Patents

Literature

83 results about "Sodium bisulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

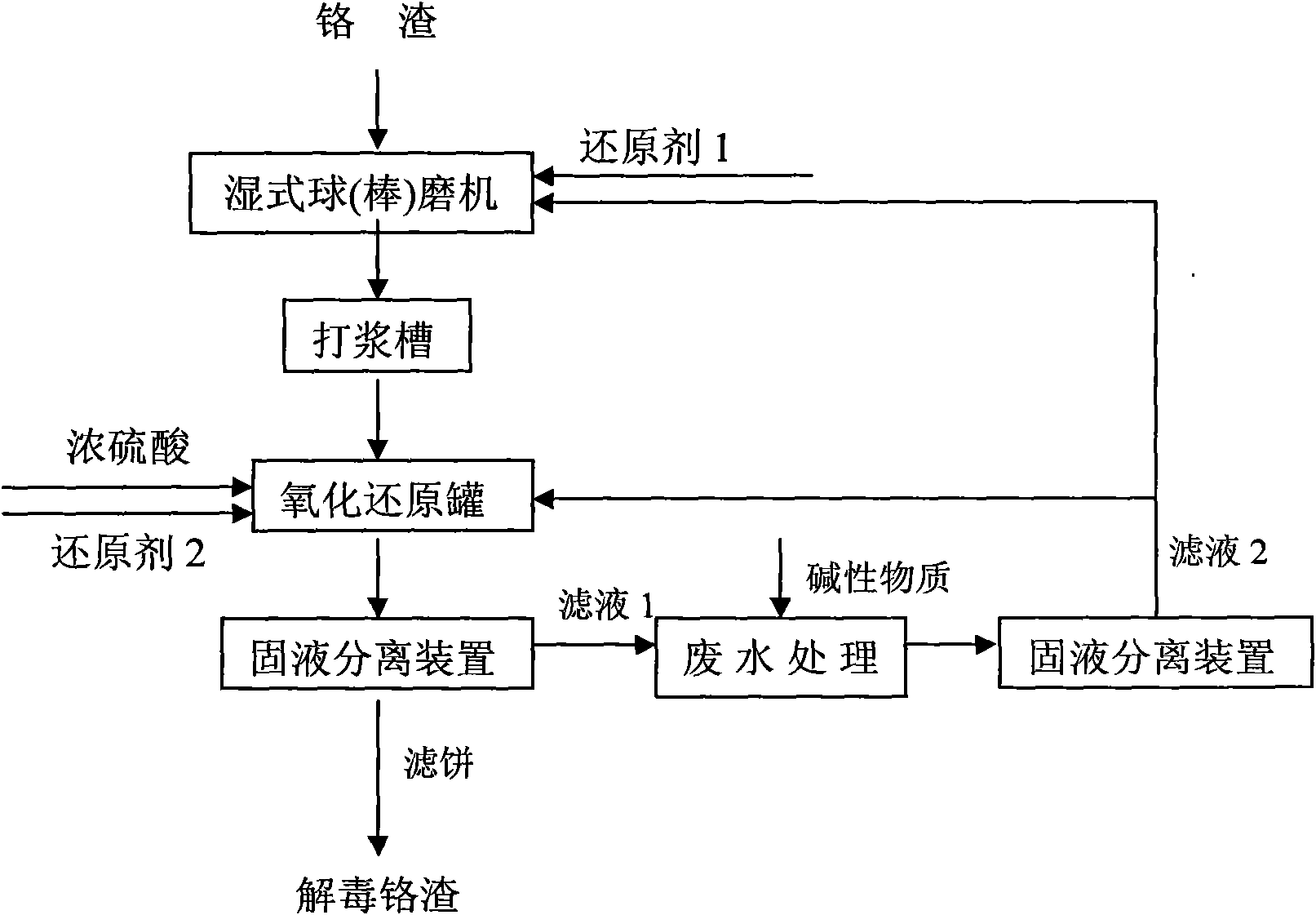

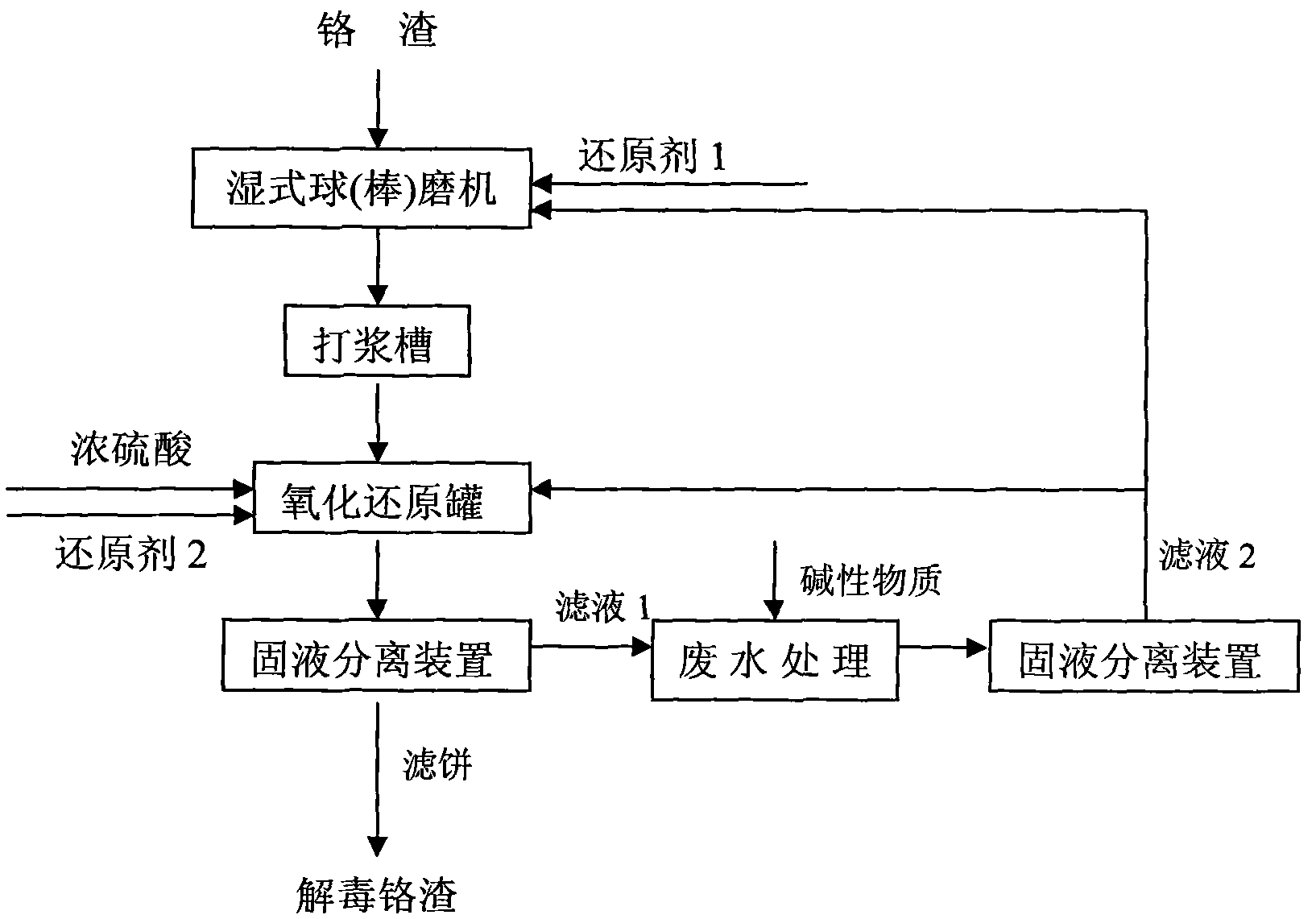

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

Technique method for producing sodium bisulfide

InactiveCN102765700AReduce power consumptionProduction costSulfur compoundsSodium bisulfideSodium hydrosulfide

The invention discloses a technique method for producing sodium bisulfide and belongs to the technical field of the chemical engineering production technology. The technique method for producing sodium bisulfide is low in production cost and can control product quality easily during production. The technique method includes: feeding buffered hydrogen sulfide and process absorption liquid with sodium sulphide as the main ingredient into an absorption tower respectively from the lower portion and the upper portion of the absorption tower, absorbing the hydrogen sulfide and the process absorption liquid on the surface of packing in the absorption tower to generate solution with the sodium bisulfide as the main ingredient, enabling the solution to flow to the bottom of the absorption tower, and discharging the unabsorbed hydrogen sulfide tail gas from the top of the absorption tower; pumping the solution at the bottom of the absorption tower out, returning most of the solution back to the absorption tower for recycling, feeding the small amount of solution to a sodium bisulfide production solution storing tank, and simultaneously adding the process absorption liquid in the absorption tower from the upper portion of the absorption tower during the absorption circulating process; and finally performing evaporation, concentration and dehydration on the solution, cooling the solution for molding, packaging and finishing the production of the sodium bisulfide.

Owner:CHENGDU DEMEI ENG TECH

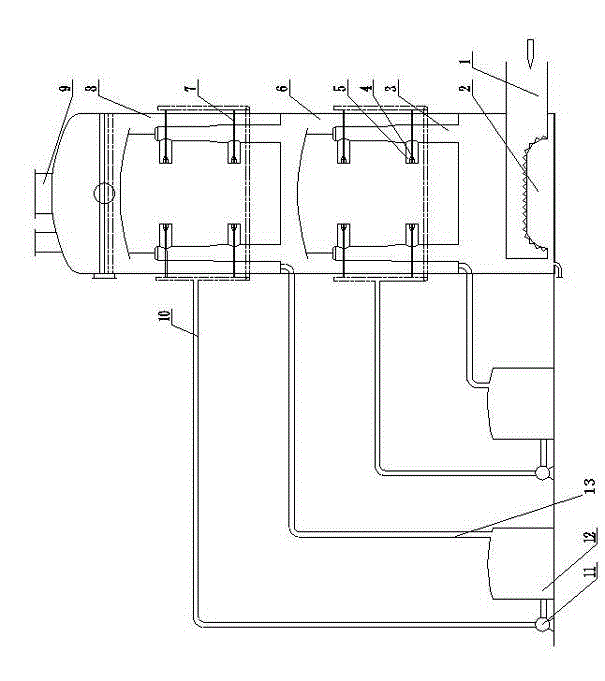

Production device for sodium bisulfide continuous absorption reaction

InactiveCN102807193AReduce power consumptionProduction costDispersed particle separationSulfur compoundsSodium bisulfideAbsorption column

The invention discloses a production device, particularly a production device for sodium bisulfide continuous absorption reaction, and belongs to the technical field of chemical engineering production equipment. The invention provides the production device for the sodium bisulfide continuous absorption reaction, which is low in power consumption and production cost and easy in control of product quality. The production device comprises an absorption tower, an absorption column bottoms pump and a sodium bisulfide production solution storage tank, a process tail gas output interface is arranged at the top of the absorption tower, a process absorption liquid input interface is arranged at the upper part of the absorption tower, a hydrogen sulfide gas input interface is arranged at the lower part of the absorption tower, an input end of the absorption column bottoms pump is connected with the bottom of the absorption tower, and an output end of the absorption column bottoms pup is connected with the process absorption liquid input interface and the sodium hydrosulfide production solution storage tank respectively.

Owner:CHENGDU DEMEI ENG TECH

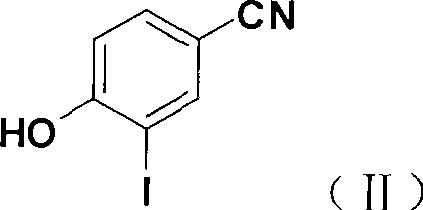

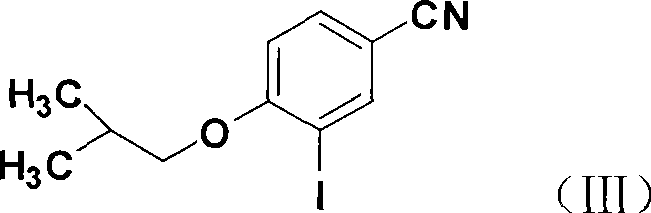

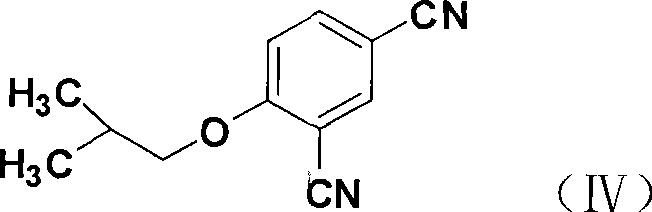

Method for synthesizing 2-(3-cyano-4- isobutoxy phenyl)-4-methyl-carboxylate

ActiveCN101497589ARaw materials are easy to getSimple and fast operationOrganic chemistrySkeletal disorderBenzeneSodium bisulfide

The invention belongs to the technical field of medicine, and relates to a method for synthesizing 2-(3-cyano-4-isobutoxy phenyl)-4-methyl-5-thiazole formic acid. The method comprises that: 4-hydroxyl cyanobenzene is used as a raw material, and subjected to iodination, hydrocarbylation and cyanation to obtain an intermediate of 4-isobutoxy-1,3-benzene dinitrile, the intermediate reacts with sodium bisulfide and anhydrous magnesium chloride to obtain a key intermediate of 3-cyano-4-isobutoxy phenyl thioformamide, and the 3-cyano group-4-isobutoxy phenyl thioformamide is subjected to cyclization and hydrolysis reaction to obtain the 2-(3-cyano-4-isobutoxy phenyl)-4-methyl-5-thiazole formic acid. The method has the advantages of easily obtained materials, simple and convenient operation, high yield, low cost and suitability for industrialized production.

