Patents

Literature

66 results about "Hydrogen peroxide product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Its structural formula is: Pure hydrogen peroxide is a colourless liquid, but it is sold on the market as solutions in water, containing up to 33 – 37% pure hydrogen peroxide and other additives to stop the product decomposing.

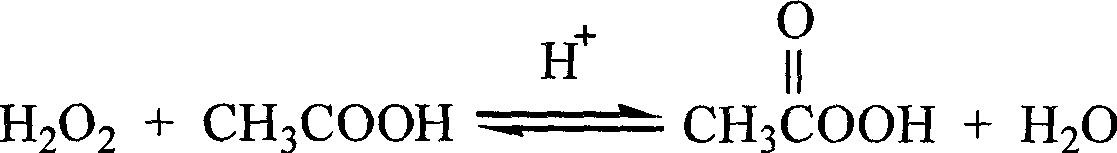

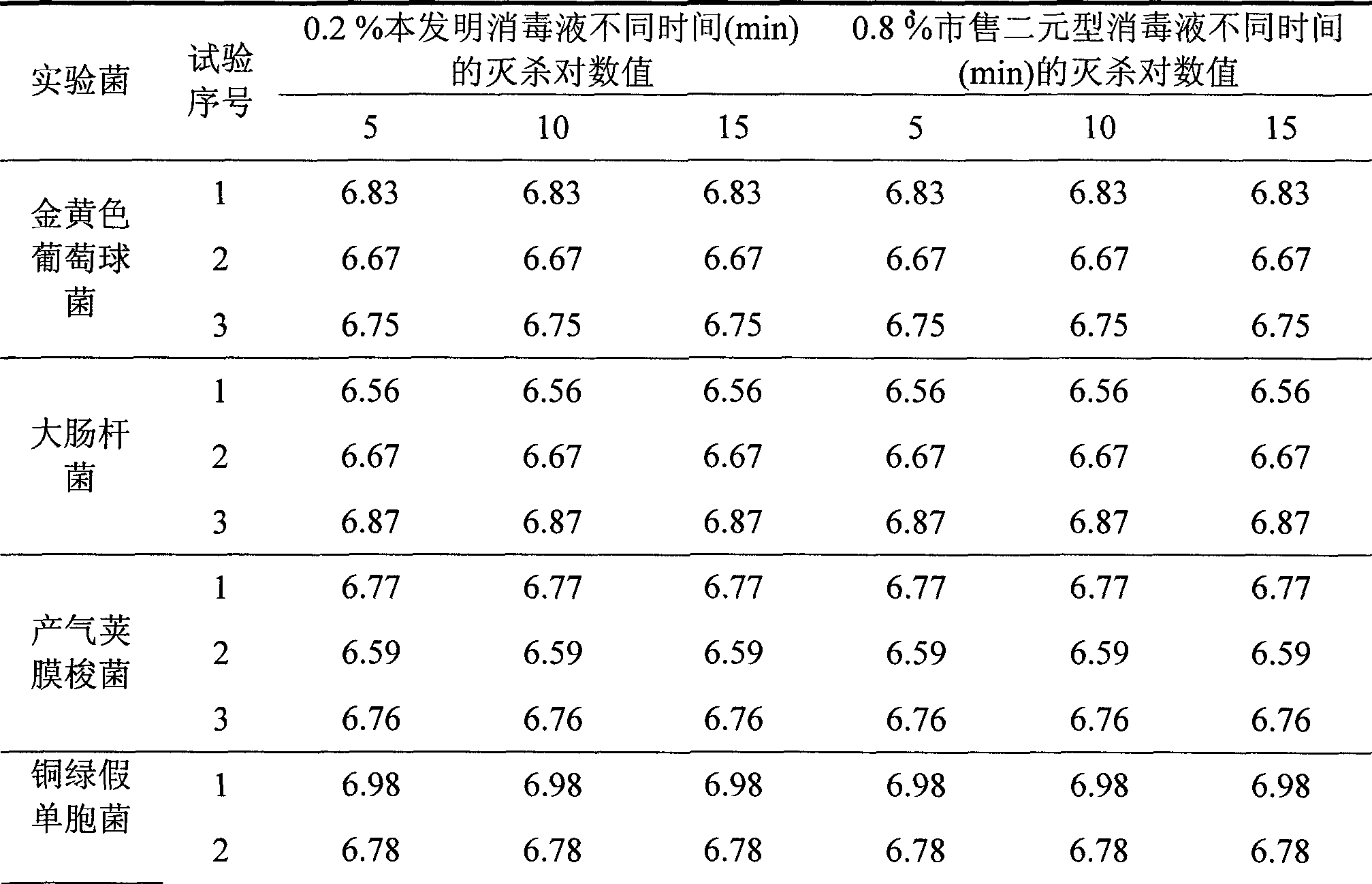

Hydrogen peroxide and peracetic acid mixed disinfectant and preparation method thereof

InactiveCN103843817AEasy to sterilizeImprove sterilization effectBiocidePeroxide active ingredientsAcetic acidDisinfectant

The invention relates to a hydrogen peroxide and peracetic acid mixed disinfectant and a preparation method of the disinfectant. The disinfectant is prepared by the steps of mixing hydrogen peroxide, acetic acid and sulfuric acid at the room temperature to prepare mixture containing peracetic acid and hydrogen peroxide, feeding a stabilizer and a surface active agent into the mixture containing the peracetic acid and the hydrogen peroxide, and mixing. The mixed disinfectant comprises 3-9g / 100g peracetic acid, 20-35g / 100g hydrogen peroxide, 5-12g / 100g acetic acid, 0.1-2g / 100g sulfuric acid, 0.05-2g / 100g stabilizer, 0.05-2g / 100g surface active agent and the balance of water. The hydrogen peroxide and peracetic acid mixed disinfectant is good in stability, is capable of rapidly killing various microorganisms such as bacteria, mould, yeast, spores and the like, and is safe, non-toxic and free from secondary pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

High-purity hydrogen peroxide preparation

InactiveCN1439600AMeet the requirements of cleaning agentsSolve the problem of relying on importsIon-exchange column/bed processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSemiconductor chipCleansing Agents

A process for preparing high-purity hydrogen peroxide from the aqueous solution of industrial hydrogen peroxide includes such steps as contacting with strong-alkaline macroreticular anionic exchange resin, contacting with strong-acidic macroreticular cationic exchange resin, contacting with mixed ionic exchange resin, and filtering via microfilter membrane. Its advantages are colourless, no order, high stability and purity, and low cost. It can be used as detergent for semiconductor chip.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hydrogen peroxide working solution and its application in preparation of hydrogen peroxide

ActiveCN103588177AReduce solubilityImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention belongs to the technical field of hydrogen peroxide, and especially relates to a hydrogen peroxide working solution and its application in the preparation of hydrogen peroxide. The hydrogen peroxide working solution comprises 2-ethylanthraquinone having a mass concentration of 120-200g / L and an organic solvent, and the organic solvent comprises, by volume, 70-80% of a C9-C10 aromatic hydrocarbon, 14-20% of trioctyl phosphate, 4-10% of 2-methylcyclohexyl acetate and 0.4-0.9% of tertiary amine When the hydrogen peroxide working solution is used in the preparation of hydrogen peroxide, the hydrogen peroxide working solution can greatly improve the hydrogenation efficiency and the oxidation efficiency of 2-ethylanthraquinone, and has the advantages of low production cost, no peculiar smell and product yield improvement.

Owner:WEIFANG MENJIE CHEM

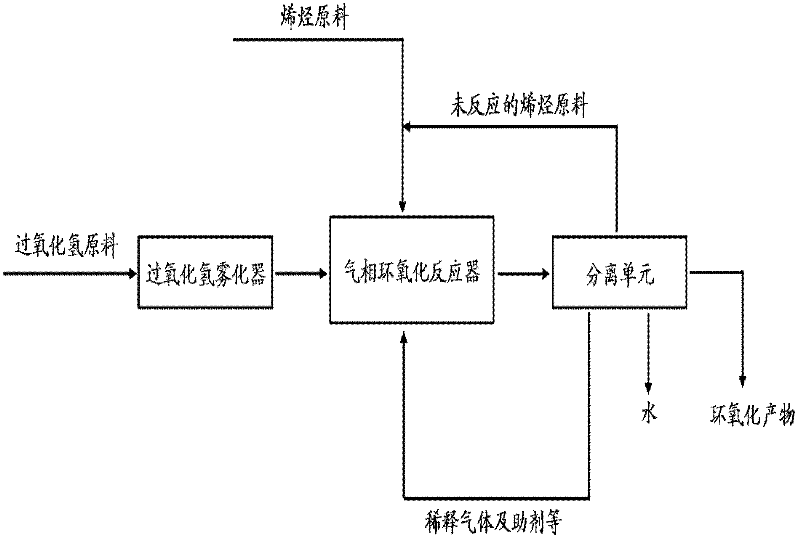

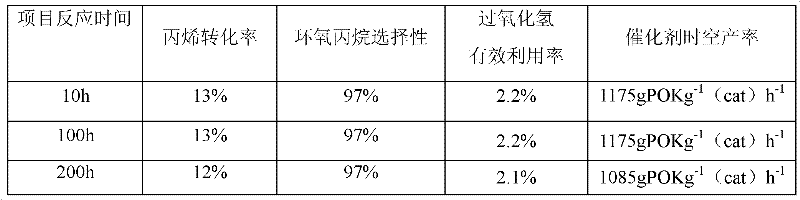

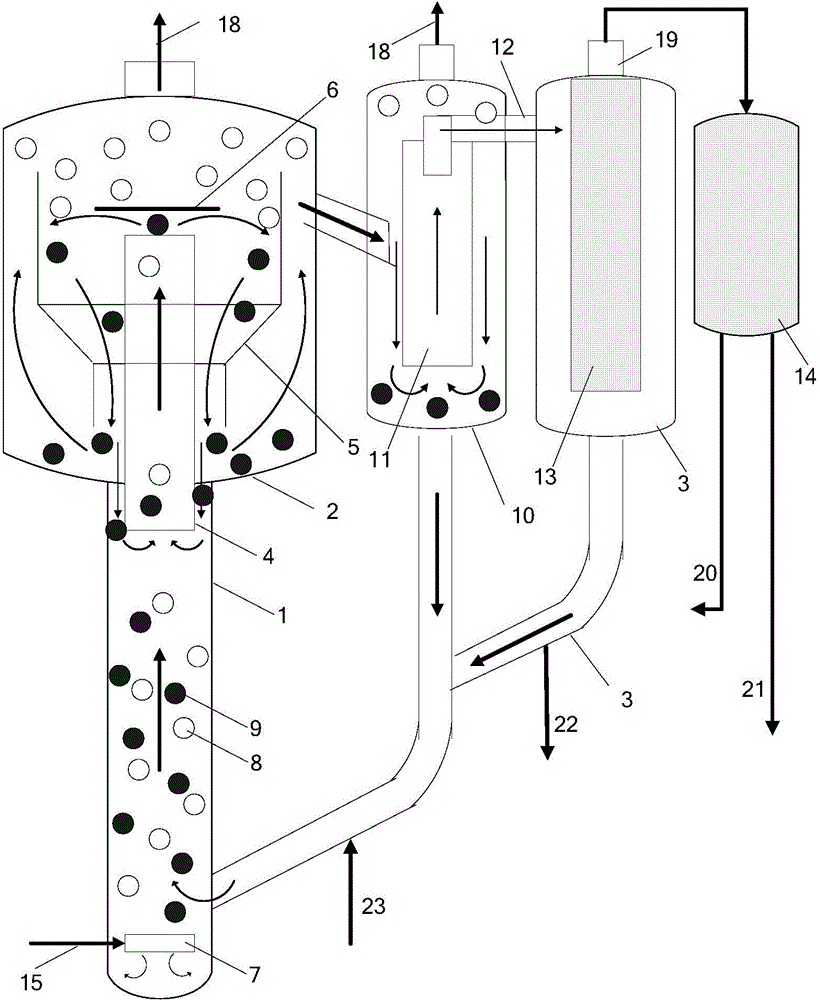

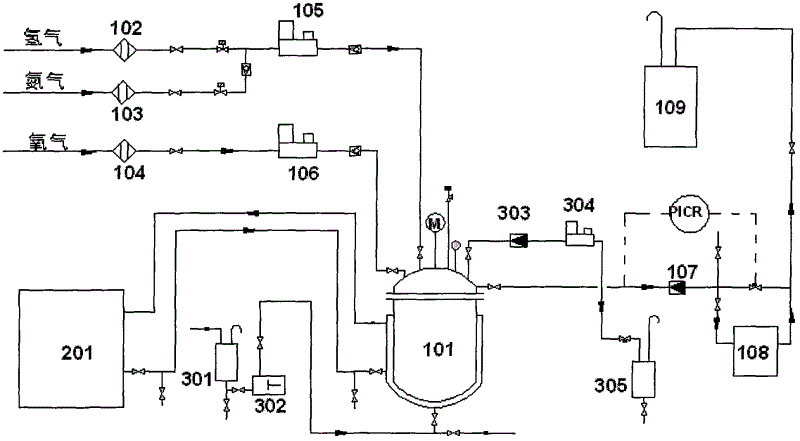

Device and method for performing olefin gaseous phase epoxidation by using industrial hydrogen peroxide

ActiveCN102532063AImprove stabilityVaporized Hydrogen Peroxide SafeOrganic chemistryChemical recyclingAlkeneMetal

The invention belongs to the technical field of organic chemical catalytic synthesis, which relates to a device and a method for performing olefin gaseous phase epoxidation by using industrial hydrogen peroxide. A reactor casing of the device is made of metal materials, the inner wall contacted with the hydrogen peroxide is passivated through acid solution, or the inner wall is coated with hydrogen peroxide inert materials. The processed raw material enters a reactor to perform reaction along with feeding materials of the olefin raw material, diluent gas, auxiliaries and the like, and after reacted materials pass through a separation unit, unreacted olefin raw material, the diluent gas and auxiliaries circulate back to the reactor. The device and the method directly use industrial hydrogen peroxide products, overcome bottlenecks of low efficiency, fast catalytic agent inactivation and poor regeneration repeatability of in-situ hydrogen peroxide preparation, are strong in raw material adaptability, safe and high in efficiency, few in gaseous phase epoxidation reactive by-product, simple in separation and high in catalyst stability.

