Patents

Literature

84results about How to "Precise control of depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel

ActiveCN109735794ASolve pollutionHigh fatigueSolid state diffusion coatingQuenchingPrepared Material

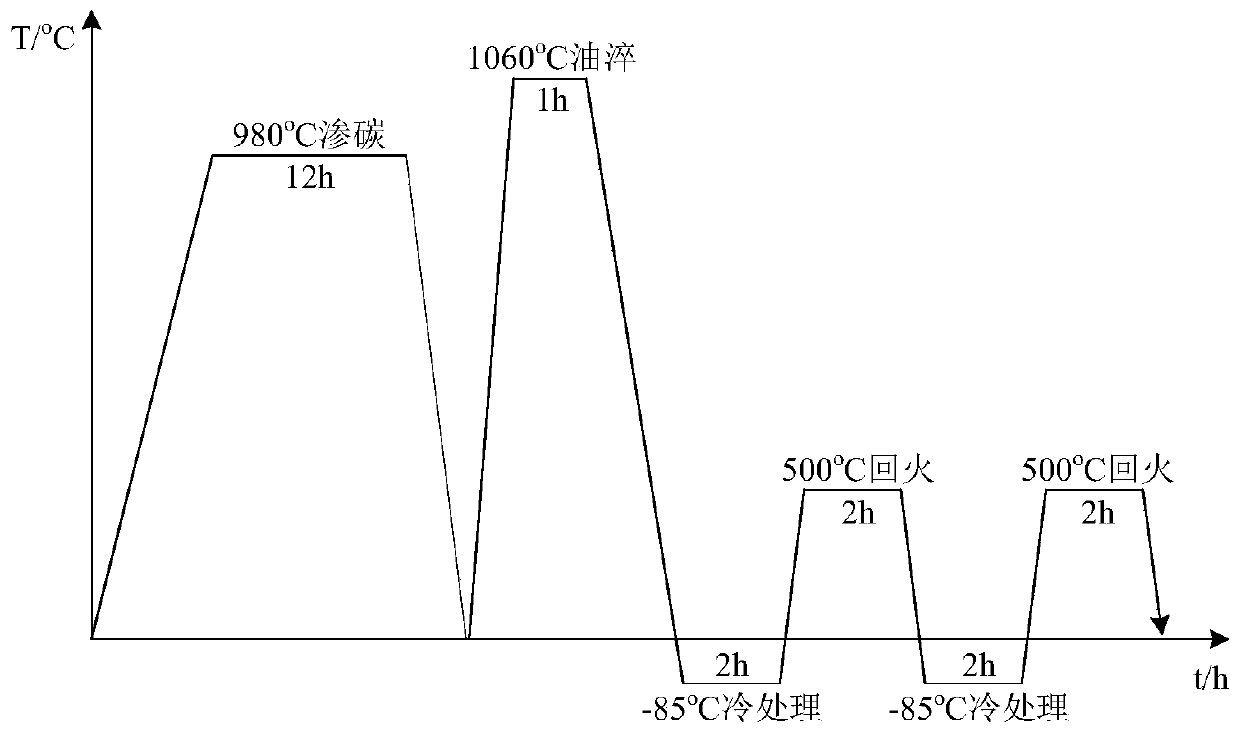

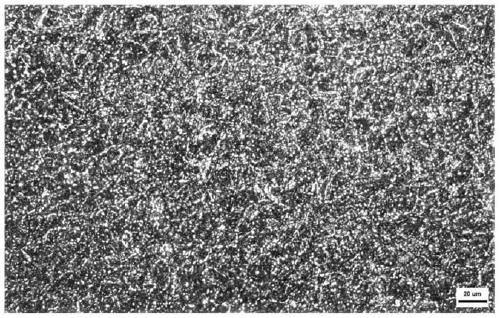

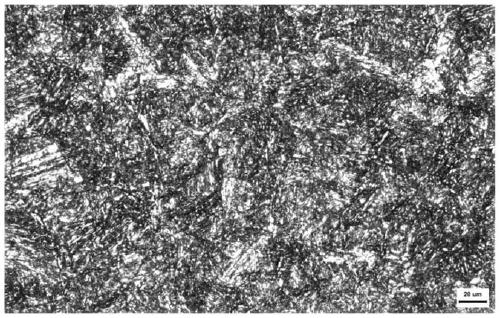

The invention relates to a low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel. The method comprises the treatment steps of low-pressure vacuum carbonizing, quenching, deep cooling and high-temperature tempering; and the steps can be repeatedly performed. The low-pressure vacuum carbonizing process uses a saturated value adjusting method for multi-section pulse carbonizing; a carbonizing agent adopts acetylene gas; the carbonizing temperature is 850-1050 DEG C; the carbonizing pressure is 100-2000 Pa; and the powerful seepage and dispersion circulating period is 20-70 times. The treatment method is safe, energy-saved and environment-friendly, can eliminate intergranular oxidation, realizes precise control of the seepage layer depth, and canguarantee excellent service performances of prepared materials above 400 DEG C.

Owner:NORTHEASTERN UNIV

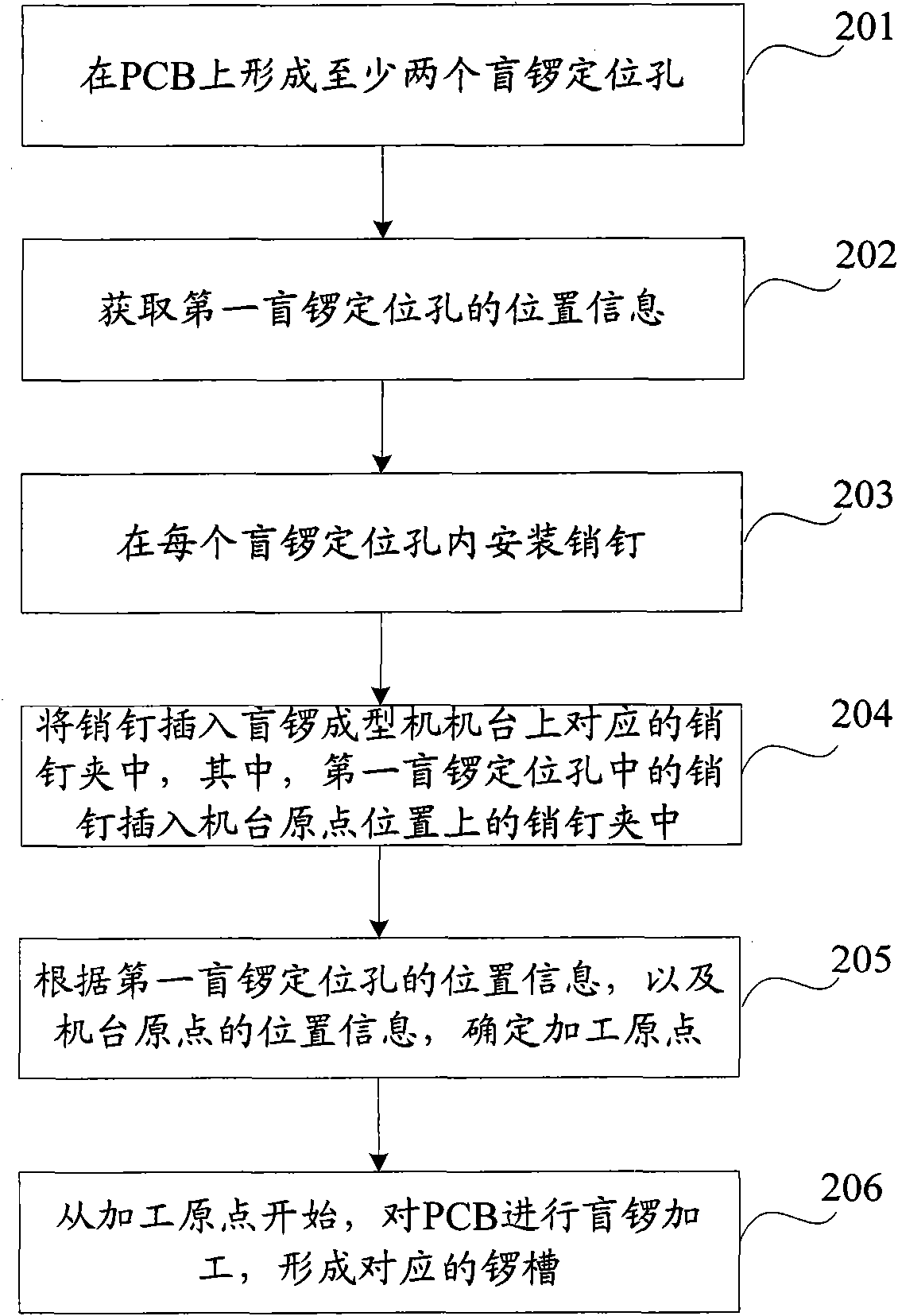

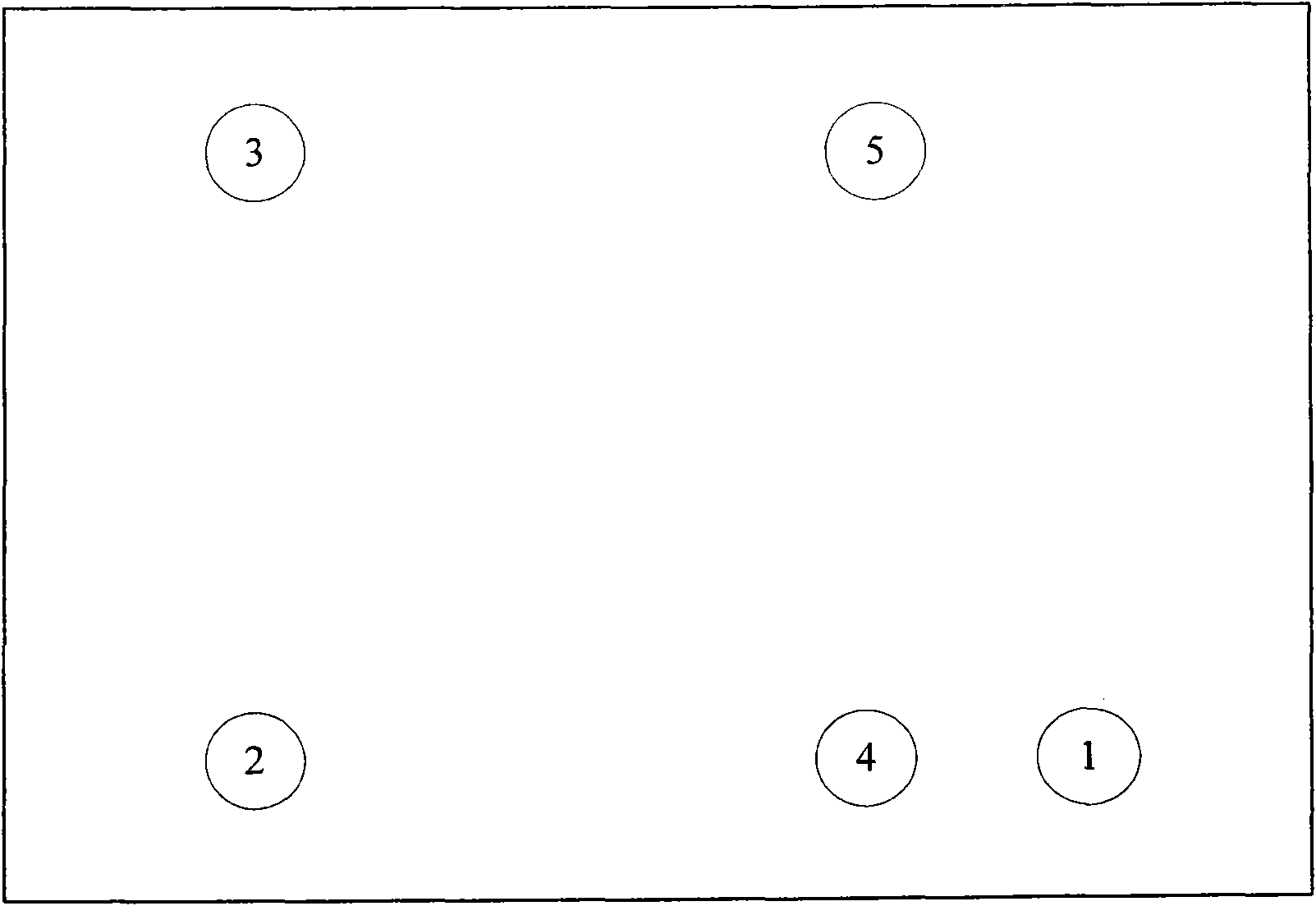

Method and system for forming blind gongs on printed circuit board (PCB) and circuit board

ActiveCN102036483AAvoid low precisionPrecise control of depthPrinted circuit detailsPrinted circuit manufacturePrinted circuit boardEngineering

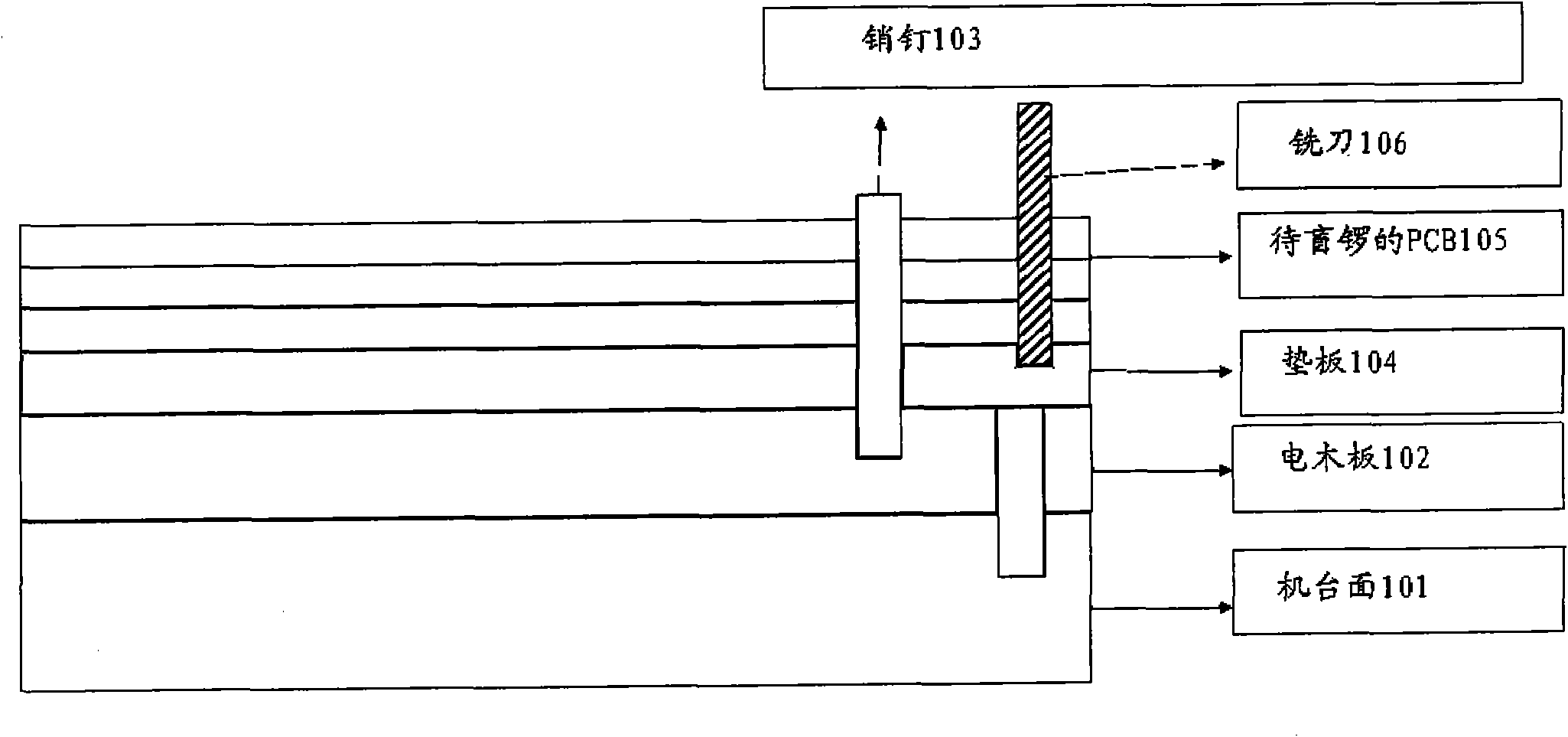

The invention discloses a method and system for forming blind gongs on a printed circuit board (PCB) and a circuit board to improve the precision of machining the blind gongs on the PCB. The method comprises the following steps: forming at least two blind gong locating holes on the PCB and obtaining the location information of the first blind gong locating hole; installing a pin in each blind gong locating hole and inserting each pin into a corresponding pin clip on a bench of a blind gong forming machine, wherein the pin in the first blind gong locating hole is inserted into the pin clip on the location of an origin of the bench; and determining the machining origin according to the location information of the first blind gong locating hole and the origin on the bench and beginning machining the blind gongs on the PCB from the machining origin to form corresponding gong slots.

Owner:CHONGQING FOUNDER HI TECH ELECTRONICS +1

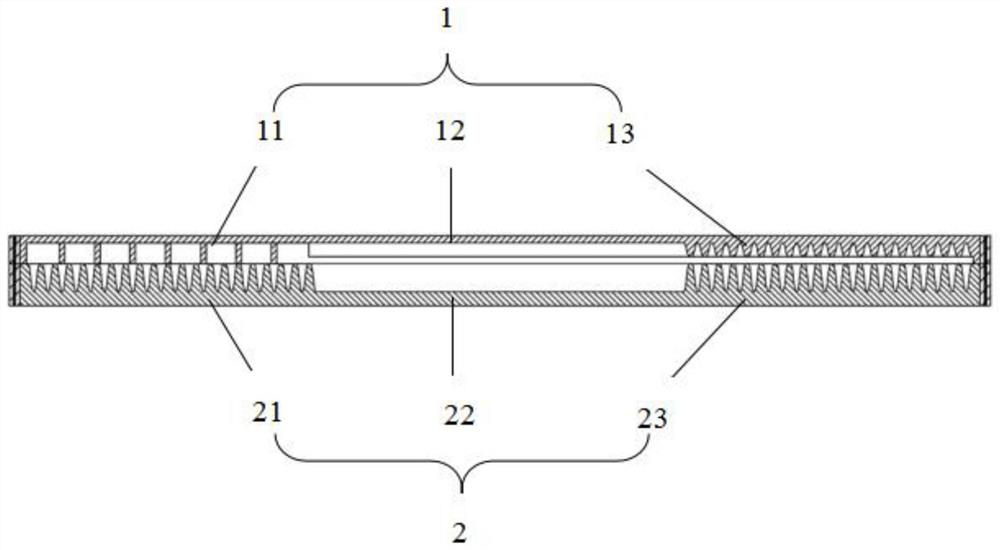

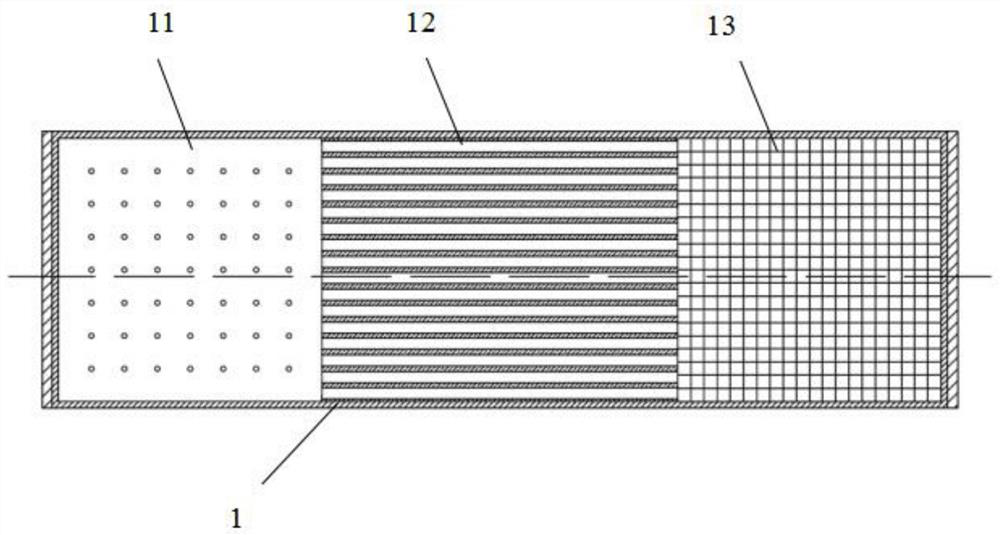

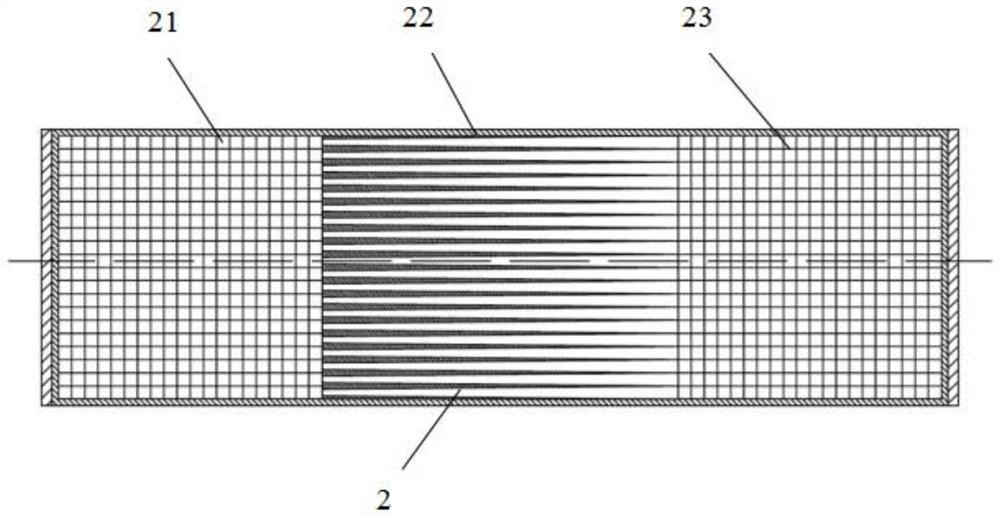

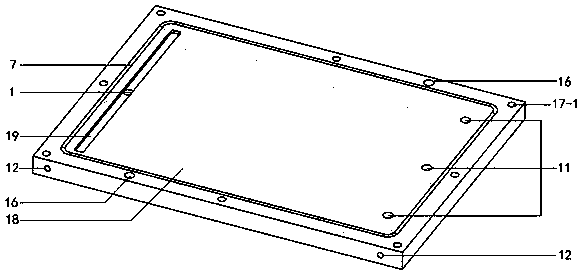

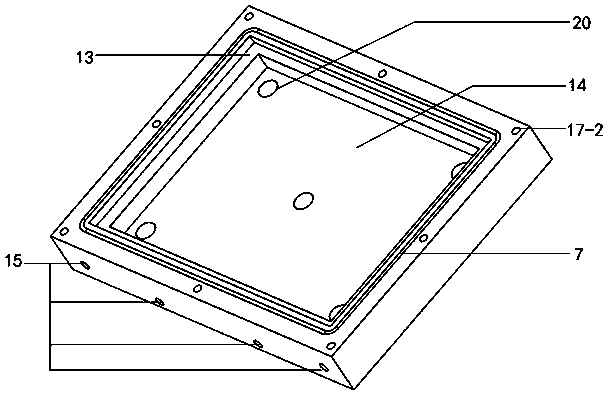

Partition-optimized ultrathin VC with thickness of 0.1-0.4 mm and preparation method

PendingCN111879158AEmission reductionSpeed up distributionIndirect heat exchangersMicro nanoNano structuring

The invention discloses a partition-optimized ultrathin VC with the thickness of 0.1-0.4 mm and a preparation method. The ultrathin VC comprises an upper cover plate and a lower cover plate, and the upper cover plate and the lower cover plate are welded. Each of the upper cover plate and the lower cover plate comprises an evaporation section, a heat insulation section and a condensation section; the surface of the evaporation section of the upper cover plate is of a super-hydrophilic cavity-shaped micro-nano structure, the surface of the heat insulation section of the upper cover plate is of asuper-hydrophilic equal-width groove micro-nano structure, and the surface of the condensation section of the upper cover plate is of a super-hydrophobic conical micro-nano structure; and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the evaporation section of the lower cover plate, a super-hydrophilic cactus-like wedge-shaped groove micro-nano structure is arranged on the surface of the area of the heat insulation section, and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the condensation section. The invention further discloses a preparation method of the ultrathin VC. A steam cavity structure, a liquid cavity structure and volume distribution in a heat pipe can be optimized, and good capillary water absorption performance and low water resistance and heat resistance of the heat pipe can be guaranteed.

Owner:绍兴镭纳激光科技有限公司

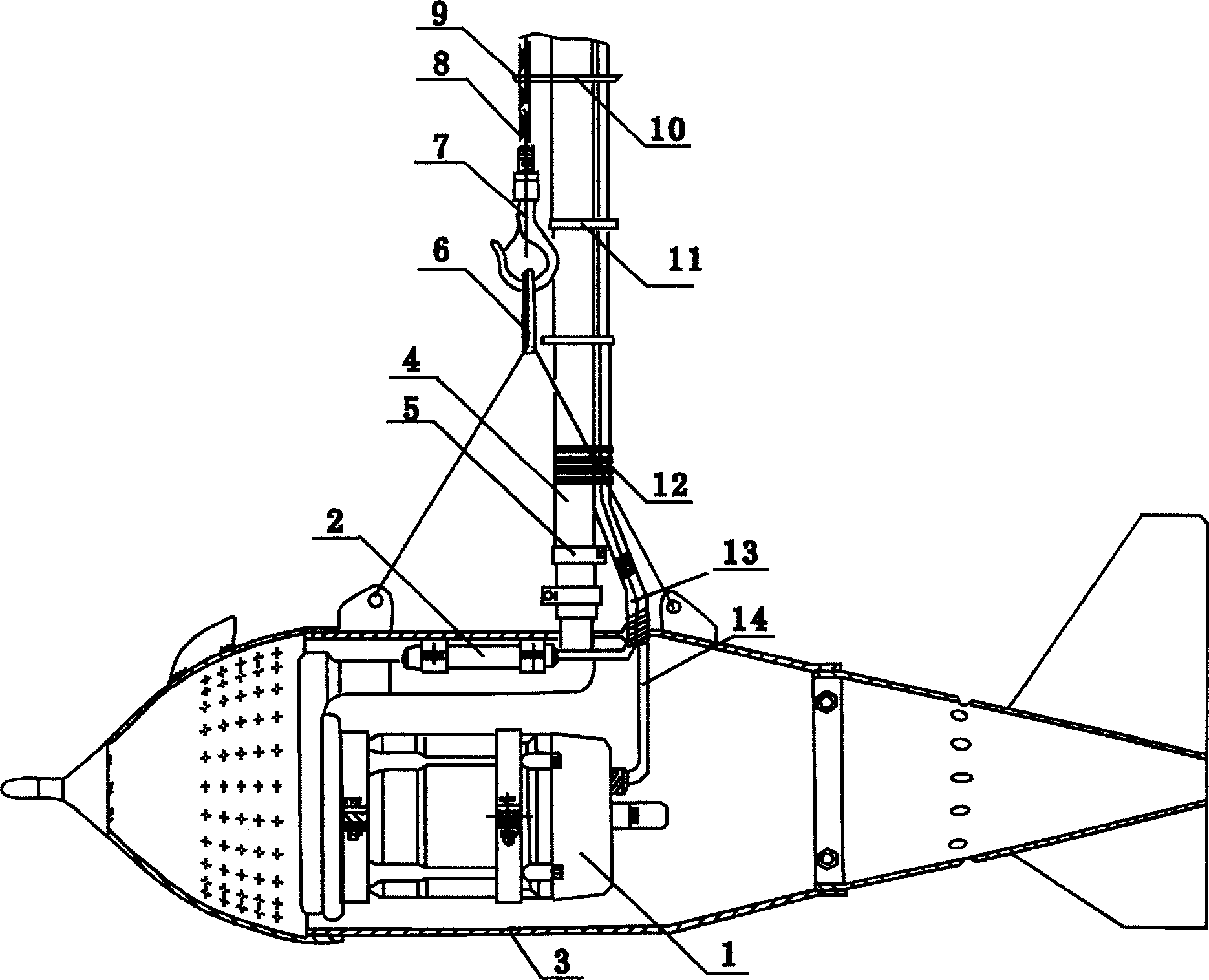

Towing type navigation water sampler

InactiveCN1595096AImprove collection efficiencyPrecise control of depthWithdrawing sample devicesEngineeringHigh intensity

It is a drag sailing water sampler with a dragged body, which has a dive pump on its middle and down part and a sensor on its middle and upper parts inside. The water-in mouth of the pipe is connected with the water-out mouth of the dive pump and the water-in mouth and water-out mouth are fixed together by use of catcher and the pipe sticks out of the drag body and the hanging hook upper end is fixed together with hook ring and nylon through steel cable and is located on the upper end of the water pipe. The wire and cable are located on one side of the water pipe through anti-water adhesive tape. The advantages in this invention are the following: first it can make water sample continuously with high intensity in sailing status; second to accurately control water sample depth and adjust sample depth when needed on real time; third to improve the sample efficiency and lower the investigate cost.