Owner:SHENYANG PHARMA UNIVERSITY +1

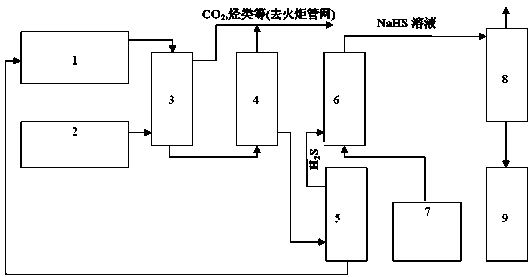

Device and method for producing sodium bisulfide by utilizing refinery dry gas

ActiveCN103754833ARaise the possibilityRealize resource utilizationSulfur compoundsResource utilizationGas composition

The invention relates to a device and method for producing sodium bisulfide by utilizing refinery dry gas. Aiming at the gas composition characteristics of the refinery dry gas, the dry gas refining desulphurization process is processed by utilizing an ultra-high gravity technology, and H2S in acid tail gas after dry gas refining desulphurization is selectively removed, so that the content of the purified H2S is over 99 percent, the purified and refined H2S is absorbed for preparing high-purity NaHS by adopting a continuous alkali liquor cycle, the concentration purity is over 42 percent, the process technology is greatly innovated, the investment is saved, secondary pollution is avoided, a process of a traditional out-dated NaHS product can be replaced, the device has a certain economic benefits and high-efficiency resource utilization rate, the H2S in the acid gas is almost recycled completely, the requirements of environment friendliness and emission are met, high social benefits are achieved, and recycling comprehensive utilization of refinery acid tail gas is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

New application of sodium bisulfide as hydrogen sulfide donor in promoting storage and preservation of fruits and vegetables

InactiveCN102550652ALow application concentrationReduce water loss rateBiocideSeed preservation using chemicalsPEARSodium bisulfide

The invention discloses a new application of sodium bisulfide (hydrogen sulfide donor) in promoting the storage and preservation of fruits and vegetables, i.e. an application of the sodium bisulfide (hydrogen sulfide donor) as fresh cut fruit-vegetable fresh-keeping agent. The sodium bisulfide (hydrogen sulfide donor) has a fresh-keeping effect on fresh cut vegetables such as broccoli, asparagus lettuce, lotus root, yam, pumpkin, sweet potato and potato and the like, and fresh cut fruits such as apple, pear, Chinese goosebeery, tomato, Hami melon and peach and the like. The sodium bisulfide can notably delay the wilting, dehydration, ripening, aging and mildewing of fresh cut fruits and vegetables, keep the quality characteristics of picked fruits and vegetables and prolong the storage periods and shelf lives of picked fresh cut fruits and vegetables by 0.5 to 12 days. The fresh-keeping agent can be used for keeping freshing on a variety of the picked fresh cut fruits and vegetables.

Owner:HEFEI UNIV OF TECH +2

Ashless and alkali sulfide free depilation liming treatment method for preparing leather from raw sheep skin

InactiveCN101265505AEasy to handleReduce pollutionPre-tanning chemical treatmentWater savingSodium bisulfide

The invention relates to an alkali depilation liming method of currying and processing goatskin without generating dust and vulcanization. The method is characterized in that sodium sulfide, sodium bisulfide and lime are not used; lime precipitate and residua do not appear to ensure the drained waste water to be more easily processed; the pollution to the environment in the currying process is greatly reduced. The dust skin washing which is a highest water cost working procedure is eliminated, and the saved water is about 20 percent to 40 percent of the total draining quantity of waster water. The damage to finished leather quality is reduced because of mechanical effect; the loose surface rate caused by mechanical effect is greatly reduced; the production period is also shortened; various materials are saved and the production combined cost is reduced.

Owner:SICHUAN UNIV

Use of hydrogen sulfide and its donor sodium hydrosulfide in the production of medicaments

