Patents

Literature

193 results about "Acetic acid ear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetic acid otic (for the ear) is an antibiotic that treats infections caused by bacteria or fungus. Acetic acid is used to treat infections in the ear canal. This medication will not treat an inner ear infection (also called otitis media).

Process for producing acetic acid

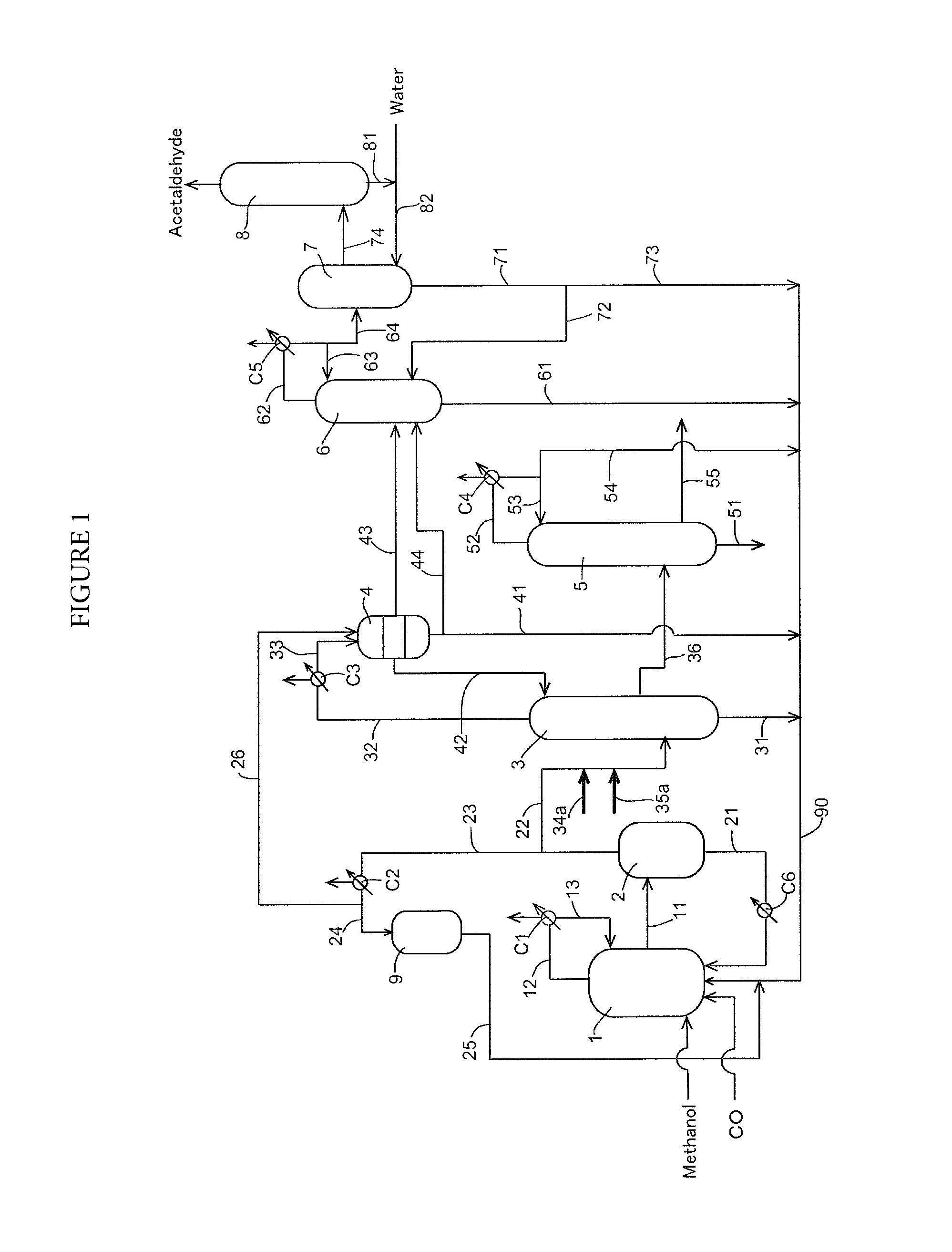

ActiveUS9006483B2Avoid pollutionEnsure stable and continuous operationOrganic compound preparationDistillation separationWater concentrationAcetic acid ear

