Patents

Literature

172 results about "Hydrogen iodide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen iodide (HI) is a diatomic molecule and hydrogen halide. Aqueous solutions of HI are known as hydroiodic acid or hydriodic acid, a strong acid. Hydrogen iodide and hydroiodic acid are, however, different in that the former is a gas under standard conditions, whereas the other is an aqueous solution of the gas. They are interconvertible. HI is used in organic and inorganic synthesis as one of the primary sources of iodine and as a reducing agent.

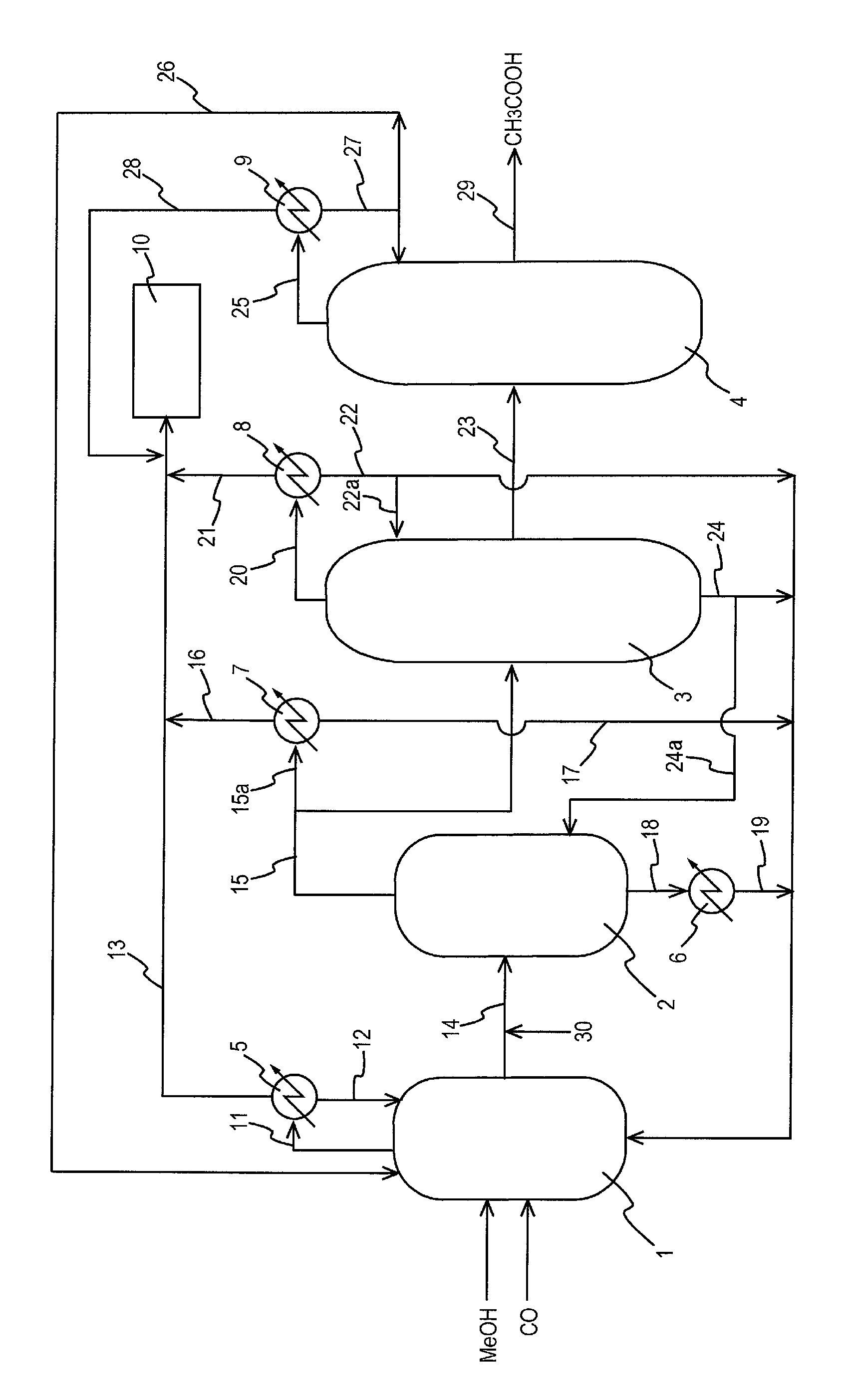

Process for producing acetic acid

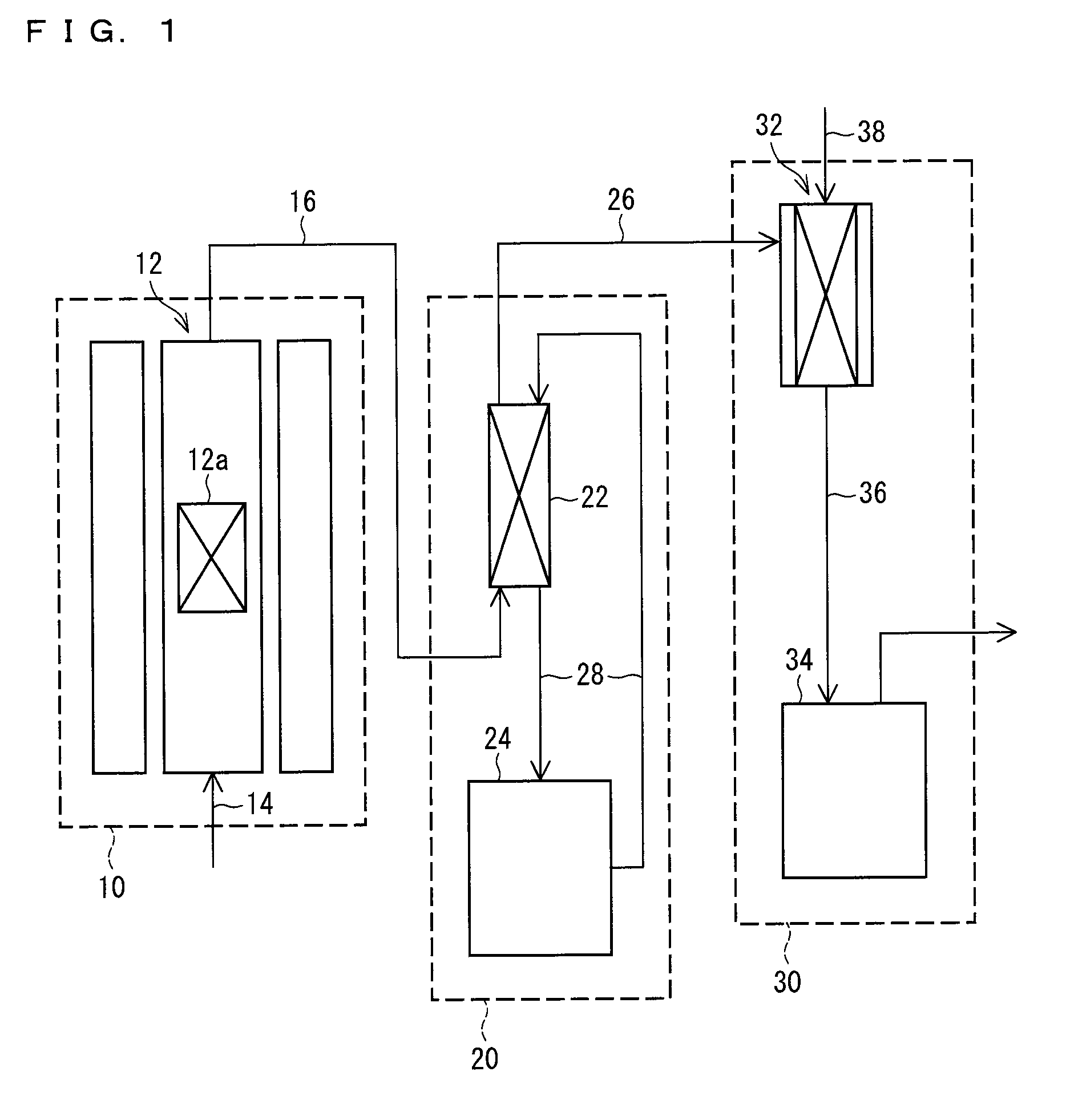

ActiveUS20130264186A1Improve concentrationEfficient executionOrganic chemistry methodsDistillation separationBoiling pointFractionating column

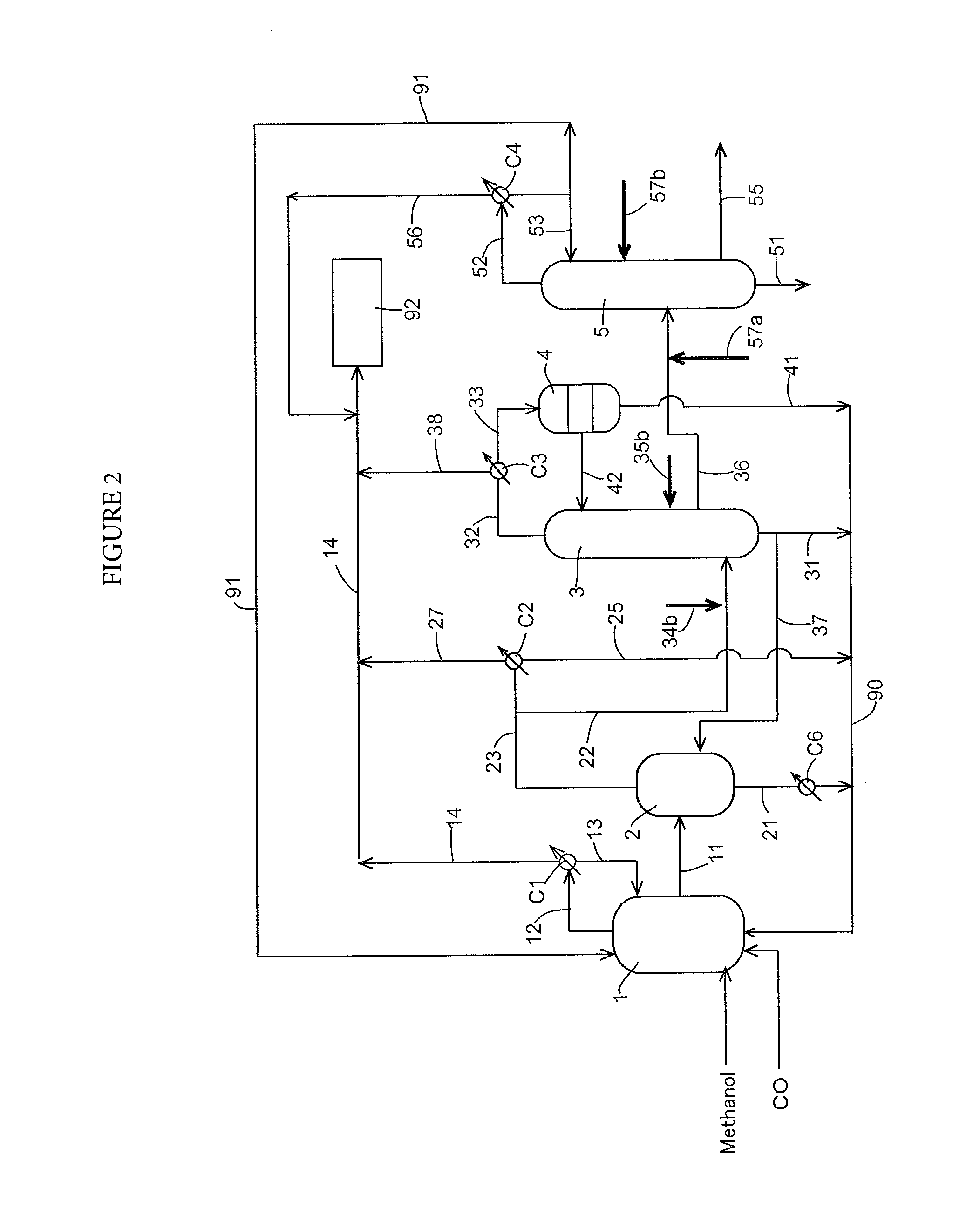

Acetic acid is produced while efficiently inhibiting condensation of hydrogen iodide in a distillation column (second distillation column) for purifying crude acetic acid by further distillation.A process for producing acetic acid comprises an acetic acid collection step for feeding a first distillation column with a volatile component at least containing acetic acid, methyl acetate, methyl iodide, water, and hydrogen iodide, separating a first lower boiling point component as an overhead, and collecting a first liquid stream mainly containing acetic acid, and an acetic acid purification step for feeding a second distillation column with the first liquid stream, further separating a second lower boiling point component as an overhead, and collecting a second liquid stream containing acetic acid, wherein an alkali component is added or mixed to the first liquid stream in the manners (1) and / or (2) for distilling a liquid object to be treated containing the first liquid stream and the alkali component in the second column: (1) the alkali component is added to or mixed with the first liquid stream before the first liquid stream is fed to the second column, (2) in the second column, the alkali component is added or mixed at the same height level as or at a height level upper than a height level at which the first liquid stream is fed.

Owner:DAICEL CHEM IND LTD

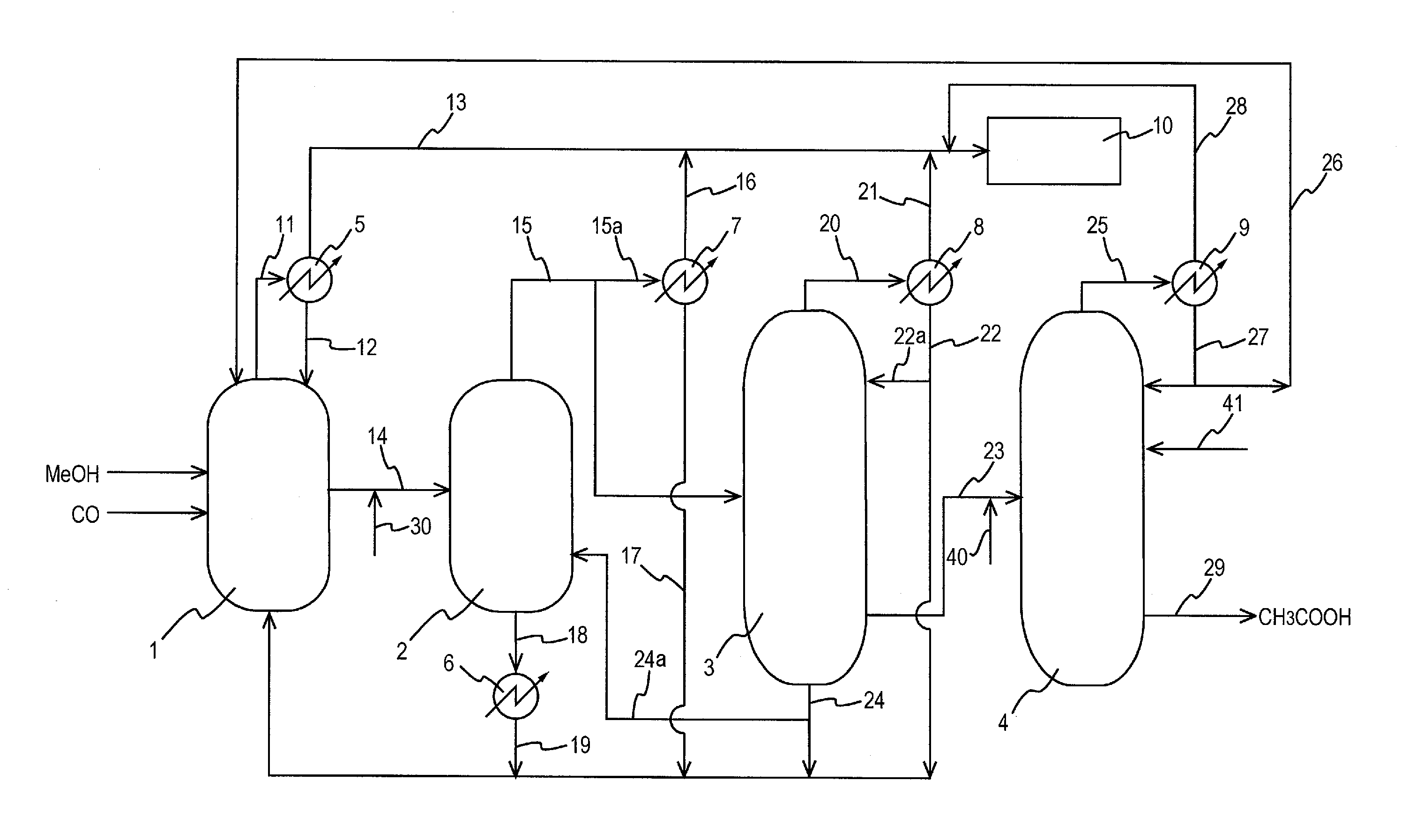

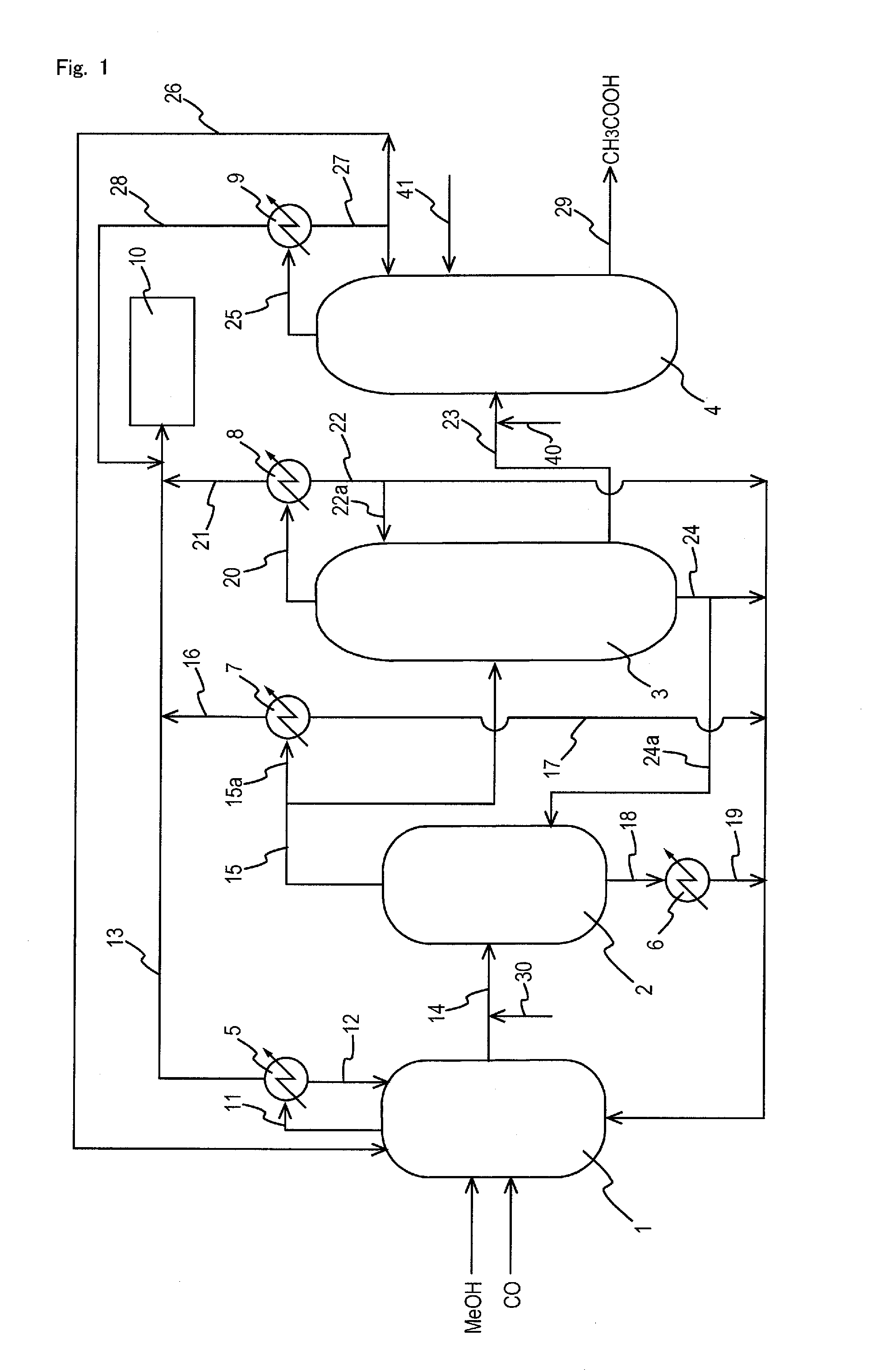

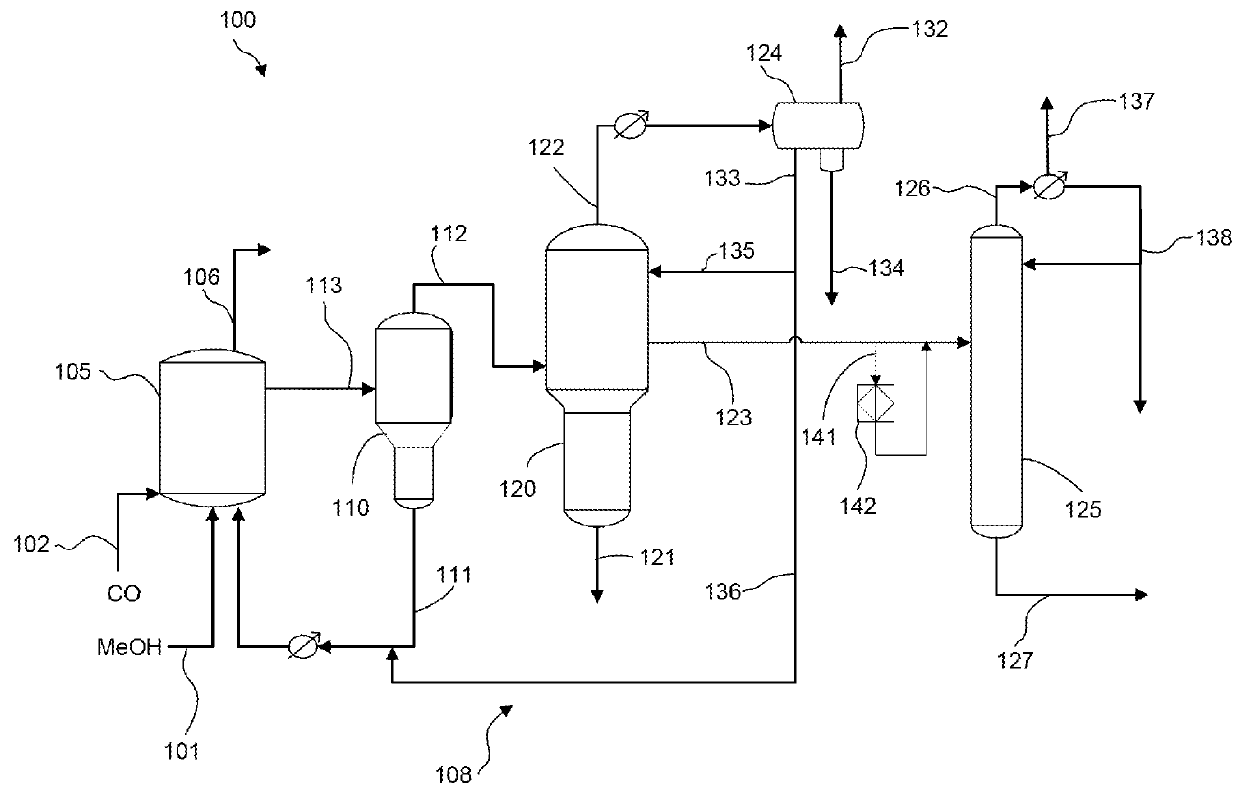

Process for producing acetic acid

ActiveUS20130310603A1Efficient productionEasy to save energyOrganic compound preparationOrganic chemistry methodsIodideReaction step

Acetic acid is produced while inhibiting an increased concentration or production of hydrogen iodide in a carbonylation reactor or corrosion of the carbonylation reactor.A production process of acetic acid comprises a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst (e.g., a rhodium catalyst), an ionic iodide (e.g., lithium iodide), and methyl iodide in a carbonylation reactor; and in the process, (i) the concentration of the metal catalyst is maintained at not less than 860 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 15% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor, and / or (ii) the concentration of the metal catalyst is maintained at not less than 660 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 3.9% by weight, the concentration of the ionic iodide is maintained at not more than 13% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor.

