Patents

Literature

125results about How to "Improve gas utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weak tumble rapid combustion system and gas engine

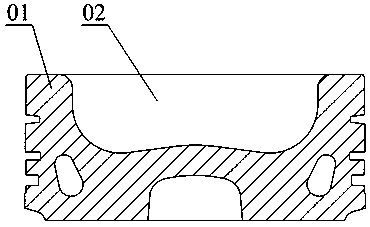

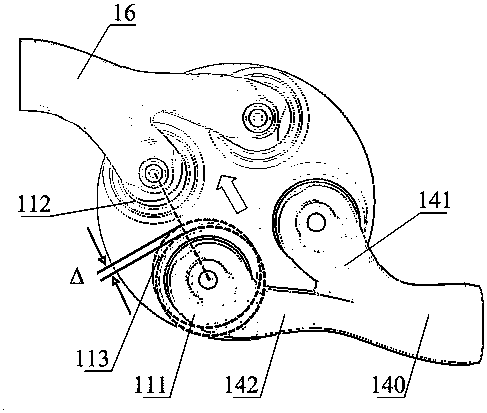

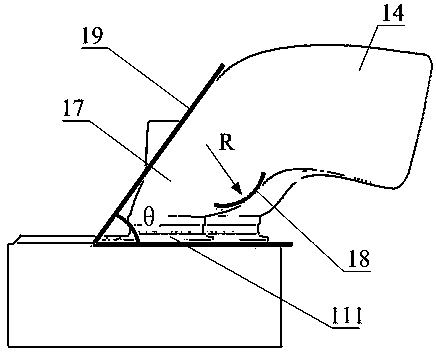

ActiveCN111287860AImprove gas utilizationHigh feasibilityInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses a weak tumble rapid combustion system and a gas engine. The weak tumble rapid combustion system comprises a piston, a cylinder cover, an air intake channel and an exhaust channel, a combustion chamber is formed between the top of the piston and the cylinder cover, the cylinder cover is provided with an air intake throat and an exhaust throat, the section, close to the air intake throat, of the air intake channel is a tumble guide air channel, the axis of the tumble guide air channel is obliquely arranged relative to the bottom face of the cylinder cover, the upper sideface of the tumble guide air channel is an undershoot guide face obliquely arranged relative to the bottom face of the cylinder cover, the lower side face of the tumble guide air channel is an arc-shaped guide face sunken towards the bottom face of the cylinder cover, an eccentric chamfer is arranged at the lower end of the air intake throat, and the eccentric direction of the eccentric chamfer deviates along the direction of a central connecting line from the air intake throat to the air outlet throat. According to the weak tumble rapid combustion system, during air suction, fuel gas forms large-scale weak tumble motion in the air cylinder and is broken into small-scale turbulent flow in the last stage of compression, so that the flame propagation speed is increased, and the fuel gas utilization rate and the engine heat efficiency are improved.

Owner:WEICHAI POWER CO LTD

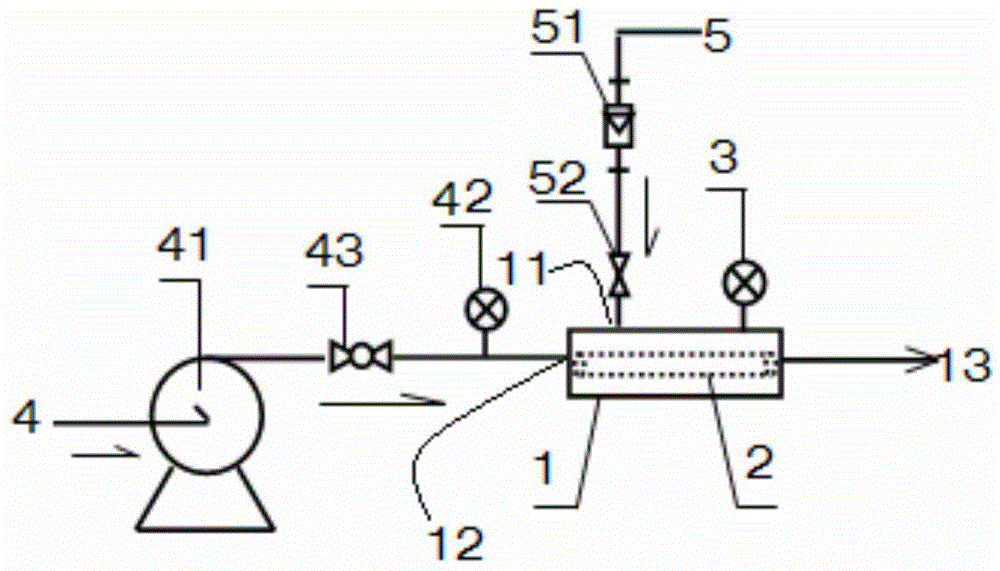

Micro-nano bubble generation device and sewage purification system

InactiveCN104888636AImprove gas utilizationReduce energy consumptionFatty/oily/floating substances removal devicesFlow mixersMicro nanoNanometre

The invention discloses a micro-nano bubble generation device and a sewage purification system. The generation device comprises a sealed space and a micro-nano membrane pipe contained in the sealed space, wherein an air inlet, a liquid inlet and an air-liquid mixture outlet are formed in the sealed space, compressed air entering the sealed space from the air inlet permeates from the first side of the micro-nano membrane pipe to the second side of the micro-nano membrane pipe; pressurized liquid entering from the liquid inlet flows towards the air-liquid mixture outlet along the second side of the micro-nano membrane pipe so that the pressurized liquid is mixed with the air permeating through the micro-nano membrane pipe and flows out of the air-liquid mixture outlet. When the pressurized liquid such as sewage flows through the surface of the second side of the micro-nano membrane pipe, the trace air permeating to the second side of the micro-nano membrane pipe can be rapidly and continuously sheared by the pressurized liquid, so that a large amount of micro-nano bubbles are efficiently generated and the air utilization rate can be greatly improved; the energy consumption for pressurizing the liquid and compressing the air can be effectively reduced; the water purification effect can be improved and the micro-nano bubble generation device is suitable for various water treatment fields.

Owner:CHINA PETROLEUM & CHEM CORP +2

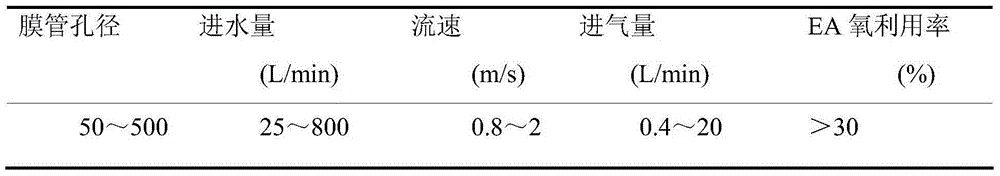

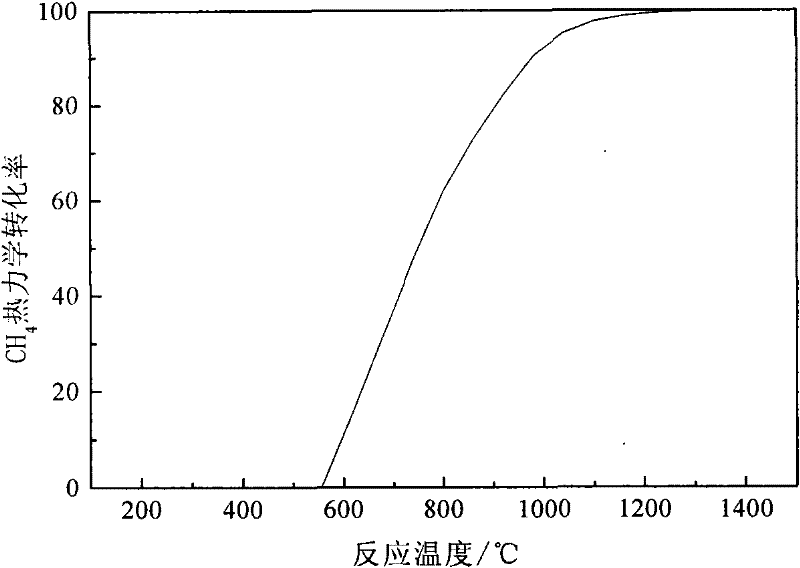

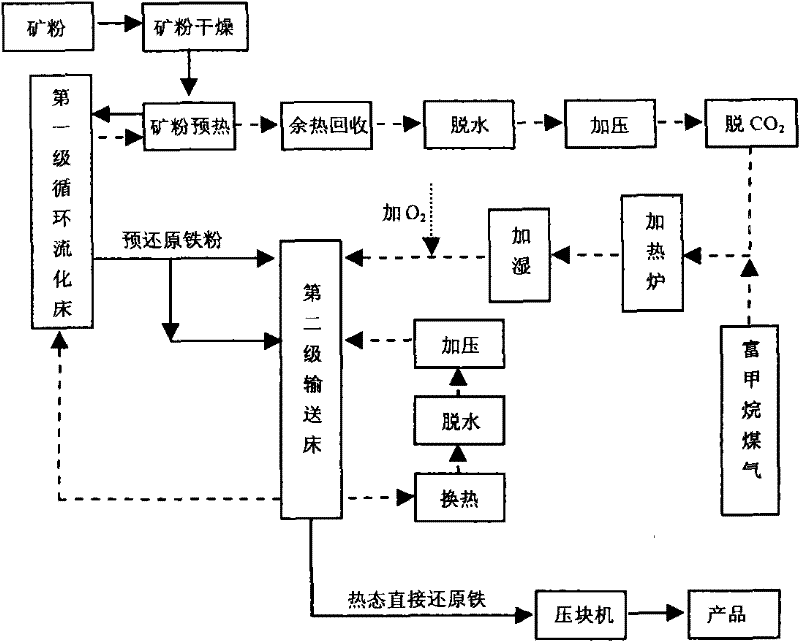

Air-base direct reduction iron-making method for reducing iron concentrate powder by self-reforming of gas rich in methane

ActiveCN102206723ARealize self-reorganizationEliminate the effects ofGas emission reductionIron powderFluidized bed

An air-base direct reduction iron-making method for reducing iron concentrate powder by self-reforming of gas rich in methane. The method provided by the invention belongs to the field of iron-making technology. The method is characterized in that through a technology combining a circulating fluidized bed and a two-section high temperature conveying bed, iron ore powder is dried and preheated andthen is fed into a circulating fluidized bed for pre-reduction; the pre-reduced iron ore powder is fed into a high temperature fast conveying bed for a deep and rapid reduction in the presence of reducing gas at a reaction temperature of 940 to 1000 DEG C and methane is cracked by a effect of direct reduction of iron simultaneously; in a cooling zone of the high temperature fast conveying bed, the reduced iron ore powder is mixed with reducing gas from a cooling circuit and is fast cooled to a temperature of 700 to 800 DEG C; and the reduced iron ore powder can be utilized for producing hot pressed blocks and cold pressed blocks produced through a cooling treatment of a third stage circulating fluidized bed. The air-base direct reduction iron-making method realizes self-reforming of gas rich in methane in a reducing furnace and has the advantages of high utilization rate, high efficiency, environmental protection, etc.