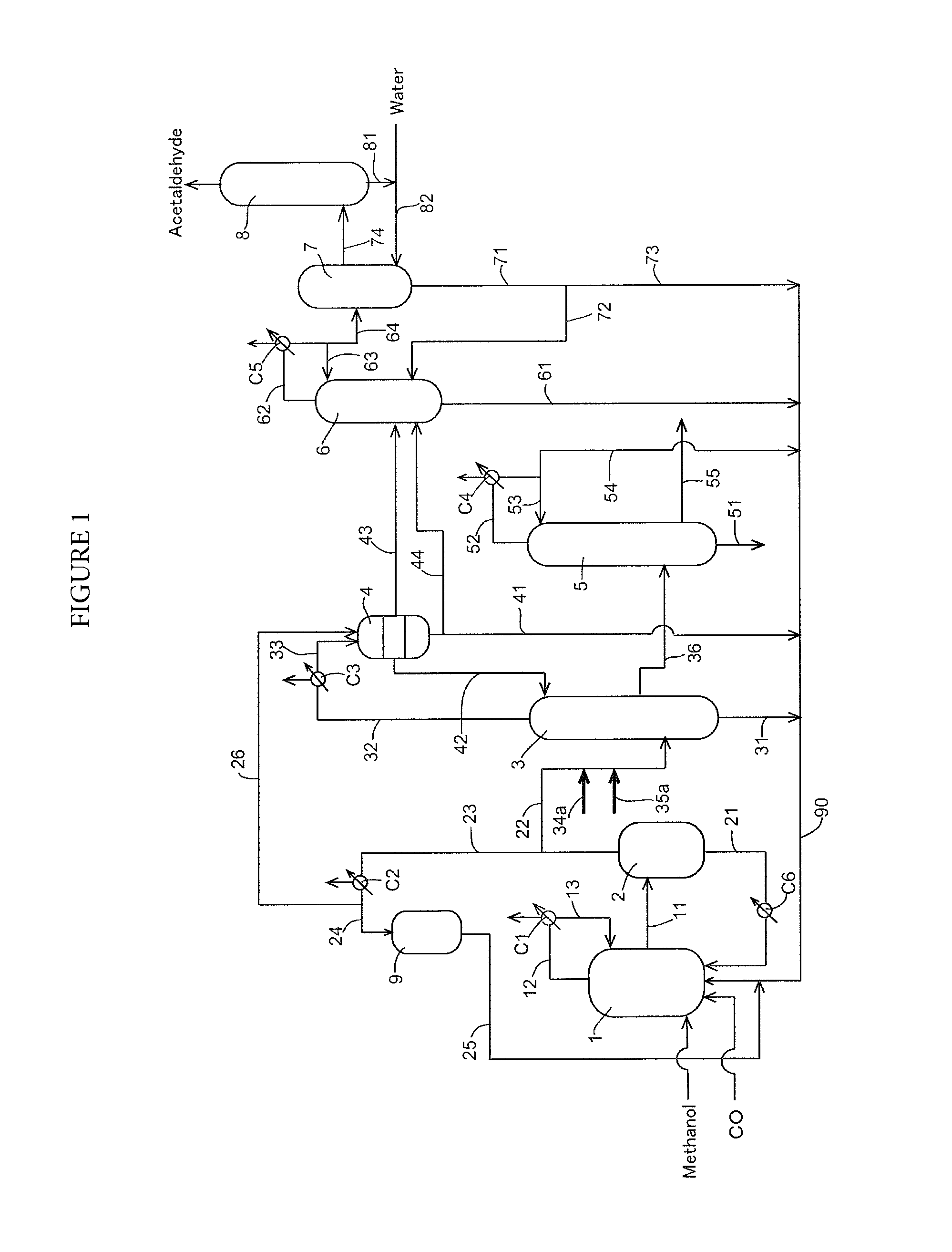

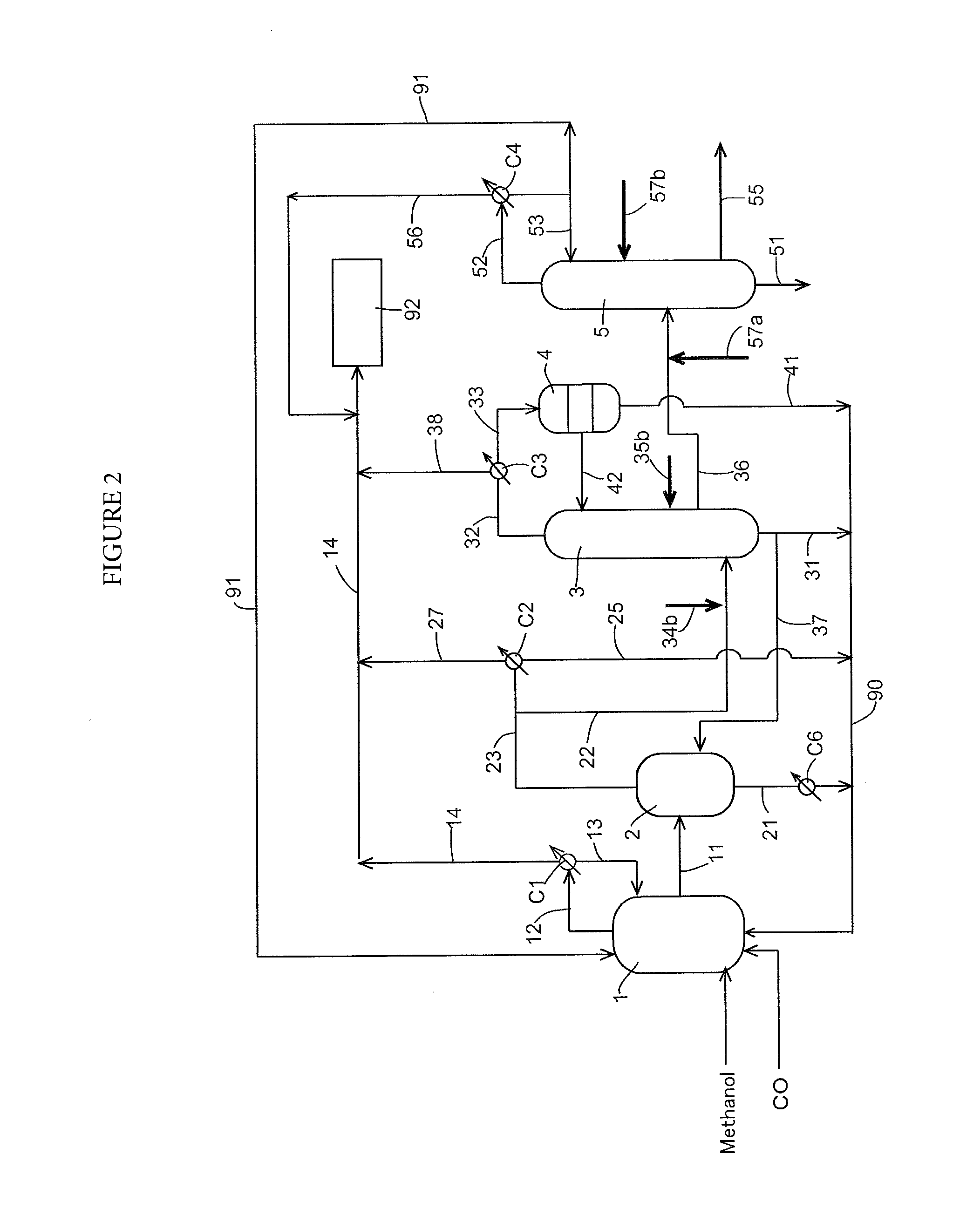

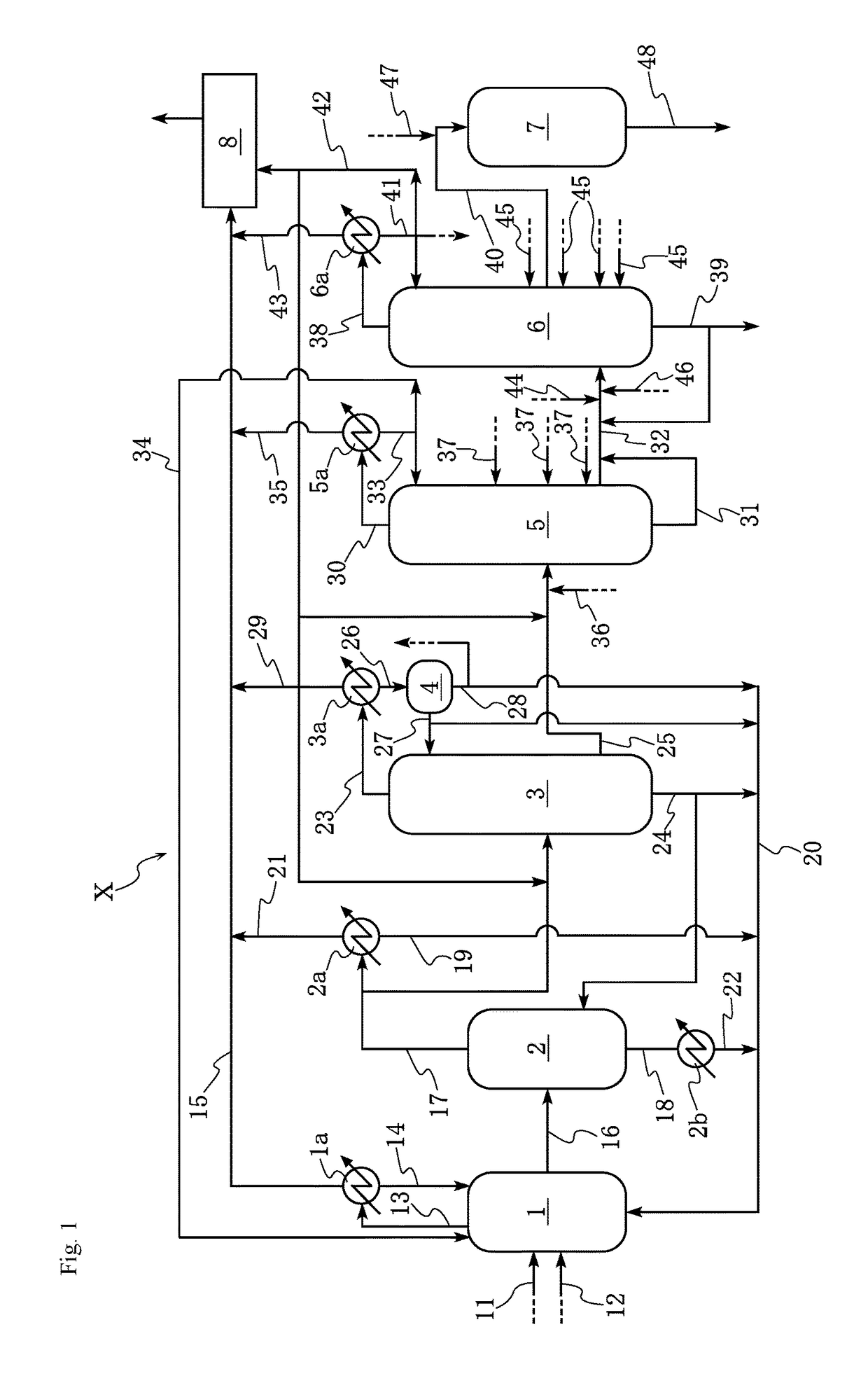

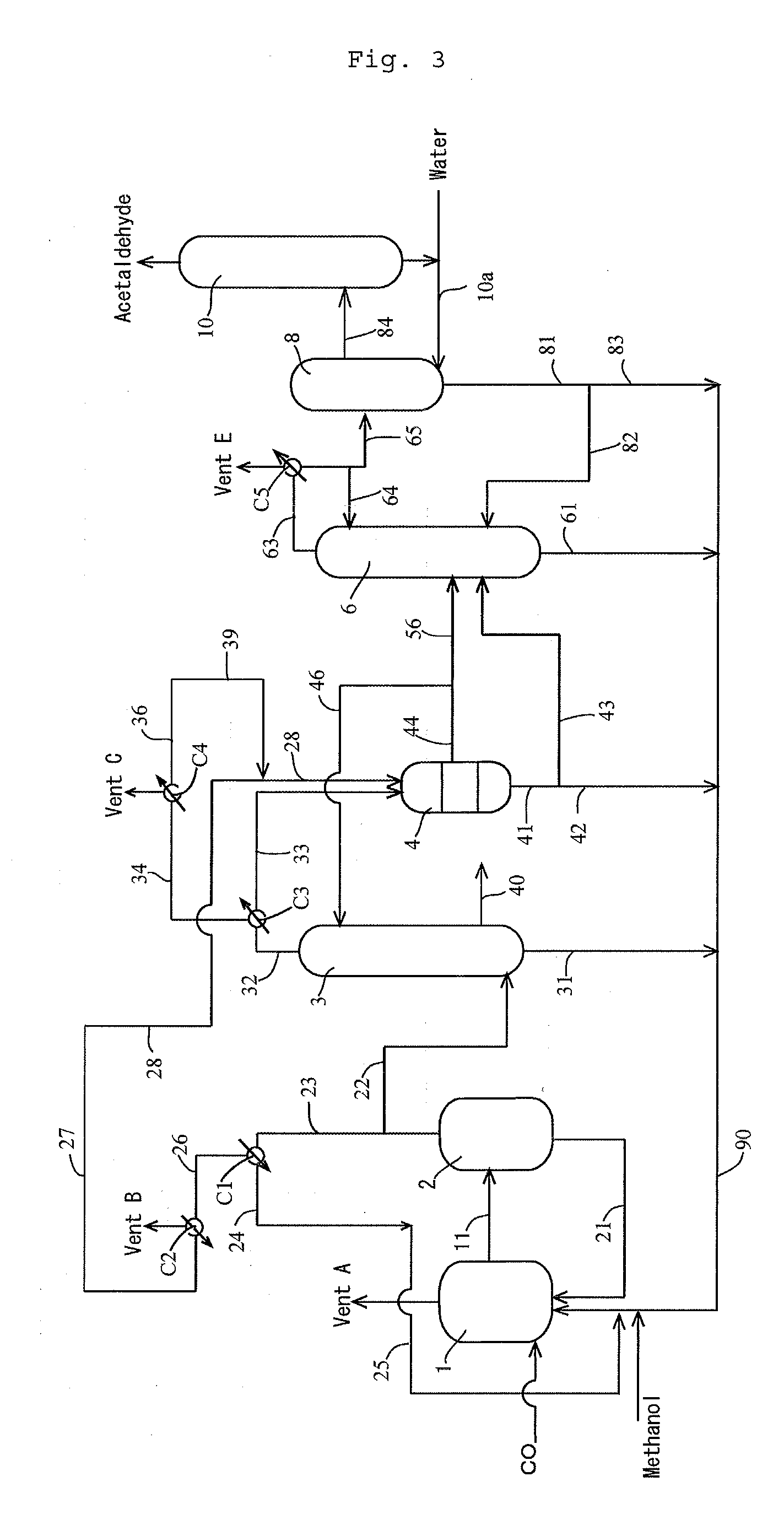

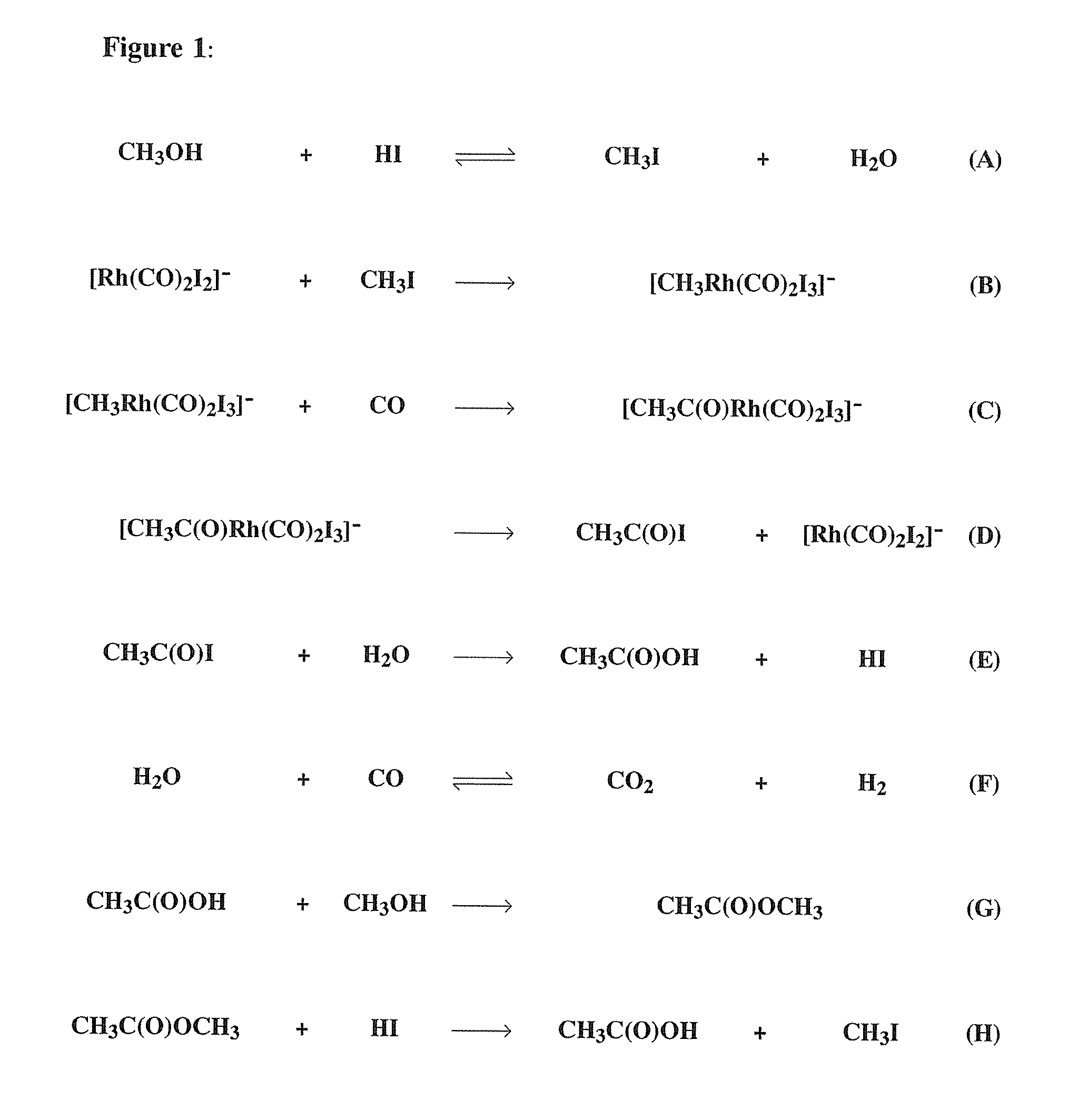

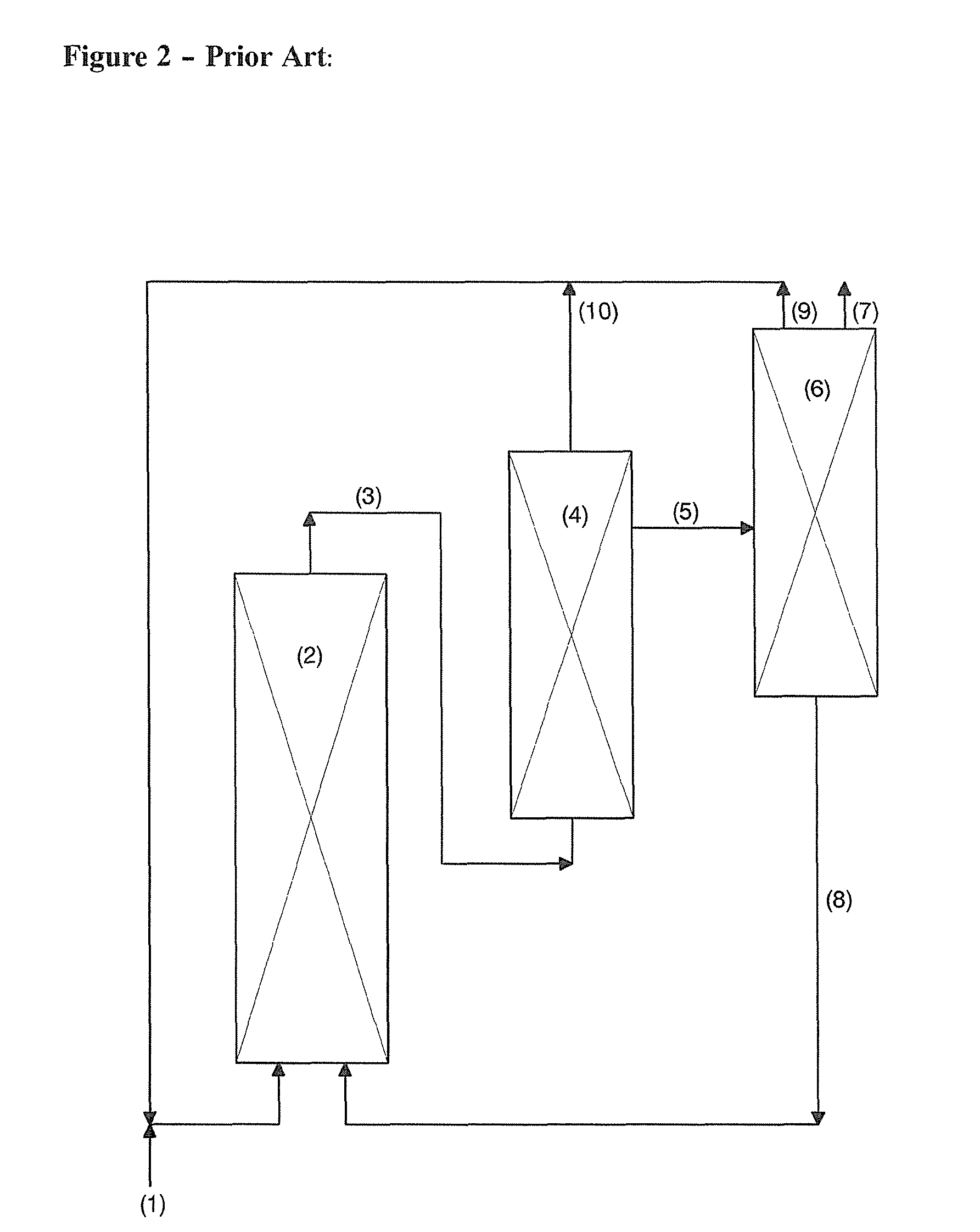

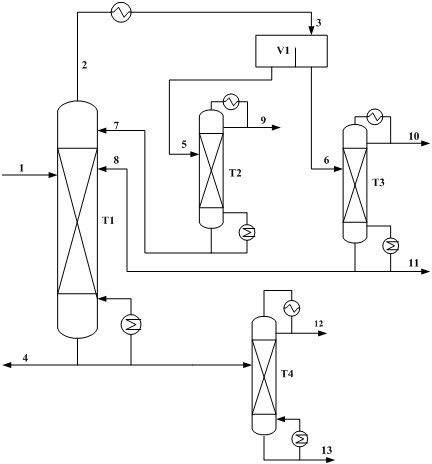

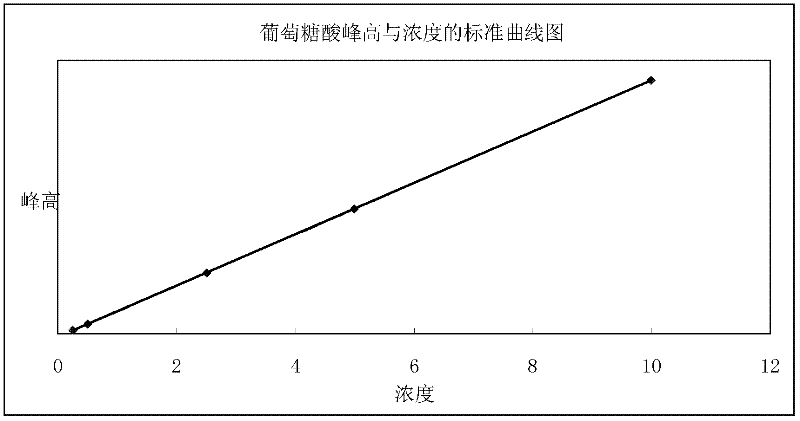

A production process of acetic acid according to the present invention inhibits concentration of hydrogen iodide and improves a liquid-liquid separation of an overhead from a distillation column. Acetic acid is produced by distilling a mixture containing hydrogen iodide, water, acetic acid and methyl acetate in a first distillation column (3) to form an overhead and a side cut stream or bottom stream containing acetic acid, cooling and condensing the overhead in a condenser (C3) to form separated upper and lower phases in a decanter (4). According to this process, a zone having a high water concentration is formed in the distillation column above the feed position of the mixture by feeding a mixture having a water concentration of not less than an effective amount to not more than 5% by weight (e.g., 0.5 to 4.5% by weight) and a methyl acetate concentration of 0.5 to 9% by weight (e.g., 0.5 to 8% by weight) as the mixture to the distillation column and distilling the mixture. In the zone having a high water concentration, hydrogen iodide is allowed to react with methyl acetate to produce methyl iodide and acetic acid.

Owner:DAICEL CHEM IND LTD

Hydrogen peroxide and peracetic acid mixed disinfectant and preparation method thereof

InactiveCN103843817AEasy to sterilizeImprove sterilization effectBiocidePeroxide active ingredientsAcetic acidDisinfectant

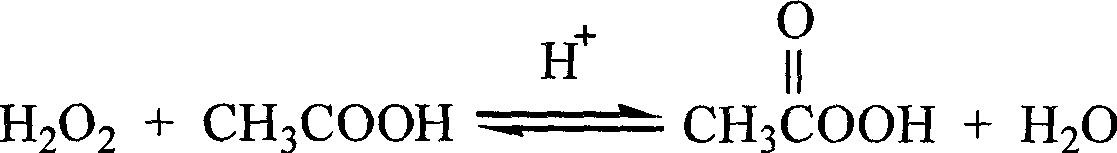

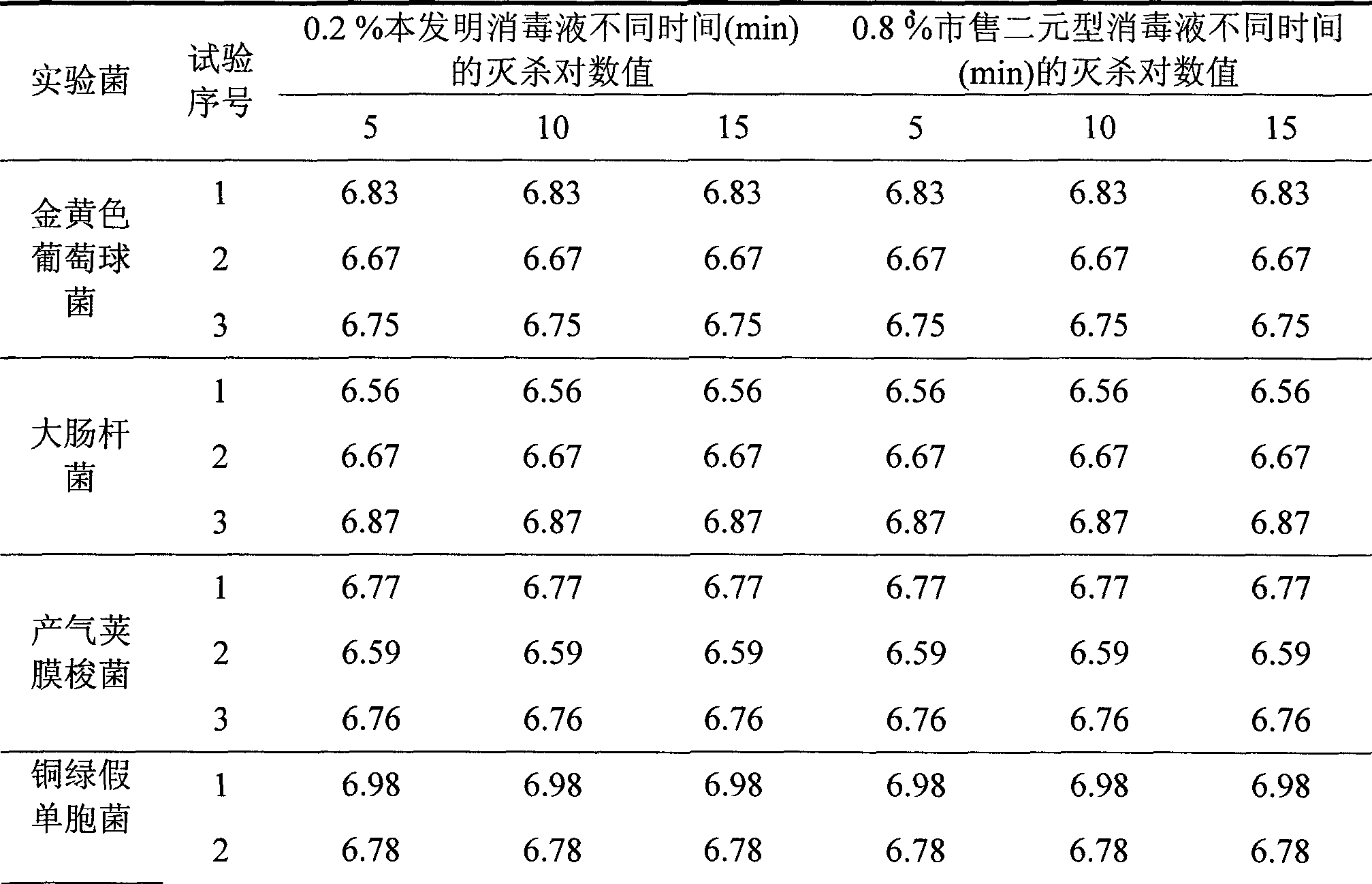

The invention relates to a hydrogen peroxide and peracetic acid mixed disinfectant and a preparation method of the disinfectant. The disinfectant is prepared by the steps of mixing hydrogen peroxide, acetic acid and sulfuric acid at the room temperature to prepare mixture containing peracetic acid and hydrogen peroxide, feeding a stabilizer and a surface active agent into the mixture containing the peracetic acid and the hydrogen peroxide, and mixing. The mixed disinfectant comprises 3-9g / 100g peracetic acid, 20-35g / 100g hydrogen peroxide, 5-12g / 100g acetic acid, 0.1-2g / 100g sulfuric acid, 0.05-2g / 100g stabilizer, 0.05-2g / 100g surface active agent and the balance of water. The hydrogen peroxide and peracetic acid mixed disinfectant is good in stability, is capable of rapidly killing various microorganisms such as bacteria, mould, yeast, spores and the like, and is safe, non-toxic and free from secondary pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Process for producing acetic acid

ActiveUS20150025270A1Avoid pollutionEnsure stable and continuous operationOrganic compound preparationDistillation separationWater concentrationAcetic acid ear

A production process of acetic acid according to the present invention inhibits concentration of hydrogen iodide and improves a liquid-liquid separation of an overhead from a distillation column. Acetic acid is produced by distilling a mixture containing hydrogen iodide, water, acetic acid and methyl acetate in a first distillation column (3) to form an overhead and a side cut stream or bottom stream containing acetic acid, cooling and condensing the overhead in a condenser (C3) to form separated upper and lower phases in a decanter (4). According to this process, a zone having a high water concentration is formed in the distillation column above the feed position of the mixture by feeding a mixture having a water concentration of not less than an effective amount to not more than 5% by weight (e.g., 0.5 to 4.5% by weight) and a methyl acetate concentration of 0.5 to 9% by weight (e.g., 0.5 to 8% by weight) as the mixture to the distillation column and distilling the mixture. In the zone having a high water concentration, hydrogen iodide is allowed to react with methyl acetate to produce methyl iodide and acetic acid.

