Patents

Literature

517 results about "Coffee grounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

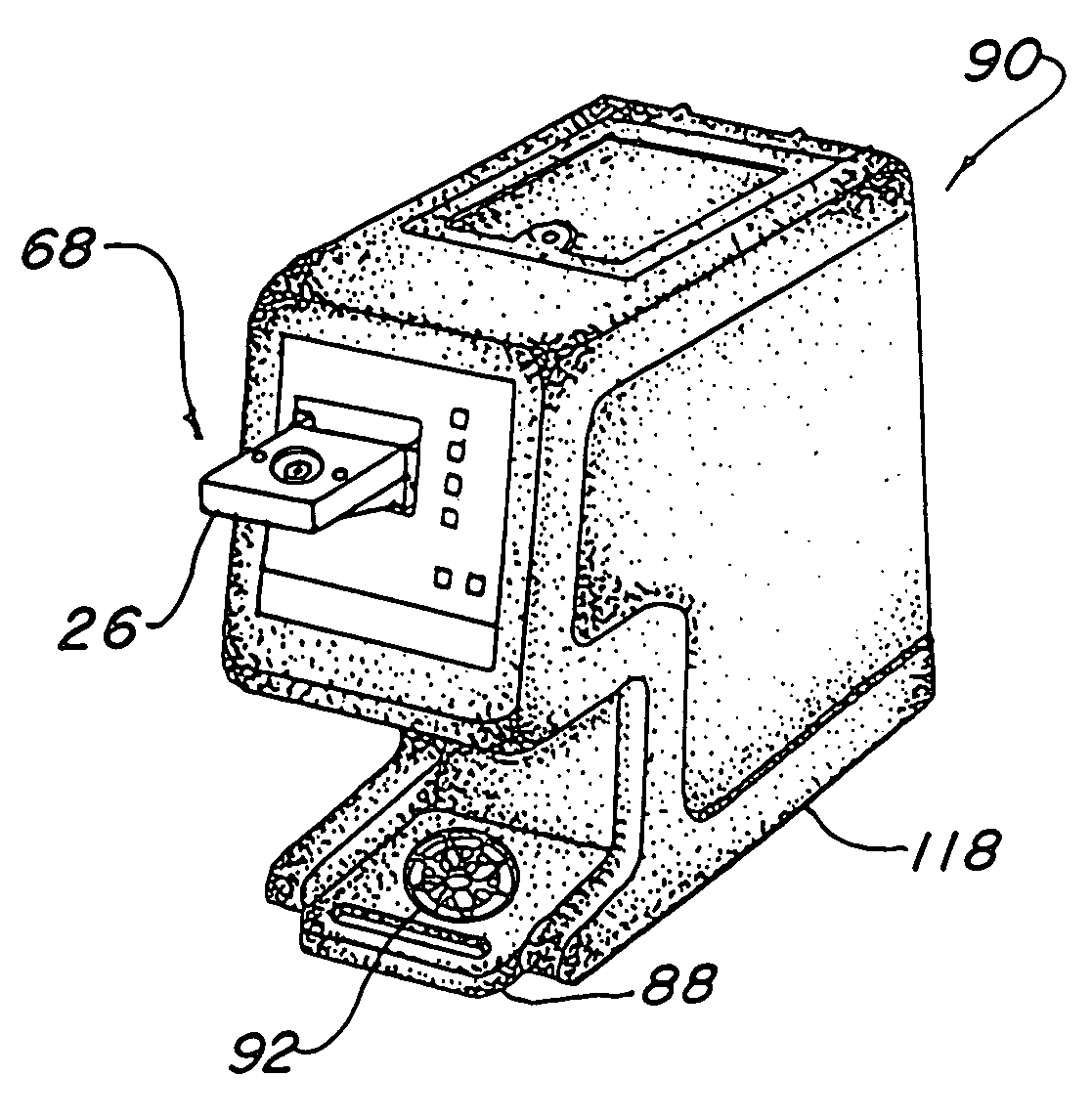

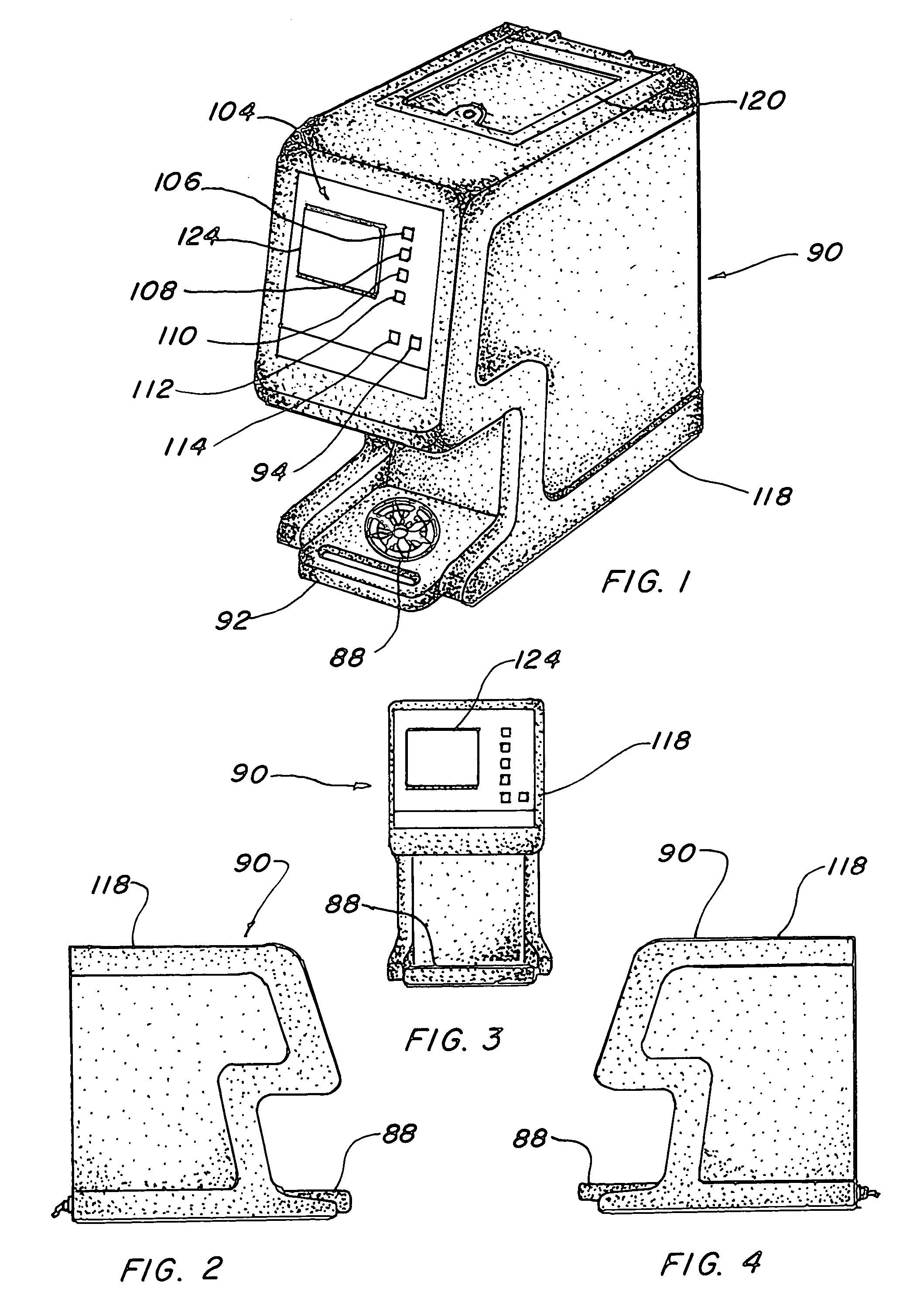

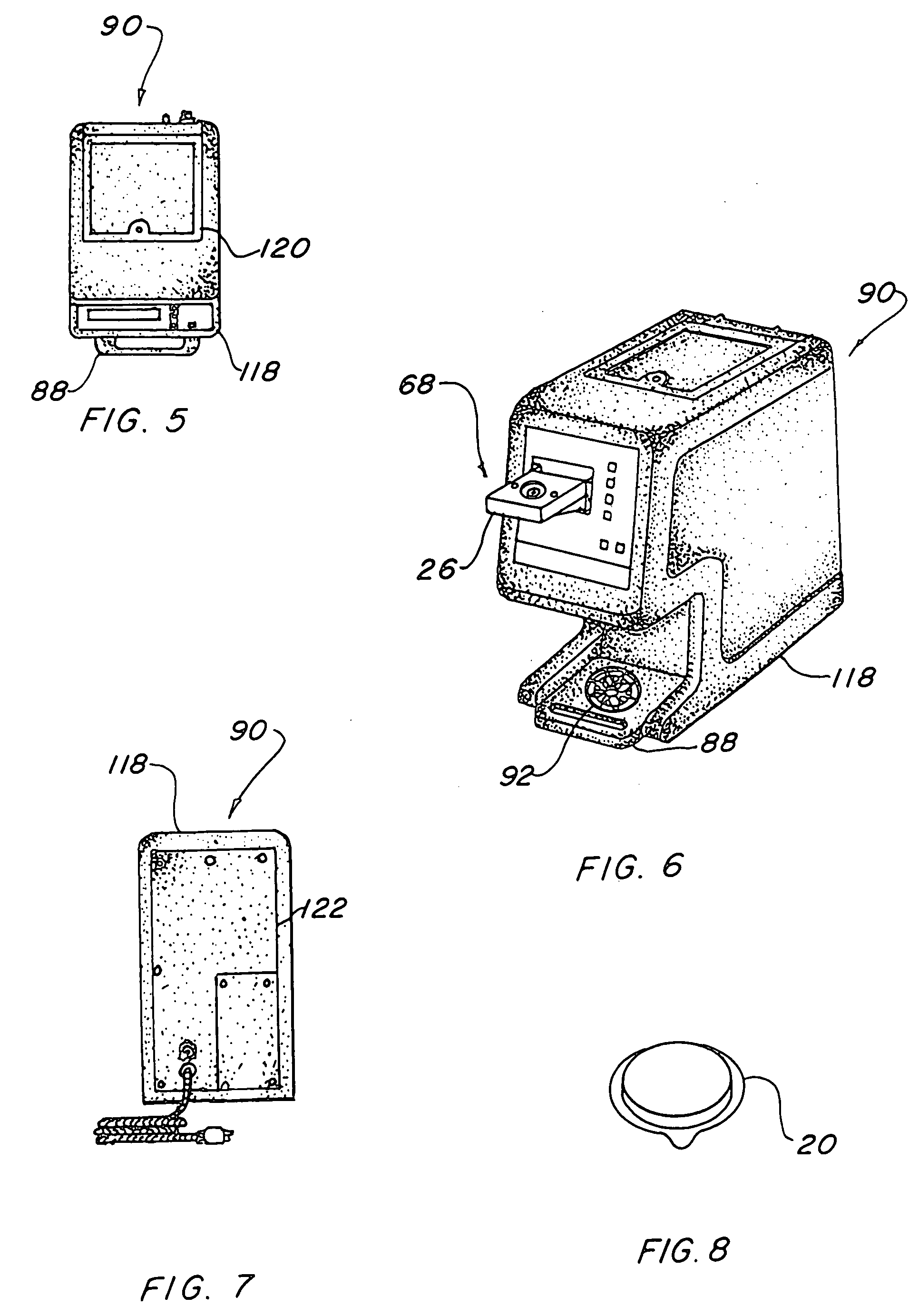

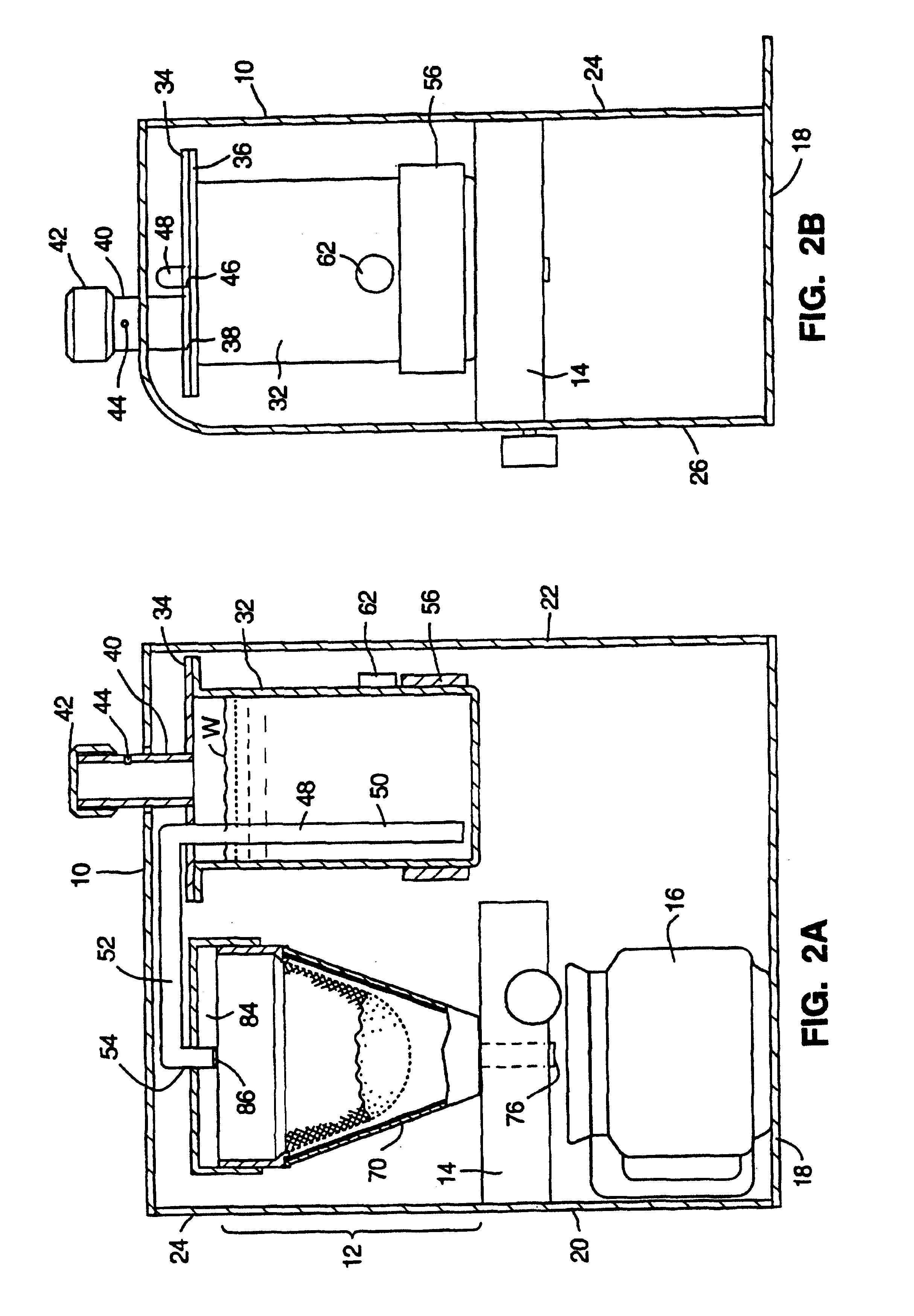

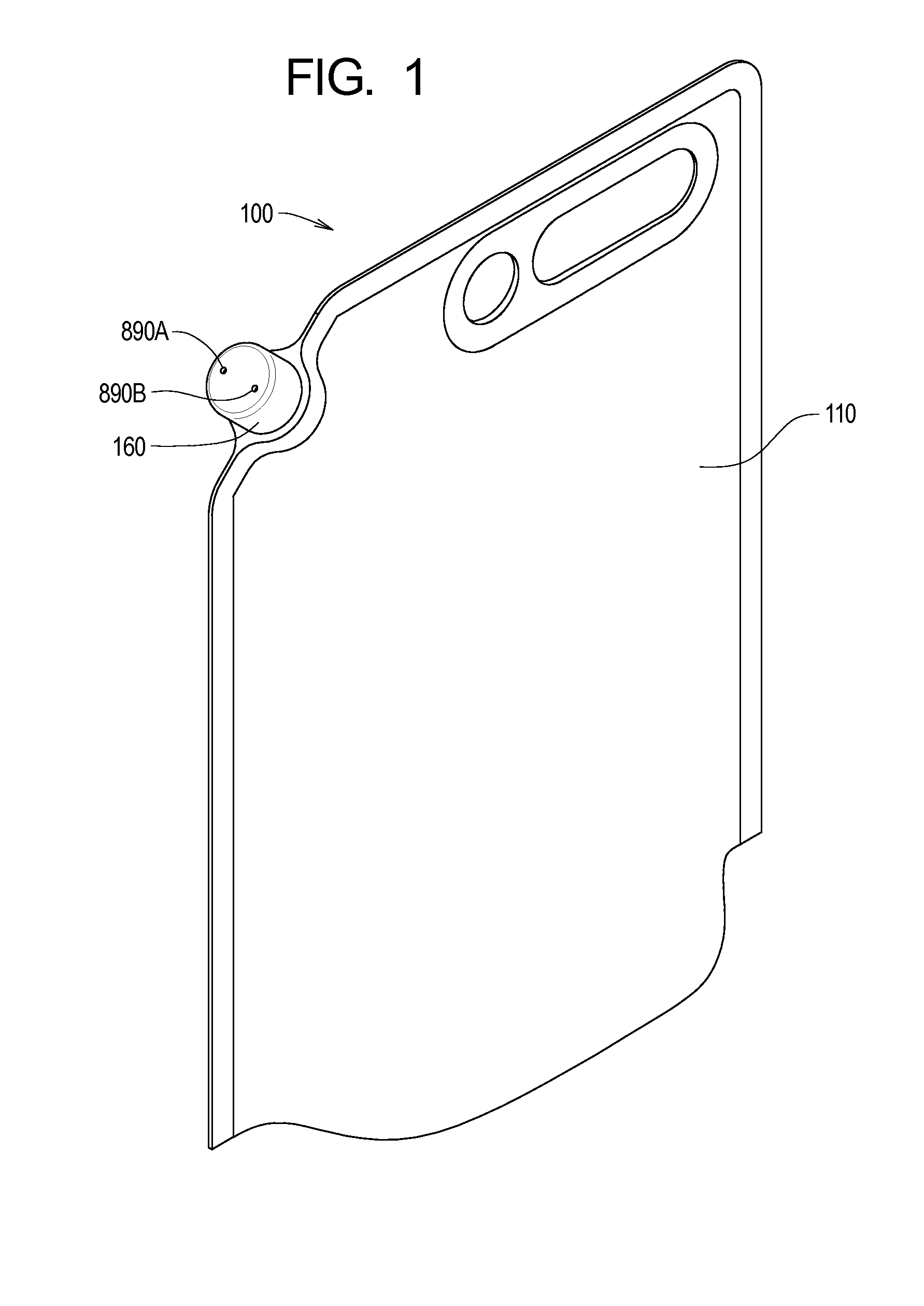

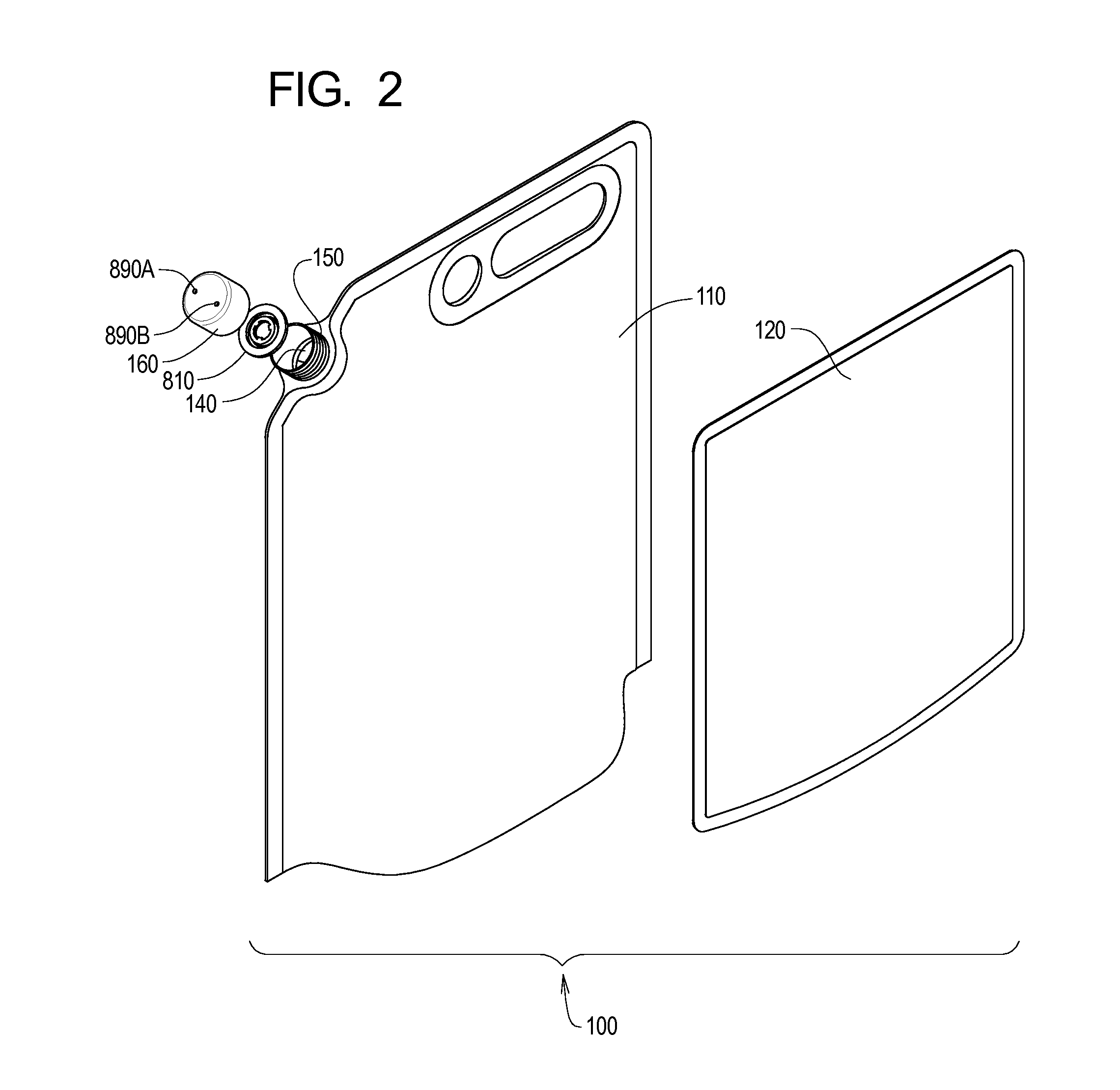

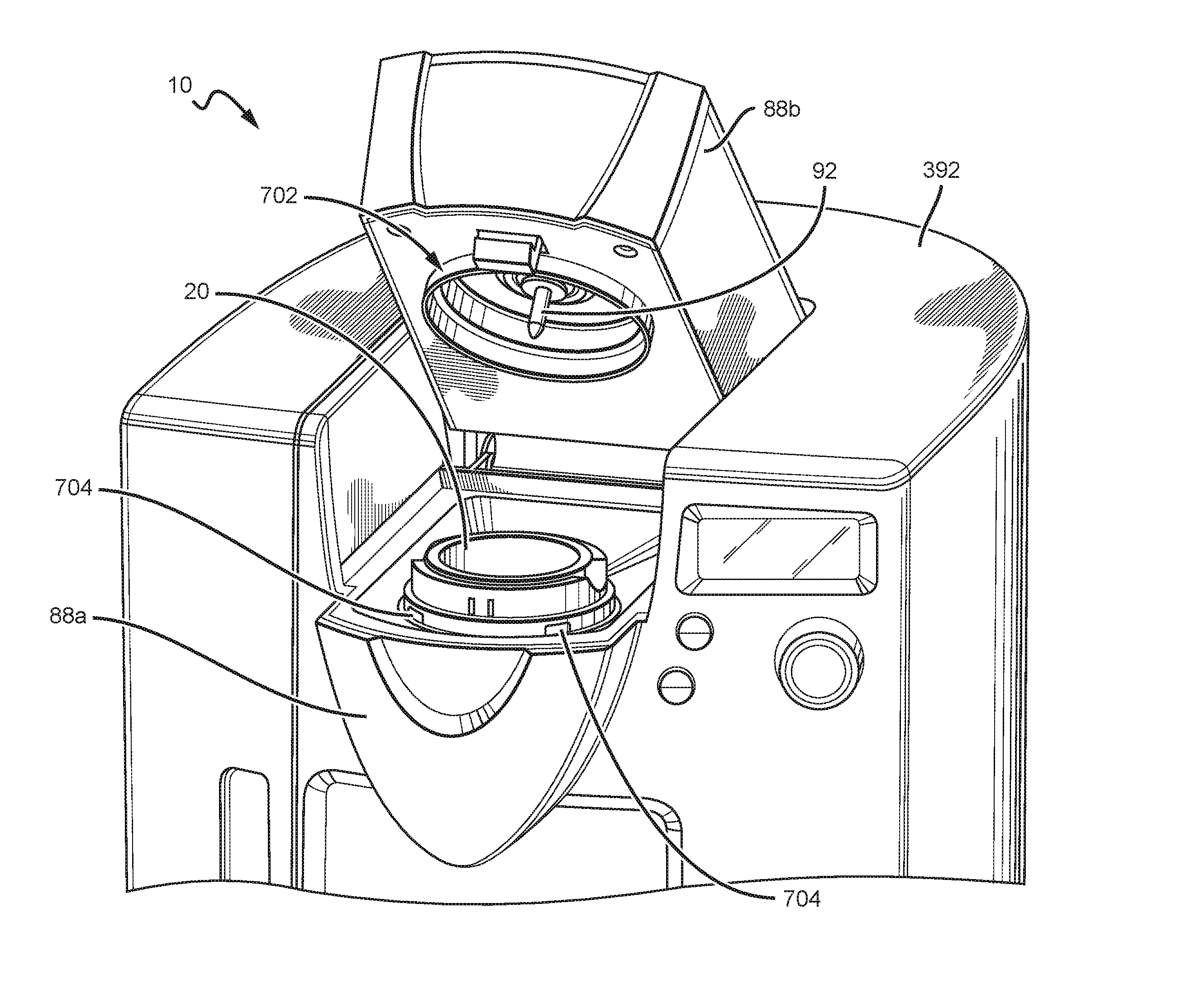

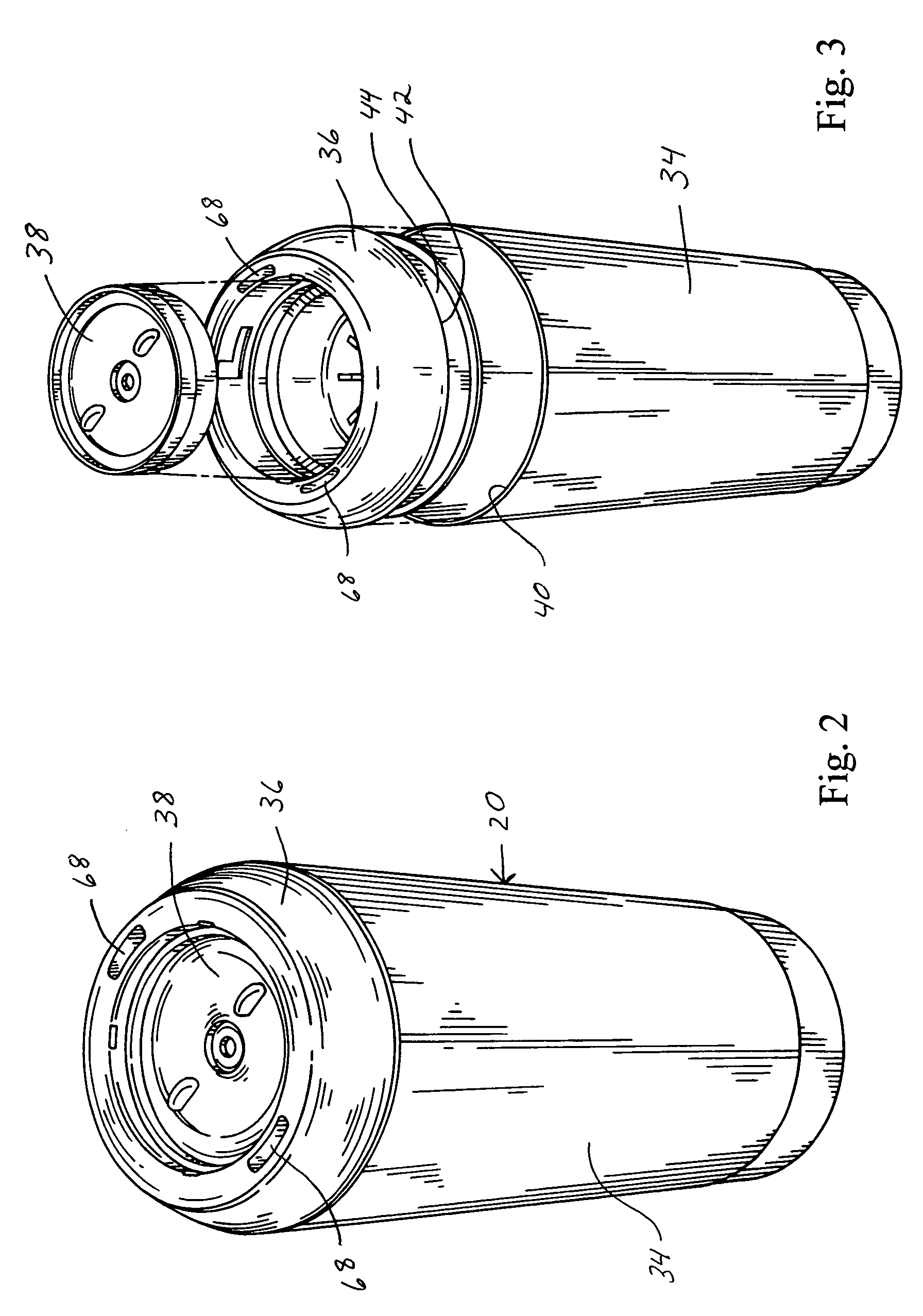

Single cup pod beverage brewer

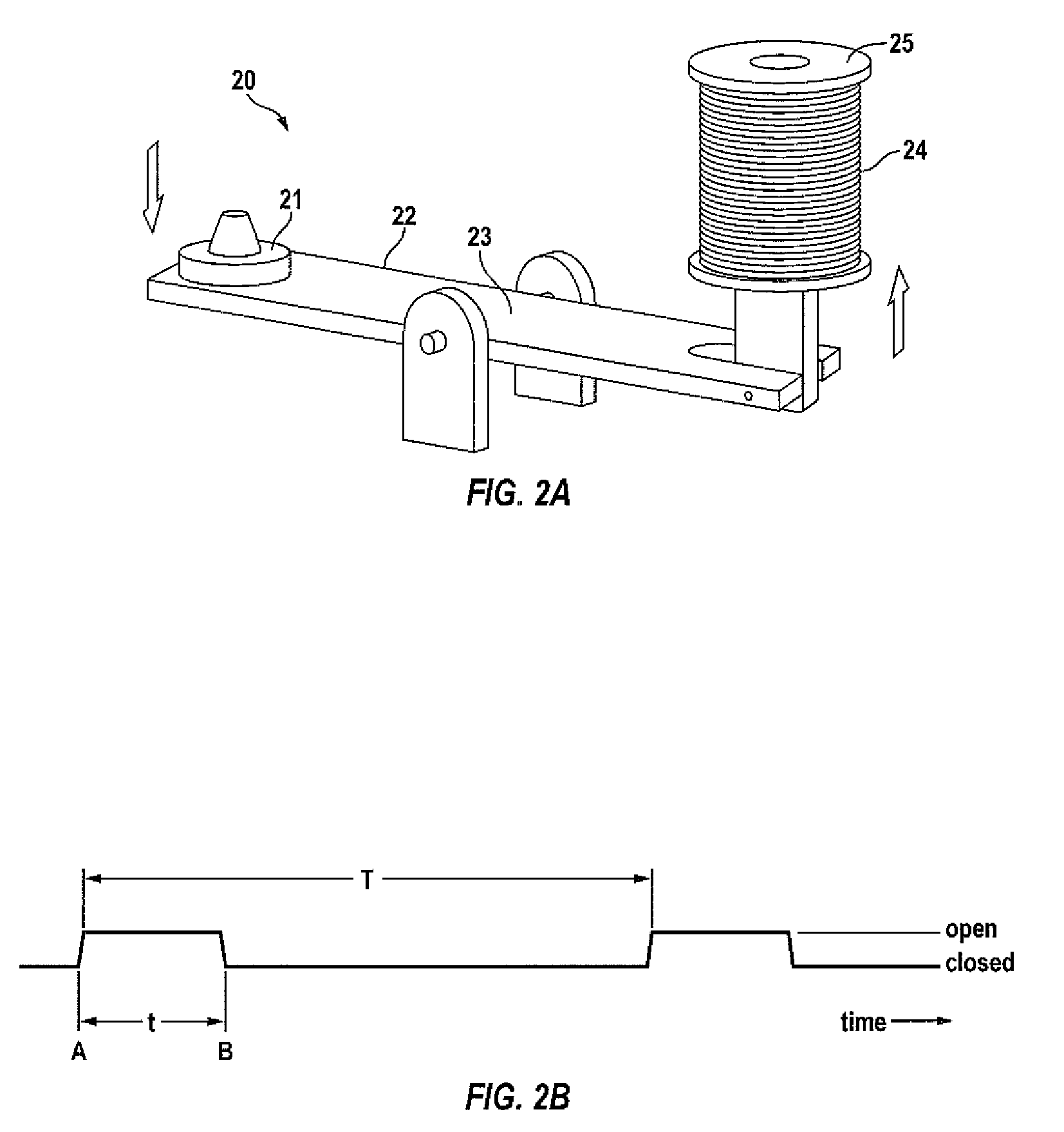

InactiveUS7210401B1Process controlIncrease power consumptionBeverage vesselsControl systemElectronic control system

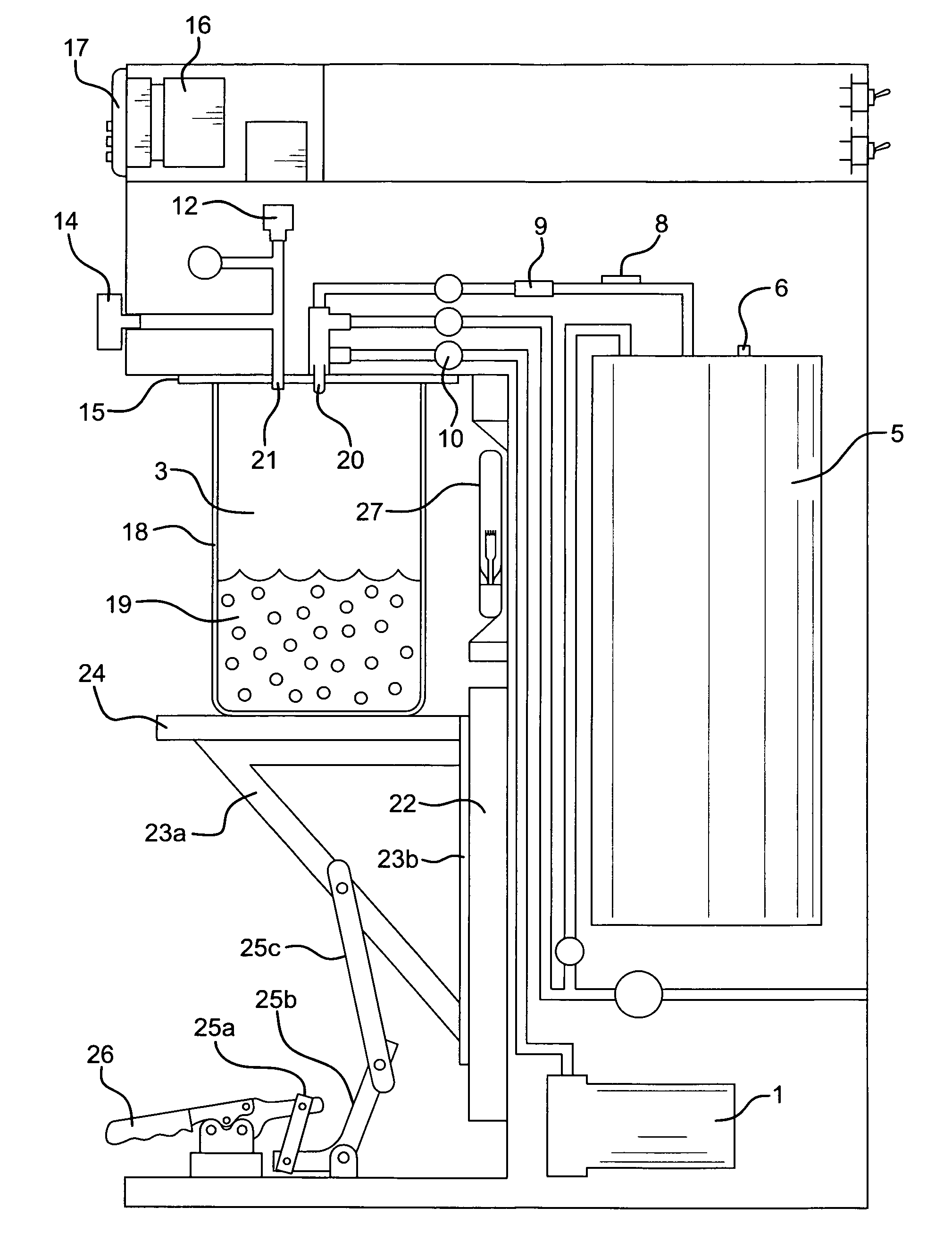

A single cup pod beverage brewer is presented utilizing a pod (20) containing coffee grounds or tea leaves surrounded by filter paper. A pod holding chamber (22) consisting of a upper head (26) and a lower head (28) having an ejection disc (42). An upper head mounting frame (48) is attached to its horizontal base (50) and includes lower head rotating arms (60) attached to a first shaft (62) with a first gear motor (66) rotating the arms into a pod loading position, a pod brewing position and a pod disposal position. A second gear motor (66a) is secured to the upper head mounting frame, driving a cam (76) through a second shaft (62a) engaging the upper head to lower, seal and raise said upper head. A pod ejector solenoid (84) is disposed on the base electromechanically propelling the pod from the chamber when the lower head in the pod disposal position. An electronic control system employs a solid state direct current arrangement for control regulation and alternating current for heating system functions. An enclosure with panels and a door (90) protects moving elements and electrical controls.

