Patents

Literature

34results about How to "Efficient precision machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

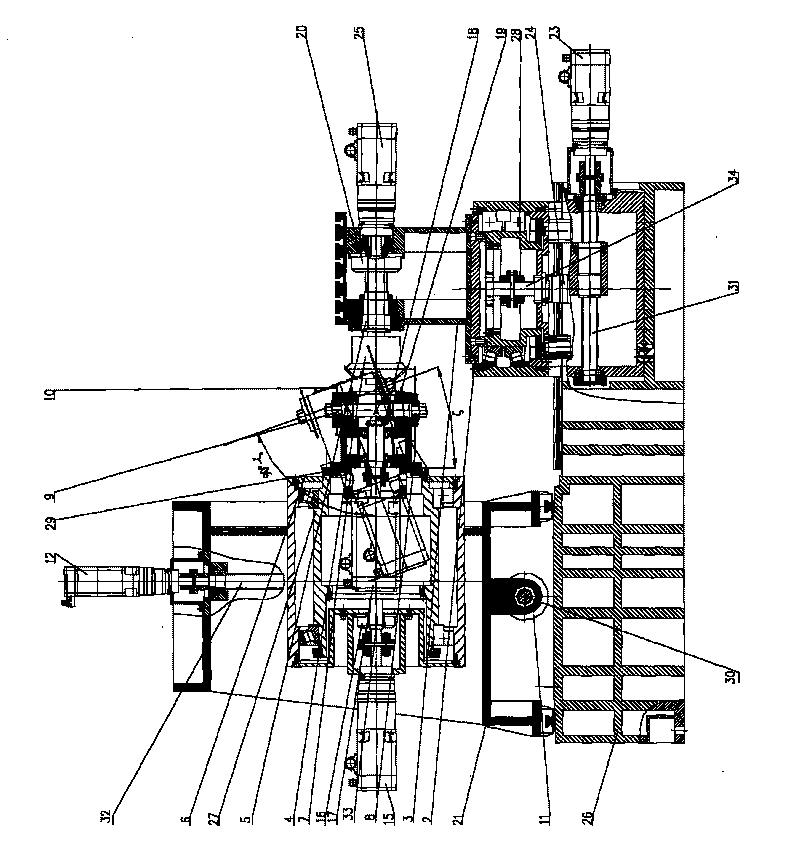

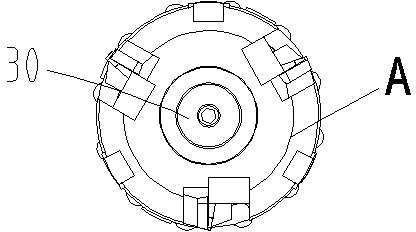

Spiral bevel gear cutting machine tool and gear cutting method

The invention discloses a spiral bevel gear cutting machine tool and a gear cutting method. The gear cutting machine tool comprises a cutting tool system, a workpiece system, a machine tool body and a numerical control system, wherein the cutting tool system comprises an XZ working table, an X-axis lead screw, a Z-axis lead screw, a short shaft, a tool base revolving drum, a tool base, No.1 milling cutters, a milling cutter shaft, No.2 milling cutters, a gear shaft and a correcting wedge. The rotating centre line of the tool base revolving drum and the rotating centre line of the short shaft are collinear; the right end surface of the tool base revolving drum is fixedly connected with an annular flange plate at the left end of the tool base by the correcting wedge; the right end of the tool base is provided with the milling cutter shaft; the rotating centre line of the milling cutter shaft and the rotating centre line of the short shaft are intersectant; and both ends of the milling cutter shaft are provided with the No.1 milling cutters, the No.2 milling cutters or grinding wheels. The left end surface of the tool base is provided with a drive motor; the drive motor is meshed with a bevel gear on the milling cutter shaft by the gear shaft; and the rotating centre line of the output shaft of the drive motor and the rotating centre line of the milling cutter shaft are vertically intersectant. The invention also provides a method for processing helical bevel gears by utilizing the machine tool.

Owner:JILIN UNIV

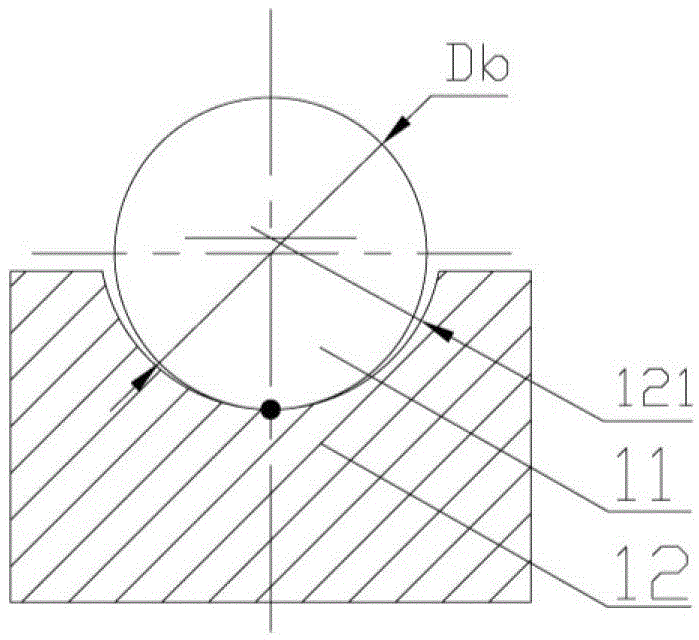

Machining method of rolling bearing formed by whole and precise hard turning and molding of sleeve ring

InactiveCN103331456AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesParticle adhesionEnvironmental resistance

The invention provides a machining method of a rolling bearing formed by whole and precise hard turning and molding of a sleeve ring. The machining method is characterized by comprising the following steps: after quenching and annealing heat treatment of the sleeve ring, carrying out the whole and precise hard turning and molding; and then combining and assembling a rolling body, wherein a sleeve ring rolling path comprises a fixed-curvature-groove-shape rolling path, a non-groove-shaped rolling path, a variable-curvature-shaped rolling path and a non-groove-shaped rolling path according to section shapes. The machining method disclosed by the invention overcomes the defects in the prior art that (1) performance defects on a machining surface, including grinding burn, a grinding metamorphic layer, grinding tensile stress, abrasive particle adhesion, scratches and the like, are caused by grinding and molding the sleeve ring; (2) shape defects on the machining surface that mutual position precision of all parts is not high, the shape of the rolling path cannot be accurately guaranteed and the like, are caused by carrying out a plurality of times of machining on different surfaces, even the same surface; (3) the defects that large investment of equipment, a tool clamp and personnel, and high machining cost are caused; and (4) the defects that a cutting solution needs to be used and the machining method is not environment-friendly enough are caused. The invention provides an anti-fatigue and green machining method which has the very great engineering actual meanings.

Owner:SHANGHAI F&S BEARING TECH

Machining method for rolling bearing with ring precisely shaped by hard finishing

ActiveCN103737024AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesRolling-element bearingBurn injury

Disclosed is a machining method for a rolling bearing with a ring precisely shaped by hard finishing. The machining method is characterized in that an inner ring and an outer ring of the bearing are integrally precisely shaped by hard finishing or the key surface of a ring part is precisely shaped by hard finishing; the key surface comprises raceways, raceway flanges, raceway oil grooves, seal grooves, ring flanges, grooved raceway edge chamfers and the like; precise shaping by hard finishing takes the place of grinding (such as the raceways) shaping and shaping by soft finishing (such as the sealing grooves), so that technical and quality problems of limited shape design of a raceway section, grinding badness even burn injuries and the like are solved; the technical and quality problems of low machining precision, heat treatment distortion and the like existing in shaping surfaces of the sealing grooves, the grooved raceway edge chamfers and the like by soft finishing are solved by precise hard finishing, so that the surfaces of the ring can be designed according to the operating condition and can be shaped precisely in a quite high mode, and the key surface of the ring can be controlled in shape and performance, and designing and manufacturing of the high-performance rolling bearing high in sealability and reliability and the like are of great practical engineering significance.

Owner:SHANGHAI F&S BEARING TECH

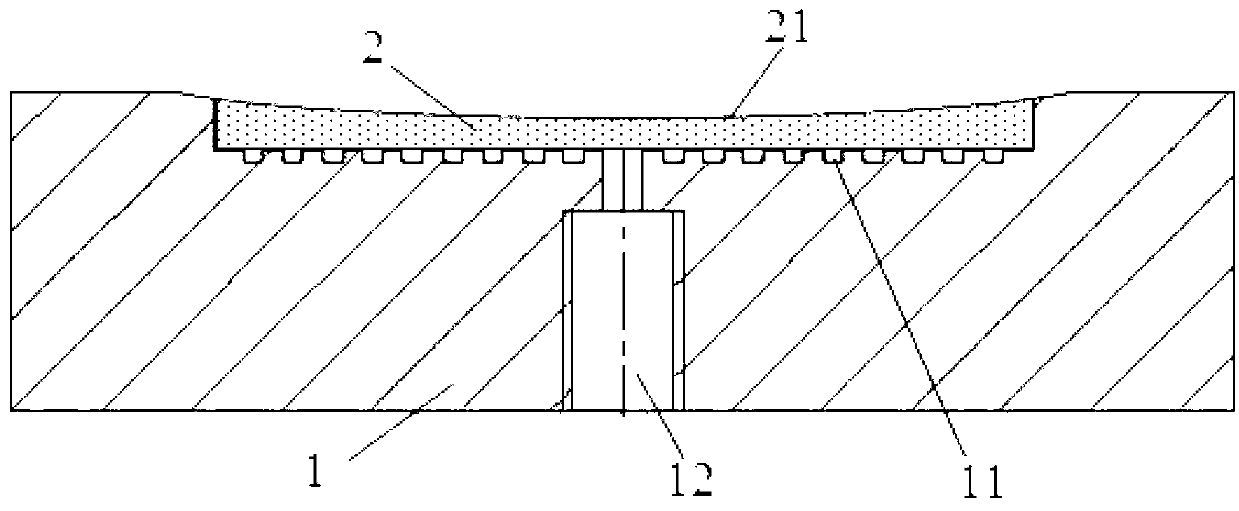

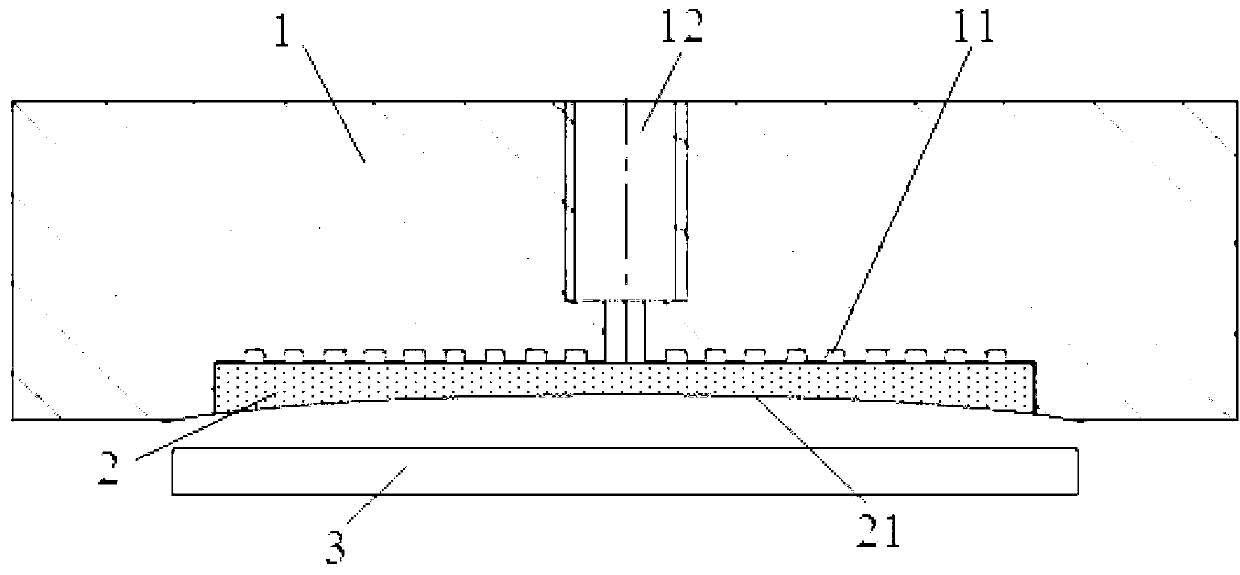

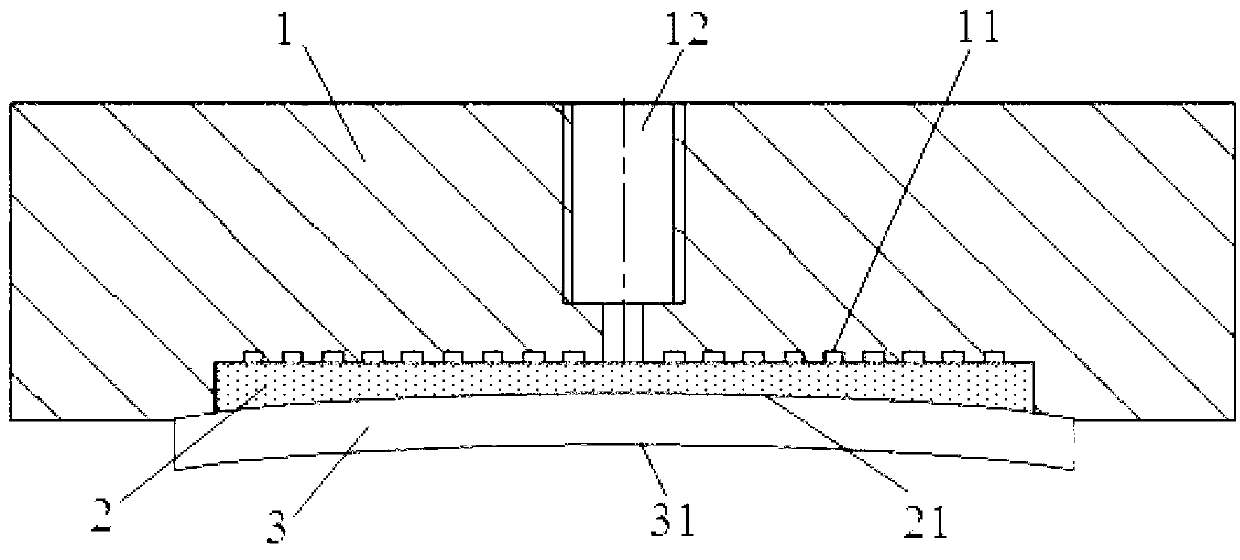

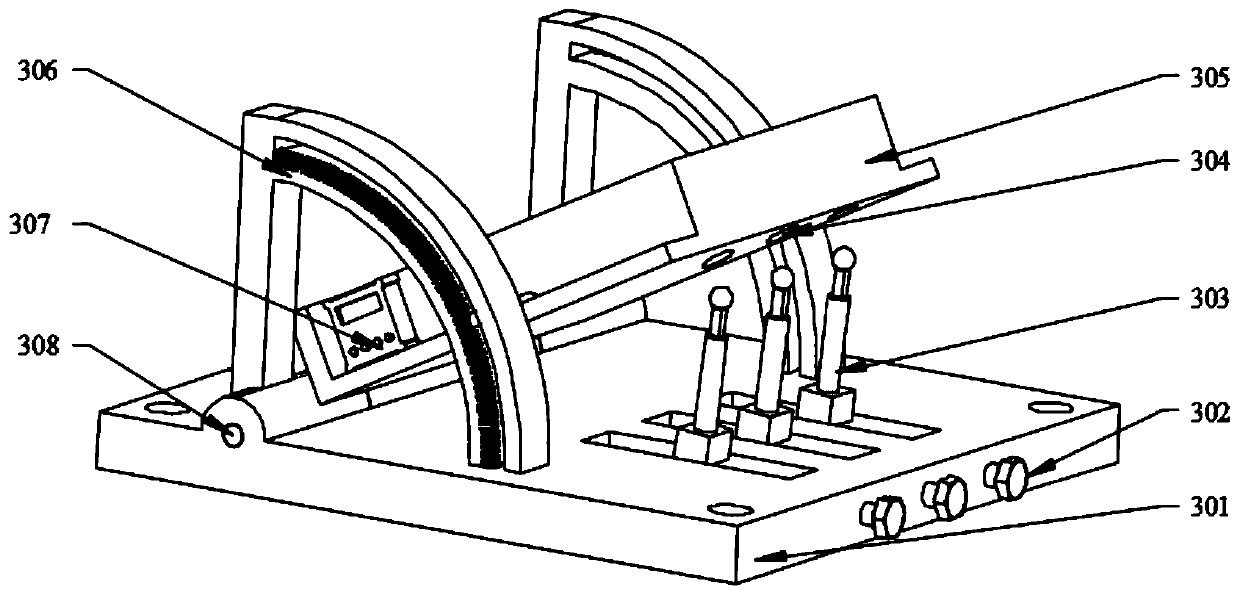

Vacuum adsorption clamp used for aspheric surface machining

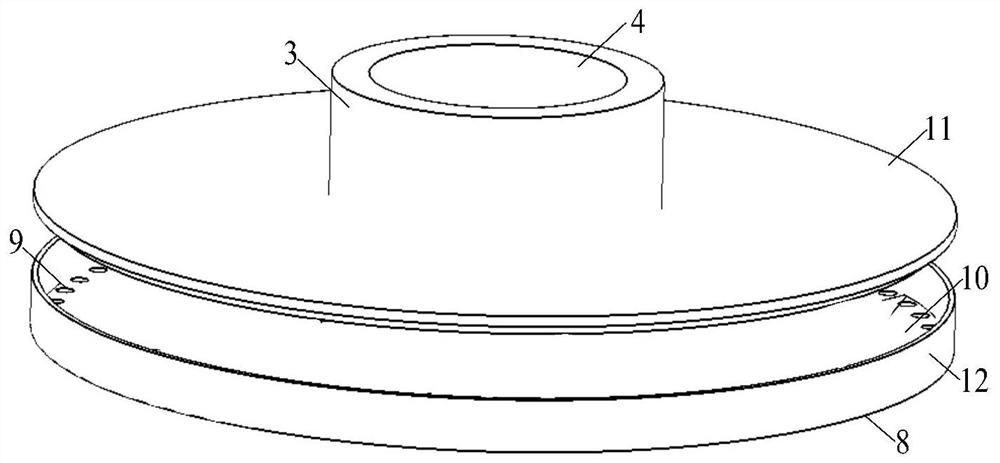

InactiveCN103341818AUniform adsorptionImprove rigidityLapping machinesWork carriersTarget surfaceSurface type

A vacuum adsorption clamp used for aspheric surface machining comprises a clamp body and a profiling mold, wherein a plurality of concentric circle grooves with radial slots are formed in the upper surface of the clamp body, a vacuum connector is arranged on the lower surface of the clamp body and communicated with the upper surface of the clamp body, and the vacuum connector is connected with an outer vacuum adsorption system through a vacuum connector clamp. The upper surface of the profiling mold is a profiling mold face, the profiling mold face is machined to be a curved surface which is opposite to a target surface shape and extends to the periphery of the clamp body, and the profiling mold is fixed on the concentric circle grooves in the upper surface of the clamp body. The vacuum absorption clamp used for the aspheric surface machining has the advantages that porous ceramics material is used, the problem that a workpiece in a groove profiling mold made of hard material is prone to cracking can be avoided, and stability and reliability of the process of elastic deformation surface type copying and machining are ensured; meanwhile, the porous ceramics material has the advantages of being even in adsorption and good in rigidity, and therefore surface type accuracy of the aspheric surface machining can be ensured.

