Patents

Literature

177results about How to "Improve injection quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

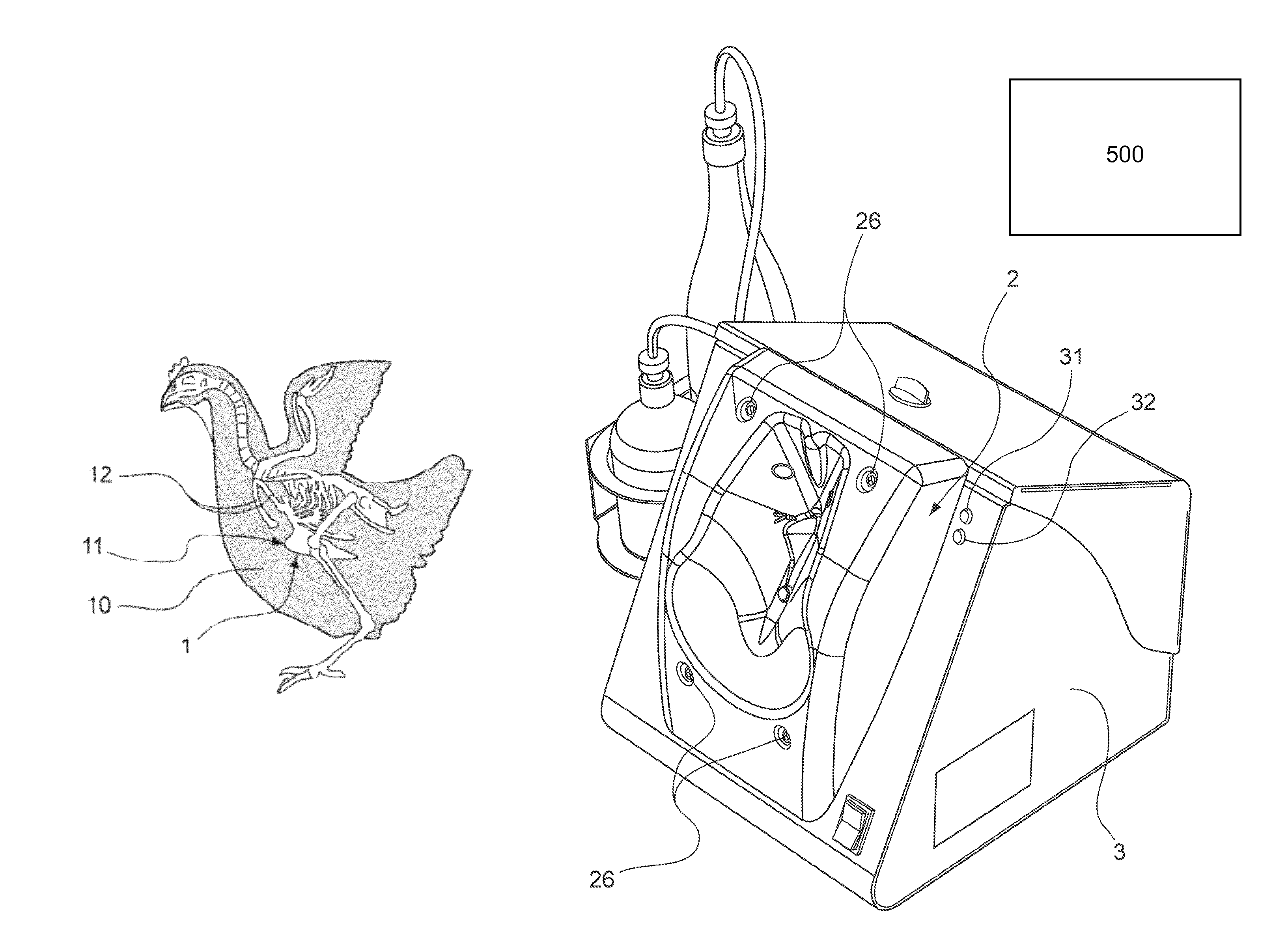

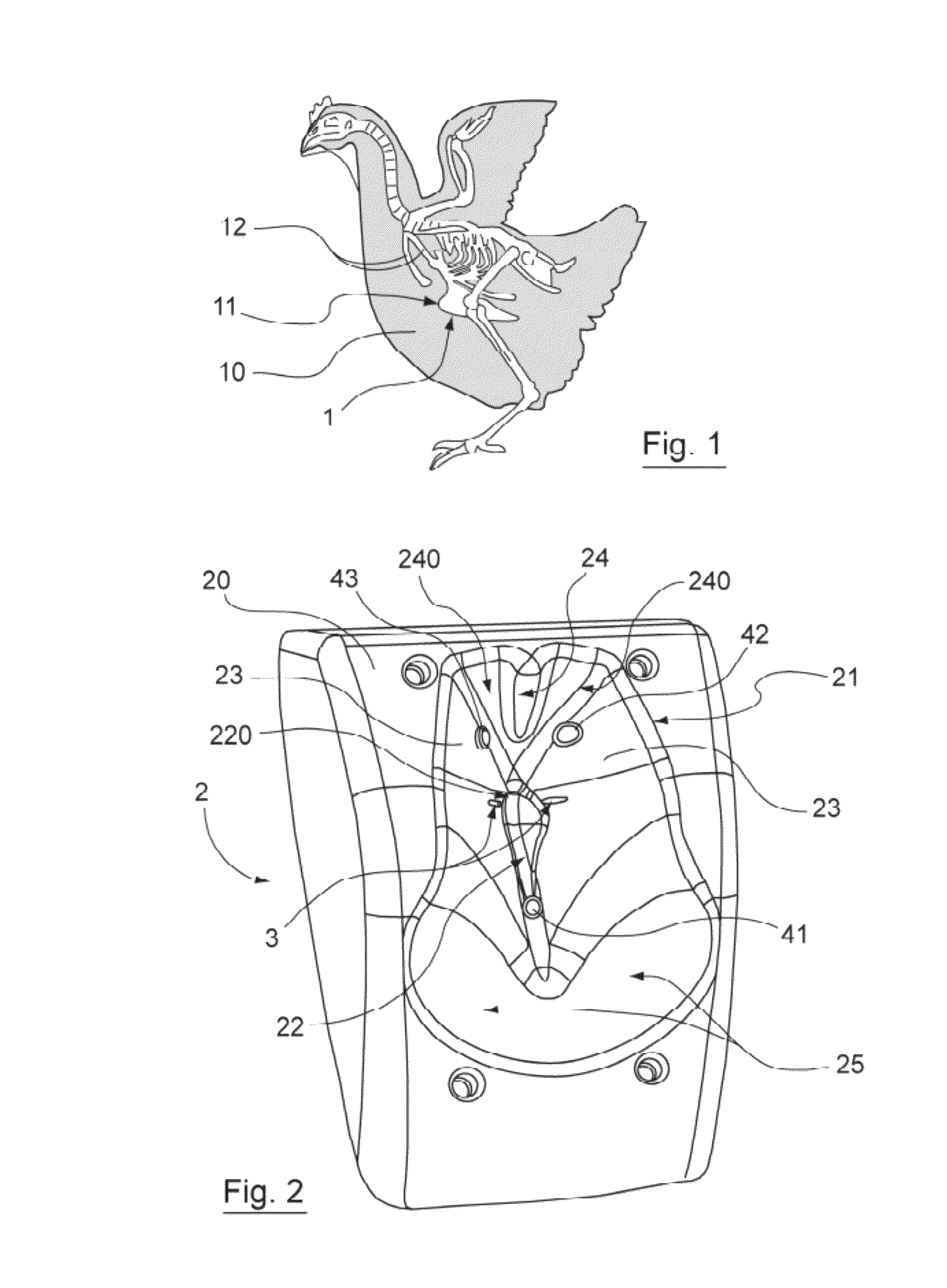

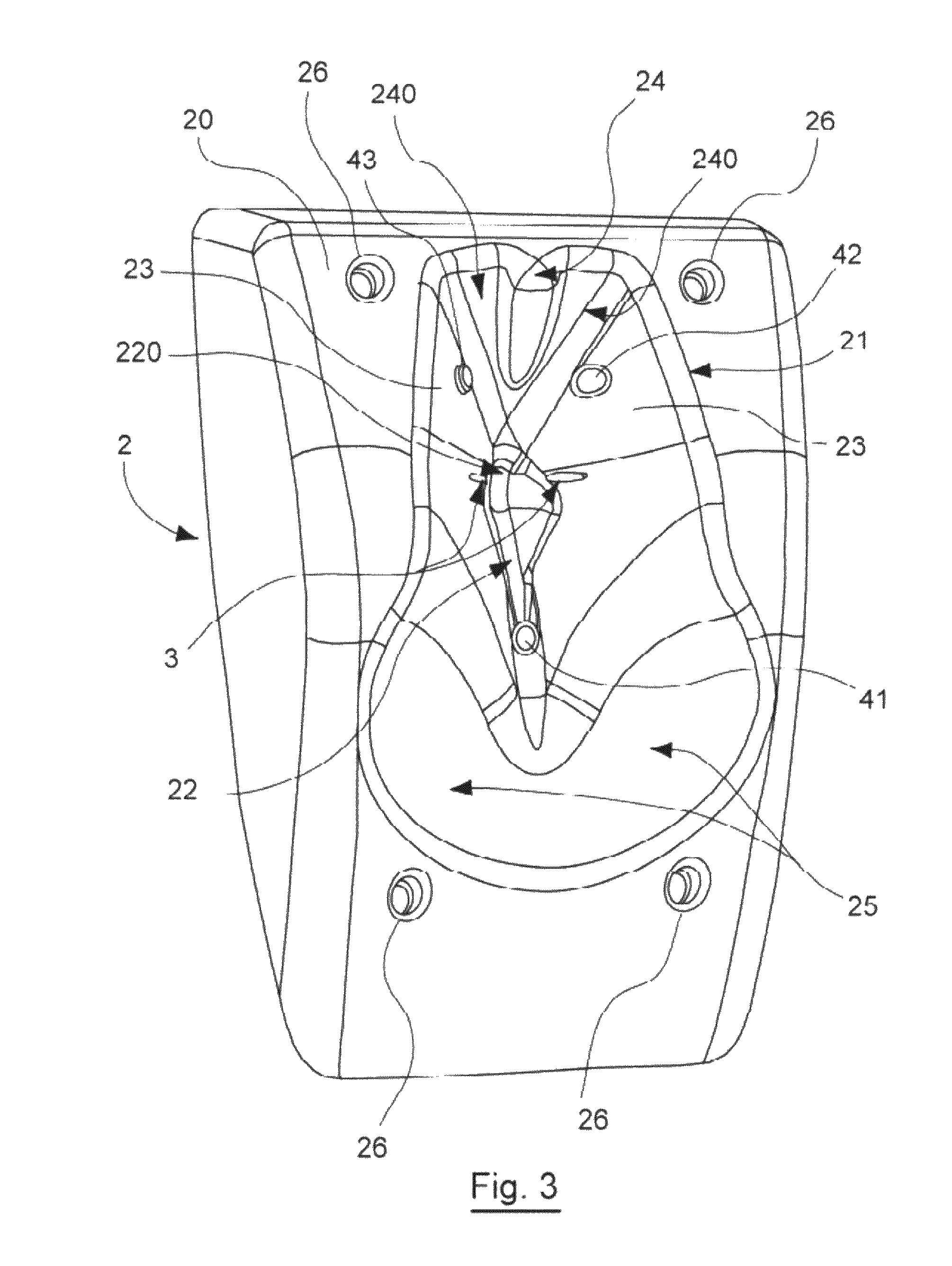

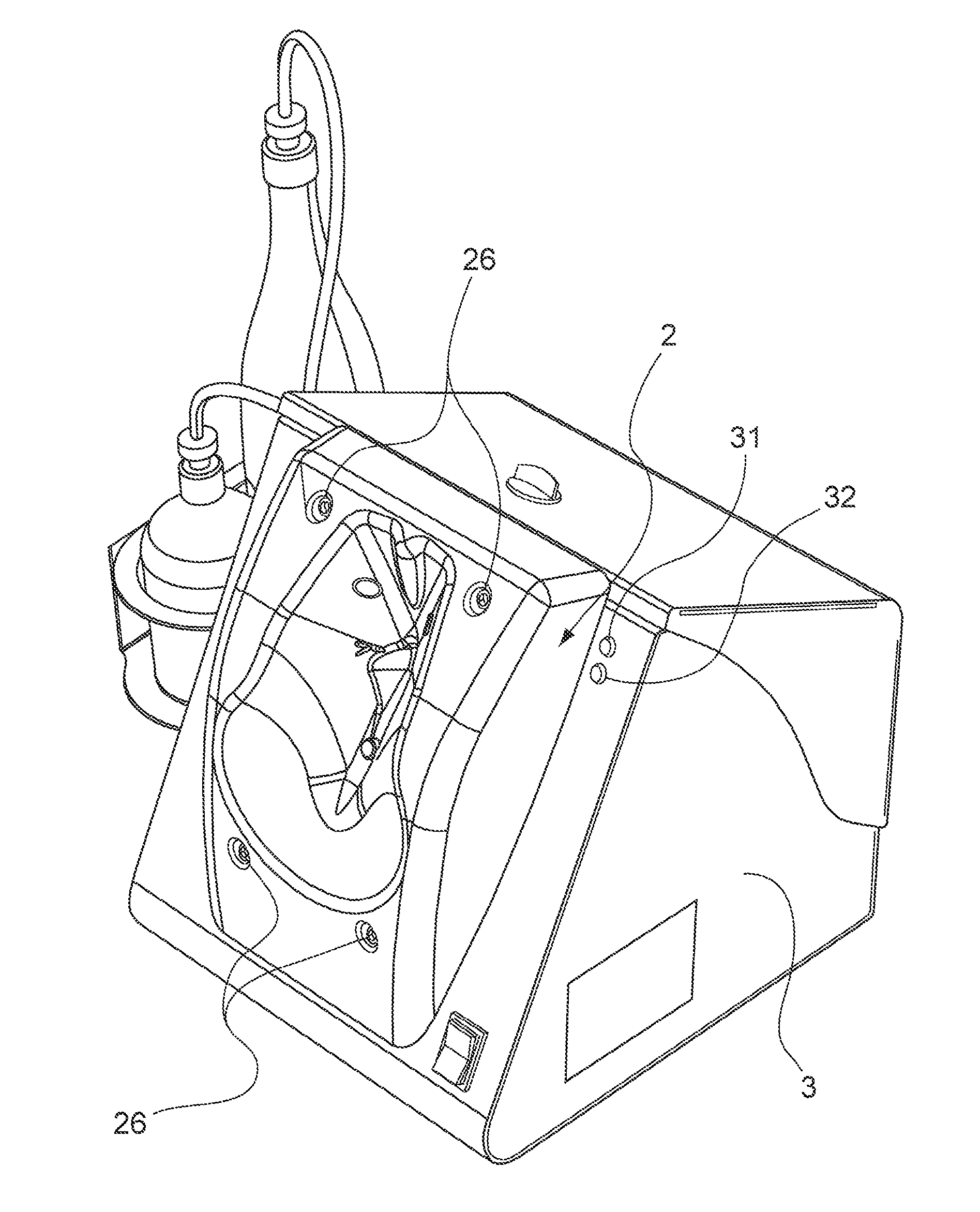

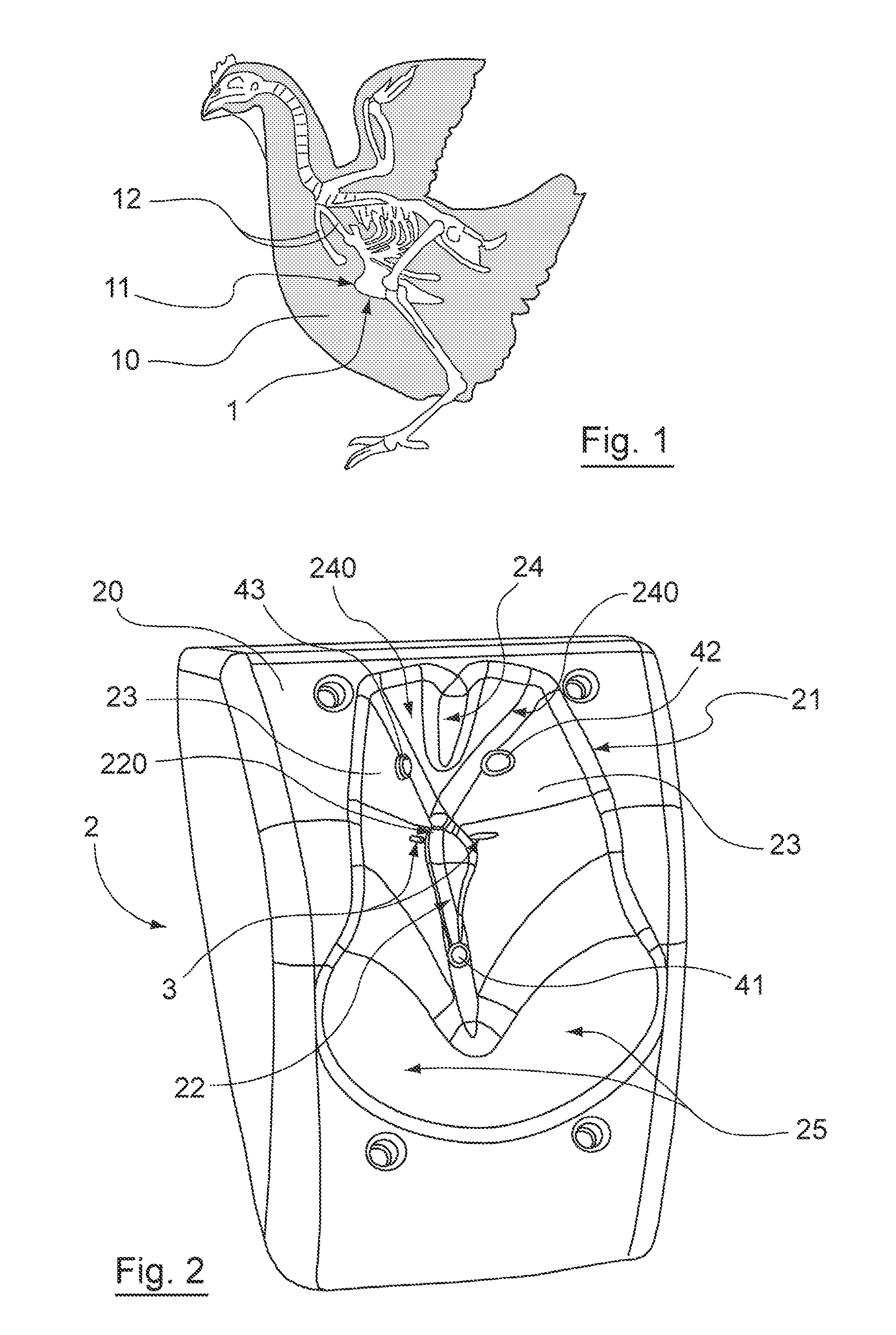

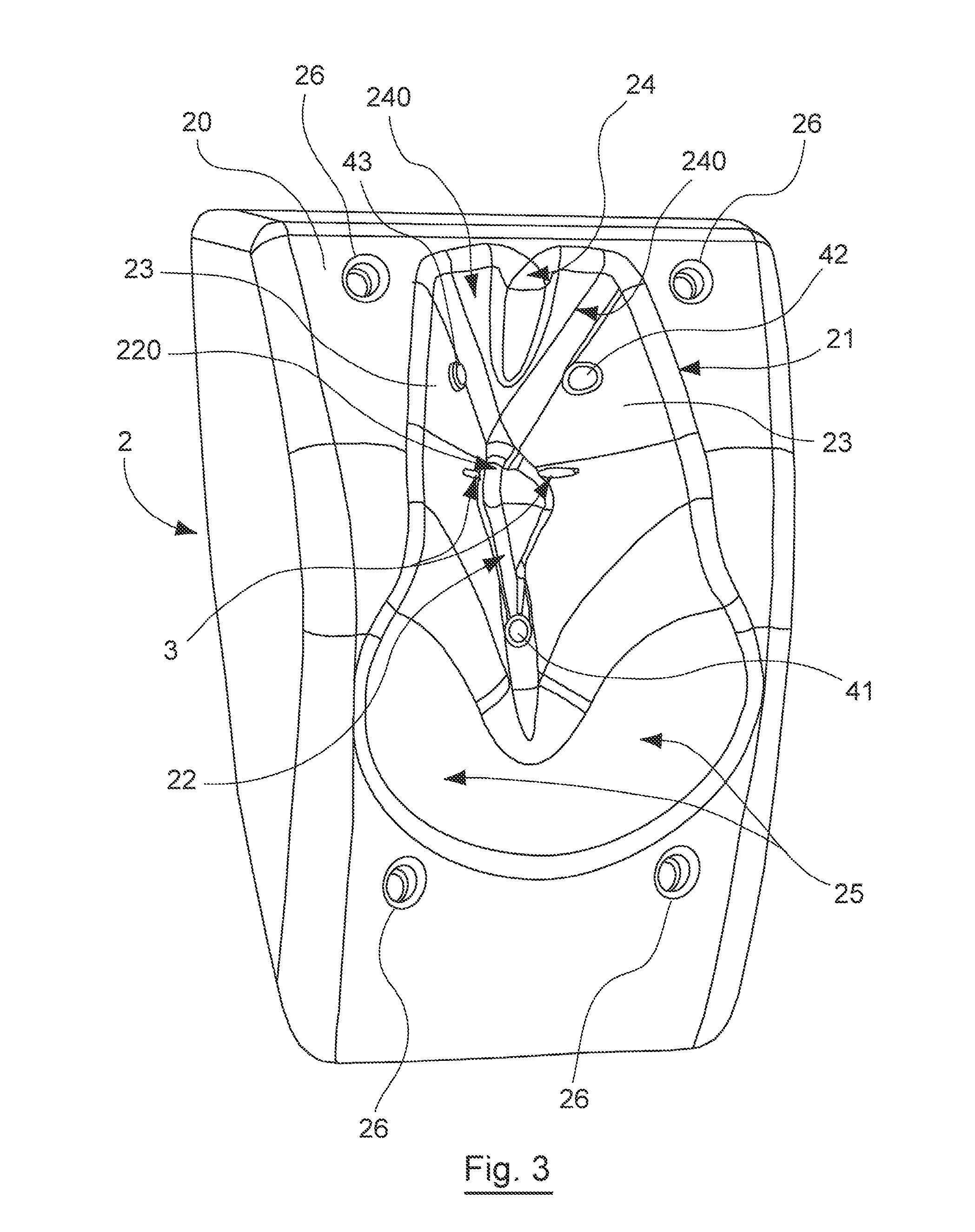

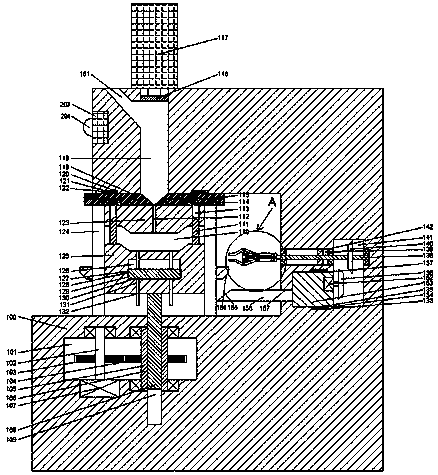

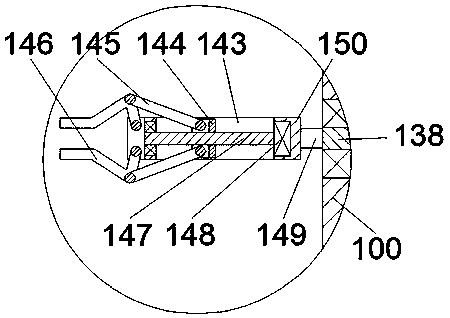

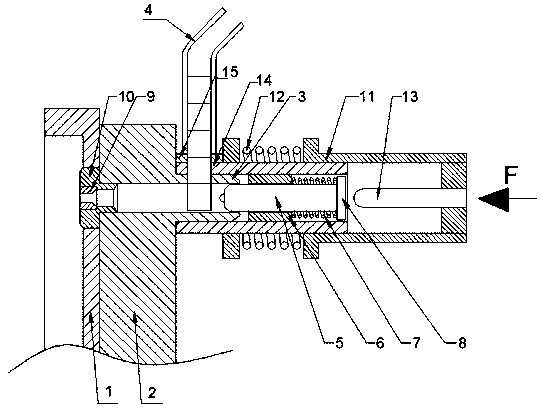

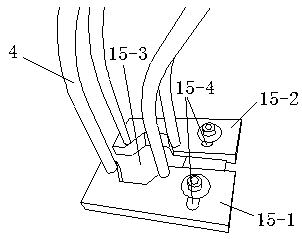

Device for injecting veterinary products to poultry including a retention member having an anatomic form with means for bracing a detectable bone

ActiveUS8211058B2Improve injection qualityAdvantageous for vaccinatingCannulasAutomatic syringesAnimal scienceIntramuscular injection

The invention relates to a device for injecting veterinary products to at least one bird by intramuscular injection, wherein said injection(s) can be carried out in the area of at least one muscle in the vicinity of a bone having a detectable shape in the body of said poultry, said device comprising: a retention member with means for bracing said detectable bone, at least one hole being formed in said retention member; at least one injection needle, said needle(s) being movable across said opening(s); characterized in that the retention member has: an anatomic shape that conforms to a portion of the body of said poultry and inside which is provided said means or bracing the detectable bone, said anatomic shape including a bearing surface for said body at said muscle; at least two contact sensors to be actuated by said poultry and provided on the anatomic shape with at least one on the bearing surface, said opening(s) being provided between said sensors.