Owner:ROLFES PATRICK J +1

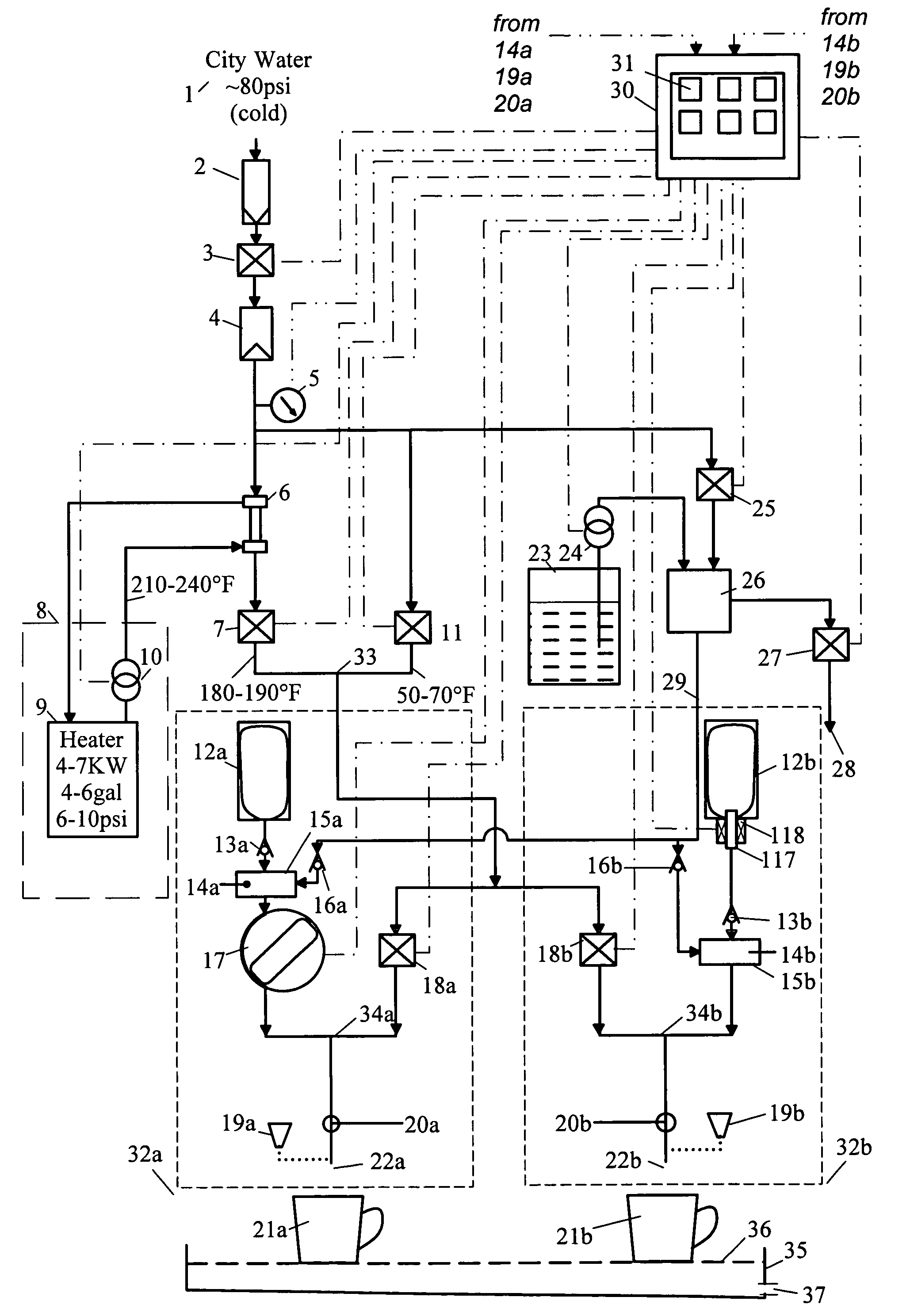

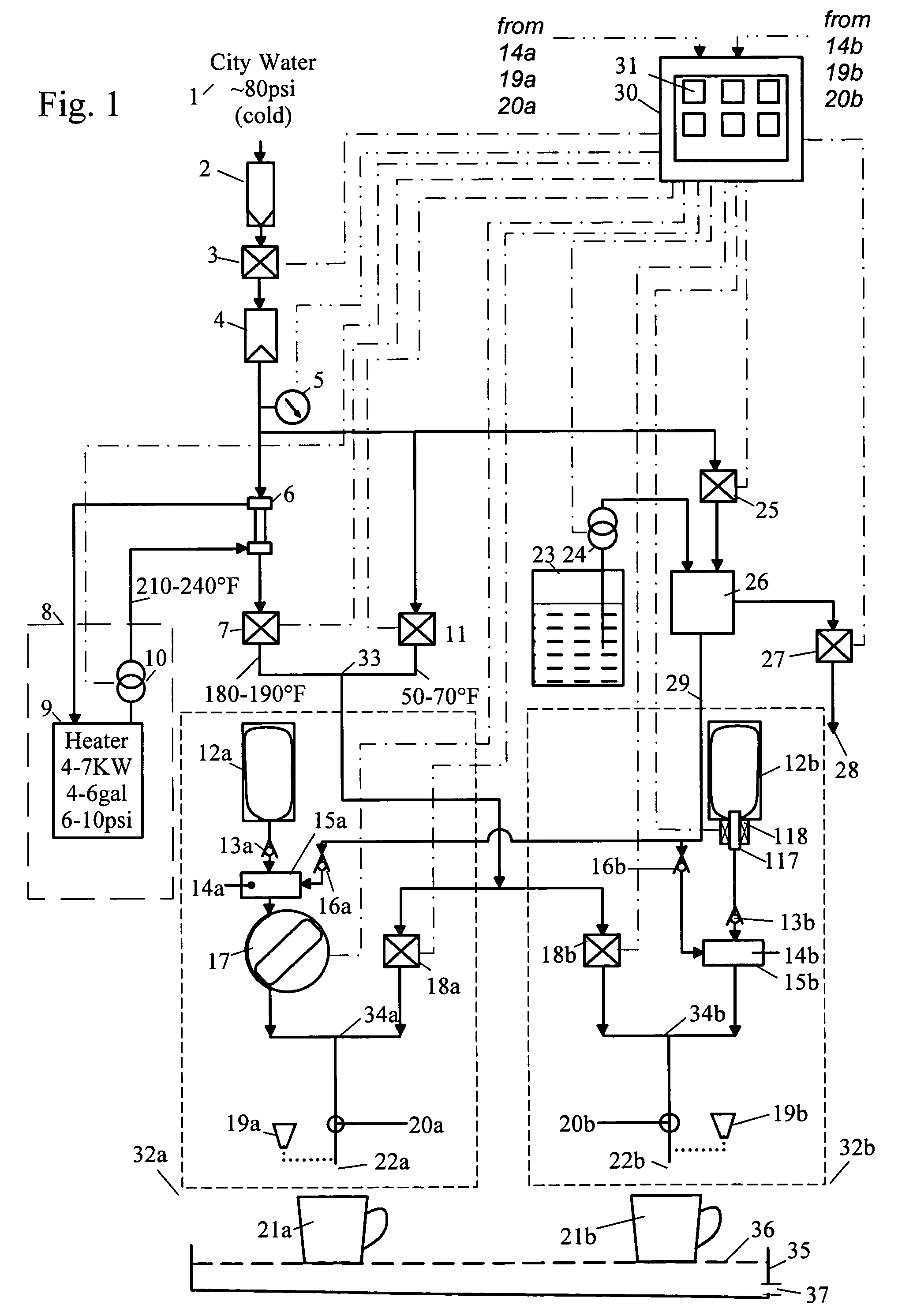

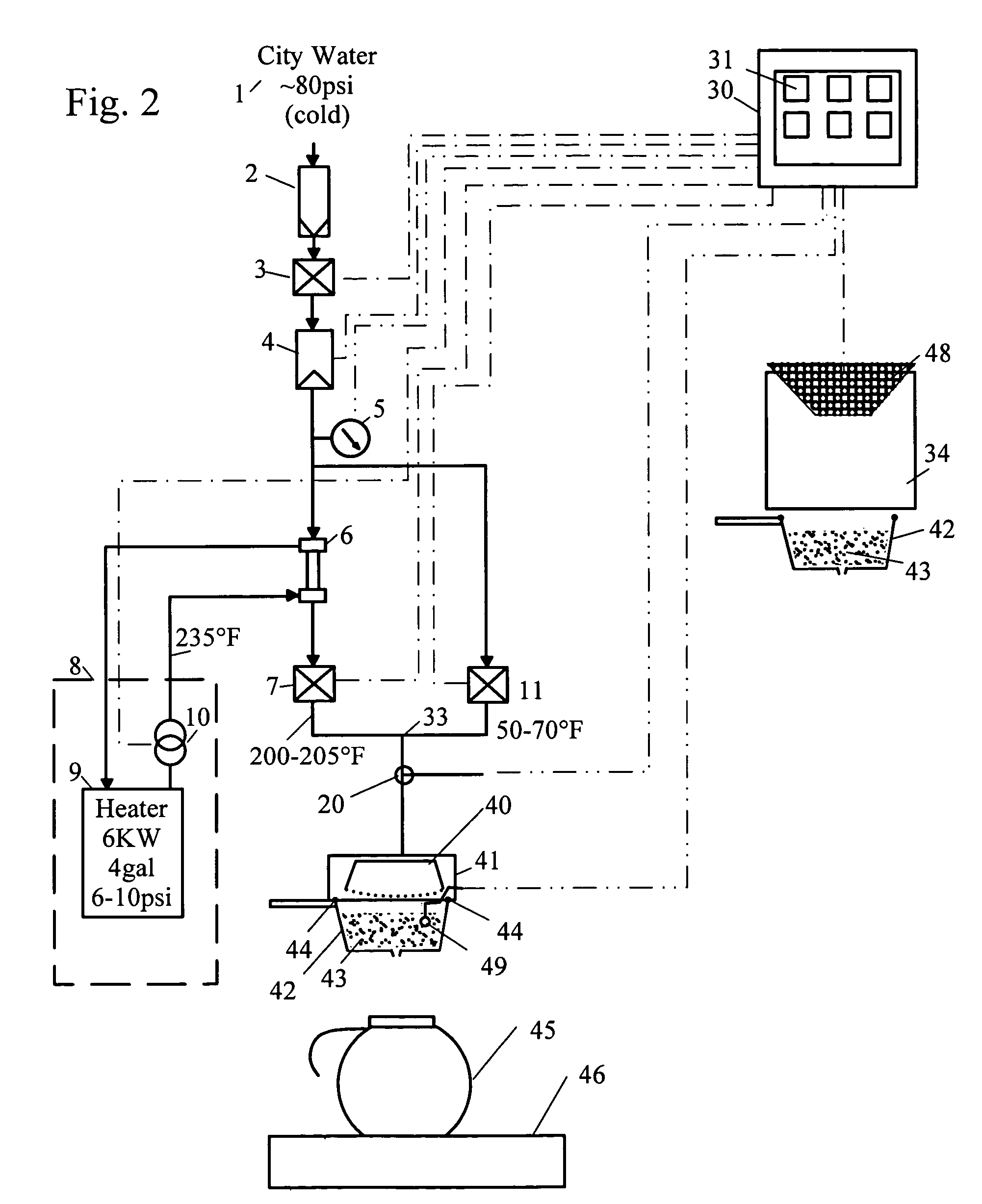

Beverage dispenser

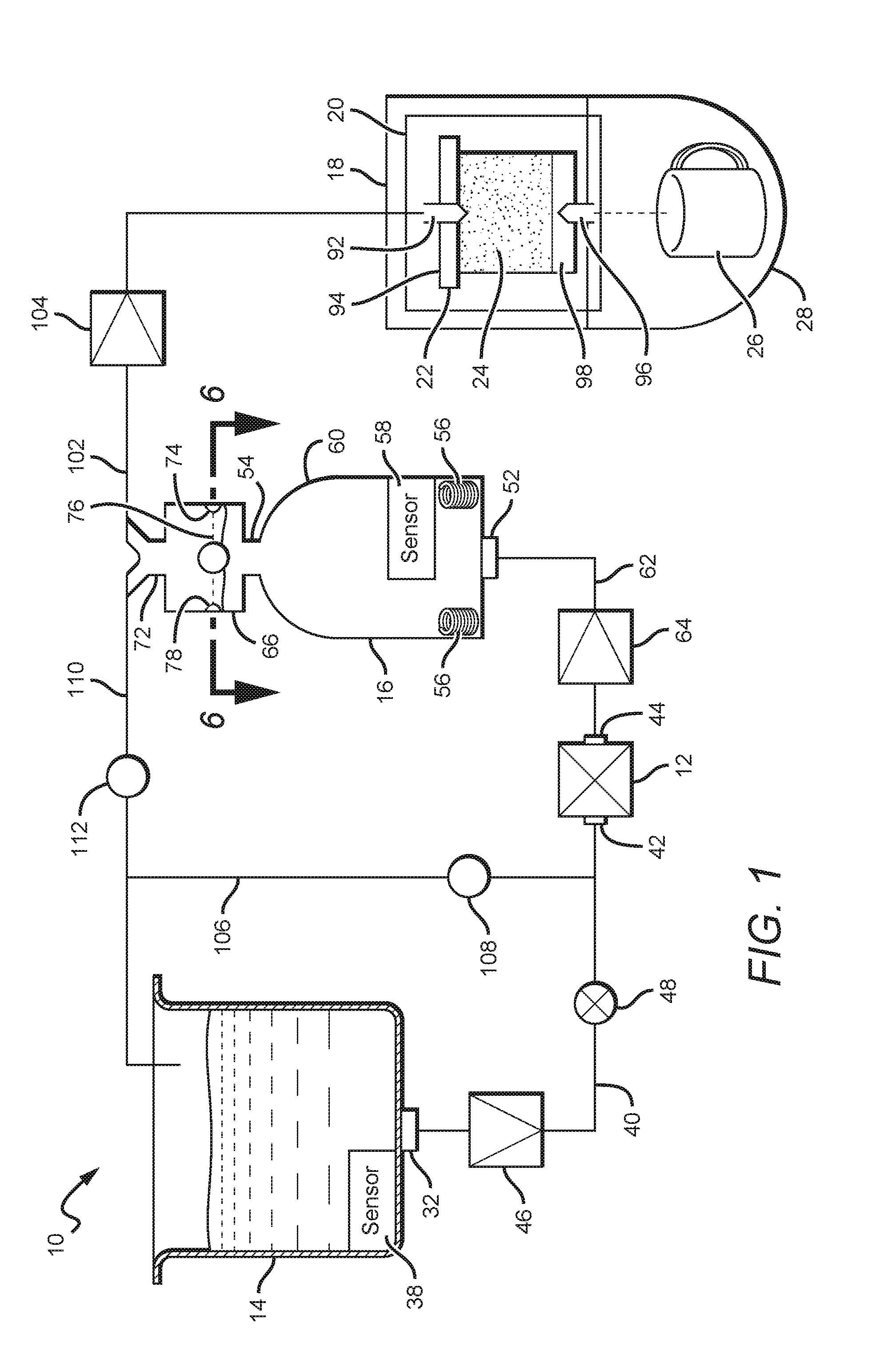

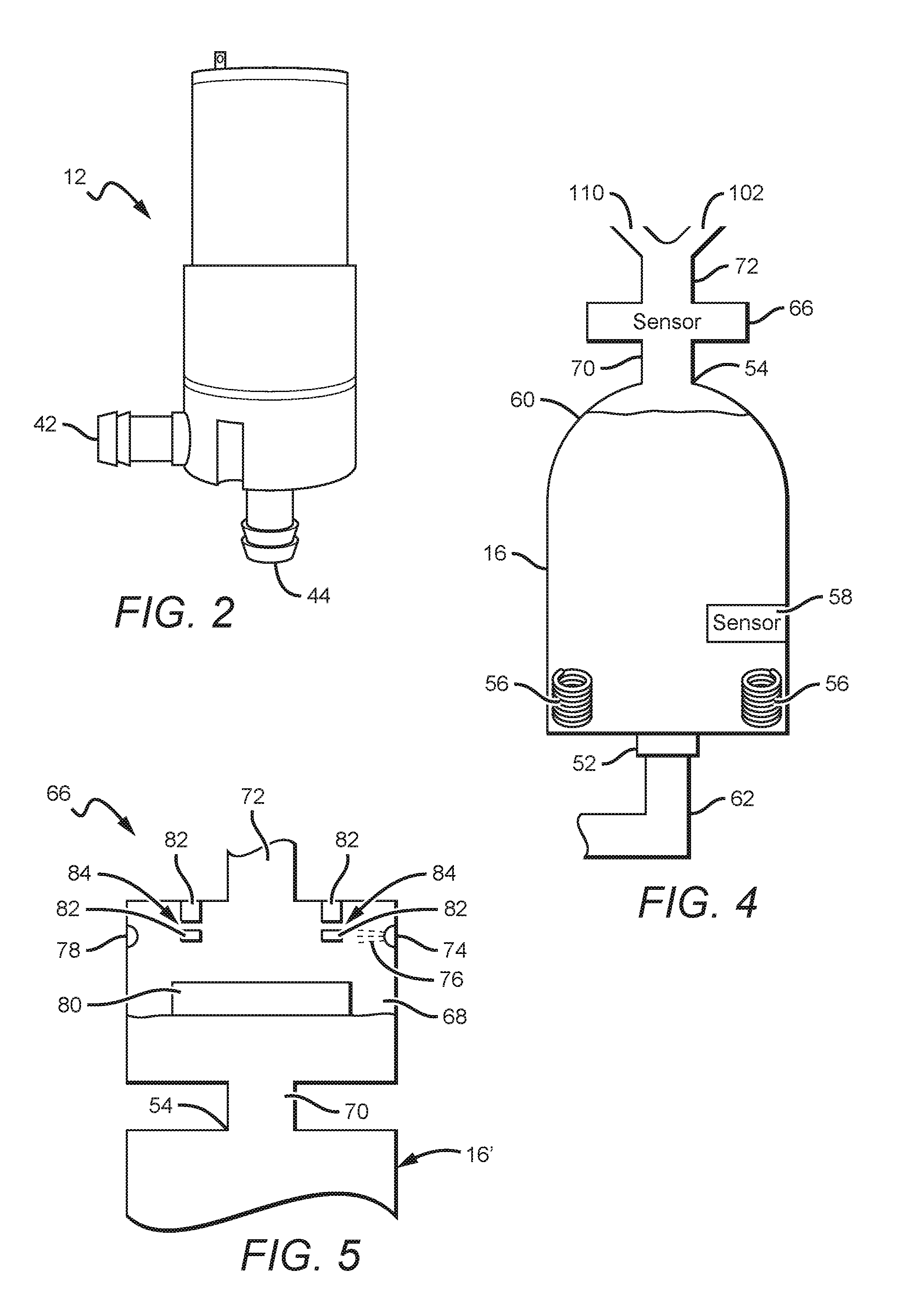

InactiveUS7654191B2Improves aroma and look and tasteEffectively sanitizedBeverage vesselsLiquid transferring devicesWater useEngineering

A beverage dispenser and method of operation, in which incoming water for beverage preparation is heated by a liquid-to-liquid heat exchanger. The heated water may be mixed with cold water using controlled valves, to generate a selected temperature stream. This controlled-temperature stream may be mixed with beverage concentrate or sprayed over coffee grounds to brew fresh coffee.

Owner:GREENWALD TECH

Coffee and tea brewing apparatus and system

InactiveUSRE37173E1Constant brew timeQuality improvementBeverage vesselsCoffee extractionEngineeringThermal water

A method and system for brewing a desired volume of coffee at a selected brew time, in which a volume of water corresponding to the desired volume of coffee is heated and directed into contact with coffee grounds in a brewing chamber. Contact between at least a portion of the heated water and the coffee grounds is maintained for approximately the selected brew time to form brewed coffee. The brewing time, however, is substantially independent of the desired volume of coffee to be brewed and is controlled by control of the rate at which heated liquid flows into or out of the brewing chamber. At the expiration of the brewing time, brewed coffee is released through an opening in the brewing chamber and into an underlying receptacle.

Owner:JEFFERSON JR HARRY D

Apparatus for preparing beverages

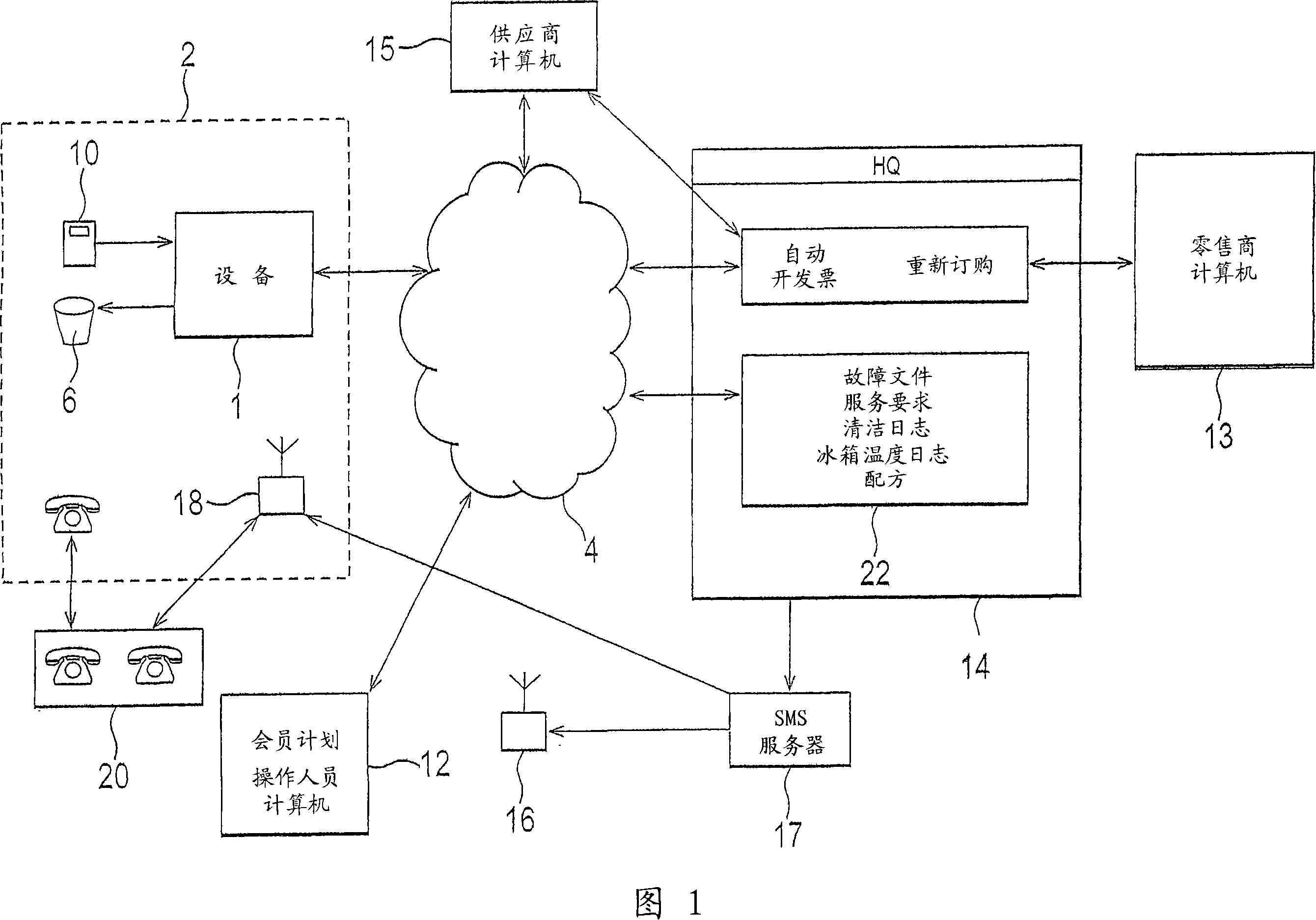

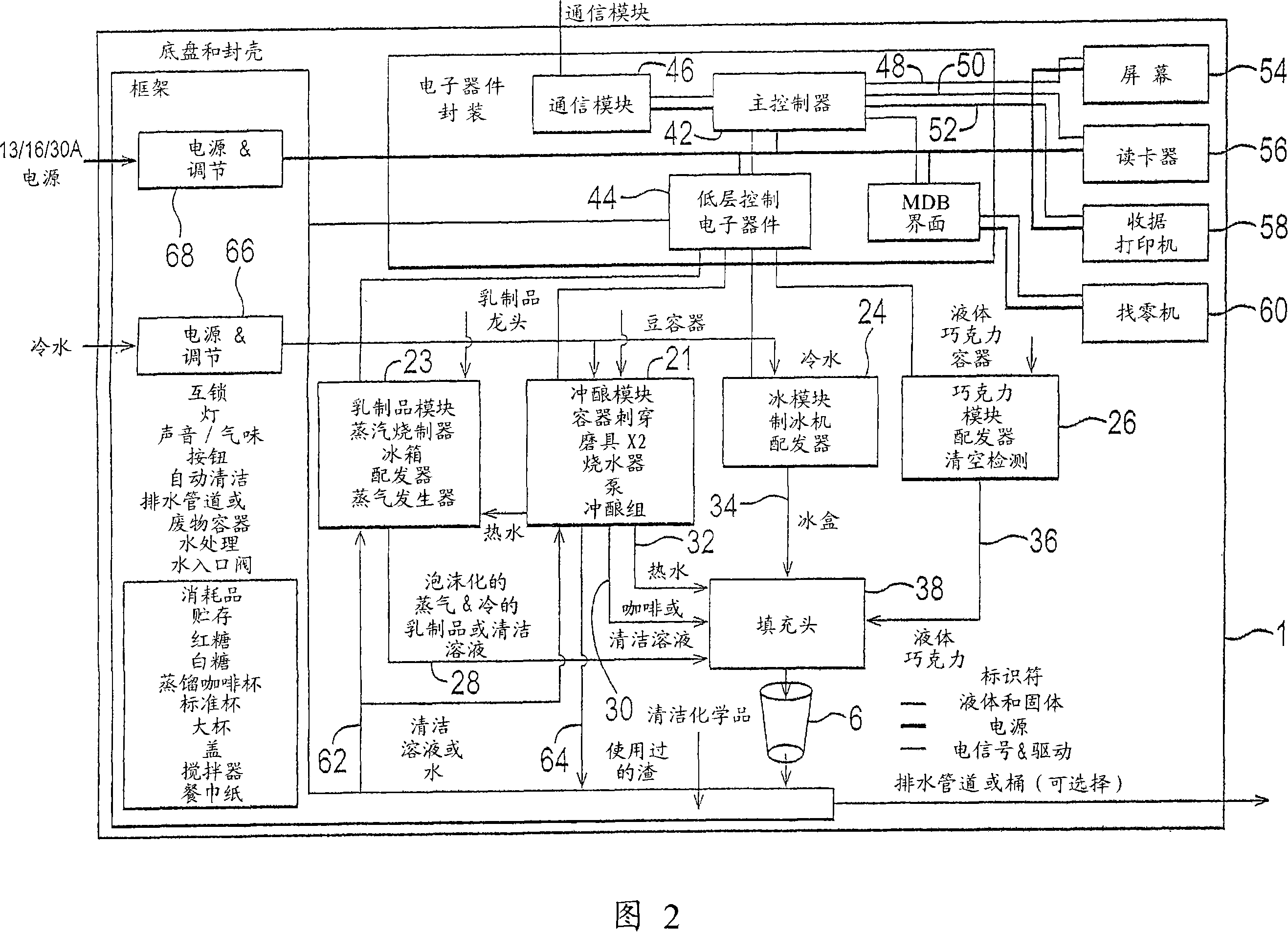

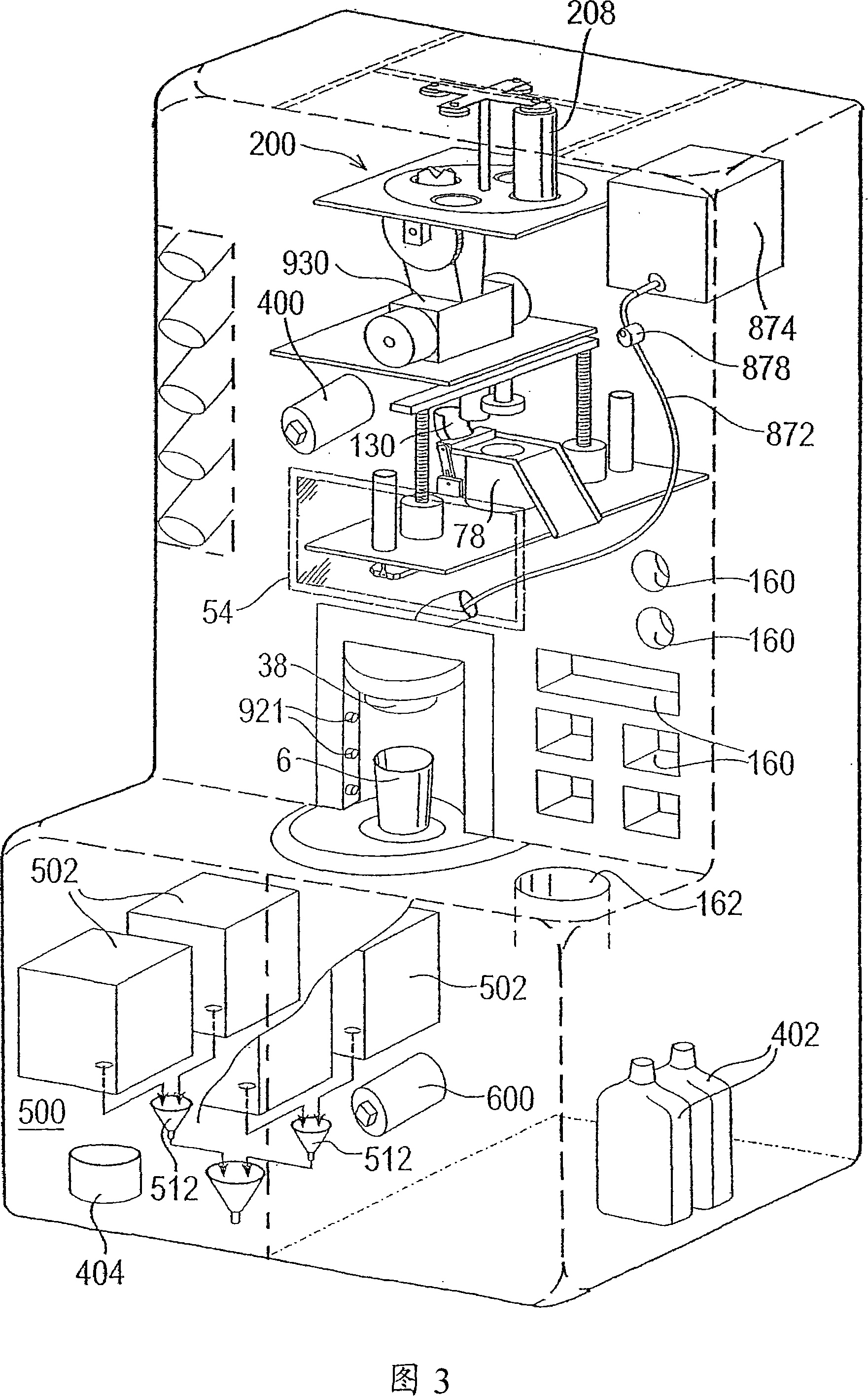

Various forms of apparatus for preparing and dispensing beverages, preferably based on coffee, can receive instructions from a customer and deliver the beverage automatically. The apparatus is preferably capable of fully automatic cleaning in a cleaning cycle in which a cleaning agent is flushed through the lines, and the apparatus is preferably arranged to ensure that not only are the lines cleaned properly but that no cleaning agent can be dispensed. The apparatus includes a brewer assembly having a chamber in which freshly ground coffee can be introduced and either espresso or filter coffee can be automatically prepared by passing hot water through the chamber and removing the spent coffee grounds . The coffee may be stored as coffee beans in sealed containers that can automatically be pierced to release the beans which are ground immediately before preparation of the beverage . The apparatus also includes a cup-size detector for ensuring that the customer offers a cup to the apparatus that is of a size appropriate to the beverage selected.

Owner:COFFEE NATION LTD

Processed solid burnable fuel composition

A solid burnable fuel composition which contains a major proportion of spent dried coffee grounds is described. The fuel composition includes at least 50% dried spent coffee grounds and a combustible wax which are mixed together and compressed into a suitable shape for combustion. The fuel composition may further include a small amount, 10% or less, of a coking agent useful to control burn rate and to prevent cracking of compressed fuel during combustion. Small amounts of cellulosic material may also be incorporated to improve the structural properties of the composition. Due to its superior heat and flame production, dried spent coffee grounds are an excellent fuel source for processed fuel products such as fire-logs and fuel pellets. The advantage is a hotter, cleaner burn which produces less soot and smoke, releases fewer harmful pollutants and provides a brighter flame over a longer period of time.

Owner:ROYAL OAK ENTERPRISES

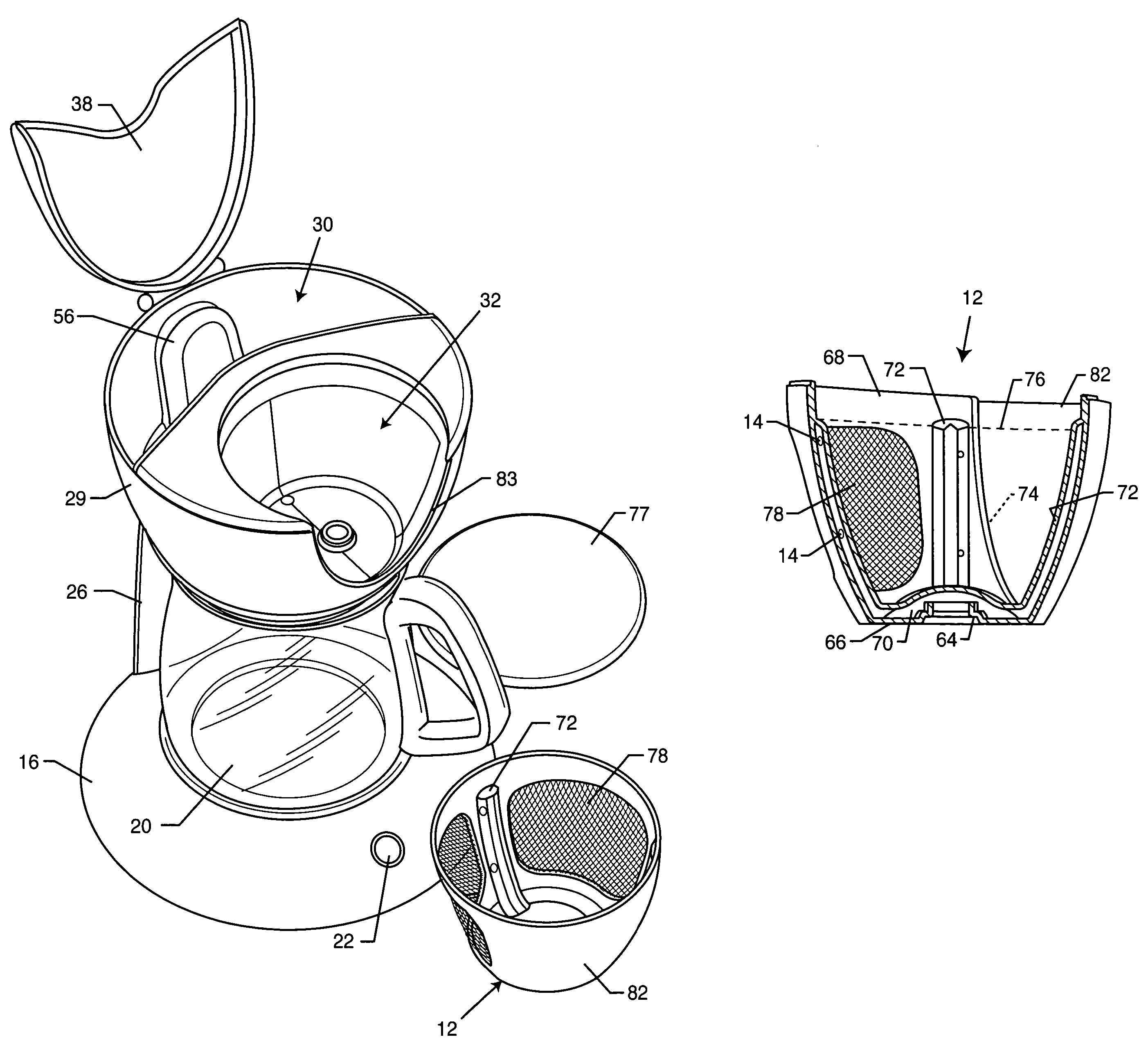

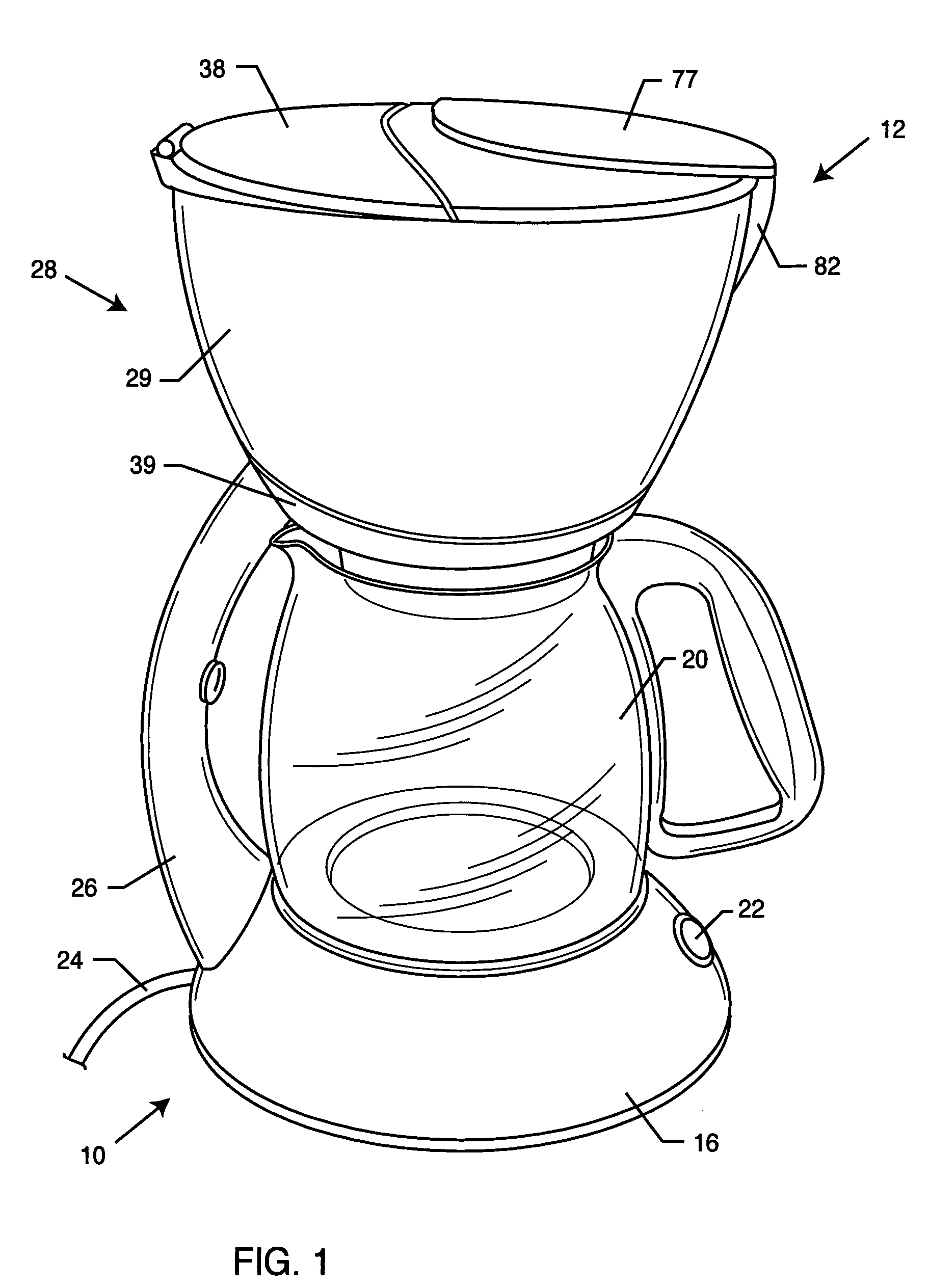

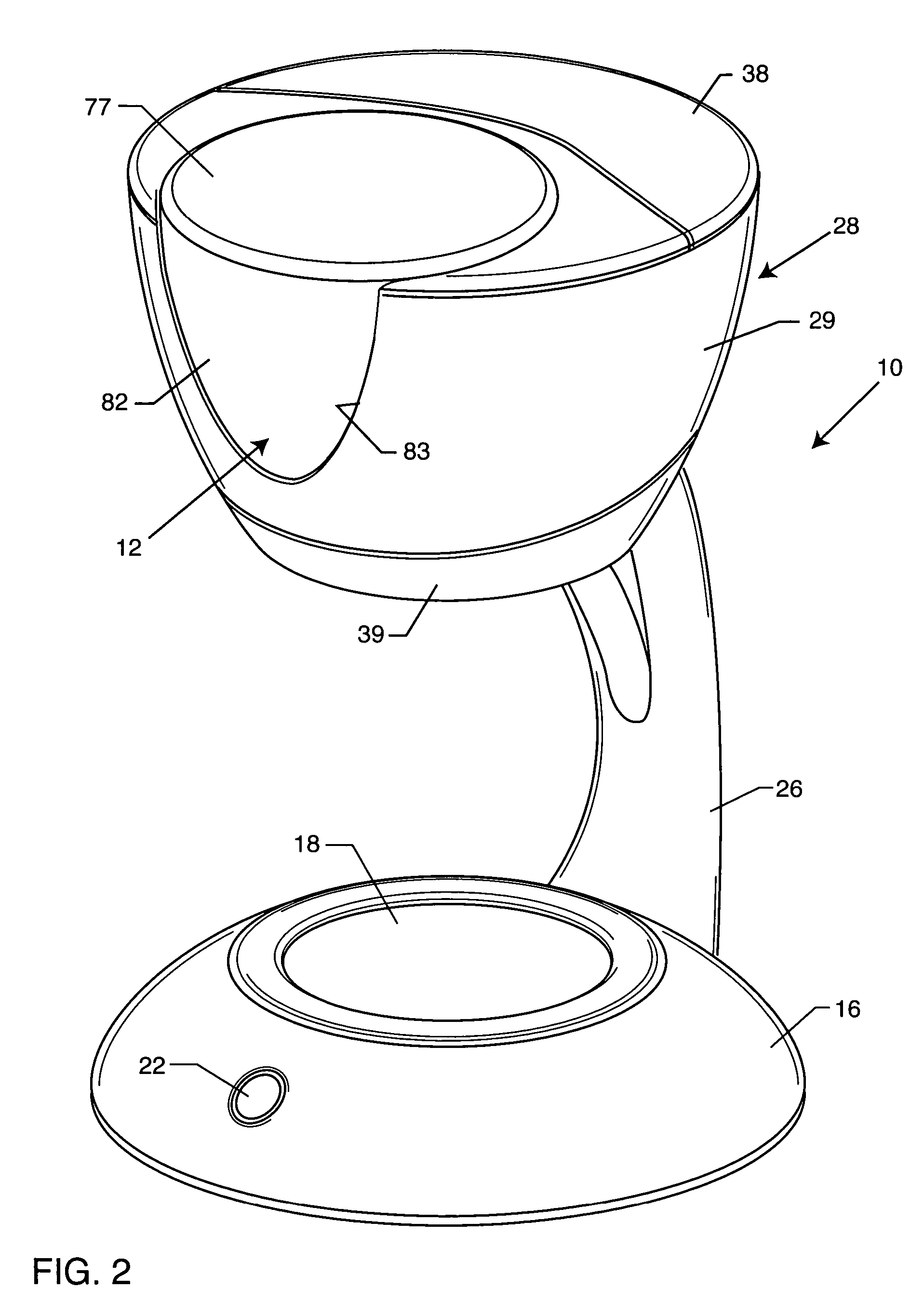

Coffee brewer

An improved coffee brewer and brewing method are provided for producing brewed coffee with improved flavor. The coffee brewer includes a brew basket having jet ports connected to a source of heated water and positioned to deliver hot water streams into the brew basket at a location beneath the level of coffee grounds contained therein. These hot water streams turbulently agitate and stir the coffee grounds to produce a substantially fluidized bed of water-borne coffee grounds for improved flavor extraction and enhanced aroma. This fluidized bed is directed against one or more mesh filter elements forming a wall portion of the brew basket for outward passage of the thus-brewed coffee which is then directed into an underlying carafe or the like. In one preferred form, a portion of the brew basket may incorporate a window to permit visual observation of the fluidized bed therein.

