Patents

Literature

1542 results about "Anthraquinone glycoside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anthraquinones are also used as laxatives such as in the drug senna glycoside. Brachmann, AO; Joyce, SA; Jenke-Kodama, H; Schwär, G; Clarke, DJ; Bode, HB (2007). "A type II polyketide synthase is responsible for anthraquinone biosynthesis in Photorhabdus luminescens".

Laundry Treatment Compositions

The present invention provides a treatment composition comprising a hydrophobic dye, having an anthraquinone structure and surfactant. A method of treating a textile with said composition is also claimed.

Owner:CONOPCO INC D B A UNILEVER

Method for marking hydrocarbons with anthraquinones

Method for invisibly marking a liquid petroleum hydrocarbon. The method comprises adding to the liquid petroleum hydrocarbon at least one dye selected from the group consisting of 1,4,5,8-tetrasubstituted anthraquinones and anthraquinone dimers. The absorption maximum of the dye(s) is in the range from 710 nm to 850 nm.

Owner:ROHM & HAAS CO

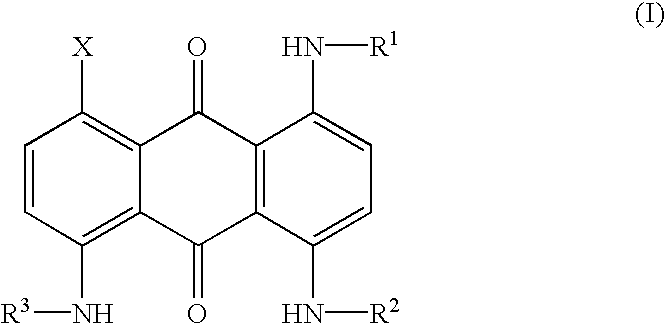

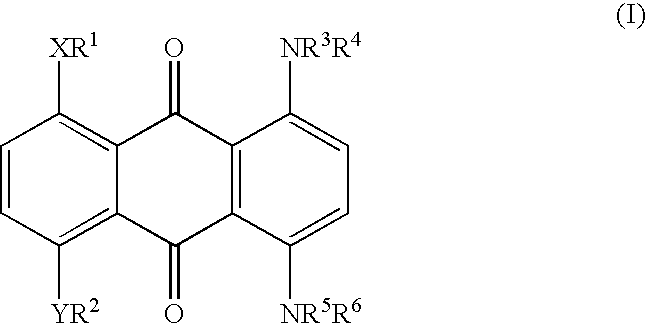

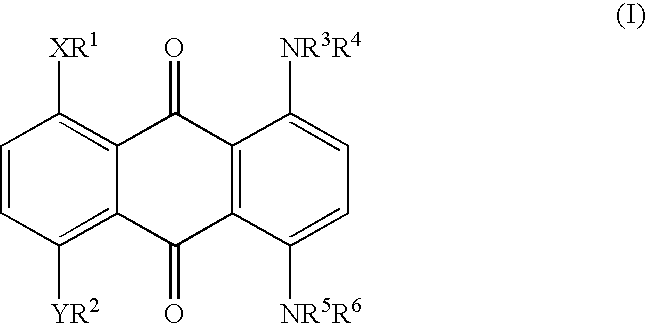

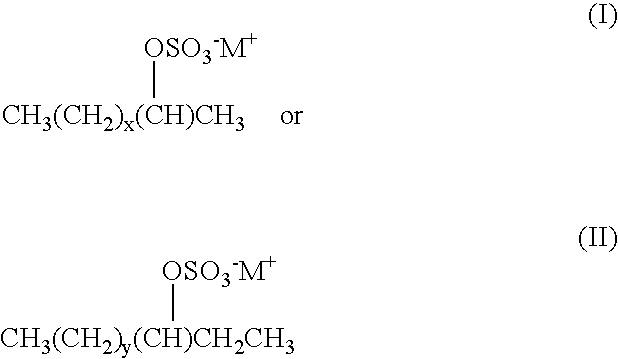

Method for marking hydrocarbons with substituted anthraquinones

ActiveUS20040250469A1Lower levelFacilitates quantitative spectrophotometric determinationEarth material testingLiquid carbonaceous fuelsArylAnthranil

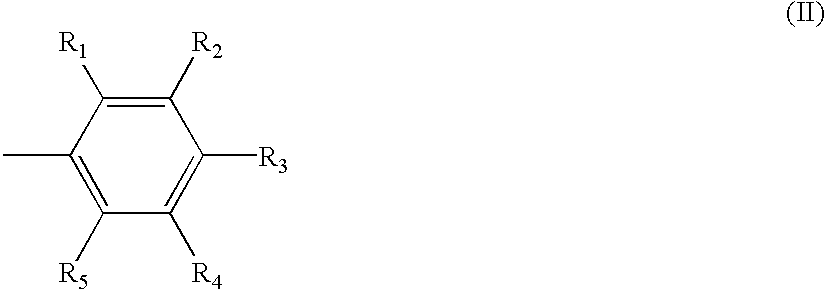

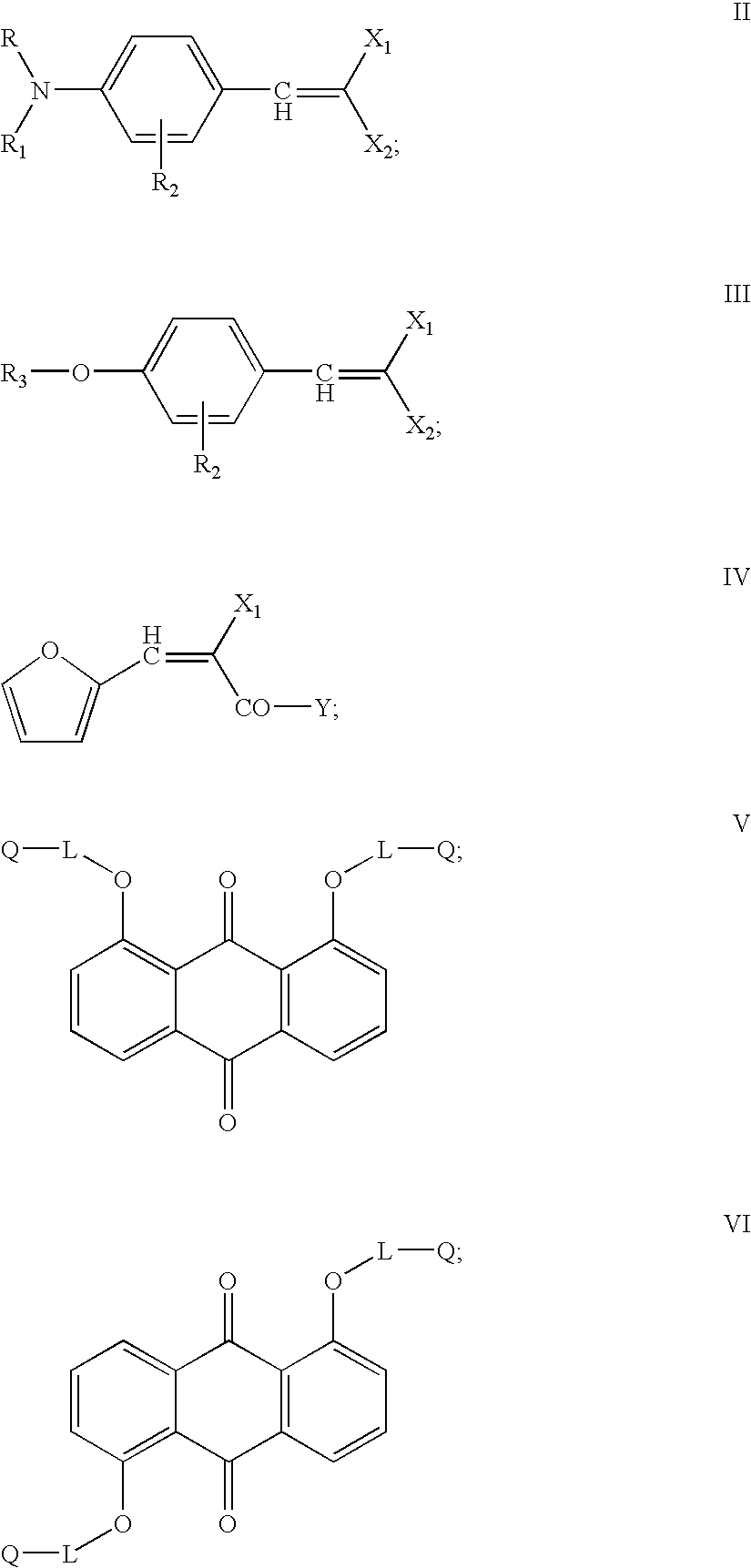

A method for marking a liquid petroleum hydrocarbon. The method comprises adding to the liquid petroleum hydrocarbon at least one substituted anthraquinone dry having formula (I) wherein X is O or S; Y is O, NR<7 >or S; R<1 >and R<2 >independently are hydrogen, alkyl, aryl, aralkyl, heteroalkyl, heterocyclic or alkanoyl; R<3 >and R<5 >independently are alkyl, aryl, aralkyl, heteroalkyl or heterocyclic; R<4 >and R<6 >independently are hydrogen or alkyl; R<7 >is hydrogen or alkyl; and wherein the substituted anthraquinone dye(s) has an absorption maximum in the range from 600 nm to 750 nm.