Owner:OCEAN UNIV OF CHINA +1

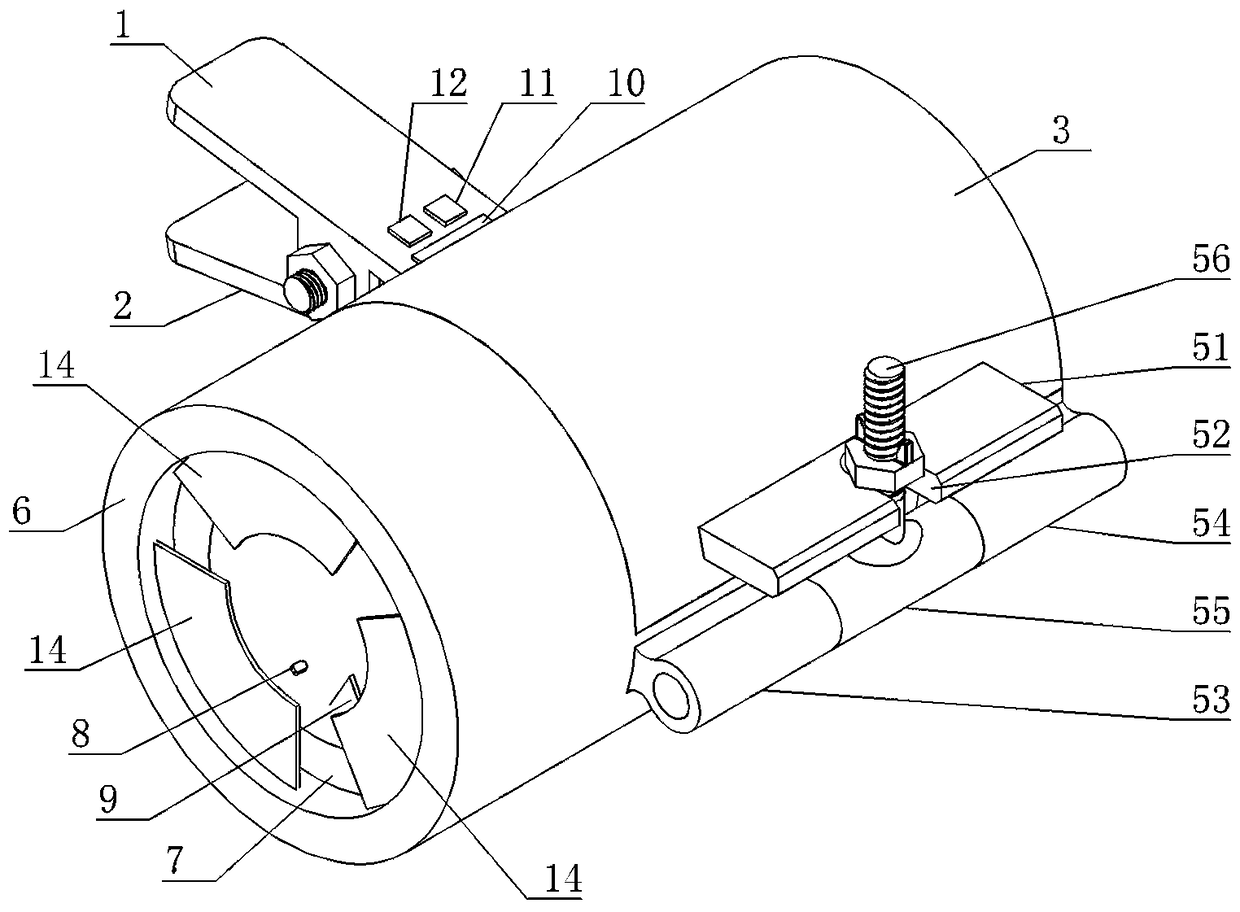

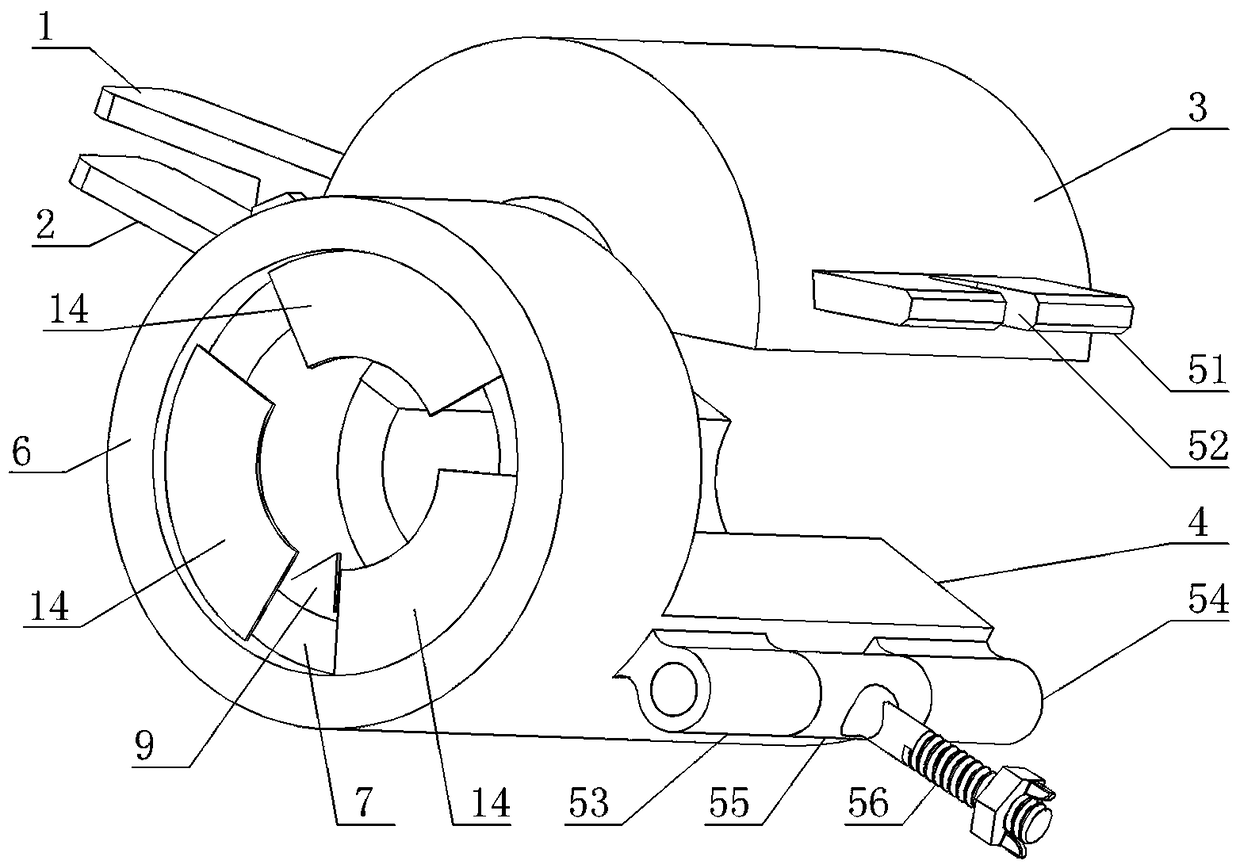

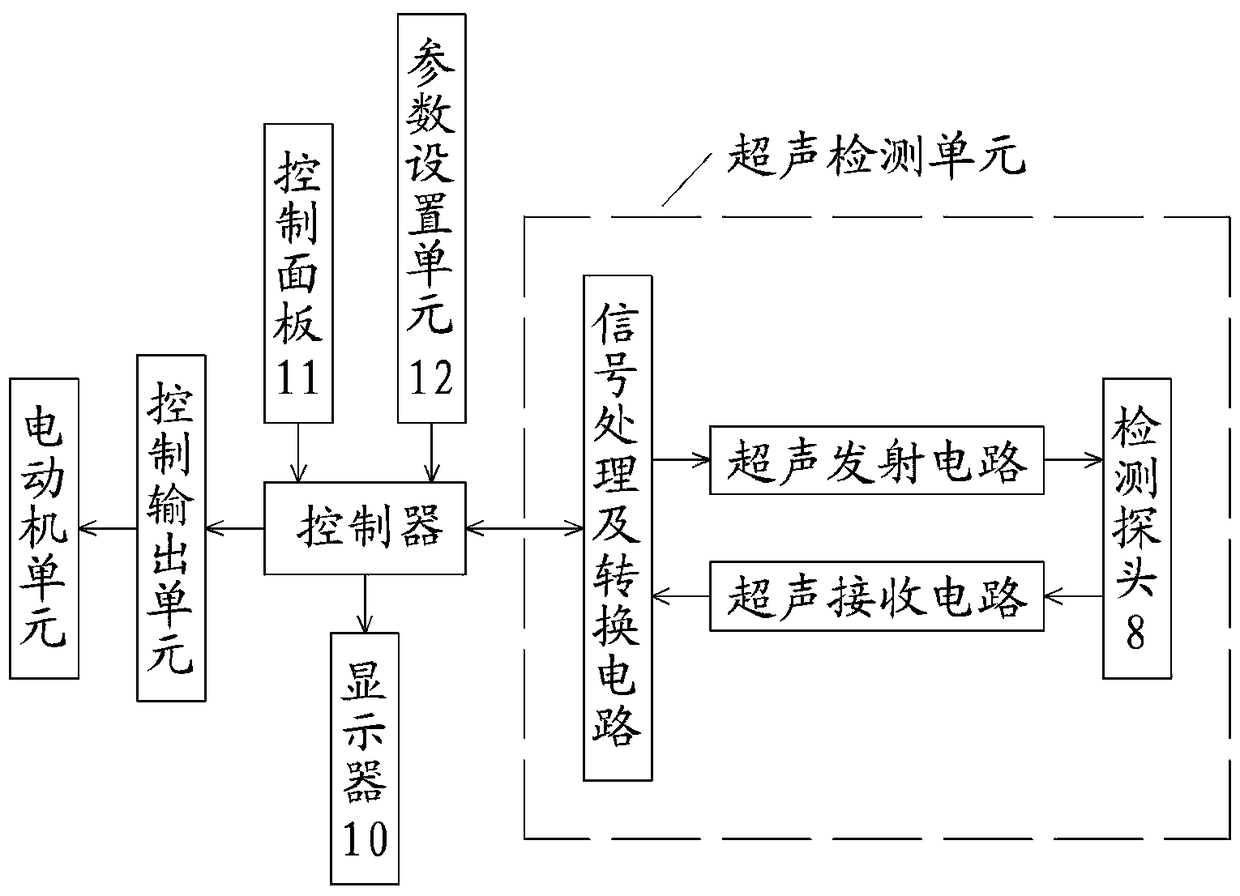

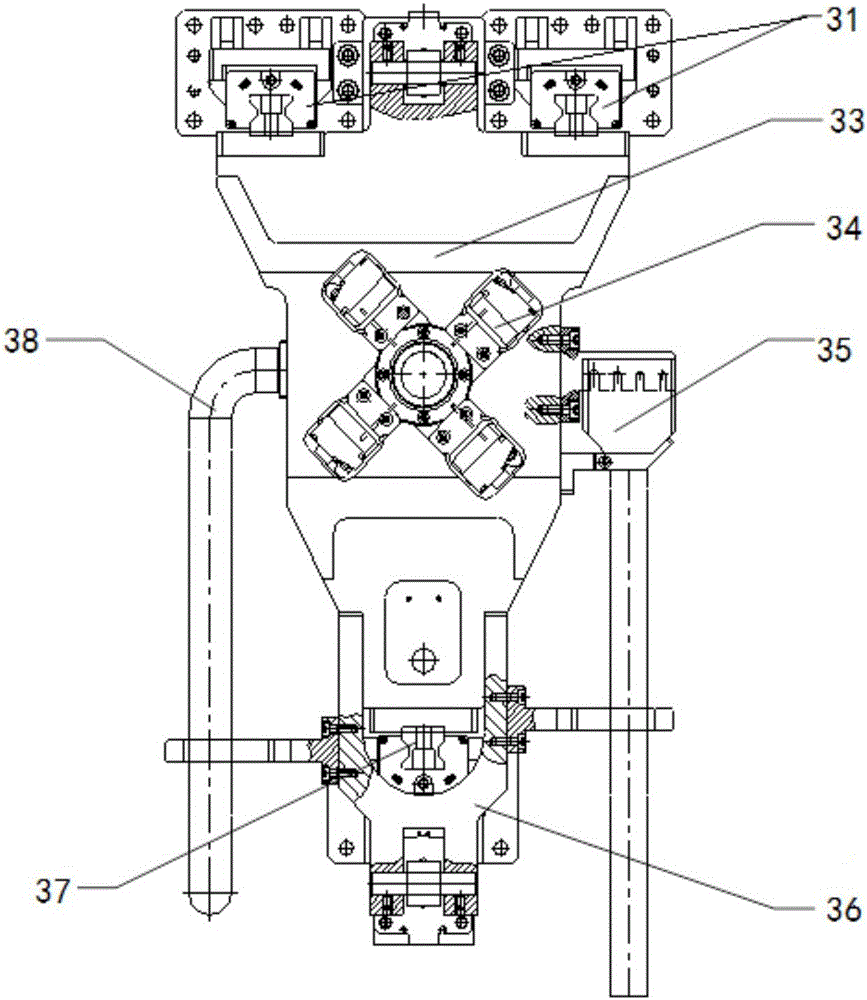

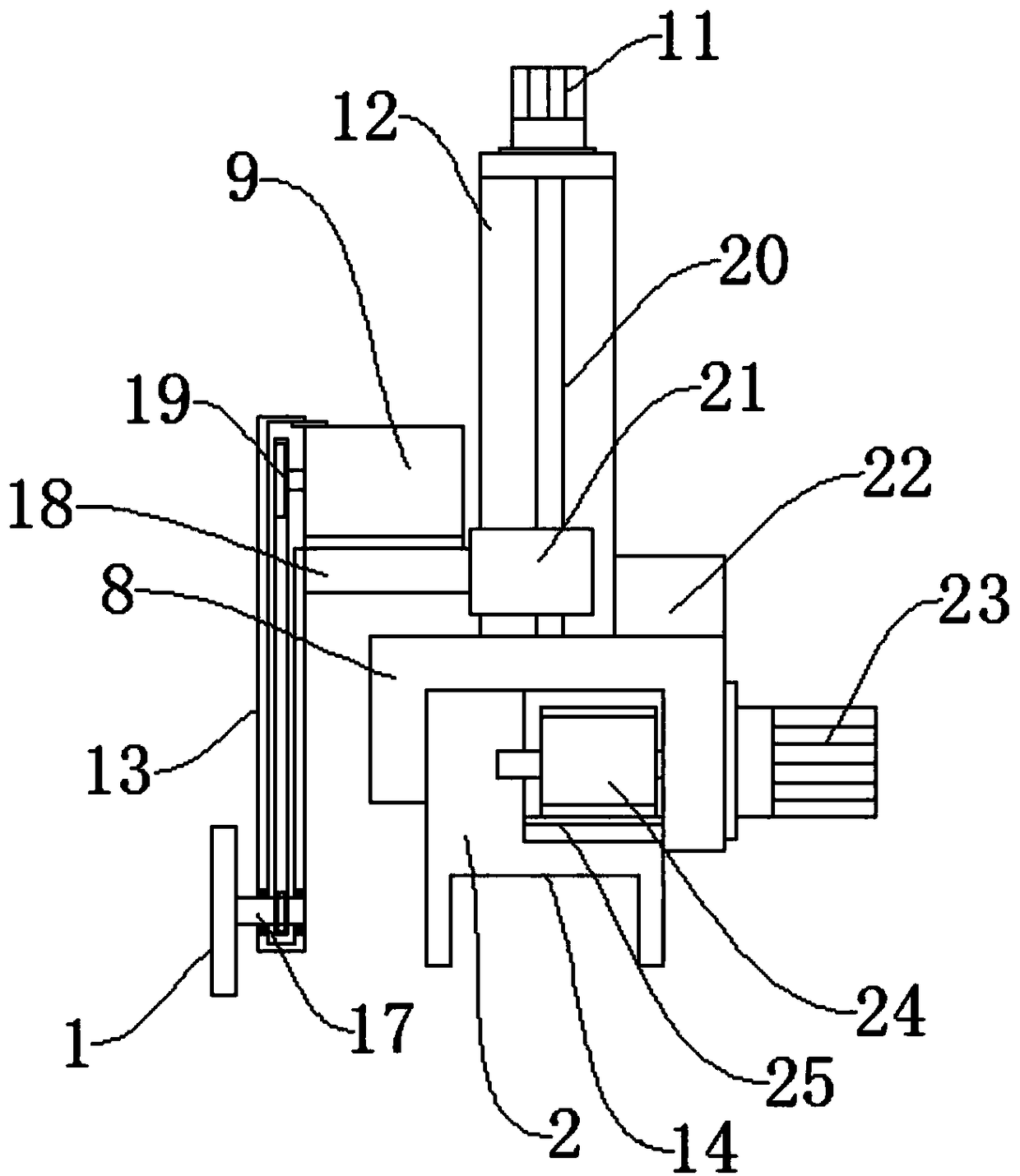

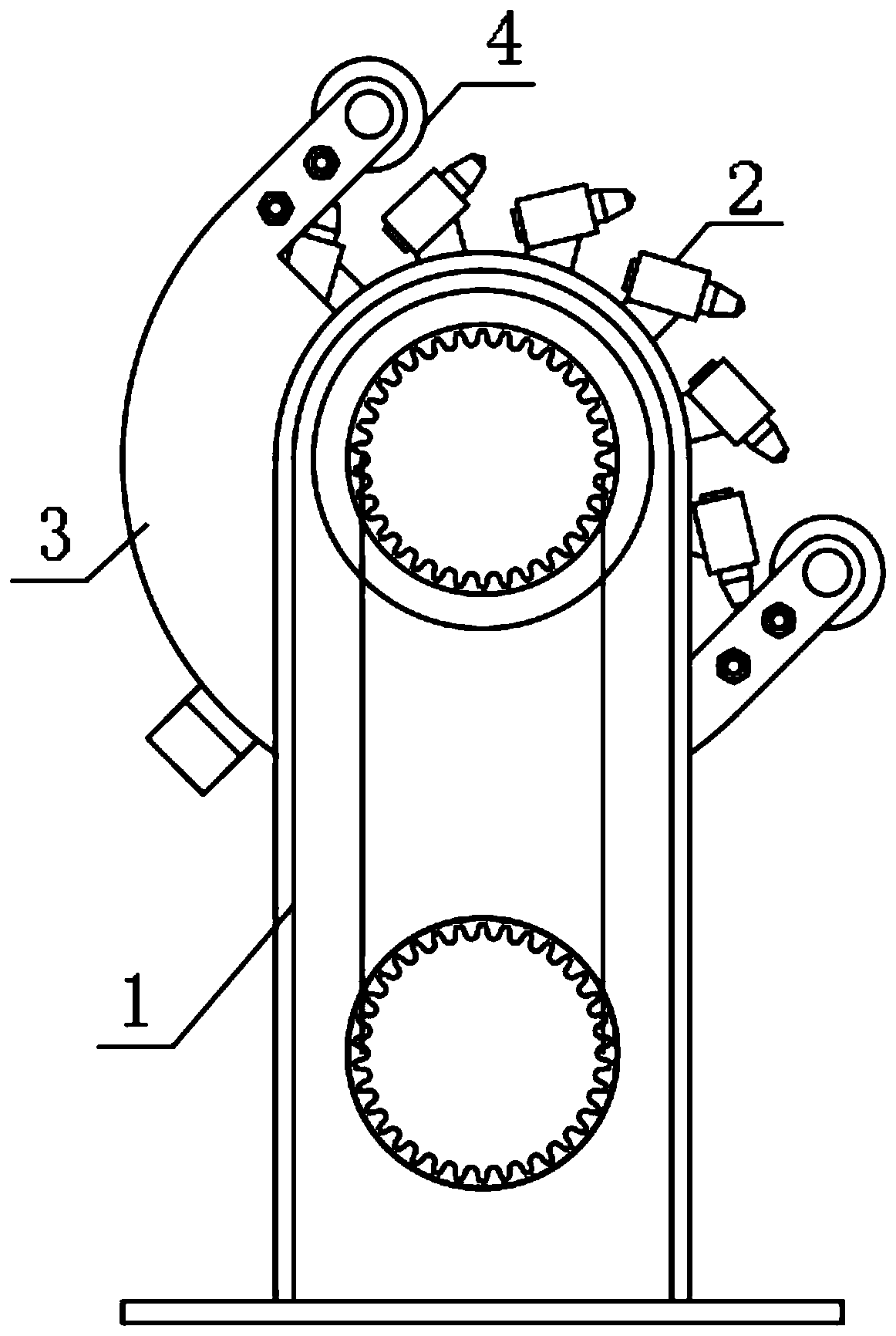

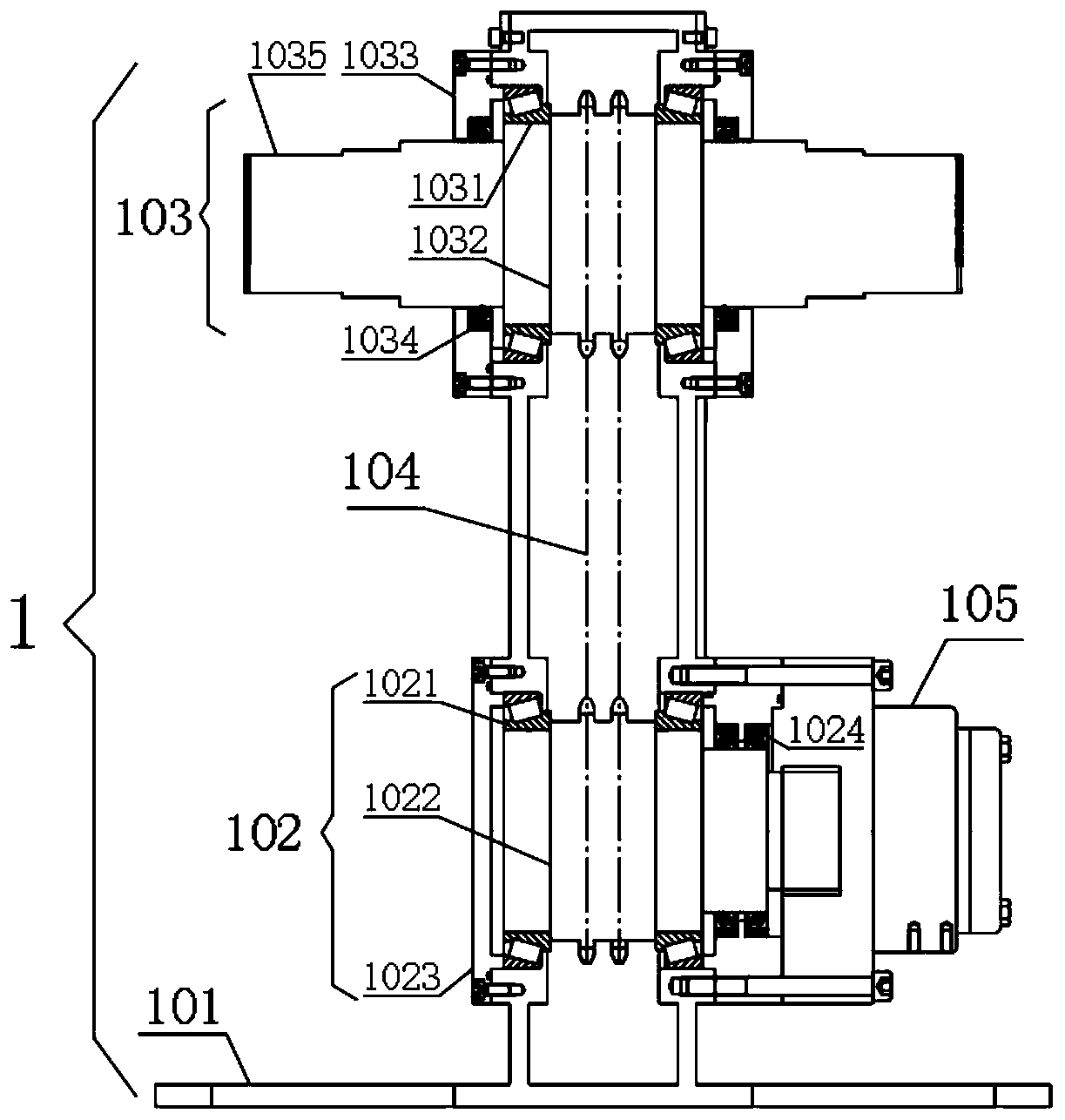

Automatic cutting device for high voltage cable insulation layer

ActiveCN108376945APrecise control of depth in real timePrecise control of depthApparatus for removing/armouring cablesGear systemEngineering

The invention discloses an automatic cutting device for a high voltage cable insulation layer and relates to the technical field of a power cable cutting device. The cutting device comprises an auxiliary mechanism, and a power mechanism, a control mechanism, a transmission mechanism and a cutting mechanism arranged on the auxiliary mechanism, wherein the transmission mechanism comprises a first transmission gear shaft system, the cutting mechanism comprises a blade arranged on the transmission mechanism, the transmission mechanism further comprises a positioning gear system, a second active gear of an electric motor unit is in mesh connection with a secondary gear of the positioning gear system, the cutting mechanism further comprises an elastic telescoping mechanism, the positioning gearsystem, the elastic telescoping mechanism and the blade are sequentially connected, the control mechanism further comprises an ultrasonic detection unit, and the ultrasonic detection unit and a controller are connected and realize bidirectional communication. The cutting device is advantaged in that through the electronic control technology, internal structures of the intelligent cutting power cable including an outer semi-conductive layer, a main insulation layer and an inner semi-conductive layer are realized, and properties of reliable operation, strong universality, firm structure and lowmanufacturing cost are realized.