Owner:BEIJING SHOUGANG INT ENG TECH

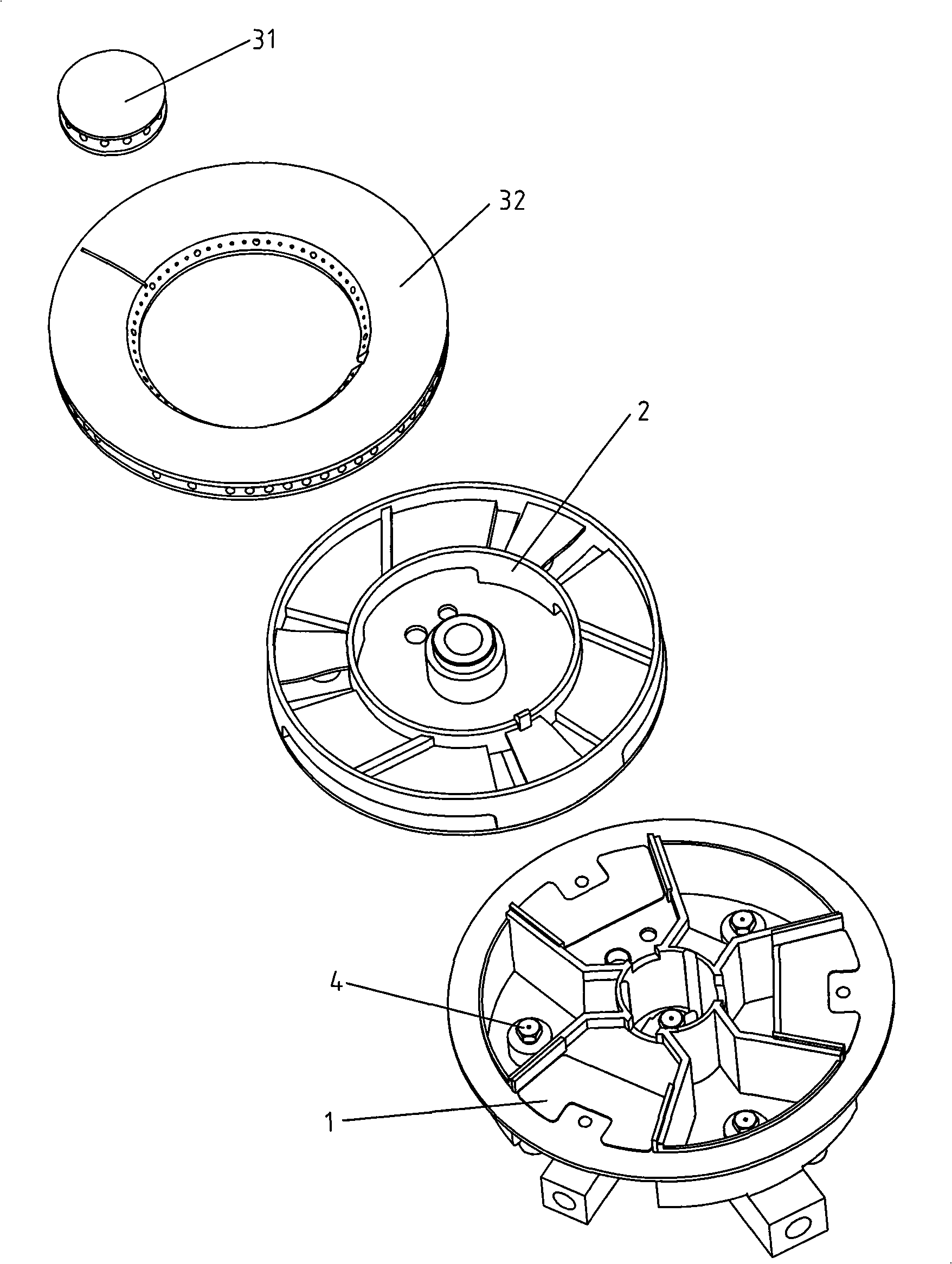

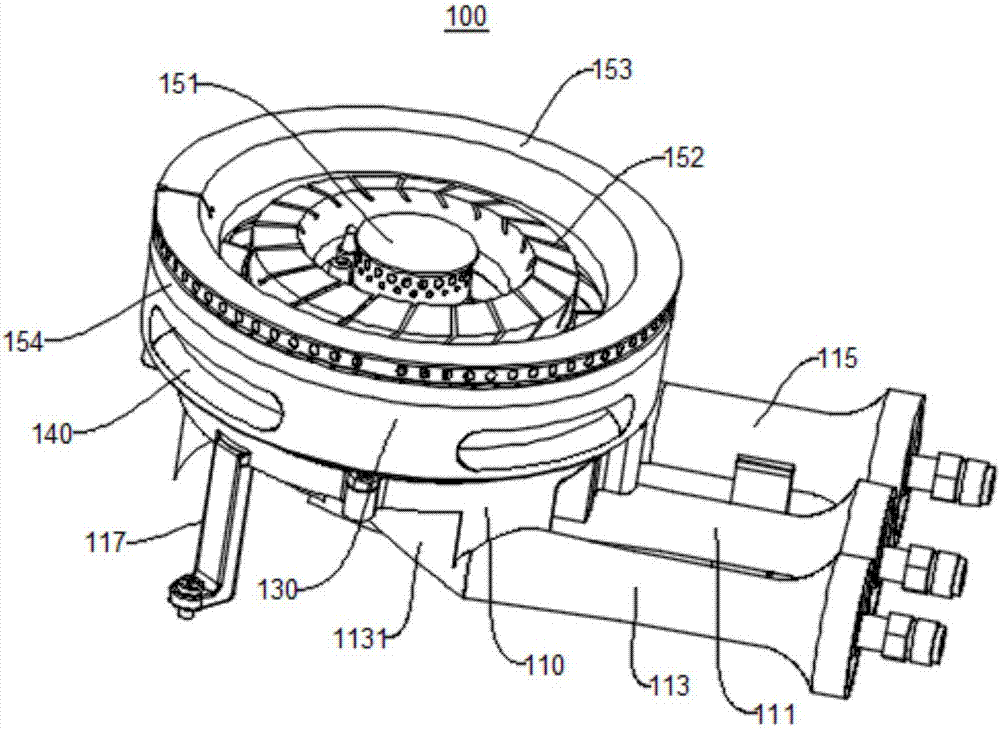

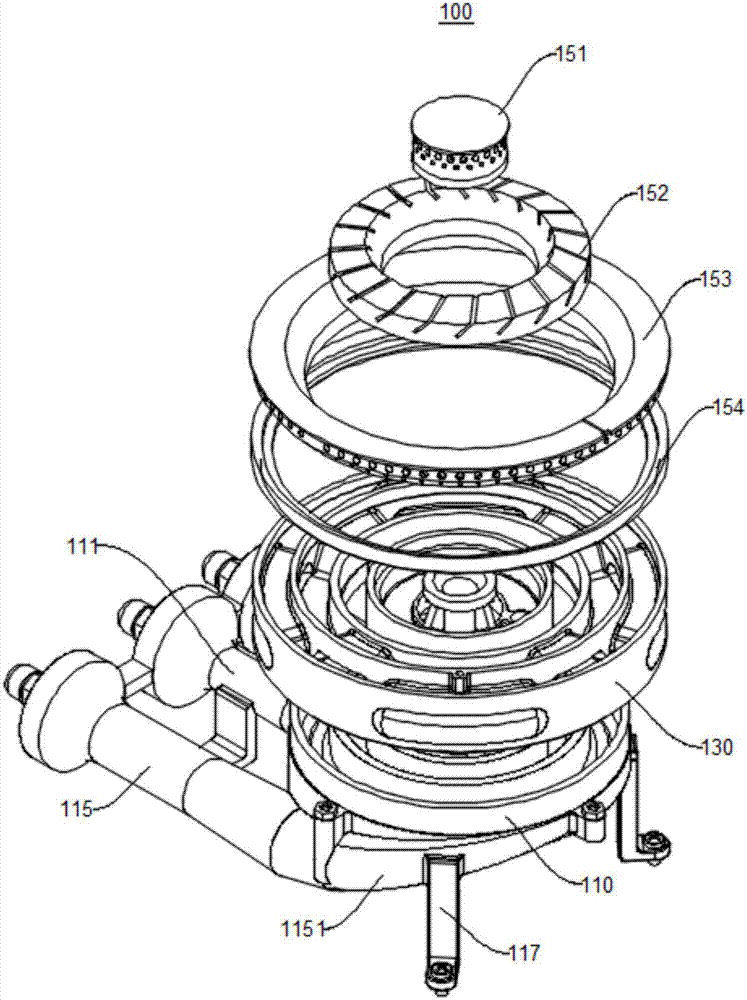

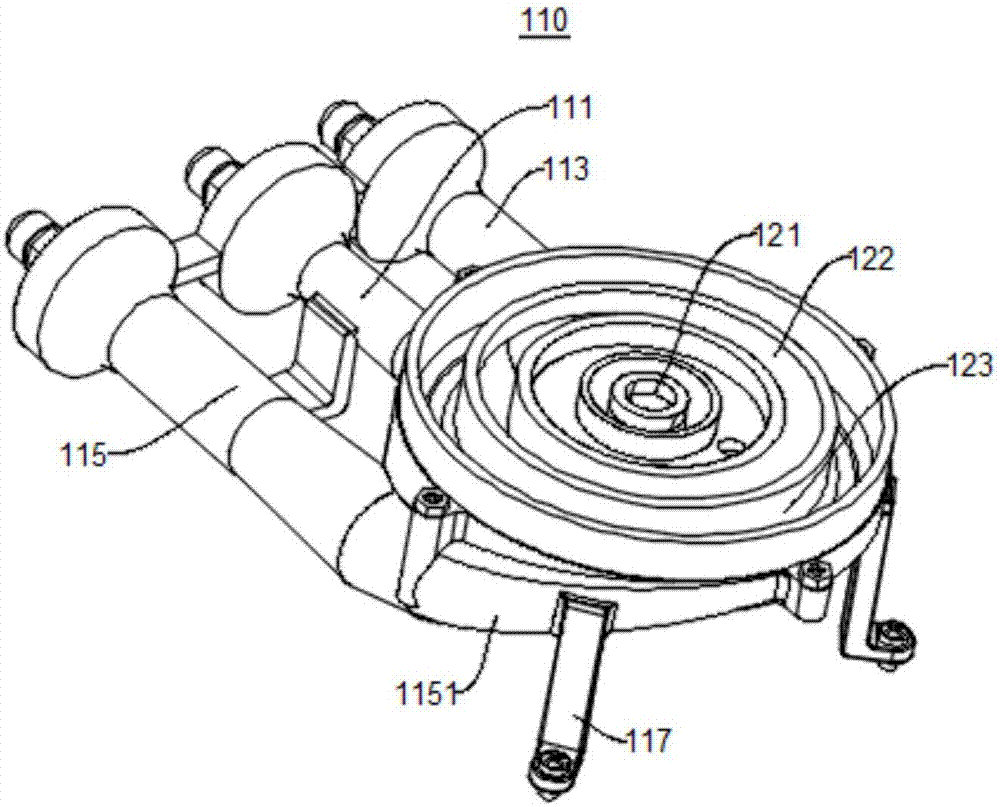

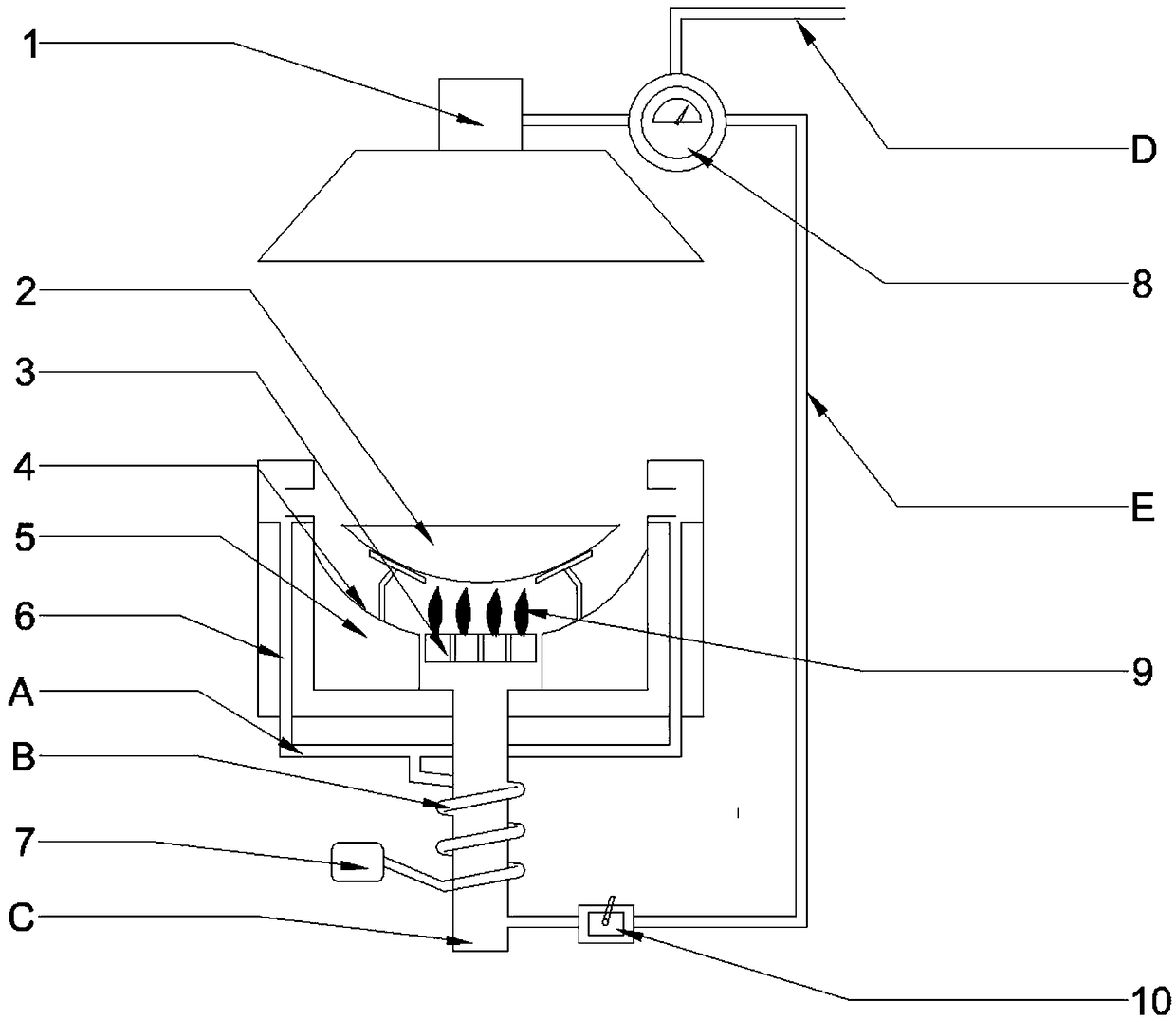

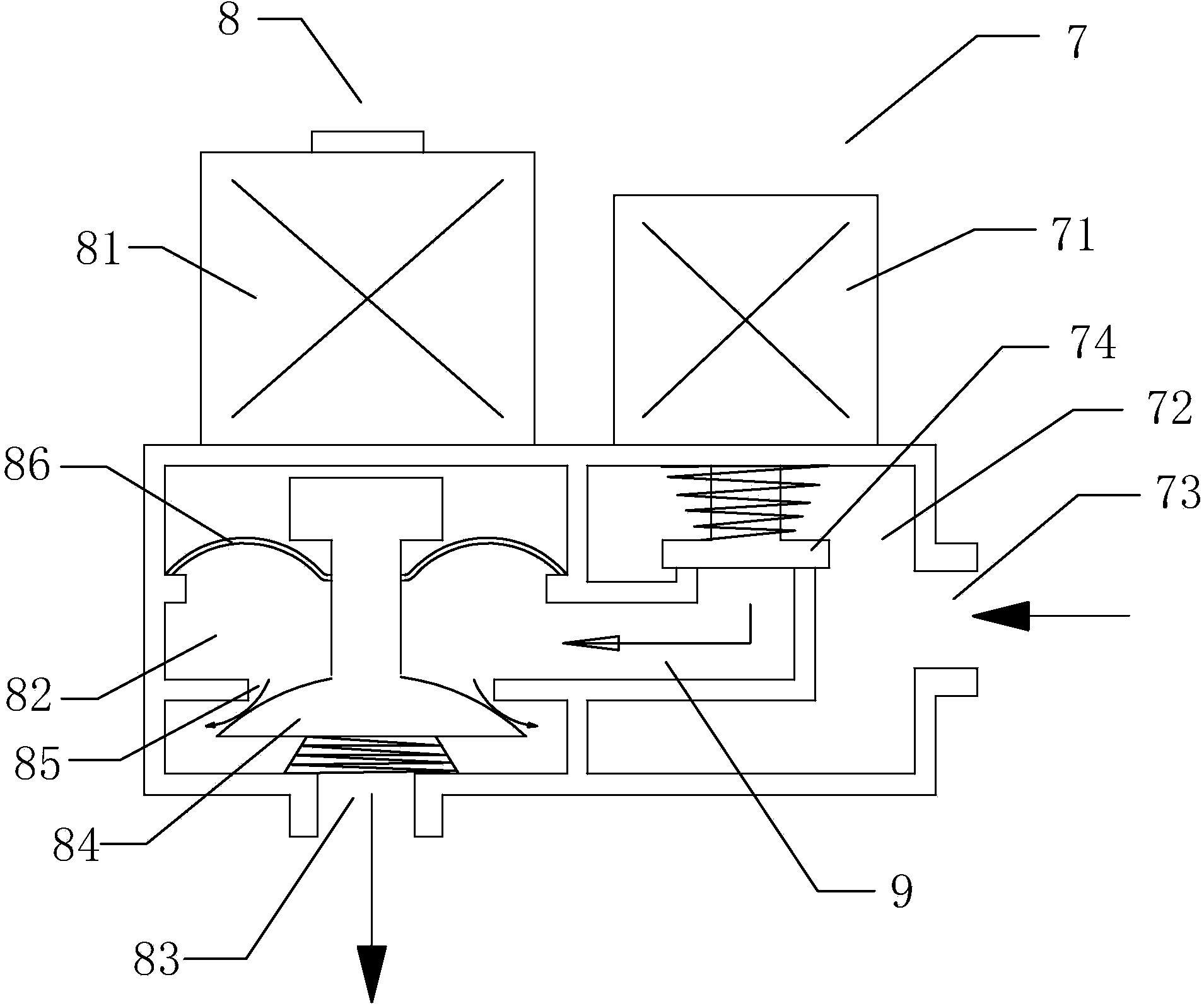

Household gas burner

The invention discloses a household gas burner, belonging to the part in the household gas kitchen range. The present household gas burner has the complex structure, poor processing precision and big accumulative error in assembling. The household gas burner comprises a nozzle, a gas distributing device, a gas mixing device and a fire lid, and characterized in that the gas distributing device and the gas mixing device are all the integrated structure, wherein the gas distributing device comprises a gas supplying pipe and a distributing chamber, a primary air inlet open is arranged on the distributing chamber, the nozzle is fixed on the orifice of the gas supplying pipe in the distributing chamber; the gas mixing device comprises a mixing pipe, a mixing chamber, a buffer baffle plate and a secondary air inlet slot, the mixing chamber is matched with the distributing chamber, the buffer baffle plate is arranged above the orifice of the mixing pipe in the mixing chamber, the secondary air inlet slot is arranged at the side surface of the gas mixing device. The gas distributing device and the gas mixing device in the invention have no accumulative error in assembling, simple assembling and safe and reliable use.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

Energy-saving gas stove

ActiveCN102620321AIncrease profitImprove gas utilizationDomestic stoves or rangesLighting and heating apparatusEngineeringPhase change

The invention discloses an energy-saving gas stove which comprises an energy collecting cavity, a stove wall, a phase change heat accumulator, ribs, an infrared radiation ceramic plate and a gas stove head, wherein the stove wall is of an opening cavity structure; the upper end of an opening is used for holding cookware; the gas stove head is arranged in the opening at the bottom center of the stove wall; the energy collecting cavity is arranged at the lower end in the stove wall cavity and is of a cylindrical cavity structure; the upper surface of the energy collecting cavity is a pot-shaped curved surface; a plurality of ribs are arranged between an upper bottom surface and a lower bottom surface in the cavity of the energy collecting cavity at intervals; the infrared radiation ceramic plate is attached to the upper surface of the energy collecting cavity; and the phase change heat accumulator is arranged in the energy collecting cavity. According to the energy-saving gas stove disclosed by the invention, the infrared radiation ceramic plate reflects and absorbs the heat which is not utilized by an iron pan and part of heat is transmitted to the energy collecting cavity for storing energy. When the energy collecting cavity releases the heat, the heat is transmitted to the infrared radiation ceramic plate and generates infrared radiation for heating the iron pan. According to the gas cooking stove disclosed by the invention, the heat energy utilization rate of the gas cooking stove is increased and the aim of saving energy is achieved.

Owner:GUANGDONG HENGLIAN FOOD MACHINERY

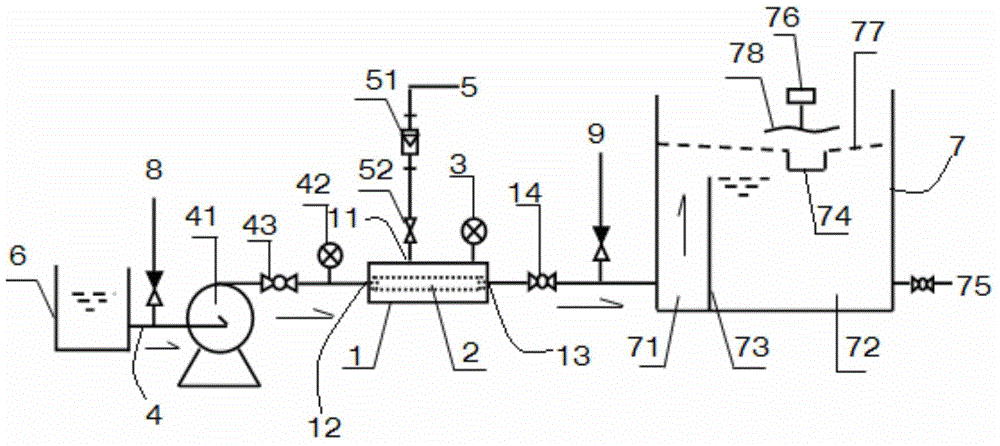

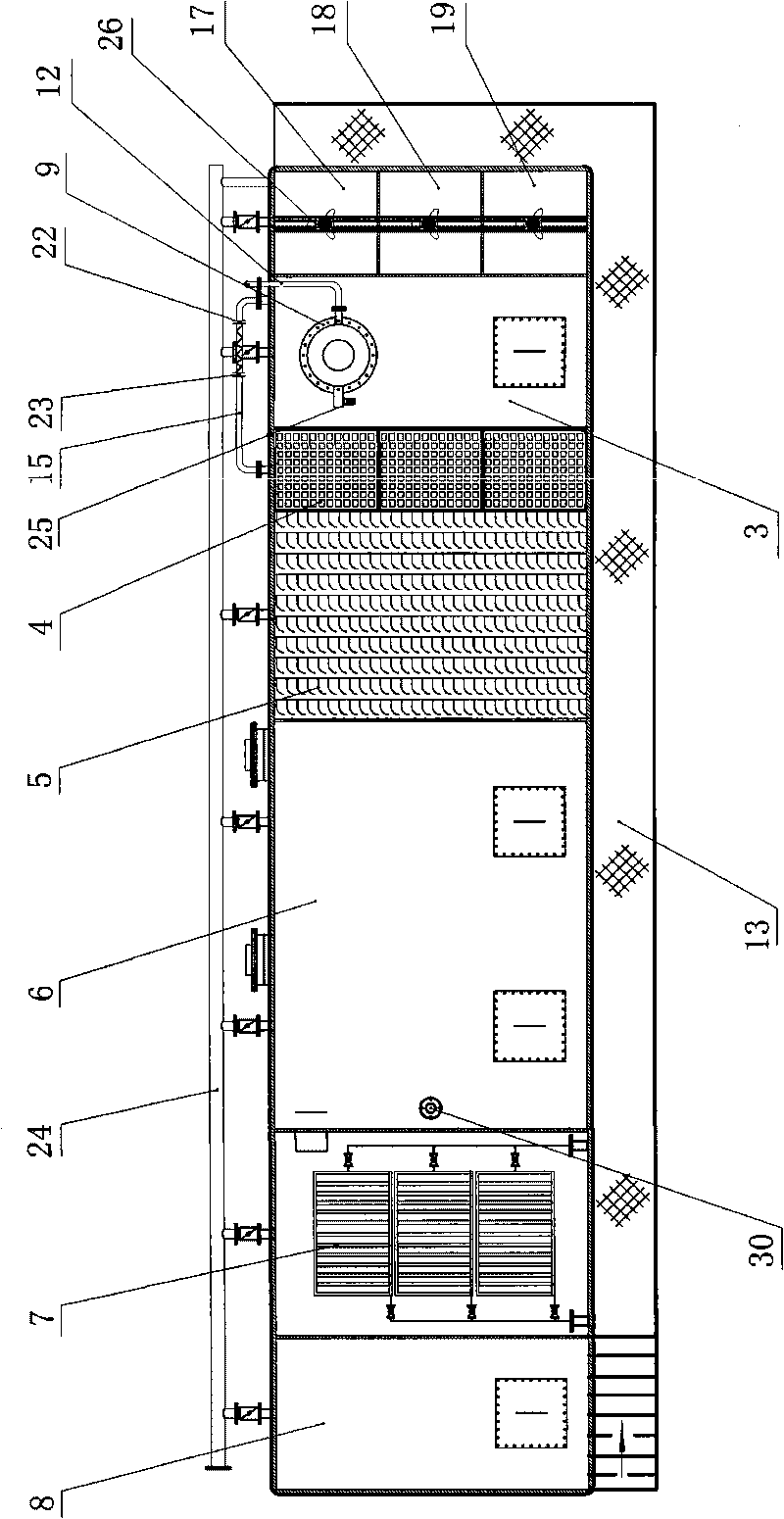

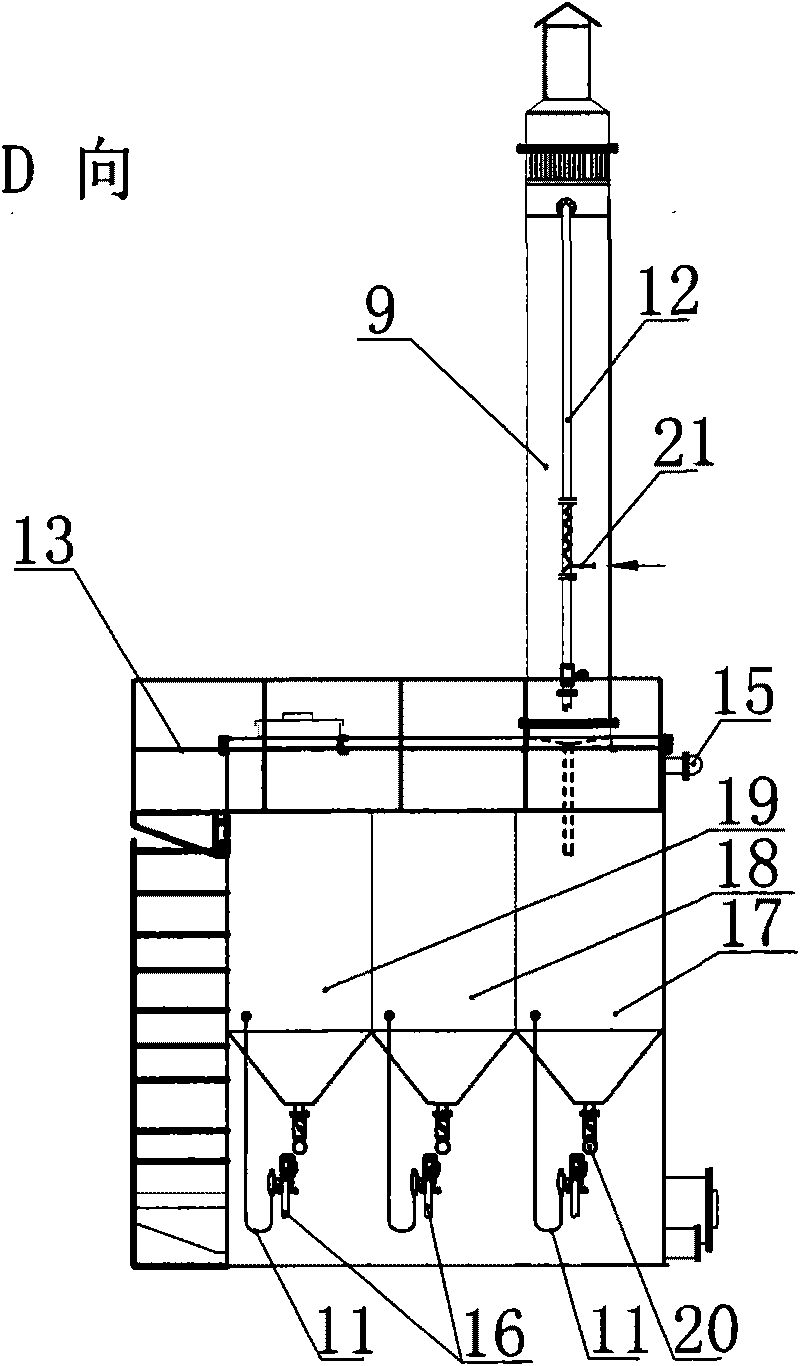

Device and method for integrally processing garbage percolate

InactiveCN101708917AEasy to handleImprove stabilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationReverse osmosis

The invention relates to a device and a method for integrally processing garbage percolate, wherein the device comprises a denitrification mechanism, a polymerizing reaction tank, a sloping plate / pipe sedimentation tank, a biochar filter bed, an SMBR reactor and a medicine dissolving and dispensing mechanism, wherein the medicine dissolving and dispensing mechanism comprises three parallel medicine dissolving tanks including an alkali liquor tank, a flocculation liquid medicine tank and a flocculation aid liquid medicine tank; the three medicine dissolving tanks are respectively communicated with an alkali liquor medicine adding hole on a liquid inlet pipe of a stripping tower and a flocculation medicine adding hole and a flocculation aid medicine adding hole of pipelines communicated with a denitrification settling water tank and the polymerizing reaction tank. The treatment method comprises ammonia nitrogen stripping, coagulating sedimentation, biochar filter bed treatment, SMBR reactor treatment, nanofiltration and / or reverse osmosis treatment. The device and the method consist of a high-efficiency ammonia nitrogen stripping tower, whirl grid coagulation, sloping plate (pipe) setting, the biochar filter bed and the SMBR reactor, integrates the advantages of a garbage percolate treatment process and solves the problem of difficult treatment and high expense of the garbage percolate. The high-efficiency ammonia nitrogen stripping tower has high utilization rate on gases, a new gas distribution structure improves the energy efficiency, and the invention has the advantages of reducing the occupied area and reducing the operation expense.