Owner:ROHM & HAAS CO

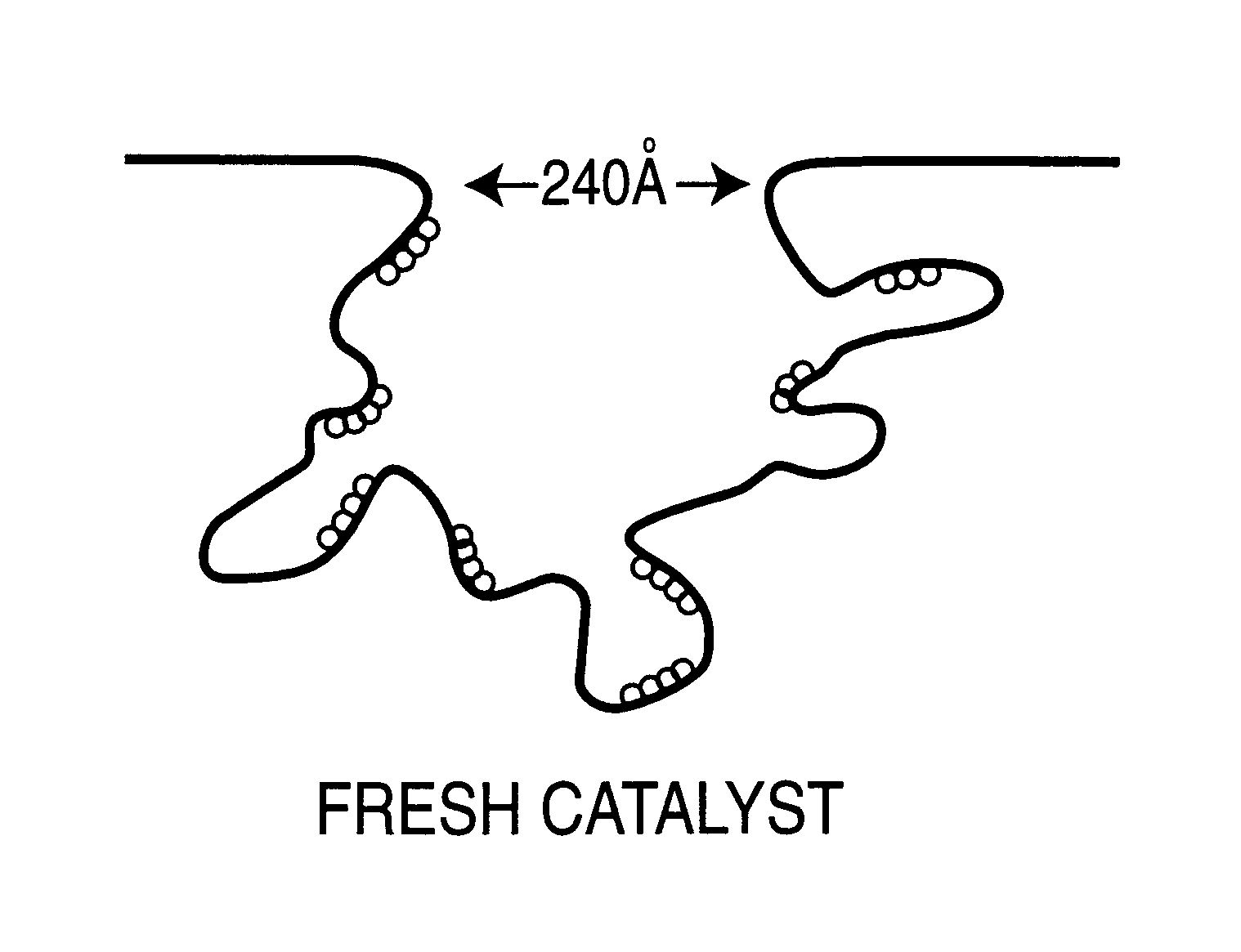

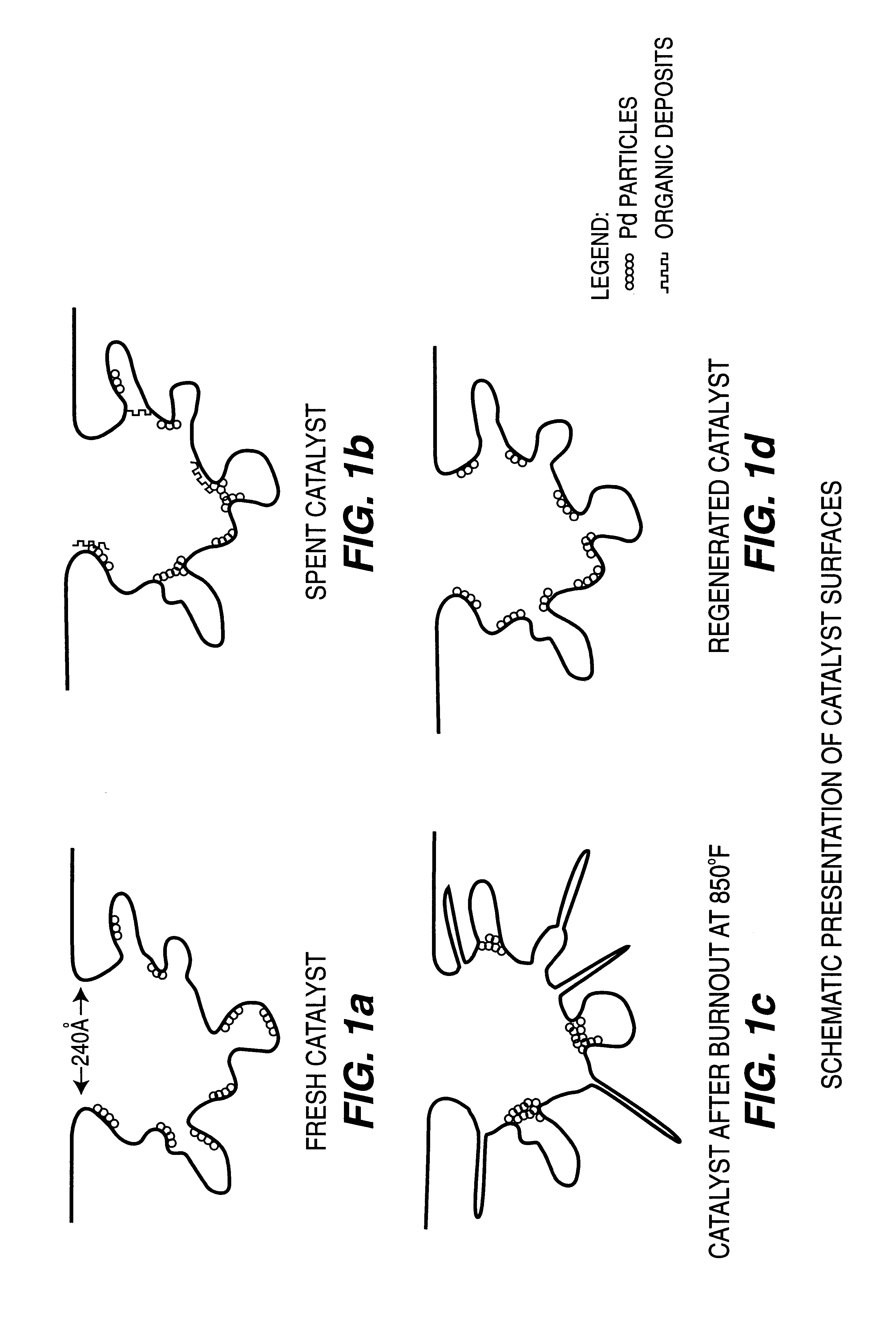

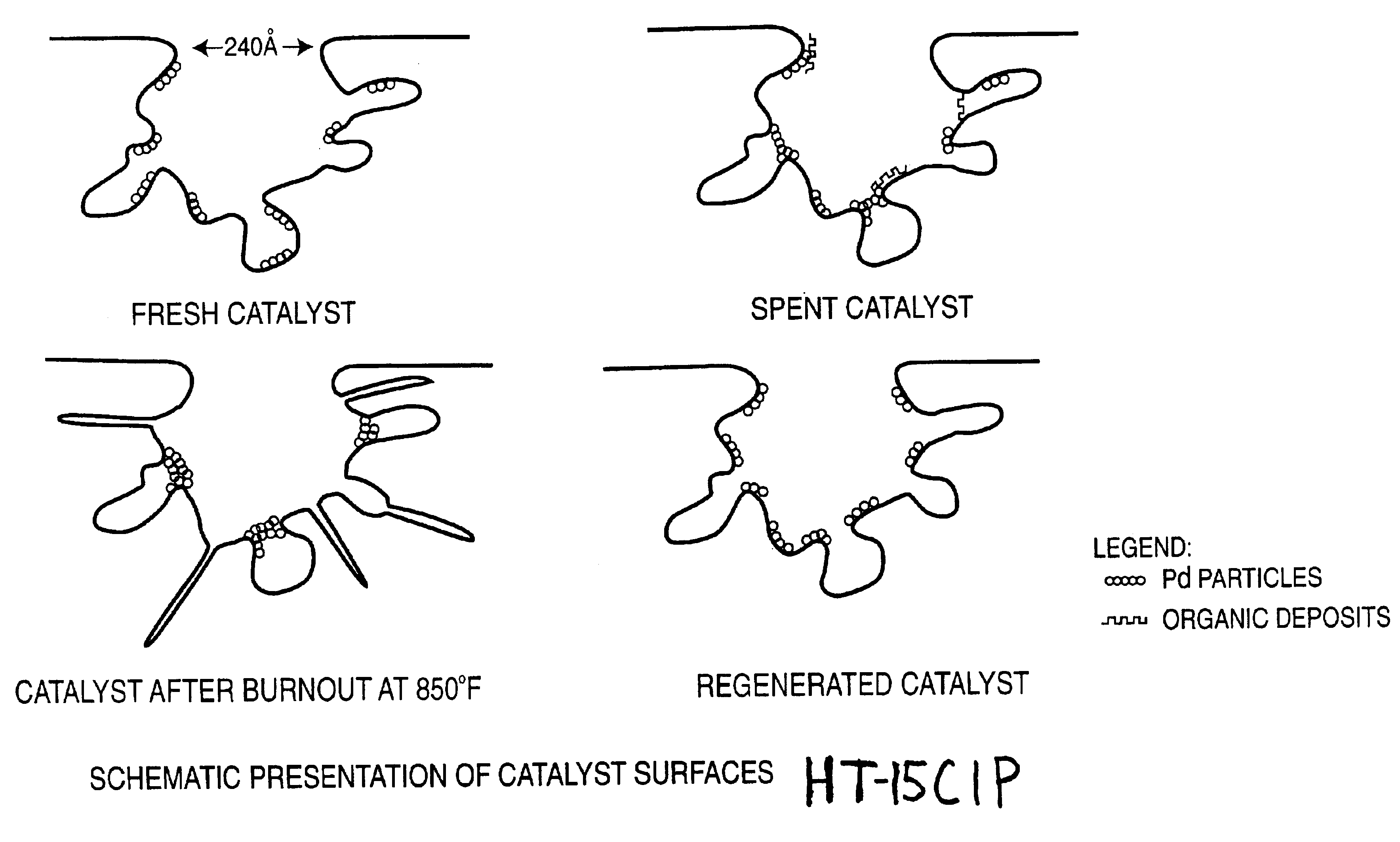

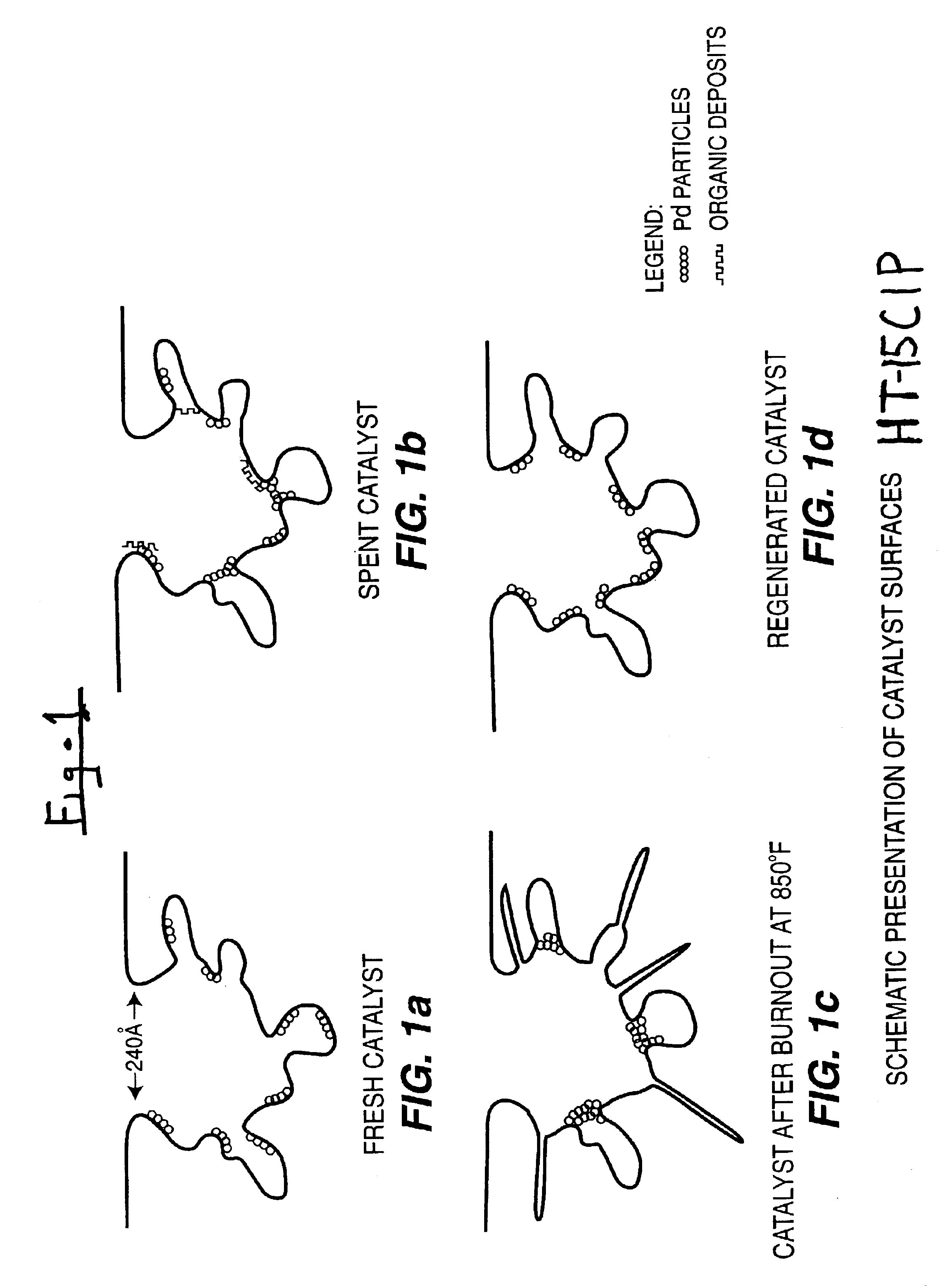

Regeneration of used supported noble metal catalysts

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

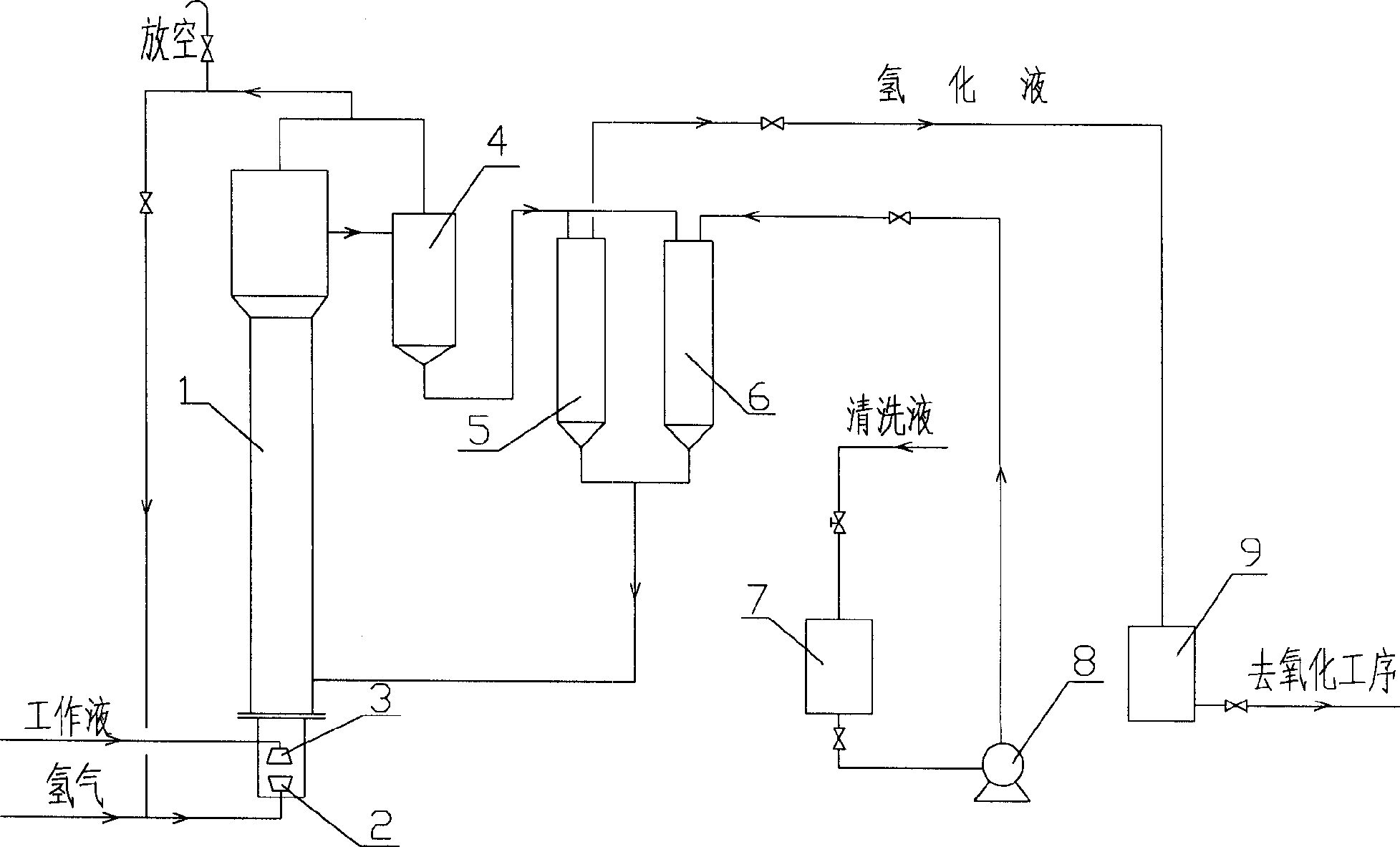

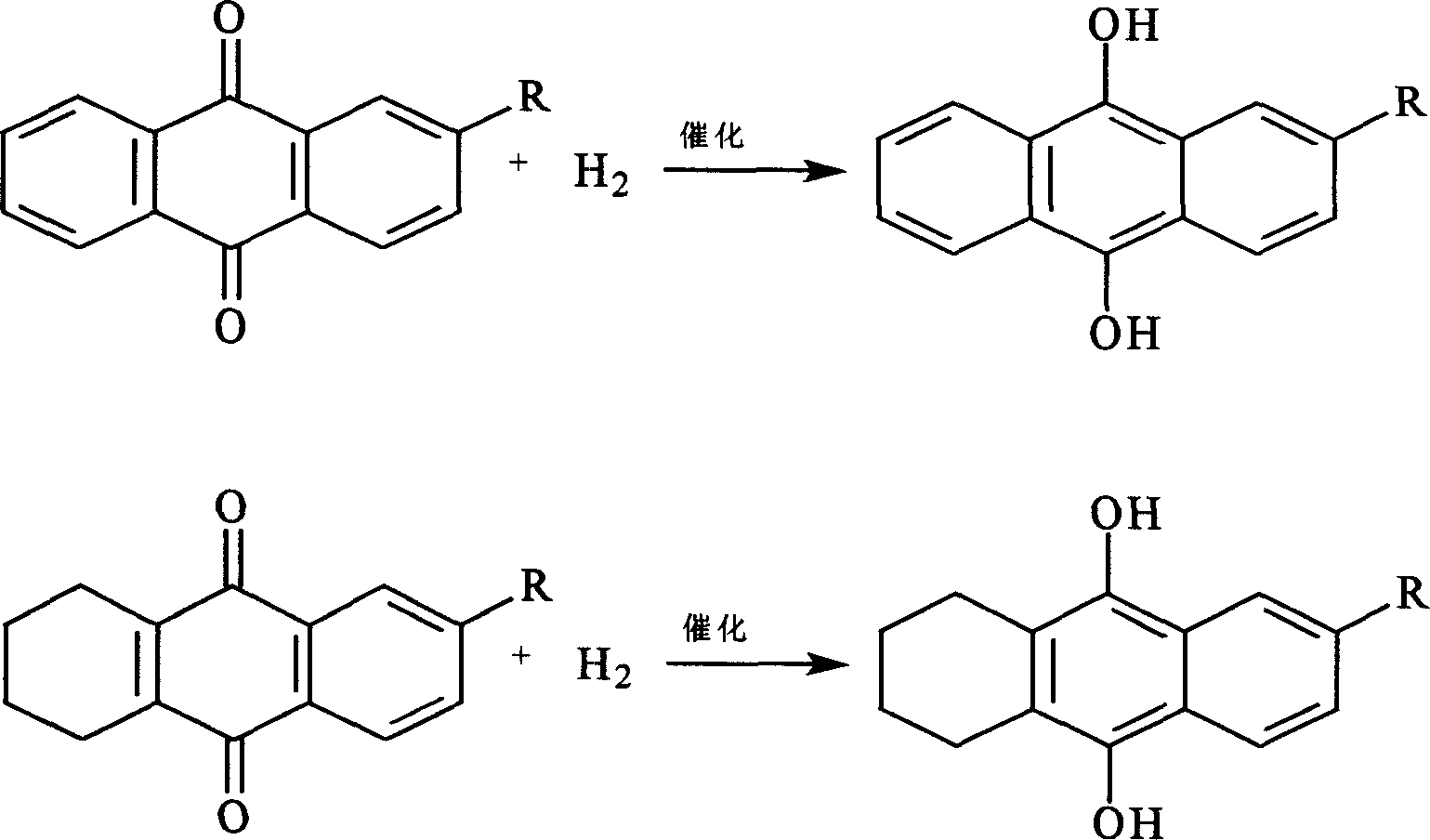

Hydrogenation process of hydrogen peroxide fluidized bed by anthraquinone

InactiveCN1817838AIncrease production capacityReduce differential pressureOrganic chemistryOrganic compound preparationFluidized bedHydrogenation process

A hydrogenation process for producing fluidized bed with hydrogen peroxide by anthraquinone method is carried out by taking empty tower hydrogenation reactor with amplification section on top, moving operating liquid and hydrogen upward at specific speed, floating powdery catalyst in tower body, hydrogenation reacting by free contacting, separating hydrogenated liquid by gas-liquid separating system, filtering by filter system and oxidizing. It has fast hydrogenation speed, low resistance, homogenous distribution and higher utilization rate.

