Patents

Literature

227 results about "Titanium based alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TITANIUM BASED. ALLOYS. Titanium and its alloys are useful engineering materials because of their excellent resistance to corrosion in oxidizing environments and / or high strength to weight ratio. They also offer resistance to erosion by flowing solutions with entrained solids and good heat transfer characteristics.

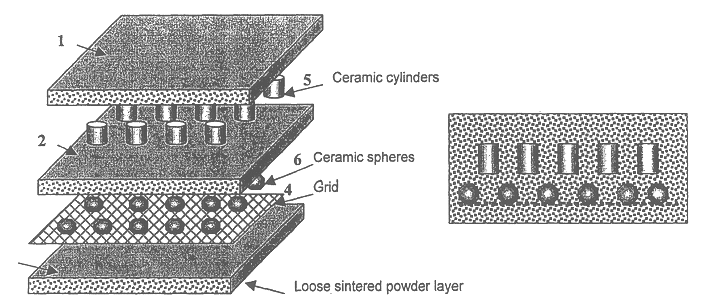

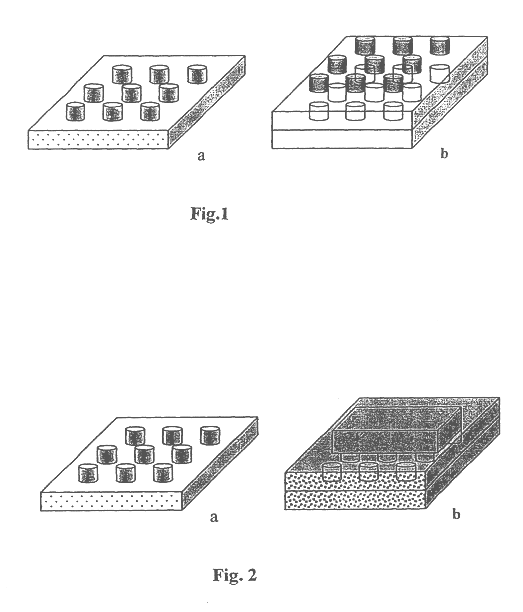

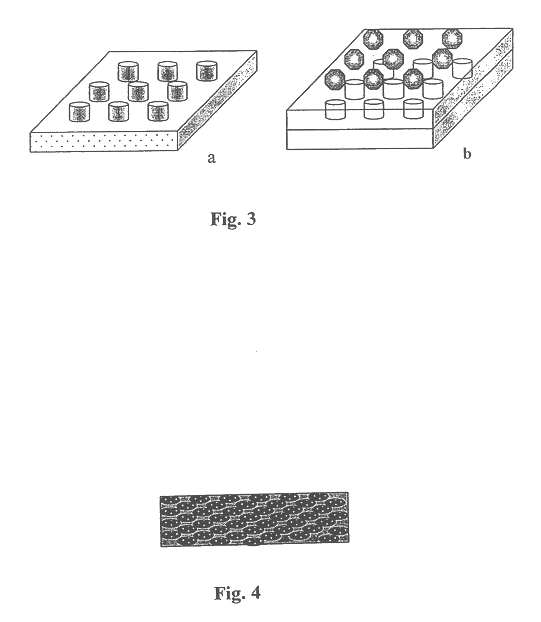

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

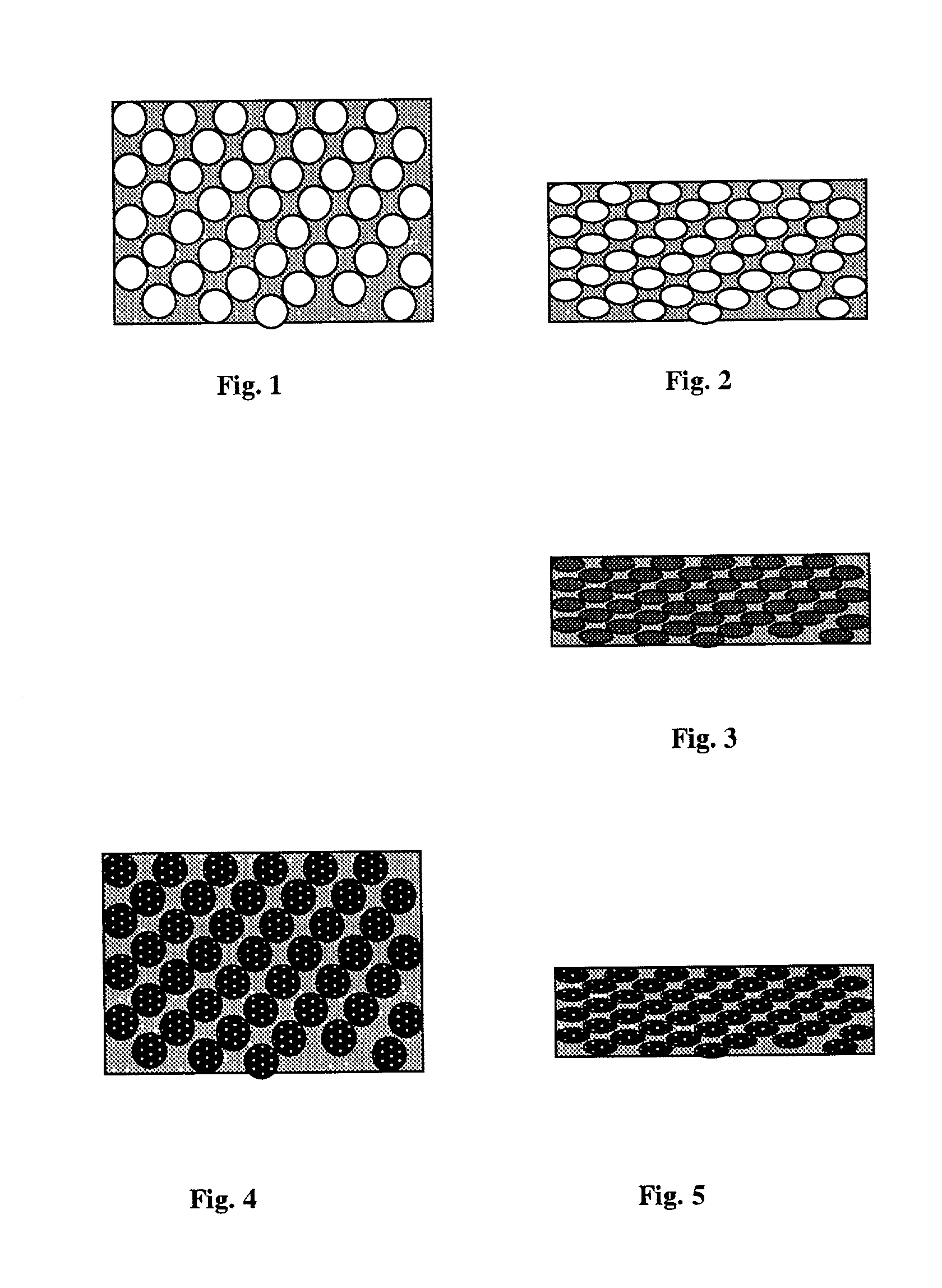

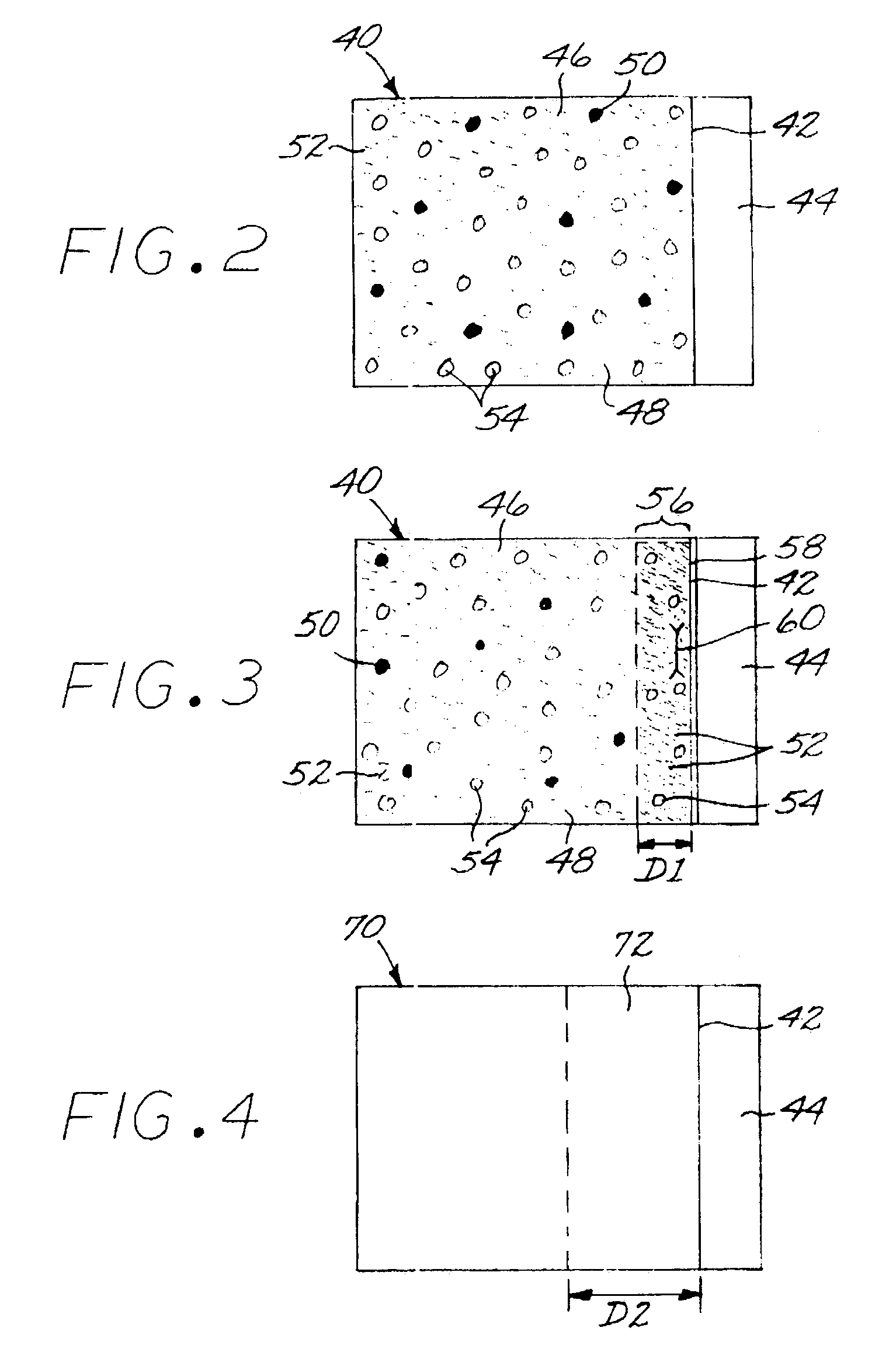

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

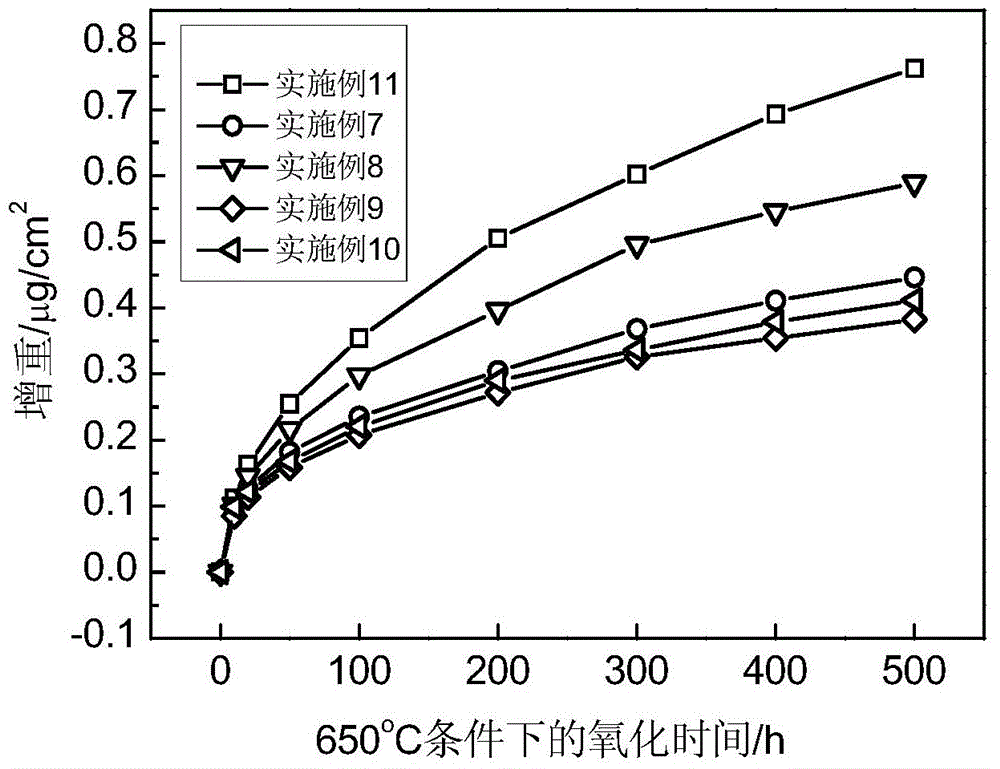

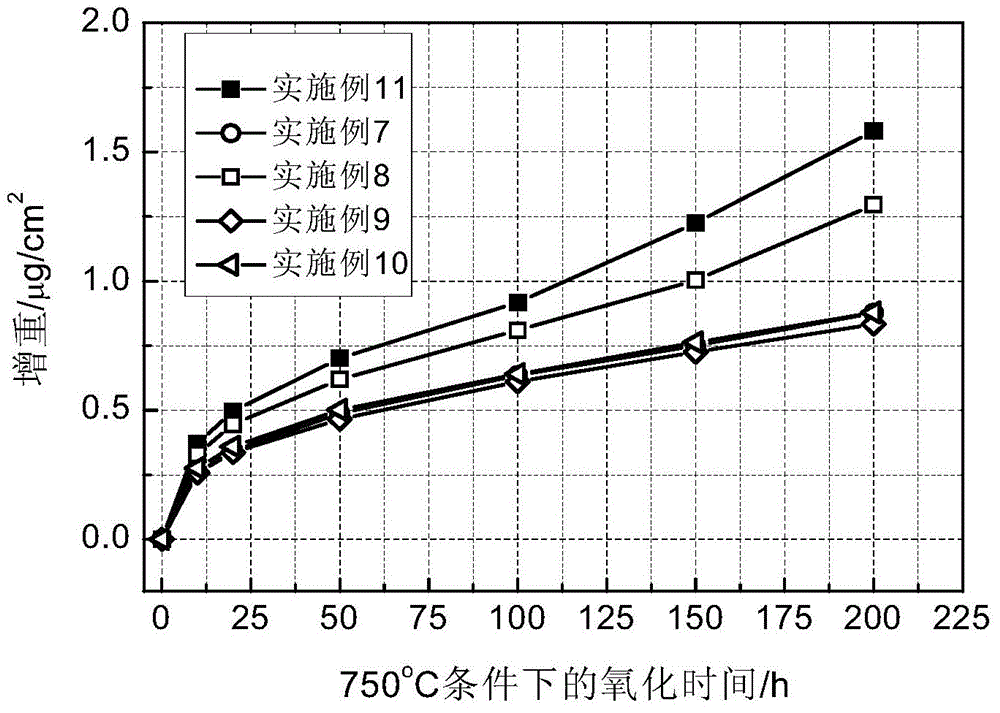

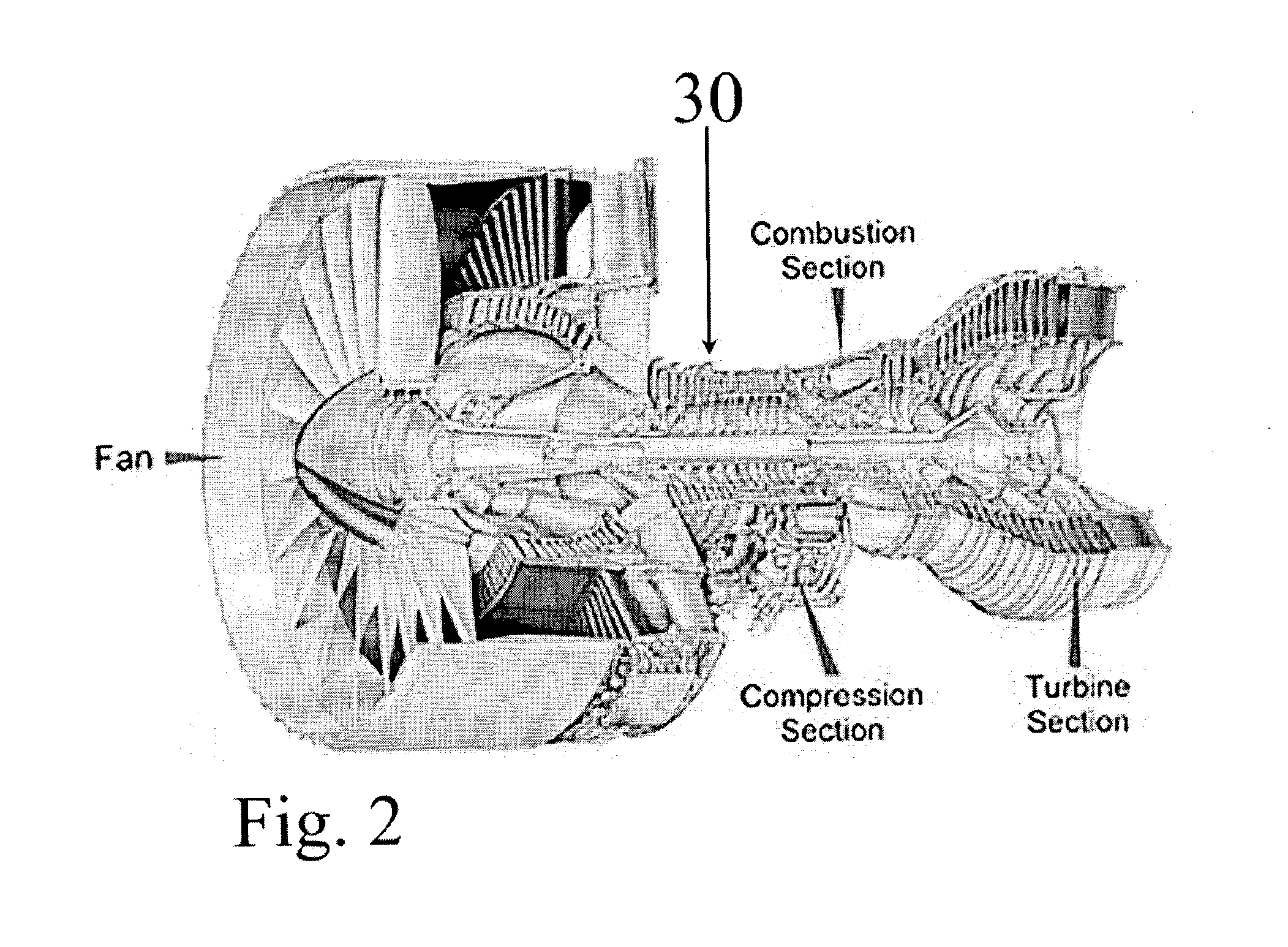

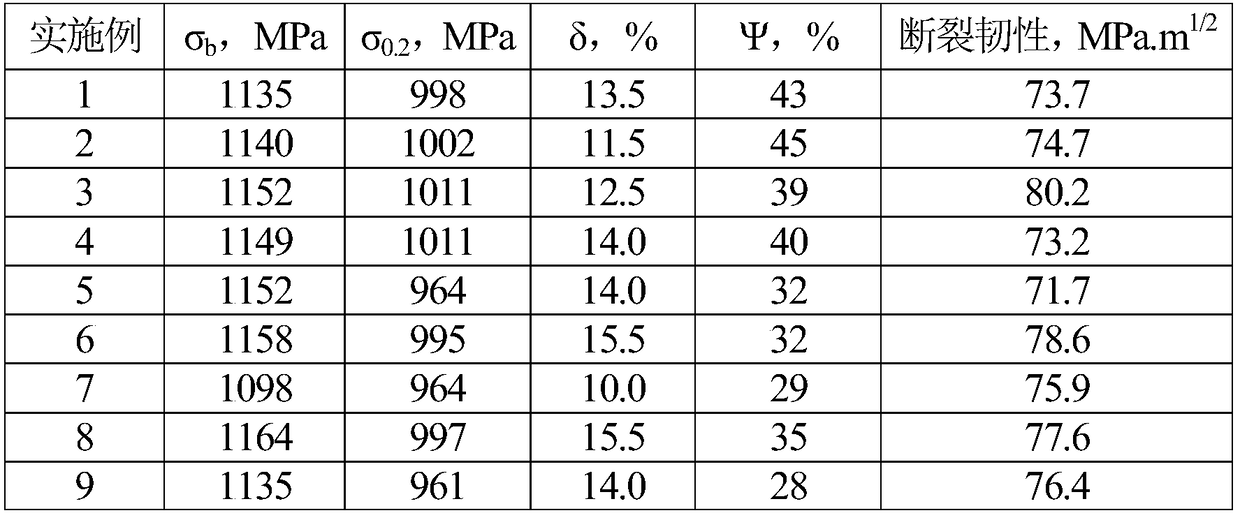

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

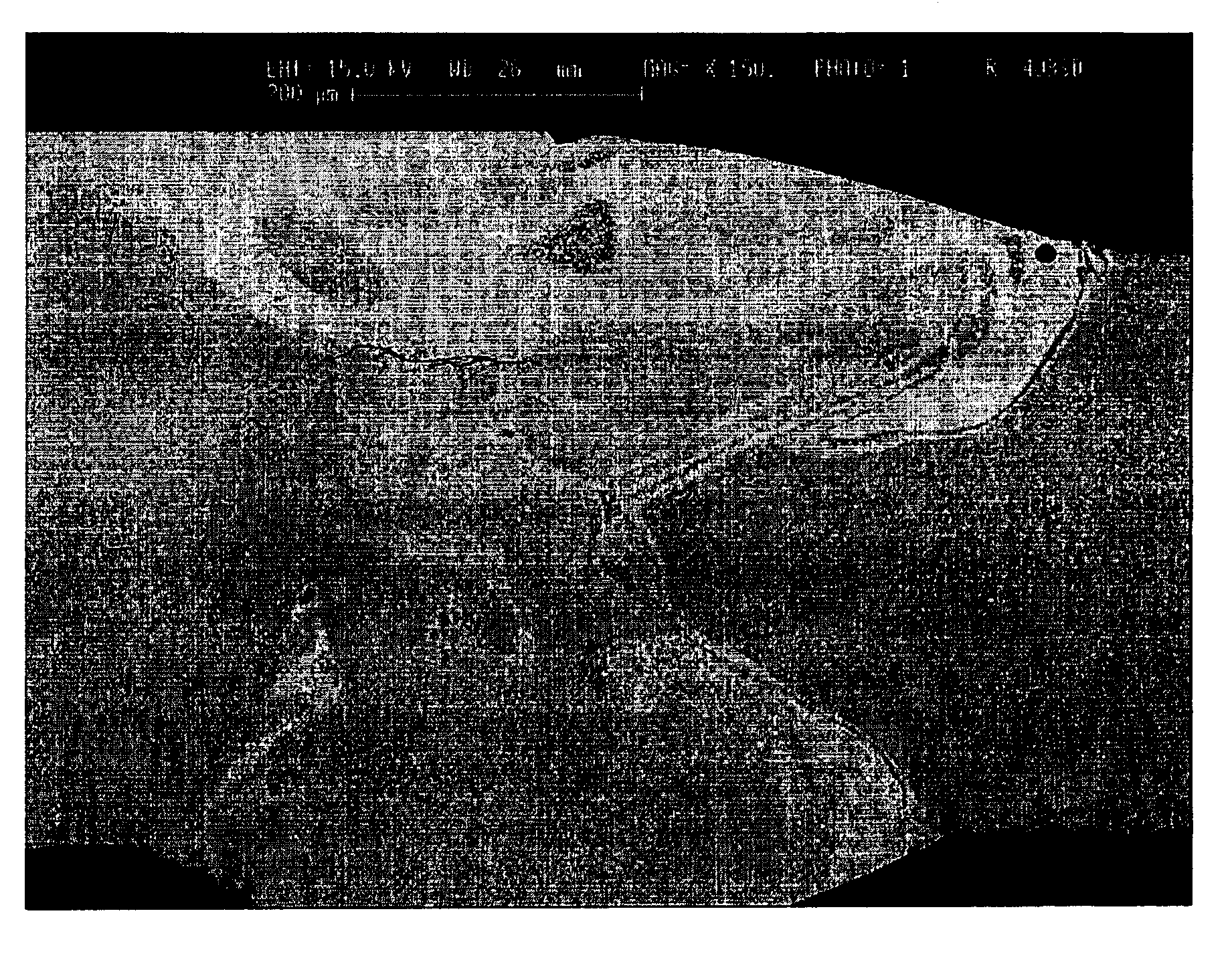

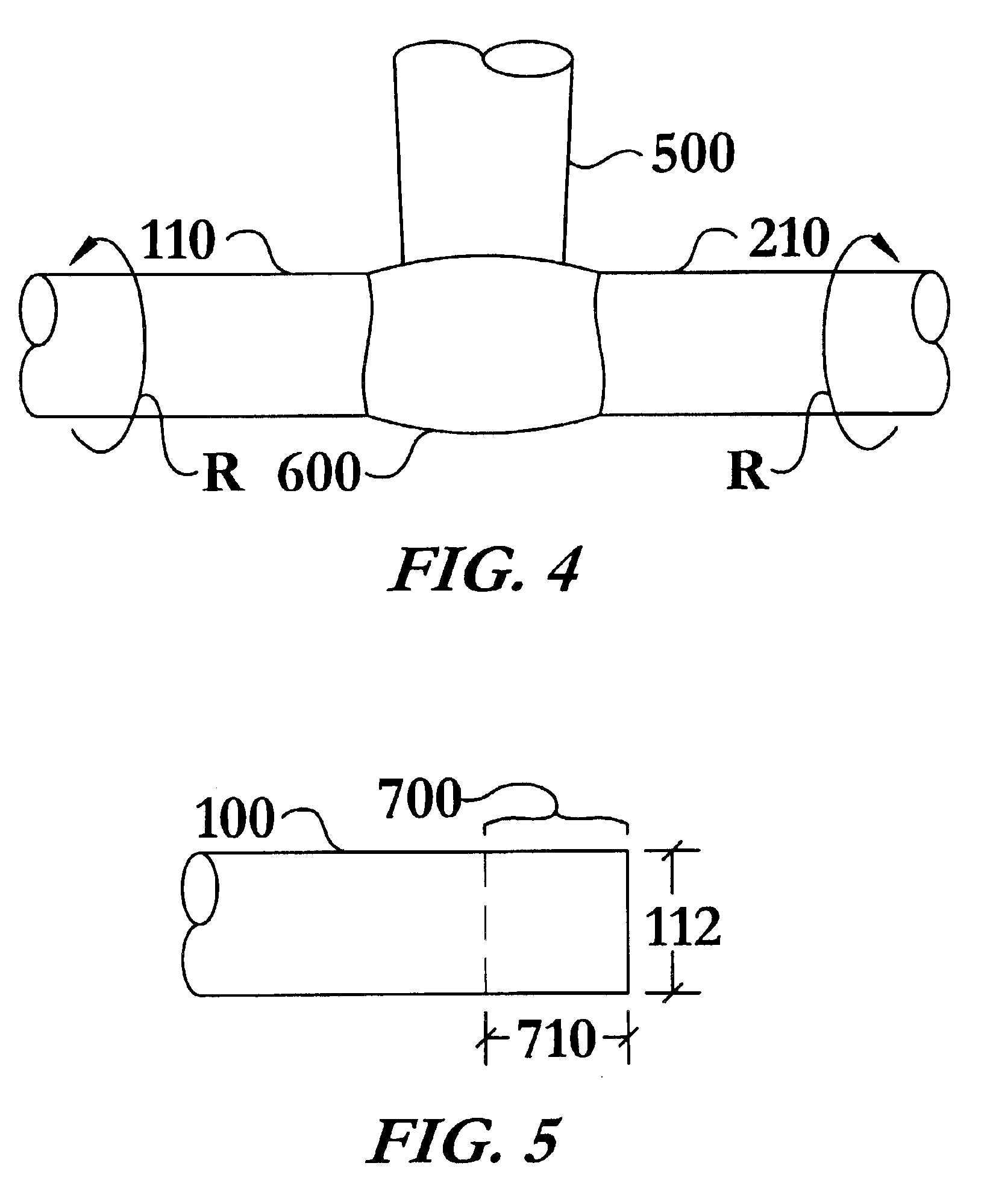

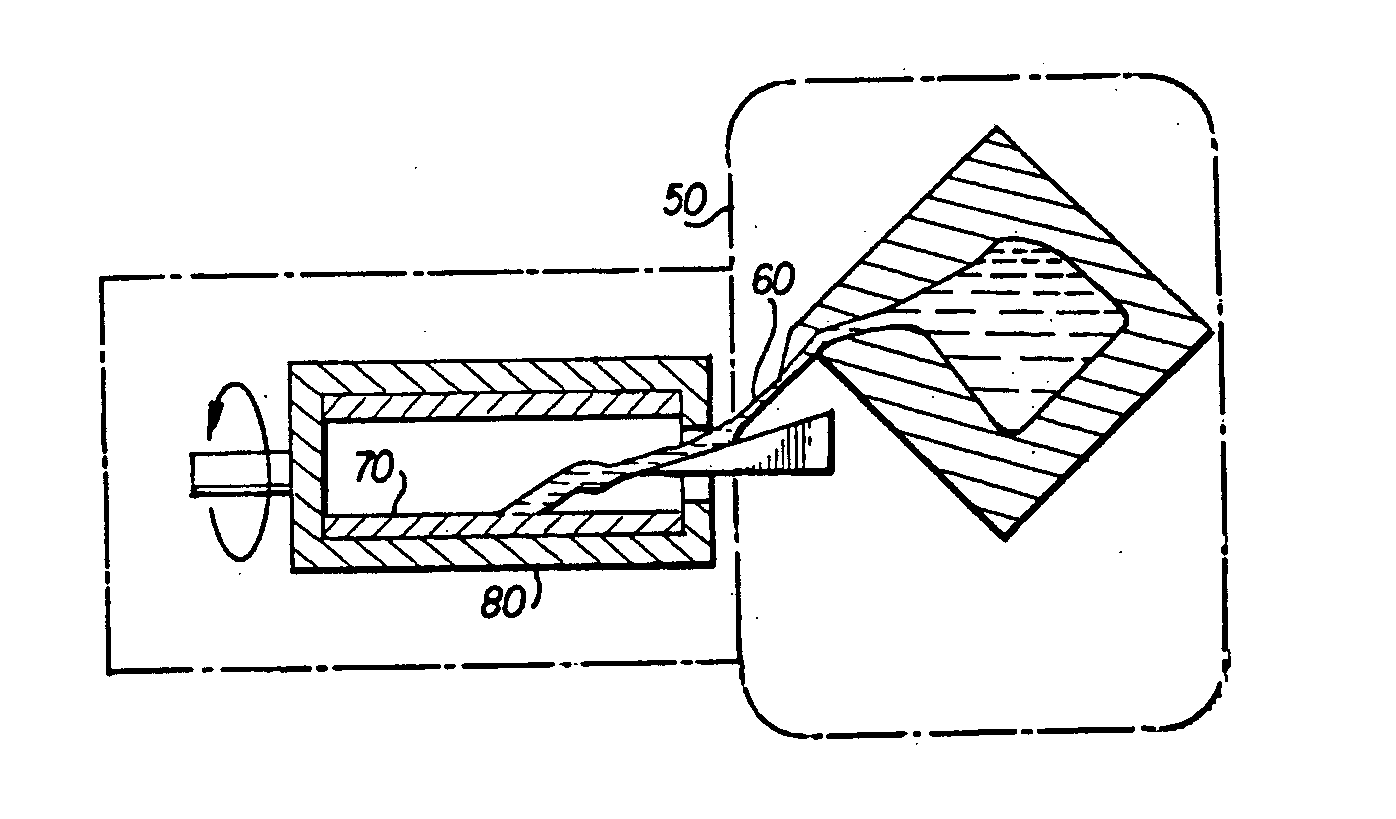

Method of welding titanium and titanium based alloys to ferrous metals

InactiveUS6875949B2Welding/cutting media/materialsWelding/soldering/cutting articlesFull recoveryPoor quality

A method of welding titanium, and titanium based alloys, to ferrous metals is described. Welding of titanium, and titanium based alloys, is plagued with poor quality and highly brittle welds, substantially due to formation of Ti—Fe intermetallics in the weld pool. The instant invention provides supplementary filler material to alter the proportions of various elements in the weld pool. Certain fillers, such as nickel or iron, added to the weld pool enable high quality welds to be fabricated utilizing a wide variety of fusion welding techniques, including laser welding, between titanium, or titanium based alloys, and ferrous metals, including but not limited to the welding of nickel-titanium and stainless steel. Filler material may be supplied in various forms, including foil, wire, powders, preformed gaskets, and numerous others. Optionally, the titanium or titanium based alloy may be stress relieved to achieve full recovery of the shape memory strain prior to welding.

Owner:EDISON WELDING INSTITUTE INC

Titanium alloy based dispersion-strengthened composites

Titanium based metal matrix composites reinforced with ceramic particulate are well known, based on a blend of titanium alloy powders with ceramic powders, e.g., aluminum oxide powders, utilizing a low energy ball milling process, followed by cold compacting and sintering to produce an appropriate composite. This prior art process is disadvantaged from the point of view that there are virtually no particles in the blend below the micrometer size range, which lack has a deleterious effect on the subsequent processing of the composite. This problem has been overcome by utilizing dry high energy intensive milling in the process, which has the effect of providing the necessary number of small particles below the micrometer size range as well as enhancing the reactivity of different particles with one another. In order to produce a titanium base alloy alumina metal matrix composite, titanium dioxide powder is blended with aluminum powder and subjected to dry high energy intensive milling until the separate particle phases achieve a size of 500 nanometers maximum. The intermediate powder product is then heated to form the titanium alloy / amumina metal matrix composite in which the ceramic particles have an average diameter of no more than 3 mu, and the oxide consists of more than 10% and less than 60% by volume fraction of the total composite. The composites have extensive application to tough and strong engineering alloys.

Owner:TITANOX DEV

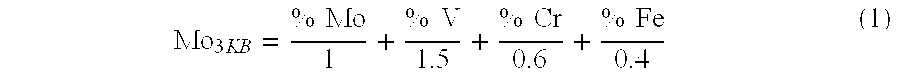

Titanium-based alloy and method of heat treatment of large-sized semifinished items of this alloy

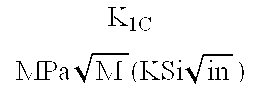

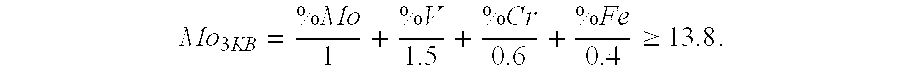

The inventive titanium alloy comprises, expressed in mass %: aluminium 4.0-6.3; vanadium 4.5-5.9; molybdenum 4.5-5.9; chromium 2.0-3.6; ferrum 0.2-0.5; the rest being titanium. An equivalent molybdenum content is determined as corresponding to Moequiv≧13.8. The inventive method for heat treatment consists in heating to tβ⇄α+β−(30-70)° C., conditioning during 2-5 hrs, air or water cooling and age-hardening at a temperature ranging from 540° C. to 600° C. during 8-16 hrs. Said alloy has a high volumetric deformability and is used for manufacturing massive large-sized forged and pressed pieces having a high strength level, satisfactory characteristics of plasticity and fracture toughness.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO KORPORATSIJA VSMPO AVISMA

