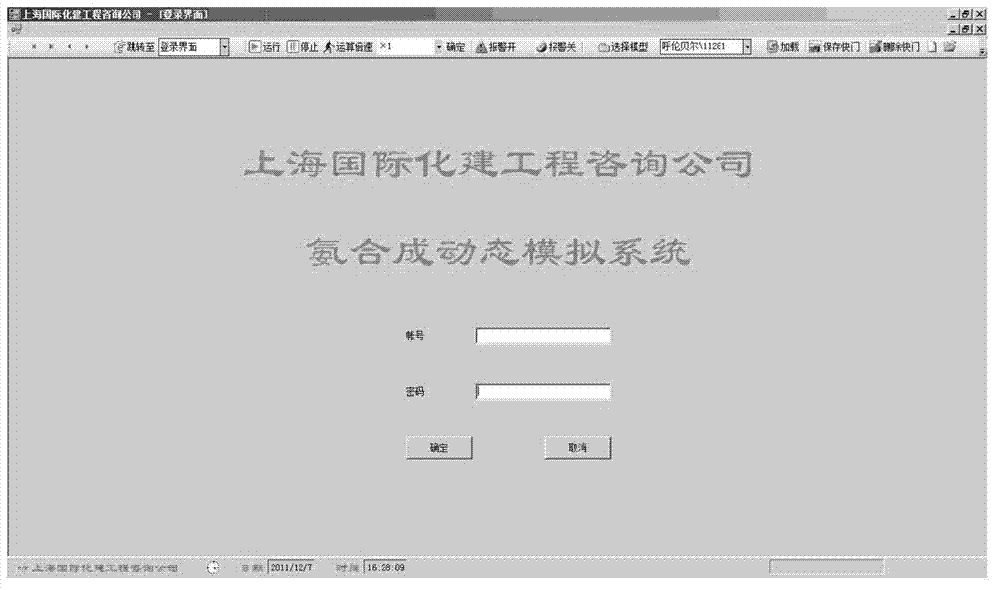

Dynamic simulation training system for synthesis gas chemical engineering and petrochemical engineering production processes

The invention discloses a dynamic simulation training system for synthesis gas chemical engineering and petrochemical engineering production processes. The dynamic simulation training system comprises a background calculation platform and a plurality of simulation operation terminals, wherein the background calculation platform is used for utilizing an HYSYS to build a dynamic model virtual plant model and serving as a dynamic simulation system, and the plurality of simulation operation terminals are provided with DSC simulating graphical user interface software. The background calculation platform is provided with an HYSYS Active X interface connected with the plurality of simulation operation terminals to achieve data interchange, and the plurality of simulation operation terminals are connected with the background calculation platform through a local area network. The dynamic simulation training system has auxiliary effects on design, training and production of a synthesis ammonia device and a methanol rectification device.

