Patents

Literature

37results about How to "Reasonable air distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950APromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

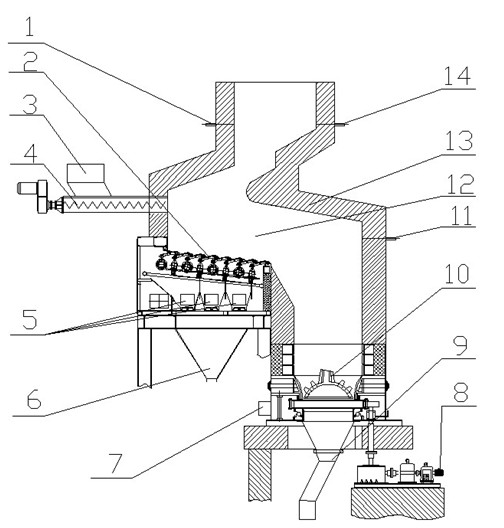

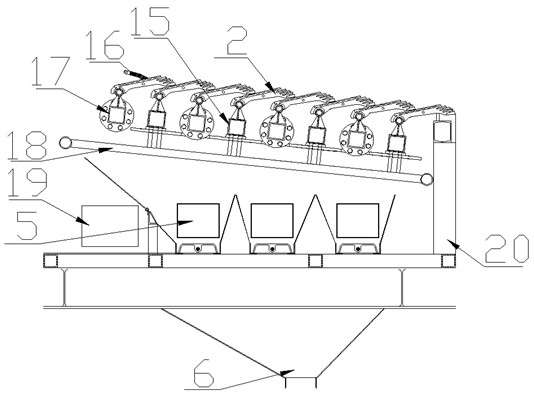

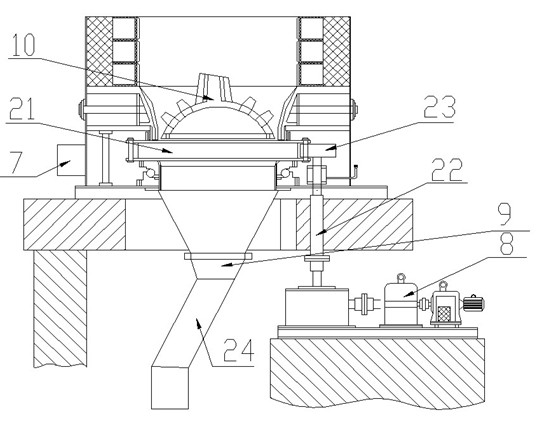

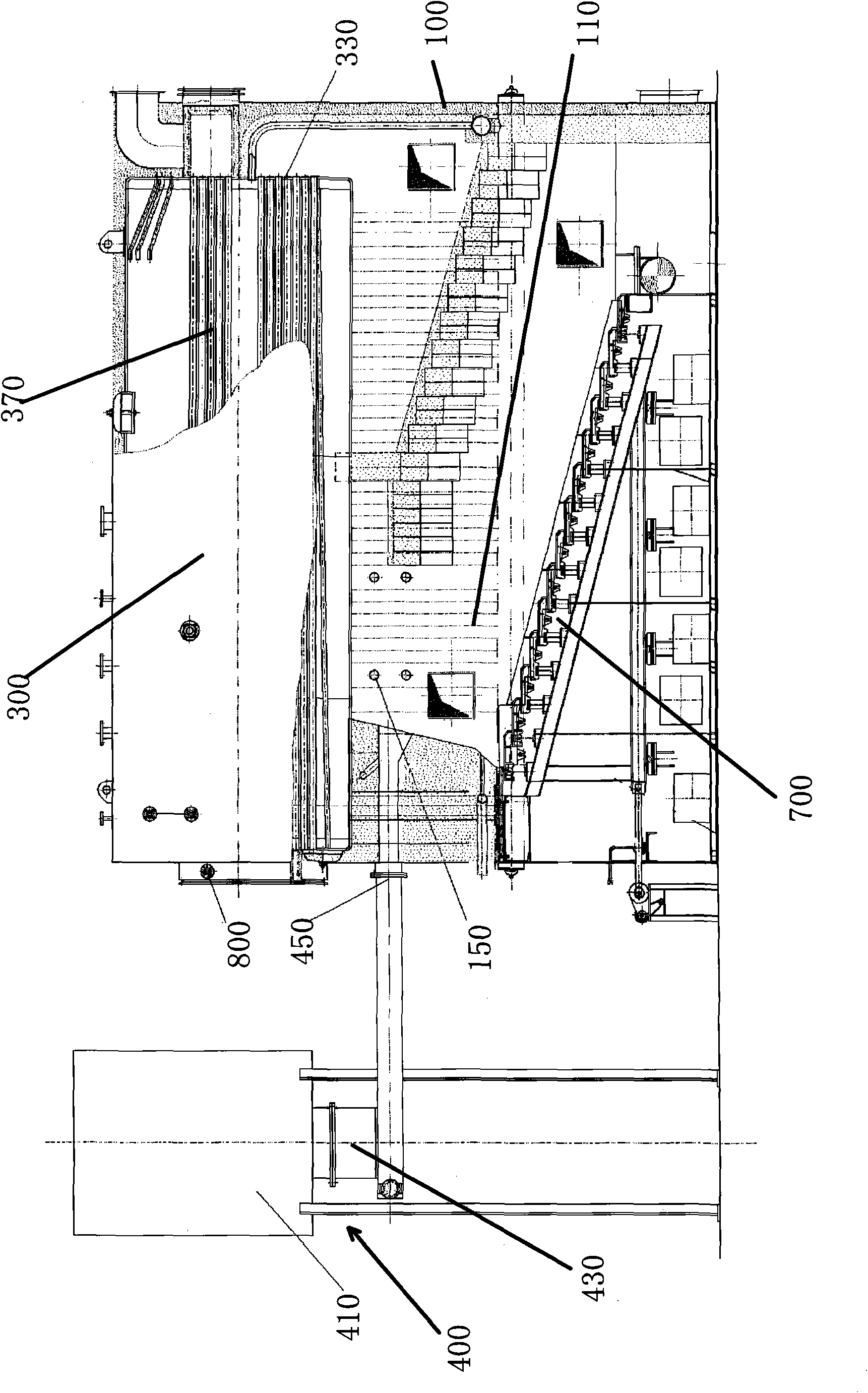

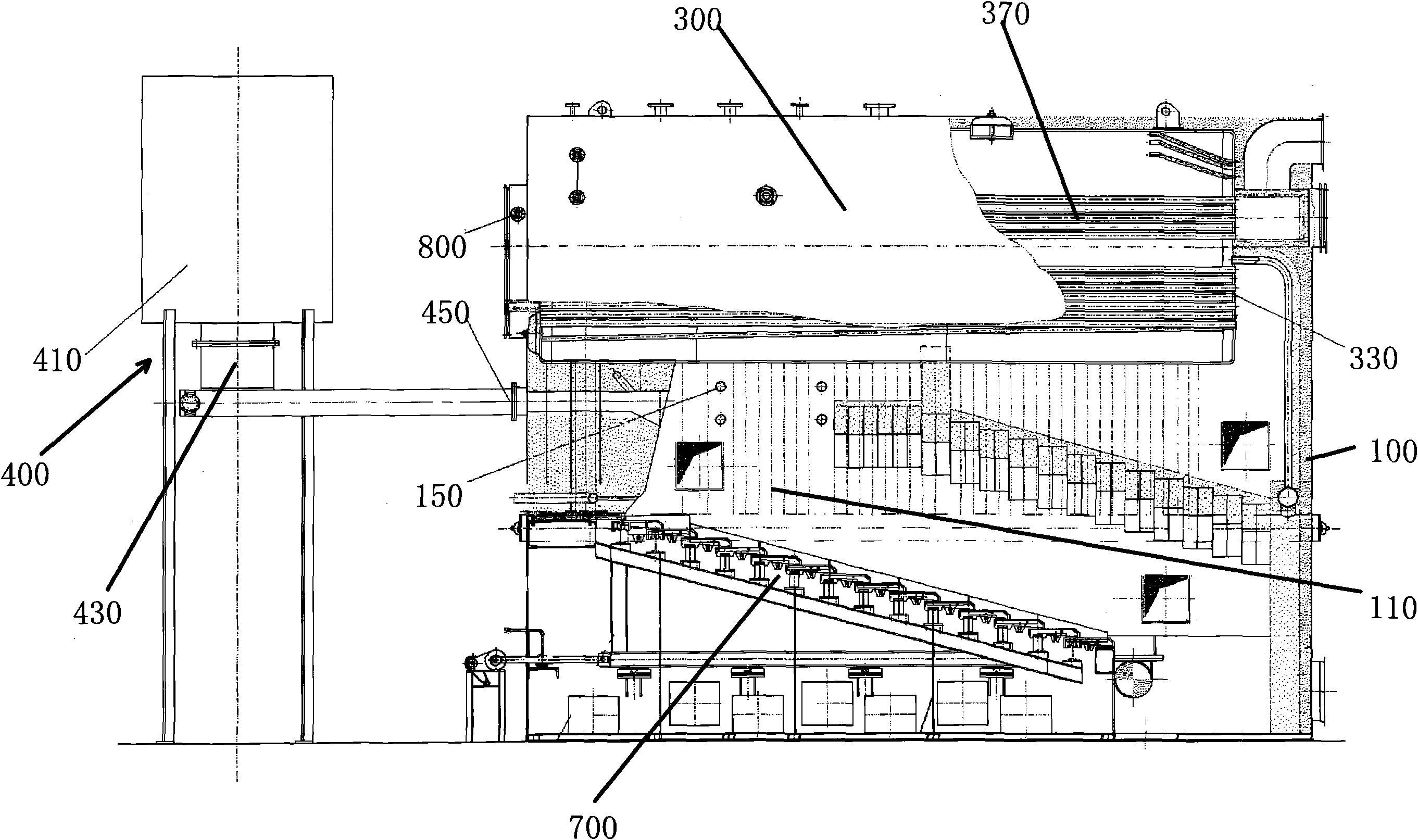

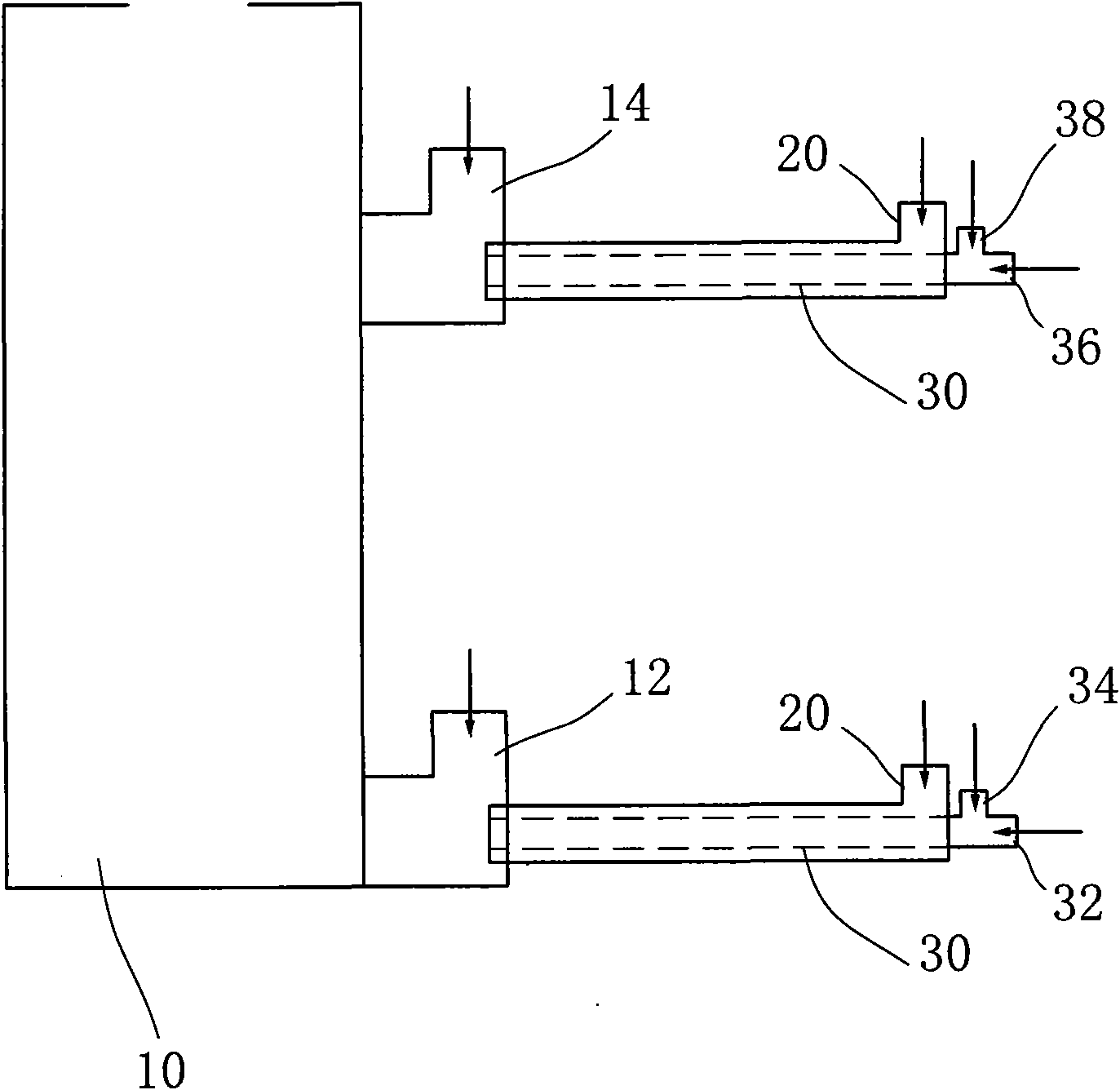

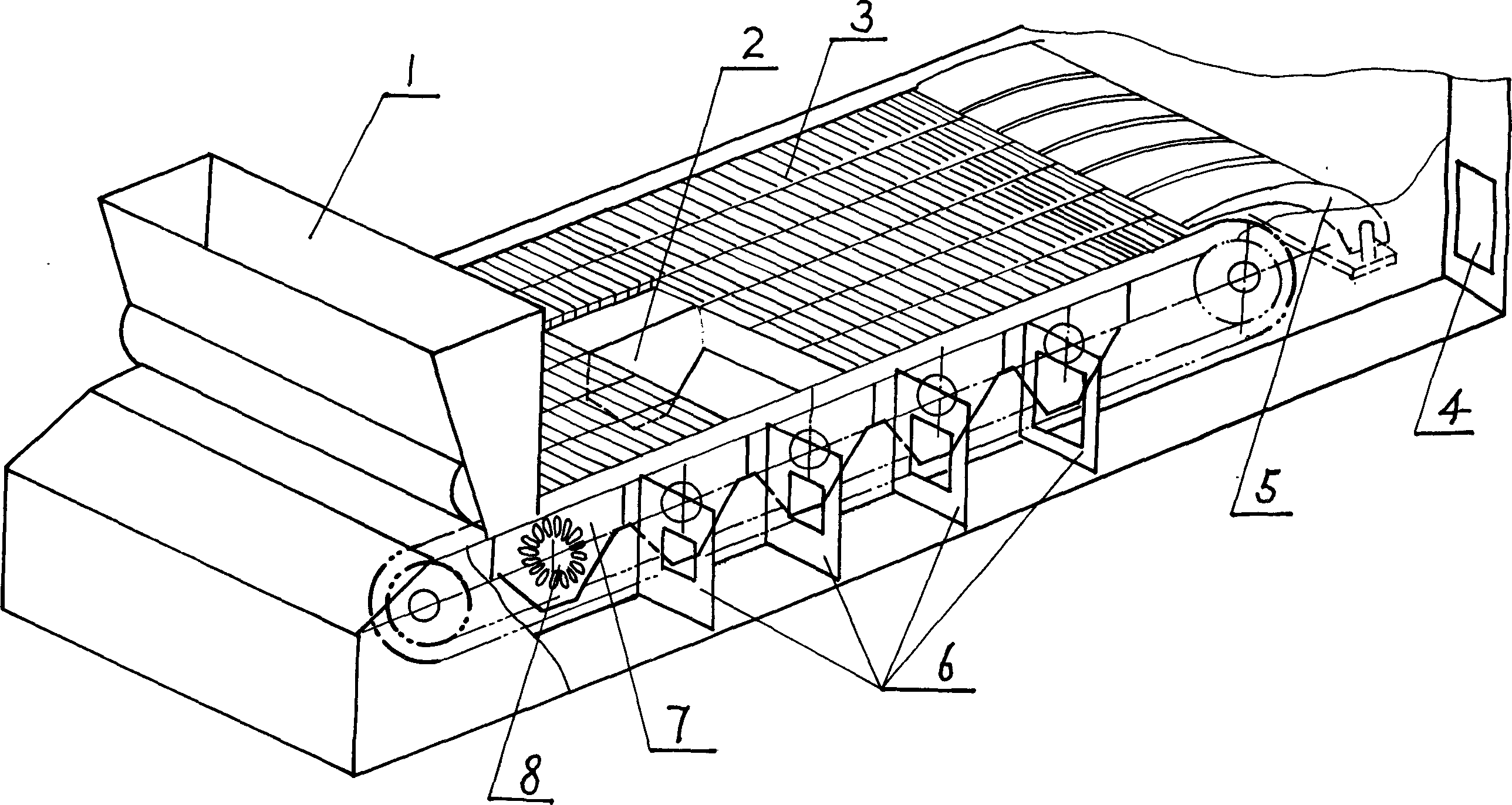

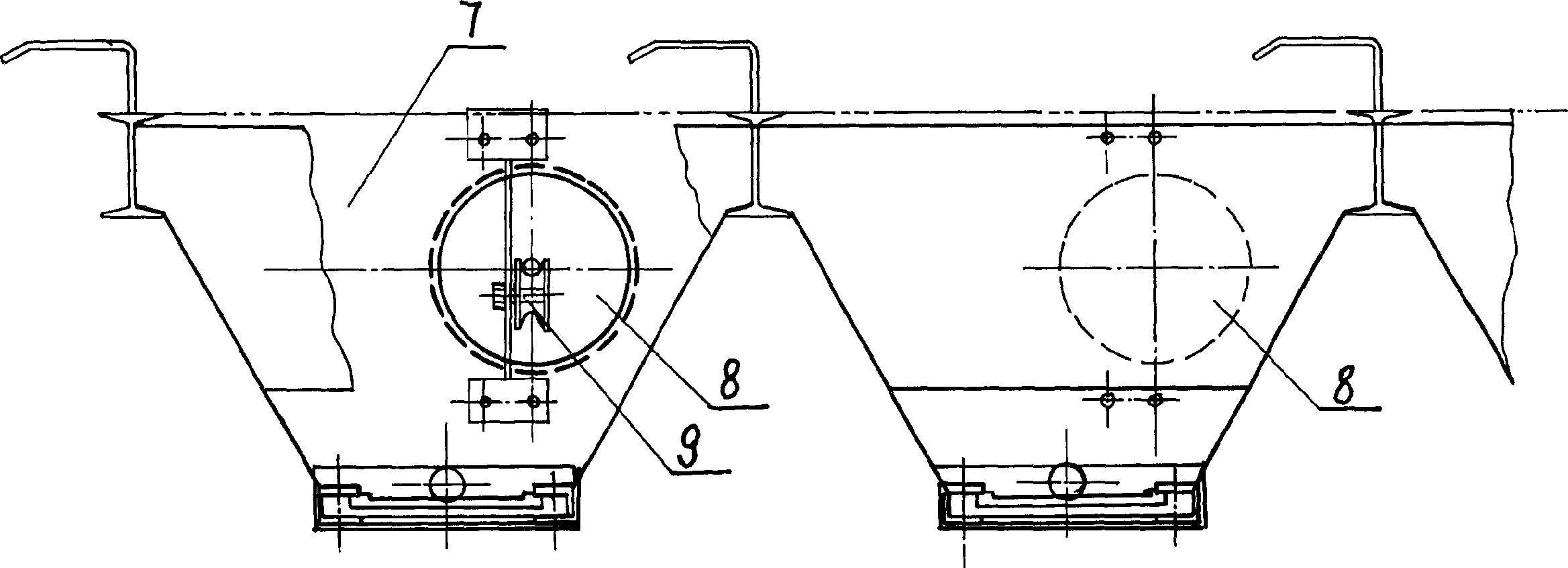

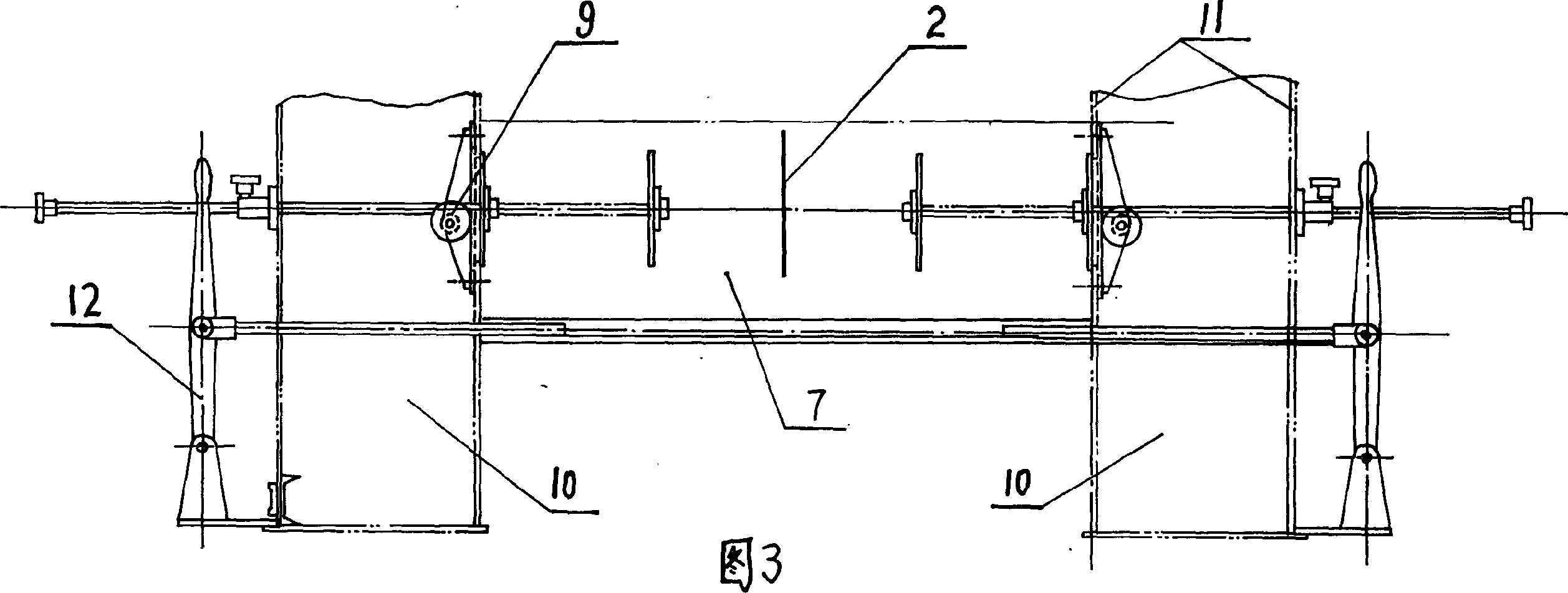

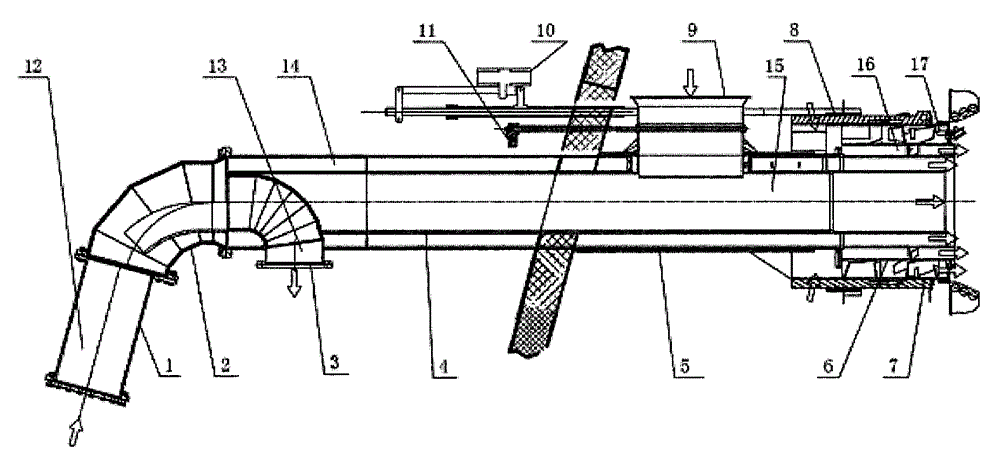

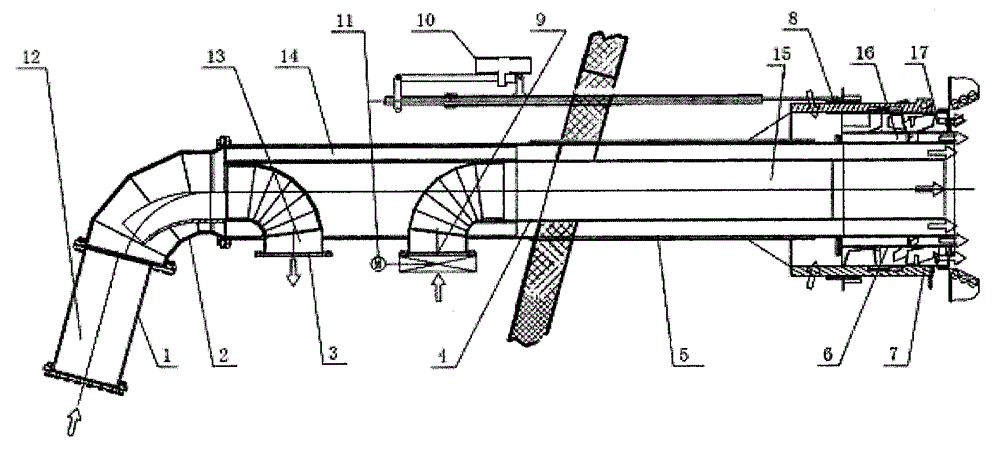

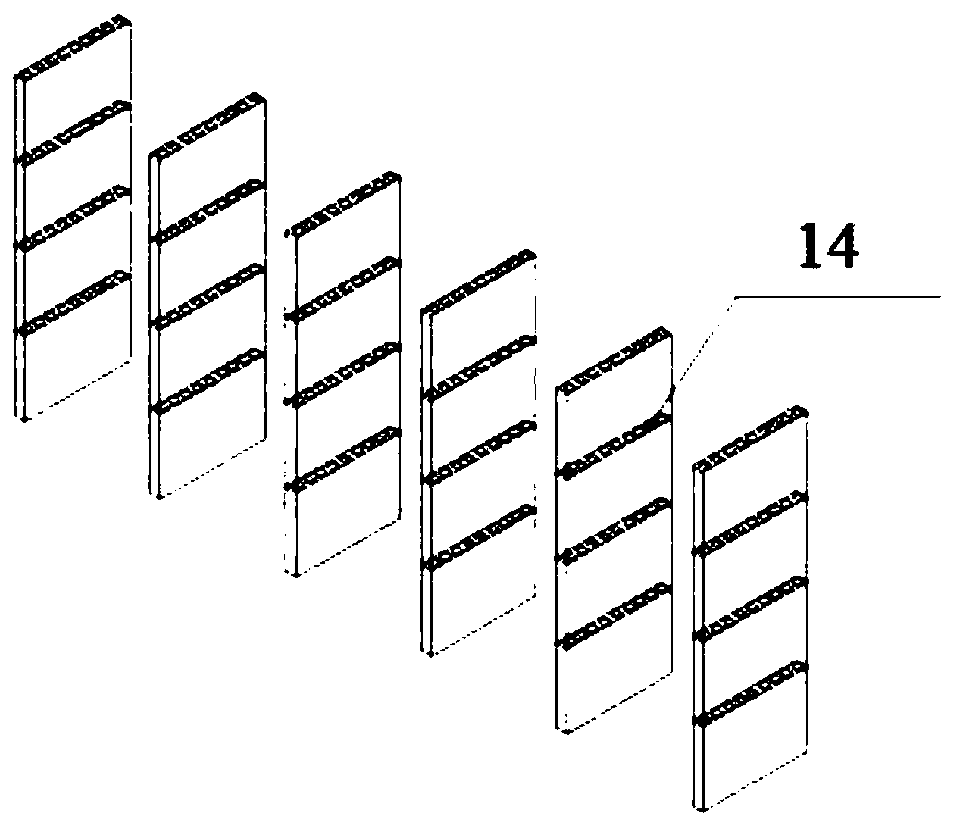

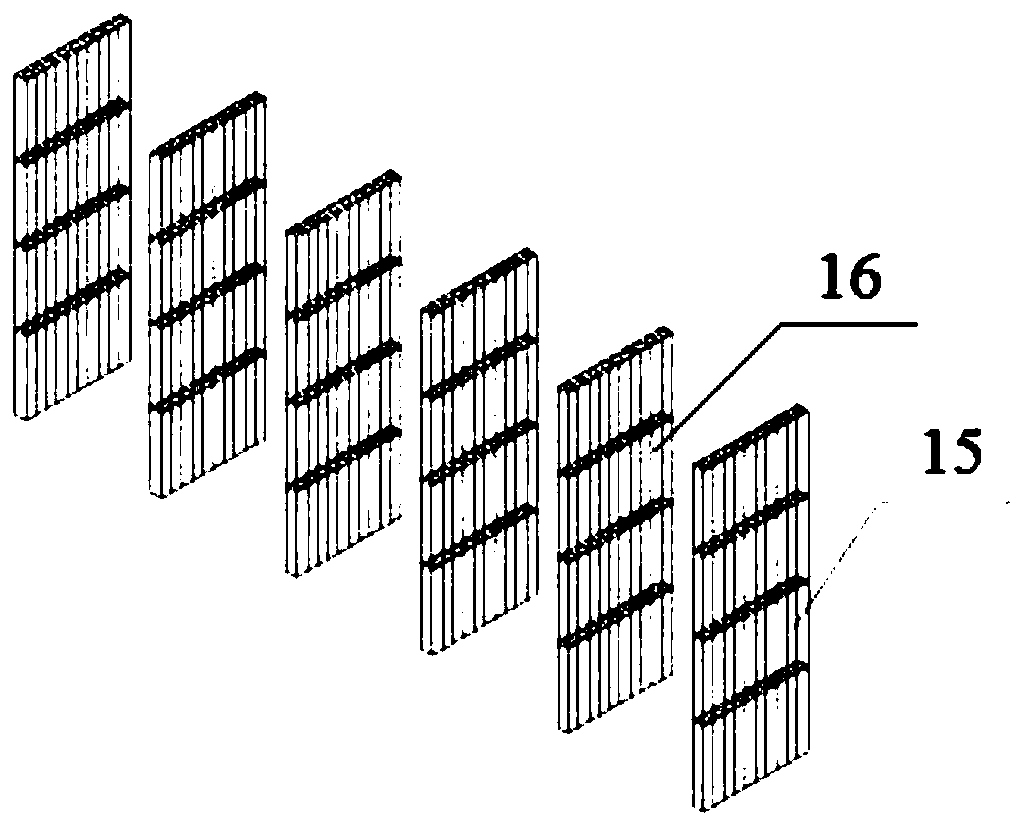

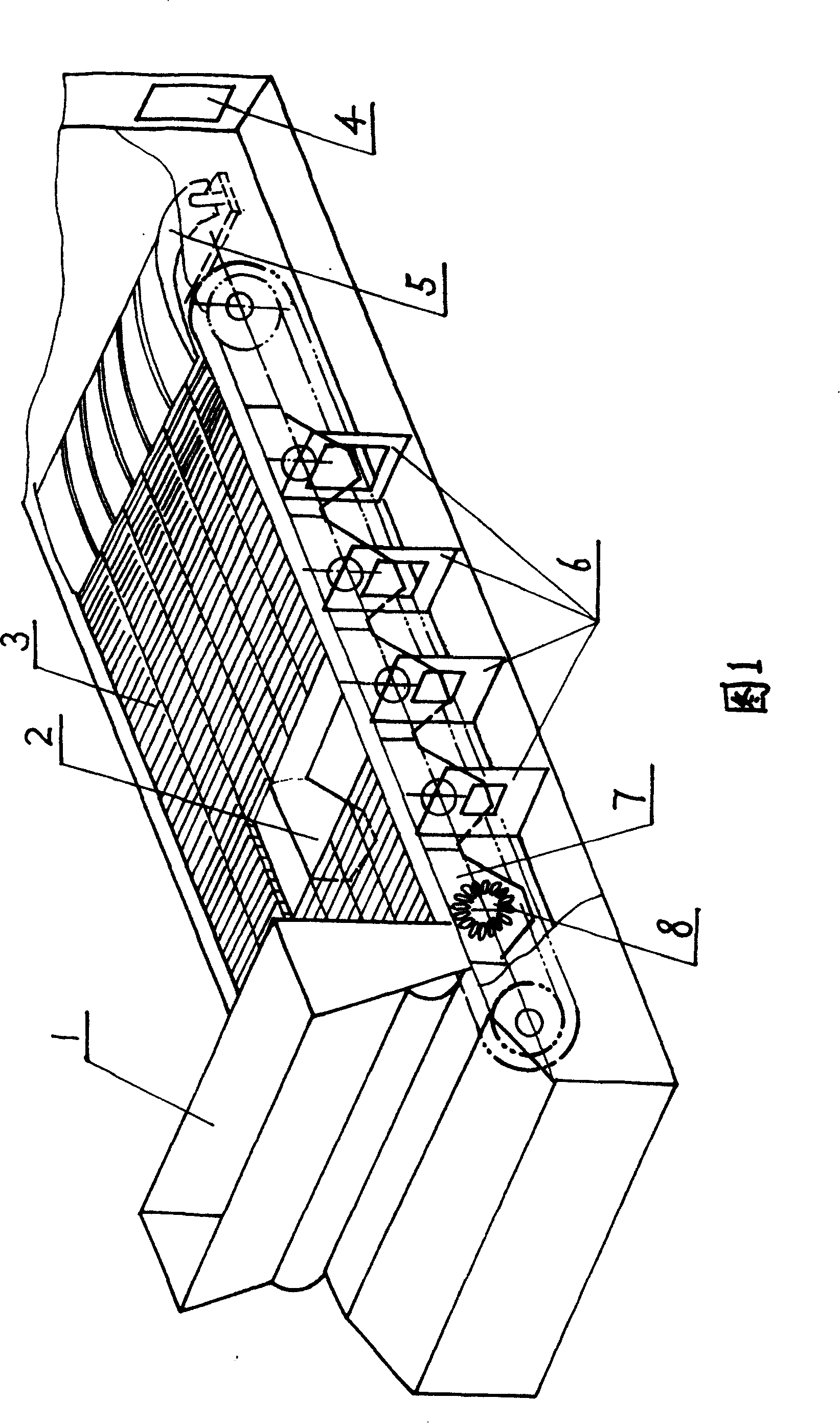

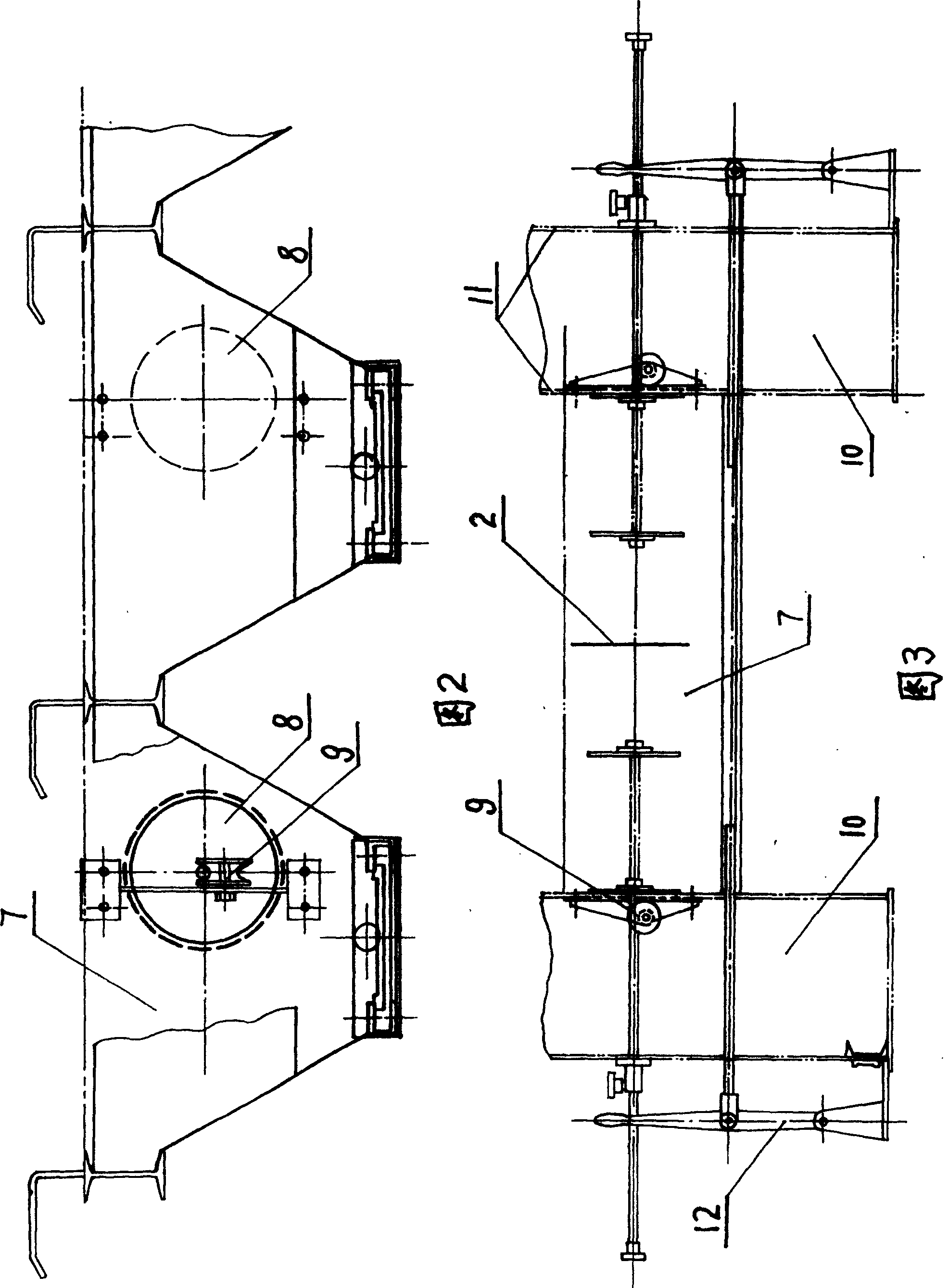

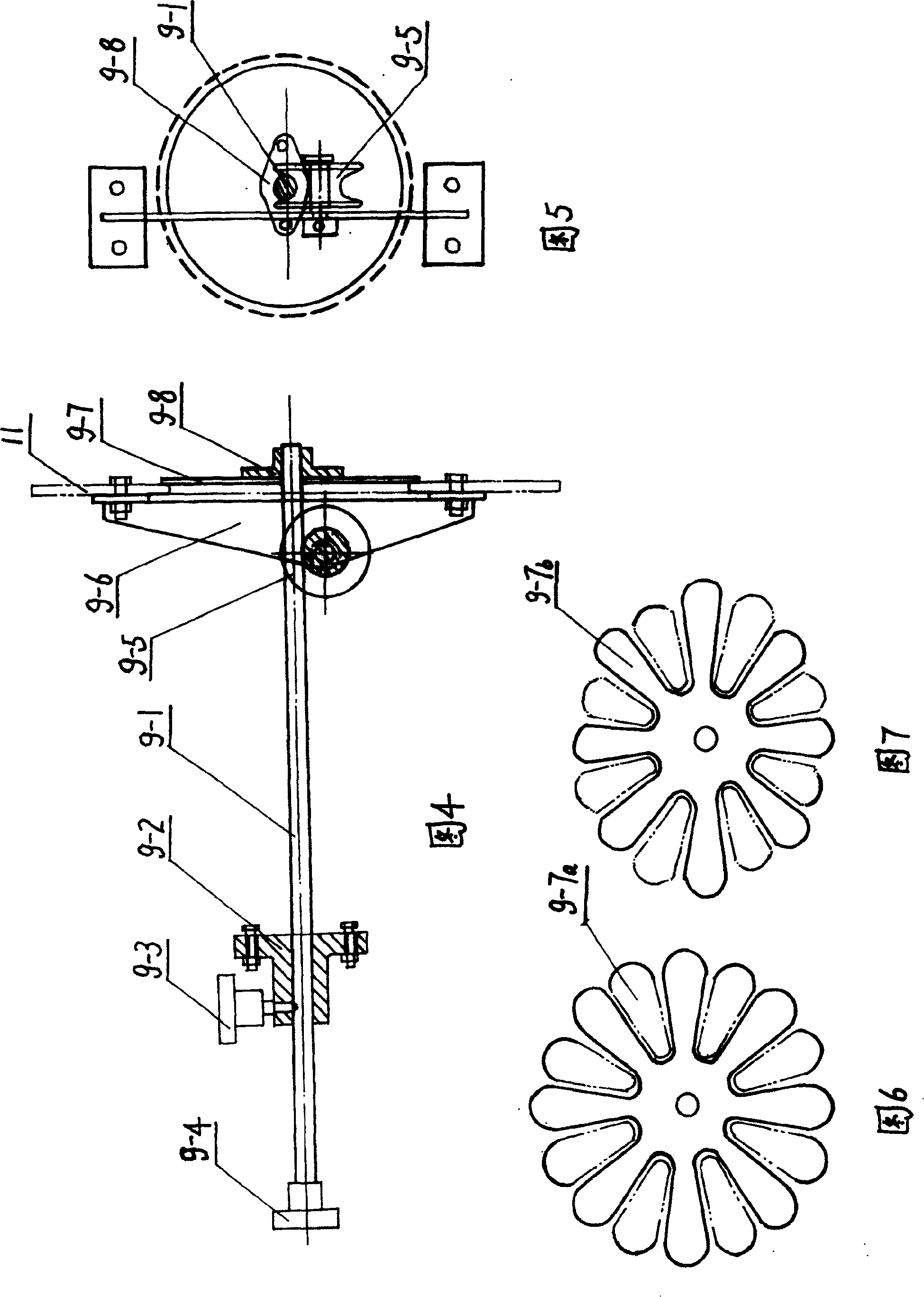

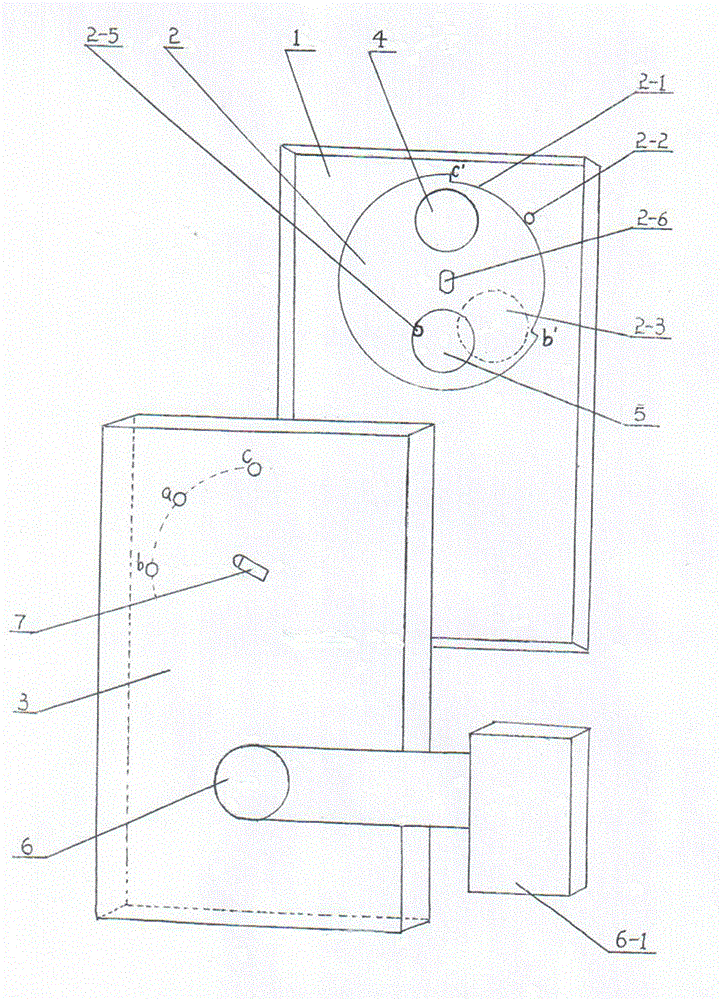

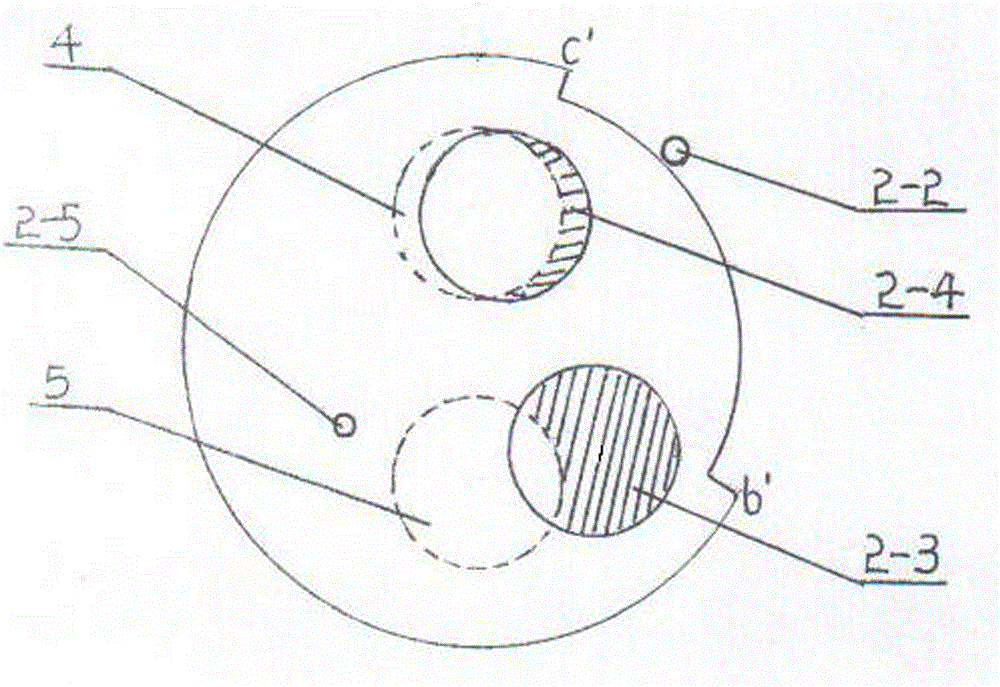

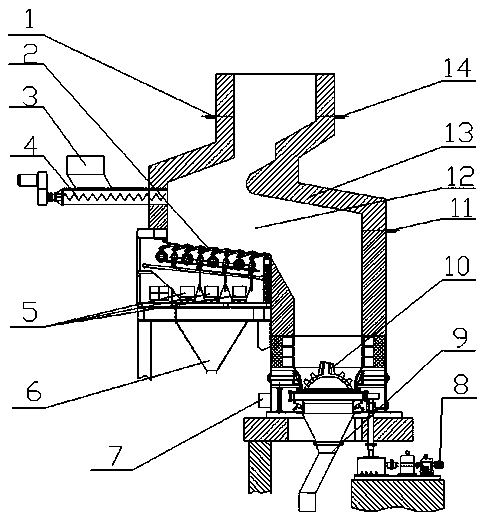

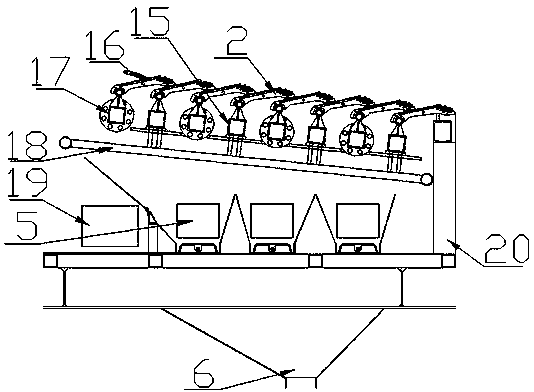

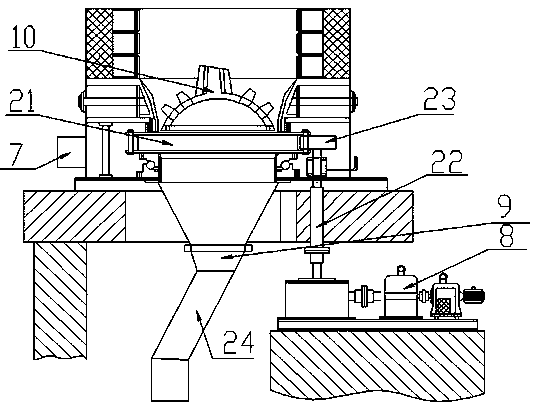

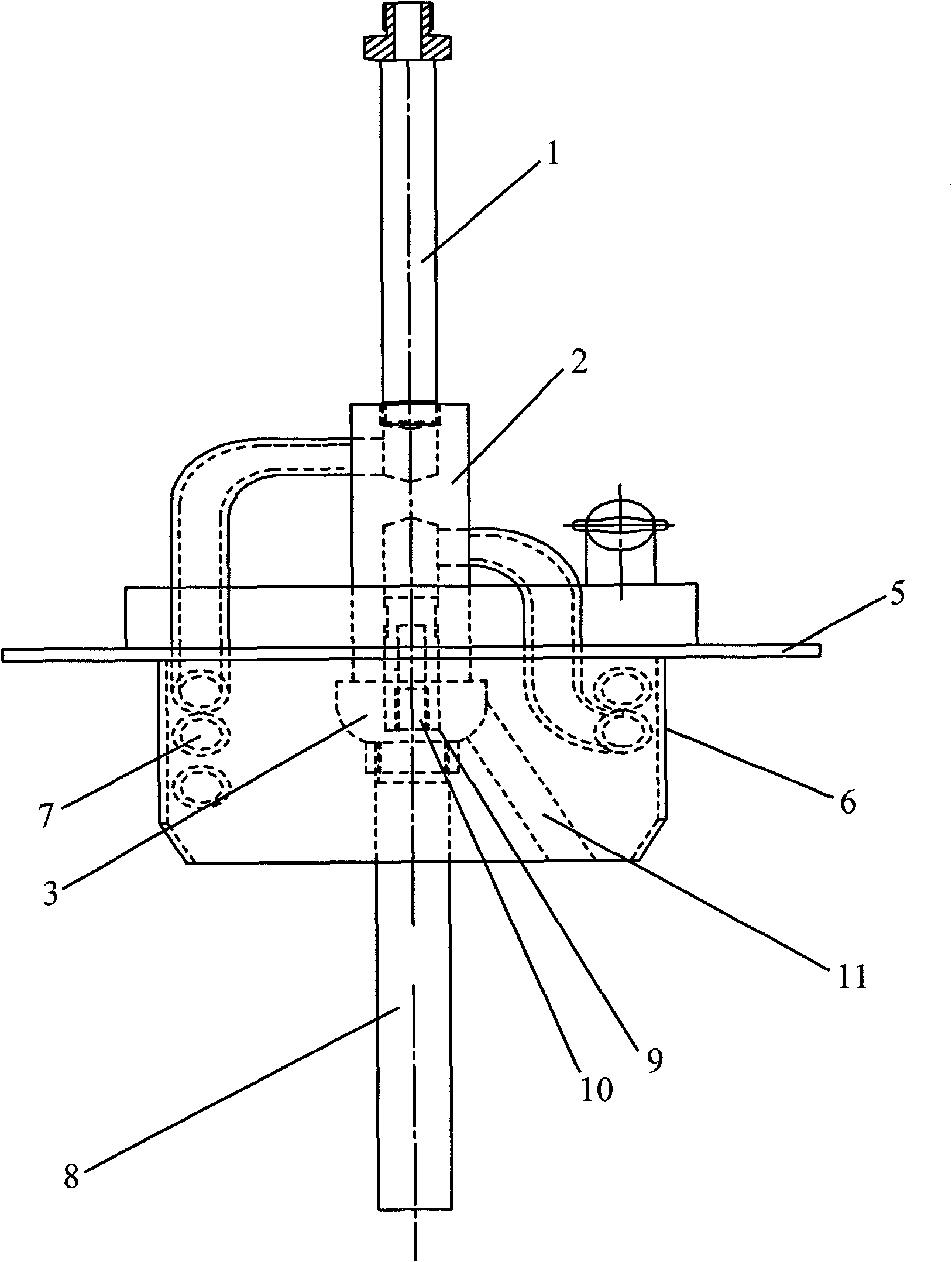

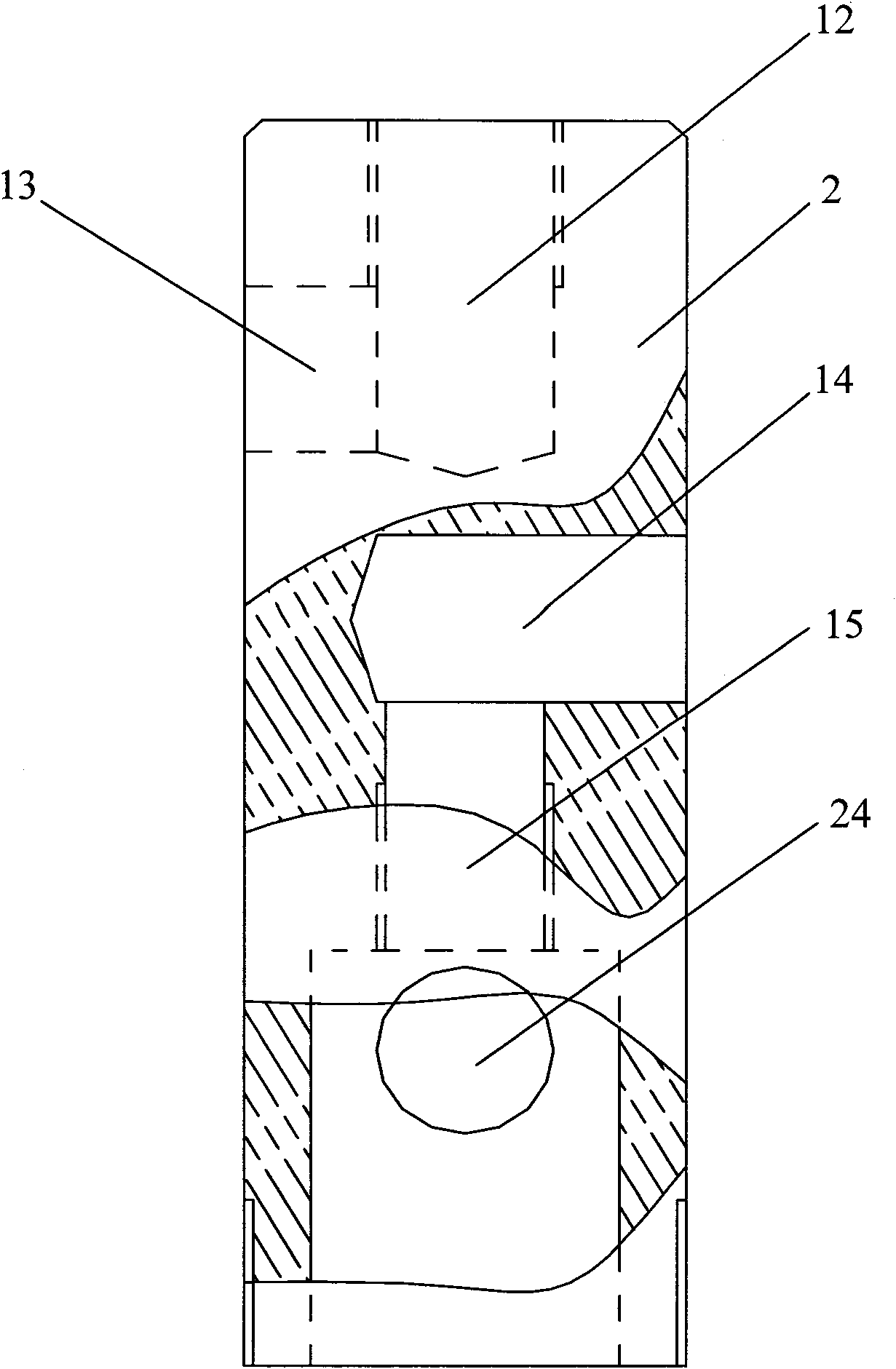

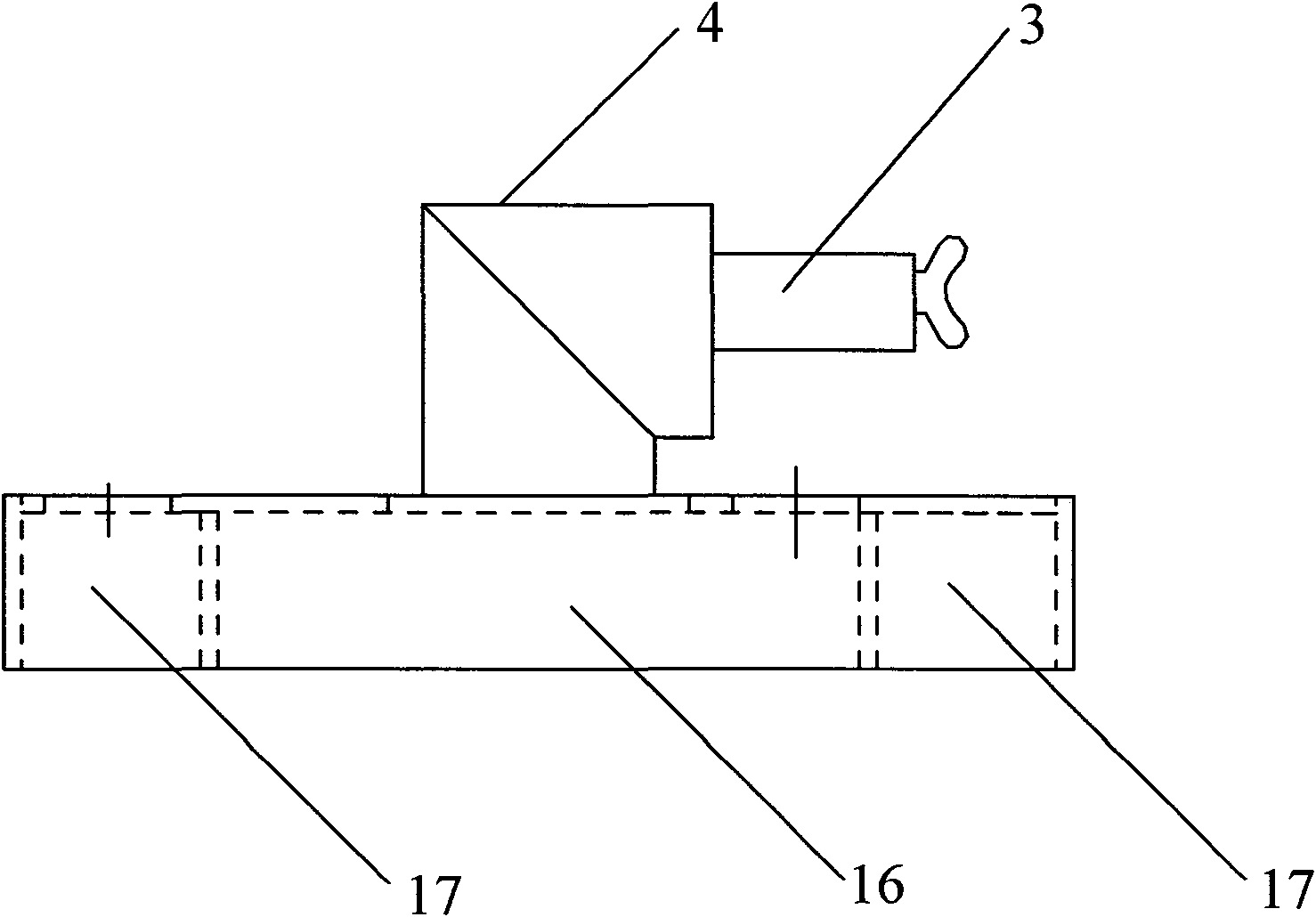

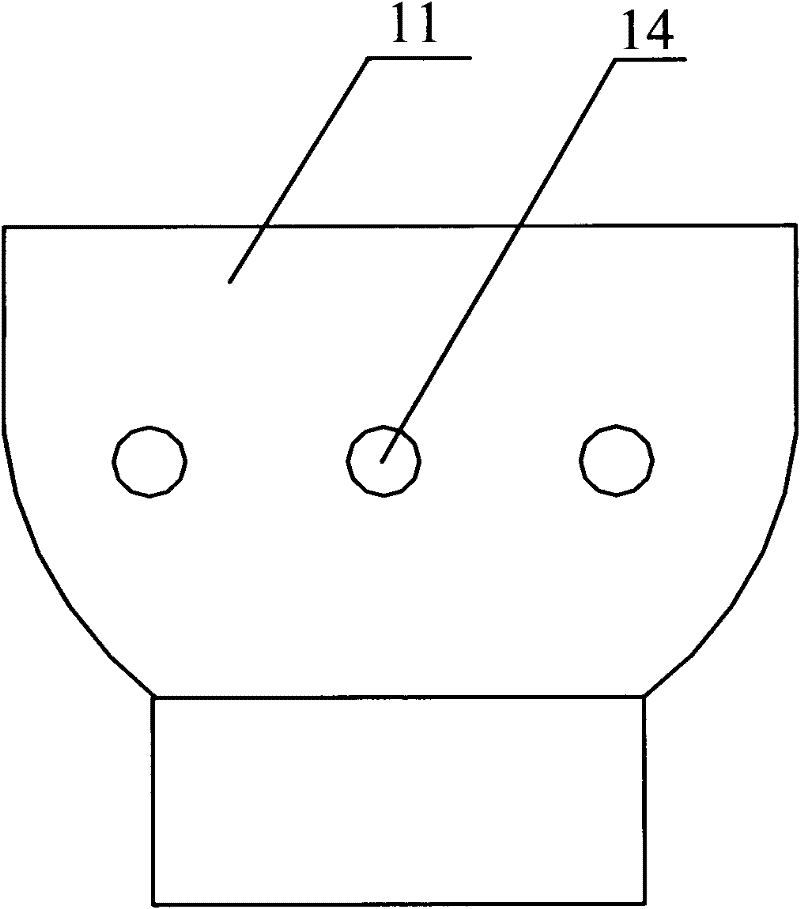

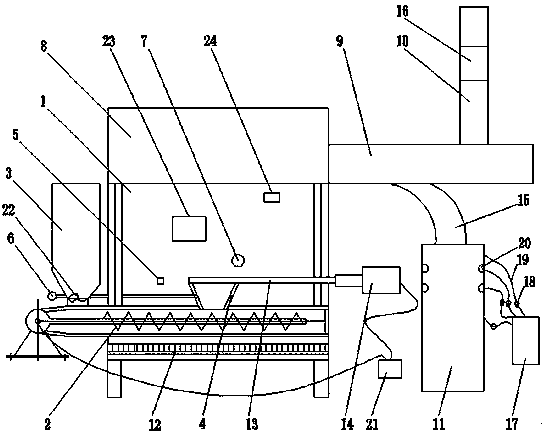

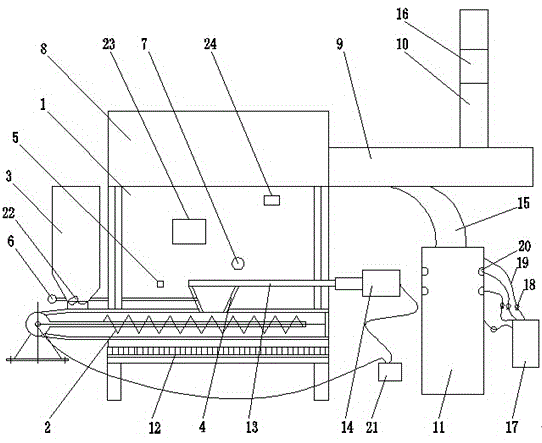

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

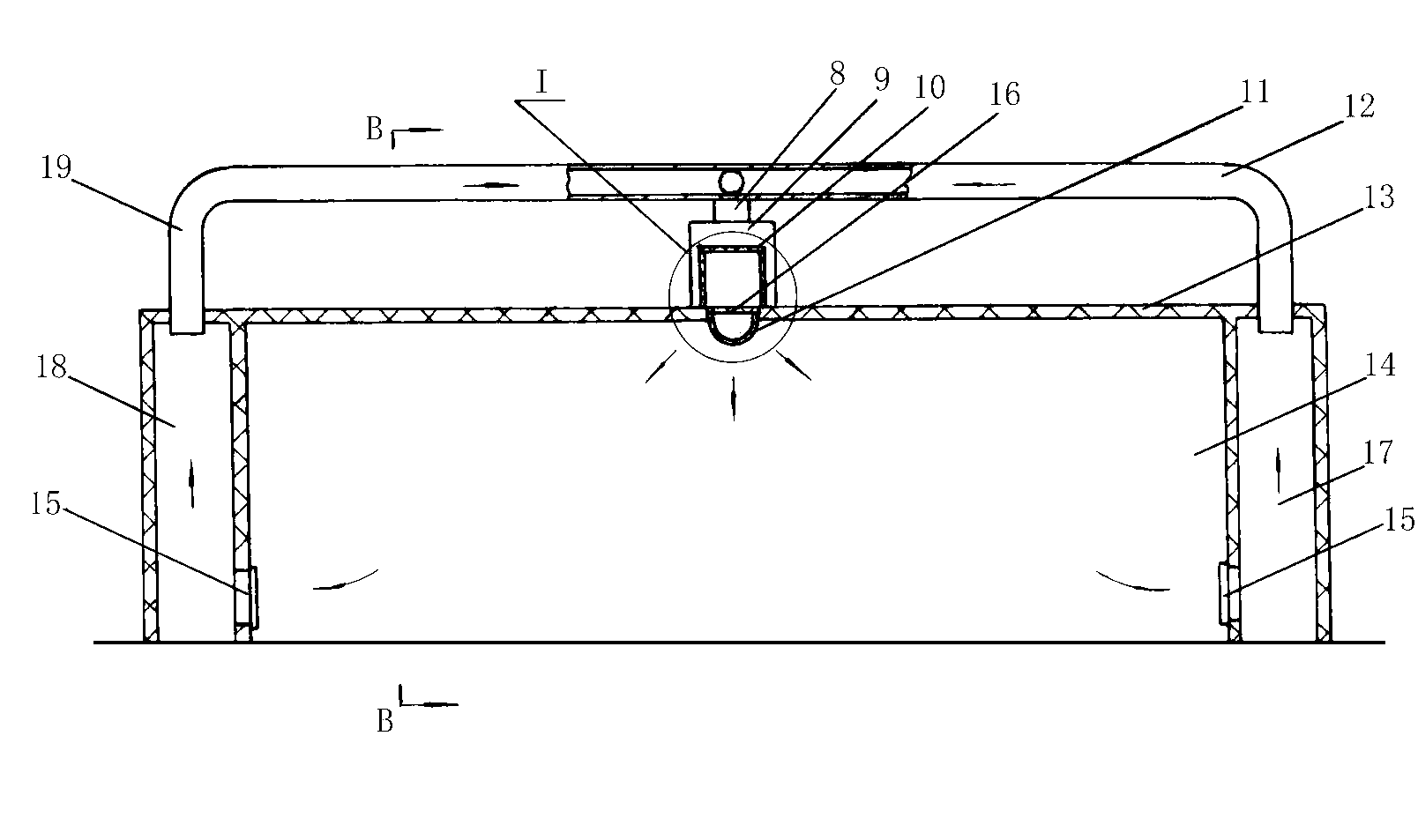

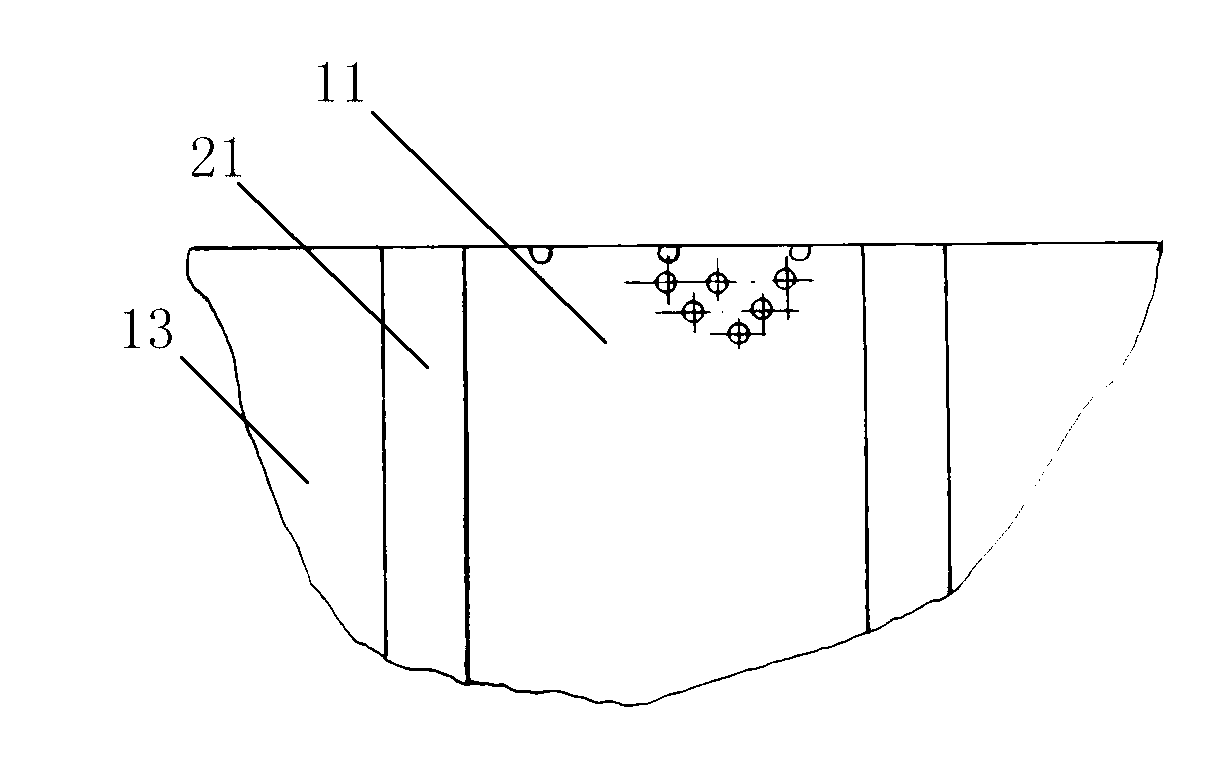

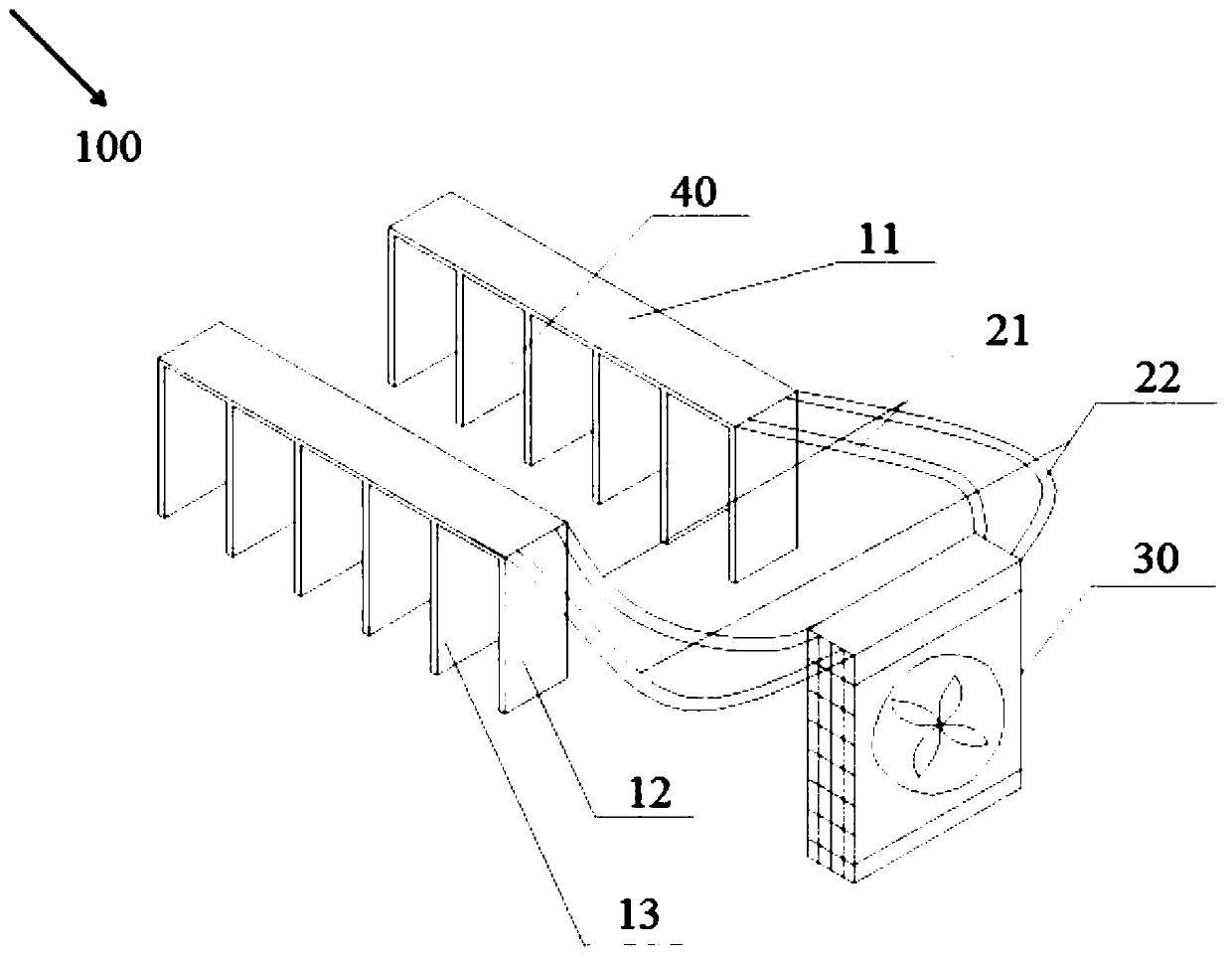

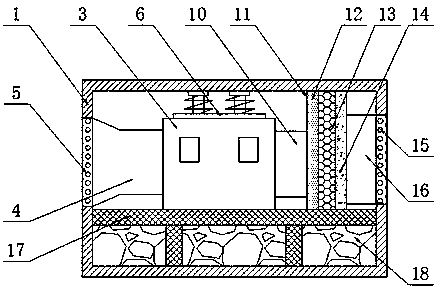

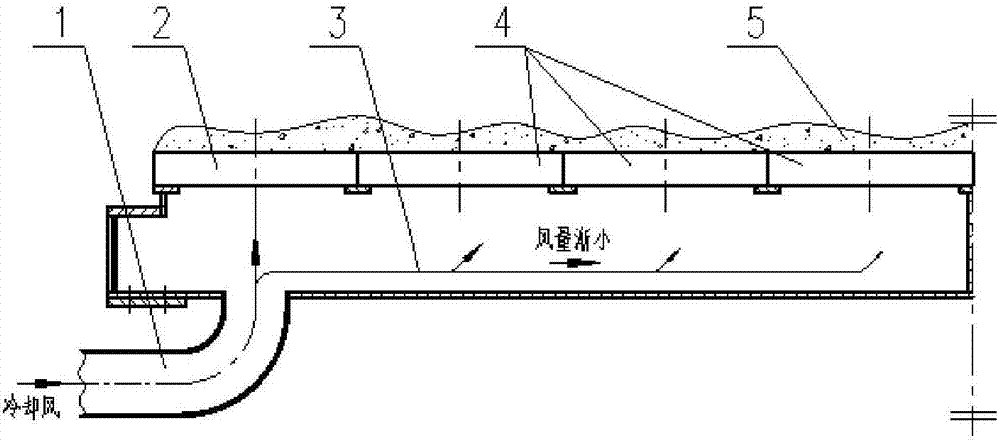

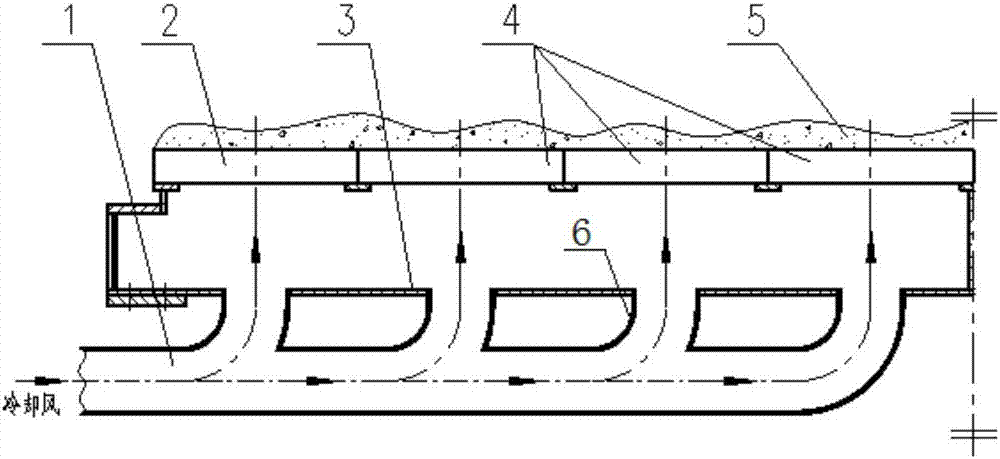

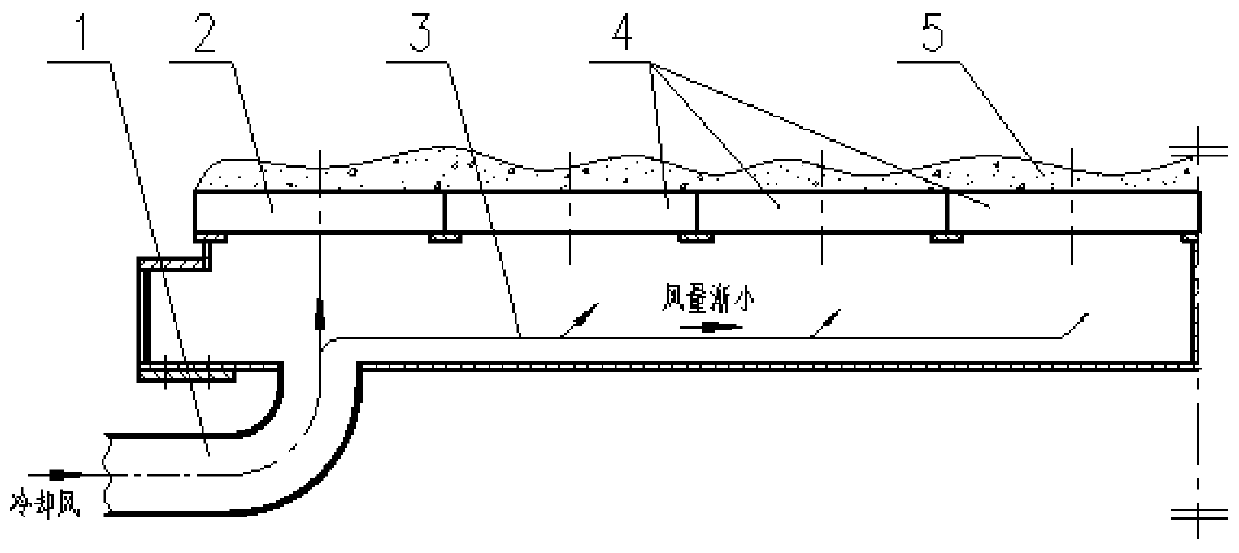