Owner:魏毅宏

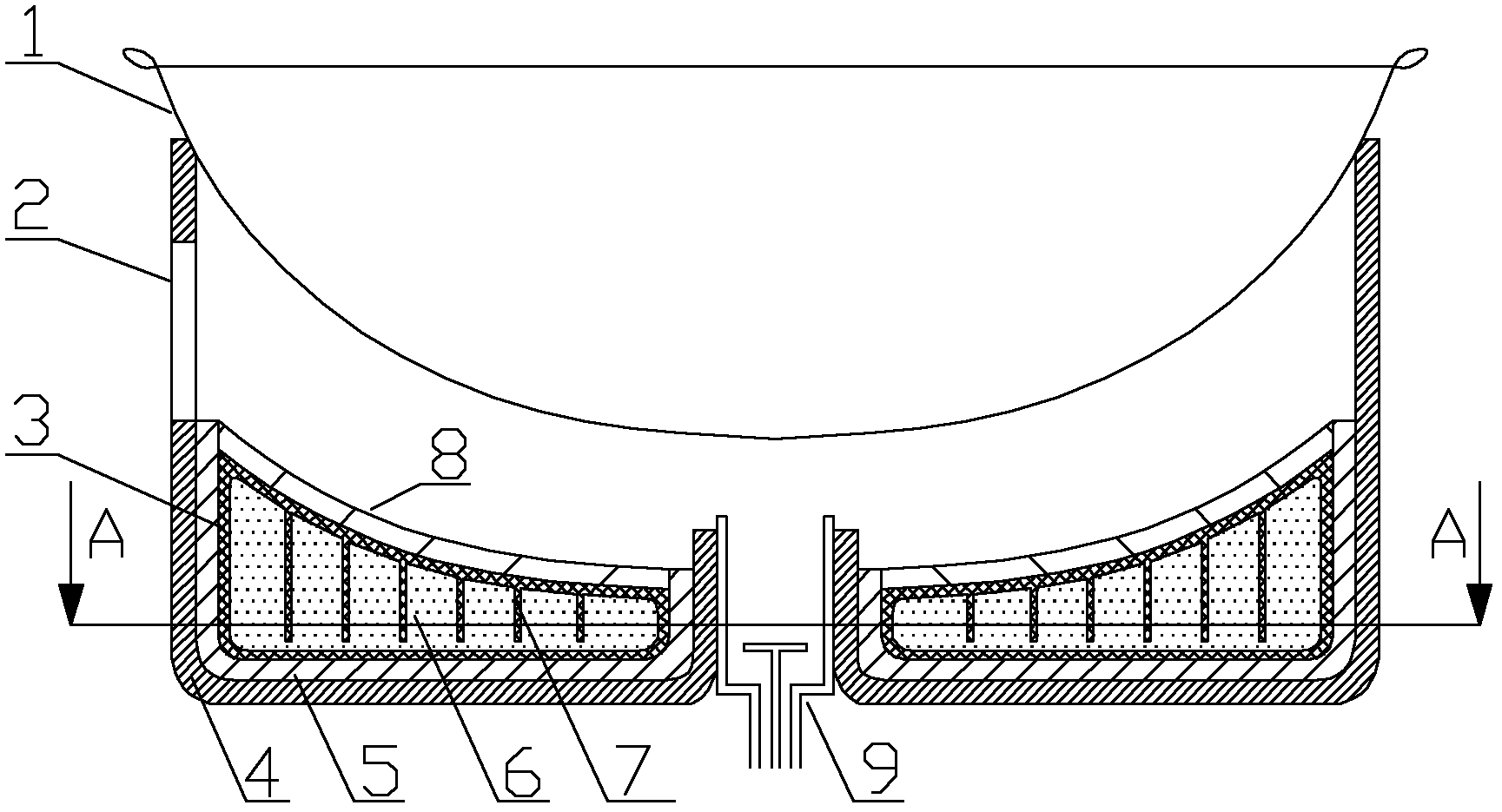

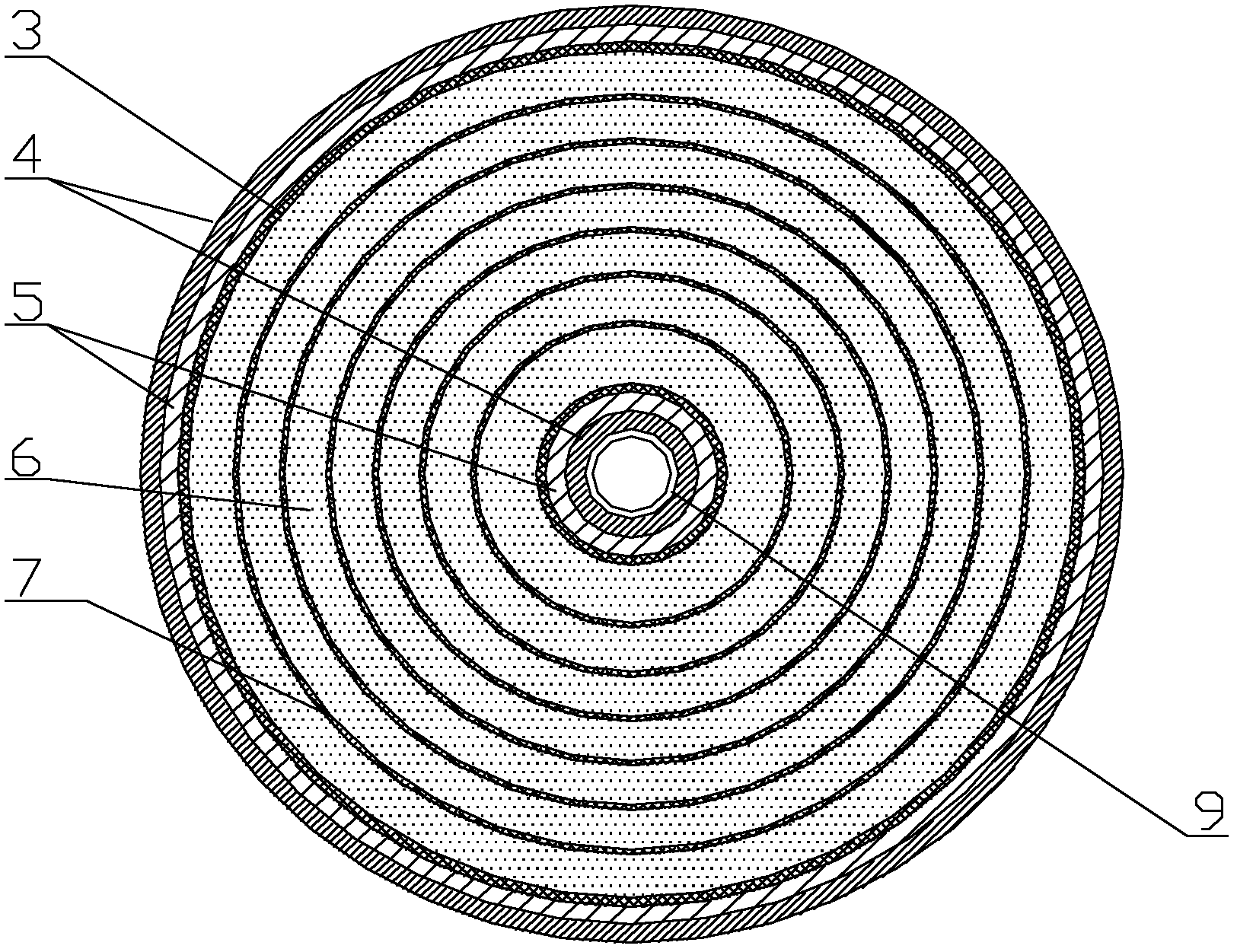

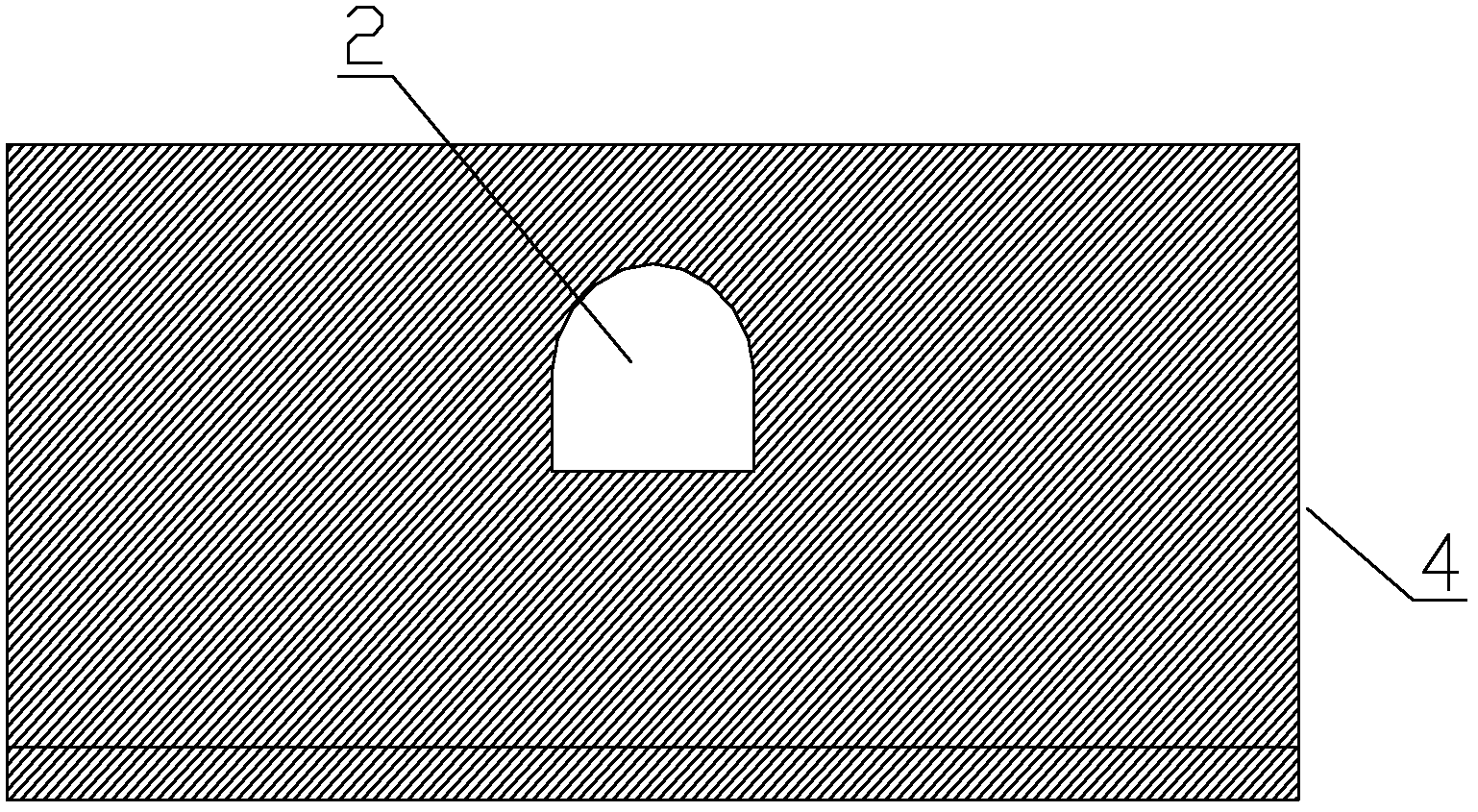

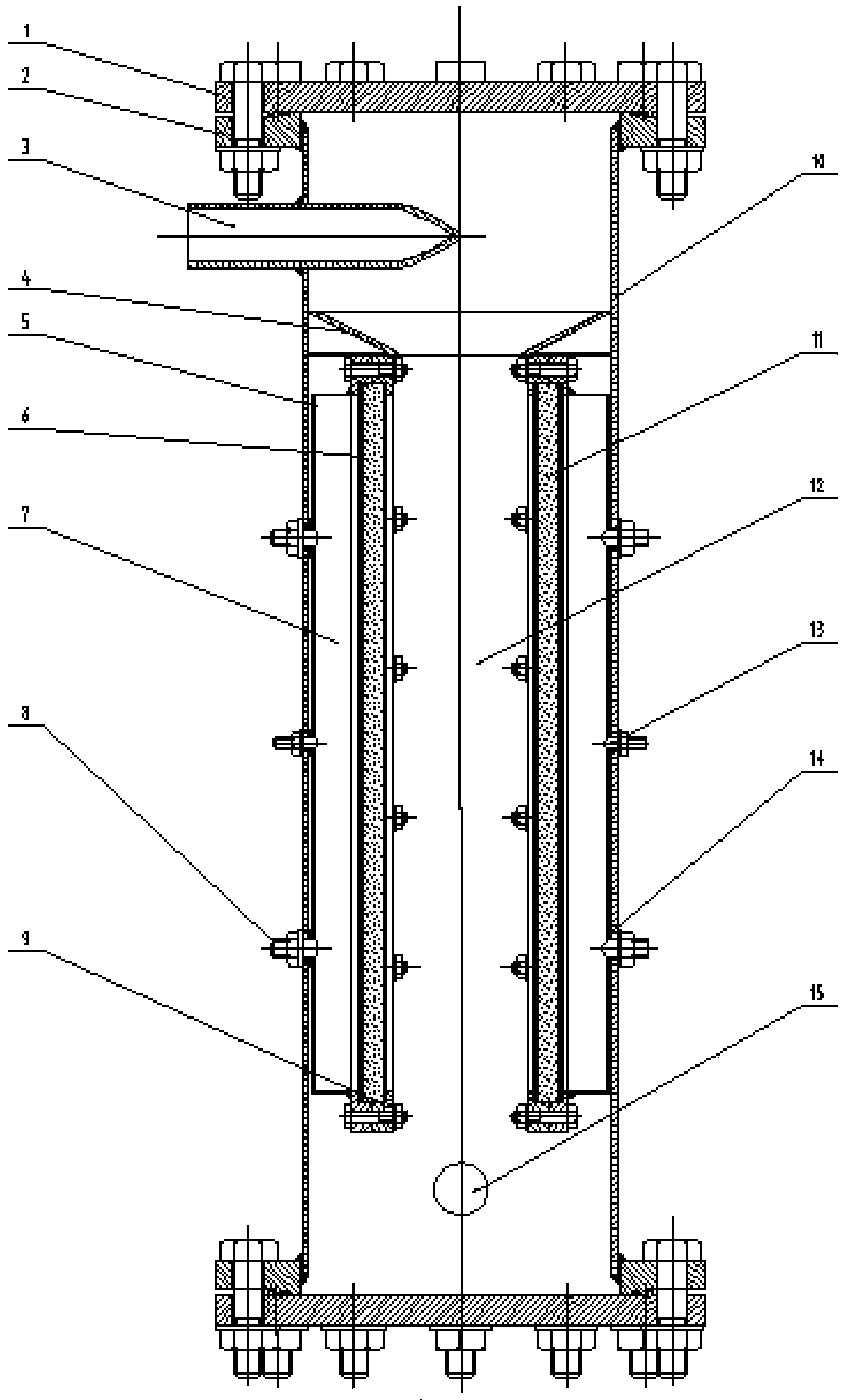

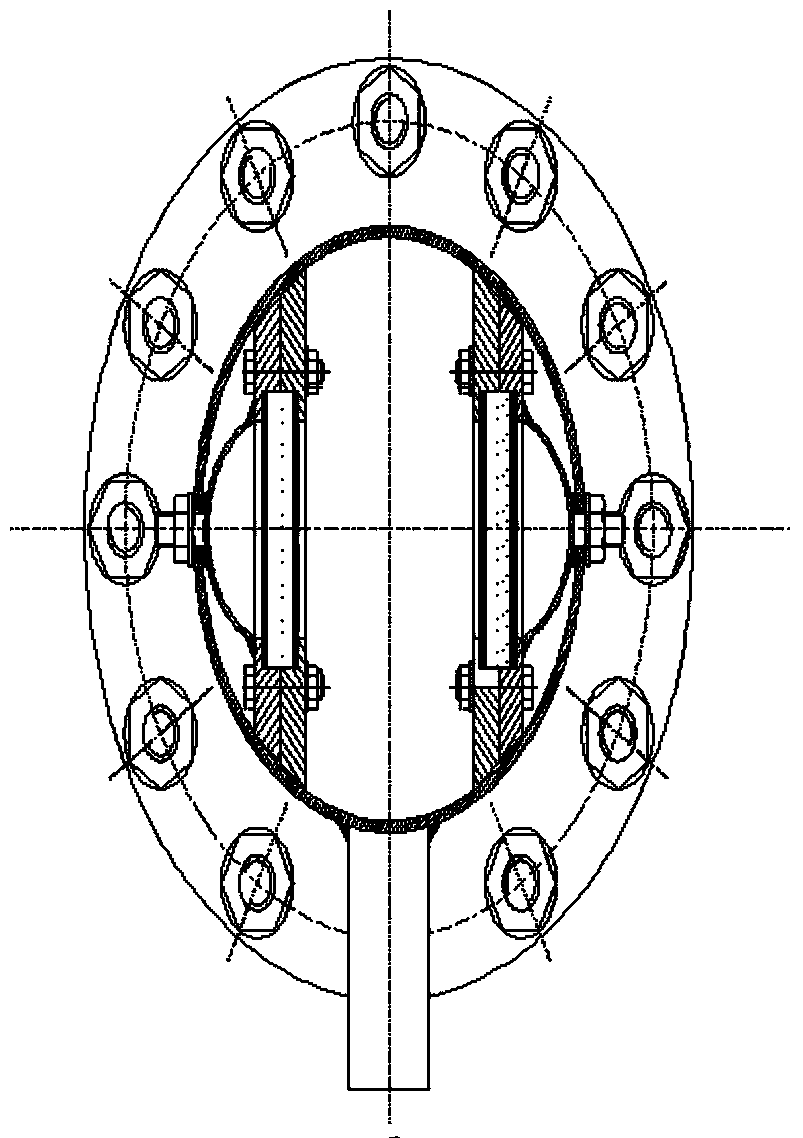

Micro-bubble generation device based on plate type microporous medium foaming mechanism

InactiveCN104003460AImprove gas utilizationLarge amount of processingWater/sewage treatment by flotationMicro bubbleWater quality

The invention discloses a micro-bubble generation device based on a plate type microporous medium foaming mechanism. The micro-bubble generation device comprises a pipe-column-shaped outer barrel body, wherein the upper end and the lower end of the outer barrel body are sealed with flange covers respectively, two independent air chambers are formed in parts close to two side walls in the outer barrel body, and the other cavity in the outer barrel body is a water flow chamber; a conical flow guide barrel is arranged at the upper part of the water flow chamber, the space in the upper part of the conical flow guide barrel is a rotational-flow cavity, a tangential water inlet pipe is arranged on the wall of the outer barrel body at the rotational-flow cavity, and a water outlet pipe is arranged on the wall at the lower part of the outer barrel body; air inlet pipes are arranged on the walls of the outer barrel body at the air chambers, and rectangular microporous plates are arranged between the air chambers and the water flow chamber. The micro-bubble generation device is high in utilization rate of air, large in handling capacity and convenient to dismount, and is mainly used for providing a large quantity of micro-bubbles for water quality air flotation purification treatment or other process with full air-liquid contact requirement.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

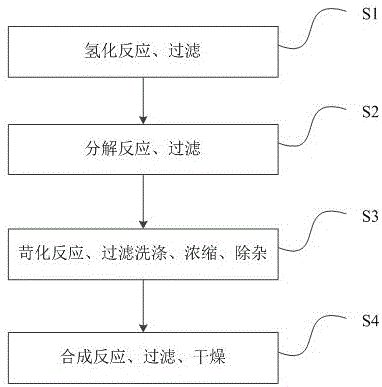

Method for preparing battery grade lithium carbonate by using impulse type hydrogenated industrial grade lithium carbonate

ActiveCN106365182AImprove gas utilizationImprove hydrogenation efficiencyLithium carbonates/bicarbonatesDecompositionLithium carbonate

The invention discloses a method for preparing battery grade lithium carbonate by using impulse type hydrogenated industrial grade lithium carbonate. The method comprises the steps of preparing the industrial grade lithium carbonate and common pure water into slurry according to a certain proportion, adding high-purity CO2 in a pulse mode, controlling reaction temperature to be within a range of 20-25 DEG C until the solution is converted into clearer liquid, and filtering the liquid; injecting filtrate into a decomposition reaction kettle, decomposing the filtrate, then transferring the decomposed filtrate into a causticizing reaction kettle, adding a right amount of a Ca(OH)2 solution into the causticizing reaction kettle, controlling reaction temperature to be within a range of 90-100 DEG C, and filtering and washing the solution while the solution is hot; injecting filtrate into a concentration kettle, and removing impurities such as Ca and Mg of concentrated liquor by using ion exchange resin; then, injecting the concentrated liquor without the impurities into a synthesis kettle, and replenishing the synthesis kettle with the high-purity CO2 gas so as to further prepare the high-purity battery grade lithium carbonate. The method utilizes the advantage of hydrogenation of lithium carbonate so as to effectively utilize the high-purity CO2 gas and avoid the loss of CO2 as much as possible in a reaction process, and enables the hydrogenation to be carried out smoothly.

Owner:JINGMEN GEM NEW MATERIAL

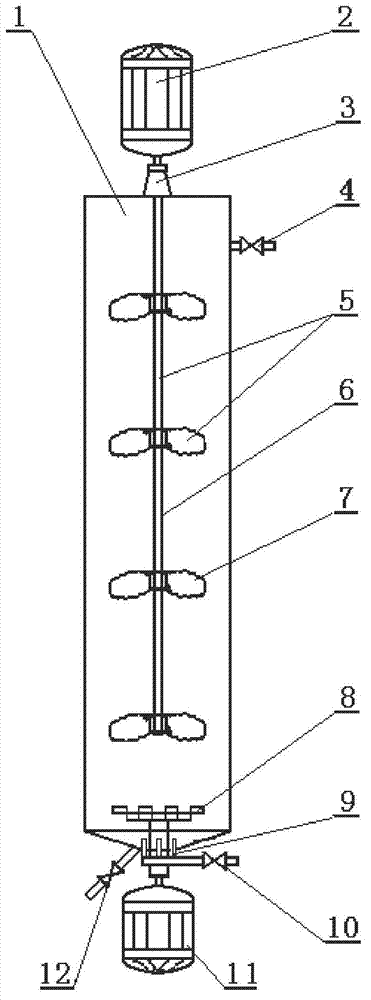

Nano-calcium carbonate carbonization reaction kettle

ActiveCN102897815AIncrease contact areaSmall diameterCalcium/strontium/barium carbonatesChemical industryImpellerControl engineering

The invention discloses a nano-calcium carbonate carbonization reaction kettle. The reaction kettle comprises a motor, a speed reducer, stirrers, a gas inlet pipe and valves, wherein the stirrer B8 is close to the bottom of a reaction kettle 1 and is connected with a variable frequency motor B11; the middle upper part of the reaction kettle 1 is provided with the stirrer A5 consisting of a stirring shaft 6 and a stirring impeller 7; the upper end of the stirring shaft 6 is sequentially connected with the speed reducer 3 on the top of the reaction kettle 1 and the motor A2; the reaction kettle 1 is provided with the valve A4; and the gas inlet pipe 9 and the valve C12 are arranged at the bottom of the reaction kettle 1. The round zigzag stirrers arranged in the reaction kettle are used for supplying high shearing force to slurry and gas in the reaction kettle, so that the effects of uniformly distributing gas, reducing bubble diameter, increasing gas-liquid contact area, sufficiently dispersing and strengthening mass transfer can be achieved, so that a macro-circulation is formed, and the utilization of carbon dioxide is improved; and the reaction kettle is simple in arrangement, small in investment, low in energy loss, easy in operation control and short in reaction time; and product quality is uniform and stable.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

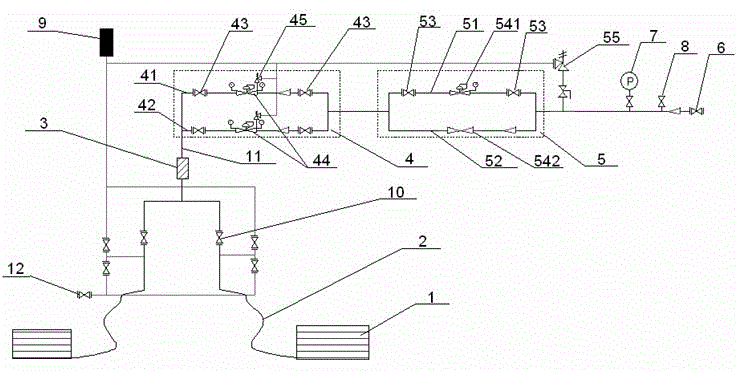

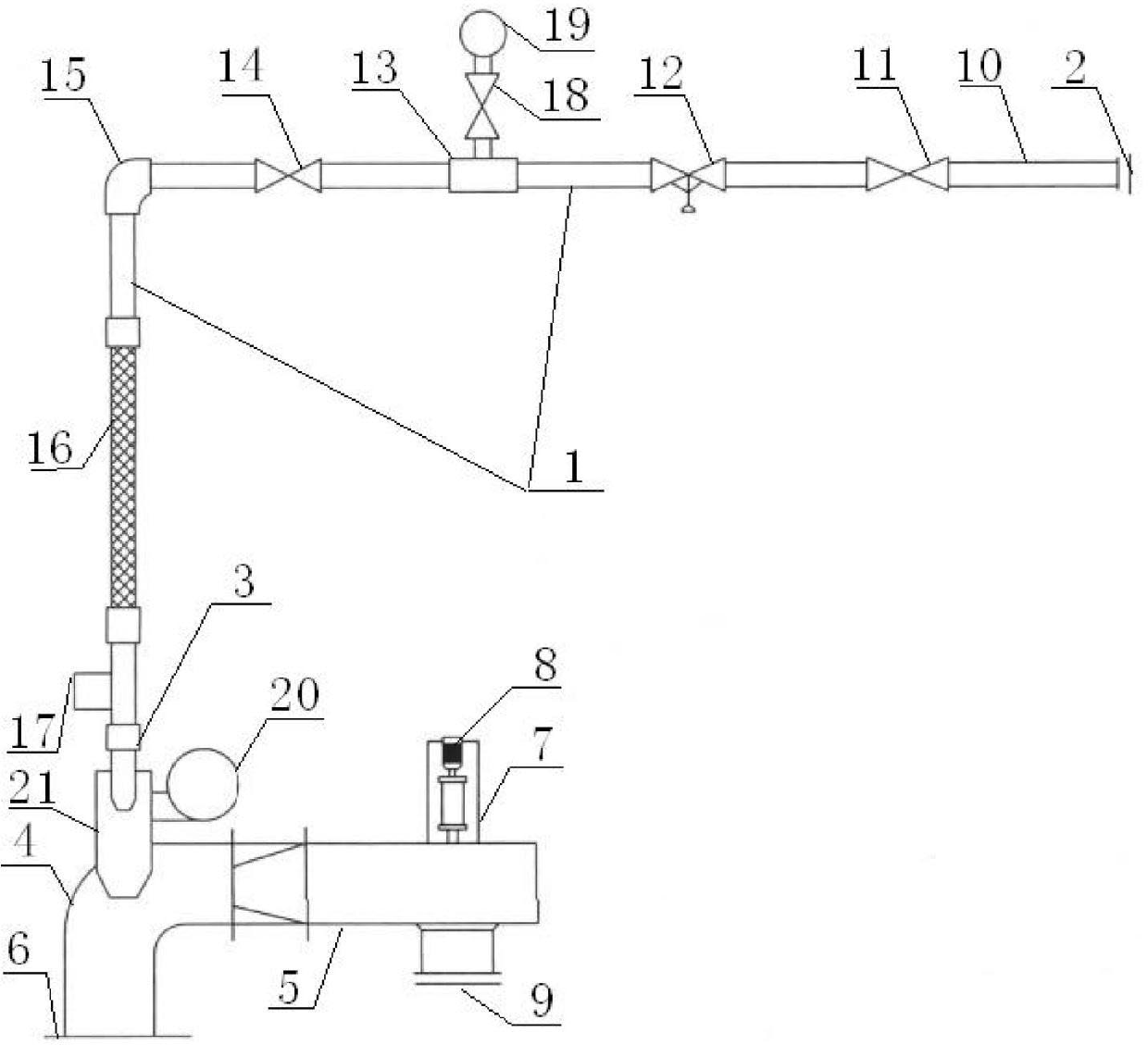

Stable gas supply method

InactiveCN102720946AStable pressureImprove gas utilizationPipeline systemsContainer filling under pressureThermodynamicsProcess engineering

The invention discloses a stable gas supply method for large-scale gas supply and a device thereof. A gas in a gas storage device such as a bundle car, after two steps of pressure reducing, maintains the outlet pressure in a pressure range needed by a user, and gas supply pressure fluctuation can be effectively reduced.

Owner:SHANGHAI QIYUAN GAS DEV

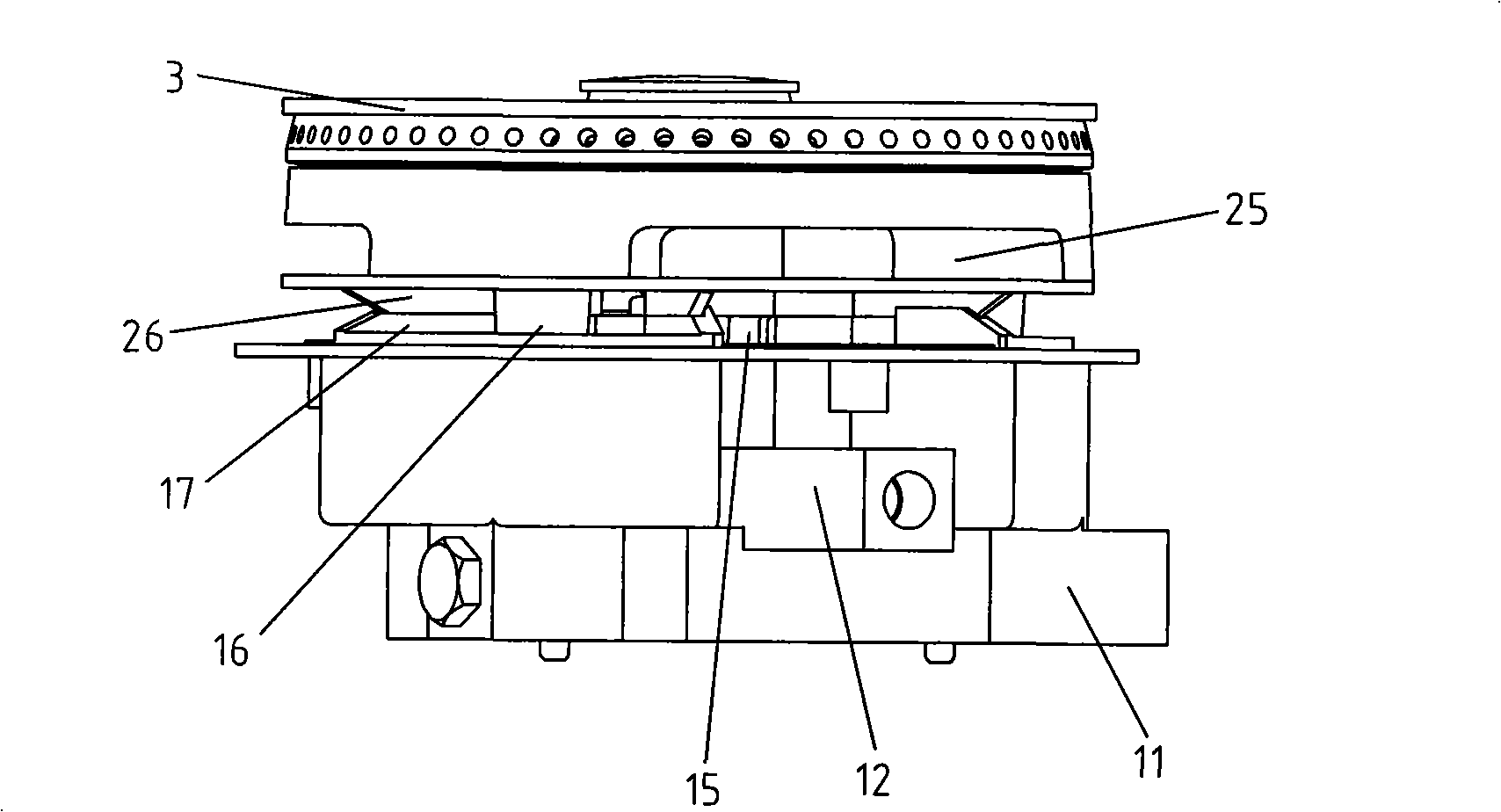

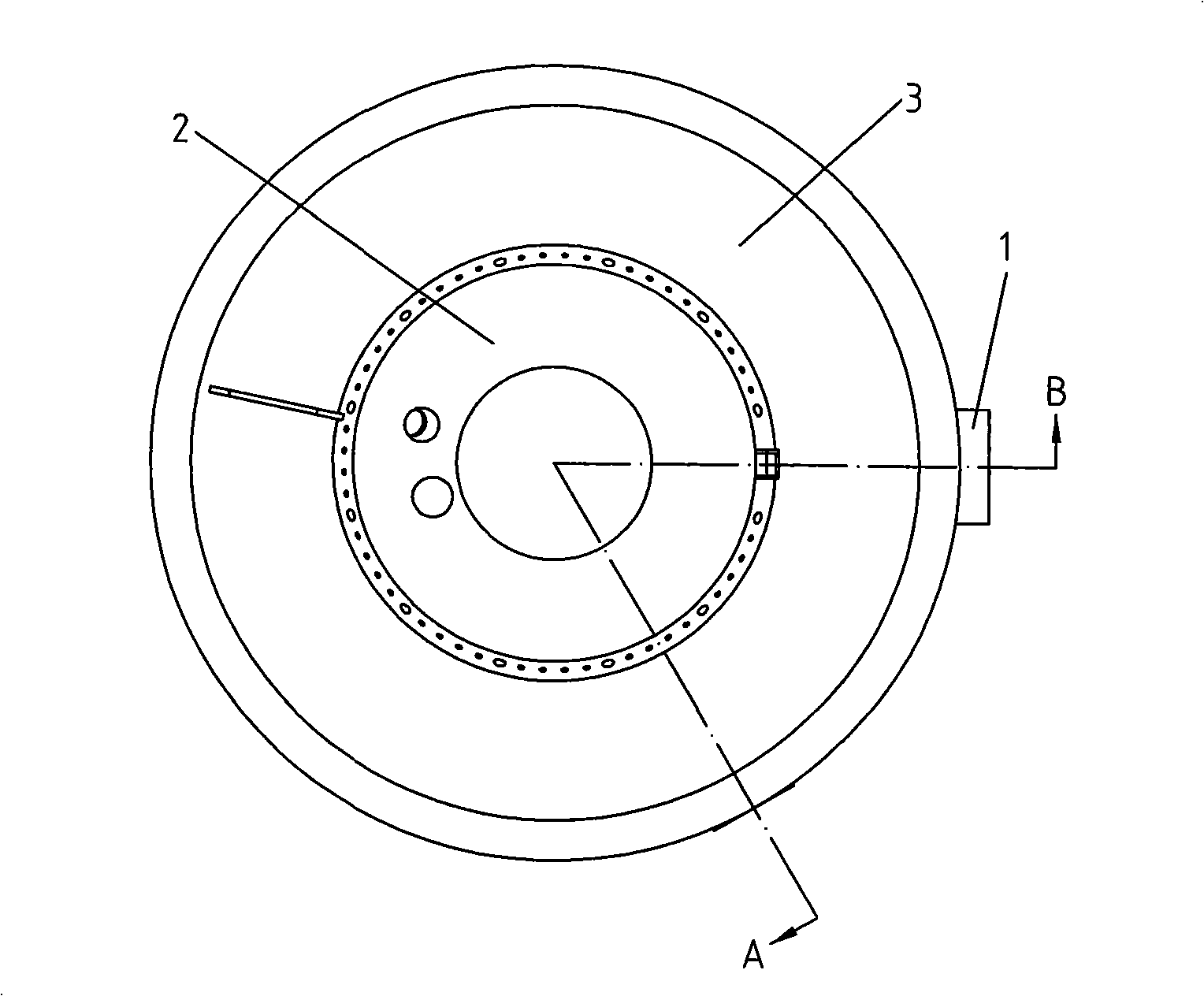

Stove combustor and gas stove

PendingCN107339694ADifficult to enterImprove combustion efficiencyDomestic stoves or rangesGaseous fuel burnerEngineeringProcess engineering

The invention provides a stove combustor and a gas stove, and relates to the technical field of stove combustors. The stove combustor comprises a furnace end, a fire distributor and a multi-ring fire cover. The fire distributor is arranged above the furnace end, and the multi-ring fire cover is arranged above the fire distributor. A plurality of ejection pipes are arranged on the furnace end, a plurality of gas mixing chambers are formed in the furnace end, and each ejection pipe communicates with one gas mixing chamber to form a gas channel. The fire distributor comprises a plurality of air cavities and a plurality of gas cavities, the gas cavities communicate with the gas channels, each air cavity communicates with external air to form an air flowing passage, and each gas channel is provided with an independent air flowing passage. According to the stove combustor, one independent air flowing passage is formed for fire in each ring, and high combustion efficiency and high gas utilization rate are achieved. The gas stove provided by the invention comprises the stove combustor, and smoke is effectively reduced and heat efficiency is increased.

