Preparation method for photocatalyst used for treating volatile organic compounds

A technology of volatile organic compounds and photocatalysts, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve high cost, complicated preparation process, and difficulty in industrial scale-up and other problems, to achieve the effects of wide absorption range, simple preparation steps, and improved catalyst efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

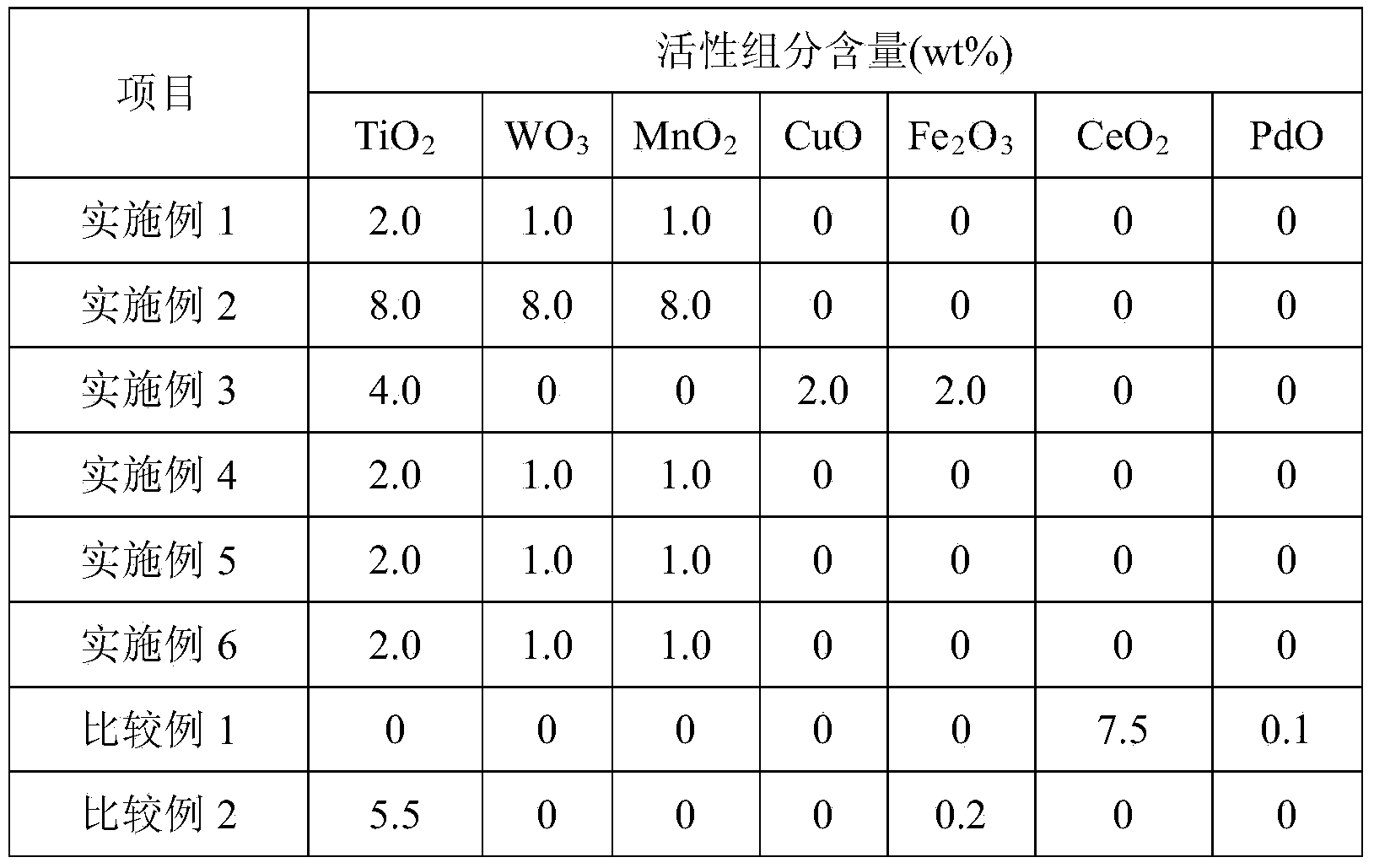

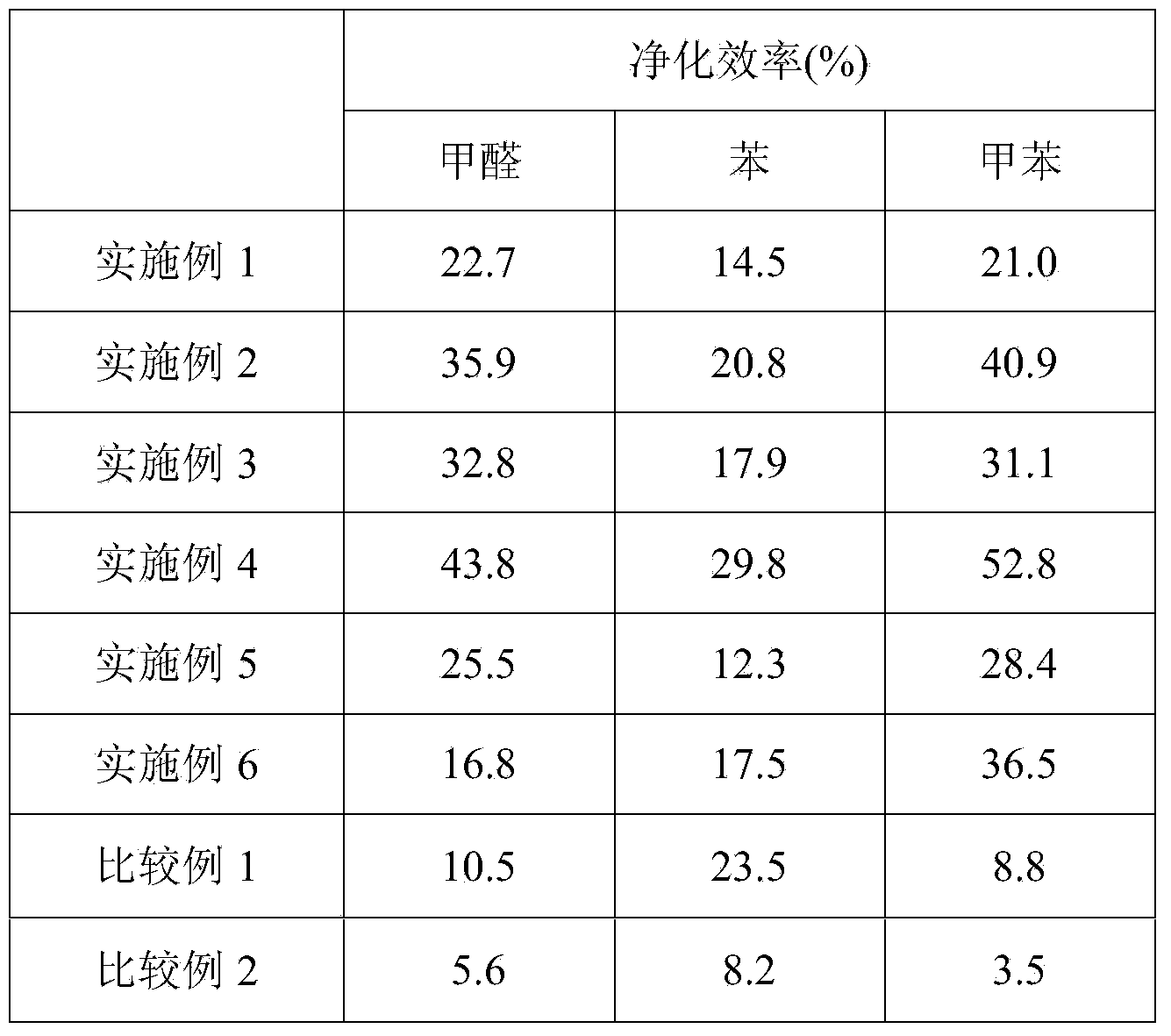

Embodiment 1

[0032] Take 10 g of titanyl sulfate, and use 300 g of deionized water to ultrasonically decompose and dissolve it into a solution. Add 10% ammonia water to adjust the pH of the reaction system to 9, precipitate for 15 min, and centrifuge to wash the precipitate until the conductivity of the eluate is below 20 μS / cm. Add 200ml of deionized water to the obtained white precipitate to make a slurry, add 15ml of hydrogen peroxide dropwise, and adjust the pH value to 7 with concentrated ammonia water to obtain a bright yellow transparent titanium sol.

[0033]Add 2 g of polyvinyl alcohol, 2 g of tungsten oxide powder, and 2 g of manganese oxide powder into the titanium sol, stir evenly, add 40 g of aluminum sol, and stir at 4000 rpm for 30 minutes to obtain a coating solution.

[0034] Spray the coating solution on the honeycomb ceramic carrier (model HA-01, CNOOC Tianjin Chemical Research and Design Institute. Carrier weight 200g, size 100*100*40mm, water absorption 10-30%), dry at...

Embodiment 2

