Patents

Literature

80 results about "Off rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This chemical equilibrium is also the ratio of the on-rate (k forward) and off-rate (k back) constants. Two antibodies can have the same affinity, but one may have both a high on- and off-rate constant, while the other may have both a low on- and off-rate constant.

METHODS OF ADMINISTERING ANTI-TNFalpha ANTIBODIES

InactiveUS20130004507A1Reduce in quantityLess frequentSenses disorderNervous disorderHuman tumorAntigen binding

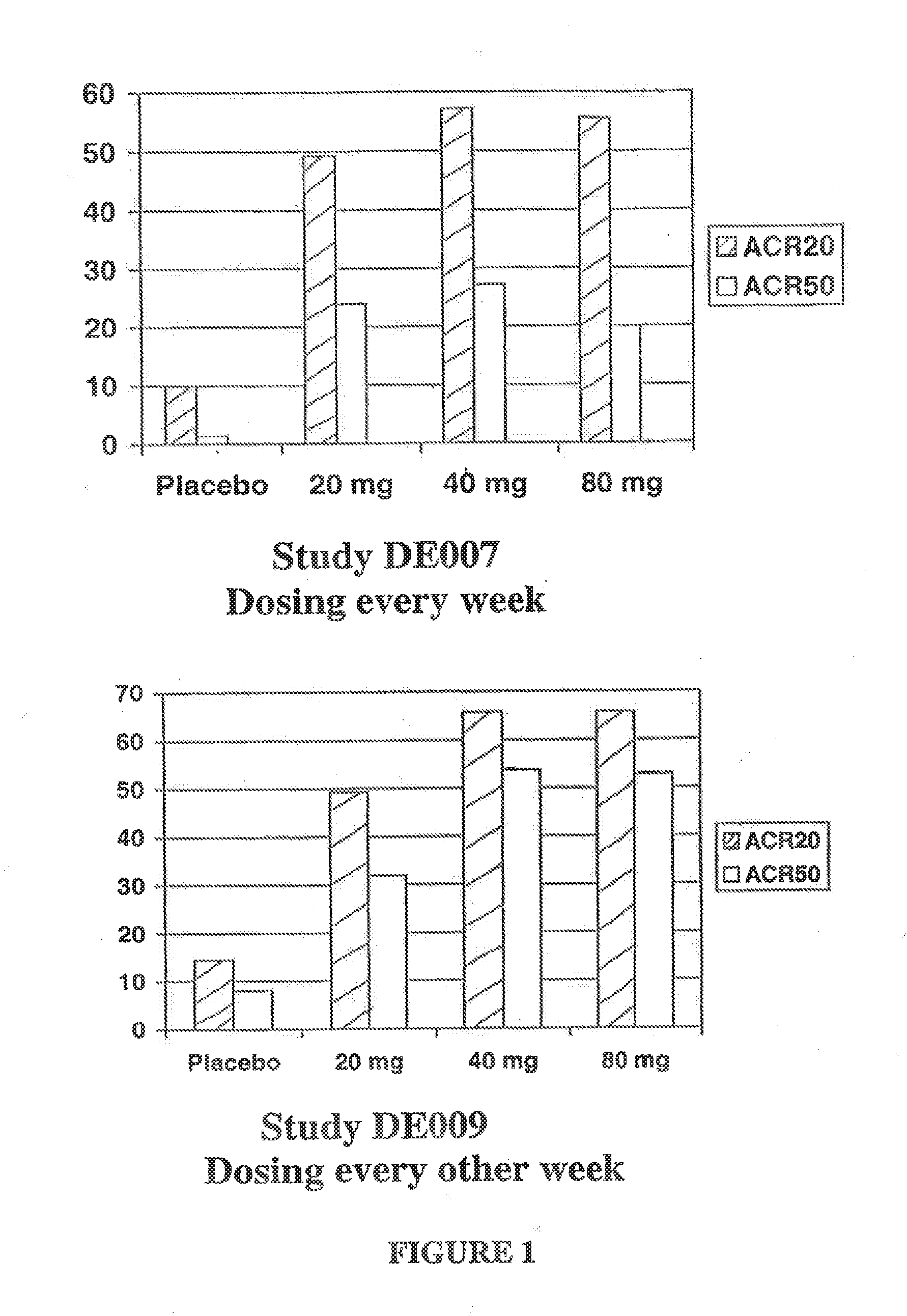

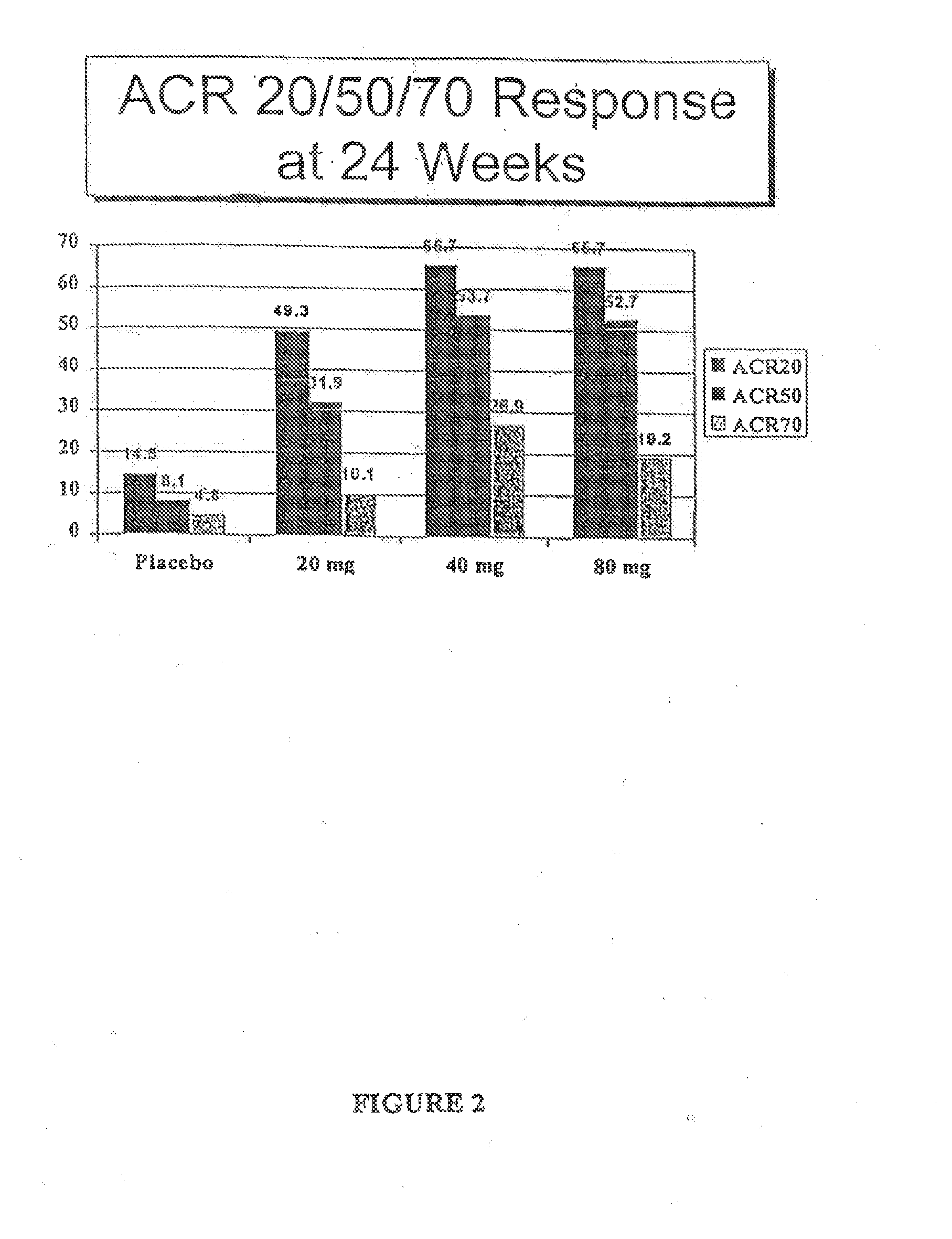

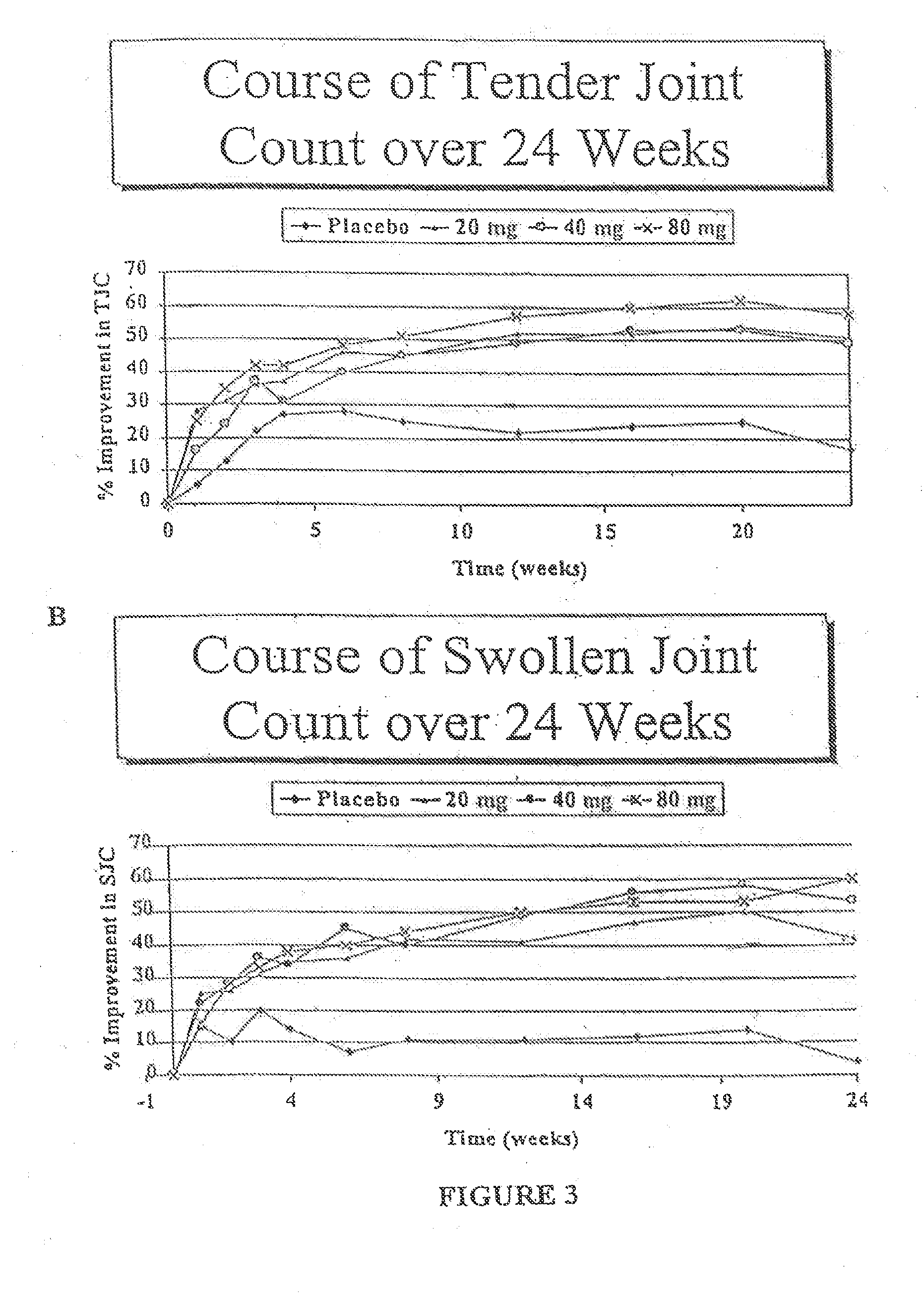

Methods of treating disorders in which TFNα activity is detrimental via biweekly, subcutaneous administration of human antibodies, preferably recombinant human antibodies, that specifically bind to human tumor necrosis factor α (hTNFα) are disclosed. The antibody may be administered with or without methotrexate. These antibodies have high affinity for hTNFα (e.g., Kd=10−8 M or less), a slow off rate for hTNFα dissociation (e.g., Koff=10−3 sec−1 or less) and neutralize hTNFα activity in vitro and in vivo. An antibody of the invention can be a full-length antibody or an antigen-binding portion thereof. Kits containing a pharmaceutical composition and instructions for dosing, and preloaded syringes containing pharmaceutical compositions are also encompassed by the invention.

Owner:ABBOTT BIOTECHNOLOGY LTD

Method and apparatus for welding

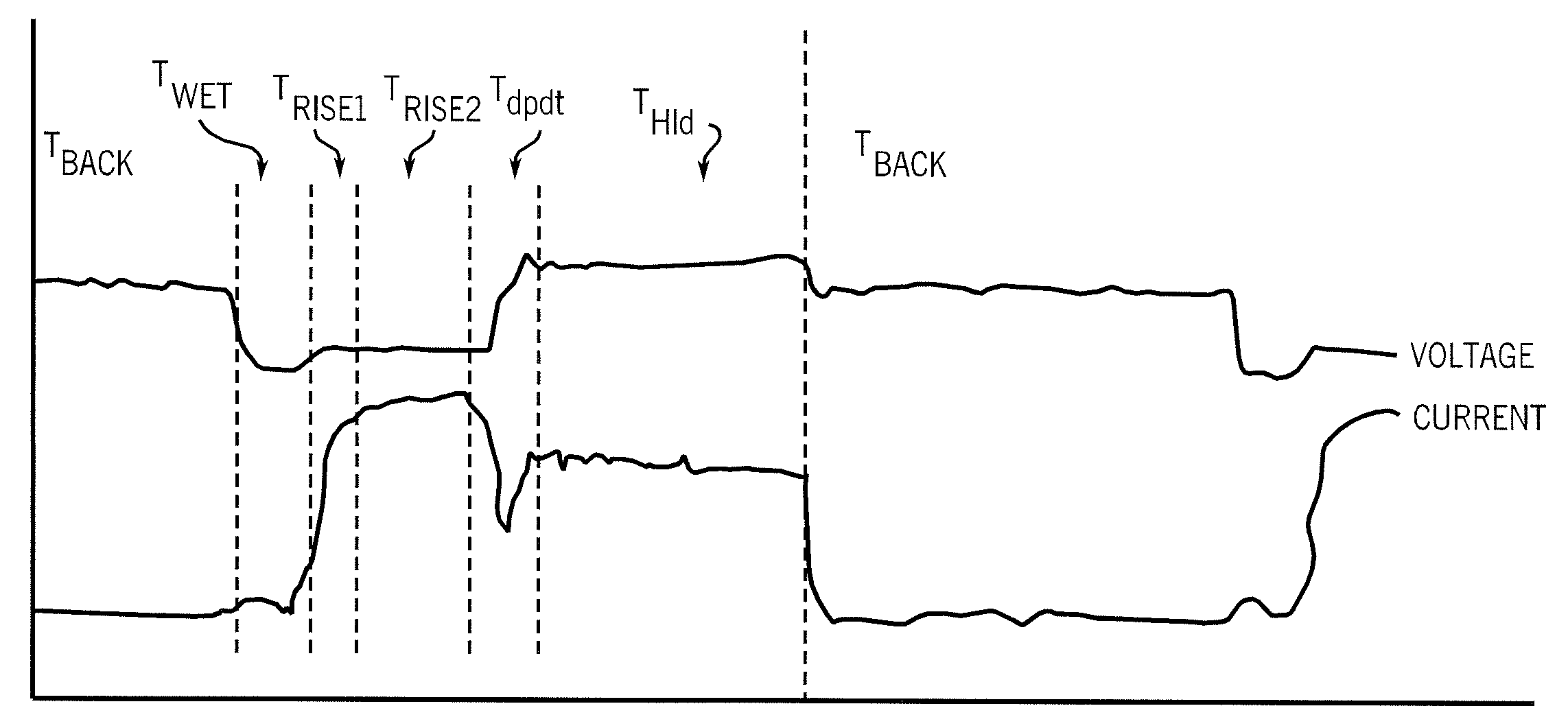

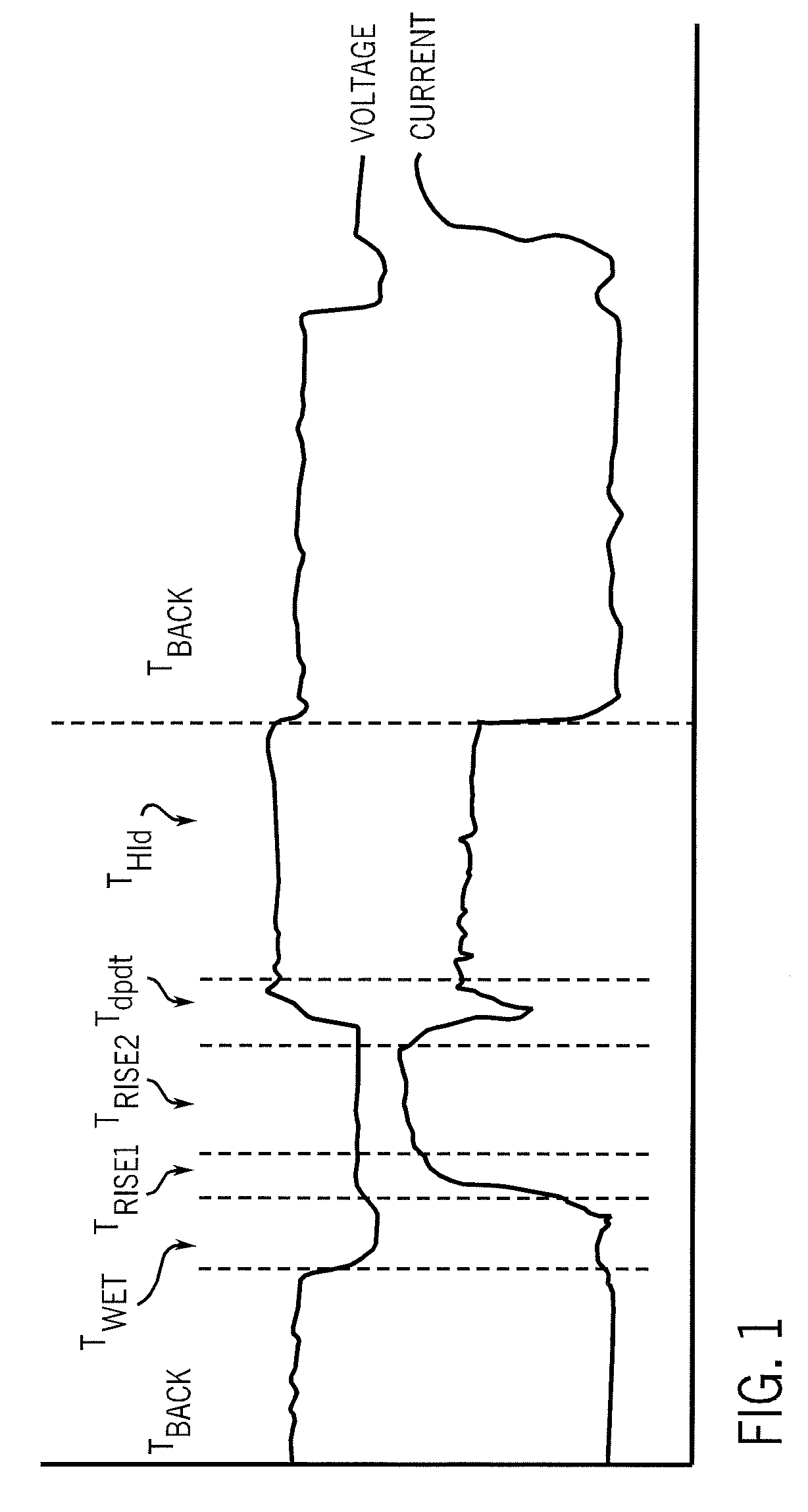

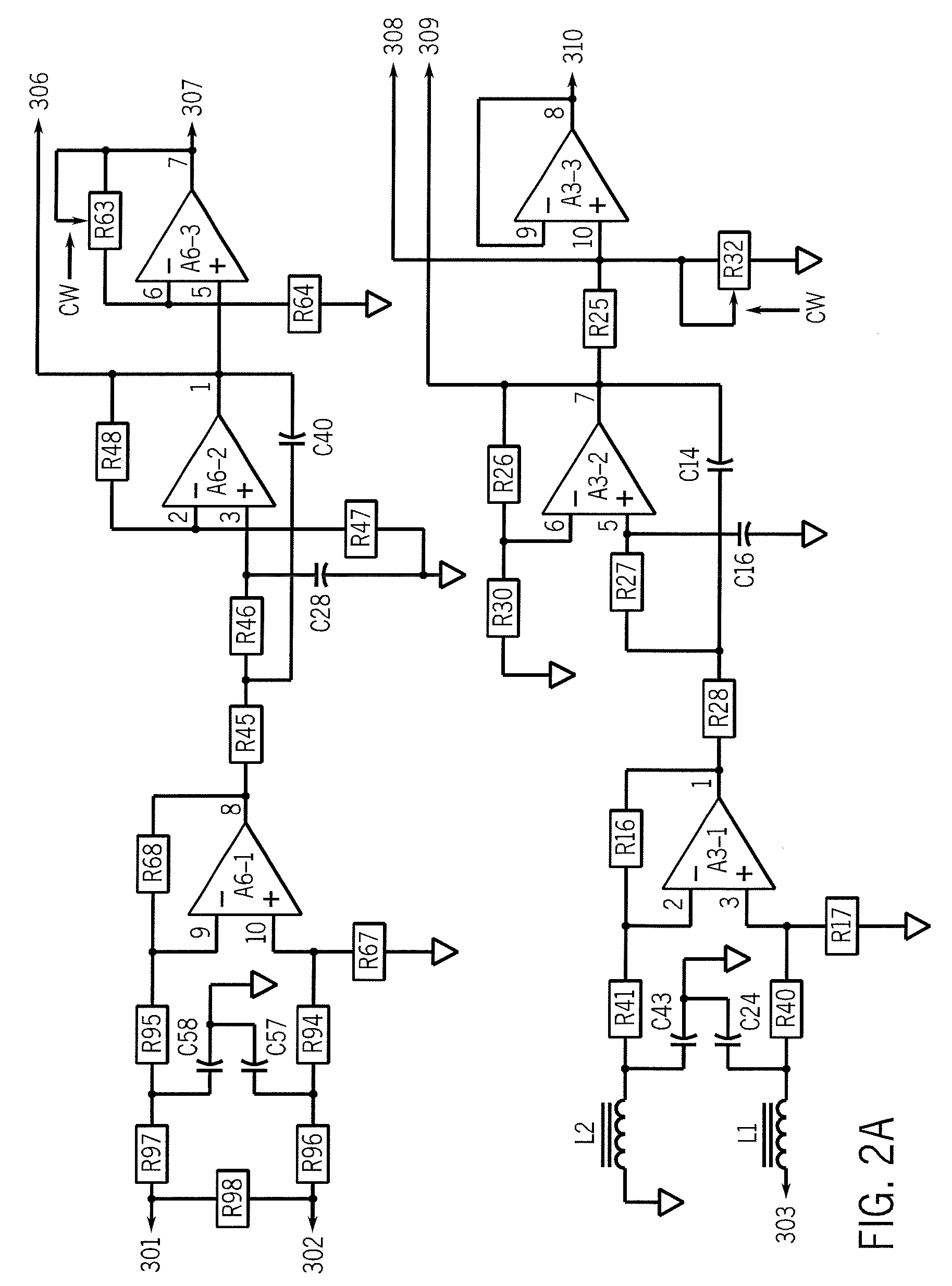

A short circuit arc welding system is disposed. The control scheme uses a current command signal to drive the output current. The command signal is comprised of a long-term current command that sets the long-term current command level and a real-time or short-by-short current command. Arc voltage feedback is used to determine if the desired arc length is present and to adjust the long-term command. The short-by-short current command is derived from real-time arc current feedback and is used to control the burn-off rate by an instantaneous, or short-by-short, adjustment of the current command. A function of the time derivative of arc power, less the time derivative of arc current, is used to detect, in real time, when the short is about to clear. A stop algorithm is employed that monitors the arc on a short-by-short basis. When the process is ending a very low current level is provided to avoid forming a ball. However, if a short is created, (indicated by a drop in arc voltage) after the low current level, a burst of energy is provided to clear of burn off the short. After the short is cleared, very low current is again provided to avoid forming a large ball. This is repeated until the wire stops and the process ends.