Low steady-speed radial flow clean room air-conditioning air supply and return system

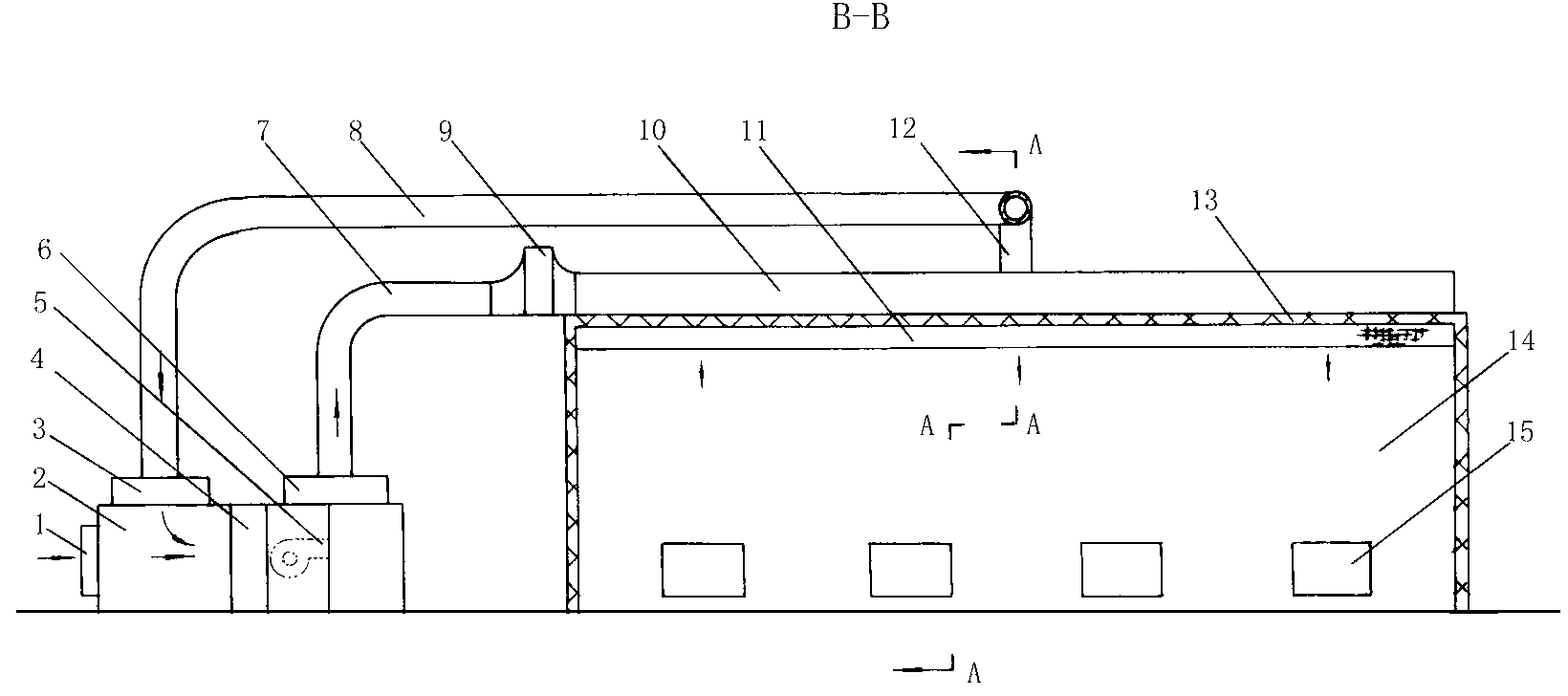

ActiveCN103322657ASmall running resistanceSlow down the spreadDucting arrangementsLighting and heating apparatusSuspended particlesFresh air

The invention relates to a low steady-speed radial flow clean room air-conditioning air supply and return system which comprises a radial flow air supply channel device, a wall-mounted air return channel device, an air-conditioning outlet static pressure box, an air-conditioning air return port static pressure box and an air-conditioning fresh air port filtering device, the radial flow air supply channel device comprises a clean room roof, a static pressure box type air supply channel, a pressure equalizing partition plate, an arc-shaped radial flow cover, a damping layer and a high efficiency filter bank, and the wall-mounted air return channel device comprises a sandwich wall type air return duct and a filtering device mounted at an air return port of the lower end of the sandwich wall type air return duct. The air supply and return system has the advantages that the operation resistance of the air supply and return system is reduced, the diffusion speed of harmful suspended particles in a clean room is the lowest, fewer high efficiency filter banks are used, the clean room is low in construction investment, energy-saving in operation and convenient to maintain, the air cleanliness class of the clean room is improved by more than 30% as compared with that of a mixed airflow clean room, clean time can be shortened by more than 40%, and airflow in the clean room is reasonably distributed.

Owner:SHIJIAZHUANG AOXIANG MEDICAL ENG

