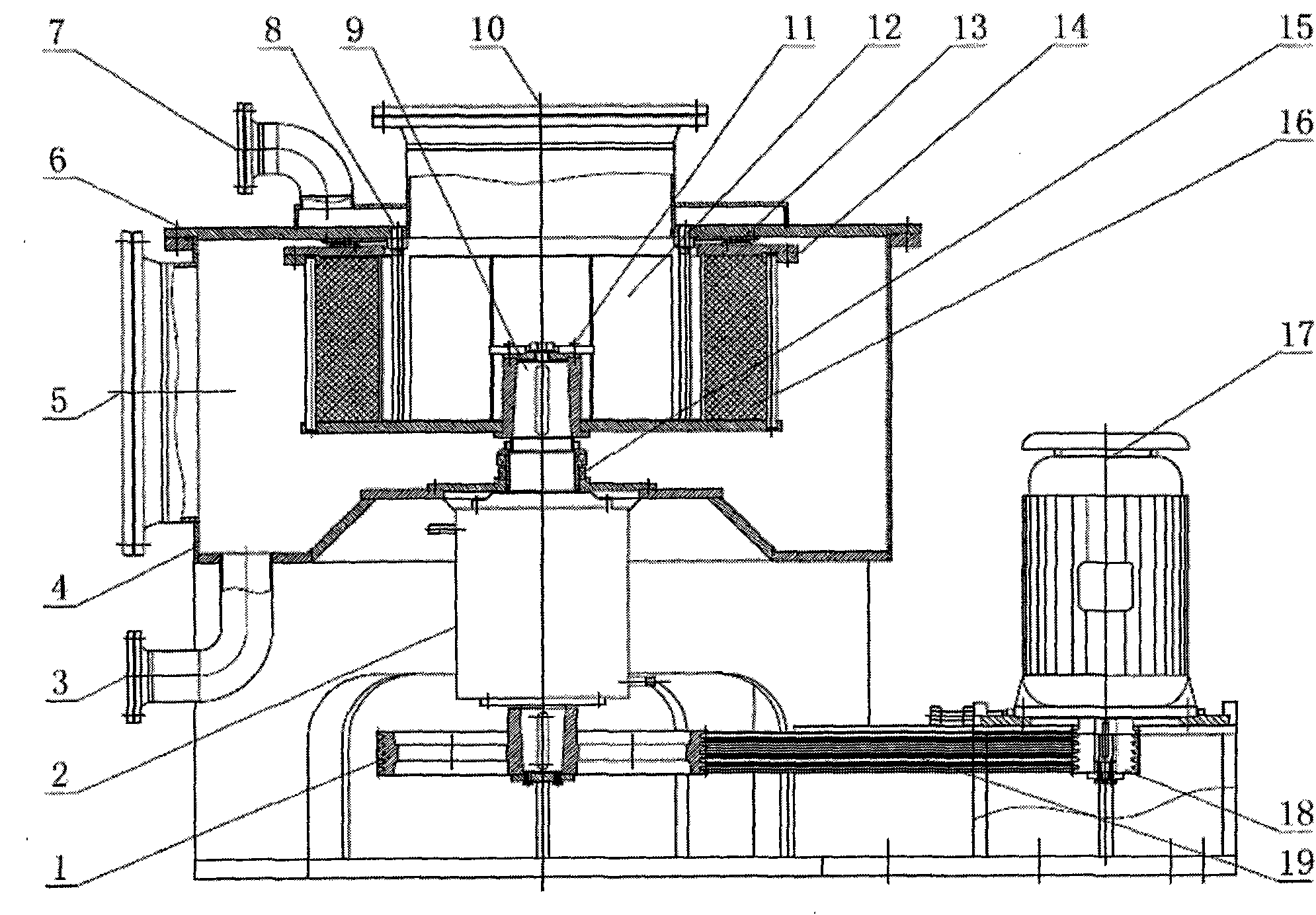

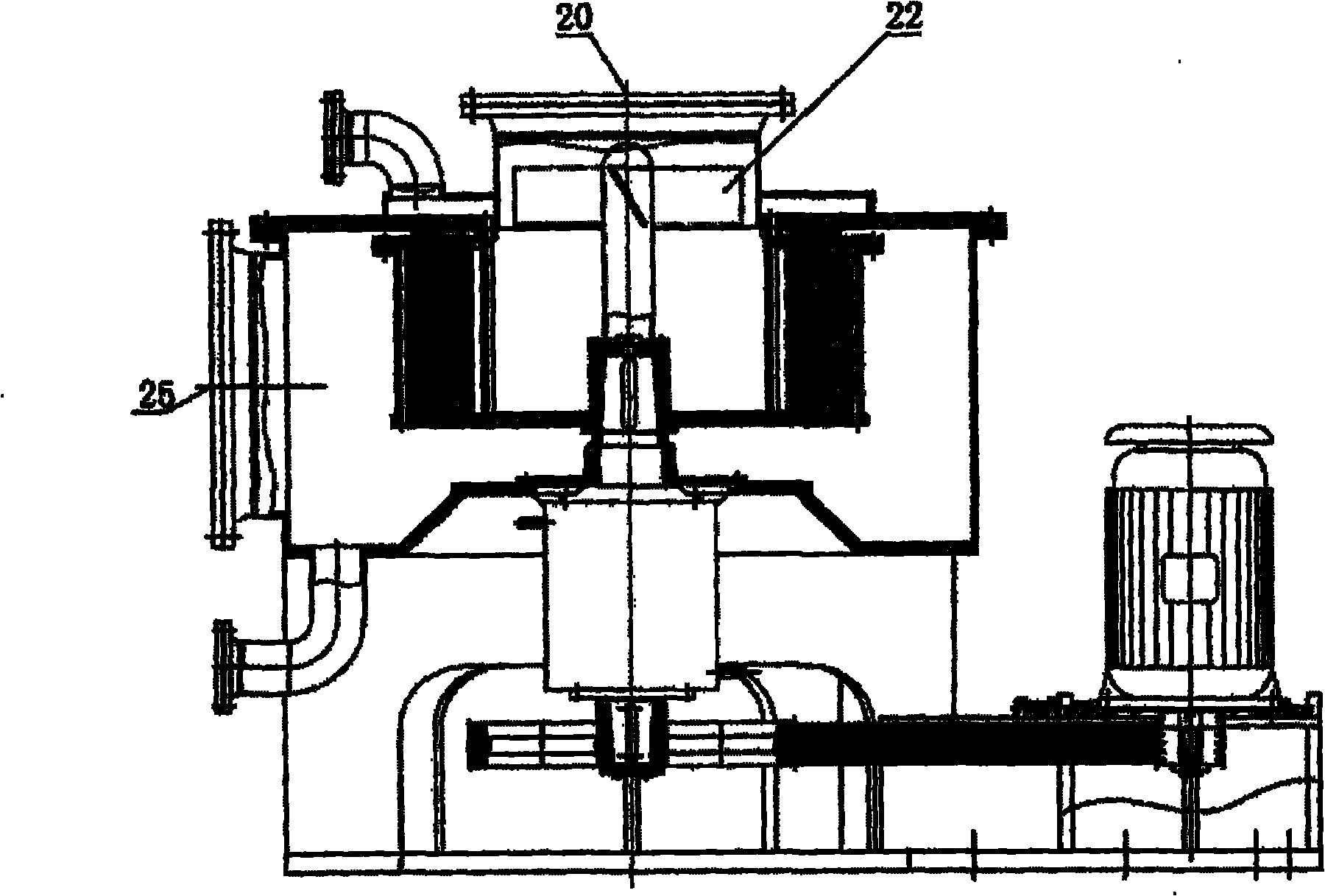

Low-pressure-drop nano/microstructure filler revolving bed supergravity device and application thereof

A structured packing and supergravity technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc. Filling irregularity and other problems, to achieve the effect of small footprint, large operating flexibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

