Patents

Literature

65 results about "Sintered titanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

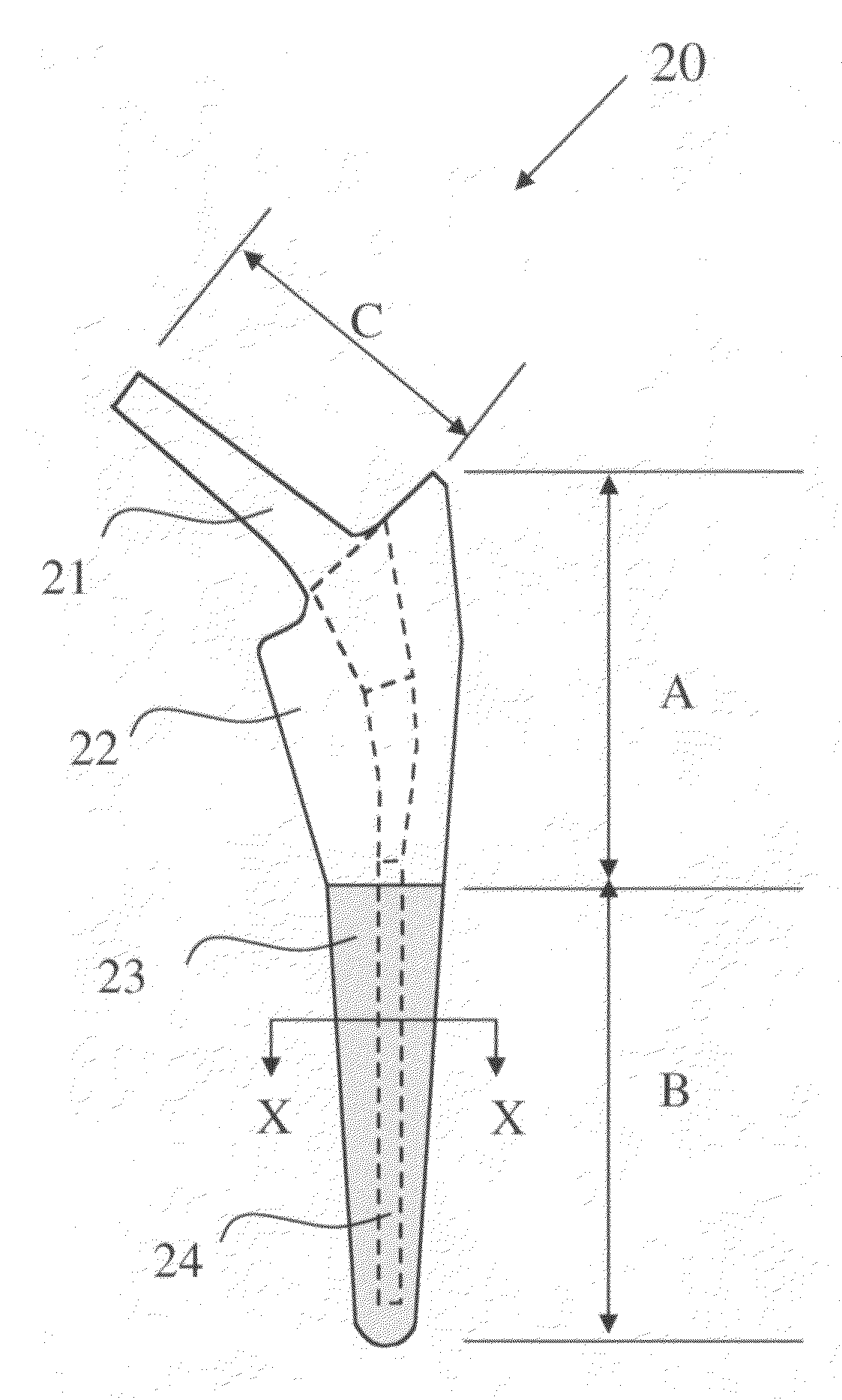

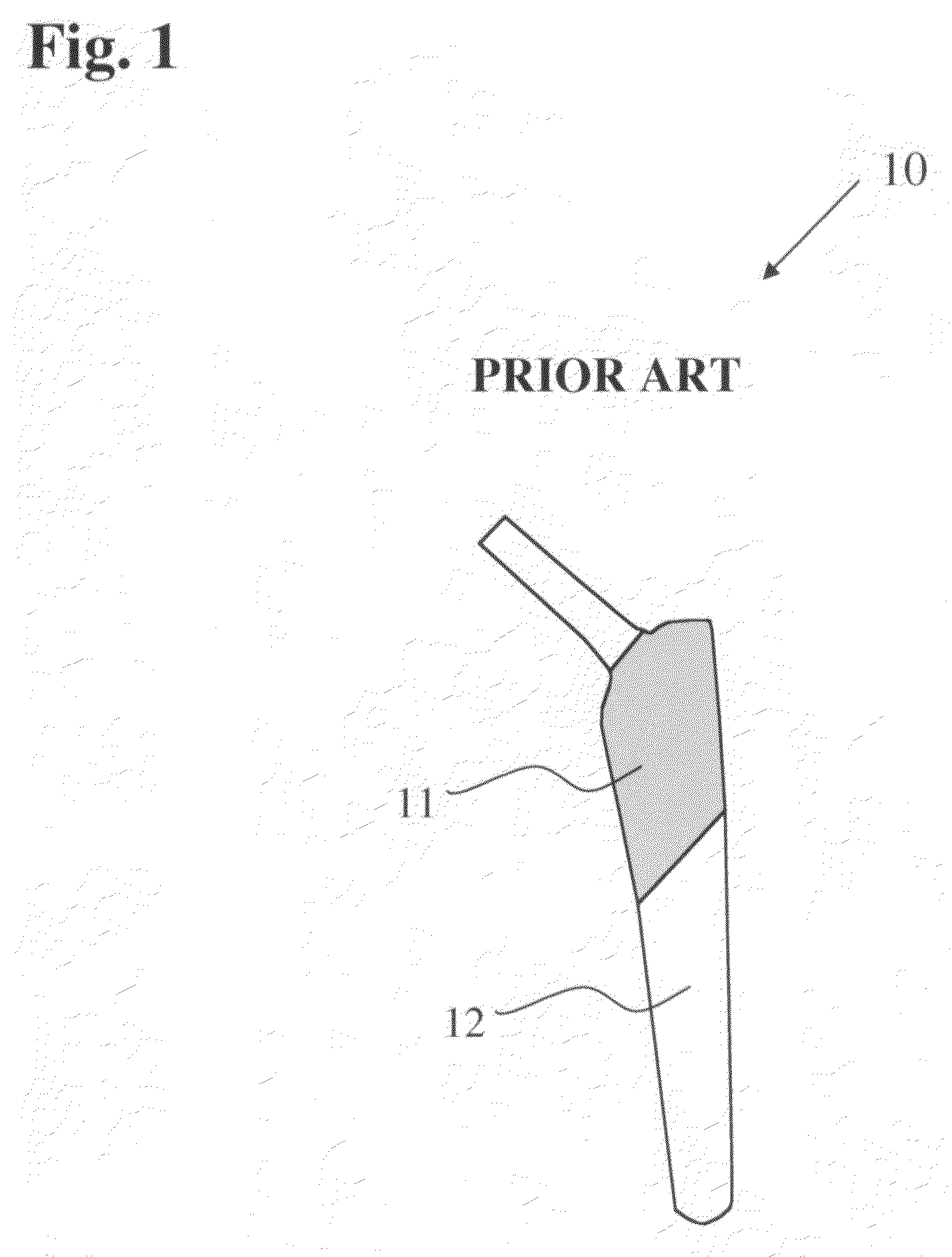

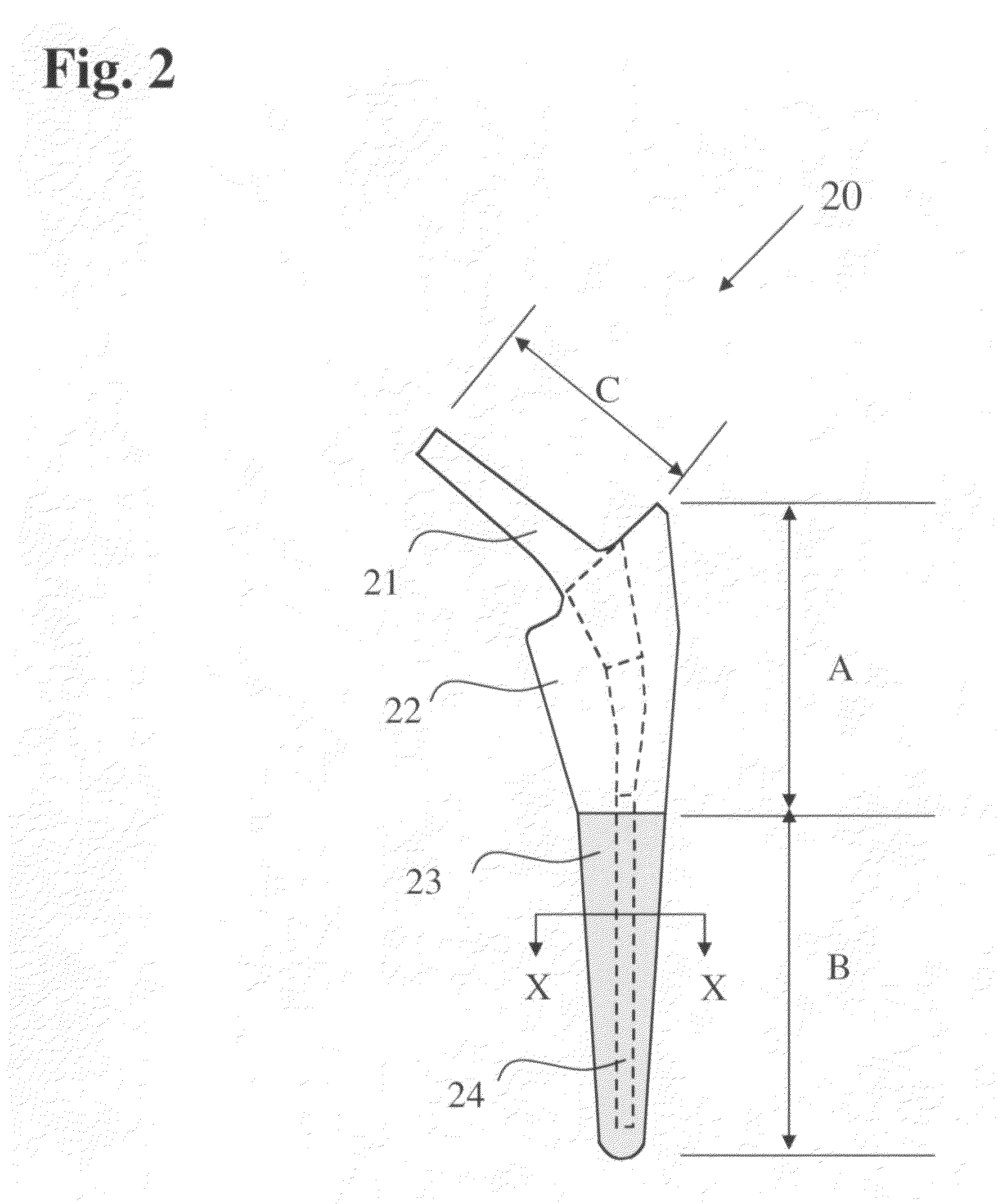

Bone-compliant femoral stem

A femoral stem for canines or humans is made bone-compliant by use of a thick sintered titanium body in a proximal bone contacting region and a polymeric or ceramic body in a distal bone contacting region of the femoral stem. An elastic modulus is thereby engineered to match that of bone tissue. The porous sintered titanium body is created by sintering spheres of titanium. It is bonded to a central solid biocompatible metallic body by diffusion bonding. The distal region has a biocompatible polymeric body or biocompatible cement body. When compression molded the distal region develops an elastic modulus matching that of bone tissue. The proximal region has a porosity designed to encourage bone ingrowth.

Owner:SIDEBOTHAM CHRISTOPHER G

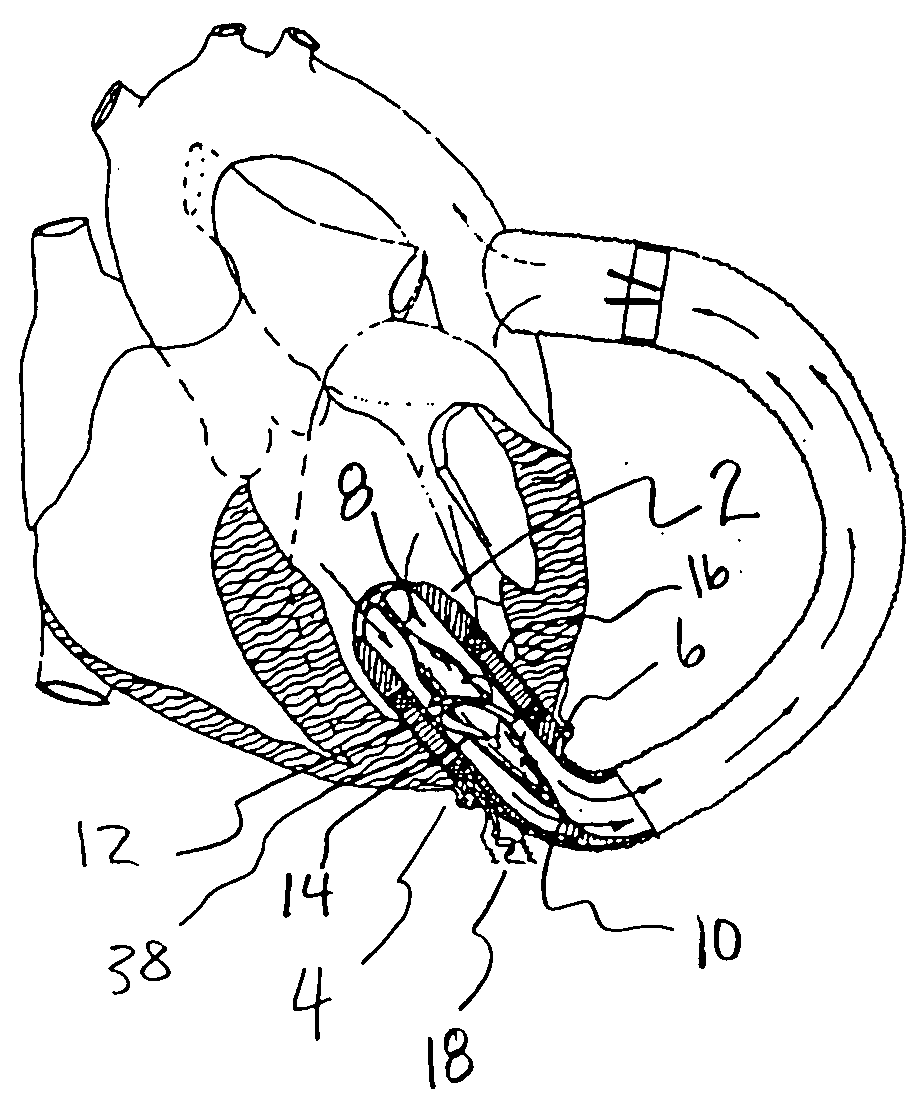

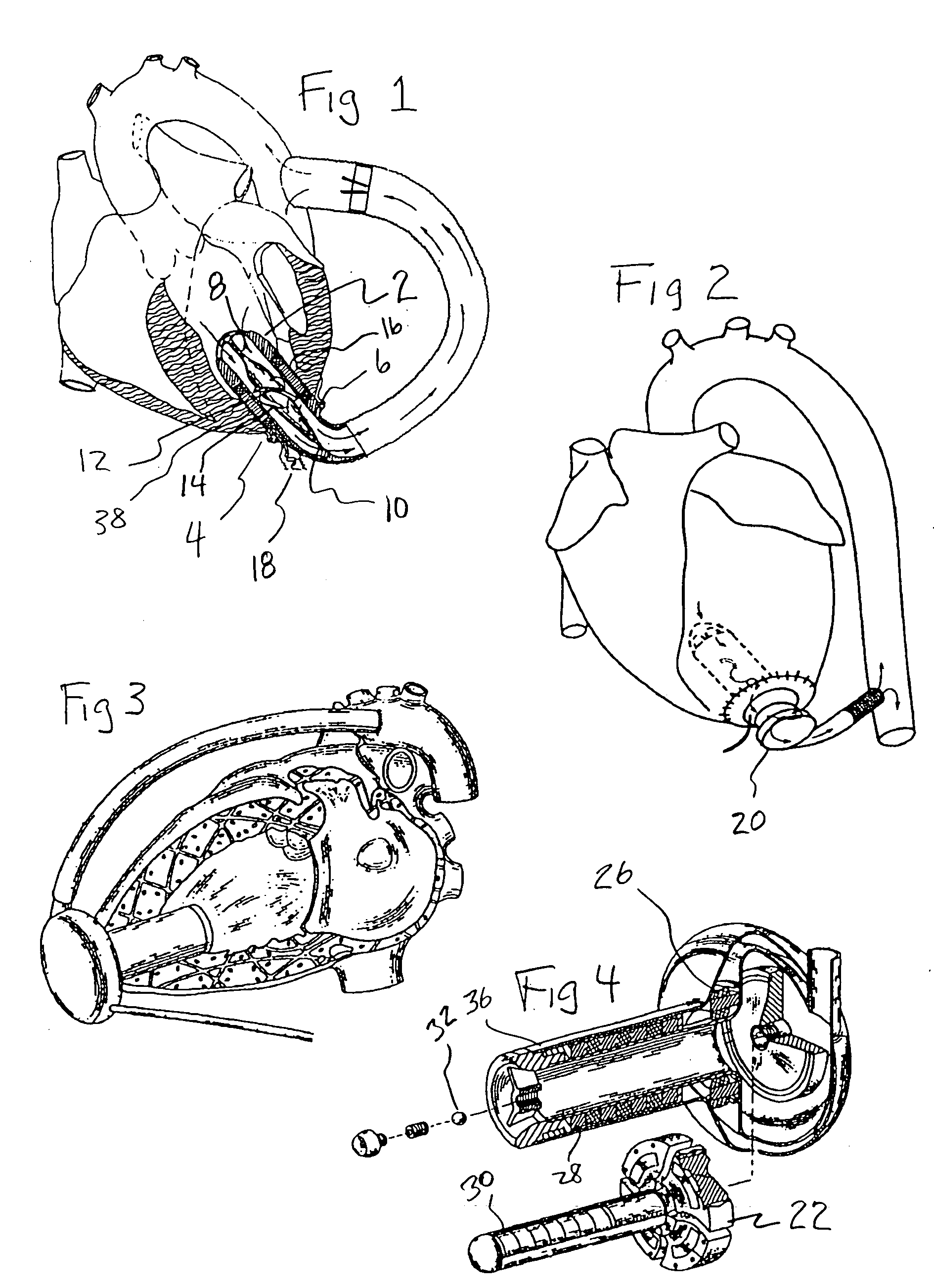

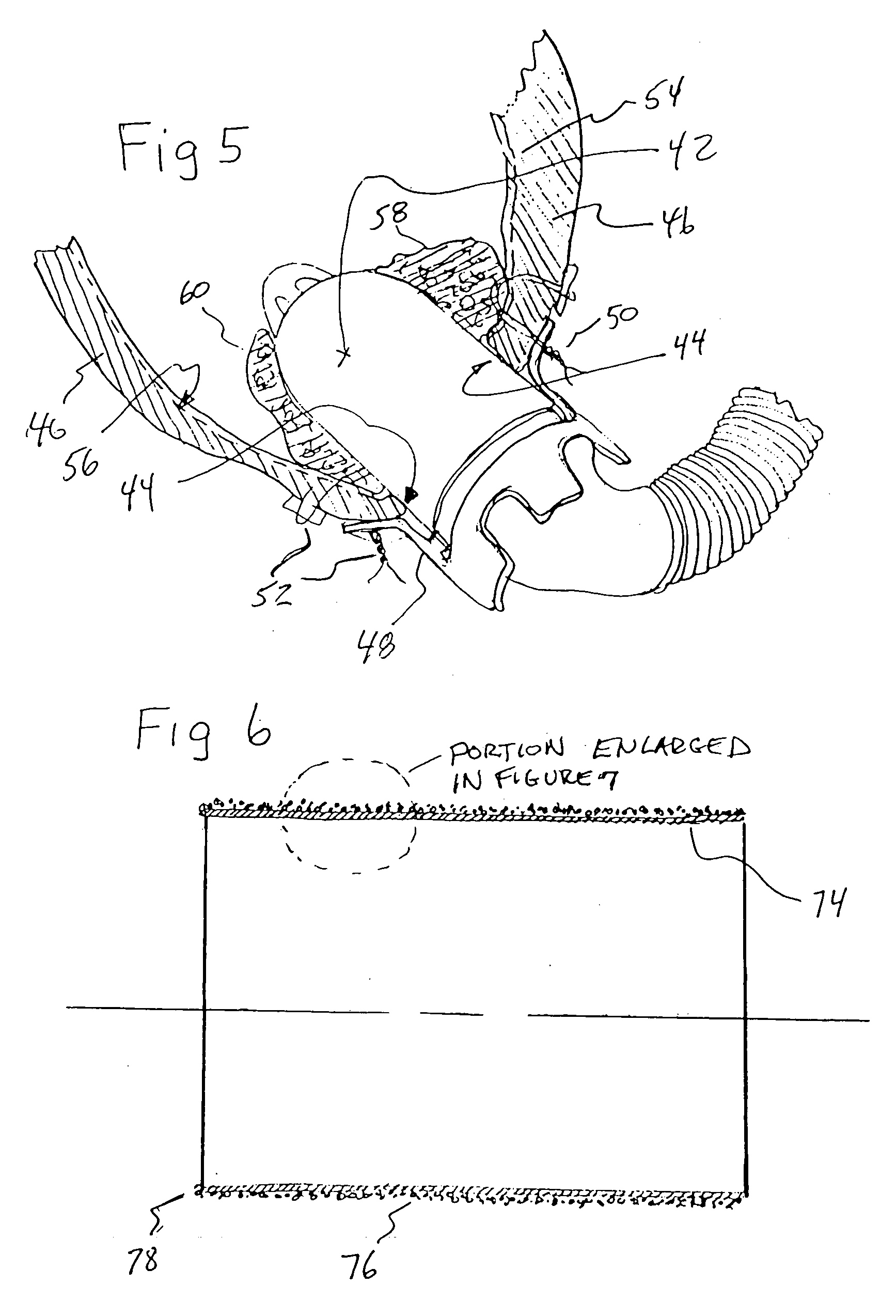

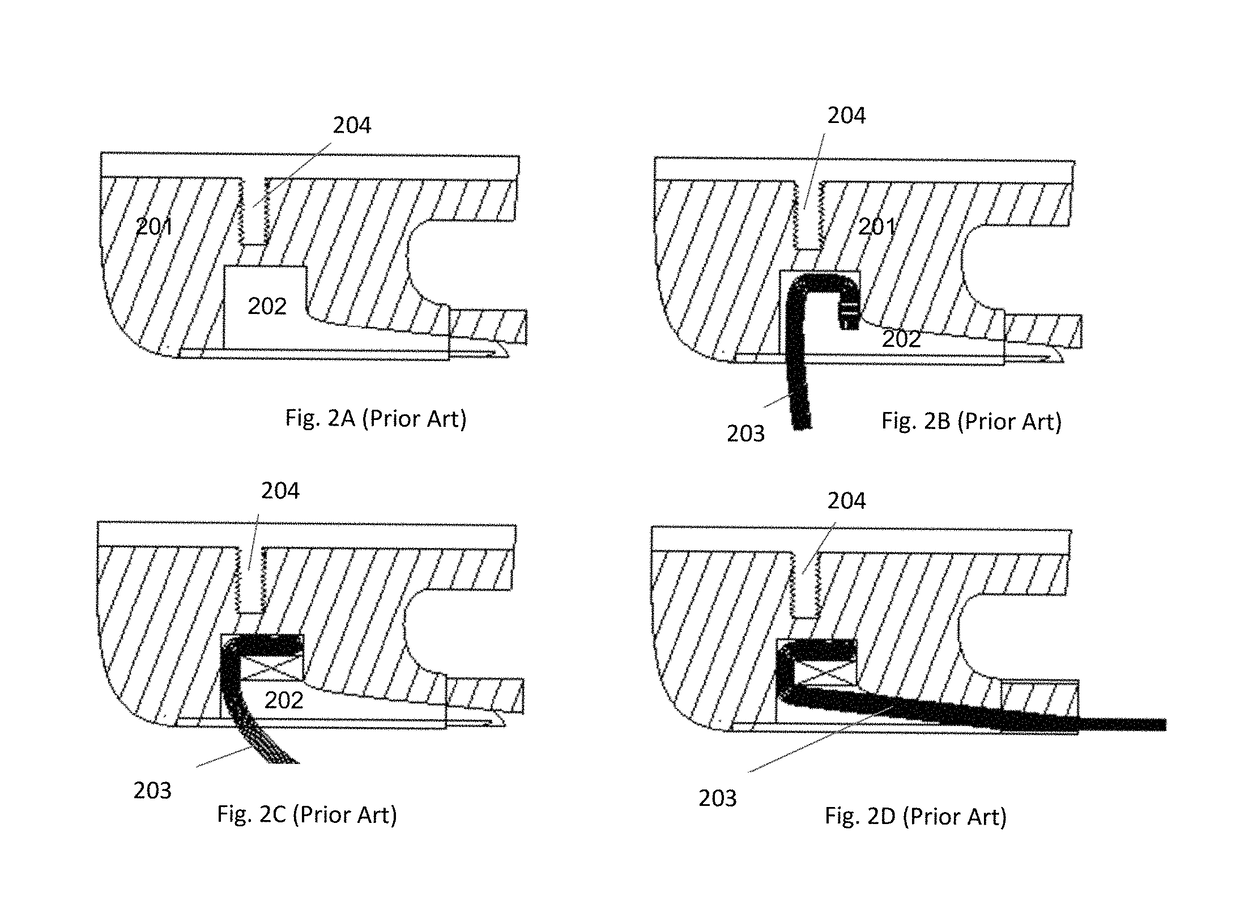

Textured conforming shell for stabilization of the interface of precision heart assist device components to tissues

InactiveUS20070299297A1Quantity minimizationPrevent thrombosisBlood pumpsMedical devicesMicrospherePolymer insulation

The blood contacting surfaces of heart assist devices must avoid excessive thrombus formation, which can break off and cause thromboembolism, become infected and cause other problems. Certain textured surface coatings, such as sintered titanium microsphere coatings, form a thin layer of living cells on the surface that becomes endothelized and is highly resistant to thrombus generation. Some of these coatings require high processing temperatures. Simple thick wall conduit tubes, which do not require high precision, coated with sintered microspheres, have been used successfully as inlet cannulae. Thick wall titanium pump components have also been successfully coated with sintered microspheres, using methods to retain their shape in the furnace and avoid excessive deformation. Blood pumps or portions of blood pumps that utilize high precision components subject to damage or warping if exposed to high temperatures cannot be directly coated. This applies to intraventricular and other blood pumps with precision heat sensitive components, such as polymer insulated wires, placed at least partly within an organ of the cardiovascular vascular system. The present invention provides a thin wall textured surface shell that is coated at high temperature and then, after finish machining, is affixed over the heat sensitive precision blood pump to serve as the interface with biological tissues.