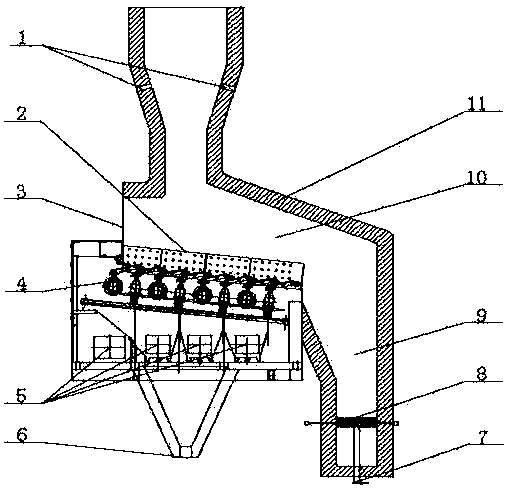

Composite type solid-waste gasifying device

InactiveCN103468321AImprove fluidizationRapid fluidizationGranular/pulverulent flues gasificationSlagEngineering

The invention discloses a composite type solid-waste gasifying device. The composite type solid-waste gasifying device is characterized in that a reciprocating grate and a bubbling fluidized-bed reactor structure are combined, waste is firstly dried, pyrolyzed and gasified on the front-section reciprocating grate, and the rear-section fluidized bed device is used for pyrolysis of residual waste and suspended combustion of gasified slag. The reciprocating grate adopts a plurality of sections of high-temperature air distribution to dry, pyrolyze and gasify the waste so as to provide partial heat, and a long rear arch maintains high temperature under high-temperature flue gas, and is used for increasing radiant heat on the grate and providing energy for pyrolyzing and gasifying the waste with low calorific value. The high-temperature flue gas generated by combustion of a fluidized bed maintains high-temperature environment of the wall surface of the rear arch of the grate, and the slag is discharged by a slag discharging hole at the middle part of an air distributing plate of the fluidized bed. The composite type solid-waste gasifying device disclosed by the invention has the beneficial effects that the advantages of the traditional grate and the traditional fluidized-bed reactor are integrated; due to the radiation of a long high-temperature rear arch, the content of tar in gasified gas can be effectively reduced; full burning out of bottom slag is realized by the fluidized bed, so that high-efficiency gasification of low-grade waste is realized.