Owner:DAICEL CHEM IND LTD

Process for producing acetic acid

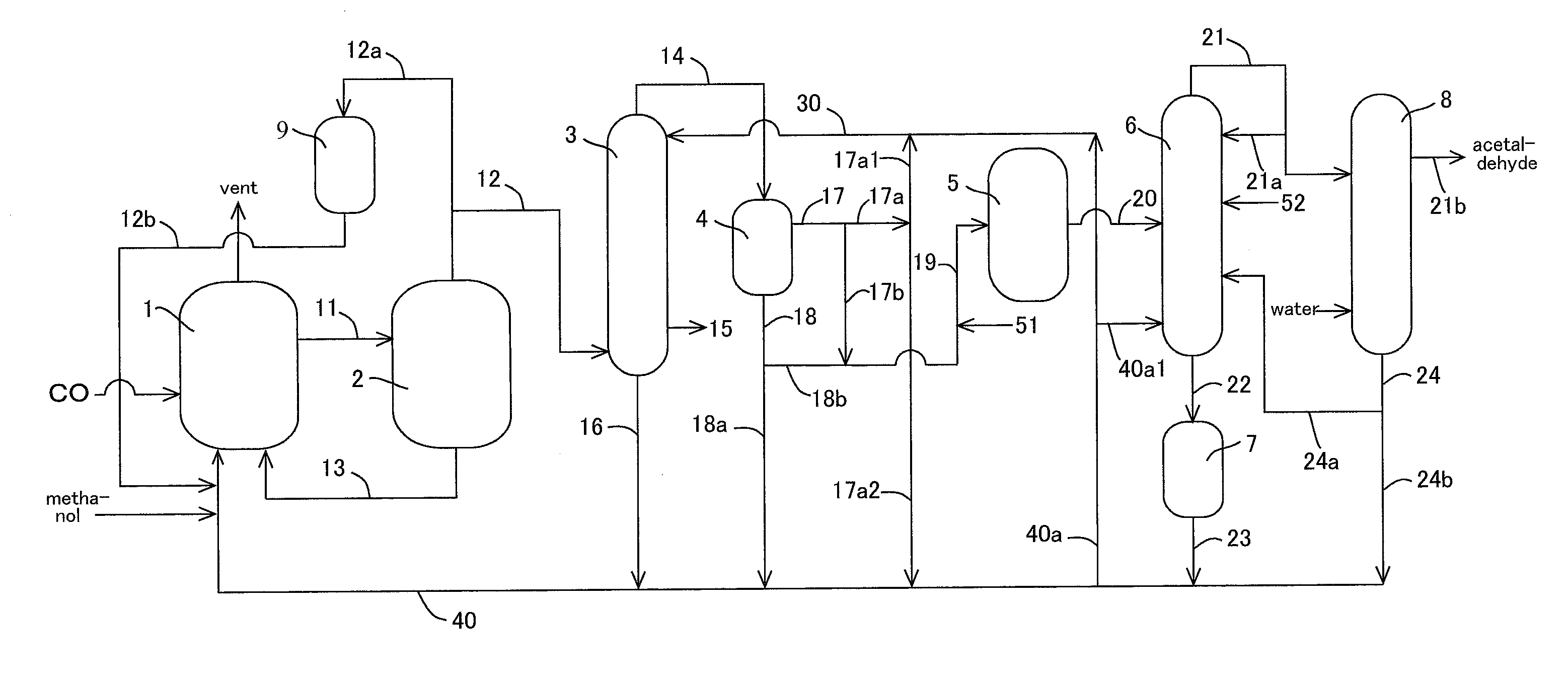

ActiveUS20130281735A1Efficient removalImprove corrosion resistanceOrganic compound preparationOrganic chemistry methodsDistillationMethyl acetate

Acetic acid is produced while inhibiting increased concentrations of hydrogen iodide and acetic acid in an acetaldehyde distillation column.A production process of acetic acid comprises a step for allowing methanol to react with carbon monoxide; a step for feeding a flasher with the reaction mixture to separate a volatile component (2A) and a low-volatile component (2B); a step for feeding a distillation column with the volatile component (2A), and separating an overhead (3A) containing methyl iodide, acetic acid, methyl acetate, water, acetaldehyde, and hydrogen iodide, and a stream (3B) containing acetic acid to collect acetic acid; and a separation step for feeding an acetaldehyde distillation column with at least part of the overhead (3A) and separating a liquid object to be treated containing the overhead (3A) into a lower boiling point component (4A) containing acetaldehyde and a higher boiling point component (4B); wherein, in the separation step, the liquid object contains methanol and / or dimethyl ether in a concentration of 0.1 to 50% by weight is subjected to distillation.

Owner:DAICEL CHEM IND LTD

Process for producing acetic acid

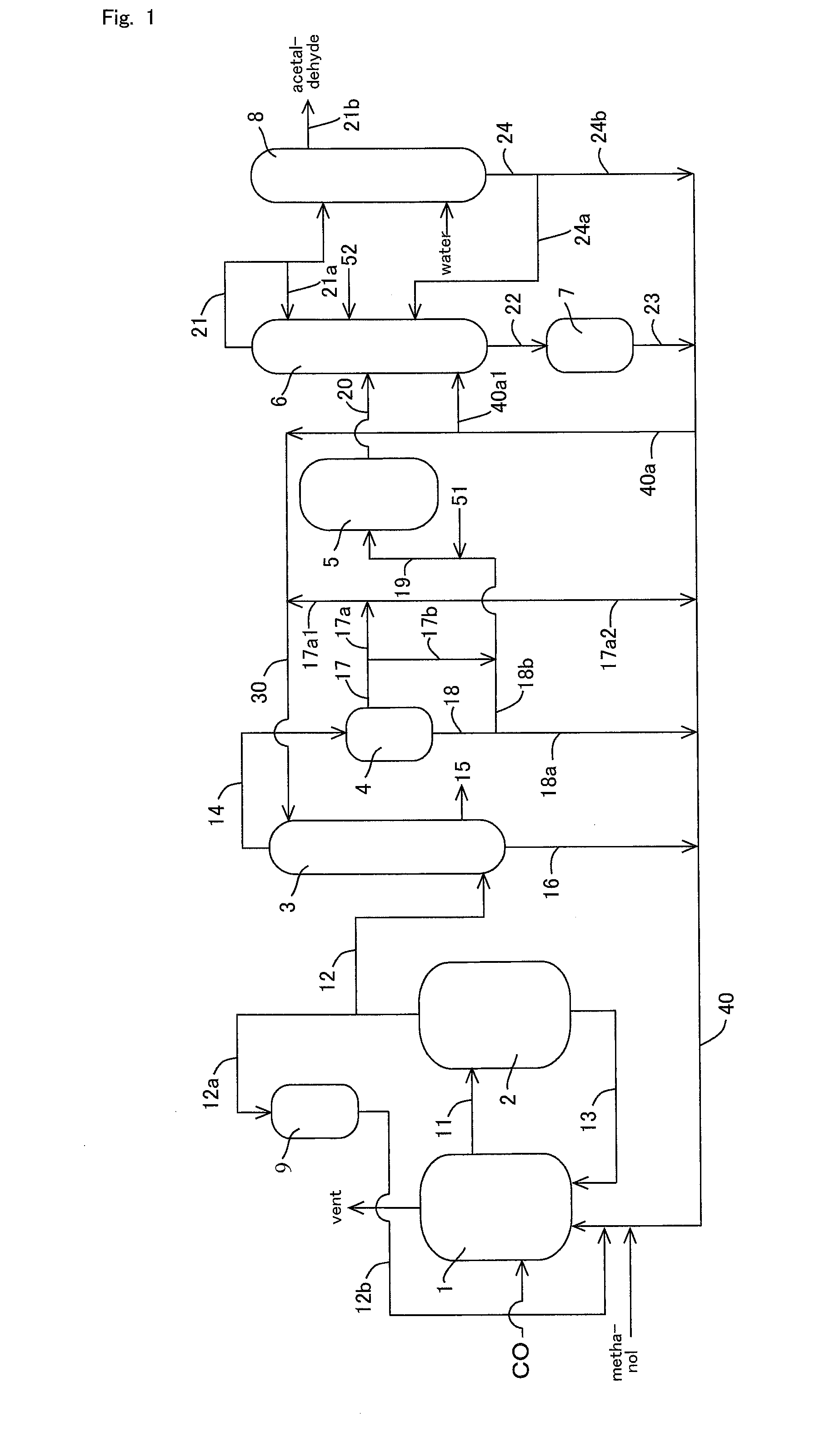

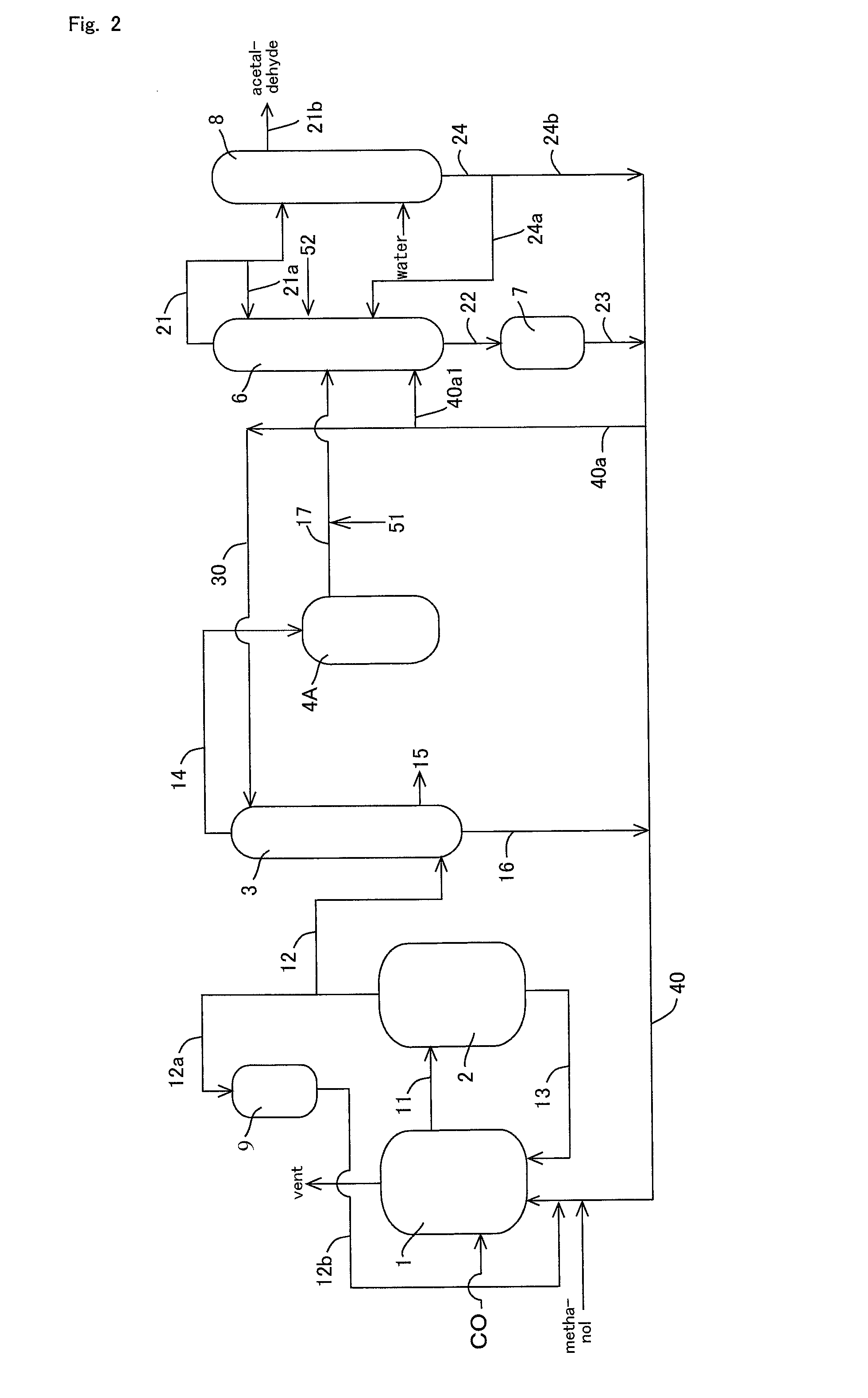

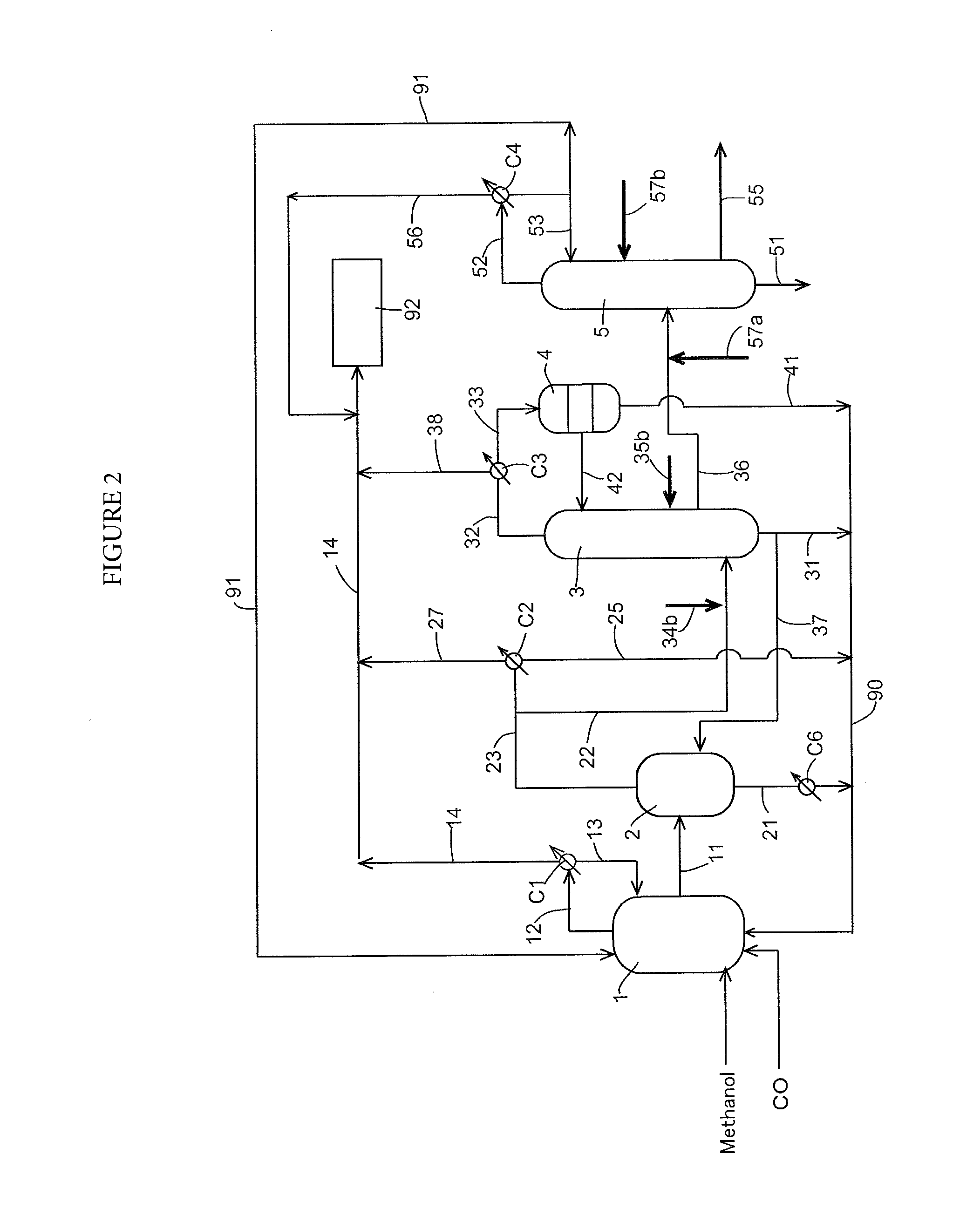

ActiveUS9006483B2Avoid pollutionEnsure stable and continuous operationOrganic compound preparationDistillation separationWater concentrationAcetic acid ear