Owner:DESVAC

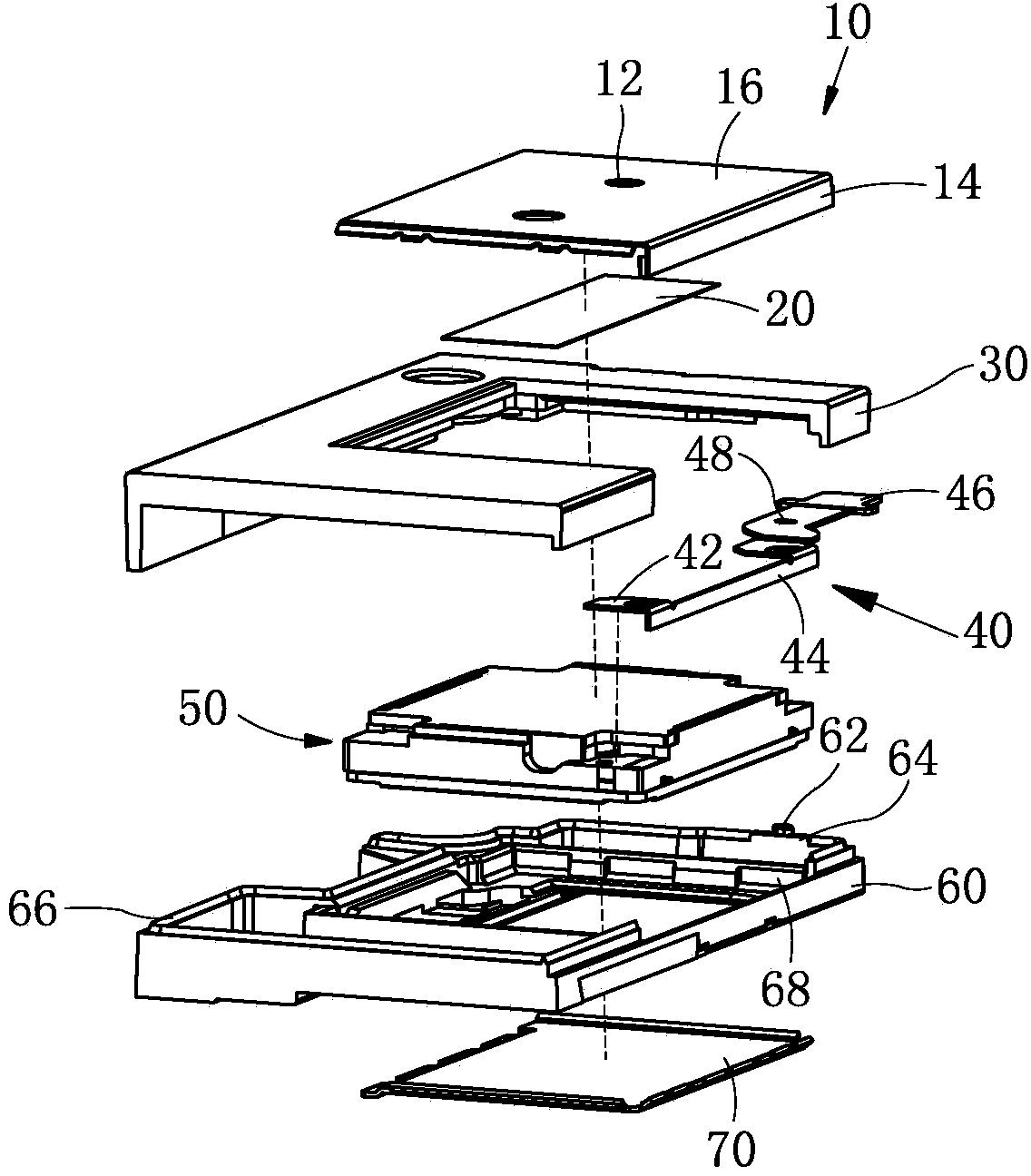

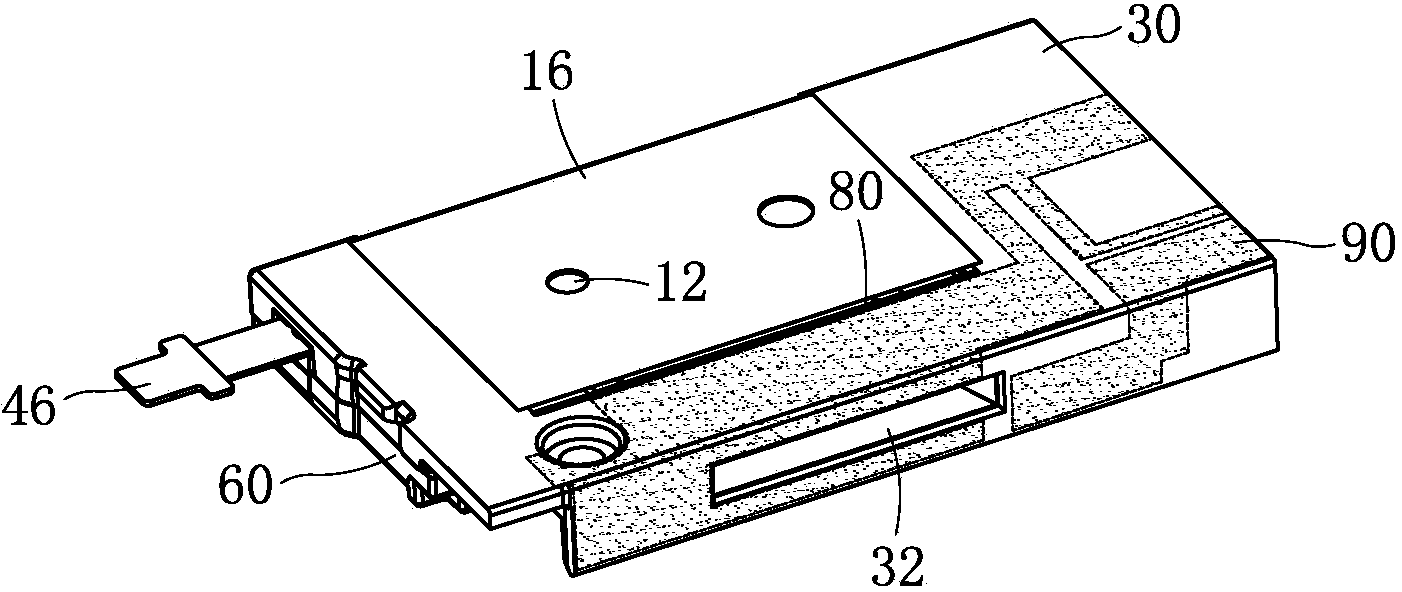

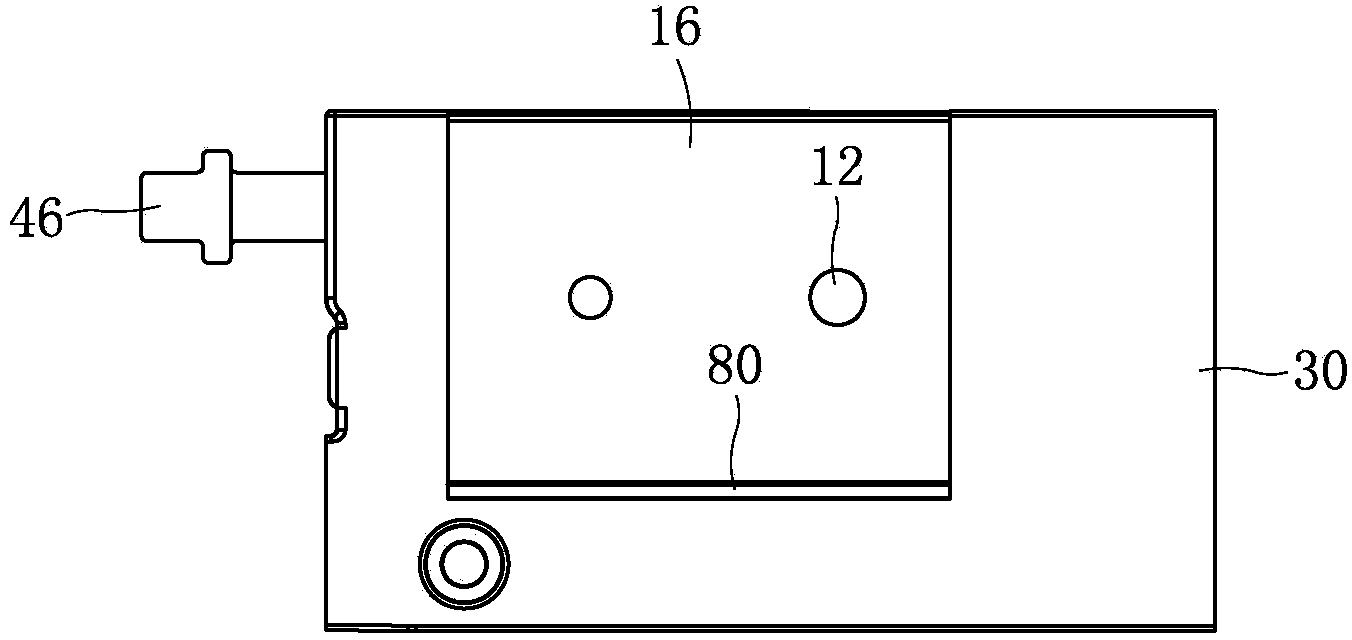

Loudspeaker module and assembly method thereof

ActiveCN104185126AAchieve conventional sealingAcoustic performance is not degradedElectrical transducersInterior spaceEngineering

The invention discloses a loudspeaker module and an assembly method of the loudspeaker module and relates to the technical field of electro-acoustic products. The loudspeaker module comprises an upper module shell and a lower module shell, wherein the upper module shell and the lower module shell are combined together. A loudspeaker monomer is contained in a space defined by the upper module shell and the lower module shell. An upper shell steel disc is combined with the position, corresponding to the loudspeaker body, of the upper module shell through injection molding. The upper shell steel disc includes a steel disc body. The side, located on the edge of the module, of the steel disc body is connected with a steel disc side extending to the lower module shell. The steel disc side and the steel disc body are formed by bending the same steel disc. The steel disc side forms the side wall of the module. According to the loudspeaker module and the assembly method of the loudspeaker module, the internal space of the module is effectively saved, the design is reasonable, the problem that in the prior art, the structural design of a loudspeaker module is affected by an LDS antenna clearance area is well solved, and therefore the loudspeaker module and the assembly method of the loudspeaker module are suitable for wide popularization in the industry of loudspeaker modules and other relevant industries.

Owner:GOERTEK INC

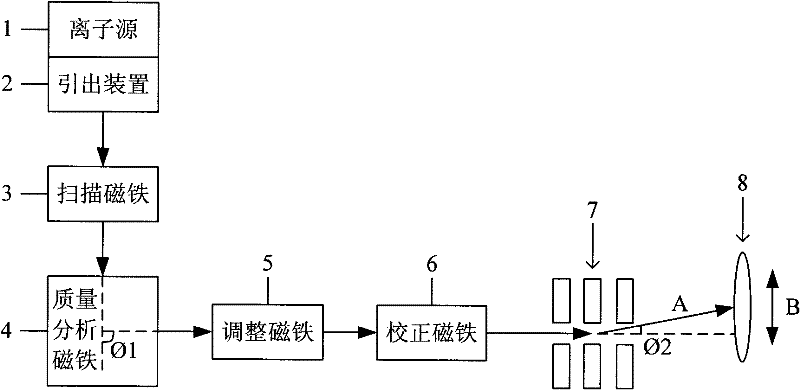

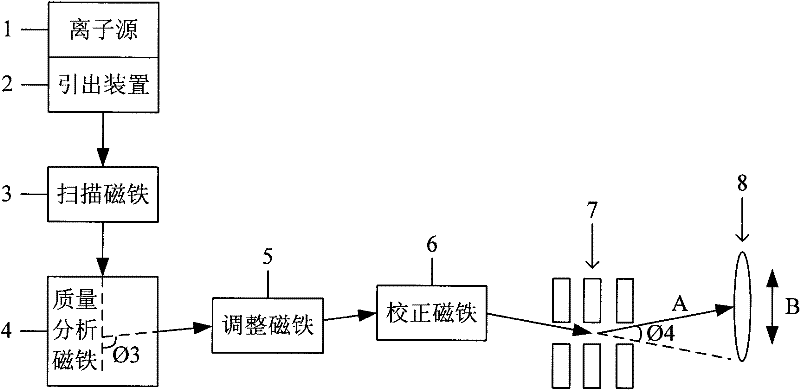

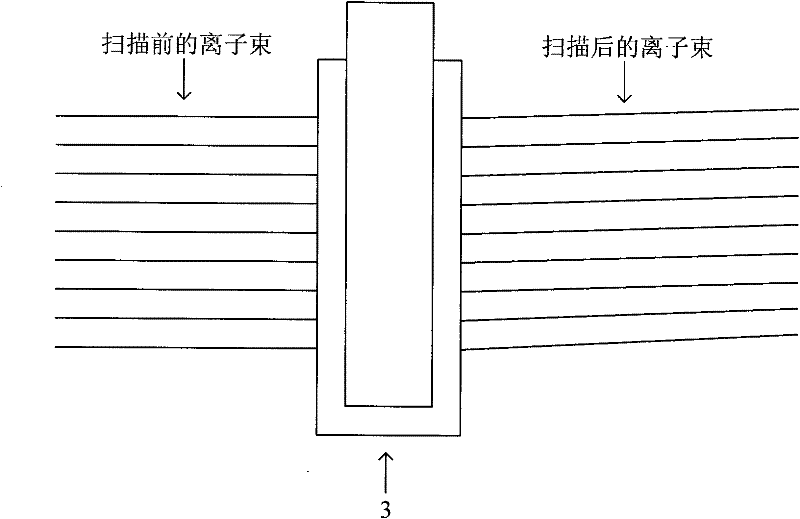

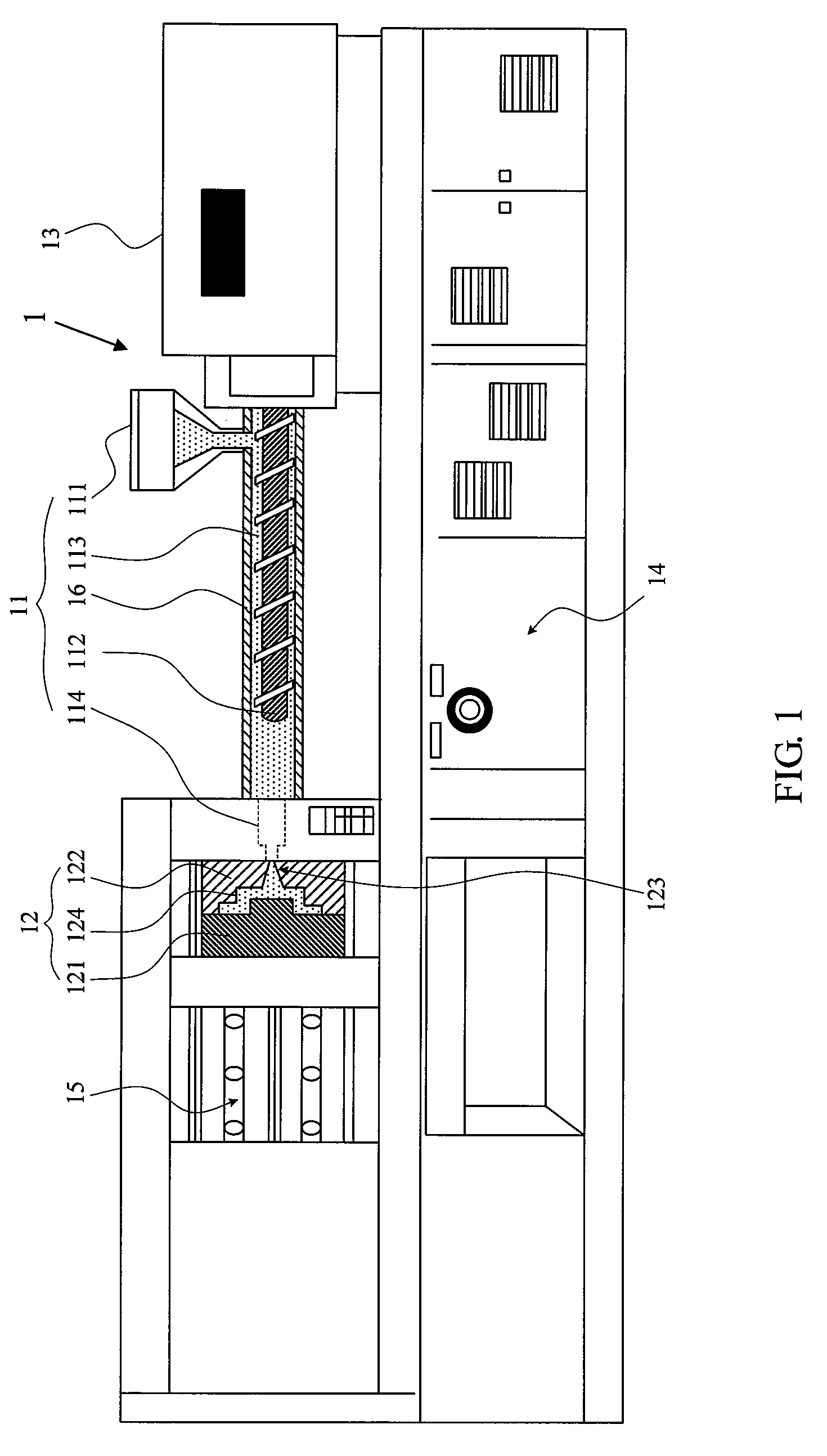

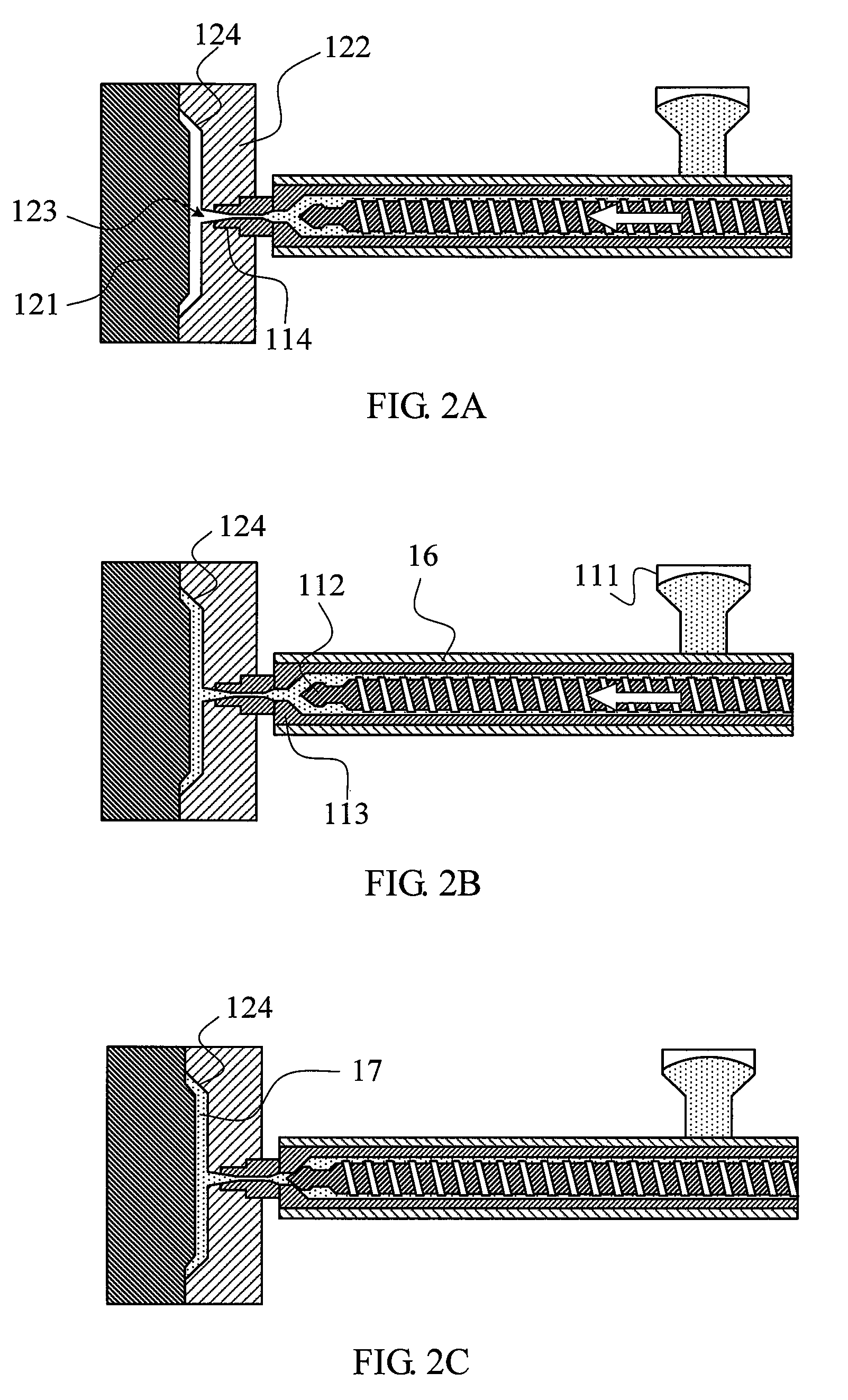

Ion implantation system and method

ActiveCN102237243AReduce hysteresisReduce design sizeElectric discharge tubesSemiconductor/solid-state device manufacturingDose uniformityIon beam

The invention discloses an ion implantation system comprising an ion source and a leading-out device, wherein a scanning magnet, a mass analysis magnet, a correcting magnet, a speed changing device and a workpiece scanning device are arranged on a transmission path of an ion beam current in sequence; the system also comprises an adjusting magnet arranged on a beam current transmission path between the mass analysis magnet and the correcting magnet; and the adjusting magnet is used for diverging or gathering beam currents in the scanning direction. The invention also discloses an ion implantation method realized by using the ion implantation system. According to the invention, lower energy consumption and higher beam current utilization efficiency are obtained so that the production efficiency can be largely enhanced; in addition, the ion implantation system and method, disclosed by the invention, are also beneficial for optimizing the dose uniformity and the angle uniformity of the beam currents.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

Device for injecting veterinary products to poultry including a contention member having an anatomic form with means for bracing a detectable bone

ActiveUS20110054401A1Improve injection qualityAdvantageous for vaccinatingCannulasAutomatic syringesIntramuscular injectionBearing surface

The invention relates to a device for injecting veterinary products to at least one bird by intramuscular injection, wherein said injection(s) can be carried out in the area of at least one muscle in the vicinity of a bone having a detectable shape in the body of said poultry, said device comprising: a retention member with means for bracing said detectable bone, at least one hole being formed in said retention member; at least one injection needle, said needle(s) being movable across said opening(s); characterized in that the retention member has: an anatomic shape that conforms to a portion of the body of said poultry and inside which is provided said means or bracing the detectable bone, said anatomic shape including a bearing surface for said body at said muscle; at least two contact sensors to be actuated by said poultry and provided on the anatomic shape with at least one on the bearing surface, said opening(s) being provided between said sensors.