Owner:LVD ACQUISITION +2

Cold Brew System and Method for Making Cold Brew Coffee or Tea Extract

A cold brew apparatus and a method of making cold brew extract are disclosed. The cold brew apparatus includes a flexible brewing bag having an opening therein. Premeasured brewable ingredients (e.g., coffee grounds, coffee beans, tea leaves, etc.) are located in the brewing bag. The opening in the brewing bag is uncovered to allow a liquid (e.g., water) to be added to the brewable ingredients. The opening in the brewing bag is covered after the liquid has been added, and the brewable ingredients and the liquid are left to steep for a period of time (e.g., approximately 8-24 hours). After the period of time has elapsed, extract (e.g., coffee extract, tea extract, etc.) is poured out of the opening in the brewing bag.

Owner:PROCREATE BRANDS

Biological pesticidal organic fertilizer and preparation method thereof

InactiveCN103724139ASimple structureAddress organic matter declineFertilizer mixturesPaulownia coreanaNematode

The invention discloses a biological pesticidal organic fertilizer and a preparation method thereof. The biological pesticidal organic fertilizer is prepared from the following raw materials in parts by weight: 40-50 parts of pig manure, 20-30 parts of tea seed pulp, 10-15 parts of coffee grounds, 8-12 parts of paulownia sawdust, 5-10 parts of phosphogypsum, 4-8 parts of corn cob, 5-10 parts of pepper seed cake, 10-15 parts of mushroom dreg, 8-12 parts of wheat bran, 15-20 parts of bentonite, 10-15 parts of opoka, 2-3 parts of ferrous sulfate, 1-2 parts of manganese sulfate, 3-5 parts of humic acid, 1-2 parts of chinese tallow tree root and bark, 2-3 parts of sophora alopecuroides, 1-2 parts of stemona, 1-3 parts of Artemisia annua, 1.5-2.5 parts of ailanthus leaf, 2-3 parts of derris and 1-2 parts of Radix Euphorbiae Ebractealatae. The organic fertilizer disclosed by the invention has multiple effects of providing nutrients, improving the soil structure, preventing and treating pests and diseases and the like, can promote the crops to quickly grow, enhances the stress tolerance of the crops, can have favorable preventing and treating effects on nematodes and soil insects, reduces or avoids use of chemical pesticides, enhances the soil fertility, regulates the ecological equilibrium of soil, improves the quality of agricultural products, has no chemical residues, and implements yield increase and income increase of agricultural products.

Owner:青岛米品品服装有限公司

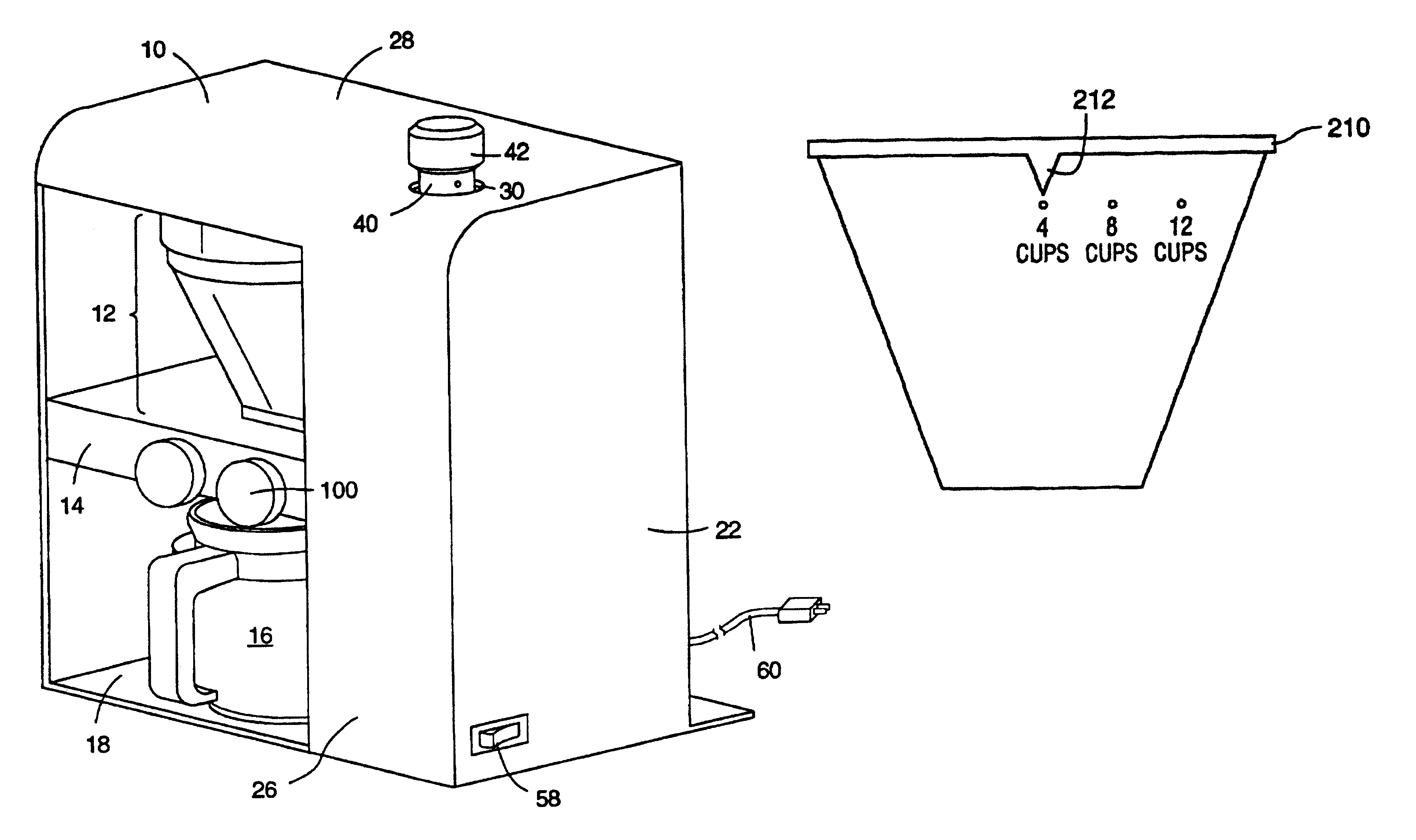

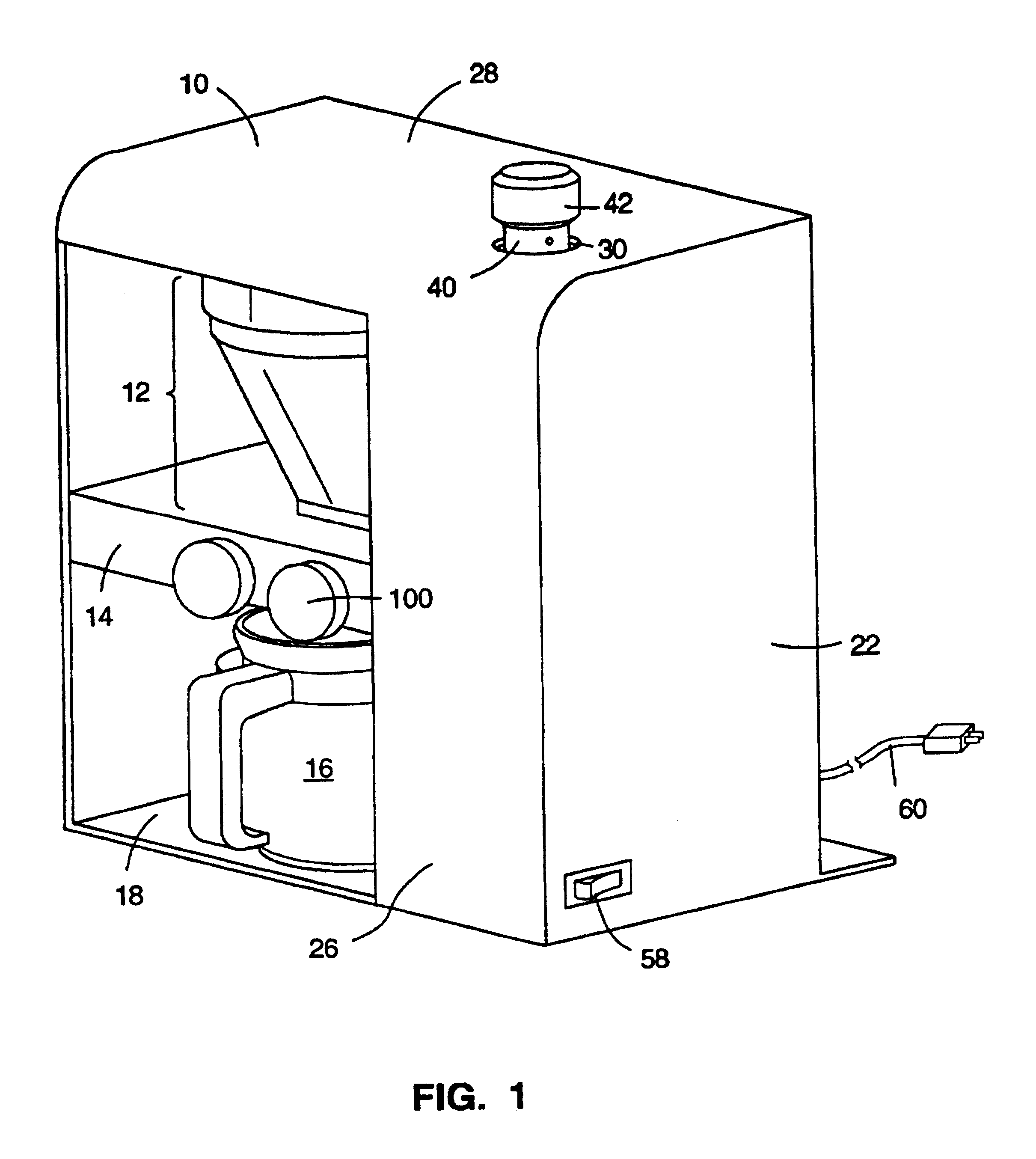

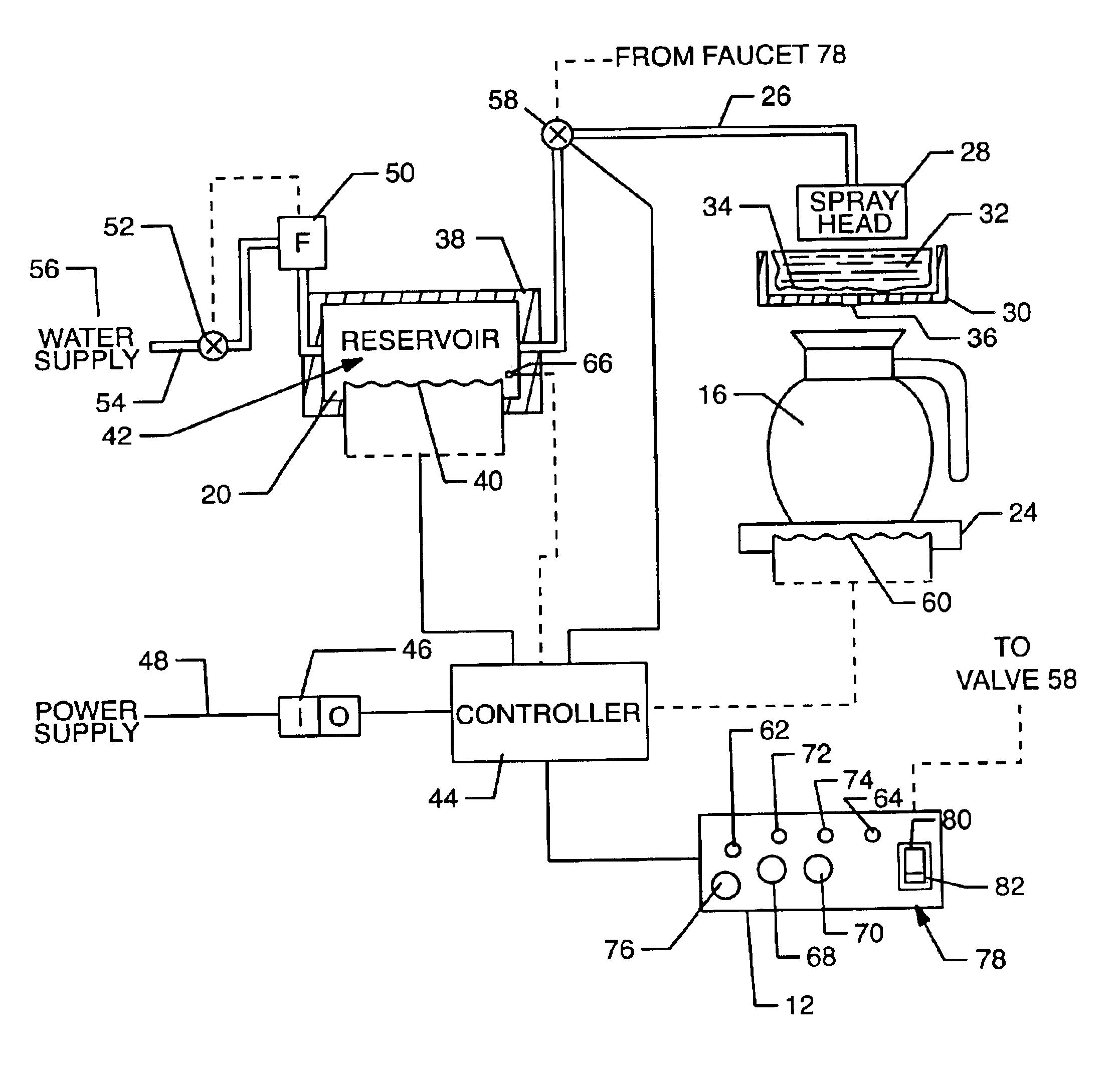

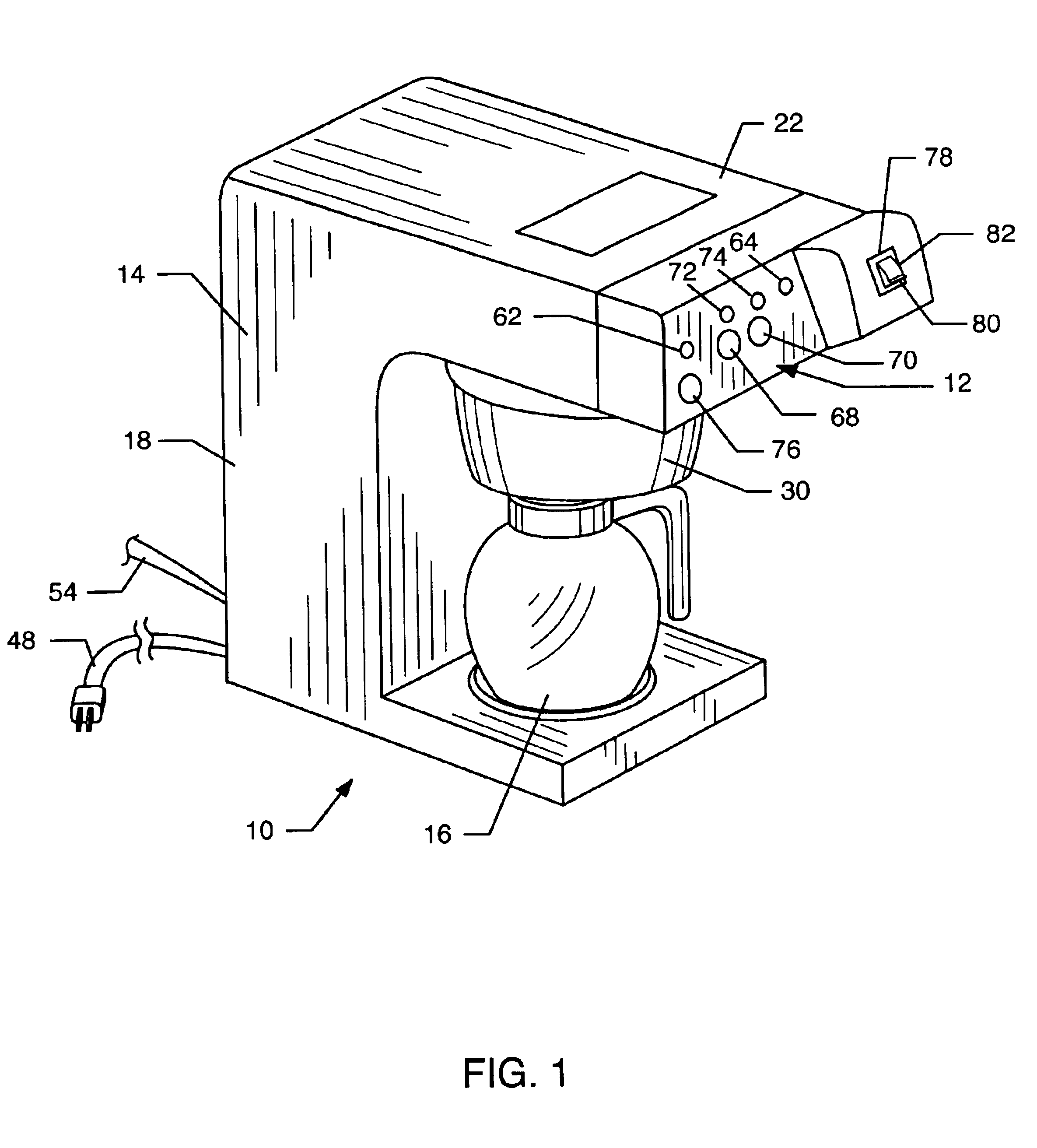

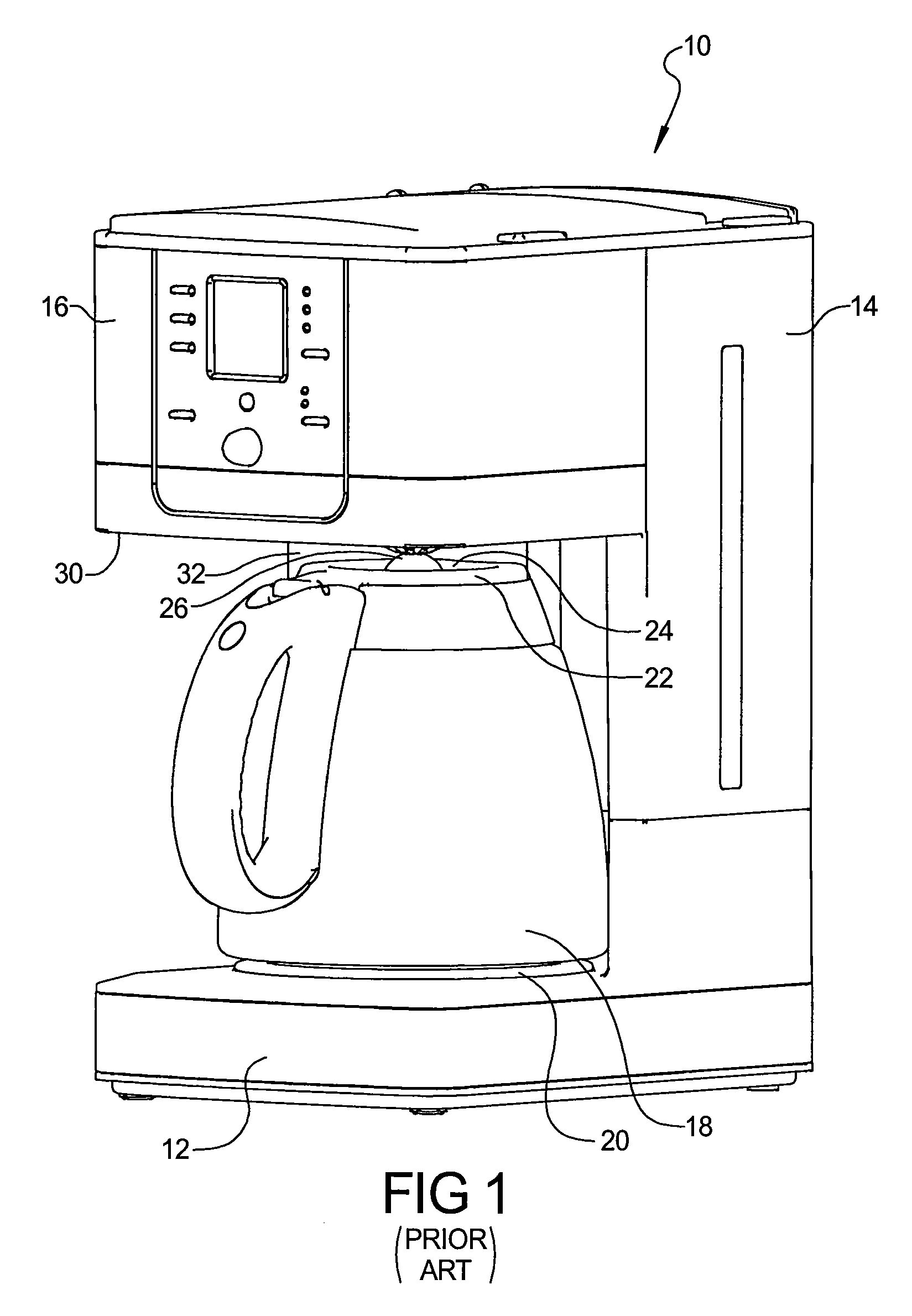

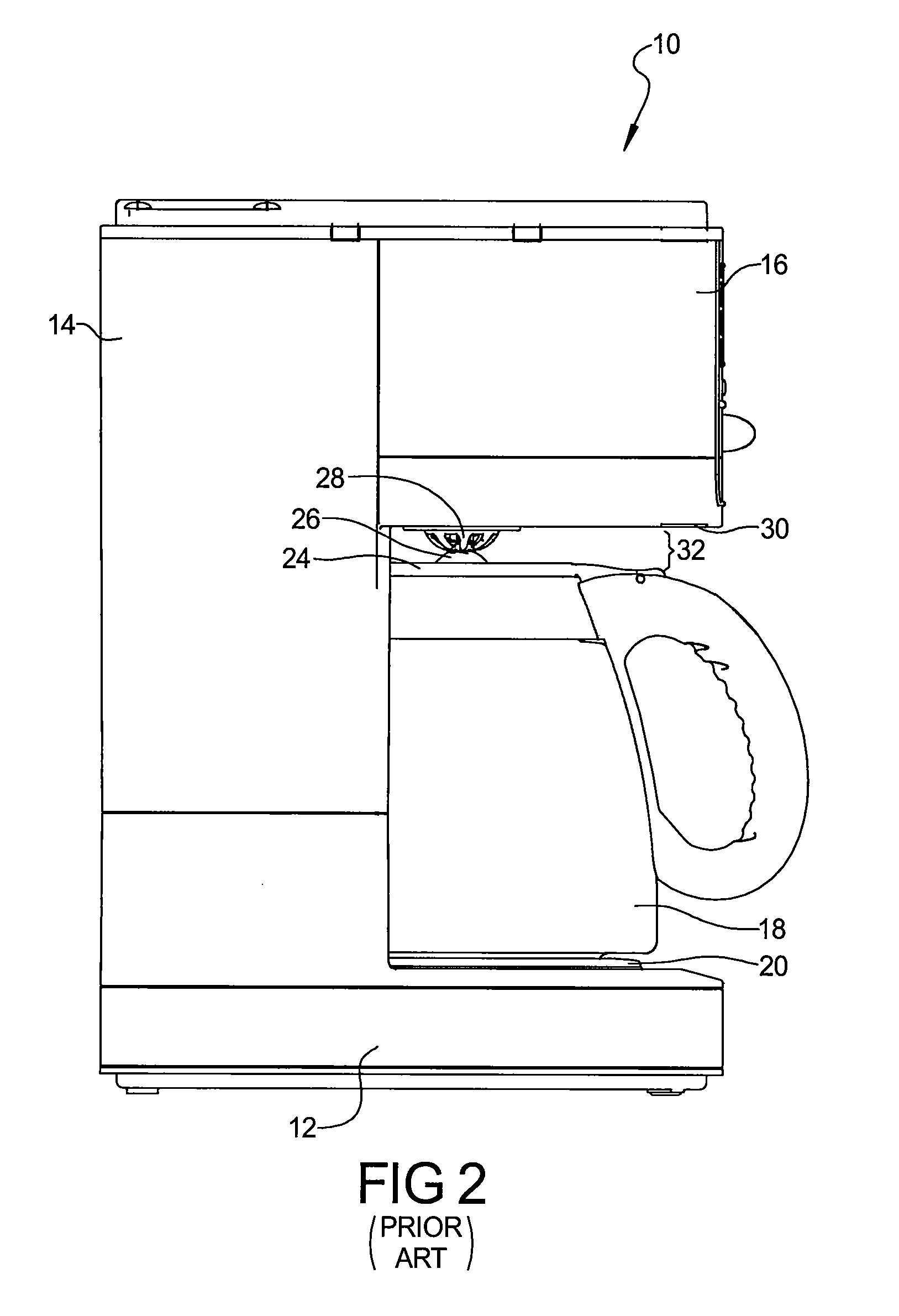

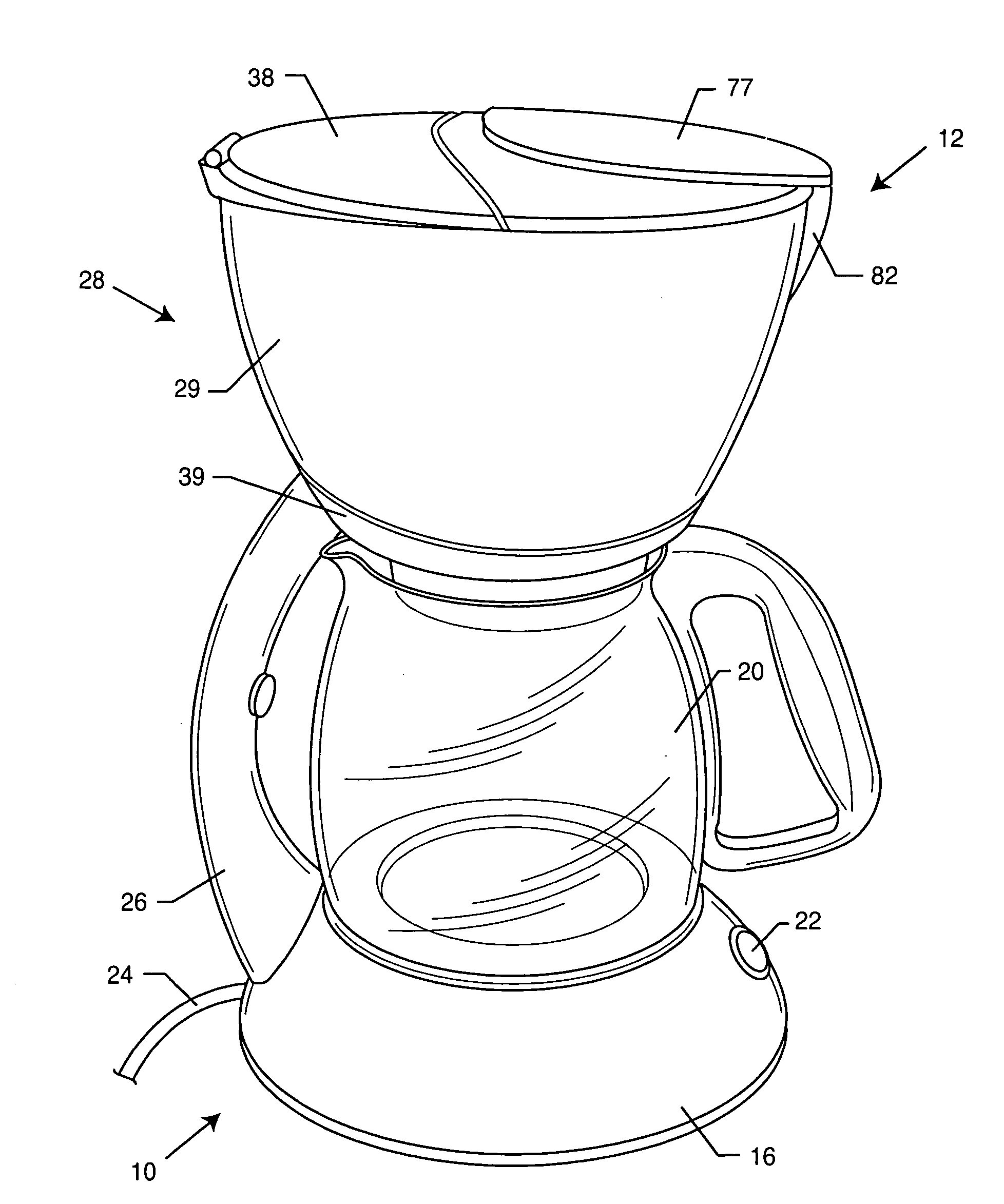

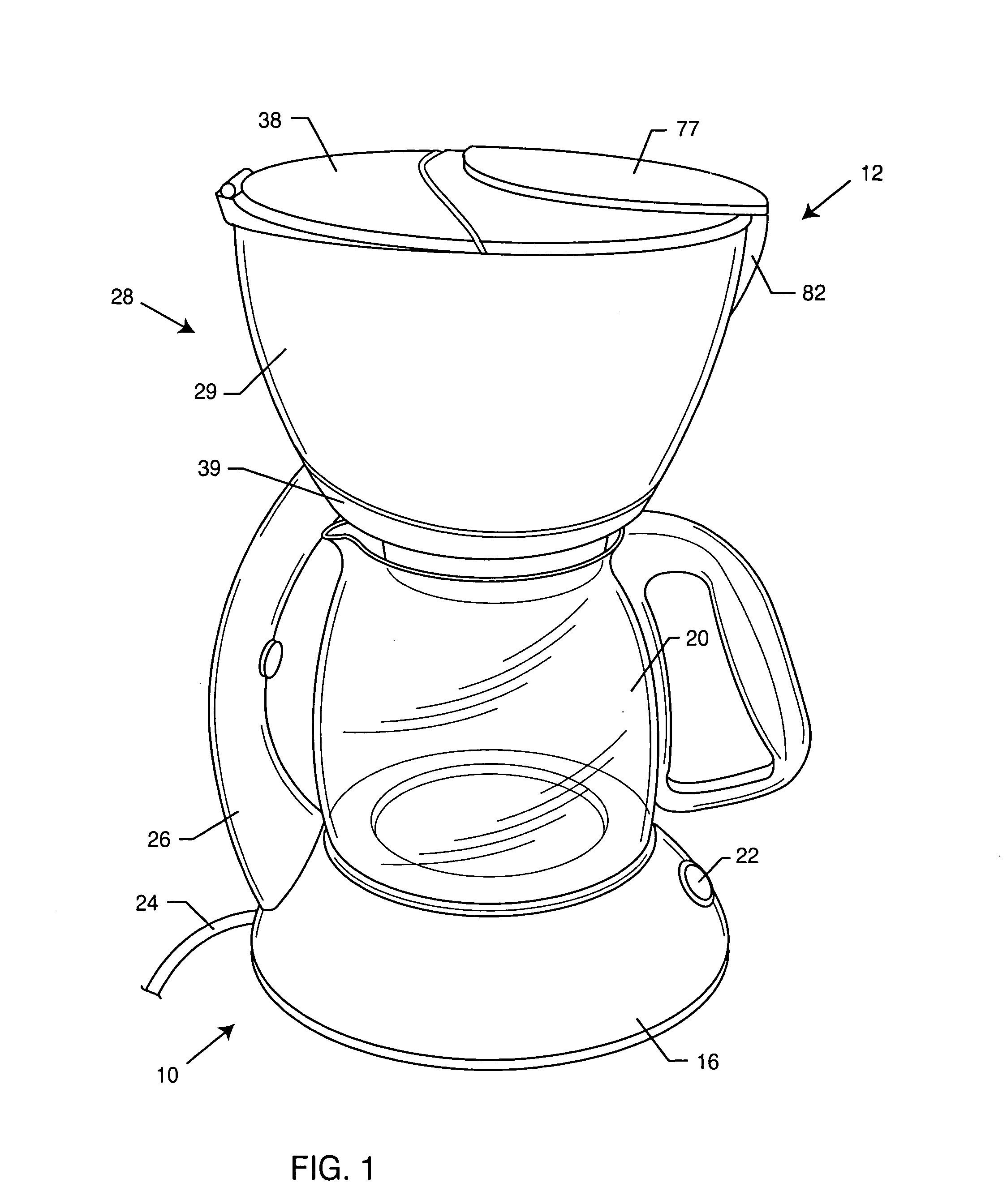

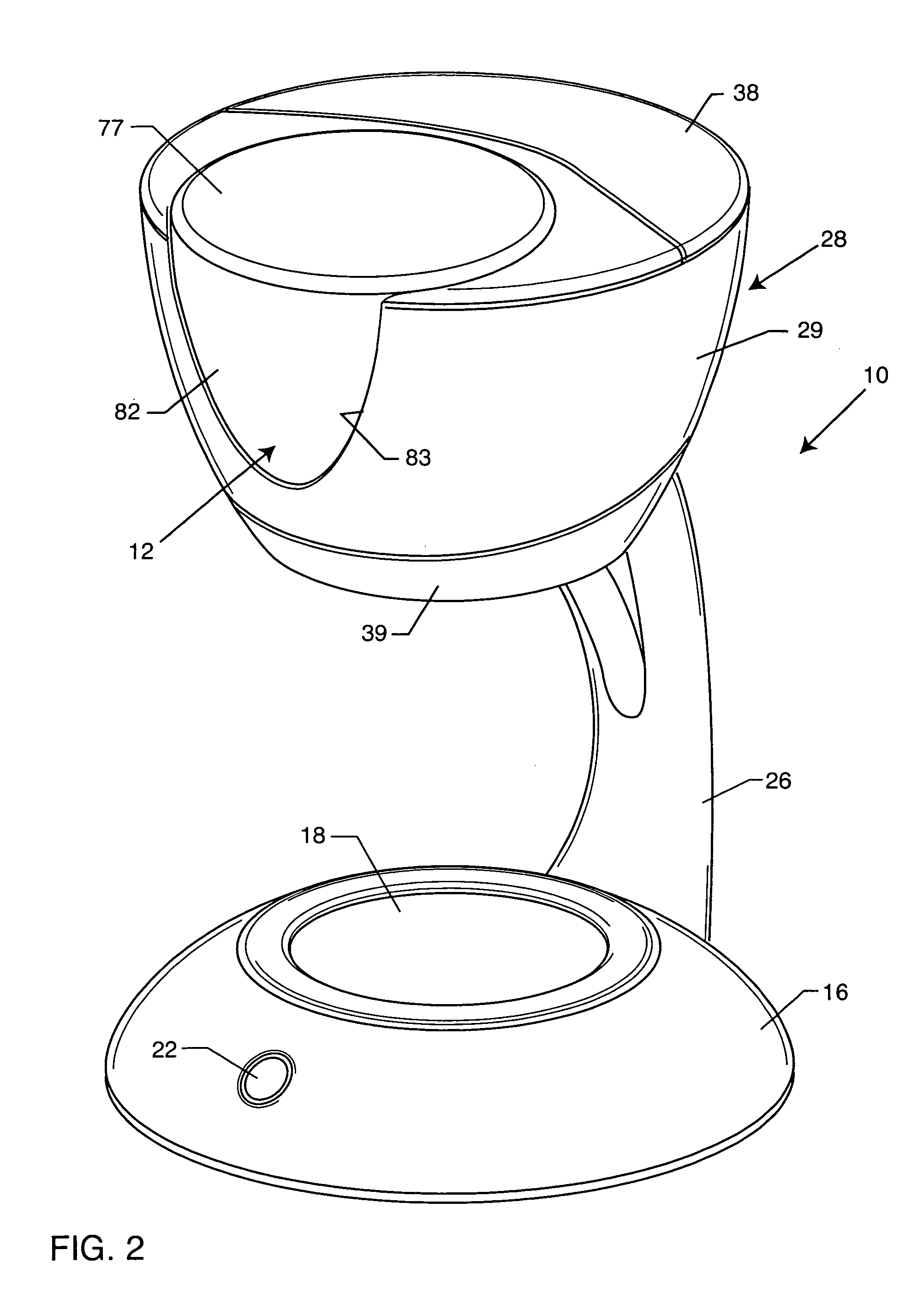

Coffee brewer

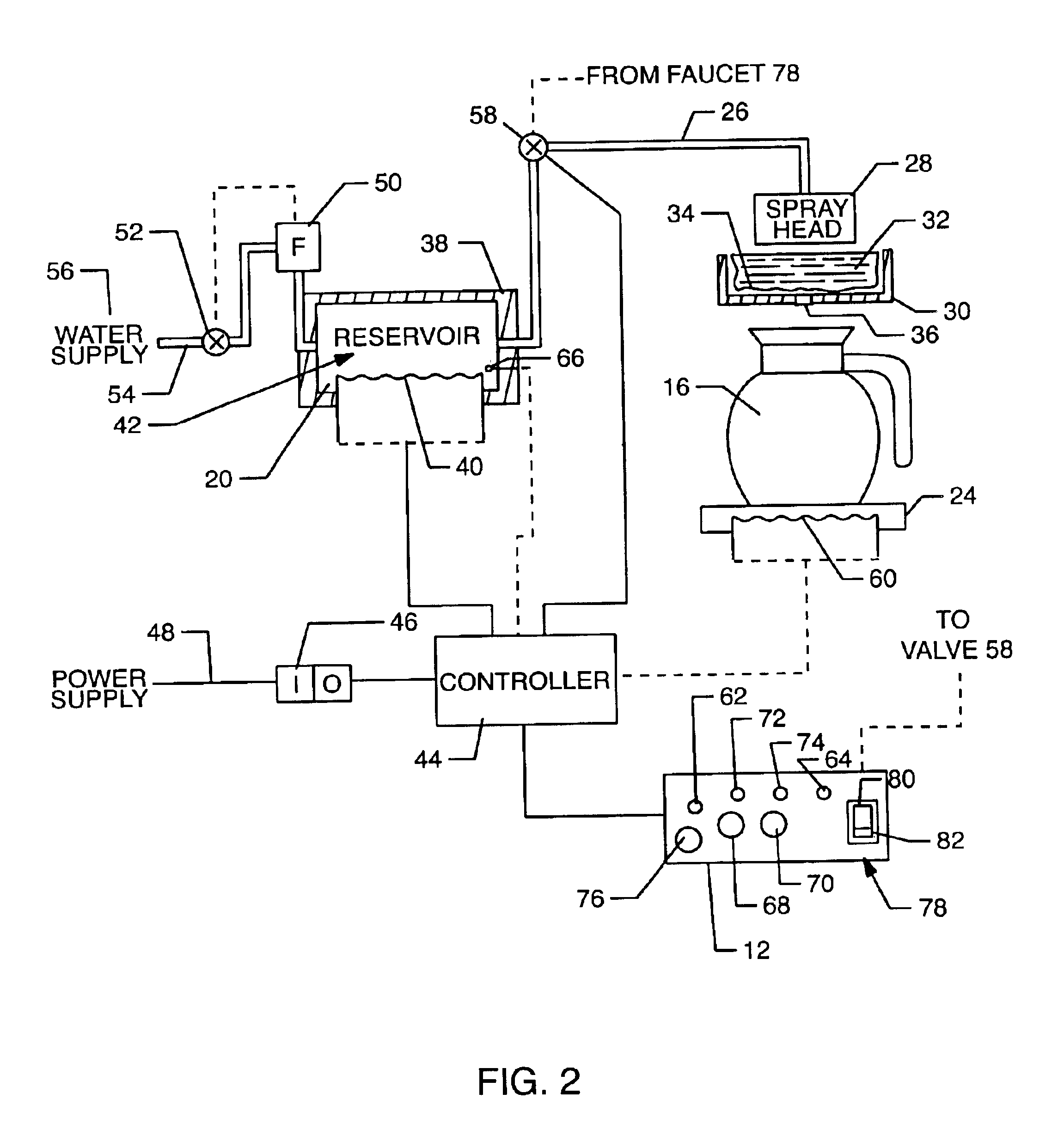

InactiveUS6843164B2Rapid and consistent high quality brewingQuickly and easily calibrating a metered volume of hot waterBeverage vesselsWater volumeThermal water

An improved coffee brewer is provided for rapid and consistent high quality brewing of coffee. The coffee brewer includes a control panel for initiating a brew cycle wherein a metered volume of hot water is delivered from an insulated water reservoir via a spray head to mix with coffee grounds contained within a filter-lined brew basket, with the resultant brewed coffee draining into an underlying pot preferably such as an insulated carafe. The control panel is further operable for precision calibration of the metered water volume delivered to the brew basket for each brew cycle. In addition, the coffee brewer incorporates a removable rail unit for supporting the brew basket, wherein the rail unit and spray head are removable quickly and easily disassembled for periodic cleaning.