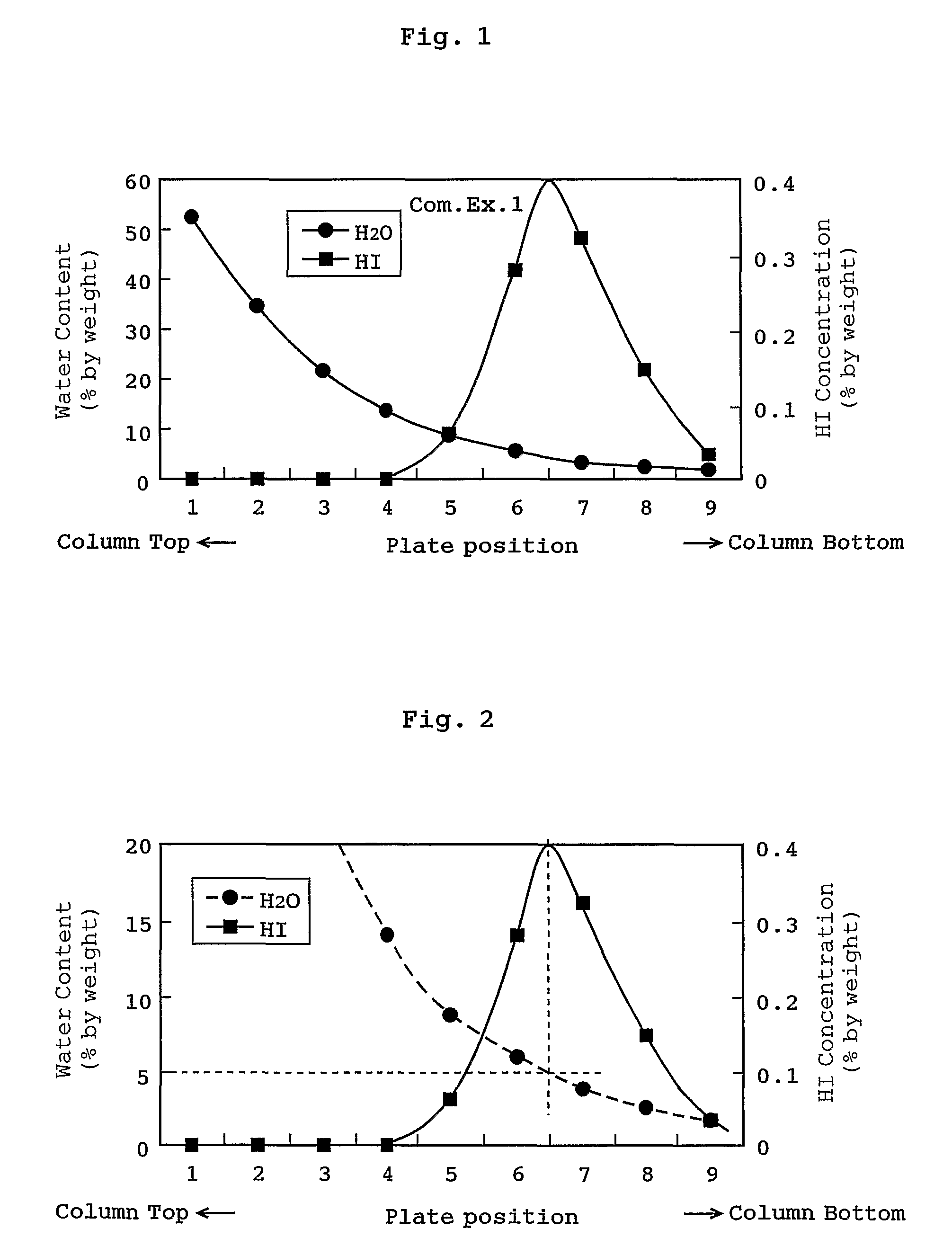

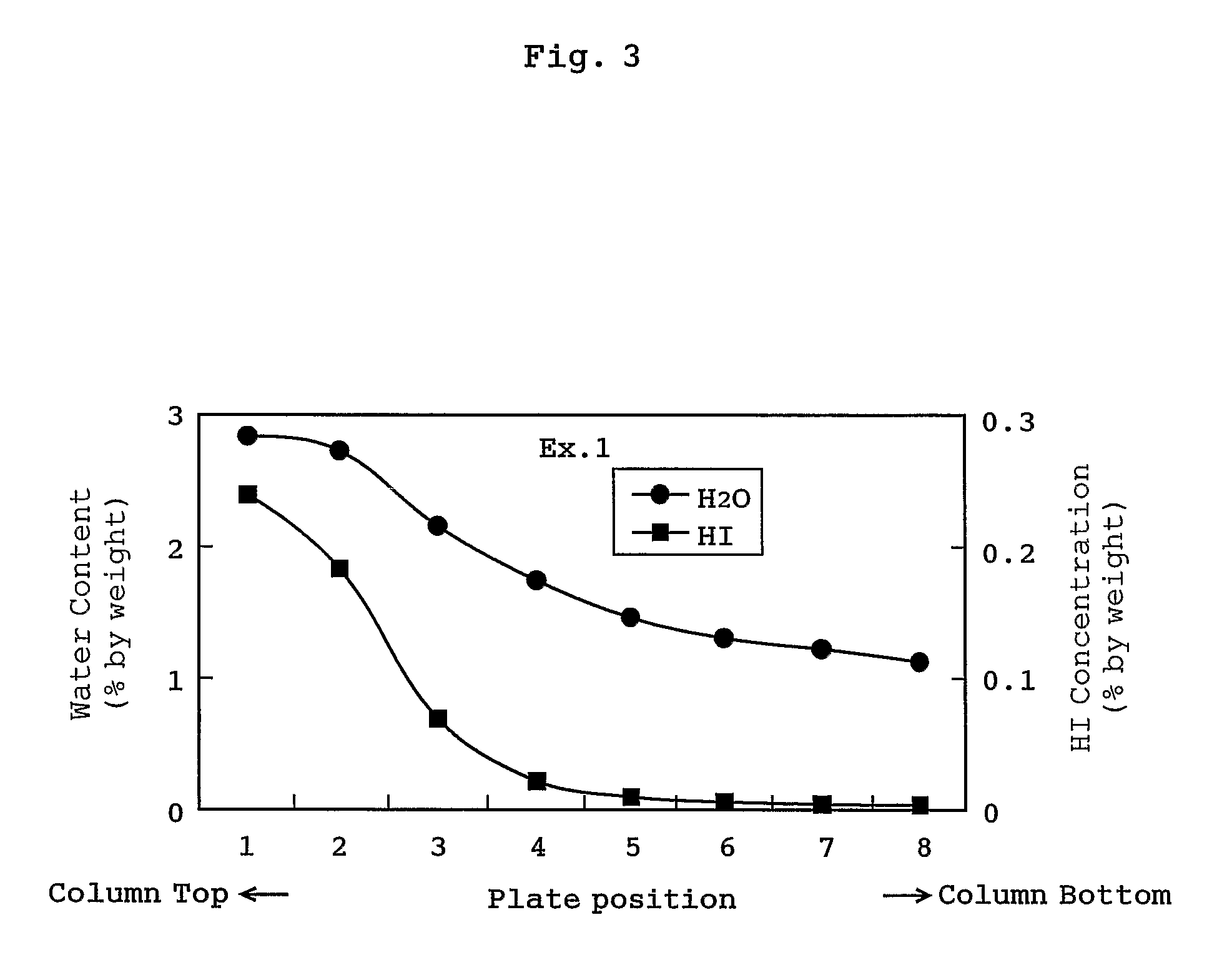

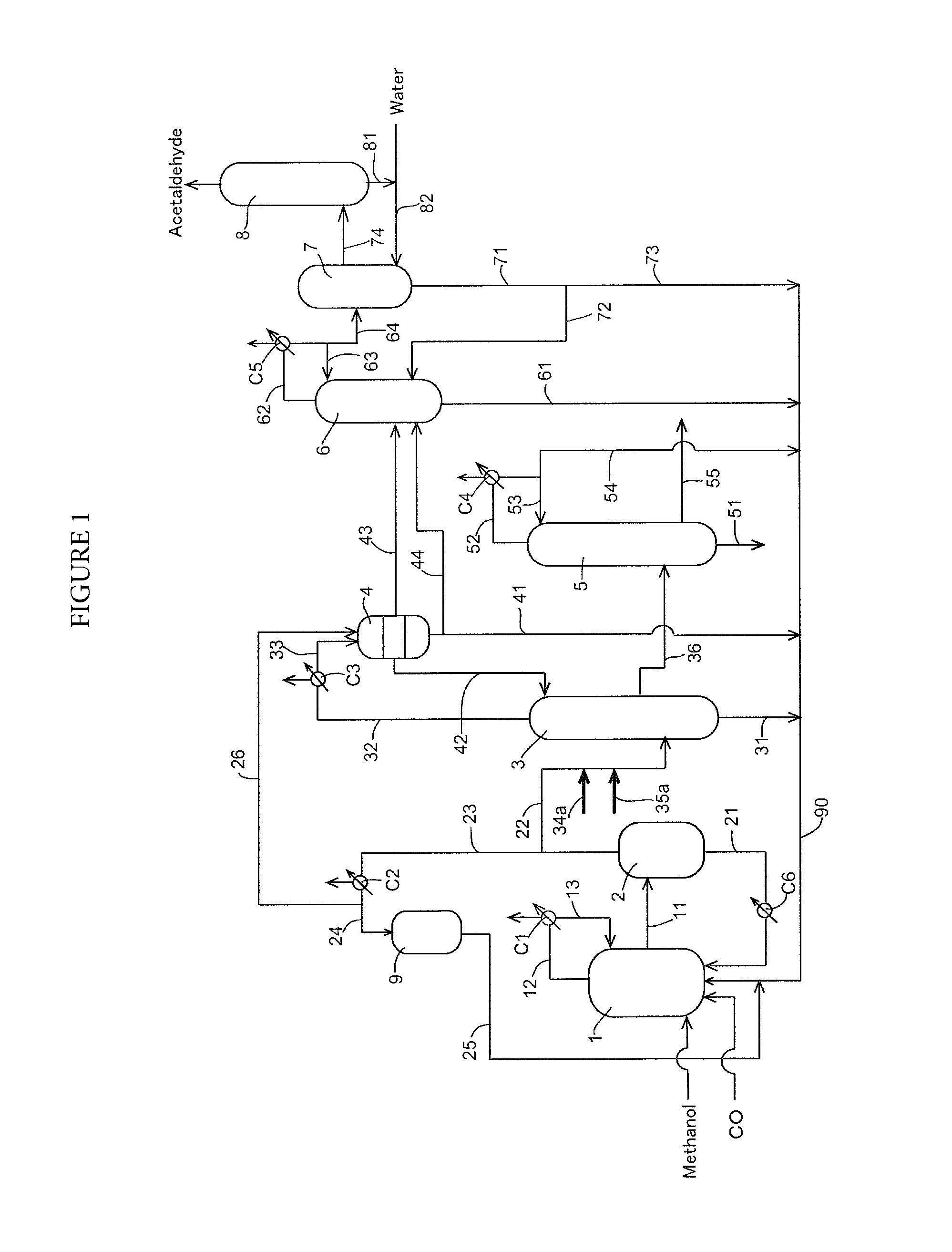

A production process of acetic acid according to the present invention inhibits concentration of hydrogen iodide and improves a liquid-liquid separation of an overhead from a distillation column. Acetic acid is produced by distilling a mixture containing hydrogen iodide, water, acetic acid and methyl acetate in a first distillation column (3) to form an overhead and a side cut stream or bottom stream containing acetic acid, cooling and condensing the overhead in a condenser (C3) to form separated upper and lower phases in a decanter (4). According to this process, a zone having a high water concentration is formed in the distillation column above the feed position of the mixture by feeding a mixture having a water concentration of not less than an effective amount to not more than 5% by weight (e.g., 0.5 to 4.5% by weight) and a methyl acetate concentration of 0.5 to 9% by weight (e.g., 0.5 to 8% by weight) as the mixture to the distillation column and distilling the mixture. In the zone having a high water concentration, hydrogen iodide is allowed to react with methyl acetate to produce methyl iodide and acetic acid.

Owner:DAICEL CHEM IND LTD

Carbonylation process

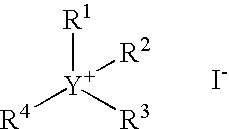

ActiveUS20070293695A1Organic compound preparationPreparation by carbon monoxide or formate reactionHydrogen halideCarboxylic acid

Disclosed is a carbonylation process for the production of carboxylic acids, carboxylic acid esters and / or carboxylic acid anhydrides wherein a carbonylation feedstock compound selected from one or more organic oxygenates such as alcohols, ethers, and esters is contacted with carbon monoxide in the presence of a carbonylation catalyst and one or more onium compounds. The carbonylation process differs from known carbonylation processes in that a halide compound such as a hydrogen halide, typically hydrogen iodide, and / or alkyl halide, typically methyl iodide, extraneous or exogenous to the carbonylation process is not fed or supplied separately to the process.

Owner:EASTMAN CHEM CO

Distillation process

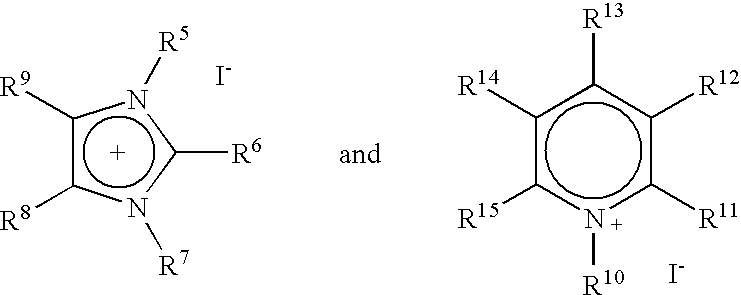

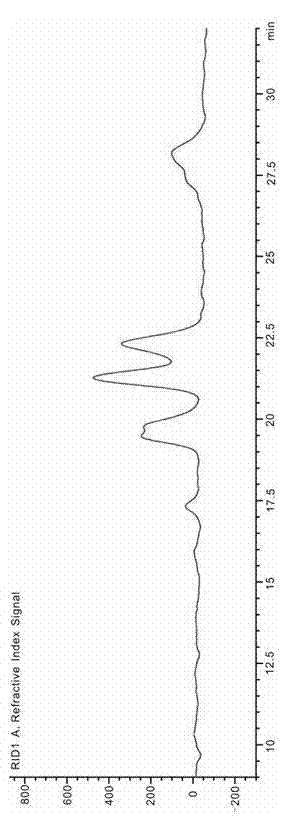

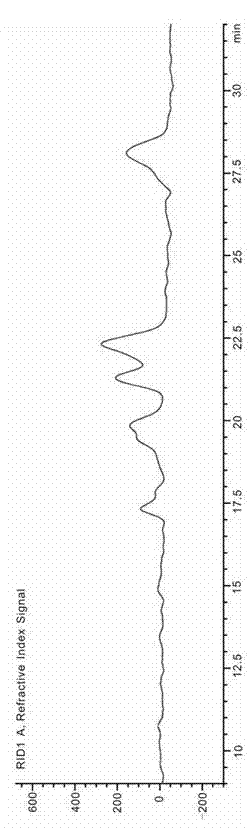

ActiveUS7884241B2Avoid condensationAvoid corrosionOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateDistillation method

A mixture containing hydrogen iodide and water and having a water content of not more than 5% by weight (particularly not more than 3% by weight) in a distillation system is distilled to prevent condensation of hydrogen iodide in the distillation system. The mixture may comprise hydrogen iodide, water, methanol, methyl iodide, acetic acid, and methyl acetate. Even when the mixture contains hydrogen iodide at a concentration of 1 to 3000 ppm on the basis of weight, an acetic acid product having a concentration of hydrogen iodide of not more than 50 ppm can be obtained by withdrawing a fraction containing hydrogen iodide from the top of the column, and withdrawing acetic acid as a side-cut stream or a stream from the bottom of the column. Such a process (distillation process) effectively inhibits condensation of hydrogen iodide in the distillation system and corrosion in the distillation system.

Owner:DAICEL CHEM IND LTD

Process for producing acetic acid

ActiveUS20150025270A1Avoid pollutionEnsure stable and continuous operationOrganic compound preparationDistillation separationWater concentrationAcetic acid ear

A production process of acetic acid according to the present invention inhibits concentration of hydrogen iodide and improves a liquid-liquid separation of an overhead from a distillation column. Acetic acid is produced by distilling a mixture containing hydrogen iodide, water, acetic acid and methyl acetate in a first distillation column (3) to form an overhead and a side cut stream or bottom stream containing acetic acid, cooling and condensing the overhead in a condenser (C3) to form separated upper and lower phases in a decanter (4). According to this process, a zone having a high water concentration is formed in the distillation column above the feed position of the mixture by feeding a mixture having a water concentration of not less than an effective amount to not more than 5% by weight (e.g., 0.5 to 4.5% by weight) and a methyl acetate concentration of 0.5 to 9% by weight (e.g., 0.5 to 8% by weight) as the mixture to the distillation column and distilling the mixture. In the zone having a high water concentration, hydrogen iodide is allowed to react with methyl acetate to produce methyl iodide and acetic acid.

Owner:DAICEL CHEM IND LTD

Process for producing iodination vegetable oil fatty acid ethyl ester

ActiveCN101245007ALight colorImprove stabilityPreparation by ester-hydroxy reactionOrganic compound preparationVegetable oilFree iodine

The invention relates to a preparation method of a stable iodized plant oil fatty acid ethyl ester, which firstly puts the plant oil into ester exchange reaction with alcohol with the effect of salt catalyst so as to produce plant oil fatty acid ethyl ester which is then put into addition reaction with hydrogen iodide to produce the iodized plant oil fatty acid ethyl ester, then heating and air ventilating methods are used for eliminating unstable iodine being combined in the iodized plant oil fatty acid ethyl ester, and lopsidedness sodium sulfite solution is used for liquid seal of the separated free iodine so as to obtain the iodized plant oil fatty acid ethyl ester with good stability; the preparation method is characterized by small viscosity, good stability and low cost.