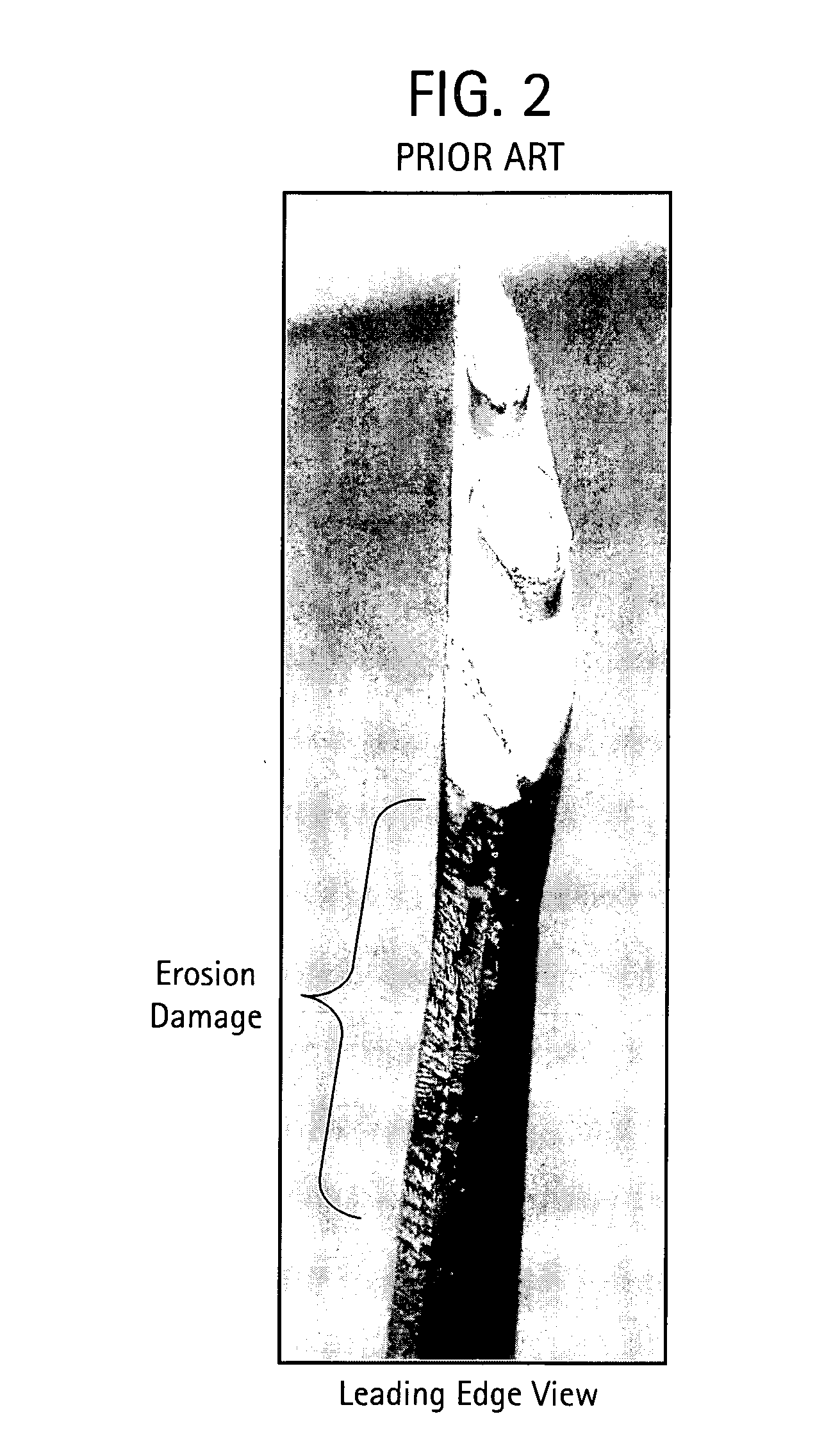

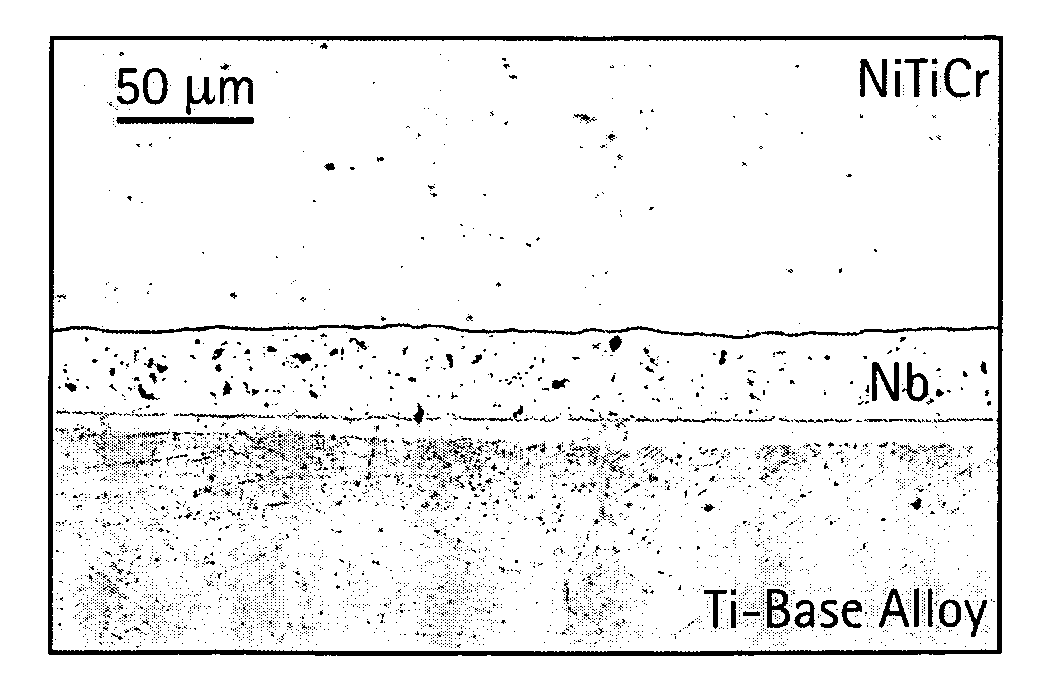

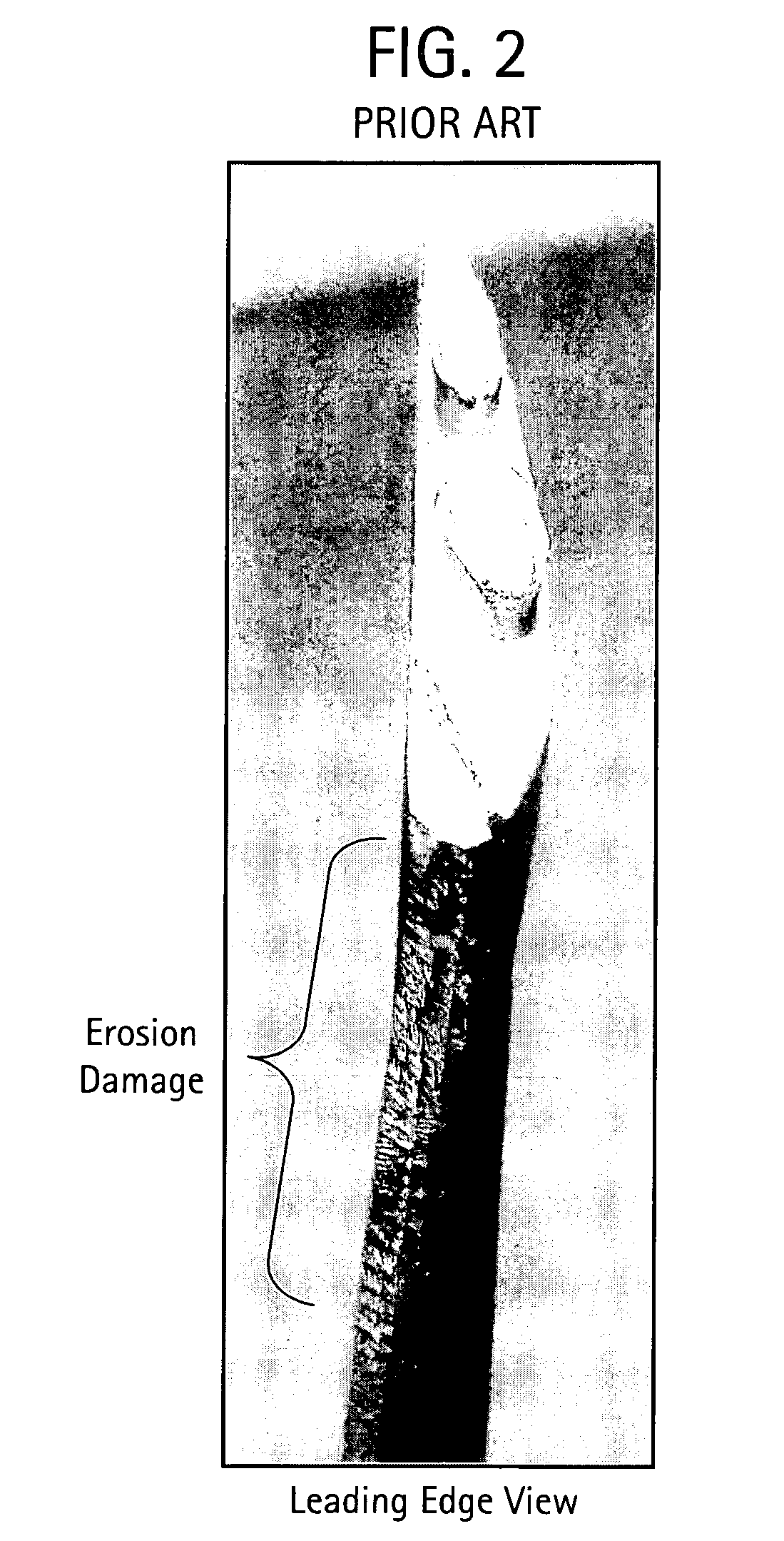

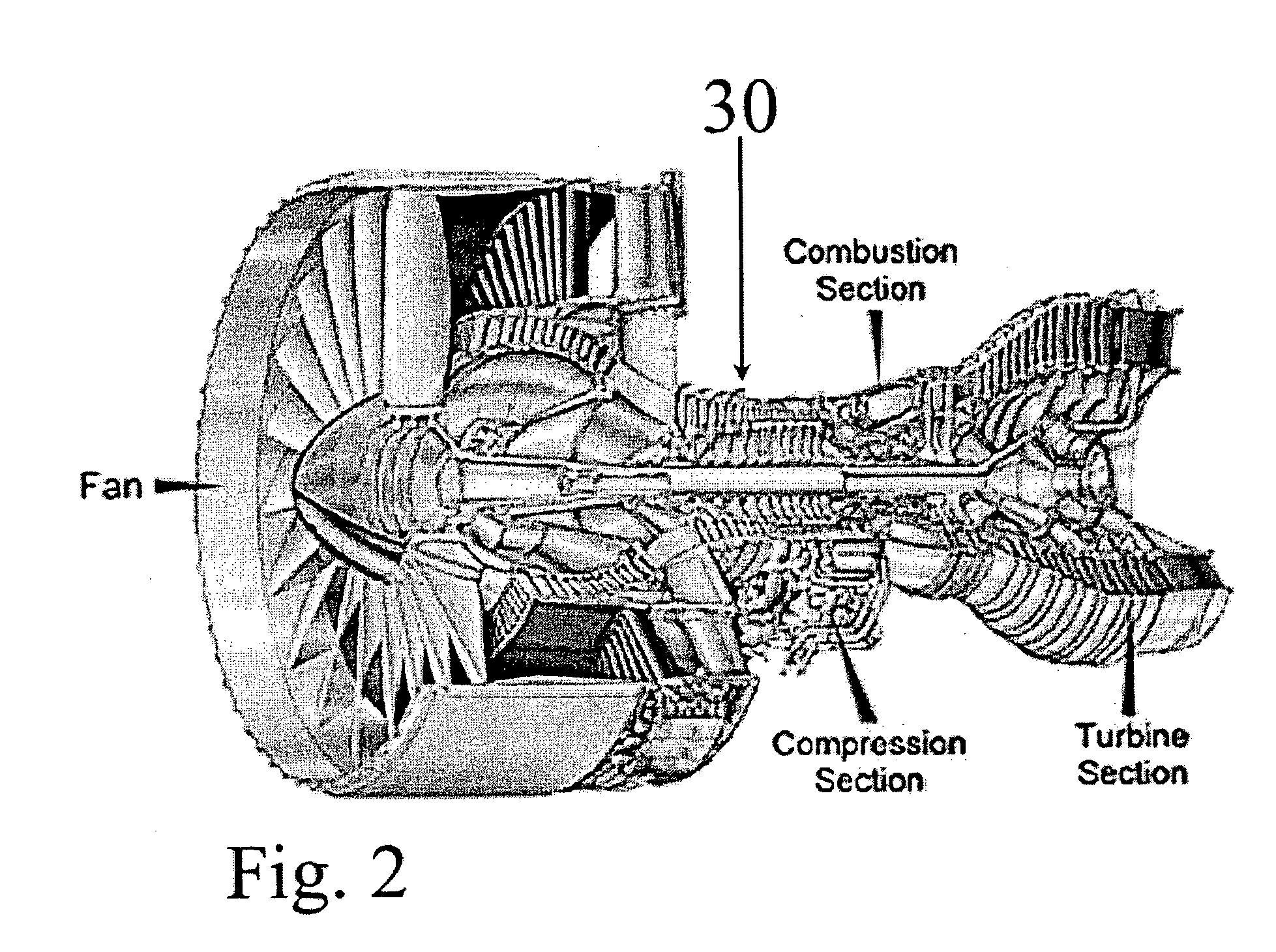

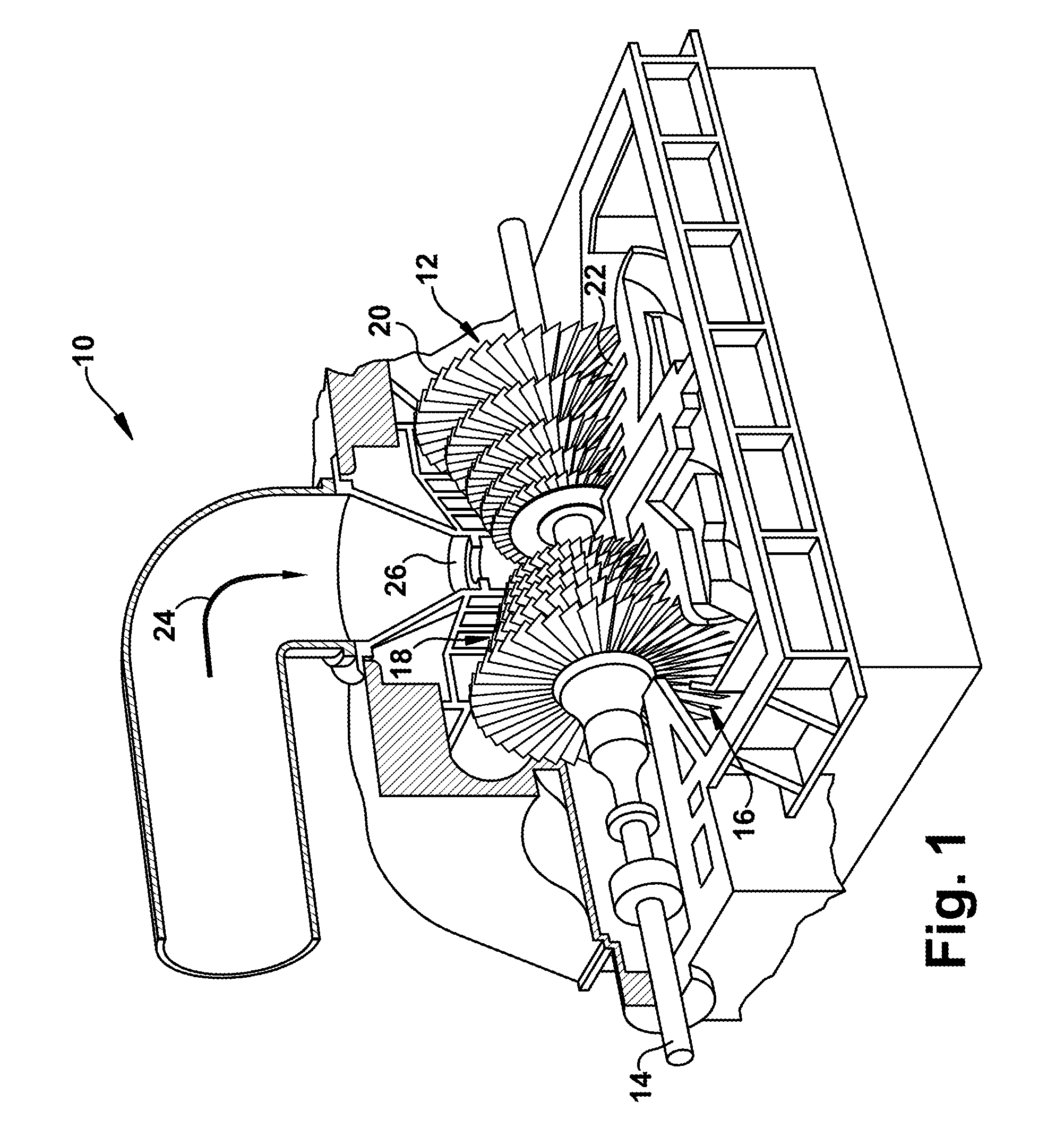

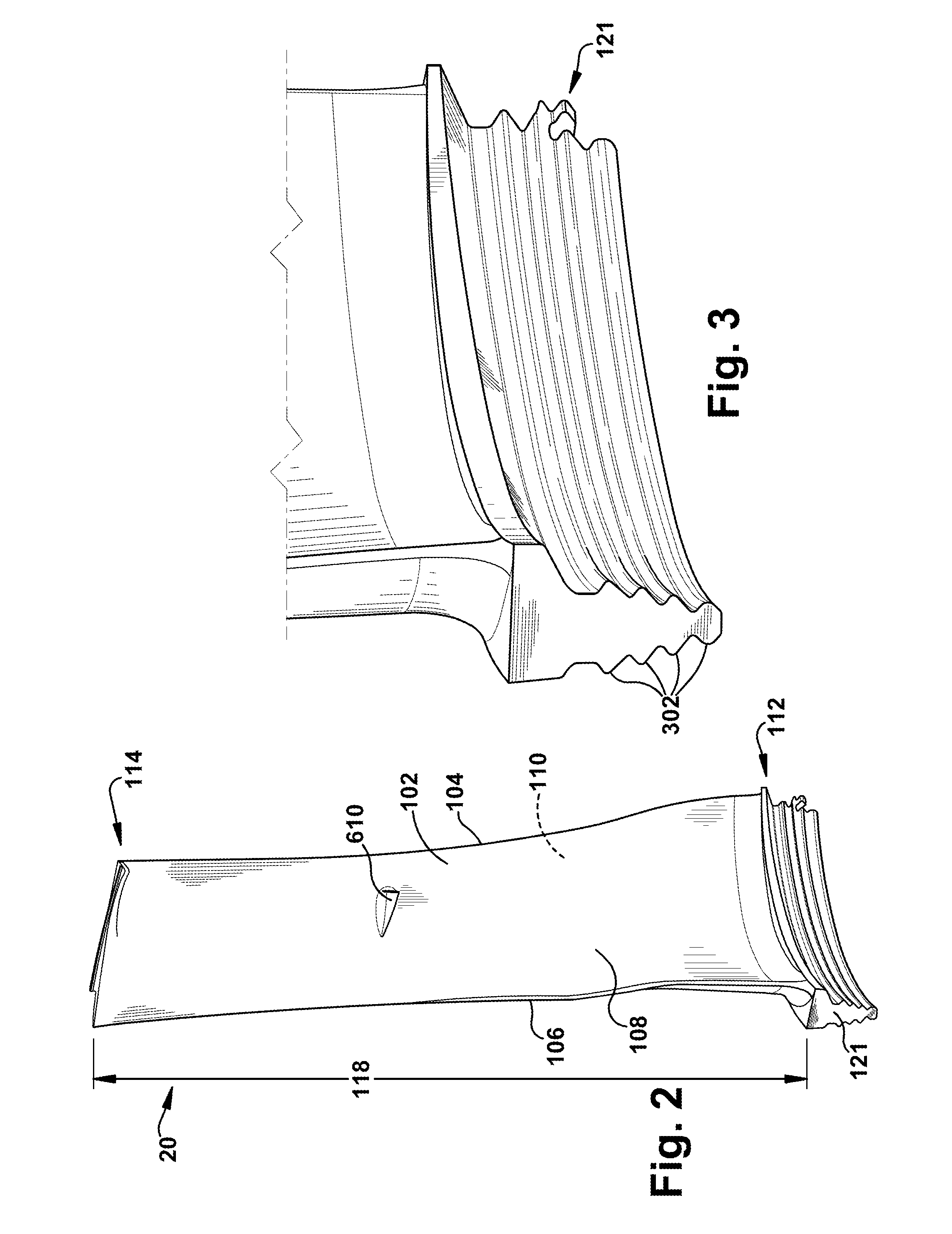

Erosion and wear resistant protective structures for turbine engine components

An erosion resistant protective structure for a turbine engine component comprises a shape memory alloy. The shape memory alloy includes nickel-titanium based alloys, indium-titanium based alloys, nickel-aluminum based alloys, nickel-gallium based alloys, copper based alloys, gold-cadmium based alloys, iron-platinum based alloys, iron-palladium based alloys, silver-cadmium based alloys, indium-cadmium based alloys, manganese-copper based alloys, ruthenium-niobium based alloys, ruthenium-tantalum based alloys, titanium based alloys, iron-based alloys, or combinations comprising at least one of the foregoing alloys. Also, disclosed herein are methods for forming the shape memory alloy onto turbine component.

Owner:GENERAL ELECTRIC CO

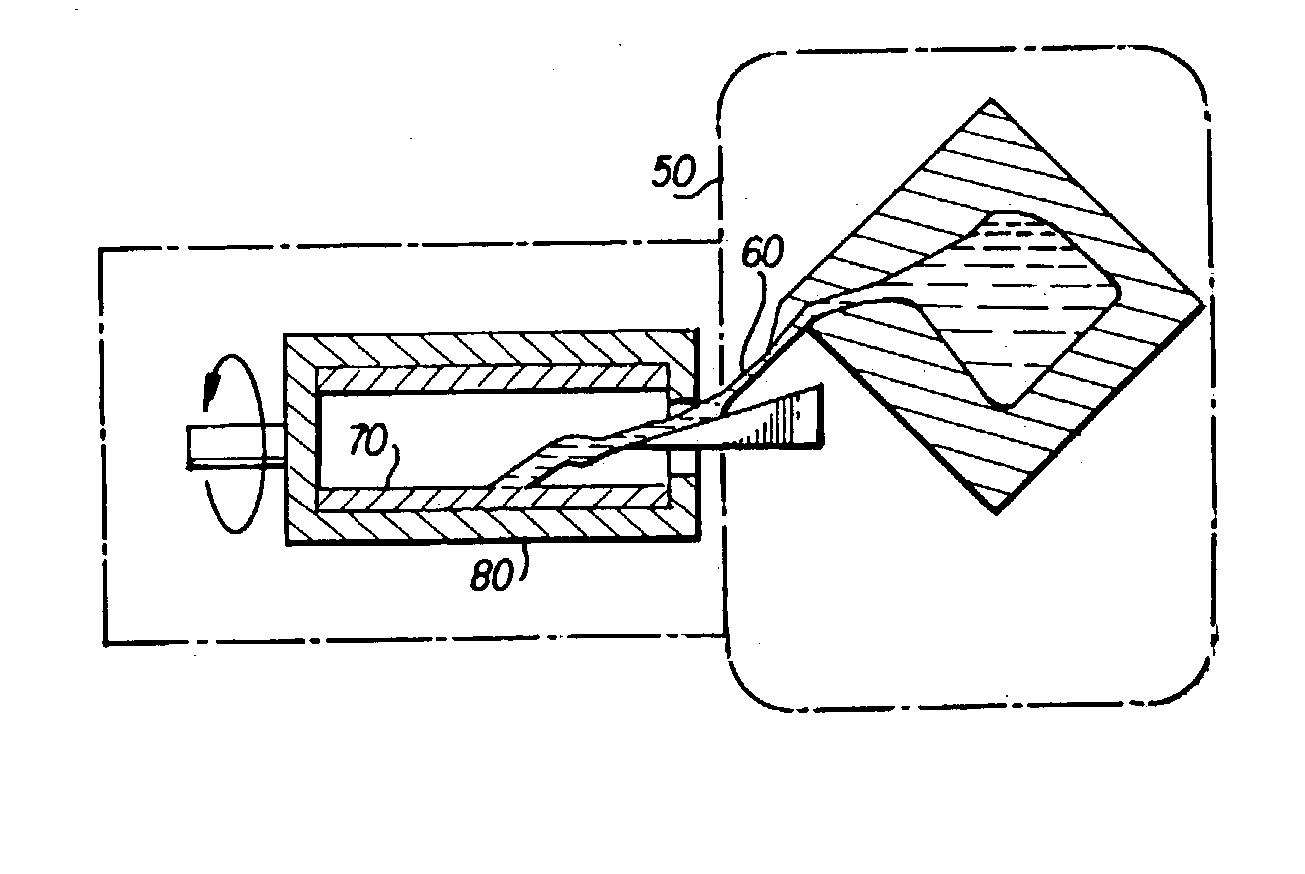

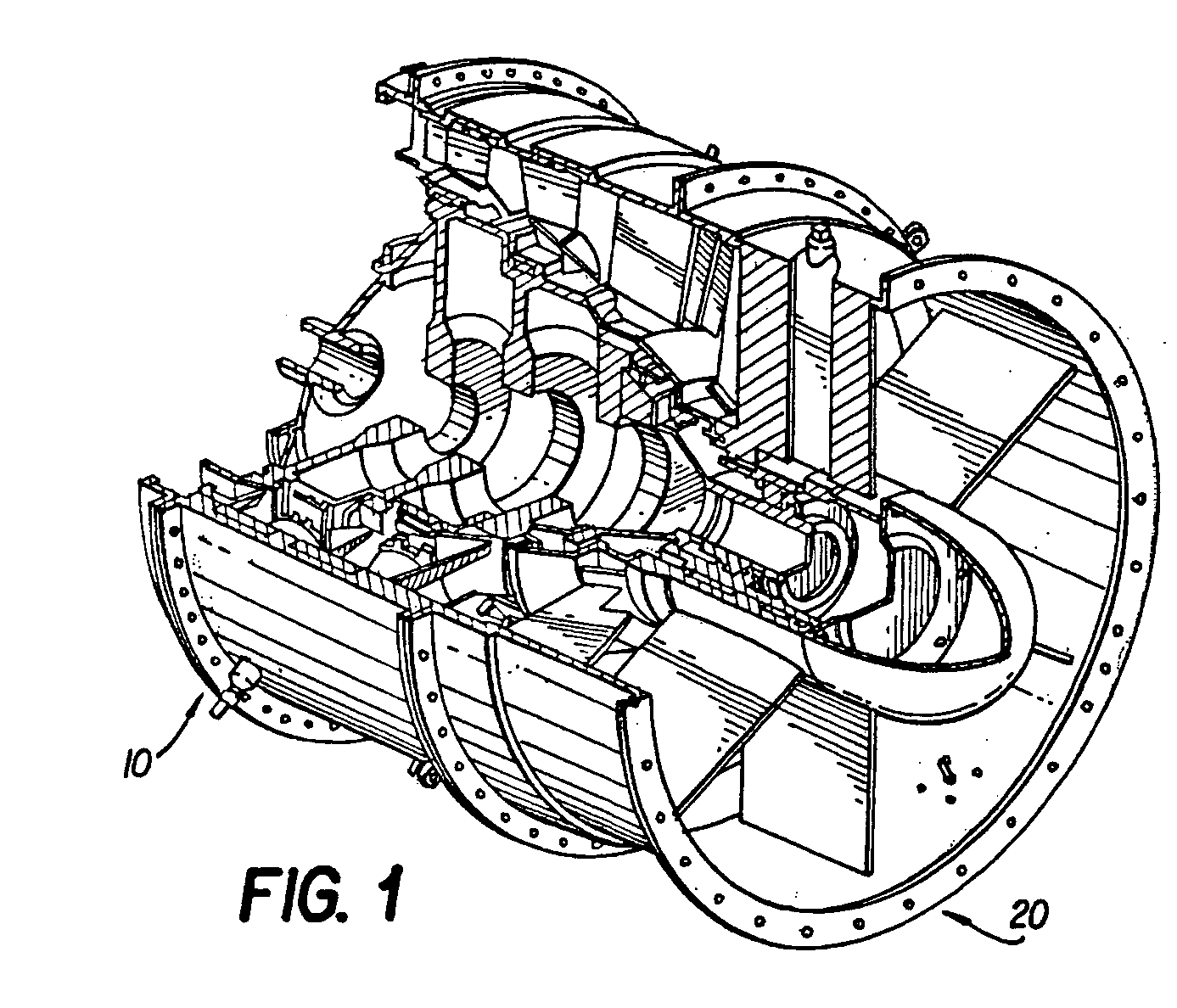

Centrifugal casting of titanium alloys with improved surface quality, structural integrity and mechanical properties in isotropic graphite molds under vacuum

InactiveUS20040040690A1Improve qualityEnhances non-reactivityFoundry mouldsRailway tracksVertical axisMechanical property