Owner:DALIAN QIYUAN TECH CO LTD

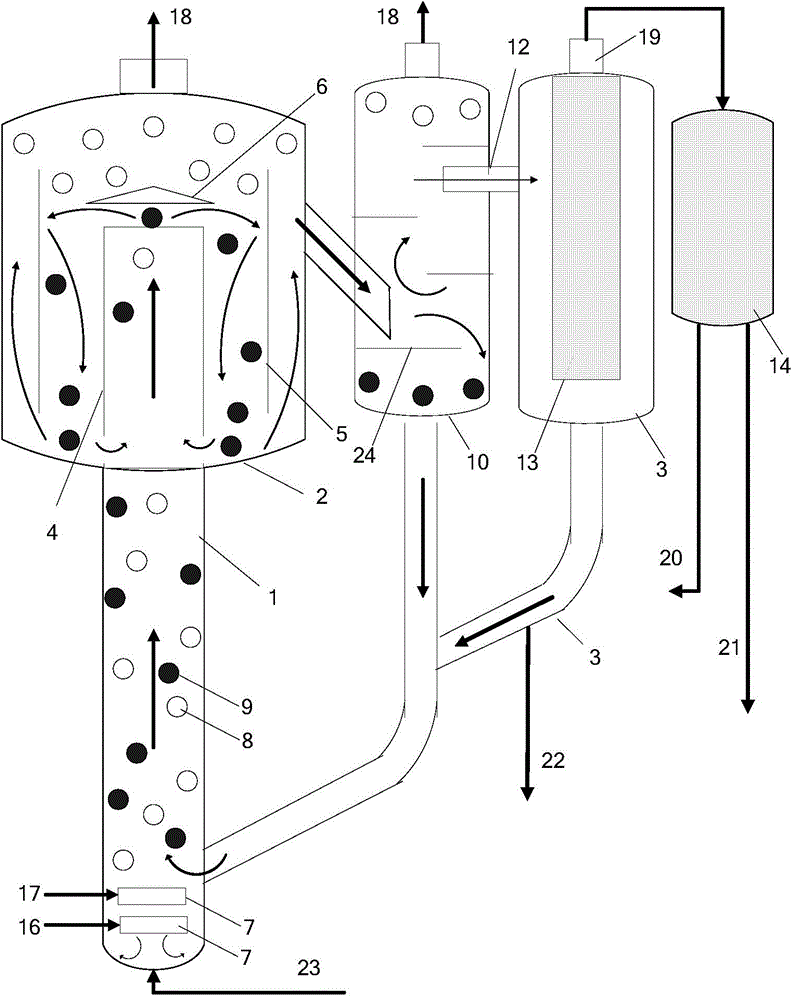

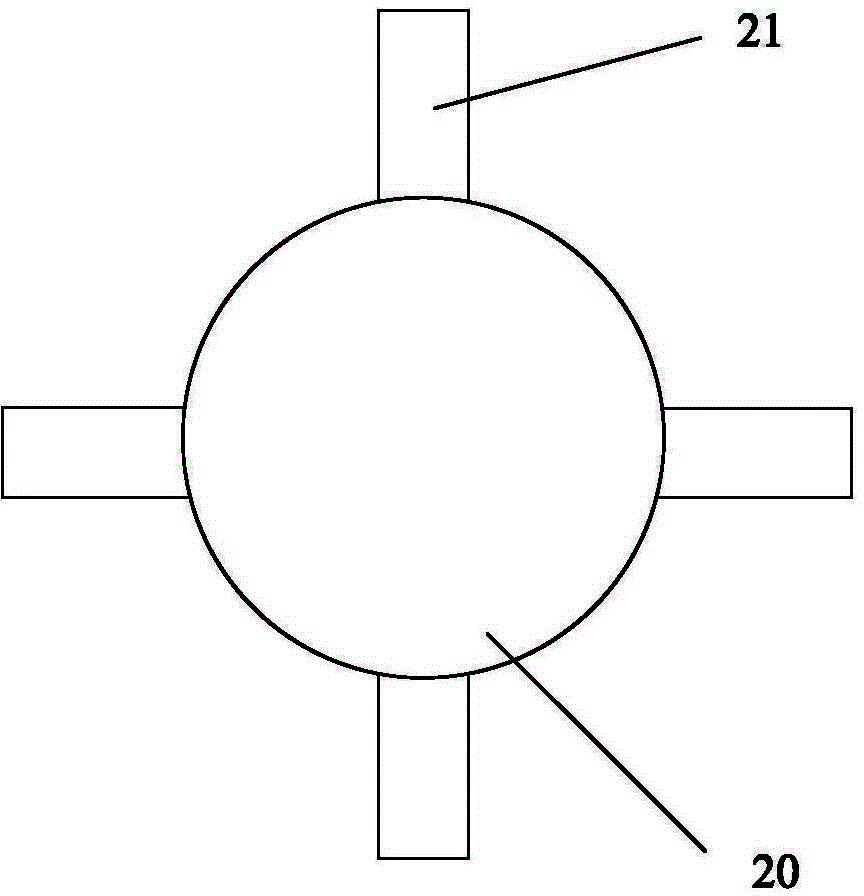

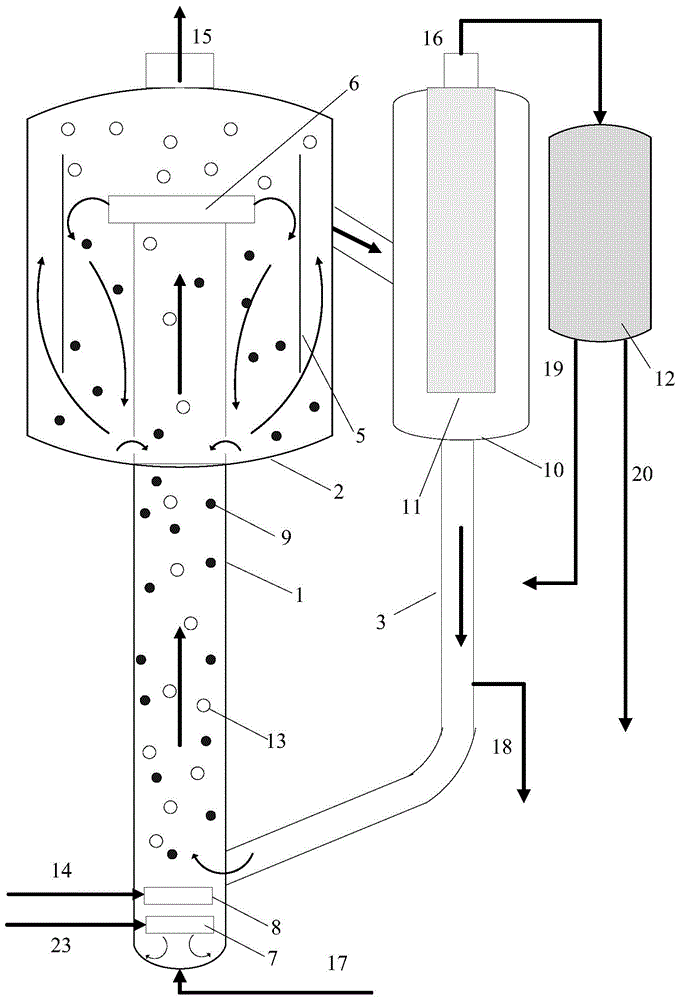

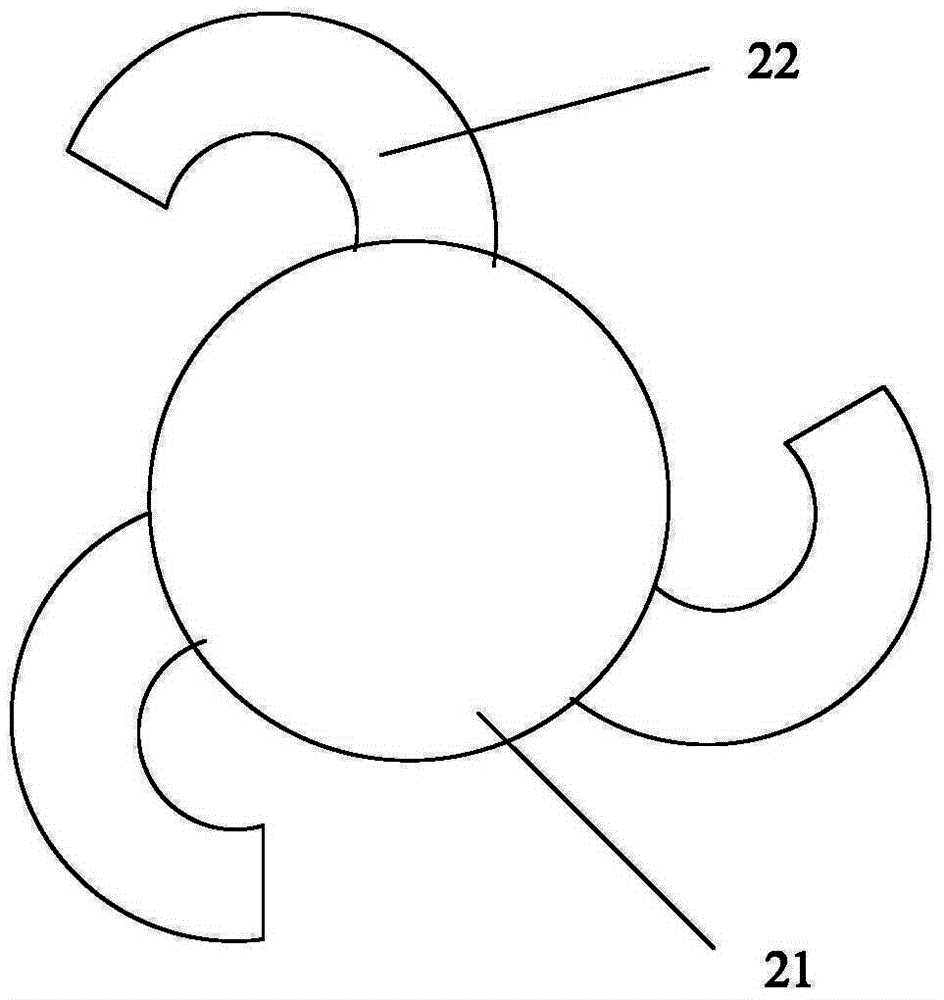

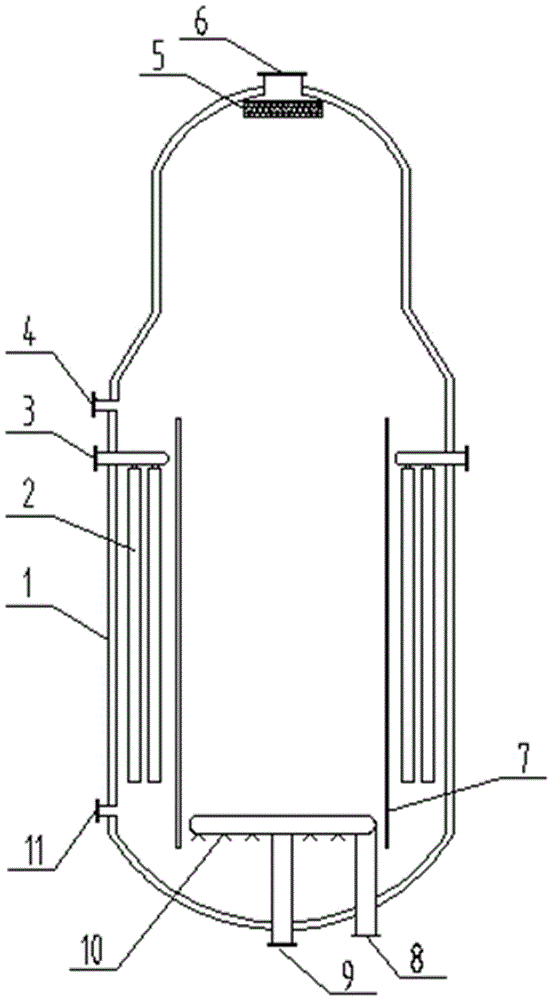

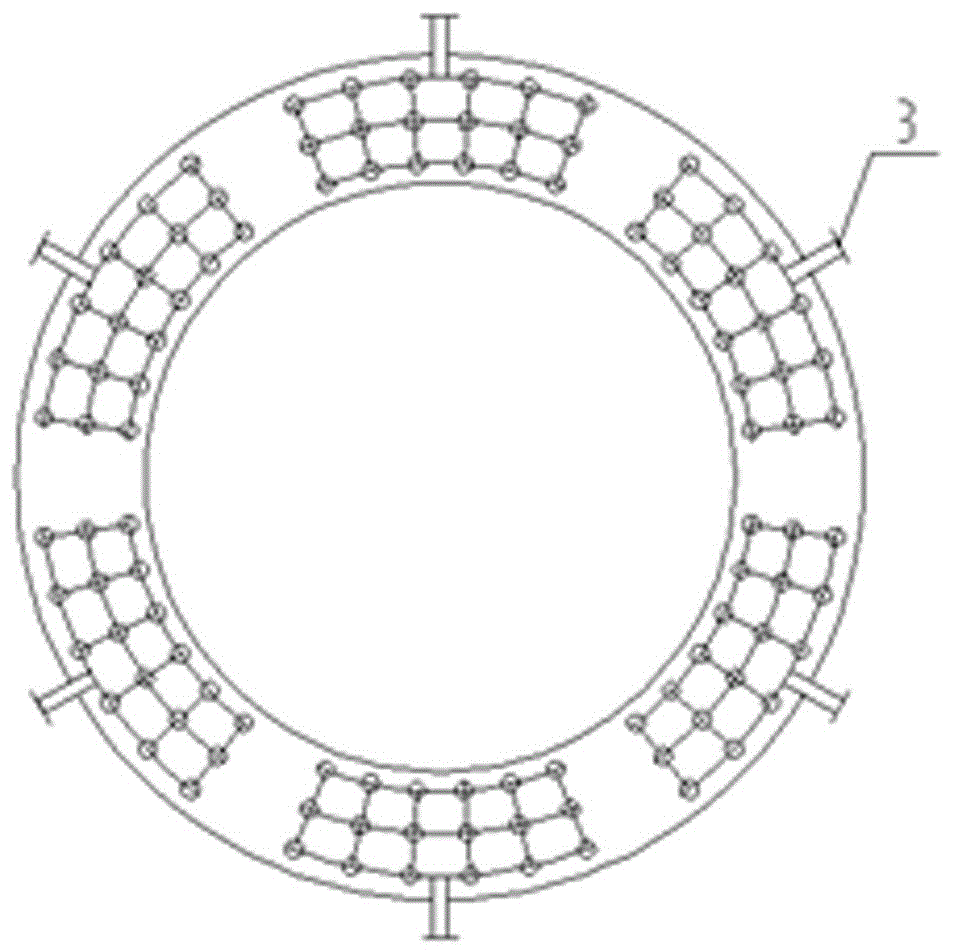

Slurry bed loop reactor, application and method for producing hydrogen peroxide

ActiveCN104549060AExtended operating cycleEasy to separatePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention relates to a slurry bed loop reactor, application and a method for producing hydrogen peroxide. The slurry bed loop reactor comprises a riser, a separation tank and a downcomer which are communicated sequentially, wherein an expansion section with expanded pipe diameter is arranged at the upper part of the riser, the upper part of the expansion section is communicated with the separation tank, a liquid phase outlet in the upper part of the separation tank is communicated with the upper part of the downcomer, the bottom of the downcomer is communicated with the bottom of the riser, and the bottom of the separation tank is communicated with the lower part of the downcomer; and a raw material inlet is formed in the bottom of the riser, gas outlets are formed in the top of the expansion section of the riser and in the top of the separation tank, a filtration component is arranged in the downcomer and a clear liquid outlet is formed in the upper part of the downcomer via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loop reaction device in slurry bed, application and method for producing hydrogen peroxide

ActiveCN104549066AExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

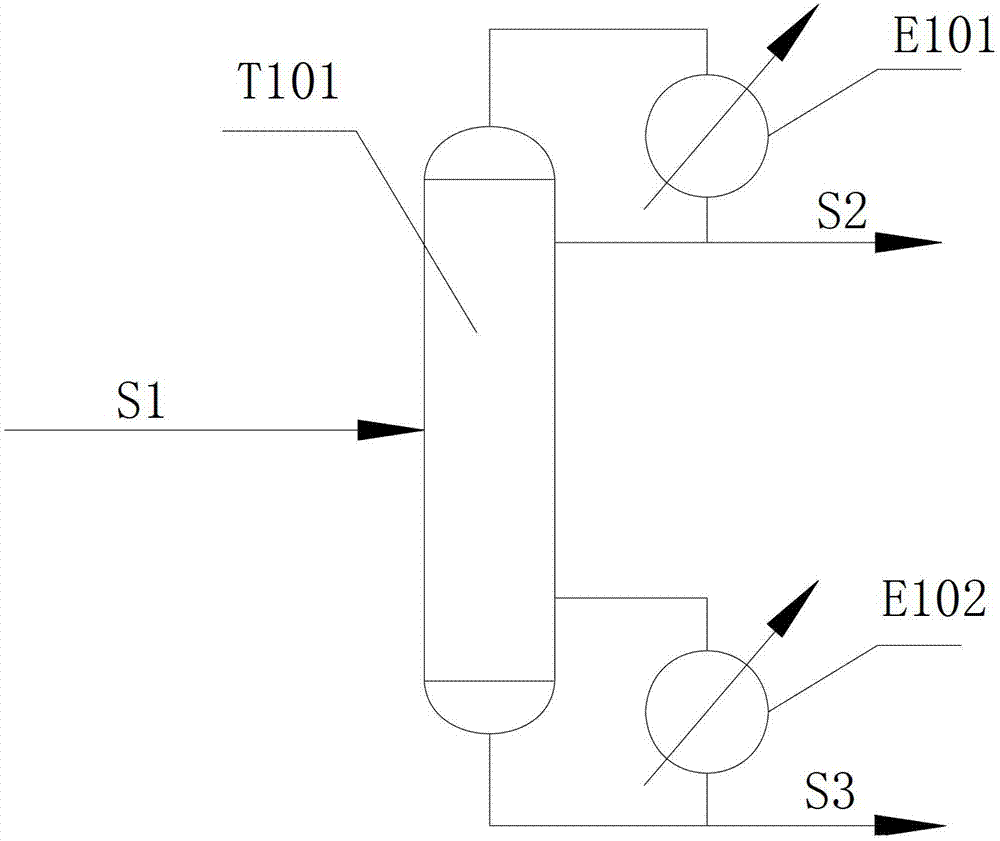

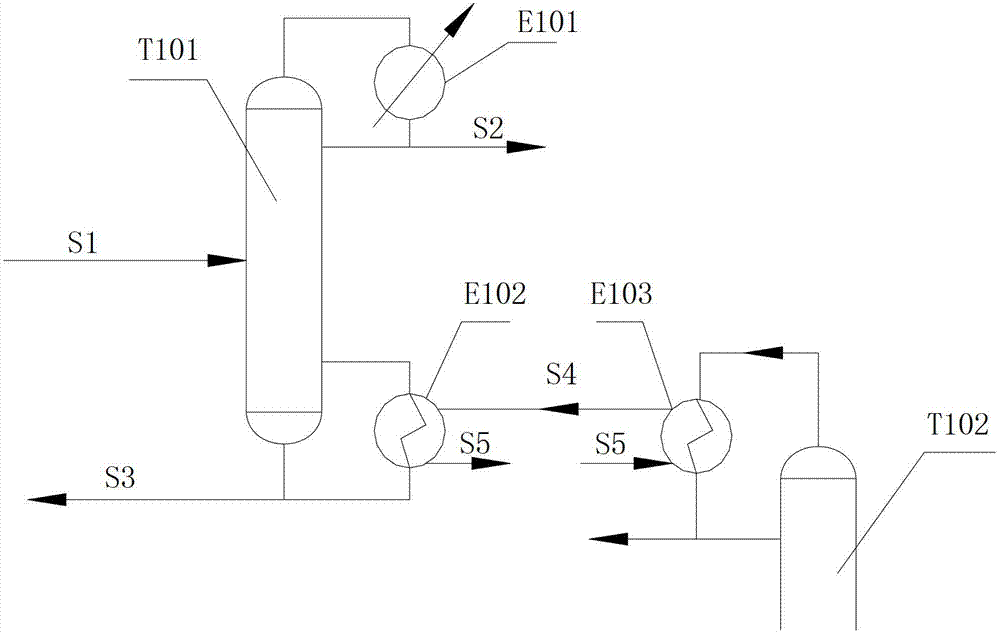

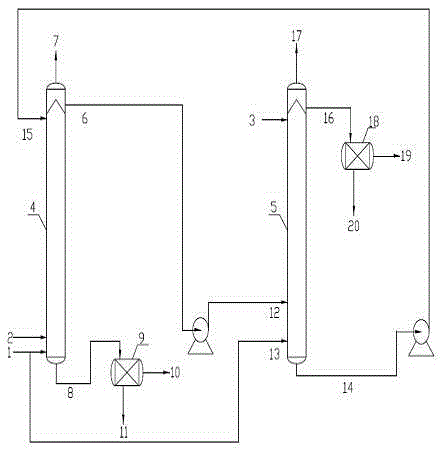

System and method for concentrating and purifying hydrogen peroxide

ActiveCN102757019AAvoid contactReduce investmentPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesEnergy inputGas phaseReboiler

The invention relates to a system and a method for concentrating and purifying hydrogen peroxide. A hydrogen peroxide concentration rectifying tower T101 is provided with a feed port; the tower top is connected with an inlet of a condenser E101; one part at the outlet of the condenser E101 is recovered and the other part at the outlet of the condenser E101 returns to a tower top reflux substance inlet of the hydrogen peroxide concentration rectifying tower T101; one part at the bottom of the hydrogen peroxide concentration rectifying tower T101 is recovered and the other part at the bottom of the hydrogen peroxide concentration rectifying tower T101 is connected with an inlet of a hydrogen peroxide concentration tower bottom reboiler E102; and an outlet of the hydrogen peroxide concentration tower bottom reboiler E102 is connected with a reflux substance inlet at the bottom of the hydrogen peroxide concentration rectifying tower T101. The method comprises the following steps: mixing 25 to 35 weight percent of hydrogen peroxide serving as a raw material with a stabilizing agent; feeding into the hydrogen peroxide concentration rectifying tower T101; and allowing the top gas phase to enter the condenser E101 to obtain the hydrogen peroxide product at the concentration of more than or equal to 50 weight percent. The system and the method adopts continuous operation and are suitable for large-scale industrial production; heating mediums are steam and soft water, so contact of organic materials and the hydrogen peroxide is avoided and the system and the method are safe and reliable; and the afterheat in a factory serves as the heat source of the rectifying tower, so low-grade energy is utilized, the public engineering investment is saved, and energy consumption is reduced.

