Patents

Literature

158results about How to "Improve hydrogenation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel process for preparing xylitol

ActiveCN101823939AIncrease contentImprove qualityIon-exchange process apparatusOrganic compound preparationChromatographic separationDistillation

The invention relates to a novel process for preparing xylitol, which belongs to the technical field of functional sugar alcohol production. Pre-treatment, hydrolysis, neutralization, decoloring, ion exchange, evaporation and concentration and chromatography are carried out to corncob or bagasse and other agricultural waste which contains hemicellulose, high-content xylose solution is collected and distillated, and then continuously hydrogenated, so that the xylose solution is converted into xylitol solution, and finally a xylitol crystal is obtained through refining, concentration, crystallization, centrifugation and drying; the process comprises: corncob-> pre-treatment->hydrolysis->neutralization and decoloring->ion exchange->evaporation and concentration->chromatography->high-content xylose solution collection and distillation-> hydrogenatio->refining->concentration->crystallization->centrifugation->drying->finished crystal xylitol product obtaining. The novel process for preparing xylitol saves a xylose crystallization procedure and a conversion process xylose crystal into sugar, shortens a production procedure, adopts a chromatography technology to improve the content of thexylose solution, facilitates the obtaining of high-content xylitol solution after hydrogenation can prepare the high-grade xylitol product, adopts a continuous hydrogenation process, improves the hydrogenation efficiency, reduces the labor intensity of a worker, and saves the production cost.

Owner:FUTASTE PHARM CO LTD

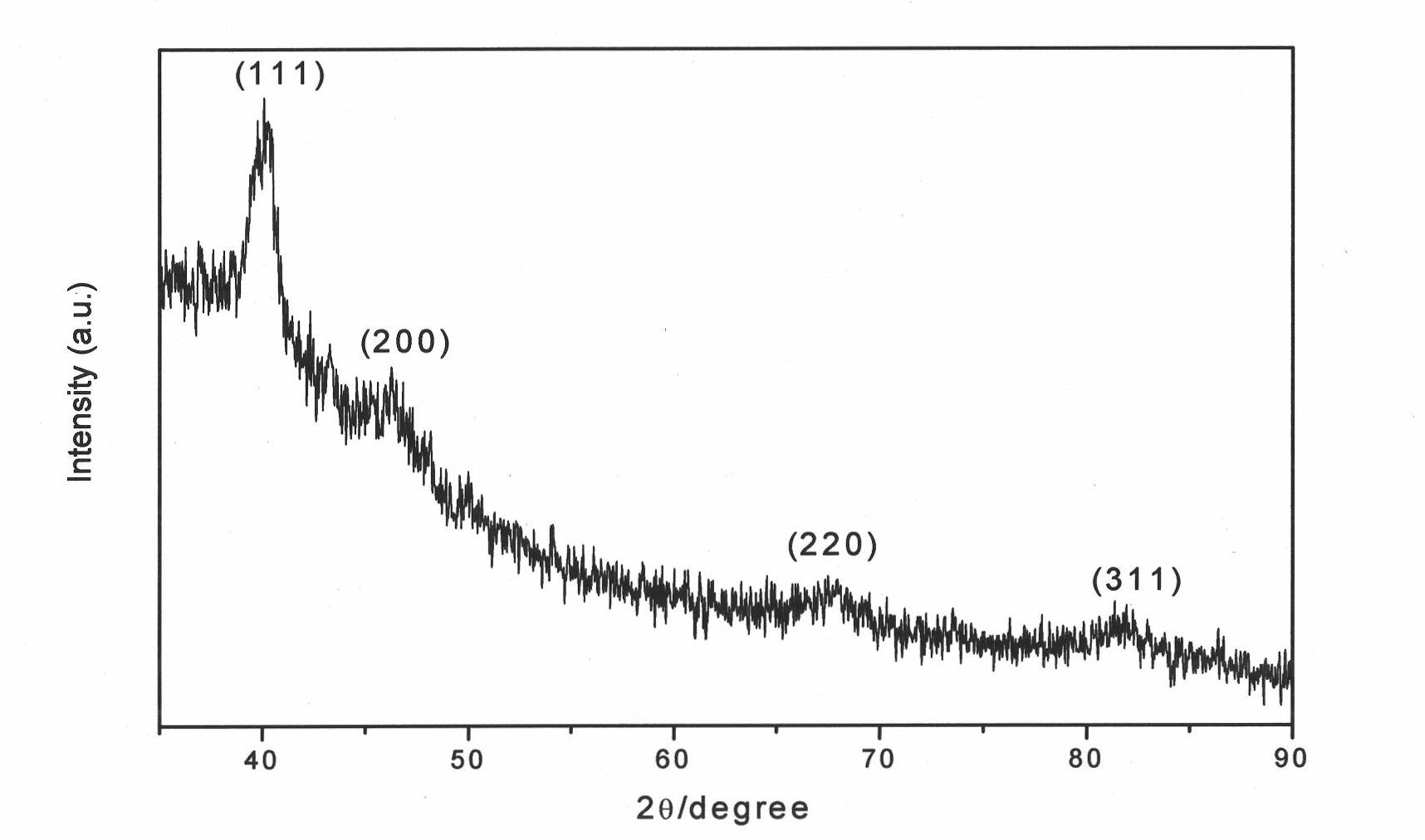

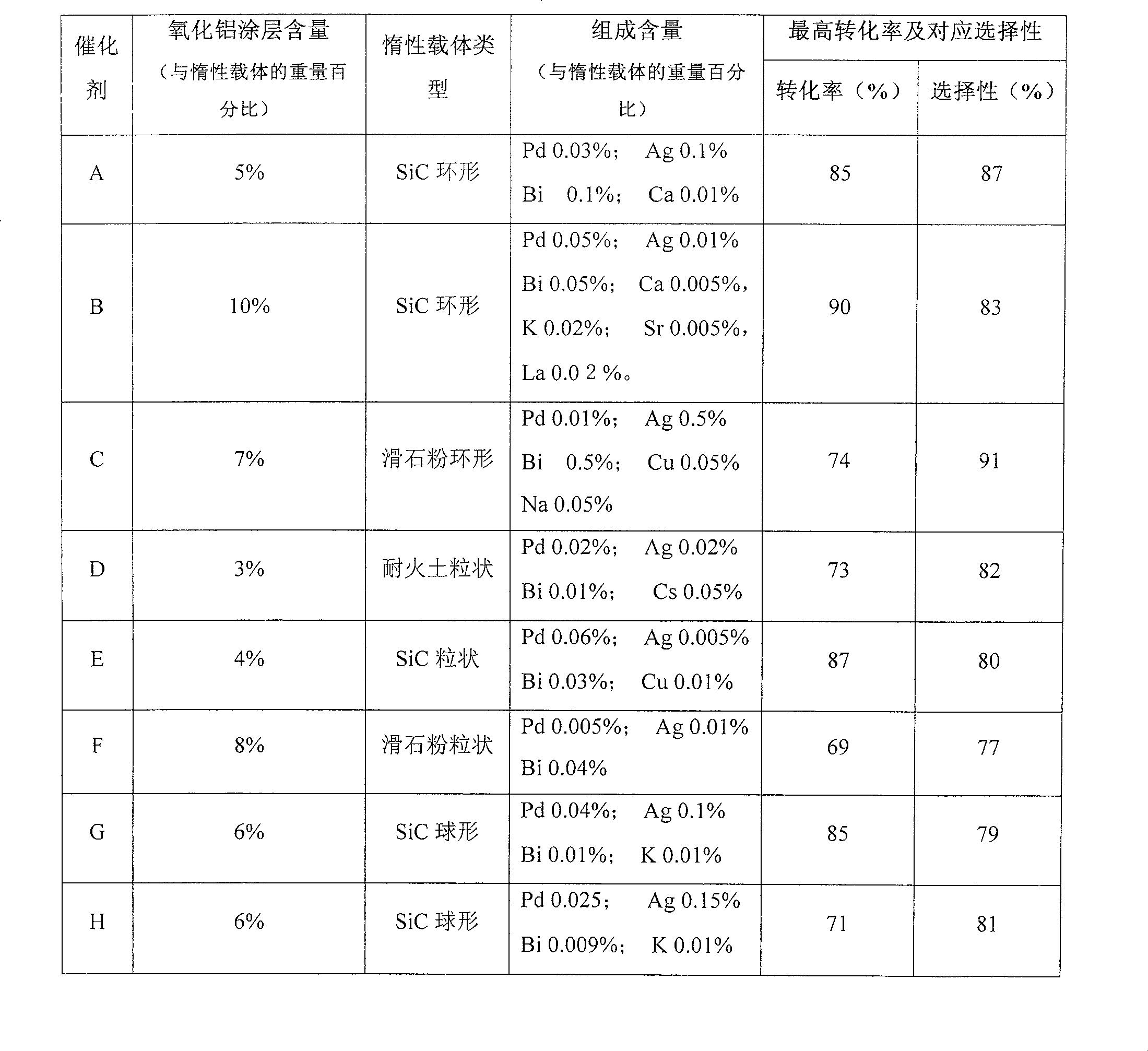

Selective hydrogenation catalyst of alkine and diolefin, preparation method and application

ActiveCN1958155AImprove hydrogenation efficiencyReduce dosageHydrocarbon purification/separationHydrocarbonsRare-earth elementChemistry

A selective hydrocatalyst for the alkine and diolefin in C2-10 fraction is composed of a inertial carrier chosen from silicon carbide, talc powder and fire-proof earth and a coated alumina layer containing Pd, Ag, Bi and at least one of Cu, Zn, alkali metal, AE metal and RE element. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

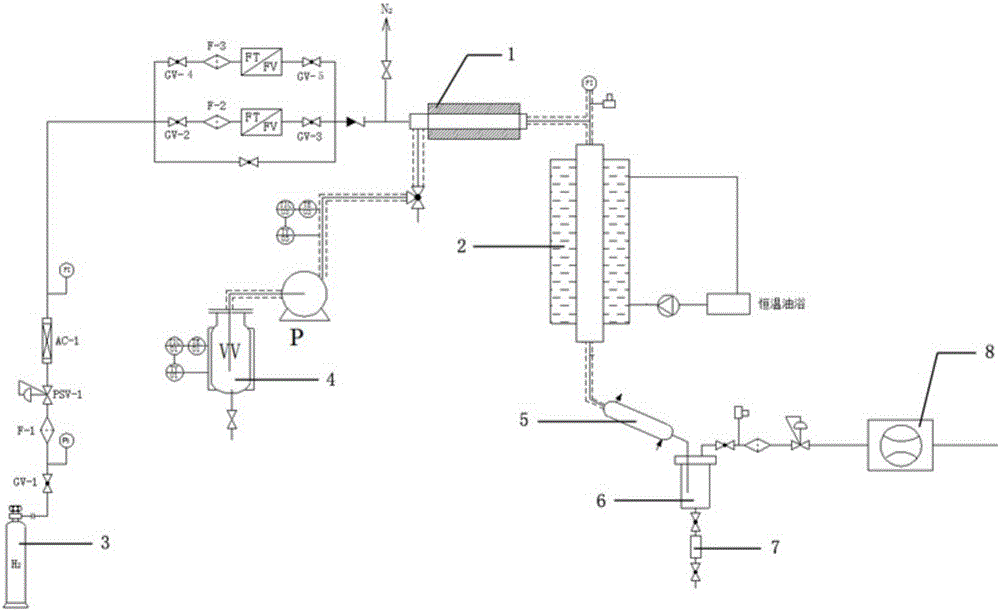

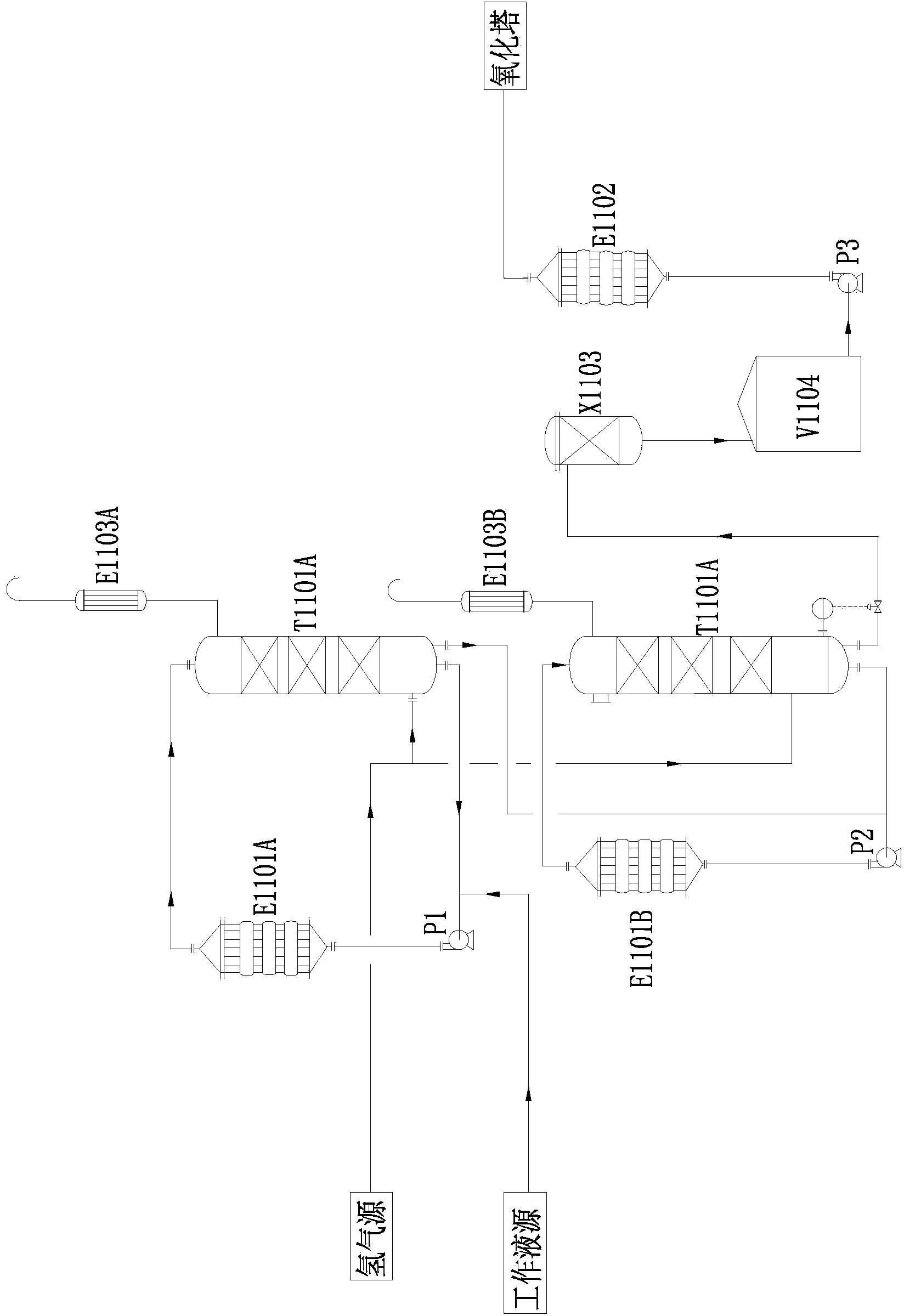

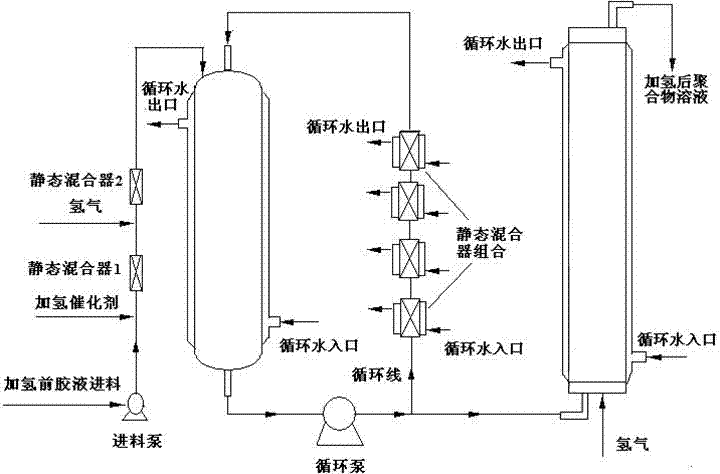

Continuous hydrogenation reaction system for liquid organic hydrogen storage carrier and hydrogenation reaction method

ActiveCN105060244AChange viscosityImprove responseHydrogenMetal/metal-oxides/metal-hydroxide catalystsTemperature controlHydrogenation reaction

The invention discloses a continuous hydrogenation reaction system for a liquid organic hydrogen storage carrier and a hydrogenation reaction method. The system comprises a feeding system, preheaters, static bed reaction stills and separation devices. The feeding system is communicated with inlets of the preheaters through pipelines. Outlets of the preheaters are communicated with inlets of the static bed reaction stills through pipelines. Outlets of the static bed reaction stills are communicated with inlets of the separation devices through pipelines. The static bed reaction stills are filled with hydrogenation catalysts and inert materials. The interiors of the reaction stills are kept at the constant temperature through circulation heat conduction media in interlayers of the surfaces of the static bed reaction stills. According to the continuous hydrogenation reaction system, the single-tube type static bed reaction stills are mainly adopted, the single-tube type static bed reaction stills are filled with the hydrogenation catalysts and the inert materials, heat tracing and heating control systems are arranged in all the pipelines in the liquid feeding system to be used for conducting temperature-control heating on liquid flowing through the system, a plurality of sets of gas quality and flow controller systems are designed in the system, the preheaters in the system are designed to be gas-liquid blending type preheaters, and the hydrogenation effect of the liquid hydrogen storage carrier is improved beneficially.