Methods for making various titanium base alloys and titanium aluminides into engineering components such as rings, tubes and pipes by melting of the alloys in a vacuum or under a low partial pressure of inert gas and subsequent centrifugal casting of the melt in the graphite molds rotating along its own axis under vacuum or low partial pressure of inert gas are provided, the molds having been fabricated by machining high density, high strength ultrafine grained isotropic graphite, wherein the graphite has been made by isostatic pressing or vibrational molding, the said molds either revolving around its own horizontal or vertical axis or centrifuging around a vertical axis of rotation.

Owner:SANTOKU CORP

Titanium Base Alloy

The invention refers to the non-ferrous metallurgy, i.e. to the creation of the modern titanium alloys, having the high genericity. Titanium-base alloy contains aluminum, vanadium, molybdenum, chromium, iron, zirconium, oxygen and nitrogen. Herewith the components of the alloy have the following ratio by weight %; aluminun—4.0-6.0; vanadium—4.5-6.0; molybdenum—4.5-6.0; chromium—2.0-3.6; iron—0.2-0.5; zirconium—0.1-less than 0.7; oxygen—0.2 max; nitrogen—0.05 max; titanium—balance. Technical result—creation of the titanium alloy with the required strength and plastic properties. The alloy may be used to produce the wide range of the products including the large-size forgings and die-forgings as well as semiproducts of small section, such as bars and plates up to 75 mm thick.

Owner:VSMPO AVISMA CORP

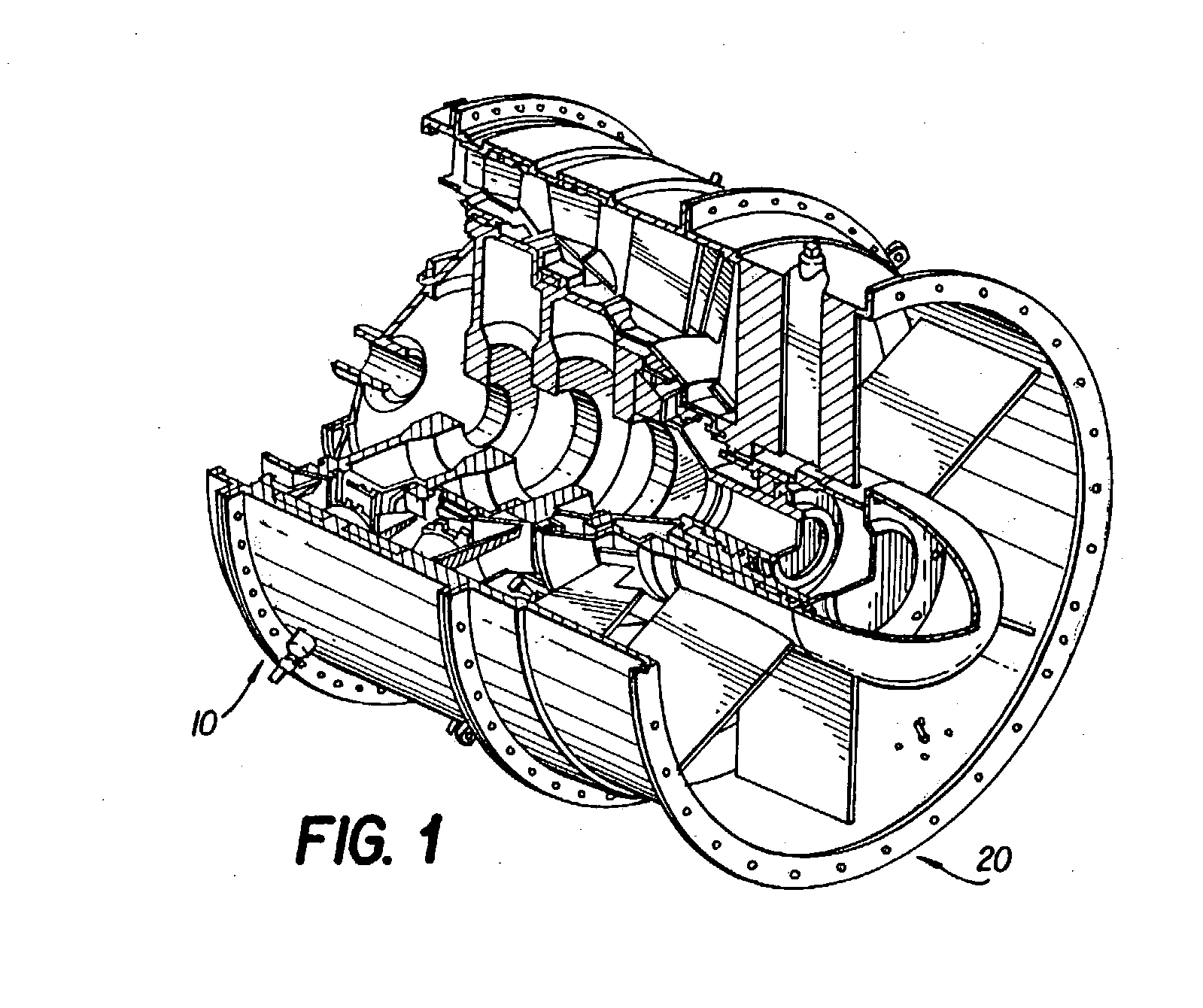

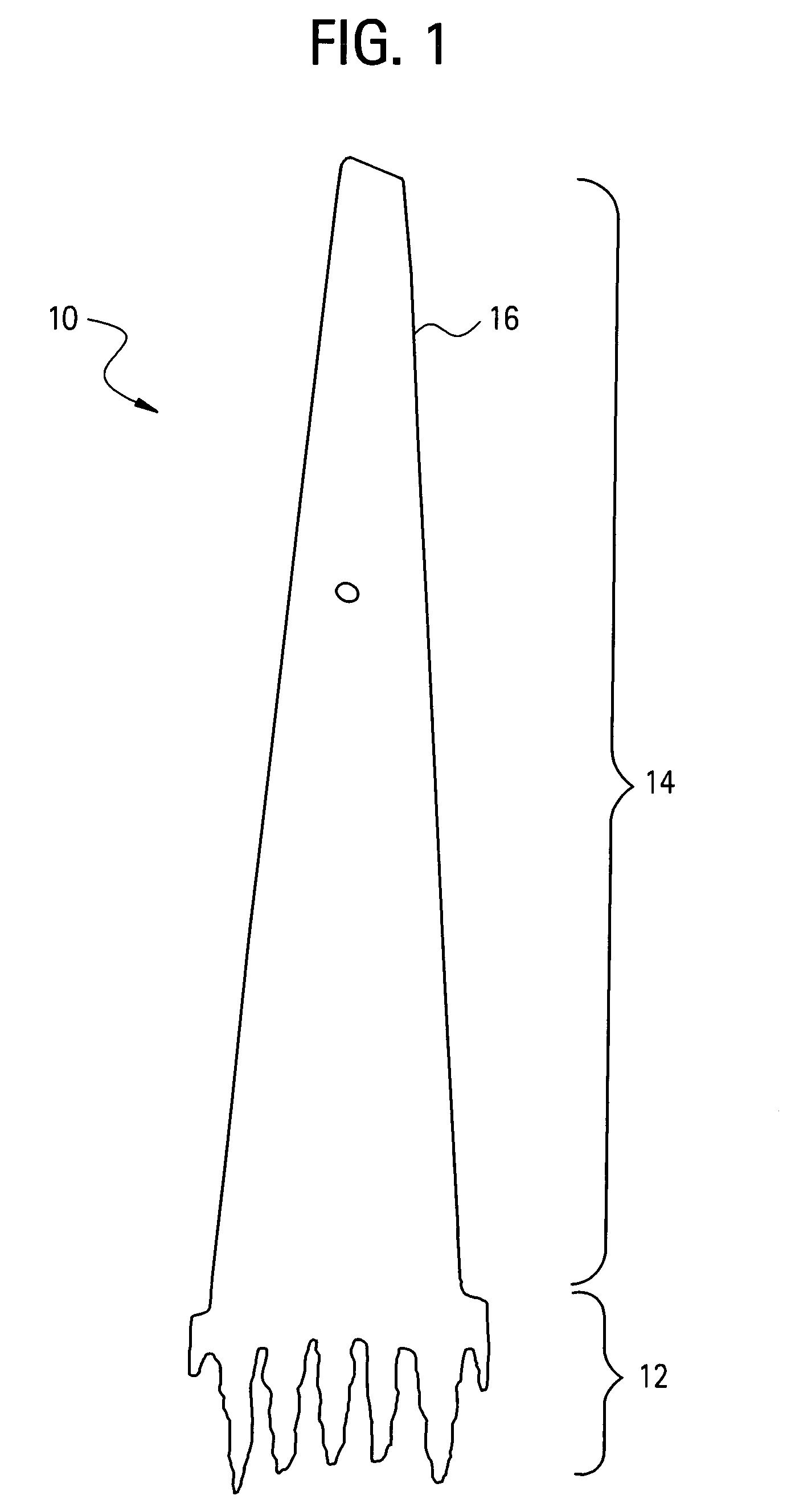

Application of high strength titanium alloys in last stage turbine buckets having longer vane lengths