Owner:DESVAC

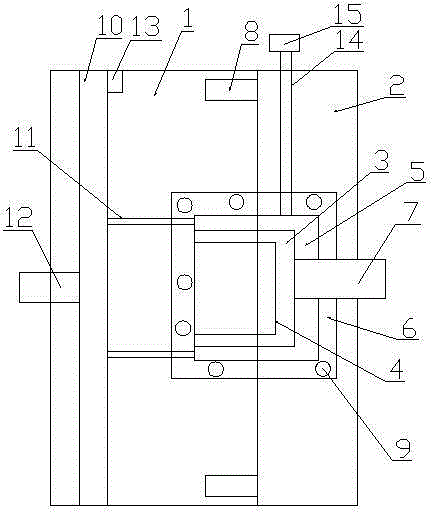

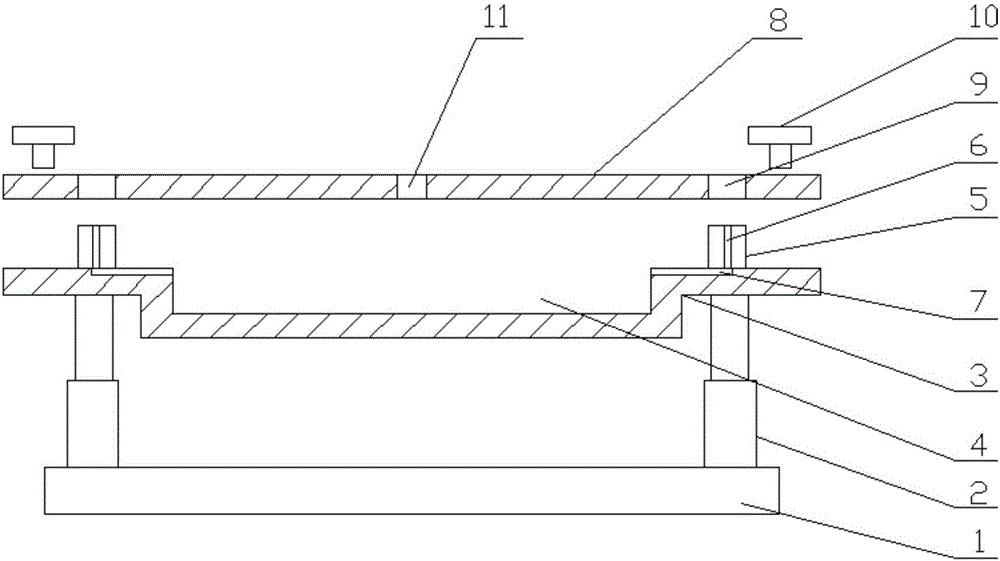

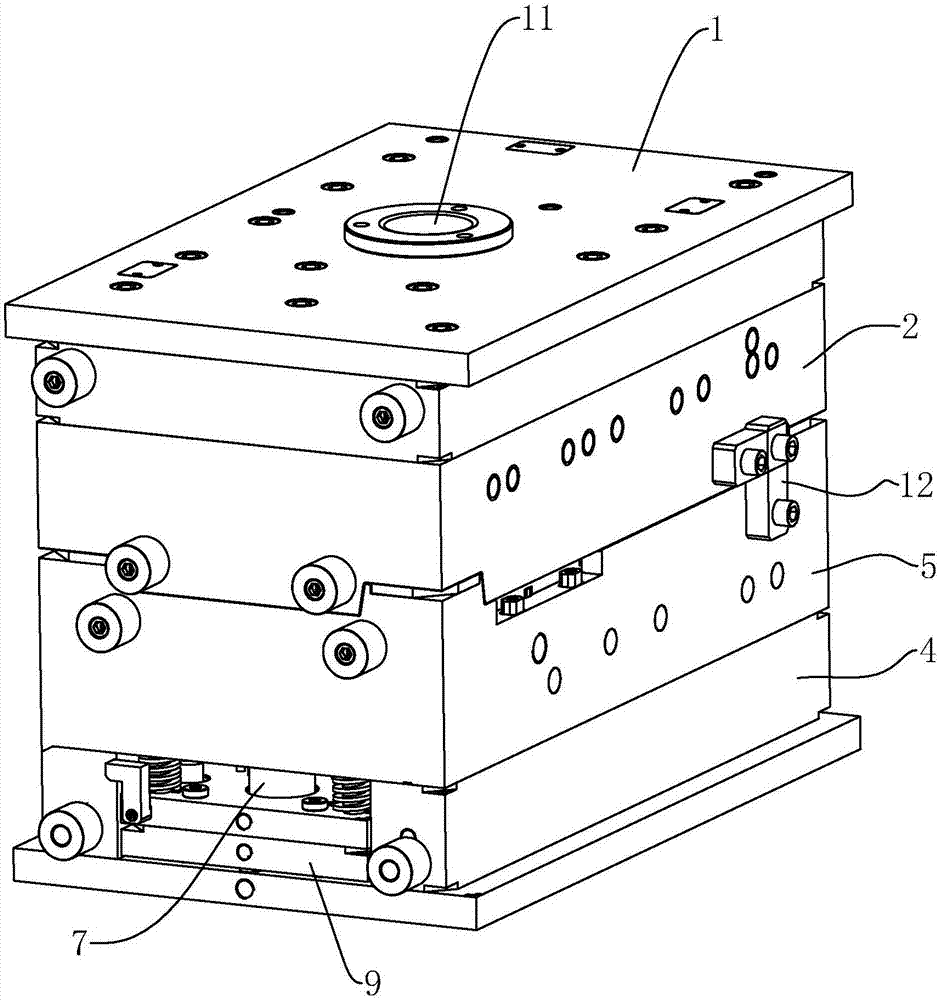

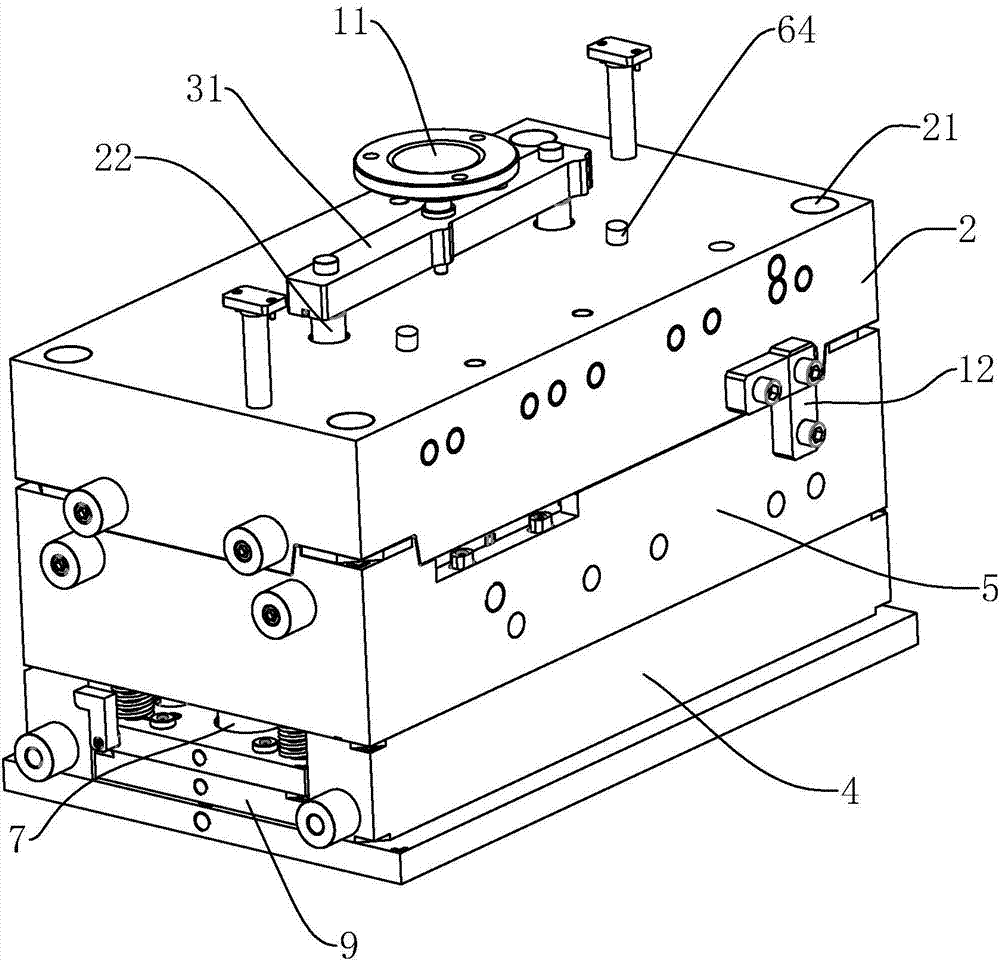

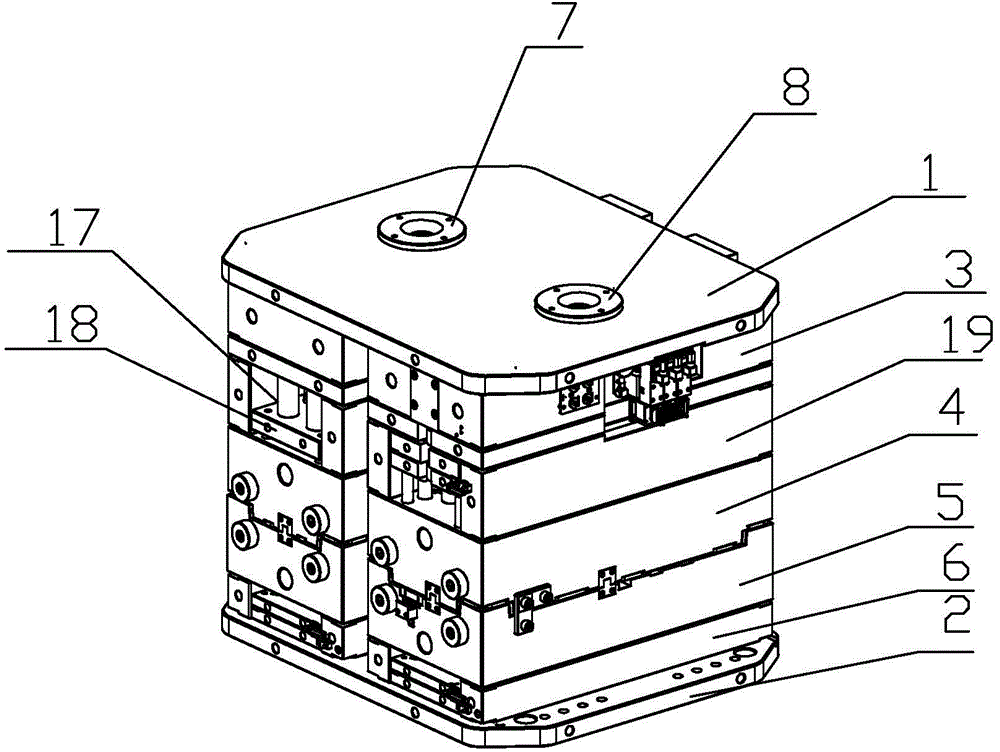

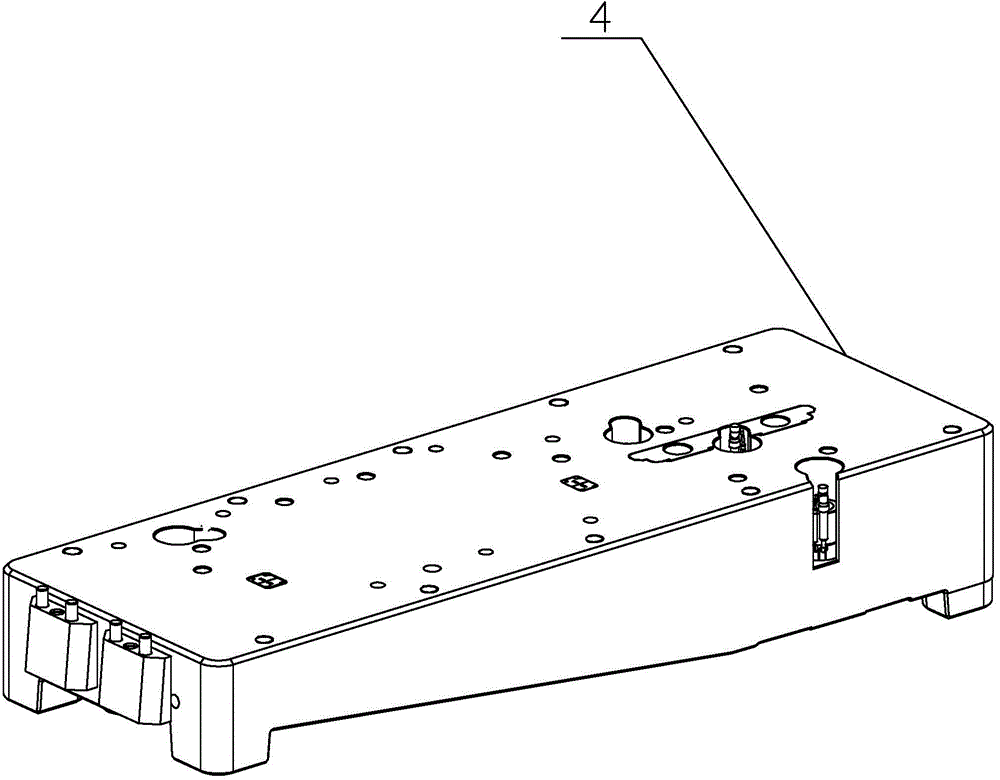

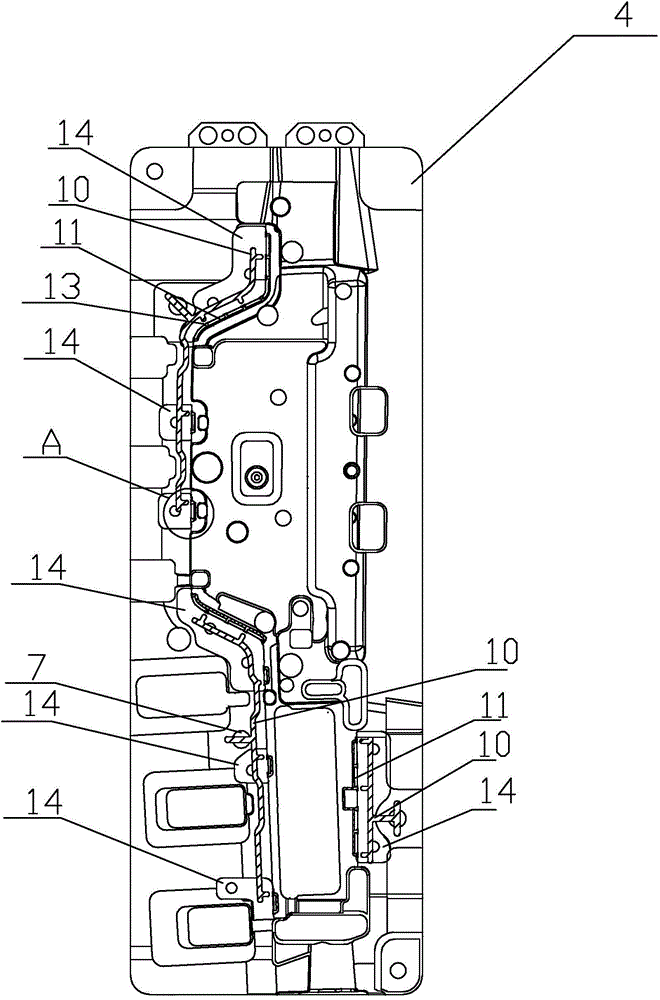

Injection mold

The invention discloses an injection mold. The injection mold comprises a machine body and a first cavity with a leftward opening, wherein the first cavity is arranged in the machine body; a lower sub-mold capable of sliding up and down is arranged in the first cavity, and first through holes with the upper part communicating with the lower part is formed in the lower sub-mold in a left-right symmetry and front-back symmetry mode, and first sliding rods which extend up and down are installed in the first through holes in a sliding fit mode; and the upper ends and the lower ends of the first sliding rods are fixedly connected to the upper end wall and the lower end wall of the first cavity correspondingly, a first sliding cavity is formed in the lower sub-mold, and a first sliding block isarranged in the first sliding cavity in an up-down sliding mode. According to the injection mold, structure is simple, the problem that mold stripping of the device is difficult is solved through an ejection mechanism, the automatic mold taking of the device is realized by utilizing a clamping device, the working procedures are coordinated with one another and are not affected by one another, labor cost is reduced, and meanwhile, the safety of the device is improved; and the device is automatic in the whole process, operation errors are reduced, the injection molding efficiency and the qualityare improved, and the practical performance of the device is improved.

Owner:宁波美丁模塑有限公司

Die for injection molding of insulating framework

The invention aims at providing a die for injection molding of an insulating framework. A cavity is formed in a movable die and a fixed die for injection molding. The cavity is connected with a casting opening for casting of raw materials. A protruding block arranged in the cavity and a forming part arranged outside the cavity are used for molding the insulating framework together. A die temperature control part is arranged for controlling the temperature. The cavity is connected with an exhaust pipe for exhausting gas so that bubbles can be prevented from being generated in a product. After the product is molded, the product is ejected out through an ejecting rod, and the insulating framework can be well molded in an injection manner. The die is simple in structure and easy to operate, the insulating framework can be efficiently and rapidly molded in the injection manner, the injection molding quality is high, and the die is suitable for production.

Owner:WUHU WANHUA PLASTIC PROD

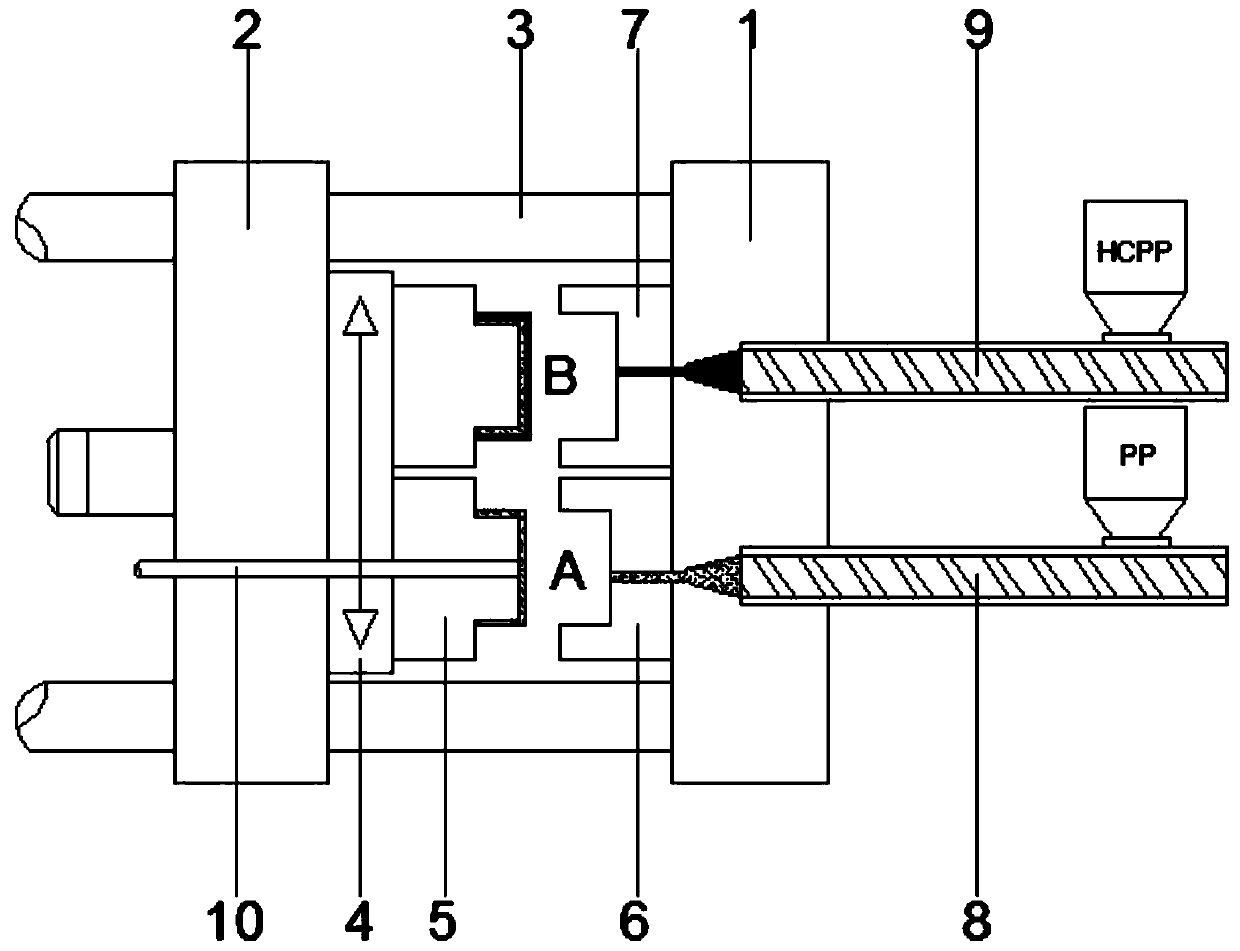

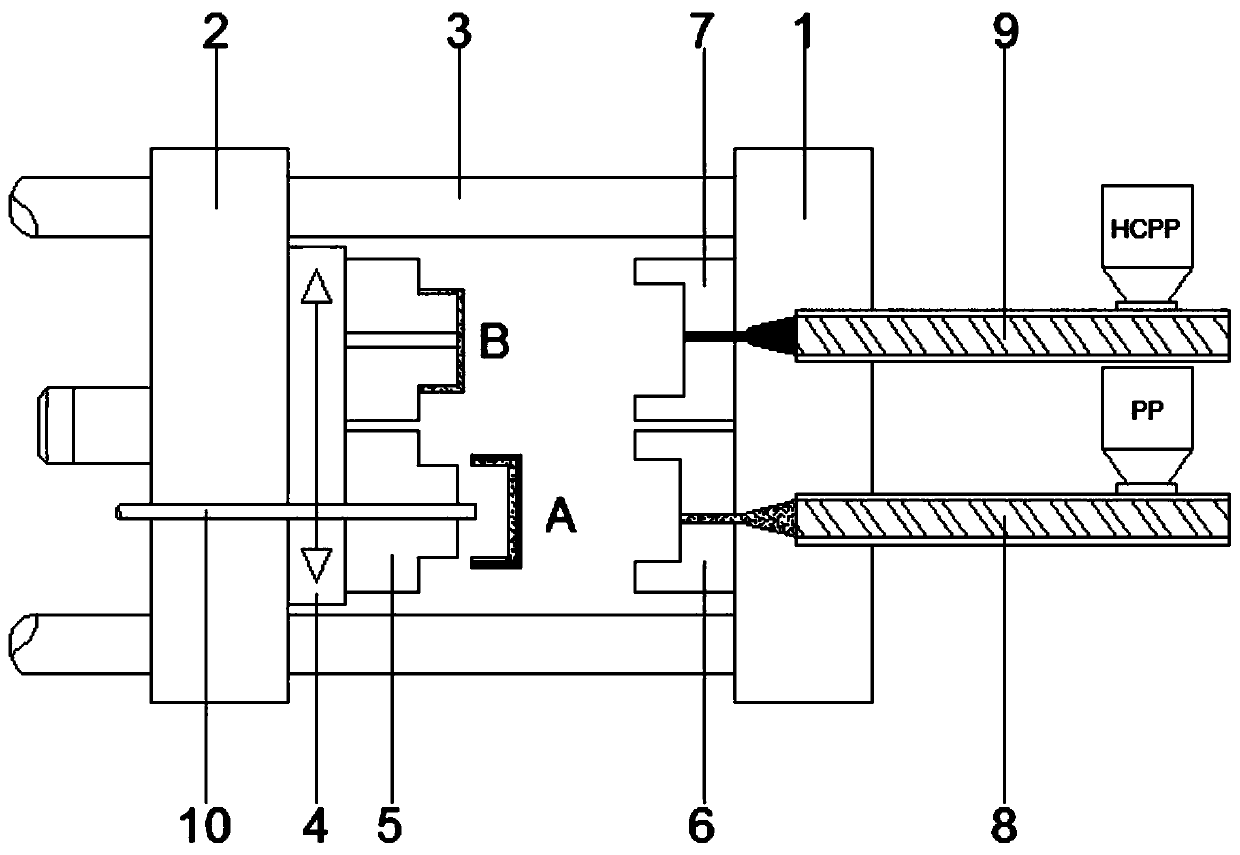

Rotary disc type double-color injection mold forming process

InactiveCN109732843AContinuous injection molding processImprove injection molding efficiencyCoatingsInjection mouldingInjection molding machine

The invention provides a rotary disc type double-color injection mold forming process. A rotary disc, a male mold core, a first female mold core and a second female mold core are involved; movable mold bases which are symmetrically installed along the central axis of a double-color injection molding machine is combined with a fixed mold base through the forward movement of a guide column, a firstinjection pipe is used for injecting a PP material into a first mold cavity A, the material temperature is controlled to be 235 DEG C, the injection molding time is 17.5-20 seconds, then the mold is opened, after the rotary disc is rotated by 180 degrees, the mold is closed again, the first injection pipe is used for injecting the PP material into the first mold cavity A, the material temperatureis controlled to be 235 DEG C, and the injection molding time is 17.5-20 seconds. Through the improvement of a structure, the rotary disc type injection mold forming process is provided, and has the advantages that the process is continuous, the injection molding efficiency is improved, the connectivity among product melts is high, and the product quality is improved, so that the problems and defects brought in the prior art are effectively solved.

Owner:苏州敏煌精密电子科技有限公司

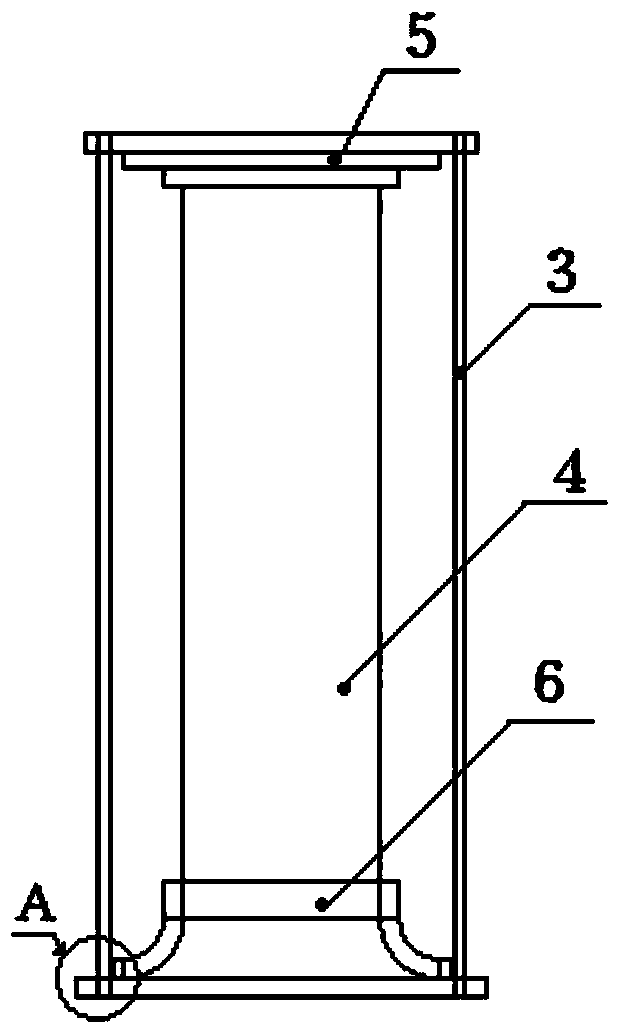

Glue injection and compaction fixture

InactiveCN103624722ASimple structureEasy to operateWork holdersMetal-working hand toolsEpoxyEngineering

The invention discloses a glue injection and compaction fixture which comprises an epoxy pipe, an upper flange and a lower flange, and further comprises an upper compaction plate, a lower compaction plate, pull rods and a base, wherein the upper compaction plate is of a square structure, a threaded hole is formed in the middle of the upper compaction plate, a groove is formed in each of two sides of the upper compaction plate, the upper flange is fixed on the lower plane of the upper compaction plate through bolts, the lower compaction plate is of a square structure, a base installing hole is formed in the middle of the lower compaction plate, grooves corresponding to the upper compaction plate are formed in two sides of the lower compaction plate, the base is fixed on an upper plane of the lower compaction plate through a bolt, the lower flange is positioned on the base, the epoxy pipe is arranged between the upper compaction plate and the lower compaction plate, and the pull rods are respectively arranged in the grooves in two sides and fixed by using regulating nuts. According to the glue injection and compaction fixture, the flanges are compacted by using the upper horizontal compaction plate and the lower horizontal compaction plate, are forced to keep horizontal, and then are tensioned by using the pull rods and the bolts, thus the total length of the glue injection and compaction fixture is controlled and no deformation of the glue injection and compaction fixture is kept in a glue injection process. The glue injection and compaction fixture has the advantages of simple structure, convenience in operation, and good glue injection quality.

Owner:山东彼岸电力科技有限公司

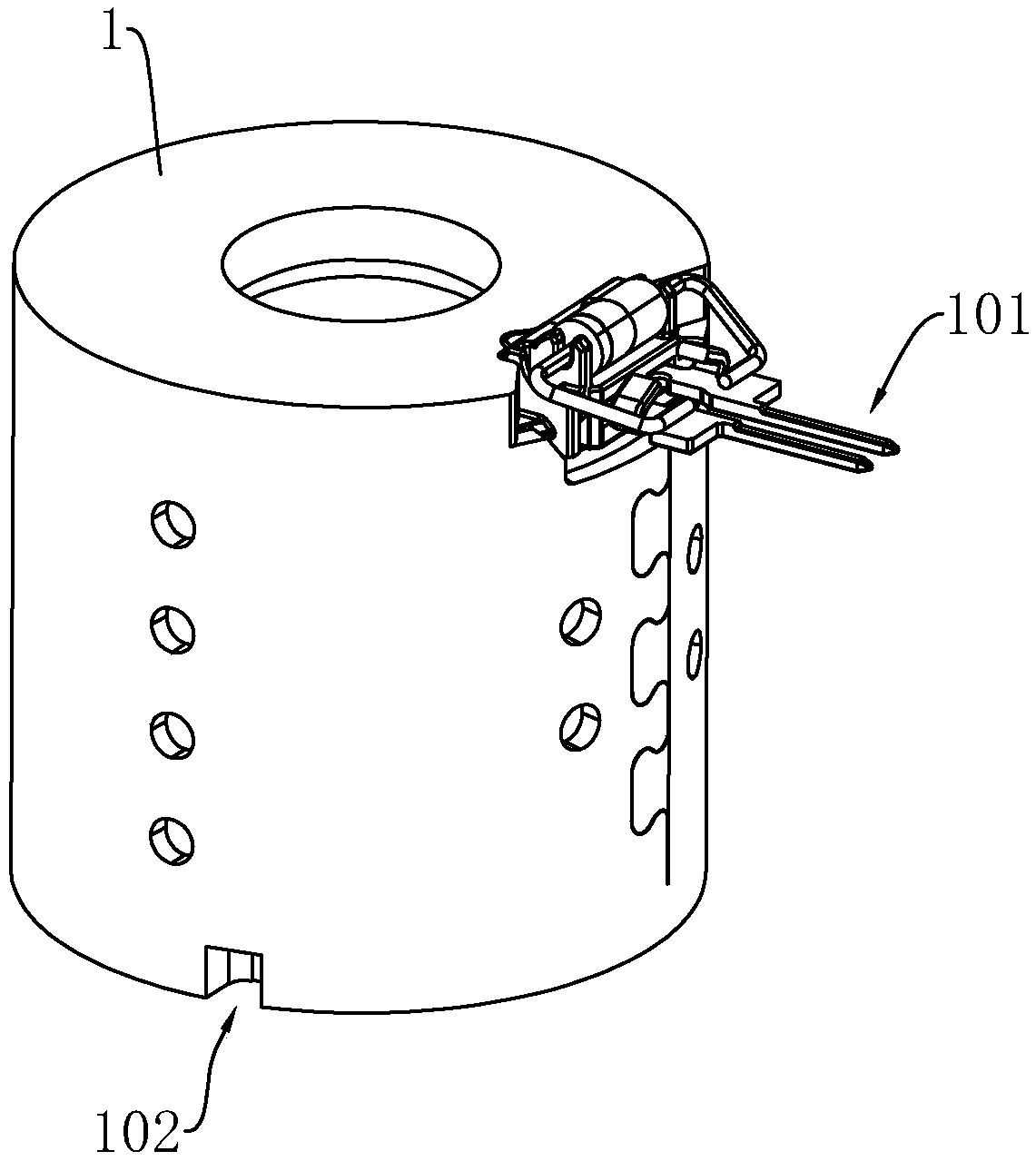

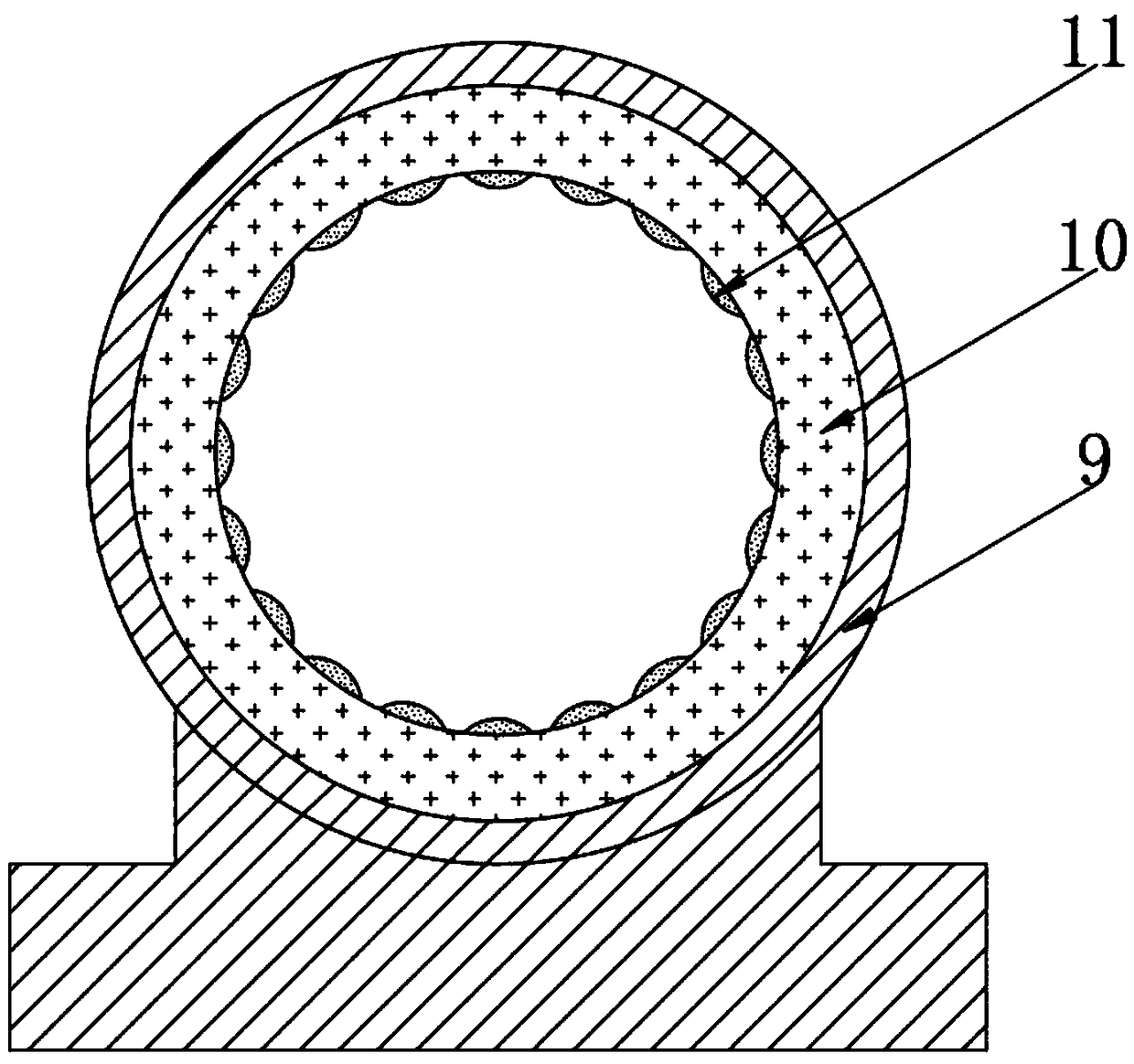

Injection-molding assembling process for magneto rotor

The invention belongs to the technical field of automatic assembling lines, and particularly relates to an injection-molding assembling process for a magneto rotor. The process includes the following steps of a, stamping a flywheel shell, b, placing a retaining ring in the flywheel shell, c, placing a magnetic shoe above the retaining ring in the flywheel shell, d, placing the flywheel shell provided with the retaining ring and the magnetic shoe in a mold of an injection molding machine, e, injecting rubber above the magnetic shoe for injection molding, and f, taking out a finished product from the injection molding machine and cooling the finished product. By means of the technical scheme, the retaining ring and the magnetic shoe can be placed in the flywheel shell according to a certain sequence, then the injection molding machine is used for direct injection molding after the rubber is injected, and manual brush coating and manual assembling are not needed.

