High-efficiency extraction process in hydrogen peroxide production process

A production process, hydrogen peroxide technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, non-metallic elements, etc., can solve the problem of low product concentration and mass transfer driving force Small, reduce the effect of raffinate, etc., to achieve the effect of advanced technology, reduce the number of trays, and reduce the number of trays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

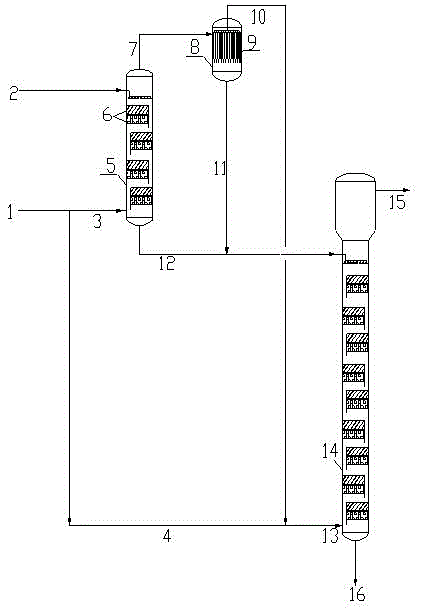

[0031] A two-stage extraction process is adopted, an extraction tower I and an extraction tower II, and a liquid / liquid separator is arranged between the stages. The total oxidizing liquid flow rate is 180m 3 / h, the water flow is 6m 3 / h, the hydrogen peroxide contained in the oxidation solution is 9.5g / L. During the extraction process, all the water is added from the top of the extraction tower I, and the 90m 3 / h Oxidation solution I is added from the bottom of extraction tower I, and the raffinate after primary extraction enters the interstage liquid / liquid separator, and the separated light phase and oxidation solution II are 90m 3 / h mixed into the bottom of the extraction tower II, the separated heavy phase mixed with the extract of the extraction tower I enters the bottom of the extraction tower II, and the top raffinate after the extraction of the extraction tower II enters the post-treatment process. The bottom extract is hydrogen peroxide product. The density ra...

Embodiment 2

[0033] A two-stage extraction process is adopted, an extraction tower I and an extraction tower II, and a liquid / liquid separator is arranged between the stages. The total oxidizing liquid flow rate is 180m 3 / h, the water flow is 6m 3 / h, the hydrogen peroxide contained in the oxidation solution is 9.5g / L. During the extraction process, all the water is added from the top of the extraction tower I, 120m 3 / h Oxidation solution I is added from the bottom of extraction tower I, and the raffinate after primary extraction enters the interstage liquid / liquid separator, and the separated light phase and oxidation solution II are 60m 3Enter the tower bottom of extraction tower II after mixing with / h, the separated heavy phase enters the tower bottom of extraction tower II after mixing with extraction tower I extract, the tower top raffinate after extracting tower II extraction enters post-treatment process, The bottom extract is hydrogen peroxide product. The density ratio of t...

Embodiment 3

[0035] A two-stage extraction process is adopted, the extraction tower I and the extraction tower II are equipped with a liquid / liquid separator between the stages, and a fine oil-water separation component-multiple sets of cyclone separators are installed at the head of the extraction tower II. The total oxidizing liquid flow rate is 180m 3 / h, the water flow is 6m 3 / h, the hydrogen peroxide contained in the oxidation solution is 9.5g / L. During the extraction process, all the water is added from the top of the extraction tower I, 120m 3 / h Oxidation solution I is added from the bottom of extraction tower I, and the overhead raffinate after primary extraction enters the interstage liquid / liquid separator, and the separated light phase and oxidation solution II are 60m 3 Enter the tower bottom of extraction tower II after the mixing of / h, the separated heavy phase enters the tower bottom of extraction tower II after mixing with extraction tower I extract, the tower top raff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com