Owner:LIMING RES INST OF CHEM IND

Method for making positive working printing plates from a heat mode sensitive image element

InactiveUS6060218AEasy to prepareIncrease the lengthPhotosensitive materialsRadiation applicationsEngineeringMerocyanine dye

According to the present invention there is provided a method for making lithographic printing plates including the following steps a) preparing a heat mode imaging element consisting of a lithographic base with a hydrophilic surface and a top layer which top layer is sensitive to IR-radiation, comprises a polymer, soluble in an aqueous alkaline solution and is unpenetrable for an alkaline developer containing SiO2 as silicates; b) exposing imagewise said heat mode imaging element to IR-radiation; c) developing said imagewise exposed heat mode imaging element with said alkaline developer so that the exposed areas of the top layer are dissolved and the unexposed areas of the top layer remain undissolved characterized in that said top layer includes an IR-dye selected from the group consisting of indoaniline dyes, cyanine dyes, merocyanine dyes, oxonol dyes, porphine derivatives, anthraquinone dyes, merostyryl dyes, pyrylium compounds, diphenyl and triphenyl azo compounds and squarylium derivatives.

Owner:EASTMAN KODAK CO

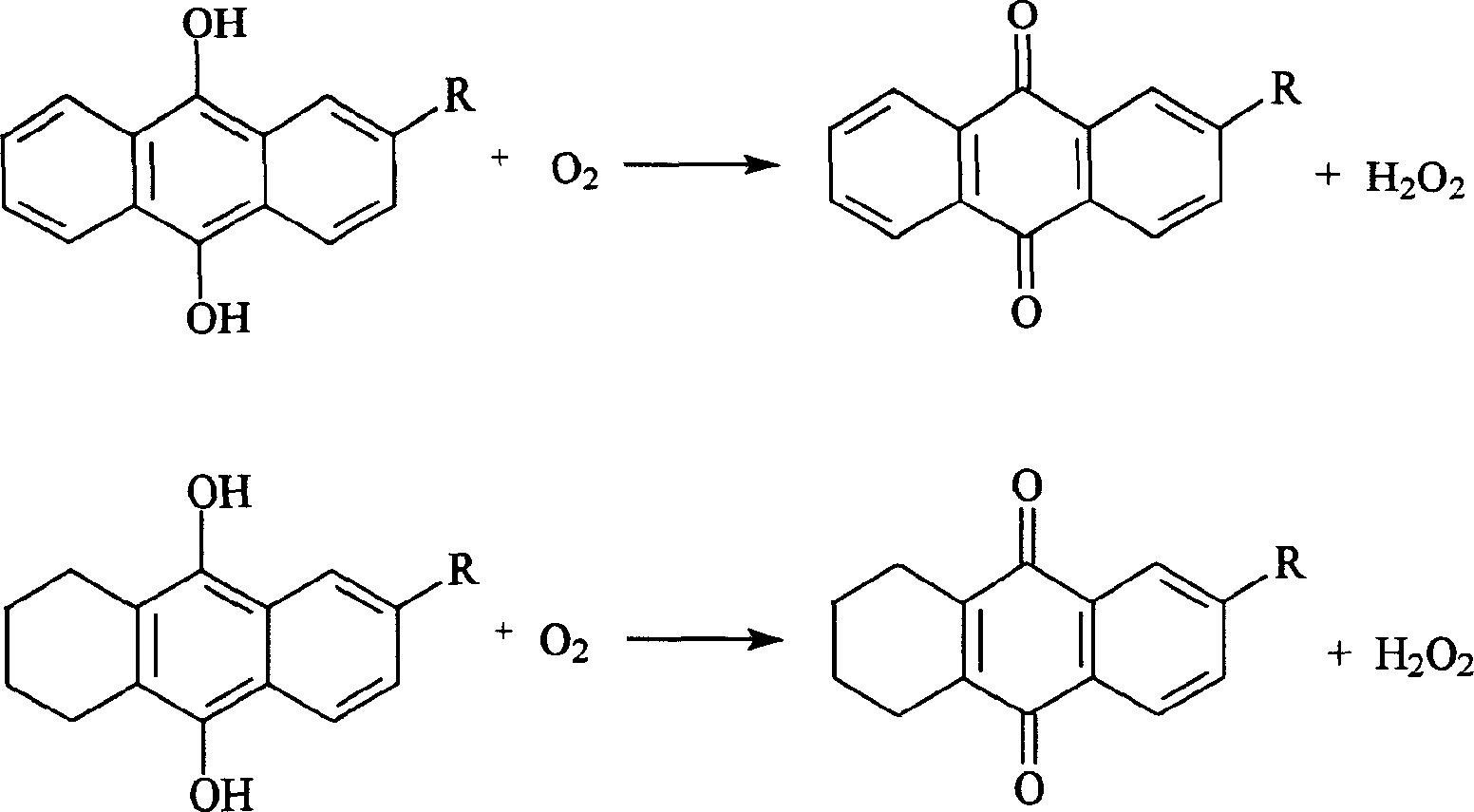

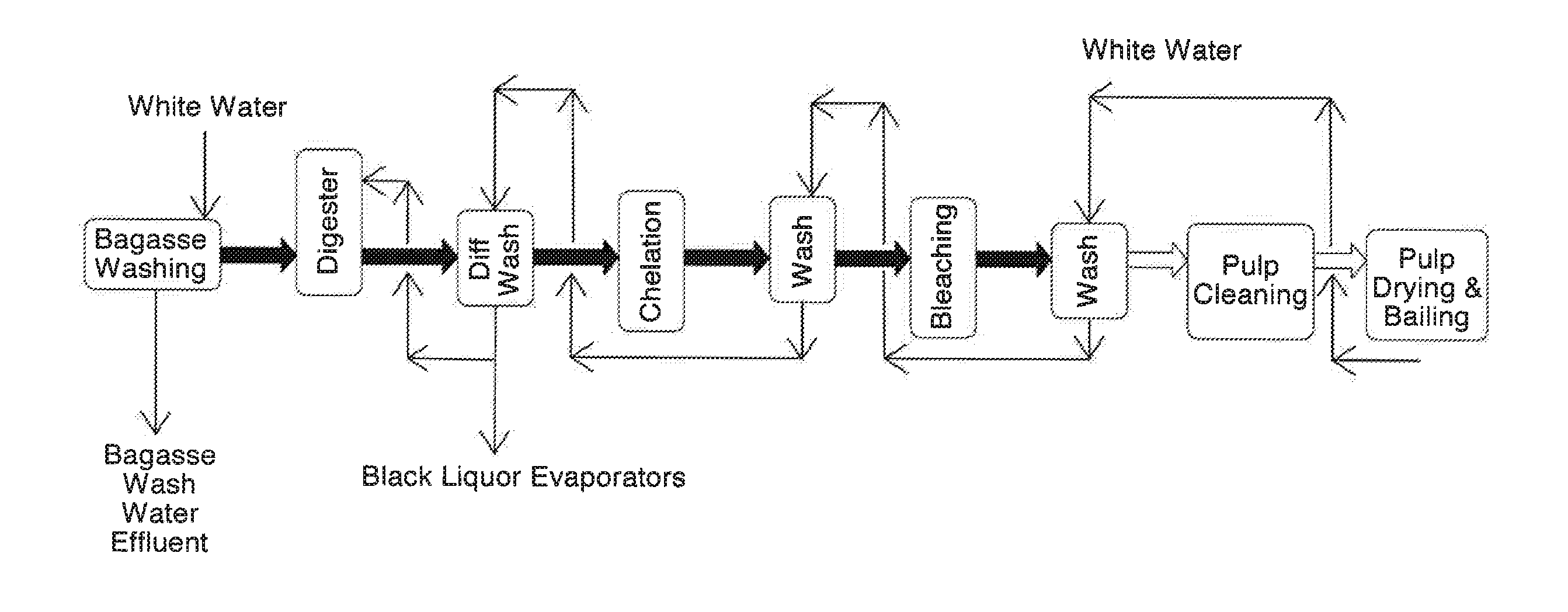

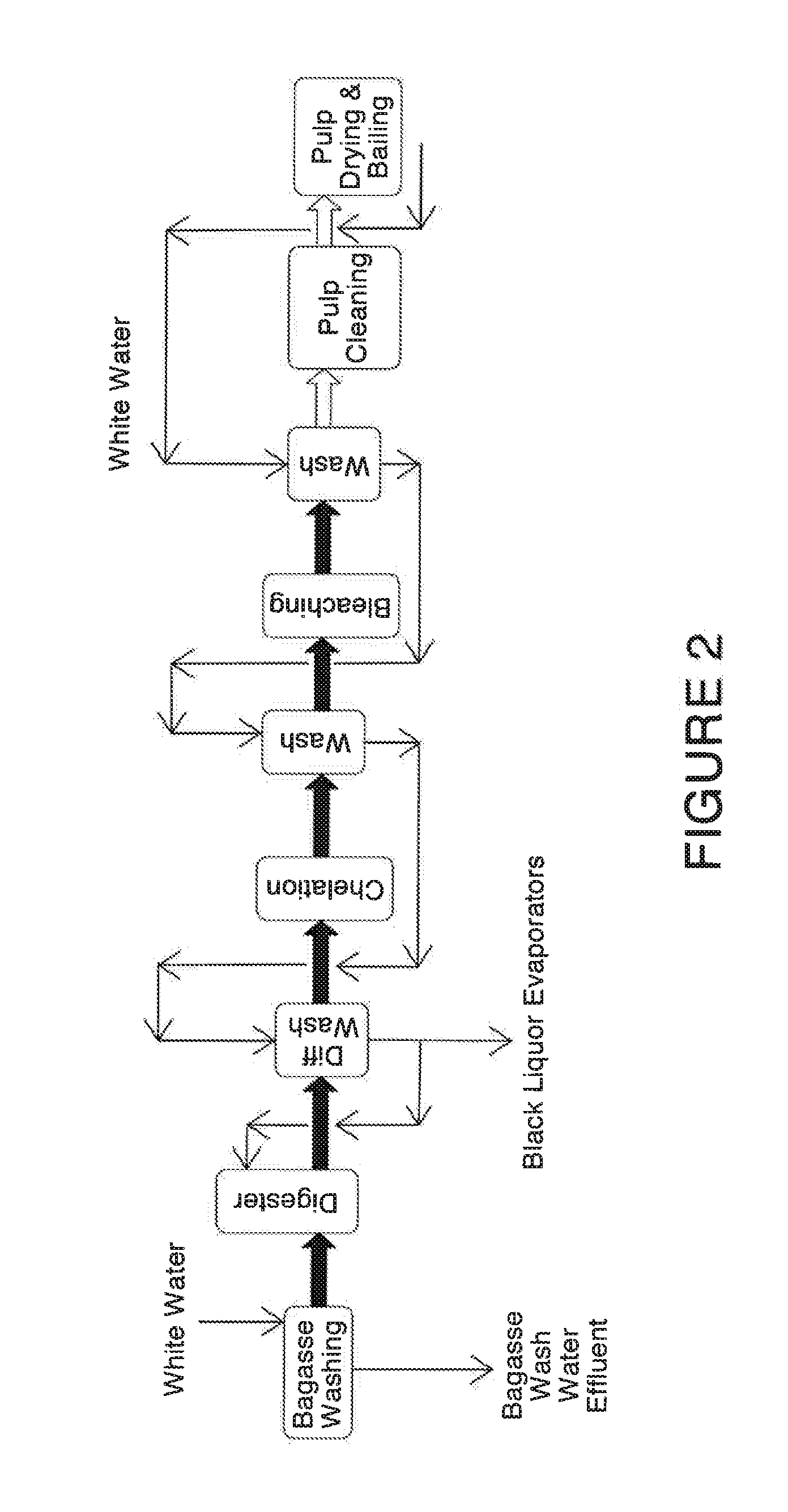

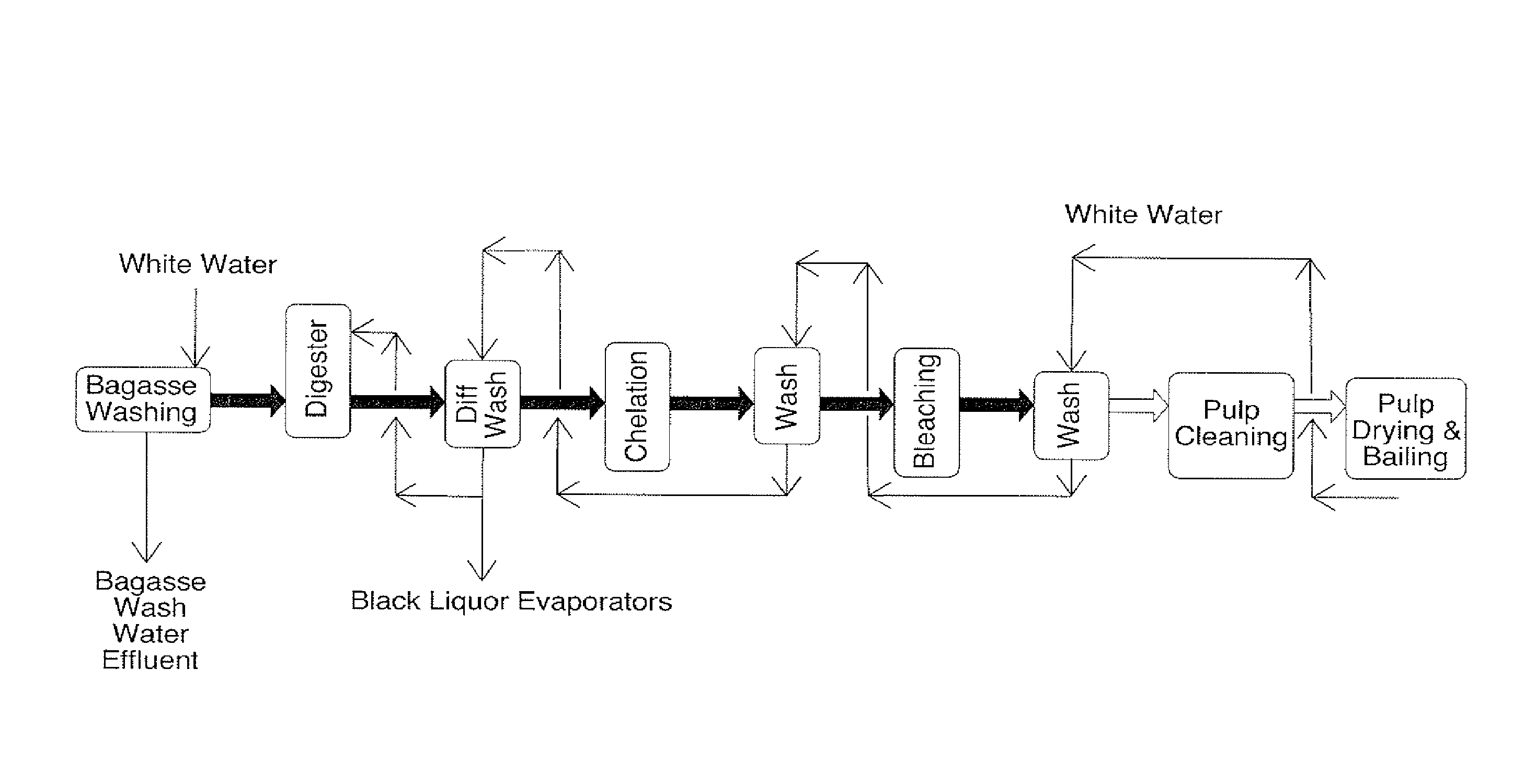

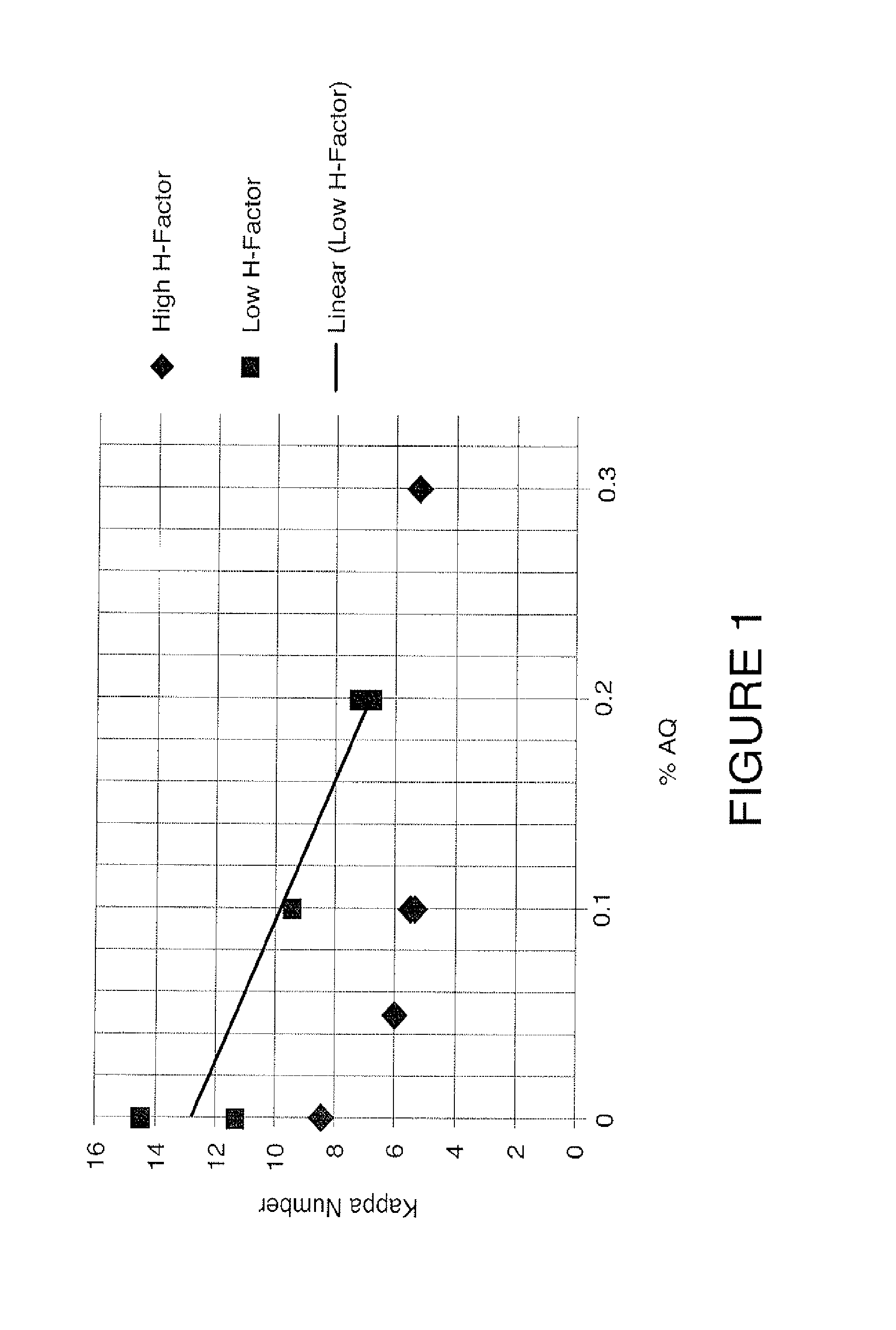

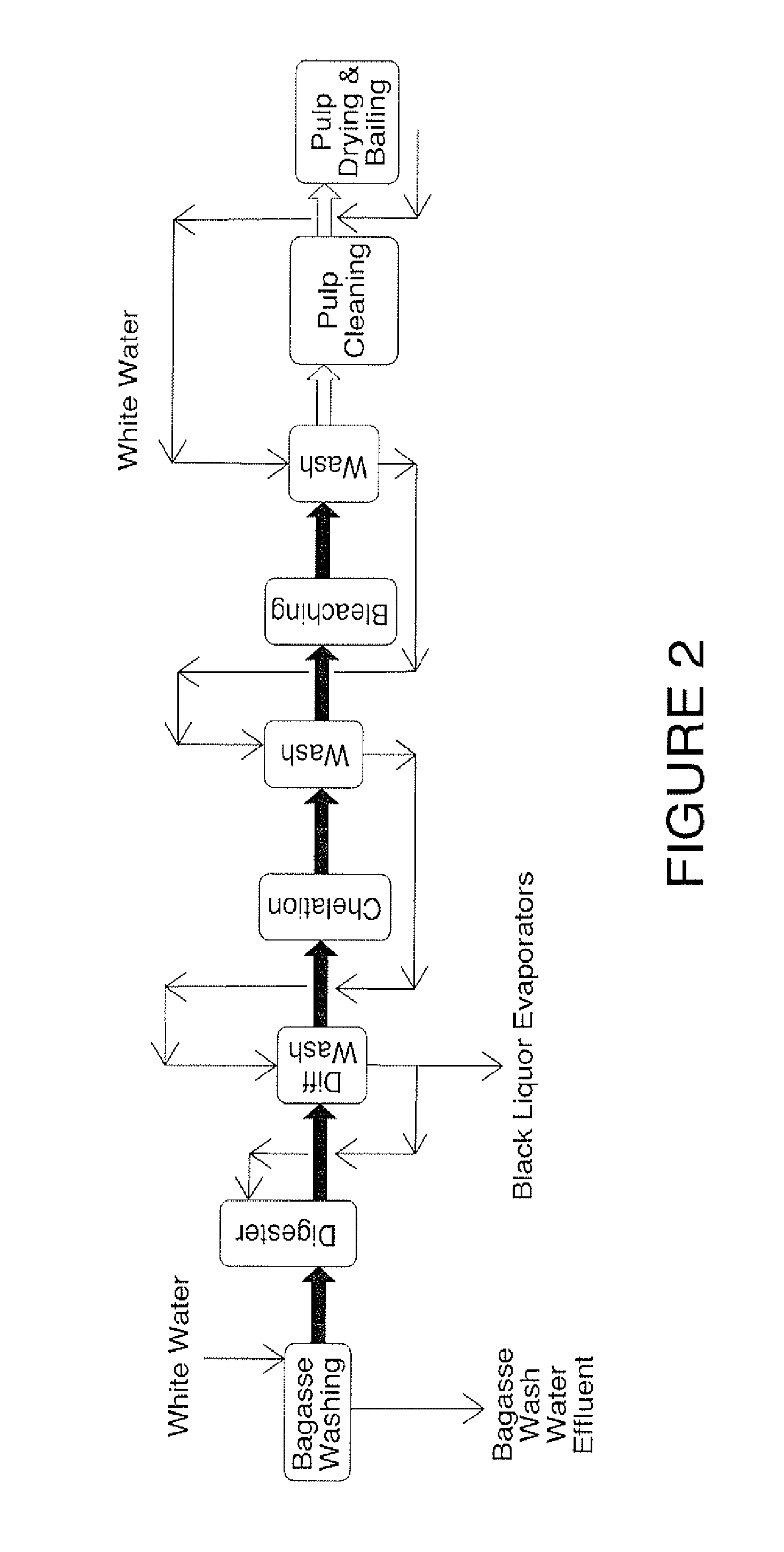

Pulping processes

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

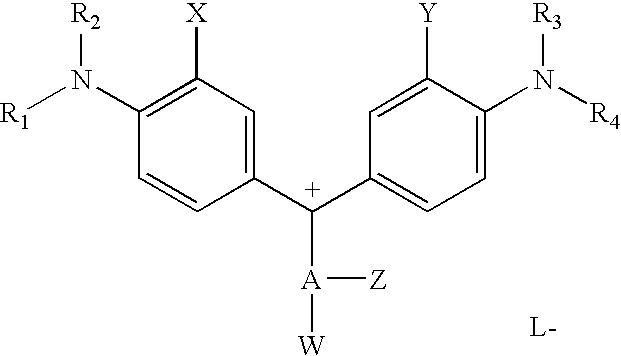

Laundry detergent compositions with hueing dye

ActiveUS20050288207A1Easy to optimizeCounter undesirable yellowingDetergent dyesNon-surface-active detergent compositionsNile blue stainOxazine dye

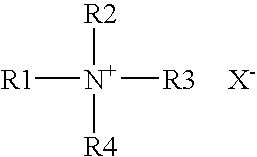

