Packing structuring method for 3D printing supergravity rotating bed

A high-gravity rotating bed and structured packing technology, applied in chemical instruments and methods, manufacturing auxiliary devices, chemical/physical/physicochemical processes, etc., can solve problems such as uneven distribution of voids, difficult maintenance and replacement, and poor dynamic balance. Achieve the effect of convenient manufacturing and installation, easy maintenance and replacement, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further illustrated by the following examples, but not limited to the following examples.

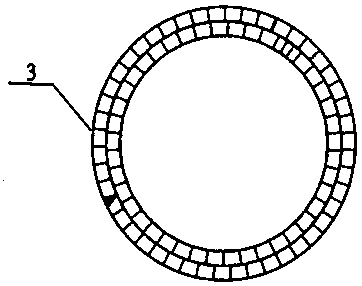

[0034] Figure 1 to Figure 6 It is the specific process of using 3D software to construct the packing model.

[0035] Such as Figure 1 to Figure 6 As shown, the packing model is constructed using 3D software. The basic unit 1 is arrayed in a ring to form a ring unit 2. The ring units 2 are staggered and nested from inside to outside to form a disc-shaped body 4 under the premise of ensuring dynamic balance. The disc-shaped body 4 In the radial direction, each layer is staggered and superimposed by 0~10° to form a packing body 5 with a regular perturbation structure in the axial direction and an interlaced axial wire mesh. Finally, the packing entity 6 is printed by 3D printing technology.

[0036] The invention provides a method for 3D printing structured packing for a high-gravity rotating bed, using three-dimensional modeling software to build a mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com