Treatment method for production wastewater of sulfonic acid group dye and dye intermediate of sulfonic acid group dye

A technology for dye intermediates and production wastewater, applied in the field of resource utilization, can solve the problems of no further treatment and recovery scheme, the problem of extraction agent stratification, engineering problems, etc., to achieve comprehensive utilization of wastewater treatment resources, and a wide range of applications , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

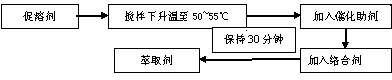

[0035] extractant according to figure 1 The preparation process shown is to prepare the solubilizer and heat it up to 50°C under stirring, then add the catalytic promoter, keep it at 60°C for 1 hour and then add the complexing agent to obtain the extractant; the complexing agent is tridecylamine, The mass percentage is 15%, the solubilizer is toluene, the mass percentage is 85%, and the catalytic promoter mass percentage is 0%.

[0036] The production wastewater is taken from the wastewater collection pool of the company's reactive dye production workshop. At this stage, the dyes produced in the workshop mainly include reactive black KNB, reactive yellow W, reactive red 090329, reactive yellow 3RFN, and acid black 1#. The appearance of the produced wastewater is dark brown, pH=6.8, and the total amount of organic matter is 19700mg / L.

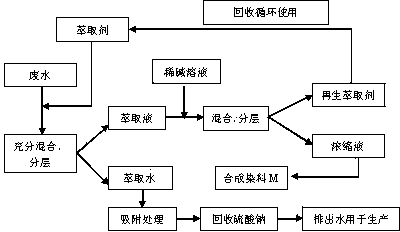

[0037] according to figure 2 In the method shown, slowly add dilute sulfuric acid with a mass concentration of 70% to the 5L of production w...

Embodiment 2

[0042] extractant according to figure 1 The preparation process shown is to prepare the solubilizing agent by raising the temperature to 60°C under stirring, then adding the catalyst promoter, and adding the complexing agent after maintaining at 50°C for 0.5 hours to obtain the extractant; the complexing agent is trioctylamine, The mass percentage is 45%, the solubilizer is xylene, the mass percentage is 50%, and the mass percentage of the catalytic assistant trialkylmethylamine chloride is 5%.

[0043] The production wastewater is taken from the H-acid mother liquor collection pool of the dye intermediate H-acid production workshop. The appearance of the obtained production wastewater is brown, pH=2.9, and the total organic matter is 39600mg / L.

[0044] according to figure 2 In the method shown, slowly add dilute sulfuric acid with a mass concentration of 30% to the 2L of waste water taken, and adjust the pH value to 1.5. Then mix it well with 1000ml of the prepared extrac...

Embodiment 3

[0049] extractant according to figure 1 The preparation process shown is to prepare the solubilizer and heat it up to 55°C under stirring, then add the catalytic promoter, keep it at 55°C for 45 minutes, and then add the complexing agent to obtain the extractant; the complexing agent is trioctylamine, The mass percentage is 20%, the solubilizer is dodecylbenzene, the mass percentage is 78%, and the mass percentage of the catalytic assistant trialkylmethylamine chloride is 2%.

[0050] The wastewater is taken from the wastewater collection pool of the company's reactive dye production workshop. At this stage, the workshop mainly produces reactive black KNB, acid black 1# and reactive yellow 3RFN and other varieties. The appearance of the collected wastewater is blue-brown, pH=2.9, and the total amount of organic matter is 22600mg / L.

[0051] according to figure 2 In the method shown, slowly add dilute sulfuric acid with a mass concentration of 50% to the 2L of waste water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com