Patents

Literature

1023 results about "Metal insert" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

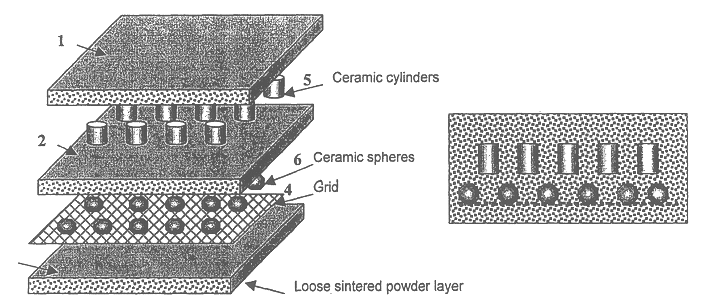

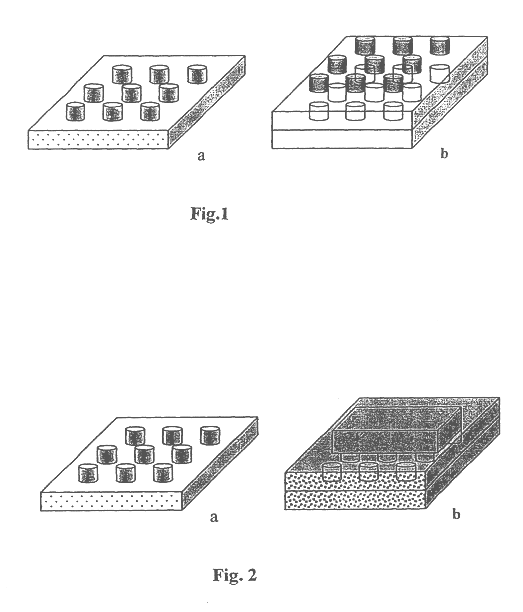

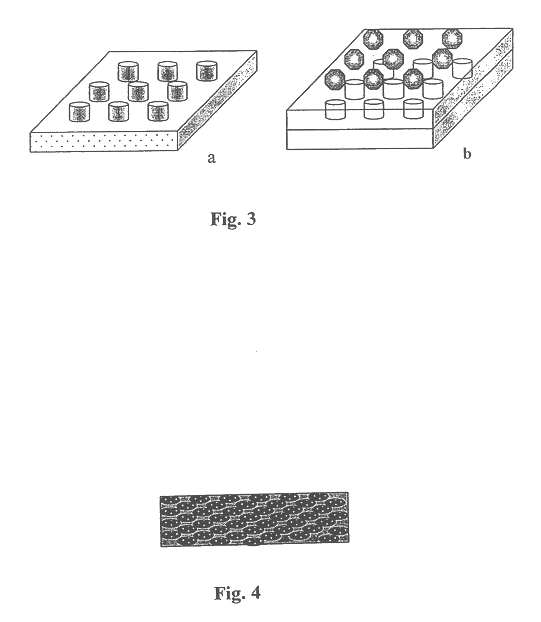

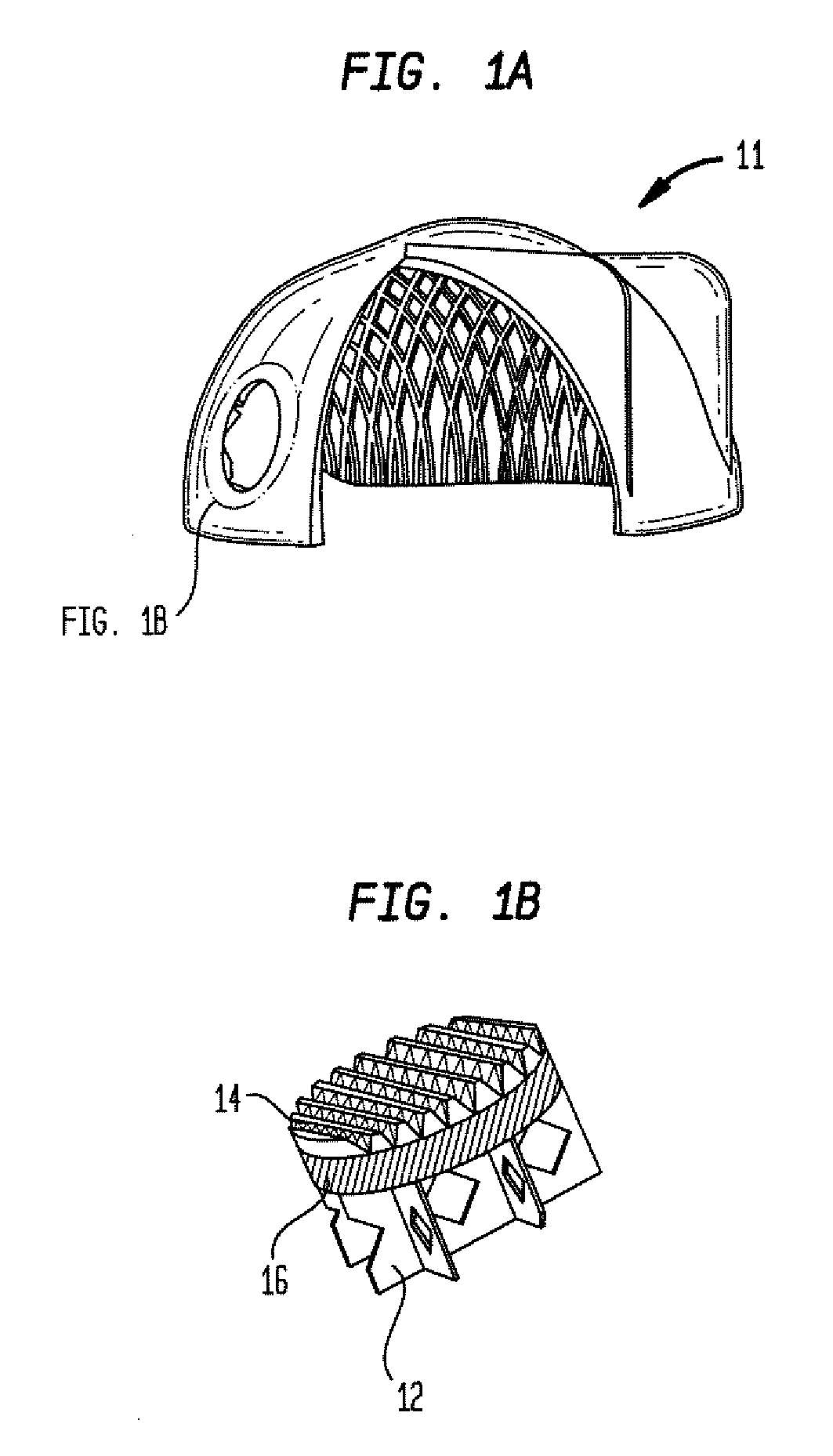

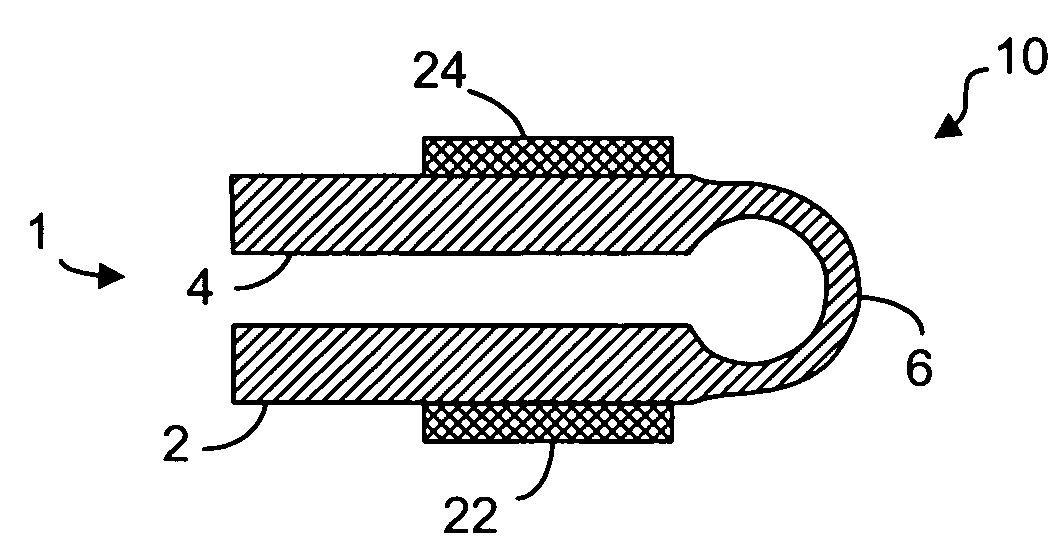

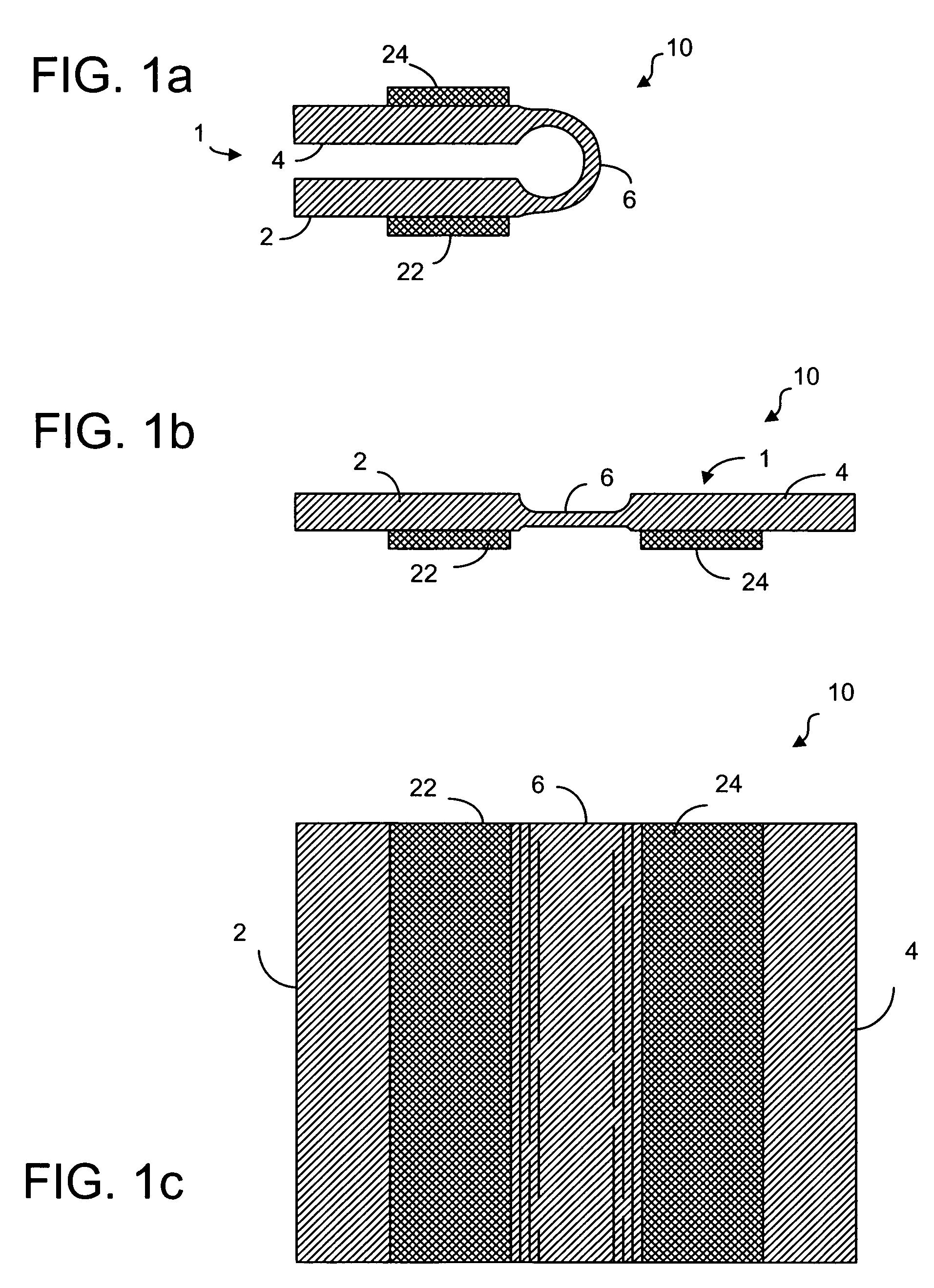

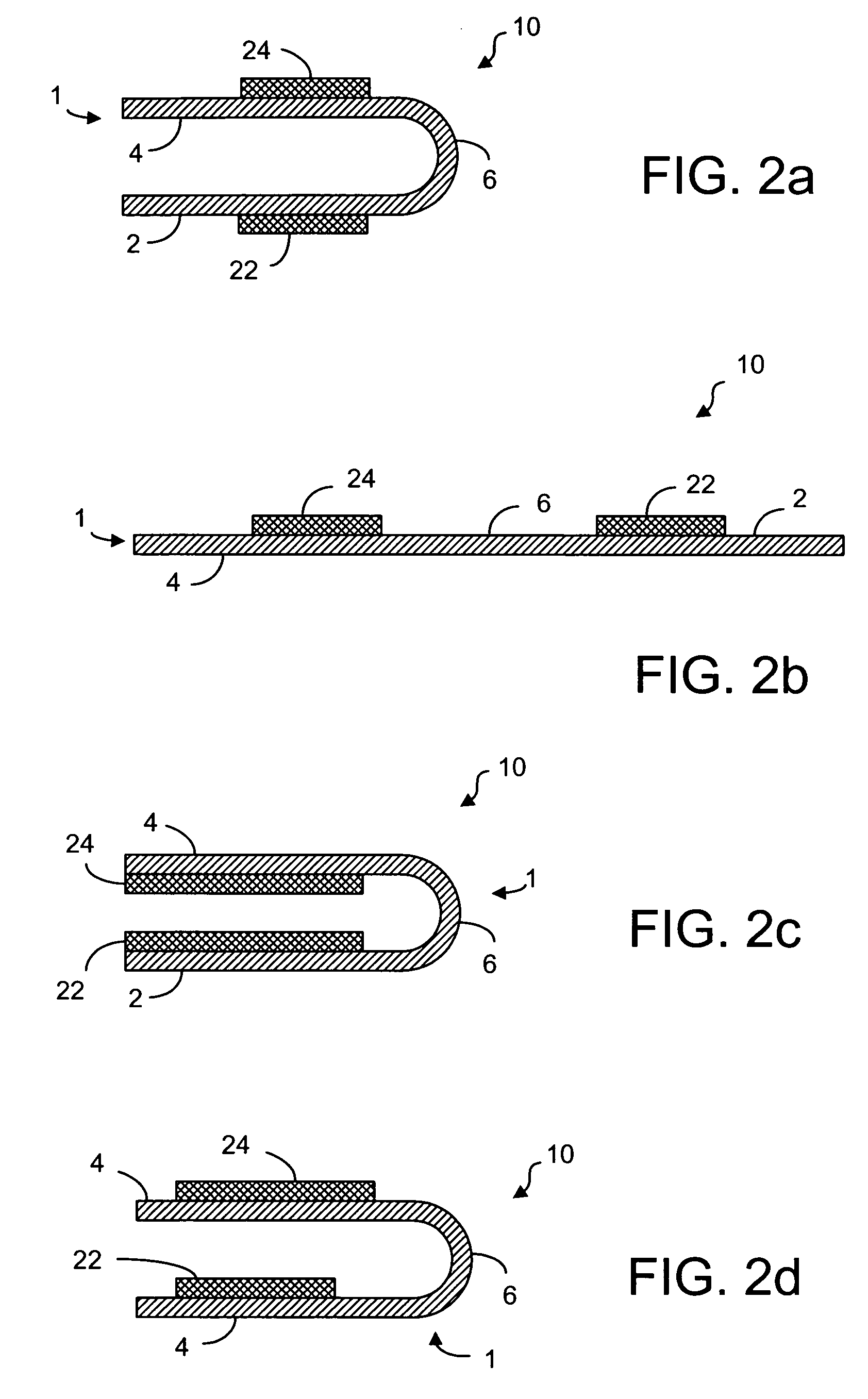

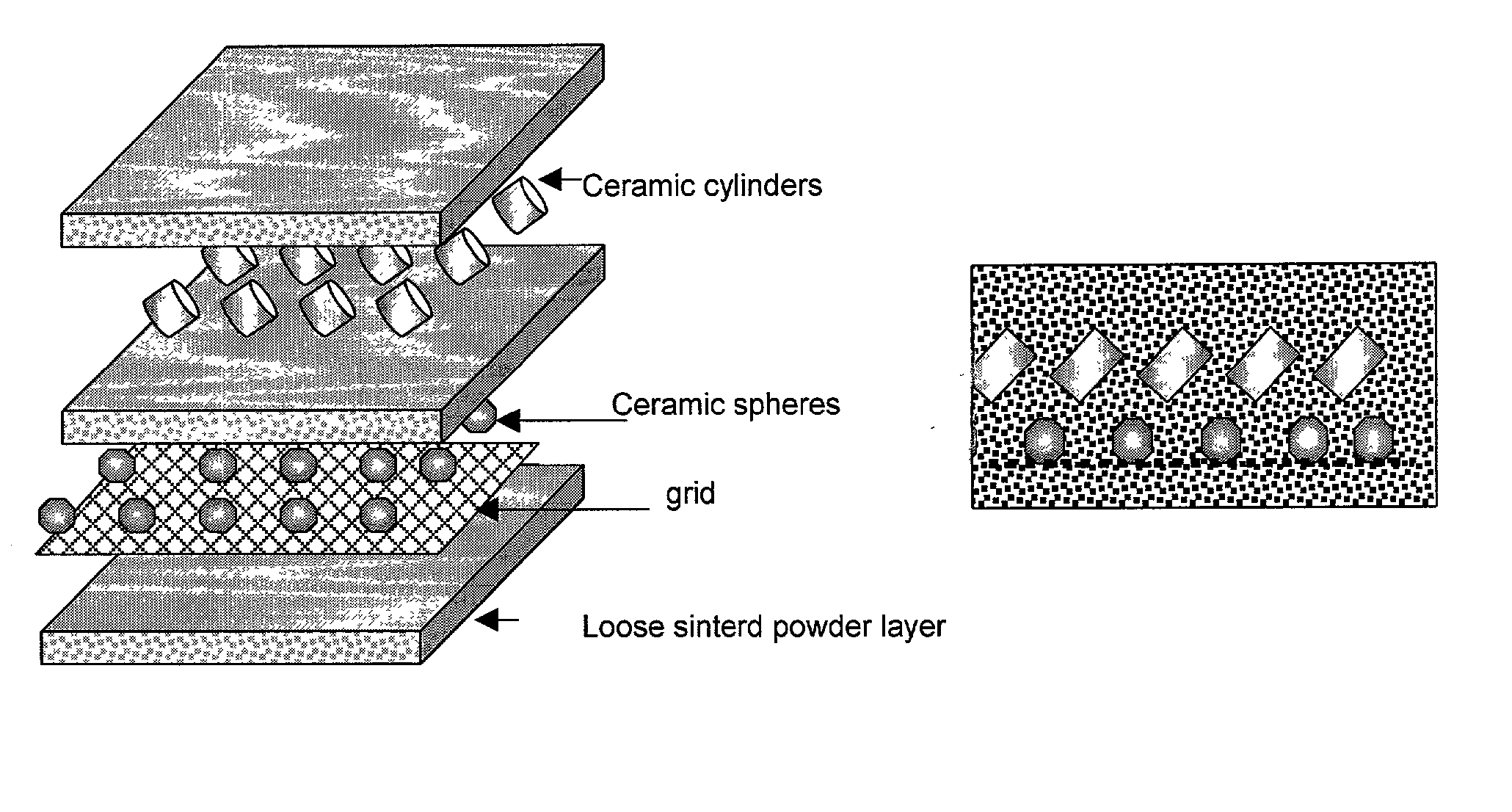

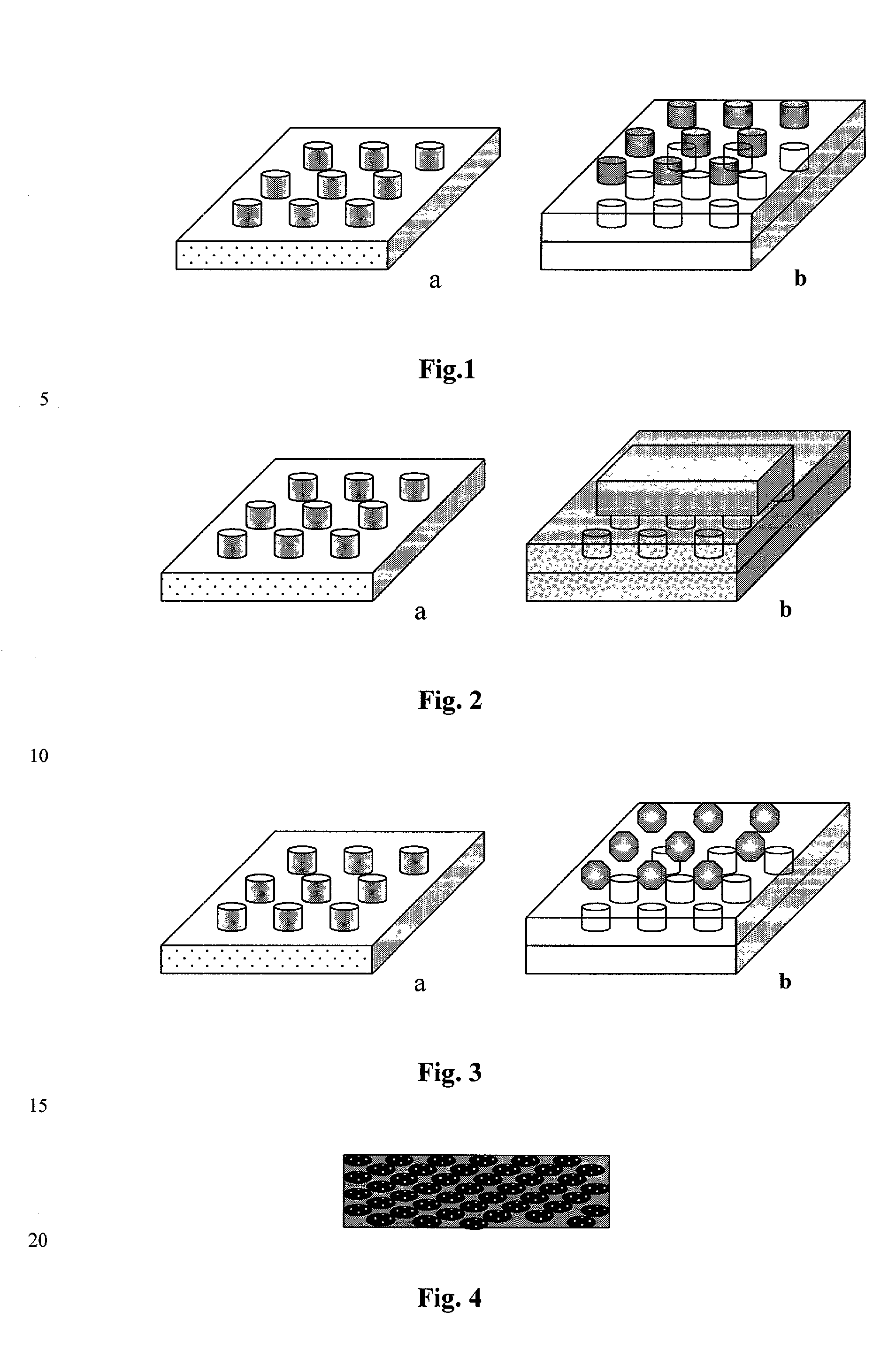

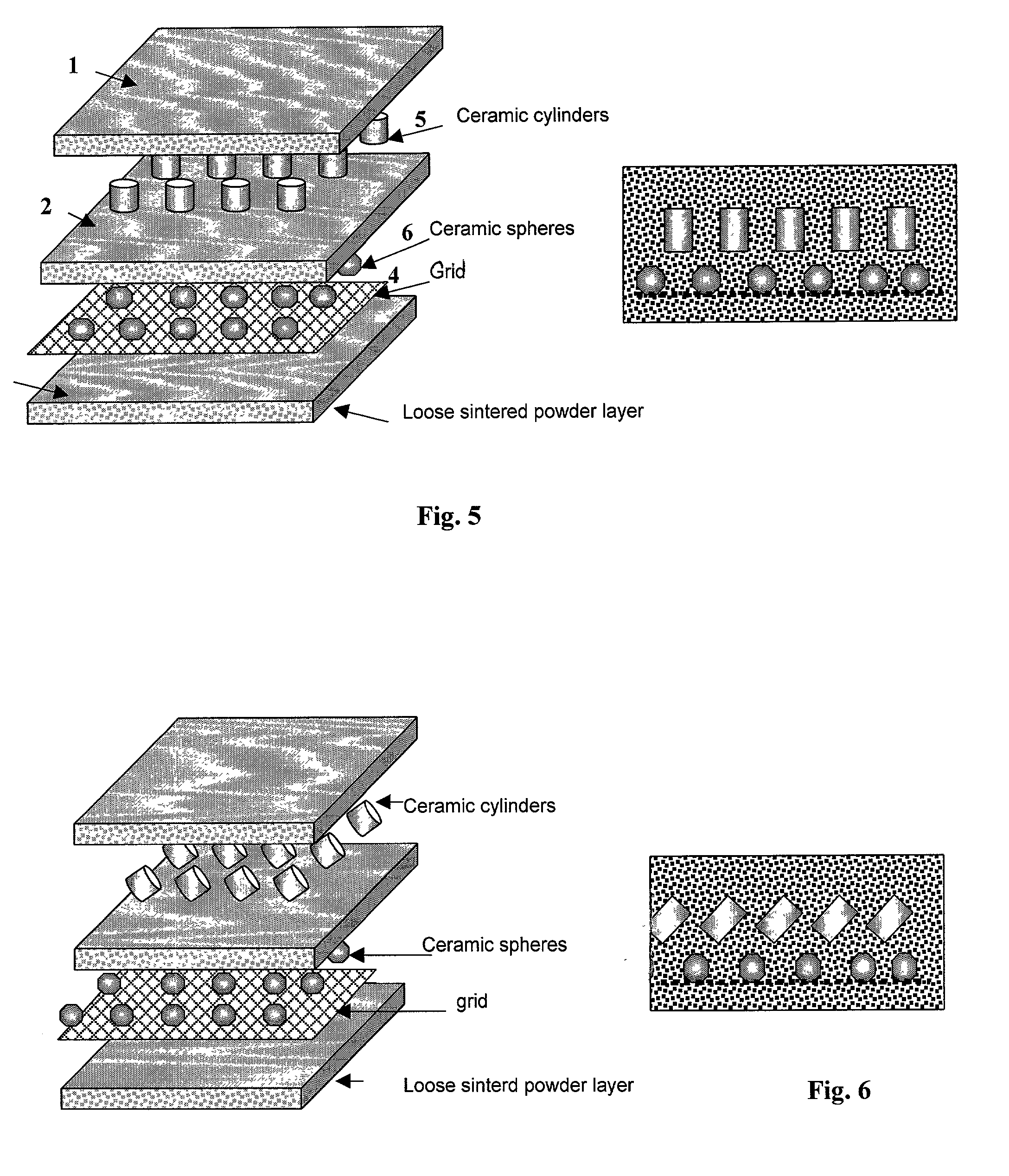

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

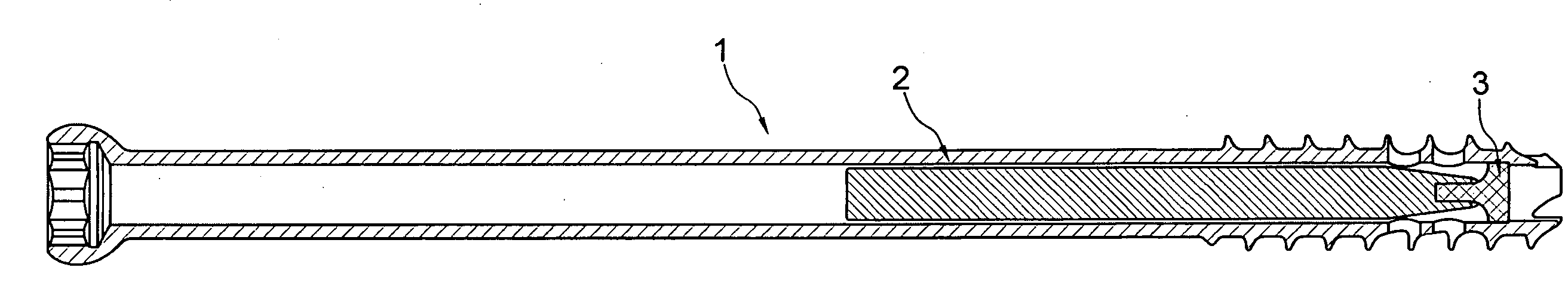

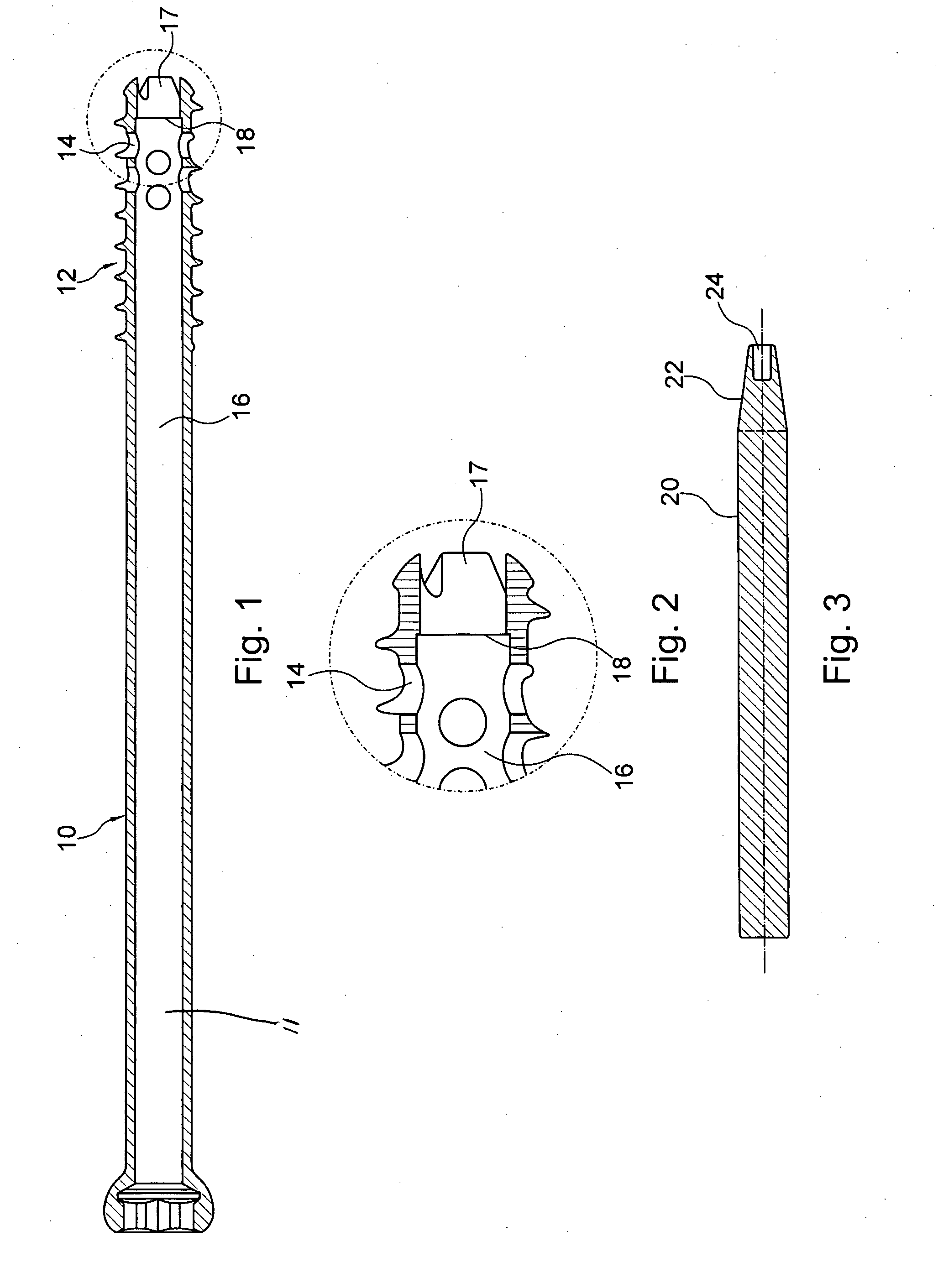

Device for fixation of bone fractures

A device and method for fixation of bone fractures has a bone screw comprising a shank with a threaded end portion, on the outer surface. The screw has a through bore with two bore portions differing in diameter. A step in the diameter is formed between these bore portions and is located within the end of the screw having the thread. This step in diameter can support a metal insert which in turn supports a polymer pin when the latter if pressurized with a sonotrode in the bone screw. Together with an applied ultrasonic vibration the pressure fluidizes the polymer pin and presses the material through holes configured in the wall of the bone screw and into surrounding bone.