Owner:重庆迈兴机电有限责任公司

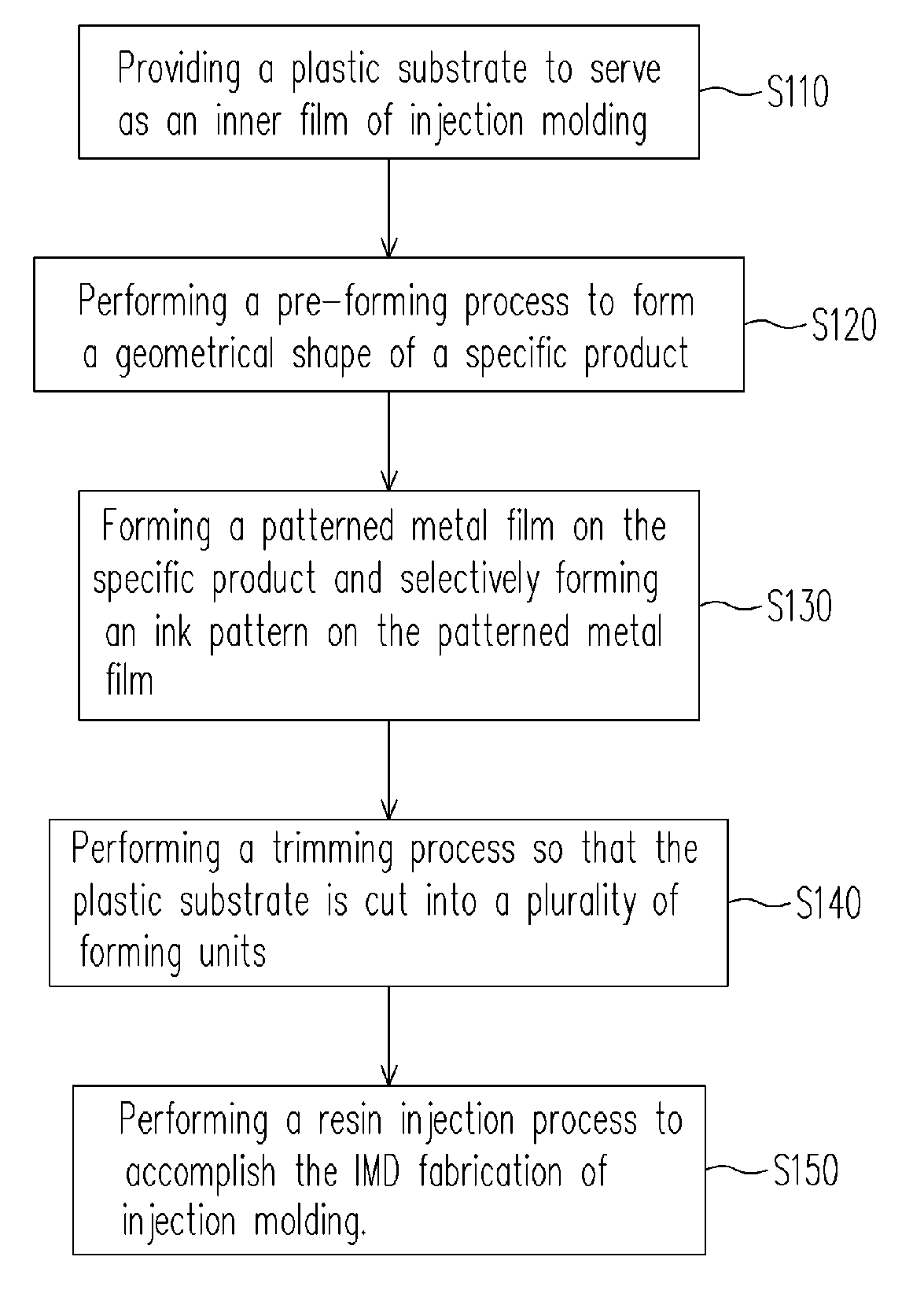

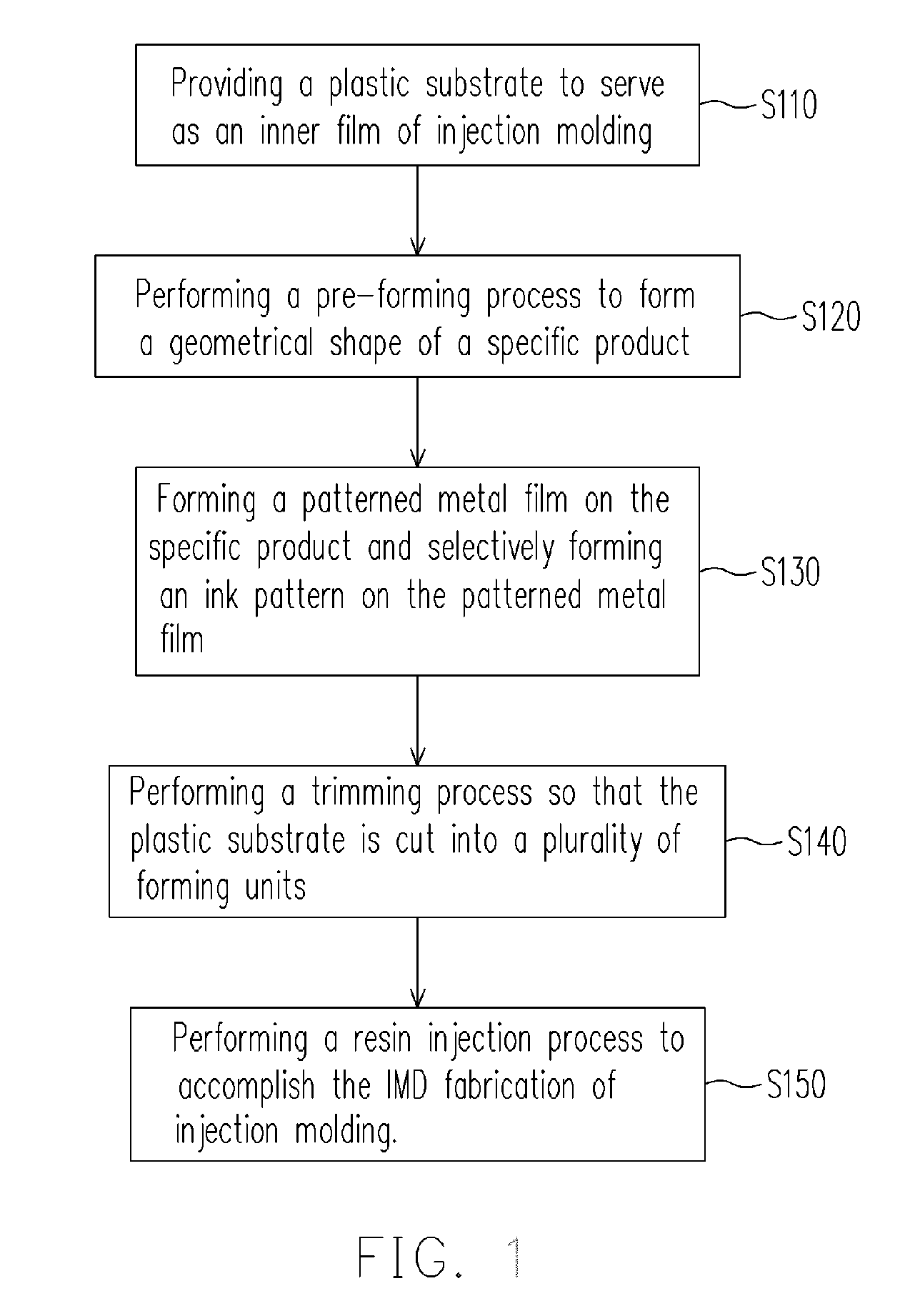

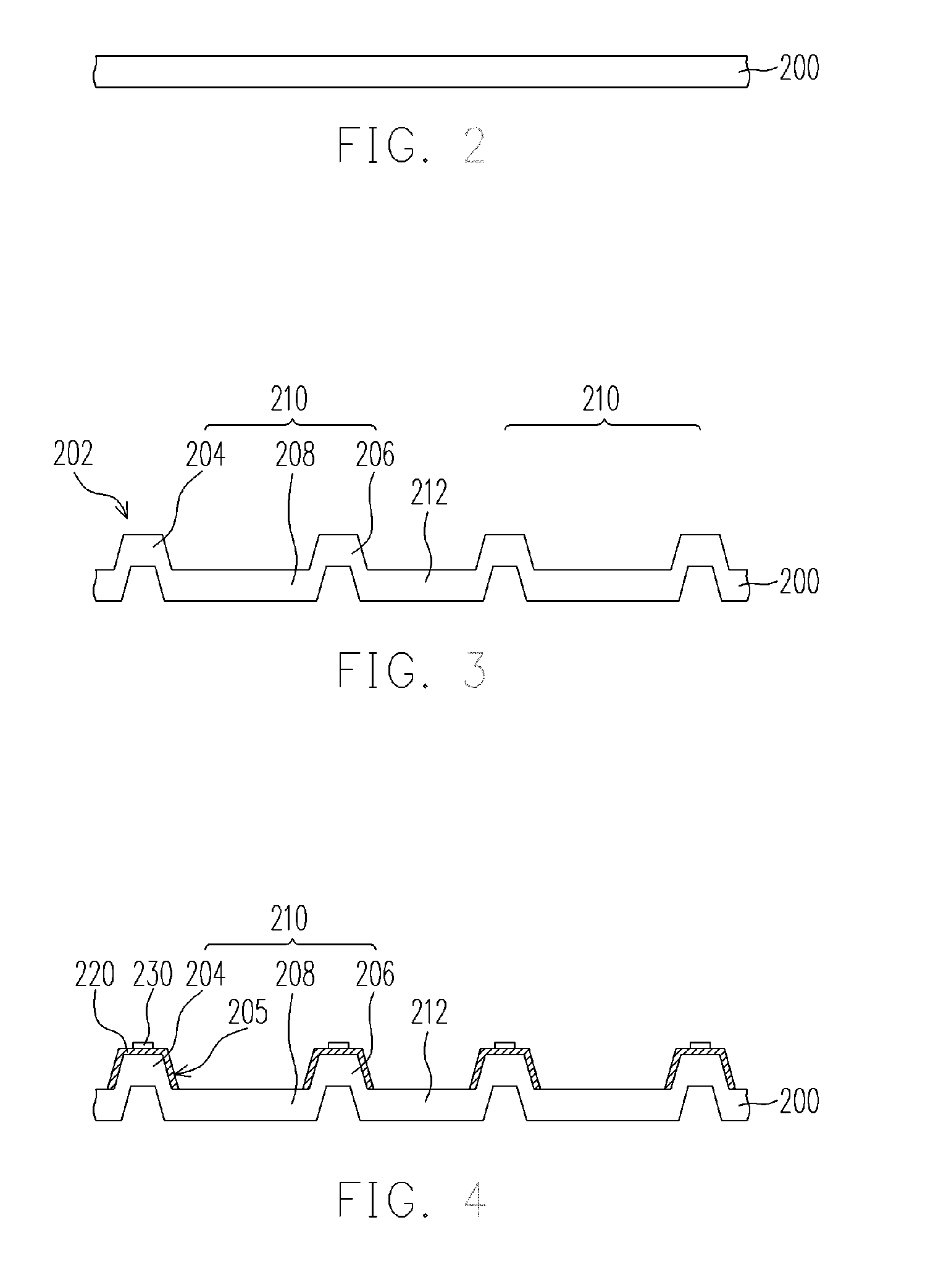

In-mold decoration fabrication of injection molding

InactiveUS20060214327A1Quality improvementSpeed up the processMouldsHollow wall articles3d shapesEngineering

An in-mold decoration fabrication of injection molding is provided as following: first, a plastic substrate is provided to perform a step of forming to form a geometric shape and / or 3D shape of a specific product on the plastic substrate; second, a patterned metal film is formed on the geometric shape of the specific product, and then an ink pattern is further formed on the patterned metal film selectively; next, a step of trimming is provided to cut the plastic substrate into a plurality of forming units; finally, a step of resin injection is provided to cover the patterned metal film, ink pattern of each of the forming units and the exposed surface thereof.

Owner:SPEED TECH

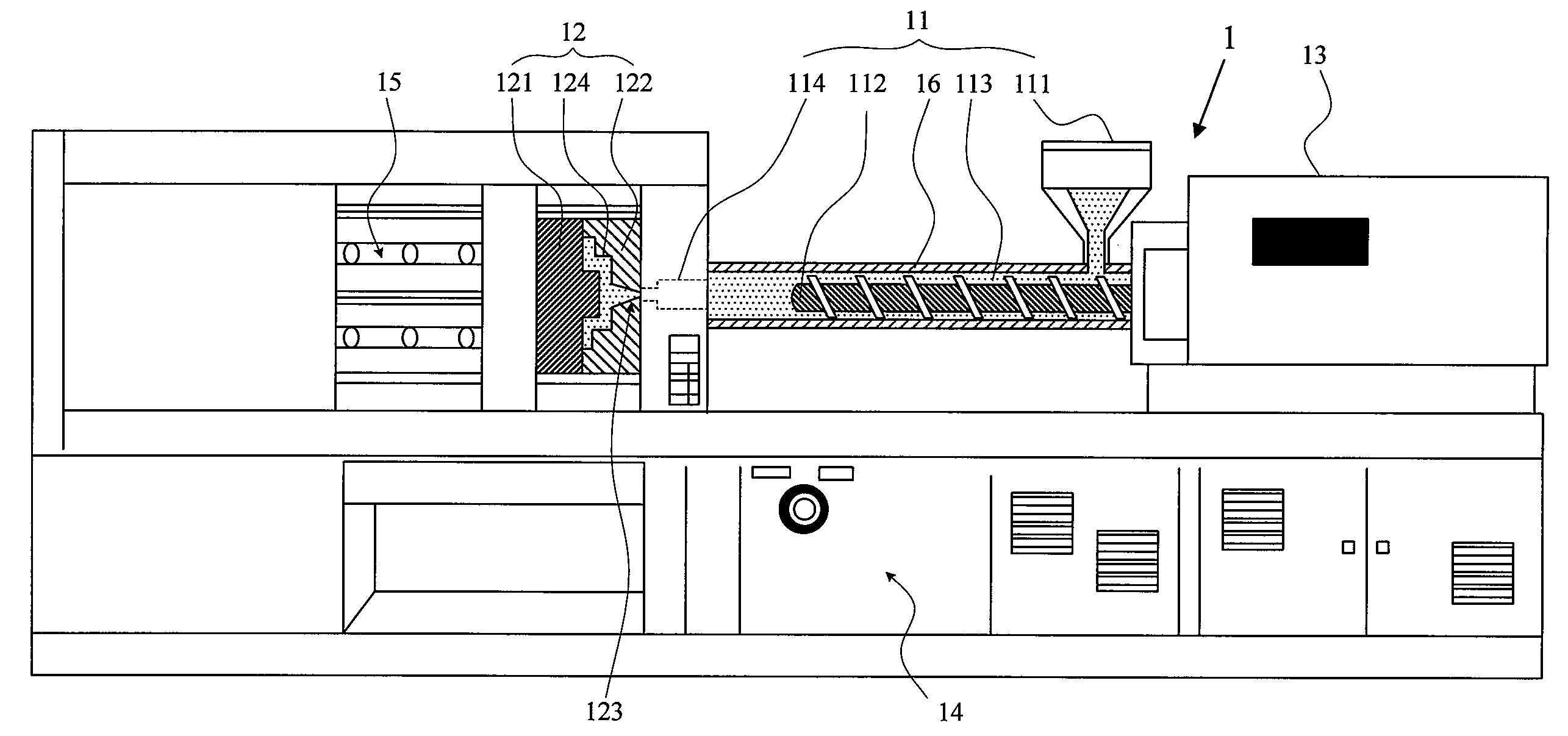

Injection molding machine having a heat insulated barrel

InactiveUS7841853B2Lower operating temperatureReduce power consumptionFood shapingInterliningEngineering

This invention discloses an injection molding machine and a heat-insulating structure of a barrel thereof. The heat-insulating structure covers the barrel of the injection molding machine. The heat-insulating structure includes a plurality of heat-insulating units and a plurality of heat-resistant interlinings. The heat-insulating units are disposed on an outer surface of the barrel in turn along an axial direction of the barrel. The heat-resistant interlinings are located between the heat-insulating units and connect the heat-insulating units, respectively. Each heat-insulating unit includes a heat-resistant layer, a heat-insulating material layer, and an insulating layer in turn. The heat-resistant layer covers the outer surface of the barrel of the injection molding machine.

Owner:MINGSHUO COMP (SUZHOU) CO LTD +1

Method for optimizing shape of ion implantation region

ActiveCN103972063AGood lookingImprove injection qualitySemiconductor/solid-state device manufacturingNitrationIon implantation

The invention provides a method for optimizing the shape of an ion implantation region. The method includes the steps that a semiconductor device substrate with a grid is provided; original oxidization layers and nitration layers are sequentially deposited on the surface of the semiconductor device substrate, the top of the grid and the side walls of the grid; the nitration layer on the top of the grid and the nitration layer on the surface of the semiconductor device substrate are subjected to over etching so that side walls can be formed; etching by-products are formed on the original oxidization layers; the semiconductor device substrate is cleaned with a wet method, and the etched by-products change into residual oxide; the surfaces of the original oxidization layers with the residual oxide or the whole original oxidization layers with the residual oxide are removed, then, an oxidization layer is grown on the semiconductor device substrate so that a new oxidization layer can be formed, and the new oxidization layer can replace the original oxidization layer to serve as a buffer layer for subsequent ion implantation. According to the method, while the residual oxide can be effectively removed in a controllable mode, the ion implantation quality is further improved, the shape of a subsequent ion implantation region is optimized, the quality of devices is improved, and the yield of the devices is increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

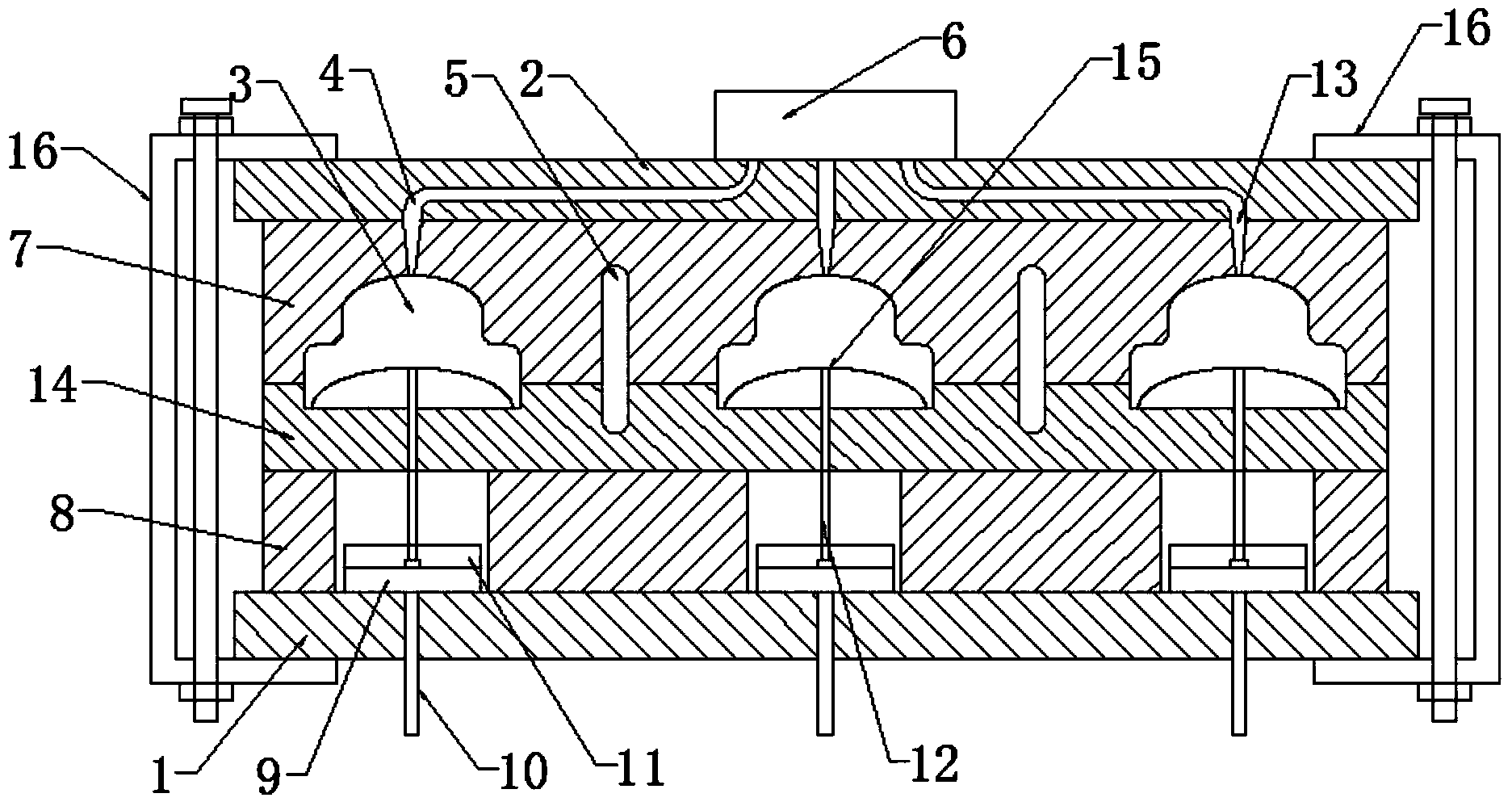

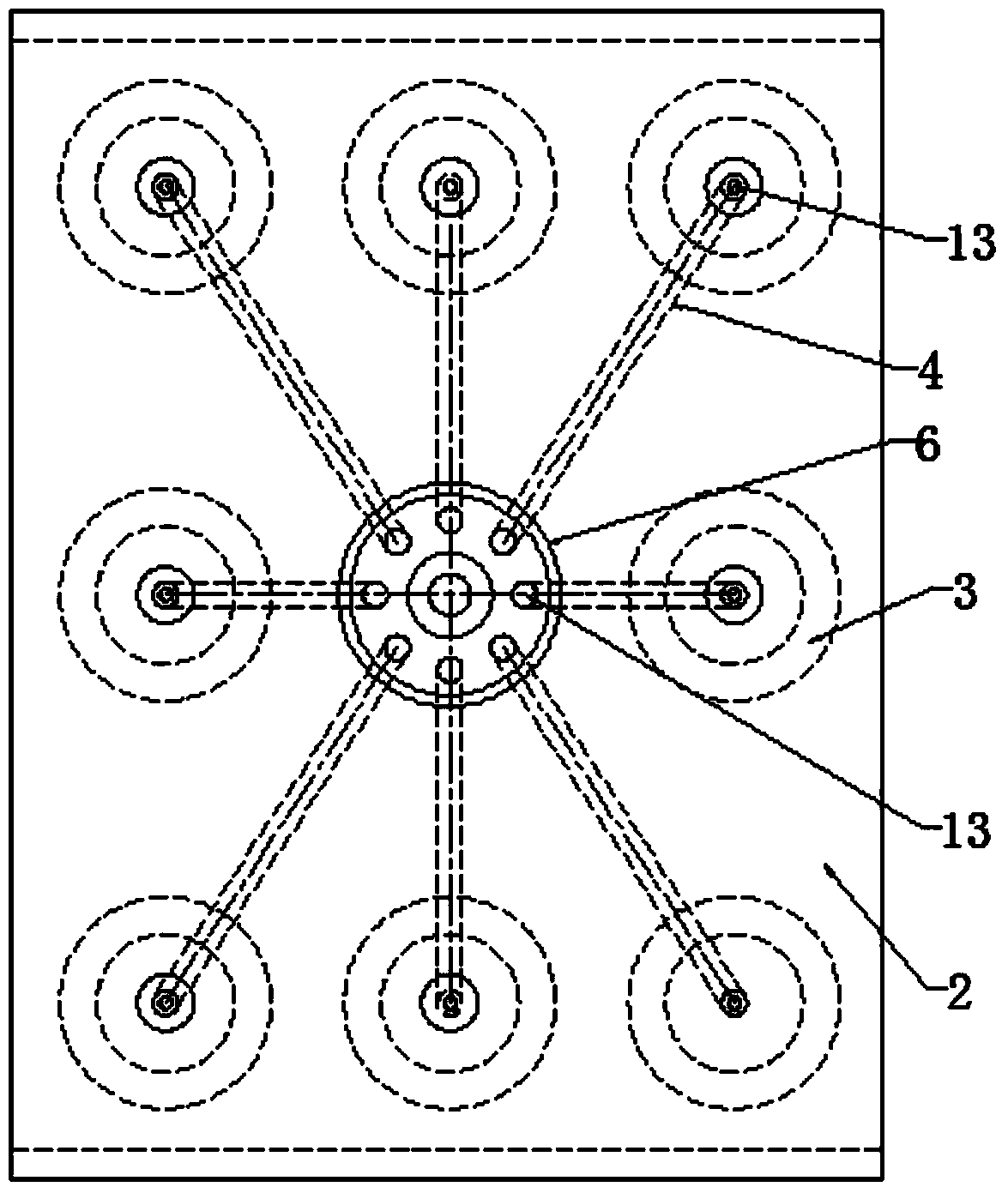

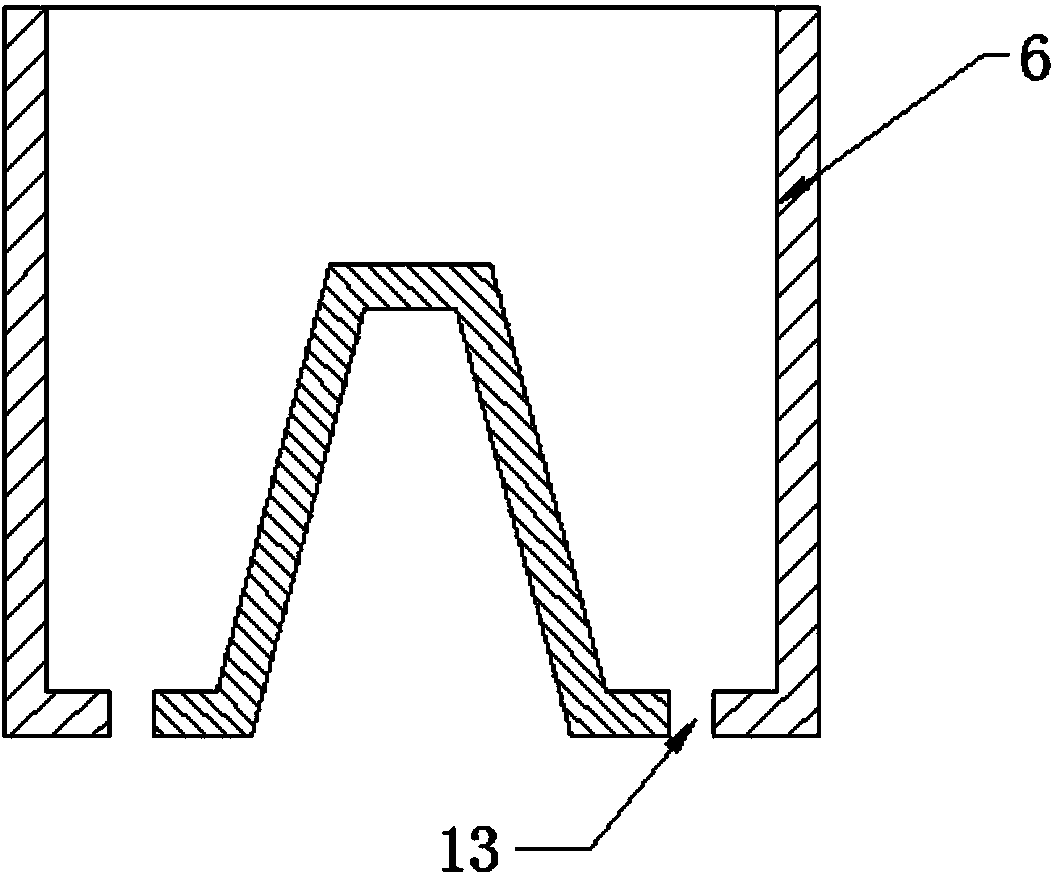

Multi-channel injection mold

The invention discloses a multi-channel injection mold. The multi-channel injection mold comprises a fixed mold plate, a mobile mold plate, a fixed mold template, a mobile mold template and a fixing clamper. A pouring device is fixed on the upper surface of the mobile mold plate; both the internal part of pouring device and the upper surface of the mobile template are provided with eight pouring openings; the mobile mold plate is provided with pouring channels adaptive to the pouring openings; the mobile mold template is fixedly installed between the lower surface of the mobile mold plate and the upper surface of the fixed mold template; a fixed mold backing plate is fixedly installed between the fixed mold template and the fixed mold plate; the fixed mold backing plate is provided with a push plate; an inner push rod fixing plate is arranged above the push plate; and the push rod fixing plate is connected to an inner push rod with a mold core. The multi-channel injection mold can finish injection simultaneously, is fast in injection molding, increases output, and effectively increases work efficiency. The distance of the pouring channel between the pouring openings is the shortest, so that injection liquid can enter the mold cavity rapidly; the phenomenon of injection liquid condensation can be prevented; injection quality is increased; and at the same time, the injection profile is pulled out of the mold for cooling.