Owner:STATE GRID CORP OF CHINA +1

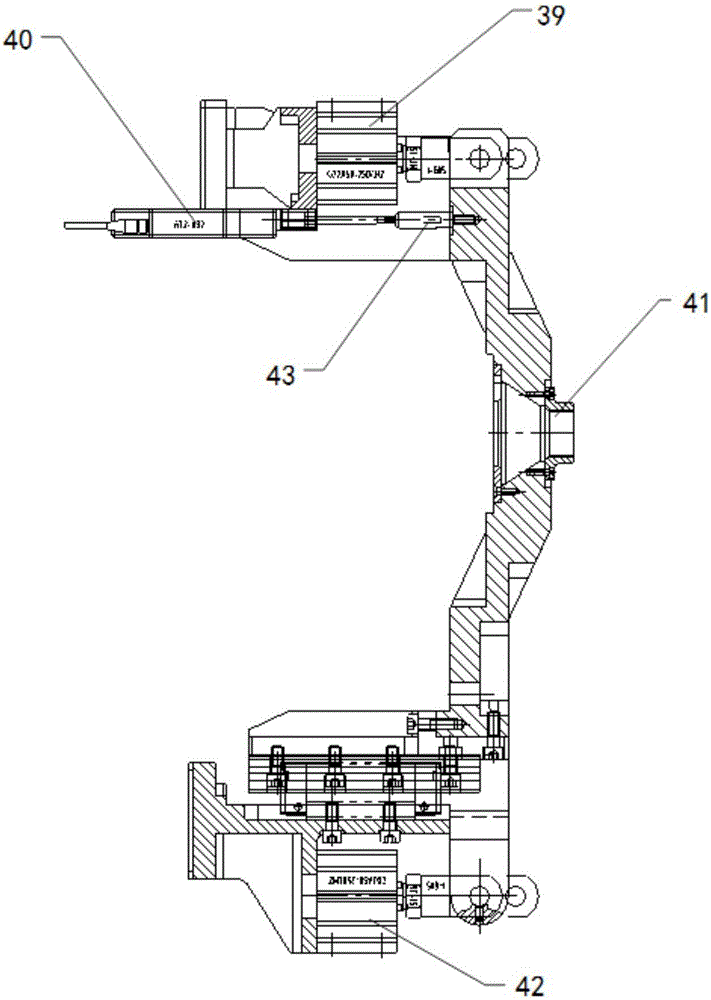

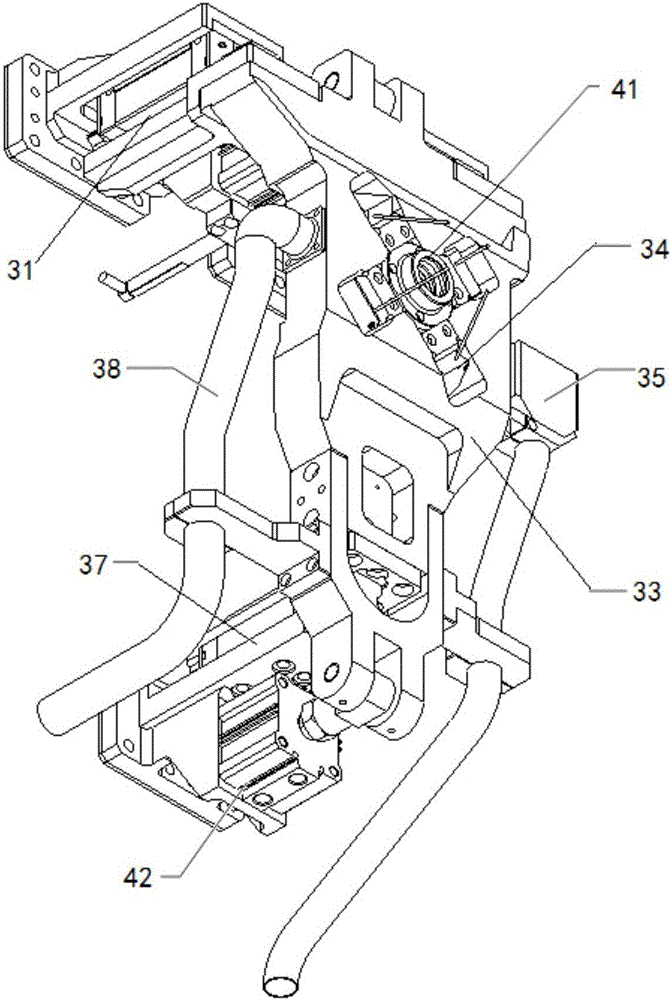

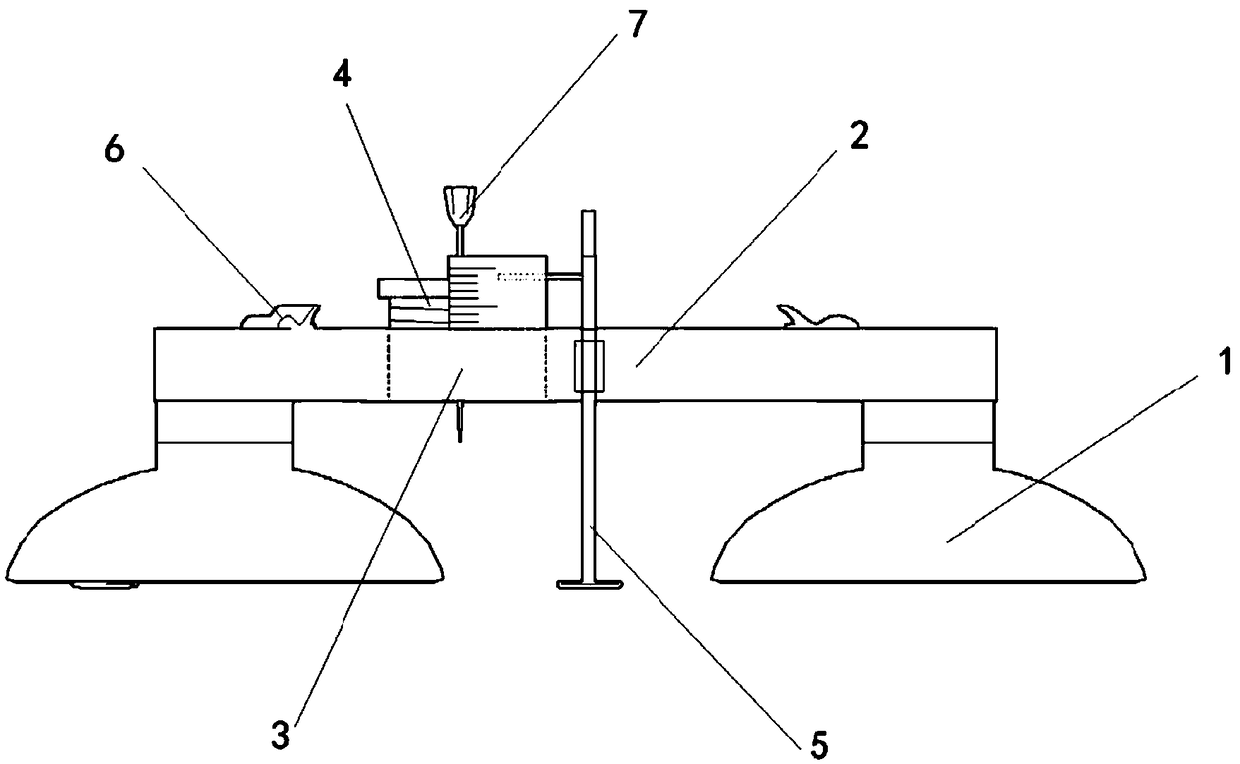

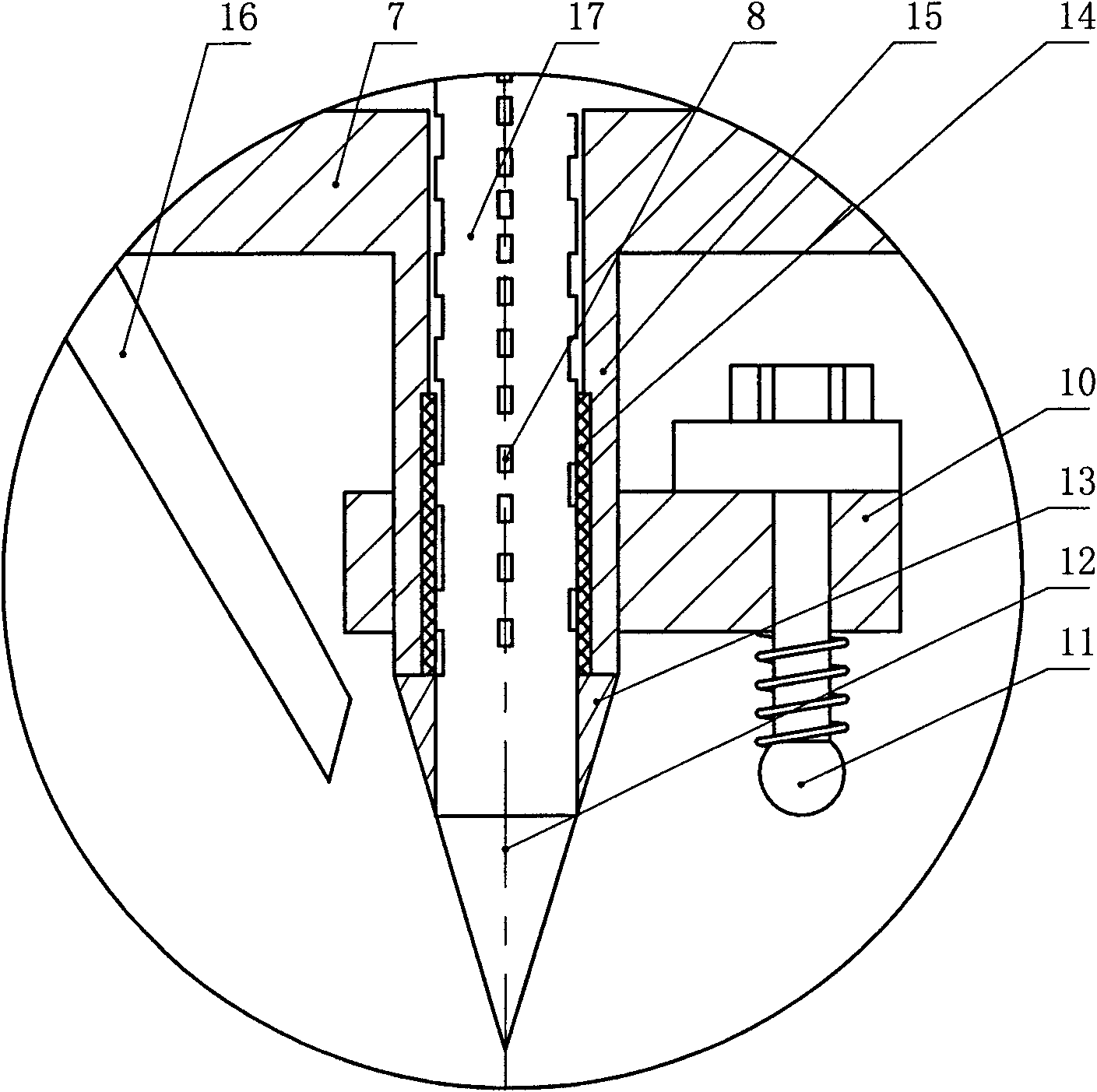

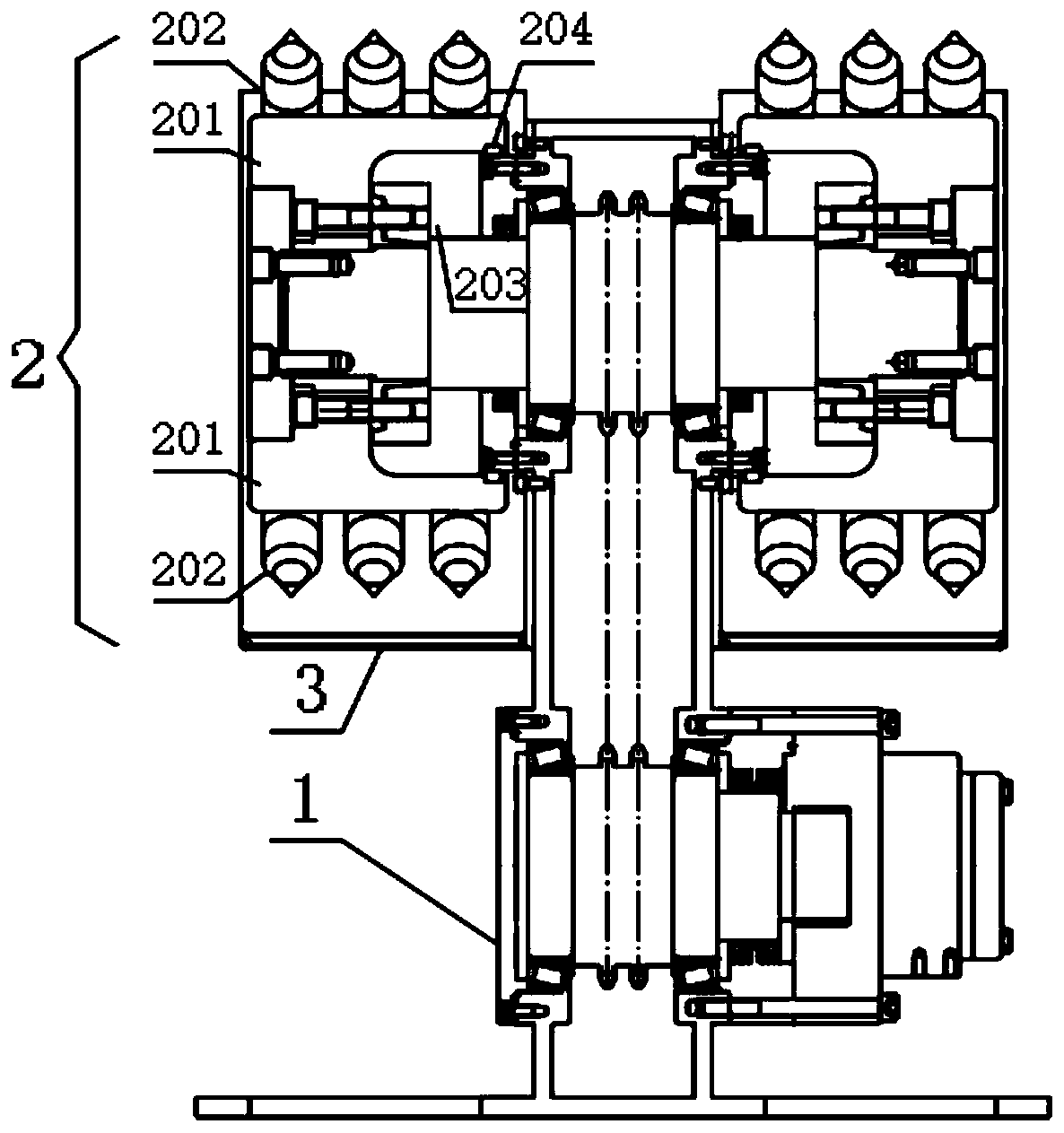

Pressure foot unit of automatic drilling and riveting machine

InactiveCN105728630AEasy to driveExclusion of subsequent riveting operationsEngineeringFeedback control

The invention discloses a presser foot unit of an automatic drilling and riveting machine. The presser foot unit comprises: a feed assembly connected with the automatic drilling and riveting machine and driving the presser foot unit; a presser foot main body installed on the feed assembly and completed Clamping action; laser distance measuring component, installed on the main body of the presser foot and providing the surface normal vector of the component processing position for the automatic drilling and riveting machine; chip removal component, installed on the main body of the presser foot and removing the debris formed by the hole Cleaning; recycling components, installed on the main body of the presser foot and recycling the unqualified rivets in the riveting process. The invention has the following advantages: through the laser distance measuring sensor, the method of riveting curved surface is determined, and the operation is controlled by feedback; the feed assembly is driven, and the riveting components are clamped tightly, eliminating the gap between the components and improving the rigidity of the components; multiple detections, realizing the hole making Precise control of depth and nail insertion depth; debris generated during hole making and riveting can be discharged through the chip discharge tube to avoid affecting subsequent operations.

Owner:ZHEJIANG UNIV

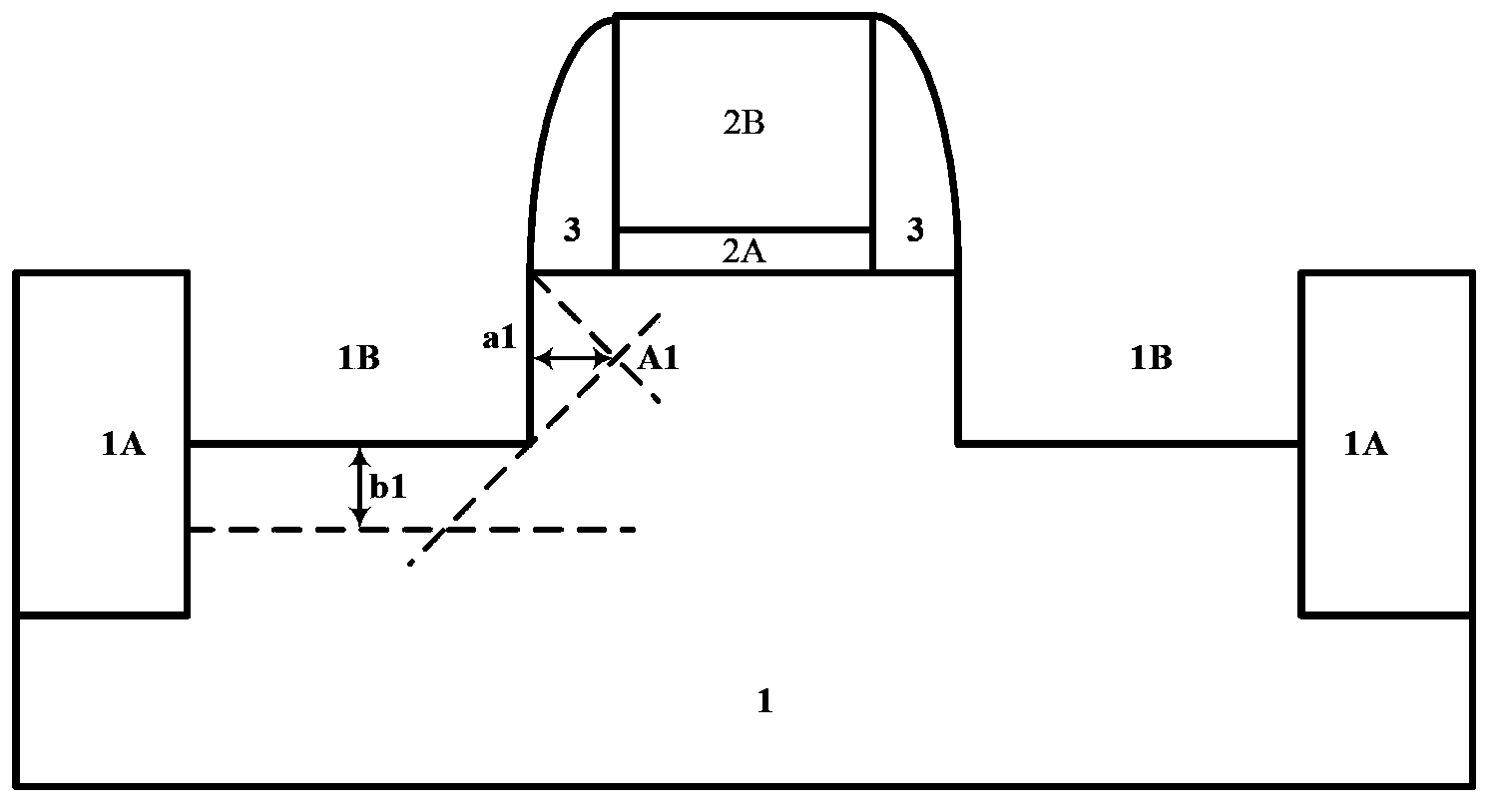

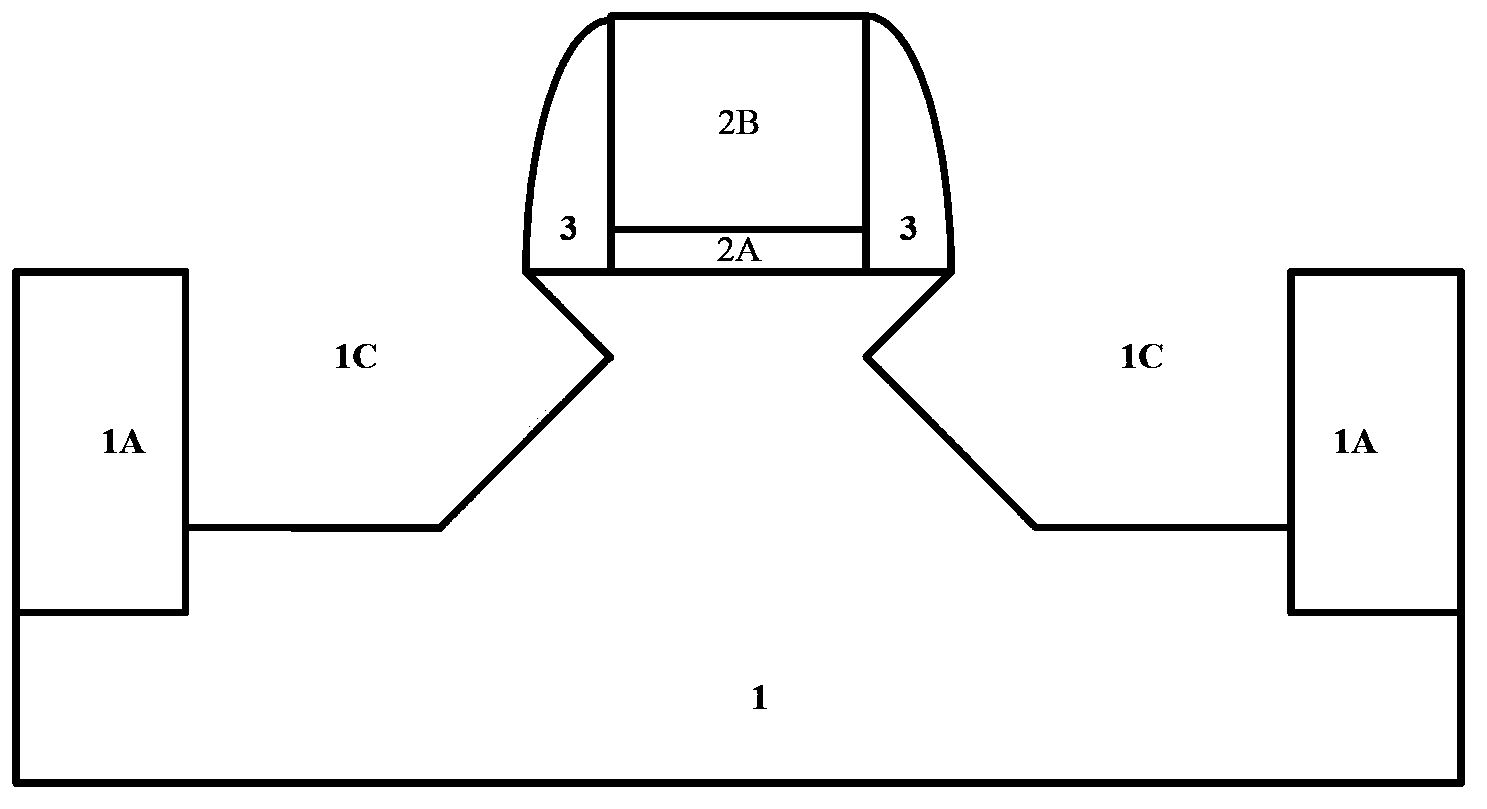

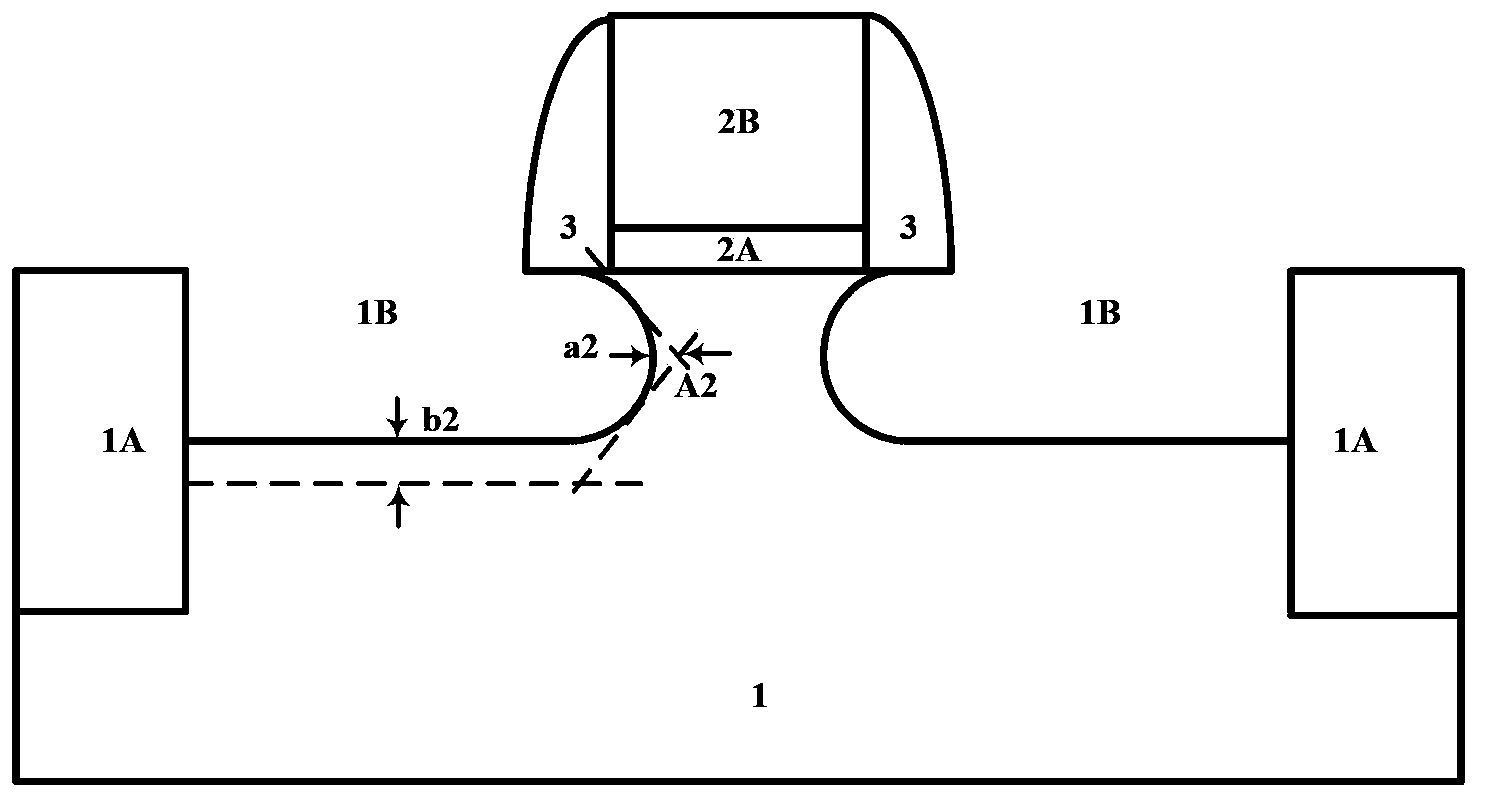

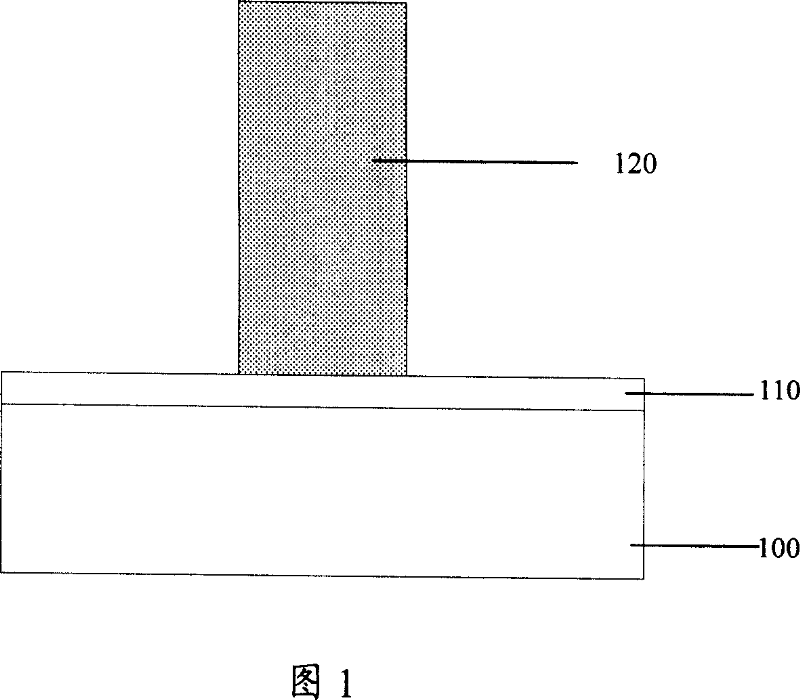

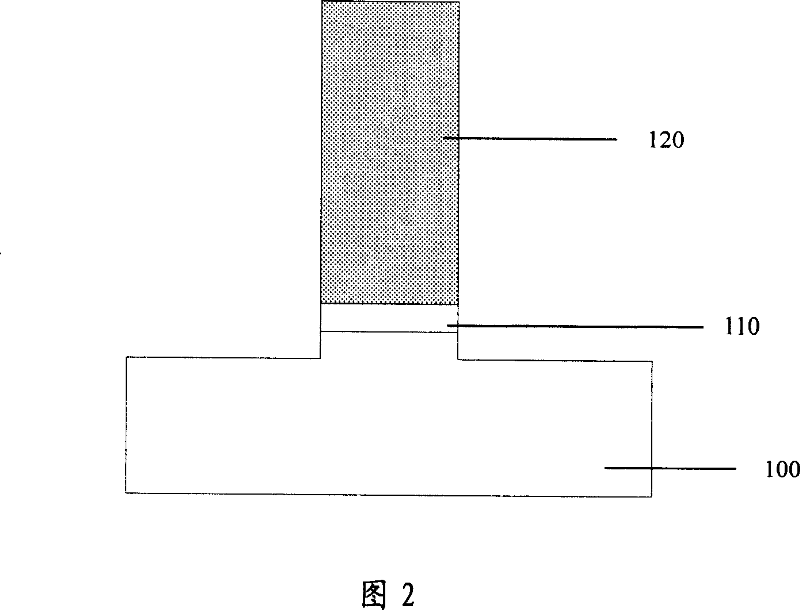

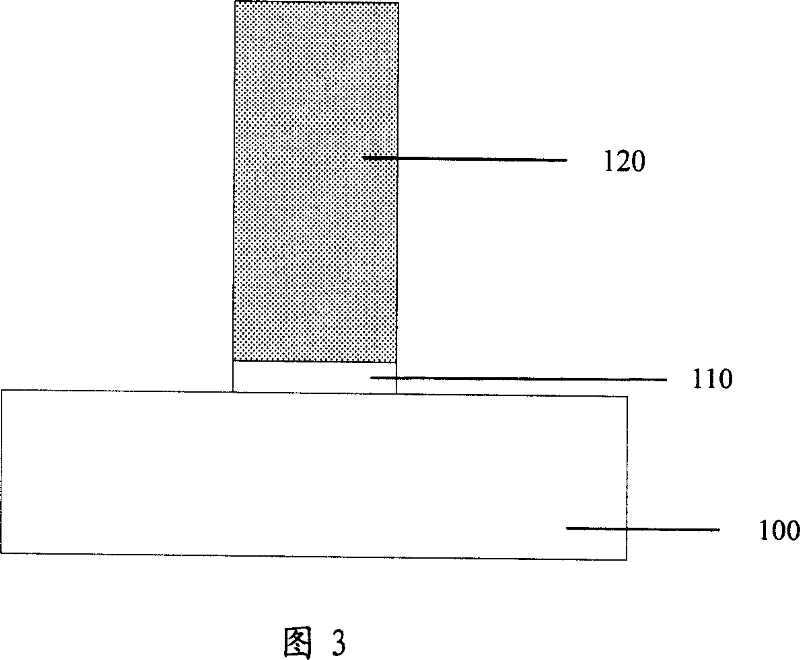

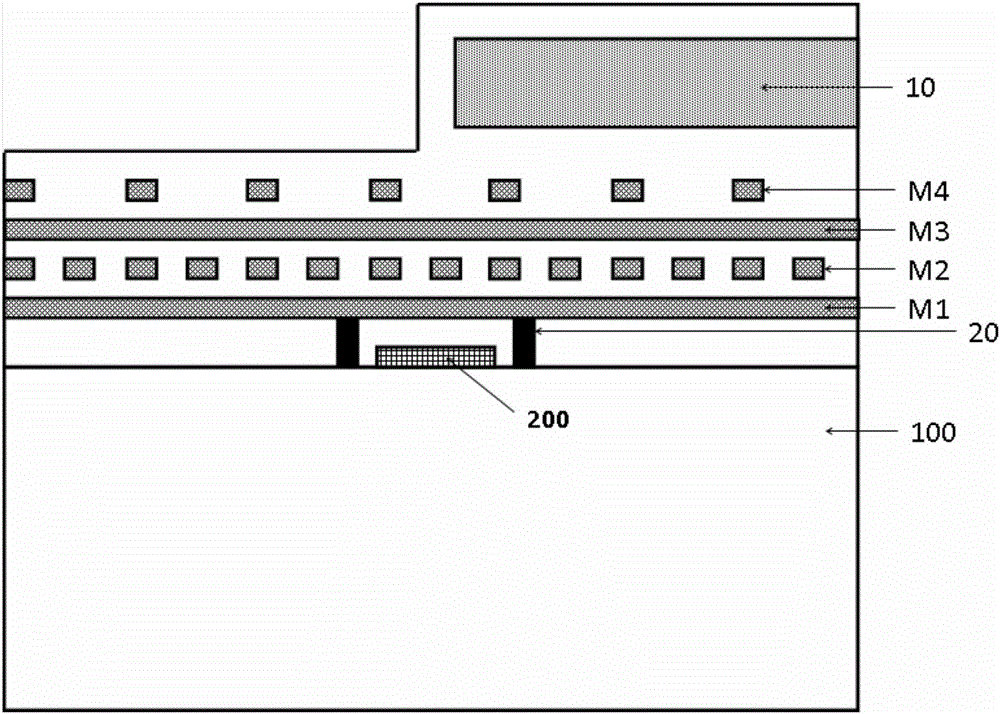

Production method of semiconductor device

ActiveCN103545212AImprove performancePrecise control of depthSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingGate stack

The invention discloses a production method of a semiconductor device. The production method includes: forming a gate stack structure on a substrate; etching parts of the substrate, on two sides of the gate stack structure, to form C-shaped source-drain trenches; wet-etching the C-shaped source-drain trenches to form sigma-shaped source-drain trenches. According to the production method of the semiconductor device, the C-shaped source-drain trenches are etched and sigma-shaped source-drain trenches are formed by further wet etching; accordingly, channel area stress is increased effectively, the depth of source-drain trenches is controlled precisely, defects are reduced, the sidewall and bottom of each trench is less rough, and the performance of the device is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