Owner:WOODWELDING +1

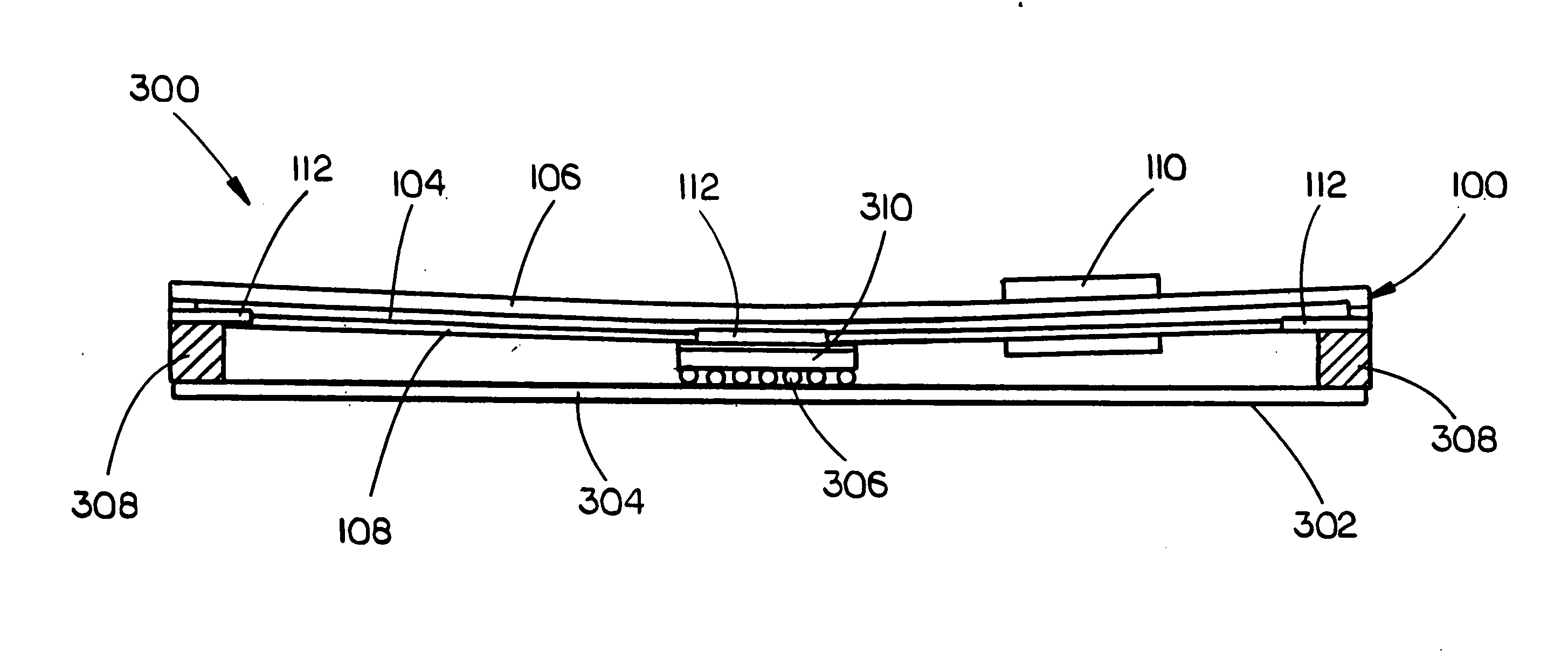

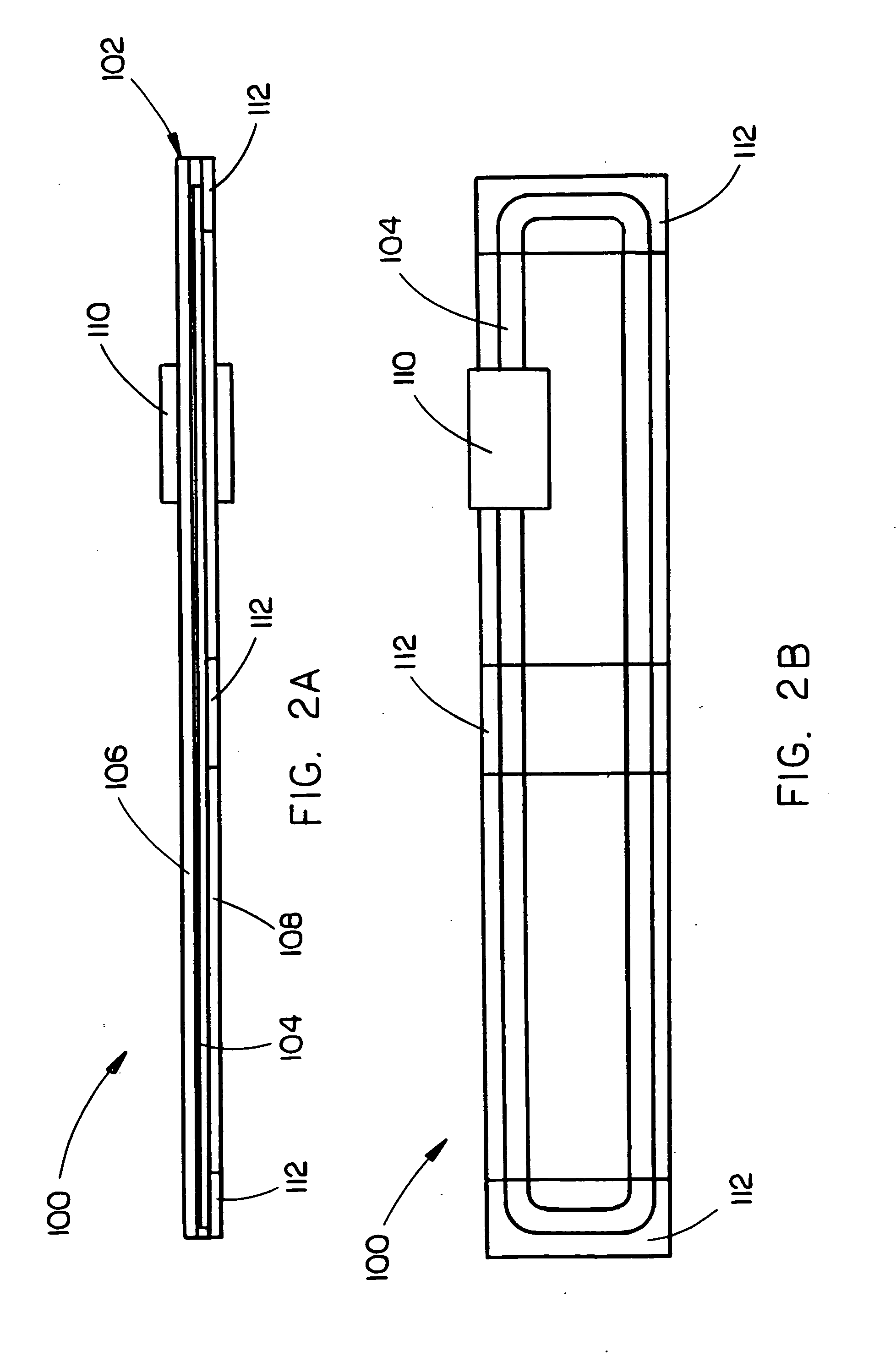

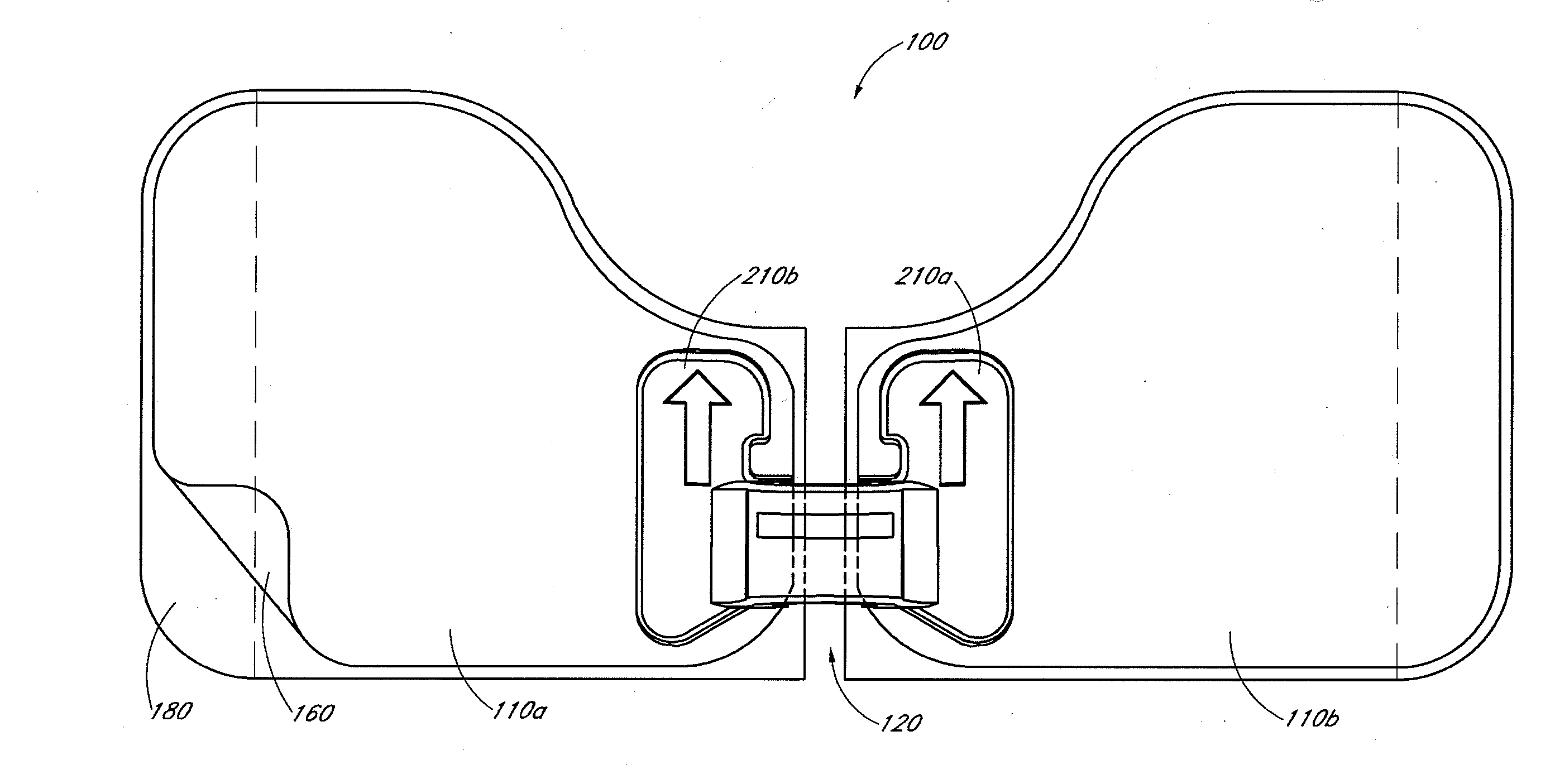

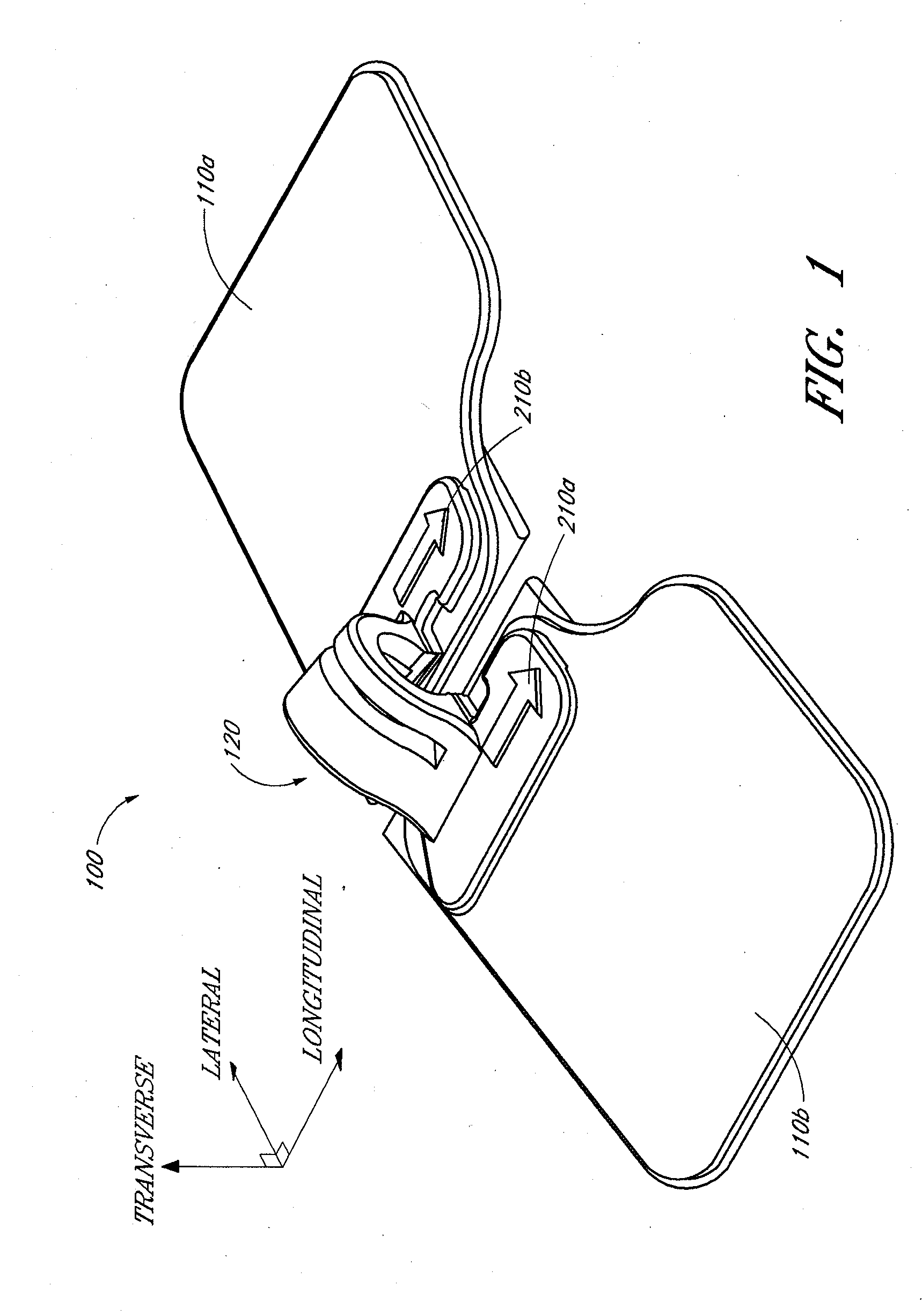

Mechanically compliant thermal spreader with an embedded cooling loop for containing and circulating electrically-conductive liquid

ActiveUS20100065256A1Additive manufacturing apparatusDigital data processing detailsEngineeringThermal contact

The present invention is a thermal spreader for providing a high effective thermal conductivity between a heat source and a heat sink. The thermal spreader may include a mechanically flexible substrate. The mechanically flexible substrate may be at least partially constructed of organic materials. The mechanically flexible substrate may form an internal channel which is configured for containing an electrically-conductive liquid. The thermal spreader may further include a pump. The pump may be configured for being connected to the substrate and for circulating the electrically-conductive liquid within the internal channel. The thermal spreader may further include one or more thermally-conductive, rigid metal inserts. Each insert may be configured for being in thermal contact with the electrically-conductive liquid and the substrate and for promoting heat transfer between the thermal spreader and the electrically-conductive liquid.

Owner:ROCKWELL COLLINS INC

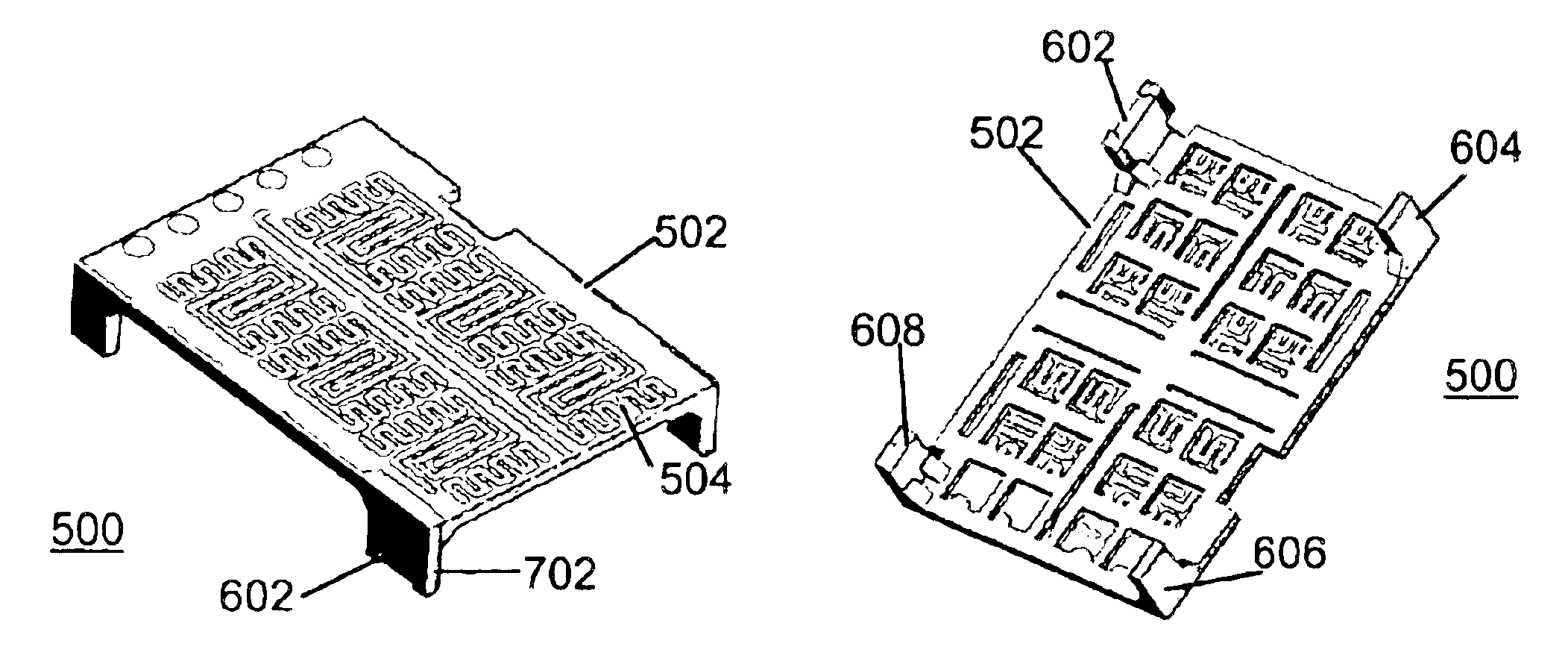

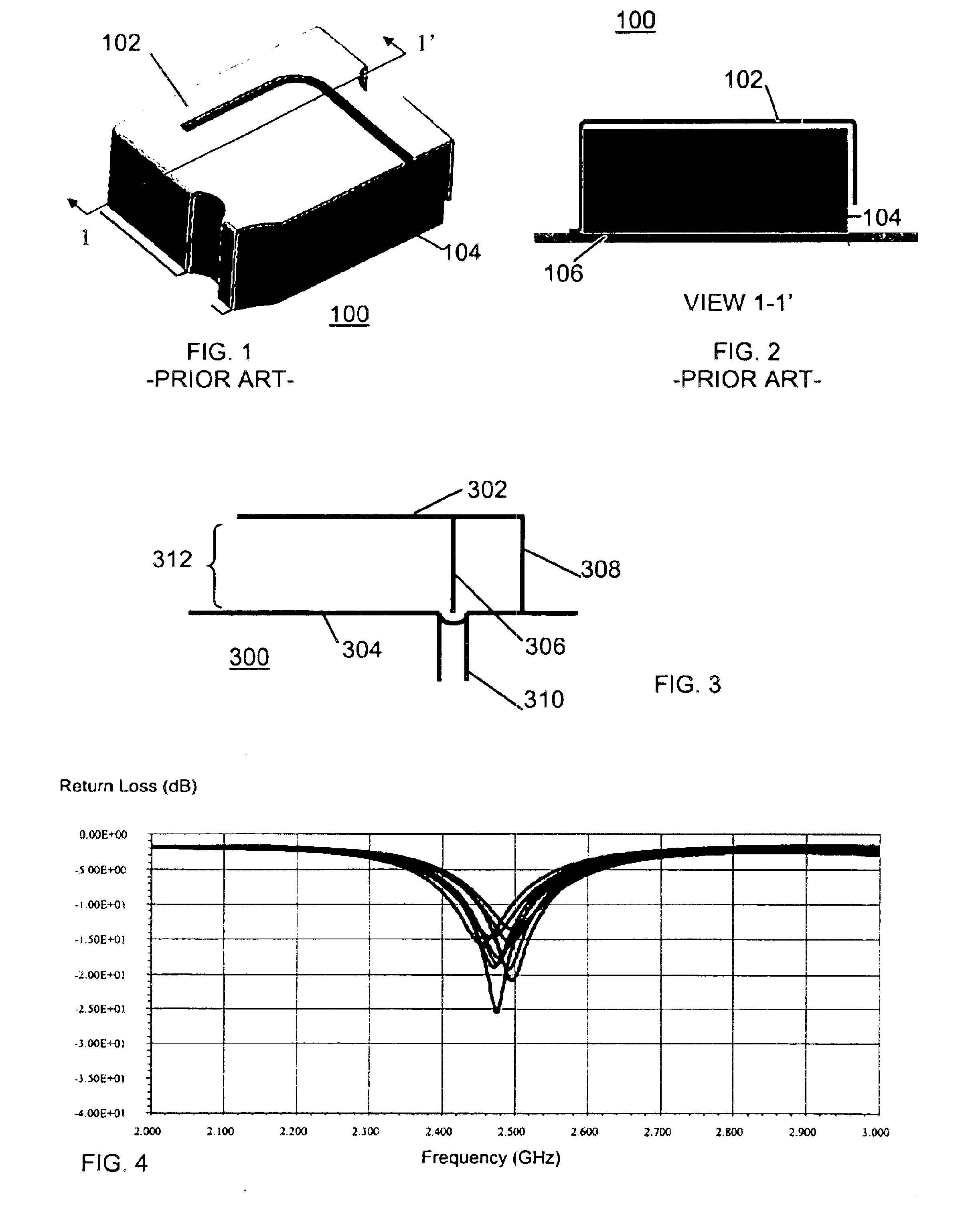

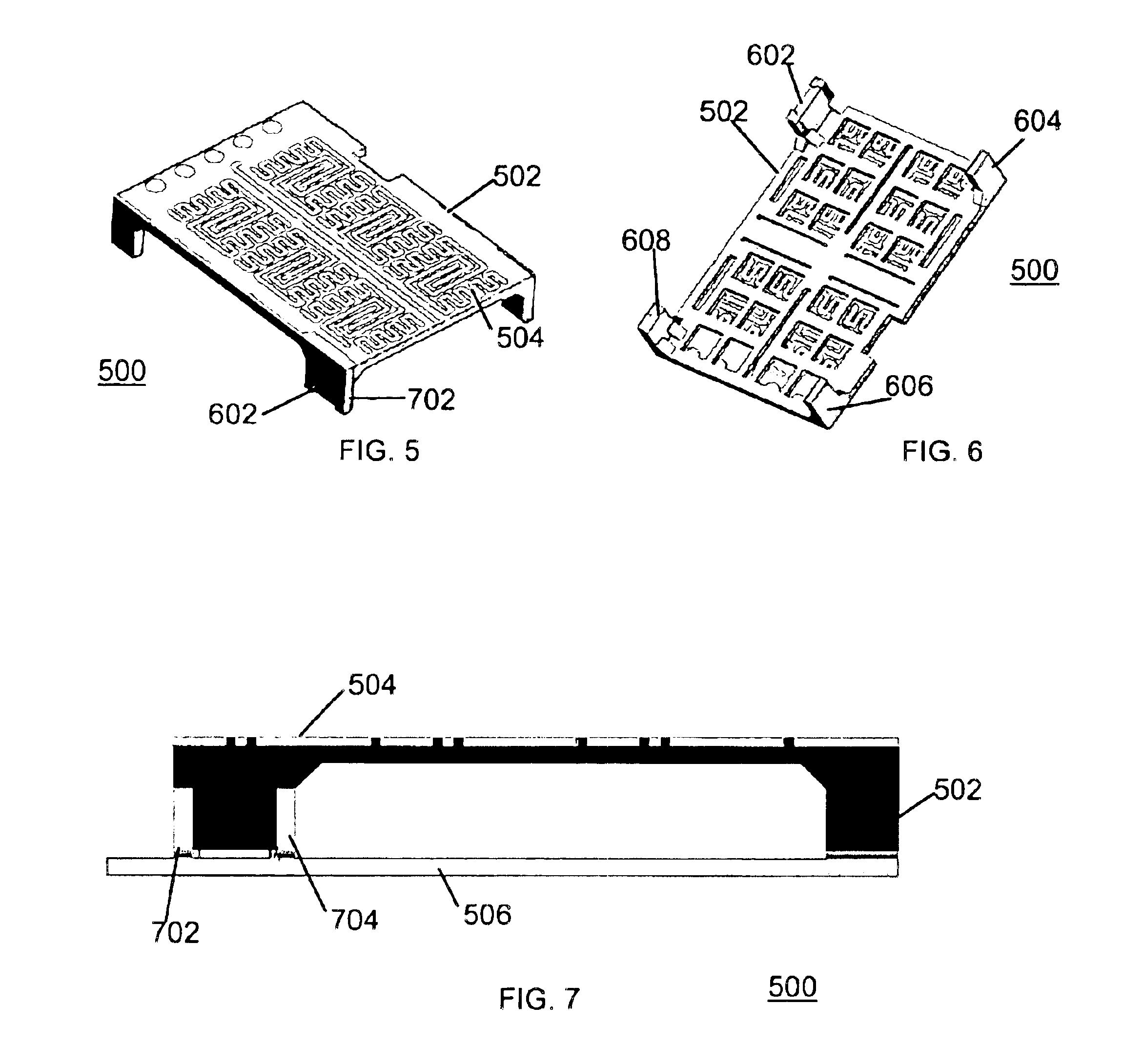

Method of manufacturing antennas using micro-insert-molding techniques

InactiveUS6822609B2Simultaneous aerial operationsAntenna supports/mountingsElectrical performanceGround plane

An antenna includes a precision micro-molded plastic spacer and a metal insert. The plastic spacer is configured for mounting to a printed circuit board (PCB) to maintain the metal insert a predetermined distance from a ground plane. Micro-insert-molding techniques produce tight mechanical dimensions including those which define the antenna height, ensuring reliable and consistent antenna electrical performance.

Owner:OAE TECH INC

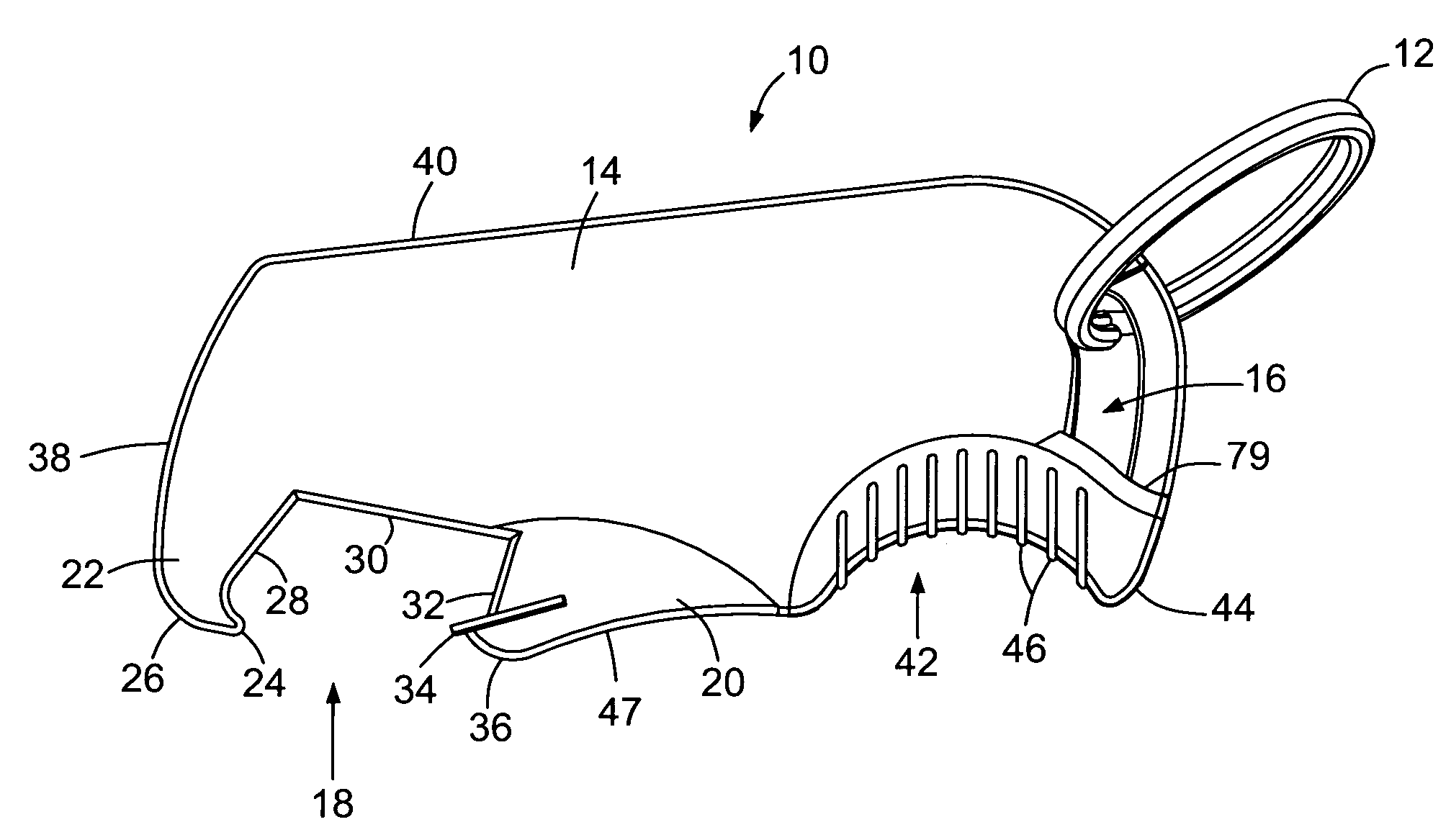

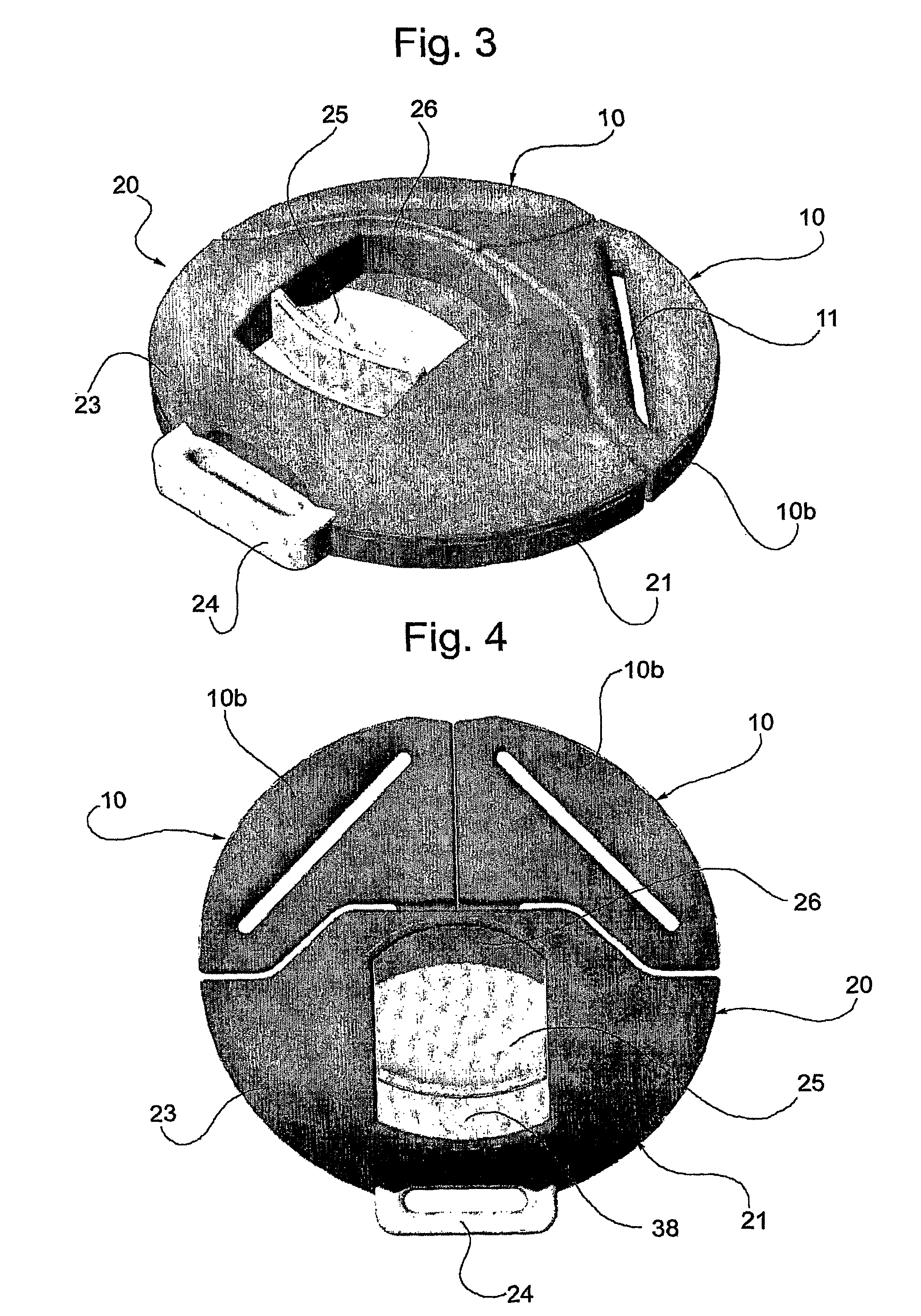

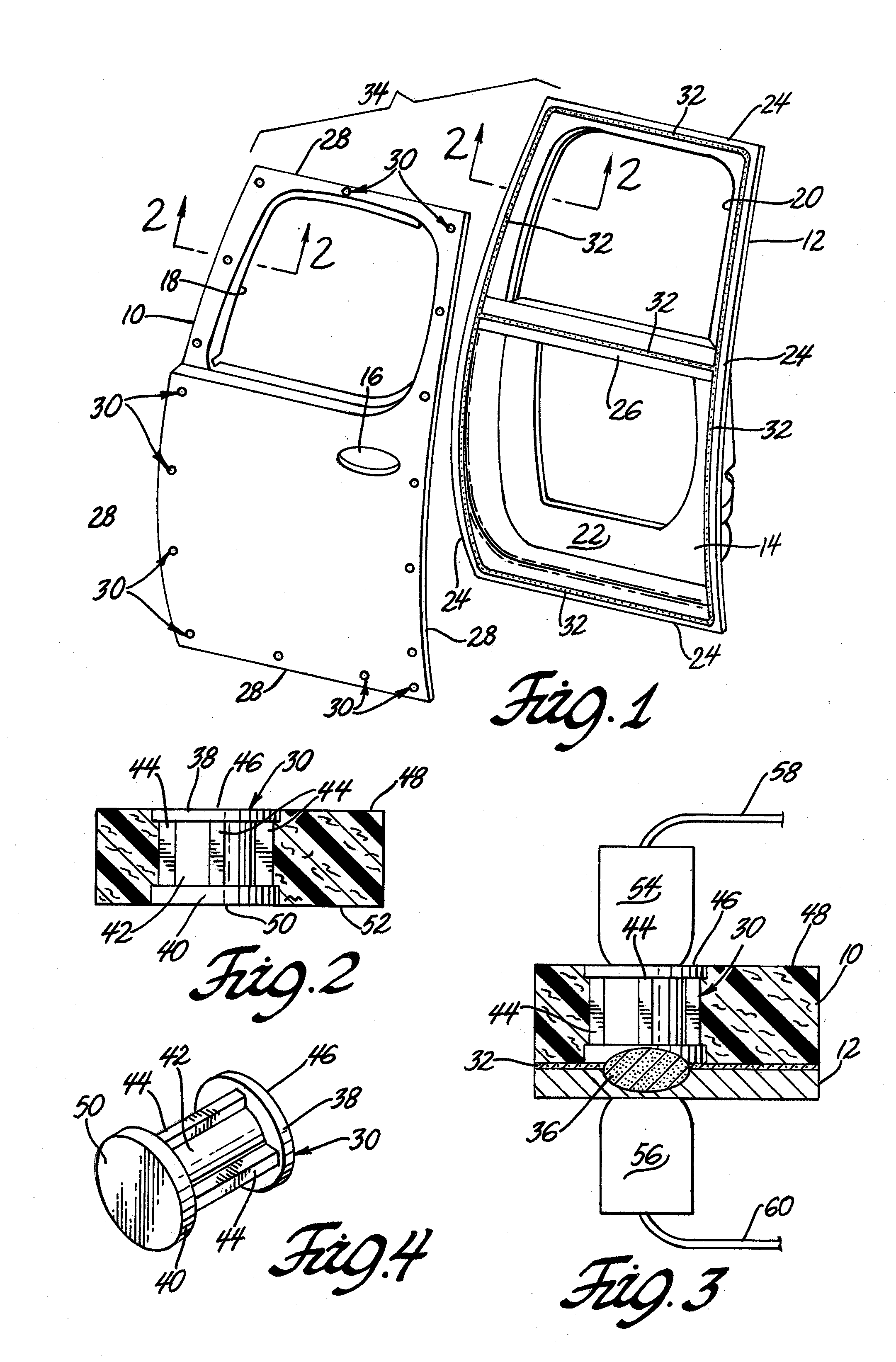

BOP assembly with metal inserts

InactiveUS6857634B2Improve reliabilityReduced diameter requirementsSleeve/socket jointsDrilling rodsElastomerEngineering