Owner:ZOHAR WATERWORKS

Vacuum brewed beverage machine and vacuum brewing method

ActiveUS20110097466A1Brewed quickly and easilyCooking-vessel materialsTea substituesGlass vesselAtmospheric pressure

The desired amount of coffee grounds, tea leaves, herbs or other beverage making material is placed in a chamber of glass vessel located on a moveable table top in its lowered position. The table top is then elevated until the upper edge of the vessel seals against a top seal. With the top sealed, the desired amount of water of about 185°-212° F. is introduced into the chamber through a port in the top. Thereafter, a vacuum is drawn in the chamber and is held within the range of about −5 to −20 Hg in. Using an external heat source, the brewing liquid is maintained at about 185°-212° F. Alternatively, the vacuum can be pulsed by turning it on and off several times during the brewing cycle. After the beverage has brewed for the desired amount of time, the heat and vacuum are removed, the chamber is returned to atmospheric pressure and the table top is lowered to release the vessel. The contents of the chamber are then strained to remove solids from the beverage.

Owner:BKON

Vacuum brewed beverage method

ActiveUS8383180B2Brewed quickly and easilyCooking-vessel materialsTea substituesGlass vesselEngineering

Owner:BKON

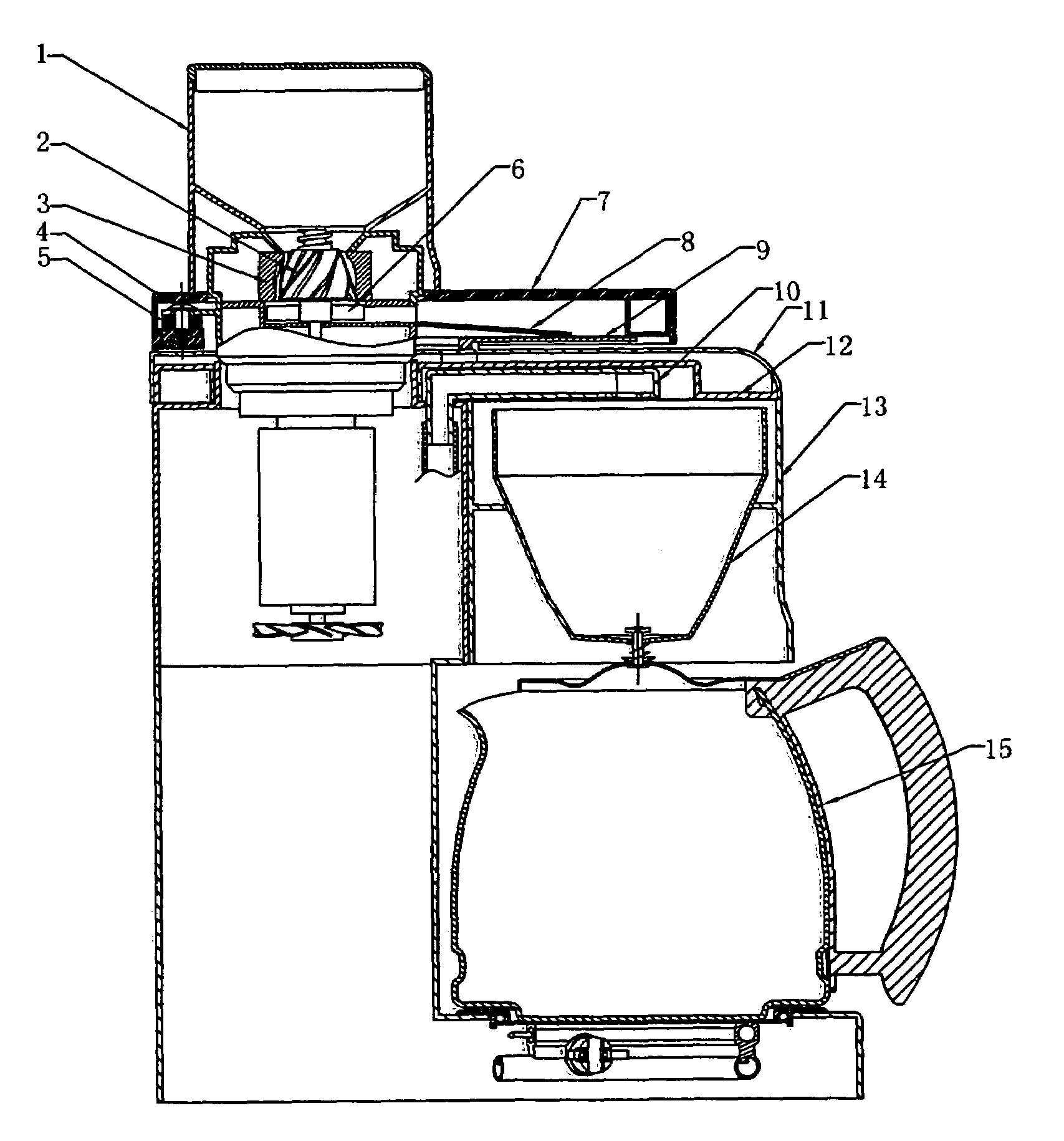

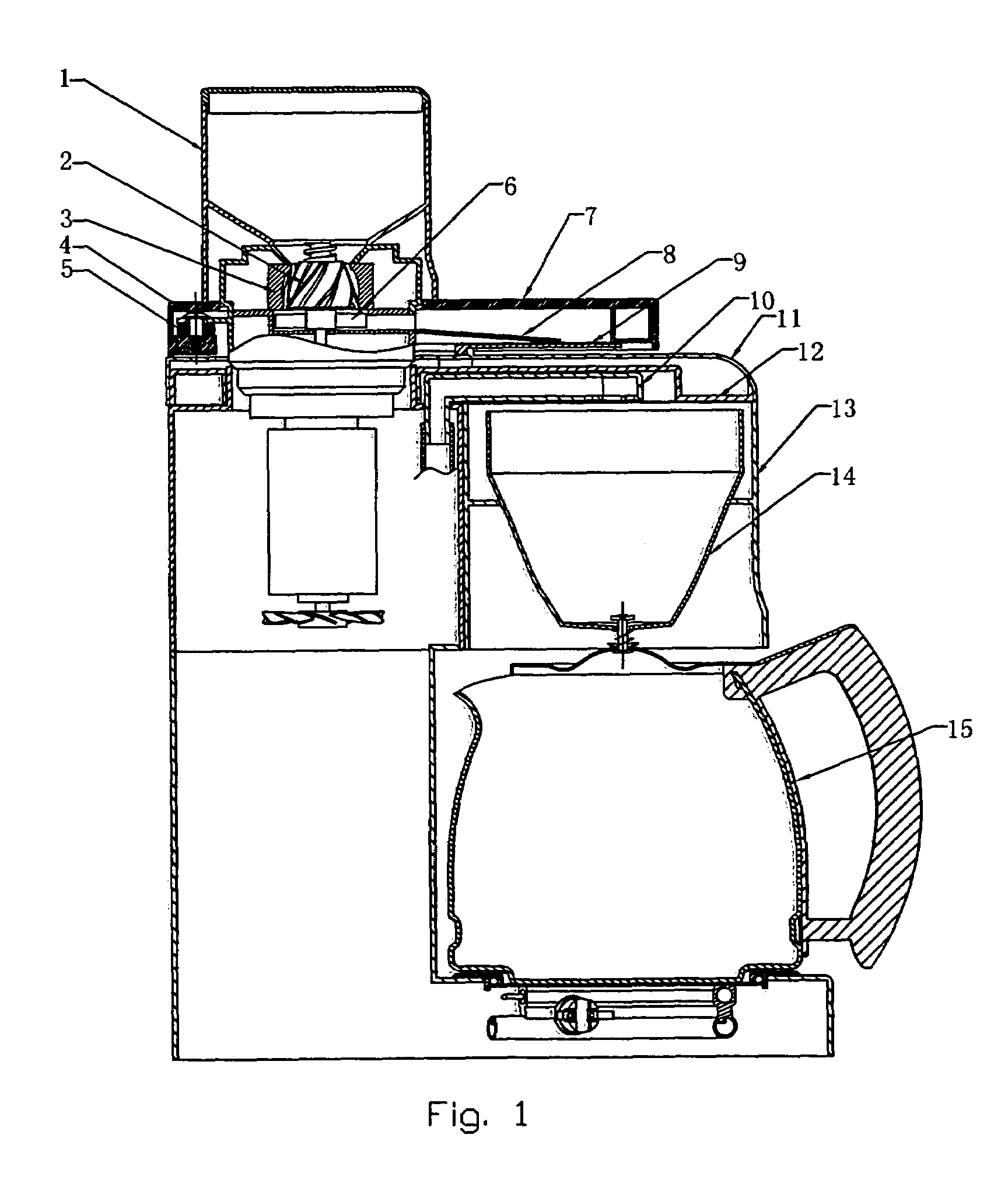

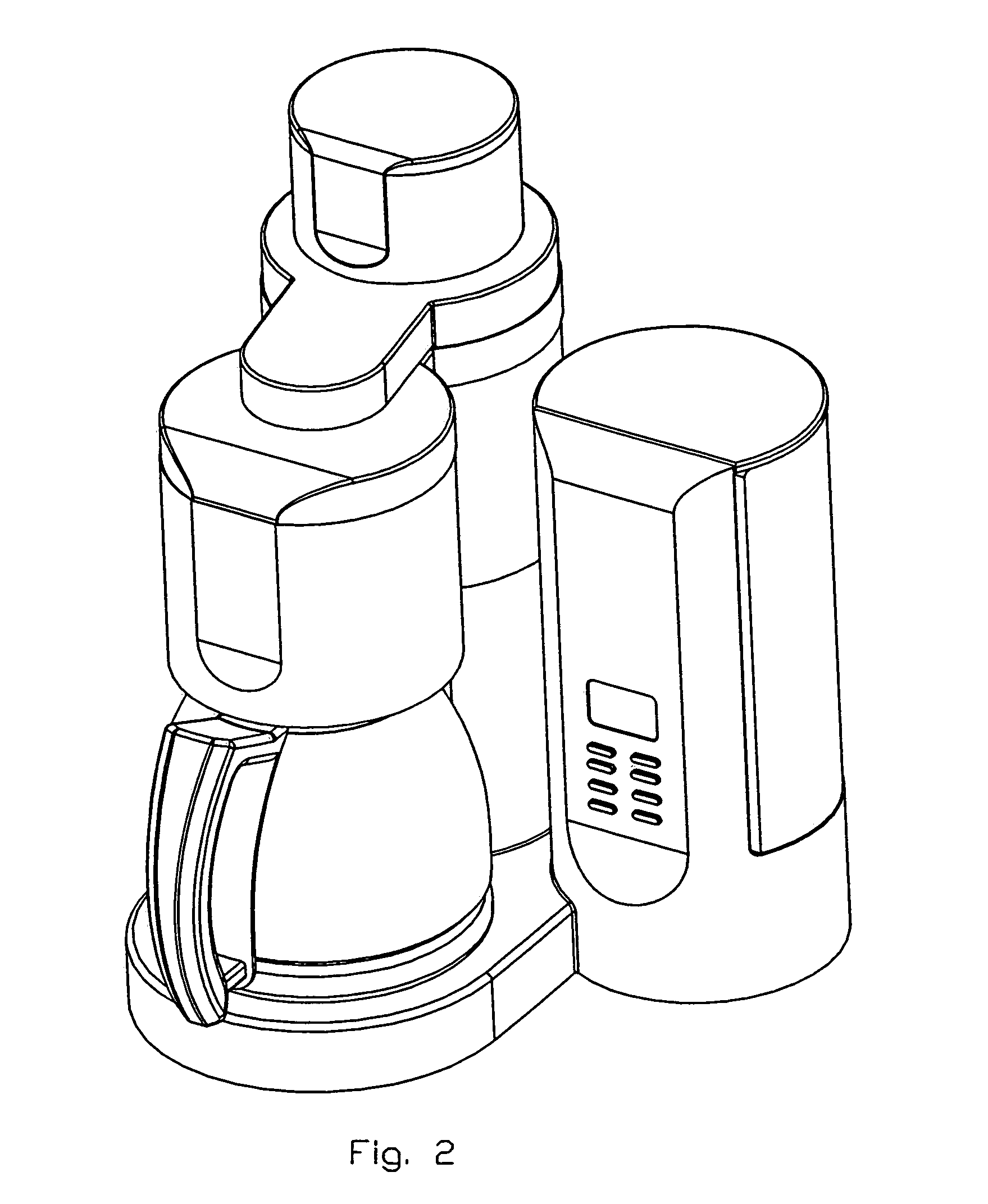

Electric automatic-drip coffee maker with grinder

This invention discloses an electric automatic-drip coffee maker with grinder, including a casing, an automatic coffee grinding device, a coffee basket assembly, a carafe for collecting coffee, a water reservoir, a heater for heating the cold water inside the water reservoir, and a water supply tube for supplying hot water to said coffee basket assembly; wherein, said grinding device further includes a coffee grounds discharge passage with its outlet positioned right above said coffee basket assembly; a partition assembly is installed between said coffee grounds discharge passage and said coffee basket assembly, said partition assembly can be rotated relative to said coffee basket assembly around a vertical axis. The coffee maker of the present invention can be used to grind and brew coffee effectively, to reduce or eventually eliminate the need for displacing the filter basket, so as to be convenient for use.

Owner:WANG DONG LEI

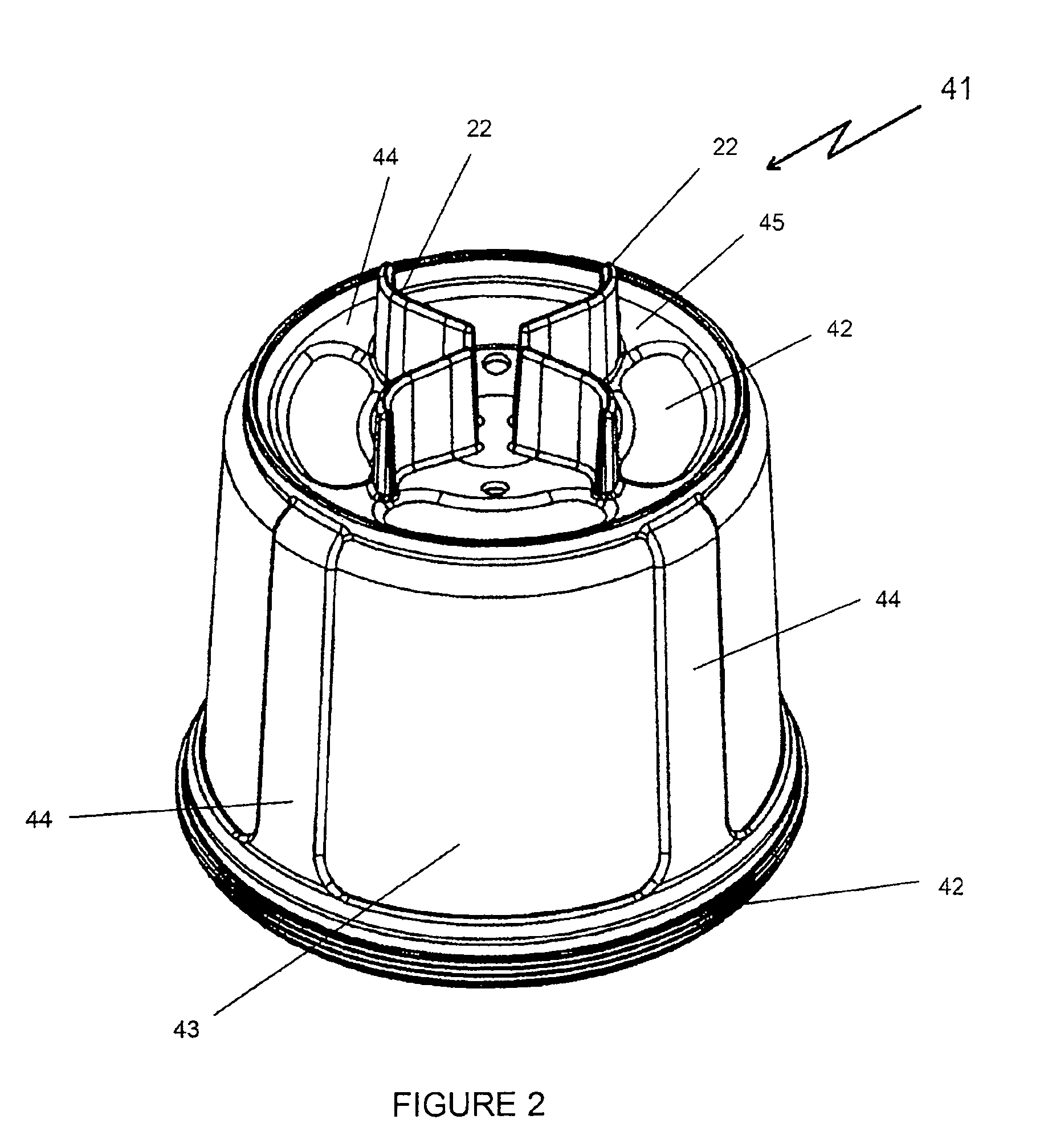

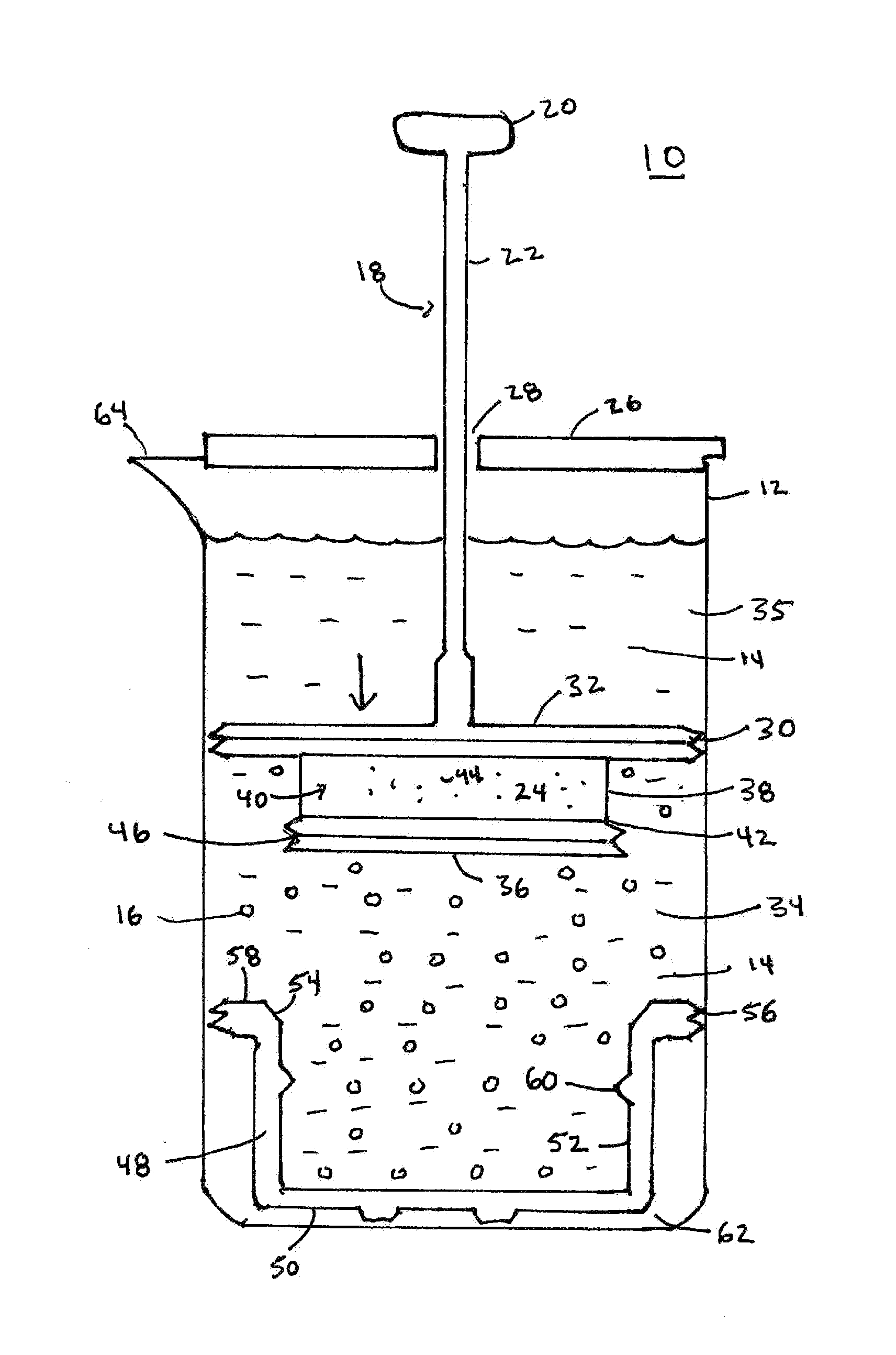

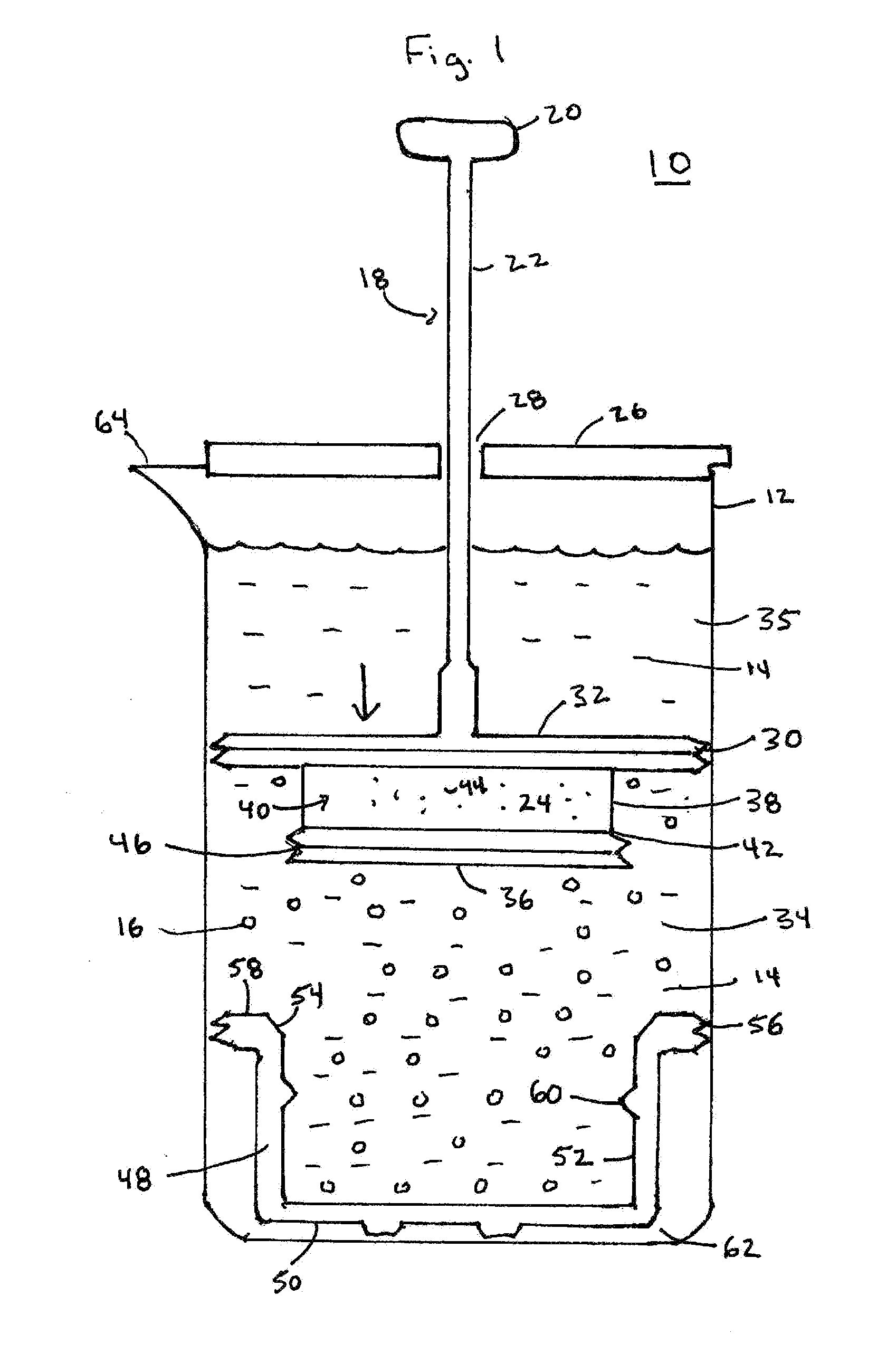

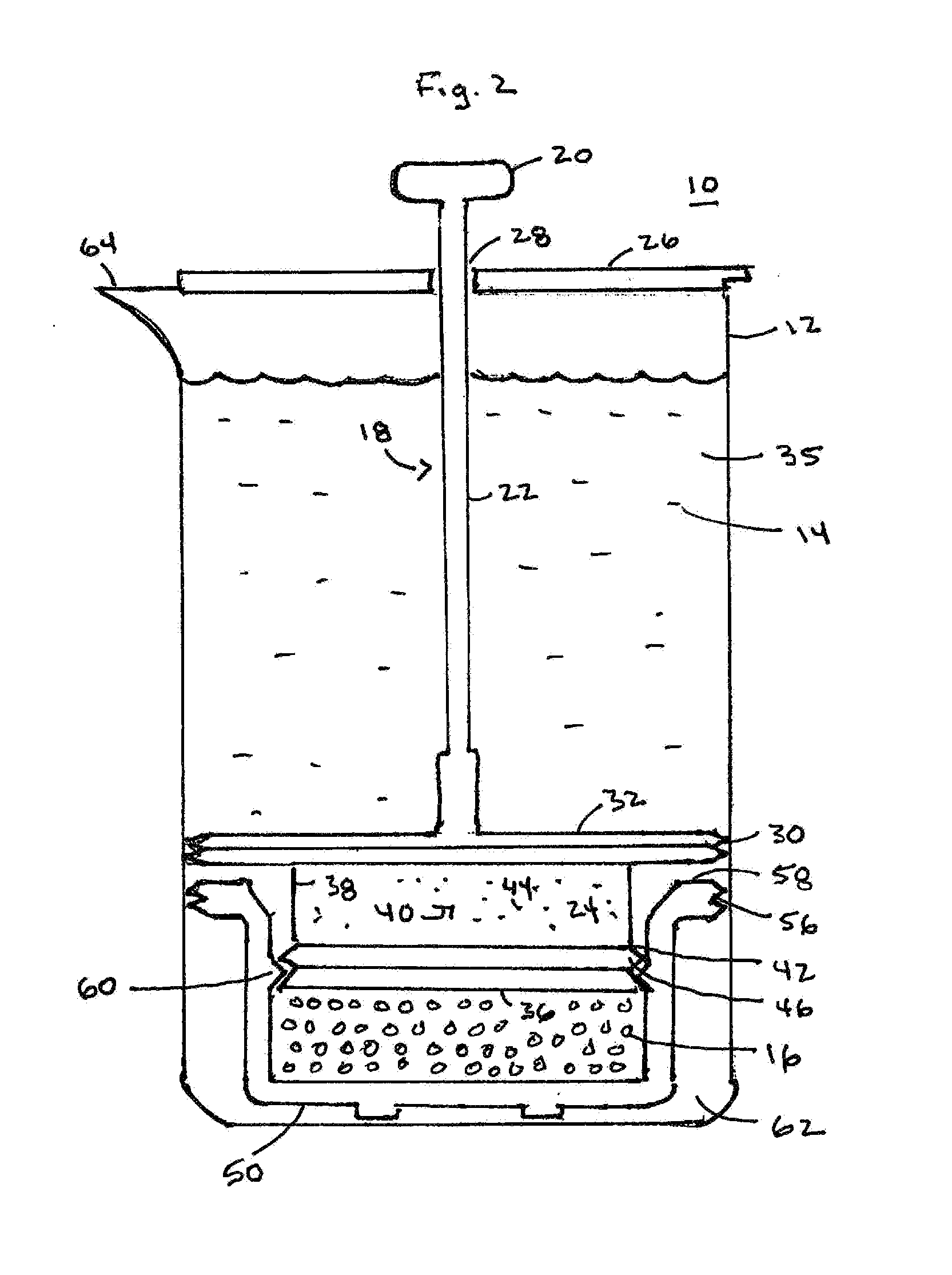

Plunger for brewing a drink

InactiveUS6964223B2Quickly and conveniently makingSimple and inexpensiveBeverage vesselsFood preparationHeat lossesEngineering

Plunger (10) for brewing a drink in a cup (12) includes two main components, a filter disc (20) and a frame (22). The filter disc (20) is shaped to extend across and abut an inside surface (24) of the cup (12). The frame (22) is dimensioned so that it can be wholly inserted into the cup (12) to be disposed below a mouth (18) of the cup. This allows a drink such as coffee or tea to be brewed in the cup from which it is to be consumed without the plunger (10) interfering with the drinking of the drink. The disc (20) is supported on the frame (22) to slide along upright posts (22). Thus the disc (20) can be pushed toward the bottom or (14) of the cup (12) that contain particulate materials such as coffee grounds or tea leaves used in brewing the drink. A heat shield (58) may be also supported on the frame (22) to minimise the rate of heat loss of a hot drink brewed in the cup (12) using the plunger (10).

