Circulated automatic grinding equipment

A kind of equipment, automatic technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of inconvenient up and down movement, low precision, large workload, etc., to ensure health and work environment safety, accuracy Control the grinding position, the effect of fast and high precision grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

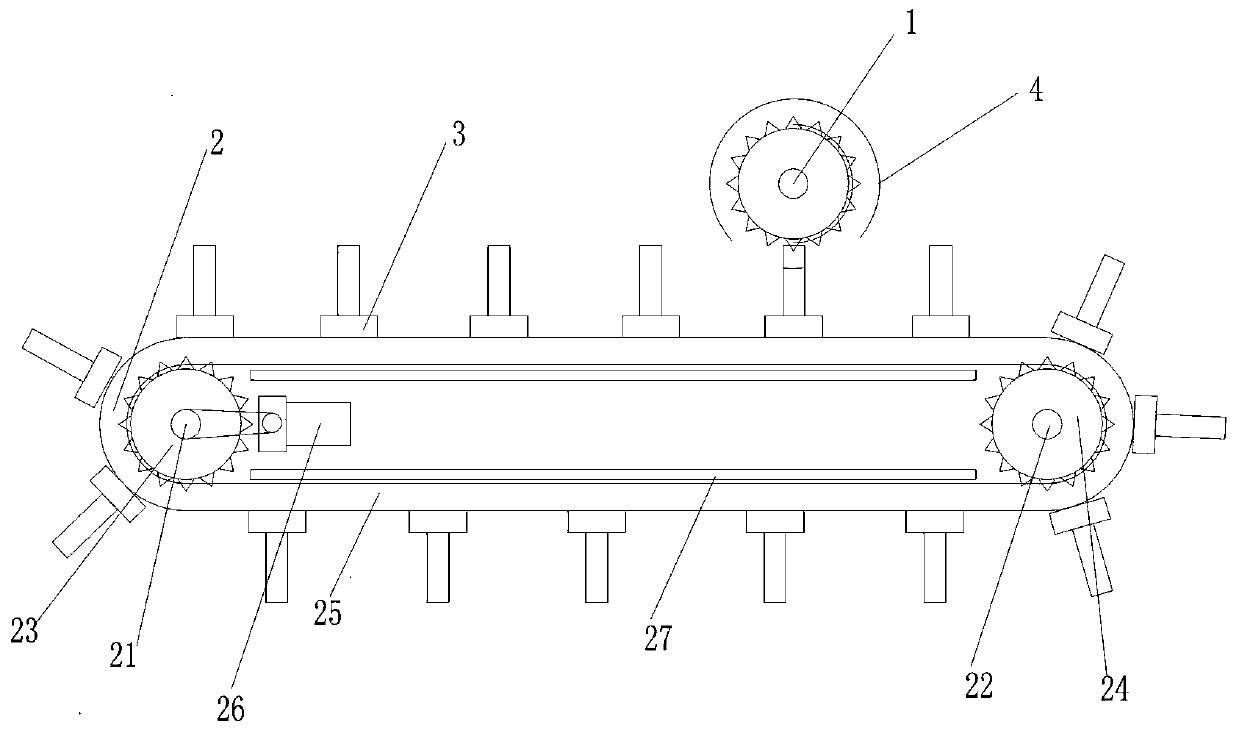

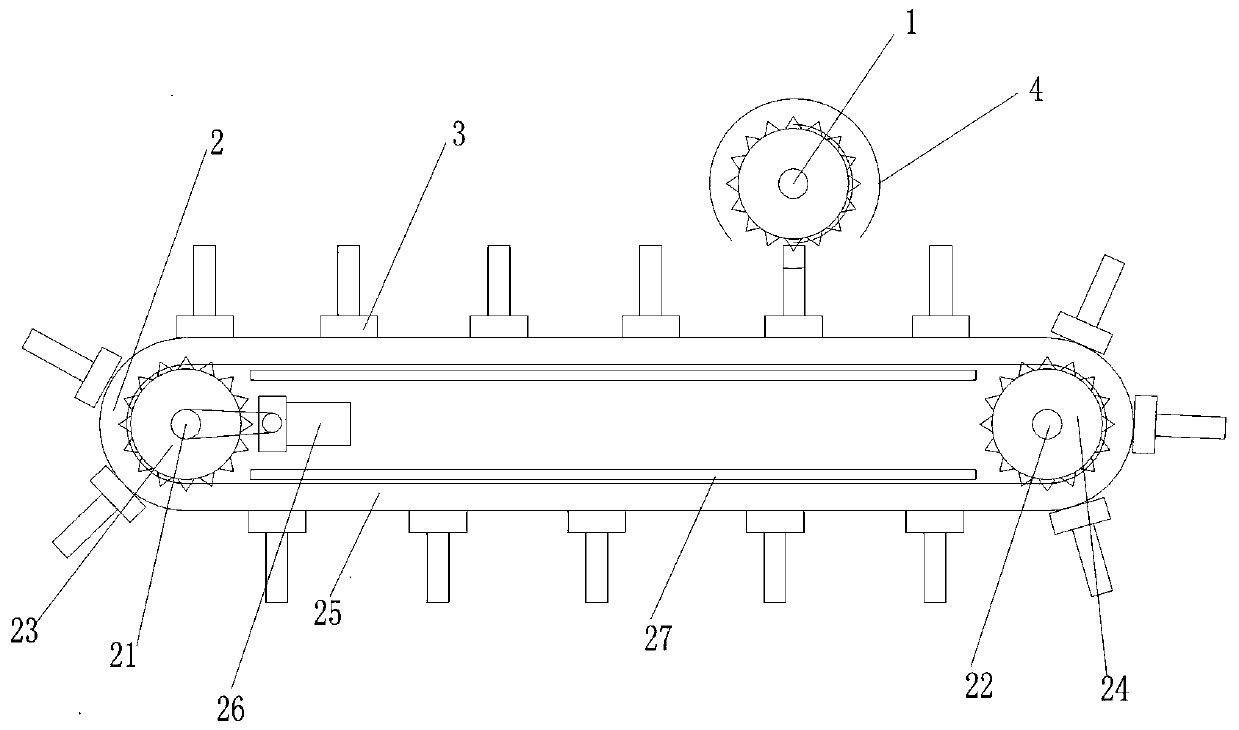

[0017] An automatic circulation polishing equipment of the present invention includes an automatic grinding head, wherein the grinding head is covered by a grinding cover, which can prevent the splashing of grinding waste and can collect waste at the same time: this kind of grinding equipment can complete the fixed position grinding of the workpiece . It also includes a circular conveying line, and several positioning mechanisms are arranged along the circulating conveying line, and the surface of the circulating conveying line is a horizontal working surface so that the positioning mechanism is opposite to the grinding head.

[0018] The positioning mechanism driven by the circulating conveying line runs in a circular manner. Each positioning mechanism is installed on the horizontal working surface of the circulating conveying line. Buckle into the positioning mechanism for positioning, and the circulating conveying line drives the accessories to be transported to the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com