Patents

Literature

606results about How to "Uniform adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

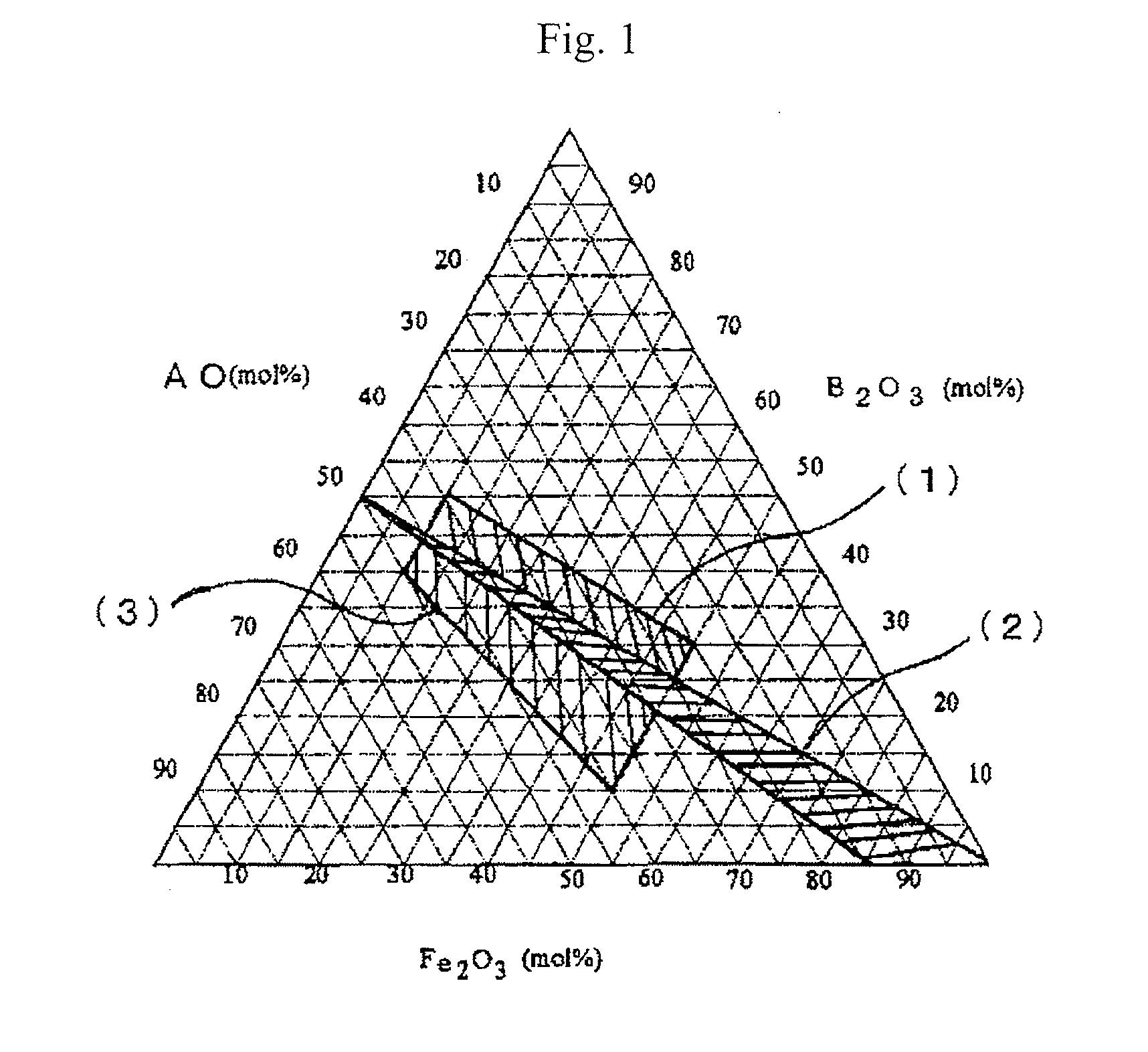

Method of manufacturing hexagonal ferrite magnetic powder, magnetic recording medium and method of manufacturing the same

ActiveUS20120244387A1Good dispersionReduce dispersion loadMagnetic materials for record carriersIron organic compoundsMagnetic liquidsSolvent

An aspect of the present invention relates to a method of manufacturing hexagonal ferrite magnetic powder. The method of manufacturing hexagonal ferrite magnetic powder comprises wet processing hexagonal ferrite magnetic particles obtained following acid treatment in a water-based solvent to prepare an aqueous magnetic liquid satisfying relation (1) relative to an isoelectric point of the hexagonal ferrite magnetic particles: pH0−pH*≧2.5, wherein, pH0 denotes the isoelectric point of the hexagonal ferrite magnetic particles and pH* denotes a pH of the aqueous magnetic liquid, which is a value of equal to or greater than 2.0, adding a surface-modifying agent comprising an alkyl group and a functional group that becomes an anionic group in the aqueous magnetic liquid to the aqueous magnetic liquid to subject the hexagonal ferrite magnetic particles to a surface-modifying treatment, and removing the water-based solvent following the surface-modifying treatment to obtain hexagonal ferrite magnetic particles.

Owner:FUJIFILM CORP

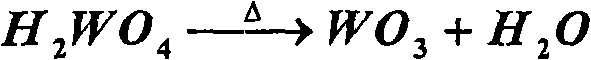

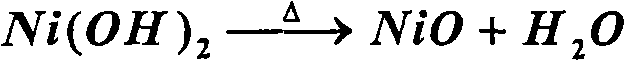

Preparation of hydrogenation catalyst

InactiveCN101298047AEvenly dispersedSmall sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHigh activationReaction temperature

The invention provides a method for preparing a hydrogenation catalyst with high activation. A disposition method is adopted to carry out step-by-step loading to the active components of the metals of VIB and VIII families; the VIB metal comprises tungsten or molybdenum, while the VIII metal comprises nickel or cobalt; a carrier is alumina. The loading of VIB metal takes a corresponding soluble salt as raw material, an acid solution as a precipitator and a cationic surface active agent as a dispersant. In a hydrothermal condition, the corresponding soluble salt, the acid solution and the cationic surface active agent produce metallic oxide particles by a liquid deposition reaction; the loading of VIII metal also takes a corresponding soluble salt as raw material and carbamide as a precipitator; the adding of the precipitator and the generation of precipitation are separated by controlling reaction temperature in sections and even precipitation is realized to disperse the particles of the active components on the carrier evenly. The hydrogenation catalyst prepared shows good effects in the respects of desulfurization and denitrification activation and can greatly reduce the usage of the active components.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

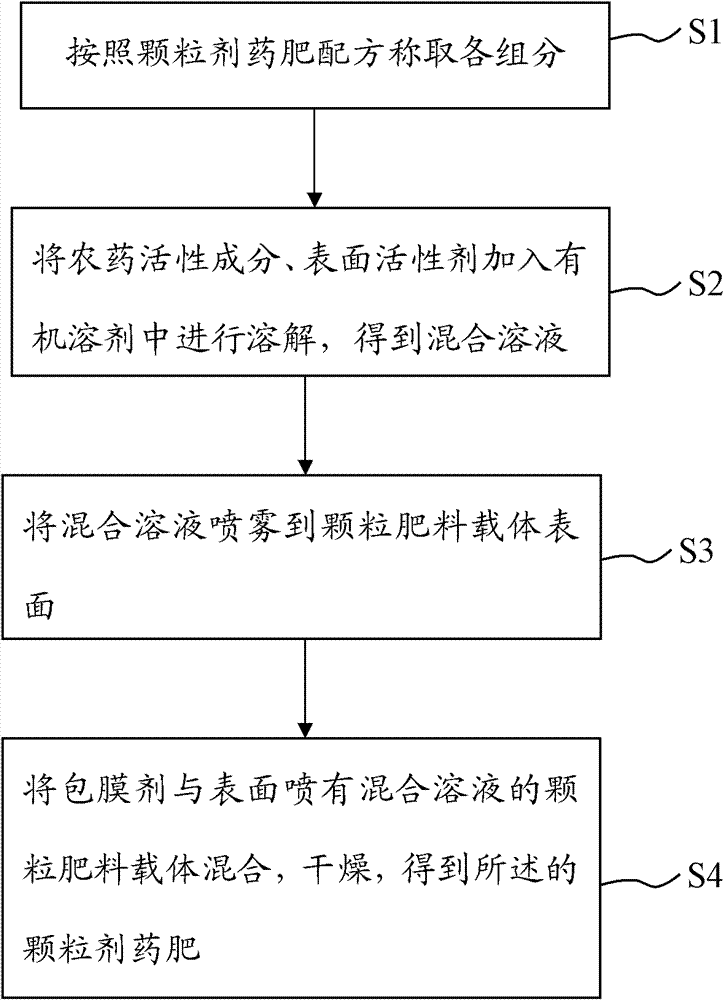

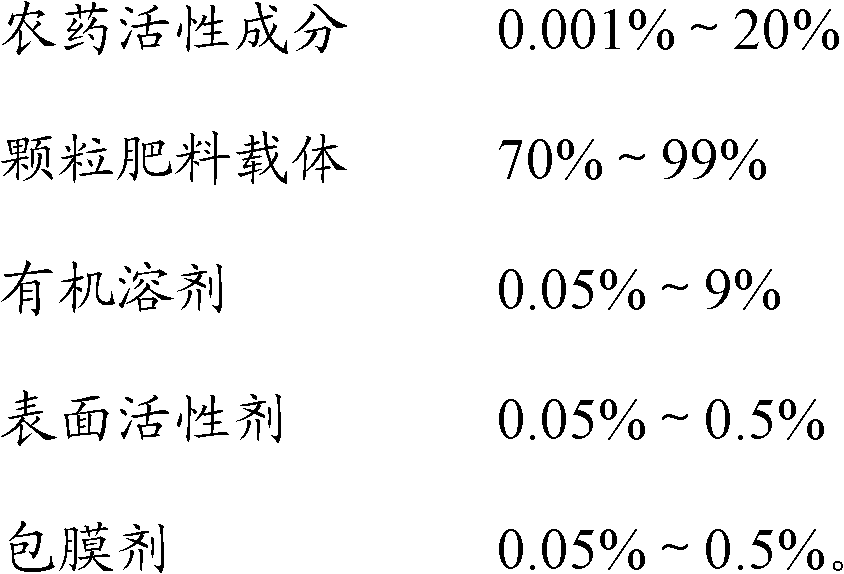

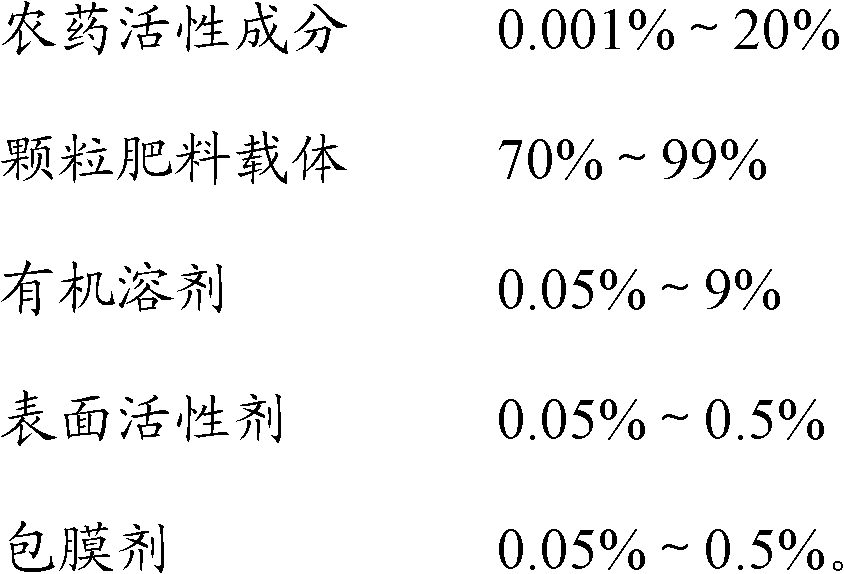

Granular pesticide fertilizer, and preparation method and application thereof

InactiveCN102775241AReduce stress on the farm environmentSave resourcesFertiliser formsFertilizer mixturesFertilizerPesticide

The invention provides a granular pesticide fertilizer, and a preparation method and application thereof. The granular pesticide fertilizer comprises the following components expressed in mass percent: on the basis that the total mass of the granular pesticide fertilizer is 100%, 0.001 to 20% of a pesticide active component, 70 to 99% of a granular fertilizer carrier, 0.05 to 9% of an organic solvent, 0.05 to 0.5% of a surfactant and 0.05 to 0.5% of a coating agent. According to embodiments in the invention, the pesticide active component and the granular fertilizer carrier in the granular pesticide fertilizer are reasonably combined, which allows the problem of damage by diseases and insects to soil in agricultural production to be effectively overcome and enables soil fertility to be improved and labor and time to be saved. The granular pesticide fertilizer is produced by using a normal temperature spraying adsorption process and a cladding process, so the preparation method for the granular pesticide fertilizer has the advantages of a simple process, low energy consumption, reduction in production cost, easiness in controlling and operating and suitability for industrial production.