Owner:DAICEL CHEM IND LTD

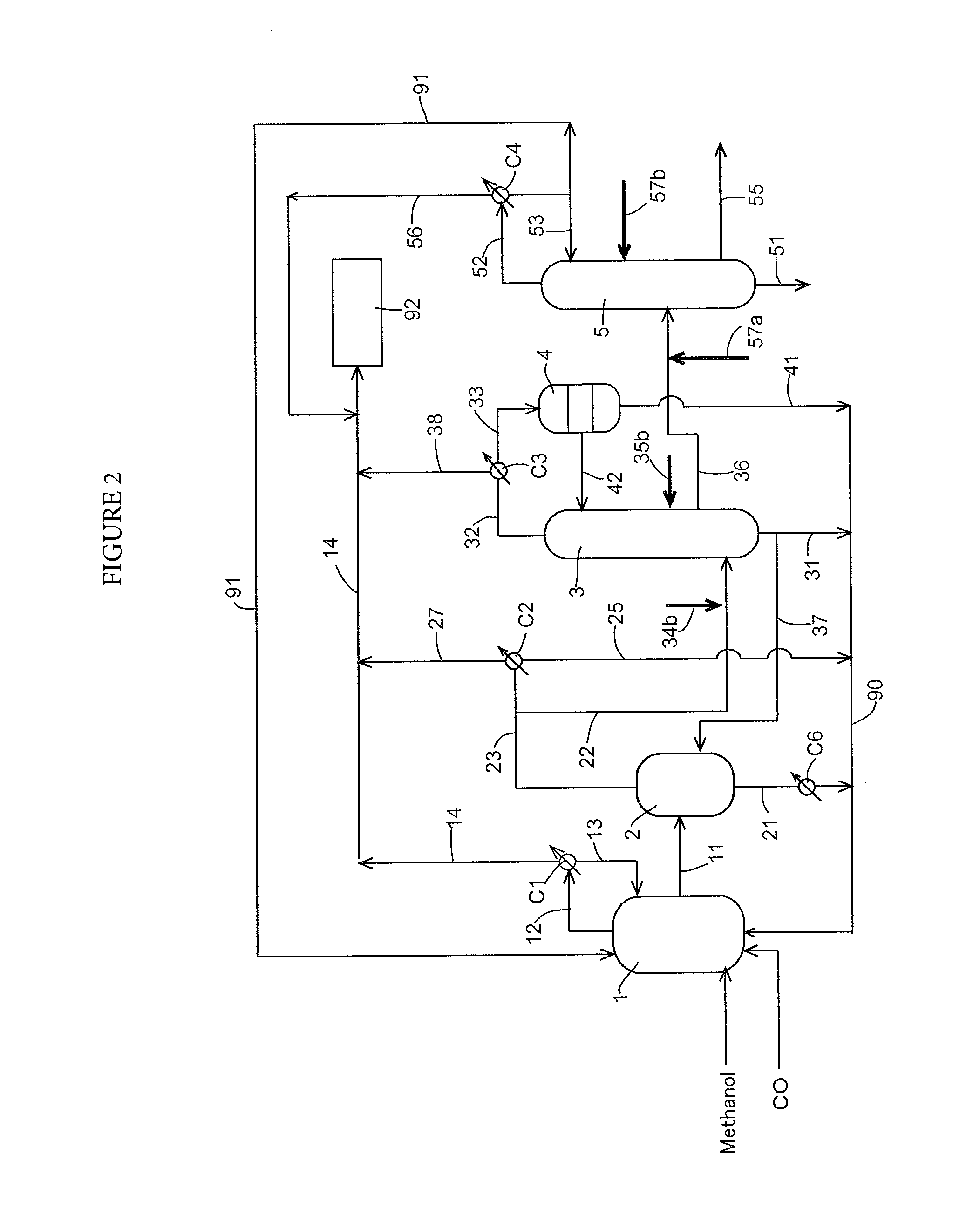

Process for producing acetic acid

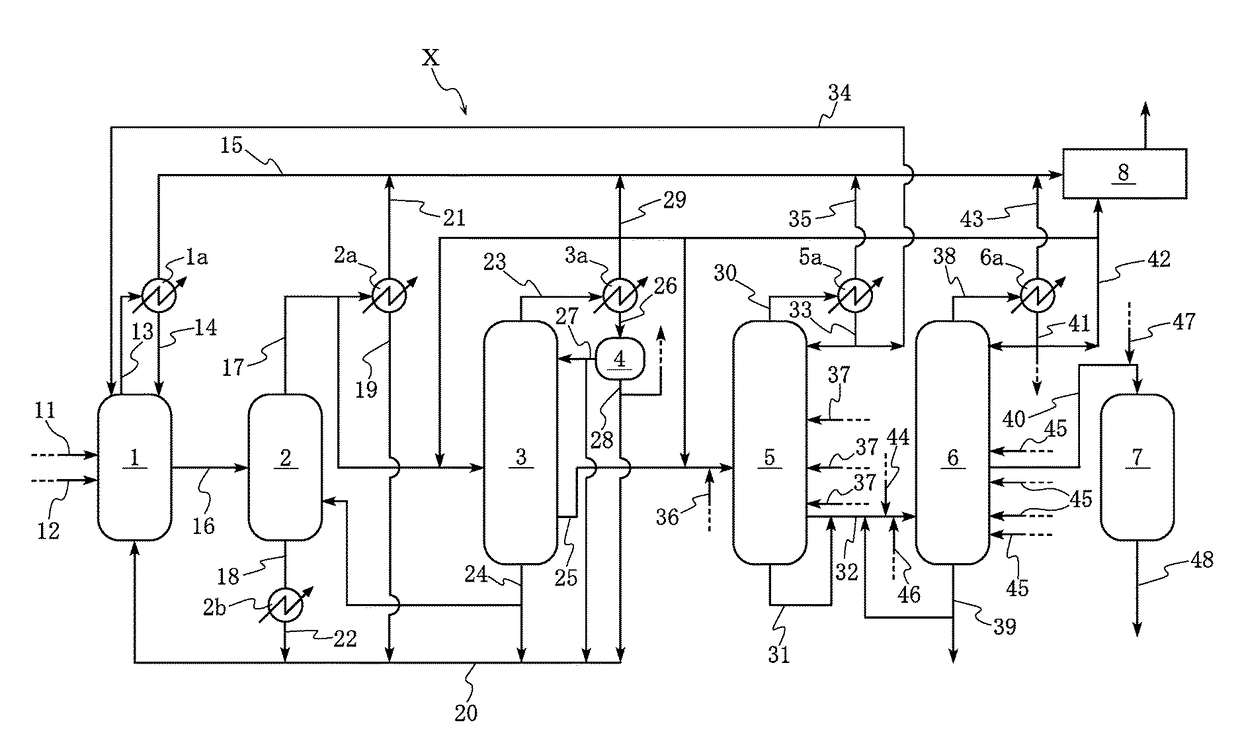

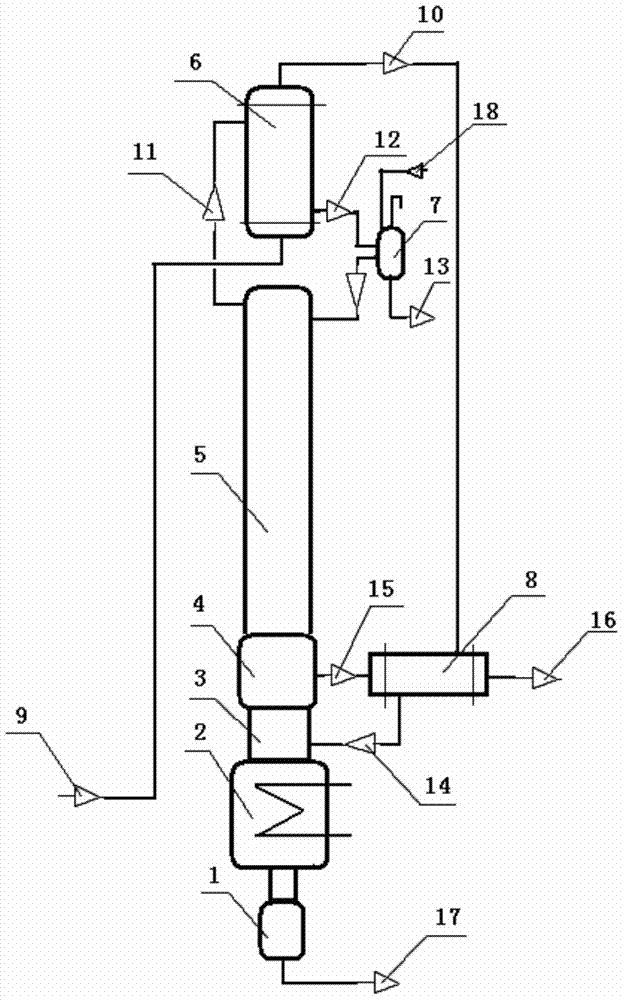

ActiveUS8957248B2High purityHigh yieldOrganic compound preparationChemical industryAcetic acid earResource saving

A production process of acetic acid comprises a reaction step for continuously allowing at least one member selected from the group consisting of methanol, dimethyl ether, and methyl acetate to react with carbon monoxide in a catalyst system comprising a rhodium catalyst, an iodide salt, and methyl iodide in the presence of acetic acid and water in a plant compromising a reactor 1; a flasher 2; and a distillation column 3; wherein part of the vaporized stream is introduced into a heat exchanger 7. The process achieves a production of acetic acid with a high purity in a resource-saving and energy-saving equipment by efficiently removing a reaction heat even in a large-sized plant.

Owner:DAICEL CHEM IND LTD

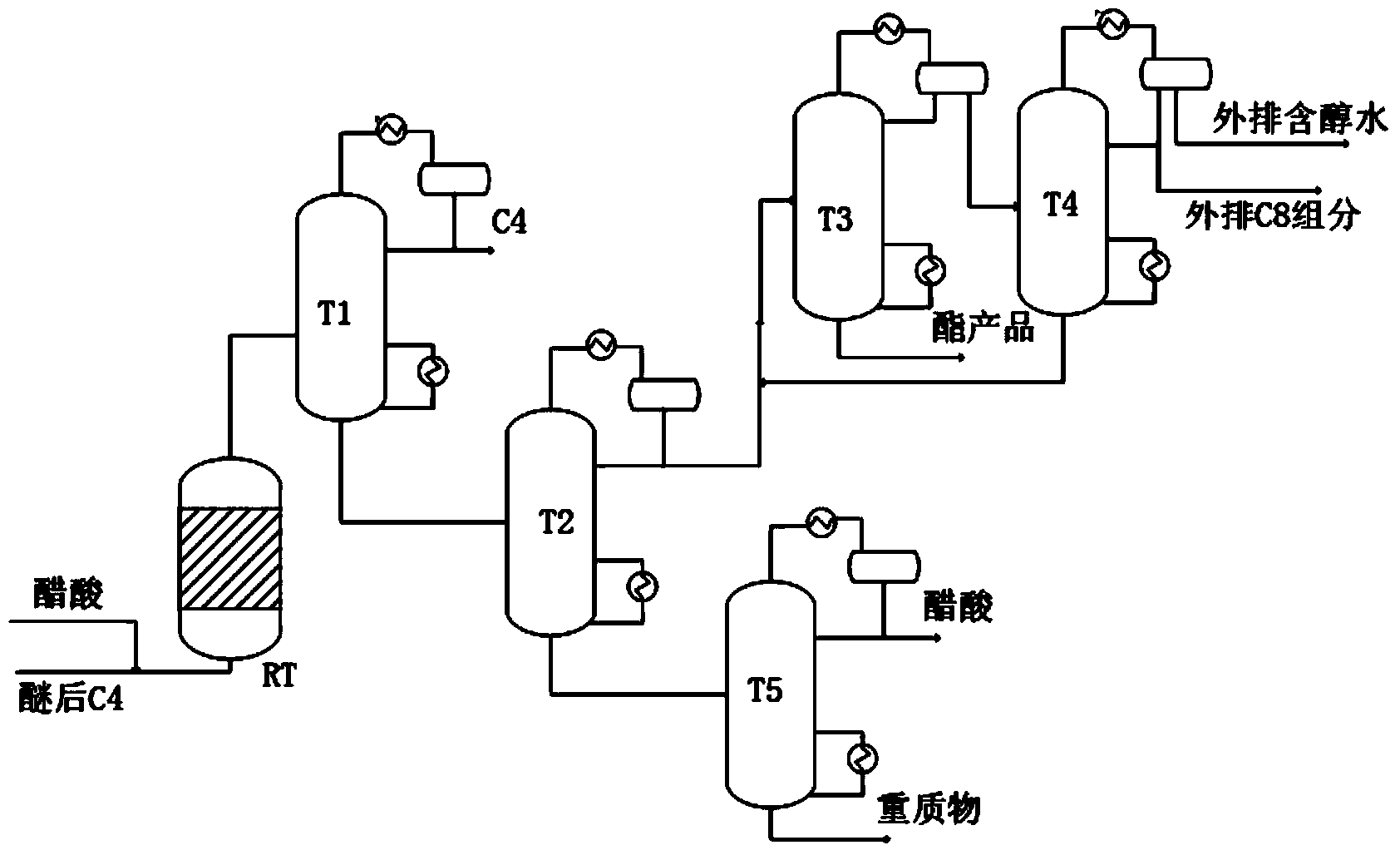

Method for recycling acetic acid sec-butyl ester from reaction product during preparation of acetic acid sec-butyl ester with high efficiency

ActiveCN103980115AIncrease concentrationReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic acid ear

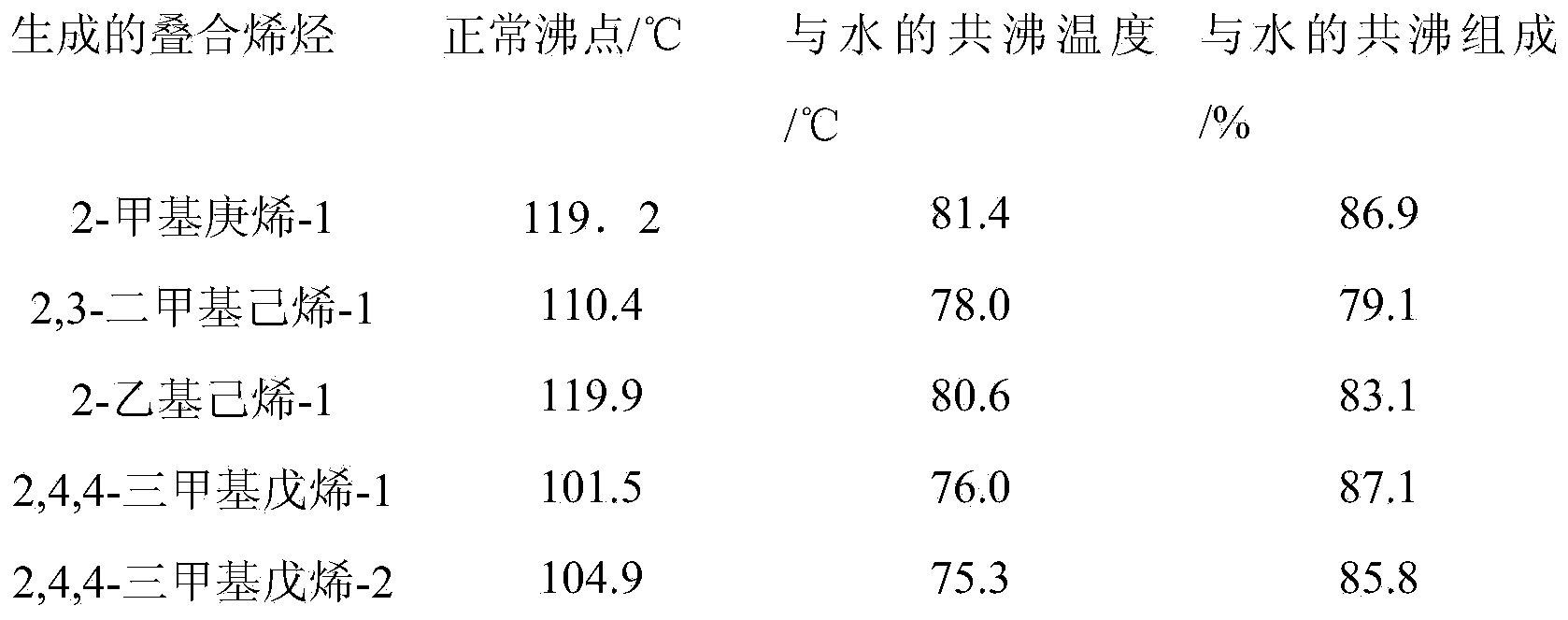

The invention provides a method for recycling acetic acid sec-butyl ester from a reaction product during preparation of the acetic acid sec-butyl ester with high efficiency. The method for recycling the acetic acid sec-butyl ester from the reaction product during preparation of the acetic acid sec-butyl ester with high efficiency comprises the following steps: directly feeding acetic acid sec-butyl ester material into an impurity removing azeotropic tower, wherein the acetic acid sec-butyl ester material is discharged outside as byproduct from the top of an ester product purification tower and contains water, C8 olefin and sec-butyl alcohol impurities, removing water, C8 olefin and part sec-butyl alcohol which are contained in the acetic acid sec-butyl ester material at the top of the impurity removing azeotropic tower while the contained water is taken as entrainer, and feeding a product at the bottom of the tower into an ester product refining tower for recycling. The method for recycling the acetic acid sec-butyl ester from the reaction product during preparation of the acetic acid sec-butyl ester with high efficiency has the advantages of simple process, low energy consumption, high separation efficiency, and more than 92% of the acetic acid sec-butyl ester in the byproduct can be recycled.

Owner:HUNAN RUIYUAN PETROCHEM

Blueberry pulp/juice acetic acid beverage and preparation method thereof

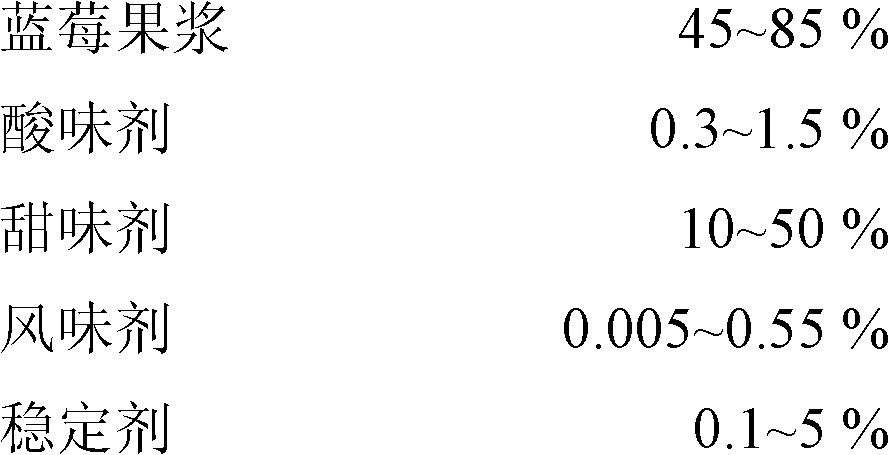

The invention relates to a blueberry pulp / juice acetic acid beverage and a preparation method thereof. The preparation method comprises the following steps: mixing a raw material liquid I with drinking water; and regulating the mixture with an edible acetic acid solution until the mass percent of acetic acid is 0.1-0.3%, wherein the raw material liquid I comprises the following components in percentage by mass: 45-85% of blueberry pulp, 0.3-1.5% of acidifying agent, 10-50% of sweetening agent, 0.005-0.55% of flavoring agent and 0.1-5% of stabilizing agent. The blueberry pulp / juice acetic acid beverage has high pulp content and natural color and is rich in nutrition as well as vitamins, acetic acid, organic acid and mineral substances; the dietary fiber content in the beverage is obviously increased, thereby being beneficial to the absorption of a human body; and the blueberry pulp / juice acetic acid beverage has dense fruit flavor, tastes pure, comfortable and palatable, is good in color, smell and taste, and can not go bad when stored for a long time at normal temperature. Thus, the blueberry pulp / juice acetic acid beverage is a new high-technology product rich in dietary fibers and nutrition.