Owner:ILLINOIS TOOL WORKS INC

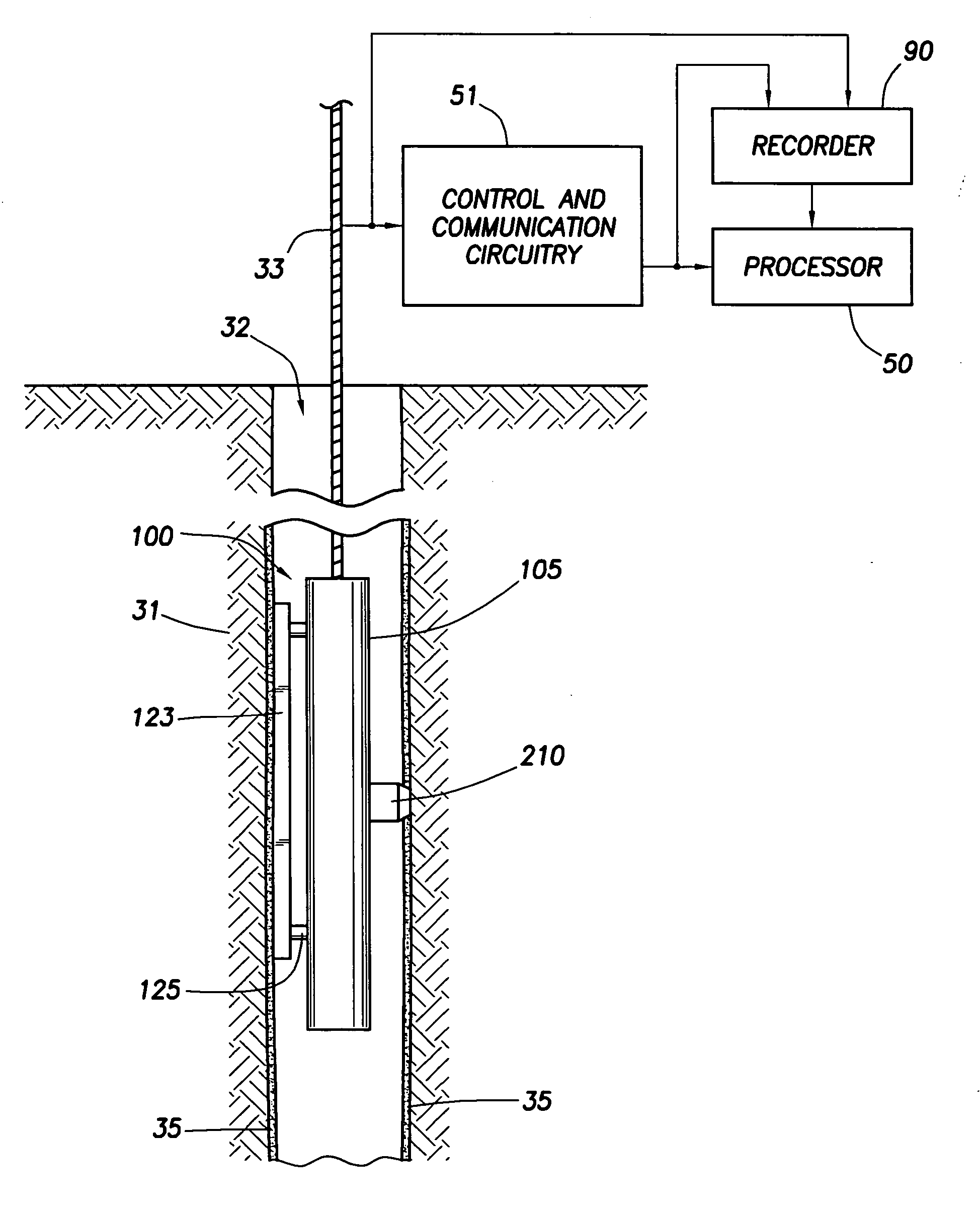

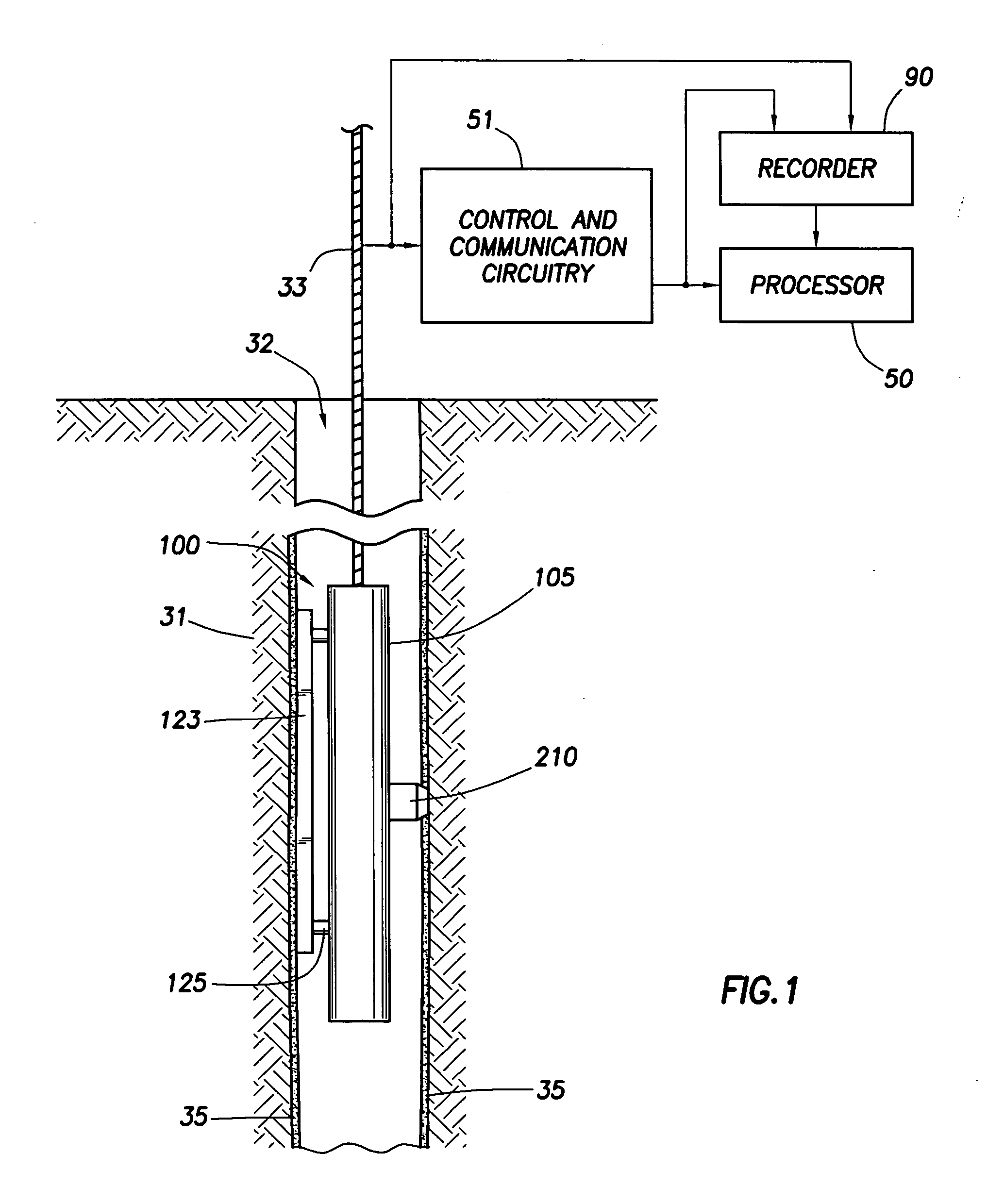

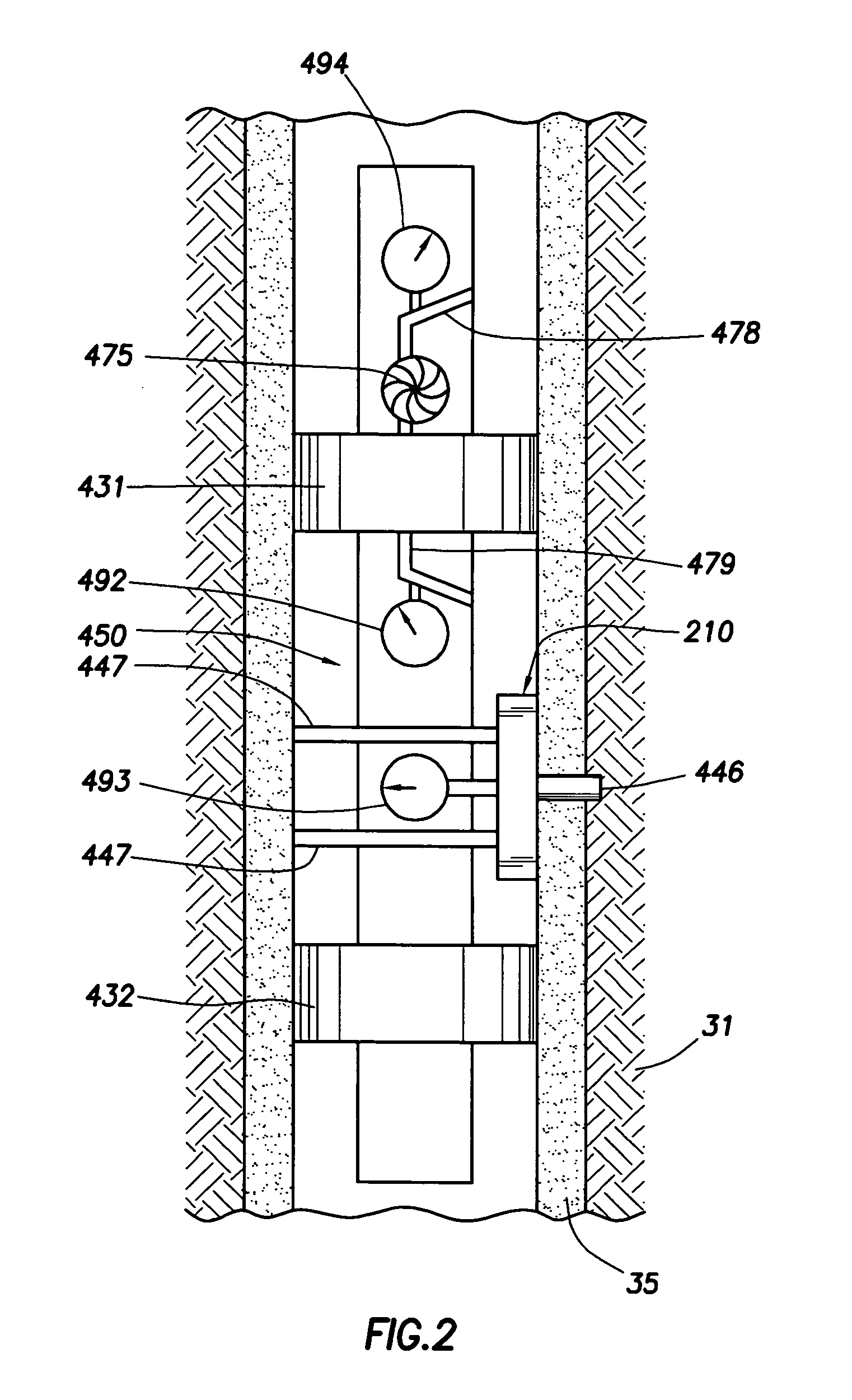

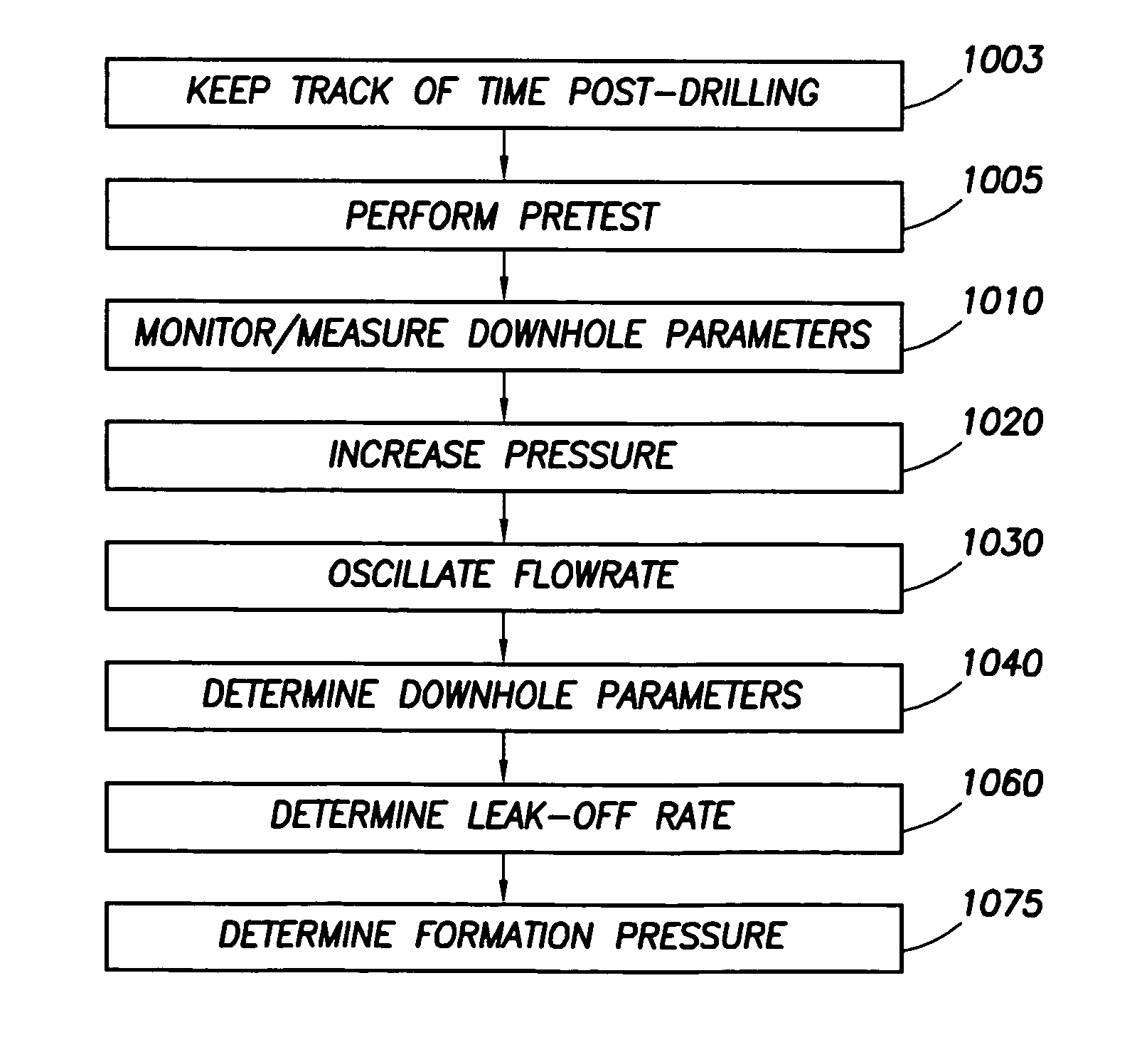

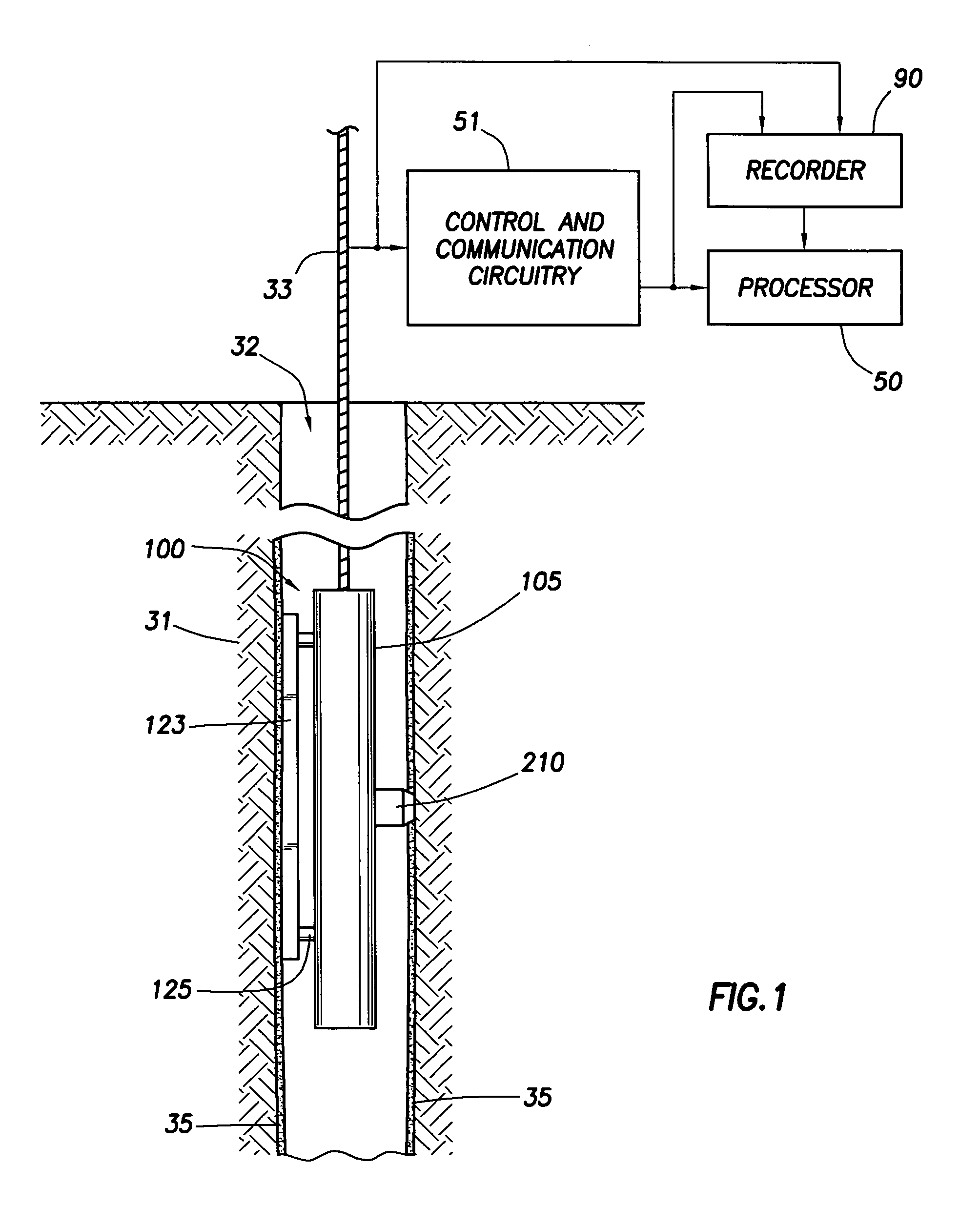

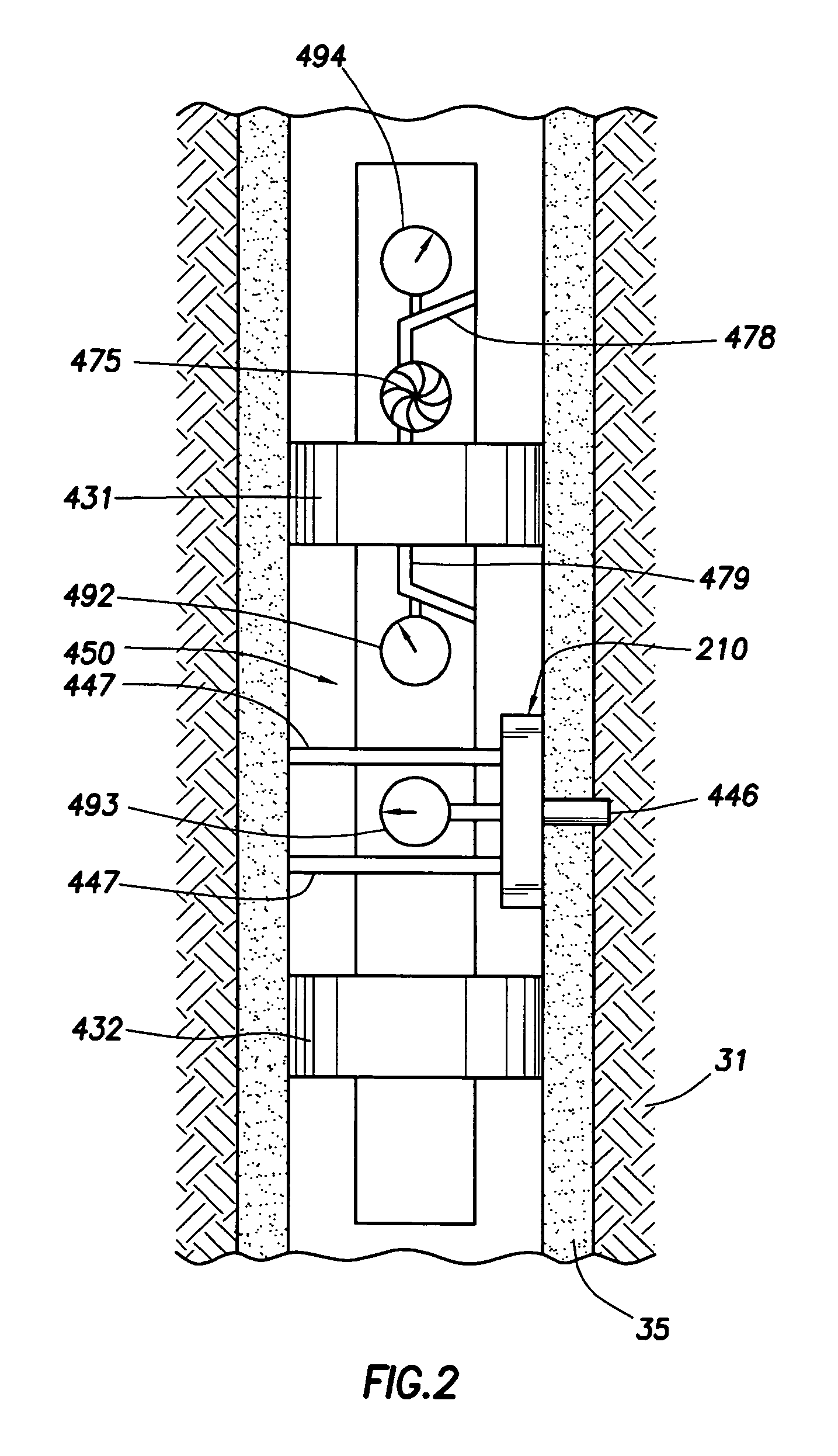

Method for determining pressure of earth formations

ActiveUS20050171699A1Electric/magnetic detection for well-loggingSurveyWell drillingRate of penetration

A method for determining formation pressure at a depth region of formations surrounding a borehole, including: keeping track of the time since cessation of drilling at the depth region; deriving formation permeability at the depth region; causing wellbore pressure to vary periodically in time and determining, at the depth region, the periodic and non-periodic component of pressure measured in the formations; determining, using the time, the periodic component and the permeability, the formation pressure diffusivity and transmissibility and an estimate of the size of the pressure build-up zone around the wellbore at the depth region; determining, using the time, the formation pressure diffusivity and transmissibility, and the non-periodic component, the leak-off rate of the mudcake at the depth region; determining, using the leak-off rate, the pressure gradient at the depth region; and extrapolating, using the pressure gradient and the size of the build-up zone, to determine the formation pressure.