Owner:GUANGDONG MACRO GAS APPLIANCE

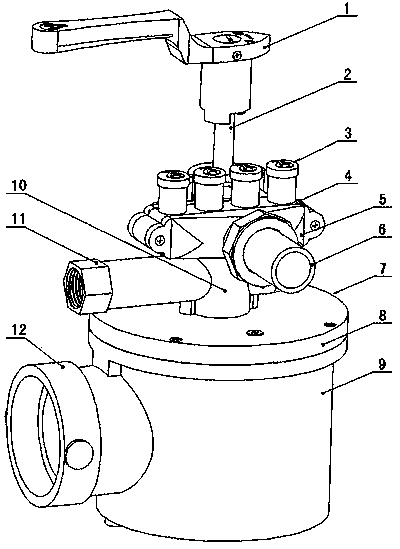

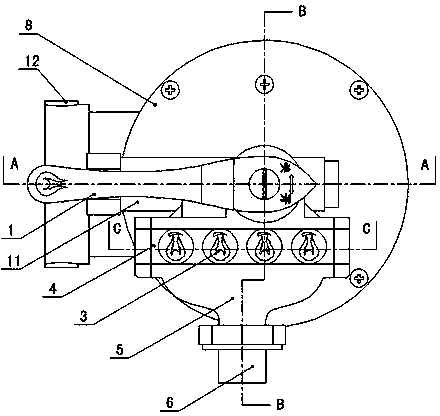

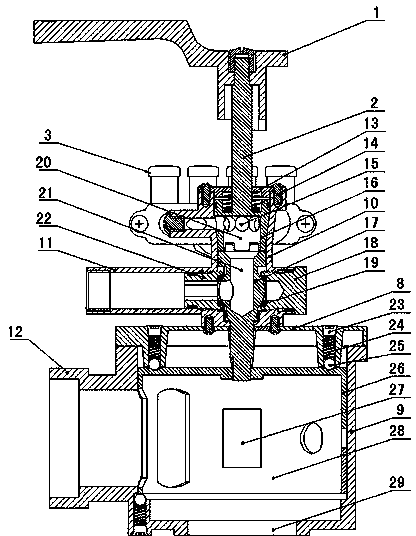

Four-speed power air and gas synchronous control valve

ActiveCN103398194ASwivel portableGood synchronizationMultiple way valvesSynchronous controlInlet valve

The invention discloses a four-speed power air and gas synchronous control valve comprising a handle (1), a valve rod (2), a gas valve and an air valve (7). The gas valve comprises a valve cover (13), an air inlet valve element (16), an air outlet valve element (17) and a valve body (10), wherein the air inlet valve element (16) and the air outlet valve element (17) are arranged on the valve body (10), the air inlet valve element (16) is provided with an air inlet cavity (20), the air outlet valve element (17) is provided with an air outlet cavity (21) communicated with the air inlet cavity (20), and the air outlet cavity (21) corresponds to an air outlet connector (11) on the valve body (10). The air valve (7) comprises an air valve cover (8), an air valve element (26) and an air valve body (9), wherein the valve rod of the air outlet valve element (17) extends into the air valve body (9) and is connected with the air valve element (26), and the valve rod (2), the air inlet valve element (16), the air outlet valve element (17) and the air valve element (26) can rotate synchronously. By means of the structure, the four-speed power air and gas synchronous control valve has the advantages of being simple in structure, convenient to operate, safe to use, accurate in gas and air ratio, high in energy utilization rate, little in environment pollution and the like.

Owner:YONGKANG HUAGANG KITCHENWARE

Ammonia synthesis waste gas recycling device

ActiveCN104190200AIncrease profitHigh economic valueHydrogen separationDispersed particle separationLiquid argonHydrogen

The invention discloses an ammonia synthesis waste gas recycling device. The device comprises a decarbonization adsorber, a first heat exchanger, a second heat exchanger, a third heat exchanger, a liquid ammonia rectifying tower, a liquid ammonia rectifying tower condenser, a methane rectifying tower, a methane rectifying tower condenser, an argon rectifying tower and an argon rectifying tower condenser, wherein the decarbonization adsorber is provided with a gas inlet and a first regenerated gas inlet, the liquid ammonia rectifying tower is provided with a liquid ammonia outlet, the methane rectifying tower is provided with a liquid methane outlet, the argon rectifying tower is provided with a liquid argon outlet and a waste gas outlet; the ammonia synthesis waste gas separating device further comprises a hydrogen pipeline with one end connected with the argon rectifying tower, a hydrogen purifying device connected with the hydrogen pipeline, a nitrogen circulating compressor, a nitrogen expander and a nitrogen supplementing port connected with the nitrogen circulating compressor; the hydrogen purifying device is provided with a hydrogen outlet and a second regenerated gas inlet; the recycling device can be used for extracting liquid ammonia, liquid methane, liquid argon, and high-pure hydrogen with relatively high purity from the waste gas.

Owner:SUZHOU XINGLU AIR SEPARATION PLANT SCI & TECH DEV CO LTD

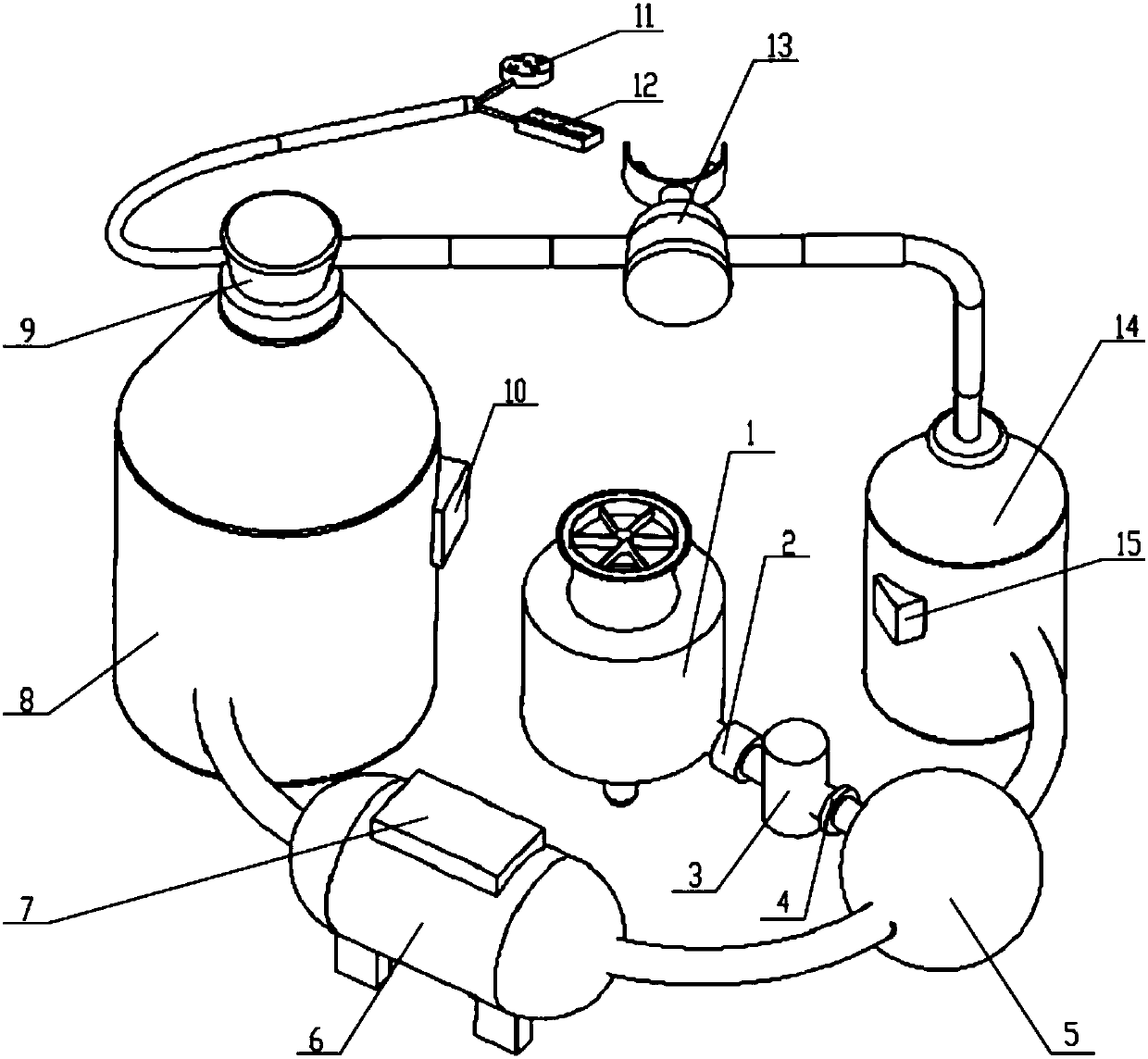

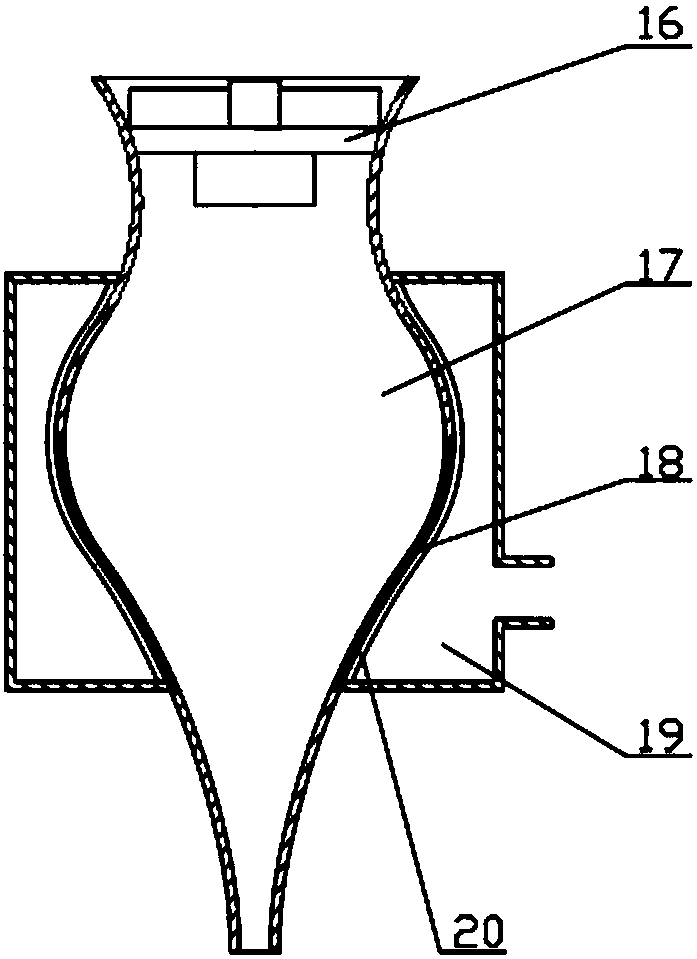

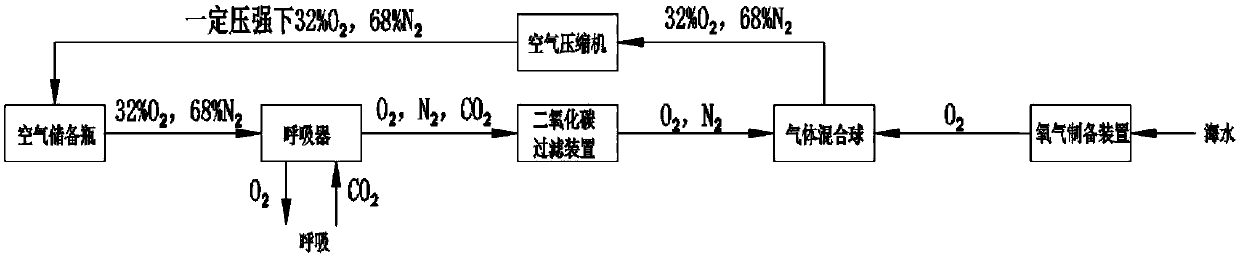

Bionic gill type underwater breathing equipment

ActiveCN108116640AImprove the effect of oxygen productionImprove gas utilizationUnderwater equipmentOxygen preparationGillCarbon dioxide

The invention discloses bionic gill type underwater breathing equipment. The bionic gill type underwater breathing equipment comprises a breathing device, a carbon dioxide filtering device, an oxygenpreparation device, a gas mixing device, an air compressor, an air storage bottle and a control system, wherein the oxygen preparation device is connected with the gas mixing device and is used for supply oxygen to the gas mixing device; the air compressor is used for compressing mixed gas from the gas mixing device and conveying compressed gas to the air storage bottle; an oxygen concentration sensor is arranged on the carbon dioxide filtering device or on a gas conveying pipeline between the carbon dioxide filtering device and the gas mixing device; and the control system is used for controlling the compression amount of the air compressor to the mixed gas and controlling oxygen production amount and oxygen conveying amount according to an oxygen concentration signal transmitted by the oxygen concentration sensor. The bionic gill type underwater breathing equipment is high in oxygen production rate and gas utilization rate, and leaking bubbles are not produced when the equipment is used by a user, so that the interference caused by marine organisms is avoided; and by utilizing the equipment, long-term underwater work can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

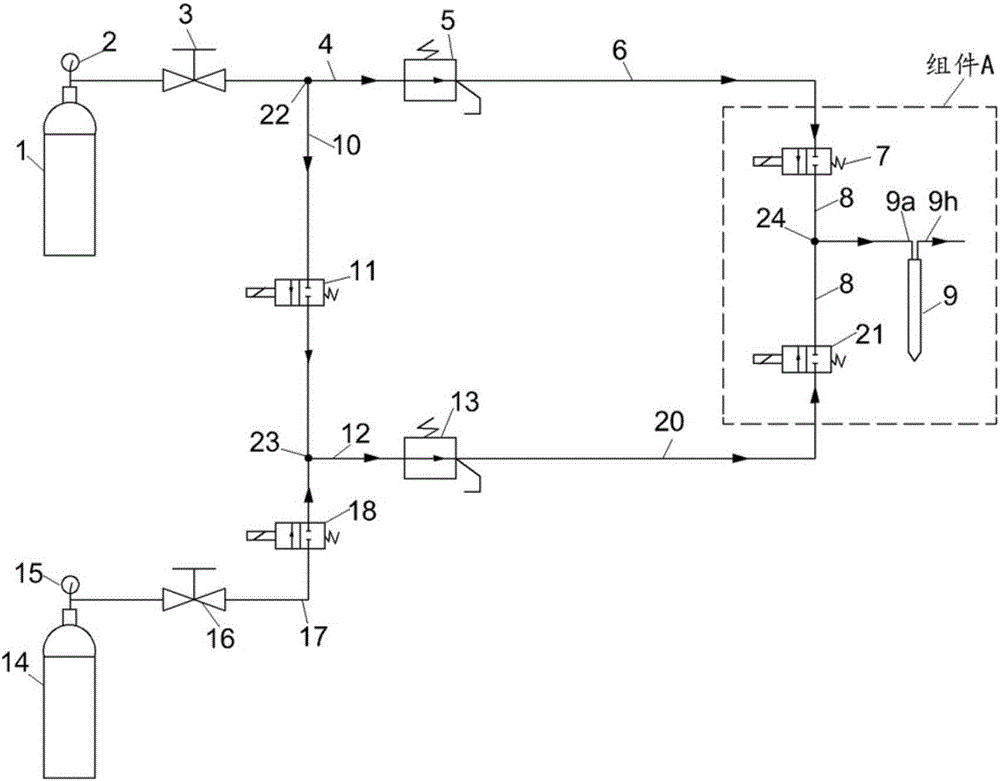

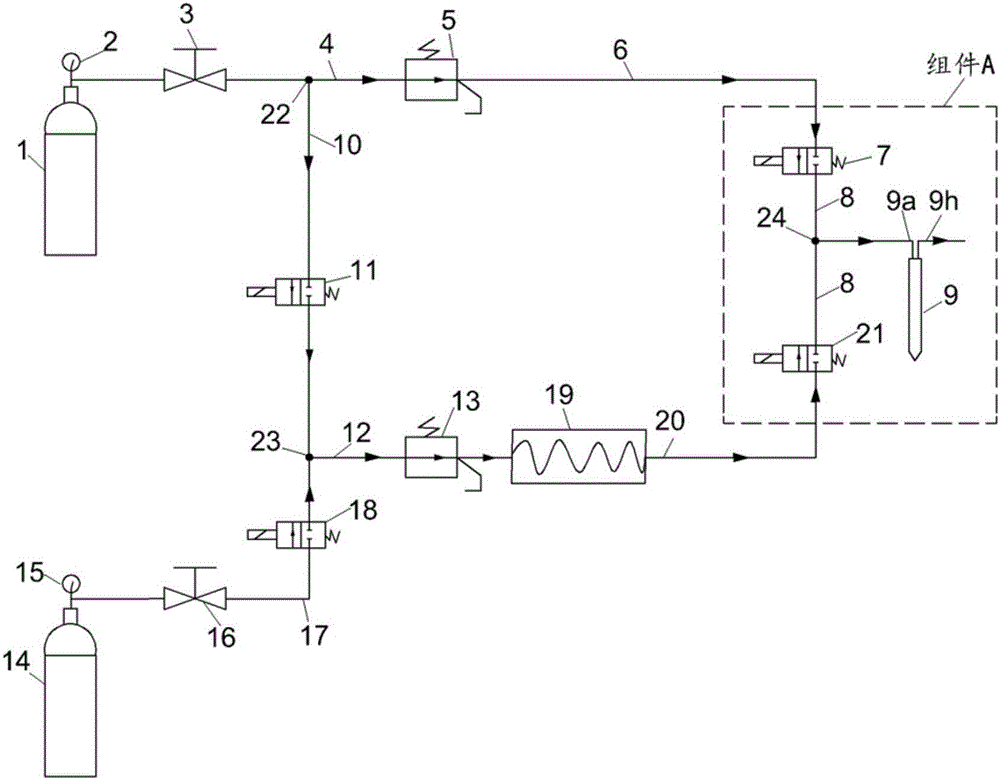

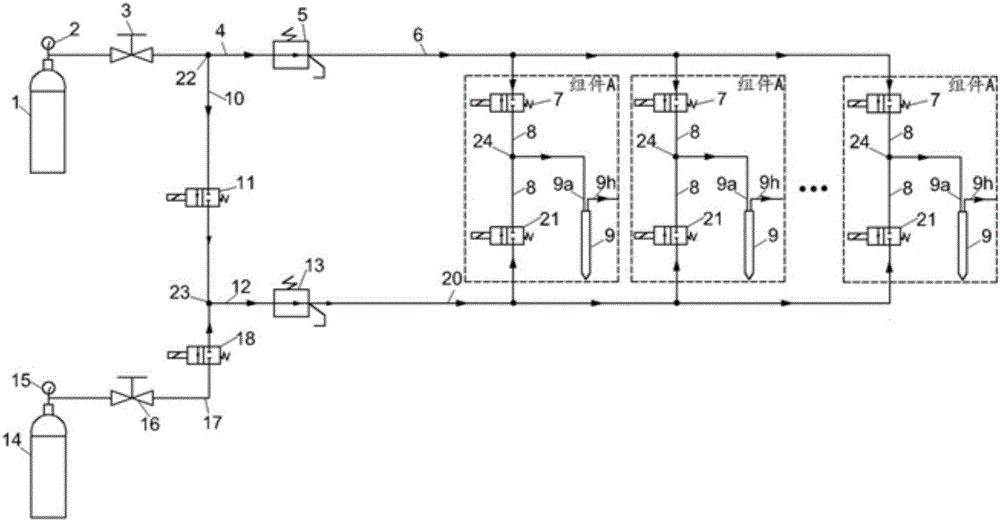

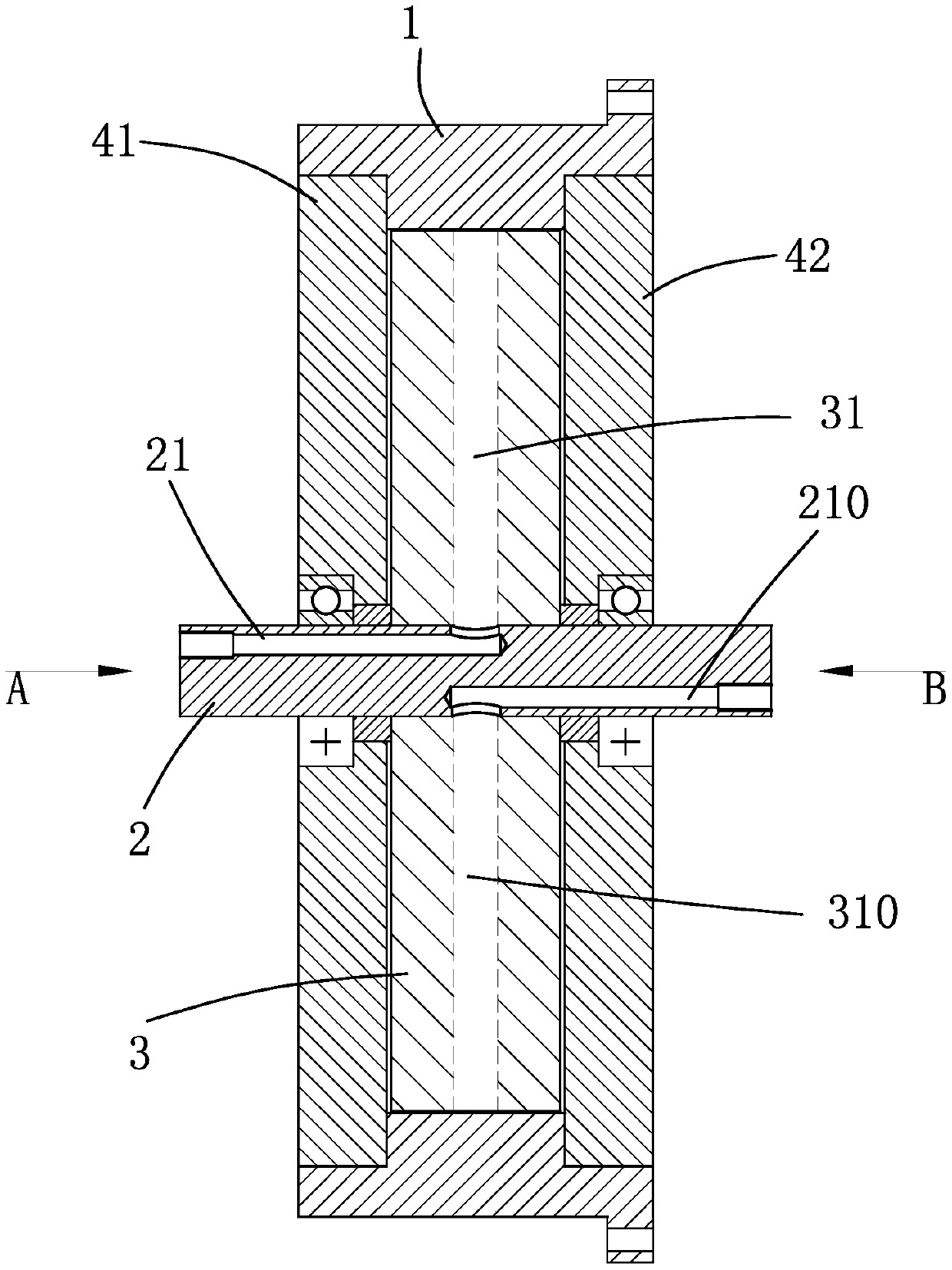

Cryosurgery device capable of achieving freezing and rewarming by adjusting gas pressure

ActiveCN105902310AImprove gas utilizationAvoid wastingSurgical instruments for coolingHigh pressure freezingCryosurgery

The present invention discloses a cryosurgery device capable of achieving freezing and rewarming by adjusting gas pressure. The cryosurgery device comprises a high-pressure gas source, a high-pressure pressure-limiting valve, a freezing gas main pipe and a freezer for throttling and freezing; high-pressure gas divided from a high-pressure gas pipe passes through a shunting electromagnetic valve and a low-pressure pressure-limiting valve for pressure limiting, and is transmitted to the freezer via a heating gas main pipe for shunting and rewarming; gas from a low-pressure gas source passes through a low-pressure electromagnetic valve and the low-pressure pressure-limiting valve for pressure limiting, and is transmitted to the freezer via the heating gas main pipe for low-pressure rewarming; and the heating gas main pipe is provided with a gas heater capable of preheating low-pressure rewarming gas and achieving a controllable heating function. The technical prejudice that throttling refrigeration type gas can only be used for freezing is corrected, warming is performed by utilization of residual gas of high-pressure freezing gas and low-pressure gas, the rewarming problem and low-temperature working medium waste problem of a gas throttling type cryosurgery device are solved, and freezing, rewarming and heating functions are achieved.

