Novel burning heating device

A heating device and combustion device technology, applied in the direction of heating device, burner, combustion method, etc., can solve the problems of short service life of hot air blower, high maintenance cost, low heat utilization rate, etc., achieve high gas utilization rate and improve production Efficiency and service life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

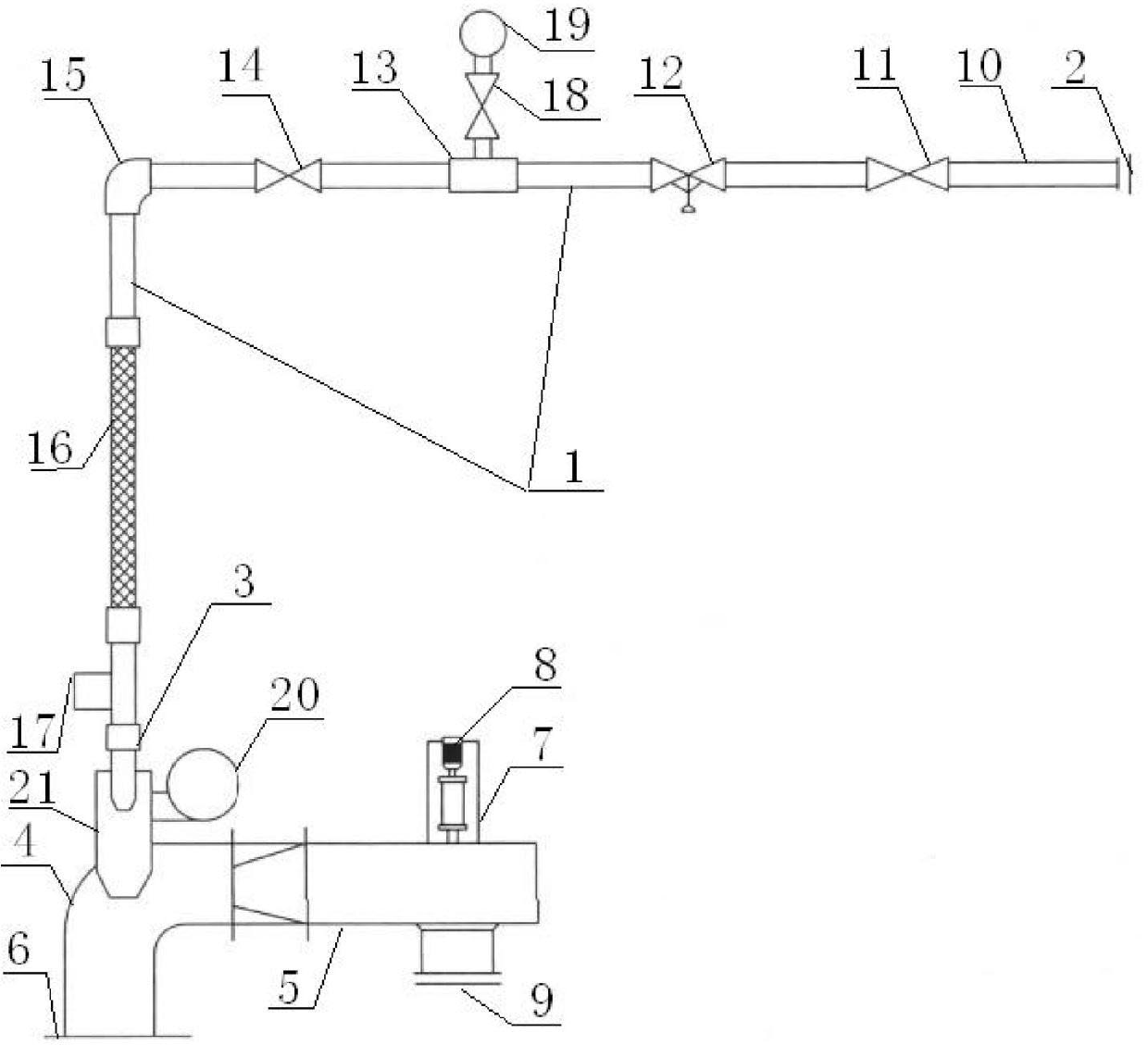

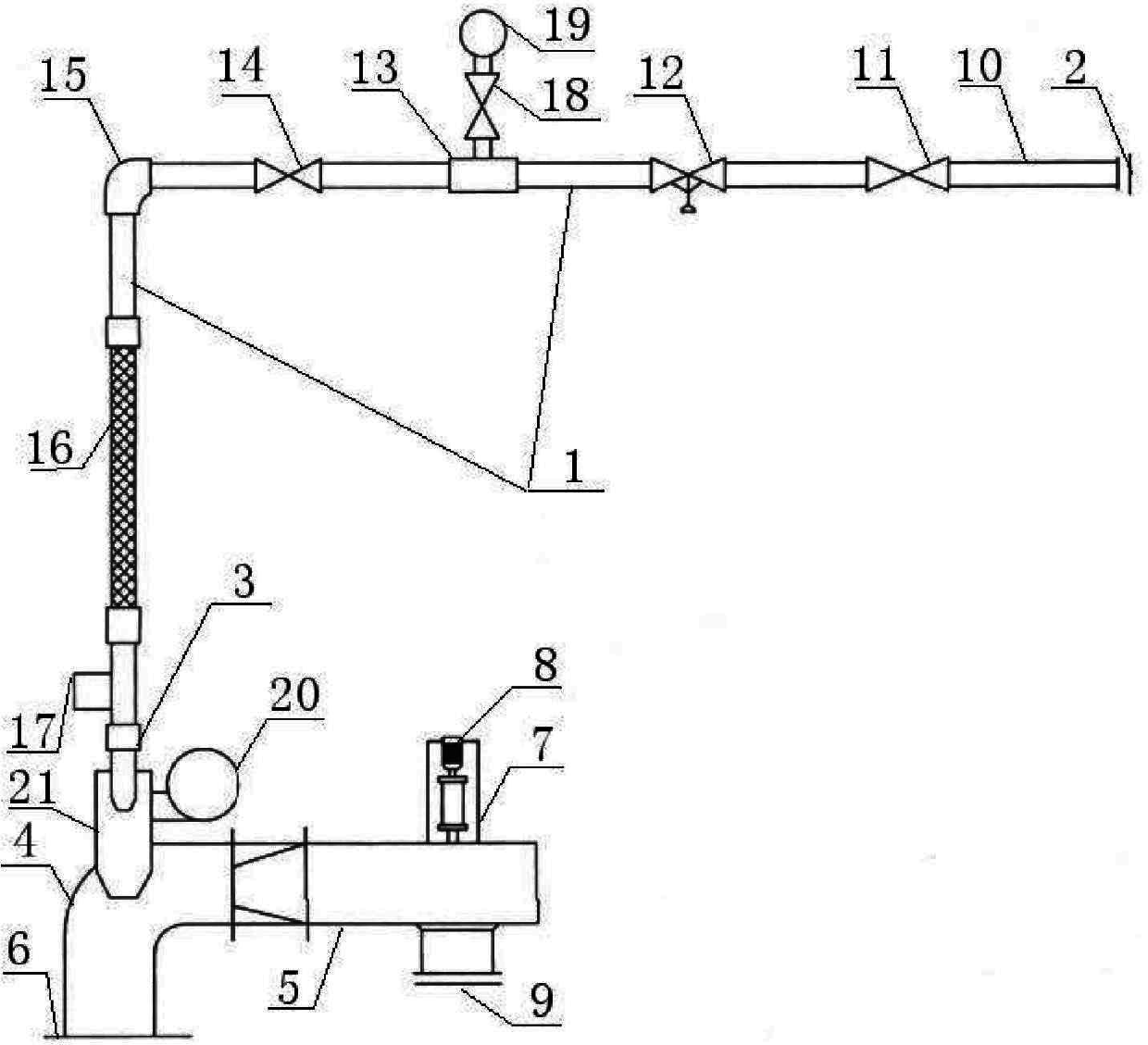

[0014] Such as figure 1 As shown, a new type of combustion heating device described in the present invention belongs to combustion equipment, and it includes a right-angled gas input device 1, one end of which is a gas inlet 2, and the other end is connected with a combustion device 3. The device 3 is connected with the curved air pipe 4, a fan 5 is provided at one end of the curved air pipe 4, and an air outlet 6 is provided at the other end, a bearing box 7 and a motor 8 are provided on one side of the fan 5, and an inlet is provided on the other side. Tuyere 9; described rectangular gas input device 1 comprises gas pipeline 10, first ball valve 11, pressure regulating valve 12, tee 13, the 3rd ball valve 14, elbow 15, hose 16 and electromagnetic valve 17, between them Sequentially connected, a second ball valve 18 and a pressure gauge 19 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com