Owner:ZHEJIANG UNIV OF TECH

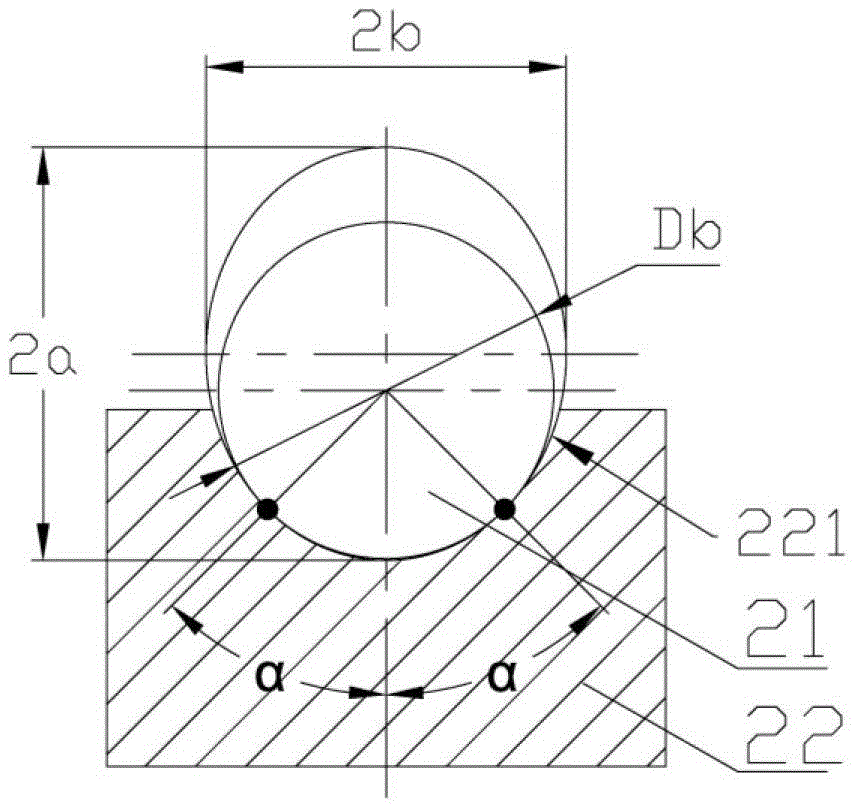

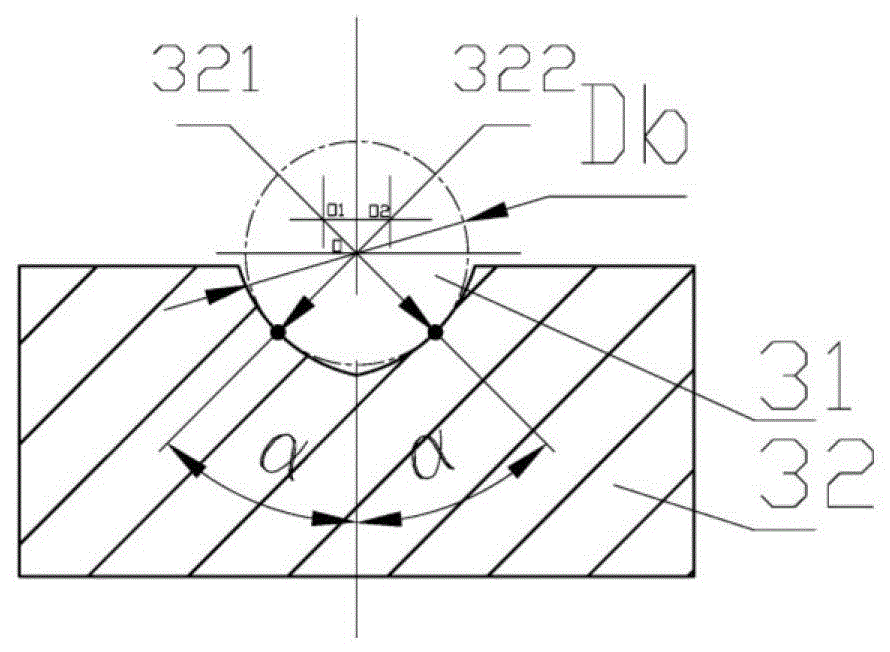

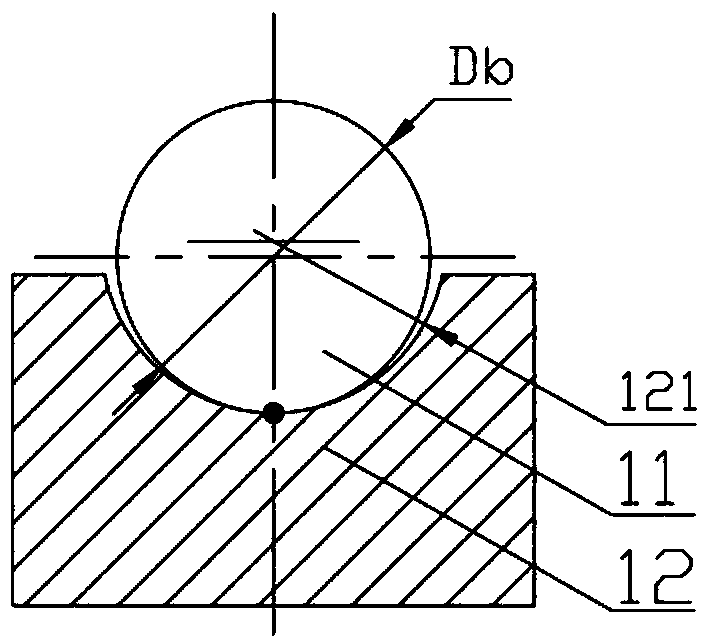

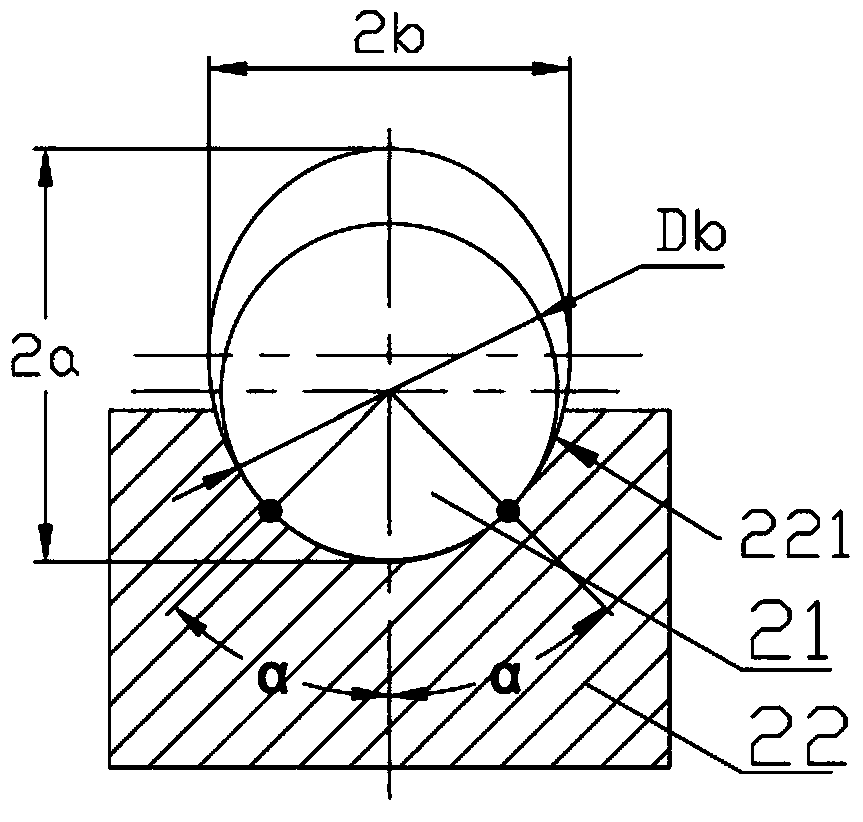

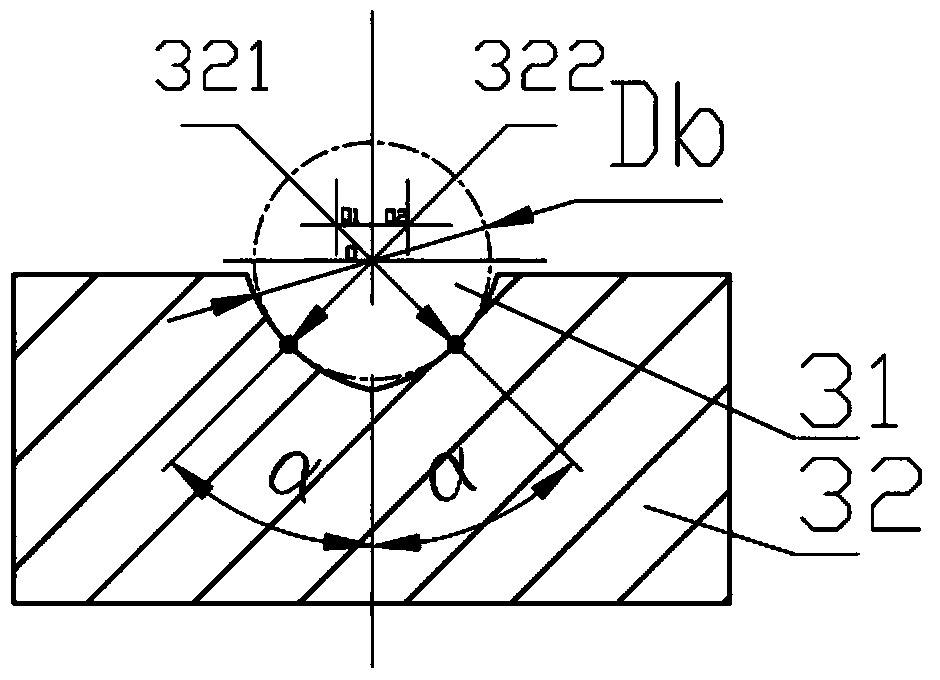

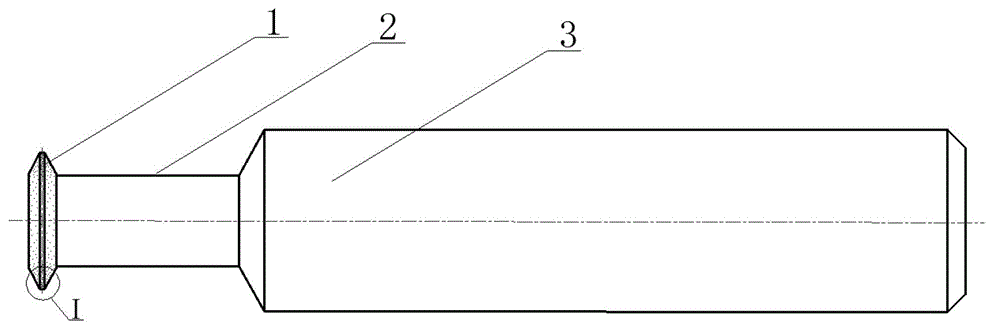

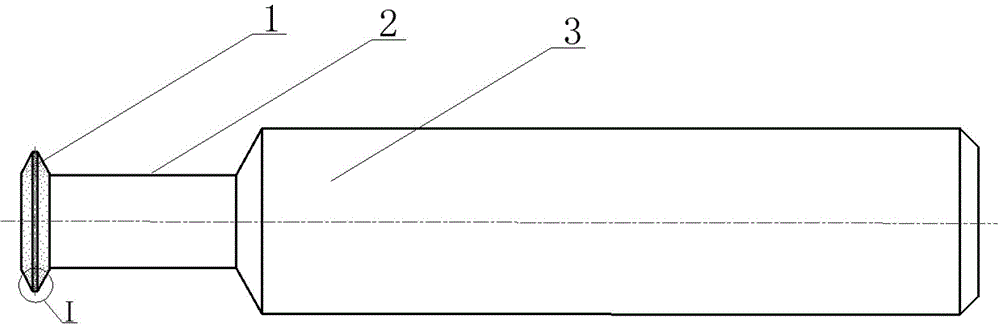

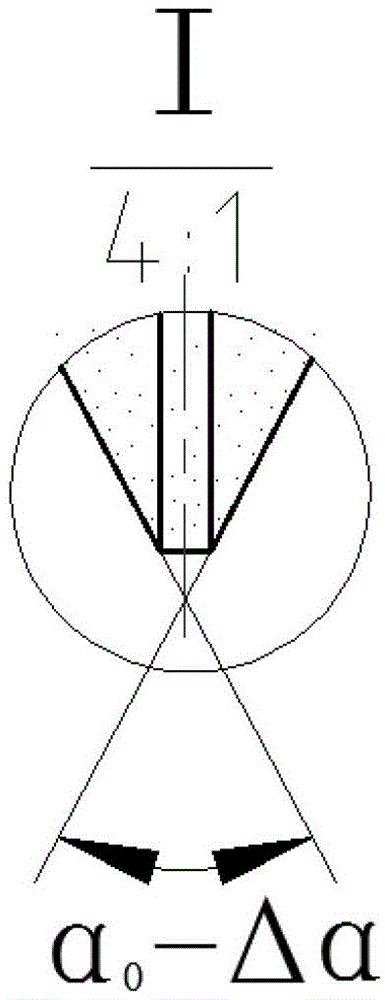

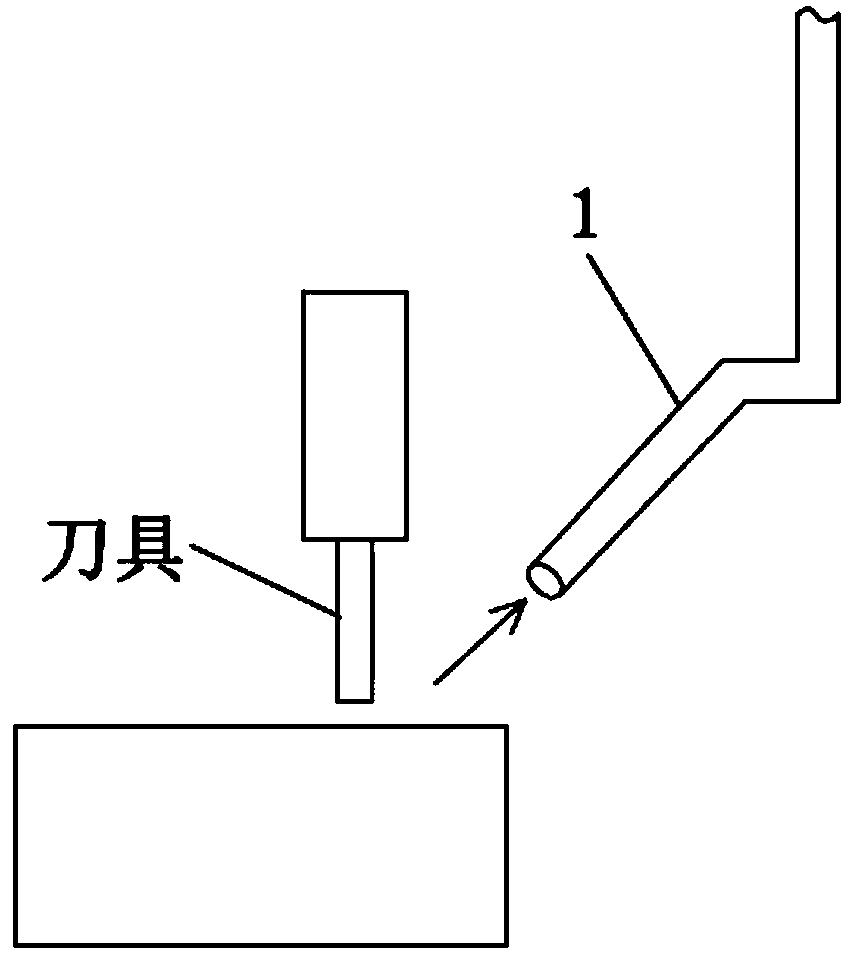

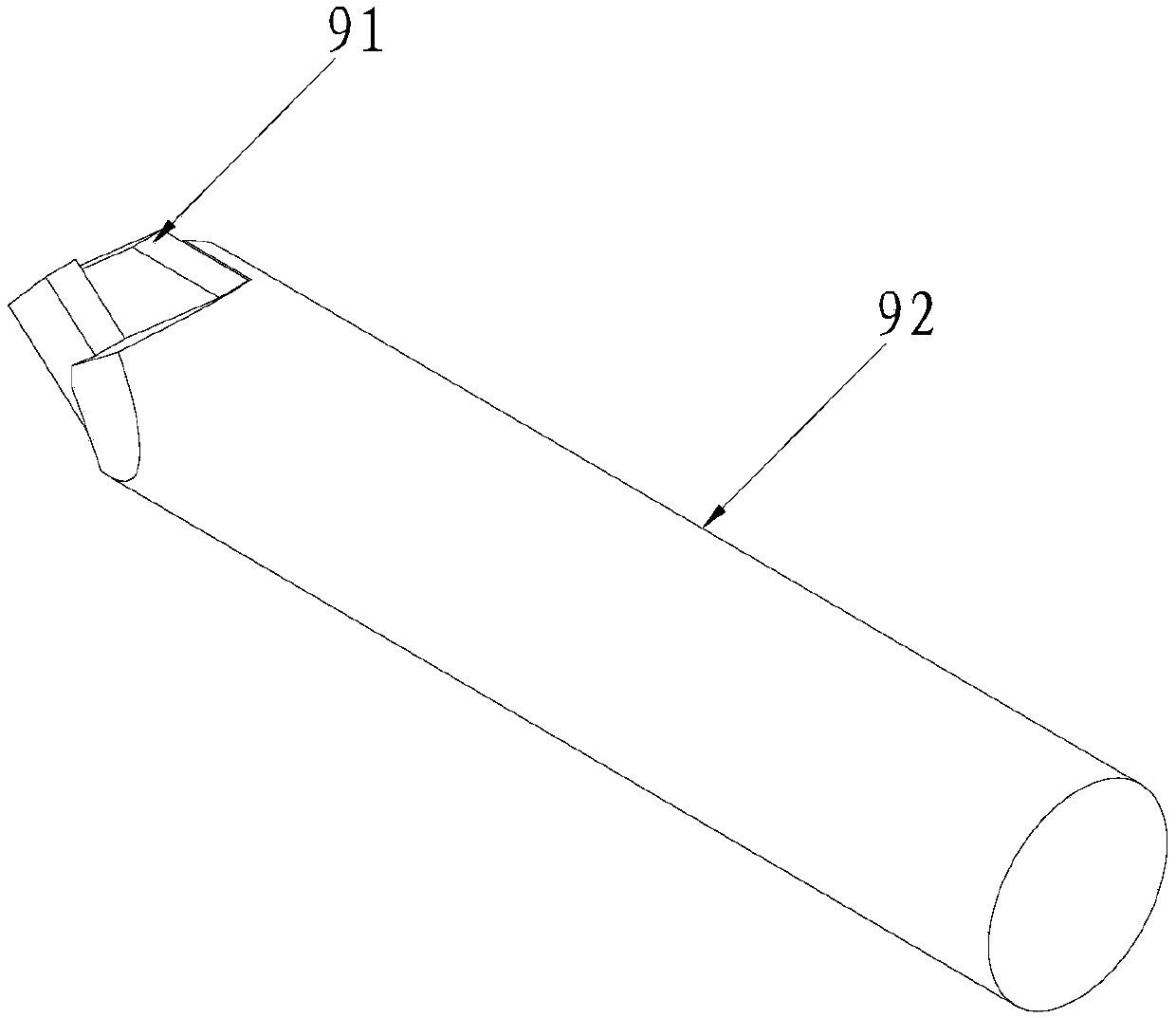

Molding grinding wheel for grinding small-hole threads of hard and brittle materials

ActiveCN102941382ASolution to short lifeEfficient precision machiningThread cutting toolsBoron nitrideGrinding wheel

The invention discloses a molding grinding wheel for grinding small-hole threads of hard and brittle materials and belongs to the technical field of machinery manufacturing. The molding grinding wheel is characterized in that the axial section included angle alpha of the disc-shaped molding grinding wheel is determined by the formula alpha=alpha0 Dalpha, wherein the alpha0 is the thread standard thread angle, the Dalpha is the grinding wheel axial section profiling quantity Dalpha corresponding to the minimum thread profile error deltamin; the diameter DS of the disc-shaped molding grinding wheel is determined by the formula DS=d0+zetah0, wherein the h0 is the height of the thread profile, the d0 is the diameter of a cutter bar, and the zeta is a correction factor; and the diameter of the cutter bar d0 is determined by the formula d0=lambdah0, wherein the lambda is a proportionality coefficient. A composite plating process is adopted to enable diamond or cubic boron nitride (CBN) micro powder grains to be solidified on the surface of a base body of the disc-shaped molding grinding wheel. The molding grinding wheel has the advantages that the problems of severe abrasion, breakage, low efficiency and failure of drying process of screw tap tools for processing the small-hole threads of hard and brittle materials are solved, chips discharge is smooth, coolants are not needed to add, and precise and efficient process of the small-hole threads of the hard and brittle materials is achieved.

Owner:DALIAN UNIV OF TECH

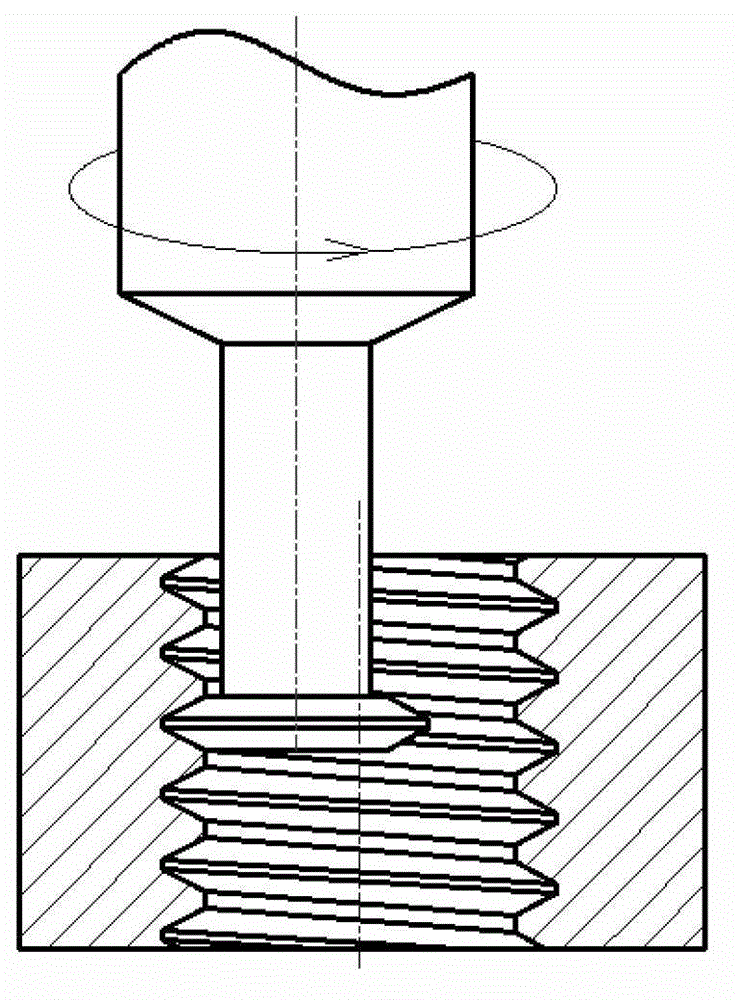

Magnetic toughening method for inhibiting machinery damage of hard and brittle materials

ActiveCN109534690AEfficient precision machiningImprove machined surface qualityCoatingsSurface layerLiquid state

The invention provides a magnetic toughening method for inhibiting machinery damage of hard and brittle materials and belongs to the technical field of quality control of machinery process. Accordingto the method, a hard and brittle material is immersed in a clamping mold filled with a magnetorheological fluid, and then the magnetorheological fluid infiltrates into pores, cracks and other defectson the surface layer of the hard and brittle material and liquid-state encapsulation is formed around workpieces; and during machining, a controllable magnetic field is applied such that the magnetorheological fluid is affected by the magnetic force to generate a magnetorheological effect and a high-viscosity elastic film having high yield strength is formed. Thereby, the magnetorheological fluidin the defects on the surface layer of the hard and brittle material is solidified to form a hole-sealed toughening mechanism. The magnetorheological fluid around the material is solidified to form three-dimensional circumferential compressive pre-stress encapsulation, and impact vibration and energy applied by cutters such as a grinding wheel, etc. on the workpieces can be absorbed, and it is helpful for inhibiting the cracks from extending in the deep radial direction or towards side edges. Thereby, defects such as cracks, surface fracture, breaking of edges, etc. are reduced, and machiningquality is improved.

Owner:中国人民解放军火箭军工程大学

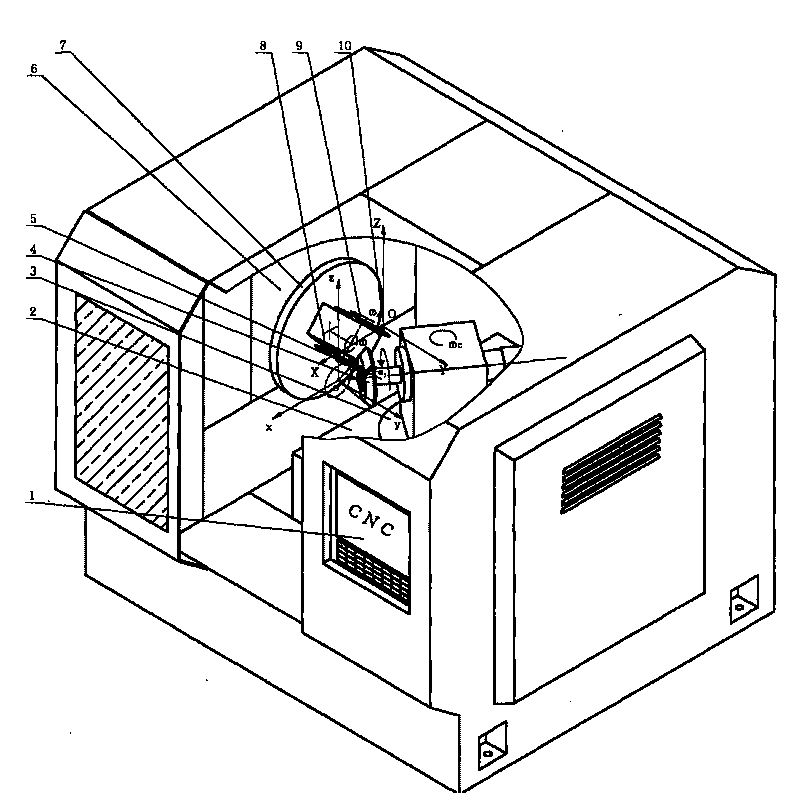

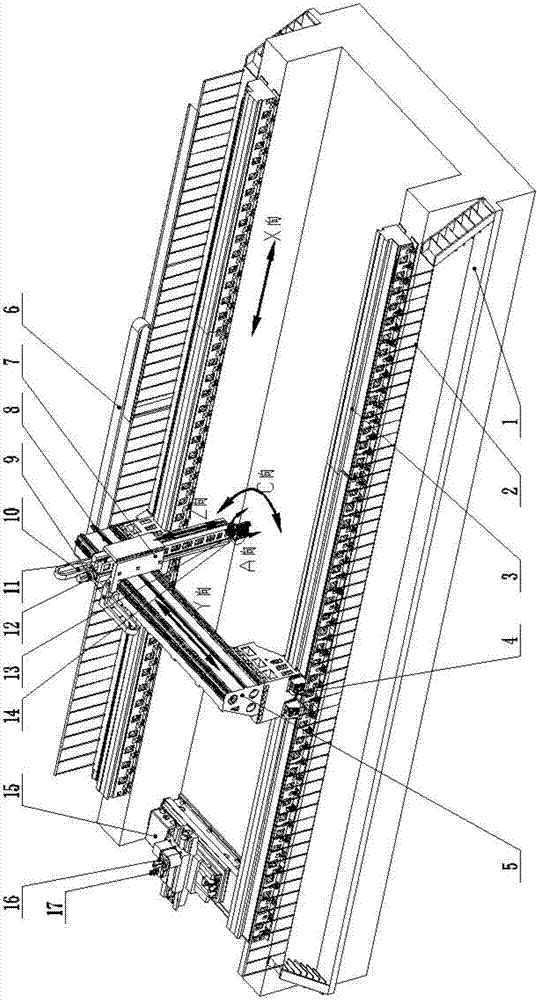

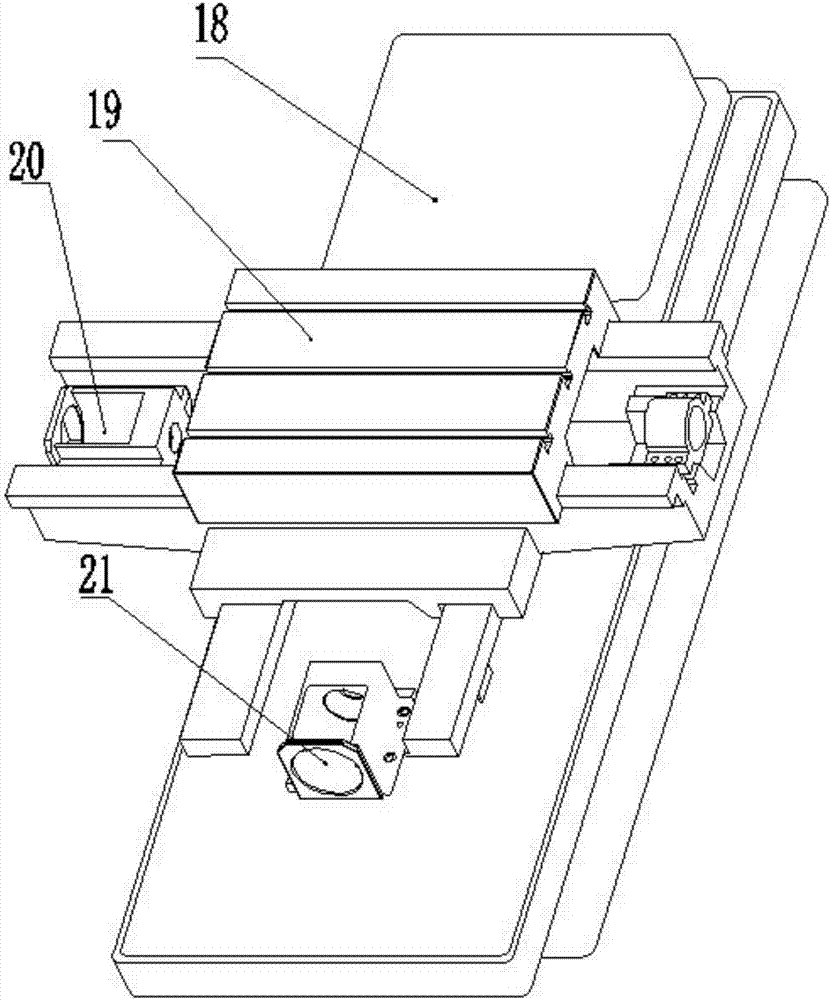

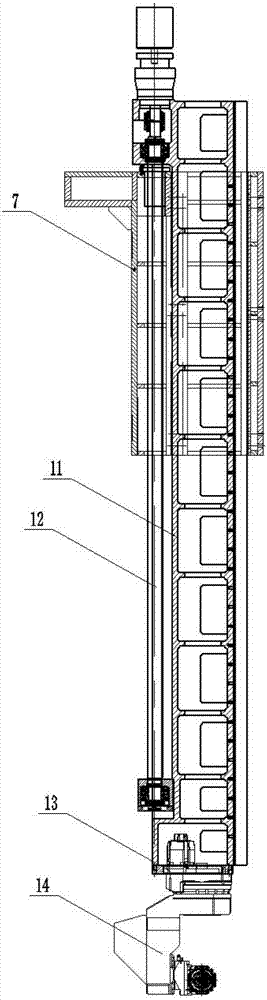

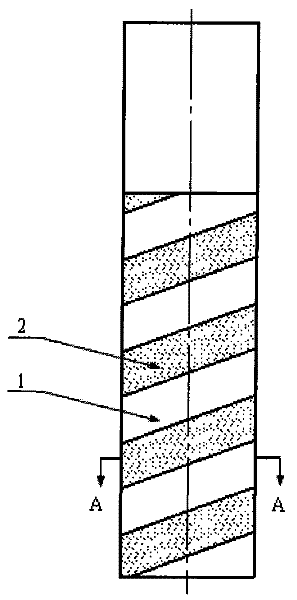

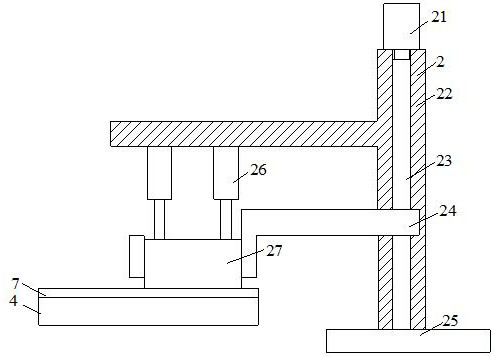

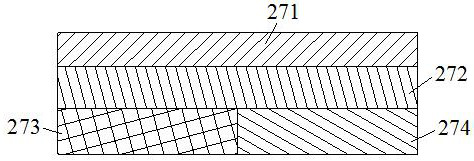

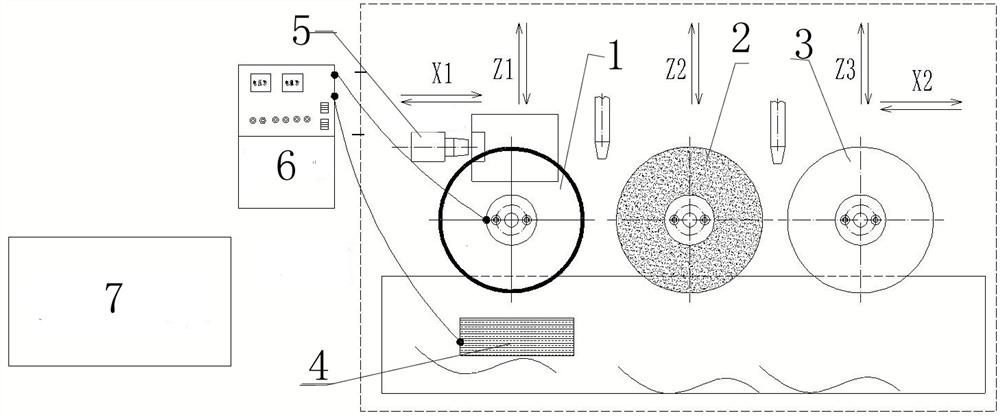

Large-sized bridge type gantry mixed machining machine tool and machining method thereof

