High-strength high-elasticity titanium alloy and preparation method thereof

A titanium alloy, high-strength technology, applied in the field of high-strength and high-elasticity titanium alloys and preparation, can solve the problems of not reaching high strength, low alloy elongation, affecting alloy processing performance and fatigue performance, etc. Simple controllable, good elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

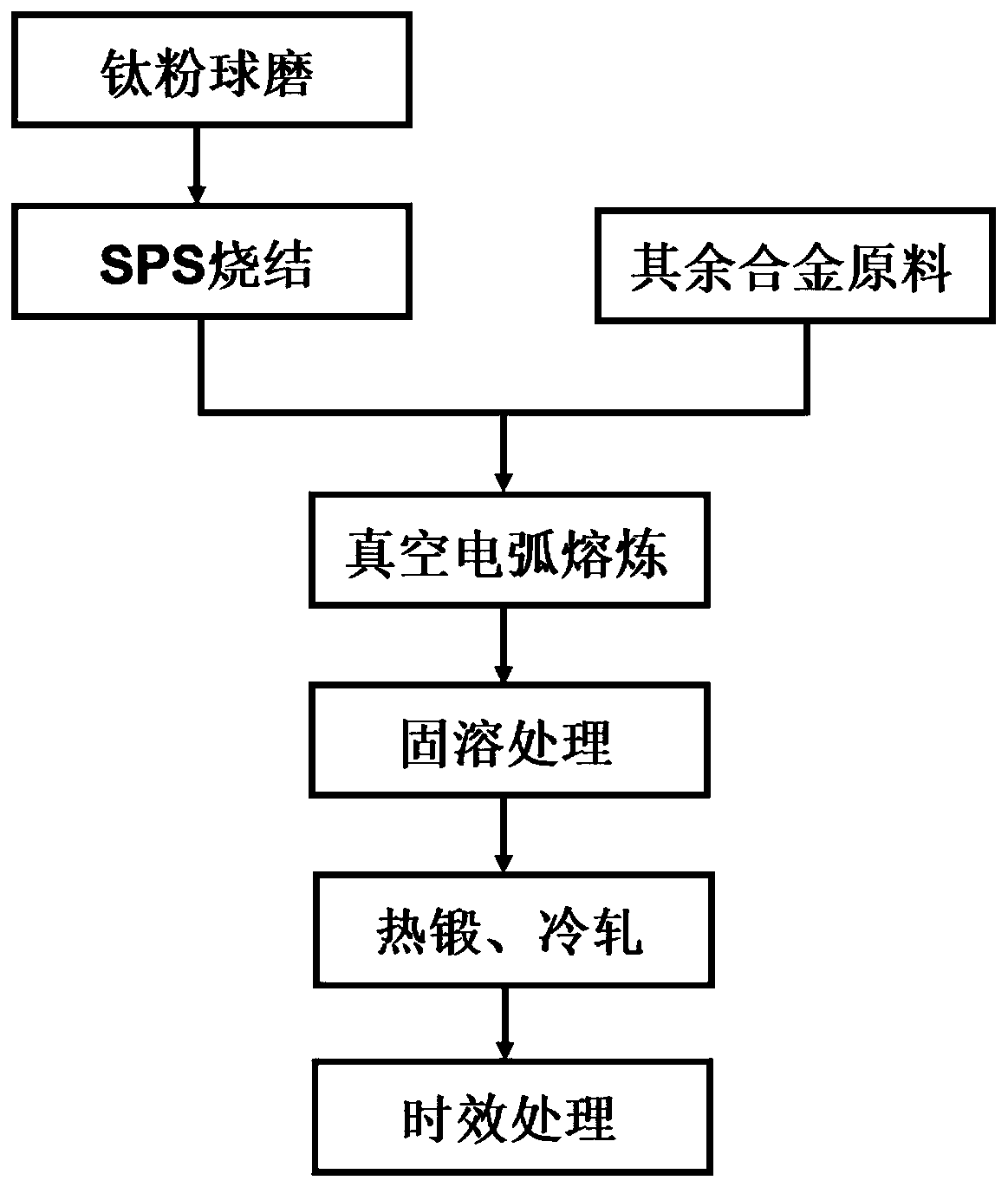

[0041] (1) Ball milling process of titanium powder: a planetary ball mill is used, and its ball milling tank and balls are made of 0Cr18Ni9 stainless steel. Put titanium powder with a particle size of 10 μm into a ball mill jar, fill it with absolute ethanol, and then ball mill it. The parameters of ball milling are: the weight ratio of balls to titanium powder is 10:1, the rotation speed is 300r / min, and the forward and reverse time is 2h;

[0042] (2) The preparation process of sintered titanium: the titanium powder after ball milling is dried naturally, put into graphite mold, and then sintered by SPS. 30min, the sintering pressure is 50MPa. According to ICP analysis, the sintered titanium contains Fe: 0.171wt%; Cr: 0.073wt%; Ni: 0.022wt%, and the rest is titanium. Divide the titanium sintered block into flakes.

[0043] (3) Raw material configuration and arc melting: the weight of each component is: flaky sintered titanium 22g; sponge titanium: 50g; Nb: 30g; Zr: 6g; Mo:...

Embodiment 2

[0049] (1) Ball milling process of titanium powder: a planetary ball mill is used, and its ball milling tank and balls are made of 0Cr18Ni9 stainless steel. Put titanium powder with a particle size of 5 μm into a ball mill jar, fill it with absolute ethanol, and then perform ball milling. The parameters of the ball mill are: the weight ratio of the ball to the titanium powder is 10:1, the rotation speed is 250r / min, and the forward and reverse time is 3h;

[0050] (2) The preparation process of sintered titanium: the titanium powder after ball milling is dried naturally, put into graphite mold, and then sintered by SPS. 15min, the sintering pressure is 60MPa. According to ICP analysis, the sintered titanium contains Fe: 0.251wt%; Cr: 0.105wt%; Ni: 0.032wt%, and the rest is titanium. Divide the titanium sintered block into flakes.

[0051] (3) Raw material configuration and arc melting: the weight of each component is: flaky sintered titanium 35g; sponge titanium: 36g; Nb: 3...

Embodiment 3

[0056] (1) Ball milling process of titanium powder: a planetary ball mill is used, and its ball milling tank and balls are made of 0Cr18Ni9 stainless steel. Put titanium powder with a particle size of 15 μm into a ball mill jar, fill it with absolute ethanol, and then ball mill it. The parameters of the ball mill are: the weight ratio of the ball to the titanium powder is 10:1, the rotation speed is 200r / min, and the forward and reverse time is 4h;

[0057] (2) The preparation process of sintered titanium: the titanium powder after ball milling is dried naturally, put into graphite mold, and then sintered by SPS. 20min, the sintering pressure is 50MPa. According to ICP analysis, the sintered titanium contains Fe: 0.204wt%; Cr: 0.081wt%; Ni: 0.022wt%, and the rest is titanium. Divide the titanium sintered block into flakes.

[0058] (3) Raw material configuration and arc smelting: the weight of each component is: 30g of flake sintered titanium; sponge titanium: 42g; Nb: 31g;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Σ0.2 | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com