Owner:ZHEJIANG UNIV

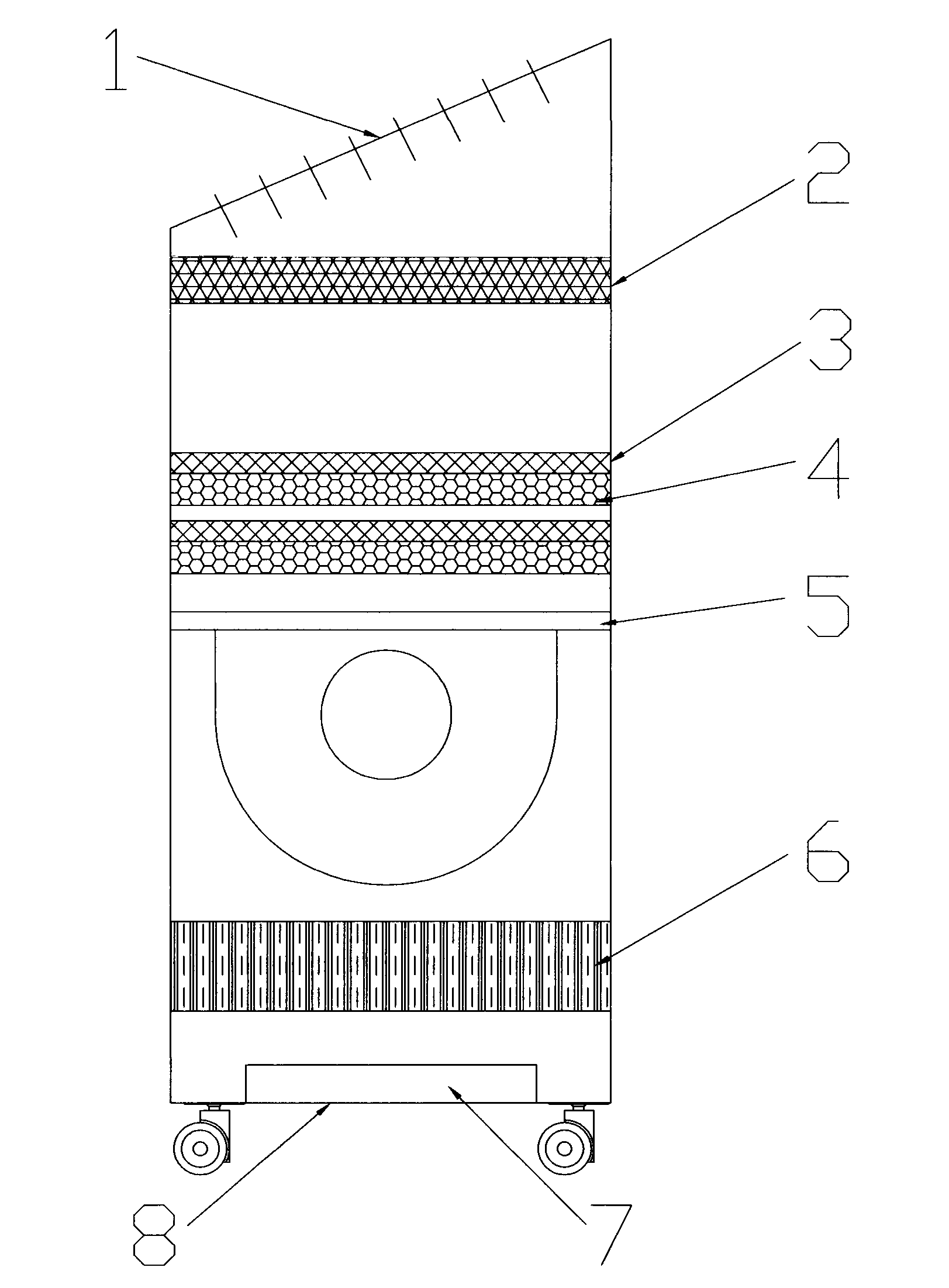

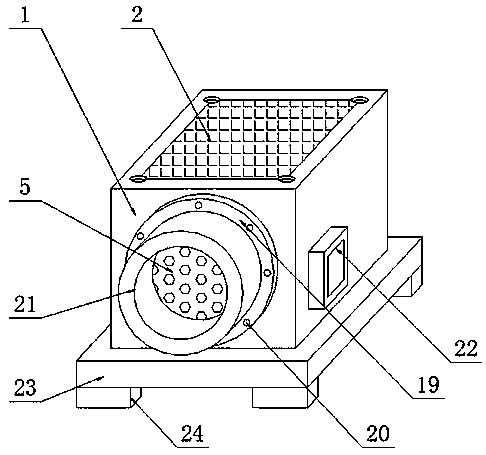

Electric bag integrated air-purifying disinfection machine

InactiveCN103267320AImprove adsorption capacityEfficient removalLighting and heating apparatusDispersed particle separationHEPAParticulates

The invention provides an electric bag integrated air-purifying disinfection machine and relates to the technical field of air-purifying disinfection machines. A bottom air inlet and a pre-filter are arranged at the bottom of an air-purifying disinfection machine body, a narrow-interval tube electrode type static electric field device is arranged above the bottom air inlet and the pre-filter, a fan is arranged above the narrow-interval tube electrode type static electric field device, a honeycomb ozone catalytic decomposition device and an impregnated activated carbon absorbing device are arranged above the fan, the upper portions of the honeycomb ozone catalytic decomposition device and the impregnated activated carbon absorbing device are provided with plastic fiber propene polymer (PP) low-resistance high efficiency particulate air (HEPA) filter devices, and an oblique upper air outlet is arranged at the top of the air-purifying disinfection machine body. An electrostatic adsorption device, the impregnated activated carbon absorbing device and an efficient filter device are reasonably combined together, and the electric bag integrated air-purifying disinfection machine is free of ozone and low in noise and greatly improves the air-purifying disinfection efficiency.