Owner:TIANJIN UNIV

Method for preparing 2,6-dichloro-4-nitroaniline through direct chlorination of chlorine gas and oxidative chlorination of hydrogen peroxide

ActiveCN104610071AThe concentration of hydrochloric acid does not changeThe reaction process is stable and easy to controlOrganic compound preparationAmino compound preparationP-NitroanilineReaction system

The invention relates to a method for preparing 2,6-dichloro-4-nitroaniline through direct chlorination of chlorine gas and oxidative chlorination of hydrogen peroxide. The method comprises the following steps: (1) adding paranitroaniline into hydrochloric acid at the concentration of 5-35wt%, heating to 40-80 DEG C, stirring for uniformly mixing, slowly inflating the chlorine gas within 0.5-5h, slowly adding hydrogen peroxide dropwise, and after adding the chlorine gas and the hydrogen peroxide, continuing to preserve heat and react for 0.3-1.5h; (2) filtering a product obtained in the step (1), washing a filter cake to be neutral, and drying to obtain the 2,6-dichloro-4-nitroaniline. By regulating a dosage ratio of the chlorine gas to the hydrogen peroxide, the concentration of the hydrochloric acid in a reaction system can be kept unchanged, the reaction process is steady and easily controlled, and the product is high in yield and purity.

Owner:昌邑新澳化工有限公司

Precesses and compositions for direct catalytic hydrogen peroxide production

InactiveUS20050025697A1Hazard reductionUsed commerciallyHydrogen peroxideHydrogenFirst-order reaction

A process is disclosed for the direct catalytic production of aqueous solutions of hydrogen peroxide from hydrogen and oxygen in the presence of a small amount of one or more water soluble organic additives (about 0.1-10% by weight). Suitable catalysts include nanometer-sized noble metal catalytic crystal particles. The catalyst particles preferably have a controlled surface coordination number of 2 to increase the selectivity of hydrogen peroxide production. The water soluble additive(s) increases catalytic activity causing significant increases in the apparent first order reaction rate constant for the direct production of aqueous hydrogen peroxide.

Owner:HEADWATERS TECH INNOVATION LLC

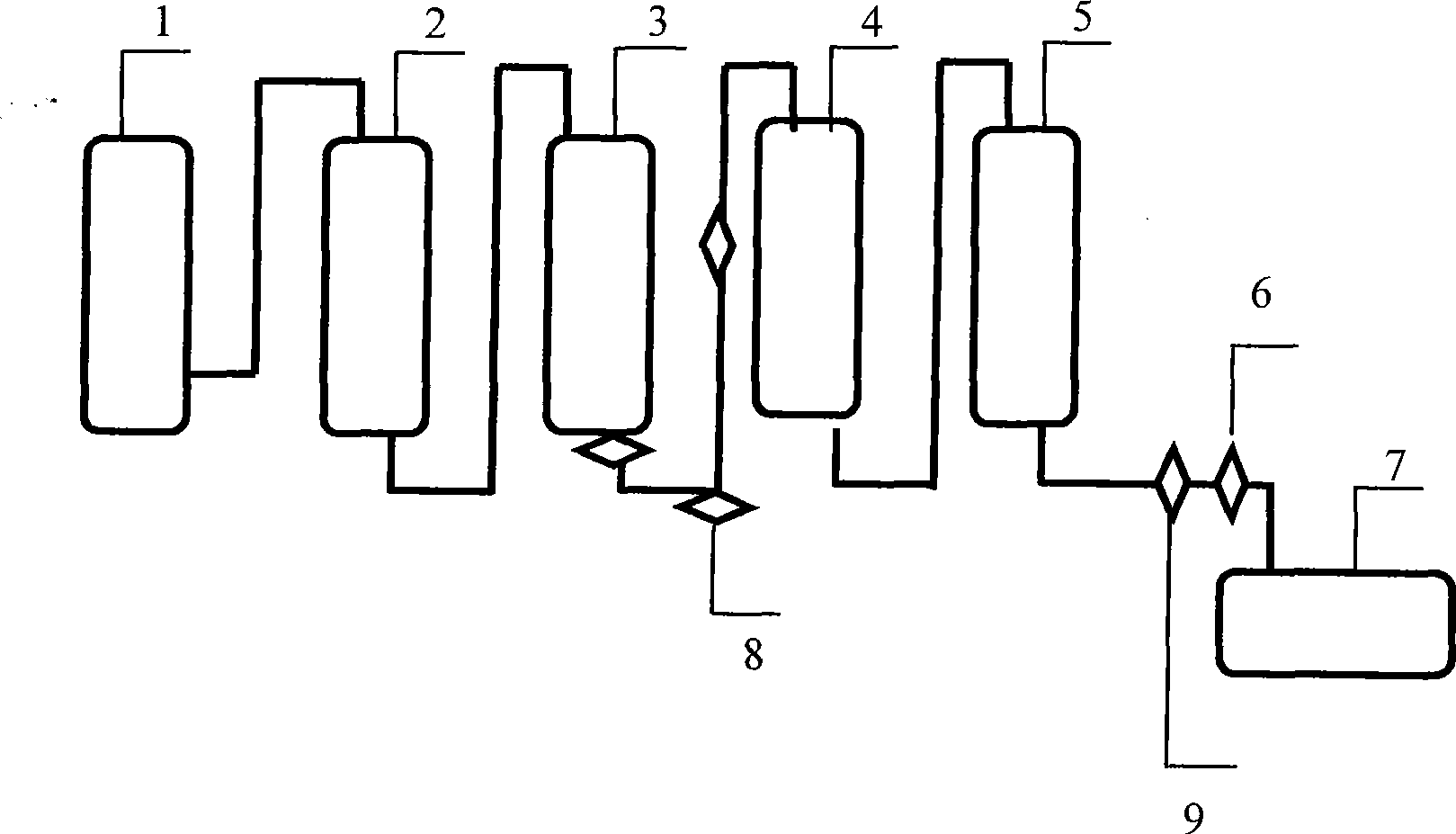

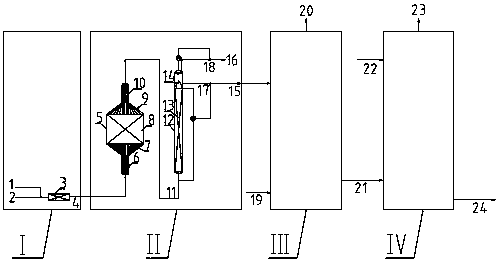

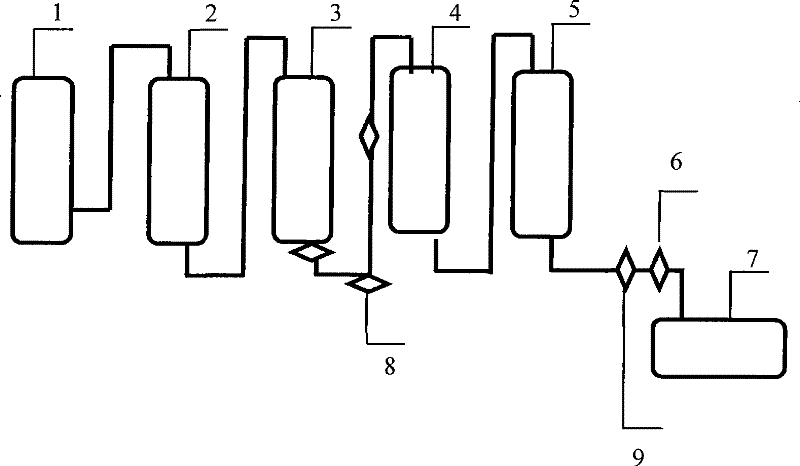

Preparation technique and device for ultra-pure hydrogen phosphide

ActiveCN101244810AReduce contentEfficient removalPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDistillationReverse osmosis

The invention provides a continuous production process for ultra-pure hydrogen peroxide, comprising the following steps: mixing the industrial hydrogen peroxide material with the modified active carbon; then classifying filter by microfiltration membrane and ultrafiltration membrane in sequence; the filtrate is pumped into the distillation column formed by a plurality of columns connected in series; adding metal ion complexing agent into the primary column; performing reverse osmosis on the semi-finished products out of the column before filtering by nanofiltration membrane to get ultra-pure hydrogen peroxide products. The device comprises the following parts: a raw material chute, an active carbon pre-mixer, a microfiltration and ultrafiltration filter, a distillation column formed by a plurality of columns connected in series, a reverse osmosis device, a nanofilter, a finished product receiver, a pump and a shaft; wherein, the raw material chute outlet is connected with the active carbon pre-mixer inlet; the microfiltration and ultrafiltration filter outlet is connected with the pump, the outlet of which is connected with the inlet of the distillation column formed by a plurality of columns connected in series; the outlet of the distillation column formed by a plurality of columns connected in series is connected with the inlet of the reverse osmosis device, the outlet of which is connected with the shaft; the outlet of the shaft is connected with the inlet of the nanofilter, the outlet of which is connected with the finished product receiver.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

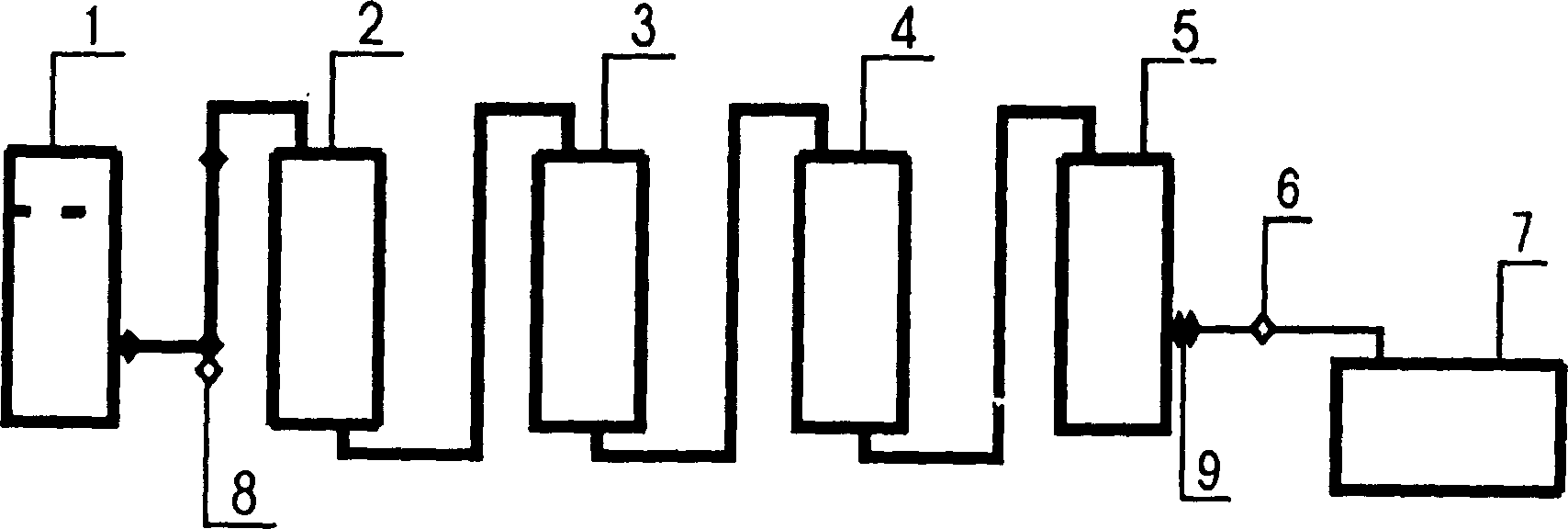

Purification continuous production process for high-purity hydrogen peroxide

InactiveCN1699144AOvercoming utilizationOvercoming separationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesIon exchangeCarbon adsorption

The invention relates to a purification continuous production process for high-purity hydrogen peroxide, which comprises preparing technical grade hydrogen peroxide raw material, feeding into macroporous adsorption resin column through pumps, carrying out organic carbon adsorption, feeding hydrogen peroxide into separate anion and cation exchange resin columns for ion exchange, inputting the hydrogen peroxide into anionic and cationic ion-exchange resin mixing column, carrying out ion exchange again, removing detrimental ionic impurities, inputting into polyvinylidene fluoride microfilter with a bore diameter of 0.05um to 0.1um, to as to remove the impurity substance.

Owner:李祥庆

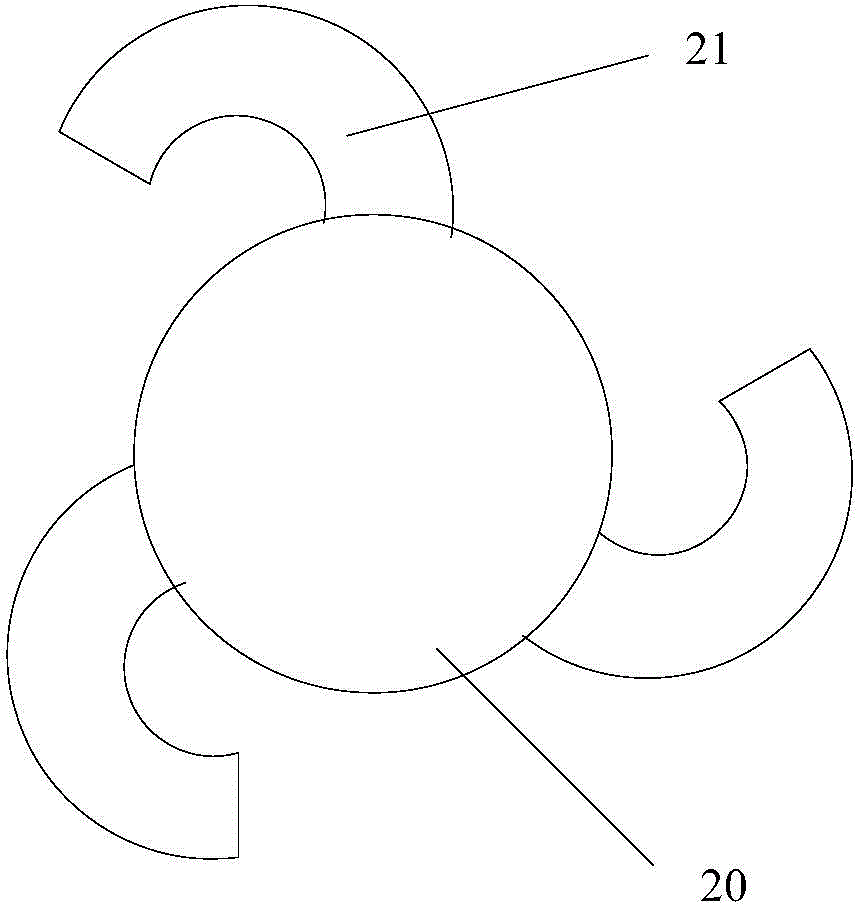

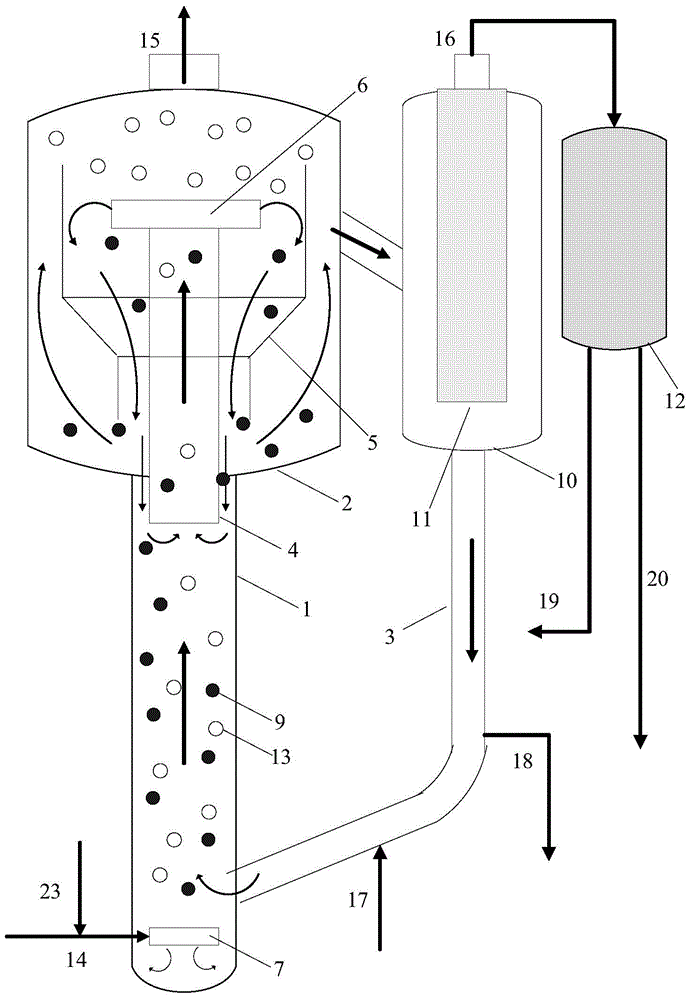

Slurry-bed circulation flow reactor and application and method for producing hydrogen peroxide

ActiveCN104549065AReduced chance of wear and tearIncrease concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention discloses a slurry-bed circulation flow reactor and an application and a method for producing hydrogen peroxide. The slurry-bed circulation flow reactor comprises an ascension pipe, an expanding section used for expanding pipe diameter of the upper part of the ascension pipe and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is communicated with the bottom of the ascension pipe; a three-phase separator of a double sleeve structure is arranged in the expanding section; a raw material inlet is formed in the bottom of the ascension pipe; a gas outlet is formed in the top of the expanding section; a filtration component is arranged in the solid-liquid separator; and a clear liquid outlet is arranged at the upper part of the solid-liquid separator by virtue of the filtration component. According to a method for producing hydrogen peroxide by taking the slurry-bed circulation flow reactor as a hydrogenation reactor, the gas-liquid-solid three-phase separation efficiency is high; the local excessive hydrogenation of the catalyst is avoided; the excessive hydrogenation possibility is reduced; the hydrogenation efficiency is high; and hydrogen peroxide products with high concentration can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