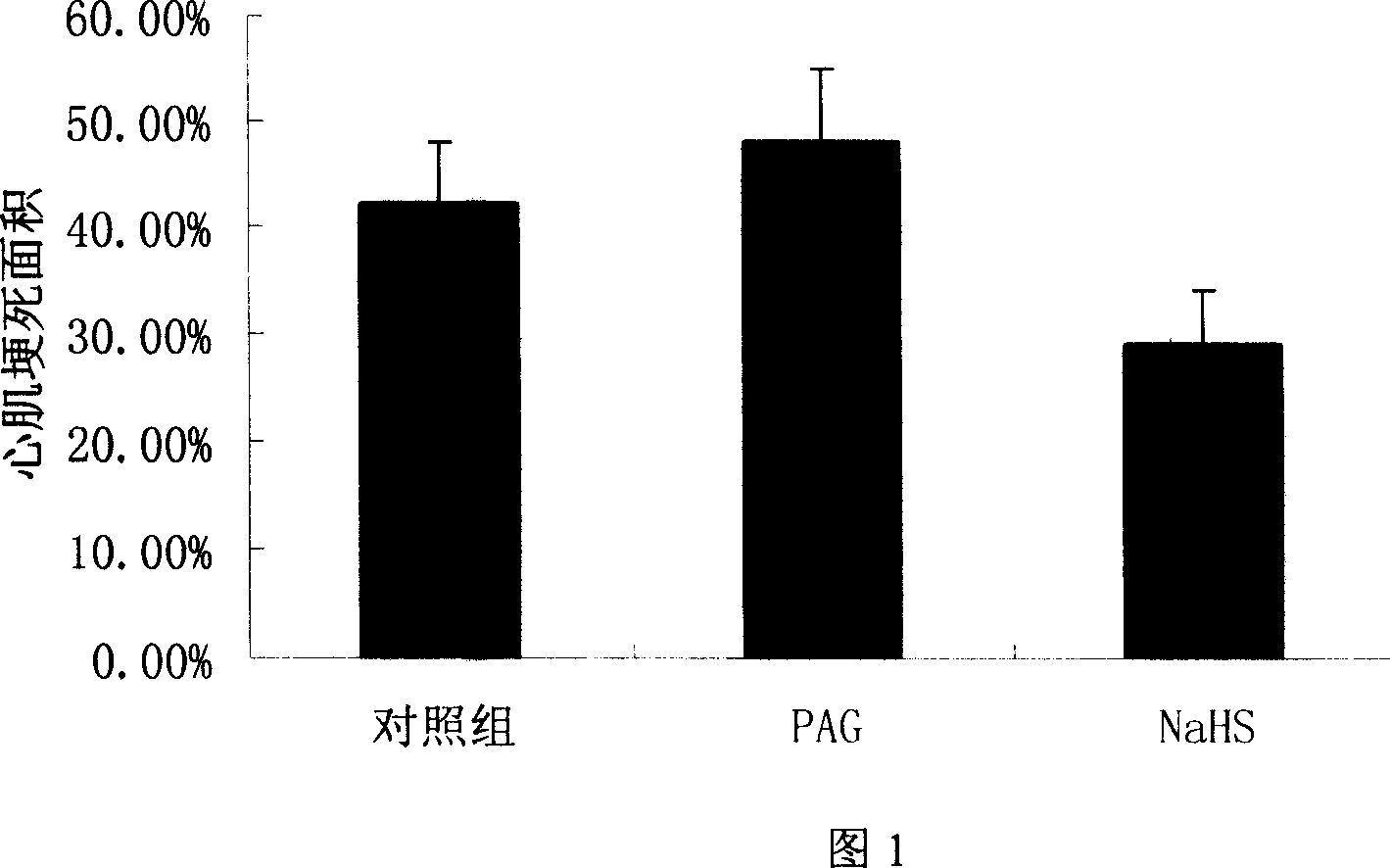

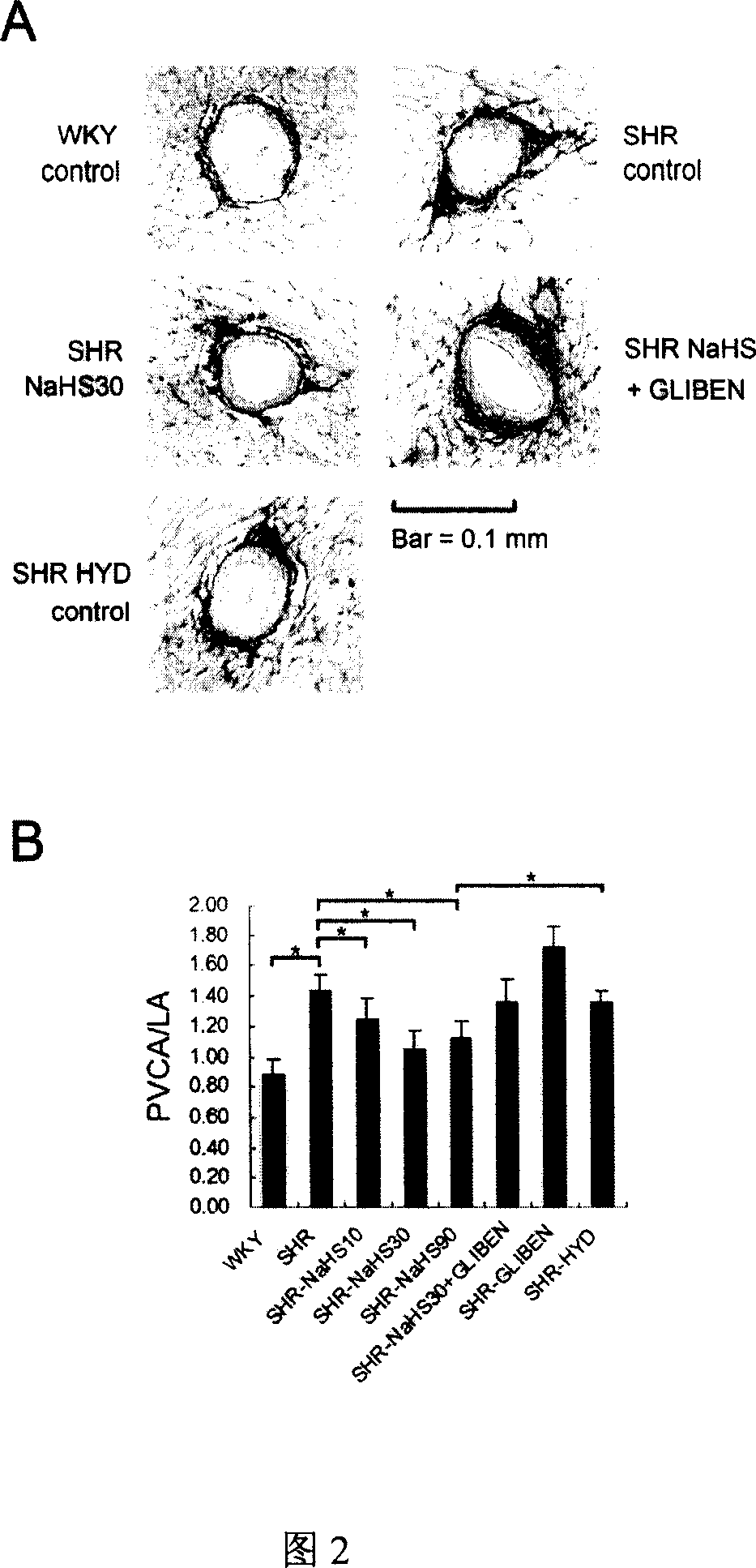

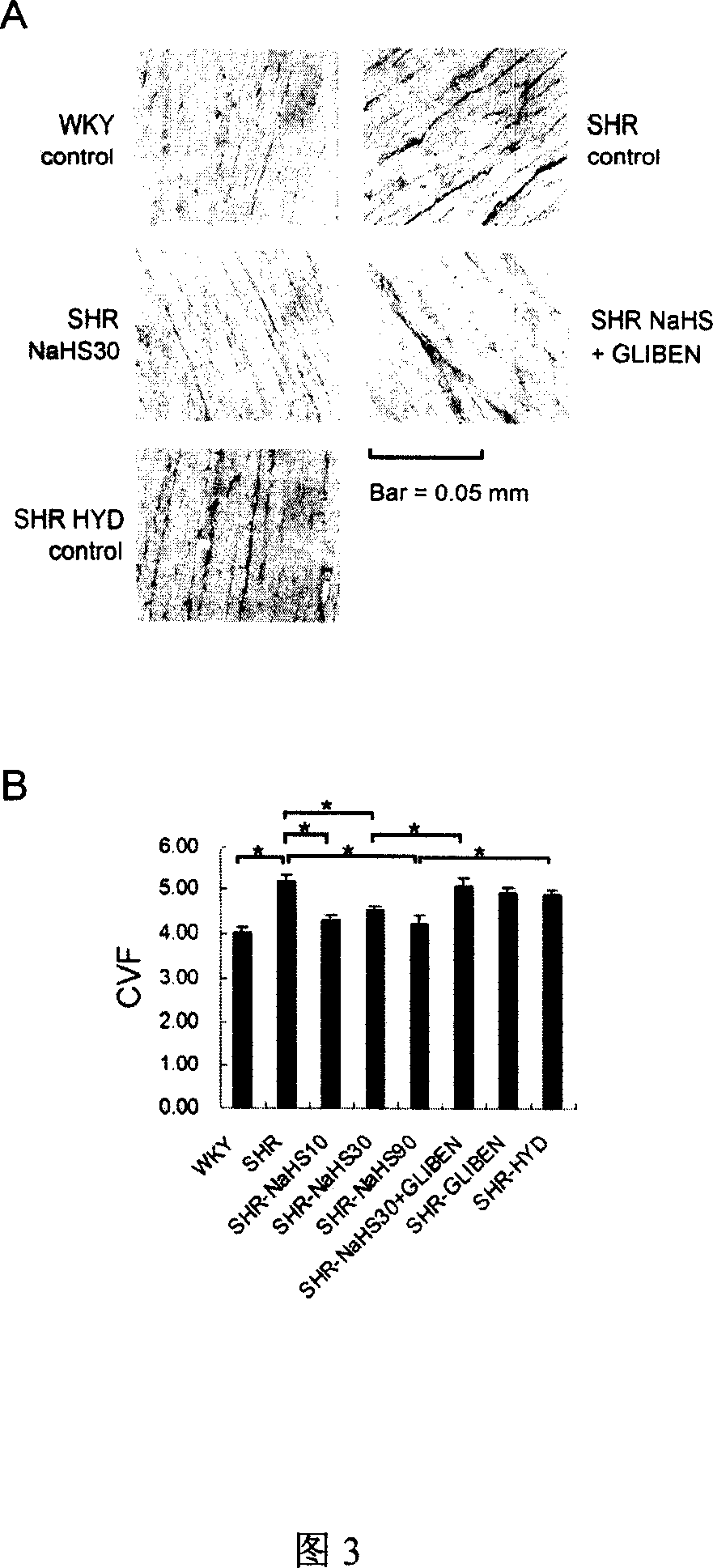

InactiveCN101011413ANegative inotropic effectReduce myocardial ischemiaMetabolism disorderAntinoxious agentsFibrosisSodium hydrosulfide

The invention relates to a method for using hydrogen sulfide and relative donator as sodium bisulfide in the drug preparation. The invention uses exogenous hydrogen sulfide and relative donator as sodium bisulfide, via serial animal models and external tests to prove that said hydrogen sulfide and relative donator as sodium bisulfide can be used to treat several cardiovascular diseases, or reduce the active oxygen, accelerate the vessel growth, negative inotropic action, or calcium antagonist. Said cardiovascular diseases comprise myocardial infarction, fibrosis, or the like.

Owner:FUDAN UNIV

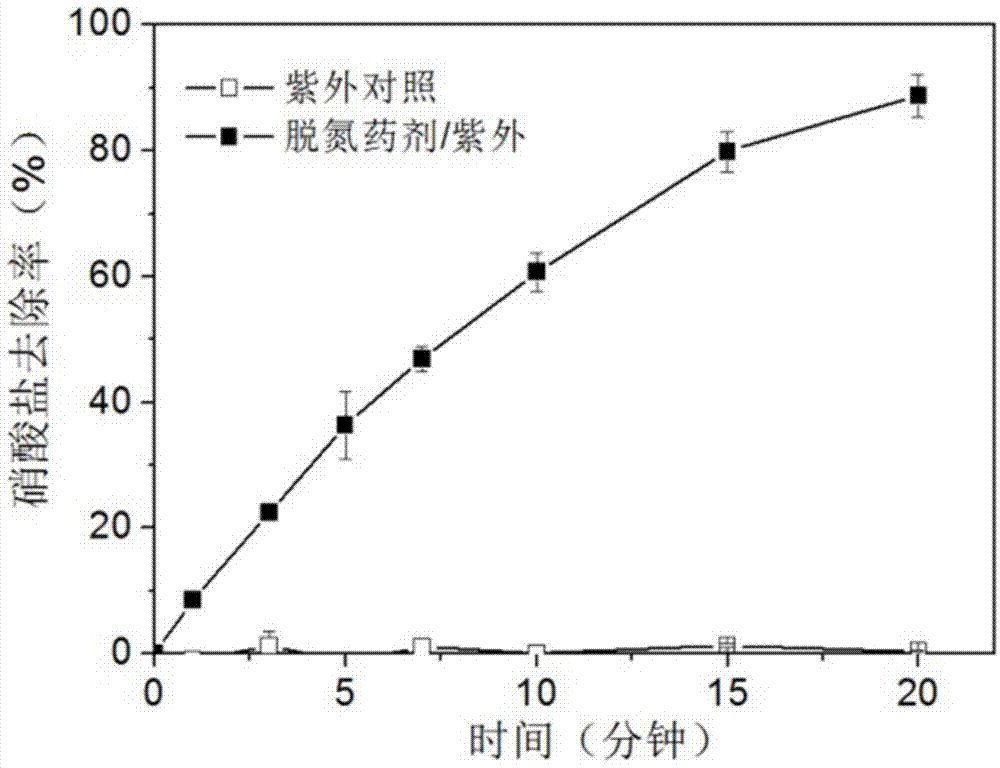

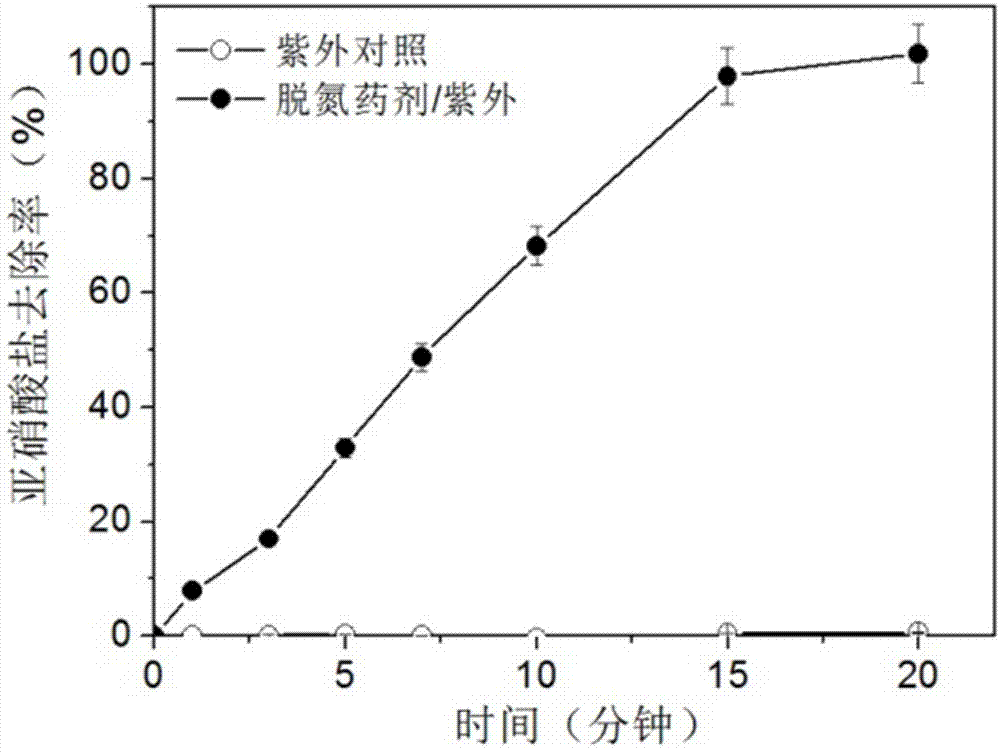

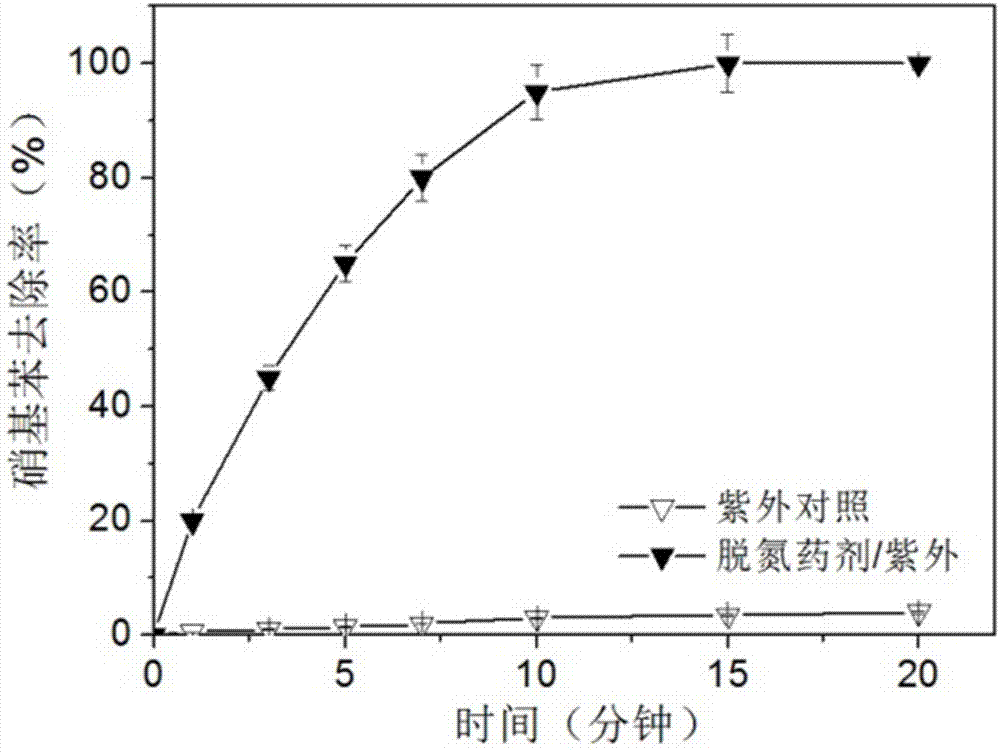

Denitrification method combining denitrification agent and ultraviolet light

InactiveCN103787448ATake advantage ofImprove light energy utilizationWater/sewage treatment by irradiationWater/sewage treatment by reductionEquivalence ratioUltraviolet lights

The invention discloses a denitrification method combining a denitrification agent and ultraviolet light and belongs to the technical field of water treatment. The denitrification method comprises the following steps: adding the denitrification agent into water for treating, after uniformly mixing, irradiating by using the ultraviolet light; or leading the water for treating into an ultraviolet light reactor, directly adding the denitrification agent into the ultraviolet light reactor to finish the denitrification treatment, wherein the wavelength of the ultraviolet light is less than 400 nanometers; the used denitrification agent is composed of one or more of sulfite, hydrosulphite, sulfur dioxide, pyrosulfite, hydro-metabisulfite, thiosulfate, sulfide, sodium bisulfide, ferrous ion and iron ion; the denitrification agent is added according to the Mole equivalence ratio of sulfur contained in the denitrification agent to nitrogen contained in nitrogen pollutants in the water for treating of being (0.1-100):1. By using the denitrification method, the purpose of efficiently and harmlessly removing nitrate, nitrite, ammonia nitrogen, nitro substituted organic matters, nitroso substituted organic matters and azo compounds in the water is achieved.