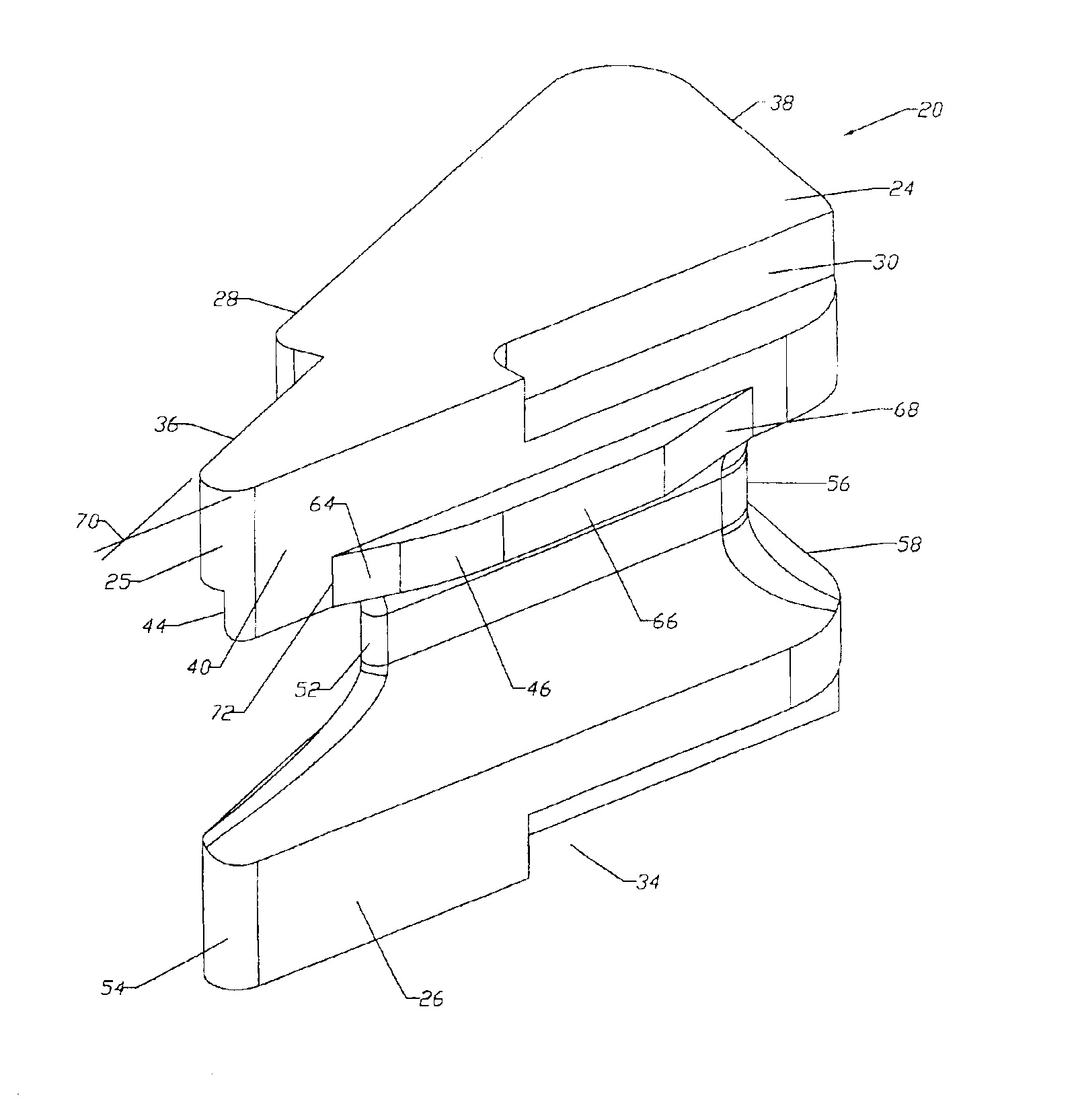

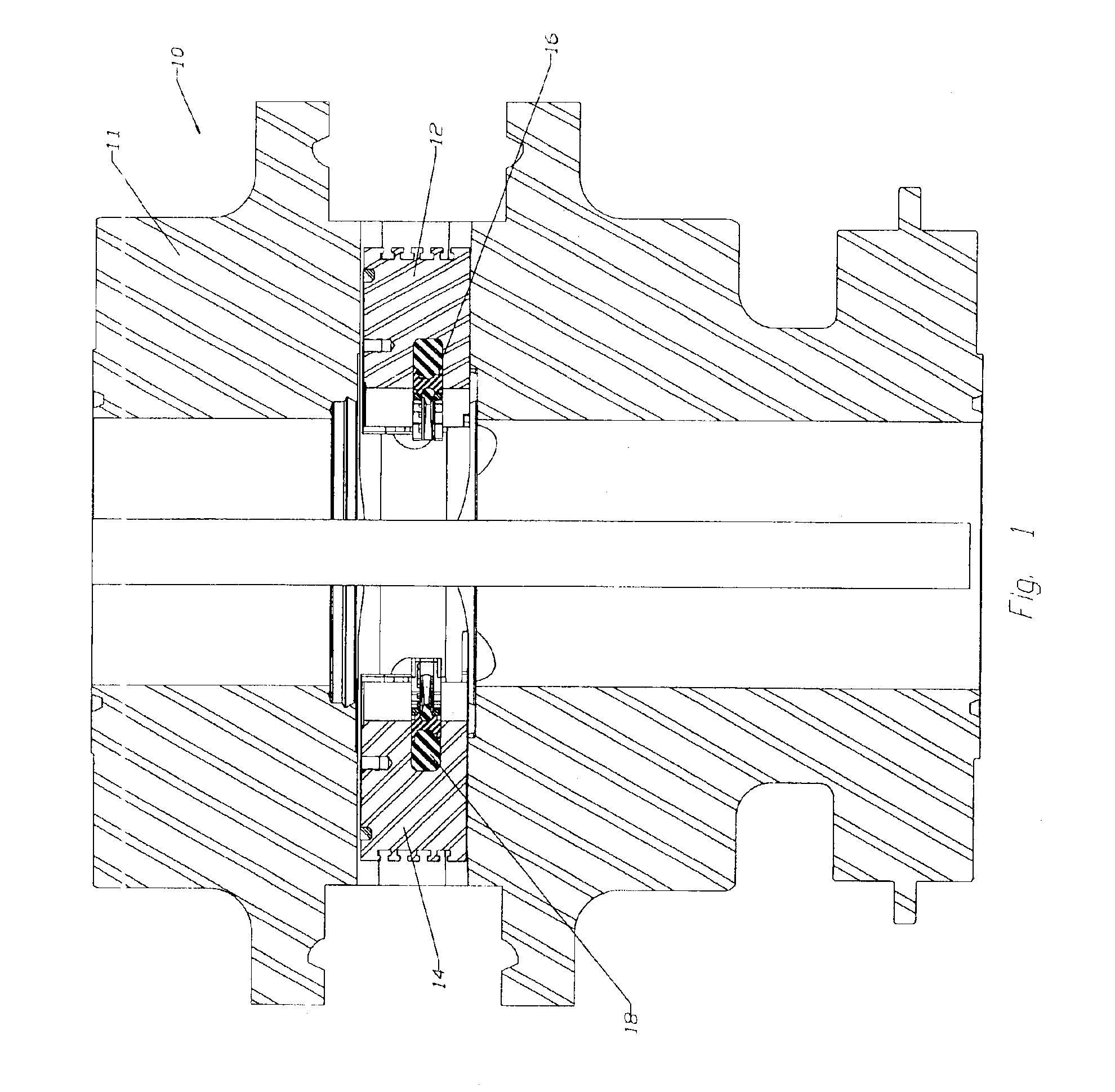

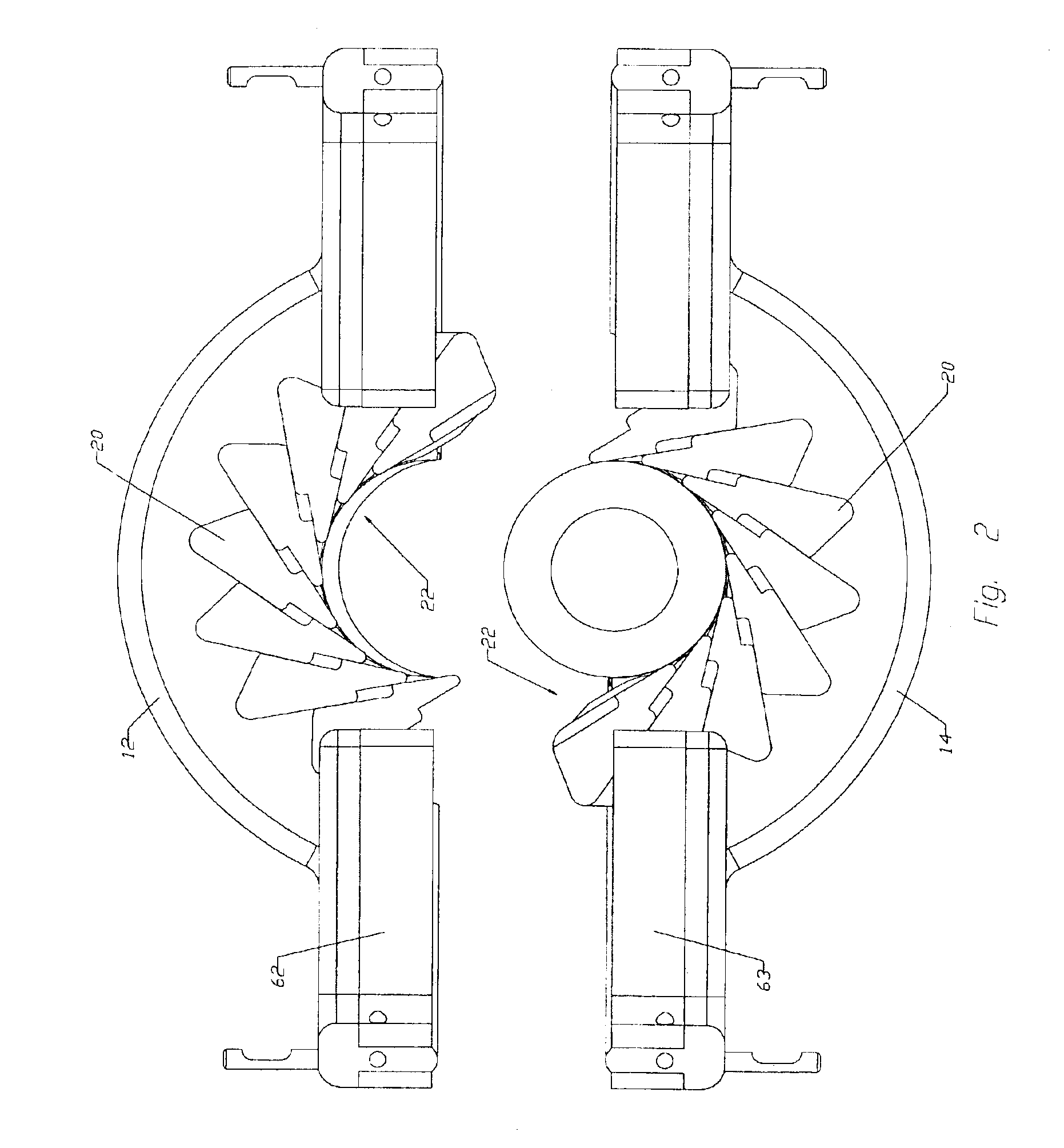

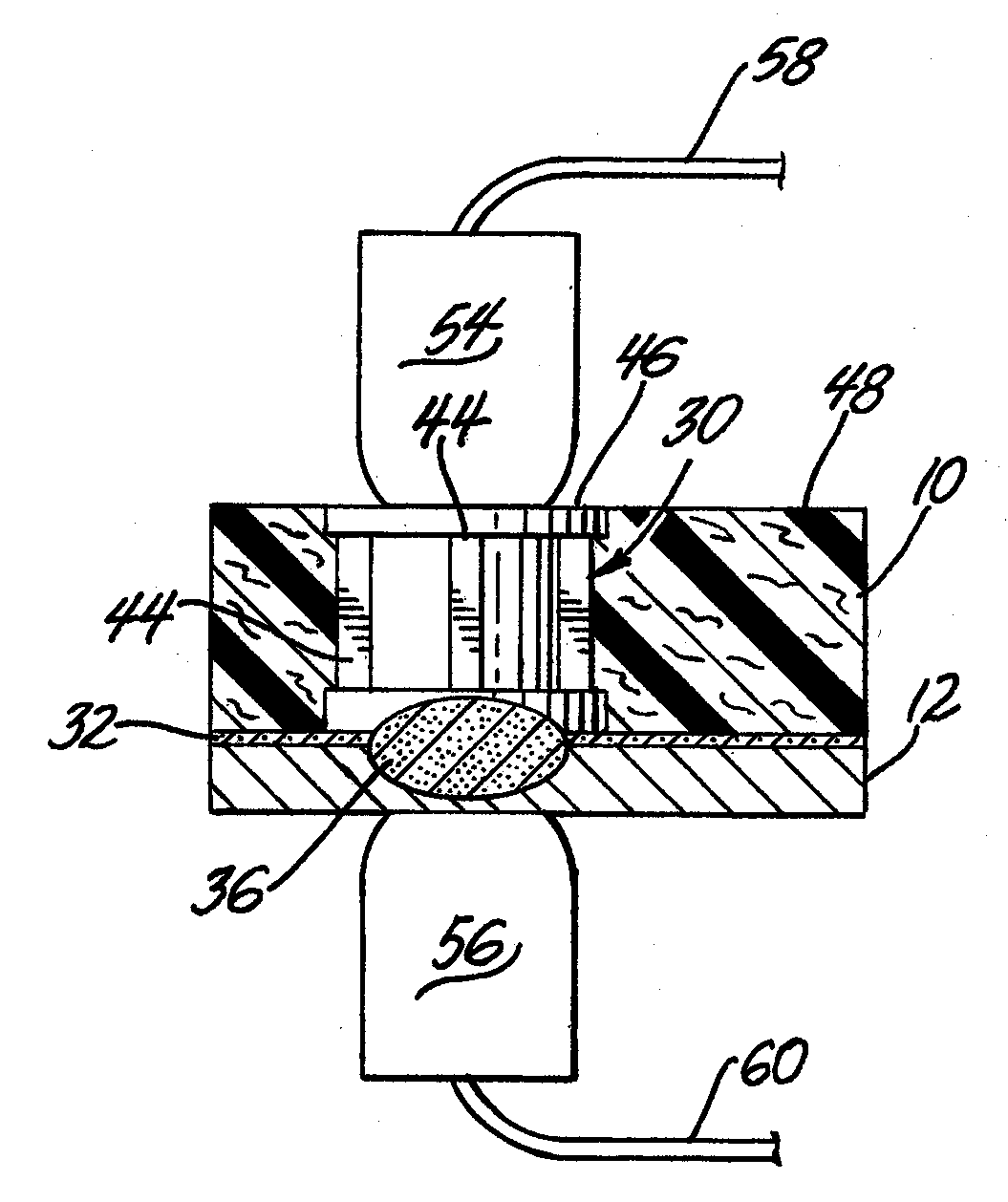

A blowout preventer assembly 10 includes opposed rams 12, 14, each including a rubber or elastomer sealing assembly 16, 18, with a plurality of inserts 20 forming an array 22 of metal inserts within each sealing assembly. Each insert has an upper body 24, a lower body 26, and a rib 50. Each upper and lower body includes a trailing face 36, a radially outward opposite face 38 and a leading face 40. An antiextrusion ledge 46 minimizes the extrusion gap between the OD of a tubular in the BOP and the leading face of the metal inserts in the array.

Owner:VARCO SHAFFER

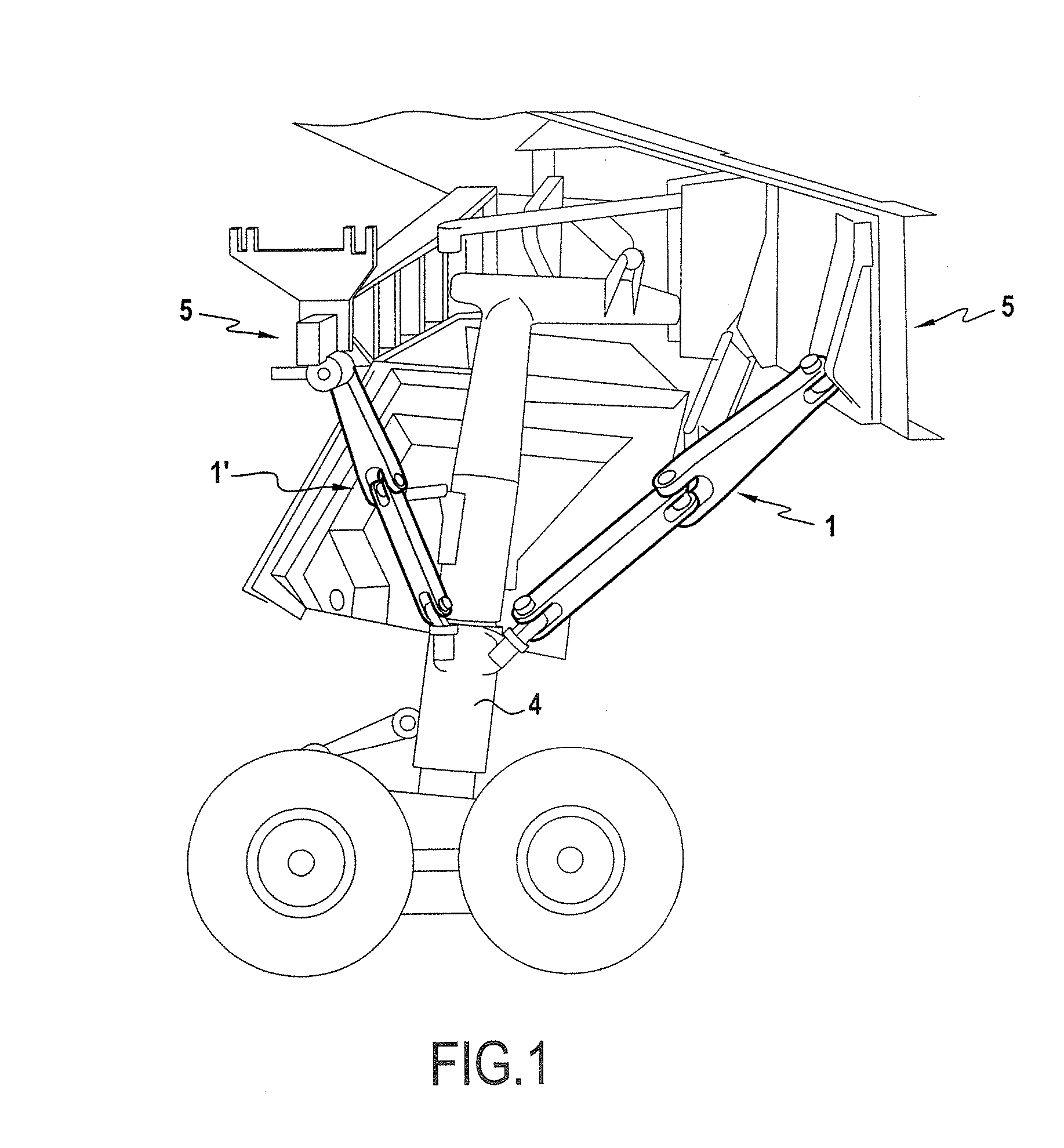

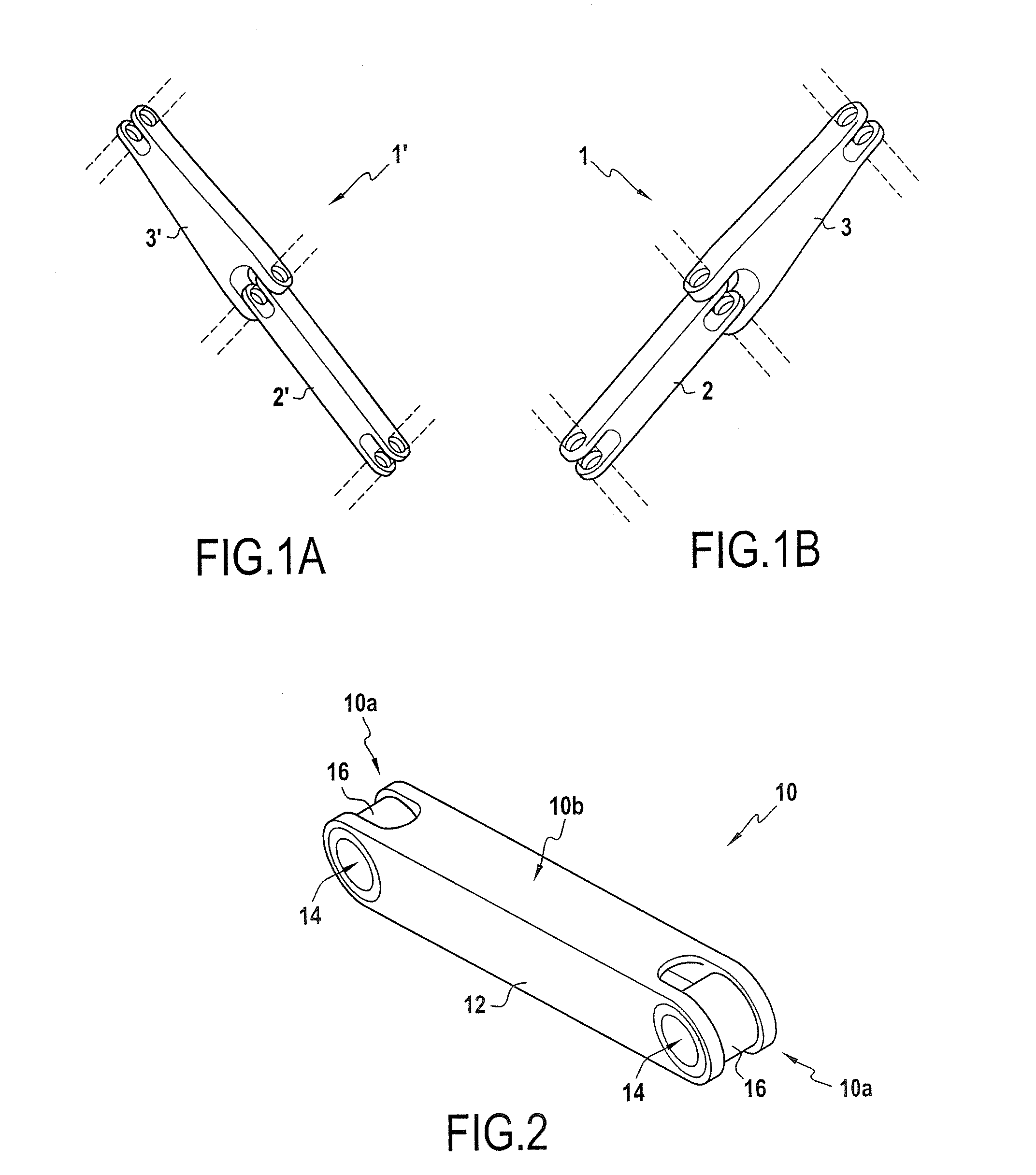

Mechanical part and method of manufacturing such a part

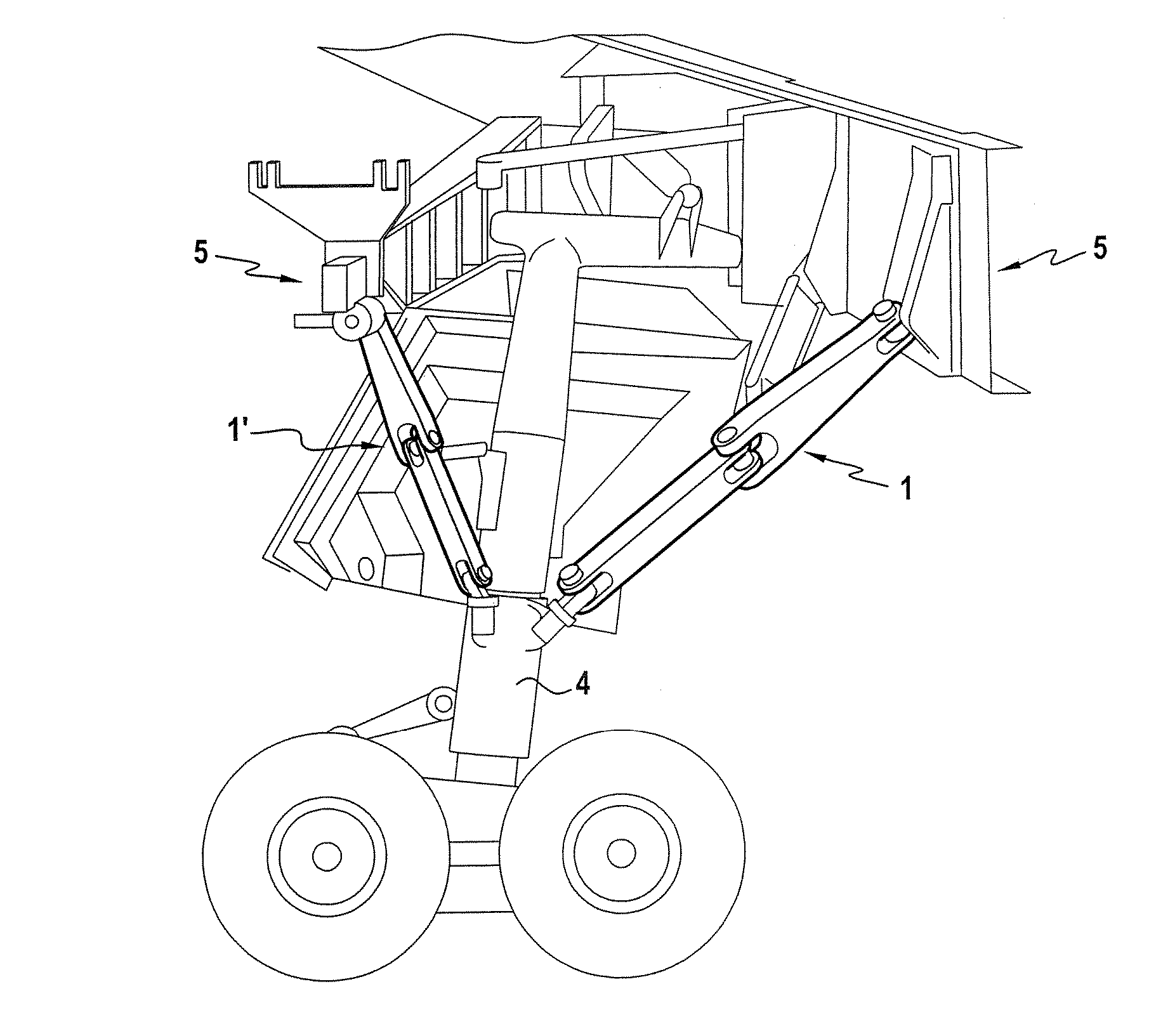

The invention provides a mechanical part for hinging to other mechanical parts at its ends, the mechanical part being made at least in part out of composite material from a central fiber preform and a peripheral fiber preform both of three-dimensional woven fabric, which preforms are assembled together while dry and then impregnated with resin, the peripheral preform surrounding the central preform in such a manner as to leave two empty spaces at the ends of the part and between the two preforms, which spaces are dedicated to hinging to said other parts. Metal inserts can be received in said spaces. The mechanical part can be used as a lever for a landing gear brace.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

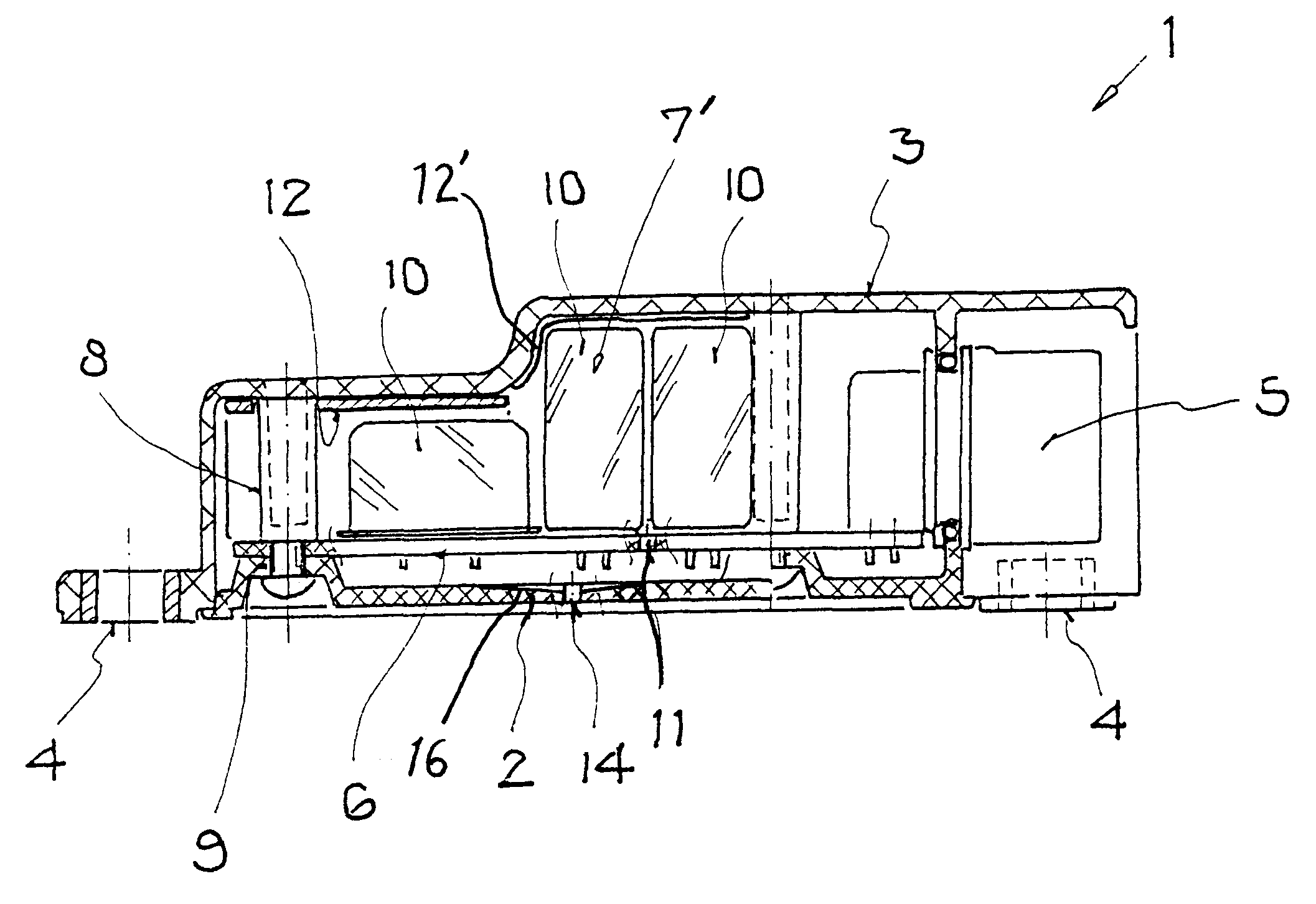

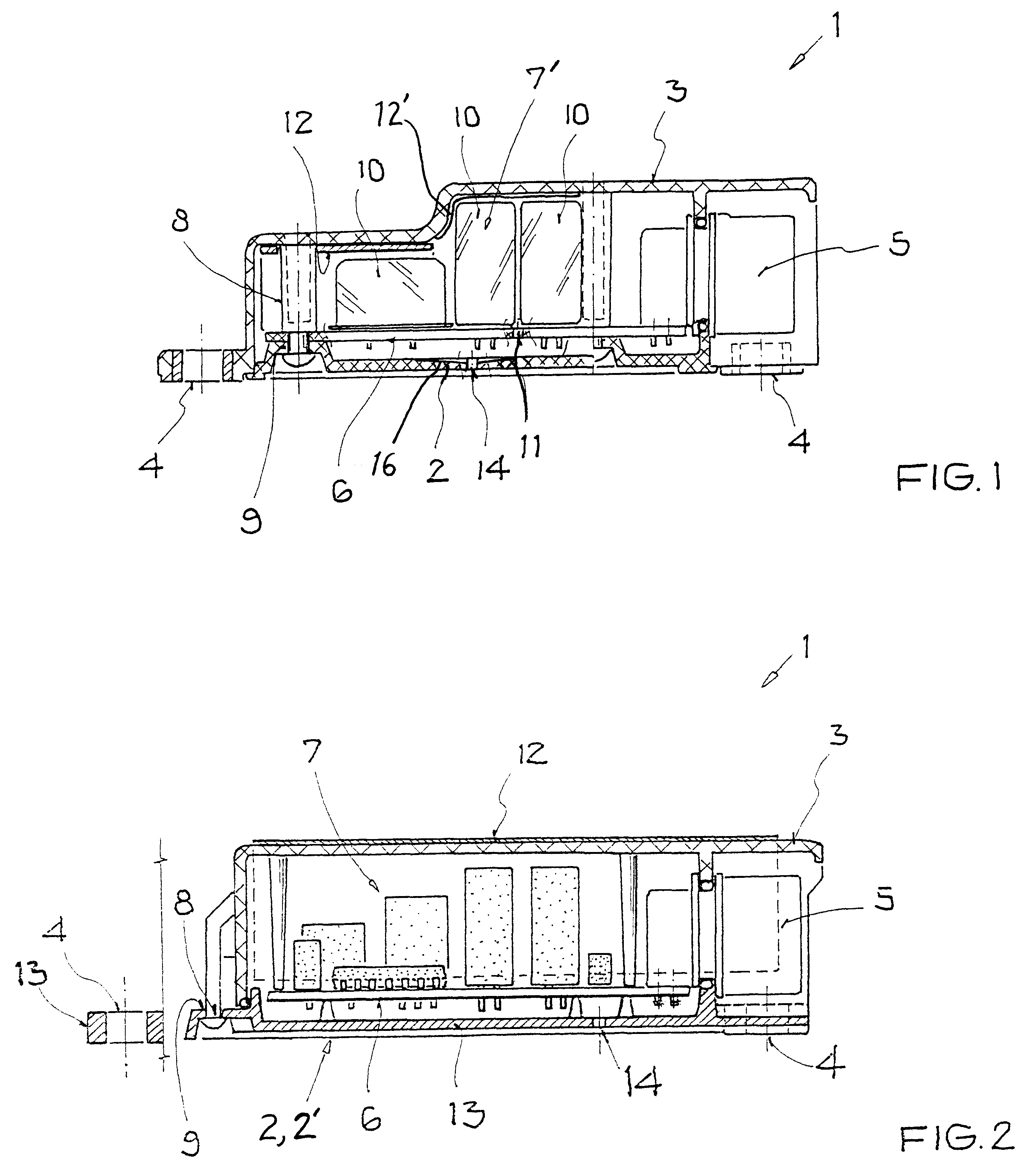

Plastic housing with condensation protection for electric and electronic assemblies

InactiveUS6445568B1Inhibit currentAvoid dangerSubstation/switching arrangement detailsDigital data processing detailsElectronic wasteElectronic component

A housing for an assembly of electronic components mounted on a circuit board is predominantly made of plastic, and includes a plastic housing cover and a housing floor. Metal surfaces are provided in the housing to preferentially condense moisture from the air in the housing upon cooling, to avoid condensation on the circuit board or the electronic components. The metal surfaces may be a metal casing around an electronic component, a metallized layer deposited on an inner surface of the housing, a metal insert in the housing, a metal housing floor, or an additional metal floor plate adjacent to a plastic housing floor. A hydrophobic film enforces condensate droplet formation, and channels and drain holes drain the condensate droplets out of the housing. An encapsulating film is unnecessary on the electronic components, because condensation on these components is avoided.

Owner:DAIMLER AG

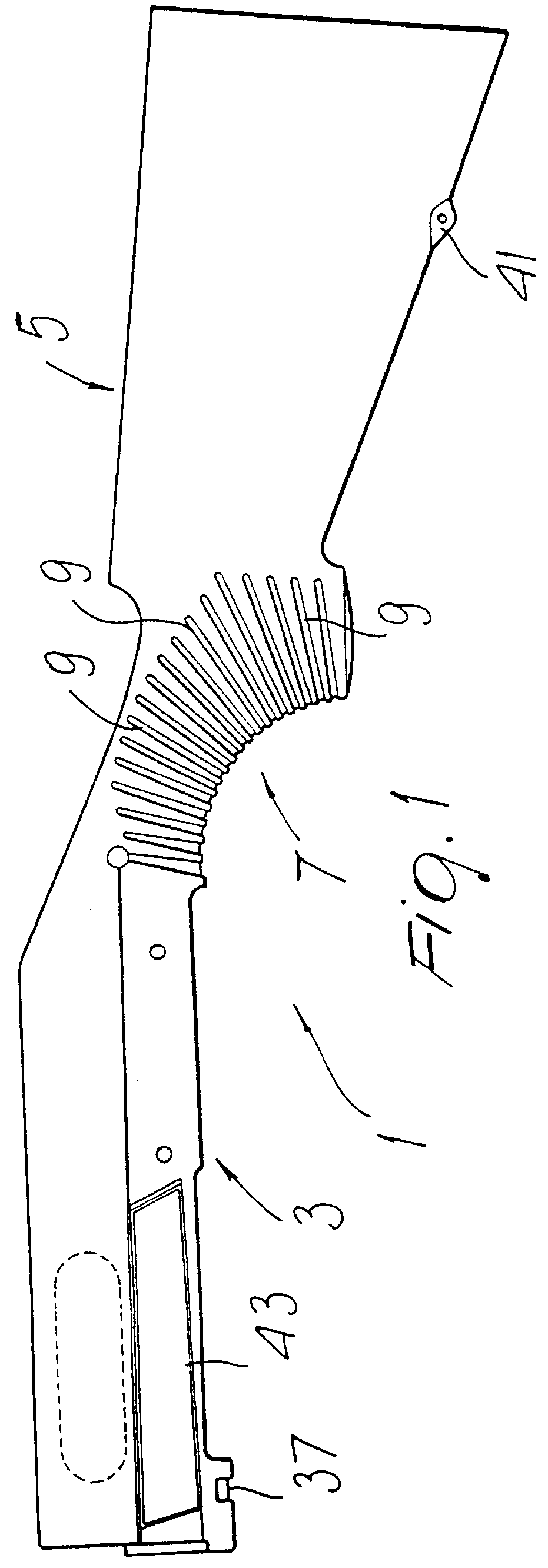

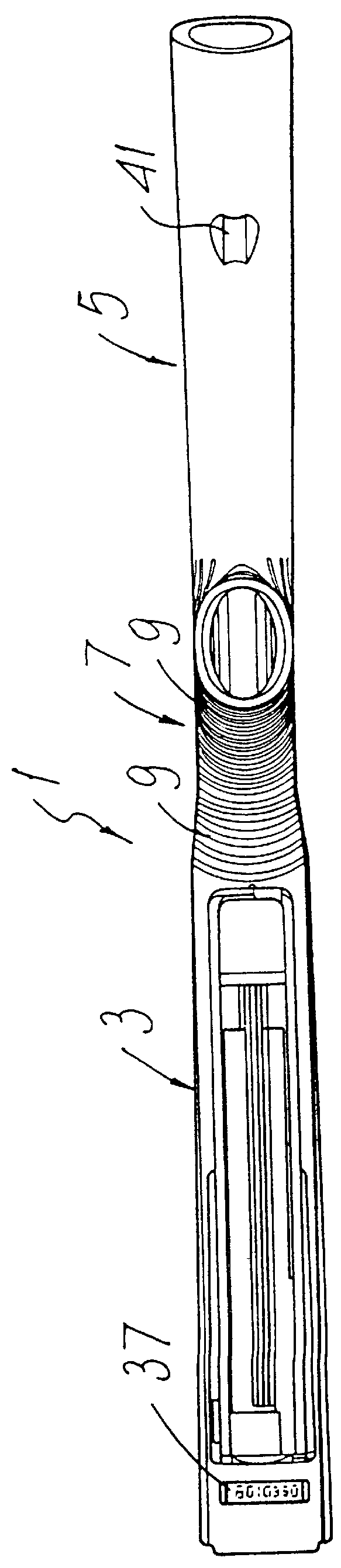

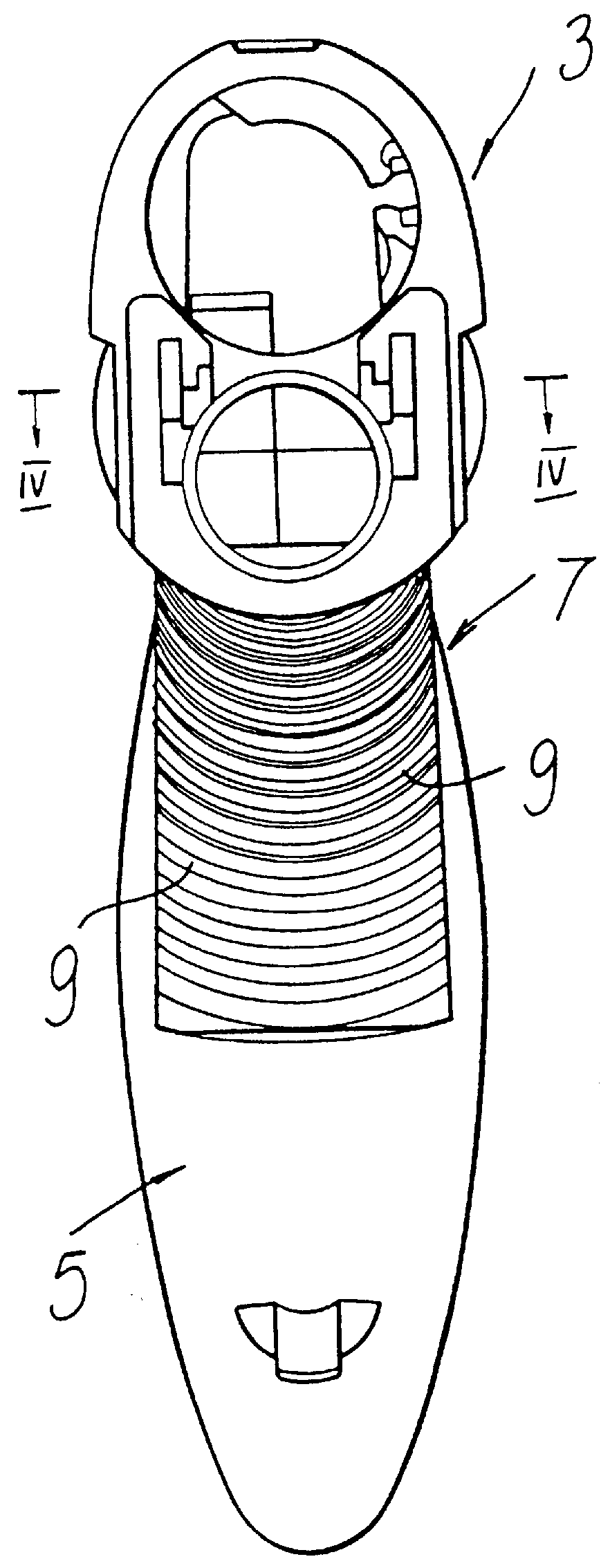

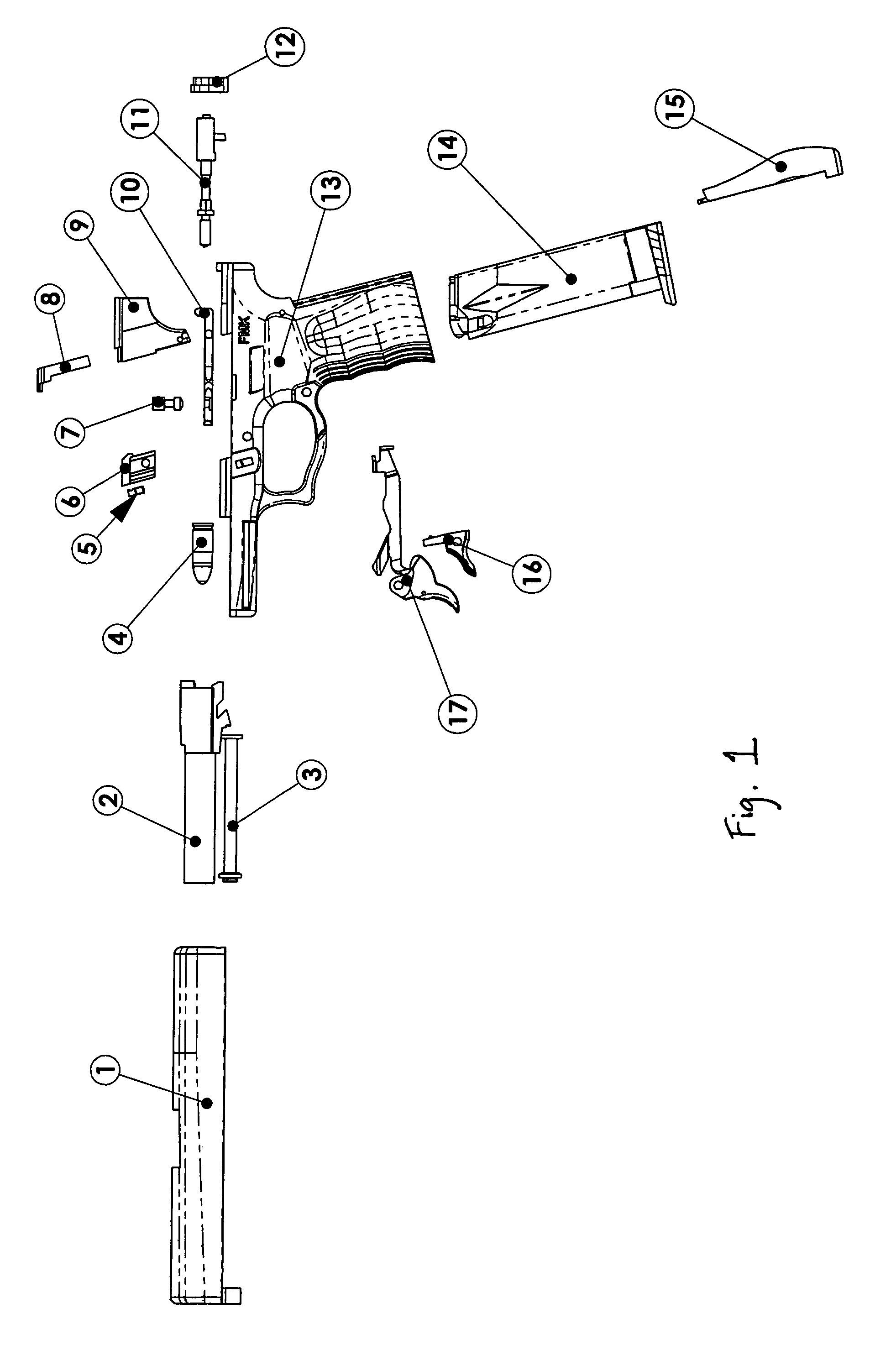

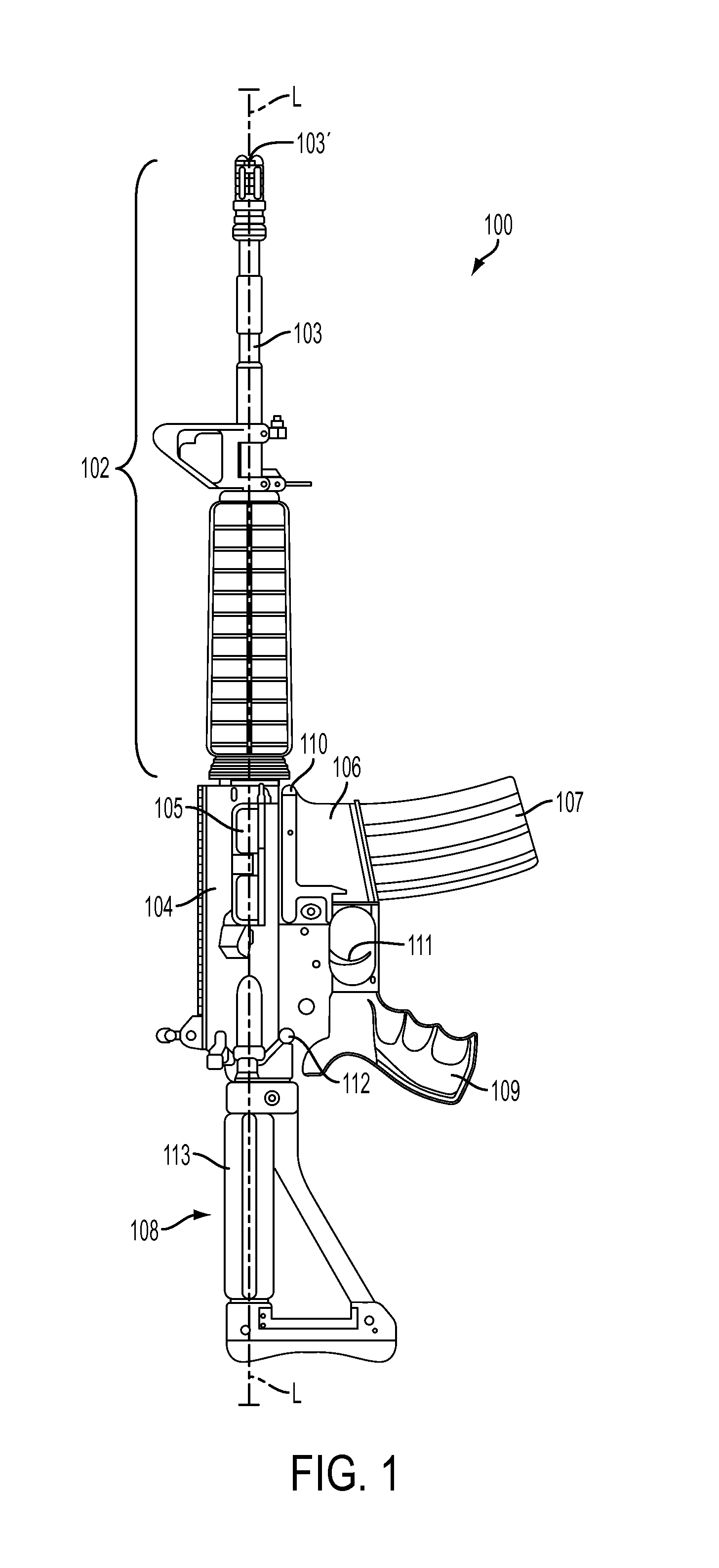

Firearm with metal insert in monolithic housing and stock

InactiveUS6070354AReduce manufacturing stepsButtsShoulder-fired smallarmsEngineeringMechanical engineering

A portable weapon having a monolithic housing and stock made of plastics and provided with a metal insert for strengthening the structure.