Laundry detergent compositions comprise (a) surfactant, and (b) a hueing dye selected from triarylmethane blue and violet basic dyes, methine blue and violet basic dyes, anthraquinone blue and violet basic dyes, azo dyes basic blue 16, basic blue 65, basic blue 66 basic blue 67, basic blue 71, basic blue 159, basic violet 19, basic violet 35, basic violet 38, basic violet 48, oxazine dyes, basic blue 3, basic blue 75, basic blue 95, basic blue 122, basic blue 124, basic blue 141, Nile blue A and xanthene dye basic violet 10, and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Liquid crystal aligning agent, polyorganosiloxane, liquid crystal aligning film, forming method thereof and liquid crystal display element

ActiveCN101735825AImprove stabilityLiquid crystal compositionsPhotomechanical apparatusEpoxyAcetophenone

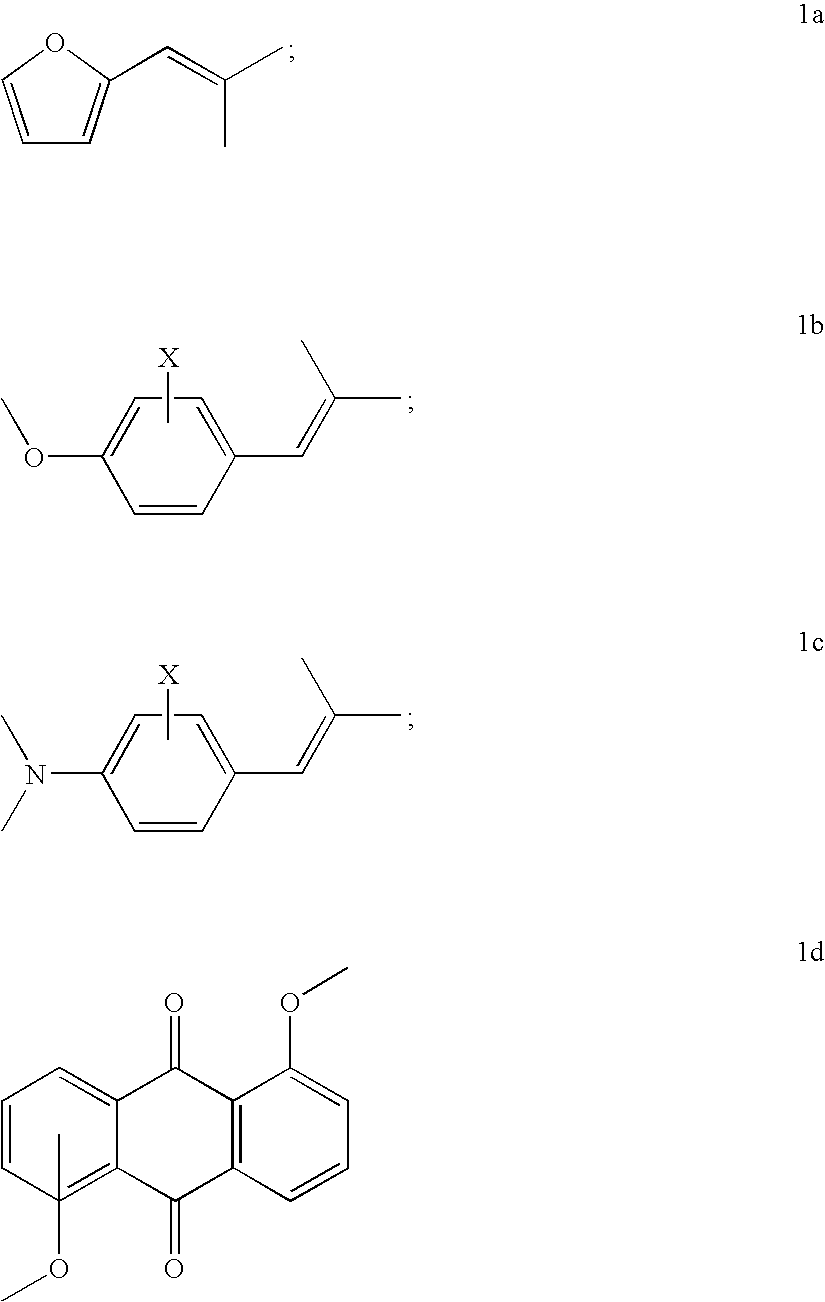

The present invention relates to a liquid crystal aligning agent, polyorganosiloxane, a liquid crystal aligning film, a forming method thereof and a liquid crystal display element. The present invention provides the liquid crystal aligning agent which can form the liquid crystal aligning film that can generate a pretilt angle with long time stability through an optical aligning method. The liquid crystal aligning agent comprises radiation-sensitive linear polyorganosiloxane which is prepared through the reaction of the following components: specific polyorgansiloxane with epoxy radical; (A) cinnamic acid derivative; and (B) a specific compound with a radiation-sensitive structure that is preferably selected from: acetophenone structure, benzophenone structure, anthraquinone structure, biphenyl structure, carbazole structure, nitro-aryl structure, fluorenes structure, naphthalene structure, anthracene structure, acridine structure and indole structure.

Owner:JSR CORPORATIOON

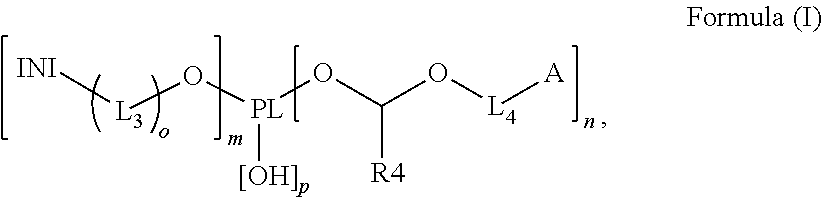

Polymerizable polymeric photoinitiators and radiation curable compositions

InactiveUS20120046376A1Simple and cost efficient procedureAvoiding unecological removal of solventInksVinyl etherPhosphine oxide