Owner:美迪纳斯(天津)科技有限公司

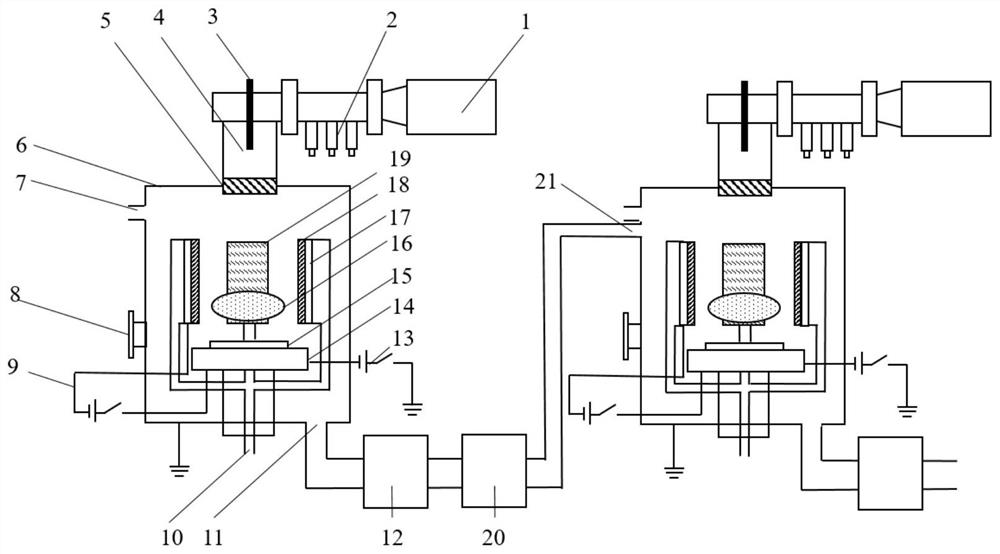

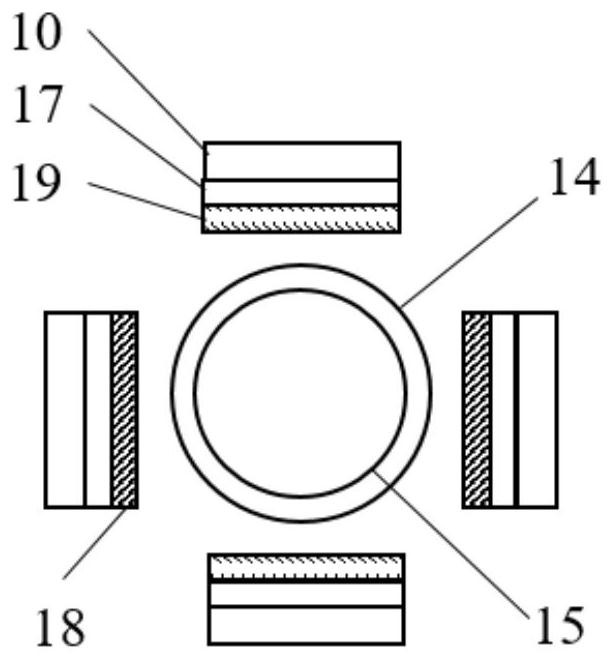

Method for in-situ preparation of 100-surface diamond through microwave plasma-magnetron sputtering composite vapor deposition and equipment thereof

ActiveCN112853482AEasy to manufactureFast manufacturingPolycrystalline material growthVacuum evaporation coatingSputteringDiamond thin film

The invention relates to a method for in-situ preparation of 100-face diamond through microwave plasma-magnetron sputtering composite vapor deposition.and equipment thereof. The method comprises the following steps: etching inorganic matters and surface defects on the upper surface of a silicon substrate by using a ground and polished monocrystalline silicon or potassium tantalate substrate and using reaction or inert gas plasma; then forming a 2-micron Ir buffer layer through magnetron sputtering, and forming SP3 bonds of the carbon element to promote growth of the diamond film; then, starting diamond 100-face bias pressure enhanced nucleation; and starting heteroepitaxial diamond growth. The diamond preparation efficiency and preparation quality are improved.

Owner:SHENZHEN RES INST OF WUHAN UNIVERISTY

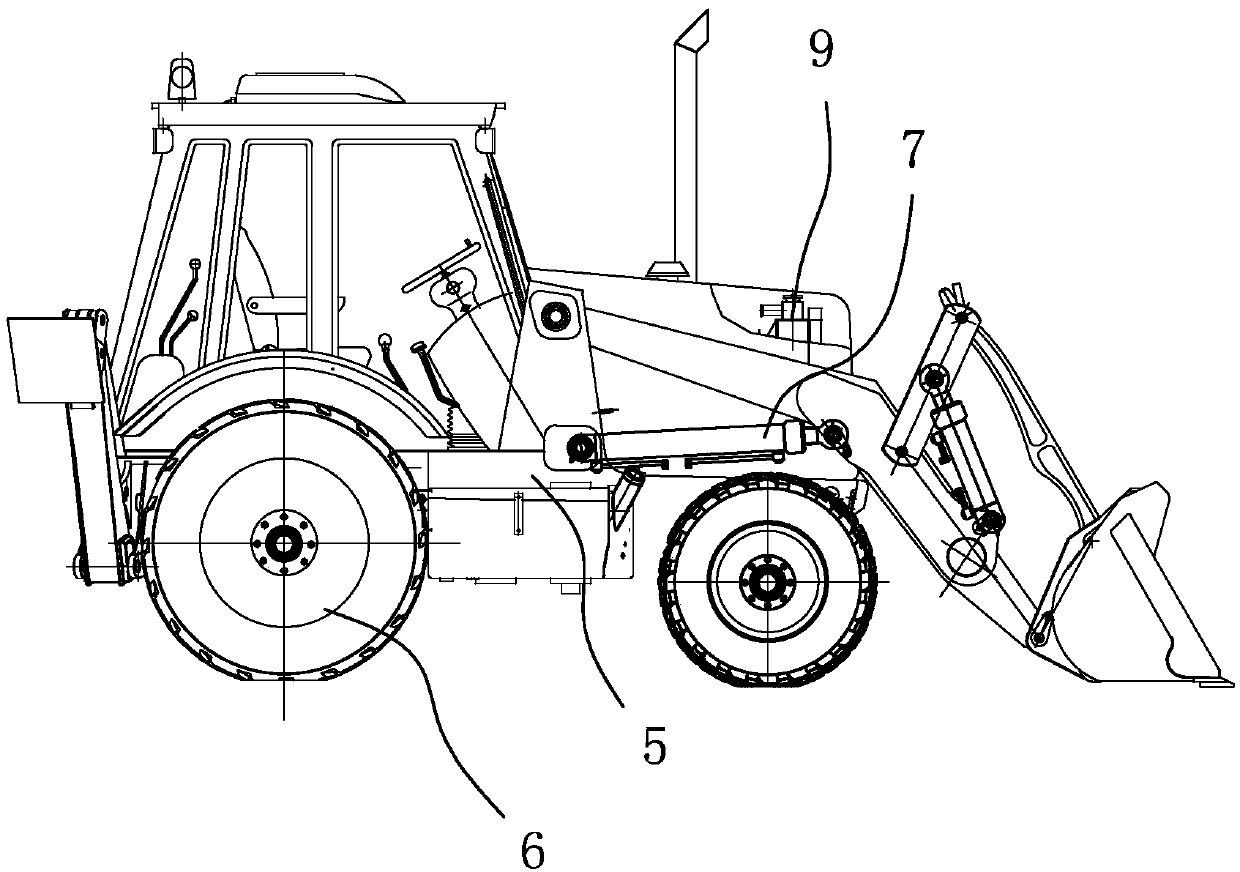

Engineering vehicle

PendingCN110834536AImprove running stabilityNo pollution in the processControl devicesHydraulic pumpGas passing

The invention discloses an engineering vehicle. A gas power device is connected to a hydraulic pump to provide an energy source for a hydraulic executing device. The engineering vehicle is simple in structure, high in torque, high in rotating speed, high in transfer efficiency and environmental-friendly. An emission is gas at a reduced pressure, so that the engineering vehicle is low in working noise and free of tail gas pollution. A standby state is extremely low in energy consumption. The gas power device used by the engineering vehicle comprises an outer ring and a core body. An at least one-step secondary flushing runner is arranged between a nozzle and an outlet of an outer ring surface of a core body. Gas enters from a gas inlet and is sprayed from the nozzle of the core body and steps of the secondary flushing runner to be acted to at least two driving concave parts on the circumference of an outer ring, thereby driving the driving concave parts to generate a thrust to push theouter ring to act rotatably so as to output power. Finally, gas is discharged by an exhausting channel through the outlet of the core body.

Owner:TRANF TECH XIAMEN CO LTD

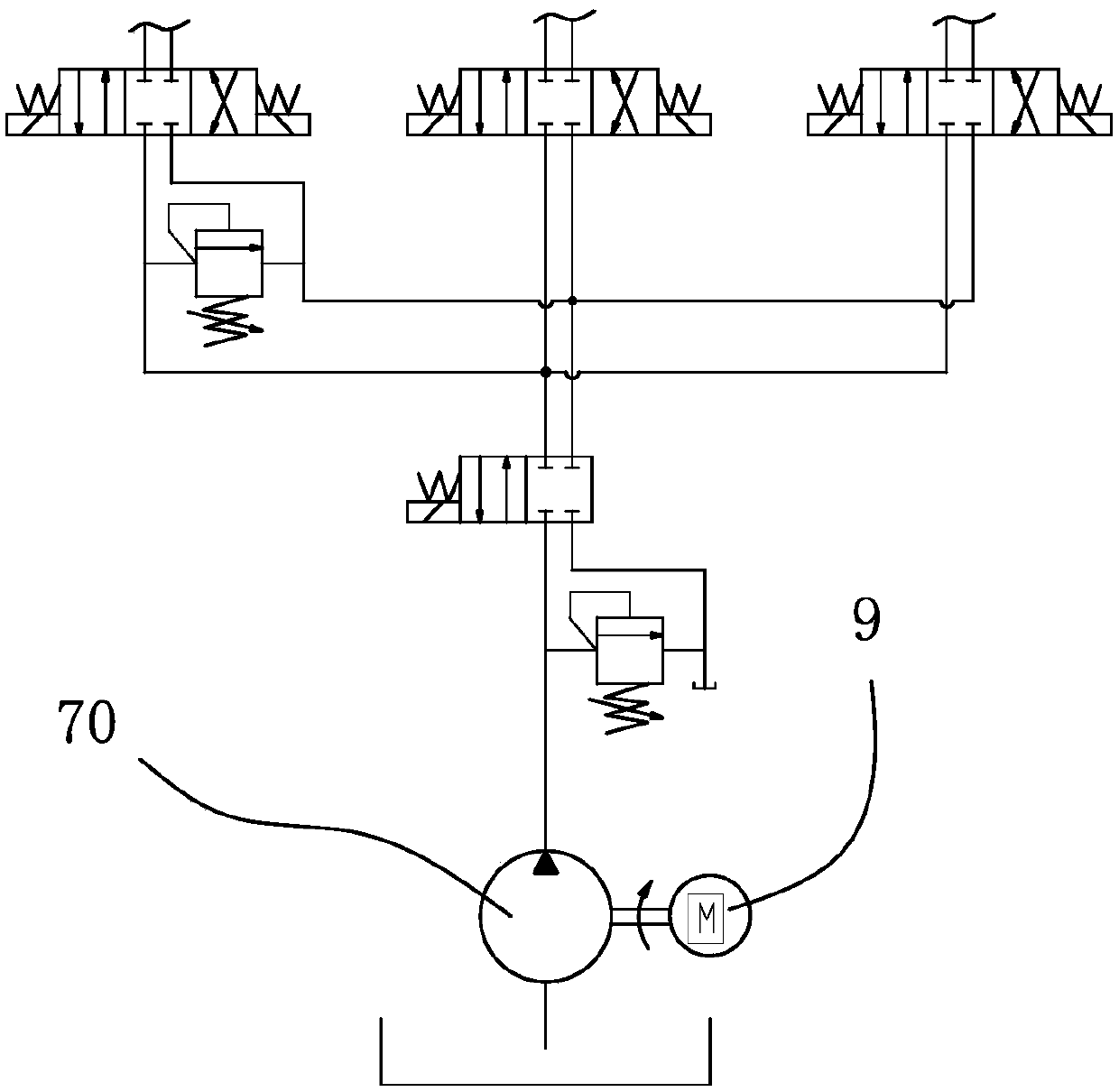

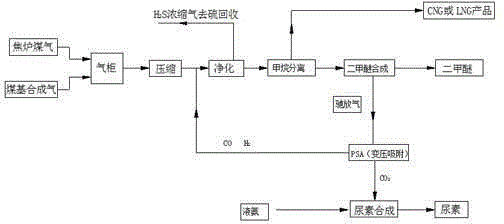

Process for production of dimethyl ether and combined production of natural gas and urea from coal-based synthetic gas and coke oven gas

ActiveCN104974022AImprove gas utilizationSolve the need for carbon supplementationUrea derivatives preparationOrganic compound preparationCompressed natural gasDimethyl ether

The invention provides a process for production of dimethyl ether and combined production of natural gas and urea from coal-based synthetic gas and coke oven gas. The process comprises the following steps: introducing coke oven gas and coal-based synthetic gas into a gasometer and carrying out uniform mixing to form crude raw material gas; carrying out compression and then purification and recovering removed hydrogen sulfide after removal of sulfur; and subjecting purified crude raw material gas to cryogenic separation so as to obtain clean raw material gas, preparing liquefied natural gas or compressed natural gas products from separated methane, synthesizing dimethyl ether from the clean raw material gas and subjecting purge gas produced after synthesis of the dimethyl ether to pressure-variable adsorption and separation, wherein separated CO and H2 are returned and purified, and separated CO2 and liquefied ammonia enter a urea synthesis apparatus for synthesis of urea. The process has the advantages of diversification of products and capacity of adjusting excess production power, facilitating energy conservation and emission reduction, regulating energy structure, increasing the utilization rate of raw material gas and reducing production cost for dimethyl ether.