Owner:NANJING UNIV

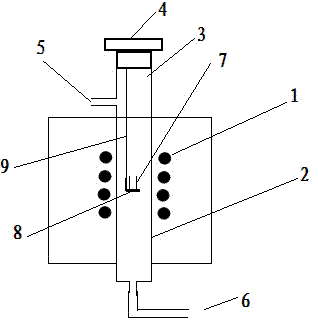

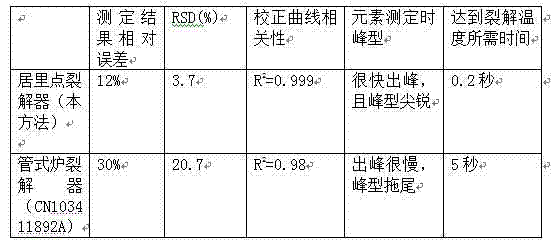

Elemental analysis determination method and device

InactiveCN103792223AReduce distractionsSlow heating ratePreparing sample for investigationAnalysis by thermal excitationSodium hydrosulfideElemental analysis

The invention discloses an elemental analysis determination method and device. The elemental analysis determination method comprises the following steps: adding an inorganic compound capable of releasing hydrogen in pyrolysis into a to-be-detected sample and mixing the inorganic compound with the sample uniformly; carrying out pyrolysis on the mixture at a certain temperature, enabling an element to form a volatile matter, and determining the volatile matter by an atom spectrogram, wherein the inorganic compound for releasing hydrogen in pyrolysis is sodium bisulfide, potassium hydrogen sulfide, ammonium sulfide, ammonia hydrogen sulfide, ammonium iodide, hydrogen sulfide or hydrogen iodide, and the weight of the added inorganic compound is 0.2-100 times the weight of the sample. According to the invention, an inorganic hydrogen release reagent and a curie point pyrolyser are used, and the advantages of low analysis cost, less interference, high element volatile matter formation speed, high sampling efficiency of to-be-detected elements and the like are realized, and the method is a rapid and accurate analysis method.

Owner:TIANJIN NORMAL UNIVERSITY

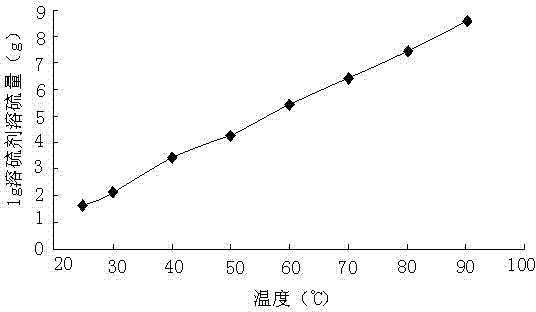

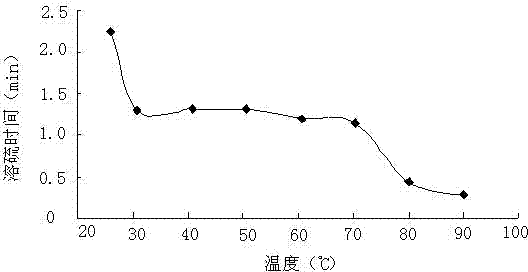

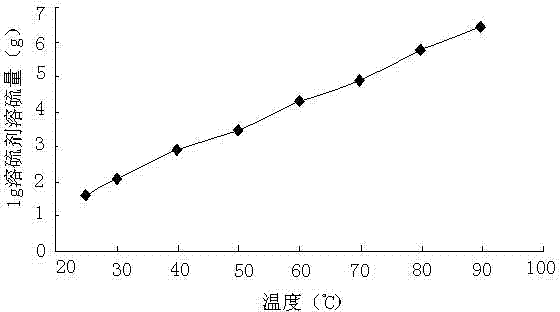

Efficient sulfur solving agent for sulfur deposits in sulfur-containing gas well

InactiveCN102408885AExcellent soluble sulfur effectLarge amount of dissolved sulfurDrilling compositionN dimethylformamideSodium bisulfide

The invention discloses an efficient sulfur solving agent for sulfur deposits in a sulfur-containing gas well, relating to the field of the sulfur solving agent. The efficient sulfur solving agent is composed of dimethyl disulfide, sodium hydroxide aqueous solution, sodium bisulfide and N, N-dimethylformamide. The efficient sulfur solving agent is high in sulfur solving capability, high in sulfur solving speed and low in cost, and thereby can be widely applied to sulfur solving of sulfur deposits in the well tube of a high sulfur-containing gas well and a surface pipeline. At 25 DEG C, 1 g of sulfur solving agent is capable of solving 1.62 g of sulfur and the time of solving is only 2.27 min; therefore, the sulfur solving effect of the efficient sulfur solving agent is obviously superior to that of the sulfur solving agent in the prior art.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing sodium carbonate from hydrogen sulfide acid gas

InactiveCN103691282AInhibition and delayed absorptionBenefit its solubilityProductsReagentsSodium bicarbonateSodium bisulfide

The invention discloses a method for preparing sodium carbonate from hydrogen sulfide acid gas and belongs to the technical field of decarbonization. The method comprises the following steps: carrying out a mixed reaction on a buffer solution containing sodium hydroxide and sodium bicarbonate and non-decarburized hydrogen sulfide acid gas for absorbing carbon dioxide and partial hydrogen sulfide of the acid gas, thus obtaining a decarburized pregnant solution containing sodium bicarbonate and sodium bisulfide; and heating the decarburized pregnant solution to ensure that the sodium bisulfide in the decarburized pregnant solution is subjected to a hydrolysis reaction and is converted into sodium hydroxide, and reacting the sodium hydroxide generated in the hydrolysis reaction with free alkali and sodium bicarbonate in the decarburized pregnant solution to obtain sodium carbonate, wherein sodium carbonate is finally generated to be fixed from the carbon dioxide in the acid gas, and the hydrogen sulfide generated by the hydrolysis reaction is finally absorbed back to the acid gas. According to the method, the carbon dioxide can be effectively removed from the acid gas and is converted into the useful product sodium carbonate, and the decarburization rate is 60-90 percent.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for treating lead-zinc sulfide ore production wastewater and recycling zinc from wastewater

InactiveCN103304062APH controlPH does not causeWaste water treatment from quariesCadmium sulfidesFerric hydroxideWater discharge

The invention discloses a method for treating lead-zinc sulfide ore production wastewater and recycling zinc from wastewater. The method comprises the following steps of: 1) adding calcium carbonate ore into the lead-zinc sulfide ore production wastewater, stirring and reacting till the pH value of the wastewater is within 6.0-7.0, filtering, adding a flocculant into the obtained filtrate, stirring, standing, precipitating, and filtering so as to respectively obtain the de-ironed wastewater and ferric hydroxide slag; 2) adding sulfide and the flocculant into the de-ironed wastewater, stirring, standing, precipitating, and filtering so as to respectively obtain dezinced and de-ironed wastewater and zinc slag, wherein the sulfide is sodium sulfide or sodium bisulfide, and the sulfide is added in a solution manner; and 3) adding ferric hydroxide slag into the dezinced and de-ironed wastewater to react up, and filtering, wherein the filtrate can meet the discharge standard. The method is simple to operate, the discharge water treated by using the method can meet relevant national water discharge standard, and the recycling of heavy metal resource products and up-to-standard emission of wastewater are realized.

Owner:中国有色桂林矿产地质研究院有限公司

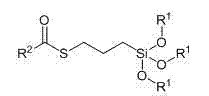

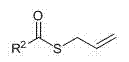

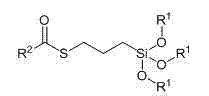

Technology for preparing terminated-type sulfur-containing silane coupling agent through hydrosilation method

ActiveCN103709188AAvoid hydrolysisGood storage stabilityGroup 4/14 element organic compoundsThiocarboxylic acidPtru catalyst

Provided is a technology for preparing a terminated-type sulfur-containing silane coupling agent through a hydrosilation method. First, acyl chloride and sodium sulfide or sodium bisulfide are reacted in a water phase to prepare an aqueous solution of sodium thiocarboxylate; under catalysis of phase-transfer catalysts, the aqueous solution of sodium thiocarboxylate is reacted with chloropropene, and thiocarboxylate allyl ester, liquid separation is carried out, after low-boiling-point substance removal, thiocarboxylate allyl ester and trialkoxysilane are subjected to a hydrosilation reaction under action of platinum catalysts, and after the reaction is over, a finished product silane coupling agent is obtained after low-boiling-point substance removal and decolouring steps. The raw material utilization rate is raised, The hydrosilation reaction process keeps anhydrous state, hydrolysis of alkoxy silane is inhibited, and the storage stability of the silane coupling agent is raised.

Owner:江西晨光新材料股份有限公司

Process for manufacturing lithium polysulfide needed by lithium sulfur battery

ActiveCN103985866ALow purityPrevent oxidationCell electrodesAlkali metal sulfides/polysulfidesLithium chlorideSodium hydrosulfide

The invention discloses a process for manufacturing lithium polysulfide needed by a lithium sulfur battery. The process comprises the following steps: replacing with inert gases in a reaction kettle, and synthesizing through N-methyl pyrrolidone, sodium bisulfide, sodium hydroxide, oxygen-free deionized water, lithium chloride and sublimed sulfur according to a molar ratio of (4.4-5.4) to 1.0 to 1.03 to 0.3 to 1.001 to (4.0-6.0) according to a formula of raw materials; heating, filtering to remove generated sodium chloride, returning the filtrate to a reaction system, adding sublimed sulfur, heating the reaction system, and reducing the preserved temperature to room temperature, thereby separating out light yellow white solid powder in the reaction system; filtering the light yellow white solid precipitates, washing and filtering by anhydrous alcohol, and drying in a drying oven, thereby obtaining a lithium polysulfide raw material needed by the lithium sulfur battery.

Owner:TAICANG LIBIAO INTELLIGENT TECH CO LTD

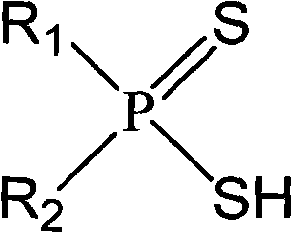

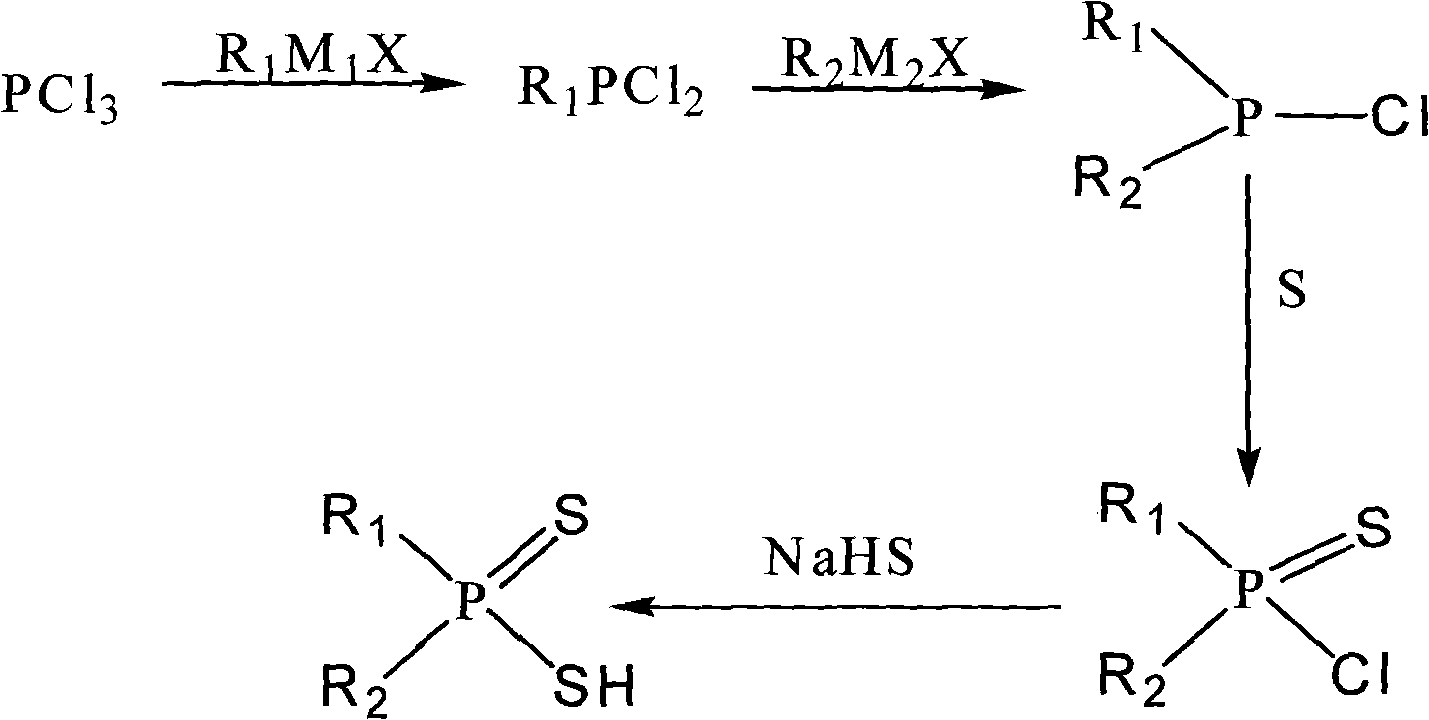

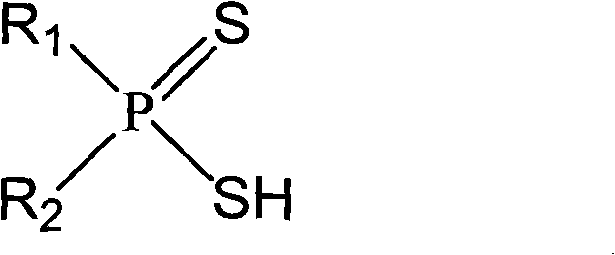

Asymmetric dithiophosphinic acid synthesis method

An asymmetric dithiophosphinic acid synthesis method comprises the following steps: adopting phosphorus trichloride as raw material to react with organic metal reagent RMX, producing asymmetric dihydroxylphosphorus chloride, then obtaining phosphinic acid by reacting the asymmetric dihydroxylphosphorus chloride, sulphur and sodium bisulfide, purifying the corresponding salt by column chromatography or recrystallization and finally obtaining asymmetric dithiophosphinic acid by converting. The method can be used in the preparation field of dithiophosphinic acid extractant compounds.