Owner:SHANGHAI INT ENG CONSULTING

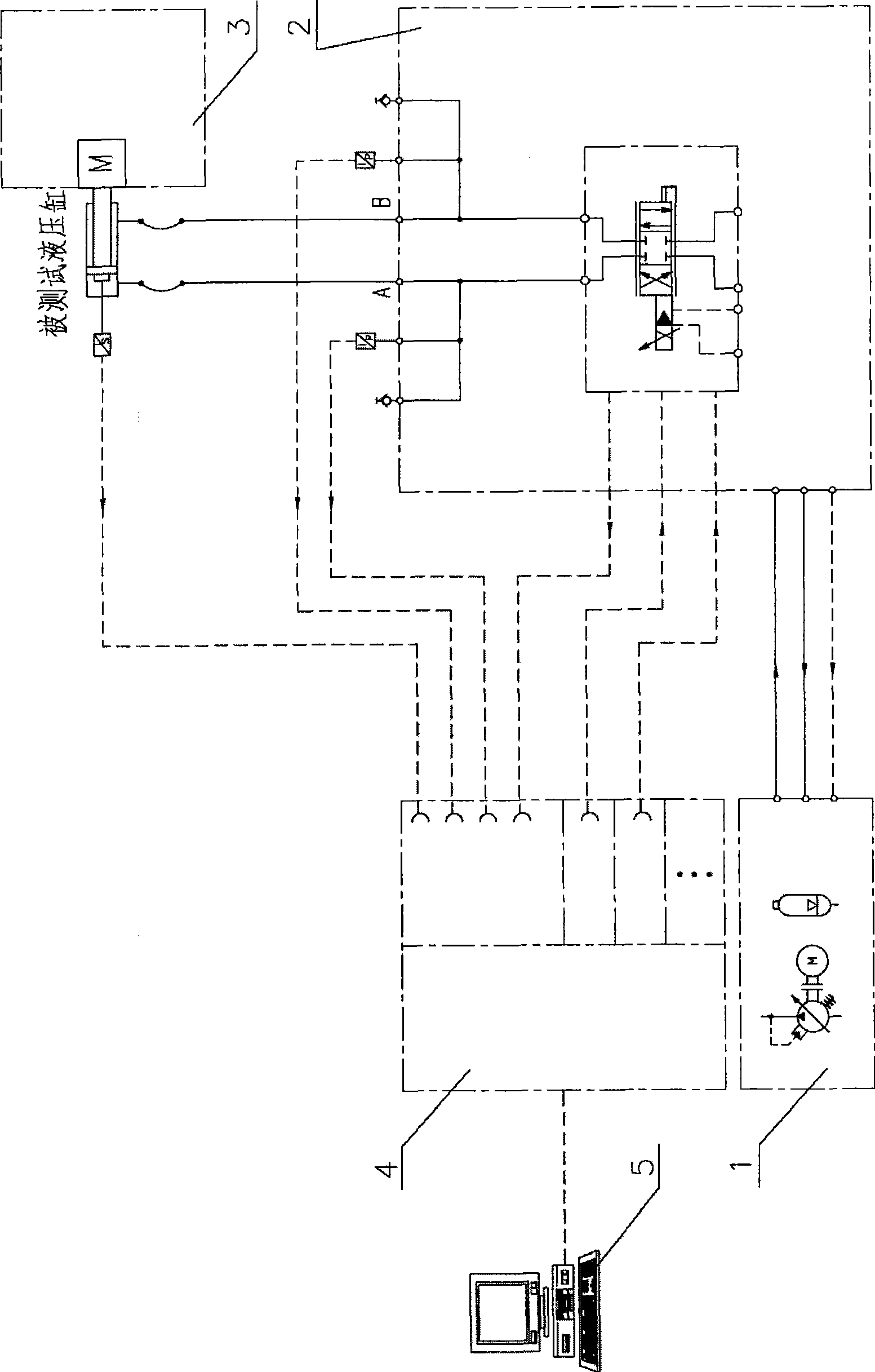

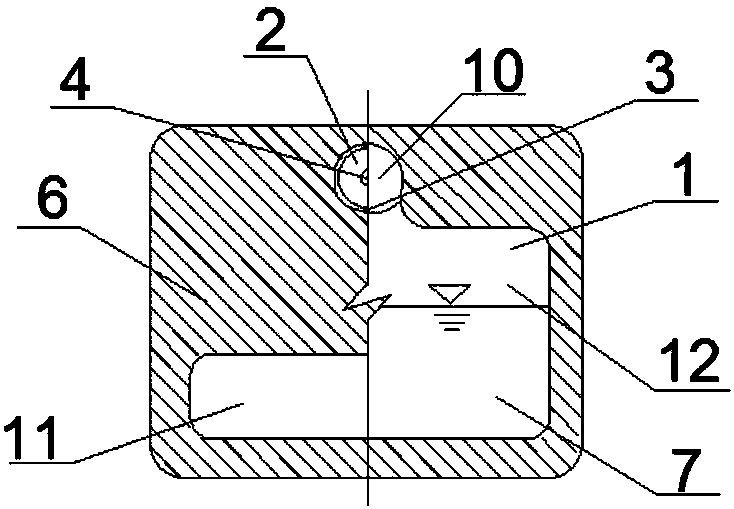

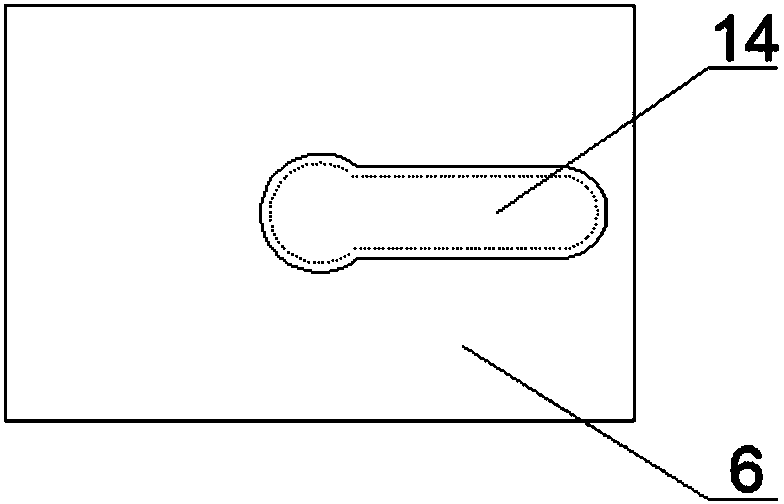

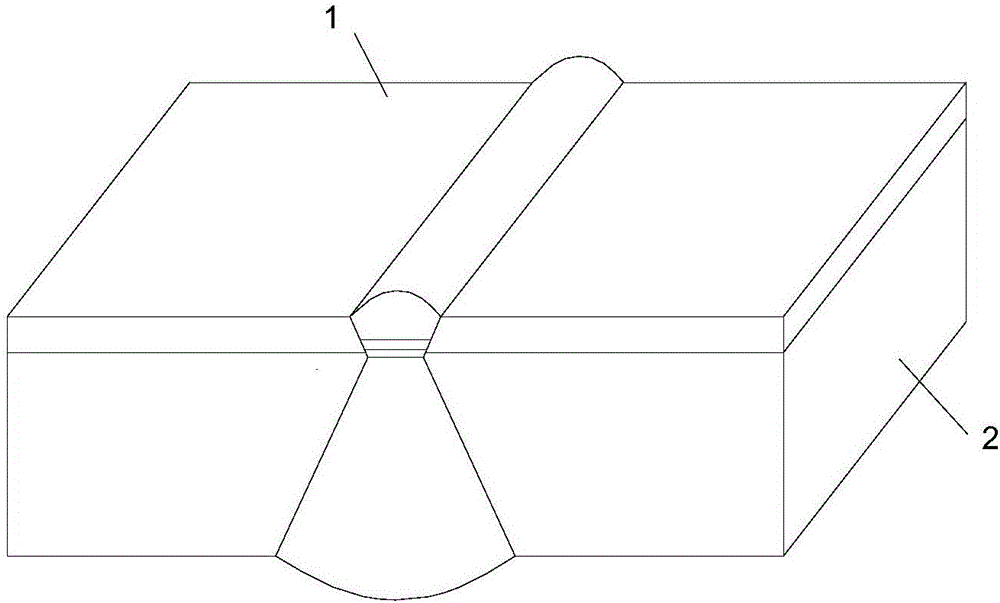

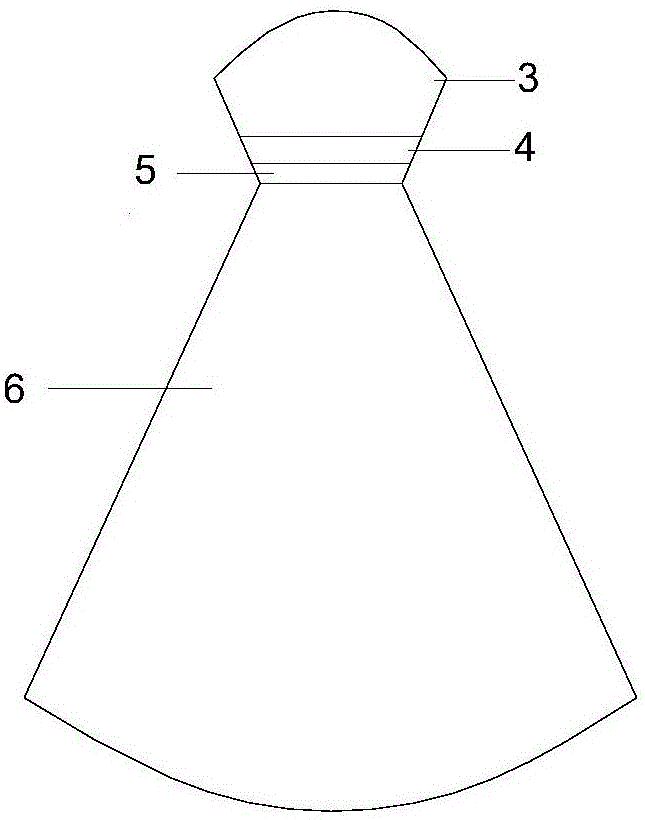

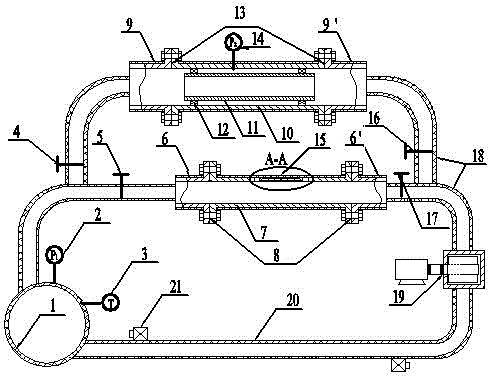

Test system and test method used for servo hydraulic cylinder

InactiveCN101520062AFull Step Response TimeEasy to operateFluid-pressure actuator testingStructural/machines measurementHysteresisHydraulic cylinder

The invention belongs to the technical field of mechanical engineering, and discloses a test system and a test method used for a servo hydraulic cylinder. In the invention, a hydraulic control device is respectively connected with the servo hydraulic cylinder to be tested, a pump source and an accumulator to build a complete hydraulic control loop; a closed-loop controller is respectively connected with the servo hydraulic cylinder to be tested, the hydraulic control device and a computer; and then the servo hydraulic cylinder to be tested is connected with a loading device to constitute a complete mechanical-hydraulic-electrical closed-loop control system used for the servo hydraulic cylinder testing. The invention has convenient operation and wide application range, and can comprehensively and systematically judge dynamic and static properties of the servo hydraulic cylinder to be tested by taking test indexes such as cleanliness, frictional characteristic, step response time, hysteresis loop, and the like aiming at different servo hydraulic cylinders in an equipment factory and engineering production field.

Owner:CISDI ENG CO LTD

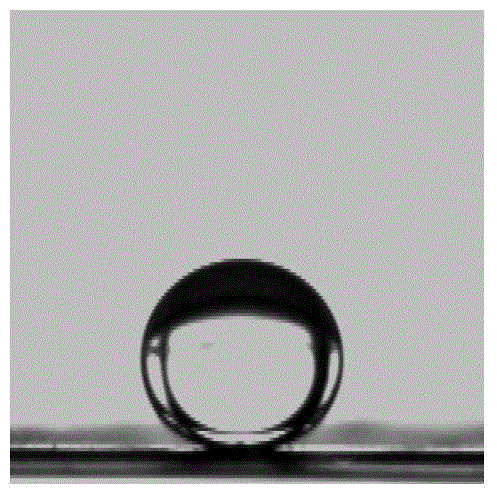

Hydrophilic-underwater oleophobic polymer porous membrane, preparation method and applications thereof

ActiveCN104368247AHigh mechanical strengthEfficient separationSemi-permeable membranesFatty/oily/floating substances removal devicesMicro nanoEngineering production

The invention discloses a hydrophilic-underwater oleophobic polymer porous membrane, a preparation method and applications thereof. The hydrophilic-underwater oleophobic polymer porous membrane is a polymer matrix membrane. The membrane surface has a coarse micro-nano level porous structure. Nano level, micrometer level and / or sub-micrometer level tunnels are distributed in the membrane. The static contact angle between the membrane and water is less than 10 degrees, and the underwater static contact angle between the membrane and oil is greater than 130 degrees. The provided membrane can be used to separate and purify oil-water mixture and emulsified oil-water generated by chemical engineering production, daily life, crude oil leakage accidents, and the like, and has a very important application value and wide application range.

Owner:SUZHOU BINARY CENTURY NANO TECH +1

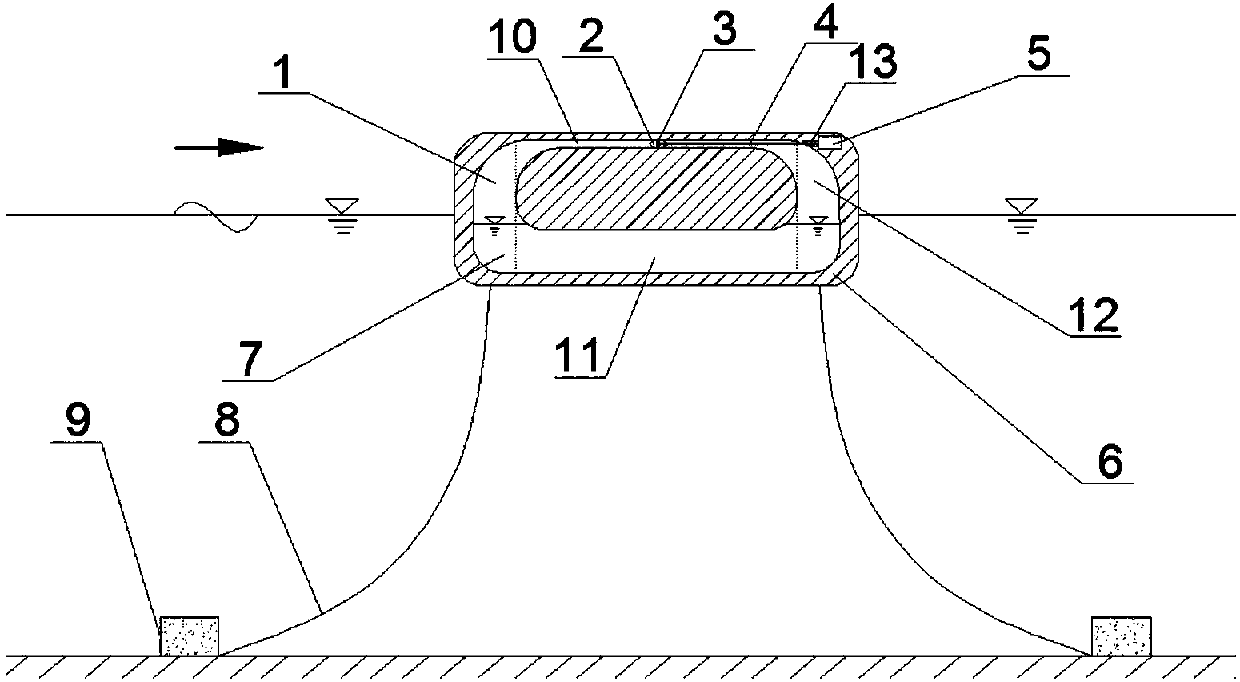

Floating breakwater capable of giving consideration to inner oscillation water column wave energy conversion function and method

The invention discloses a floating breakwater and a method capable of giving consideration to an inner oscillation water column wave energy conversion function. In the floating breakwater capable of giving consideration to the inner oscillation water column wave energy conversion function, the exterior of a floating body is anchored into a seabed through an anchor rope connection sinking block; anoverhauling channel is arranged at the upper part of the floating body; and wave energy conversion related configurations are arranged in the floating body, and comprise an air chamber, an air turbine, a turbine bracket, a linkage shaft, a generator, a cushion layer and an air chamber inner water body. A realization method of the floating breakwater capable of giving consideration to the inner oscillation water column wave energy conversion function comprises the steps of a breakwater arrangement process, a process of the floating body eliminating the wave effect, a wave energy conversion output process and an overhauling process. On the basis of maintaining traditional wave retaining and eliminating functions of the floating breakwater, the wave energy conversion function is realized byusing the oscillation design of water in an air chamber, and the power output in the wave energy conversion process is continuous, so that the reliability is good; the stress design of the breakwateris reasonable, and the durability is excellent; and meanwhile, the construction cost is low, and the engineering production advantages are obvious.

Owner:ZHEJIANG UNIV

Pure titanium or titanium alloy/carbon steel laminar composite plate welding method

ActiveCN105798440AEffective butt weld connectionImprove barrier propertiesArc welding apparatusWelding/soldering/cutting articlesButt weldingTitanium

The invention discloses a pure titanium or titanium alloy / carbon steel laminar composite plate welding method. A pure titanium or titanium alloy / carbon steel laminar composite plate is formed by metallurgically connecting an industrial pure titanium or titanium alloy plate with a carbon steel plate through explosion and hot rolling processes; a welding groove is finely designed and machined for the composite plate; MAG and TIG fusion welding technologies are combined; the plate-plate butt welding connection is performed for the pure titanium or titanium alloy / carbon steel laminar composite plate by a spraying transition technology; and a spraying layer is excellent in formation, compact and high in bonding force with a lower-layer material, achieves an excellent metallurgy transition connecting effect, and prevents generation of brittle and hard phases in welding lines. The welding method realizes engineering production of metallurgy butt welding connection of the pure titanium or titanium alloy / carbon steel laminar composite plate, is better in appearance and excellent in mechanical performance of metallurgy connection welding lines, guarantees corrosion resistance of the welding lines, and realizes reliable metallurgy connection of the welding lines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

