Injection device for fat beef injection adipose

An injection device and fat technology, applied in application, slaughtering, meat tenderization, etc., can solve the problems of difficult to achieve marbling, low production efficiency, poor injection effect, etc., to save labor costs, improve efficiency, and improve taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

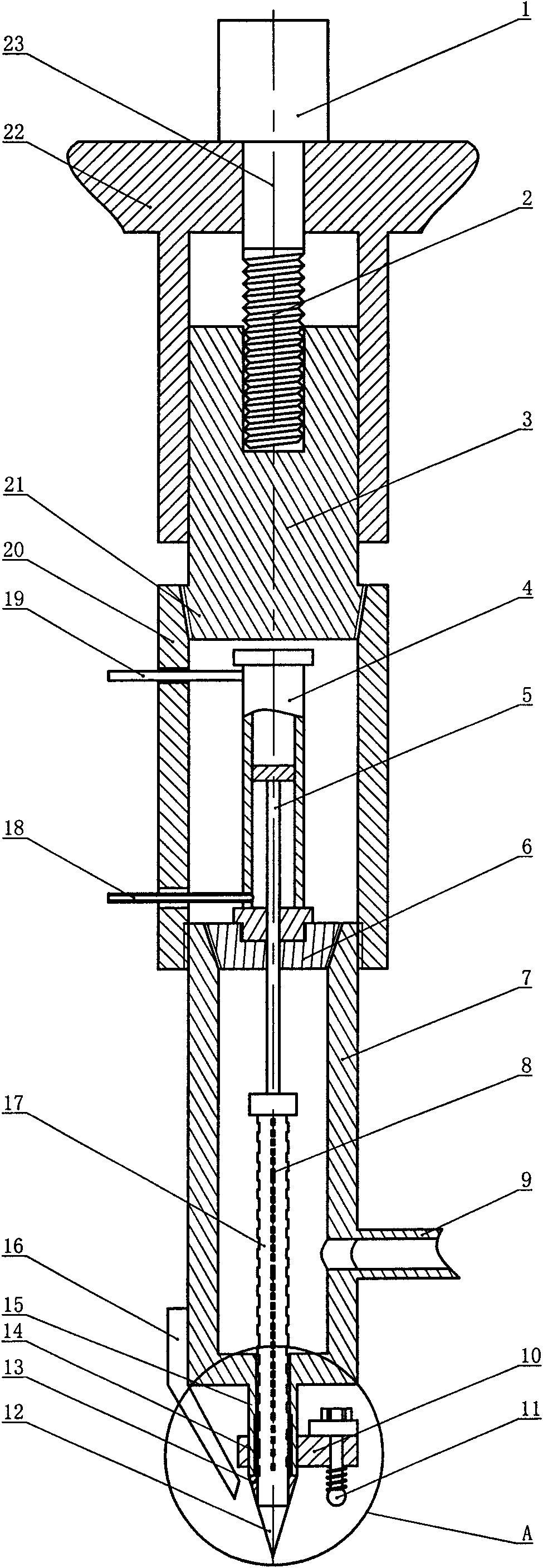

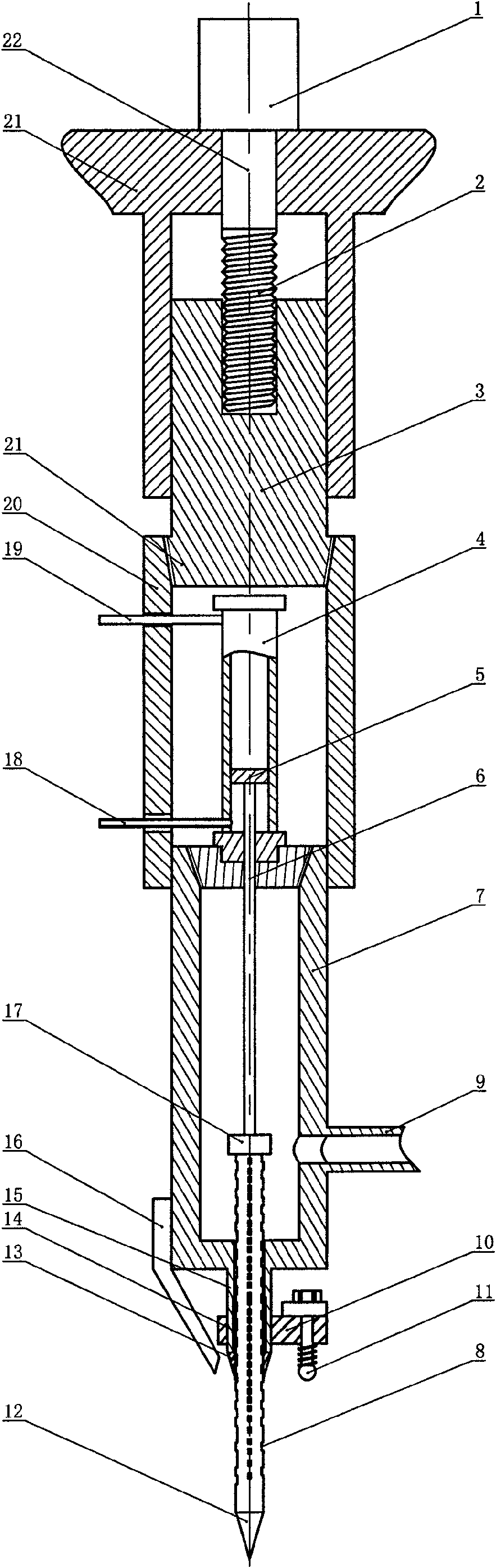

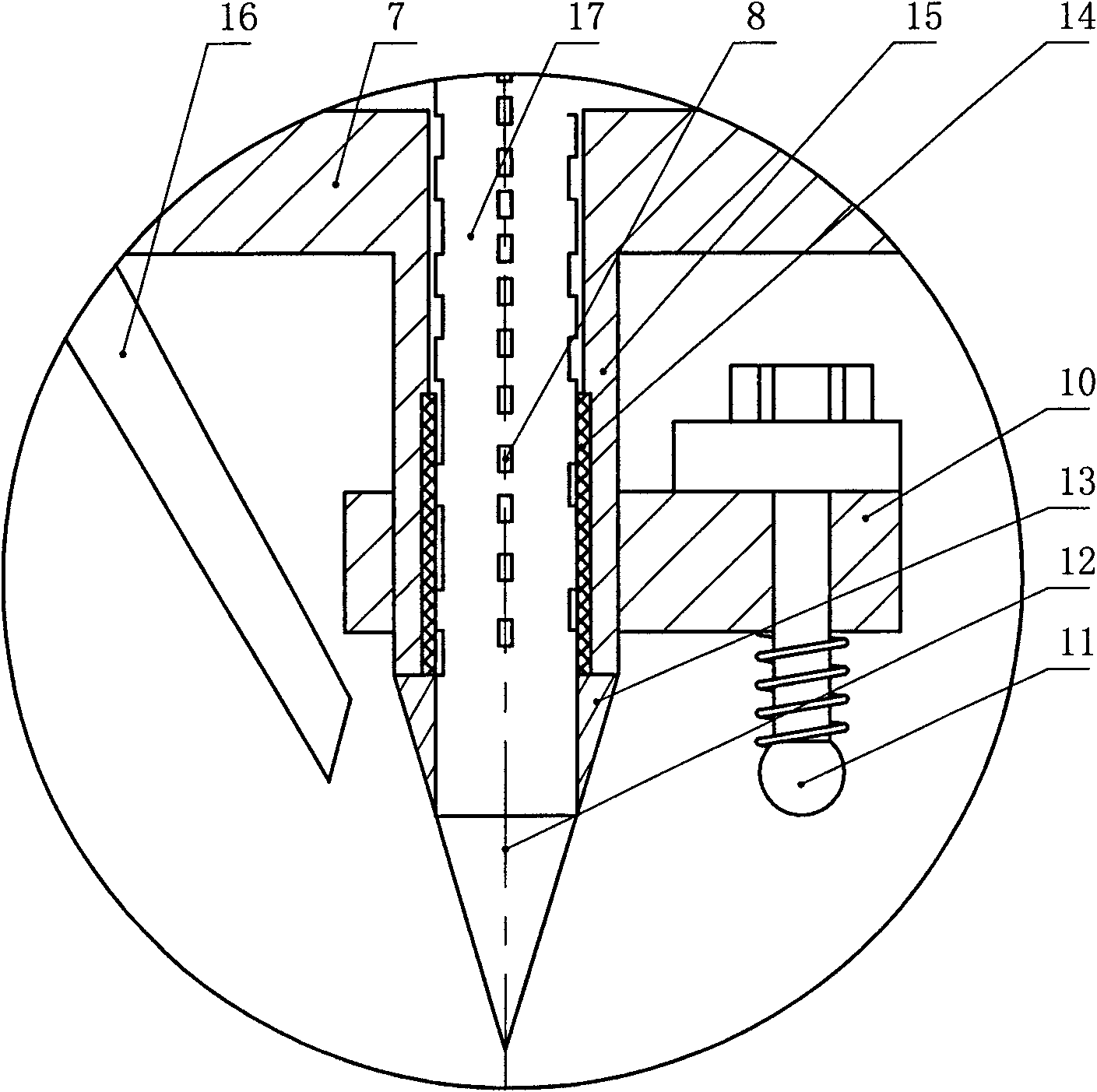

[0026] An injection device for fat injection of fat cattle, which is mainly composed of a slider 3, a motor 1, a screw 2, an upper sleeve 22, a middle sleeve 20, a lower sleeve 7 and an injection needle. The slider is placed on the upper sleeve Inside, the upper end is fixed by the output shaft 23 of the motor fixed on the upper end of the upper sleeve and the screw rod. The motor is a stepping motor. A taper thread 21 is formed at the lower end of the slider to connect with the upper end of the middle sleeve. The inner wall of the lower end of the middle sleeve is connected with the outer wall of the upper end of the lower sleeve by threads. A cylinder 4 is arranged in the middle sleeve. The cylinder is a linear cylinder. The two vent pipes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com