Hydrogen peroxide and peracetic acid mixed disinfectant and preparation method thereof

A technology of hydrogen peroxide and peracetic acid, applied in the direction of active ingredients of peroxygen compounds, disinfectants, botany equipment and methods, etc., can solve the problems of limited application, low application value, inconvenient use, etc., and achieve the goal of killing microorganisms Enhanced ability, strong effect of killing microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

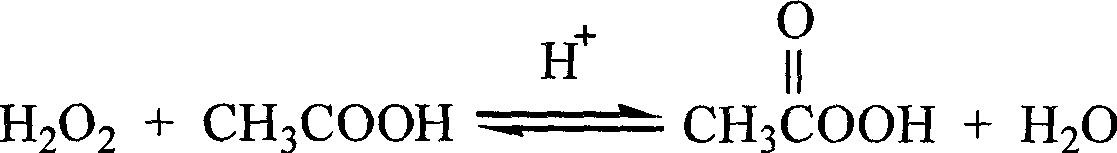

Method used

Image

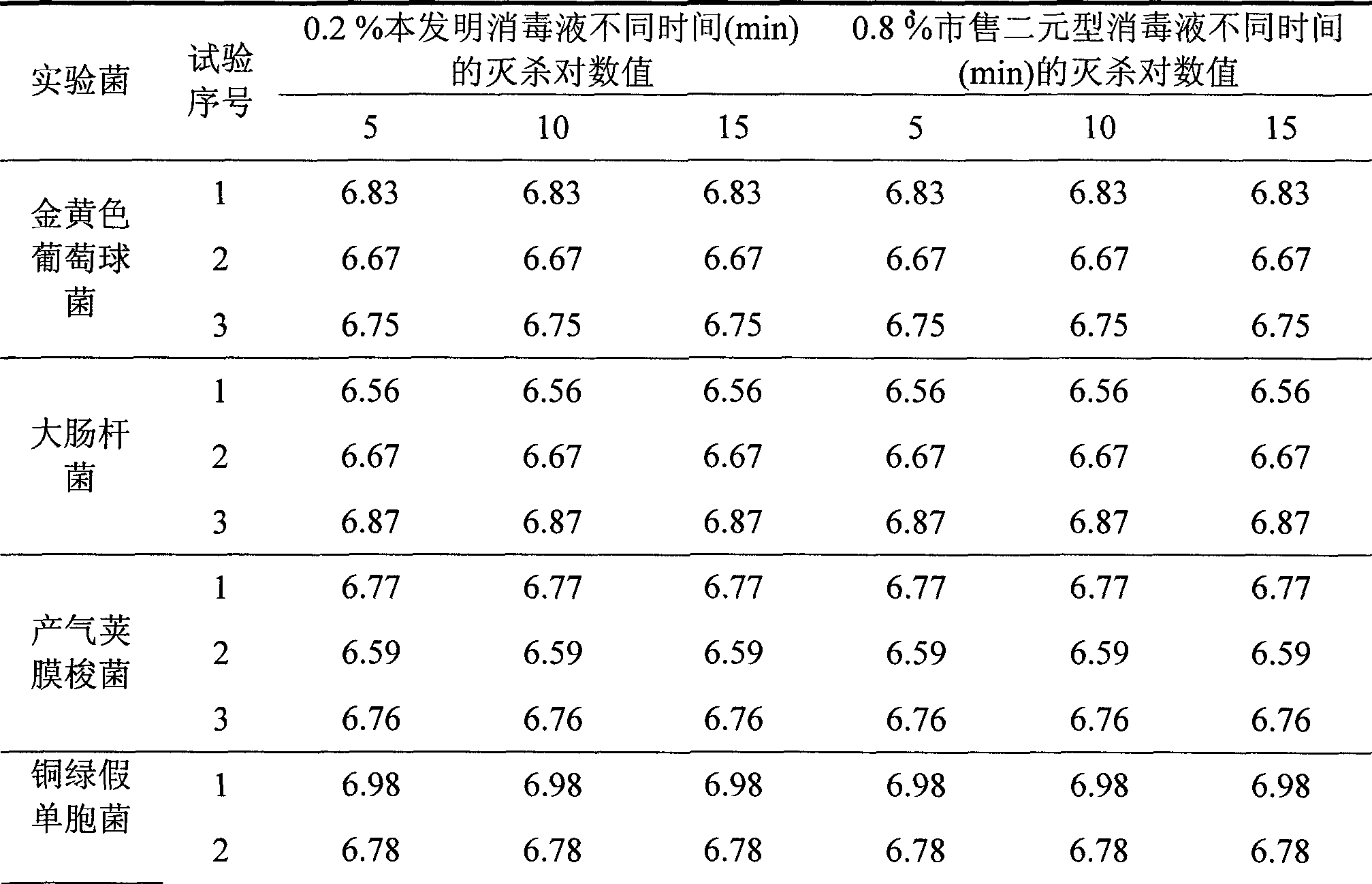

Examples

Embodiment 1

[0080] Raw material preparation: take by weight percentage:

[0081] Hydrogen peroxide (concentration: 35%): 72%

[0082] Acetic acid: 12%

[0083] Sulfuric acid: 1%

[0084] Ethylenediaminetetramethylenephosphonic acid: 2%

[0085] Sodium Lauryl Sulfate: 1%

[0086] water 12%

[0087] Preparation Process:

[0088] Mix the weighed hydrogen peroxide, acetic acid and sulfuric acid, stir the reaction, then dissolve ethylenediamine tetramethylene phosphonic acid and sodium dodecylsulfonate in water, add them to the above reaction system after dissolving, and Stir for 12 to 36 hours and take samples for measurement. The content of peracetic acid reaches 4-7%, the content of hydrogen peroxide reaches 25-30%, and when the pH is less than 3, it is qualified. Then filter it with a filter membrane with a pore size of 0.2 microns and pack it into the warehouse. .

Embodiment 2

[0090] Raw material preparation: take by weight percentage:

[0091] Hydrogen peroxide (concentration: 40%): 75%

[0092] Acetic acid: 15%

[0093] Sulfuric acid: 0.1%

[0094] Hydroxycresyl diphosphonic acid: 1%

[0095] Sodium pyrophosphate: 1%

[0096] Sodium octane sulfonate: 1%

[0097] Deionized water: 6.9%

[0098] The preparation process is the same as in Example 1 (note: after the system reaction is balanced, peracetic acid is produced, and the concentration of hydrogen peroxide and acetic acid will be lower than the concentration when adding, so as to reach the index in the claims. The same below).

Embodiment 3

[0100] Raw material preparation: take by weight percentage:

[0101] Hydrogen peroxide (concentration: 50%): 80%

[0102] Acetic acid: 10%

[0103] Sulfuric acid: 0.5%

[0104] Hydroxyethylene diphosphonic acid: 0.5%

[0105] Pyrophosphoric acid: 0.5%

[0106] Sodium dodecylbenzenesulfonate: 0.5%

[0107] Distilled water: 8%

[0108] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com