PendingCN107214523AEfficient precision machiningLess investmentMeasurement/indication equipmentsOther manufacturing equipments/toolsManufacturing engineeringConventional casting

The invention discloses a large-sized bridge type gantry mixed machining machine tool which is characterized by comprising a base (1), a working corridor (2), a machine tool body (3), an X-axis feeding system (4), a cross beam (5), a Y-axis feeding system (8), a slide carriage (7), a square ram (11), a Z-axis feeding system (12), a C-axis feeding system, an A-axis feeding system, an actuation mechanism interface (13) and an actuation unit library (15). By combination of a modern additive manufacturing process and a milling process, efficient and precision machining of a large-size die is realized, and the efficiency is 10 times or much higher than that of machining with a conventional die, but the cost is only 30 percent of that of a conventional process; and the large-sized bridge type gantry mixed machining machine tool meets a customization requirement and intelligence and flexibility requirements in the future and has good prospect. The large-sized bridge type gantry mixed machining machine tool replaces a conventional casting die, can quickly make a response to a demand of a client, and saves the die investment by 60 percent or above.

Owner:NANJING GONGDA CNC TECH

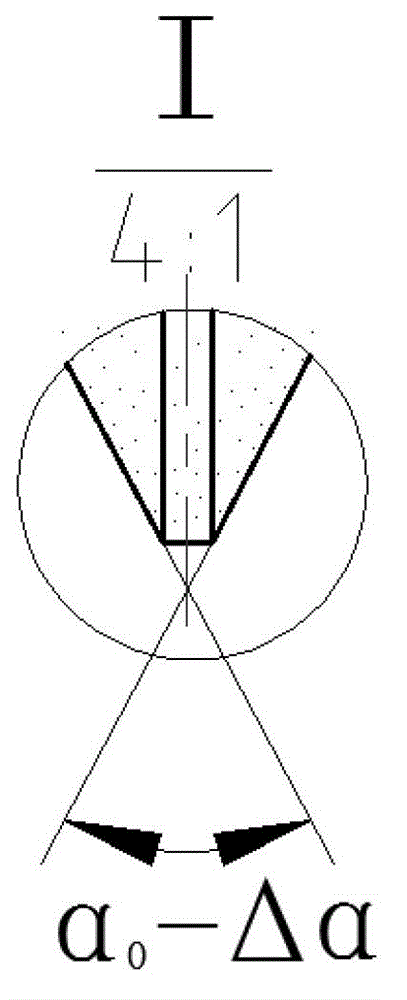

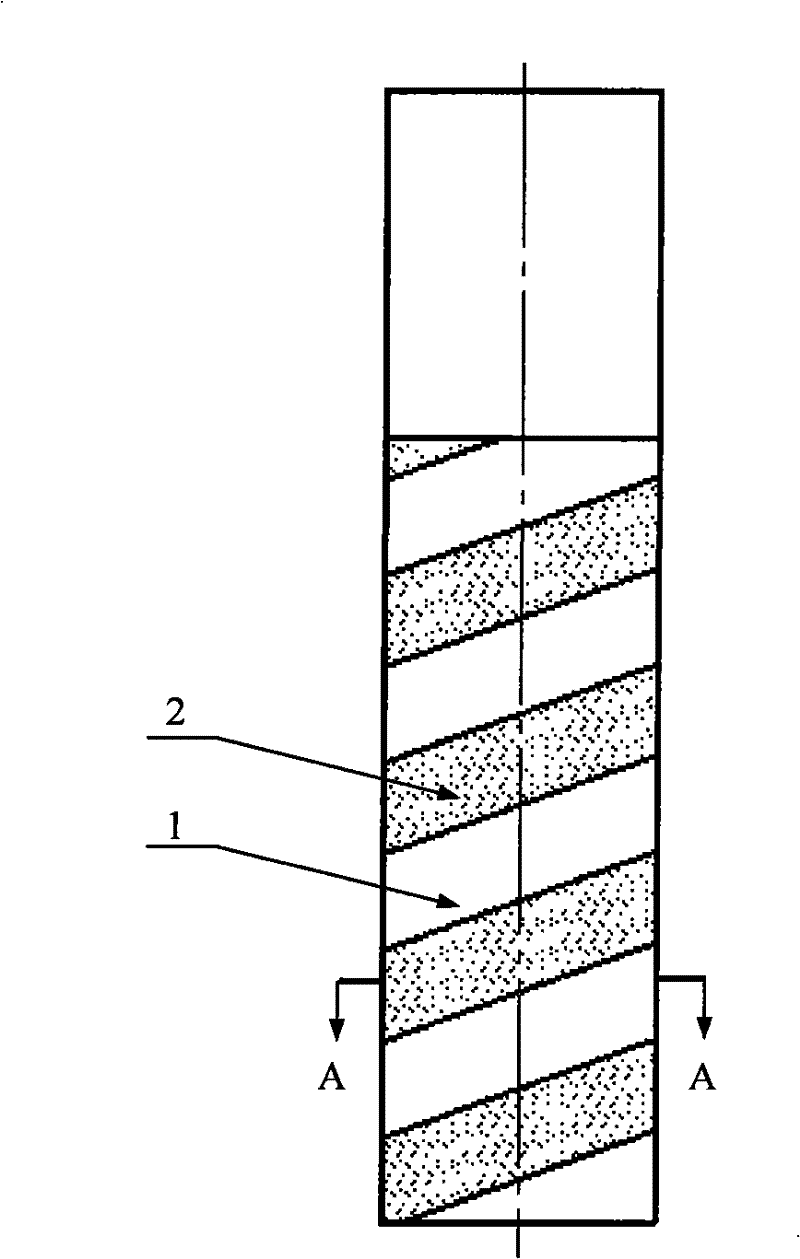

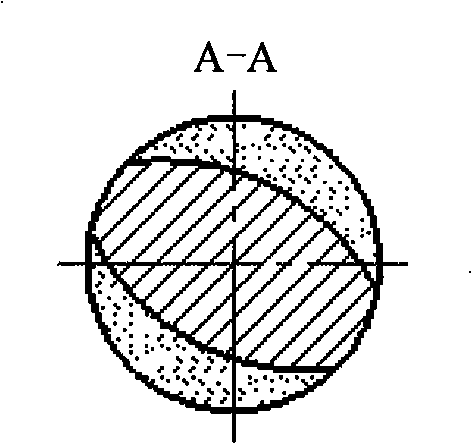

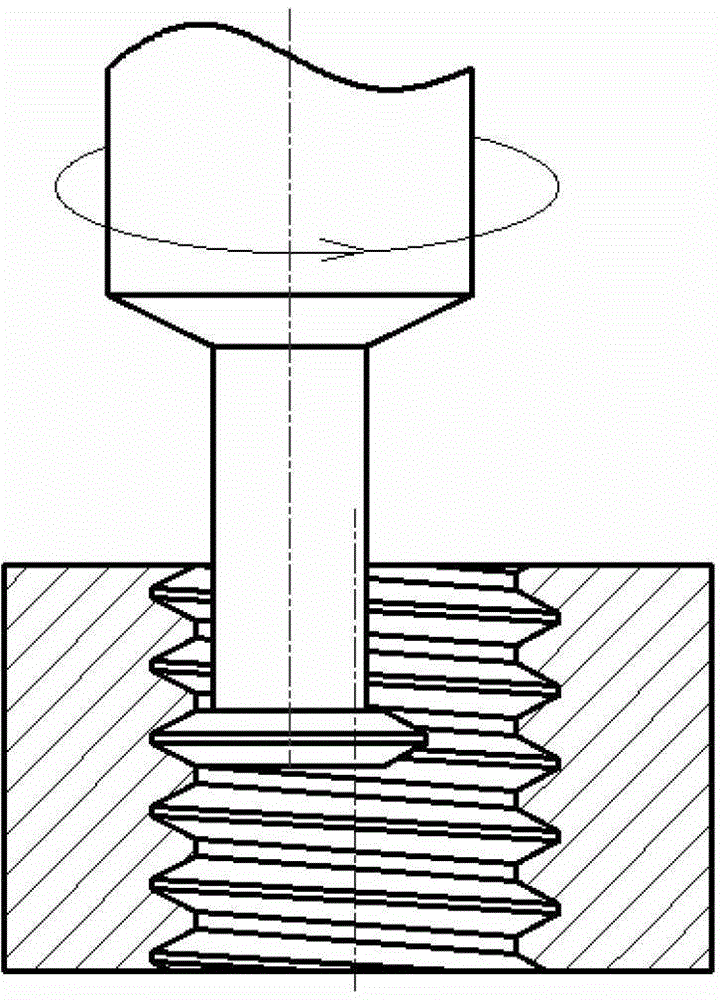

Electric spark milling and mechanical grinding composite machining tool electrode

ActiveCN101497142BImprove stabilityAvoid stable arcingElectrical-based machining electrodesEngineeringPulse power supply

The invention relates to an electric spark milling and mechanical grinding combined machining tool electrode, and belongs to the field of non conventional machining. The tool electrode consists of two parts, namely a metal tool electrode 1 and a grinding body 2, wherein the metal tool electrode 1 is cylindrical, and the periphery of the metal tool electrode 1 is provided with a spiral groove; thegrinding body 2 is an insulated sand-containing rubbing block; and the grinding body 2 is filled and consolidated in the spiral groove of the metal tool electrode 1, and the diameter of the grinding body 2 is the same as that of the metal tool electrode 1. When the tool electrode performs processing, the tool electrode of the invention and a workpiece are connected with two poles of a pulse powersource, and the tool electrode realizes electric spark milling and mechanical grinding combined machining for the workpiece through electric spark milling of the metal tool electrode 1 and the mechanical grinding of the grinding body 2. The electric spark milling and mechanical grinding combined machining tool electrode has the advantages of simple structure, high processing efficiency and precision, low cost, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

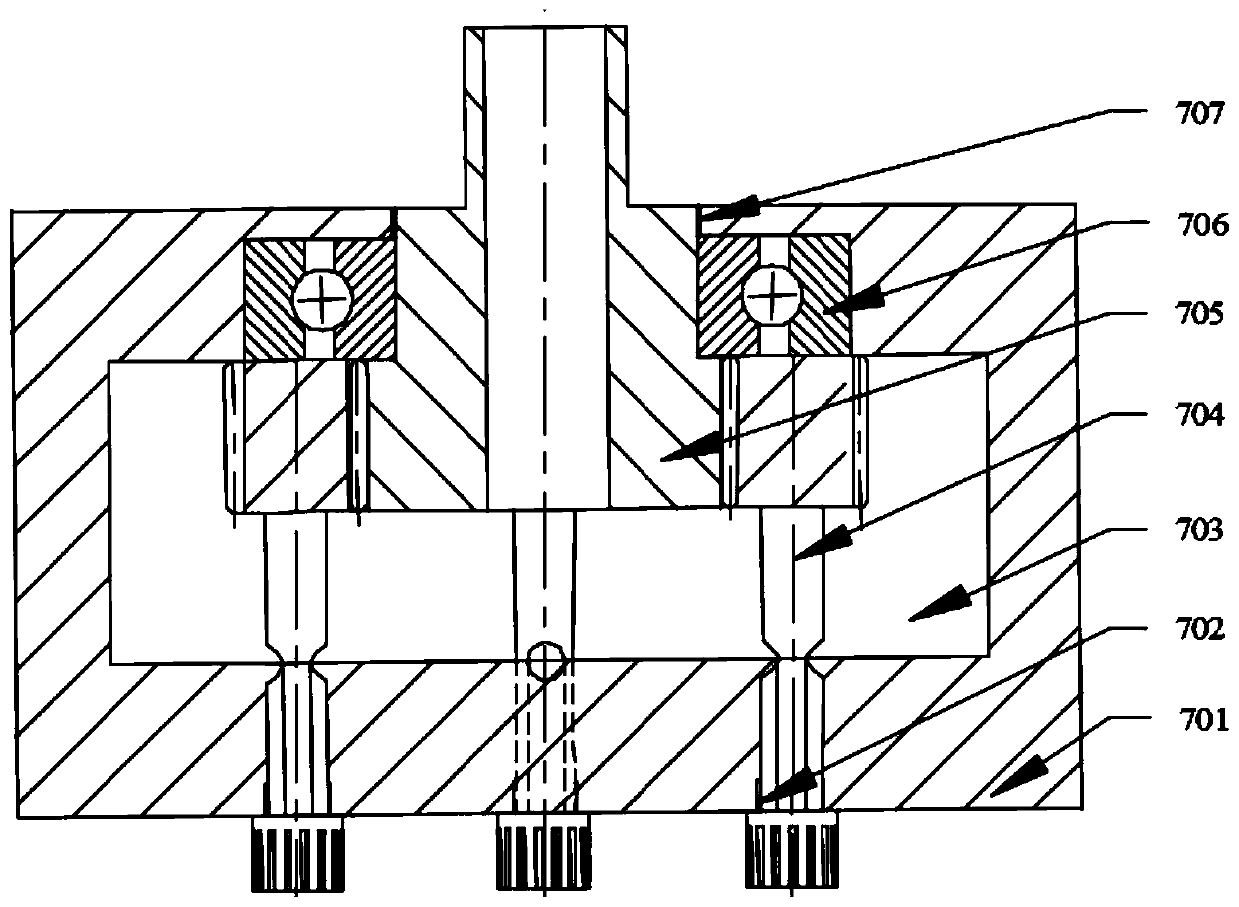

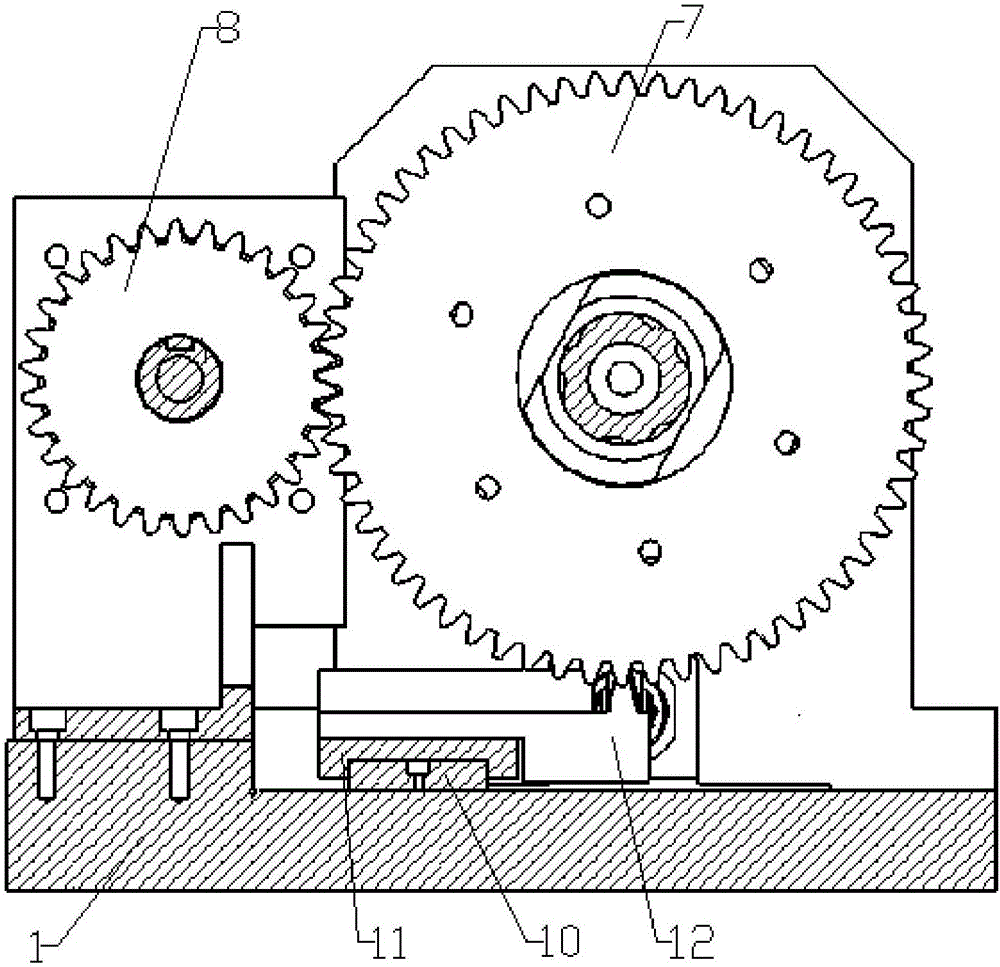

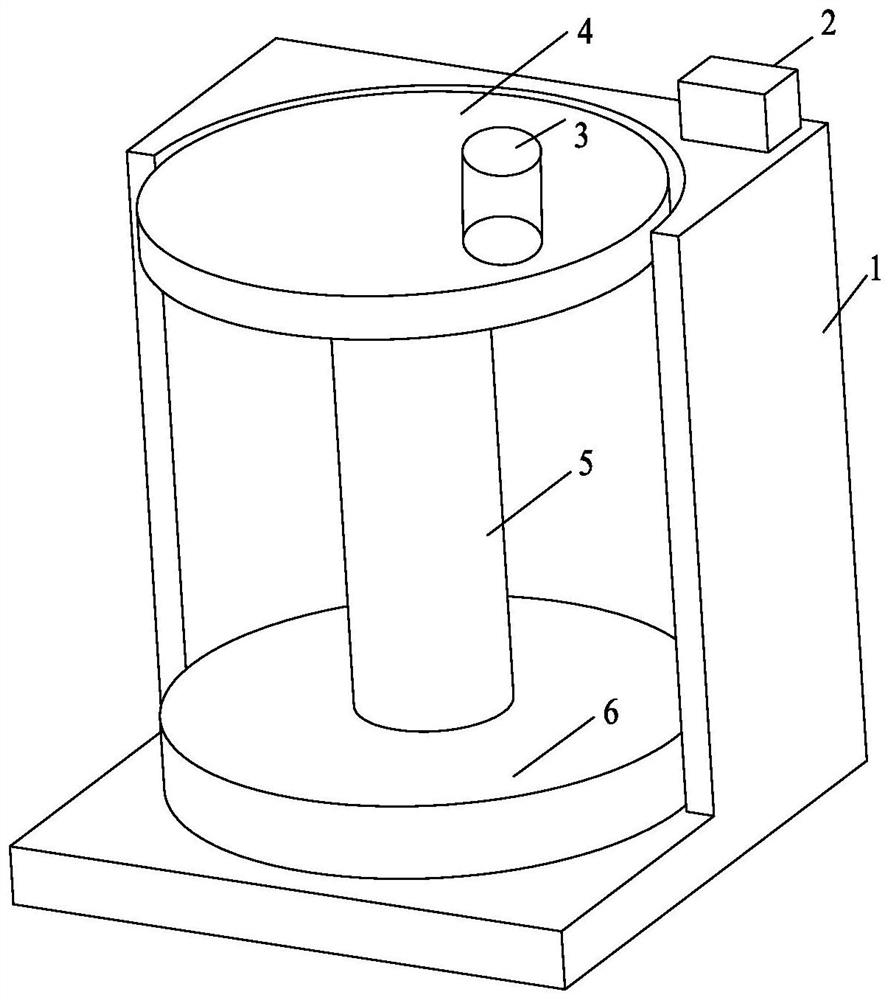

Ultrasonic vibration assisted electrolysis matrix oblique square hole processing system and method

InactiveCN111151830APromote breakdownIncrease dissolution rateMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolytic agentVibration amplitude

The invention provides an ultrasonic vibration assisted electrolysis matrix oblique square hole processing system and a method. The ultrasonic vibration assisted electrolysis matrix oblique square hole processing system includes a three-dimensional motion mechanism, a control device, a transition device, a workbench, an ultrasonic vibration device and a hollow electric spindle. The three-dimensional movement can drive the hollow electric spindle to move in a three-dimensional mode relative to the worktable, the ultrasonic vibration device can apply ultrasonic cavitation to the hollow electricspindle during the process of supplying electrolyte by an inner hole of the hollow electric spindle, the transition device is arranged between the hollow electric spindle and an electrode assembly, the transition device includes a plurality of gear shafts and dynamic sealing rings which revolve around the hollow electric spindle and can rotate, and the dynamic sealing rings can connect the ends ofthe gear shafts and tube electrodes. The tube electrodes and conducting rings are all synergistically driven by the transition device and a pulsed power supply, the workbench is used to carry components to be processed, and the angle is variable. By adjusting the electrolytic grinding current, ultrasonic vibration frequency, amplitude, rotating speed of the hollow electric spindle and the angle of the workbench, precision machining of an oblique square hole is realized.

Owner:SHANDONG UNIV

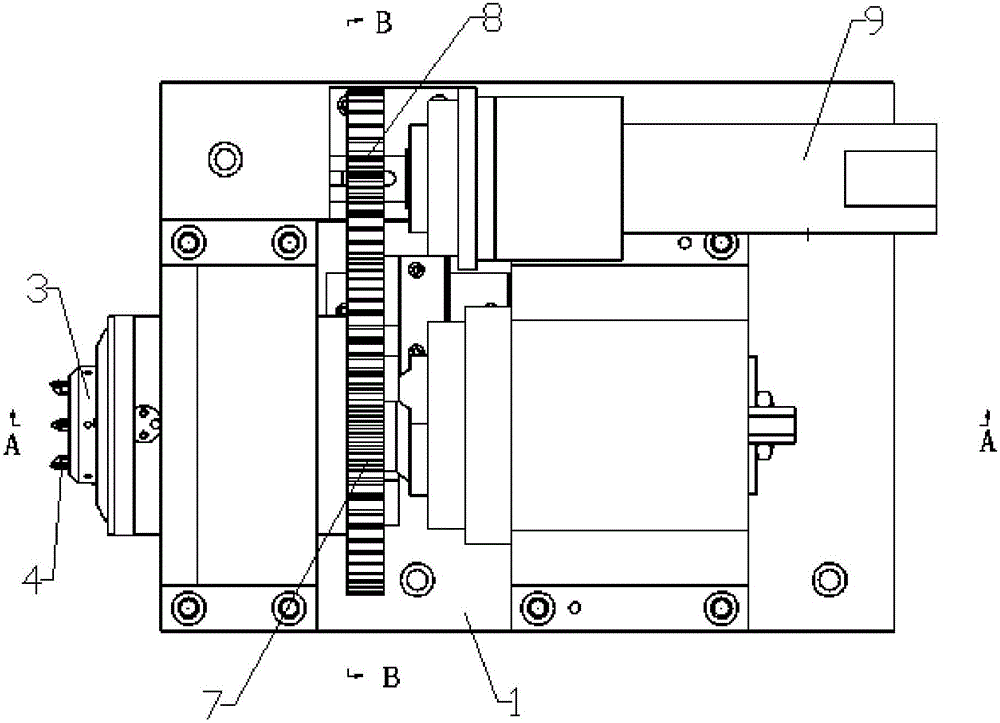

Sharp knife device capable of changing knives

InactiveCN106563964AEfficient precision machiningGuaranteed machining accuracyMeasurement/indication equipmentsFeeding apparatusEngineeringLinear motor

The invention discloses a sharp knife device capable of changing knives. The sharp knife device capable of changing the knives comprises a base, a linear motor, a slide part, a grating ruler used for detecting sliding displacement of the slide part, and a drive assembly for driving the slide part to rotate, wherein the slide part comprises a fixed part and a slide part; the fixed part can be rotatably mounted on the base; the drive assembly can drive the fixed part of the slide part to rotate; when the fixed part rotates, the slide part rotates along with the fixed part; one end of the slide part can be rotatably connected onto an output shaft of the linear motor; the other end of the slide part is fixedly equipped with a knife disc; the motion direction of the output shaft of the linear motor is parallel to or superposed with the slide direction of the slide part; and two knives are mounted on the knife disc. The sharp knife device capable of changing the knives provided by the invention also can guarantee part processing precision after changing the knives.