Owner:WUHAN HYNERTECH CO LTD

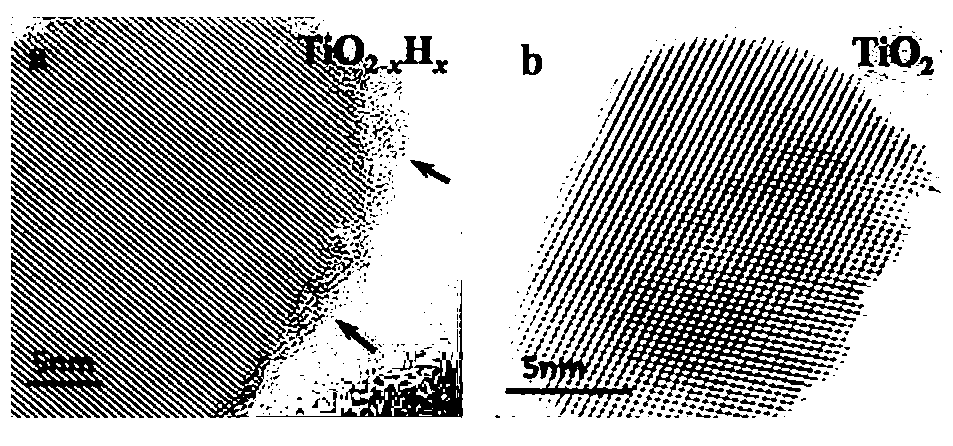

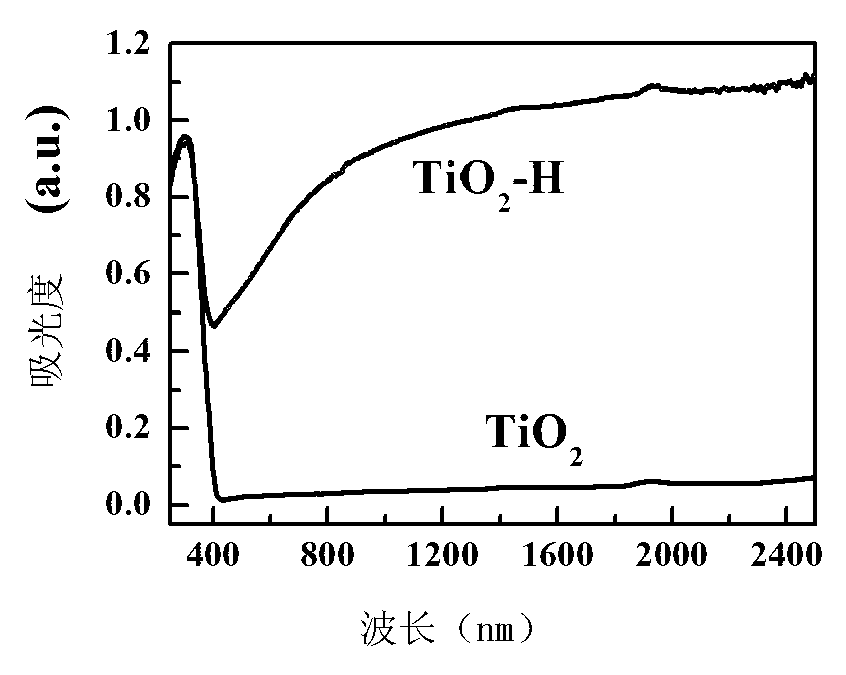

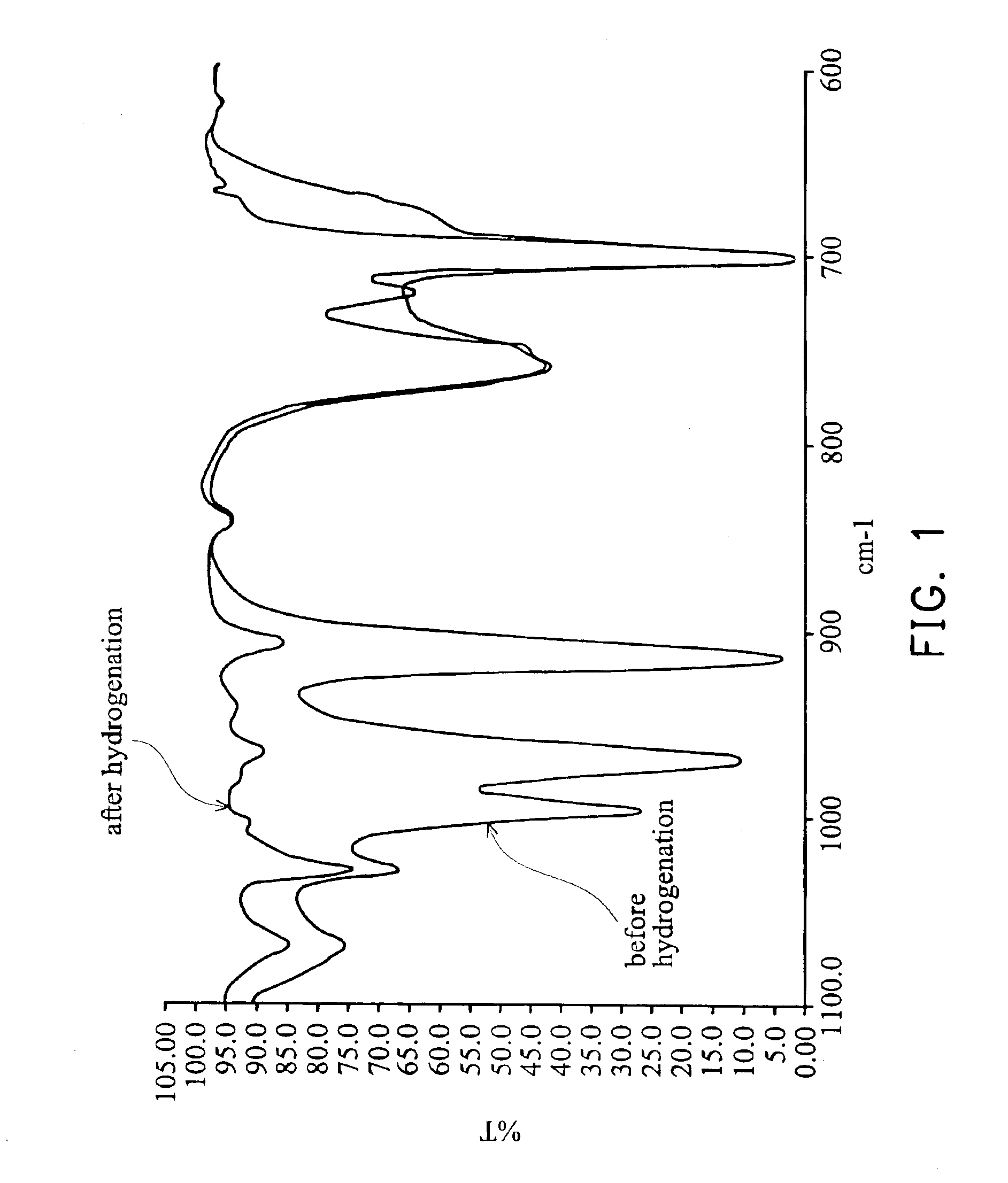

Method for preparing black titanium dioxide through auxiliary hydrogenation of hydrogen plasma

ActiveCN103214032AImprove hydrogenation efficiencyLarge particle sizeTitanium dioxideVacuum pumpingHydrogen molecule

The invention relates to a method for preparing black titanium dioxide through auxiliary hydrogenation of hydrogen plasma. The method comprises the following steps of placing the titanium dioxide into a closed system, and vacuum pumping the closed system to ensure the pressure of the closed system to be less than 30Pa; inputting a mixed atmosphere of hydrogen and argon into the closed system; heating the titanium dioxide, and adjusting the mixed atmosphere so as to ensure the pressure in the closed system to be 50 to 500Pa; and starting a radio-frequency power supply to generate the active hydrogen plasma to process the titanium dioxide within a specified time, and utilizing the hydrogen molecules ionized by the radio-frequency power supply to generate the active hydrogen plasma which is used for reducing the titanium dioxide to the black titanium dioxide.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