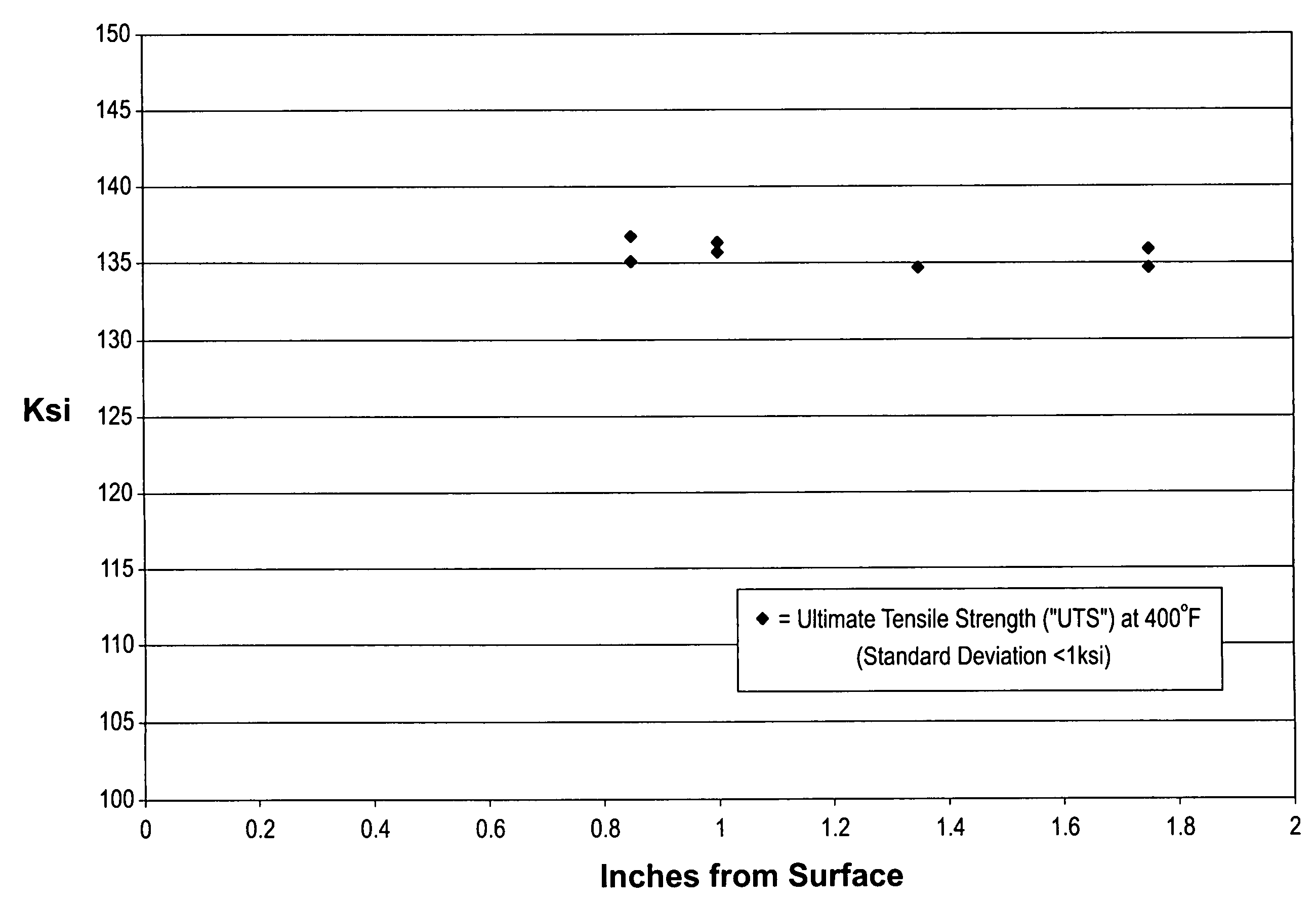

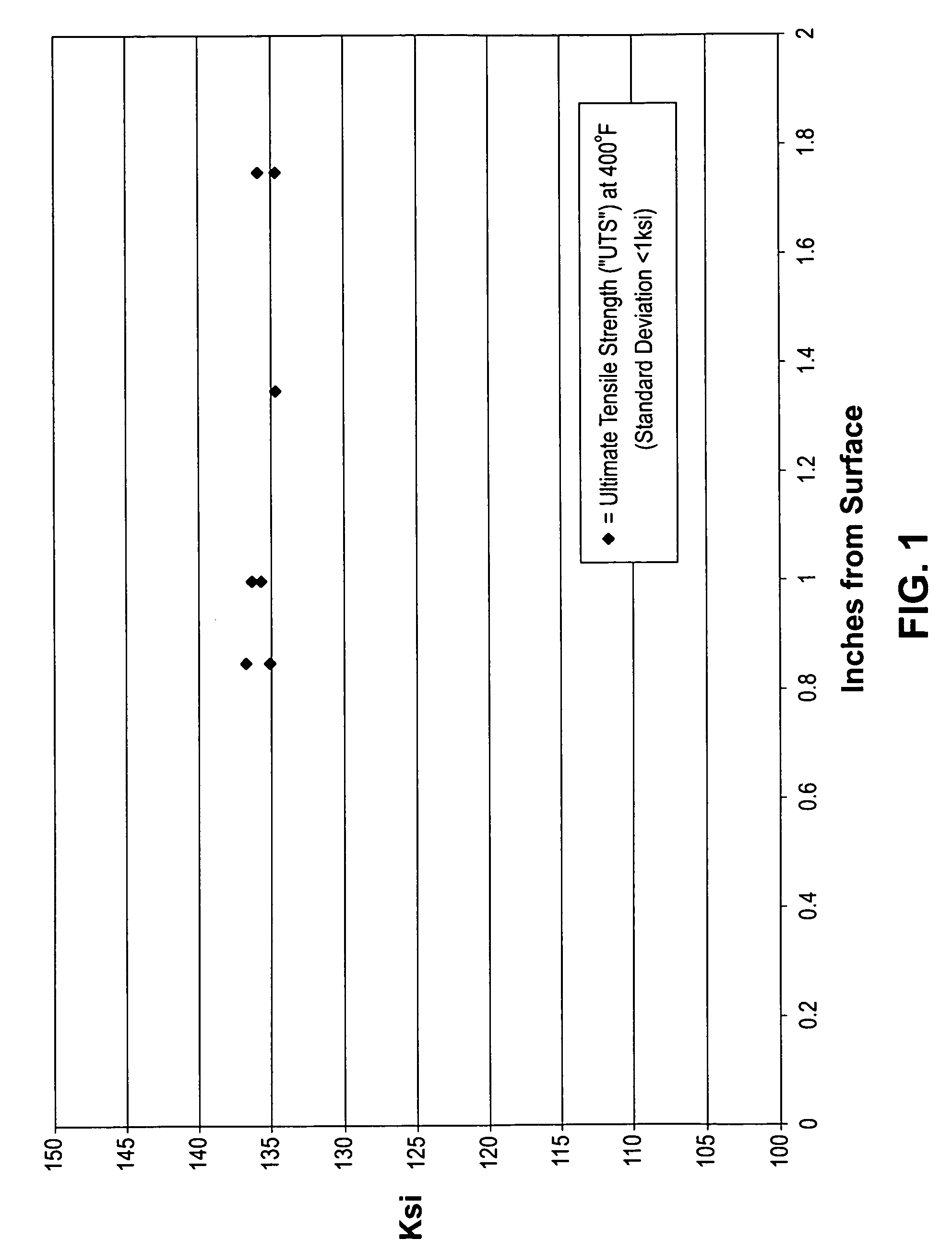

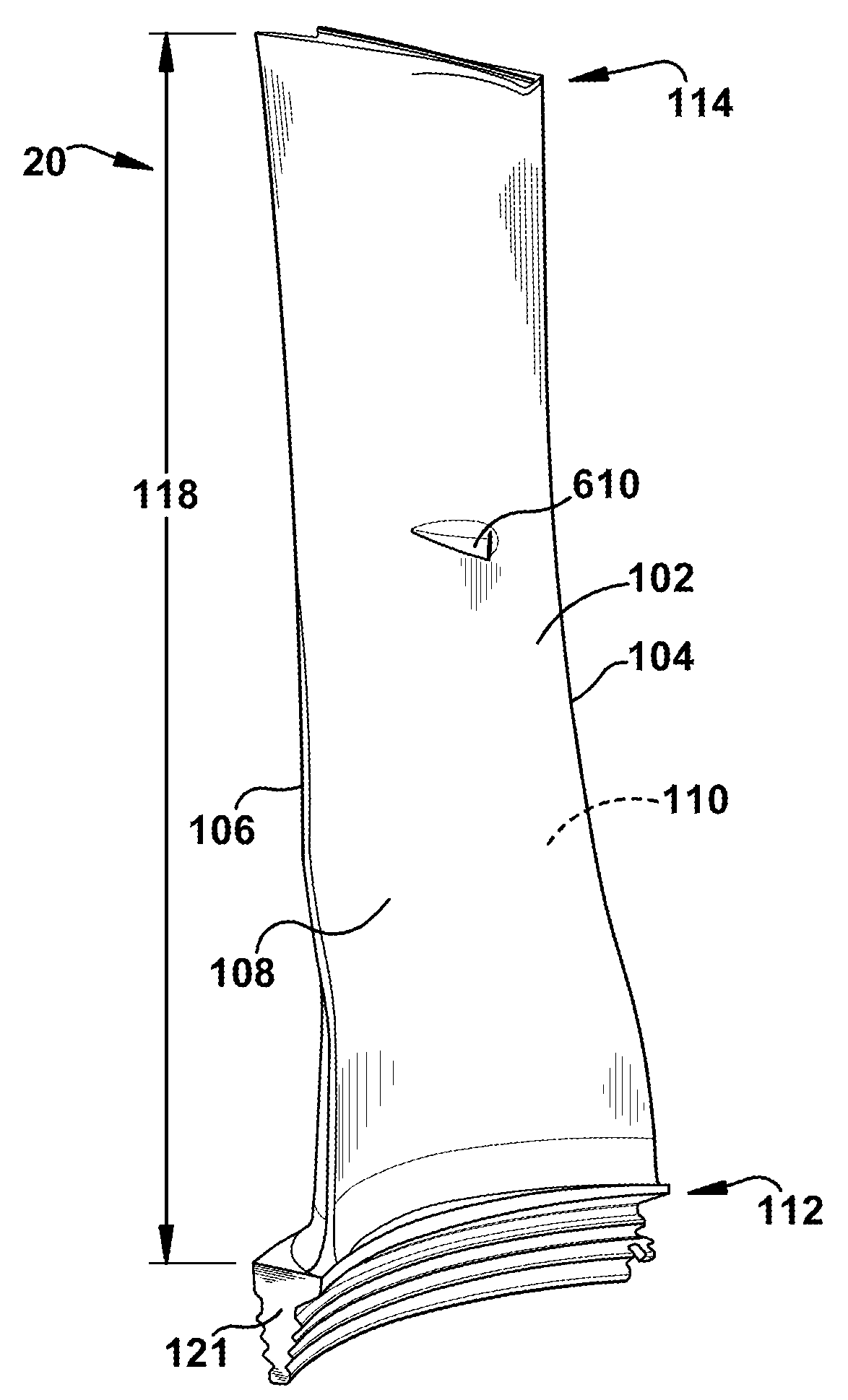

InactiveUS7195455B2Low control pressureHigh strengthPump componentsReaction enginesStress reliefHeat treated

A new high-strength titanium-based alloy bucket specifically suited for use as the last stage buckets in steam turbine engines having vane lengths of about 40 inches or greater and the method for forming such bucket. Exemplary buckets according to the invention are formed from a titanium-based alloy containing up to about 6.25% aluminum; (b) about to 3.5% vanadium; (c) about 2.25% tin, (d) about 2.25% zirconium, (e) about 1.75% molybdenum, (f) about 2.25% chromium, (g) about 0.7% silicon; and (h) about 2.3% iron, with the balance being titanium. After forming, the bucket can be heat treated to provide stress relief and then machined in a conventional manner.

Owner:GENERAL ELECTRIC CO

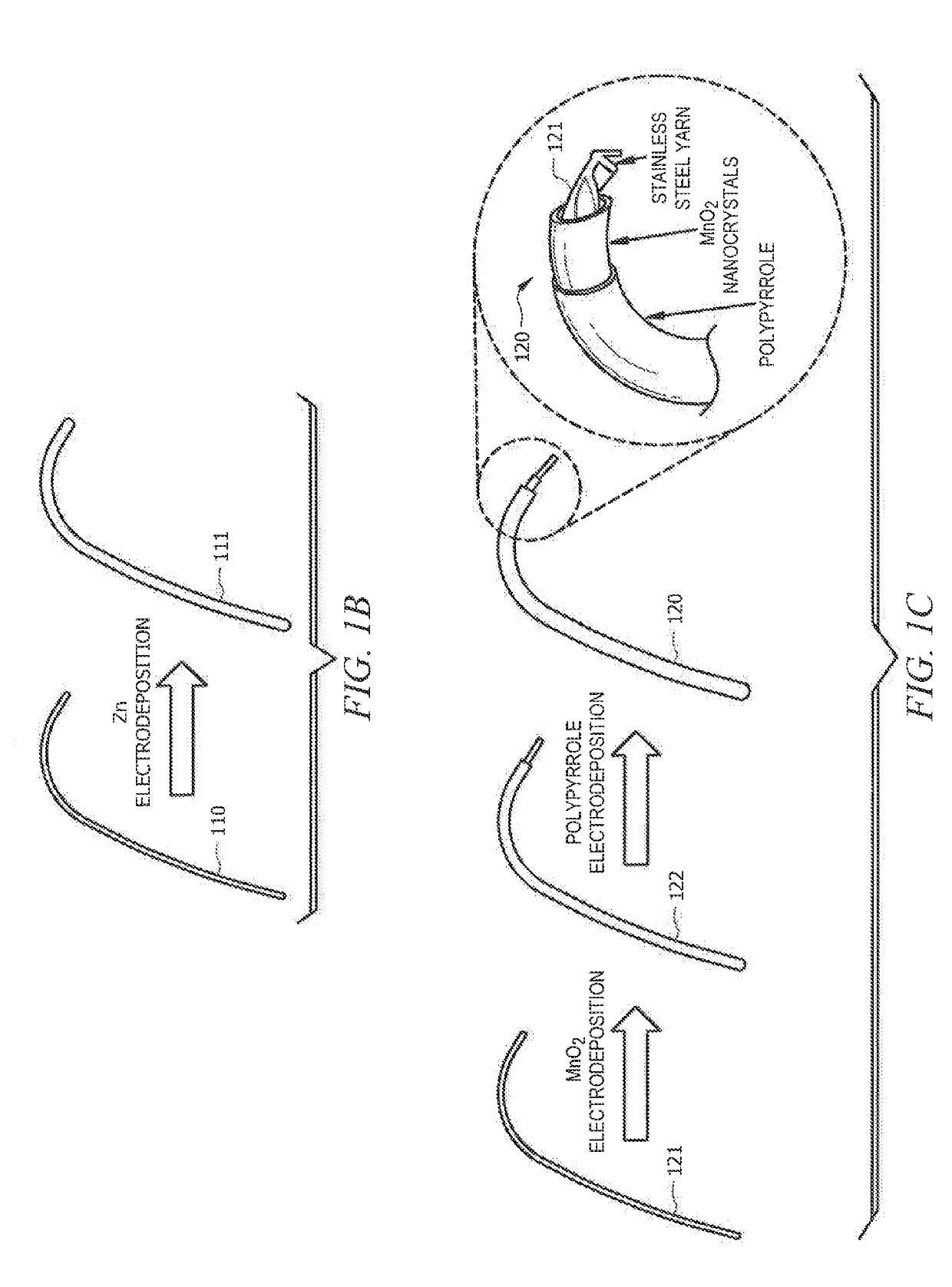

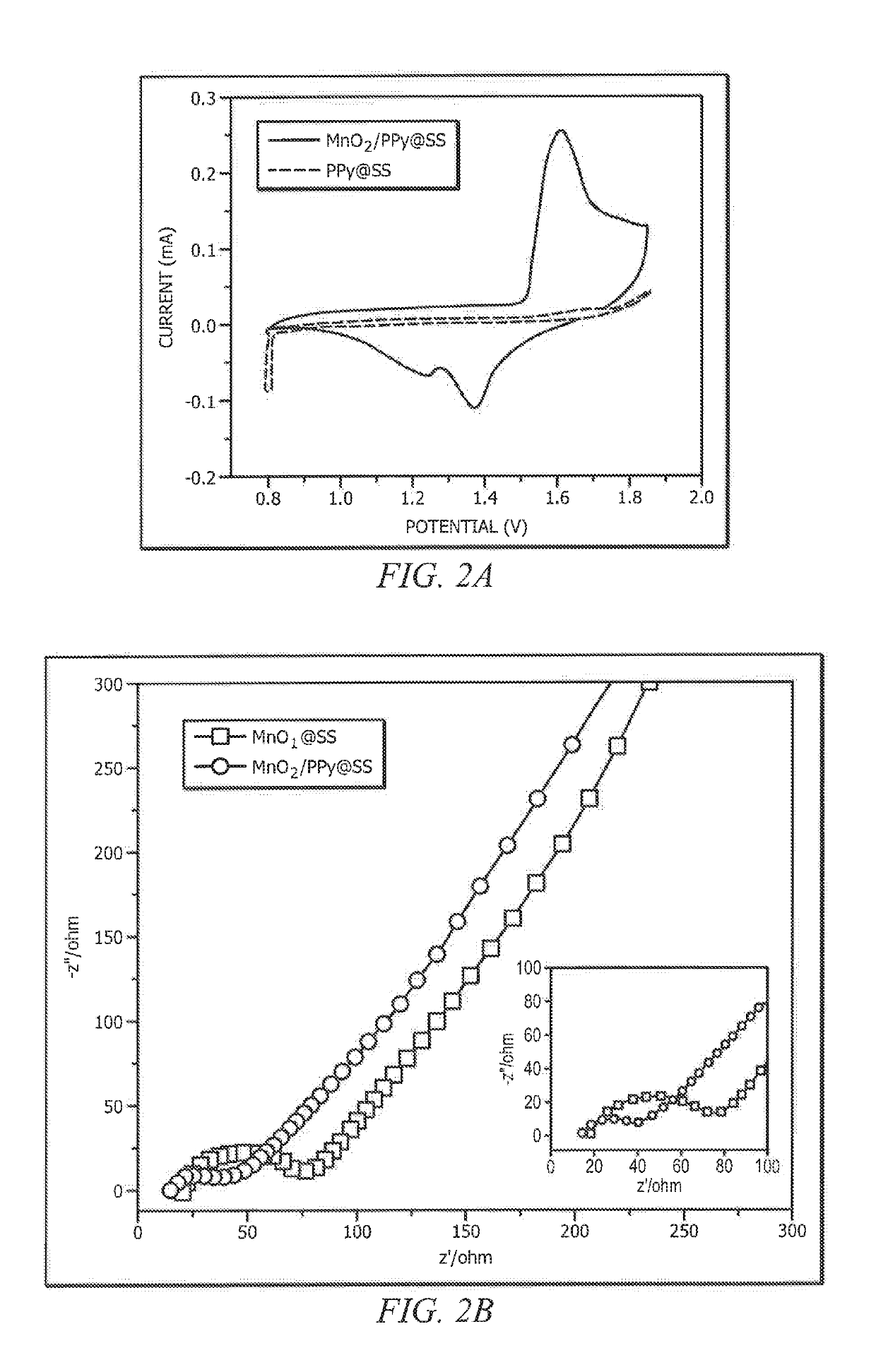

Rechargeable zinc-ion batteries having flexible shape memory

ActiveUS20190140270A1Increased mechanical flexibilityPromote recoveryElectrochemical processing of electrodesFinal product manufactureFiberYarn

Systems and methods which provide flexible zinc ion (Zn-ion) battery configurations with shape memory are described. For example, embodiments of flexible shape memory yarn batteries (SMYBs) may be fabricated using shape memory material wire, filament, and / or fiber and flexible conductive material yarn as flexible substrate materials. In accordance with some embodiments, Nickel-Titanium-based alloy wire may be coated with a zinc material to provide a flexible anode electrode for a SMYB. Additionally or alternatively, flexible stainless steel (SS) yarn may be coated with a manganese dioxide (MnO2) material to provide a flexible cathode electrode for a SMYB of embodiments. An aqueous electrolyte may be combined with the flexible cathode and anode electrodes to provide a SMYB in accordance with the concepts herein. The aqueous electrolyte may, for example, comprise a polymer gel electrolyte (e.g., gelatin-borax polymer gel electrolyte).

Owner:CITY UNIVERSITY OF HONG KONG

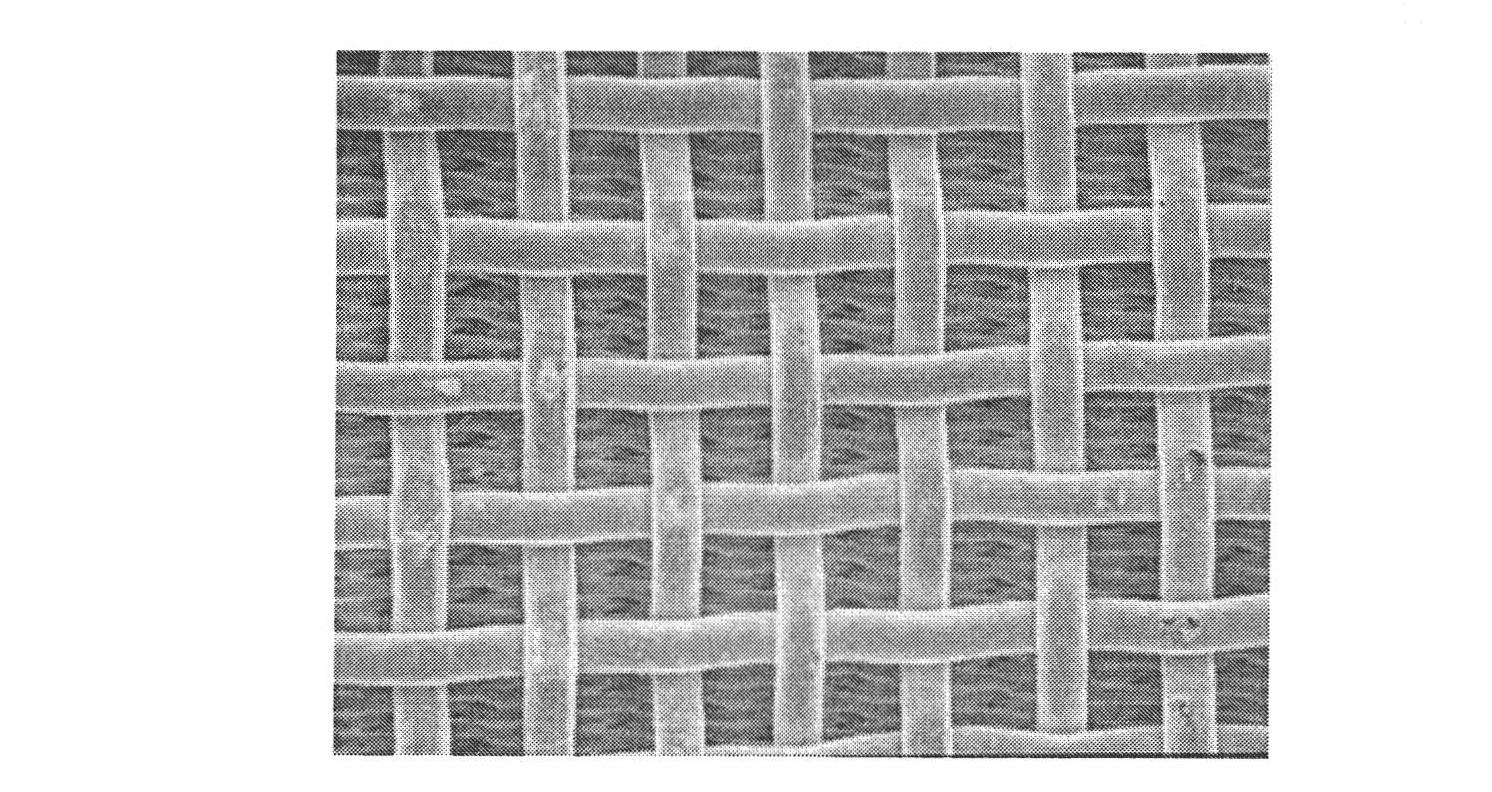

Manufacture of lightweight metal matrix composites with controlled structure

Lightweight metal matrix composites containing a skeleton structure of titanium, titanium aluminide, or Ti-based alloy are manufactured by low temperature infiltration with molten Mg-based alloy or Mg-Al alloy at 450-750° C., with molten In, Pb, or Sn at 300-450° C., or with molten Ag and Cu at 900-1100° C. The skeleton structure with a density of 25-35% is produced by loose sintering of Ti or Ti-based alloy powders. A primary deformation of the Ti skeleton structure before the infiltration is carried out by cold or hot rolling or forging to obtain a porous flat or shaped preform with a porosity <50% and pores drawn out in one direction such as the direction of future rolling of the composite plate. A secondary deformation of the infiltrated preform is carried out by multistage cold, or especially hot rolling, to refine the microstructure of the infiltrated skeleton structure and transform it into the textured microstructure strengthened by intermetallic phases such as TiAl, Ti3Al, and TiAl3. Subsequent re-sintering or diffusion annealing form a fully dense final structure of the resulting material having improved mechanical properties. The molten Mg-based infiltrate is alloyed with Al, Si, Zr, Nb, and / or V with the addition of TiB2, SiC, and Si3N4 sub-micron particles as infiltration promoters. The molten Ag- or Cu-based infiltrate can be alloyed with elements depressing its melting point. The method allows for control of the microstructure of composite materials by changing parameters of deformation, infiltration, and heat treatment. The method is suitable for the manufacture of flat or shaped metal matrix composites having improved ductility, such as lightweight bulletproof plates and sheets for aircraft and automotive applications, composite electrodes, heat-sinking lightweight electronic substrates, sporting goods such as helmets, golf clubs, sole plates, crown plates, etc.

Owner:ADMA PRODS

Erosion and wear resistant protective structures for turbine engine components

An erosion resistant protective structure for a turbine engine component comprises a shape memory alloy. The shape memory alloy includes nickel-titanium based alloys, indium-titanium based alloys, nickel-aluminum based alloys, nickel-gallium based alloys, copper based alloys, gold-cadmium based alloys, iron-platinum based alloys, iron-palladium based alloys, silver-cadmium based alloys, indium-cadmium based alloys, manganese-copper based alloys, ruthenium-niobium based alloys, ruthenium-tantalum based alloys, titanium based alloys, iron-based alloys, or combinations comprising at least one of the foregoing alloys. Also, disclosed herein are methods for forming the shape memory alloy onto turbine component.