Owner:JARVIK ROBERT

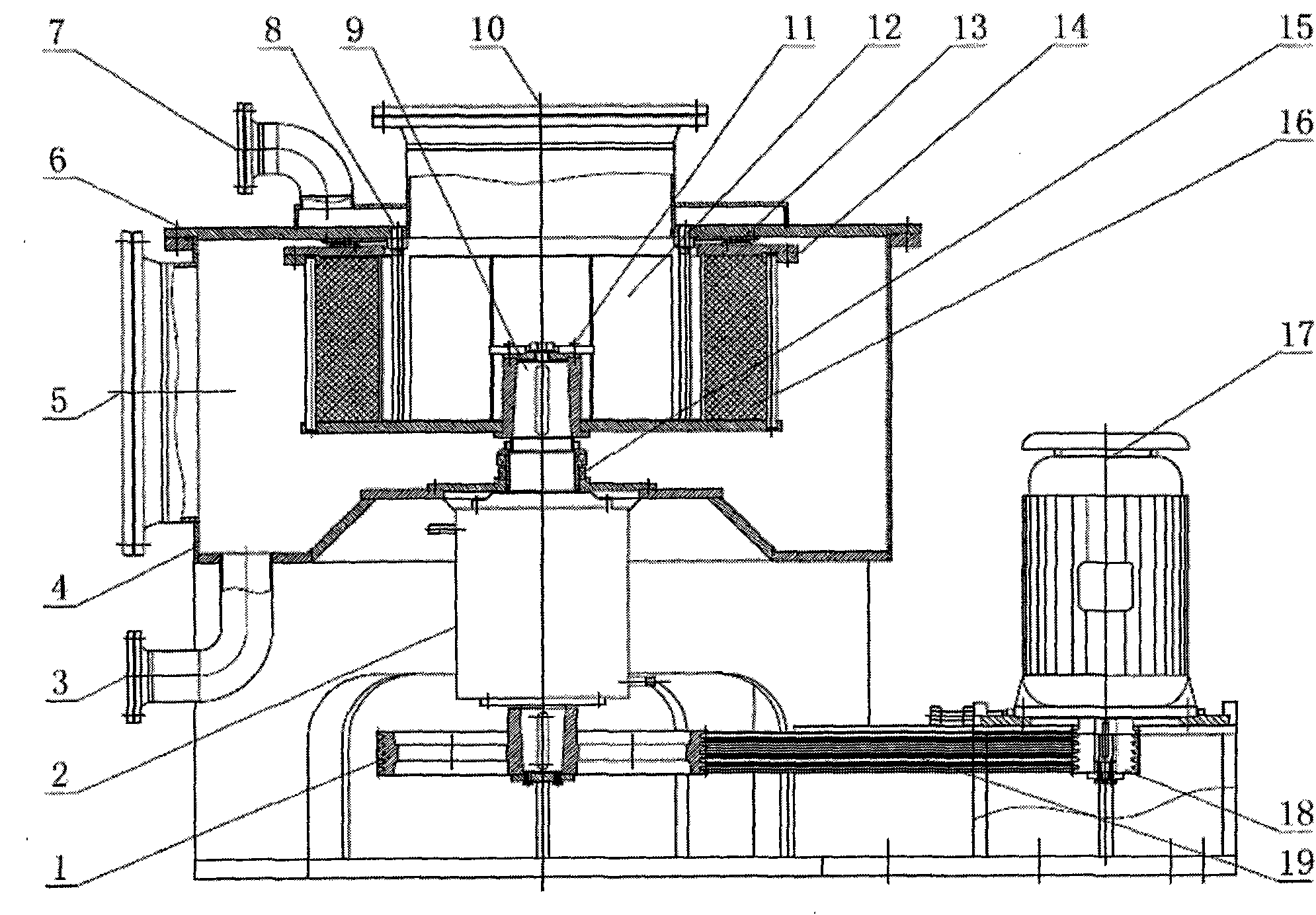

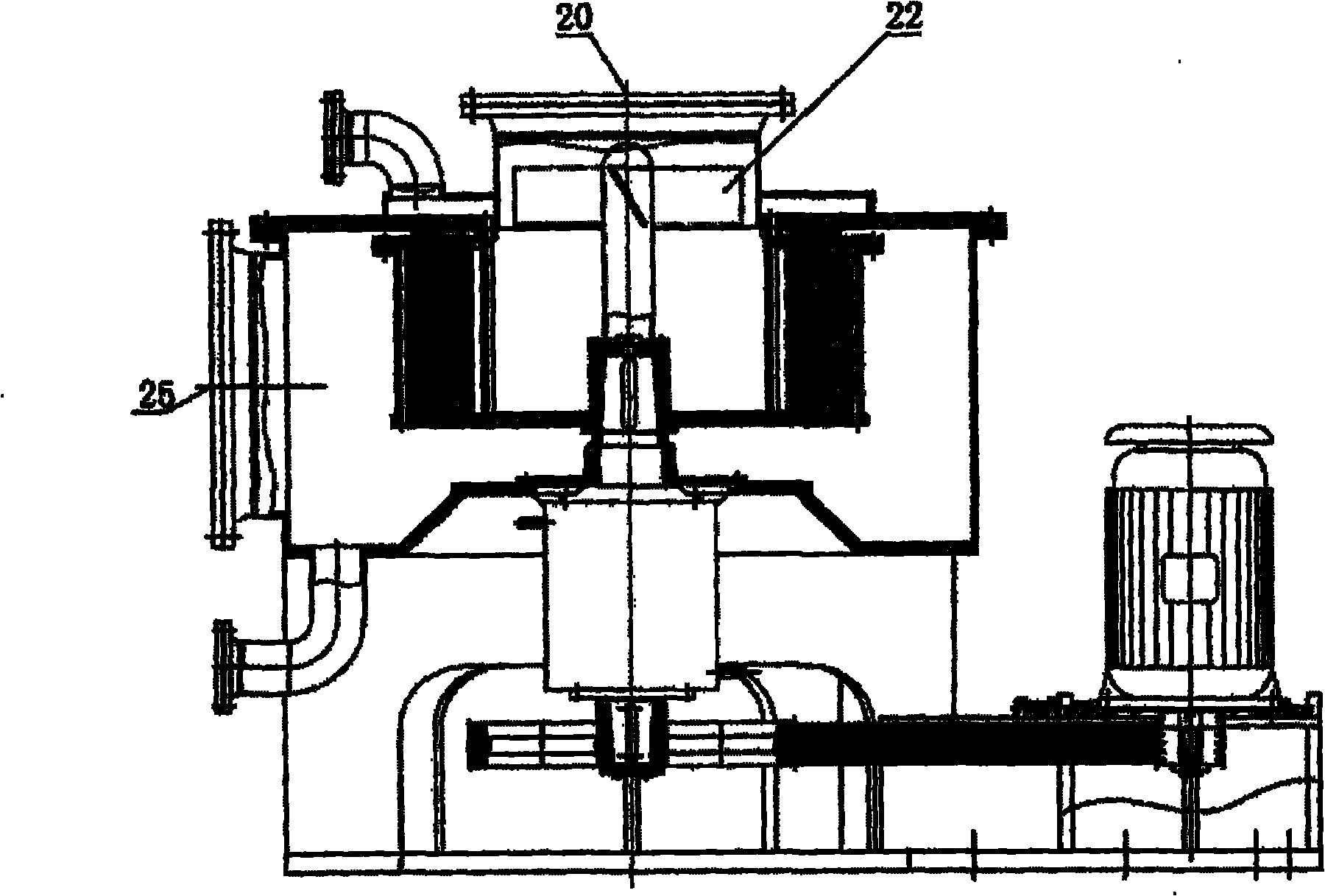

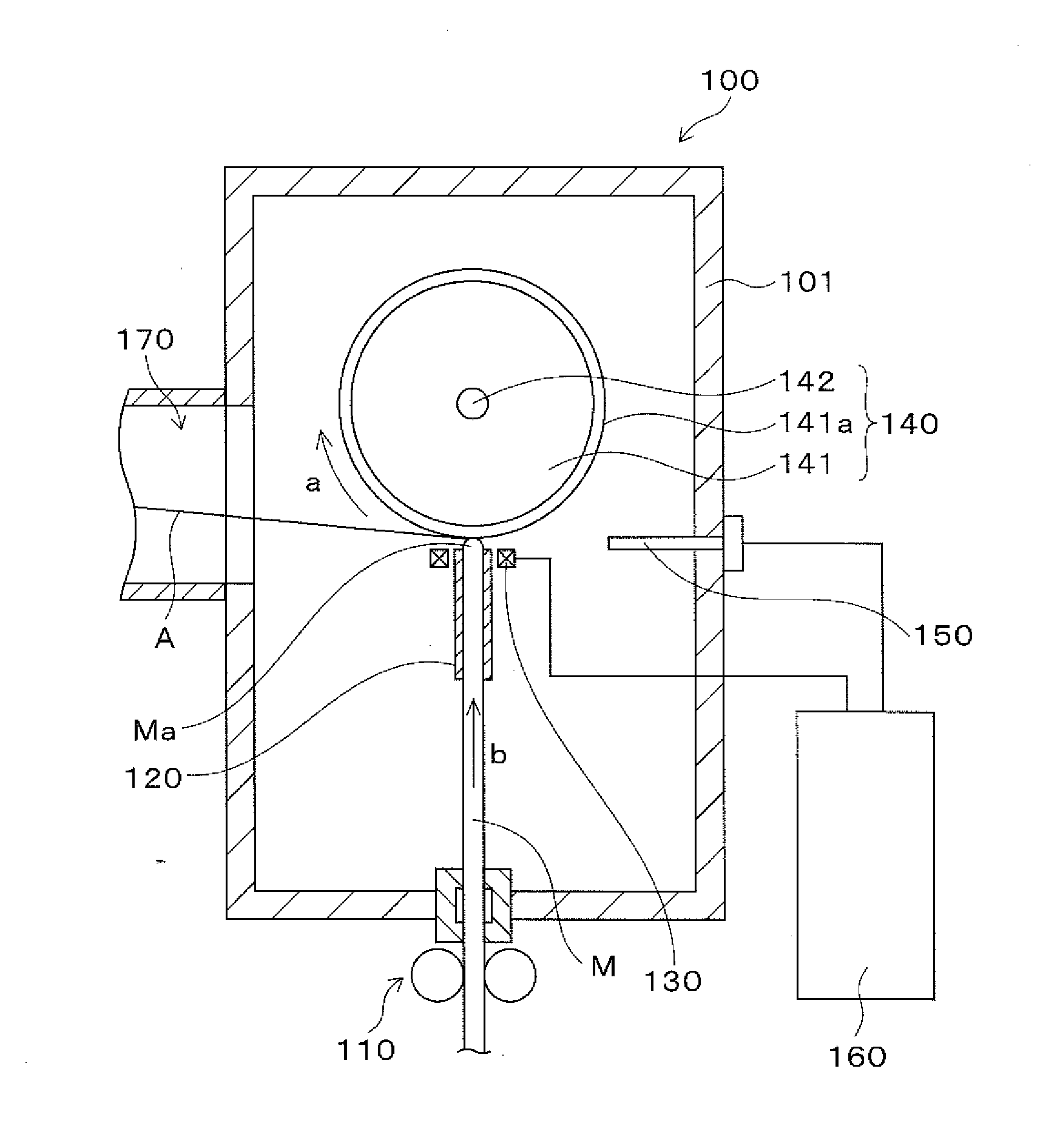

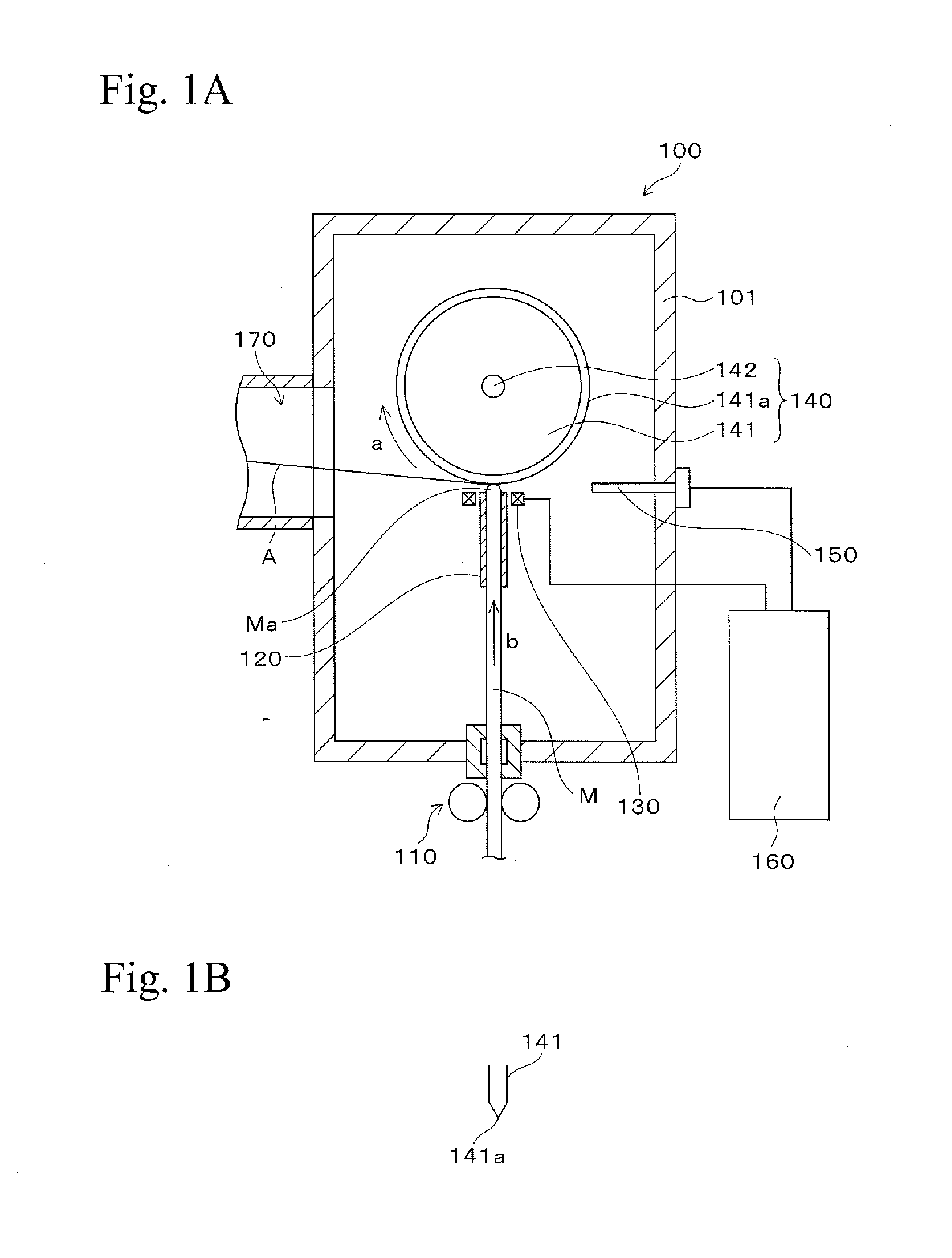

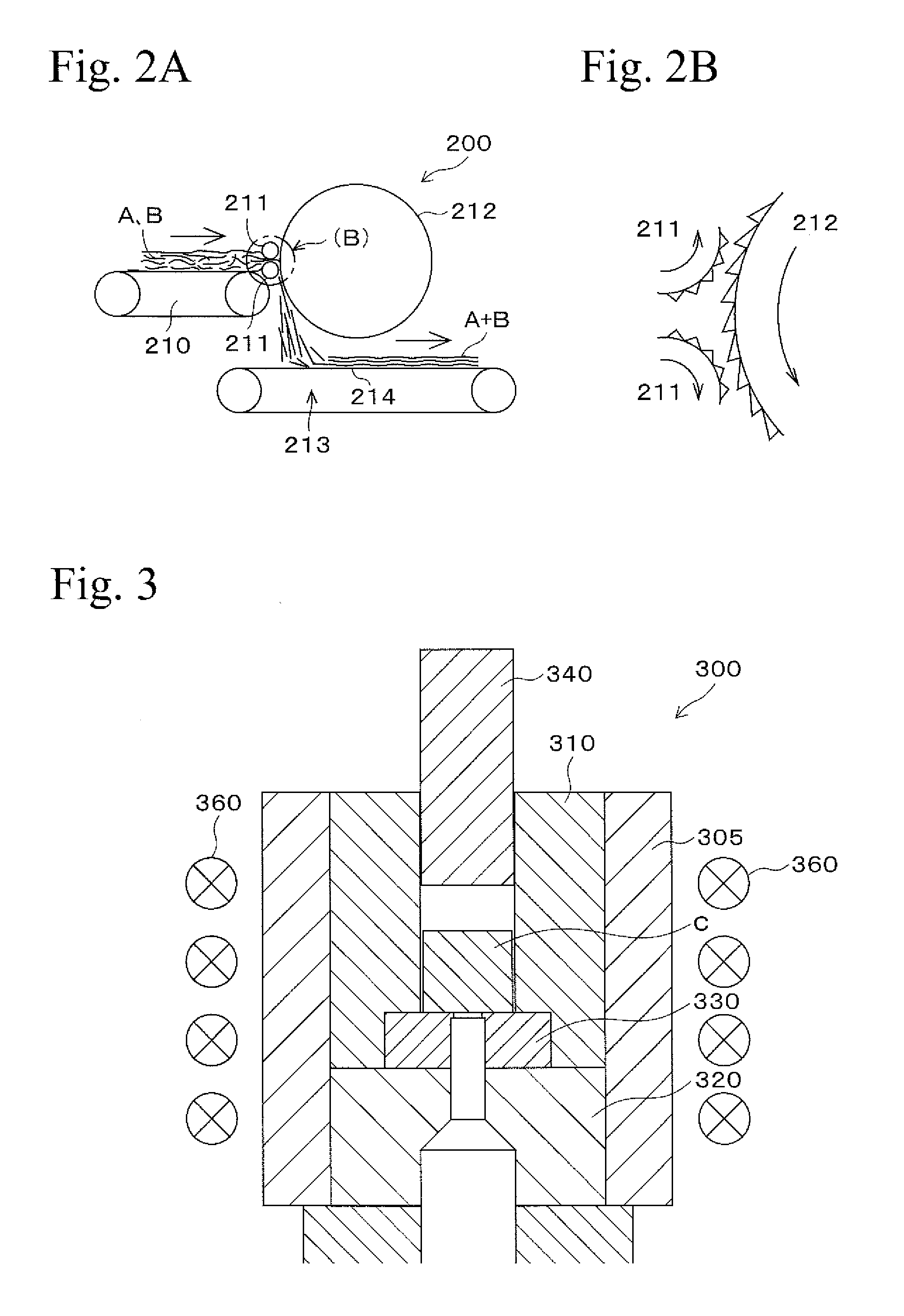

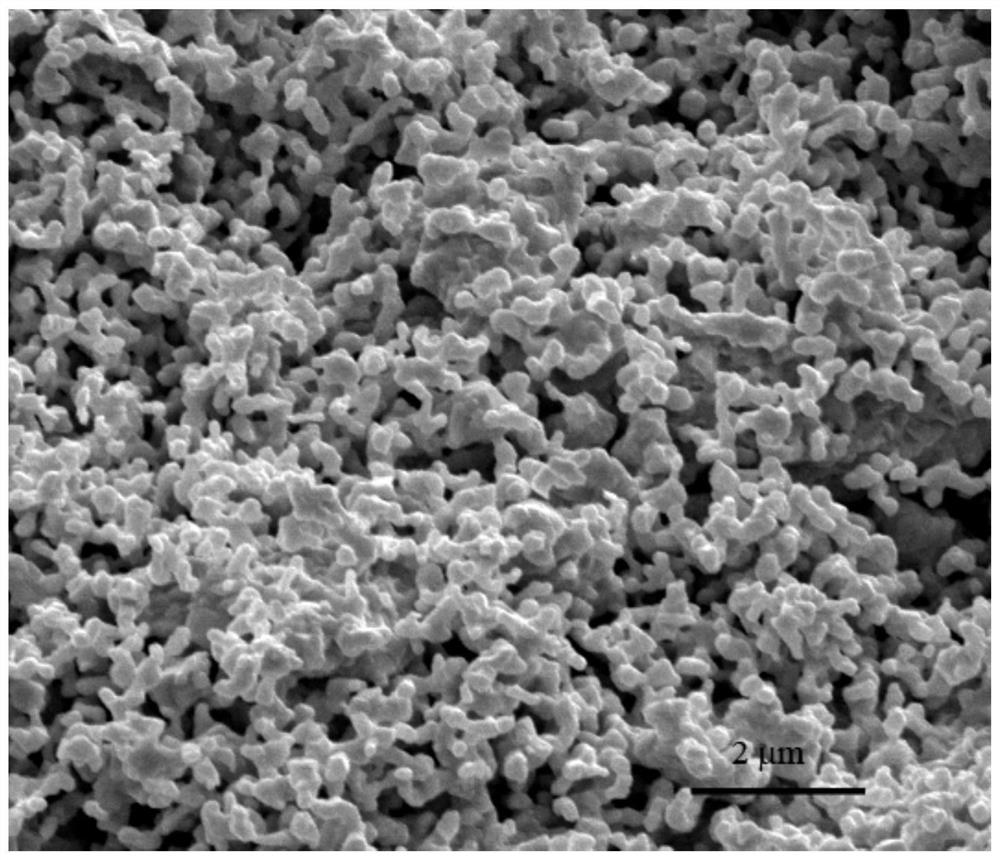

Low-pressure-drop nano/microstructure filler revolving bed supergravity device and application thereof

ActiveCN102120172AGas phase pressure drop is smallImprove mass transfer efficiencyDispersed particle separationChemical/physical/physico-chemical stationary reactorsPorosityEngineering

The invention discloses a low-pressure-drop nano / microstructure filler revolving bed supergravity device and application thereof and belongs to the technical field of supergravity. The supergravity device comprises a rotating part formed by arranging a rotor and a filler in a closed shell, wherein the shell and an upper cover have a liquid inlet, a liquid outlet, a gas inlet and a gas outlet; and a liquid distributor extending into a central cavity of the rotor is arranged in the liquid inlet. In the device, the filler in the rotating part is a structuralized SiC, sintered ceramic and powder sintered titanium-based alloy filler with a nano / microstructure, the runner diameter of the structuralized filler is 0.1 to 5mm, the porosity is 55 to 97 percent, the surface of the filler has a 0.01 to 3-micrometer convexoconcave nano / microstructure, and the specific surface area of the filler is 200 to 2,000m<2> / m<3>. When the device is used for deeply removing sulfur dioxide from industrial gases such as sulfuric acid industrial tail gas with low-pressure-drop requirement, the pressure drop of the supergravity device is lowered by 40 to 80 percent, and the harmful gas content after treatment is lower than 20 to 100ppm.

Owner:BEIJING UNIV OF CHEM TECH +1

Method of Manufacturing Pure Titanium Hydride Powder and Alloyed Titanium Hydride Powders By Combined Hydrogen-Magnesium Reduction of Metal Halides

ActiveUS20130315773A1Reduce oxideFacilitated DiffusionMultiple metal hydridesTransition element hydridesTitanium chloridePowder mixture

The invention relates to energy-saving manufacturing of purified hydrogenated titanium powders or alloying titanium hydride powders, by metallo-thermic reduction of titanium chlorides, including their hydrogenation, vacuum separation of titanium hydride sponge block from magnesium and magnesium chlorides, followed by crushing, grinding, and sintering of said block without need for hydrometallurgical treatment of the produced powders.Methods disclosed contain embodiments of processes for manufacturing high-purity powders and their use in manufacturing near-net shape titanium and titanium-alloy articles by sintering titanium hydride and alloyed titanium hydride powders produced from combined hydrogen-magnesium reduction of titanium chlorides, halides and hydrides of other metals. Additional titanium hydride powder introduced with titanium tetrachloride beneficially affects the kinetics of magnesium-thermic reduction due to formation of the additionally-emitted atomic hydrogen, which helps to reduce presence of oxides and so cleans inter-particle interfaces of the product and enhances diffusion between all of components of the powder mixture.