Owner:SEDIN ENG

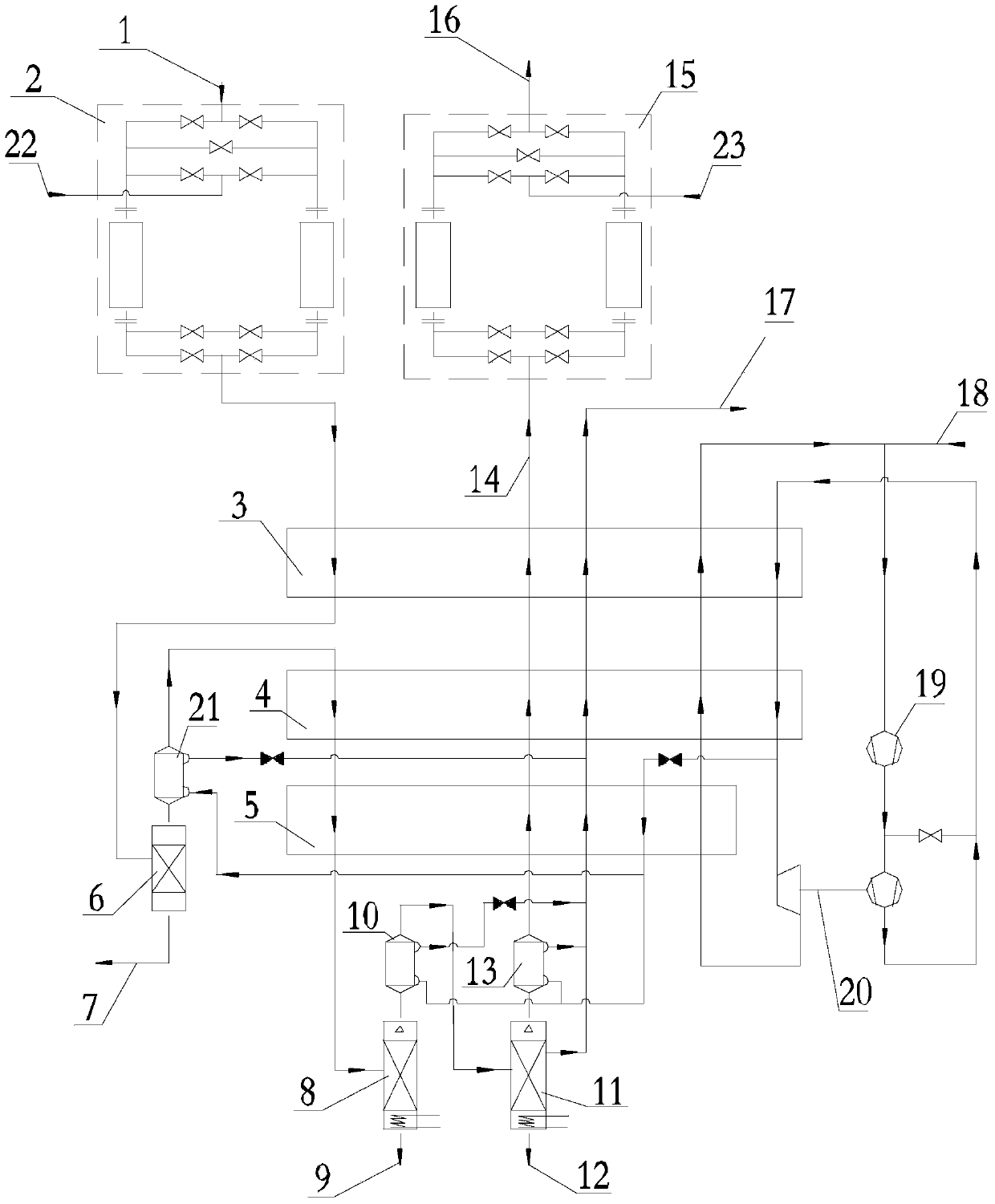

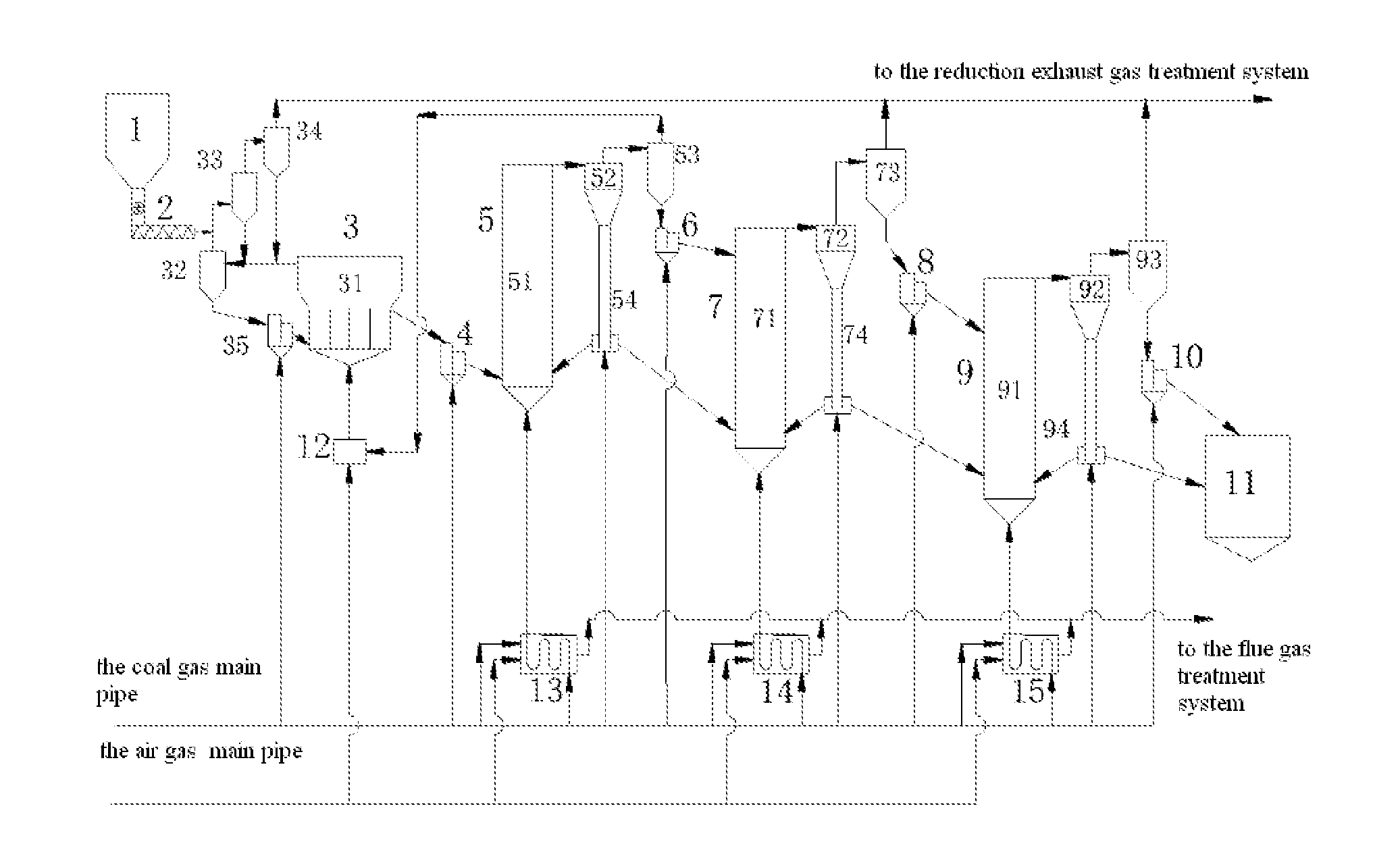

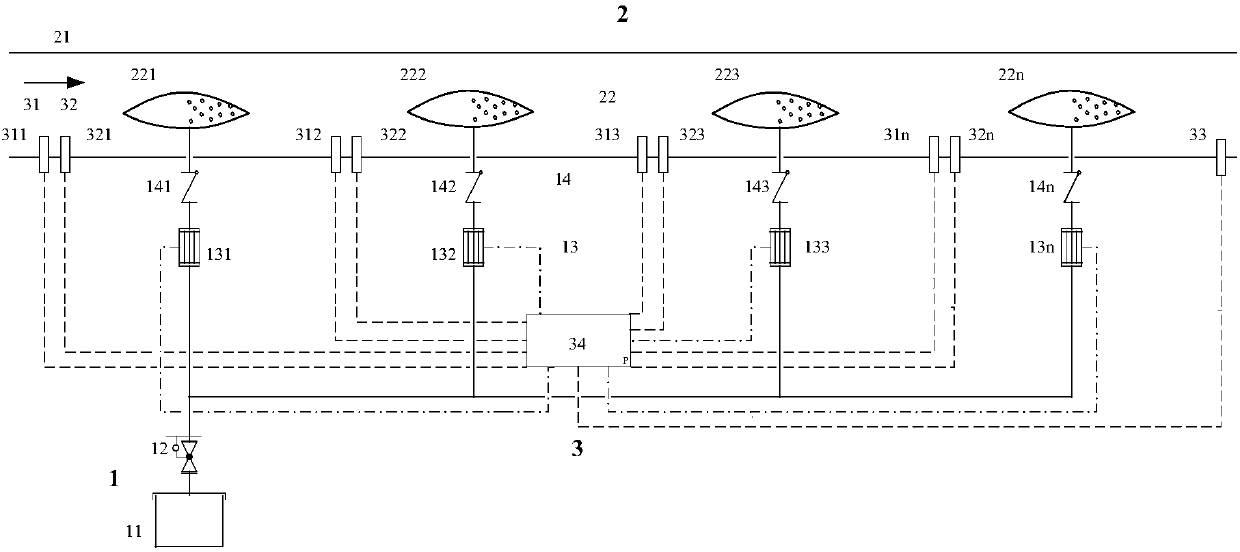

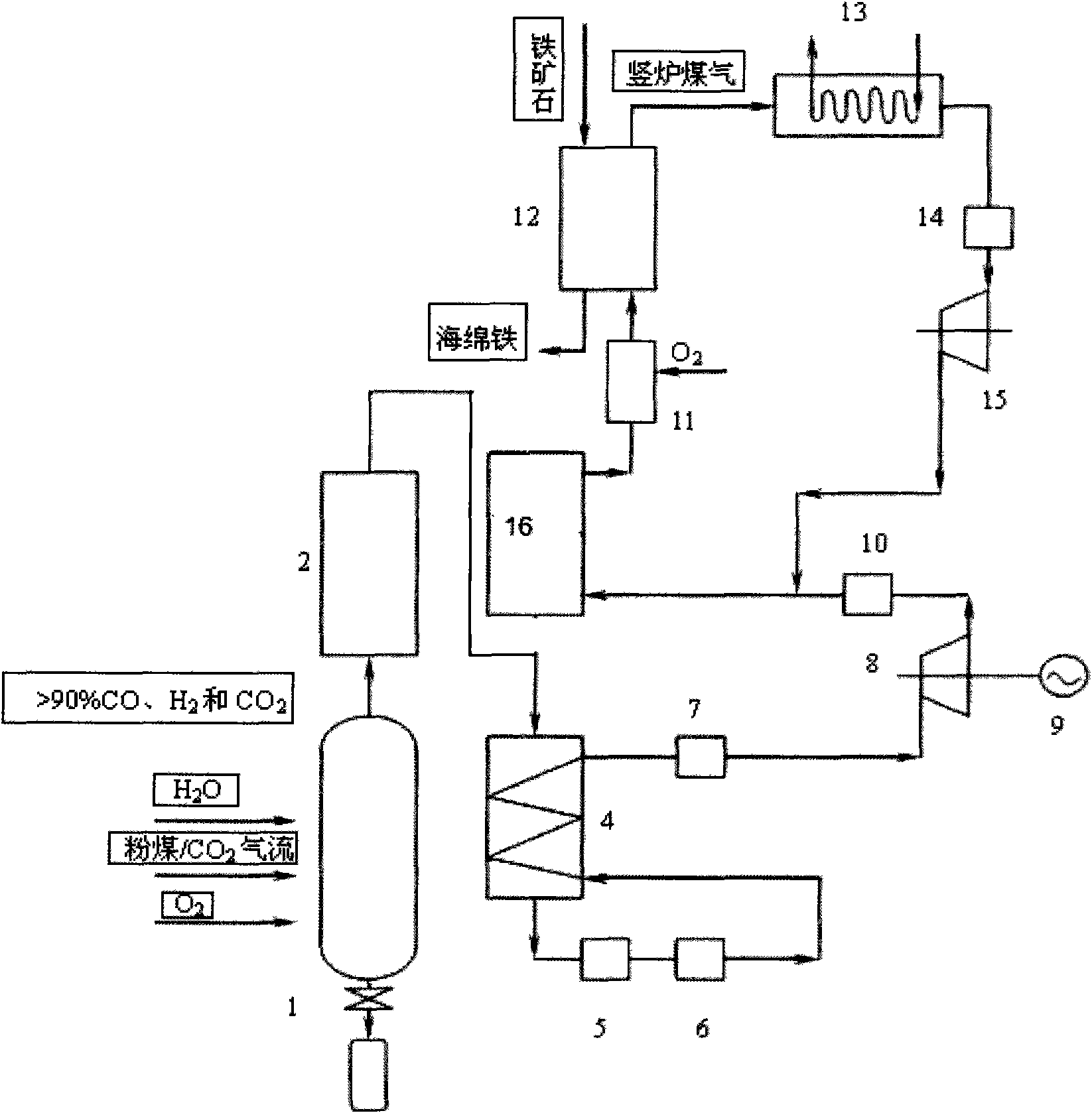

System and method for fluidized bed reduction of powdered iron ore

ActiveUS20160348197A1Improve gas utilizationReduce probabilityFluidised-bed furnacesProcess efficiency improvementSingle stageGas passing

A system for fluidized bed reduction of powdered iron ore. Use of high-gas-velocity processing accelerates iron ore reduction speed and greatly improves the gas-treatment capabilities of a unit-cross-sectional fluidized bed. Use of parallel connections involving reduced coal gas lessens the volume of gas passing through a single-stage fluidized bed. Use of serial / parallel-connection processing involving reduced coal gas increases the coal gas utilization rate. The invention achieves the highly-effective reduction of powdered iron ore in a fluidized bed under near-atmospheric pressure. A reduction method based on the present system is also disclosed.

Owner:BEIJING ZHONGKAIHONGDE TECH +1

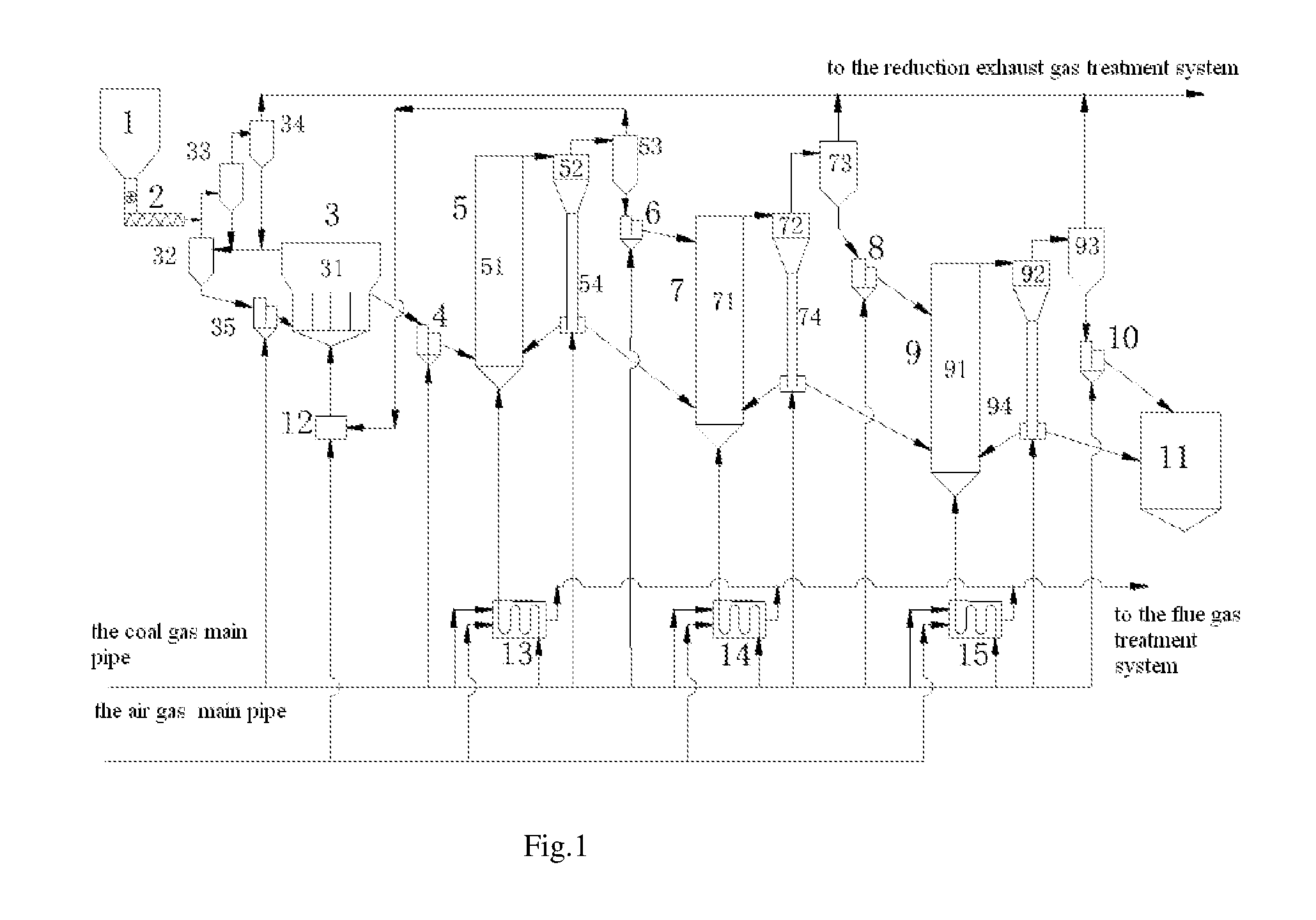

Pressure swing adsorption gas separation energy-saving technique

The invention relates to a separation energy saving technology for pressure-swing adsorption gas; feed gas is dried by apyretic regenerating drying equipment; each of drying towers of the drying equipment works for regenerating periodically and alternately; the dried feed gas is separated by a pressure-swing adsorption plant so as to produce finished gas; each of adsorption towers of the pressure-swing adsorption plant also works for regenerating periodically and alternately; a blow-down tail gas produced by the adsorption tower in a regenerating state and resurgent gas regenerated by blowing conversely the finished gas to the adsorption tower are all conducted to the drying tower in the regenerating state for regenerating to the drying tower; and the regenerated gas is discharged. By using the technology of the invention, PSA plant and the apyretic regenerating drying equipment are joined together to be used; the waste gas produced by the regenerating adsorption tower of the PSA plant is utilized to regenerate to the drying tower without consuming the qualified feed gas, thereby reducing the drying energy consumption greatly, improving the quality of the dried feed gas and decreasing the energy consumption cost of the entire gas separation technology.

Owner:WENZHOU RUIQI AIR SEPARATION EQUIP

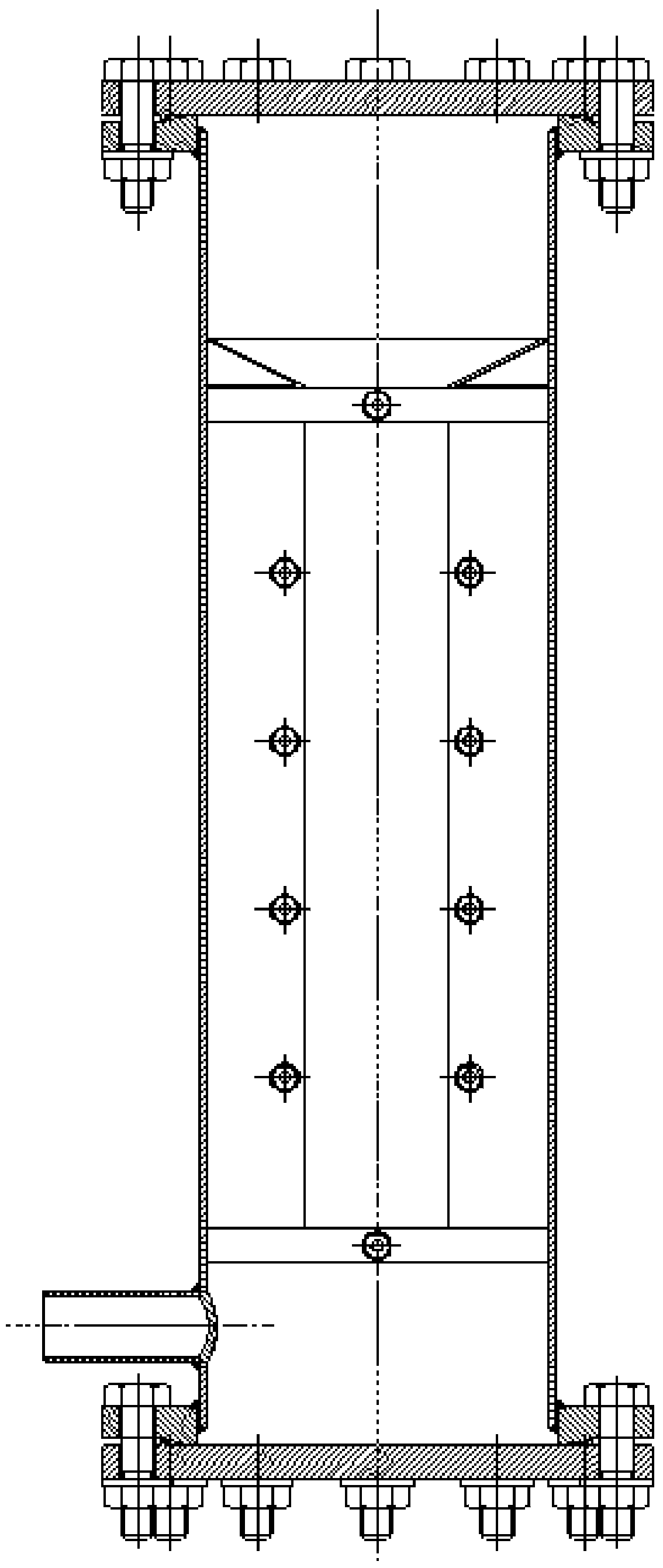

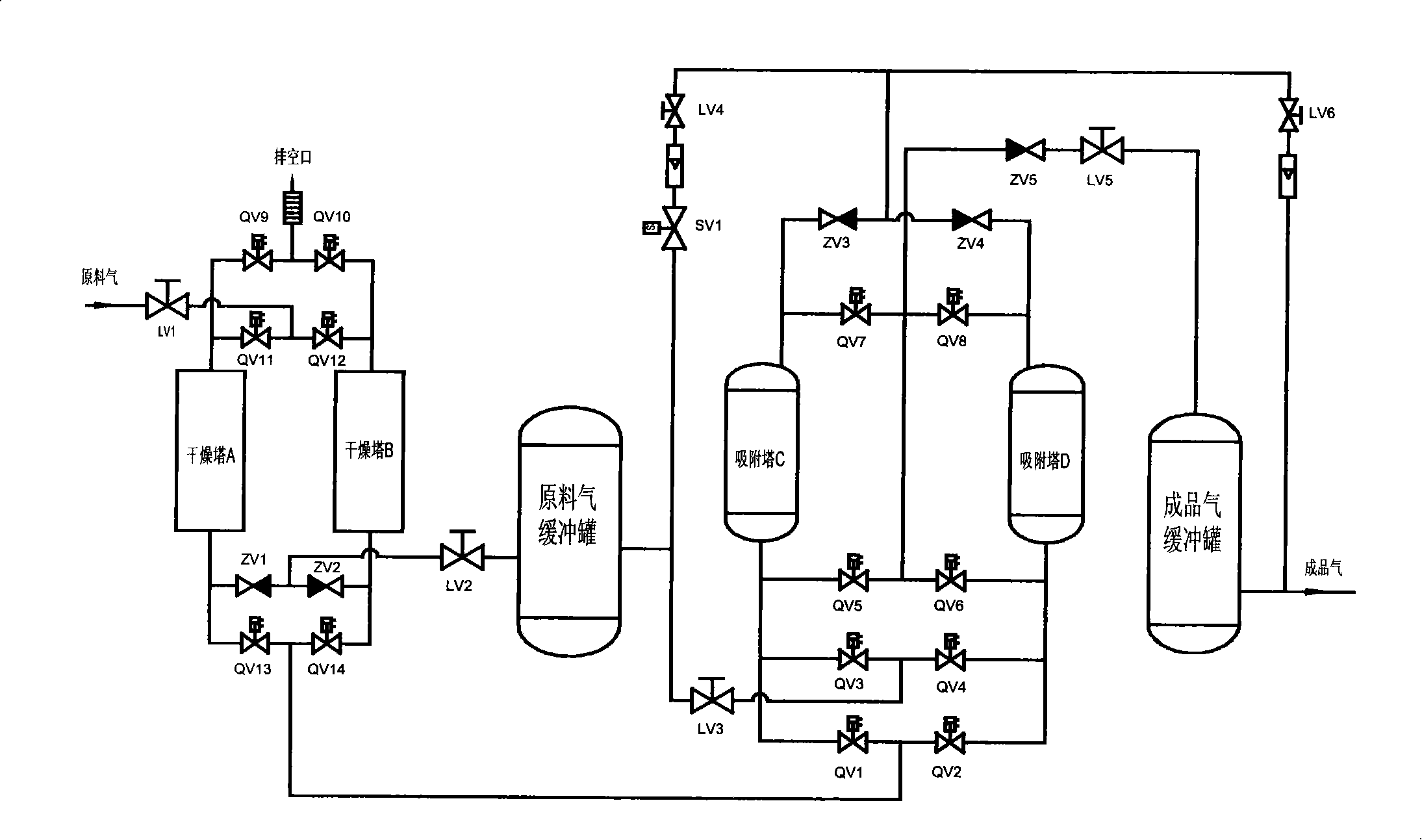

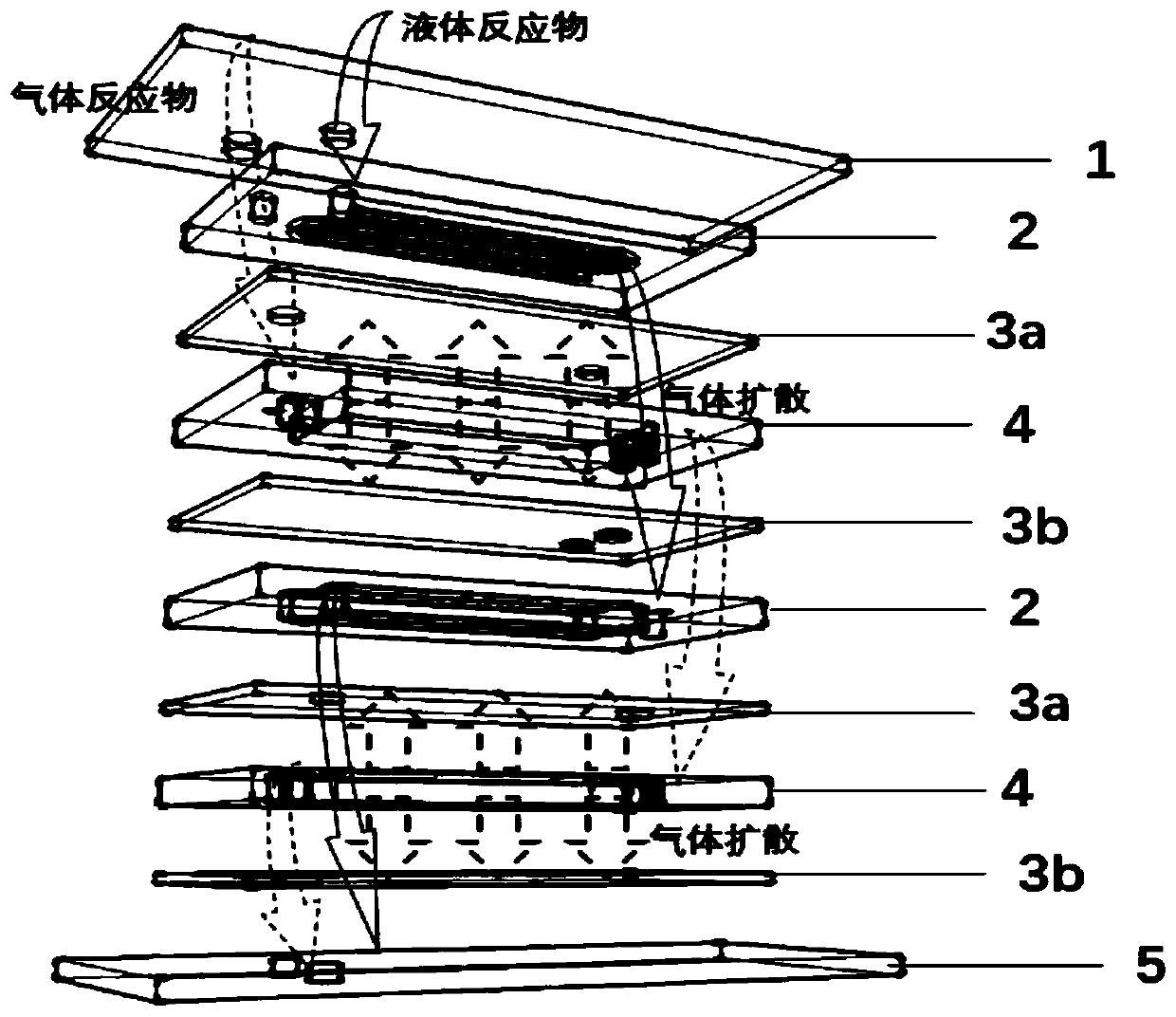

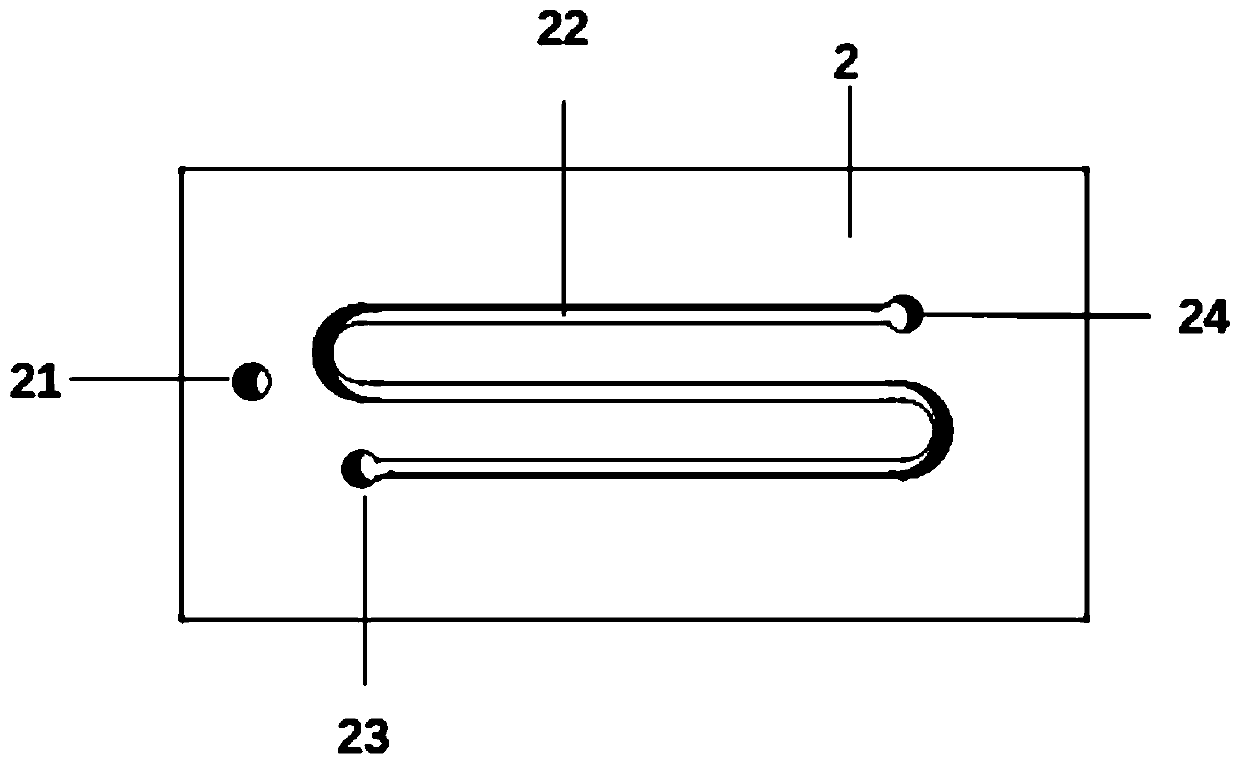

Gas-liquid-solid three-phase membrane microreactor with stacked structure

ActiveCN110813208ALarge amount of processingHigh yieldChemical/physical/physico-chemical microreactorsMicroreactorFluid phase

The invention discloses a gas-liquid-solid three-phase membrane microreactor with a stacked structure. The gas-liquid-solid three-phase membrane microreactor comprises an upper cover plate and a lowercover plate, wherein a liquid-phase inlet and a gas-phase inlet are formed in the upper cover plate, and the lower cover plate is provided with a liquid-phase outlet and a gas-phase outlet. The membrane microreactor is characterized in that a plurality of three-phase micro-reaction units are arranged between the upper cover plate and the lower cover plate in an up-down stacking manner; each three-phase micro-reaction unit is formed by stacking a liquid-phase micro-channel layer, a first gas-permeable membrane, a gas-phase micro-chamber layer and a second gas-permeable membrane in sequence from top to bottom; the first gas-permeable films and the second gas-permeable films have hydrophobicity and gas permeability; a liquid-phase reactant and a gas-phase reactant respectively enter from theliquid-phase inlet and the gas-phase inlet, sequentially flow through all the three-phase micro-reaction units from top to bottom, and respectively flow out from the liquid-phase outlet and the gas-phase outlet; the liquid-phase micro-channel layers are provided with vent holes and micro-channels for liquid-phase circulation; and the micro-channels are all of an up-down through structure. The gas-liquid-solid three-phase membrane microreactor can be widely applied to the fields of chemical engineering, energy, environmental protection and the like.

