Hydrogenation process of hydrogen peroxide fluidized bed by anthraquinone

A technology of hydrogen peroxide and anthraquinone method, applied in peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, organic chemistry, etc. Catalyst fluidization, affecting catalyst utilization efficiency and other issues, to achieve the effect of small bottom pressure difference, short space time and low bed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

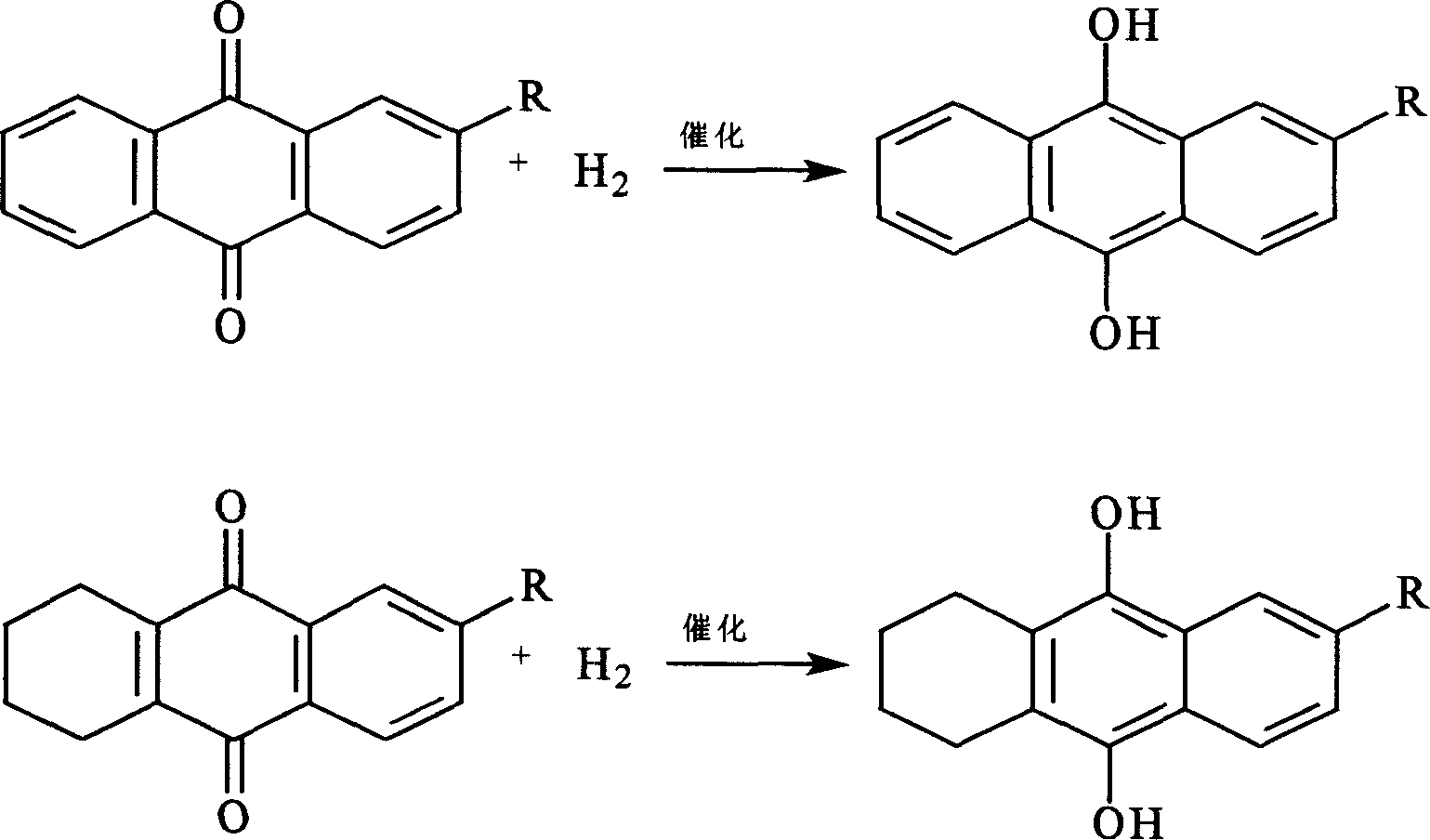

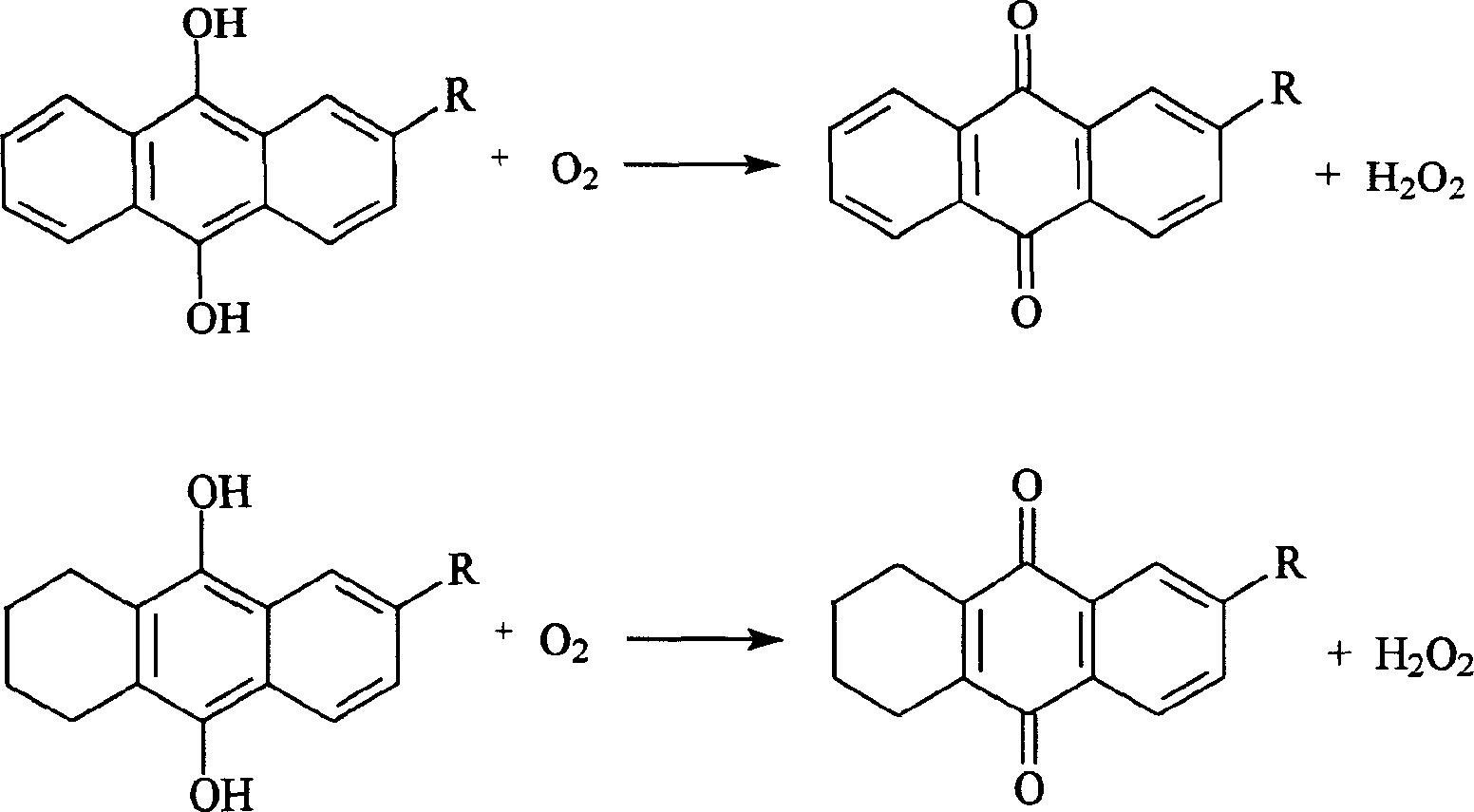

Method used

Image

Examples

Embodiment 1

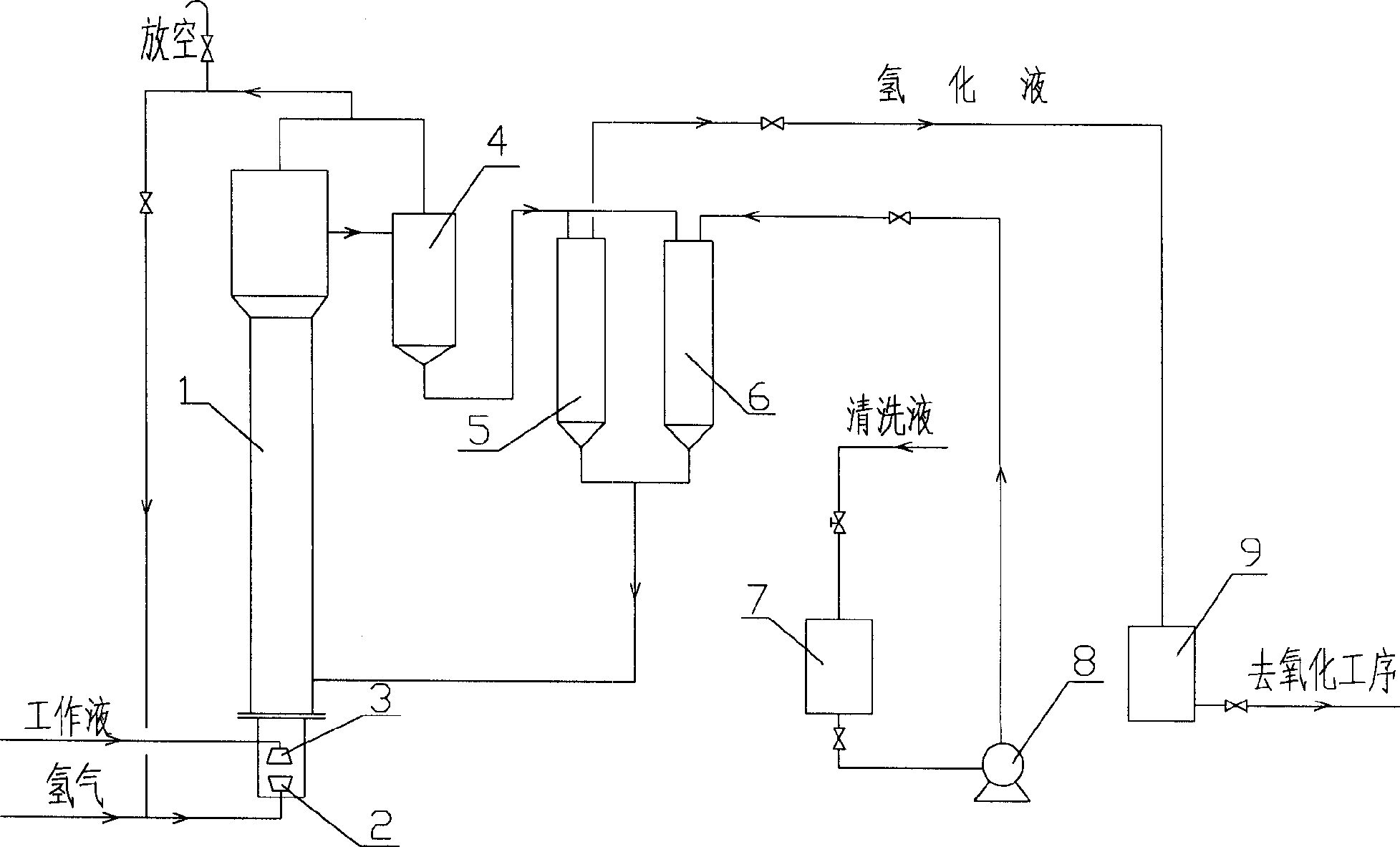

[0036] Hydrogen peroxide is prepared on a hydrogen peroxide device in the whole process (including hydrogenation, oxidation, extraction, and post-treatment processes), and the hydrogenation process adopts the process of the present invention (see accompanying