Owner:SCHLUMBERGER TECH CORP

Method for determining pressure of earth formations

A method for determining formation pressure at a depth region of formations surrounding a borehole, including: keeping track of the time since cessation of drilling at the depth region; deriving formation permeability at the depth region; causing wellbore pressure to vary periodically in time and determining, at the depth region, the periodic and non-periodic component of pressure measured in the formations; determining, using the time, the periodic component and the permeability, the formation pressure diffusivity and transmissibility and an estimate of the size of the pressure build-up zone around the wellbore at the depth region; determining, using the time, the formation pressure diffusivity and transmissibility, and the non-periodic component, the leak-off rate of the mudcake at the depth region; determining, using the leak-off rate, the pressure gradient at the depth region; and extrapolating, using the pressure gradient and the size of the build-up zone, to determine the formation pressure.

Owner:SCHLUMBERGER TECH CORP

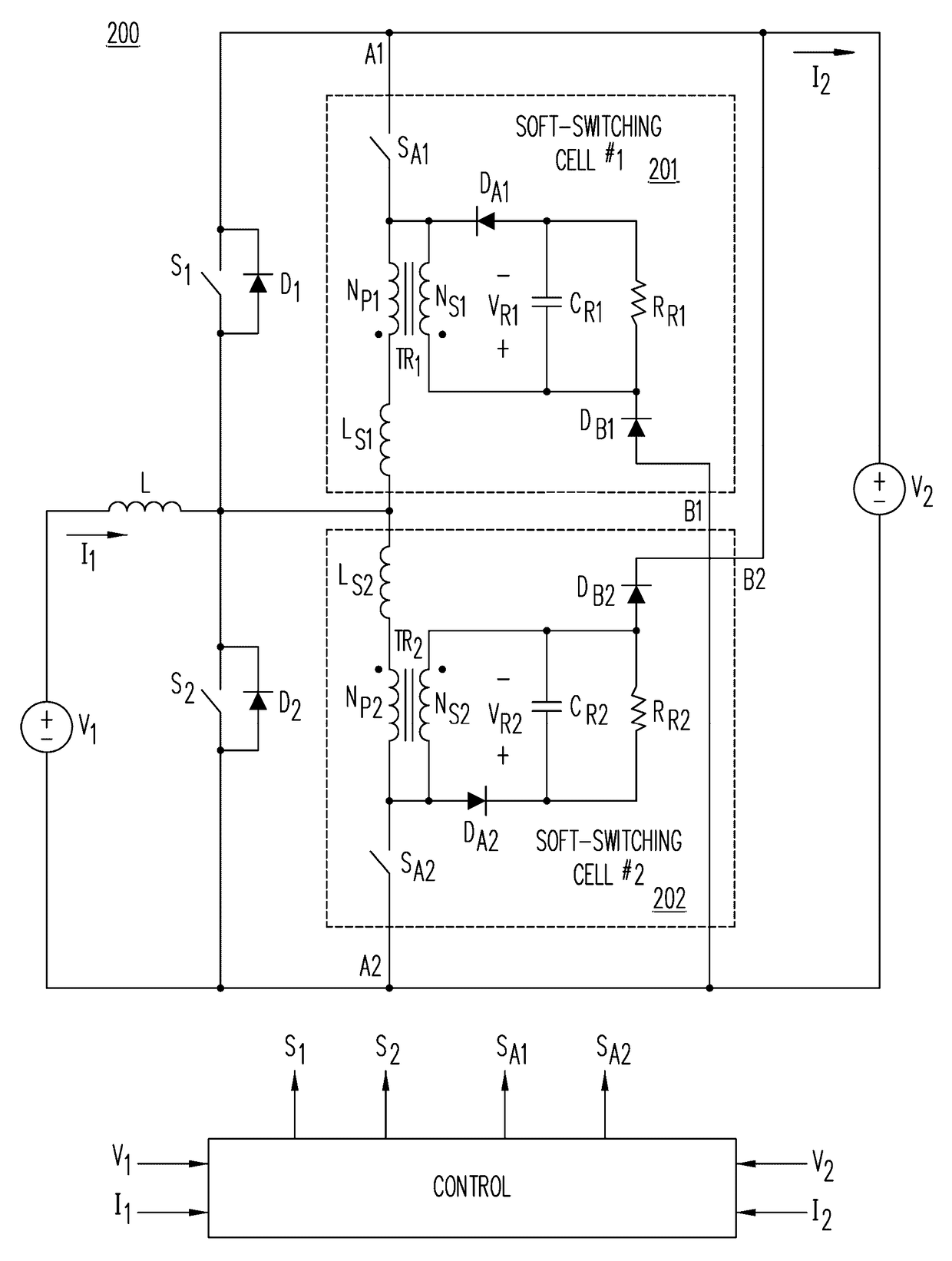

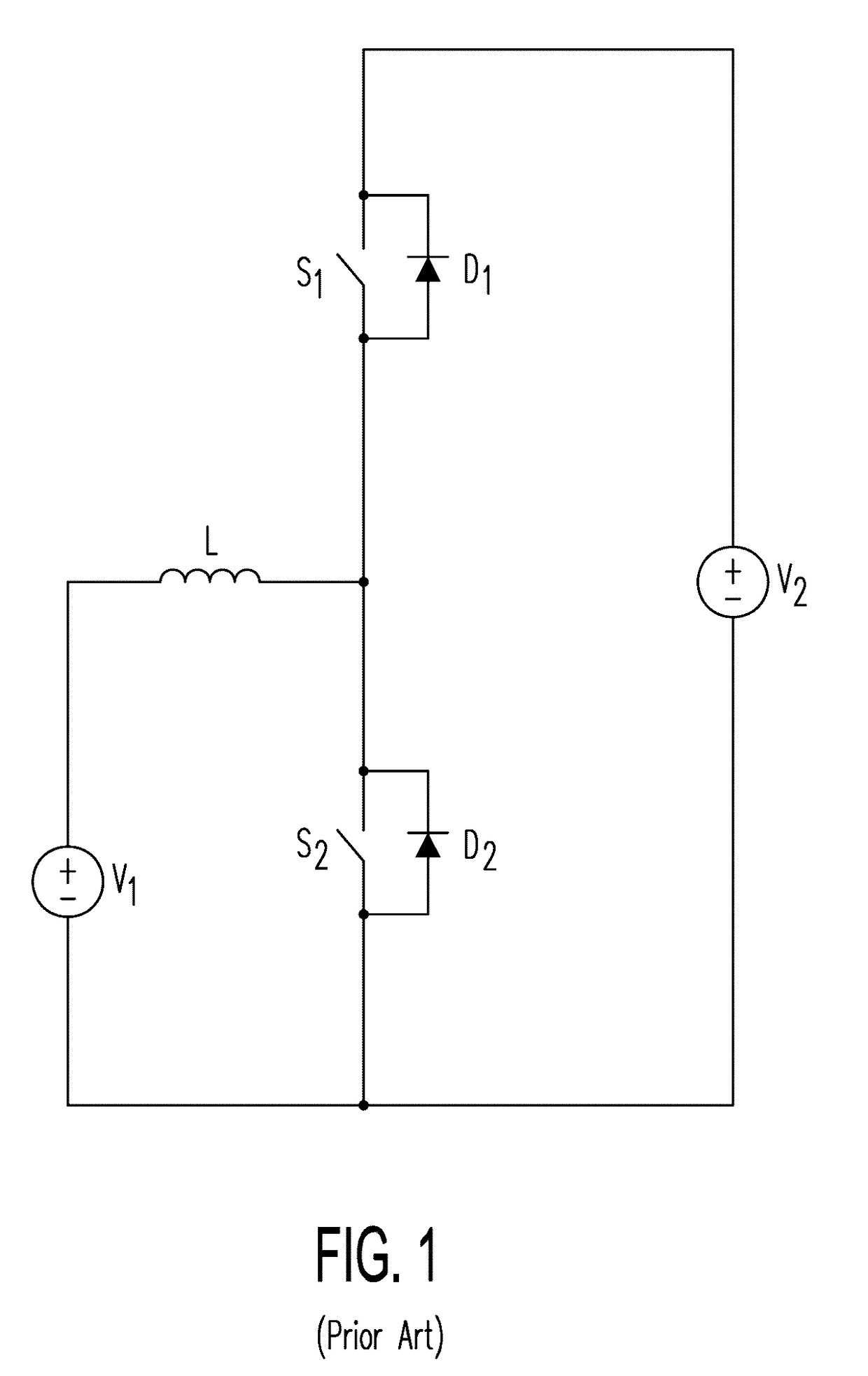

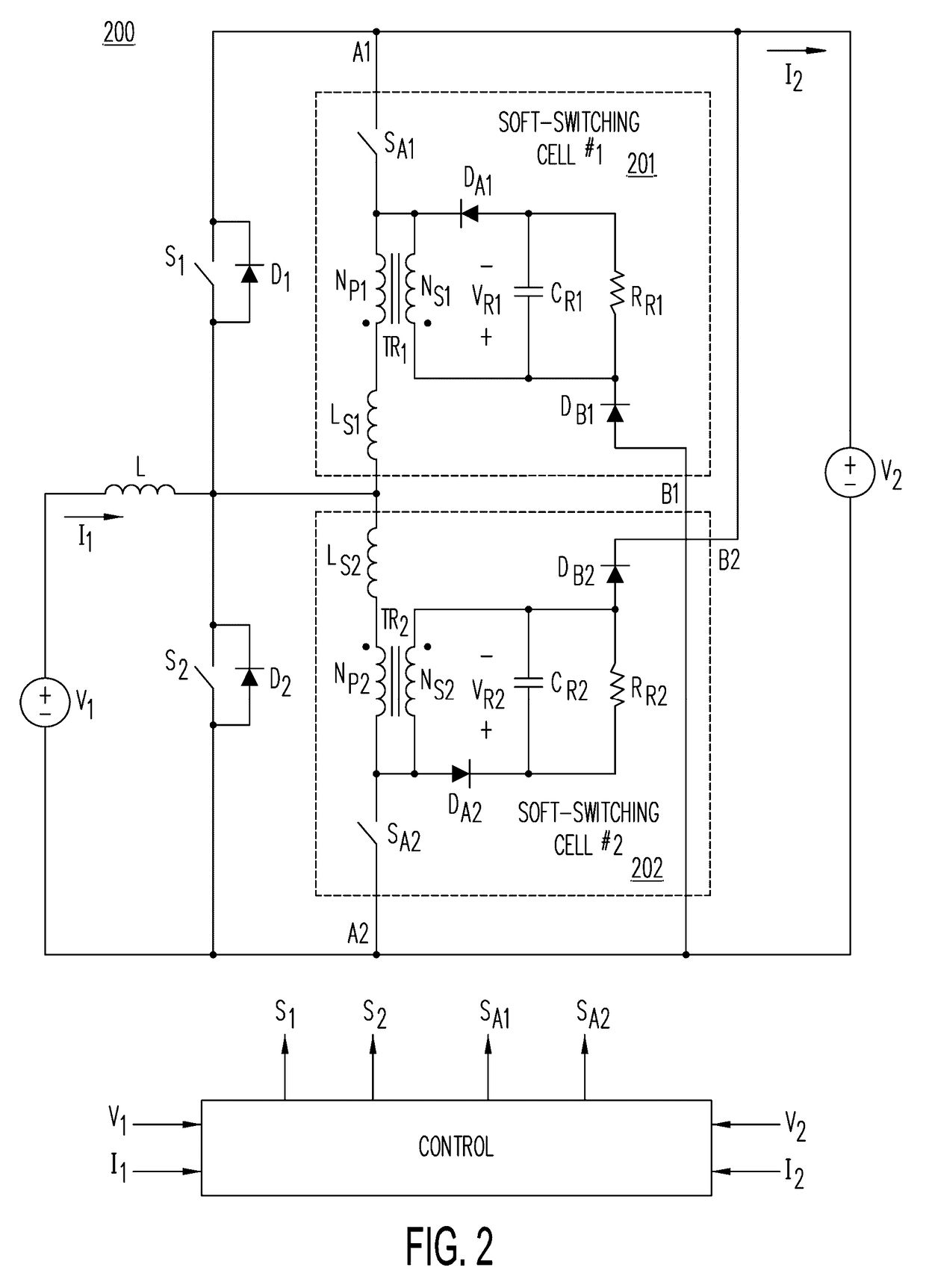

Soft-switched bidirectional buck-boost converters

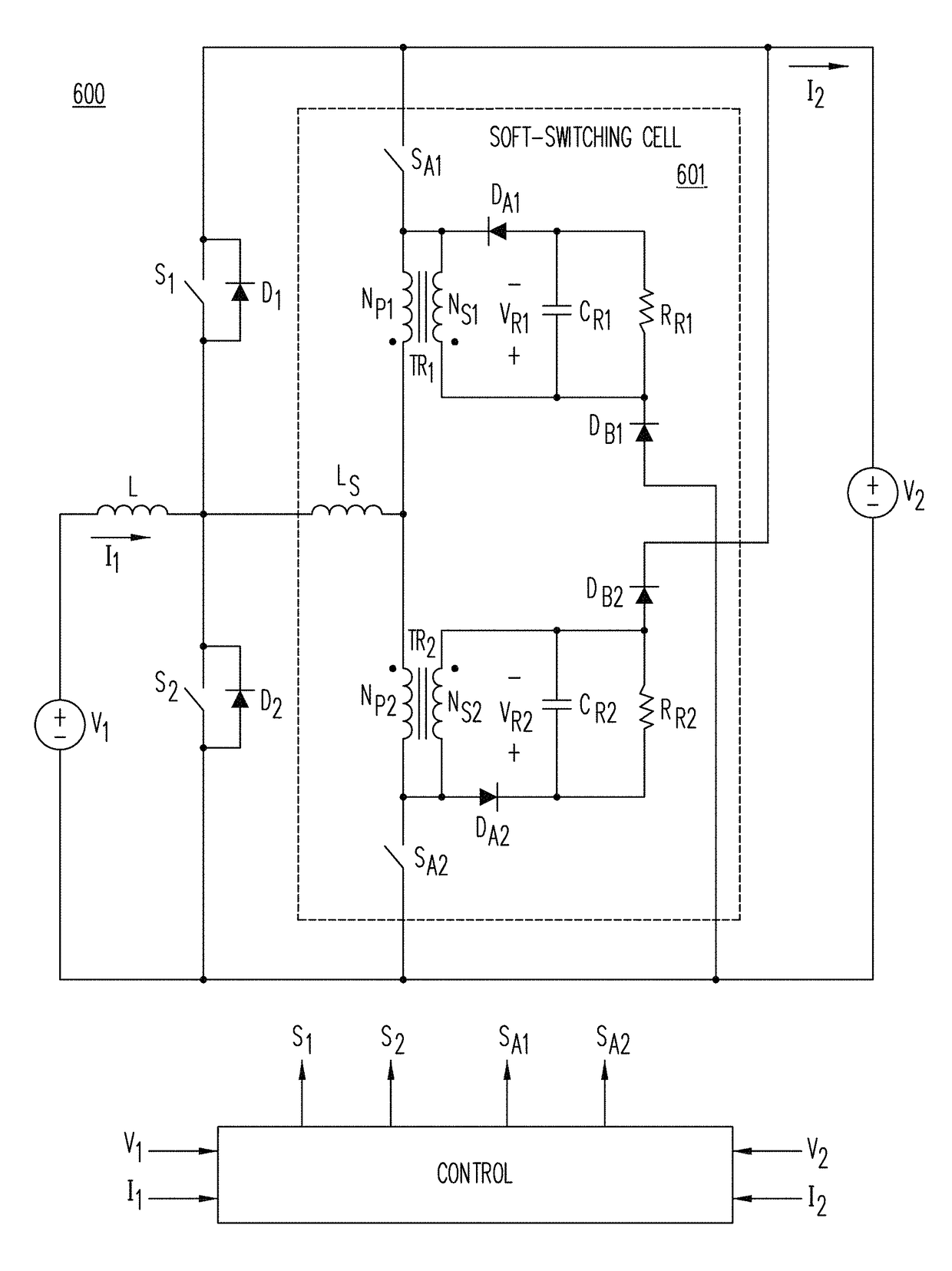

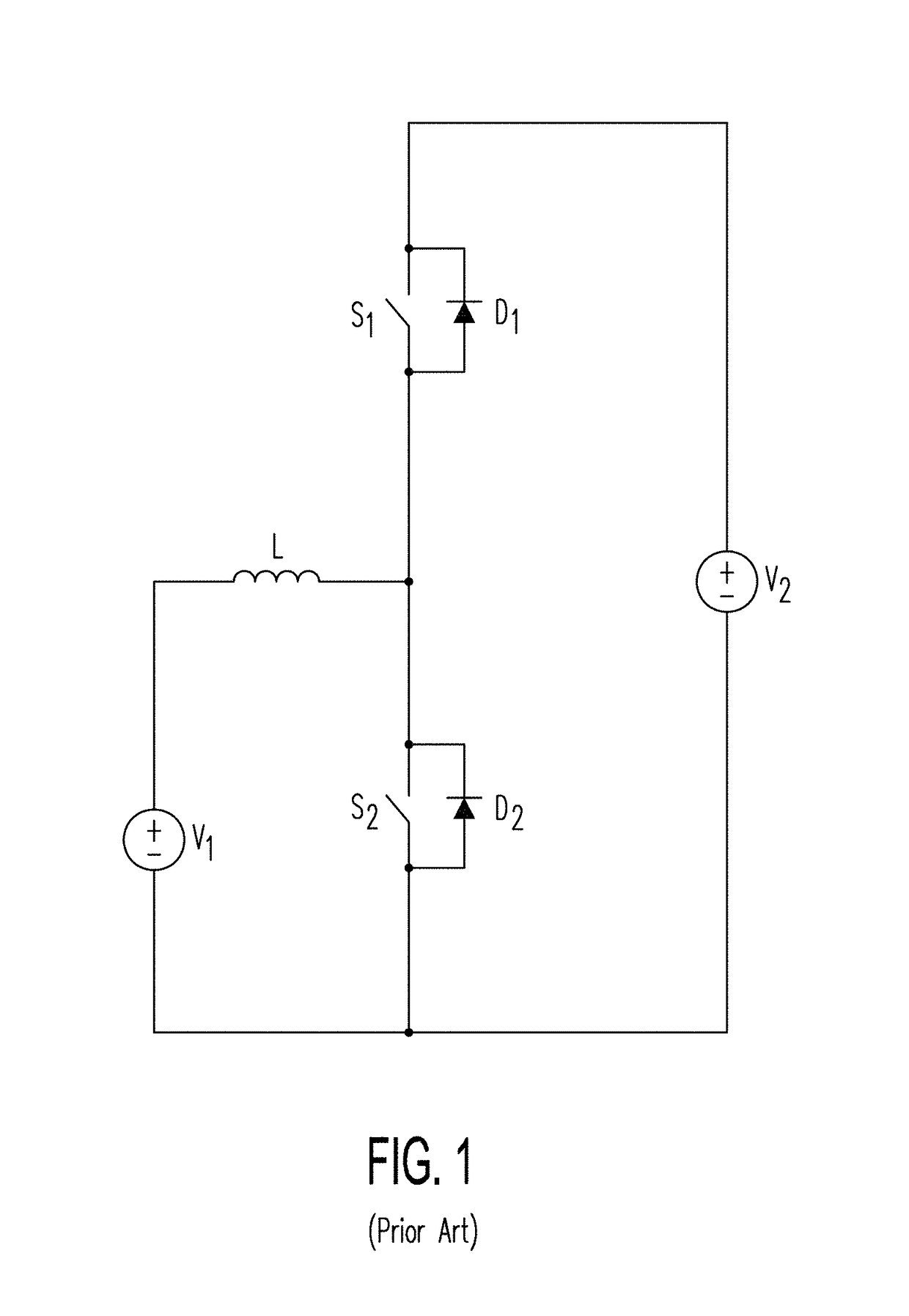

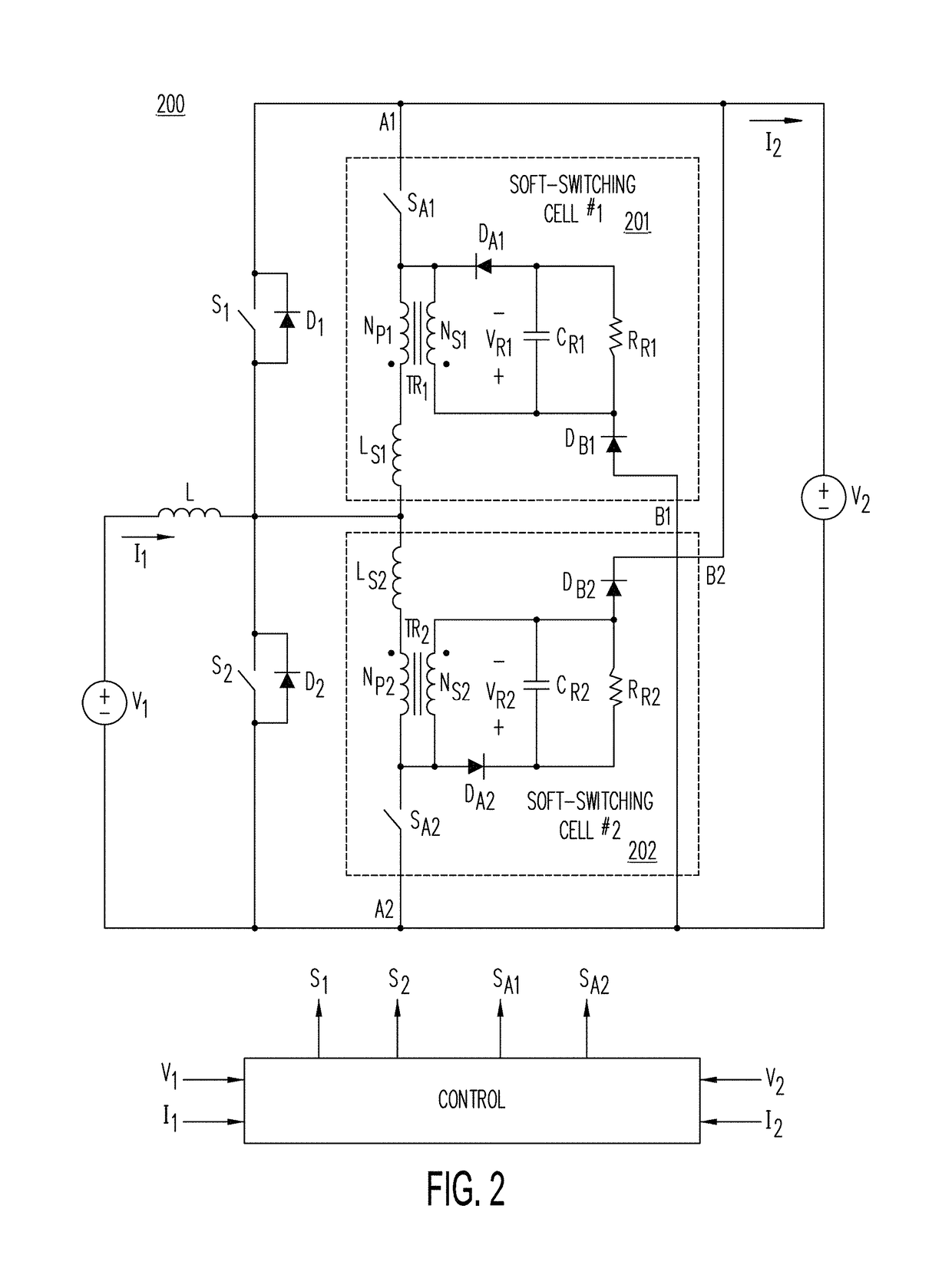

ActiveUS20170163163A1Reduce switching lossesMinimize reverse-recovery lossEfficient power electronics conversionDc-dc conversionTransformerActive switch

A bidirectional buck-boost converter includes at least one soft-switching cell to reduce switching losses by providing soft-switching of all semiconductor devices. A soft-switching cell comprises an active switch coupled in series with an inductor, a two-winding transformer, and a reset-voltage circuit. The soft-switching cells enable the buck and boost rectifiers to turn off with a controlled turn-off rate of their current to minimize their reverse-recovery losses, the power-controlling buck and boost switch to turn on with zero-voltage switching (ZVS), and the switch of the soft-switching cell to turn off with zero-current switching (ZCS).