Owner:CHONGQING UNIV

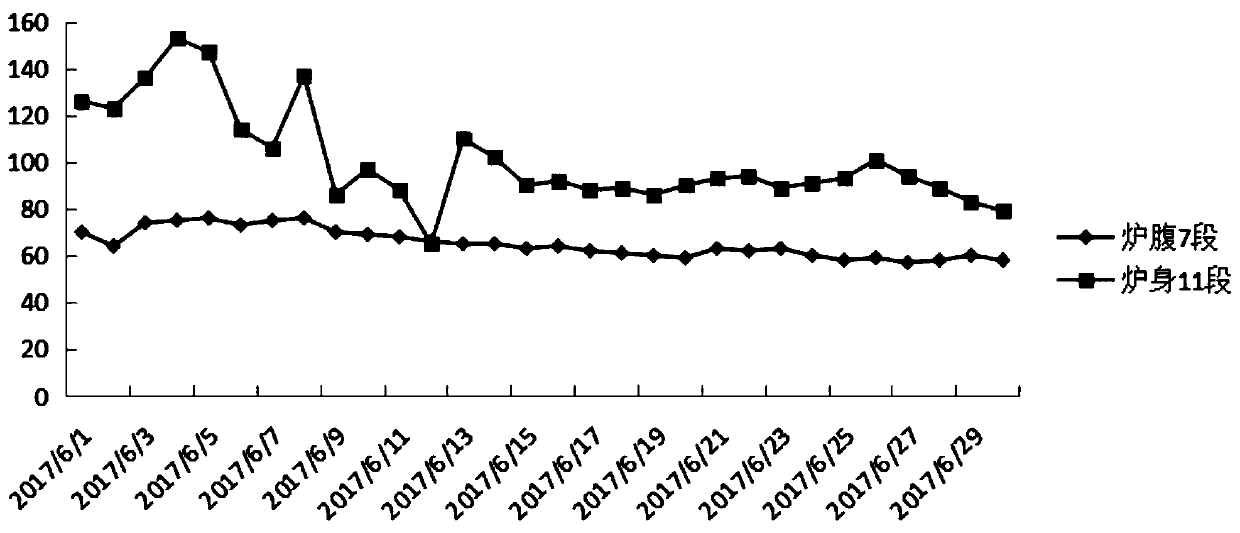

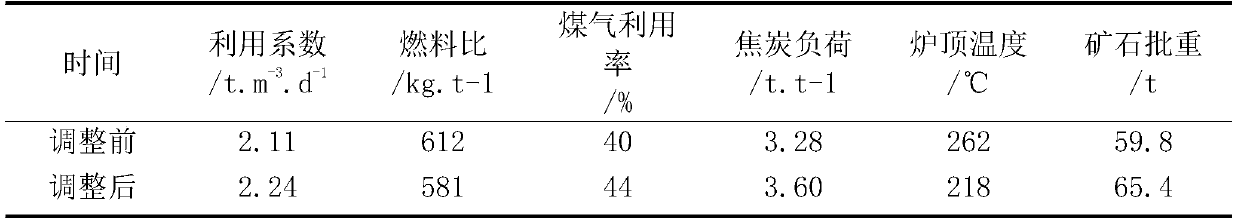

Process method for cancelling central coke charging

InactiveCN110257574AReasonable air distributionImprove gas utilizationBell-and-hopper arrangementBlast furnace detailsAirflowEngineering

The invention discloses a process method for cancelling central coke charging. The process method for cancelling central coke charging comprises the steps of S1, reducing an ore platform, loosening an edge airflow, and enlarging a central zone after a heat load is stabilized and the edge airflow is homogenized; S2, after the cross beam temperature measuring of a center tends to be stable, reducing the central coke amount, setting a coke matrix transition grade, adjusting the center and edge ore circle number, and reducing the impact of a distribution platform change on two airflows; and S3, stabilizing the distribution platform, and increasing a coke load; and after cancelling central coke charging step by step, increasing the ore batch weight according to the coke batch thickness suitable for a blast furnace.

Owner:BAOTOU IRON & STEEL GRP

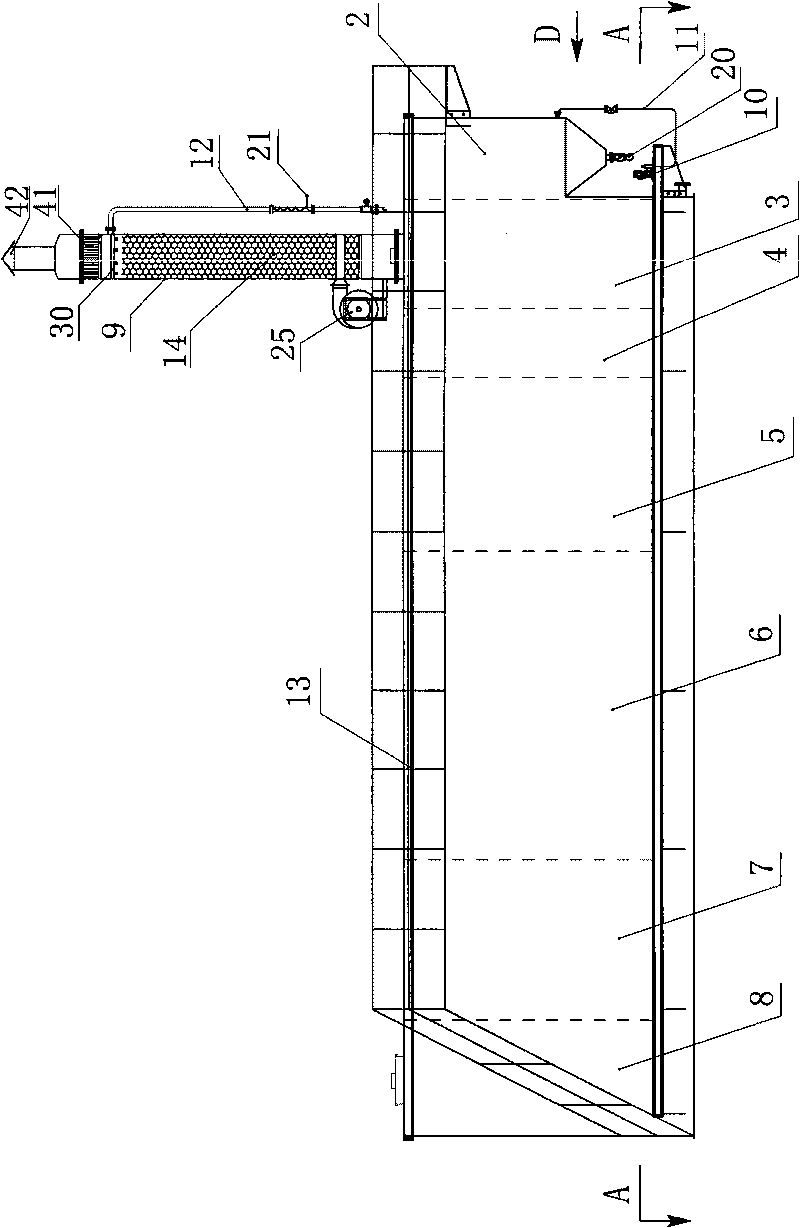

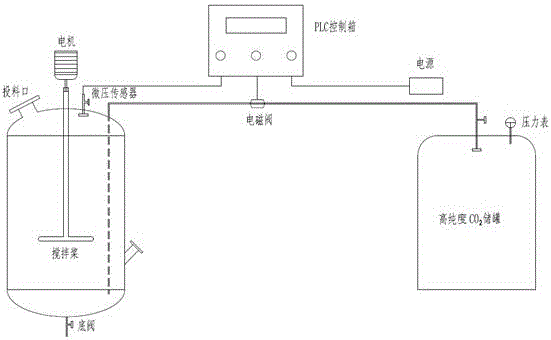

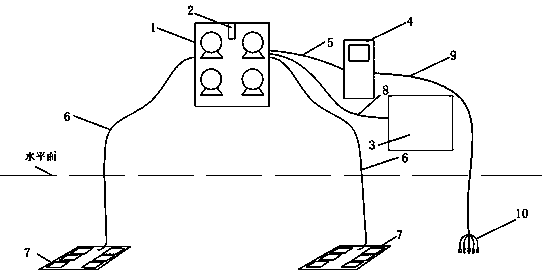

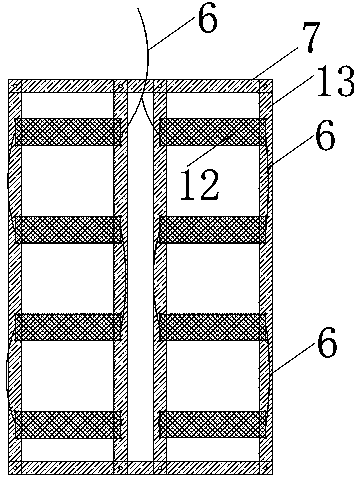

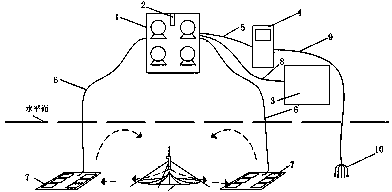

Ecological gene nano-regulation and control device for lakes and reservoirs

InactiveCN103739099AAvoid cloggingFirmly connectedWater aerationSustainable biological treatmentMicro nanoAutomatic control

The invention relates to an ecological gene nano-regulation and control device for lakes and reservoirs. The ecological gene nano-regulation and control device is as follows: one end of a water body ecological nano-gene regulation and control unit is connected with one end of a combined gas hose, the other end of the combined gas hose is connected with an array controllable nano-aeration disk, and the array controllable nano-aeration disk is linked with a micro-bubble and micro-nano-bubble diffusion device to enable a large-scale water body to form an inverted laminar flow effect; a PLC (programmable logic controller) program automatic control platform is connected with the water body ecological nano-gene regulation and control unit through a control wire; the PLC program automatic control platform is connected with an environmental factor probe group through a signal wire; and one end of a gas source treatment unit is connected with a gas inlet end of the water body ecological nano-gene regulation and control unit through a gas source purification hose, and a pressure flow rate control unit is arranged in the water body ecological nano-gene regulation and control unit. The ecological gene nano-regulation and control device provided by the invention has the advantages of simplicity, convenience and quickness in connection, firm structure and aesthetic appearance.

Owner:林映津

High-pressure pipeline gas and liquid reactor for hydrogen sulfide treatment of oil well and treatment method thereof

ActiveCN107913648AIncrease profitImprove solubilityRefining with non-metalsLiquid-gas reaction processesAutomatic controlTherapeutic effect

The invention belongs to the field of safety production and environment protection, and particularly relates to a high-pressure pipeline gas and liquid reactor for hydrogen sulfide treatment of an oilwell and a treatment method thereof. The high-pressure pipeline gas and liquid reactor consists of a gas supply unit, a dissolved gas mixing reaction unit and an automatic control unit, wherein the gas supply unit is connected with the dissolved gas mixing reaction unit, and is used for supplying required oxygen for the dissolved gas mixing reaction unit; the automatic control unit is used for detecting the contents of hydrogen sulfide and dissolved oxygen in each node of the dissolved gas mixing reaction unit, and controlling the supply amount of oxygen in each node of the dissolved gas mixing reaction unit. The high-pressure pipeline gas and liquid reactor has the advantages that the equipment is compact, and the land occupation area is small; the automation degree is high, and the maintenance is convenient; the treatment is performed at high pressure, the pressure-relief releasing and pressurizing transportation process of the hydrogen sulfide gas is not needed, and the energy consumption is low; by adopting the multiple stages of gas supply, the gas is uniformly distributed, the gas dissolving efficiency is high, the utilization rate of the gas is high, the treatment effect isgood, and the removal rate of the hydrogen sulfide reaches 99.5% or above; the high-pressure pipeline gas and liquid reactor can be widely applied into the hydrogen sulfide treatment technology of the oil well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel burning heating device

InactiveCN102679343AExtended service lifeNew structureGaseous fuel burnerHeating arrangementEngineeringFuel gas

The invention relates to a novel burning heating device which comprises a perpendicular fuel gas input device. A fuel gas inlet is arranged at one end of the perpendicular fuel gas input device, and the other end of the perpendicular fuel gas input device is connected with a burning device. The burning device is connected with a bending air pipe, one end of the bending air pipe is provided with a fan, the other end of the bending air pipe is provided with an air outlet, a bearing box and a motor are arranged on one side of the fan, and an air inlet is arranged on the other side of the fan. The novel burning heating device is high in heat utilization ratio and less in fuel gas usage, prolongs service life of the fan and is low in integral maintenance cost.

Owner:宜兴市金鱼陶瓷有限公司

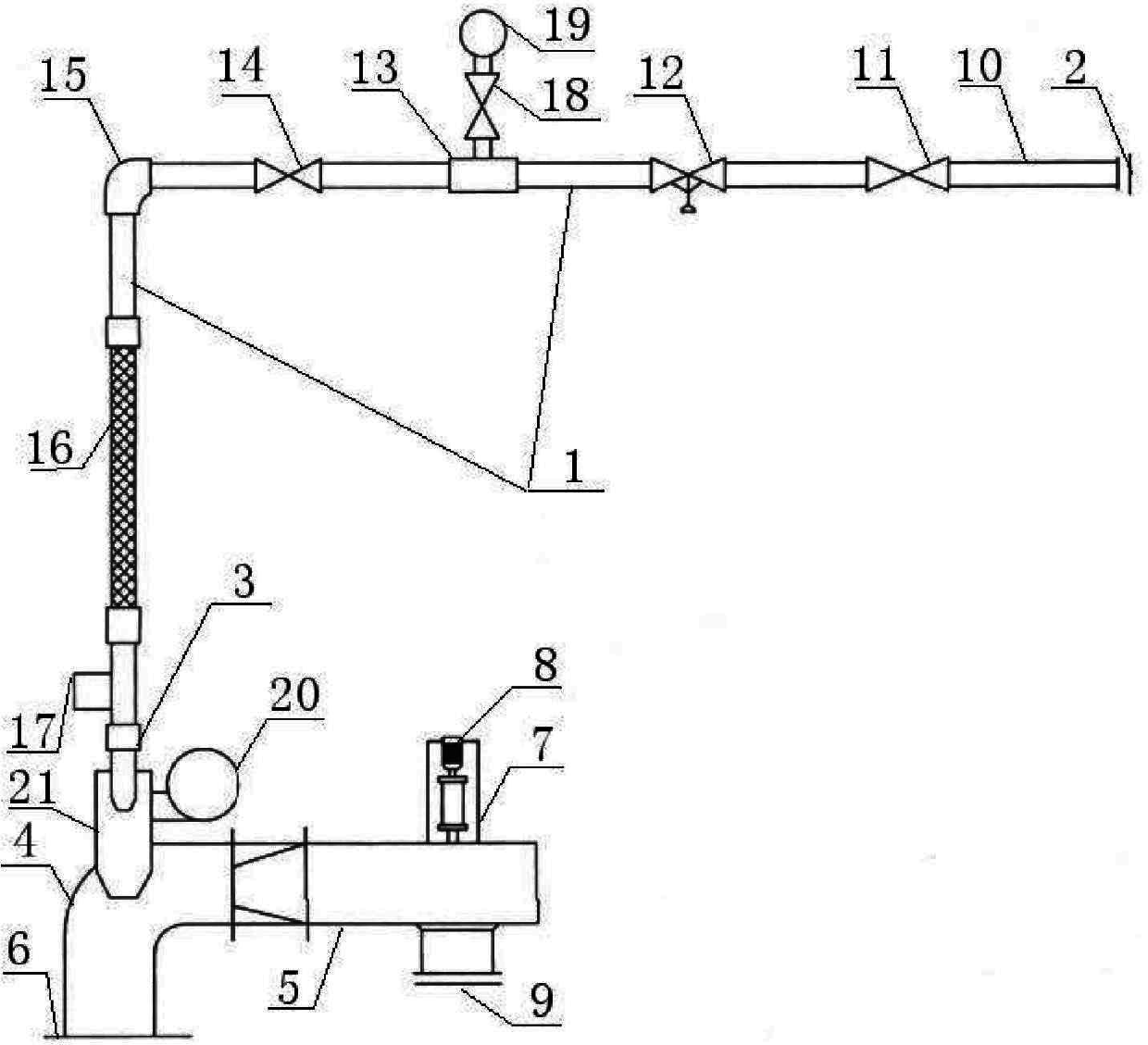

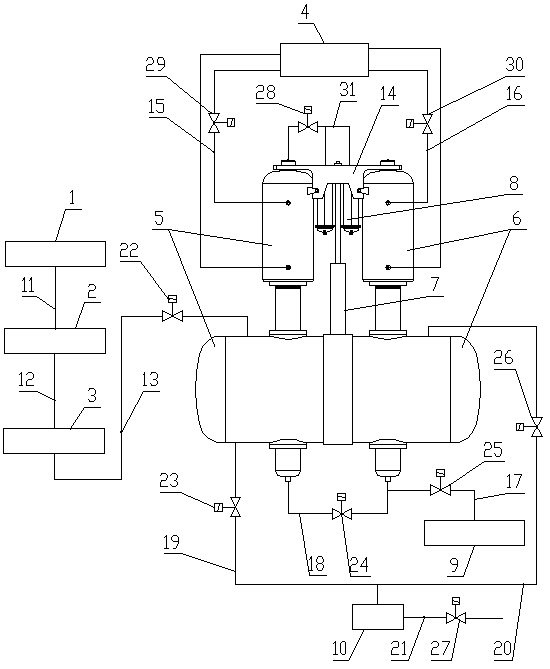

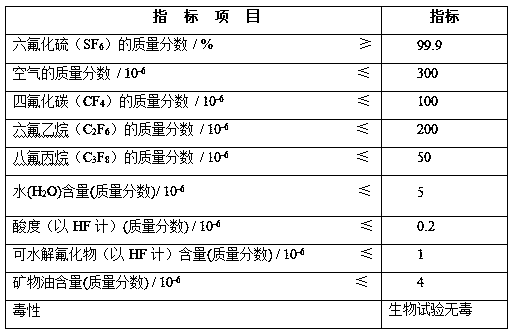

Equipment and method for recycling and purifying sulfur hexafluoride gas by virtue of liftable rectifying tower

PendingCN109224758ASatisfy the separation conditionSave spaceDispersed particle filtrationSocial benefitsProcess engineering

The invention relates to equipment for recycling and purifying sulfur hexafluoride gas by virtue of a liftable rectifying tower. The equipment comprises a raw material gas inlet joint, a filtering-absorbing device, a compressor, a refrigerating unit, a first rectifying tower, a second rectifying tower, a hydraulic jacking device, a first tail gas processor, a second tail gas processor and a supercharger. The invention further discloses a method for recycling and purifying sulfur hexafluoride gas by virtue of the liftable rectifying tower. According to the equipment and the method, an SF6 wastegas purification and regeneration technique meet the fresh gas standard GB / T12022-2014 Sulphur Hexafluoride for Industrial Use, the development of SF6 waste gas regeneration technique equipment is promoted, the problems in the regeneration and repeated use of SF6 waste gas are solved, the utilization rate of SF6 gas is increased, the emission of SF6 gas is reduced, the development of green poweris promoted, and the equipment and the method have great economic and social benefits.

Owner:HENAN RELATIONS

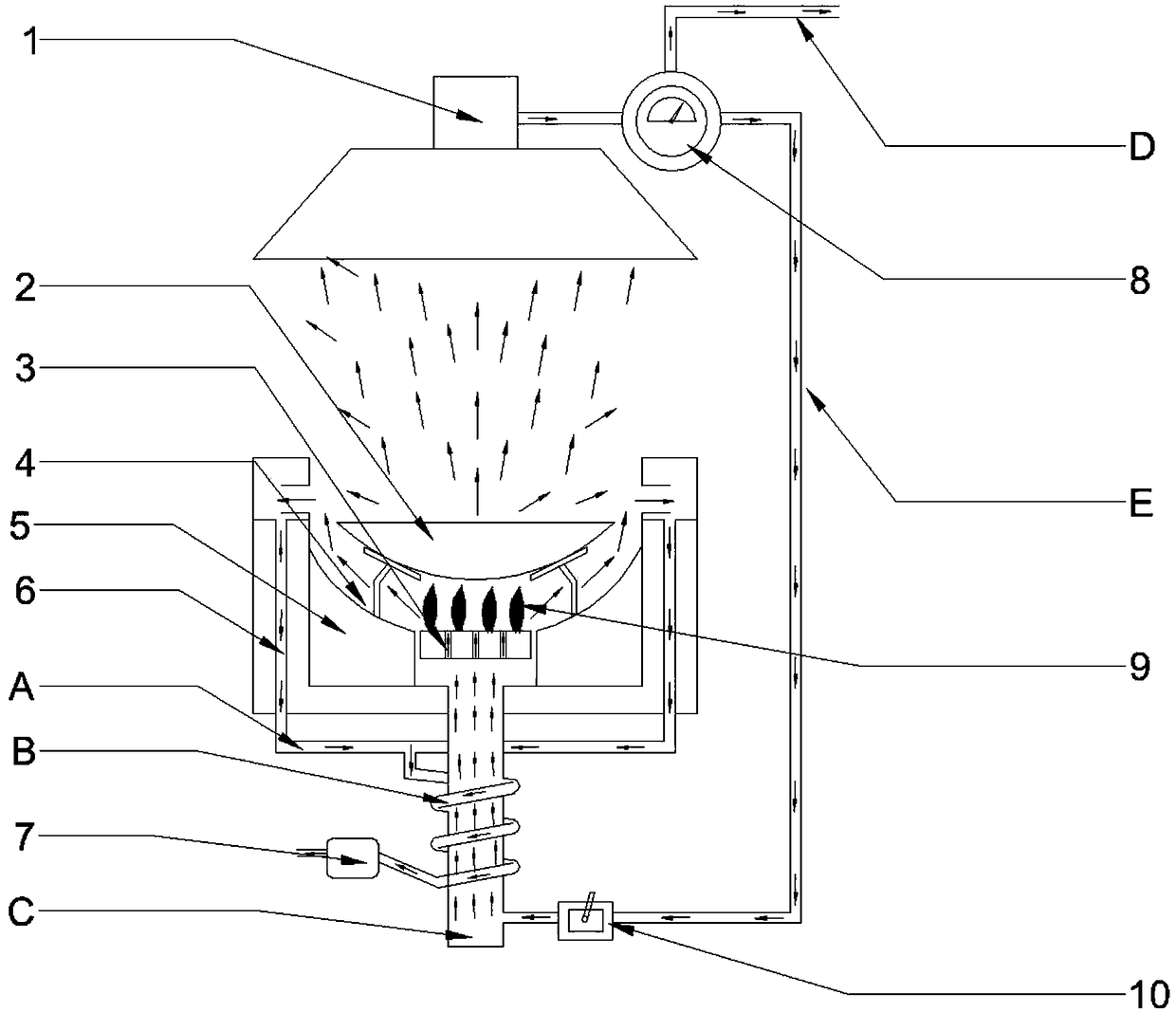

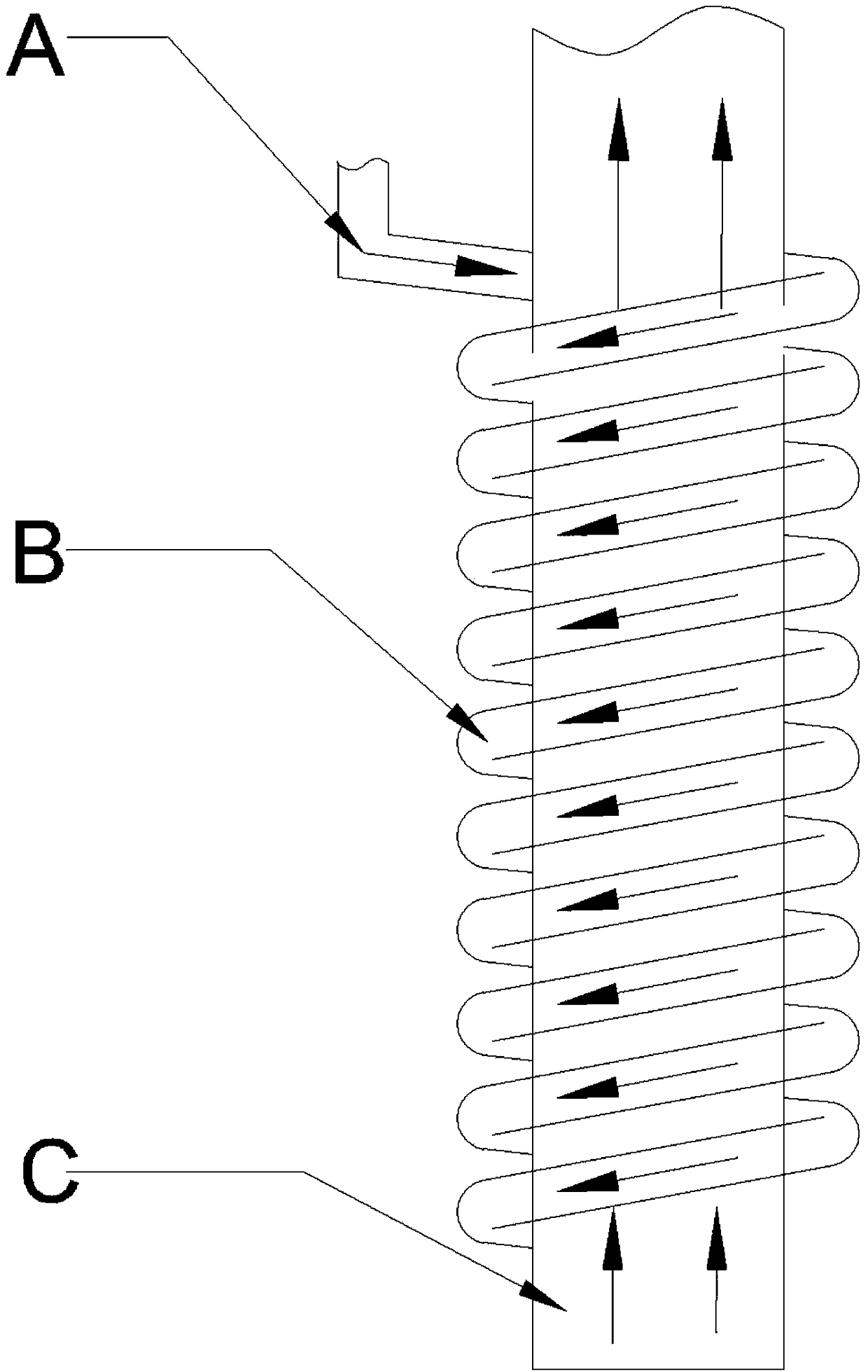

Cooking fume recirculation type energy-saving gas stove

InactiveCN109084299AEmission reductionIncrease temperatureDomestic stoves or rangesCooking fumes removalInsulation layerProcess engineering

The invention provides a cooking fume recirculation type energy-saving gas stove. The cooking fume recirculation type energy-saving gas stove comprises a stove base, a combustor, a range hood, a negative-pressure pump, an automatic cooking fume detection and control valve and a safety valve. The stove base is of a cylindrical structure. The upper portion of the stove base is of a downward-concavespherical surface structure, and the downward-concave spherical surface is coated with a radiative heat-dissipation paint coating. A hollow annular heat insulation layer is arranged on the stove base.The combustor is arranged at the center of the downward-concave spherical surface, and the lower portion of the combustor is connected with a gas and air premixing pipeline. A spiral preheating pipeis wound outside the gas and air premixing pipeline. One end of the preheating pipe is connected with the negative-pressure pump, and the other end of the preheating pipe is connected with the hollowannular heat insulation layer through a smoke return pipe. The range hood is arranged over the stove base. A smoke pipe is guided out from a smoke discharging pipeline of the range hood and is connected with the automatic cooking fume detection and control valve. One path of cooking fume from the automatic cooking fume detection and control valve is discharged through a first pipeline, and the other path of the cooking fume is connected to the safety valve through a second pipeline and then is connected to the gas and air premixing pipeline.