Owner:BEIJING HIGH PRECISION TECH DEV

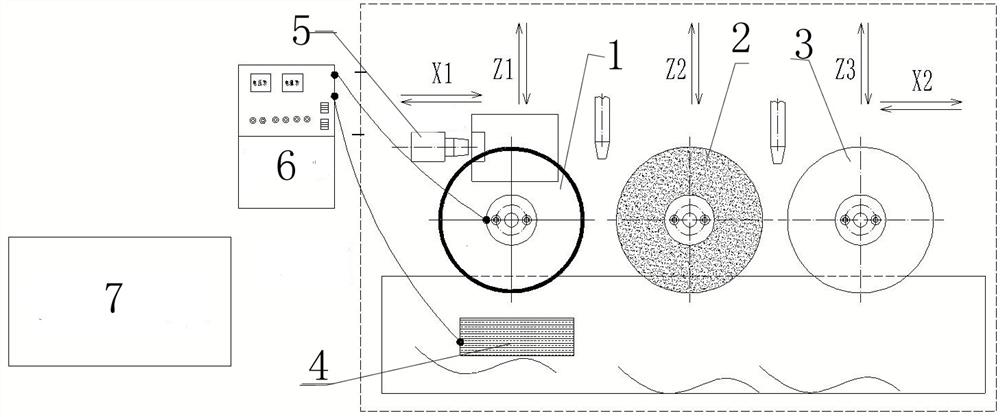

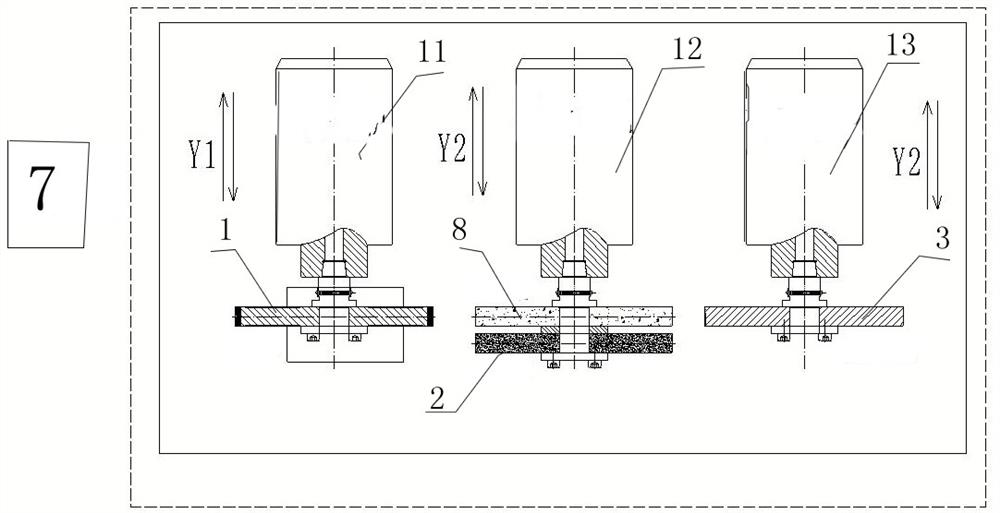

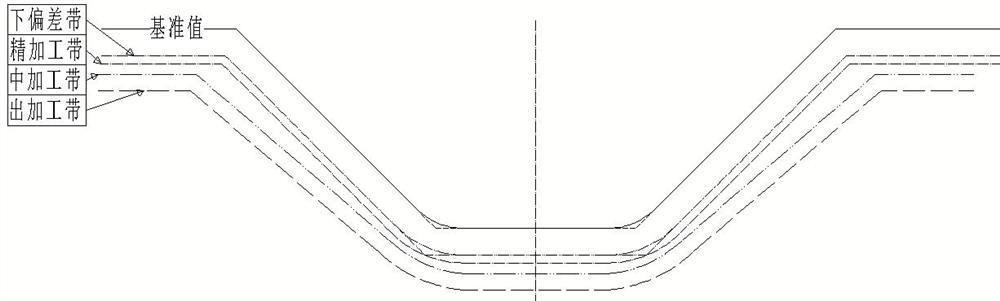

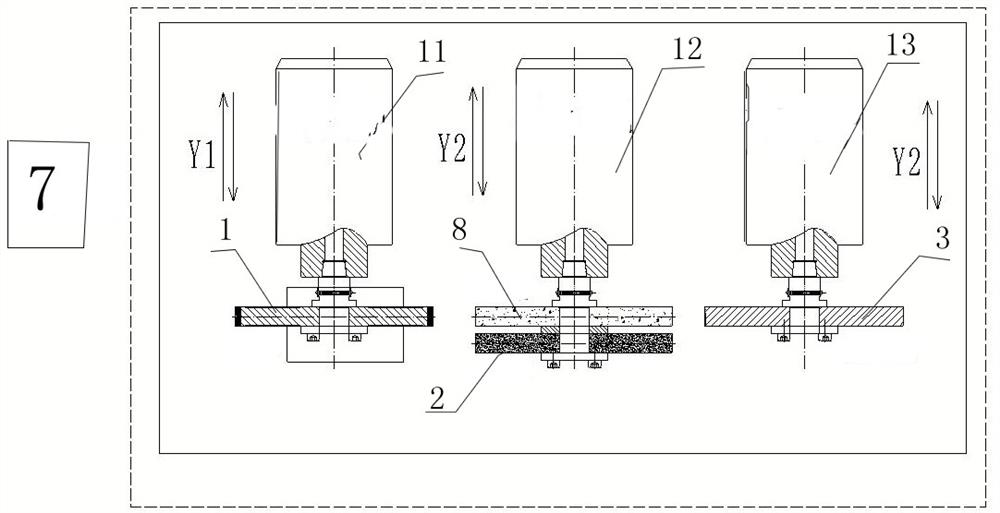

Superhard material grinding wheel dressing method and device

ActiveCN112454171AEfficient precision trimming and sharpeningEfficient processingAbrasive surface conditioning devicesSuperhard materialMachine parts

The invention discloses a superhard material grinding wheel dressing method and device. The superhard material grinding wheel dressing method comprises the steps that firstly, a groove profile of a machined part is preliminarily dressed through electrosparking; the primarily dressed machined part is recorded as a first machined part; rough machining, medium machining and finish machining are sequentially performed on the machined part through a first electrode, a second electrode and a third electrode in an electric spark machining module; the first machined part is precisely dressed through transfer printing cooperation of a diamond roller and a dressing grinding wheel; and finally, a diamond roller is adopted as a dressing tool for a second machined part, and the dressing grinding wheelis replaced to perform precise dressing on the second machined part. Efficient and precise dressing and sharpening of metal-contained superhard material grinding wheels with conductive properties suchas metal binders and composite binders are implemented; the problems that the superhard material grinding wheels are poor in dressing precision and sharpening precision, high in machining efficiencyand the like are solved; and groove shape precision controllable efficient machining and precise sharpening machining of superhard material grinding wheel precise grooves are implemented.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

Equal-arc-length slotting method of non-circular gears

The invention belongs to the field of numerical control machining of gears and relates to an equal-arc-length slotting method of non-circular gears. Through the equal-arc-length slotting method of the non-circular gear, a workbench, gear blanks, a main shaft and a gear slotting cutter are used, wherein the workbench is used for driving the gear blanks to rotate; the main shaft drives the gear slotting cutter to rotate; a gear slotting cutter divided circle is tangent to a gear blank section curve and is capable of purely rolling; the gear slotting cutter moves along an X-axis direction in the plane to form the gear blank section curve; the gear slotting cutter moves along a Z-axis direction to form the whole-tooth depth of the gear blanks; the gear slotting cutter or the gear blanks are also capable of additionally rotating; the gear blanks also carry out equal-arc-length movement relative to a machine tool in the end surfaces of the gear blanks; other shafts are linked relative to the machine tool. The equal-arc-length slotting method is capable of slotting internally-meshed non-circular straight gears and bevel gears and is also capable of slotting externally-meshed non-circular straight gears and bevel gears; the gear blanks are also capable of additionally rotating during slotting the bevel gears; through the equal-arc-length slotting method, the purpose of processing the non-circular gears with high efficiency and high accuracy can be achieved; compared to other methods, the machining efficiency is highest under the requirement of same accuracy.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

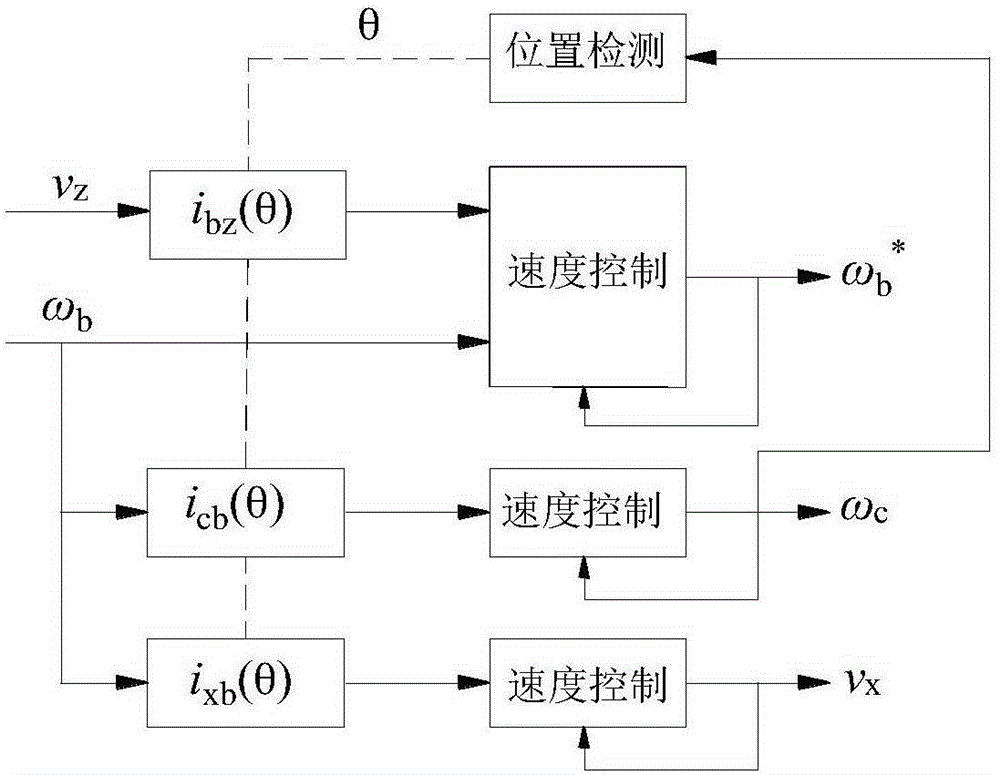

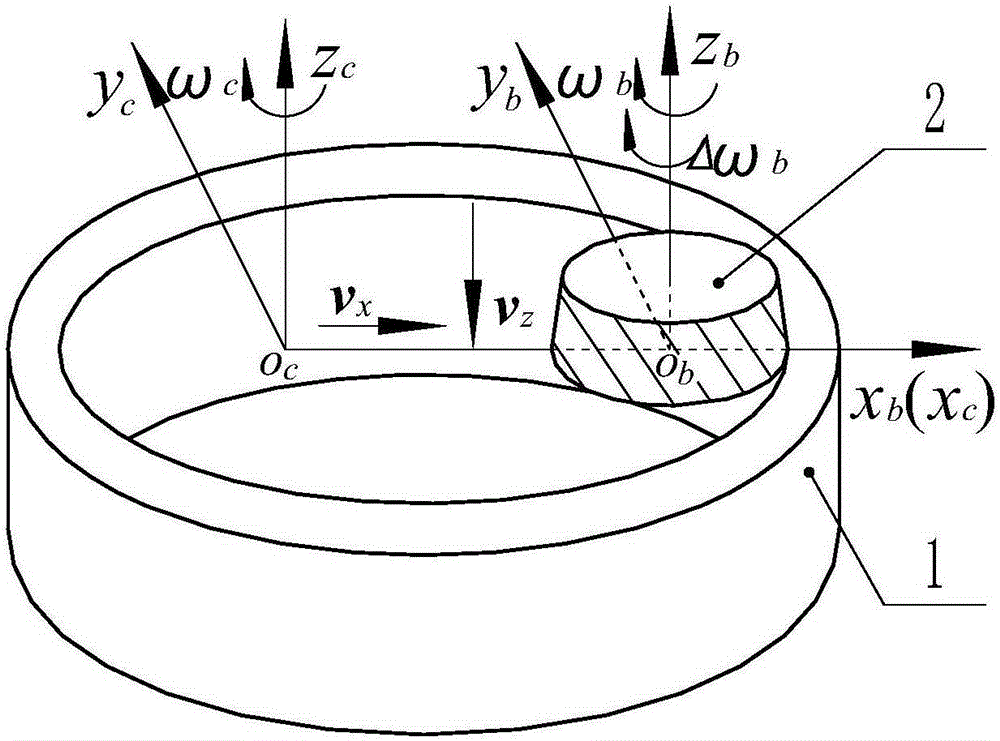

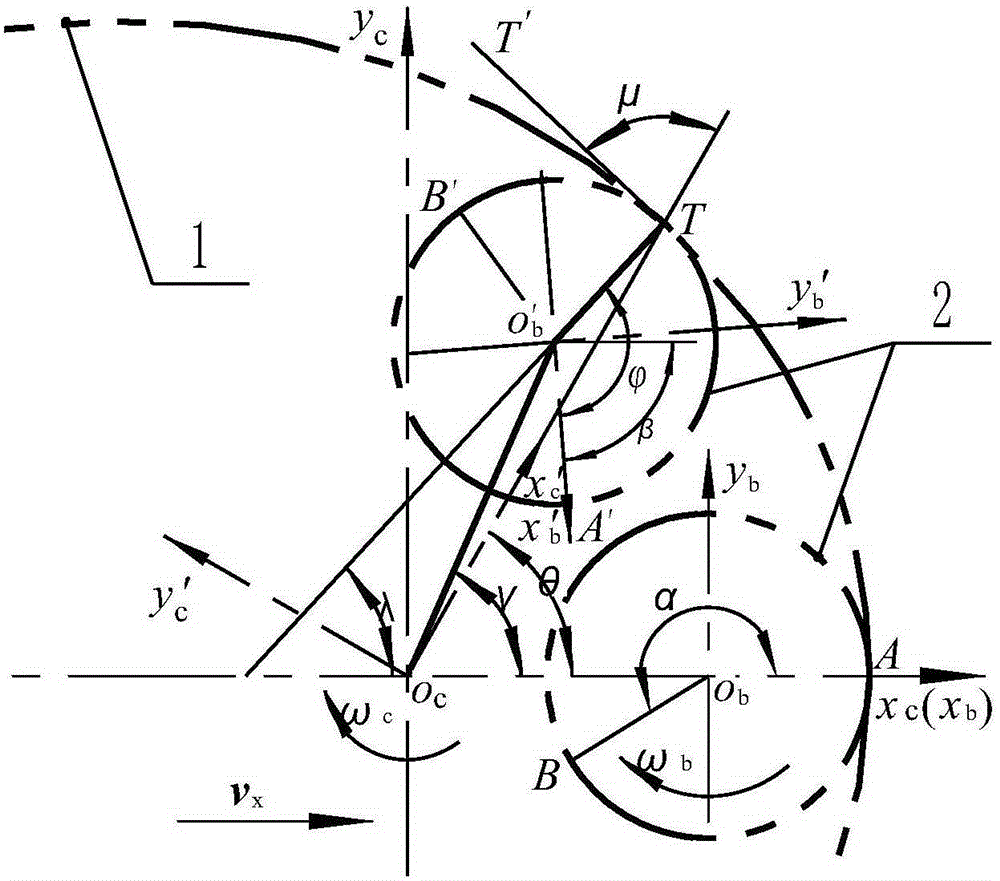

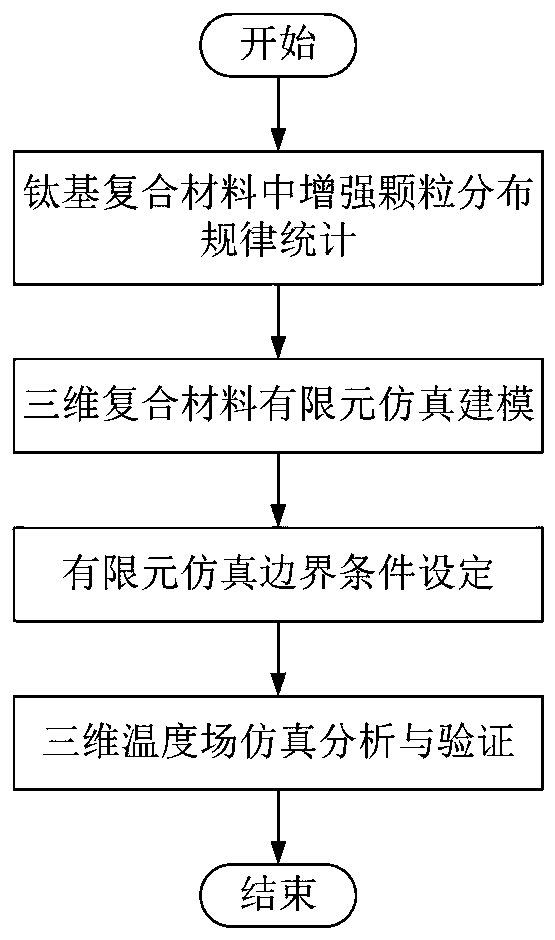

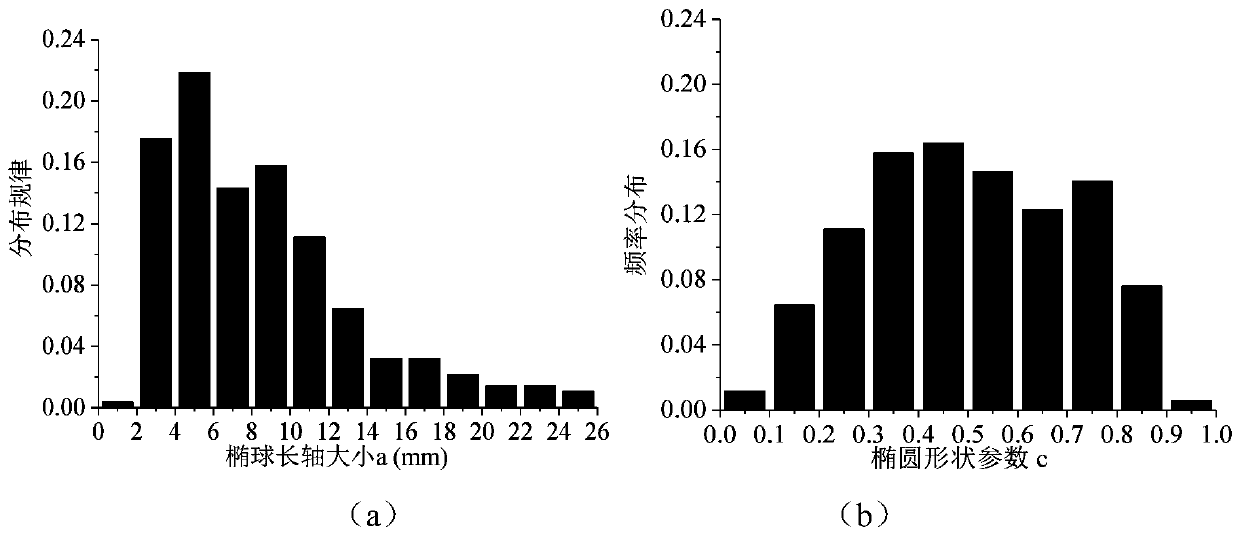

High-speed grinding temperature prediction method for particle reinforced titanium-based composite material

PendingCN110046375AEnhanced TiC shapeSmall sizeDesign optimisation/simulationSpecial data processing applicationsTitanium matrix compositesHigh-speed grinding

The invention provides a high-speed grinding temperature prediction method for particle reinforced titanium-based composite material, which belongs to a transient heat transfer simulation analysis method and comprises the following steps: 1, counting the distribution law of reinforced particles in the particle reinforced titanium-based composite material; 2, performing finite element simulation modeling on the three-dimensional composite material; 3, setting finite element simulation boundary conditions; and 4, performing simulation analysis and verification on the three-dimensional temperature field. The method can predict the grinding temperature of the titanium-based composite material and has the advantages of being higher in accuracy, higher in calculation efficiency and the like compared with an existing method. By means of the method, the high-speed grinding temperature of the particle reinforced titanium-based composite material can be accurately predicted, and basic data and theoretical support are provided for avoiding grinding burn and improving the grinding quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