Owner:DELTA ELECTRONICS INC

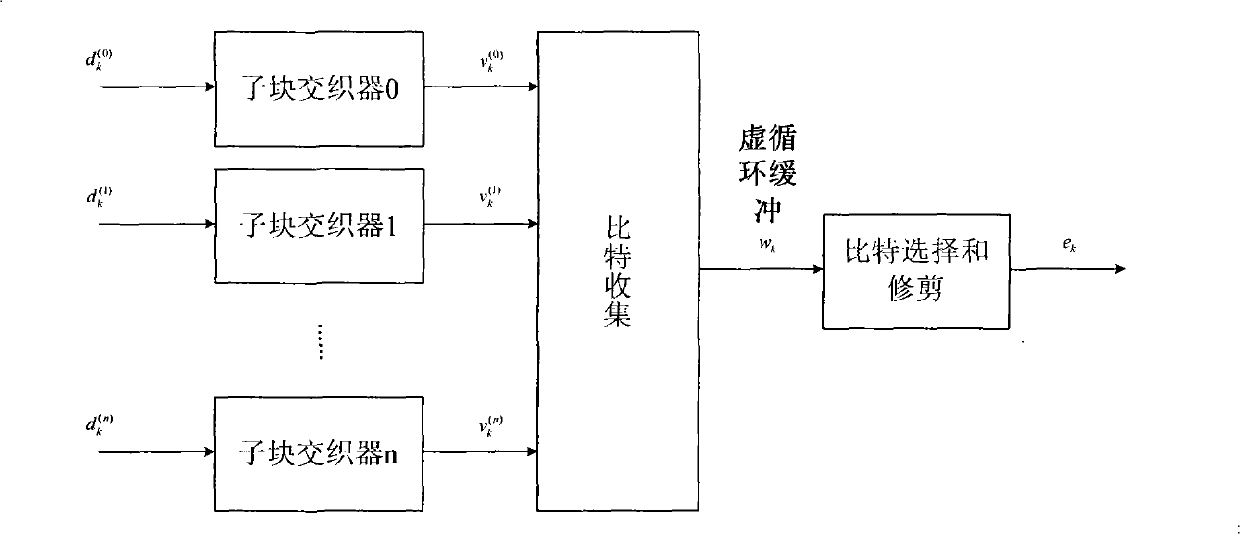

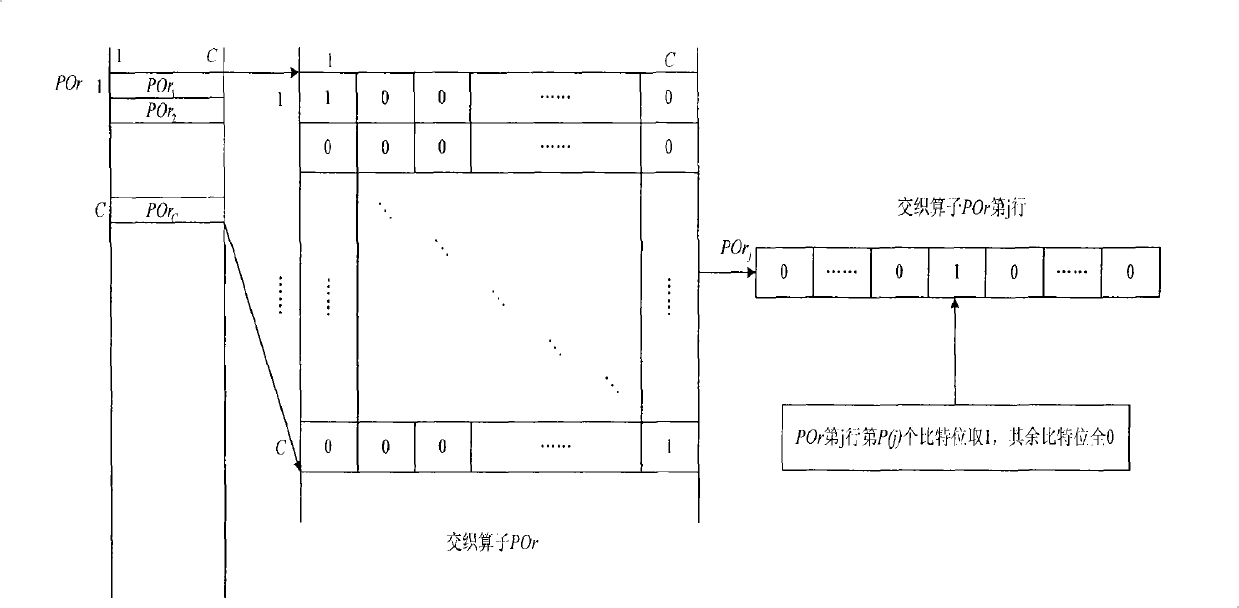

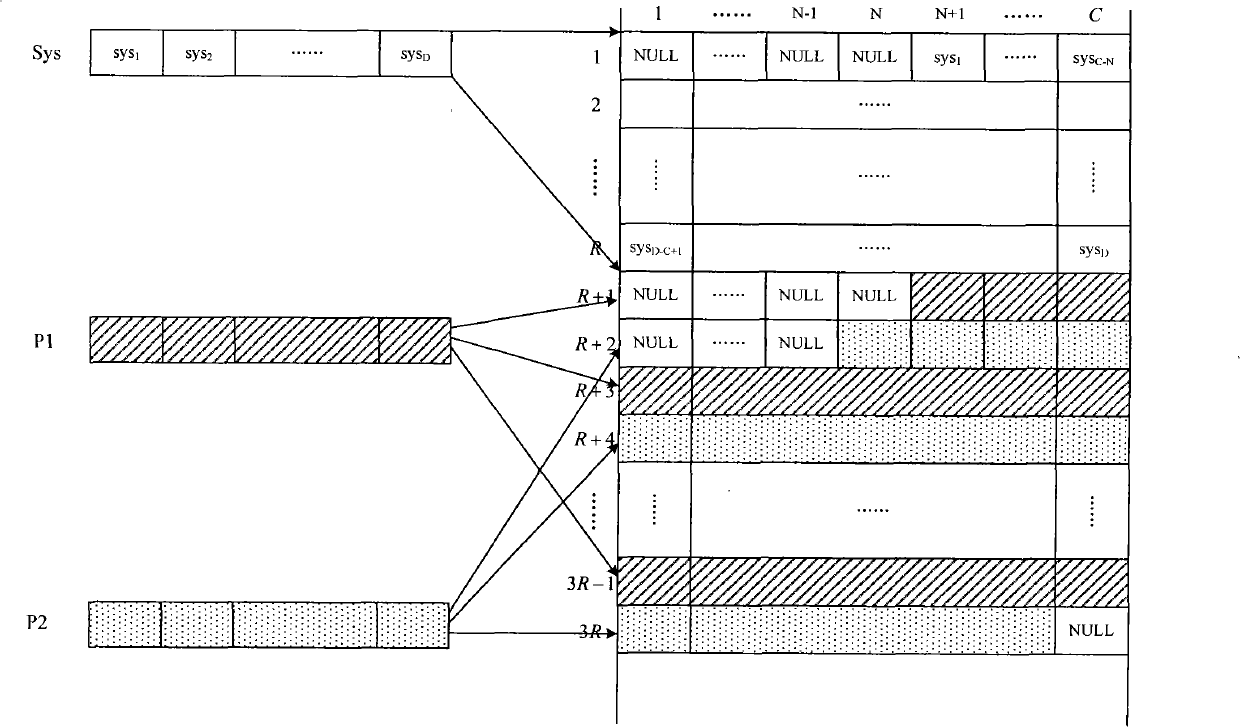

Method for interlacing rate matching and de-interlacing off-rate matching

InactiveCN101540654AReduce read and write operationsError preventionNetwork traffic/resource managementComputer scienceOff rate

The invention discloses an interlacing matching method. The method determines interlacing operators according to a column interlacing mode, and uses the sequence of the interlacing operators to carry out interlacing processing for a sub-block interlacing matrix, wherein in one mode, the method uses the interlacing operators to carry out the interlacing processing for bits needing to be output in the sub-block interlacing matrix according to the requirement of a redundancy version, and directly outputs sub-block interlacing results ordered by a protocol at the same time of finishing sub-block interlacing till reaching corresponding code rate requirement; and in the other mode, the method can use the interlacing operators to carry out the interlacing processing for the sub-block interlacing matrix one by one, outputs sub-block interlacing results ordered by the protocol to a cyclic buffer at the same time of finishing sub-block interlacing, and outputs corresponding interlaced bits according to the requirement of the redundancy version. Moreover, the invention also discloses a de-interlacing off-rate matching method corresponding to the interlacing rate matching method. The method can be applied to interlacing rate matching and de-interlacing off-rate matching, and greatly reduces used caches and read-write operations for the caches.

Owner:POTEVIO INFORMATION TECH CO LTD

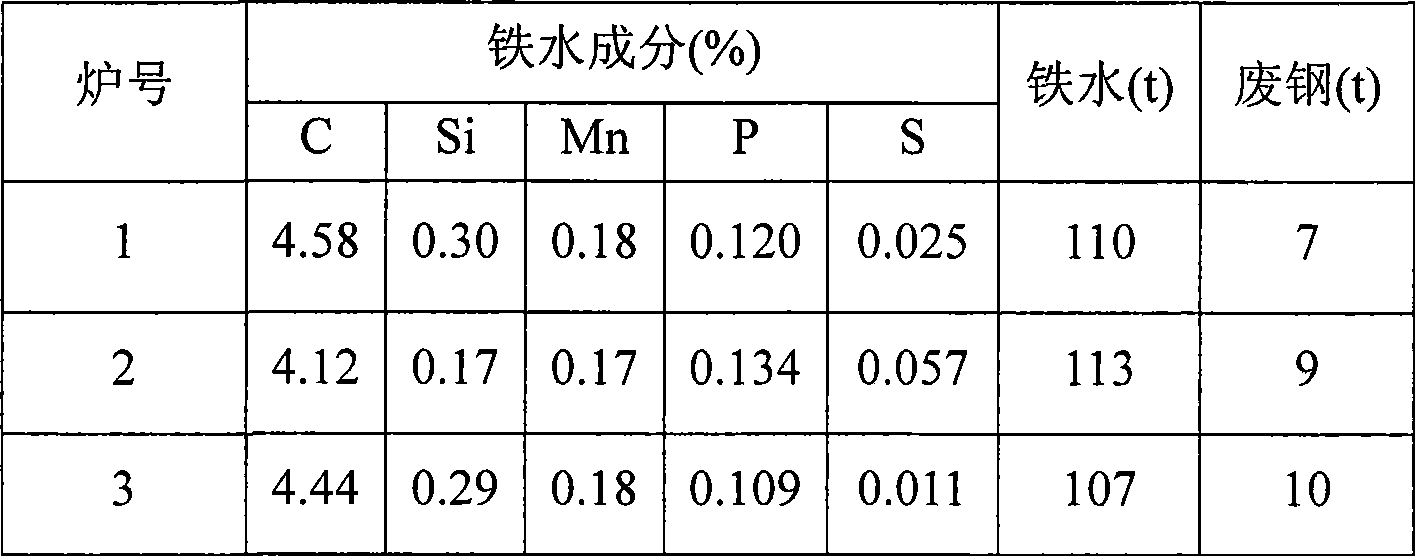

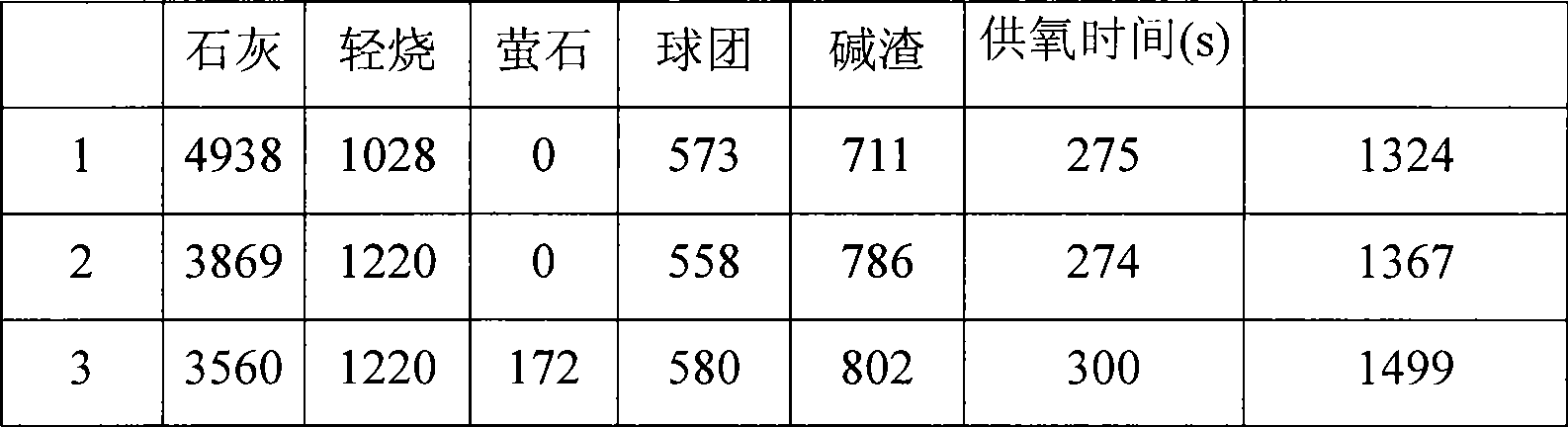

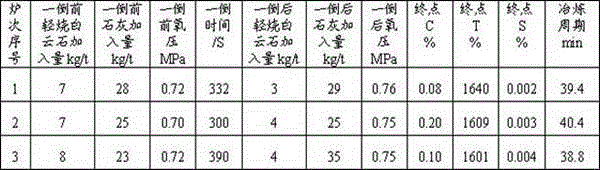

Converter smelting process using dephosphorization agent

InactiveCN101476013ALow investment costShorten the smelting cycleManufacturing convertersSteelmakingSmelting process

The invention pertaining to the field of convertor steelmaking technology provides a technique of converter smelting by using a dephosphorization agent. In a same convertor, dephosphorization is performed by using a CaO-base ephosphorization agent containing a few CaCl2 under favorable thermodynamics and combined-blowing dynamics conditions such as low temperature at the prior period, high content of iron oxide and the like, the prior period, desilication and dephosphorization slags of 50-70% are poured away in the molten iron preprocessing process, in the later period, decarburization process is performed and decarburization slag is formed and is then utilized as dephosphorization slag of the lower converter. According to the smelting technology, CaCl2 is added to the CaO-base ephosphorization agent to accelerate the burn-off rate of CaO by using the eutectic point character of CaCl2 and CaO binary system, the utilization ratio of lime is also improved, the utilizing of decarburization slag not only fully utilizes the physics heat brought by the decarburization slag, but also provides high content iron oxide for the dephosphorization of the prior period and accelerates the dephosphorization reaction.The invention has advantages of low cost of investment, shortened smelting period, carbon content of 0.4% at the end point of smelting, phosphorus content capable of being reduced to 0.006% and dephosphorization ratio up to 95.5%.

Owner:CHINA IRON & STEEL RES INST GRP +1

Replacing method of converter tap hole

The invention relates to a replacing method of a converter tap hole and belongs to the technical field of steel smelting. The replacing method of the converter tap hole provided by the invention comprises the following steps: 1, placing a whole set of brick in a brick cup channel and adjusting the angle and position; and 2, fixing the whole set of brick on the converter body, filling the gap between the brick cup and whole set of brick with a tapping hole grouting material and sintering the tapping hole grouting material by the waste heat in the converter. The invention has the following beneficial effects of the replace time shortened by about 10 minutes compared with an existing method, the service life of the tapping hole prolonged by about 250 furnace compared with the existing method, the success rate for pushing off the slag improved by 10% compared with the existing method and the cost on per ton of steel reduced by about 0.15 yuan, so as to achieve the purposes of shortening replace time for converter tapping hole, prolonging the service life of tapping hole, improving slag pushing-off rate, reducing production mistake, improving product quality and reducing production cost.

Owner:张家港联峰钢铁研究所有限公司

Highly effective deep-grinding process for engineering ceramic material

InactiveCN1788931AIncreased Plastic Removal RatioSlow down the feed rateAbrasion apparatusGrinding machinesWater basedUltra high speed

The technological process of deeply grinding engineering ceramic material in high efficiency includes: 1. trimming with resin combined super high speed diamond grinding wheel to outer circle jitter not greater than 5 microns and dressing with a dynamic balance system to make the grinding wheel possess dynamic unbalance amount less than 0.1 micron; 2. adopting water base cooling liquid with liquid pressure of 6-10 MPa; 3. grinding in the technological conditions of grinding off rate per unit grinding wheel width 20-120 cu mm / mm.s, grinding wheel linear speed 40-160 m / s, grinding depth 1-6 mm and workpiece feeding speed 0.5-6 mmin. The present invention has high structure ceramic machining efficiency, low ceramic part cost, improved ceramic part surface quality and greatly raised part reliability.

Owner:HUNAN UNIV

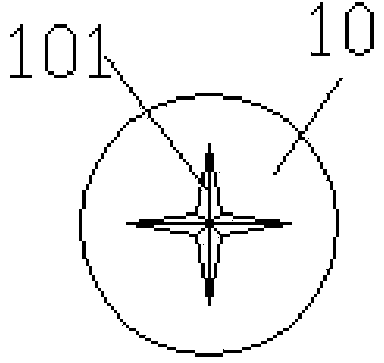

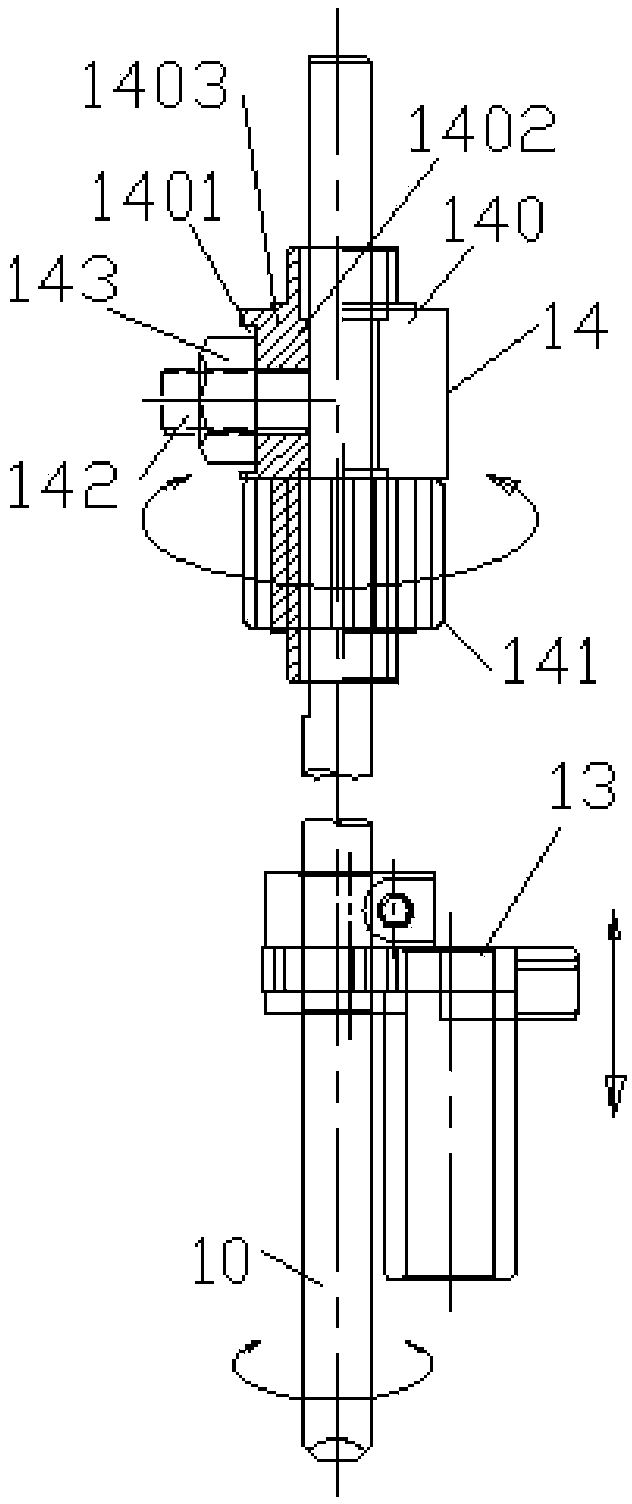

Eyelet embroiderer

The invention discloses an eyelet embroiderer. The eyelet embroiderer comprises a cutter bar. The bottom of the cutter bar is provided with a cutter head. The top end of the cutter head is provided with a cutting edge part. The cutter bar above the cutter head is provided with upper and lower driving mechanisms. The cutter bar above the upper and lower driving mechanisms is provided with a rotation driving mechanism. The cross section of the cutting edge part is rhombic. An angle of the cutting edge part in a width direction is in a range of 20-90 degrees and an angle of the cutting edge part in a thickness direction is in a range of 5-20 degrees. The eyelet embroiderer is provided with the rotation driving mechanism except the upper and lower driving mechanisms and thus the cutter bar drives the cutter head to punch upward and downward and to carry out rotation cutting. The angle of the cutting edge part in the thickness direction is in a range of 5-20 degrees so that cutting-off efficiency is improved and the angle of the cutting edge part in the width direction is in a range of 20-90 degrees so that eyelet width is adjusted easily and cutting-off efficiency is improved. The eyelet embroiderer improves a cutting-off rate, guarantees cut surface cleanliness and obviously improves punching efficiency and punching quality.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

Soft-switched bidirectional buck-boost converters

ActiveUS9705411B2Reduce switching lossesMinimize reverse-recovery lossEfficient power electronics conversionDc-dc conversionTransformerActive switch

A bidirectional buck-boost converter includes at least one soft-switching cell to reduce switching losses by providing soft-switching of all semiconductor devices. A soft-switching cell comprises an active switch coupled in series with an inductor, a two-winding transformer, and a reset-voltage circuit. The soft-switching cells enable the buck and boost rectifiers to turn off with a controlled turn-off rate of their current to minimize their reverse-recovery losses, the power-controlling buck and boost switch to turn on with zero-voltage switching (ZVS), and the switch of the soft-switching cell to turn off with zero-current switching (ZCS).