Owner:TSINGHUA UNIV

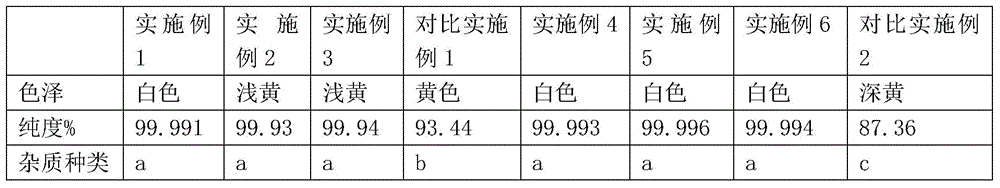

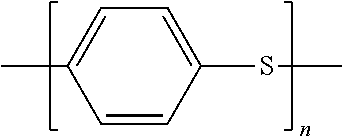

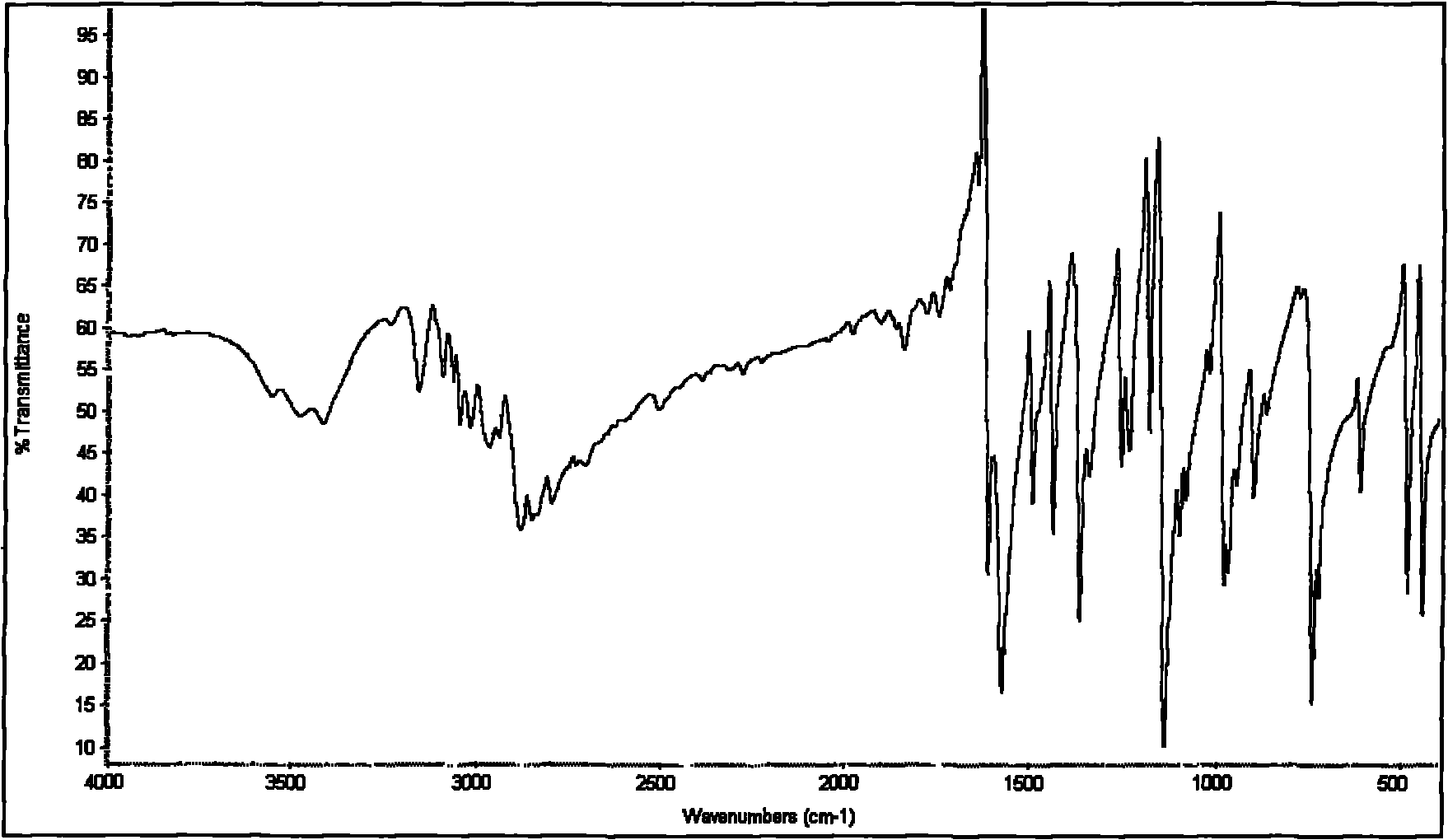

A fiber-grade polyphenylene sulfide resin synthesis method

The present invention discloses a fiber-grade polyphenylene sulfide resin synthesis method, taking sodium bisulfide and p-dichlorobenzene as raw materials, N-methyl pyrrolidone as the solvent and C5-C6 fatty acid salt formed through dehydration to C5-C6 fatty acid and sodium hydroxide as the polymerization additive for synthesis through polymerization. White polyphenylene sulfide resin is obtained through acidification and washing of reaction slurry. In view of the fact that MFR is below 125 g / 10 min, weight-average molecular weight as measured by GPC is over 4.2×104, and whiteness is over 90, it can satisfy requirements for fiber polyphenylene sulfide resin. C5-C6 fatty acid salt according to the method of the present invention has a higher solubility in NMP, which can better promote polymerization. It is to be fully diverted into the filtrate after filter prior to conversion into free fatty acid again through acidification with hydrochloric acid. C5-C6 fatty acid is available for azeotropy with water, which has a limited solubility in water. Therefore, it is applicable to recycle C5-C6 fatty acid from the filtrate through azeotropy with water, and thereby solve the problem with separation of additive and sodium chloride that are soluble in water.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +3

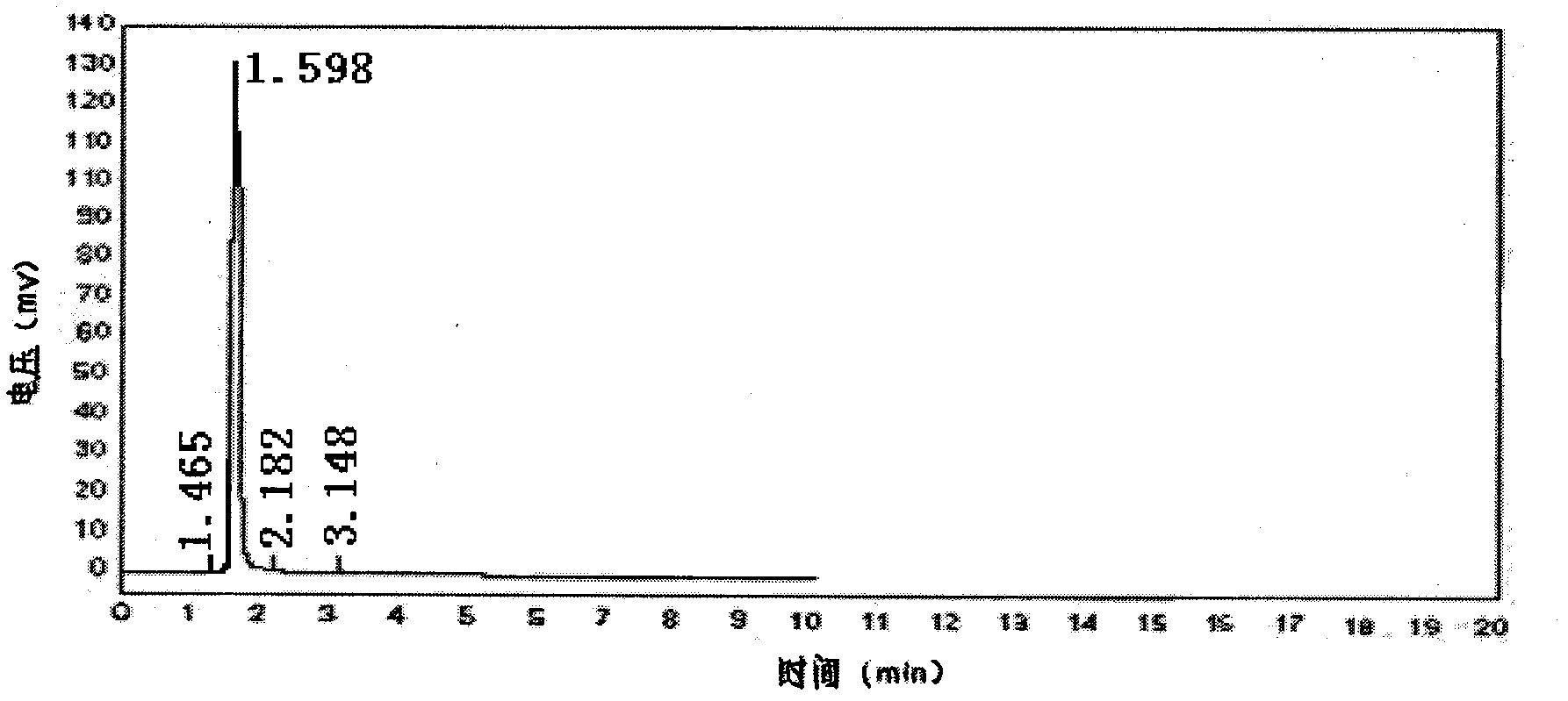

Method for producing sodium bisulfide products by viscose fiber industrial waste gas

The invention relates to a method for producing sodium bisulfide products by viscose fiber industrial waste gas, which is characterized in that the viscose fiber industrial waste gas is used as a raw material, and after the viscose fiber industrial waste gas is absorbed by NaOH solution, sodium bisulfide products with the concentration conforming to the national standard are prepared through steps of preheating, evaporation concentration, crystallization settlement, secondary evaporation concentration, package and the like. The method has the advantages that the sodium bisulfide products capable of being utilized are prepared, the economic benefit of the viscose fiber industrial production is improved, simultaneously, the emission of hydrogen sulfide in the viscose fiber industrial waste gas is also reduced, and the environment pollution caused by the viscose fiber industrial waste gas is reduced.