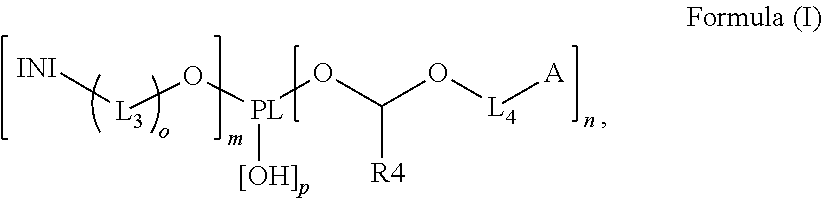

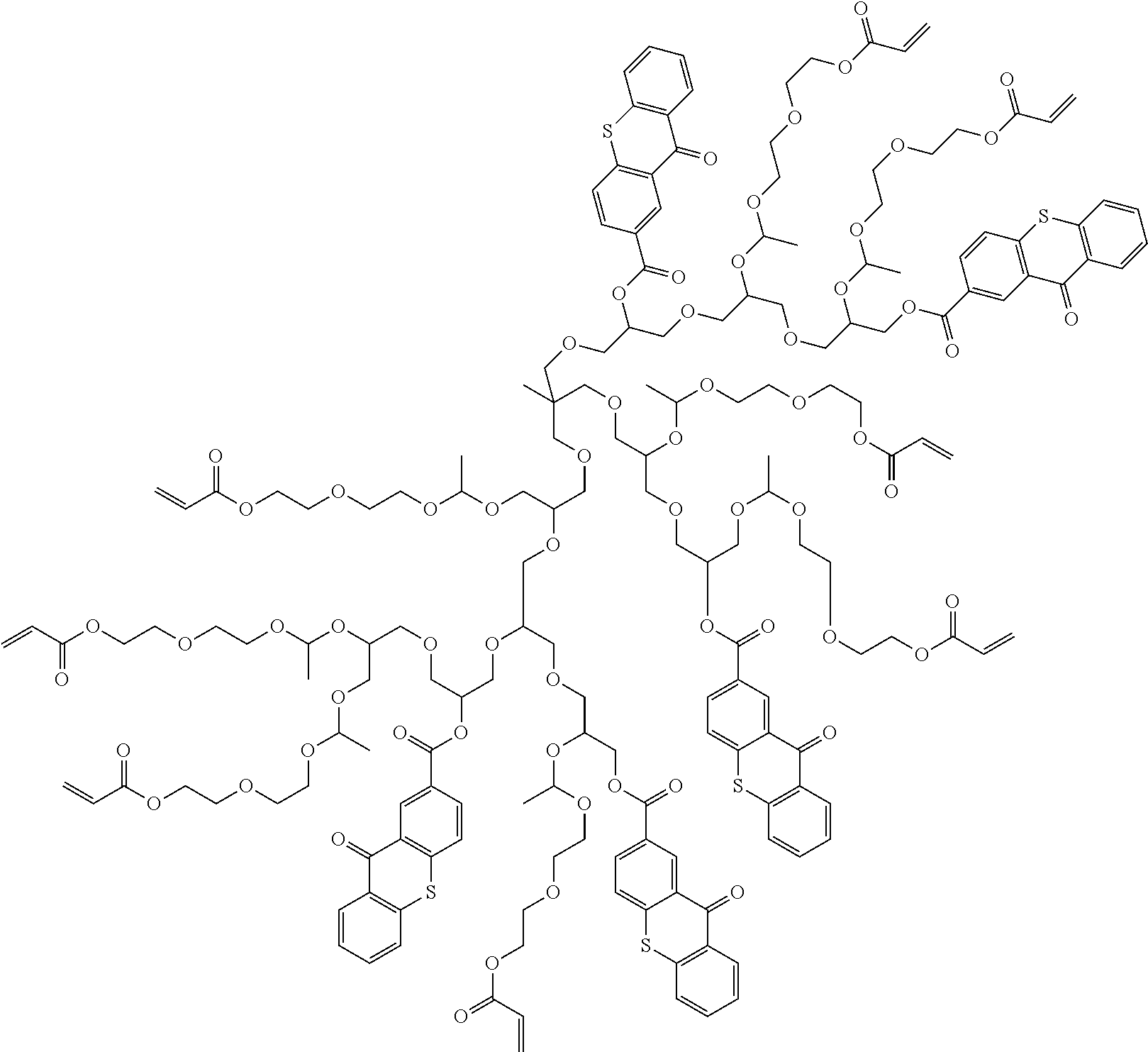

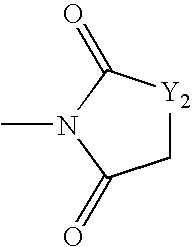

A polymerizable polymeric photoinitiator according to Formula (I):wherein:PL represents an n+m+p-functional polymeric core;n and m independently represent an integer from 1 to 30;p represents an integer from 0 to 10;o is 0 or 1;INI represents a group selected from the group consisting of a benzophenone, a thioxanthone, a carbazole, a anthraquinone, a camphor quinone, an α-hydroxyalkylphenone, an α-aminoalkylphenone, an acylphosphine oxide, a bisacyl phosphine oxide, an acylphosphine sulfide, a phenyl glyoxalate, a benzoin ether, a benzyl ketal, an α-dialkoxyacetophenone, a carbazolyl-O-acyl-oxime, an α-haloarylketone and an α-haloaryl sulfone;L3 and L4 represent a substituted or unsubstituted divalent linking group comprising 1 to 14 carbon atoms;A represents a radically polymerizable functional group selected from the group consisting of an acrylate, a methacrylate, a styrene, an acryl amide, a methacryl amide, a maleate, a fumarate, an itaconate, an vinyl ether, an allyl ether, an allyl ester, a maleimide, a vinyl nitrile and a vinyl ester; andR4 represents a substituted or unsubstituted alkyl group.Radiation curable compositions containing the polymerizable polymeric photoinitiator and methods for preparing the polymerizable polymeric photoinitiator are also disclosed.

Owner:AGFA NV

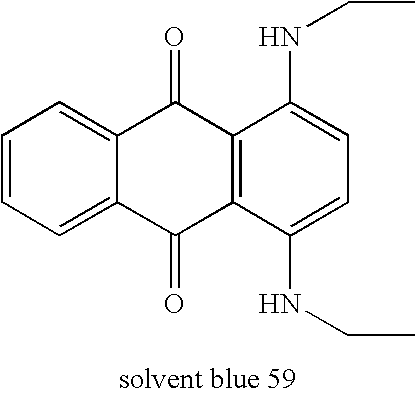

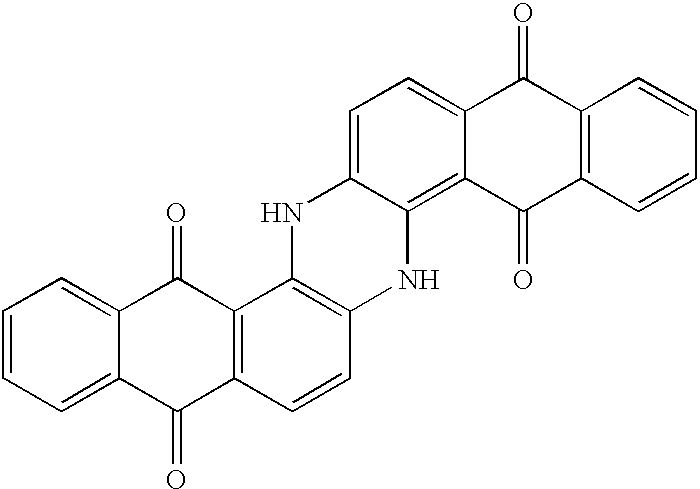

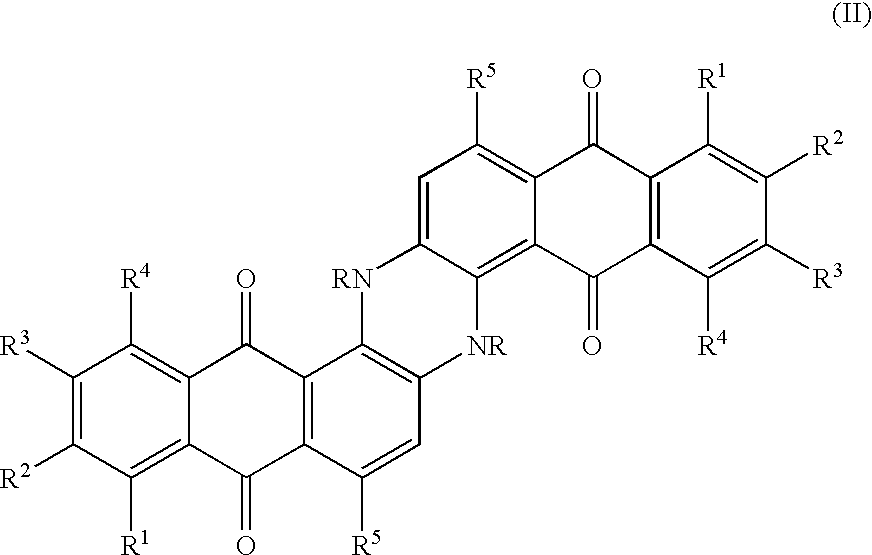

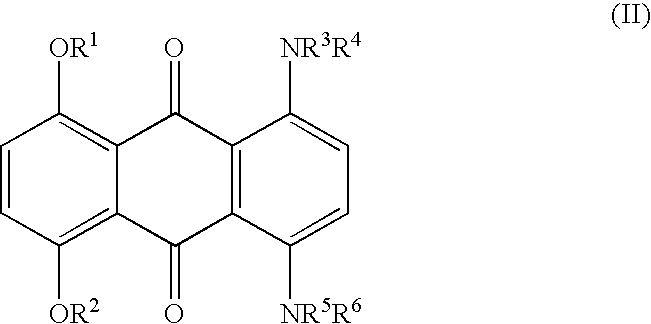

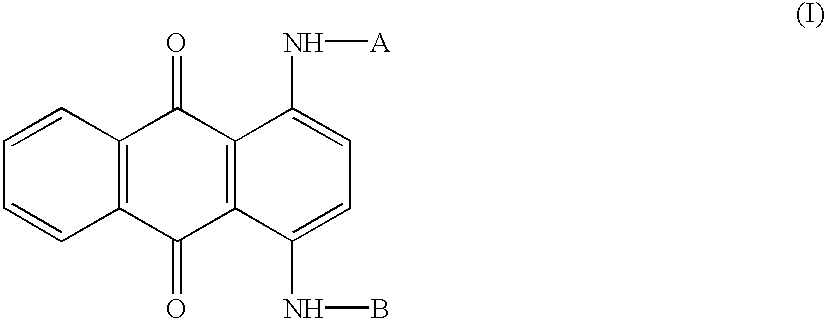

Articles comprising novel polymeric blue anthraquinone-derivative colorants

A blue colorant comprising a chromophore having at least one poly(oxyalkylene) chain attached, through aromatic amino group (or groups), to the 1-position, the 4-position, or both, of an anthraquinone backbone is provided. Such colorants exhibit excellent amine / base stability and thermal stability, effective colorations, excellent low extraction rates, and high lightfastness levels, particularly when incorporated within certain media and / or on the surface of certain substrates, particularly polyesters, polyolefins, and polyurethanes. The poly(oxyalkylene) chain or chains can be conveniently tailored to increase the solubility or compatibility in different solvents or resins thereby permitting the introduction of such excellent coloring chromophores within diverse media and / or or diverse substrates as well as provides a liquid colorant which facilitates handling. Compositions and articles comprising such colorants are provided as well as methods for producing such inventive colorants.

Owner:MILLIKEN & CO

Copolymerizable methine and anthraquinone compounds and articles containing them

InactiveUS20060115516A1Reduce intensityLoss of absorption propertyOrganic chemistryAmino-anthraquinone dyesUltraviolet lightsPhotochemistry

This invention relates to polymerizable ultraviolet light absorbers and yellow colorants and their use in ophthalmic lenses. In particular, this invention relates to polymerizable ultraviolet light absorbing methine compounds and yellow compounds of the methine and anthraquinone classes that block ultraviolet light and / or violet-blue light transmission through ophthalmic lenses.

Owner:ADVANCED MEDICAL OPTICS

Integral catalyst for producing hydrogen dioxide solution as well as preparation and application thereof

InactiveCN101497040AImprove mass transfer efficiencyReduce internal mass transfer resistancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationActive componentHydrogenation reaction

The invention provides a monolithic catalyst for oxydol production and a preparation method thereof. The catalyst uses ceramic monolithic honeycomb or metal monolithic honeycomb as a substrate, one or more of Al2O3, SiO2, CaO, MgO, TiO2, ZrO2, La2O3, CeO2, Fe2O3 and Cr2O3 as a coating material, and noble metal palladium as an active component to be used in an anthraquinone hydrogenation reaction of oxydol production. The monolithic catalyst adopts a preparation method of fractional support so as to effectively control depth of impregnation of the active component. The monolithic catalyst used in the anthraquinone hydrogenation process has the advantages of high activity, good selectivity and 82.21kg (100 percent of H2O2) / mcat.h of space-time yield of the oxydol, which is over 3 times more than a commercial bead catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Supported palladium catalyst for producing hydrogen peroxide by anthraquinone process and preparing method thereof

InactiveCN1435277AImprove catalytic performanceImprove overall lifespanPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsPhosphateActive component

A carried Pd-alumina catalyst for preparing hydrogen peroxide by anthraquinone method is prepared from Pd as main active component and Al2O3 as carrier through impregnation. Said Al2O3 has been coated by RE oxide and calcined at 900-1000 deg.C. It has high hydrogenating efficiency of 8-9 gH2O2 / L for 2-ethyl anthraquinone / heavy arene plus trioctyl phosphate or 10-13 gH2O2 / L for (2-tert-butyl anthraquinone plus 2-ethyl anthraquinone) / (heavy arene plus tetrabutyl urea).

Owner:FUZHOU UNIV

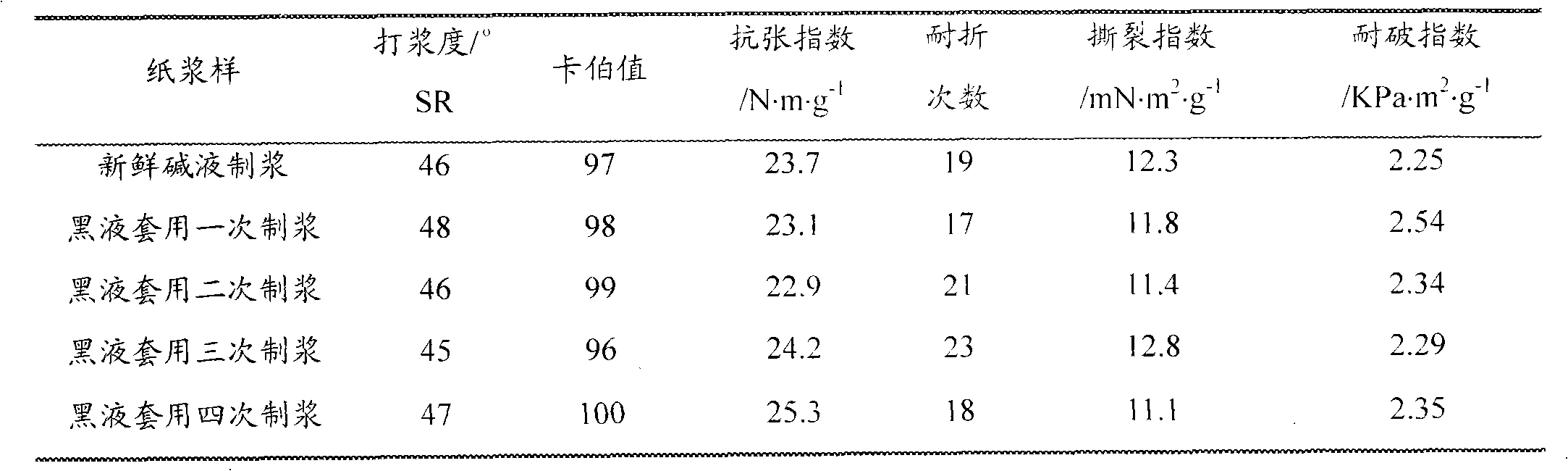

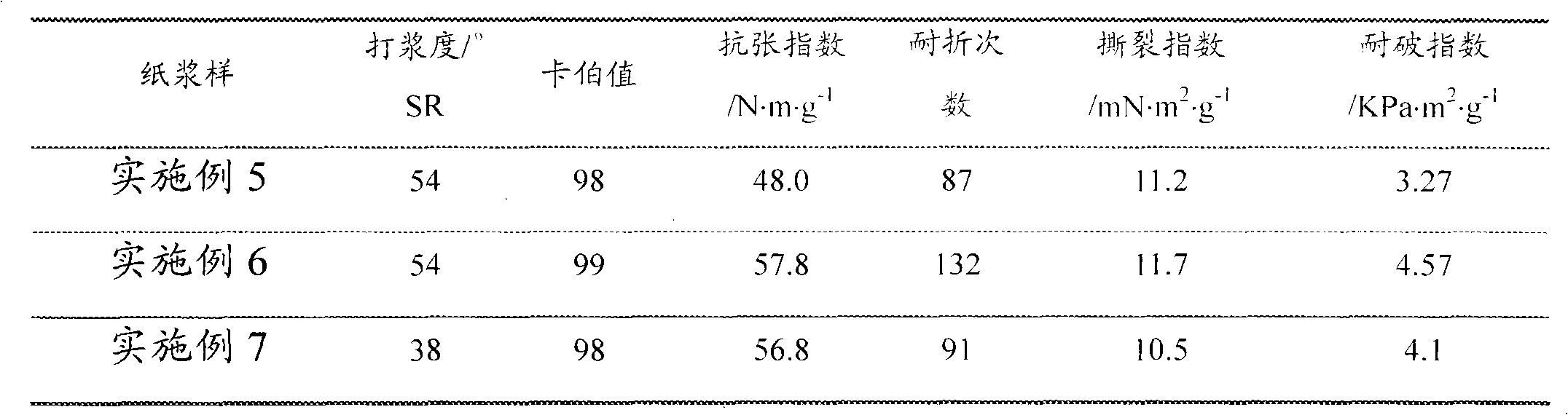

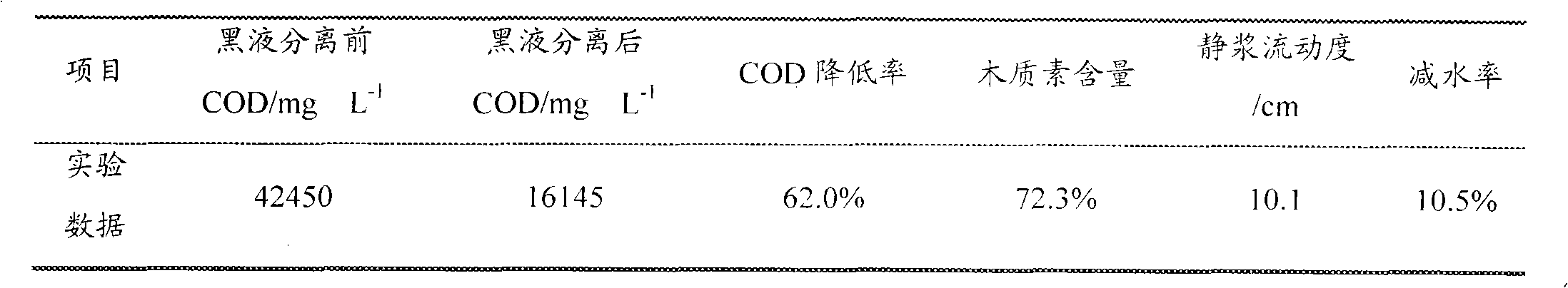

Novel pulping process for obtaining high performance fiber at high yield from plants