Owner:BENELLI ARMI

Laser-Produced Porous Surface

An implant having a porous tissue ingrowth structure and a bearing support structure is disclosed. The implant includes a metal insert having a bone ingrowth structure, an intermediate structure and a bearing support structure. A bearing surface is formed from a polymer material and attached to the bearing support structure. The intermediate structure has a porosity sufficient to inhibit the polymer material from translating through the bearing support structure to the bone ingrowth structure.

Owner:UNIV OF LIVERPOOL +1

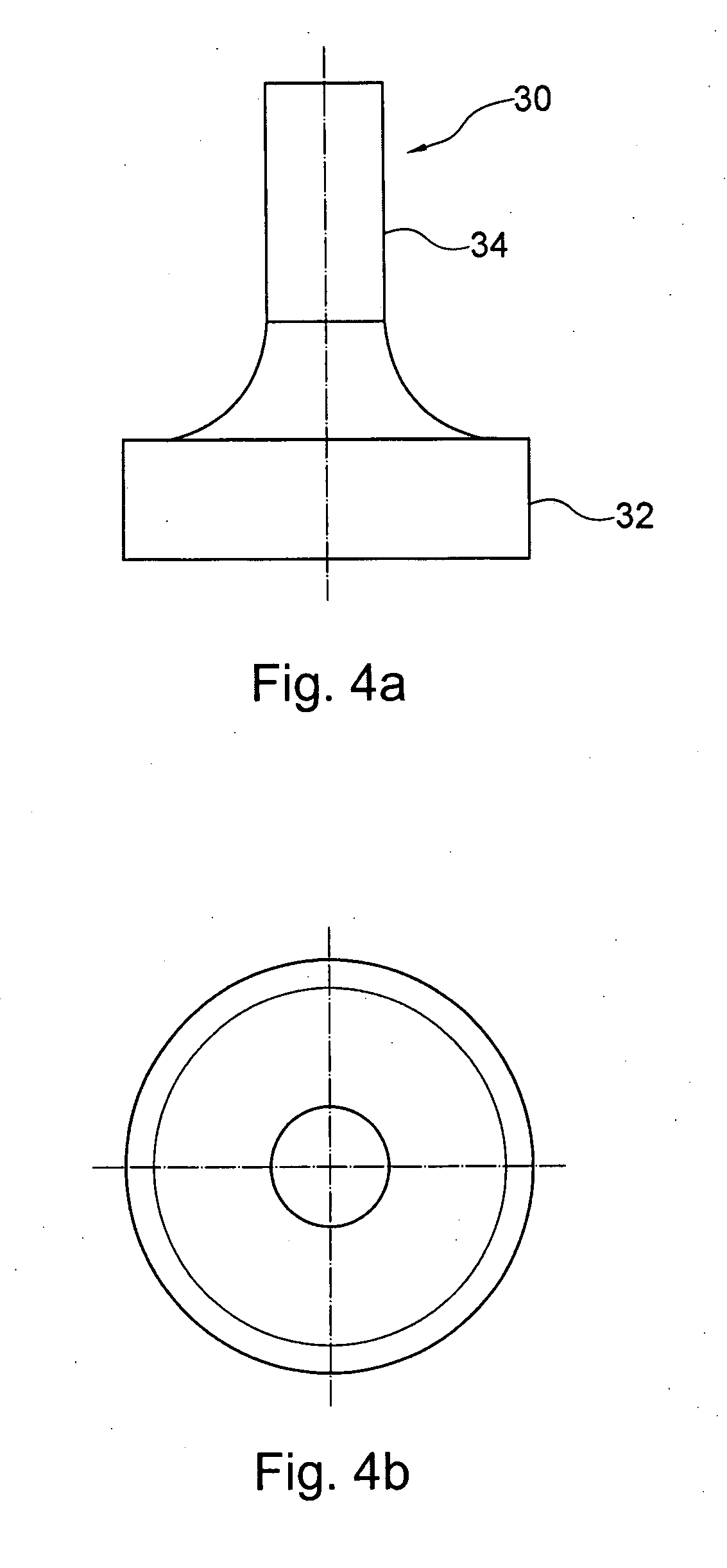

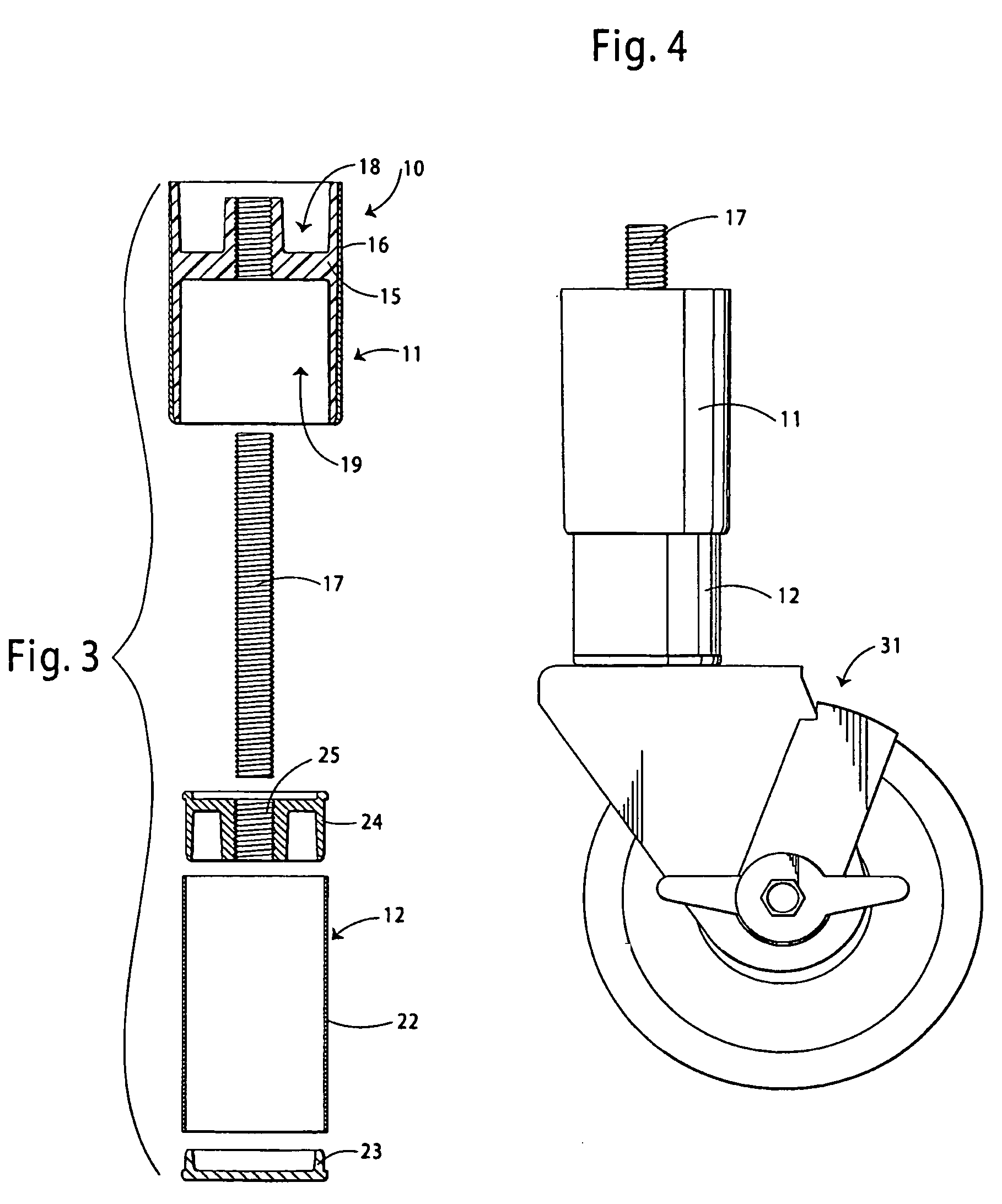

Height adjustable support for food service equipment

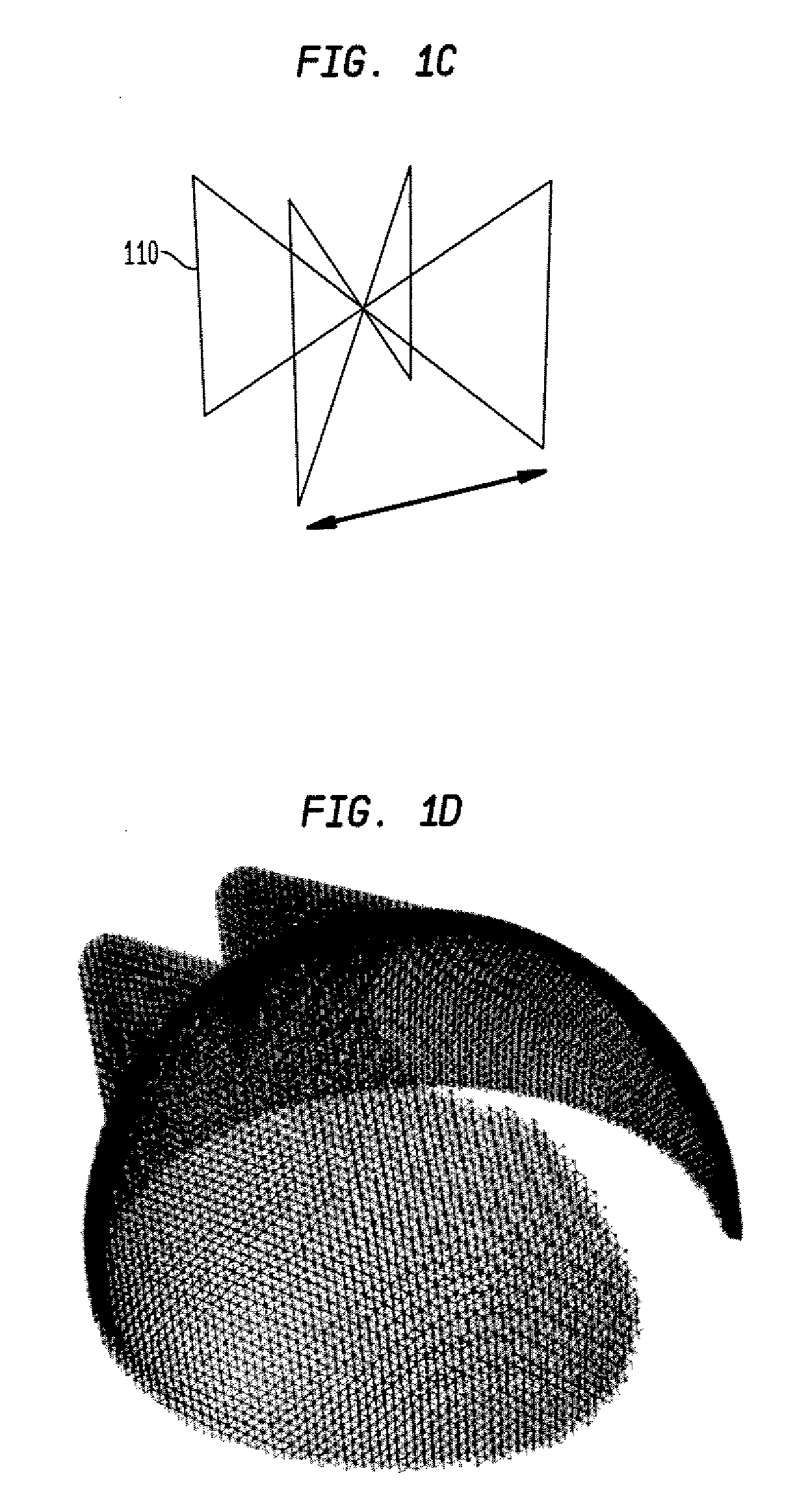

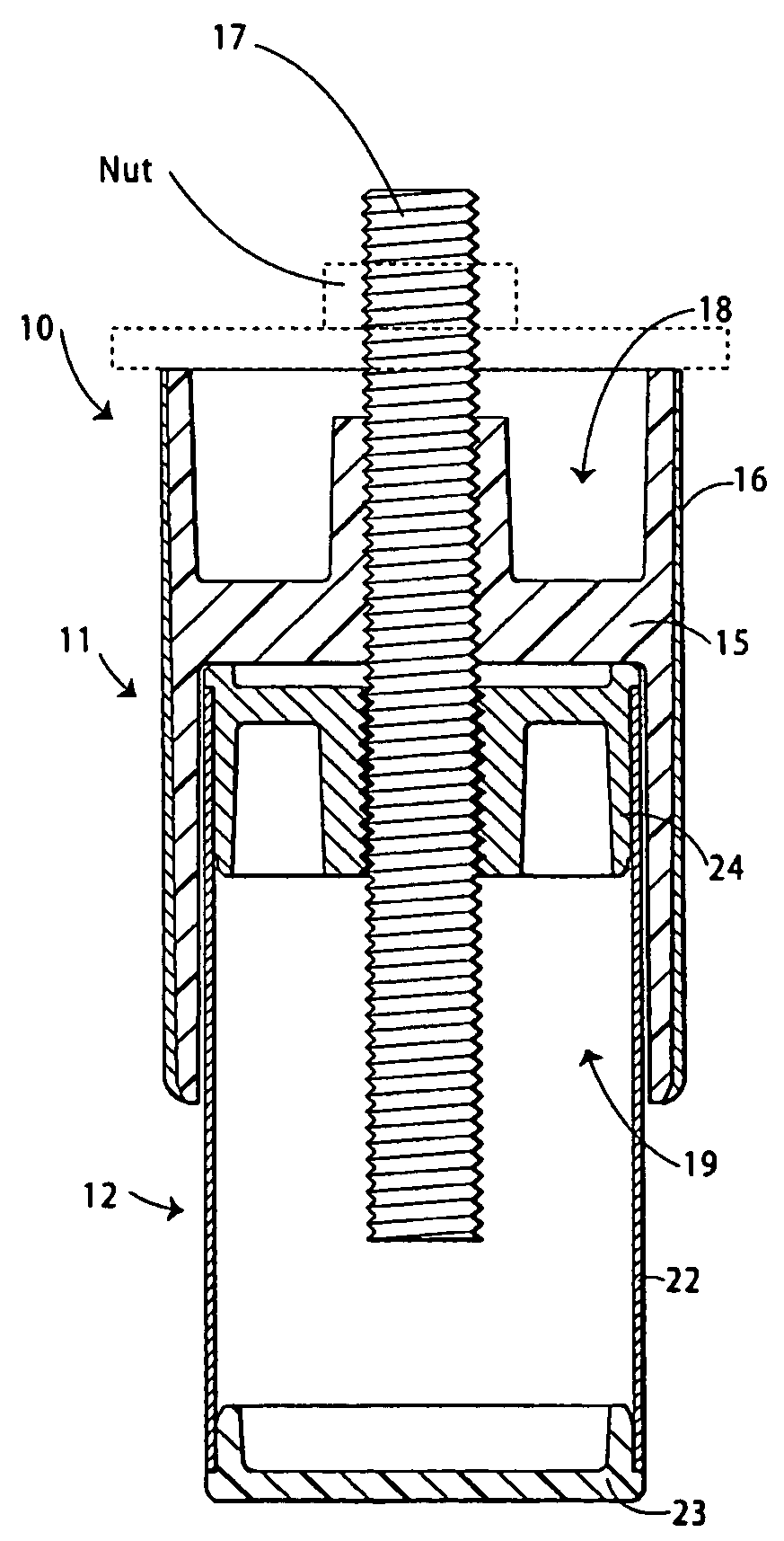

A support (10) is disclosed for use with food service equipment. The support has a tubular upper portion (11) and a tubular lower portion (12) telescopically mounted within the upper portion for adjustable vertical movement. The upper portion has a plastic support body (15) surrounded by a stainless steel support sleeve (16). A steel, externally threaded stud (17) is mounted to the support body. The lower portion includes a stainless steel, tubular foot (22) having a plastic glide (23) press fitted into its lower end and metal insert (24) mounted in its top end. The metal insert has internally threaded, central channel (25) extending completely therethrough. The insert is threaded onto the bottom end of the threaded stud for threaded vertical movement along the stud.

Owner:KASON IND INC

Plastic living hinge with metal support

InactiveUS20070283529A1High strengthEnhanced living hinge structureWing accessoriesPinless hingesAdhesiveEngineering

A living hinge structure has two plastic side sections and a plastic connecting section, wherein the plastic side sections are integrated with metal supports so as to enhance the strength of the living hinge structure. The metal supports can be metal inserts bonded to the plastic side sections in an over-molding process. Each of the metal supports can be located on the outside surface or the inside surface of the plastic section. When the metal sections are located on the outside surfaces, they can be used to restrict the opening angle of the hinge. The metal supports can also be a part of a device that uses the hinge for mechanically coupling two device parts. As such, the living hinge is directly integrated into the device without the need for post-assembling by using screws, adhesive, welding or heat stacking.

Owner:NOKIA CORP

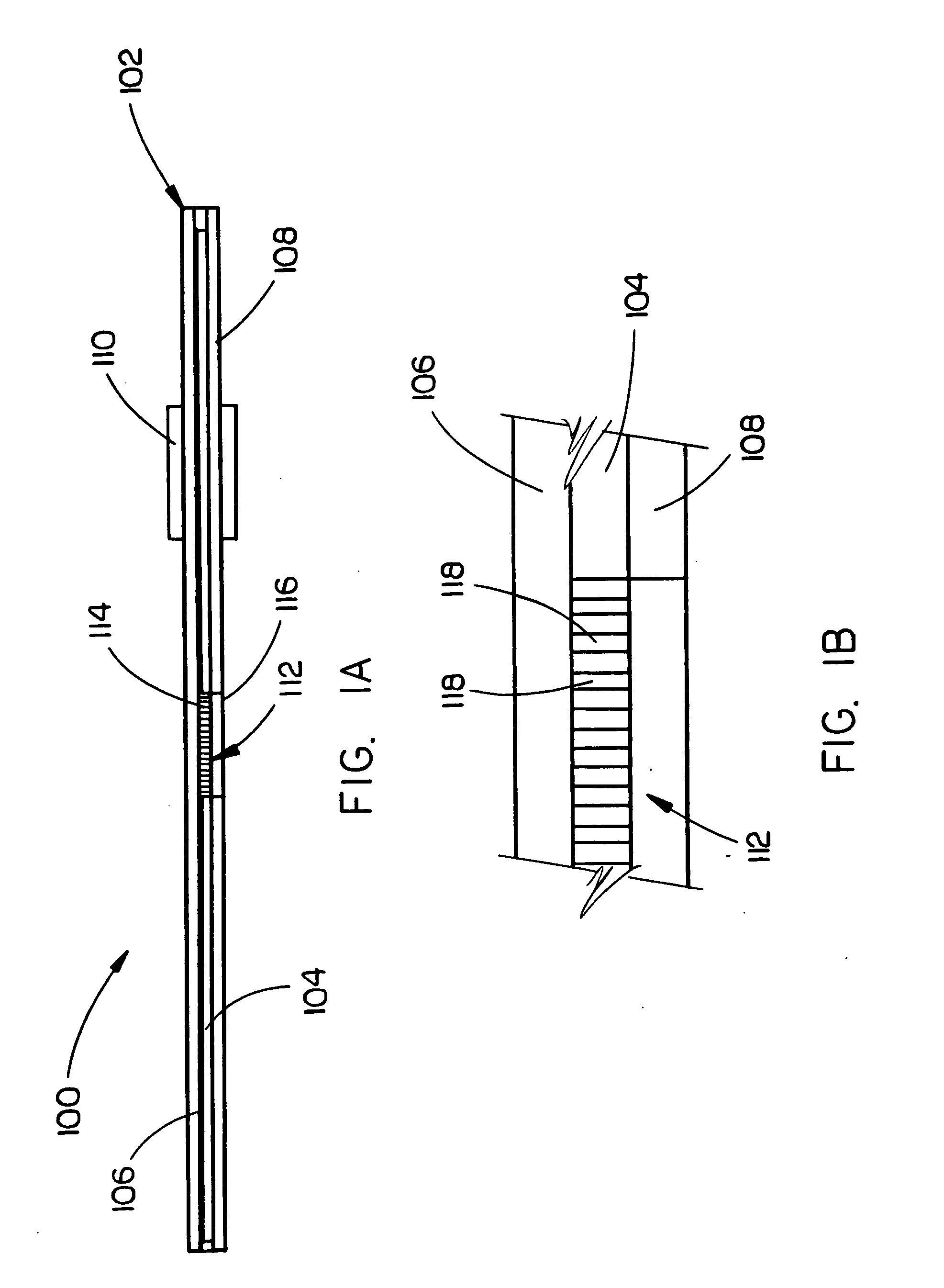

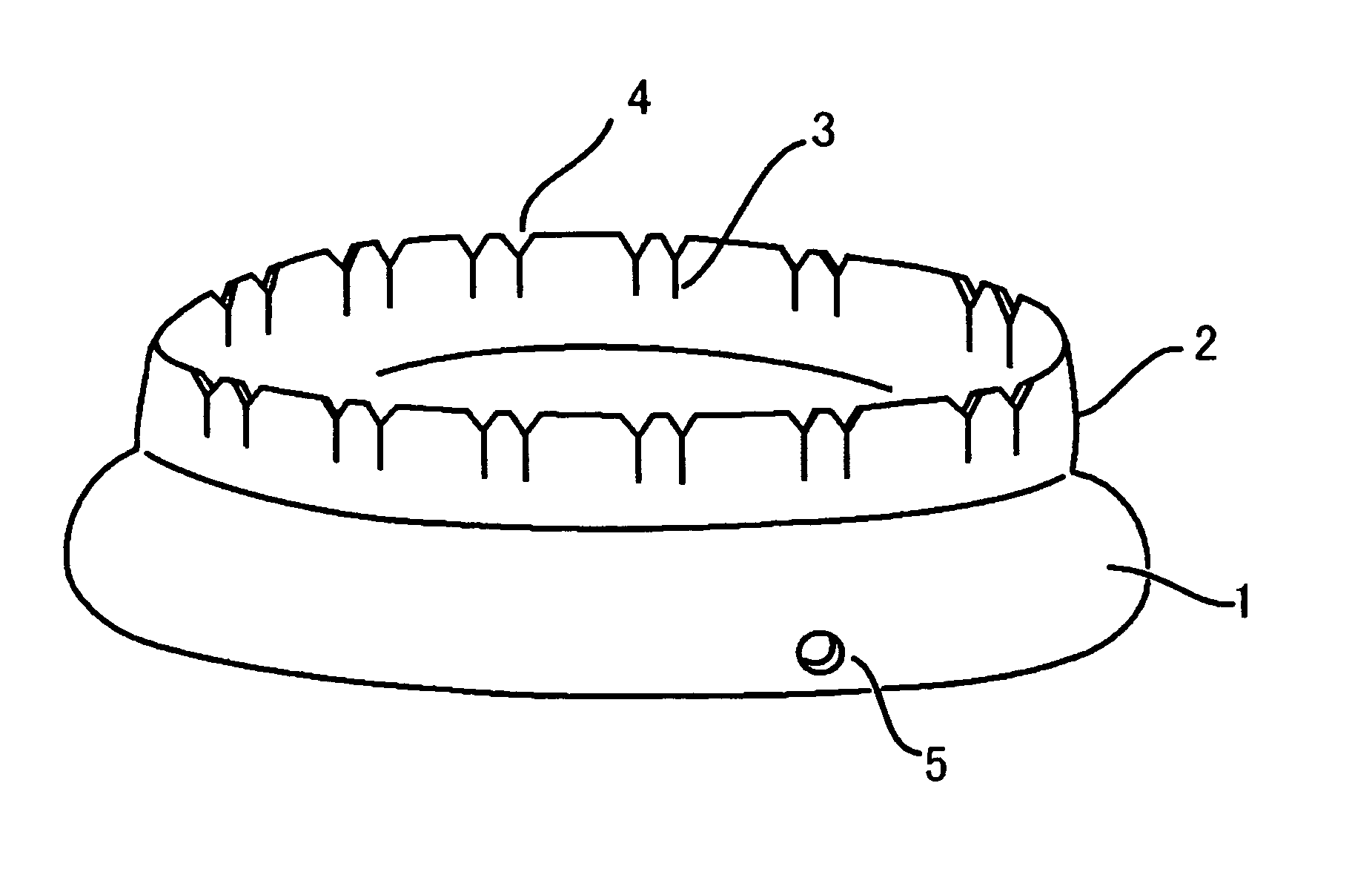

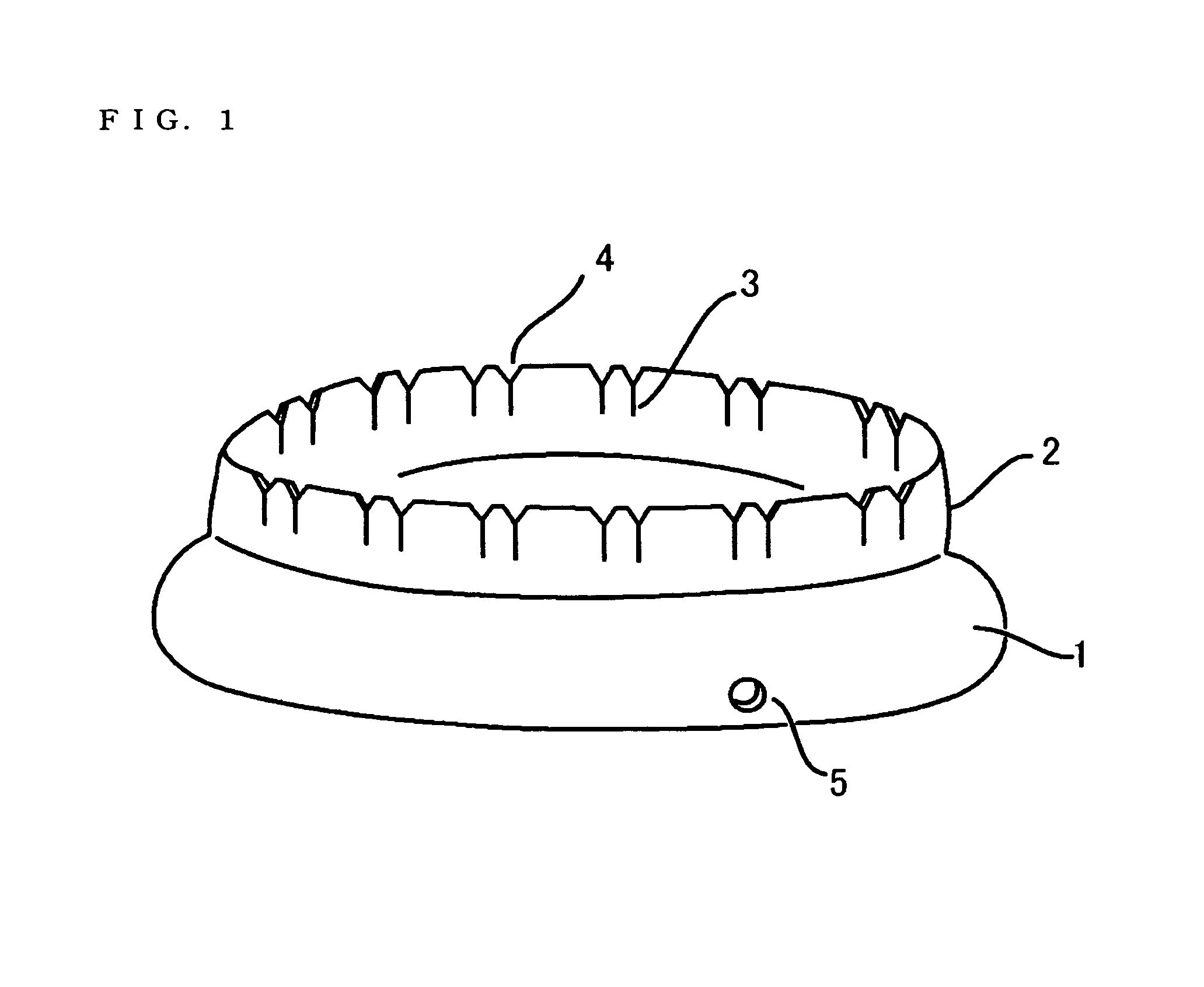

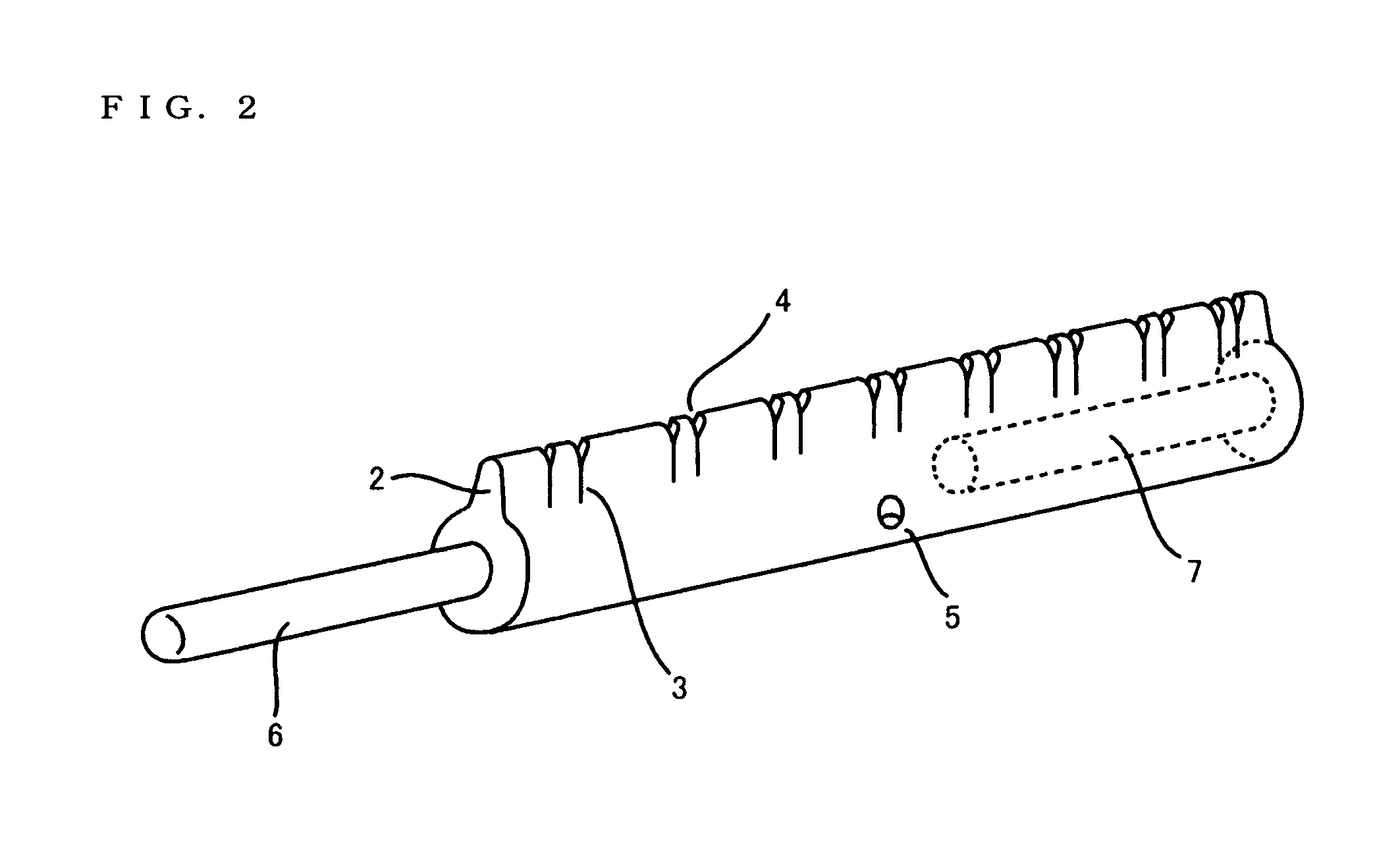

Apparatus for holding and arranging threads in surgical operations

InactiveUS7244260B2Lower manufacturing requirementsReduce distribution costsSuture equipmentsDiagnosticsSurgical operationEngineering

An apparatus for holding and arranging threads in surgical operations with a flexible structure being in a ring form, connecting straight linear forms or divided linear forms, with flexible metal inserted within foaming material. V shape ditches are cut on the upper portion, and the base has adhesiveness. Affordable and simple manufacturing method is established with extrusion molding process or heat press molding process, after which extrusion cut process is conducted with the mold. Labor within hospitals can be reduced, by providing an affordable apparatus which prevents the threads from being damaged, also solving the concern of tissue damage due to thread tension, as the threads are accurately held and arranged without any mixing up with neighboring threads, and the apparatus size, the fixing position of the apparatus, and the operating tissue area can be adjusted at the surgeon's will.

Owner:SHIRAI MOMOKO

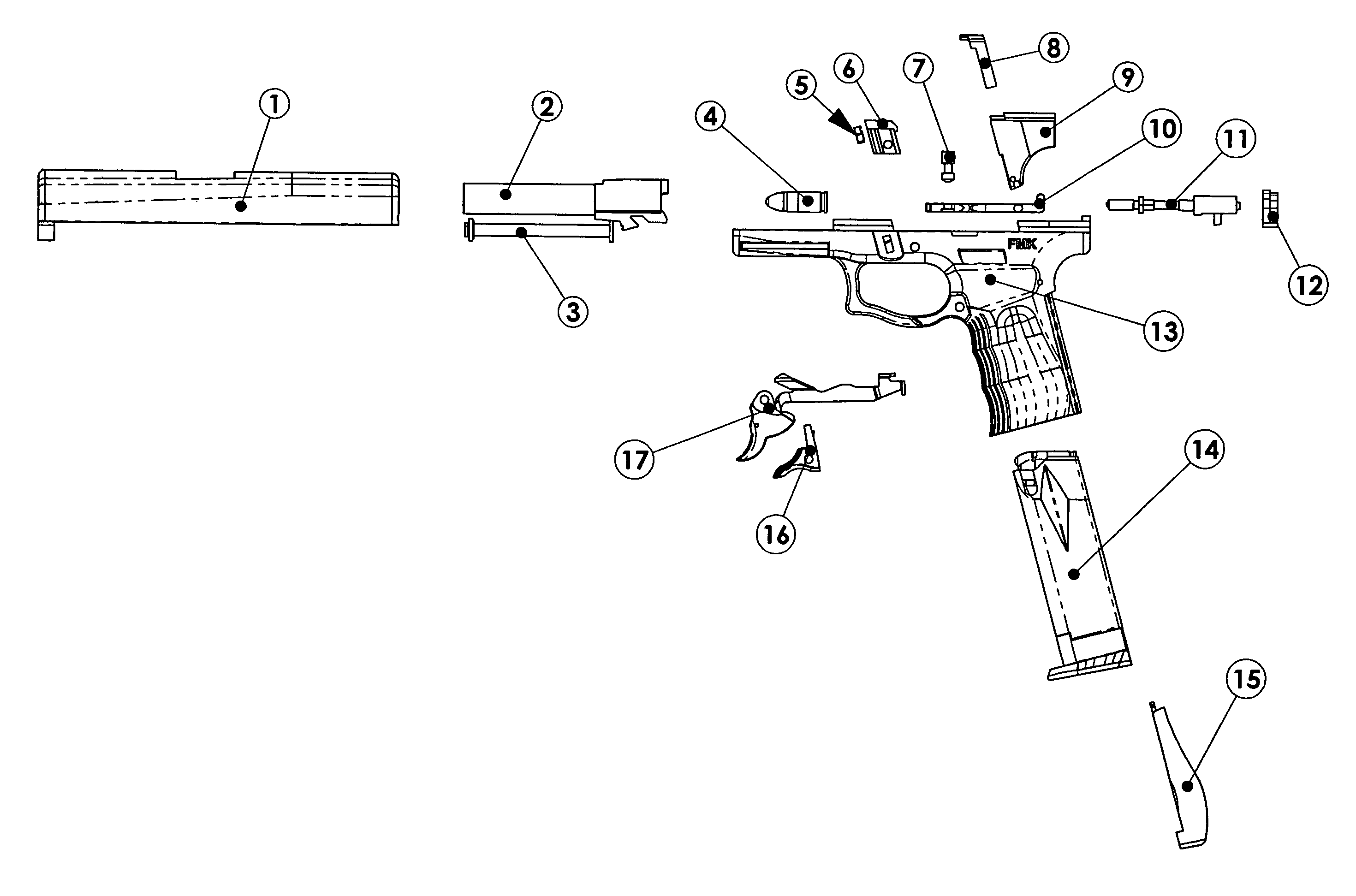

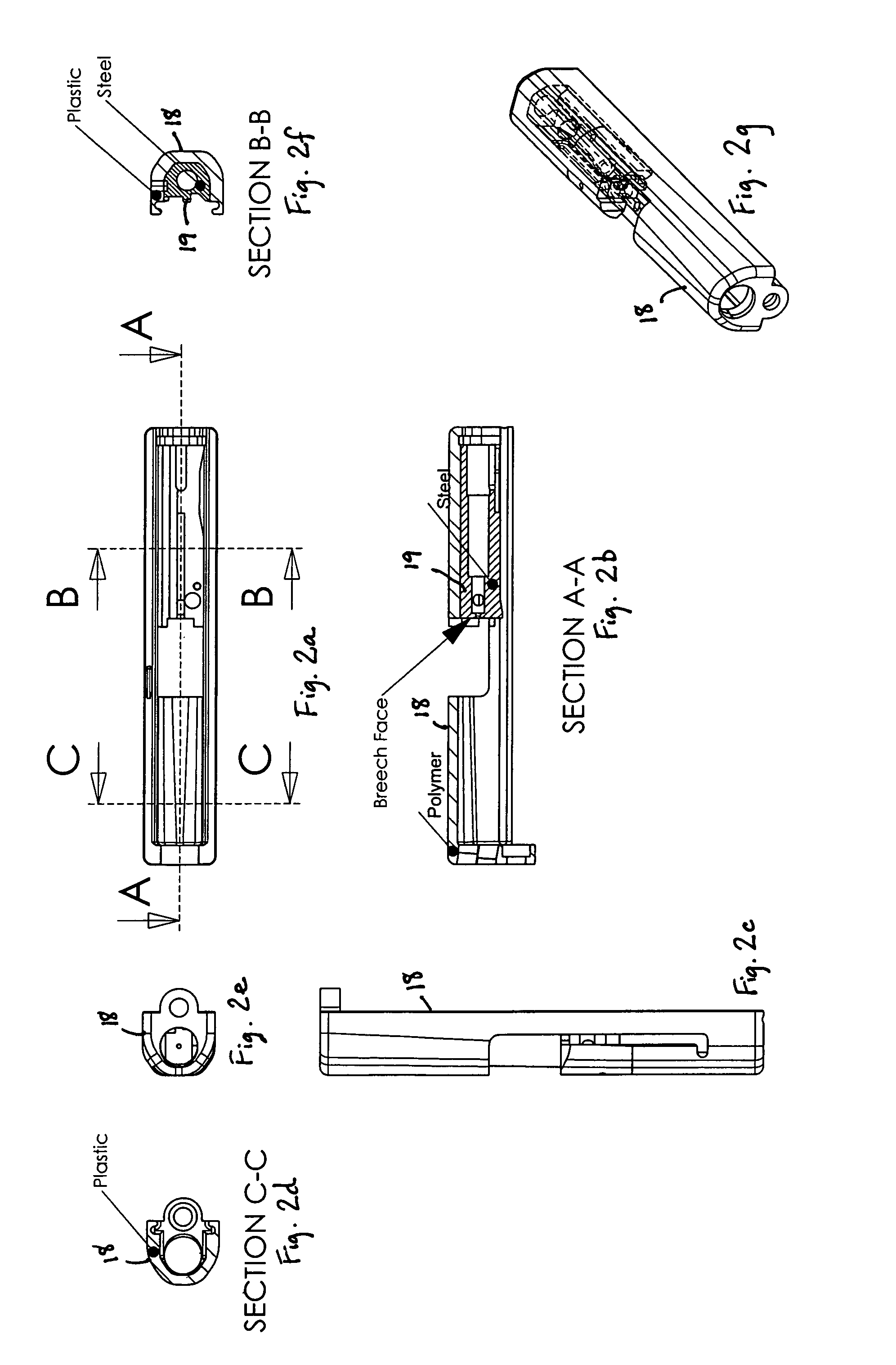

Plastic pistols

The present invention comprises plastic pistols and individual parts therefore having an increased use of plastic in comparison to prior art plastic pistols, reducing the number and simplifying the design of the metal parts to reduce the cost of the pistols while still maintaining gun quality. One aspect of the invention is the use of plastic in certain critical areas, simplifying the configuration of the metal inserts used. In many cases, this can eliminate expensive machining of metal parts in favor of parts injection molded to finished dimensions. In that regard, legal requirements can still be met with respect to metal content, yet that metal content may be simplified in configuration for ease of manufacture. Certain preferred embodiments of the invention are illustrated.