Owner:DELTA ELECTRONICS INC

Industrial coal briquette and preparation method thereof

ActiveCN101580749AReduce dosageHigh calorific valueSolid fuelsFuel additivesCoal briquetteFoaming agent

The invention provides an industrial coal briquette which comprises the following components according to weight by parts: 90 to 98 parts of coal, 0.25 to 1.0 part of caking agent, 0.0025 to 0.01 part of cross linker, 1.5 to 8 parts of hot-setter and 0.25 to 0.65 part of waterproof agent. The preparation method of the coal briquette is simple, a small amount of caking agent is used, and applicability is strong; the prepared product has the advantages of high dry and wet strength, favorable water resistance, favorable thermal stability and the like, burn-off rate of coal briquette is high, and the content of fume pollutants is low.

Owner:SHANXI UNIV

Method for adjusting and controlling running off of microorganisms and juice of unfrozen fresh-cut fruits through pretreatment

PendingCN110447712AControl quantityReduce churnFood freezingFruits/vegetable preservation by irradiation/electric treatmentEscherichia coliPretreatment method

The invention relates to a method for adjusting and controlling running off of microorganisms and juice of unfrozen fresh-cut fruits through pretreatment, and belongs to the technical fields of processing of fruits and vegetables and safety control. According to the method, epsilon-polylysine and ultrasonic waves are in synergistic treatment, kelp carbon quantum dot / chitosan film coating bacterialpretreatment can be combined, and microorganisms on surfaces of fresh-cut fruits can be effectively controlled; and then through infrared-vacuum drying pre-dehydrating, the fresh-cut fruits are quickly frozen to minus 18 DEG C at the temperature of minus 40 DEG C, and then the quick-frozen fresh-cut fruits are stored at the temperature of minus 18 DEG C. By the bacterial pretreatment method, thetotal quantity of the microorganisms can be effectively controlled to be within 10<3> CFU / g, and coliform groups (or escherichia coli) can reach the standard (negative). After frozen fruits obtained through pretreatment adjustment and control are unfrozen, the texture of the fruits can be maintained to the maximum extent, and the hardness value is increased by 13%-17% than that of frozen fruits not be subjected to pretreatment adjustment and control treatment; and besides, the running off rate of the juice of the fruits and the running off of nutrient components of the fruits are reduced, andthe running off rate of the juice of the fruits is reduced by 13%-16% than that of fruits not subjected to pretreatment adjustment and control.

Owner:JIANGNAN UNIV +1

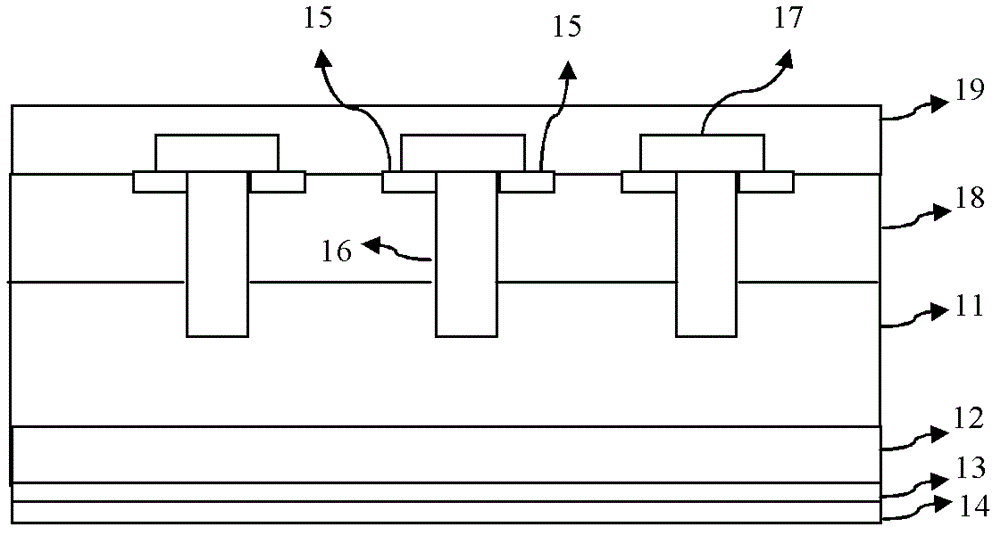

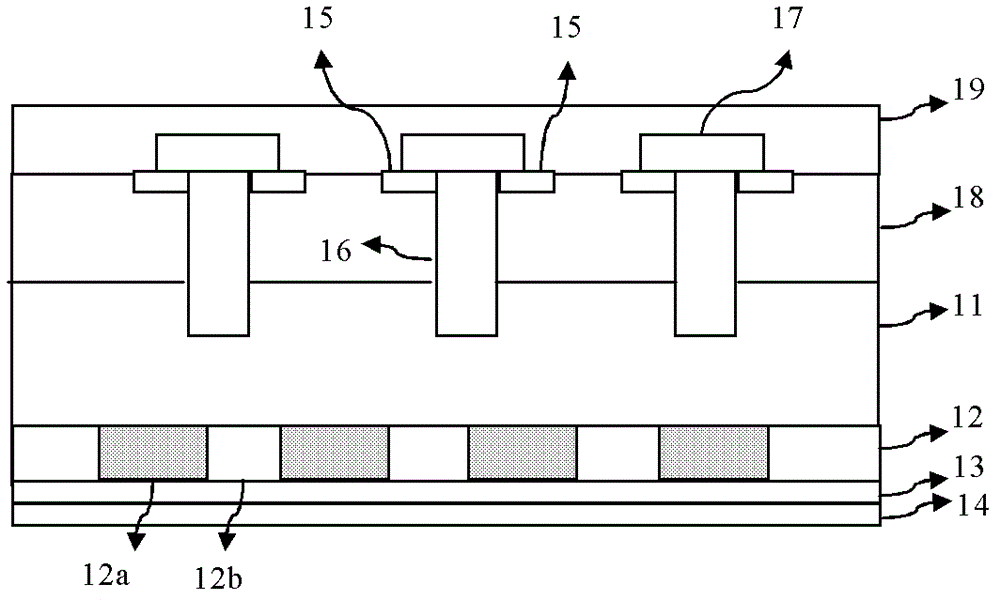

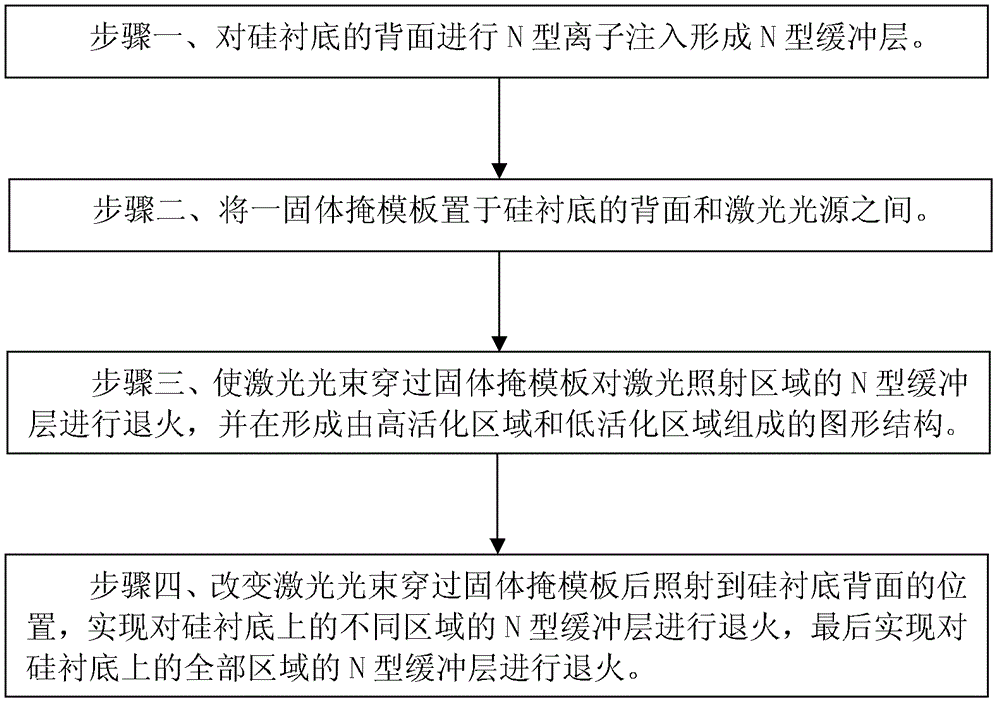

Manufacturing method of insulated gate bipolar transistor (IGBT)

ActiveCN103065962APrecise Control of SpacingEvenly distributedSemiconductor/solid-state device manufacturingHigh activationLaser light

The invention discloses a manufacturing method of an insulated gate bipolar transistor (IGBT). A backside technology comprises the following steps that N-iron implantation is performed on a back side of a silicon substrate so as to form an N-buffer; a solid mask plate is placed between the back side of the silicon substrate and a laser light source; a laser beam passes through the solid mask plate and carries out annealing on the N-buffer in a laser irradiation area so as to form a graphic structure which is formed by a high activation area and a low activation area; the laser beam reaches a position of the back side of the silicon substrate after passing through the solid mask plate and the position is changed so as to realize carrying out annealing on the N-buffers of different areas on the silicon substrate; finally, the annealing can be performed on the N-buffers of all the areas on the silicon substrate. By using the method of the invention, a space between the high activation area and the low activation area of the N-buffer can be accurately controlled; when a device is started, stable carrier distribution balance can be formed; when the device is started, diffuser efficiency of a collector region hole can be inhibited and a turn-off rate of the device is increased.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Production method of converter smelted low-sulphur steel

InactiveCN106566908AReduce sulfur contentAverage smelting cycle shortenedManufacturing convertersSulfurSlag

The invention relates to a production method of converter smelted low-sulphur steel. The production method comprises following steps: 1, molten iron KR stirring desulfurized lime powder, fluorite, and aluminium slag are mixed at a ratio of 10:1:1, wherein ladle slagging-off rate is controlled to be 90% or higher, and the S content of molten iron put into a furnace is controlled to be 0.003% or lower; 2, reactor washing after smelting of a former batch of non low sulphur steel and before smelting of a first batch of low-sulphur steel is carried out; 3, remaining slag and double slag operation is adopted in smelting of low-sulphur steel. According to the production method, reactor washing, remaining slag, and double slag treatment are combined for smelting in a converter, and reactor washing after smelting of a former batch of non low sulphur steel and before smelting of a first batch of low-sulphur steel is carried out, so that the sulphur introduced by remaining slag operation of the first batch of low-sulphur steel smelting is reduced, combination of remaining slag and double slag is beneficial for stable control of end point low sulphur content, converter end point sulphur content is controlled to be 0.005% or lower stably, the lowest sulphur content is 0.001%, technical guarantee is provided for development of low-sulphur novel steel; and at the same time, converter average smelting period is shortened by 4min or longer, converter operation efficiency is increased, and production capacity is increased.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

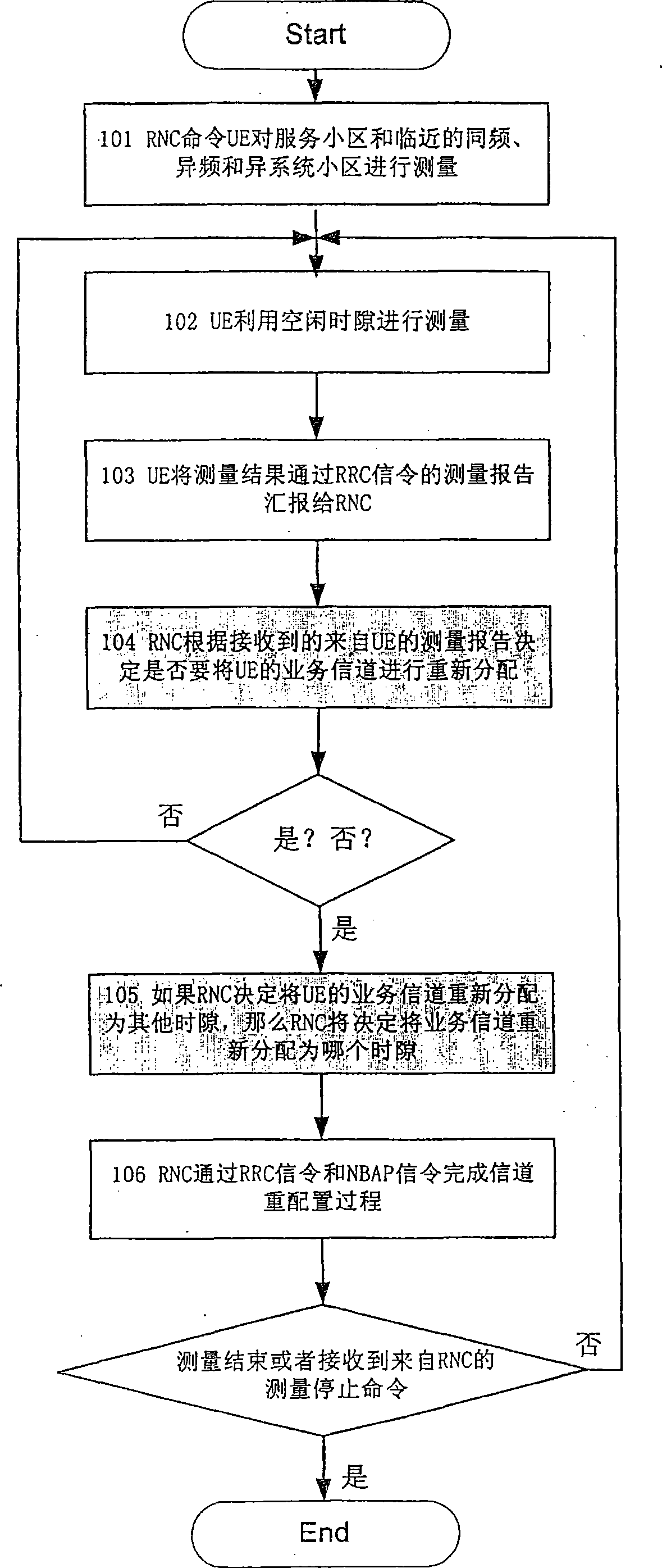

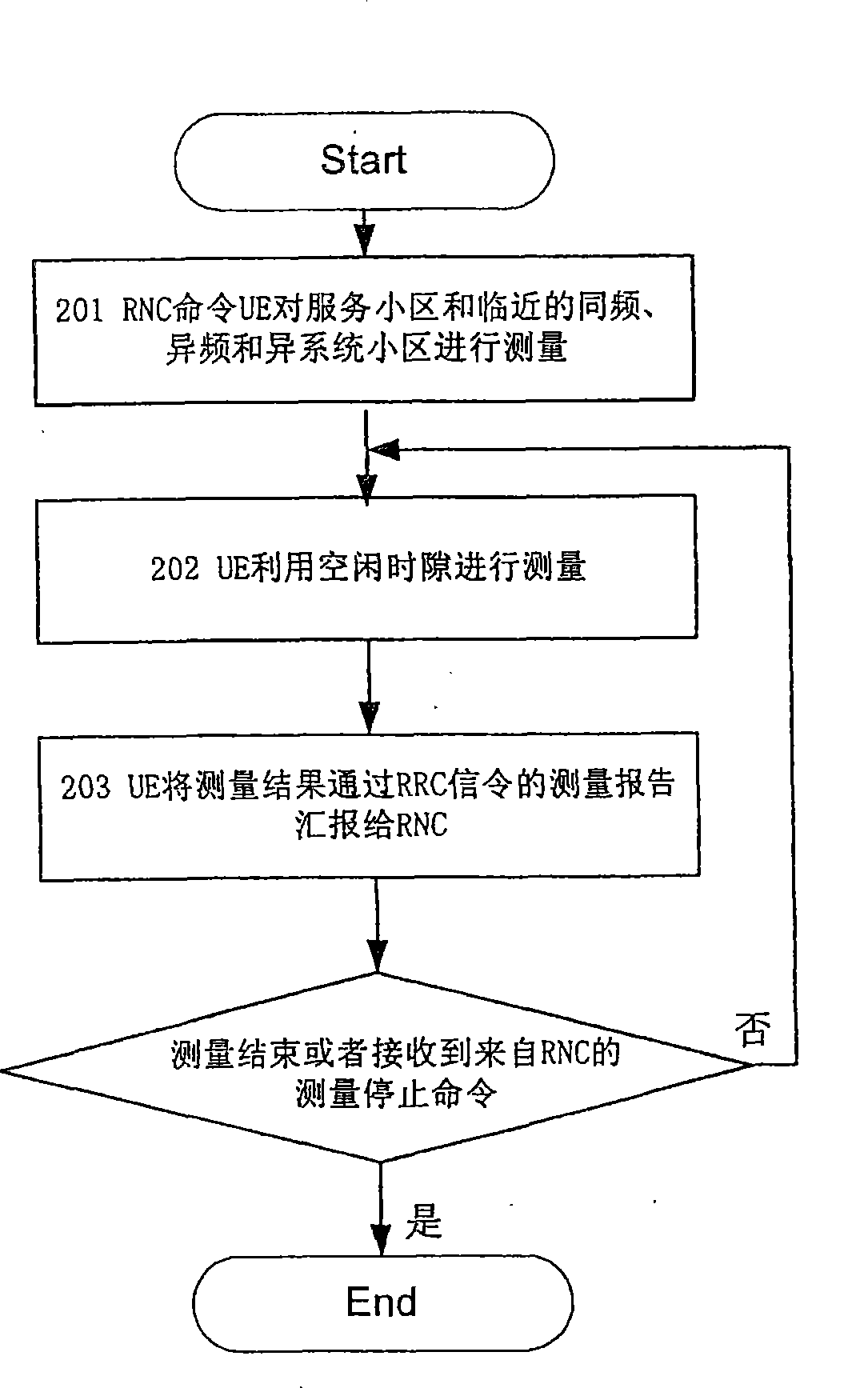

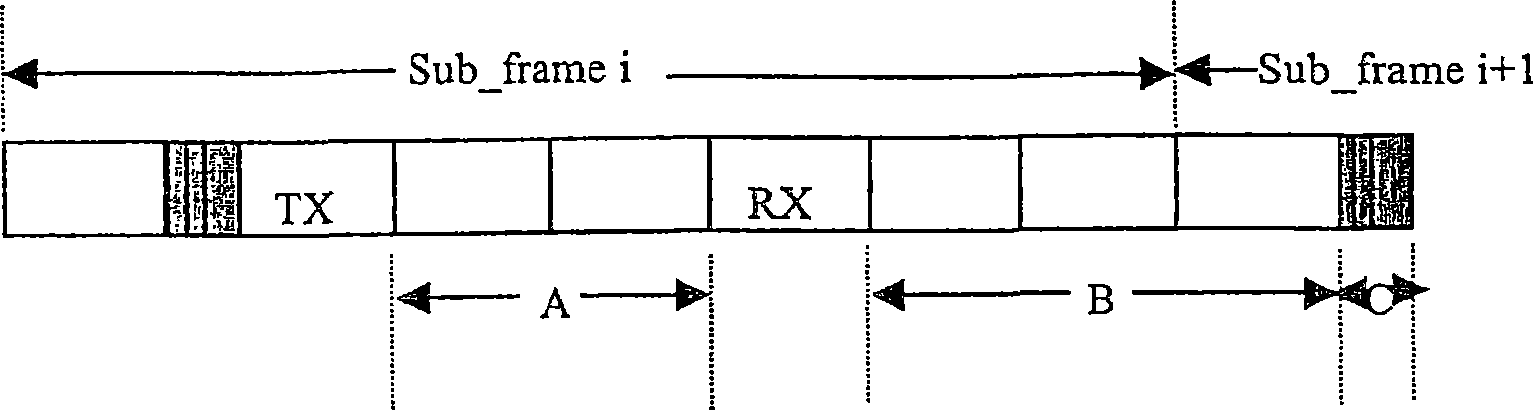

Method for controlling inter-frequency and inter-system handover measurement by RNC

InactiveCN101431776AAvoid measurement failuresReduce call drop rateSynchronisation arrangementTime-division multiplexOff rateHandover

The invention relates to a method for switching measurement between an RNC control frequency and a system, comprising the following steps: an RNC decides whether to redistribute a traffic channel of a UE according to received measurement report from the UE; and if the RNC decides to redistribute the traffic channel of the UE, the RNC decides which time slot to redistribute the traffic channel of the UE. The method synthetically considers according to signal strength condition of a peripheral cell and a cell reflected in measurement report of the UE, and decides whether to more the channel. If the signal of the UE is strong in the cell or weakens in the cell, but the periphery has other cells with stronger signals, the method can ignore and bear measurement failure during measurement of a target cell; and if the signal of the UE is weak in the cell, and the periphery has no any synchronous cell, or has a synchronous cell, but is not suitable for switching, and the method needs to move the channel of the UE. Therefore, the method can avoid measurement failure, so as to reduce cutting off rate.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