Owner:山东尼尔逊科技有限公司

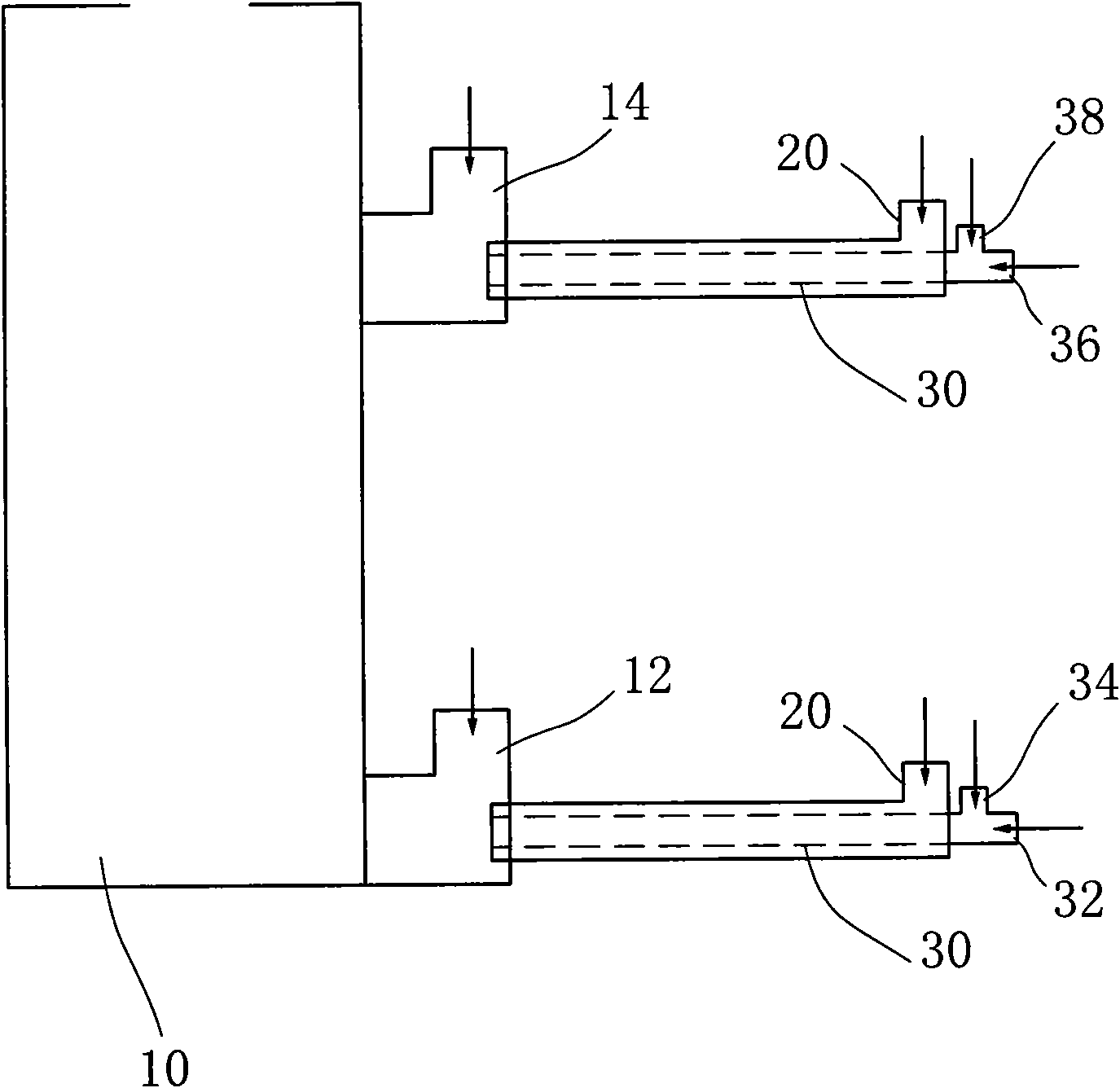

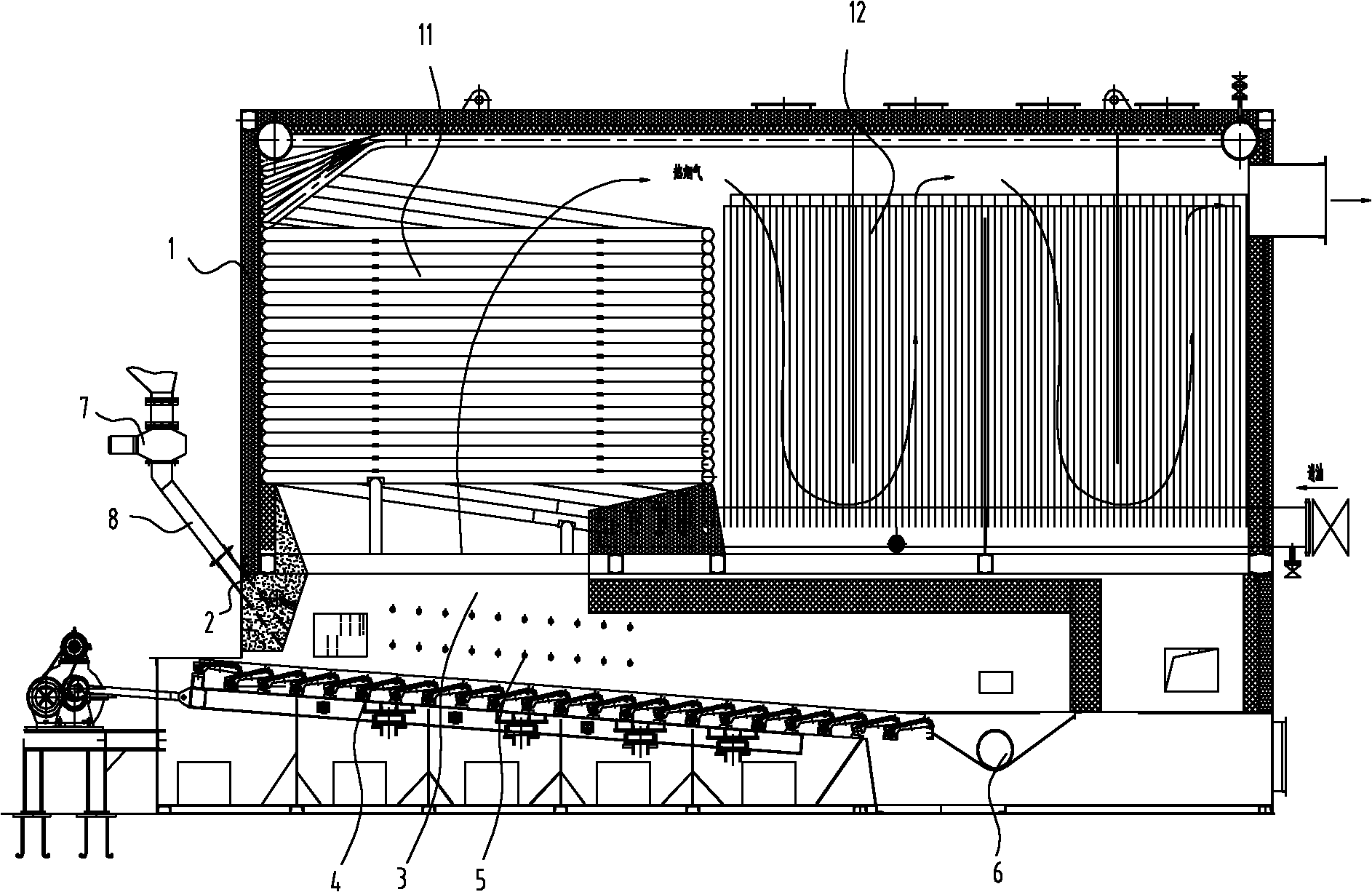

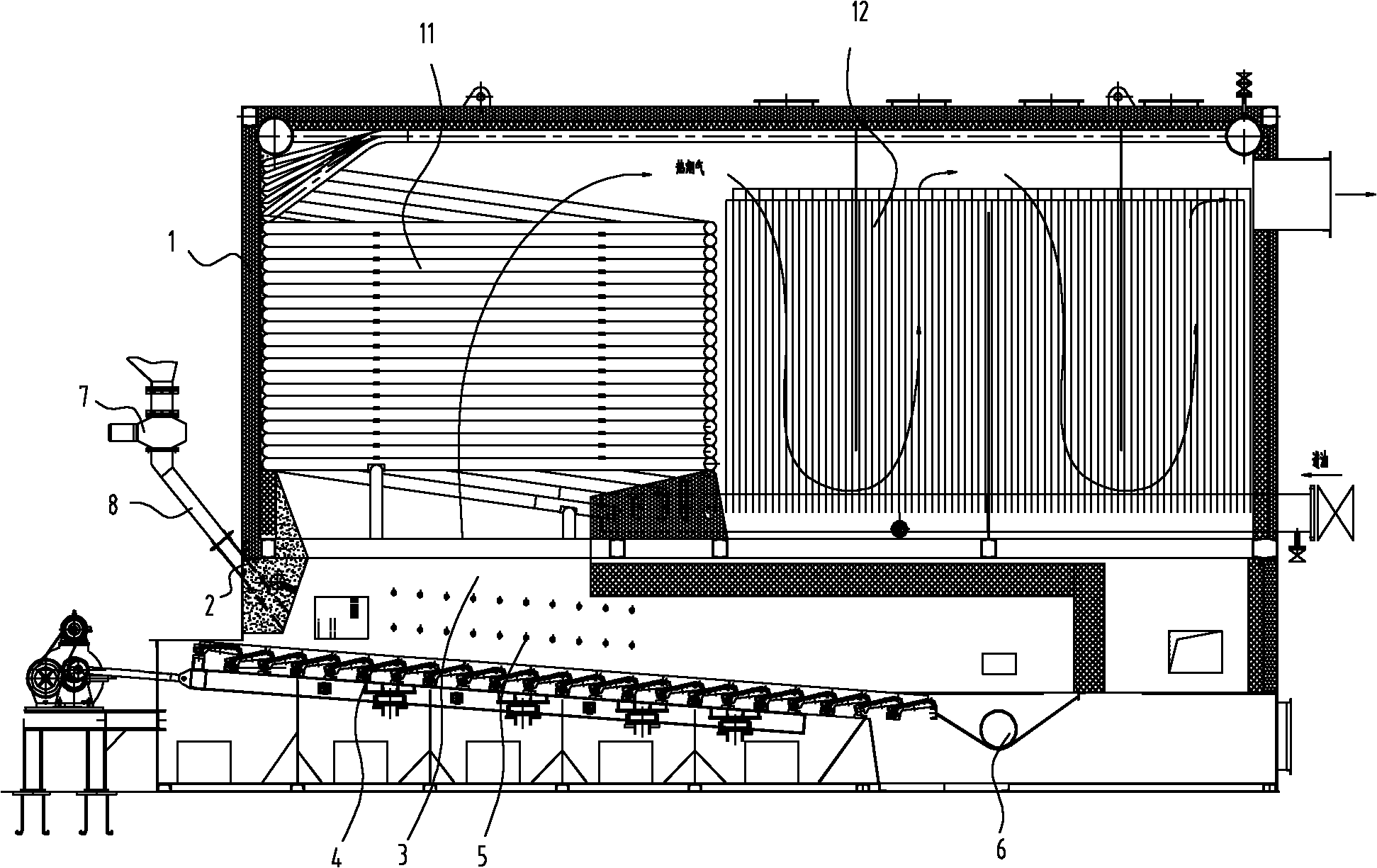

Steam boiler capable of burning biomass

InactiveCN101881433AHigh heat resistanceBig spaceTravelling grateAir/fuel supply for combustionCombustionHearth

The invention discloses a steam boiler capable of burning biomass, comprising a boiler body, a loading system and a vapour-water pipe system, wherein the boiler body is provided with a hearth in which the biomass fuel burns so as to release heat and a heat exchange device positioned above the hearth; the loading system is connected with the boiler body so as to convey the biomass fuel to the hearth for burning; the vapour-water pipe system is connected with the heat exchange device so as to exchange heat generated by the burning of the biomass; the hearth is internally provided with a reciprocal grate which downward slopes relatively to the level in an angle of inclination of 5-25 degrees from the end of the hearth close to the loading system to the far end far away from the loading system so as to enable the biomass fuel falling on the fire grate to be pushed and extruded and to roll relatively to the fire grate. In the invention, the fire grate moves relatively to fuel, the fuel is constantly extruded in the process of being pushed so as to damage coke and ash shells; and the fuel rolls slowly, thereby enabling the material layer to be loosened and facilitating full combustion.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Circulating fluidized bed boiler

InactiveCN101865457ASolve the low utilization rate of combustion heatReasonable air distributionFluidized bed combustionIndirect carbon-dioxide mitigationCirculating fluidized bed boilerCoal slurry

The invention relates to the technical field of boilers, in particular to a circulating fluidized bed boiler, which comprises a boiler, wherein the boiler is provided with a primary air inlet and a secondary air inlet, both the primary air inlet and the secondary air inlet are provided with a humidifying and oxygen supplying device, the humidifying and oxygen supplying device comprises a peroxide passage and a steam passage which are communicated with the air inlet. The invention can provide rich-oxygen water steam in the boiler environment to build the necessary conditions for generating rich-oxygen water gas, the tasks of humidification, oxygen supply and the like in site are continuously and stably completed in real time, the rich-oxygen hot water steam environment is created for the combustion of the circulating fluidized boiler, the superior integral conditions of the water-coal-slurry combustion, rich-oxygen combustion and water gas combustion not possessed by the circulating fluidized bed boiler are created, so the heat efficiency of the boiler is improved above the value, and the environment protection effect is obvious.

Owner:广东中拓能源科技有限公司

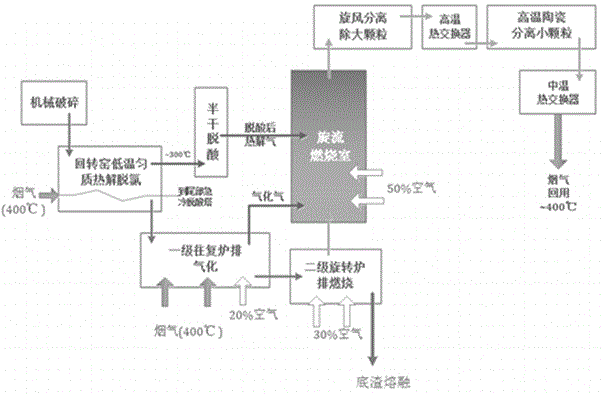

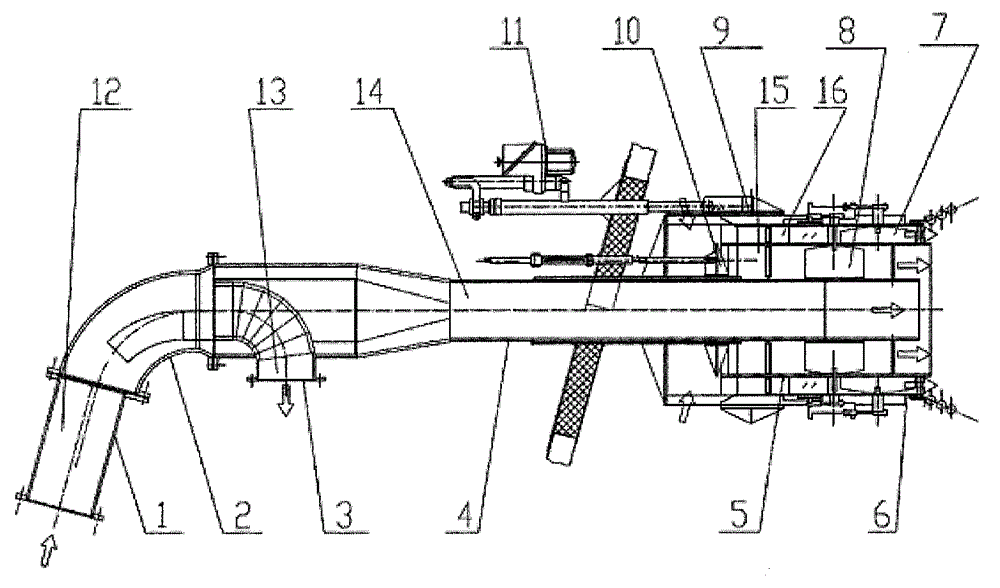

Efficient mobile bed gasifier device with pre-dechlorinating function and dechlorinating method of efficient mobile bed gasifier device

The invention relates to an efficient mobile bed gasifier device with a pre-dechlorinating function and a dechlorinating method of the efficient mobile bed gasifier device. In a rotary kiln, waste is subjected to drying and pyrolysis and most chlorine of the waste is removed under hot flue gas, after being dechlorinated by using a semi-dry method, separated volatiles and inflammable gas are used as raw material gases to be sent to a turbulent burner for use, the dechlorinated waste is gasified and partially burnt, and the unburnt part of the waste falls on a secondary-level rotary grate device at the rear end, is extruded and crushed and is burnt up after being fully mixed. The erosion to subsequent equipment and the generation of pollutants are greatly reduced, a first-level reciprocation grate adopts a multi-wind port subsection wind distribution mode and achieves the reasonable wind distribution effect, the radiation heat on the grate is increased by a long rear arch, the burning of the waste with low heat value is facilitated, the equipment erosion and environment pollution problems are greatly reduced, the deficiencies of poor mixing and low burn-off rate of the traditional grate incinerator are effectively improved, the area of a high-temperature-resistent grate sheet is reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