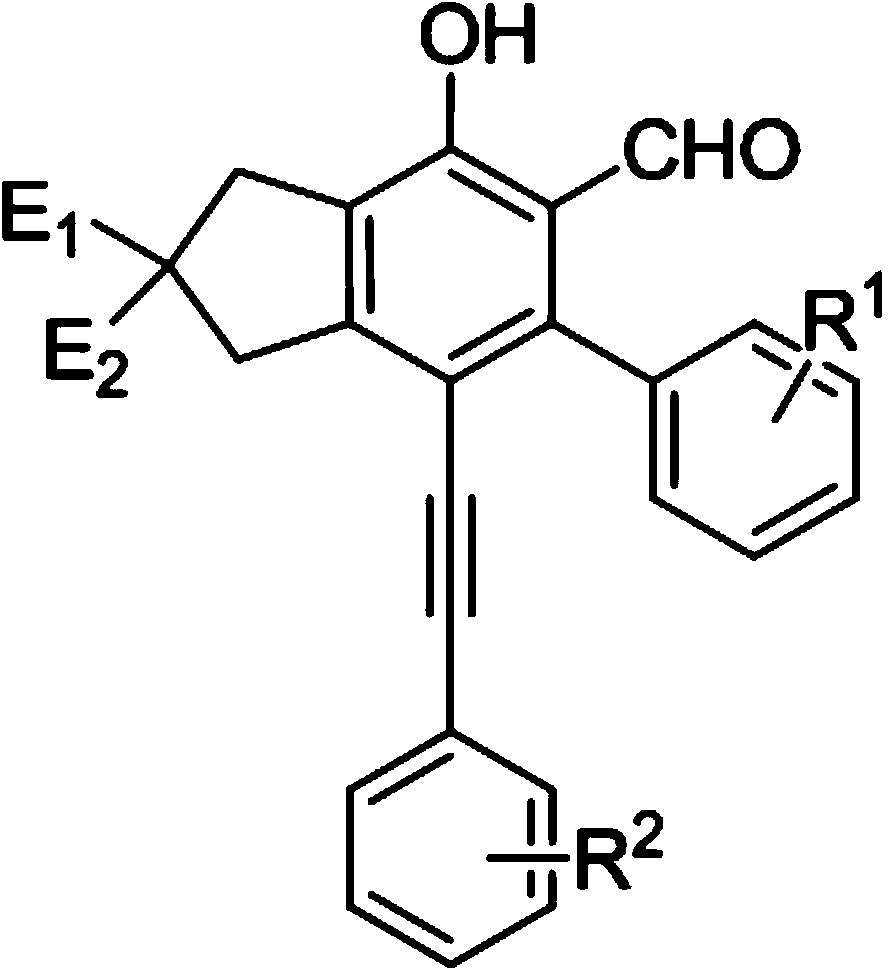

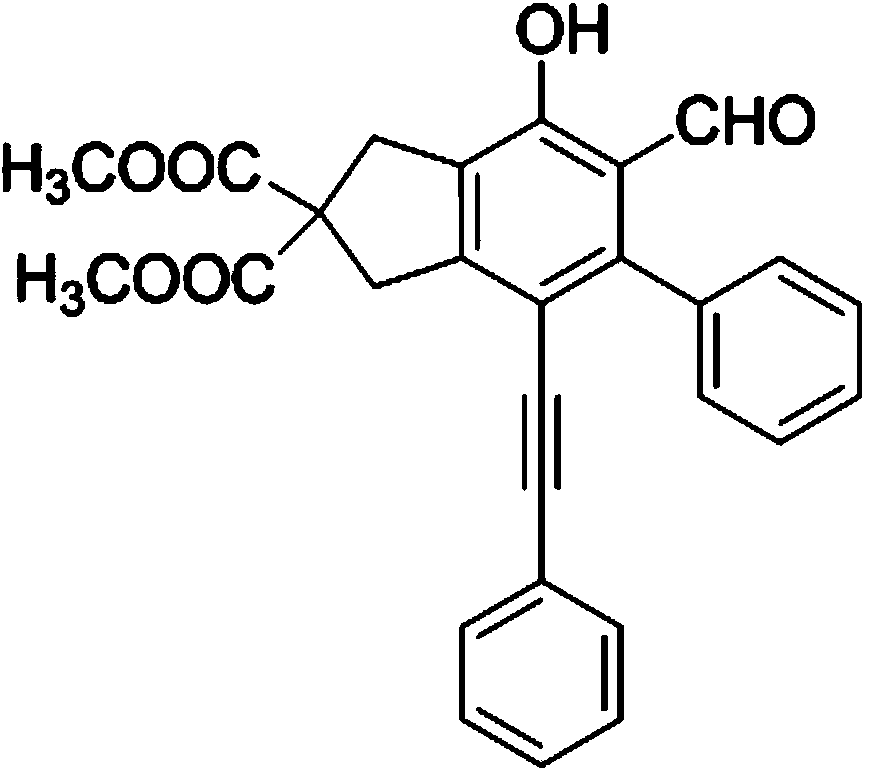

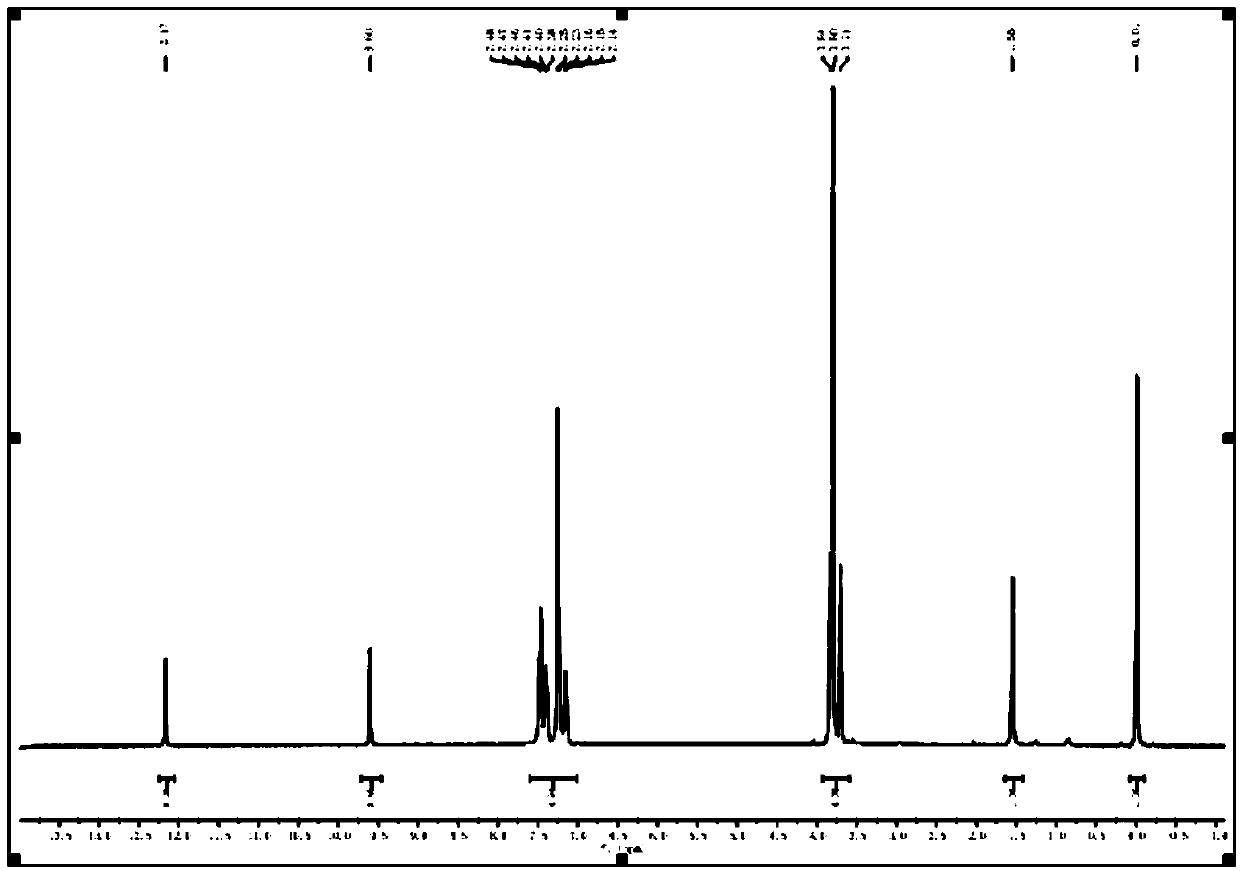

Salicylaldehyde derivatives and preparation method thereof

ActiveCN103992225AComplex structureBroad use prospectsOrganic compound preparationCarboxylic acid esters preparationSalicylaldehydeSynthesis methods

The present invention provides salicylaldehyde derivatives and a preparation method thereof. The preparation method comprises: a, precursor synthesis; b, target product synthesis; and c, purification. Compared with the salicylaldehyde derivative and the preparation method thereof in the prior art, the salicylaldehyde derivative and the preparation method thereof of the present invention have the following characteristics that: the completely-new poly-substituted salicylaldehyde derivative synthesis method is provided, a series of the new salicylaldehyde derivatives are produced, and compared with the ordinary salicylaldehyde derivative, the prepared salicylaldehyde derivative of the present invention has multiple rings so as to have the complex and diverse structure, and presents wide application prospects in chemical engineering production and clinical medicine.