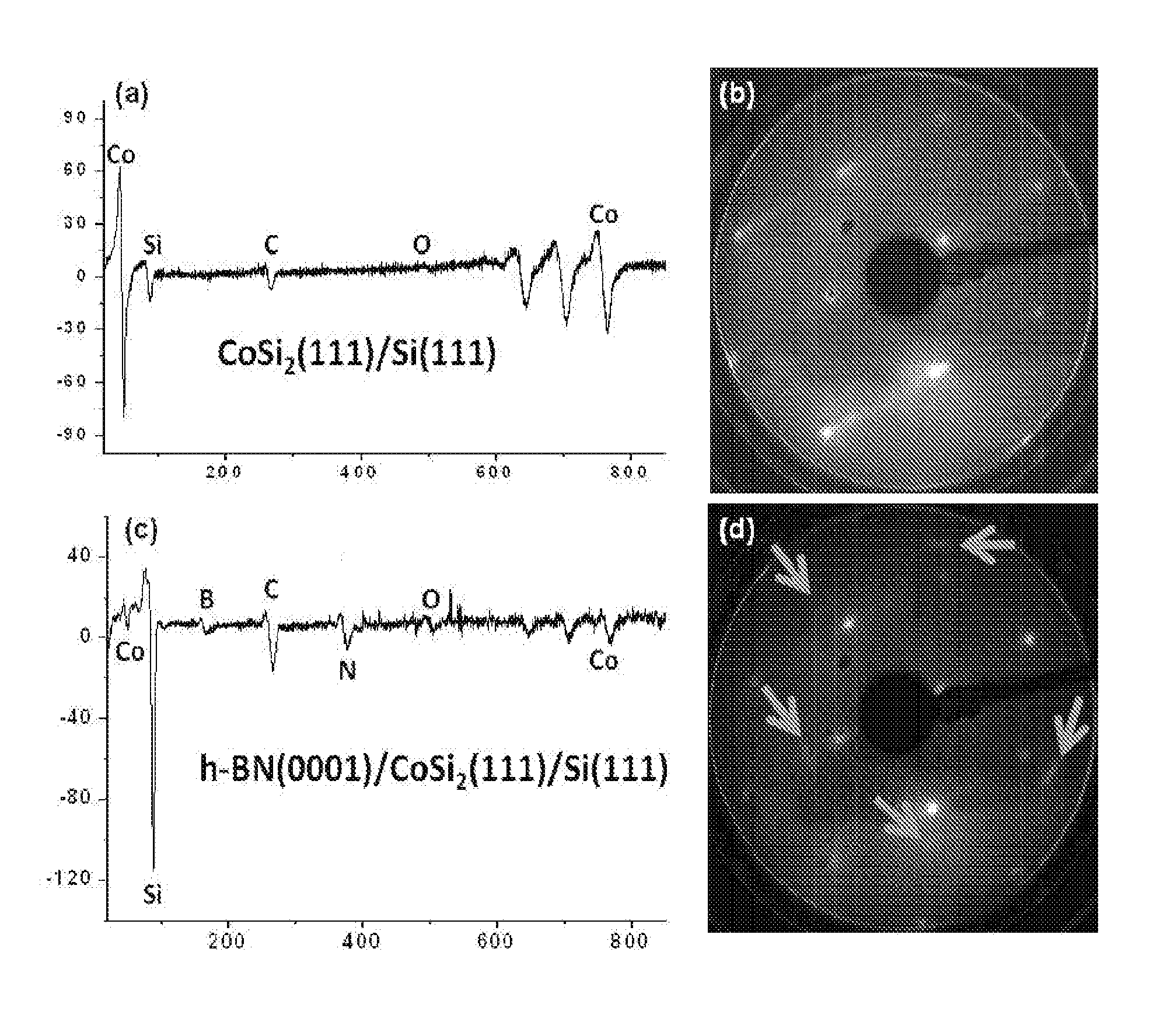

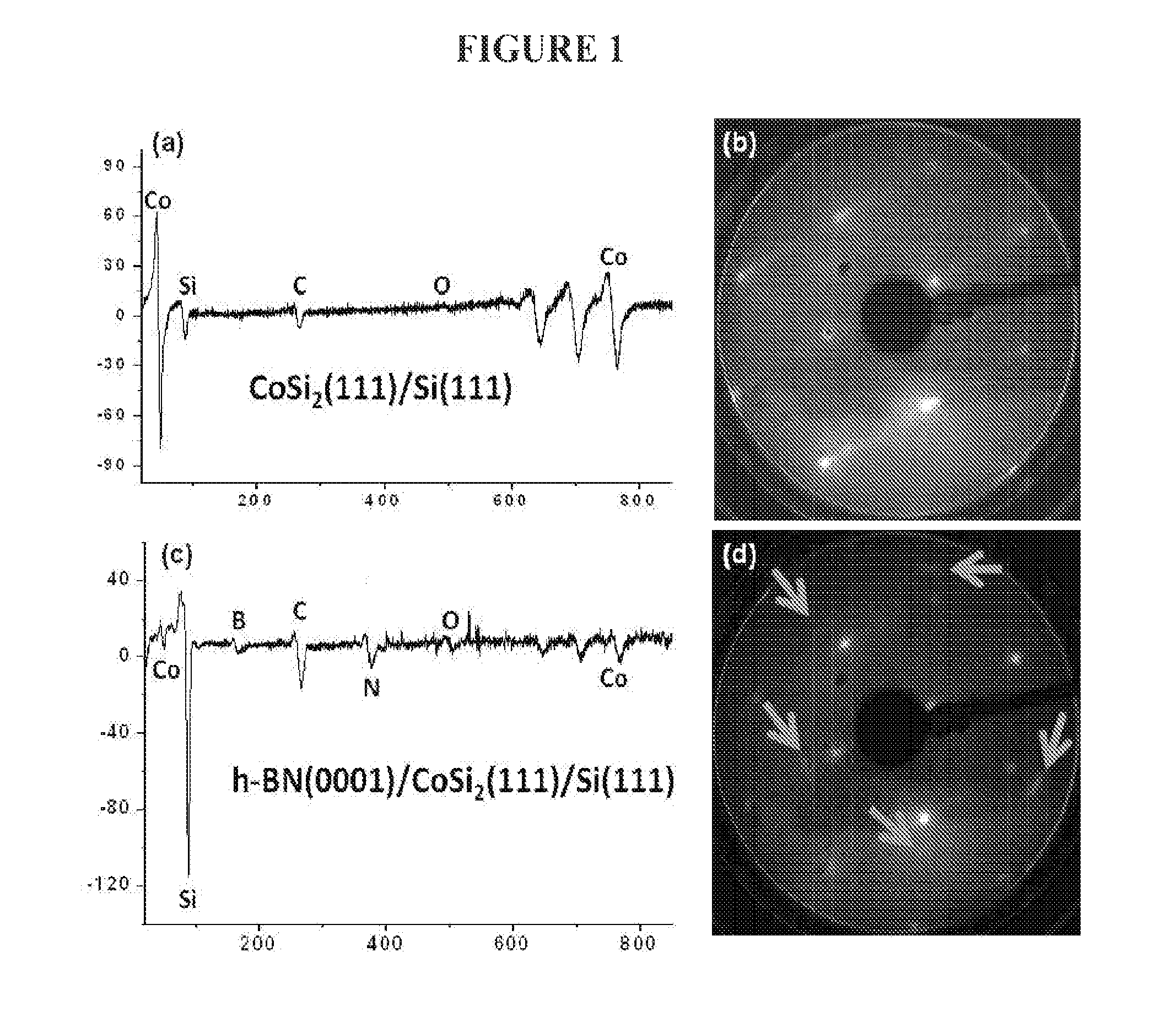

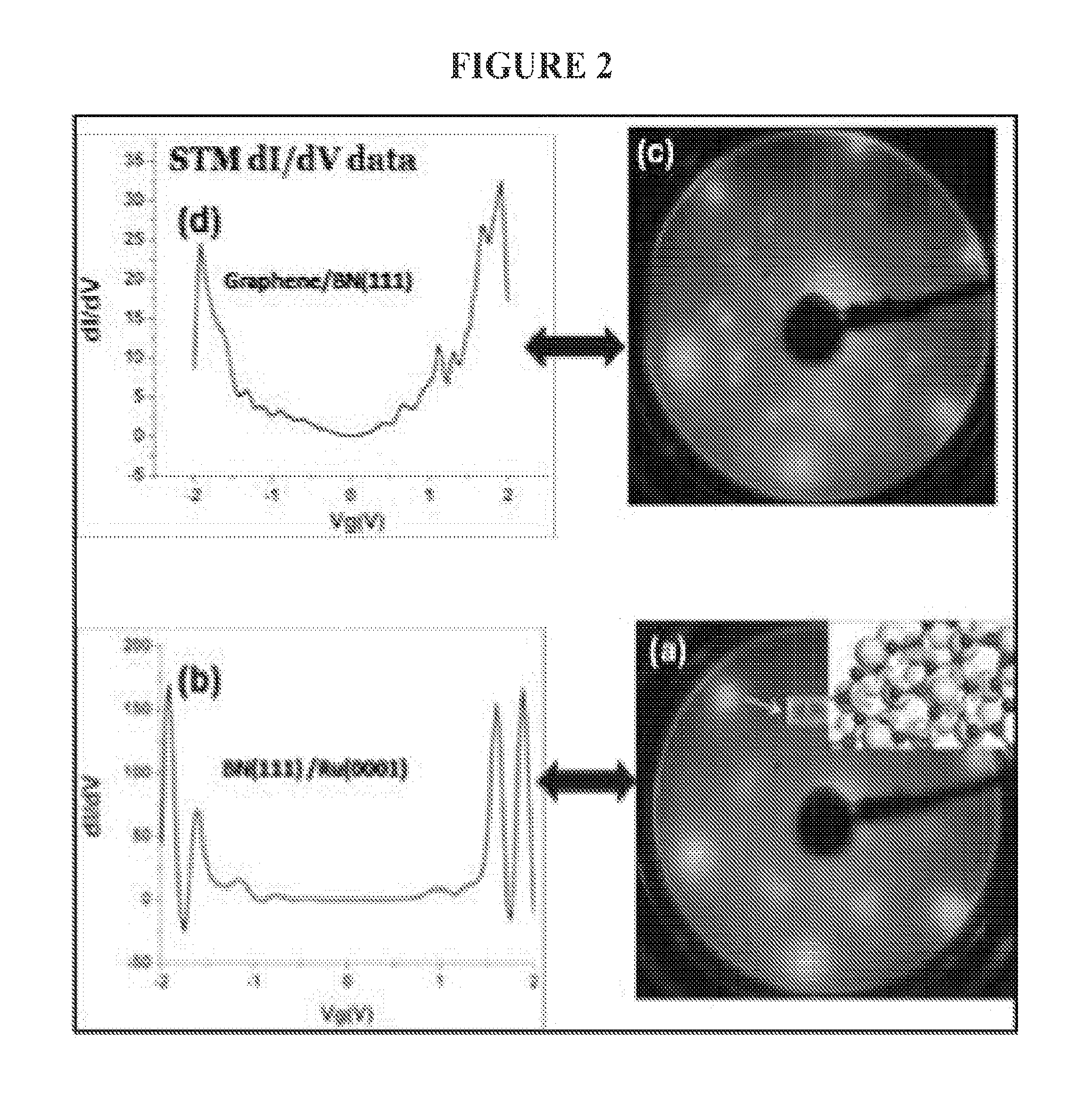

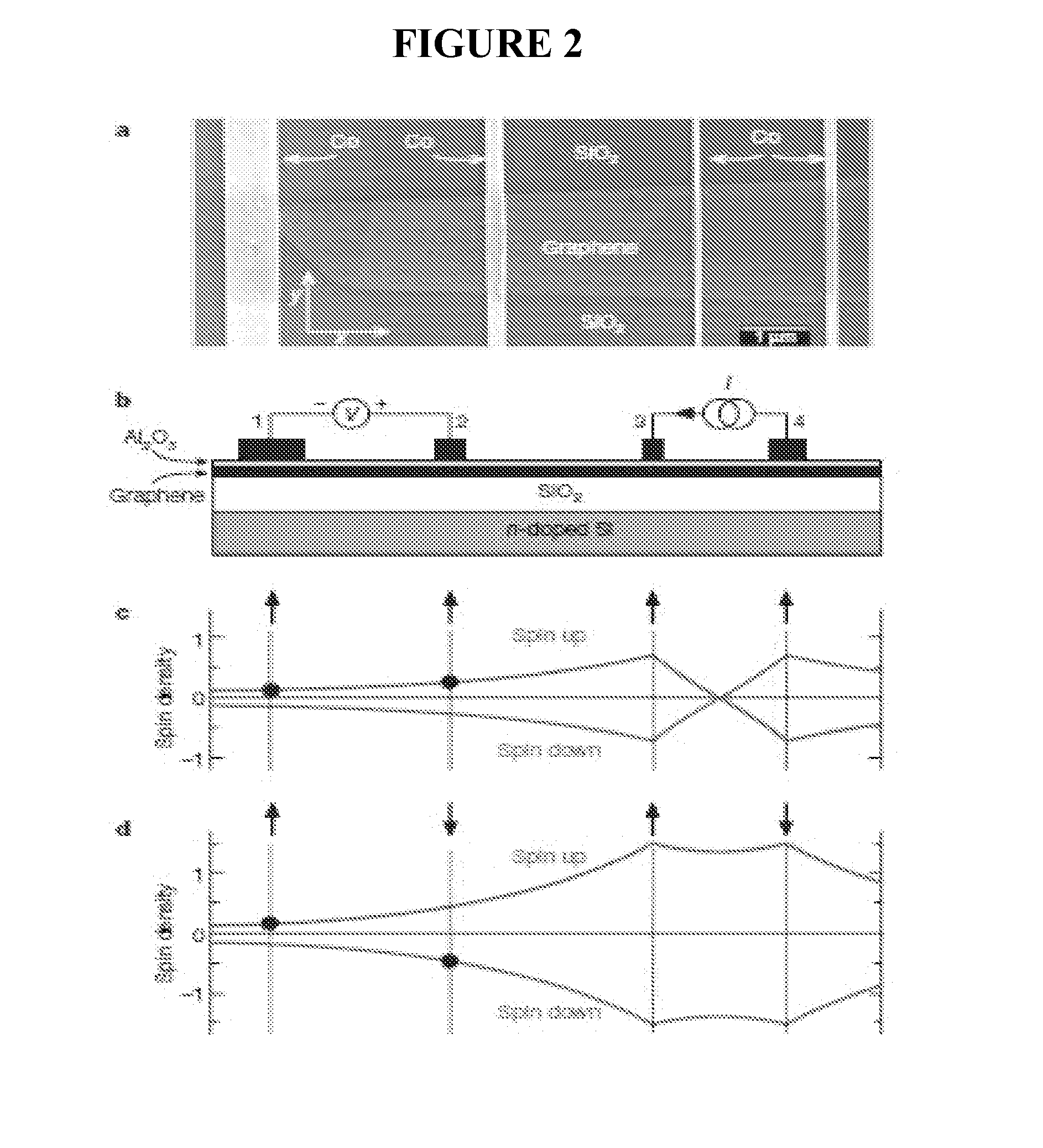

Controlled epitaxial boron nitride growth for graphene based transistors

InactiveUS9331198B2Semiconductor/solid-state device manufacturingSemiconductor devicesCMOSBoron nitride

We have demonstrated controlled growth of epitaxial h-BN on a metal substrate using atomic layer deposition. This permits the fabrication of devices such as vertical graphene transistors, where the electron tunneling barrier, and resulting characteristics such as ON-OFF rate may be altered by varying the number of epitaxial layers of h-BN. Few layer graphene is grown on the h-BN opposite the metal substrate, with leads to provide a vertical graphene transistor that is intergratable with Si CMOS technology of today, and can be prepared in a scalable, low temperature process of high repeatability and reliability.

Owner:UNIVERSITY OF NORTH TEXAS

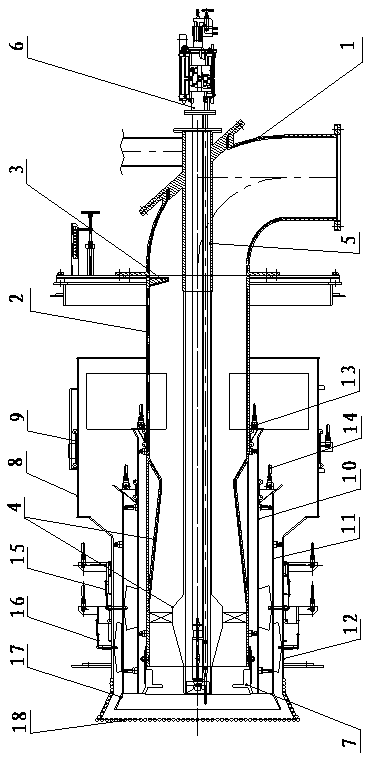

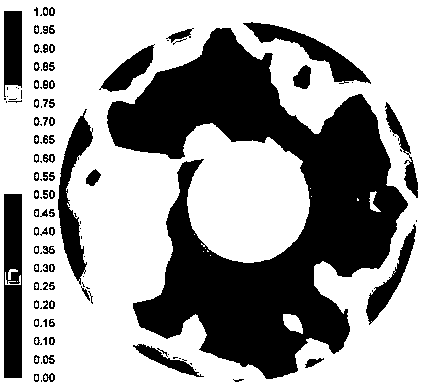

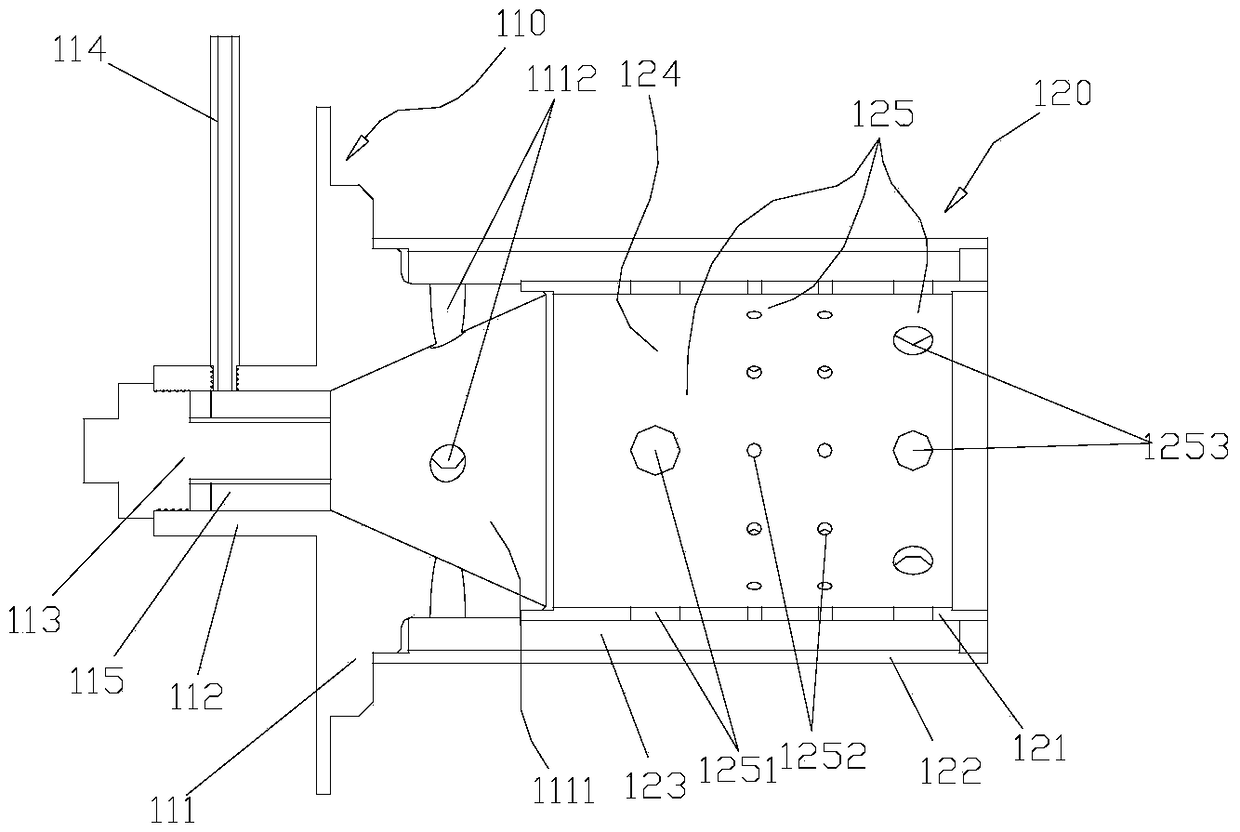

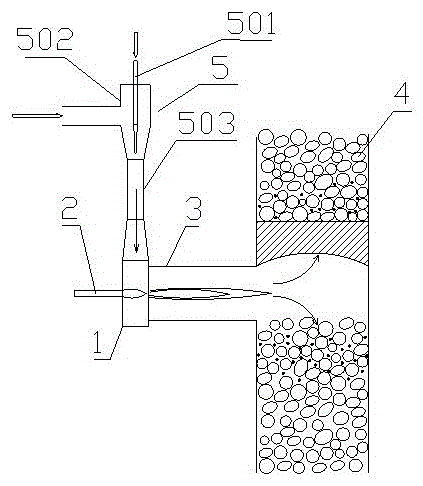

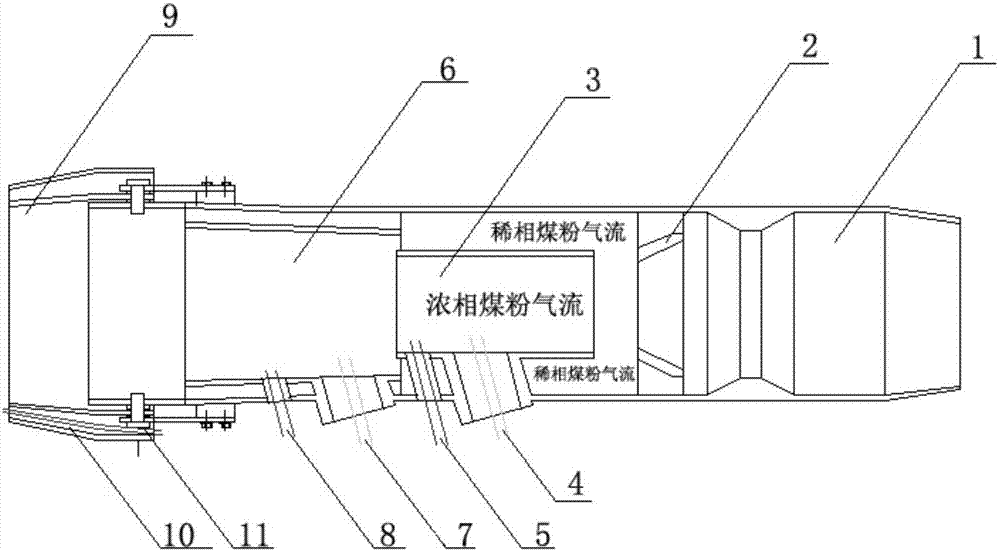

Multi-level separation annular backflow type axial cyclone burner

InactiveCN106196041AEmission reductionSmall running resistancePulverulent fuel combustion burnersCycloneDistributor

The invention discloses a multi-level separation annular backflow type axial cyclone burner. According to the existing cyclone burner technology, emission of NOx needs to be further reduced, and the burn-off rate needs to be further increased. A primary air pipe bend (1) and a primary air pipe horizontal section (2) are connected. A center air pipe assembly (5) is arranged in the center of the primary air pipe horizontal section, a pulverized coal uniform distributor (3) is arranged at an inlet, a Venturi pulverized coal concentrator (4) is arranged close to an outlet, and the outlet is connected with a burning stabilizer (7). A secondary air pipe (10) and a secondary air brake (13) are arranged at the outer portion of the primary air pipe horizontal section. A tertiary air pipe (11) and a tertiary air brake (14) are arranged at the outer portion of the secondary air pipe. An outlet of the tertiary air pipe is connected with a tertiary air flaring (17). The tertiary air pipe is provided with a tertiary air cyclone adjusting mechanism (15). A quartic air pipe (12) is arranged at the outer portion of the tertiary air pipe and provided with a quartic air cyclone adjusting mechanism (16), and an outlet of the quartic air pipe is connected with a water wall tube panel (18). The multi-level separation annular backflow type axial cyclone burner is used in the field of multi-level separation annular backflow type axial cyclone burners.

