Coffee infusing device

A brewing and coffee technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of coffee powder flying around, polluting coffee preparation machines, and inconvenient cleaning of coffee preparation machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

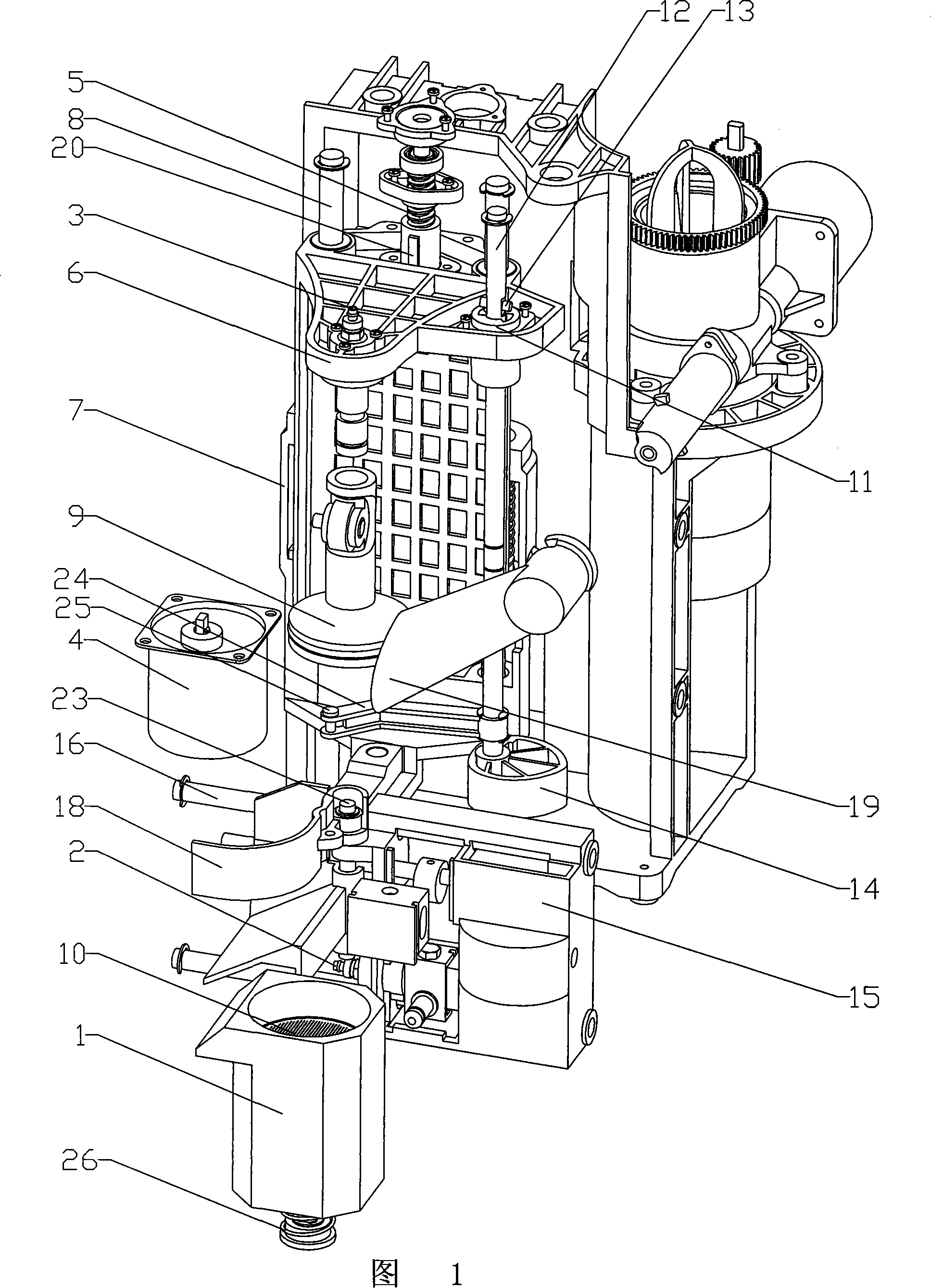

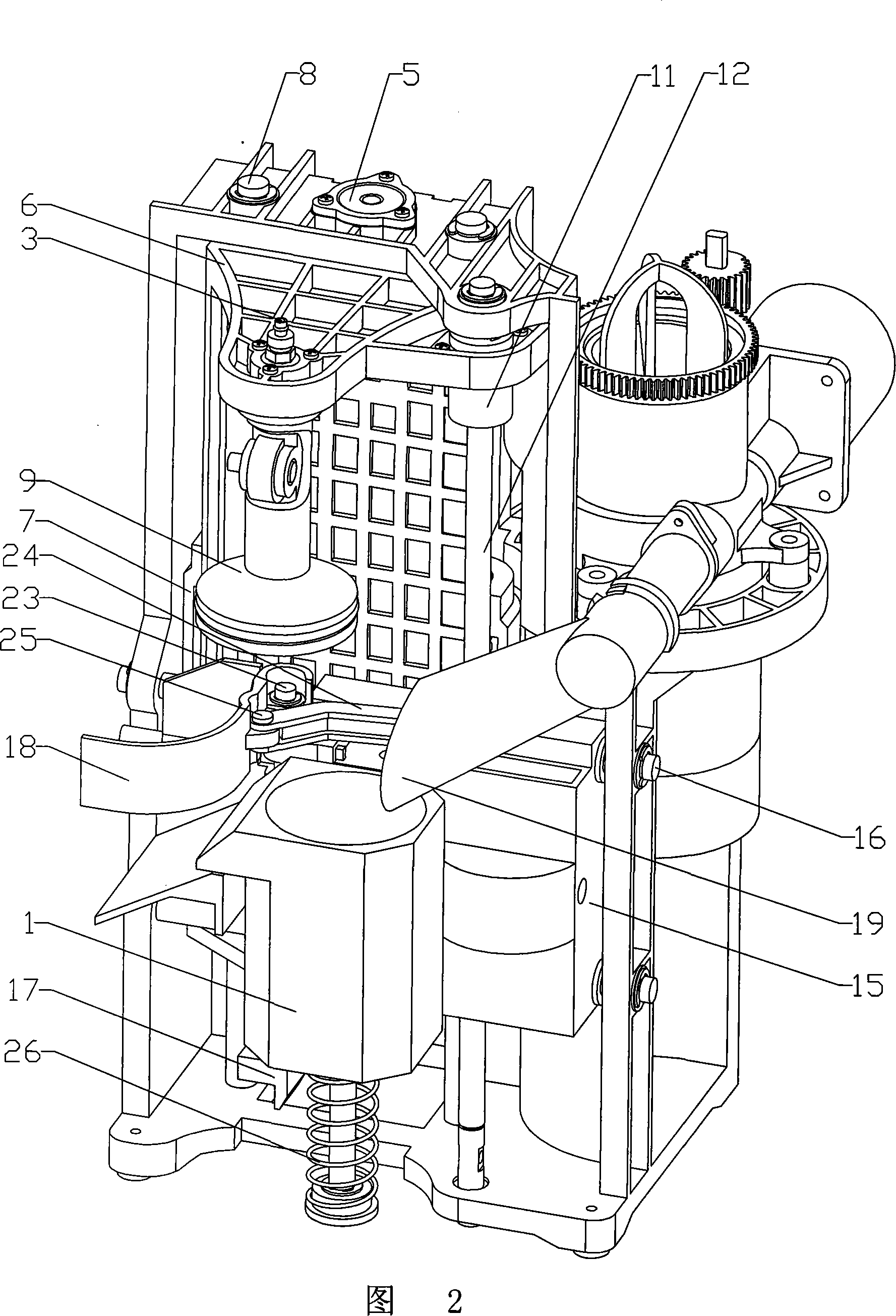

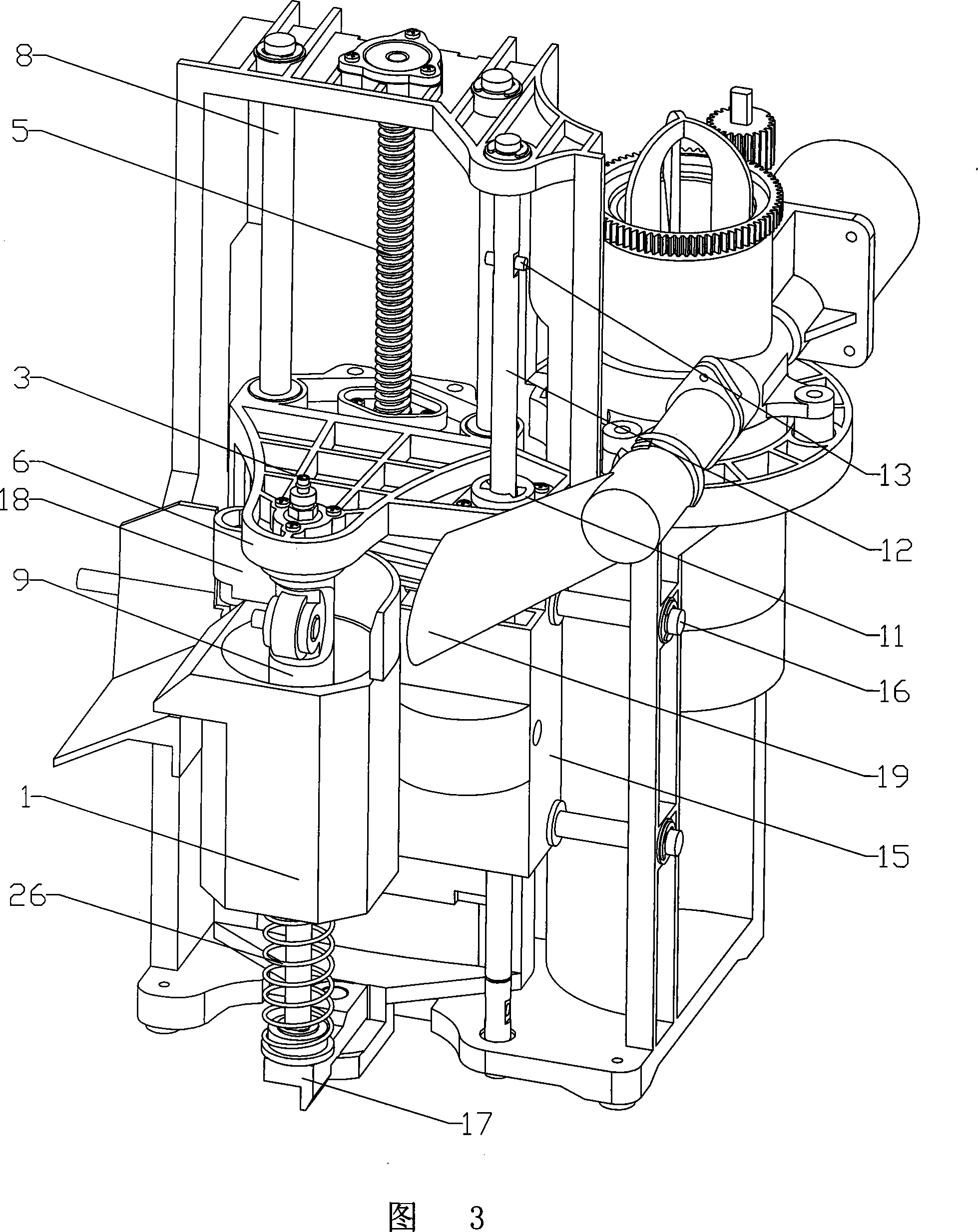

[0021] As shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, and Figure 7: the coffee brewing device of this embodiment includes: a cylinder body 1 that can be filled with coffee powder, and the cylinder body is connected to the water inlet 2 and the liquid outlet 3, the upper and lower pistons can move in the cylinder body, the coffee brewing device is provided with a motor 4, and the motor drives the screw rod 5 to rotate. The screw rod can drive the upper supporting plate 6 and the lower supporting plate 7 to move along the longitudinal guide rail 8, the upper supporting plate 6 is connected with an upper piston 9, and the lower piston 10 is installed in the cylinder body 1. The coffee brewing device is provided with a horizontal supporting plate 15, the cylinder body 1 is connected to the horizontal supporting plate 15, the driving mechanism of the horizontal supporting plate drives the horizontal supporting plate to move 16 along the horizontal guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com