Owner:PONTILLO II JAMES V

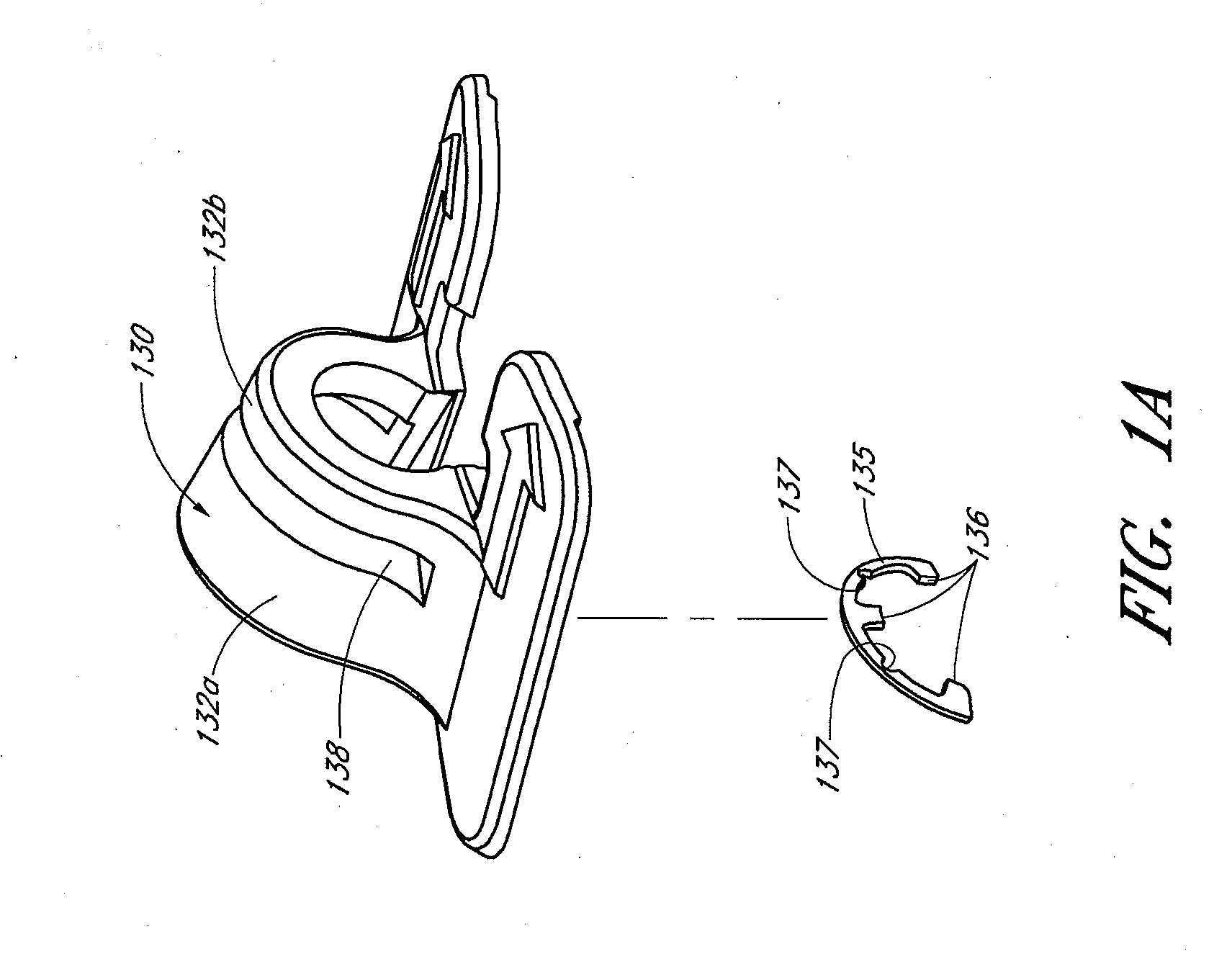

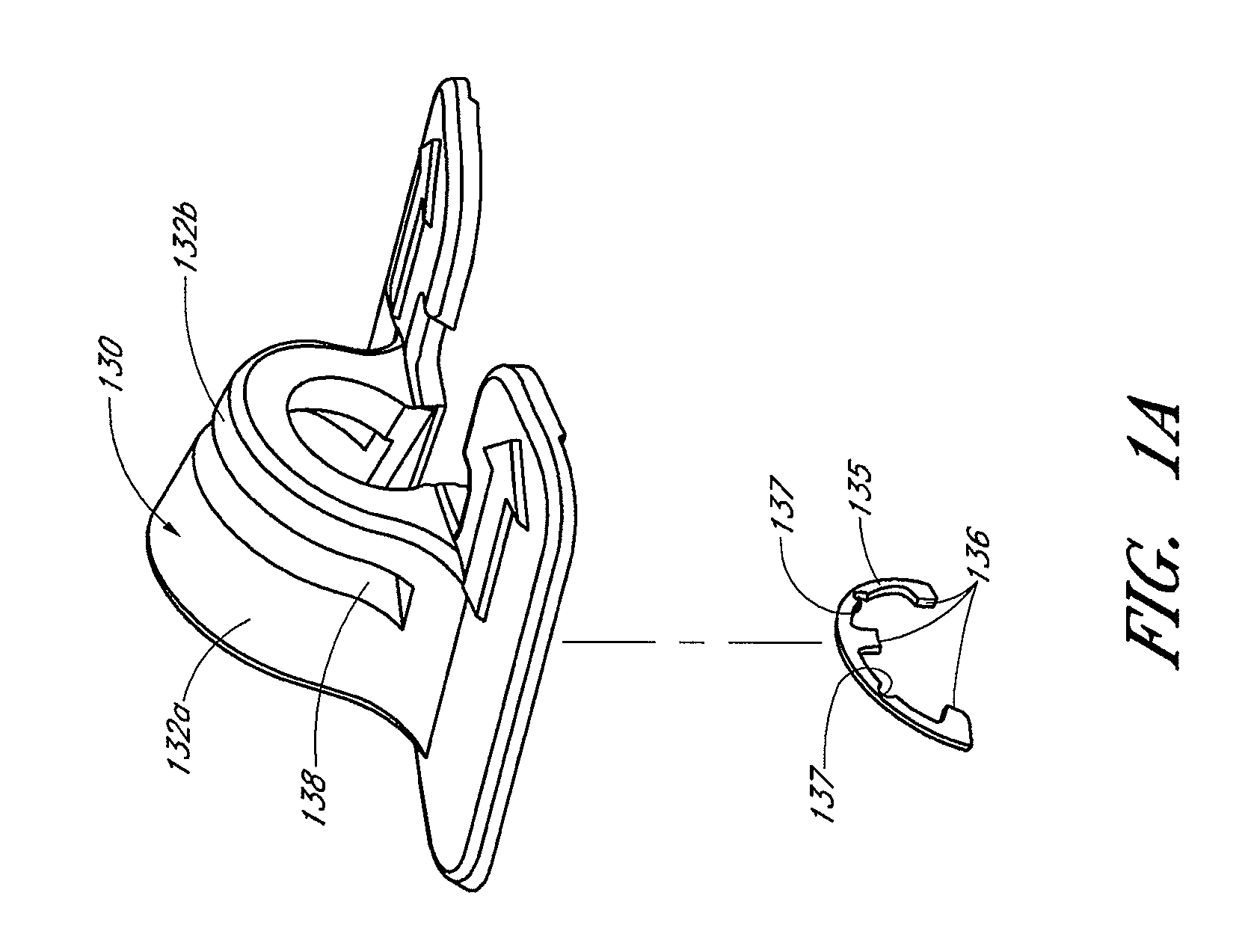

Securement device

A securement device holds a medical article such as a catheter hub in position upon the body of a patient and at least inhibits longitudinal movement of the medical article. The securement device includes a retainer and at least one anchor pad. The retainer includes a metallic insert having barbs or teeth extending into a central channel. The metallic barbs or teeth dig into the retained catheter hub. The metal insert springs open as the hub is inserted in to the device and retains the hub by virtue of its metallic barbs.

Owner:VENETEC INT INC

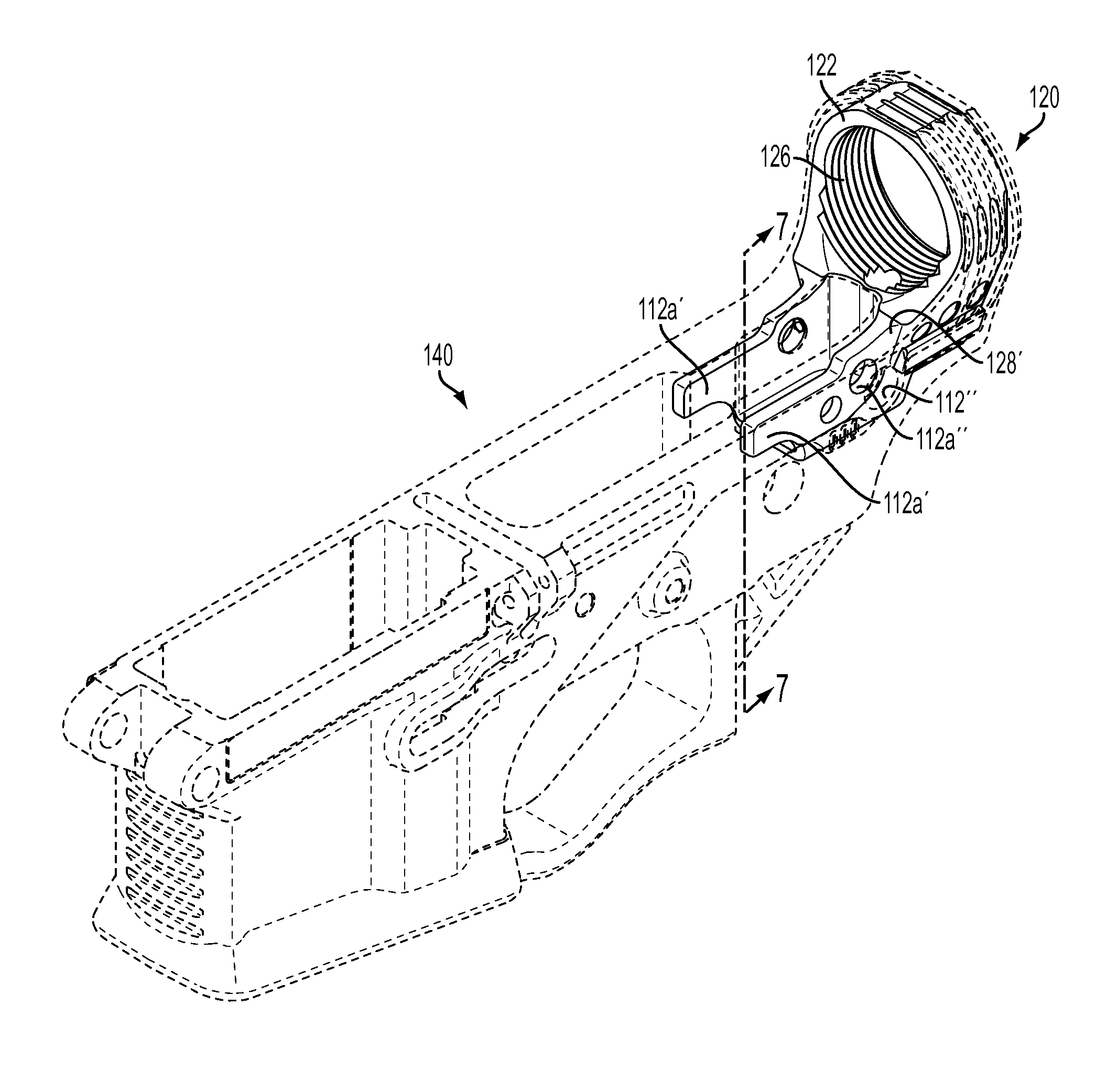

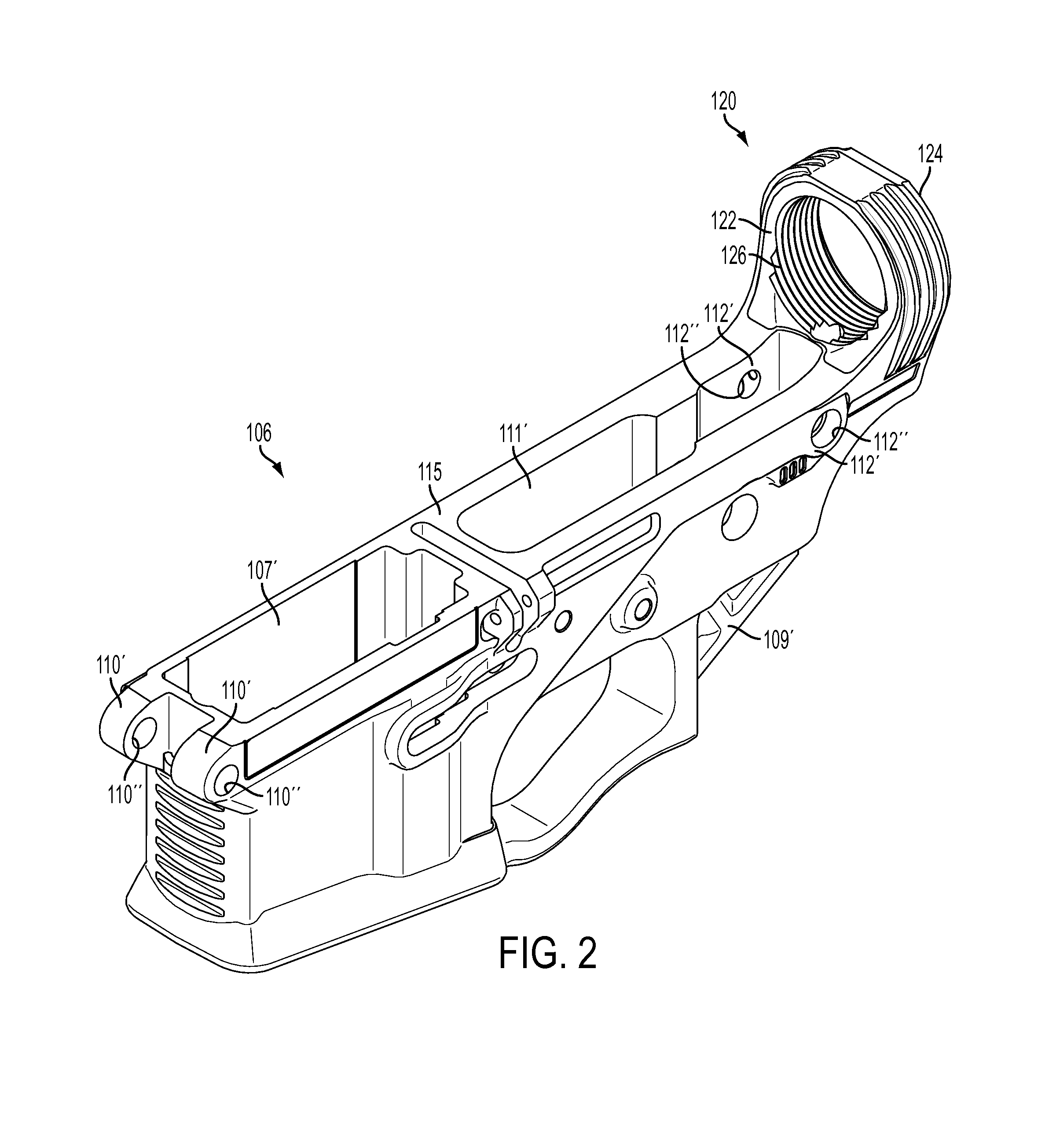

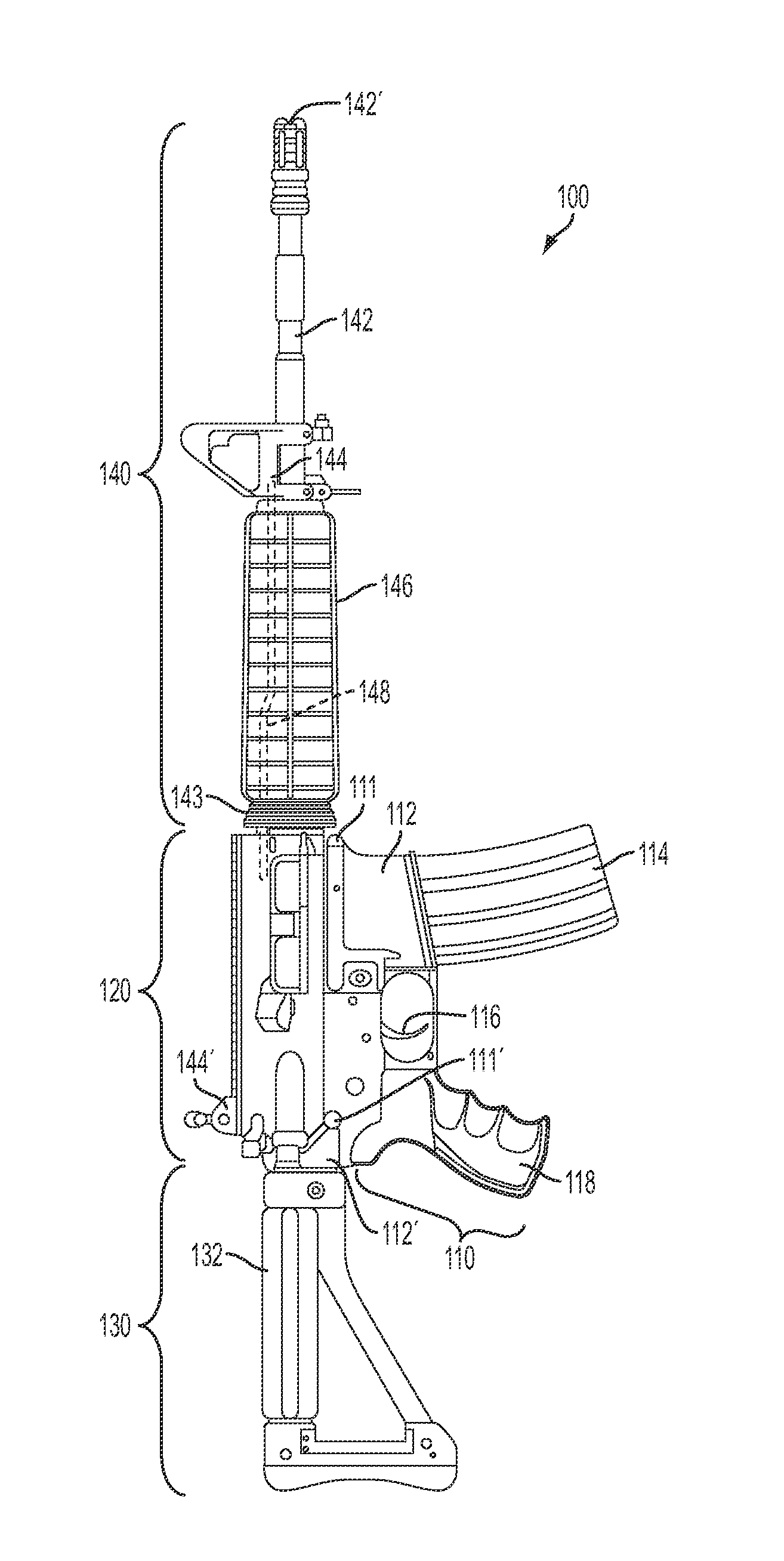

Hybrid lower receiver for a rifle

ActiveUS8789305B1Reduce material costsMaintain structural integrityWeapon assembly/disassemblyBreech mechanismsPolymerMetal insert

A combination metal / polymer lower receiver for use in a rifle. The lower receiver attaches to a buttstock including a receiver extension, and an upper receiver having a bolt carrier group. The lower receiver comprises a polymeric lower receiver housing having an integral polymeric upwardly extending lobe. The polymeric receiver housing engages with mounting features on the upper receiver to attach the lower receiver to the upper receiver. A metal insert is secured within the polymeric upwardly extending lobe and engages the receiver extension. The metal insert includes insert side walls incorporated within the polymer sidewalls of the lower receiver housing such that the sidewalls are adapted to receive a takedown pin to secure the upper receiver to the lower receiver. The metal insert can further include an elevated plate for displaying component identifiers.

Owner:AMERICAN TACTICAL INC

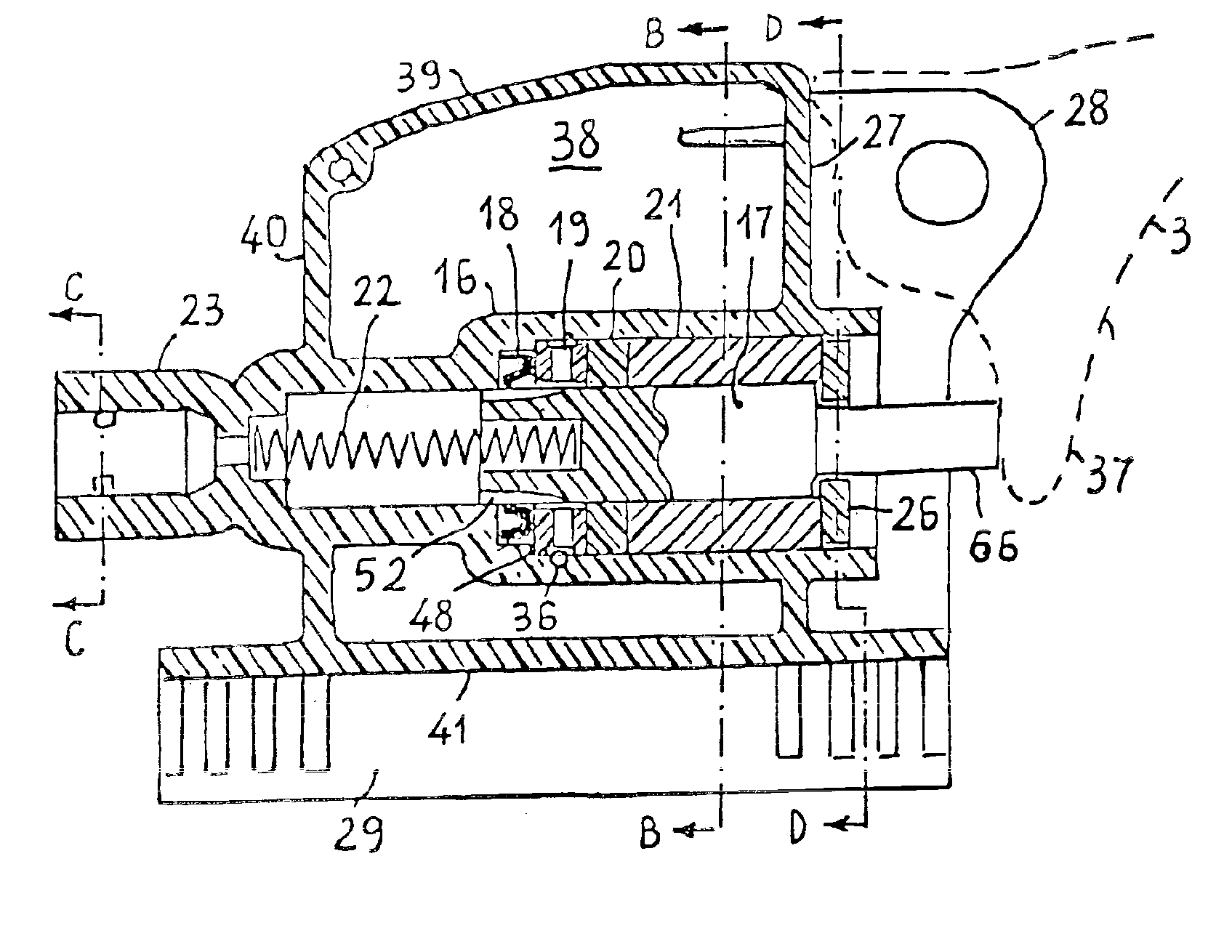

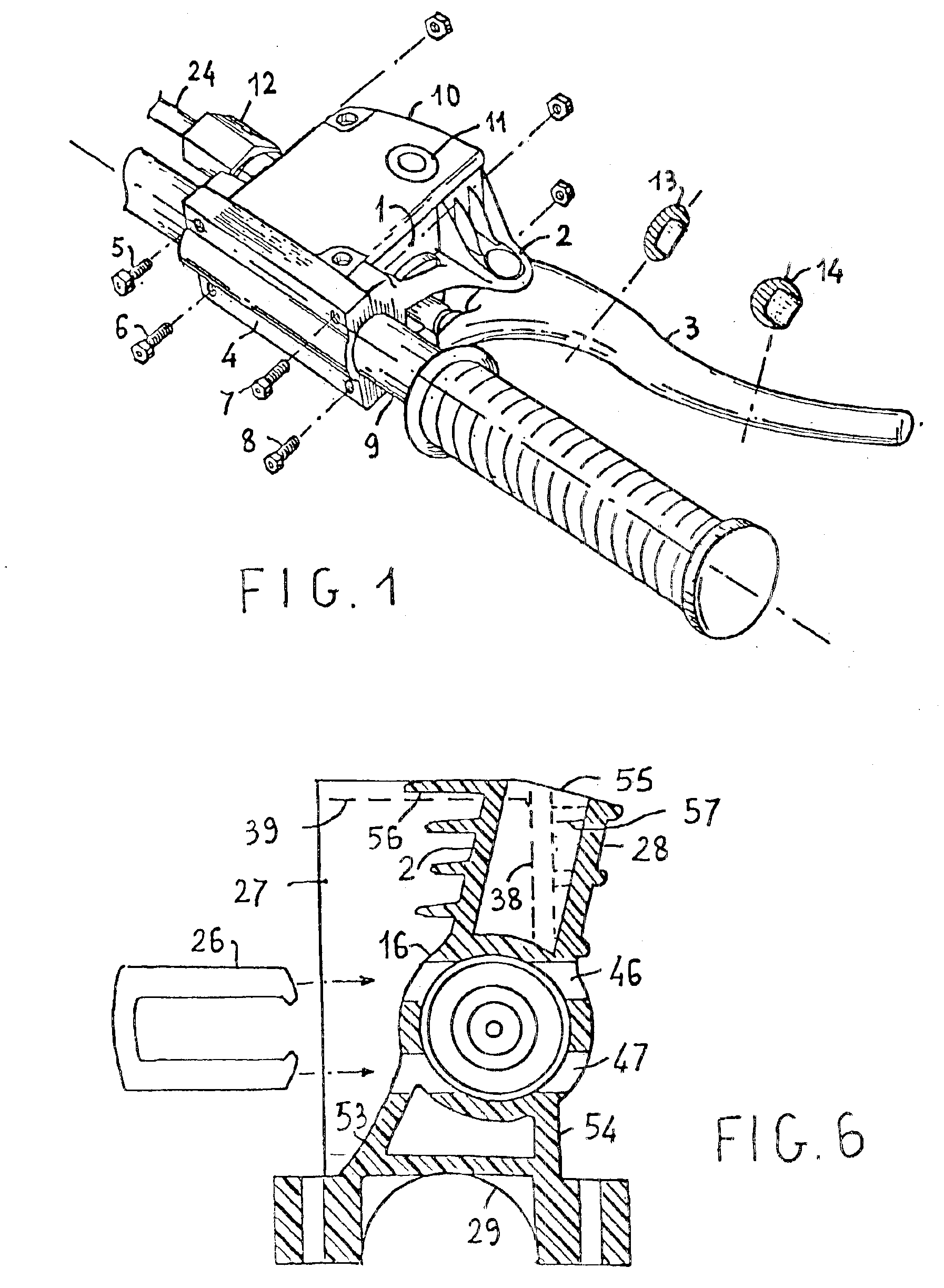

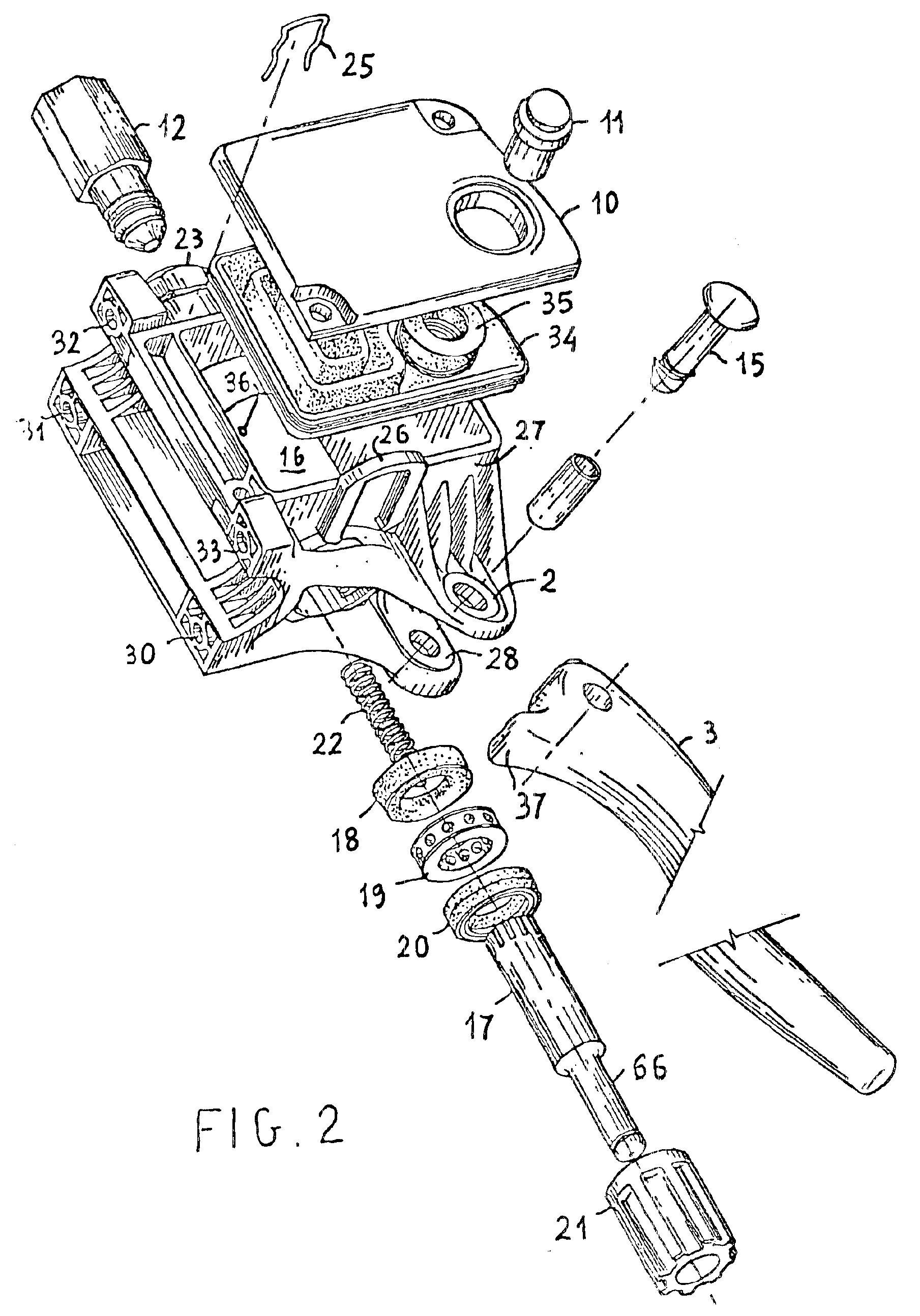

Master cylinder for a brake or clutch of a motorcycle or bike

InactiveUS6871729B2Simple structureRotary clutchesFluid actuated clutchesGlass fiberPlastic materials

A brake / clutch master cylinder for a motorcycle / bicycle or the like, with a body which is produced by moulding of plastics material reinforced by glass fibre without the need for machining operations or metal inserts and which forms, together with the cylindrical shell of the master cylinder, a hydraulic-fluid reservoir, a coupling sleeve for a male quick-fit hydraulic connector, and a seat for fixing to a handlebar, the body having a high degree of structural stiffness with respect to working stresses and adequate resilience for impact stresses imparted to the body by means of the hand operating lever.