Owner:季珉

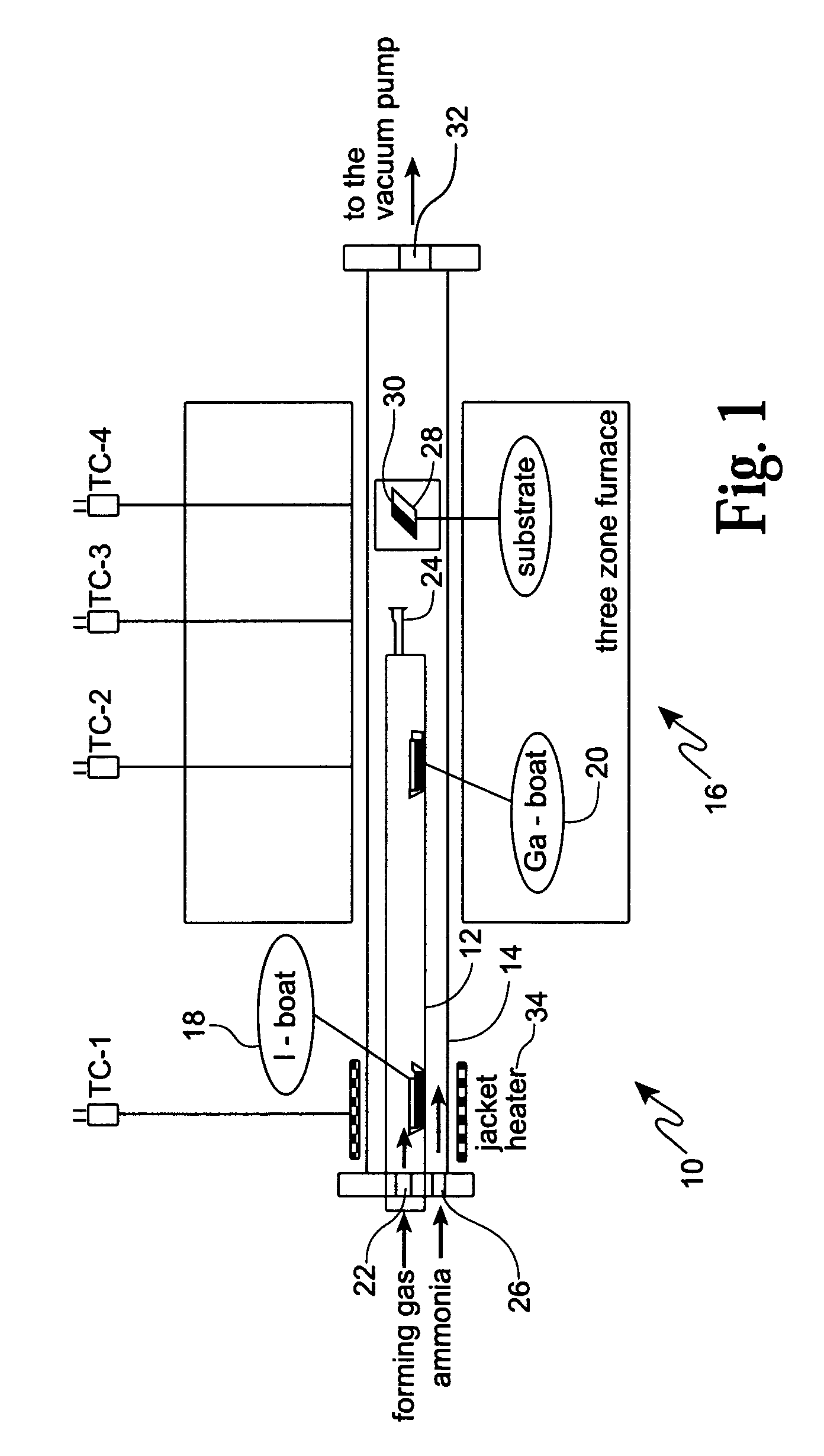

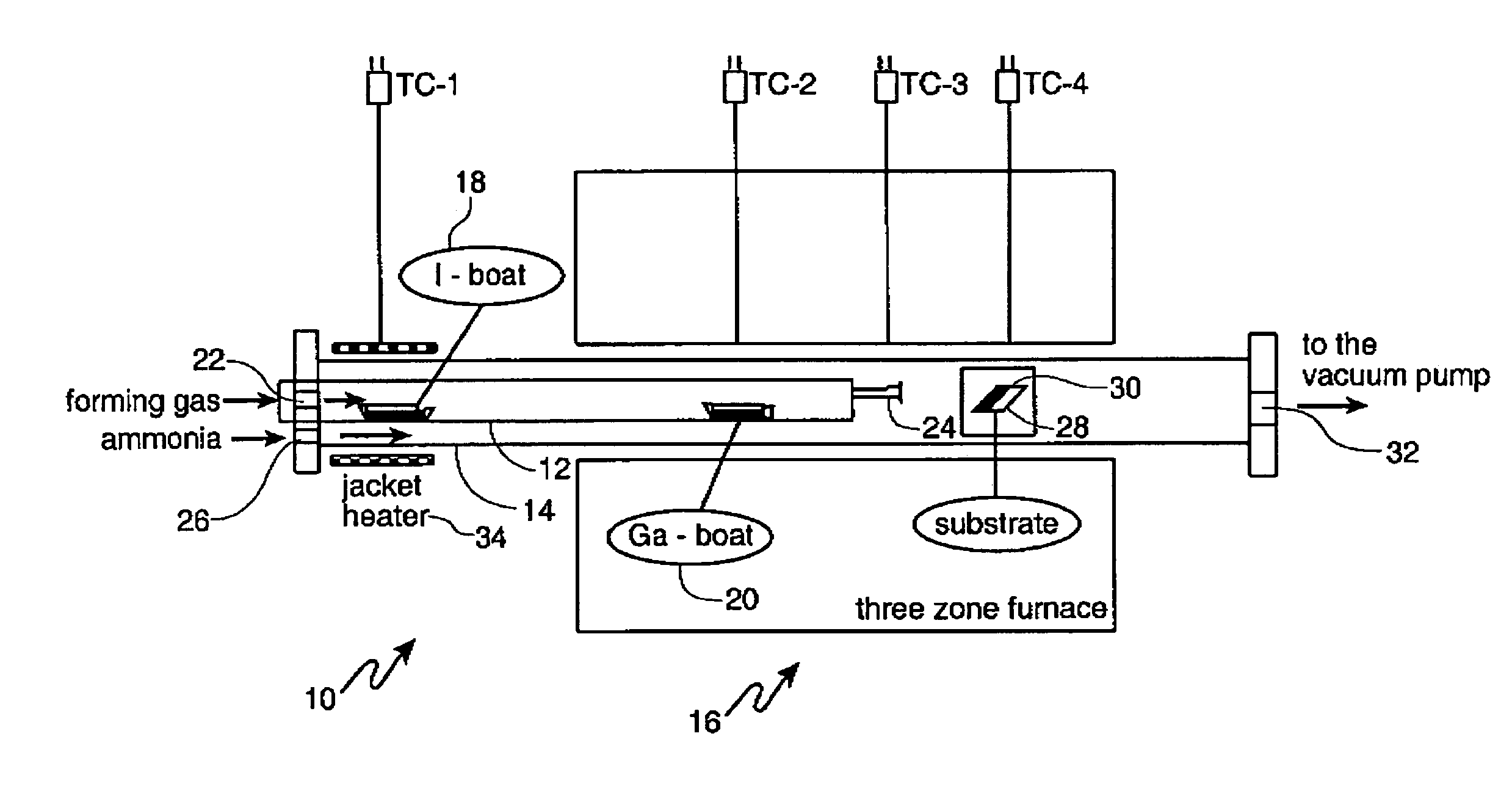

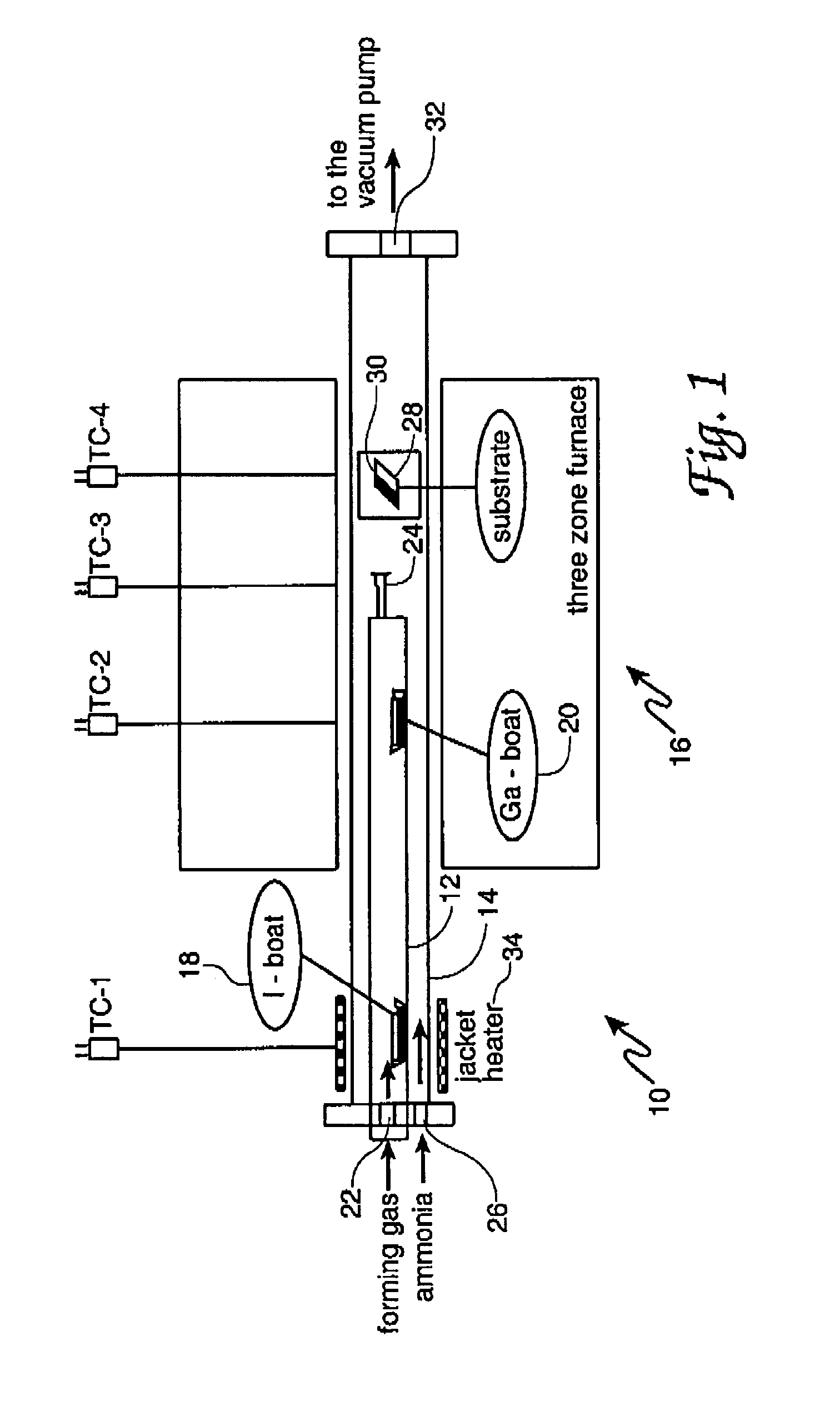

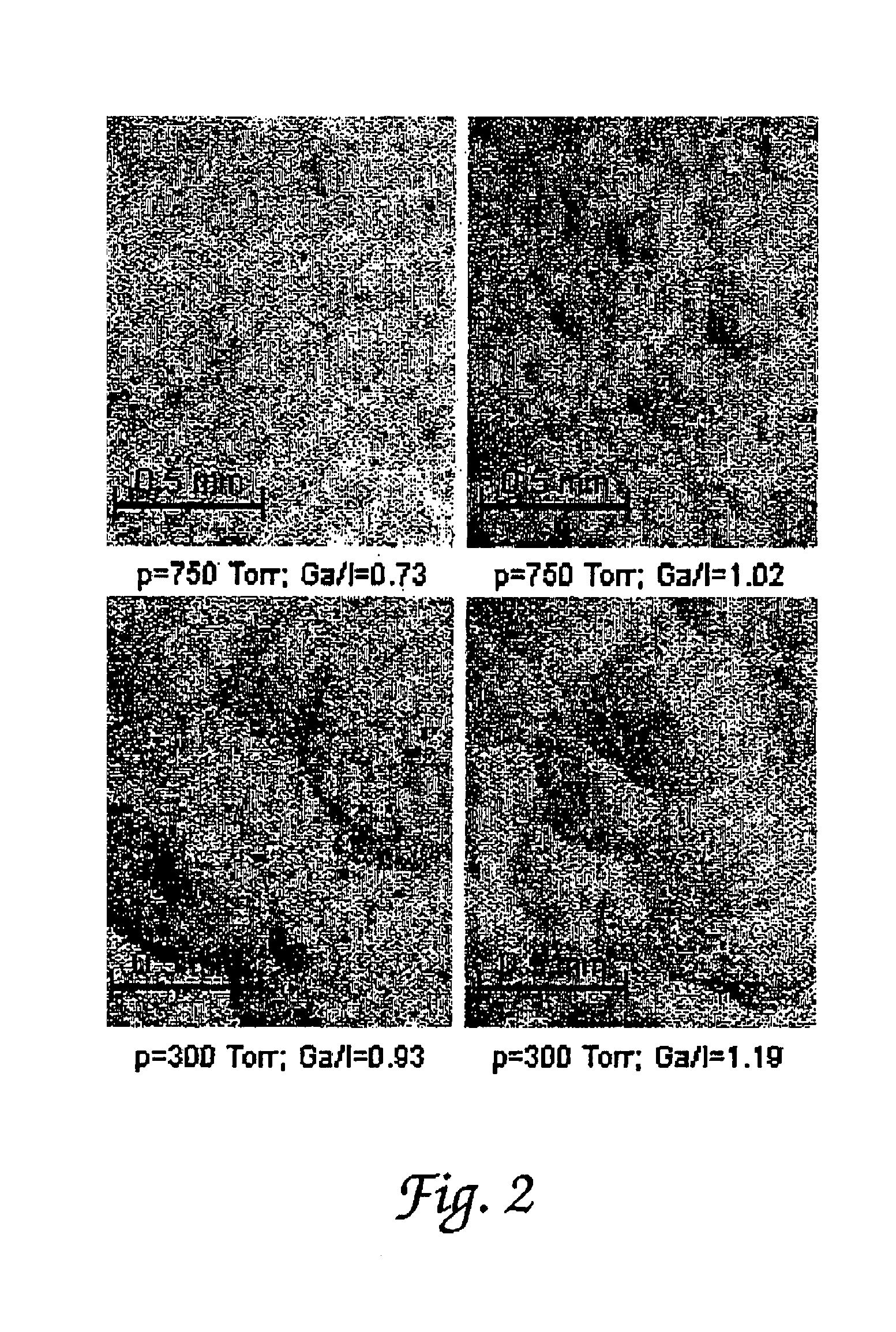

Forming improved metal nitrides

InactiveUS6969426B1Unity of formCellsPolycrystalline material growthMicrowaveSemiconductor materials

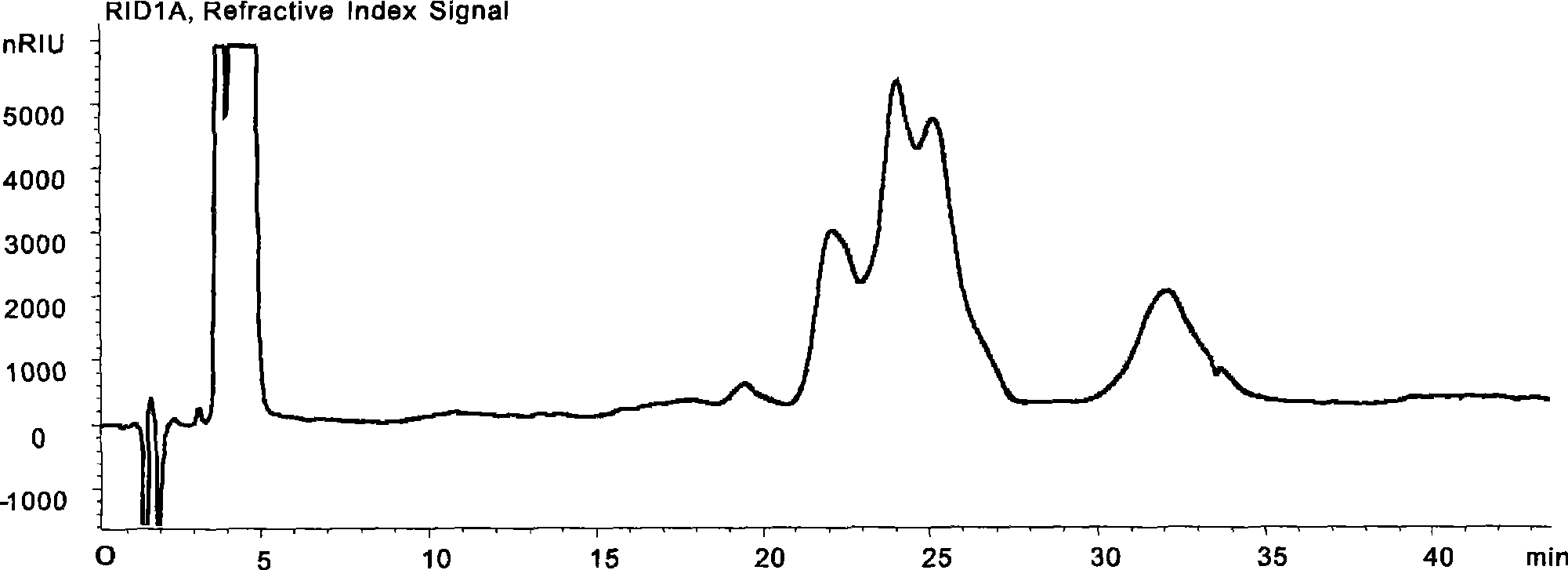

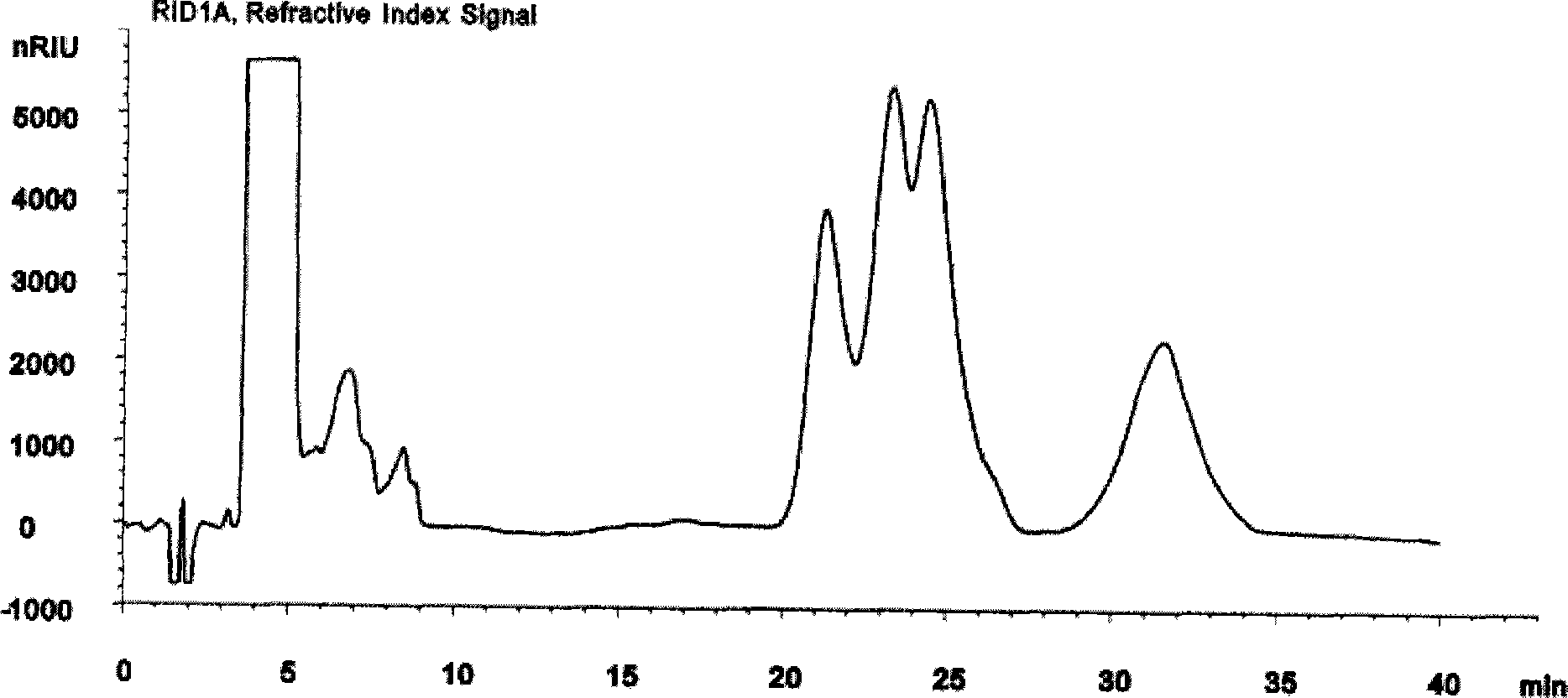

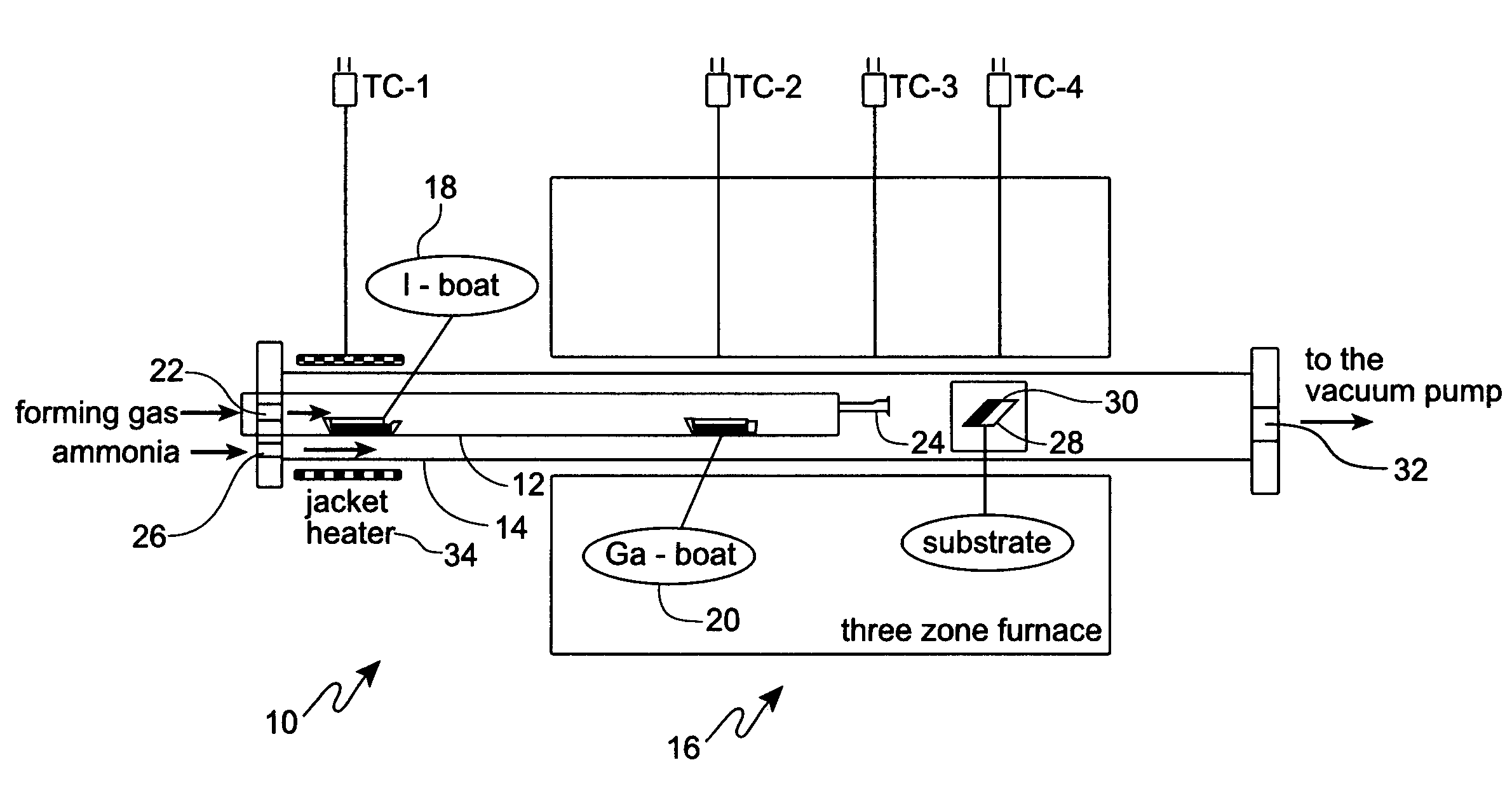

Method and apparatus are provided for forming metal nitride (MN), wherein M is contacted with iodine vapor or hydrogen iodide (HI) vapor to form metal iodide (MI) and then contacting MI with ammonia to form the MN in a process of reduced or no toxicity. Such method is conducted in a reactor that is maintained at a pressure below one atmosphere for enhanced uniformity of gas flow and of MN product. The MN is then deposited on a substrate, on one or more seeds or it can self-nucleate on the walls of a growth chamber, to form high purity and uniform metal nitride material. The inventive MN material finds use in semiconductor materials, in nitride electronic devices, various color emitters, high power microwave sources and numerous other electronic applications.

Owner:AIR FORCE US SEC THE

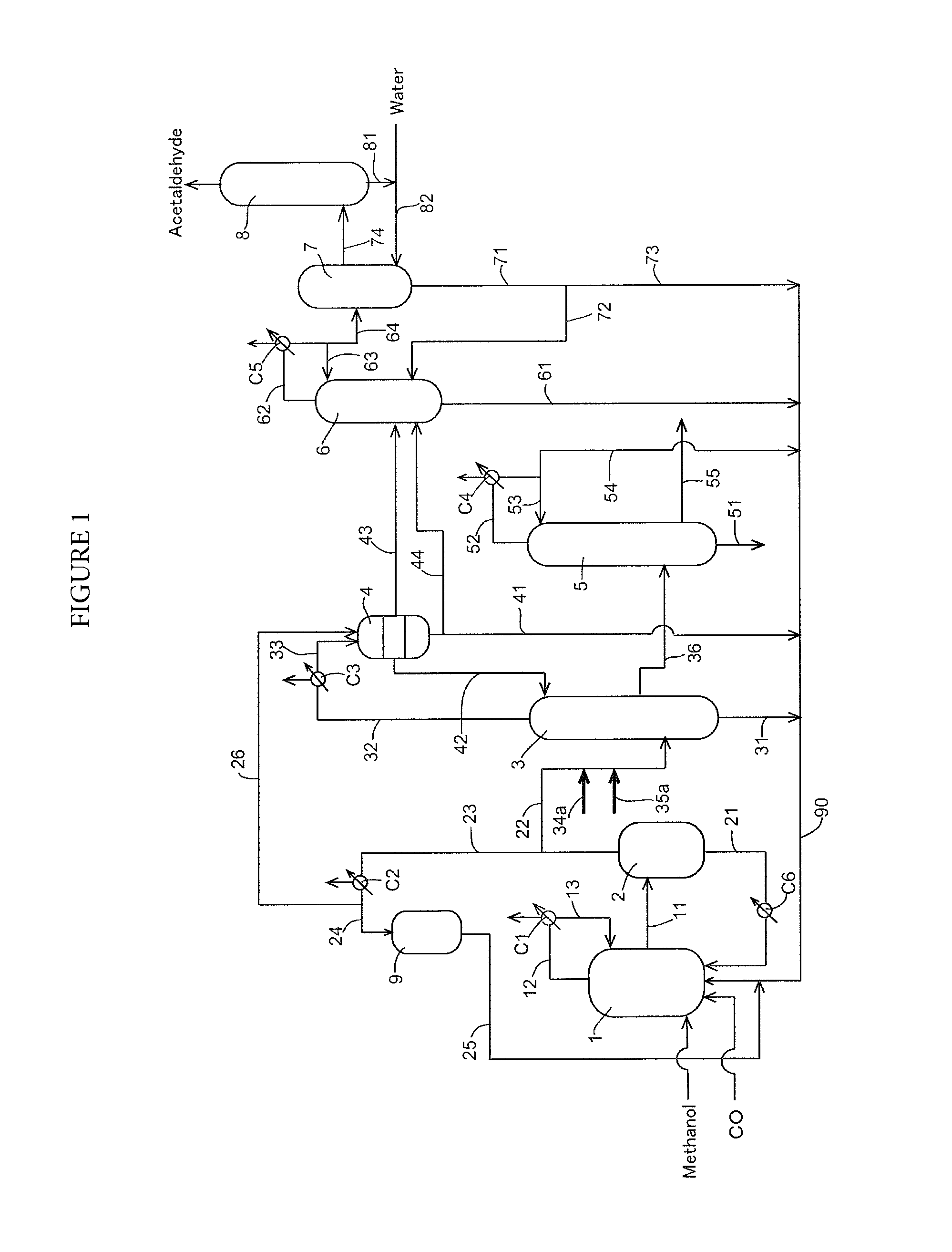

Process for producing acetic acid

ActiveUS9382186B1Stay focusedPreparation from carboxylic acid esters/lactonesCarboxylic preparation from carbon monoxide reactionAcetic acidWater concentration

A process for producing acetic acid is disclosed in which the water concentration is controlled in the side stream between two columns. Controlling the water concentration by the liquid light phase recycle controls the hydrogen iodide concentration in the side stream to be less than or equal to 50 wppm.