Owner:ANHUI NORMAL UNIV

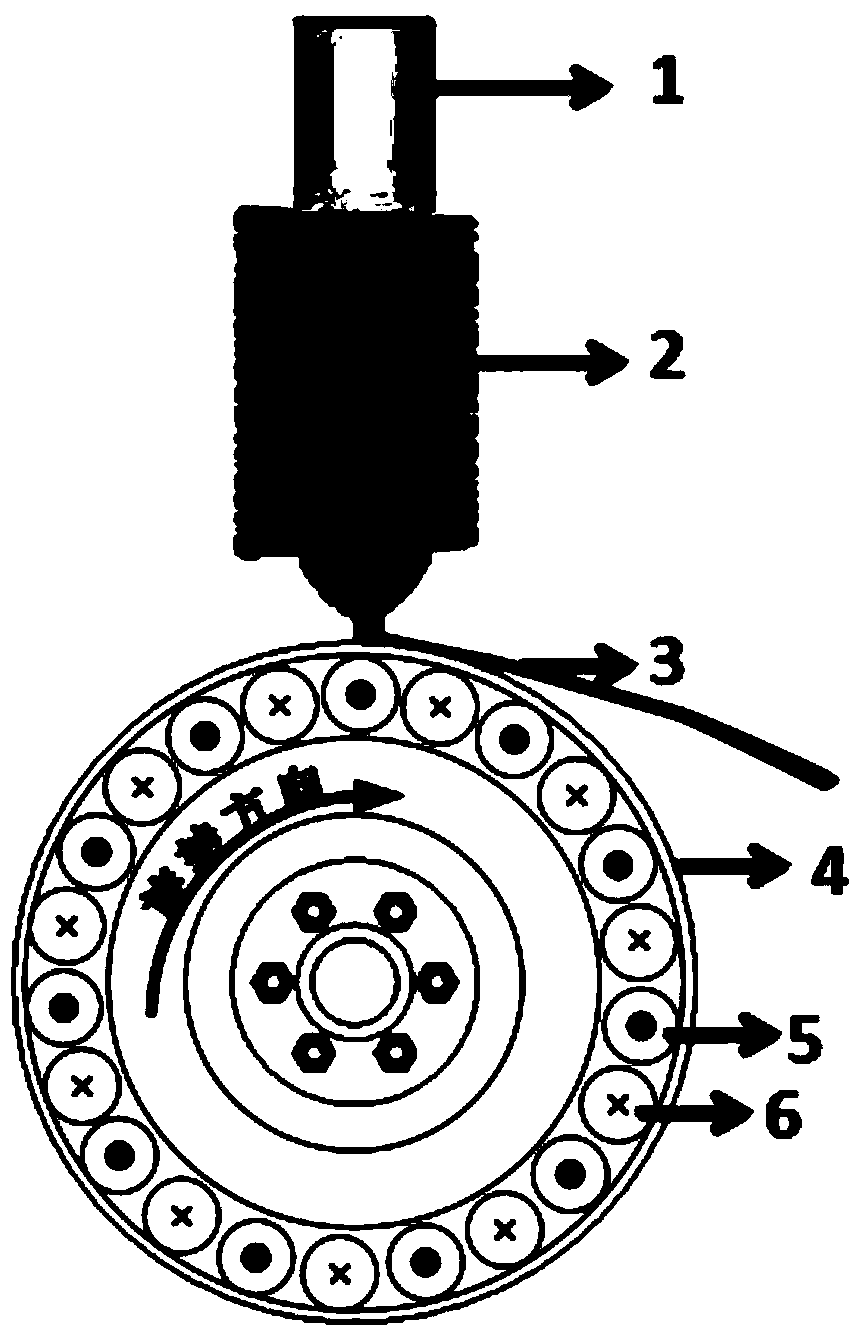

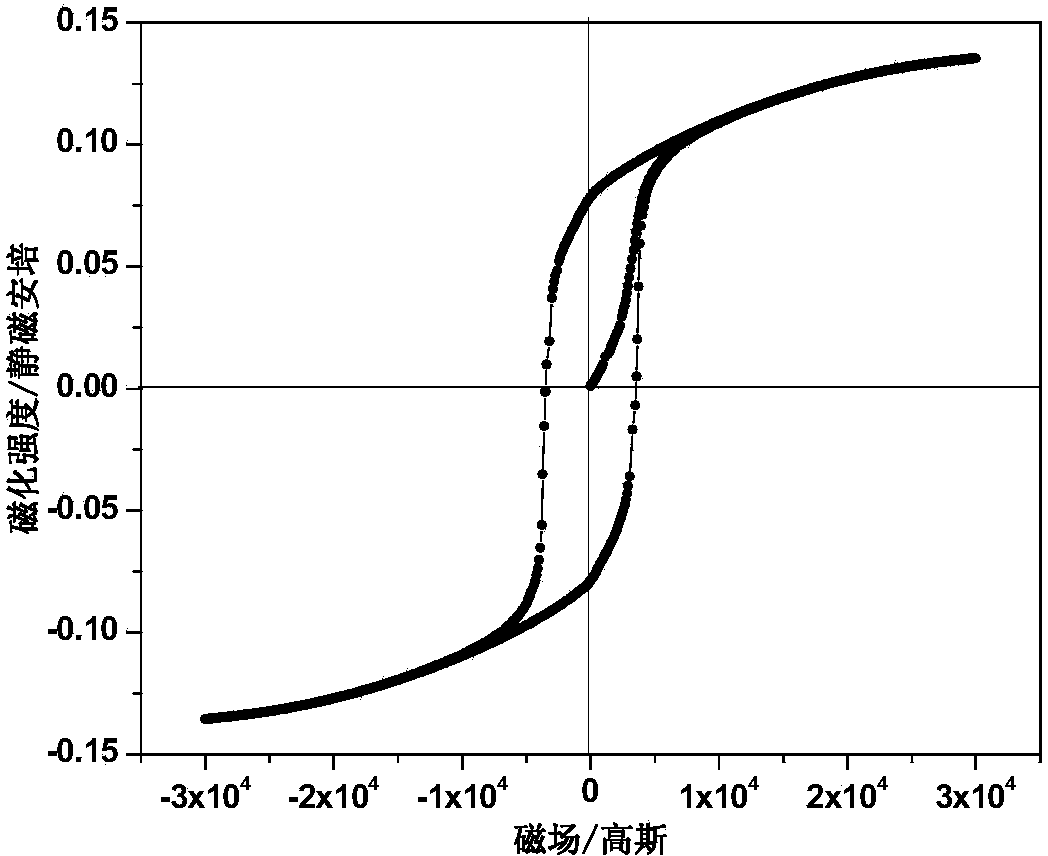

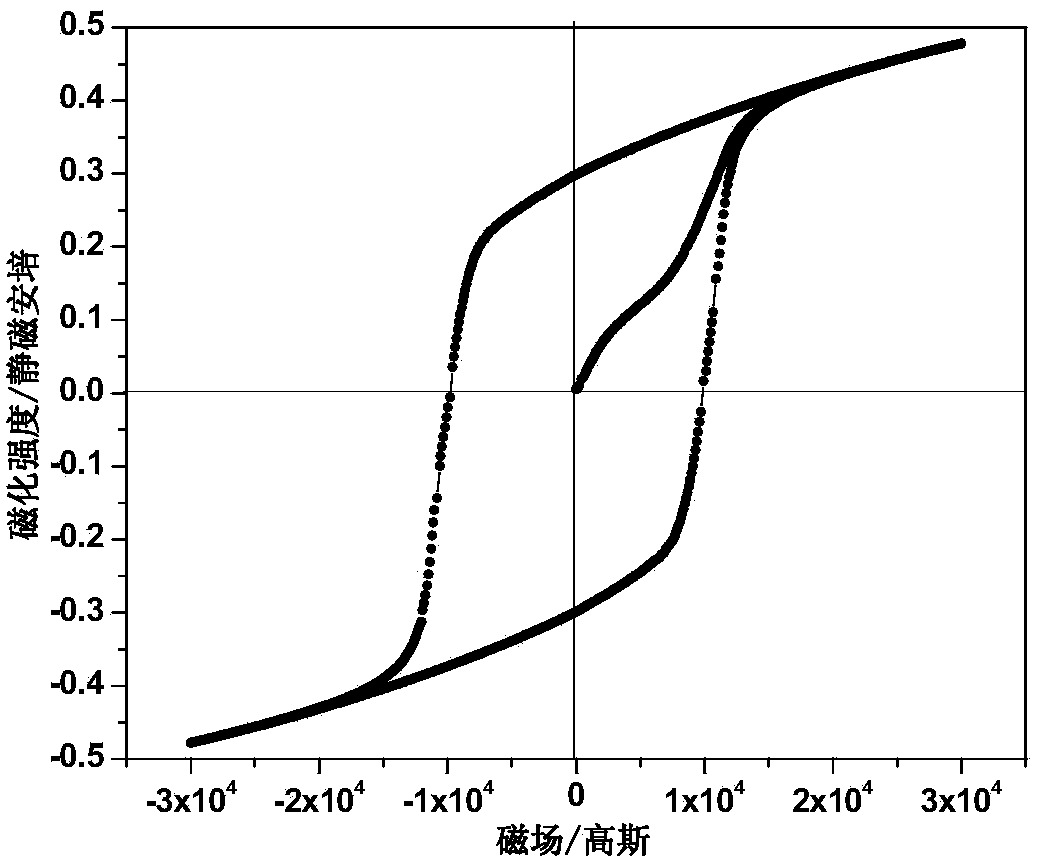

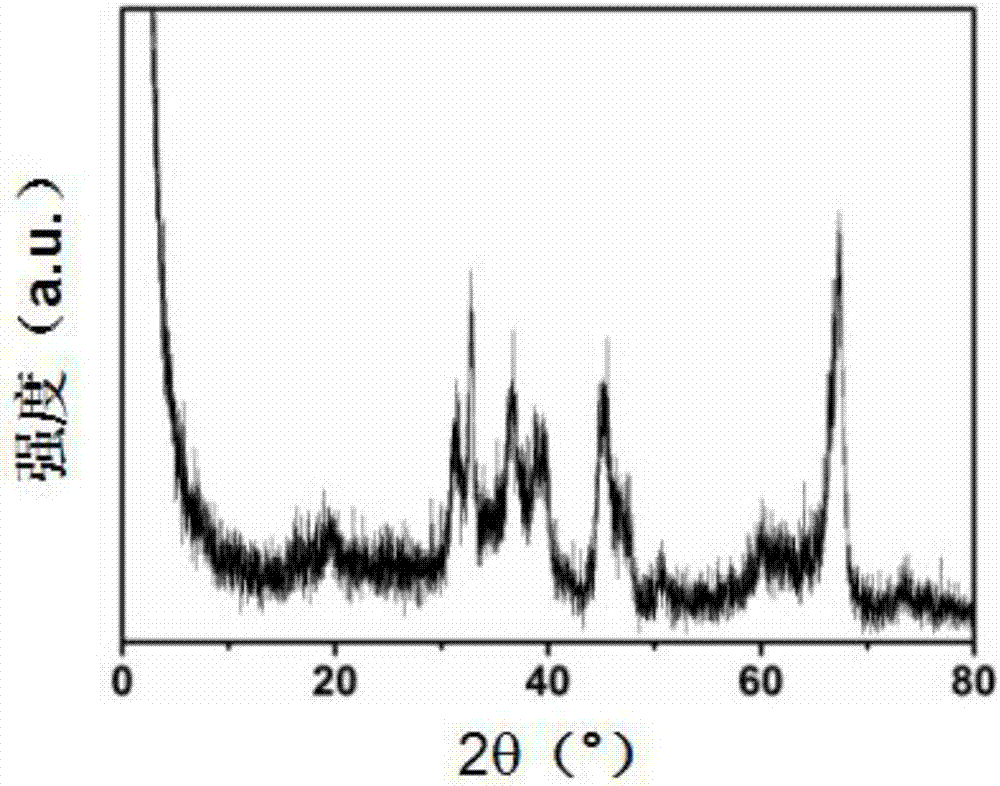

Ferro-cerium-based rapid quenching permanent magnet powder and preparation method of ferro-cerium-based rapid quenching permanent magnet powder

ActiveCN103714928ALower melting temperatureShorten smelting timeInorganic material magnetismCeriumEngineering production

The invention relates to ferro-cerium-based rapid quenching permanent magnet powder and a preparation method of the ferro-cerium-based rapid quenching permanent magnet powder. The alloy composition chemical formula of the ferro-cerium-based rapid quenching permanent magnet powder is [Ce100-x, Rex]aFe100-a-b-cBbTMc, wherein the x is the mass percent of the rare earth gross, the a, the b and the c show the mass percents of corresponding elements respectively, 0<=x<=50%, 27.5%<=a<=32%, 0.8%<=b<=1.5%, 0.5%<=c<=5%, the Re is one or more of Nd, Pr, Dy and Tb, and the TM is one or more of Ga, Co, Cu, Nb and Al. According to the preparation method, the ferro-cerium-based rapid quenching permanent magnet powder and Re'-Fe-B without Ce can be prepared with a water-cooling electromagnetic roller (a copper alloy roller or a molybdenum roller), and a ferro-cerium-based hot-pressing magnet with double hard magnetic principal phases or multiple hard magnetic principal phases can be prepared with the two kinds of magnetic powder. The ferro-cerium-based rapid quenching permanent magnet powder fills up blanks of middle-grade magnet powder and lower-grade magnet powder on the market at present, the product performance cost ratio is high, and the ferro-cerium-based rapid quenching permanent magnet powder and the preparation method are suitable for engineering production.

