Flue gas purification plant with electric fields combined with super-gravity fields

A technology for flue gas purification and supergravity field, which is applied to combined devices, gas treatment, chemical instruments and methods, etc., and can solve the problems of low dust removal efficiency, high energy consumption, and large device footprint of fine particles. The effect of small land area, low cost and low operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

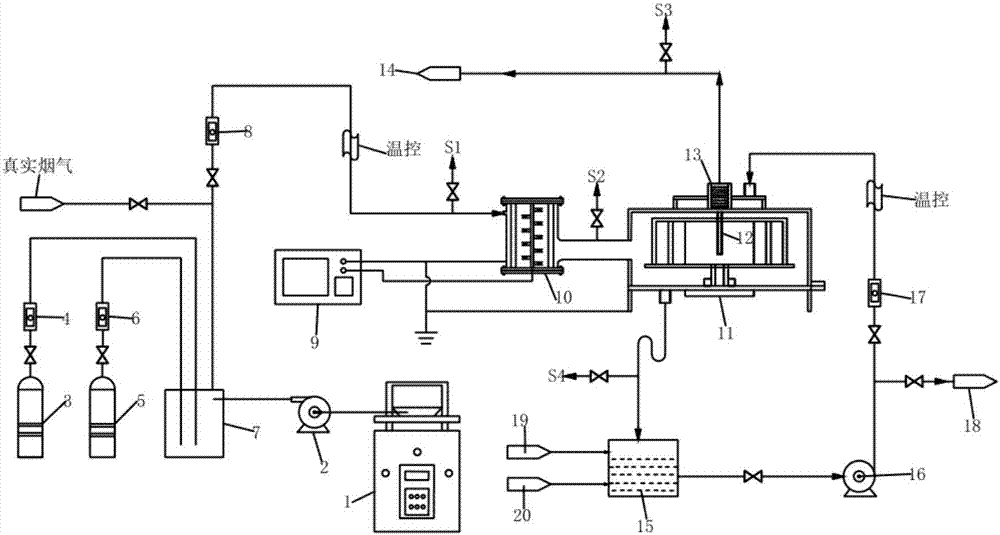

[0051] A supergravity-electric field combined flue gas purification device, its composition diagram is as follows figure 1 shown. The device includes a dust generating system 1, a fan 2, a sulfur dioxide gas source 3, a nitrogen monoxide gas source 5, a gas buffer tank 7, a high-voltage power supply 9, an electric field device 10, a supergravity purification system 11, a solution circulation tank 15, and a centrifugal pump 16; The gas outlet of the dust generation system 1 is connected to the gas inlet of the fan 2; the gas outlet of the fan 2 is connected to the inlet of the gas buffer tank 7; After measuring 6, it is connected with the gas buffer tank 7 inlet; after the gas buffer tank 7 outlet passes through the third gas flow meter 8, it is connected with the gas inlet of the electric field device 10; the gas outlet of the electric field device 10 is connected with the gas inlet of the supergravity purification system 11; The gas purified by supergravity passes through th...

Embodiment 2

[0073] Applying the system device of the present invention to carry out the technological parameters of simulated flue gas purification is set as: gas volume 10Nm 3 / h, the liquid volume is 40L / h, adjust the dust generator so that the PM2.5 concentration in the dust is 5.26mg / m 3 , PM10 concentration is 38.6mg / m 3 , the total dust concentration is 67.9mg / m 3 . The high-voltage power supply is adjusted to 40kV, the mass fraction of sodium sulfite is 1.55%, the temperature of the supergravity machine is normal temperature, the pressure is 1.36MPa, and the level of the supergravity dust removal equipment is 800g. The gas containing dust is passed into the electric field device 10 by the fan 2, and then the charged gas is passed into the supergravity machine 11, and the concentration of different particle sizes of the dust at the outlet is detected, and the removal rate of PM2.5 is 96.8 %, the PM10 removal rate is 99.4%, and the total dust removal rate is 99.6%.

Embodiment 3

[0075] Applying the system device of the present invention to carry out the technological parameters of simulated flue gas purification is set as: gas volume 10Nm 3 / h, the liquid volume is 40L / h, adjust the dust generator so that the PM2.5 concentration in the dust is 6.26mg / m 3 , PM10 concentration is 35.6mg / m 3 , the total dust concentration is 73.9mg / m 3 . The high-voltage power supply is adjusted to 40kV, the temperature of the supergravity machine is normal temperature, the pressure is 1.31MPa, and the level of the supergravity dust removal equipment is 800g. The gas containing dust is passed into the electric field device 10 by the fan 2, and then the charged gas is passed into the supergravity machine 11, and the dust concentration of different particle sizes at the outlet is detected, and the removal rate of PM2.5 is 96.9%. , PM10 removal rate is 99.2%, total dust removal rate is 99.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com