Owner:CELANESE INT CORP

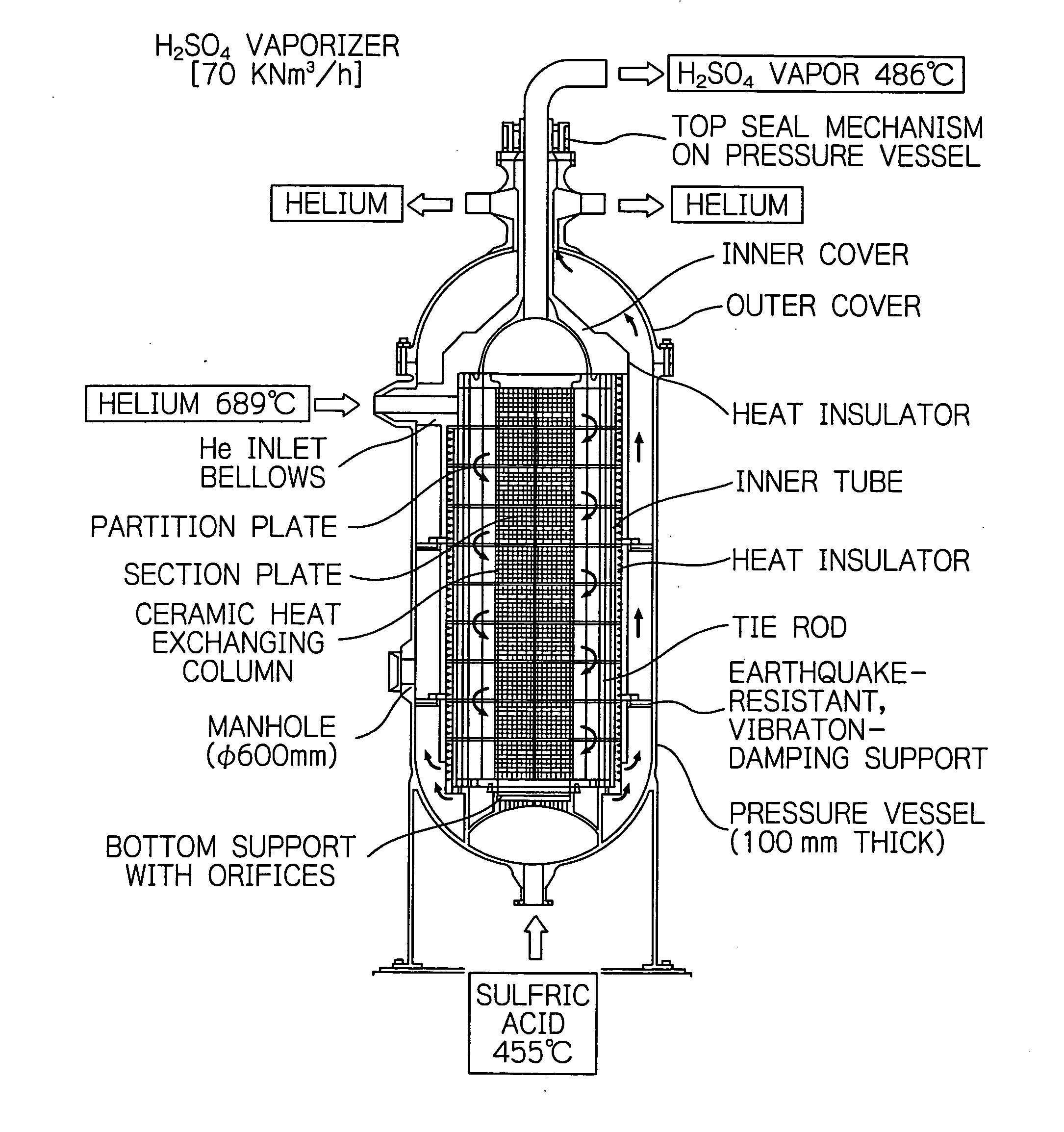

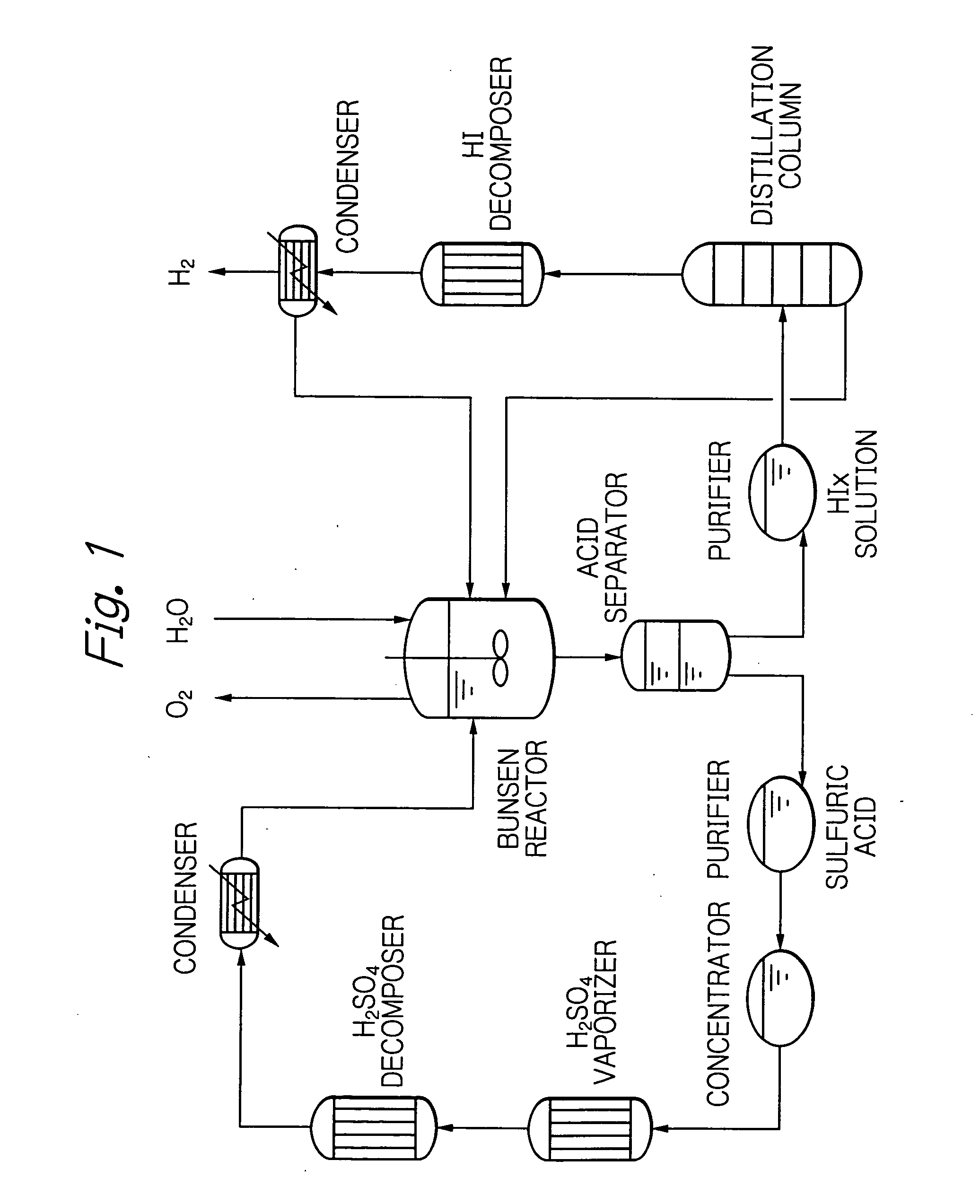

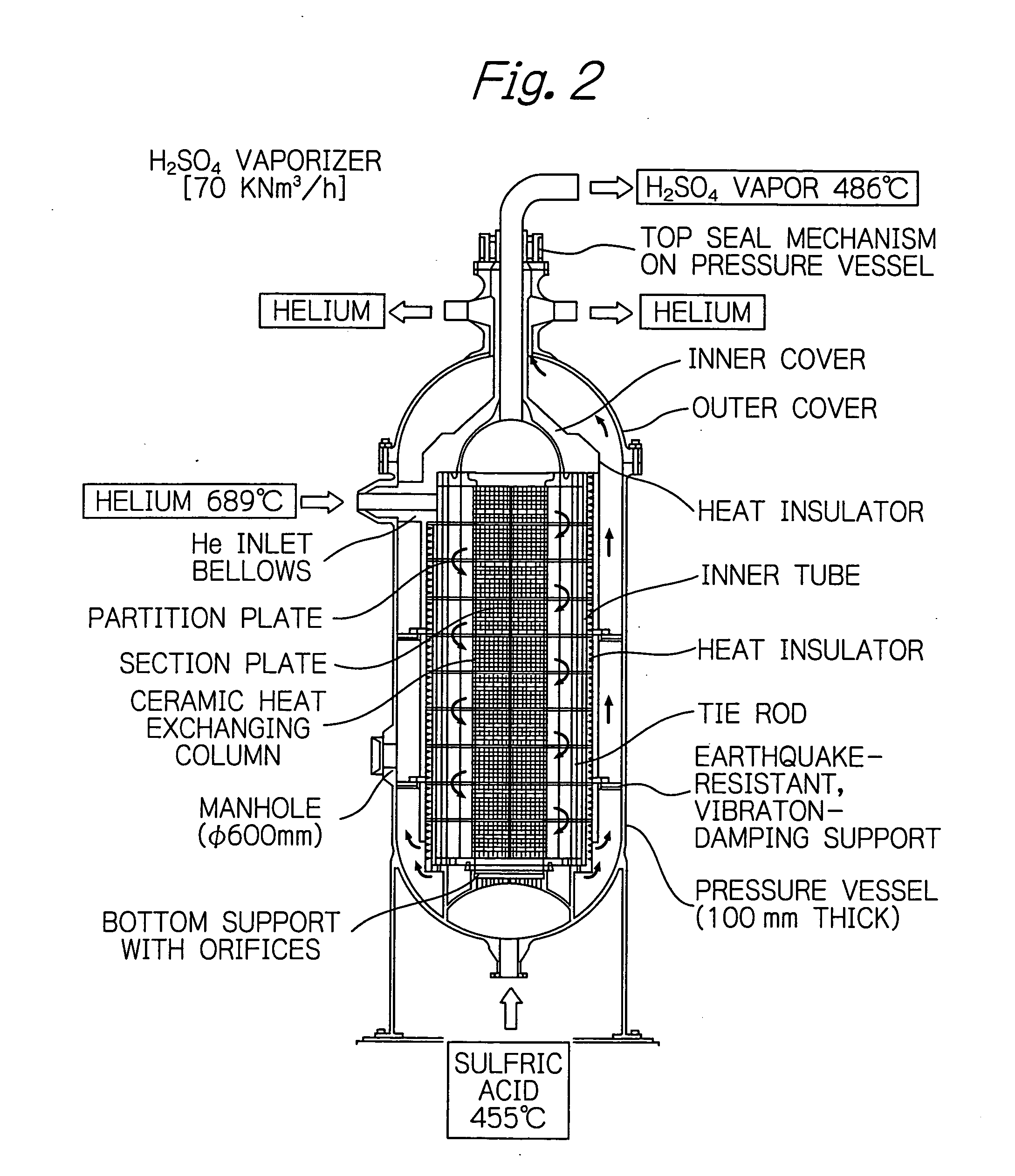

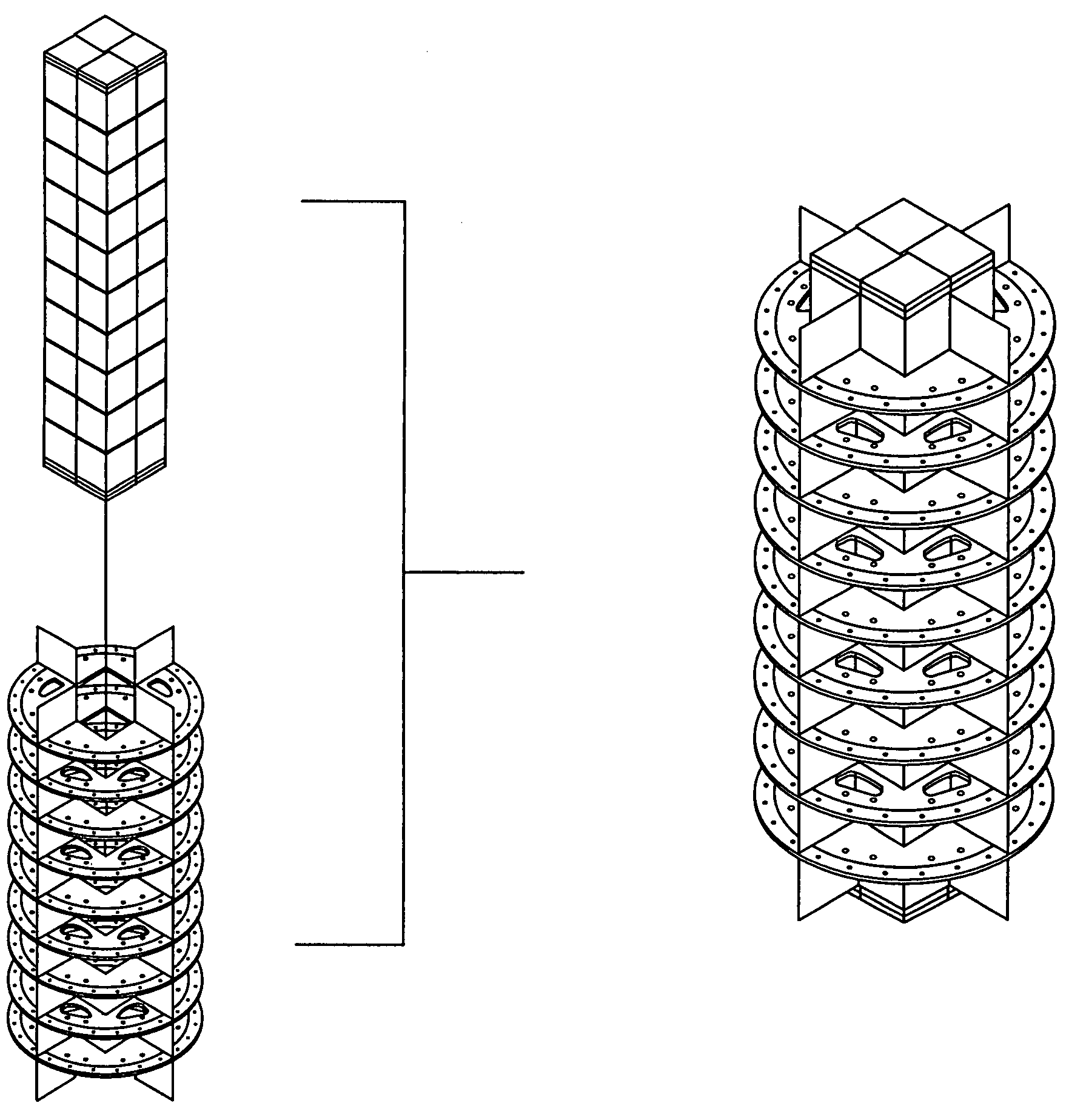

Compact heat exchanger made of ceramics having corrosion resistance at high temperature

InactiveUS20050056410A1Increase resistanceStationary tubular conduit assembliesHeat exchange apparatusStrong acidsUltimate tensile strength

Ceramic materials that are highly resistant to strong acids such as concentrated sulfuric acid and halides such as hydrogen iodide are employed to make block elements through which a large number of circular ingress channels extend in perpendicular directions and which are joined and piled in the heat exchanging medium section to provide a compact heat exchanger that excels not only in corrosion resistance but also in high-temperature strength.

Owner:JAPAN ATOM ENERGY RES INST +1

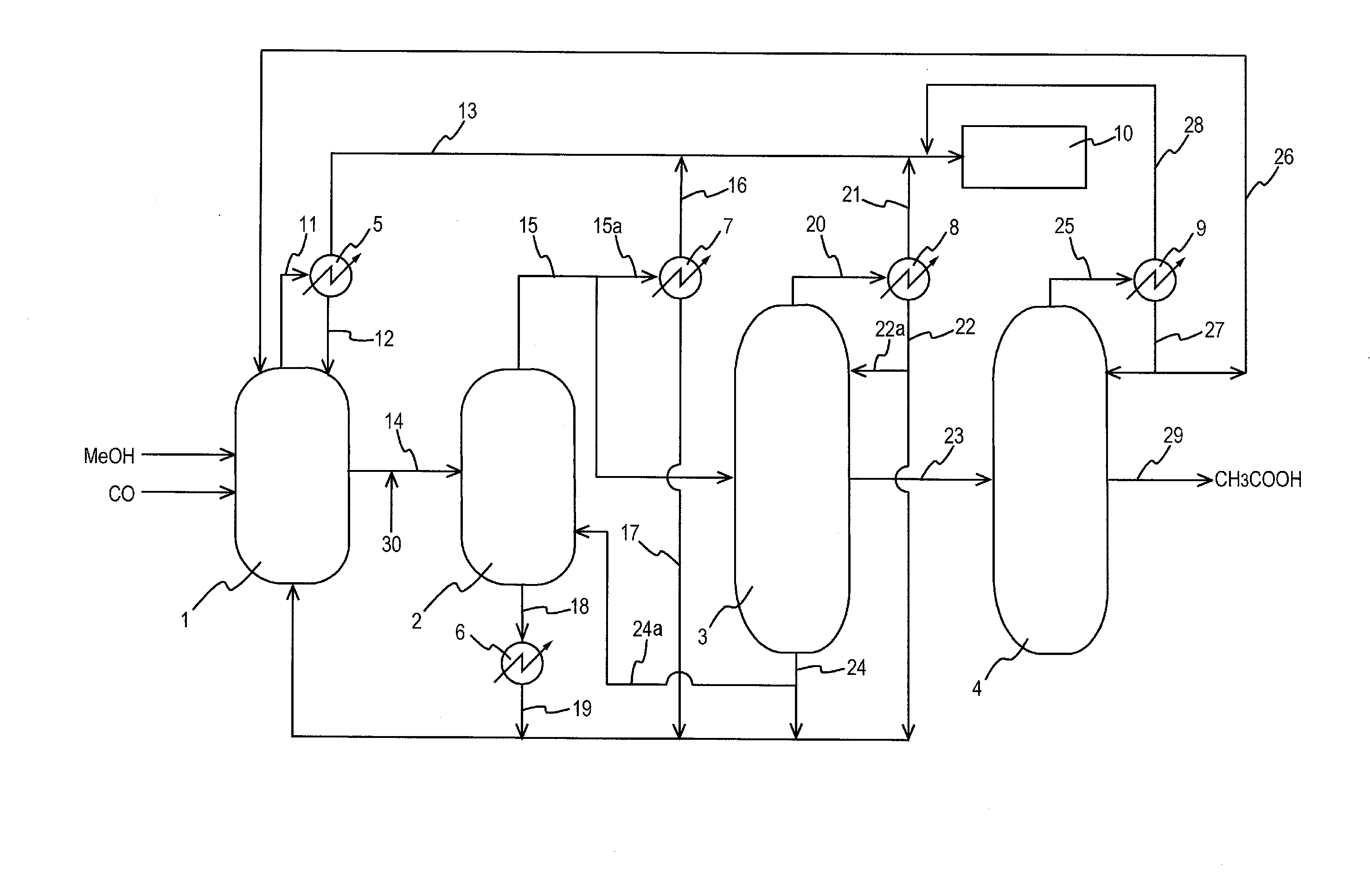

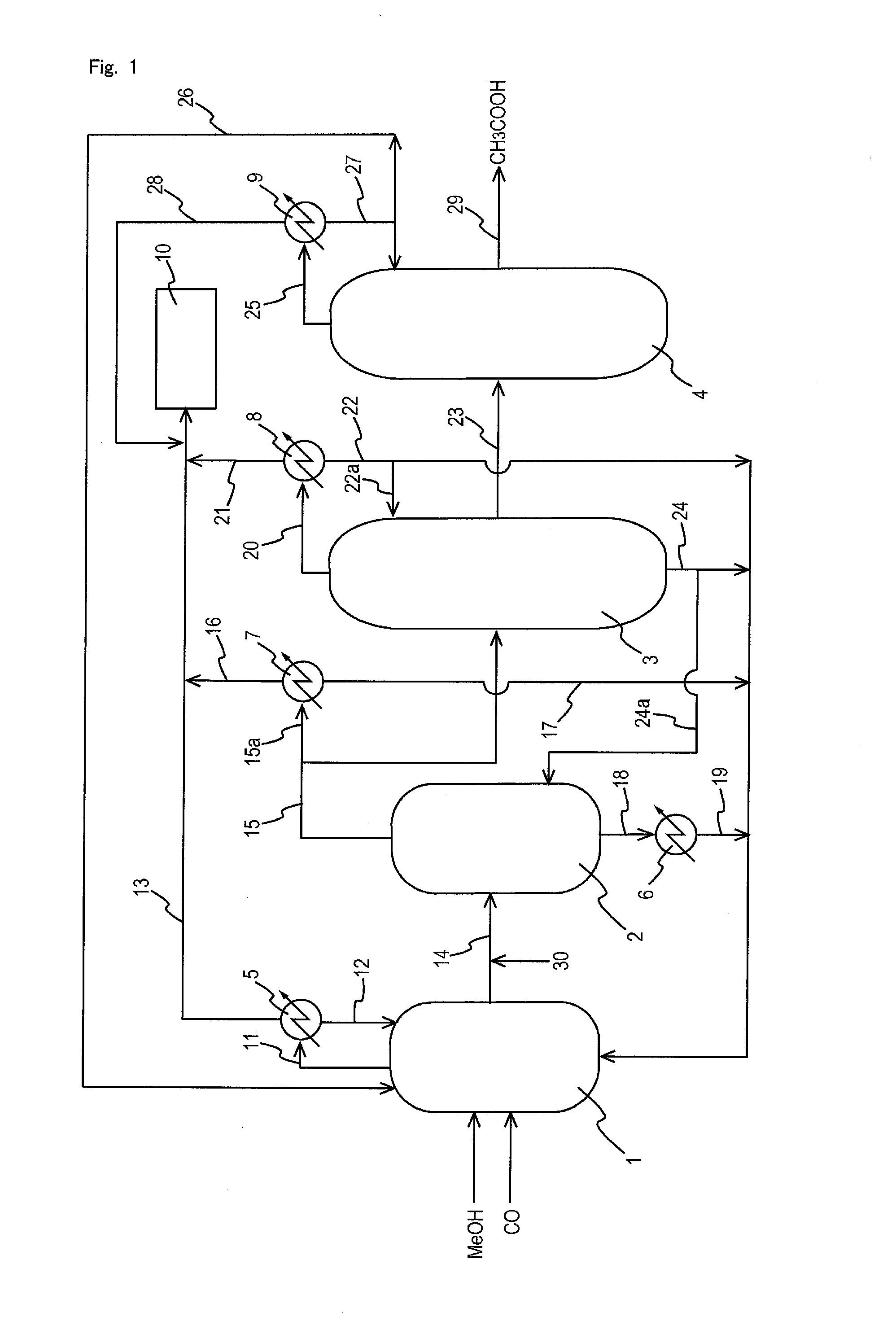

Process for producing acetic acid

ActiveUS9115071B2Inhibiting (or preventing) increaseEfficient productionOrganic compound preparationOrganic chemistry methodsIodideReaction step

Acetic acid is produced while inhibiting an increased concentration or production of hydrogen iodide in a carbonylation reactor or corrosion of the carbonylation reactor.A production process of acetic acid comprises a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst (e.g., a rhodium catalyst), an ionic iodide (e.g., lithium iodide), and methyl iodide in a carbonylation reactor; and in the process, (i) the concentration of the metal catalyst is maintained at not less than 860 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 15% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor, and / or (ii) the concentration of the metal catalyst is maintained at not less than 660 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 3.9% by weight, the concentration of the ionic iodide is maintained at not more than 13% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor.