Owner:GENERAL ELECTRIC CO

Titanium-based alloy

Titanium-based alloy contains, % by mass: aluminum 2.2 to 3.8; vanadium 4.5 to 5.9; moloybdenum 4.5 to 5.9; chromium 2.0 to 3.6; iron 0.2 to 0.8; zirconium 0.0l to 0.08; carbon 0.01 to 0.25; oxygen 0.03 to 0.25; titanium being the balance. The alloy possesses high ability to volume deformation in cold state (is easily rolled into rods), does not have tendency to form high-melting inclusions and is efficiently enforced with thermal treatment with obtaining of high level of strength and plasticity characteristics.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO KORPORATSIJA VSMPO AVISMA

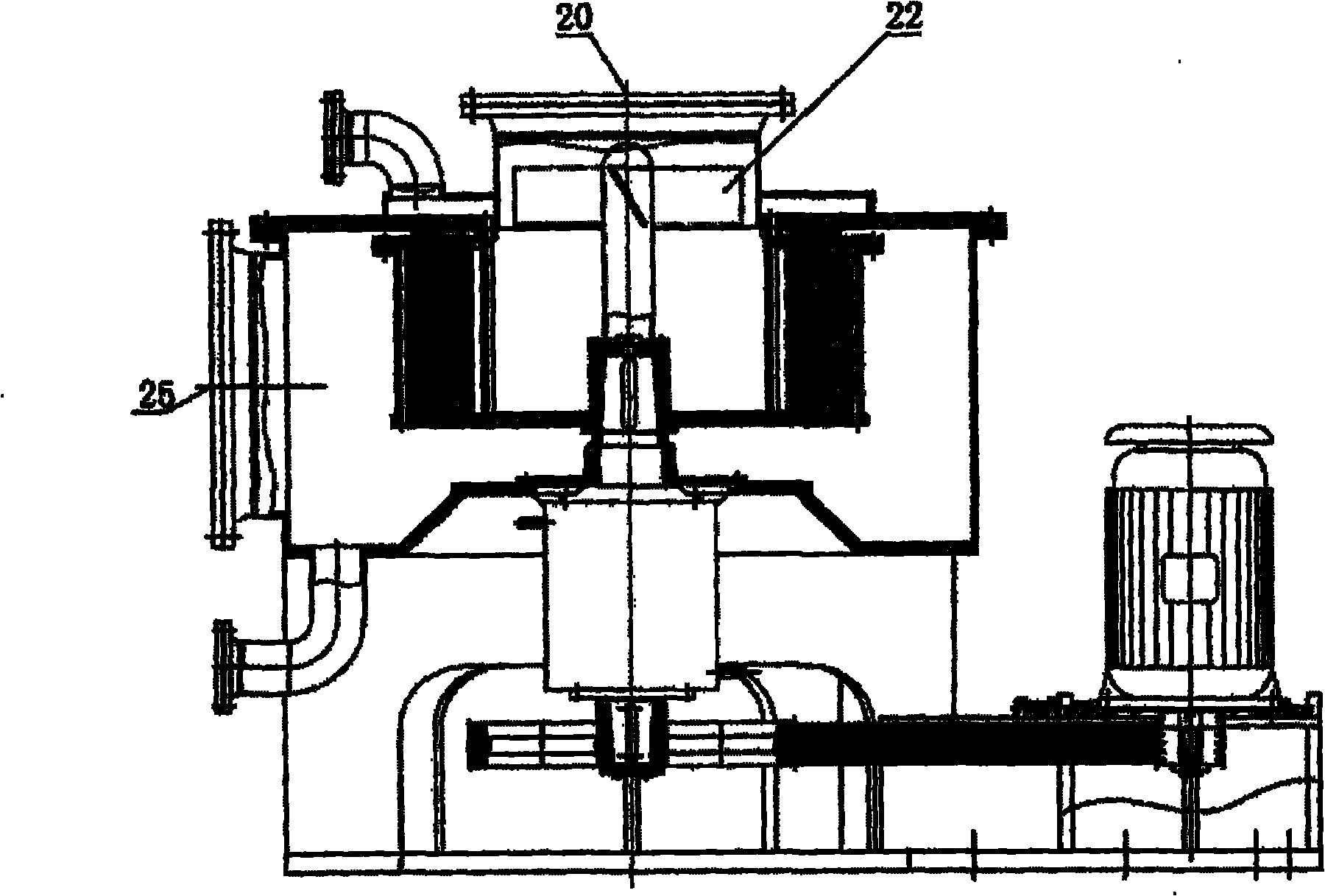

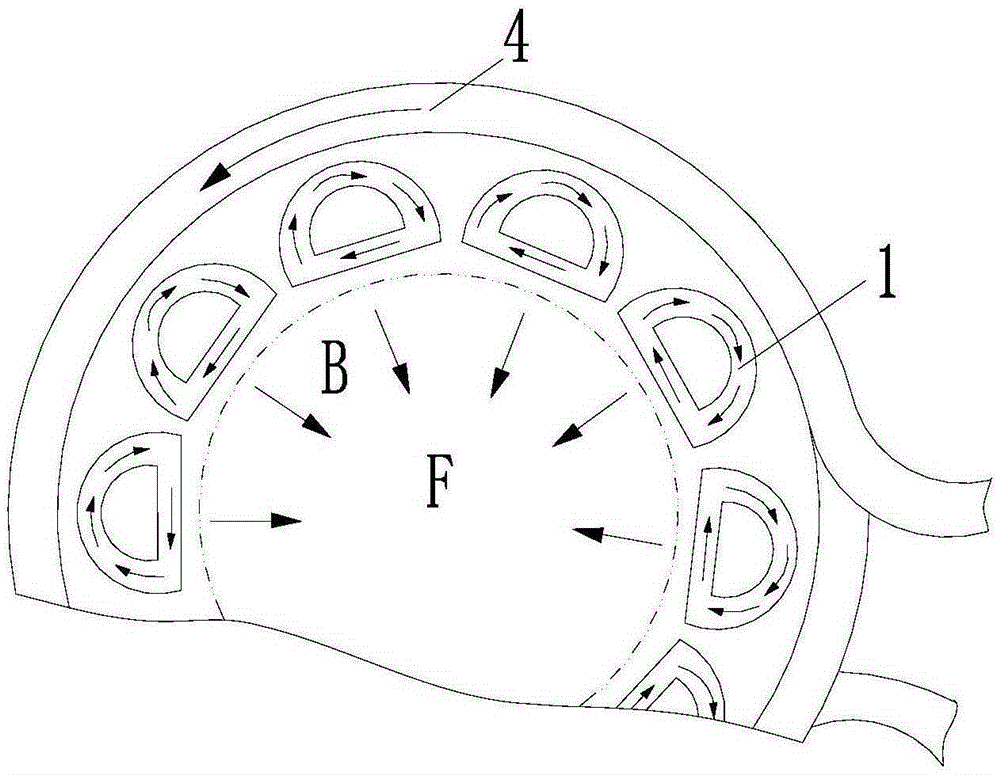

Low-pressure-drop nano/microstructure filler revolving bed supergravity device and application thereof

ActiveCN102120172AGas phase pressure drop is smallImprove mass transfer efficiencyDispersed particle separationChemical/physical/physico-chemical stationary reactorsPorosityEngineering

The invention discloses a low-pressure-drop nano / microstructure filler revolving bed supergravity device and application thereof and belongs to the technical field of supergravity. The supergravity device comprises a rotating part formed by arranging a rotor and a filler in a closed shell, wherein the shell and an upper cover have a liquid inlet, a liquid outlet, a gas inlet and a gas outlet; and a liquid distributor extending into a central cavity of the rotor is arranged in the liquid inlet. In the device, the filler in the rotating part is a structuralized SiC, sintered ceramic and powder sintered titanium-based alloy filler with a nano / microstructure, the runner diameter of the structuralized filler is 0.1 to 5mm, the porosity is 55 to 97 percent, the surface of the filler has a 0.01 to 3-micrometer convexoconcave nano / microstructure, and the specific surface area of the filler is 200 to 2,000m<2> / m<3>. When the device is used for deeply removing sulfur dioxide from industrial gases such as sulfuric acid industrial tail gas with low-pressure-drop requirement, the pressure drop of the supergravity device is lowered by 40 to 80 percent, and the harmful gas content after treatment is lower than 20 to 100ppm.

Owner:BEIJING UNIV OF CHEM TECH +1

Centrifugal casting of titanium alloys with improved surface quality, structural integrity and mechanical properties in isotropic graphite molds under vacuum

Methods for making various titanium base alloys and titanium aluminides into engineering components such as rings, tubes and pipes by melting of the alloys in a vacuum or under a low partial pressure of inert gas and subsequent centrifugal casting of the melt in the graphite molds rotating along its own axis under vacuum or low partial pressure of inert gas are provided, the molds having been fabricated by machining high density, high strength ultrafine grained isotropic graphite, wherein the graphite has been made by isostatic pressing or vibrational molding, the said molds either revolving around its own horizontal or vertical axis or centrifuging around a vertical axis of rotation.

Owner:SANTOKU CORP

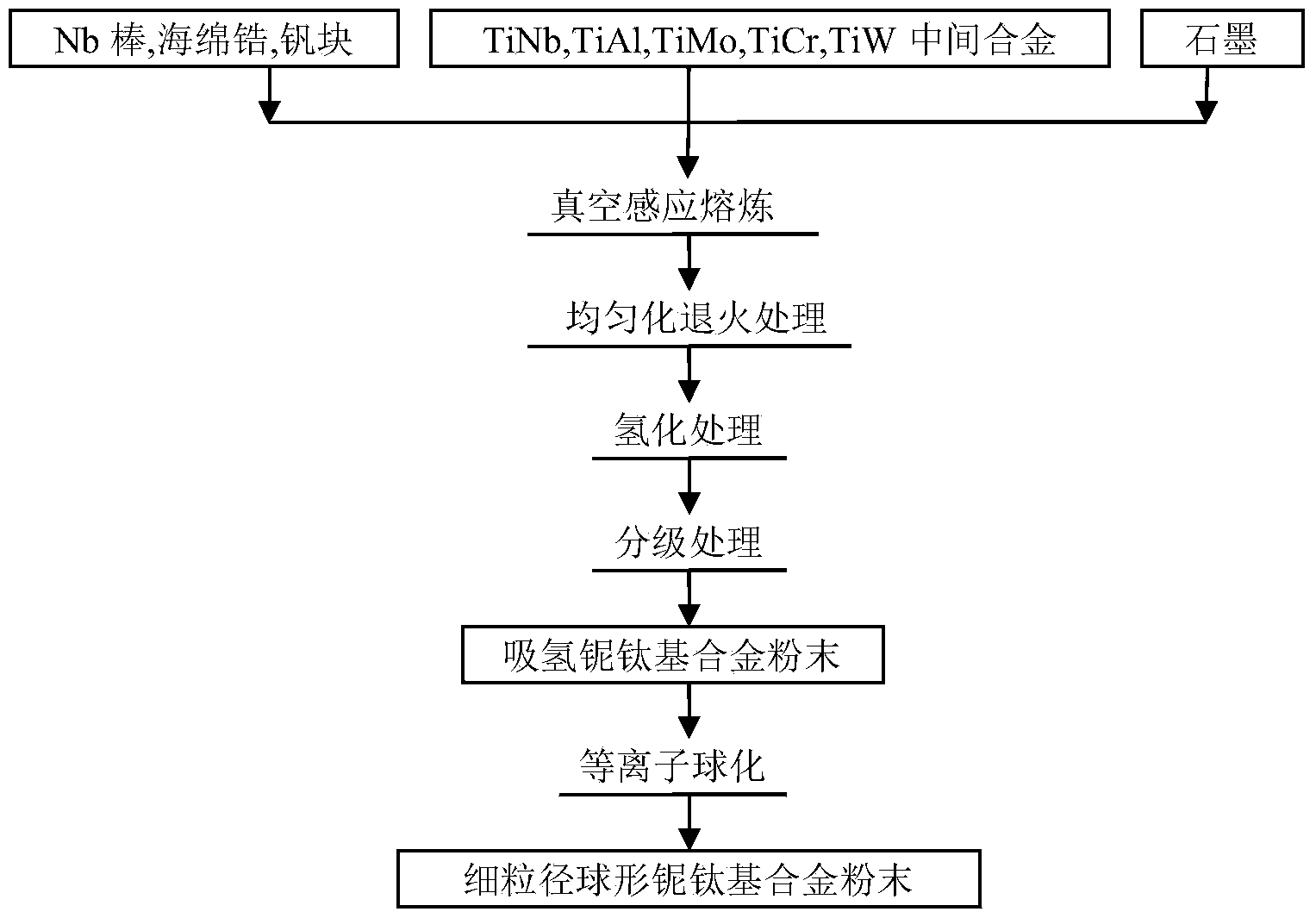

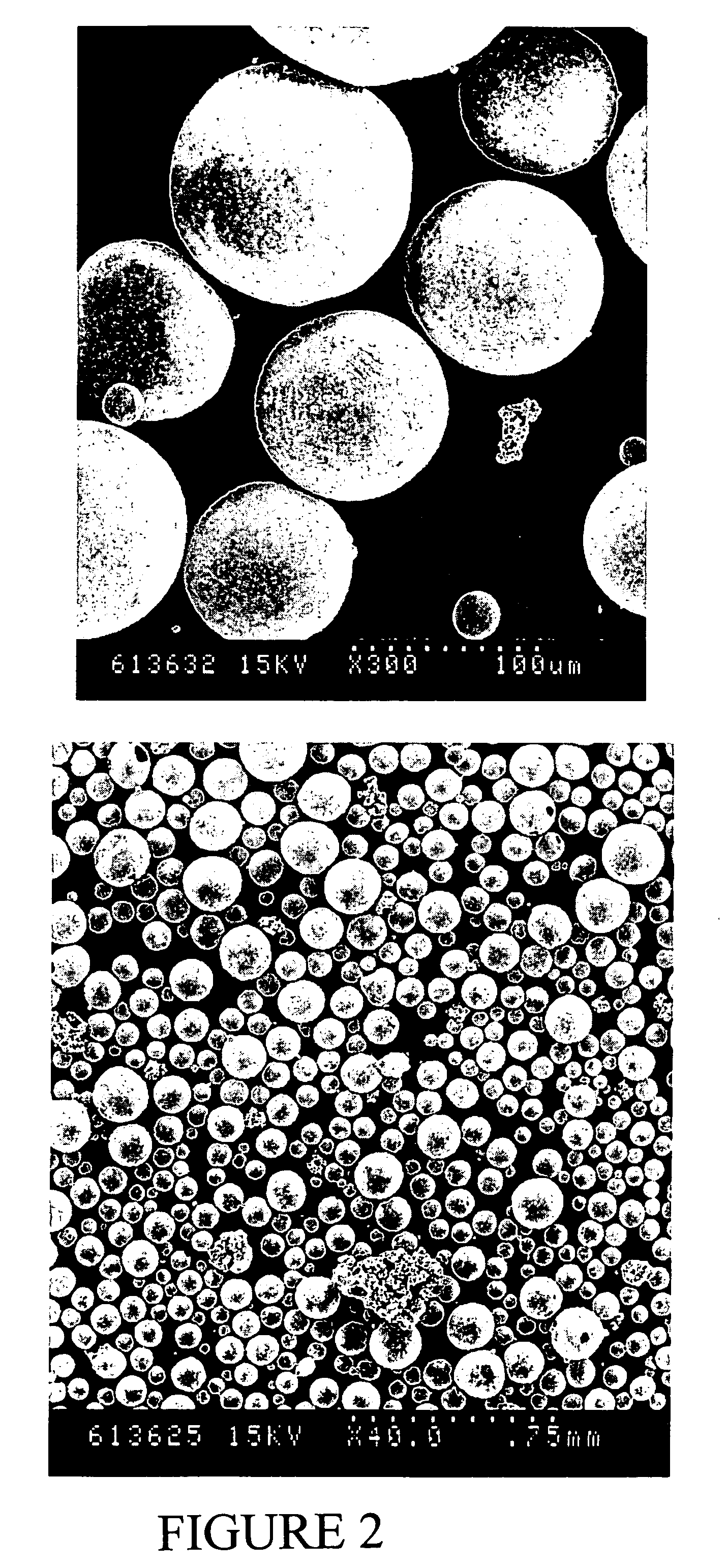

Method for manufacturing spherical niobium and titanium-based alloy powder with small particle size

The invention discloses a method for manufacturing spherical niobium and titanium-based alloy powder with a small particle size. The spherical niobium and titanium-based alloy powder is manufactured by the aid of vacuum induction melting, hydrogen treatment and plasma spheroidization technologies. The method includes firstly, manufacturing niobium and titanium-based spherical alloy ingots by the aid of the vacuum induction melting technology to realize a purification melting effect, reducing the quantity and the size of non-metallic inclusion to the greatest extent and performing homogenization thermal treatment on the niobium and titanium-based spherical alloy ingots to obtain ingots with uniform alloy contents; secondly, performing hydrogen treatment on the ingots to acquire hydrogen absorption niobium and titanium alloy powder; thirdly, sieving the hydrogen absorption niobium and titanium alloy powder, and then performing plasma spheroidization on the hydrogen absorption niobium and titanium alloy powder. The method has the advantages that output power, the powder feeding rate and the airflow rate are optimized in spheroidization procedures, accordingly, hollow powder can be prevented, and the fine powder yield can be increased; the spherical powder obtained by the method is excellent in dispersibility and flowability and uniform in particle size; the niobium and titanium-based alloy powder finally manufactured by the method is small in particle size, uniform in composition, good in flowability, high in spheroidization rate and low in oxygen content and is applicable to the technical field of injection molding, quick molding and thermal spraying.

Owner:UNIV OF SCI & TECH BEIJING

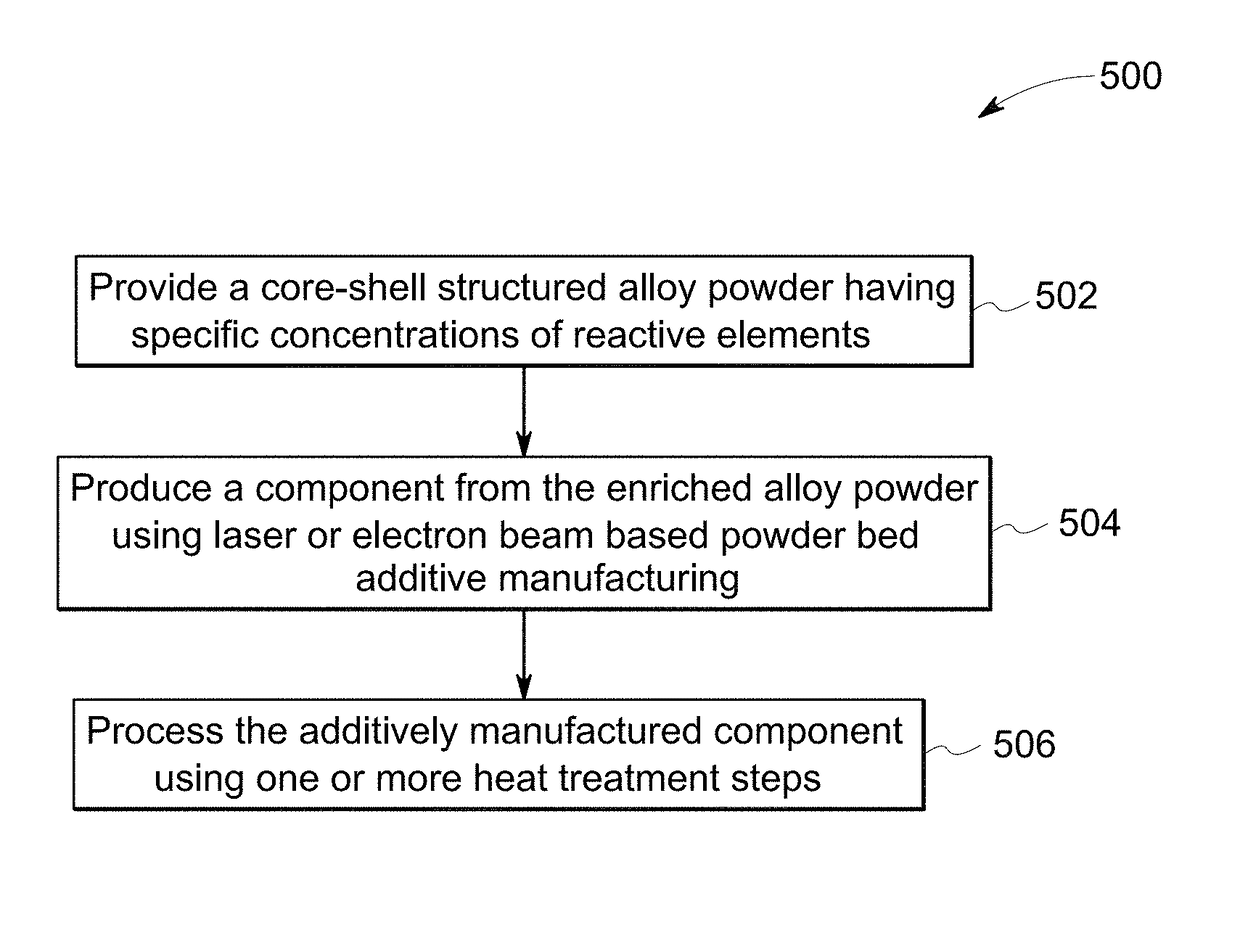

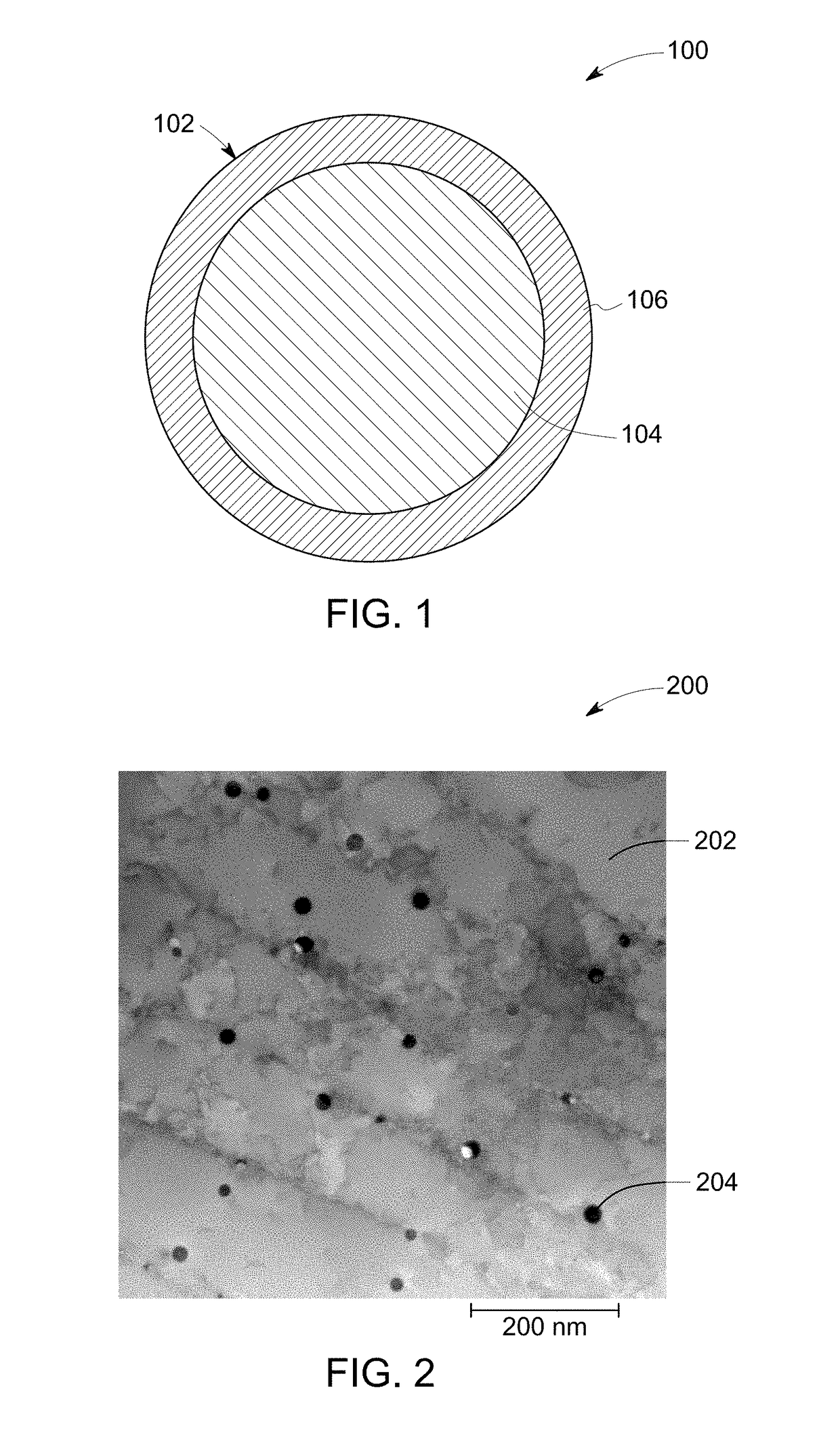

Additive manufacturing method and materials

PendingUS20180193916A1Additive manufacturing apparatusTransportation and packagingOxygen richAdditive layer manufacturing

A core-shell structured alloy powder for additive manufacturing, an additively manufactured precipitation dispersion strengthened alloy component, and a method for additively manufacturing the component are provided. The alloy powder comprises a plurality of particles, where one or more of the plurality of particles comprise an alloy powder core and an oxygen or nitrogen rich shell disposed on at least a portion of the alloy powder core. The alloy powder core comprises an alloy constituent matrix with one or more reactive elements, where the reactive elements are configured to react with oxygen, nitrogen, or both. The alloy constituent matrix comprises stainless steel, an iron based alloy, a nickel based alloy, a nickel-iron based alloy, a cobalt based alloy, a copper based alloy, an aluminum based alloy, a titanium based alloy, or combinations thereof. The alloy constituent matrix comprises reactive elements present in a range from about 0.01 weight percent to 10 weight percent of a total weight of the alloy powder.