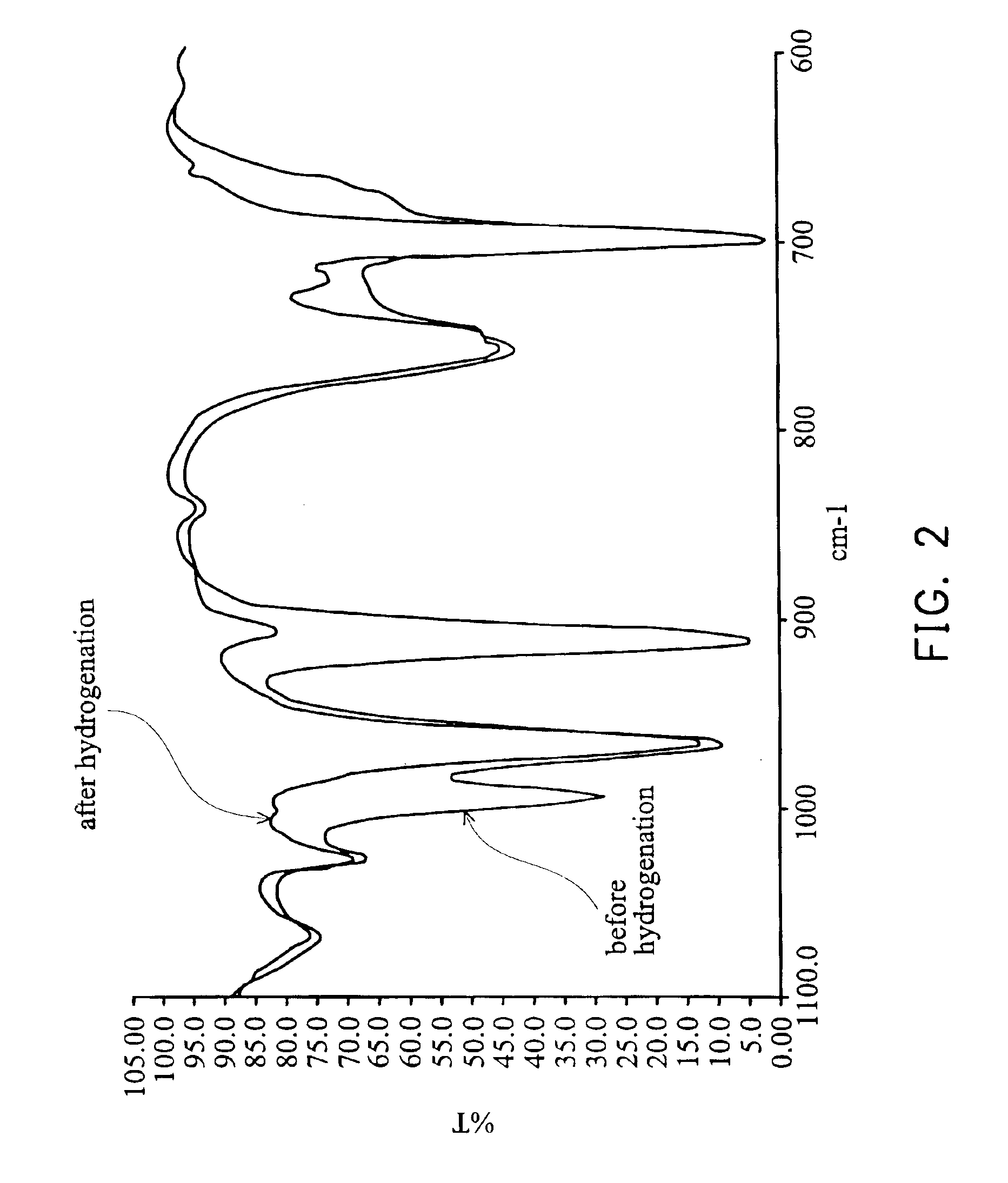

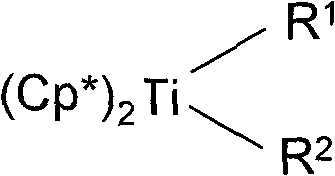

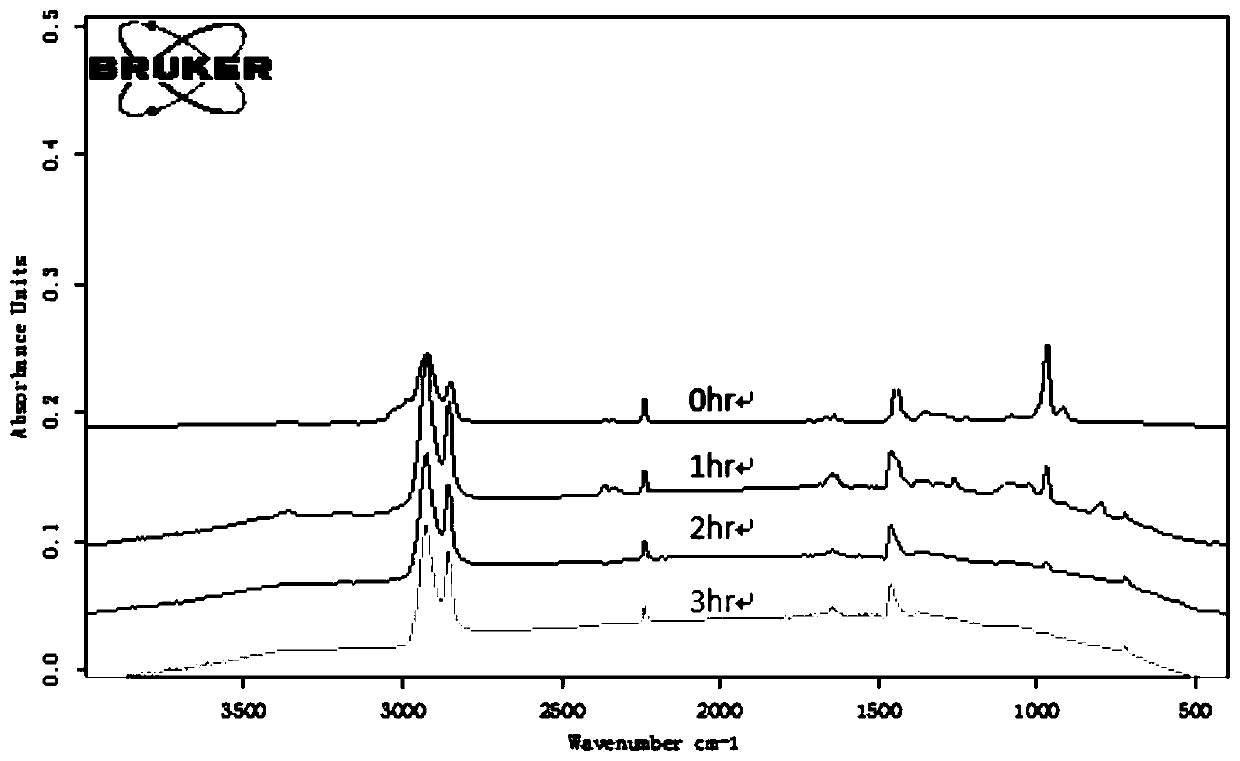

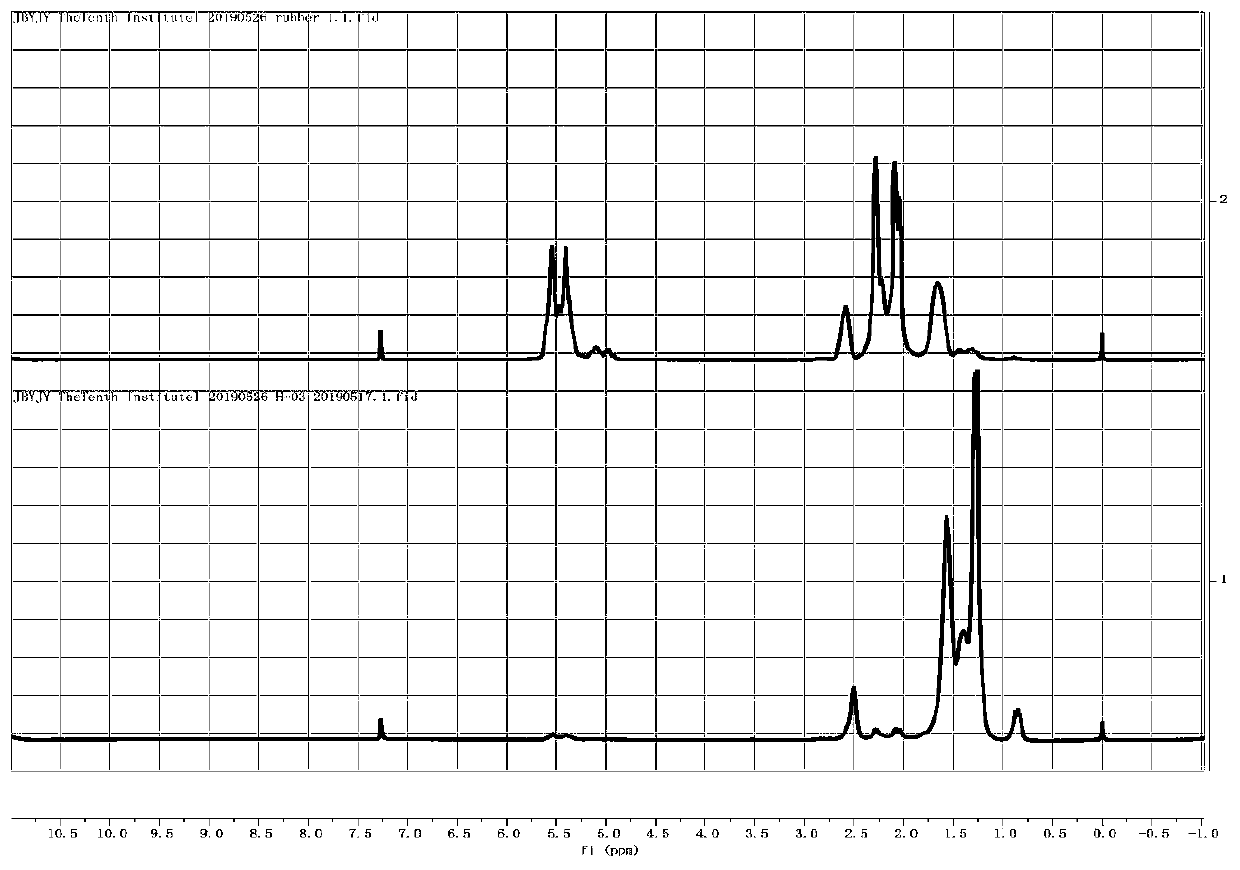

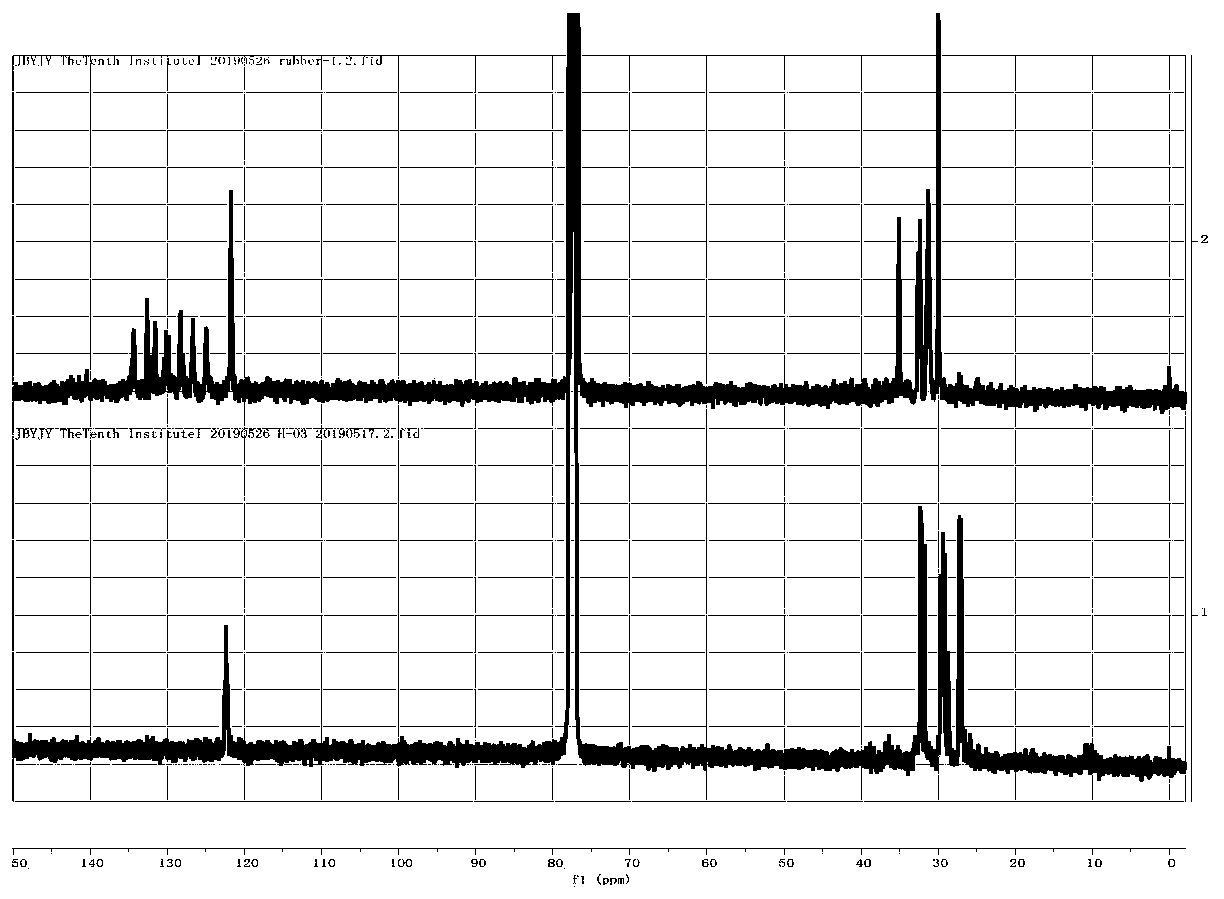

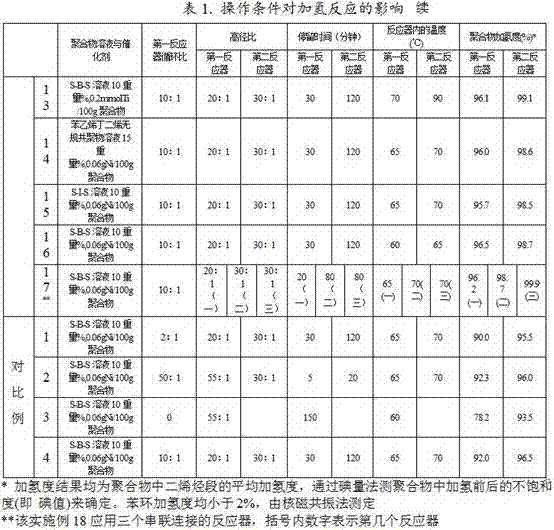

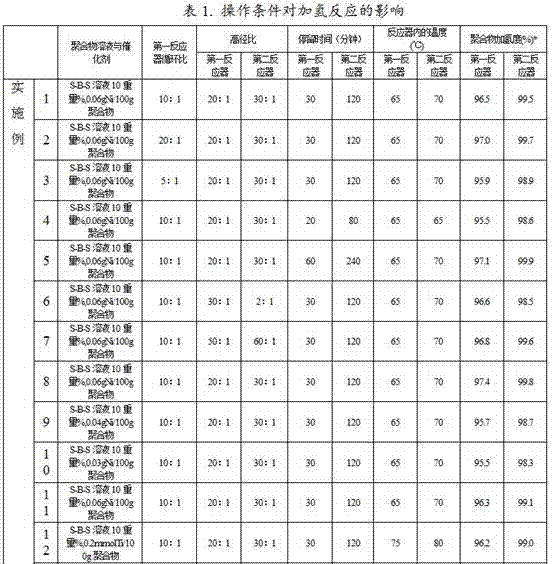

Process for hydrogenation of conjugated diene polymer

A process for hydrogenation of a conjugated diene polymer. The conjugated diene polymer in an inert organic solvent is brought into contact with hydrogen in the presence of a hydrogenation catalyst composition to selectively hydrogenate the unsaturated double bonds in the conjugated diene units of the conjugated diene polymer. The hydrogenation catalyst composition includes: (I) a titanium compound; (II) a compound represented by formula (II): wherein L is a Group IVB element, R is C1-C12 alkyl or C1-C12 cycloalkyl, X can be the same or different and is C1-C12 alkyl, C1-C12 alkoxy, C1-C12 cycloalkoxy, halogen, or carbonyl; and (III) a trialkylaluminum compound.

Owner:TSRC CORP

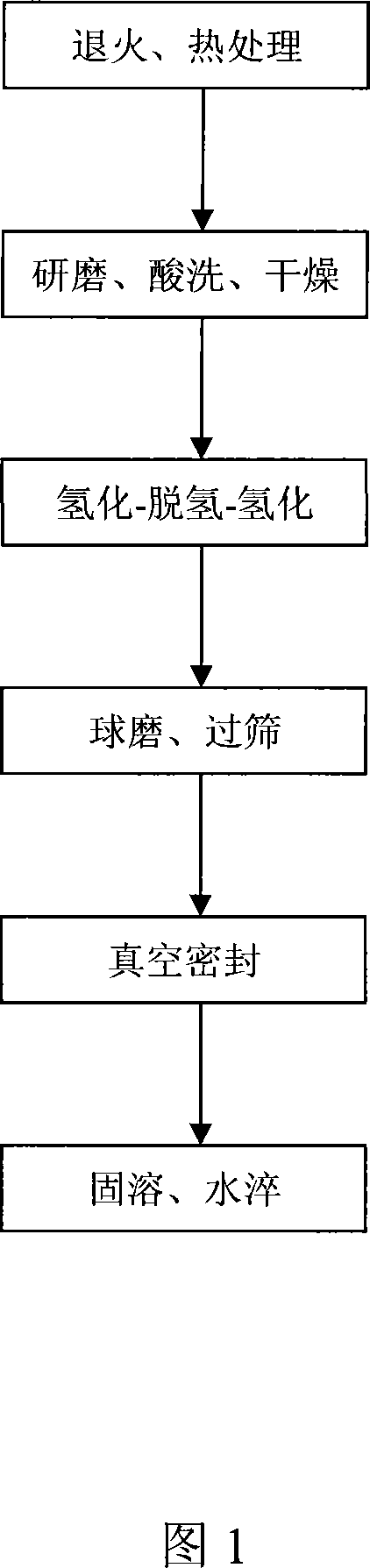

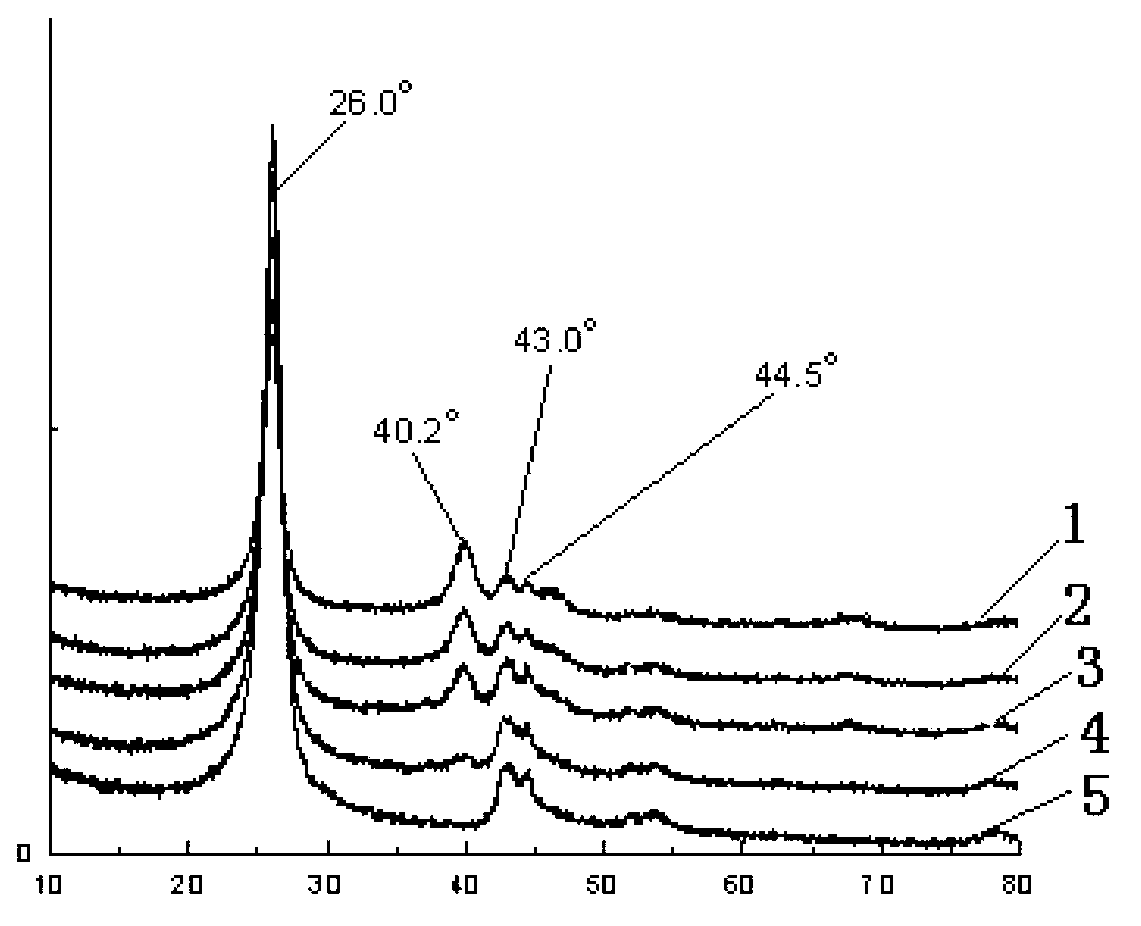

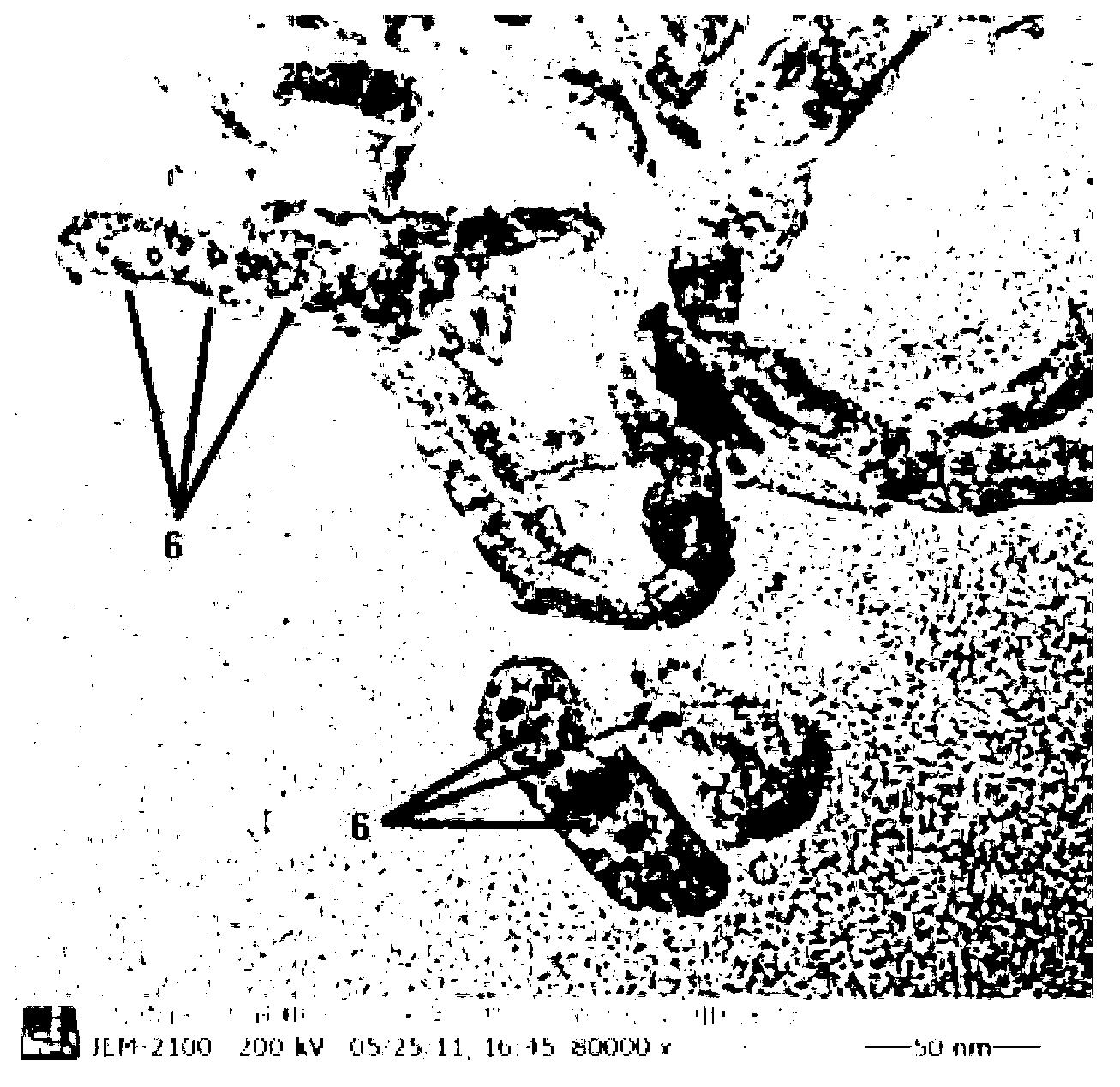

Preparation technology for gamma phase U-Mo alloy powder

The invention relates to the processing for gamma U-Mo alloy power that annealing the U-(2-10)%Mo alloy bar in 800-1000deg.C for 2-6 hours in vacuum conditions, surface grinding, acid cleaning and drying, hydrogenization in 60-250deg.C, under 0. 2-0. 4MPaH2 pressure for 2-6 hours, then vacuum dehydrogenation in 350-550deg.C, under pressure no more than 100Pa for 1-4 hours, then hydrogenization in 60-250deg.C, under 0. 2-0. 4MPaH2 pressure for 2-6 hours, ball grinding, screening, sealing in the quartz tube, solutionizing and water quenching. The process only needs one time hydrogenization, dehydrogenization, simple, reliable, highly efficient, low impurity level, stable and pure, with grain size being 40-140mum.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