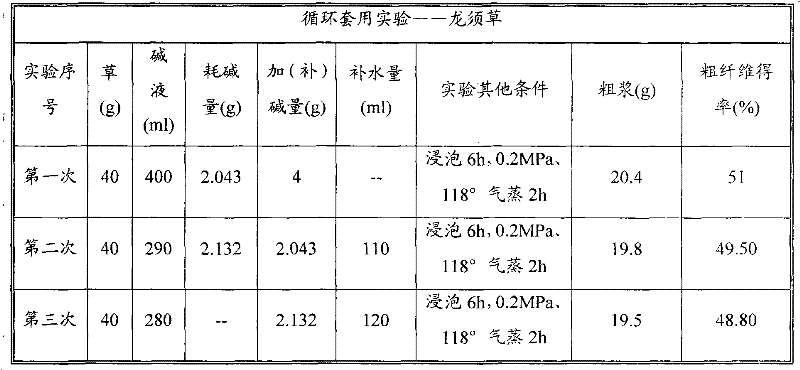

ActiveCN102337687AGood physical propertiesAvoid influencePulp beating methodsPulping with inorganic basesChemical treatmentFiber

The invention relates to a cleaning process for extracting high quality fiber with high efficiency, high yield and low energy consumption from plant raw materials by a combination method of chemistry and machinery in a sectional type. The process comprises the following steps: a raw material is fully immersed in a NaOH solution or a KOH solution or limewater with low concentration (black liquor is used for supplementing into the corresponding alkaline for repeated and circular use) under the normal temperature or certain temperature, wherein the concrete immersion temperature and immersion time can be determined according to the types and the water content of the raw materials so that the alkaline liquor is fully, uniformly and properly absorbed and diffused into plants; steaming under normal pressure or steaming with pressure or no liquid steaming with pressure is used; the steamed material can be selected according to the paper quality requirement by using a blowout slurrying mode or a mode of pulp refining after blowing to form slurry or by using thread rolling and pulp refining to relief material once or multitime to prepare slurry. The novel process combines the advantages of chemical treatment and mechanical pulping, so that the uniform mass transfer and uniform heat transfer can be ensured and the damage to cellulose and hemicellulose by excessive alkali can be reduced, the yield of fiber is raised to about 75% from about 45% of the prior art, so that the novel pulping process is capable of avoiding the usage of auxiliary agents like sulfured and anthraquinone, conveniently extracting and using the cellulose and lignin in black liquor, and overcoming the influence on environment during the process of pulping and post-treating lignin.

Owner:BEIJING INSIGHT BIOMASS

Regeneration of spent supported metal catalysts

InactiveUS6908873B2Efficient removalImproves expositionOther chemical processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal catalystPalladium catalyst

Owner:EVONIK OPERATIONS GMBH

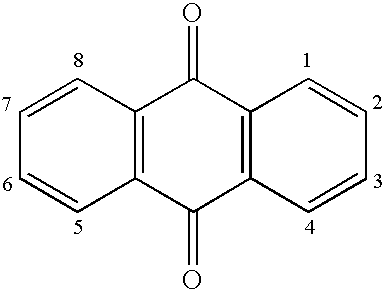

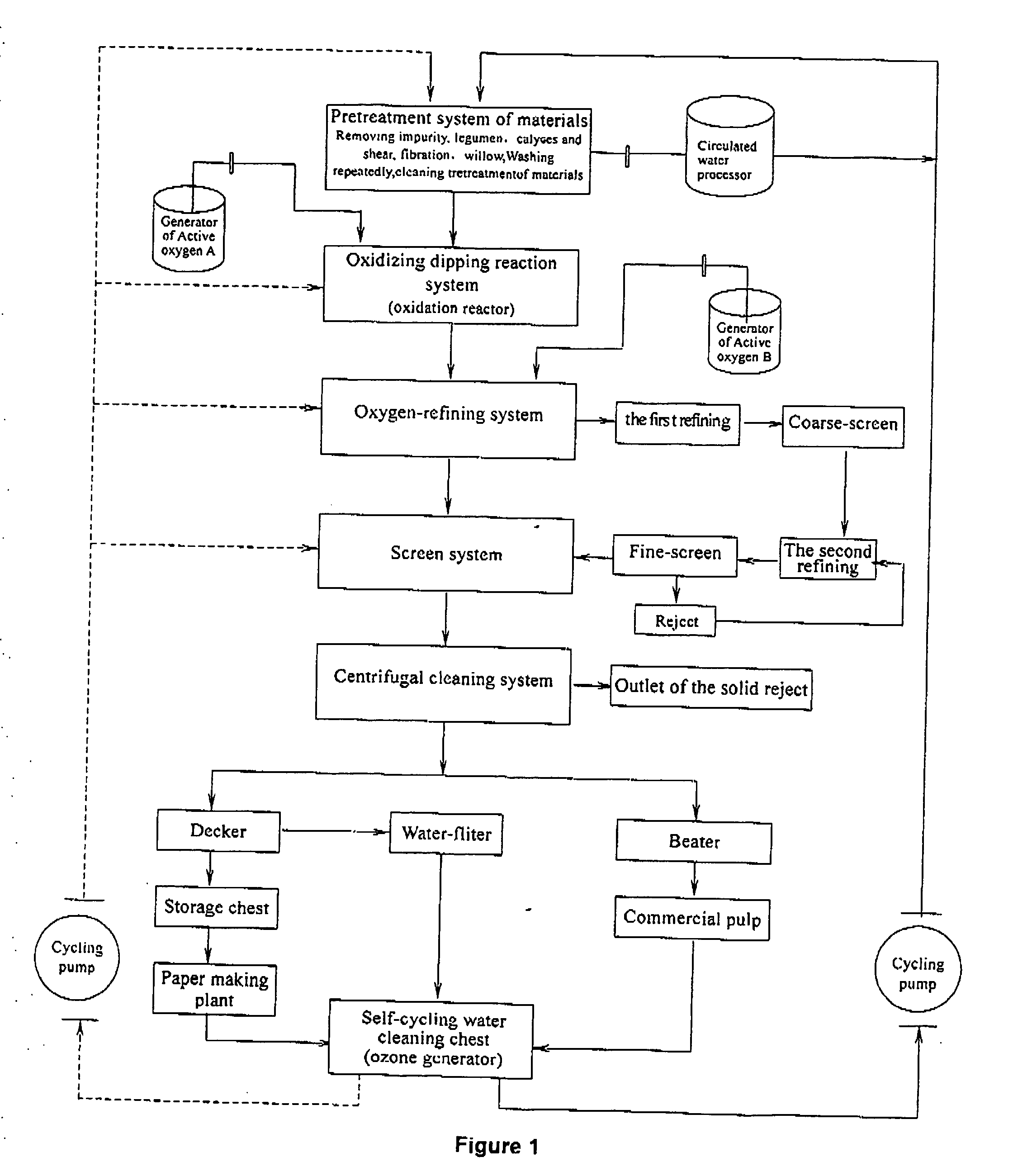

Odor-reducing quinone compounds

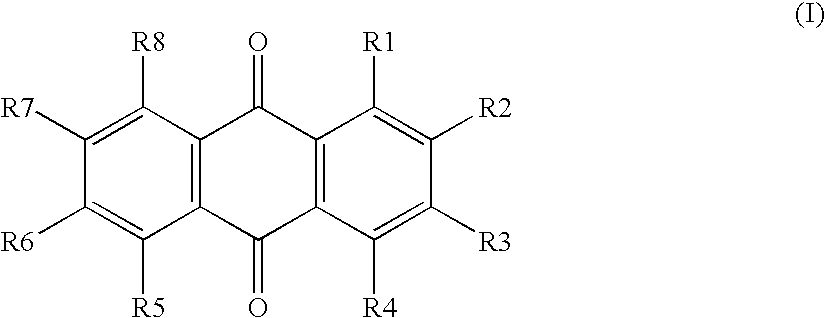

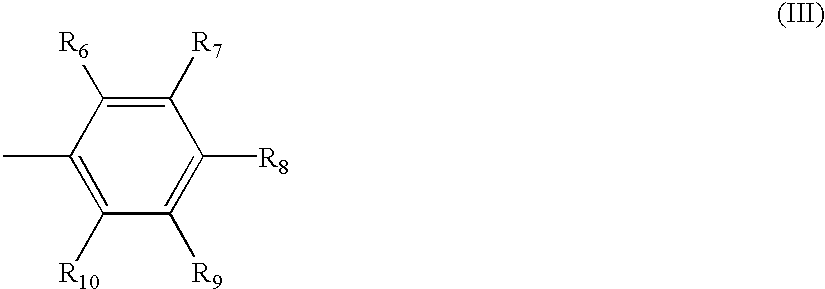

An odor control composition that comprises an odor-reducing quinone compound and optionally high surface area particles is provided. In one embodiment, the odor-reducing quinone compound is an anthraquinone having the following structure: wherein the numbers 1 through 8 refer to optional substitution positions for functional groups. For example, positions 5 through 8 of the anthraquinone may be unsubstituted with functional groups. Examples of such quinone compounds may include those obtained from a dye selected from the group consisting of Acid Blue 25, Acid Green 41, Acid Blue 45, Mordant Violet 5, Acid Blue 129, Acid Green 25, D&C Green No. 5, Acid Green 27, and combinations thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Textile ink composition

A textile ink composition and a method of manufacturing a textile ink composition are disclosed. The textile ink composition is formed from a cationically charged metal oxide and a dye, and is capable of durably dyeing different types of fabric. The cationically charged metal oxide is typically an oligomer, such as an alumina oligomer. A suitable alumina oligomer is aluminum chlorohydrate. Typical dyes have anthraquinone, catechol, hydroxyazo or salicylic acid groups or are mordant dyes, such as Carminic Acid, Alizarin Red, Acid Blue 45, Acid Green 41, Hematoxylin, Chromoxane Cyanine R, Calconcarboxylic Acid, Plasmocorinth B, Pyrocatechol, Acid Alizarin Violet N, Alizarin Yellow GG, Mordant Yellow 12 and Mordant Blue 9.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Anthraquinone hydrogenation catalyst

ActiveCN1990100APeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsCeriumManganese

The invention disclosed a anthraquinone hydrogenation catalyst; its character is the catalyst is made up of the matrix, support body and active component. The said matrix have openings at both ends of the rules parallel channel structure cordierite or foam alumina, the said support body coat on the surface of the matrix, mainly made up of gamma - alumina, zirconia and selected from cerium oxide, lanthanum oxide and oxidized protactinium in one or more, the weight is 5% to 35% of the body weight, the said active ingredient is loaded on the surface of the support body, made from A component or components A and B components of the mixture composition, Group A is Pd and / or platinum, it's weight is 0.5% to 5% of the support body, Group B is selected from titanium, zirconium, hafnium, manganese, drilling, cerium, lanthanum in one or more, it's weight is 0% to 1% of the support body.

Owner:CHINA PETROLEUM & CHEM CORP +1

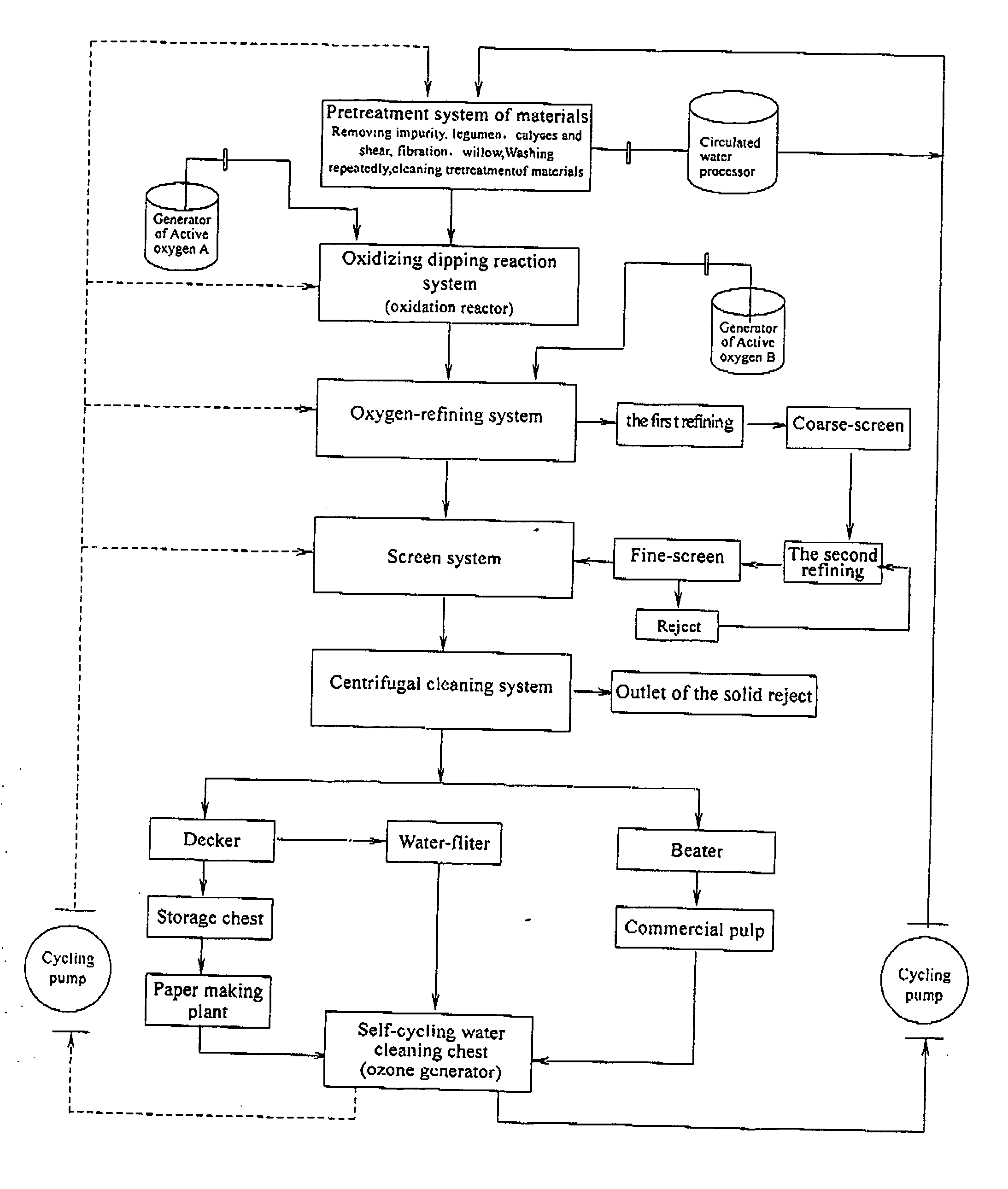

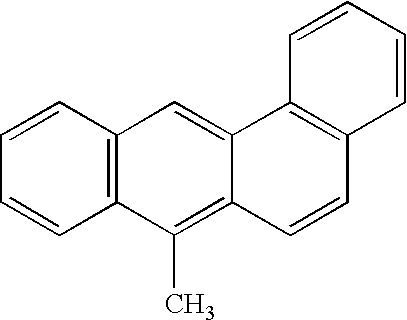

Fully Closed, Zero Discharge, Clean Oxidizing Pulping Technology and Process

InactiveUS20070272377A1Avoid pollutionSave energyPulp properties modificationPulp bleachingFiberLignin degradation

The aim of the present invention is to provide a close-loop, zero discharge and clean oxidation pulping method and technology. In accordance with present invention, it takes advantage of active oxygen free radical generated by reduction reaction of molecular oxygen in process reactor to transform and separate lignin to change chromophoric group in the intercellular space and obtain paper pulp. The conventional pulping technologies which use harmful polluting chemicals such as acid, alkaline, chlorine, anthraquinone and so on are basically changed in the present invention. The cooking and bleaching process, generating severe pollution, can be avoided. The abundant yearly grown fiber materials can be utilized in this process, and water and energy can be saved. The present invention can cut down production cost and have excellent social, economic and environmental performance.