Owner:ADVANCED MATERIALS PRODS

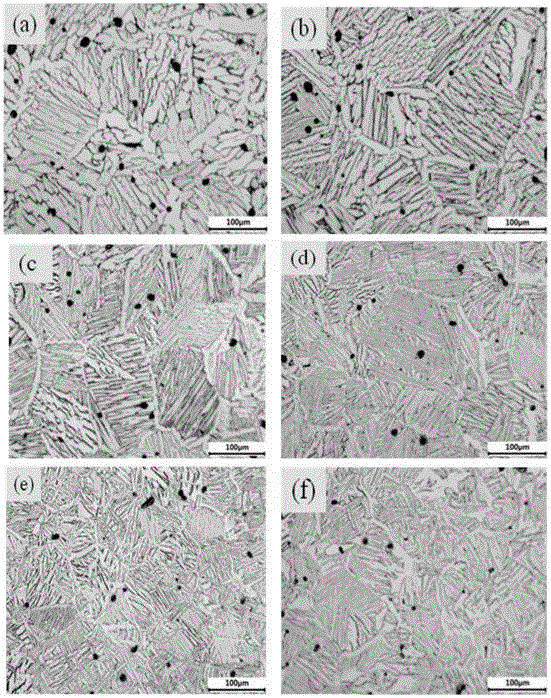

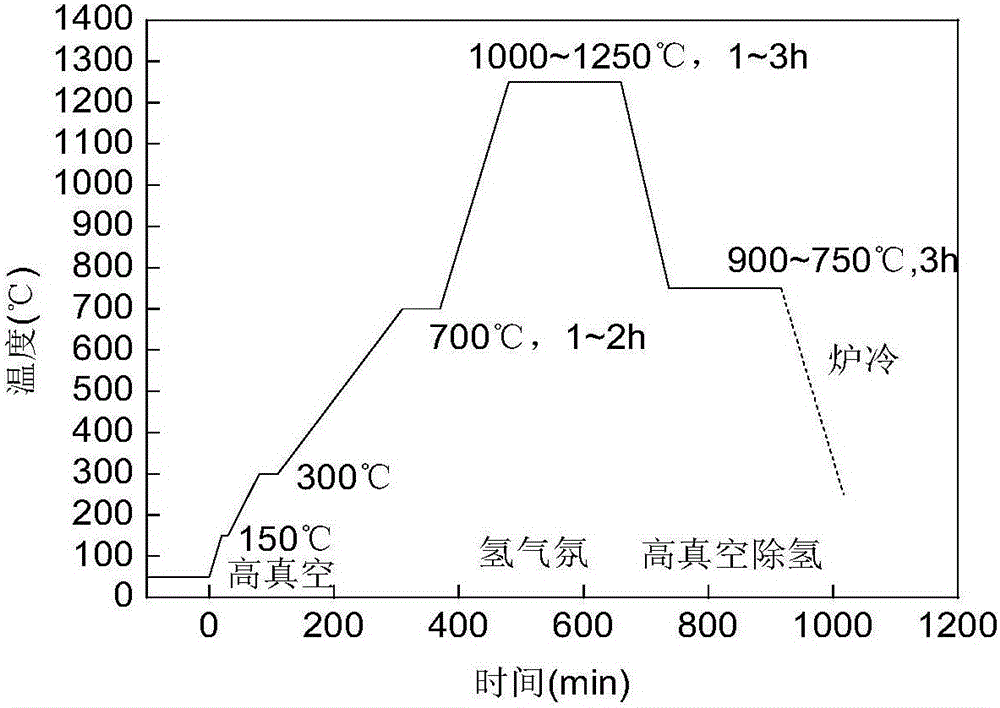

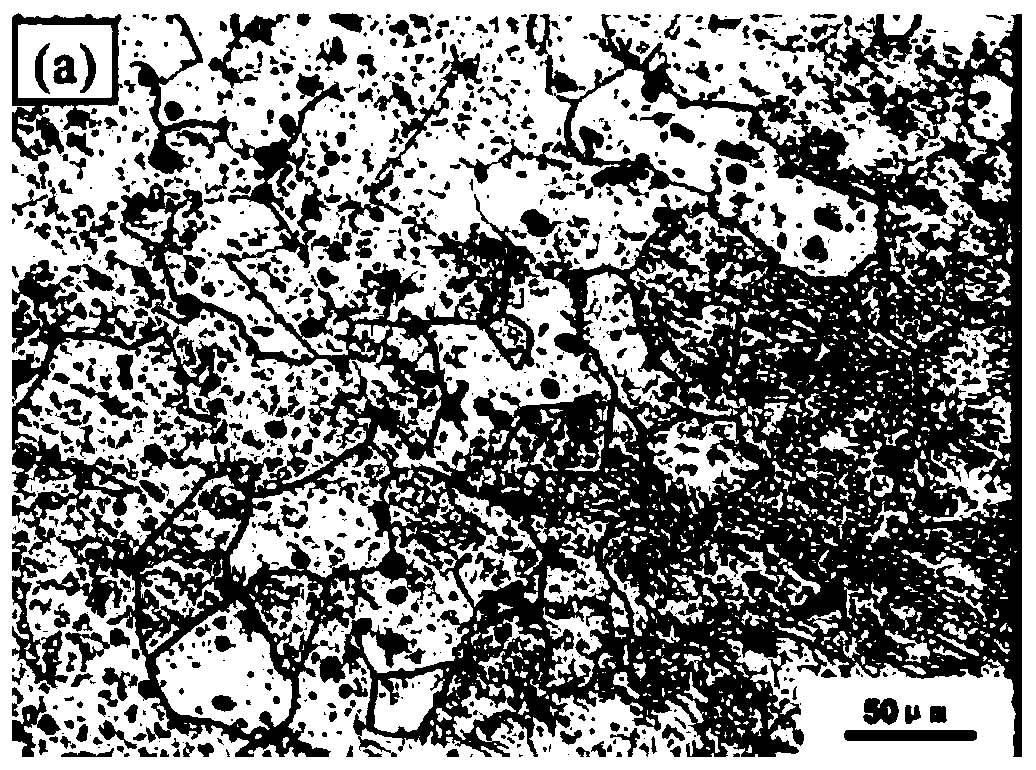

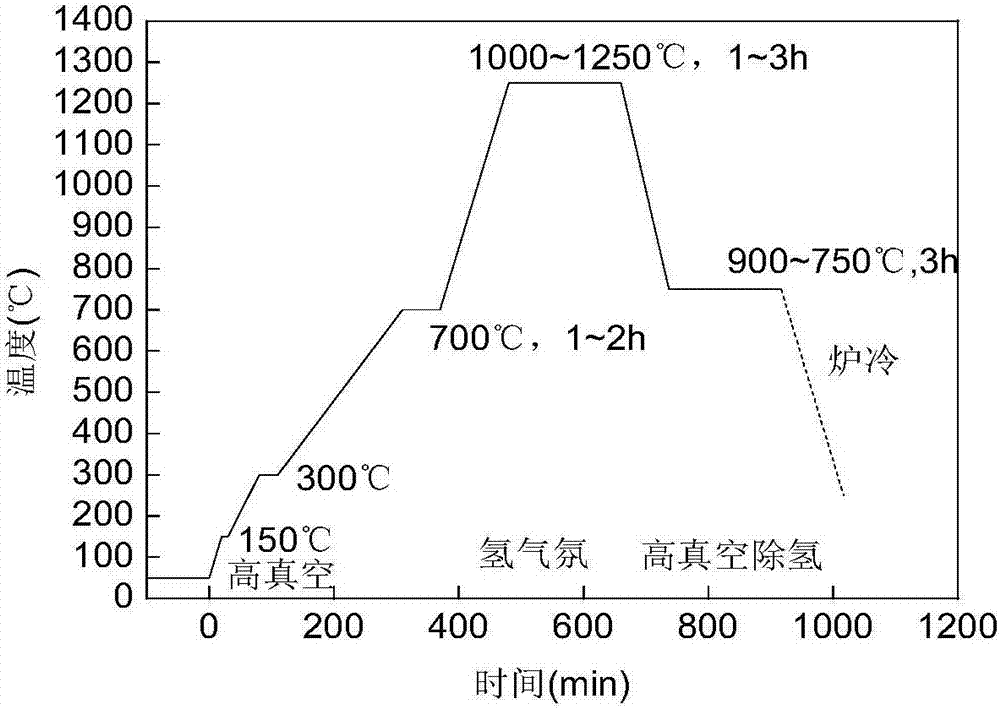

Preparing method for powder metallurgy titanium alloy

The invention relates to a preparing method for a powder metallurgy titanium alloy. The preparing method includes the following steps that TiH2 powder, Ti powder and other alloy elements serve as raw materials and are evenly mixed to be subject to compression molding, wherein the adding amount of TiH2 accounts for 3%-25% of the total mass of the raw materials; the TiH2 is heated in a high-vacuum environment to be decomposed and is sintered in a hydrogen atmosphere; then the temperature is reduced to 750 DEG C to 1000 DEG C, and vacuum pumping is conducted for hydrogen removing; and finally, the powder metallurgy titanium alloy product is obtained after cooling. According to the preparing method, the element H is added into the powder metallurgy titanium alloy in the form of titanium hydride, and the adding amount of the H is controlled by controlling the amount of the titanium hydride; and meanwhile, the organization structure of the sintered titanium alloy is adjusted by controlling the H removing temperature of the hydrogen atmosphere sintered titanium alloy, and the high-performance titanium alloy is obtained. Compared with a method without adding titanium hydride, the density of the alloy obtained in the preparing method is increased, and the tensile strength is increased.

Owner:HUNAN UNIV

Titanium dioxide scouring media and method of production

The present invention relates to a round and spherical titanium dioxide scouring media and a method for producing the media. The scouring media is effective in removing titanium dioxide buildup on the walls of a titanium dioxide reaction vessel. The method consists of forming green titanium dioxide pellets in a high intensity mixer by mixing commercially available titanium dioxide dust and water. The high intensity mixer produces substantially round and spherical green pellets which are subsequently sized and sintered in a kiln to form round and spherical titanium dioxide sintered pellets that are suitable as a scouring media. The high intensity mixer allows the operator to closely control the size and shape of the pellets during the forming process to produce substantially round and spherical green pellets. Because the sintered titanium dioxide pellets are substantially round and spherical in shape, they are much less abrasive to the walls of the reaction vessel. Furthermore, as the pellets themselves abrade away, they do not contaminate the titanium dioxide product, and they can even be reprocessed into round and spherical scouring media.

Owner:CARBO CERAMICS

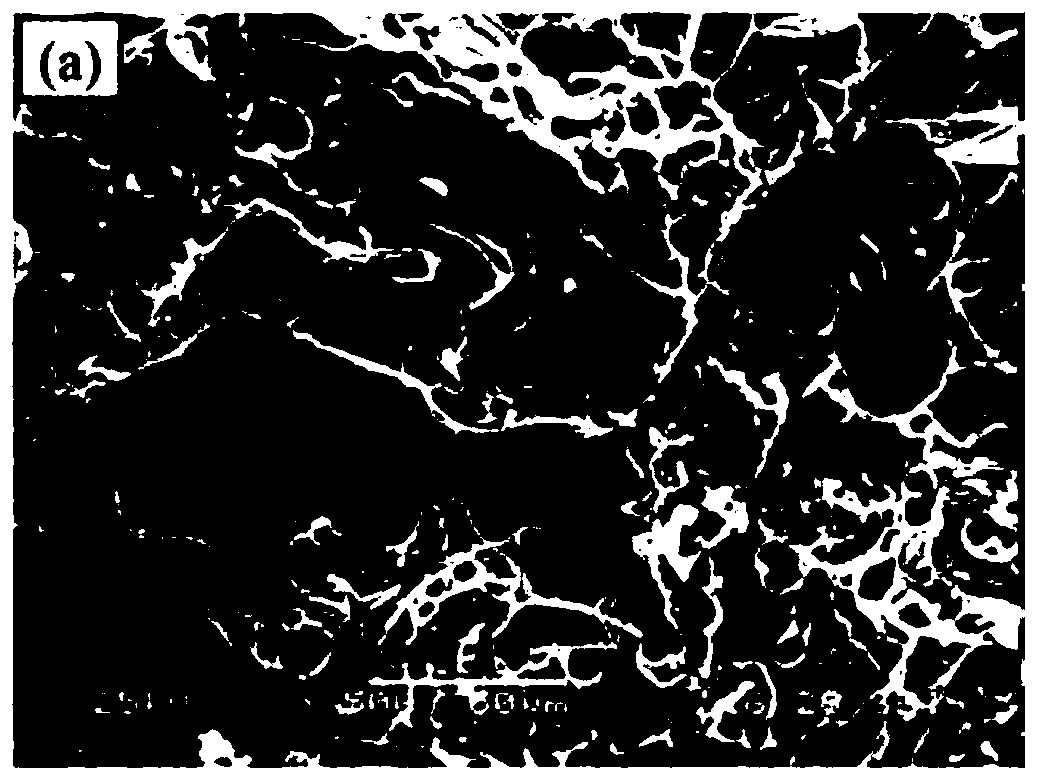

Manufacture of near-net shape titanium alloy articles from metal powders by sintering at variable pressure

InactiveUS20030211001A1Improve mechanical propertiesImprove plasticityCoatingsPowder mixtureDecomposition

The process includes (a) mixing a titanium hydride powder having a particle size of <=150 mum with alloying metal powders (master alloys or elemental metal powders) having a particle size in the range of {fraction (1 / 15-2 / 5 of the maximal particle size of titanium hydride powder, (b) compacting the resulting powder mixture by molding at the pressures of 400-1000 MPa, (c) heating up to the sintering temperature of the predetermined alloy composition at variable pressures in a furnace chamber: initial heating to 400° C. in vacuum of less than 10<-2 >Pa, then, heating to a temperature range of 400-900° C. with the pressures up to 10<4 >Pa, which is controlled by hydrogen being emitted by the decomposition of titanium hydride contained in the compacted powdered alloy, and finally, heating to over 900° C. to the sintering temperature at the pressure continually decreasing to the starting vacuum level, and (d) sintering. Heating to the sintering temperature is performed at the rate of 10-15 grad / min. The new technology allows the purity and mechanical properties of sintered titanium alloys and the manufacture of near-net shape sintered titanium articles to be controlled by a cost-effective method.

Owner:ADVANCED MATERIALS PRODS

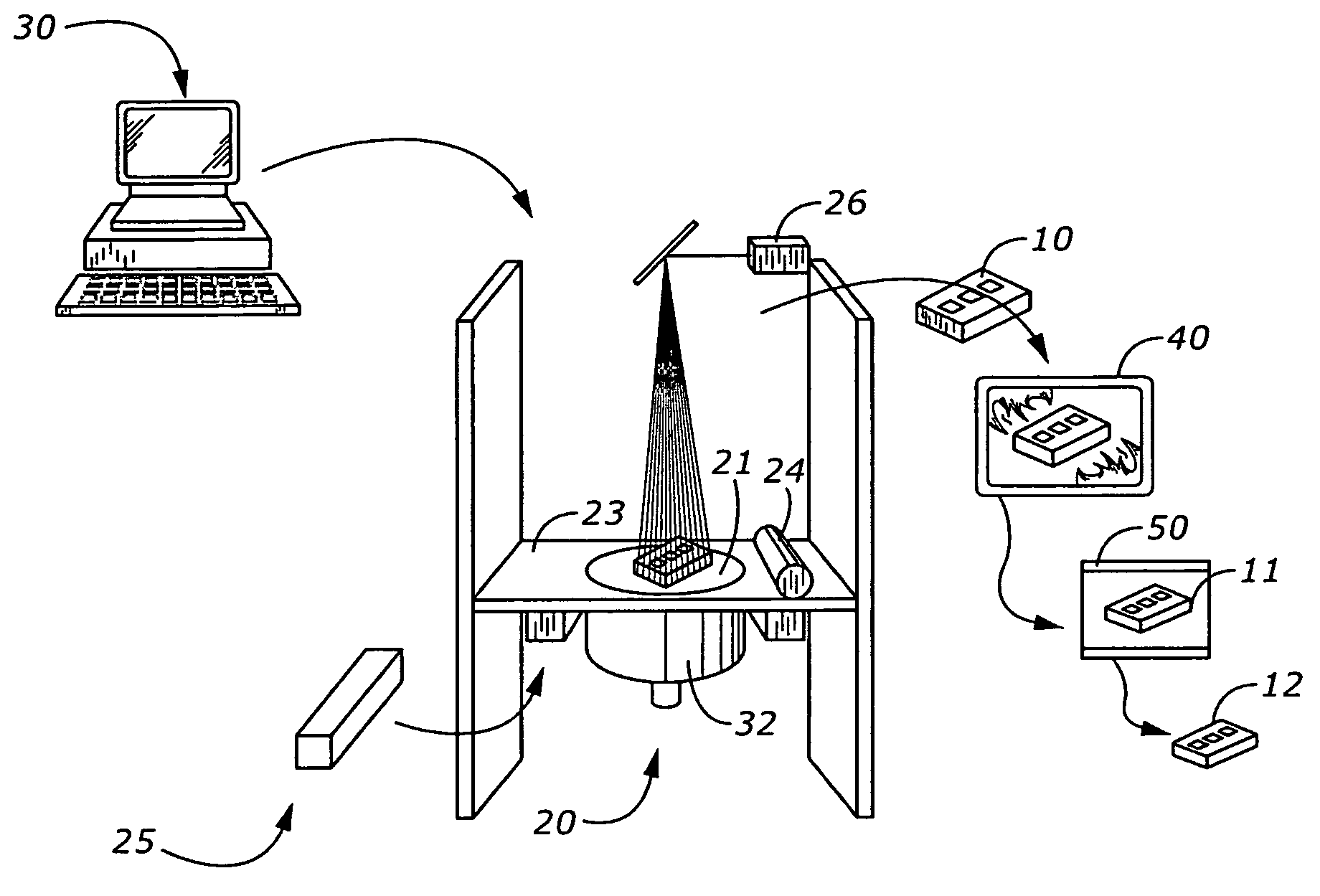

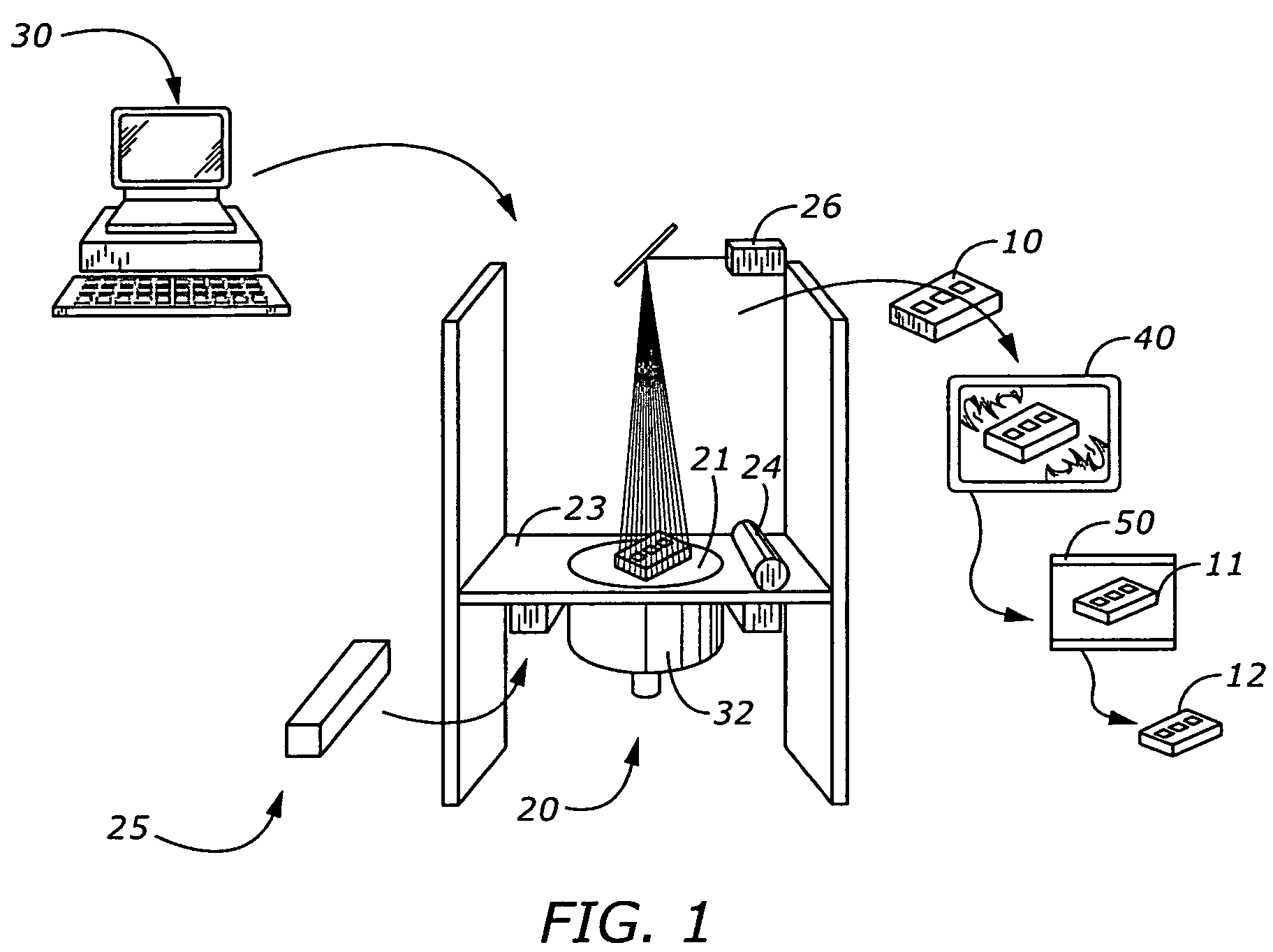

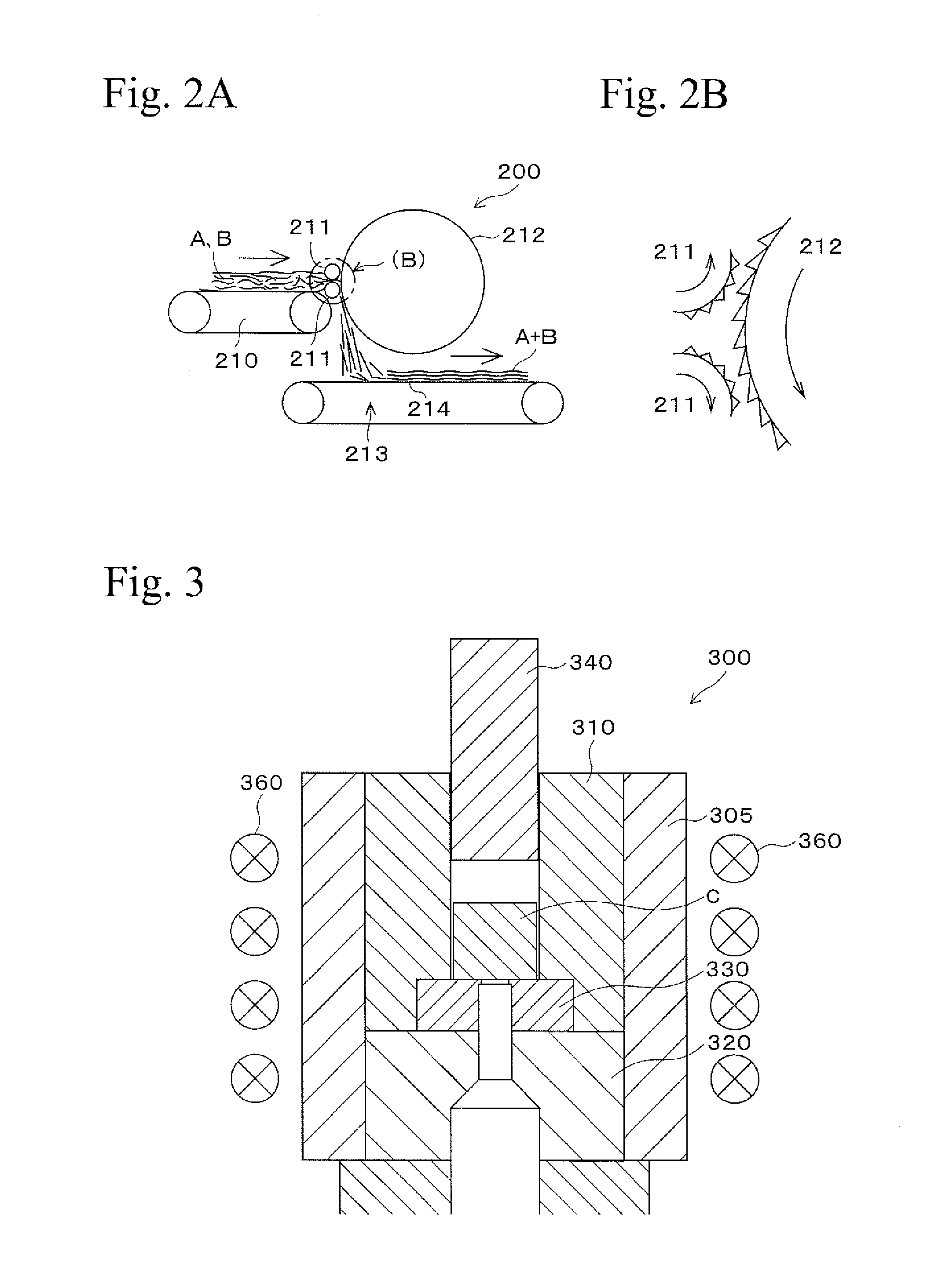

Laser sintered titanium alloy and direct metal fabrication method of making the same

ActiveUS7540996B2Additive manufacturing apparatusIncreasing energy efficiencyPowder mixtureSintered titanium

Methods and powder blends are provided for fabricating a metal part. One method includes the first steps of spreading a layer of a powder blend on a platform, the powder blend including a titanium base metal or alloy, and an alloying metal having a lower melting temperature than that of the base metal or alloy. Next, an energy beam is directed onto selected areas of the powder blend layer to thereby melt the alloying metal. Then, the alloying metal is re-solidified by withdrawing the energy beam from the powder blend layer. Then, a preform part is built up by iteratively performing the spreading, melting, and re-solidifying steps on additional adjacently formed layers. A metal liquid phase sintering process is performed at a temperature sufficient to melt the alloying metal but not the base metal or alloy.