Owner:YANSHAN UNIV

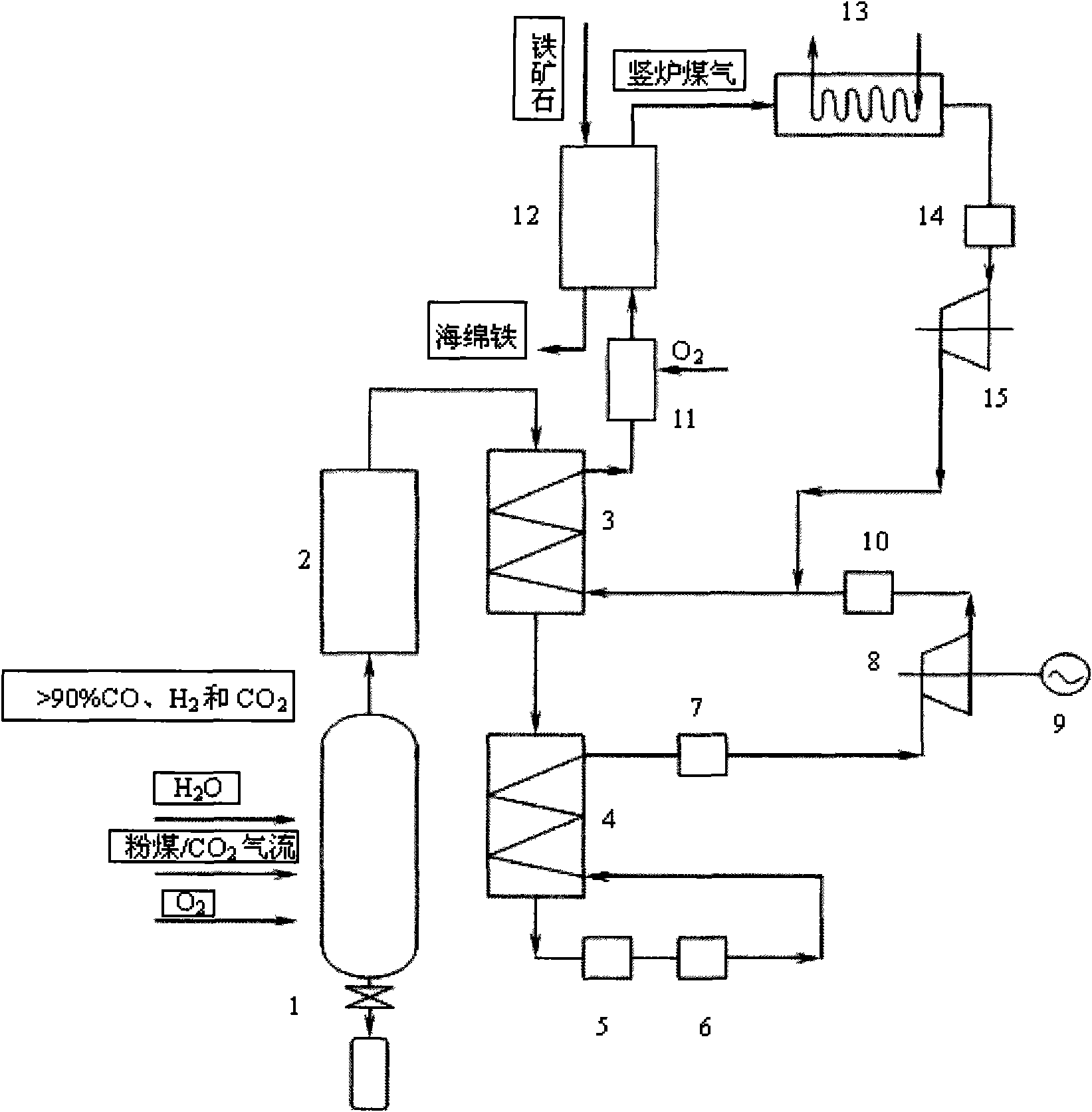

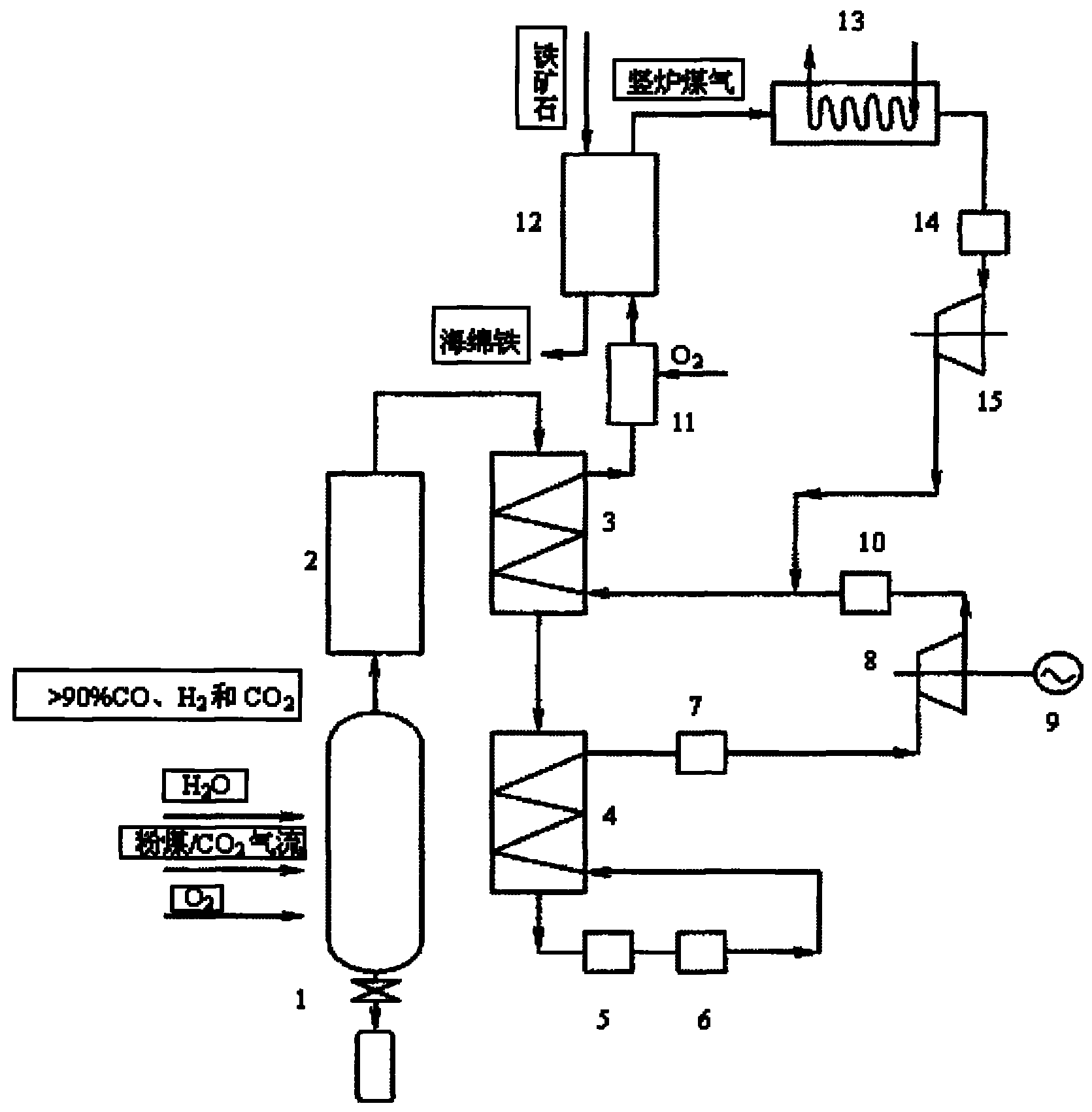

Energy recovery system for preparing sponge iron by gasification of high-pressure pulverized coal and method thereof

ActiveCN101597663BImprove gasification efficiencyNo depositionShaft furnaceCombustion chamberWater vapor

The invention provides an energy recovery method for preparing sponge iron by gasification of high-pressure pulverized coal and a system thereof. In the energy recovery method for preparing sponge iron through a coal-based shaft furnace process and the system thereof, oxygen, pulverized coal and water vapor are sent into a high-pressure pulverized coal gasification furnace for completing high-temperature pure oxygen gasification to generate synthesis gas with CO and H2 in a relatively high ratio; the synthesis gas is successively cooled to a specific temperature through a two-stage heat recovery plant after radiant cooling, and sulfur and nitrogen are removed from the synthesis gas through a dust remover and a gas purifier; the purified high-pressure low-temperature synthesis gas absorbs the sensible heat of coal gas through a secondary heat recovery plant and then is heated to a specific temperature and mixed with treated and recovered shaft furnace coal gas in a combustion chamber; the heated coal gas enters the shaft furnace and is reacted with sent-into iron ore to generate the sponge iron and the shaft furnace coal gas. The invention has the advantages that the gasification efficiency of coal is high, the invention is suitable for coal types of different tenors, and the invention greatly improves the recovery rate of the shaft furnace coal gas, simplifies the system for utilization of the shaft furnace coal gas, and synchronously realizes zero emission of sponge iron manufacture.

Owner:SHANGHAI BOILER WORKS +1

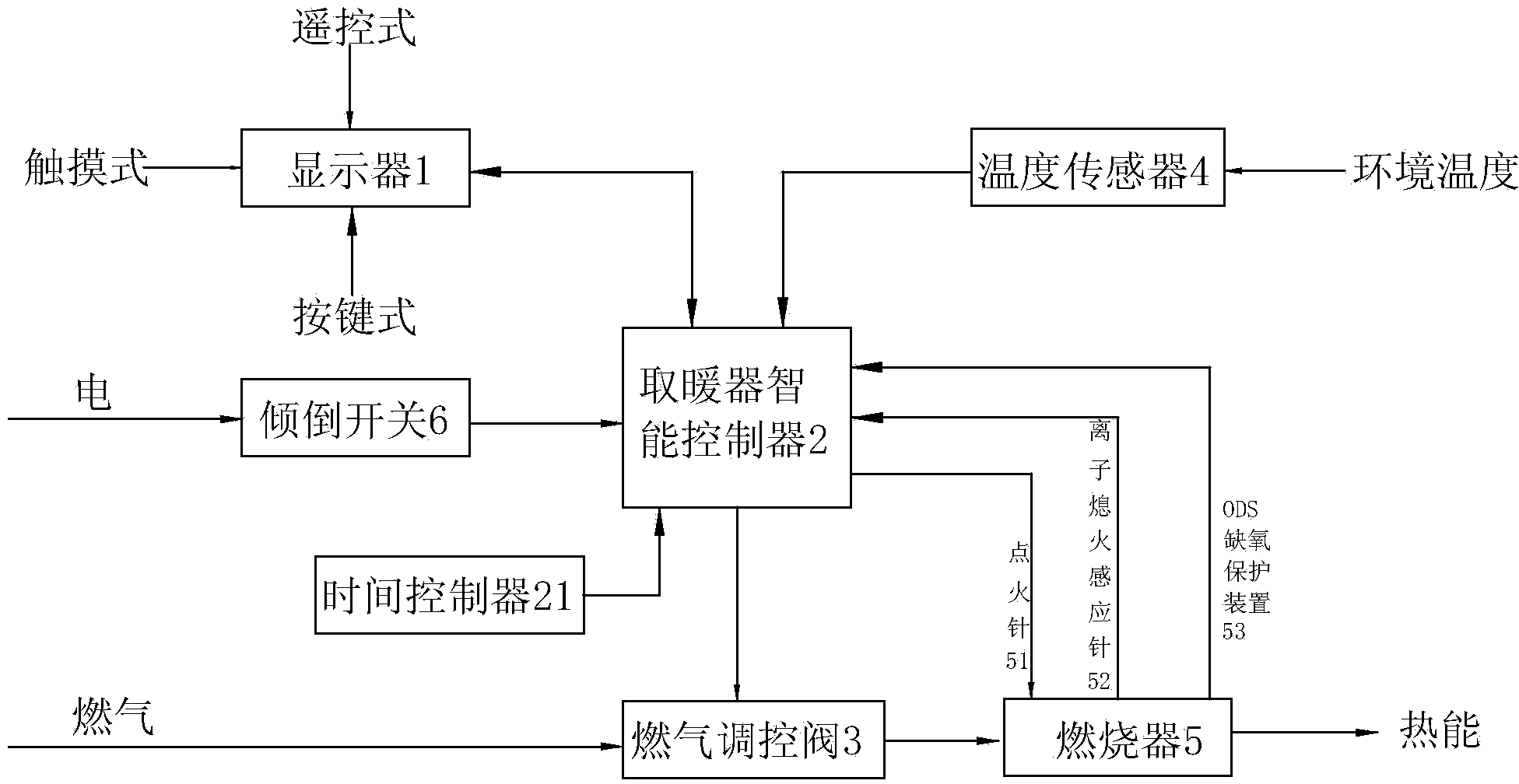

Intelligent dynamic equilibrium type burning heater

InactiveCN103836710ARealize dynamic combustionRealize indoor constant temperature heatingLighting and heating apparatusSpace heating and ventilation detailsSocial benefitsDisplay device

The invention discloses an intelligent dynamic equilibrium type burning heater which comprises a displayer, an operation input device, an intelligent heater controller, a gas proportioning valve, a temperature sensor, a burner, a toppling switch, an ignition needle, an ion flameout induction needle and an ODS oxygen deficiency protector. The intelligent dynamic equilibrium type burning heater has the functions of automatic constant-temperature dynamic equilibrium burning, presetting of switch-on and switch-off at fixed time, setting of programmed autonomous burning modes with different fire magnitudes in multiple time periods, oxygen deficiency protection, flameout warning and the like, and is reasonable in design, compact in structure, high in gas utilization rate, and capable of realizing automatic constant-temperature variable-power burning and particularly reducing non-effective gas burning, thereby achieving the purpose of saving energy and having positive social benefits.

Owner:中山雄益精密机电有限公司

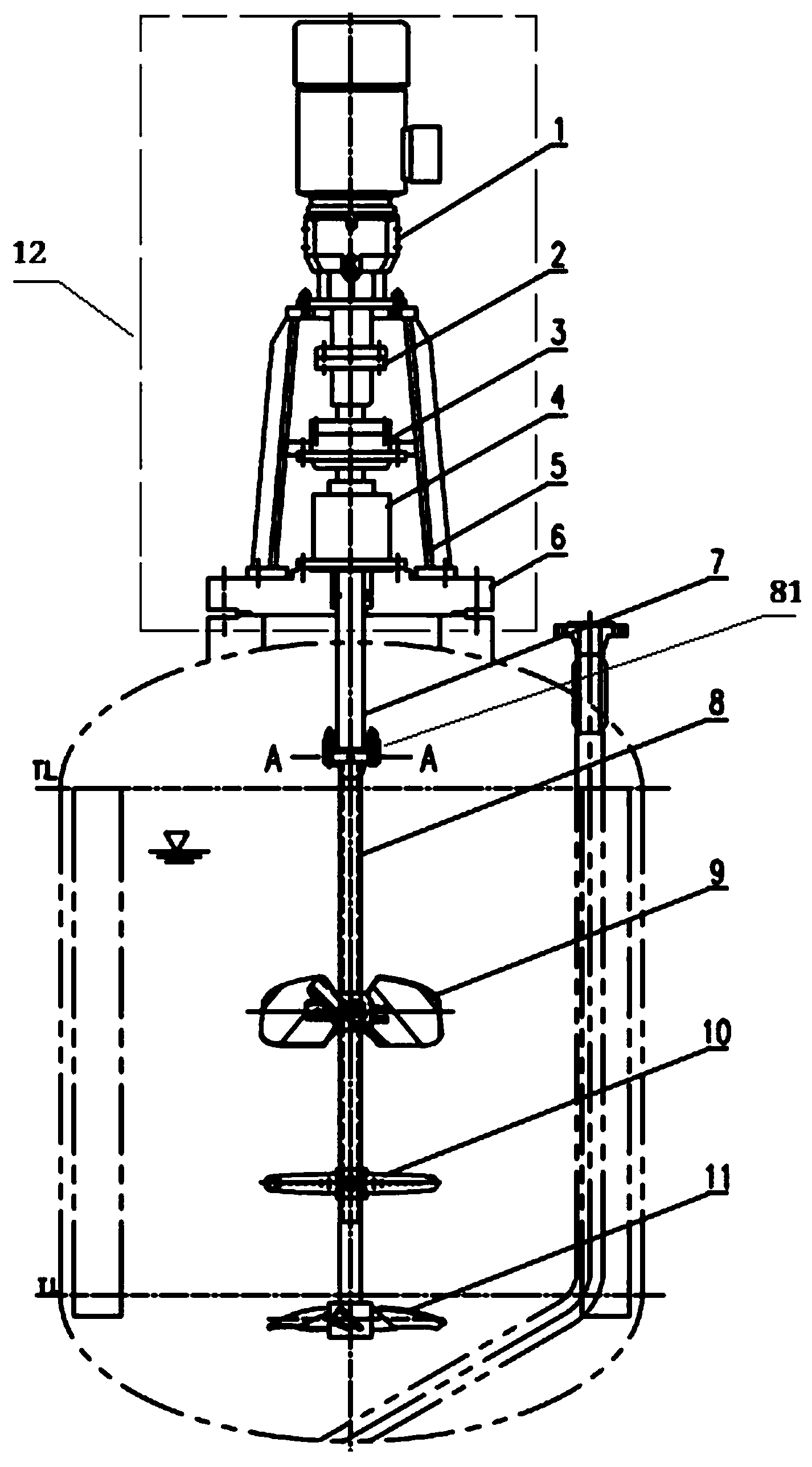

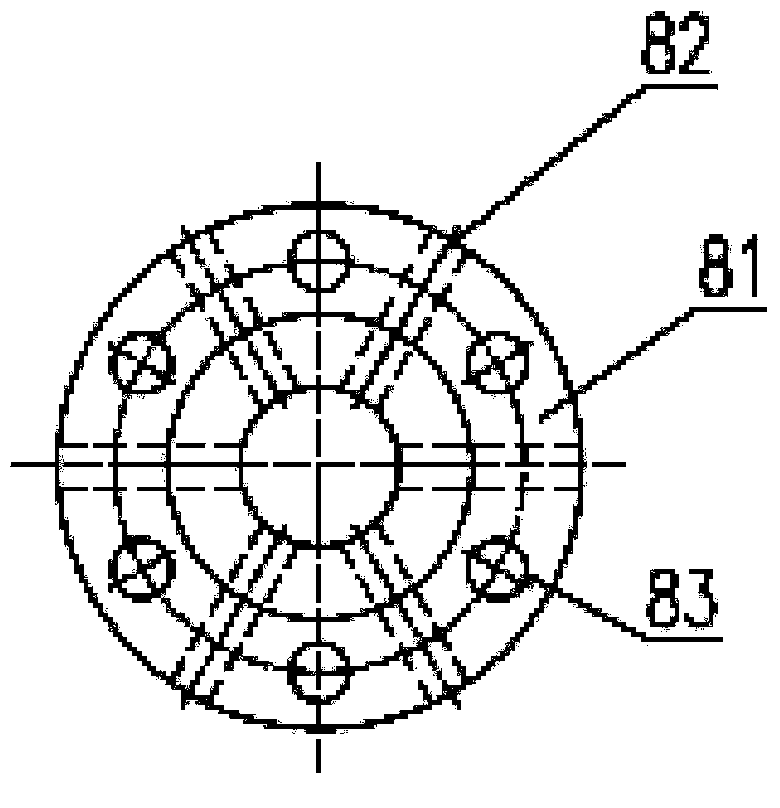

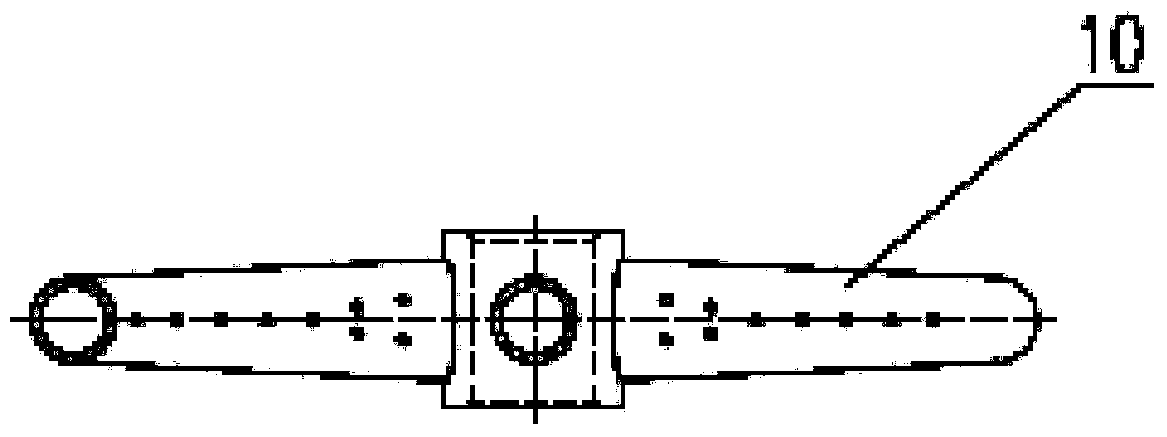

Self-suction type efficient stirring device

ActiveCN103406050AImprove gas utilizationSave equipment costs and operating expensesTransportation and packagingRotary stirring mixersSolid phasesRADIUS

The invention provides a self-suction type efficient stirring device. The self-suction type efficient stirring device consists of necessary stirring driving parts such as a speed reducing motor, a hollow stirring shaft, an upper auxiliary stirring paddle, a self-suction type stirring paddle and a lower auxiliary stirring paddle, wherein the self-suction type stirring paddle is a reducing pipe type stirrer; the transverse radius of a stirring pipe is gradually decreased outwards along the circumferential direction; the stirring pipe is of an all-directional porous structure; gas outlets are formed in an outlet and the back liquid level side of the stirring pipe; the upper auxiliary stirring paddle and the lower auxiliary stirring paddle are different types of axial flow type stirring paddles. The self-suction type efficient stirring device has the advantages that the gas suction critical rotation speed is low, the gas suction speed rate is high, the bubble size is small; gas is uniformly mixed with liquid and solid phases; the contact area between heterogeneous phases is large; mass transfer coefficients are high; a solid-phase medium can be effectively prevented from being settled; the reaction speed rate and the yield are increased.

Owner:上海森永工程设备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com