Owner:SHENZHEN NOPOSION AGROCHEM

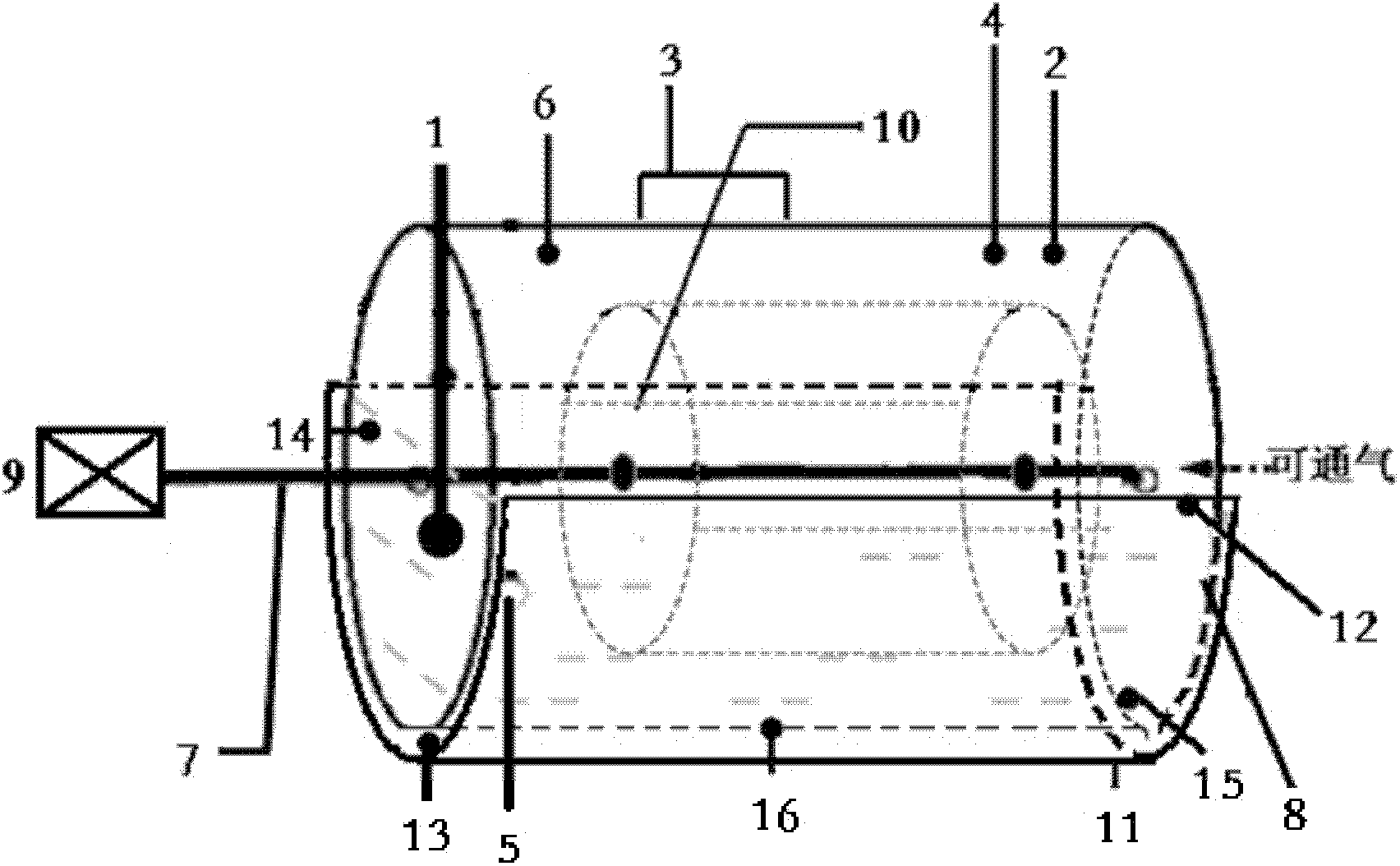

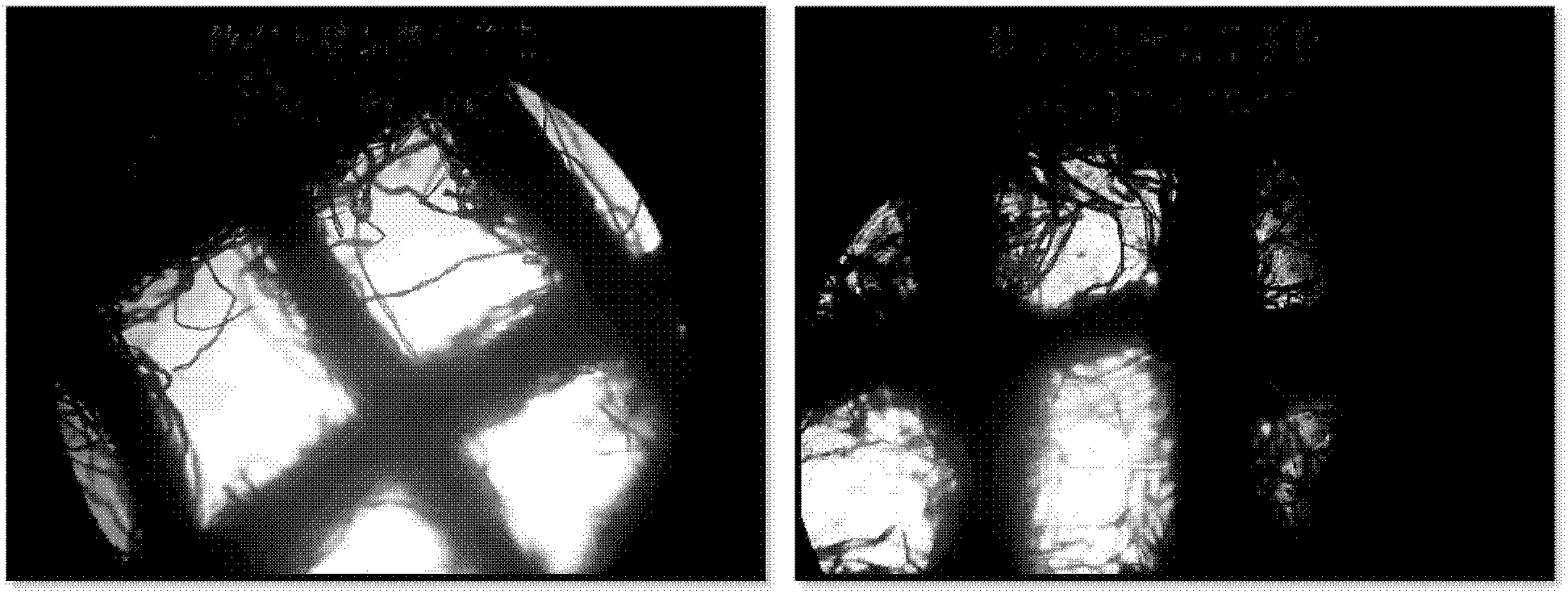

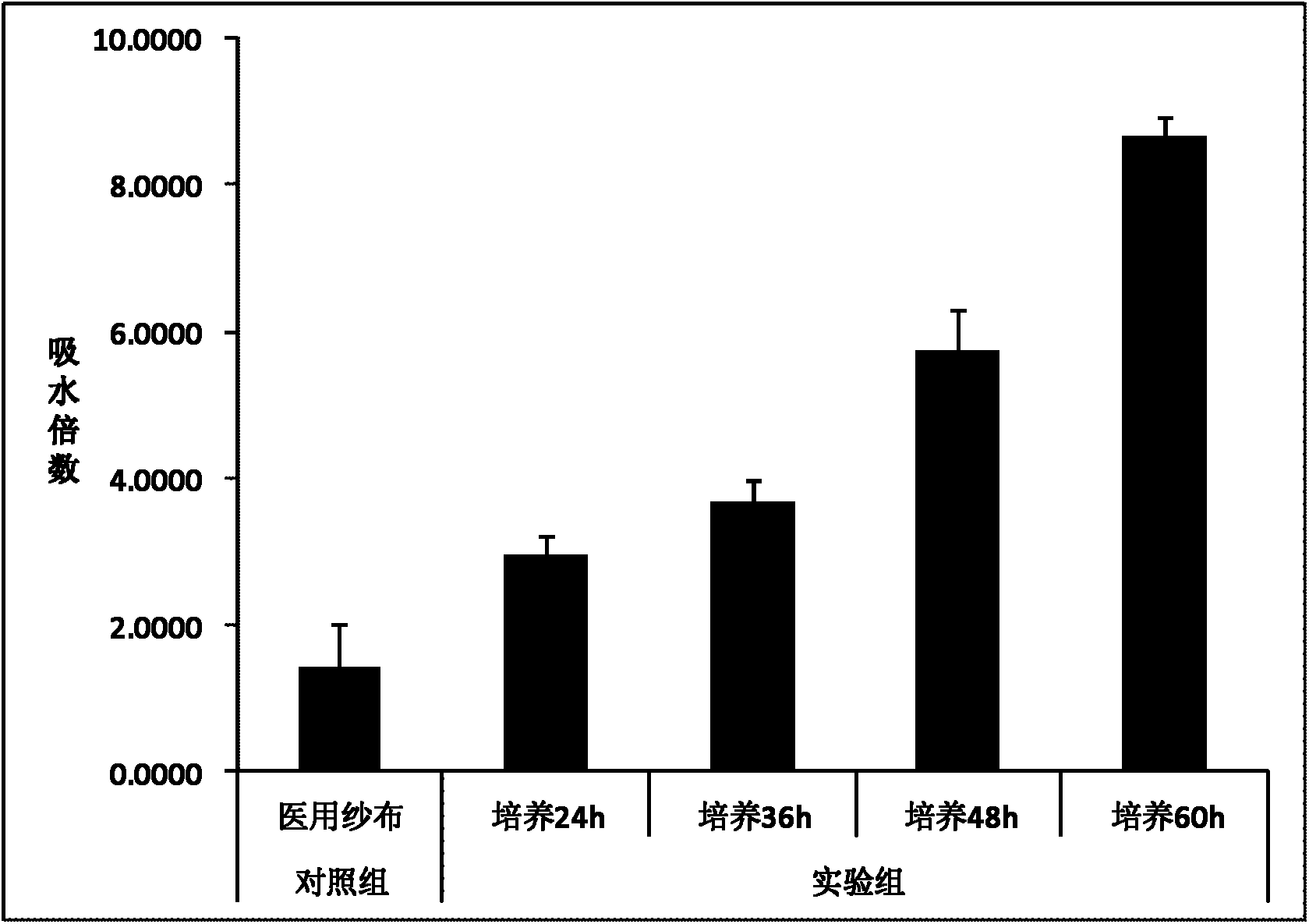

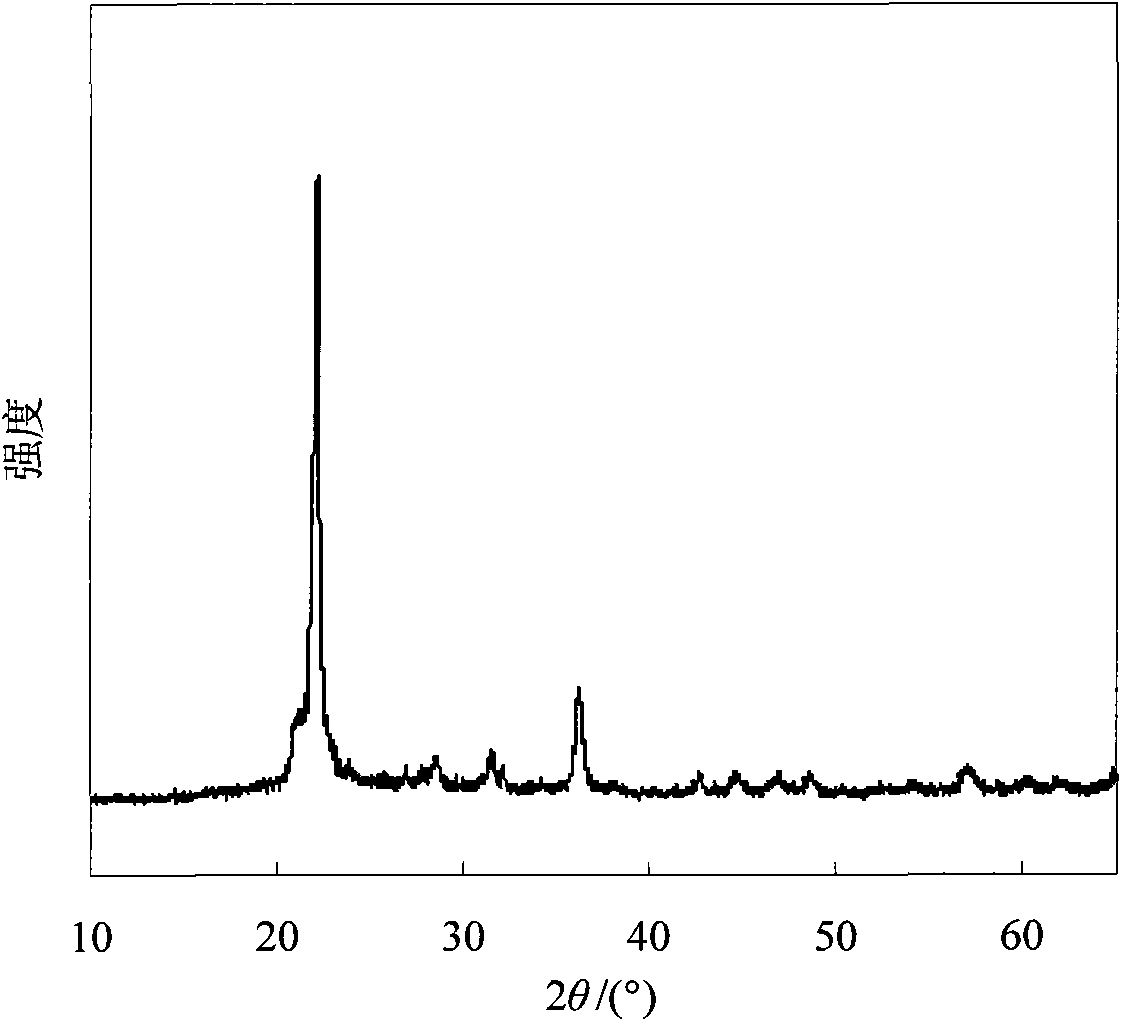

Method and device for preparing bacterial cellulose composite material quickly on large scale

ActiveCN102533904AReduce dosageGuaranteed StrengthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumFermentation

The invention relates to a method and device for preparing bacterial cellulose composite materials quickly on a large scale. The method comprises the steps as follows: (1) a bacterial cellulose producing strain is inoculated in liquid medium for propagation and then transferred into a biological reactor containing framework material for perturbation cultivation, so that bacterial cellulose composite material can be obtained; and (2) bacterial cellulose of the bacterial cellulose composite material is peeled off from the framework material or the cellulose composite material is soaked in NaOH solution to be washed. The device comprises a thermometer opening, an acid liquor and alkali liquor feeding opening, a handle, an air vent, a pH meter opening, a nutrition feeding opening, a rotating shaft, a fermentation tank, a motor, a rotating drum, a fermentation tank jacket, a circulating water inlet, a circulating water outlet, a nutrient fluid inlet, a nutrient fluid outlet and a condensed water outlet. The rotating drum is fixed on the rotating shaft in the fermentation tank. The device provided by the invention has the advantages of simplicity, convenience, detachable die, low cost, high production efficiency and high degree of automation; and the obtained bacterial cellulose composite material can be widely applied.

Owner:DONGHUA UNIV

Microwave synthesis method of fiber carbamate

The invention discloses a technology of a microwave heating synthesis method of fiber carbamate; the method is that: firstly, the fiber is soaked in carbamide aqueous solution for completely adsorbing the carbamide, the fiber / carbamide even mixture is obtained by filtering and drying, and then the fiber / carbamide mixture is placed in a microwave oven for being heated, thereby obtaining the fiber carbamate. The synthesis technology of the fiber carbamate provided by the invention has no solvent pollution, organic solvents and any catalyzers do not need, the reacting time is speed, and the energy consumption is low. The synthesized fiber carbamate products has good dissolubility in 6 to 10 wt% of NaOH aqueous solution within the temperature range of -10 to 5 DEG C, and the concentrated solution which is stable, transparent and is suitable for industrial spinning and membrane manufacturing can be prepared.

Owner:WUHAN UNIV

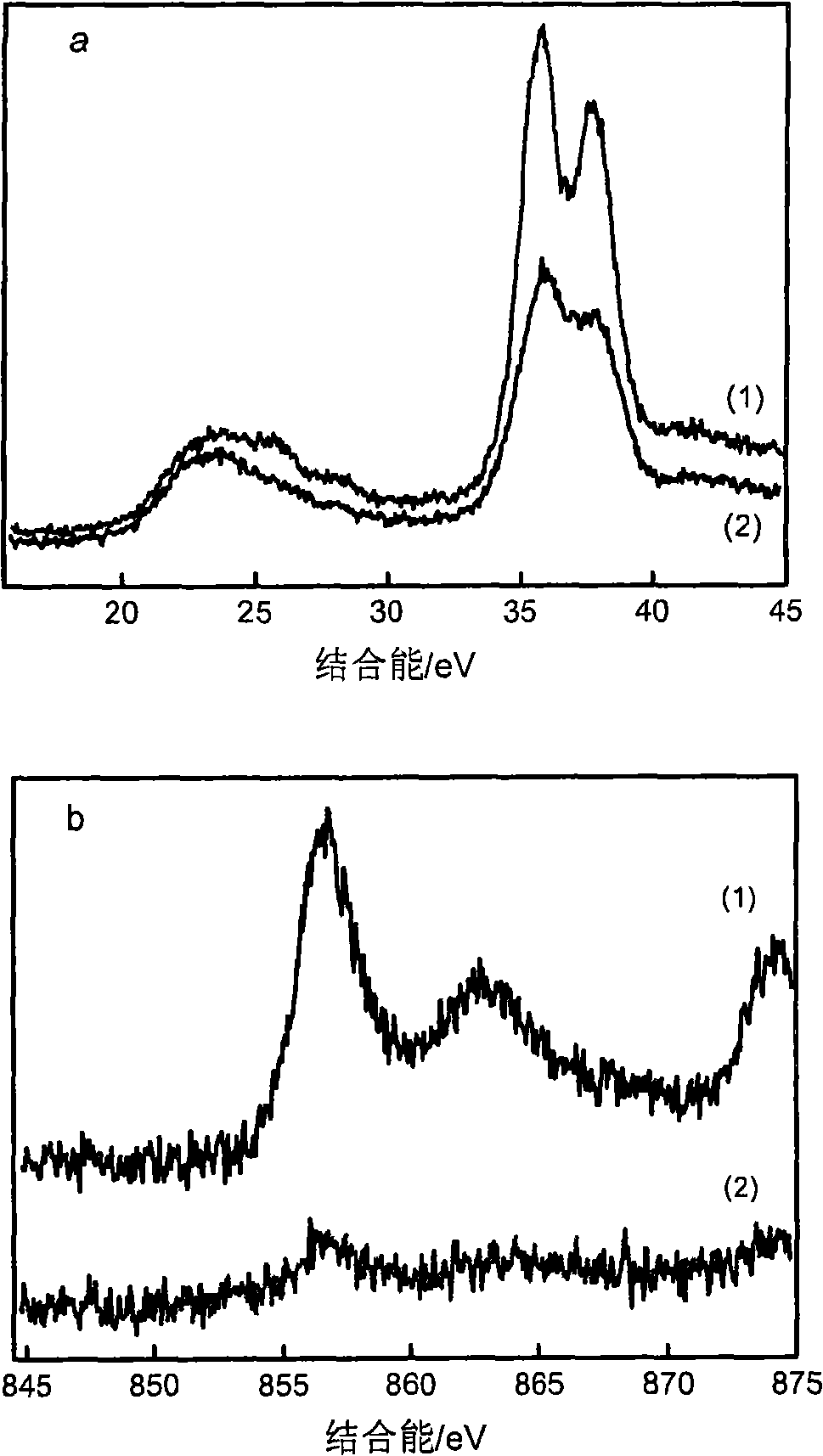

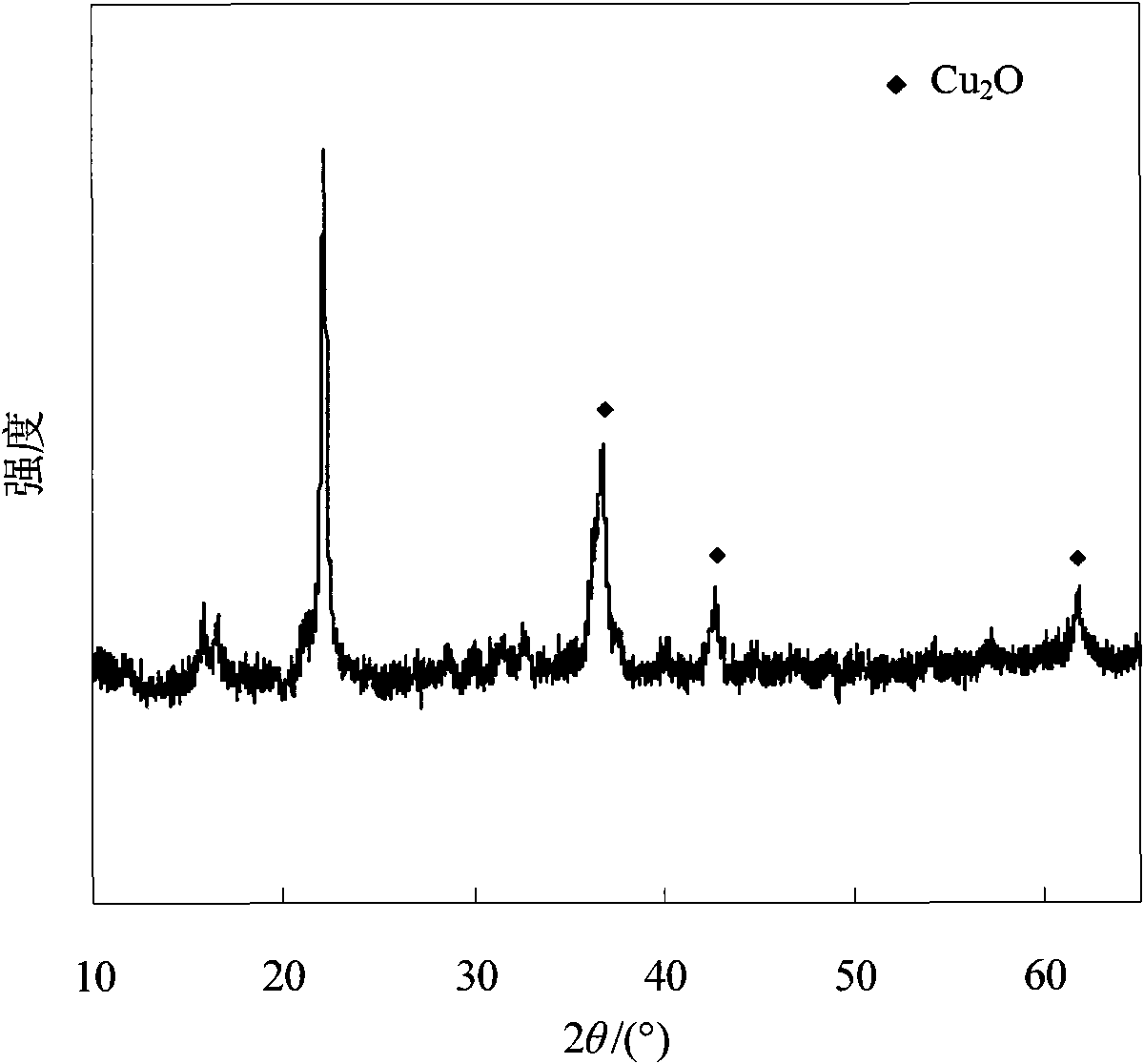

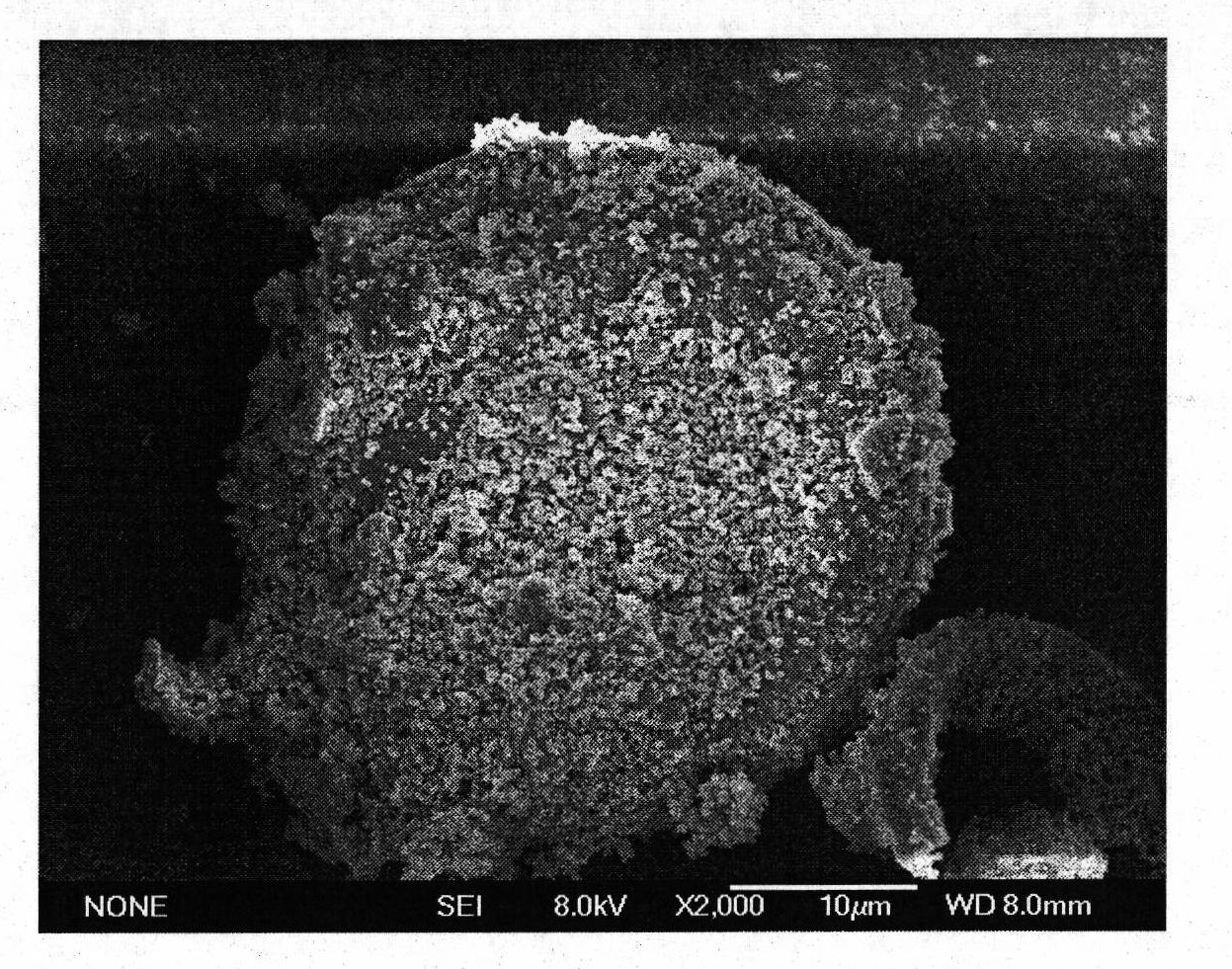

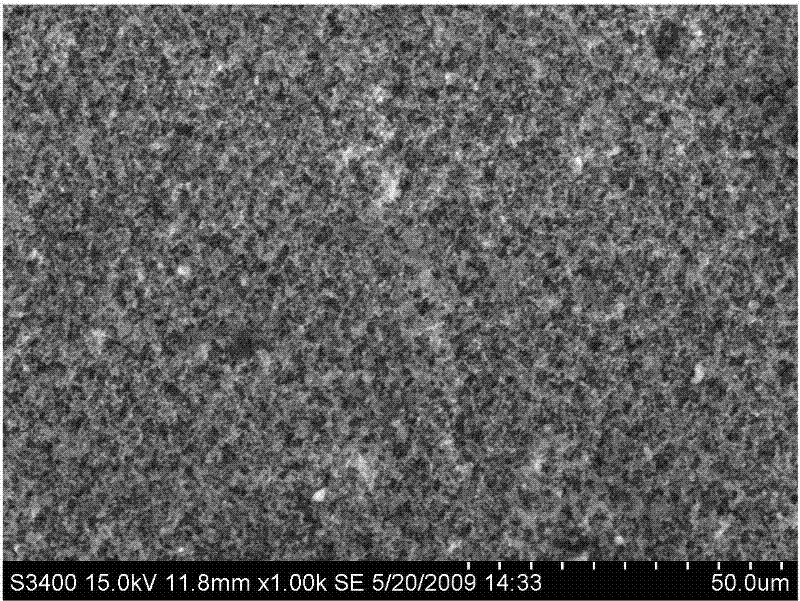

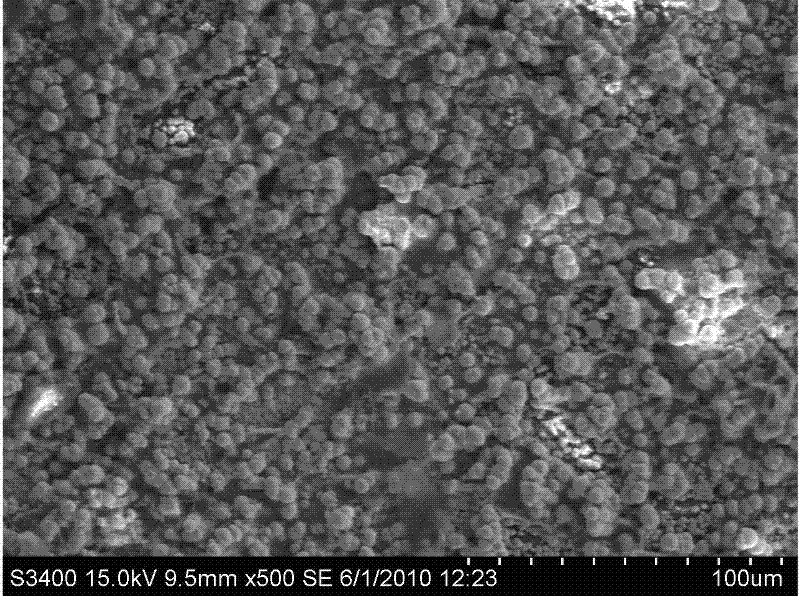

Photocatalyst, preparation method and application thereof

InactiveCN102107138AImprove filtration efficiencyEasy to separateWater/sewage treatment by irradiationCatalyst activation/preparationNanoparticleWastewater

The invention relates to an organic waste water decoloration treatment technology, in particular to a photocatalyst, a preparation method and application thereof. The grain size of the photocatalyst is 1 to 100 nanometers; nano cuprous oxide particles are attached to the surface of fine kieselguhr to form a nano cuprous oxide / kieselguhr carrier photocatalyst, wherein the weight ratio of cuprous oxide to kieselguhr is (0.58-0.87) to (1.0-2.0). By using the nano cuprous oxide / kieselguhr carrier photocatalyst, visible light or sunshine can be used as a light source for decoloration of organic colored waste water of pharmacy, papermaking or printing and dyeing industries. The production process is simple, industrialization is easy to realize, the problem of solid and liquid separation in the process of producing nano Cu2O by a hydrolysis method is solved, nanoparticles are effectively prevented from being agglomerated and the photocatalyst can be conveniently recycled and utilized.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