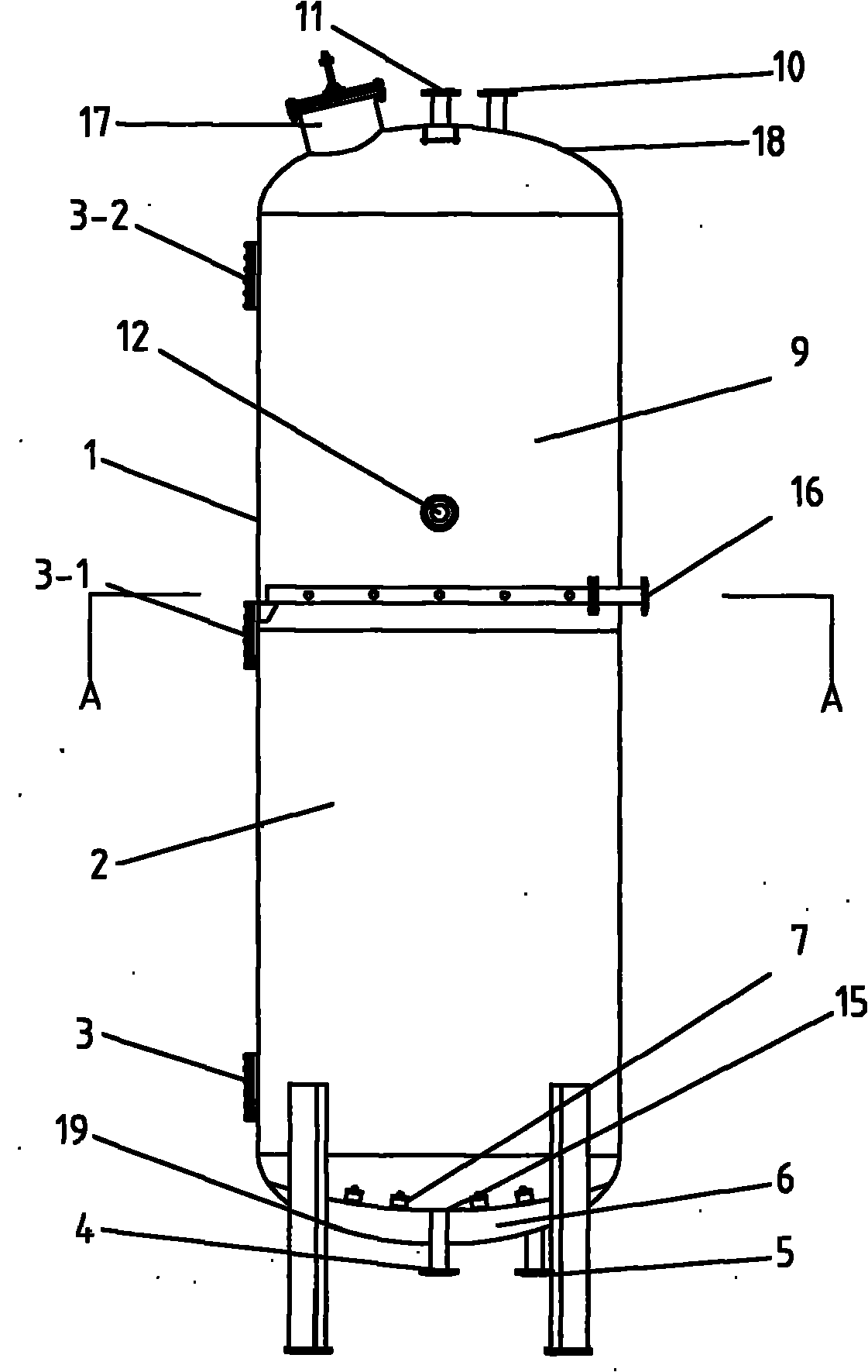

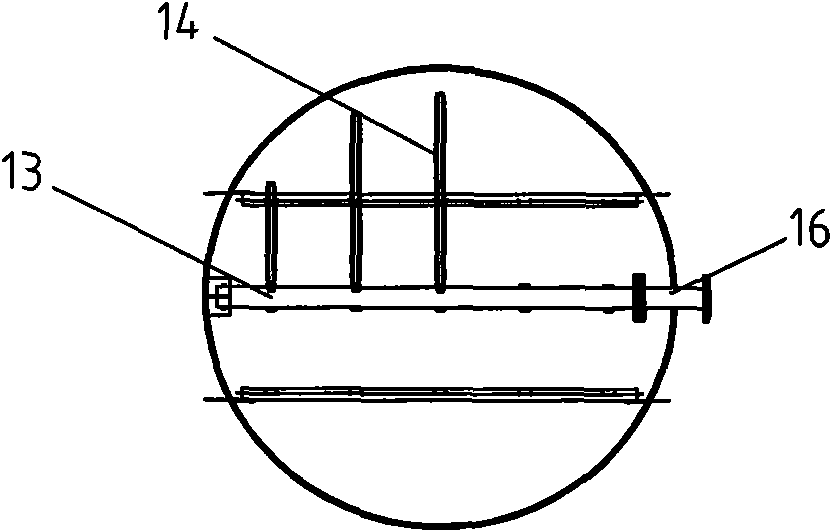

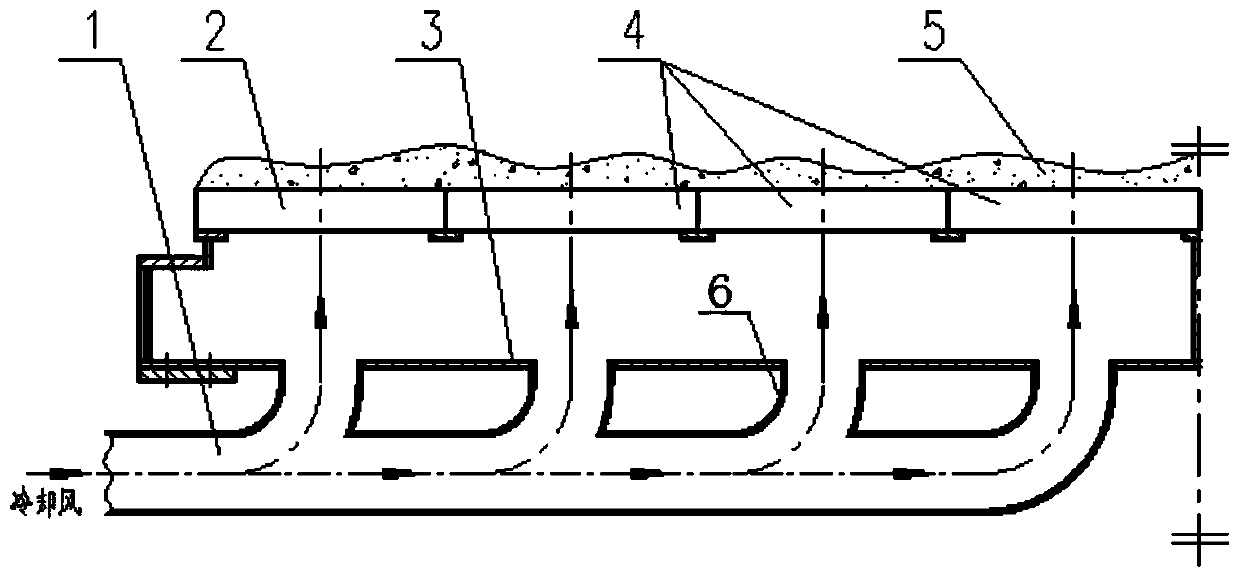

Front-located cation bed cation regenerating column

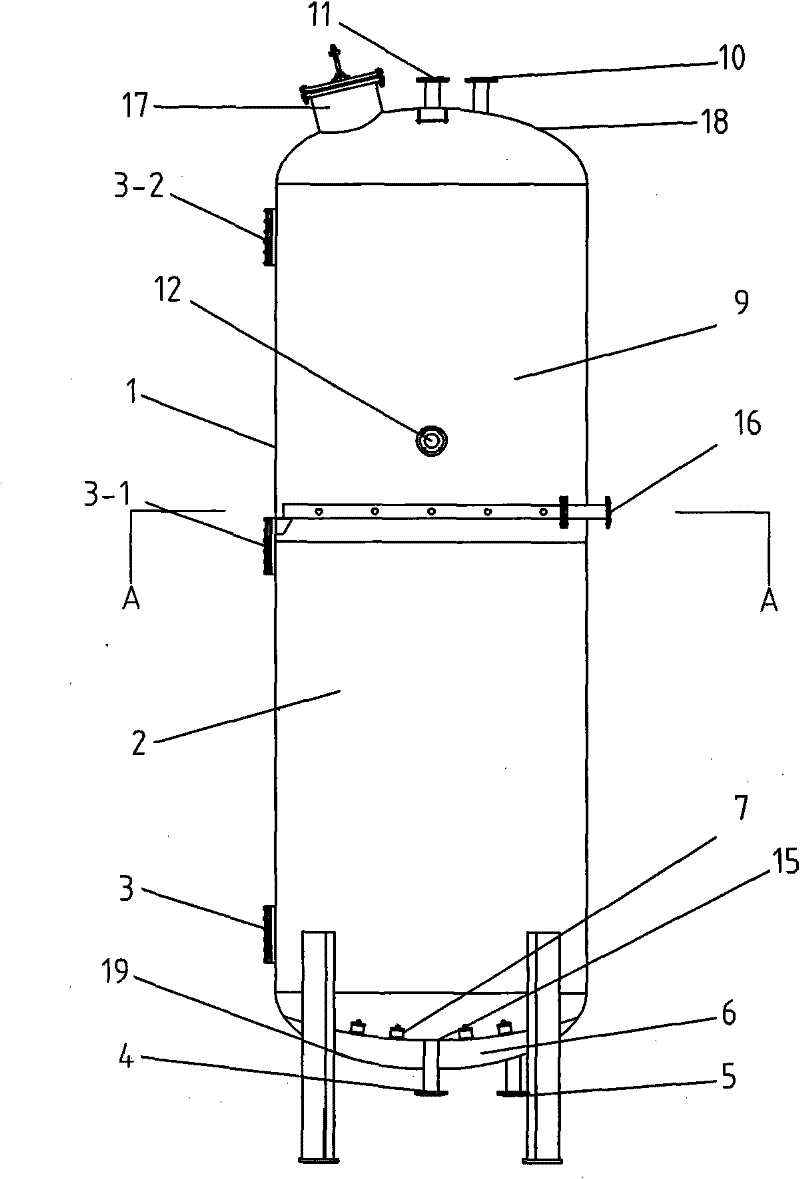

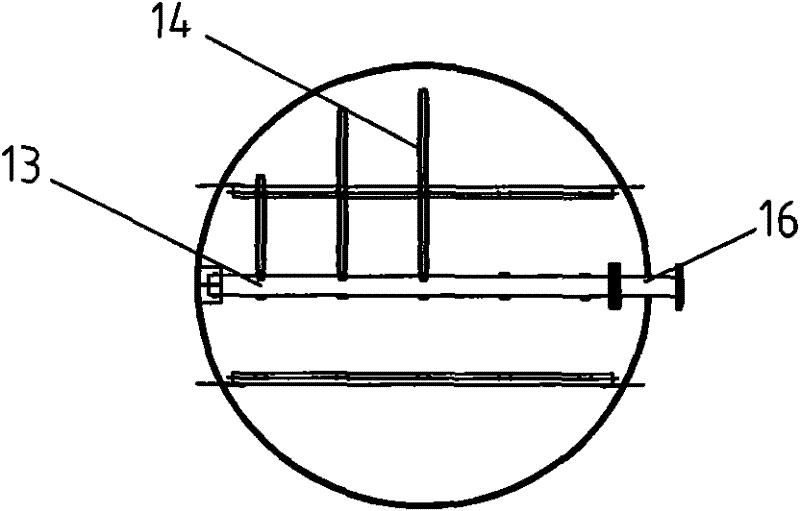

ActiveCN101816960AAdapt to regeneration requirementsStable collectionIon-exchanger regenerationWater/sewage treatment by ion-exchangeWash waterEllipse

The invention relates to a front-located cation bed cation regenerating column, belonging to the technical field of reclaim equipment for precision processing of power plant condensation water. The front-located cation bed cation regenerating column comprises a housing, wherein two ends of the housing are enclosed by adopting an ellipse head curved surface form; the upper end of the housing is provided with an air inlet-outlet, an order washing water inlet and a manhole; the upper part of the housing is provided with a resin expansion space; the lower part in the housing is a resin layer; the bottom of the housing is provided with a bottom distribution device above which the resin layer is arranged; a distribution and collection device is arranged above the resin layer; the resin expansion space is arranged above the distribution and collection device; the housing of the resin expansion space is provided with a resin inlet; the lower end of the housing is provided with a resin outlet pipe and a back washing outlet; the resin outlet pipe is arranged in center of a lower ellipse head curved surface axis; and the back washing outlet is connected with the bottom distribution device.

Owner:ZHEJIANG HAIYAN POWER SYST RESOURCES ENVIRONMENTAL TECH

Rotary and sliding fire grate air conditioner of chain

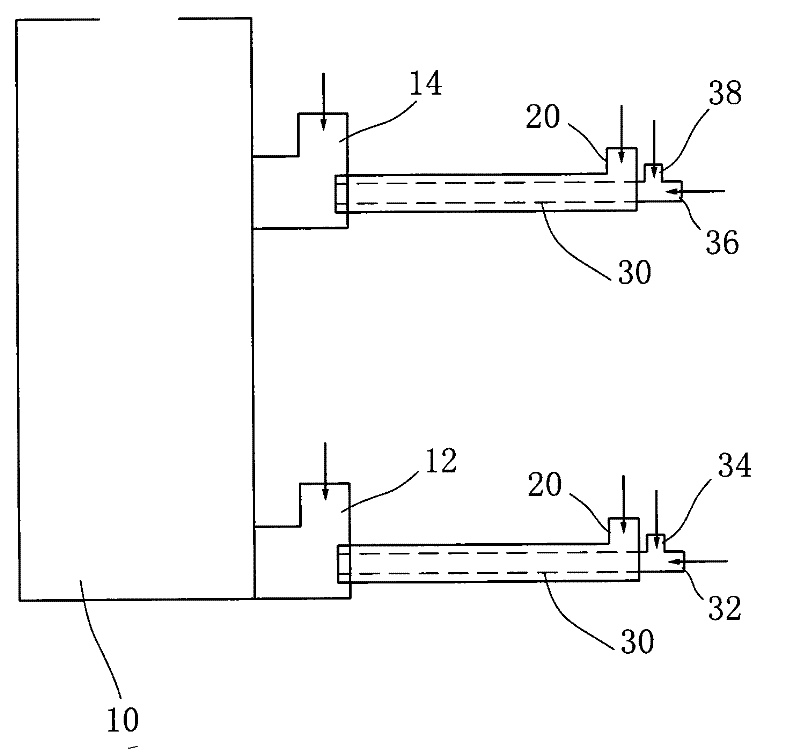

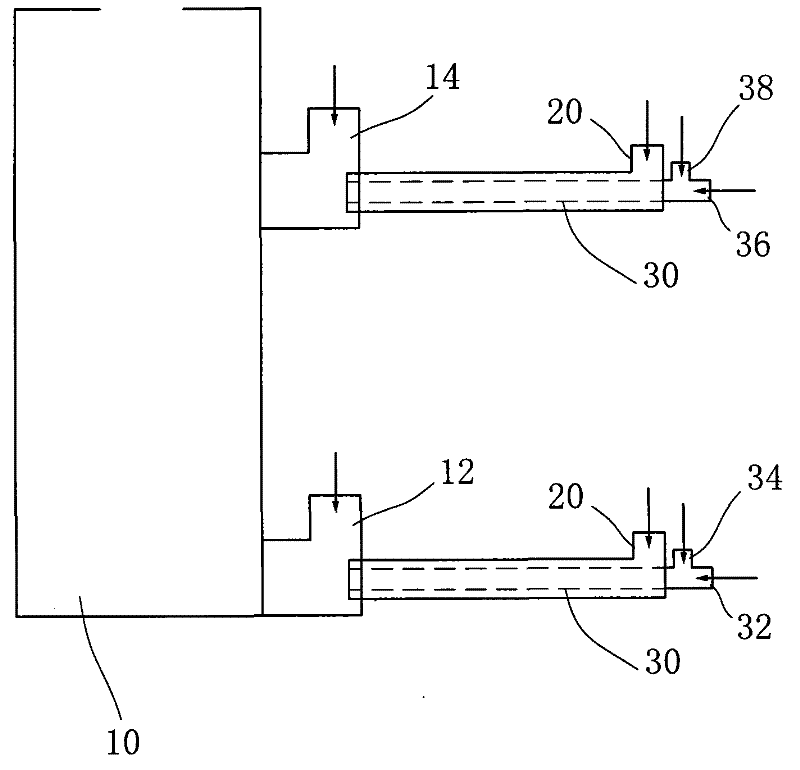

InactiveCN1779325AReasonable air distributionUniform air distributionDamper arrangementAir/fuel supply for combustionAir volumePush pull

The invention relates to a rotary push-pull chain grate air-delivering air-controlling device, in which the air-delivering device has five plenums. A blast-regulating plate is arranged in the air passage on both sides of the plenum and a rotary push-pull damper air-regulating assembly is disposed at the air inlet of each plenum. The fuel and the air are mixed well via the air-regulating device to make the fuel burn up.

Owner:HENAN UNIVERSITY

Process method for cancelling central coke charging

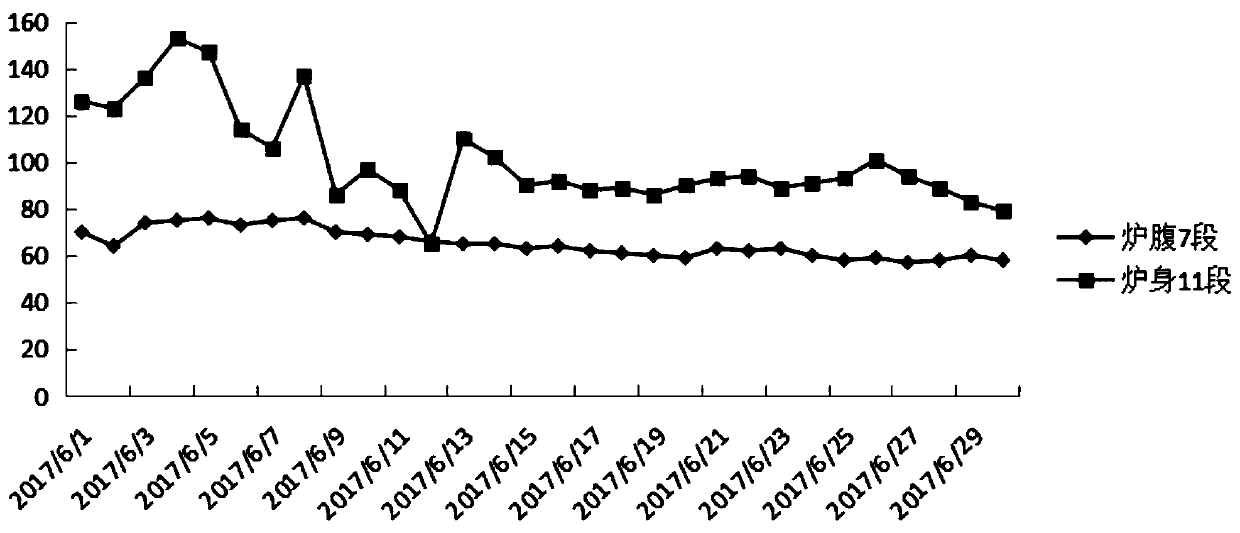

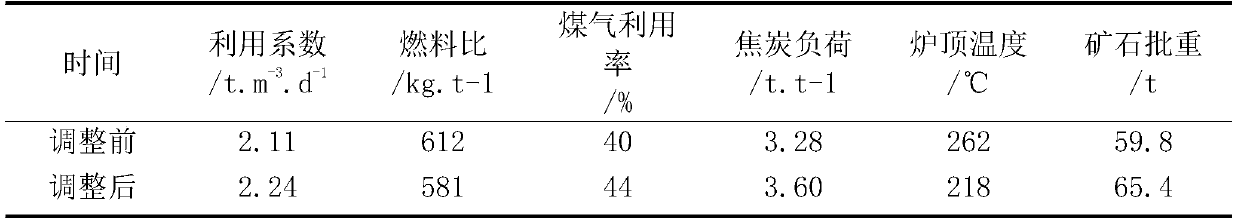

InactiveCN110257574AReasonable air distributionImprove gas utilizationBell-and-hopper arrangementBlast furnace detailsAirflowEngineering

The invention discloses a process method for cancelling central coke charging. The process method for cancelling central coke charging comprises the steps of S1, reducing an ore platform, loosening an edge airflow, and enlarging a central zone after a heat load is stabilized and the edge airflow is homogenized; S2, after the cross beam temperature measuring of a center tends to be stable, reducing the central coke amount, setting a coke matrix transition grade, adjusting the center and edge ore circle number, and reducing the impact of a distribution platform change on two airflows; and S3, stabilizing the distribution platform, and increasing a coke load; and after cancelling central coke charging step by step, increasing the ore batch weight according to the coke batch thickness suitable for a blast furnace.

Owner:BAOTOU IRON & STEEL GRP

Center air ring concentrated type turbulent burner

InactiveCN104154532AIncrease profitAir distribution optimizationPulverulent fuel combustion burnersCoal pipelineFly ash

A center air ring concentrated type turbulent burner comprises a primary air pulverized coal pipeline, an internal secondary air duct, an external secondary air duct, an exhaust gas pipe, a deflective guide pipe, an elbow and a pulverized coal nozzle. A center air pipeline is arranged in the primary air pulverized coal pipeline, the primary air pulverized coal pipeline and the center air pipeline form an annular channel, pulverized coal is heated by high-temperature center air and internal secondary air in the annular channel and can be heated more uniformly, and therefore more volatiles can be easily separated out, and timely ignition and steady burning of the pulverized coal can be easily achieved. The pulverized coal nozzle is of a circular ring shape, the pulverized coal is surrounded by the center air, the internal secondary air and the external secondary air after being ejected out from the circular-ring-shaped nozzle, two layers of flames are formed after the pulverized coal is ignited, burning of the pulverized coal is more violent and more efficient, and the fly ash carbon content and the cinder carbon content can be effectively decreased.

Owner:TRANSTEK IND HK LTD KOWLOON

Blast furnace screw material distribution correcting method

ActiveCN104894318AReduce weightActive central airflowBell-and-hopper arrangementBlast furnace smeltingAirflow

The present invention provides a blast furnace screw material distribution correcting method. According to the method, an inverse carrying material distribution performing mark button is arranged in a screw material distribution list image; a material distribution correcting process is additionally set in a blast furnace top material distribution process; a screw material distribution performing ring position Xj corresponding to the final material distribution ring position X1 is set in advance; during an ore material distribution process, the material distribution sluice tilting angle of the X1 is performed according to the Xj tilting angle; during the material distribution process, when the weight displayed by a weighing cabinet produces the large change, the material distribution collecting process is manually started, and the material distribution sluice automatically tilts upward according to the retrieved tilting angle of the screw material distribution performing ring position Xj; and after the batch material distribution is completed, the tilting angle of the screw material distribution recovers to perform the originally-set furnace top material distribution process. With the method of the present invention, the condition that the material at the final ring position is centralized and distributed at the center position in the furnace can be avoided, such that the center gas flow in the blast furnace is active, the distribution of the gas flow in the furnace is rational, the furnace condition is improved, and the smooth blast furnace smelting production can be ensured.

Owner:ANGANG STEEL CO LTD

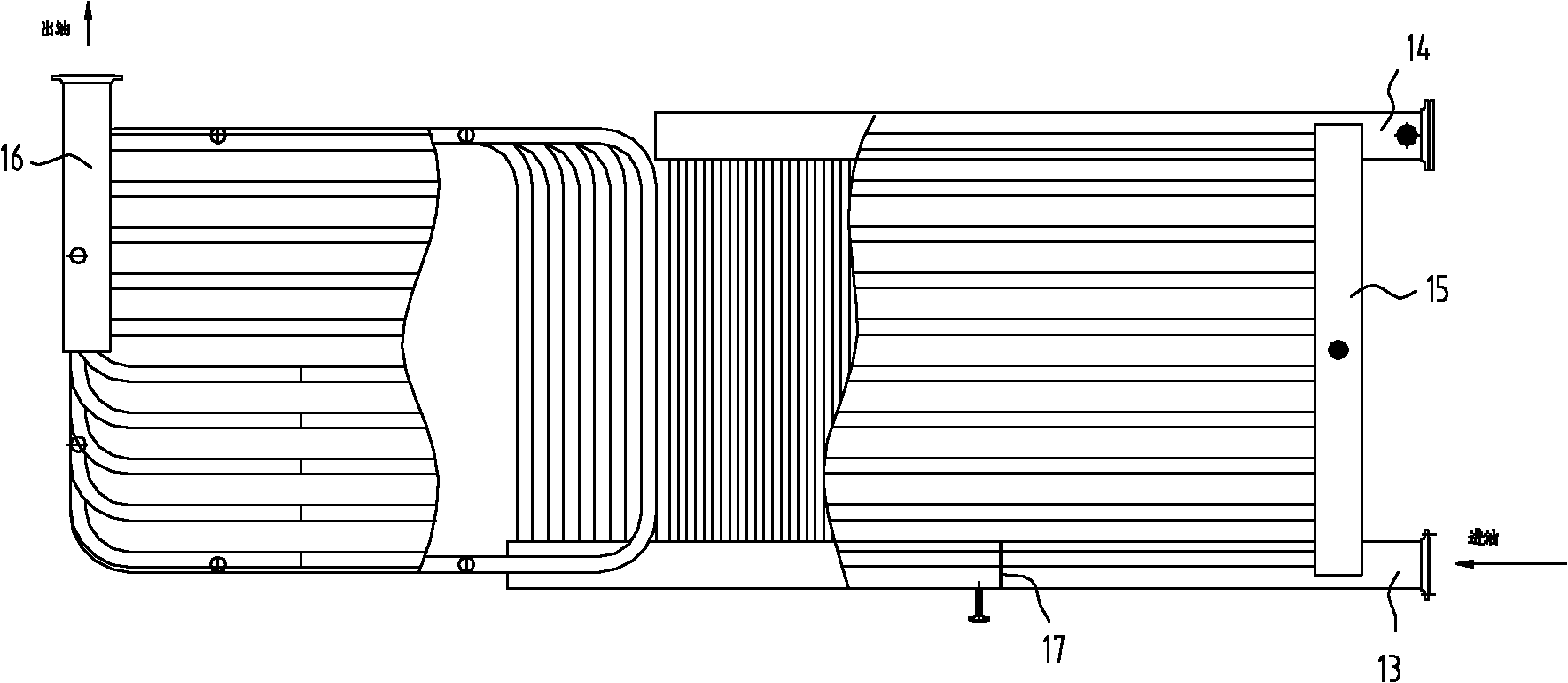

Organic biomass heat carrier furnace

The invention discloses an organic biomass heat carrier furnace, comprising a furnace body, a front furnace feeding system connected with a feeding inlet of the furnace body, a hearth air distribution system in the furnace body, a heat exchange system above a hearth and a slag tapping system at the back of the hearth, wherein the hearth air distribution system comprises a primary air device at the bottom of a fire grate in the furnace body, a secondary air device in front of the furnace body and tertiary air devices at the two sides of the hearth. The furnace is reasonable in air distributionand sufficient in diffused air supply and avoids the defect that the discharged smoke is black and even strong yellow because of improper air supply and unburned organic volatiles.