Owner:DALIAN POLYTECHNIC UNIVERSITY

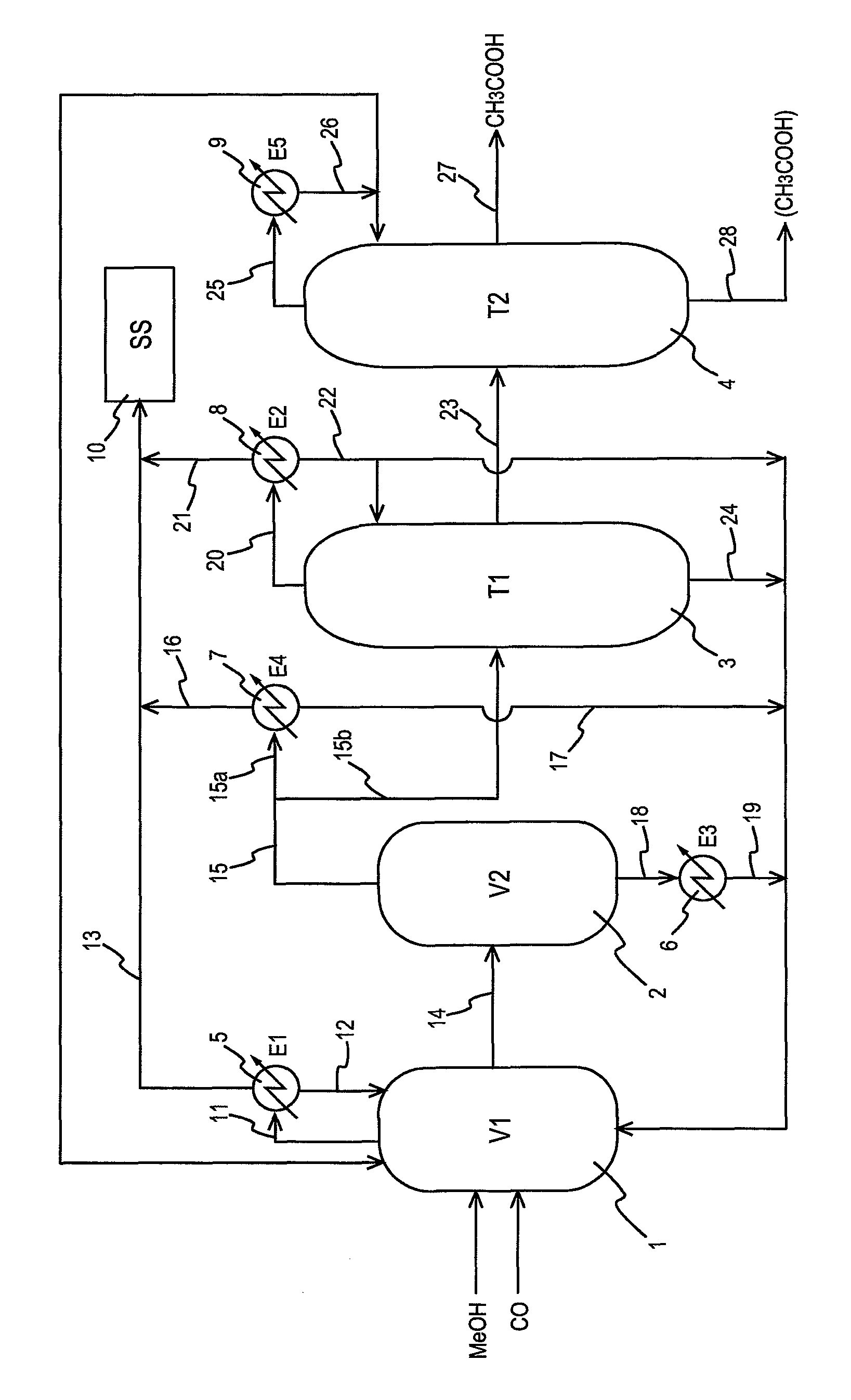

Method for producing acetic acid

ActiveUS20170349521A1Reduce probabilityHigh purityHydrogenDistillation regulation/controlAcetic acidDistillation

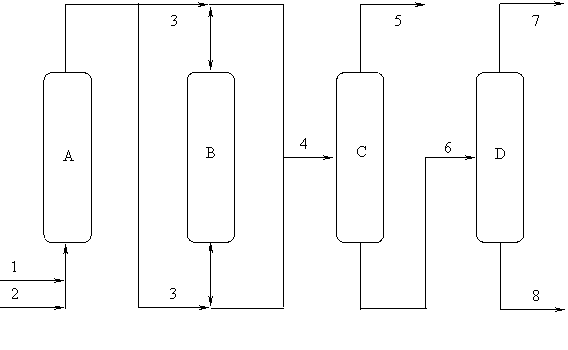

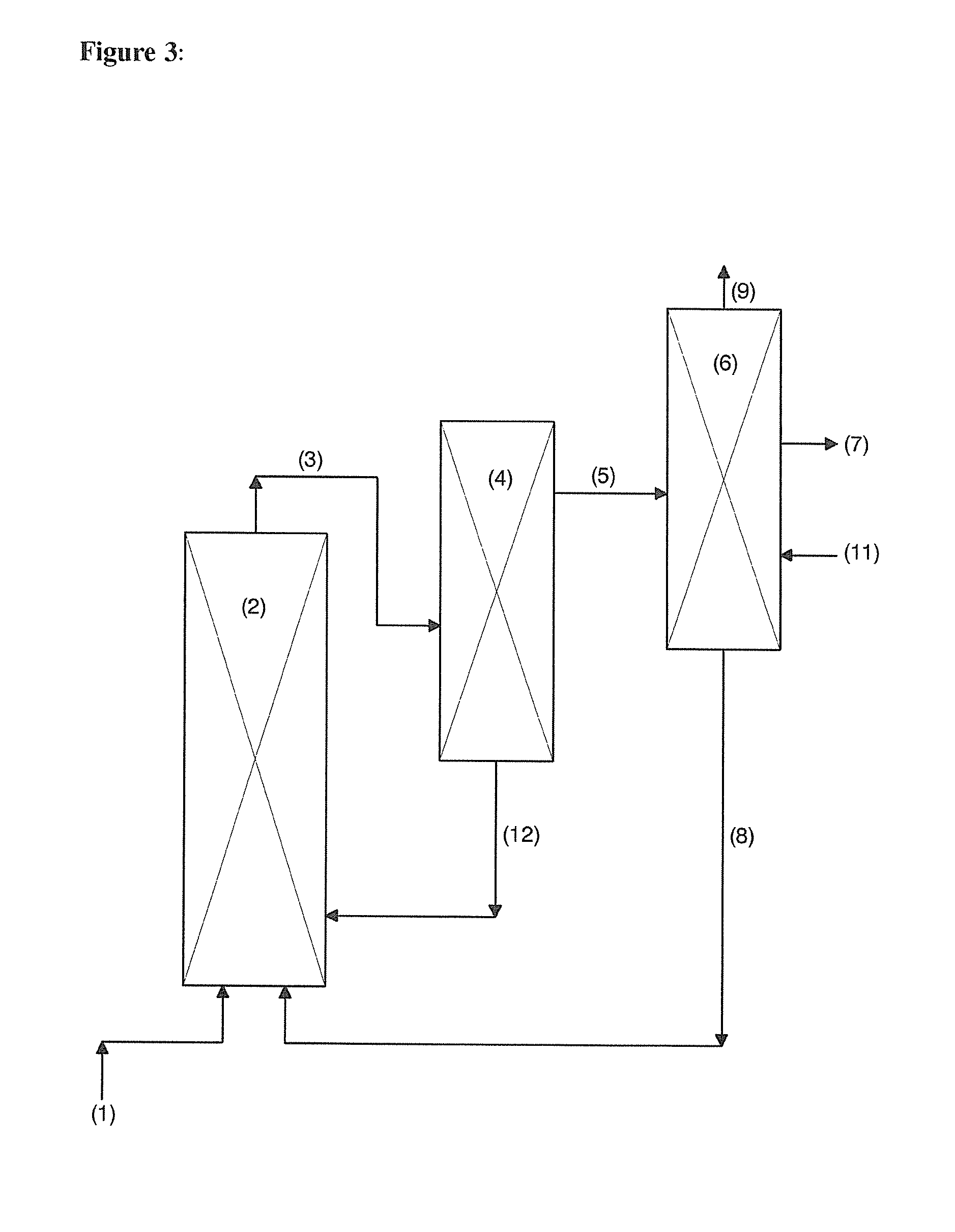

A method produces acetic acid and includes a reaction step, a first purification step, a second purification step, and a third purification step. In the reaction step, a material mixture including methanol, carbon monoxide, a catalyst, and an iodide is subjected to a methanol carbonylation reaction in a reactor (1) to form acetic acid. In the first purification step, a crude acetic acid stream including acetic acid formed in the reaction step is subjected to distillation in a distillation column (3) to give a first acetic acid stream enriched with acetic acid. In the second purification step, the first acetic acid stream is subjected to distillation in a distillation column (5) to give a second acetic acid stream further enriched with acetic acid. In the third purification step, an acetic acid stream is subjected to purification in an additional purification unit (e.g., a distillation column (6)) while controlling the corrosive iodine concentration in the acetic acid stream passing through the unit to 100 ppm or less, to give a third acetic acid stream still further enriched with acetic acid. The method for producing acetic acid is suitable for restraining corrosion of the acetic acid production equipment.

Owner:DAICEL CHEM IND LTD

Process for producing acetic acid

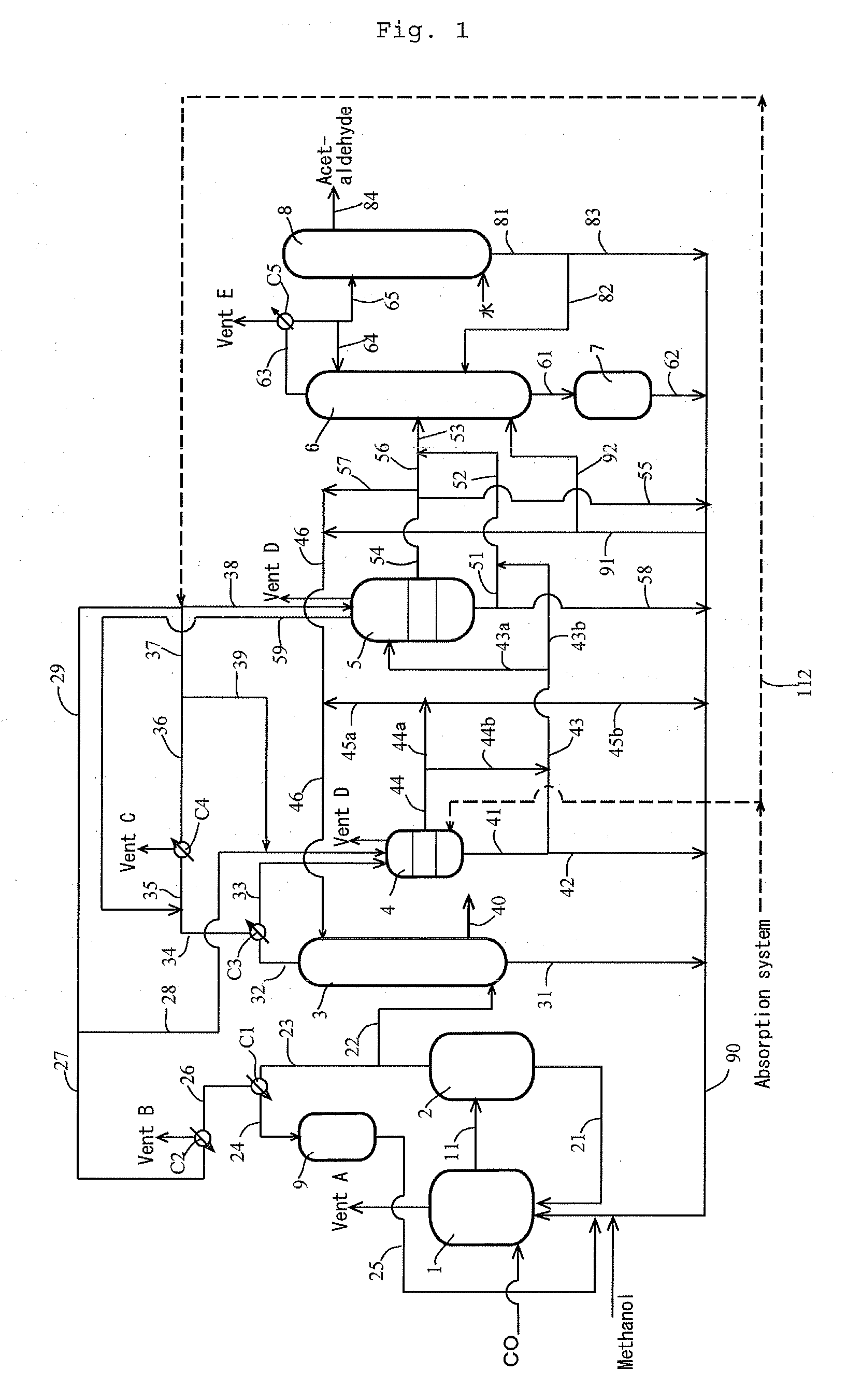

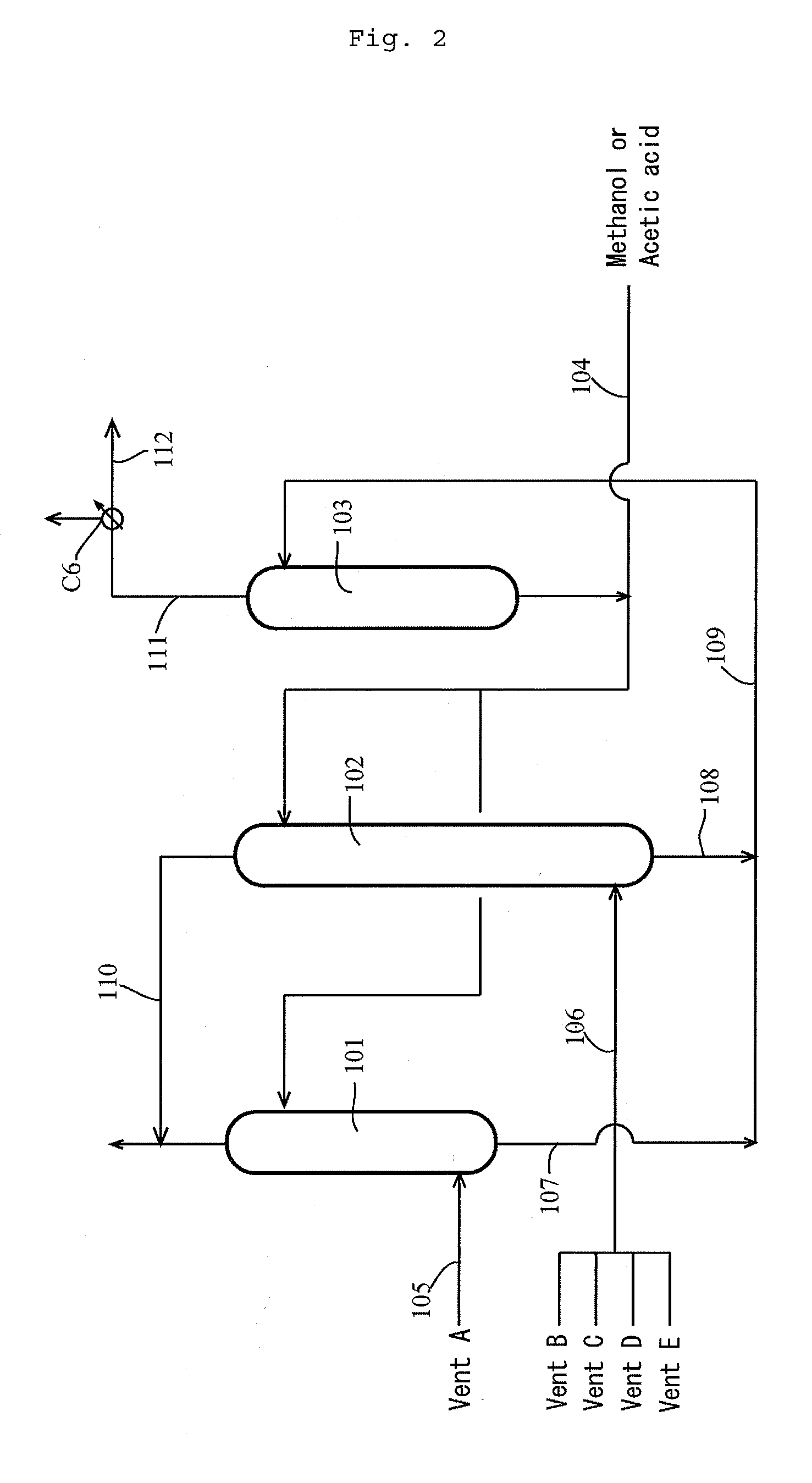

ActiveUS20150299084A1Good removal effectEasy to purifyOrganic compound preparationSolvent extractionAcetic acidAcetic acid ear

A process for removing acetaldehyde efficiently and producing high-purity acetic acid stably is provided. Methanol is allowed to continuously react with carbon monoxide in a carbonylation reactor 1 in the presence of a catalyst system; the reaction mixture is continuously fed to a flasher 2 to form a volatile phase (2A) containing acetic acid and methyl iodide; the volatile phase (2A) is continuously fed to a splitter column 3 to form an overhead (3A) containing methyl iodide and acetaldehyde and a stream (3B) containing acetic acid; the volatile phase (2A) and / or the overhead (3A) is cooled by a first condenser C1, C3 at a predetermined cooling temperature; and the noncondensed gaseous component is further cooled by a second condenser C2, C4 to form a concentrate having a lower temperature and a higher acetaldehyde concentration. Acetaldehyde is efficiently removed by distilling the concentrate having a high acetaldehyde concentration.

