A kind of processing method of weak rigid semi-cured aramid paper honeycomb water guide groove for acoustic lining member

A processing method and technology of aramid paper, which can be used in metal processing, hydropower, climate sustainability, etc., can solve problems such as cutting damage, and achieve the effects of high-efficiency precision processing, good repeatability and obvious technical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

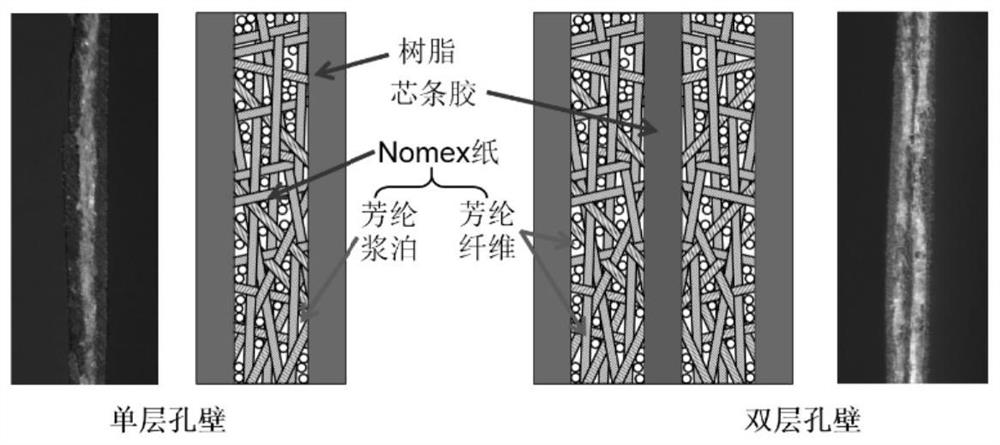

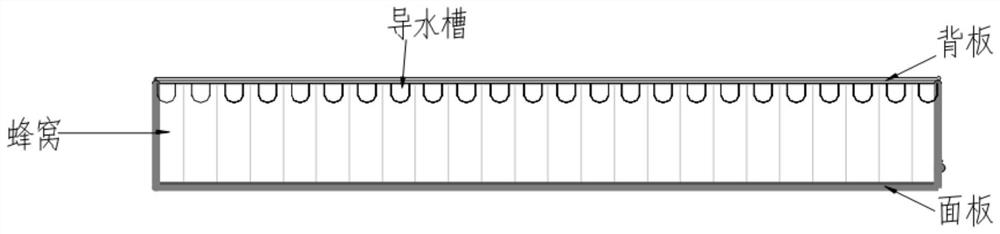

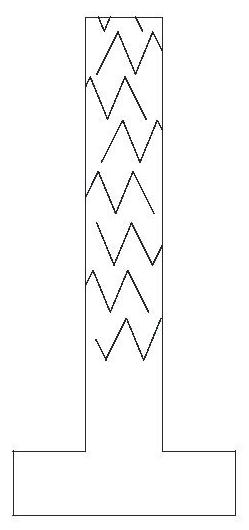

[0057] The weakly rigid semi-cured aramid paper honeycomb water guide groove for the acoustic lining member described in the embodiment of the present invention is distributed along the honeycomb laterally on the honeycomb wall; the water guide groove is a nearly U-shaped groove, the groove depth is 4mm, and the groove width is 3mm. The paper material of the aramid paper honeycomb is Nomex aramid paper, the cell side length is 5.5mm, the honeycomb height is 20mm, and the honeycomb nominal density is 32kg / m 3 ; The water guiding groove is machined on the double-layer honeycomb walls of the glue joints along the longitudinal direction of the honeycomb, and is centered on the edge of each double-layer honeycomb wall.

[0058] The method for processing a weakly rigid semi-cured aramid paper honeycomb water guide groove for the acoustic lining member is characterized by comprising the following steps:

[0059] 1) The semi-cured aramid paper honeycomb is fixed on the flat operating ...

Embodiment 2

[0066] The weak rigid semi-cured aramid paper honeycomb water guide groove for the acoustic lining member described in the embodiment of the present invention is distributed along the honeycomb laterally on the honeycomb wall; the water guide groove is a nearly U-shaped groove, the groove depth is 4mm, and the groove width is 4mm. The paper material of the aramid paper honeycomb is Nomex aramid paper, the cell side length is 5.5mm, the honeycomb height is 24mm, and the honeycomb nominal density is 48kg / m 3 ; The water guiding groove is machined on the double-layer honeycomb walls of the glue joints along the longitudinal direction of the honeycomb, and is centered on the edge of each double-layer honeycomb wall.

[0067] The method for processing a weakly rigid semi-cured aramid paper honeycomb water guide groove for the acoustic lining member is characterized by comprising the following steps:

[0068] 1) The semi-cured aramid paper honeycomb is fixed on the flat operating ta...

Embodiment 3

[0075] The weak rigid semi-cured aramid paper honeycomb water guide groove for the acoustic lining member described in the embodiment of the present invention is distributed along the honeycomb laterally on the honeycomb wall; the water guide groove is a nearly U-shaped groove, the groove depth is 3mm, and the groove width is 2mm. The paper material of the aramid paper honeycomb is Nomex aramid paper, the cell side length is 3.67mm, the honeycomb height is 15mm, and the honeycomb nominal density is 48kg / m 3 ; The water guiding groove is machined on the double-layer honeycomb walls of the glue joints along the longitudinal direction of the honeycomb, and is centered on the edge of each double-layer honeycomb wall.

[0076] The method for processing a weakly rigid semi-cured aramid paper honeycomb water guide groove for the acoustic lining member is characterized by comprising the following steps:

[0077] 1) The semi-cured aramid paper honeycomb is fixed on the flat operating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com