Owner:MEI XIUQUAN

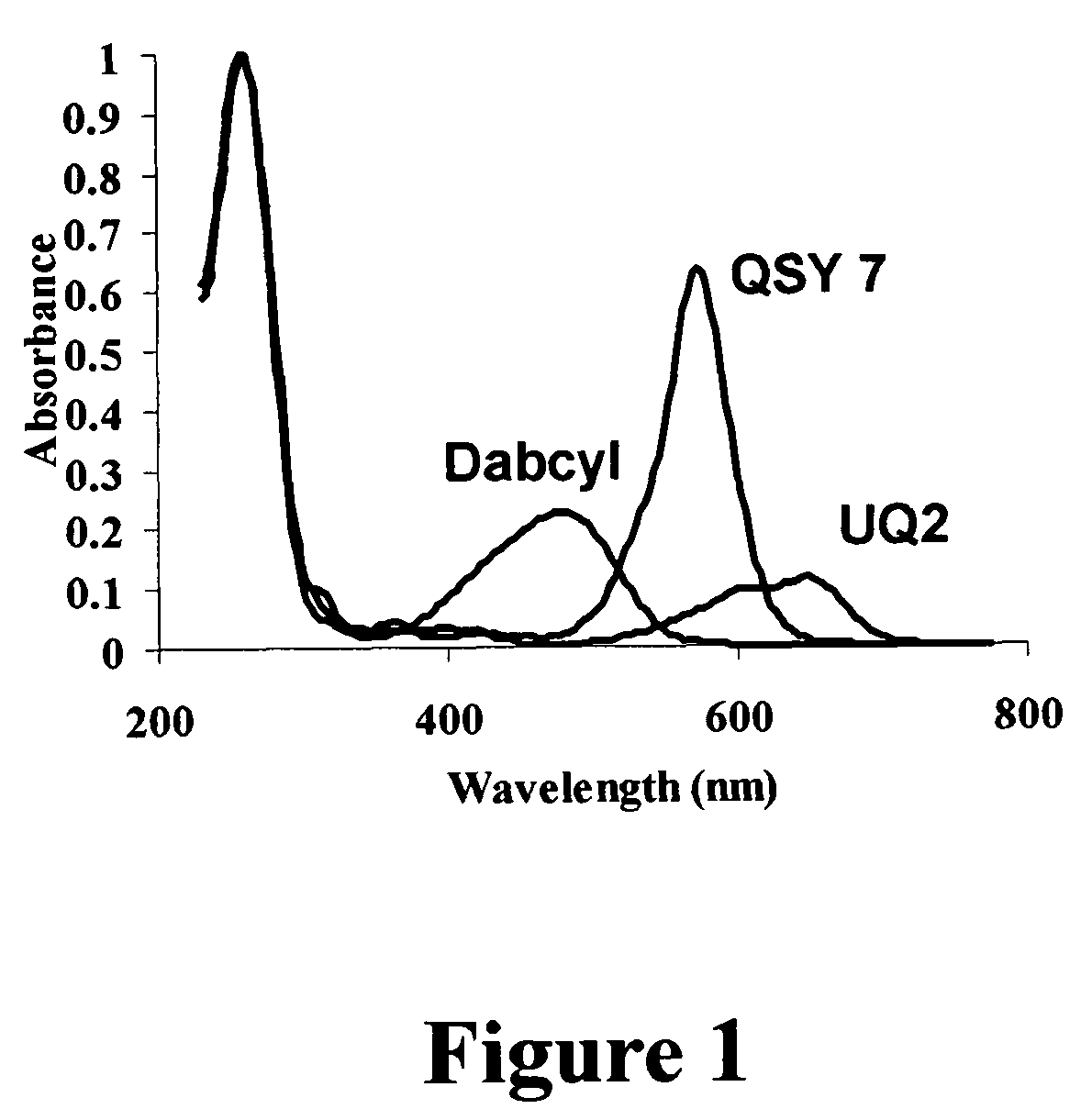

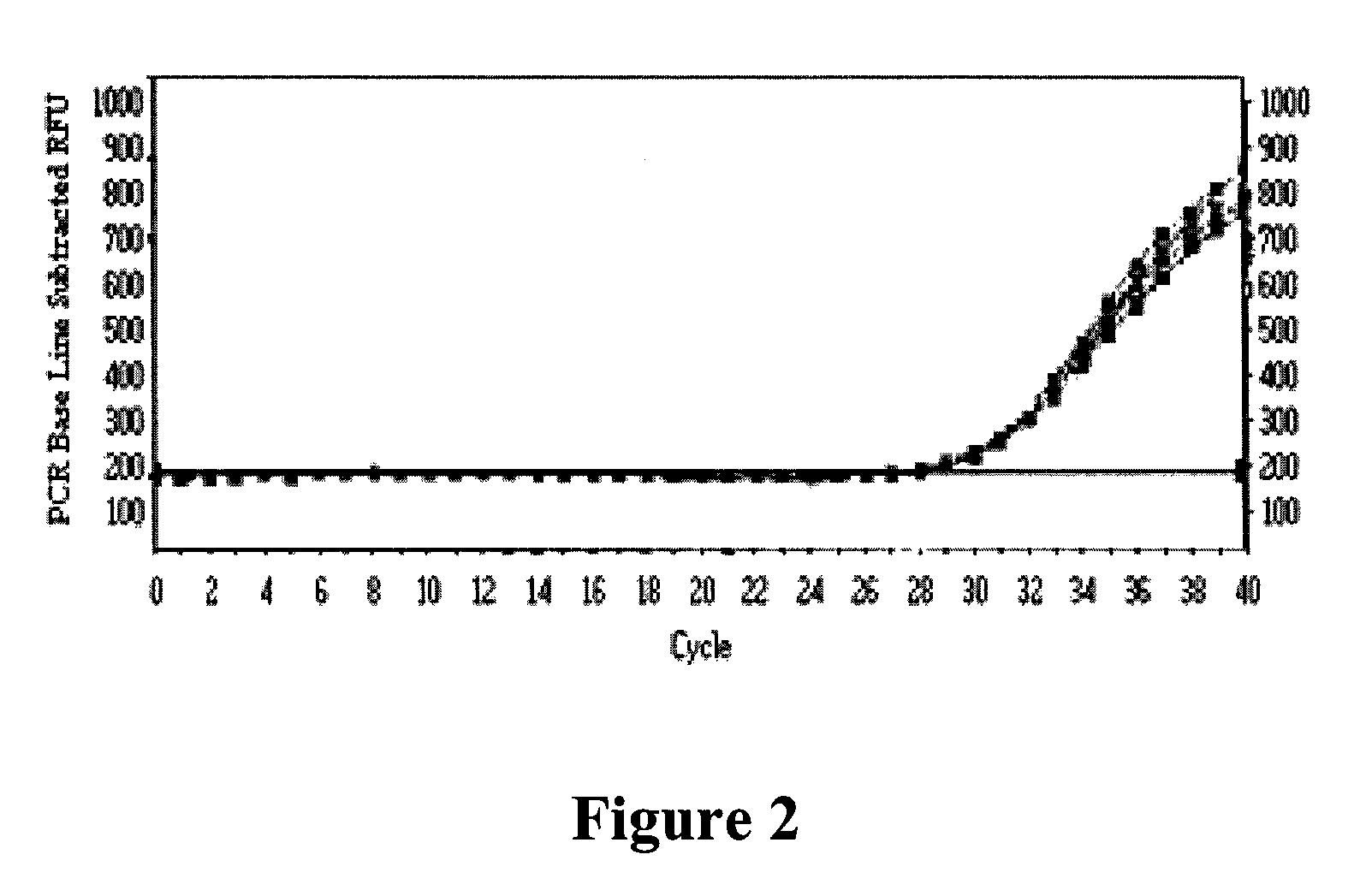

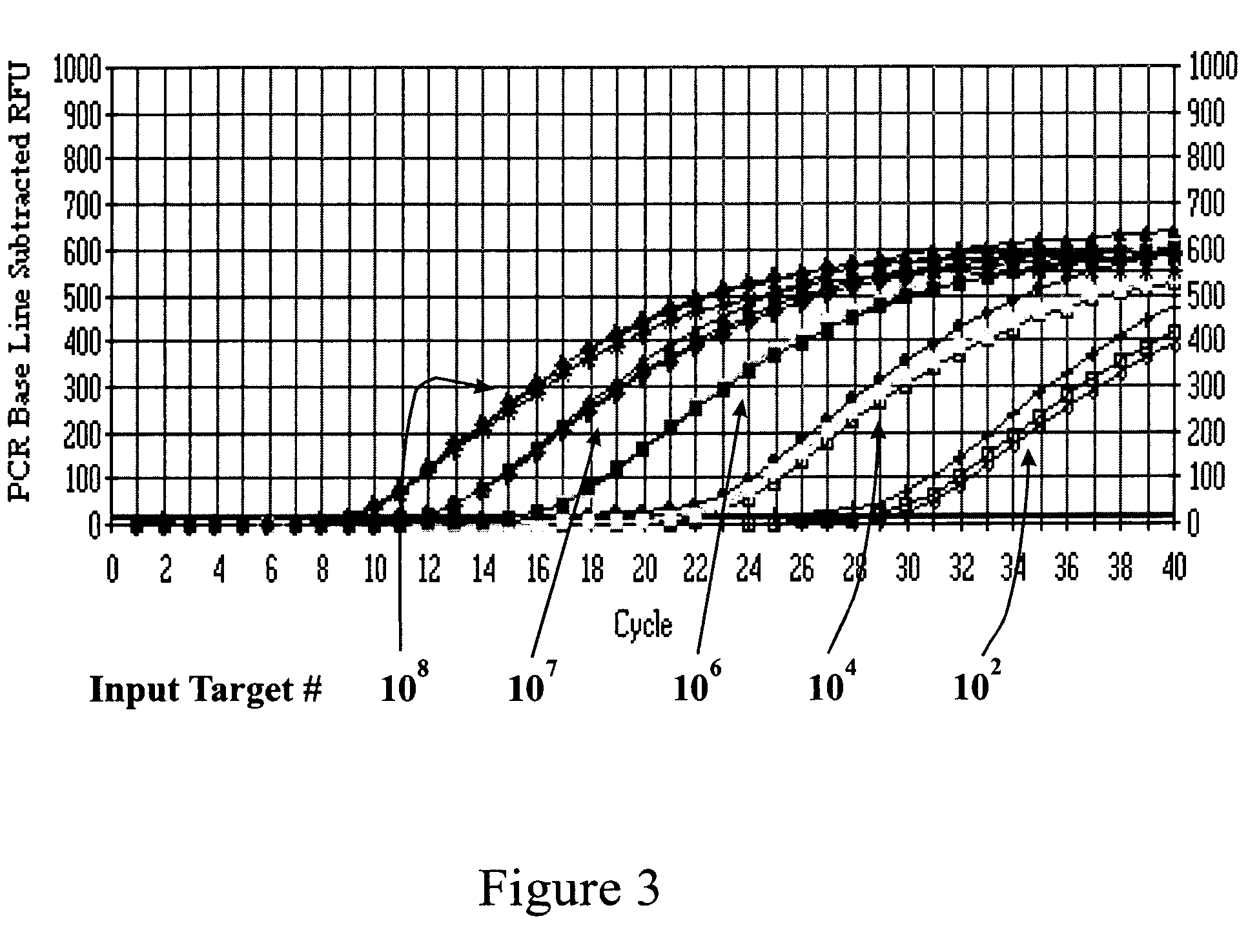

Methods of detecting fluorescence with anthraquinone quencher dyes

The invention provides novel anthraquinone compositions that are useful as broad-spectrum quenchers of fluorescence and provides methods for making and using them. The anthraquinone quenchers can be conjugated to a variety of biologically relevant compounds, including lipids, nucleic acids, polypeptides, and more specifically antigens, steroids, vitamins, drugs, haptens, metabolites, toxins, environmental pollutants, amino acids, peptides, proteins, nucleotides, oligonucleotides, polynucleotides, carbohydrates, and their analogs. The invention also provides kits comprising, in one or more containers, at least one anthraquinone quencher dye composition of the present invention, and instructions for using that composition.

Owner:INTEGRATED DNA TECHNOLOGIES

Method for production of polymer-encapsulated pigments

The invention relates to a method for production of an aqueous dispersion of polymer-encapsulated pigments, characterised in that (a) an aqueous pigment dispersion, containing at least one organic pigment (P), selected from the group of azo, isoindolinone, isoindoline, anthanthrone, thioindigo, thiazinindigo, triarylcarbonium, quinophthalone, anthraquinone, dioxazine, phthalocyanine, quinacridone, quinacridonquinone, indanthrone, perylene, perinone, pyranthrone, diketopyrrolopyrrole, isoviolanthrone and azomethine pigments, at least one detergent (T), and water is prepared, (b) a monomer miniemulsion, stabilised by a hydrophobic organic compound with a water solubility at 20 DEG C of at most 5x10<-5> g / l, is prepared from a polymerisable monomer (M) and at least one detergent (T) in water, (c) a monomer pigment emulsion is prepared, whereby the aqueous dispersion from (a) and the monomer miniemulsion from (b) are mixed and homogenised and (d) the pigment-containing monomer from (c) is polymerised in the presence of a polymerisation initiator and / or by heat, whereupon an encapsulation of the pigment with the polymer thus formed occurs.

Owner:CLARIANT PROD DEUT GMBH

Oxidation method for preparing hydrogen peroxide by anthraquinone method

ActiveCN102009961AUniform distributionIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical reactionAnthraquinone Derivatives

The invention discloses an oxidation method for preparing hydrogen peroxide by an anthraquinone method in the technical field of chemical reaction. The method comprises the following steps of: dispersing an oxygen-containing gaseous phase into hydrogenated anthraquinone derivative-containing working solution to prepare a micron-sized bubble-containing gas-liquid mixed fluid, and finishing oxidation reaction when the gas-liquid mixed fluid flows through a delay pipeline. The method can improve the oxidation efficiency of a hydrogenated anthraquinone derivative, shorten oxidation reaction time, reduce the hold-up of the oxidization working solution in a reaction system and improve the safety of the oxidation process.

Owner:TSINGHUA UNIV

Articles of manufacture made from pulp composition

InactiveUS20140205777A1Strength parameter sufficientSynthetic resin layered productsPulp bleachingFiberKappa number

One aspect of the invention relates to an article of manufacture made from a pulp composition comprising an ARF pulp. In one embodiment, the pulp composition made from agricultural renewable fibers (ARF) having low Kappa number with unexpected quality sufficient for papermaking (e.g., high strength parameters and high freeness). In another embodiment, the ARF pulp has ISO brightness of 60% or higher, and unexpected quality sufficient for papermaking (e.g. high strength.parameters and high freeness). In another embodiment, the ARF pulp is made from a pulping process comprising using a high concentration of anthraquinone (AQ).