Owner:NINGBO POLYTECHNIC

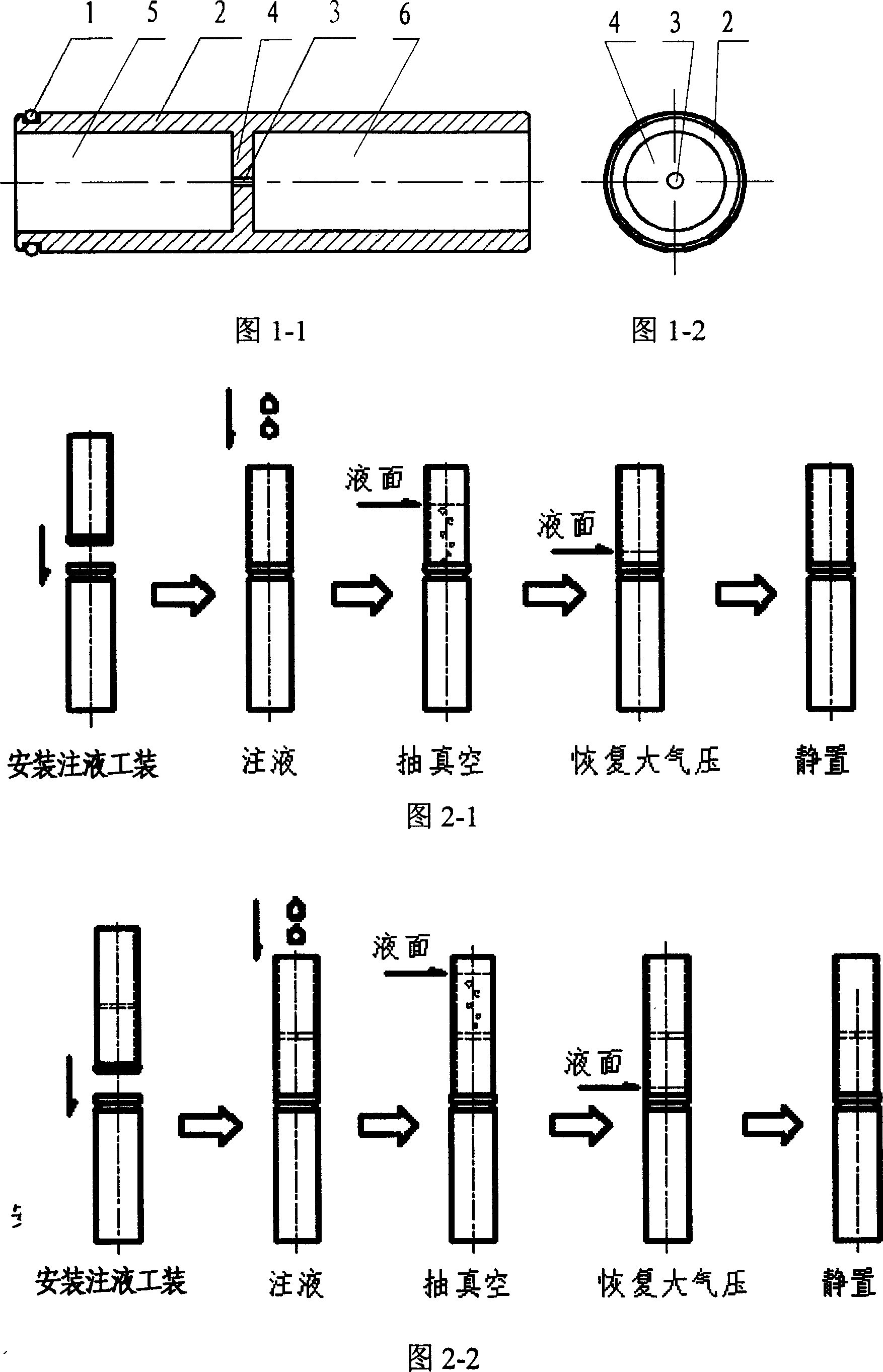

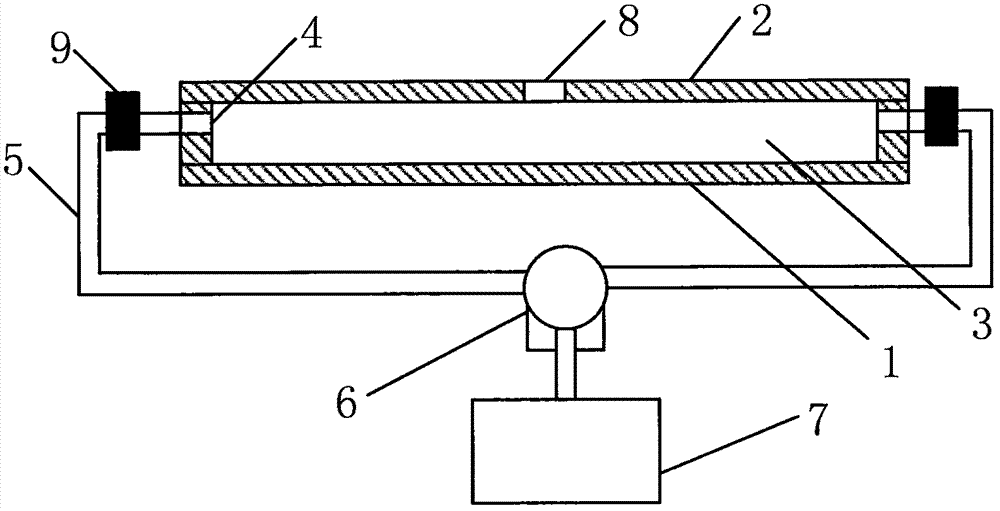

Liquid injection industrial installation for the column lithium ion battery

InactiveCN101017888AShorten injection timeImprove injection qualityNon-aqueous electrolyte cellsSecondary cellsHigh densityEngineering

The disclosed liquid-injecting device for cylinder Li-ion cell comprises: a sealing ring set on outside of the cylinder bottom, a layering plate arranged in the cylinder to sealing connect with the cylinder wall, and a small hole on middle of the plate. Wherein, the layering plate is integrated with the cylinder. This invention avoids the electrolyte enters into cell between vacuumizing and recovering air pressure to cut the injection time, and special fit to the production of large-capacity high-density cylinder cell.

Owner:TIANJIN LISHEN BATTERY

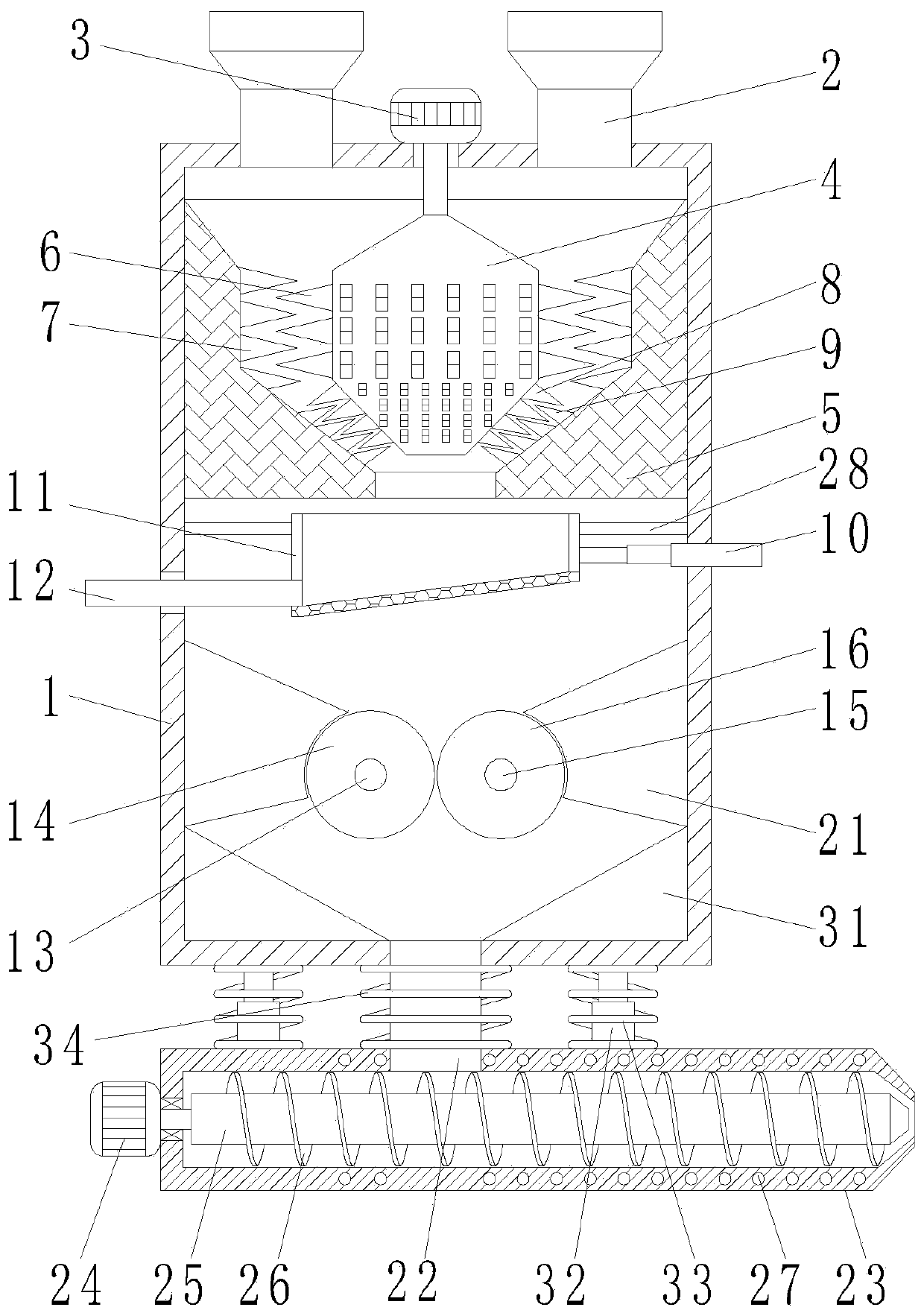

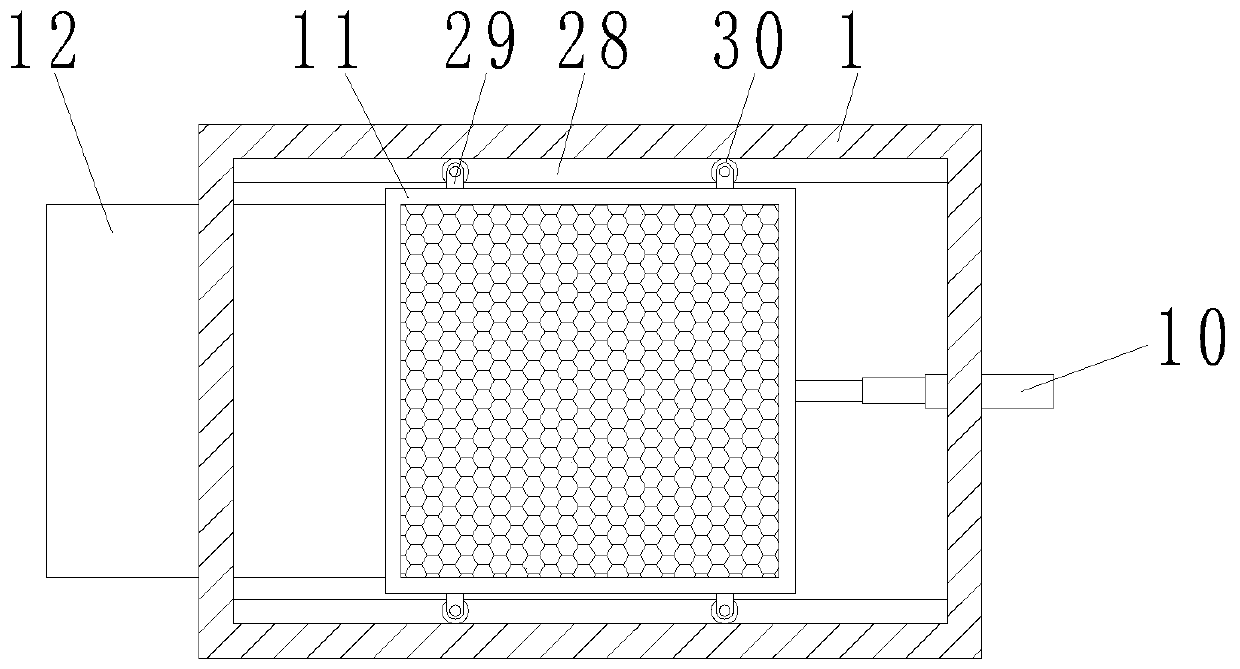

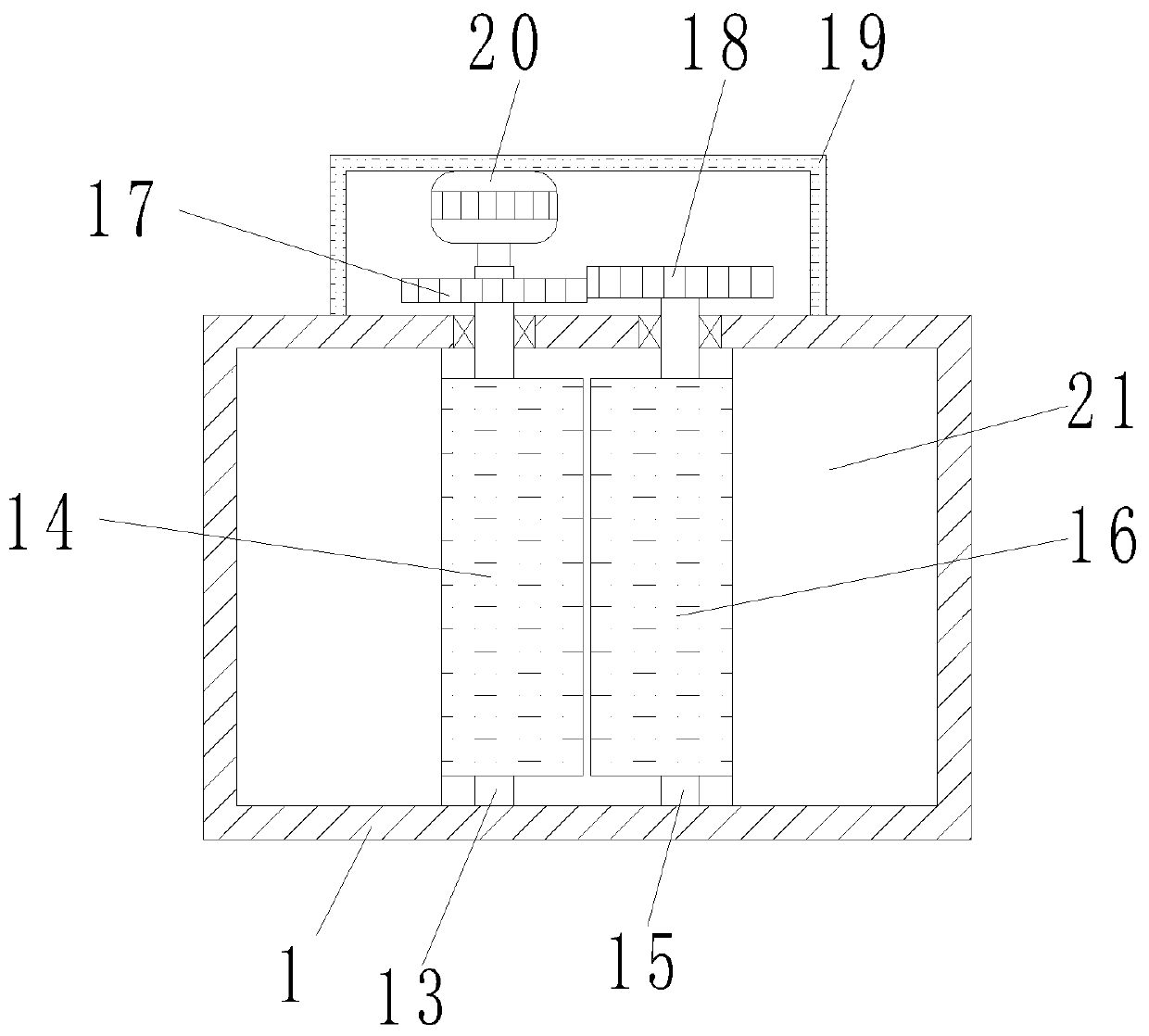

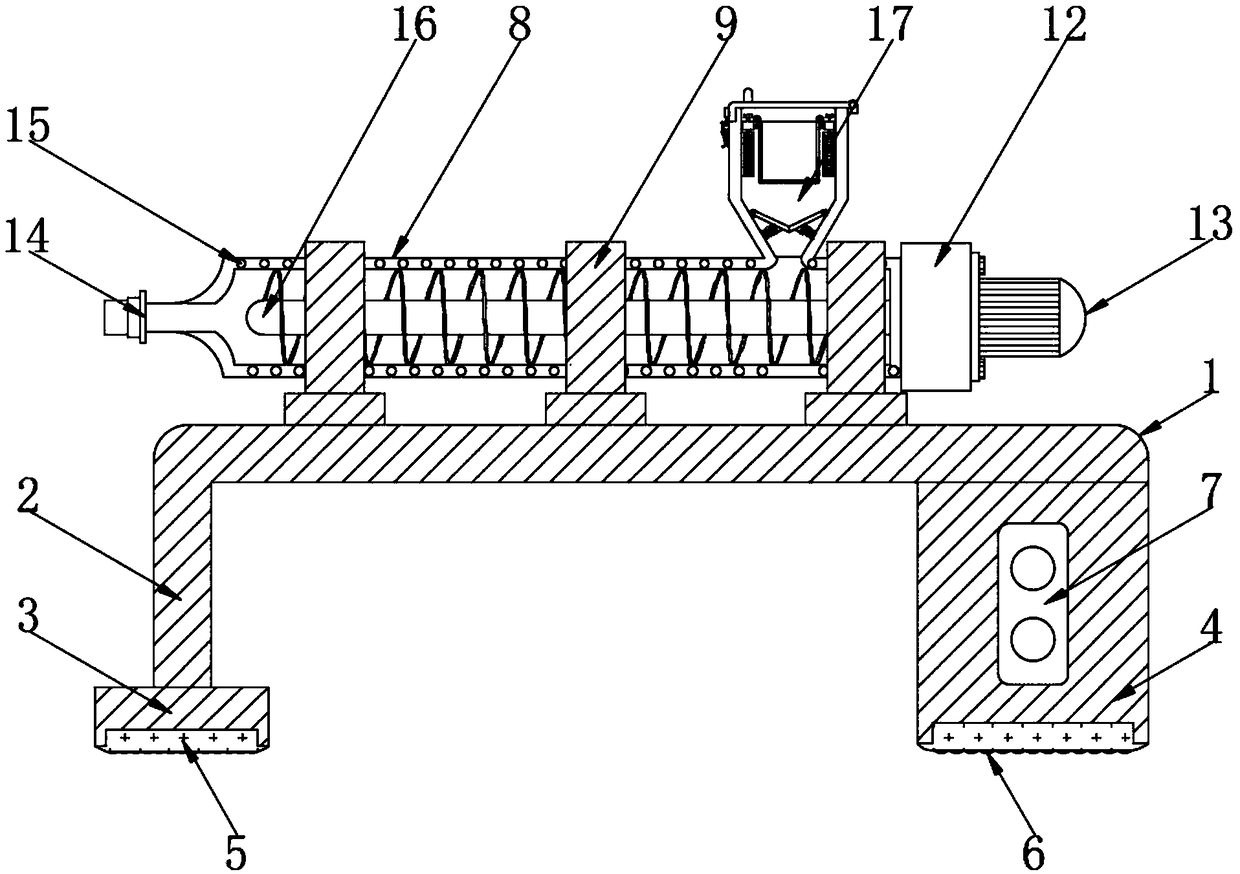

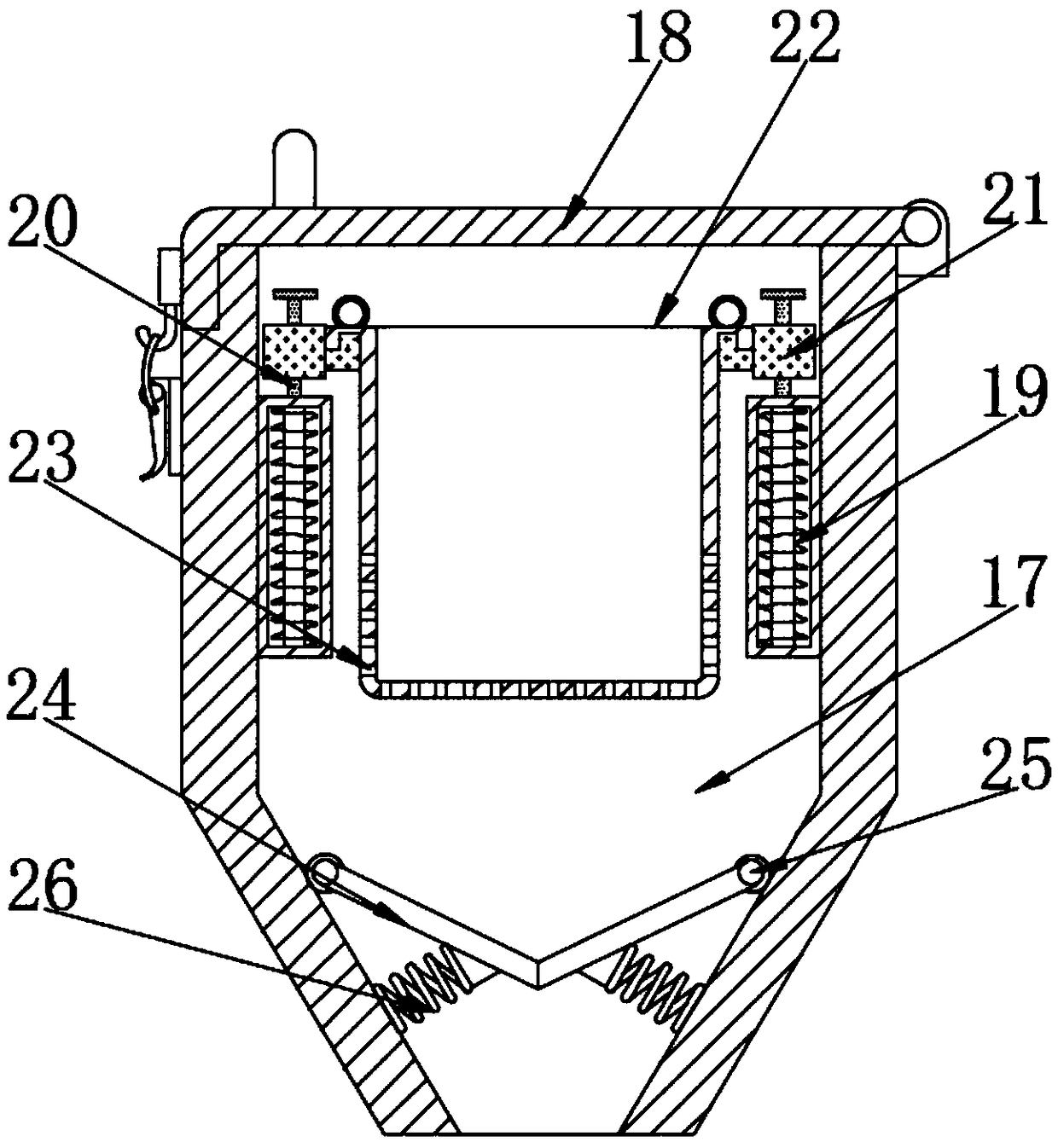

Injection molding device for automobile parts

InactiveCN111497059AEvenly heatedImprove injection qualitySievingScreeningElectric machineryAutomotive engineering

The invention discloses an injection molding device for automobile parts. The injection molding device for automobile parts comprises a box body, wherein two sides of the top of the box body respectively communicate with feeding pipes, a first motor is fixedly connected to the top of the box body, the bottom of a rotating shaft of the first motor penetrates to an inner cavity of the box body and is fixedly connected with a crushing rod, a circular ring table is fixedly connected to the inside of the box body, the crushing rod is positioned in the inner cavity of the circular ring table, and afirst large blade and a first small blade are fixedly connected to the surface of the crushing rod from top to bottom respectively. The injection molding device has the advantages that an injection molding material can be crushed and ground in advance, so that the injection molding material is heated uniformly in the heating process, and the injection molding quality of a finished product is improved. The problems that an existing injection molding device for automobile parts cannot crush and grind the injection molding material in advance, the injection molding material is heated non-uniformly in the heating process, a steam pocket is prone to generating in the finished product, the injection molding quality of the finished product is affected, and the finished product is scrapped in severe case are solved.

