Blind hole processing method for multilayer printed board

A multi-layer printed board and processing method technology, which is applied in multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problem of increasing the manufacturing cost of printed boards, the inability to realize leaking pads, and the unusable finished printed boards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

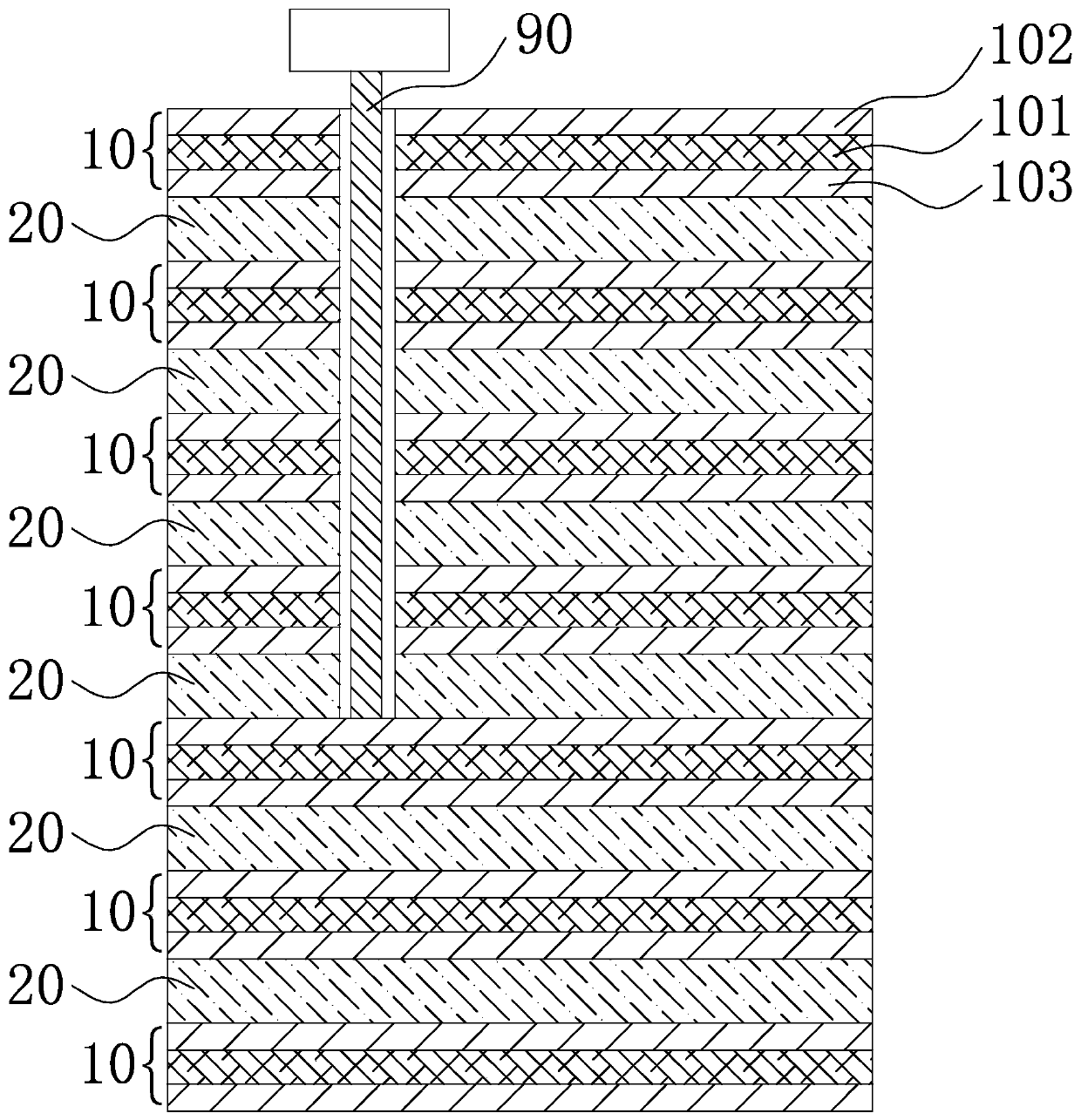

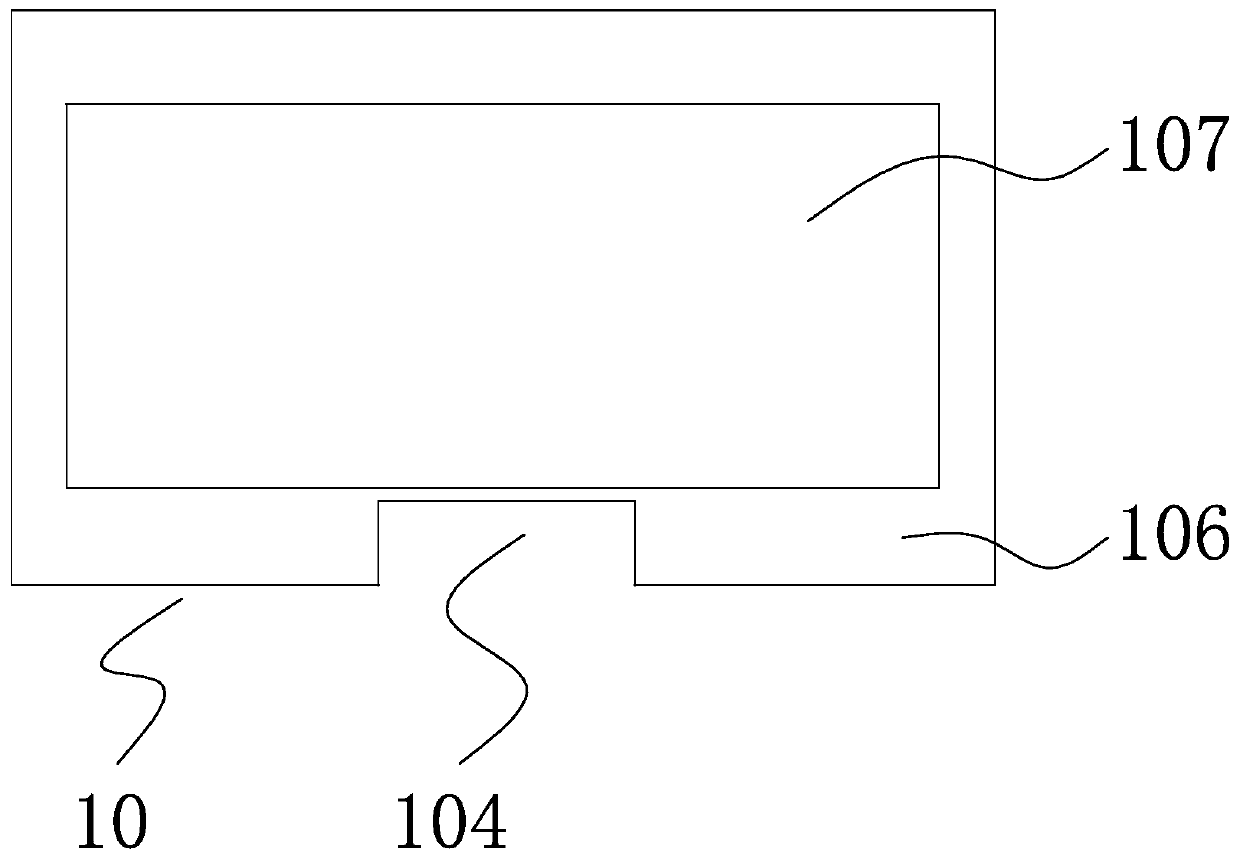

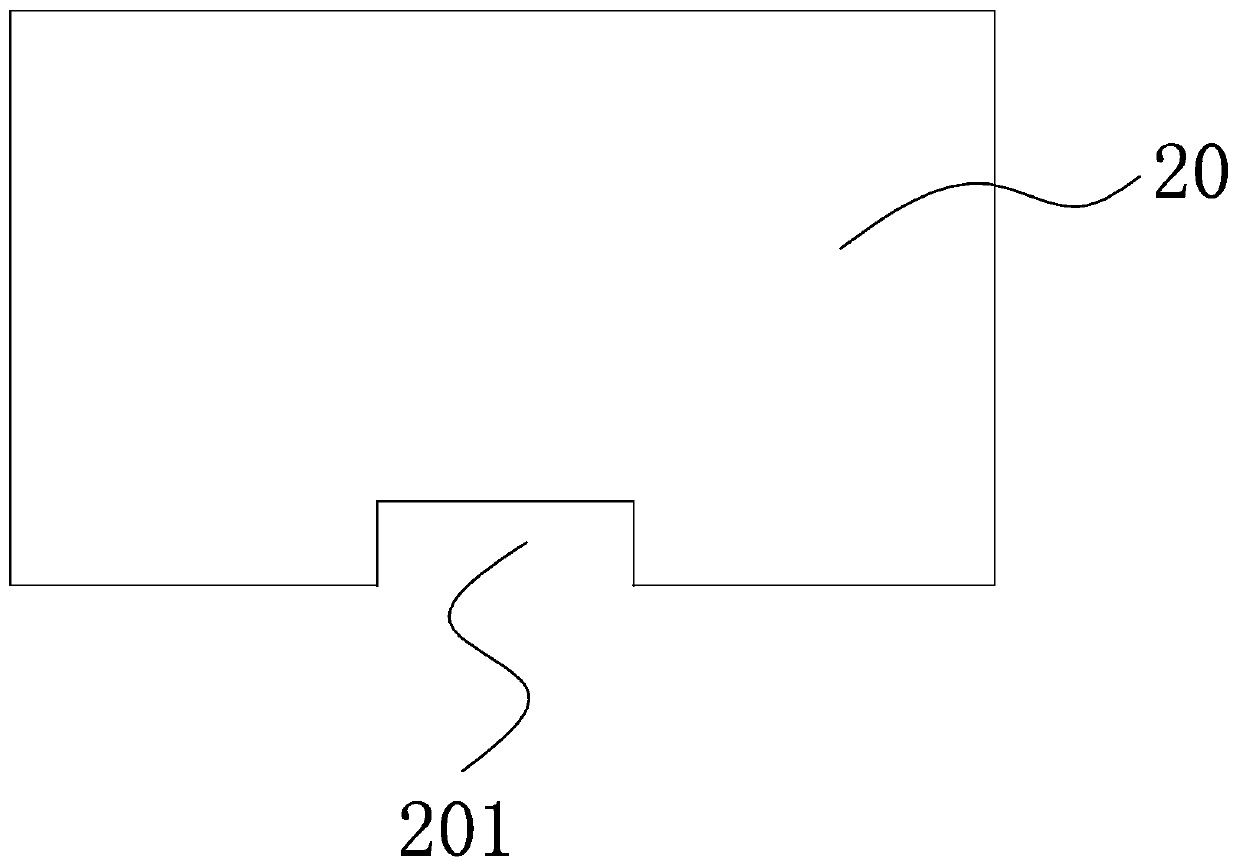

[0026] see figure 1 , in a blind hole processing method of a multilayer printed board of the present invention, the multilayer printed board includes an N+M layer core board 10, which is formed by laminating N+M layer core boards 10, wherein two adjacent layers There are prepregs 20 between the core boards, and the prepregs have a total of N+M-1 layers, that is, the multilayer printed board follows the first layer of core board, the first layer of prepreg, the second layer of core board, the second layer of prepreg... N-1 layer core board, N-1 layer prepreg, N layer core board... N+M-1 layer core board, N+M-1 layer prepreg, N+M layer core board arrangement order pressing The core board 10 includes a base material layer 101 and a first copper foil 102 and a second copper foil 103 respectively arranged on the upper and lower surfaces of the base material layer. When the probe 90 of the component is inserted into the blind hole 60, it needs to be The core board is inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com