Owner:FRENI BREMBO SPA

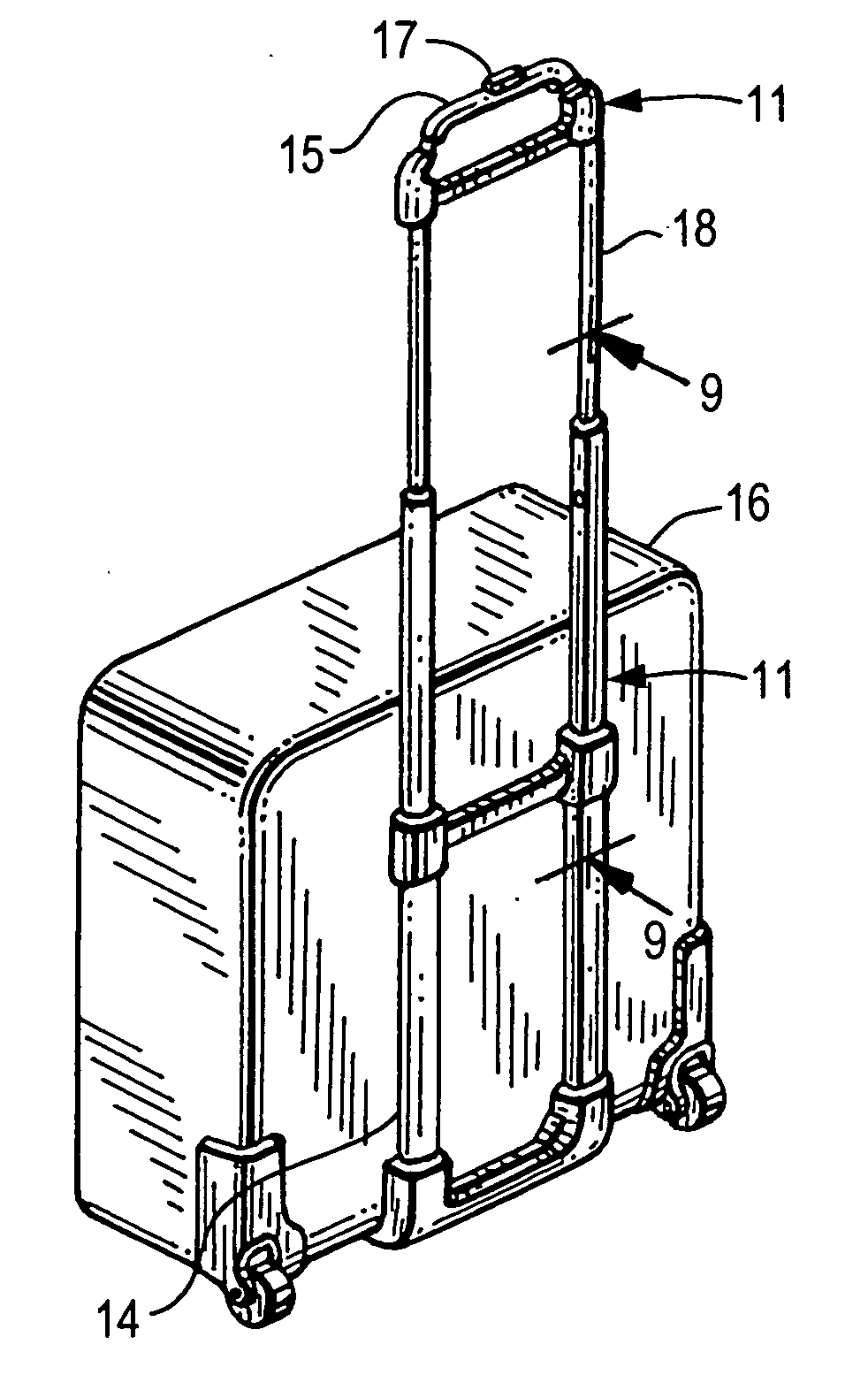

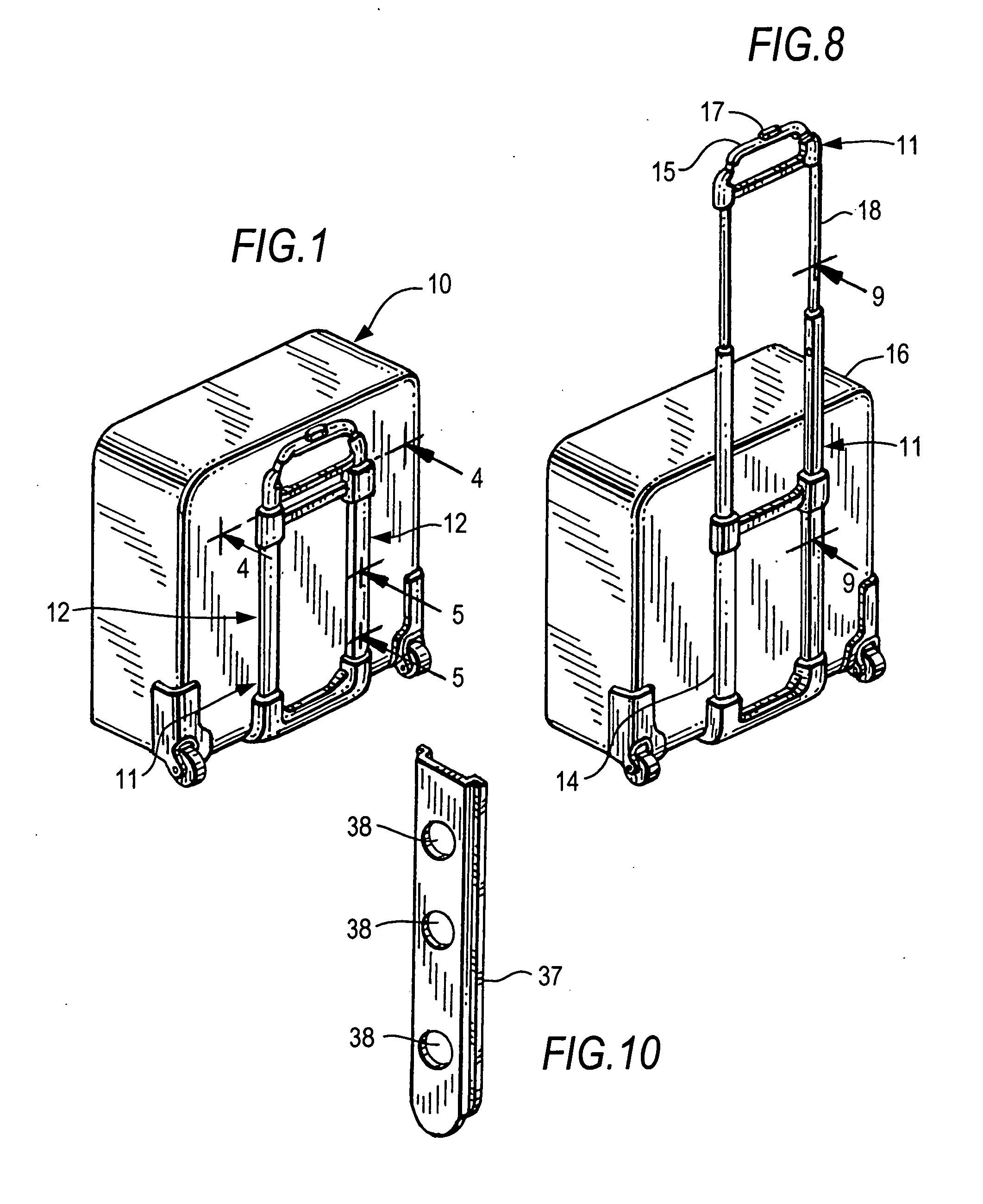

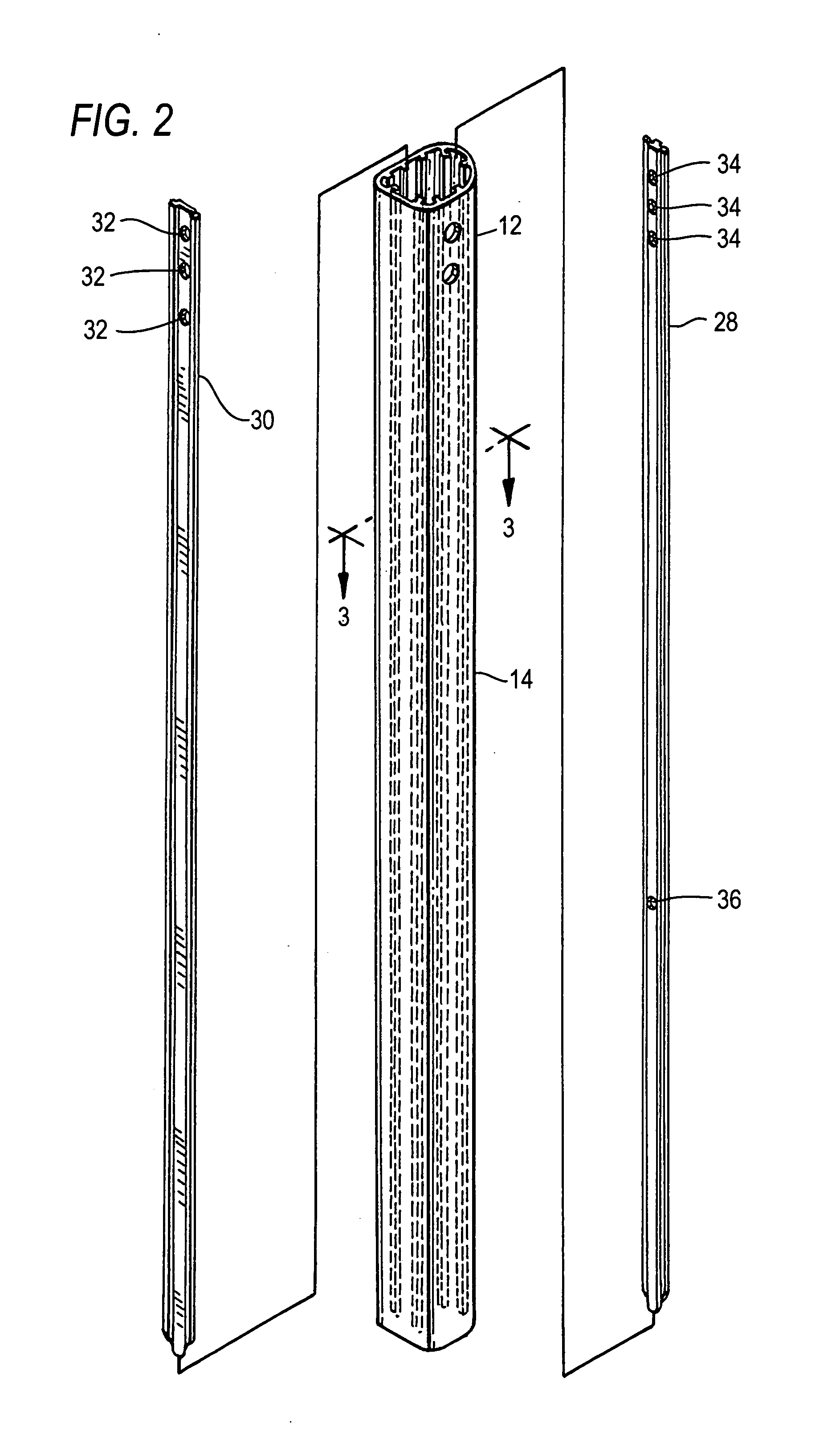

Reinforced extruded tubing for telescopic handle for trolley-type carry case and carry case incorporating same

Lightweight reinforced modular tubes of extruded plastic material are provided for the first stage of a trolley-type carry case, in combination with a locking mechanism, which facilitates effective extension and collapse of a multi-telescopic handle system. The tubes are made of extruded plastic material and include a pair of opposed metal strips having appropriately spaced and dimensioned apertures for reception of spring loaded locking pins of the telescopic system. The metal strips are respectively retained in position by a pair of radially extending elongated flange members which overlap marginal positions of the strips. The tubes and the metal strips can easily and quickly be cut to size to fit any size carry case. While the metal insert strips are preferably made of aluminum, any material stronger than the extruded plastic of the first stage tube can be used, i.e., steel, nylon, PVC, polyethylene, polycarbonate, or the like.

Owner:BRIGGS & RILEY TRAVELWARE

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS20030161750A1Stop crack propagationPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityGeometric pattern

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing. The positioning of the ceramic inserts in Ti-based powder is carried out by using a metal grid aiding the placement of inserts in a predetermined geometric pattern, and said grid becomes the integral part of the macrocomposite material. The technology is suitable for the manufacture of flat or shaped metal matrix macrocomposites having improved ductility and impact energy absorption such as lightweight bulletproof plates and sheets for airplane, helicopter, and automotive applications.

Owner:ADVANCED MATERIALS PRODS

Rotator with bearing, and method for manufacturing the same

InactiveUS6860639B2Low production costLow costGearingBall bearingsRolling-element bearingEngineering

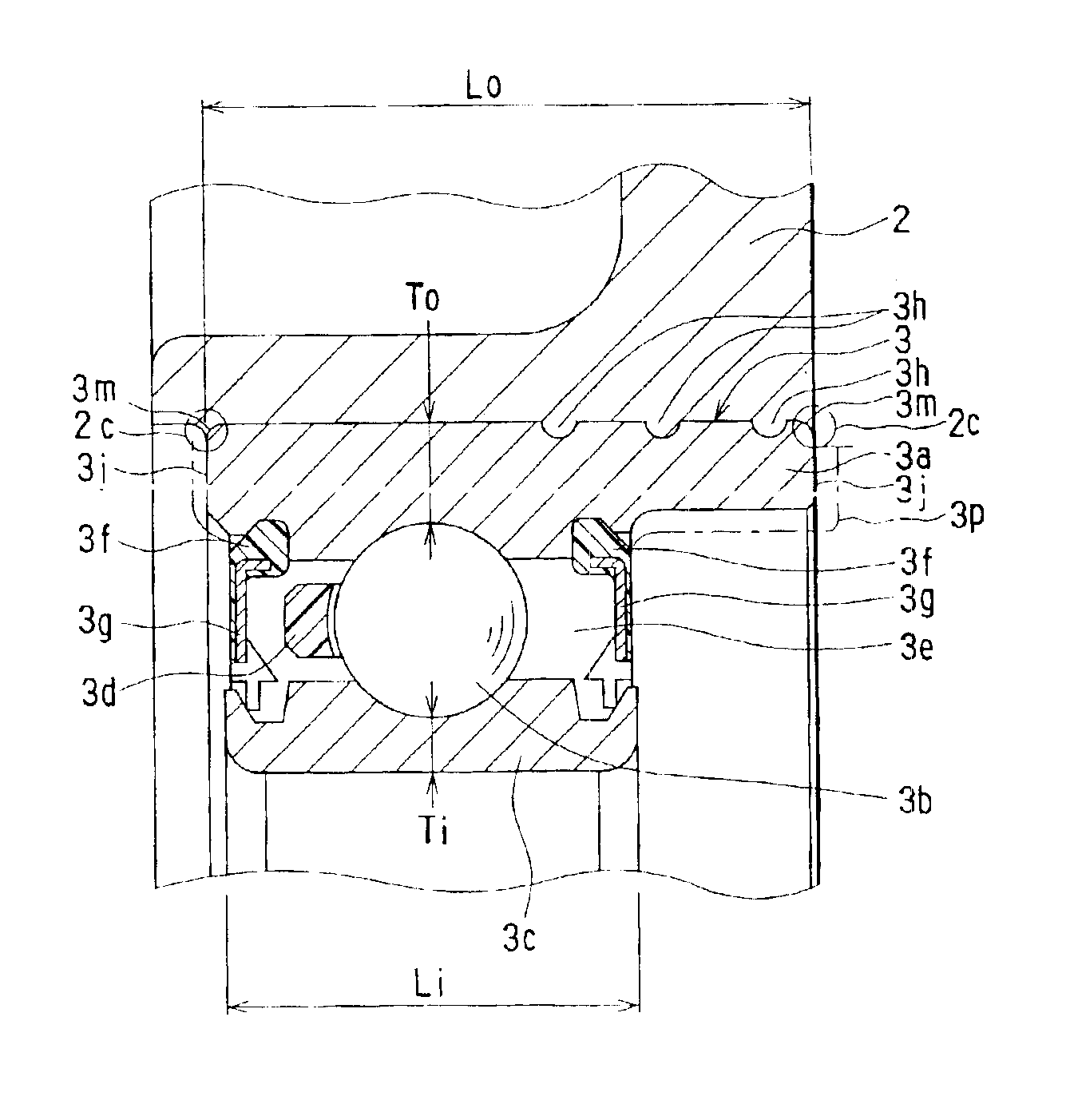

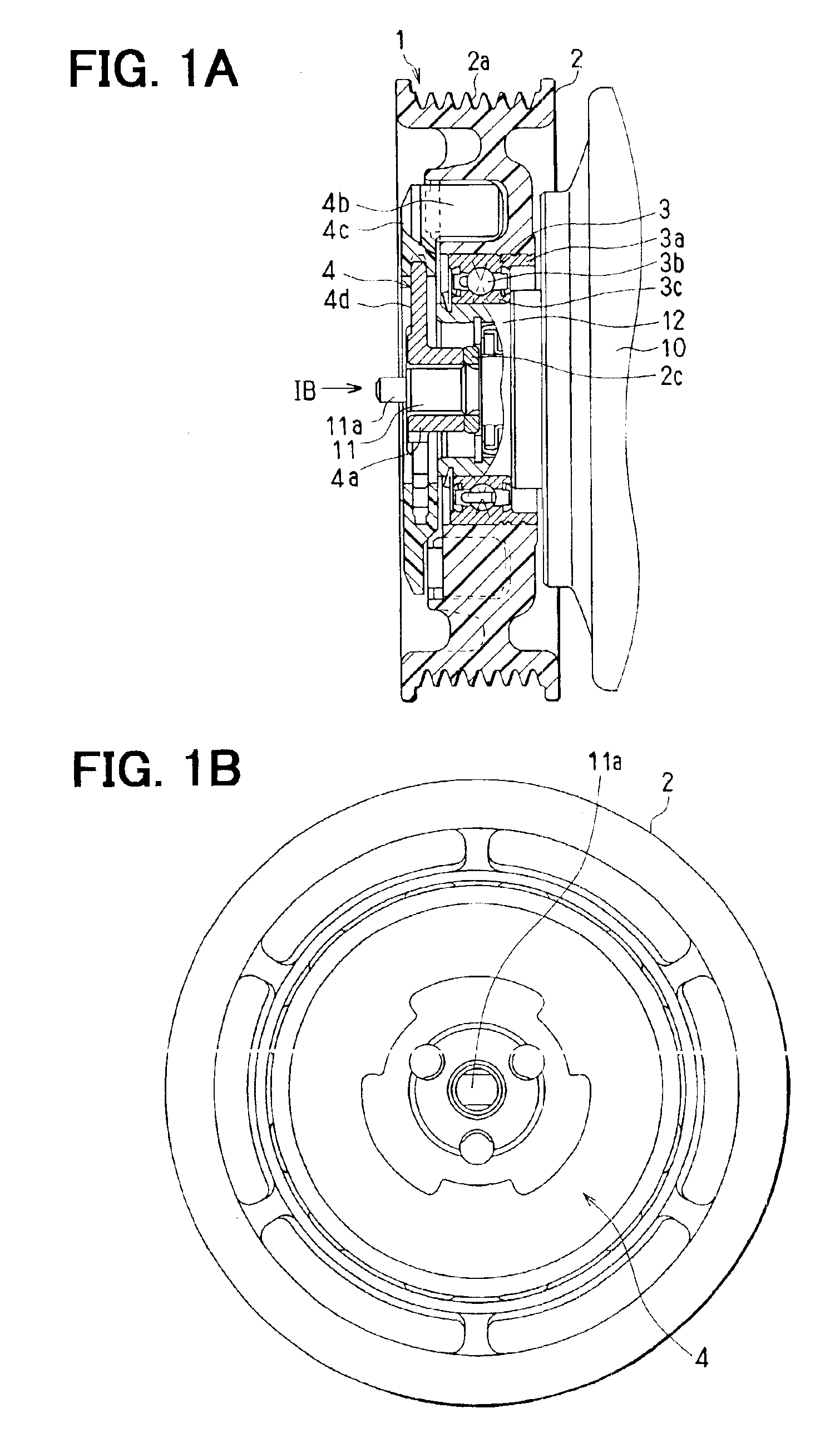

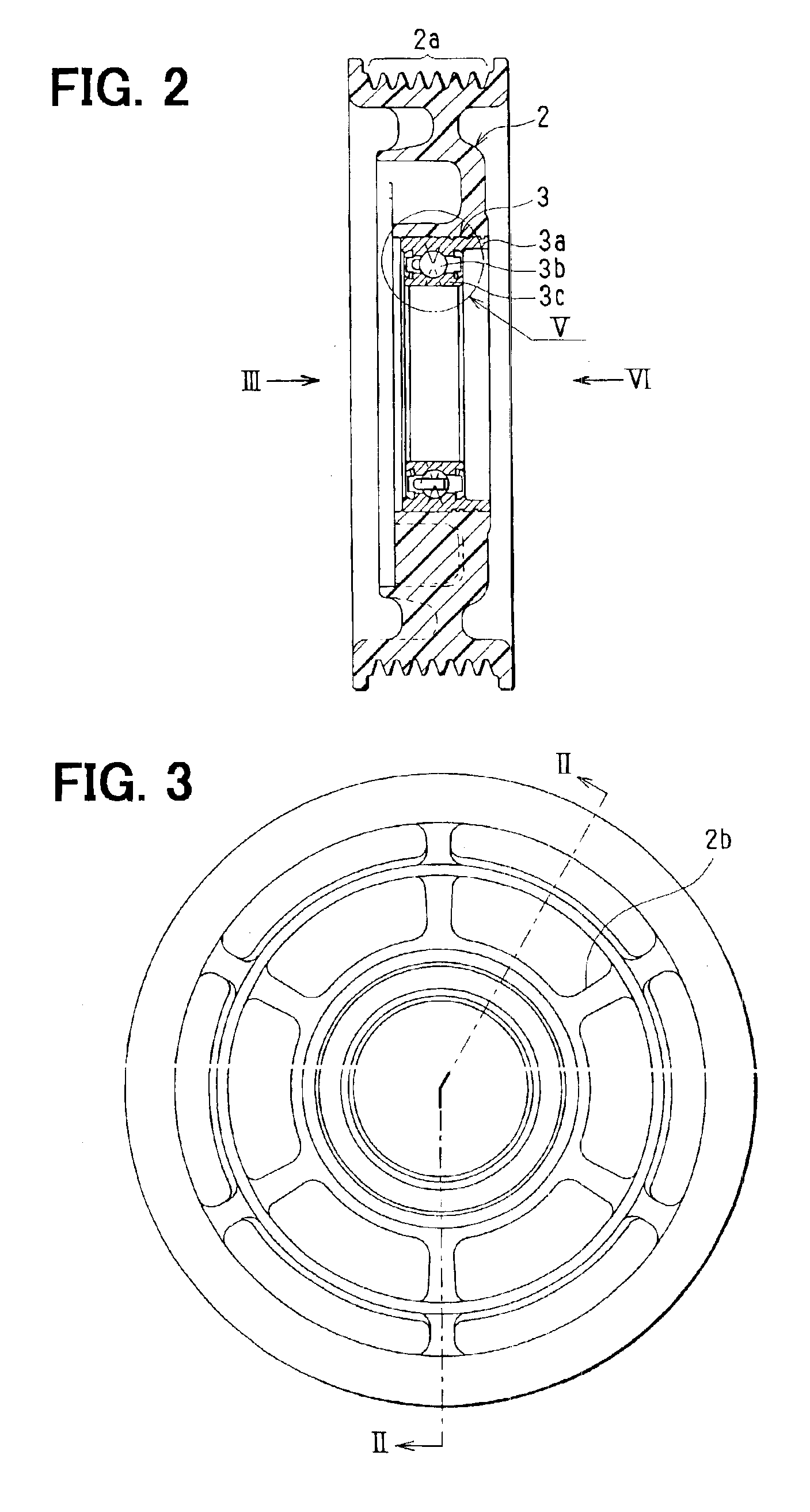

A pulley includes a radial rolling bearing and a pulley main body which are integrated to each other by an insert molding method. Therefore, a metal insert member is not required between the resin pulley main body and the radial rolling bearing, thereby reducing production cost of the pulley. Further, an axial dimension of an outer ring of the radial rolling bearing is set larger than an axial dimension of an inner ring thereof, so that a contact area between the radial rolling bearing and the pulley main body is increased. Therefore, a connection strength between the radial rolling bearing and the pulley main body is increased, and a surface area of the radial rolling bearing is increased, thereby improving heat radiation performance of the radial rolling bearing.

Owner:DENSO CORP

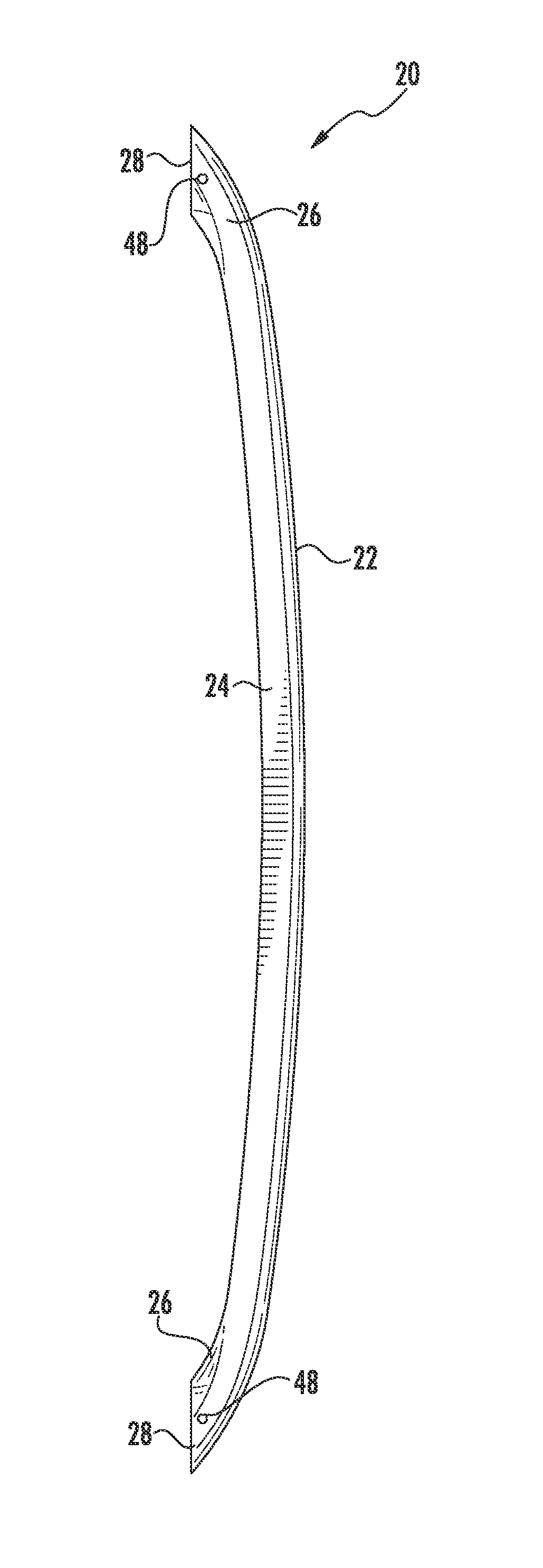

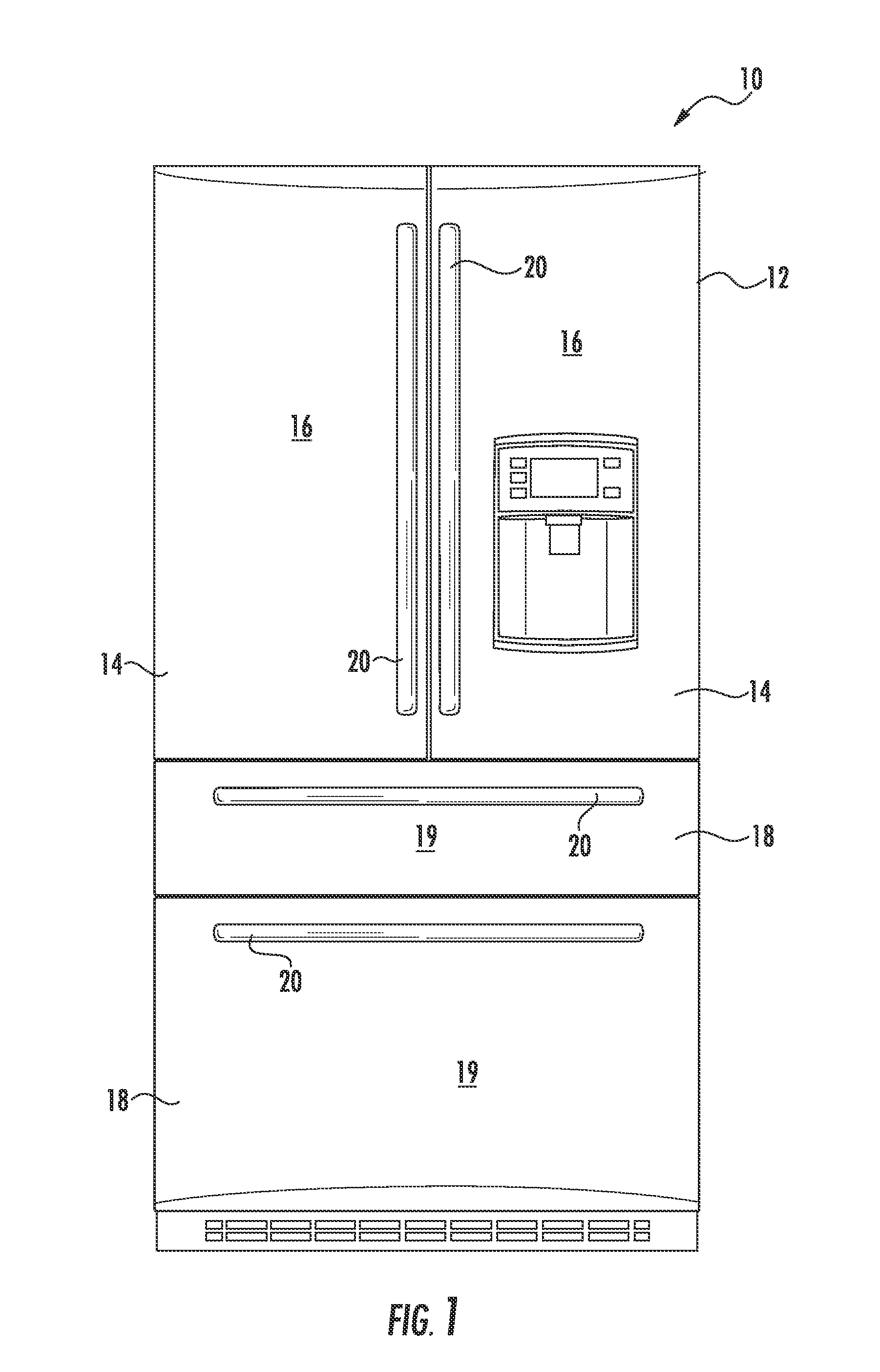

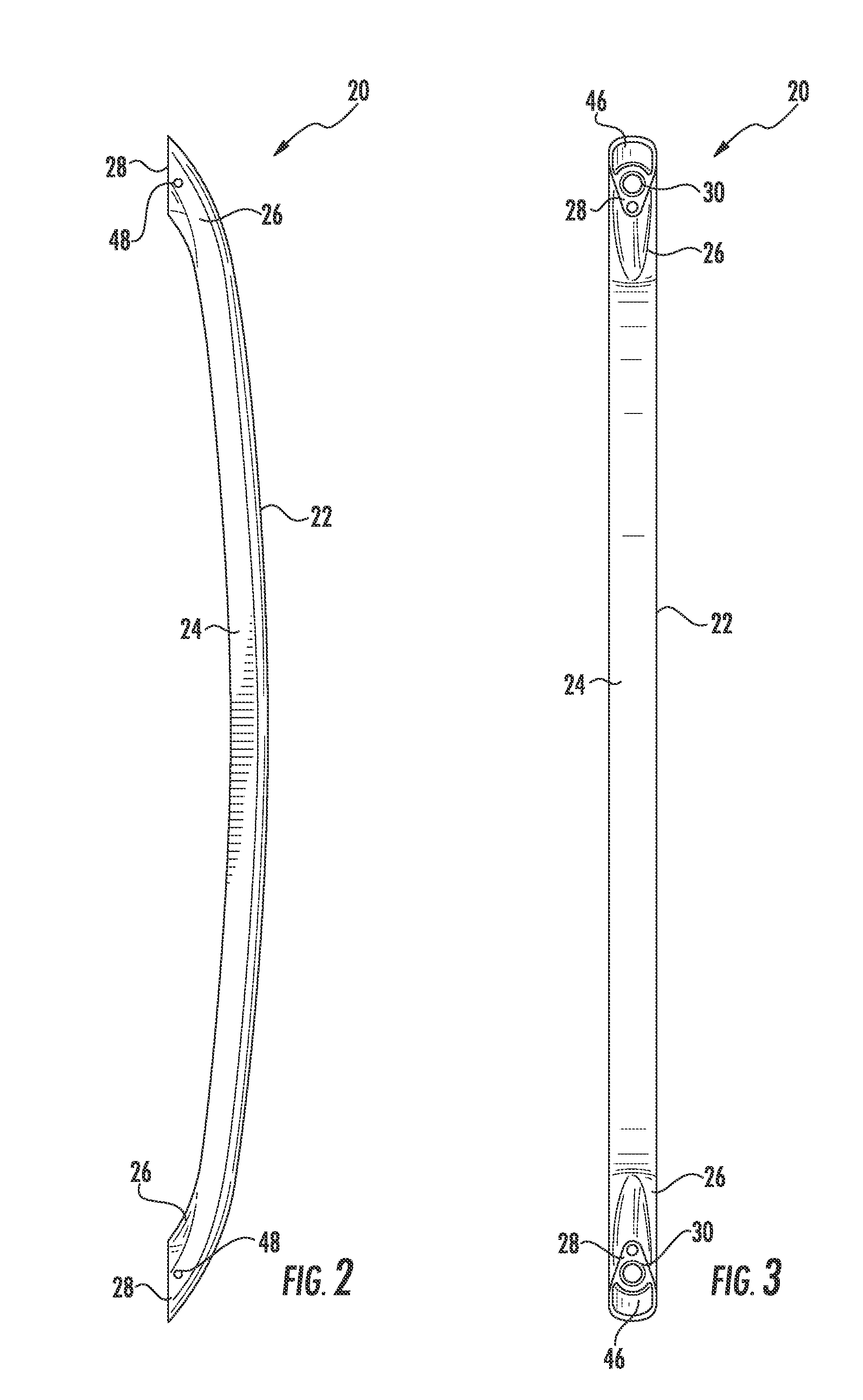

Thermoplastic refrigeration appliance handle with overmolded inserts

A door handle configured for mounting onto a surface of an appliance door, such as a refrigerator door, includes a thermoplastic molded body having a central grip section intermediate of a mounting foot provided at each opposite end of the body. Each mounting foot has a flat planar cross-sectional end face configured for mounting flush against the surface of the appliance. A tubular metal insert is overmolded in each mounting foot, with the insert having an open end generally flush with the mounting foot end face. The insert has an inner cross-sectional profile configured for engagement over a stud provided on the surface of the appliance with, for example, a setscrew inserted through a setscrew hole.

Owner:HAIER US APPLIANCE SOLUTIONS INC

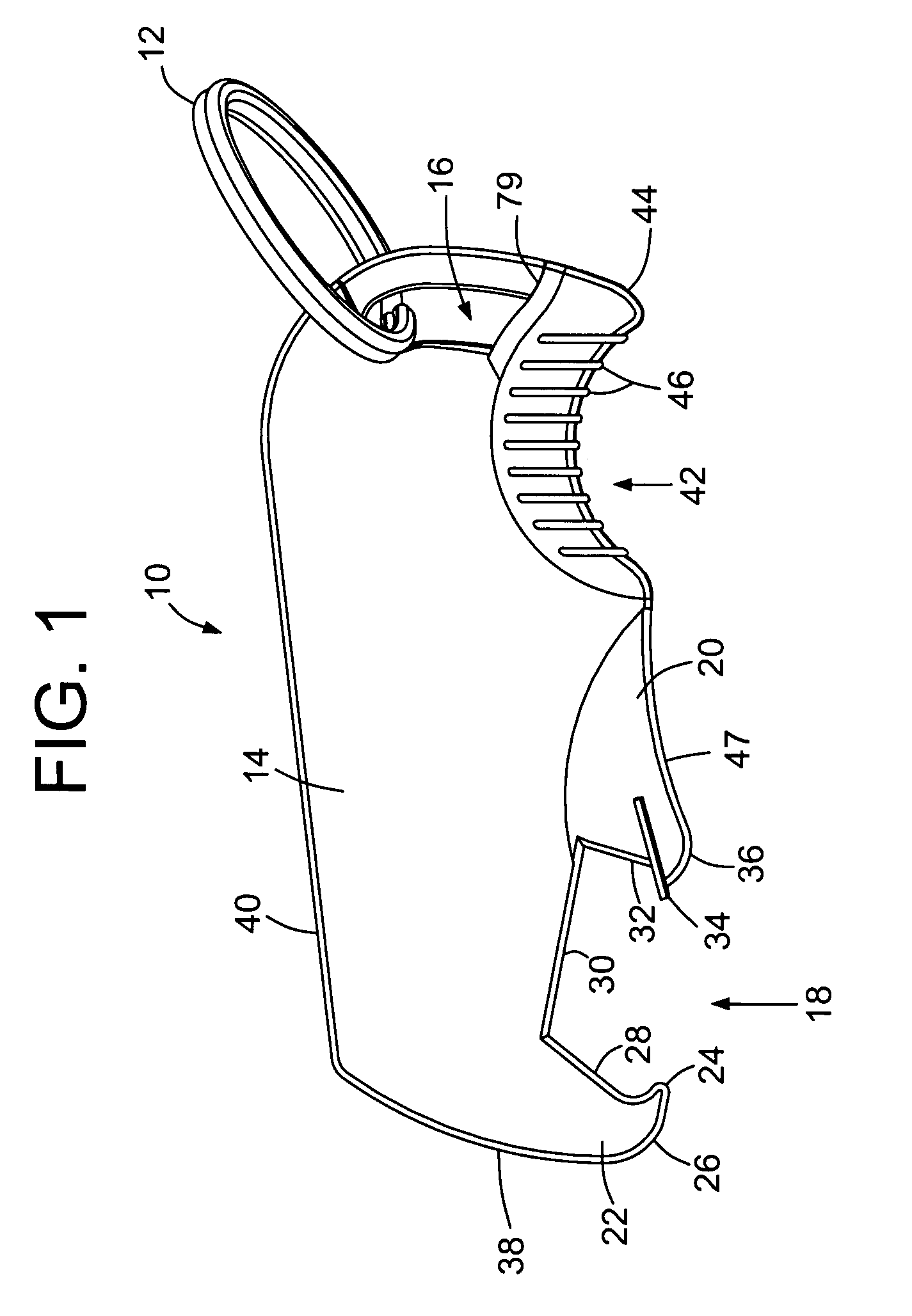

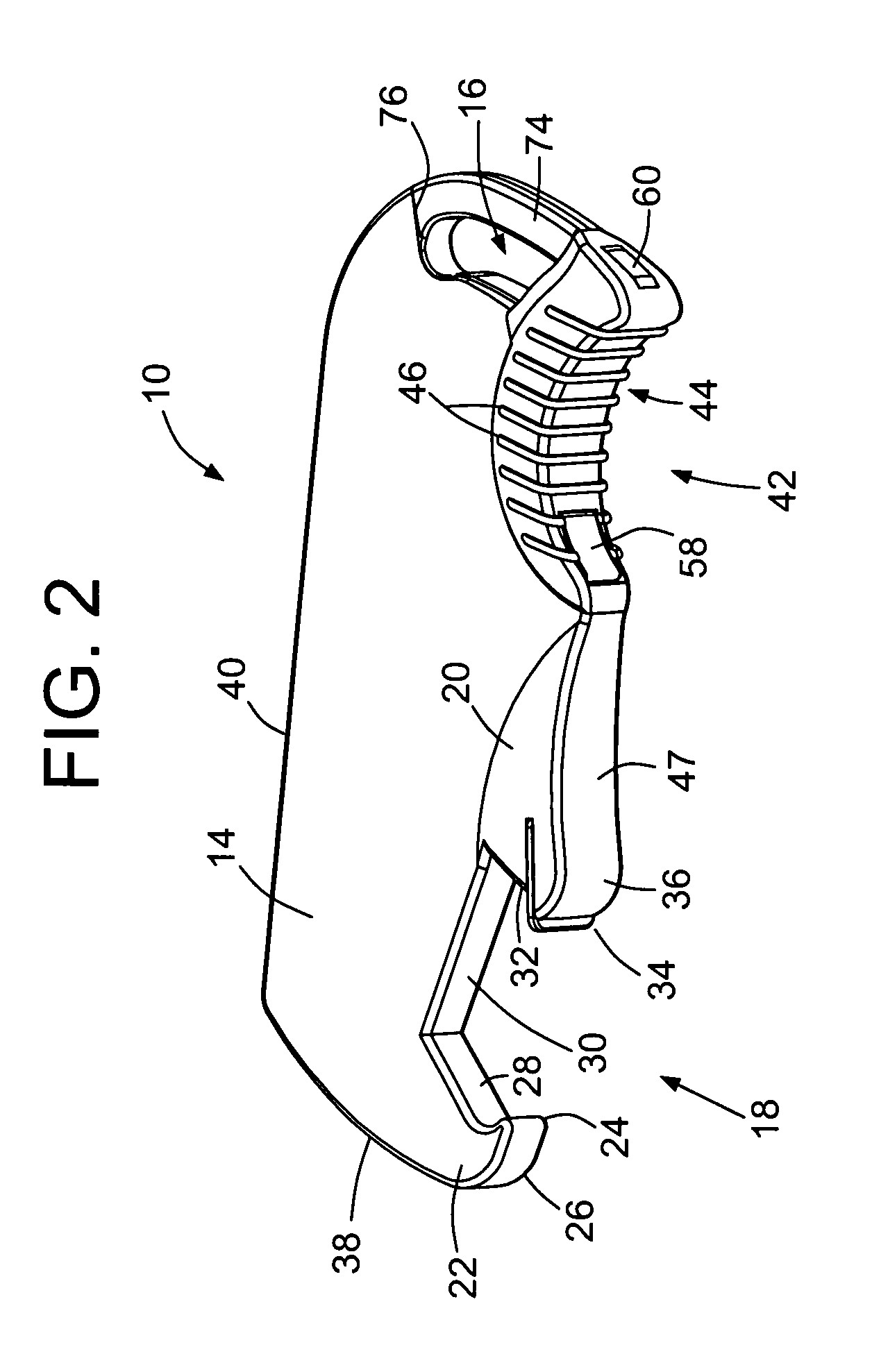

Bottle opener

A compact, ergonomic, pocket-sized bottle opener having a thin, generally flat body. The bottom edge of the body includes a jaw opening and at least one area for receiving a lifting finger. A plug of resiliently yielding material is mounted in the finger-receiving area to cushion the lifting finger. A hook at the forward end of the jaw opening forms a fulcrum point for engaging the top of the bottle cap. The hook also serves to lift pull-tabs on cans. An opening at the rear of the body holds a key ring. The key ring can be slipped into the opening during assembly by flexing the leg so as to open a slot that separates the distal end of the leg from the body. The cushioning plug mounts over both the distal end of the leg and the lower edge of the body so as to hold the leg in place after the ring has been installed. The two sides of the body form broad, generally flat display surfaces for application of logos, advertising, or other information. The body is preferably formed of strong, molded plastic, with a metal insert being installed in the jaw opening for engaging the edges of bottle caps.