Owner:DAICEL CHEM IND LTD

Esterifying Acetic Acid To Produce Ester Feed For Hydrogenolysis

InactiveUS20130131396A1Organic compound preparationCarboxylic acid esters preparationAcetic acidHydrogen

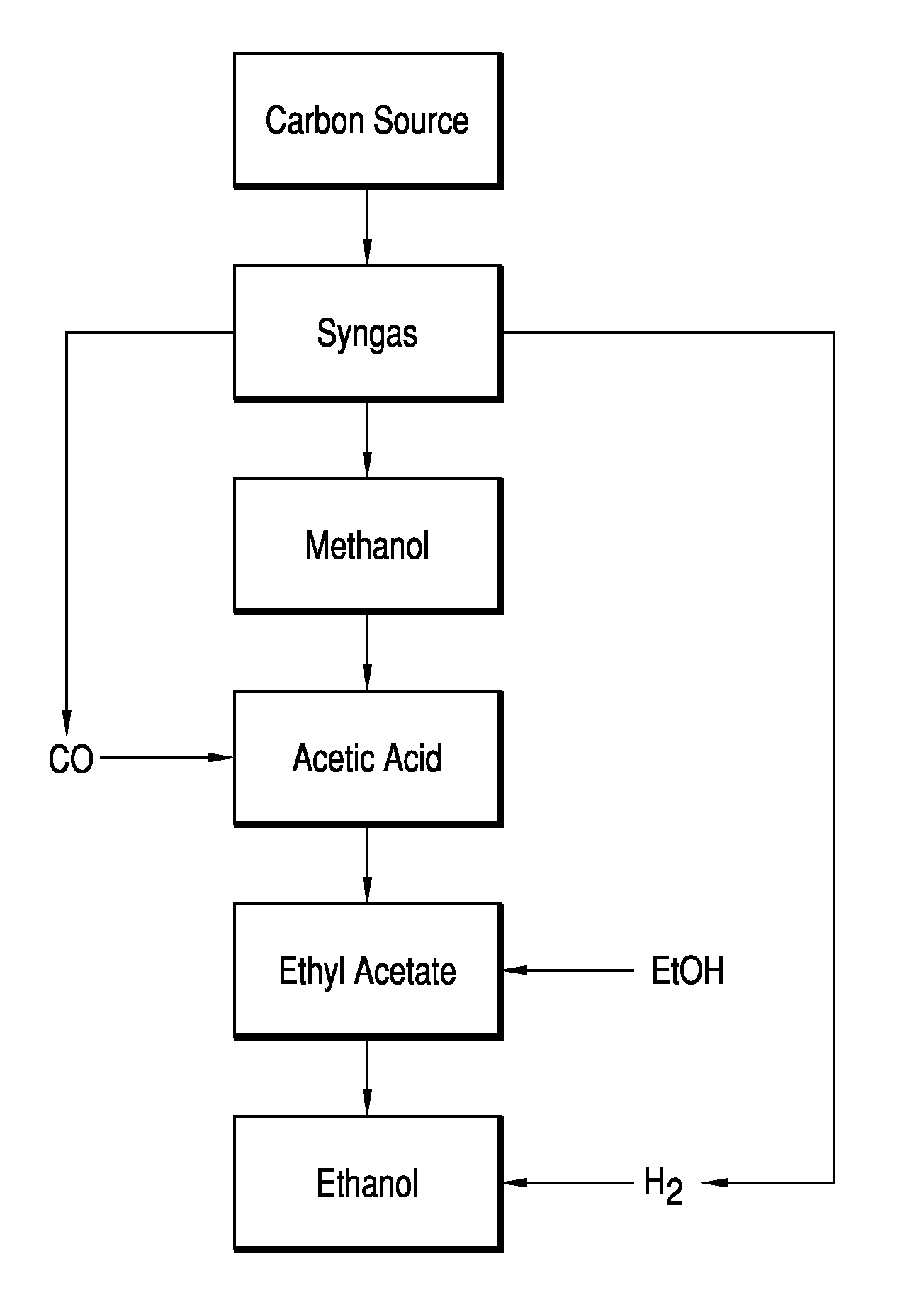

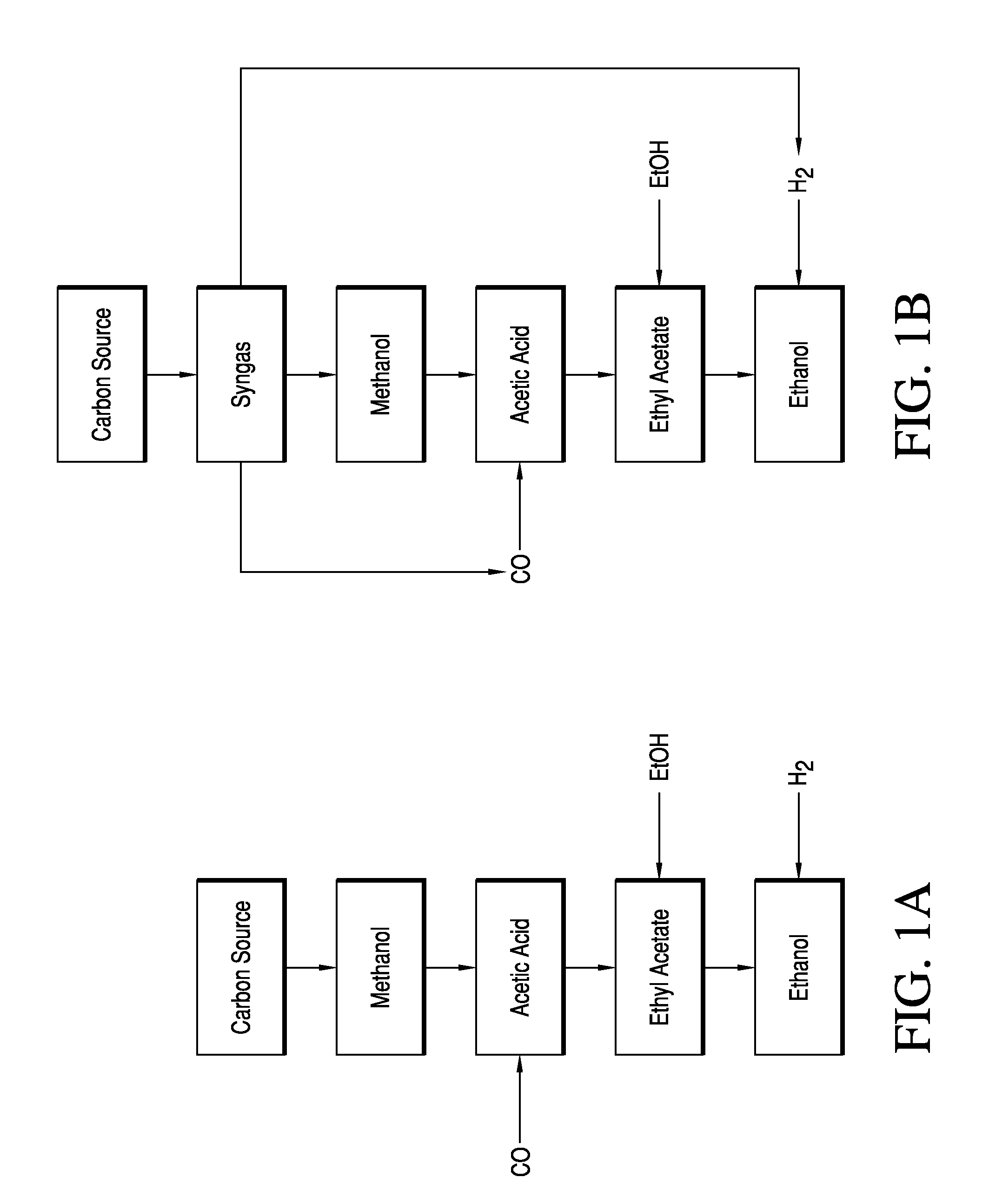

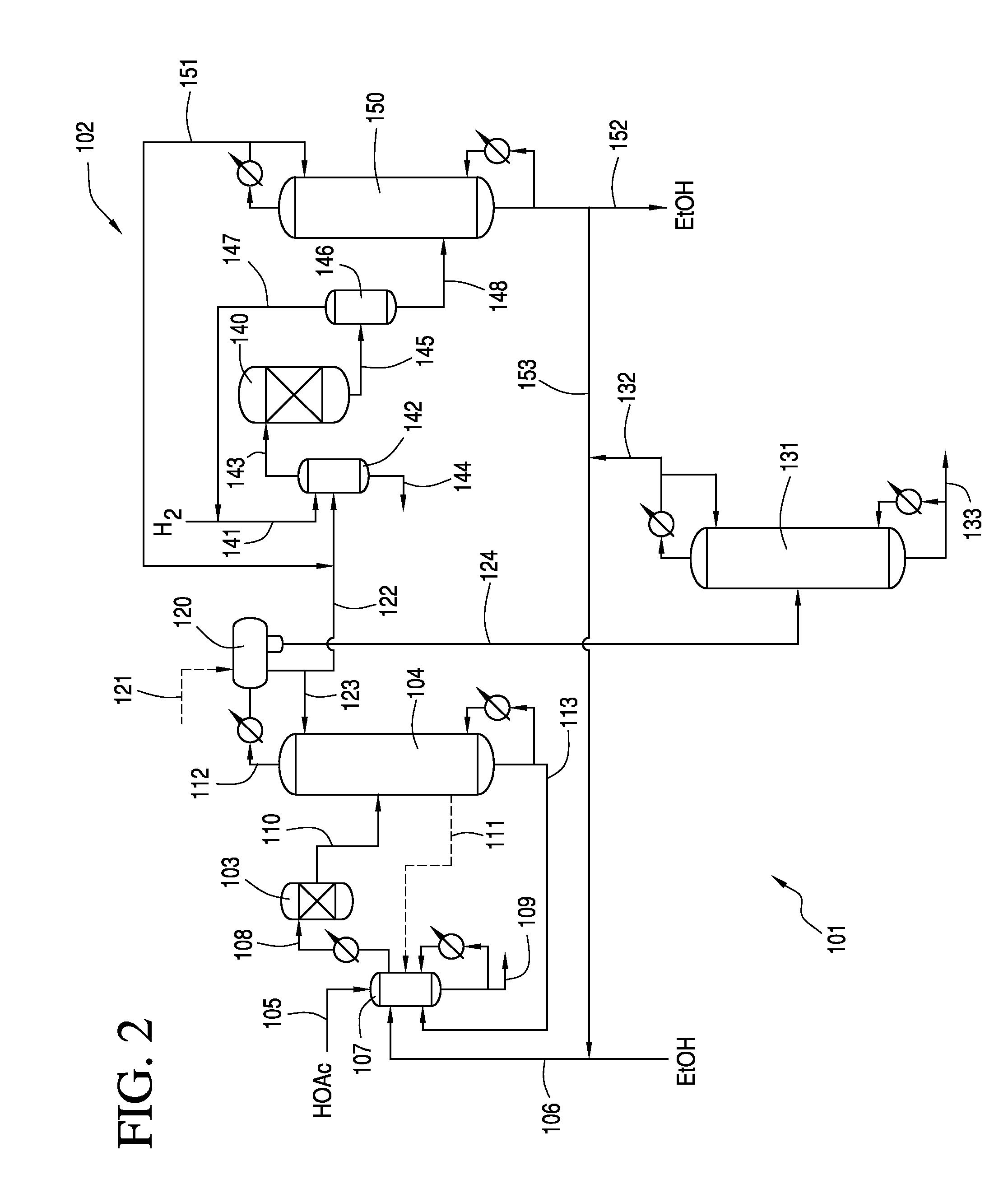

Disclosed herein are processes for alcohol production by reducing an esterification product, such as ethyl acetate. The processes comprise esterifying an excess molar ratio of acetic acid with an alcohol, such as ethanol, to produce the esterification product. The esterification product is reduced with hydrogen in the presence of a catalyst to obtain a crude reaction mixture comprising the alcohol, in particular ethanol, which may be separated from the crude reaction mixture.

Owner:CELANESE INT CORP

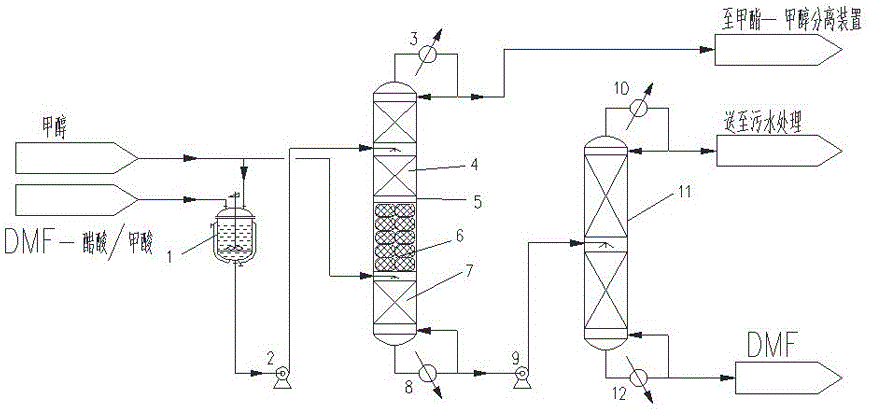

Method for removing small amount of acetic acid or methanoic acid and refining DMF

ActiveCN106831471AEasy to separateAvoid inactivationChemical industryCarboxylic acid amide separation/purificationAlcoholAcetic acid ear

The invention discloses a process method for separating DMF and acetic acid or methanoic acid in sucralose production. The process method comprises the following steps: adding methyl alcohol, a DMF mixed liquid containing acetic acid or methanoic acid, and a solid acid catalyst into a pre-reactor; entering a reaction rectification tower after pre-reaction; filling the reaction rectification tower with the solid acid catalyst; further reacting the acetic acid or methanoic acid which does not react with methyl alcohol in the reaction rectification tower; and feeding a mixture of methyl alcohol, water and methyl acetate or methyl formate at the top of the reaction rectification tower into an existing methyl ester and methyl alcohol separation device in sucralose production, feeding a mixture of DMF and water at the tower bottom into a DMF dehydration tower, and reclaiming at the tower bottom to obtain high-purity DMF. By adopting the method, the problem of separating the highest azeotrope DMF and acetic acid or methanoic acid in actual production can be solved, acetic acid is transformed into useful methyl acetate or methyl formate, the economic benefit is increased, the DMF having a purity more than 99 percent can be reclaimed, and the production cost is greatly reduced.

Owner:FUZHOU UNIV

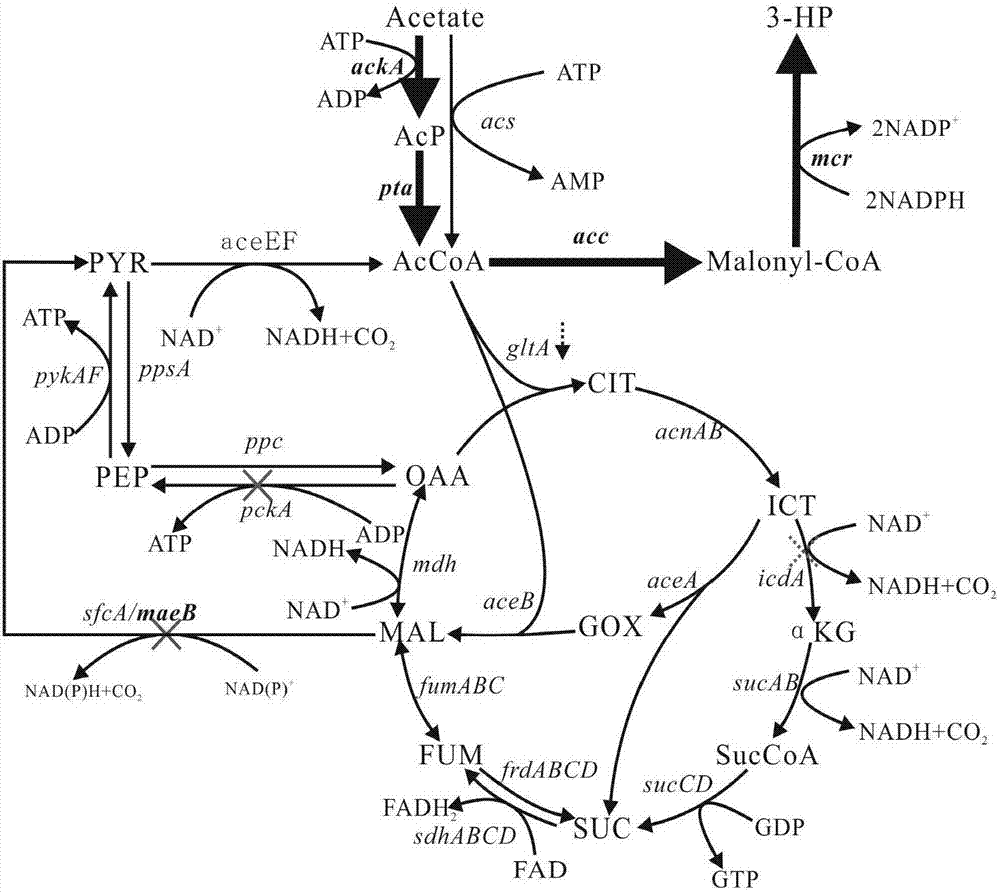

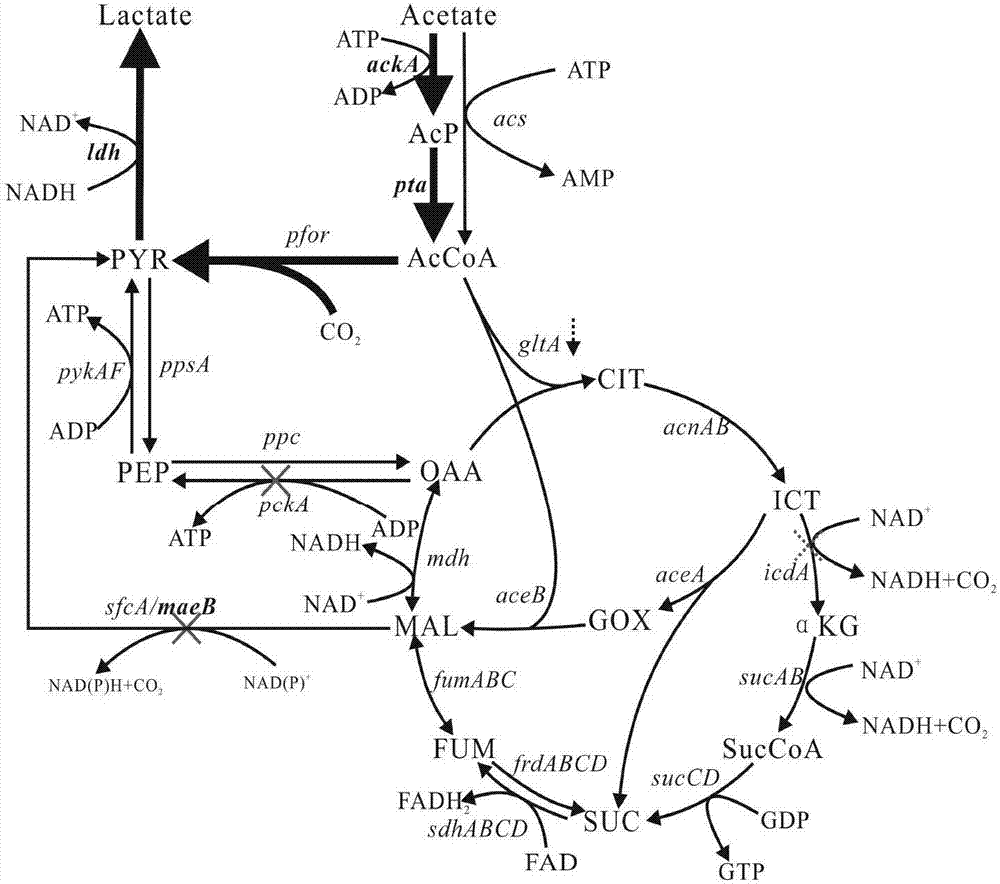

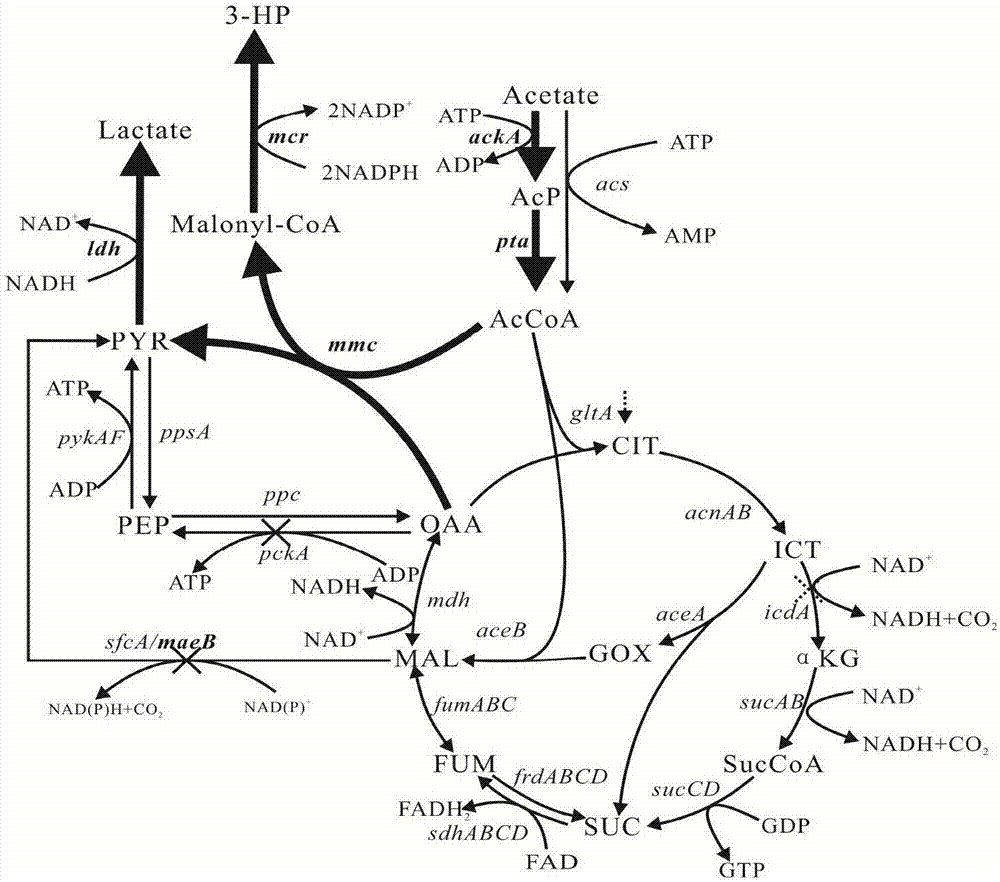

Construction method and application of metabolic engineering escherichia coli strain for producing hydracrylic acid from acetic acid