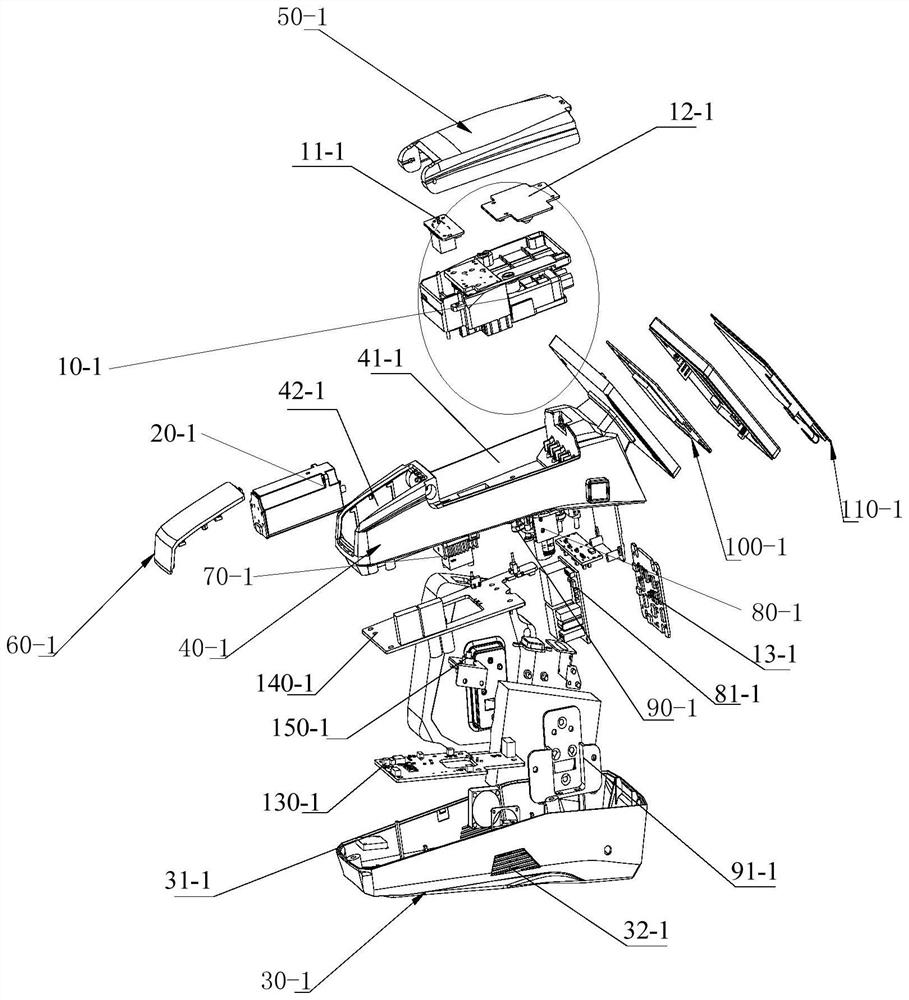

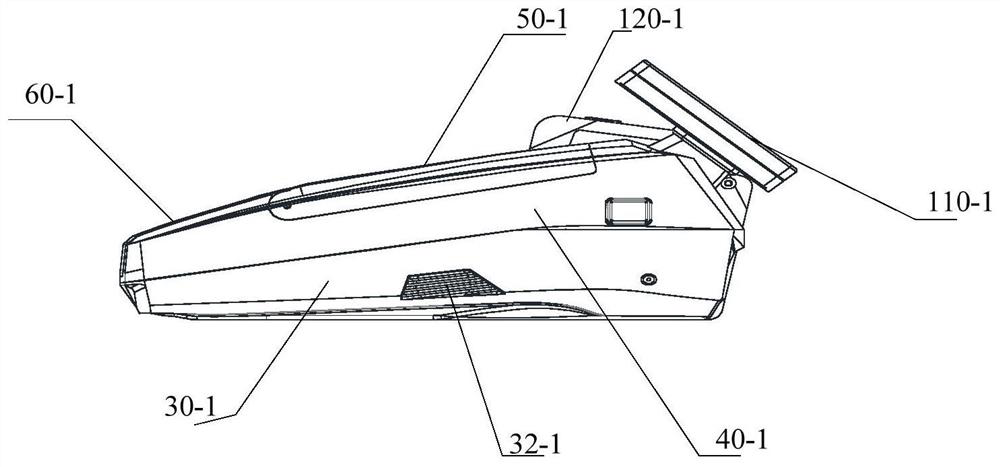

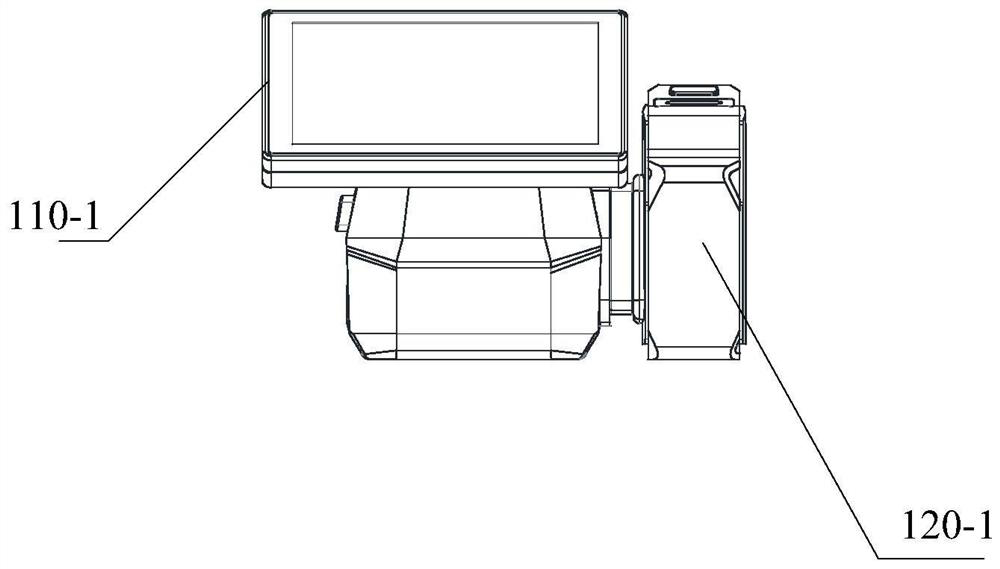

PCR reaction device

ActiveCN113174324AImprove continuityHighly integratedBioreactor/fermenter combinationsHeating or cooling apparatusTemperature controlAnalytical chemistry

The invention relates to a PCR reaction device. The device comprises a PCR reaction main body, a display module and a power supply device, the PCR reaction main body comprises a nucleic acid extraction device, a nucleic acid purification device, an amplification reaction device and a shell, and the nucleic acid extraction device is used for cracking a sample to obtain a mixture; the nucleic acid purification device is used for independently separating nucleic acid from the mixture; the nucleic acid amplification reaction device is used for amplifying nucleic acid at a specified temperature by utilizing a temperature control unit, and the nucleic acid extraction device, the nucleic acid purification device and the nucleic acid amplification reaction device are all arranged in the shell; the display module is arranged at the end part of the PCR reaction main body and is used for displaying the working states of the nucleic acid extraction device, the nucleic acid purification device and the amplification reaction device; the power supply device is used for supplying power to the PCR reaction main body and the display module, and the power supply device is arranged on the right side of the PCR reaction main body. Therefore, the integration level of experimental equipment is high, the continuity of an experiment is high, and extraction, purification and amplification can be realized on one pipeline layer.

Owner:INTEGRATED BIOSYSTEMS CO LTD

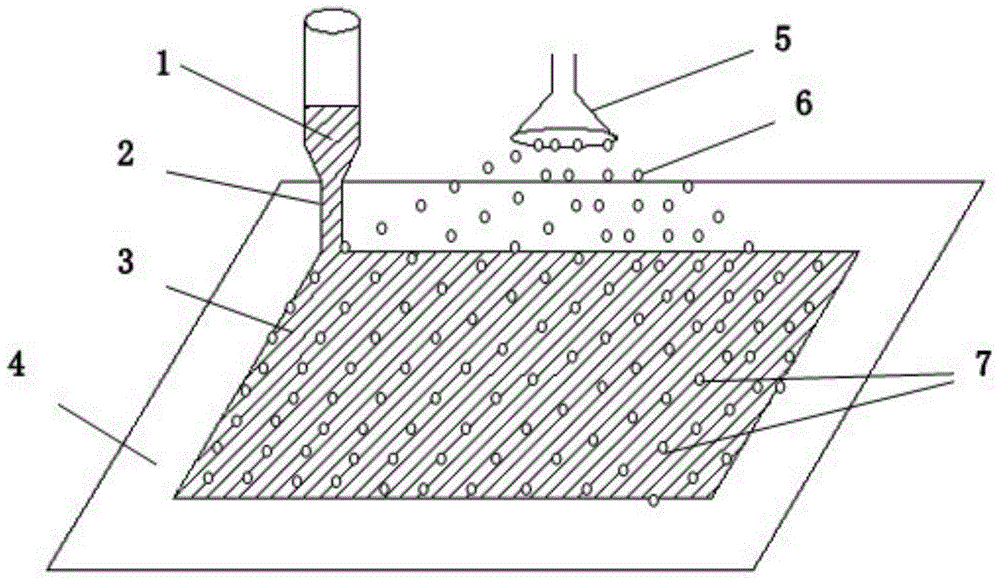

Method for curing and shaping slurry spray used for 3D printing

ActiveCN104959613ASpray evenlyUniform adsorptionAdditive manufacturing apparatusMaterials preparationProgram graph

The invention provides a method for curing and shaping slurry spray used for 3D printing and belongs to the field of material preparation of advanced rapid manufacturing. The method is characterized by comprising the steps that first a 3D printer prints a front 'ink' layer according to a 2D contour cross section program graph with prepared 'ink' slurry; then, a sprayer atomizes liquid curing agent into tiny spray beads according to the mass ratio ranging from 0.01% to 2% between the liquid curing agent and powder to be cured, the spray beads fall into the surface of the 'ink' layer uniformly, a solidified layer with the thickness ranging from 1 um to 200 um is formed, and after the front 'ink' layer is cured and shaped, the 3D printer prints a rear 'ink' layer according to the 2D contour cross section program graph; finally, the printing is conducted repeatedly until a part blank is formed through printing. By means of the method, the problems that in the traditional curing agent jet technique, the curing agent is not jetted uniformly, the surface of the 'ink' layer is defective, the jetting time is too long and the parts are prone to 'collapse' are effectively solved, and it is facilitated to print complex parts of large dimensions more conveniently and more rapidly and promote the development of the 3D printing technique.

Owner:UNIV OF SCI & TECH BEIJING

Electroplating pretreatment method for acrylonitrile butadiene styrene (ABS) plastic surface

InactiveCN102409320ASimple processEasy to operateLiquid/solution decomposition chemical coatingPretreatment methodSodium phosphates

The invention relates to an electroplating pretreatment method for an acrylonitrile butadiene styrene (ABS) plastic surface. The electroplating pretreatment method comprises the following process steps of: eliminating stress, performing alkali washing for oil removal, pickling, roughening, performing neutralizing treatment, performing chemical activation, and performing the conventional electroplating, wherein in the chemical activation process, plastic base materials are put in to an activation solution and are subjected to hyperthermic treatment in a water bath for a certain period of time, each liter of the activation solution comprises 10 to 12g of nickel sulfate, 20 to 25g of sodium hypophosphite and 5 to 8g of sodium citrate, the pH is 9 to 11, and the temperature is between 70 and 75 DEG C. In the invention, a novel method in which metal palladium activation is not used is provided, can be used for replacing a sodium borohydride and methanol activation process and contributes to environment friendliness; and on the basis of pretreatment, the plastic surface can be directly electroplated, so that the problems of complicated treating processes, high PdCl2 prices, high pollution possibility of a plating solution and the like are solved.

Owner:SHENYANG POLYTECHNIC UNIV

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

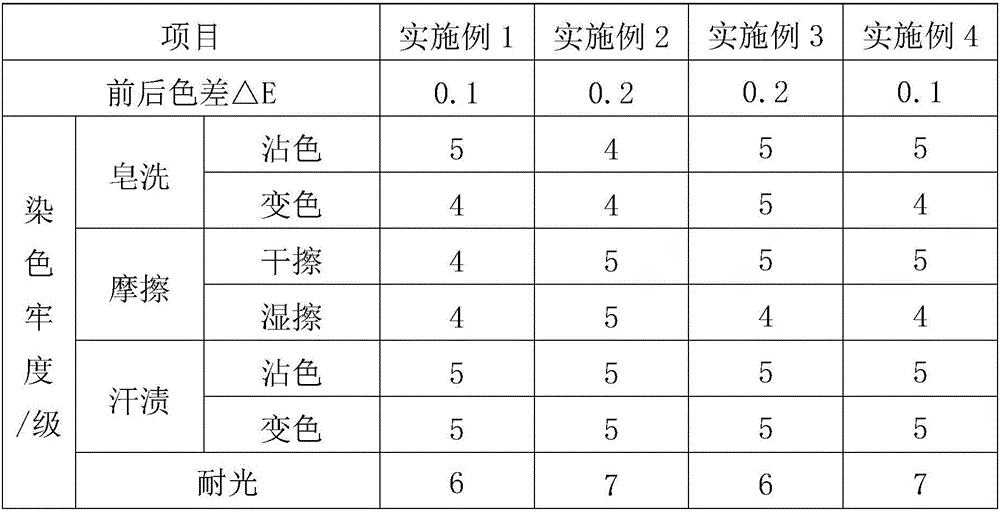

Dispersion-reduction dyeing process for cotton-polyester blended fabric

ActiveCN106087463AImprove reducibilityImprove dyeing effectSucessive textile treatmentsDyeing processDisperse dyeVat dye

The invention discloses a dispersion-reduction dyeing process for a cotton-polyester blended fabric. The dispersion-reduction dyeing process comprises a disperse dyestuff treating procedure and a vat dye treating procedure which are successively carried out. The disperse dyestuff treating procedure comprises dyeing, reduction cleaning, washing and pickling; the vat dye treating procedure comprises dip padding with a vat dye suspension, dip padding with a reducing solution, steaming, oxidation, soaping, hot washing and drying; in the disperse dyestuff treating procedure, a disperse dyestuff microcapsule method is used for dyeing; and in the vat dyestuff treating procedure, vat dye wet rapid-steaming pad dyeing process is employed. The dispersion-reduction dyeing process for the cotton-polyester blended fabric has the advantages of good level dyeing effect, small chromatic aberration and high color fastness, and is simple in process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

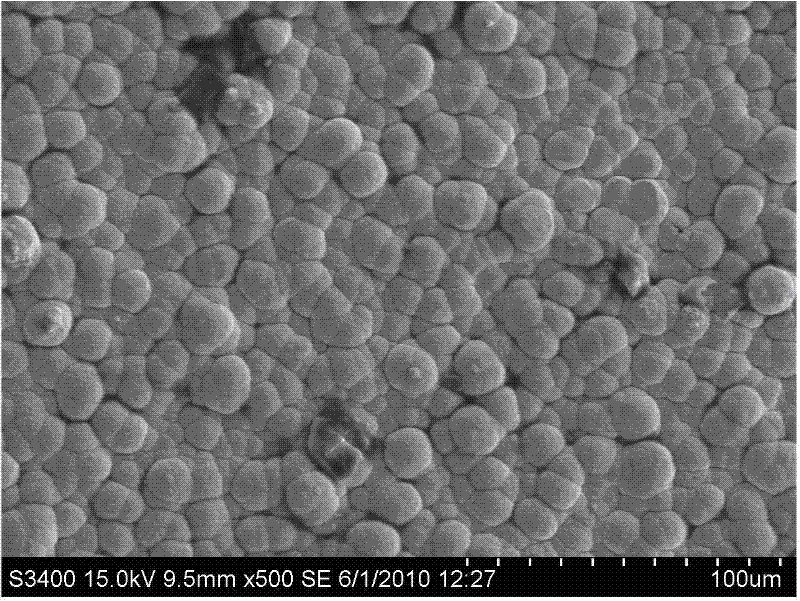

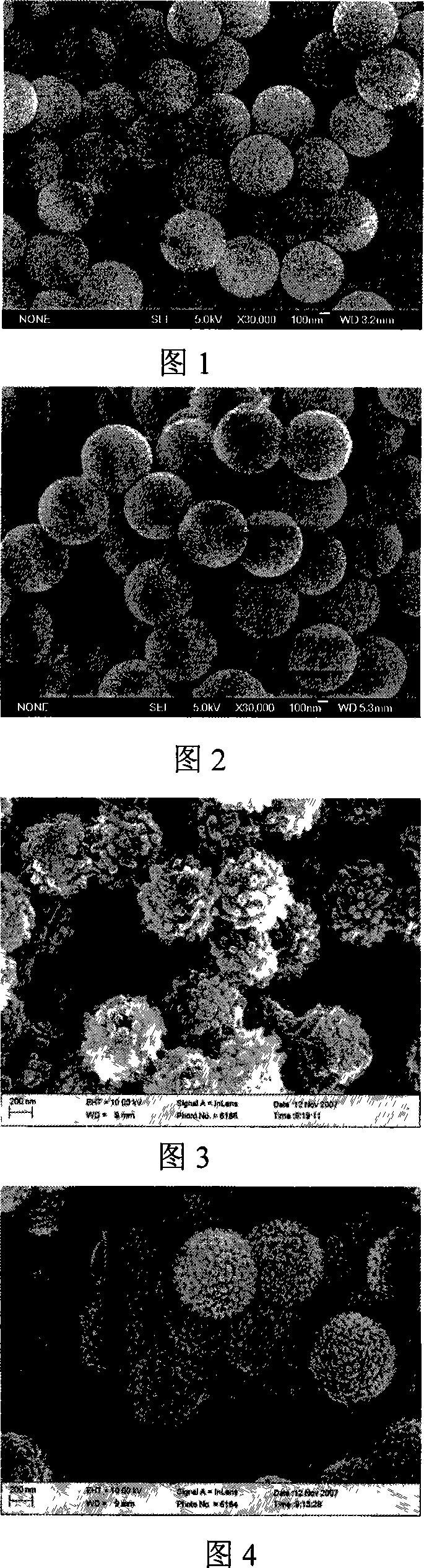

Method for preparing morphology-controlled polyphenylethene/polyaniline conductive polymeric composite microspheres

The invention relates to a preparation method of polystyrene / polyaniline conductive polymer composite microspheres with controllable shape and appearance, belonging to the polymer composite technical field, which is characterized in that: firstly, a plurality of PS microspheres with a certain diameter are prepared by the emulsifier-free emulsion polymerization, the PS microspheres are taken as the hard template and added into deionized water in which a plurality of aniline monomers are dispersed, the mixture is stirred by magnetic force to form homogenous emulsion at the ambient temperature; secondly, oxidant solution is added into the former mixture one-time, the PS microspheres are taken as the hard template and the micelle formed by the aniline monomers are taken as the ''soft template''; at last, the polystyrene / polyaniline conductive polymer composite microspheres are obtained by conventional post-processing. The preparation method of polystyrene / polyaniline conductive polymer composite microspheres with controllable shape and appearance has the advantages that: the shape and appearance of the polystyrene / polyaniline conductive polymer composite microspheres can be controlled just by regulating the redox ability of the oxidant; meanwhile, the wall thickness of the core-shell structure and the diameter and the length of the nanometer fiber can be controlled by regulating the addition of the aniline monomers and the redox ability and the addition of the oxidant.

Owner:UNIV OF SCI & TECH BEIJING

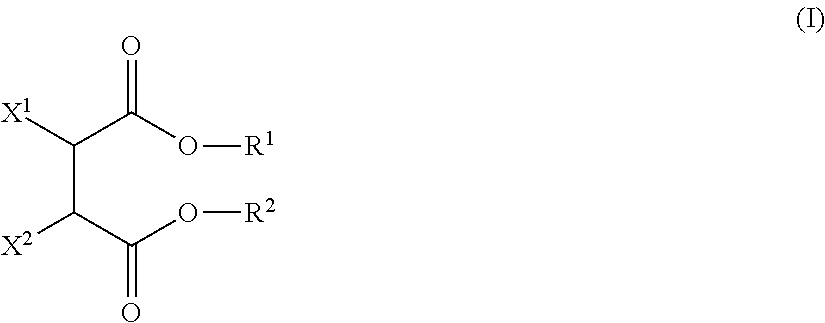

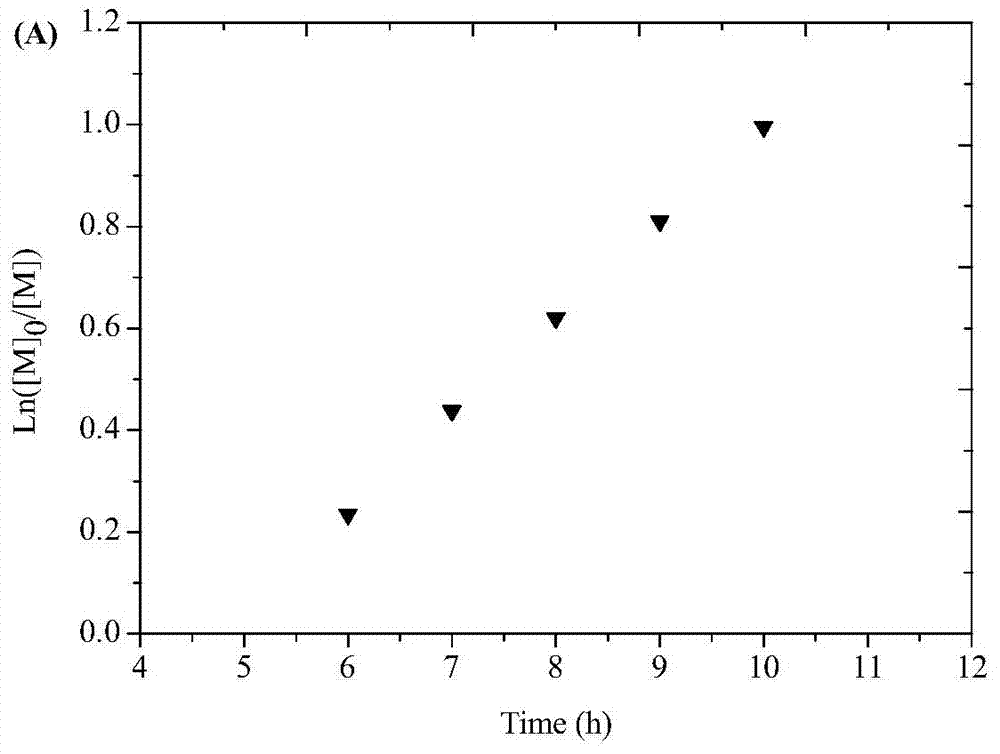

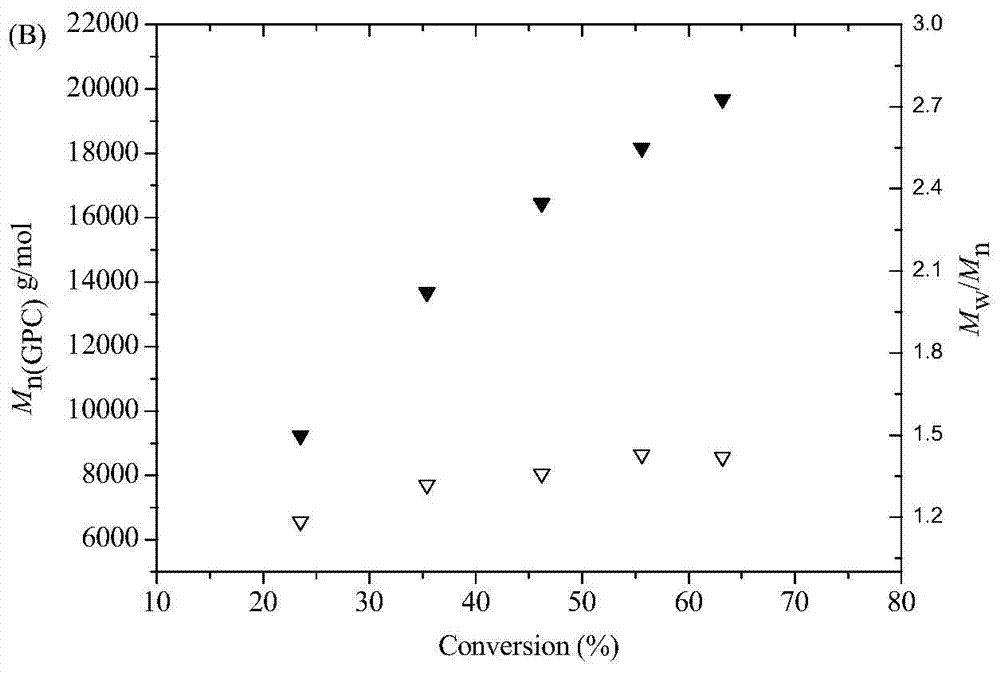

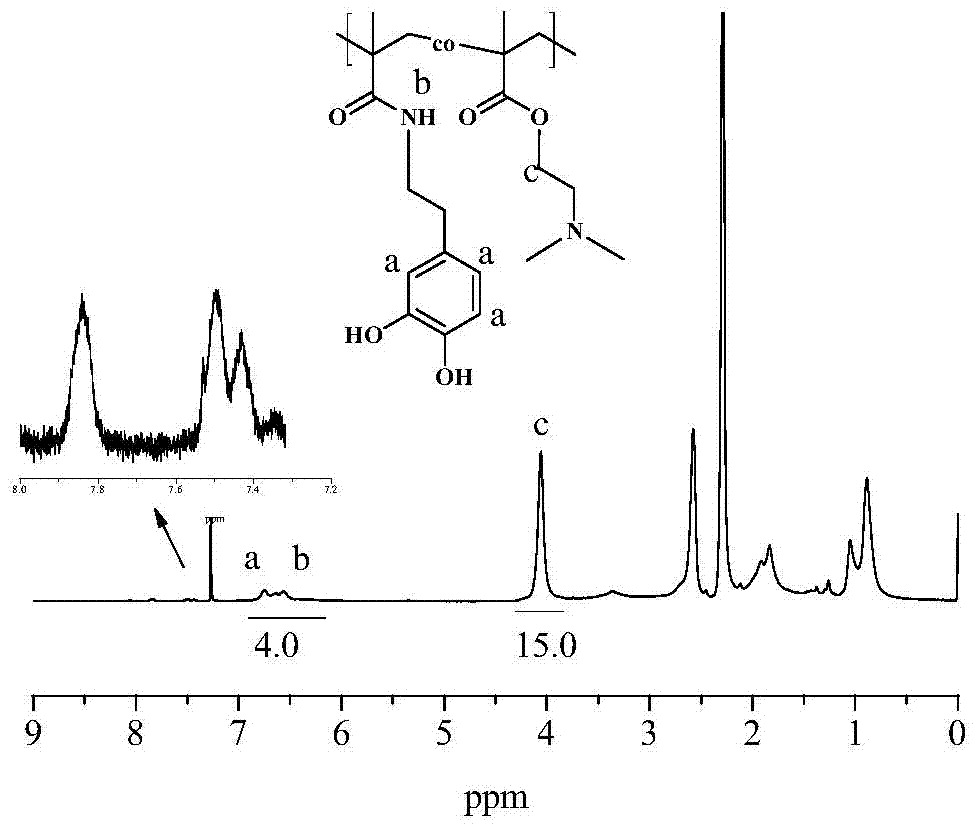

Dopamine-containing random copolymer, and fine preparation method and application thereof