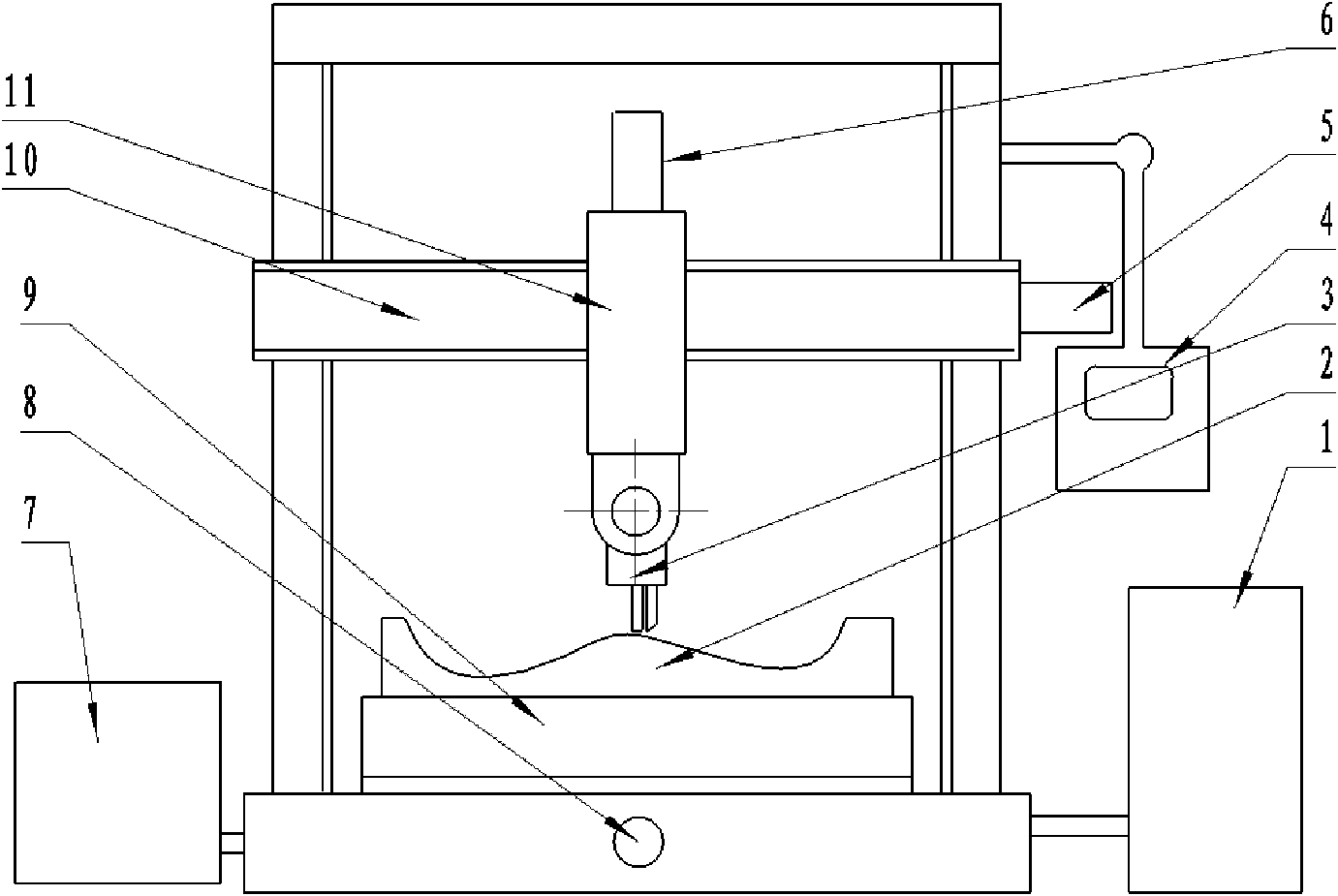

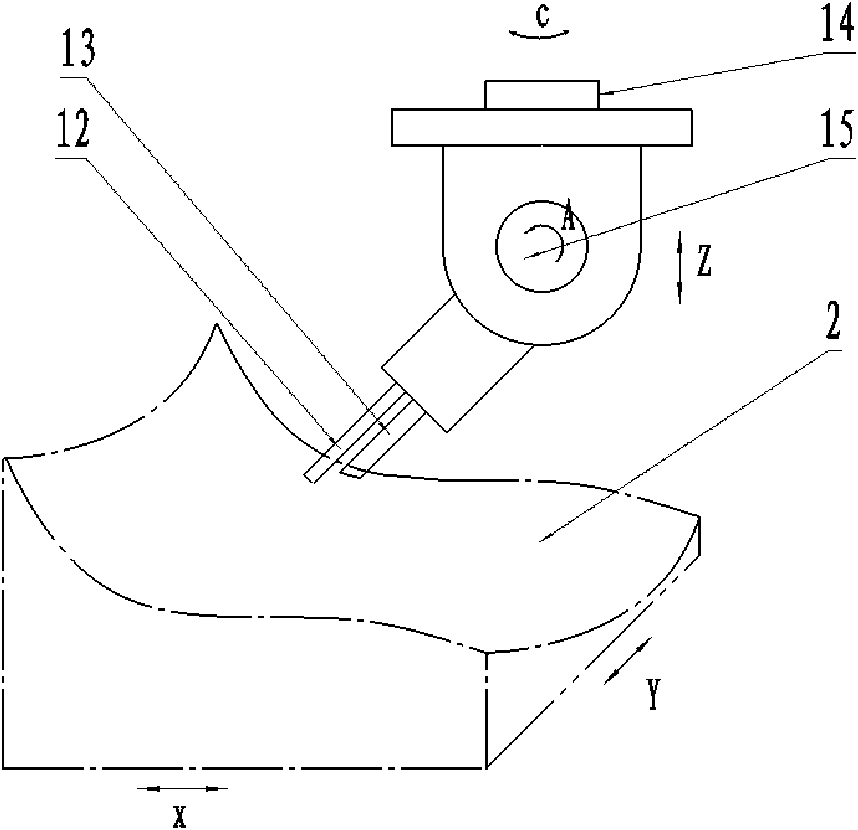

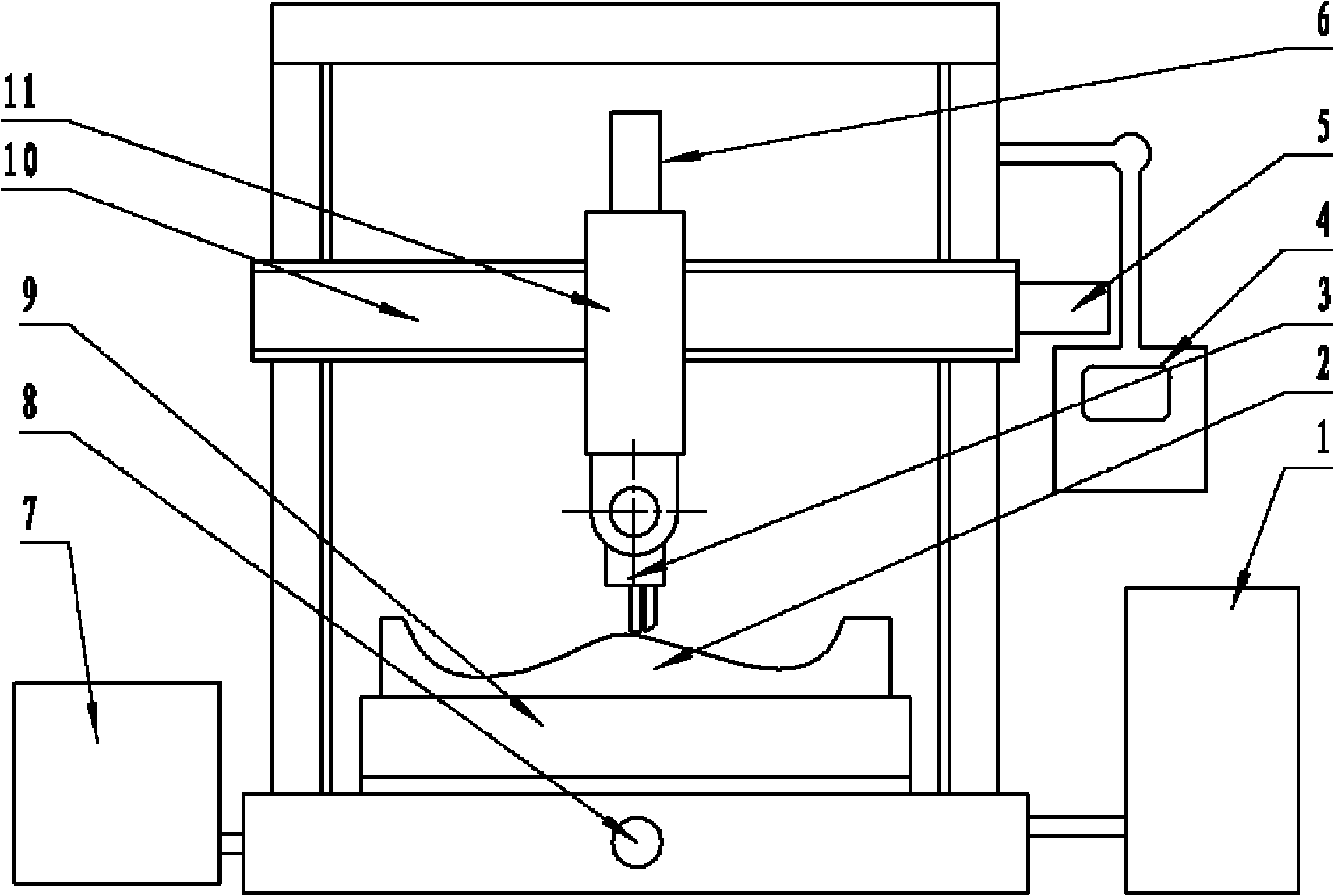

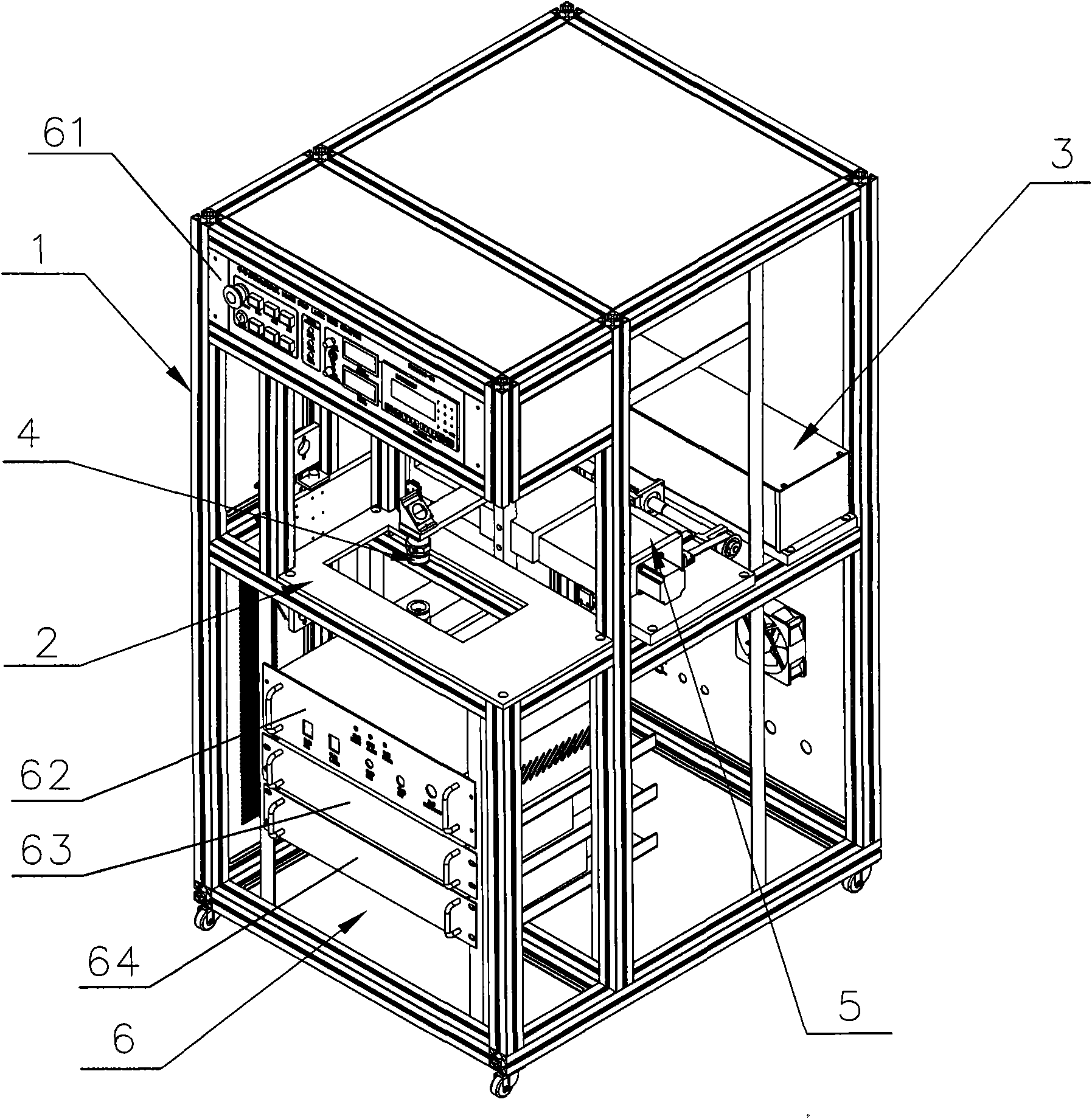

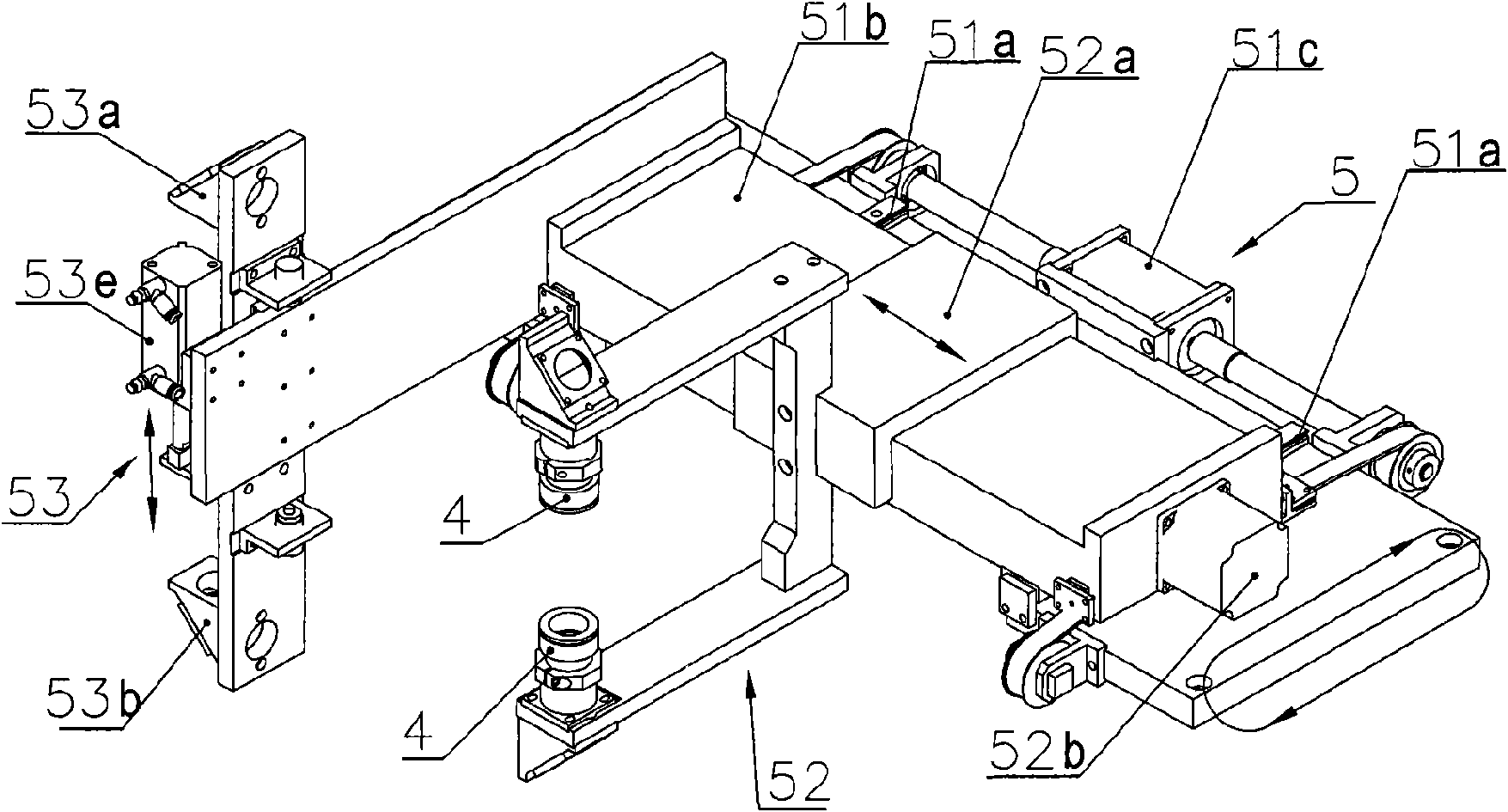

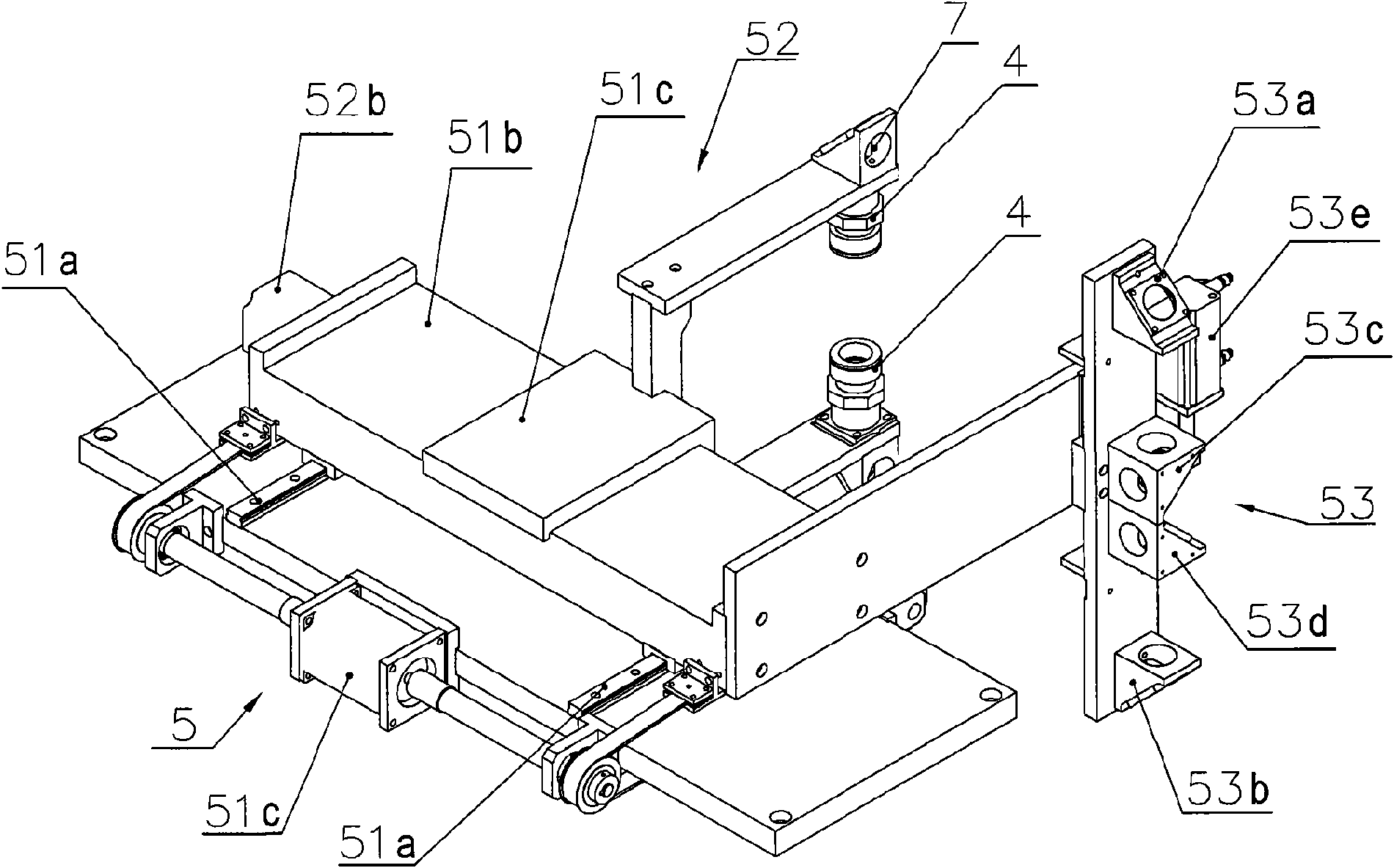

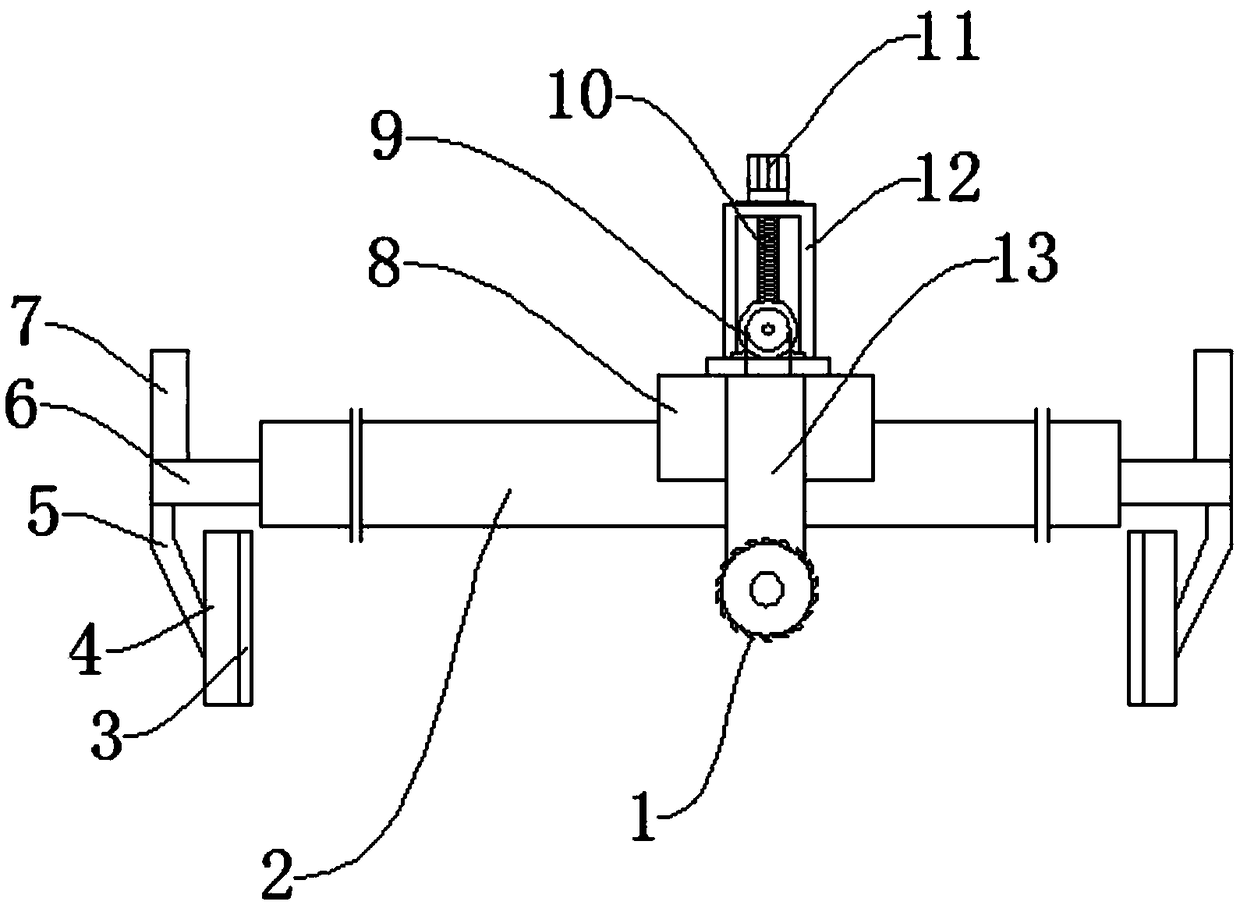

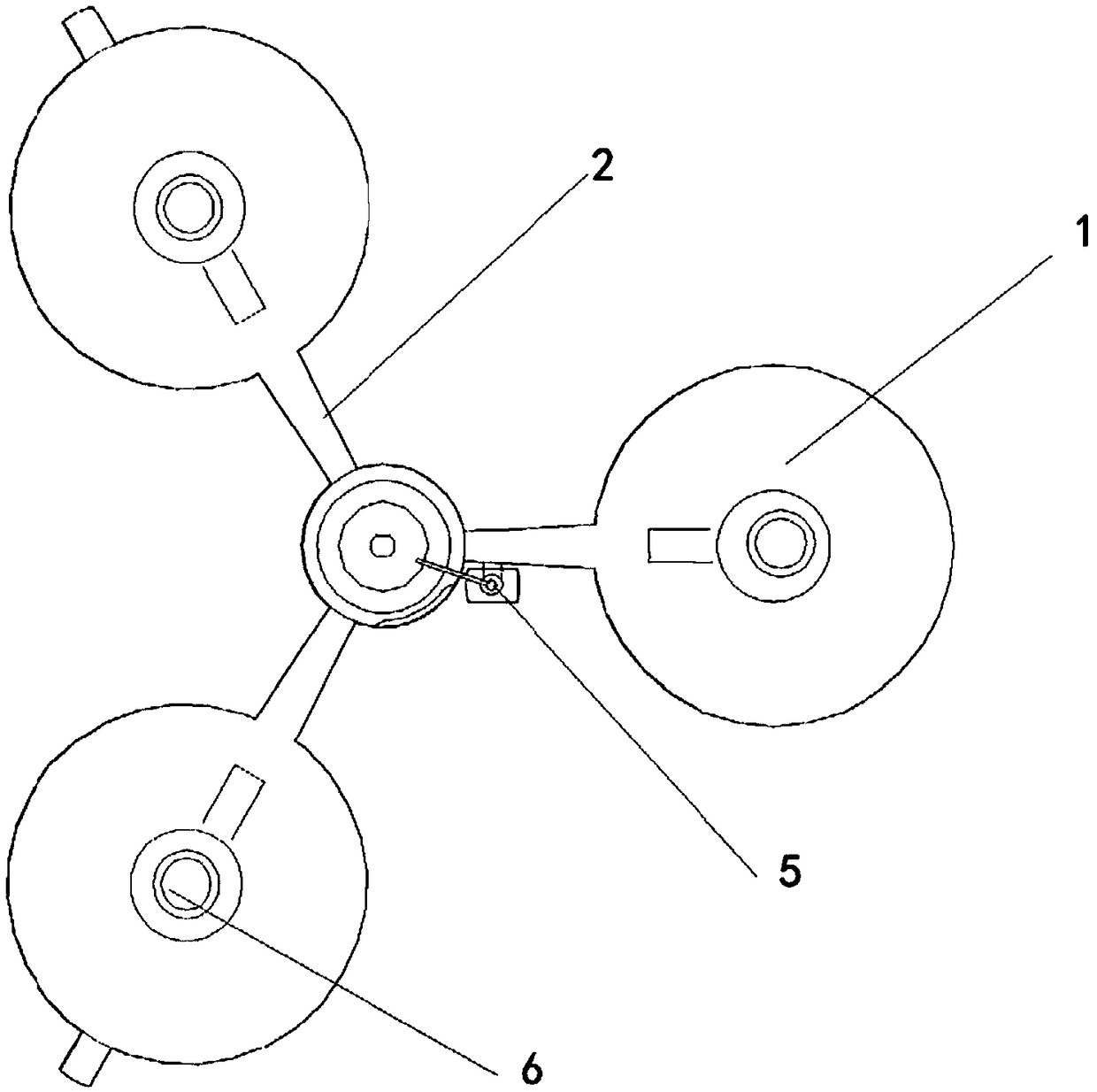

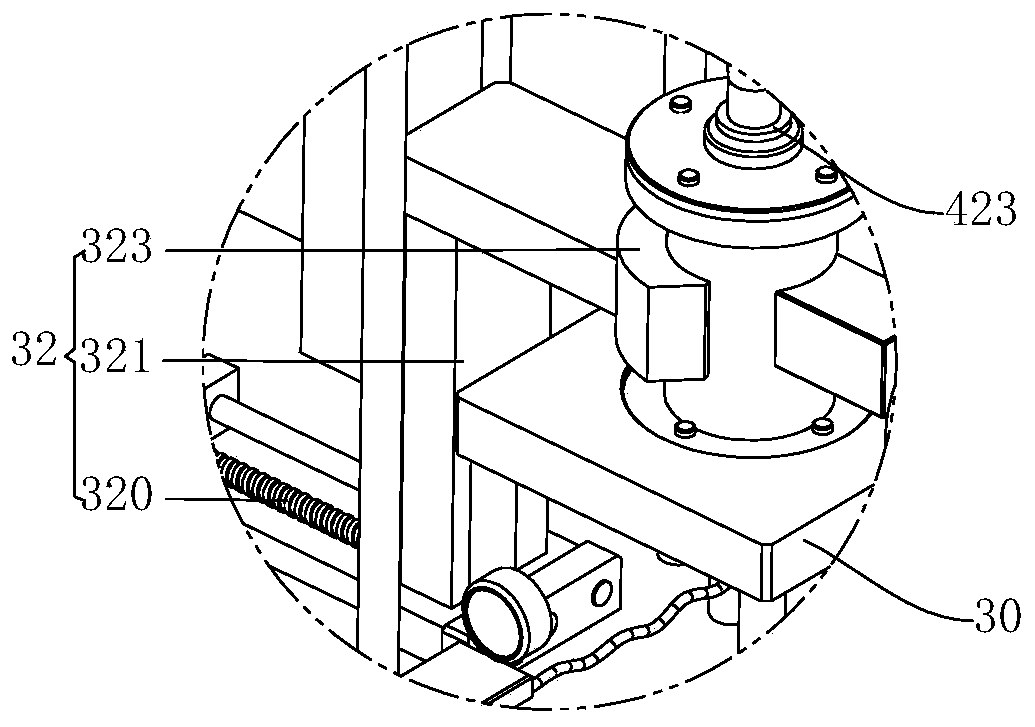

Complex-space curved-surface dot-motion induction heating hardening device and method

ActiveCN102051451AQuenching strengtheningLow powerIncreasing energy efficiencyHeat treatment process controlMaterial typeInduction heater

The invention relates to a complex-space curved-surface dot-motion induction heating hardening device and method. The complex-space curved-surface dot-motion induction heating hardening device mainly comprises a numerical control system (4), a five-axis servo mechanism, an induction heater (12) and a cooling liquid sprayer (13), wherein the numerical control system (4) and the five-axis servo mechanism are arranged on a frame; the induction heater (12) and the cooling liquid sprayer (13) are driven by the five-axis servo mechanism to respectively make a three-dimensional continuous motion along the complex-space curved surface of a part; after the induction heater heats the surface of the part to austenite transition temperature, the cooling liquid sprayer sprays out a cooling medium to cool the surface of the part, thereby realizing the hardening reinforcing treatment of the surface of the part. By utilizing the device, the method is realized in a way that: the current frequency, motion speed and route of an induction power source (1) is selected according to the material type and heat treatment technique of the treated part, and the process of heating and cooling on the surface of the part is completed while the induction heater and the cooling liquid sprayer respectively make a three-dimensional continuous dot motion on the surface of the part. The invention can accurately control the depth of hardening layer, and has the advantages of high work efficiency, low loss of heat energy, no pollution and the like; and the surface structure after hardening is uniform.