Owner:BOOK STEVEN C

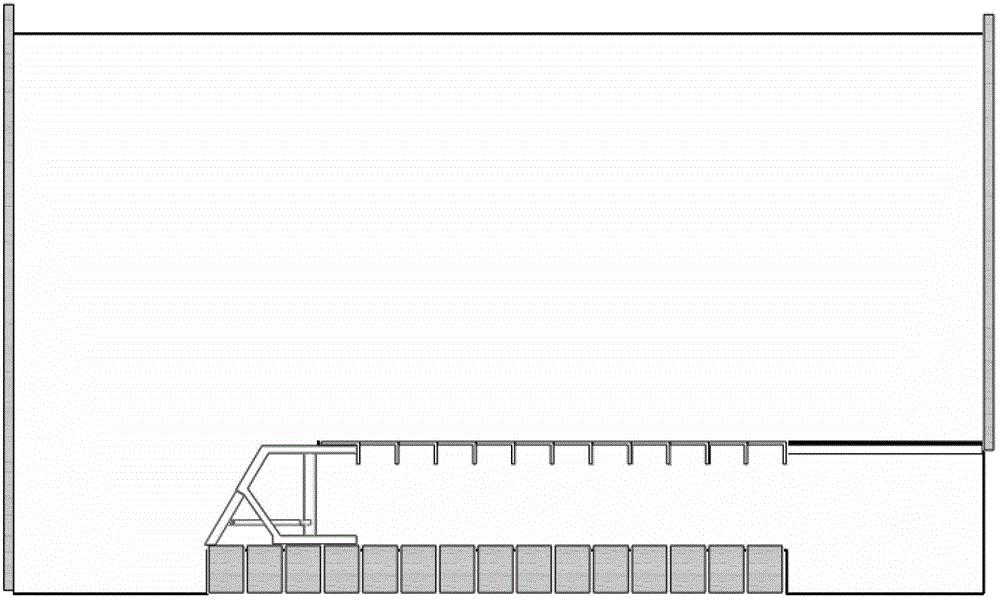

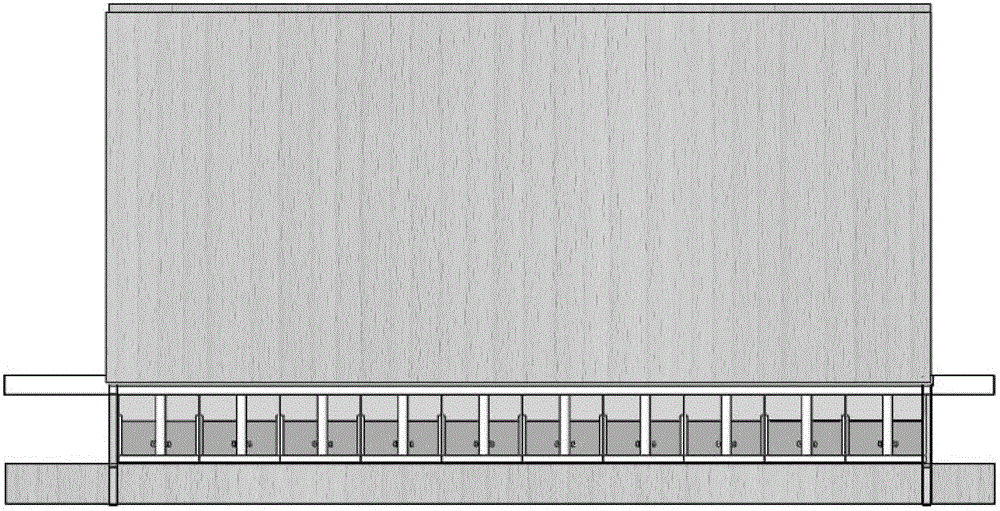

Fully mechanized caving top coal caving three-dimensional simulation experiment platform and experiment method

InactiveCN102749432ARemove the influence of recovery statisticsSolve the roof fall problemFuel testingThree dimensional simulationEngineering

The invention discloses a fully mechanized caving top coal caving three-dimensional simulation experiment platform and an experiment method. The platform and the method are used for researching the influences of elements in coal mine fully mechanized caving working face, such as mining-caving ratio, caving manner, caving technology, bracket tail beam inclination angle, coal caving port size, and broken top coal particle sizes, upon fully mechanized caving working face top coal recovery rate, and for verifying the influence of the spatial arrangement of an onsite top coal tracker upon onsite actual measurement precision of top coal recovery rate. According to the experiment platform provided by the invention, a mobile immediate roof is arranged, such that the influence of roof caving during an experiment process upon the recovery rate can be avoided. Coal pillars are preserved on the boundary, and only central-area recovery rate is counted, such that the influence of experiment method boundary conditions upon recovery rate statistics can be basically eliminated. Experimental-area residual coal amount can be obtained by using sheet metal inserts, such that top coal recovery rates under different conditions can be obtained. Therefore, guidance can be made for actual engineering, and an optimal fully mechanized caving scheme can be selected.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

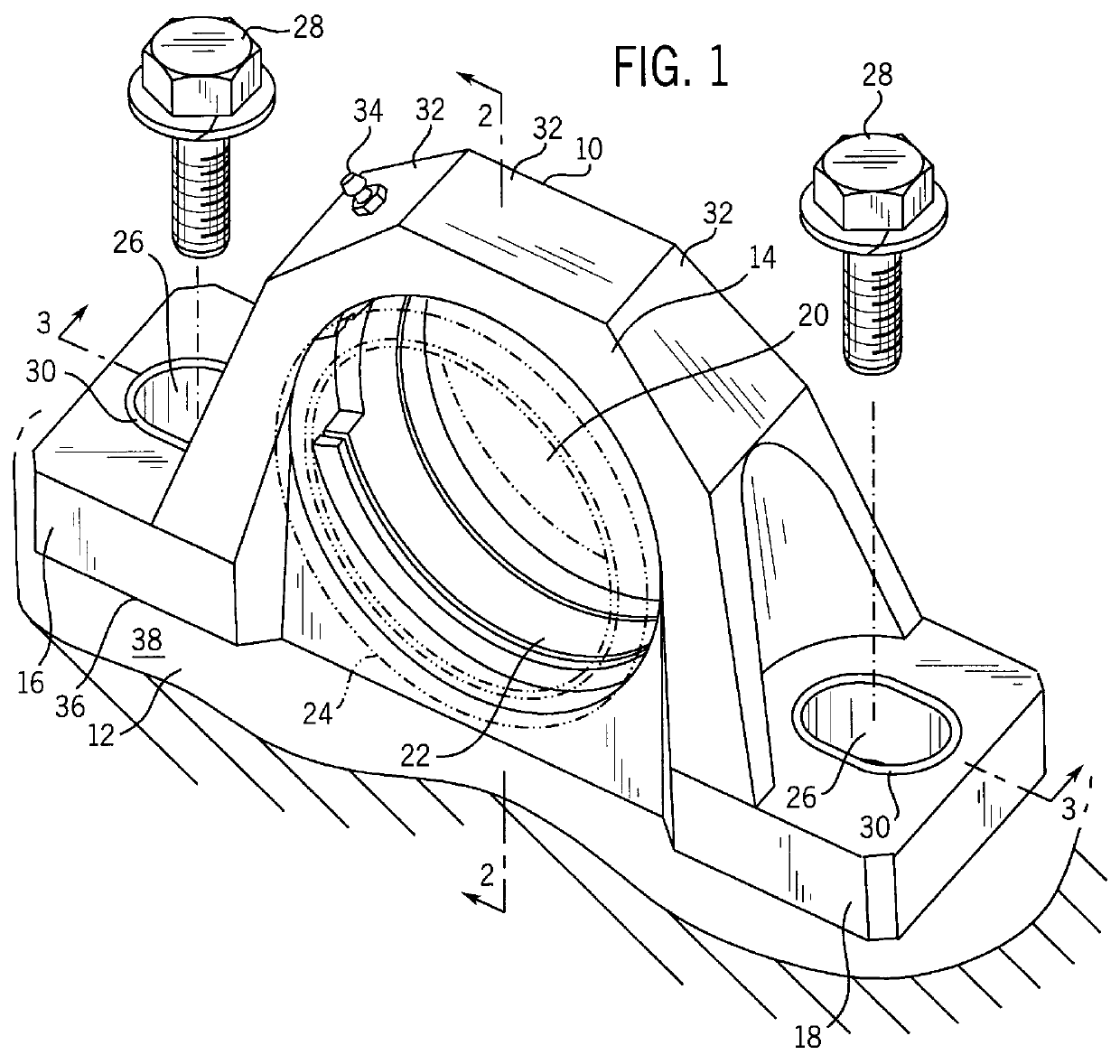

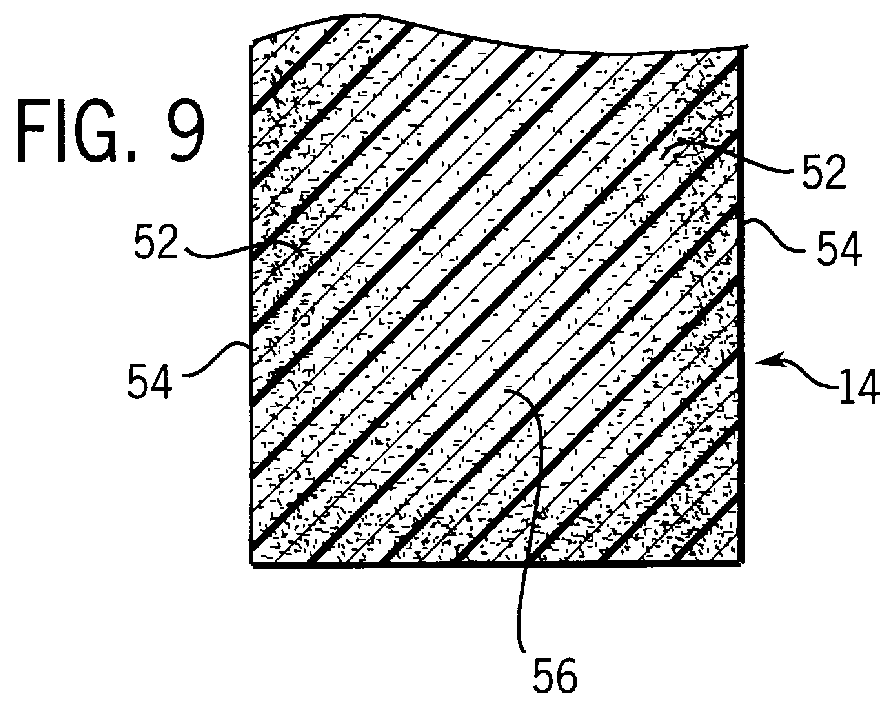

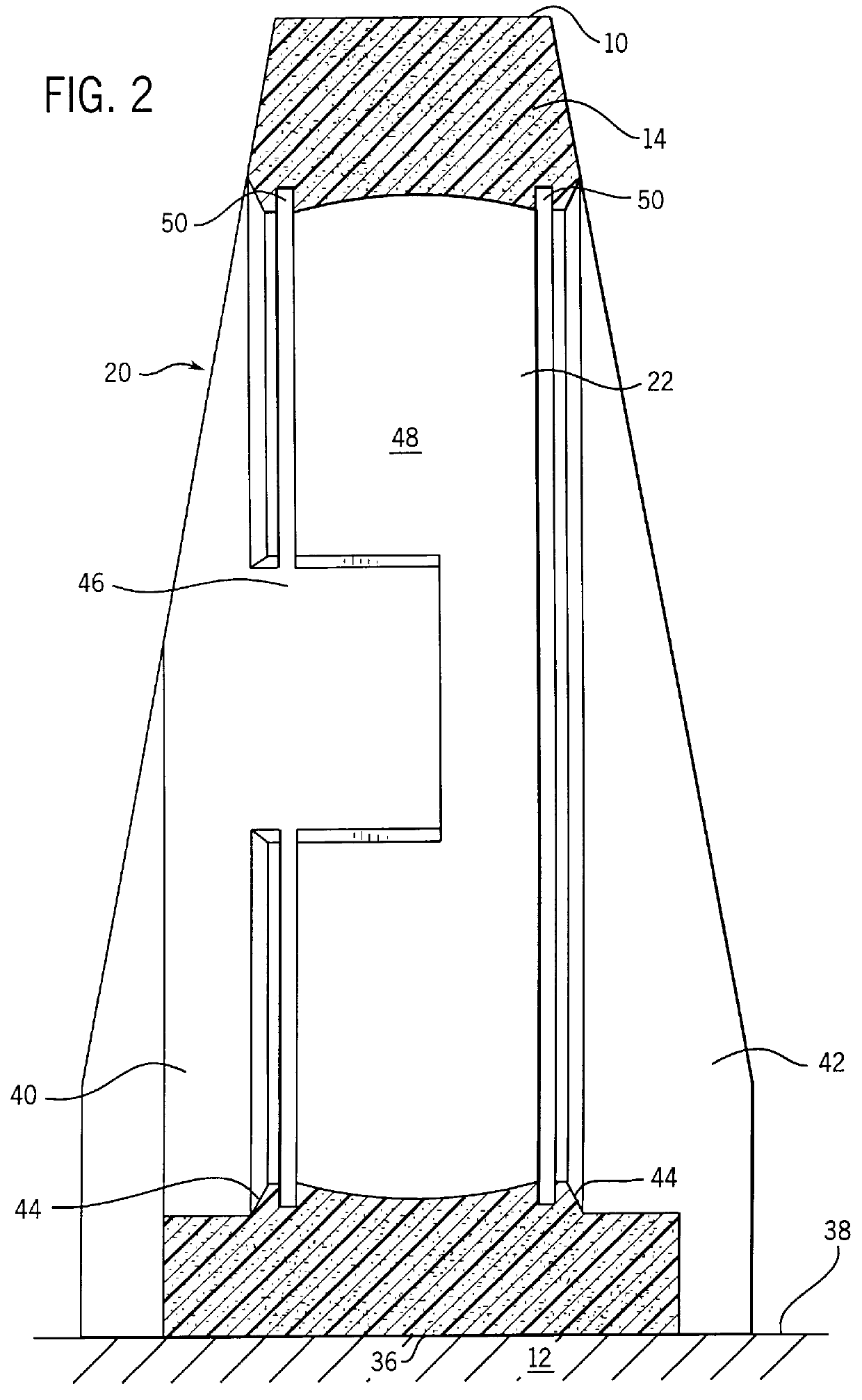

Molded polymeric bearing housing and method for making same

A molded polymeric bearing housing is formed of a moldable polymer base material in combination with a glass fiber reinforcing component. A foaming agent is added to the base material to create a fine structural foam within interior regions of the housing. A density gradient is established between regions adjacent to the surfaces of the housing and the internal regions, thereby reducing the need for reinforcing ribs particularly in a base or mounting portion of the housing. An antimicrobial agent may be added to the housing material to inhibit the growth and proliferation of fungi, molds, bacteria, and so forth. Structural features of the housing may be formed subsequent to the molding process, such as by turning operations. Metal inserts may be provided to avoid crushing of regions of the housing, such as by attachment fasteners. The housing forms a mounting base surface in a single plane coextensive with the footprint of the housing. When the housing is placed in service moisture and debris is prevented from collecting below the housing by conformity of the mounting base surface with the machine support surface. The housing may be formed in a variety of styles, including pillow block styles, tapped base pillow block styles, two and four bolt flange styles, take up frame styles, flange bracket styles and so forth.

Owner:BALDOR ELECTRIC COMPANY

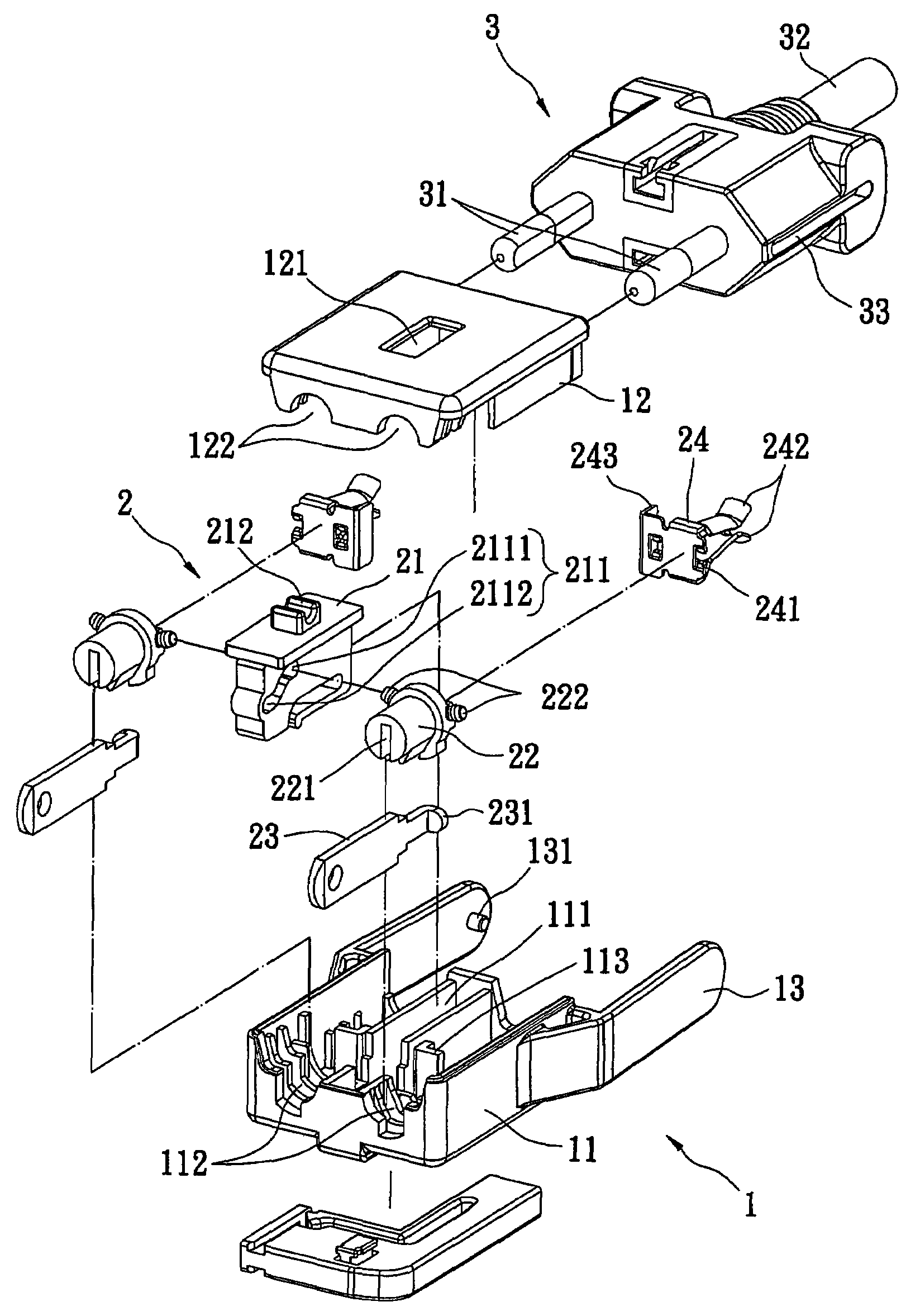

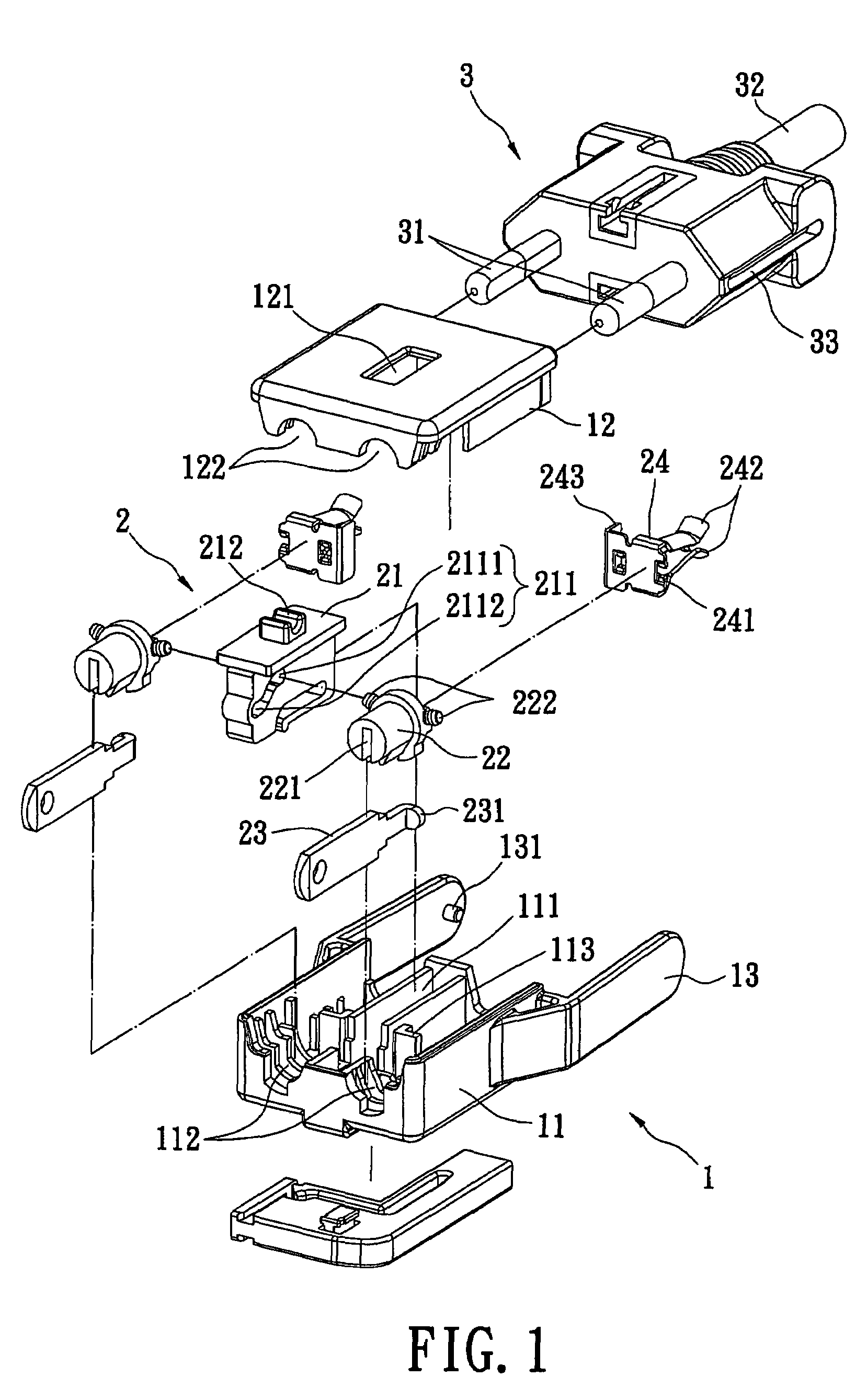

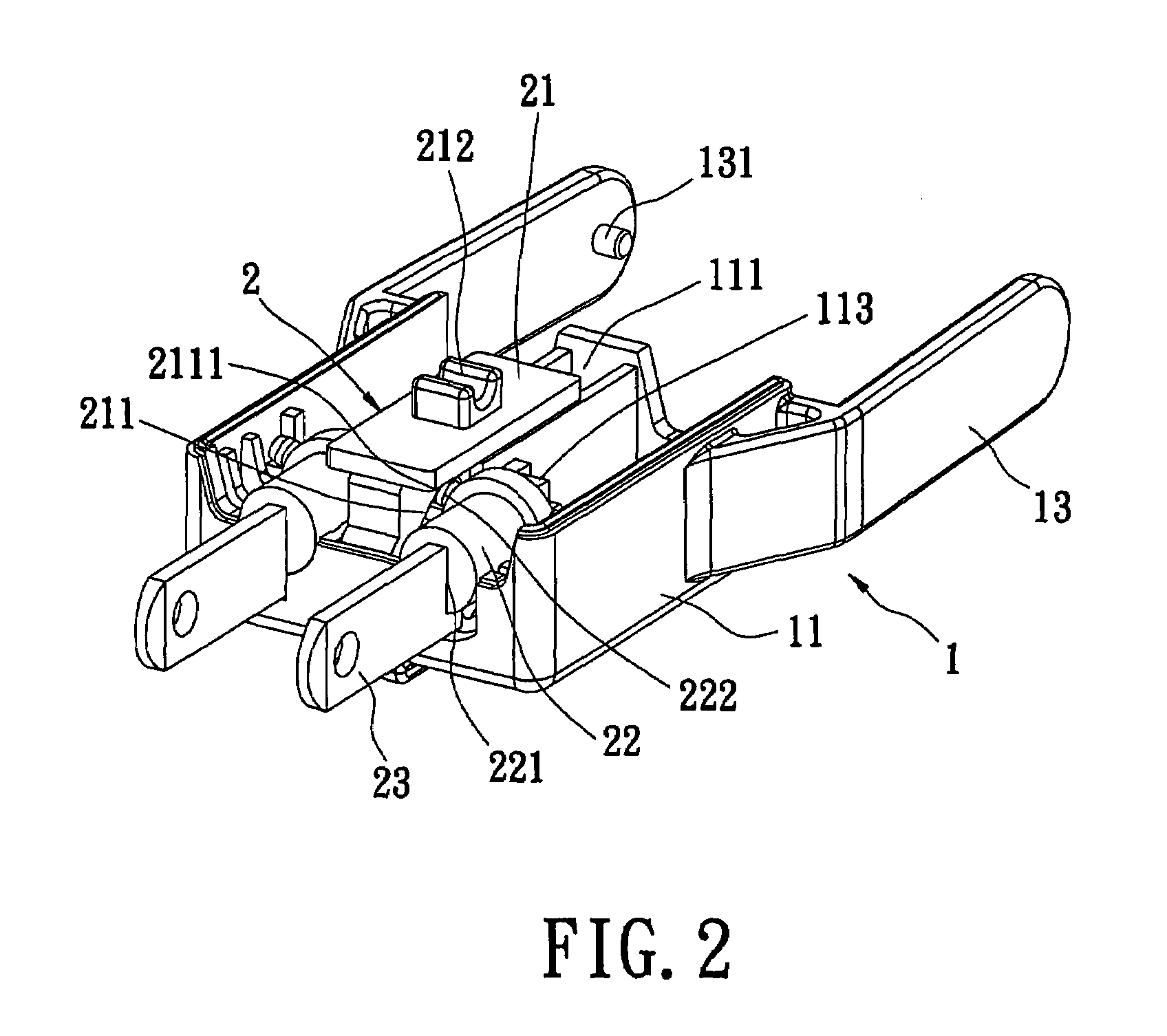

Compound conversion plug structure with adjustable angle and adapter

InactiveUS7303416B1Reduce manufacturing costConvenient for userTwo pole connectionsTwo-part coupling devicesEngineeringMechanical engineering

A compound conversion plug structure with an adjustable angle includes an adapter and a plug component. The adapter includes an outer shell, a moving block, a plurality of transfer pieces, a plurality of metal inserting pieces, and a plurality of engaging pieces. The moving block defines a guiding groove thereon, and protruding pieces defined on the transfer pieces respectively are set in the guiding groove, the metal inserting pieces are assembled with the transfer pieces, one end of which extends out of the outer shell, and additional ends of the metal inserting pieces engage with the engaging pieces respectively. Because of the structure of the moving block and the transfer piece of the adapter, the metal inserting pieces can be inserted into two types and standards of sockets. Hence, the adapter provides multiple changes to suite actual needs.

Owner:LIAO SHENG HSIN

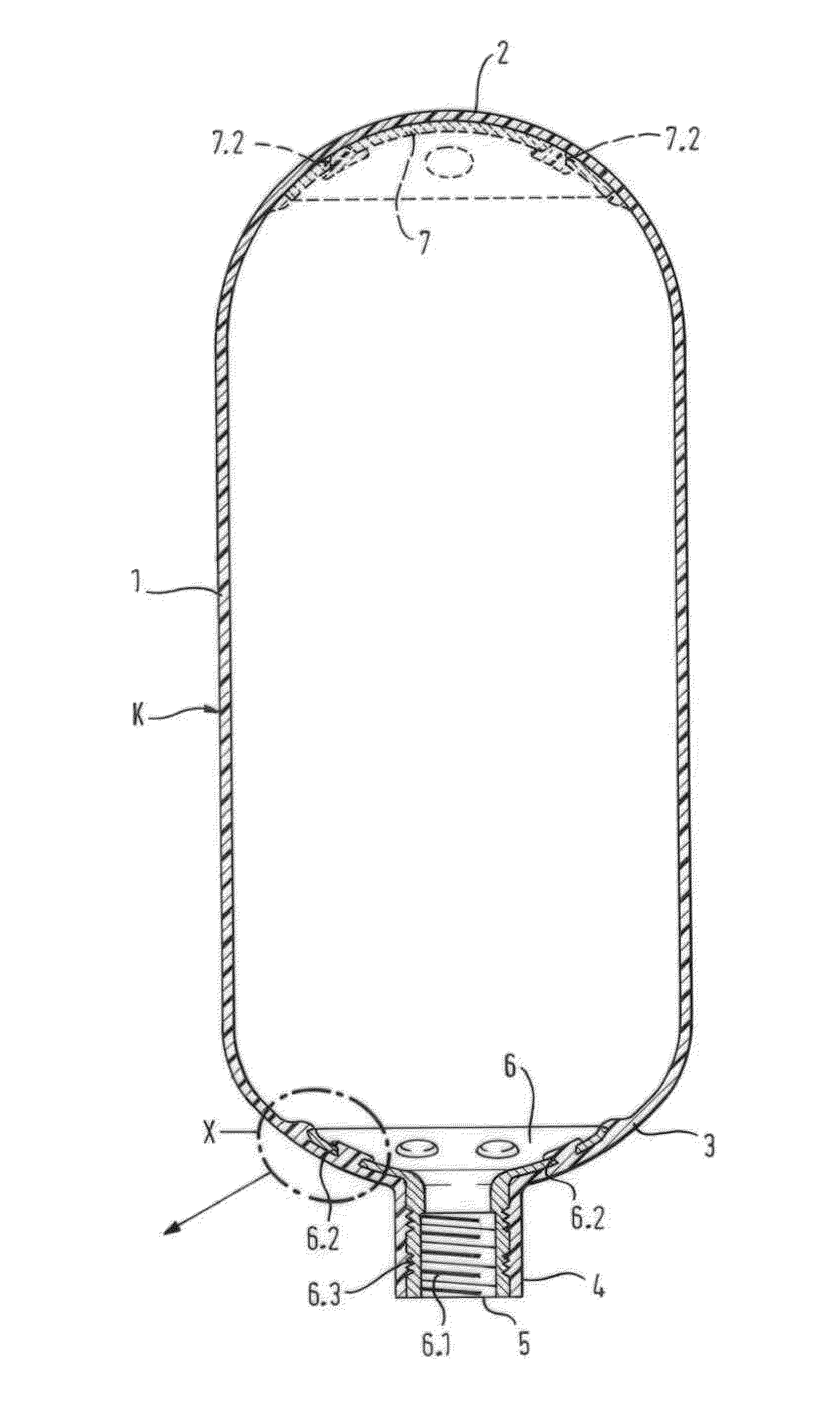

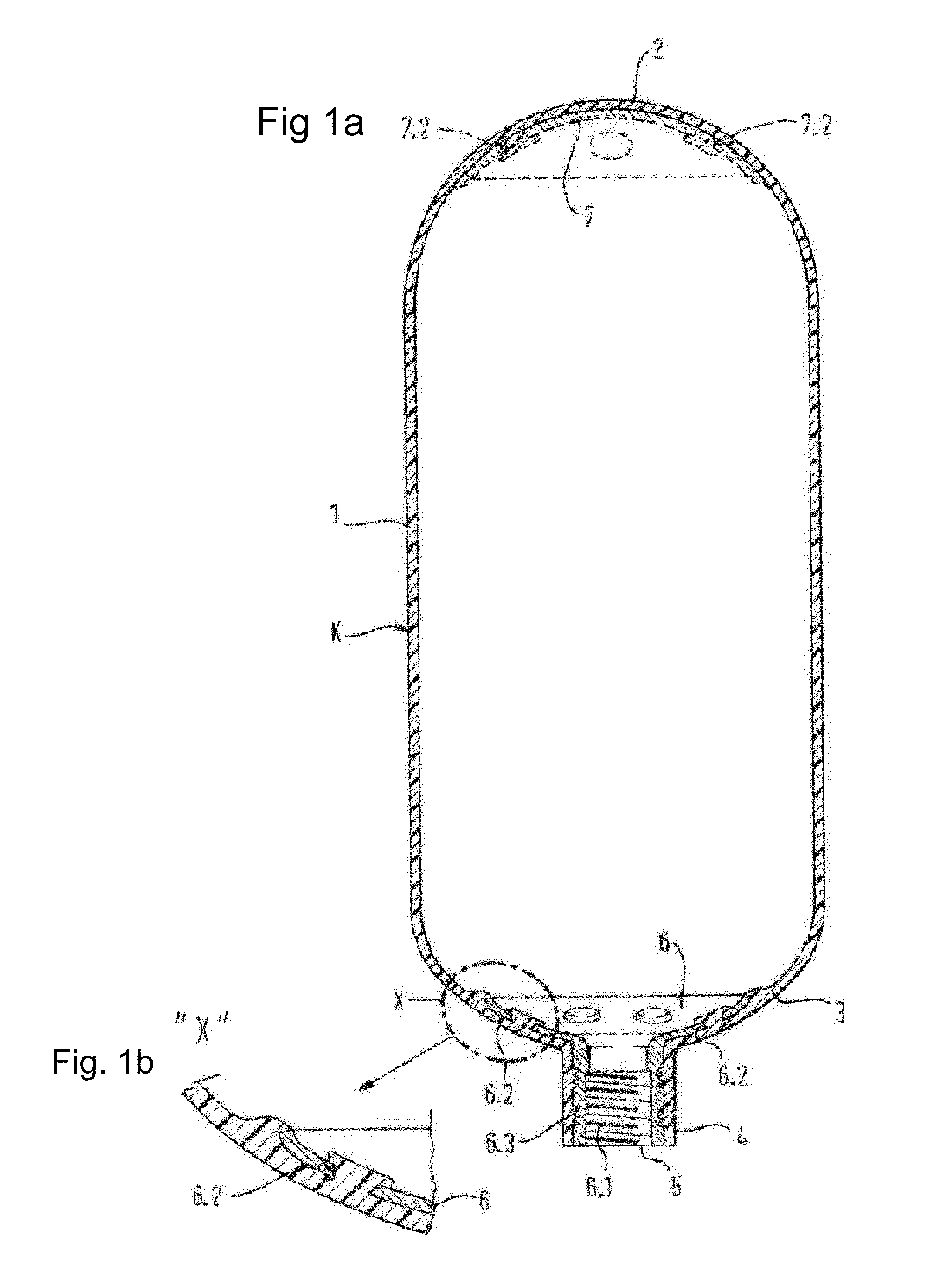

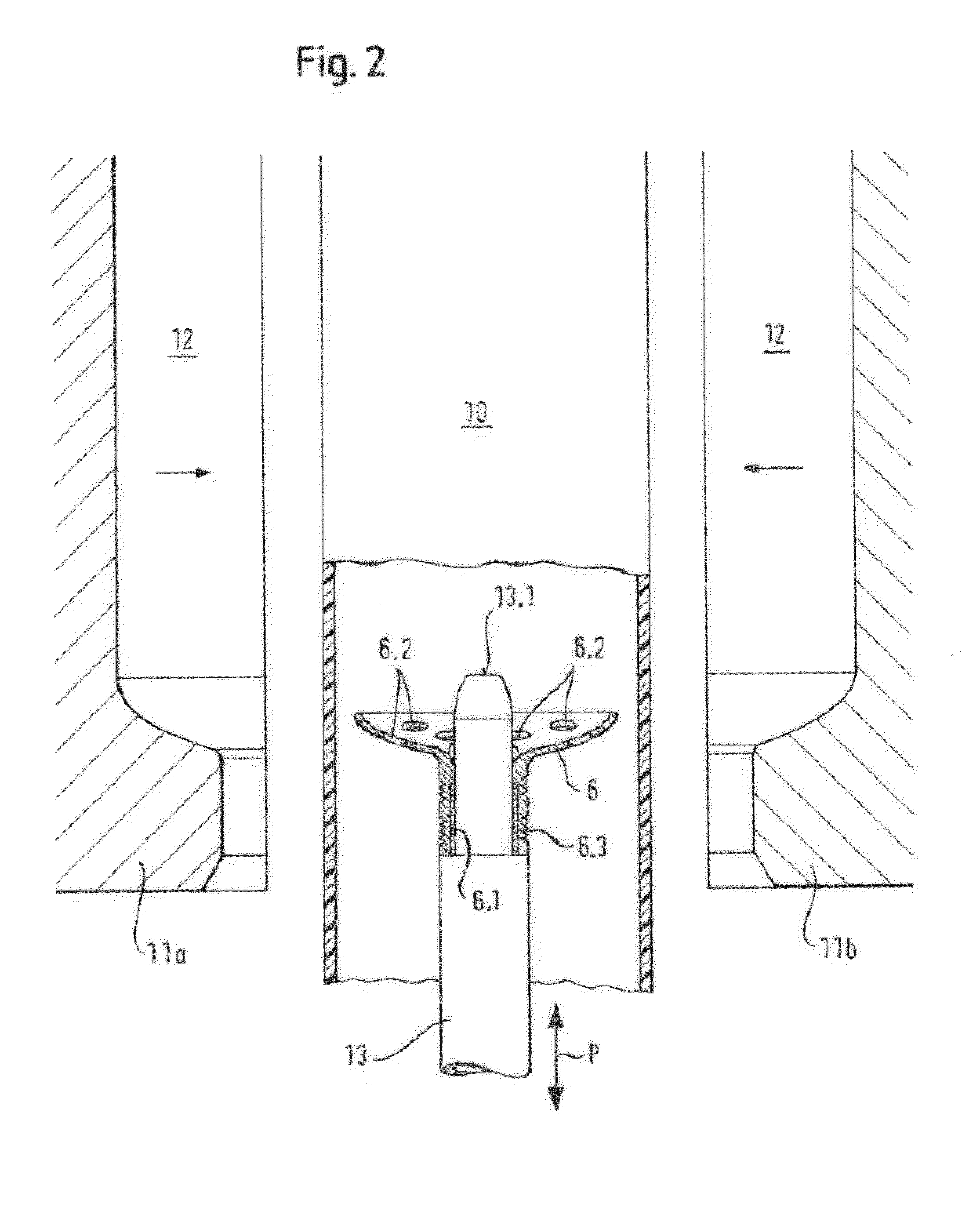

Pressure Tank and Method and Blow-Molding Station for the Production Thereof

InactiveUS20100255234A1Easy to useEasy to fixPreformed elementsThin material handlingThermoplasticBlow molding

A pressure tank blank made of a thermoplastic, having a body, which merges via a shoulder into a neck and a mouth, which is implemented for screwing in a valve, is usable for gases under high pressure, if the blank has a metal insert enveloped by the plastic on the interior to reinforce at least the shoulder of the blank. This pressure tank blank may be produced in an extrusion blow-molding method. For this purpose, with open blow mold, a metal insert having the inner contour of at least the shoulder of the blank is introduced into the corresponding area of the cavity of the blow mold and the tube, enclosing this metal insert, is extruded into the blow mold, before it is closed.