Owner:重庆鼎鼎科技有限公司

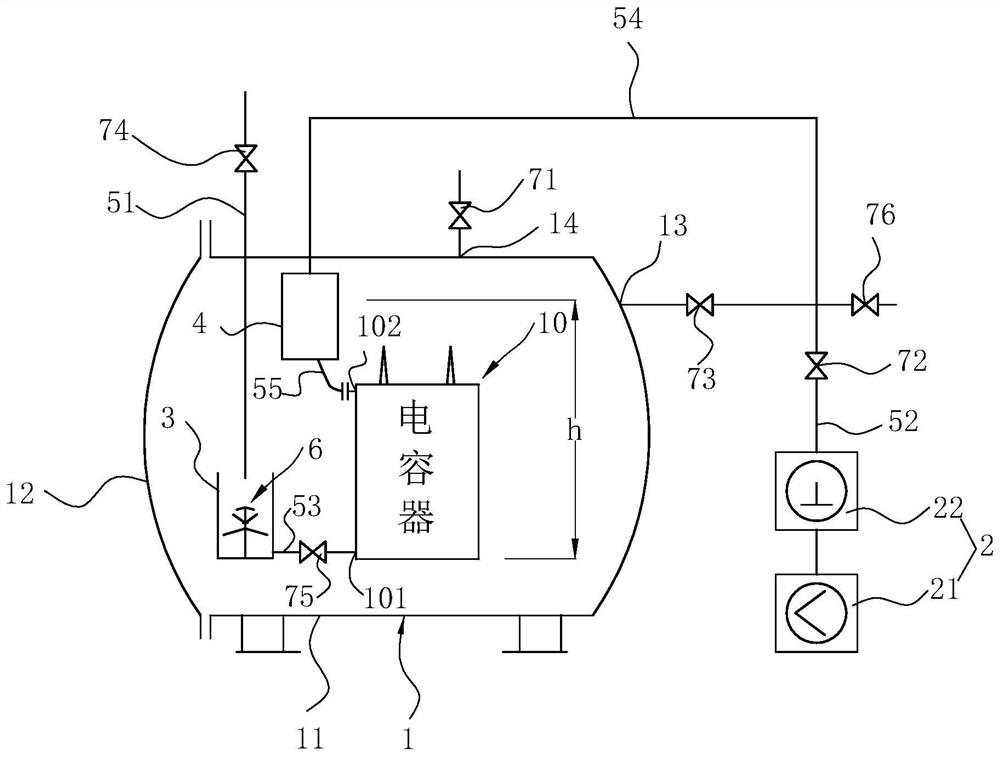

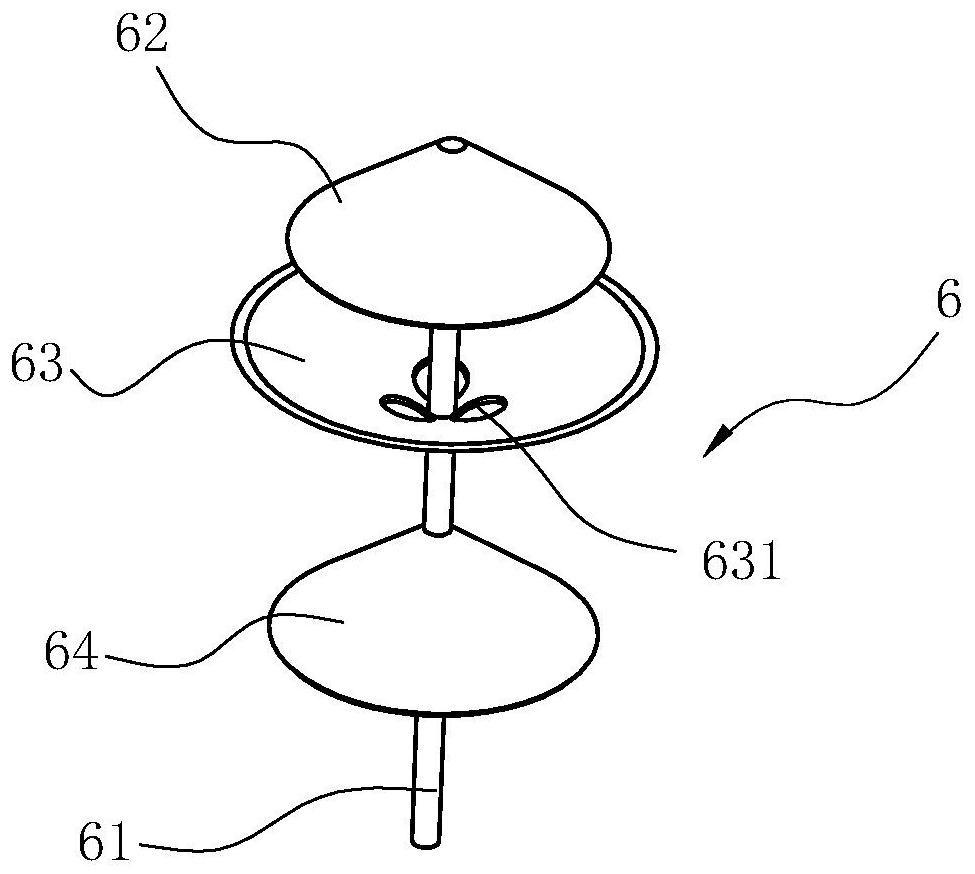

Vacuum glue injection device and glue injection method of capacitor

PendingCN112403813AImprove injection qualityWill not cause damageLiquid surface applicatorsCoatingsHigh capacitancePumping vacuum

The invention relates to a vacuum glue injection device of a capacitor. The vacuum glue injection device is improved on the basis of the existing glue injection tank, vacuum pump, glue injection pipeand the like, namely a degassing barrel with an open opening and a closed glue supplementing tank are also arranged in the glue injection tank; the glue injection pipe extends into the glue injectiontank and then is inserted into the degassing barrel; the degassing barrel communicates with a capacitor shell through a glue conveying pipe with a glue injection valve; an air inlet and outlet valve is arranged on an air suction pipe between a vacuumizing valve and an air suction opening; the upper part of the glue supplementing tank communicates with the air suction pipe through a connecting pipe; the lower part of the glue supplementing tank communicates with the capacitor shell through a glue supplementing pipe; the air suction pipe between the air inlet and outlet valve and the vacuumizingvalve is also connected with a high-pressure air source through a pressurizing valve; and meanwhile, an air relief opening controlled by an air relief valve is also formed in the glue injection tank.The invention also discloses a glue injection method adopting the vacuum glue injection device. By adopting the vacuum glue injection device and the glue injection method, gaps and bubbles in the capacitor can be effectively eliminated, and the glue injection quality of the capacitor can be obviously improved, so that the vacuum glue injection device and the glue injection method are worthy of popularization and application.

Owner:宁波海融电器有限公司

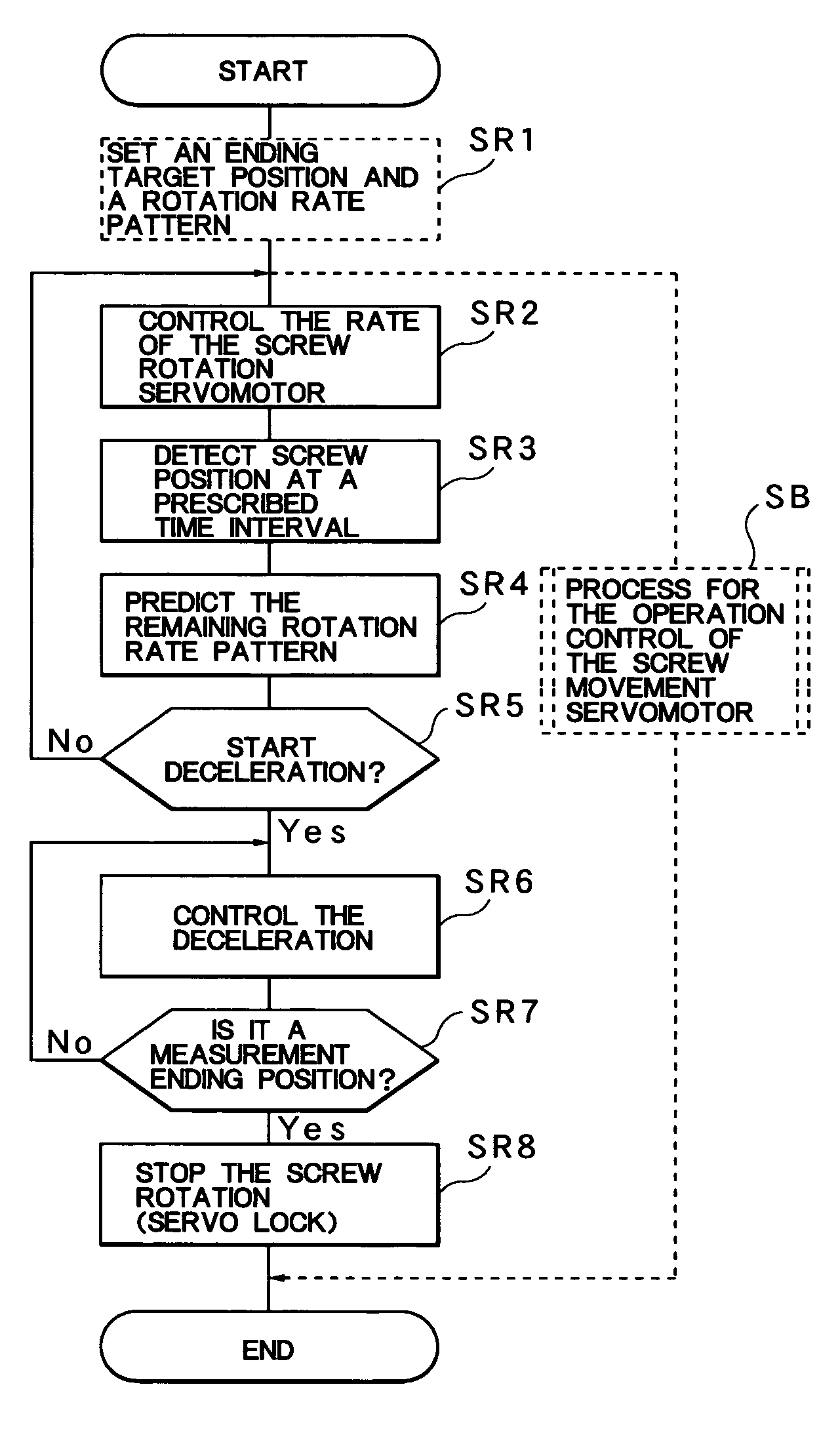

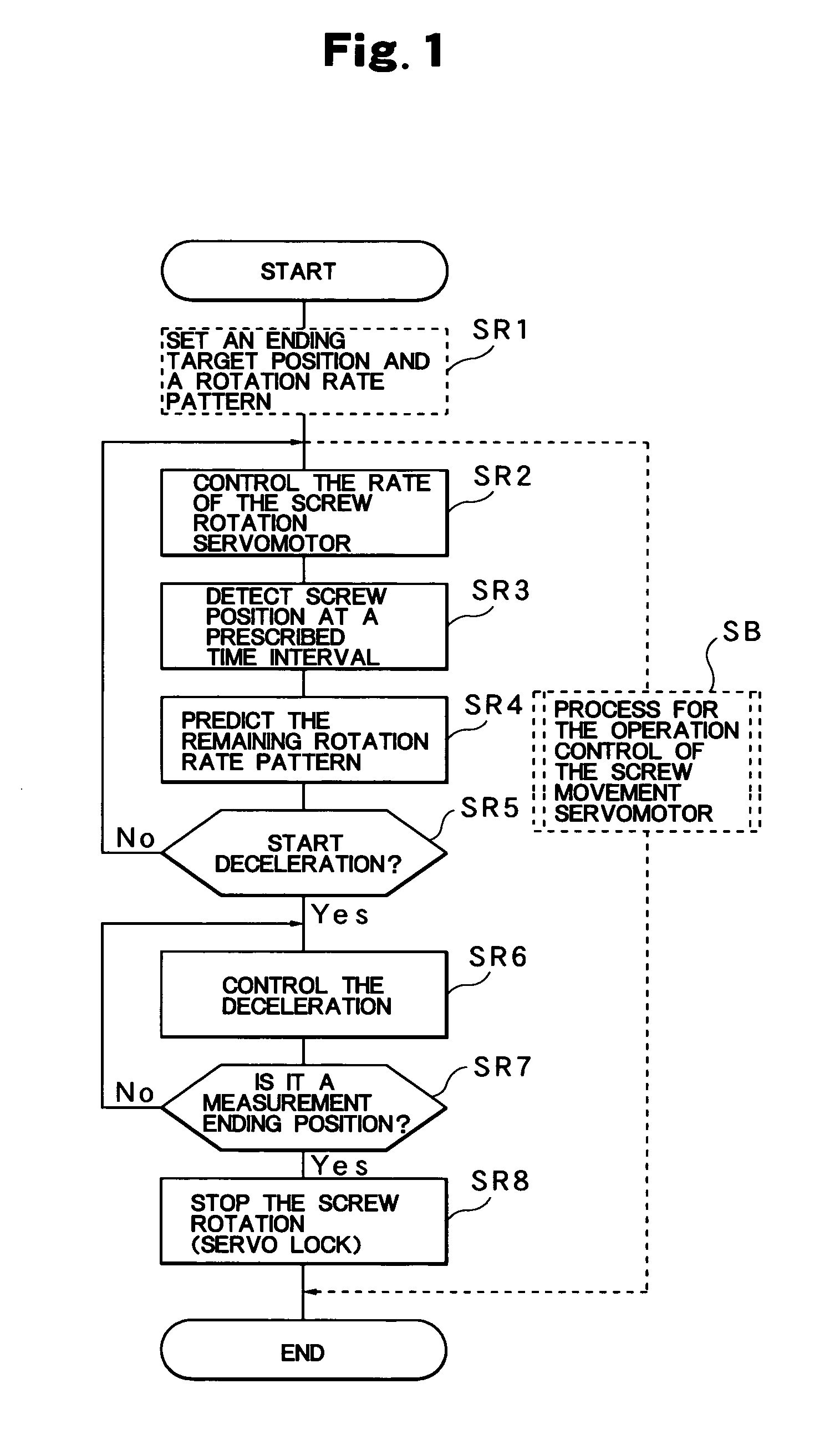

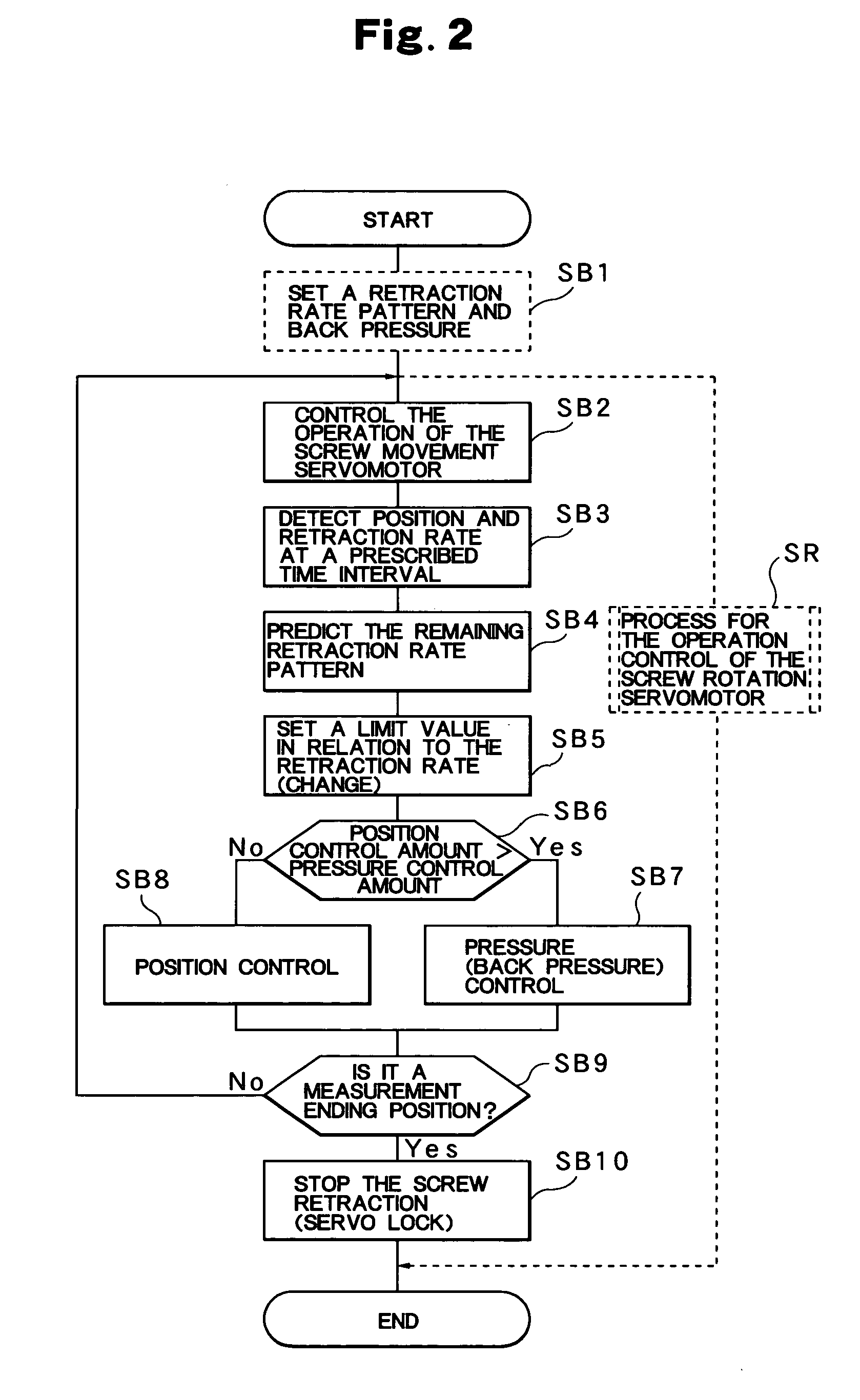

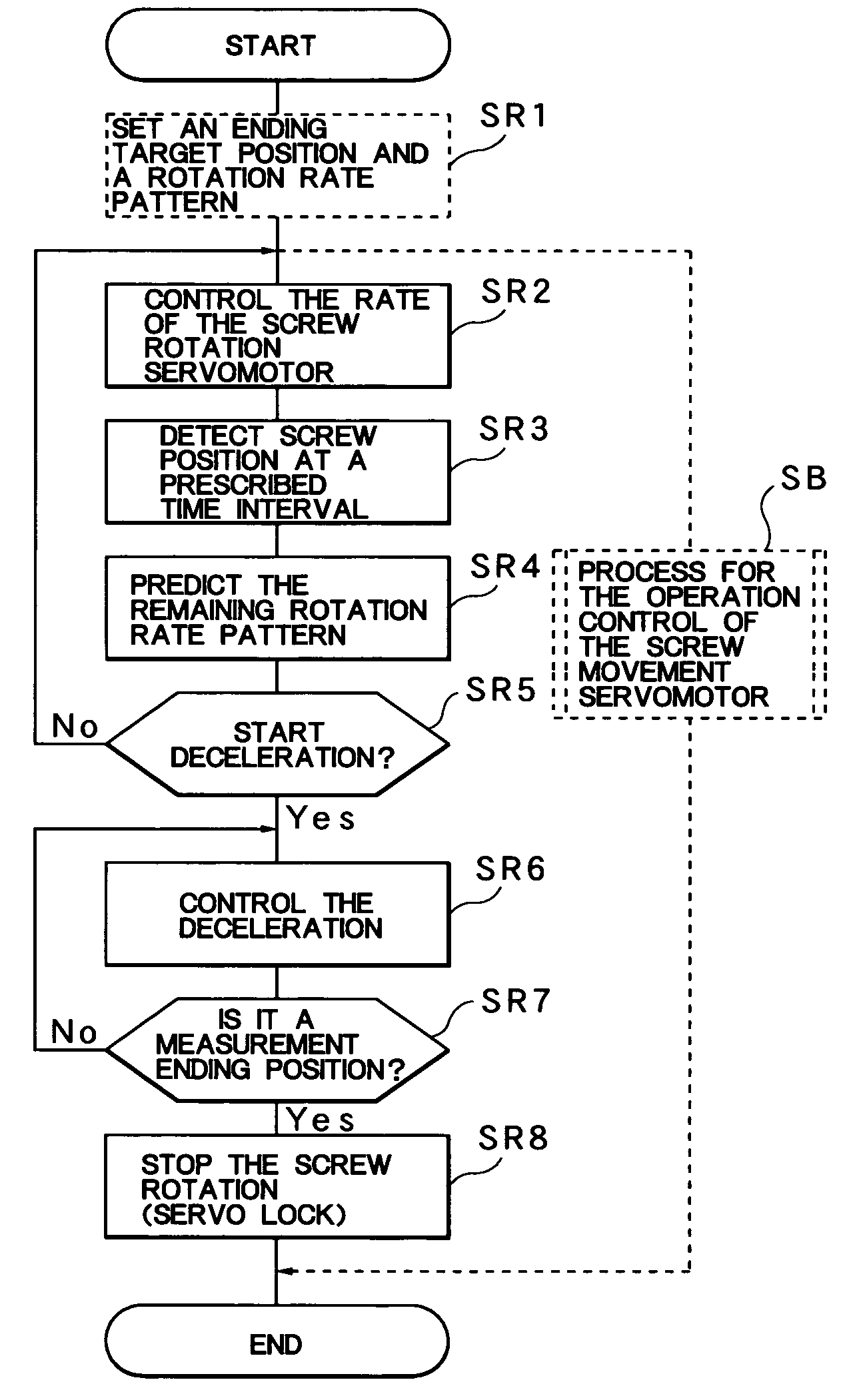

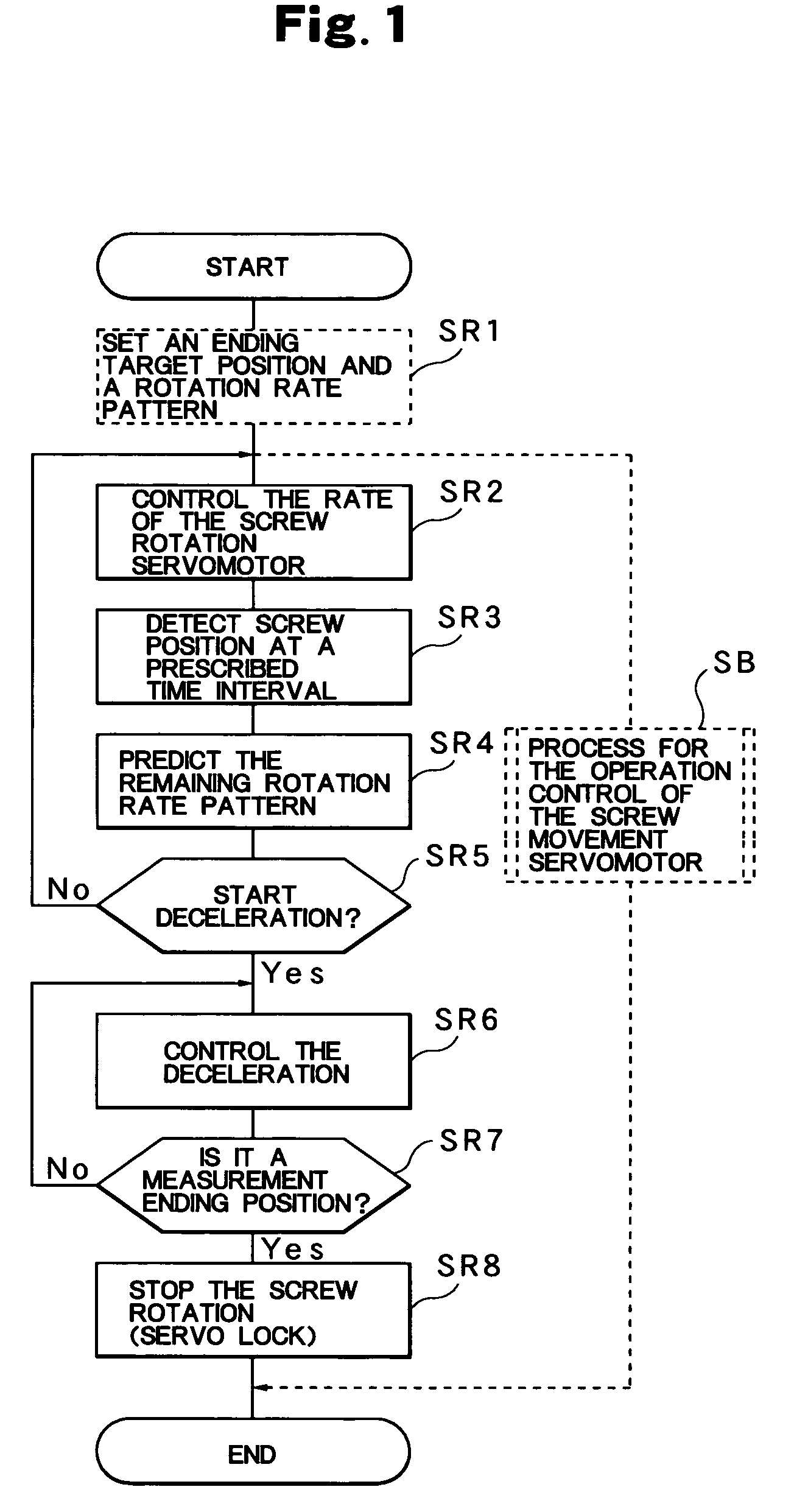

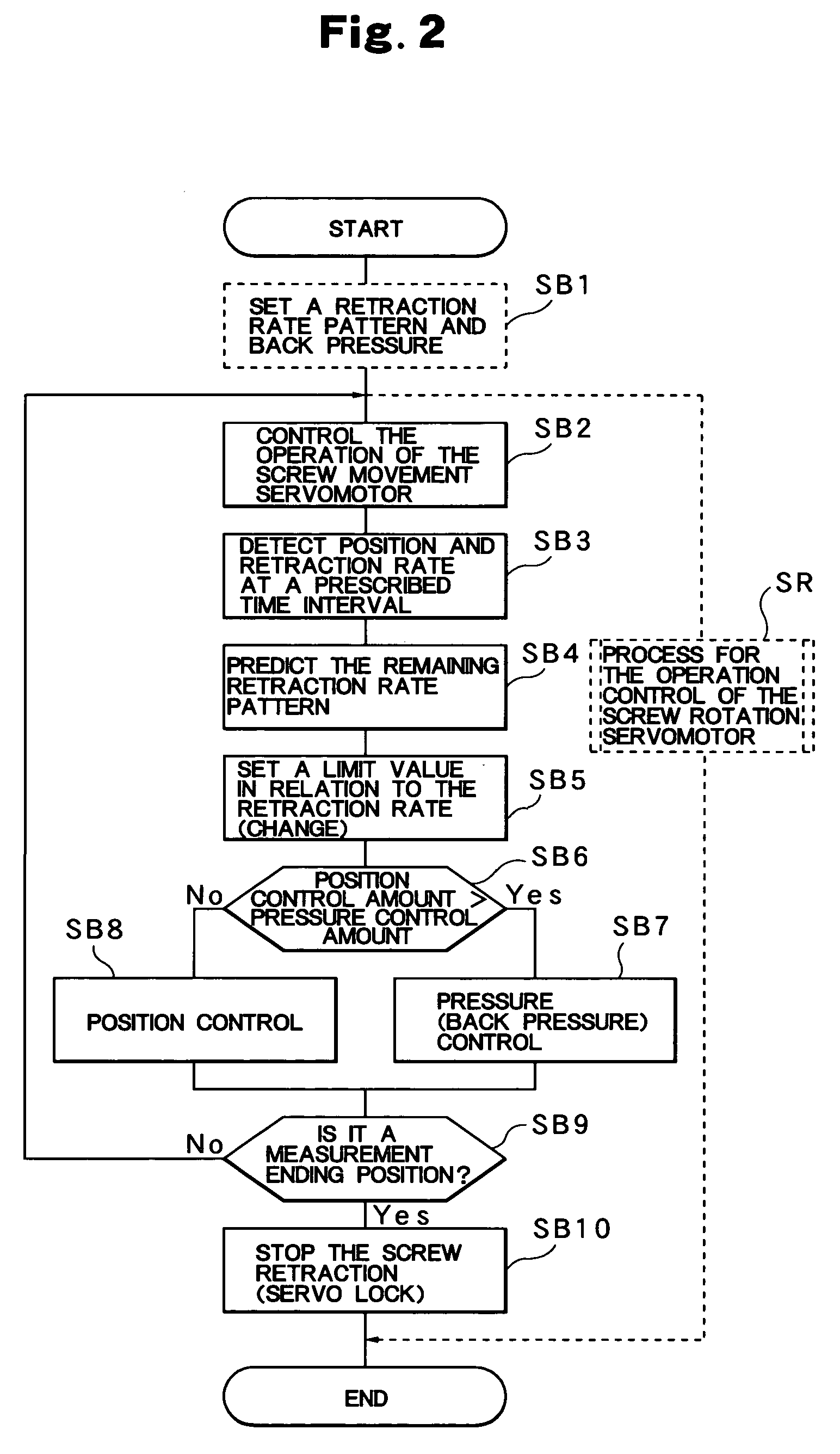

Measurement control method of an injection molding machine

ActiveUS20060288791A1High degree of measurement precisionStop rotatingFluid pressure measurement using ohmic-resistance variationAuxillary shaping apparatusScrew positionEngineering

An ending target position Xes in which a prescribed length Ls is added to a measurement ending position Xe, a rotation rate pattern Ar for rotating a screw 2, a back pressure Ps in relation to the screw 2, and a hypothetical retraction rate pattern Ab for the screw 2 to retract, are set in advance while the remaining rotation rate pattern Ar to stop the rotation of the screw 2 at the ending target position Xes from the detected screw position X, is predicted by calculation at the time of measurement, and the rotation of the screw 2 is stopped based on the prediction. Further, the remaining retraction rate pattern Ab is predicted by calculation from the detected retraction rate Vd, and the retraction of the screw 2 is stopped based on the prediction.