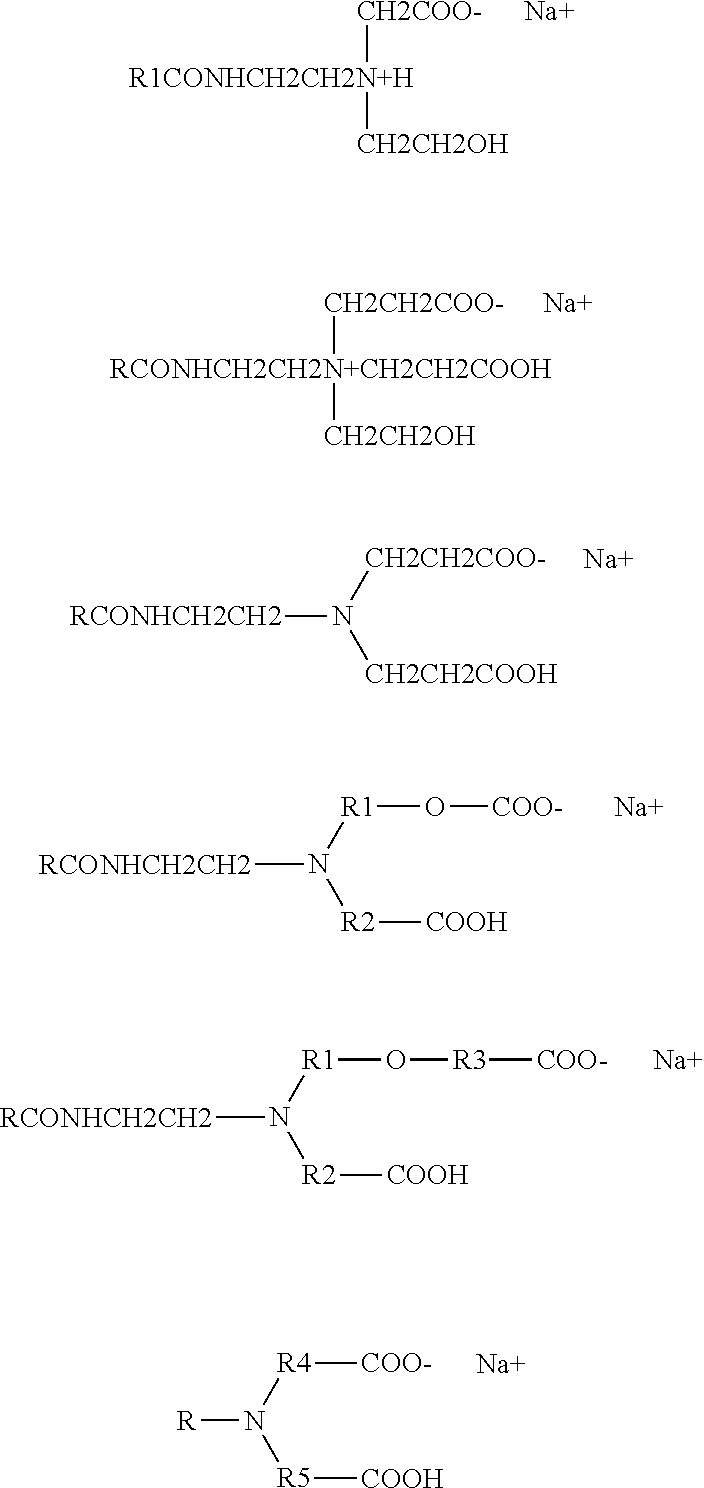

Hydrogen peroxide-based skin disinfectant

ActiveUS20110129435A1Increase attractivenessImprove propertiesCosmetic preparationsBiocideBetaineDisinfectant

A skin disinfectant in ready-to-use concentrated liquid or dry powdered form. Ready-to-use liquid forms have a pH of from about 2 to about 6 and include:(a) hydrogen peroxide in a concentration of from about 0.01 to about 4% w / w of the solution;(b) at least one surfactant chosen from imidazoline derivatives, alkyl betaines, alkyl amidopropyl betaine amides, alkyl amidopropyl betaines, alkylsulfo betaines, amine oxides and derivatives thereof in a concentration of from about 0.01 to about 15% w / w of the solution;(c) at least one hydrogen peroxide stabilizer in a concentration of from about 0.01 to about 4% w / w of the solution;(d) at least one member chosen from cyclic carboxylic acids and salts thereof in a concentration of from about 0.01 to about 4% w / w of the solution; and(e) at least one skin conditioning agent in a concentration of from about 0.01 to about 10% w / w of the solution.