Owner:CENT IRON & STEEL RES INST

High-temperature high-pressure tubular-flow erosion corrosion experiment device

A high-temperature high-pressure tubular-flow erosion corrosion experiment device mainly includes: a high-temperature high-pressure kettle, a first pressure meter, a temperature meter, a sample test tube, an actual object test tube, a sample trough, a magnetic pump, a liquid transporting pipe, and an ultrasonic flow rate meter. The high-temperature high-pressure kettle is used for providing a fluid at certain temperature and under certain pressure. The actual object test tube is connected to a third joint and a fourth joint of the liquid transporting pipe through a second flange. An actual object tube is fixed in the actual object test tube through a first corrosion-resistant sealing ring. The sample test tube is connected to a first joint and a second joint of the liquid transporting pipe through a first flange. The sample trough, in which a sample is hung, is formed in the sample test tube. The magnetic pump is used for providing power to the experiment device for driving fluid circulation. The ultrasonic flow rate meter is used for testing the speed of the circulated fluid. The whole experiment device is made of corrosion-resistant alloy and a heat insulation layer covers external walls of all parts, so that temperature loss is avoided. The device is suitable for drilling production engineering of petroleum and natural gas.

Owner:SOUTHWEST PETROLEUM UNIV

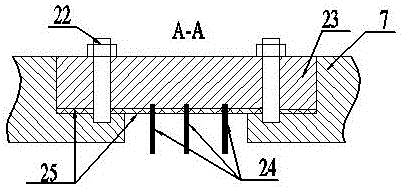

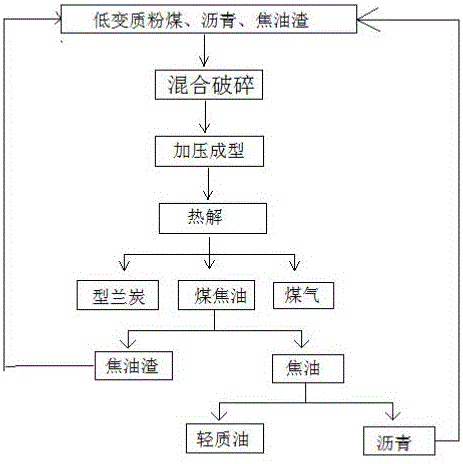

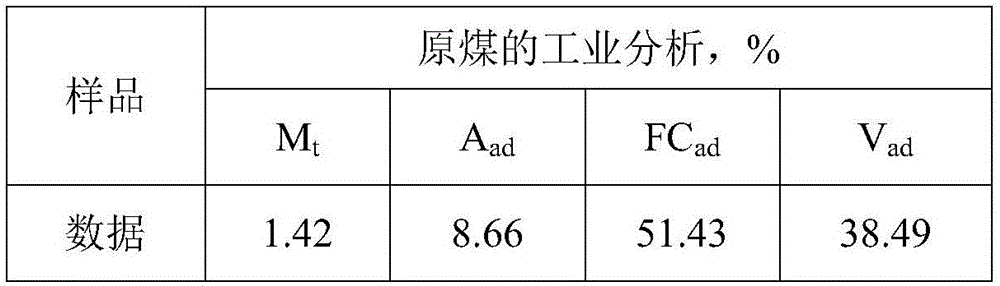

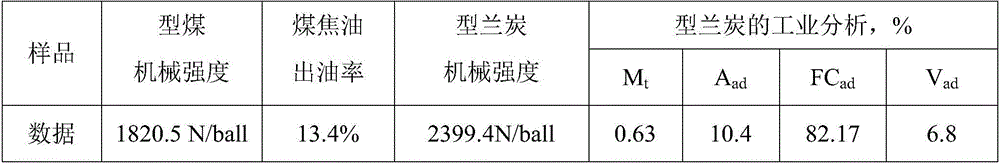

Forming destructive distillation method for crushed low metamorphic coal powder, asphalt and tar residues

ActiveCN106701133AImprove oil yieldSolve the problem of low utilization valueLiquid hydrocarbon mixture productionCoking carbonaceous materialsAdhesiveTar

The invention discloses a method of preparing formed semi-coke by using low metamorphic coal powder, asphalt and tar residues as raw materials and belongs to the technical field of coal chemical engineering. The method comprises the following steps: mixing and crushing low metamorphic coal, asphalt and tar residues to obtain raw material powder; pressurizing and forming the raw material powder in a forming mould to obtain molded coal; and pyrolyzing the molded coal in a destructive distillation device to obtain molded semi-coke, coal tar and gas. By taking the coal ash as the raw material, the utilization efficiency is improved, so that the problem that the semi-coke producing raw material is insufficient is solved, and meanwhile, the situation that the coal resource is short is also alleviated; by using asphalt and tar residues as an adhesive, not only is the problem that waste residues generated in the chemical engineering production process cannot be effectively treated and the utilization value is low to realize recycle of the abandoned resource, but also remarkably improves the oil yield of the coal tar. The stability and mechanical strength of the molded coal and the molded semi-coke are remarkably enhanced, and the economical benefit of an enterprise is extremely improved, thereby developing a novel path for semi-coke production.

Owner:YULIN UNIV

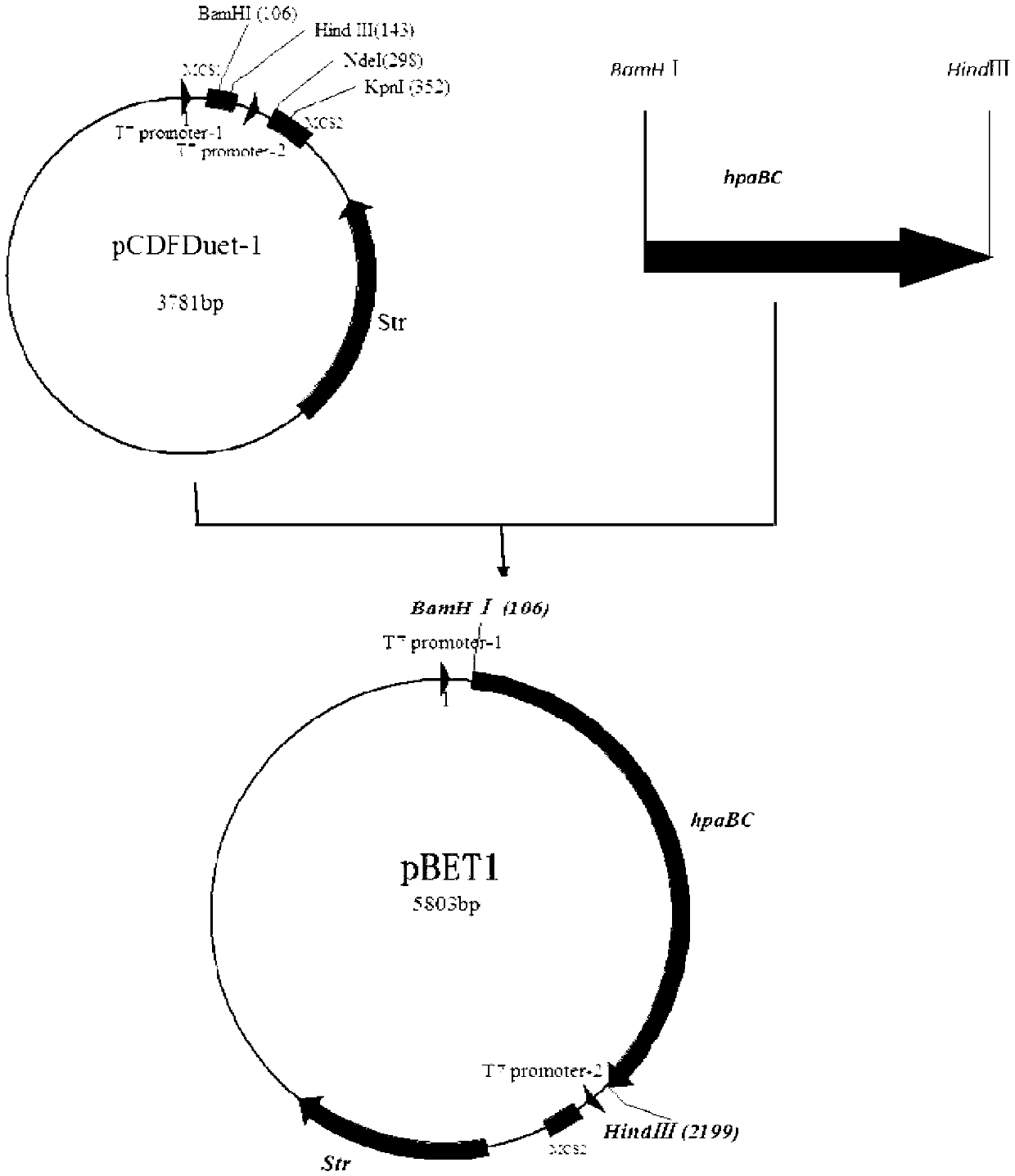

Method for improving biosynthesis of levodopa

InactiveCN103122361AOptimizing BioprocessingIncrease productionBacteriaMicroorganism based processesEscherichia coliBiotechnology

The invention discloses a method for improving biosynthesis of levodopa. The method comprises the following steps of: (1) using SEQ ID No.1 and SEQ ID No.2 as the primers, using an E.coli BL21 strain as the template, amplifying and recycling so as to obtain a hpaBC gene segment, conducting double digestion on a pCDFDuet-1 plasmid and the hpaBC gene segment, connecting and preparing a recombinant plasmid pBET1; (2) introducing the recombinant plasmid pBET1 into host escherichia coli so as to obtain transformed host cells; and (3) selecting the transformed host cells so as to obtain a levodopa production engineering bacteria single colony, taking 1ml of the levodopa production engineering bacteria single colony and putting into 100ml of a first culture medium, cultivating and measuring OD600, adding an isopropyl-beta-D-sulfo-pyran galactoside water solution and ascorbic acid, continuing cultivating and measuring the content of the levodopa. By utilizing the method disclosed by the invention, the output of the levodopa is increased, the production cost is lowered, and the operation process is simplified.