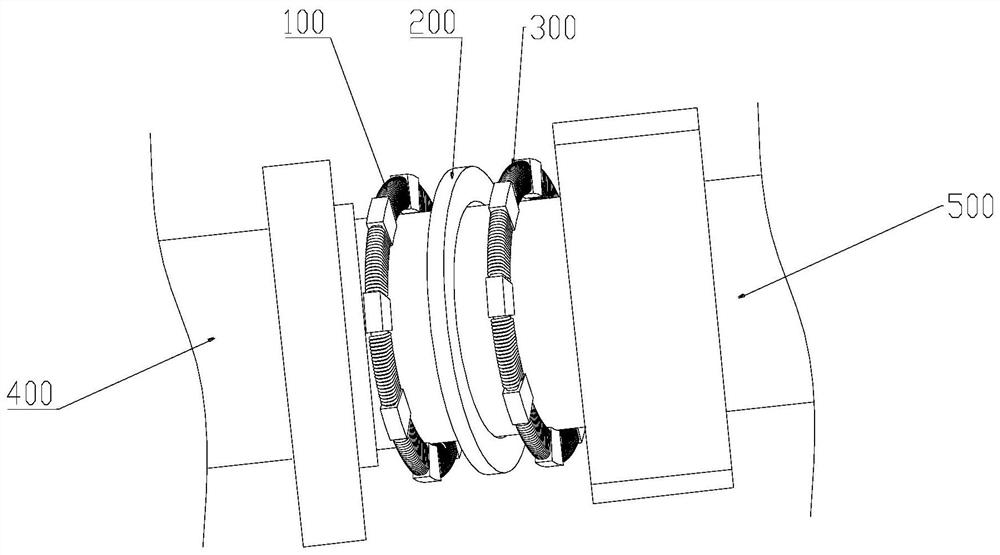

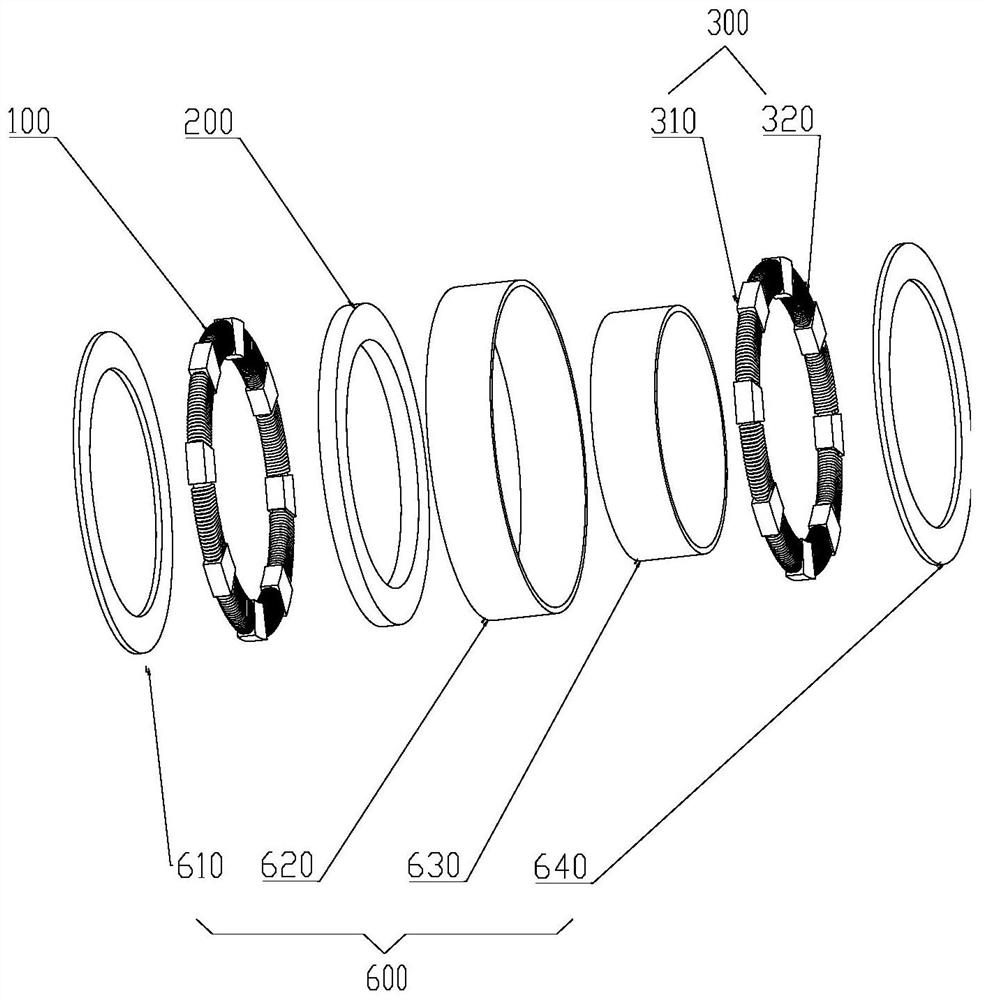

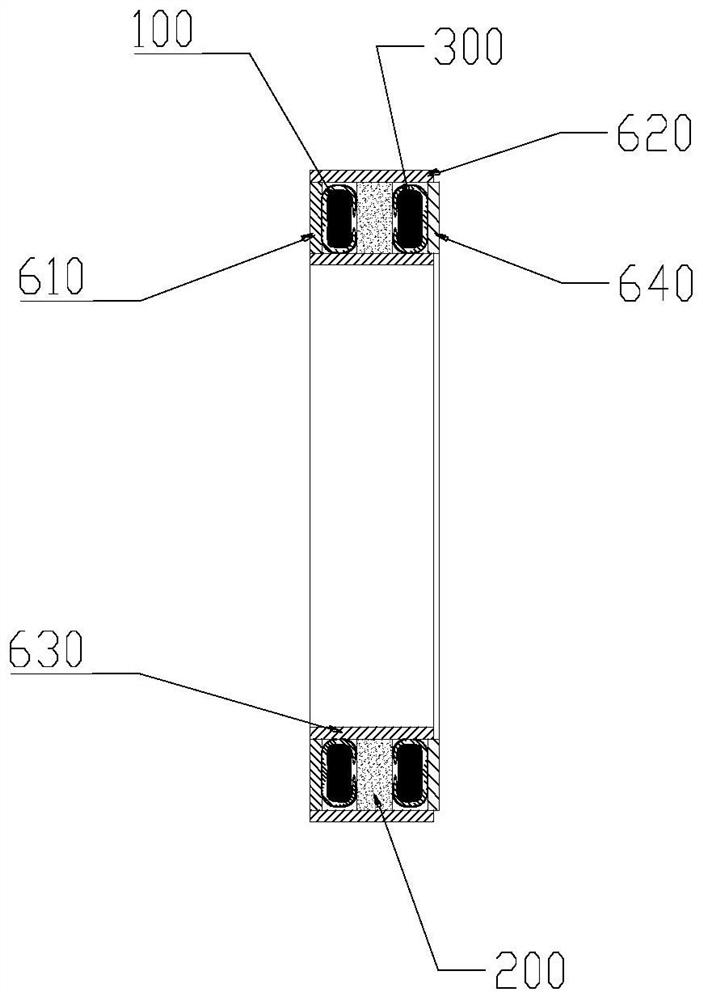

Bearing pretightening force adjusting device, electric spindle and machine tool

ActiveCN114101719APreload real-time adjustmentSimple structureLarge fixed membersWind energy generationMachine toolMagnetic field magnitude

The invention provides a bearing pre-tightening force adjusting device, and belongs to the technical field of machine tool equipment, the adjusting device comprises a driving power supply, a first electromagnetic coil, a magnetostrictive part and a second electromagnetic coil, the first electromagnetic coil, the magnetostrictive part and the second electromagnetic coil are sleeved on a shaft body, and the magnetostrictive part is located between the first electromagnetic coil and the second electromagnetic coil. When the driving power source drives the magnetic field intensity between the first electromagnetic coil and the second electromagnetic coil to change, the magnetostriction piece generates axial expansion and contraction in the axial direction of the shaft body, and axial acting force is applied to the bearing of the shaft body. The adjusting device can adjust the pre-tightening force of the bearing in real time according to different working conditions of the motorized spindle, and is simple in structure, good in stability and high in reliability. The invention further provides an electric spindle comprising the bearing pretightening force adjusting device and a machine tool.

Owner:GREE ELECTRIC APPLIANCES INC

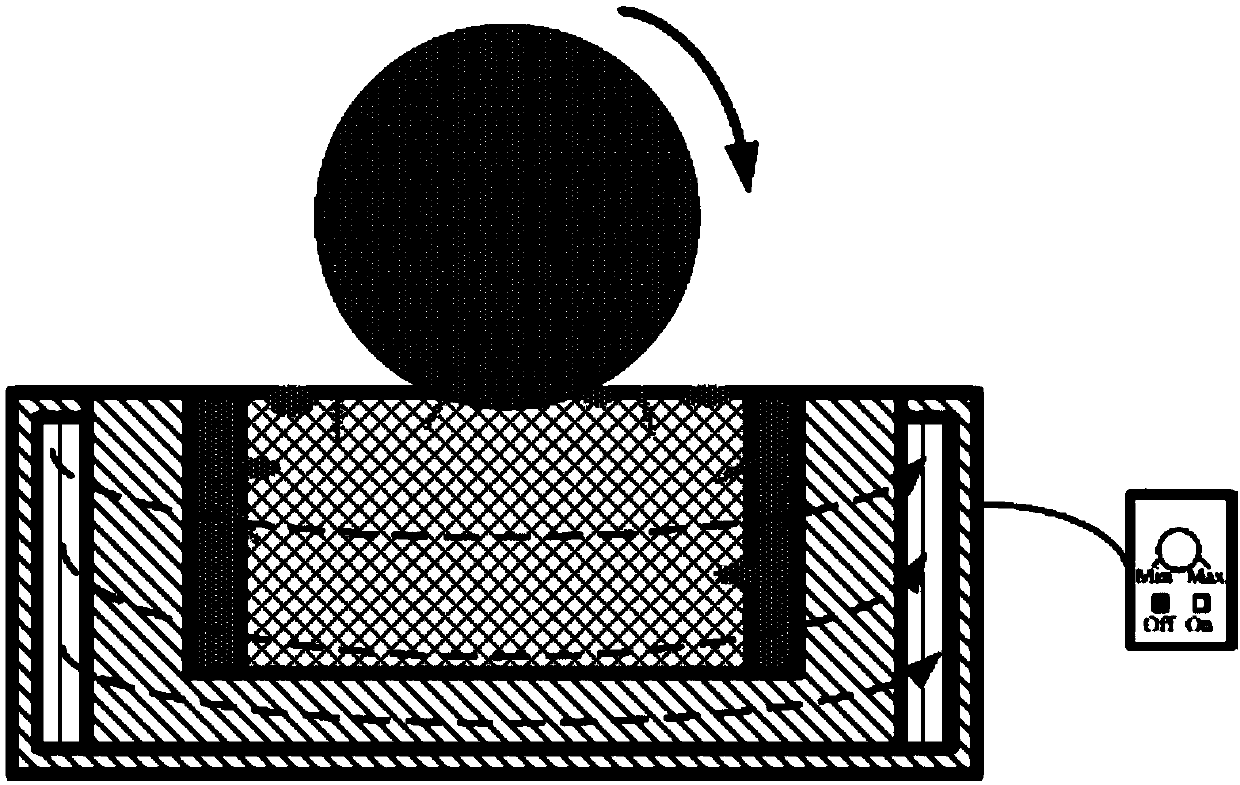

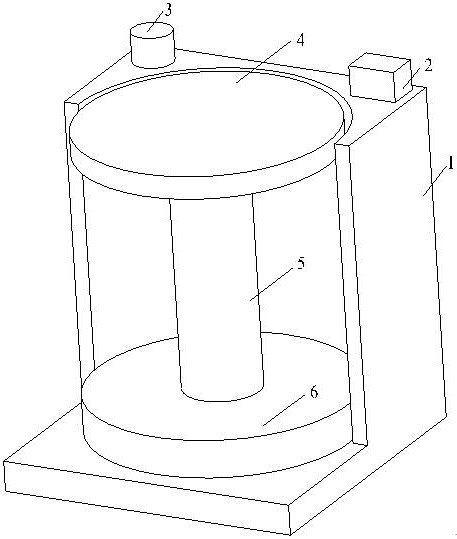

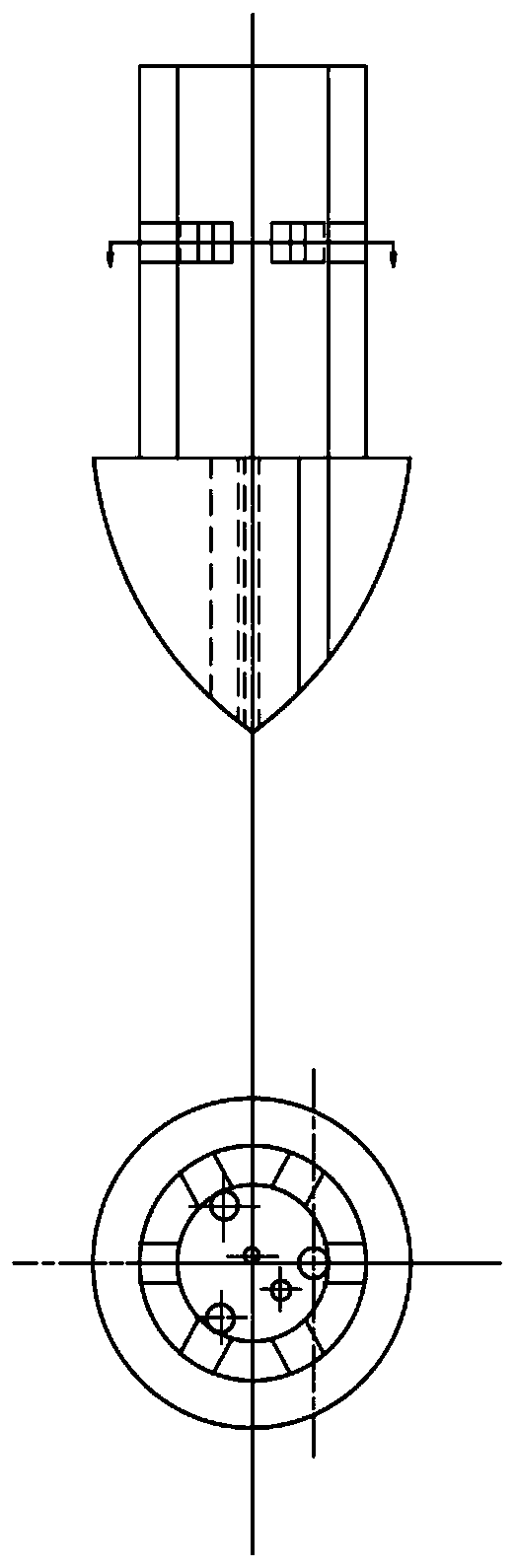

Polishing pad self-finishing polishing device and using method thereof

InactiveCN113714918AImprove surface qualityEfficient precision machiningGrinding carriagesPolishing machinesPolishingDrive shaft

The invention belongs to the technical field of precision machining, and particularly relates to a polishing pad self-finishing polishing device and a using method thereof. The polishing pad self-finishing polishing device comprises a shell, a finishing module, a polishing module, a polishing disc, a transmission shaft, a driving module, a polishing pad and a controller; the shell is placed horizontally; the finishing module is installed at the right end of the upper side of the shell; the polishing module is located at the left end of the upper side of the shell; the polishing disc is located at the upper part of an inner cavity of the shell and used for containing the polishing pad; the polishing pad adheres to the upper side of the polishing disc; the upper end of the transmission shaft is connected with the polishing disc, and the lower end of the transmission shaft is connected with the driving module; the driving module is used for driving the polishing disc to rotate; the controller is used for controlling work of each module. According to the polishing device, the finishing module, the polishing disc, the polishing module and the transmission shaft are matched to work, so that high-flatness polishing can be carried out on a workpiece, the surface quality of the polished workpiece is effectively improved, and then efficient and precise machining of the workpiece is realized.

Owner:JINLING INST OF TECH

Method and device for dressing superhard material grinding wheel

ActiveCN112454171BEfficient precision trimming and sharpeningEfficient processingAbrasive surface conditioning devicesSuperhard materialSharpening

The invention discloses a superhard material grinding wheel dressing method and device. Firstly, the groove shape of the workpiece is preliminarily trimmed by electric discharge machining, and the obtained workpiece after preliminary trimming is recorded as the first workpiece: the workpiece is processed by electric discharge machining. The first electrode, the second electrode and the third electrode in the spark processing module are subjected to rough machining, medium machining and finishing in sequence; the first workpiece is finely trimmed by the transfer cooperation of the diamond roller and the dressing wheel; finally, the The second workpiece uses a diamond roller as a dressing tool, and the sharpening wheel is replaced to perform precision sharpening on the second workpiece. The invention realizes high-efficiency and precise dressing and sharpening of superhard material grinding wheels containing metals such as metal binders and composite binders with conductive properties, solves the problems of poor dressing precision, poor sharpening precision, and processing efficiency of superhard material grinding wheels, and realizes The groove shape accuracy of the precision groove of the superhard material grinding wheel is controllable, efficient processing, and precision sharpening.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

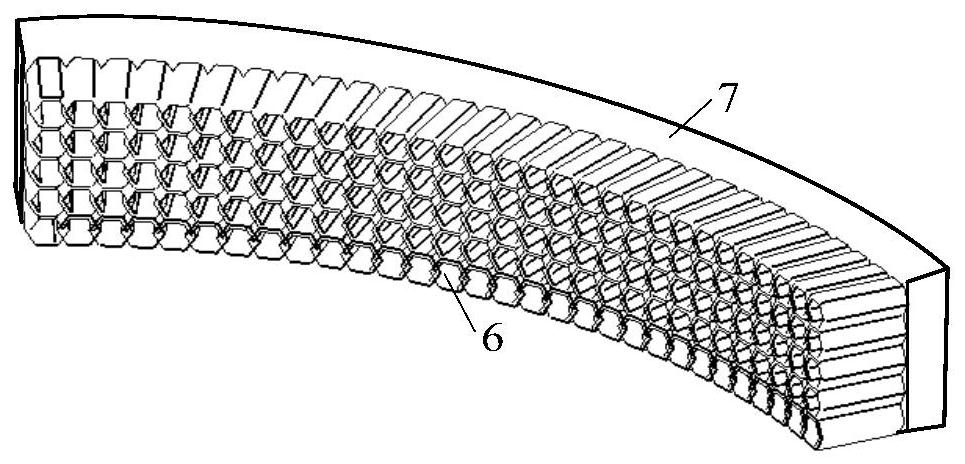

High-efficiency electrolytic grinding device and processing method for honeycomb segment

ActiveCN110744155BNovel structureSimple structureMetal working apparatusElectrical-based auxillary apparatusMachined surfaceHoneycomb

A honeycomb segment high-efficiency electrolytic grinding device and processing method, belonging to the field of special processing technology, including a workbench, a power supply, a honeycomb segment and a tool grinding wheel, the device has a novel structure, and the principle of the processing method is clear, which is different from the traditional processing of the honeycomb segment Compared with other methods, the present invention avoids defects such as tool loss, deformation of the honeycomb ring, and surface recasting layer caused by other processing methods; the present invention adopts the method of cutting the large-diameter tool grinding wheel from the side of the honeycomb sector, and through the internal spray tool The grinding wheel directly sprays the working fluid on the processing surface of the honeycomb segment, which greatly increases the removal efficiency of the honeycomb material; the inner spray liquid of the present invention can conduct the conductive forming grinding wheel, realize the efficient and precise machining of the honeycomb parts, and reduce the processing time of the honeycomb parts. Performance requirements for machine tool equipment; the feeding direction of the tool grinding wheel in the present invention is perpendicular to the direction of the honeycomb holes of the honeycomb belt, which avoids the phenomenon that the processed products block the honeycomb holes and simplifies the cleaning process after processing.

Owner:YANGZHOU UNIV

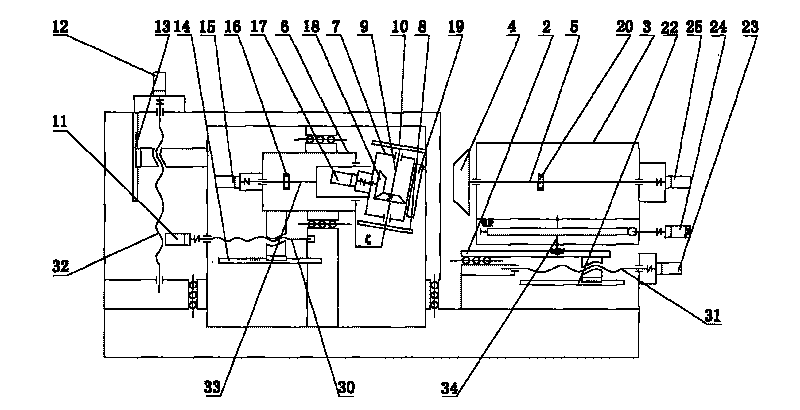

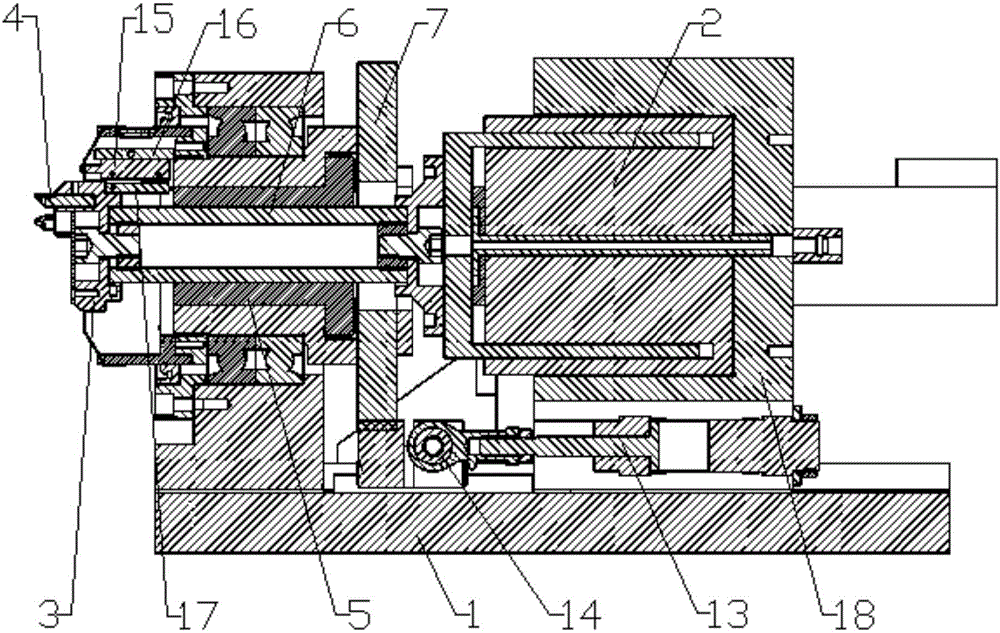

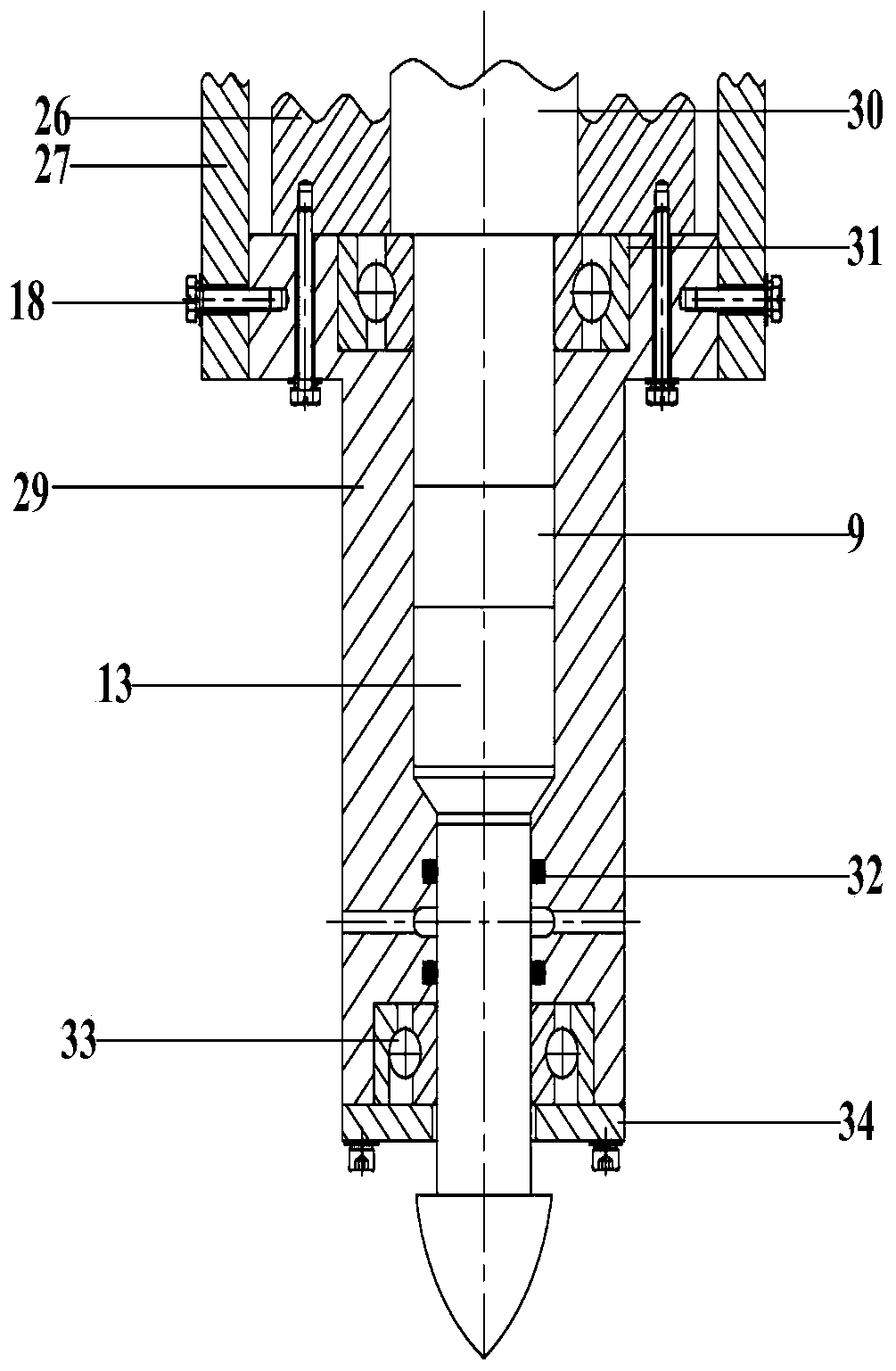

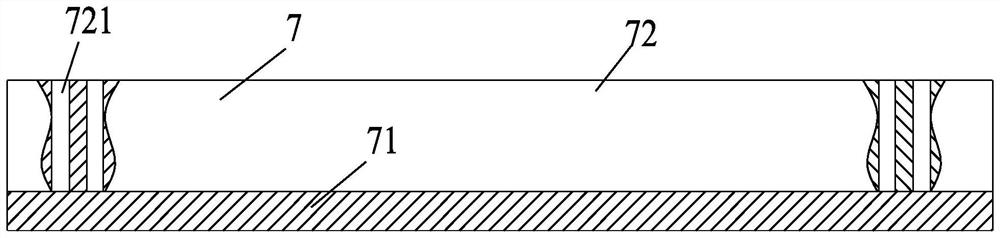

Boring, scraping and rolling integrated compound cutter with adjustable axial distance

ActiveCN102500776BGuaranteed support stabilityGuaranteed rotational stabilityTurning toolsEngineeringAxial distance

The invention discloses a boring, scraping and rolling integrated compound cutter with an adjustable axial distance. The compound cutter comprises a rolling head component, wherein the rolling head component comprises a retaining sleeve base, a retaining sleeve and a core; the retaining sleeve is fixedly connected with the front end of the retaining sleeve base; the core is embedded into an inner cavity of the retaining sleeve in a matched mode; a connection component comprises a mandrel; a first oil cylinder is embedded into a front hole of the retaining sleeve base in a matched mode; an inner ring of the first oil cylinder is matched with the outer ring surface on the middle section part of the mandrel, and the first oil cylinder controls the retaining sleeve base to slide forwards; a travel mandril is arranged in the mandrel; and a first spring is sleeved outside the rear end of the travel mandril in a matched mode, and controls sliding retaining sleeve base to reset. The compound cutter is integrated with boring, scraping and rolling, so that the operation efficiency is improved; an inclined conical ring surface structure is adopted, and a rolling needle is driven to move axially, so that the height of the rolling needle is adjustable; the spring is arranged under a scraper supporting block, so that a floating running mode is formed; the compound cutter has a rational structure, so that relatively high roundness and straightness can be guaranteed during scraping motion; the compound cutter can automatically stretch when moving back, so that the surface of a workpiece cannot be damaged.