InactiveCN103755870APrecise control of molecular weightPrecise control of apertureMethacrylateStructural formula

The invention discloses a dopamine-containing random copolymer. The dopamine-containing random copolymer is characterized in that the general formula of the dopamine-containing random copolymer is PDMA-co-PM, wherein DMA is N-(3,4dihydroxyl phenethyl) methacrylamide, while the monomer M is any one selected from methacrylate monomers, including N,N-dimethylaminoethyl methacrylate DMAEMA, methyl methacrylate MMA and ethyl methacrylate EMA, and in the meantime, the chemical structural formula of the copolymer is shown in description, wherein R1 is shown in description, R2 is one of the group in description, CH3 and CH3CH2. The copolymer has strong adsorption capability on various substances, and thus is suitable for further preparing various inorganic / organic hybrid porous materials and organic porous materials. The invention also provides a fine preparation method of the copolymer and a method for preparing inorganic / organic hybrid porous materials from the copolymer, wherein the preparation method only requires simple polymerization operation and does not need large instruments and also high-tech excellent assembly technology, and therefore, the preparation method is suitable for popularization and application.

Owner:SUZHOU UNIV

Preparation method for hydrogenation catalyst

ActiveCN104588024AUniform precipitationUniform adsorptionMetal/metal-oxides/metal-hydroxide catalystsNickel catalystPtru catalyst

The invention discloses a preparation method for a hydrogenation catalyst. The catalyst is a nickel catalyst. The preparation method for the hydrogenation catalyst comprises the following step: preparing slurry from a part of active metal nickel, an auxiliary agent and a carrier and subjecting the slurry and a precipitating agent to parallel-flow precipitation; then adding a filter cake obtained after filtration into a solution prepared from rest active metal nickel and dropwise adding an alkaline solution; successively carrying out aging, washing and drying; and carrying out molding, drying and roasting so as to prepare the hydrogenation catalyst. The catalyst prepared by using the method is particularly applicable to hydro-decolorization of C5 petroleum resin, C9 petroleum resin and blended C5 and C9 petroleum resin and has the advantages of good activity, high selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

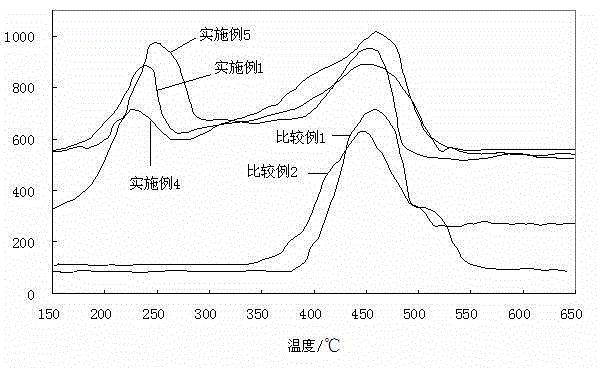

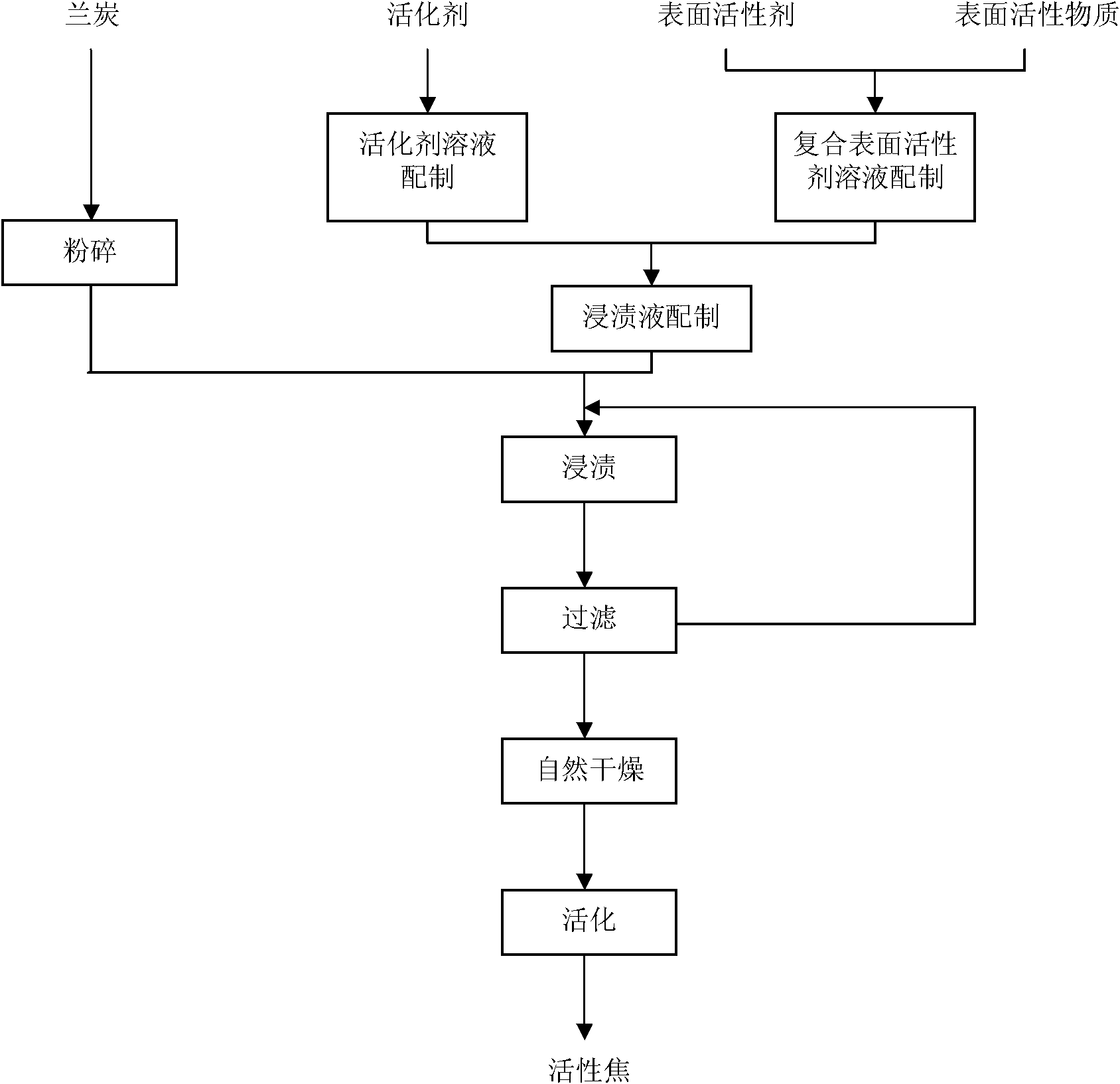

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

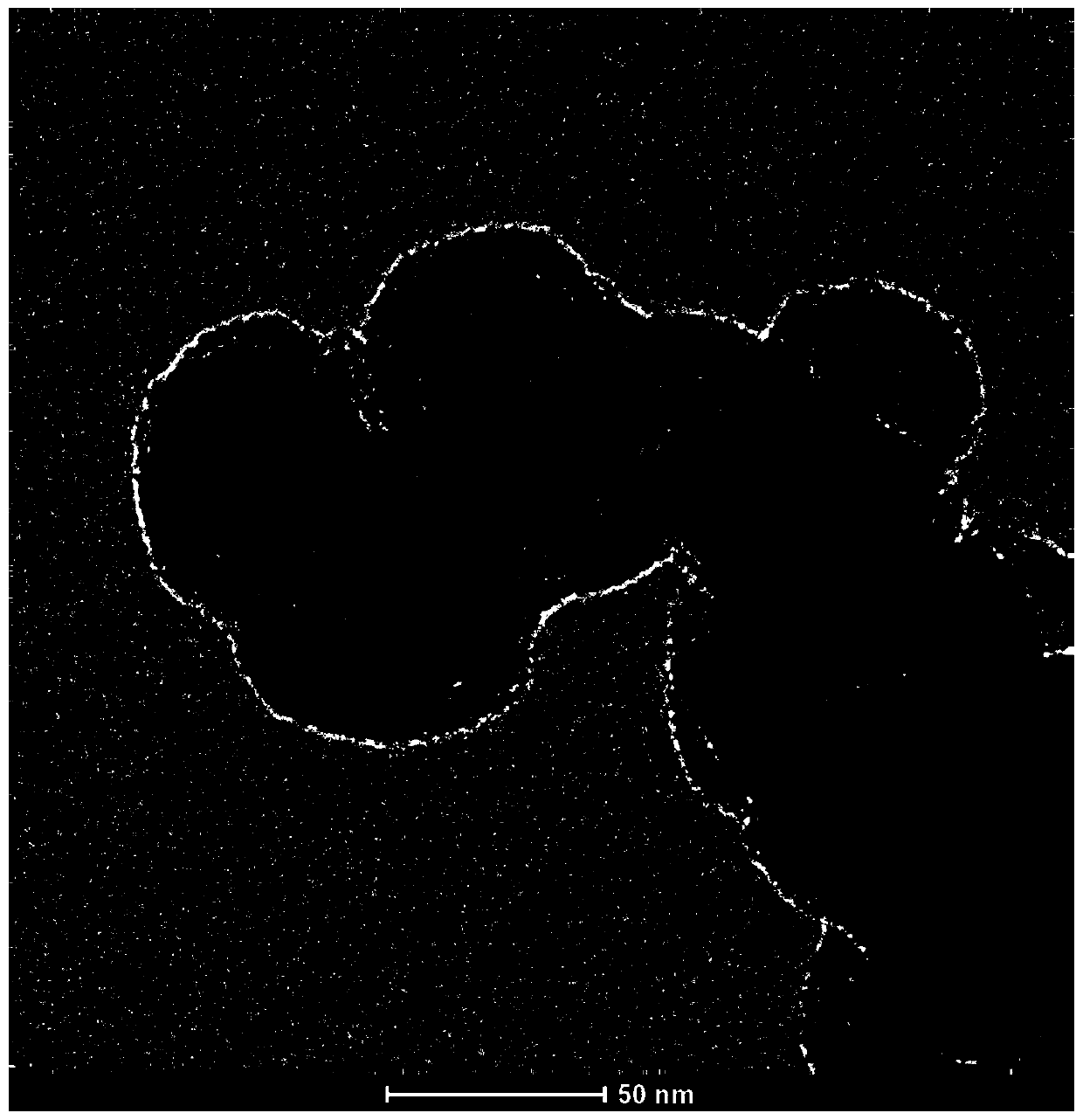

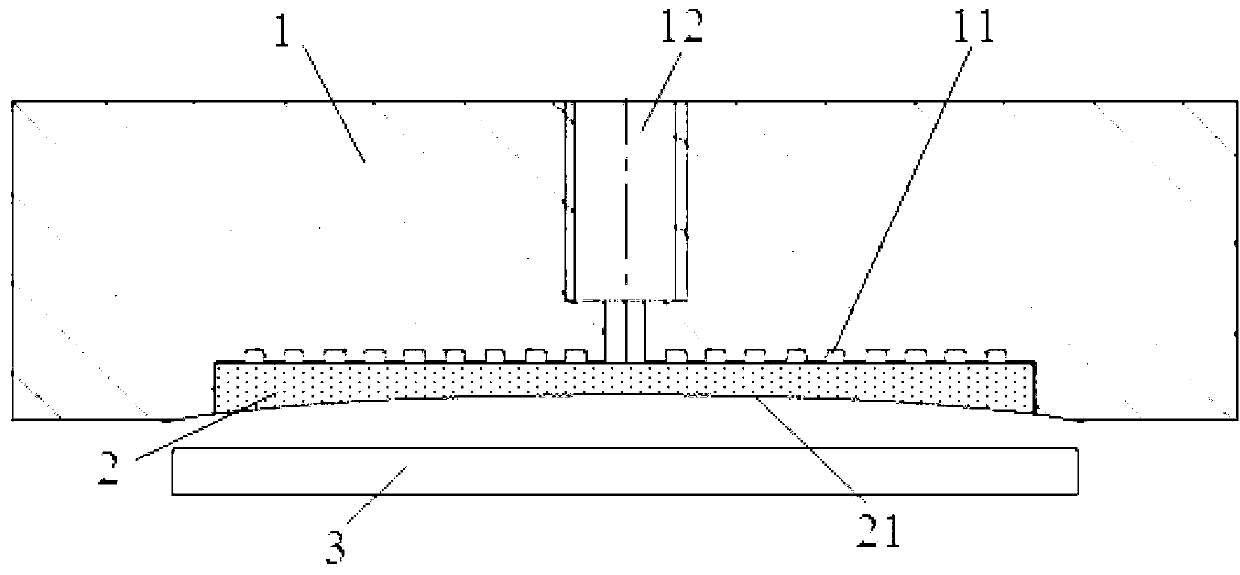

Carbon-loaded super-small-size precious metal nanoparticle catalyst and preparation method

InactiveCN109745969ARapid atomization dryingInhibition of nucleation growthMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsAlcoholReducing atmosphere

The invention discloses a carbon-loaded super-small-size precious metal nanoparticle catalyst and a preparation method. The preparation method comprises the following steps: firstly enabling commercial active carbon to be mixed with a precious metal precursor, wherein precious metal contained in the precious metal precursor is one or any two of Pt, Pd, Ru or Rh; then adding water and ethyl alcohol, and forming turbid liquid; and adequately ultrasonic-dispersing, rapidly atomizing and drying in a high temperature, finally acquiring a solid powder-like precursor; calcining the solid powder-likeprecursor in a reducing atmosphere, enabling precious metal ions adsorbed on the surface thereof to be nucleated in situ and forming super-small-size precious metal nanoparticles which are loaded on the surface of a commercial active carbon carrier, to obtain the catalyst. The method is pollution-free, and low in cost. An average diameter of the loaded precious metal nanoparticles does not exceed3 nm, and the precious metal nanoparticles are uniformly loaded on the surface of the active carbon carrier. The catalyst has a higher effective catalytic activity area and excellent catalytic capacity.