Owner:THE BOEING CO

Cost-effective titanium alloy powder compositions and method for manufacturing flat or shaped articles from these powders

ActiveUS20090252638A1Improve mechanical propertiesImprove plasticityCoatingsDecompositionVolumetric Mass Density

The invention relates to the cost-effective manufacture of near-net shape titanium articles from sintered powders containing titanium and all required alloying elements. The cost-effective initial powder composition for subsequent room temperature consolidation and sintering contains: (a) 10-50 wt. % of underseparated titanium powder with ≦500 μm in particle size manufactured from underseparated titanium sponge comprising up to 2 wt. % of chlorine and up to 2 wt. % of magnesium. The underseparated titanium powder costs significantly less than that for fully separated powder of completely reduced sponge; (b) 10-90 wt. % of hydrogenated titanium powder, whereby this powder is a mixture of two hydrogenated powders A and B containing different amount of hydrogen: powder A contains amount of hydrogen in the range of 0.2-1 wt. % and powder B contains amount of hydrogen in the range of 2-3.9 wt. %. The powder with high hydrogen content provides purification of underseparated titanium powder during heat treatment and sintering, while the powder with low hydrogen content provides sufficient strength of green compacts as well as perfect structure and quality of the final sintered article; (c) 0-90 wt. % of standard grade refined titanium powder, and / or 5-50 wt. % of alloying metal powders: master alloys or elemental powders. The method includes (a) mixing said underseparated titanium powder, the C.P. titanium powder, the hydrogenated titanium powders containing different amount of hydrogen, (b) compacting the obtained blend by room temperature consolidation such as die pressing, molding, direct powder rolling, cold isostatic pressing, and / or metal injection molding to density at least 60% of the theoretical density, (c) additional crushing titanium hydride powders into fine fragments during consolidation at the pressure of 400-960 MPa to provide forming a uniform network of fine pores promoting healing effects during sintering, chemical cleaning and refining titanium powders in the compacted articles by heating to 300-900° C. and holding for at least 30 minutes to provide a reaction of Cl, Mg, and oxygen, with hydrogen emitted due to decomposition of titanium hydride, (e) heating in vacuum for sintering in β-phase zone of titanium in the temperature range of 1000-1350° C. and holding for at least 30 minutes, and cooling. The new technology allows the purity and mechanical properties of sintered titanium alloys and the manufacture of near-net shape sintered titanium articles to be controlled by a cost-effective process.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

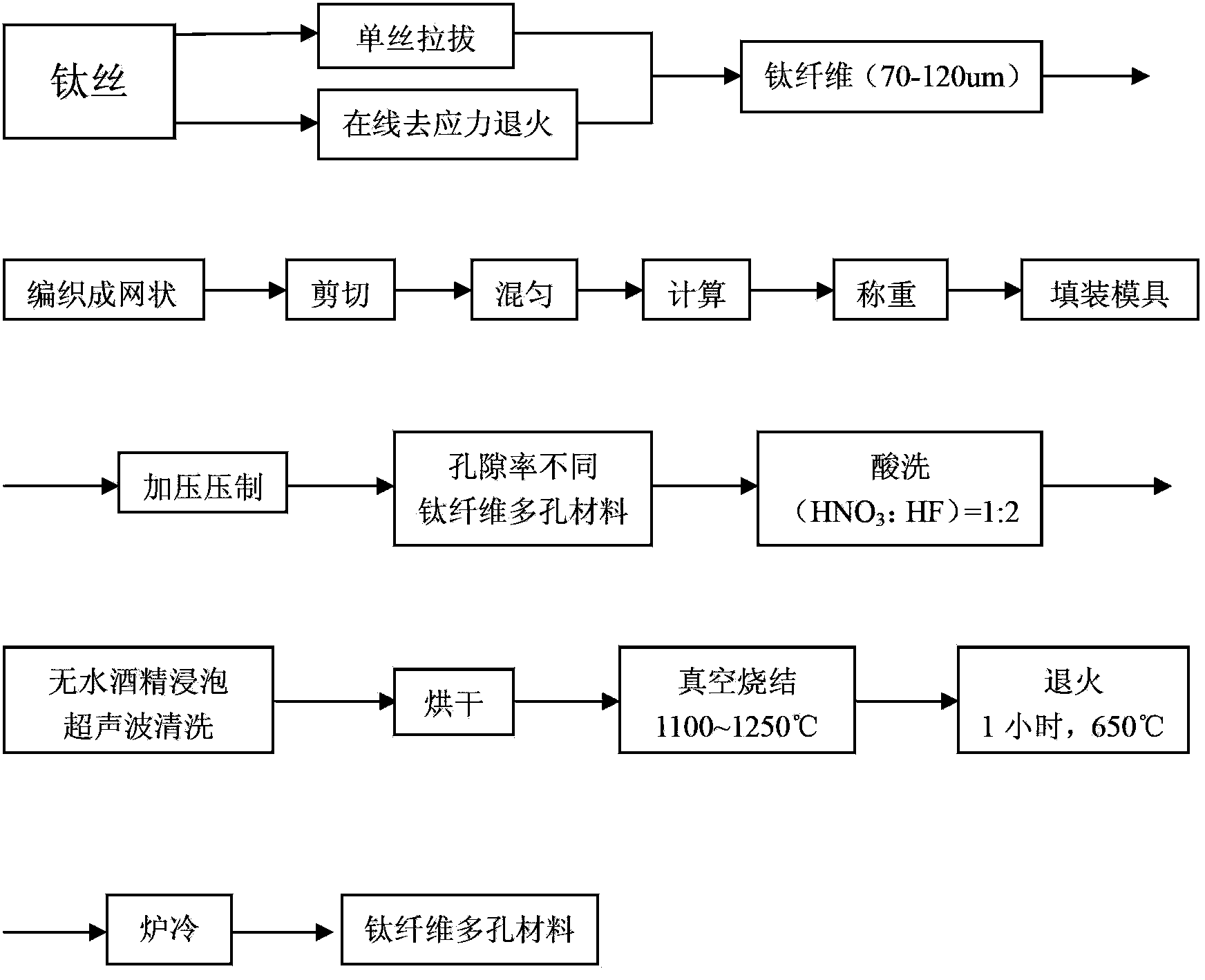

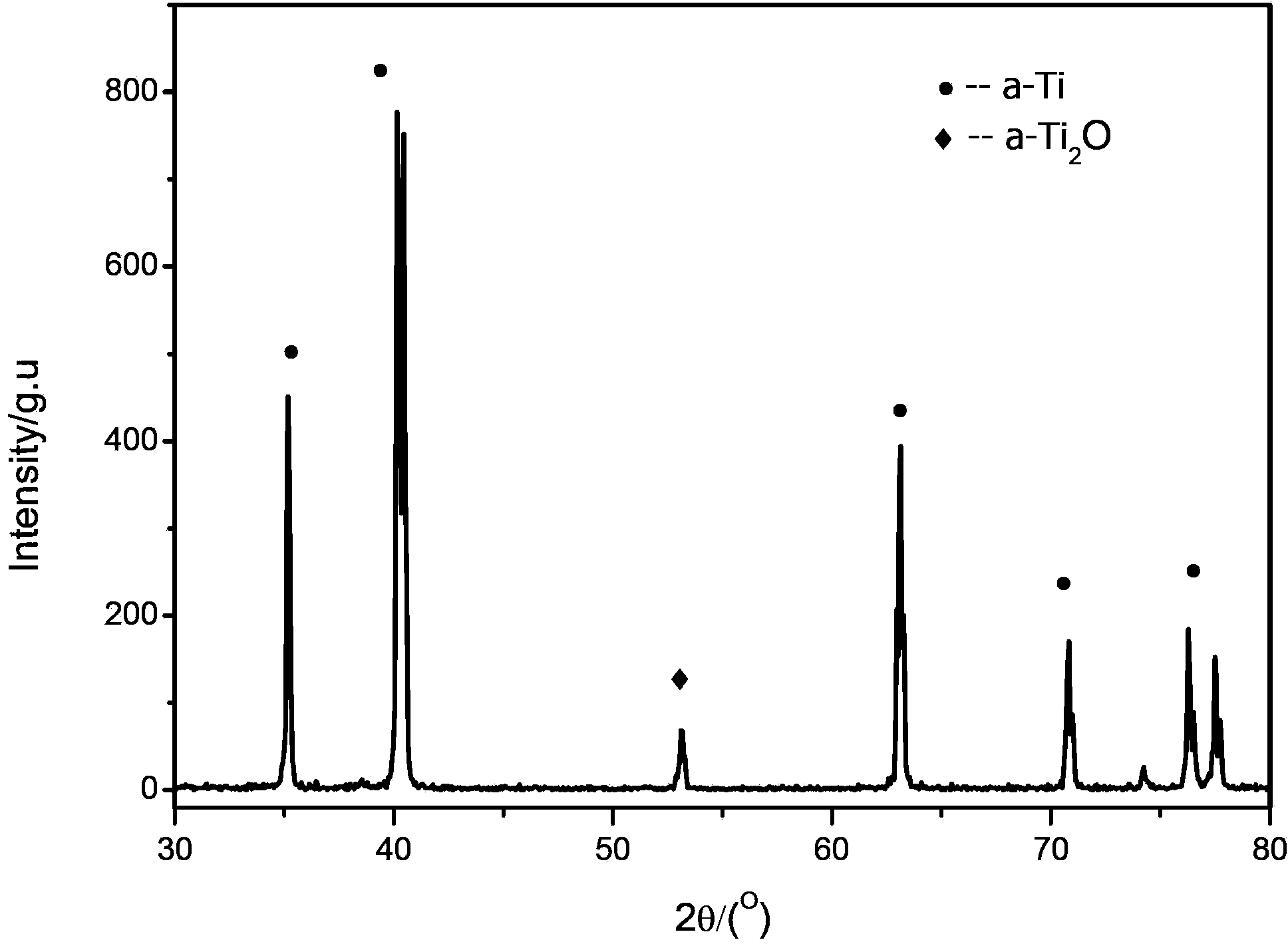

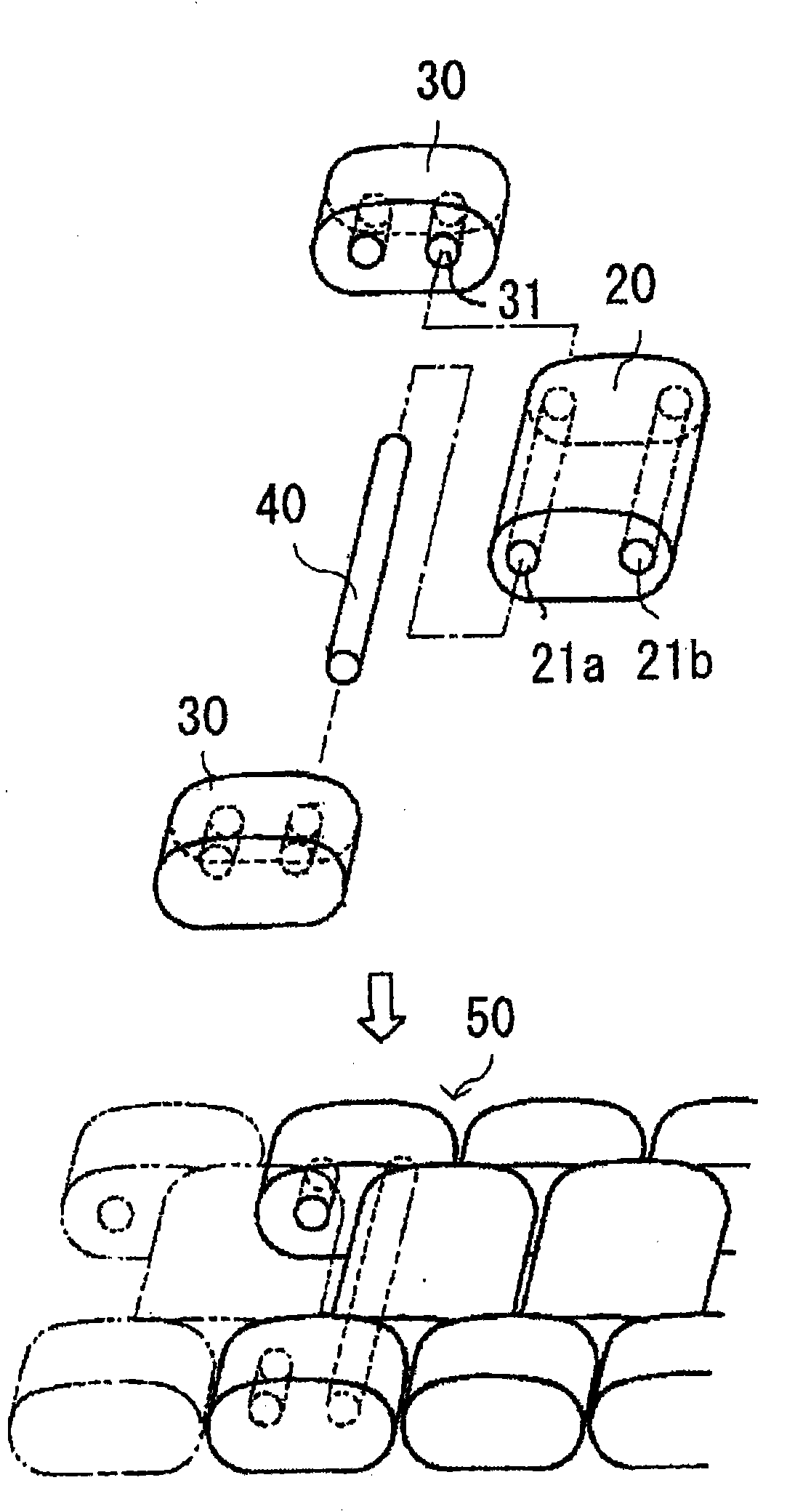

Preparation method of titanium fiber porous material

The invention provides a preparation method of a titanium fiber porous material, which has controllable fiber diameter and porosity. The material is prepared by: drawing a titanium wire into a fibrous state, and then carrying out weaving and compression molding. After the material is prepared, pickling is conducted to remove of the oxide on the surface of the titanium fiber porous material, and then the material is subjected to high temperature sintering by a vacuum sintering furnace. By means of the method provided in the invention, a sintered titanium fiber porous material can be obtained, and all properties of the titanium fiber porous material are greatly improved. Thus, the method provides an important basis for realization of product industrialization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Titanium dioxide scouring media and method of production

InactiveUS7255815B2Reduce eliminatePigmenting treatmentTitanium dioxideSintered titaniumHigh intensity

The present invention relates to a round and spherical titanium dioxide scouring media and a method for producing the media. The scouring media is effective in removing titanium dioxide buildup on the walls of a titanium dioxide reaction vessel. The method consists of forming green titanium dioxide pellets in a high intensity mixer by mixing commercially available titanium dioxide dust and water. The high intensity mixer produces substantially round and spherical green pellets which are subsequently sized and sintered in a kiln to form round and spherical titanium dioxide sintered pellets that are suitable as a scouring media. The high intensity mixer allows the operator to closely control the size and shape of the pellets during the forming process to produce substantially round and spherical green pellets. Because the sintered titanium dioxide pellets are substantially round and spherical in shape, they are much less abrasive to the walls of the reaction vessel. Furthermore, as the pellets themselves abrade away, they do not contaminate the titanium dioxide product, and they can even be reprocessed into round and spherical scouring media.

Owner:CARBO CERAMICS

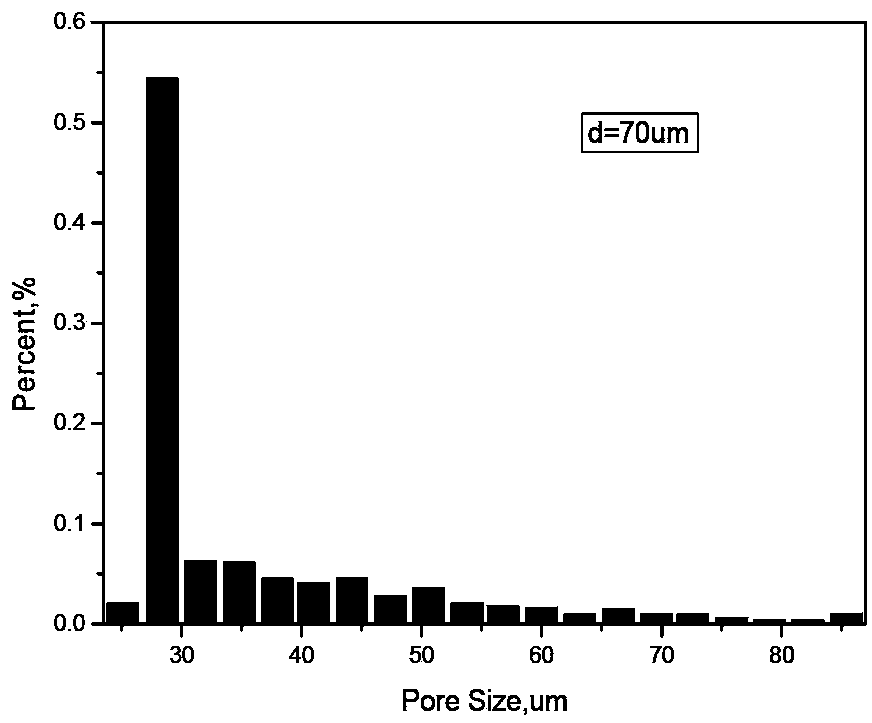

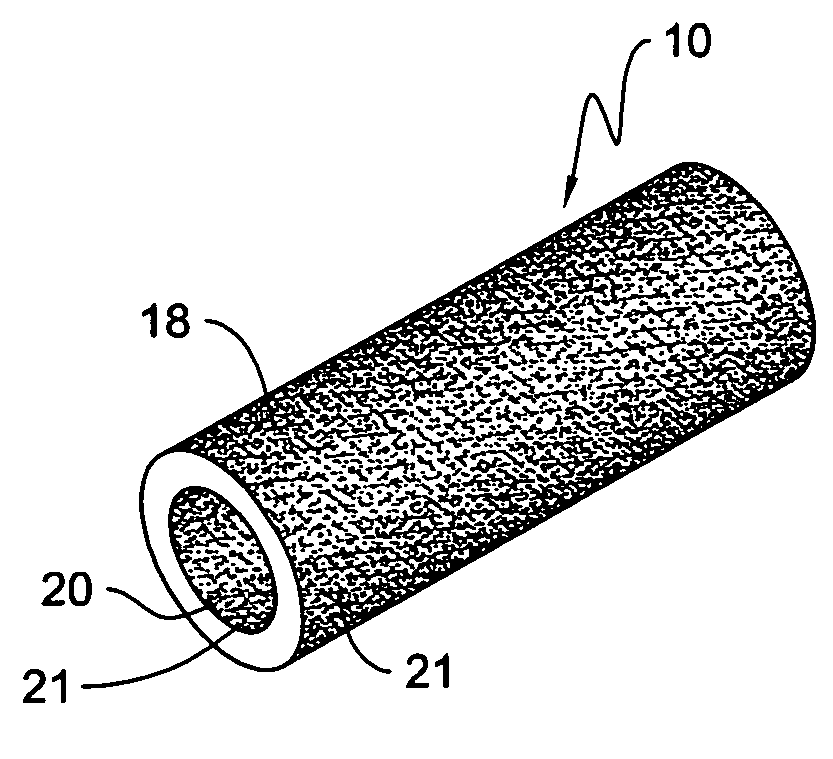

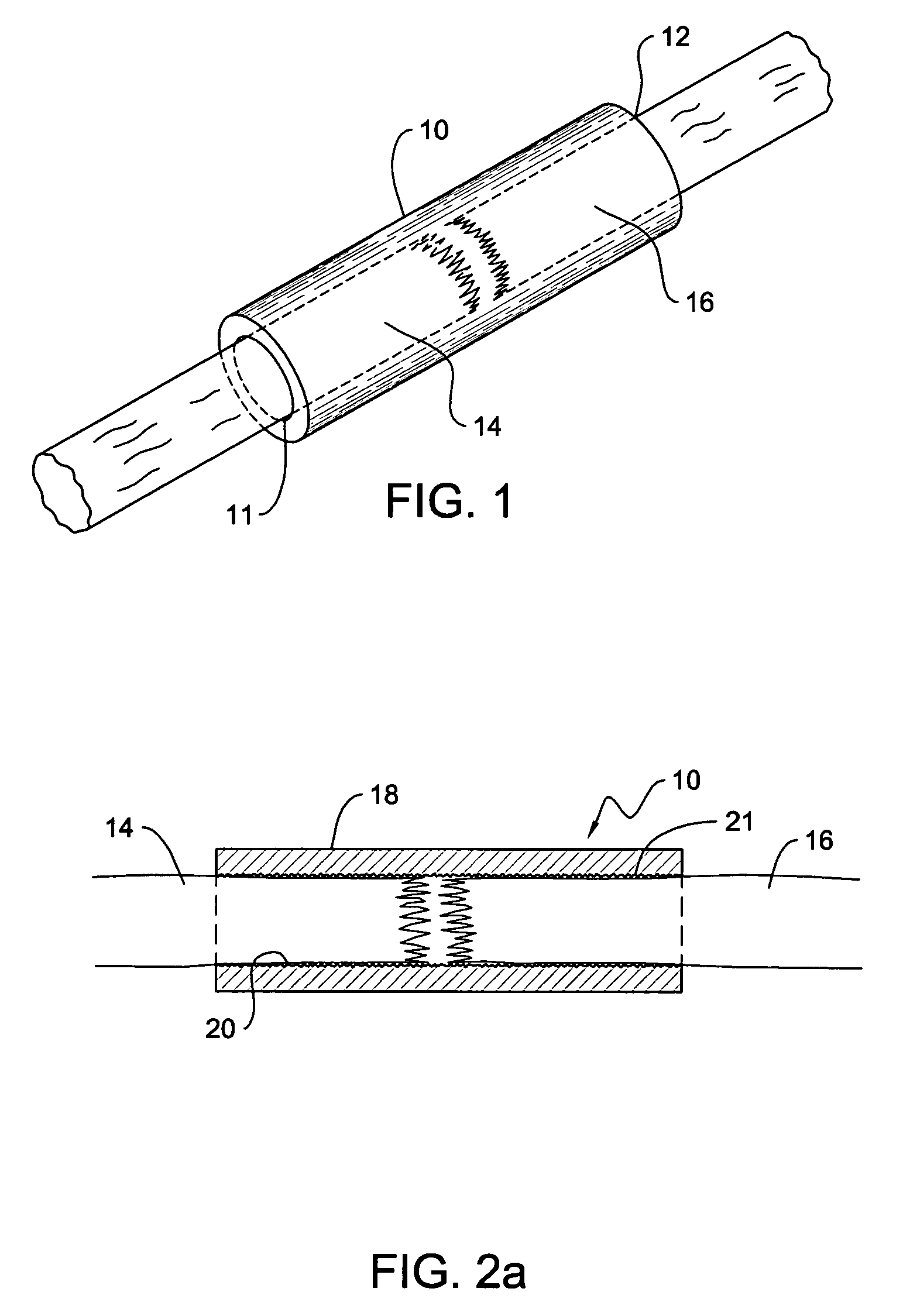

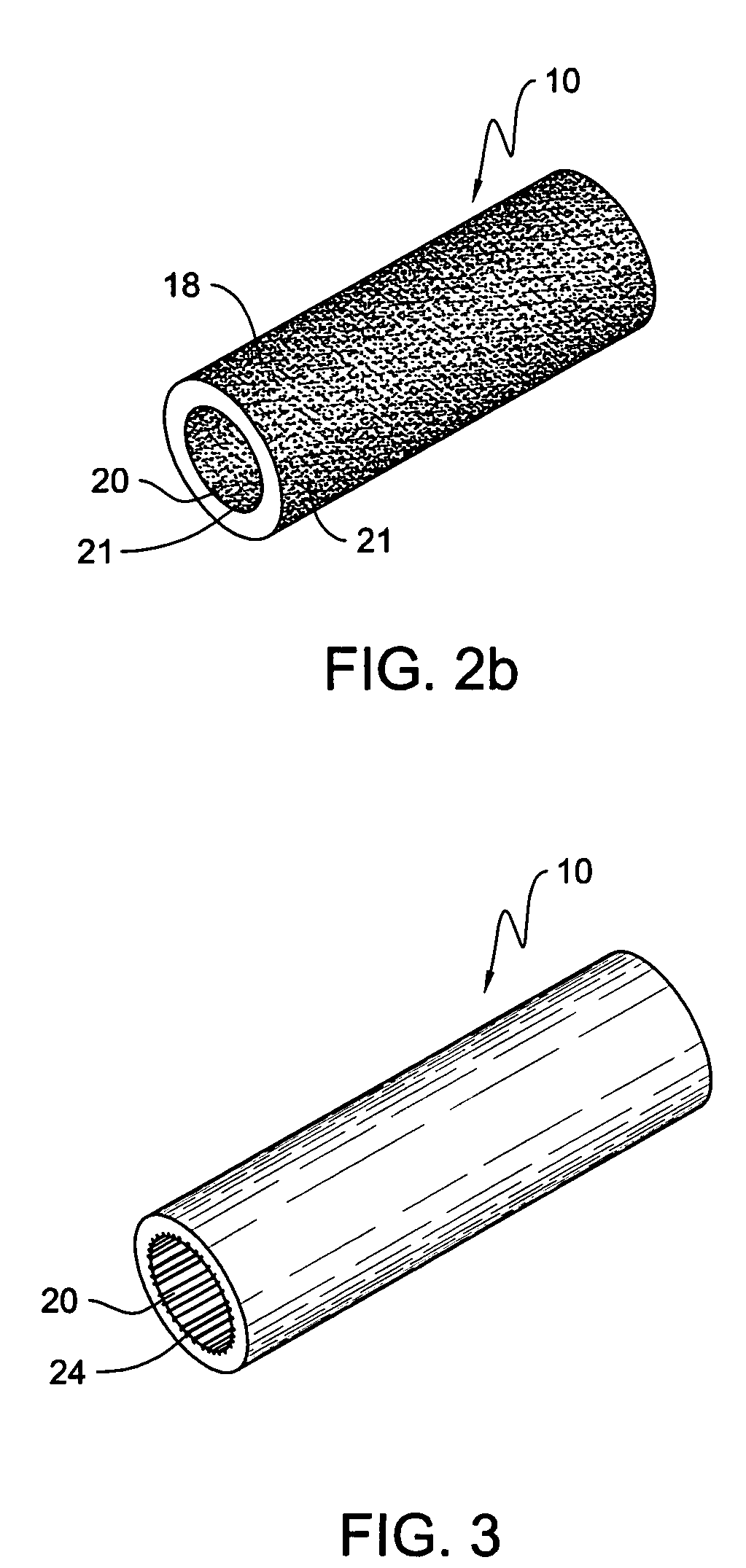

Sintered titanium tube for the management of spinal cord injury

A device and method for the treatment of damaged nerves and, more particularly, a tubular membrane having a microtextured surface for the treatment of central or peripheral nerve injuries. The microtextured surface of the tubular membrane inhibits the growth of fibrous tissue, which prevents the reattachment of nerve fiber ends.

Owner:MEDTRONIC INC

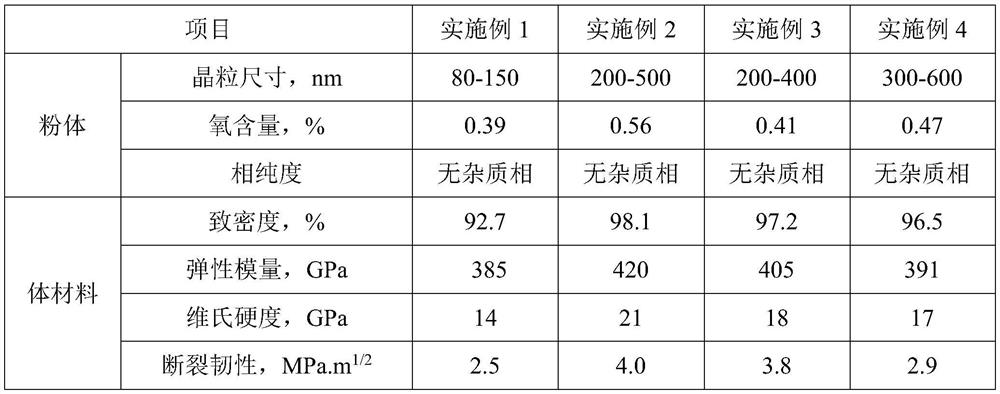

Sintered titanium alloy and preparation method thereof

ActiveCN110527857AReduce manufacturing costImprove performanceTransportation and packagingMetal-working apparatusCompression moldingAdhesive

The invention discloses a sintered titanium alloy and a preparation method thereof. The titanium alloy is prepared from, by weight, 0.2-0.8% of rare earth nitride and the balance HDH titanium powder,and the preparation method comprises the following specific steps: firstly, mixing the raw materials to obtain mixed powder; 2, carrying out compression molding on the mixed powder obtained in the step 1 to obtain a green body; or mixing the mixed powder obtained in the first step with an adhesive to obtain a feed; carrying out injection molding on the feed to obtain an injection blank; degreasingthe injection blank to obtain a degreased green body; and 3, subjecting the green body obtained in the second step to vacuum sintering, and obtaining the sintered titanium alloy. By adding the rare earth nitride into the titanium alloy, the effect of capturing oxygen can be achieved, no by-product is generated, no residue is left, and the titanium alloy is relatively safe. And meanwhile, the rareearth nitride has the advantage of low price, the cost can be reduced, and the application field is expanded.