Owner:HUBEI TRI RING FORGING

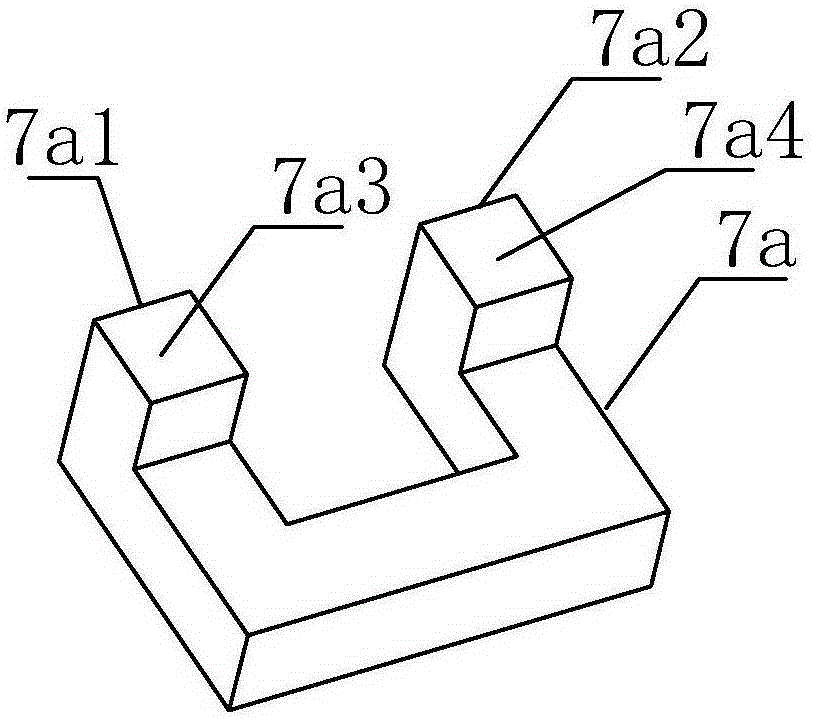

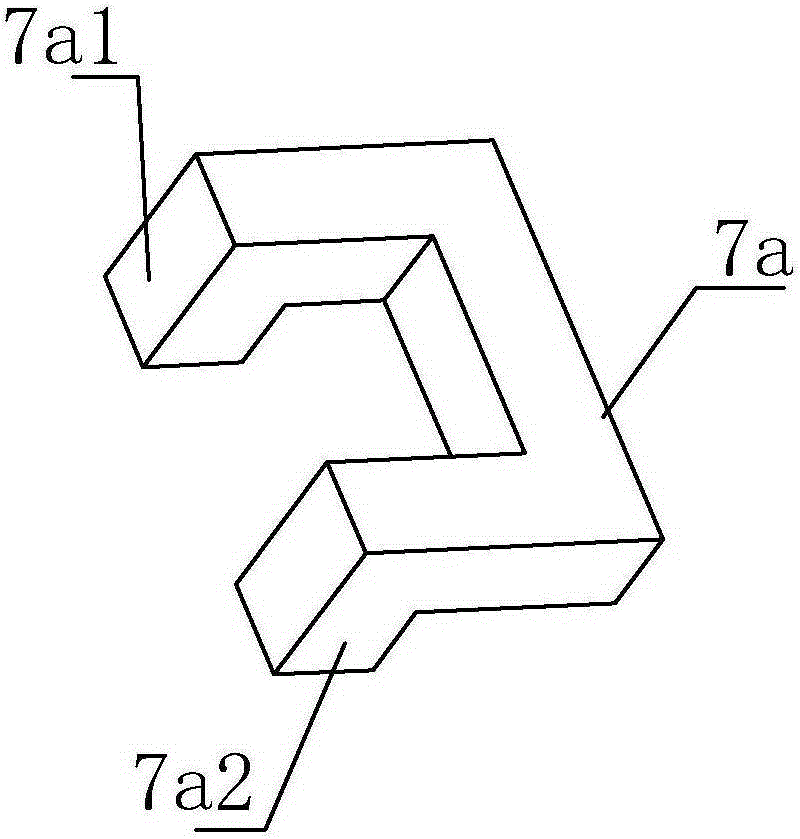

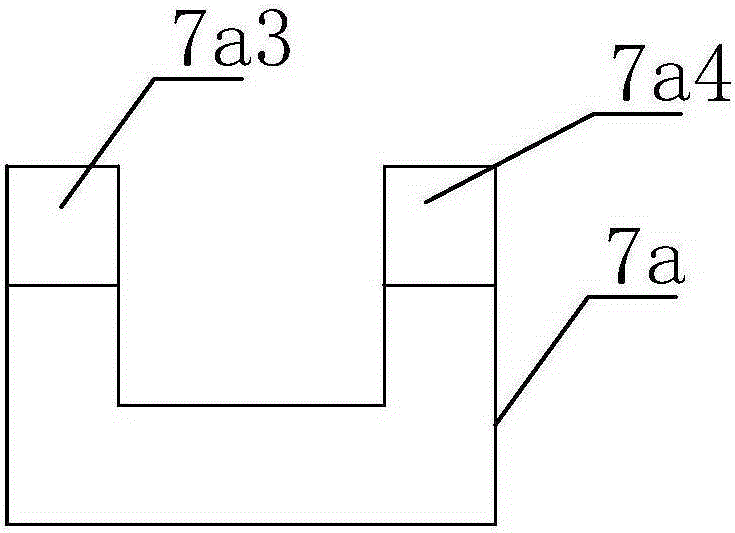

Magnet used for high-frequency welding device, high-frequency welding device and automatic peeling welding machine

ActiveCN105252133AImprove efficiencyFast heatingLine/current collector detailsHigh frequency current welding apparatusEngineeringAutomatic testing

The invention provides a magnet used for a high-frequency welding device, the high-frequency welding device and an automatic peeling welding machine. The automatic peeling welding machine comprises a fixed cable clamp device, an initial cable cutting device, a locating movable cable clamp device, a peeling and cable trimming device, a forking and cable cutting device, the welding device and a cable supporting frame. The locating movable cable clamp device is arranged on one side of the fixed cable clamp device, and the initial cable cutting device, the forking and cable cutting device, the peeling and cable trimming device, a stamping block with an inverted-V-shaped opening and the welding device are arranged on the other side of the fixed cable clamp device in sequence. The cable supporting support is arranged outside the cable clamp fixing device. The magnet is in the U shape, and bosses are extended from the same sides of the two ends of the magnet symmetrically. The automatic peeling welding machine is high in automation level, high in production efficiency and low in equipment cost, and the technical effect that the production efficiency and the product quality are high is achieved. The high-frequency welding device used in the automatic peeling welding machine and the specially-used magnet for the high-frequency welding device are provided at the same time.

Owner:东莞市镭邦光电科技有限公司

Method for manufacturing grid structure of semiconductor device

ActiveCN101038870APrecise thickness controlPrecisely control the depth of etchingSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorManufacturing grid

The invention provides a mehtod for making grid structure of semiconductor device, which includes providing a semiconductor substrate, and forming a grid medium layer on the substrate, and forming a grid electrode layer on the grid medium layer, and forming a mask layer on the grid electrode layer, and then inducing etching gas to etch the polysilicon grid electrode layer by employing plasma output by a plasma source, wherein the plasma source etches the grid medium layer in pulse outputting power manner. The invention provide method for making grid structure of semiconductor device is very effective for accuracy controlling the thickness of the grid oxide layer in a process node no more then 65 nm, and the etching depth can perfectly stop at the surface of the grid oxide layer without hurting the surface of an active region.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Laser wire stripping device

InactiveCN101599623ANo deformationIncrease productivityLine/current collector detailsApparatus for removing/armouring cablesCoaxial cableElectrical conductor

The invention provides a laser wire stripping device, comprising a rack, a working platform, a laser generation chamber, laser heads, a movement mechanism and a control mechanism; wherein, the laser generated by the laser generation chamber is transmitted to the laser heads by a reflection mirror group to realize laser light path transmission; the movement mechanism controls the laser heads to realize wire stripping; the laser heads are symmetrically arranged with one at an upper position and the other at a lower position by taking the working platform as a symmetrical surface; the movement mechanism comprises a Y axis movement part for realizing forward and back motion, an X axis for realizing side-to-side motion and an upper and lower laser switching mechanism for realizing up-and-down motion; the device of the invention has the advantages of high working efficiency and low equipment cost, in addition, the device can well strip coaxial cable metallic shield layers and aluminium foil shield layers, does not cause shield layer deformation, does not damage insulating layers and conductors, features high yield and the like.

Method for preparing transmission electron microscope sample

ActiveCN106289909AShorten the timeWon't hurtPreparing sample for investigationIon beamElectron microscope

The invention provides a method for preparing a transmission electron microscope sample. The method comprises the following steps: I, forming a marker for marking a specific target for the specific target to be analyzed on a sample; II, injecting a focused ion beam into a chip sample, finding an area of the specific target according to the marker, and cutting the chip sample till a position which is in a preset distance from the specific target by using an ion beam perpendicular to the sample; III, inclining the sample, cutting a target structure by using another ion beam in a preset inclined angle, observing a graph at the target by using an electron beam, judging, and cutting the part above the specific target till a position of a residual preset thickness; IV, inclining a sample plane to be perpendicular to the ion beam, and depositing a metal protection layer above the target structure; V, manufacturing the transmission electron microscope sample by using the metal protection layer, thereby forming the transmission electron microscope sample.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

P type doping method for cubic boron nitride thin film

InactiveCN101174558AEase of mass productionPrecise control of depthDiffusion/dopingSemiconductor/solid-state device manufacturingP type dopingOhm

The invention relates to a p-type doping method of heteroepitaxial cubic boron nitride thin film, belonging to the wide band-gap semiconductor thin film doping field. The invention overcomes the difficulty that wide band-gap superhard material c-BN thin film is difficult to realize the p-type doping, and realize the effective p-type doping of the c-BN thin film. The invention comprises the following steps: firstly, low pressure gas phase thin film is used to deposit a layer of intrinsic c-BN thin film on growth equipment, the thickness of the intrinsic c-BN thin film is 200 to 800 nm, the content of cubic phase is 40 to 95 percent, the electrical conductivity is 10<-9> to 10<-11> ohm<-1> cm<-1>; secondly, metal beryllium ions are chosen as p-type dopant, the energy range of the ion-implanted beryllium is 80 to 200 kiloelectronvolt; the dosage range of the ion-implanted beryllium is 5 x 10<15> to 1 x 10<17>ion / cm<2>; secondly, slow rate annealing: the slow rate annealing temperature is 600 to 900 DEG C; the constant temperature time is 40 to 60 minutes; fourthly, the thin film which is annealed through the step three is irradiated by laser and the second impurity activation process is operated to the thin film, the annealing temperature is1000 to 1050 DEG C, and the annealing time is 20 to40 minutes. The invention leads the electrical conductivity of the c-BN thin film with above 40 percent of the cubic phase content is increased by about hundred thousand times.

Owner:BEIJING UNIV OF TECH

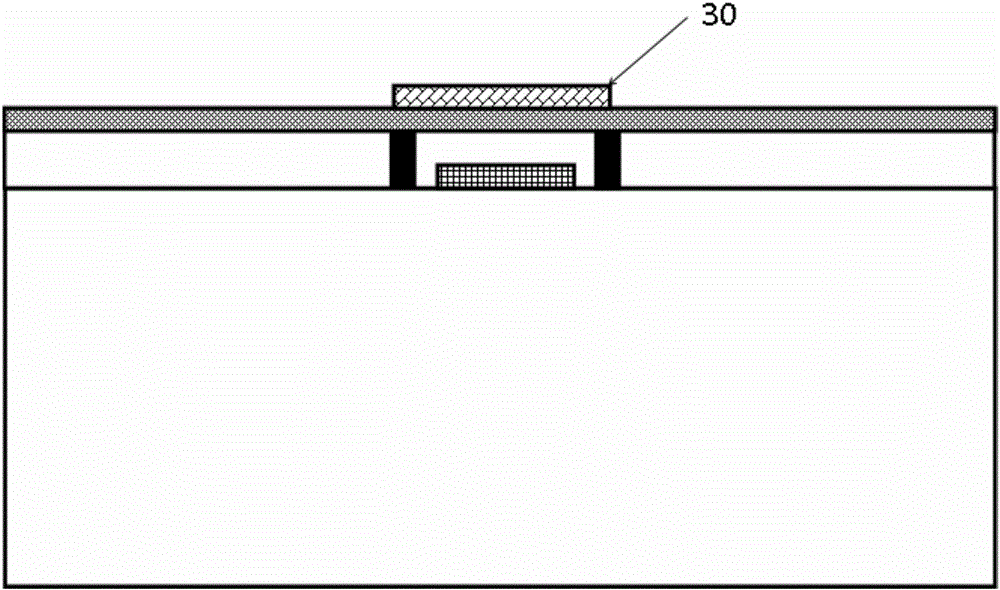

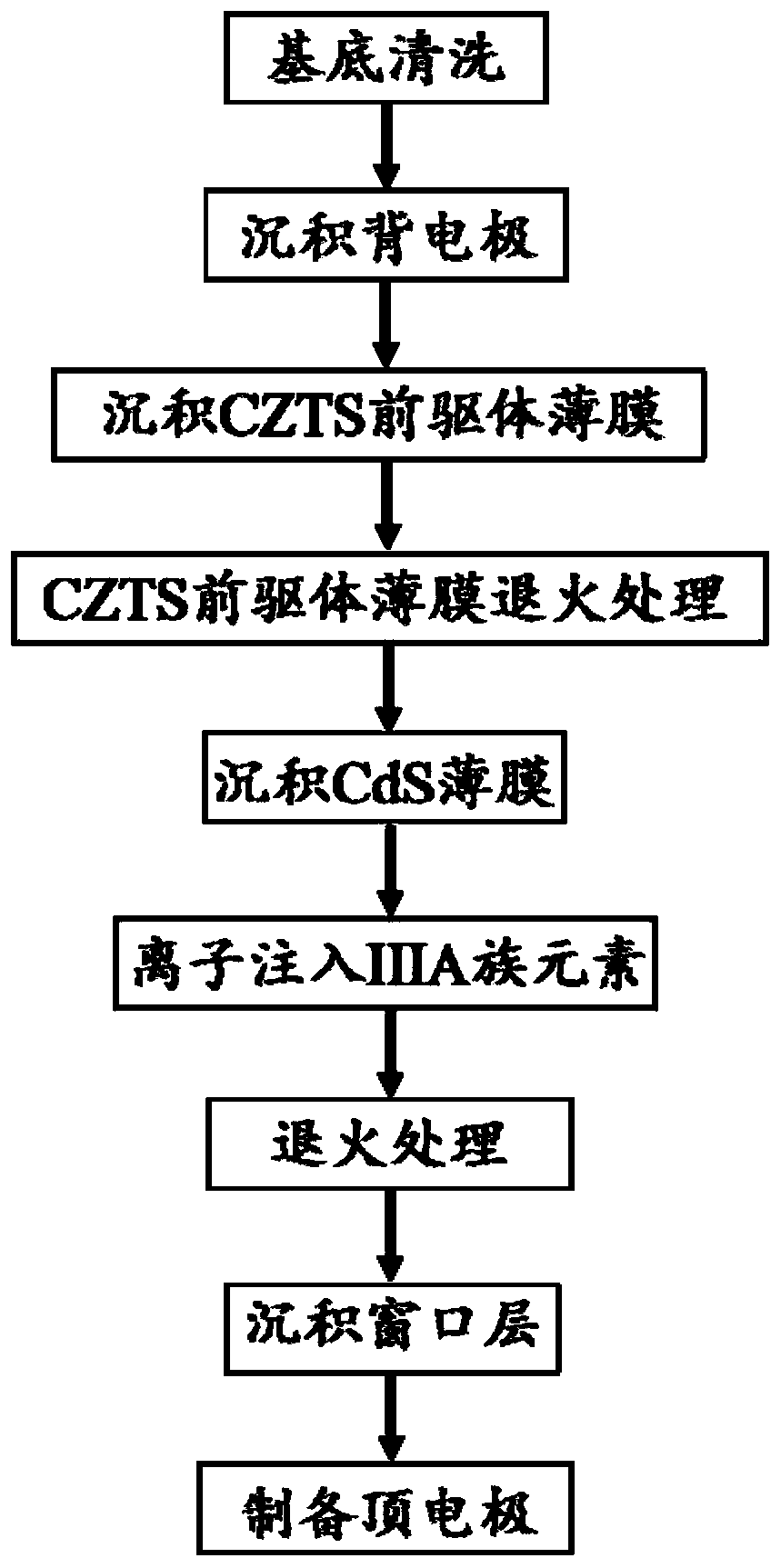

Method for preparing CZTS thin film solar cell using group IIIA element doped cadmium sulfide film

InactiveCN110112062APrecisely control the total dosePrecise control of depthFinal product manufactureSemiconductor/solid-state device manufacturingCZTSCadmium sulfide

The invention discloses a method for preparing a CZTS thin film solar cell using a group IIIA element doped cadmium sulfide film. The method comprises the steps of: cleaning a substrate; depositing metal molybdenum as a back electrode on the cleaned substrate; depositing a CZTS precursor film on the back electrode; annealing the CZTS precursor film to obtain a CZTS absorbing layer film; depositinga CdS film on the CZTS absorbing layer film, and doping the CdS film with a group IIIA element by ion implantation; and annealing the sample doped with CdS, then depositing a window layer on the doped CdS; preparing a top electrode on the window layer to obtain the CZTS thin film solar cell. Doping the Group IIIA element can improve the photoelectric performance of CdS, increase the width of a depletion region, and ensure high long-wave collection efficiency and photoelectric conversion efficiency. The ion implantation method can precisely control the concentration and depth distribution of the implanted ions, and the implanted layer does not peel off.

Owner:CENT SOUTH UNIV

Slotting device for producing antistatic aramid composite floor and method of using slotting device

InactiveCN109203133ASimple structureEasy to fixWood mortising machinesWood slotting machinesHobbingEngineering

The invention discloses a slotting device for producing an antistatic aramid composite floor and a method of using the slotting device. The slotting device comprises a slotting knife and a base, wherein a lower mounting groove is formed inside the lower end of the base, an inner fixing plate is disposed in the lower mounting groove, a return spring is disposed on one side of the inner fixing plate, and a sliding block is disposed on one side of the return spring. A handle is disposed above the outer end of the sliding block, a support arm is disposed below the outer end of the sliding block, and a side splint is disposed at an end of the support arm. An anti-slip mat is disposed on a side of the side splint, and a rack is disposed above the base. A gear hobbing is disposed above the rack,a horizontal moving seat is disposed above the gear hobbing, and a horizontal moving motor is disposed on one side of the horizontal moving seat. The beneficial effects include that 1. the structure is simple, the installation and fixing are convenient, and the transportation and use are convenient; 2. the slotting depth and length can be precisely controlled through control by a servo motor, andslotting at different positions on the floor is convenient.

Owner:鑫材泰克(天津)复合材料有限公司

Drilling positioner

PendingCN108941699AReduce difficultyPrecise position controlDrilling/boring measurement devicesEngineering

The invention relates to a drilling positioner. The drilling positioner comprises a fixing seat used for being connected with the surface of an object, a telescopic pipe used for positioning, and a support connected between the fixing seat and the telescopic pipe. The telescopic tube is far away from the fixing base, and the axial direction of the telescopic pipe is perpendicular to the plane where the fixing seat is located; the telescopic tube comprises an inner tube and an outer tube, and the inner tube is located in the outer tube and can move in the axial direction of the outer tube; scale lines are arranged on the telescopic tube, the scale lines are arranged in the axial direction of the telescopic tube, and the distance between the upper end face of the telescopic tube and the surface of the object can be read out through the scale lines. According to such an arrangement, the drilling position and depth can be accurately controlled by the drilling positioner, difficulty of drilling work can be reduced, working efficiency and quality of the drilling are improved, and then the problem that secondary damage of cracks caused by improper operation is avoided.

Owner:SHENZHEN ZHIZONGSIHAI TECH CO LTD

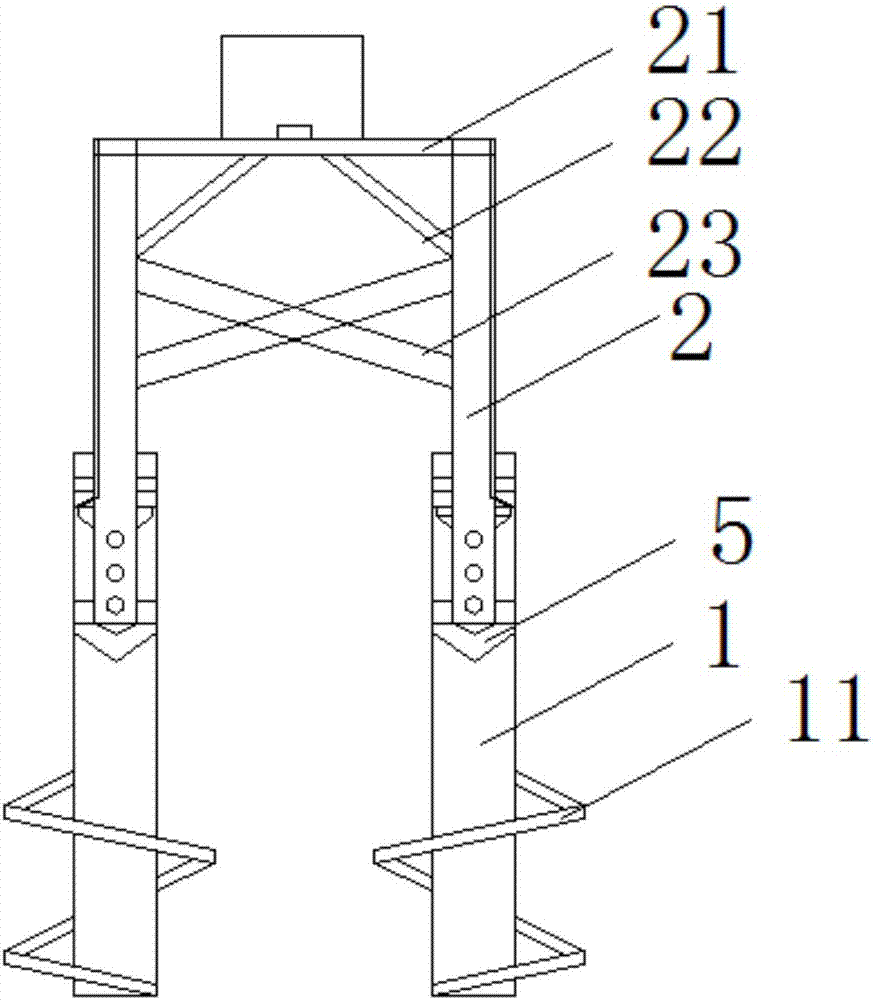

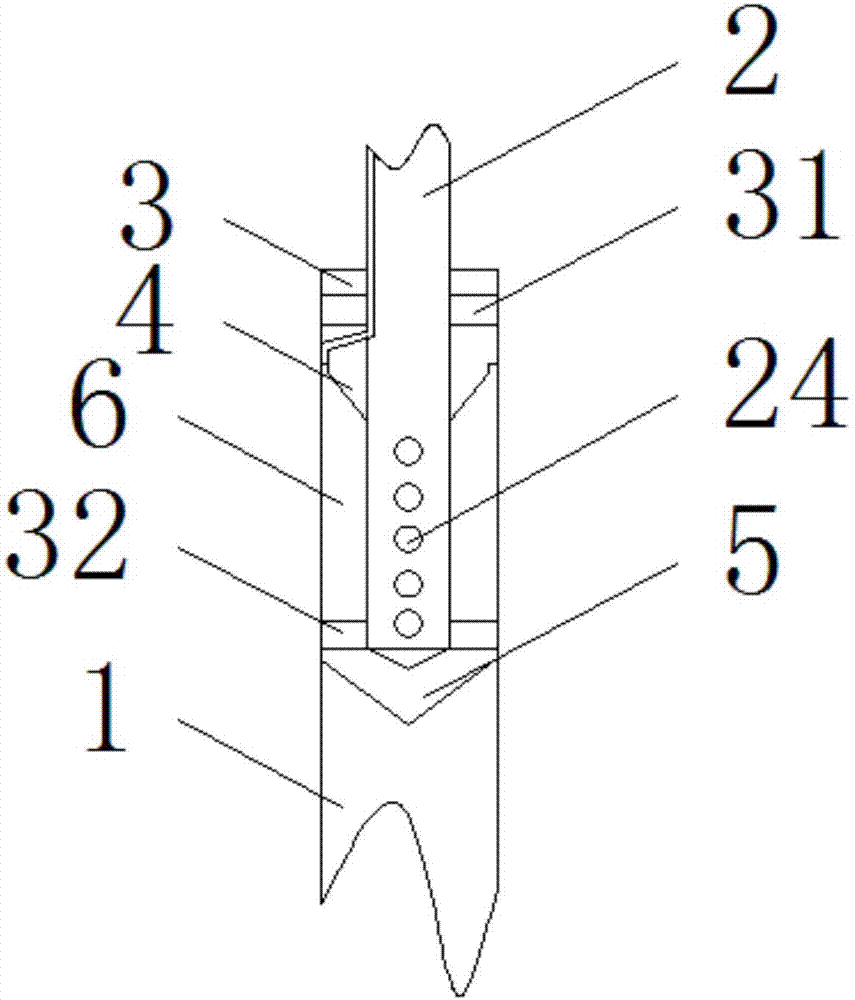

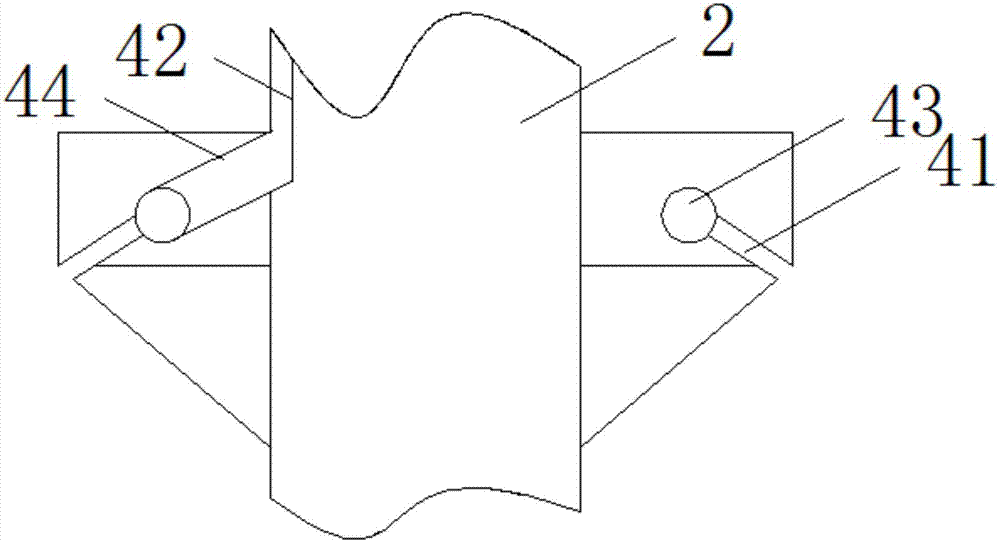

Jacket foundation structure and construction method

The invention discloses a jacket foundation structure and a construction method in the field of jacket foundations. A grouting chamber is formed between the columns and the support rods, a platform is provided on the top of the support rods, a connecting frame is provided between two adjacent groups of the support rods, grouting holes are uniformly arranged on the bottom side walls of the support rods, The support rod is provided with a cover plate, the bottom of the cover plate is provided with a sealing ring, the bottom end of the support rod is provided with a second guide block, and the second guide block is provided with a groove. The top of the second guide block is provided with a second sealing ring. The existence of the spiral plate enables the pile to precisely control the depth of the pile, and can effectively prevent the pile from slipping when it encounters a soft soil layer or an underground river. The first guide block and the second guide The presence of the blocks facilitates the insertion of the support rods, and the presence of the grouting holes makes the grouting in the grouting chamber easier and more convenient.

