Environment-friendly biomass fuel rod

A biomass fuel, fuel rod technology, applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of inconvenient use of fuels, unsatisfactory molding structure, and reduced heat energy utilization rate, and achieve easy ignition and oxygen circulation. , the effect of improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

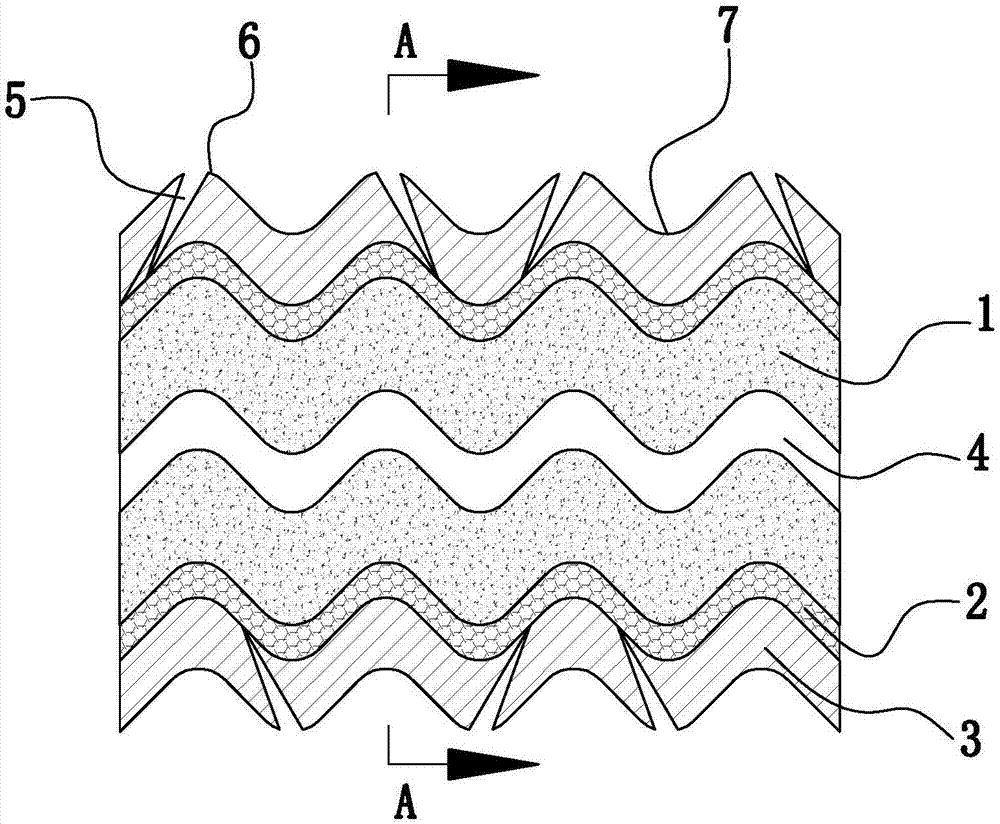

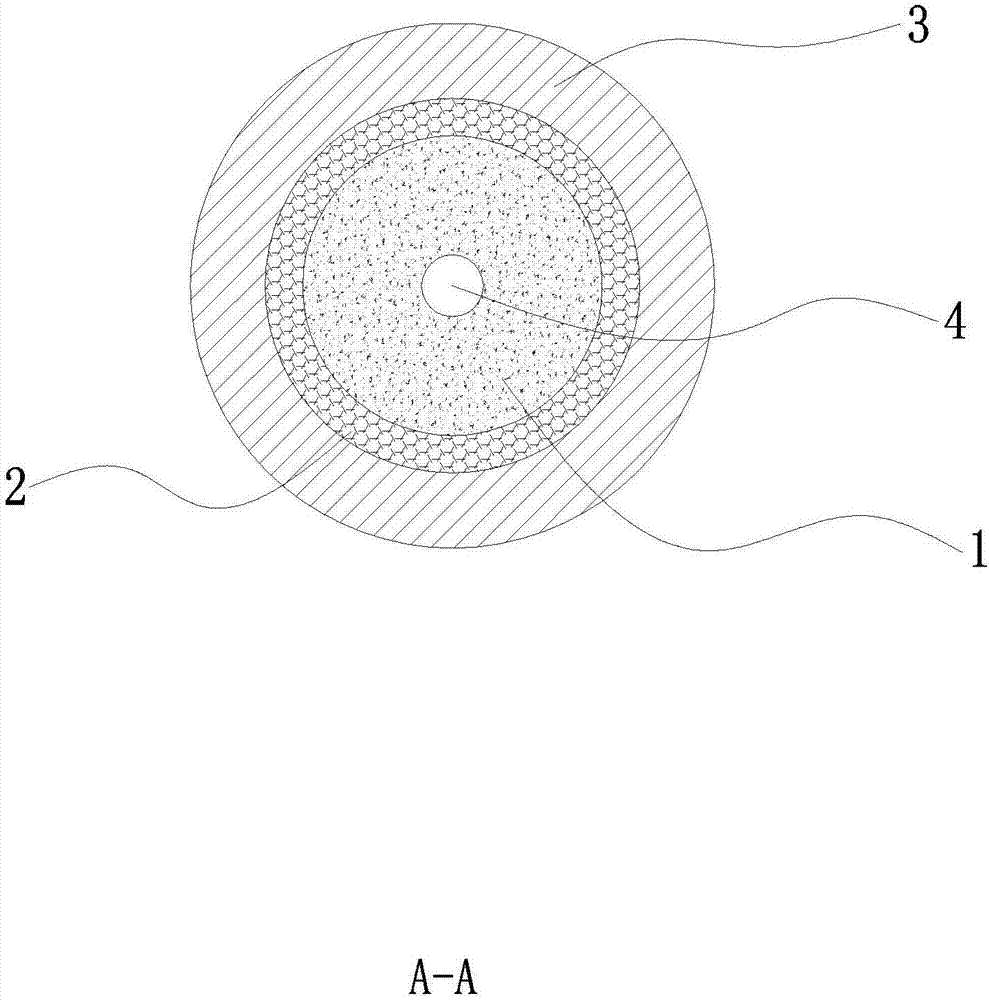

[0025] Embodiment 1: as Figure 1-2 As shown, an environmentally friendly biomass fuel rod includes a fuel rod body with a circular cross section, and the fuel rod body includes a rod body 1, a bonding layer 2 and a combustion-supporting layer 3 sequentially connected from the inside to the outside; the rod The body 1 is a cylinder extruded from combustible waste powder, and a through hole 4 is formed in the middle of the cylinder, and the through hole 4 is arranged along the length direction of the rod body 1;

[0026] The through hole 4 is set to increase the air permeability of the biomass fuel rod, reduce the ignition temperature, improve the combustion performance, facilitate the circulation of oxygen, and improve the overall combustion performance without adding foreign agents; the cylindrical fuel rod body is adopted, which is convenient Transportation, storage, transmission, and combustion can be automatically controlled. At the same time, the fuel rod body is solid pa...

Embodiment 2

[0036] The content of this example is basically the same as that of Example 1, and the content of the same part will not be repeated. The difference from Example 1 is that the components by weight of rod body 1 in this example are formulated as follows: 10 parts of wheat straw, 10 parts of rice straw, 10 parts of corn stalks, 40 parts of sawdust, 1 part of adhesive, 0.8 parts of dechlorination agent.

Embodiment 3

[0038] The content of this example is basically the same as that of Example 1, and the content of the same part will not be repeated. The difference from Example 1 is that the component formula of rod body 1 in this example is as follows: 13 parts of wheat straw, 13 parts of rice straw, 13 parts of corn stalks, 30 parts of sawdust, 2 parts of adhesive, 0.55 parts of dechlorination agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com