Owner:GUANGZHOU DEVOTION THERMAL TECH

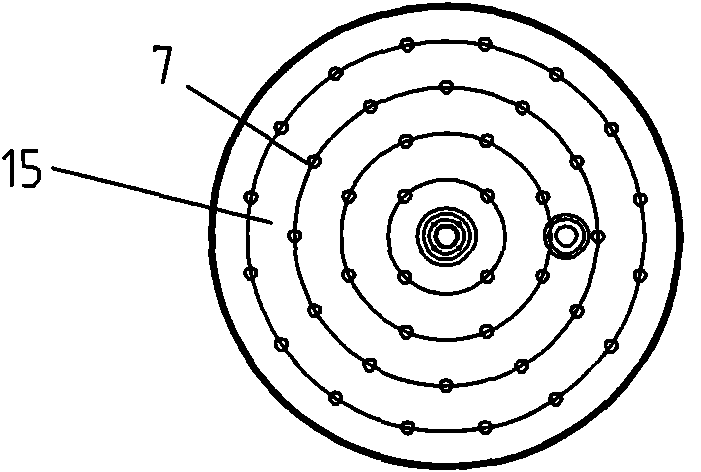

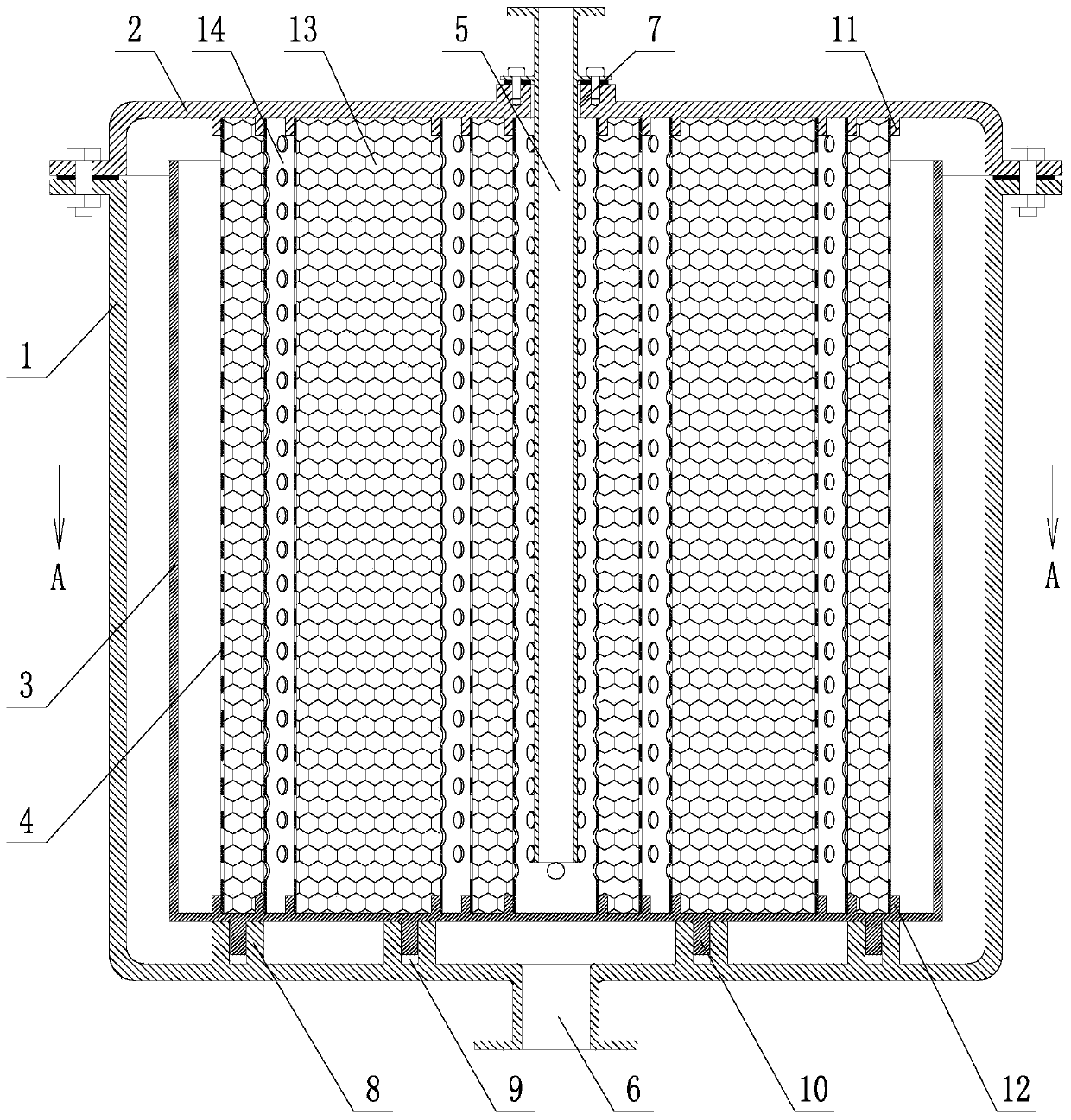

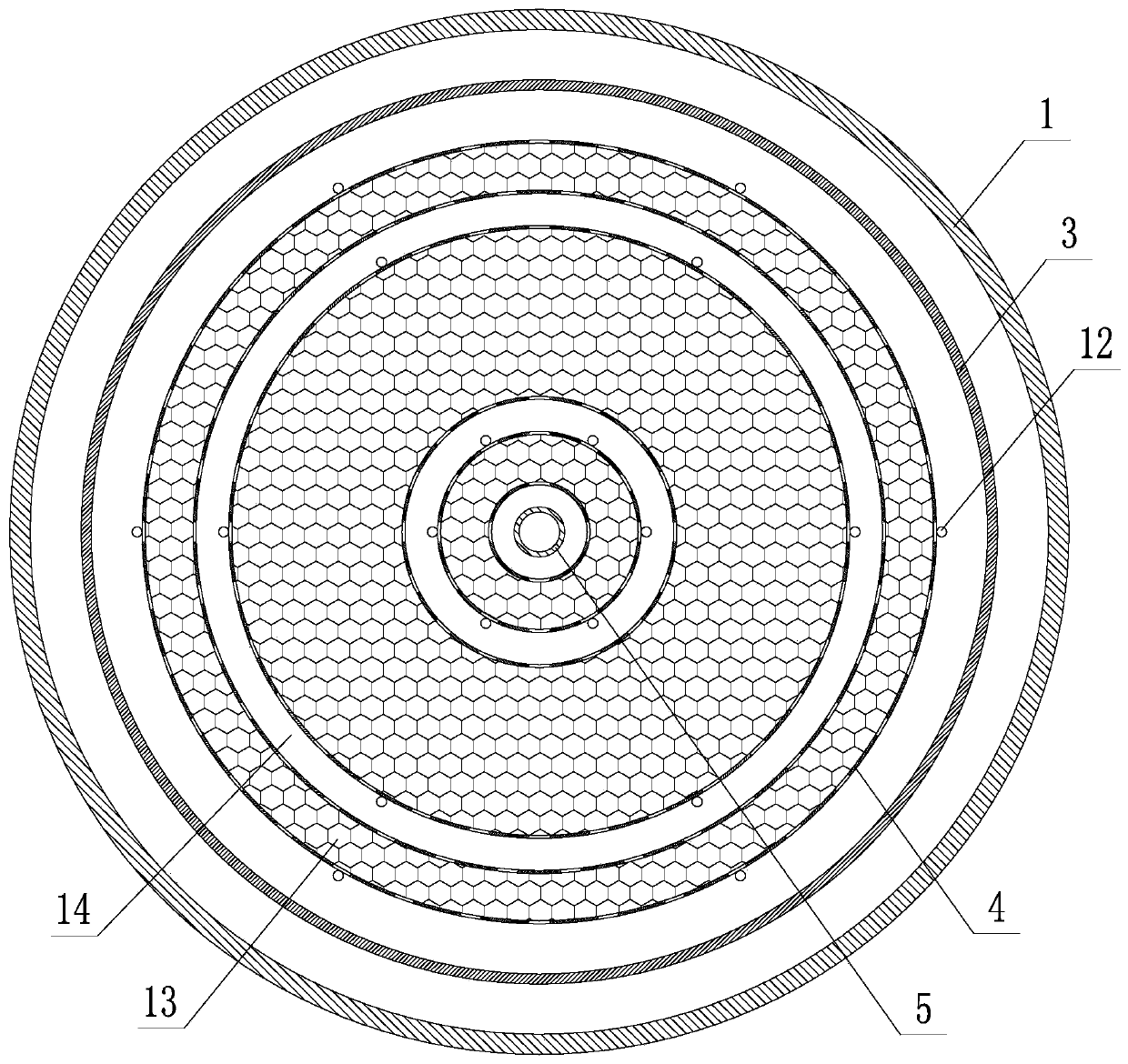

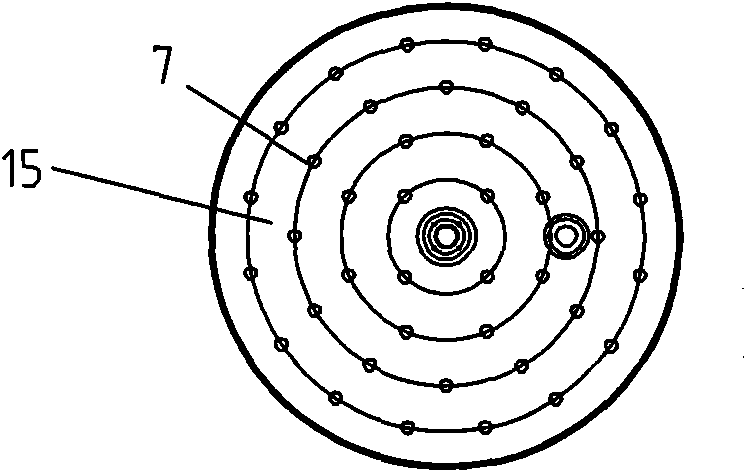

Radial flow equalization pressure swing adsorption tower

InactiveCN110201488APurge thoroughlyUniform distribution of flow fieldDispersed particle separationEngineeringEqualization

The invention relates to a radial flow equalization pressure swing adsorption tower, which comprises an outer shell, a sealing cover, a flow guiding cylinder, wind distribution cylinders and a ventingpipe, wherein a venting port is arranged on the bottom portion of the outer shell, the venting pipe is inserted in the center of the sealing cover, and extends into the outer shell, the flow guidingcylinder is concentrically arranged in the outer shell, support blocks are arranged in front of the bottom plates of the flow guiding cylinder and the outer shell, the support blocks and the flow guiding cylinder are positioned by positioning pins and positioning holes, the wind distribution cylinders are concentrically arranged inside the flow guiding cylinder, and are fixedly arranged between the sealing cover and the bottom plate of the flow guiding cylinder through positioning snapping blocks, the surface of the wind distribution cylinder is uniformly provided with gas-permeable holes, a plurality of the wind distribution cylinders are arranged and have different diameters, the plurality of the wind distribution cylinders are arranged concentrically, the circumferential gaps between the wind distribution cylinders are respectively arranged as adsorption chambers and gas chambers, the adsorption chambers and the gas chambers are alternately distributed in the radial direction, and the adsorption chamber is filled with an adsorbent. According to the present invention, at the adsorption phase and the backflush stage, the flow field inside the adsorption tower is uniformly distributed, the gas flow distribution is reasonable during the gas producing, and the purging is clean and complete during the backflushing, such that the gas production efficiency and the gas production quality can be effectively improved.

Owner:NORTHEASTERN UNIV

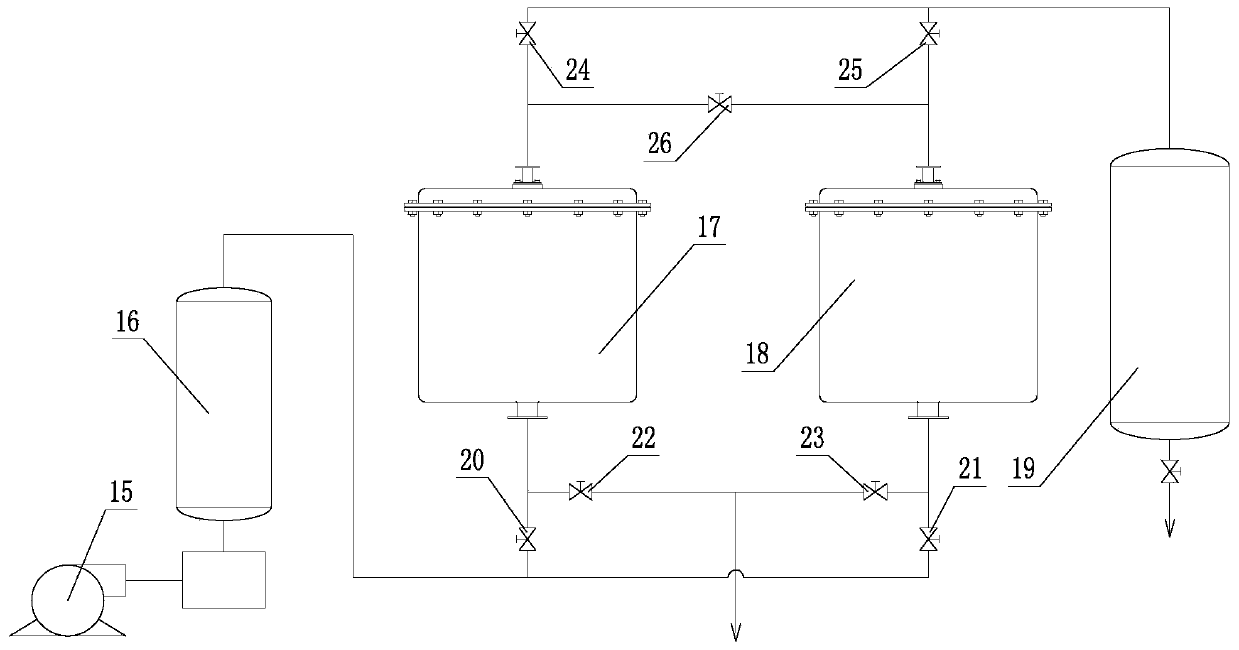

Device for keeping fruits and vegetables fresh by using differential-pressure controlled-atmosphere precooling plates

InactiveCN110012932AWill not affect normal storageReasonable air distributionFruits/vegetable preservation by freezing/coolingDifferential pressurePre cooling

The invention provides a device for keeping fruits and vegetables fresh by using differential-pressure controlled-atmosphere pre-cooling plates. The device is used for keeping fruits and vegetables fresh. The device comprises: a differential-pressure controlled-atmosphere pre-cooling plate assembly which comprises two differential-pressure controlled-atmosphere pre-cooling plates, and multi-groupalternately-arranged differential-pressure controlled-atmosphere air supply plates and differential-pressure controlled-atmosphere pre-cooling air return plates which are fixed below the two differential-pressure controlled-atmosphere pre-cooling plates; a pipeline assembly which is used for connecting the two differential-pressure controlled-atmosphere pre-cooling plates and comprises an air return pipeline and an air supply pipeline; and a differential-pressure controlled-atmosphere pre-cooling unit which is simultaneously connected to the air return pipeline and the air supply pipeline, isused for receiving heat transmitted by the air return pipeline, and performs heat exchange through air cooling and radiation so as to dissipate the heat, wherein both the differential-pressure controlled-atmosphere pre-cooling air supply plates and the differential-pressure controlled-atmosphere pre-cooling air return plates are provided with internal air passages, the differential-pressure controlled-atmosphere pre-cooling air supply plates are provided with air supply ports, and the differential-pressure controlled-atmosphere pre-cooling air return plates are provided with air return ports.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Rotary and sliding fire grate air conditioner of chain

InactiveCN100404957CReasonable air distributionUniform air distributionDamper arrangementAir/fuel supply for combustionAir volumePush pull

The invention relates to a rotary push-pull chain grate air-delivering air-controlling device, in which the air-delivering device has five plenums. A blast-regulating plate is arranged in the air passage on both sides of the plenum and a rotary push-pull damper air-regulating assembly is disposed at the air inlet of each plenum. The fuel and the air are mixed well via the air-regulating device to make the fuel burn up.

Owner:HENAN UNIVERSITY

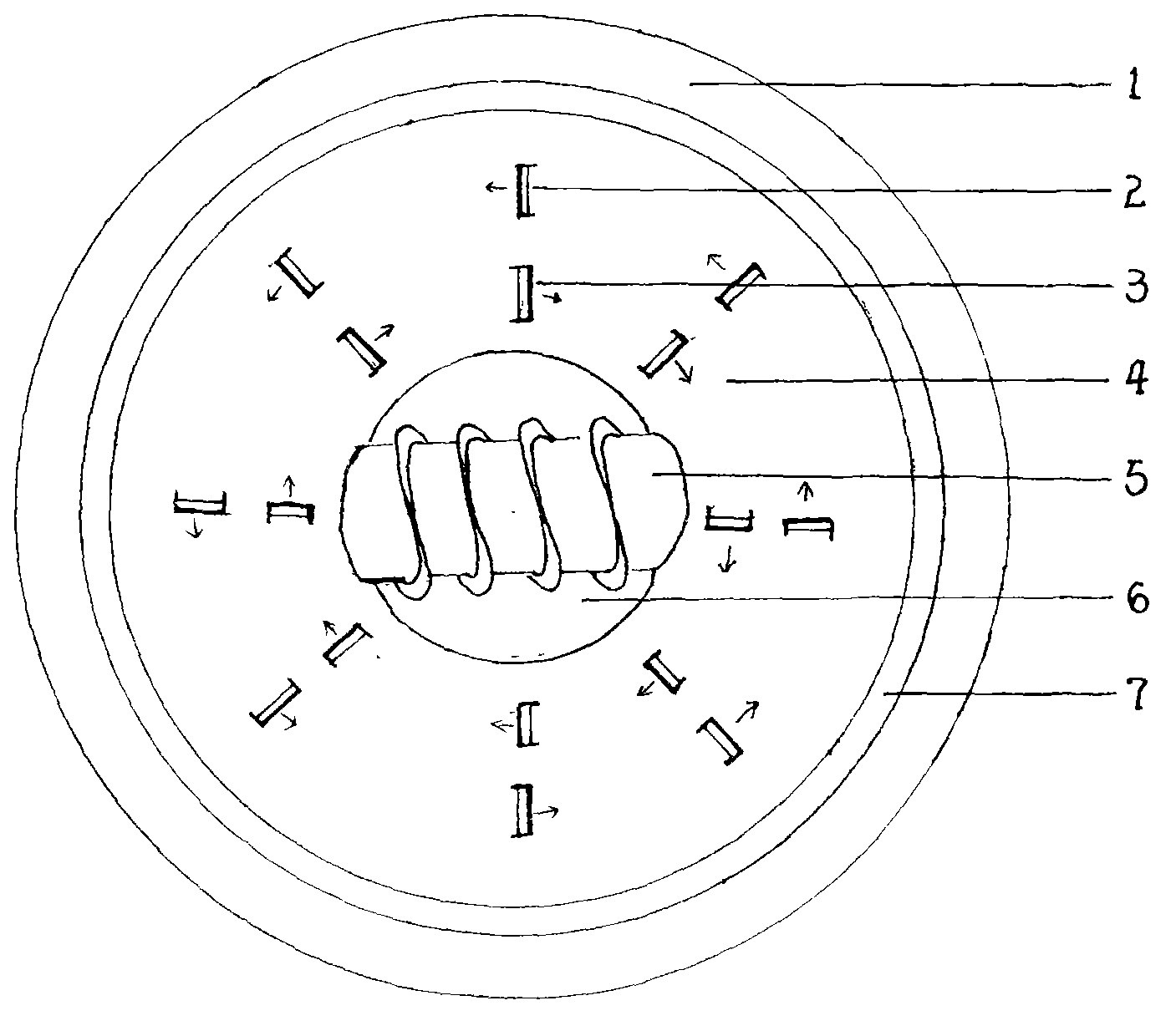

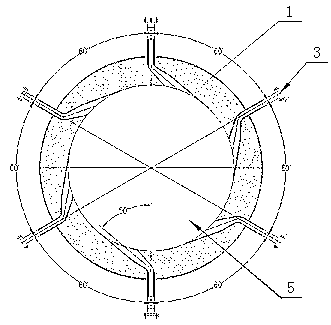

Forward and reverse air distribution structure for biomass burner

InactiveCN102798121AImprove heat utilizationNo dead angle of air distributionCombustion apparatusCombustionDrift angle

The invention discloses a forward and reverse air distribution structure for a biomass burner, which comprises a panel, secondary forward air distribution holes, secondary reverse air distribution holes, a burning chamber, a feed shaft, primary air distribution and a bellows, wherein the feed shaft is arranged in the middle of the interior of the burning chamber; and an upper layer of air distribution holes and a lower layer of air distribution holes are uniformly formed in the upper side wall of the periphery of the burning chamber, i.e., a layer of secondary forward air distribution holes and a layer of secondary reverse air distribution holes. A bypass of the secondary forward air distribution holes forms a drift angle with the section of the burning chamber; the drift angle of the bypass of air distribution holes in the same layer leans in the same direction; the drift angle of the bypass of the secondary reverse air distribution holes leans in the direction opposite to the leaning direction of the drift angle of the bypass of the secondary forward power distribution holes; the air in the bellows enters the burning chamber from the secondary forward air distribution holes to flow in circulation so as to form the circulation of air distribution of the upper layer or enters the burning chamber from the secondary reverse power distribution holes to flow cyclically to form the circulation of air distribution of the lower layer; and the circulation of air distribution of the lower layer is reverse to the direction of air distribution of the upper layer. The forward and reverse air distribution structure for a biomass burner has the advantages of sufficient combustion, reasonable air distribution and increased thermal utilization rate of fuel.