Owner:虞温乐

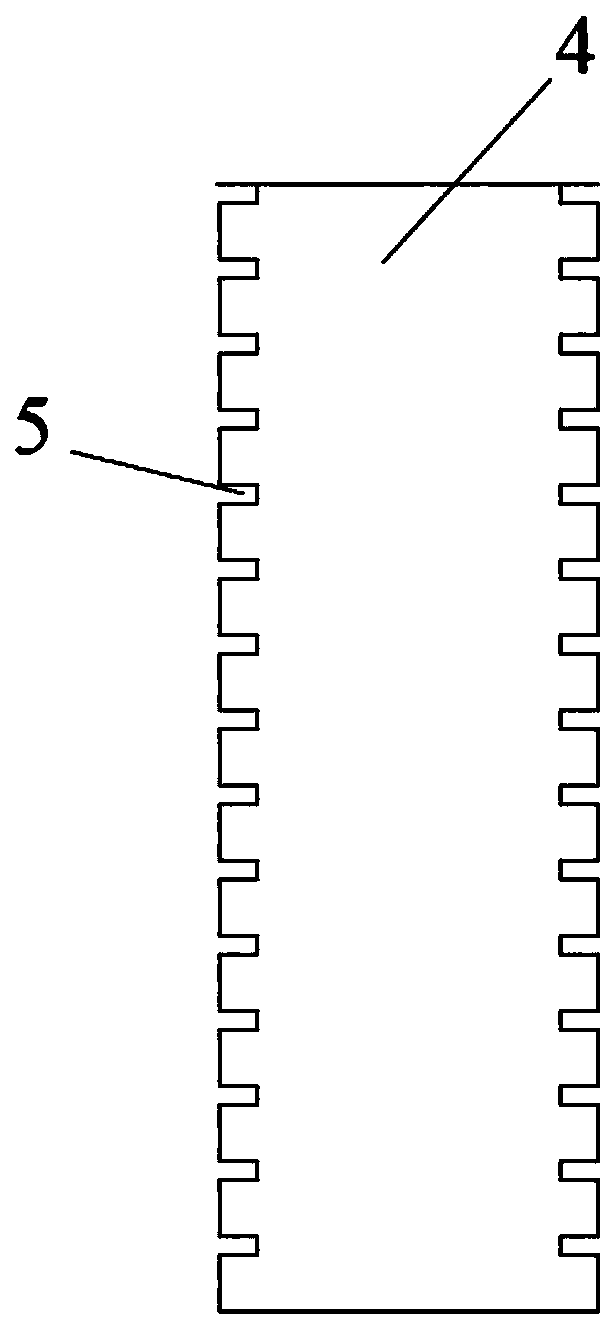

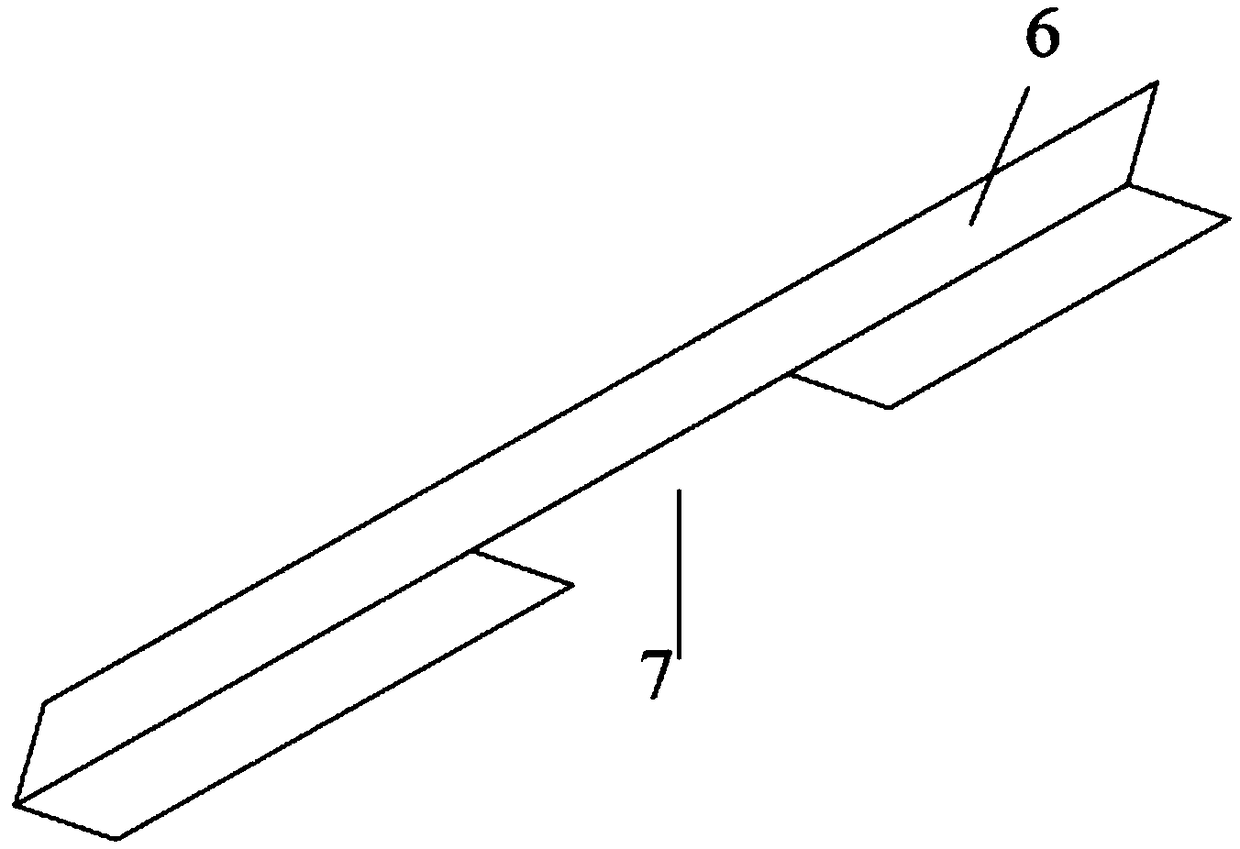

Precise layered sampling soil sampler

InactiveCN109000961AWill not affect each otherPrecise control of sampling depthWithdrawing sample devicesComputer scienceMutual influence

The invention discloses a precise layered sampling soil sampler, comprising a collection frame and a scraper. The collection frame is inserted on the edge of to-be-sampled soil to form a rectangular collection frame. A plurality of scale slots are symmetrically and equidistantly set at two sides of the scraper. The scraper scrapes the to-be-sampled soil, along a direction parallel to long edges ofthe collection frame, at the inner side of the collection frame. According to the precise layered sampling soil sampler provided by the invention, sampling depth can be precisely controlled through the scale slots on the scraper, gradual downward sampling is carried out from the surface of the soil, mutual influence of the soil among different depths is avoided, and precise layering is ensured.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

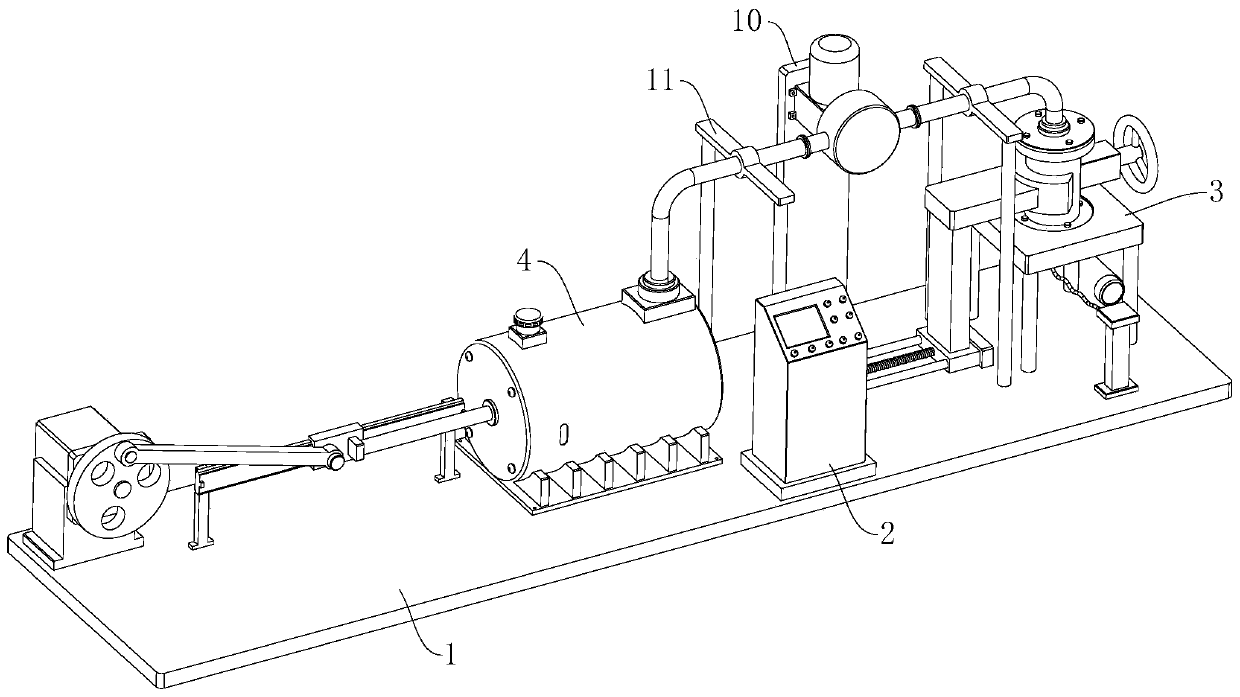

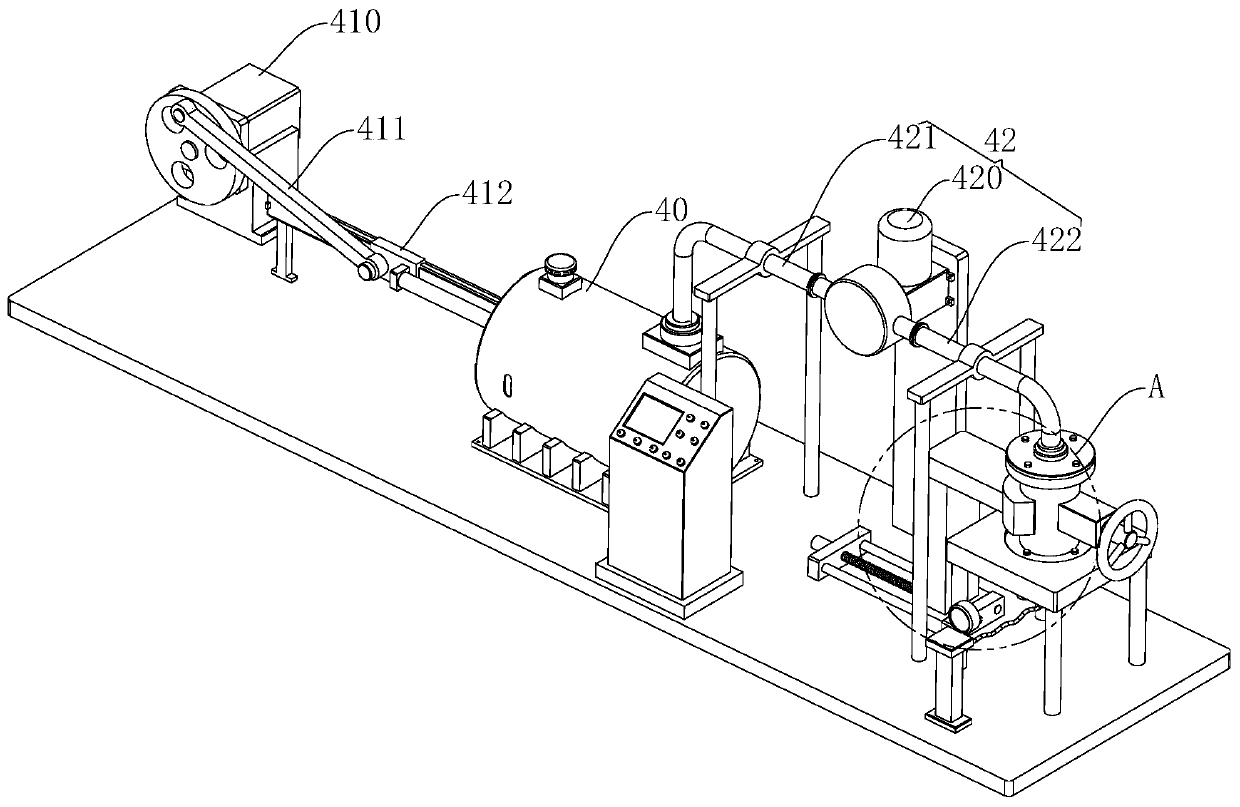

Valve water pressure resistance detection device and detection method thereof

PendingCN111289375APrecise control of depthReduce property damageMaterial strength using tensile/compressive forcesWater resourcesWater temperature

The invention relates to the technical field of valve detection, in particular to a water pressure resistance detection mechanism applied to a valve. The water pressure resistance detection mechanismis arranged in a water pressure resistance detection system. The water pressure resistance detection mechanism is arranged at the other end of the top of the base and used for detecting the water pressure resistance of the valve; the water pressure resistance detection mechanism comprises a water supply tank, an extrusion part, a conveying part, a heating part and a counting part; and the clampingpart, the extrusion part, the conveying part, the heating part and the counting part are all electrically connected with the controller. According to the valve water pressure resistance detection mechanism, the water pressure resistance of the valve at different water level heights in the valve and the water pressure resistance of the valve at different water temperatures can be detected, meanwhile, water seepage of equipment can be prevented, then waste of water resources is avoided, and the practicability of the device is further improved.

Owner:段建辉

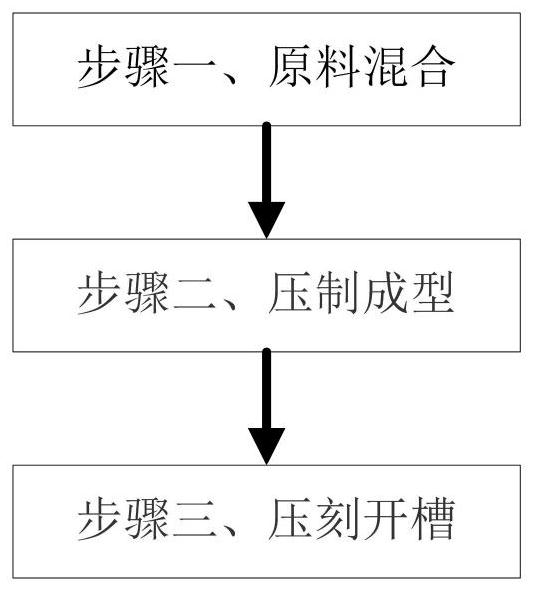

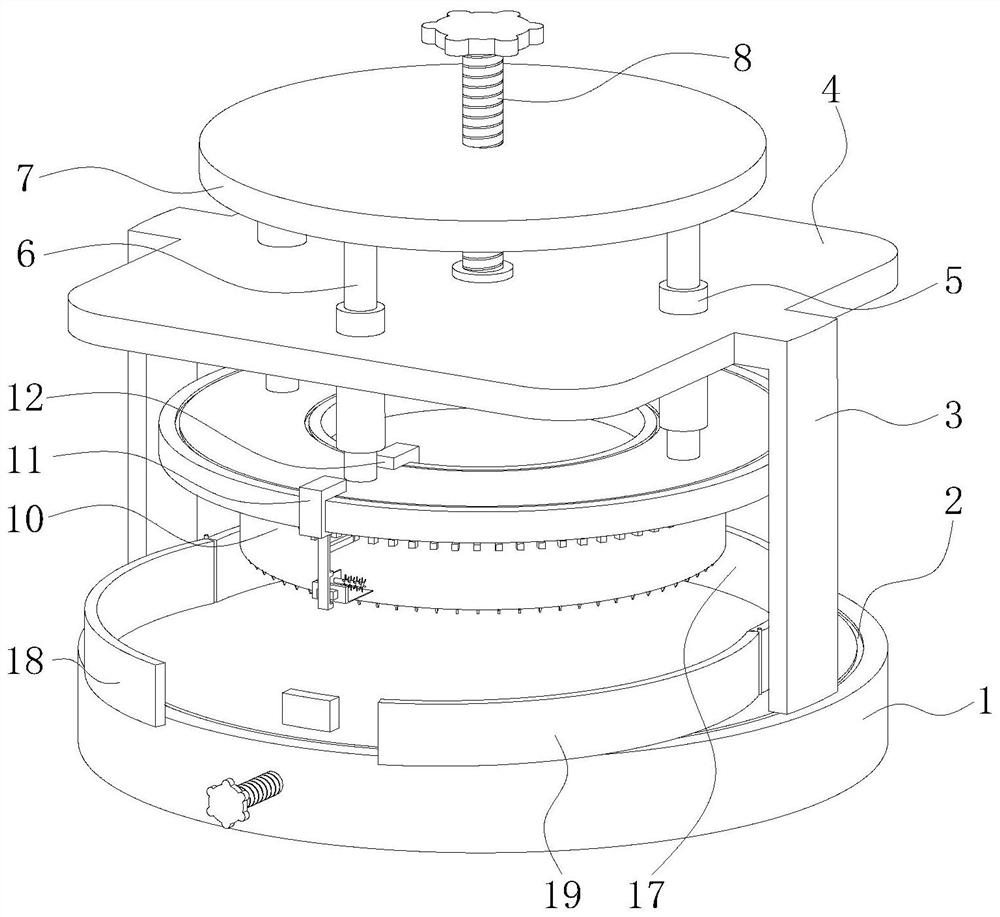

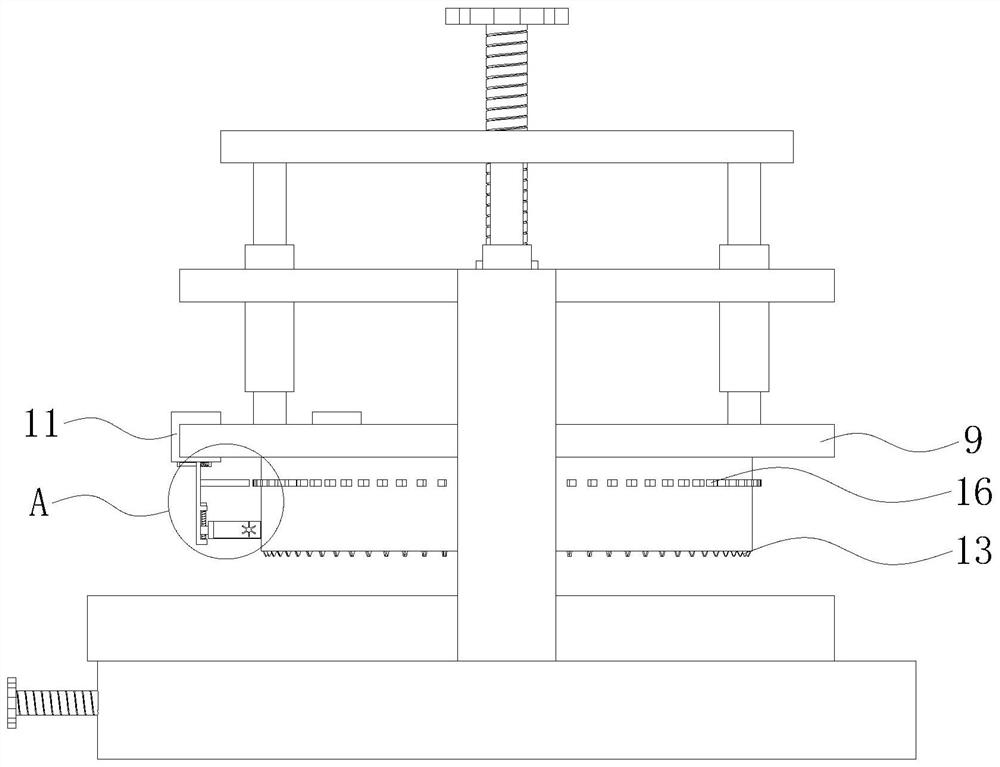

Forming processing method of brick and cement prefabricated part

ActiveCN111941614AEnsure consistent depthImprove molding qualityAuxillary shaping apparatusCleaning using toolsCoal gangueManufacturing engineering

The invention belongs to the technical field of brick manufacturing, and specifically relates to a forming processing method of a brick and cement prefabricated part. The forming processing method comprises the following steps of (1) mixing raw materials: uniformly mixing coal ash, coal gangue, tailing slag, chemical slag and cement so as to obtain a mixture; (2) performing compression molding: performing compression molding on the mixture prepared in the step (1) so as to form a cylindrical prefabricated block; and (3) pressing and slotting: forming an annular anti-skid groove in the surfaceof the prefabricated block prepared in the step (2), wherein the pressing and slotting process in the step (3) is cooperatively performed by a forming processing machine of the brick and cement prefabricated part. According to the forming processing method, the consistent depth of all positions of the anti-skid groove is guaranteed, the raw materials which are accumulated on both sides of the anti-skid groove can be removed, the forming quality of the anti-skid groove is increased, and cracks can be prevented from being generated on the side wall of the cylindrical brick and cement prefabricated block or in the cylindrical brick and cement prefabricated block in the slotting process.

Owner:界首市嘉宇新型建材有限公司

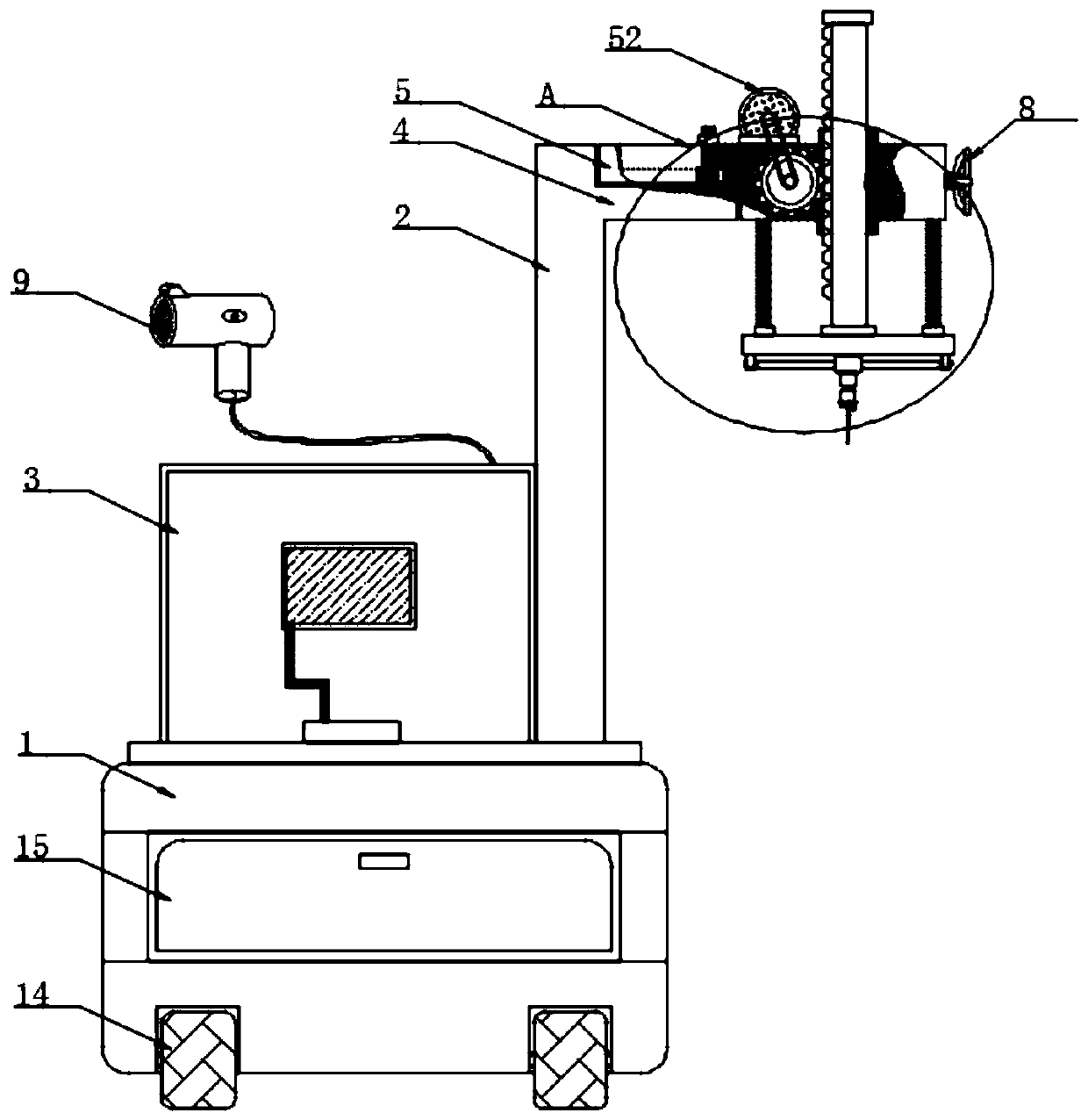

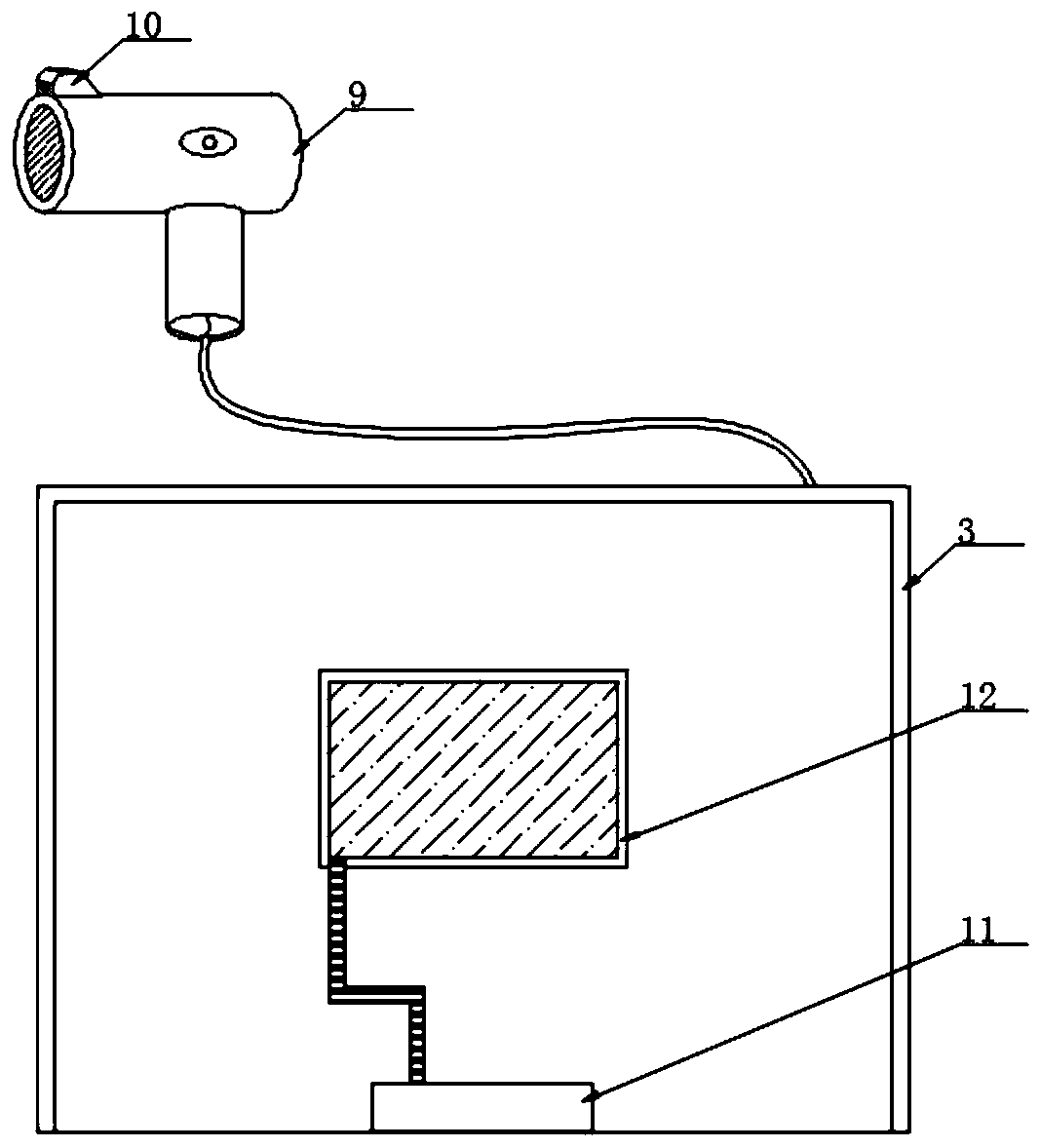

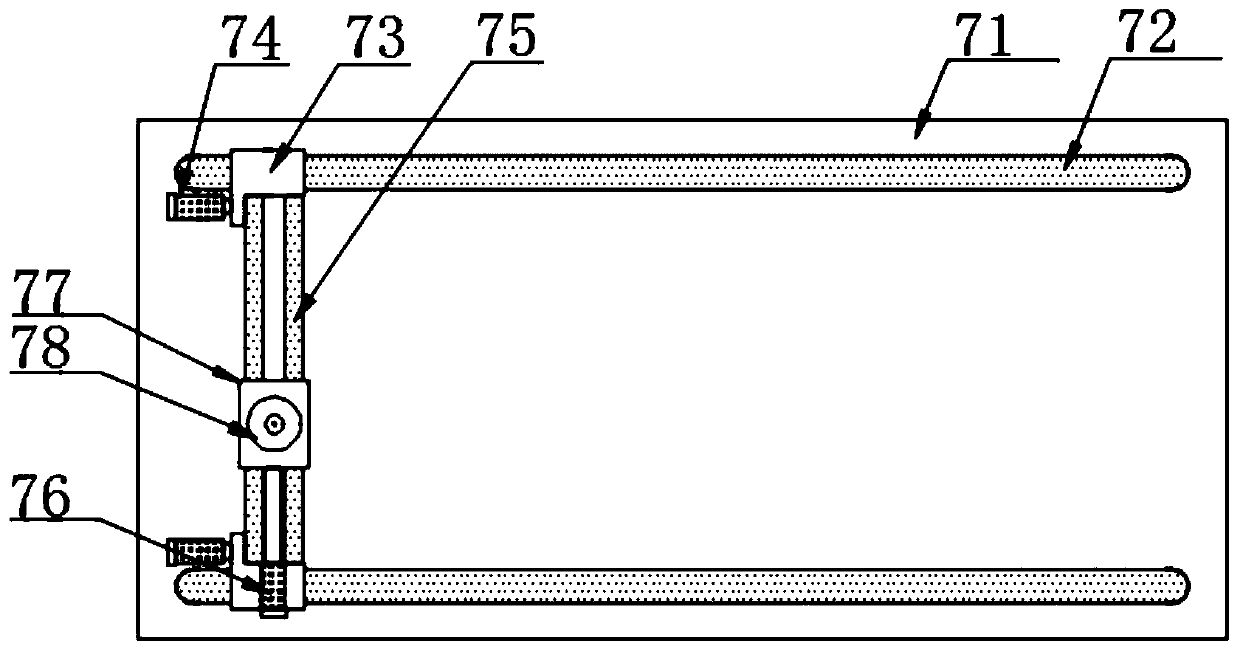

Intelligent skin precise perforation device

PendingCN110236649ARelieve painControl piercing depthDiagnosticsSurgical needlesMicrocomputerMicrocontroller