The invention discloses a construction method of a metabolic engineering escherichia coli strain for producing hydracrylic acid from acetic acid. Escherichia coli reformed by metabolic engineering isutilized for producing hydracrylic acid by fermenting acetic acid; and construction ways are as follows: constructing a metabolic way for producing hydracrylic acid from acetyl CoA, and / or over-expressing relevant genes of an acetic acid intake way so as to increase the transmission rate of acetic acid, and / or blocking or decreasing TCA circle so as to increase metabolic flow of acetyl CoA flowingtowards a target metabolite, and / or reducing decarboxylic reaction between malic acid or oxaloacetic acid so as to delete a byproduct generation way, and / or deleting key genes in an alcohol production way so as to regulate metabolic flow of an acetyl CoA node and / or regulating intracellular oxidation reduction balance through coenzyme engineering. According to the construction method, a production way for exogenously expressing hydracrylic acid is constructed, the metabolic ways, the adjustment and control are analyzed, and escherichia coli is reformed by virtue of a metabolic engineering measure, so that the prepared strain can be utilized for producing hydracrylic acid in a culture medium taking acetic acid as a carbon source.

Owner:EAST CHINA UNIV OF SCI & TECH

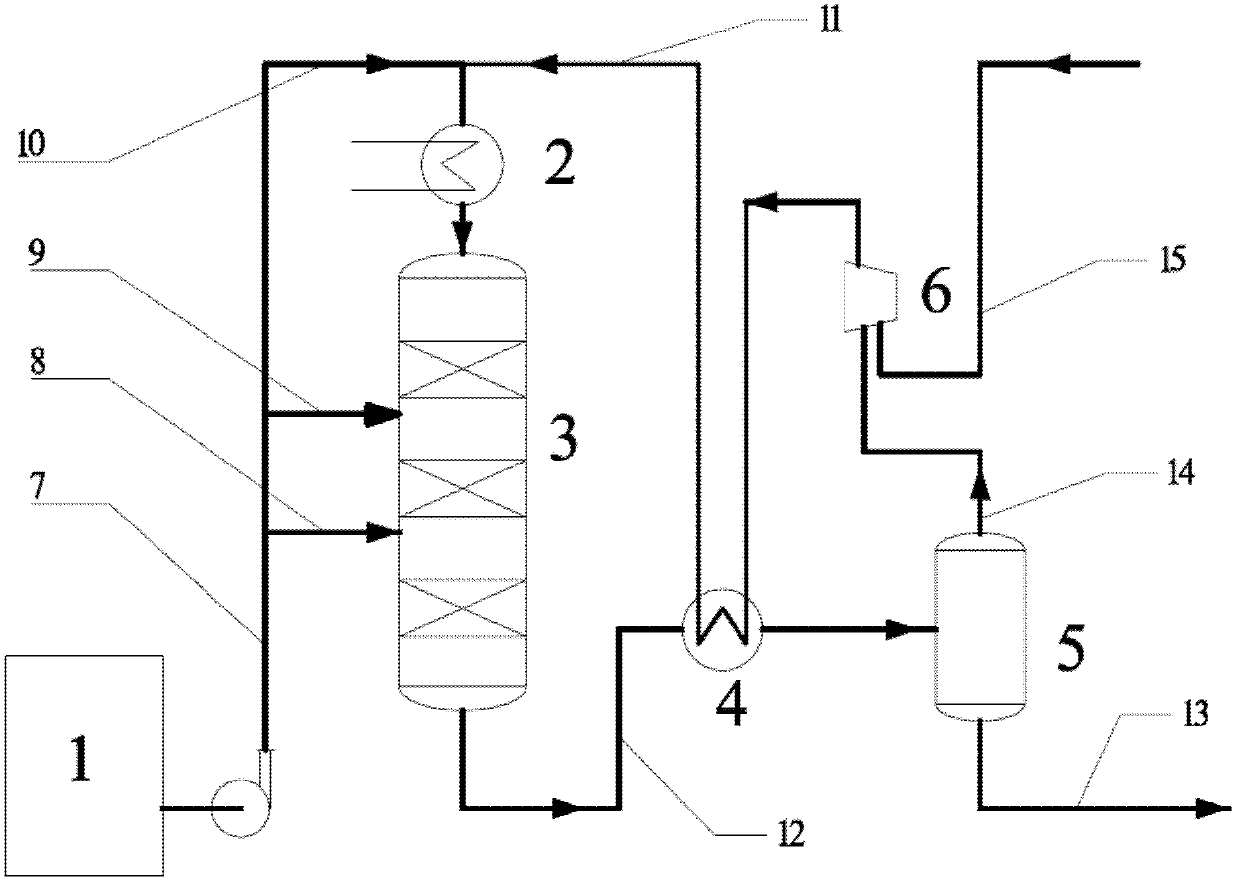

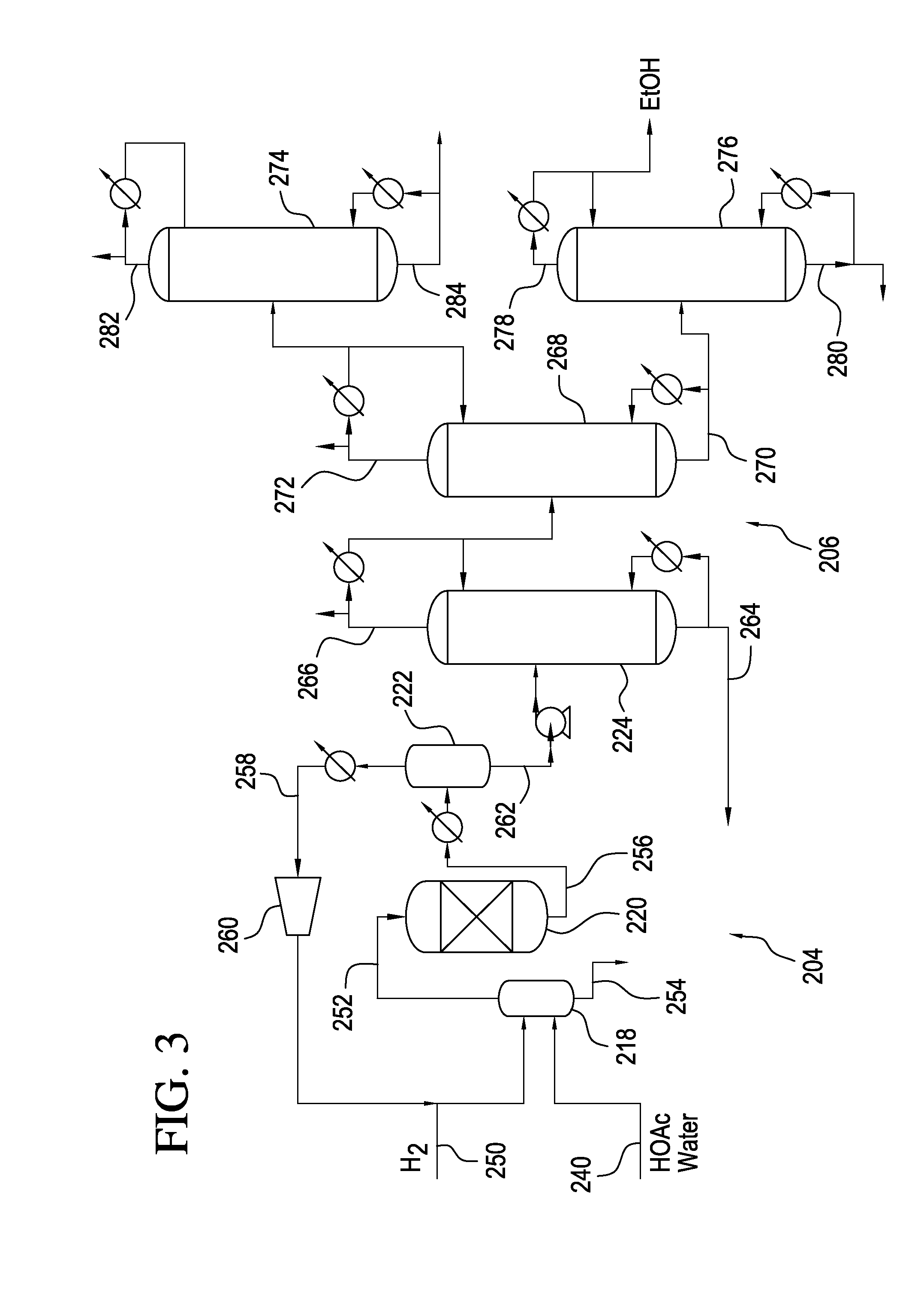

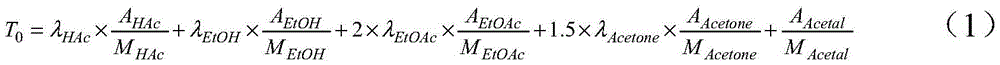

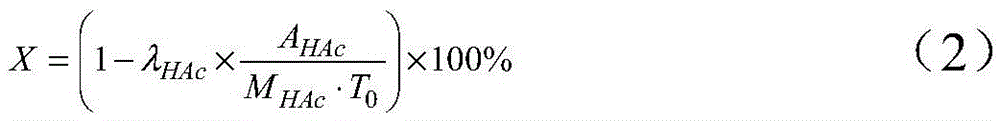

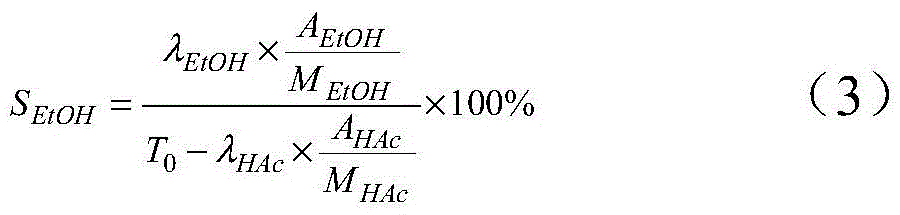

Device and method for preparing ethanol through acetic acid or acetic ester catalytic hydrogenation reaction

ActiveCN103373899AReduced hydrogen-acid ratioSolve the problem of high operating costsOrganic compound preparationHydroxy compound preparationAcetic acidAcetic acid ear

The invention relates to a device and method for preparing ethanol through acetic acid or acetic ester catalytic hydrogenation reaction. According to the device and method, acetic acid or acetic ester and hydrogen are used as raw materials, at least two reaction sections are connected in series, the acetic acid or acetic ester raw material is divided into two or more sections which enter each hydrogenation reaction section, liquid acetic acid or acetic ester or partially-liquid acetic acid or acetic ester feeds among the reaction sections to play a role in direct heat exchange and cooling and raw material supplementation, and a reaction system is provided with one recycle hydrogen compressor, so that the hydrogen acid ratio of the whole acetic acid or acetic ester hydrogenation reaction system is greatly reduced under the condition that the hydrogen acid ratio of each reaction area is higher. Compared with the prior art, by adopting the device and the method, industrial amplification of a process for producing ethanol through acetic acid or acetic ester hydrogenation is well realized, so that the device and the method can be widely applied to industrial production of ethanol.

Owner:PUJING CHEM IND SHA +1

Preparation of acetic acid

ActiveUS8076512B2Reduce the presence of impuritiesOrganic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidAlcohol

A method for reducing aldehydes in an acetic acid production process is disclosed. The acetic acid is produced by reacting methanol and carbon monoxide in the presence of a carbonylation catalyst. The method comprises reacting an aldehyde-containing stream with an alcohol to form an acetal-containing stream. An acetal-enriched stream is separated from the acetal-containing stream and then hydrolyzed to form a hydrolysis mixture comprising the alcohol and the aldehydes. The alcohol is isolated from the hydrolysis mixture and used to react with the aldehyde-containing stream to form the acetal-containing stream. The invention reduces aldehydes in the acetic acid produced.

Owner:LYONDELLBASELL ACETYLS

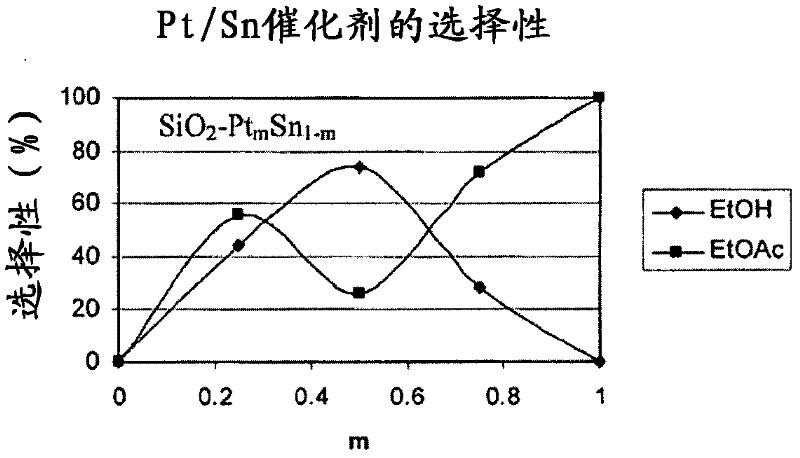

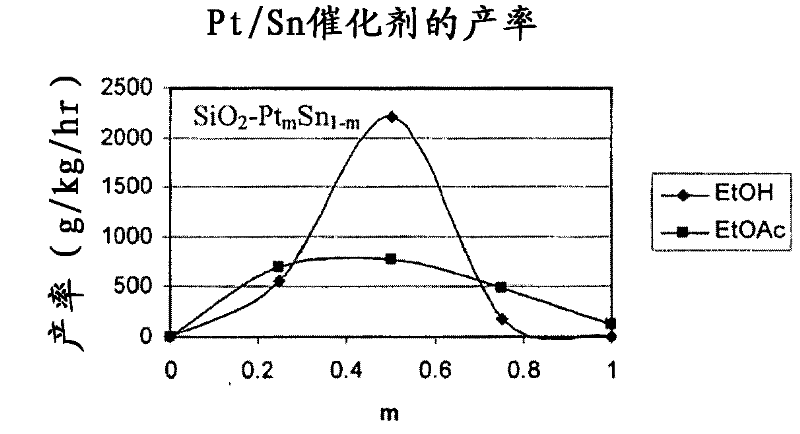

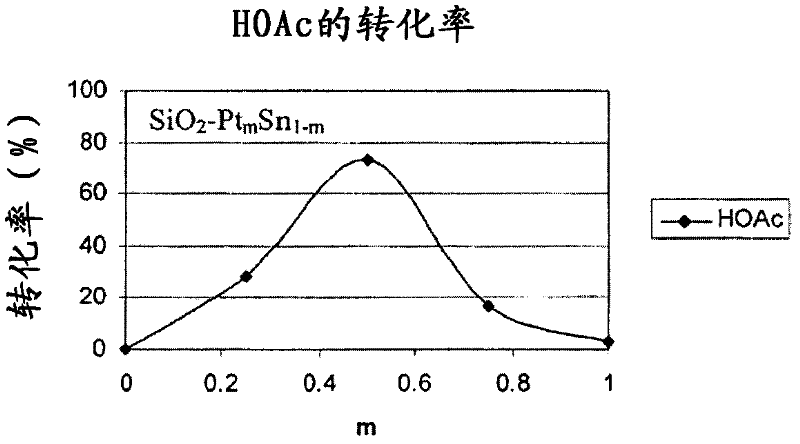

Catalyst for the preparation of ethyl acetate from acetic acid

InactiveCN102300638AOrganic compound preparationHeterogenous catalyst chemical elementsAcetic acid earEthyl acetate

Catalysts and processes for making catalysts suitable for use in processes for hydrogenating acetic acid to form of ethyl acetate and mixtures of ethyl acetate and ethanol. In a first embodiment, the catalyst includes a high loading of nickel, palladium or platinum. In a second embodiment, the catalyst comprises a first metal selected from nickel and palladium and a second metal selected from tin and zinc. In a third embodiment, the catalyst comprises one or more metals on a support that has been modified with an acidic support modifier or a redox support modifier.

Owner:CELANESE INT CORP

Ethanol and ethyl acetate production using an acetic acid and acetic anhydride mixed feed

InactiveUS20140275641A1Organic compound preparationOxygen compounds preparation by reductionAcetic anhydrideGas phase

Ethanol production processes using a mixed feed comprising from 20 to 95 wt. % acetic acid, from 5 to 80 wt. % acetic anhydride, and from 0 to 20 wt. % esters selected from the group consisting of methyl acetate, ethyl acetate, or mixtures thereof are disclosed herein. The process comprises contacting the mixed feed with hydrogen in the vapor phase in a reactor in the presence of a catalyst comprising tin, cobalt, platinum, and combinations thereof to form a crude ethanol product having an ethanol to water molar ratio of greater than 1 and separating the crude ethanol product in one or more distillation columns to yield an ethyl acetate stream and an ethanol stream. The process may be integrated with an acetic anhydride production process to obtain further economic savings.