Owner:JOHNSONDIVERSEY INC

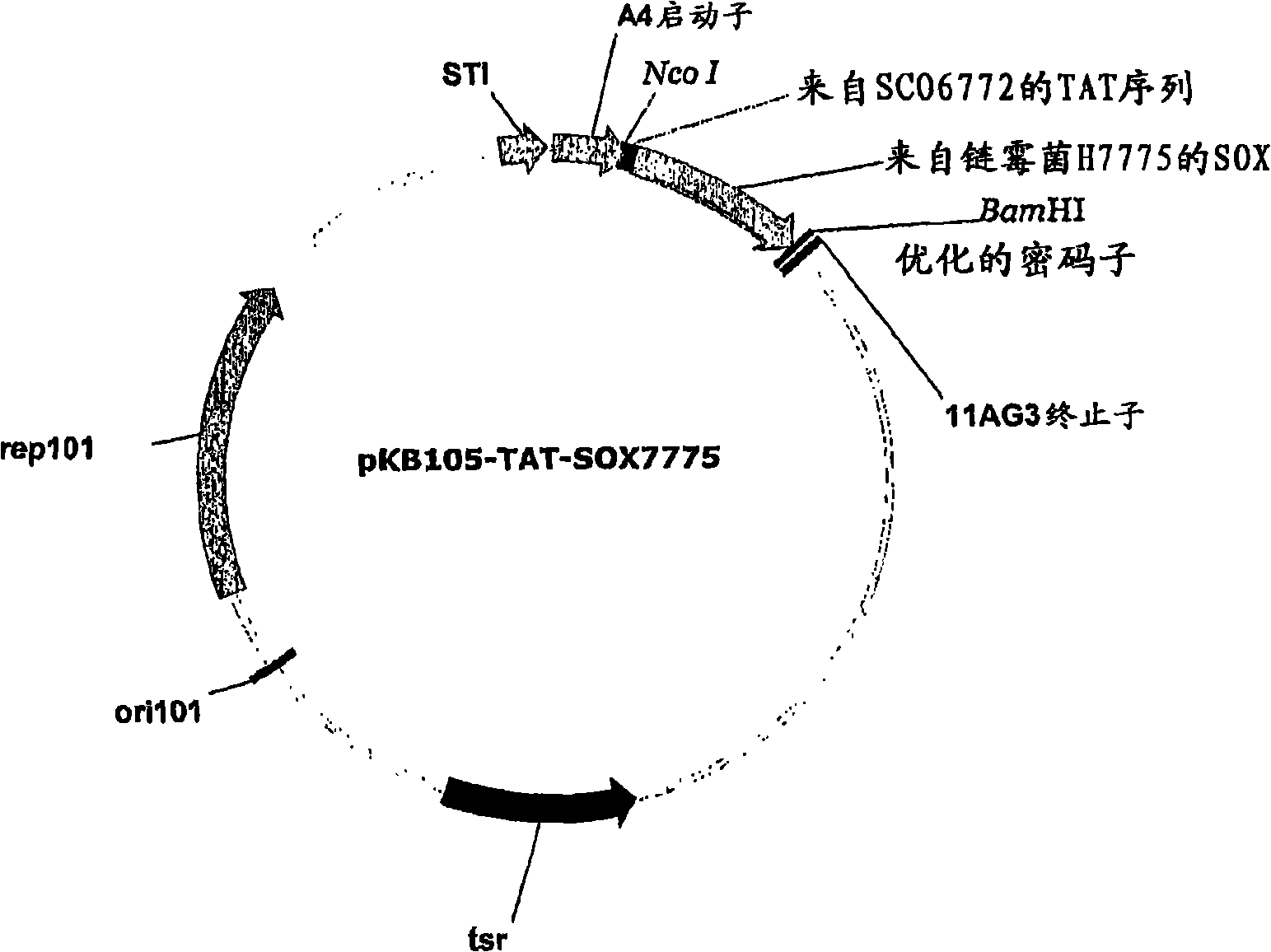

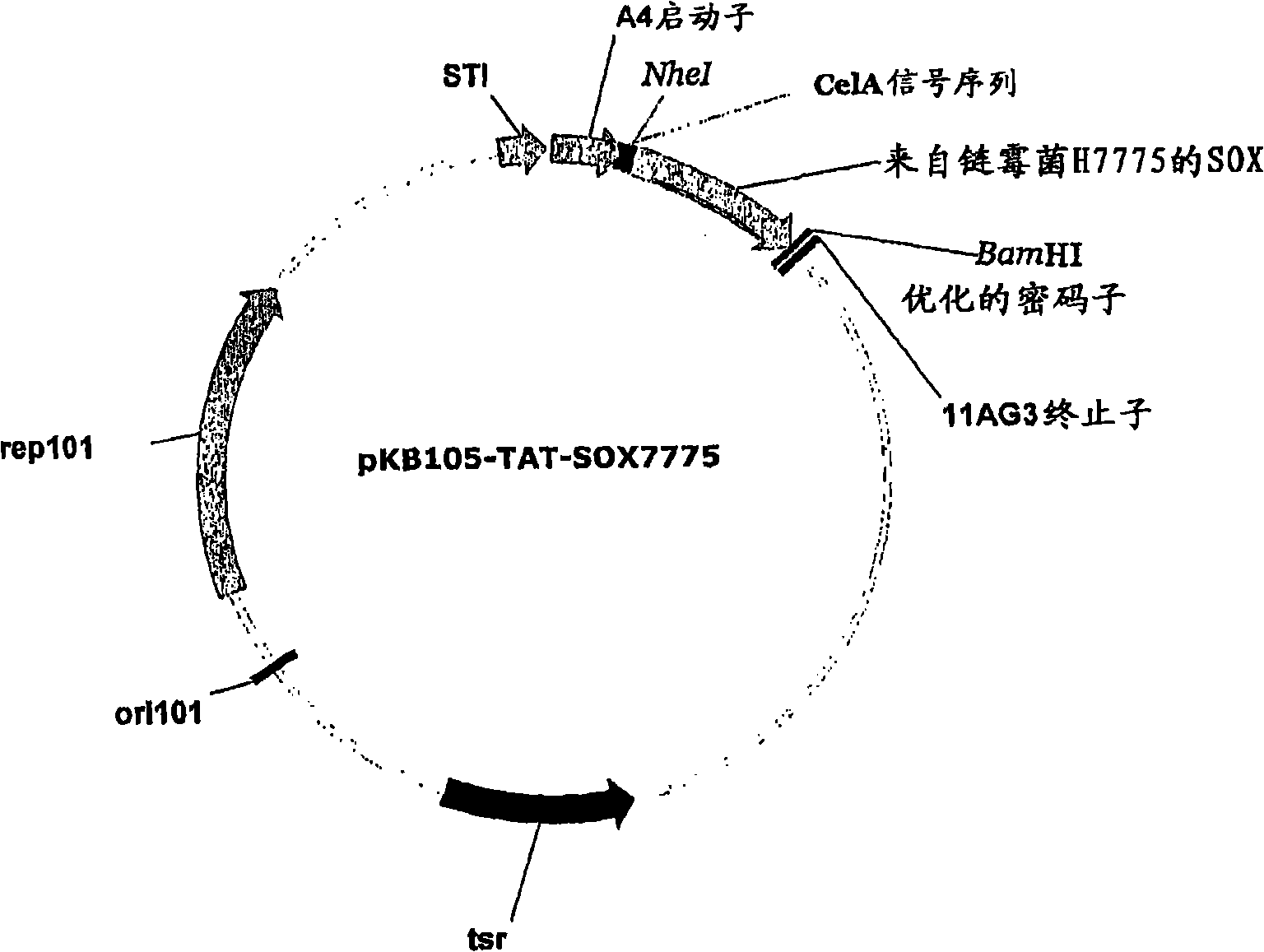

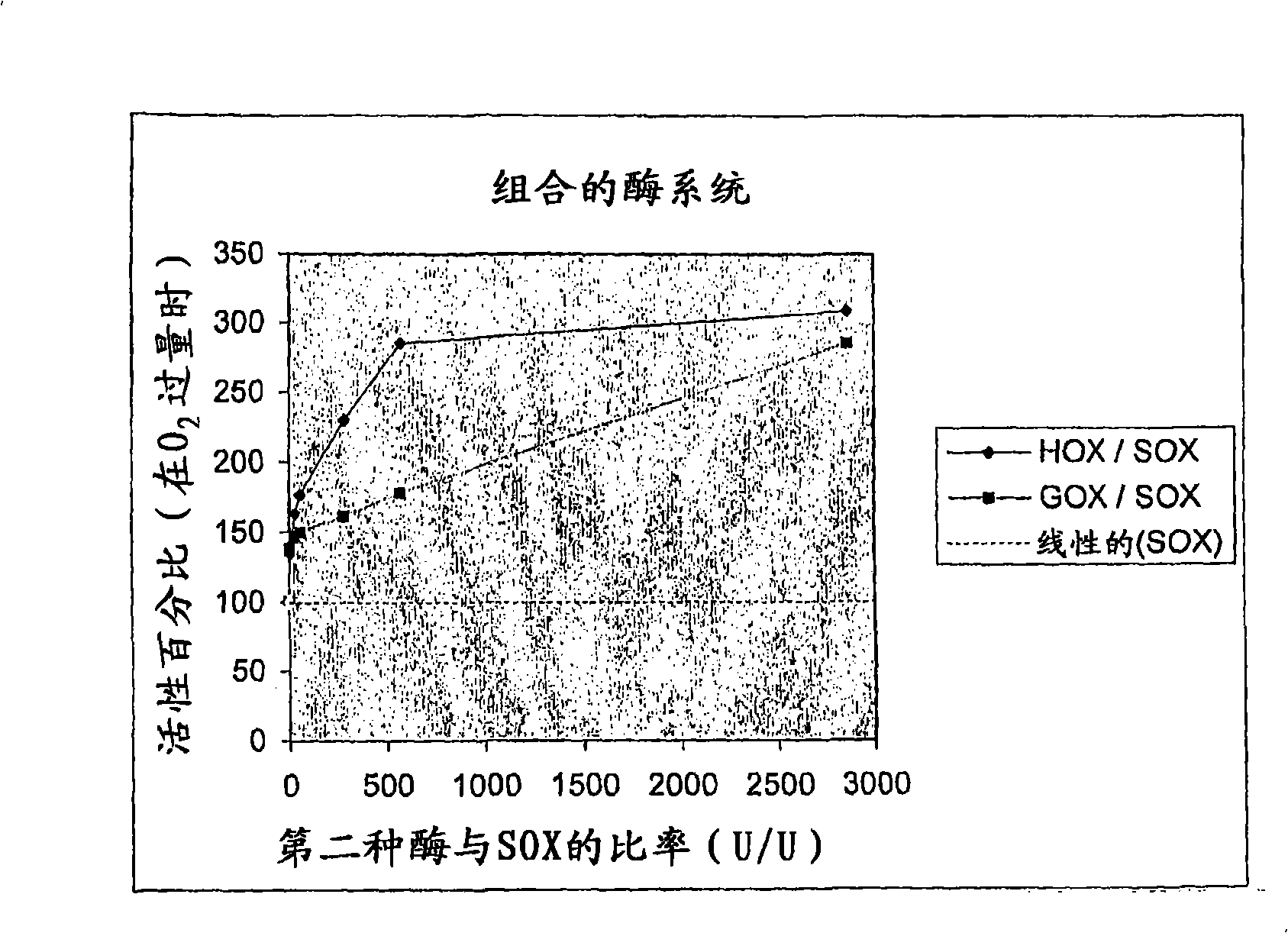

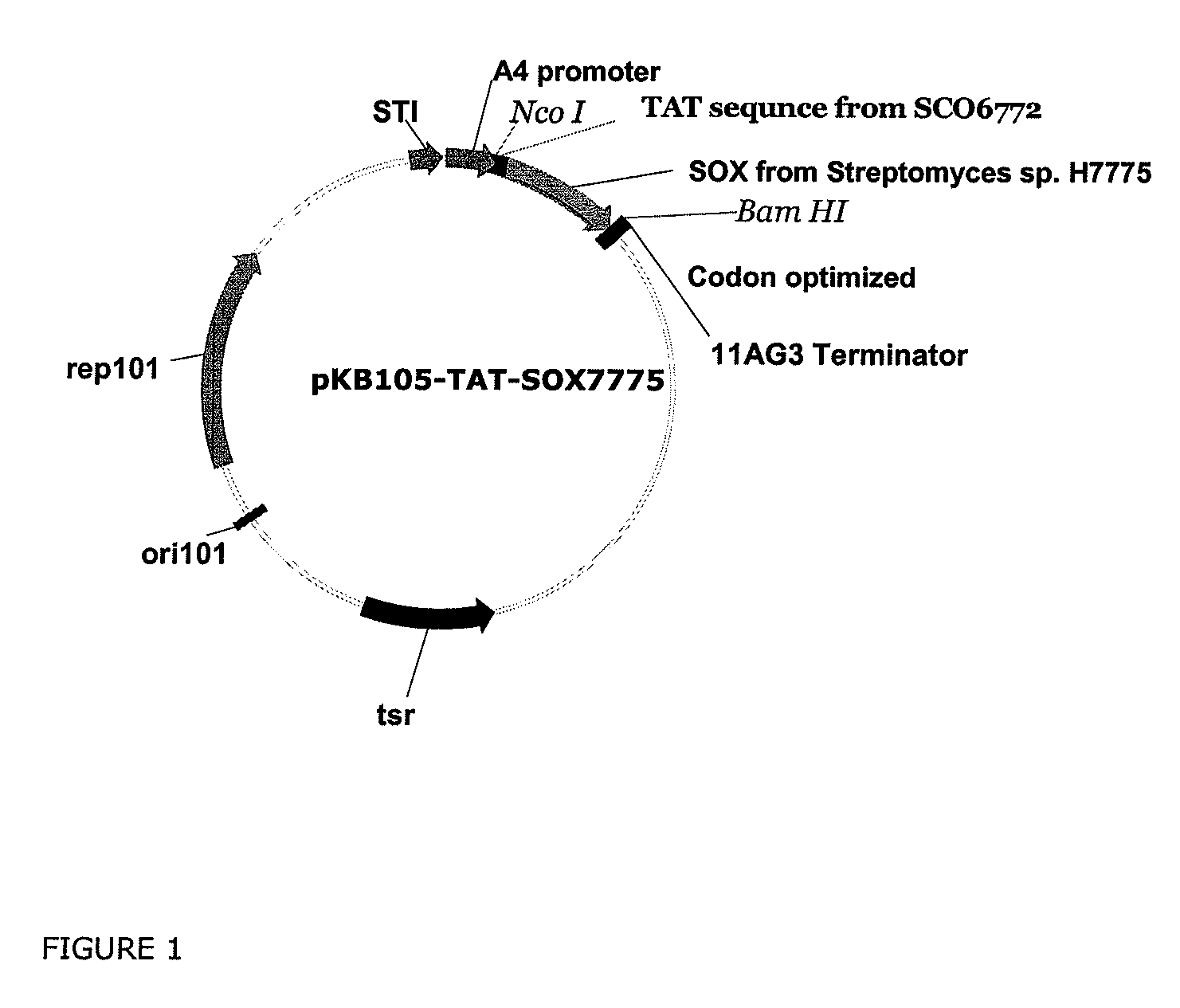

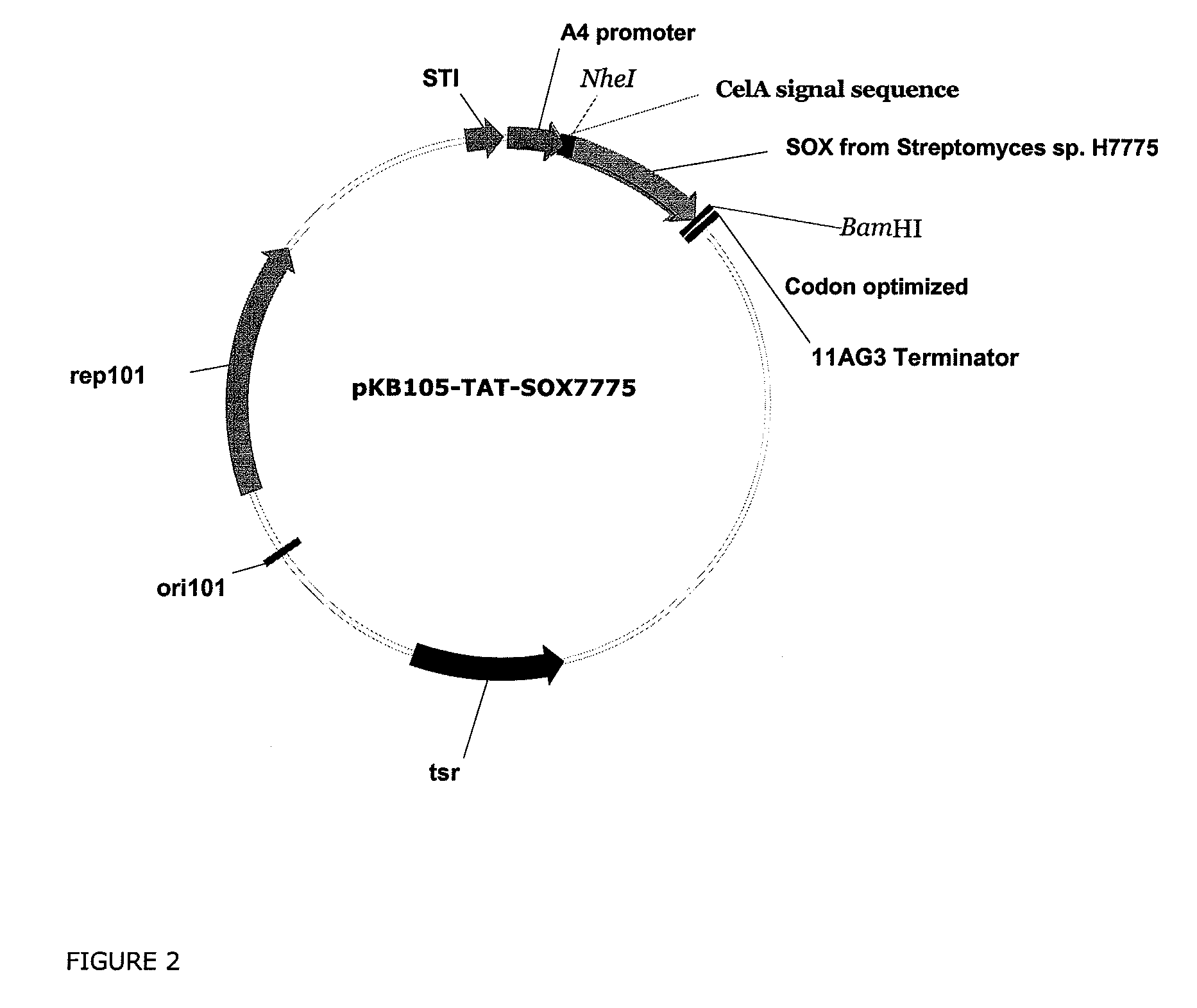

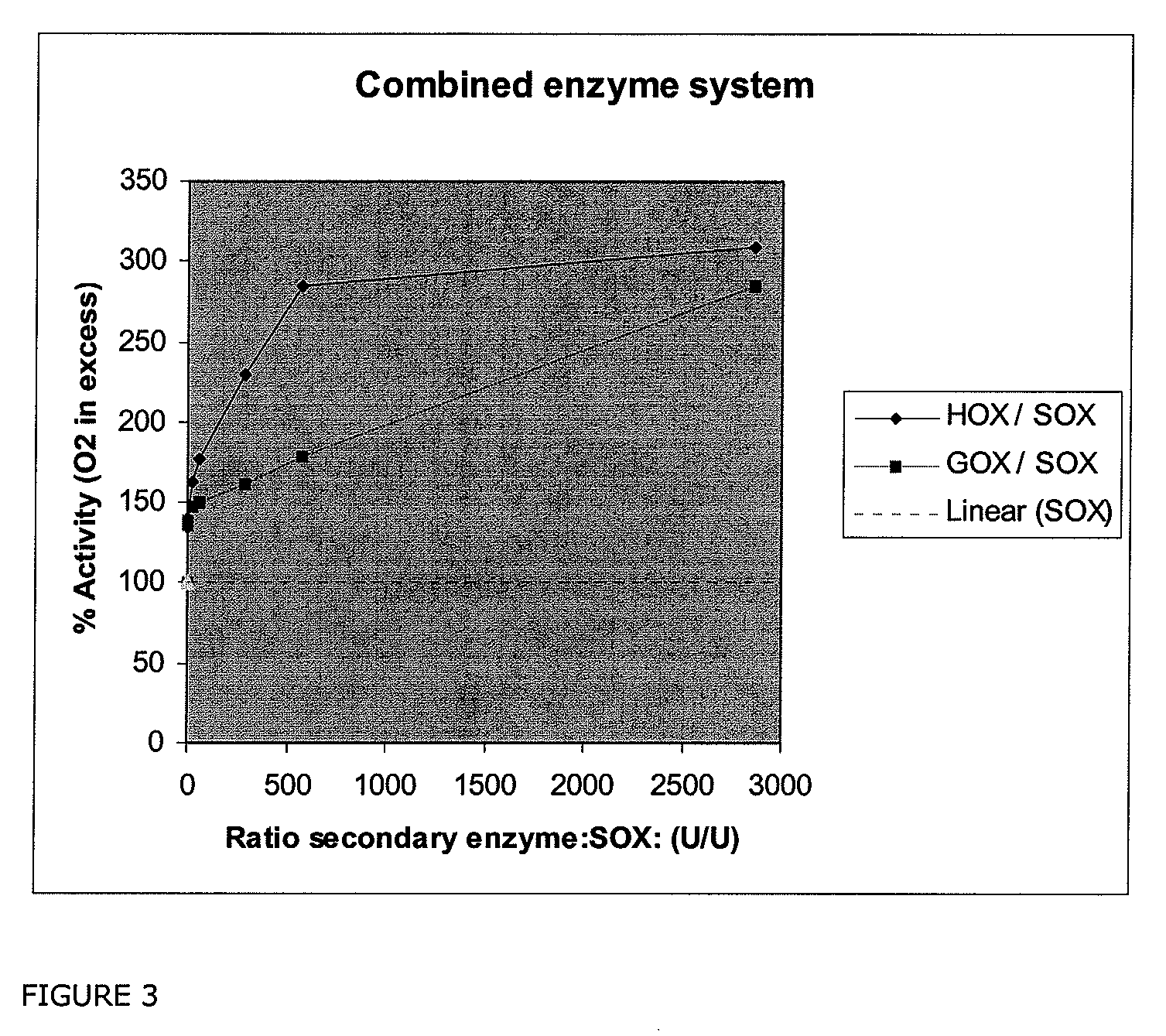

A composition comprising a coupled enzyme system

InactiveCN101316576ABeneficial probiotic effectExtended shelf lifeAntibacterial agentsCosmetic preparationsCouplingEnzyme system

The present invention relates to a composition comprising a coupled enzyme system for the rapid and efficient production of hydrogen peroxide by the coupling of a first enzyme system capable of hydrogen peroxide generation, to a second enzyme system which utilizes the non hydrogen peroxide product of the first enzyme system, and optionally is capable of generating further hydrogen peroxide.

Owner:DUPONT NUTRITION BIOSCIENCES APS

High-purity hydrogen peroxide preparation

InactiveCN1189387CMeet the requirements of cleaning agentsSolve the problem of relying on importsIon-exchange column/bed processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSemiconductor chipCleansing Agents

A process for preparing high-purity hydrogen peroxide from the aqueous solution of industrial hydrogen peroxide includes such steps as contacting with strong-alkaline macroreticular anionic exchange resin, contacting with strong-acidic macroreticular cationic exchange resin, contacting with mixed ionic exchange resin, and filtering via microfilter membrane. Its advantages are colourless, no order, high stability and purity, and low cost. It can be used as detergent for semiconductor chip.

Owner:TIANJIN UNIV OF SCI & TECH

Oxidation-extraction technology for production of hydrogen peroxide by anthraquinone process

ActiveCN106672911AIncrease speedImprove extraction efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesReaction rateOxygen

The invention discloses an oxidation-extraction technology for production of hydrogen peroxide by anthraquinone process. The oxidation-extraction technology for production of hydrogen peroxide by anthraquinone process comprises the following contents: (1) introducing hydrogenation liquid and oxygen-containing gas from the bottom of an oxidation-extraction reactor to carry out concurrent-flow oxidation reaction from the bottom to the top inside the reactor so as to continuously generate H2O2; (2) introducing an extraction agent through the upper middle part of the oxidation-extraction reactor while the reaction in the step (1) is carried out, letting the extraction agent flow from the top to the bottom in the reactor, and gradually extracting out the H2O2 generated by the oxidation reaction; and (3) carrying out gas-liquid separation on the material from the bottom to the top, removing residual moisture with a working solution and flowing out, settling the material from the top to the bottom in the settling section, removing the residual working solution in water, and purifying or concentrating to obtain a hydrogen peroxide product. According to the technology, the two processes of oxidation and extraction are coupled to each other. The oxidation reaction is carried out while extraction of H2O2 is conducted. Meanwhile, oxidation reaction rate and extraction efficiency are enhanced, the technological process is simplified, and the technology is beneficial to save investments and reduce energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of methyl ethyl ketazine by utilizing hydrogen peroxide method

InactiveCN103044285AChange the face of backwardnessSolve intractableHydrazone preparationHydrazine compoundKetone

The invention discloses a formula and a production process for preparing methyl ethyl ketazine by utilizing a hydrogen peroxide method, which carries out an in-depth study on the hydrogen peroxide method, thereby improving the hydrogen peroxide method to form a ketazine production method suitable for the situations in China. In the method, hydrogen peroxide is used as an oxidant, ammonia and butanone (methyl ethyl ketone) are used as raw materials and formamide and an inorganic oxide are used as a catalyst and a cocatalyst respectively to interact with each other so as to prepare the ketazine, wherein the hydrogen peroxide belongs to an industrial product and has the concentration of 25% to 30%; ammonia is added in a form of ammonia water with the concentration of 20% to 25%; and the butanone, the formamide and the inorganic oxide are all in the industrial product level. The method disclosed by the invention can be used for solving the problems that the existing initial coarse products for producing hydrazine hydrate are low in concentration, high in energy consumption, low in efficiency and high in cost and the by-products are difficult to treat, thereby being suitable for the situations in China.

Owner:重庆蓝苗生物科技开发有限公司

Composition Comprising A Coupled Enzyme System

InactiveUS20090142281A1Beneficial teeth bleachingGood whitening effectAntibacterial agentsPeptide/protein ingredientsCouplingEnzyme system

The present invention relates to a composition comprising a coupled enzyme system for the rapid and efficient production of hydrogen peroxide by the coupling of a first enzyme system capable of hydrogen peroxide generation, to a second enzyme system which utilizes the non hydrogen peroxide product of the first enzyme system, and optionally is capable of generating further hydrogen peroxide.

Owner:DUPONT NUTRITION BIOSCIENCES APS

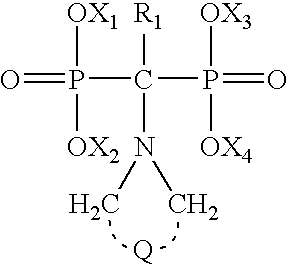

Stabilized hydrogen peroxide solutions

InactiveUS8802613B2High hydrogen peroxide stabilityAvoid disadvantagesOrganic detergent compounding agentsAnionic surface-active compoundsHydrogenPeroxide

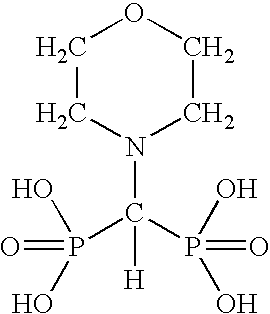

The present invention is directed to a stabilized hydrogen peroxide solution containing stabilizers that maintain relatively high hydrogen peroxide stability in both concentrated form and when formulated into a cleaning solution that has a pH above 6 and contains components that normally would have a destabilizing effect on the hydrogen peroxide. The stabilizers include a first cyclic amino methane diphosphonic acid compound stabilizer in combination with a second phosphonic acid based stabilizer (different from the cyclic amino methane diphosphonic acid compound), wherein the weight ratio of the first stabilizer to the second stabilizer is at least about 2:1.

Owner:AKZO NOBEL NV

Multistage hydrogenation technology for producing hydrogen peroxide by anthraquinone process

ActiveCN104418307AInhibitory activityAvoid clumpingPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingQuality levelHydrogenation reaction

The invention discloses a multistage hydrogenation technology for producing hydrogen peroxide by an anthraquinone process, which comprises the following steps: operating fluid and hydrogen-containing gas in the hydrogenation technology for producing hydrogen peroxide by the anthraquinone process pass through at least two hydrogenation reactors which are connected in series for a hydrogenation reaction in order along flowing direction of materials in the reactors, and a hydrogenation catalyst and a regeneration agent are alternatively filled in an inter-bed or in a bed layer of each hydrogenation reactor. The technology can improve quality level of the operating fluid, prolong the service life of the catalyst and increase the hydrogen peroxide product quality, and has good application prospect in hydrogen peroxide production technology by the anthraquinone process.

Owner:CHINA PETROLEUM & CHEM CORP +1

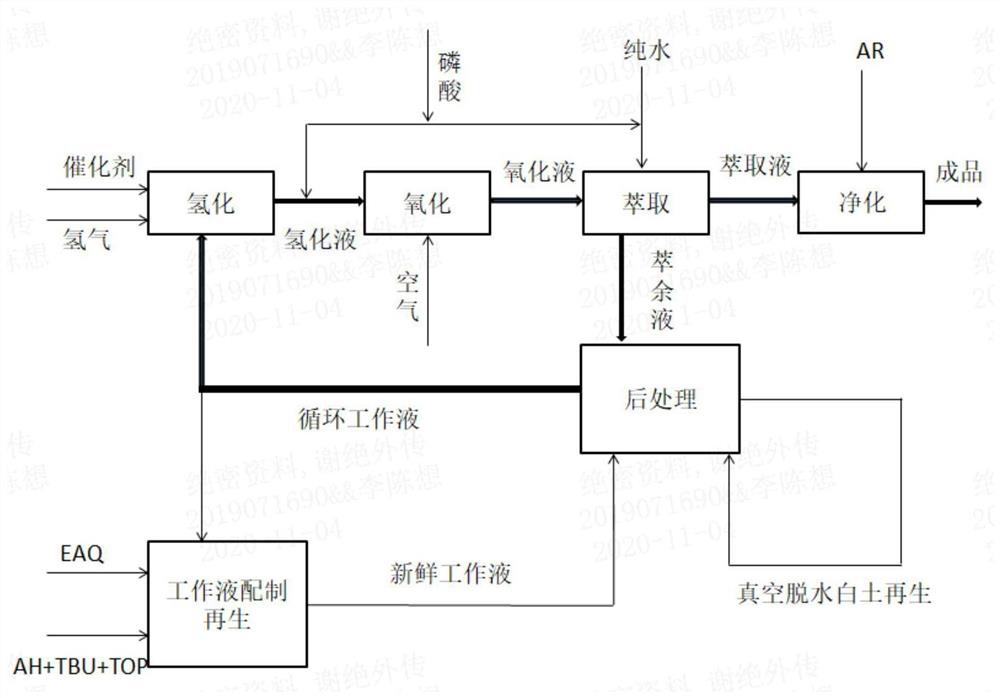

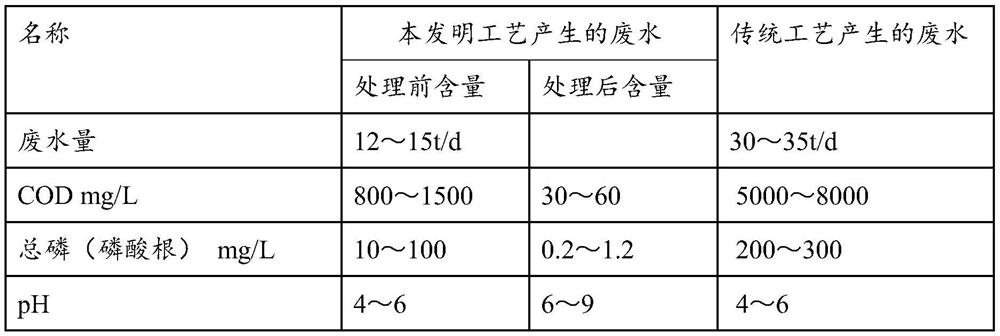

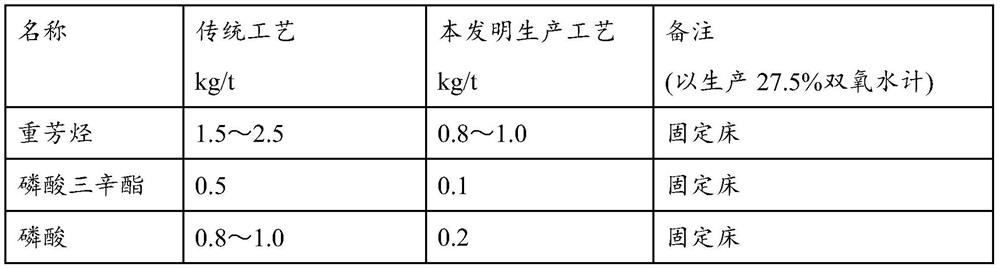

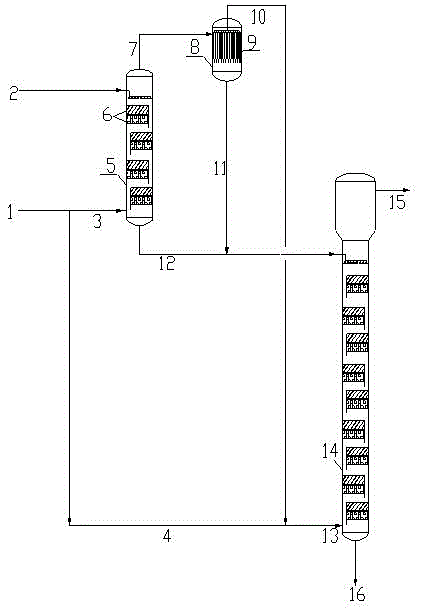

Multi-component all-acid fixed bed hydrogen peroxide production process

PendingCN112499595AAvoid it happening againReduce entrainmentPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesO-Phosphoric Acid