Owner:DAICEL CHEM IND LTD

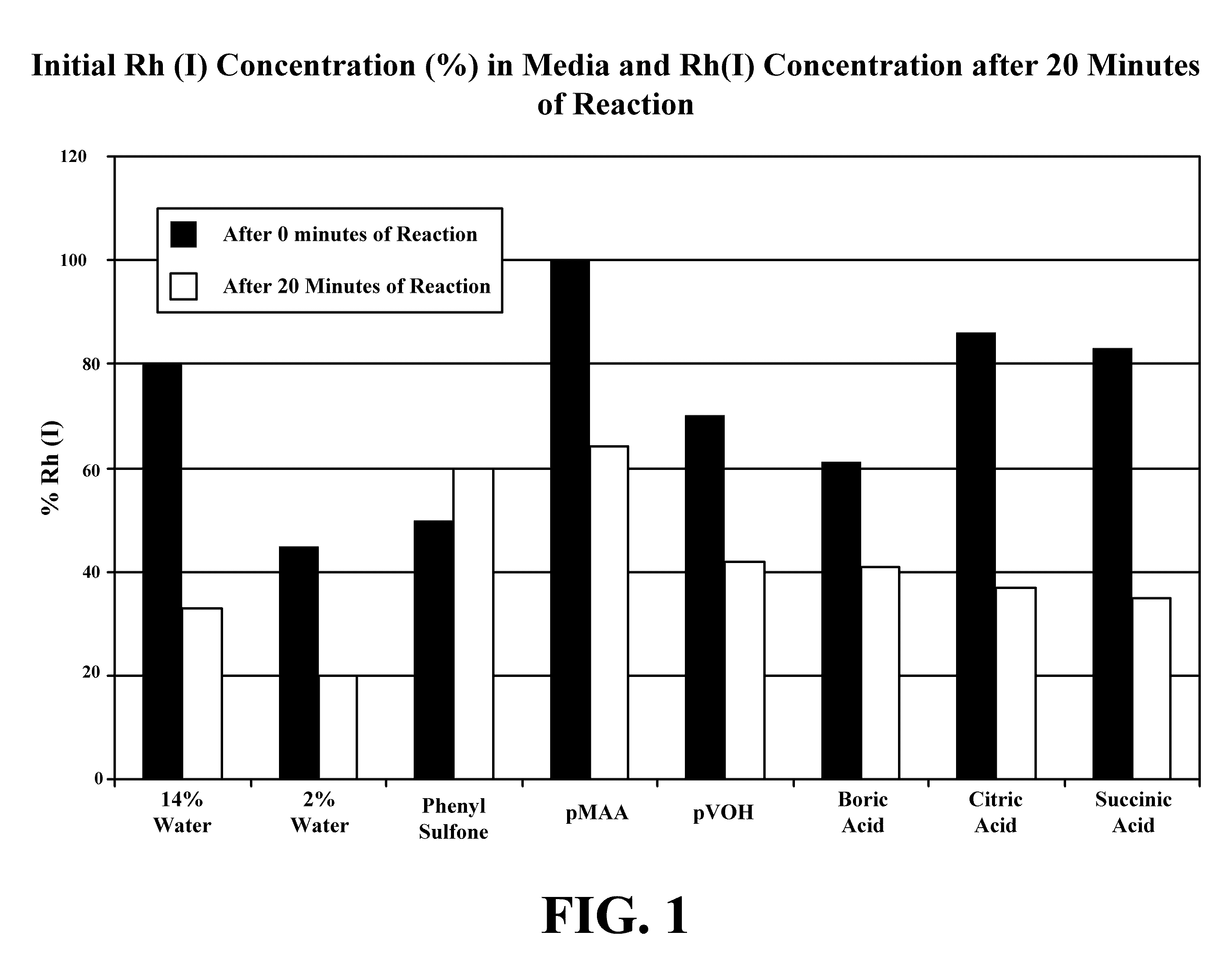

Compositions for carboxylic acid production and methods for making and using same

InactiveUS20090326268A1Improve catalytic stabilityReduce formationOther chemical processesOrganic compound preparationPtru catalystAlcohol

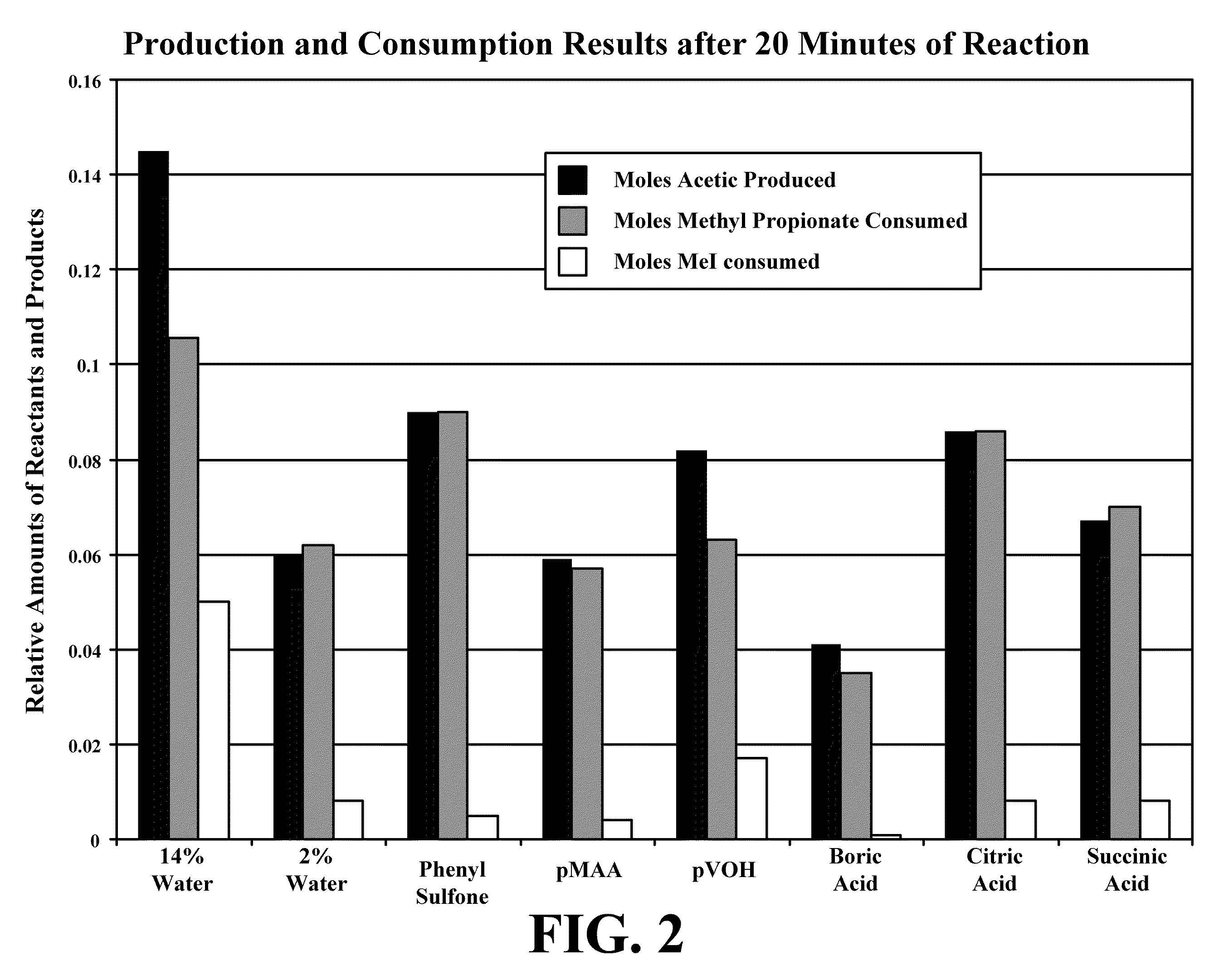

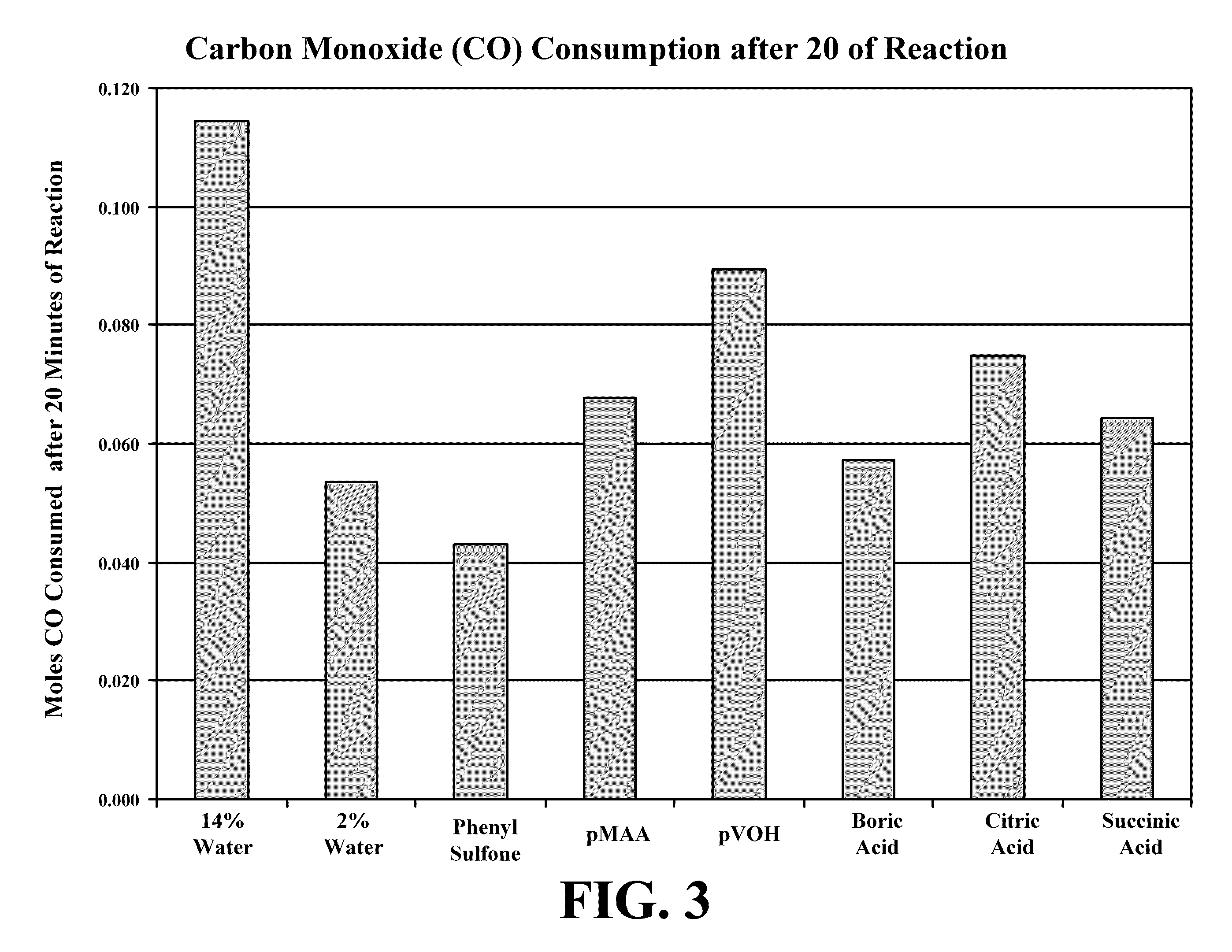

An alcohol such as methanol is reacted with carbon monoxide in a liquid reaction medium including a catalyst, an alkyl iodide such as methyl iodide, alkyl acetate such as methyl acetate in specified proportions, an additive, and an effective amount of water, where the additive increases an ionic character of the hydrogen iodide bond and the effective amount of water is sufficient to facilitate carboxylic acid release after carbonylation at the catalyst and to reduce anhydride formation. The present reaction system not only provides an acid product at water levels considerable below levels currently used, but also provides unexpected reaction rates and unexpected high catalyst stability.

Owner:PRETIUM VENTURES AA

Prepn process of iodized plant ethyl oleate

ActiveCN101020633AImprove conversion rateMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationVegetable oilEthyl ester

The present invention relates to preparation process of iodized vegetable oil ethyl ester. Iodized vegetable oil is first produced with vegetable oil and hydrogen iodide gas through addition reaction, and iodized vegetable oil and ethanol then produce ester exchange reaction under the action of alkali catalyst to produce iodized vegetable oil ethyl ester, with the hydrogen iodide gas being produced through reaction of iodine, red phosphorus and water. The present invention has facile cheap materials and high conversion rate of ester exchange reaction, and the product has low viscosity.

Owner:季珉

Compact heat exchanger made of ceramics having corrosion resistance at high temperature

InactiveUS7168481B2Excels not only in corrosion resistance but also in high-temperature strengthStationary tubular conduit assembliesHeat exchange apparatusStrong acidsUltimate tensile strength

Ceramic materials that are highly resistant to strong acids such as concentrated sulfuric acid and halides such as hydrogen iodide are employed to make block elements through which a large number of circular ingress channels extend in perpendicular directions and which are joined and piled in the heat exchanging medium section to provide a compact heat exchanger that excels not only in corrosion resistance but also in high-temperature strength.

Owner:JAPAN ATOM ENERGY RES INST +1

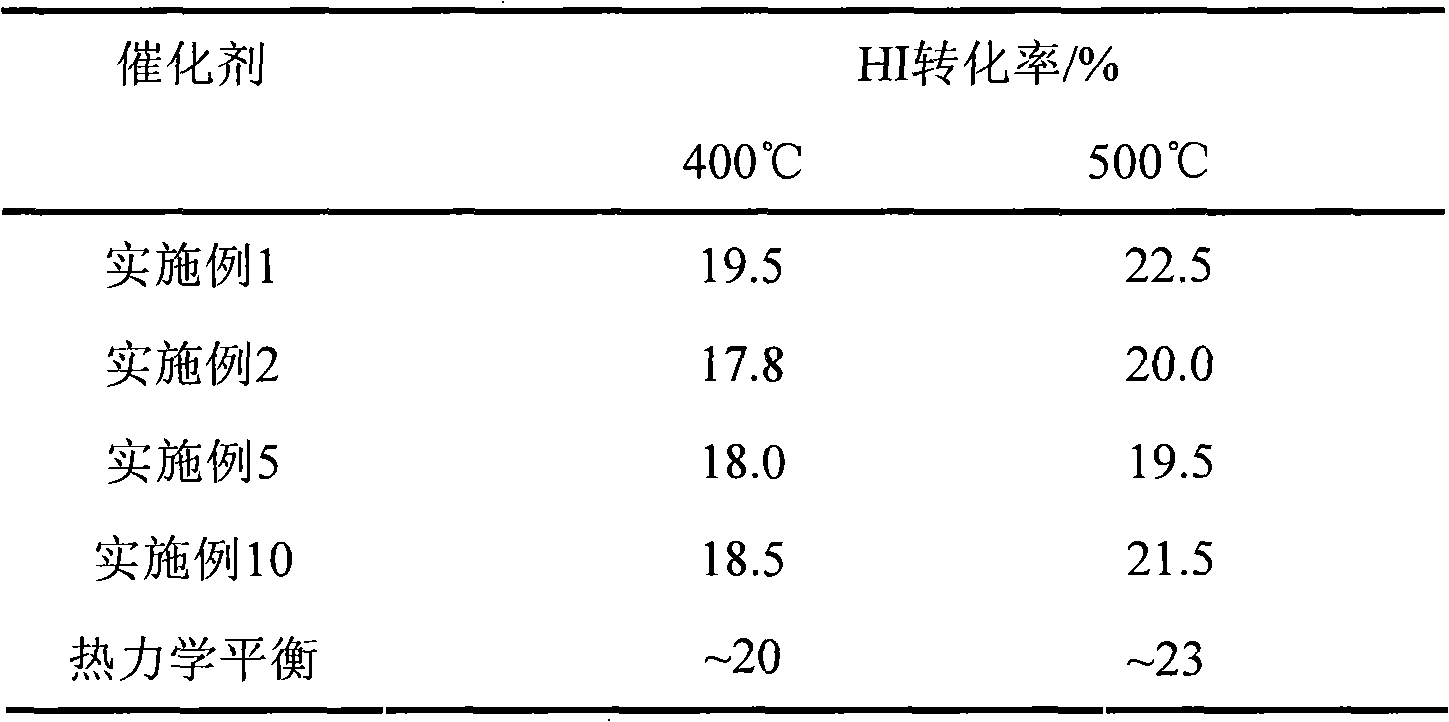

Process for preparation of catalysts for catalytic decomposition of hydrogen iodide

InactiveCN101138721AHigh catalytic activityGood dispersionMolecular sieve catalystsHydrogen productionCatalytic decompositionBiological activation

A preparation method for a catalyst used for catalytic decomposition of hydrogeniodide belongs to the catalyst preparation technical field. A method of immersion is first adopted by the present invention. A carrier is immersed in a dissolvable salt comprising a noble metal used for activation or a soluble acid water solution, and then dried to get an activated precursor. The mass of the noble metal for activation is 0.1 to 5 percent of the mass of the carrier. The activated precursor is added into a reducer solution to manufacture an activated substrate by reducing. Finally, the activated substrate is put in a chemical platinum plating solution to realize oriented deposition of activated platinum metal on the carrier. Thus, the catalyst for decomposition of hydrogeniodide is manufactured. The mass content of platinum in the catalyst is 1 to 50 percent. The catalyst preparation method is provided with the advantage of the good repeatability for mass production, the good platinum dispersion and the high catalytic activity. The catalyst manufactured with the method is not only applicable for the catalytic decomposing reaction of hydrogeniodide, but also can be used as the catalyst for the catalytic hydrogenation reaction.