Owner:宁波市精恒凯翔机械有限公司

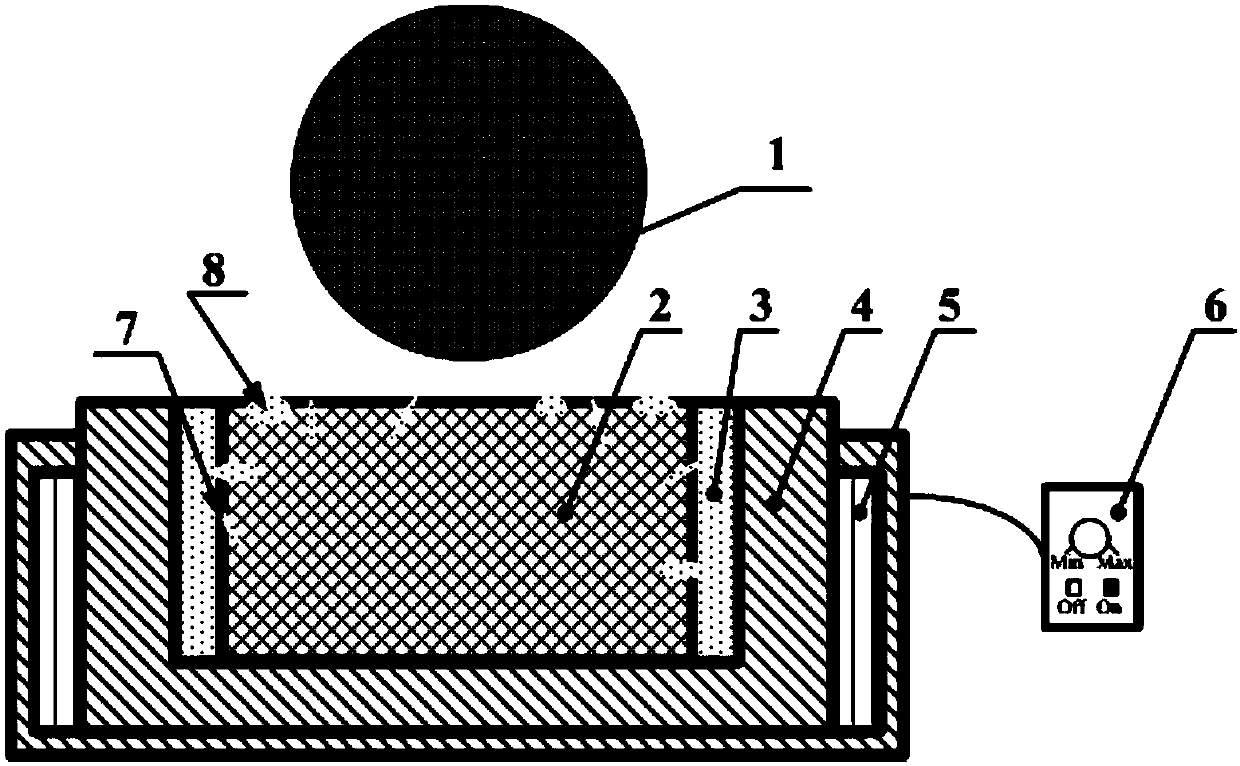

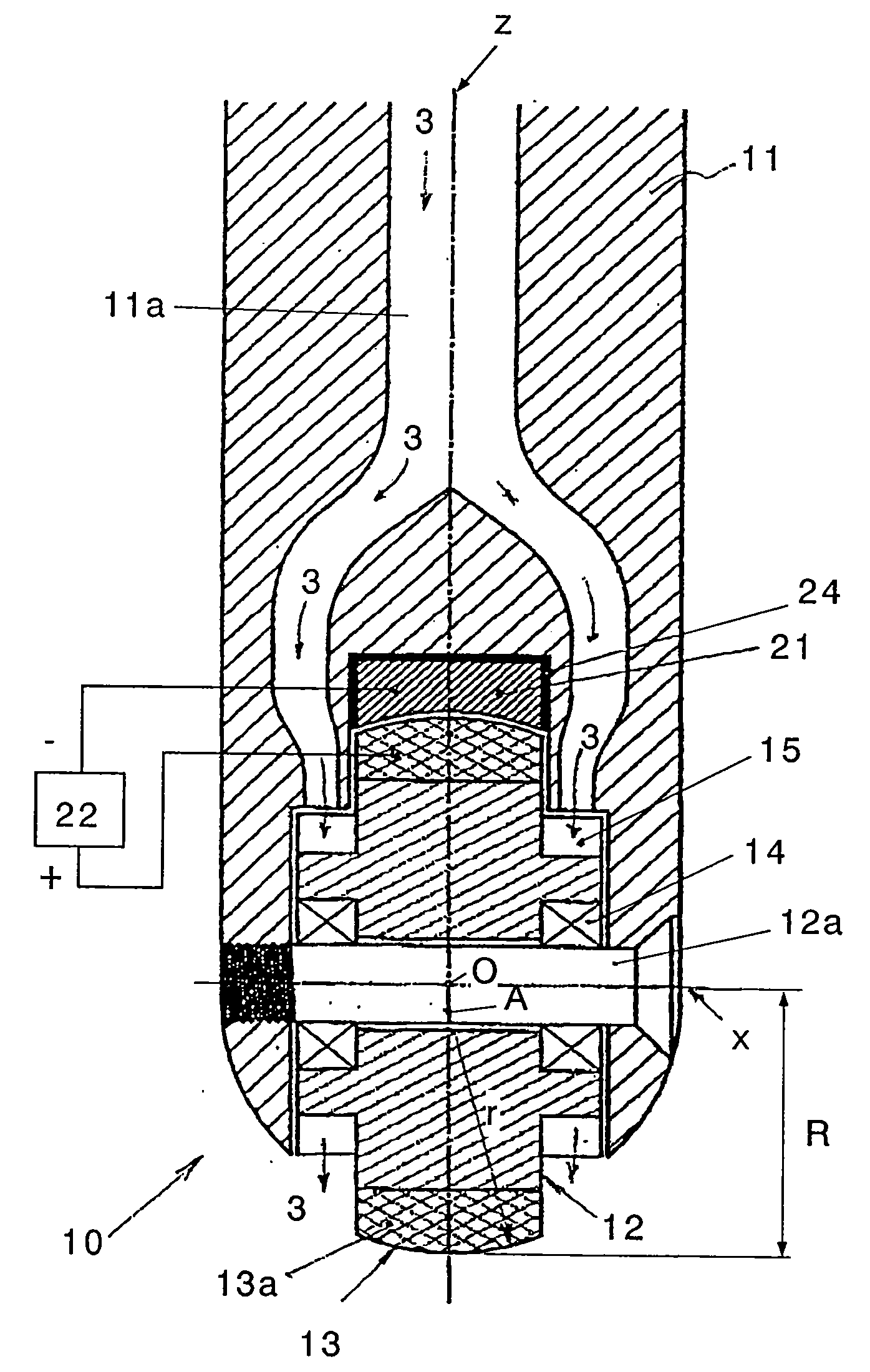

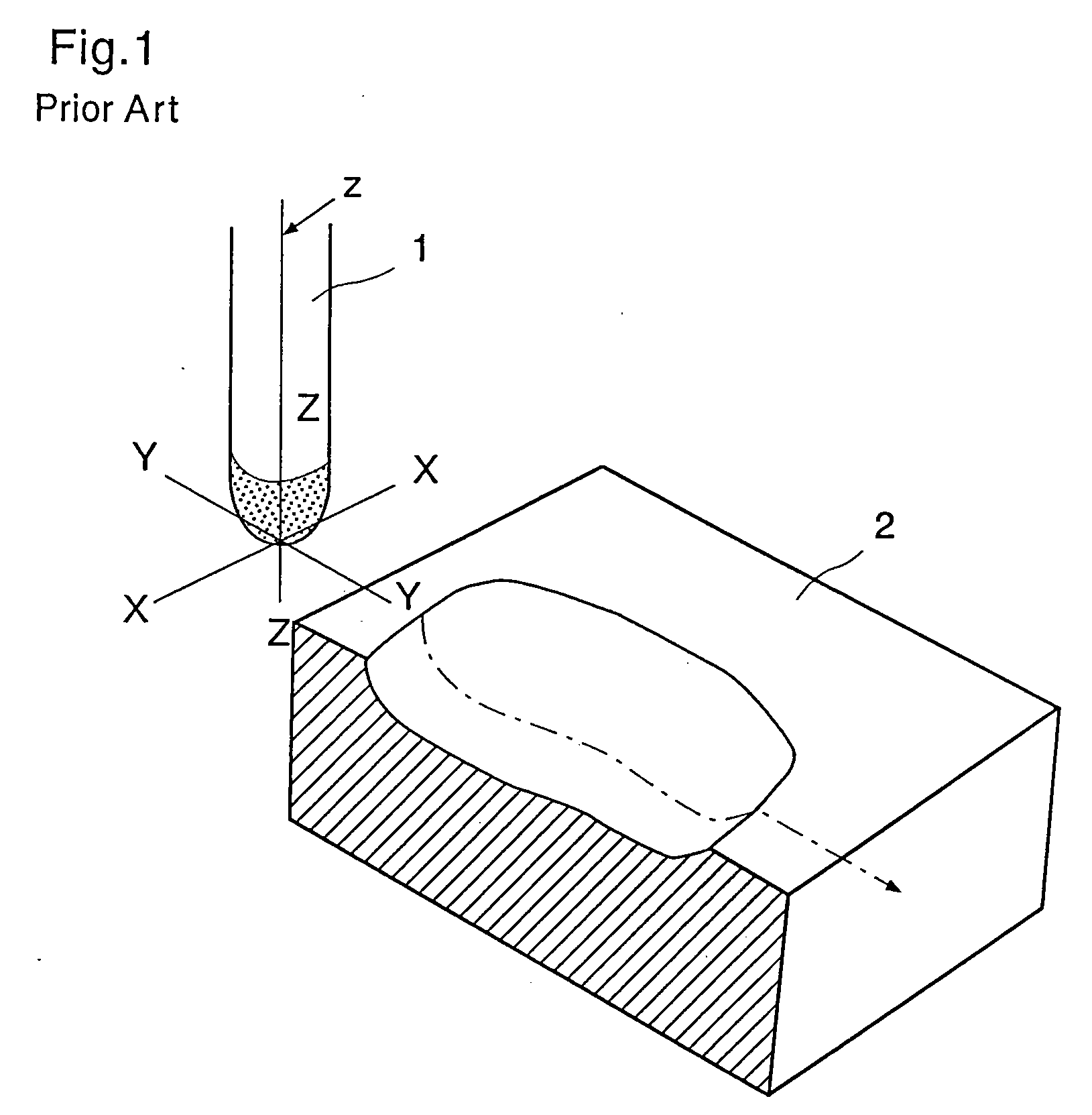

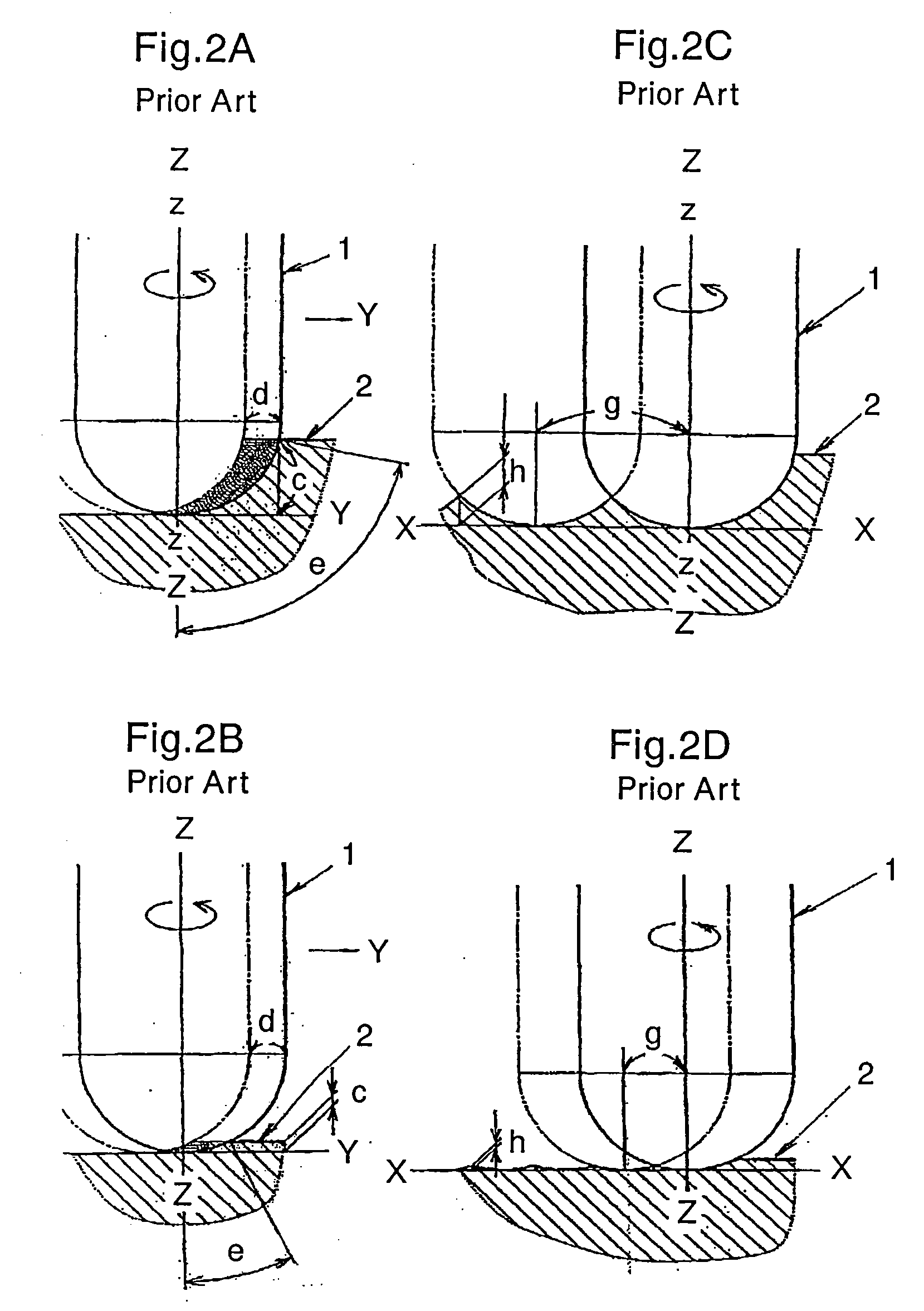

Free curved surface precision machining tool

InactiveUS20070004318A1Efficient precision machiningMaintain clarityMilling cuttersGrinding feed controlMachined surfaceConvex side

A free curved surface precision machining tool for precision-machining a surface to be machined with the lower end in contact therewith by rotation around an axis x. It includes a drum-shaped tool having a rotation axis x orthogonal to the axis z and rotationally driven around the rotation axis x. This drum-shaped tool has a convex machining surface in the form of an arcuate rotary body obtained by rotating an arc of a radius r with the center at the intersection O between the axis z and the rotation axis x around the rotation axis x. The convex machining surface contacts the surface to be machined to precision-machine the latter, while the convex machining surface is rotated around the orthogonal axis x so as to disperse the machining position of the convex machining surface.

Owner:RIKEN +2

A small hole thread forming grinding wheel for grinding hard and brittle materials

ActiveCN102941382BSolution to short lifeEfficient precision machiningThread cutting toolsEngineeringBoron nitride

The invention discloses a molding grinding wheel for grinding small-hole threads of hard and brittle materials and belongs to the technical field of machinery manufacturing. The molding grinding wheel is characterized in that the axial section included angle alpha of the disc-shaped molding grinding wheel is determined by the formula alpha=alpha0 Dalpha, wherein the alpha0 is the thread standard thread angle, the Dalpha is the grinding wheel axial section profiling quantity Dalpha corresponding to the minimum thread profile error deltamin; the diameter DS of the disc-shaped molding grinding wheel is determined by the formula DS=d0+zetah0, wherein the h0 is the height of the thread profile, the d0 is the diameter of a cutter bar, and the zeta is a correction factor; and the diameter of the cutter bar d0 is determined by the formula d0=lambdah0, wherein the lambda is a proportionality coefficient. A composite plating process is adopted to enable diamond or cubic boron nitride (CBN) micro powder grains to be solidified on the surface of a base body of the disc-shaped molding grinding wheel. The molding grinding wheel has the advantages that the problems of severe abrasion, breakage, low efficiency and failure of drying process of screw tap tools for processing the small-hole threads of hard and brittle materials are solved, chips discharge is smooth, coolants are not needed to add, and precise and efficient process of the small-hole threads of the hard and brittle materials is achieved.

Owner:DALIAN UNIV OF TECH

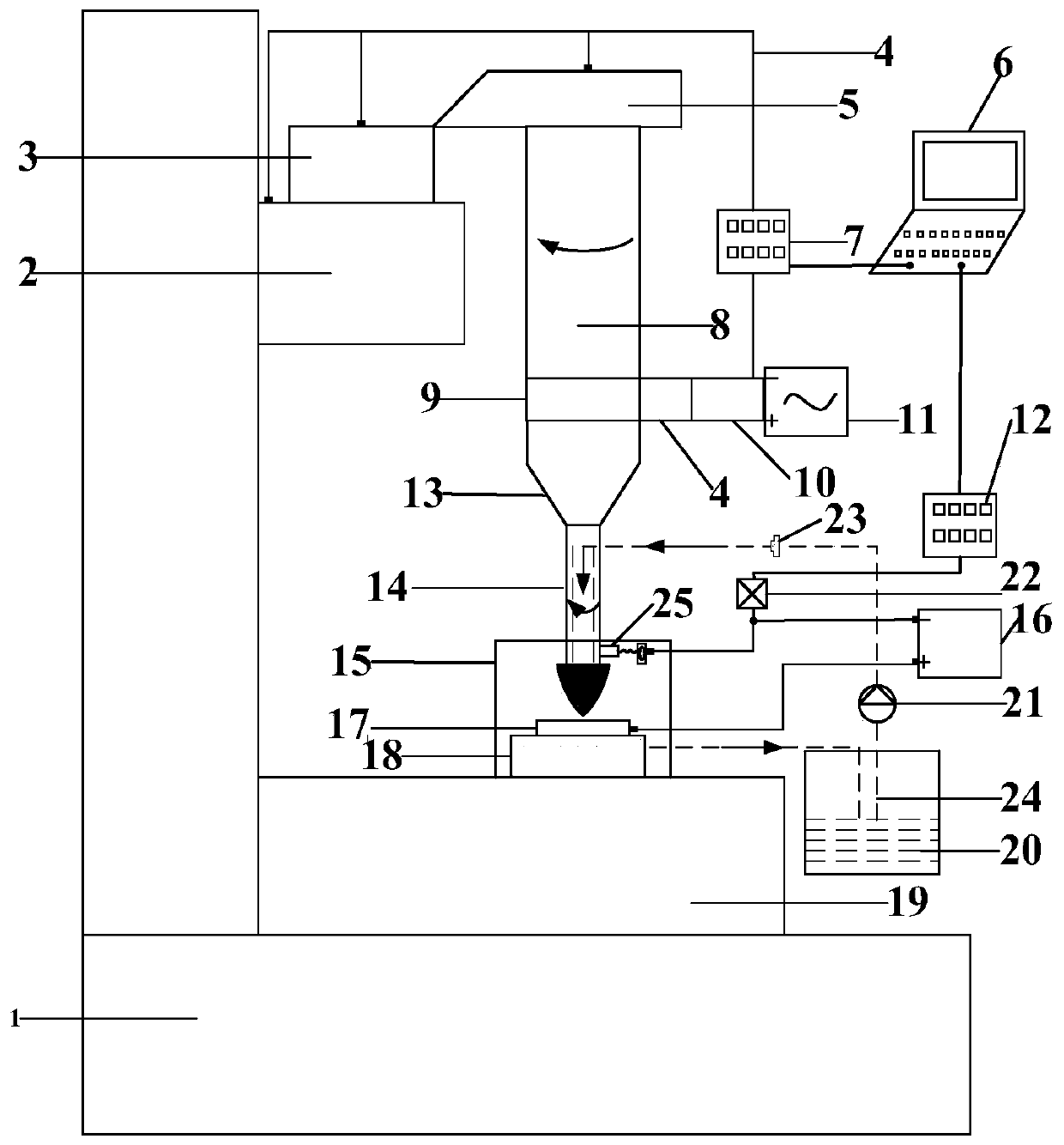

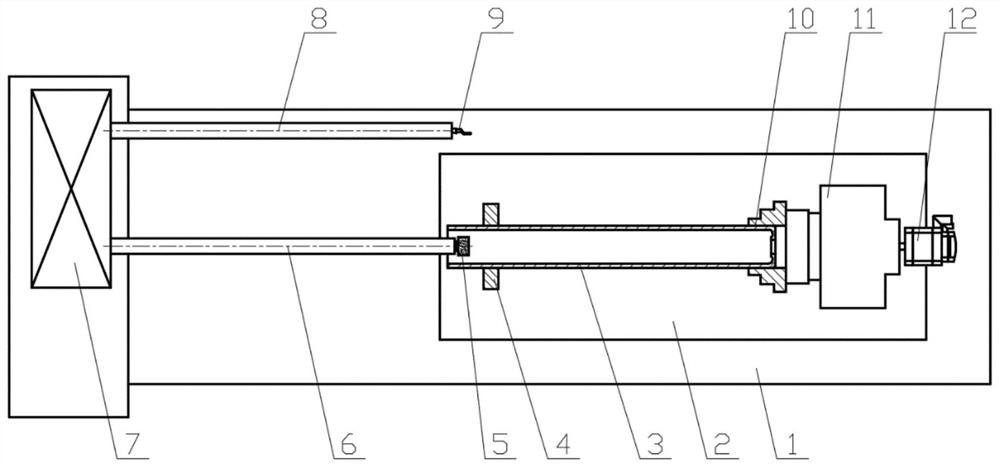

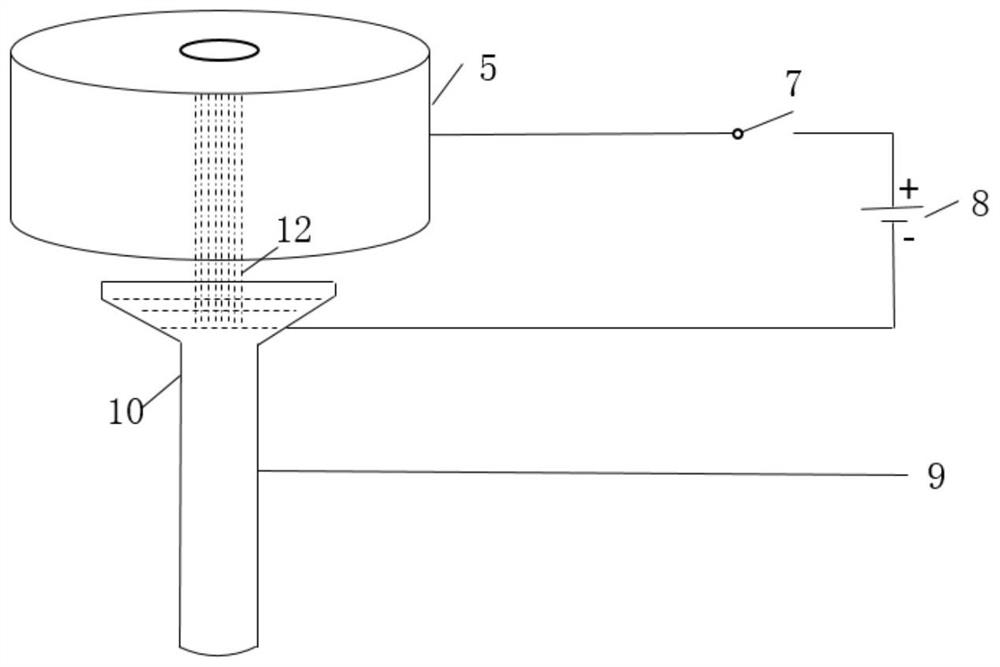

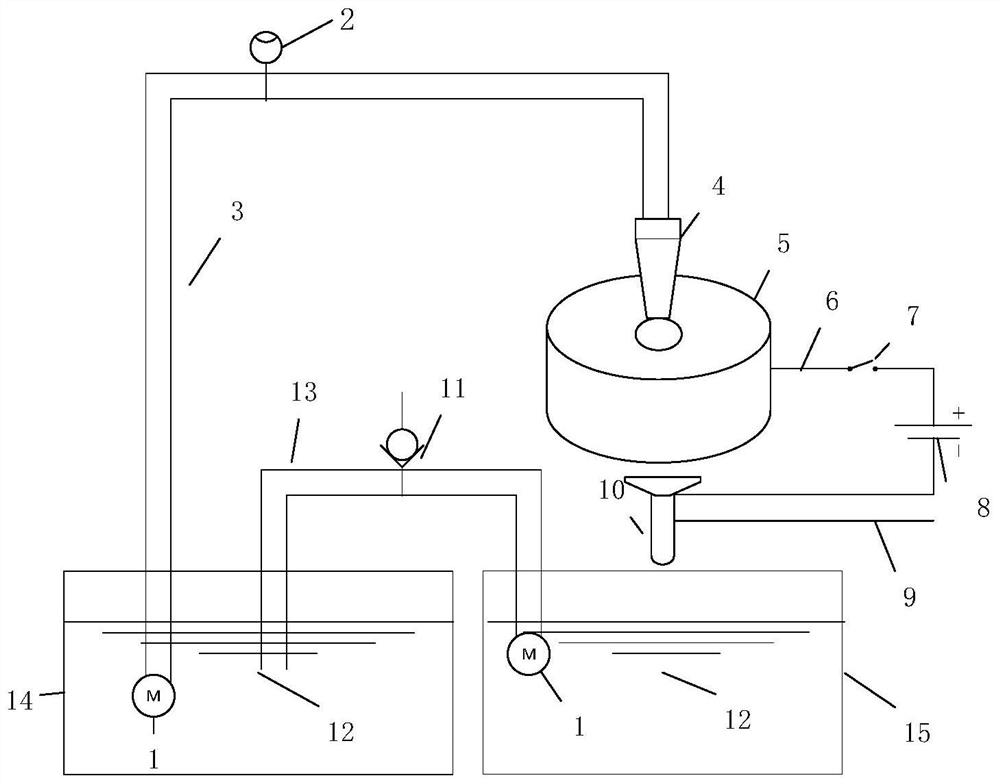

Internal channel ultrasonic vibration assisted internal spray electrolytic grinding system and method

The invention discloses an internal channel ultrasonic vibration auxiliary internal spraying type electrolytic grinding system and method. The system and method solves the problem that the machining efficiency of a deep hole, a cavity and an inner channel is low at present, and the system and method can improve the machining efficiency and reduce the roughness of the machining surface. The systemmainly comprises a motion control device, a current detection control device, an electrolyte circulating device, an ultrasonic vibration device and an inner spraying type tubular conductive grinding head, wherein the motion control device is used for controlling the high-speed rotation and feeding stability of a main shaft, the current detection control device is used for detecting the current size and controlling the generation of sudden change current in the machining process in real time, the electrolyte circulating device is used for realizing supply, filtering and recycling of the electrolyte, the ultrasonic wave vibration device is used for realizing the effects that the conductive grinding head rapidly removes a passivation film on the surface of a workpiece under the ultrasonic cavitation effect of the electrolyte and the electrochemical reaction is enhanced, and the inner spraying type tubular conductive grinding head avoids the turbulence effect between the grinding head andthe workpiece in the machining process, and maintains the stability of an electrolyte flow field.