drawing). Working fluid system: heavy aromatics + methylcyclohexyl acetate + 2-ethylanthraquinone + tetrahydro 2-ethylanthraquinone. Wherein: heavy aromatics: methylcyclohexyl acetate (V: V) = 1: 1; 2-ethylanthraquinone: tetrahydro 2-ethylanthraquinone (m: m) = 2: 1. The catalyst adopts aluminate as a carrier to support palladium, with an average diameter of 0.18mm and a palladium content of 1.86%. The reaction section of the hydrogenation reactor is Φ40×3500mm, and the enlarged settling section is Φ100×7000mm. The operating conditions of the hydrogenation process: the gas phase pressure at the top of the hydrogenation reactor is 0.2MPa, the temperature inside the hydrogenation reactor is 45°C, the empty time of the work...

Embodiment 2

[0038]Hydrogen peroxide is prepared on a hydrogen peroxide device in the whole process (including hydrogenation, oxidation, extraction, and post-treatment processes), and the hydrogenation process adopts the process of the present invention (see accompanying drawing). Working fluid system: heavy aromatics + trioctyl phosphate + 2-ethylanthraquinone + tetrahydro 2-ethylanthraquinone. Wherein: heavy aromatic hydrocarbon: trioctyl phosphate (V: V) = 3: 1; 2-ethylanthraquinone: tetrahydro 2-ethylanthraquinone (m: m) = 2: 1. The catalyst adopts silicate as a carrier to support palladium, with an average diameter of 0.14mm and a palladium content of 2%. The reaction section of the hydrogenation reactor is Φ500×15000mm, and the enlarged settling section is Φ100mm×3000mm. The operating conditions of the hydrogenation process: the gas phase pressure at the top of the hydrogenation reactor is 0.3MPa, the temperature inside the hydrogenation reactor is 50°C, the empty time of the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com