Owner:OLOUGHLIN NICK

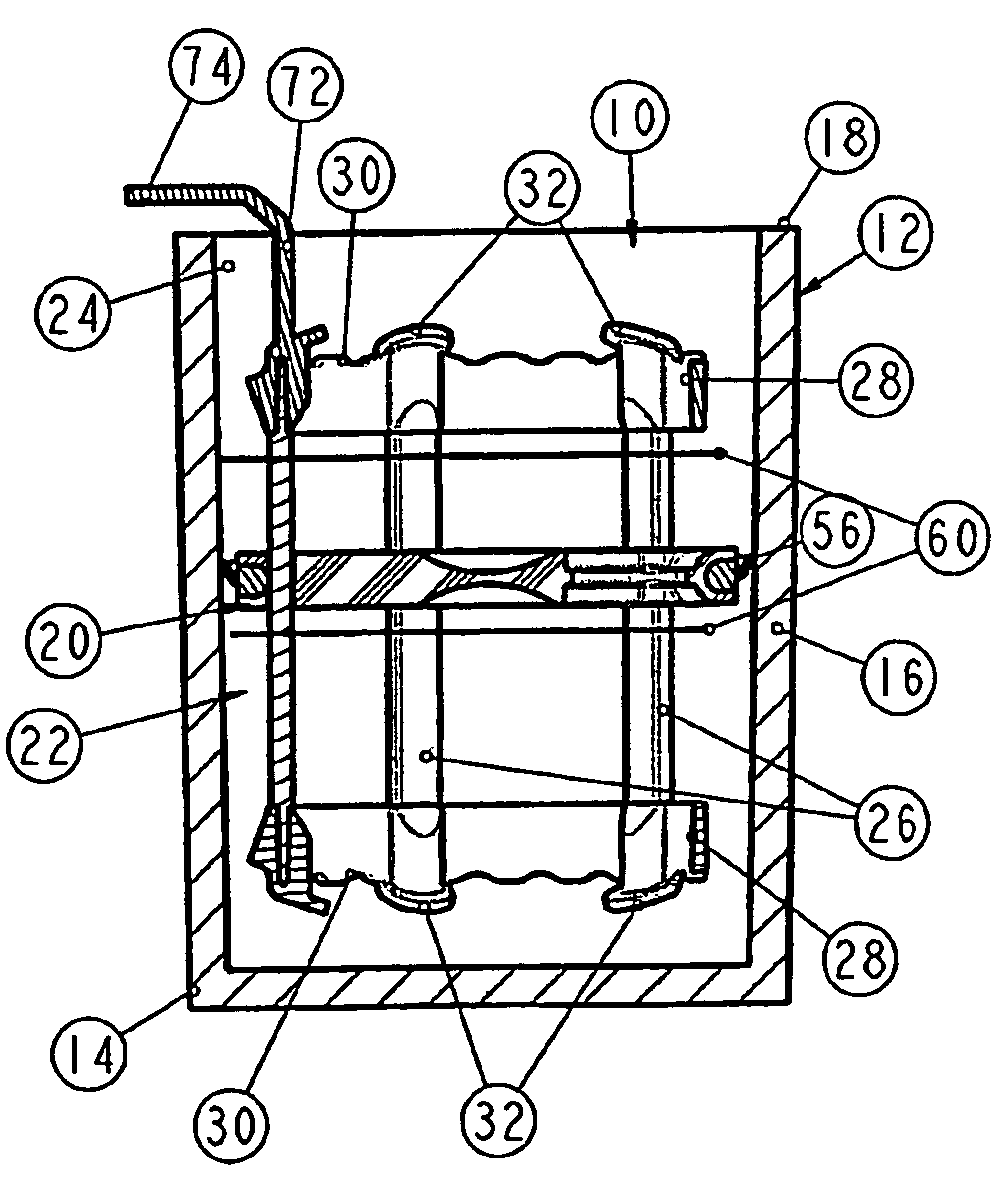

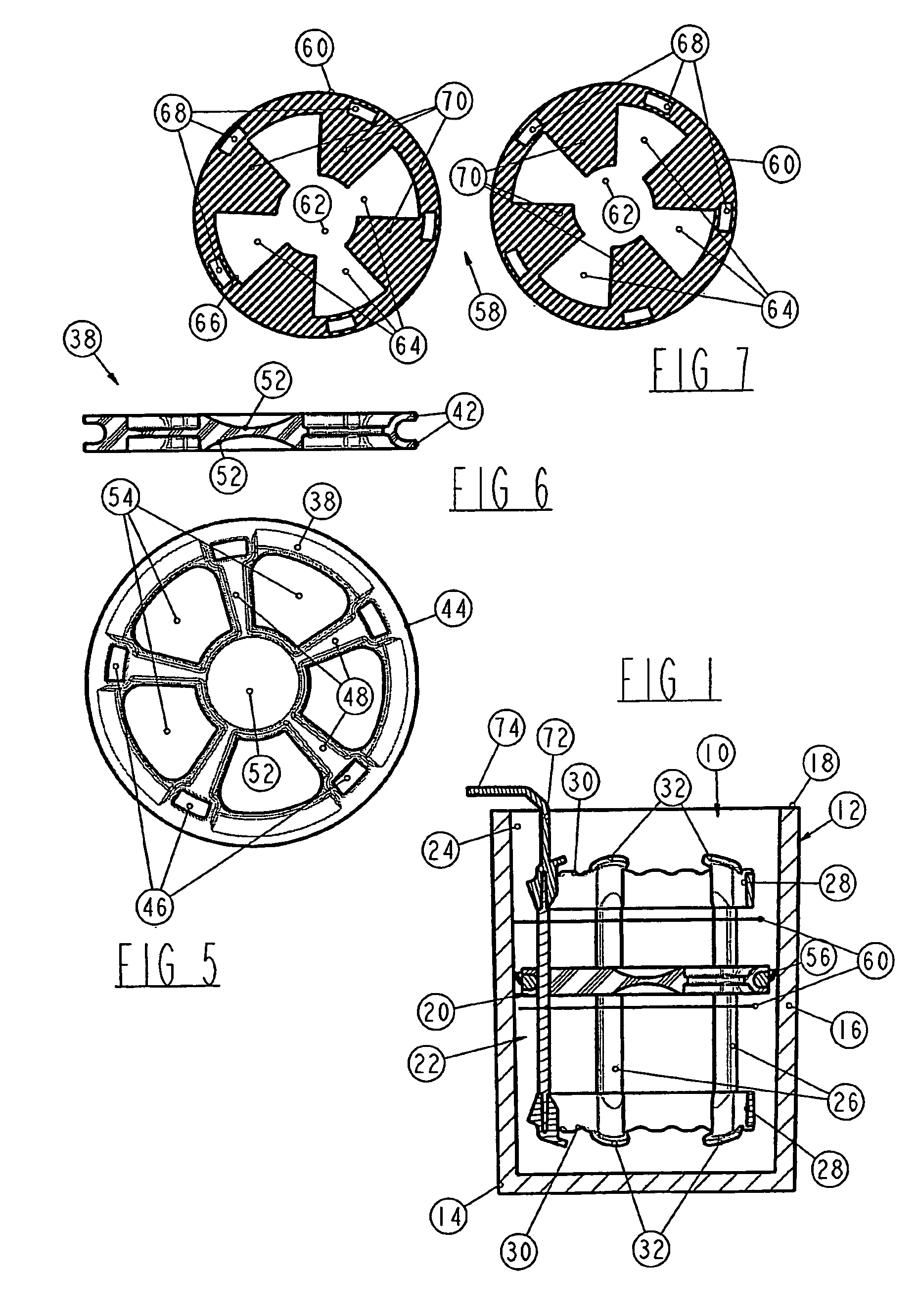

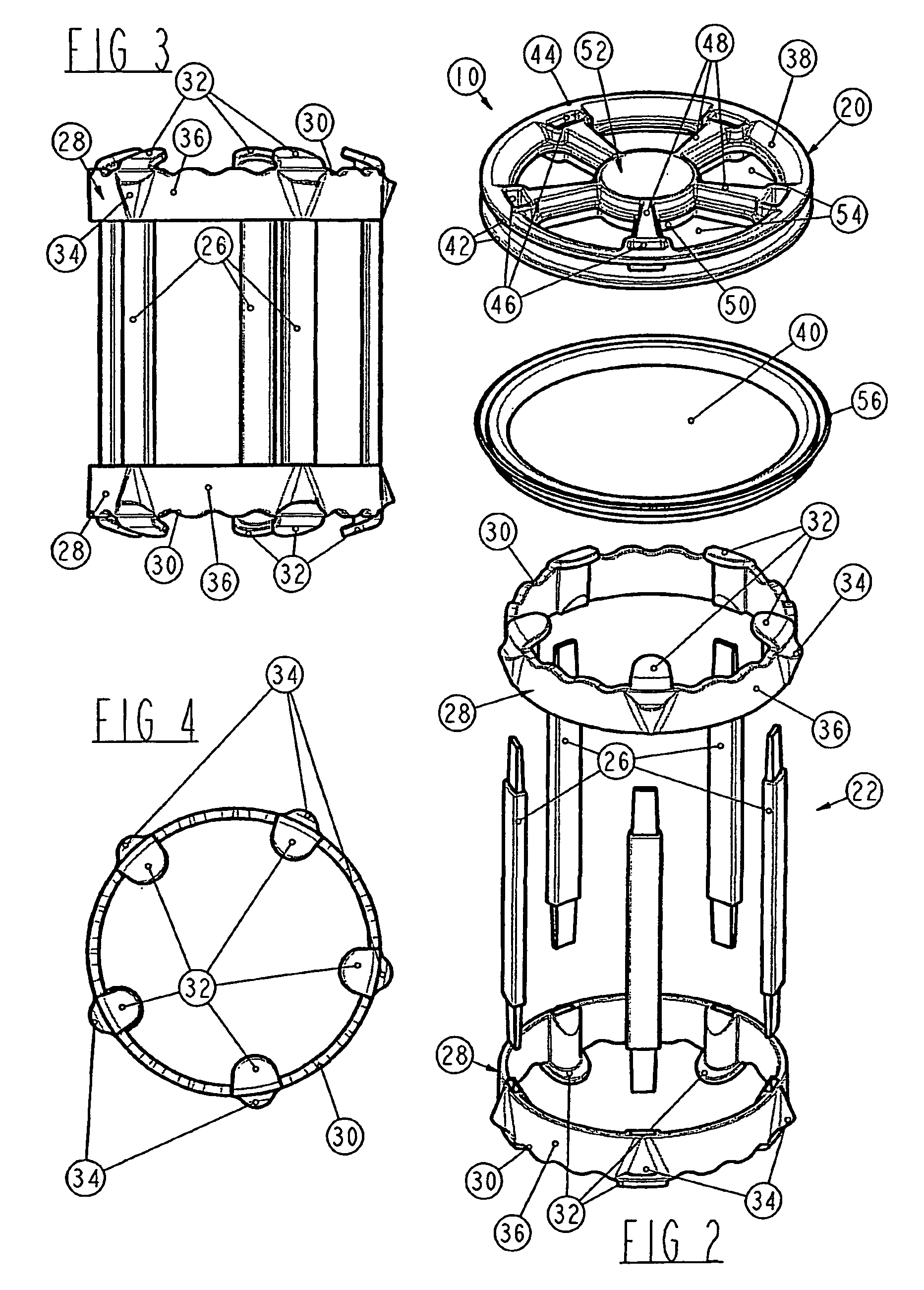

Apparatus for brewing beverages such as coffee and the like

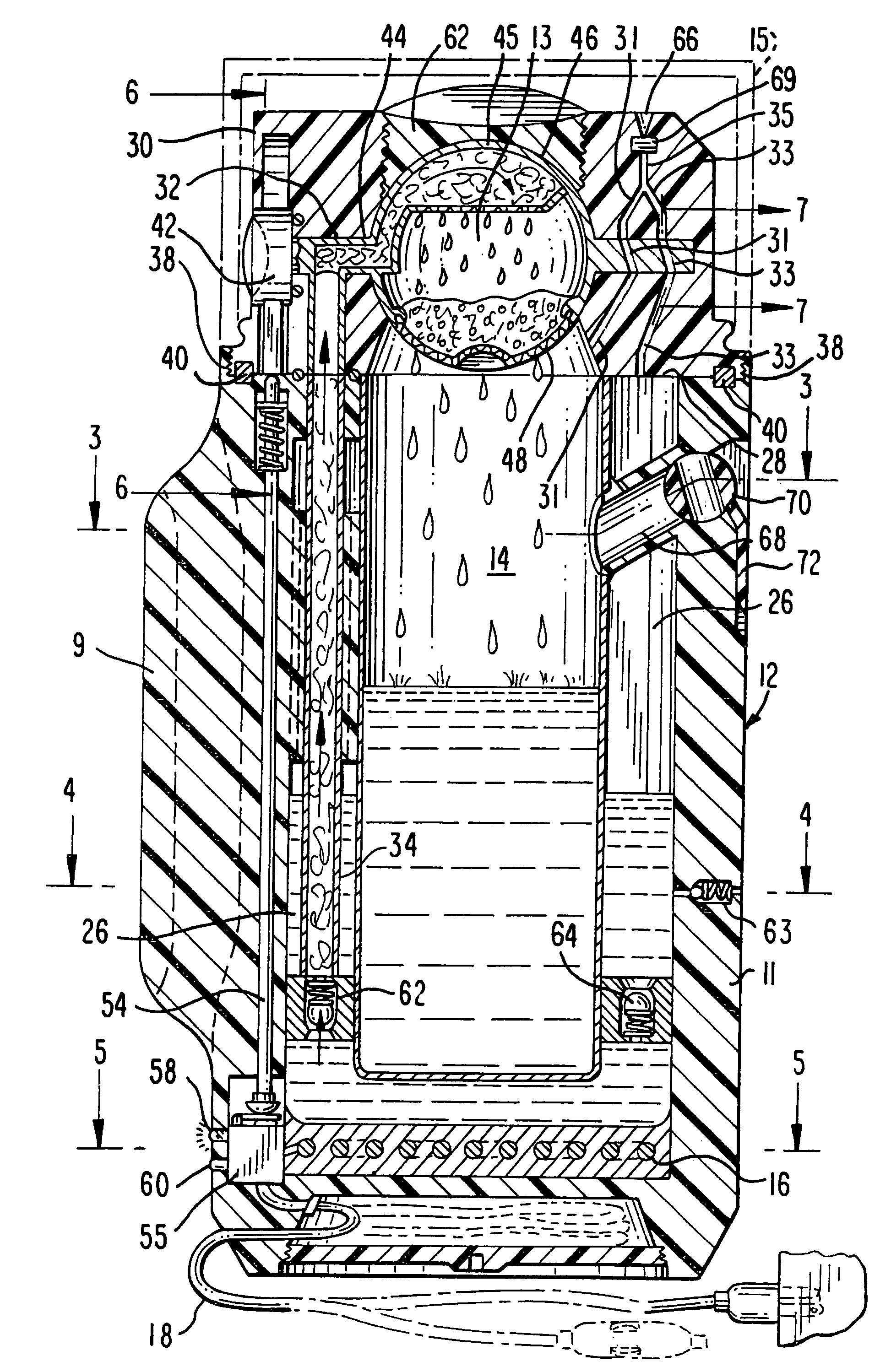

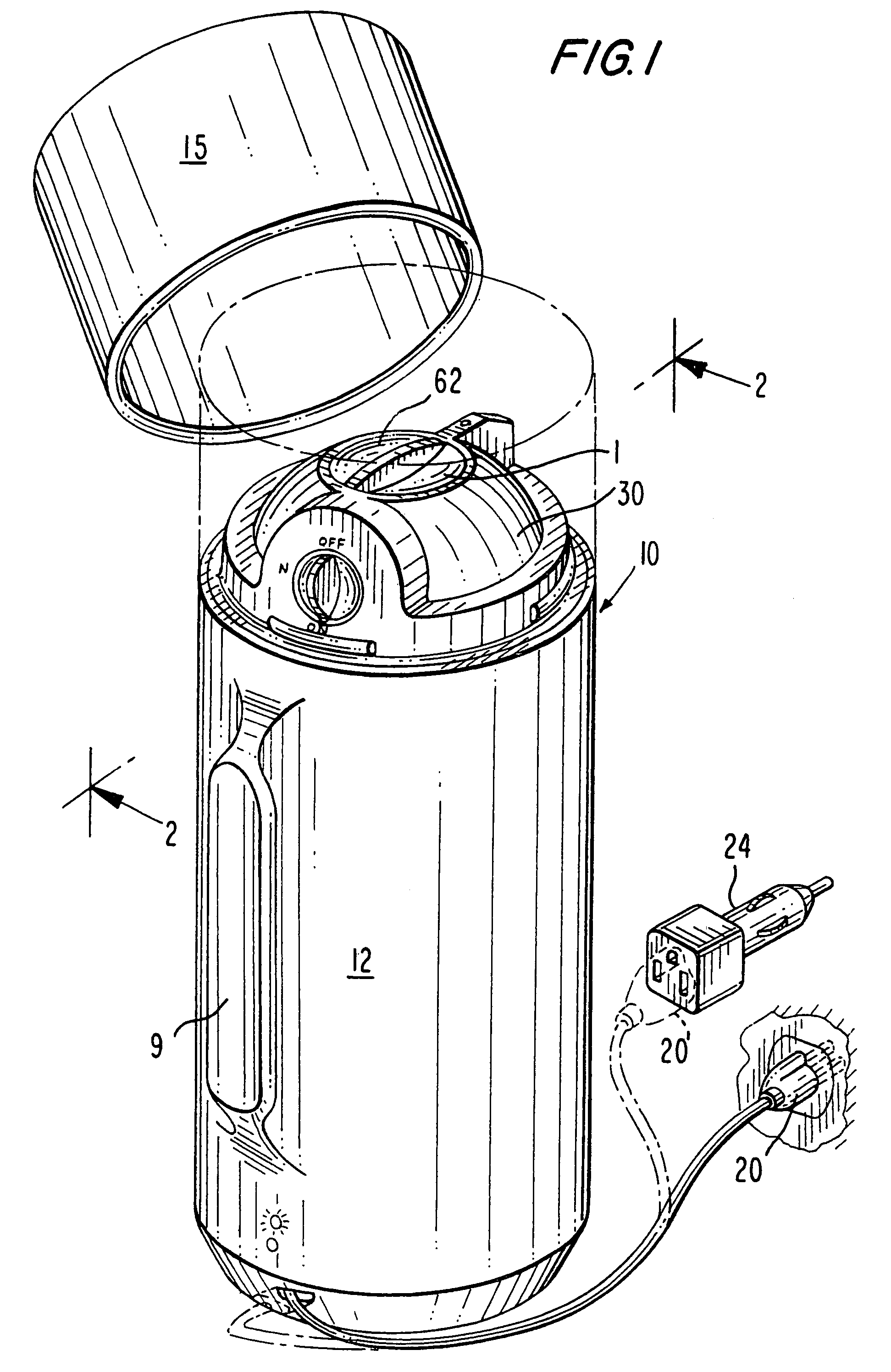

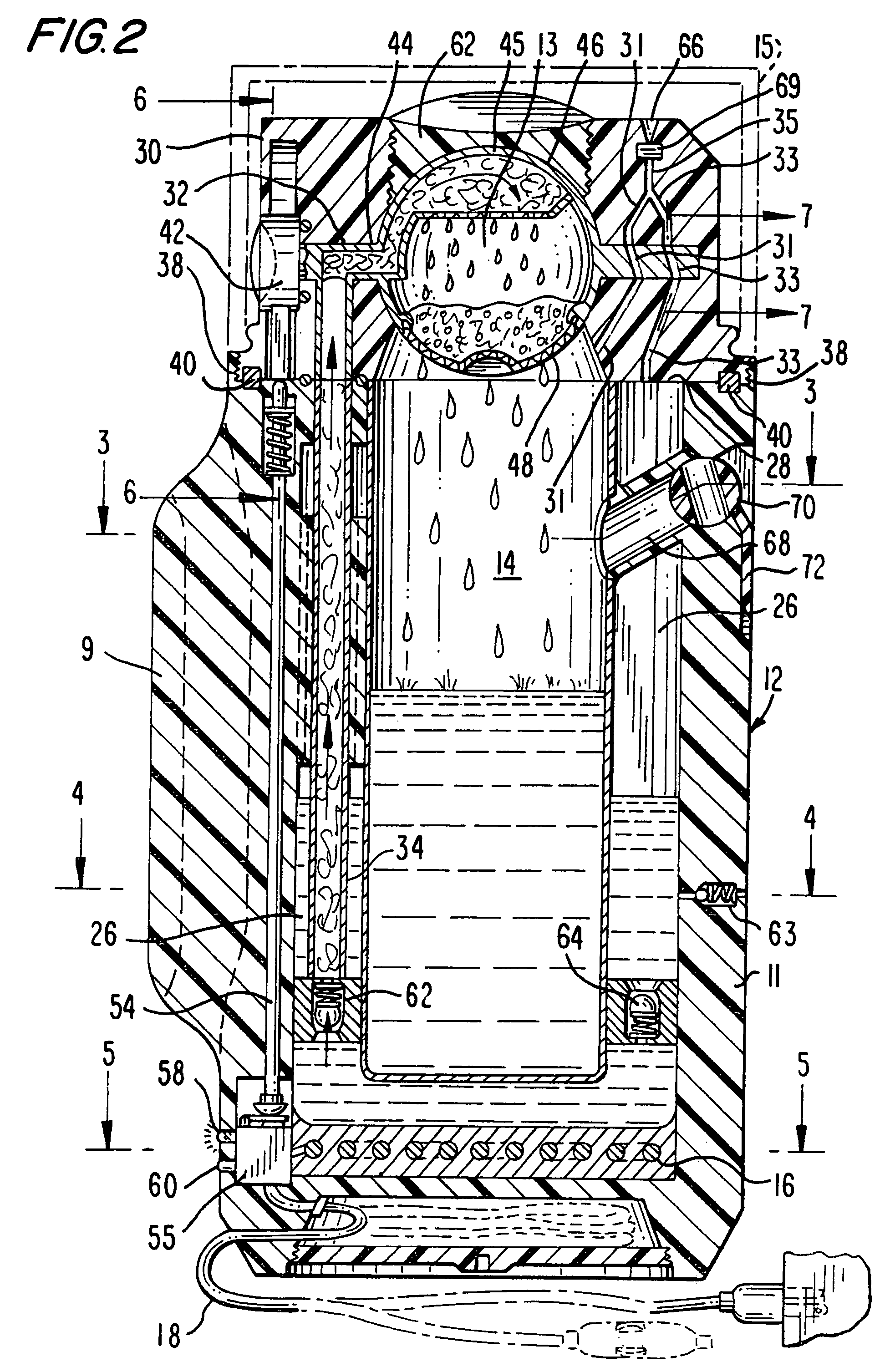

An apparatus is disclosed for brewing coffee, which includes a housing having an inner chamber for receiving and retaining brewed coffee, a water reservoir adjacent to and generally surrounding the inner chamber, for receiving water, and an electrically powered coil for heating the water contained in the water reservoir. A brew valve is positioned above the inner chamber for supporting coffee grounds, the brew valve being rotatable between a first inactive position and a second active position for brewing coffee. A conduit is positioned within the water reservoir for directing heated water from the water reservoir to the brew valve and to the coffee grounds. When the brew valve is rotated to an on position, the heating coil is electrically activated to heat the water in the water reservoir, such that heated water flows to the brew valve and to the coffee grounds to produce brewed coffee, and into the inner chamber.

Owner:SCELZA JOSEPH

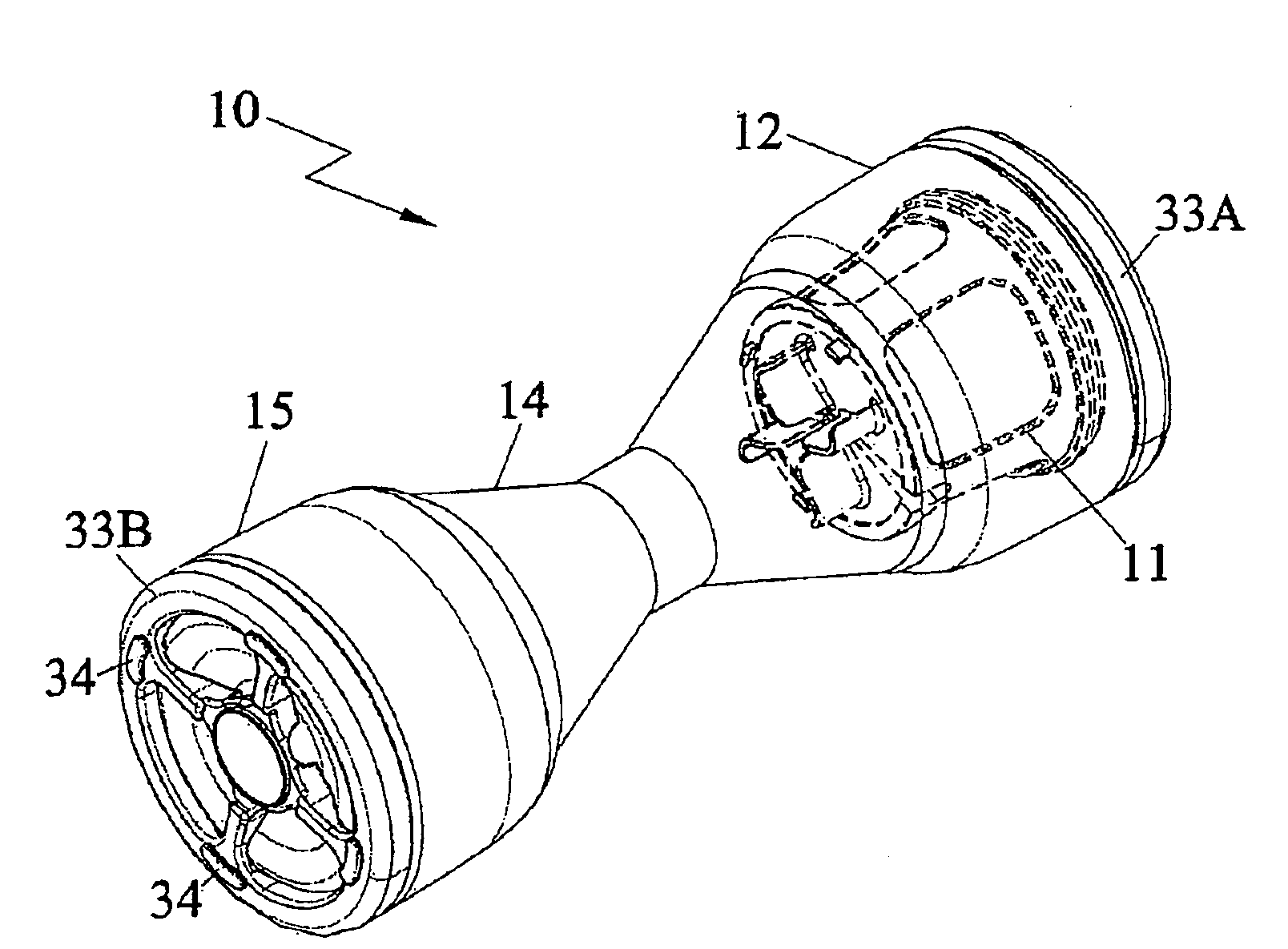

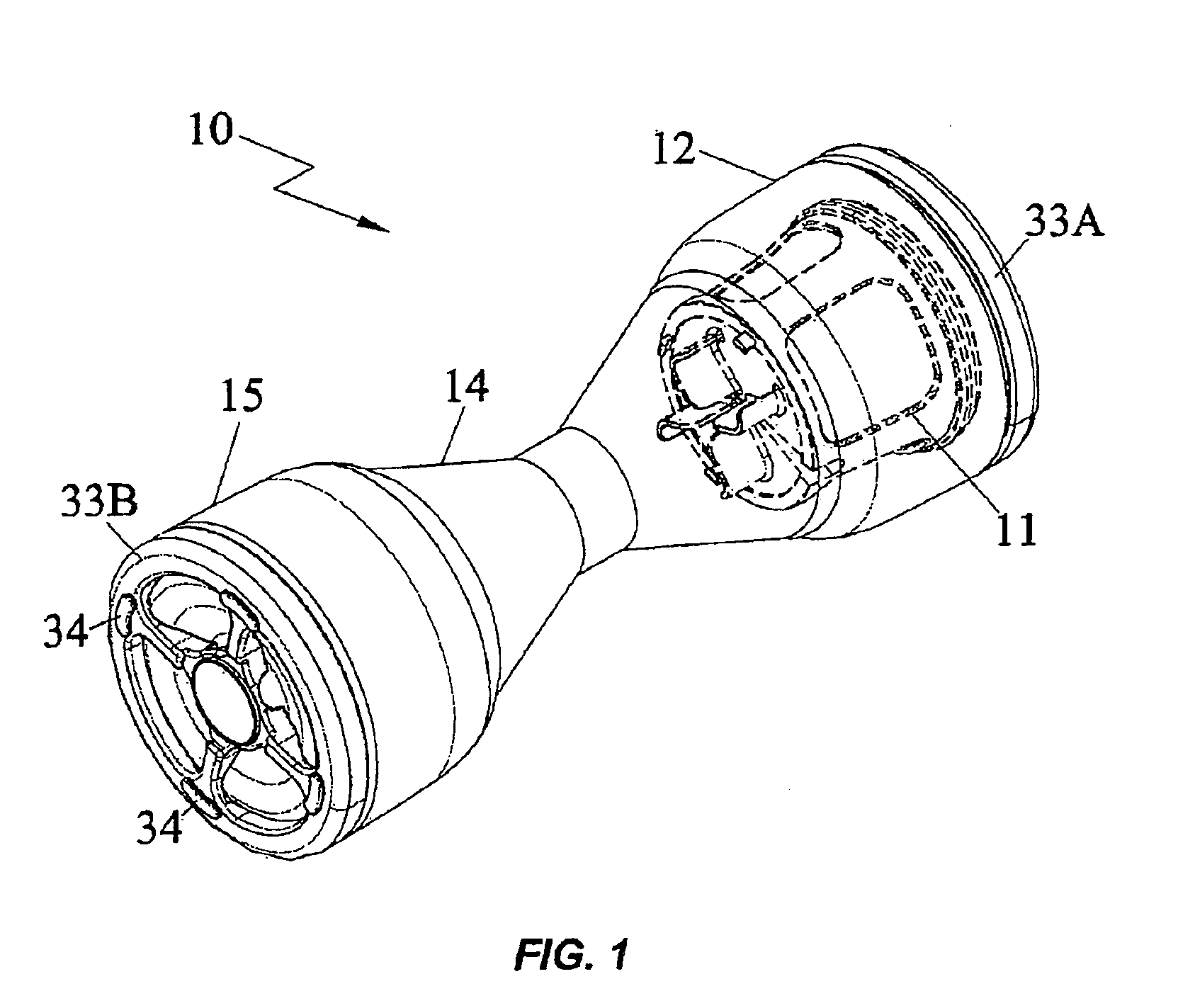

Apparatus for Extracting Cold-Brewed Coffee Concentrate

The invention provides an hourglass shaped apparatus for cold brewing coffee, comprising a brew chamber, and extract chamber and a middle unit connecting the brew and extract chambers. The extract and brew chambers comprise two ends of the hourglass shaped middle unit. The brew chamber houses a free-standing self-contained filter containing coffee grounds inside a water-permeable barrier. Water is poured into the brew chamber to generate coffee extract through cold water infusion. After the brewing process, the apparatus is inverted, and the coffee travels into the extract chamber through the middle unit for dispensing. Coffee brewed in this manner is less acidic and more flavorful than the conventionally hot-brewed beverage. All the components of the apparatus, the filter, the brew chamber, the extract chamber, and the middle unit, are detachable.