Owner:SHANXI RONGSHENDA SCI & TECH

Establishment method of power station boiler combustion intelligent distribution model

InactiveCN110397949AReasonable air distributionStable combustionFuel supply regulationSpecial data processing applicationsBoiler efficiencyPower station

The invention discloses an establishment method of a power station boiler combustion intelligent distribution model. The establishment method comprises the following steps that S1, for a combustion boiler, air entering a furnace mainly comprises primary air and secondary air, primary air carries pulverized coal from a fuel nozzle to a hearth, the secondary air enters the furnace from an air nozzlethrough an adjusting baffle, primary air flow is determined by the coal feeding amount of a coal mill, and primary air flowing resistance is provided by a primary fan; the secondary air flow fed intothe furnace from the air nozzle is determined by the air box pressure and the baffle opening degree of the air nozzle, and the secondary air flow resistance is provided by an air supply device; the air distribution model is determined, so that the boiler is reasonable in air distribution; and the proportion of the air powder is reasonably adjusted, so that the combustion is relatively stable, theheat loss of the smoke can be effectively reduced, the carbon content of the fly ash can be reduced, the heat loss of the mechanical and chemical incomplete combustion of the pulverized coal can be reduced, and the boiler efficiency can be improved.

Owner:杭州涌复科技有限公司

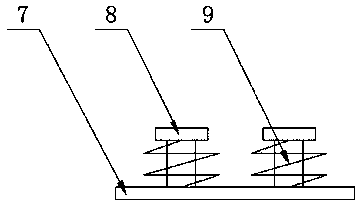

Grid plate beam uniform air supply structure

The invention provides a grid plate beam uniform air supply structure which comprises a grid plate beam, side grid plates and a middle grid plate, wherein the side grid plates are mounted on the two sides of the grid plate beam, the middle grid plate is arranged between the side grid plates, the structure further comprises a main air supply pipe, a plurality of air supply branch pipes are arranged on the main air supply pipe from left to right sequentially, and the air outlet ends of the air supply branch pipes are communicated with the inside of the grid plate beam. According to the grid plate beam uniform air supply structure, uniform air supply cooling of all the materials on the grid plate can be ensured, the air distribution can be more reasonable, and more energy is saved.

Owner:NANJING KISEN INT ENG

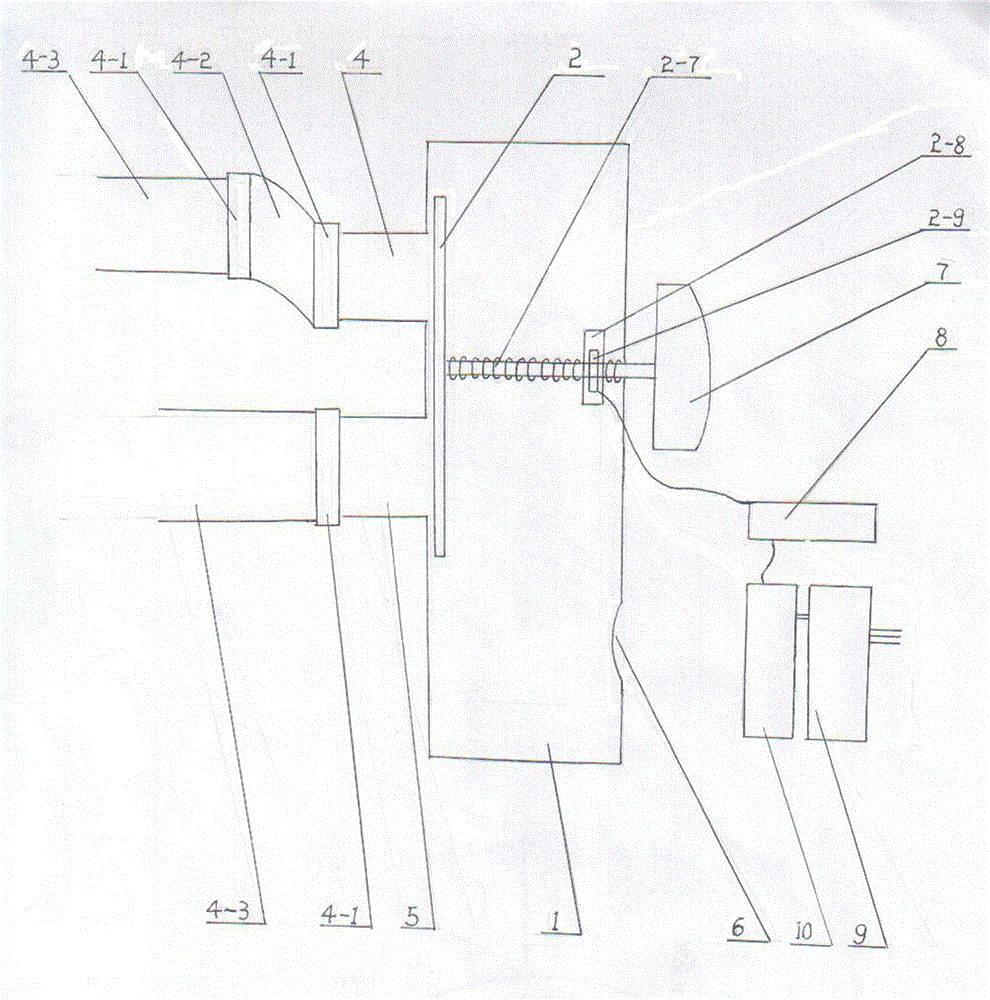

Intelligent air-distribution device for solid fuel combustion

InactiveCN104964309ABurn fully and completelyFair useAir supply regulationMicrocomputerSmoke detectors

The invention discloses an intelligent air-distribution device for solid fuel combustion. The intelligent air-distribution device comprises an air-distribution cavity, an air-distribution baffle plate, a rotary shaft, an outer cover of the air-distribution cavity, secondary and third air inlets, a primary air inlet, an air inlet, a rotary button, a driving motor, a smoke detector and a microcomputer. The air-distribution cavity is internally provided with a movable air-distribution baffle plate and a fixed limiting device. The air-distribution baffle plate is in the shape of a circular plate with an empty groove. The secondary and third air inlets are arranged in the air-distribution baffle plate. The primary air inlet has the same hole diameter as a second ventilating duct and a first ventilating duct of the back side of the air-distribution cavity. A spring, a rotary device and the rotary button are arranged on the rotary shaft of the air-distribution baffle plate. The rotary device is driven by a driving motor to perform motion for rotating the rotary shaft. The driving motor is connected with the microcomputer. The microcomputer is connected with the smoke detector. The lower portion of the outer cover of the air-distribution cavity is provided with an air inlet and the upper portion of the outer cover of the air-distribution cavity is provided with the rotary button. The intelligent air-distribution device for solid fuel combustion is uniform and reasonable in air distribution and used intelligently and manually such that combustion is performed completely.

Owner:SHANXI RONGSHENDA SCI & TECH

Circulating fluidized bed boiler

InactiveCN101865457BReasonable air distributionSolve UtilizationFluidized bed combustionIndirect carbon-dioxide mitigationCombustionFluidized bed

The invention relates to the technical field of boilers, in particular to a circulating fluidized bed boiler, which comprises a boiler, wherein the boiler is provided with a primary air inlet and a secondary air inlet, both the primary air inlet and the secondary air inlet are provided with a humidifying and oxygen supplying device, the humidifying and oxygen supplying device comprises a peroxide passage and a steam passage which are communicated with the air inlet. The invention can provide rich-oxygen water steam in the boiler environment to build the necessary conditions for generating rich-oxygen water gas, the tasks of humidification, oxygen supply and the like in site are continuously and stably completed in real time, the rich-oxygen hot water steam environment is created for the combustion of the circulating fluidized boiler, the superior integral conditions of the water-coal-slurry combustion, rich-oxygen combustion and water gas combustion not possessed by the circulating fluidized bed boiler are created, so the heat efficiency of the boiler is improved above the value, and the environment protection effect is obvious.

Owner:广东中拓能源科技有限公司

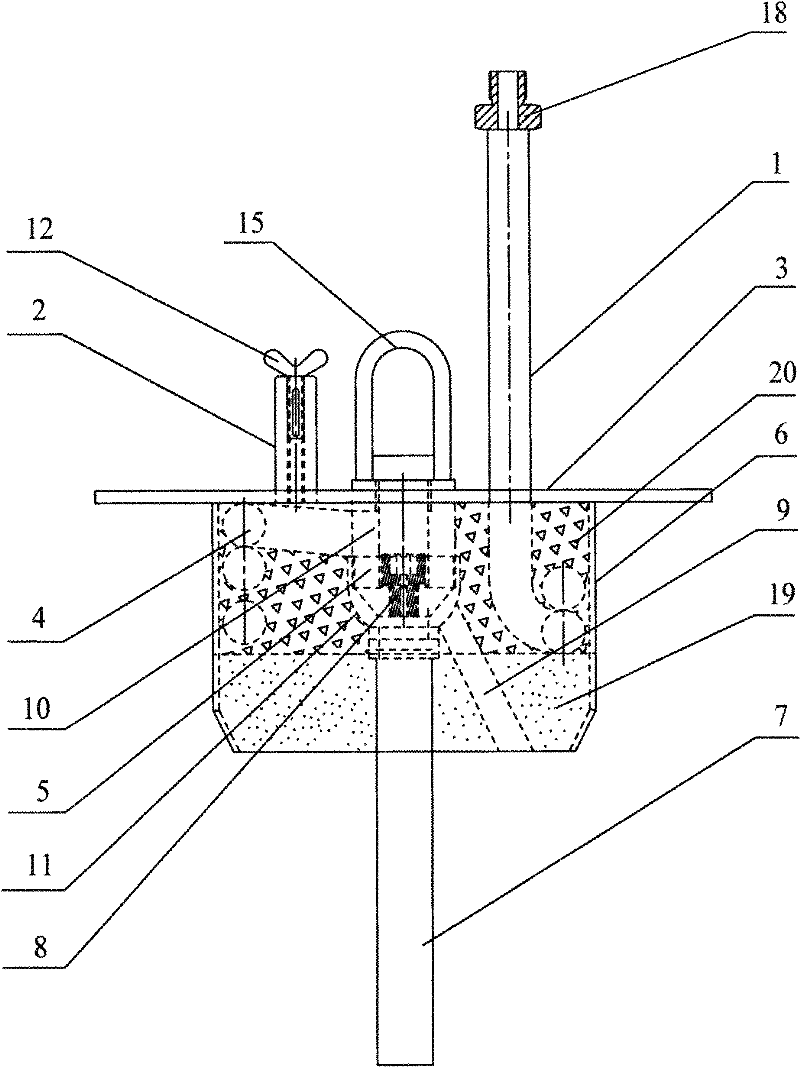

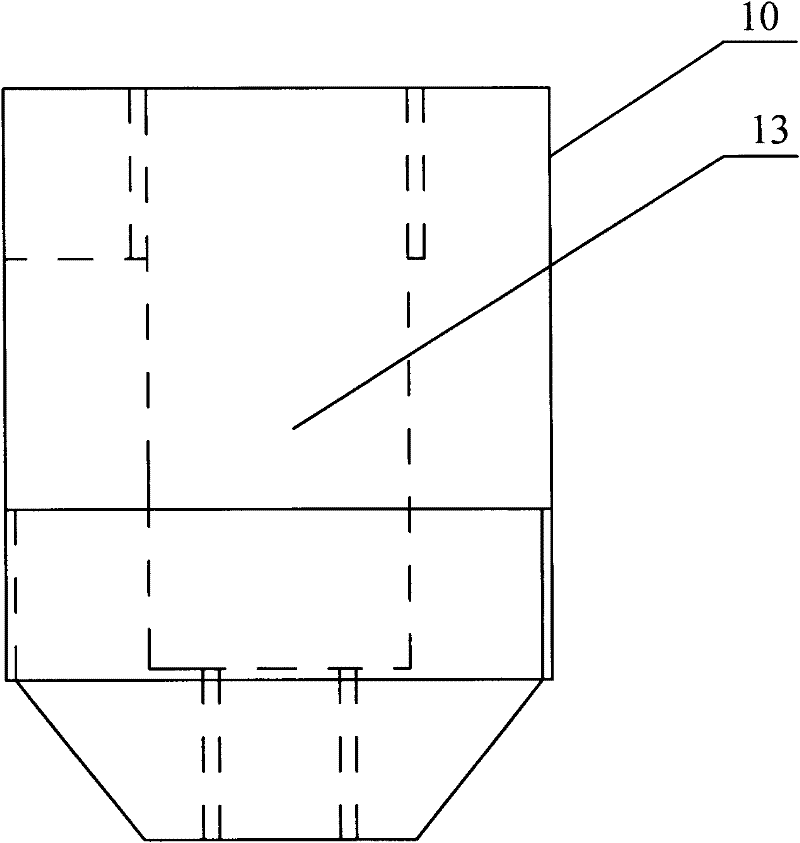

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950BPromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

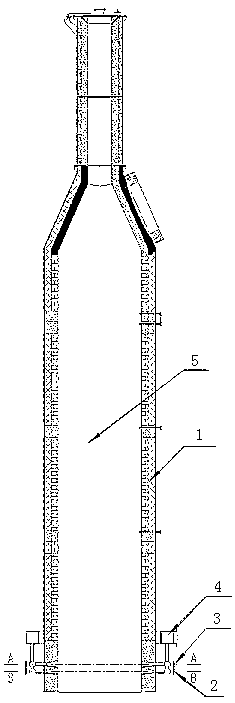

Injector gas fume preheating efficient combustor

ActiveCN101614393BEfficient reuseFully warmed upIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention discloses an injector gas fume preheating efficient combustor, mainly comprising an upper wall (5) and an air preheating channel and a bottom bucket (6) respectively fixed at the upper end and lower end of the upper wall; the combustor is characterized in that the bottom bucket (6) is internally provided with a fuel gas preheating pipeline (7), the lower end of a hybrid tube (2) is connected with a pipe clamp reducing nipple (3) in the bottom bucket (6) through the air preheating channel and the upper wall (5); the inlet and outlet of the fuel gas preheating pipeline (7) are connected with the hybrid tube (2), meanwhile, the wall of the bottom bucket (6) is further provided with a gas fume inlet (11) connected with the pipe clamp reducing nipple (3).The invention can effectively reuse the high temperature gas fume in a flame path, can not only fully preheat fuel gas which enters the flame path to raise temperature thereof rapidly but also have very good thermal vibrationtransmission effect.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

A correction method for blast furnace spiral cloth

ActiveCN104894318BActive airflowReasonable air distributionBell-and-hopper arrangementBlast furnace smeltingMaterial distribution

The present invention provides a blast furnace screw material distribution correcting method. According to the method, an inverse carrying material distribution performing mark button is arranged in a screw material distribution list image; a material distribution correcting process is additionally set in a blast furnace top material distribution process; a screw material distribution performing ring position Xj corresponding to the final material distribution ring position X1 is set in advance; during an ore material distribution process, the material distribution sluice tilting angle of the X1 is performed according to the Xj tilting angle; during the material distribution process, when the weight displayed by a weighing cabinet produces the large change, the material distribution collecting process is manually started, and the material distribution sluice automatically tilts upward according to the retrieved tilting angle of the screw material distribution performing ring position Xj; and after the batch material distribution is completed, the tilting angle of the screw material distribution recovers to perform the originally-set furnace top material distribution process. With the method of the present invention, the condition that the material at the final ring position is centralized and distributed at the center position in the furnace can be avoided, such that the center gas flow in the blast furnace is active, the distribution of the gas flow in the furnace is rational, the furnace condition is improved, and the smooth blast furnace smelting production can be ensured.

Owner:ANGANG STEEL CO LTD

Front-located cation bed cation regenerating column

ActiveCN101816960BAdapt to regeneration requirementsStable collectionIon-exchanger regenerationWater/sewage treatment by ion-exchangeWash waterEllipse

The invention relates to a front-located cation bed cation regenerating column, belonging to the technical field of reclaim equipment for precision processing of power plant condensation water. The front-located cation bed cation regenerating column comprises a housing, wherein two ends of the housing are enclosed by adopting an ellipse head curved surface form; the upper end of the housing is provided with an air inlet-outlet, an order washing water inlet and a manhole; the upper part of the housing is provided with a resin expansion space; the lower part in the housing is a resin layer; thebottom of the housing is provided with a bottom distribution device above which the resin layer is arranged; a distribution and collection device is arranged above the resin layer; the resin expansion space is arranged above the distribution and collection device; the housing of the resin expansion space is provided with a resin inlet; the lower end of the housing is provided with a resin outlet pipe and a back washing outlet; the resin outlet pipe is arranged in center of a lower ellipse head curved surface axis; and the back washing outlet is connected with the bottom distribution device.

Owner:ZHEJIANG HAIYAN POWER SYST RESOURCES ENVIRONMENTAL TECH

A grate beam uniform air supply structure

ActiveCN106904851BUniform supply air coolingReasonable air distributionEngineeringMechanical engineering

The invention provides a grid plate beam uniform air supply structure which comprises a grid plate beam, side grid plates and a middle grid plate, wherein the side grid plates are mounted on the two sides of the grid plate beam, the middle grid plate is arranged between the side grid plates, the structure further comprises a main air supply pipe, a plurality of air supply branch pipes are arranged on the main air supply pipe from left to right sequentially, and the air outlet ends of the air supply branch pipes are communicated with the inside of the grid plate beam. According to the grid plate beam uniform air supply structure, uniform air supply cooling of all the materials on the grid plate can be ensured, the air distribution can be more reasonable, and more energy is saved.

Owner:NANJING KISEN INT ENG

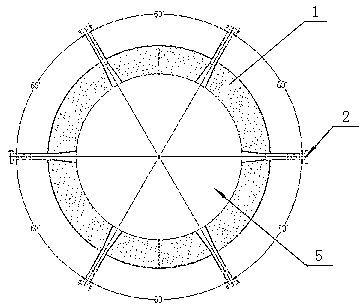

Secondary combustion chamber air-distribution device of hazardous waste incineration system

PendingCN109185899ASimple structureReasonable air distributionIncinerator apparatusNon-combustible gases/liquids supplyAir volumeCombustion chamber

The invention relates to the technical field of hazardous waste incineration and particularly discloses a secondary combustion chamber air-distribution device of a hazardous waste incineration system.The secondary combustion chamber air-distribution device of the hazardous waste incineration system comprises a secondary combustion chamber, and is characterized in that a plurality of bottom-layerair inlets and a plurality of upper-layer air inlets are arranged at the bottom of the secondary combustion chamber in an upper-lower two-layer distribution manner; the bottom-layer air inlets and theupper-layer air inlets are uniformly distributed in one and the same cross section of a furnace wall of the secondary combustion chamber; the bottom-layer air inlets are perpendicular to the furnacewall of the secondary combustion along the radial direction and then lead to the interior of a furnace hearth; and the upper-layer air inlets lead to the interior of the furnace hearth along the clockwise tangential direction of the inner wall of the furnace hearth, namely the direction along with which the upper-layer air inlets communicate with the secondary combustion chamber. The secondary combustion chamber air-distribution device disclosed by the invention is simple in structure and reasonable in air distribution; the flow direction and the flow rate of flue gas entering the secondary combustion chamber can be adjusted, the strong turbulence of the flue gas can be formed in the secondary combustion chamber, the national-standard flue gas residence time can be reached, and the combustion effect can be improved; and for the same air volume requirements, the height and the diameter of the secondary combustion chamber can be greatly reduced, and the equipment manufacturing cost can be reduced.

Owner:山东福航新能源环保股份有限公司

Injector type smoke preheating burner with high efficiency

InactiveCN101696804BEfficient reuseFully warmed upIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention discloses an injector type smoke preheating burner with high efficiency, mainly comprising an upper plate (3), a bottom barrel (6) fixed with the upper plate (3) into a whole and provided with a chamber inside, a spray pipe (7) connected with the bottom barrel (6), and a gas inlet pipe (1), wherein the gas outlet end of the gas inlet pipe (1) is positioned in the bottom barrel (6) through the upper plate (3). The injector type smoke preheating burner is characterized in that a gas preheating channel (4) is arranged in the bottom barrel (6), wherein one end of the gas preheating channel (4) is connected with the gas inlet pipe (1), and the other end of the gas preheating channel (4) is connected with a mixture connection pipe (5) positioned in the bottom barrel (6); the gas outlet end of an air inlet pipe (2) arranged on the upper plate (3) is communicated with the chamber in the bottom barrel (6), and emery with good heat storage effect is filled in the chamber to preheat the air; and a smoke inlet pipe (9) connected with the mixture connection pipe (5) is arranged at the bottom of the bottom barrel (6). In the invention, the high-temperature smoke generated in a fire channel can be effectively and repeatedly utilized, gas entering the fire channel can be sufficiently preheated to increase the temperature of the gas quickly, and very good heat vibration conduction effect is achieved.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

Down-feed biomass combustion boiler

InactiveCN105782955BReasonable air distributionBurn fullySolid fuel combustionAir/fuel supply for combustionCombustionEngineering

The invention relates to a biomass combustion boiler, in particular to an underfeed type biomass combustion boiler to solve the problems that in the prior art, air distribution is not reasonable, reverse combustion is likely to happen, combustion is not sufficient, and the heat efficiency is low. A feeding cylinder is arranged in a hearth. The lower end of the feeding cylinder communicates with the interior of a spiral feeder. A primary air distribution pipe communicates with the feeding cylinder. A secondary air distribution pipe is located above the primary air distribution pipe and communicates with the hearth. A flue is arranged at the upper end of the hearth. A smoke outlet pipe is arranged at the outlet end of the flue. A chimney is arranged on the smoke outlet pipe. A settling chamber is arranged below the smoke outlet pipe and communicates with the smoke outlet pipe through a pipeline. An inflaming retarding plate is inserted in the side wall of the hearth, and one end, located outside the hearth, of the inflaming retarding plate is connected with an electric push rod. When the electric push rod is elongated, an upper port of the feeding cylinder is covered with the inflaming retarding plate, and when the electric push rod is shortened, the inflaming retarding plate disengages from the upper port of the feeding cylinder, and the chimney is provided with an induced draught fan. The biomass combustion boiler is used for combusting biomass fuel.

Owner:嘉兴骏博精密机械有限公司

Underfeed type biomass combustion boiler

InactiveCN105782955AReasonable air distributionBurn fullySolid fuel combustionAir/fuel supply for combustionHearthEngineering

The invention relates to a biomass combustion boiler, in particular to an underfeed type biomass combustion boiler to solve the problems that in the prior art, air distribution is not reasonable, reverse combustion is likely to happen, combustion is not sufficient, and the heat efficiency is low. A feeding cylinder is arranged in a hearth. The lower end of the feeding cylinder communicates with the interior of a spiral feeder. A primary air distribution pipe communicates with the feeding cylinder. A secondary air distribution pipe is located above the primary air distribution pipe and communicates with the hearth. A flue is arranged at the upper end of the hearth. A smoke outlet pipe is arranged at the outlet end of the flue. A chimney is arranged on the smoke outlet pipe. A settling chamber is arranged below the smoke outlet pipe and communicates with the smoke outlet pipe through a pipeline. An inflaming retarding plate is inserted in the side wall of the hearth, and one end, located outside the hearth, of the inflaming retarding plate is connected with an electric push rod. When the electric push rod is elongated, an upper port of the feeding cylinder is covered with the inflaming retarding plate, and when the electric push rod is shortened, the inflaming retarding plate disengages from the upper port of the feeding cylinder, and the chimney is provided with an induced draught fan. The biomass combustion boiler is used for combusting biomass fuel.

Owner:嘉兴骏博精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com