The invention relates to a multi-component all-acid fixed bed hydrogen peroxide production process which comprises the following steps: (1) in a hydrogenation tower, carrying out hydrogenation reaction on raw material hydrogen and a carrier anthraquinone under the action of a palladium-gold catalyst to generate a hydroanthraquinone hydrogenation solution; (2) adding phosphoric acid into the hydroanthraquinone hydrogenation solution to adjust the pH value to 3.5 + / -0.2, and reacting with oxygen in the air to obtain an oxidation liquid; and (3) taking pure water as an extraction agent, carryingout countercurrent extraction in an extraction tower to obtain an extraction solution containing hydrogen peroxide, and then purifying with heavy aromatics in a purification tower to obtain a qualified hydrogen peroxide product. According to the production process, a full-acid fixed bed process technology is adopted, balanced regeneration of a working solution system is optimally controlled, partial aluminum peroxide adsorption regeneration is adopted, dust entrainment is reduced, meanwhile, the filtering precision is improved, dust and salt entrainment in a product is greatly reduced, and indexes such as free acid, organic carbon and non-volatile matter are far away; and the product purity is superior to the national standard and companies.

Owner:PINGHU PETROCHEM

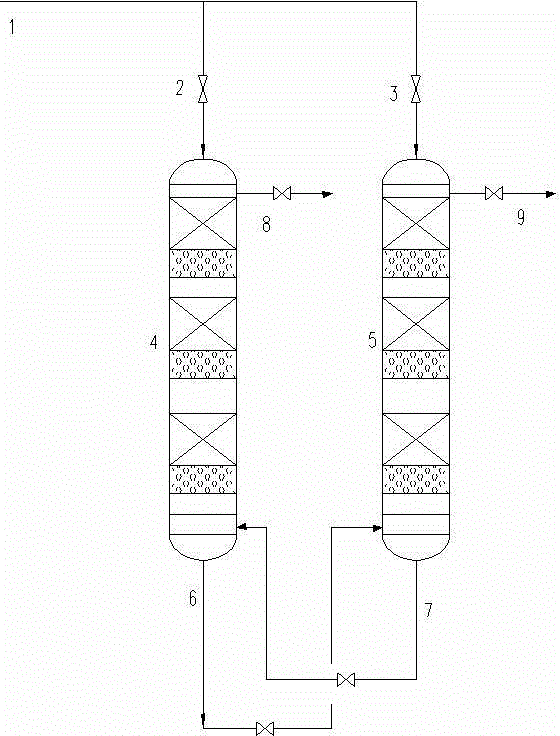

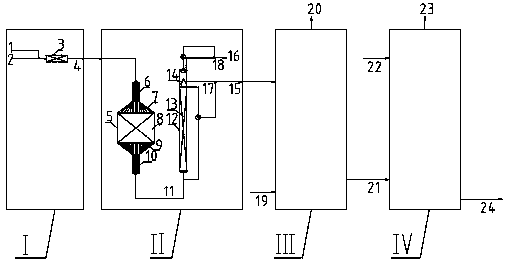

High-efficiency extraction process in hydrogen peroxide production process

ActiveCN105621364AImprove extraction efficiencyReduce the number of platesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationTower

The invention discloses a high-efficiency extraction process in a hydrogen peroxide production process. According to the invention, in an extraction process of an anthraquinone method for producing hydrogen peroxide; an extraction tower I and an extraction tower II are arranged; an oxidation liquid is divided into two parts which are an oxidation liquid I and an oxidation liquid II; pure water is introduced from the top of the extraction tower I, and the oxidation liquid I is introduced from the bottom of the extraction tower I; the two phases are subjected to countercurrent extraction in the extraction tower I; raffinate is discharged from the top of the extraction tower I, and is subjected to separation in a liquid / liquid separator, such that a heavy phase and a light phase are obtained; the heavy phase is mixed with extract liquid from the bottom of the extraction tower I, and the mixture of the heavy phase and the extract liquid from the bottom of the extraction tower I is introduced from the top of the extraction tower II; the light phase is mixed with the oxidation liquid II, and the mixture of the light phase and the oxidation liquid II is introduced from the bottom of the extraction tower II; the two phases are subjected to countercurrent extraction in the extraction tower II; a tower top raffinate phase is introduced into a post-treatment process; and the tower bottom extraction liquid is the high-concentration hydrogen peroxide product. The high-efficiency extraction process provided by the invention is provided aiming at the defects of prior arts. The process has the advantages of high mass transfer rate, high Murphree efficiency, high product concentration, low raffinate content, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

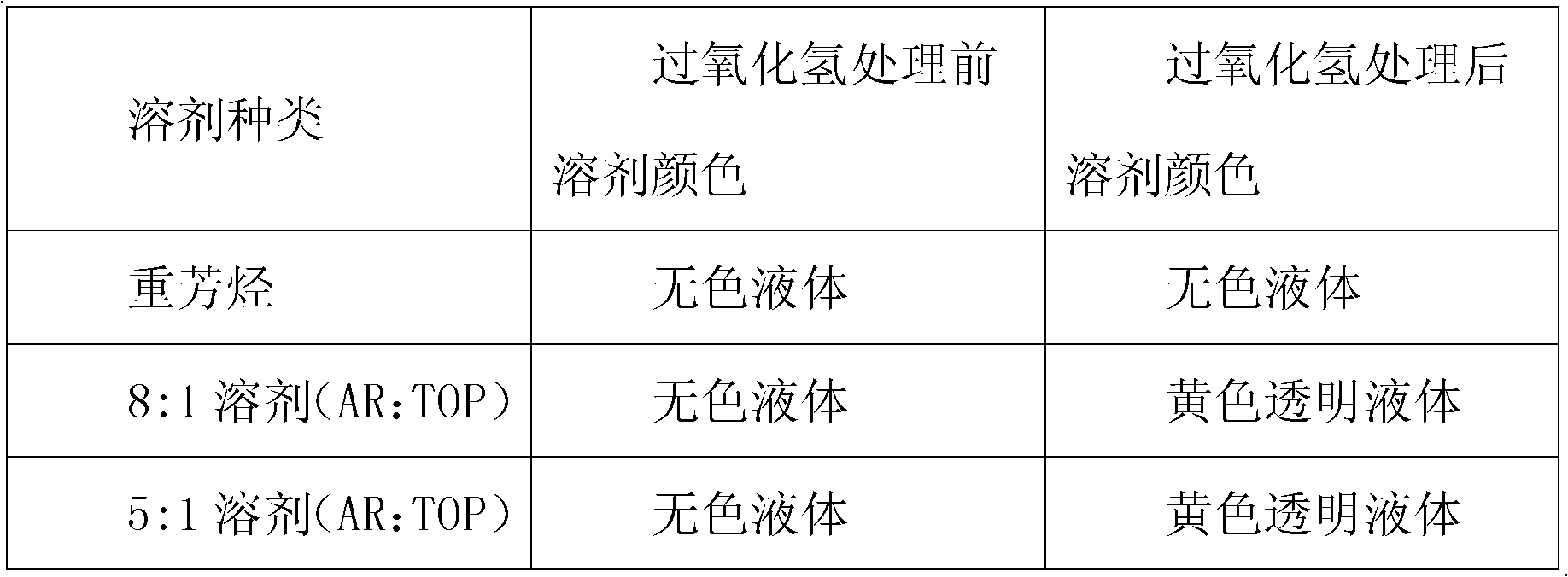

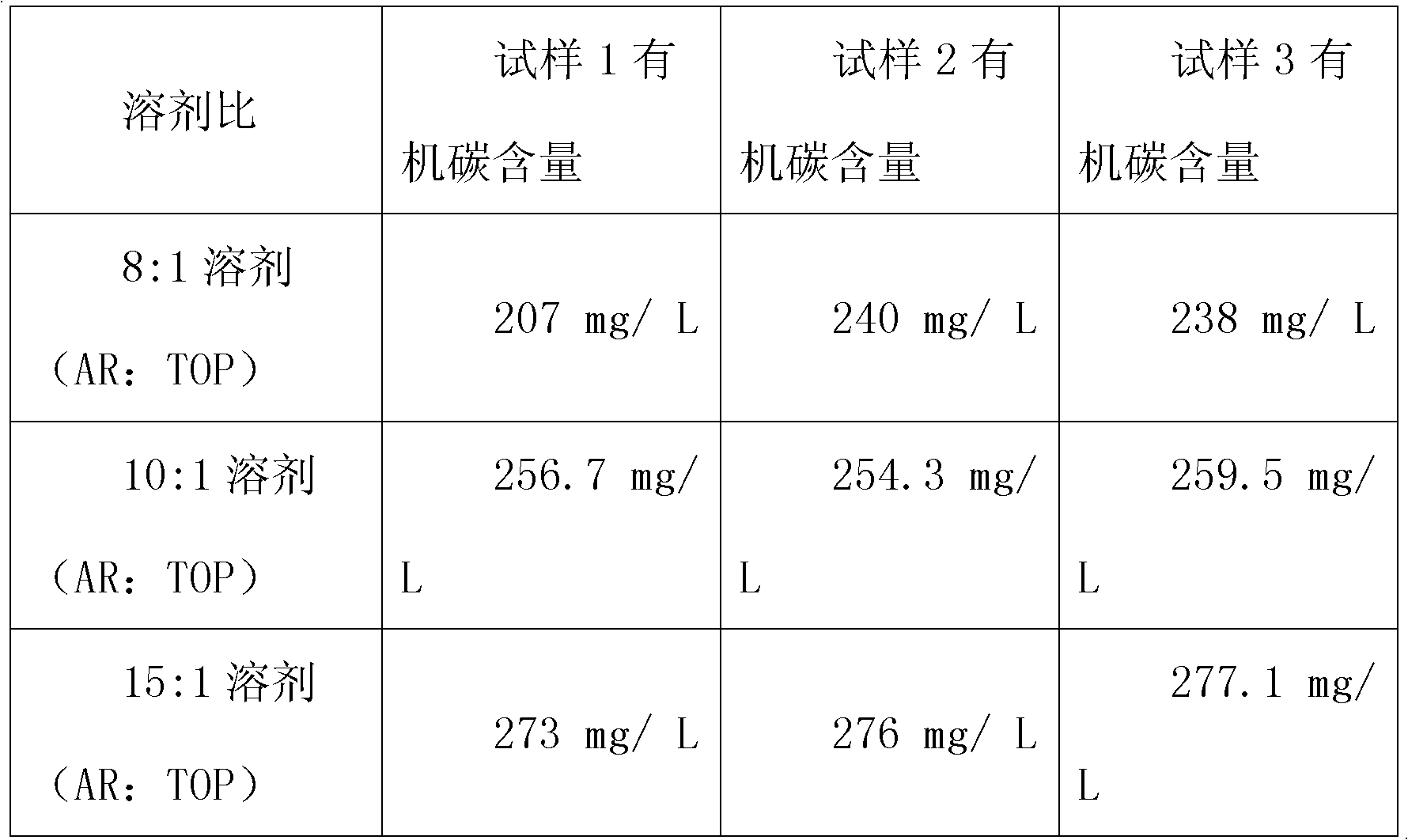

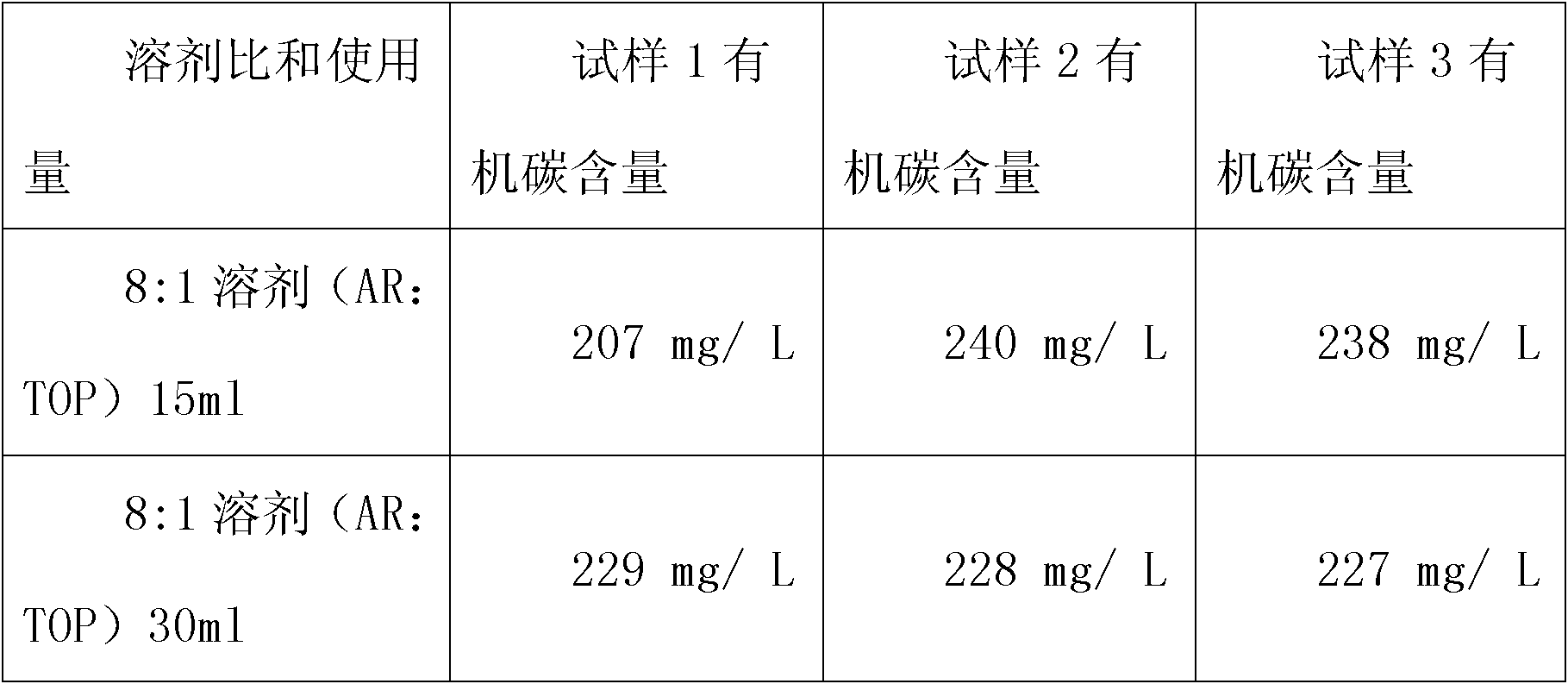

Method for purifying hydrogen peroxide

InactiveCN102424362AImprove product qualityQuality improvementPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphateOrganic matter

The invention discloses a method for purifying hydrogen peroxide, comprising the following steps: preparing heavy aromatics and trioctyl phosphate according to a volume ratio of heavy aromatics to trioctyl phosphate being 5-15 to 1into a mixed solution, then adding the mixed solution in a purification tower, and carrying out organic matter removal and purification on extracted crude hydrogen peroxide by using a conventional method at a temperature of 30-50 DEG C, wherein, the hydrogen peroxide is mixed with the mixed solution for purification according to the volume ratio of 100: 1-30. According to the invention, the quality of the hydrogen peroxide product is increased, the anthraquinone effective ingredient is recovered, and the situations that organic matters are precipitated in the device and concentrated hydrogen peroxide contains a lot of organic matters in condensation technology are improved.

