Structure filter core for removing molybdenum in drinking water and preparation method of structure filter core

A drinking water and filter element technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of frequent regeneration, large one-time investment, incomplete regeneration, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

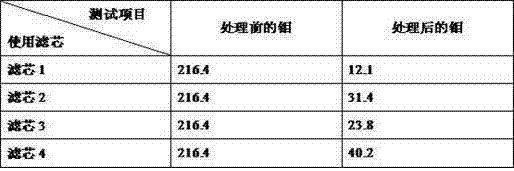

Examples

example 1

[0033] By mass percentage:

[0034] 170 mesh diatomite 35% iron-copper-zinc mixed powder 9% (80 mesh)

[0035] Acrylic adhesive 10% Azoaminobenzene 8%

[0036] 10 million molecular weight PTFE 38% (110 mesh)

[0037] Its preparation method is as follows:

[0038] Weigh each raw material according to the formula quantity, mix and stir evenly, place in a honeycomb mold, sinter at 500°C for 180 minutes, cool to room temperature and demould to obtain a porous honeycomb structure filter element.

example 2

[0040] By mass percentage:

[0041] 170 mesh diatomite 40% iron-copper-zinc mixed powder 6% (90 mesh)

[0042] Acrylic adhesive 8% Azoaminobenzene 6%

[0043] 9 million molecular weight PTFE 40% (140 mesh)

[0044] Its preparation method is as follows:

[0045] Weigh each raw material according to the formula amount, mix and stir evenly, place in a honeycomb mold, sinter at 400°C for 200 minutes, cool to room temperature and demould to obtain a porous honeycomb structure filter element.

example 3

[0047] By mass percentage:

[0048] 170 mesh diatomite 30% iron-copper-zinc mixed powder 10% (100 mesh)

[0049] Acrylic adhesive 10% Azoaminobenzene 10%

[0050] 11 million molecular weight PTFE 40% (100 mesh)

[0051] Its preparation method is as follows:

[0052] Weigh each raw material according to the formula quantity, mix and stir evenly, place in a honeycomb mold, sinter at 450°C for 300 minutes, cool to room temperature and demould to obtain a porous honeycomb structure filter element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com