Method for in-situ preparation of 100-surface diamond through microwave plasma-magnetron sputtering composite vapor deposition and equipment thereof

A magnetron sputtering composite and microwave plasma technology, applied in sputtering plating, ion implantation plating, chemical instruments and methods, etc., can solve the problems of cumbersome dispersion, affecting the preparation speed of diamond films, and long time consumption, and achieve Simplify the preparation process, increase the preparation speed, and enhance the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

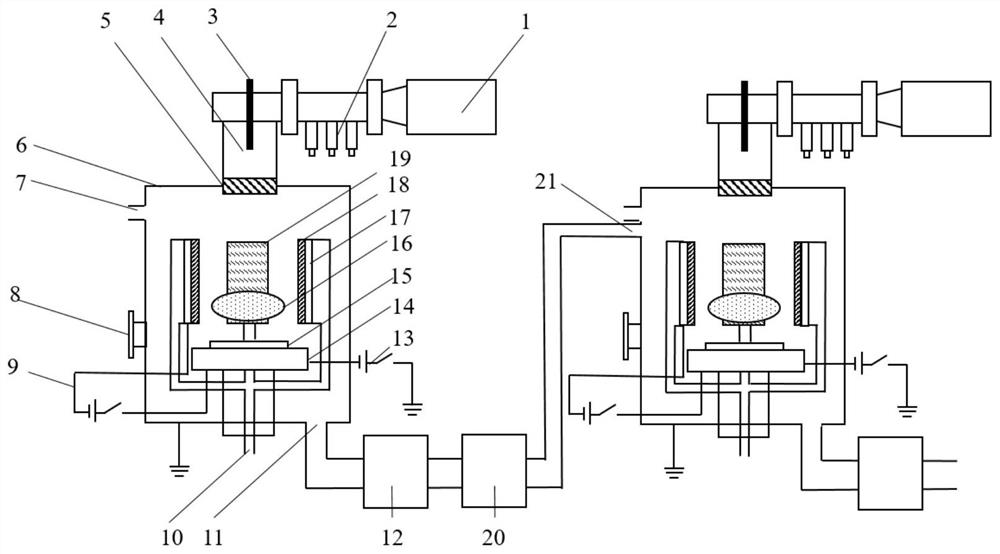

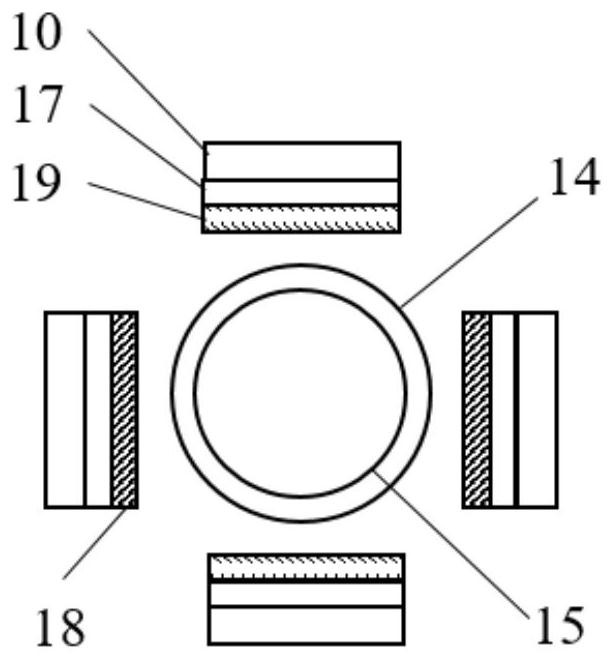

[0035] In order to make the technical means, creative features, work flow, usage method, purpose and effect of the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings.

[0036] The microwave plasma-magnetron sputtering composite vapor deposition method designed by the present invention prepares 100 face diamonds in situ, comprising the following steps:

[0037] S1: Use a ground and polished single crystal silicon or potassium tantalate substrate, and use reactive or inert gas plasma to etch the surface inorganic substances and surface defects on the silicon substrate;

[0038] S2: Use magnetron sputtering to sputter a layer of 2um Ir buffer layer and form SP3 bond of carbon element to promote the growth of diamond film;

[0039] S3: Start diamond 100-face bias enhanced nucleation;

[0040] S4: start heteroepitaxial diamond growth.

[0041] Wherein, the specific process of step S1 is as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com