Owner:TSINGHUA UNIV

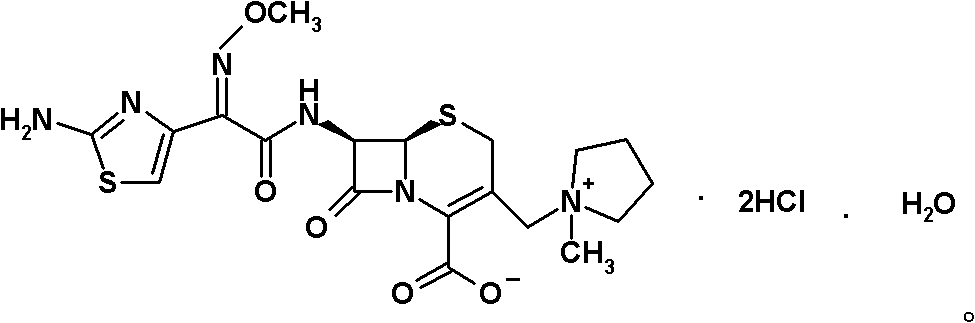

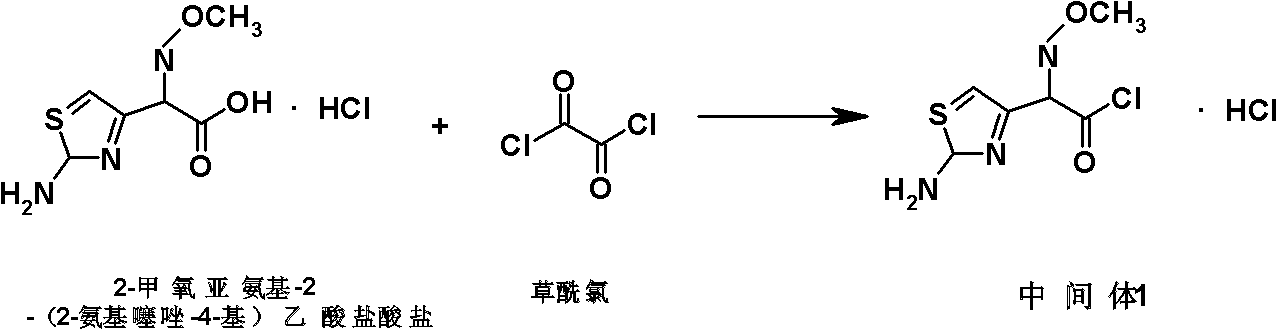

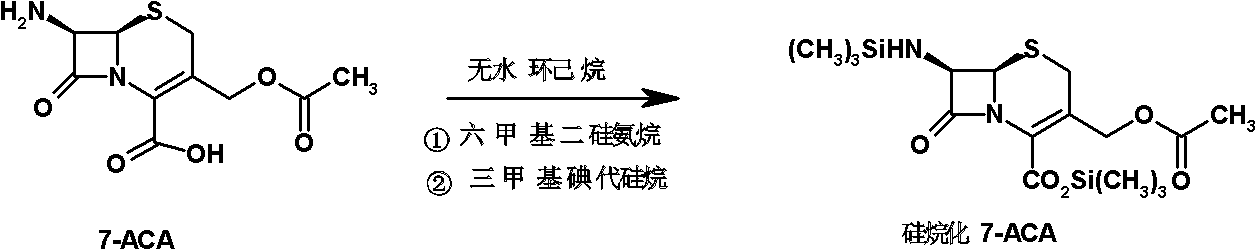

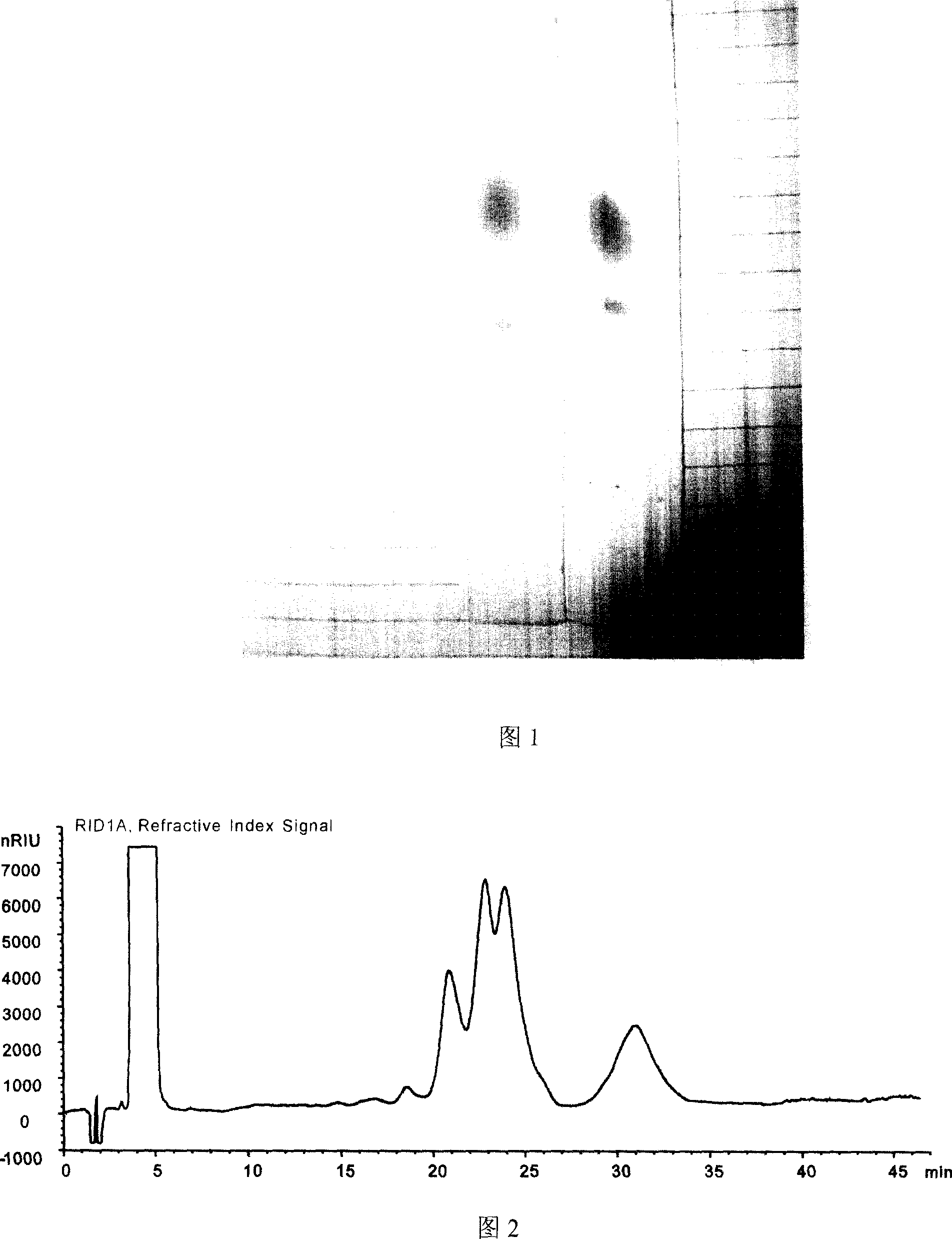

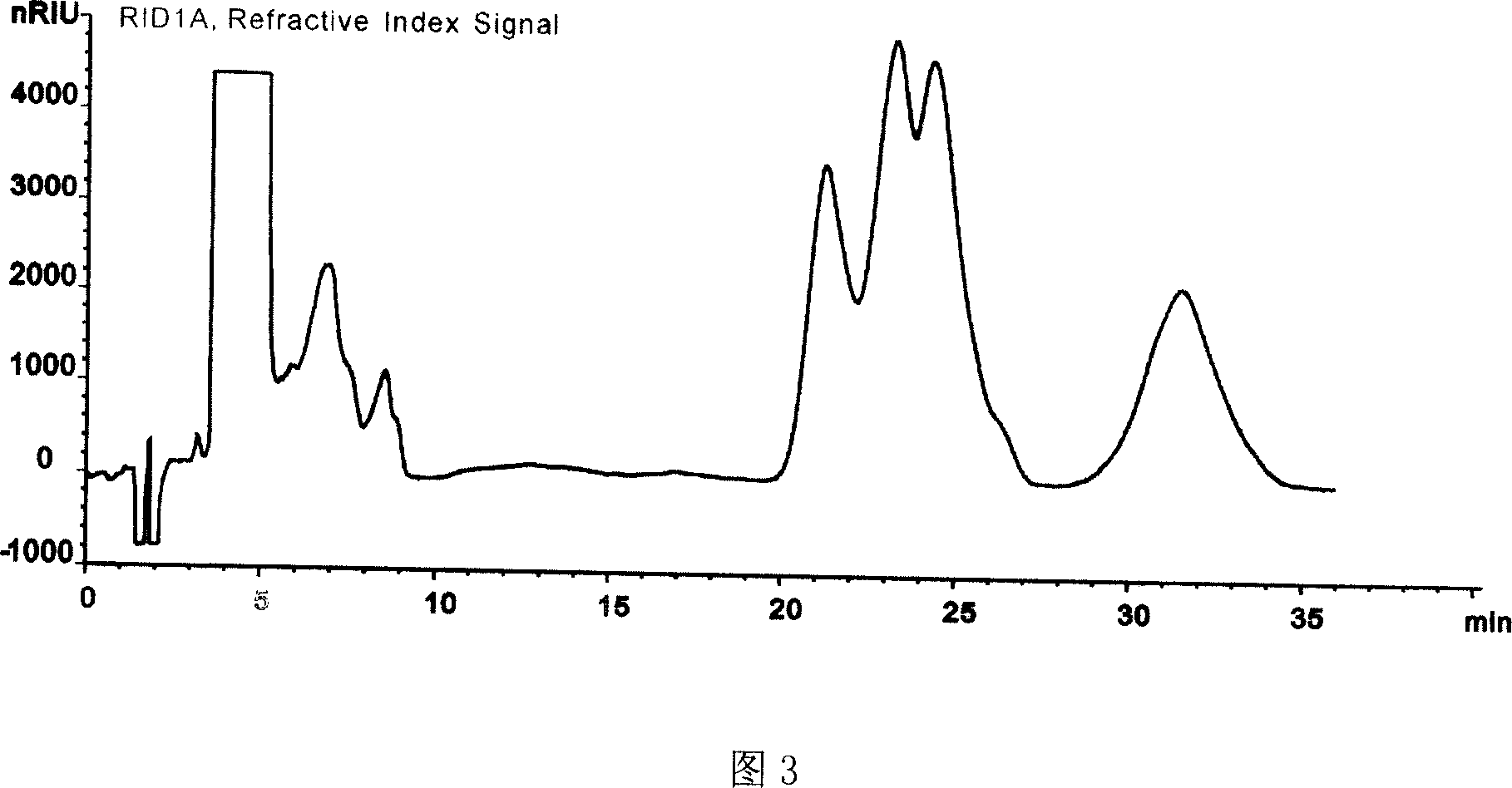

Preparation method of cefepime hydrochloride

ActiveCN101935325ASimple processAvoid the phenomenon of inhomogeneous crystal form and poor fluidityOrganic chemistryCefepime hydrochlorideBetaine

The invention discloses a preparation method of cefepime hydrochloride, comprising the following steps of: reacting oxalyl chloride with 2-methoxyimino-2-(2-aminothiazole-4-yl) acetic acid hydrochloride to obtain a midbody I, i.e. 2-methoxyimino-2-(2-aminothiazole-4-yl) acetyl chloride hydrochloride; mixing silanized 7-aminoce-phalosporanic acid and silanized N-methylpyrrolidine, and reacting to obtain a midbody II, i.e. hydriodic acidification (6R, 7R)-7-amino-3-[(1-methyl-1-tetrahydro pyrrolidine) methyl]-3-cephem-4-formic betaine, in the presence of trimethyl idodine silicon hydride, isopropanol and an aqueous solution of hydrogen iodide; dissolving the midbody II into dichloromethane, sequentially adding trimethylchlorosilane and hexamethyldisilazane for reaction, and then adding the midbody I and triethylamine to react to prepare the cefepime hydrochloride. The cefepime hydrochloride prepared by the method has the advantages of uniform crystal form, good flowability and simple process and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Synthesis of iodized plant ethyl oleate for injection

ActiveCN101020634AMild reaction conditionsRaw materials are easy to getOrganic compound preparationCarboxylic acid esters preparationAnhydrous ethanolVegetable oil

The present invention is process of synthesizing iodized vegetable oil ethyl ester. Vegetable oil ethyl ester is first produced through the ester exchange reaction of vegetable oil and anhydrous ethanol under the action of alkali catalyst, and then addition reacted with hydrogen iodide gas to produce iodized vegetable oil ethyl ester, with the hydrogen iodide gas being produced through reaction of iodine, red phosphorus and water. The present invention has facile cheap materials, and the product has high stability, low viscosity, light color and other features.

Owner:季珉

Preparation method for stable iodinated vegetable oil ethyl ester

The invention relates to a preparation method for stable iodinated vegetable oil ethyl ester. The method mainly includes the following steps: performing addiction reaction between vegetable oil and hydrogen iodide gas to generate iodinated vegetable oil; removing unstable iodine incorporated in the iodinated vegetable oil by adding hydrogen peroxide; eliminating removed iodine by using sodium metabisulfite solution to obtain stable iodinated vegetable oil; and performing ester exchange reaction between the stable iodinated vegetable oil and ethanol under the function of basic catalyst to produce the stable iodinated vegetable oil ethyl ester. The iodinated vegetable oil ethyl prepared by using the method has the characteristics of small viscosity and environmental-friendly technology.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing graphene/polyaniline composite film electrode

ActiveCN105810455ASimple and fast operationShort timeHybrid capacitor electrodesHybrid/EDL manufactureFiberComposite film

The invention discloses a method for preparing a graphene / polyaniline composite film electrode. The method comprises the following steps: adding aniline in hydrochloric acid, and stirring to obtain a product A; adding ammonium persulfate in the hydrochloric acid, and stirring to obtain a product B; mixing the product A with the product B, stirring, filtering, cleaning through distilled water and alcohol, and drying a sample obtained by filtering to obtain a product C; adding the product C in deionized water, and carrying out an ultrasonic oscillating treatment until a homogeneous polyaniline aqueous solution is obtained, namely, a product D; adding graphite oxide in the product D, and carrying out the ultrasonic oscillating treatment to obtain a product E; stewing the product E to obtain a product F; depositing the product F on a flexible plastic film, and drying to obtain a product G; soaking the product G in a hydrogen iodide solution, reducing, and cleaning to obtain a product H; soaking the product H in a hydrochloric acid solution, and drying to obtain a product I. The composite film of graphene / polyaniline fibers prepared by the method disclosed by the invention can be directly used as an electrode material of a flexible film super capacitor, and the method is simple to operate, short in time consumption, little in material consumption and is environmental friendly.

Owner:GUIZHOU UNIV

Production method of hydrogen iodide

The invention discloses a production method of hydrogen iodide, which adopts a red phosphorus method and comprises a reacting step, a filtering step and a distilling step sequentially. In the reacting step, deionized water is added into reaction equipment; after red phosphorus and iodine are added, the weight ratio of the reaction material liquid is measured and is controlled to be between 1.2 and 1.4; and hydroiodic acid steam is absorbed by a water spraying pump. The filtering step includes two times of filtering. The production method provided by the invention solves the problem of difficult realization of mass production, and avoids the occurance of explosion, has high production efficiency and contributes to environmental protection at the same time.

Owner:自贡市金典化工有限公司

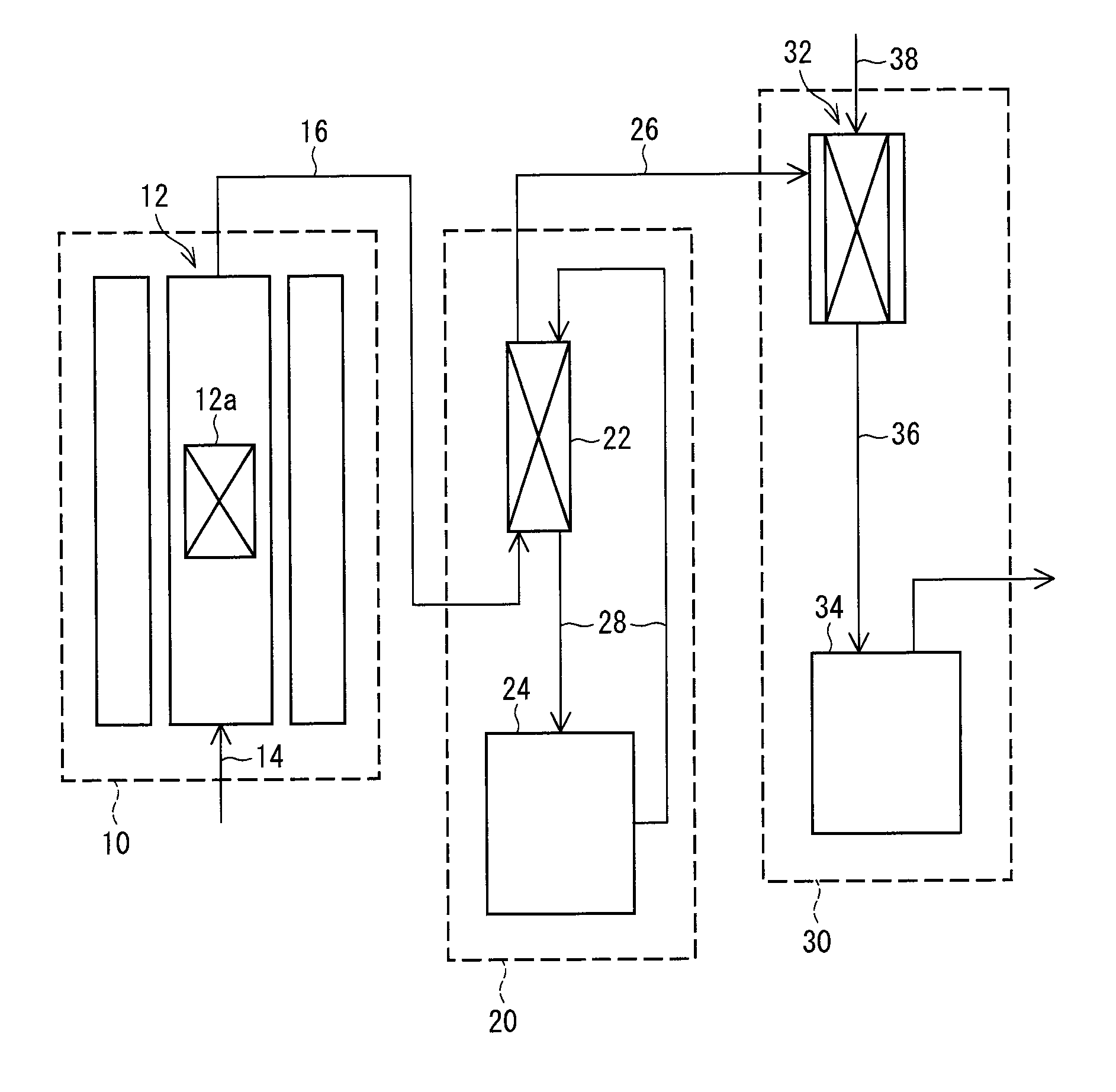

Inorganic iodide, production method thereof, and production system thereof

ActiveUS20100303708A1Low costSimple methodAmmonium iodideGaseous chemical processesIodideHydrogen iodide

According to a method for producing an inorganic iodide in accordance with the present invention, it is possible to efficiently produce a highly pure inorganic iodide by reacting a hydrogen iodide gas with an inorganic base compound by bringing the hydrogen iodide gas into contact with the inorganic base compound. As such, it is possible to provide a simple and efficient method for producing an inorganic iodide.

Owner:NIPPON CHEMICALS CO LTD

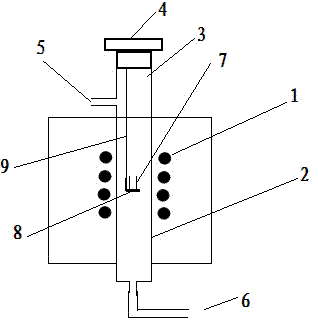

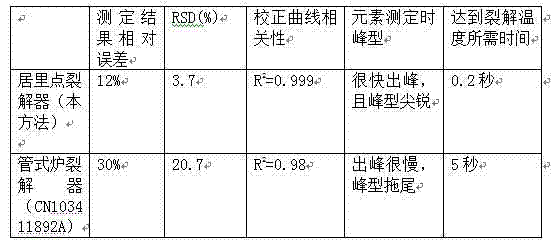

Elemental analysis determination method and device

InactiveCN103792223AReduce distractionsSlow heating ratePreparing sample for investigationAnalysis by thermal excitationSodium hydrosulfideElemental analysis

The invention discloses an elemental analysis determination method and device. The elemental analysis determination method comprises the following steps: adding an inorganic compound capable of releasing hydrogen in pyrolysis into a to-be-detected sample and mixing the inorganic compound with the sample uniformly; carrying out pyrolysis on the mixture at a certain temperature, enabling an element to form a volatile matter, and determining the volatile matter by an atom spectrogram, wherein the inorganic compound for releasing hydrogen in pyrolysis is sodium bisulfide, potassium hydrogen sulfide, ammonium sulfide, ammonia hydrogen sulfide, ammonium iodide, hydrogen sulfide or hydrogen iodide, and the weight of the added inorganic compound is 0.2-100 times the weight of the sample. According to the invention, an inorganic hydrogen release reagent and a curie point pyrolyser are used, and the advantages of low analysis cost, less interference, high element volatile matter formation speed, high sampling efficiency of to-be-detected elements and the like are realized, and the method is a rapid and accurate analysis method.