Owner:KUNSTVERARBEITUNG KOETKE

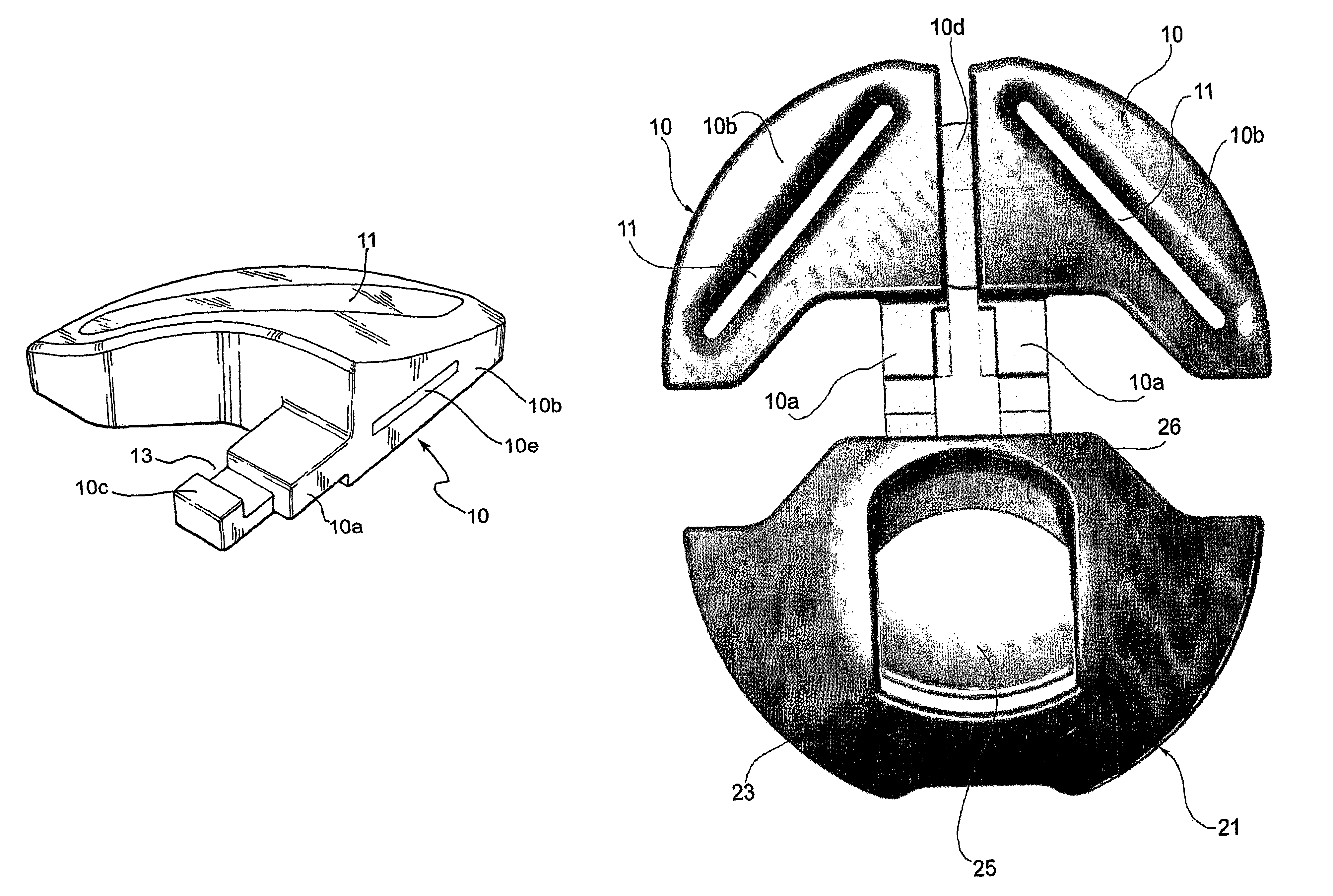

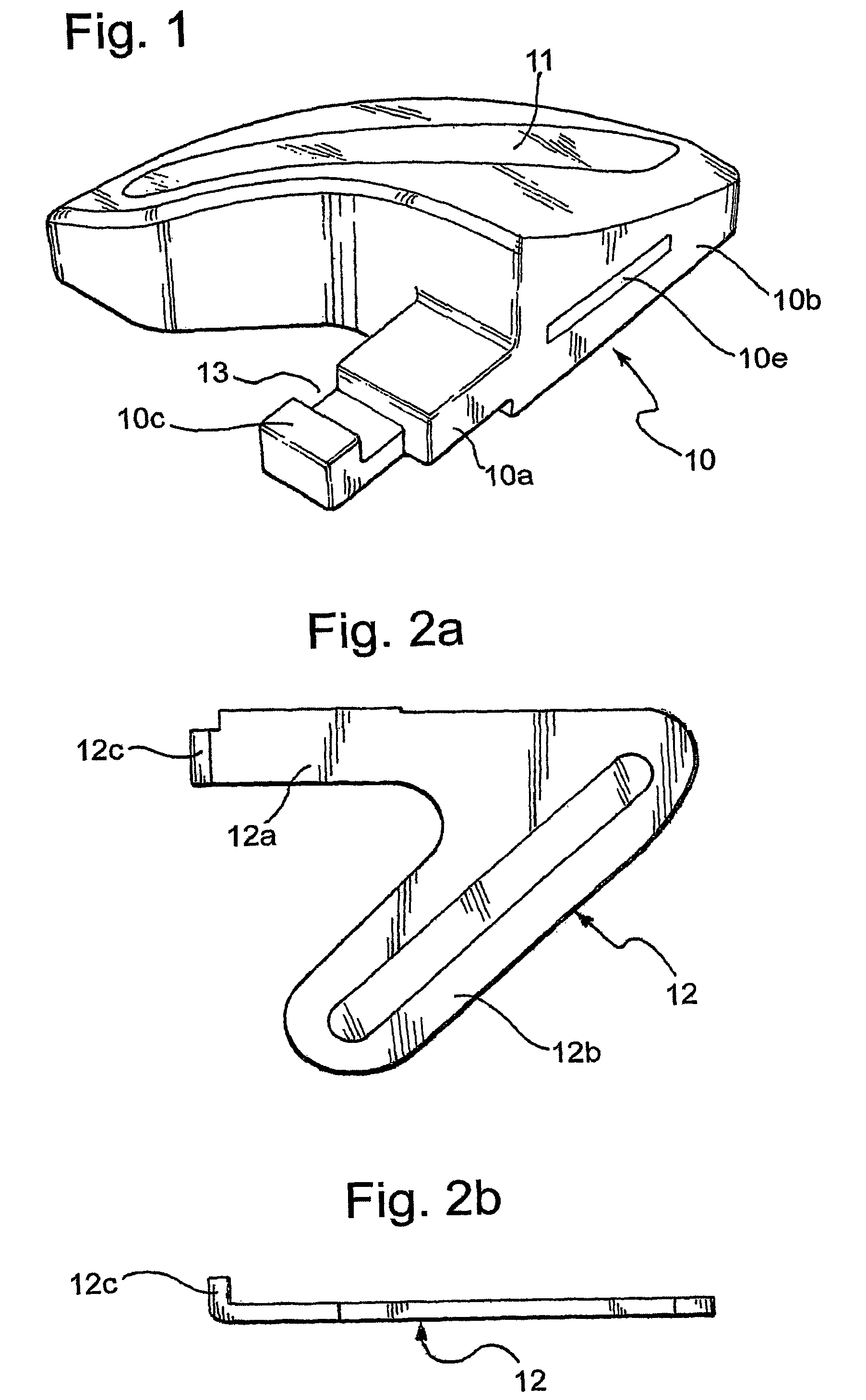

Coupling device for restraining belts, particularly for children's safety seats for motor vehicles

ActiveUS7360287B2Simple and strong structureGuaranteed uptimeSnap fastenersSafety beltsExposure sunlightMotorized vehicle

A coupling device for restraining belts, particularly for children's safety seats for motor-vehicles, which includes a body intended to be connected to at least one belt branch and a pair of tongue elements intended to be connected to respective belt branches, each tongue element including an attachment portion for connection with the respective belt branch and a stem portion arranged to be received and locked in the body and forming a catch tooth for locking the tongue element in the body. Each tongue element further comprises a metal insert wholly covered by a plastic or rubber housing or coating to protect user from burning from the coupling device which has been exposed to the sun.

Owner:SABELT

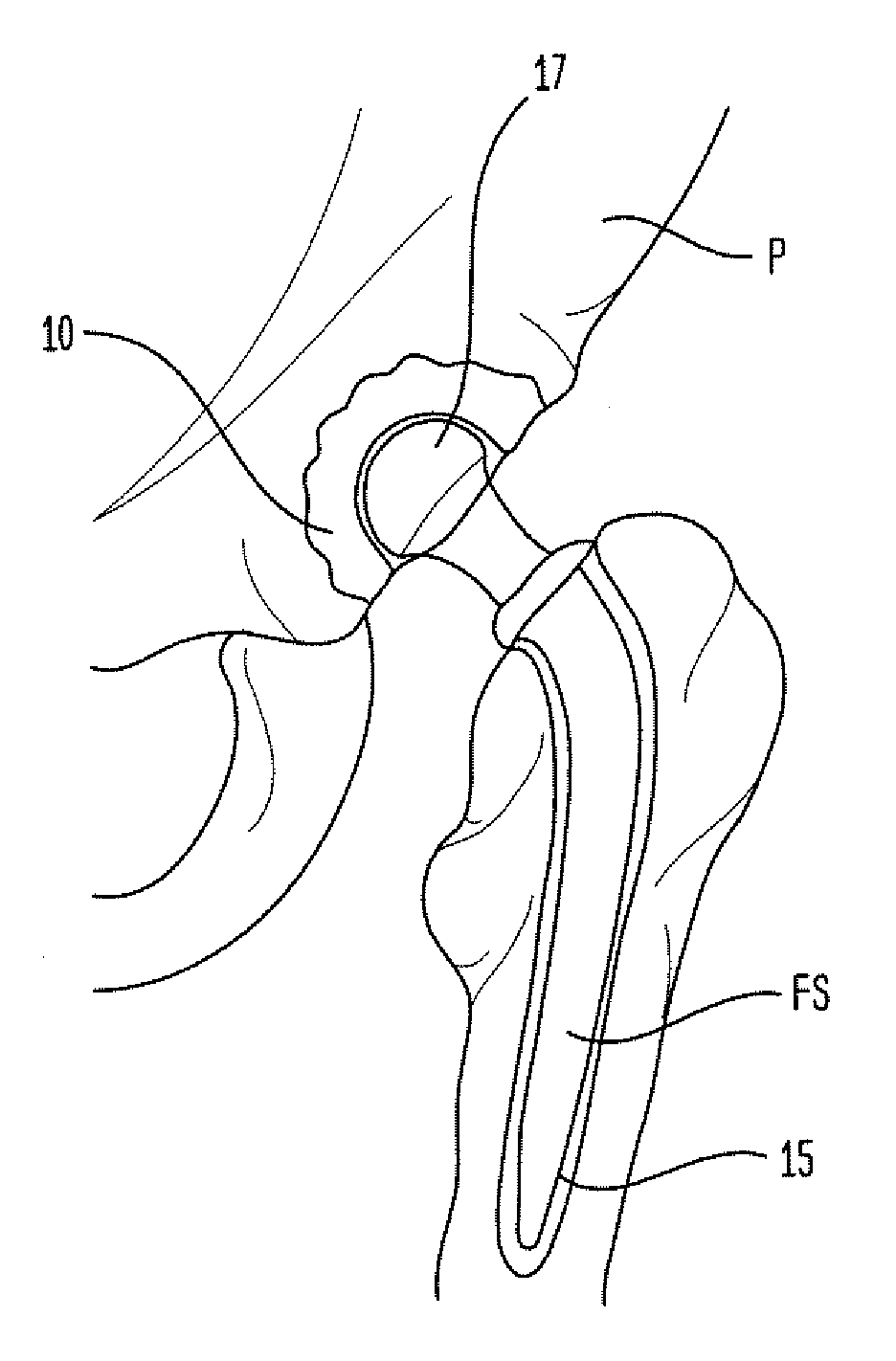

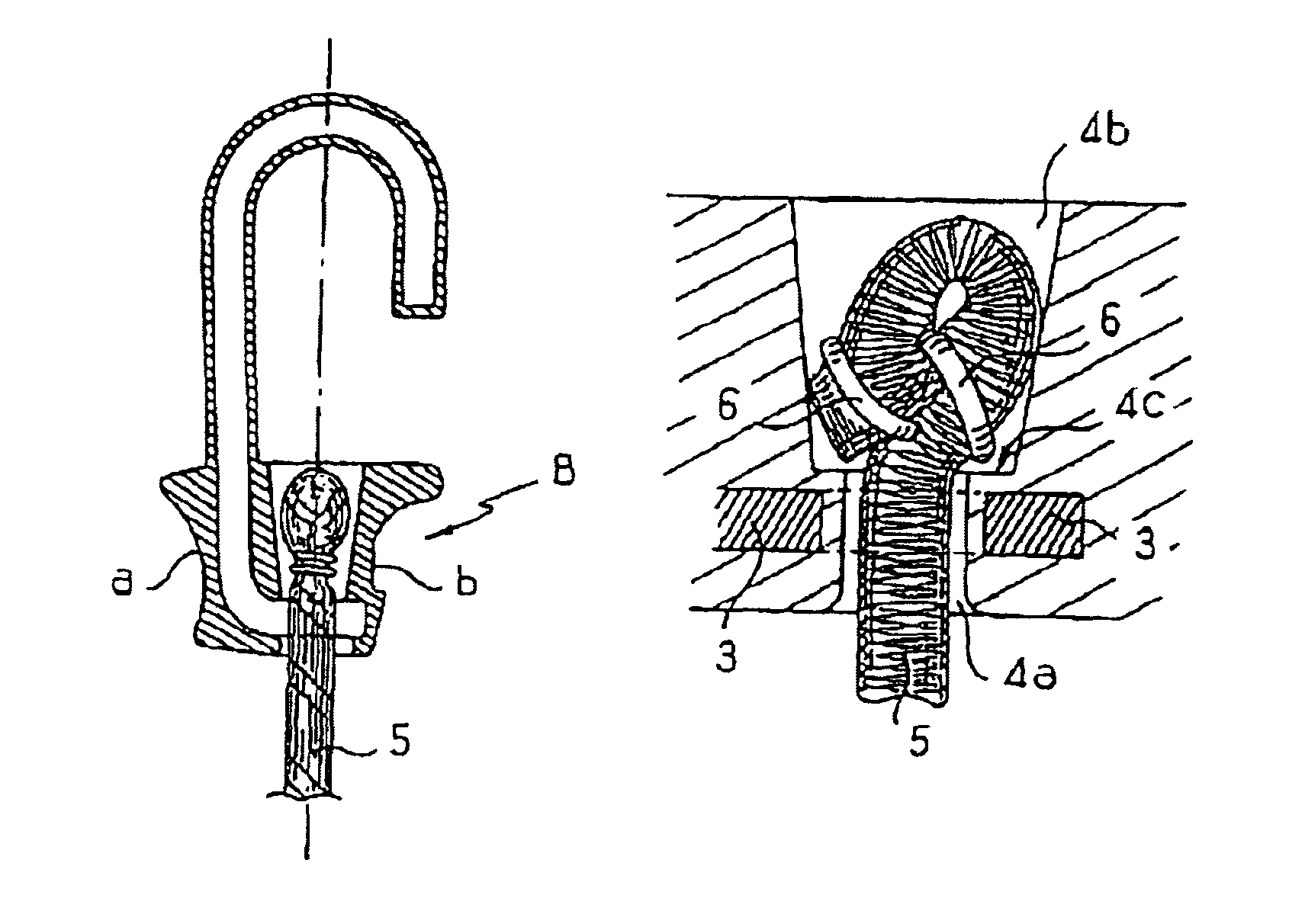

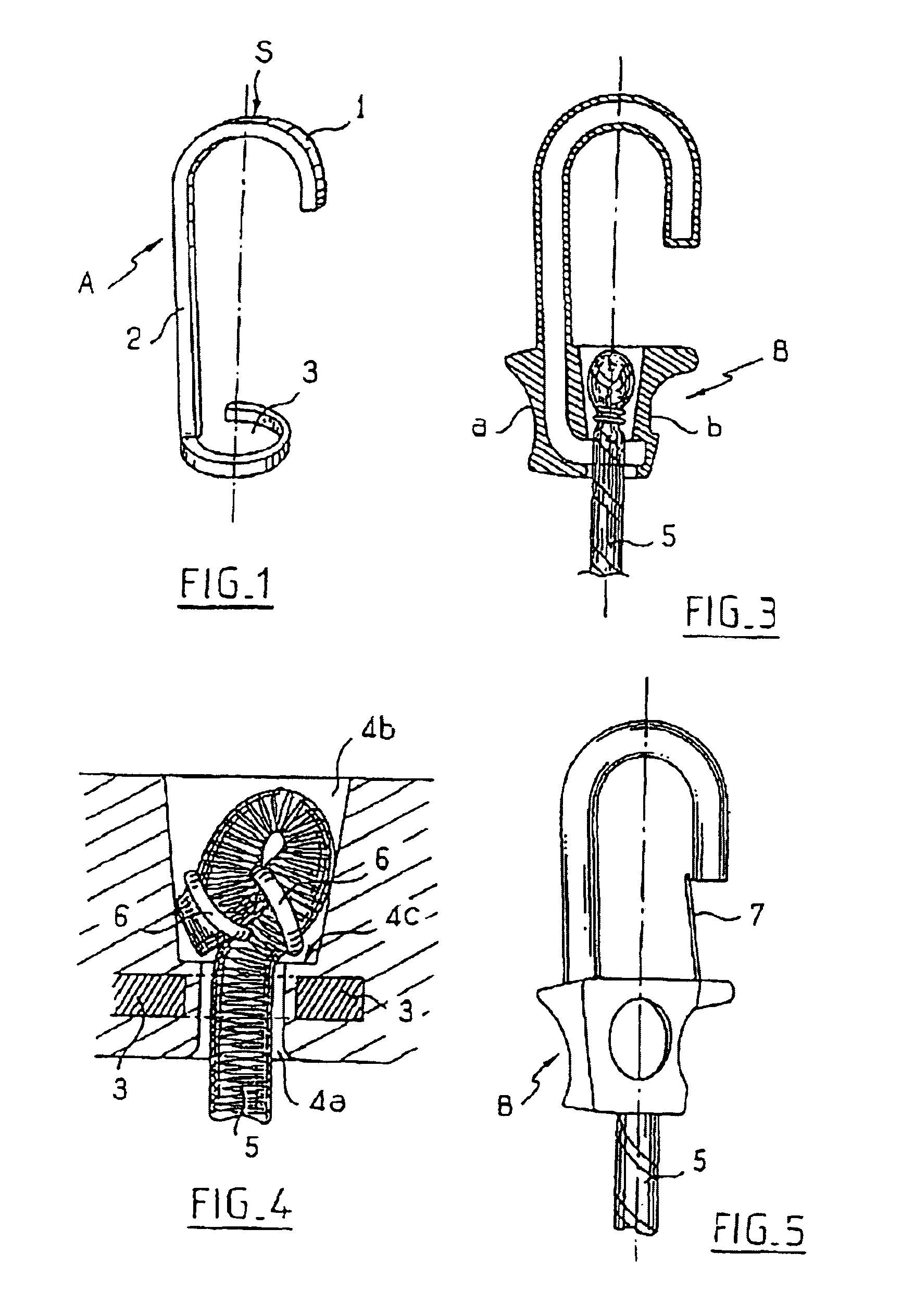

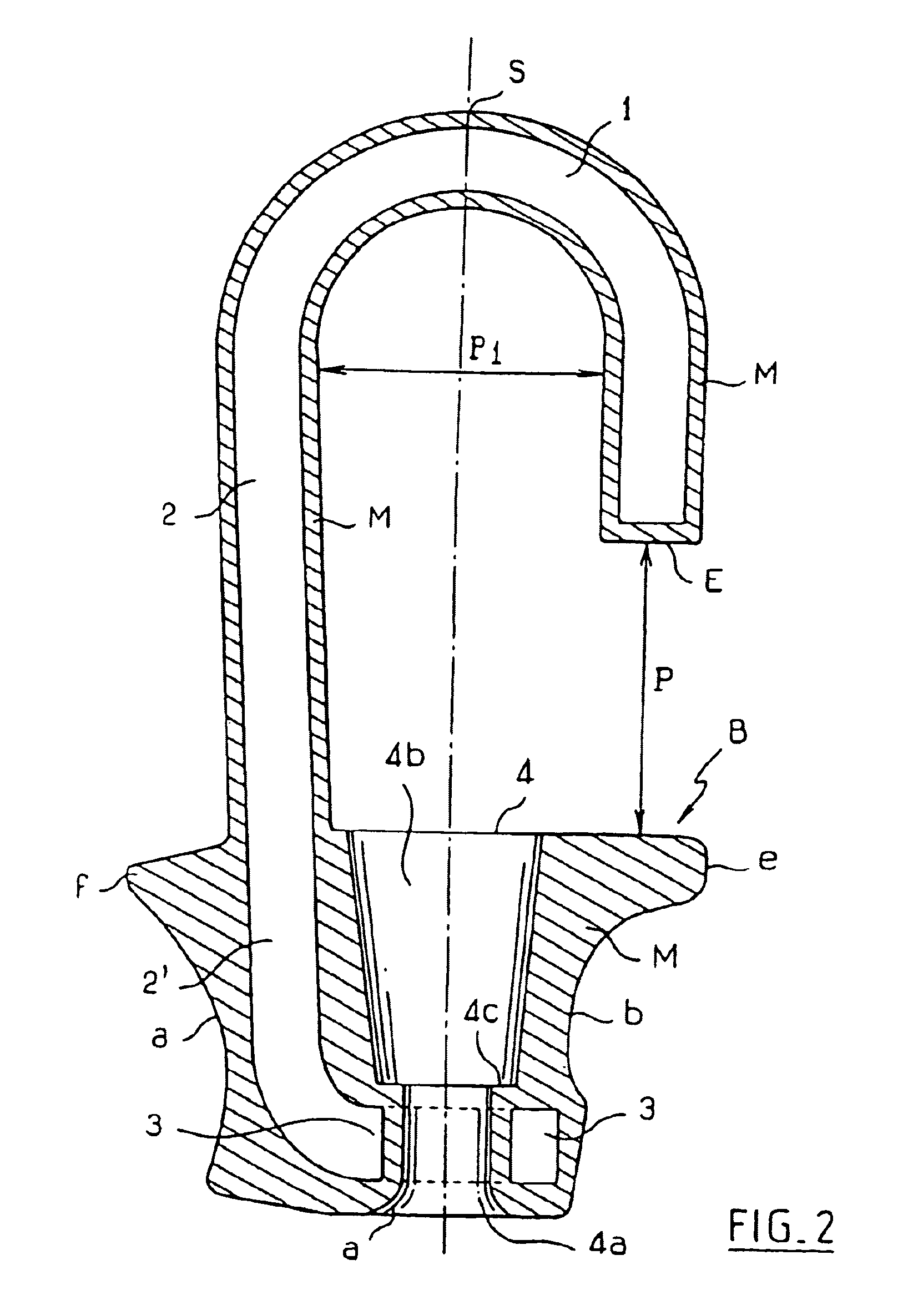

High strength hook, in particular for elastic cable

The invention relates to a high strength hook. The hook comprises an annular metal insert (3) embedded in a synthetic material end block of the hook around a passage (4) for slidably receiving the end of a cable (5) in the vicinity of a stop abutment (4c) designed to stop the end of the cable in the traction direction. The invention is applicable to hooks comprising a metal hook having an end embedded in a handle block.

Owner:JOUBERT SA

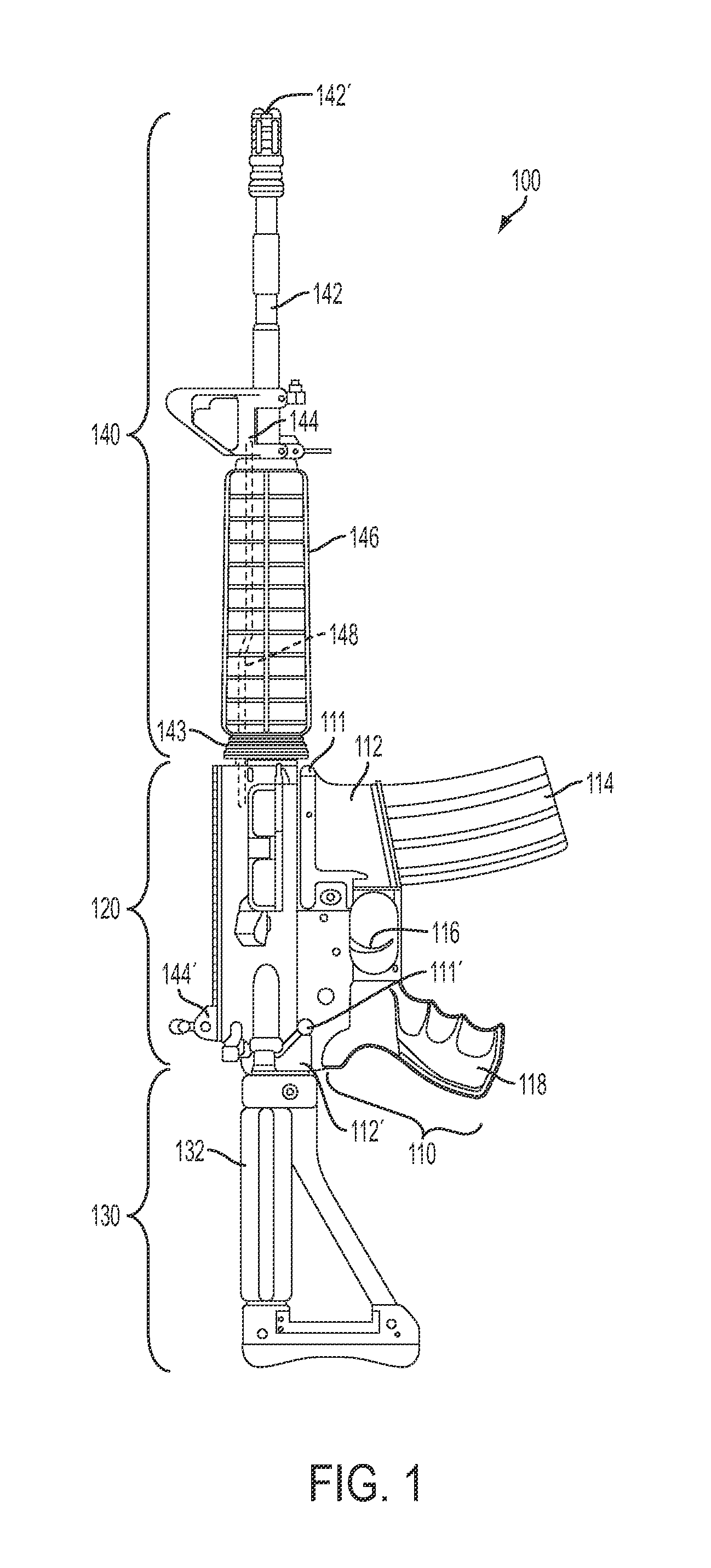

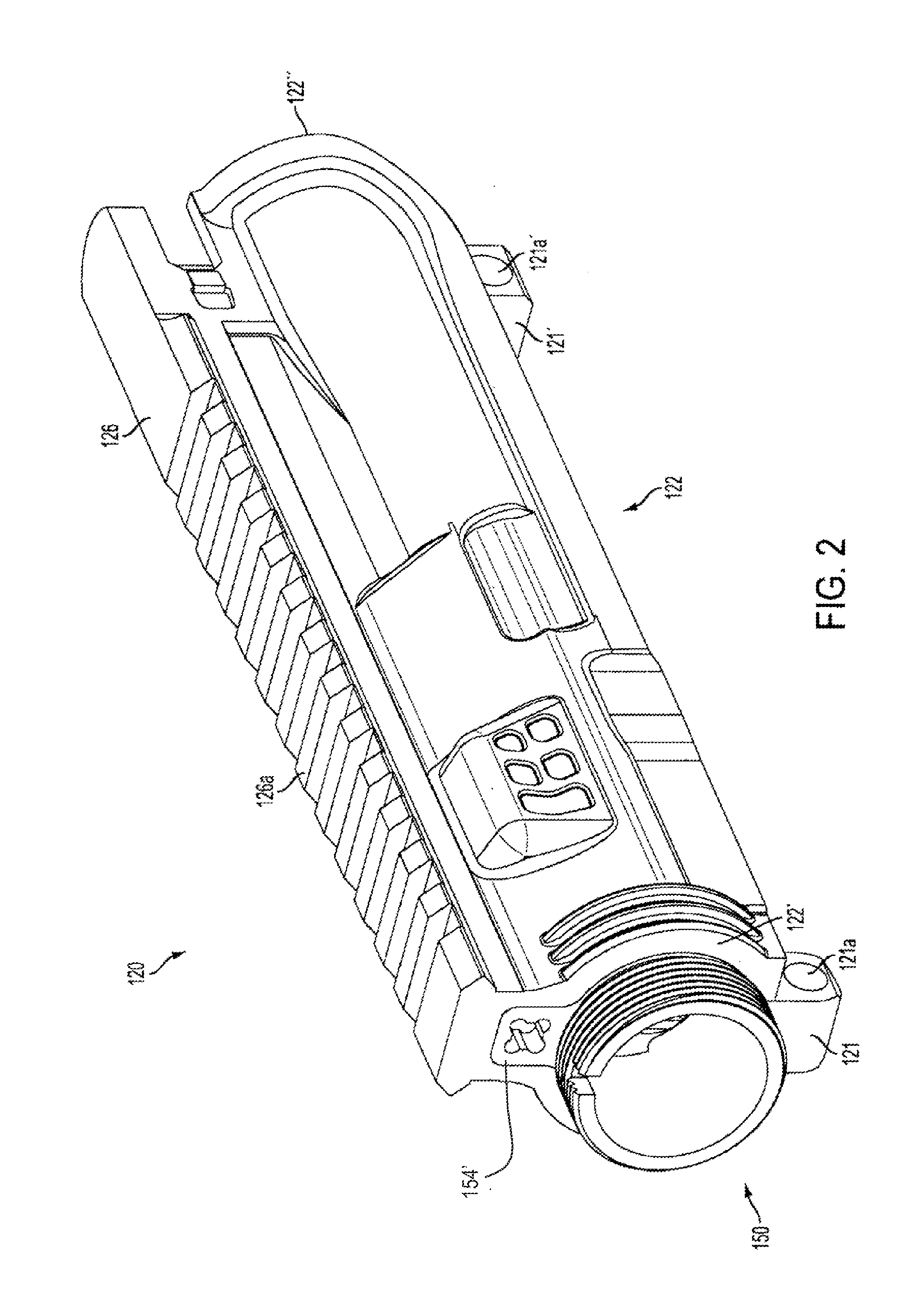

Hybrid upper receiver for a rifle

ActiveUS20150135573A1Maintain structural integrityReduce material costsBreech mechanismsBarrel mountingMetal insertPolymer

A combination metal / polymer upper receiver for use in a rifle, with the upper receiver attachable to a lower receiver and to a barrel. The upper receiver comprises a polymeric upper receiver housing defining a chamber. The polymeric upper receiver housing is adapted to engage with mounting features on the lower receiver to attach a lower receiver to the upper receiver at a first connection. A metal insert is secured within the polymeric upper receiver housing and is adapted to engage the barrel. The metal insert further includes an extended member embedded within the polymeric upper receiver housing such that the extended member receives the impact from a bolt carrier group residing within the chamber. An optional metal gas tube channel is located along an upper internal surface of the polymeric upper receiver housing and extends the length of the polymeric upper receiver housing.

Owner:AMERICAN TACTICAL INC

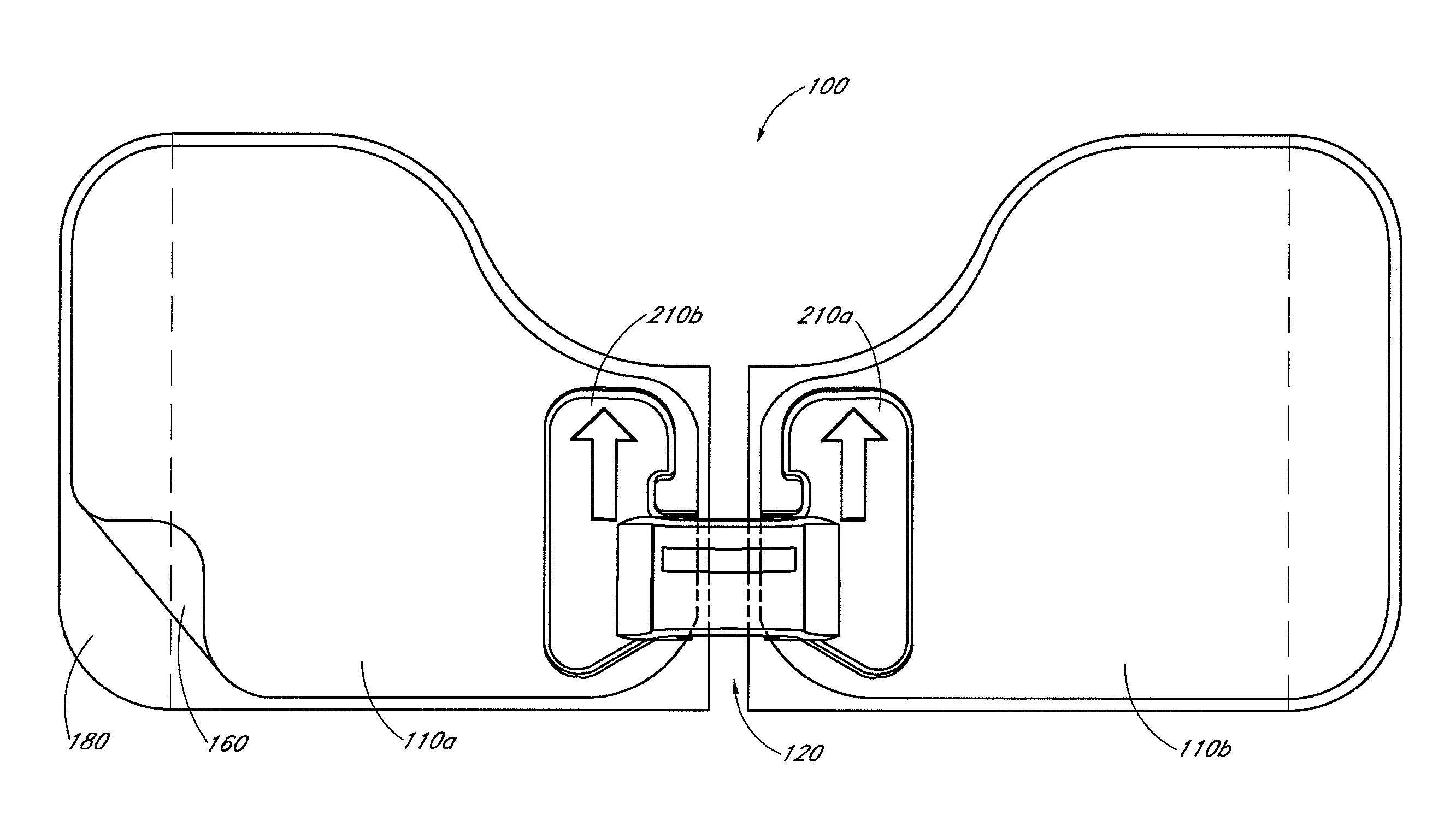

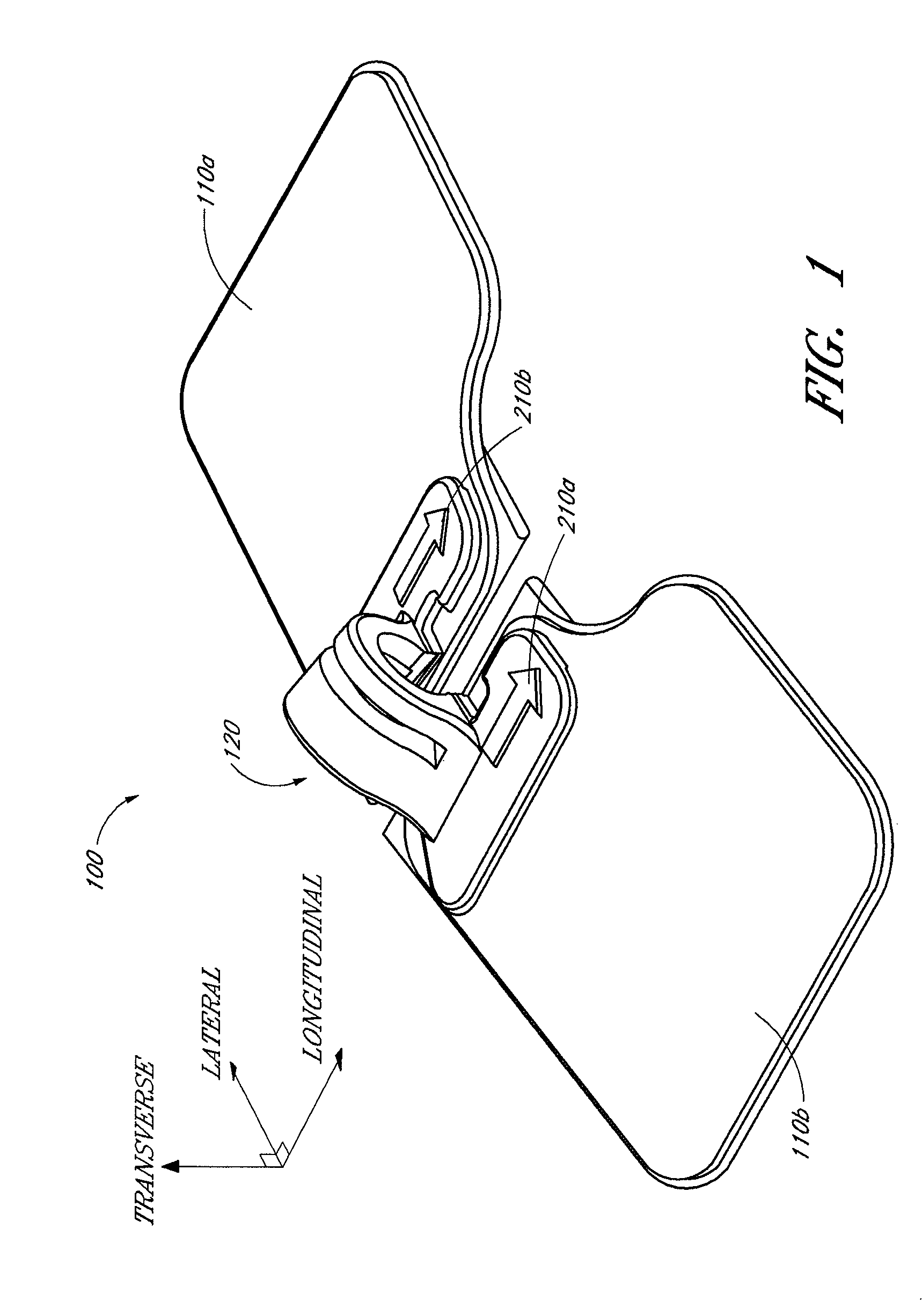

Welding polymeric panels to metal surfaces

InactiveUS20090065484A1Sufficient cross-sectional areaEasy to placeArc welding apparatusVehicle componentsEngineeringSpot welding

A joining portion of a polymeric component, such as a vehicle door panel, may be welded (for example, a spot weld) to a metal component, such as a mating vehicle panel, using a molded-in-place metallic welding insert. The welding insert is shaped to provide welding surfaces at both surfaces of the joining portion of the plastic component and to conduct a welding current between the surfaces. When the workpieces are assembled for welding, opposing spot welding electrodes bear against the outer surfaces of the metal part and the metal insert in the plastic part. A spot welding operation produces a weld nugget between the facing surface of the metal part and the metal insert anchored in the plastic part. Continuous seam welds or a series of stitch seam welds may be made using suitably shaped welding inserts.

Owner:GM GLOBAL TECH OPERATIONS LLC

Securement device

A securement device holds a medical article such as a catheter hub in position upon the body of a patient and at least inhibits longitudinal movement of the medical article. The securement device includes a retainer and at least one anchor pad. The retainer includes a metallic insert having barbs or teeth extending into a central channel. The metallic barbs or teeth dig into the retained catheter hub. The metal insert springs open as the hub is inserted in to the device and retains the hub by virtue of its metallic barbs.

Owner:VENETEC INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com