Owner:CELANESE INT CORP

Coproduction of acetic acid and acetic anhydride

ActiveUS20120123156A1Organic compound preparationCarboxylic acid esters preparationAcetic anhydrideAcetic acid ear

Disclosed is a process for the coproduction of acetic acid and acetic anhydride by producing in a first carbonylation reactor a carbonylation product mixture containing acetic anhydride, removing the carbonylation mixture from the first carbonylation reactor, contacting the carbonylation mixture with methanol to react with and convert some or all of the acetic anhydride contained in the mixture to acetic acid and methyl acetate, feeding the resulting reaction composition to a second carbonylation reactor and contacting the reaction composition to carbonylation.

Owner:EASTMAN CHEM CO

Method for preparing industrial ethanol from acetic acid

InactiveCN103772143AImprove conversion rateMild reaction conditionsOrganic compound preparationHeterogenous catalyst chemical elementsAcetic acidHydrogen

The invention relates to a method for preparing ethanol, and particularly relates to a method for preparing ethanol from acetic acid. The method adopts raw materials and a catalyst, wherein the raw materials are acetic acid and hydrogen. The method is characterized in that the catalyst is a Cu-based catalyst, and the method comprises the steps of loading the Cu-based catalyst into a reactor, and reducing with hydrogen at 220-270 DEG C; feeding the hydrogen and acetic acid at a molar ratio of (10-50):1 to enable contact between the raw materials and the catalyst; reacting for 24 hours at a reaction temperature of 180-300 DEG C under a reaction pressure of 0.5-6.0MPa; reacting to generate ethanol and water when the mass air speed of the acetic acid is 0.1-0.5 / h; separating the product to obtain an ethanol product. The adopted Cu-based catalyst effectively adjusts the acid-base property of the catalyst, can inhibit the generation of diethyl ether, and converts acetic acid into ethanol to the greatest degree, thus the selectivity and stability are good, and the per-pass conversion of the reaction is high; meanwhile, the reaction conditions are mild, the energy consumption is low, and a good technical effect is obtained.

Owner:上海海源硅材料科技有限公司

Method for preparing sec-butyl acetate by using acetic acid and butane

ActiveCN102911043ARealize continuous productionGood radial blending effectOrganic compound preparationCarboxylic acid esters preparationButeneAcetic acid ear

The present invention discloses a method for preparing sec-butyl acetate by using acetic acid and butane. The acetic acid and n-butene are sufficiently mixed by continuously passing through a static mixer, and are fed into a reactor filled with a strongly acidic cation-exchange resin catalyst for an addition reaction; the materials after the reaction are fed into a phase separator for a gas-liquid separation; and a fractional distillation of the liquid phase obtained by the gas-liquid separation is performed in a fractionation column to obtain the sec-butyl acetate. Compared with the prior art, the process of the present invention has the advantages of a simple process, high conversion of acetic acid, high selectivity of sec-butyl acetate, less byproducts, and low energy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

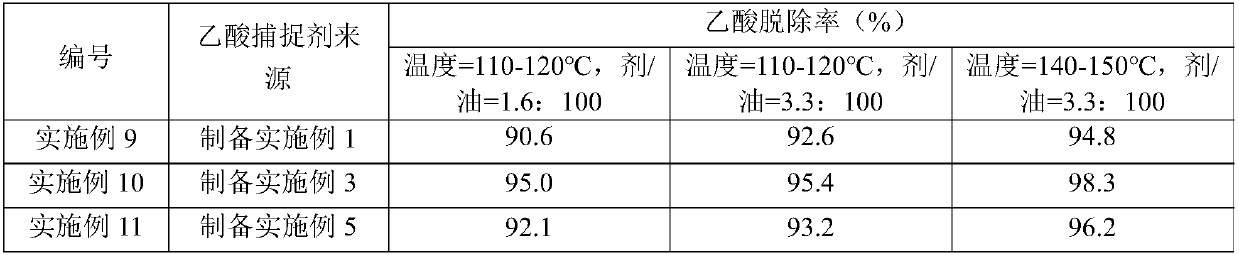

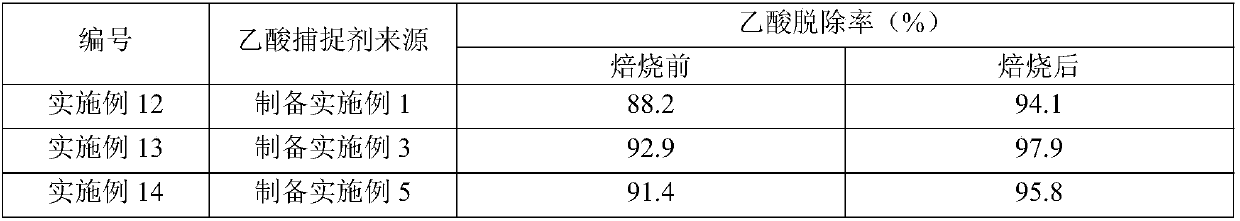

Method for removing acetic acid, production method for cyclohexyl acetate, and production method for cyclohexanol

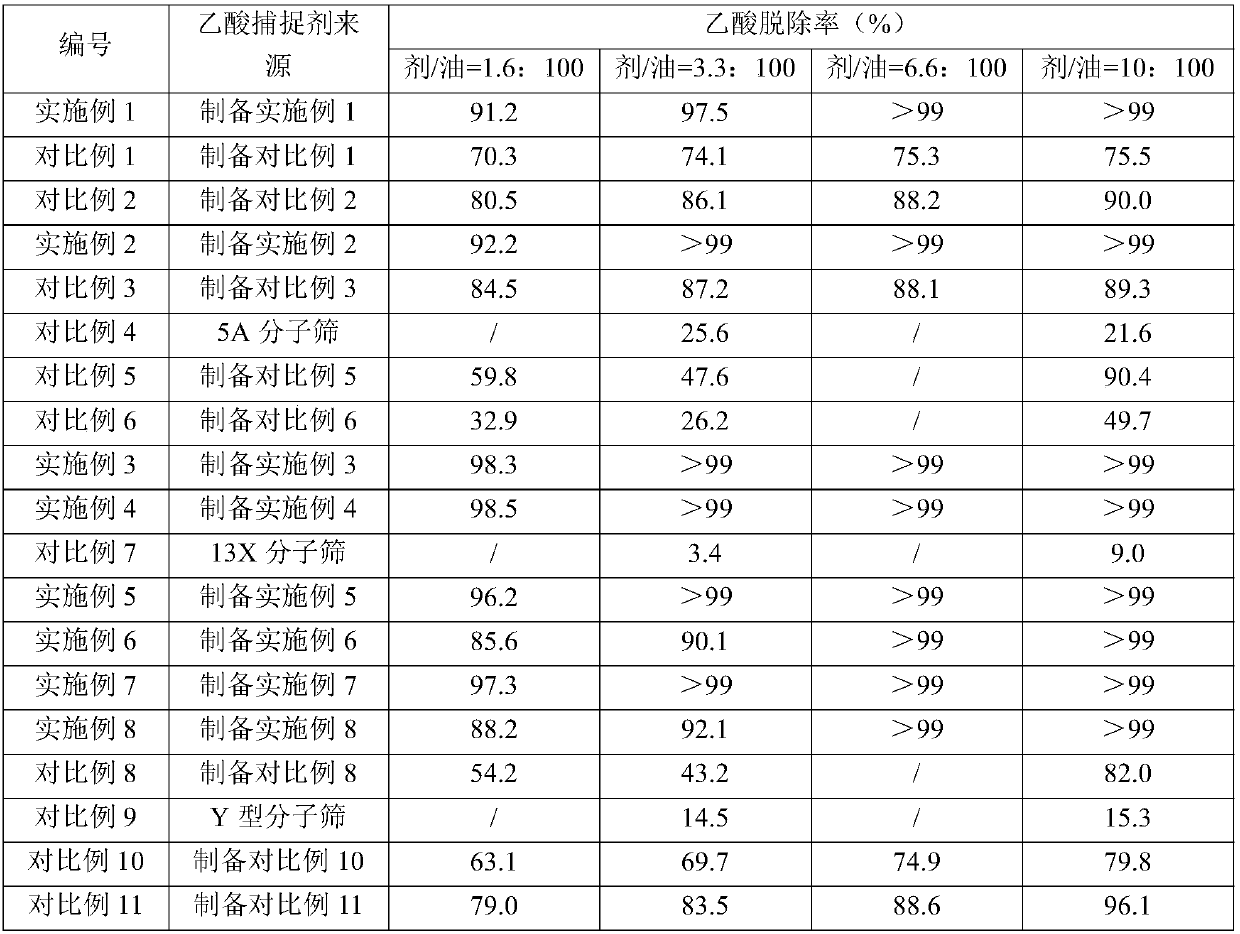

ActiveCN108017498AGood effect of removing acetic acidEfficient captureOrganic compound preparationMolecular sieve catalystAcetic acidMolecular sieve

The invention discloses a method for removing acetic acid. The method comprises a step of contacting cyclohexane and / or cyclohexanol containing acetic acid with an acetic acid capturing agent, whereinthe acetic acid capturing agent contains CaO, MgO, a molecular sieve and a binder, the binder is selected from a group consisting of heatproof inorganic oxide and clay, and on the basis of the totalamount of the acetic acid capturing agent, the contents of CaO and MgO are 50 wt% or above and 5 wt% or above, respectively. The invention also discloses production methods for cyclohexyl acetate andcyclohexanol, wherein the production methods adopt the acetic acid removal method for removing trace acetic acid in cyclohexane and cyclohexanol. According to the acetic acid removal method, the acetic acid capturing agent can effectively capture trace acetic acid in cyclohexane and cyclohexanol and has good acetic acid capturing capability even at a high temperature; and the acetic acid capturingagent can be regenerated through heating treatment, and the regenerated acetic acid capturing agent still has good acetic acid capturing capability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the manufacture of acetic acid

ActiveUS8637699B2Organic compound preparationCarboxylic preparation from carbon monoxide reactionIodised saltAcetic acid

Owner:LYONDELLBASELL ACETYLS

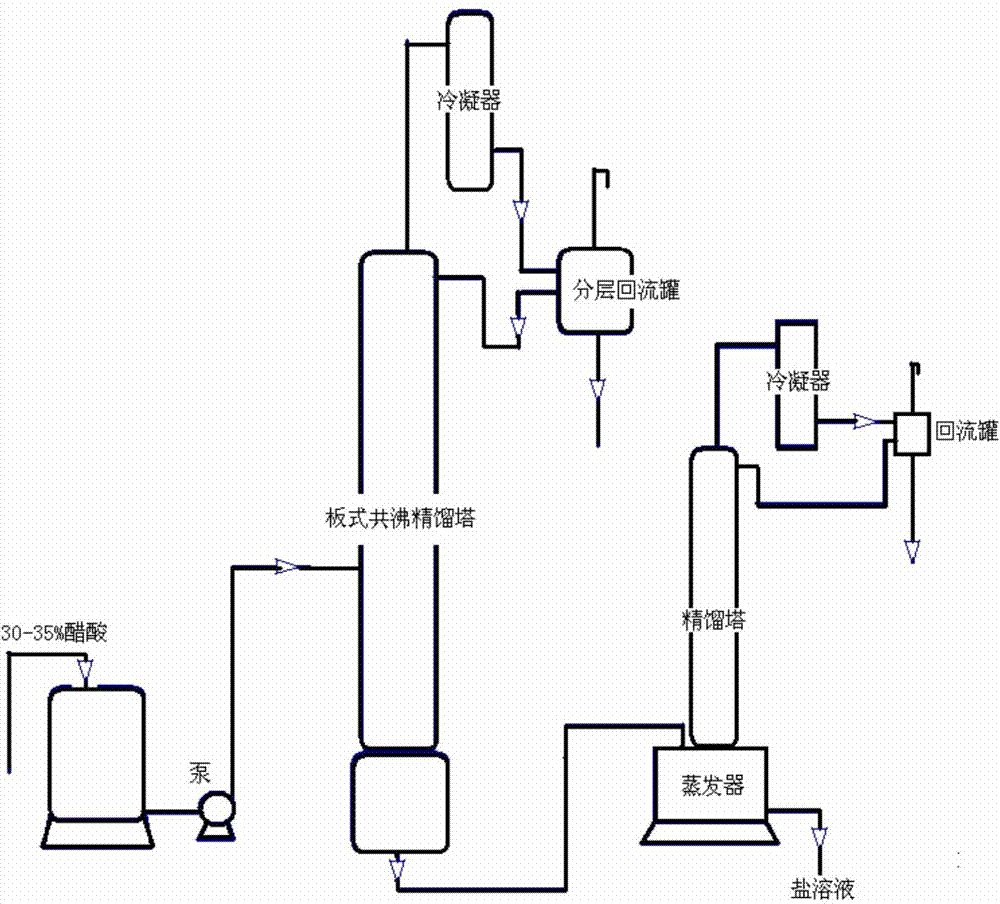

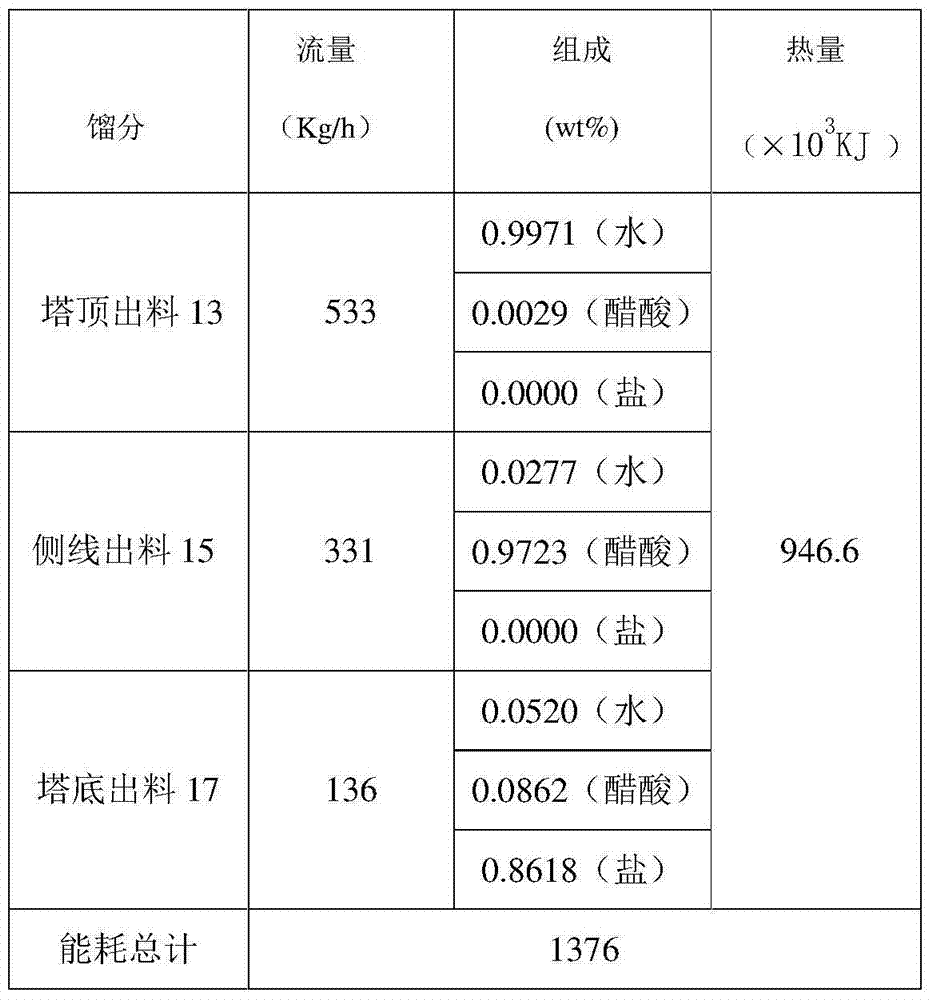

Method for extracting acetic acid in salt-containing acetic acid aqueous solution by one-sided line heat integration azeotropic rectification method

ActiveCN104844444ARealize comprehensive utilizationReduce consumptionCarboxylic compound separation/purificationRefluxAcetic acid ear

A method for extracting acetic acid in a salt-containing acetic acid aqueous solution by a one-sided line heat integration azeotropic rectification method is provided. The method is characterized in that, a raw material salt-containing acetic acid aqueous solution enters a rectifying still of a one-sided line azeotropic rectifying tower after being pre-heated by an overhead condenser and a side line condenser; an azeotropic agent, which is a mixed solution of cyclohexane and n-butyl acetate, is added to the one-sided line azeotropic rectifying tower from the top of the tower; after azeotropic rectification and separation, overhead steam is condensed in the overhead condenser, and then is layered in a liquid-liquid layering tank; a water phase is extracted, and an organic phase flows back to the one-sided line azeotropic rectifying tower; after a side line discharged material is condensed in the side line condenser, acetic acid is extracted; and a salt reducing chamber is disposed under the rectifying still, and a salt-containing solution is discharged. Under conditions that a proportion of cyclohexane to n-butyl acetate in the azeotropic agent is 1: 1, an overhead reflux ratio is controlled to be 2.5: 1, top temperature is 89.5 to 90.7 DEG C, temperature of a side line discharge hole is 117.3 to 118.1 DEG C, and bottom temperature is 123.4 to 125.7, content of acetic acid reaches more than 97%, yield reaches more than 98.0%, and energy consumption can be saved by about 53% compared with an azeotropic rectification and rectification combination method.

Owner:NANJING NORMAL UNIVERSITY

Integrated process for recovering acetic acid and methyl acetate in production process of aromatic carboxylic acid

ActiveCN102653512AReduce back flowReduce acetic acid contentOrganic compound preparationCarboxylic acid esters preparationAcetic acid earPhase splitter

The invention relates to an integrated process for recovering acetic acid and methyl acetate in a production process of aromatic carboxylic acid. The integrated process is as follows: water solution of acetic acid from an oxidation unit enters the upper part of a dehydrating tower, steam at the top of the dehydrating tower enters a condenser at the tower top for cooling, and concentrated acetic acid extracted from a tower kettle directly returns to an oxidation reactor; condensed fluid at the top of the dehydrating tower enters a phase splitter and is automatically splitted into an oil phase and a water phase, the oil phase enters an entrainer refining tower, methyl acetate is extracted from the tower top and is recovered, and the entrainer in the tower kettle returns to the top of the dehydrating tower; the water phase enters a methyl acetate recovering tower, methyl acetate extracted from the tower top and methyl acetate at the top of the entrainer refining tower are recovered together, water part in the tower kettle flows back to the top of the dehydrating tower, and part of water is extracted and treated. When the entrainer in the acetic acid of the tower kettle of the dehydrating tower is higher than 5 percent, the tower kettle material firstly enters an entrainer separating tower, the condensed acetic acid extracted from the tower top returns to the oxidation reactor, and excess entrainer is separated from the tower kettle. By utilizing the process, the quantity of the entrainer flowing back can be greatly reduced, and the oxidation reaction can be stably performed.