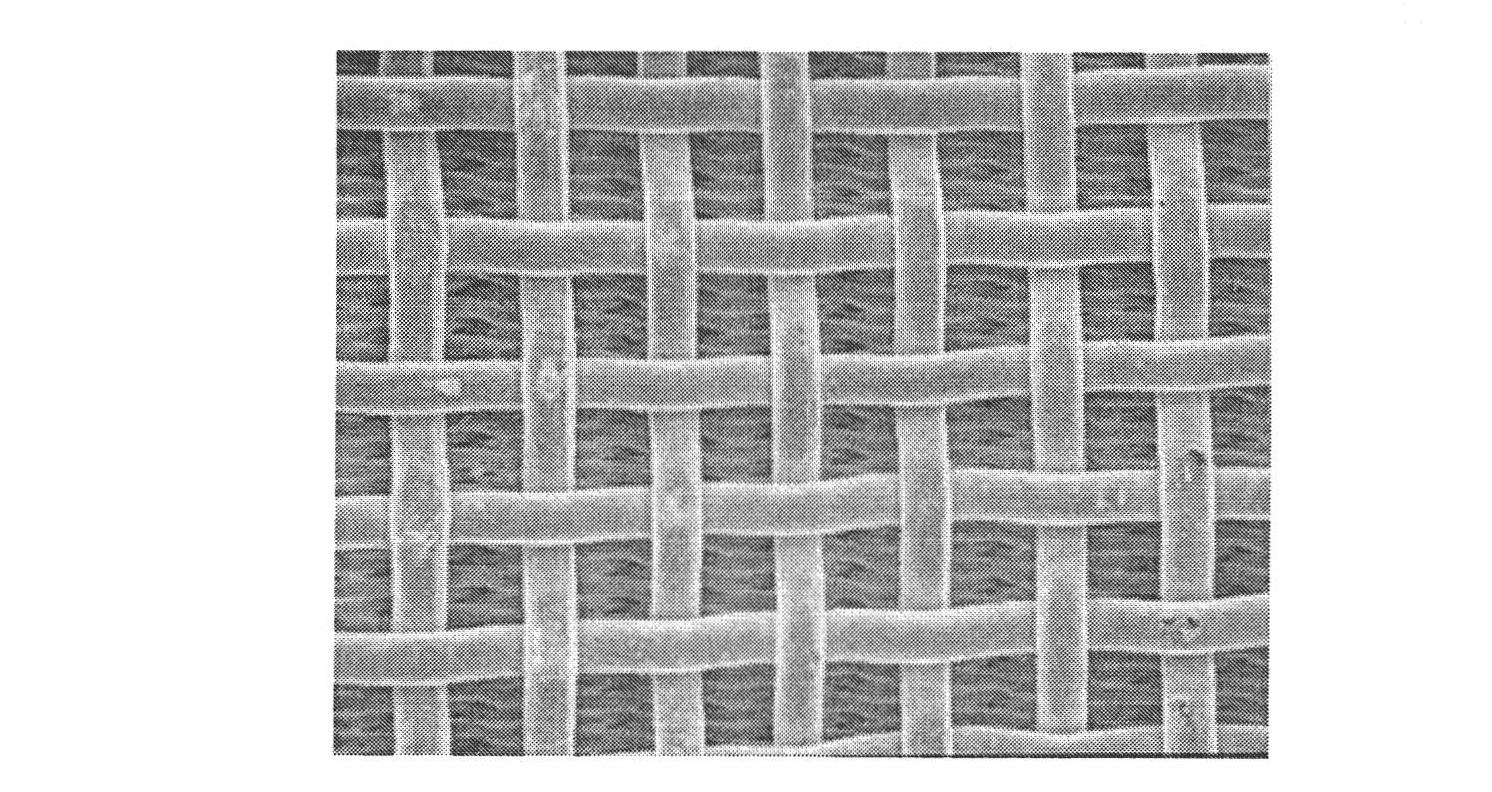

[0036] The harmful gas in the raw gas is sulfur dioxide, the content φ i It is 1960ppm, and the absorption liquid is ammonia solution. The system temperature T in the absorption process was 50°C. Rotating bed speed N is 500r / min, filler type is sintered ceramic filler specific surface area ζ is 900m 2 / m 3 , gas-liquid countercurrent, wind-inducing blades, the gas-liquid flow ratio η is 800:1. The content of harmful gas sulfur dioxide in the outlet gas of the rotating bed φ o 50ppm, the inlet and outlet pressure drop Δp is 1200Pa.

Embodiment 2-21

[0038] The process flow and steps are the same as in Example 1, and the process conditions and operating conditions of each embodiment and the corresponding experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com