[0040] Take 40g of titanyl sulfate, and use 1000g of deionized water to ultrasonically decompose and dissolve it into a solution. Add 5% ammonia water to adjust the pH value of the reaction system to 9, precipitate for 30 min, and centrifuge to wash the precipitate until the conductivity of the eluate is below 20 μS / cm. Add 800 ml of deionized water to the obtained white precipitate to make a slurry, add 60 ml of hydrogen peroxide dropwise, and adjust the pH value to 7 with concentrated ammonia water to obtain a bright yellow transparent titanium sol.

[0041] Add 80 g of polyvinyl alcohol, 16 g of tungsten oxide powder, and 16 g of manganese oxide powder into the titanium sol, stir evenly, and 600 g of aluminum sol, and stir at 12,000 rpm for 60 minutes to obtain a coating solution.

[0042] Spray the coating solution on the honeycomb ceramic carrier (model HA-01, CNOOC Tianjin Chemical Research and Design Institute. Carrier weight 200g, size 100*100*40mm, water absorption 10...

Embodiment 3

[0045] Take 20g of titanyl sulfate, and use 600g of deionized water to ultrasonically decompose and dissolve it into a solution. Add 10% ammonia water to adjust the pH of the reaction system to 8, precipitate for 30 min, and centrifuge to wash the precipitate until the conductivity of the eluate is below 20 μS / cm. Add 400 ml of deionized water to the obtained white precipitate, add 30 ml of hydrogen peroxide dropwise, and adjust the pH value to 7 with concentrated ammonia water to obtain a bright yellow transparent titanium sol.

[0046] Add 4g of polyvinyl alcohol, 4g of copper oxide powder, and 4g of iron oxide powder to the titanium sol, stir evenly, and 40g of aluminum sol, and stir at 8000 rpm for 40 minutes to obtain a coating solution.

[0047] Spray the coating solution on the honeycomb ceramic carrier (model HA-01, CNOOC Tianjin Chemical Research and Design Institute. Carrier weight 200g, size 100*100*40mm, water absorption 10-30%), dry at 80°C for 2hr, and spray repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com