Owner:HARBIN BOILER

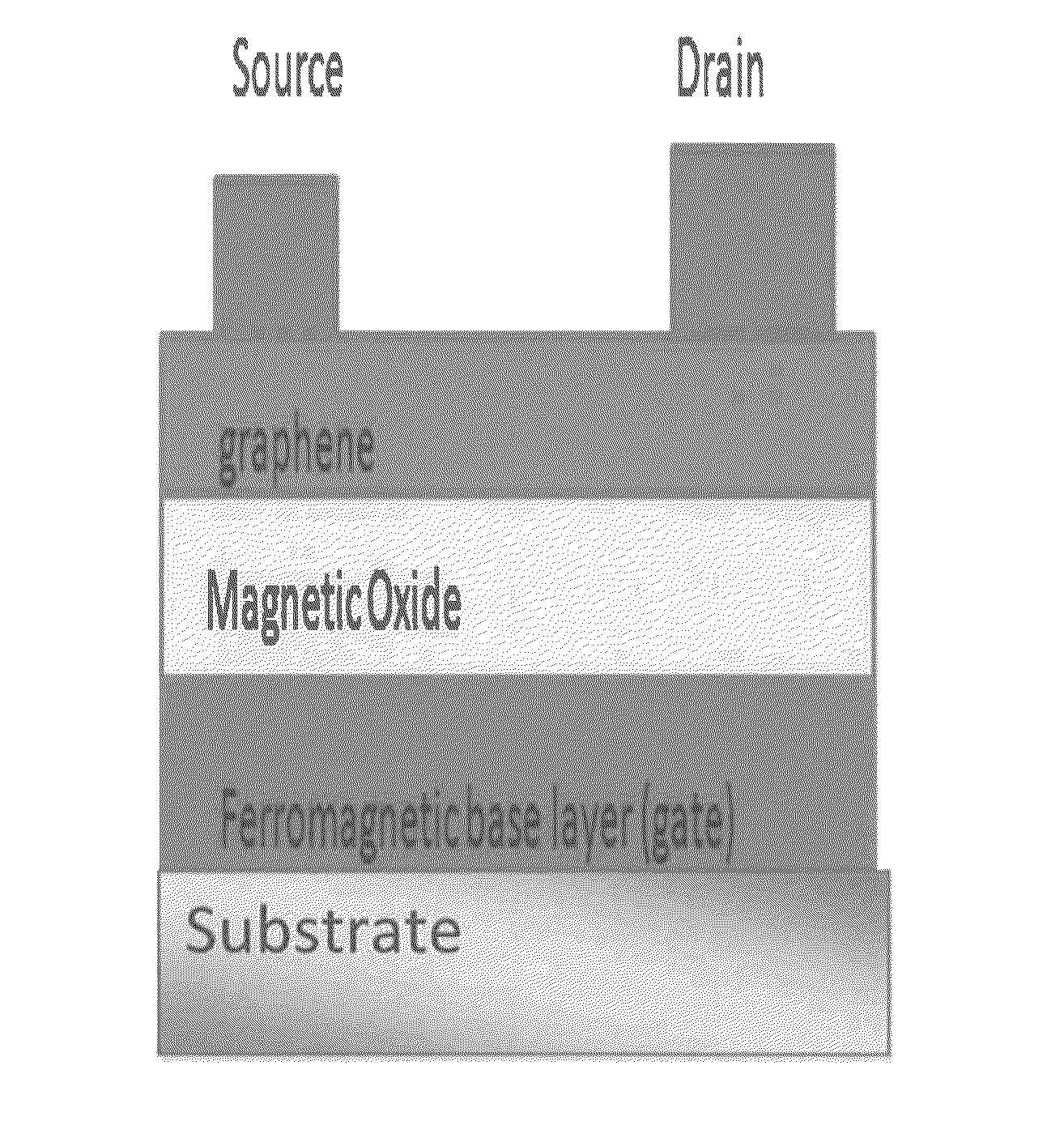

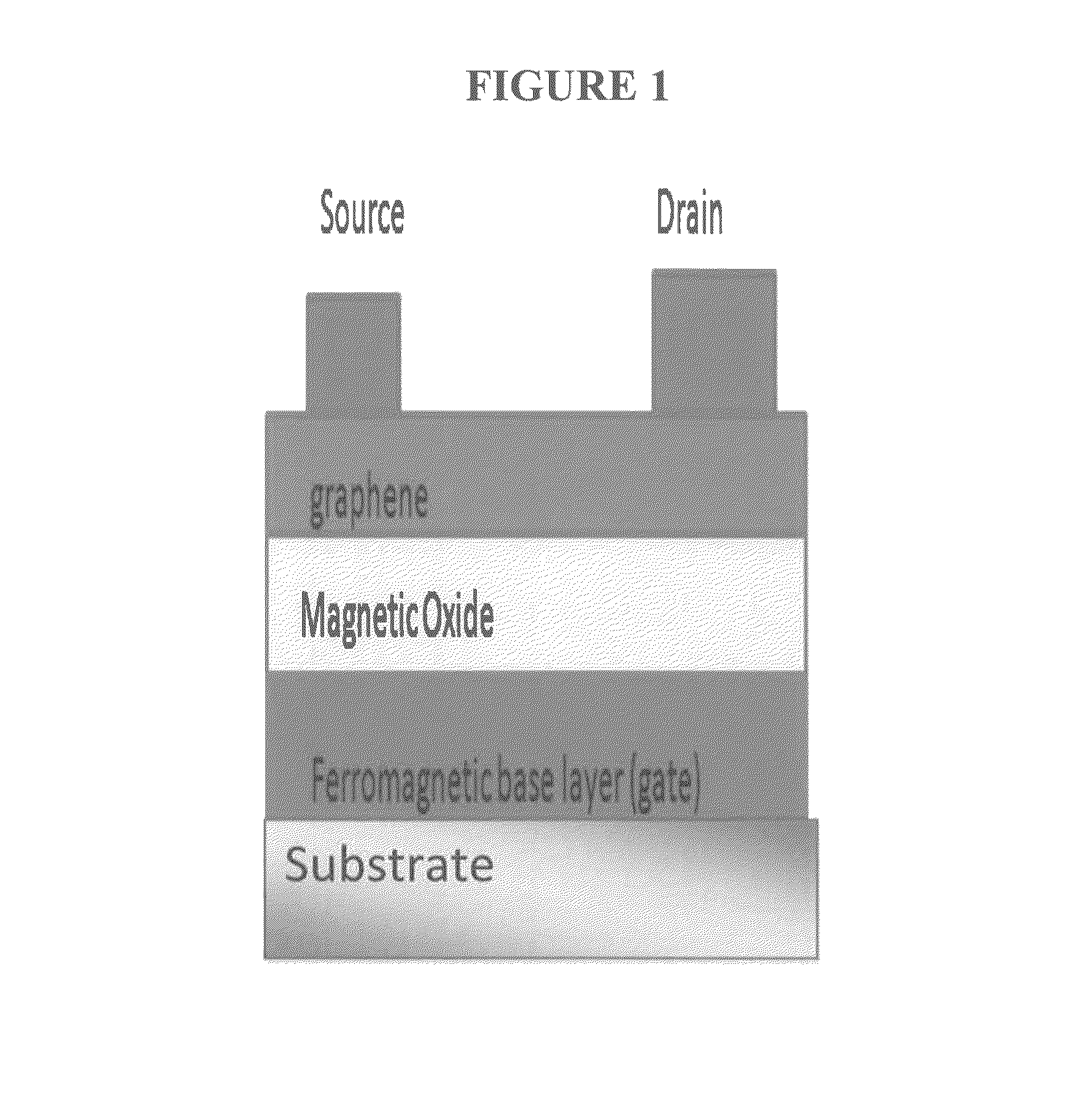

Coherent spin field effect transistor

InactiveUS8748957B2Semiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentSpinsRoom temperature

A coherent spin field effect transistor is provided by depositing a ferromagnetic base like cobalt on a substrate. A magnetic oxide layer is formed on the cobalt by annealing at temperatures on the order of 1000° K to provide a few monolayer thick layer. Where the gate is cobalt, the resulting magnetic oxide is Co3O4(111). Other magnetic materials and oxides may be employed. A few ML field of graphene is deposited on the cobalt (III) oxide by molecular beam epitaxy, and a source and drain are deposited of base material. The resulting device is scalable, provides high on / off rates, is stable and operable at room temperature and easily fabricated with existing technology.

Owner:QUANTUM DEVICES

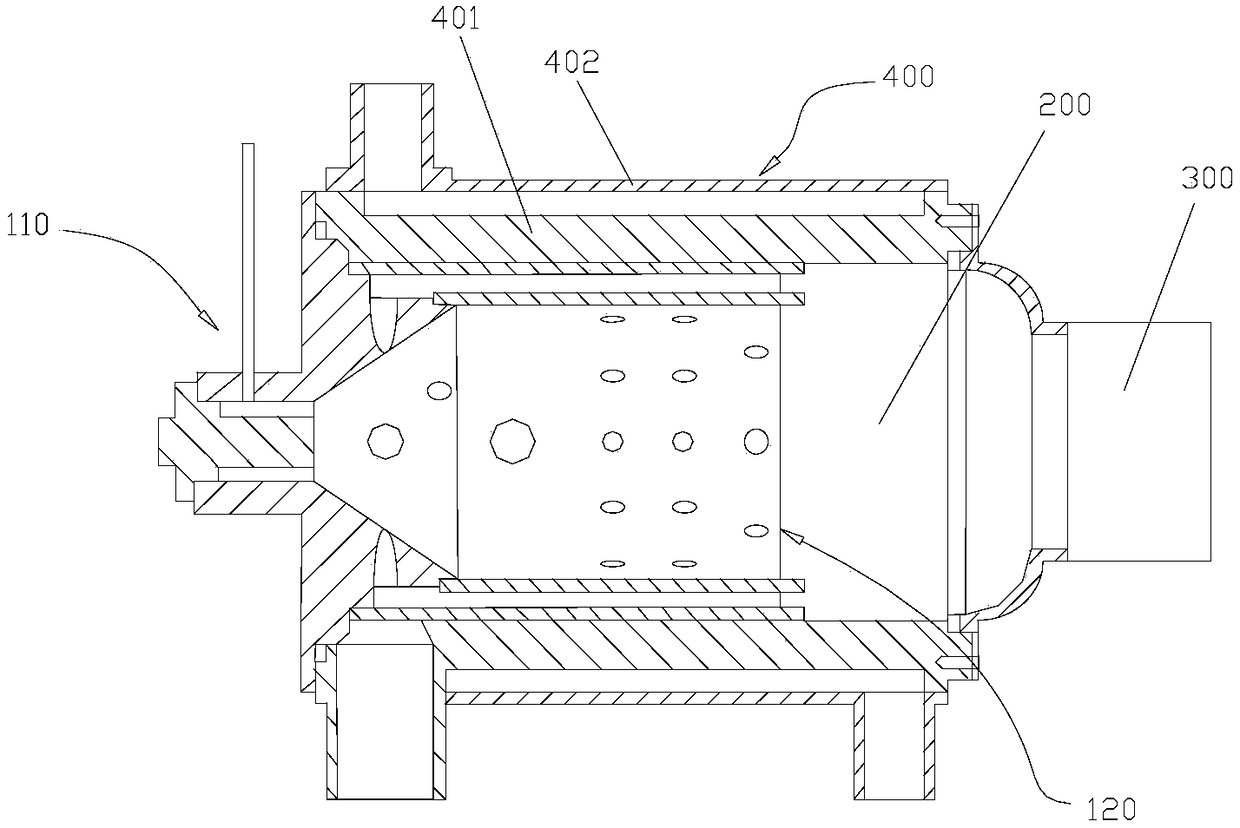

Fuel heater

PendingCN108656898AIncrease temperatureImprove burnout rateAir-treating devicesVehicle heating/cooling devicesInlet channelCombustion chamber

The invention discloses a fuel heater which comprises a gasification mechanism, a combustion mechanism, a blasting mechanism and a heat exchange mechanism. The gasification mechanism is used for supplying gasified fuel to a combustion chamber to enable the fuel to be combusted in the combustion chamber. The blasting mechanism is used for supplying air to the combustion chamber and the gasificationmechanism. The combustion chamber is surrounded by a gas inlet channel, and the gas inlet channel communicates with the combustion chamber to enable the air in the air inlet channel to flow oppositely with the fuel and flames in the combustion chamber. The blasting mechanism enables the air to enter the air inlet channel, the flowing direction of the air in the air inlet channel is opposite to the flowing direction of the combusting fuel and the flames in the combustion chamber, and heat generated by fuel combustion is rightly used for preheating the air opposite to the direction of a fuel flow channel, so that the air in the air inlet channel is preheated and then enter the combustion chamber. Accordingly, the temperature of the air mixed with the gasified fuel is improved, the gasification ignition condition and the combustion condition are improved, and the burn-off rate of the fuel is improved.

Owner:中山劲牛科技有限公司 +1

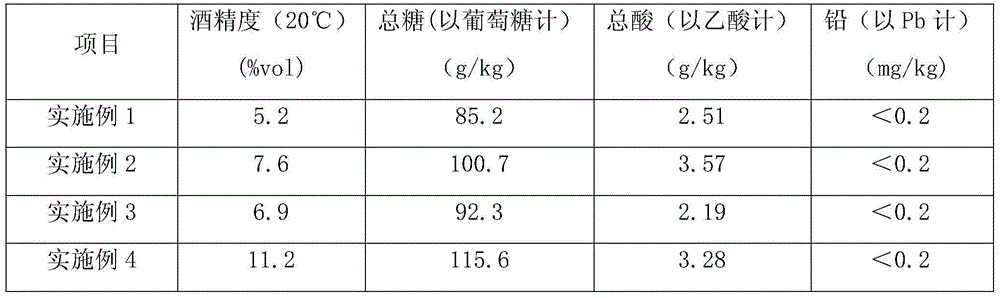

Preparation method for pure natural sipping wine

InactiveCN104099217AEasy to operateImprove product qualityAlcoholic beverage preparationMicroorganism based processesFlavorSorghum

The invention discloses a preparation method for pure natural sipping wine. The preparation method comprises the following steps: S1, raw material selecting: taking sorghum as raw materials; S2, raw material processing: adding water in the raw materials for soaking for 36-48 h, washing and changing water after soaking for 12 h, and the time number for washing and changing water is greater than or equal to 2; S3, boiling: putting the soaked and washed sorghum in boiling water to boil, getting sorghum out of water when the cracking-off rate of the sorghum is greater than or equal to 70%, and draining water for later use; S4, stewing: after steaming, stewing the drained sorghum for 50-70 min; S5, fermenting: cooling down the stewed sorghum, and adding bacillus mesentericus, wine yeasts and aroma yeasts for fermenting; S6, storing: after fermentation, storing in a dark room for more than 25 d to prepare the pure natural sipping wine. The preparation method is simple to operate, short in production cycle, convenient to prepare and easy to realize industrialized mass production by quantifying the fermentation technology; the sipping wine product prepared by adopting the preparation method is excellent in quality and pleasant and mellow in taste, and guarantees the most traditional flavor of the sipping wine.

Owner:四川省宕府王食品有限责任公司

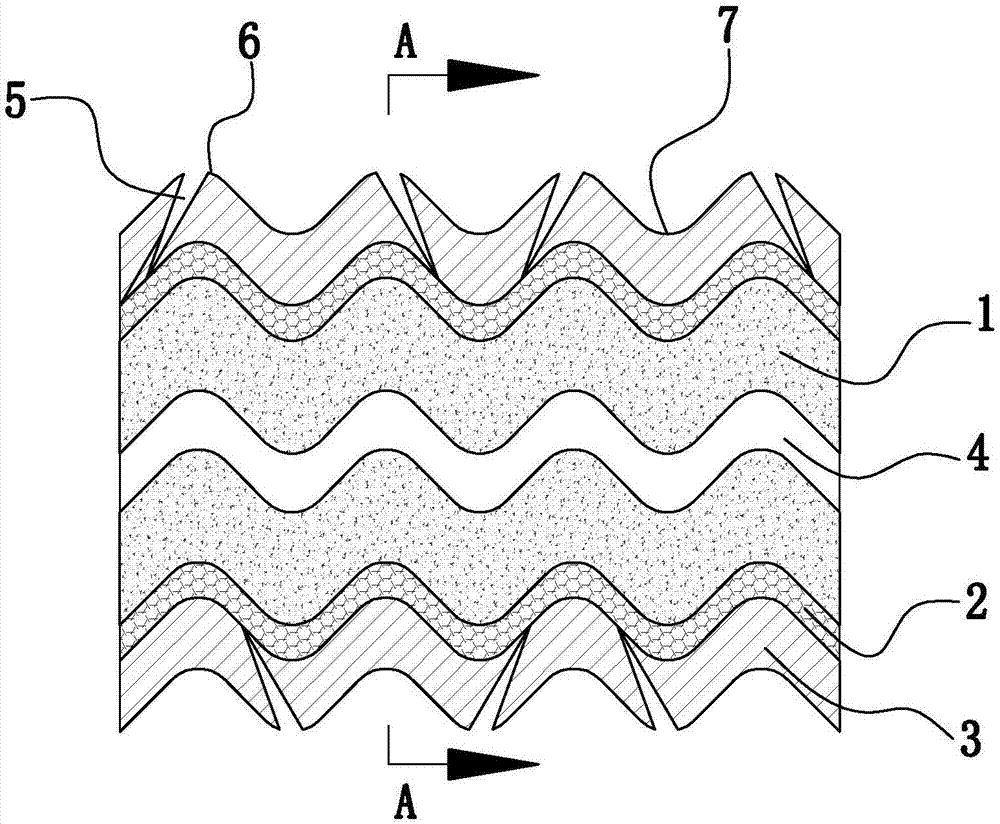

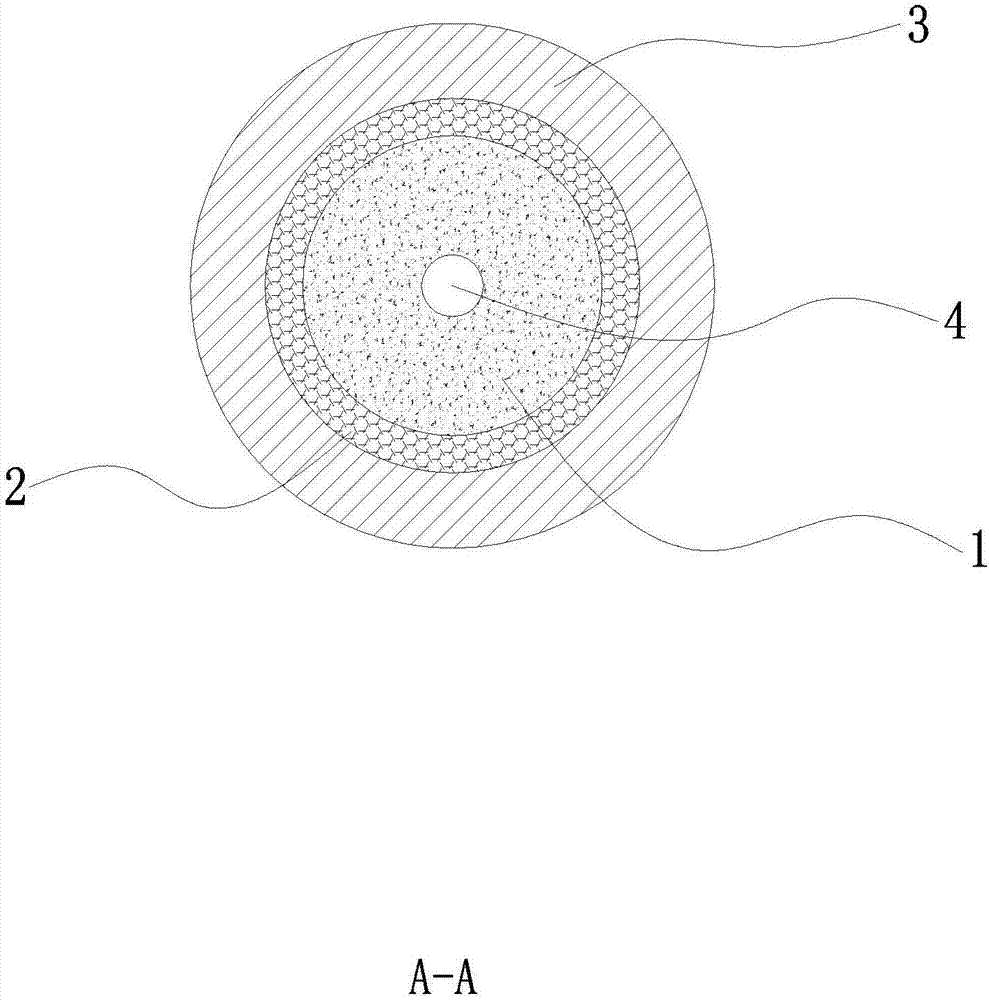

Environment-friendly biomass fuel rod

The invention relates to an environment-friendly biomass fuel rod, comprising a fuel rod body having a circular cross section; the fuel rod body comprises a rod body, a bonding layer and a combustion-supporting layer which are sequentially connected from inside to outside; the rod body is a cylinder formed by carrying out extrusion molding on combustible waste powder; a through hole is formed in the middle of the cylinder; the through hole is formed along the length direction of the rod body; a plurality of lateral notches are formed in the combustion-supporting layer and are distributed in the fuel rod body in an inclined way; the fuel rod body is in a wave shape and comprises wave peak sections and wave trough sections; the lateral notches are positioned in the wave peak sections of the fuel rod body and abut against the outer side of the bonding layer, so that the fuel rod is easy to ignite when burning for the first time, the burning velocity and breathability of the interior of the biomass fuel rod are increased, the ignition temperature is reduced, and the contact area between the biomass fuel rod and oxygen is enlarged; the biomass fuel rod is easy to ignite, good in breathability and high in heat energy utilization rate, can realize rapid and clean combustion, and is good in combustion characteristics, high in burn-off rate and high in heat productivity.