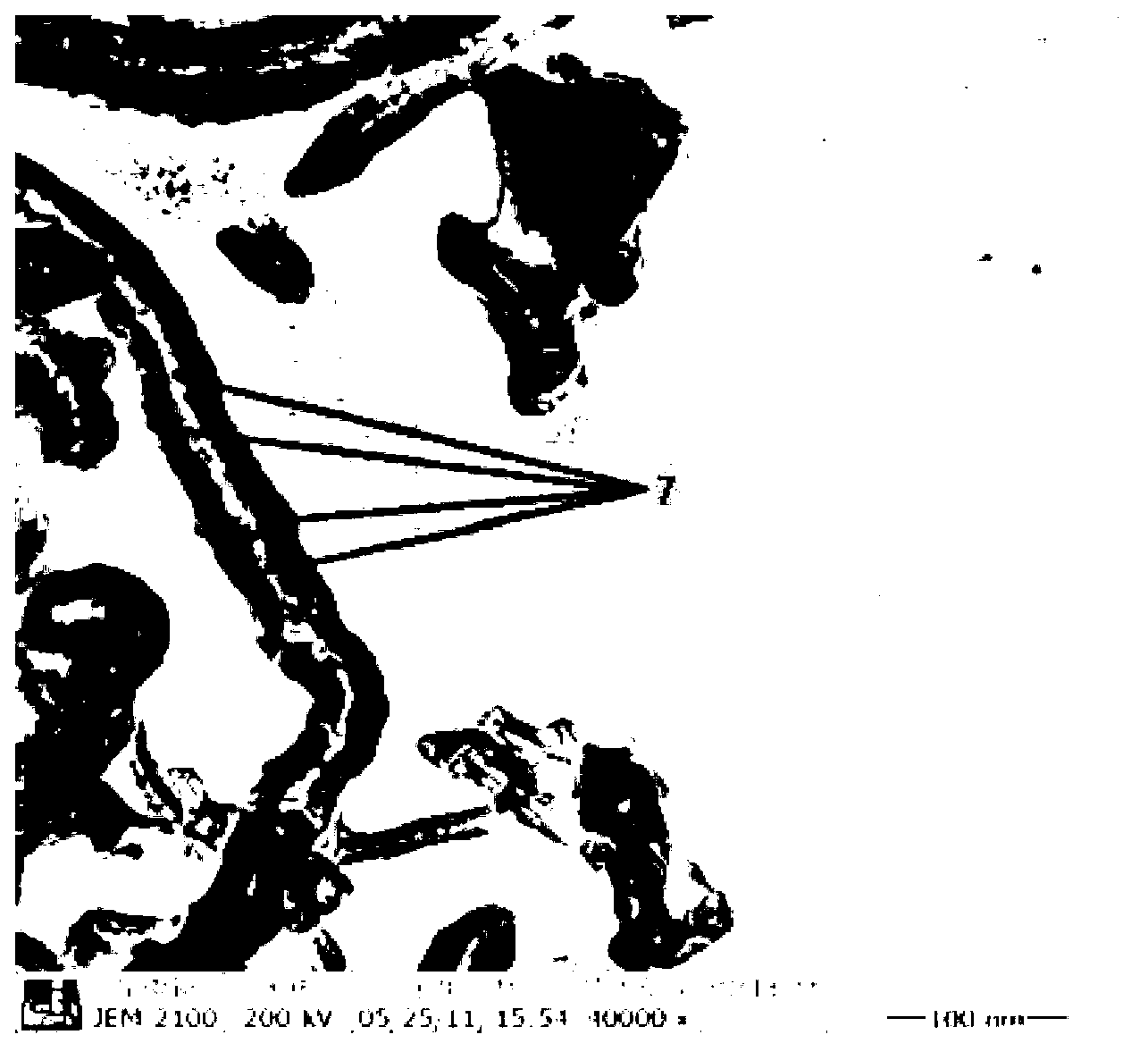

Highly dispersed palladium/carbon nanometer tube catalyst for anthraquinone hydrogenation and preparation method thereof

ActiveCN103055852AReduce dosageReduce storagePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsAnthraquinonesSlurry reactor

The invention discloses a highly dispersed palladium / carbon nanometer tube catalyst for anthraquinone hydrogenation and a preparation method thereof, and relates to a catalyst and a preparation method. According to the invention, a carbon nanometer tube industrial product with good conductivity, heat conductivity, high mechanical strength and huge external specific surface is used as a palladium carrier; simultaneously ultrasonic is utilized to further enhance the dispersity and uniformity of palladium and the carbon nanometer tube; and a nanometer palladium catalyst uniformly loaded on the surface of the carbon nanometer tube is prepared in a slurry reactor by adopting a liquid phase reduction method. The catalyst needs no extrusion molding and can be directly suspended in the liquid phase for normal-pressure or pressurized hydrogenation of anthraquinone; the activity of the catalyst is not reduced after the catalyst is used for a plurality of times by filtration and separation; moisture, acid and alkaline do not influence the use effect; the catalytic activity of the new catalyst is 4-8 times higher than that of the traditional Pd / gamma-Al2O3 catalyst, and the amount of the catalyst used can be greatly reduced. The catalyst can be used for replacing the traditional catalyst, the post treatment of the traditional catalyst is simplified, the treatment capability of a device is greatly increased, and the operation cost is lowered.

Owner:XIAMEN UNIV +2

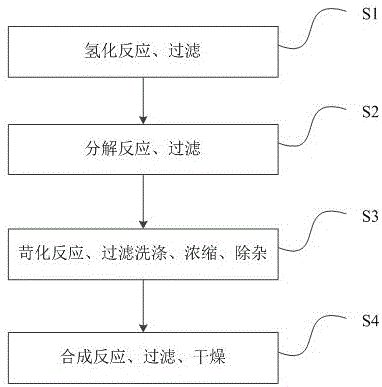

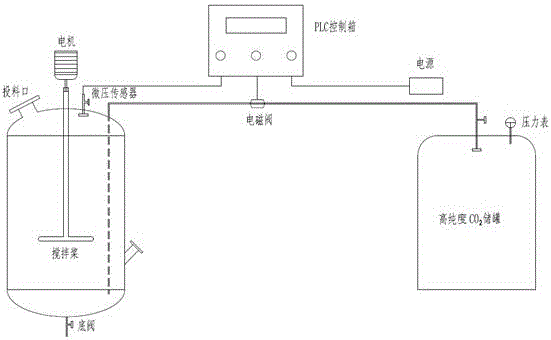

Method for preparing battery grade lithium carbonate by using impulse type hydrogenated industrial grade lithium carbonate

ActiveCN106365182AImprove gas utilizationImprove hydrogenation efficiencyLithium carbonates/bicarbonatesDecompositionLithium carbonate

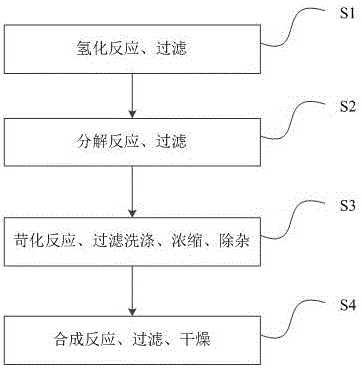

The invention discloses a method for preparing battery grade lithium carbonate by using impulse type hydrogenated industrial grade lithium carbonate. The method comprises the steps of preparing the industrial grade lithium carbonate and common pure water into slurry according to a certain proportion, adding high-purity CO2 in a pulse mode, controlling reaction temperature to be within a range of 20-25 DEG C until the solution is converted into clearer liquid, and filtering the liquid; injecting filtrate into a decomposition reaction kettle, decomposing the filtrate, then transferring the decomposed filtrate into a causticizing reaction kettle, adding a right amount of a Ca(OH)2 solution into the causticizing reaction kettle, controlling reaction temperature to be within a range of 90-100 DEG C, and filtering and washing the solution while the solution is hot; injecting filtrate into a concentration kettle, and removing impurities such as Ca and Mg of concentrated liquor by using ion exchange resin; then, injecting the concentrated liquor without the impurities into a synthesis kettle, and replenishing the synthesis kettle with the high-purity CO2 gas so as to further prepare the high-purity battery grade lithium carbonate. The method utilizes the advantage of hydrogenation of lithium carbonate so as to effectively utilize the high-purity CO2 gas and avoid the loss of CO2 as much as possible in a reaction process, and enables the hydrogenation to be carried out smoothly.

Owner:JINGMEN GEM NEW MATERIAL

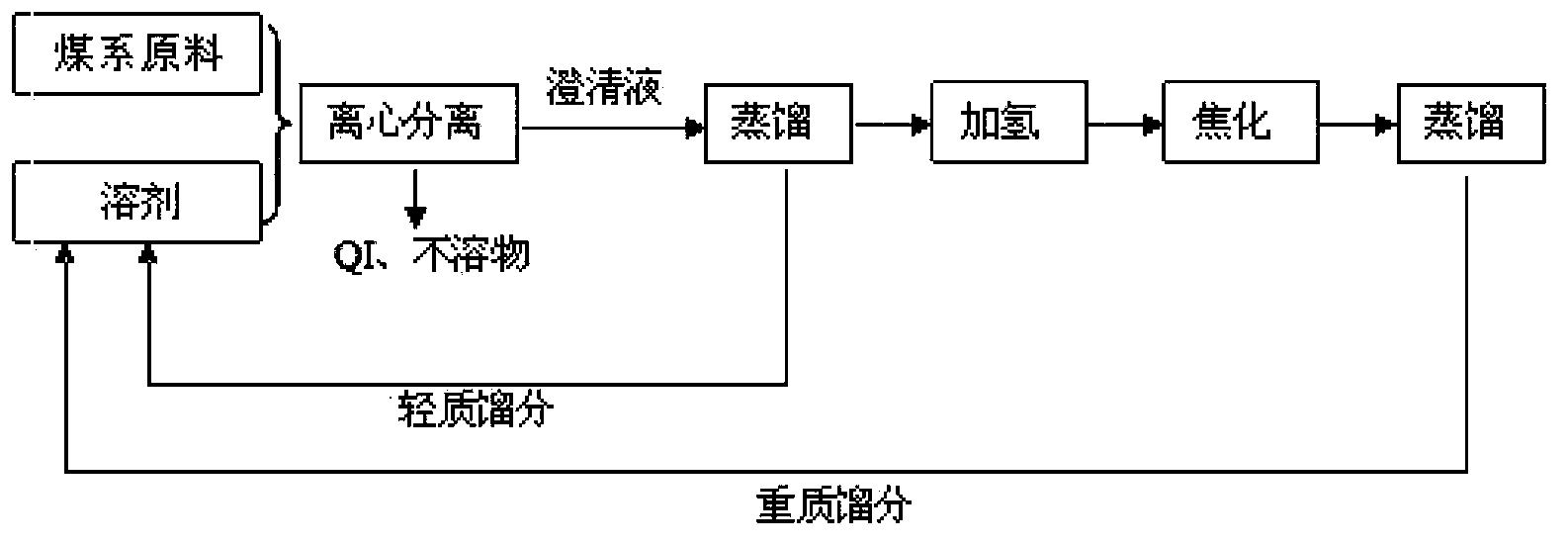

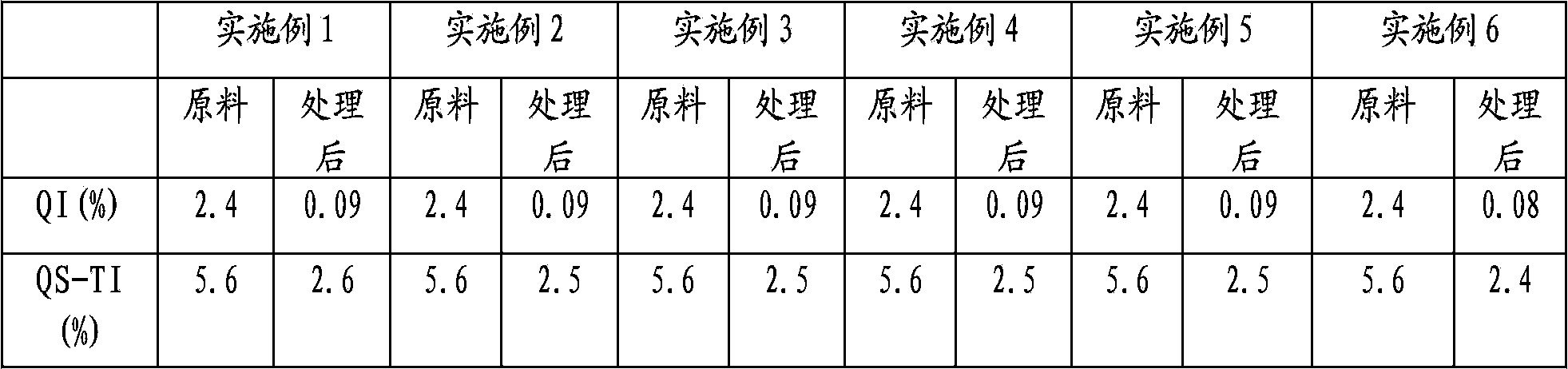

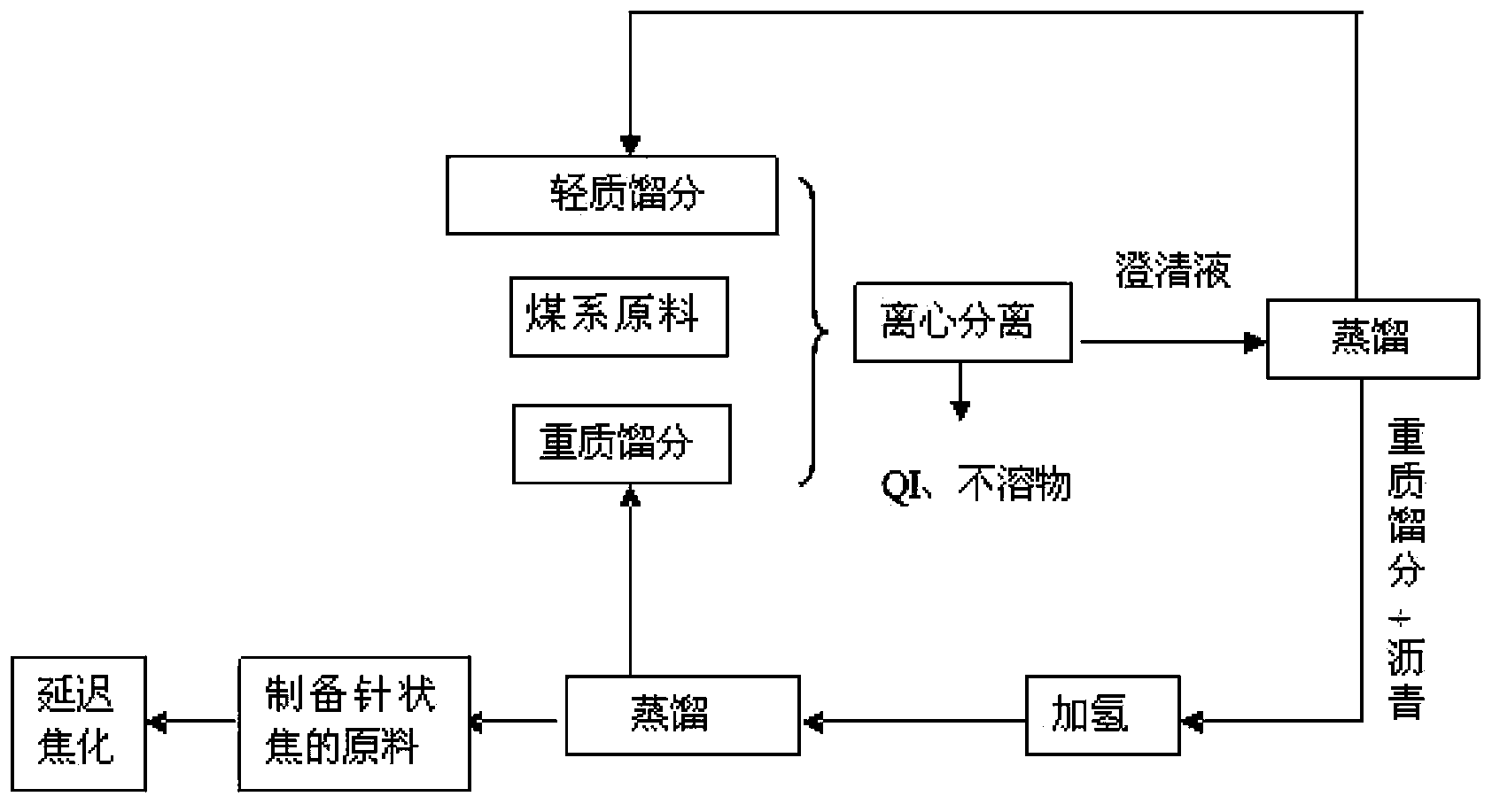

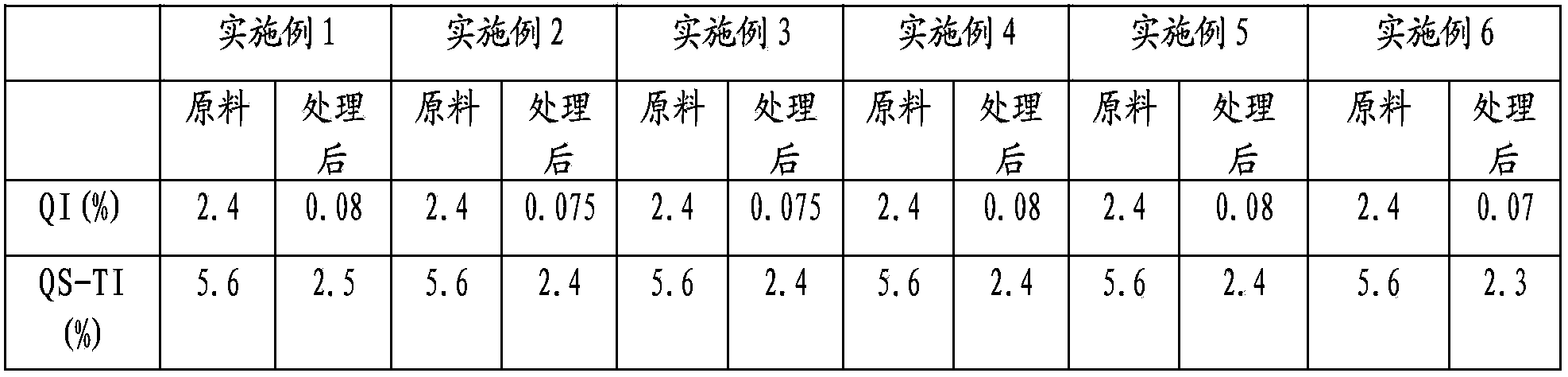

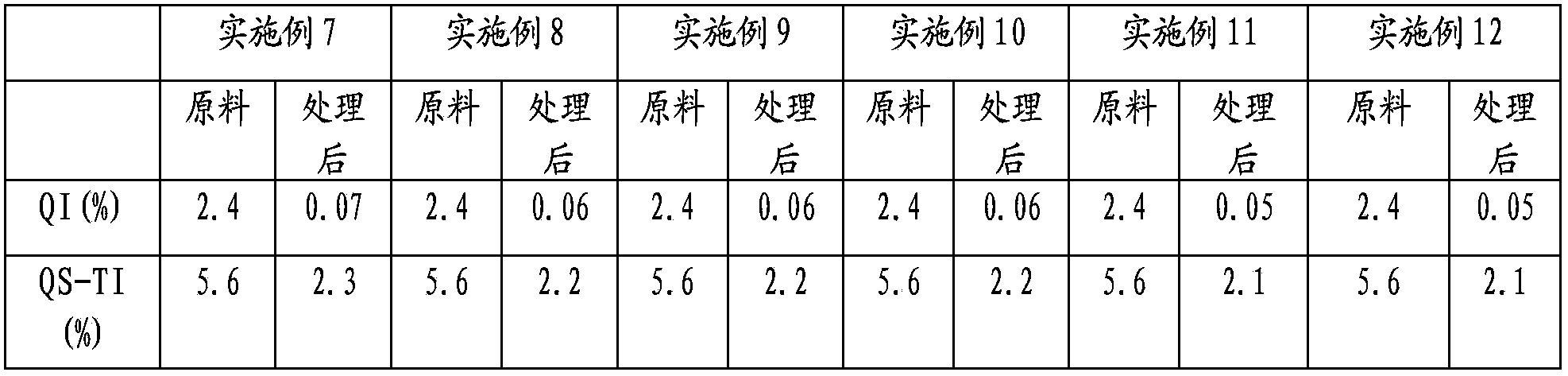

Solvent process for preparation of high-quality coal-based needle coke

ActiveCN103509572AEfficient removalImprove separation efficiencyWorking-up pitch/asphalt/bitumen by selective extractionCoking carbonaceous materialsDistillationQuinoline