Owner:TIANJIN NORMAL UNIVERSITY

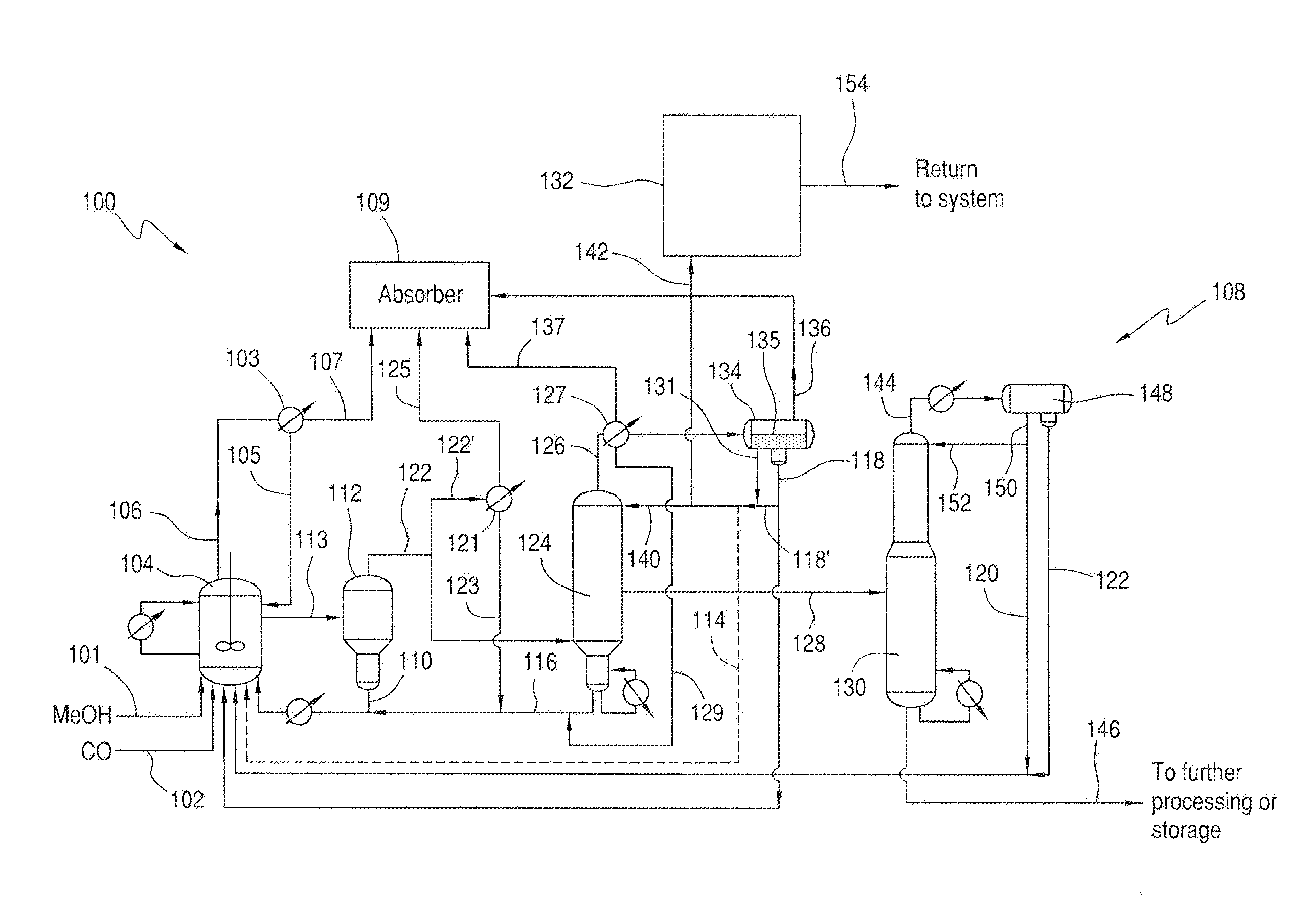

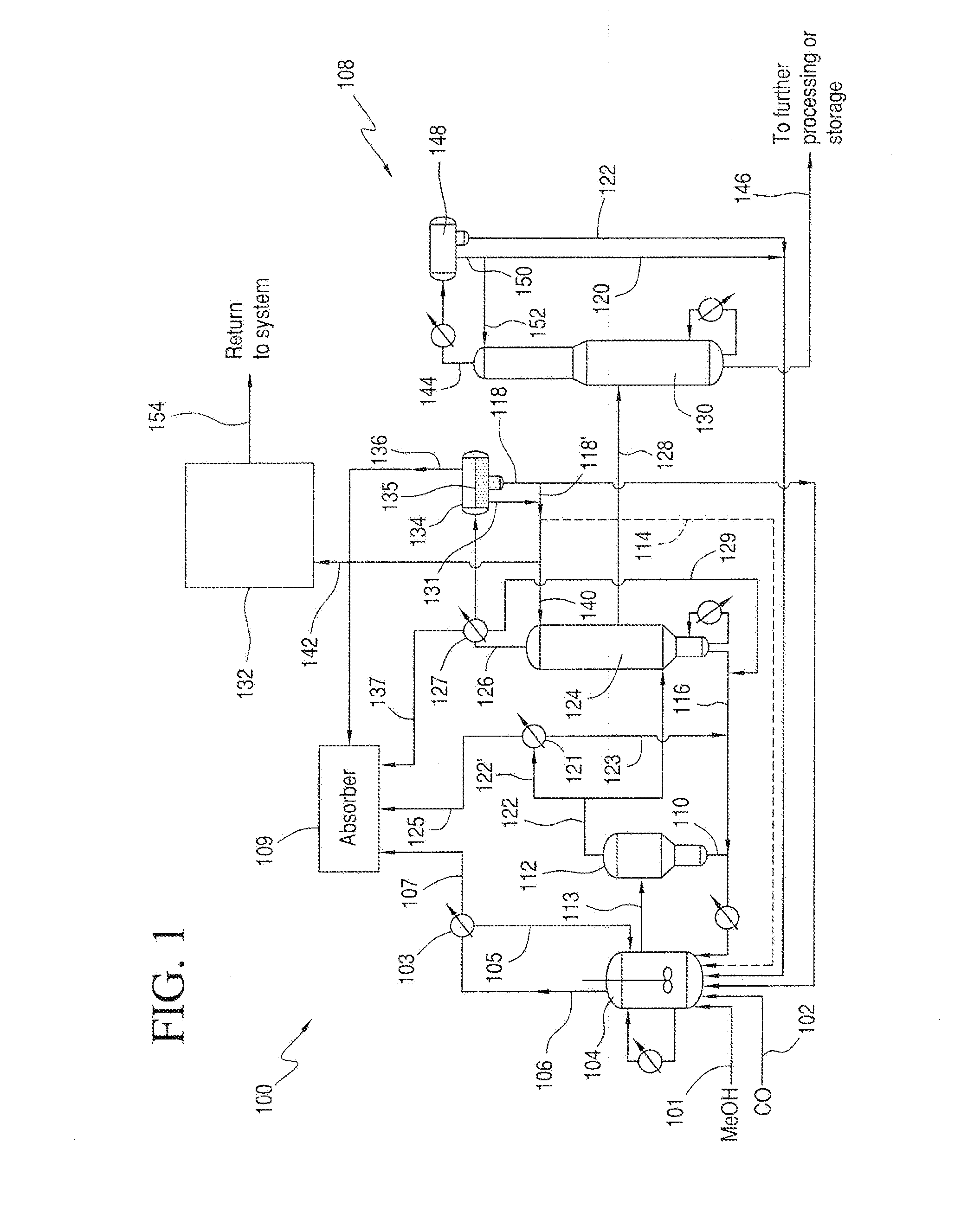

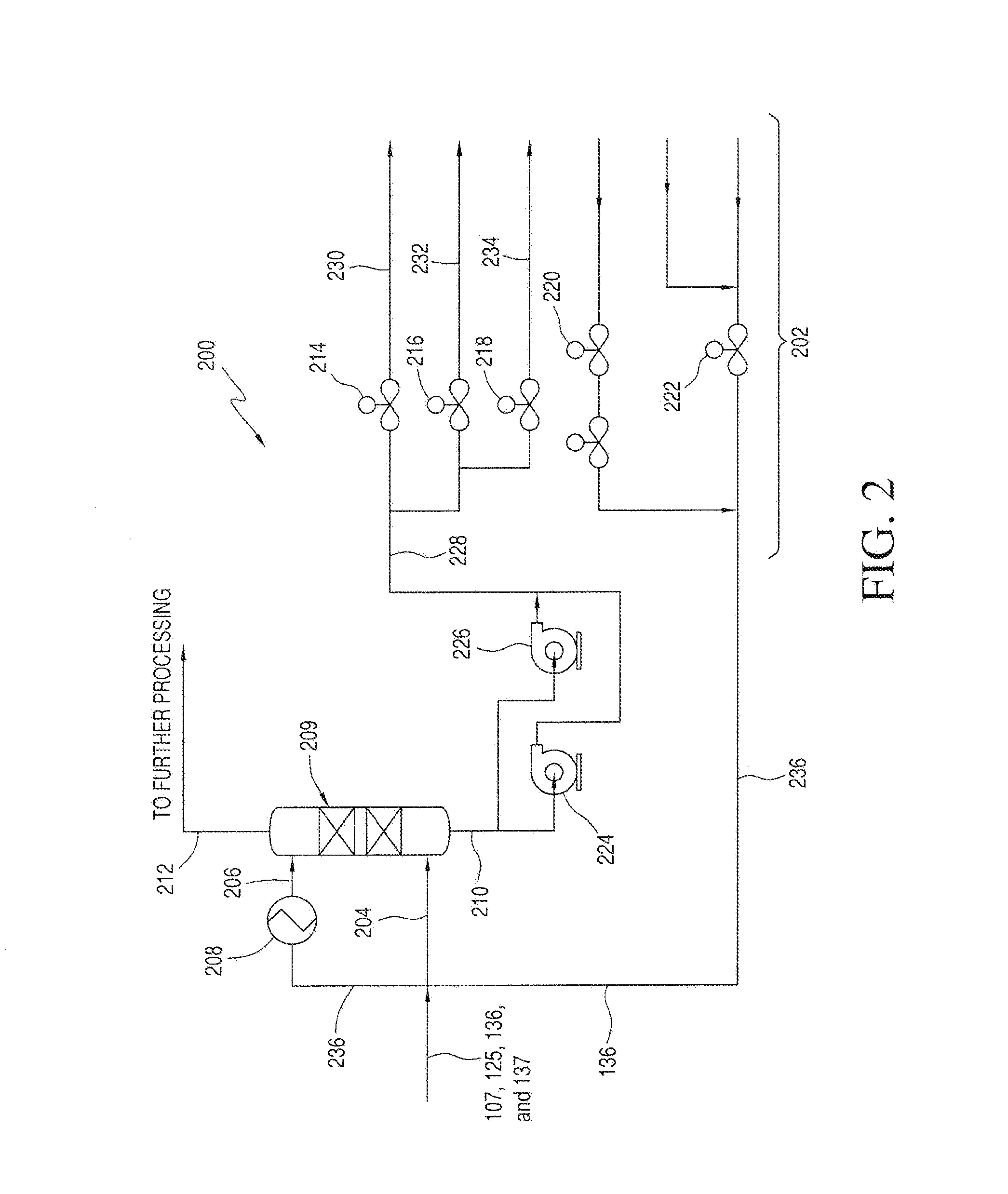

Reducing Hydrogen Iodide Content in Carbonylation Processes

ActiveUS20160137574A1Organic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateCarbonylation

Processes for producing acetic acid wherein at least one process vent stream is treated in an absorber column that utilizes a scrubber solvent, e.g., acetic acid, methanol, and / or methyl acetate to remove hydrogen iodide therefrom.

Owner:CELANESE INT CORP

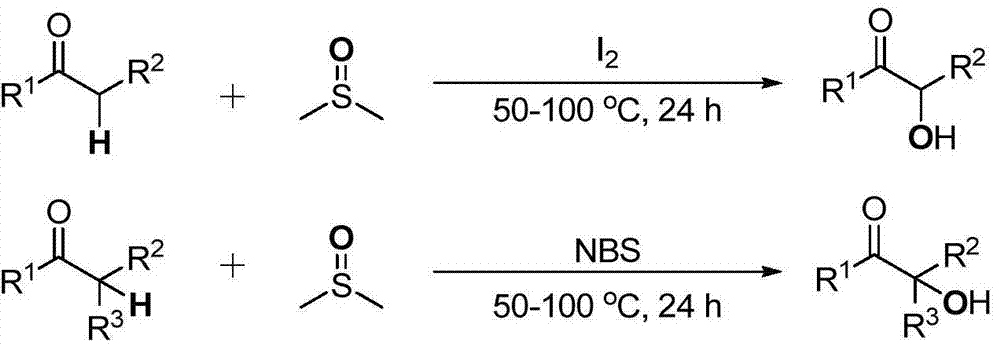

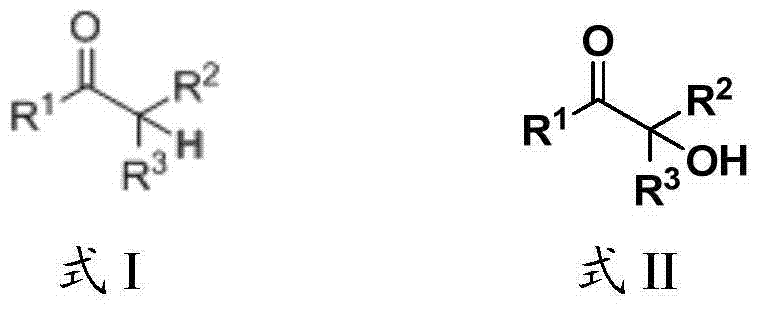

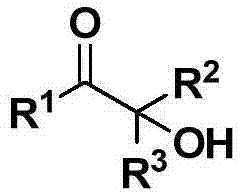

Cheap and efficient synthesis method of alpha-hydroxyketone compound

ActiveCN104710256AEmission reductionHigh yieldOrganic compound preparationHydroxy group formation/introductionSynthesis methodsEthyl acetate

The invention discloses a cheap and efficient synthesis method of an alpha-hydroxyketone compound. The synthesis method is characterized in that a carbonyl compound undergoes an oxidation hydroxylation reaction at 10-120DEG C under normal pressure with iodine simple substance, N-bromosuccimide, copper bromide, bromine simple substance, hydrogen bromide, N-iodosuccimide or hydrogen iodide as a catalyst, sulfoxide as an oxidant, water or sulfoxide as a hydroxy source and sulfoxide, ethyl acetate, N,N-dimethyl formamide, acetonitrile, toluene, 1,4-dioxane, 1,2-dichloroethane, tetrahydrofuran or H2O as a solvent, and converts into the alpha-hydroxyketone compound in a high selectivity manner. Compared with traditional synthesis methods, the method disclosed in the invention has the advantages of simple operation, high yield, simple conditions, easy purification, small waste discharge amount, simple reaction apparatus, and easy industrial production. The method has wide applicability and can be used for synthesizing various alpha-hydroxyketone compounds.

Owner:QINGDAO RUIJI MEDICAL TECH CO LTD

Forming improved metal nitrides

InactiveUS7276121B1After-treatment apparatusPolycrystalline material growthMicrowaveSemiconductor materials

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Iodine extraction processes

ActiveUS20110108486A1Process economyFlexible for changingWater contaminantsSolid sorbent liquid separationActivated carbonIodide

Processes for extracting iodine from an aqueous solution, such as brine, are disclosed. Activated coconut carbon particles are mixed with the solution to adsorb iodide through pores in the activated carbon particles. The activated carbon particles are then treated with sulfur dioxide gas and water to form hydrogen iodide. The hydrogen iodide is then reacted with chloride to obtain elemental iodine (I2).

Owner:IOFINA CHEM

Degradable gemini quaternary ammonium salt bactericide and preparation method thereof

InactiveCN105503631ARaw materials are cheap and easy to getMild reaction conditionsBiocideOrganic compound preparationQuaternary ammonium cationCell wall

The invention discloses a degradable gemini quaternary ammonium salt bactericide and a preparation method thereof. The method comprises steps as follows: Step one, N,N-dimethyl glycine, long-chain fatty alcohol (carbon atom numbers are 8, 10, 12, 14, 16 and 18) and benzyl alcohol have an esterification reaction in the presence of a coupling reagent to produce corresponding N,N-dimethyl glycine ester; Step two, the obtained N,N-dimethyl glycine ester and hydrogen chloride, hydrogen bromide or hydrogen iodide react to produce corresponding salt; Step three, products obtained in previous two steps and epichlorohydrin are subjected to quaternization, and degradable gemini quaternary ammonium salt is obtained. The gemini quaternary ammonium salt is more beneficial to adsorption of bacterium surfaces by bactericide molecules due to the electrostatic interaction of two quaternary nitrogen ions contained in molecules and the induction of carbonyl groups in ester groups, so that bacteria are broken through change of permeability of cell walls; hydrophilic groups and hydrophobic groups extend into lipoid layers and protein layers of bacterium cells more conveniently to cause protein denaturation and enzyme deactivation. The bactericide has higher bactericidal ability under the synergistic effect. The gemini quaternary ammonium salt bactericide is efficient, low in toxicity, easily degradable and environment-friendly.

Owner:SICHUAN UNIV

Catalyst for catalytic decomposition of hydrogen iodide and preparation method thereof

InactiveCN101327429AImprove stabilityHigh catalytic activityHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsIridiumFiber

The present invention relates to a hydrogen iodide catalytic decomposition catalyst and a preparation method thereof which belong to the technical field of catalyst preparation. The catalyst consists of carbon nanotube, carbon molecular sieve, graphite, carbon fiber and black carbon as supports to load active metal platinum and a second active metal which is palladium, iridium, ruthenium, rhodium, molybdenum, cobalt or nickel. The weight percentage content of the active metal platinum in the catalyst is 0.05 percent to 50 percent, and the weight percentage content of the second active metal in the catalyst is 0 percent to 20 percent. The supports of the carbon nanotube or the carbon molecular sieve are dipped in mixture solution of a compound containing the platinum and a second metal element in a dipping method to be dried to obtain a target catalyst. The catalyst is not required to be calcined and reduced and can be directly used in hydrogen iodide catalytic decomposition reaction. The method has the advantages of simple preparation technology, low cost and the high hydrogen iodide catalytic decomposition activity of the catalyst.

Owner:TSINGHUA UNIV

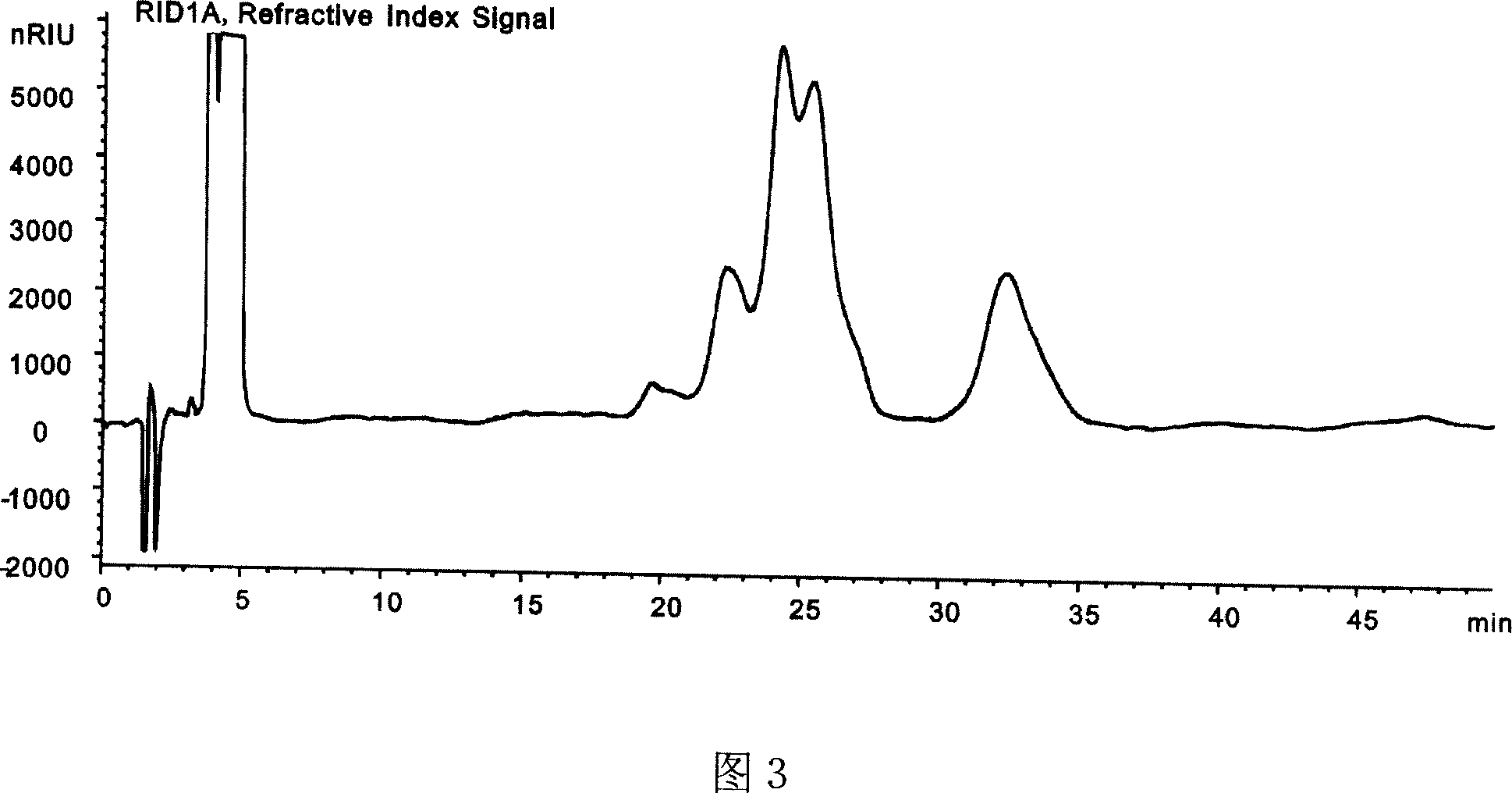

Preparation method of biodegradable plastic poly(butylene succinate)

InactiveCN107365412ALow costImprove reaction efficiencyPreparation by hydrolysisPolyolefinReaction temperature

The invention provides a preparation method of a biodegradable plastic poly(butylene succinate). The traditional polyolefin plastic is undegradable, so that the serious problem of environmental pollution is caused; as a molecular main chain of a degradable plastic contains an easily hydrolyzable ester bond, the degradable plastic is decomposed and metabolized easily in nature and is finally decomposed into carbon dioxide and water. The specific technical scheme is described as follows: performing a ring-opening reaction on tetrahydrofuran and a promoter hydrogen iodide, adding a product into a succinic acid device with functions of heating for temperature control, stirring and nitrogen protection and performing an esterification reaction for 1-3h under the action of a catalyst at the temperature of 95-200 DEG C; finally, performing a polycondensation reaction under a vacuum condition for 2-3h, so as to obtain a poly(butylene succinate) crude product, wherein the absolute pressure is 20-80Pa, and the reaction temperature is 135-235 DEG C; dissolving the crude product with purification-used trichloromethane, precipitating with absolute methanol, filtering and drying, so as to obtain poly(butylene succinate).

Owner:淄博长宝新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com