Owner:SHANDONG UNIV

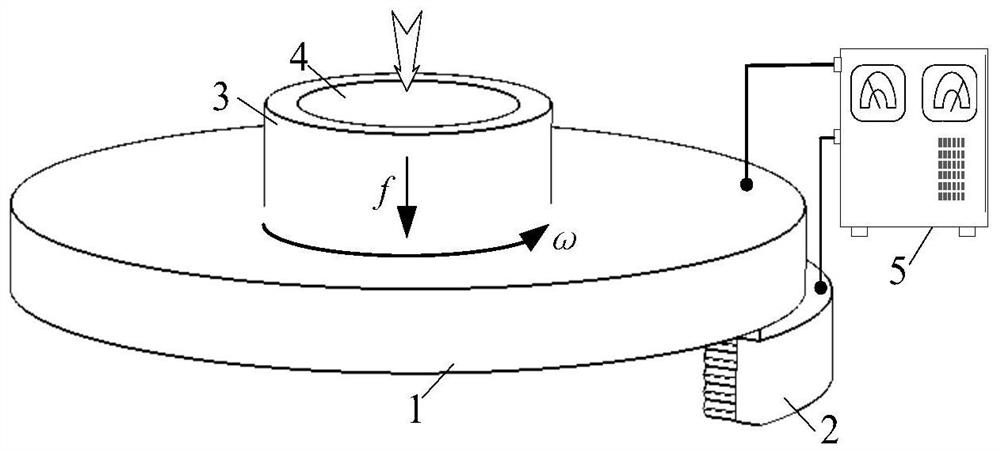

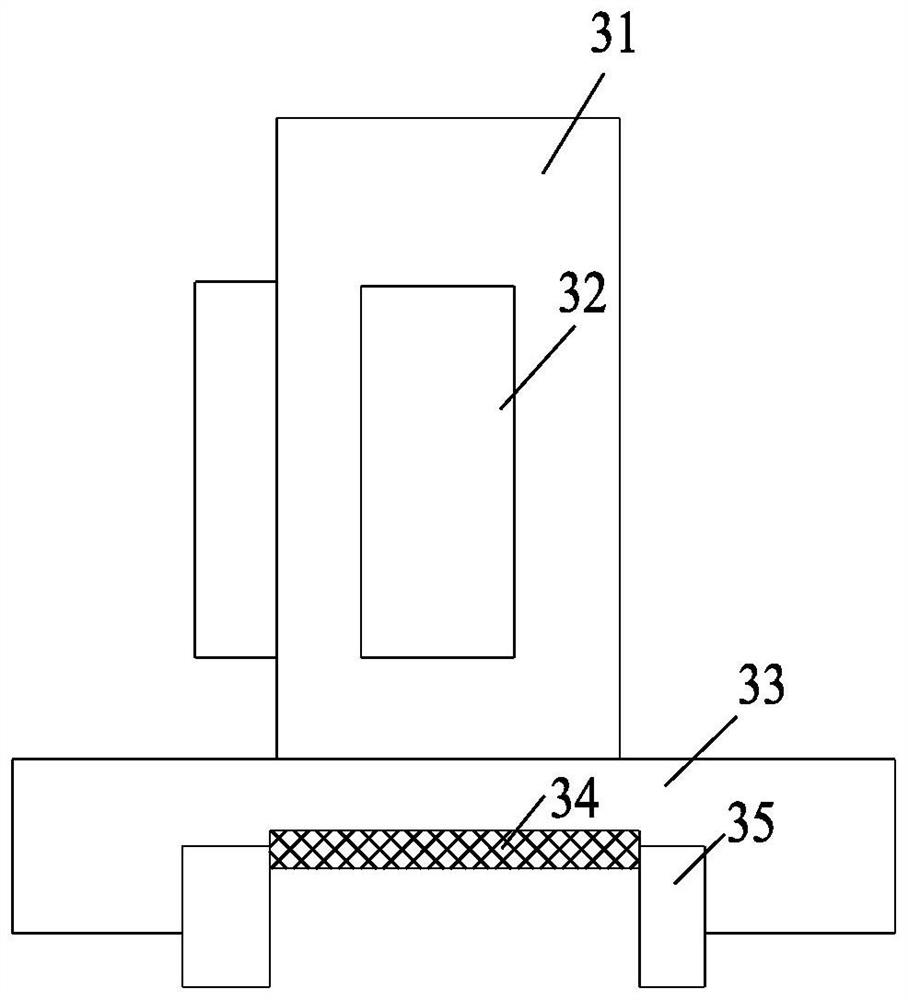

Flexible grinding device for soft and brittle materials

PendingCN114310652AQuality improvementImprove surface qualityLapping machinesWork carriersEngineeringCeramic

The invention provides a flexible grinding device for soft and brittle materials. The flexible grinding device comprises a grinding disc and a workpiece fixing device. A grinding pad is arranged on the grinding disc, and the grinding disc and the grinding pad can rotate; the workpiece fixing device is arranged above the grinding disc and used for clamping a to-be-ground workpiece, and the to-be-ground workpiece is driven by the workpiece fixing device to rotate; the lower end of the to-be-ground workpiece is in contact with the grinding pad and generates relative friction with the grinding pad in the rotating process, so that the grinding effect is achieved; the workpiece fixing device comprises a connecting body, a liquid bag and a clamping mechanism, and the liquid bag is in contact with a to-be-ground workpiece; a vibration rod is fixedly arranged above the connecting body, piezoelectric ceramics are arranged on the vibration rod, and the piezoelectric ceramics vibrate in the radial direction. The high-efficiency and high-quality grinding of soft and brittle materials can be realized, the surface quality of a ground workpiece is improved, the efficient precision machining of the workpiece is further realized, and meanwhile, the high-efficiency and high-quality grinding device is simple in structure, convenient to operate and use and high in practicability.

Owner:JINLING INST OF TECH

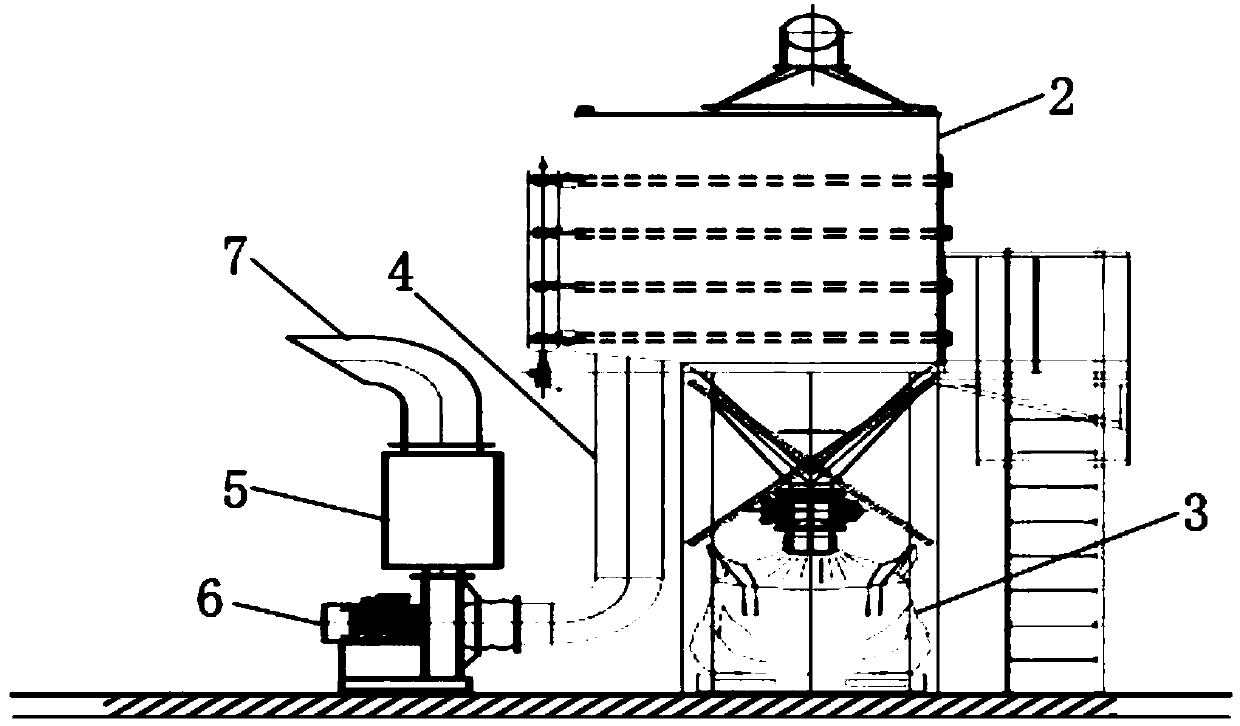

Cleaning device for precision machining powder of advanced ceramic green body

PendingCN109649703AInfluence of precision machiningEfficient precision machiningSolid materialAssistive technologyElectric machinery

The invention relates to a cleaning device for precision machining powder of an advanced ceramic green body. The cleaning device comprises a material collecting pipe, a material falling barrel, a material collecting bag, a connecting pipe, a suction device and a motor; the material collecting pipe is connected with a feeding port of the material falling barrel, and the suction port end of the material collecting pipe is arranged on the side of a ceramic green body finishing tool obliquely and fixedly, and can be moved along the tool for suction; the material collecting bag is connected with adischarging port of the material falling barrel, and the suction device is connected with the material falling barrel through the connecting pipe, and can be used for vacuumizing the material fallingbarrel; and the suction device is driven by the motor. According to the cleaning device, real-time mechanical cleaning of powder in precision machining procedures of the advanced ceramic green body can be achieved, and the cleaning efficiency and safety are improved; the precision machining effect of the green body is improved, and reliable auxiliary technical support is provided for precision machining of the advanced ceramic green body so that large ceramic components are produced more efficiently; and meanwhile the cleaning device benefits recycling of ceramic powder.