The invention discloses a solvent process for preparation of high-quality coal-based needle coke. According to the process, raw materials and a solvent are mixed, quinoline insolubles are removed through physical separation, a clear liquor is distillated after separation, and a lightweight fraction obtained after distillation is used as a solvent; a heavy fraction obtained after distillation is subjected to hydrotreatment, then coking is carried out so as to obtain the coal-based needle coke, distillation is carried out on oil gas produced in coking, and a fractionated heavy fraction is used as a solvent. The process can prepare the high-quality coal-based needle coke with less than 0.1% of the quinoline insolubles and low content of toluene insoluble-quinoline soluble substances while the raw materials are cyclically used.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

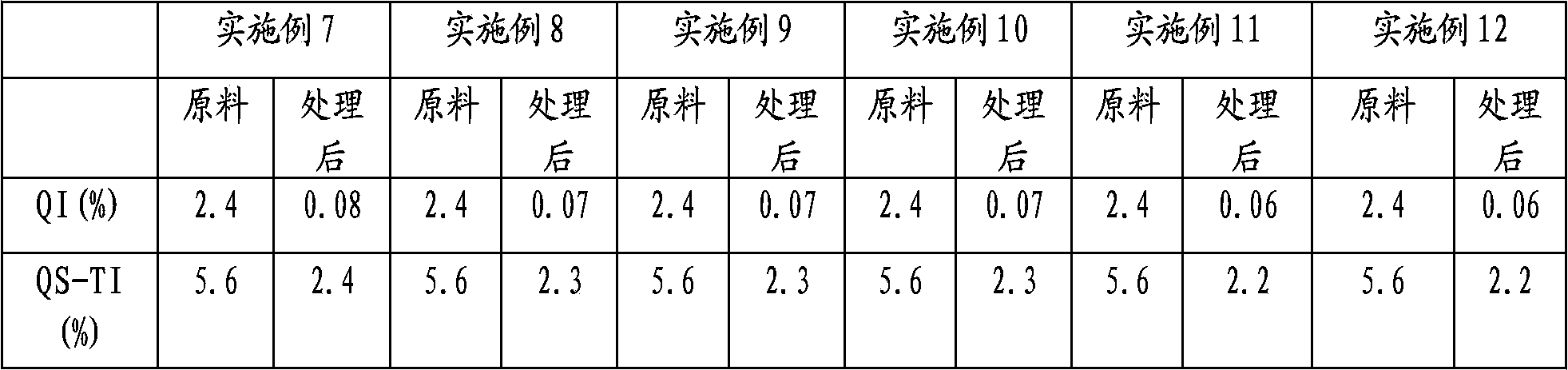

Catalytic hydrogenation method for olefin

ActiveCN101209951AImprove hydrogenation efficiencyEasy to controlHydrocarbon by hydrogenationHydrocarbon oils refiningHydrogenation reactionAlkene

The invention relates to a catalytic hydrogenation method of alkene. Under the conditions of alkene hydrogenation and the existence of hydrogenation catalysts, the alkene is reacted with hydrogen in contact way in a reactor; wherein, the reactor comprises a reacting tower and a reacting vessel, and the reacting tower and the reacting vessel are communicated with each other; the reaction tower is positioned above the reacting vessel; the hydrogen is sent into the reacting vessel from the bottom of the reacting vessel; the alkene is sent into from the middle-upper part of the reacting tower and / or the reacting vessel and contacts hydrogen in a countercurrent way; during the hydrogenation, the production separation is carried out; the light fraction exacted from the reacting tower after hydrogenation and the heavy fraction left on bottom of the reacting vessel after hydrogenation are reclaimed. The method of the invention saves the separation step and separation equipment of the ordinary alkene hydrogenation, thus greatly simplifying technology process. Besides, by directly applying reaction heat to separation of products, the energy consumption is decreased. In addition, the catalysis is carried out by taking the way of suspending and dispersing the hydrogenation catalyst into the reaction compound containing hydrogen and alkene so as to greatly improve catalysis effect and efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

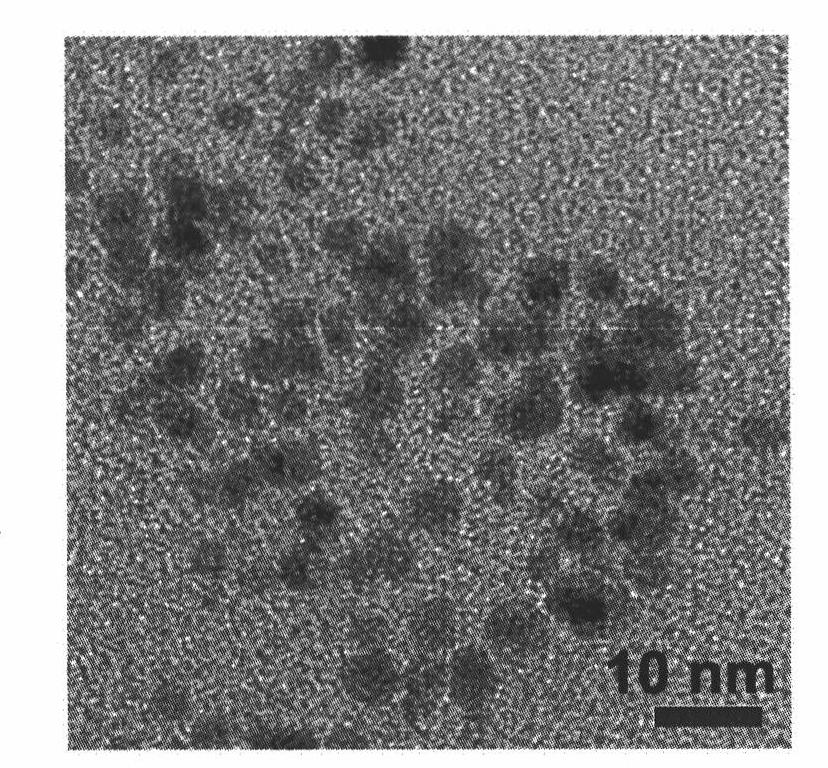

Nanometer palladium catalyst for hydrogenation of anthraquinone and preparation method thereof

InactiveCN101804346AImprove hydrogenation efficiencyReduce dosageCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthranilNanoparticle

The invention relates to a nanometer palladium catalyst for hydrogenation of anthraquinone and a preparation method thereof, relating to a palladium catalyst. The invention provides the nanometer palladium catalyst for the hydrogenation of anthraquinone and the preparation method thereof, wherein natural plants are taken as a reducing agent and a carrier. The nanometer palladium catalyst is prepared by dispersing nanometer palladium granules on a Cape jasmine carrier, and based on weight percent, the loaded palladium accounts for 1.2-3.6 percent of Cape jasmine, and the size of the nanometer palladium granules is 3-10 nm. Cape jasmine lixivium is prepared by dipping Cape jasmine in water, and the nanometer palladium catalyst is prepared by preparing palladium chloride into palladium chloride and Cape jasmine mixing solution by using the Cape jasmine lixivium, reducing and drying to obtain the nanometer palladium catalyst loaded on the Cape jasmine, i.e. the nanometer palladium catalyst for the hydrogenation of anthraquinone.

Owner:XIAMEN UNIV

Selective hydrogenation catalyst of alkine and diolefin, preparation method and application

ActiveCN100512955CImprove hydrogenation efficiencyReduce dosageHydrocarbon purification/separationHydrocarbonsCarbide siliconAlkaline earth metal

A selective hydrocatalyst for the alkine and diolefin in C2-10 fraction is composed of a inertial carrier chosen from silicon carbide, talc powder and fire-proof earth and a coated alumina layer containing Pd, Ag, Bi and at least one of Cu, Zn, alkali metal, AE metal and RE element. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

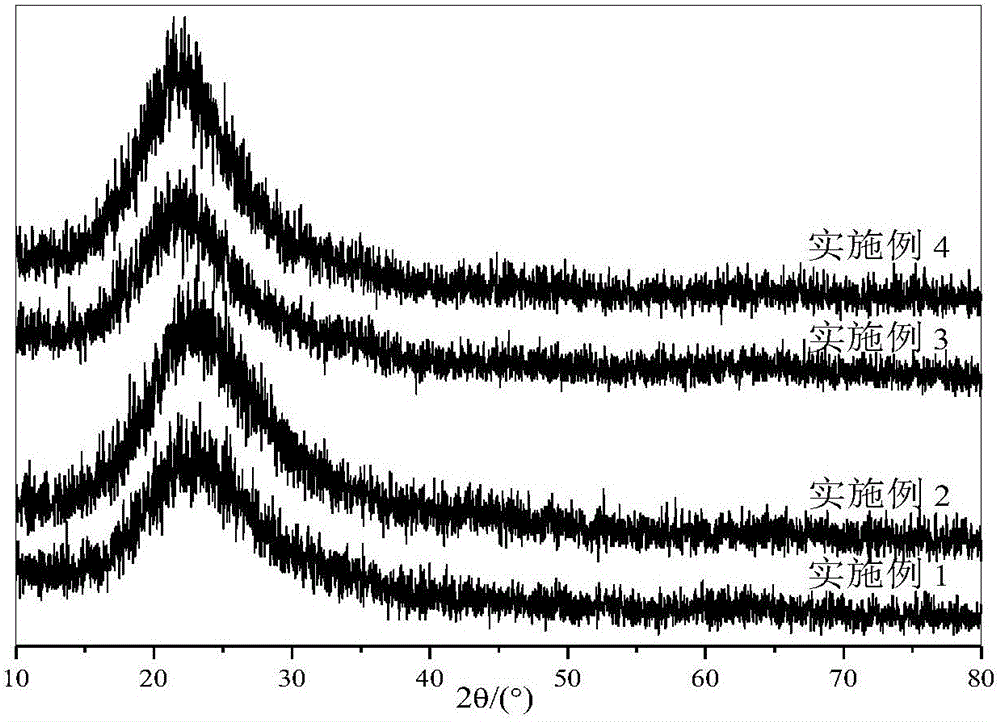

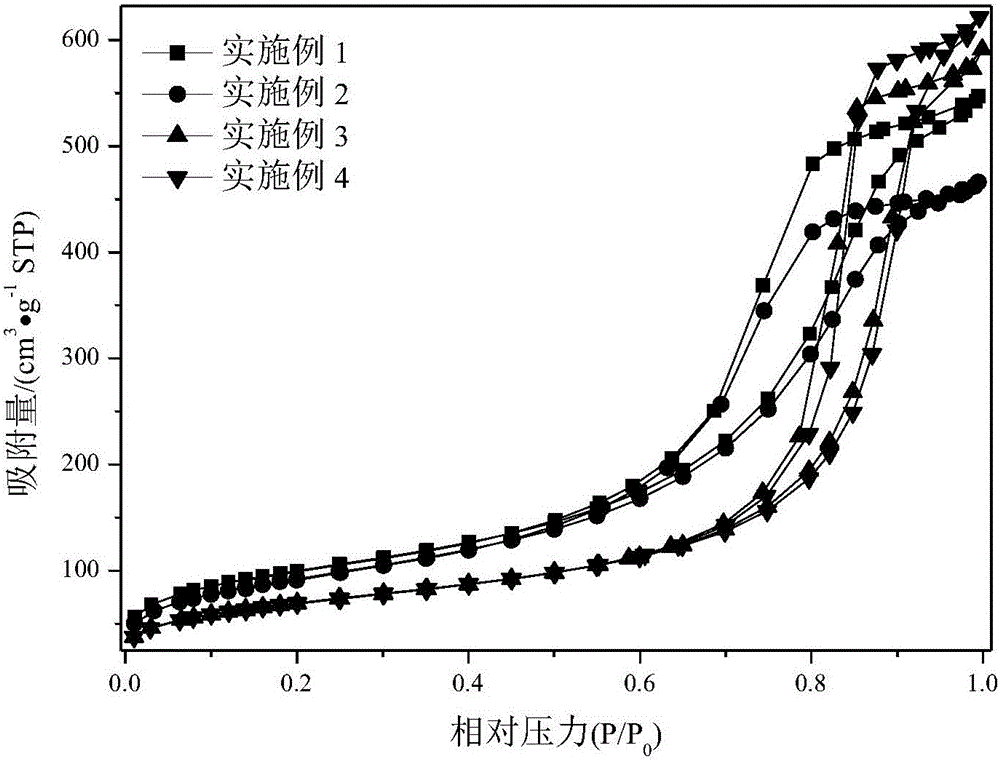

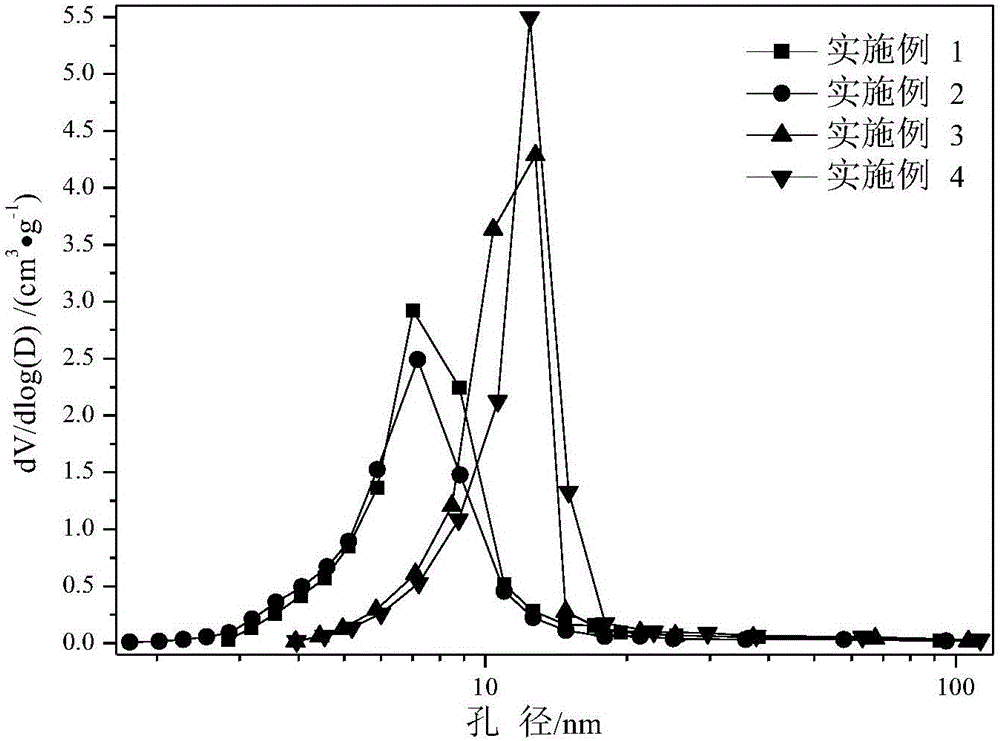

Preparation method of Pd-Fe/SiO2 hydrogenation catalyst

InactiveCN105797748AInhibit growthImprove catalytic stabilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsNitrateHydrogenation reaction

The invention provides a preparation method of a Pd-Fe / SiO2 hydrogenation catalyst. The method comprises the following steps that 1, tetraethyl orthosilicate, ferric nitrate and one of P123 or tetrapropyl ammonium hydroxide (TPAOH) are mixed, the mixture is dissolved with a HNO3 solution under magnetic stirring at room temperature, and then a hydrothermal reaction is conducted; 2, obtained precipitates are adjusted to be certain pH with the HNO3 solution and aged at room temperature, centrifugal washing, drying and roasting are sequentially conducted, and a carrier is obtained; 3, the carrier is subjected to equivalent-volume impregnation with a palladium nitrate solution, excessive impregnation is conducted with a NaOH solution, washing, drying and roasting are sequentially conducted, and the efficient loaded-type palladium catalyst is obtained. The preparation method of the Pd-Fe / SiO2 hydrogenation catalyst has the advantages that the preparation conditions are mild, and the Fe-additive is introduced in one step in the process of preparing the carrier precursor through a hydrothermal method; the prepared catalyst has good activity, selectivity and stability to an anthraquinone hydrogenation reaction, and the highest catalytic activity of the catalyst is increased by 143% compared with an industrial catalyst.