Owner:XI AN JIAOTONG UNIV

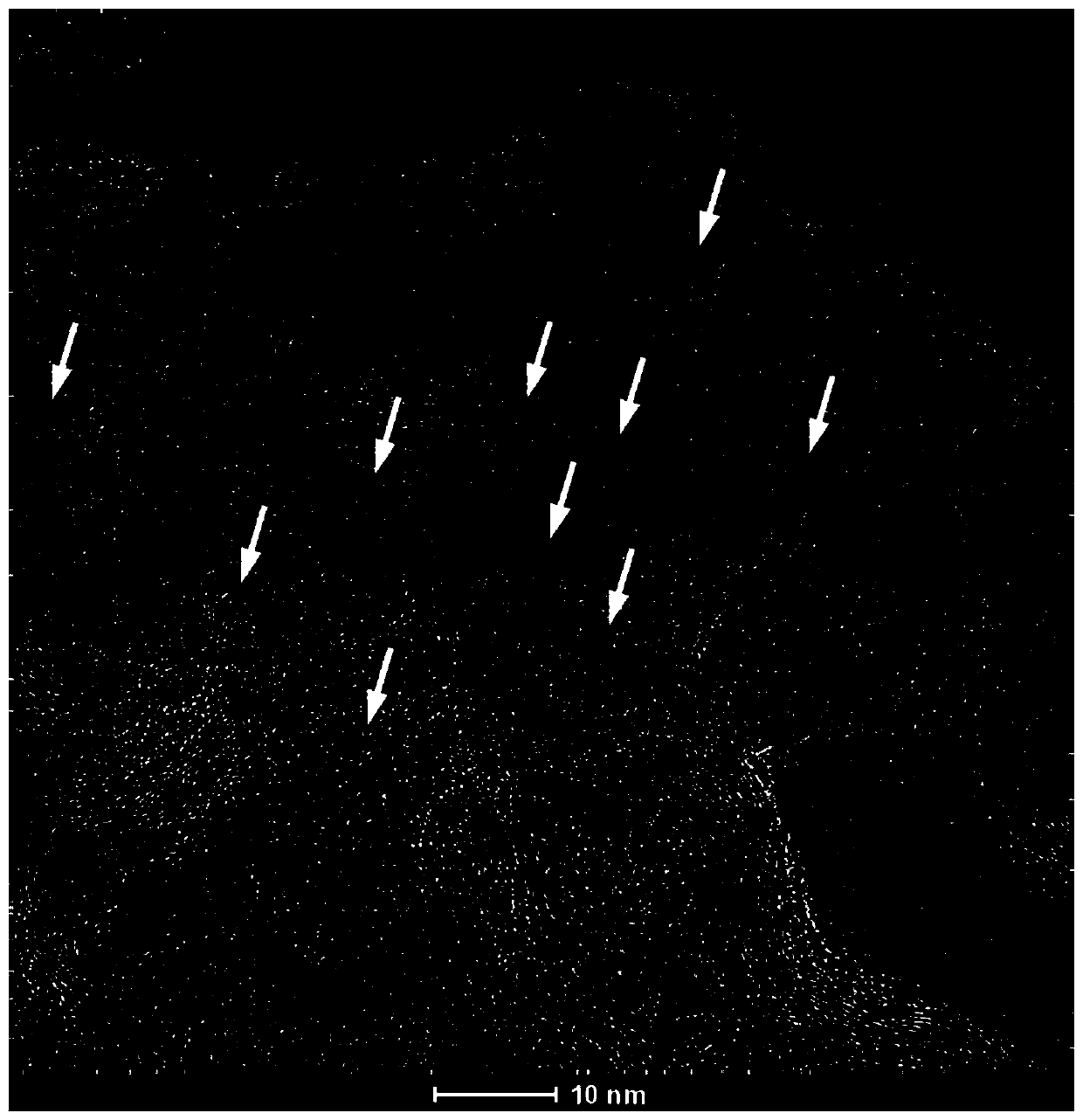

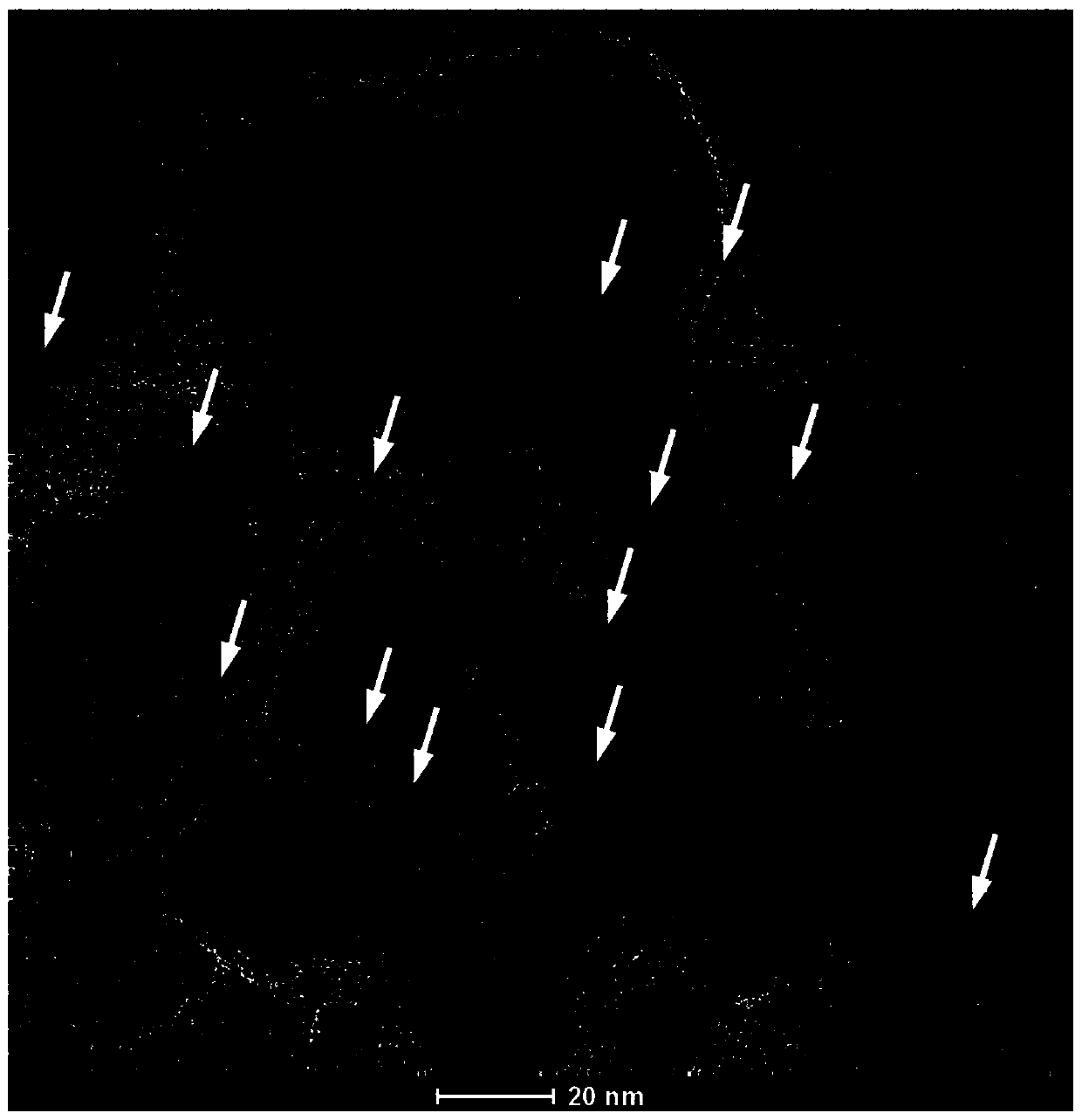

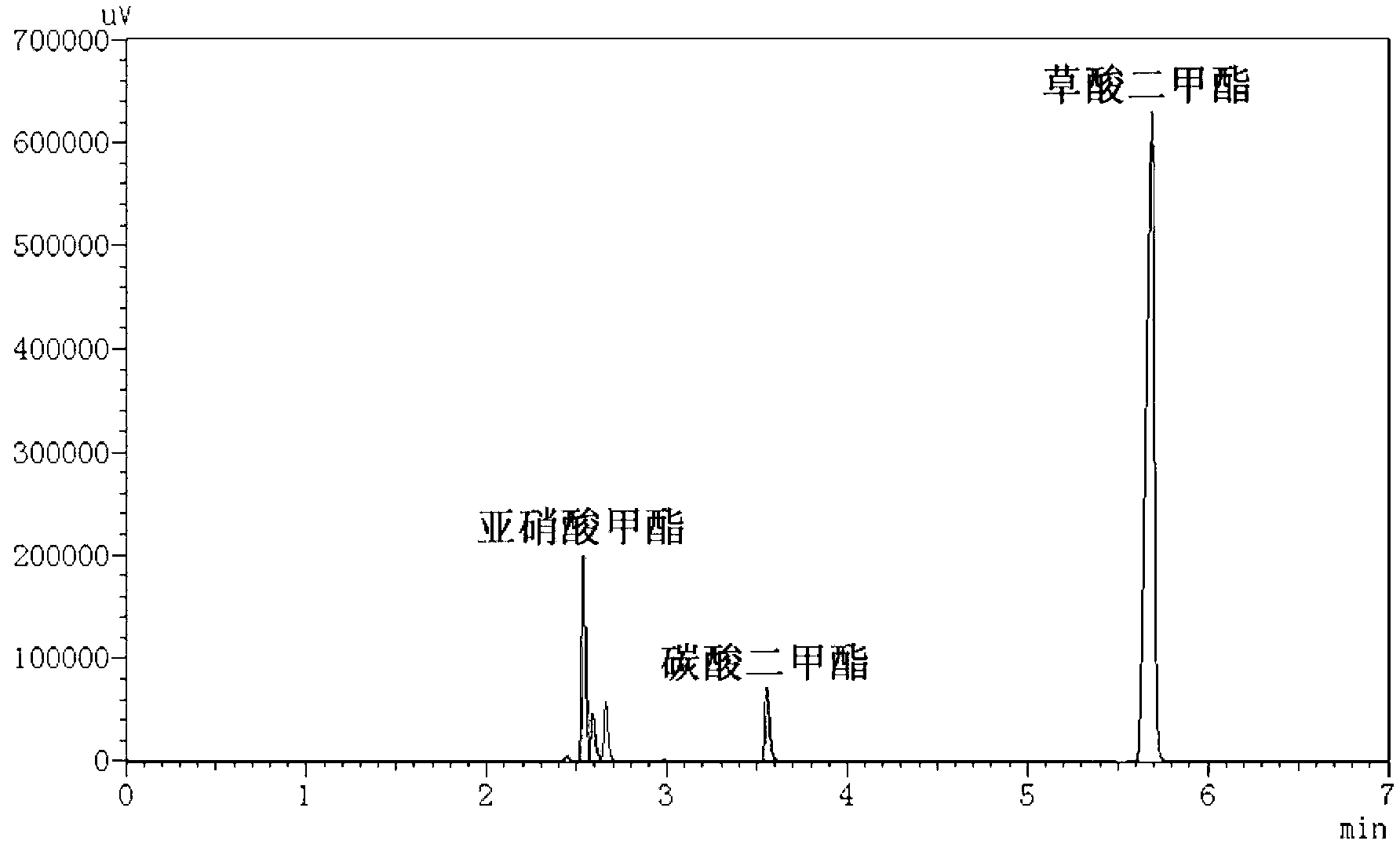

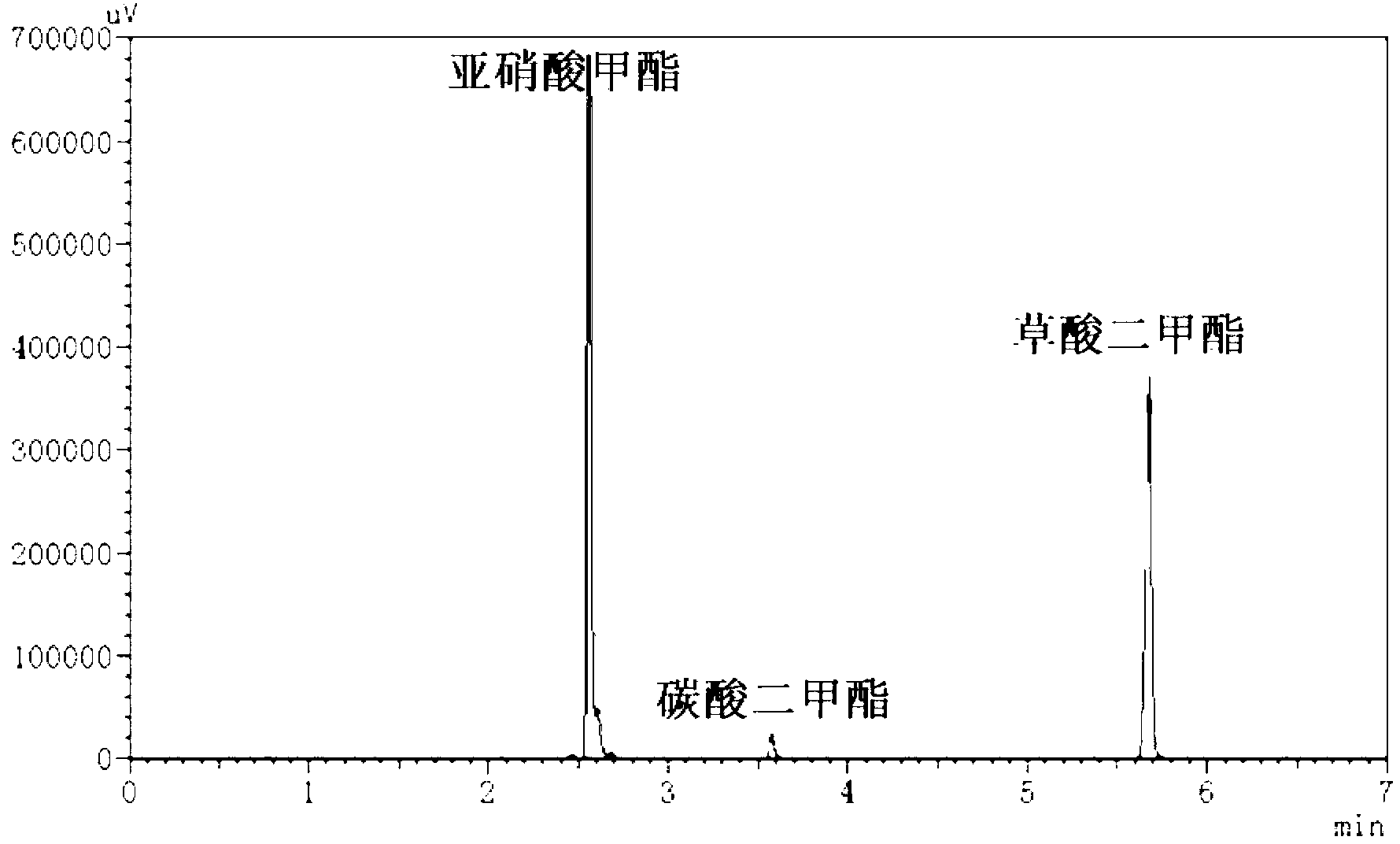

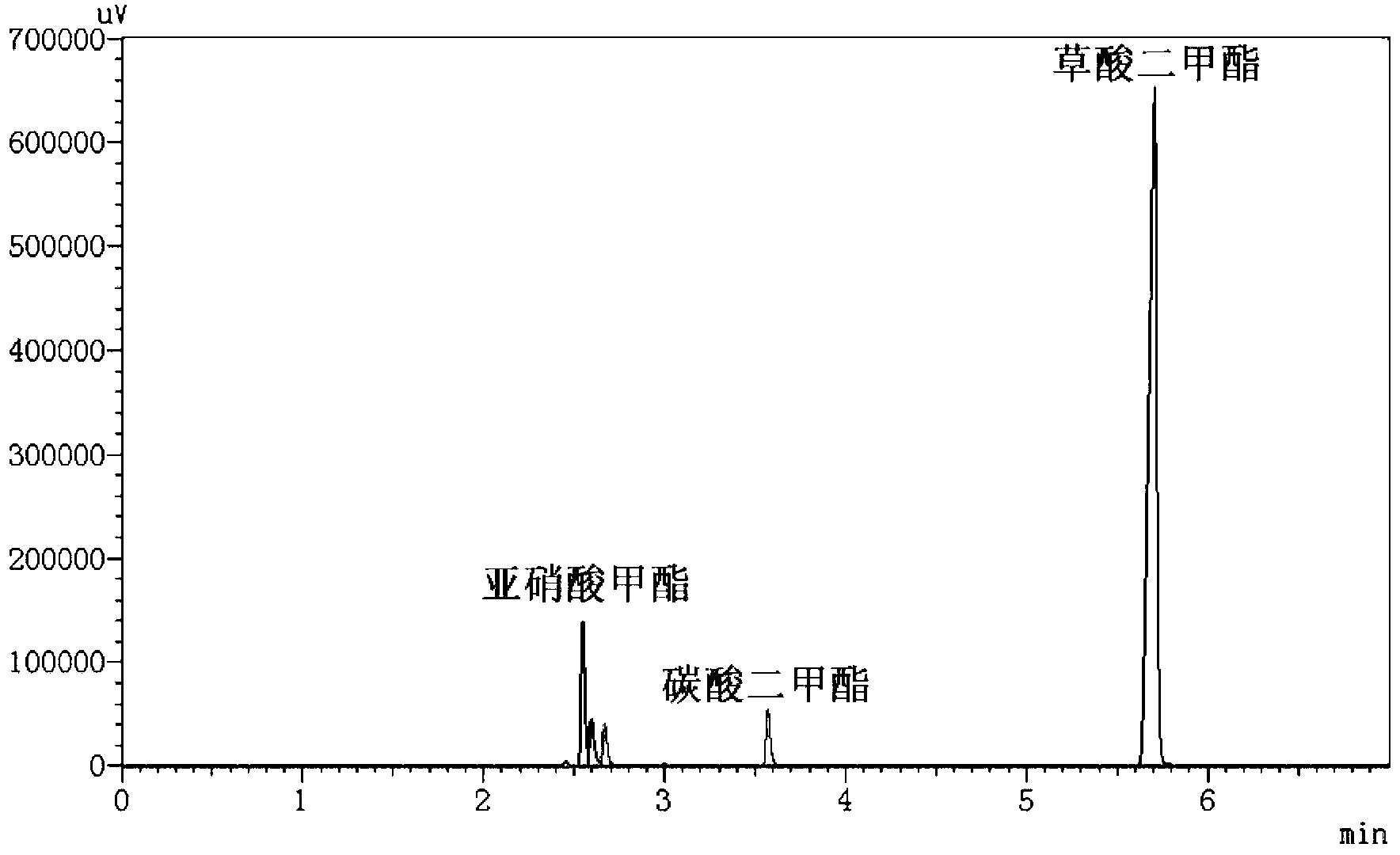

Catalyst for synthesizing oxalic ester through oxidative coupling of CO gas phase as well as preparation and application method thereof

InactiveCN103055851AHigh catalytic activityUniform adsorptionPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsCouplingActive component

The invention discloses a catalyst for synthesizing oxalic ester through oxidative coupling of CO gas phase as well as a preparation and application method thereof, belonging to the technical field of oxalic ester preparation. Nanometer magnesia is used as a carrier of the catalyst, and the active component of the catalyst is noble metal palladium; and the content of the active component palladium is 0.01-2 percent by the mass of the carrier of the catalyst. The catalyst is prepared by adopting an improved steeping method which is beneficial to realization of large-scale production of the catalyst. The catalyst disclosed by the invention is characterized in that the commercial nanometer magnesia is used as the carrier of the catalyst while alpha-alumina is used as the carrier of a conventional catalyst. Experiments show that compared with a catalyst taking alpha-aluminum oxide as a carrier, which is prepared under same conditions, the catalyst disclosed by the invention shows better catalytic activity in reaction of synthesizing oxalic ester through oxidative coupling of CO gas phase. The per-pass conversion of CO is up to 65 percent, the selectivity of the oxalic ester is higher than 95 percent, and the space time yield of the oxalic ester is greater than 1200g.L<-1>.h<-1> (airspeed is 3000h<-1>).