Owner:CHINA PETROLEUM & CHEM CORP +1

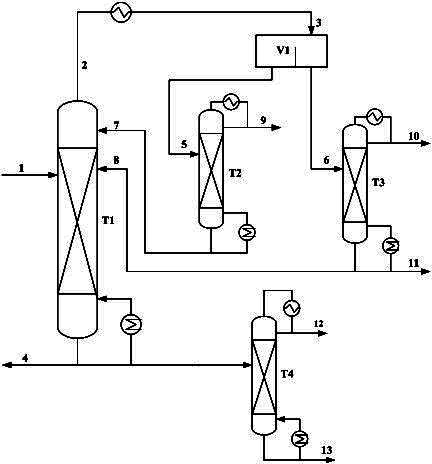

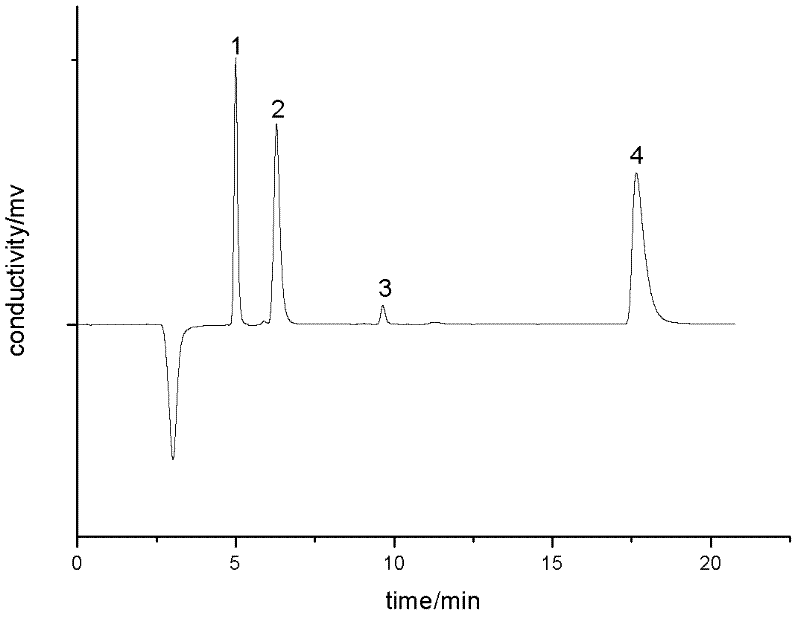

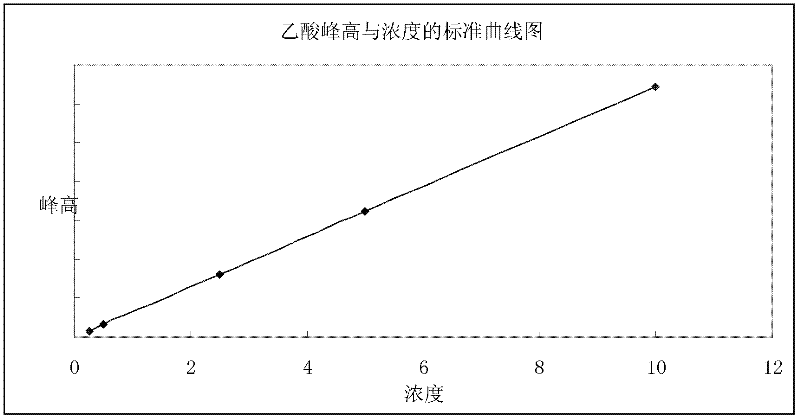

Method for simultaneous determination of dichloroacetic acid, gluconic acid and acetic acid in compound diisopropylamine dichloroacetate tablets by ion chromatography

ActiveCN102565212ASolve productivitySolve the problem of determining the content of impuritiesComponent separationSodium acetateAcetic acid

The invention discloses a method for simultaneous determination of dichloroacetic acid, gluconic acid and acetic acid in compound diisopropylamine dichloroacetate tablets by ion chromatography. The contents of dichloroacetic acid, gluconic acid and acetic acid in compound diisopropylamine dichloroacetate tablets aqueous solution are measured by ion chromatography, and then are converted to the contents of diisopropylamine dichloroacetate, sodium gluconate and sodium acetate by formulas. The method disclosed by the invention is used for monitoring a production process of compound diisopropylamine dichloroacetate tablets, has the characteristics of rapidness, simplicity, no interference, high accuracy and simplicity and feasibility in operation, and has strong practicability in improvement of pharmaceutical synthesis process and product quality control.

Owner:ANHUI WAYEE SCI & TECH CO LTD

Catalyst system for methanol low-pressure carbonyl synthesis of acetic acid and application thereof

ActiveCN101954295AImprove stabilityEasy to adjustOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionAcetic acid earSolvent

The invention relates to a catalyst system used for methanol low-pressure carbonyl synthesis of acetic acid, which uses rhodium compounds as the active component carbonylation of carbonyl synthesis catalyst and uses alkyl iodide, water, hydroiodic acid, alkali metal iodate and sulfonate as promoters, and uses acetic acid as polar solvent. Because sulfonate is added to the catalyst system, better catalytic activity and stability are achieved. In methanol carbonylation, the catalyst system can convert methanol into acetic acid at high speed with high selectivity under lower temperature and pressure. The reaction reduces the concentration of water and hydroiodic acid, and reduces corrosivity to equipment.

Owner:HUALU ENG & TECH

Genetic engineering bacteria for producing PHA (polyhydroxyalkanoates) from acetic acid and propionic acid as well as construction method and application of genetically engineering bacteria

ActiveCN108359628AReduce fermentation costsBacteriaMicroorganism based processesPropanoic acidAcetic acid ear

The invention discloses genetic engineering bacteria for producing PHA (polyhydroxyalkanoates) from acetic acid and propionic acid as well as a construction method and an application of the genetic engineering bacteria. The method for preparing the engineering bacteria for producing PHA comprises the following steps: improving expression and / or activity of acetokinase, phosphotransacetylase, PHA synthetase, beta-ketothiolase, acetoacetyl-CoA reductase, succinate hemiacetal dehydrogenase, 4-hydroxybutyrate dehydrogenase, 4-hydroxybutyl CoA:CoA-transferase and propionyl CoA transferase in recipient bacteria, and reducing expression and / or activity of non-CoA-cycle succinate hemiacetal dehydrogenase in the recipient bacteria to obtain the engineering bacteria for producing PHA, wherein the recipient bacteria can grow with acetic acid as a carbon source. The prepared engineering bacteria are used for producing PHA with acetic acid as the carbon source, PHA yield can reach a higher level, and the bacteria have better industrial application prospect. The genetic engineering bacteria have great application value.

Owner:BEIJING UNIV OF CHEM TECH

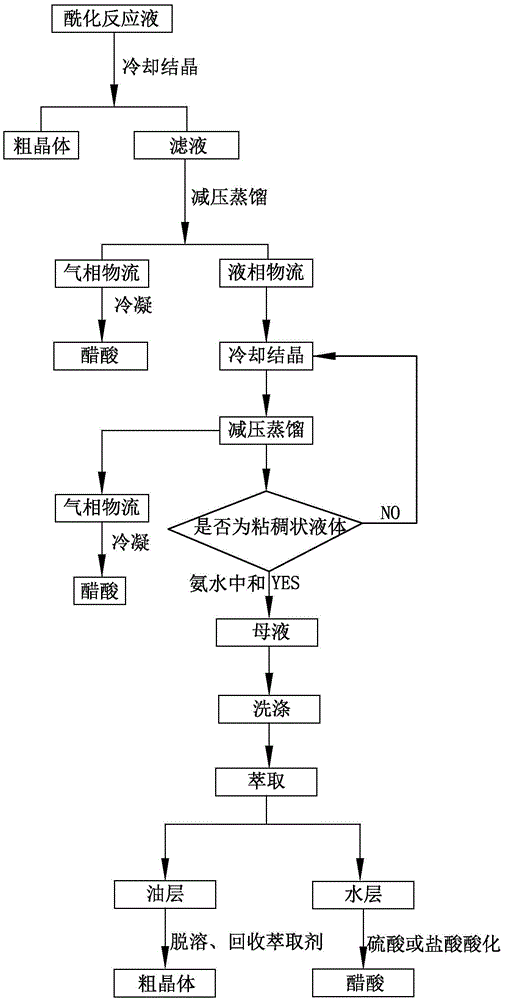

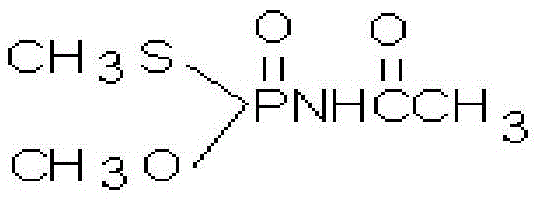

Separation method for acetic acid in acylation reaction liquid

InactiveCN105541604AEasy to separateReduce decomposition lossCarboxylic compound separation/purificationAcetic acid earDistillation

The invention provides a separation method for acetic acid in acylation reaction liquid. The method comprises the following steps of 1, performing cooling crystallization on the acylation reaction liquid to separate coarse crystals and filtrate by adopting a cooling crystallization process; 2, performing reduced pressure distillation on the filtrate to separate a gas-phase material flow and a liquid-phase material flow by adopting a reduced pressure distillation process, and condensing the obtained gas-phase material flow to obtain acetic acid; 3, recycling acetic acid from the liquid-phase material flow obtained in Step 2 by adopting an ammonia water neutralization method. According to the acetic acid separation method, most of acetic acid is directly recycled from the acylation reaction liquid by reduced pressure distillation, and a small amount of acetic acid is recycled by the ammonia water neutralization method, so that introduction of a water phase in an acetic acid direct recycling process is avoided, and production of wastewater and decomposition loss of acephate are reduced. The acetic acid separation method has a good separation effect, and an industrial requirement can be met.

Owner:XIANGTAN UNIV

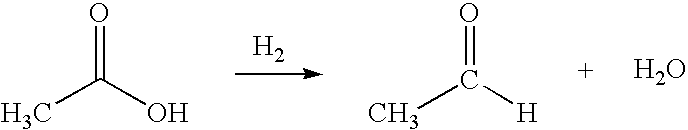

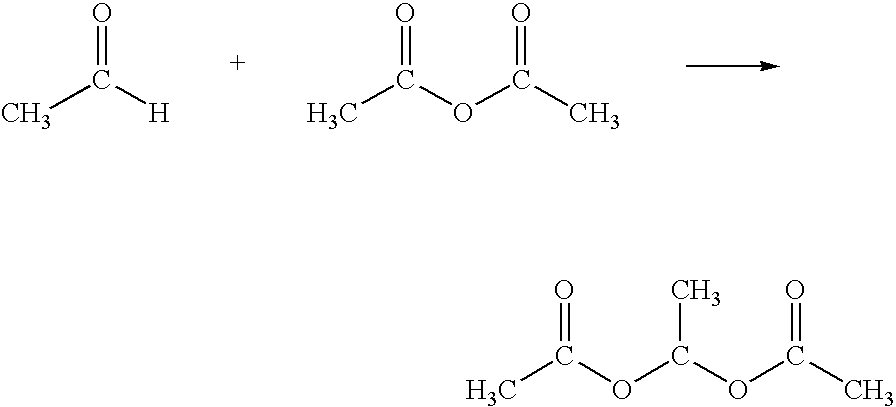

Integrated process for the production of vinyl acetate from acetic acid via acetaldehyde

This invention provides an integrated multistep economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form acetaldehyde. Acetaldehyde so formed can be converted to ethylidene diacetate via reaction with acetic anhydride. In a subsequent step so formed ethylidene diacetate is thermally decomposed to form VAM and acetic acid. Alternatively, acetaldehyde formed in the first step can selectively be reacted with ketene to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C., which is selectively hydrogenated over platinum supported catalyst to form ethanol and dehydrated over NAFION catalyst to form ethylene at a temperature of about 185° C., which is mixed with molecular oxygen, acetic acid and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

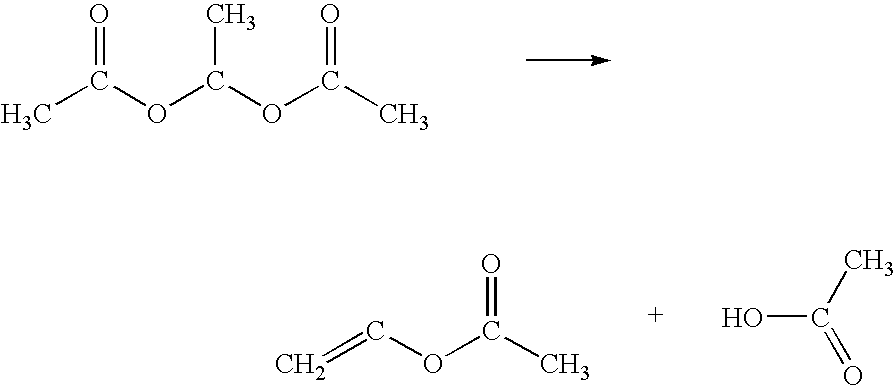

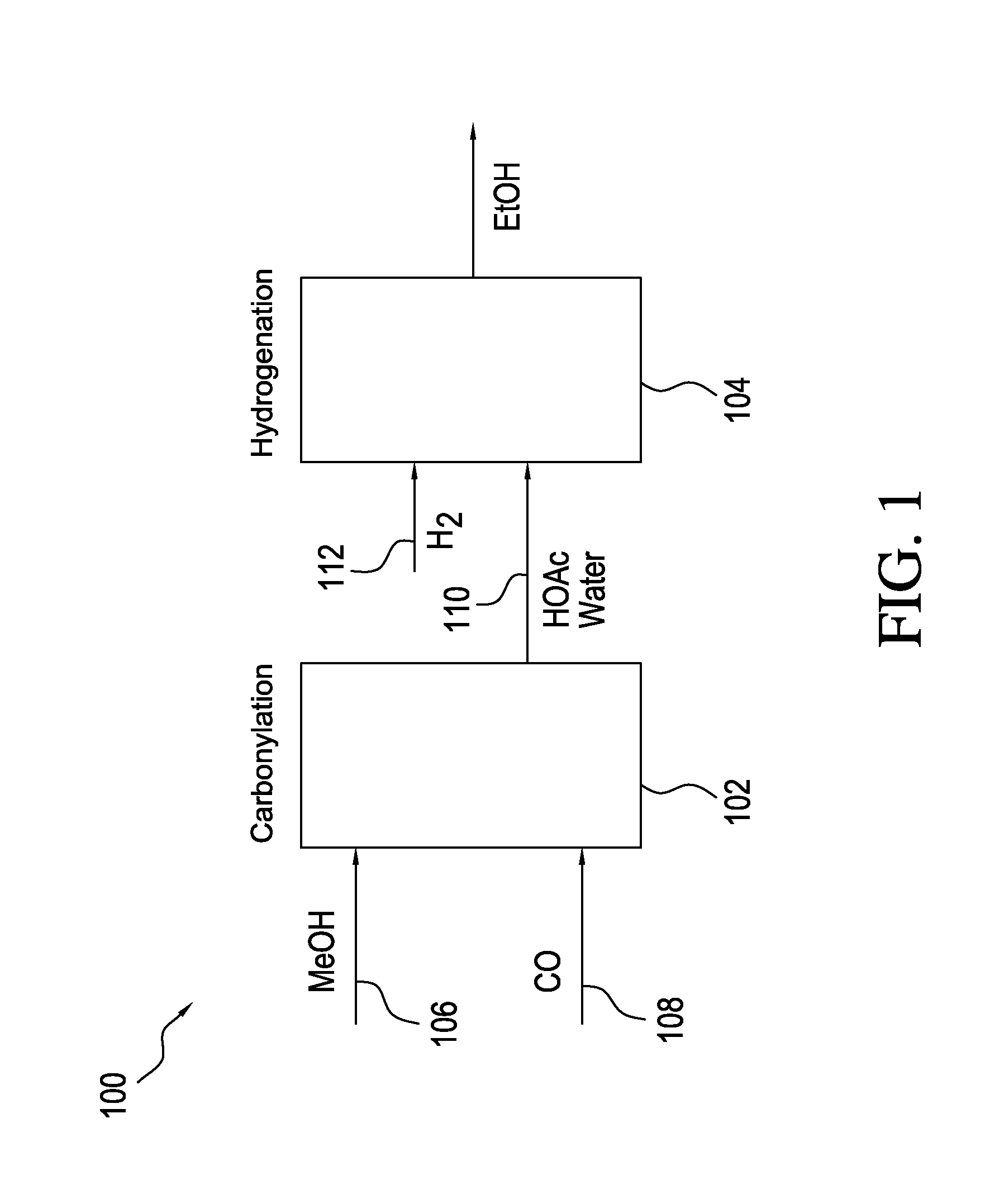

Alcohol production process integrating acetic acid feed stream comprising water from carbonylation process

InactiveUS20120059197A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidDistillation

In one embodiment, the invention is to a process for producing ethanol, comprising the step of providing from a distillation column in a carbonylation process a purified acetic acid stream comprising up to 25 wt. % water. The process further comprises the step of hydrogenating acetic acid of the purified acetic acid stream in the presence of a catalyst and under conditions effective to form a crude ethanol product comprising ethanol and water. Ethanol is recovered from the crude ethanol product.

Owner:CELANESE INT CORP

Method for preparing ethanol by hydrogenating acetic acid

ActiveCN105646148ALow priceReduce manufacturing costPhysical/chemical process catalystsOrganic compound preparationTransition metal carbidesAcetic acid

The invention discloses a method for preparing ethanol by hydrogenating acetic acid. The method comprises the following steps of mixing the acetic acid and hydrogen under the conditions that the temperature is 250 to 400DEG C, the pressure is 0.5 to 10.0MPa, the weight hourly space velocity is 0.2 to 8.0h<-1>, and the feeding mole ratio of the hydrogen to the acetic acid is 1:1 to 20:1; performing contact reaction on a mixture and a loaded transition metal carbide catalyst; hydrogenating the acetic acid to prepare the ethanol. The method disclosed by the invention has the advantages that the process flow is simple, the price of the catalyst is lower, the performance stability of the catalyst is good, and the stable operation time of the device is long; frequent switching operation of reaction and regeneration of a reactor can be avoided, the catalyst can be regenerated, posttreatment of a large amount of waste catalysts can be avoided, and further the influence on the environment is little.

Owner:ZHEJIANG UNIV OF TECH

Method for production of ethanol by direct hydrogenation of acetic acid

InactiveCN104211569AEasy to separateImprove qualityOrganic compound preparationHydroxy compound separation/purificationAcetic acidAlcohol

Belonging to the field of production technologies for alcohol substances, the invention discloses a method for production of ethanol by direct hydrogenation of acetic acid. In order to solve the defects of an ethanol purification process in the prior art, improve the ethanol product quality and reduce energy consumption, the inventor specifically puts forward a technological process through in-depth and meticulous research. The process includes: subjecting acetic acid to direct hydrogenation to obtain a crude ethanol product, then removing ketone components, separating unreacted acetic acid and ethyl acetate, and removing water in order, thus obtaining the ethanol product. The method provided by the invention can effectively separate ketone, acetaldehyde and other substances generated in the hydrogenation process, thus facilitating improving the separation effect of a distillation tower and effectively reducing impurities in the product. Therefore, the quality of the final ethanol product can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com