Owner:WUHAN UNIV OF TECH

Preparation method of eggshell type anthraquinone hydrogenation fixed bed catalyst

InactiveCN103706356AEasy to makeReduce manufacturing costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsBiological activationPalladium

The invention relates to a preparation method of an eggshell type anthraquinone hydrogenation fixed bed catalyst, wherein the eggshell type anthraquinone hydrogenation fixed bed catalyst is prepared from a spherical Al2O3 carrier through the steps of pre-drying processing, medium temperature soaking, desalted water washing, drying, activation calcination and the like. The preparation method has the beneficial effects that the preparation process of the catalyst is simple, the production cost is low, the hydrogenation efficiency is high, the selectivity is good, the hydrogenation efficiency is greater than 9 g / L, and the selectivity is grater than 99.5%; active metal palladium of the catalyst is tightly attached to the outer surface of the catalyst and is distributed in an eggshell type, and the thickness of a soaking layer is 50-80 microns and is beneficial to efficient utilization of precious metal palladium. The working procedure of washing is introduced in the preparation process of the catalyst, and the washing process is quantified.

Owner:CHINA TIANCHEN ENG +1

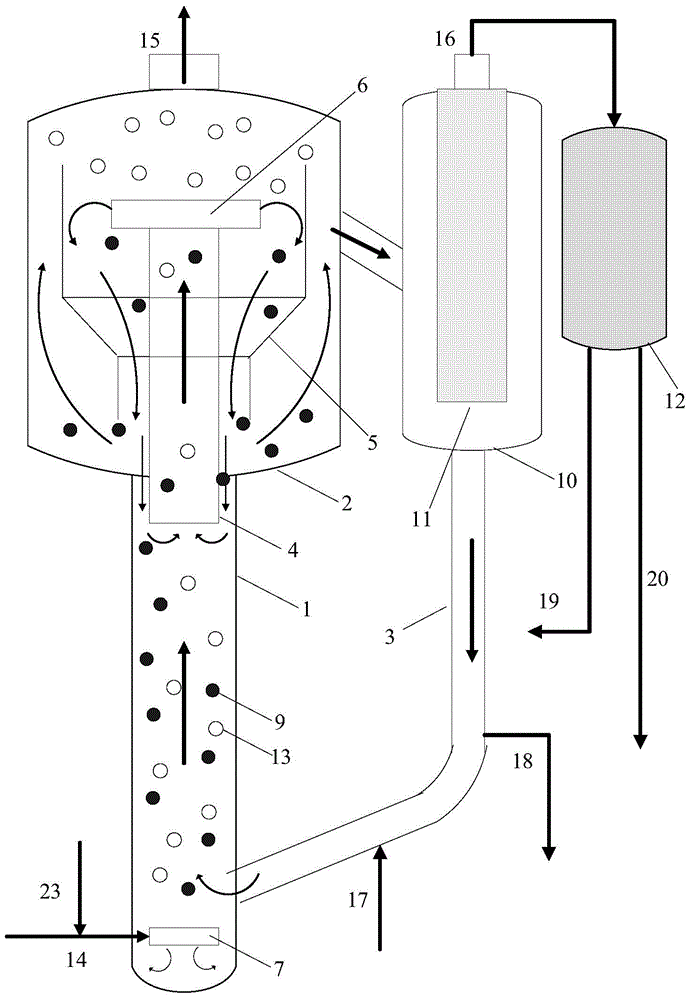

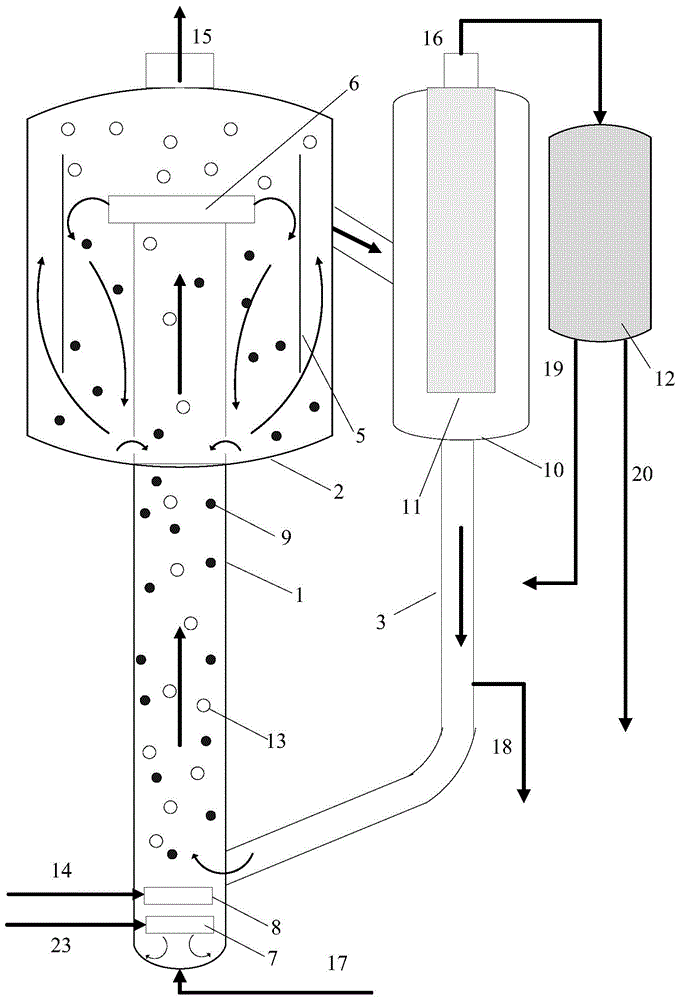

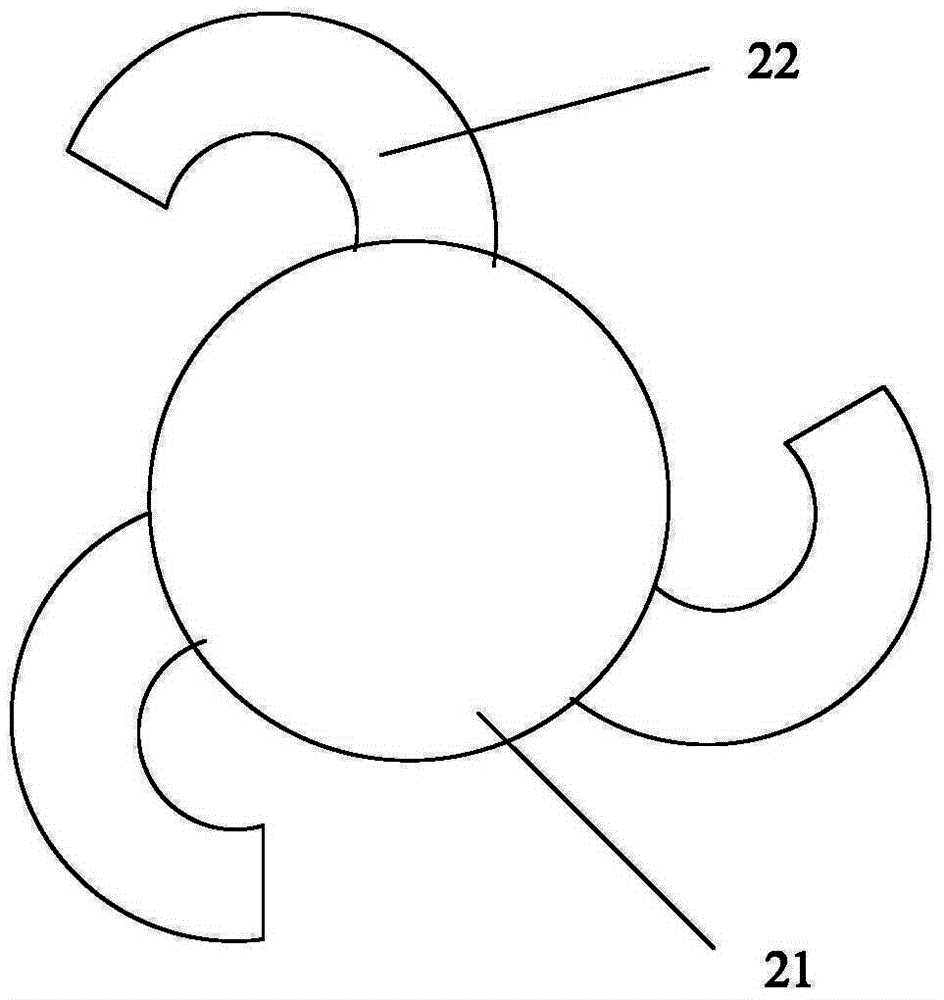

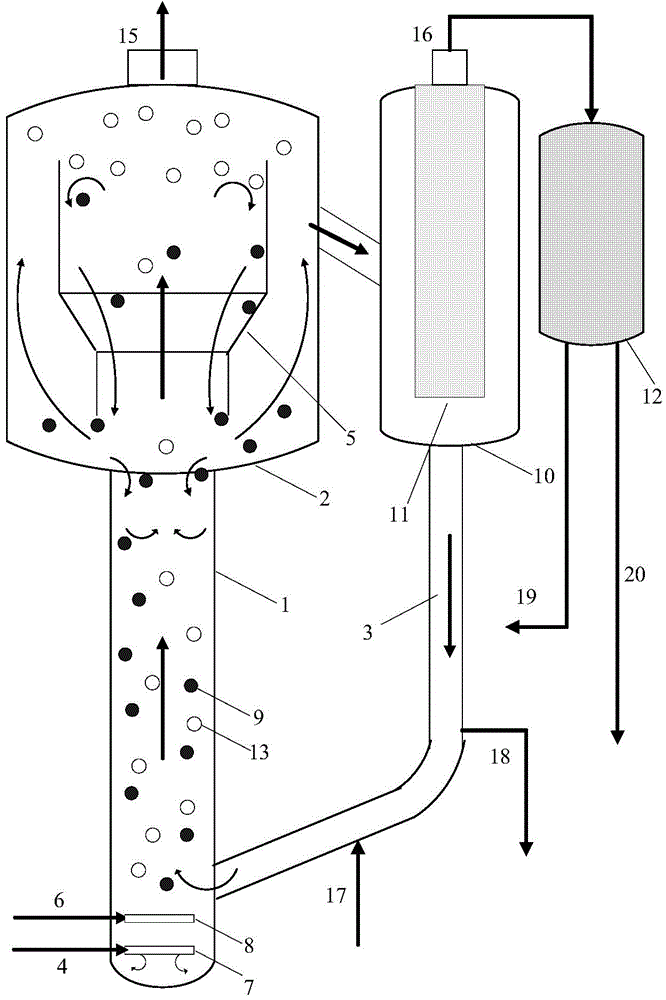

Slurry-bed circulation flow reactor and application and method for producing hydrogen peroxide

ActiveCN104549065AReduced chance of wear and tearIncrease concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention discloses a slurry-bed circulation flow reactor and an application and a method for producing hydrogen peroxide. The slurry-bed circulation flow reactor comprises an ascension pipe, an expanding section used for expanding pipe diameter of the upper part of the ascension pipe and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is communicated with the bottom of the ascension pipe; a three-phase separator of a double sleeve structure is arranged in the expanding section; a raw material inlet is formed in the bottom of the ascension pipe; a gas outlet is formed in the top of the expanding section; a filtration component is arranged in the solid-liquid separator; and a clear liquid outlet is arranged at the upper part of the solid-liquid separator by virtue of the filtration component. According to a method for producing hydrogen peroxide by taking the slurry-bed circulation flow reactor as a hydrogenation reactor, the gas-liquid-solid three-phase separation efficiency is high; the local excessive hydrogenation of the catalyst is avoided; the excessive hydrogenation possibility is reduced; the hydrogenation efficiency is high; and hydrogen peroxide products with high concentration can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

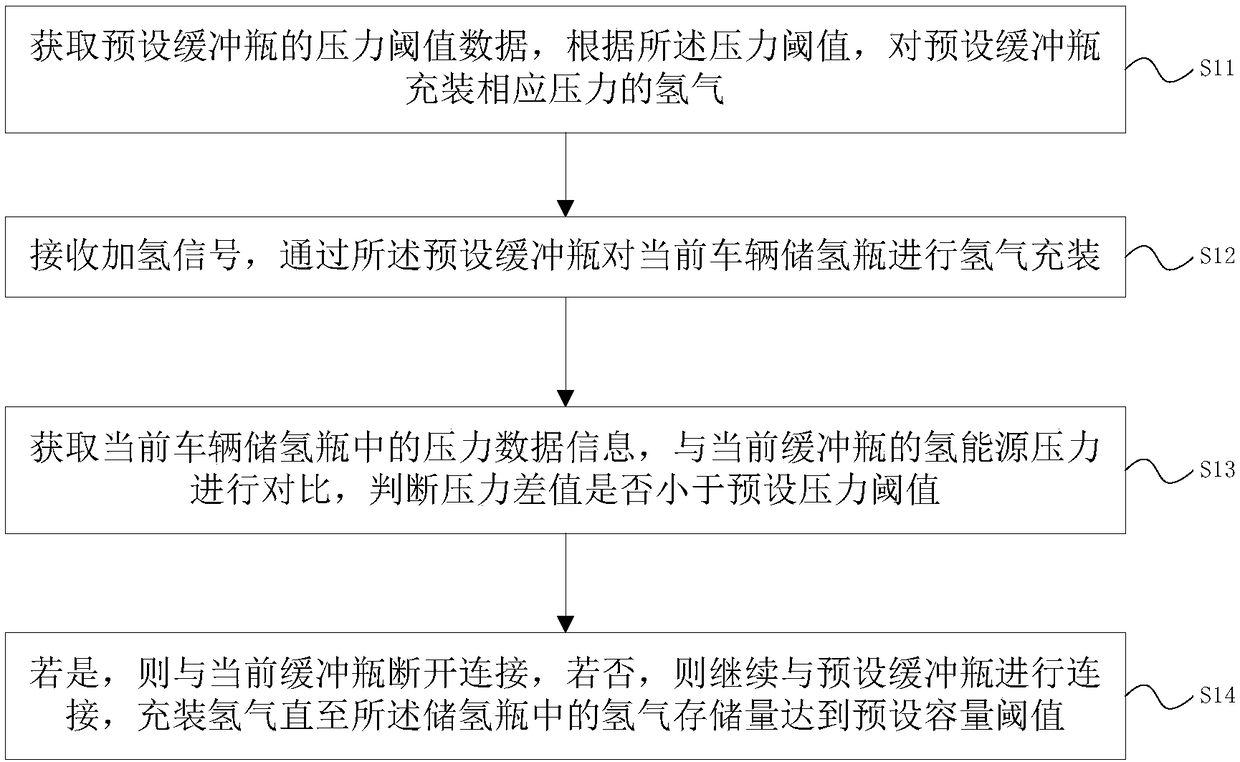

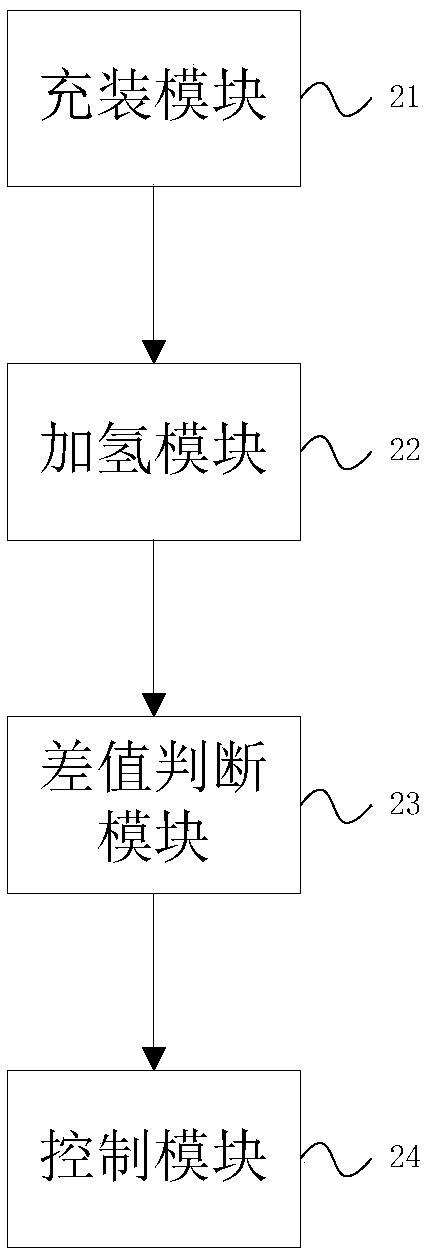

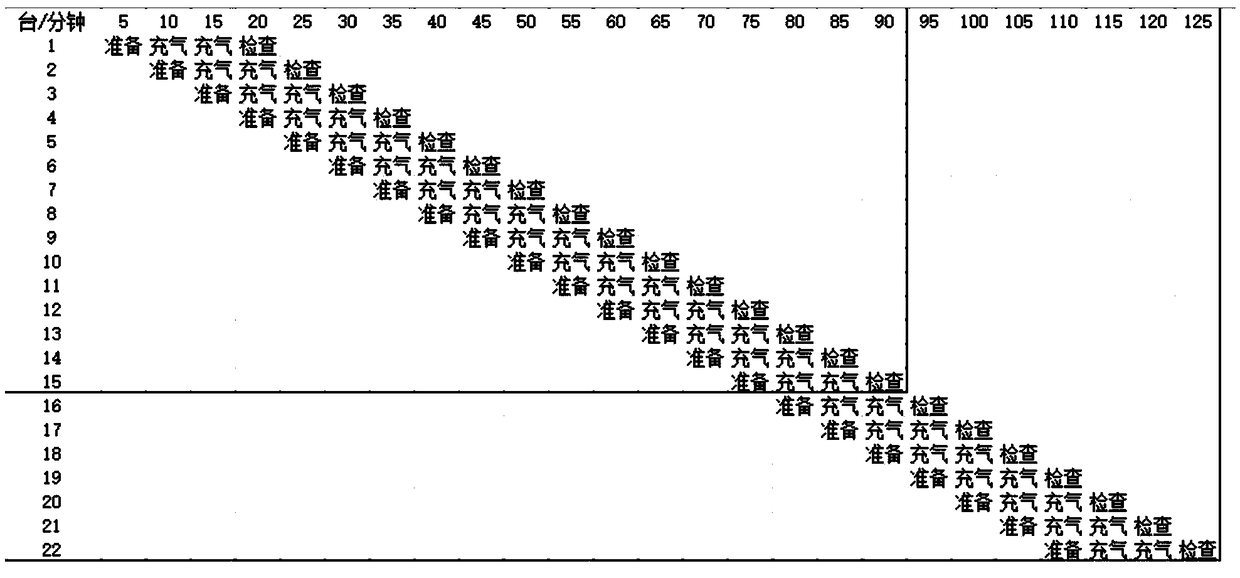

Method and system for rapid filling of hydrogen energy in hydrogen fueling station