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

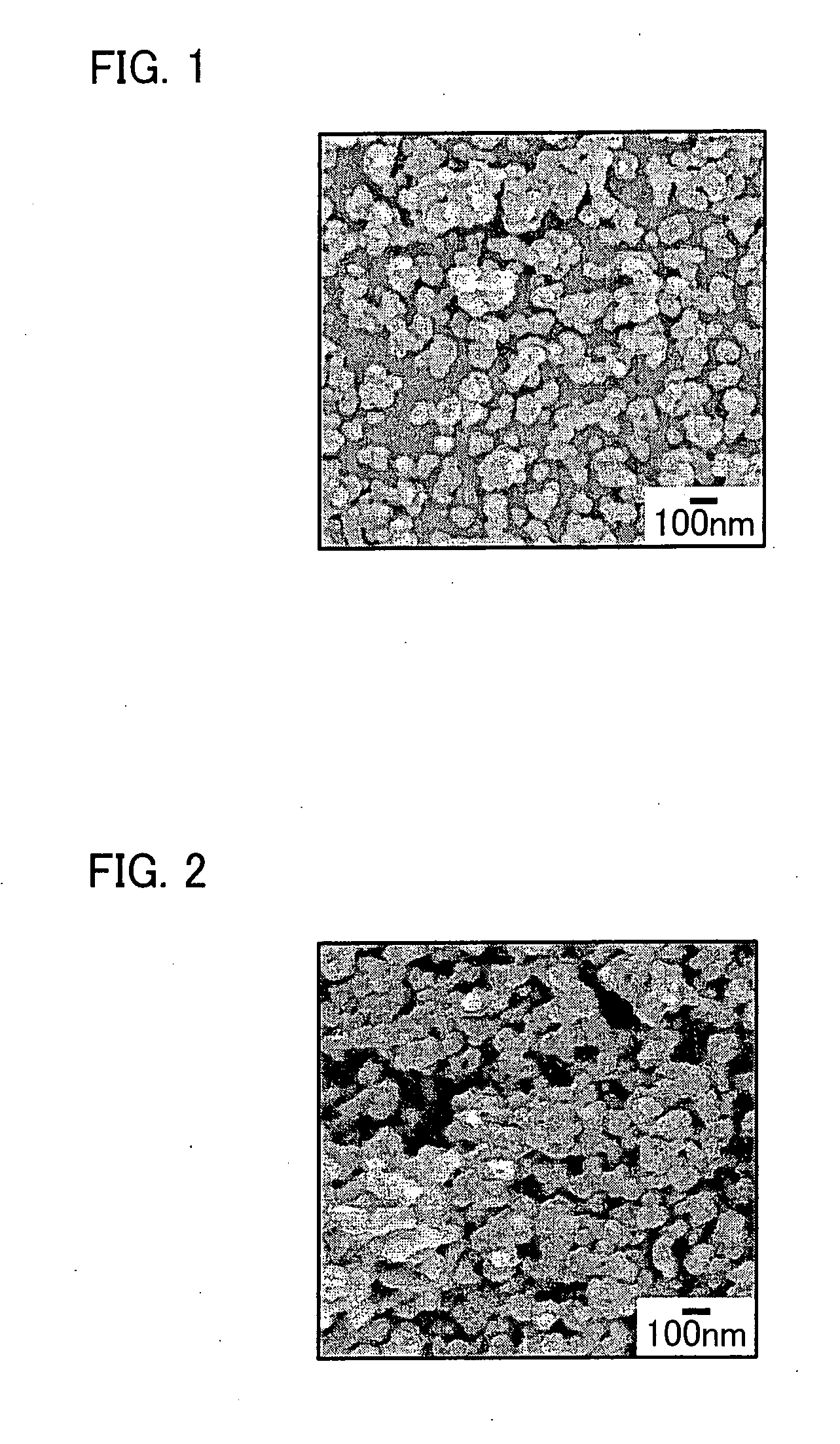

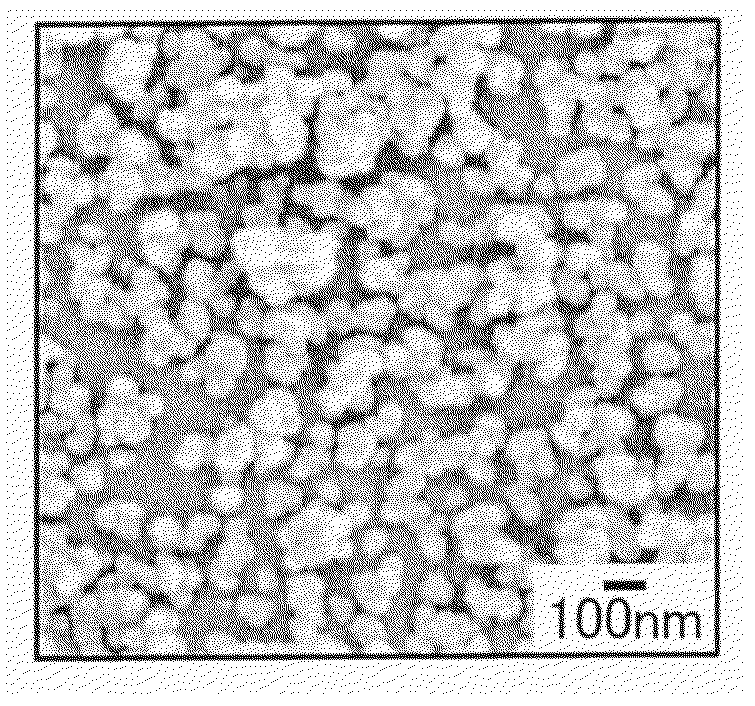

Ceramic Particle Group and Method for Production Thereof and Use Thereof

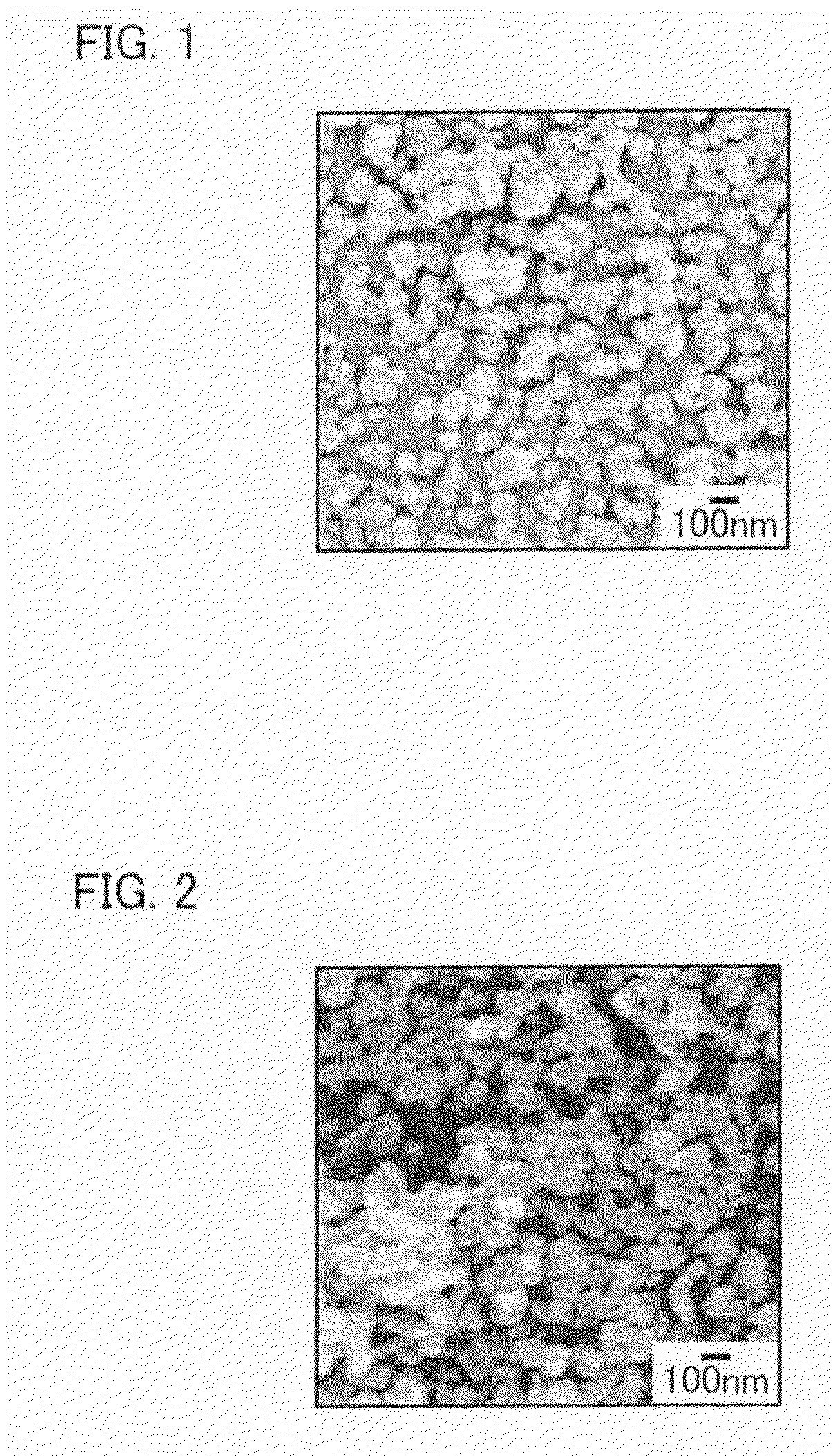

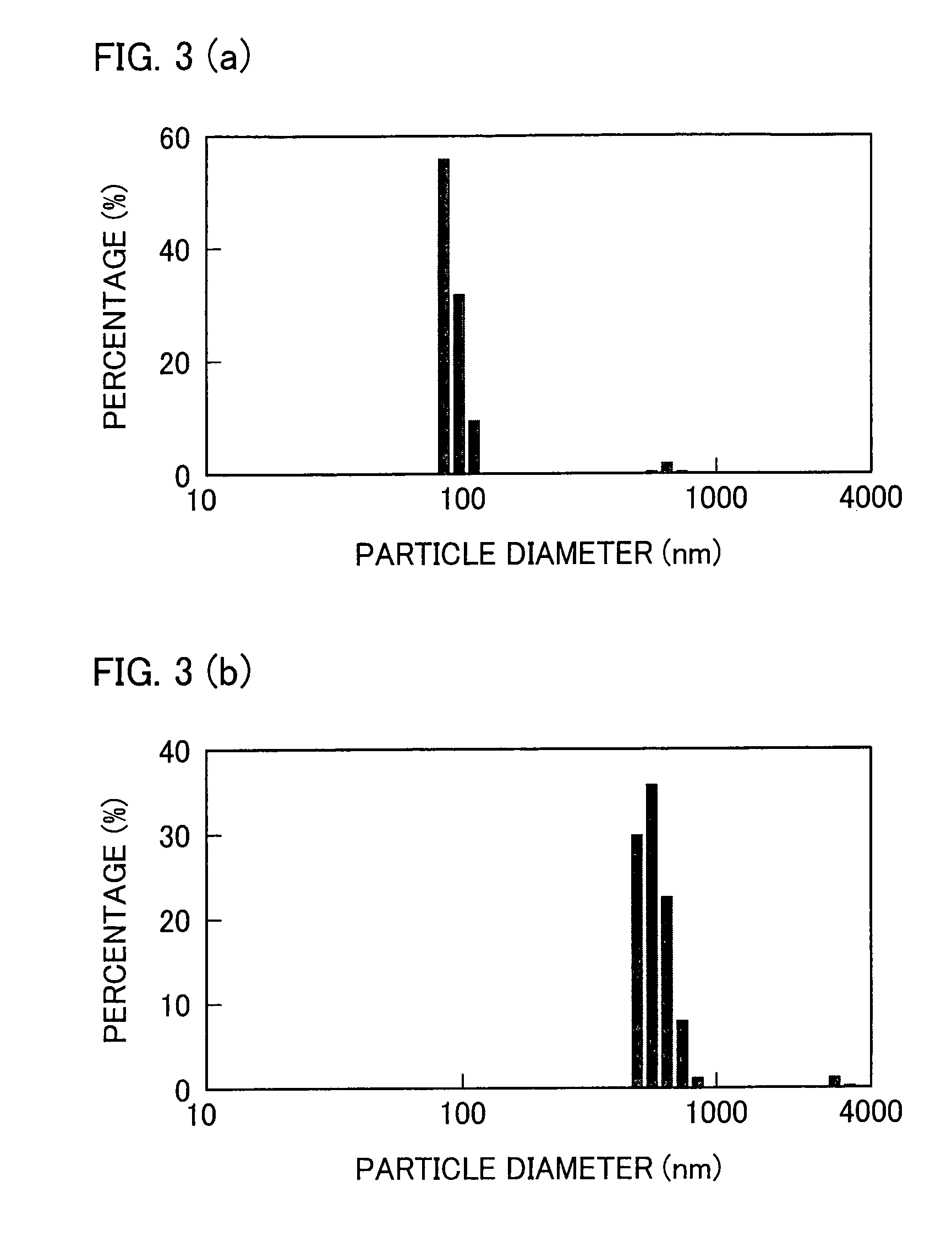

ActiveUS20070259181A1Uniform particle sizeSmall particle sizeMaterial nanotechnologyImpression capsApatiteSingle crystal

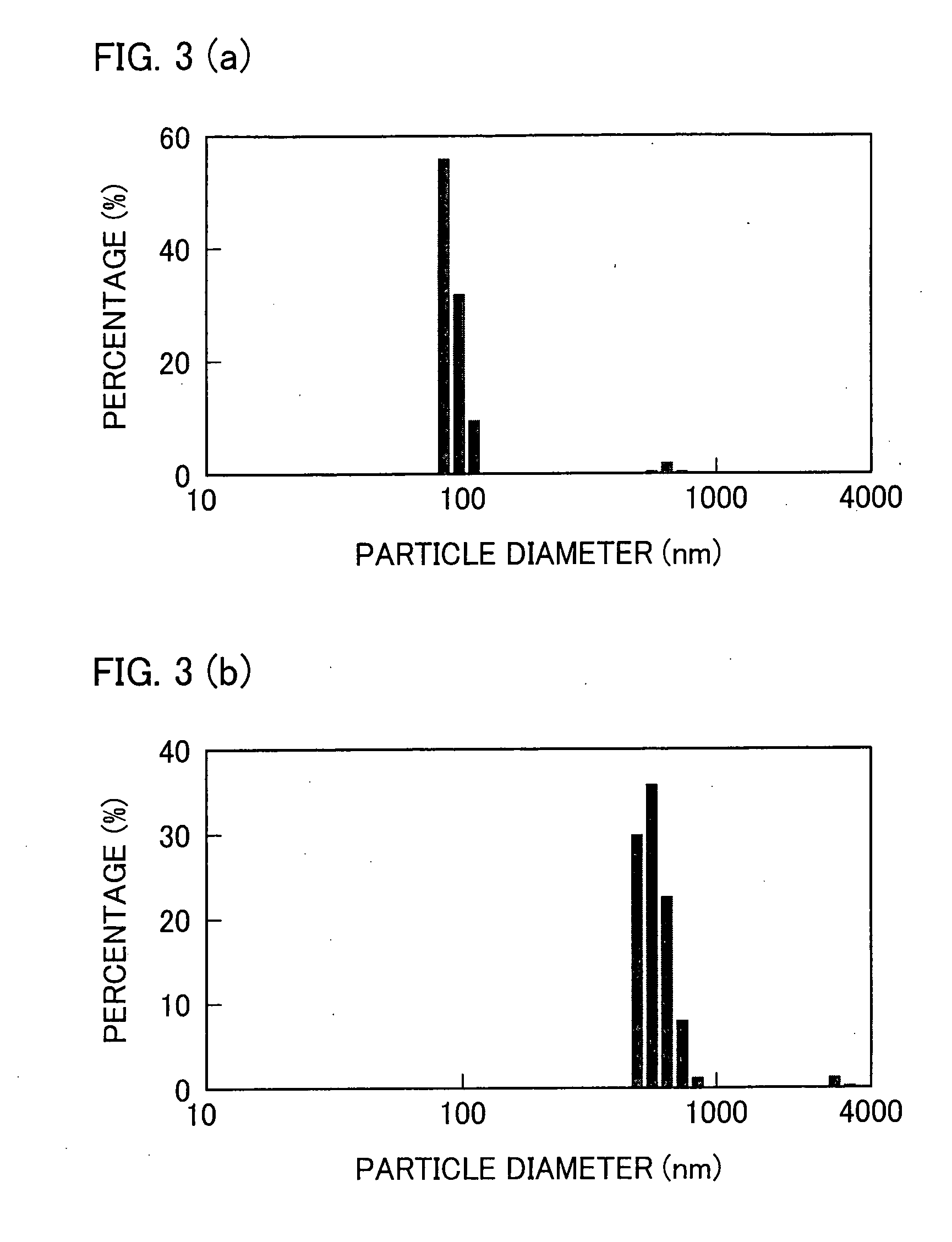

A ceramic particle group dispersed in a solvent in a state of primary particles of single crystal, a method for production thereof and a use thereof are disclosed. In one embodiment a method is disclosed for producing a sintered particle (ceramic particle) group of hydroxyapatite (HAp), which includes a step of subjecting a system wherein calcium carbonate is present between primary particles of hydroxyapatite (HAp) to sintering and then dissolving calcium carbonate with water to remove calcium carbonate. A hydroxyapatite (HAp) sintered particle group produced by the above method is a nanometer size particle group having a particle diameter of about 70 to about 120 nm, and is a particle group having a uniform particle diameter (coefficient of variation: 12%), and further 96% of the particle group is dispersed as a single crystal particle.

Owner:JAPAN SCI & TECH CORP

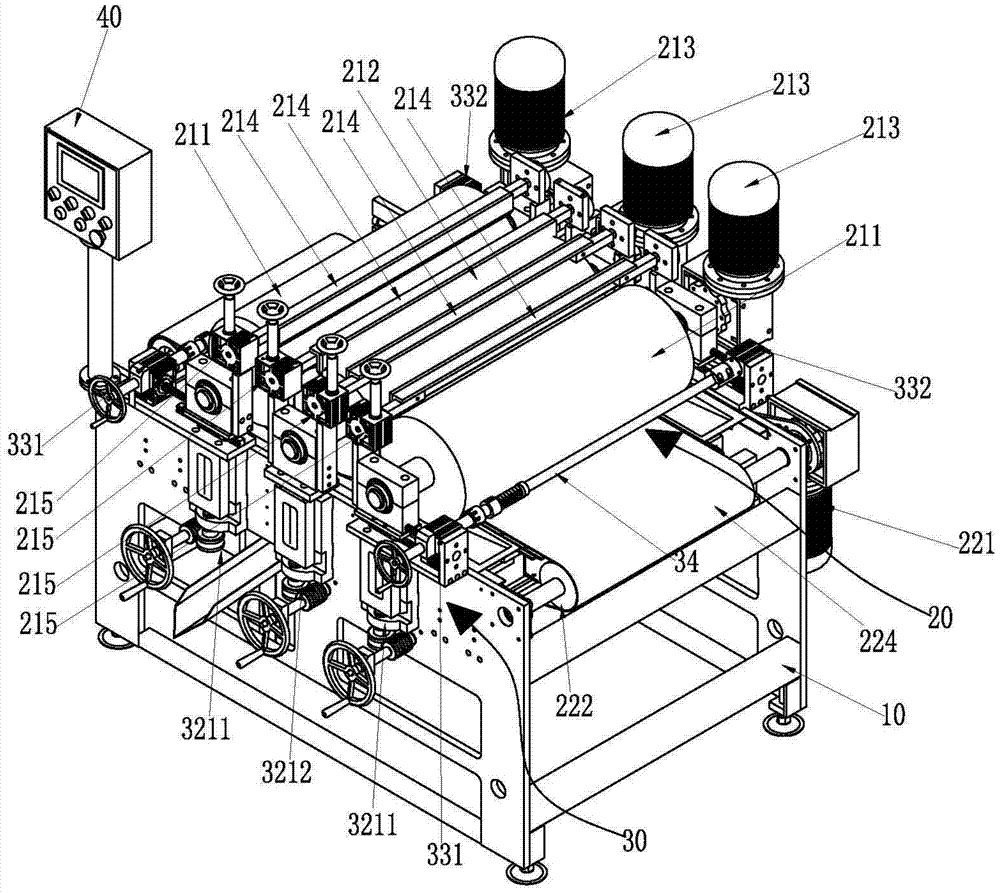

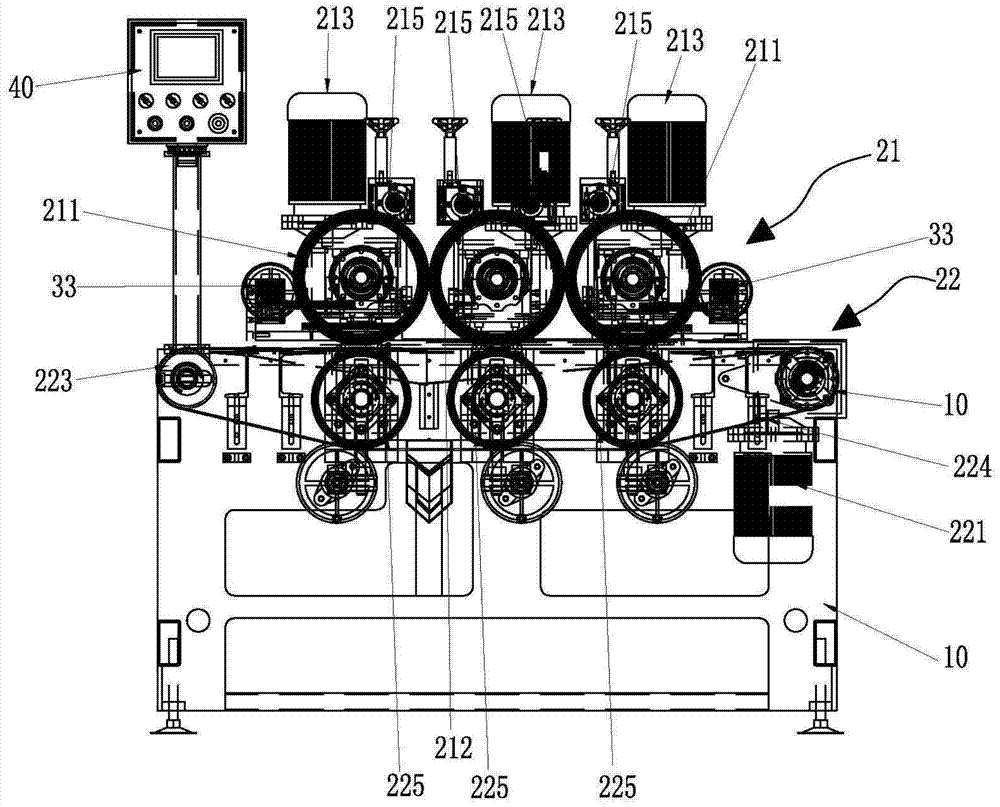

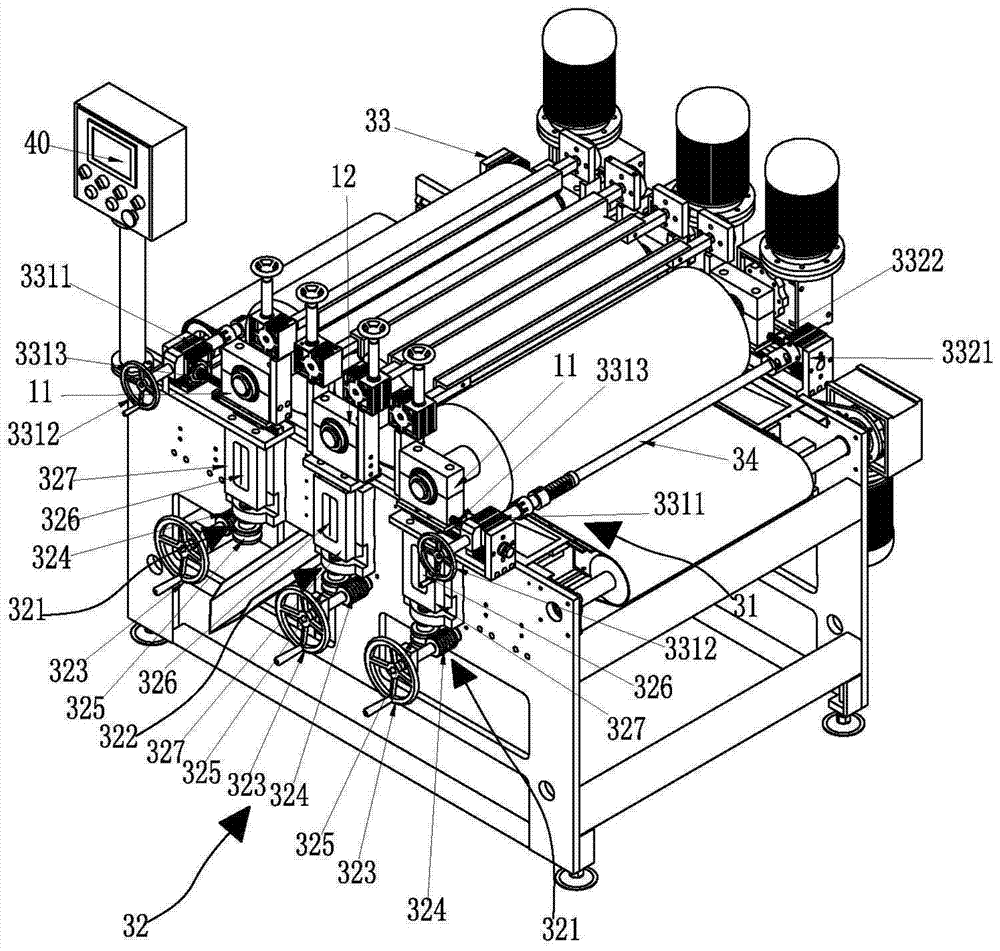

Multifunctional roller coater

The invention discloses a multifunctional roller coater which comprises a rack, a coating system, a roller adjustment system and a control system. The coating system comprises a roller set and a conveying mechanism, the roller adjustment system comprises a horizontal adjustment mechanism and a vertical adjustment mechanism, the horizontal adjustment mechanism is used for adjusting the distance, in the horizontal direction, between steel wheels and soft rubber transfer printing wheels, and the vertical adjustment mechanism is used for adjusting rollers to be vertically lifted. According to the multifunctional roller coater, the horizontal distances between the rollers and the positions, in the vertical direction, of the rollers can be conveniently and rapidly adjusted to achieve the aim that the coating thickness and the thickness uniformity are controlled; as the roller set and the conveying mechanism can be effectively assembled and matched, the whole coating system is stable in running, accurate in operation and long in service life, and meanwhile due to the fact that the steel wheels with patterns on the surfaces are adopted, a product can have multiple surface effects, coating is even, and the quality is good.

Owner:东莞市欧西曼机械设备有限公司

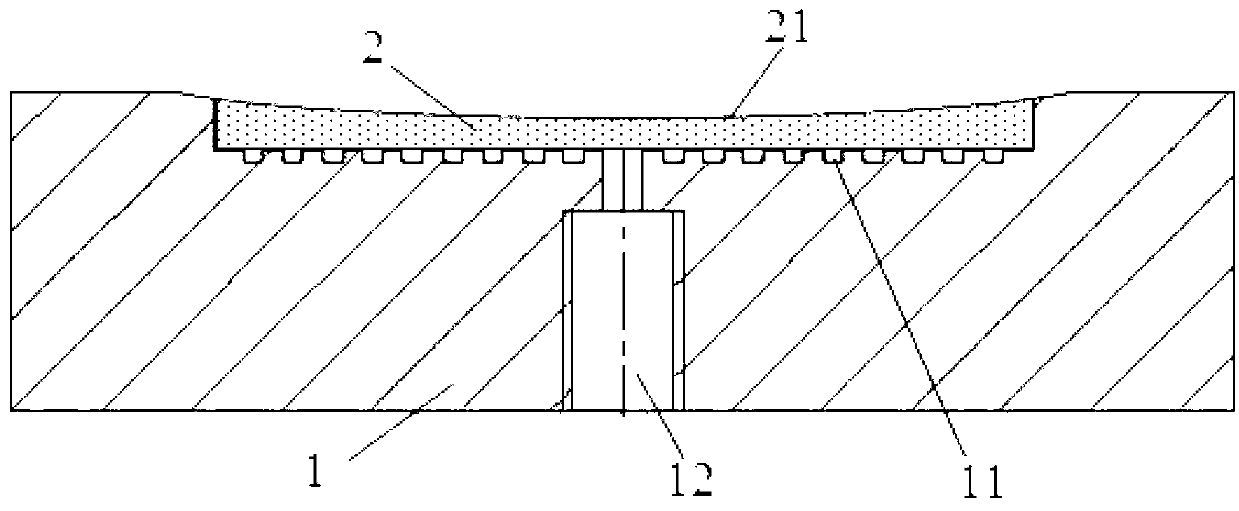

Vacuum adsorption clamp used for aspheric surface machining

InactiveCN103341818AUniform adsorptionImprove rigidityLapping machinesWork carriersTarget surfaceSurface type

A vacuum adsorption clamp used for aspheric surface machining comprises a clamp body and a profiling mold, wherein a plurality of concentric circle grooves with radial slots are formed in the upper surface of the clamp body, a vacuum connector is arranged on the lower surface of the clamp body and communicated with the upper surface of the clamp body, and the vacuum connector is connected with an outer vacuum adsorption system through a vacuum connector clamp. The upper surface of the profiling mold is a profiling mold face, the profiling mold face is machined to be a curved surface which is opposite to a target surface shape and extends to the periphery of the clamp body, and the profiling mold is fixed on the concentric circle grooves in the upper surface of the clamp body. The vacuum absorption clamp used for the aspheric surface machining has the advantages that porous ceramics material is used, the problem that a workpiece in a groove profiling mold made of hard material is prone to cracking can be avoided, and stability and reliability of the process of elastic deformation surface type copying and machining are ensured; meanwhile, the porous ceramics material has the advantages of being even in adsorption and good in rigidity, and therefore surface type accuracy of the aspheric surface machining can be ensured.