The invention discloses an intelligent skin precise perforation device, and particularly relates to the field of medical apparatuses. The intelligent skin precise perforation device comprises a machine base. A support is arranged on the top of the machine base. A working host is arranged on one side of the support. A transverse support is arranged on the top of the support. A transverse movement frame is movably connected with the top of the transverse support. A slide hole runs through the surface of the transverse movement frame. An adjusting rod is arranged in the slide hole. By means of an image recognizing technology, sensing distance information and image signals are sent to a single-chip microcomputer for analysis treatment, the single-chip microcomputer calculates the required skin shape and area, draws the perforation movement trajectory, and intelligently controls a first cylinder and a second cylinder to promote the perforation movements, a perforation needle moves along the perforation movement trajectory of a wound, a third cylinder is controlled for perforation, a second infrared sensor is matched with the single-chip microcomputer, the perforation depth is controlled, the perforation shape, size and depth are precisely controlled, it is avoided that the needle pierces in the skin too deeply or the skin taken down is not matched with the wound, the pains of a patient are relieved, and the effect of uniform perforation density is easily realized.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

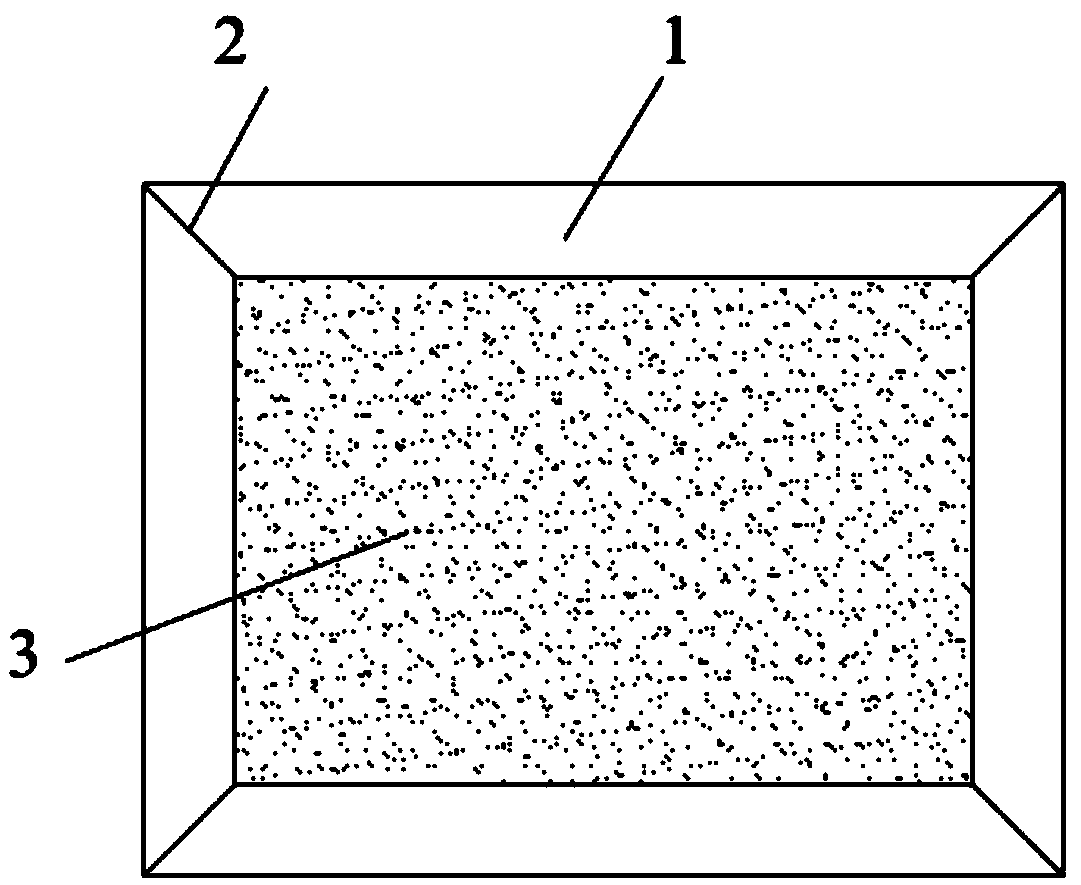

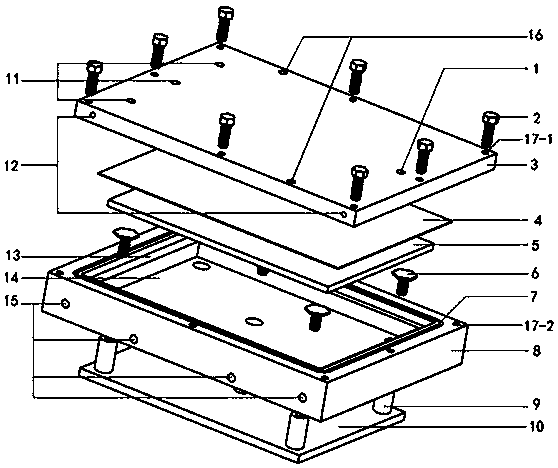

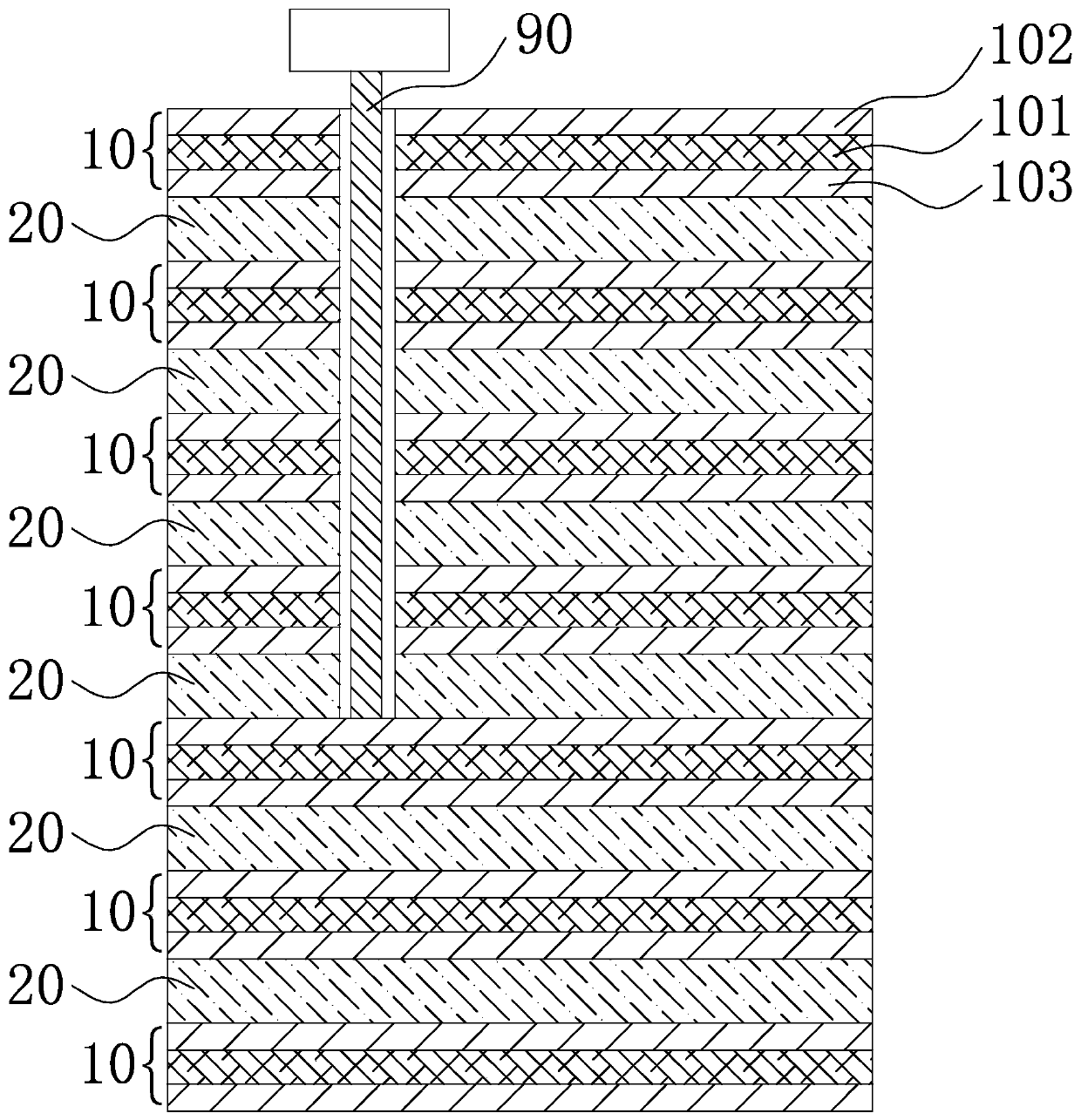

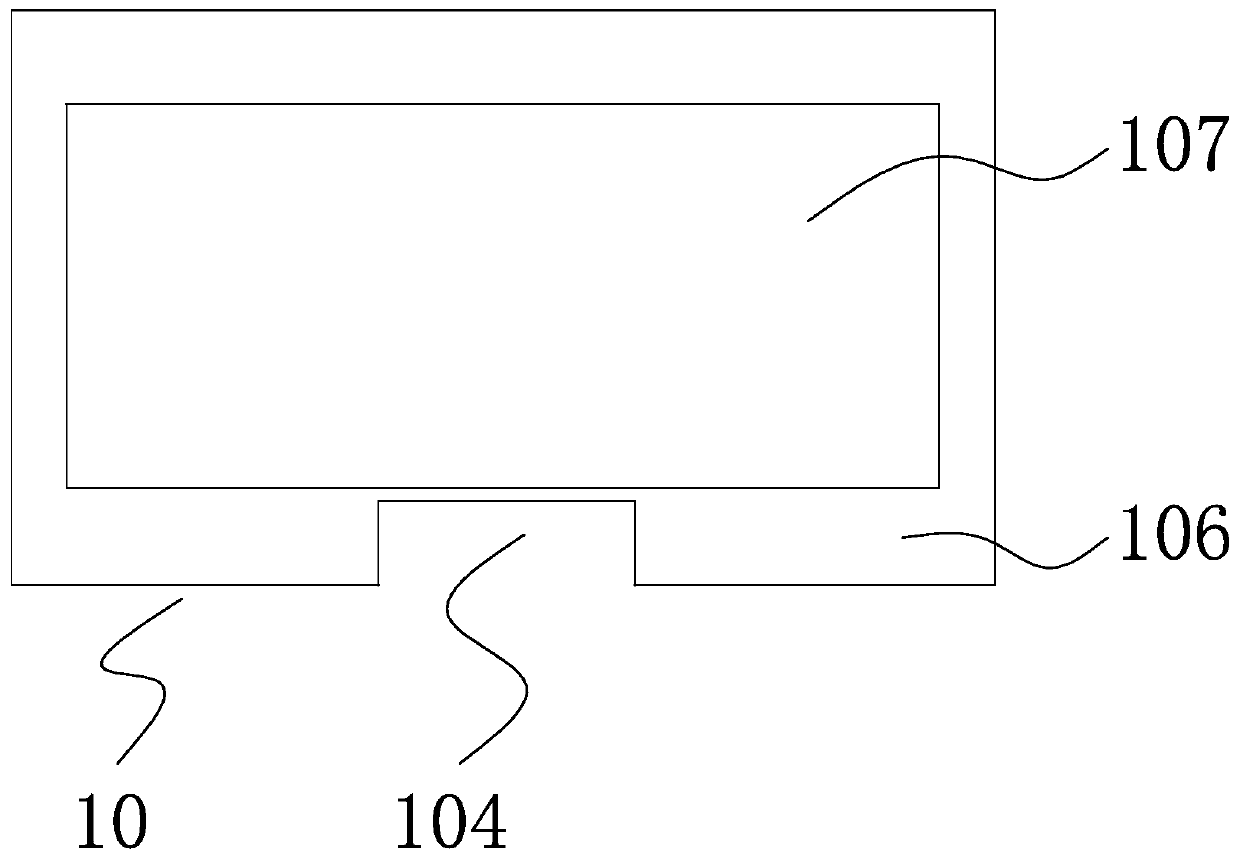

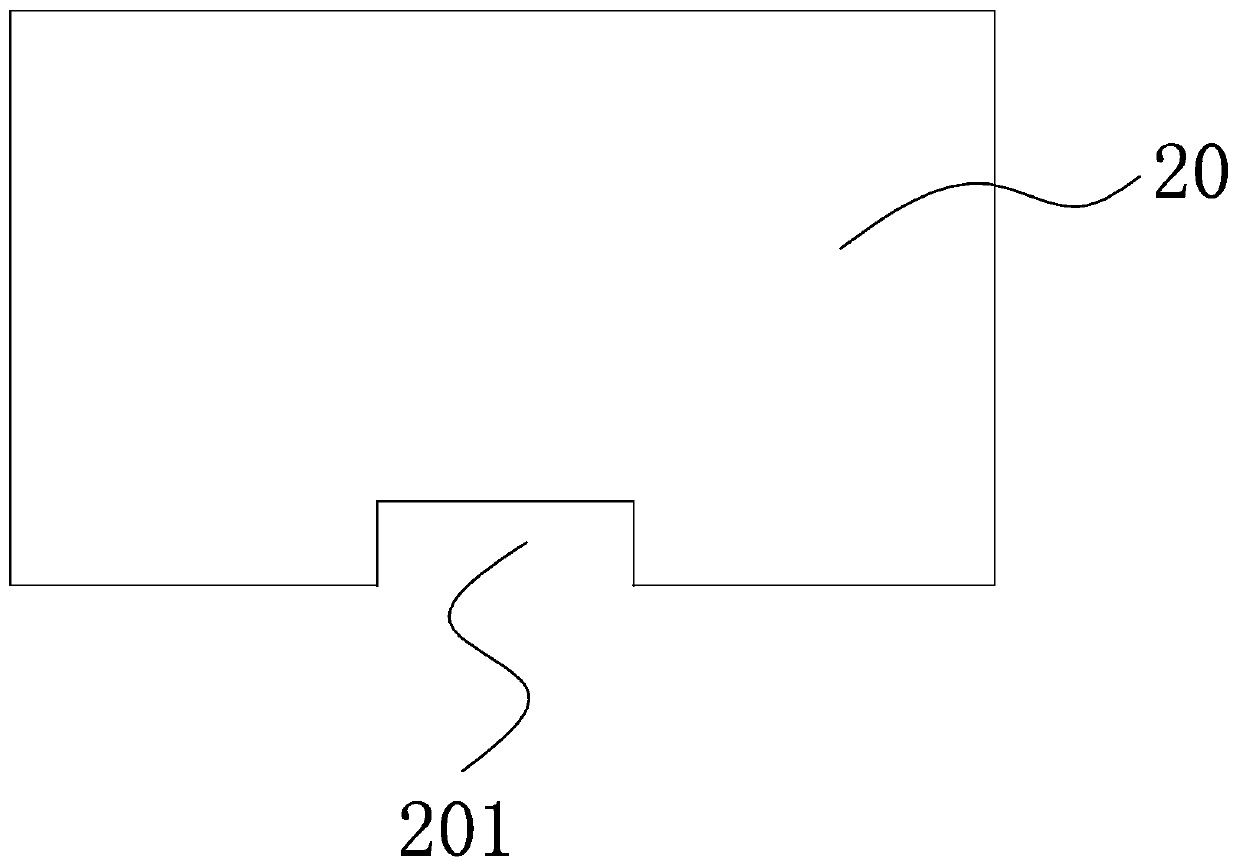

Composite laminated plate manufacturing mold

The invention discloses a composite laminated plate manufacturing mold. Through the composite laminated plate manufacturing mold, the thickness of laminated plates can be adjusted continuously and accurately. A lower mold surface is provided with stepped grooves. The first stepped groove is internally provided with the lower mold surface. The second stepped groove is provided with an upper top plate. The lower mold surface is provided with ejector pin holes allowing ejector pins to move vertically. The bottom surface of a lower mold is provided with locking devices used for locking push rods.The push rods are provided with graduations. The thickness of a mold cavity can be visually observed through the graduations. The upper and low mold surfaces are provided with sealing grooves for containing seal rings to guarantee the airtightness of the mold cavity. Heating pipes are arranged in an upper mold and the lower mold and can increase the temperature of the mold, so that the fluidity ofresin in the mold cavity is improved. Different thicknesses of laminated plates can be set according to different fiber cloth thicknesses. The fiber volume fraction of products can be controlled by calculating and controlling the content of resin in the laminated plates. Accordingly, the product quality is improved.

Owner:JILIN UNIV

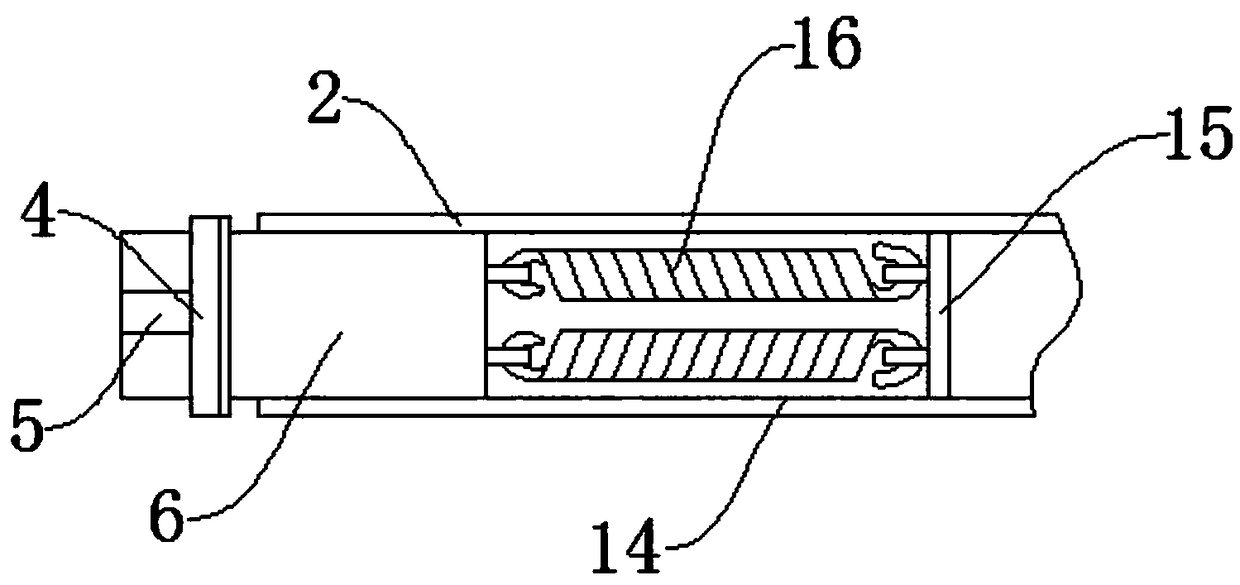

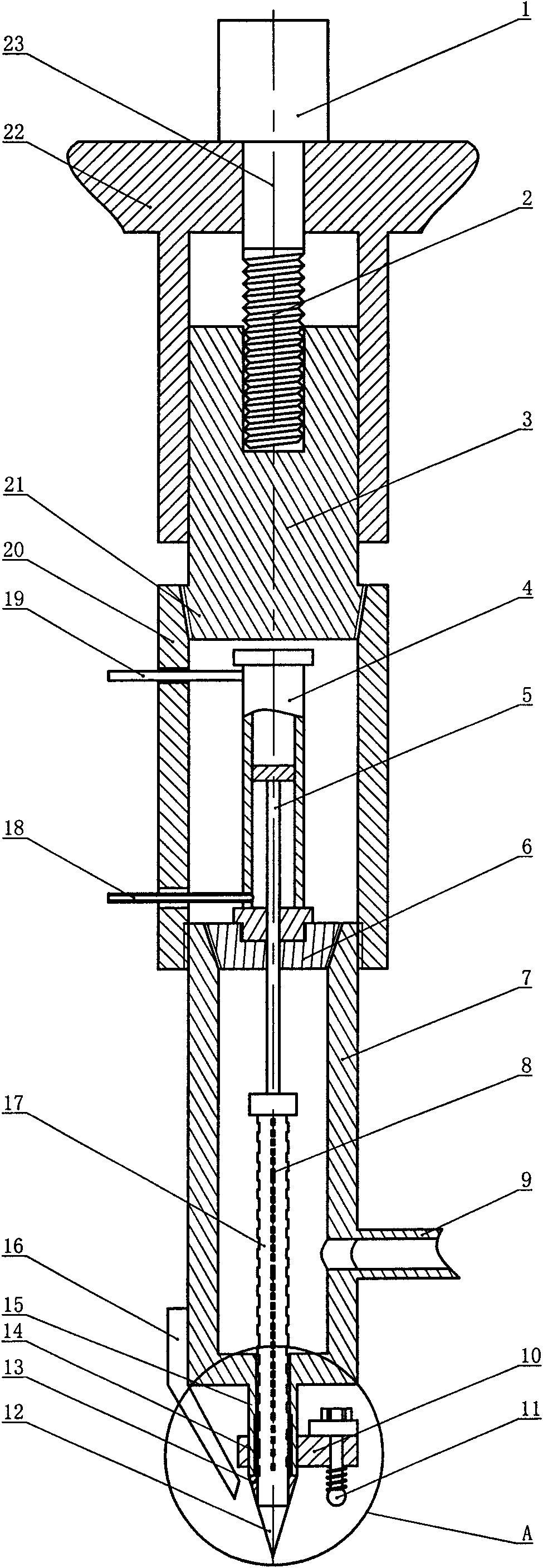

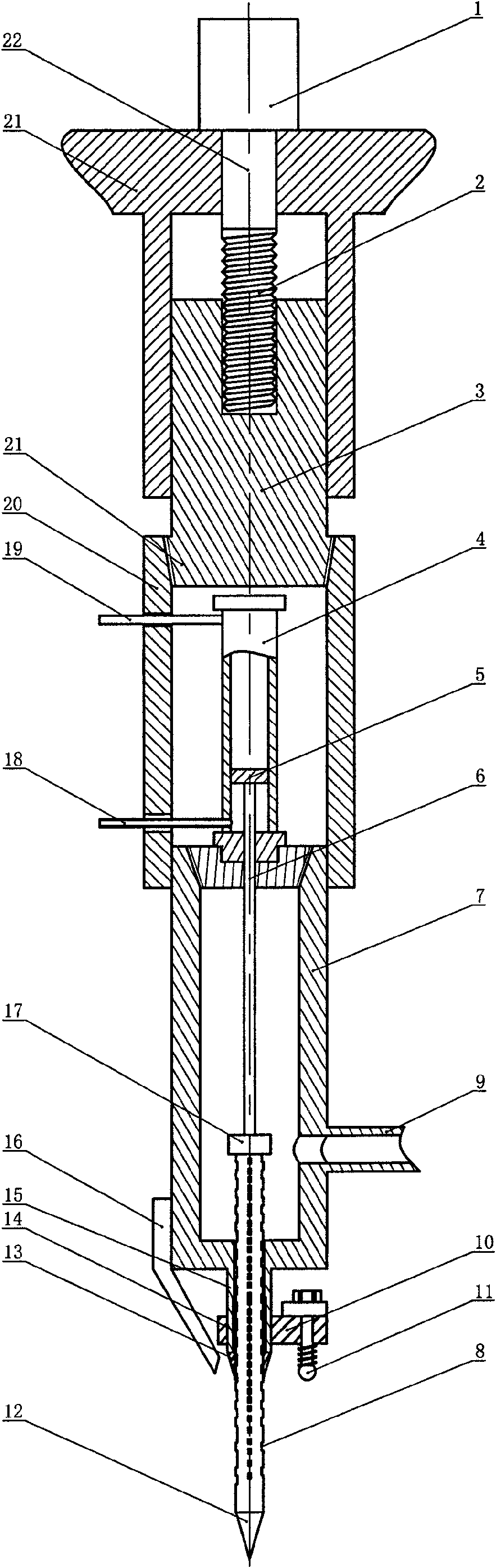

Injection device for fat beef injection adipose

InactiveCN101632462APrevent spillagePrecise control of depthFood preparationMeat tenderisingEngineeringSyringe needle

The invention relates to an injection device for fat beef injection adipose which comprises a sliding block, a motor, a screw, an upper sleeve, a middle sleeve, a lower sleeve and a syringe needle, wherein the sliding block is arranged in the upper sleeve and meshed with the screw; the screw is coaxially connected with an output shaft of the motor which is fixedly arranged on the upper end of the upper sleeve; the lower end of the sliding block and the upper end of the middle sleeve are fixedly arranged; the lower end of the middle sleeve and the upper end of the lower sleeve are fixedly arranged; the middle sleeve is internally provided with an air cylinder; the lower end part of the air cylinder and the upper end part of the lower sleeve are fixedly arranged; an air cylinder push rod and the upper end of the syringe needle in the lower sleeve are coaxial and fixedly arranged; the syringe needle comprises a needle head and a needle body; the needle head is inverted cone-shaped and fixedly arranged on the lower end of the needle body; the needle body is of cylindrical hollow structure and liquid inlet holes are uniformly manufactured on the cylindrical surface; a sensor is arranged on the outer wall of a contracted opening of the lower end of the lower sleeve; and an liquid inlet opening is manufactured on the outer wall of the lower sleeve. The injection device has simple structure, scientific and reasonable design, can effectively increase the efficiency of beef injection adipose, has good injection effect and saves labor cost.

Owner:TIANJIN AGRICULTURE COLLEGE

Embedded gate structure and manufacturing method thereof

PendingCN110911476AIncrease channel lengthSmall structure sizeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineering physicsSemiconductor

The invention provides an embedded gate structure and a manufacturing method thereof, and the method comprises the steps: providing a semiconductor substrate, and forming an active region and a shallow trench isolation structure for isolating the active region in the semiconductor substrate; forming an active trench in the active region and forming an isolation trench in the shallow trench isolation structure, wherein the active trench comprises a front-section active trench formed in the active region and a rear-section active trench formed at the bottom of the front-section active trench, and the width of the rear-section active trench is greater than that of the front-section active trench; the isolation trench comprises a front-section isolation trench formed in the shallow trench isolation structure and a rear-section isolation trench formed at the bottom of the front-section isolation trench, and the width of the rear-section isolation trench is greater than that of the front-section isolation trench; and forming a gate structure in the active trench and the isolation trench. According to the invention, the problem that the existing transistor cannot simultaneously consider the performance and the integration level is solved.

Owner:CHANGXIN MEMORY TECH INC

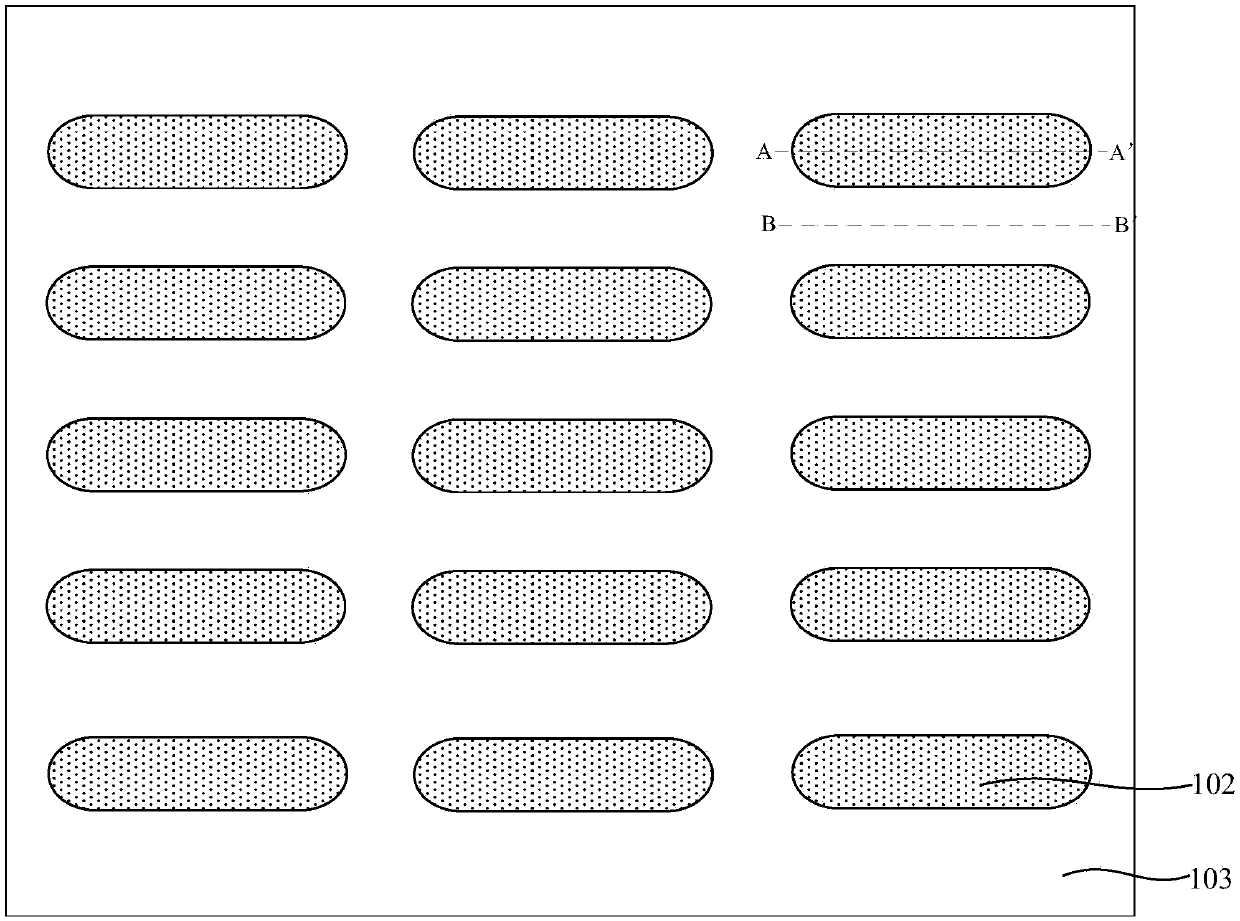

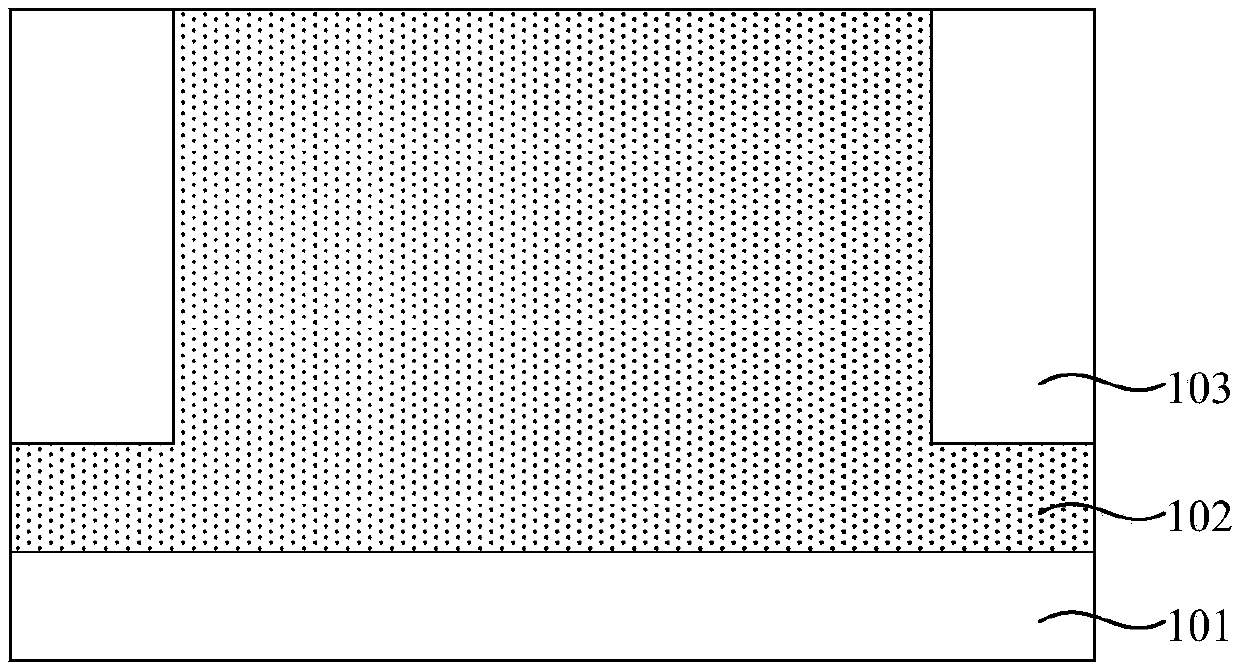

Blind hole processing method for multilayer printed board

ActiveCN110740591AGuaranteed accuracyPrecise Control of DepthPrinted circuit aspectsMultilayer circuit manufactureCopper foilMachining process

The invention relates to the technical field of circuit board manufacturing, and discloses a blind hole processing method of a multi-layer printed board. The blind hole processing method comprises thefollowing steps: S1, processing process edge; S2, windowing of PP sheet; S3, hollowing out the PP sheet; S4, pressing in the early stage; S5, first back drilling; S6, pressing all chips; S7, second back drilling; and S8, obtaining the finished product. The setting of notches and windows in the steps S1 and S2 of the processing method can ensure that the first copper foil on the upper surface of the Nth layer core board at the notches is exposed and the pressing feet of the drilling machine can be pressed on the first copper foil of the Nth core plate after pressing of the core plate. Therefore, when the drill bit contacts the first copper foil on the upper surface of the Nth layer core plate, the press feet of the drilling machine and the drilling bit form a circuit to generate current and the drill bit stops drilling. Compared with the method of pressing the presser feet of the drilling machine on the first copper foil on the upper surface of the first layer core plate, the drillingdepth can be accurately controlled to ensure that the first copper foil on the upper surface of the Nth layer core plate is just drilled without drilling through the copper foil, thus ensuring the accuracy of the drilling depth and greatly improving the success rate of processing.