PendingCN108775506AReduce recovery pressureImprove hydrogenation efficiencyVessel geometry/arrangement/sizeSecondary cellsData informationHydrogen pressure

The invention provides a method and system for rapid filling of hydrogen energy in a hydrogen fueling station. The method and system overcome the problems of long waiting time for hydrogen fueling andlow hydrogen fueling efficiency of fuel-cell vehicles in the prior art. The method comprises the following steps: S1, acquiring the pressure threshold data of preset buffer bottles, and filling the preset buffer bottles with hydrogen with corresponding pressure according to the pressure threshold; S2, receiving a hydrogen fueling signal, and filling the hydrogen storage bottle of a current vehicle with hydrogen via the preset buffer bottles; S3, acquiring the interior pressure data information of the hydrogen storage bottle of the current vehicle, and comparing the pressure data with the hydrogen pressure of a current buffer bottle to determine whether a pressure difference is less than the preset pressure threshold; and S4, if so, disconnecting the hydrogen storage bottle with the current buffer bottle, or if not, continuing the connection between the hydrogen storage bottle and the preset buffer bottles and filling the hydrogen storage bottle with hydrogen until the hydrogen storageamount of the hydrogen storage bottle reaches a preset volume threshold. With the method and system of the invention, superimposed hydrogen fueling via the buffer bottles with different pressures isemployed for the vehicle, so the hydrogen fueling efficiency of the fuel-cell vehicle is improved, and a plurality of vehicles can be filled with hydrogen simultaneously.

Owner:浙江昊凡科技有限公司

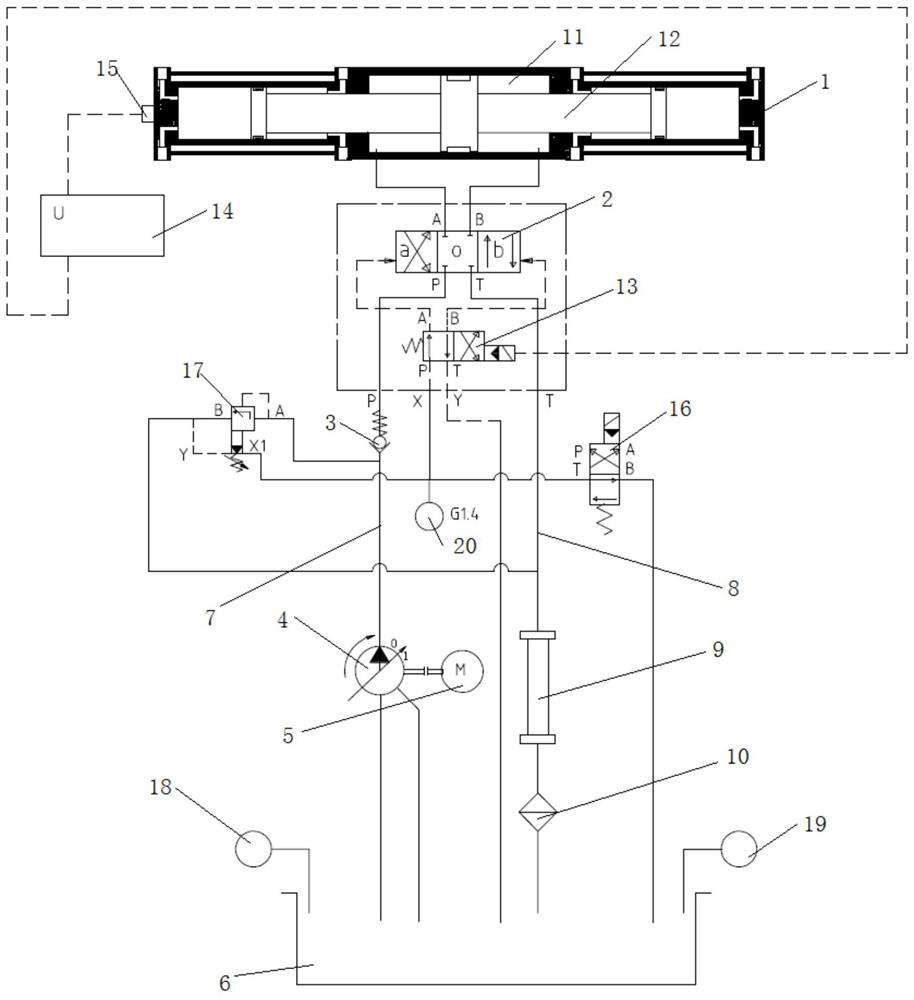

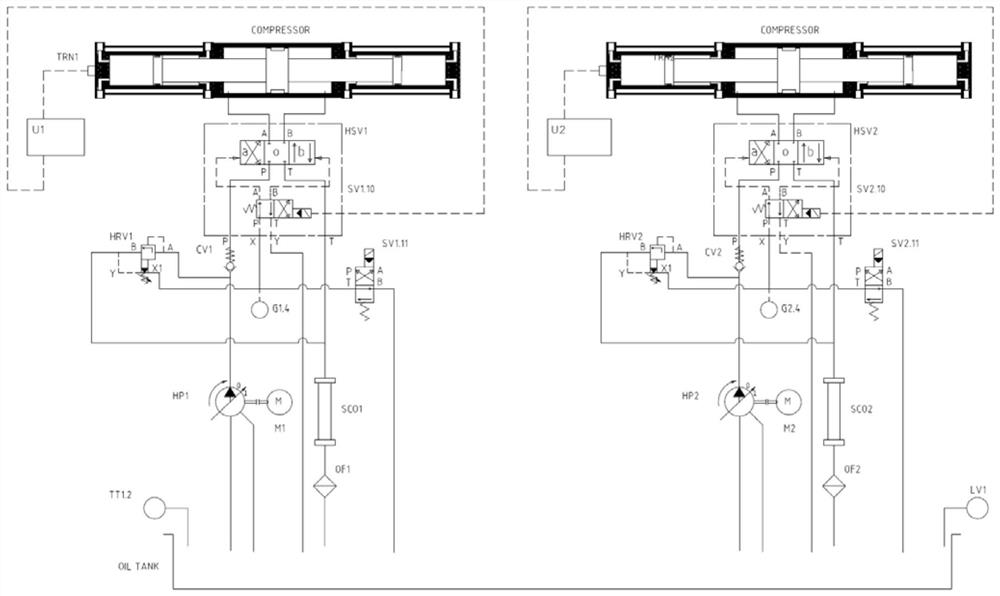

Quick start and stop system for hydrogen compressor

ActiveCN111765064AShorten hydrogenation timeReduce energy consumptionFluid-pressure actuator safetyServomotorsSpool valveHydraulic pump

The invention provides a quick start and stop system for a hydrogen compressor. The quick start and stop system is characterized in that an oil conveying pipe is connected with an oil port A of a compression cylinder in the hydrogen compressor through a hydraulic pump, a one-way valve and an oil path A of a hydraulic sliding valve; hydraulic oil returns to the oil tank from an oil port B of the compression cylinder in the hydrogen compressor through the oil conveying pipe, an oil path B of the hydraulic sliding valve, an oil tank heat exchanger and a hydraulic oil filter; the quick start and stop system further comprises a quick start branch; the quick start branch comprises an electromagnetic unloading valve and an overflow valve; and after the oil conveying pipe passes through the hydraulic pump, one path of the oil conveying pipe is connected with the corresponding oil port through the one-way valve, the hydraulic sliding valve and the compression cylinder, and the hydraulic oil returns to the oil tank from the other path through the overflow valve and the electromagnetic unloading valve. Before the hydrogen compressor is started, the electromagnetic unloading valve and the overflow valve are opened, the hydraulic pump remains in the no-load state, and a motor used for driving the hydraulic pump is started; after the start of the motor is completed, the electromagnetic unloading valve and the overflow valve are closed, the hydraulic pump enters the supercharging mode, and the hydrogen compressor is started; and accordingly, the purpose of quickly starting the hydrogen compressor is fulfilled.

Owner:BEIJING PROVA ENERGY DEV

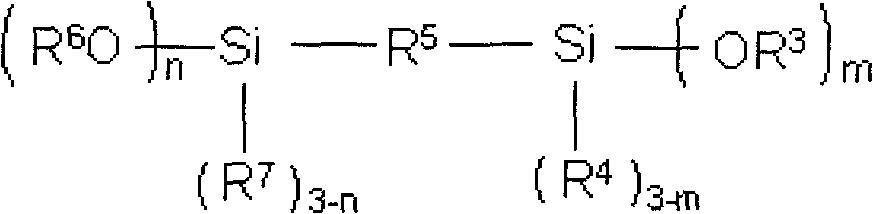

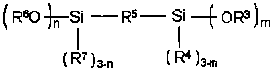

Hydrogenation catalyst composition and hydrogenation method thereof

ActiveCN101829600AEasy to storeImprove hydrogenation efficiencyHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsKetoneDouble bond

Owner:TSRC CORP

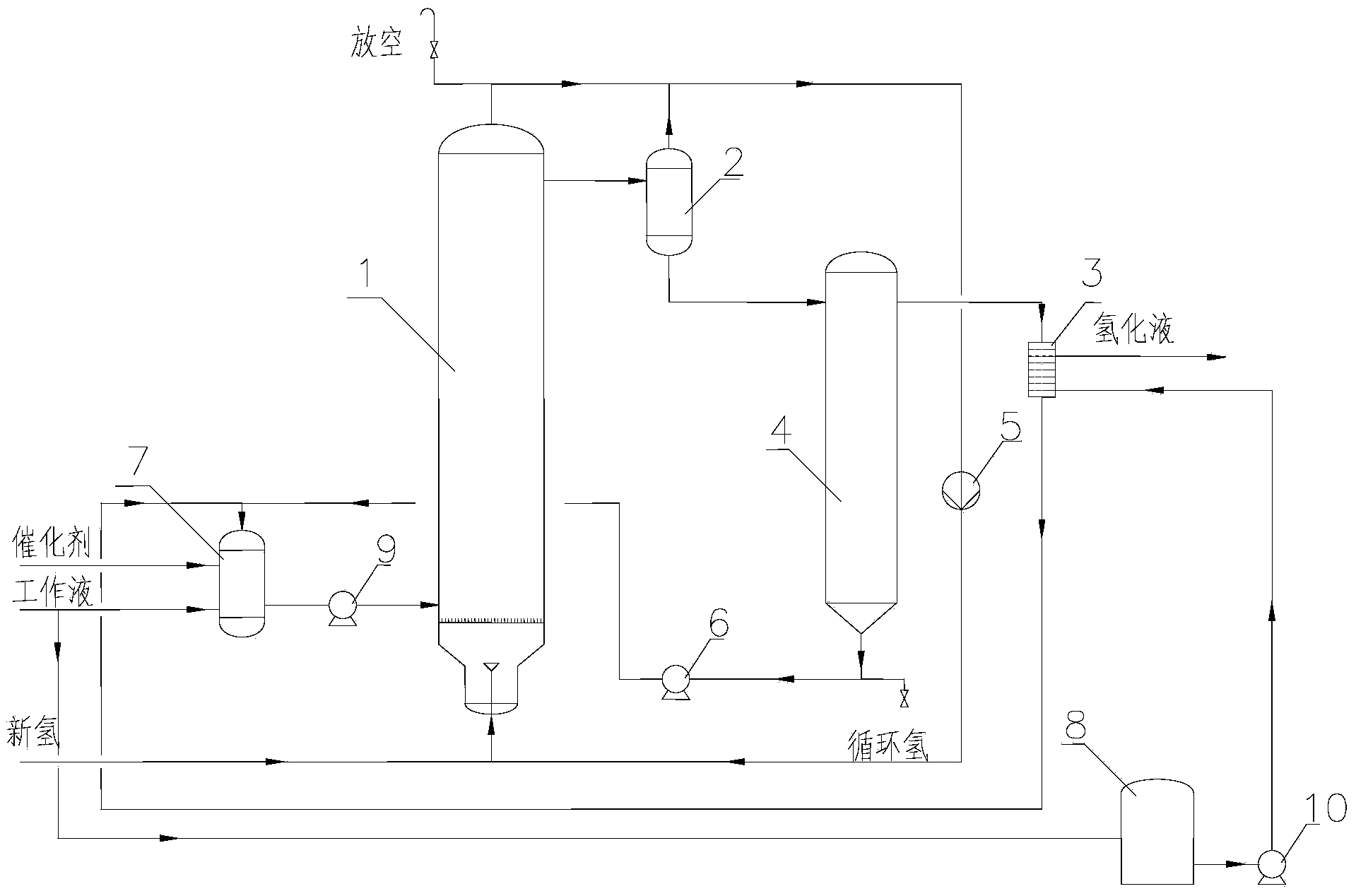

Hydrogenation system for hydrogen peroxide production

ActiveCN103964394AImprove efficiencyImprove hydrogenation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesThermodynamicsLiquid storage tank

The invention relates to a hydrogenation system for hydrogen peroxide production. The hydrogenation system comprises two hydrogenation towers and is characterized in that the two hydrogenation towers are provided with tower kettles; an inlet of the tower top of the first tower is connected with an outlet of a first working liquid cooler, and a hydrogen inlet in the upper part of the tower kettle of the first tower is connected with a hydrogen source; one outlet of the kettle bottom of the first tower is connected with an inlet of the first working liquid cooler, and the inlet of the first working liquid cooler is connected with a circulation working liquid source; another outlet of the kettle bottom is connected with an inlet of a second working liquid cooler, and an outlet of the second working liquid cooler is connected with a hydrogenated liquid inlet in the tower top of the second tower; an outlet of the kettle bottom of the second tower is connected with the inlet of the second working liquid cooler through a second hydrogenated liquid circulating pump, and another outlet of the tower kettle is connected with a hydrogenated liquid filter; the hydrogenated liquid filter is connected with a hydrogenated liquid storage tank, and the hydrogenated liquid storage tank is connected with a hydrogenated liquid cooler; the hydrogenated liquid cooler is connected with an oxidizing tower. The hydrogenation system solves the problems that gas and liquid do not flow uniformly in a static bed, and local working liquid flows obliquely and is in retention, which cause that anthraquinone is excessively hydrogenated to be degraded.

Owner:POLYTEX CHEM ENG CO LTD

Method for preparing hydrogen peroxide

InactiveCN102001631ALow costReduce contentPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention discloses a method for preparing hydrogen peroxide. The hydrogen peroxide is prepared by hydrogenating, oxidizing and extracting working solution prepared from alkyl anthraquinone and an organic solvent. The method is characterized in that: the working solution is prepared from ethyl anthraquinone, amyl anthraquinone, tetrahydro amyl anthraquinone, tetrahydro ethyl anthraquinone and the organic solvent; the total anthraquinone accounts for 16 to 30 mass percent of the working solution; the total ethyl anthraquinone accounts for 46 to 75 molar percent of the total anthraquinone; the total amyl anthraquinone accounts for 25 to 54 molar percent of the total anthraquinone; the molar ratio of the tetrahydro ethyl anthraquinone to the ethyl anthraquinone is 0.26-2.67:1; and the organic solvent is mixture of arene and trioctyl phosphate, mixture of heavy aromatic and tetra-n-butylurea or mixture of the heavy aromatic, the trioctyl phosphate and the tetra-n-butylurea. Compared with the prior art, the method has the advantages of simplicity, convenience in operation, safety, readily available raw materials, low cost, high productivity and no environmental pollution, and is a hydrogen peroxide production process with extremely high industrial production value.

Owner:SHANGHAI FULEI INT TRADING

Preparation method of ortho-methyl cyclohexyl alcohol

The present invention discloses a preparation method of ortho-methylcyclohexyl alcohol. The method includes the following steps: in the presence of catalyst the hydrogenation reaction of ortho-cresol can be used for producing ortho-methylcyclohexyl alcohol, and it is characterized by that the described catalyst uses gamma-delta Al2O3 as carrier and includes active component Ni with catalytic effective amount, the catalyst Ni content is 0.5-50 wt%. Its reaction pressure is 0.1-0.5 MP, reaction temp. is 150-250 deg.C. The activity of the described catalyst is high, can be up to 95%, under the condition of 0.2 MP and 190-200 deg.C, if the pressure is 0.2-1 MP, its conversion rate can be further raised, and the life of said catalyst can be prolonged.