Owner:嘉兴正森新能源科技有限公司

Method for improving boiler combustion economy of tangential combustion anthracite coal boiler

InactiveCN104251487AReduce smoke temperature deviationReduce the adverse effects of smoke temperature deviation, etc.Fluidized bed combustionBlast-producing apparatusLow loadEngineering

The invention discloses a method for improving the boiler combustion economy of a tangential combustion anthracite coal boiler. The combustors of the coal-fired boiler comprise a main combustor and an upper tertiary air combustor, wherein the main combustor is positioned in a main combustion region in a coal-fired boiler body, and the upper tertiary air combustor is next to the upper part of the main combustion region. The method comprises the following steps: (1) adding a layer of tertiary air jet nozzle below secondary air of the lowermost layer of the main combustion region to serve as a lower tertiary air combustor; (2) forming openings in original tertiary air pipes on the four corners of the boiler, and guiding original tertiary air to the added tertiary air jet nozzle by an added pipeline so as to increase the burn-off rate of coal powder without influence of low-load stable combustion capability of the boiler. According to the method, the boiler efficiency can be improved by more than 3% on the basis of guaranteeing the stable combustion capability of the boiler; the efficiency of the anthracite coal boiler is greatly improved, and the combustion stability of the boiler cannot be influenced; by the method provided by the invention, the investment and the running expense are low and the national conditions of China are met.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +2

Biomass briquette with cornstalk as base material and manufacturing method thereof

The invention discloses biomass briquette with cornstalk as a base material. A sulfur-fixation combustion improver is added. By cooperation of components of the combustion improver, flue gas generated during the briquette combustion process is turned into coal gas, flame is increased, and emission of lots of fume and harmful gas is reduced. Meanwhile, biomass generated by fermentation is modified with a sodium hydroxide solution, lye releases -OH which enters lignin of biomass' cell walls to destroy pyranoid ring in lignin, separate cellulose and hemicellulose tangled in lignin and relieve a spatial three-dimensional cross-linked network structure of lignin and hemicelluloses. Through recombination, a complex spatial network structure is formed, and cohesiveness is raised, briquetting pressure is then reduced, and abrasion of equipment is relieved. The prepared biomass briquette has integrated advantages of low cost, low ignition point, high burn-off rate and waterproofness, and is of great significance for energy conservation and environmental protection.

Owner:安徽徽明建设集团有限公司

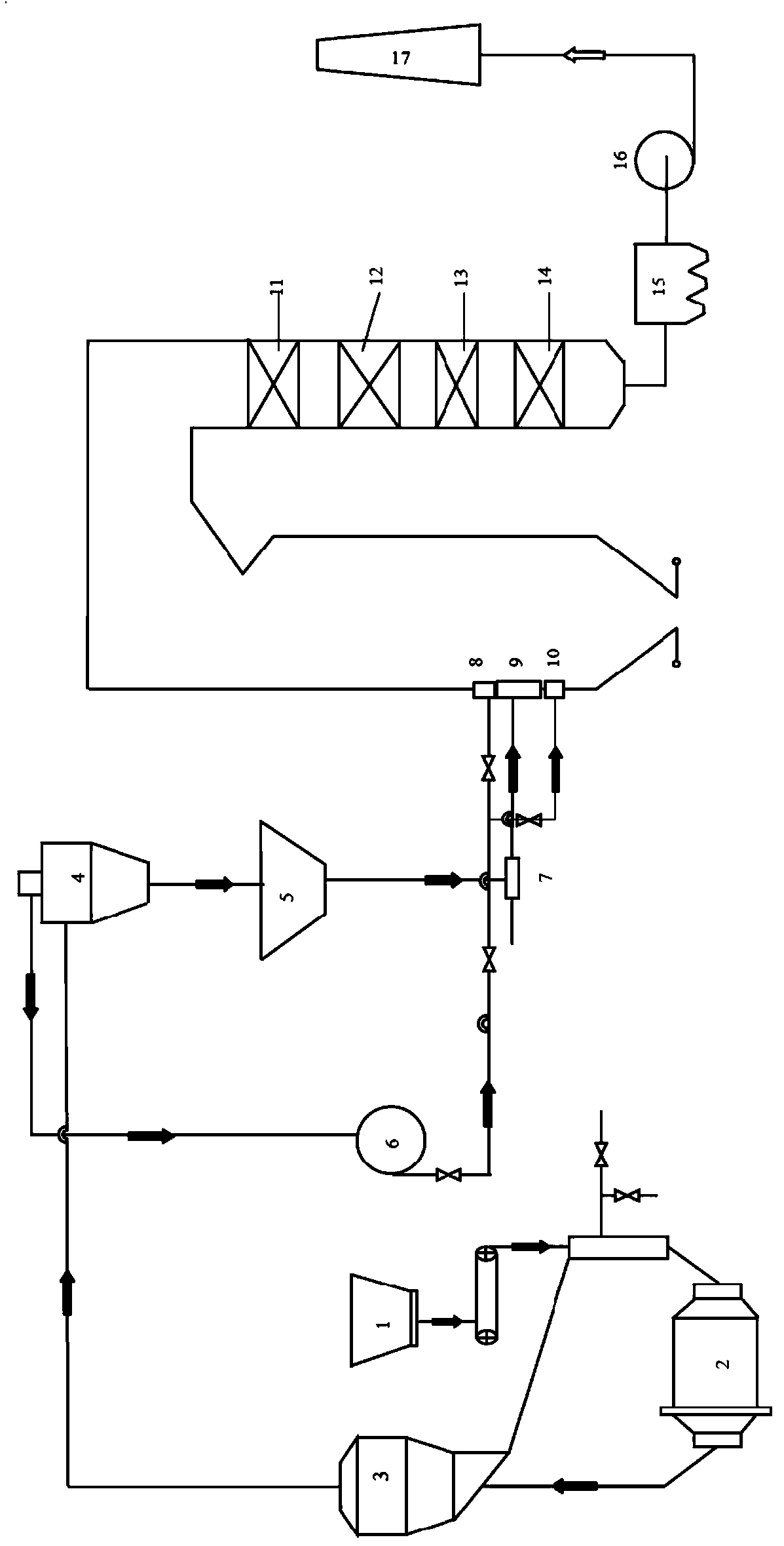

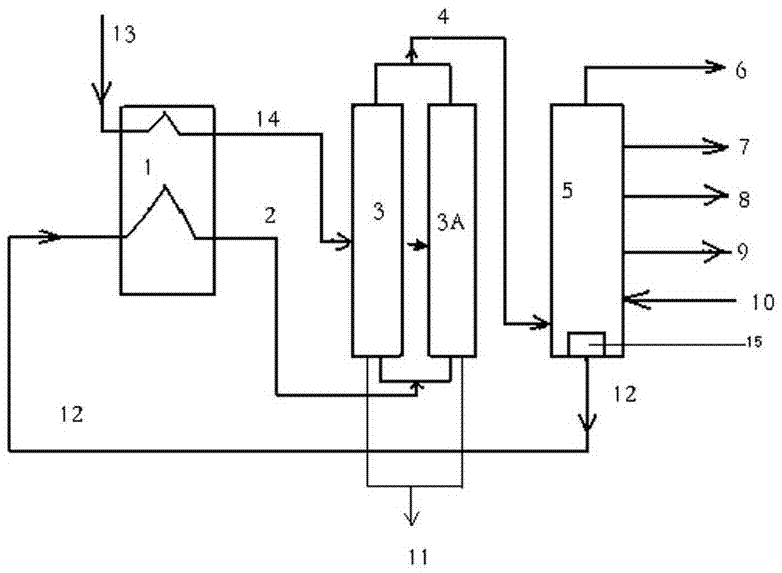

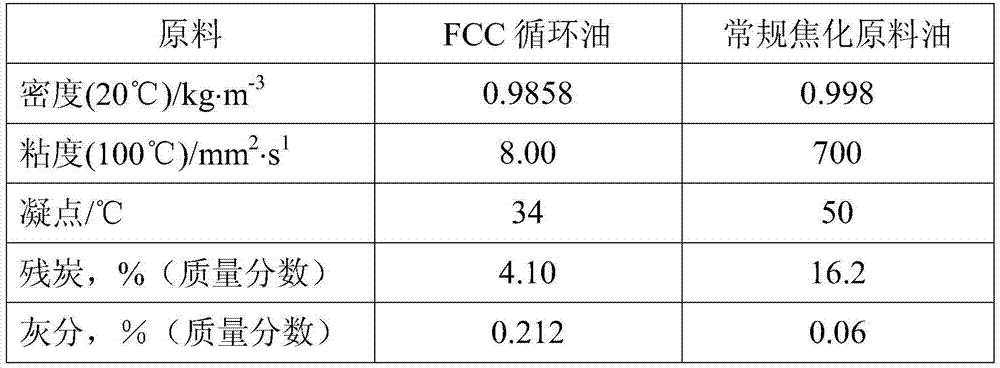

Method for producing needle-shaped coke raw material by delayed coking process

InactiveCN106867554AExpand sourceThe method flow is simpleCoking carbonaceous materialsWaxCavitation

The invention discloses a method for producing a needle-shaped coke raw material through treating FCC circulating oil and a conventional coked raw material by a delayed coking process. The method comprises the steps: low temperature FCC circulating oil is introduced to a medium-upper part of a delayed coking tower and makes contact with a high temperature oil gas phase produced from high temperature cracking of the conventional coked raw material introduced from the bottom of the delayed coking tower, a reaction is performed under delayed coking conditions, generated oil and gas enter a coking fractionating tower and are separated, and thus the needle-shaped coke raw material is obtained. An ultrasonic generator is mounted at the bottom of the coking fractionating tower, the ultrasonic wave cavitation principle is utilized, and the fractionation effect is improved, so the wax oil distilling-off rate is improved, and the high-quality high-yield needle-shaped coke raw material is obtained.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

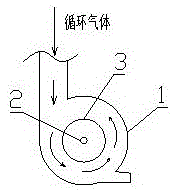

Pulverized coal combustion process in annular lime kiln and application thereof

ActiveCN105036573AReduce the probability of reactionInhibition productionCombustion chamberReaction rate

The invention relates to a pulverized coal combustion process in an annular lime kiln and application thereof. The process comprises the following steps: (1) anoxic ignition combustion of pulverized coal in a volute; (2) combustion of pulverized coal volatile matters in a combustion chamber; and (3) combustion of pulverized coal fixed carbon in a material bed. The process provided by the invention is used for calcining limestone. The process has the advantages that because of oxygen debt, the combustion temperature level and the combustion speed level are low, the combustion process is delayed, the NOx reaction rate is reduced in a reducing atmosphere, and the NOx yield in the area is inhibited; the circulating gas in the step (2) has large overall weight and high flow rate, the heat generated by combustion of volatile matters can be diluted and quickly transferred into a limestone material bed, the decreasing amplitude of the temperature of the combustion chamber is relatively large, and thus coal ash fusion nodulation and refractory material damage caused by accumulation of the heat in the combustion zone are avoided; and the burn-off rate of fixed carbon in the step (3) is improved, the content of CO in the tail gas is reduced to be 100-150mg / Nm<3>, and when the process provided by the invention is used for calcining limestone, the heat loss is reduced to 860kCal / kg from 930kCal / kg.

Owner:包头东盛科技有限公司 +1

Technological method for recycling germanium from corrosive liquid containing germanium and fluoride

ActiveCN106906364ASolving Recycling ProblemsSimple stepsProcess efficiency improvementLiquid wasteLoss rate

The invention discloses a technological method for recycling germanium from corrosive liquid containing germanium and fluoride and relates to the technical field of hydrometallurgy, in particular to a technological method for recycling germanium from corrosive liquid containing germanium and fluoride through the methods of boric acid germanium precipitation for fluoride removal and fluoride removal through silicon dioxide. The technological method for recycling germanium from corrosive liquid containing germanium and fluoride is characterized in that boric acid and silicon dioxide are added at the same time, heating and volatilization are carried out, fluoride is removed, germanium is precipitated and enriched, and therefore germanium metal is recycled. According to the technological method, the fluoride removal rate can reach 78% or above, the fluoride content of slag containing germanium and residual liquid which are finally transferred into the chloridizing distillation step is smaller than 0.05%, the germanium slag grade obtained through precipitation can reach 25% or above, the germanium recycling rate before chloridizing distillation is carried out can reach 95% or above, the loss rate of germanium metal is smaller than 1.2% in the whole fluoride removal process, and some supernatant liquid waste obtained after fluoride removal is subjected to recycle recovery secondary germanium precipitation treatment. When chloridizing distillation is carried out on slag containing germanium and residual liquid, the germanium distil-off rate can reach 98% or above, and production technological requirements can be met.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

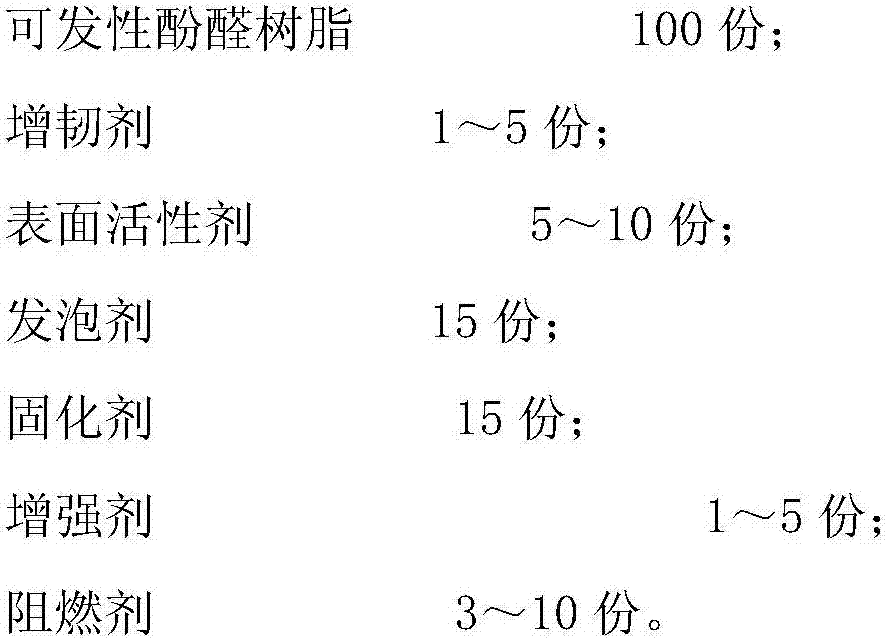

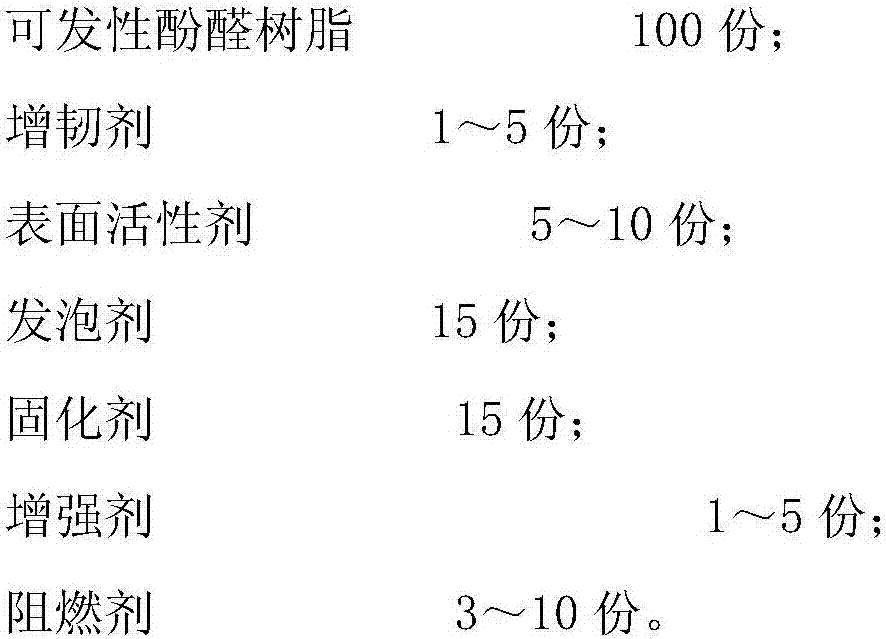

Whisker strengthening toughening halogen-free flame retardance phenolic aldehyde foamed plastic and preparation method thereof

The invention discloses a whisker strengthening toughening halogen-free flame retardance phenolic aldehyde foamed plastic and a preparation method thereof. The plastic is prepared from, by weight, 100 parts of expandable phenolic resin, 1-5 parts of flexibilizer, 5-10 parts of surface active agent, 15 parts of foaming agent, 15 parts of curing agent, 3-10 parts of flame retardant and 1-5 parts of whisker fortifier. The invention further discloses the preparation method of the flame retardance toughening phenolic aldehyde foamed plastic. According to the plastic, intensity and toughness of the phenolic aldehyde foamed plastic are improved by using a few whiskers, the flame retardance property of the foamed plastic is improved by adding composite flame retardant, meanwhile the flame retardant of the phenolic aldehyde foamed plastic is further improved by adopting the new compound emulsifier, wherein the compression strength is higher than 0.2MPa, the heat conductivity coefficient is lower than 0.04W / m*k, the oxygen index is larger than 50%, the scaling-off rate is lower than 3%, and the flame retardance property (DIN 4102) reaches grade A; the plastic is a halogen-free flame retardance phenolic aldehyde foamed plastic with excellent comprehensive performance, the plastic can be applied to heat preservation field such as architecture, and fire prevention safety of heat preservation in building is greatly improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

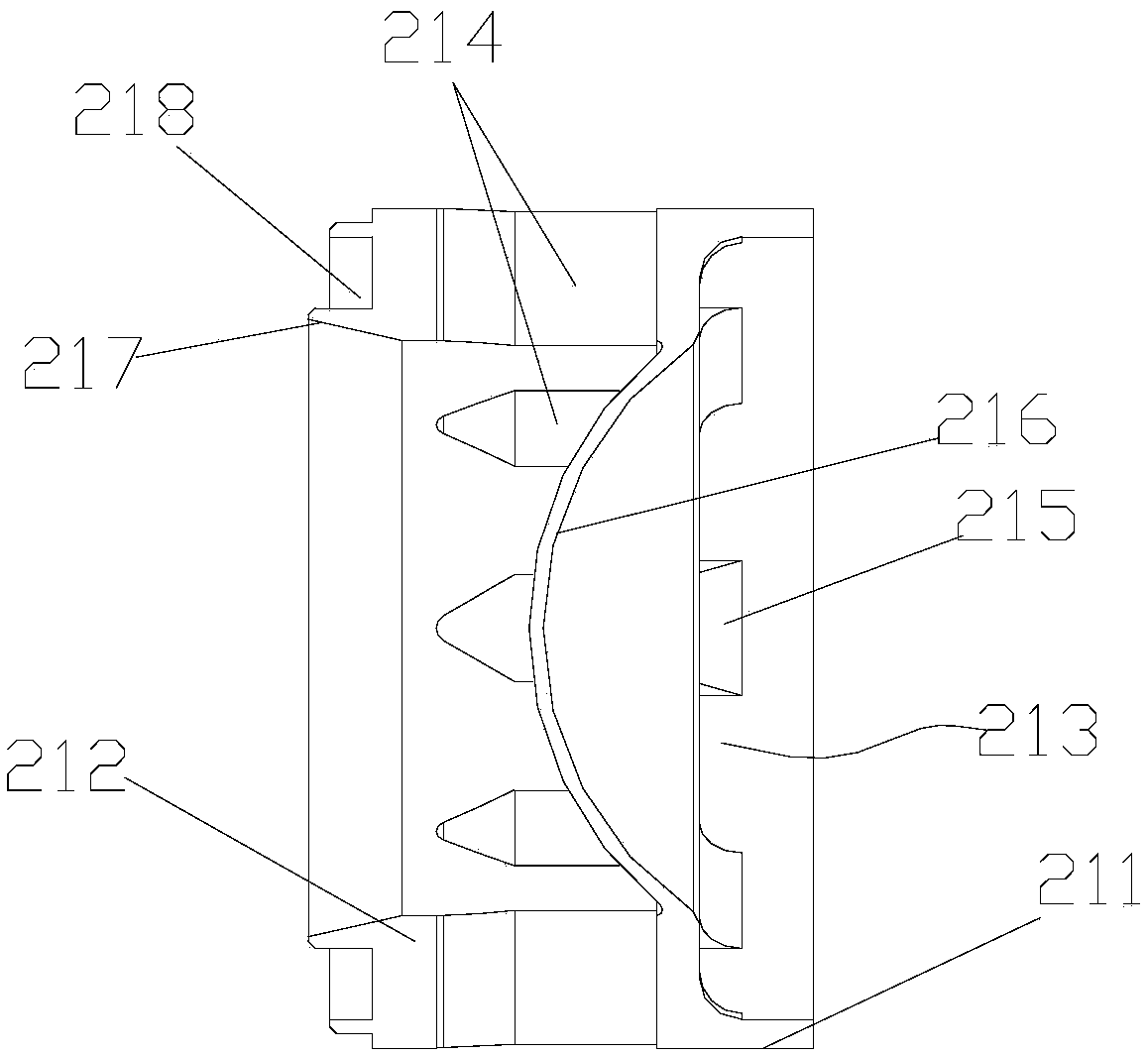

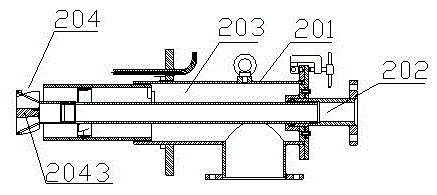

Oxygen-adding ignition burner for coal-fired boiler of power station and ignition combustion-stabilizing method for oxygen-adding ignition burner

PendingCN107575859ALow ignition temperatureImprove burnout ratePulverulent fuel combustion burnersCombustion chamberCombustor

The invention provides an oxygen-adding ignition burner for a coal-fired boiler of a power station and an ignition combustion-stabilizing method for the oxygen-adding ignition burner. The oxygen-adding ignition burner comprises a primary air channel, a pulverized-coal dense-thin separating device, a first-stage combustion chamber and a second-stage combustion chamber, wherein the pulverized-coal dense-thin separating device, the first-stage combustion chamber and the second-stage combustion chamber are arranged in the primary air channel in sequence. The oxygen-adding ignition burner is reasonable in structure, simple in design, high in combustion efficiency, low in oil consumption for ignition, low in equipment loss, environmentally friendly and reliable. According to the ignition combustion-stabilizing method for the oxygen-adding ignition burner for the coal-fired boiler in the power station, a low-oil oxygen-adding ignition method is provided by oil gun grading and an added gradedoxygen lance, adaption to the coal type is high, and the coal type with low volatile component can be effectively ignited; and the ignition combustion-stabilizing method can be used for low load combustion stabilizing of the boiler and ensures combustion stability of the boiler during running at a very low load, and the burn-off rate of pulverized coal is improved, so that the pulverized coal releases more heat by sufficient combustion, the flue gas temperature is raised, and the problems of instable combustion and the low flue gas temperature of an SCR inlet in low load running of the boilerare solved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Helium-recovery plant

ActiveUS20130104597A1Low costSimple procedureSolidificationLiquefactionProcess engineeringHelium gas

A helium recovery plant adapted to filter, compress, and purify helium gas collected from one or more helium-using instruments, as well as to liquefy and redistribute the purified gas within a closed system. The recovery plant is adapted to match the purification and liquefaction rate of the system with the consumption rate of the coupled instruments. Additionally, the recovery plant is adapted to match the liquefaction rate of a liquefaction module with a boil-off rate of liquid helium within a Dewar thereof. The recovery plant is further adapted to recycle helium therein in an effort to achieve zero loss.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com