Owner:BL PATENTS LLC

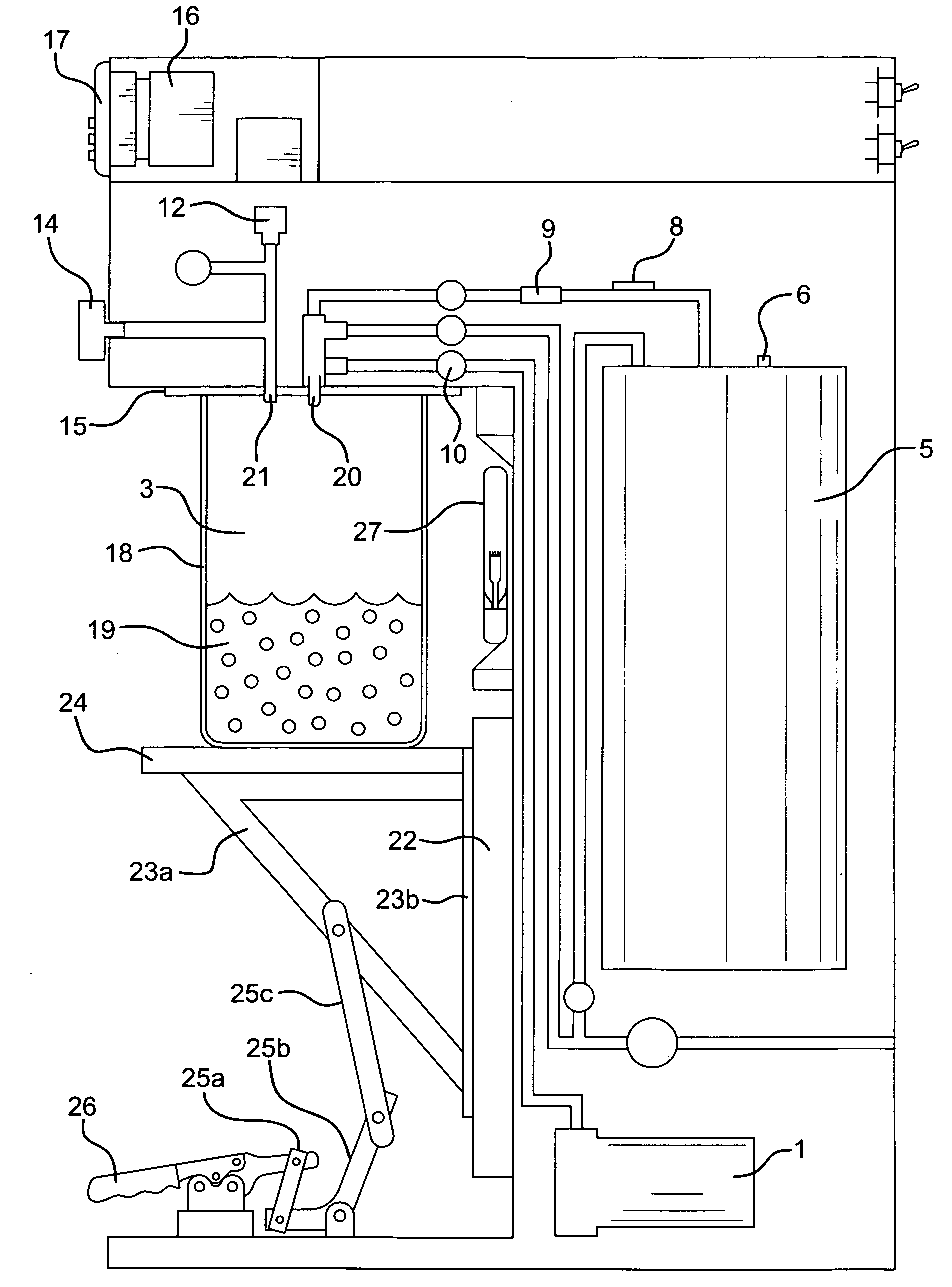

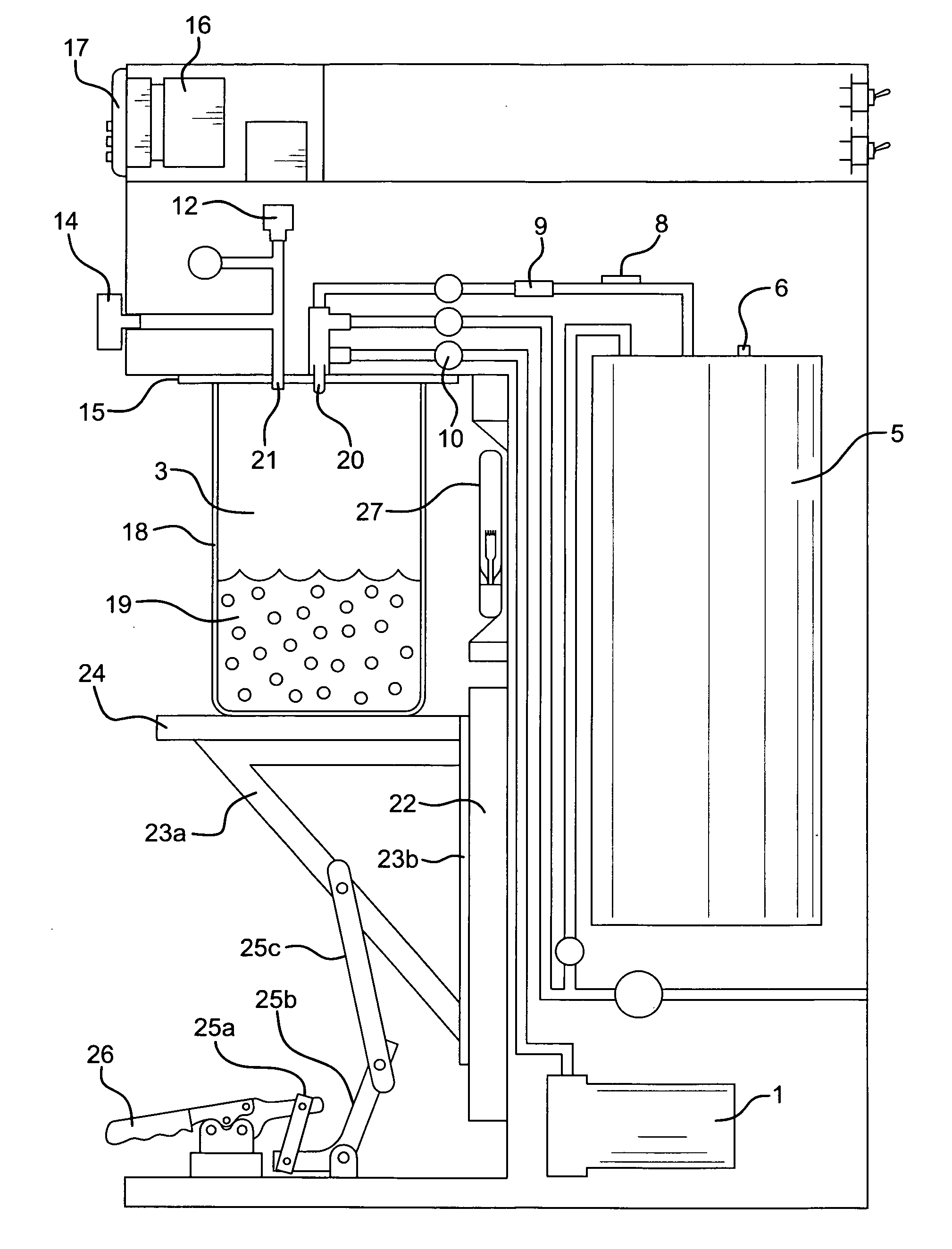

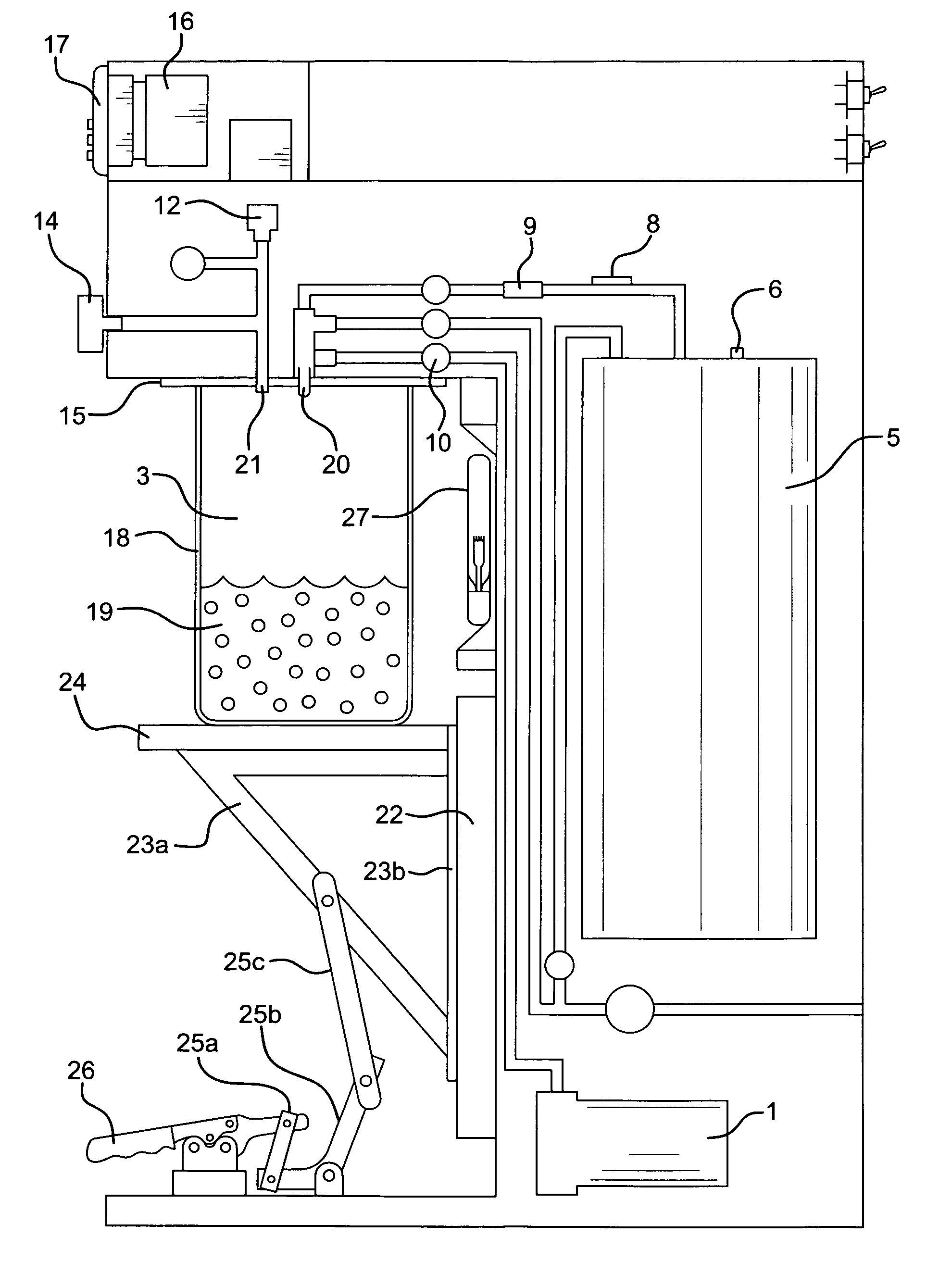

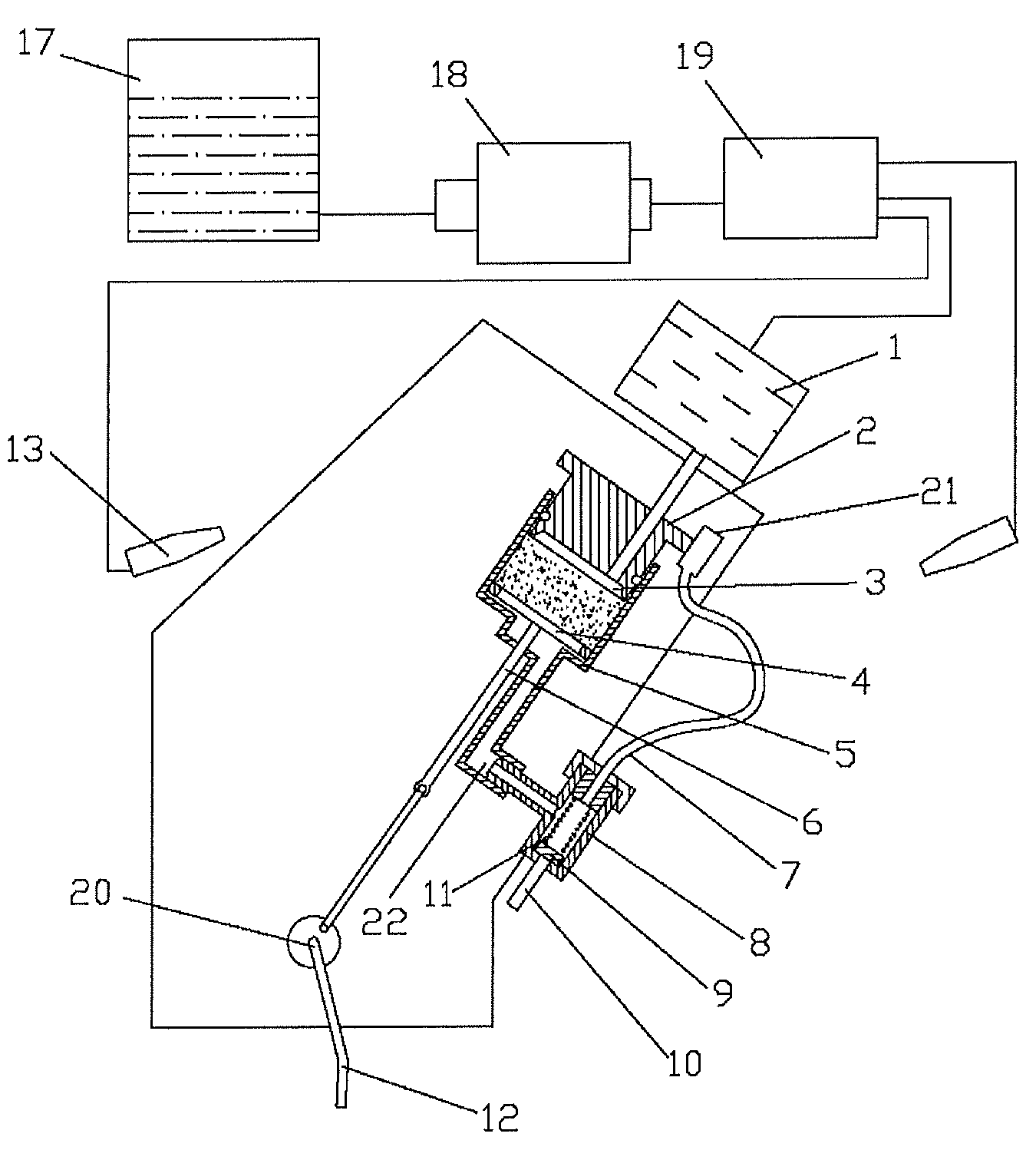

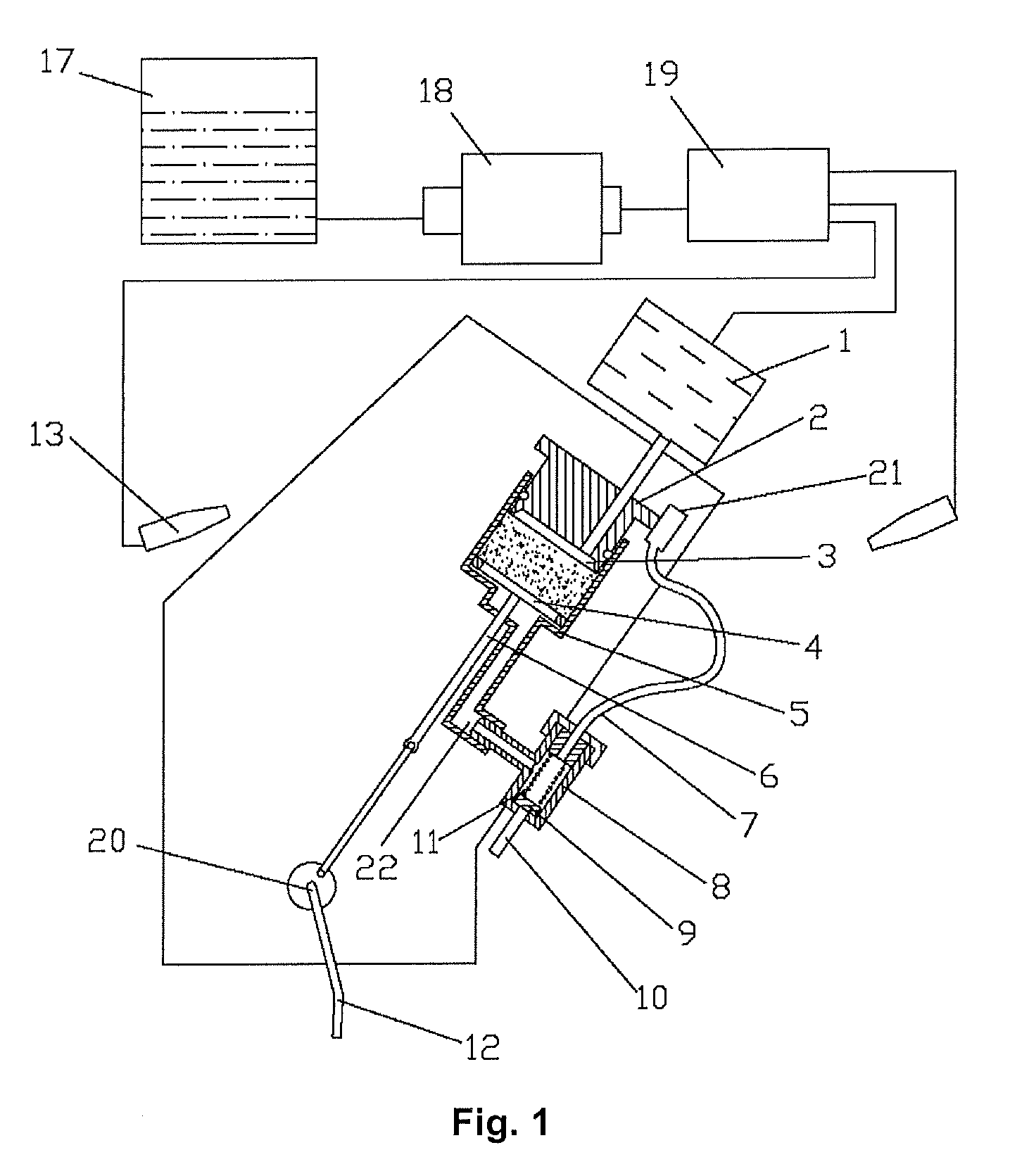

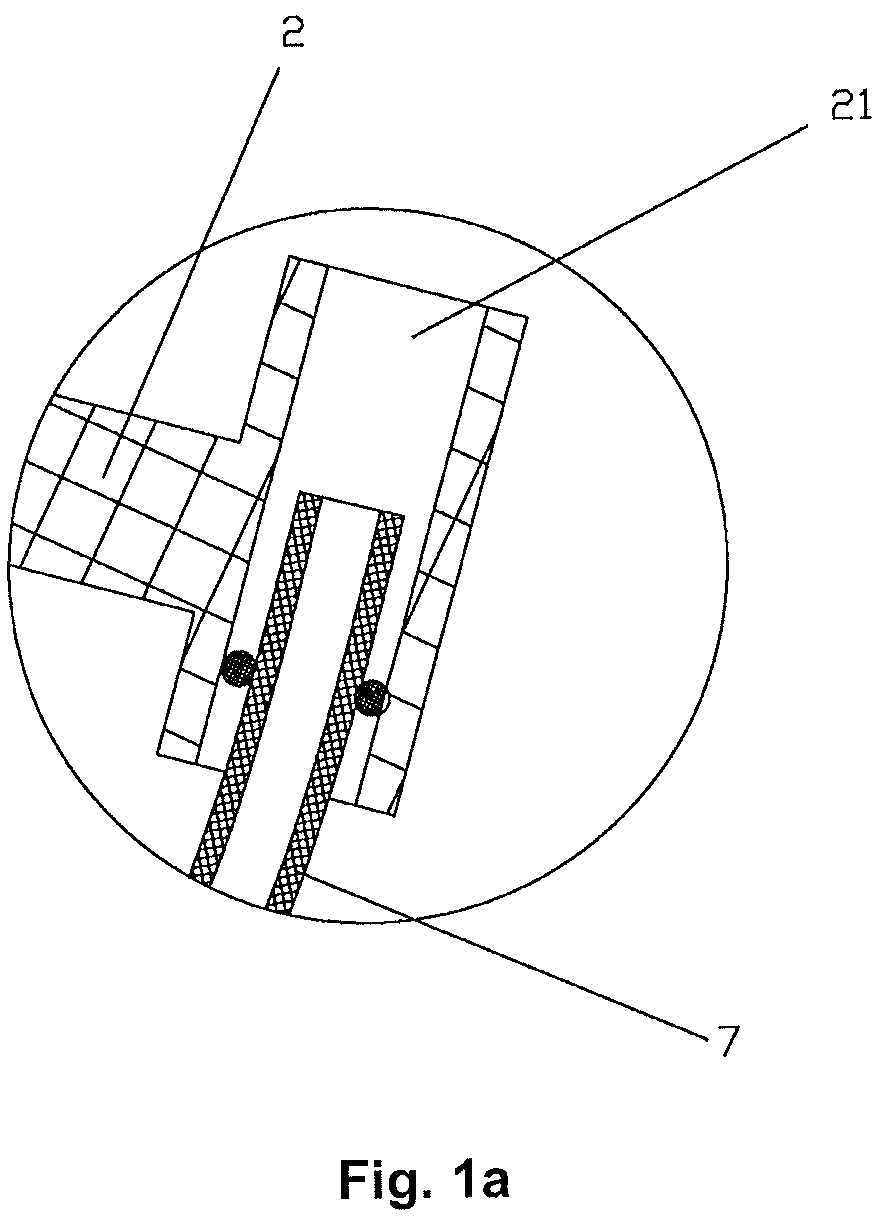

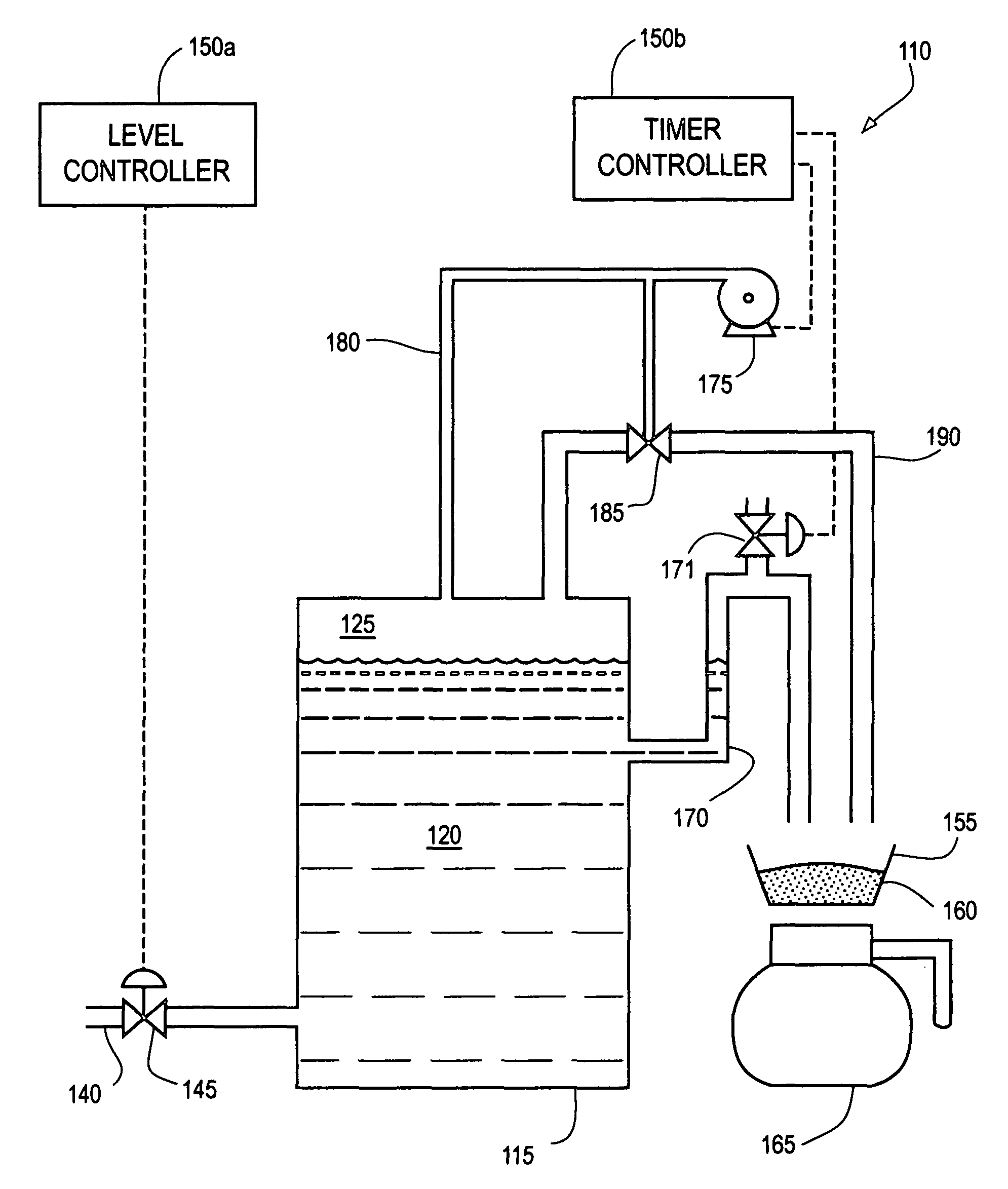

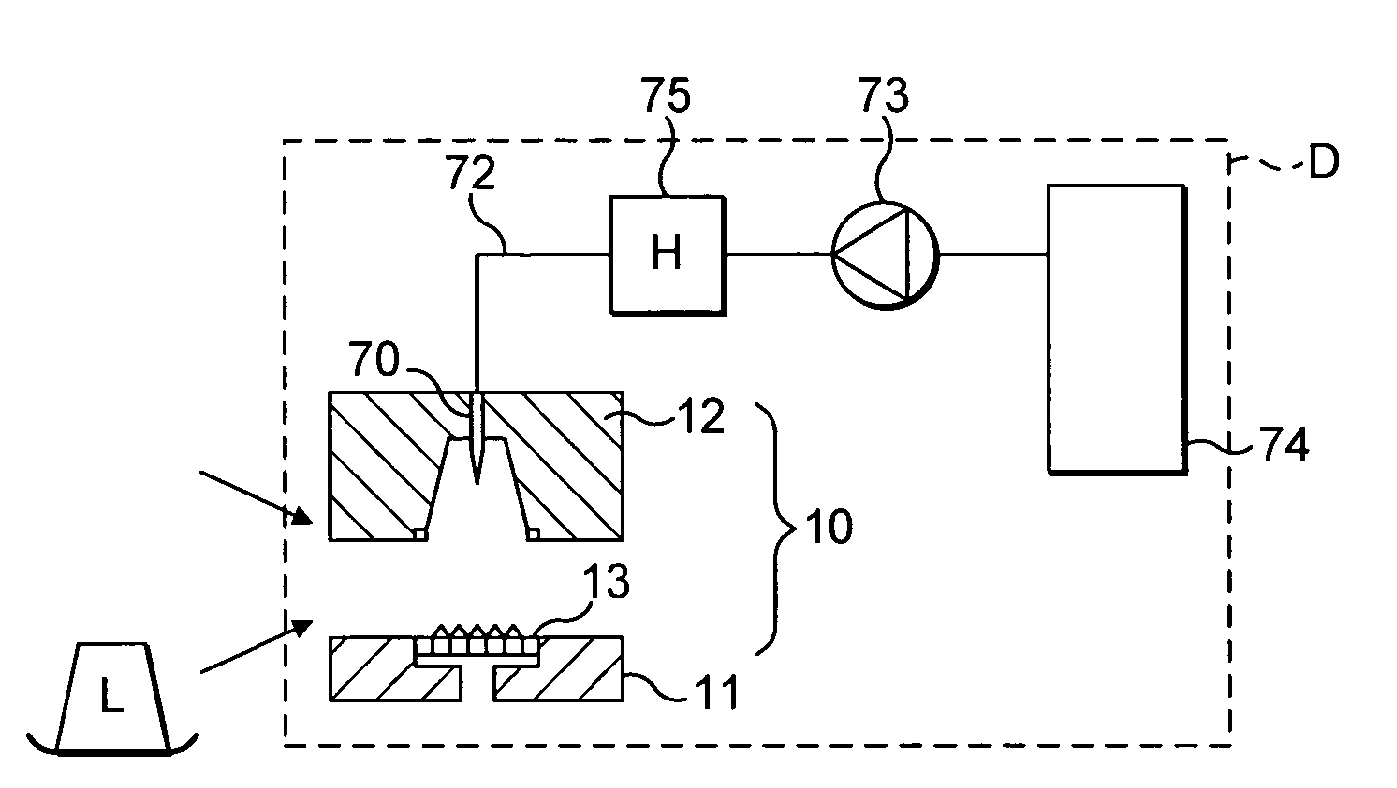

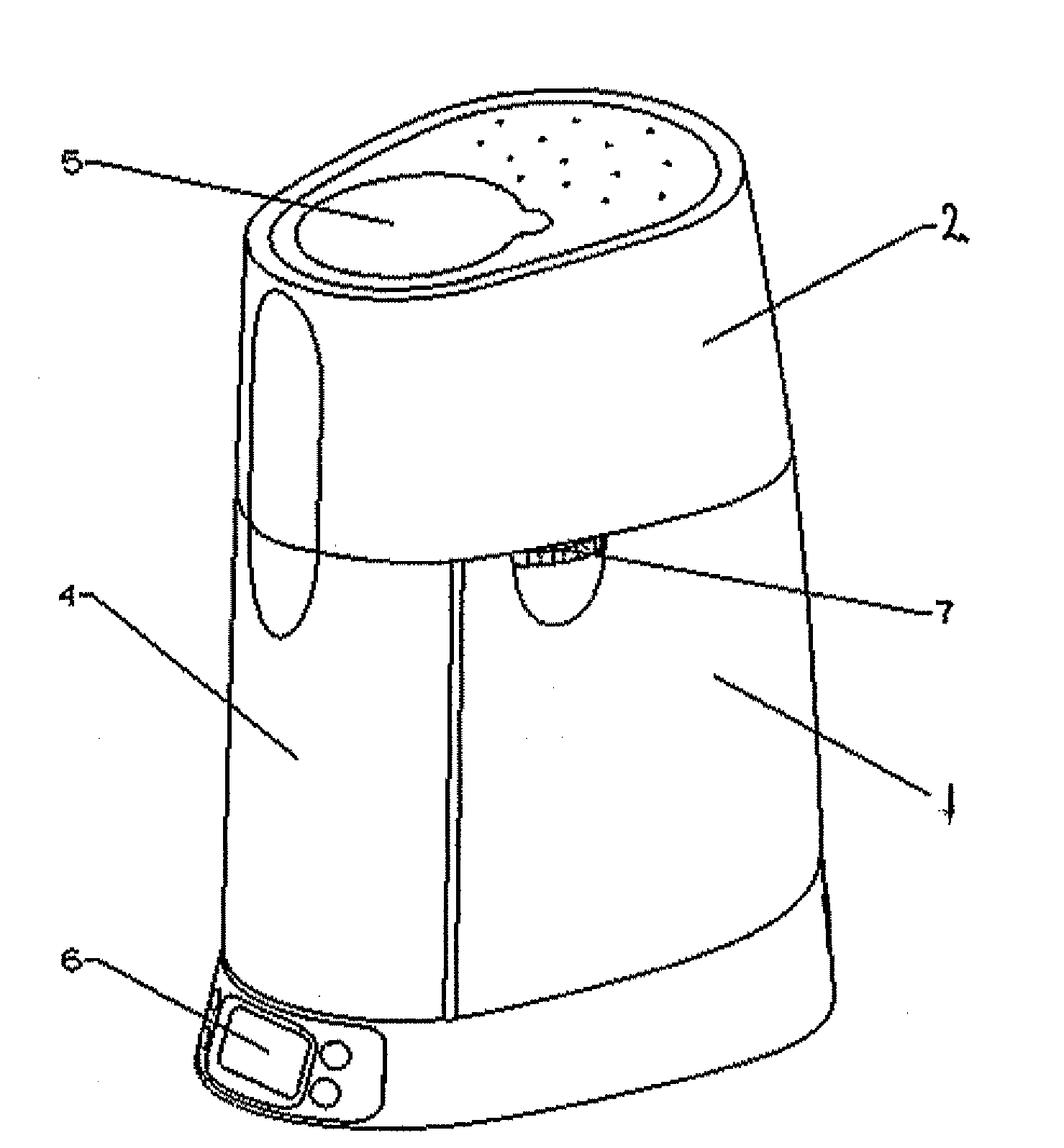

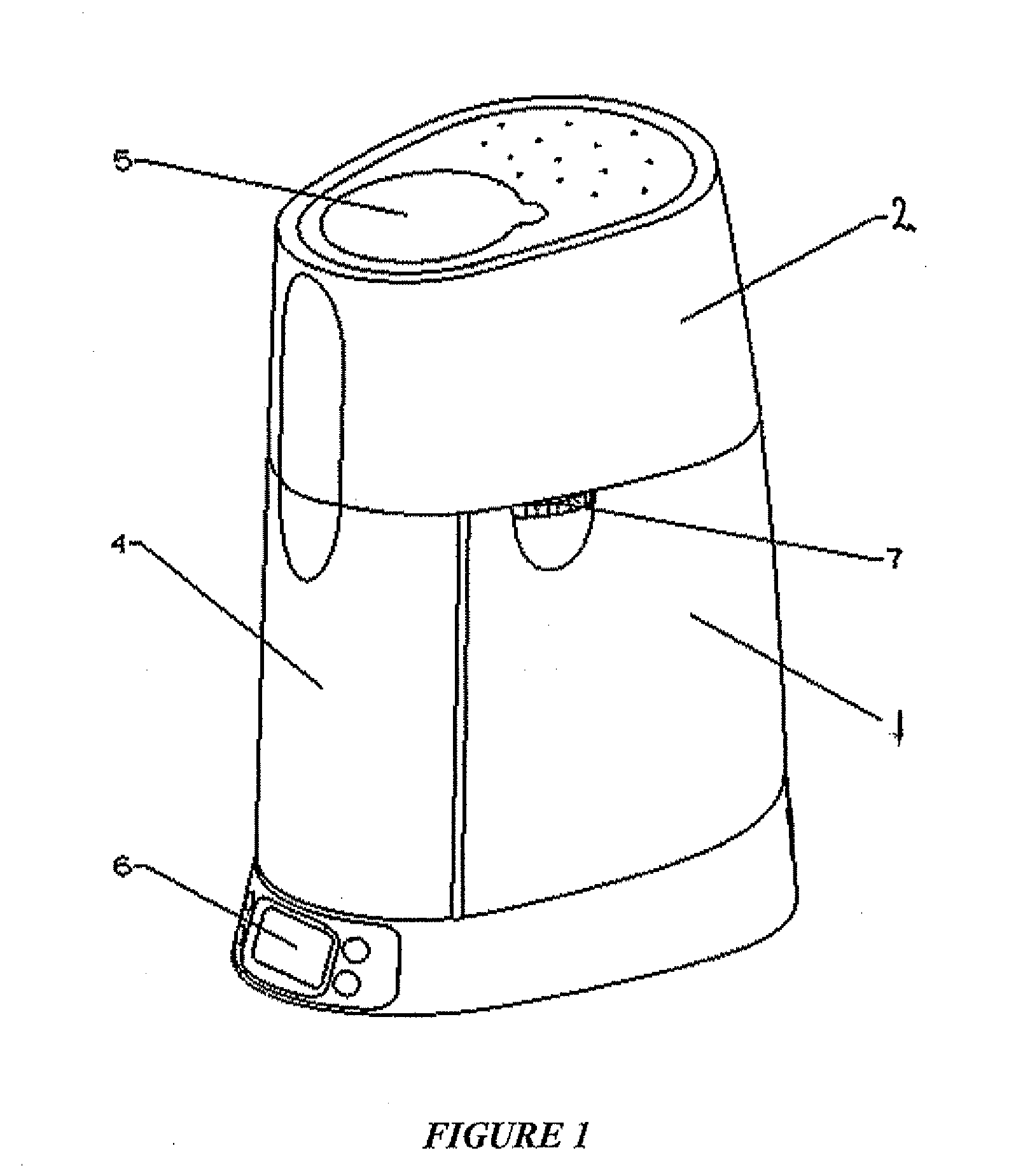

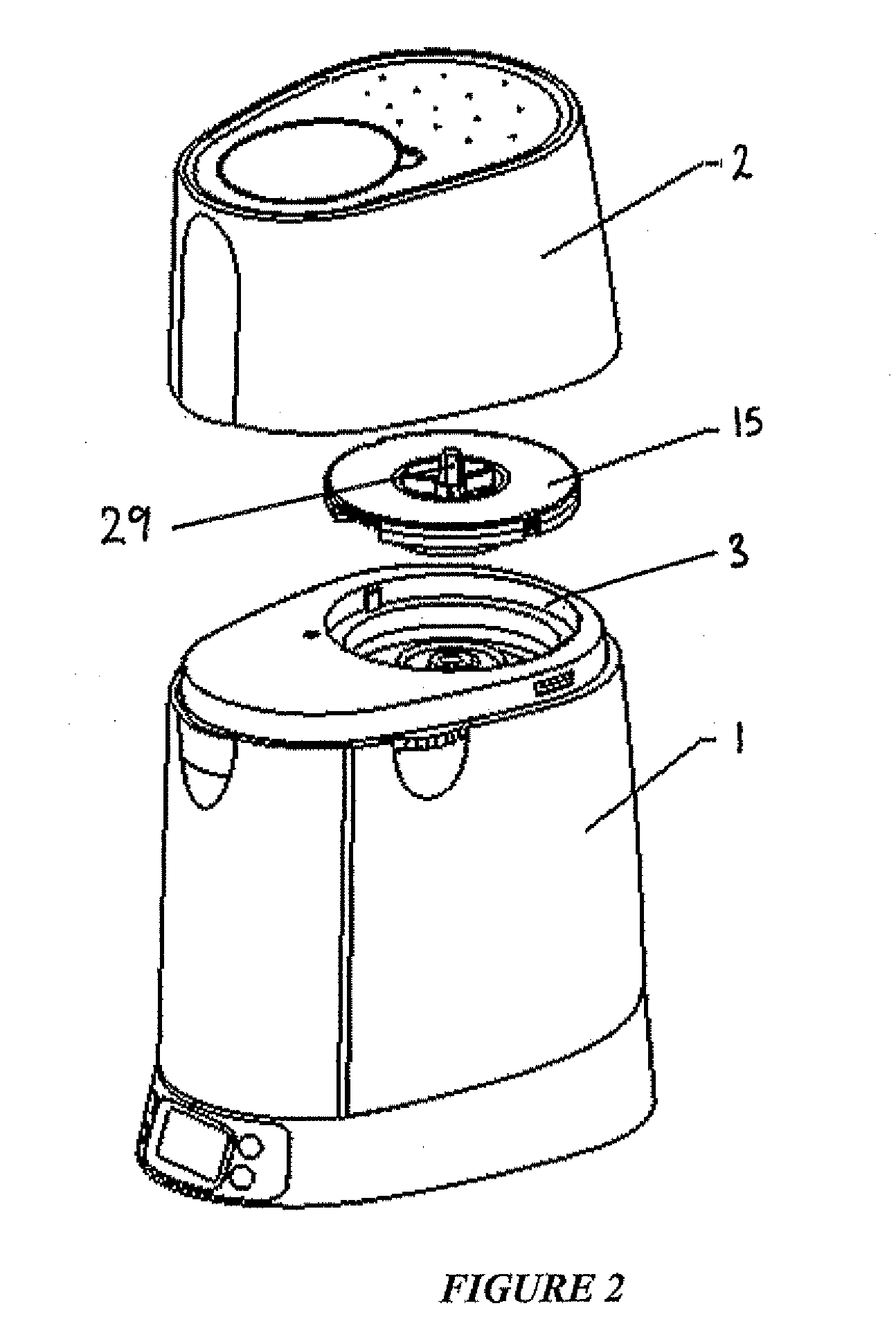

Automatic coffee brewing apparatus and control method

InactiveUS7571674B2Easy to clean automaticallyFor automatic dischargeBeverage vesselsWater dischargeWater flow

This invention provides for a coffee brewing apparatus and its control method, which comprises a control circuit and a water loop comprising a water reservoir, a pump, a control valve, a boiler, a brewing assembly, a three-way connector and a connecting hose. When coffee is to be brewed, hot water flows top-down through the brewing chamber cover, the upper filter, the coffee grounds, the lower filter, the brewing chamber, the first port of the three-way connector, the second port of the three-way connector and the connecting hose; the brewed coffee finally flows out from said connecting hose. This coffee brewing apparatus has additional functions of automatic residue discharge, automatic water discharge and automatic cleaning.

Owner:TOP TECH CO LTD

Coffee maker

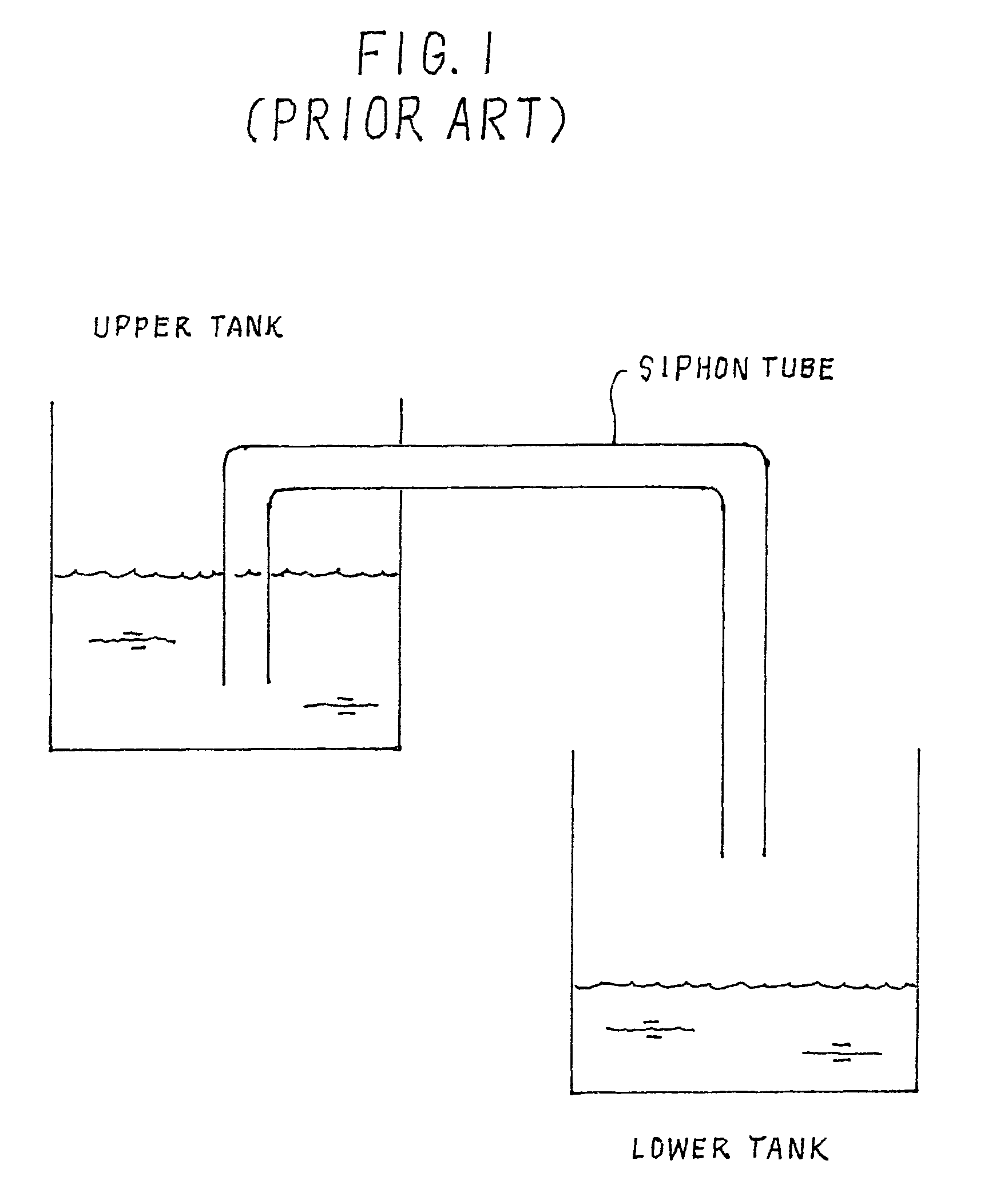

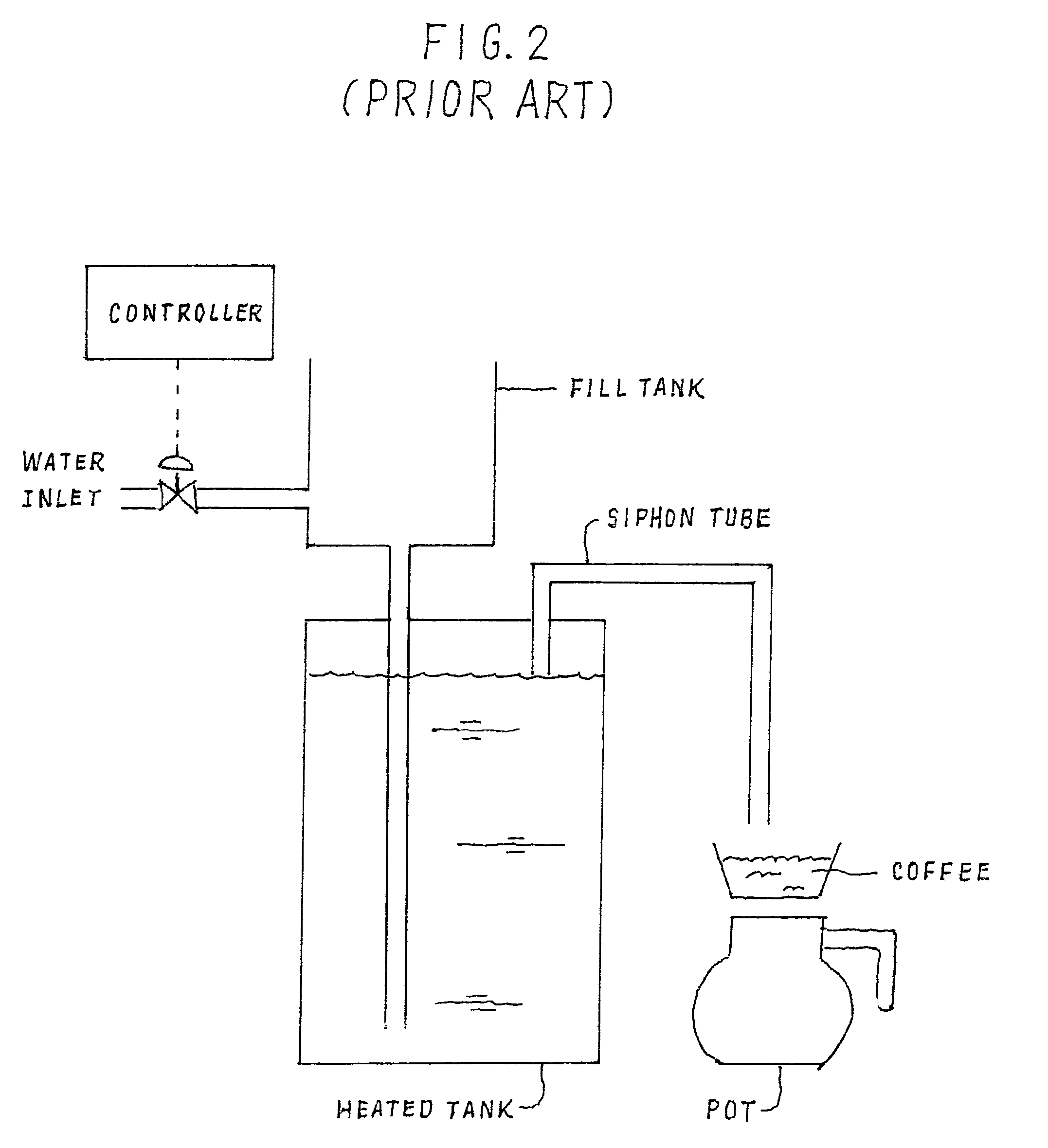

A coffee maker contains a siphon tube for discharging hot water from a heated reservoir to a container for coffee grounds. Flow through the siphon tube is initiated by pressurizing the air space in the heated reservoir with an air pump. A siphon flow of hot water through the siphon tube to a coffee grounds container then continues without pressurization. The flow is ended when the desired volume of coffee is brewed.

Owner:REYNOLDS D MICHAEL

Coffee brewing system and method of using the same

The brewing system disclosed herein includes a reservoir for storing ambient temperature water used to brew coffee. A pump displaces water from the reservoir to a heater tank for heating thereof before delivery to a coffee cartridge in a brew head. Initially, the pump displaces a small volume of heated water under pressure through a rotating inlet needle to pre-wet and pre-heat coffee grounds in the cartridge. The pump then pumps a fairly consistent and larger volume of heated water under pressure to the cartridge via the spinning needle. Near the end of the brew cycle, the pump pumps a small quantity of air to purge the brewer head conduit, the brew head check valve, and the spinning needle, and to purge coffee from the coffee cartridge and to reduce dripping.