Owner:YICHANG SUPENG TECH CO LTD

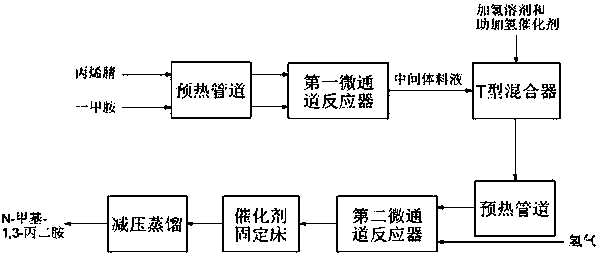

Preparation process method of N-methyl-1, 3-propane diamine

ActiveCN111454159AQuick disperse transferWell mixedCarboxylic acid nitrile preparationOrganic compound preparationAminopropionitrilePtru catalyst

The invention discloses a preparation process method of N-methyl-1, 3-propane diamine, and belongs to the technical field of organic synthesis. According to the method, monomethylamine and acrylonitrile are used as raw materials, an intermediate 3-methylaminopropionitrile is generated through a reaction in a micro-channel reactor, the intermediate is mixed with hydrogen and enters a catalyst fixedbed for a hydrogenation reaction, and finally the product N-methyl-1, 3-propane diamine is obtained. According to the preparation process method of N-methyl-1, 3-propane diamine, the method is simple, continuous production can be achieved, the reaction time is short, the side reaction occurrence probability is low, the product yield reaches 90-95%, and the productivity is improved.

Owner:DALIAN UNIV OF TECH +1

Process for preparing high-quality coal-series needle-coke

ActiveCN103509574AReduce quinoline insoluble contentEfficient removalCoking carbonaceous materialsSolventSubstance content

The invention discloses a process for preparing a high-quality coal-series needle-coke. The process comprises the steps: mixing a raw material with a solvent, removing a quinoline insoluble substance by physical separation, after separation, distilling the clarified liquid, and employing a distilled light fraction as the solvent in a raw material tank; after carrying out hydrogenation treatment of a distilled heavy fraction, distilling again to obtain a raw material for preparation of the needle-coke, and carrying out delayed coking to obtain the needle-coke; and employing a heavy fraction fractionated from oil gas obtained by the secondary distillation as the solvent. While recycling the raw material, the high-quality coal-series needle-coke raw material with the quinoline insoluble substance content of less than 0.1% and lower toluene insoluble-quinoline soluble substance content can be prepared.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting anthraquinone process and application of slurry bed hydrogenation reactor

ActiveCN104549059AReduce operational burdenReduced chance of wear and tearPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesAnthraquinone processHigh concentration

The invention discloses a slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting an anthraquinone process and application of the slurry bed hydrogenation reactor. The hydrogenation reactor comprises an ascension pipe, an expanding section for expanding the upper pipe diameter of the ascension pipe, and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is connected with the bottom of the ascension pipe; a guide cylinder is arranged in the expanding section; the bottom of the ascension pipe is provided with a raw material inlet; the top of the expanding section is provided with a gas outlet; a filter assembly is arranged in the solid-liquid separator and provided with a purified liquor outlet. The method for preparing the hydrogen peroxide is characterized in that the slurry bed hydrogenation reactor is applied to a hydrogenation unit, the gas-liquid-solid three-phase separation efficiency is high, the catalyst locality cannot be excessively hydrogenated, the excessive hydrogenation possibility is reduced, the hydrogenation efficiency is high, and a hydrogen peroxide product with the relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

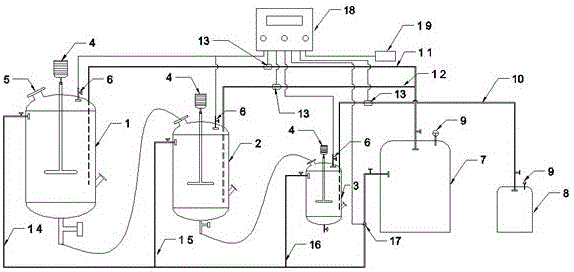

Process for suspended hydrogenating of anthraquinone compound

ActiveCN103449381AEvenly distributedIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenVapor–liquid separator

The invention relates to a process for suspended hydrogenating of an anthraquinone compound. The process comprises the following specific steps that a working solution containing alkyl anthraquinone and a powdered suspended bed catalyst are sufficiently mixed in a working station preparation kettle, and the mixture is pumped into a suspended bed hydrogenation tower through a pump, wherein the working solution in the tower is mixed with the hydrogen and moves upwards at a certain speed; a hydrogenated liquid flows out from the top of a suspended bed and enters a gas-liquid separator, and unreacted hydrogen is discharged from the top end of the gas-liquid separator and is mixed with new hydrogen to enter the bottom of the hydrogenation tower; a hydrogenated liquid containing the catalyst is discharged from the bottom of the gas-liquid separator and enters a settling tower, the catalyst in the settling tower drops to the bottom of the tower, the working solution containing a large amount of catalyst is pumped into the preparation kettle through a mud pump, and a clarified hydrogenated liquid at the upper part of the settling tower passes through a filter; the hydrogenated liquid is filtered and then enters a subsequent oxidation process. According to the process for hydrogenation of the anthraquinone, the catalyst is uniformly distributed in the reactor, the utilization rate of the catalyst is high, the gas-liquid heat transfer speed is high, the hydrogenation efficiency is high, the space time yield is stable and the like.

Owner:CHINA TIANCHEN ENG +1

Preparation method of battery grade lithium carbonate

ActiveCN106517258AReduce usageImprove hydrogenation efficiencyLithium carbonates/bicarbonatesFiltrationFirst-order reaction

The invention provides a preparation method of battery grade lithium carbonate. The preparation method is characterized by preparing slurry from industrial lithium carbonate, pumping the slurry into a first-order reaction kettle, introducing collected CO2, carrying out full reaction, then carrying out filtration to obtain filter residues, preparing slurry from the filter residues, pumping the slurry into a second-order reaction kettle, introducing collected CO2, carrying out full reaction, then carrying out filtration to obtain filter residues, preparing slurry from the filter residues, pumping the slurry into a third-order reaction kettle, introducing high-purity CO2, carrying out full reaction and then carrying out filtration; firstly pumping the filtrate obtained after each-order filtration into a decomposition reaction kettle, then transferring the filtrate to a causticization reaction kettle, adding a Ca(OH)2 solution, carrying out immediate filtration and washing to obtain filtrates, pumping the filtrates into a concentration kettle, pumping the concentrate into a synthesis kettle after the concentrate passes through a column filled with ion exchange resin and introducing high-purity CO2, thus preparing high-purity battery grade lithium carbonate. The preparation method has the beneficial effects that by utilizing the advantage that lithium carbonate can undergo hydrogenation and efficiently utilize high-purity CO2, CO2 is recycled in the reaction process and foreign ions in the kettles can be ensured to be removed, thus reducing the production cost.

Owner:JINGMEN GEM NEW MATERIAL

Selective hydrogenation method for conjugated diene latex

The invention provides a selective hydrogenation method for conjugated diene latex. The method comprises the step of subjecting the conjugated diene latex to a hydrogenation reaction with a compound catalyst of metal of a family VIII represented by a formula (I) shown in the description, thereby obtaining a hydrogenated polymer. According to the method, latex hydrogenation of the conjugated dienelatex is catalyzed by employing the compound catalyst of the metal of the family VIII represented by the formula (I); during the use of the catalyst, no cocatalyst and no organic solvent are employed,and no substance except for the catalyst is employed; compared with the prior art, the method has the advantages that the catalyst has high hydrogenation efficiency to NBR latex, and the consumptionof the catalyst is low; and hydrogenation conditions of the catalyst are not harsh, the temperature and pressure are not high, the catalyst has high catalyzing activity to the latex under the condition of moderate temperature and pressure, and thus, realization of rapid industrialization is facilitated.

Owner:QINGDAO UNIV OF SCI & TECH +2

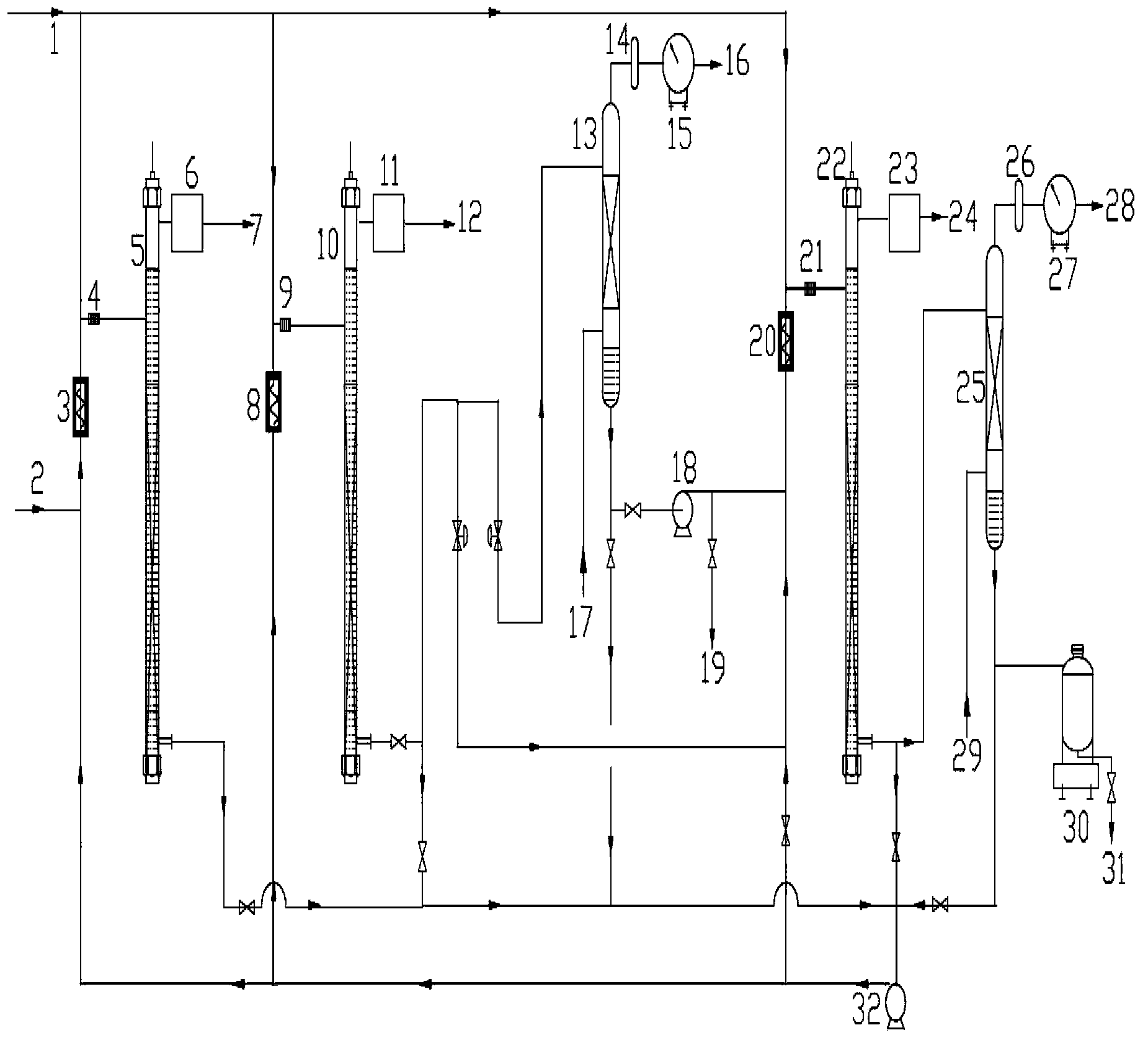

Distillate oil hydrotreatment process

InactiveCN104099127AImprove hydrogen dissolving abilityLow investment costTreatment with hydrotreatment processesWaxCycle oil

The invention relates to a distillate oil hydrotreatment process. The distillate oil hydrotreatment process comprises the following steps of 1, carrying out mixing heating on raw material oil and recycle oil, feeding the mixed oil and hydrogen into a first hydrogen-oil mixer, and feeding the mixture obtained by the first hydrogen-oil mixer into a first reactor, 2, (1) recycling the product oil, or (2) carrying out individual heating on the product oil or mixing heating on the product oil and recycle oil, then feeding the heated oil and hydrogen into a second hydrogen-oil mixer, carrying out mixing, and feeding the mixture into a second reactor, 3, (1) carrying out individual heating on the product oil or mixing heating on the product oil and the recycle oil, then feeding the heated oil and hydrogen into a third hydrogen-oil mixer, carrying out mixing and feeding the mixture into a third reactor, or (2) recycling the product oil obtained by the reactor, or (3) feeding the product oil into a first separator, carrying out stripping separation, recycling the separated liquid oil, feeding the separated liquid oil into a heating furnace or a storage tank and discharging separated gas from the system, and 4, (1) recycling the product oil obtained by the third reactor, or (2) feeding the product oil into a second separator, carrying out stripping separation, recycling the separated liquid oil product or directly feeding the liquid oil product into the storage tank, and discharging separated gas from the system. A distillate oil product produced by heavy and inferior wax oil hydrorefining can be used as a high-quality raw material for a catalytic cracking device or a hydrocracking device.

Owner:PETROCHINA CO LTD

A hydrogenation method for a polymer comprising an olefin unsaturated bond

A hydrogenation method for a polymer comprising an olefin unsaturated bond is disclosed. The method includes bringing a solution of the polymer comprising the olefin unsaturated bond into contact with hydrogen in reactors under a hydrogenation condition and with the existence of a hydrogenation catalyst. The method is characterized in that the reactors are at least two reactors in series connection, the first reactor is formed by combining a tower reactor or a stirring reactor with a static mixer, materials in the reactors are allowed to be in a near complete mixing state through controlling the recycle ratio of the first reactor, the recycle ratio of the first reactor is 1-40:1, the second and latter reactors are tower reactors, and materials in the second and latter reactors are in a near plug-flow state. The method can allow the hydrogenation degree of the polymer to reach an ideal value stably.

Owner:苏州双湖化工技术有限公司

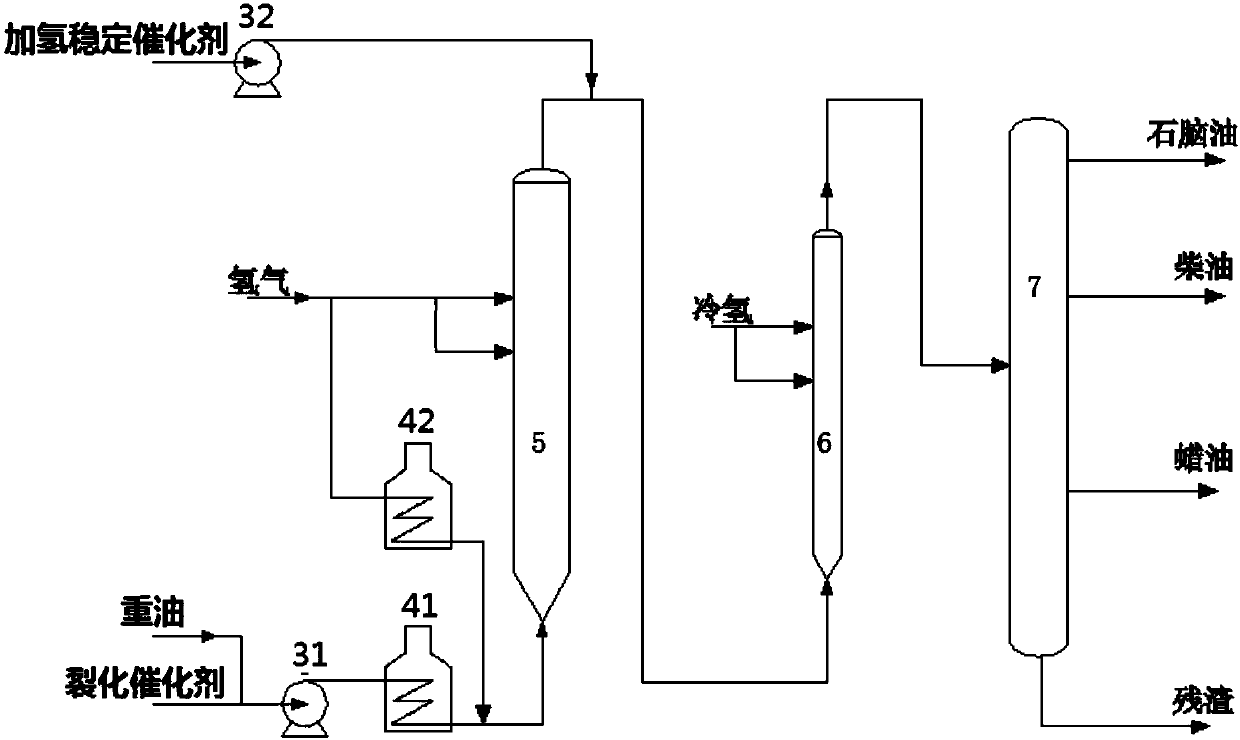

Suspended bed hydrogenation combination process and system

ActiveCN107641525AImprove hydrogenation efficiencyDelayed inactivation timeHydrocarbon oil crackingChemistryPetrochemical

The invention relates to the technical field of coal and petrochemical industries and discloses a suspended bed hydrogenation combination process and system. The hydrogenation combination process comprises the steps: after mixing heavy oil with a cracking catalyst, conveying the mixture to a suspended bed hydrocracking reactor to carry out high-temperature cracking; and after mixing a high-temperature cracking product with a hydrogenation stabilizing catalyst, conveying the mixture into a suspended bed hydrogenation stabilizing reactor, and carrying out hydrorefining in the suspended bed hydrogenation stabilizing reactor. The invention further discloses the hydrogenation combination system in which the process is adopted. If the process and system are used for heavy oil hydrogenation lightening, thermal cracking and hydrogenation are completed under different reaction conditions, so that all functions can be sufficiently exerted, the hydrogenation efficiency is increased, meanwhile, the deactivation time of the hydrogenation stabilizing catalyst is prolonged, and the additive amount of the hydrogenation stabilizing catalyst is reduced.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com