Owner:山东雅美科技有限公司 +2

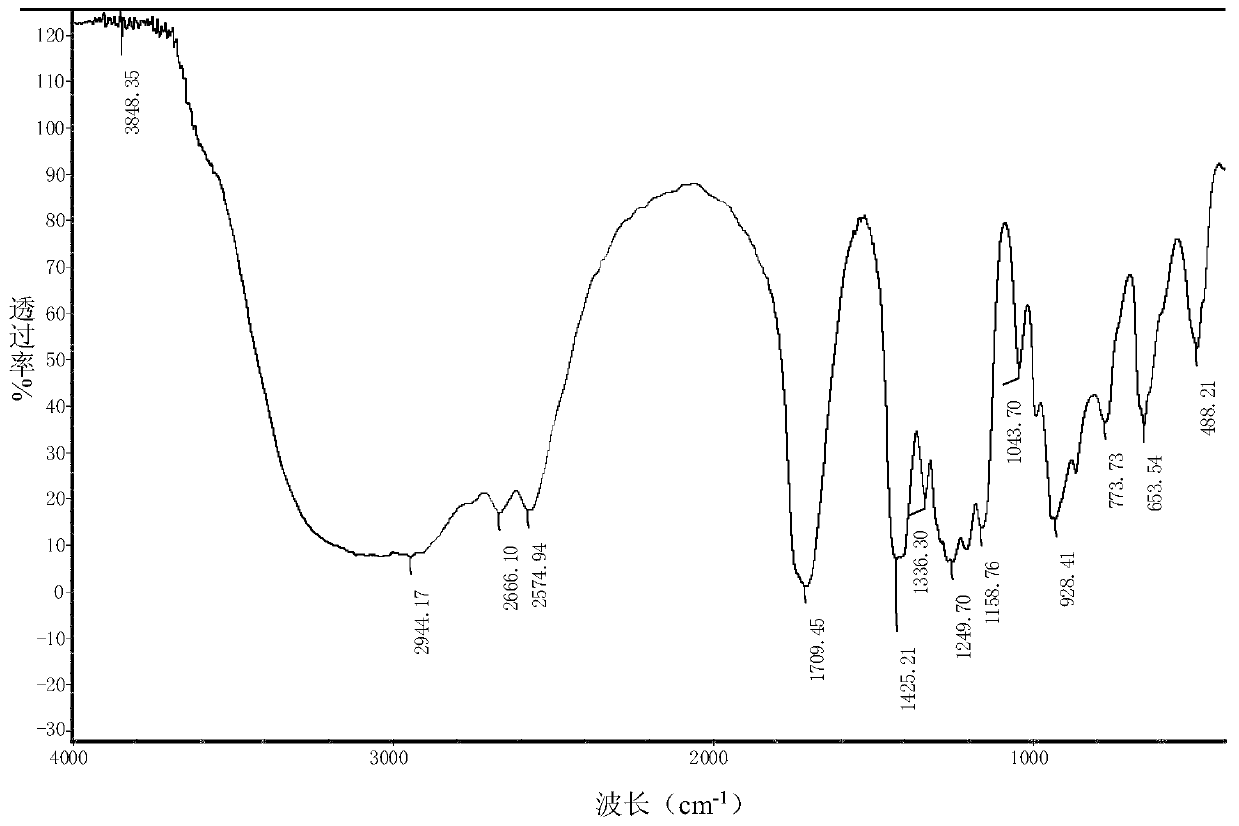

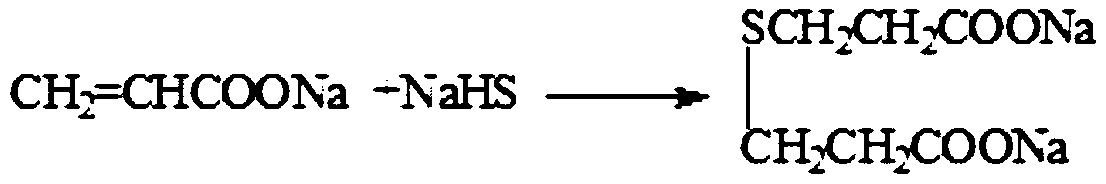

Preparation method of 3-mercaptopropionic acid

ActiveCN110372551AHigh yieldHigh purityThiol preparationOrganic compound preparationSodium bisulfideSulfur

Owner:HEBEI HOFMANN NEW MATERIAL TECH CO LTD

Ashless and alkali sulfide free depilation liming treatment method for preparing leather from goatskin

InactiveCN101265506AEasy to handleReduce pollutionPre-tanning chemical treatmentWater savingSodium bisulfide

The invention relates to a goatskin currying processing method of alkali depilation liming without dust and vulcanization. The method is characterized in that sodium sulfide, sodium bisulfide and lime are not used; lime precipitate and residua do not appear to ensure the drained waste water to be more easily processed. The pollution to the environment in the currying process is greatly reduced. The washing dust skin which is a highest water cost working procedure is eliminated, and the saved water is about 20 percent to 40 percent of the total draining quantity of waster water. The damage to finished leather quality caused by mechanical effect is reduced; the loose surface rate caused by mechanical effect is greatly reduced; the production period is also shortened; various materials are saved and the production combined cost is reduced.

Owner:SICHUAN UNIV

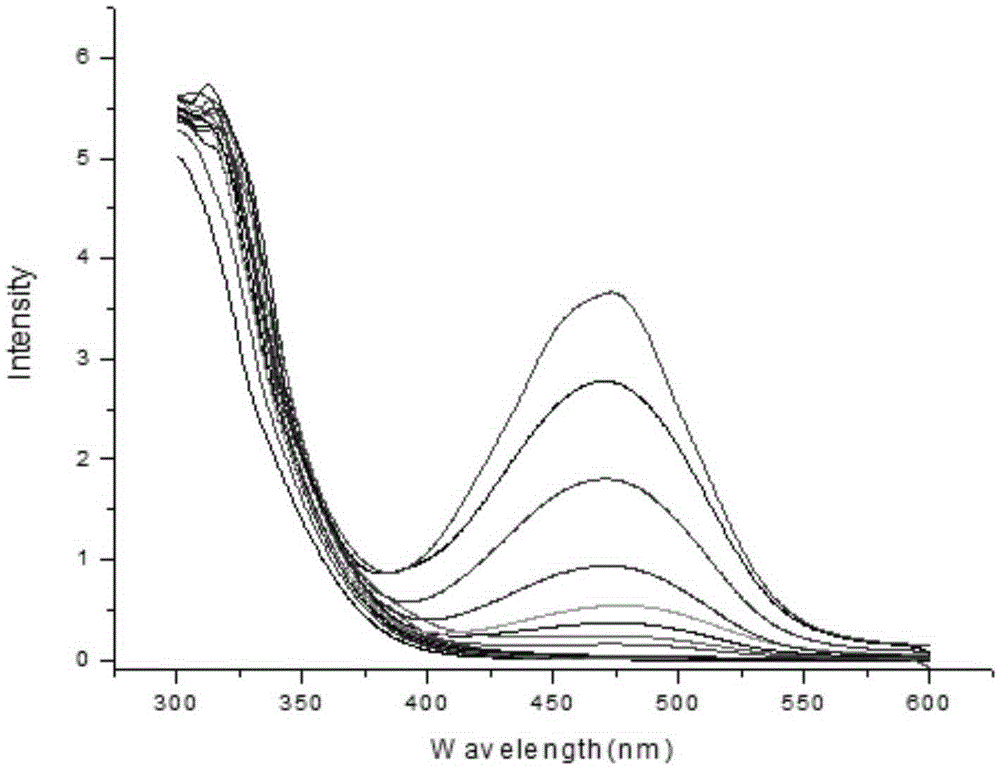

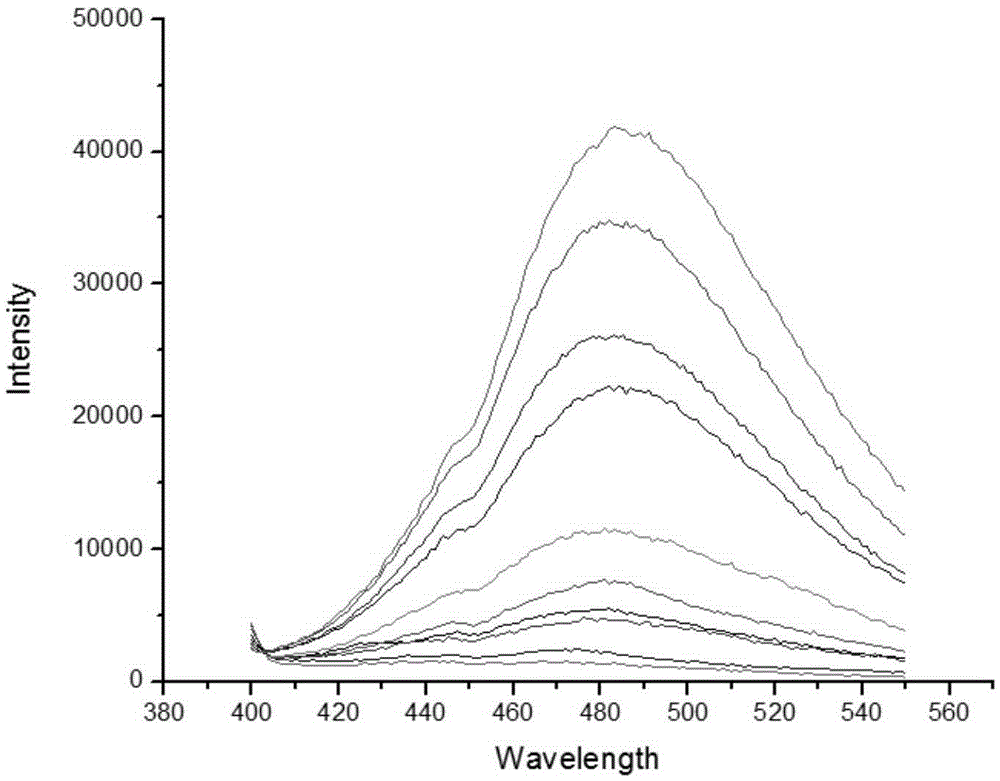

Fluorescence probe rapidly responding to hydrogen sulfide and preparation method and application thereof

InactiveCN105348106ALarge Stokes shiftReduce self-absorptionOrganic chemistryOrganic compound preparationCompound nameNematode

The invention discloses a fluorescence probe rapidly responding to hydrogen sulfide and a preparation method and application thereof. The structural formula of the compound can be seen in the specification. The preparation method includes the step of making hydroxystyrene and 2,4-dinitrosalicylic bromobenzene react under the conditions of catalysts and heating to generate the compound named as TPE-NP. Probe molecules have large Stokes shift, self-absorption is effectively reduced, and imaging accuracy is improved. In addition, the fluorescence probe is quite sensitive to hydrogen sulfide, and fluorescence is enhanced by 40 times in the process of increasing the concentration of sodium bisulfide to 10 equivalent weights of the probe concentration from 0. The fluorescence probe has a high molar extinction coefficient (larger than 60000 M<-1>.CM<-1> except for water), has a good dyeing effect on living cells and nematode, and is short in dyeing time (15 min) and high in dyeing efficiency. After living cells and nematode are dyed, confocal imaging is directly conducted without conducting the washing process which must be conducted on other probes in the prior art, and the imaging operation process is greatly simplified.

Owner:SHANDONG NORMAL UNIV

Hydrogen sulfide slow-release inhibitor as well as preparation method and application thereof

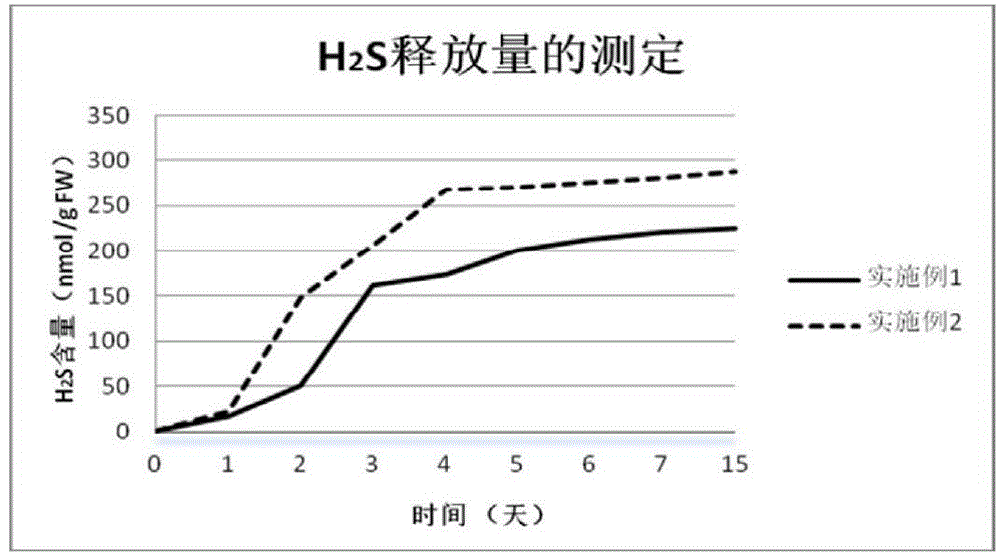

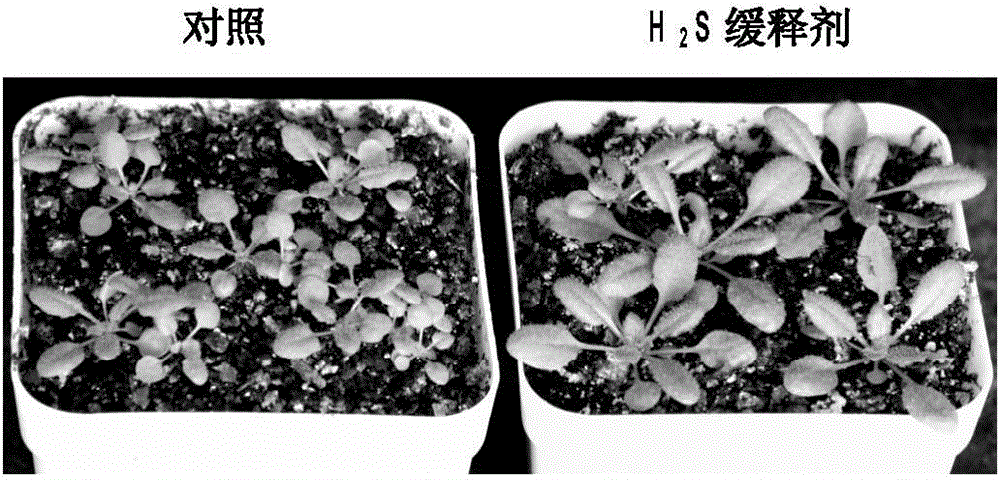

ActiveCN104782622AOvercome the disadvantage of too fast releaseLow costBiocidePlant growth regulatorsParaffin waxMass ratio

