Technique method for producing sodium bisulfide

A technology of sodium hydrosulfide and process methods, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of personnel poisoning and death, large power consumption, and many operating steps, so as to ensure quality and reduce power consumption , The effect of producing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

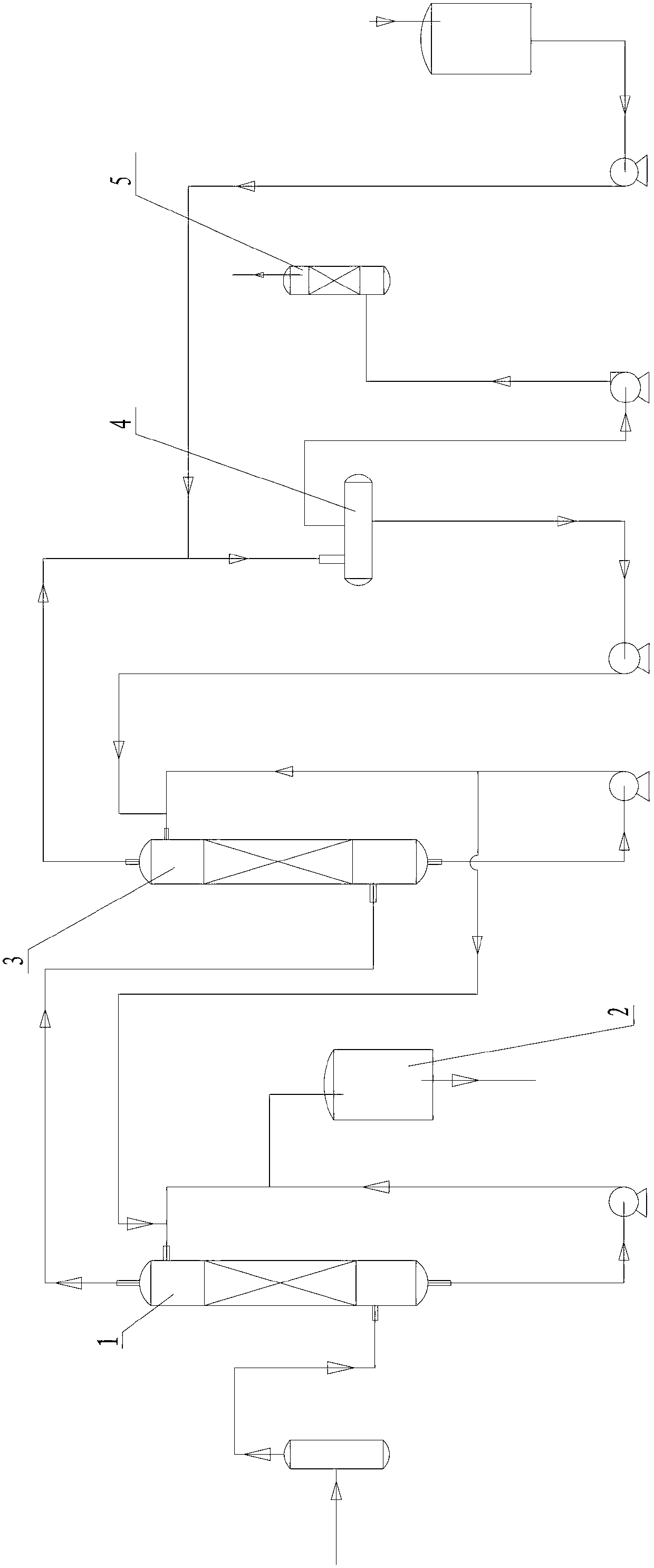

[0025] Such as figure 1 Shown is that a kind of production cost provided by the invention is low, in the production process, the processing method of the production sodium hydrosulfide that product quality is easy to control. The process method comprises the following steps,

[0026] Firstly, the hydrogen sulfide feed gas is sent to the hydrogen sulfide gas buffer tank for buffering, and the process absorption liquid whose main component is sodium sulfide is prepared;

[0027] Then, the buffered hydrogen sulfide gas and process absorption liquid are sent into the absorption tower 1 from the lower part and the upper part of the absorption tower 1 respectively, and the rising hydrogen sulfide gas is absorbed by the process of being sprayed down on the packing surface in the absorption tower liquid absorption, generate sodium hydrosulfide solution, and flow into the bottom of the absorption tower 1, and the unabsorbed hydrogen sulfide tail gas is discharged from the top of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com