Owner:长沙得悦科技发展有限公司

Method for preparing high-compactness titanium product by virtue of titanium hydride powder

The invention discloses a method for preparing a high-compactness titanium product by virtue of a titanium hydride powder. The method comprises the following steps: taking the titanium hydride powder as a raw material, carrying out partial dehydrogenation, then carrying out pressing formation through common die-pressing, and preparing the titanium product through vacuum sintering. According to the method disclosed by the invention, a titanium hydride (TiH2) powder is transformed into an unsaturated TiHx (X is greater than 0 and less than 2) powder trough the partial dehydrogenation treatment, and then traditional die-pressing formation is adopted, so that a high-compactness green blank can be obtained, and high green blank strength and high surface smoothness can be obtained; and meanwhile, the diffusion speed of titanium atoms is increased at a high temperature by virtue of the reversible alloying effect of hydrogen of residual TiH2 / TiHx during a sintering process, so that improvement for the sintering activity of titanium is benefited, and preparation for the high-compactness titanium product is promoted due to the synergistic effect of the high green blank compactness and the high sintering activity. The invention overcomes the problems of low sintering activity of a hydrogenated-dehydrogenated titanium powder and difficult formation of a titanium hydride powder in the prior art, and provides a simple and feasible method for preparing a high-compactness titanium product in a short flow.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Preparation method of titanium-doped zinc oxide transparent conducting thin film

InactiveCN103173726AReduce volumeEvenly heatedVacuum evaporation coatingSputtering coatingOxide ceramicEvaporation

The invention belongs to the technical field of transparent conducting thin films, and in particular relates to a preparation method of a titanium-doped zinc oxide transparent conducting thin film. The preparation method comprises the following steps of: firstly, manually grinding or mechanically milling ZnO and TiO2 powder serving as raw materials, uniformly mixing, feeding the mixed powder into a powder tablet machine so as to make a columnar target blank material, putting the target blank material into a corundum crucible, covering and putting into a single crystal furnace, sintering for 8-12 hours at 800-1200 DEG C, so as to obtain a titanium-doped zinc oxide ceramic target material, putting the sintered titanium-doped zinc oxide ceramic target material into a crucible of electron beam evaporation coating film equipment, vacuuming till the bottom is in a vacuum state, carrying out electron beam evaporation film coating, and controlling the electron beam current and the deposition time so as to obtain the titanium-doped zinc oxide transparent conducting thin film. The preparation method has the characteristics of simplicity and control easiness in operation, short time, high deposition velocity and the like, and has bright application prospects in the fields of solar batteries and transparent electronic devices.

Owner:HANGZHOU DIANZI UNIV

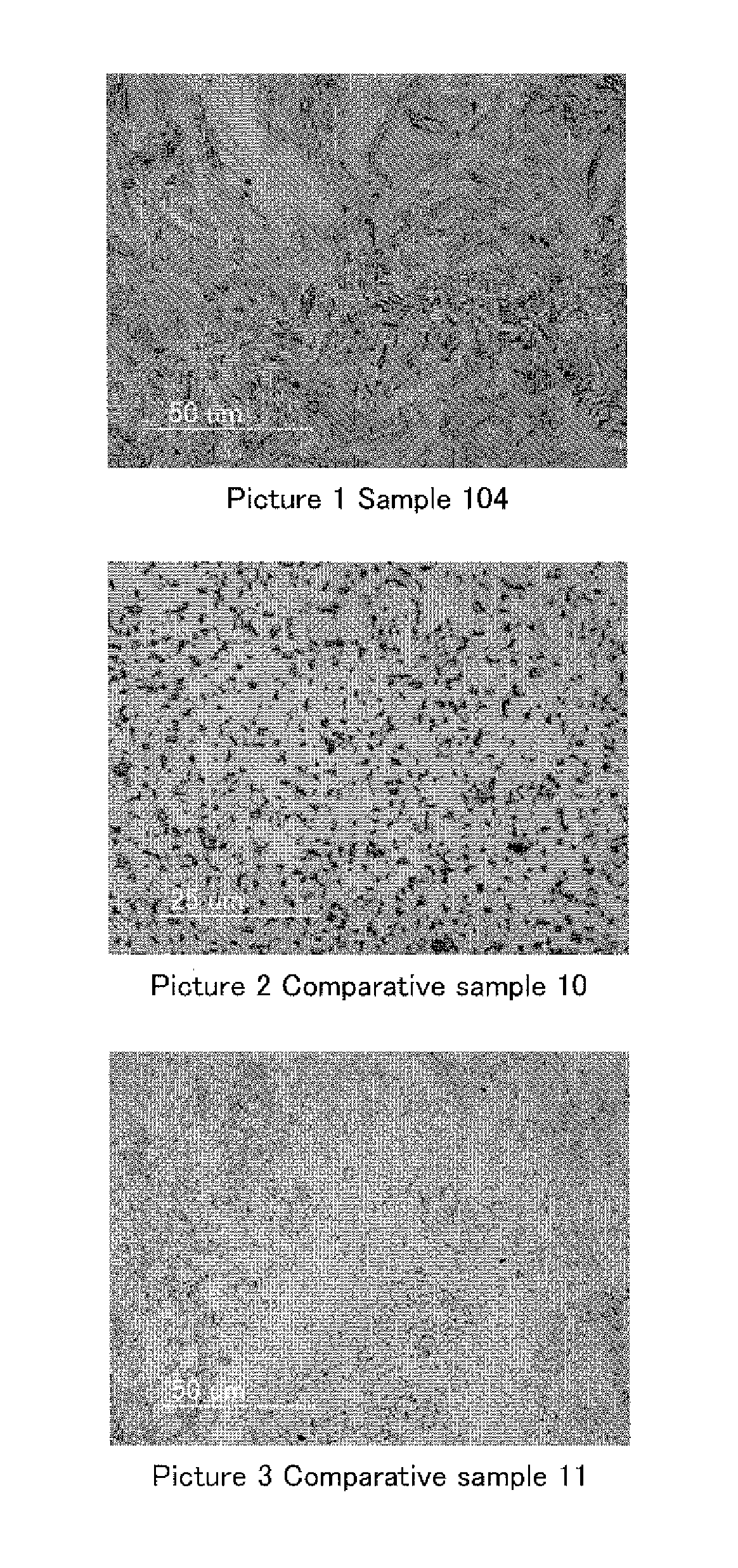

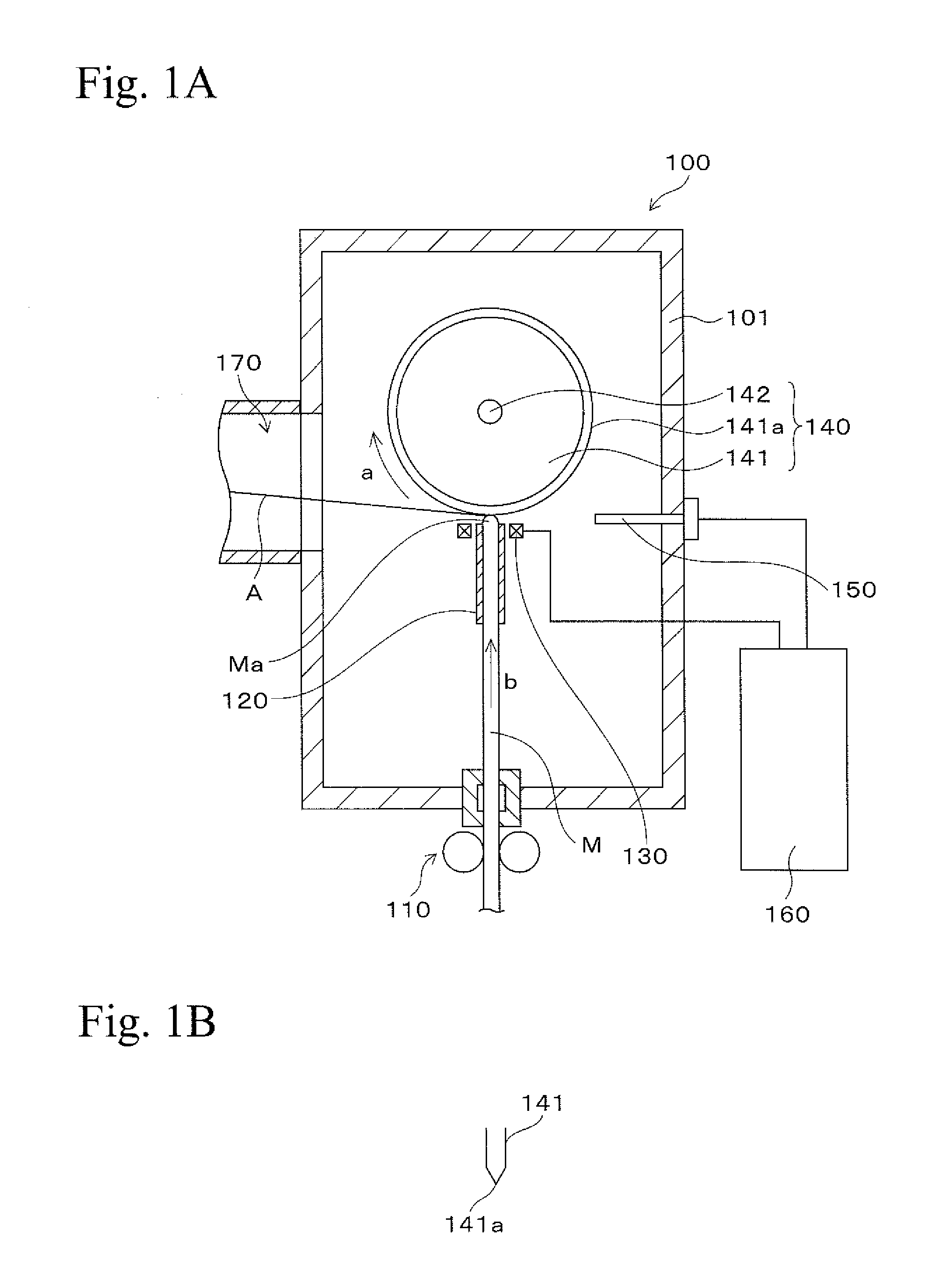

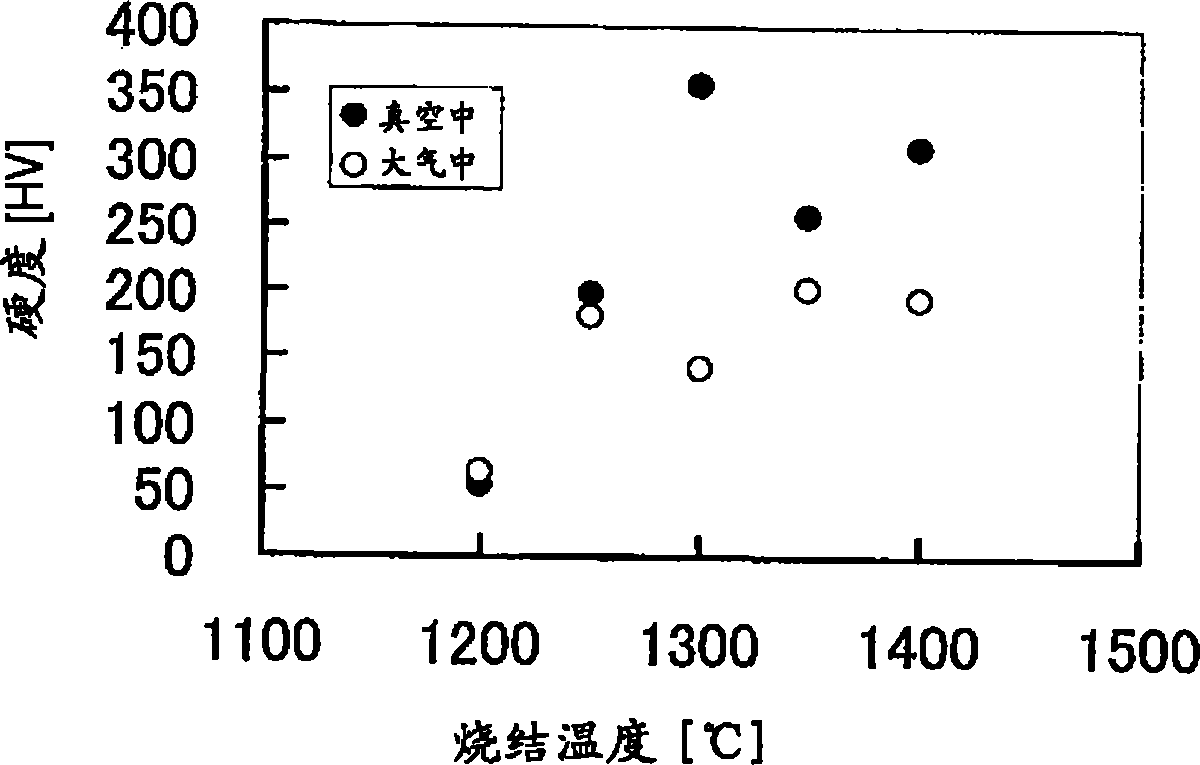

Titanium alloy member and production method therefor

InactiveUS20140212319A1High strengthImprove fatigue resistanceTransportation and packagingMetal-working apparatusSurface layerSintered titanium

A high strength titanium alloy member with superior fatigue resistance, and a production method therefor, are provided. The production method includes preparing a raw material made of titanium alloy, nitriding the raw material to form a nitrogen-containing raw material by generating a nitrogen compound layer and / or a nitrogen solid solution layer in a surface layer of the raw material, mixing the raw material and the nitrogen-containing raw material to yield a nitrogen-containing mixed material, sintering the nitrogen-containing mixed material to obtain a sintered titanium alloy member by bonding the material together and uniformly diffusing nitrogen in solid solution from the nitrogen-containing raw material to the entire interior portion of the sintered titanium alloy member, hot plastic forming and / or heat treating the sintered titanium alloy member to obtain a processed member, and surface treating the processed member to provide compressive residual stress.

Owner:NHK SPRING CO LTD

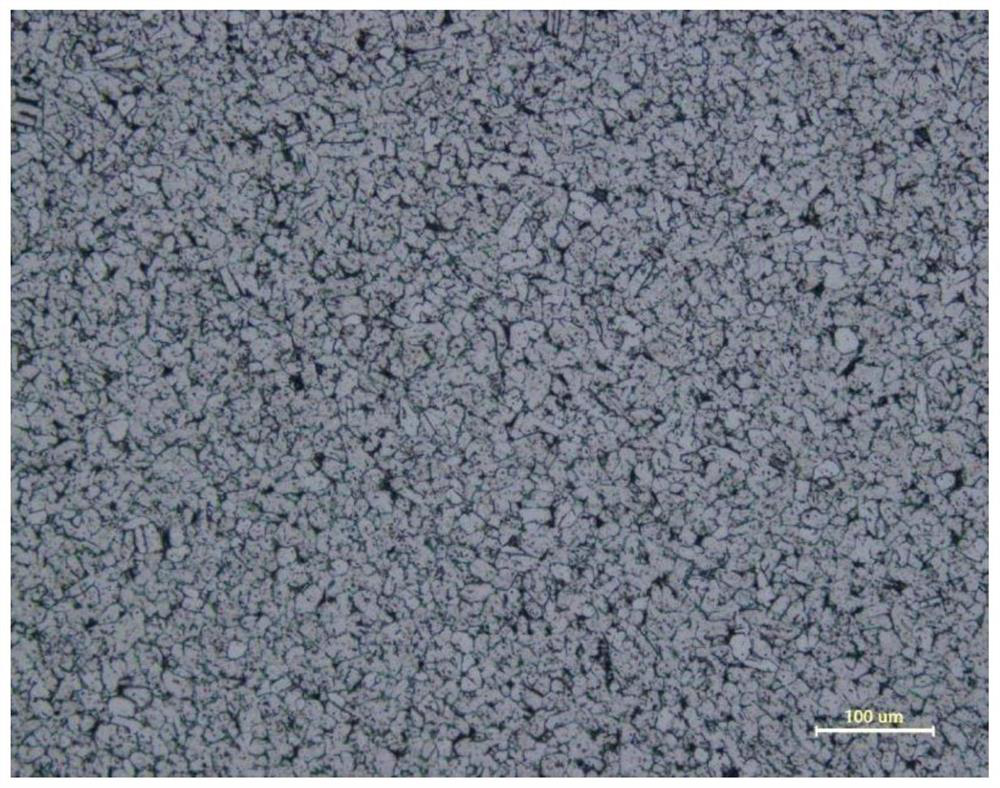

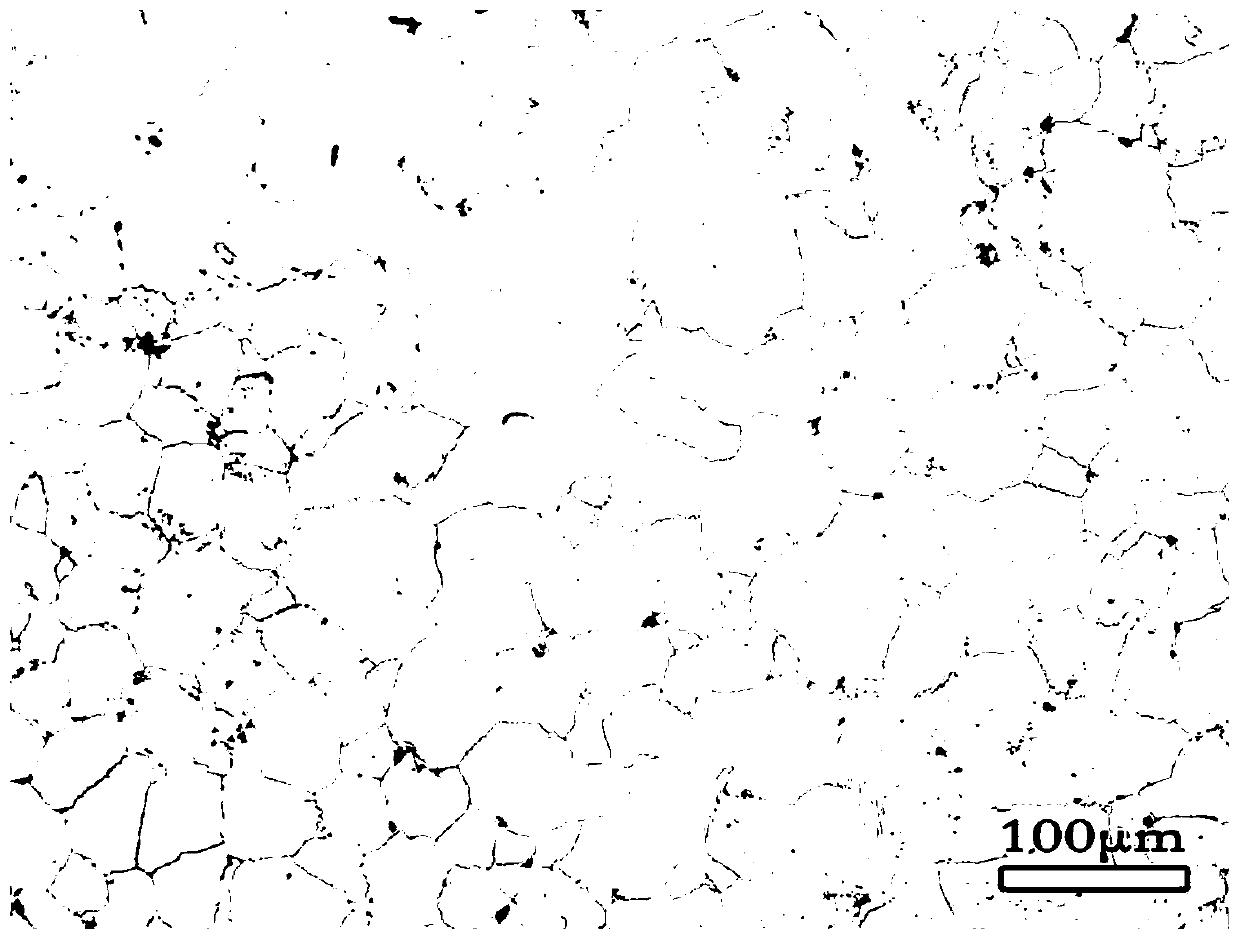

Preparation method of ultrahigh fatigue strength powder metallurgy titanium and titanium alloy

ActiveCN112941351ASolve the problem of poor fatigue performanceImprove fatigue strengthSintered titaniumHot working

The invention discloses a preparation method of ultrahigh fatigue strength powder metallurgy titanium and titanium alloy, and belongs to the field of powder metallurgy titanium. According to the method, an ultrahigh fatigue strength powder metallurgy titanium product is obtained from titanium sponge and alloy element powder as raw materials through hydrogenation, crushing, dehydrogenation, cold isostatic pressing, low-temperature vacuum sintering and high-temperature hot working. According to the method, low-temperature vacuum sintering of the powder metallurgy titanium alloy is achieved through the superfine titanium powder, sintered grains do not grow up, and due to the promoting effect of the fine powder on sintering, a sintered titanium blank does not crack in the subsequent hot working process. High temperature is adopted for hot working, the sintered titanium blank still has certain pores, and the pores hinder grain growth in the hot working process, so that uniform and fine equiaxed structures are obtained, the number of fine grain boundaries is increased, and the fatigue strength of the material is improved. The method is short in technological process, high in operability, suitable for industrial production and capable of effectively achieving application and popularization of the powder metallurgy titanium alloy.

Owner:UNIV OF SCI & TECH BEIJING

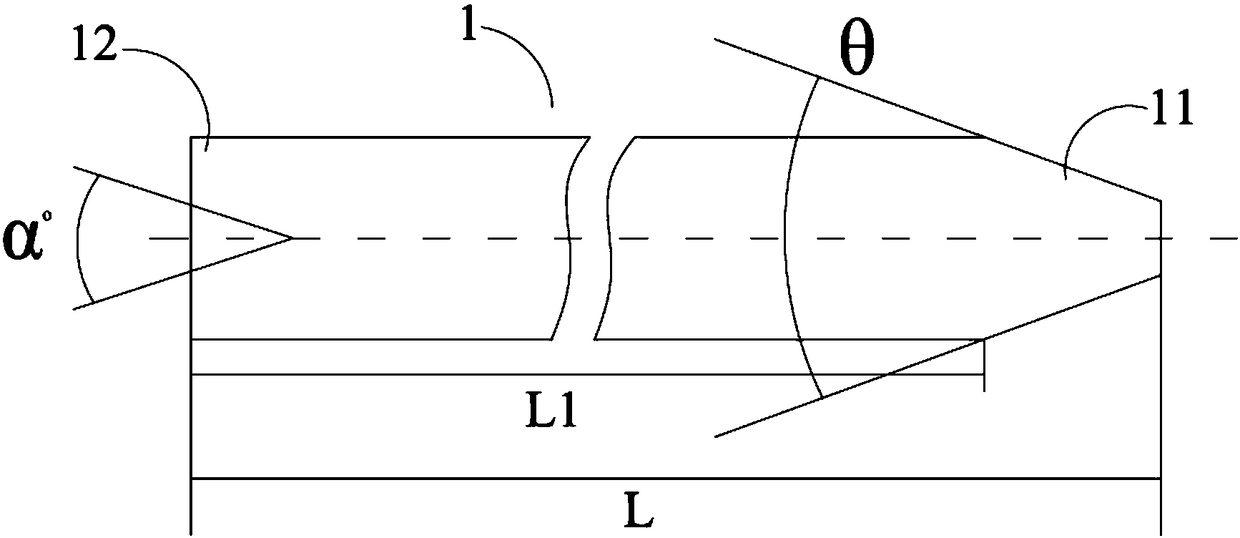

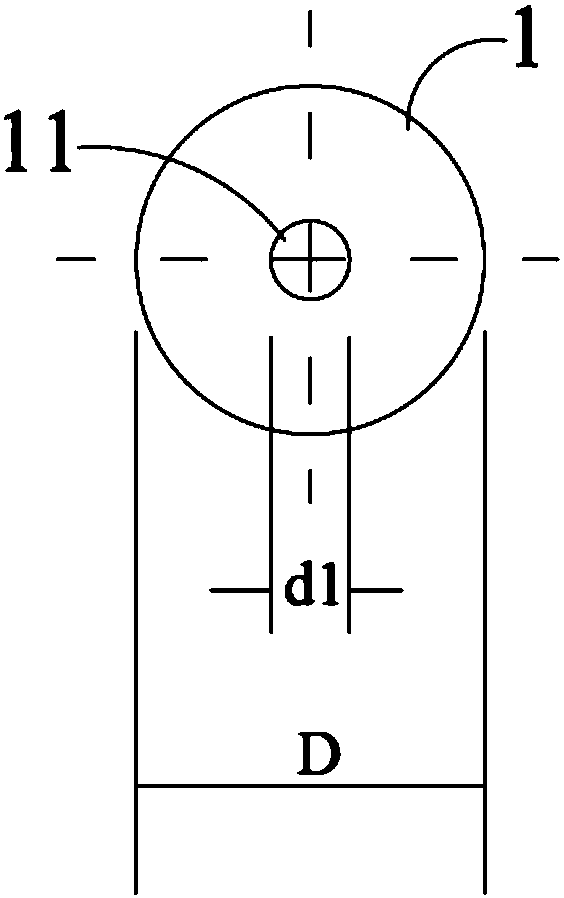

High-performance water jet scalpel ceramic sand tube and production method thereof

The invention provides a high-performance water jet scalpel ceramic sand tube and a production method thereof. The high-performance water jet scalpel ceramic sand tube comprises a tube body, and one end of the tube body is a tapered end. The production method comprise the following steps: performing compaction molding on a raw material pressureless-sintered silicon carbide, pressureless-sintered boron carbide or pressureless-sintered titanium boride granules by a cold isostatic pressing molding process, performing ceramic compact sintering through a pressureless sintering process, performing cooling to obtain a ceramic blank, and performing ground finishing on the ceramic blank to obtain the finished ceramic sand tube. The silicon carbide, boron carbide, titanium boride or other high-hardness and high-wear resistance ceramic materials can be processed to develop the high-hardness, good-wear resistance and long-service life wear-resistant sand tube for a water jet scalpel, so the cutting efficiency of the water jet scalpel is further improved.