Owner:NISSEI PLASTIC IND CO LTD

Injection mould of automotive plate structure

The invention discloses an injection mould of an automotive plate structure. The injection mould comprises a base, wherein supporting rods are mounted on two sides of the base, and a mould body is mounted at the upper ends of the supporting rods; a downward-concave cavity is formed in the middle part of the mould body; positioning blocks are further mounted on two sides of the mould body, penetrating injection ports are formed in the positioning blocks, injection channels communicating with the injection ports are further formed on the upper end faces on two sides of the mould body, and the injection channels extend into the cavity. According to the injection mould disclosed by the invention, positions of the cavity for injection moulding, the injection ports and the injection channels as well as an air outlet for exhausting are relatively reasonably designed; the injection ports are formed in the positioning blocks and extend downward to communicate with the injection channels, thus, the injection mould can be easily connected to an external injection moulding tube or an injection moulding machine; moreover, the positioning blocks also play a role of positioning a mould cover plate, so that injection mould serves a double purpose and is very convenient to use.

Owner:无锡雄伟精工科技有限公司

Automatic injection molding die

Owner:FENGHUA GUOSHENG INSTR

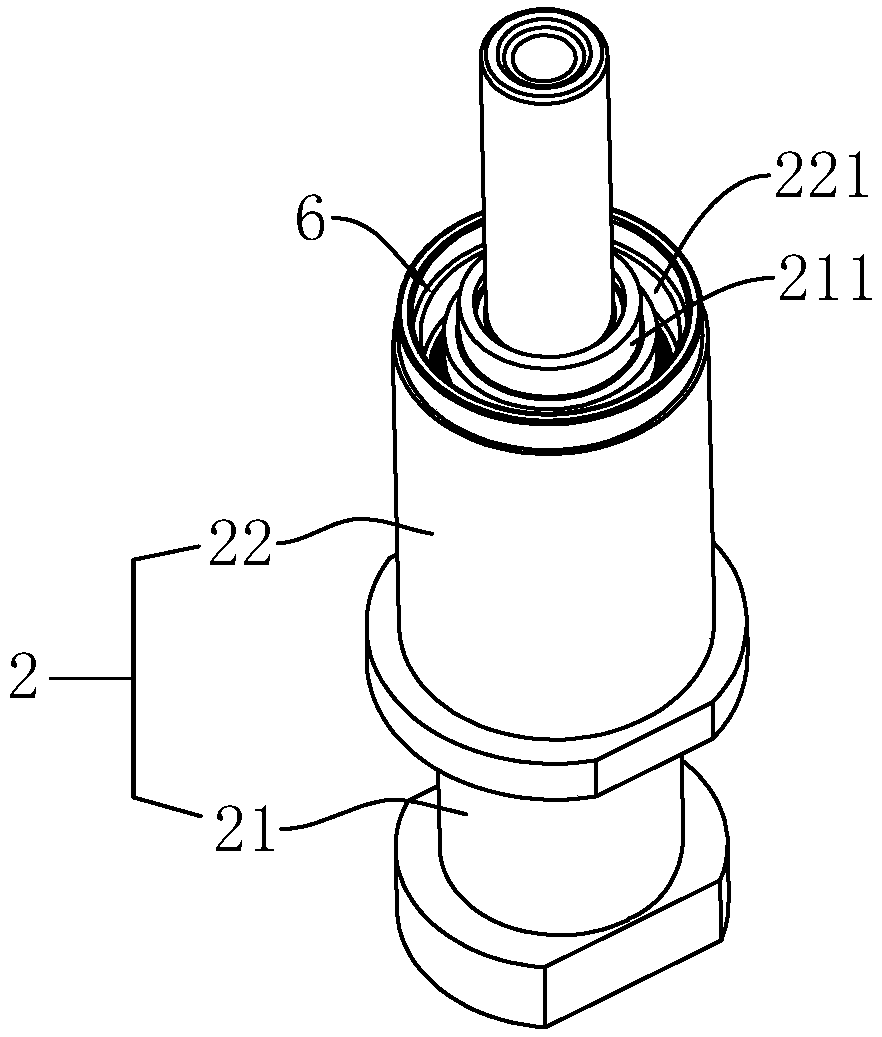

Injection molding pre-buried device

InactiveCN109016335APrecise manual placementManual placement is fastCoatingsFeeding catheterEngineering

The invention relates to an injection molding pre-buried device, and comprises a support block, a limiting slide, a positioning plate and a pushing mechanism. The support block is internally providedwith a feed passage arranged in a horizontal direction, one end of the feed passage is connected with a fixed hole of a pre-buried part on a injection molding mold plate through a positioning ring ofthe pre-buried part, and the other end is connected with a feed catheter; and the positioning ring of the pre-buried part is coaxial with the feed passage; the positioning ring of the pre-buried partis provided with a shrink neck section, and the end of the shrink neck section is provided with a fastening ring which is used for fastening limit of the pre-buried part; a plurality of pre-buried parts are successively arranged from top to bottom in the limiting slide, and the bottom end of the limiting slide is connected with the feed catheter; the positioning plate is arranged between the bottom of the limiting slide and the feed catheter, and the position of the outlet of the corresponding limiting slide on the locating plate is provided with a limiting through hole; and the pushing mechanism is arranged on one side of the feeding catheter and is used for pushing the pre-buried part into the feeding catheter into the fixed hole of the pre-buried part on the injection mold plate. According to the injection molding pre-buried method, accurate placement of insert on the mold is accurately and quickly realized, and the high stability after placement is ensured.

Owner:SUZHOU XIAOYAN AUTOMATION EQUIP

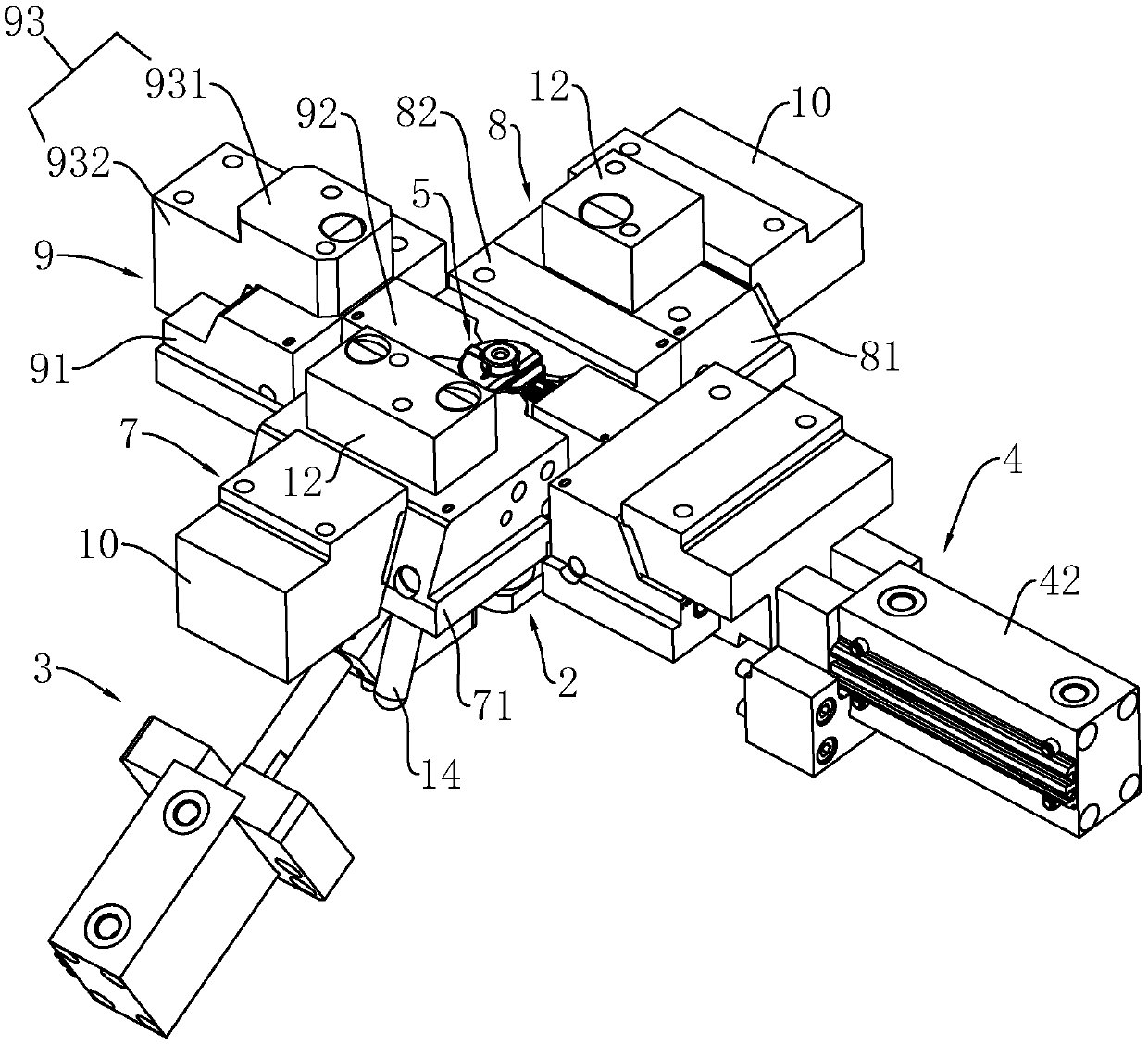

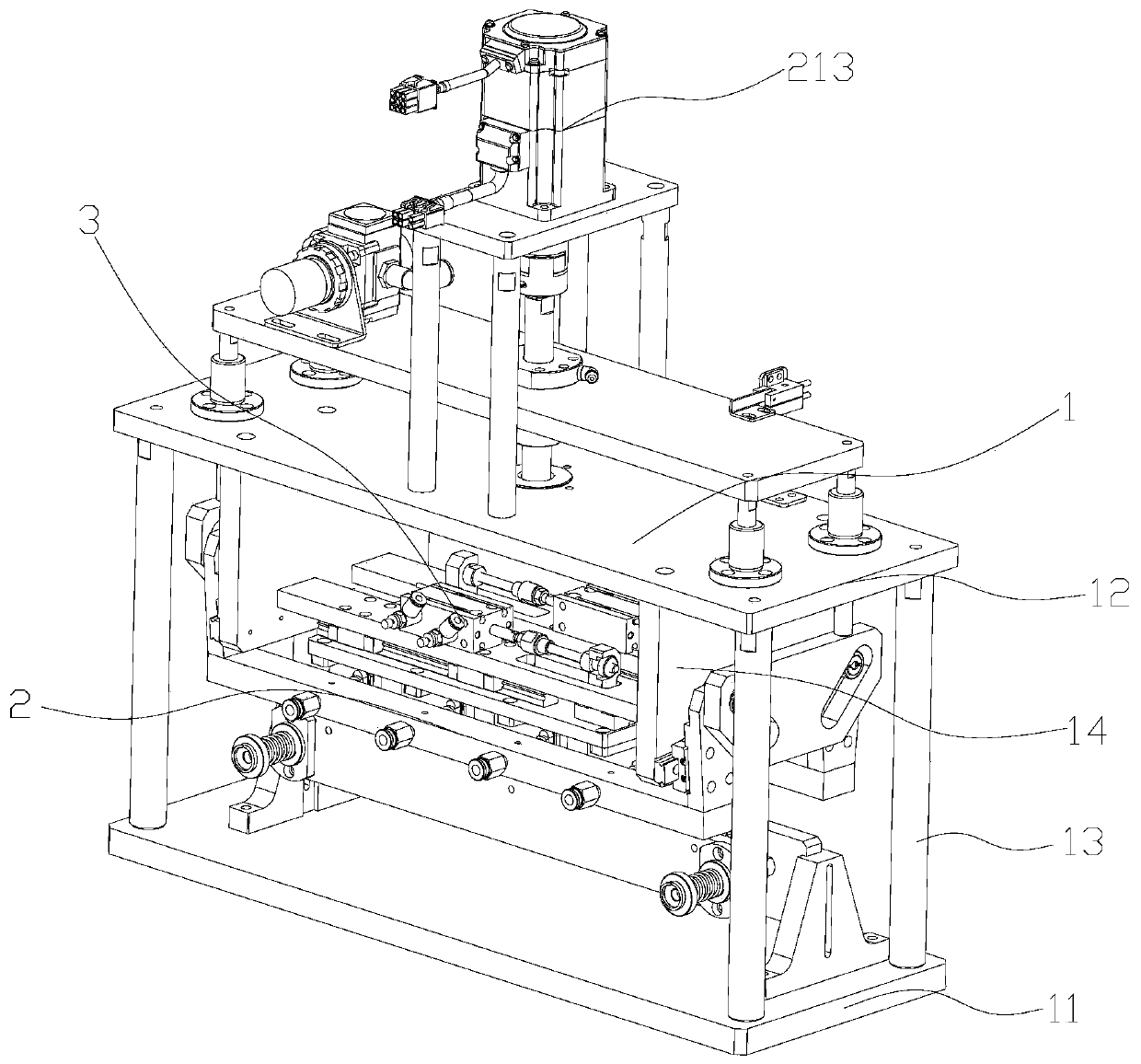

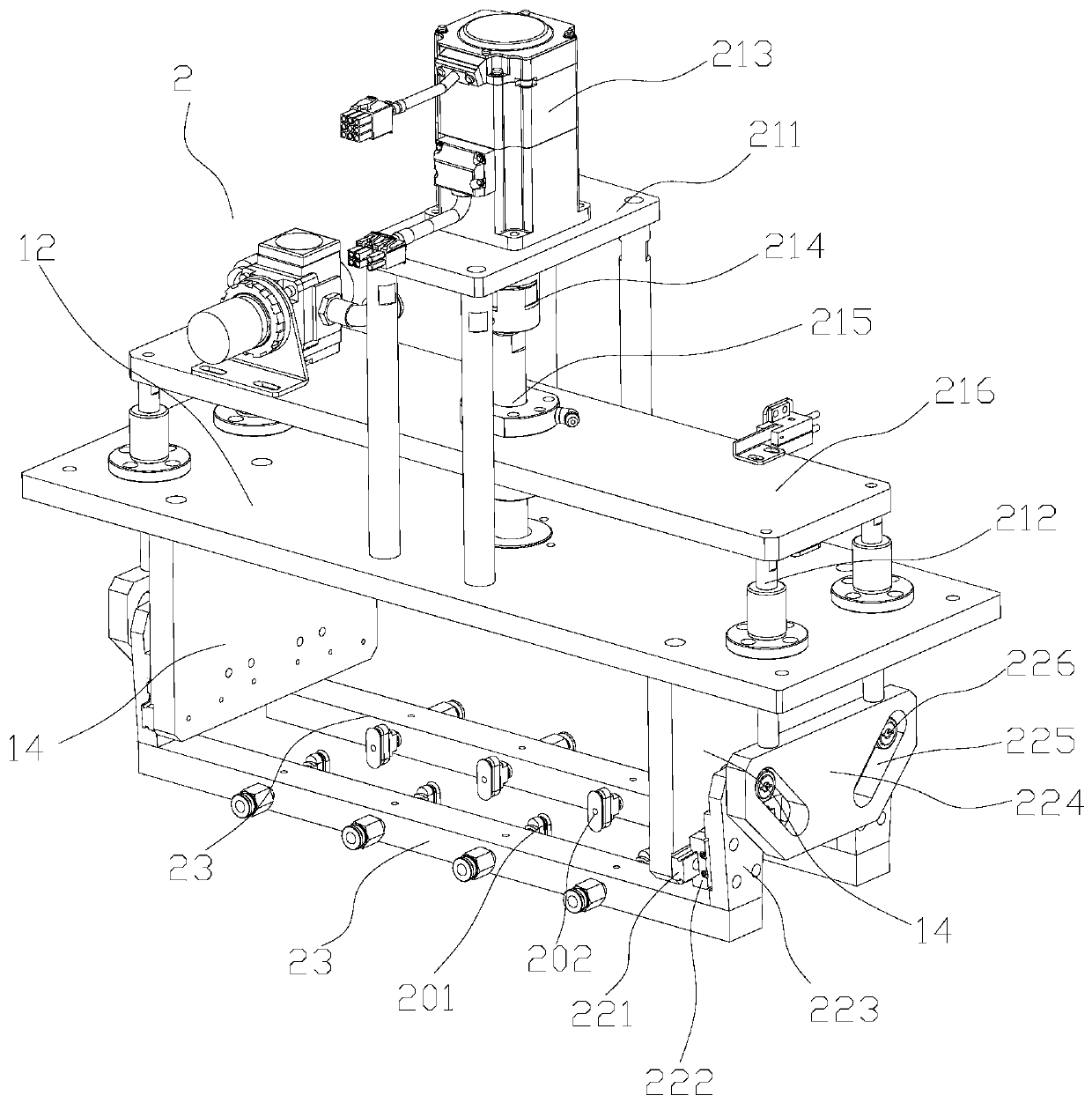

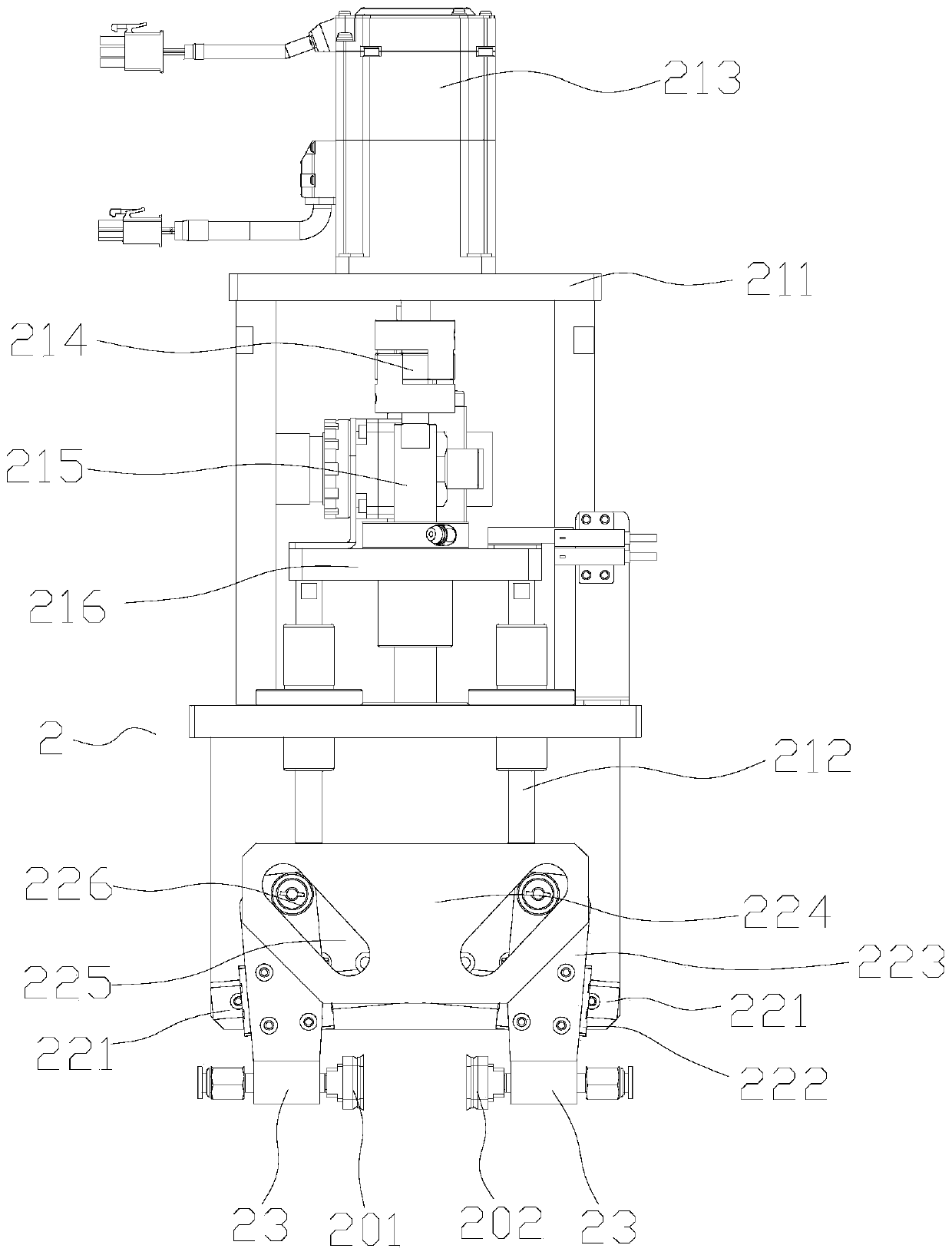

Motor housing injection molding method with metal insert and injection mold of motor housing injection molding method

ActiveCN109531919AAccuracy and Convenience GuaranteedImprove product injection qualityDomestic articlesMetal insertInjection molding machine

The invention discloses a motor housing injection molding method with a metal insert and an injection mold of the motor housing injection molding method, and relates to the technical field of injection molds. The motor housing injection molding method with the metal insert comprises the steps of preparing, axial locating, pre-locating, final locating, mold compounding, injection molding and the like. The injection mold comprises an axial locating assembly, a pre-locating assembly, a final locating assembly and a mold compounding assembly. The pre-locating assembly comprises a first drive part,the first drive part is connected with a pre-locating combined sliding block, and a pre-locating structure is formed on the pre-locating combined sliding block. The final locating assembly comprisesa first combined sliding block, the first combined sliding block is connected with a second drive part, and an inserted cooperation part is arranged on the first combined sliding block. By means of the motor housing injection molding method with the metal insert and the injection mold of the motor housing injection molding method, operation is convenient, the injection molding quality and production efficiency can be improved easily, and the product rejection rate can be reduced.