Owner:珠海杰赛科技有限公司 +1

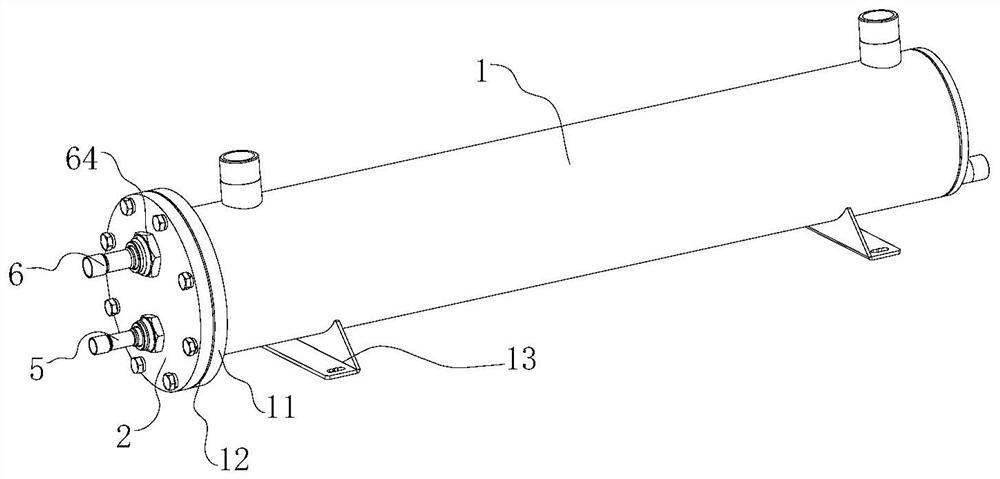

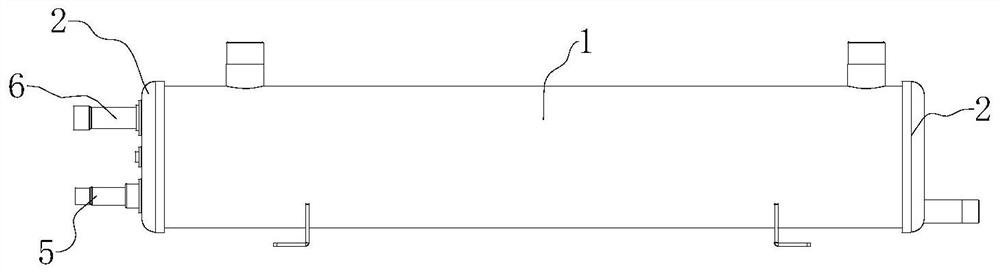

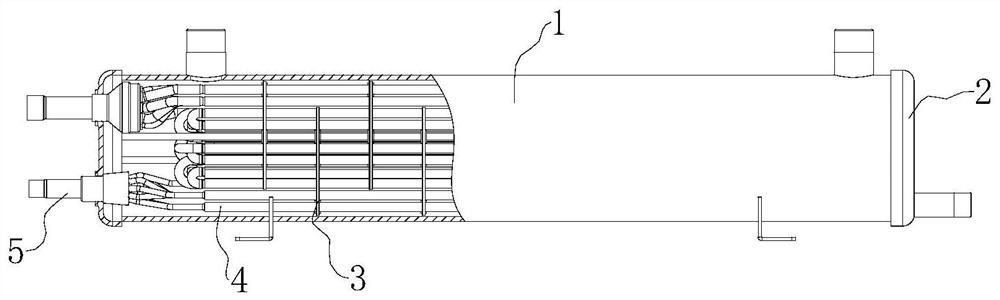

Shell and tube heat exchanger

InactiveCN112484535ASimplify manufacturing difficultyGuaranteed thicknessHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerEngineering

The invention relates to the field of heat exchangers, in particular to a shell and tube heat exchanger. The shell and tube heat exchanger comprises a heat exchanger shell and a tube pass assembly arranged in an inner cavity of the heat exchanger shell. The tube pass assembly comprises a tube bundle support, a copper tube, a distributor and a collector, wherein the copper tube is arranged on the tube bundle support, and the distributor and the collector are connected with the ends of the copper tube correspondingly. A liquid inlet and a liquid outlet which are communicated with an inner cavityof the heat exchanger shell are formed in the heat exchanger shell. The heat exchanger shell comprises a barrel and end plates welded to the edges of openings in the two ends of the barrel in a sealed mode. The shell and tube heat exchanger has the advantages that the structure is simplified, machining is convenient, cost is reduced, and sealing performance is guaranteed.

Owner:EXTEK ENERGY EQUIP ZHEJIANG

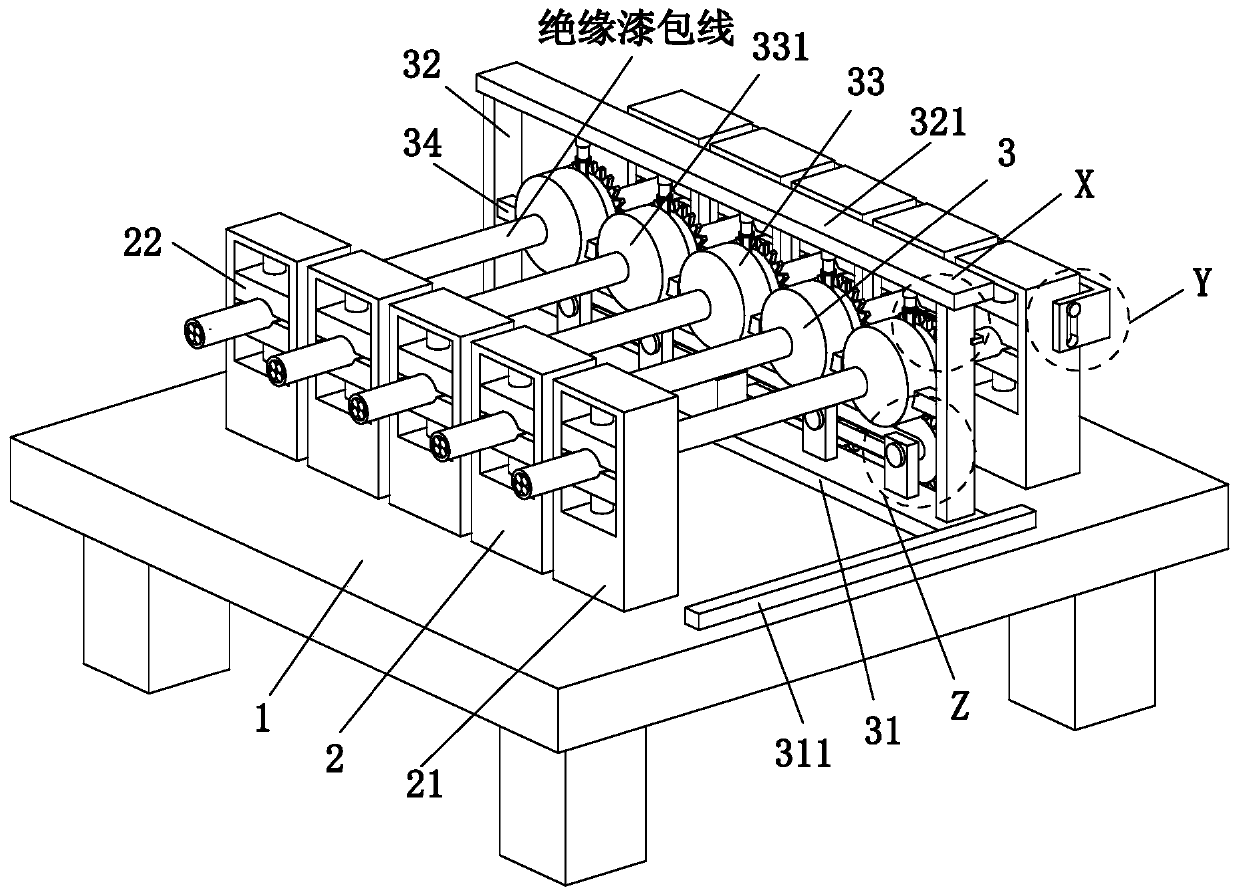

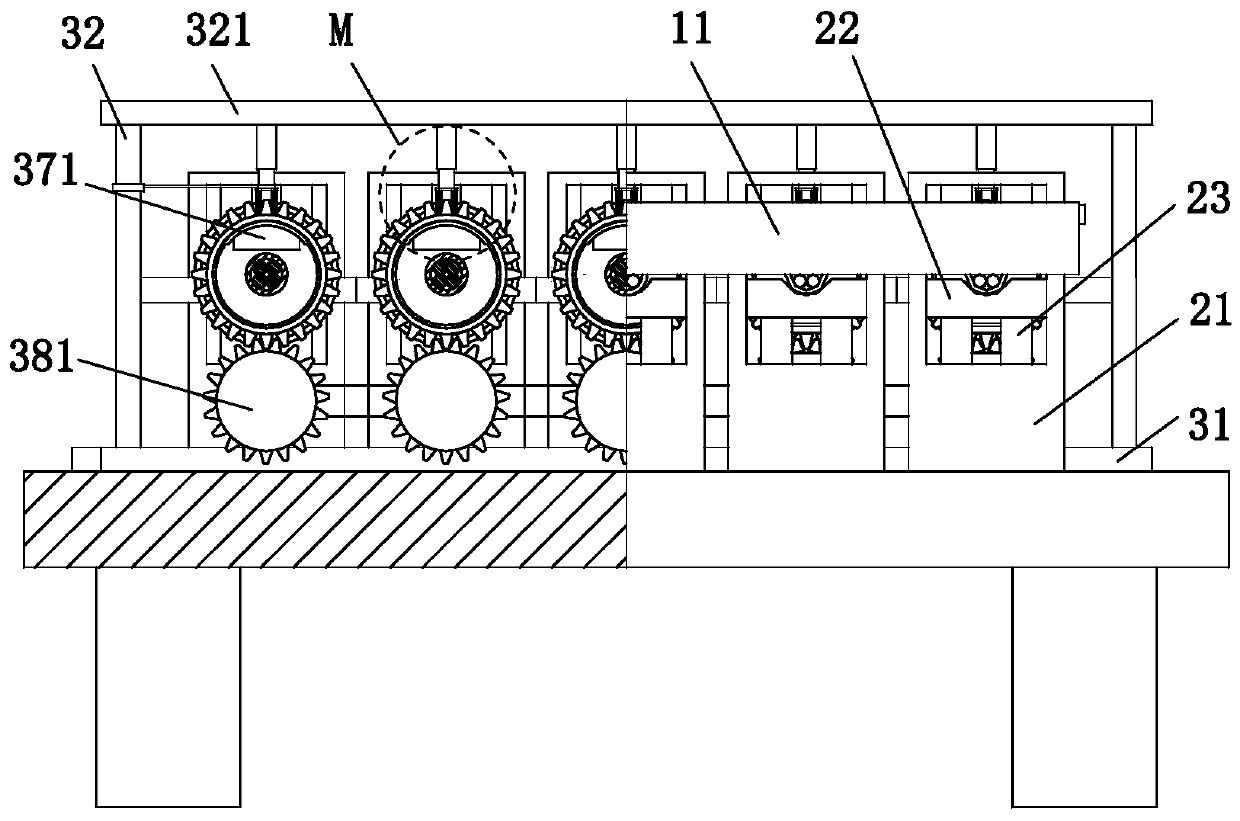

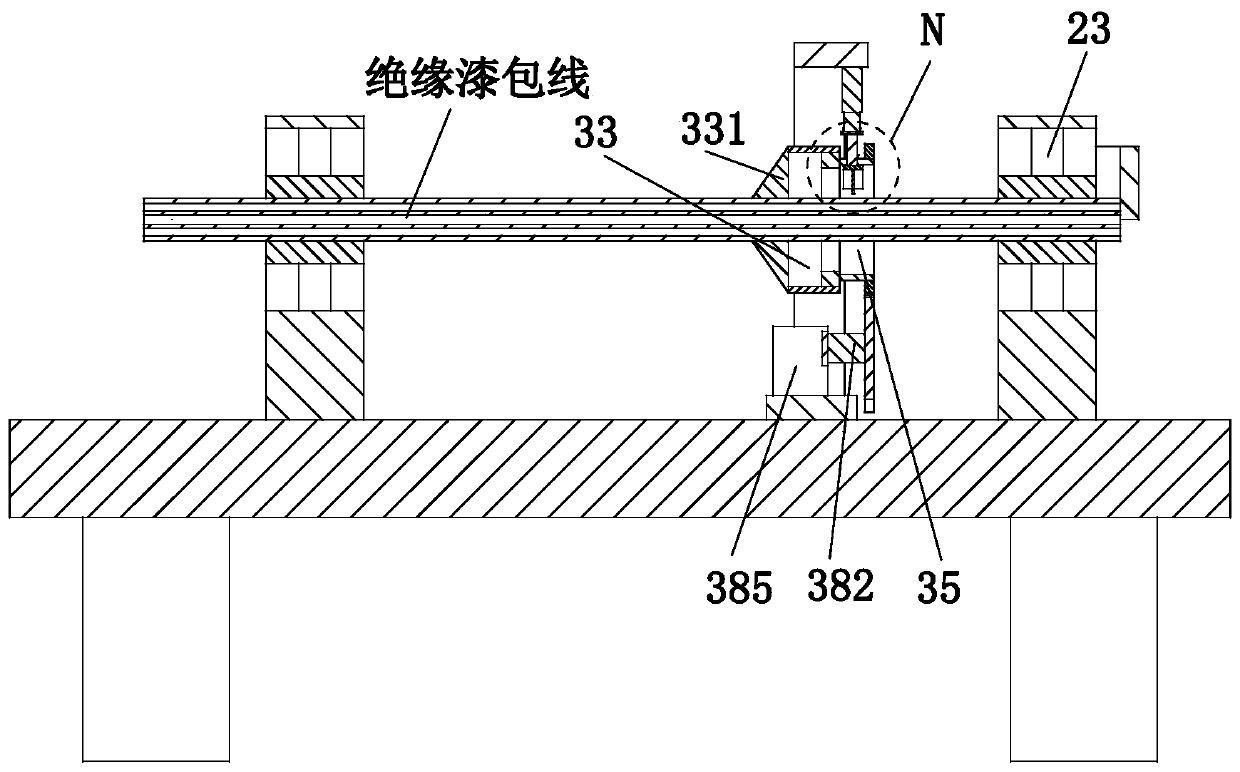

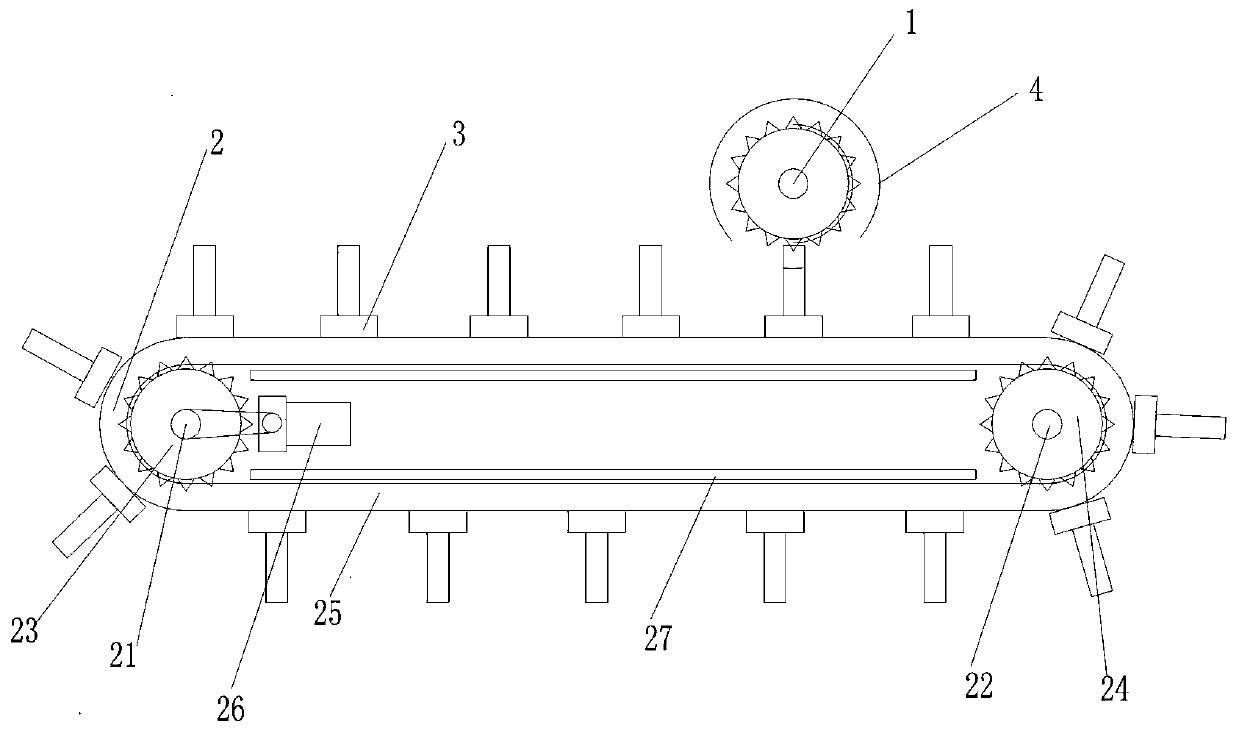

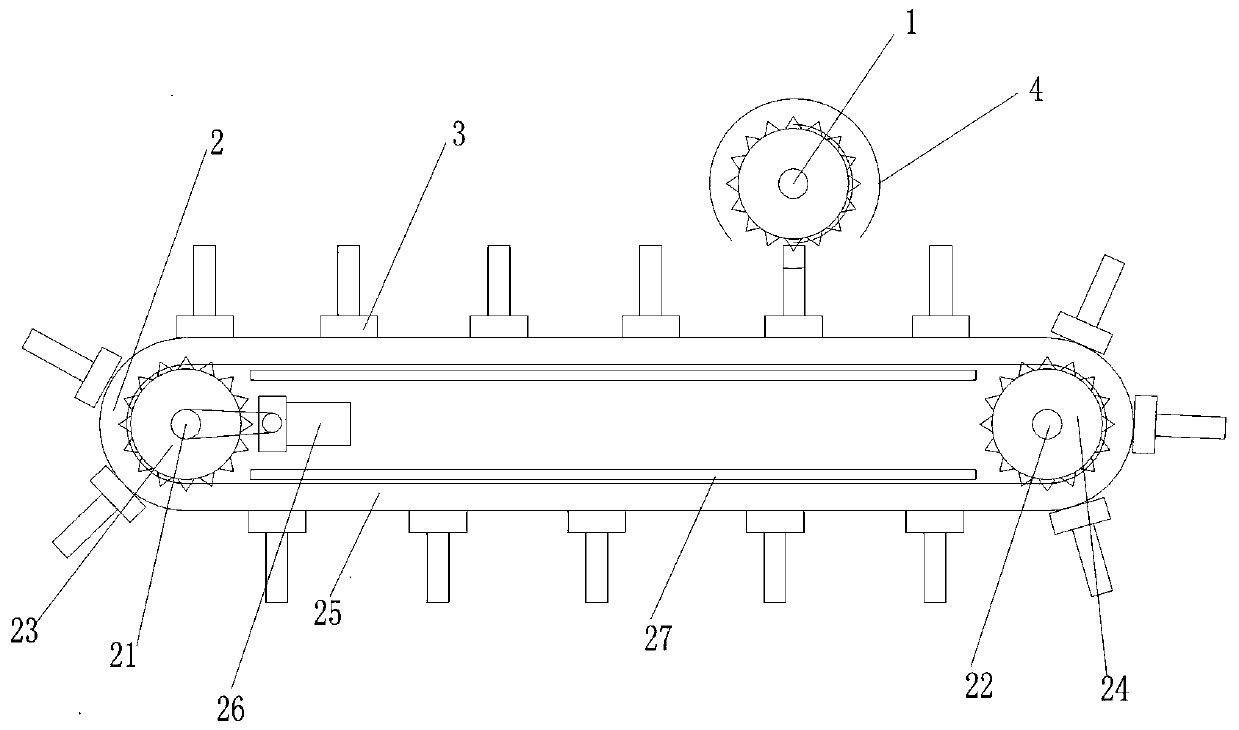

Insulated enamelled wire producing manufacturing cutting device and cutting machining method

ActiveCN110814224AHigh precisionIncrease profitApparatus for cutting/splicing cablesApparatus for removing/armouring cablesMachiningIndustrial engineering

The invention relates to an insulated enamelled wire producing manufacturing cutting device. The insulated enamelled wire producing manufacturing cutting device comprises a worktable, fastening devices and a cutting device, the fastening devices are symmetrically mounted at the front and back of the upper end face of the worktable, the cutting device is mounted on the middle part of the upper endface of the worktable in a slide fit mode, and the cutting device is located between the fastening devices. According to the insulated enamelled wire producing manufacturing cutting device and a cutting machining method, a design idea of adjustable structure is adopted to perform cutting treatment on an insulated enamelled wire, so that one equipment can adapt to the full cutting and peeling requirements of the insulated enamelled wire, the utilization rate of the equipment is improved, the cutting device plays an assisting transporting role on a cutting part of the insulated enamelled wire while the cutting effect is realized, and the labor strength of workers is reduced.

Owner:HENGYANG NORMAL UNIV

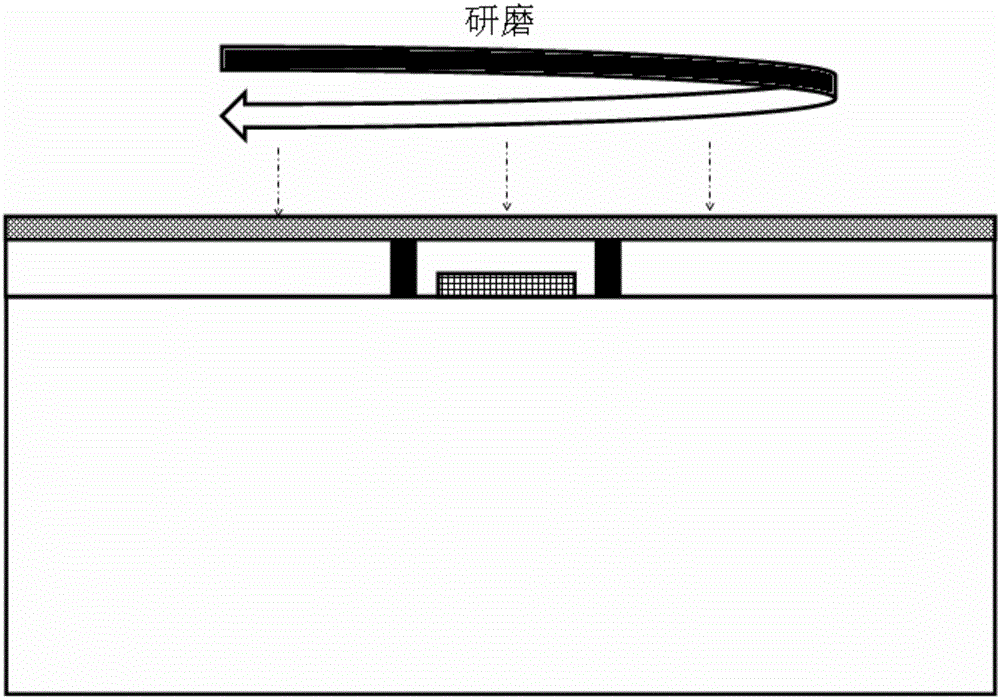

Circulated automatic grinding equipment

InactiveCN109834591AImprove processing efficiencyKeep healthyGrinding machinesGrinding work supportsEngineeringFixed position

The invention relates to circularly operated automatic grinding equipment, in particular to the circularly operated automatic grinding equipment. The circularly operated automatic grinding equipment has the technical effects of being simple and mature in structure, and convenient and safe to use. The circularly operated automatic grinding equipment comprises an automatic grinding head, wherein thegrinding head is covered by a grinding cover so that grinding waste can be prevented from being splashed, meanwhile, the waste can be collected, the grinding equipment can complete fixed-position grinding of workpieces, the circularly operated automatic grinding equipment further comprises a circulation conveying line, a plurality of positioning mechanisms are arranged along the circulation conveying line, the face portion of the circulation conveying line is a horizontal working face, so that the positioning mechanisms are opposite to the grinding head.

Owner:沈阳益泰科信息技术有限公司

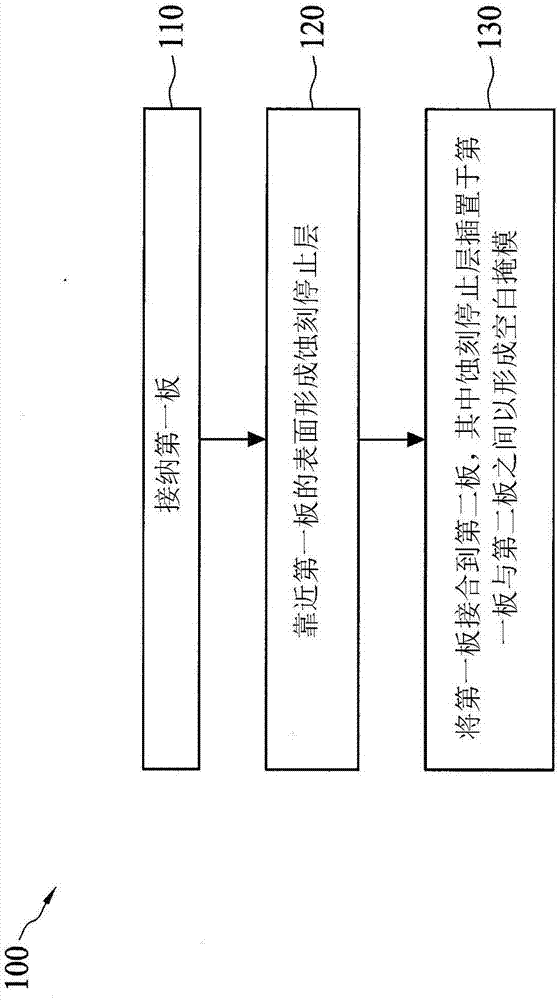

Mask blank

InactiveCN106896637APrecise control of depthPrecisely control the phase shift valueSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEmbedded system

A mask blank and a mask are provided. The mask blank includes a substrate, and an etching stop layer embedded in the substrate. The mask includes the mask blank with the embedded etching stop layer, and a plurality of recesses formed in the mask blank. The recess exposes the embedded etching stop layer.

Owner:TAIWAN SEMICON MFG CO LTD

Novel milling and excavating machine

PendingCN111188378AEasy to adjust flexiblyReduce overall widthMechanical machines/dredgersGearingManufacturing engineeringDust control

The invention discloses a novel milling and excavating machine, and belongs to engineering mechanical equipment. The novel milling and excavating machine comprises a case, a milling and excavating head, a suction hood and a telescopic roller, the suction hood can flexibly rotate to adapt to different working angles, and the telescopic roller is used for adjusting the milling and excavating depth.According to the milling and excavating machine structure, a synchronous belt and chain transmission scheme is used in the case for the first time to replace a traditional gear transmission scheme, flexible adjustment of the length of a machine body is facilitated, and miniaturized arrangement of the whole machine body is also facilitated; and meanwhile, by additionally arranging the suction hood,the functions of dust removal and ash removal are achieved, the construction environment is remarkably improved, the environment value is wide, and the application prospect is huge.

Owner:陕西力明众创机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com