Owner:TIANJIN UNIV

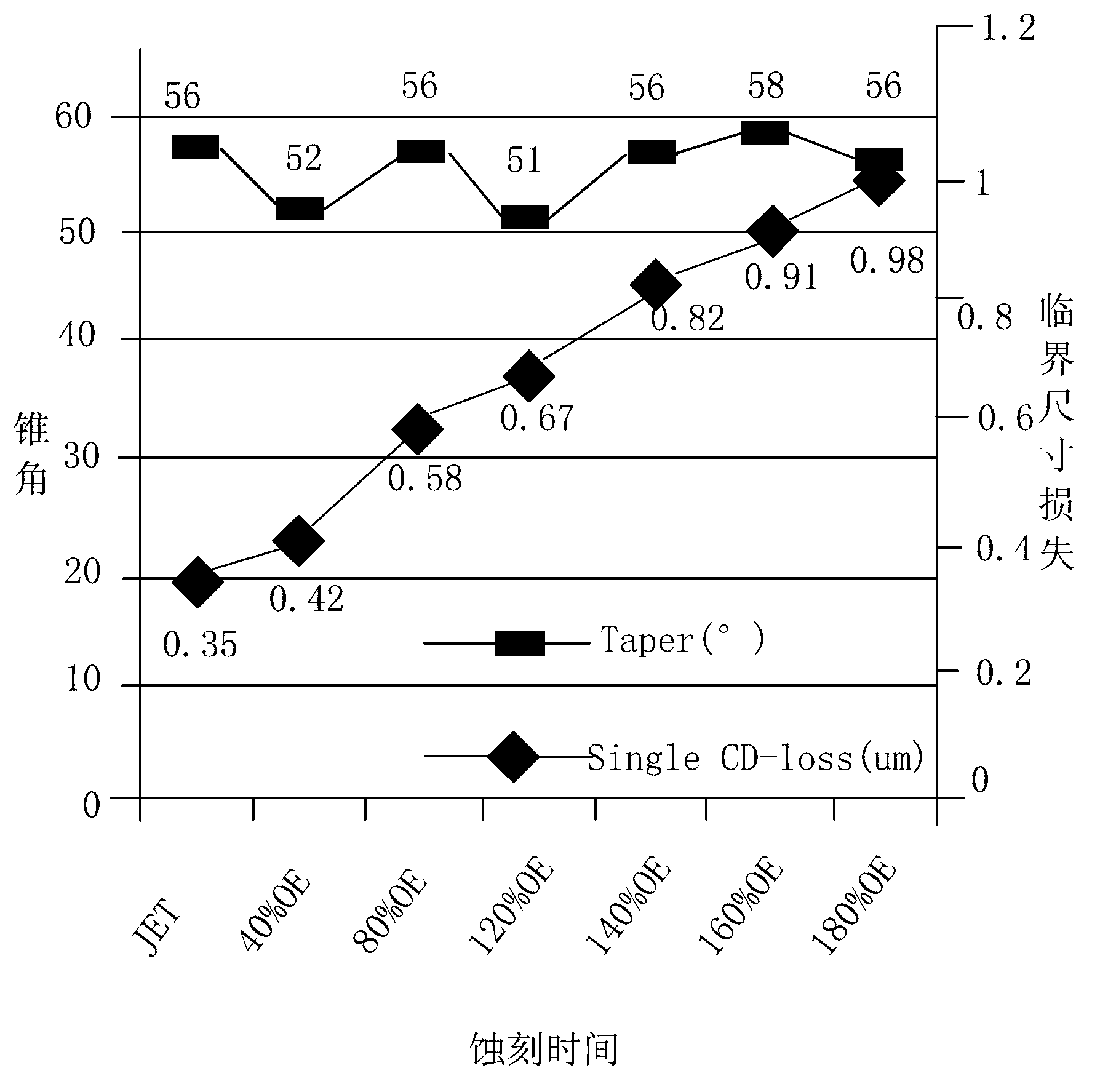

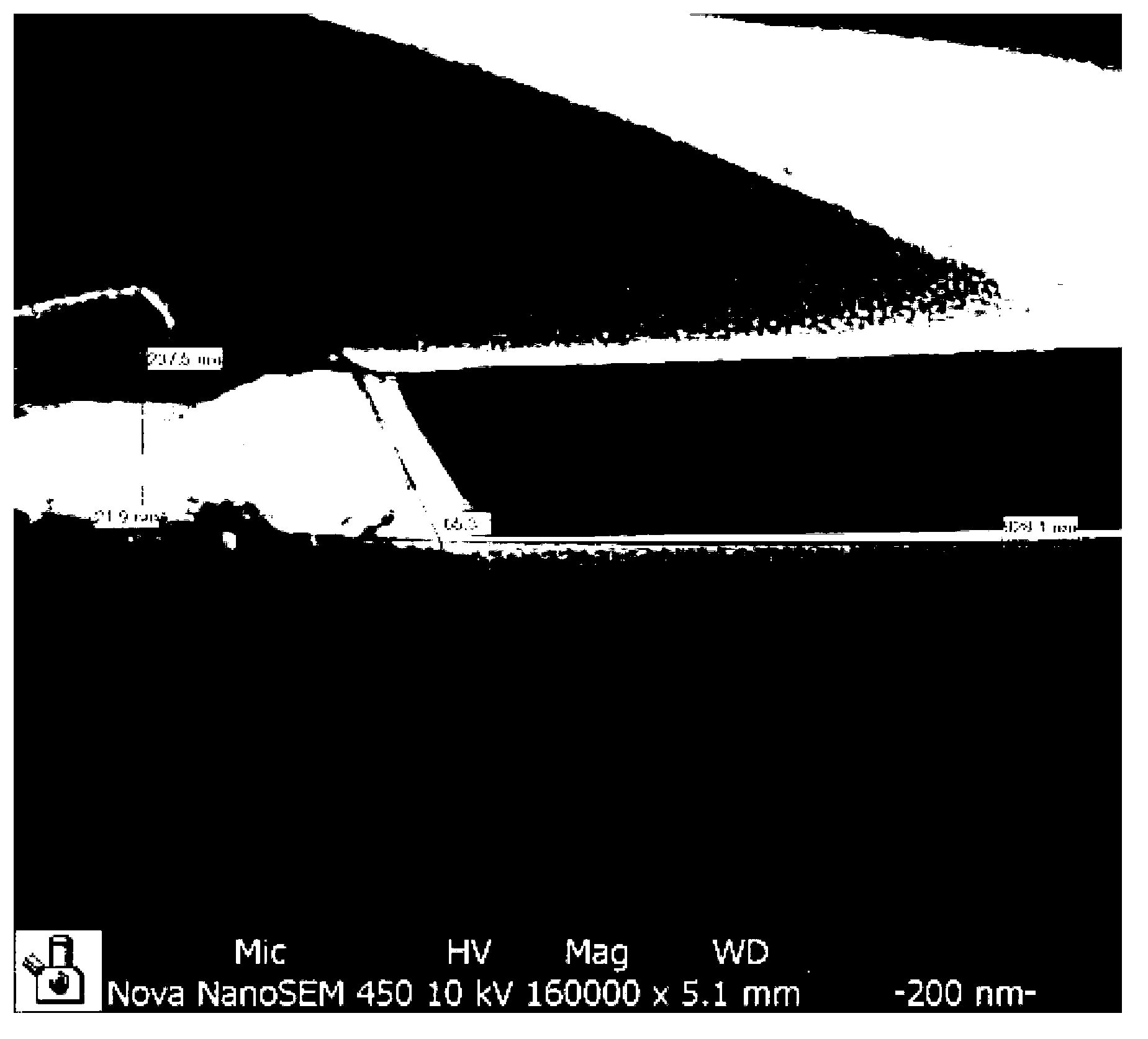

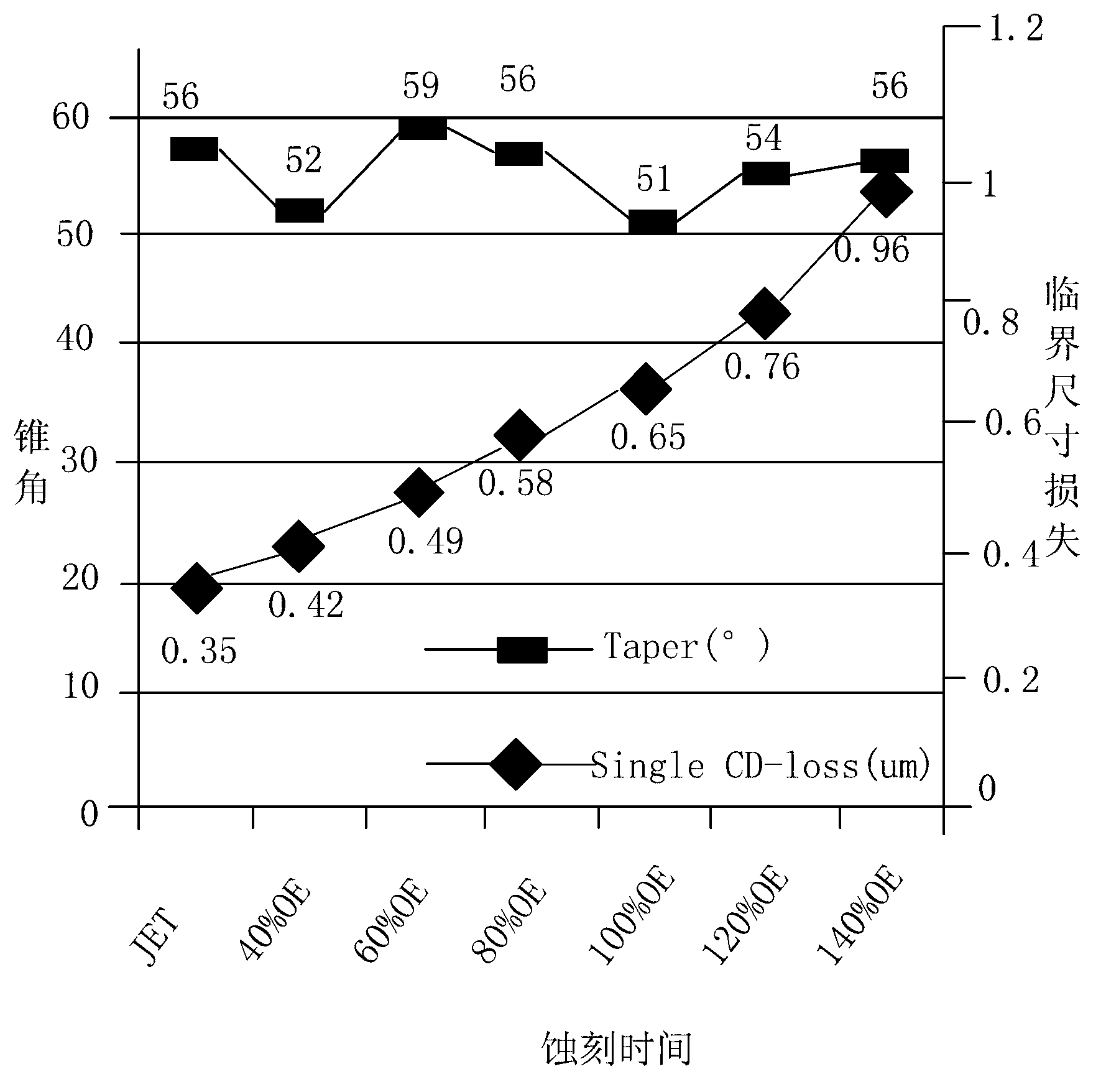

Etching liquid for TFT (thin film transistor)array substrate copper conductor

ActiveCN102703902AImproved feature of shorter process windowImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingCopper conductorPhosphoric acid

The invention relates to etching liquid for a TFT (thin film transistor)array substrate copper conductor. The etching liquid comprises primary oxidant, secondary oxidant, a chelating agent, inhibitor and additive, wherein the primary oxidant is hydrogen peroxide; the secondary oxidant is phosphoric acid, sulfuric acid and nitric acid; the chelating agent is amino compounds; the inhibitor is aminoimidazole compounds and carboxylic acid compounds; and the additive is amine compounds containing ammonia nitrogen and carboxy oxygen coordination atoms. According to the etching liquid, the characteristic of shorter process windows of the etching liquid for the copper conductors is obviously improved, the engineering control difficulty is reduced, and the stability of engineering production and the output yield are improved by means of the components and the types of the novel chelating agent and the additive; the shelf-time stability is improved, and the stability of the etching performance can be kept in the later shelf-time storage period; and the service life (more than or equal to 5,000 ppm) is prolonged, the process windows are not obviously narrowed in the later processing period, and the properties and the like are relatively stable.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Micro-spherical silicon oxide/aluminum oxide based noble metal catalyst and preparation method thereof

ActiveCN107233881ALarger than surfaceLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsDispersityPetrochemical

The invention provides a micro-spherical SiO2-Al2O3 based noble metal catalyst and a preparation method thereof. The preparation method comprises the following steps: dispersing silica sol into a silica sol system, so that silica sol is mixed with alumina sol and a coagulant to form formed sol, forming the sol by virtue of an atomizing dispersion-oil column formation method, and carrying out aging, washing, drying and roasting to obtain micro-spherical SiO2-Al2O3; and loading noble metal active components with the micro-spherical SiO2-Al2O3 as a carrier, obtain the micro-spherical SiO2-Al2O3 based noble metal catalyst. The catalyst has the characteristics that the specific surface area and the pore volume are large, the dispersity of active components is high, the abrasion index is relatively low, and the wear resistance is high. The catalyst is mainly applied to a hydrogenation process of preparing hydrogen peroxide by using a fluidized bed anthraquinone method and has relatively high catalytic activity, selectivity and stability. The catalyst can be also applied to reaction processes such as hydrorefining, selective hydrogenation and selective oxidation in petrochemical engineering and fine chemical engineering production.

