Vacuum adsorption clamp used for aspheric surface machining

A curved surface processing and vacuum adsorption technology, which is applied in the direction of manufacturing tools, metal processing equipment, working carriers, etc., can solve the problems of unstable processing and fragile workpieces, so as to avoid fragile workpieces, good rigidity, precision and high efficiency The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

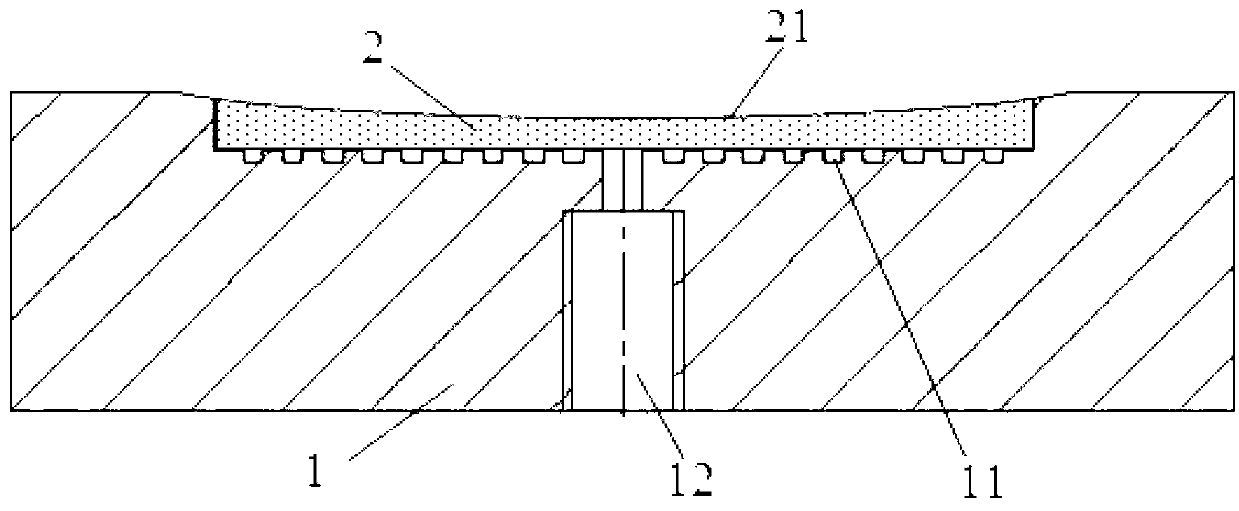

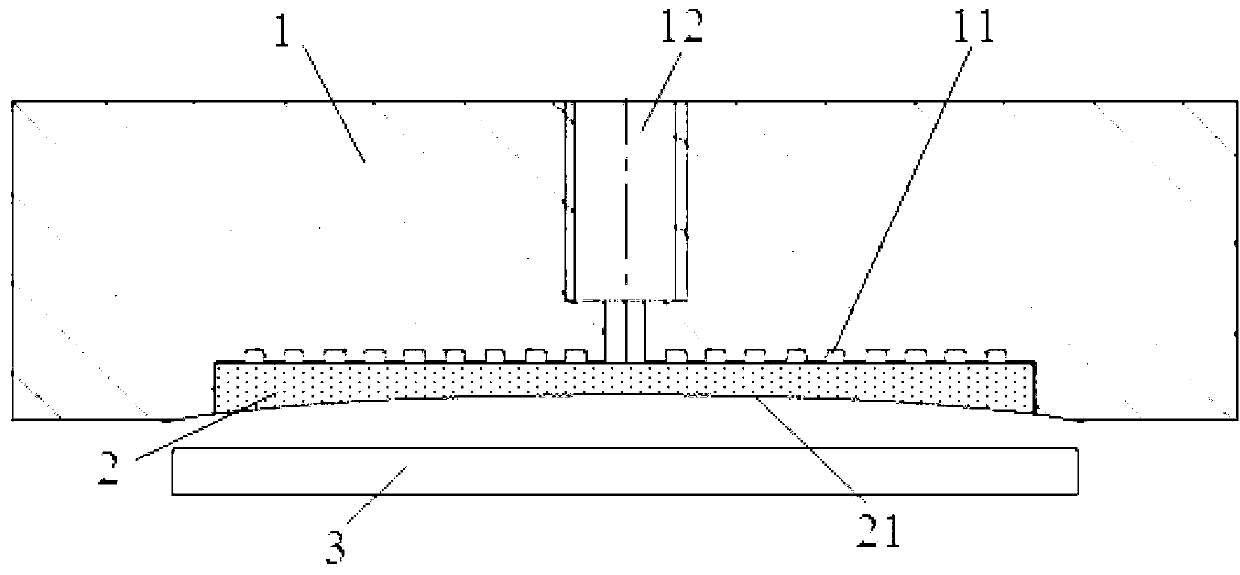

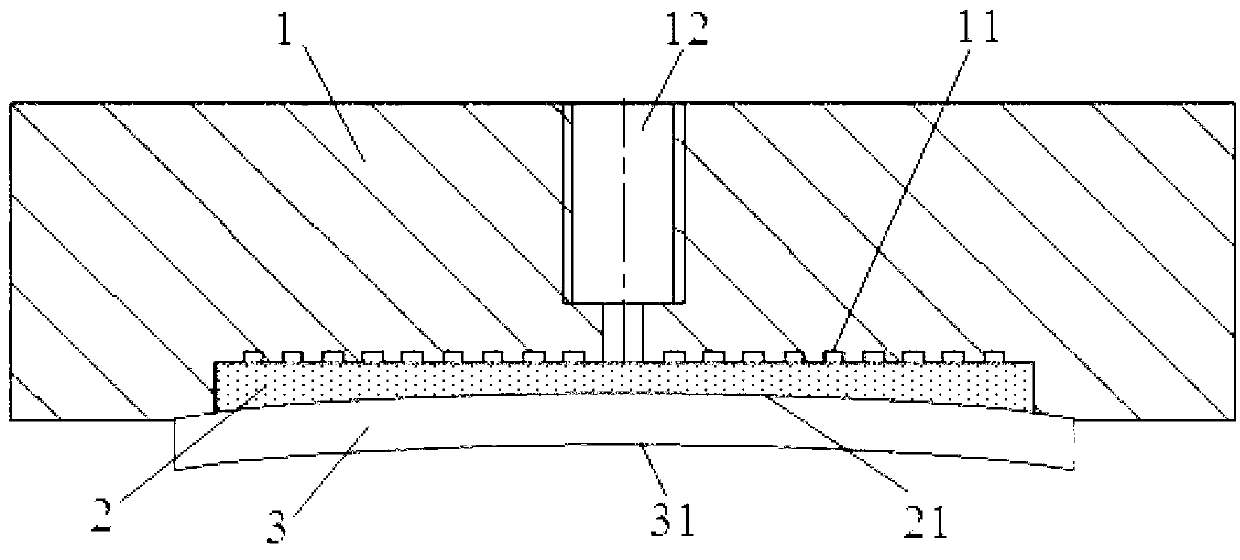

[0024] Embodiment 1 The vacuum adsorption fixture for processing aspheric surfaces according to the present invention includes a fixture body 1 and a master mold 2, and the upper surface of the fixture body 1 is provided with several concentric circular grooves with radial grooves Groove 11, the lower surface of the clamp body 1 is provided with a vacuum interface 12 communicated with the upper surface of the clamp body, and the vacuum interface 12 is connected with an external vacuum adsorption system through a vacuum interface clamp; The surface is a pattern surface 21, and the pattern surface 21 is processed into a curved surface opposite to the target surface shape and extending to the periphery of the clamp body, and the pattern 2 is fixed on the concentric surface of the upper surface of the clamp body 1 on groove 11.

[0025] The clamp body 1 is made of rigid hard material.

[0026] The master model 2 is made of porous ceramic material.

[0027] The upper surface of t...

Embodiment 2

[0031] Example 2 Using the aspheric surface vacuum adsorption jig involved in the present invention, an aspheric surface processing test based on the principle of elastic deformation surface shape replication was carried out. The material of the external clamp of the vacuum adsorption fixture is No. 45 steel, the material of the template is corundum porous ceramics with a porosity of 50% and an average pore diameter of 100 μm, and the surface of the template is a concave paraboloid with a diameter of 40 mm and a central curvature radius of 2500 mm. The workpiece material to be processed is quartz glass, and the plane grinding disc used is cast iron material plane grinding disc. The specific processing parameters are shown in Table 1:

[0032] Table 1 Processing parameter settings

[0033]

[0034] The machining process is stable and reliable, the phenomenon of workpiece fragmentation does not occur, and the sealing performance between the workpiece and the mold surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com