Owner:ZHEJIANG UNIV OF TECH

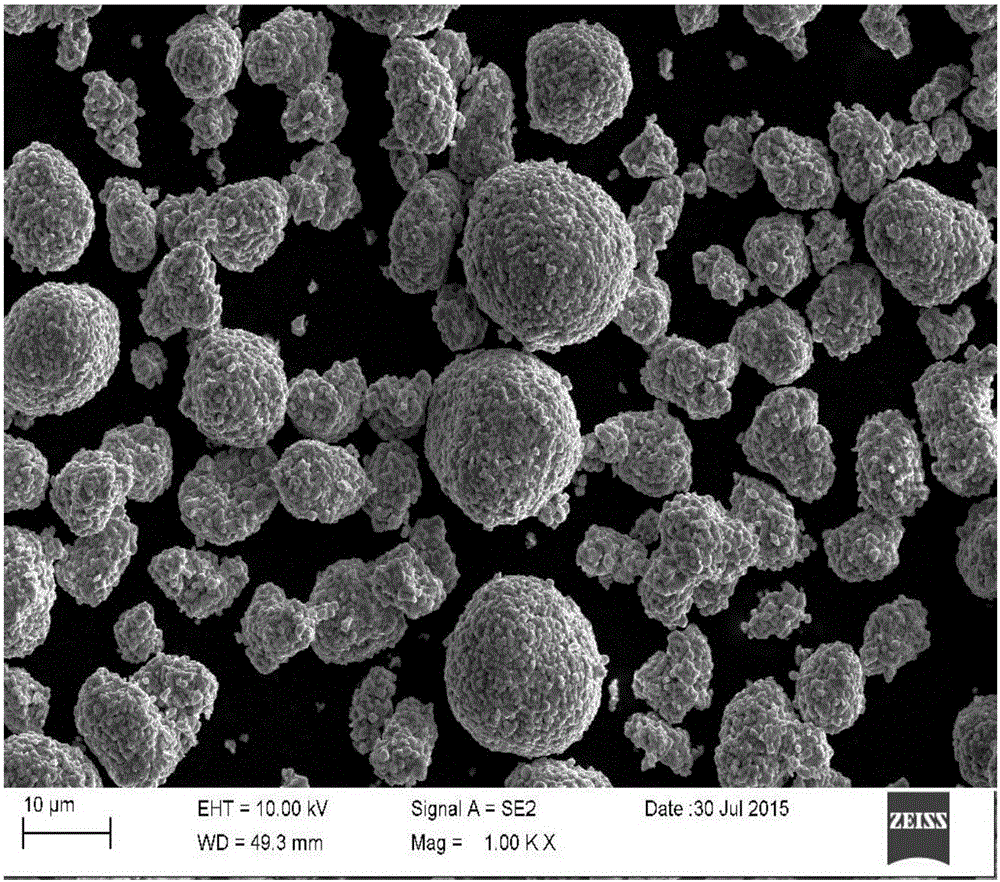

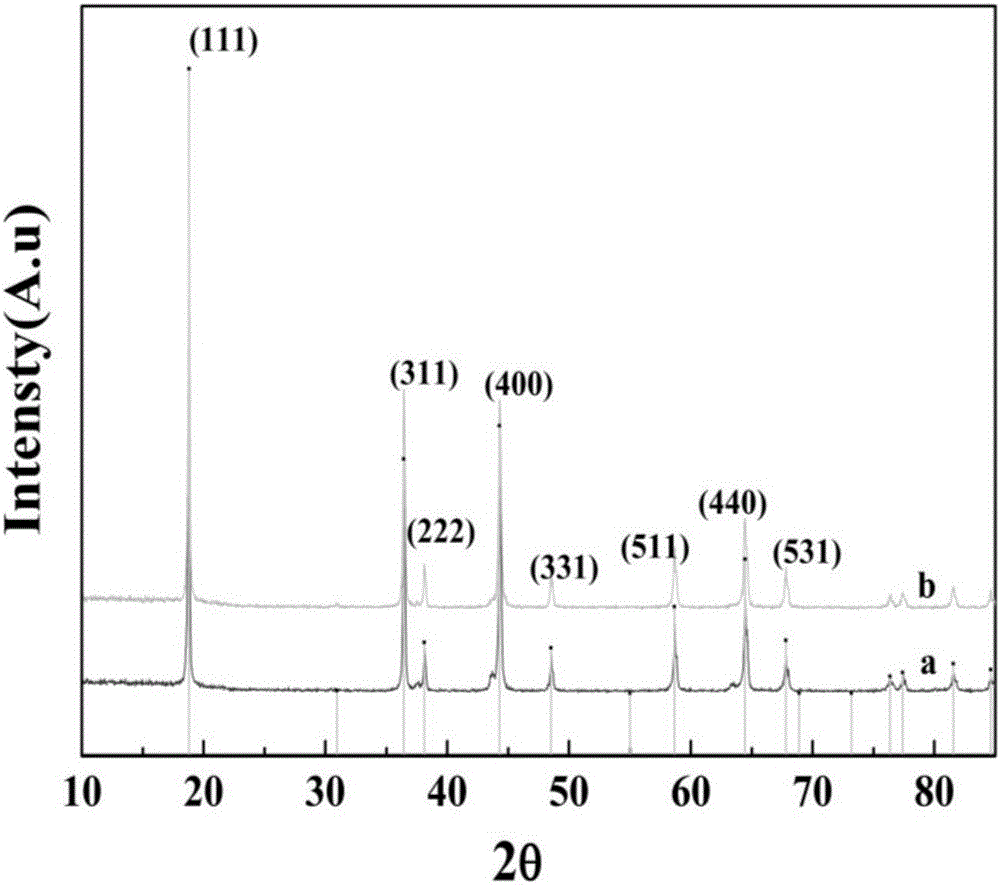

Al2O3-coated modified lithium nickel manganese oxide positive electrode material and preparation method thereof

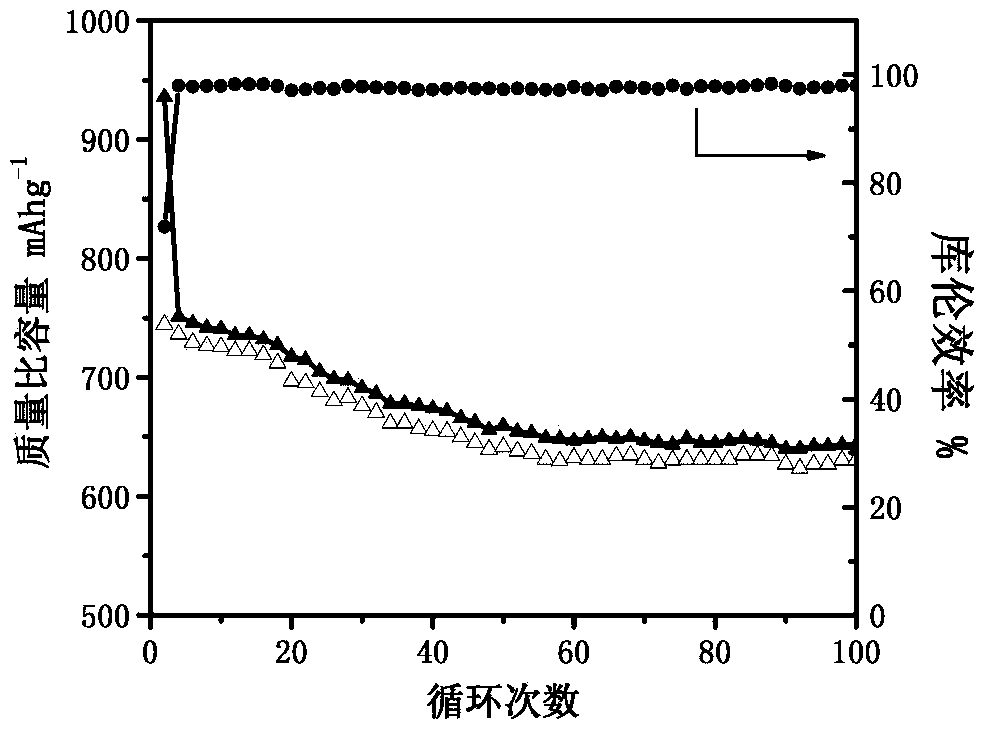

ActiveCN106129348AControllable growth rateImprove securityCell electrodesSecondary cellsCharge dischargeCrystal growth rate

The invention discloses an Al2O3-coated modified lithium nickel manganese oxide positive electrode material. A preparation method of the Al2O3-coated modified lithium nickel manganese oxide positive electrode material comprises the following steps of (1) preparing a solution; (2) dispersing lithium nickel manganese oxide into deionized water to form a turbid liquid and adding an anionic surfactant for ultrasonic dispersion for 15-30 minutes; (3) adding an Al(NO3)3 solution to an ultrasonic dispersed solution, carrying out ultrasonic dispersion for 15-30 minutes and then adding an NaAlO2 solution while stirring; (4) adding a citric acid solution of which the concentration is 0.5mol / L to the mixed solution obtained in the step (3) while stirring; (5) carrying out ageing, cleaning and drying; and (6) carrying out high-temperature pyrolysis. The crystal growth rate is consistent with the nucleation rate in the preparation process; coating is uniform; the prepared material is high in safety and low in cost; the energy density and the charge-discharge capacity at high voltage are obviously improved; and the capacity retention ratio reaches 86.3% after 500 charge-discharge cycles at a room temperature under the condition of 1C.

Owner:四川省有色冶金研究院有限公司

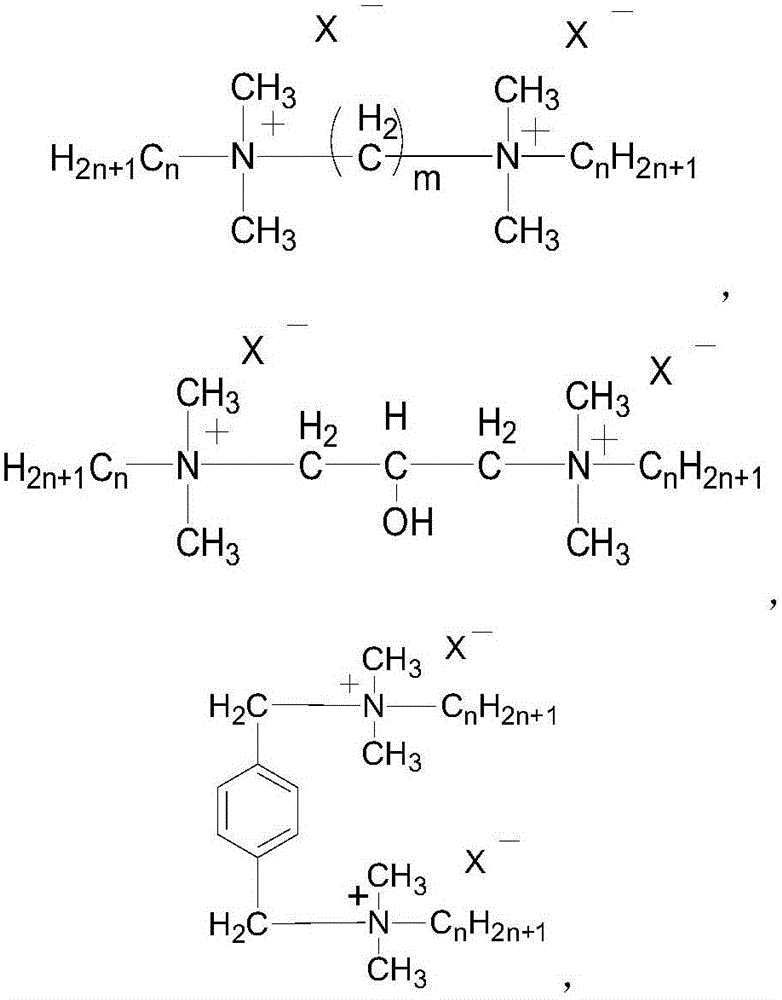

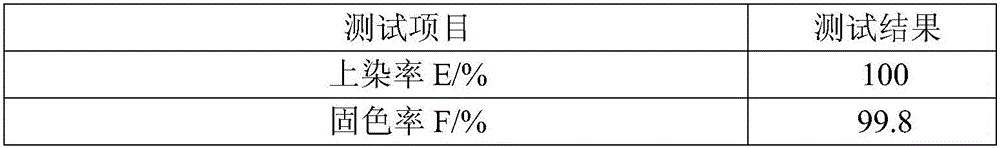

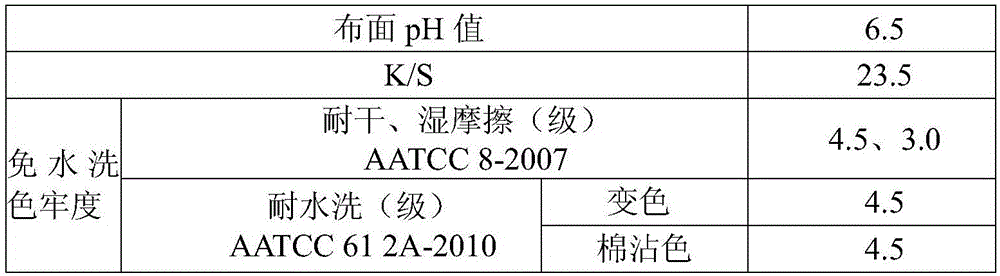

Non-aqueous solvent dyeing method of washing-free reactive dye

The invention provides a non-aqueous solvent dyeing method of a washing-free reactive dye. The non-aqueous solvent dyeing method comprises the following steps: mixing pre-treated loose fibers, yarns, fabric or clothes with an reactive dye, a micro-molecular quaternary ammonium salt and a good solvent of the reactive dye, so as to form a mixing system; raising the temperature of the mixing system; adding a bad solvent of the reactive dye into the mixing system before raising the temperature or in a temperature rising process; keeping the heat after raising the temperature to a dyeing temperature, wherein the volume ratio of the good solvent of the reactive dye and the bad solvent of the reactive dye is 1 to (3-30), the ratio of the volume of the good solvent of the reactive dye to the mass of the loose fibers, the yarns, the fabric or the clothes is (0.8-10)mL to 1g, and the mass ratio of the micro-molecular quaternary ammonium salt to the reactive dye is (0.1-0.5) to 1; and then drying and putting into a color fixation solution and carrying out color fixation treatment, wherein the color fixation solution contains a 5-100g / L color fixation agent.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Air purifying device

InactiveCN102824791AUniform adsorptionSpeed up circulationDispersed particle filtrationEngineeringAir blower

Owner:WUXI LAIJITE INFORMATION TECH

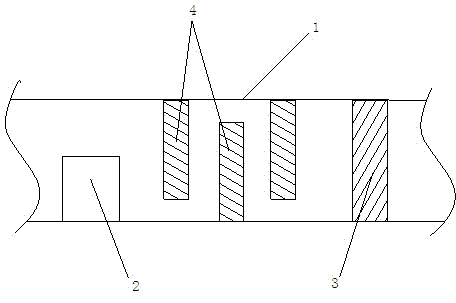

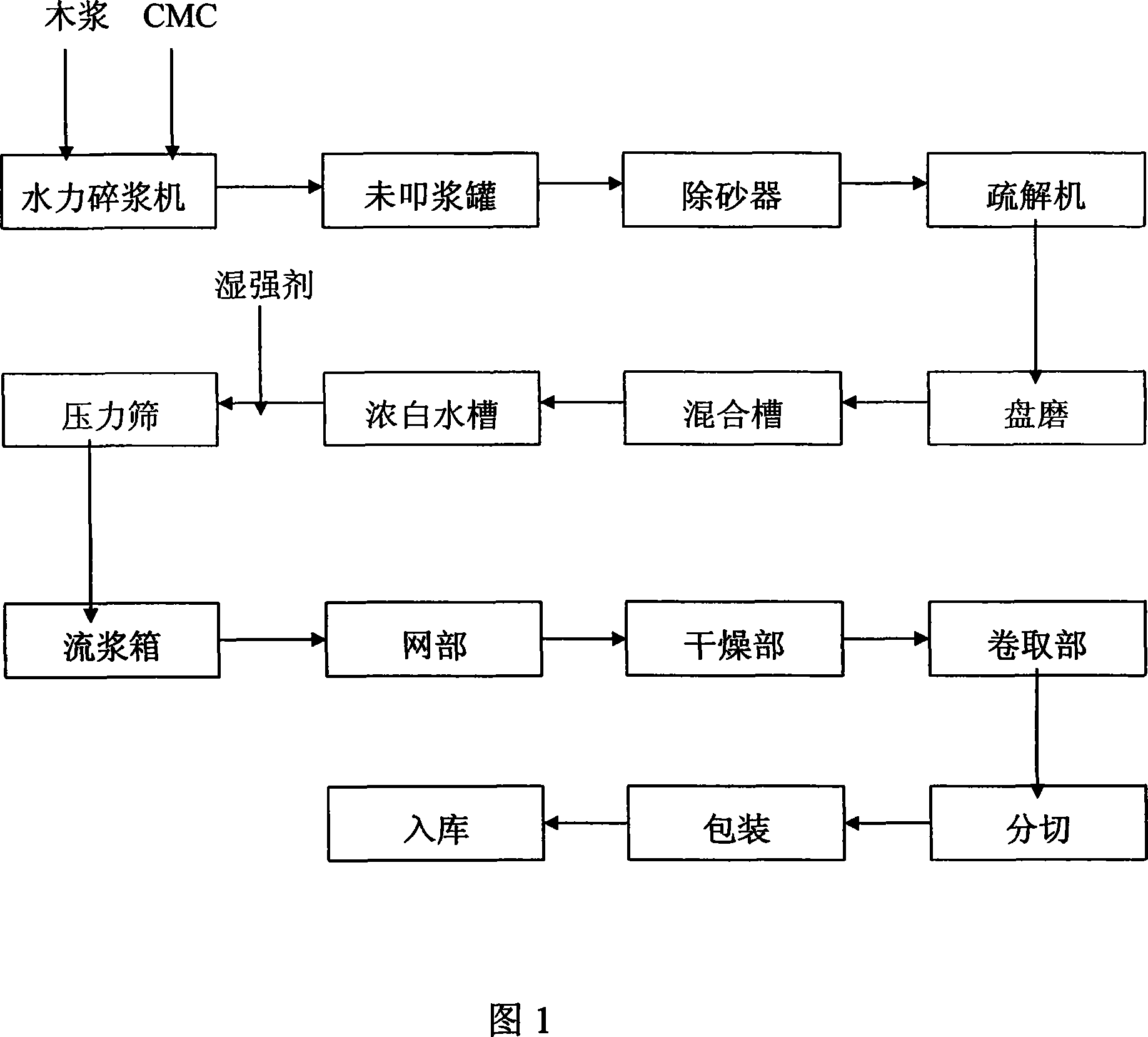

Method of manufacturing high ventilating adsorption lining paper

InactiveCN101058956AImprove breathabilityImprove wet strengthNatural cellulose pulp/paperReinforcing agents additionPapermakingSlip sheet

The present invention discloses a manufacturing method of high permeability adsorption lining paper. It uses natural wood pulp as raw materials and includes brashing pulp, desanding, easing, papermaking and other steps. It is characterized by: said wood pulp is mixed by coniferous pulp and broadleaf pulp, the weight ratio of coniferous pulp is 80-90% and thereof broadleaf pulp is 10-20%, the beating current is 320-340A and the papermaking screening concentration is 0. 05%. The adsorption lining paper prepared through the invention has good air permeability, the polymer adsorption is uniform, the wet strength is high, particularly it is suited for one-time adsorption pet supplies, such as women's sanitary napkins, baby paper diaper and pet pad.

Owner:SHANDONG HENGLIAN INVESTMENT

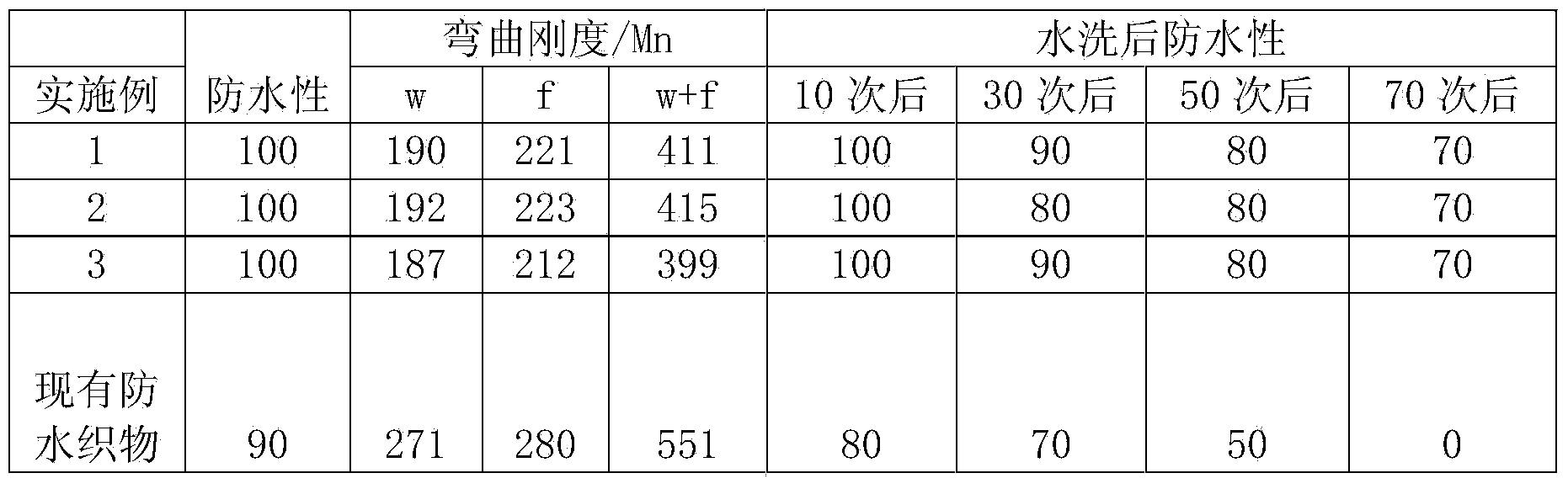

Manufacturing method of waterproof braided fabric

InactiveCN104179000AGood flexibilityEffective combinationUltrasonic/sonic fibre treatmentEmulsionDistilled water

The invention discloses a manufacturing method of a waterproof braided fabric. The method comprises the following steps: performing corona treatment on the fabric, then soaking the fabric in an amino organic silicon waterproof treatment agent, and drying the fabric to obtain the soft fabric with a waterproof function. Compared with the prior art, the pH of the prepared waterproof agent is adjusted to 5.5 to 6.5, and amino groups are converted to ammonium salt groups under an acidic condition, so that the amino organic silicon waterproof agent is positively charged and is more likely to adsorb on the surface of the fabric which is negatively charged, and the softness of the fabric and the firmness of a waterproof membrane can be improved; in the emulsification process, a stirring emulsification way for adding the distilled water for multiple times is adopted, the particle size of the emulsion is smaller and more stable, and the emulsion is easier and more uniformly adsorbed on the surface of the fabric to form a membrane; after the corona treatment, hydroxyl, carboxyl, epoxy groups and active groups of peroxide are generated on the surface of the fabric, and the groups with negative charge on the surfaces are increased, so that the fabric is more effectively combined with the amino organic silicon waterproof treatment agent, and the water resistance, softness and combination firmness of the fabric can be improved.

Owner:王朗

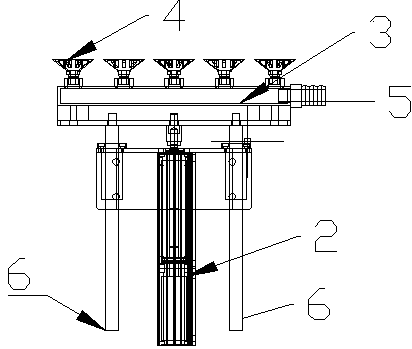

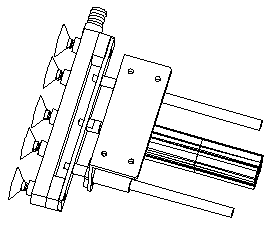

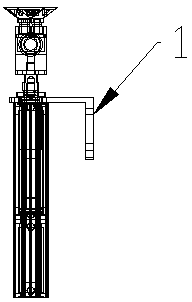

Vacuum sucker type bag opening mechanism

The invention relates to a vacuum sucker type bag opening mechanism. The vacuum sucker type bag opening mechanism comprises a fixed support, a bag opening cylinder, a vacuum cavity and suckers. Three guide rail devices are connected to the fixed support. The bag opening cylinder is located between two guide rails located on the two sides. The suckers are of a parallel and integral structure. One end of each sucker is connected to the vacuum cavity, and the other end of each sucker is in a trumpet flower shape. The suckers drive a device to move up and down through the guide rails so that the device can reach the bag sending position. The vacuum cavity acts to smoothly adsorb one side of a package bag so that the bag opening action can be completed. The vacuum sucker type bag opening mechanism is reasonable in design and simple in structure, the suckers can evenly conduct adsorption and protect the bag, the whole mechanism can achieve the continuous bag sending function, time and labor are saved, and production efficiency is improved.