The invention discloses a hydrogen sulfide slow-release inhibitor as well as a preparation method and an application thereof. The method comprises the following steps: respectively dissolving a hydrogen sulfide donor such as sodium bisulfide (NaHS) and a coating agent into absolute ethyl alcohol, mixing and swirly mixing to obtain a mixed solution; adding the mixed solution into fused paraffin, ultrasonically mixing to obtain a paraffin solution containing the NaHS and the coating agent; dipping the paraffin solution into cold water to obtain a paraffin globule, cooling and drying to obtain the hydrogen sulfide slow-release inhibitor, wherein the mass ratio of the NaHS, the coating agent, the absolute ethyl alcohol to the paraffin is (0.5-5%): (1.5-15%): (5-20%): (60-93%). By adopting an ultrasonic-assisted dispersion technology, the mutual diffusion efficiency and effect of two solvents are improved. The concentration and the speed for releasing the H2S by the prepared slow-release inhibitor are stable and controllable and the slow-release inhibitor has an obvious promoting effect for the plant growth.

Owner:SHANXI UNIV

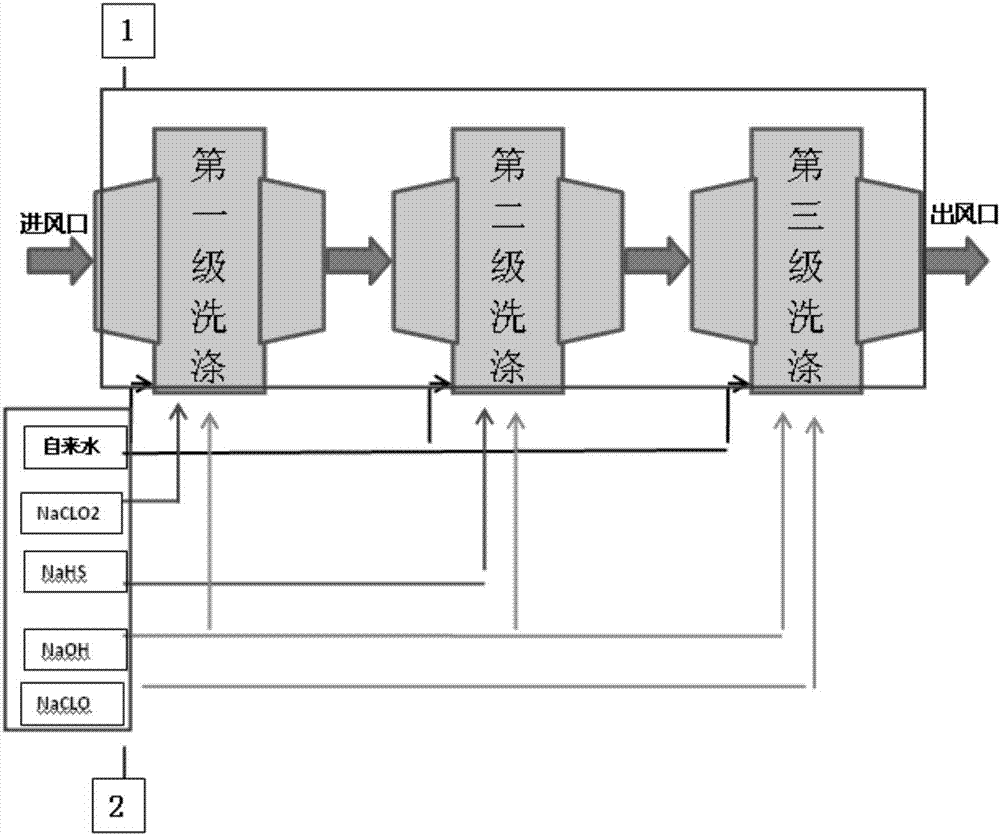

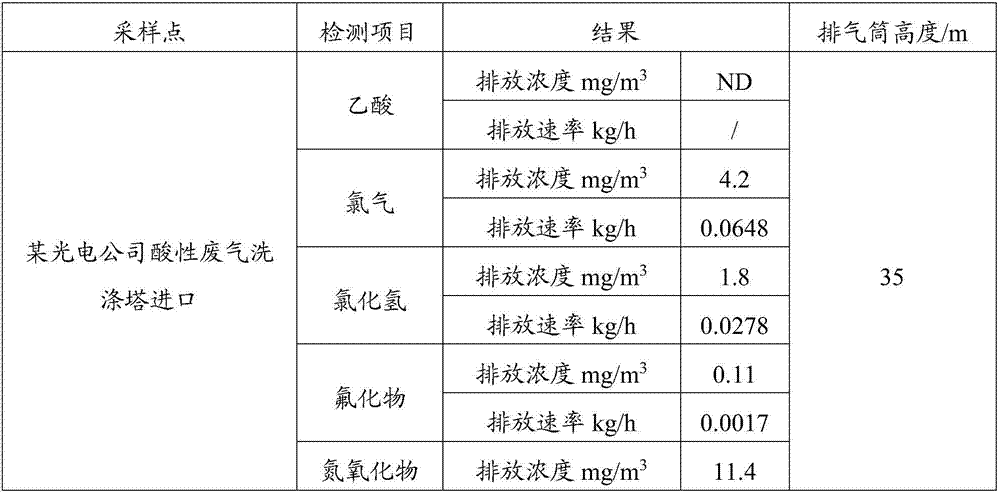

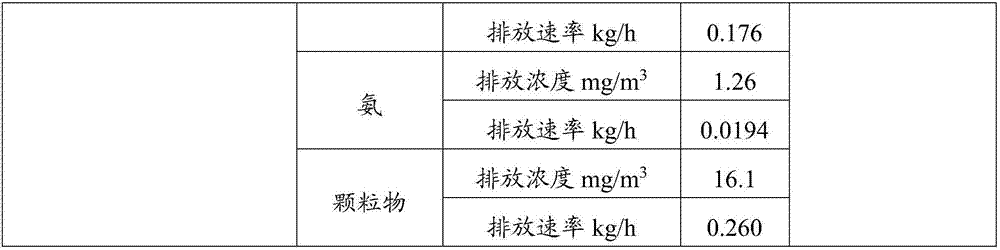

Treatment method of waste gas containing nitride oxides

InactiveCN107029539AImprove processing efficiencyDispersed particle separationHypochloriteSodium bisulfide

The invention provides a treatment method of waste gas containing nitride oxides. The method includes the following steps that firstly, the waste gas containing the nitride oxides is subjected to oxidization washing to obtain a first washed gas, wherein the oxidization washing uses chemicals including chlorite and a first soluble alkaline substance; secondly, the first washed gas is subjected to reduction washing to obtain a second washed gas, wherein the reduction washing uses chemicals including sodium bisulfide and a second soluble alkaline substance; thirdly, the second washed gas is subjected to oxidization and deodorization washing to obtain purified treated gas, wherein oxidization and deodorization washing uses chemicals including hypochlorite and a third soluble alkaline substance. The oxidization, reduction and oxidization treatment technical process is developed according to the waste gas containing the nitride oxides, and the treatment process can effectively improve the treatment efficiency of the nitride oxides at normal temperature and normal pressure.

Owner:SHANGHAI SHENGJIAN ENVIRONMENTAL SYST TECH

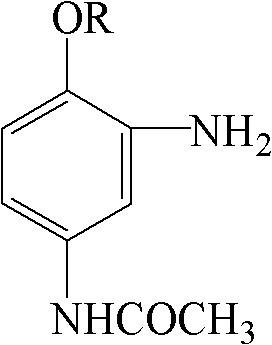

Method for producing 2-amino-4-acetamido benzene alkyl ether by reduction with sodium bisulfide

ActiveCN102633669AHigh reaction yieldQuality improvementOrganic compound preparationCarboxylic acid amides preparationSulfite saltResource utilization

The invention relates to a method for producing 2-amino-4-acetamido benzene alkyl ether by reduction with sodium bisulfide. The method comprises the following steps: adding 2-nitro-4-acetamido benzene alkyl ether in water the mass of which is 3-5 times of that of a reactant; adding glacial acetic acid; regulating the pH value of the material to 5-6 by using liquid caustic soda; raising the temperature to 90-105 DEG C, dropwise adding a 10-25% sodium bisulfide solution, carrying out insulation reaction for 1 hour after dropwise addition; cooling slowly to crystallize and separate out the product; filtering the crystal, washing the crystal with cold water until the pH value of the filtrate is 7 to obtain 2-amino-4-acetamido benzene alkyl ether, wherein the washing sleeve is still used in the next-batch reduction. The method disclosed by the invention has the advantages that (1) the reaction yield is above 90%; (2) the reaction speed is high so that the product is not easy to oxidize, and has good colour and high quality; (3) complex aftertreatment is not required, and the equipment and operation are simple; (4) wastewater is little and easy to treat, thus the method is a low-emission clean process; and (5) resource utilization is realized for recycling and managing hydrogen sulfide waste gas so as to obtain the sodium bisulfide solution in industries such as petrifaction industry, and cost is low.