Owner:SHANGHAI COMPANION PRECISION CERAMICS

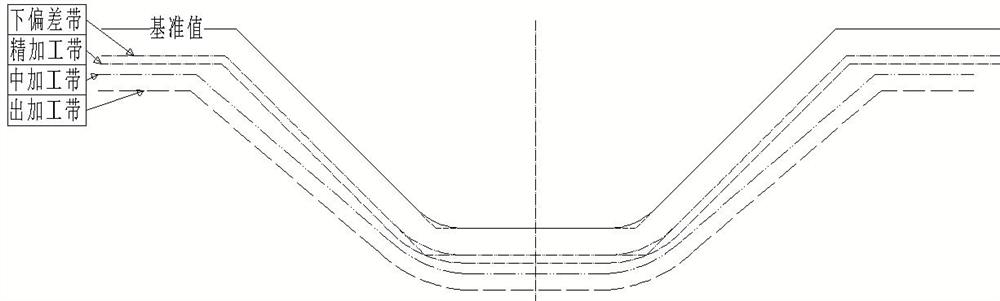

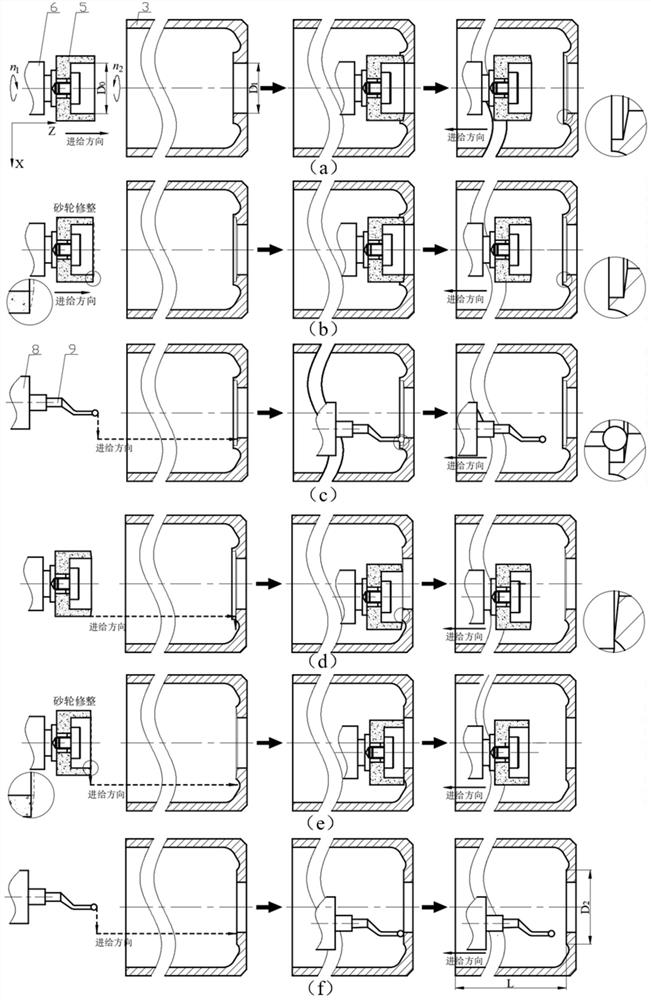

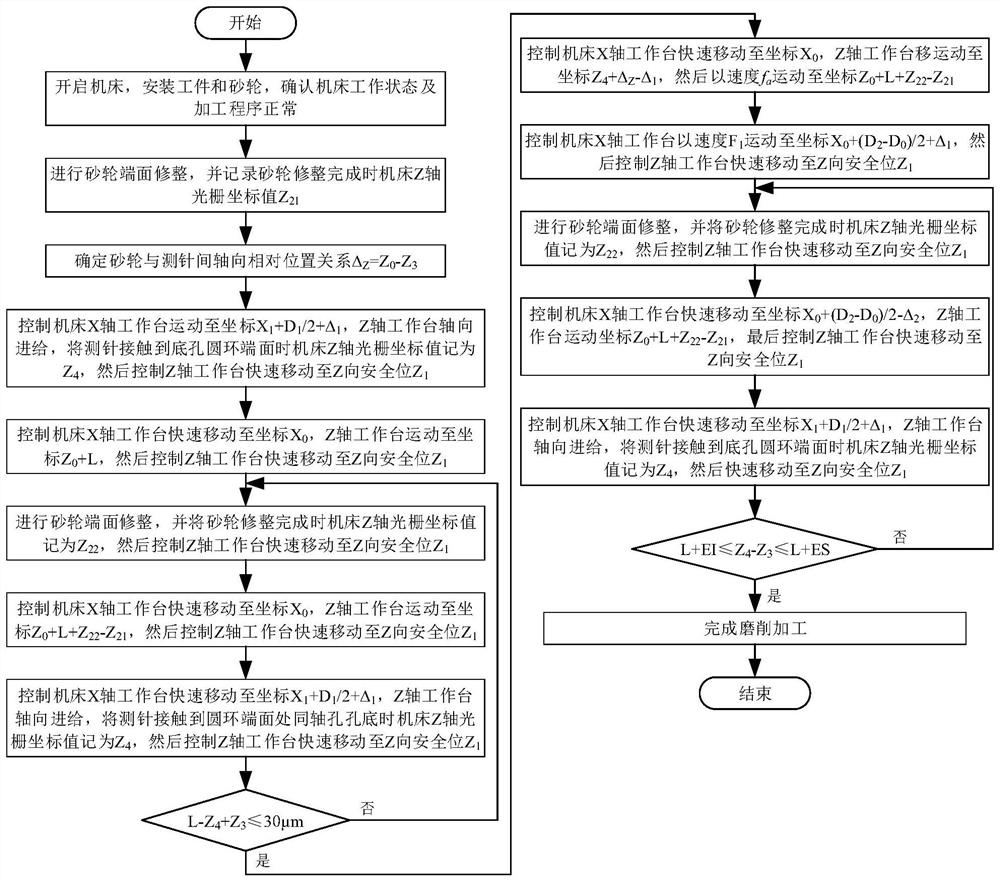

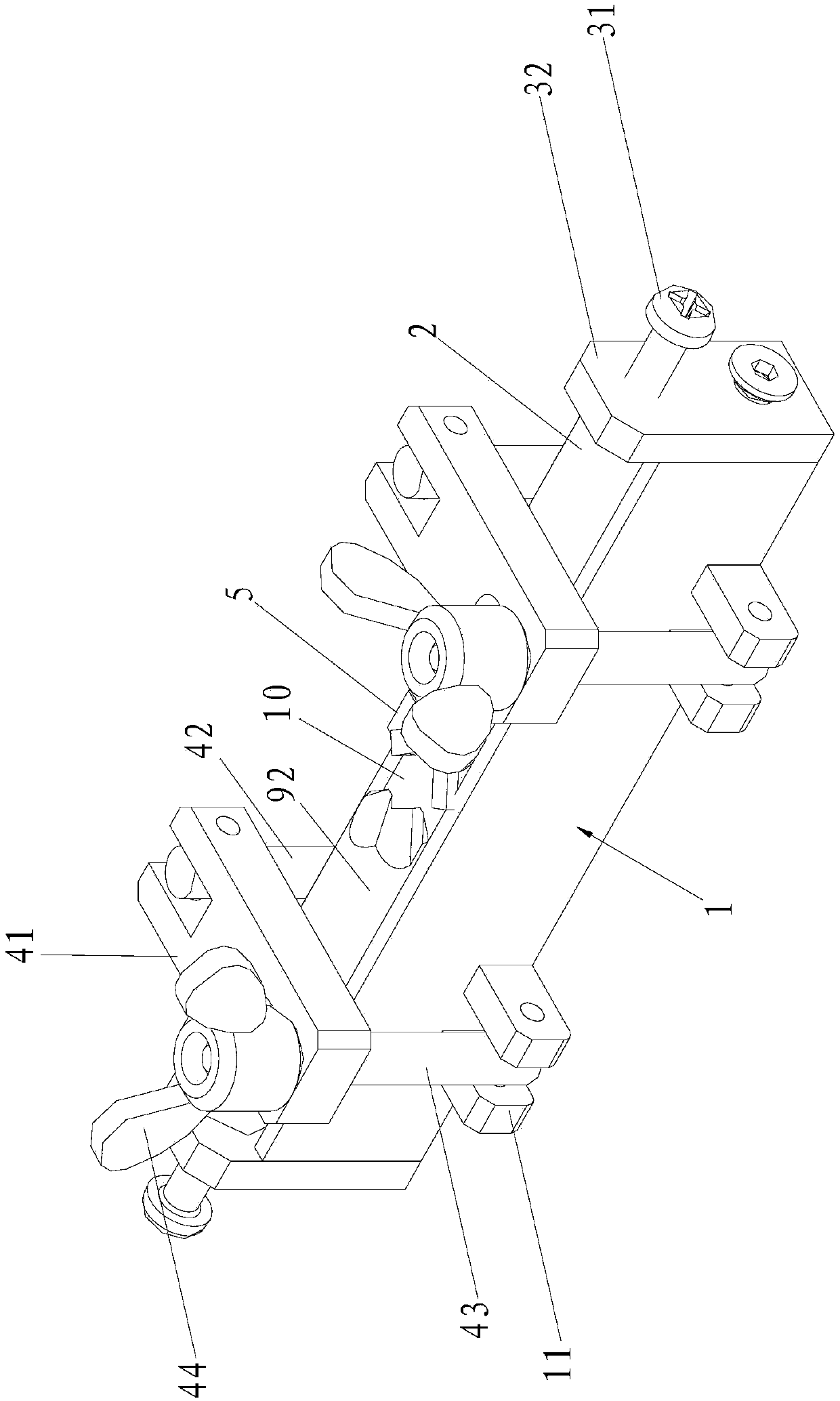

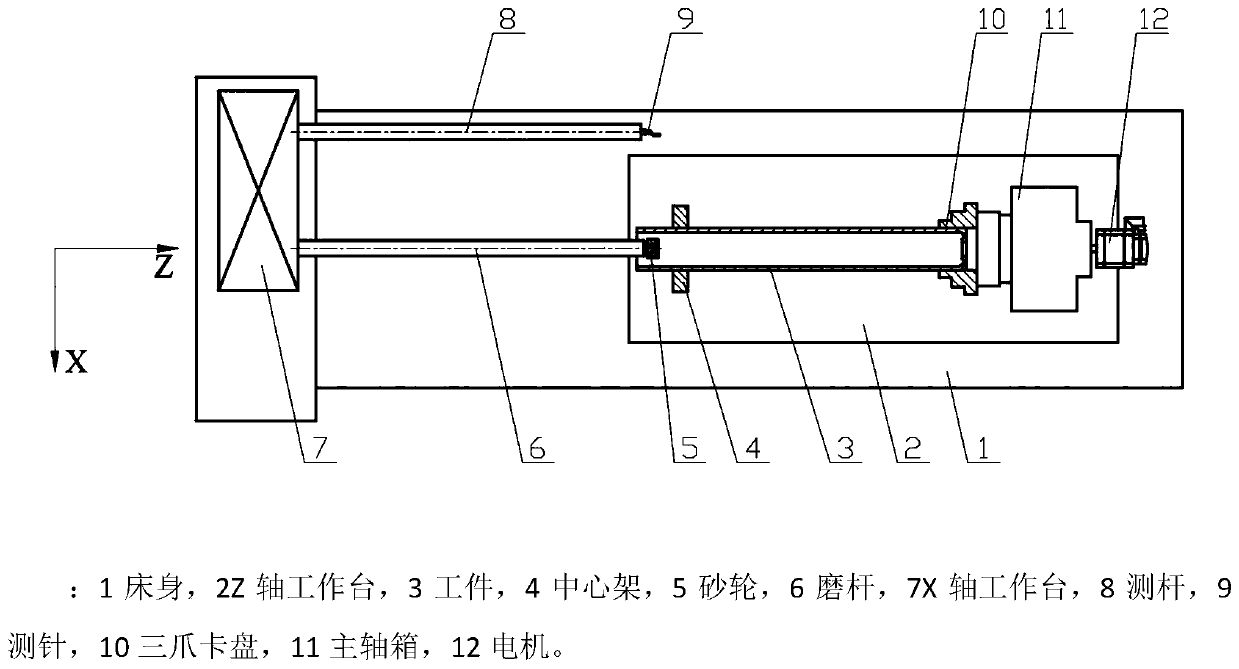

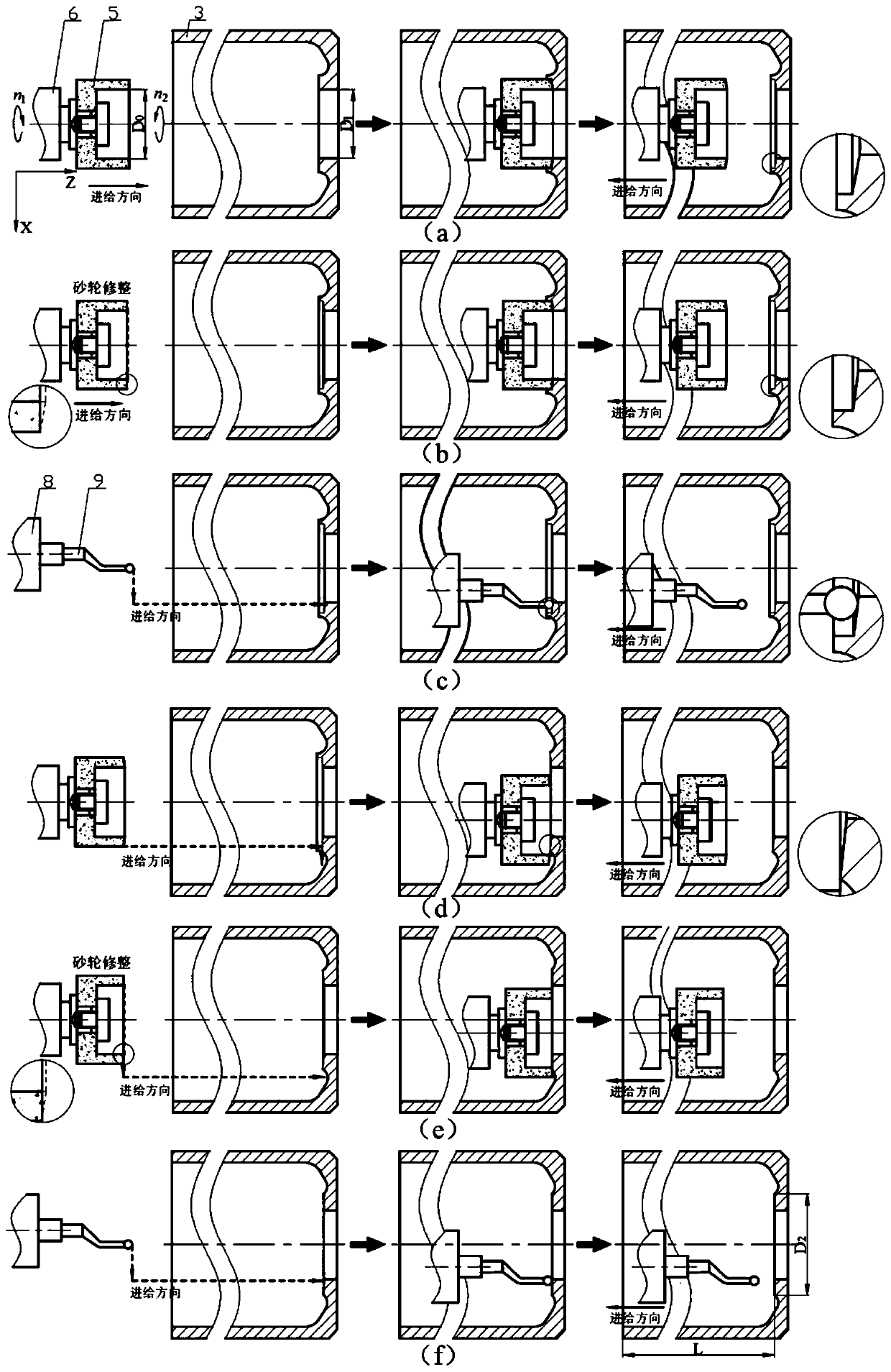

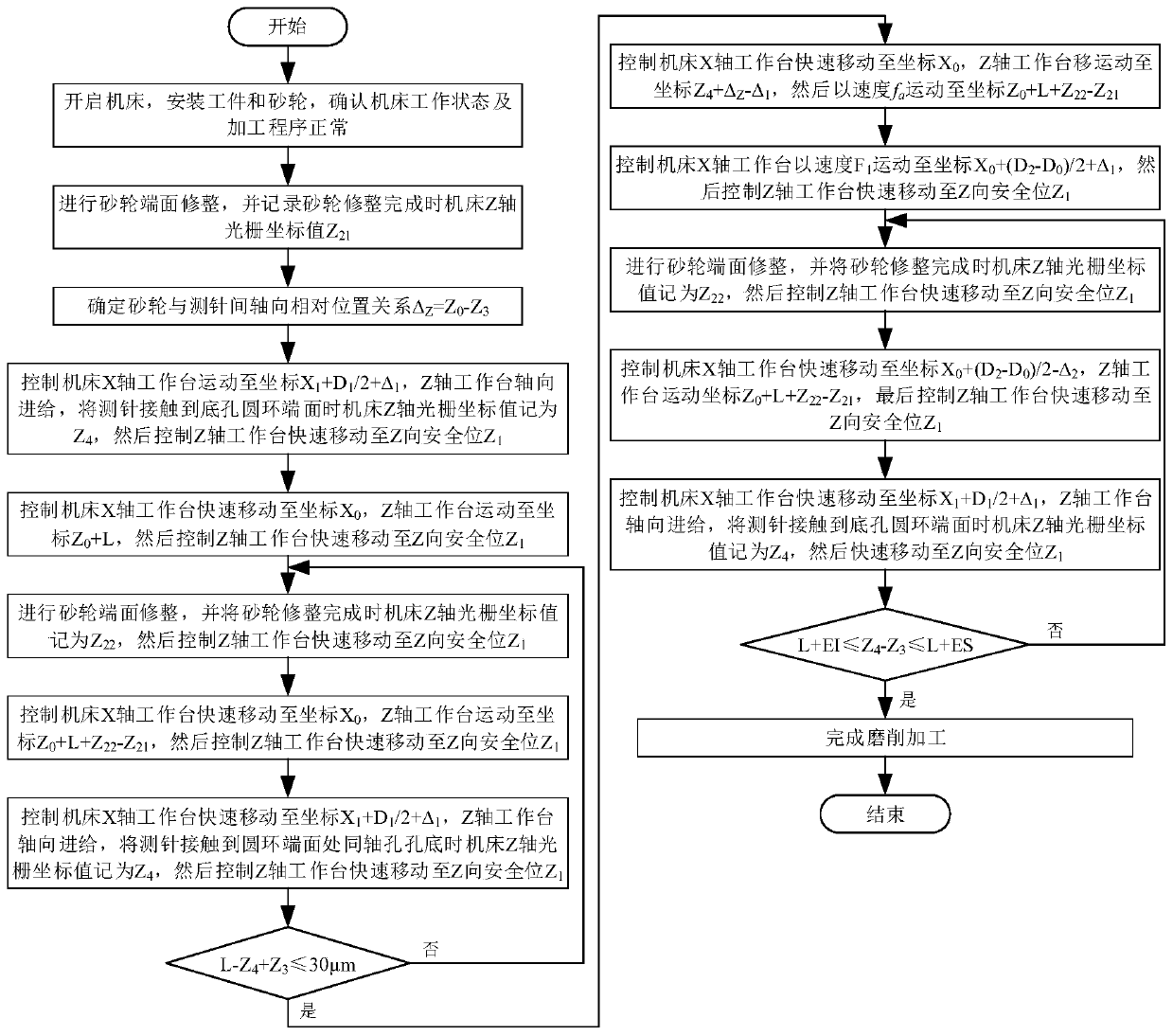

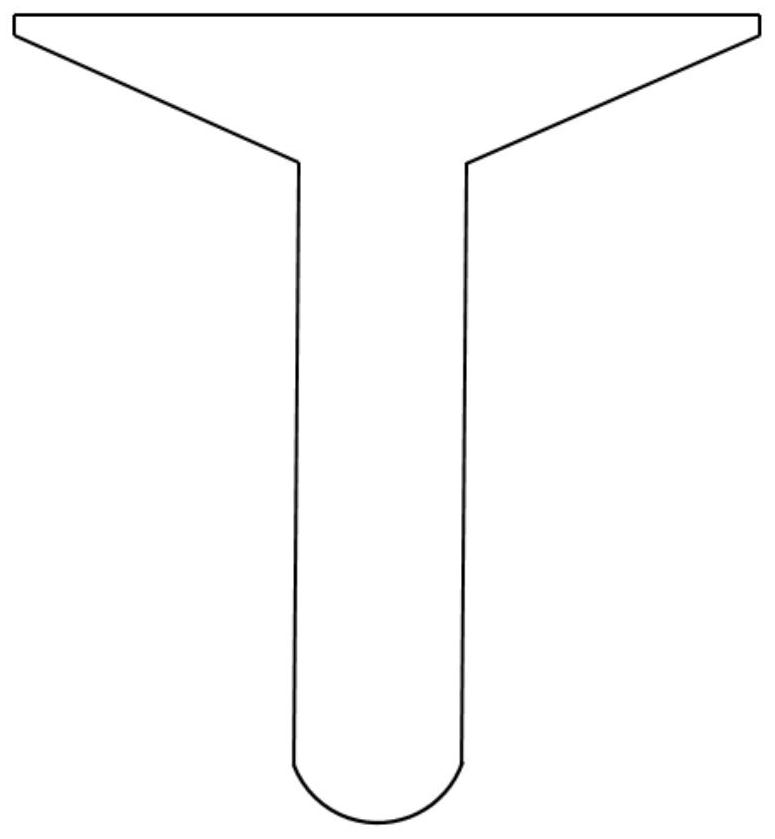

Machining Method of Large L/D Ratio and Weak Rigid Grinding Rod Grinding Circular End Face

ActiveCN110328568BReduce dependency on technology levelReduce dependenceGrinding drivesGrinding feed controlStructural engineeringLarge aspect ratio

The invention discloses a processing method for grinding a circular ring end surface through a grinding rod with large slenderness ratio and weak rigidity. The processing of the circular ring end surface is divided into three steps of grinding a coaxial hole at the circular ring end surface of a bottom hole, removing the hole wall of the coaxial hole, and finish-machining the circular ring end surface of the bottom hole. In the coaxial hole processing process, the distance Z4 to Z3 between the hole bottom of the coaxial hole and the left end surface of a workpiece is measured through a probe and is differed from the nominal dimension L between the circular ring end surface of the bottom hole on a workpiece drawing and the left end surface of the workpiece; when L-Z4+Z3 is smaller than or equal to 30mum, the hole wall of the coaxial hole is removed, and finally the circular ring end surface of the bottom hole is finish-machined; and the distance between the circular ring end surface ofthe bottom hole and the left end surface of the workpiece is measured through the probe until meeting the tolerance requirement of the drawing dimension, so that grinding processing is accomplished. According to the method provided by the invention, the occurrence of the problem that according to a traditional workpiece self-rotating grinding processing method, the chattering unstability of the grinding rod caused by the functions of axial and radial grinding forces causes fast falling or local crushing of grinding wheel abrasives is avoided, the processing efficiency and the service life of agrinding wheel are improved, the rejection rate is reduced, and automation can be easily realized.

Owner:DALIAN UNIV OF TECH

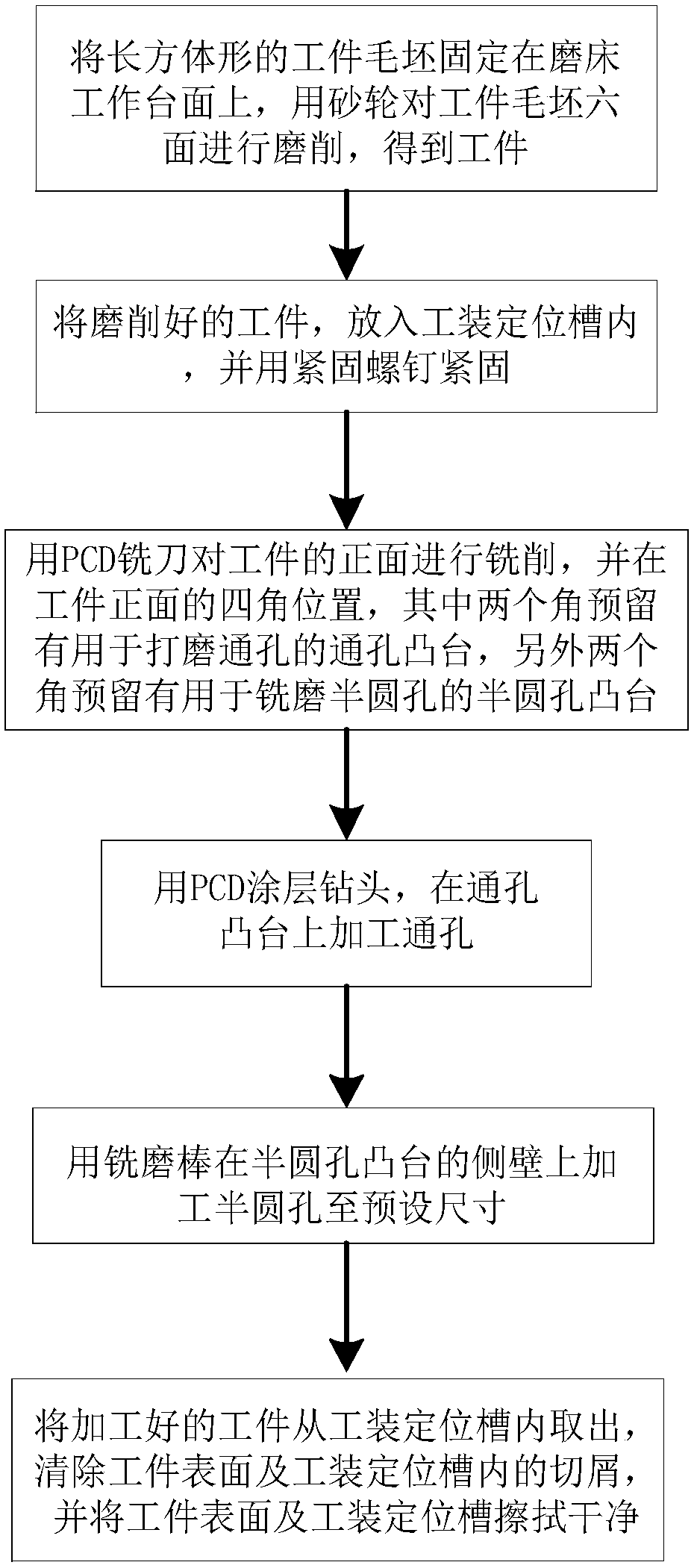

A method for processing semi-circular holes in high volume fraction SiC-Al matrix composites

ActiveCN106239158BMeet miniaturizationImprove practicalityOther manufacturing equipments/toolsMilling cutterRejection rate

The invention discloses a method for machining semi-circular holes in silicon carbide-aluminum-based composite materials with high volume fractions. The method comprises steps as follows: a workpiece blank is ground with a grinding wheel, a ground workpiece is placed in a tool positioning groove to be fastened, the front side of the workpiece is milled with a PCD milling cutter, two through hole bosses and two semi-circular hole bosses are reserved on four corners of the front side of the workpiece, through holes are machined in the through hole bosses with PCD coated drills, the semi-circular holes are machined in the semi-circular hole bosses with milling rods, the machined workpiece is taken out of a positioning tool, and the workpiece and the tool positioning groove are cleaned. With the technical scheme, problems of large machining difficulty, high rejection rate, low machining efficiency and poor precision during precision machining of the semi-circular holes in the hard and brittle silicon carbide-aluminum-based composite materials with the high volume fractions are well solved, high-precision size machining of the semi-circular holes in parts made of the materials is realized, the machining cost is low, the yield is high, the flexibility is high, and the method is suitable for batch production and has very high practicability.

Owner:BEIJING INST OF RADIO MEASUREMENT

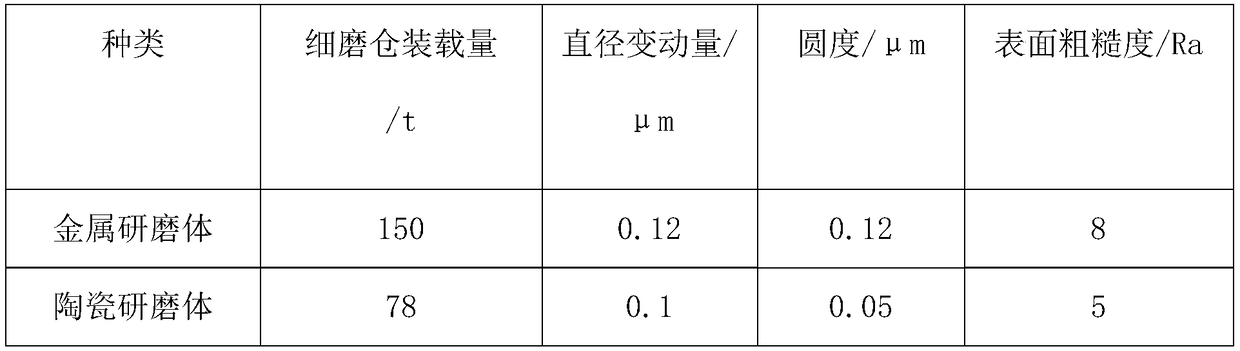

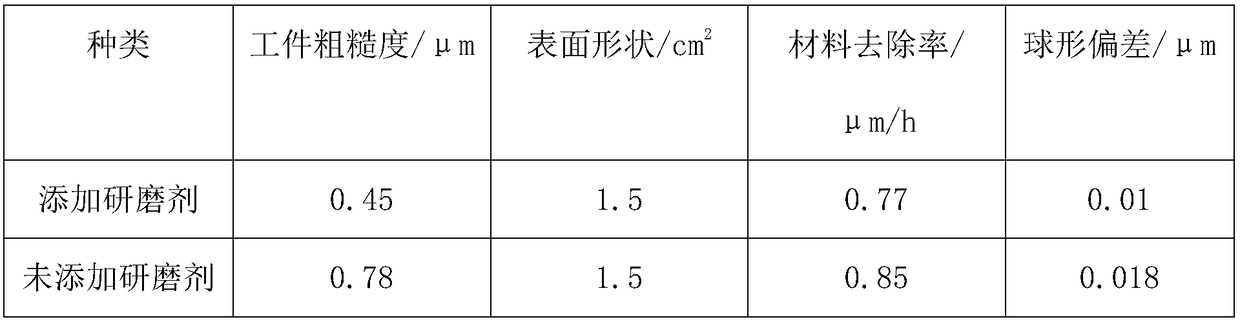

Ceramic rod grinding method

ActiveCN108857587AEfficient processingEfficient precision machiningOther chemical processesLapping machinesMicrometerSurface roughness

The invention discloses a ceramic rod grinding method which comprises the following ceramic rod manufacturing steps: step 1, manufacturing of a ceramic rod; step 2, a stage of rough machining of the ceramic rod; step 3, a stage of finish machining of the ceramic rod; and step 4, chemo-mechanical polishing. According to the manufacturing steps of the ceramic rod grinding method, a technical schemefor the efficient precision machining process of a hard rod can be achieved; the high-quality hard ceramic rod which is manufactured by adopting equipment involved in the ceramic rod grinding method through batch machining can reach the roundness of 0.05 micrometers, the ceramic rod diameter variation of 0.10 micrometers and the surface roughness of Ra 5 nm; compared with the efficiency of a conventional free abrasive grinding machining method, the machining efficiency of the ceramic rod grinding method can be improved by 2 times; and the efficient and high-precision grinding machining of a hard precision ball can be preliminarily achieved.

Owner:FOSHAN HUAQIANG XIEXING CERAMIC CO LTD

Superhard blade and cutting tool substrate welding fixture and welding method

ActiveCN105965194BImprove machining accuracyImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProcessing accuracy

The invention is applicable to the technical field of super hard blade production, and discloses a super hard blade and cutter substrate welding and fixing device and a welding method. The device comprises a locating base and a locating carrier, a blade groove is formed in one end of the locating carrier, a locating groove used for axially accommodating the locating carrier and a blade substrate is formed in the locating base, the locating carrier is cylindrical and equal with the diameter of the blade substrate, an axial locating part which is used for keeping abut joint of the super hard blade in the locating carrier and the blade substrate is connected to the locating base, and a radial locating part which is used for pressing the locating carrier and the blade substrate is connected to the locating base. The welding method uses the super hard blade and cutter substrate welding and fixing device. According to the super hard blade and cutter substrate welding and fixing device and the welding method, the processing accuracy of the blade is improved favorably, batch stable welding production is easy to realize, and further efficient precision processing of the materials which are difficult to process is effectively guaranteed.

Owner:SHENZHEN JINZHOU PRECISION TECH

Processing method for grinding circular ring end surface through grinding rod with large slenderness ratio and weak rigidity

ActiveCN110328568AReduce dependency on technology levelReduce dependenceGrinding drivesGrinding feed controlRejection rateGrinding wheel

The invention discloses a processing method for grinding a circular ring end surface through a grinding rod with large slenderness ratio and weak rigidity. The processing of the circular ring end surface is divided into three steps of grinding a coaxial hole at the circular ring end surface of a bottom hole, removing the hole wall of the coaxial hole, and finish-machining the circular ring end surface of the bottom hole. In the coaxial hole processing process, the distance Z4 to Z3 between the hole bottom of the coaxial hole and the left end surface of a workpiece is measured through a probe and is differed from the nominal dimension L between the circular ring end surface of the bottom hole on a workpiece drawing and the left end surface of the workpiece; when L-Z4+Z3 is smaller than or equal to 30mum, the hole wall of the coaxial hole is removed, and finally the circular ring end surface of the bottom hole is finish-machined; and the distance between the circular ring end surface ofthe bottom hole and the left end surface of the workpiece is measured through the probe until meeting the tolerance requirement of the drawing dimension, so that grinding processing is accomplished. According to the method provided by the invention, the occurrence of the problem that according to a traditional workpiece self-rotating grinding processing method, the chattering unstability of the grinding rod caused by the functions of axial and radial grinding forces causes fast falling or local crushing of grinding wheel abrasives is avoided, the processing efficiency and the service life of agrinding wheel are improved, the rejection rate is reduced, and automation can be easily realized.

Owner:DALIAN UNIV OF TECH

Electrolytic machining method, cathode for electrolytic machining and electrolytic machining device

InactiveCN112894037AHigh precisionEfficient precision machiningMachining electrodesElectrical-based machining electrodesElectrochemical dissolutionTitanium alloy

The invention discloses an electrolytic machining method, a cathode for electrolytic machining and an electrolytic machining device. The method comprises the steps that a part serves as an anode, an electrolyte is introduced into an internal structure from a surface port of the part, the electrolyte makes contact with the inner wall of the internal structure for a reaction, then the electrolyte flows out of the other surface port of the part and continues to flow through the cathode arranged at the other surface port, an electrolytic machining loop is formed, and the internal structure of the part is treated; the disclosed cathode is provided with an electrolyte collection container, and the collection container is provided with an electrolyte collection port and an electrolyte outflow port; and the electrolytic machining device comprises the cathode and an electrolyte tank. According to the method, a workpiece is machined and formed on the basis of an oxygen electrode metal electrochemical dissolution principle, the efficient and precise machining problem of internal structure metal parts such as titanium alloy and high-temperature alloy manufactured through laser additive manufacturing is effectively solved, and the metal workpiece internal structure surface high in precision and good in surface quality can be effectively machined.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

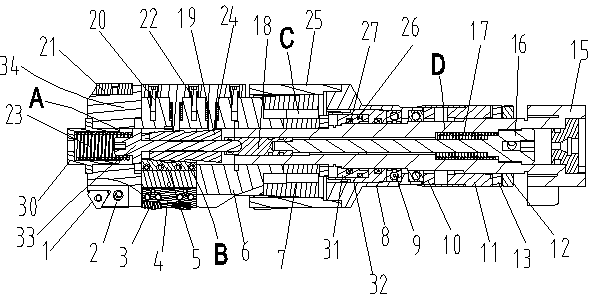

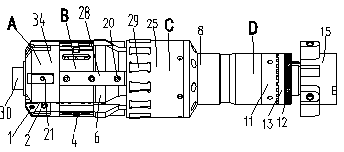

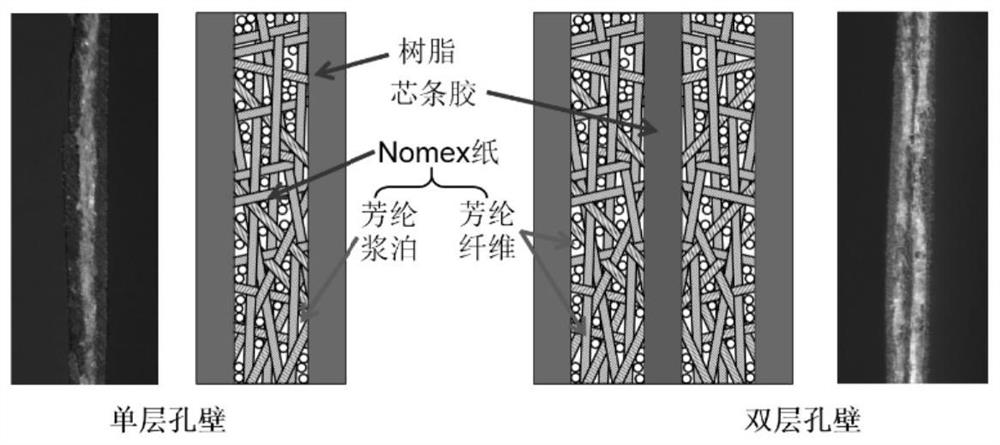

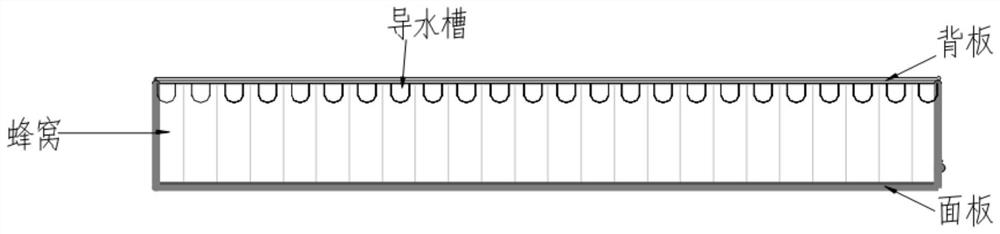

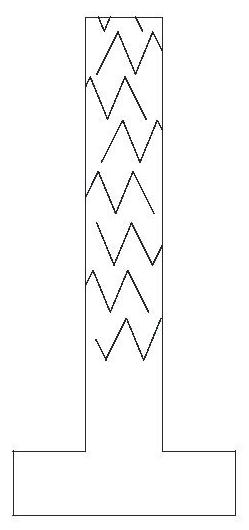

A kind of processing method of weak rigid semi-cured aramid paper honeycomb water guide groove for acoustic lining member

ActiveCN112405674BEfficient processingEfficient precision machiningEfficient propulsion technologiesMetal working apparatusHoneycombMachining process

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com