Owner:TIANJIN DAGU CHEM CO LTD

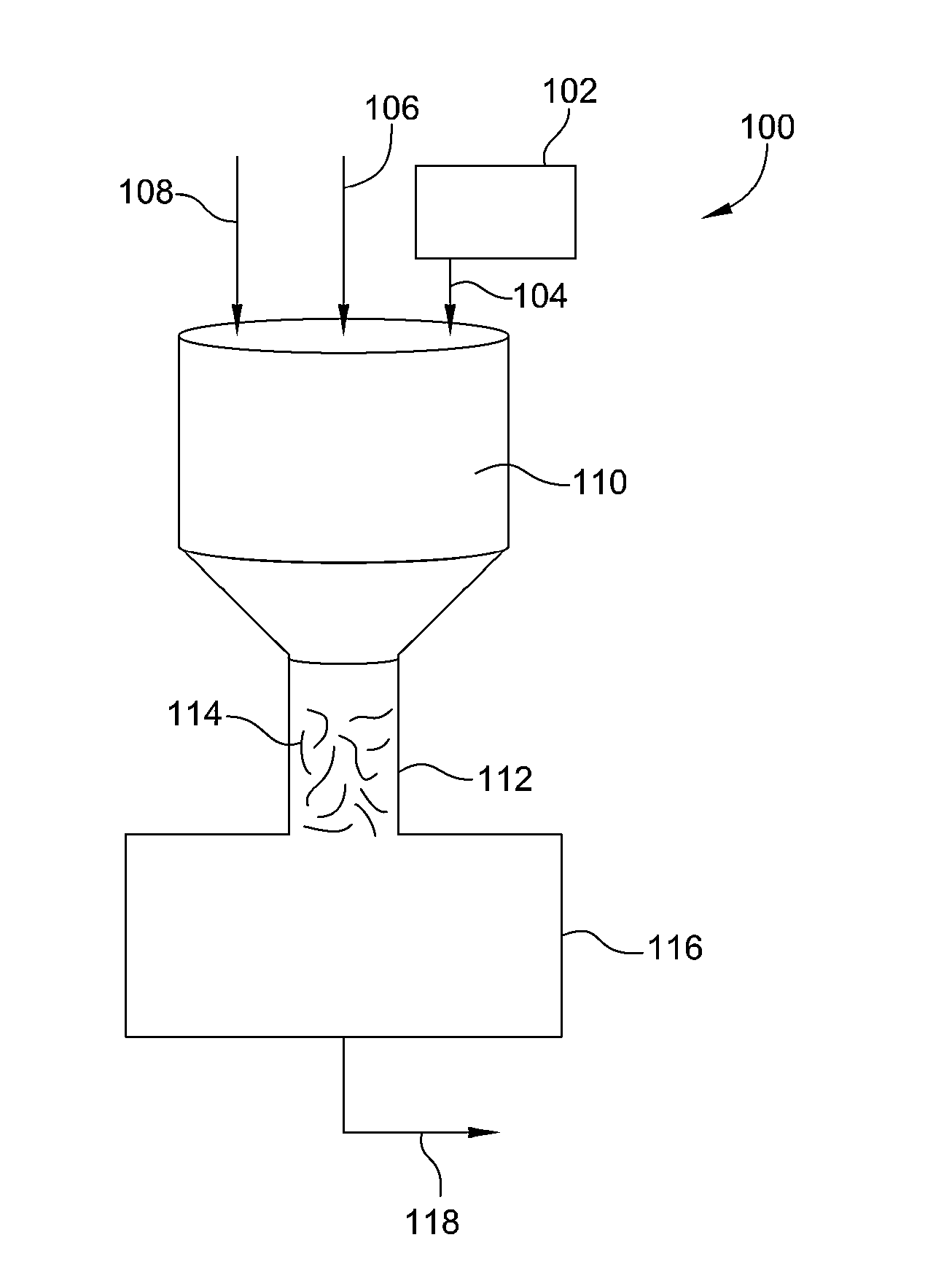

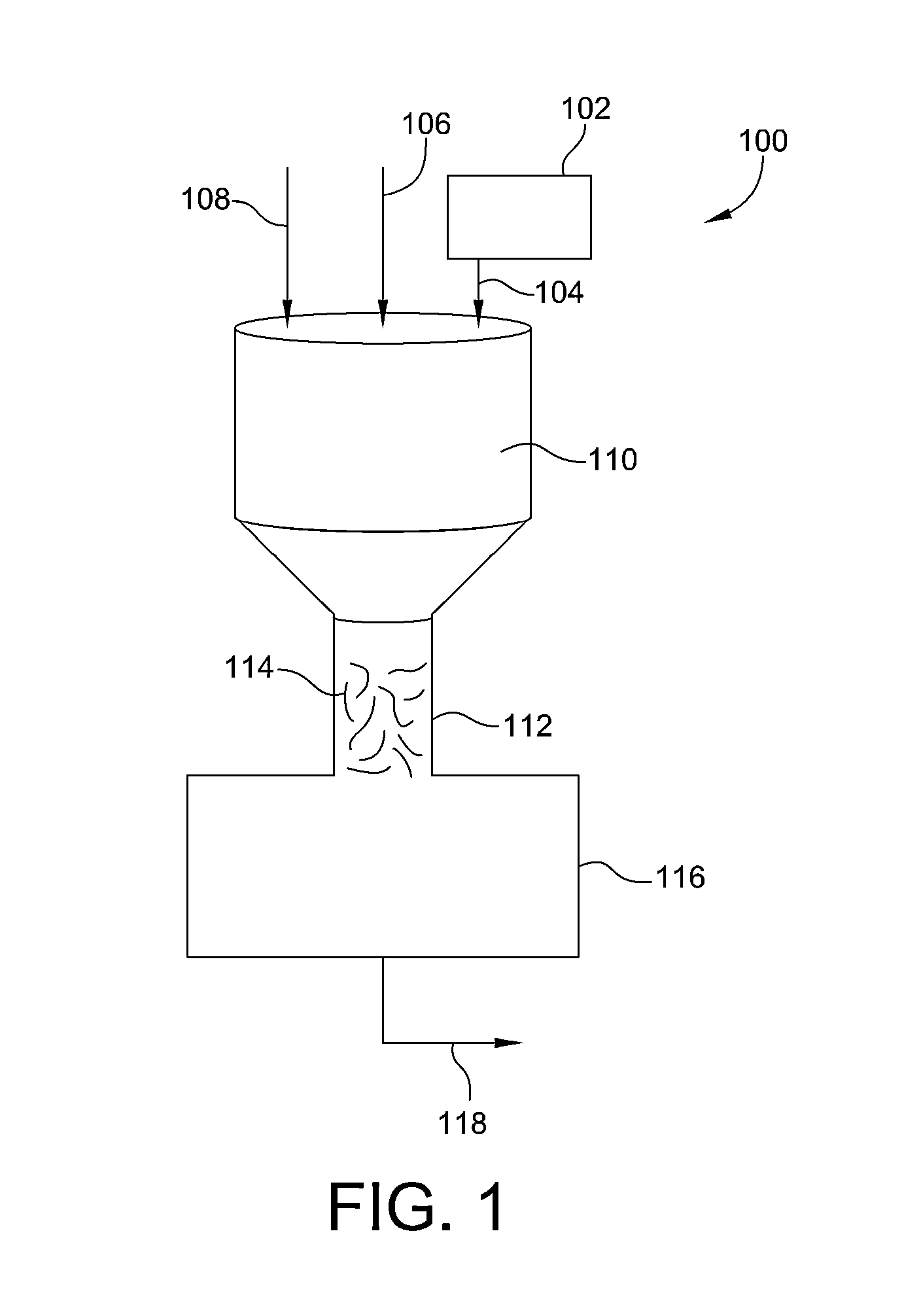

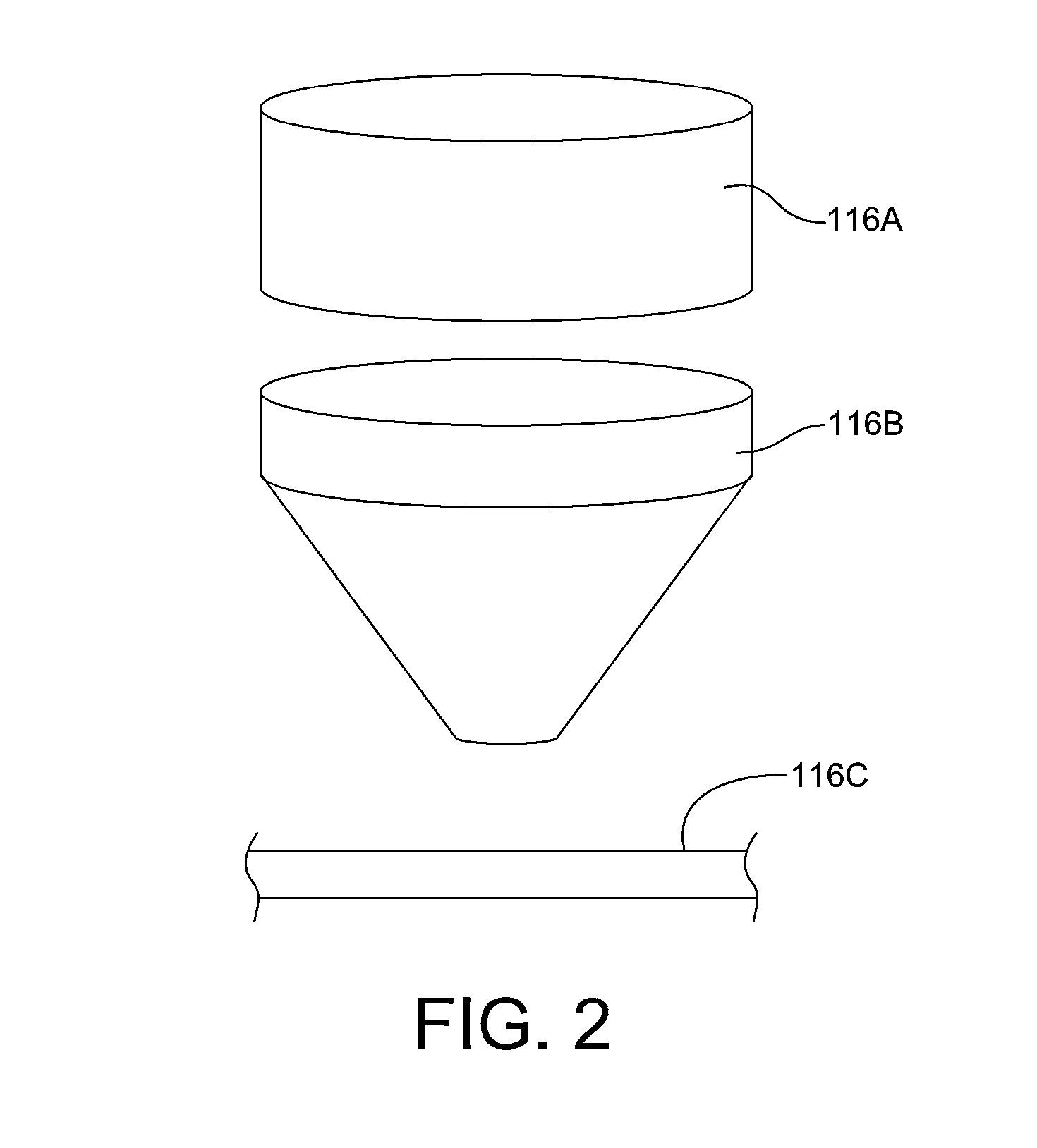

Process and system for removing urea from an aqueous solution

A process for removing urea from an aqueous solution is disclosed herein, the process comprises the steps of: feeding an aqueous solution comprising urea into a mix tank; feeding hydrogen peroxide into the mix tank; feeding at least one soluble catalyst into the mix tank separately from the hydrogen peroxide feed; mixing the aqueous solution comprising urea, hydrogen peroxide, and the at least one soluble catalyst in the mix tank, forming a reactant mixture; and oxidizing the urea in the reactant mixture yielding CO2, N2, and H2O. The soluble catalyst is selected from a group of catalysts that when mixed with the hydrogen peroxide and urea causes the rate of reaction of the oxidation of the urea by hydrogen peroxide to accelerate; such as soluble iron salts. A system configured to carry out the process for removing urea from an aqueous solution is also disclosed herein. The disclosed process and system may be added to or incorporated with existing processes and systems for treating aqueous solutions.

Owner:KLING MILLER LUISA +1

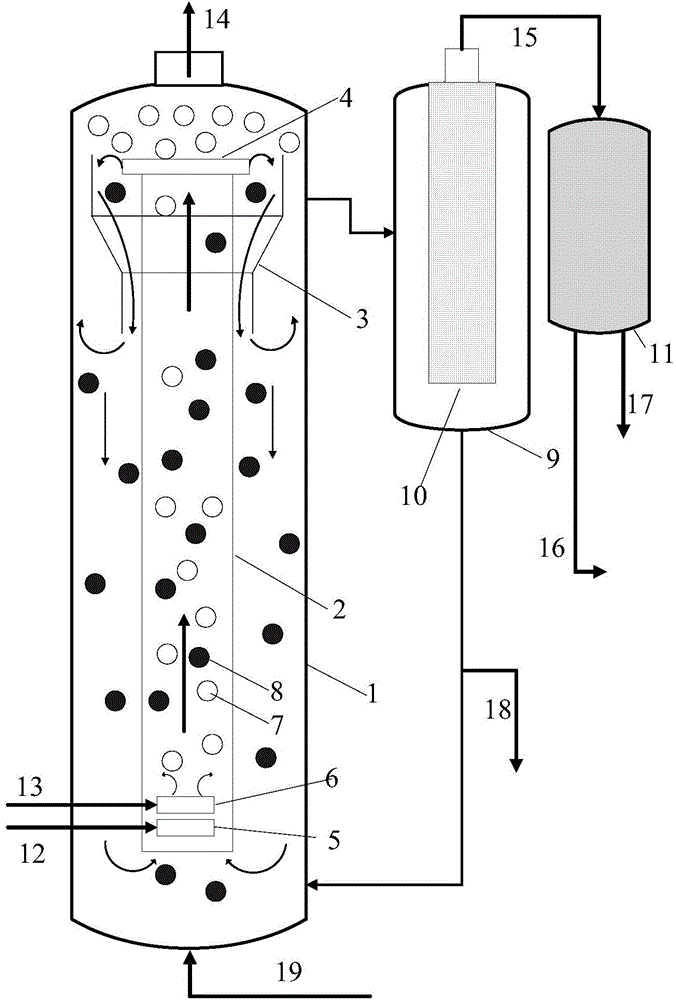

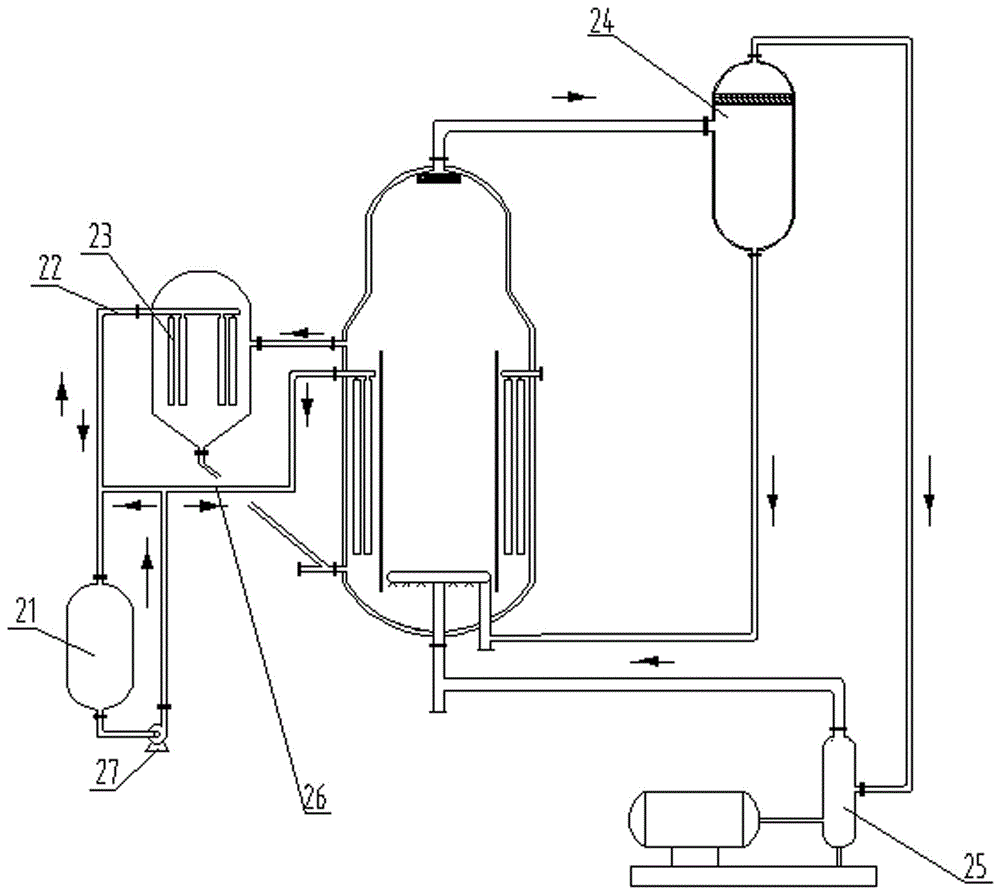

Fluidized bed hydrogenation reaction and separation process and device for producing hydrogen peroxide by virtue of anthraquinone method

ActiveCN106629618AWell mixedImprove effective utilizationSemi-permeable membranesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationFluidized bed

The invention discloses a fluidized bed hydrogenation reaction and separation process and device for producing hydrogen peroxide by virtue of an anthraquinone method. A working solution and hydrogen are continuously added into a fluidized bed reactor with a catalyst for hydrogenation reaction, reacting materials are driven by gas to upwards move to the top of a draft tube, and are downwards filtered through a membrane separator, filtered hydrogenation liquor flows to a hydrogenation liquor storage tank, and the catalyst is retained on a filter element, and returns into the reactor to continue participating in reaction through backflush operation. On the upper part of the reactor, incompletely reacted hydrogen mixed up with a small amount of working solution overflows, and returns to the reactor to participate in reaction through a circulating compressor after the working solution is separated through a circulating gas separator. During regeneration of the built-in membrane separator, an external membrane separator is adopted for separation. According to the process and the device, the raw materials and the catalyst are uniformly mixed, the reaction homogeneity is high, the utilization efficiency of the catalyst is high, and a high-concentration hydrogen peroxide product can be obtained with fewer side reactions. The device is simple in structure, and can run stably.