Owner:GENERAL ELECTRIC CO

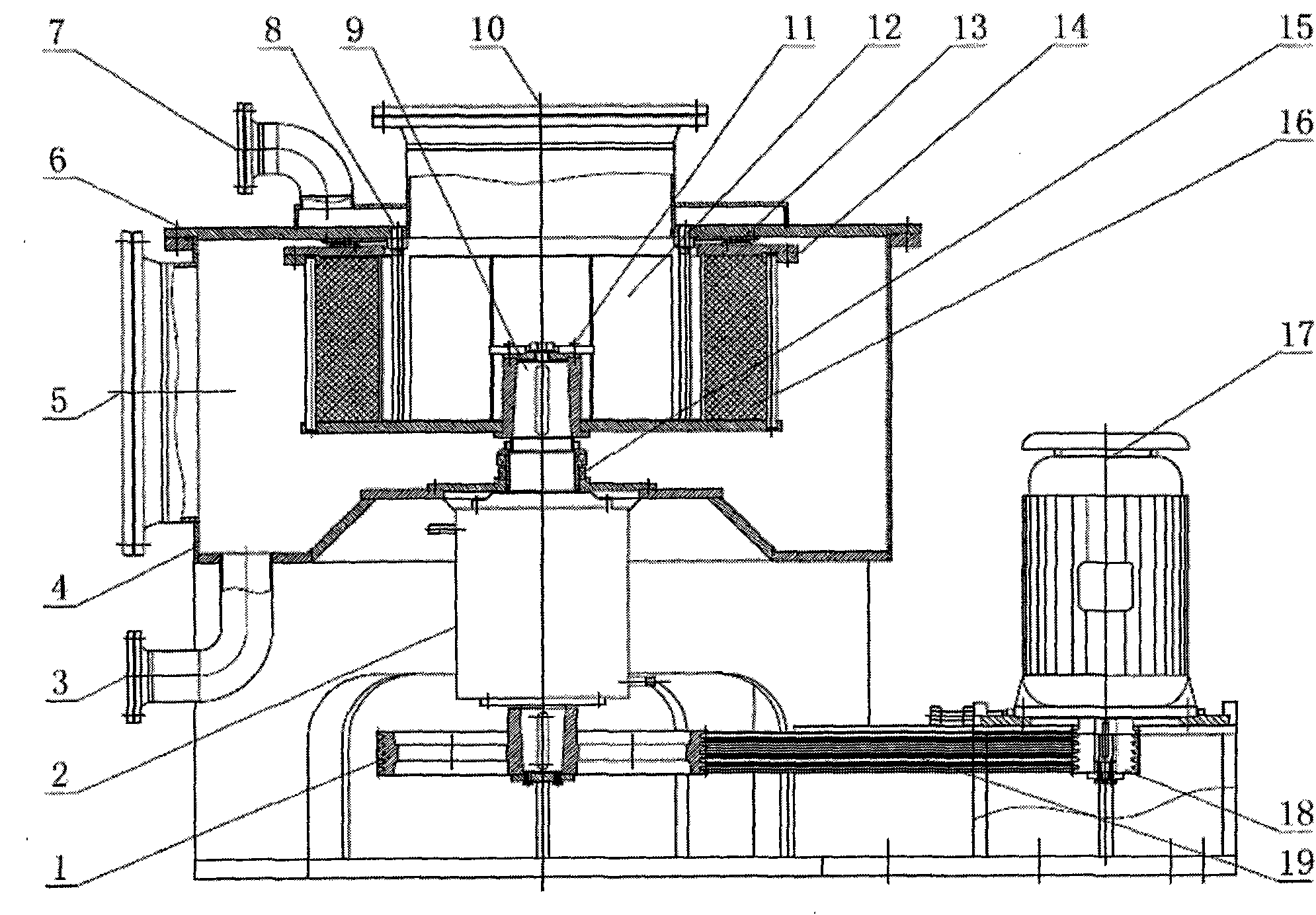

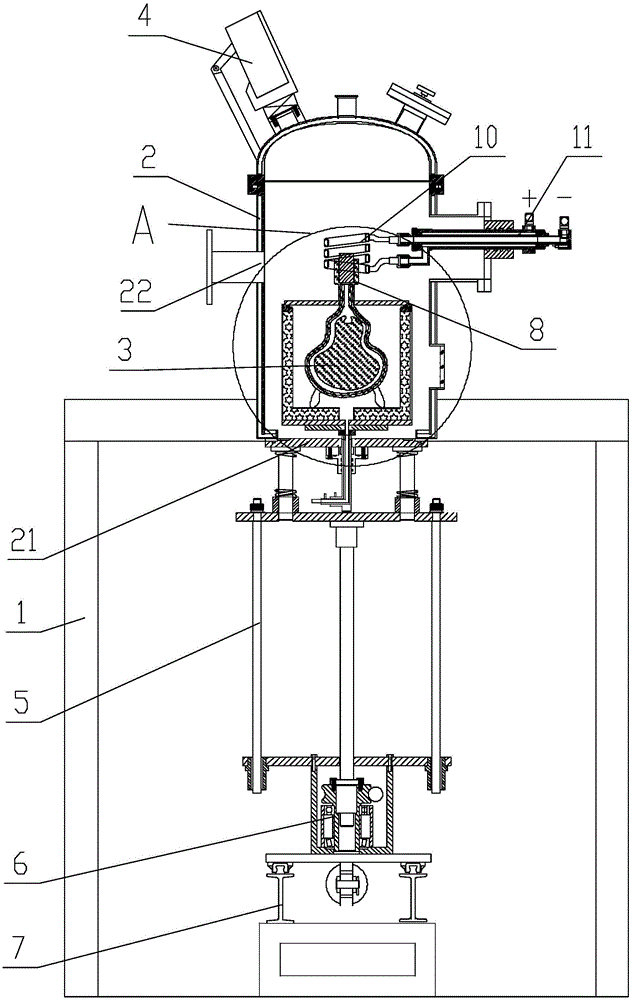

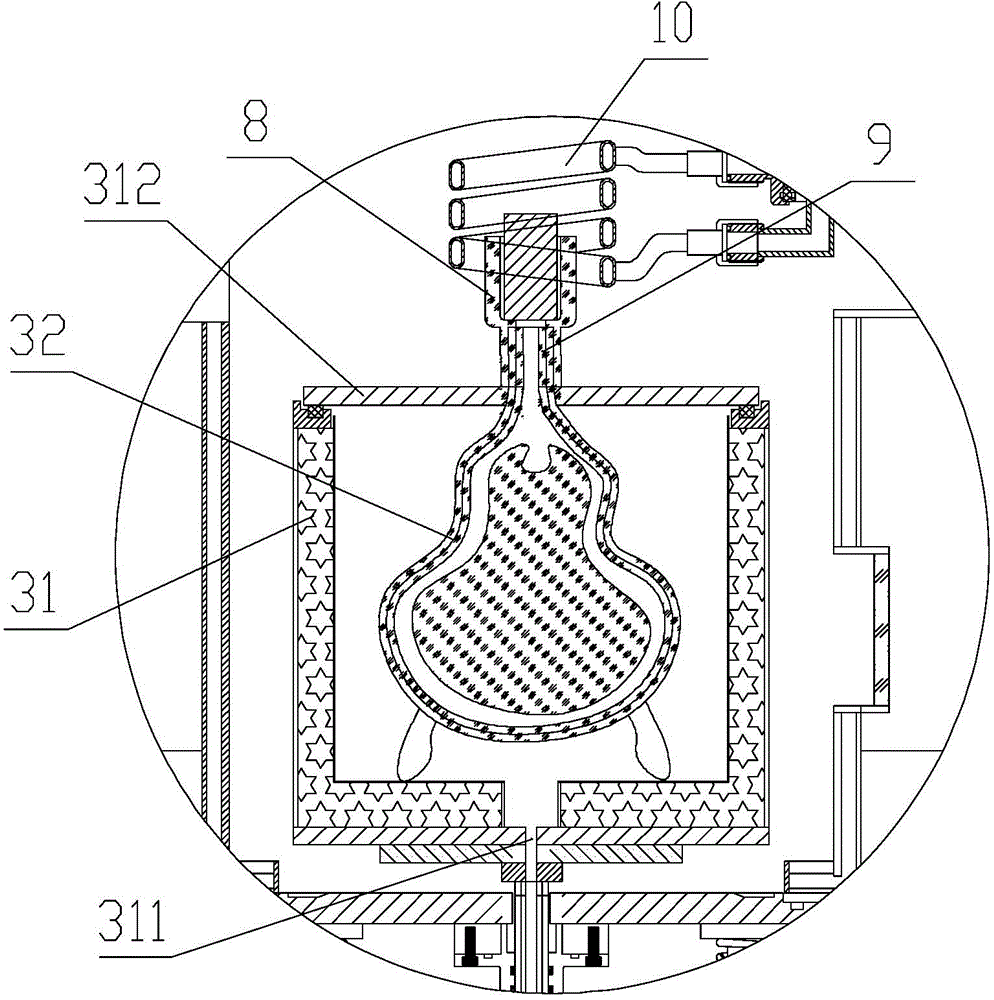

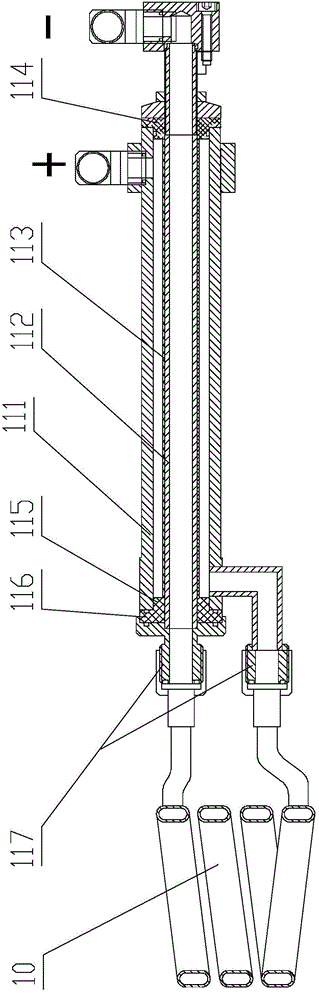

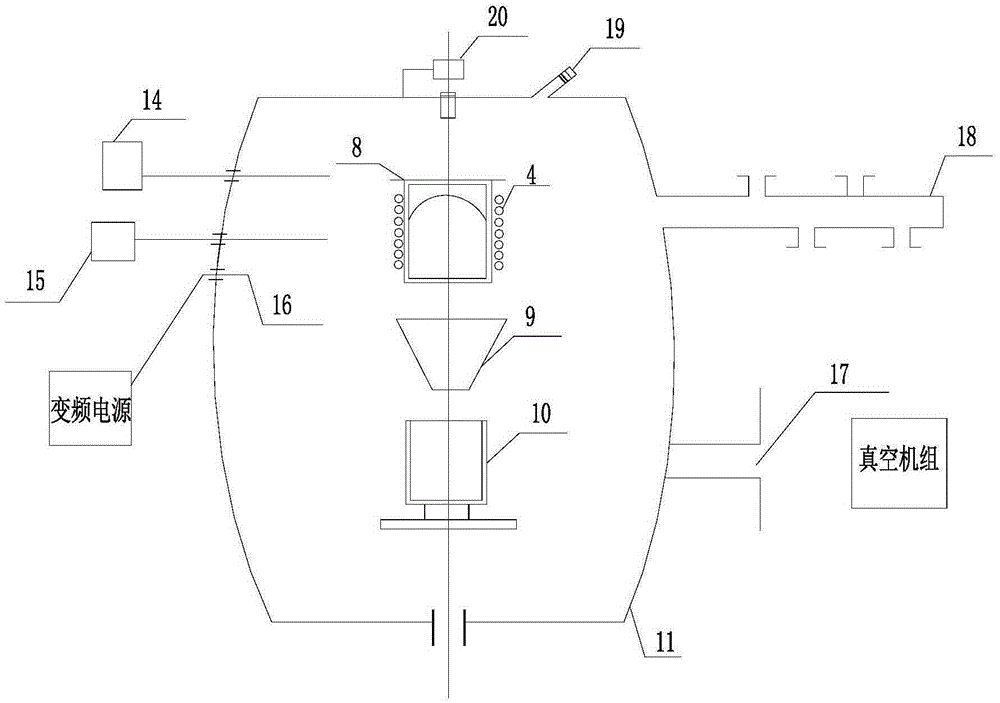

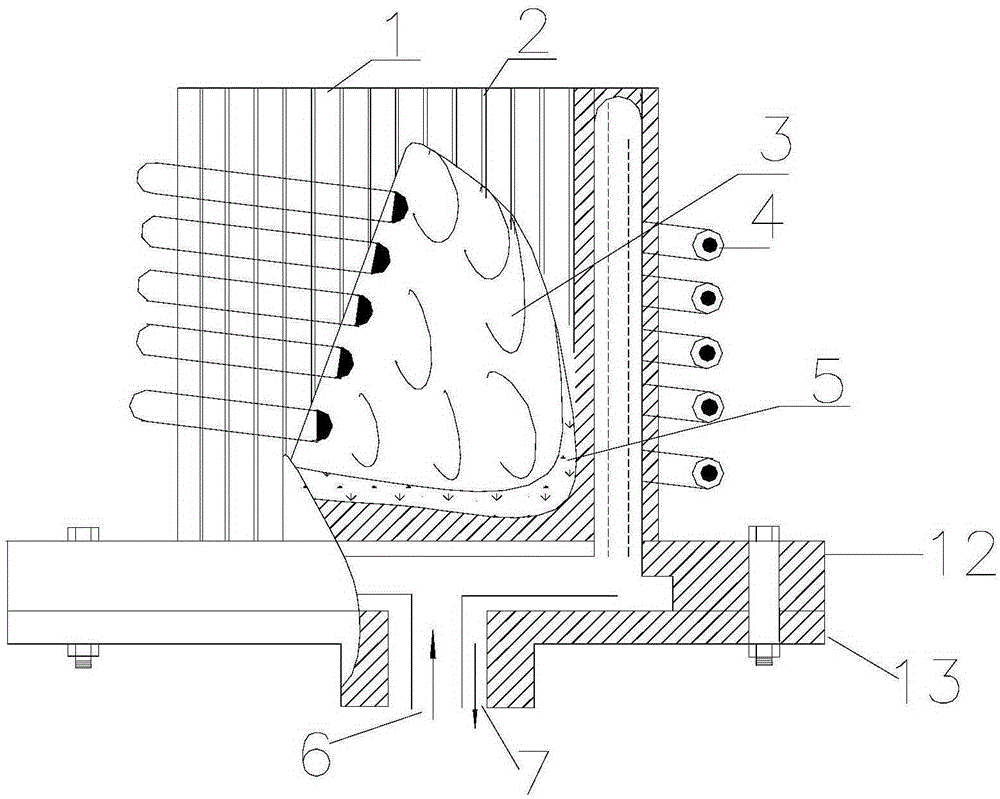

Titanium-based alloy induction melting bottom leakage type vacuum suction casting device and control method

The invention discloses a titanium-based alloy induction melting bottom leakage type vacuum suction casting device and a control method, relates to the technical field of titanium-based alloy melting suction casting and solves the problems of low efficiency, high cost, complicated technology and the like of an existing titanium-based alloy melting suction casting device. The titanium-based alloy induction melting bottom leakage type vacuum suction casting device provided by the invention can be used for carrying out vacuum induction melting on titanium-based alloy by adopting a ceramic crucible; since no any shielding effect works on an electromagnetic force by ceramic, all electromagnetic induction energy generated by an induction coil can totally act on titanium metal, energy saving and environment protection are realized, the utilization rate of metal raw materials is up to 60%-70%, and the metal cost is greatly reduced; an isolating layer is formed on the inner surface of a crucible body of the ceramic crucible, materials which are used for manufacturing the isolating layer comprise yttrium oxide, the yttrium oxide has good inertia on the titanium metal under high temperature and can be used for isolating ceramic materials which can react with the titanium metal during a melting process, and titanium-based alloy melting is enabled to be reliably proceeded.

Owner:北京博瑞杰特科技发展有限公司

Titanium alloy

InactiveUS20070017319A1Small amountTransportation and packagingMetal-working apparatusAlkaline earth metalMetal

A titanium base alloy powder having lesser amounts of aluminum and vanadium with an alkali or alkaline earth metal being present in an amount of less than about 200 ppm. The alloy powder is neither spherical nor angular and flake shaped. 6 / 4 alloy is specifically disclosed having a packing fraction or tap density between 4 and 11%, as is a method for making the various alloys.

Owner:CRISTAL US INC

Low pressure section steam turbine bucket

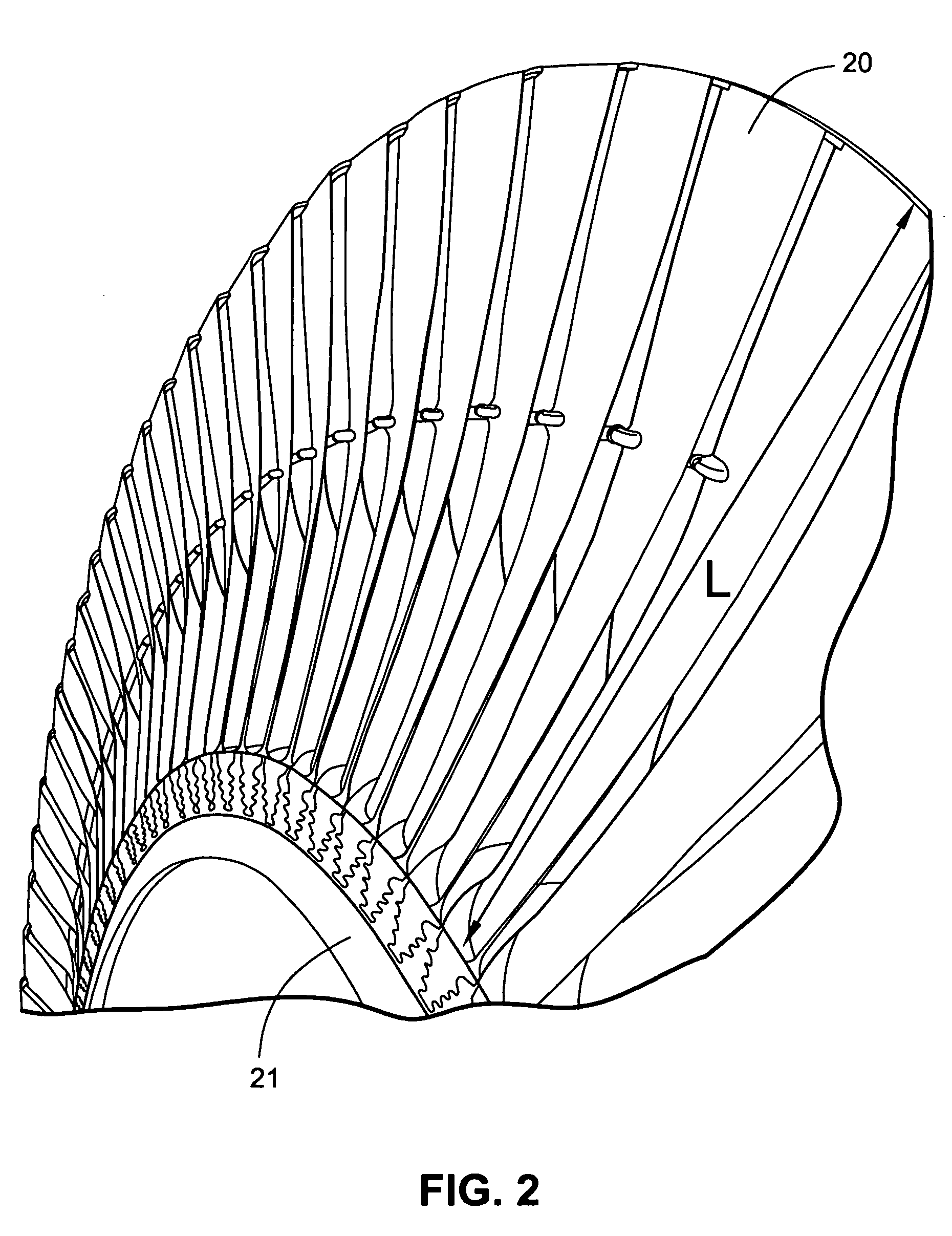

InactiveUS20090214345A1Increase stiffnessReduce vibration stressPropellersPump componentsRadial positionEngineering

A bucket for use in the low-pressure section of a steam turbine engine is provided. The bucket has a vane length of at least about 45 inches. The bucket is comprised of a dovetail section disposed near an inner radial position of the bucket, a tip shroud disposed near an outer radial position of the bucket and a part span shroud disposed at an intermediate radial position. The intermediate radial position is located between the inner and outer radial positions. The bucket is comprised of a titanium-based alloy having between about 2% and about 6.25% by weight aluminum, up to about 3.5% vanadium, up to about 2.25% tin, up to about 2.25% zirconium, between about 1.75% and about 5.0% molybdenum, up to about 2.25% chromium, up to about 0.7% silicon and up to about 2.3% iron, with the balance being titanium.

Owner:GENERAL ELECTRIC CO

Method for preparing titanium product

ActiveCN102120261AEasy to manufactureSave on recasting processIncreasing energy efficiencyLithographic artistTitanium

The invention discloses a method for preparing a titanium product. The method is characterized by adopting pure titanium or titanium alloy powder as material and preparing the titanium product by laser sintering. A three-dimensional design or reversely reconstructed three-dimensional stereo lithography (STL) data model is taken as a basis, and is converted into stereo-lithography apparatus (SLA) two-dimensional slice data serving as an instruction for the laser sintering; the pure titanium or titanium base alloy powder with certain particle size is sintered to prepare a blank which is subject to subsequent thermal treatment and polishing process to prepare the complex integrated titanium product. As the method combines the characteristics of integral design, net forming, high precision and the like, the problem of difficult processing of titanium alloy is solved, the subsequent processing cost is saved, the yield is high, and the method is suitable for preparing the titanium base products with a complex structure.

Owner:FUJIAN CTRUE MATERIALS TECH

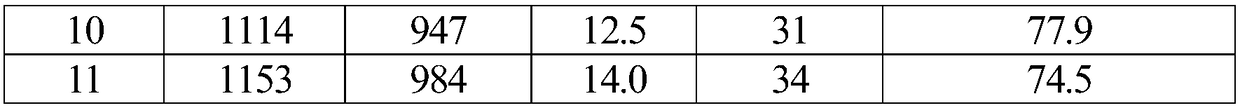

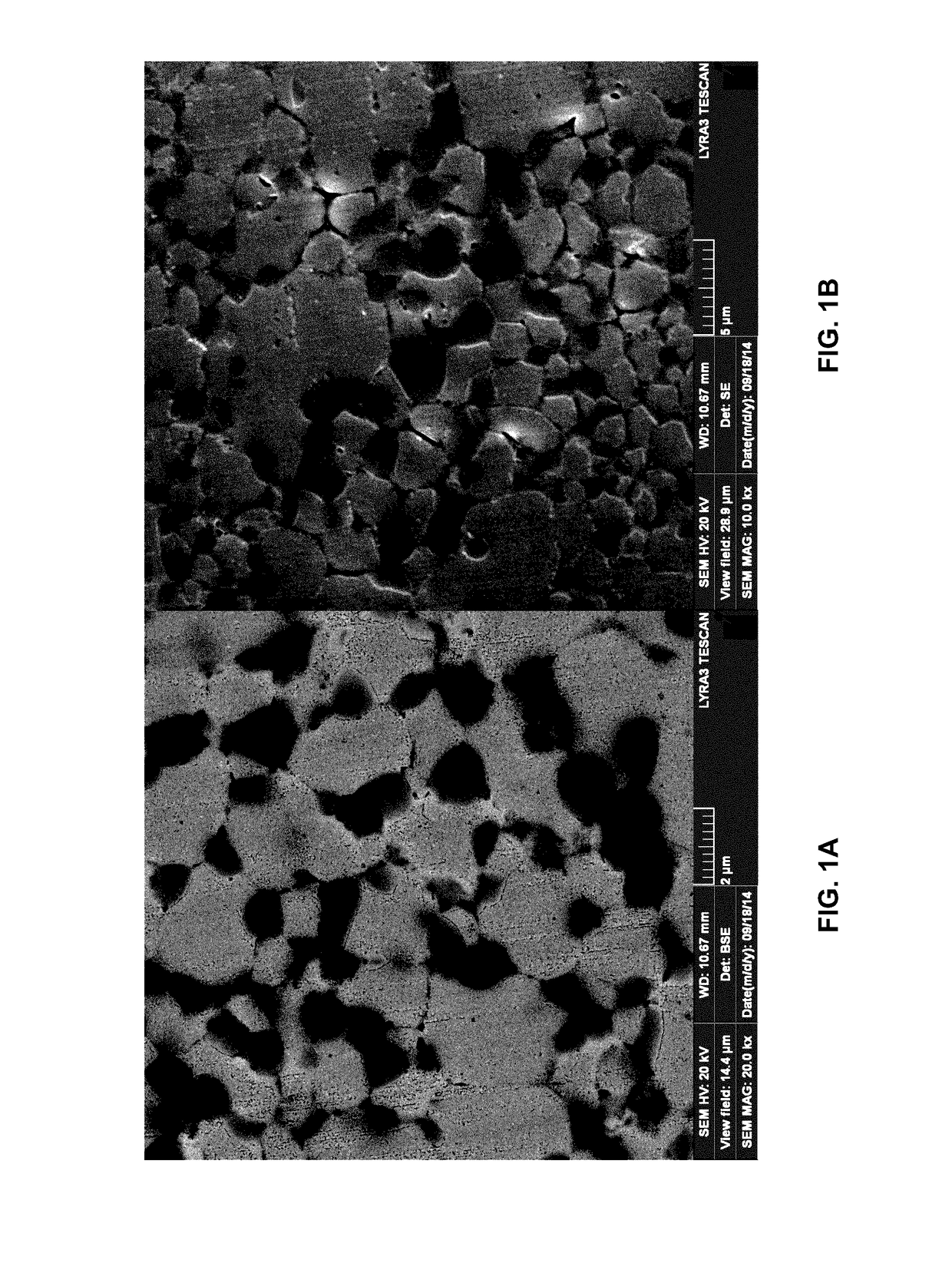

Preparation method of oxygen-containing titanium-based alloy through powder metallurgy

The invention provides a preparation method of an oxygen-containing titanium-based alloy through powder metallurgy, which belongs to the technical field of the preparation of powder metallurgy structured materials. Through the adoption of pure titanium powder or titanium alloy powder, an oxygen-containing titanium alloy with a high temperature is prepared by using a high-performance solid-state surface oxygen impregnating-activated sintering method. The preparation process is implemented as follows: 1) carrying out solid-state surface oxygen impregnating on pure titanium powder or titanium alloy powder at high temperature in an oxygen environment, and then cooling the obtained powder; and 2) sintering the powder subjected to high-temperature oxygen impregnating into blocks by way of activated sintering in a hot-pressing sintering furnace or a plasma sintering furnace. According to the invention, through a reasonable microstructure design, and by fully using the reinforcement action of cheap oxygen and reducing the damage thereof on plasticity, an oxygen-containing titanium-based alloy with simple compositions and a low price is prepared, so that resources can be reduced, and the cost can be reduced. The preparation method disclosed by the invention is simple in process, and can be suitable for industrial production.