Owner:COFFEE SOLUTIONS LLC

Coffee infusing device

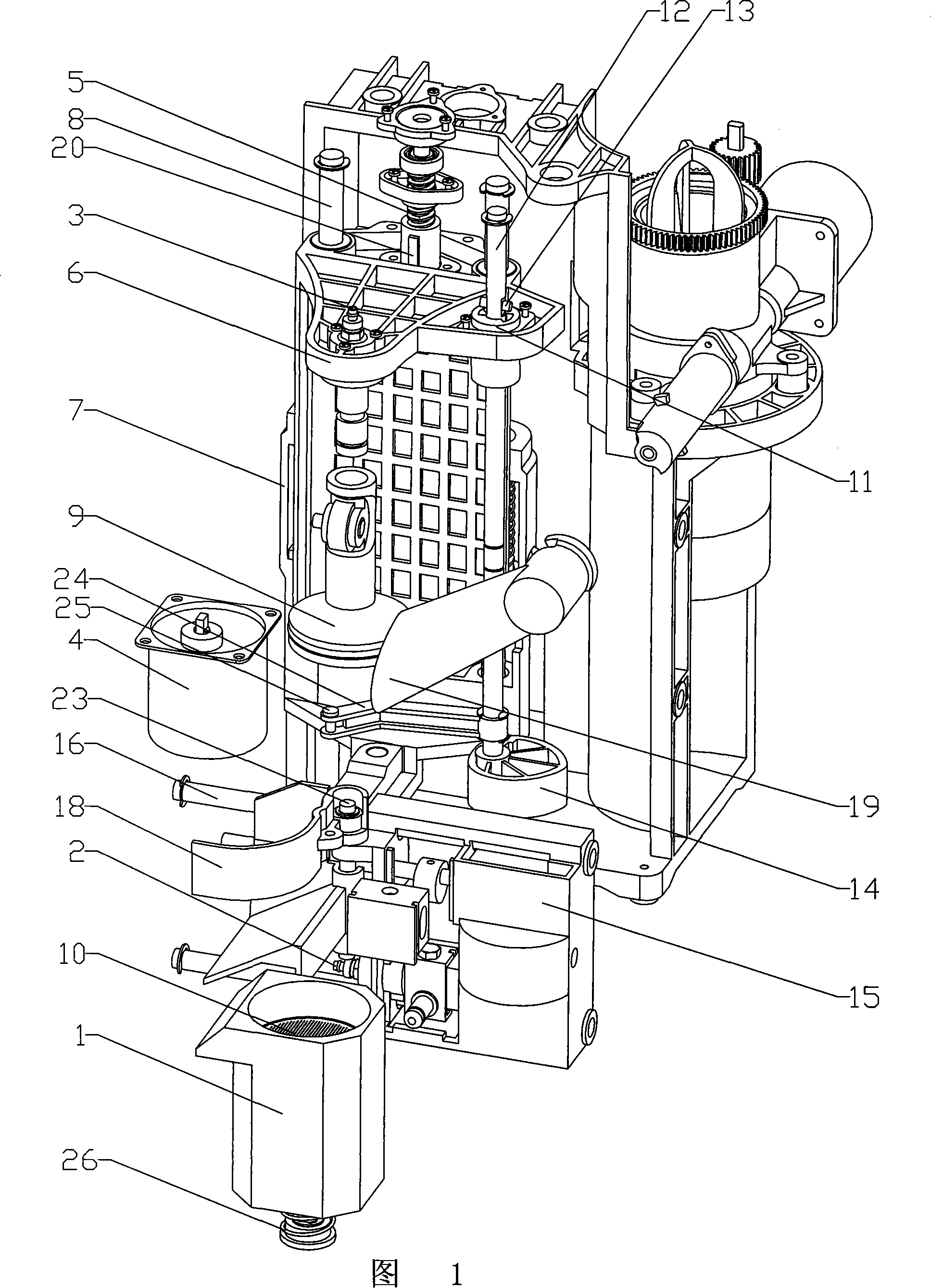

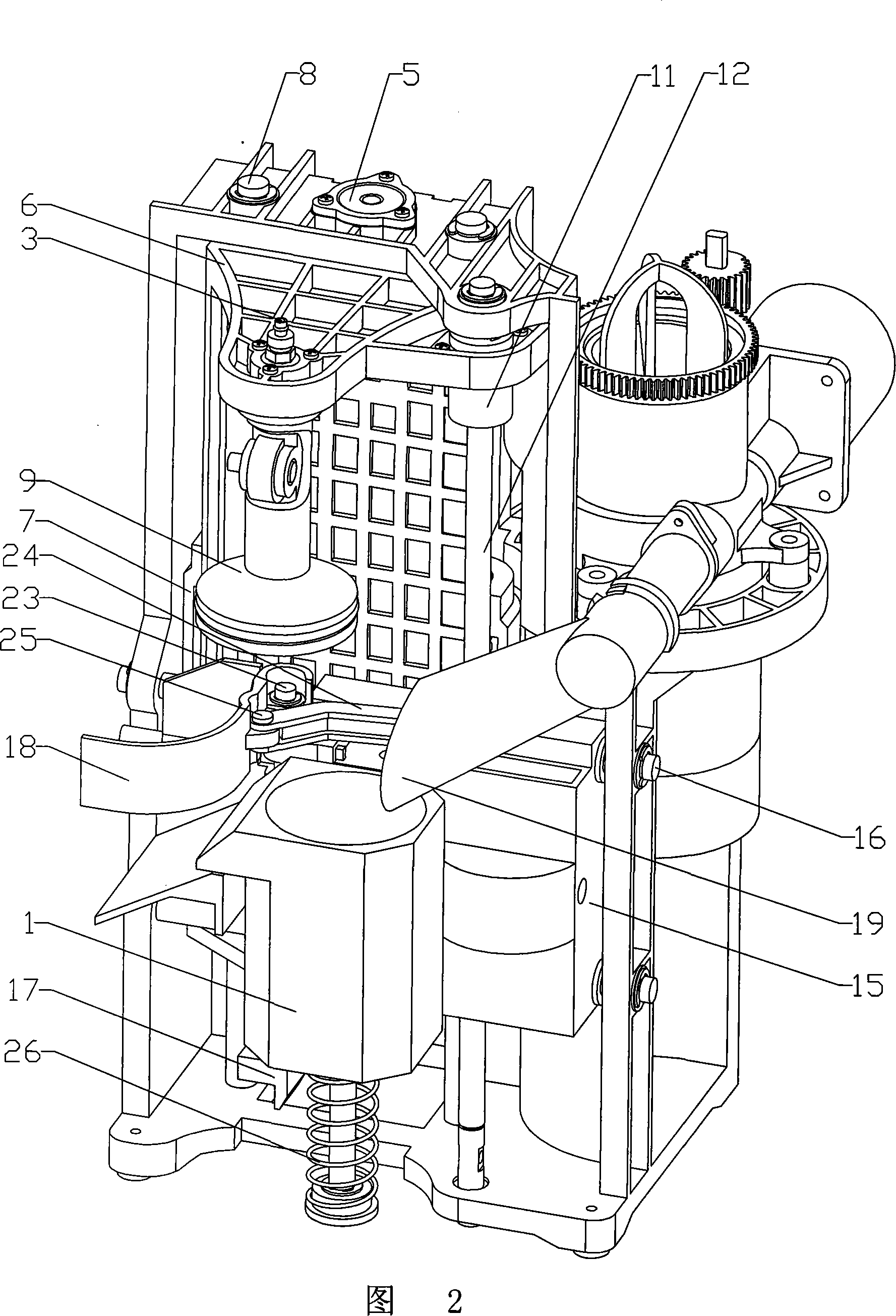

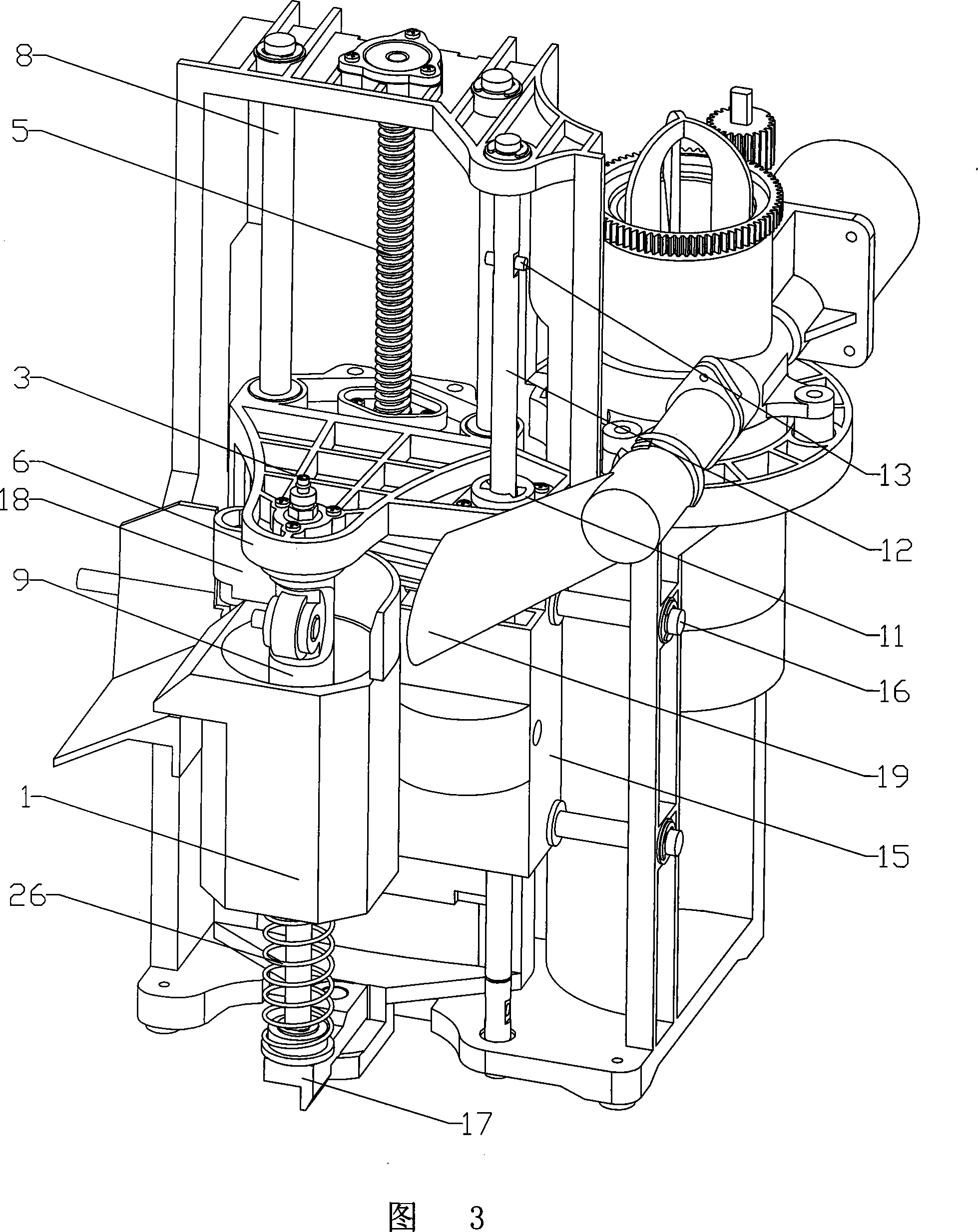

InactiveCN101108069AReduce flying aroundDoes not affect movementBeverage vesselsMotor driveEngineering

A coffee device is provided, which comprises a cylinder body for placing ground coffee. An upper and a lower piston are capable of moving in the cylinder body; a motor drives a screw rod to rotate and the screw rod drives an upper and a lower splint to move along a vertical slideway; a horizontal splint is positioned in the coffee device, which is connected with the cylinder body; a horizontal splint driving mechanism drives the horizontal splint to move horizontally; the lower splint is provided with a roof plate and the piston on the lower splint moves upward driven by the roof plate; outlet of the ground coffee is arranged beside the upper piston. For the horizontal splint can move along the horizontal slideway, which enables the cylinder body can be moved below the outlet mentioned to reduce the fly apart of the ground coffee during adding it into the cylinder body. The device can add, press, make coffee and eliminate the coffee grounds, which is especial suitable for automatic coffee maker.

Owner:李行

Apparatus for brewing beverages such as coffee and the like

An apparatus is disclosed for brewing coffee, which includes a housing having an inner chamber for receiving and retaining brewed coffee, a water reservoir adjacent to and generally surrounding the inner chamber, for receiving water, and an electrically powered coil for heating the water contained in the water reservoir. A brew valve is positioned above the inner chamber for supporting coffee grounds, the brew valve being rotatable between a first inactive position and a second active position for brewing coffee. Heated water is directed from the water reservoir to the brew valve and to the coffee grounds to brew coffee. and to the coffee grounds to produce brewed coffee, and into the inner chamber.

Owner:SCELZA JOSEPH

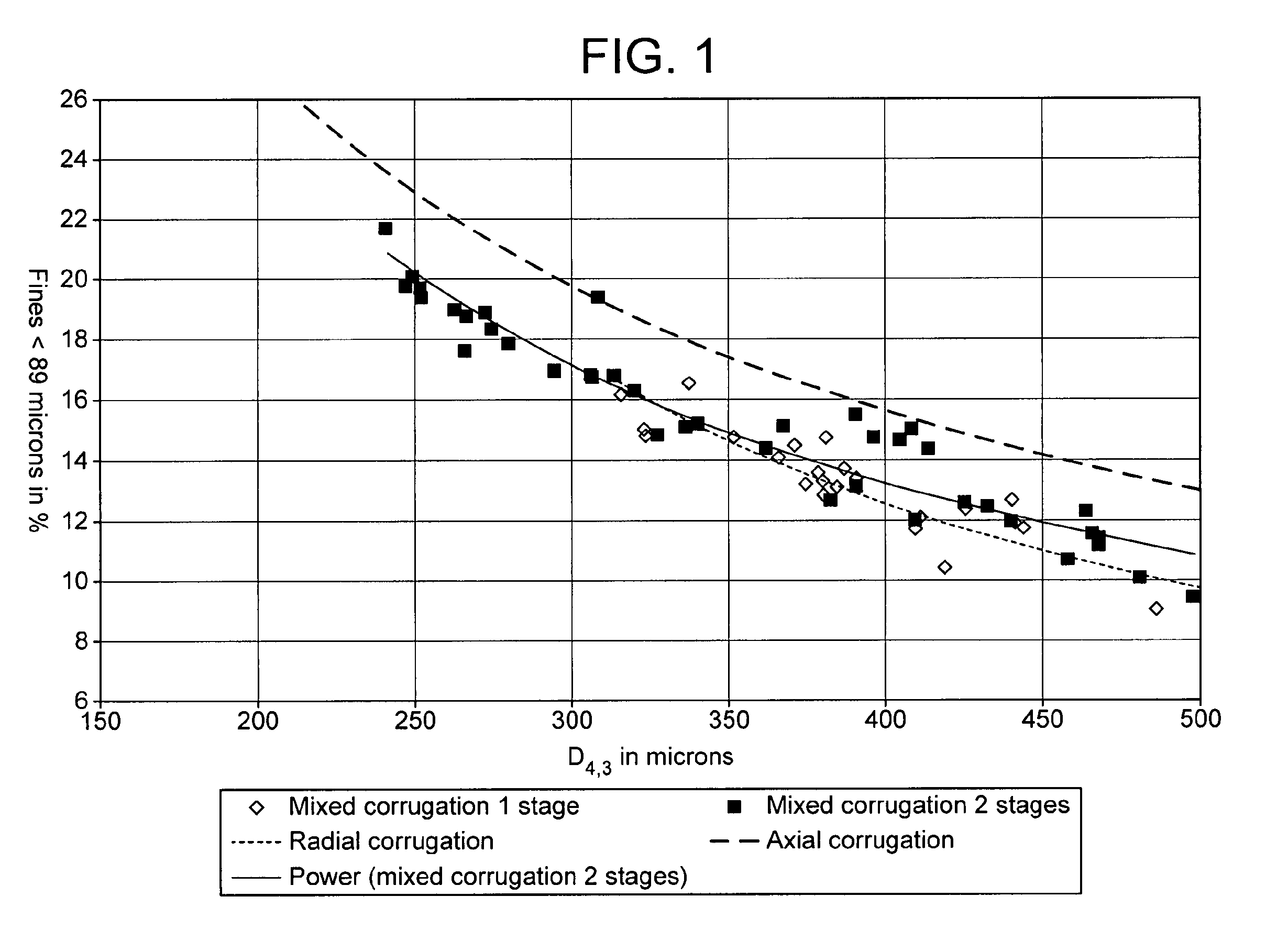

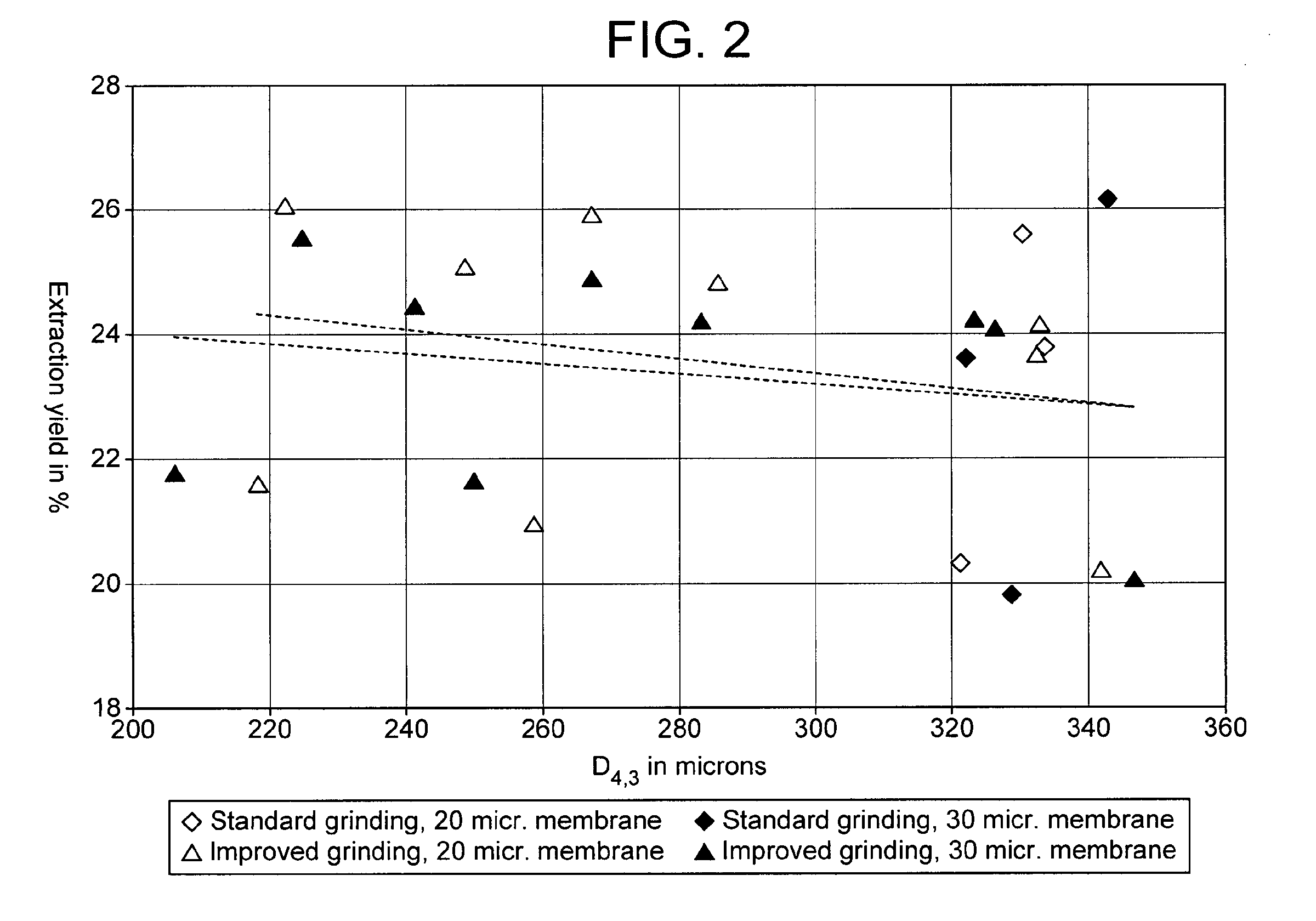

Method for delivering a coffee extract from a capsule

ActiveUS8088423B2Reduce total pressure lossIncreased pressure lossBeverage vesselsCoffee grinding methodsFlow timeBiomedical engineering

A method for delivering a long coffee extract from a capsule containing ground coffee within a flow time of 50 seconds or less by injection of water under pressure within the capsule. The capsule is filled with ground coffee and has a delivery membrane. The capsule is extracted in a coffee extraction device, and pressurized water is injected in the capsule under pressure. The coffee beverage is released through the beverage delivery membrane of the capsule with engaging means engaging in and / or against the membrane. The pressure loss is reduced in the coffee bed by providing in the capsule coffee ground having a controlled percentage of fines (F) depending on the average particle size (D4,3). The flow time can be lowered to 40 seconds or even less while maintaining a coffee extraction yield within a high range of 15 to 30%.

Owner:SOC DES PROD NESTLE SA

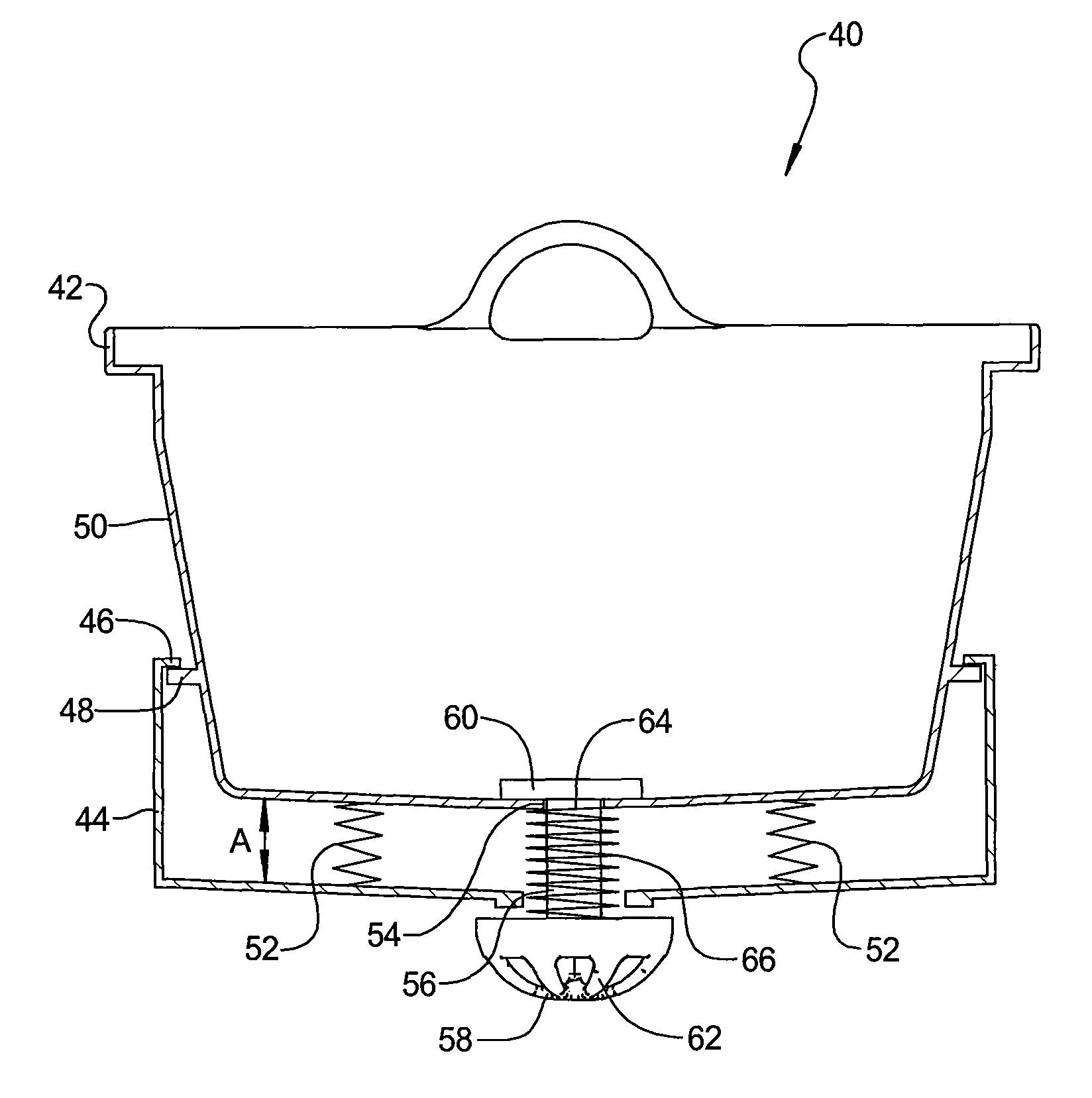

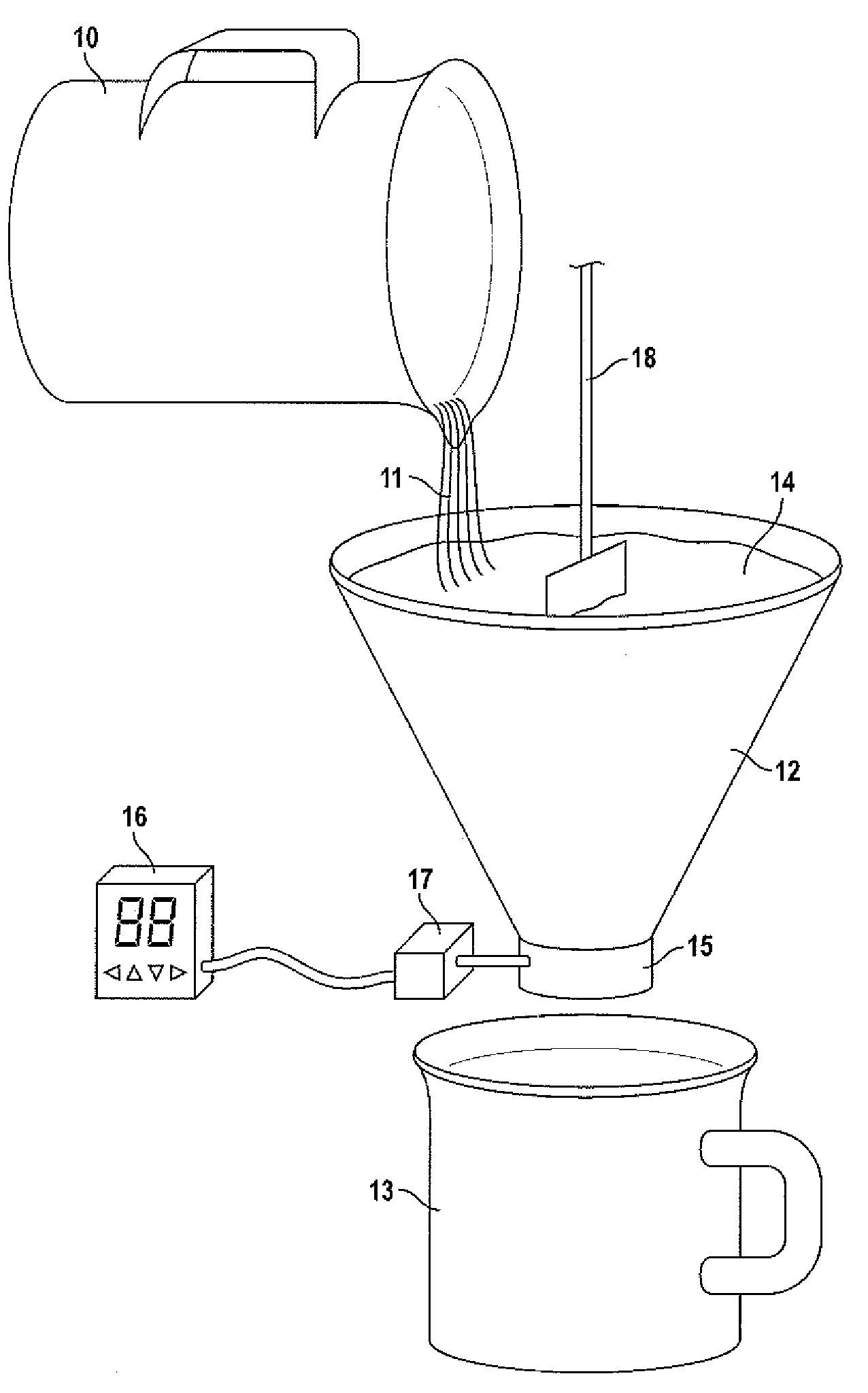

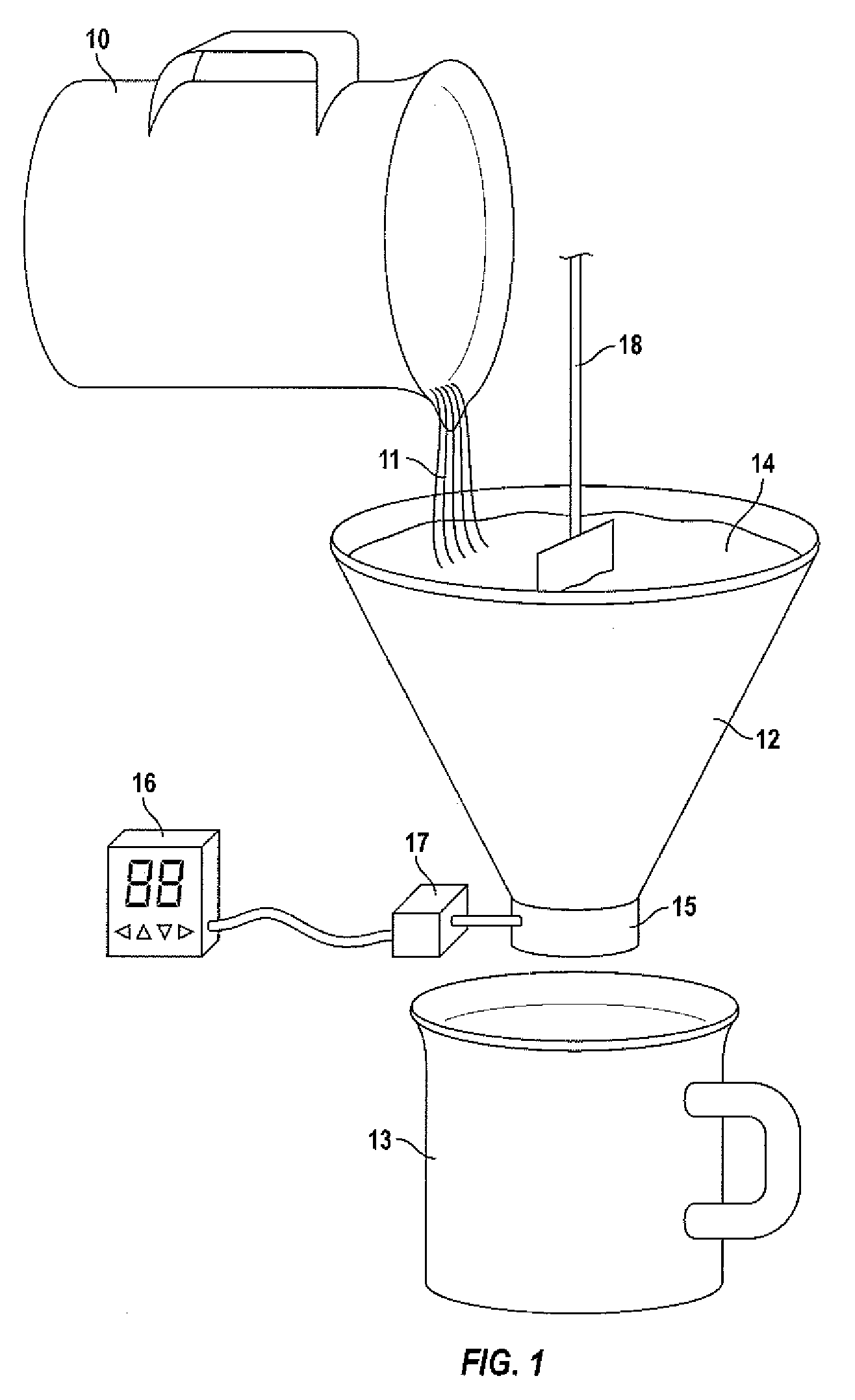

Brewing device having a delayed release mechanism

A drip coffee maker is provides including a means for delaying the release of brewed coffee from the brew basket assembly position in a brew basket housing. The brew basket assembly includes an upper basket portion vertically movably mounted with respect to a lower basket portion. A bias member is interposed between the basket portions, vertically biasing the upper basket portion with respect to the lower basket portion. A basket valve is included in the upper and lower basket portions, and is actuatable between an open and a closed position. A carafe is included, and has a lid portion with a lid aperture therein. The carafe is removably positionable under the brew basket assembly with the lid aperture proximal to the basket valve. The basket valve opens when the weight of the hot water and coffee grounds in the upper basket portion exceeds a threshold weight of the bias members.

Owner:SUNBEAN PROD INC

Coffee brewing system

A device for brewing coffee including a basket for retaining coffee grounds, the basket having an opening to receive water at a user-selected temperature for contacting the coffee grounds within the basket. A control valve is provided for controlling the discharge of brewed coffee from the basket only after all of the water intended to be brewed has steeped within the coffee grounds.

Owner:SHEARWATER INVESTMENT

Coffee mill

InactiveUS20080098901A1Ameliorate spoilingAmeliorate stalingCoffee millsSpice millsEngineeringMechanical engineering

A coffee grinder has a lower body with an opening for receiving coffee beans and a removable coffee bean container mounted on the lower body. The container has a discharge opening which, in situ, communicates with the opening in the body. A grinder is located in the body in communication with the opening for grinding coffee beans into smaller coffee grounds. A closure is located with the coffee bean container for selectively closing the discharge opening when required.