Owner:苏州汉尼威电子技术有限公司

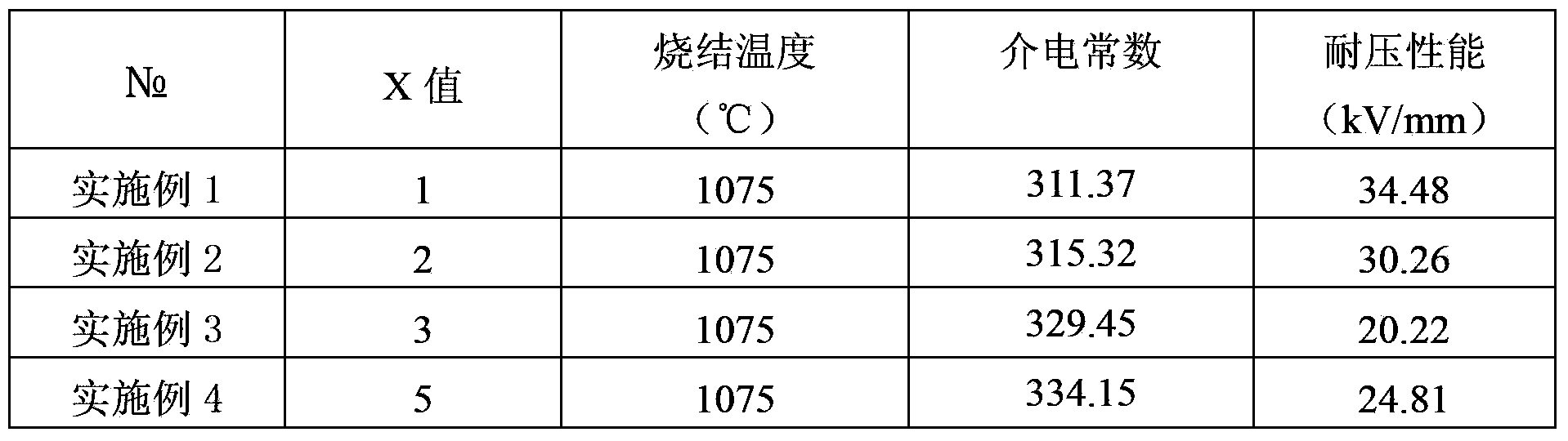

Low-temperature sintered strontium titanate energy-storing medium ceramic material and preparation method thereof

InactiveCN103396117AHigh dielectric constantHigh compressive strengthStrontium titanium oxideCompressive strength

The invention discloses a low-temperature sintered strontium titanate energy-storing medium ceramic material with a chemical formula of (Sr[0.9]Mg[0.1])(Ti[0.96]Zr[0.04])O[3] + x mol% BaCuB[2]O[5] (0<x<=5). By employing a conventional solid phase method and sintering at 1000 DEG C-1175 DEG C, the strontium titanate energy-storing medium ceramic material with a higher dielectric constant, higher compressive strength and a lower sintering temperature is prepared and has a wide application prospect.

Owner:TIANJIN UNIV

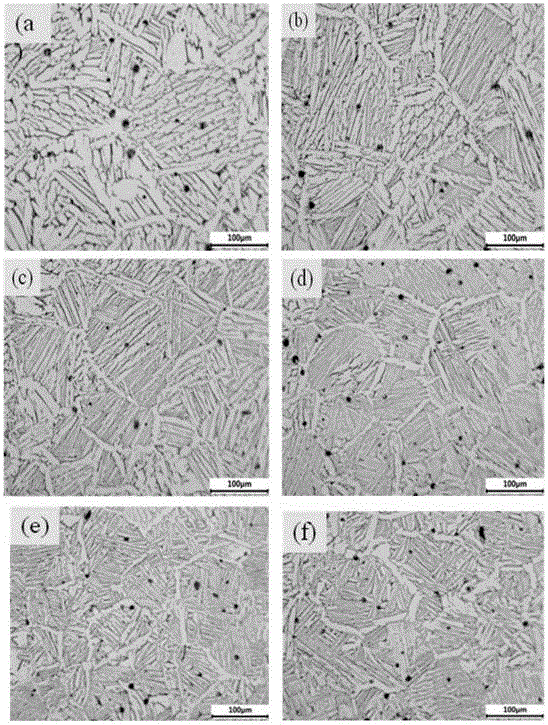

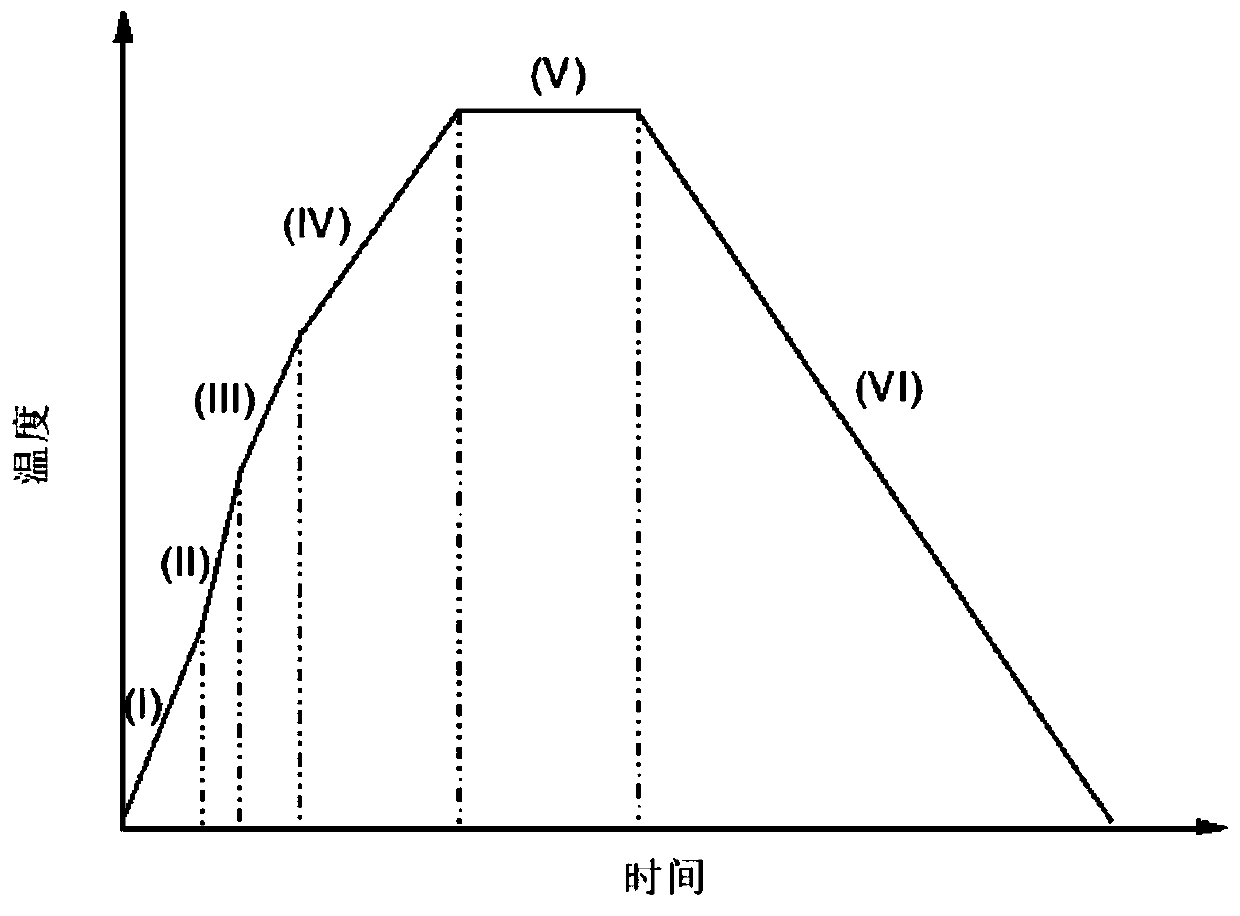

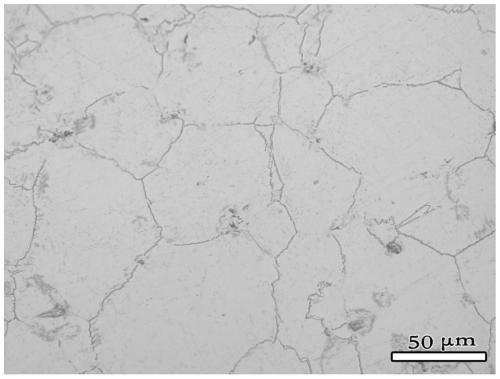

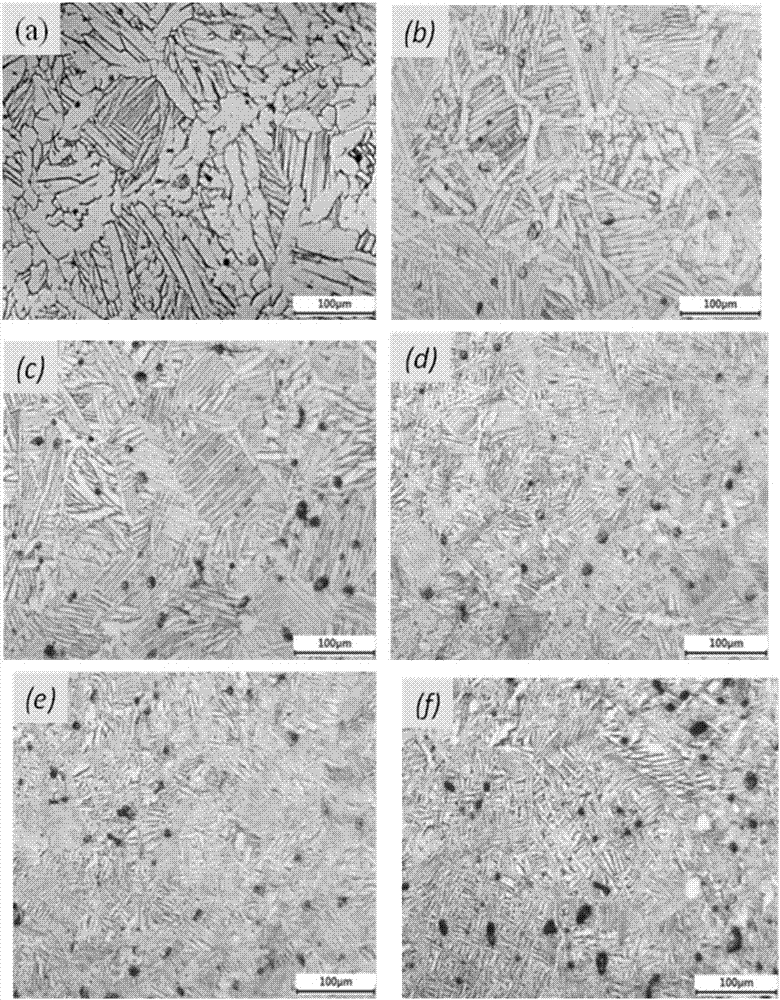

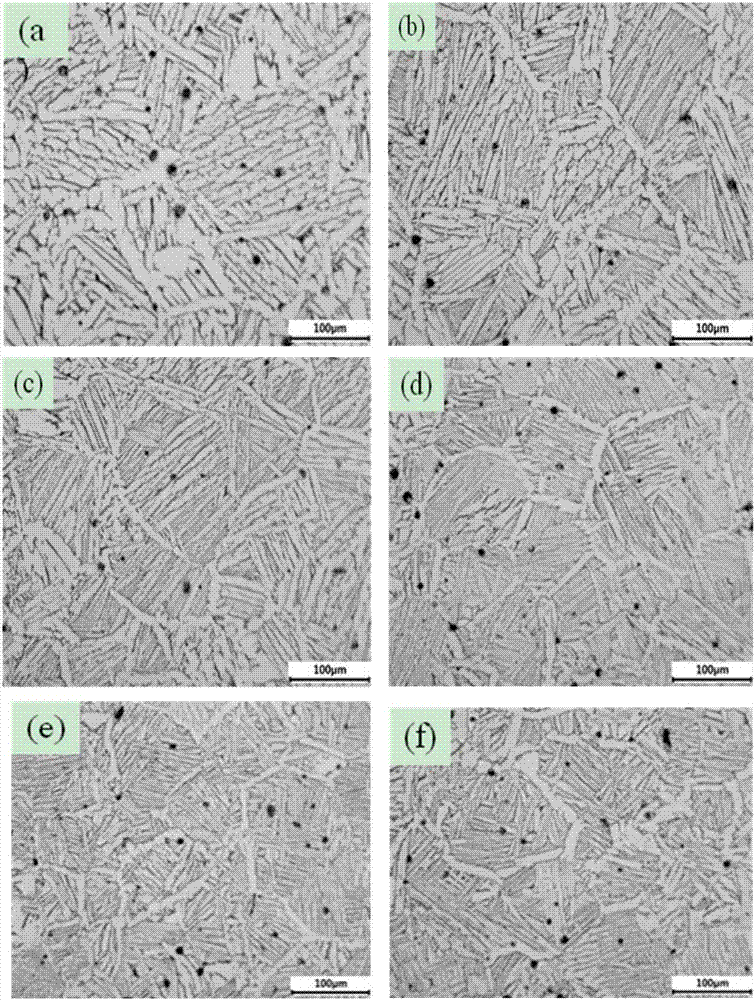

Normal-pressure multi-step sintering method for powder metallurgy of high-density Ti-Nb-Mo series alloy

ActiveCN111203531AHigh densityHomogeneous organizationTransportation and packagingMetal-working apparatusSintered titaniumCompressive strength

The invention provides a normal-pressure multi-step sintering method for powder metallurgy of a high-density Ti-Nb-Mo series alloy, and belongs to the technical field of alloys. According to the method, the multi-step sintering is carried out under normal pressure by adopting a temperature programming mode, and different protective atmospheres and gas flow rates are adopted at different temperature programming stages of the sintering, so that the capability of titanium hydride to improve the density of the powder metallurgy titanium alloy is maximally exerted, and the sintered titanium alloy is high in density and uniform and consistent in structure and performance. The results of the method show that the density of the Ti-Nb-Mo series alloy obtained by using the normal-pressure multi-stepsintering method can reach 99% or above, the average grain size is 30.2-39.7 microns, the yield strength of the alloy can reach 960 MPa, the compressive strength can reach 1287 MPa, and the criticalfailure strain is more than 0.7.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

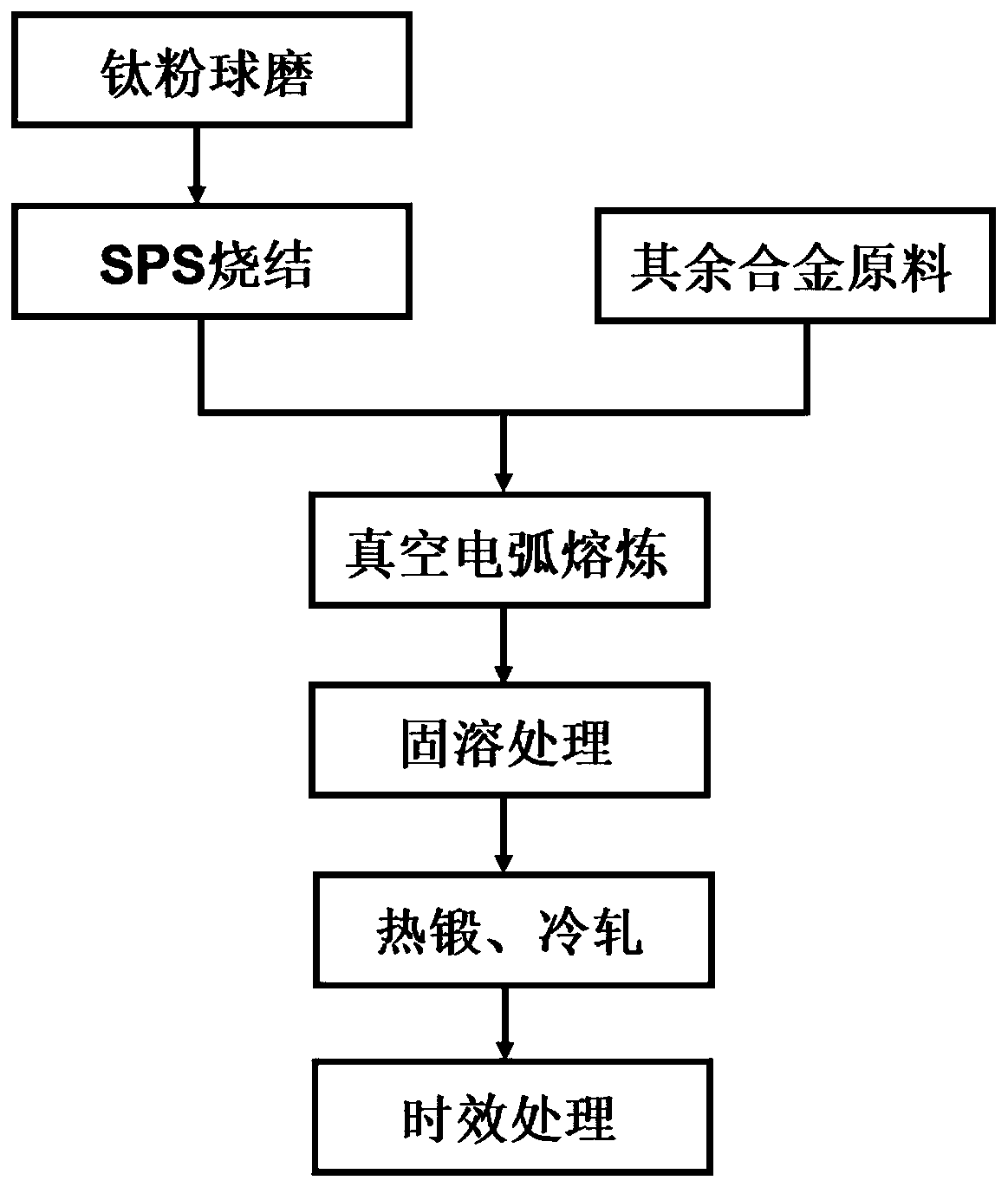

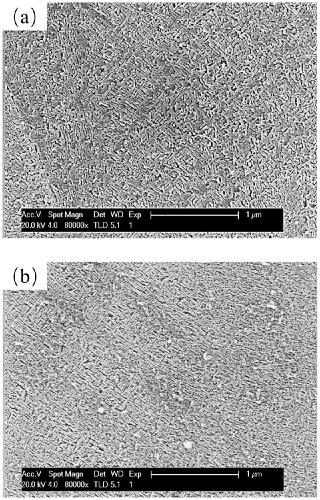

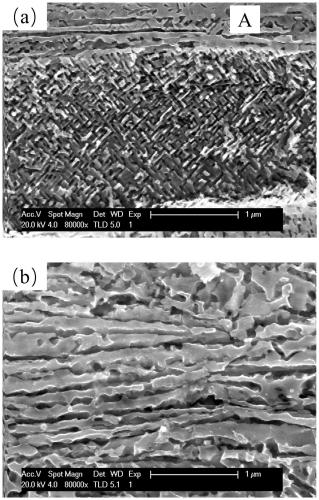

High-strength high-elasticity titanium alloy and preparation method thereof

ActiveCN109971997AHigh strengthRaise σ <sub>0.2<</sub> Increasing energy efficiencyElectric arc furnaceTitanium alloy

The invention relates to a high-strength high-elasticity titanium alloy and a preparation method thereof. The alloy comprises the following components of, in percentage by weight, 30%-32% of Nb, 4%-6%of Zr, 2%-3% of Mo, 0.038%-0.088% of Fe; 0.016%-0.037% of Cr, 0.005%-0.011% of Ni and the balance titanium; the preparation method of the alloy comprises the following specific steps of carrying outmechanical ball milling on titanium powder and absolute ethyl alcohol in a ball milling tank and a ball milling system composed of 0Cr18Ni9, and then performing SPS sintering on the titanium powder toobtain titanium sintering block containing trace Fe, Cr and Ni oxides; smelting flaky sintered titanium, titanium sponge, Nb, Zr and Mo raw materials in an electric arc furnace to obtain an alloy ingot; carrying out hot forging on the cast ingot into a bar material and carrying out solid solution treatment, and then carrying out cold rolling deformation processing; and finally, carrying out agingheat treatment, so that the alpha phase with the extremely fine nanometer size is separated out from a beta-precipitation matrix body. The obtained titanium alloy has high strength and high elastic performance, is low in elasticity modulus and high in elongation rate, is very suitable for manufacturing high-elasticity parts in the fields of aerospace, machinery and the like, and can also be applied to the preparation of biomedical implants.

Owner:SOUTHEAST UNIV

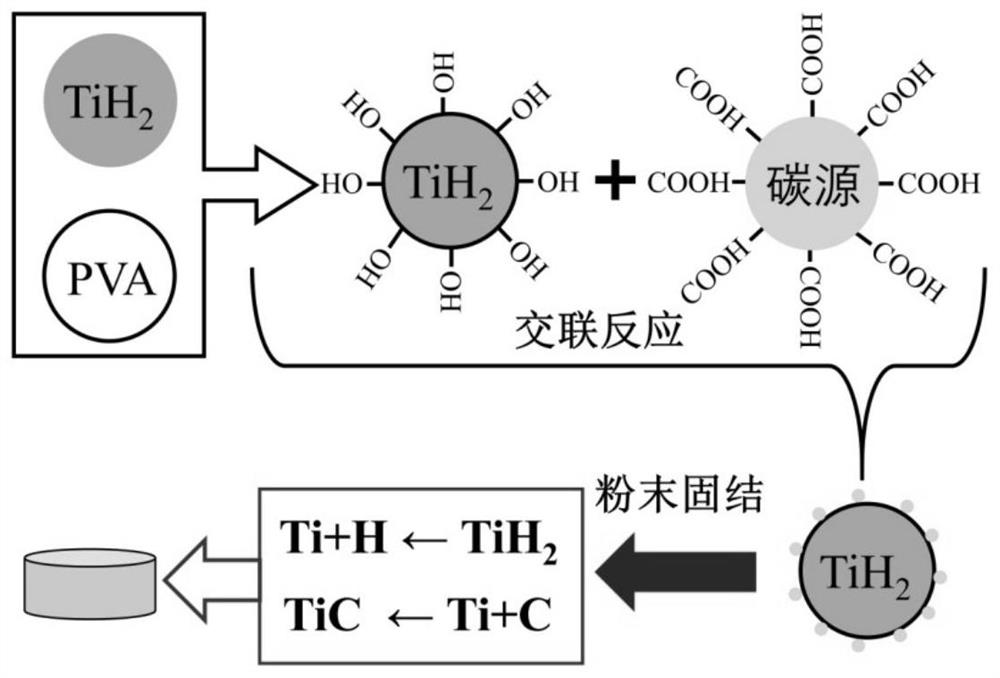

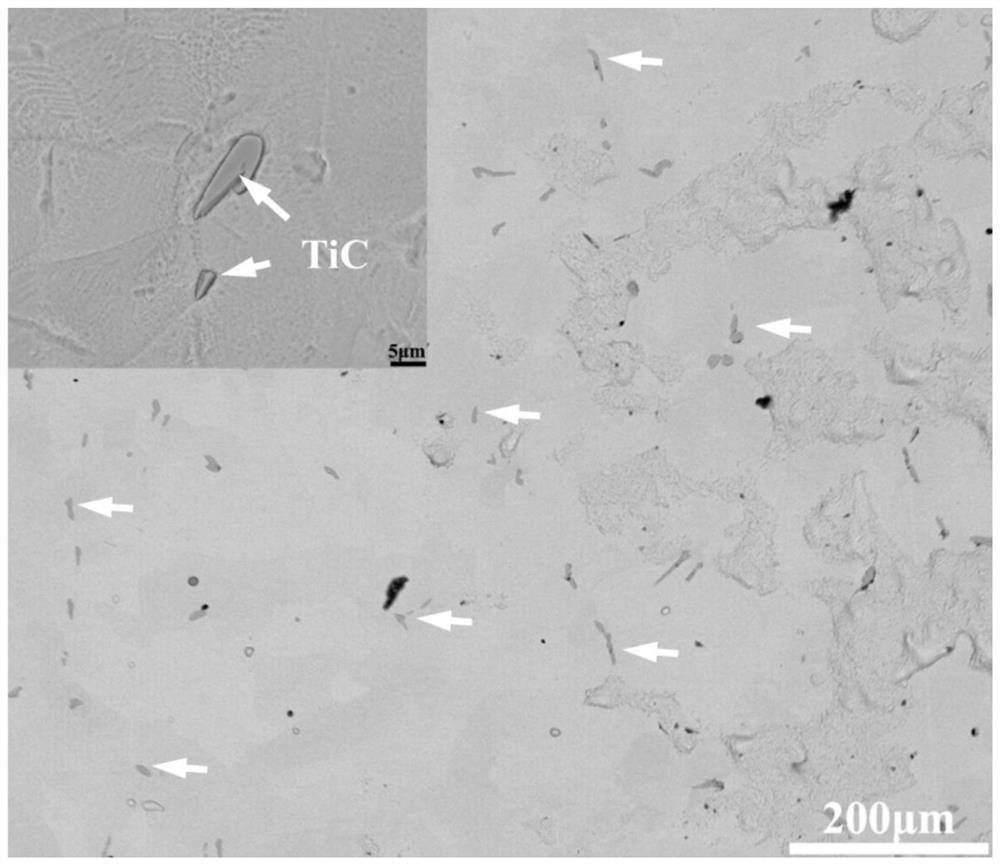

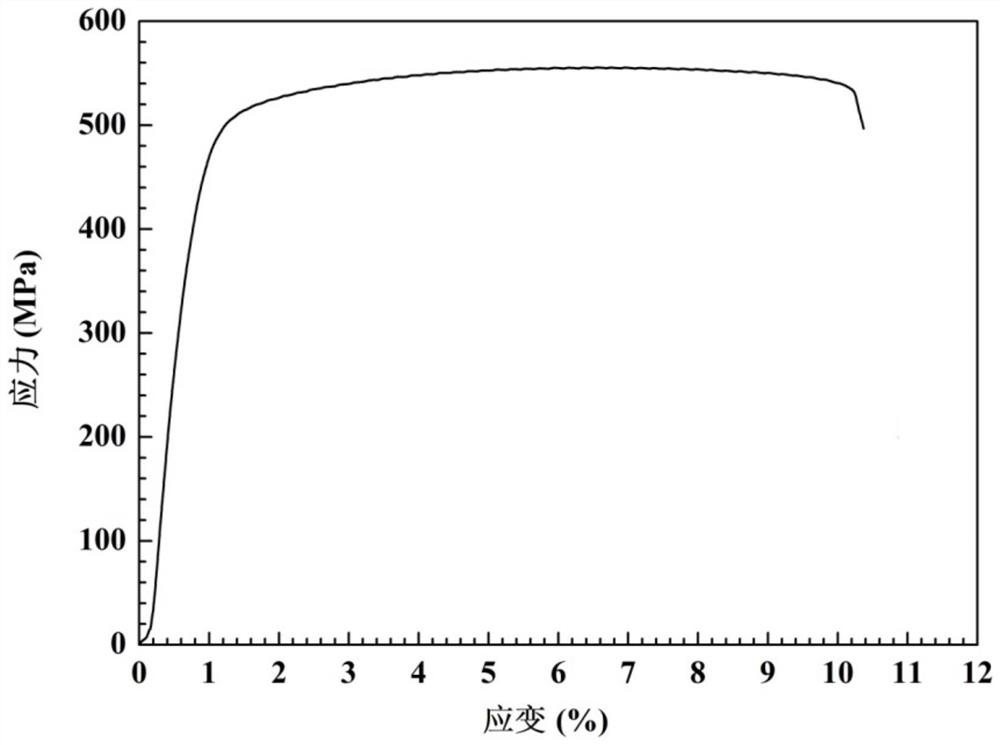

Method for preparing TiC reinforced titanium-based composite material based on cross-linking modified sintered titanium hydride

