Motor housing injection molding method with metal insert and injection mold of motor housing injection molding method

A metal insert, injection mold technology, applied in other household appliances, household components, household appliances, etc., can solve problems such as scrapping, damage to the pin 101, collision, etc., to reduce scrap rate, improve production efficiency, and ensure accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

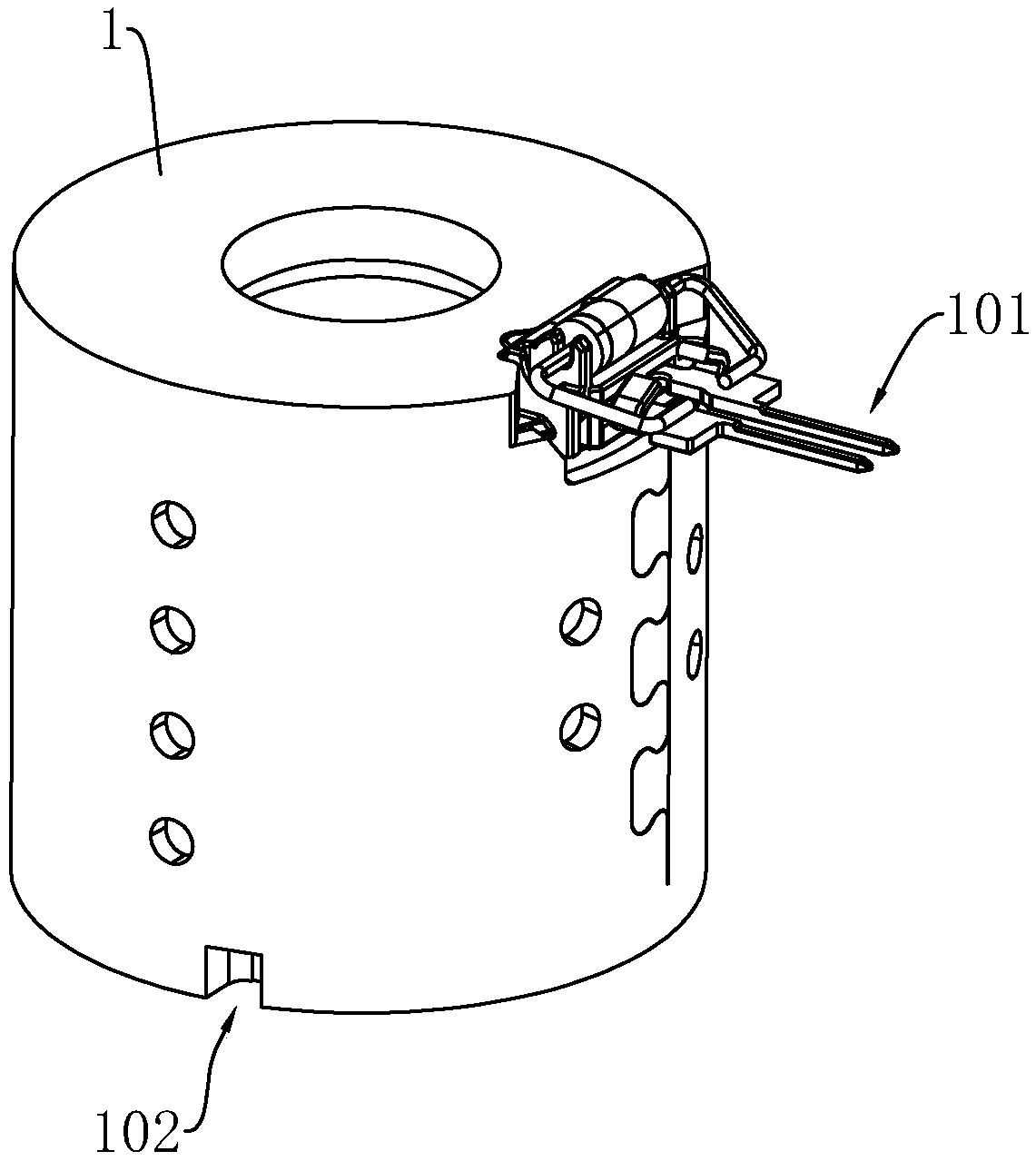

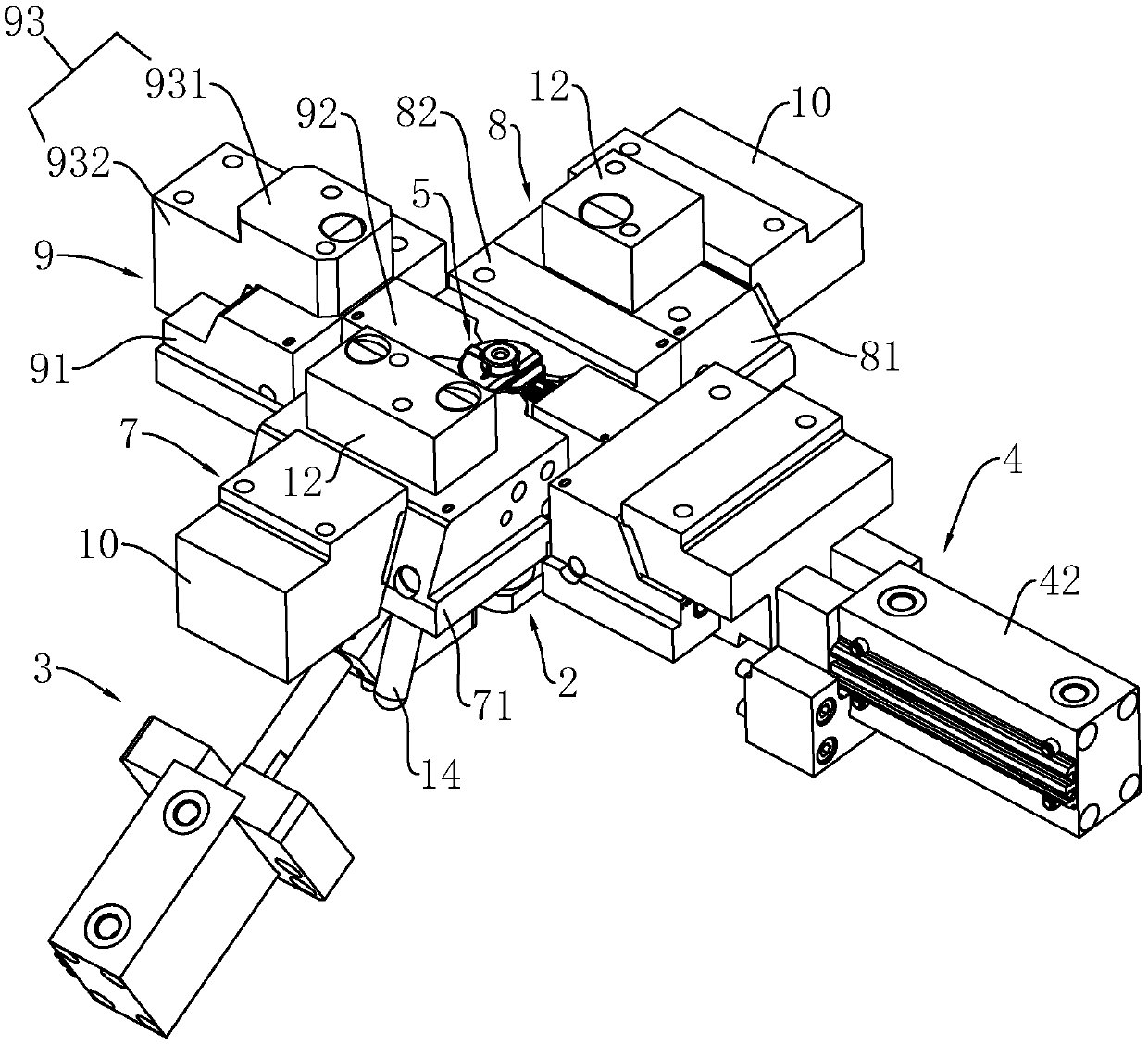

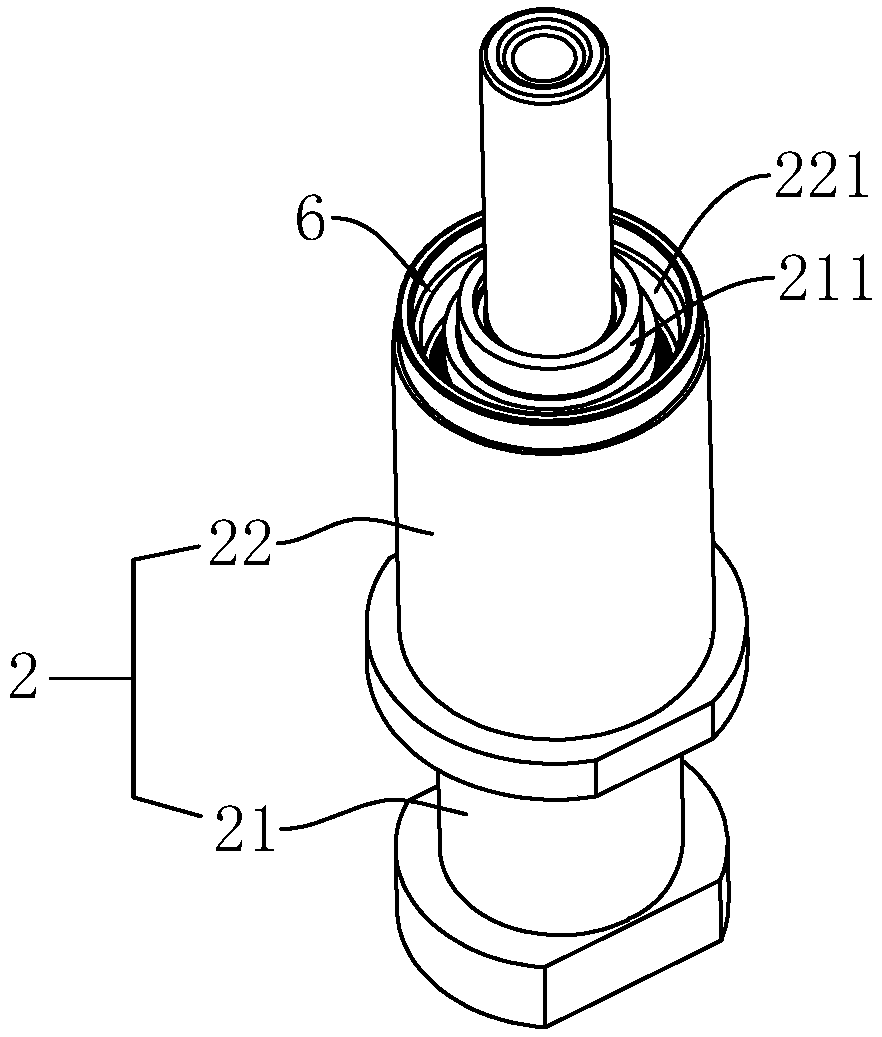

[0050] See attached figure 2 , an injection mold mainly used for the injection molding operation of a motor casing with a metal insert 1, which includes an axial positioning assembly 2, a pre-positioning assembly 3, a final positioning assembly 4 and a mold clamping assembly arranged on a workbench . The axial positioning component 2 can be used to install the metal insert 1 and realize the axial positioning of the metal insert 1 . After the axial positioning component 2 realizes the axial positioning of the metal insert 1, the pre-positioning component 3 can realize the circumferential pre-positioning of the metal insert 1, so that the installation angle of the metal insert 1 on the axial positioning component 2 can be determined . After the pre-positioning component 3 realizes the circumferential pre-positioning of the metal insert 1 , the final positioning component 4 can form an insertion fit with the pin 101 on the metal insert 1 , and realize precise positioning of th...

Embodiment 2

[0066] See attached Figure 8 , a method of injection molding a motor housing with a metal insert, comprising the steps of:

[0067] S1. Preparation, setting predetermined positioning points on the outer wall of the metal insert 1 . Before actually starting the injection molding operation, preparatory work should be carried out; considering the ring structure of the metal insert 1, in order to facilitate the determination of the installation angle of the metal insert 1, a predetermined position can be set on the outer wall of the metal insert 1. In conjunction with the accompanying drawings, the predetermined location point can be a positioning notch 102; in actual operation, the positioning notch 102 can form a snap-fit fit with the positioning protrusion 3221 on the positioning fitting block 322, thereby realizing predetermined positioning of the metal insert 1. bit.

[0068] S2, axial positioning. After the above-mentioned preparatory work is completed, the first drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com