Owner:CENT SOUTH UNIV

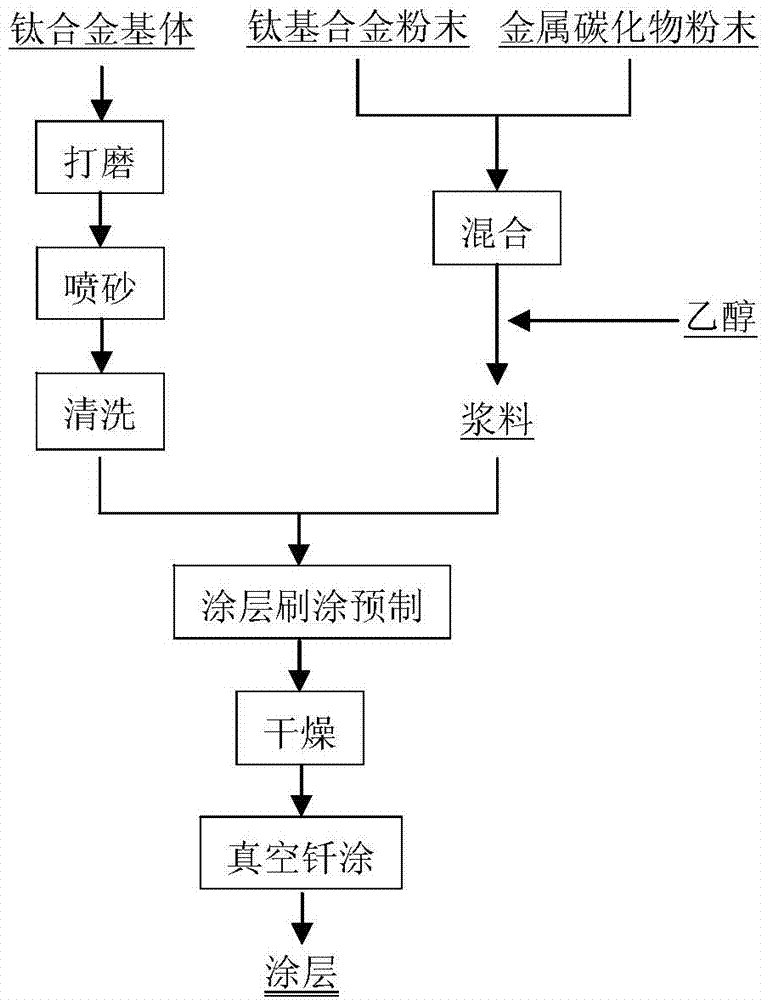

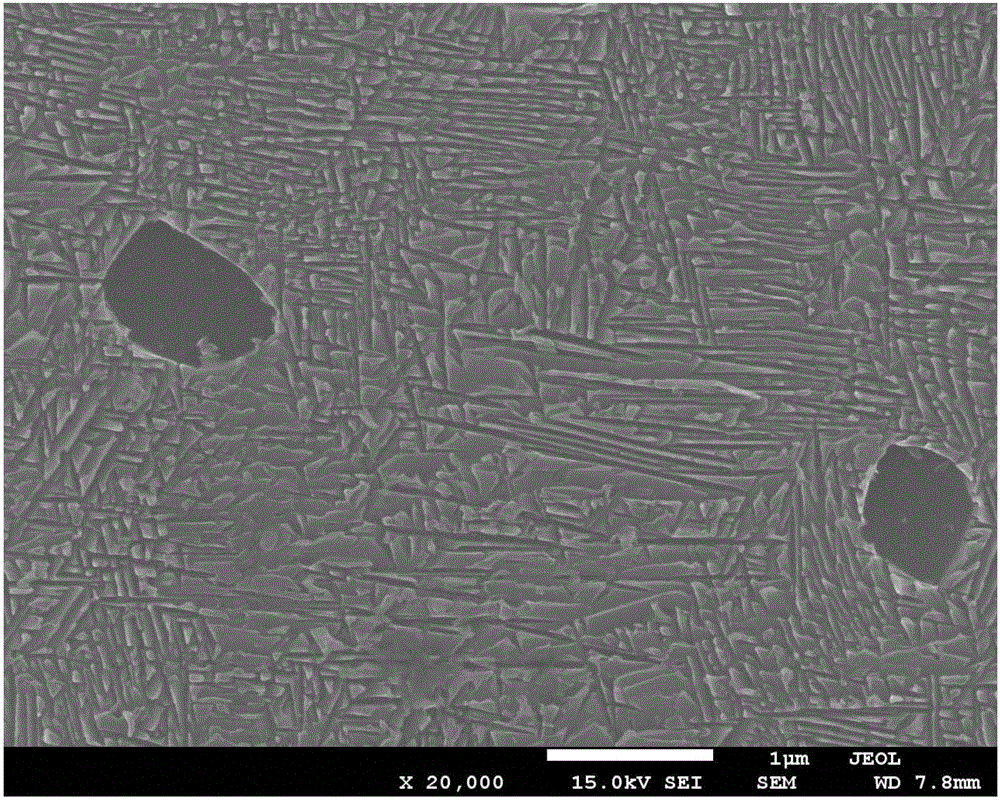

Method for brazing metal ceramic composite coating on titanium alloy surface in vacuum

The invention relates to a method for brazing a metal ceramic composite coating on a titanium alloy surface in vacuum, belonging to the field of material engineering. The method uses titanium alloy, metal carbide powder and titanium-base alloy powder as raw material. The method comprises the following steps: carrying out base pretreatment to remove oxidation films and oil stains on the base surface and increase the surface roughness of the base; powder mixing and brushing: uniformly mixing the powder raw materials proportionally (the volume percent of metal carbide is 10-60%) to obtain a slurry, and brushing the slurry on the titanium alloy base; and vacuum brazing: putting a test sample into a vacuum furnace, vacuumizing, heating and cooling. The metal ceramic composite coating, which has certain hardness and thickness and is metallurgically bonded with the base, is obtained on the titanium alloy surface, thereby implementing surface modification of the titanium alloy. The method has the advantages of simple technique, stable production process, environment friendliness and low cost, can easily implement industrialization, and has obvious economic, environmental and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

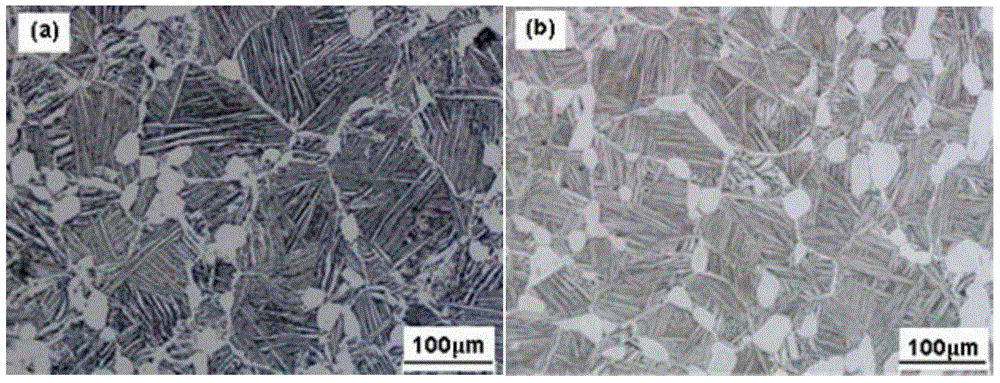

Repeated solid solution aging thermal treatment process of titanium alloy

The invention relates to a repeated solid solution aging thermal treatment process of titanium alloy. The process includes the steps that a titanium alloy forge is subjected to heat preservation at the temperature T for t minutes, wherein T is larger than or equal to Tbeta-15 DEG C but smaller than or equal to Tbeta+15 DEG C, t is equal to eta*delta max, delta max is the maximum section thickness of the forge and is shown in millimeters, and eta is the heating coefficient and ranges from 0.2 min / mm to 0.8 min / mm; then the forge is discharged out of a furnace to be air-cooled or wind-cooled or water-cooled to be at the room temperature, then the cooled forge is subjected to heat preservation at the temperature of T for t minutes, wherein T is larger than or equal to Tbeta-25 DEG C but smaller than or equal to Tbeta-50 DEG C, the computational formula of t is as above, namely t=eta*delta max, and the heating coefficient eta ranges from 0.3 min / mm to 1.2 min / mm; then the forge is discharged out of the furnace to be air-cooled or wind-cooled or water-cooled to be at the room temperature, the cooled forge is subjected to heat preservation at the temperature T ranging from 540 DEG C to 600 DEG C, and the heat preservation time t ranges from 0.5 hour to 2 hours; the forge is discharged out of the furnace to be air-cooled to be at the room temperature, the cooled forge is subjected to heat preservation at the temperature T ranging from 400 DEG C to 540 DEG C, and the heat preservation time t ranges from 4 hour to 24 hours; and then the forge is discharged out of the furnace to be air-cooled to be at the room temperature. The repeated solid solution aging thermal treatment process of the titanium alloy is suitable for thermal treatment of near-beta type, metastable beta type and steady beta type ultrahigh-toughness titanium alloy so as to obtain required microscopic structures with high overall performance and multi-scale precipitated phases mixed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

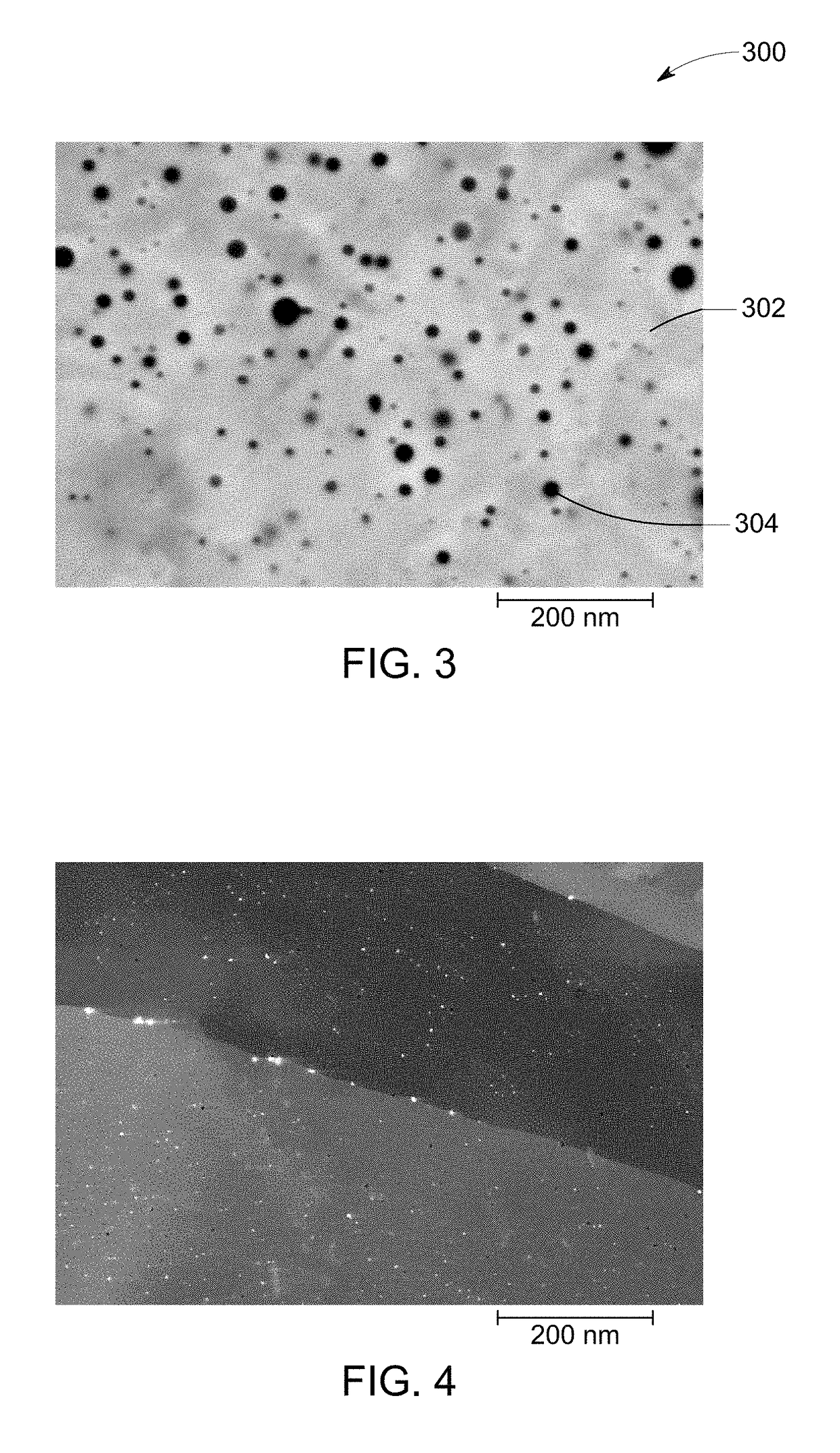

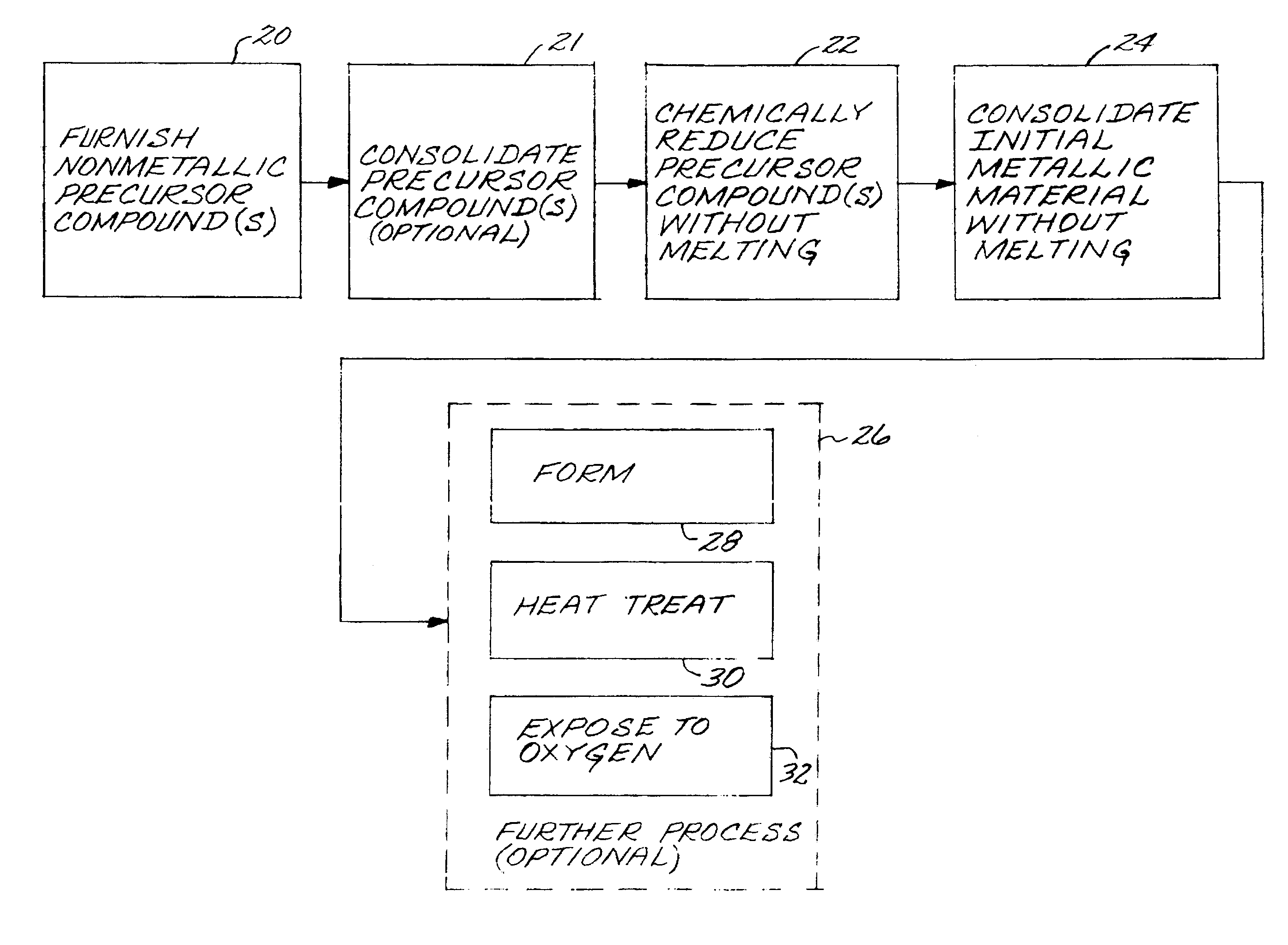

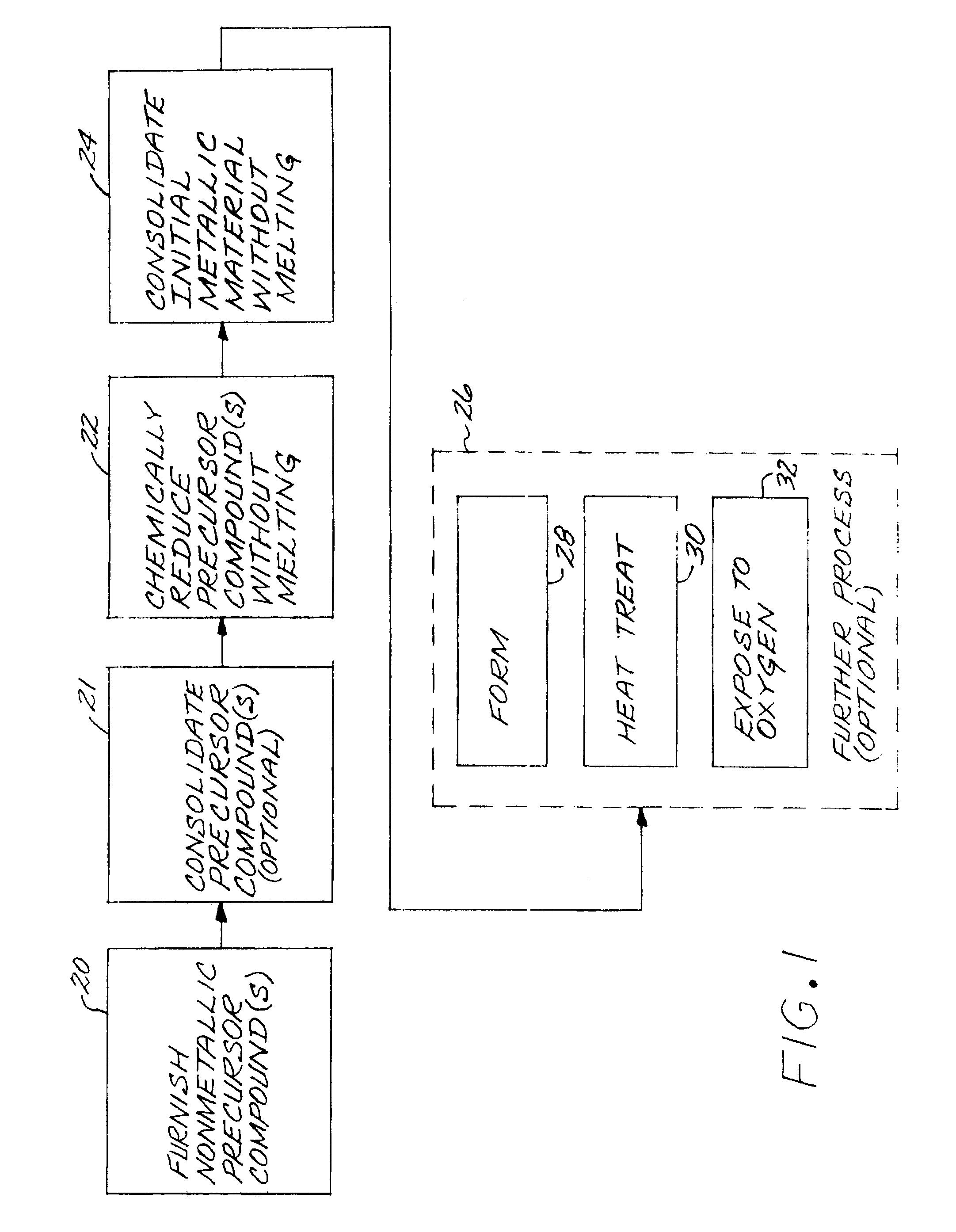

Method for producing a titanium-base alloy having an oxide dispersion therein

A metallic article is prepared by first furnishing at least one nonmetallic precursor compound, wherein all of the nonmetallic precursor compounds collectively containing the constituent elements of the metallic article in their respective constituent-element proportions. The constituent elements together form a titanium-base alloy having a stable-oxide-forming additive element therein, such as magnesium, calcium, scandium, yttrium, lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium, and mixtures thereof. The stable-oxide-forming additive element forms a stable oxide in a titanium-based alloy. At least one additive element is present at a level greater than its room-temperature solid solubility limit in the titanium-base alloy. The precursor compounds are chemically reduced to produce an alloy material, without melting the alloy material. The alloy material may be consolidated. The alloy material, or consolidated metallic article, is thereafter desirably exposed to an oxygen-containing environment at a temperature greater than room temperature.

Owner:GENERAL ELECTRIC CO

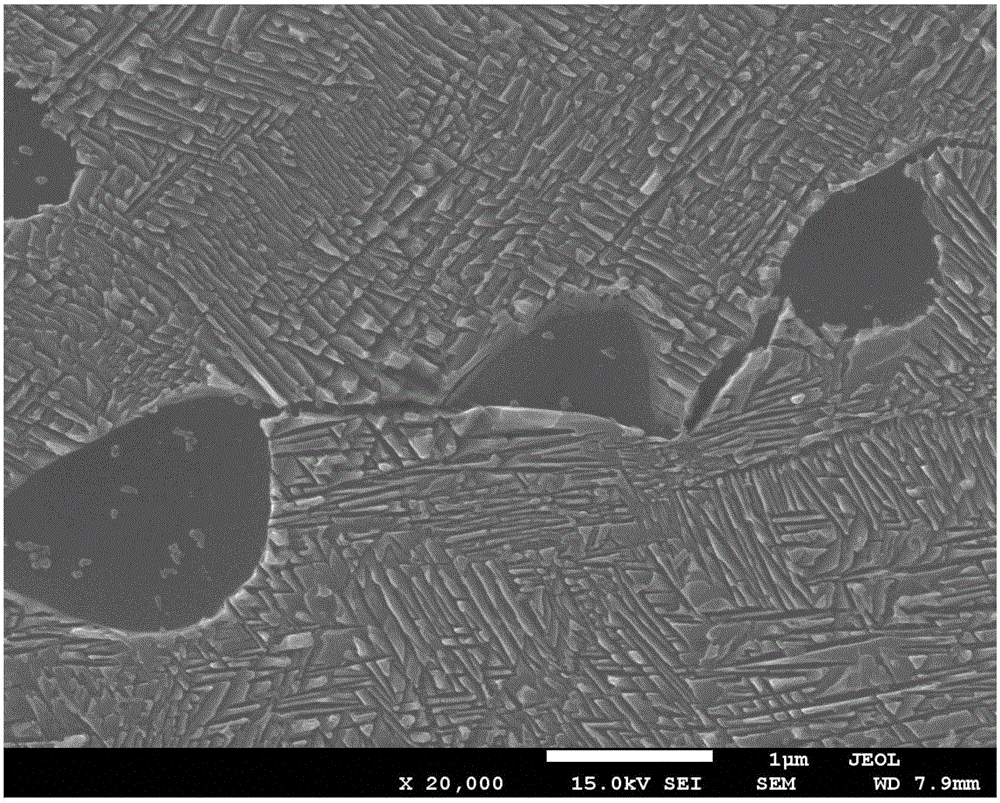

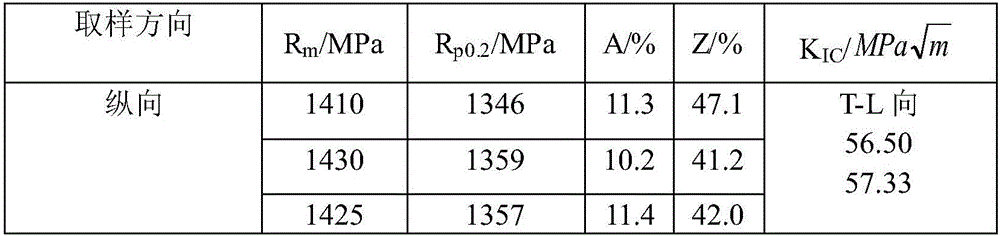

Preparation method of high-temperature, high-thermal stability and high-fracture toughness titanium alloy bar material

The invention belongs to the field of titanium-based alloys, and specifically relates to a preparation method of a high-temperature titanium alloy bar material, wherein the preparation method includesthe steps: heating a prepared TC25G titanium alloy ingot to 1100 DEG C-1200 DEG C, and then cogging and forging in a beta phase region by a fast forging machine or a hydraulic press; heating to 1030DEG C-1100 DEG C, repeatedly carrying out upsetting and drawing-out forging by the fast forging machine or the hydraulic press, then heating the forged blank to T[beta]-110 DEG C-T[beta]-20 DEG C (T[beta] is a [alpha]+[beta] / [beta] phase transition temperature of an TC25G titanium alloy), and repeatedly carrying out upsetting and drawing-out forging by the fast forging machine or the hydraulic press; and finally, heating the forged blank after forging to T[beta]-110 DEG C-T[beta]-30 DEG C, and drawing out to the required size by the fast forging machine or the hydraulic press, to obtain the titanium alloy bar material with a low-power structure of blurred crystals and a uniform high-power structure. The prepared TC25G titanium alloy bar material has high tensile strength of the bar material at room temperature and high temperature, good thermal stability and high fracture toughness after double heat treatment. The preparation method has the advantages of convenient operation and strongprocess controllability, and the prepared TC25G titanium alloy bar material has good batch stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +2