Owner:YANCHENG OUHUA CHEM IND

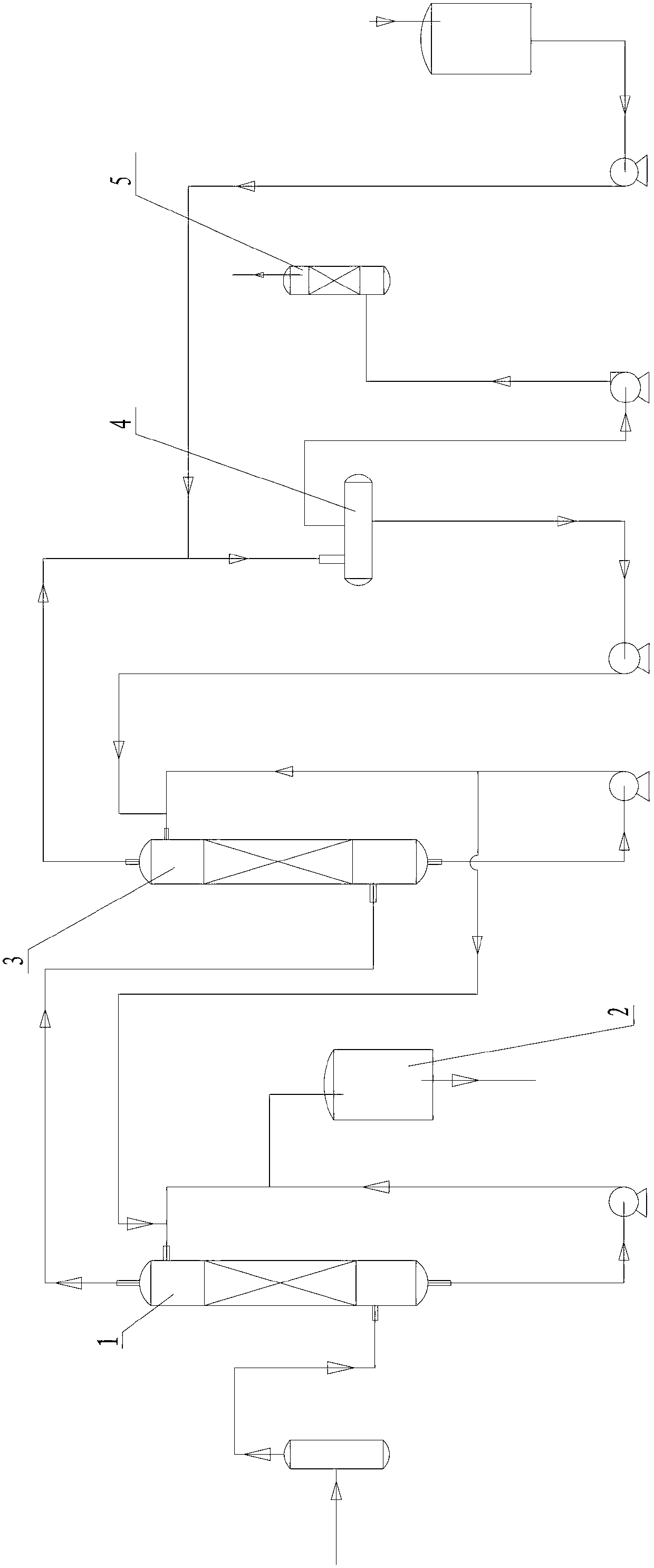

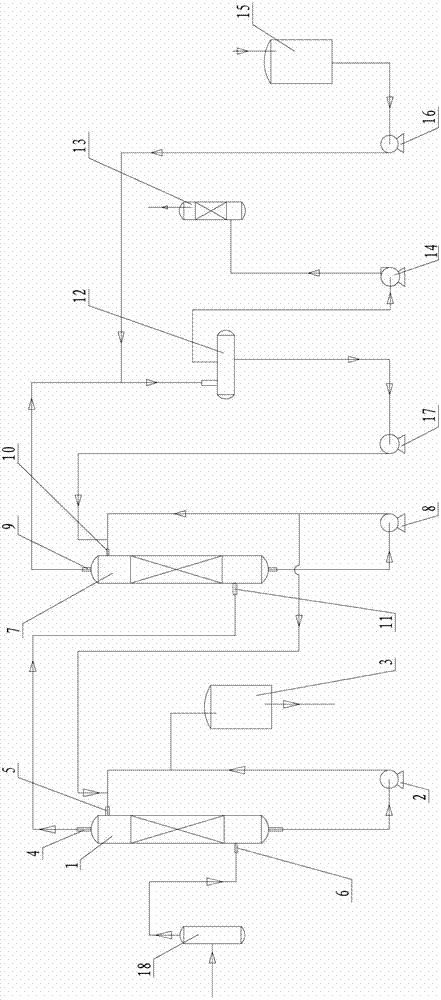

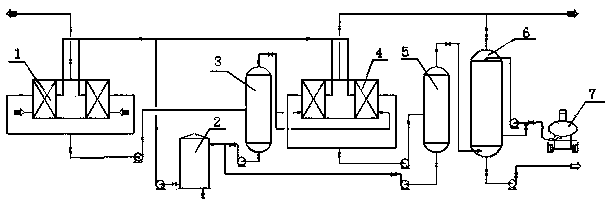

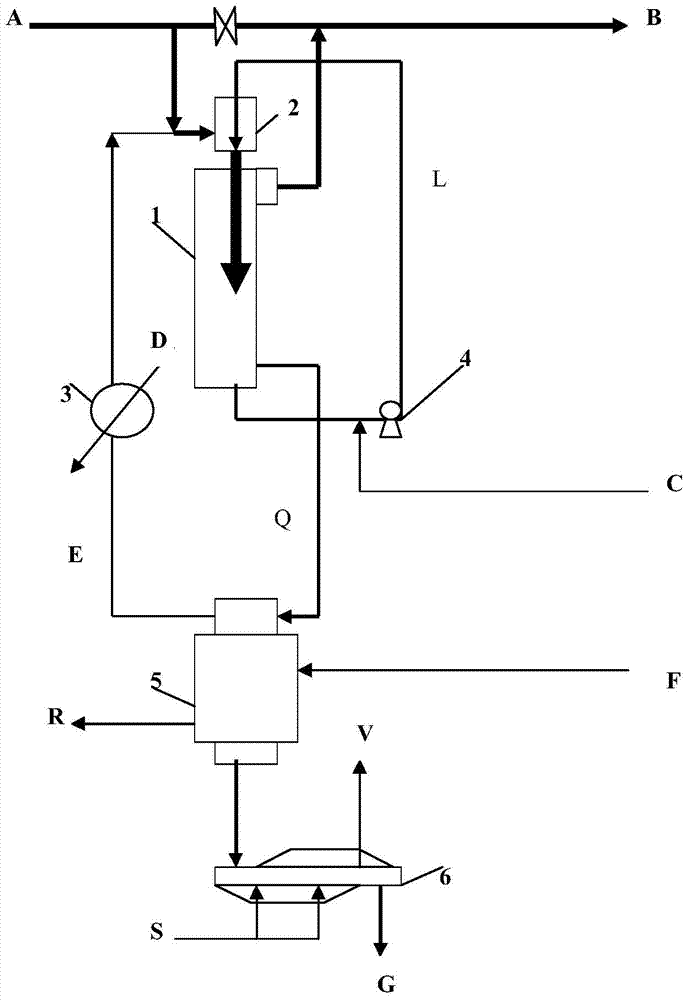

Membrane absorption method and device for producing sodium bisulfide with refinery acid gases

The invention discloses a membrane absorption method and a device for producing sodium bisulfide with refinery acid gases. The device mainly consists of a storage tank, primary and secondary membrane absorption assemblies, a hydrogen sulfide refinement and solvent recovery device, a solvent regeneration tower, an evaporator, molding (slicing) equipment and the like. According to the method and the device, the primary and secondary membrane absorption assemblies are used and flow rates of the acid gases and MDEA (methyldiethanolamine) are controlled, so that hydrogen sulfide is absorbed fully, and carbon dioxide, inert gases and hydrocarbon are not absorbed or are absorbed rarely; the hydrogen sulfide subjected to refinement and solvent recovery is contacted with and reacts with a sodium hydroxide solution, and the sodium bisulfide is produced. The method and the device are low in energy consumption and investment cost and significant in economic benefit.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Water-phase preparation method of low-impurity light-smell polysulfide silane coupling agent

InactiveCN103804410AReduce manufacturing costLess impuritiesGroup 4/14 element organic compoundsPtru catalystDistillation

The invention aims at provide a water-phase preparation method of a low-impurity light-smell polysulfide silane coupling agent. The water-phase preparation method comprises the following specific steps: a, synthesis of a sodium polysulfide aqueous solution, namely adding sodium bisulfide or sodium sulfide, sodium hydroxide, sodium chloride, sulfur and water to a reaction device capable of stirring and heating, stirring and heating to the range from 70 to 80 DEG C, and preserving heat; b, addition of catalyst, namely feeding a catalyst aqueous solution into the sodium polysulfide aqueous solution; c, synthesis of coarse product, namely dropwise adding chloropropyltriethoxysilane to the sodium polysulfide aqueous solution, controlling the temperature of the reaction system within the range from 75 to 95 DEG C, and preserving heat after finishing dropwise adding; d, phase separation, namely separating the organic phase of the upper layer and the water phase of the lower layer and filtering the organic phase of the upper layer; e, purification of the organic phase, namely purifying the filtered organic phase by means of filtering or distillation, and then obtaining the product, namely, the polysulfide silane coupling agent.

Owner:南京曙光硅烷化工有限公司

Copper-molybdenum separation electric potential flotation process

The invention discloses a copper-molybdenum separation electric potential flotation process. The copper-molybdenum separation electric potential flotation process comprises the steps of raw ore crushing, ore grinding, mixed flotation and separation flotation. In the separation flotation step, the ph value of pulp is kept at 10-11, and rougher flotation pulp electric potential is controlled to -510 mv to -530 mv; and then 180 ml / min of polyacrylamide modified matter is added as a copper inhibitor, the grade of separation rougher flotation foam molybdenum is controlled to 9%-12%, the copper grade is controlled to 11.2%-15%. Electric potential flotation is adopted, rougher flotation electric potential is controlled to be within a certain range, copper minerals can be restrained to the maximum, the foam grade of corresponding work is stabilized, a large amount of sodium bisulfide can be saved, the molybdenum recovery rate is increased, meanwhile, mutual containing in copper-molybdenum concentrate is lowered, and the effect is also very significant.

Owner:CHINA GOLD INNER MONGOLIA MINING

Processing method and processing device of production waste gas containing hydrogen sulfide

InactiveCN102743970AEasy to handleSimple structureDispersed particle separationSodium bisulfideVolumetric Mass Density

Provided is a processing method of production waste gas containing hydrogen sulfide. The processing method includes adopting impinging stream technology to conduct high pressure collision on absorbing alkali liquid and waste gas containing hydrogen sulfide and enabling the absorbing alkali liquid to absorb and process hydrogen sulfide in the waste gas. Two absorption towers are connected in series vertically, and the insides of the two absorption towers are communicated. A gas inlet pipe, an alkali inlet pipe and an alkali outlet pipe are arranged in each absorption tower. A gas inlet branch pipe communicated with the gas inlet pipe is arranged on each gas inlet pipe, and a high pressure nozzle is installed in each gas inlet branch pipe port. Each alkali inlet pipe is connected with the corresponding high pressure nozzle through a corresponding alkali inlet branch pipe, and the alkali inlet pipe is connected with the bottoms of the absorption towers. Each alkali inlet pipe and each alkali discharge pipe are respectively connected with an alkali liquid circulation tank, and a centrifugal pump is arranged between the alkali inlet pipe and the alkali liquid circulation tank. A waste gas processing device adopts the impinging stream technology to improve absorption rate of hydrogen sulfide, and is good in waste gas processing effect. The absorption towers are low in resistance, and sodium bisulfide produced in the reaction is high in density.

Owner:唐山三友集团兴达化纤有限公司

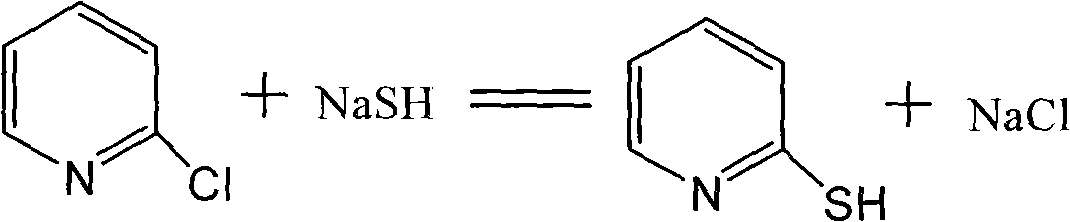

Industrialized method for preparing 2-mercaptopyridine

InactiveCN101941942ASolve the problems of industrial productionSimple production processOrganic chemistryRefluxSodium bisulfide

The invention discloses an industrialized method for preparing 2-mercaptopyridine, which comprises the following production processes of: adding anhydrous sodium bisulfide and an organic solvent into a conical reactor with a stirrer, a thermometer, a reflux device, a distilling device, a heating device and a charging device, heating to a certain temperature, adding 2-chloropyridine in batches from a charging opening, performing reaction for several hours until the reaction is completed, removing a solvent by distilling, adding an appropriate amount of distilled water, regulating the pH value by using acid, extracting by using the organic solvent, and removing an extracting agent by distilling to obtain faint yellow 2-mercaptopyridine crystals. The preparation method of the invention has the advantages of simple and convenient production process, mild reaction conditions, and high yield and purity of products; and the industrialized method for synthesizing the 2-mercaptopyridine in one step is provided and the problem of industrialized production of the 2-mercaptopyridine is solved.

Owner:TIANJIN NORMAL UNIVERSITY

Ecological automobile leather manufacturing method by adopting novel enzyme unhairing

ActiveCN103555866AReduce dosageReduce nitrogen contentPre-tanning chemical treatmentSodium bisulfideEnvironmental engineering

The invention relates to a manufacturing method of cow leather, and particularly relates to an ecological automobile leather manufacturing method by adopting novel enzyme unhairing. The method comprises the following processes: 1) a pre-tanning process; 2) a combined tanning process; 3) a dry finishing workshop section process; and 4) a coating workshop section process, wherein the pre-tanning process comprises the following steps: soaking in water; enzyme unhairing; liming; deliming and softening; and tanning by salt-free non-dipping acid. The enzyme unhairing step adopts an enzyme unhairing formula system consisting of an enzymic preparation, a degreasant, a liming agent, sodium bisulfide, a small amount of lime and sodium sulphide. The enzyme unhairing formula system comprises the following main components in percent by weight: 0.2-0.3% of enzymic preparation, 0.1% of degreasant, 0.3% of liming agent and 1.8% of sodium bisulfide. The method provided by the invention overcomes the deficiencies that enzyme in cow leather production is slow to permeate and small hair is not easy to remove thoroughly, and prevents hair shafts from being dissolved, and cow hair integrally falls from pelt. Meanwhile, the stability of the product can be improved, and the method is free from environmental pollution.

Owner:ZHEJIANG MINGXIN XUTENG LEATHER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com