Owner:BEIJING UNIV OF CHEM TECH

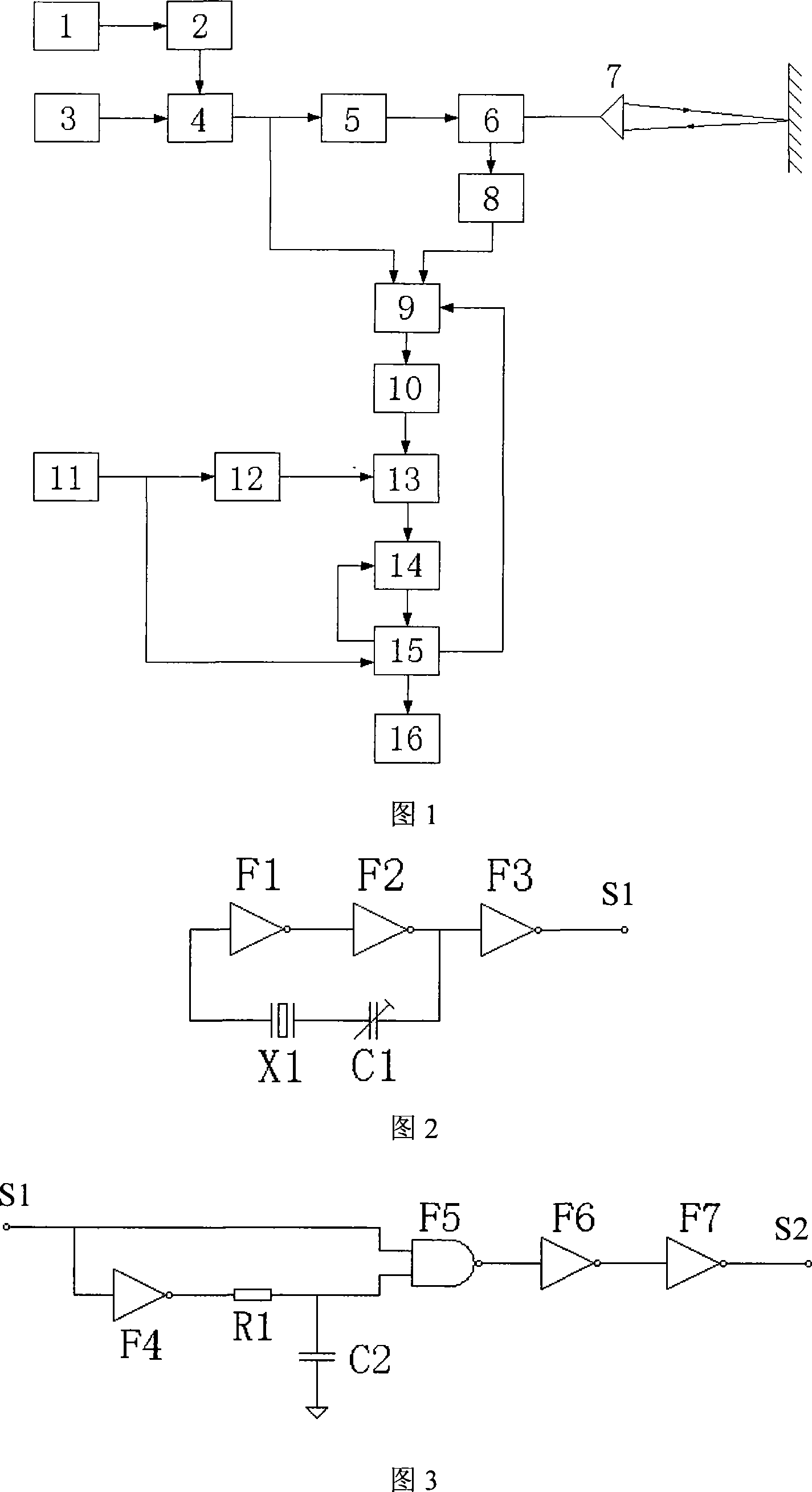

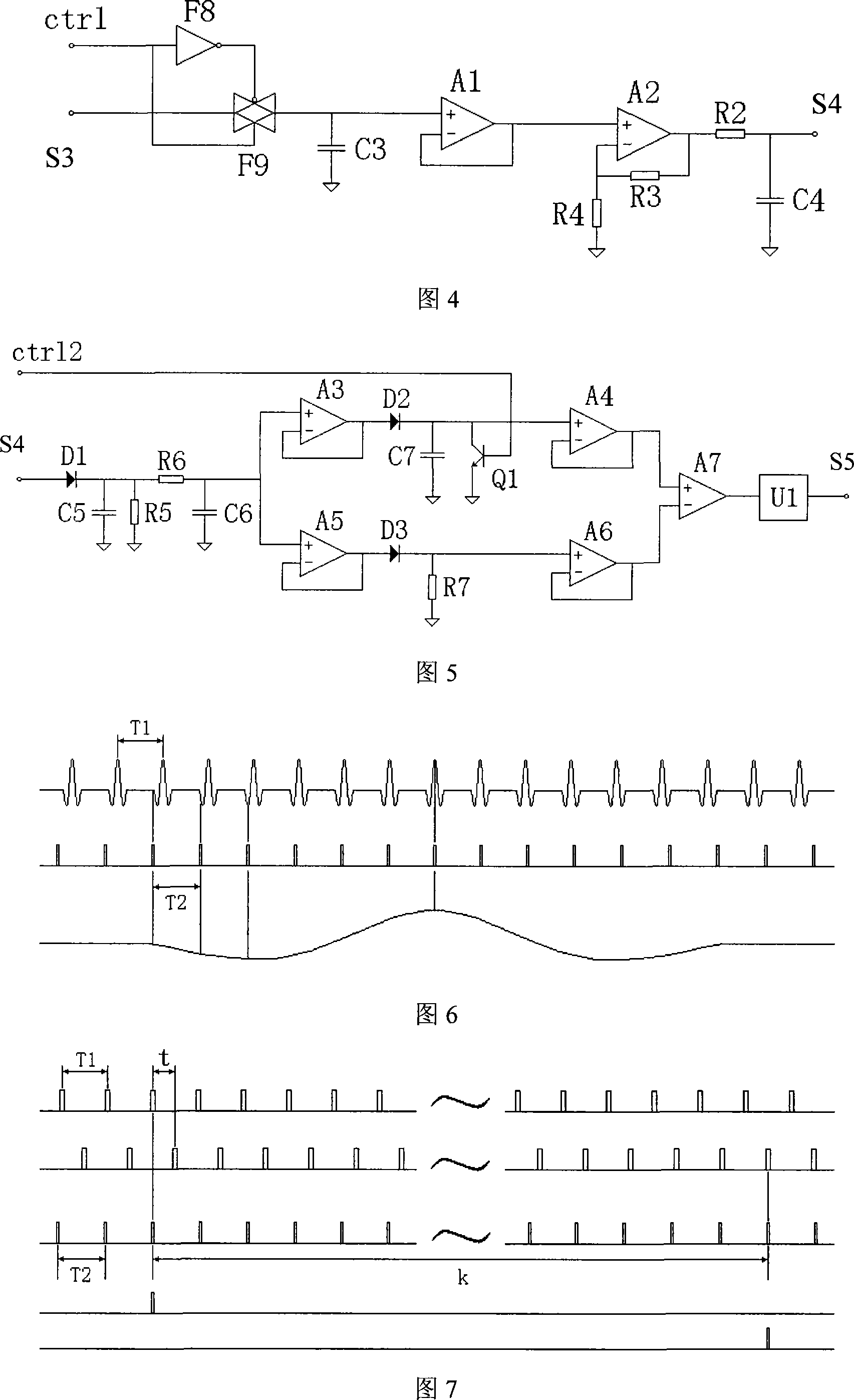

Microwave geodimeter

InactiveCN101162268AHigh resolutionSmall frequency differenceMachines/enginesLevel indicatorsMicrowave methodDisplay device

A microwave geodimeter relates to a distance measuring device, in particular to a high-accuracy noncontact distance measuring device with microwave method, mainly suitable for measuring material lever or liquid lever in containers or storehouses in industrial production engineering. The invention provides a microwave geodimeter which can realize a high-resolution distance measuring by using the prior electric elements. The invention comprises a transmitting device, a receiving device and a signal processing device. The transmitting device is provided with a first clock signal generator, a second clock signal generator, a pulse generator, a local oscillator, a switch, a power amplifier, a ring coupled circuit and an antenna. The receiving device is provided with an antenna, a ring coupled circuit and a low-noise amplifier; the input of the low-noise amplifier is connected with the output of the ring coupled circuit of the receiving device. The signal processing device is provided with a receiving / transmitting switch unit, a filter, a second clock signal generator, a pulse generator, a sampling smoothing circuit, a peak value testing circuit, a microprocessor and a display device.