Owner:MAIN POWER ELECTRICAL FACTORY

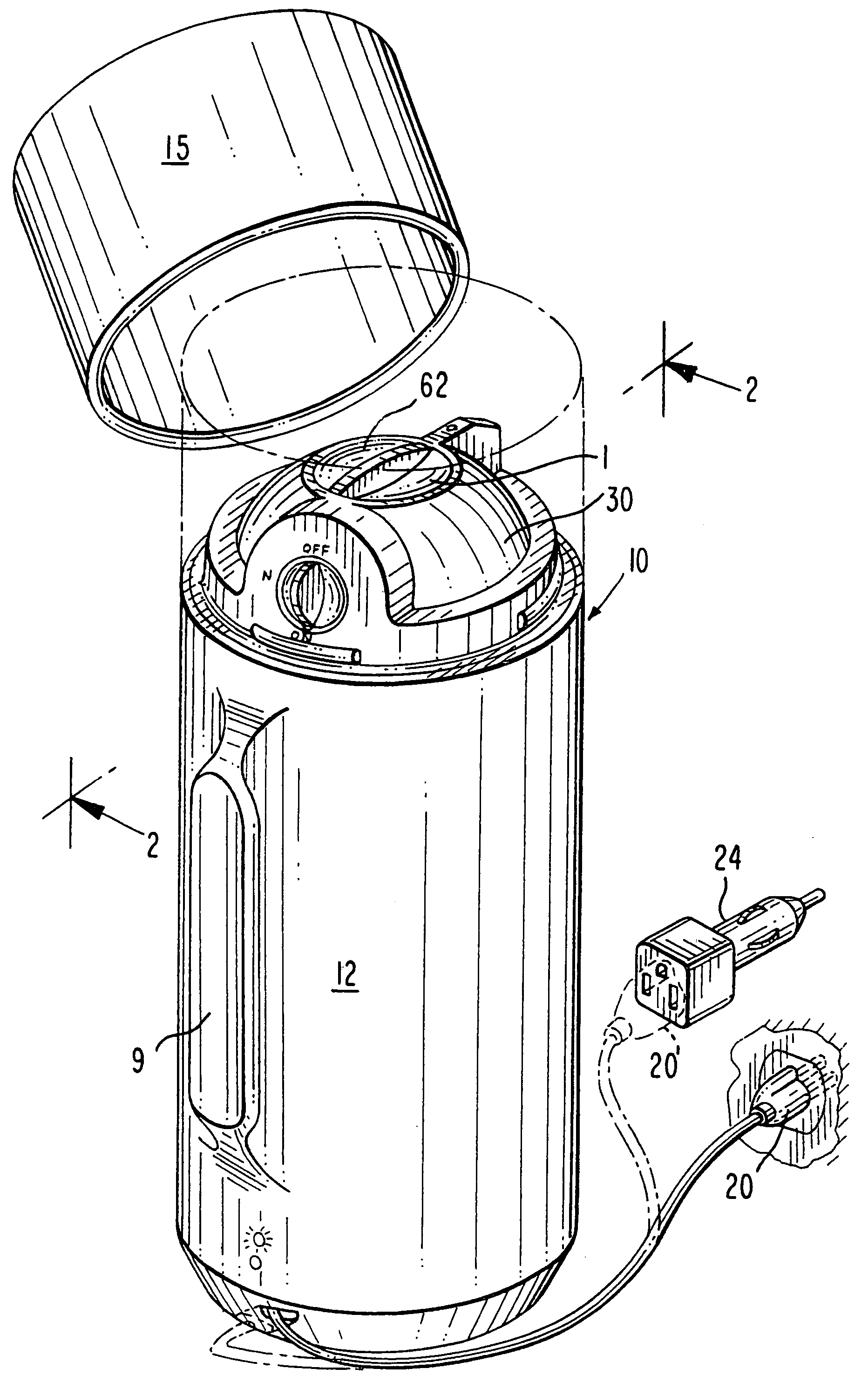

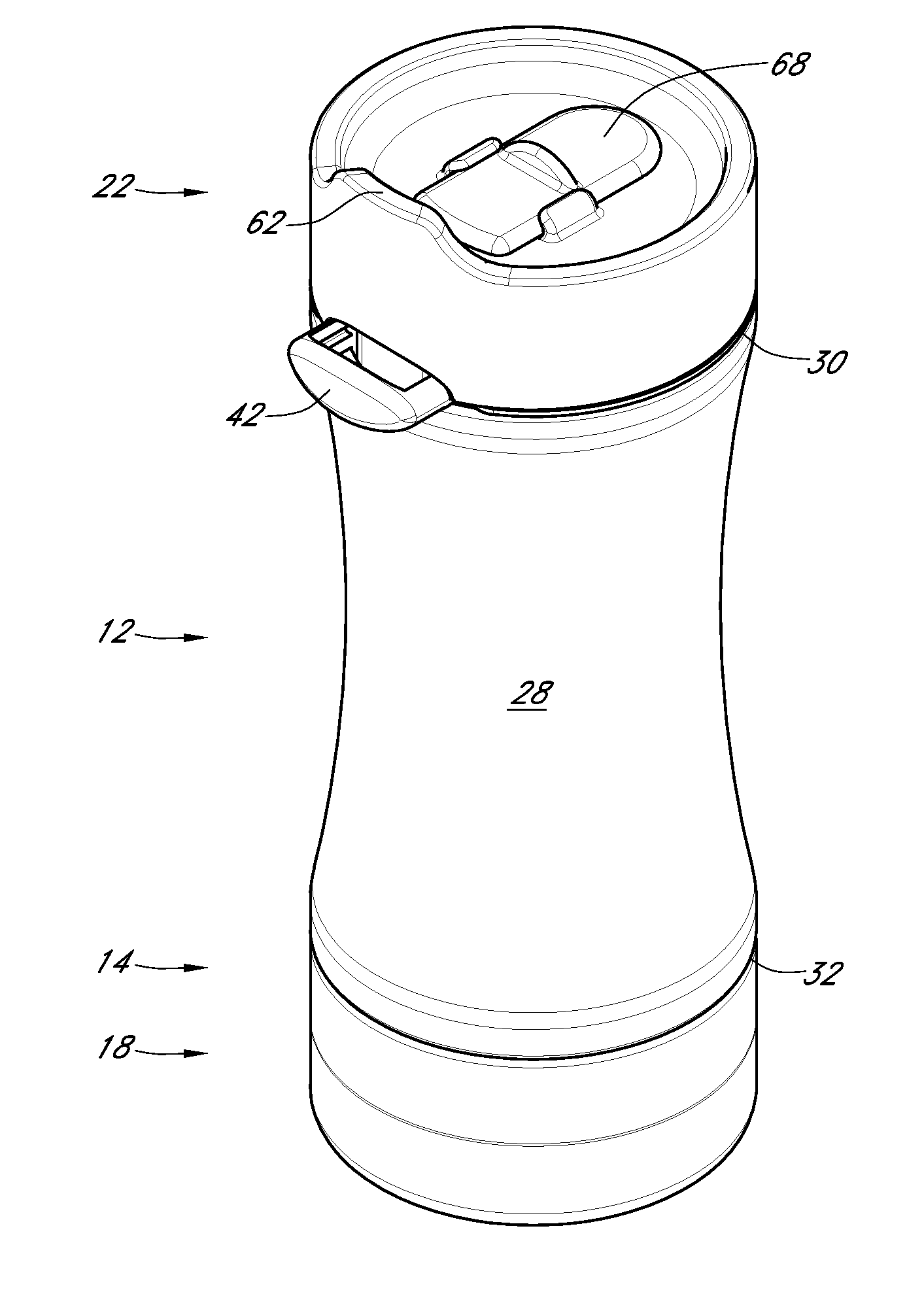

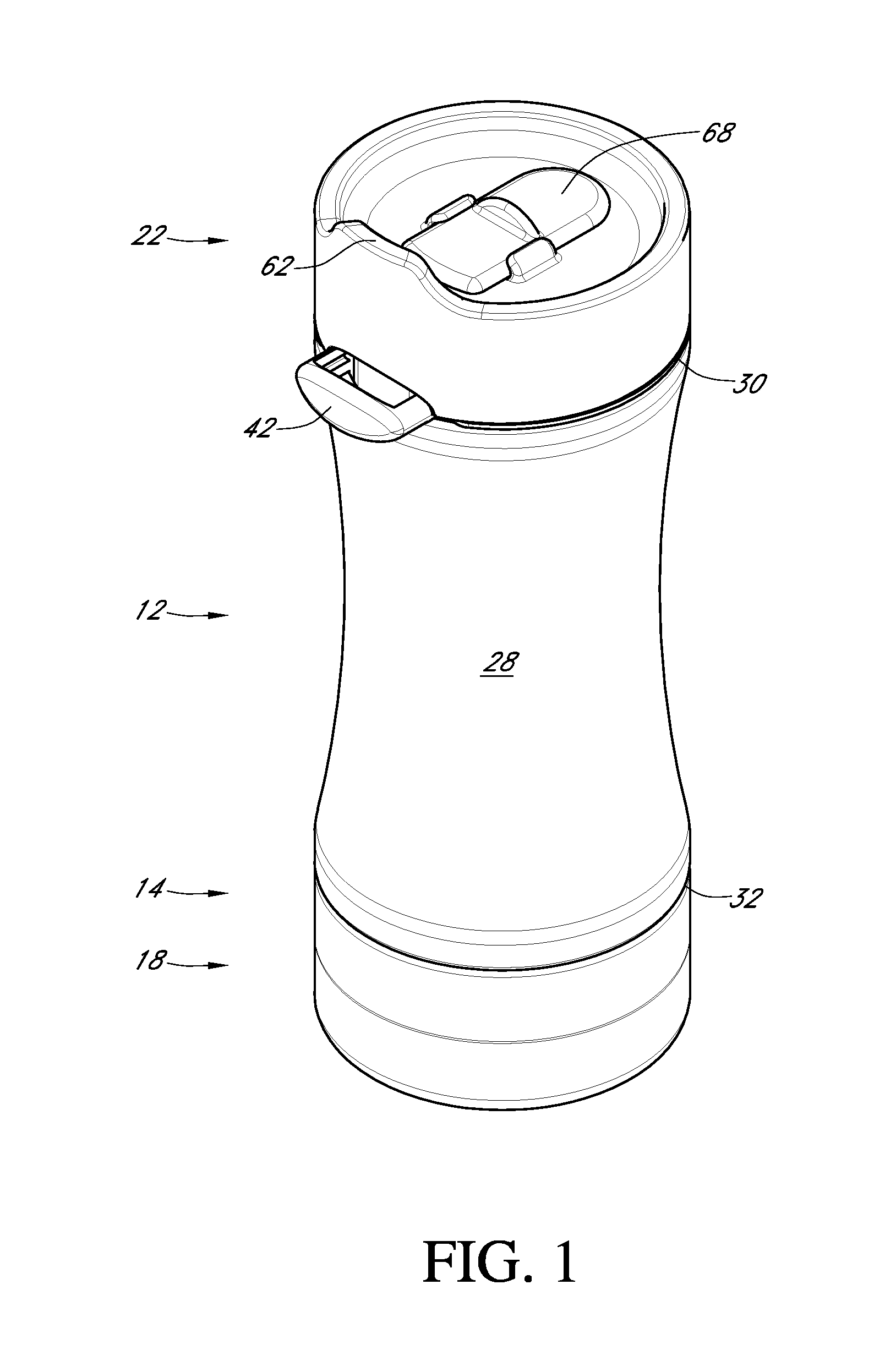

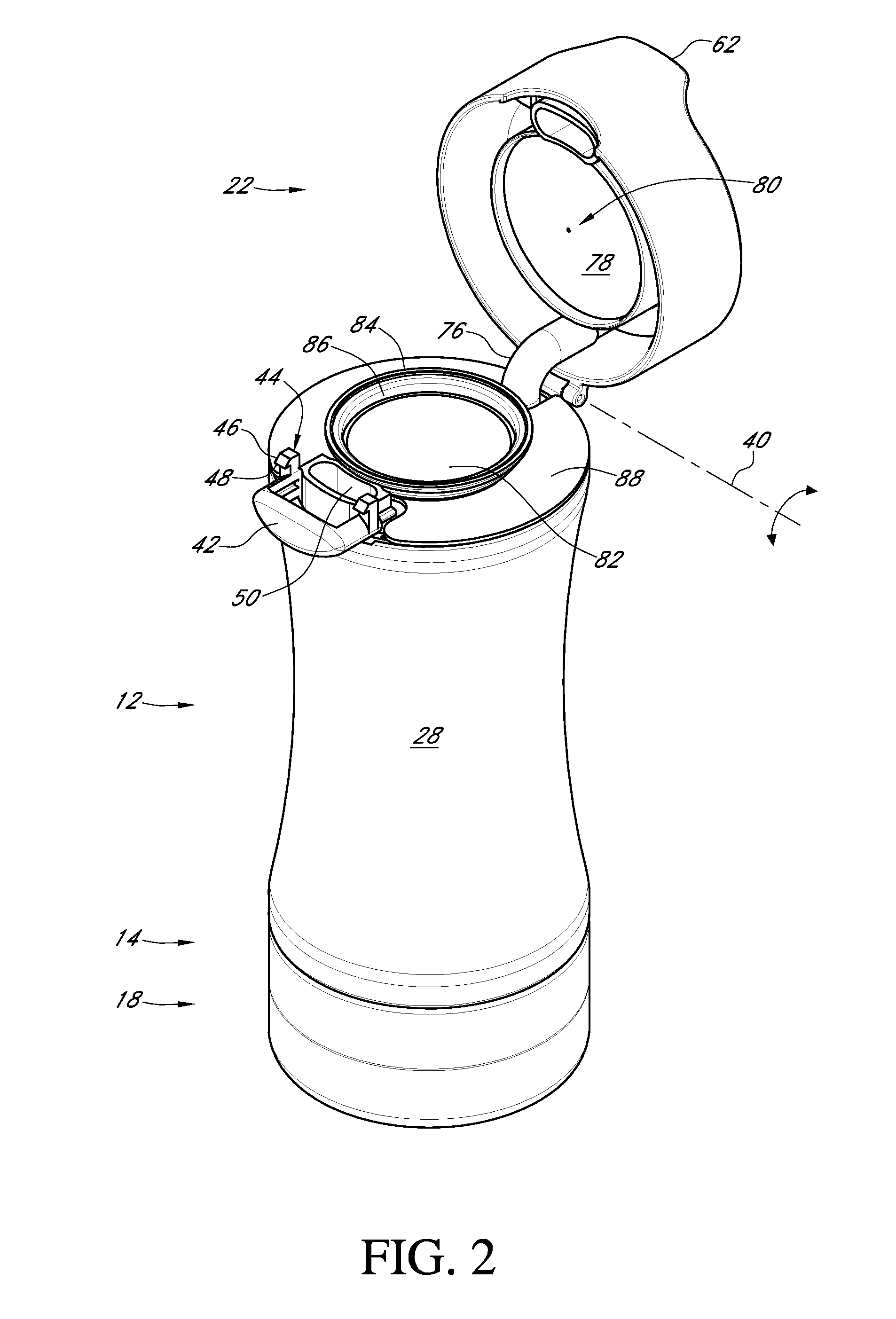

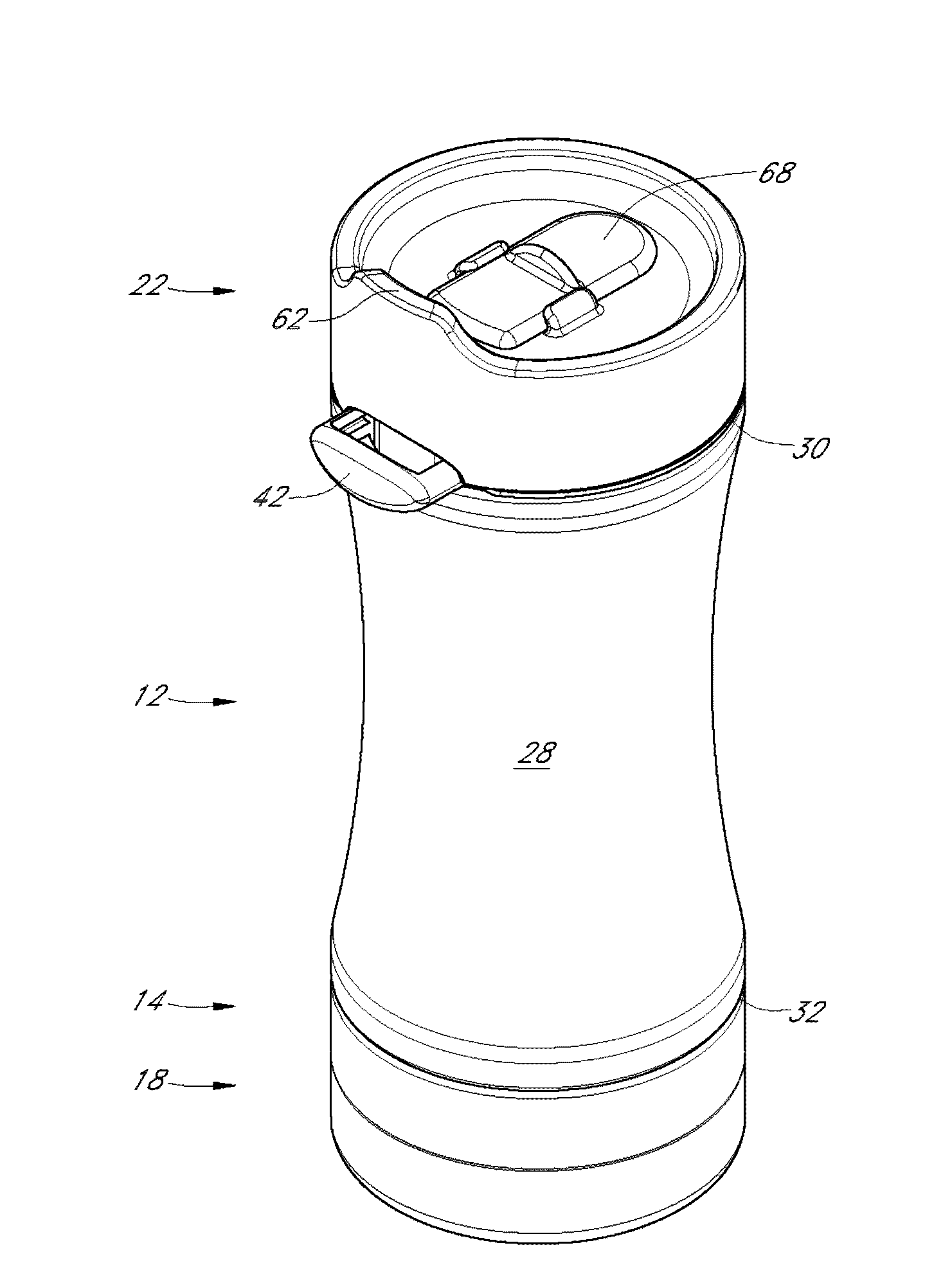

Portable coffee brewing device

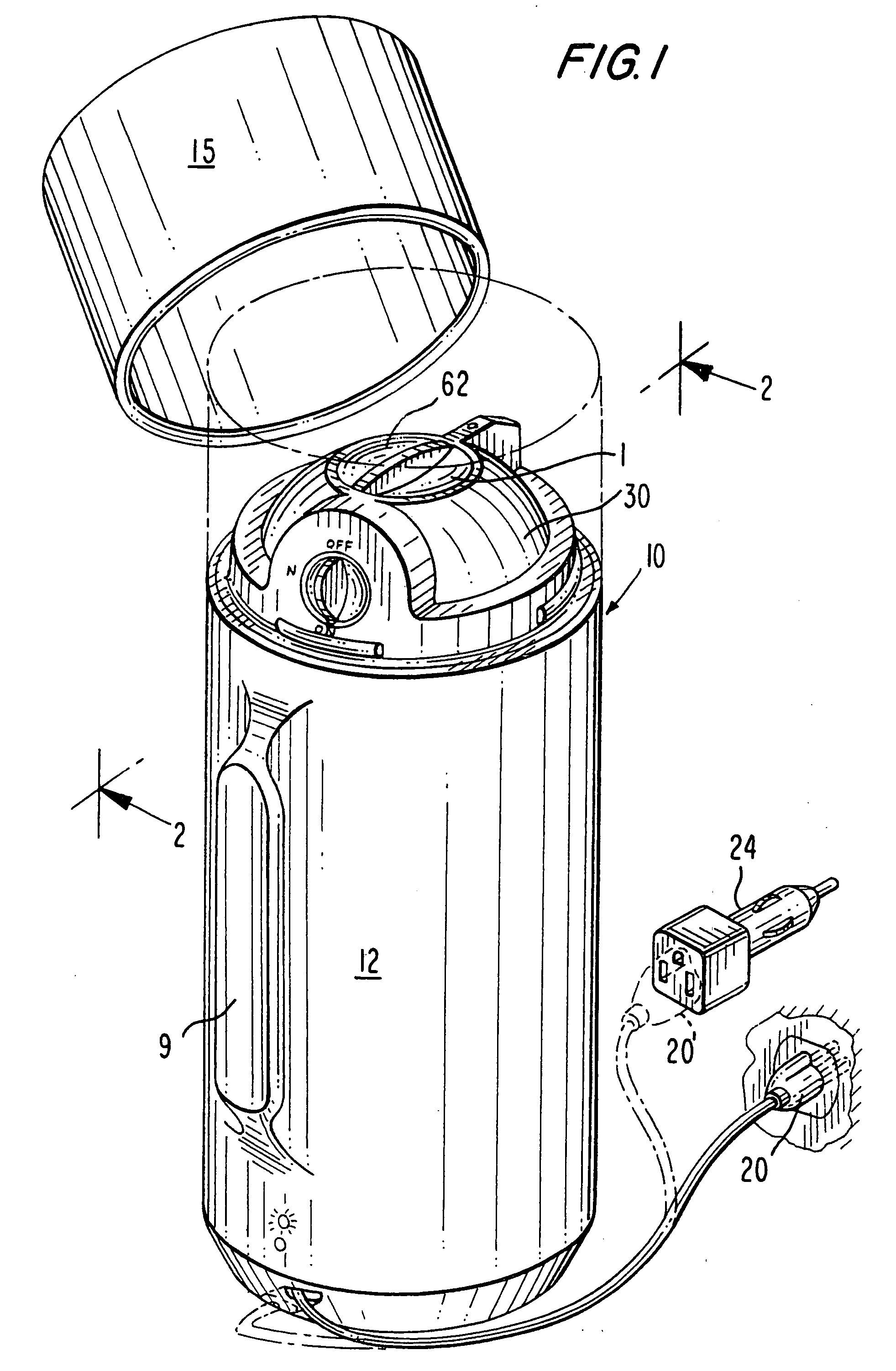

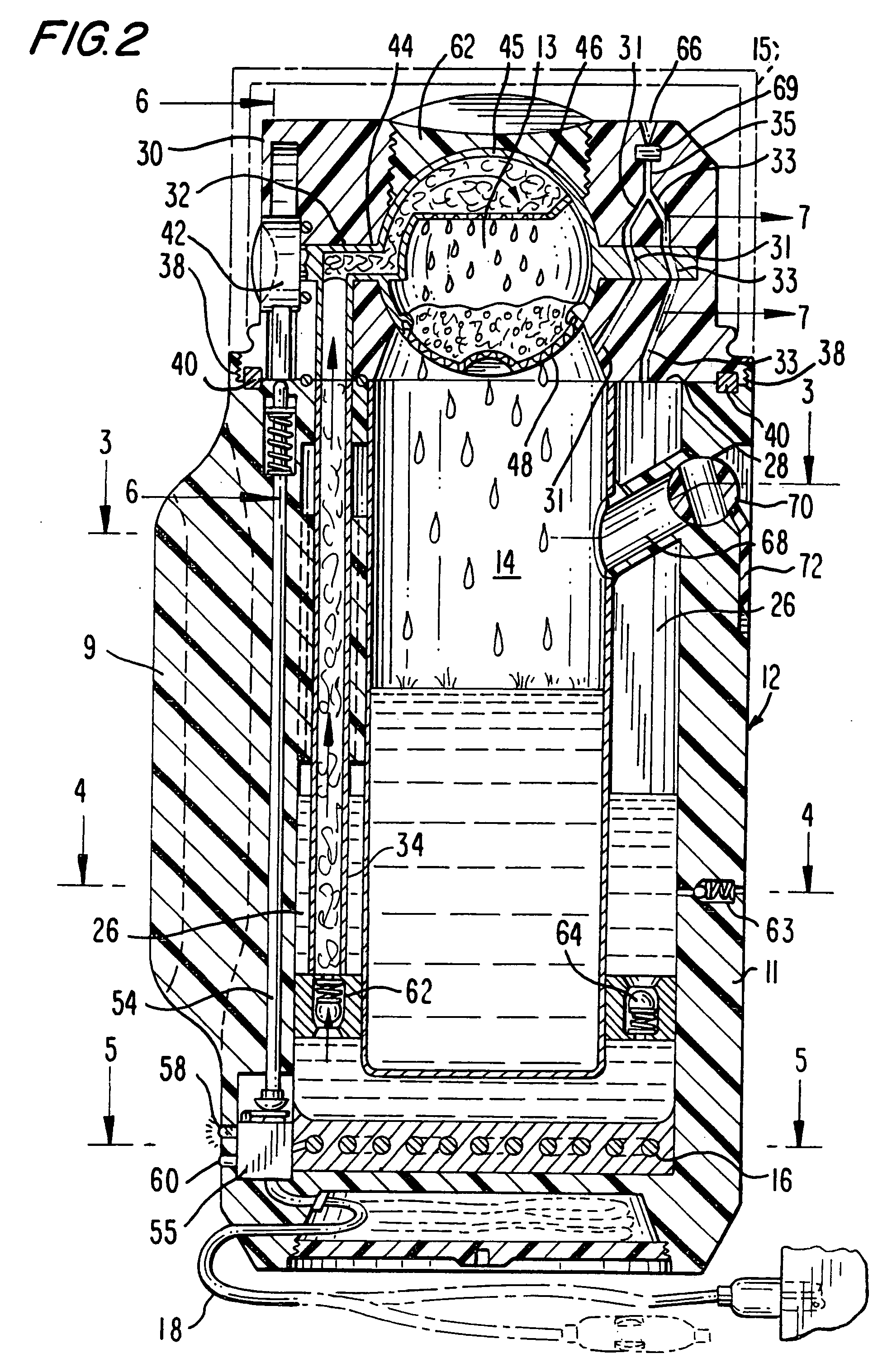

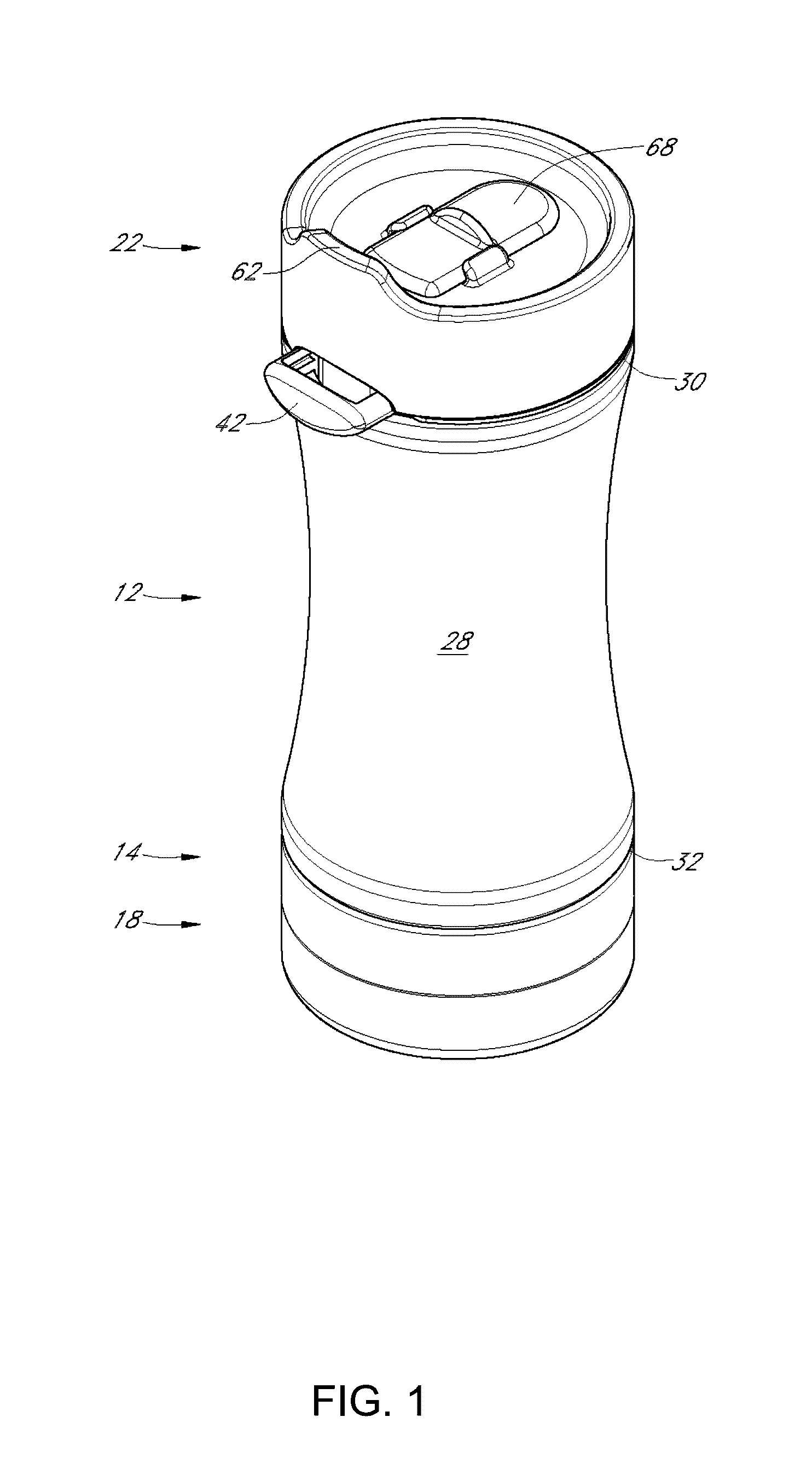

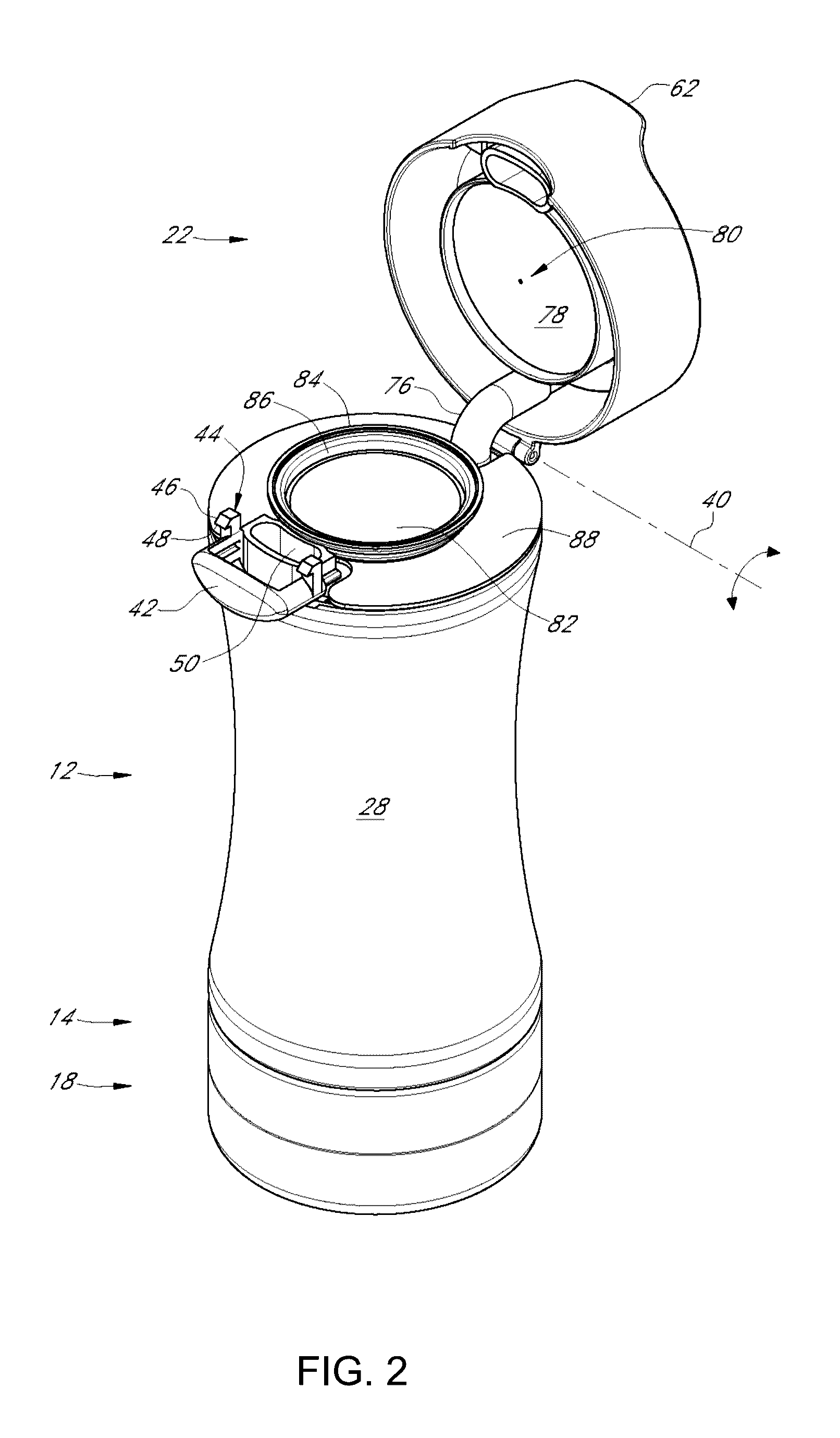

A portable coffee brewing device includes a lid pivotally connected to an upper end of the container by a hinge and button. A heating element housing and an electrical component housing is connected to a lower end of the container. A drain is positioned in a bottom wall of the container and is fluidly connected to a heating element positioned within the heating element housing. The heating element is controlled by electrical components positioned in the electrical components housing. A drip tube is fluidly connected to the heating element and the lid. A single serve coffee holding device is positioned below the lid. When the container is filled with fluid and the heating element is powered, heated fluid is forced up the drip tube through the passageway in the lid and into the coffee grounds holding device in a continuous cycle. The device is connectable to an external power source.

Owner:ADRIAN RIVERA MAYNEZ ENTERPRISES INC

Portable Coffee Brewing Device

A portable coffee brewing device includes a lid pivotally connected to an upper end of the container by a hinge and button. A heating element housing and an electrical component housing is connected to a lower end of the container. A drain is positioned in a bottom wall of the container and is fluidly connected to a heating element positioned within the heating element housing. The heating element is controlled by electrical components positioned in the electrical components housing. A drip tube is fluidly connected to the heating element and the lid. A single serve coffee holding device is positioned below the lid. When the container is filled with fluid and the heating element is powered, heated fluid is forced up the drip tube through the passageway in the lid and into the coffee grounds holding device in a continuous cycle. The device is connectable to an external power source.

Owner:ADRIAN RIVERA MAYNEZ ENTERPRISES INC

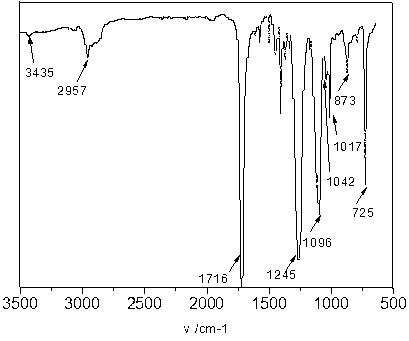

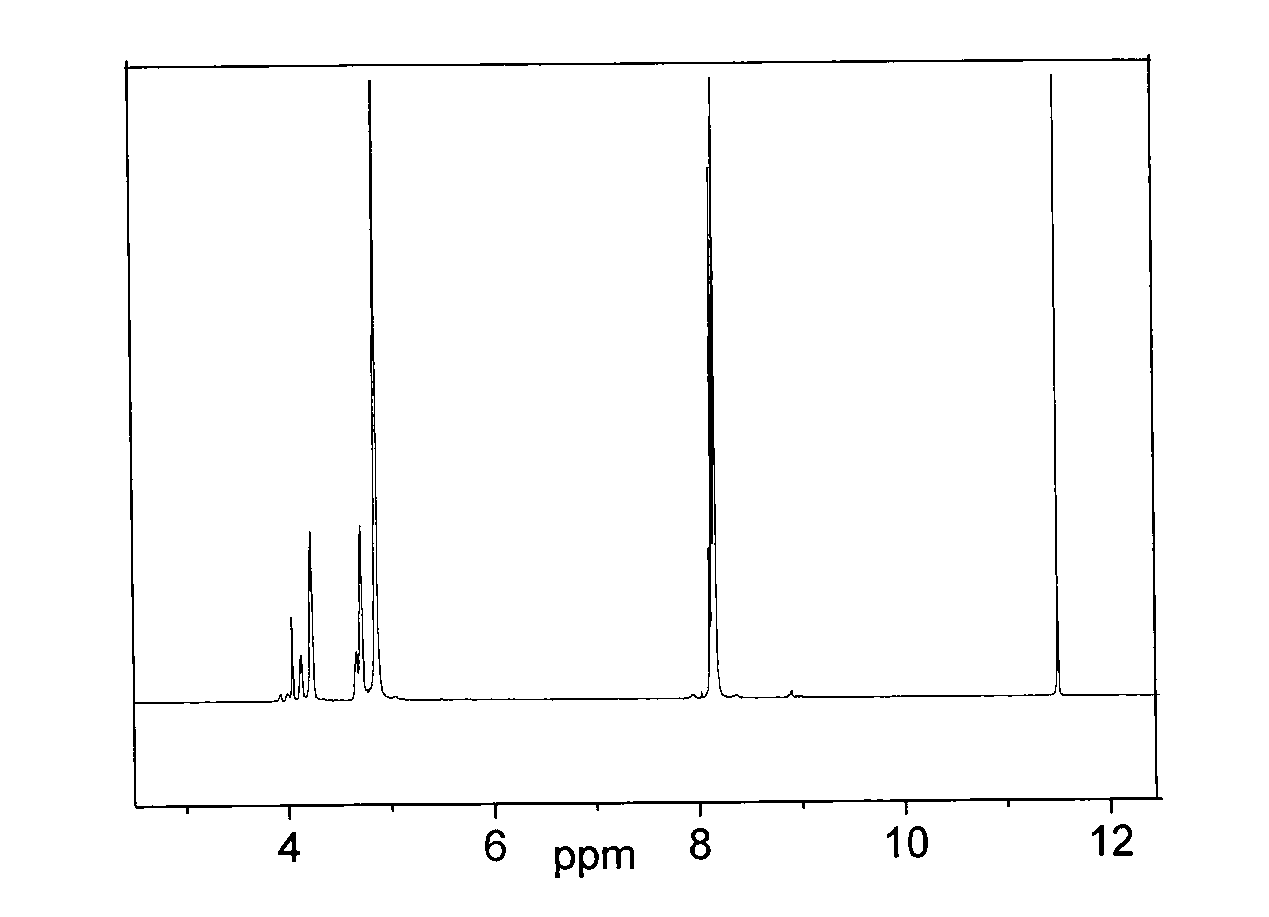

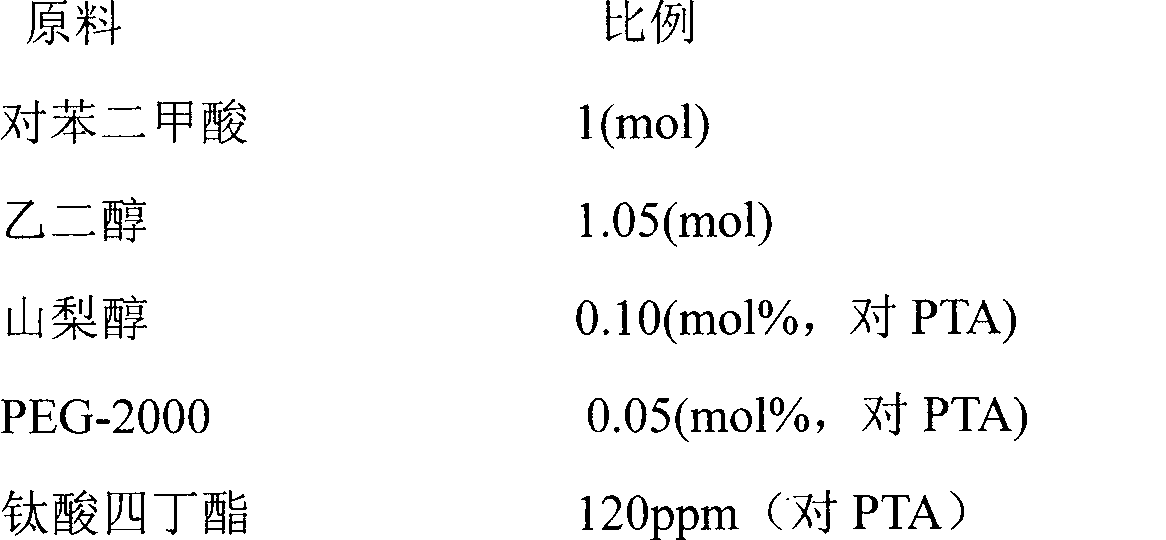

Preparation method of inflaming retarding hydrophilic polyester fiber

ActiveCN103014906AImprove hydrophilicityNo reactionFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention provides a preparation method of inflaming retarding hydrophilic polyester fiber. The preparation method is characterized by comprising the specific steps of: 1, mixing terephthalic acid with ethylene glycol to prepare slurry, adding the mixture into an esterification reaction kettle for primary esterification reaction, adding sorbitol and polyethylene glycol for carrying out secondary esterification reaction when the collecting quantity of byproducts reaches 82-95 percent of a theoretical value, after the esterification reaction is completed, carrying out a condensation polymerization on an esterification product to prepare a hydrophilic polyester slice; 2, after coffee grounds are dried, calcining to obtain coffee carbon, activating the nano-level coffee carbon powder body, adding a fire retardant to obtain a fire retardant-containing nano-level coffee carbon powder body; 3, smelting and pelleting the fire retardant-containing nano-level coffee carbon powder body and the hydrophilic polyester slice to obtain a functional master batch; and 4, smelting and spinning the functional master batch and the hydrophilic polyester slice to obtain the inflaming retarding hydrophilic polyester fiber. The inflaming retarding hydrophilic polyester fiber has the advantages of good hydrophilic performance and has a long-term continuous function of the fire retardant and the coffee carbon.

Owner:中国化学纤维工业协会

Infusion extracting apparatus and method

ActiveUS20150196158A1Easy extractionEasy to insertBeverage vesselsDomestic vesselsFiltrationEngineering

A piston-type extraction apparatus and methods for making and using the same are disclosed. The apparatus includes a cylindrical container with lid and pour spout, a container insert, and plunger element including piston, rod, handle, and filtration chamber. The container insert is designed to catch coffee grounds or other infusible material which may be easily removed from the container when the container is empty or when the extract fluid remains in the container. The filtration chamber is adapted for use with a paper filter. The plunger element may temporarily couple with the insert to allow the insert to be pulled up through the container with the grounds of other infusible material captured between the insert and the plunger element allowing for quick and easy cleanup. The extraction apparatus is adapted for a use in a variety of sizes and may be adapted for manufactured at low cost.

Owner:MADE SIMPLI

Coffee brewer

An improved coffee brewer and brewing method are provided for producing brewed coffee with improved flavor. The coffee brewer includes a brew basket having jet ports connected to a source of heated water and positioned to deliver hot water streams into the brew basket at a location beneath the level of coffee grounds contained therein. These hot water streams turbulently agitate and stir the coffee grounds to produce a substantially fluidized bed of water-borne coffee grounds for improved flavor extraction and enhanced aroma. This fluidized bed is directed against one or more mesh filter elements forming a wall portion of the brew basket for outward passage of the thus-brewed coffee which is then directed into an underlying carafe or the like. In one preferred form, a portion of the brew basket incorporates an illuminated window to permit visual observation of the fluidized bed therein.

Owner:LVD ACQUISITION +1

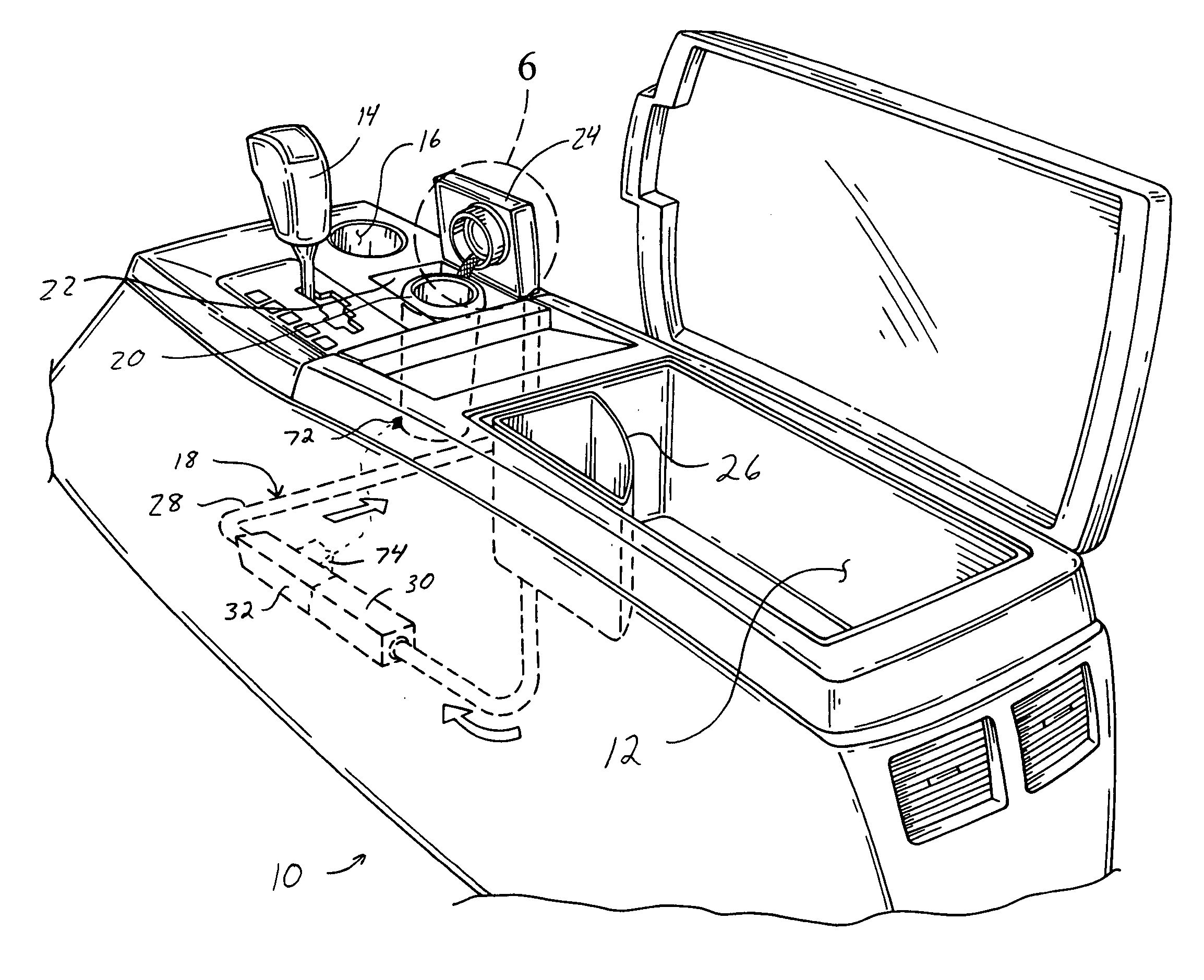

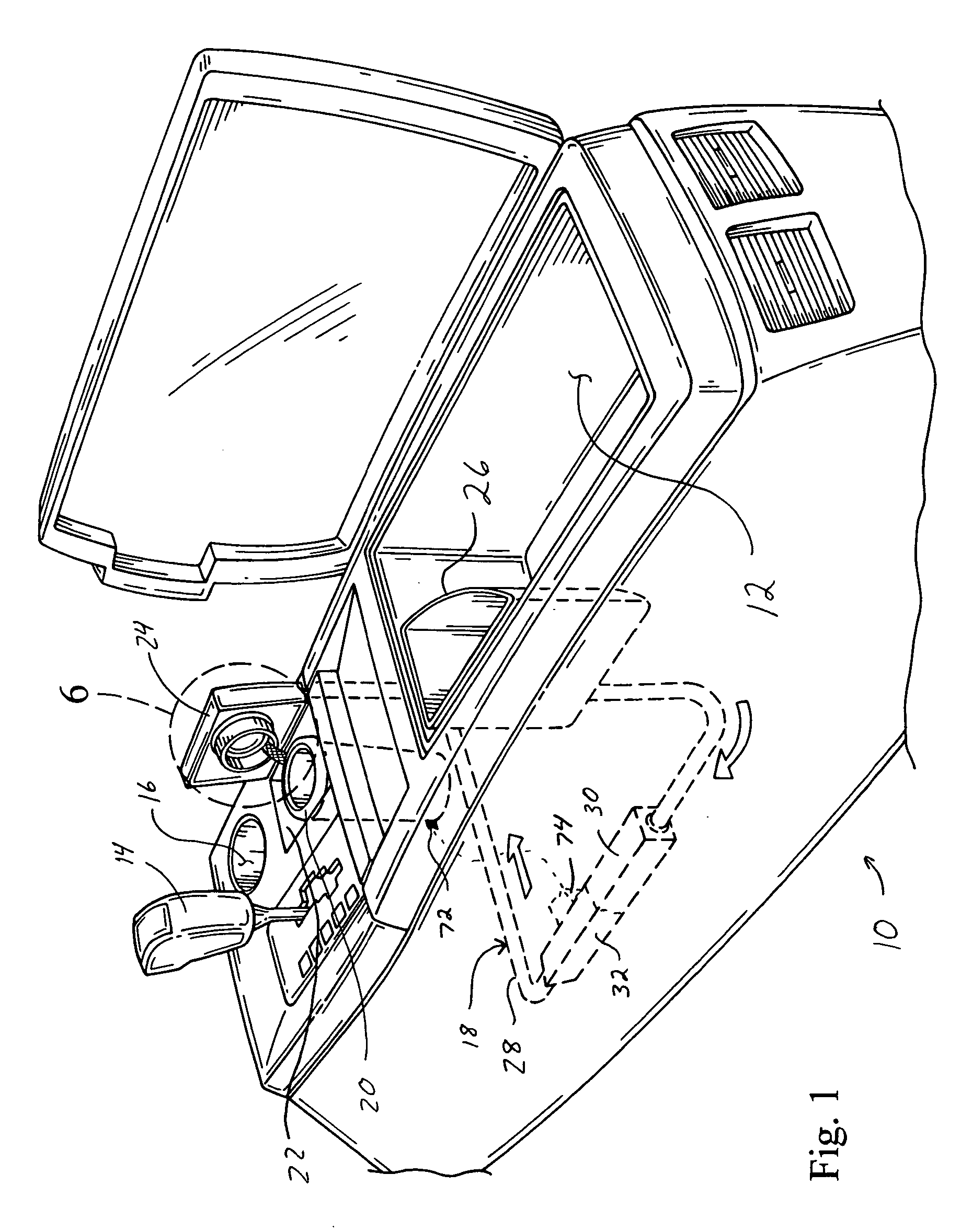

In-vehicle coffee maker

An in-vehicle coffee maker includes a coffee mug and a brewing station that receives the mug, and has a lid that secures the mug therein. A pump supplies water to the lid from a water reservoir via a water line. A heating element heats the water to a predetermined temperature. The mug includes a mug portion, a drink cap, and a pod retainer. The drink cap includes a pod chamber to hold coffee grounds, and the pod retainer secures the coffee grounds therein. The pod retainer includes a opening for water to pass through, into the pod chamber, which in turn includes an opening for water to drain downward into the mug. The lid of the brewing station includes a nozzle that forms a sealed engagement with the opening in the pod retainer so water supplied from the reservoir to the lid flows into the pod chamber.

Owner:VISTEON GLOBAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com