ActiveCN112342419ATensile plasticity achievedWear volume reductionTransition element hydridesTitanium matrix compositesNonferrous metal

The invention belongs to the technical field of non-ferrous metal processing, and discloses a method for preparing a TiC reinforced titanium-based composite material based on cross-linking modified sintered titanium hydride and the prepared composite material. Particularly, composite powder is prepared through the cross-linking reaction of hydroxylated titanium hydride and a carbon source, and theTiC reinforced titanium-based composite material is generated in situ through high-temperature sintering. According to the composite material prepared through the method, TiC with the size of 1-50 microns is evenly distributed in a Ti matrix, and the density of a sintered block is larger than or equal to 99%; and the tensile plasticity can reach 8%, the tensile strength can reach 570 MPa, and theabrasion volume is reduced by 19% compared with pure titanium. By means of the method, the problem of poor mechanical properties of a titanium-based composite material prepared by taking titanium hydride as a raw material in the prior art is solved, the preparation cost of the composite material is reduced, and the obtained TiC reinforced titanium-based composite material with excellent properties can be applied to preparation of high-strength wear-resistant structural parts in the fields of aerospace, armored cars, weapons, ships, automobiles and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

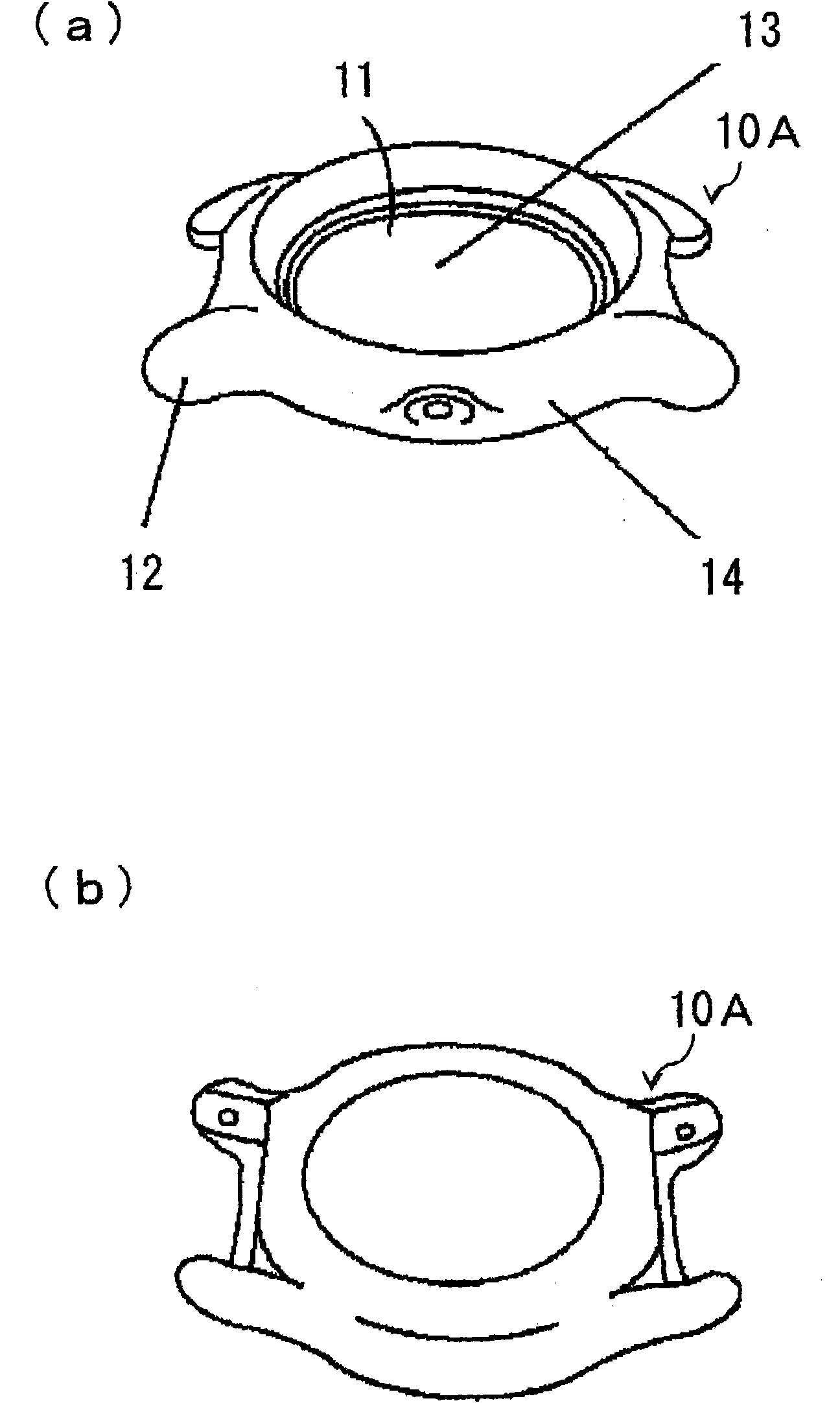

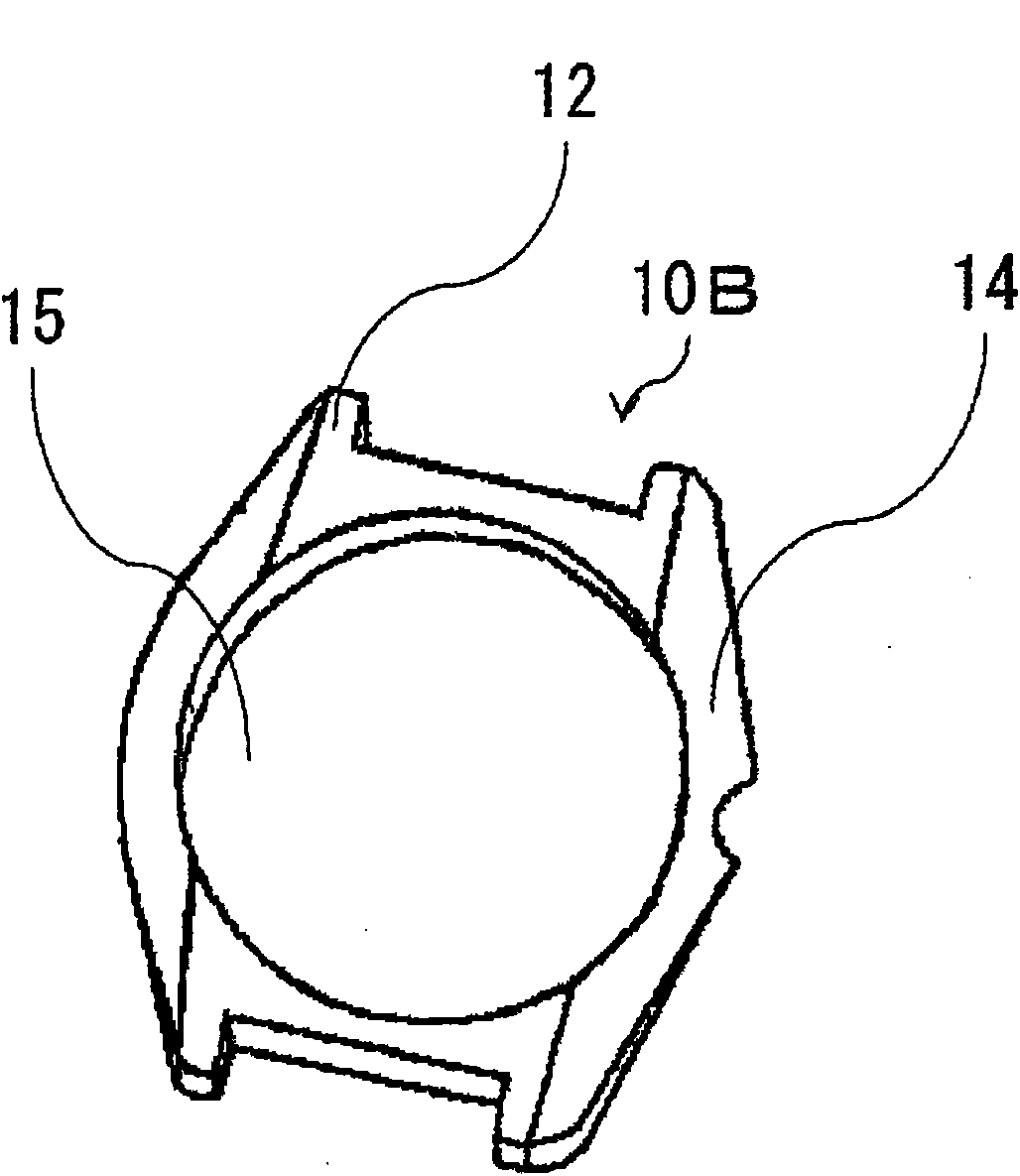

Titanium alloy member and production method therefor

InactiveUS20140112819A1High stressHigh strengthTransportation and packagingMetal-working apparatusSurface layerSintered titanium

A titanium alloy member with high strength and high proof stress not only in the surface but also inside, using a general and inexpensive α-β type titanium alloy, and a production method therefor, are provided. The production method includes preparing a raw material made of titanium alloy, nitriding the raw material to form a nitrogen-containing raw material by generating a nitrogen compound layer and / or a nitrogen solid solution layer in a surface layer of the raw material, mixing the raw material and the nitrogen-containing raw material to yield a nitrogen-containing mixed material, sintering the nitrogen-containing mixed material to obtain a sintered titanium alloy member by bonding the material together and uniformly diffusing nitrogen in solid solution from the nitrogen-containing raw material to the entire interior portion of the sintered titanium alloy member, and hot plastic forming the sintered titanium alloy member.

Owner:NHK SPRING CO LTD

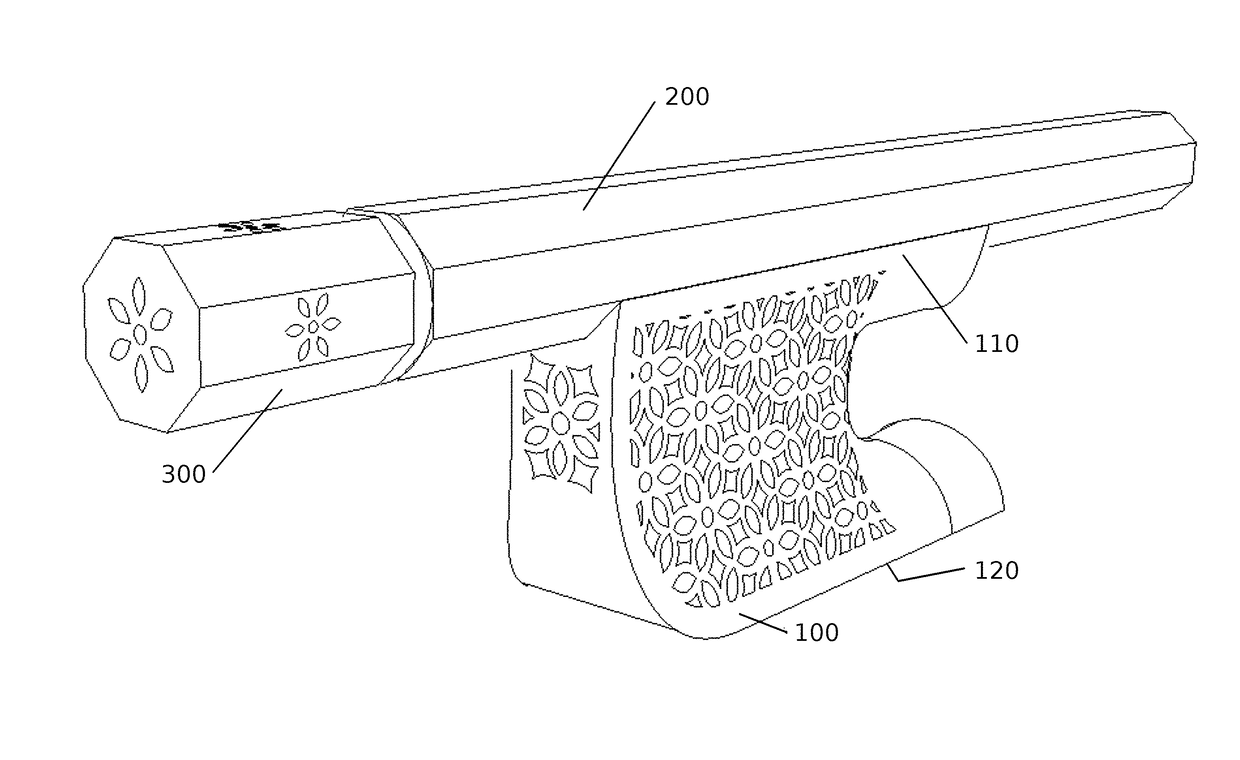

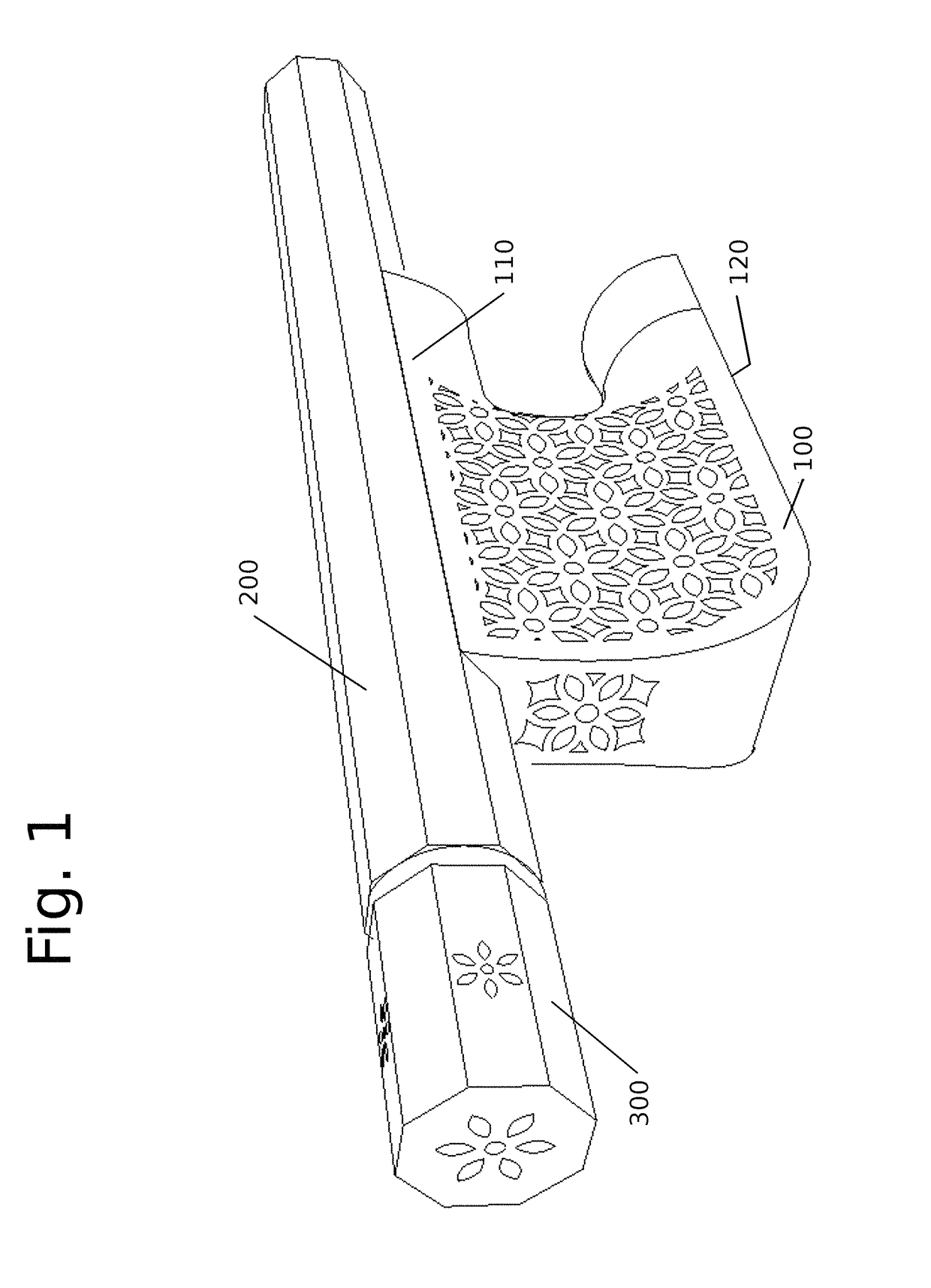

Metal frog for a violin bow

InactiveUS9959846B1Without negatively impacting qualityReduce usageStringed musical instrumentsSintered titaniumEngineering

A frog for a stringed instrument bow is disclosed which has a hollow metal body, which may be made, for example, of direct laser metal sintered titanium. The hollow body has a top side adapted to engage a bow stick of the stringed instrument bow, and a bottom side adapted to support a hair bundle of the stringed instrument bow. A back stop is positioned proximate the bottom side in the interior of the hollow metal body and a cam attached to the bottom side of the hollow metal body is adapted to slide or rotate with respect to the hollow metal body, from an open position in which a hair bundle can be inserted in the hollow metal body and a closed position in which the cam forms a pinch point with the back stop to secure the hair bundle.

Owner:LANDON CHRISTOPHE +1

A kind of preparation method of powder metallurgy titanium alloy

The invention relates to a preparing method for a powder metallurgy titanium alloy. The preparing method includes the following steps that TiH2 powder, Ti powder and other alloy elements serve as raw materials and are evenly mixed to be subject to compression molding, wherein the adding amount of TiH2 accounts for 3%-25% of the total mass of the raw materials; the TiH2 is heated in a high-vacuum environment to be decomposed and is sintered in a hydrogen atmosphere; then the temperature is reduced to 750 DEG C to 1000 DEG C, and vacuum pumping is conducted for hydrogen removing; and finally, the powder metallurgy titanium alloy product is obtained after cooling. According to the preparing method, the element H is added into the powder metallurgy titanium alloy in the form of titanium hydride, and the adding amount of the H is controlled by controlling the amount of the titanium hydride; and meanwhile, the organization structure of the sintered titanium alloy is adjusted by controlling the H removing temperature of the hydrogen atmosphere sintered titanium alloy, and the high-performance titanium alloy is obtained. Compared with a method without adding titanium hydride, the density of the alloy obtained in the preparing method is increased, and the tensile strength is increased.

Owner:HUNAN UNIV

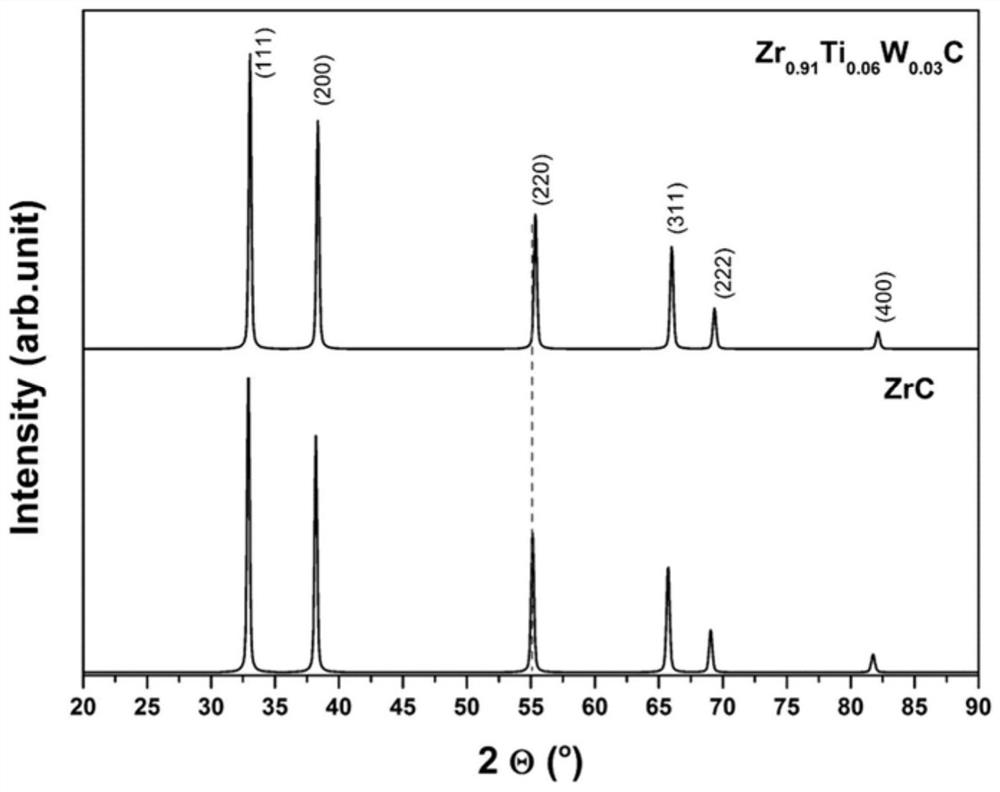

Easy-to-sinter titanium and tungsten co-doped zirconium carbide powder and preparation method thereof

The invention relates to the technical field of ultrahigh-temperature ceramics, in particular to easy-to-sinter titanium and tungsten co-doped zirconium carbide powder and a preparation method thereof. The chemical formula of the easy-to-sinter titanium and tungsten co-doped zirconium carbide powder is Zr<1-x-y>Ti<x>WyC, x is larger than 0 and smaller than or equal to 0.05, and y is larger than 0and smaller than or equal to 0.05. The preparation method comprises the following steps: subjecting ZrO2, TiO2, WO3 and carbon black which are adopted as raw materials to high-temperature carbon thermal reduction reaction under the protection of vacuum or argon to prepare the titanium and tungsten co-doped zirconium carbide powder. The titanium and tungsten co-doped zirconium carbide powder easy to sinter is small in grain size, low in oxygen content, high in phase purity, high in sintering activity and wide in application range, and can be used as a raw material for pressureless sintering ofa zirconium carbide body material, an ultrahigh-temperature heat-proof coating material, a solar absorbing material and a base material of an ultrahigh-temperature composite material. The invention also provides the preparation method which is low in raw material cost, simple in technological process, low in equipment requirement and suitable for large-scale production.