Owner:XIAMEN UNIV

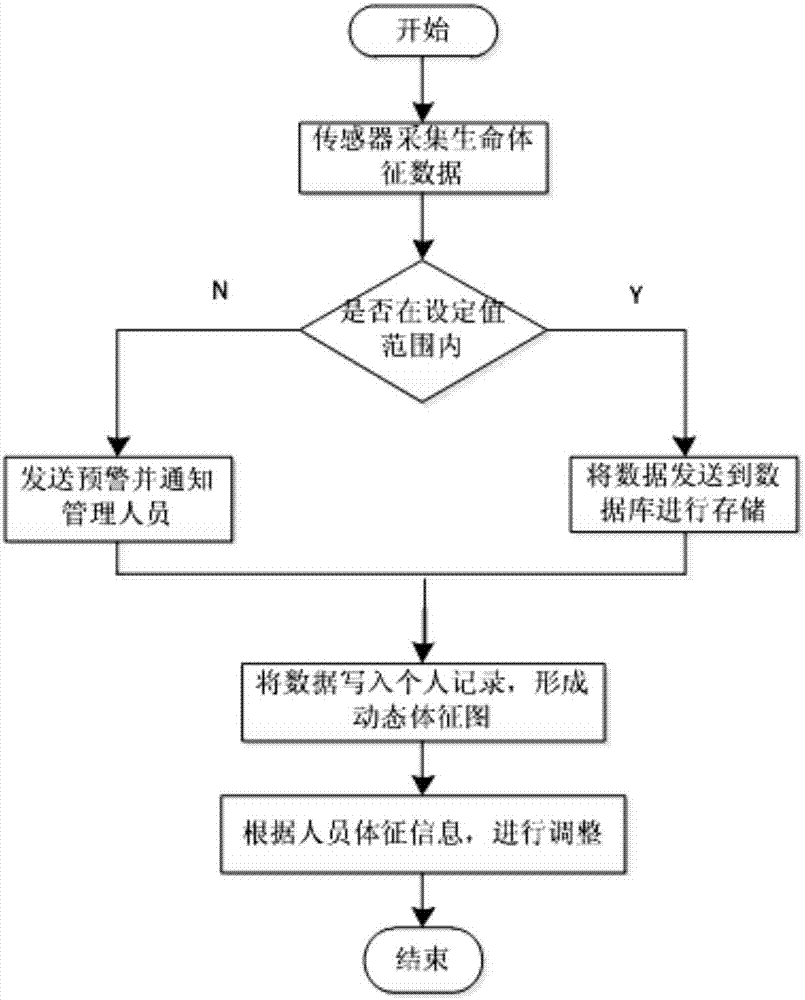

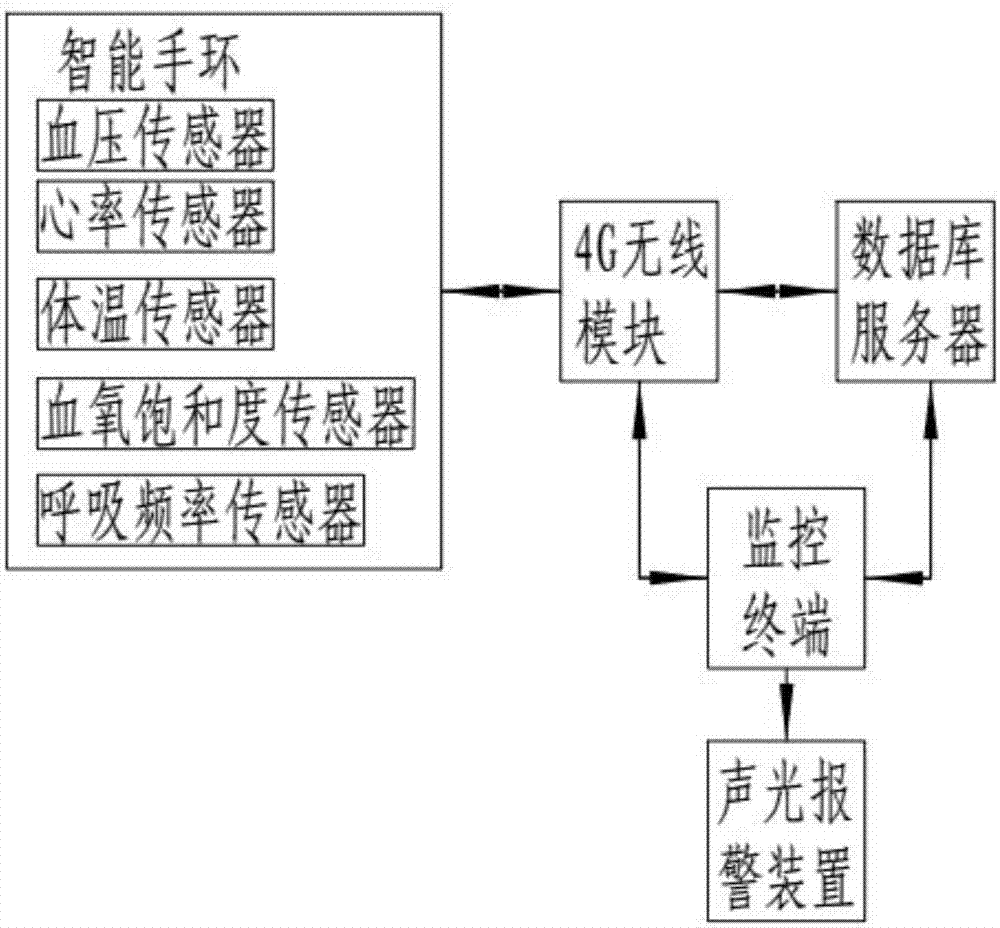

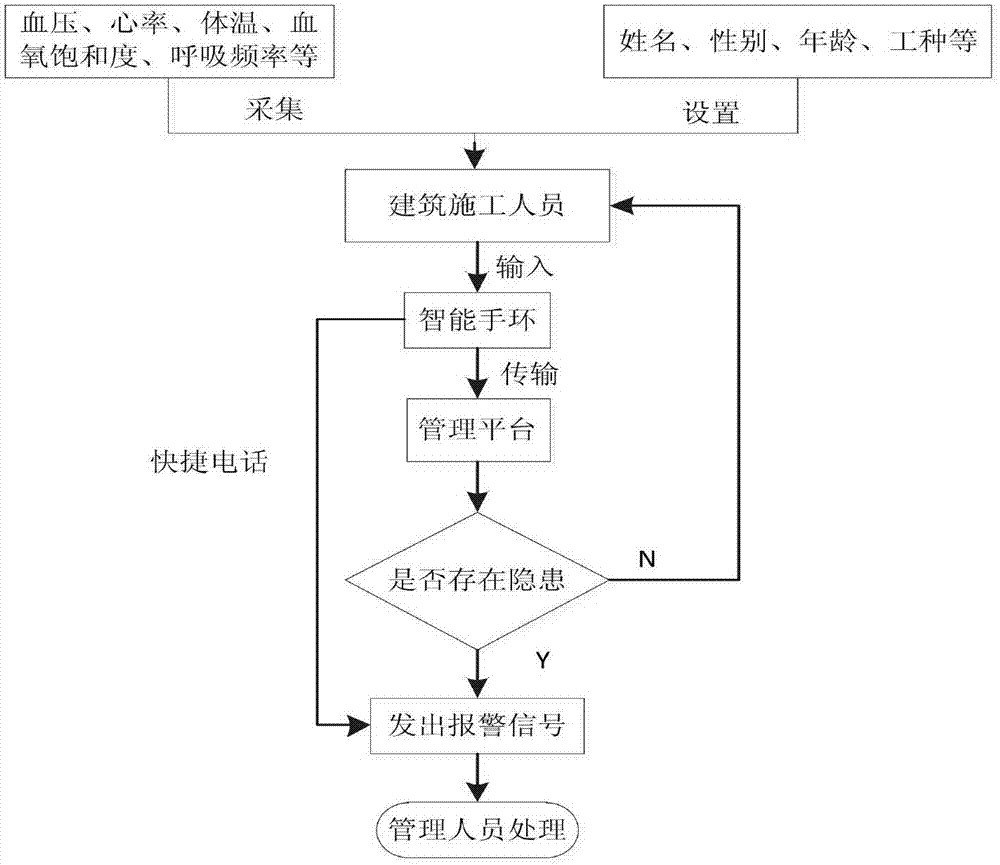

Construction worker vital sign monitoring system and method

PendingCN107874749AVital Signs MonitoringStrengthen security managementUser/patient communication for diagnosticsSensorsDatabase serverArchitectural engineering

The invention discloses a construction worker vital sign monitoring system and method. the construction worker vital sign monitoring system comprises an intelligent wristband and a monitoring terminal, wherein the intelligent wristband is provided with a sensor module capable of measuring blood pressure, heart rate, body temperature, oxyhemoglobin saturation and breath frequency, and a positioningmodule; the intelligent wristband is connected to the monitoring terminal via a wireless module; the system further has a database server; the database server is connected to the intelligent wristband; the monitoring terminal is connected to the database server via a network module; and the monitoring terminal is connected with an acoustic-optical alarm module. Construction worker vital signs canbe effectively monitored by the system and an alarm can be given out in time; potential safety dangers can be eliminated for construction workers and accidents can be prevented; construction workerscan be saved in time and rescue time is earned; construction worker life and property safety can be guaranteed; traditional construction worker safety management is greatly optimized; and constructional engineering production efficiency can be improved.

Owner:GUIZHOU UNIV

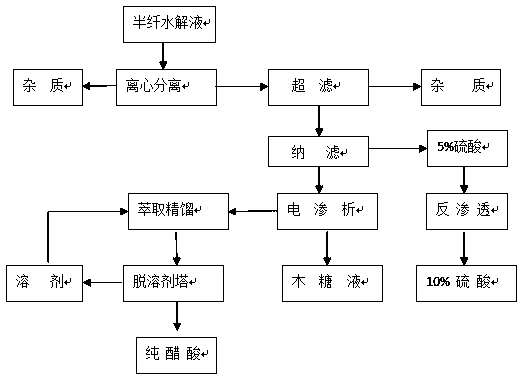

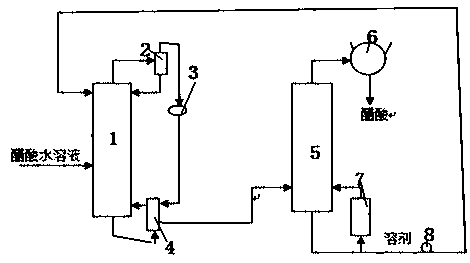

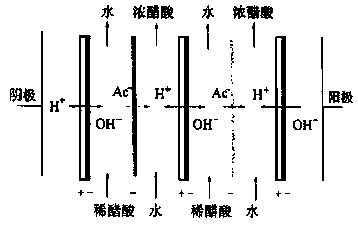

Refining method of xylose in hemicellulose hydrolysate

ActiveCN109575088AReduce recycling stepsReduce pollutionSugar derivativesXylose productionUltrafiltrationHydrolysate

The invention relates to the technical field of chemical engineering production, in particular to a refining method of xylose in hemicellulose hydrolysate. The method comprises the following steps of(1) removing impurities from the hemicellulose hydrolysate; feeding the hemicellulose hydrolysate into an ultrafiltration membrane to obtain transmission liquid; (2) separating the transmission liquidby the nanofiltration membrane; remaining sulfuric acid into concentrated liquid, wherein the transmission liquid contains acetic acid and xylose; (3) performing electrodialysis separation on aceticacid and xylose water solution; (4) directly using the xylose water solution for furfural production; (5) performing extraction and rectification on the acetic acid by solvents to obtain acetic acid with the concentration being 98.5 percent. The method has the advantages that the operation is simple; the obtained xylose water solution can be directly used for the furfural production; the acetic acid with the mass concentration being about 20 percent can be obtained; a solvent extraction rectification device is used for extraction separation to obtain the acetic acid with the mass concentrationbeing 98.5 percent. In the process, the separated sulfuric acid returns to the hydrolysis work procedure to be continuously used; active ingredients are recovered and reused; the production cost is reduced.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Gelled material for soil solidification

The invention provides a gelled material for soil solidification, belonging to the technical field of gelled materials. The gelled material comprises the following raw materials in percentage by mass: 20-40% of aluminum dreg micropowder, 30-50% of slag micropowder, 5-20% of fly ash, 10-15% of desulfurized gypsum and 1-5% of additive. The aluminum dreg micropowder adopted by the gelled material disclosed by the invention is aluminum-containing solid waste generated during production engineering of electrolytic aluminum, so that the waste is reused, the cost is saved, and the environment can be protected.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com