Owner:HEFEI SANGUAN PACKING SCI & TECH

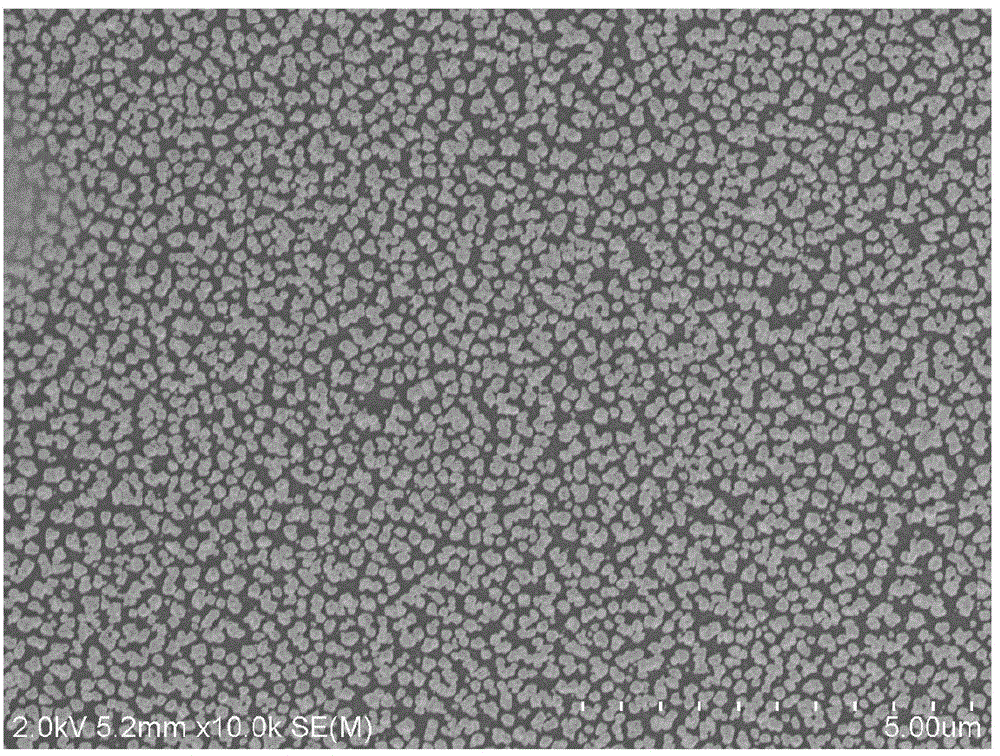

Preparation method of tin oxide-graphene composite carbon film

The invention discloses a preparation method of a tin oxide-graphene composite carbon film. The method comprises the steps of feeding ethylene glycol into graphene oxide water dispersion solution, evenly dispersing in an ultrasonic way, feeding a tin source and PVP, dissolving by stirring, and carrying out microwave heating; after reaction, cooling to the room temperature, carrying out suction filtration, washing by distilled water, and carrying out vacuum drying; and carrying out heat treatment to obtain the composite carbon film. In the reaction system, ethylene glycol is taken as not only a solvent but also a reducing agent, and the reduction products, namely oxalic acid and PVP, have the function of stabilizing the sizes of nano particles; a microwave way is used for heating, so that the temperature of the system is increased rapidly, and tin oxide particles with small sizes can be easily prepared; before the reaction, tin source ions are evenly absorbed on the surface of graphene oxide, so that the tin oxide particles in the product can be evenly distributed, oxidation hydrolysis of the tin source and the reduction of graphene oxide can be realized synchronously, and the components can be controlled. The prepared material is stable in structure, and can be directly used as an electrode for assembling a lithium ion battery after being simply cut.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

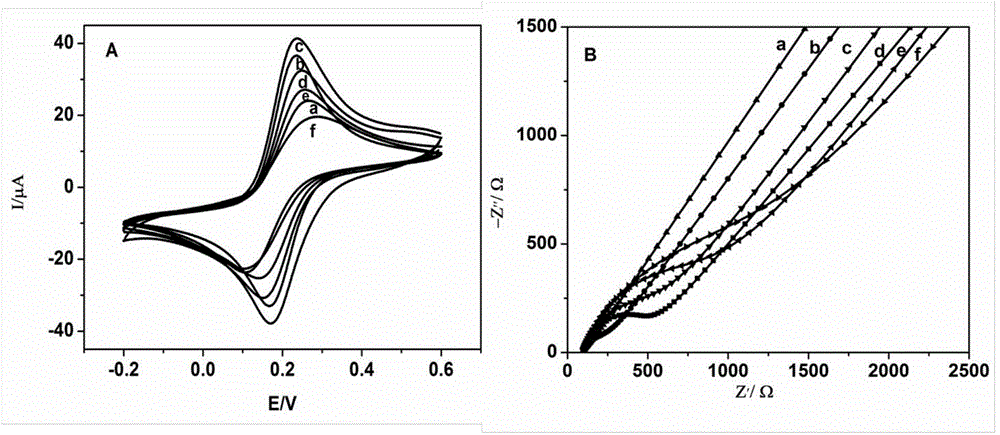

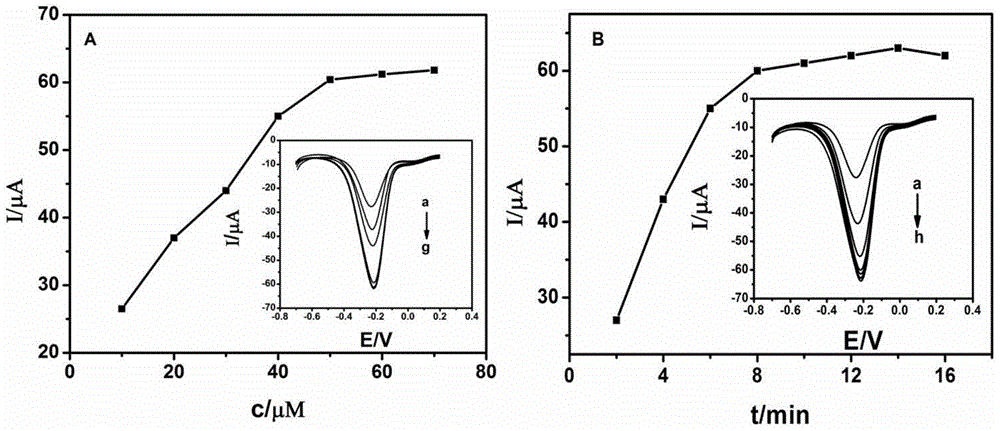

DNA sensor for detecting staphylococcus aureus as well as preparation method and application of DNA sensor

ActiveCN104630869AInhibit aggregationGood dispersionElectrolytic coatingsMaterial electrochemical variablesStaphylococcus aureusA-DNA

The invention discloses a DNA sensor for detecting staphylococcus aureus as well as preparation method and application thereof, belonging to the technical field of rapid pathogenic bacteria detection. A electrochemical carbon nano tube / gold nano particle composite membrane DNA sensor is prepared by utilizing the biological fixation effect and electrochemical electron transfer rate enhancing function of the gold nano particle, and is capable of effectively improving the detection sensitivity. According to the invention, a detection method, having high universality, high sensitivity and high accuracy, and detection conditions for staphylococcus aureus are preliminarily established through a detection technology in which specific staphylococcus aureus gene sequence is synthesized to be used as probe ssDNA so as to form a hybridization system with a complementation target ssNDA segment and methylene blue is used as a hybridization indicator.

Owner:JIANGNAN UNIV

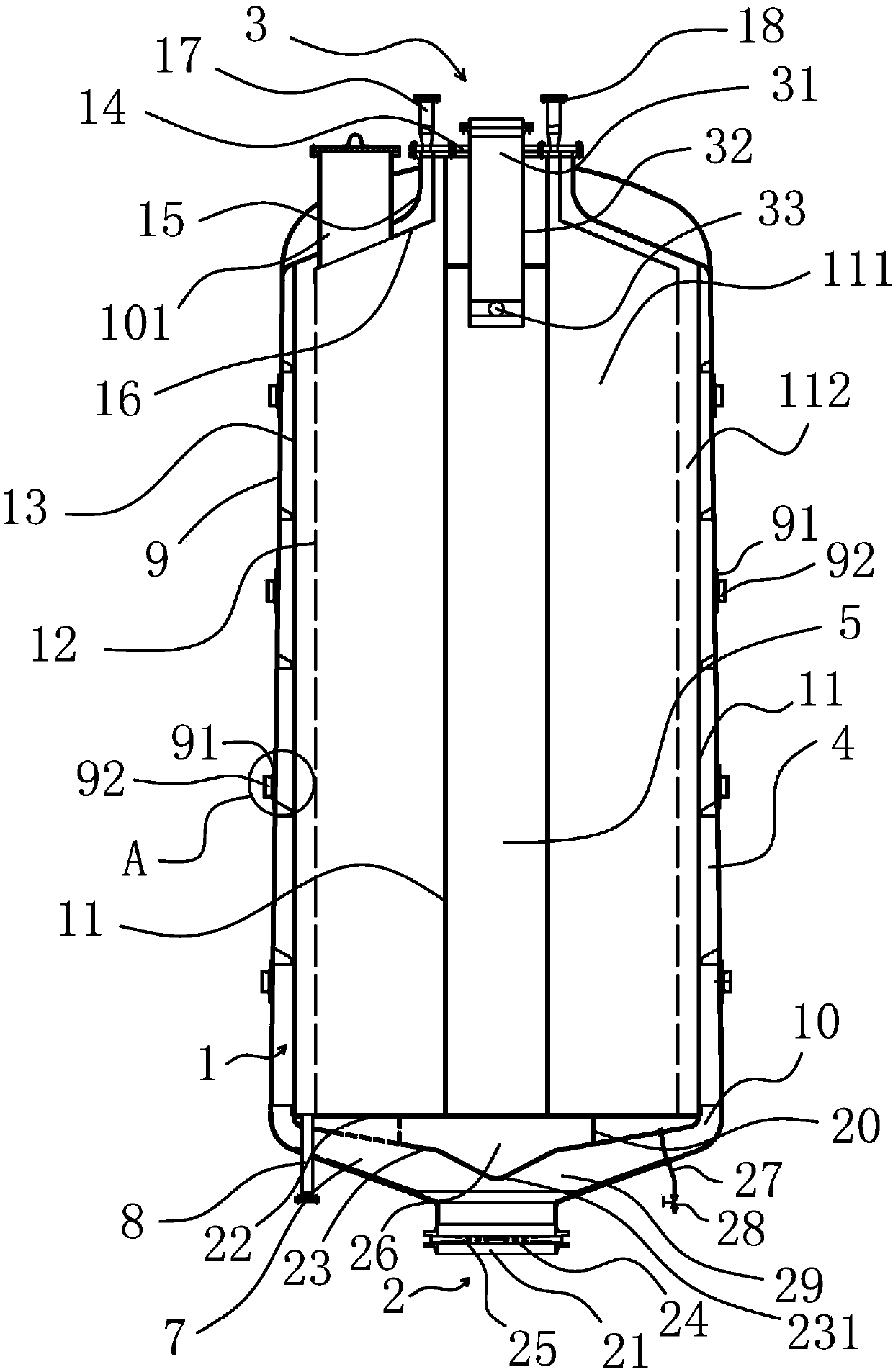

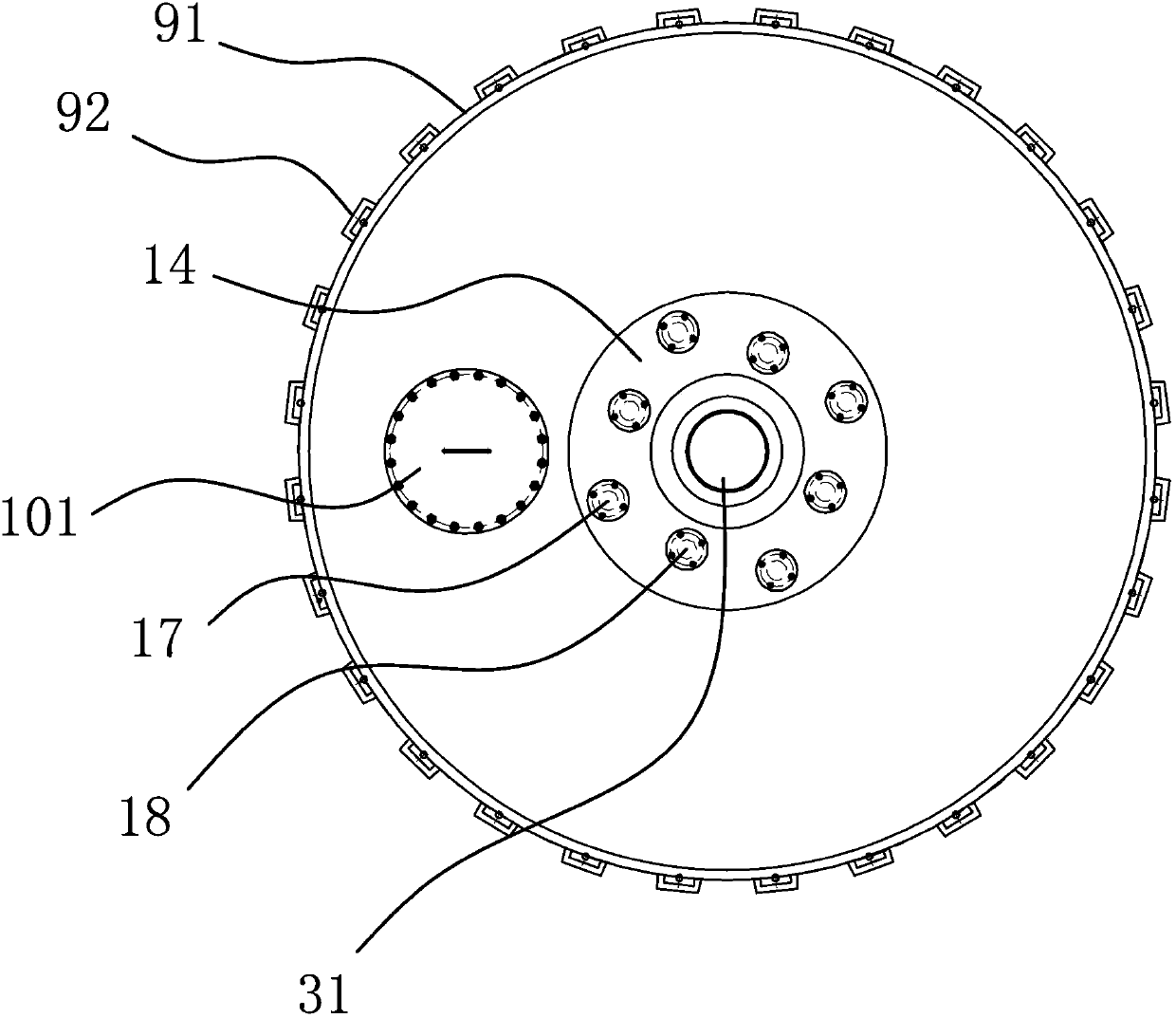

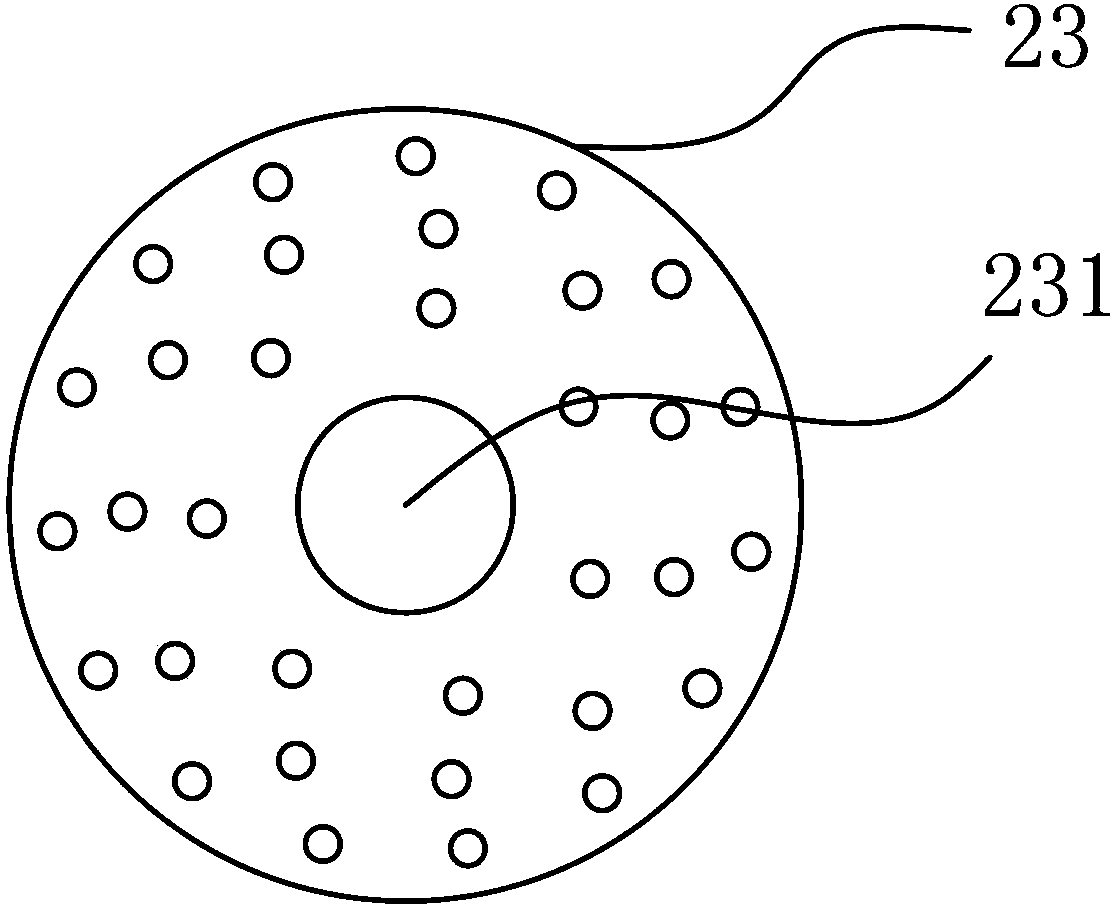

Radial oxygen production adsorption tower

ActiveCN103357243AUniform adsorptionImprove adsorption efficiencyDispersed particle separationOxygen preparationDiameter ratioMechanical equipment

The invention provides a radial oxygen production adsorption tower, belongs to the technical field of mechanical equipment, and solves the technical problems of too small height-diameter ratio, too large occupied floor space, non-uniform adsorption and the like in the prior art. The oxygen production adsorption tower comprises a cylindrical tower body, an gas inlet assembly disposed at the bottom of the tower body, an gas outlet assembly disposed at the top of the adsorption assembly, an adsorption assembly disposed in the tower body and a circular gas transportation cavity formed between the inner wall of the tower body and the outer wall of the adsorption wall, wherein the gas inlet assembly is provided with a circular gas vent disposed at the periphery of the lower end of the adsorption assembly; the circular gas vent is communicated with the gas transportation cavity; a gas flow can be transported to the adsorption assembly radially by the gas transportation cavity; two ends of the adsorption assembly are sealed; the center of the adsorption assembly is provided with a gas collection channel for collecting finished product oxygen; the lower end of the gas collection channel is sealed; and the upper end of the gas collection channel is communicated with the gas outlet assembly. The radial oxygen production adsorption tower has the advantages of uniform adsorption, high adsorption efficiency, small occupied floor space, large-scale designability, etc.

Owner:杭州普菲科空分设备有限公司

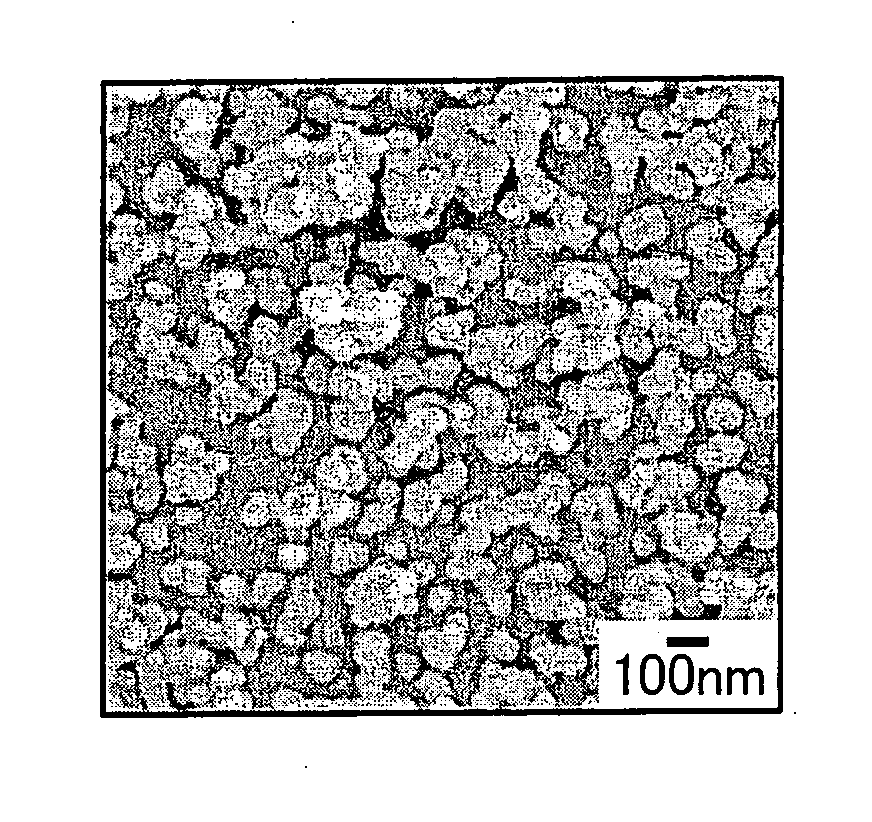

Ceramic particle group and method for production thereof and use thereof

ActiveUS7749429B2High resolutionDesirable reproducibilityMaterial nanotechnologyImpression capsSingle crystalSolvent

A ceramic particle group dispersed in a solvent in a state of primary particles of single crystal, a method for production thereof and a use thereof are disclosed. In one embodiment a method is disclosed for producing a sintered particle (ceramic particle) group of hydroxyapatite (HAp), which includes a step of subjecting a system wherein calcium carbonate is present between primary particles of hydroxyapatite (HAp) to sintering and then dissolving calcium carbonate with water to remove calcium carbonate. A hydroxyapatite (HAp) sintered particle group produced by the above method is a nanometer size particle group having a particle diameter of about 70 to about 120 nm, and is a particle group having a uniform particle diameter (coefficient of variation: 12%), and further 96% of the particle group is dispersed as a single crystal particle.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com