Owner:CARGILL INC

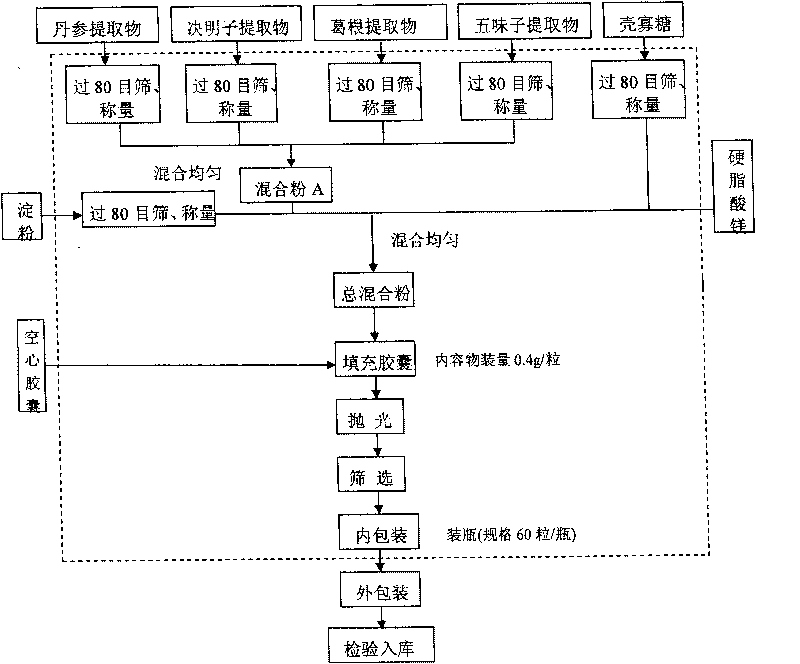

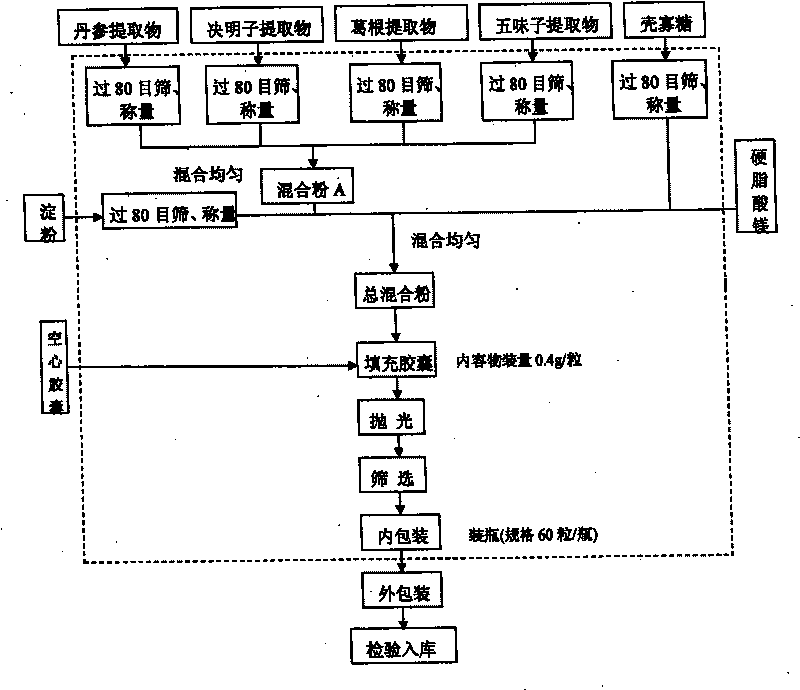

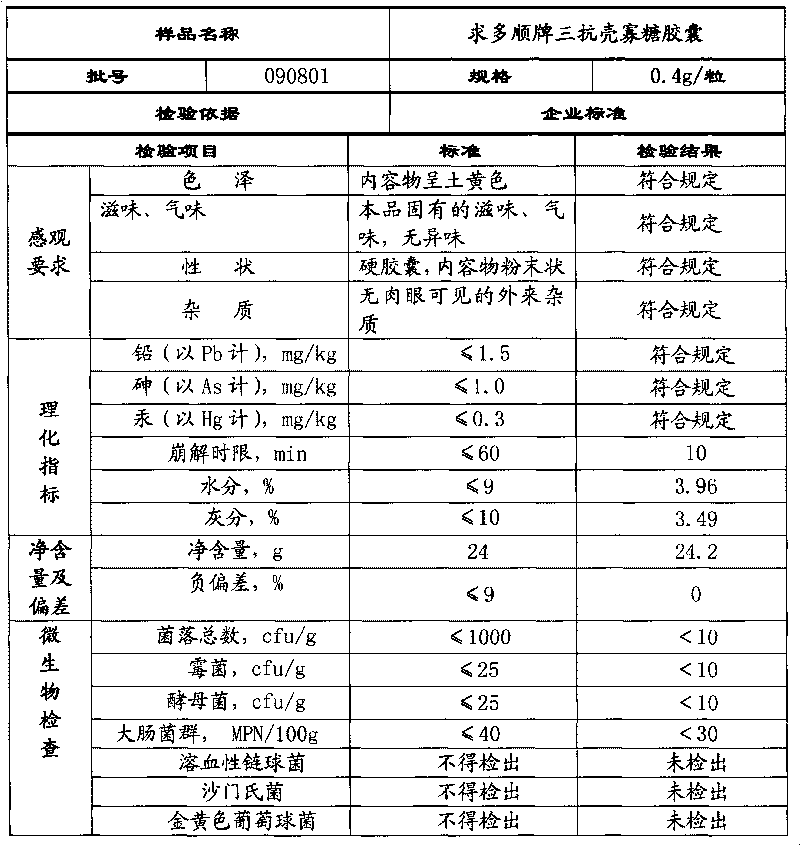

Chitosan oligosaccharide capsule

ActiveCN101744164AGood development valueHuge market potentialFood preparationAdditive ingredientPuerariae Radix extract

The invention discloses a chitosan oligosaccharide capsule; chitosan oligosaccharide with 2000-10000 of molecular weight, radix salviae miltiorrhizae extract, pueraria root extract, obtuseleaf senna seed extract and schisandra extract are used as main materials; starch and magnesium stearate are taken as auxiliary raw materials; the weight components of the formula of the chitosan oligosaccharide capsule include the chitosan oligosaccharide, the radix salviae miltiorrhizae extract, the pueraria root extract, obtuseleaf senna seed extract, schisandra extract, the starch and the magnesium stearate; the production process of the capsule is that: sieving, weighting, mixing, capsule filling, polishing, screening, inside and outside package, warehouse-in inspection are carried out to prepare the health-care product. The chitosan oligosaccharide capsule has the advantages that the main composition of the capsule comprises the chitosan oligosaccharide, general flavone and total anthraquinone; the capsule is taken orally two times one day, 3 granules each time, and the capsule has auxiliary protection function to the chemical liver damage.

Owner:江西省三抗保健品有限公司

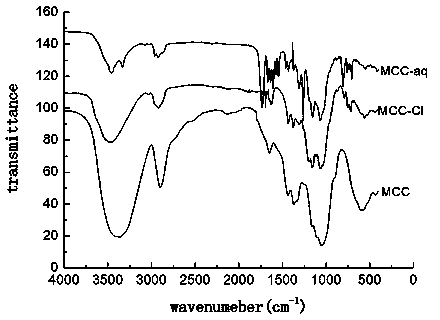

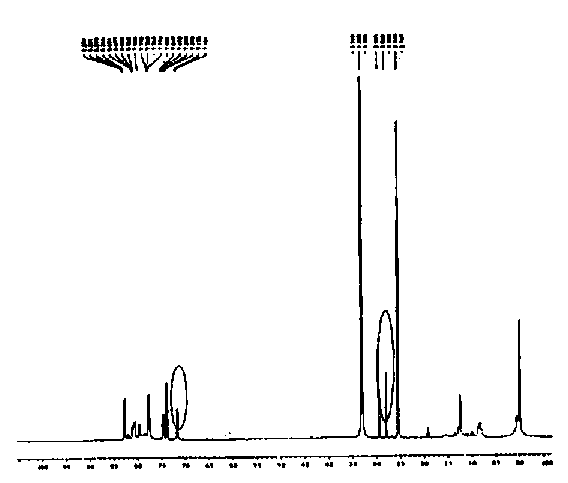

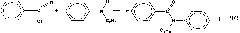

Anthraquinone functional cellulose membrane and preparation method thereof

InactiveCN103724668APromote biodegradationSimple preparation processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisIonic liquidRaw material

The invention belongs to the technical field of crossing of chemical engineering, materials engineering and environmental engineering, particularly relates to an improvement technology of cellulose membrane materials and a chemical grafting and fixing technology for treating anthraquinones compound carriers of wastewater containing nitrogen, and particularly relates to a method for preparing an anthraquinone functional cellulose membrane by fixing an anthraquinone compound on microcrystalline cellulose by chemical grafting. According to the method, the microcrystalline cellulose is used as a raw material; firstly, ionic liquid is used as a solvent for dissolving the microcrystalline cellulose; thionyl chloride modified cellulose is used for preparing cellulose chloride and then the cellulose chloride is reacted with amino anthraquinone in dimethylformamide to prepare an anthraquinone functional cellulose membrane material; the substitution degree of the prepared cellulose chloride can reach 1.89 and the anthraquinone grafting rate of the anthraquinone functional cellulose membrane reaches 82%; the anthraquinone functional cellulose is prepared by the two-step reaction; the content of anthraquinonyl is high and the grafting rate is high; the fixing effect is stable; finally, the anthraquinone functional cellulose is changed into the membrane by a phase transferring method; the membrane material can be used for accelerating and strengthening the biological degradation process in the treatment of the wastewater containing the nitrogen.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Formula of working liquid for hydrogen peroxide production based on anthraquinone process

InactiveCN101798065AReduce consumptionImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityBenzene

The invention provides the formula of a working liquid for hydrogen peroxide production based on the anthraquinone process. The working liquid comprises solvent and a working carrier, wherein the solvent comprises the following components by volume percentage: 65% to 80% of alkyl benzene, 5% to 25% of trioctylphosphate (TOP) and 4.5% to 17.8% of N-phenyl-N-ethyl-benzamide; the working carrier is particularly a mixture of alkyl anthraquinone and alkyl tetrahydroanthraquinone with the total content thereof being 130g / L to 200g / L in the working liquid. The working liquid of the invention has the advantages of high working carrier solubility, moderate density and high working load, and reduces the degradation rate of anthraquinone. Therefore, the produced hydrogen peroxide has high yield and low material consumption, and the production process is simple and easy-to-operate.

Owner:江山市双氧水有限公司

Recycling method for waste sulfuric acid of dye intermediate product

InactiveCN102219191ANo secondary pollutionSimple methodSulfur-trioxide/sulfuric-acidSulfateRoom temperature

The invention relates to a recycling method for waste sulfuric acid of a dye intermediate product, which comprises the following steps of: recovering waste sulfuric acid with a mass fraction of 40+ / -2%, settling, filtering, dewatering and concentrating, then oxidizing with an oxidant (oxyful or ozone) at 80-200 DEG C to obtain colorless transparent sulfuric acid, removing exhaust gases generated during the oxidation process under negative pressure, cooling to room temperature, storing, and directly using for producing an inorganic fertilizer, a sulfate, or a water treatment agent; or mixing the oxidized sulfuric acid with fuming sulfuric acid or sulfur trioxide to obtain 98wt% sulfuric acid, storing, and reusing for synthesizing a dye intermediate product or producing a sulfate. The waste sulfuric acid is acquired by oxidizing 1,4-diamino-2,3-dicyano anthraquinone as a raw material with sulfuric acid, then hydrolyzing to obtain a dye intermediate product namely 1,4-diaminoanthraquinone-2,3-dicarboxyl imine and hydrolyzing the dye intermediate product. The recycling method is simple and practical, the recovery rate of the waste sulfuric acid of the dye intermediates is up to 96.9%, and the recovered sulfuric acid can be used as fresh industrial sulfuric acid.

Owner:JIANGSU YABANG DYE

Novel cellulose extraction process

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

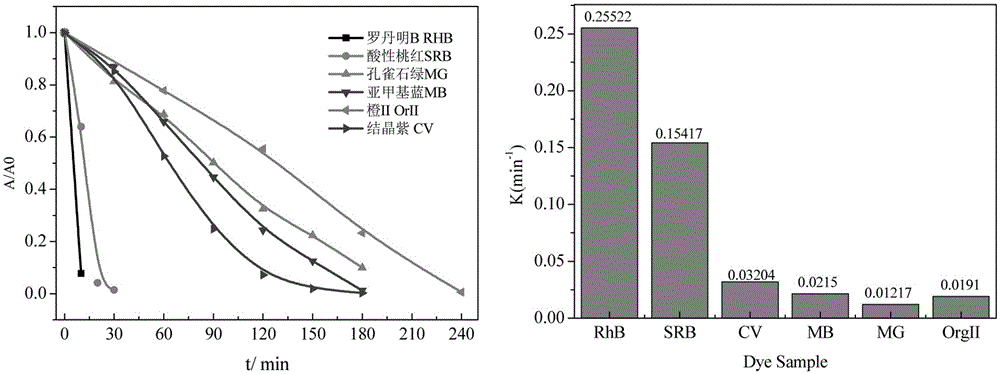

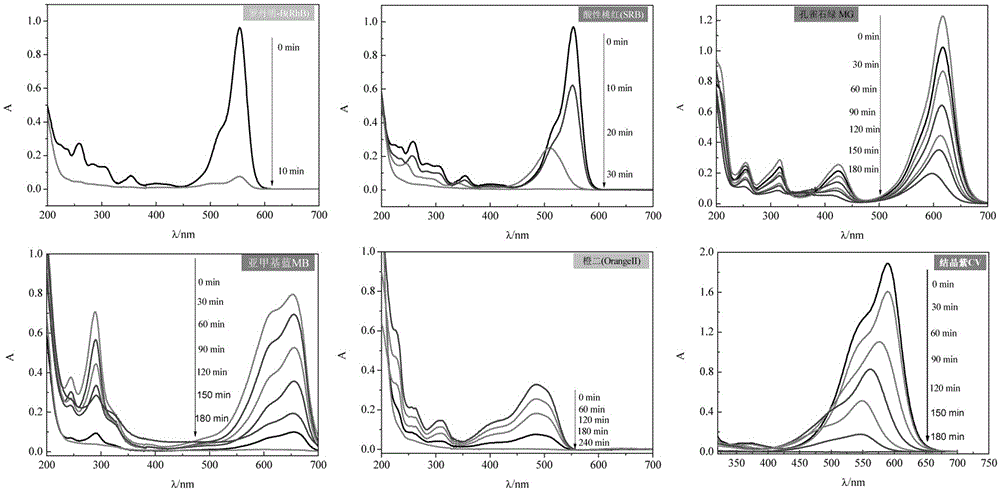

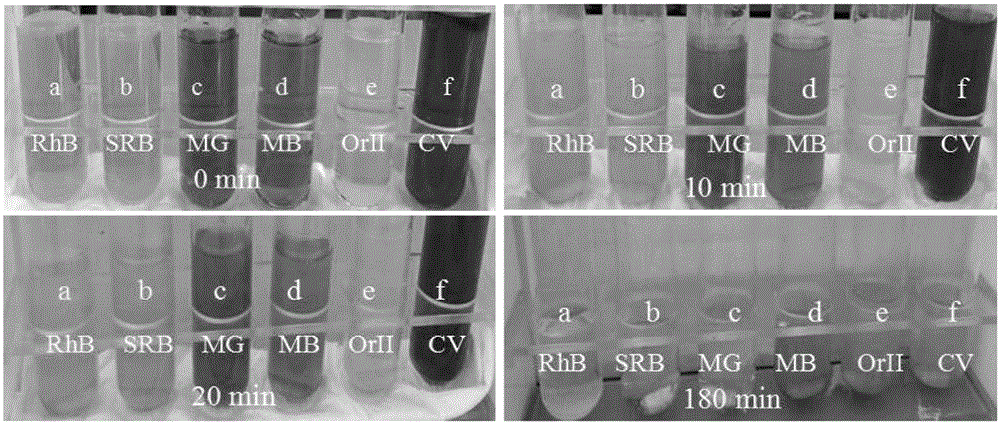

Preparation method and application of BiVO4-BiOBr photocatalyst

InactiveCN104998665AGuaranteed stabilityGood UV-Vis catalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationUltraviolet lightsNanostructure

The invention discloses a preparation method of BiVO4-BiOBr photocatalyst has a visible-light response, wherein the catalyst may be used under visible light, ultraviolet light, or sunlight. The preparation method of BiVO4-BiOBr photocatalyst that is in a multilevel nest-like nanostructure and is formed by nanosheets is: heating for 8 to 24 h under an alcohol-heating temperature of 100 to 200 DEG C with pH of 5 to 10. The catalyst of the invention can decompose water-soluble organic pollutant containing chlorine and sulfur, water-soluble organic pollutant of azo, xanthene, and anthraquinone type, and biological contaminant microcystic toxins generated by harmful algal bloom.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com