Owner:河北美邦工程科技股份有限公司

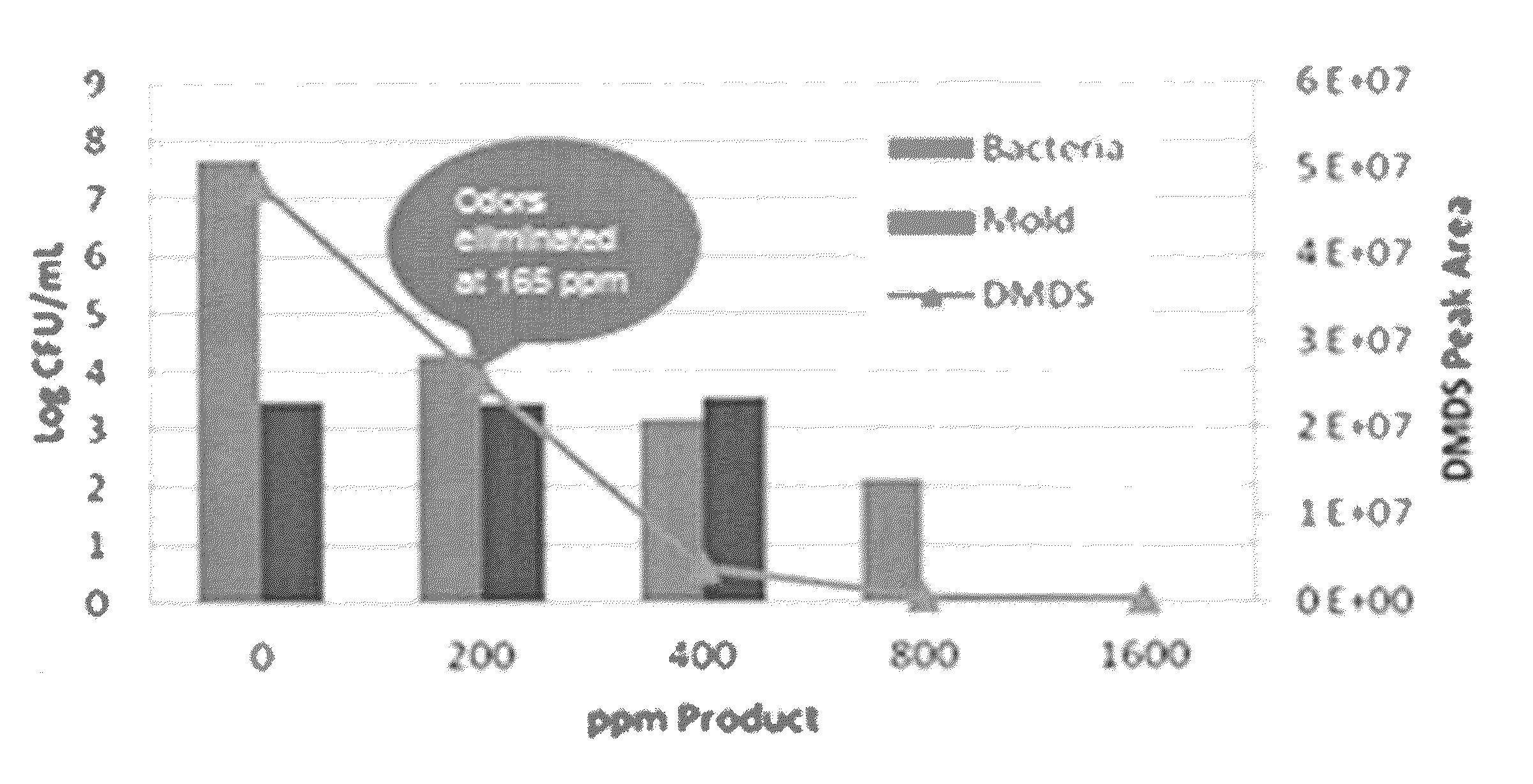

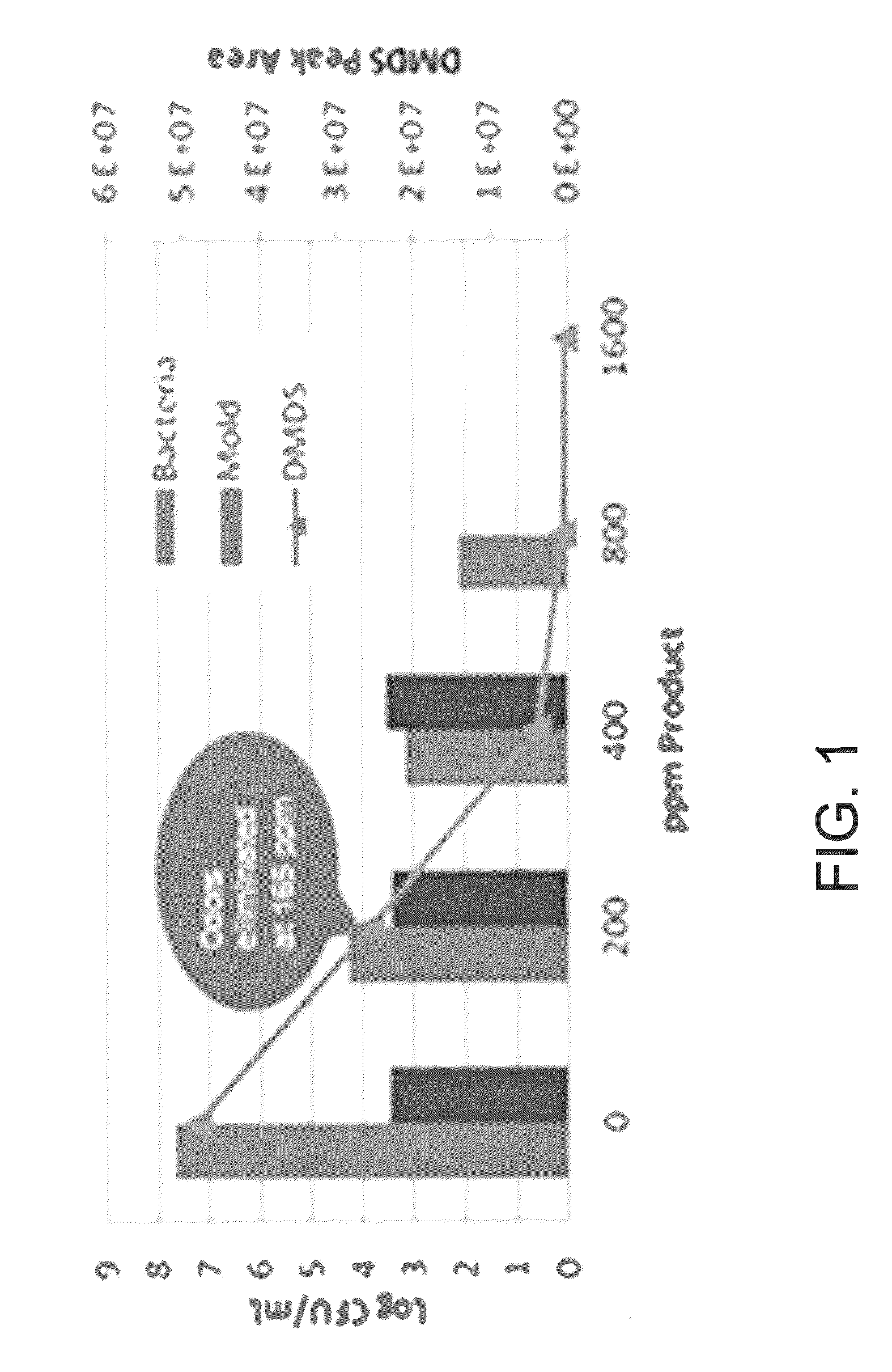

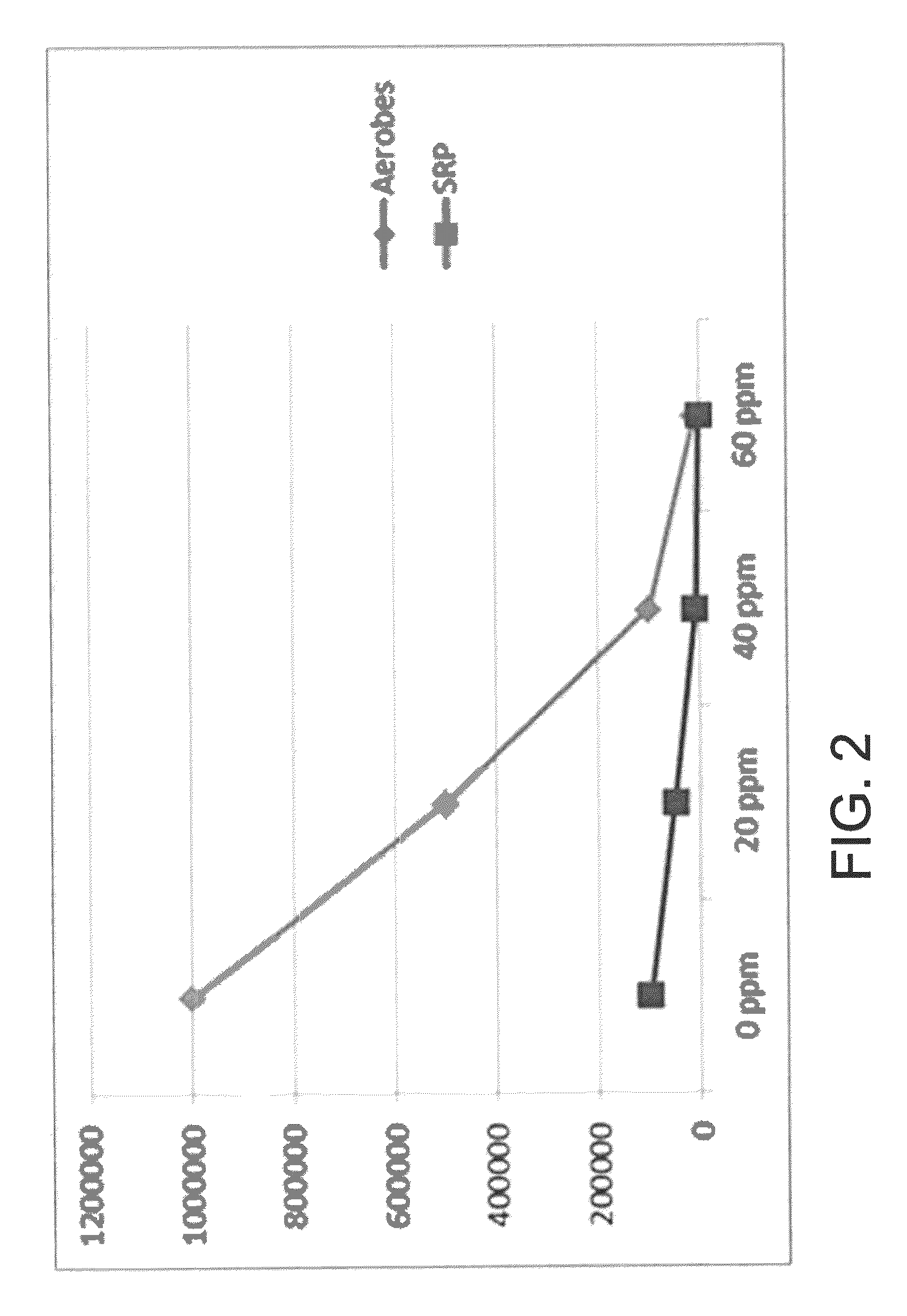

Reduction of hydrogen sulfide and/or malodor gassing from water via the addition of peroxyacetic acid/hydrogen peroxide product

ActiveUS8992780B2Reduce odorKeep activeWater treatment parameter controlBiological treatment regulationWater treatment systemSulfate

The invention provides methods and compositions for reducing the malodorous sulfide gas released by a wastewater treatment system. The method preserves the vitality of waste consuming organisms within the system. The method comprises the steps of: determining the SRP PAA demand of the system, determining the aerobic PAA demand of the system, and adding a composition in an amount such that it is in excess of the SRP PAA demand but is below the aerobic PAA demand. Even though the composition increases the amount of sulfates within the wastewater it reduces the amount of SRP which prevents the malodorous sulfite gas release. The composition comprises at least one percarboxyacid.

Owner:CHAMPIONX USA INC

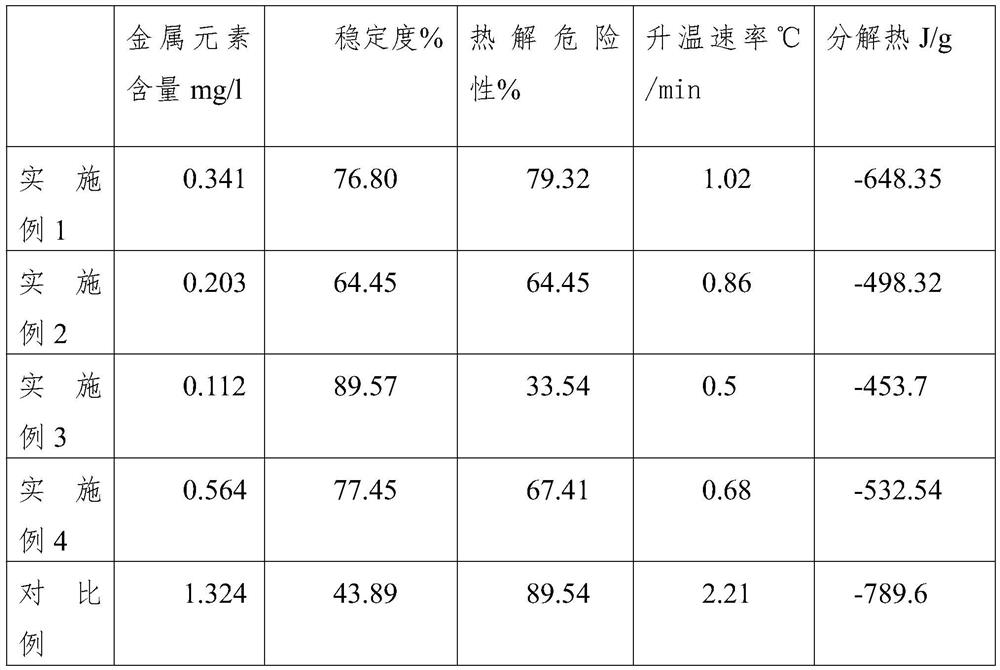

Novel purification process of hydrogen peroxide

InactiveCN112830457ALow impurity contentReduce processing costsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSpecific water treatment objectivesBiochemical engineeringDistillation

The invention discloses a novel purification process of hydrogen peroxide, belonging to the technical field of hydrogen peroxide purification. The novel purification process specifically comprises the following steps: step 1, an adsorption procedure; step 2, a separation and purification procedure; step 3, a distillation procedure; and step 4, an extraction procedure. According to the purification process for hydrogen peroxide provided by the invention, metal ions in a hydrogen peroxide solution can be well removed, the impurity content of a hydrogen peroxide product is greatly reduced, and the quality requirement for high quality is ensured; meanwhile, in a purification process, reaction stability and pyrolysis risks are relatively low, and production safety is relatively high; and moreover, ion exchange resin is low in process cost and good in economic benefit, and the purification mode combining the ion exchange resin with a reverse osmosis membrane is economical, safe and environmentally friendly, and therefore, the hydrogen peroxide purification technology can achieve large-scale industrial production.

Owner:安瑞森(宁夏)电子材料有限公司

Method for synchronously synthesizing hydrogen peroxide and peroxyacetic acid

ActiveCN102616751AThe synthesis process is simpleReduce contentOrganic compound preparationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical synthesisDisinfectant

The invention discloses a method for synchronously synthesizing hydrogen peroxide and peroxyacetic acid, wherein, hydrogen and oxygen are taken as gas sources, alcohol, water and acetic acid are taken as reaction solvent, and phosphoric acid and salt or acid which can generate Br- after being dissolved are taken as reaction assistants; and hydrogen peroxide and peroxyacetic acid can be synthesized synchronously under the conditions that the pressure ranges from 1 to 20 MPa and the temperature ranges from minus 20 to 15 DEG C. The mixed solution that is prepared according to the method can be used as raw material for preparing compound disinfectant and bleaching agents and can also be used as intermediates for other chemical synthesis.

Owner:LIMING RES INST OF CHEM IND

System and method for producing hydrogen peroxide through anthraquinone method

ActiveCN109678119AUniform responseQuality improvementPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationFixed bed

The invention discloses a system and method for producing hydrogen peroxide through an anthraquinone method. The system comprises the four unit processes of hydrogen dissolving, hydrogenation, oxidation and extraction, wherein a hydrogenation unit comprises a series fixed bed and upflow-type tubular reactors, and working liquid and hydrogen are subjected to a hydrogenation reaction in the hydrogenation unit to obtain hydrogenation liquid; an oxidation unit comprises an oxidation tower, the hydrogenation liquid and oxygen-containing gas are subjected to an automatic oxidation reaction to obtainoxidation liquid; and an extraction unit comprises an extraction tower, hydrogen peroxide in the oxidation liquid is extracted by the water, and thus a high-concentration hydrogen peroxide product isobtained. According to the system and method, the anthraquinone hydrogenation reaction rate can be significantly improved, the anthraquinone hydrogenation reaction efficiency can be significantly improved, the uniformity of the reaction process is maintained, side reactions are less, the obtained hydrogenation liquid is good in quality, small in by-product number and low in viscosity, the gas-liquid mass transfer rate in the oxidation process is increased, the extraction efficiency in the extraction process is improved, the oxidation time is significantly shortened, and the number of actual tower plates of the extraction tower is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation technique and device for ultra-pure hydrogen phosphide

ActiveCN101244810BPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDistillationUF - Ultrafiltration

The invention provides a continuous production process for ultra-pure hydrogen peroxide, comprising the following steps: mixing the industrial hydrogen peroxide material with the modified active carbon; then classifying filter by microfiltration membrane and ultrafiltration membrane in sequence; the filtrate is pumped into the distillation column formed by a plurality of columns connected in series; adding metal ion complexing agent into the primary column; performing reverse osmosis on the semi-finished products out of the column before filtering by nanofiltration membrane to get ultra-pure hydrogen peroxide products. The device comprises the following parts: a raw material chute, an active carbon pre-mixer, a microfiltration and ultrafiltration filter, a distillation column formed by a plurality of columns connected in series, a reverse osmosis device, a nanofilter, a finished product receiver, a pump and a shaft; wherein, the raw material chute outlet is connected with the active carbon pre-mixer inlet; the microfiltration and ultrafiltration filter outlet is connected with the pump, the outlet of which is connected with the inlet of the distillation column formed by a plurality of columns connected in series; the outlet of the distillation column formed by a plurality of columns connected in series is connected with the inlet of the reverse osmosis device, the outlet of which is connected with the shaft; the outlet of the shaft is connected with the inlet of the nanofilter, the outlet of which is connected with the finished product receiver.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com