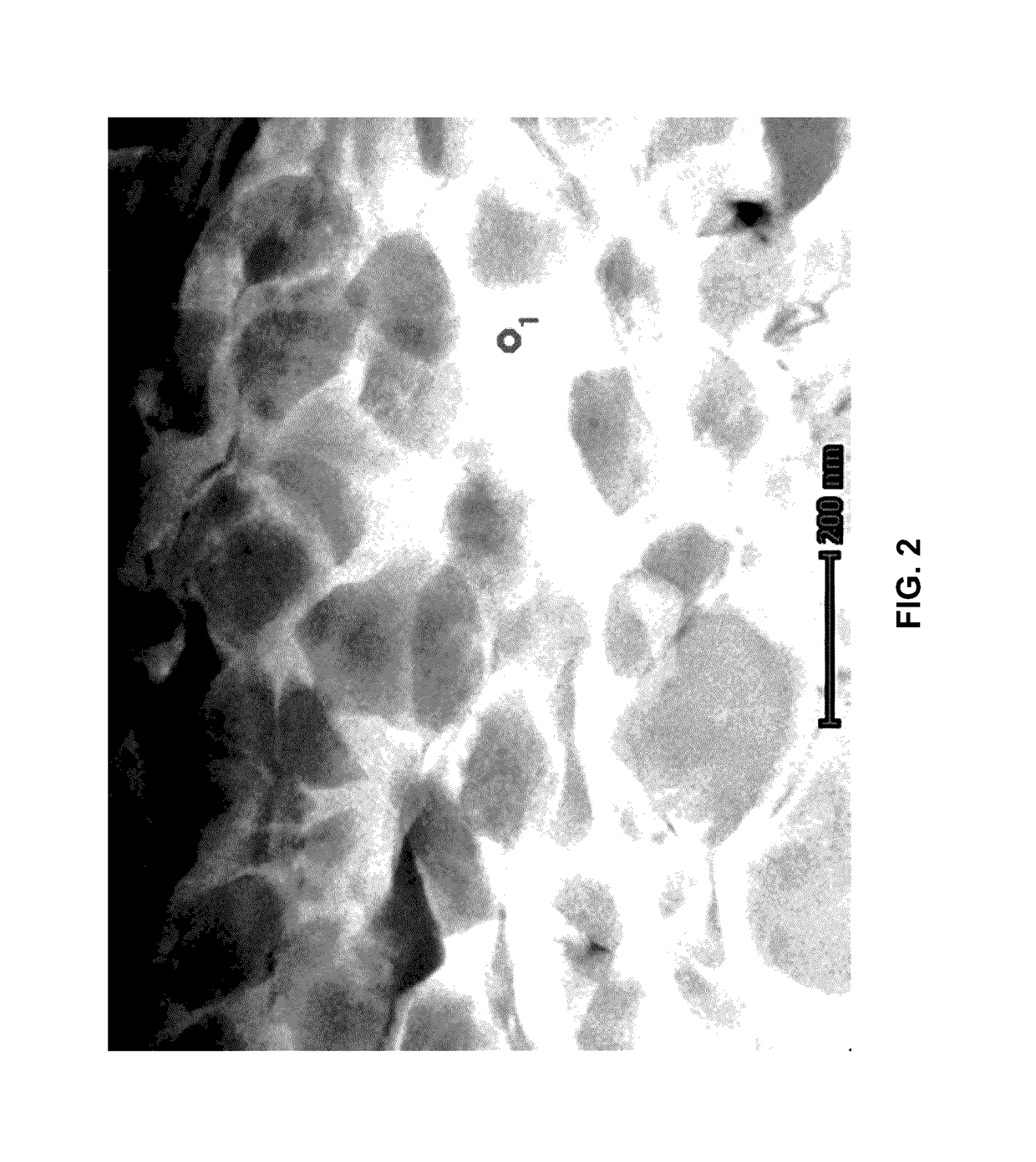

Titanium alloys for biomedical applications and fabrication methods thereof

Alloys of titanium with 20-22 at. % niobium and 12-13 at. % zirconium. The alloys are prepared by mechanical alloying of elemental powders and densification by spark plasma sintering. The alloys have a nano-scaled, equiaxed granular structure, a microhardness of at least 650 HV and a modulus of 90-140 GPa. The inventive alloy is corrosion resistant, biocompatible, and is of a higher wear resistance and durability compared to the Ti-6Al-4V alloy. The bioactive surface of the inventive nanostructured alloy promotes a higher protein adsorption that stimulates new bone formation than other titanium-based alloys. These alloys are suitable for various biomedical and dental applications.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Electromagnetic induction vacuum device for titanium-based alloy smelting and mix-melting

Owner:XIAN AOBANG TECH

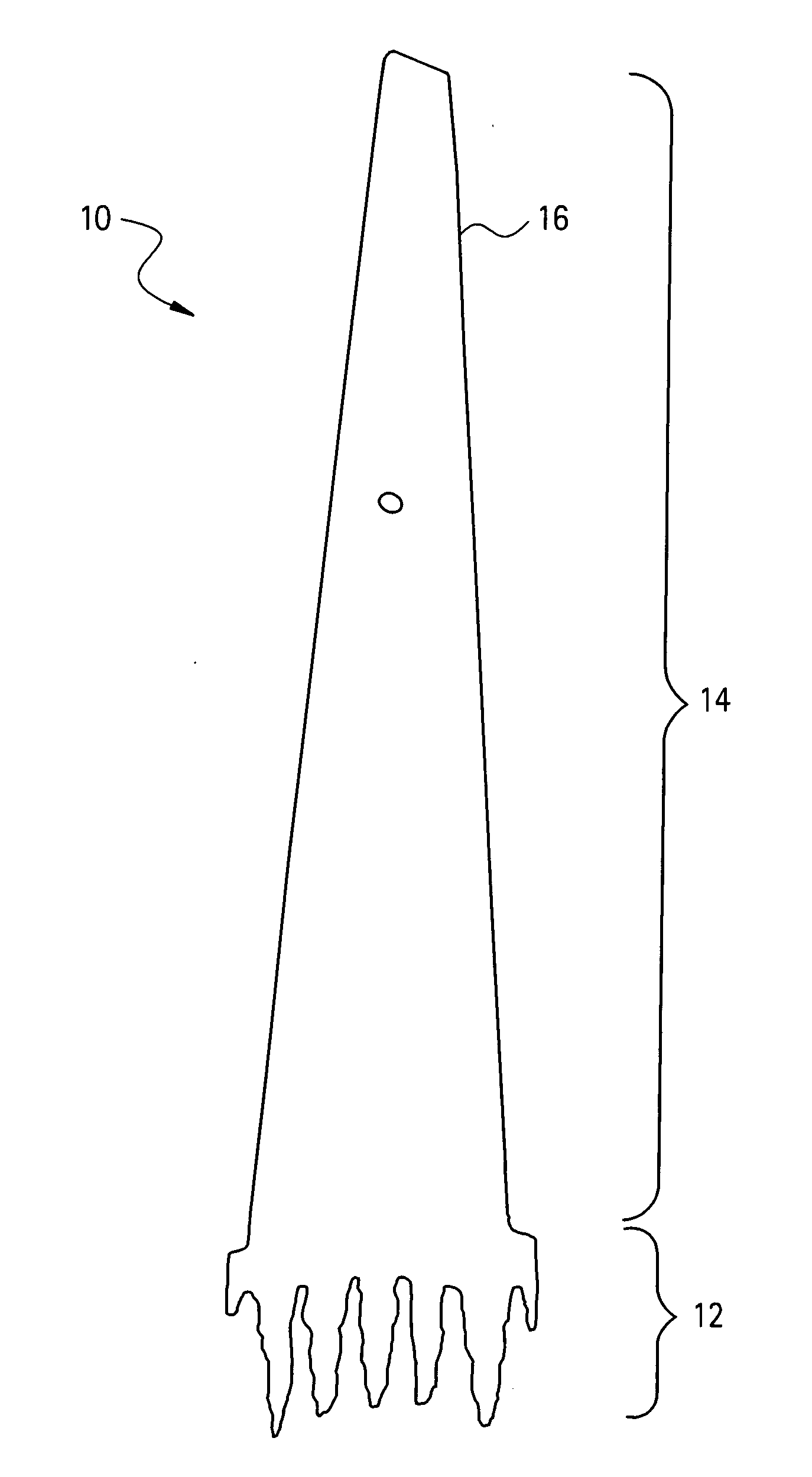

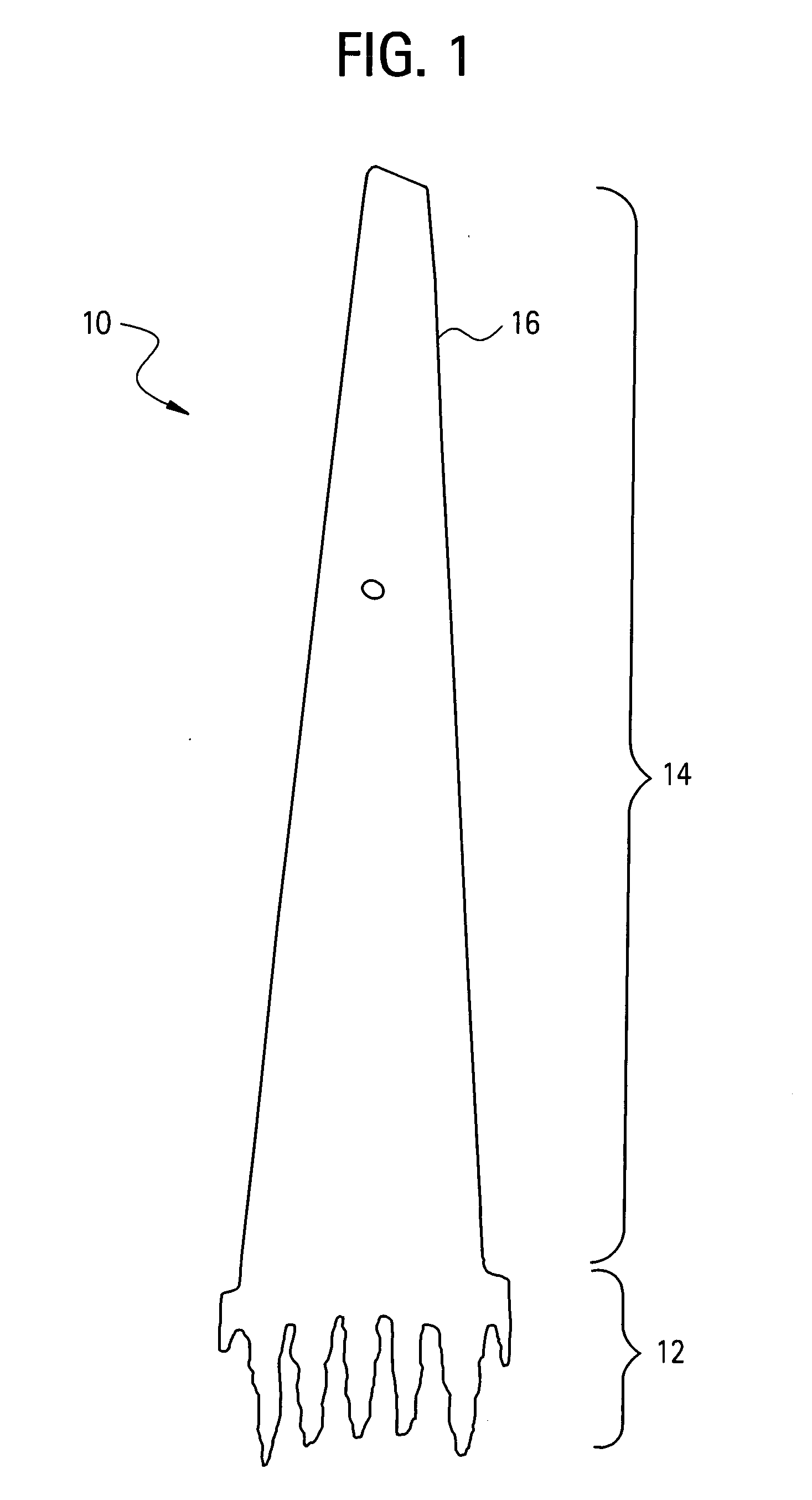

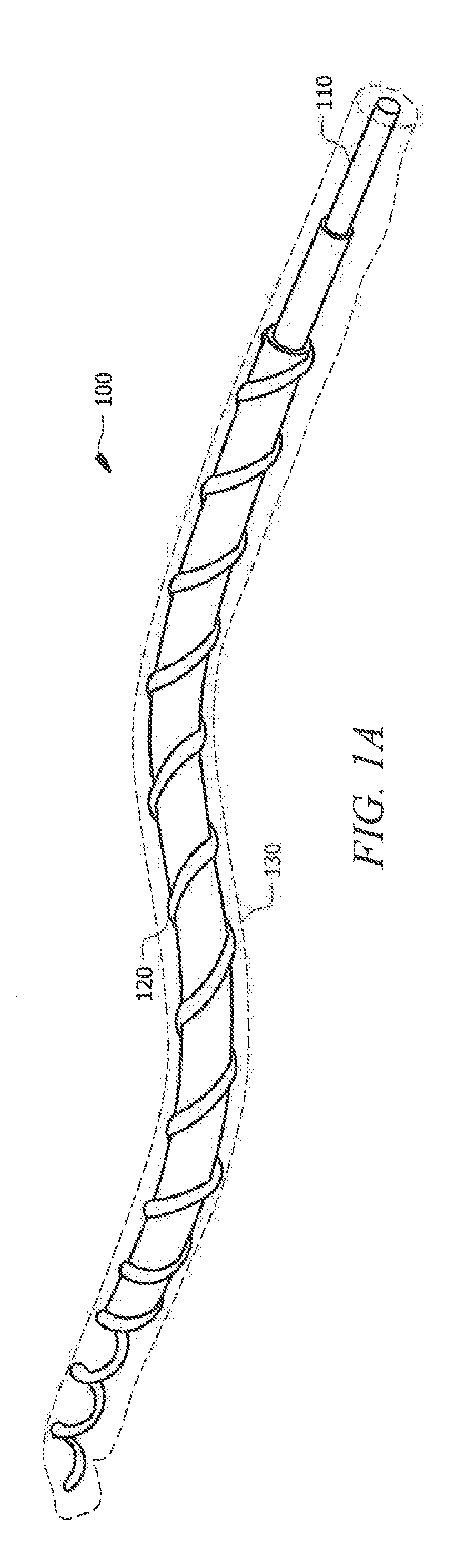

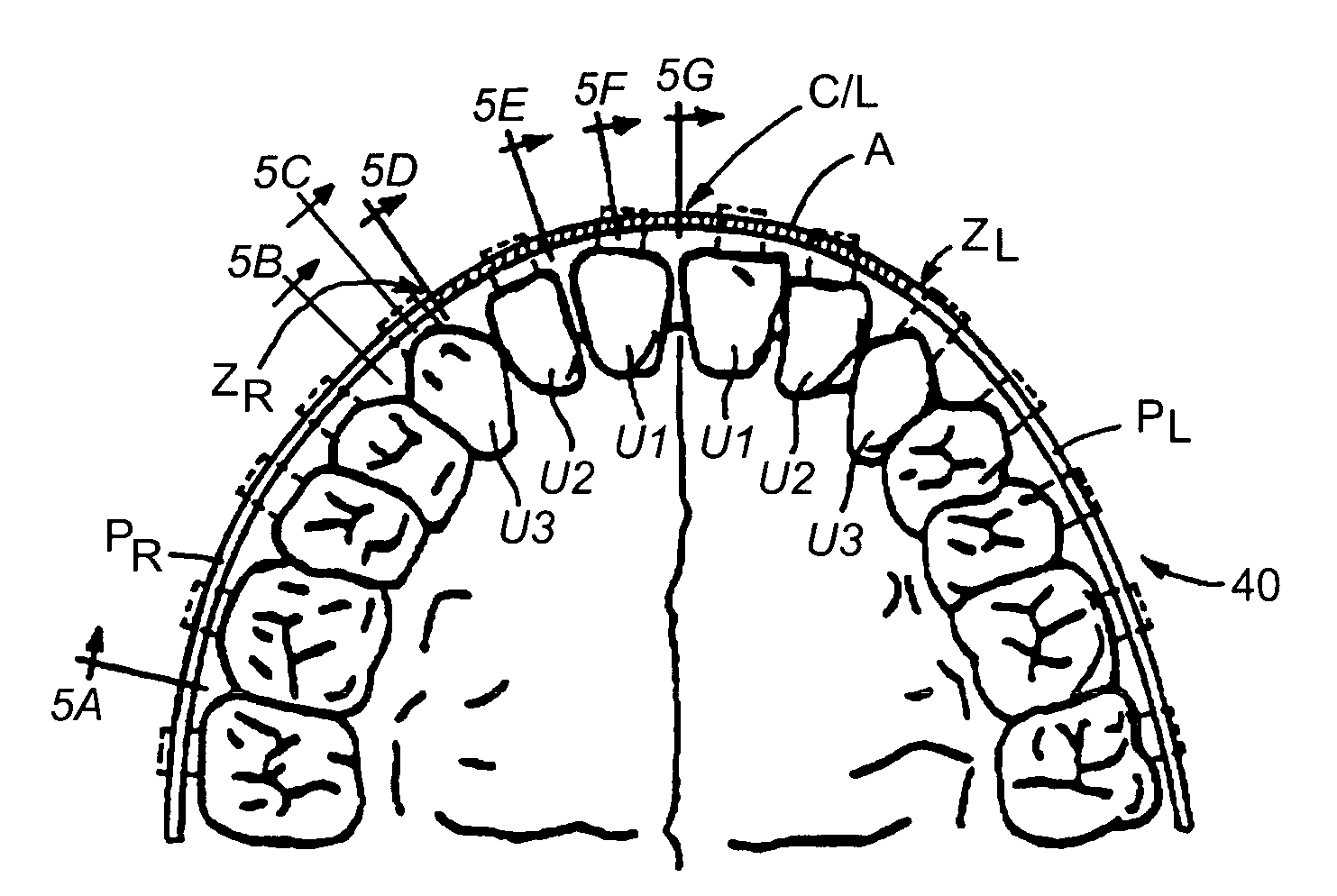

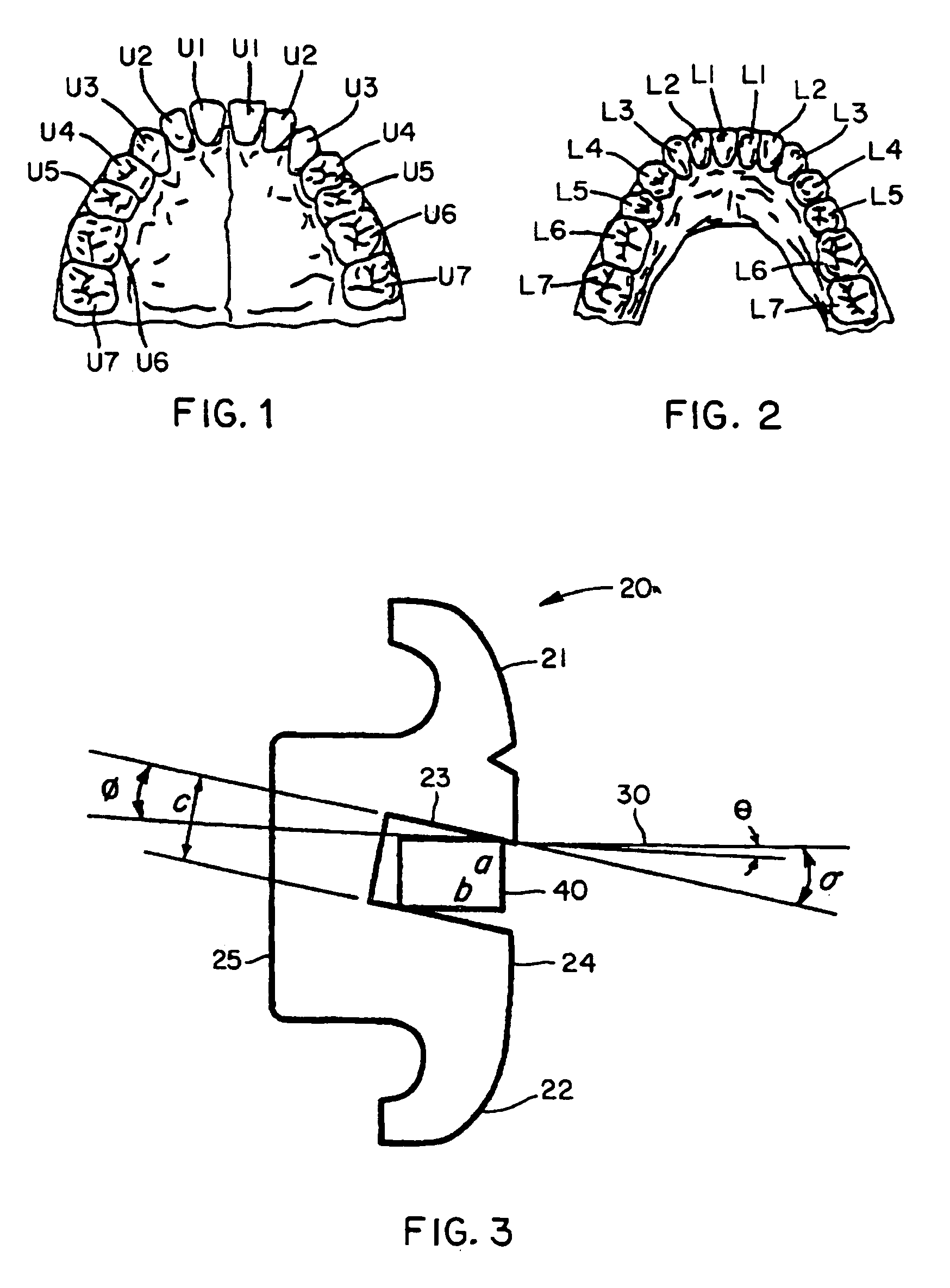

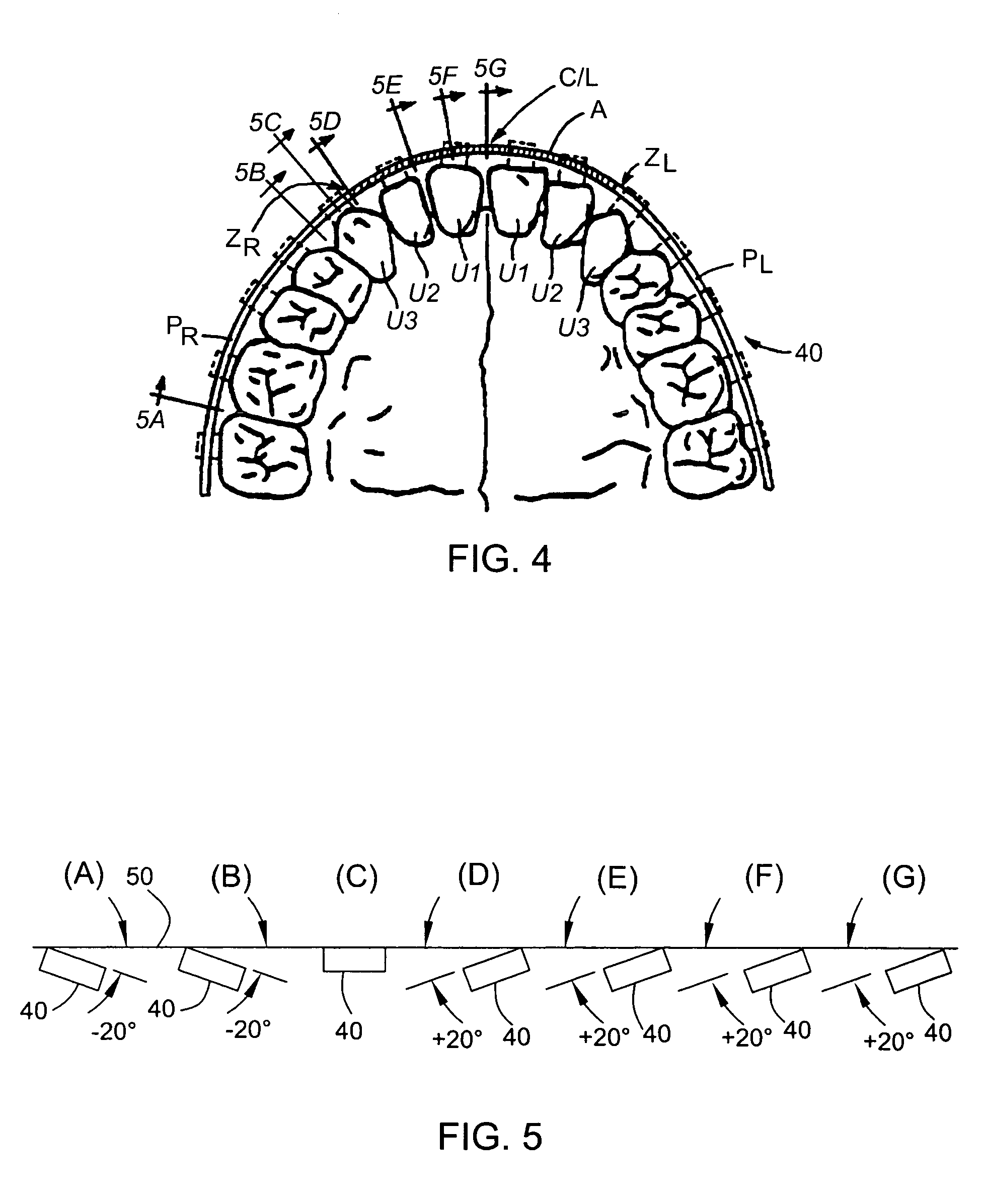

Torqued titanium-based archwire

A torqued archwire for use in an edgewise orthodontic bracket system. The archwire is substantially rectangular in cross-section, is made of titanium-based alloy and has a plurality of segments, including an anterior segment which is sized to cooperate with brackets attached to a person's central and lateral teeth. Positive torque is built into this anterior segment, with substantially the same positive torque being used across the entire length of the segment. Extending from the respective ends of the anterior segment are a pair of transition segments, in which the torque built into the archwire is approximately zero. Posterior segments of the archwire, which extend distally from the transition segments, each have a negative built-in torque, with substantially the same negative torque being used across the entire lengths of these segments. For ease of reference by an orthodontist, the “active” anterior segment of the archwire is laser etched or colored with non-toxic ink.

Owner:BROSIUS DAVID J

Method for electrochemical coloring of metallic titanium and titanium-based alloys

The invention relates to a method for electrochemical coloring of metallic titanium and titanium-based alloys. Through electrochemical coloring at normal temperature and under normal pressure, the electrochemical anode on the surface of metallic titanium and a titanium-based alloy can be rapidly oxidized to blue, yellow and other colors, and the corrosion resistance and wear resistance of metallic titanium and titanium-based alloys can be effectively improved. The method provided by the invention has the advantages of low cost, environment friendliness, high efficiency and simple process, is easy for industrial application, and has wide application prospect.

Owner:ANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com