Owner:上海超日精密模具有限公司

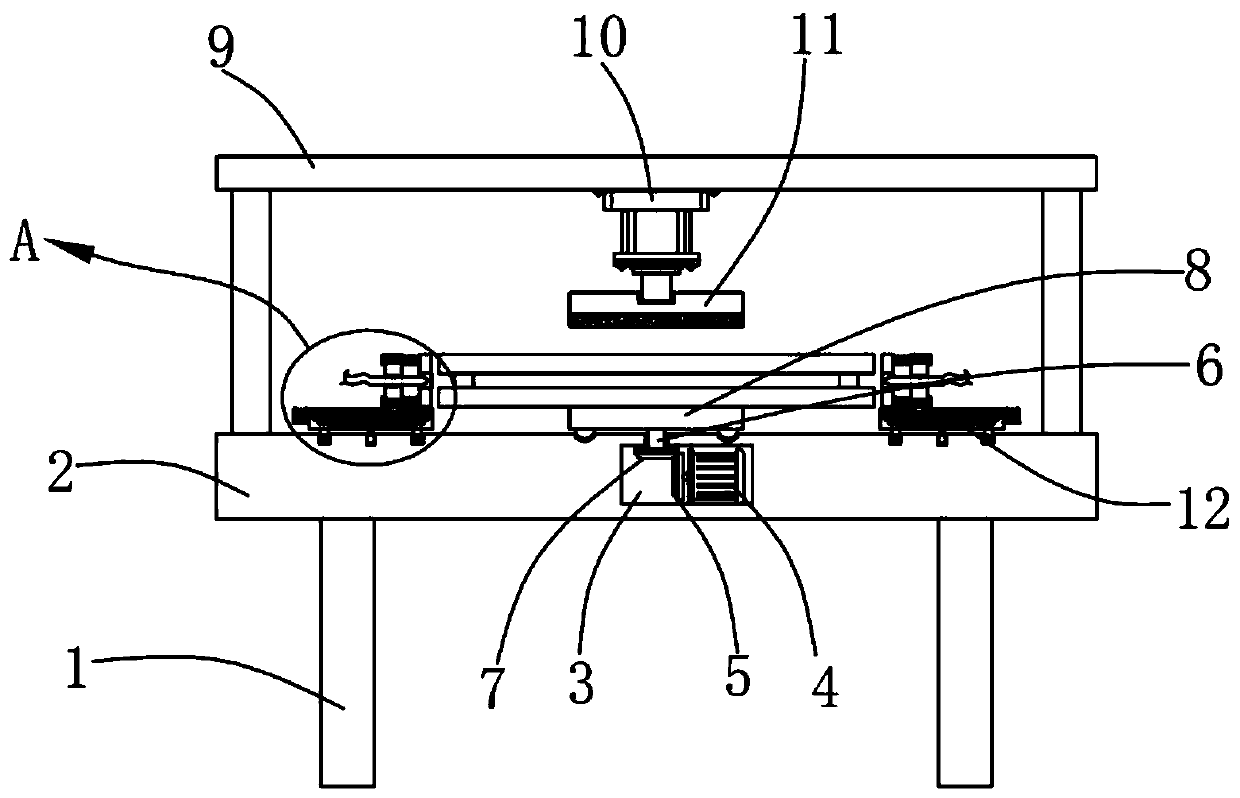

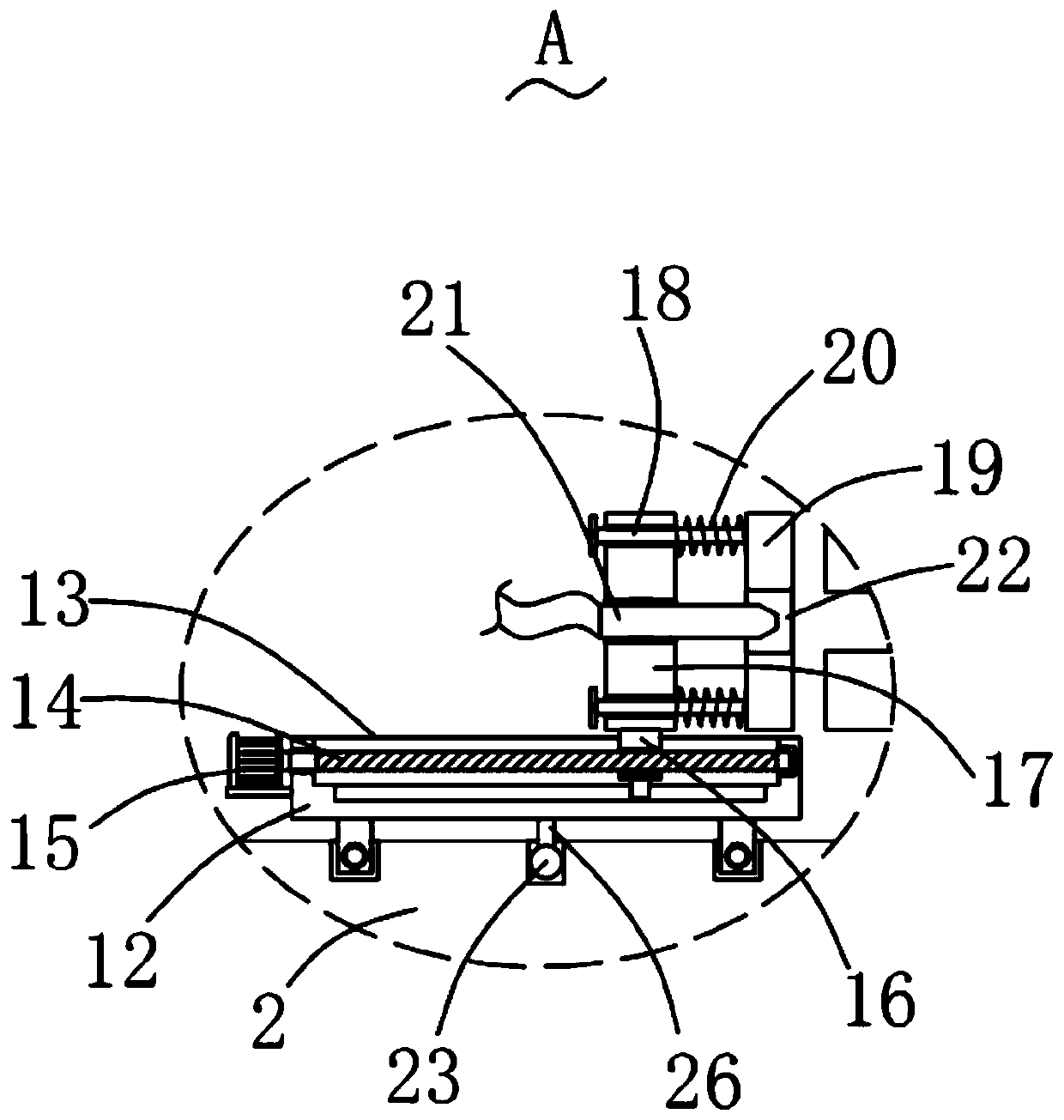

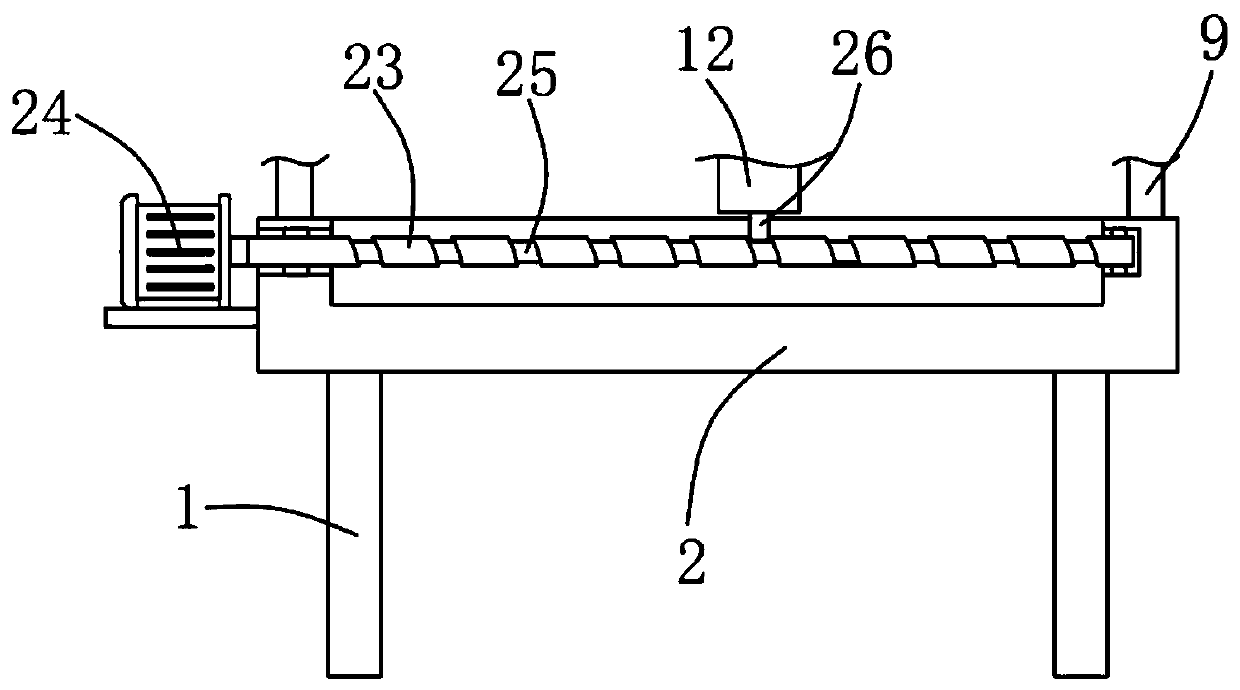

Hollow glass glue-injecting and laminating integration machine

InactiveCN111362594AGlue evenly distributedEvenly distributedElectric machineryManufacturing engineering

The invention belongs to the technical field of hollow glass production, and concretely relates to a hollow glass glue-injecting and laminating integration machine. The machine comprises four supporting rods, the same mounting plate is fixedly mounted at the top ends of the four supporting rods, a cavity is formed in the mounting plate, a first motor is fixedly mounted in the cavity, a first bevelgear is fixedly mounted on an output shaft of the first motor, a rotating shaft is rotatably mounted on the mounting plate, the bottom end of the rotating shaft extends into the cavity and is fixedlyprovided with a second bevel gear, the second bevel gear is engaged with the first bevel gear, a rotating disc is fixedly mounted at the top end of the rotating shaft, a mounting frame is fixedly mounted at the top of the mounting plate, and a hydraulic cylinder is fixedly mounted on the mounting frame. The machine is easy to operate and high in practicability, the position of glass can be automatically adjusted, glue injection can be conducted on the two sides at the same time, the glue injection efficiency is high, glue injection is uniform and tidy, and the glue injection quality is improved.

Owner:LIAONING TIANLI ALUMINUM & PLASTIC BUILDING MATERIALS

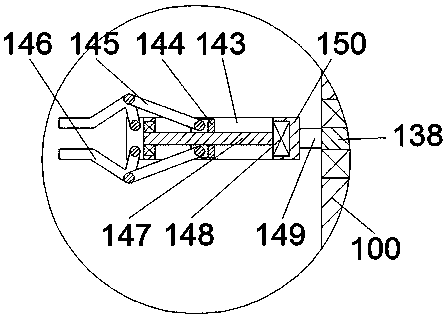

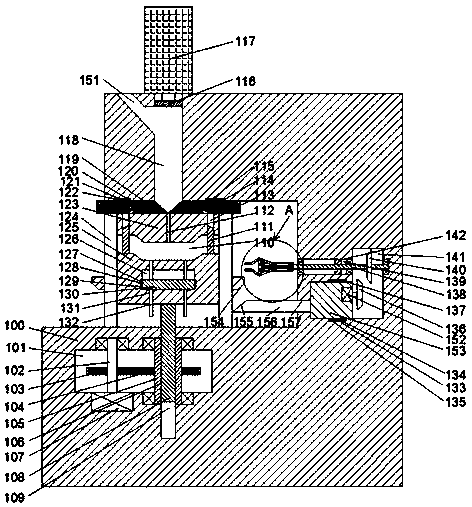

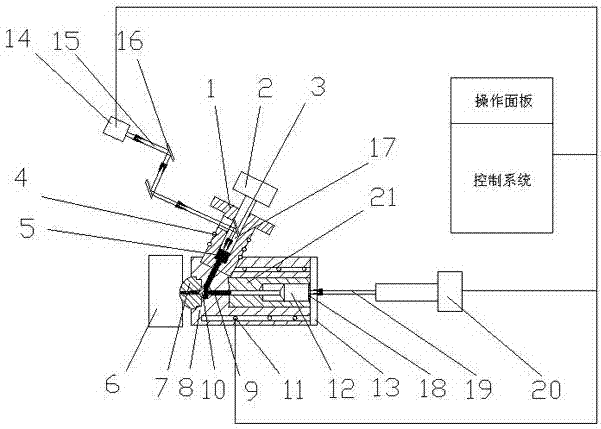

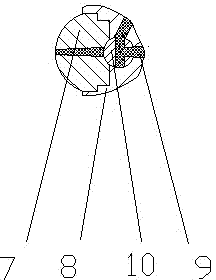

Micro-injection moulding method based on laser plasticizing and impacting technology and apparatus

ActiveCN103042651AEfficient Micro PlasticizationLaser plasticizing time is shortCoatingsComputer control systemTemperature control

The invention discloses a micro-injection moulding method based on laser plasticizing and impacting technology and an apparatus, and relates to a plastic micro-moulding field, particularly a plastic micro-injection moulding method based on the laser plasticizing and impacting action, suitable for plastic micro-injection moulding process. The apparatus comprises: a plastic plasticizing system, which is composed of a laser, a laser beam controller, a plasticizing cylinder, a valve and a heating and temperature controlling device; an impact propulsion and injection system, which is composed of a laser generator, a restraint layer, a laser absorbent, a impact injection push rod, and a heating and temperature controlling device; a mould; and a computer control system, for controlling the plasticizing system, the impact propulsion injection system and the valve, and controlling the temperature. The invention provides a novel micro-injection moulding method and an apparatus, resolves the problems in the plastic plasticization and melt injection propulsion manners for micro-injection moulding, and implements the purposes of energy saving, environmental protection and high efficiency for micro-injection moulding.

Owner:JIANGSU UNIV

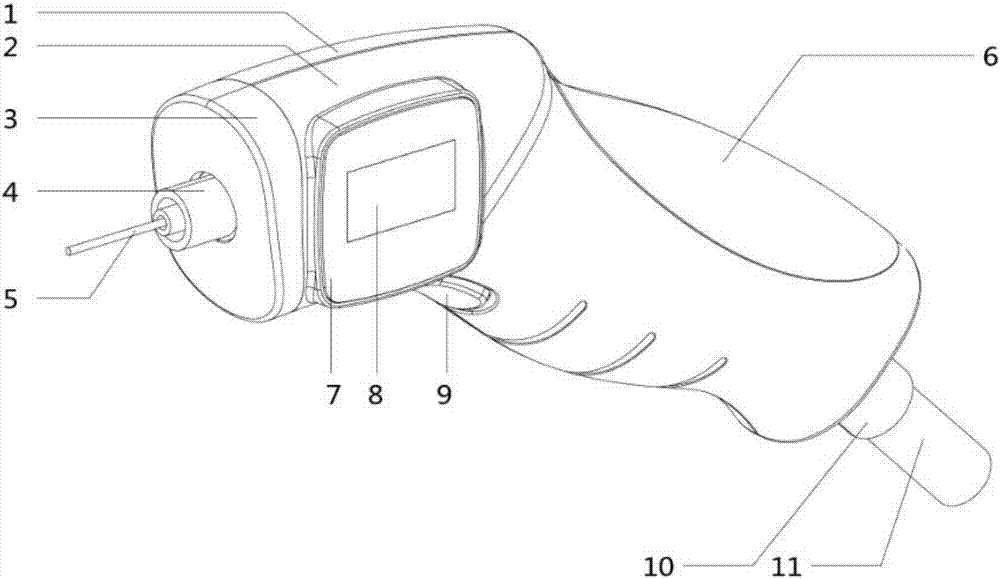

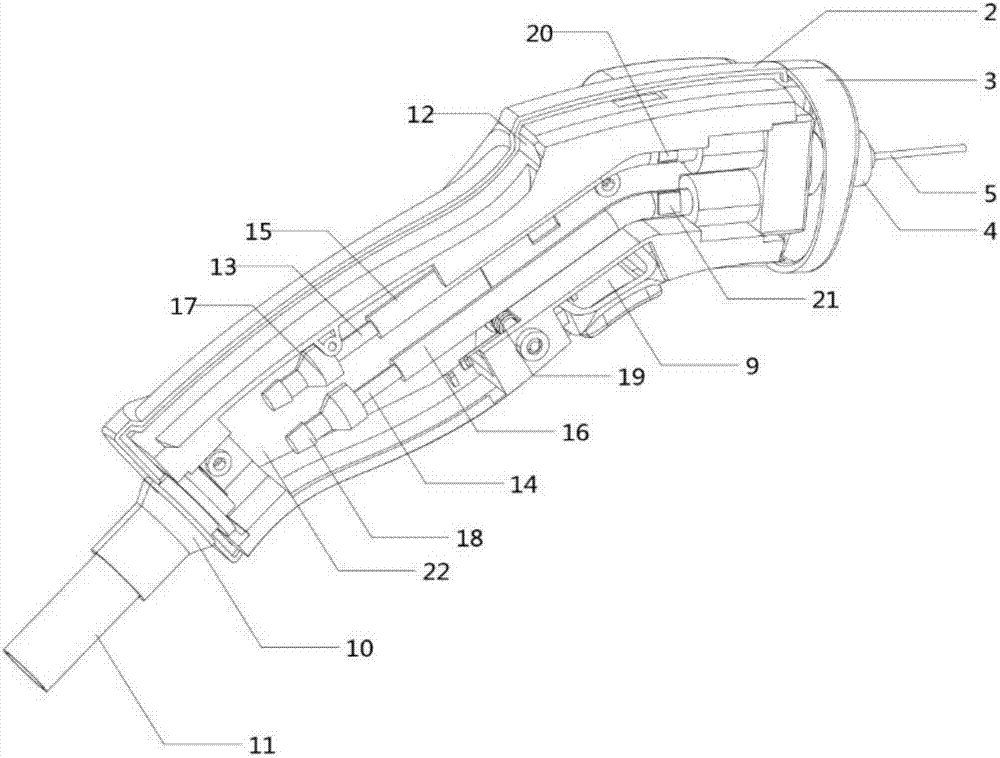

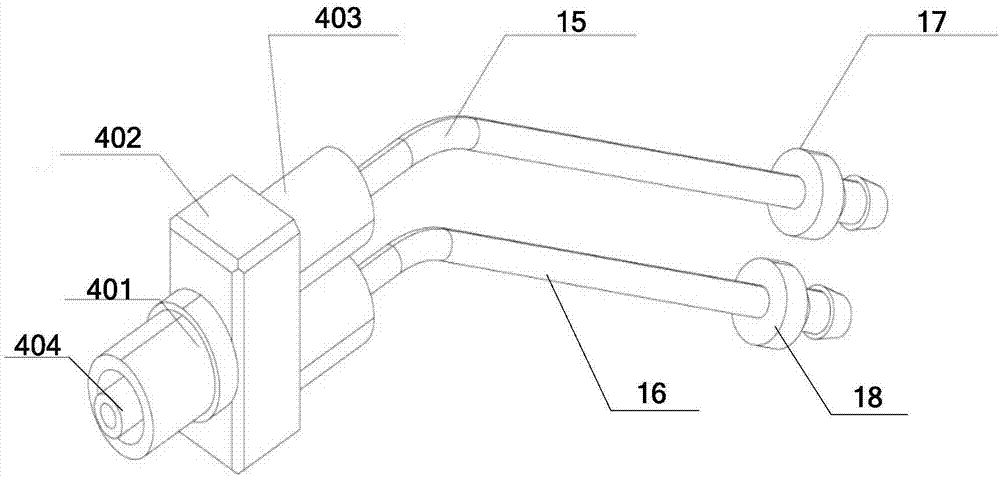

Injection device

The invention provides an injection device. The injection device comprises a shell body and an injection head which is disposed inside the shell body, wherein the injection head includes a one-way valve, an injection cavity which is communicated with the output end of the one-way valve, and at least two infusion tubes which are communicated with the input end of the one-way valve and gather in the injection cavity inside the one-way valve; the shell body includes a gripping part and an injection part, and the injection cavity stretches out of the injection part of the shell body and is removably connected with a syringe needle. The injection device is provided with a portable injection handle, and the whole shell body is jointly formed by a double-layer shell body, thereby the injection device is light in weight and easy to carry; a plurality of infusion tubes are communicated with the input end of the one-way valve, thereby the injection device can achieve a simultaneous mixed injection or a continuous injection in a specific order of a plurality of vaccines; simultaneously, the vaccines flow in one direction isolated-inside the infusion tubes, an infusion cavity, the one-way valve and the injection cavity, thereby resolving the backflow, contamination and leakage of the vaccines; besides, a heating component and a temperature sensor are arranged outside the infusion tubes, thereby the temperature of the vaccines can be controlled at any time and the injection quality is improved.

Owner:青岛澳德思瑞智能免疫技术有限公司

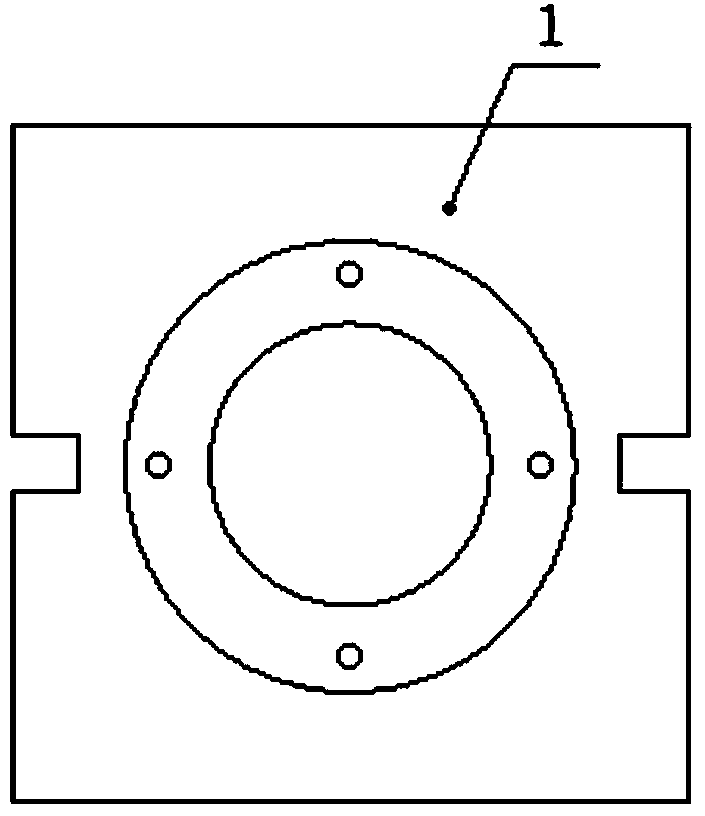

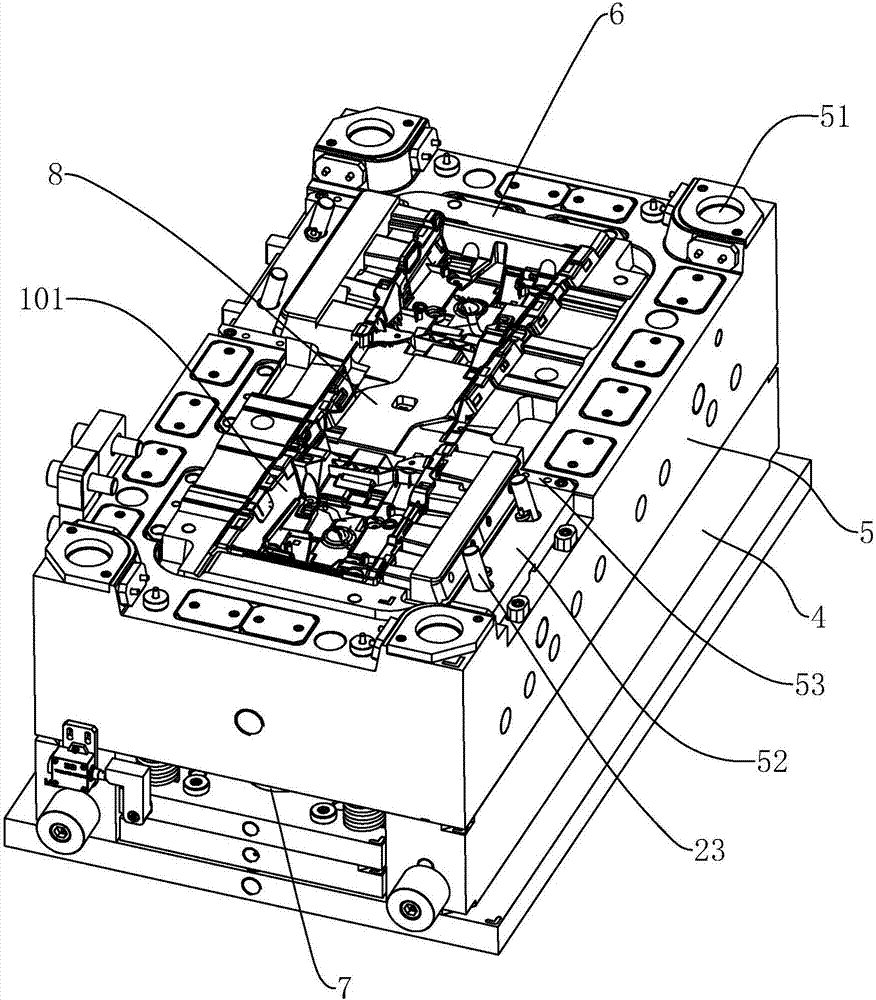

Forming mold for auxiliary instrument middle mounting support

The invention discloses a forming mold for an auxiliary instrument middle mounting support. The forming mold comprises a fixed mold seat plate, a fixed mold plate, an upper mold core, a movable mold seat plate, a movable mold plate, a lower mold core, a driving device, a forming column, a vertical male mold insert, a hook face male mold insert, a side wall male mold insert, a forming male mold insert and a forming female mold insert. The fixed mold plate is provided with a guiding column, and the movable mold plate is slidably provided with a sliding block. The guiding column is arranged in the sliding block in a penetrating mode, the tail end of the guiding column is inserted in the movable mold plate and slidably connected with the movable mold plate, and an orientation assembly is arranged between the sliding block and the movable mold plate. A first punching male mold, a second punching male mold, a third punching male mold and a fourth punching male mold are connected to the sliding block. The forming column, the vertical male mold insert, the hook face male mold insert, the side wall male mold insert, the forming male mold insert, the forming female mold insert, the upper mold core and the lower mold core form the cavity wall of a model cavity. The auxiliary instrument middle mounting support is formed through integrated injection molding, the workpiece surface evenness of the auxiliary instrument middle mounting support is improved, and thus the forming quality of the auxiliary instrument middle mounting support of the middle of an auxiliary instrument is improved.

Owner:宁波斯穆汽车模具有限公司

Opening mechanism and opening method of soft package battery air bag

PendingCN109888362AIncrease productivityImprove product qualityFinal product manufactureSecondary cells manufactureEngineeringAirbag deployment

The invention discloses an opening mechanism and an opening method of a soft package battery air bag; the opening mechanism of the soft package battery air bag comprises a rack, a vacuum suction cup module, an air bag clamping block module and a battery positioning module, wherein the vacuum suction cup module comprises a vacuum suction cup; the air bag clamping block module comprises an air bag clamping block; the vacuum suction cup is used for performing vacuum adsorption on the two side surfaces of the battery air bag and pulling open the battery air bag; the air bag clamping block can apply pressure to the side edges of the battery air bag while the battery air bag is pulled open by the vacuum suction cup; and the opening method comprises the steps that the two side surfaces of the battery air bag are sucked by the two vacuum suction cups and are pulled open in the direction, and the two air bag clamping blocks are adopted to apply side pressure on the side edges of the battery airbag. The opening mechanism and the opening method of the soft package battery gas bag have the advantages that the air bag opening efficiency is high, the battery liquid injection is facilitated, theliquid injection quality is good, and the like.

Owner:SHENZHEN LIDE TECH

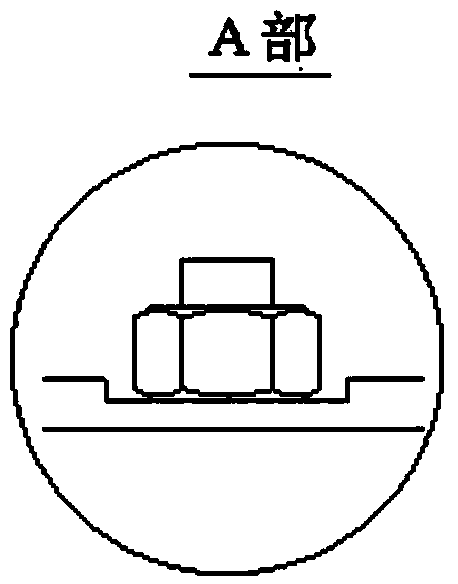

Two-color die for automobile instrument boards

InactiveCN104943070AStable fluid temperatureGuarantee the quality of injection moldingPlastic injection moldingEngineering

The invention discloses a two-color die for automobile instrument boards. The two-color die comprises a fixed die plate (1), a movable die rotation disc (2), a product (9), a first die and a second die, the fixed die plate (1) is provided with a soft plastic injection molding port (7) and a hard plastic injection molding port (8), the soft plastic injection molding port (7) is arranged on the first die, the hard plastic injection molding port (8) is arranged on the second die, one end of the first die is fixed on the fixed die plate (1), the other end of the first die is fixed on the movable die rotation disc (2), one end of the second die is fixed on the fixed die plate (1), the other end of the second die is fixed on the movable die rotation disc (2), and the first die and the second die respectively comprises a fixed die fixing plate (3), a fixed die (4), a movable die (5) and a movable die fixing plate (6). The two-color die for automobile instrument boards has the advantages of no generation of wastes, low cost, and guaranteeing of the injection molding quality through controlling the temperature of plastics in a runner.

Owner:宁海县现代模具有限公司

High-stability injection molding machine for plastic shoes

ActiveCN109177029AScientific and reasonable structureEasy to useDomestic articlesPower flowEngineering

The invention discloses a high-stability injection molding machine for plastic shoes. The injection molding machine comprises a feeding hole, electromagnets, sliding rods, magnets, a screening basketand screening holes, wherein the electromagnets are mounted on the inner wall in the feeding hole, the sliding rods are mounted at the top ends of the electromagnets and are externally sleeved with the magnets, a screening screen is fixedly mounted on one sides of the magnets through buckles, and the screening holes are formed in the bottom end and bottom of the screening screen. The injection molding machine is scientific and reasonable in structure and safe and convenient to use; by arranging the electromagnets, the sliding rods, the magnets, the screening basket and the screening holes, alternating current in the electromagnets is continuously changed so as to change the magnetism of the electromagnets constantly, the to-and-fro shaking of the screening basket is effectively realized through the cooperation with the magnets, and the automatic screening of the raw materials in the feeding process can be realized through the cooperation with the screening holes, so that the raw material screening time is saved, the working efficiency of the injection molding machine is improved, and the injection molding quality of the injection molding machine is improved.

Owner:揭阳市新华龙机械设备有限公司

Measurement control method of an injection molding machine

ActiveUS7914716B2High measurement accuracyAccurately and reliably stoppingFluid pressure measurement using ohmic-resistance variationAuxillary shaping apparatusScrew positionMachine

A measurement control method uses an ending target position Xes calculated by adding a prescribed length Ls to a measurement ending position Xe. A rotation rate pattern Ar for rotating a screw 2, a back pressure Ps in relation to the screw 2, and a retraction rate pattern Ab for the screw 2 to retract, are set in advance. The remaining rotation rate pattern Ar to stop the rotation of the screw 2 at the ending target position Xes from the detected screw position X, is calculated at the time of measurement, and the rotation of the screw 2 is stopped based on the calculation. Further, the remaining retraction rate pattern Ab is calculated from the detected retraction rate Vd, and the retraction of the screw 2 is stopped based on the calculation. The result is the stopping of the screw at the measurement ending position Xe.

Owner:NISSEI PLASTIC IND CO LTD

High-performance injection molding automobile part

InactiveCN106881828AImprove injection qualityNot easy to produceDomestic articlesInjection molding machineMaterials science

Owner:黑龙江圣邦投资咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com