Owner:SHANDONG ULSTREETCARING FINE CERAMICS +3

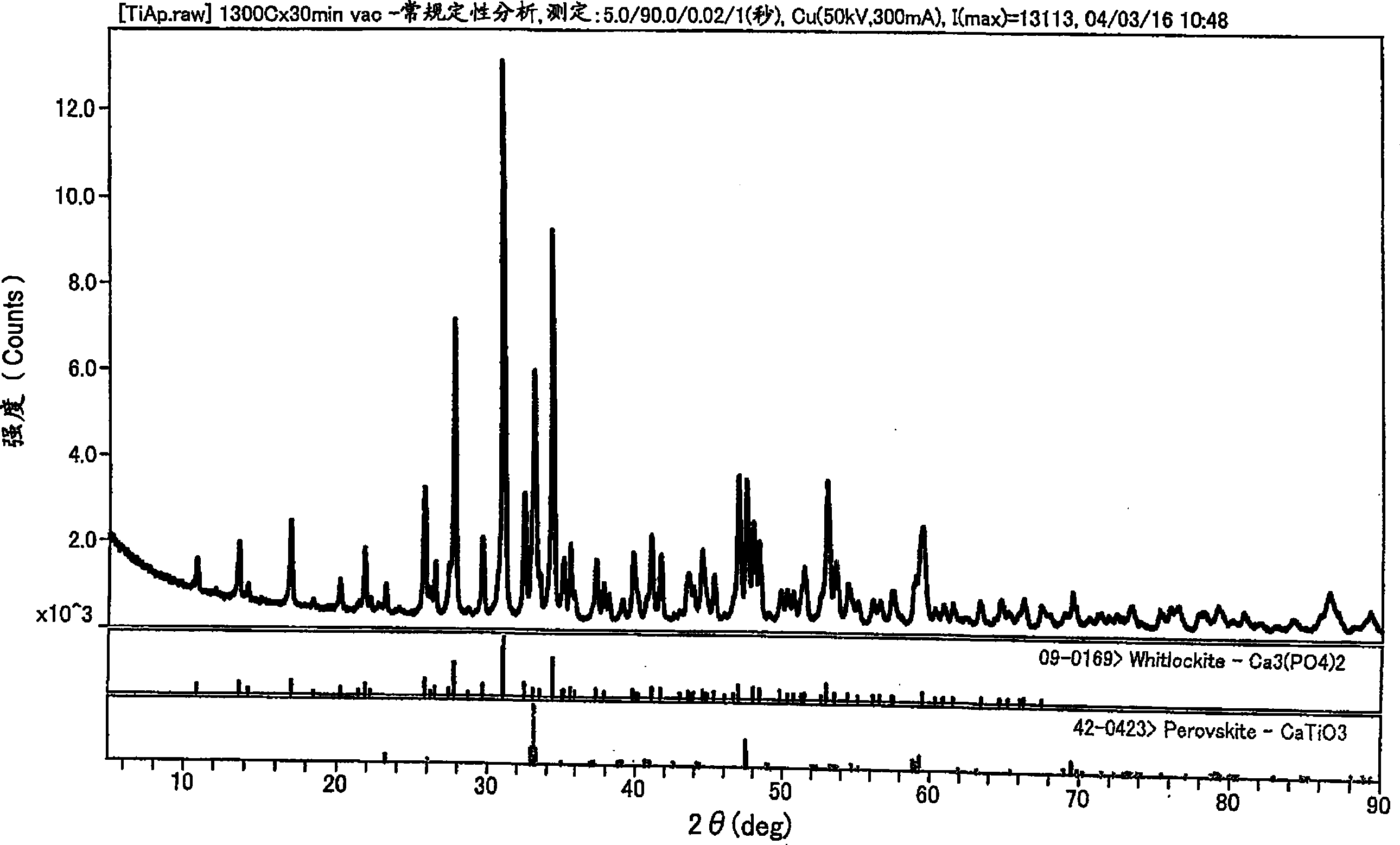

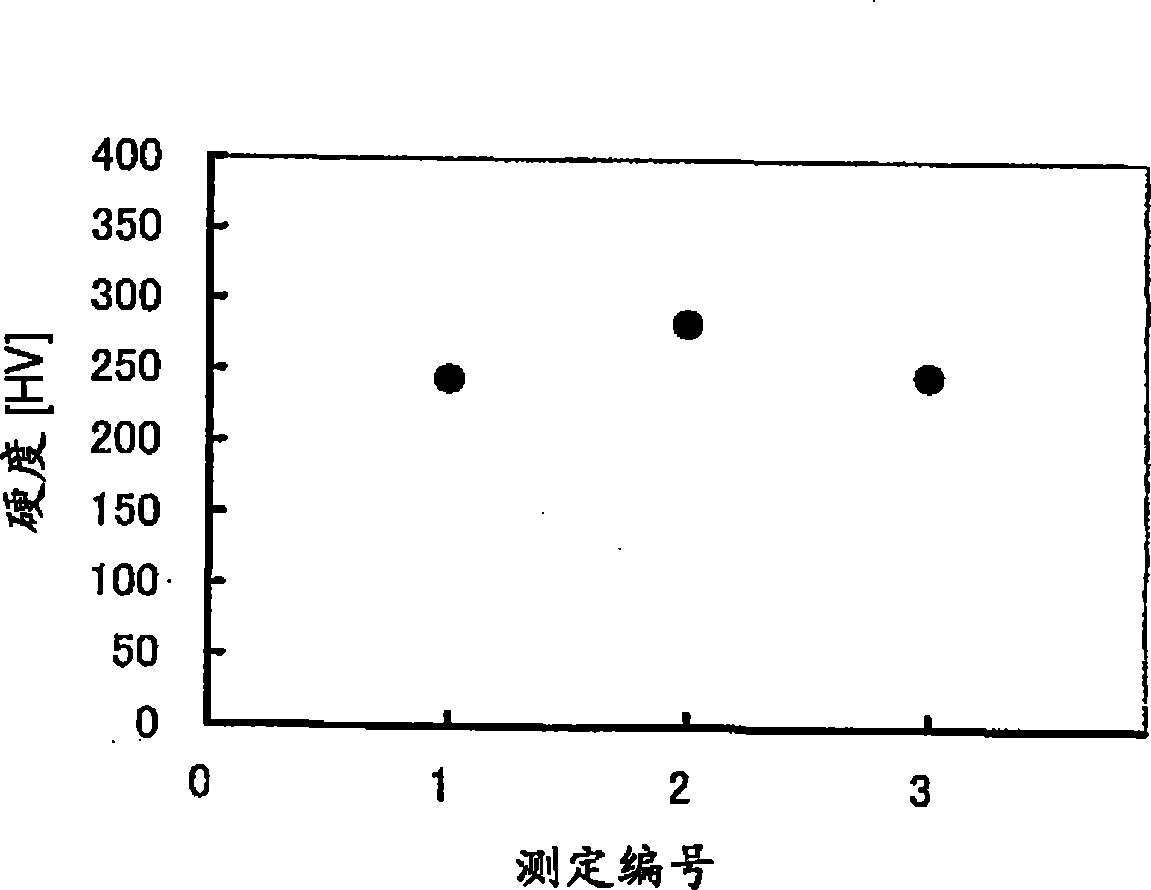

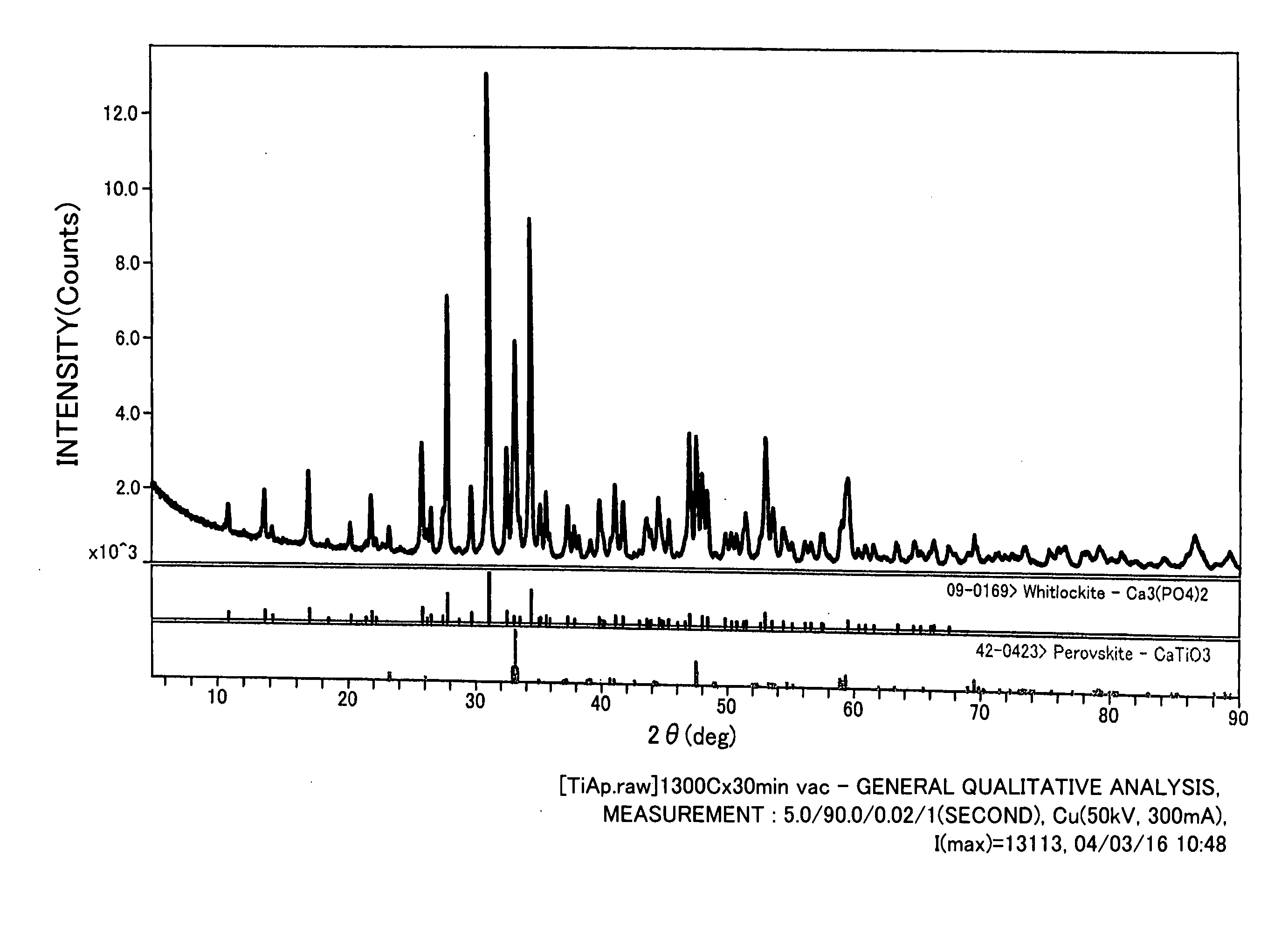

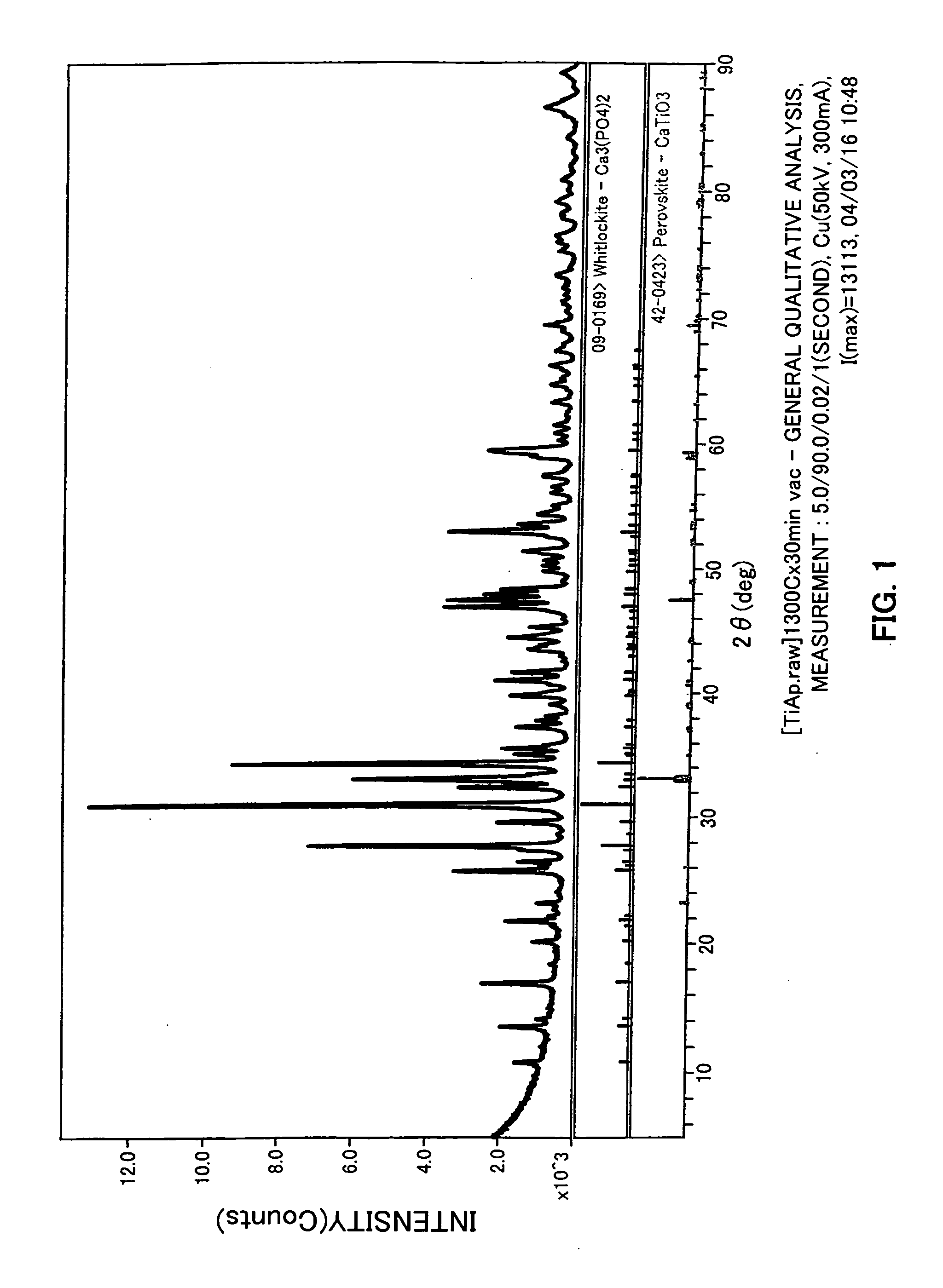

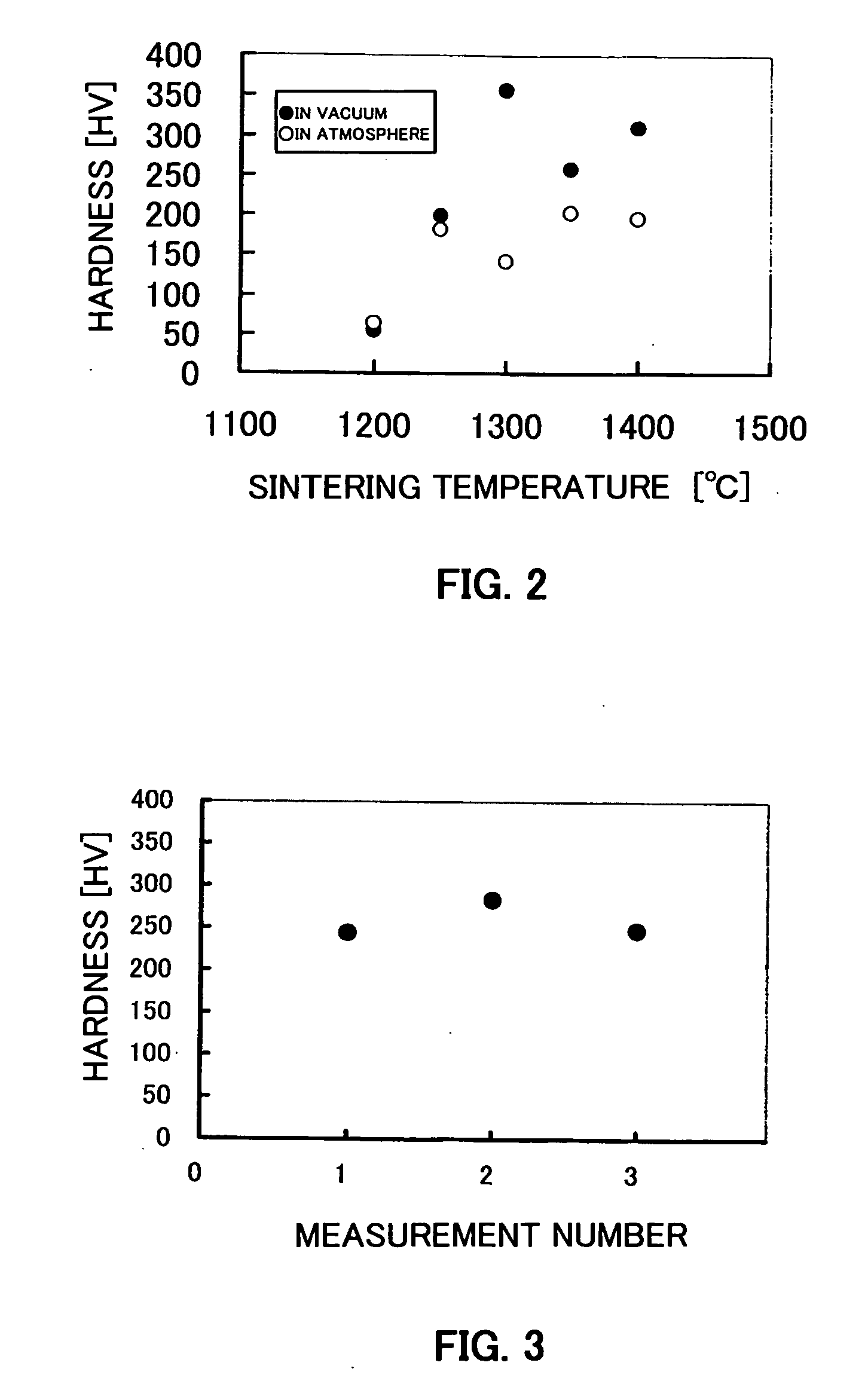

Sintered body of titanium compound

The present invention provides a sintered body of a titanium compound obtained by sintering the titanium compound and a preparation method thereof. This method is to prepare a sintered body by sintering a titanium compound represented by the following formula (1) or (2). [Ca10(PO4)6]TiO3·nH2O (1) [Ca10(PO4)6]TiO2(OH)2 (2) (wherein, n represents an integer of 0 to 3). The obtained sintered body was substantially composed of perovskite and calcium white phosphorite.

Owner:IMMUNO SCI

Sintered body of titanium compound

The present invention provides a sintered body of titanium compound obtained by sintering the titanium compound and a method for producing the same. A titanium compound represented by the formula (1) or (2) below is sintered. [Ca10(PO4)6]TiO3.nH2O (1) [Ca10(PO4)6]TiO2(OH)2 (2) (In the formulae, n is an integer of from 0 to 3). The obtained sintered body substantially consists of perovskite and whitlokite.

Owner:IMMUNO SCI

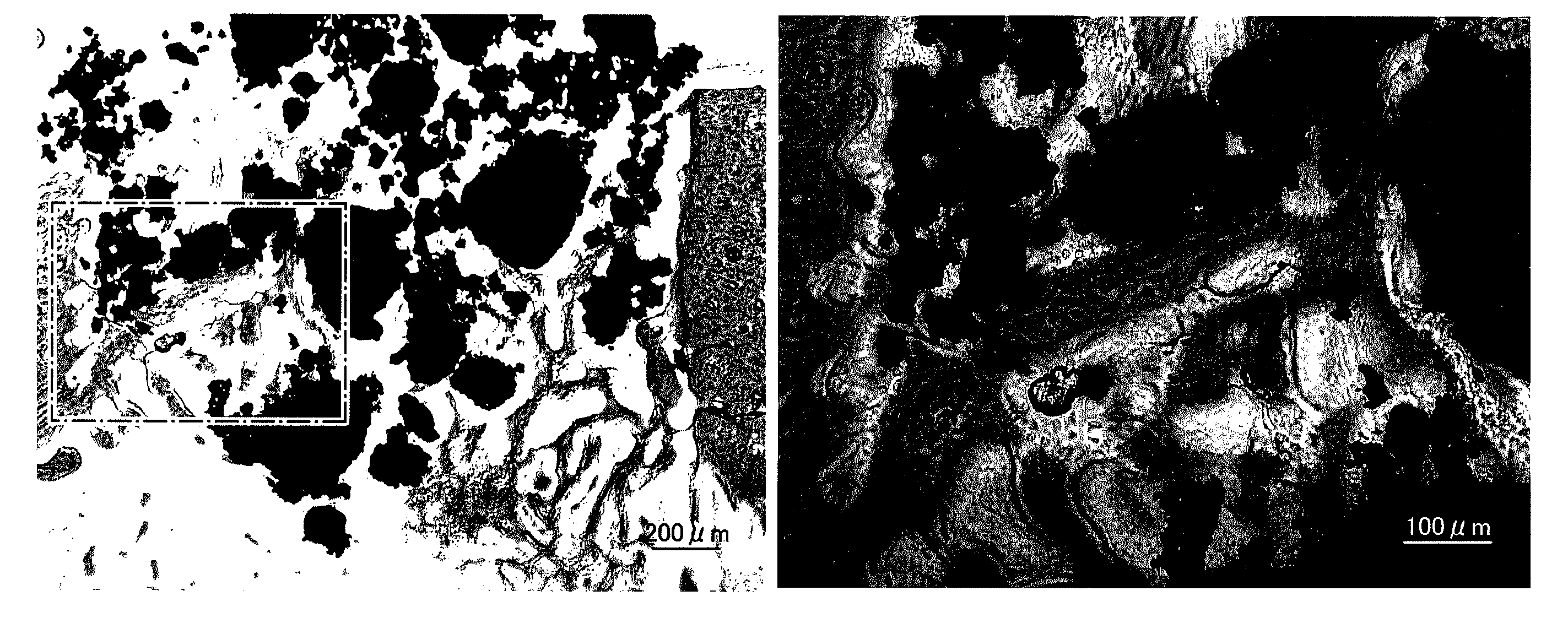

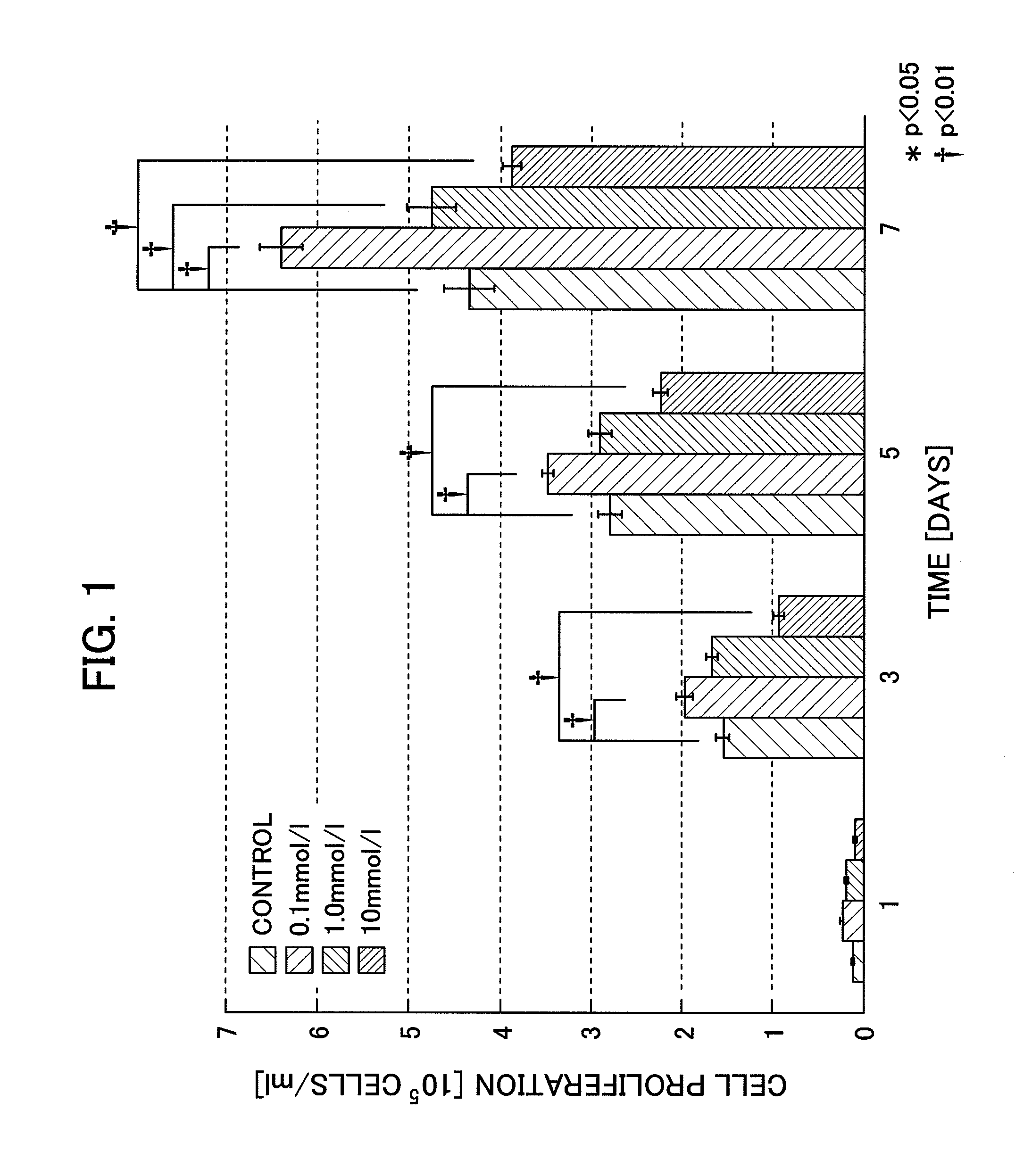

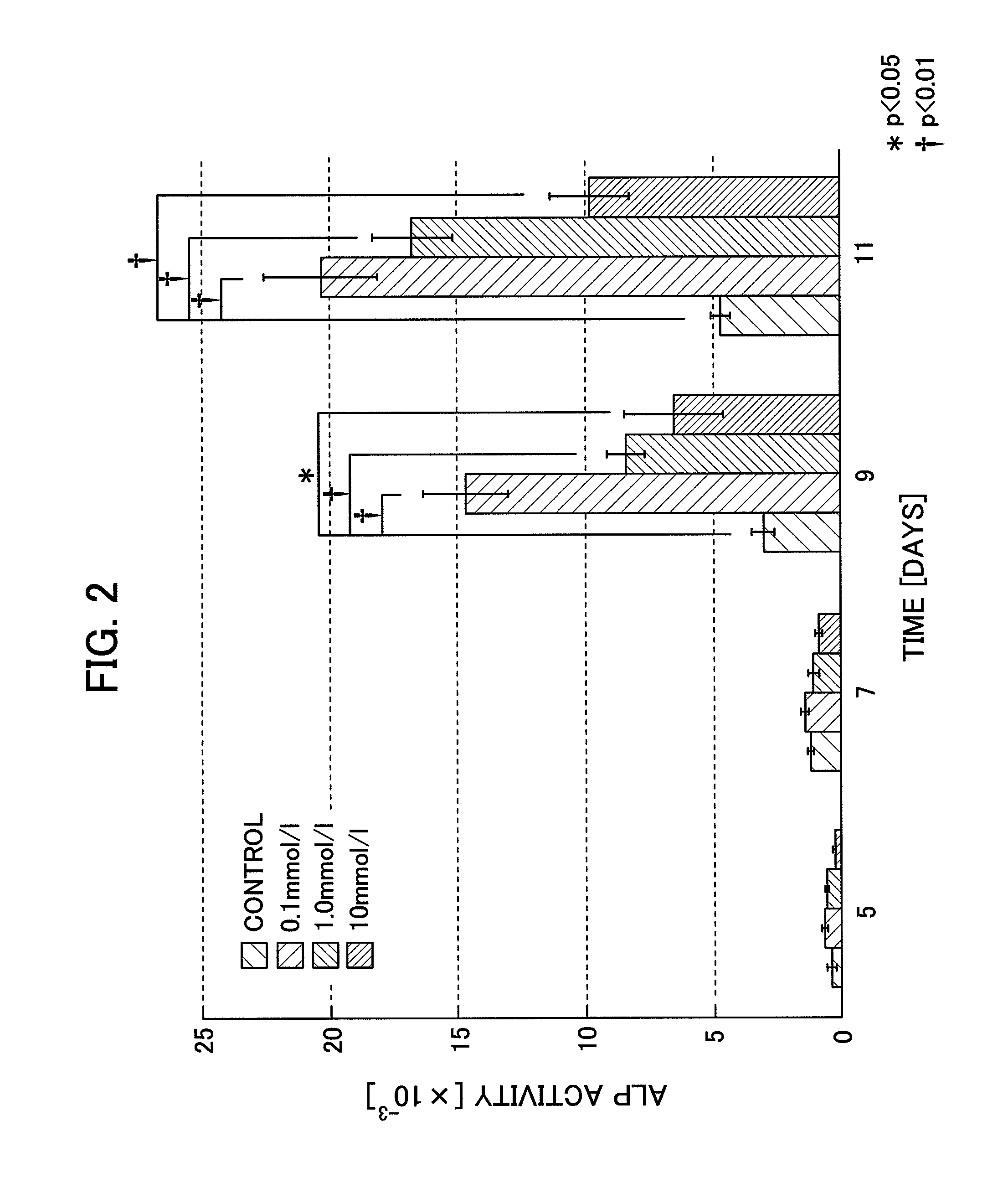

Bone filling material comprising sintered titanium dioxide and dextrin and method for reconstructing bone defects using the same

ActiveUS20120064172A1Good cell compatibilityGood biocompatibilityHeavy metal active ingredientsBiocideMedicineFilling materials

A bone filling material comprising sintered titanium dioxide and dextrin and a method for reconstructing bone defects which comprises filling the bone defects in an animal with the bone filling material. The bone filling material of the invention has excellent cell compatibility, biocompatibility and shape-imparting property.

Owner:AICHI GAKUIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com