Efficient mobile bed gasifier device with pre-dechlorinating function and dechlorinating method of efficient mobile bed gasifier device

A moving bed and gasifier technology, which is applied in the field of high-efficiency moving bed gasifier devices, to achieve the effects of improving resource utilization, low carbon content in ash and slag, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

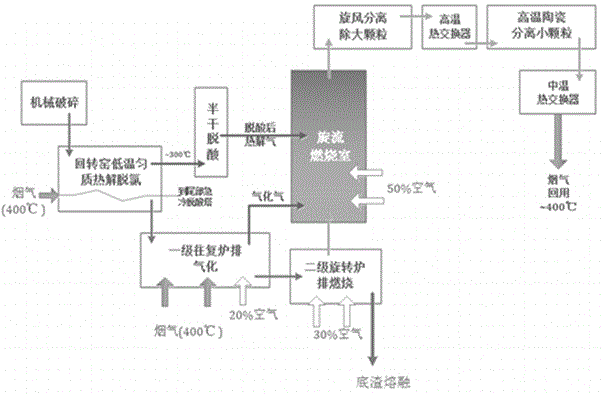

Image

Examples

Embodiment Construction

[0024] In the two-stage fire grate device, the inclination angle of the first-stage reciprocating fire grate is 5°, which is supported by joists. The reciprocating grate is driven by hydraulic pressure, in which the fixed grate piece is connected with the fixed beam, and the movable grate is driven by the movable beam, so as to realize the reciprocating motion of the grate and drive the fuel to move continuously. Coal retaining devices are arranged on the left and right sides of the front section of the grate to prevent side leakage of fuel. A cooling pipe is arranged under the reciprocating fire grate, which can cool the fire grate and prevent the temperature of the fire grate from being too high.

[0025] The pre-dechlorinated waste falls on the first-stage reciprocating grate for gasification and partial combustion.

[0026] The primary tuyere is arranged under the reciprocating fire grate, and the air chamber is made of acid and alkali resistant stainless steel. The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com