Patents

Literature

95results about How to "Suitable for industrial scale-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

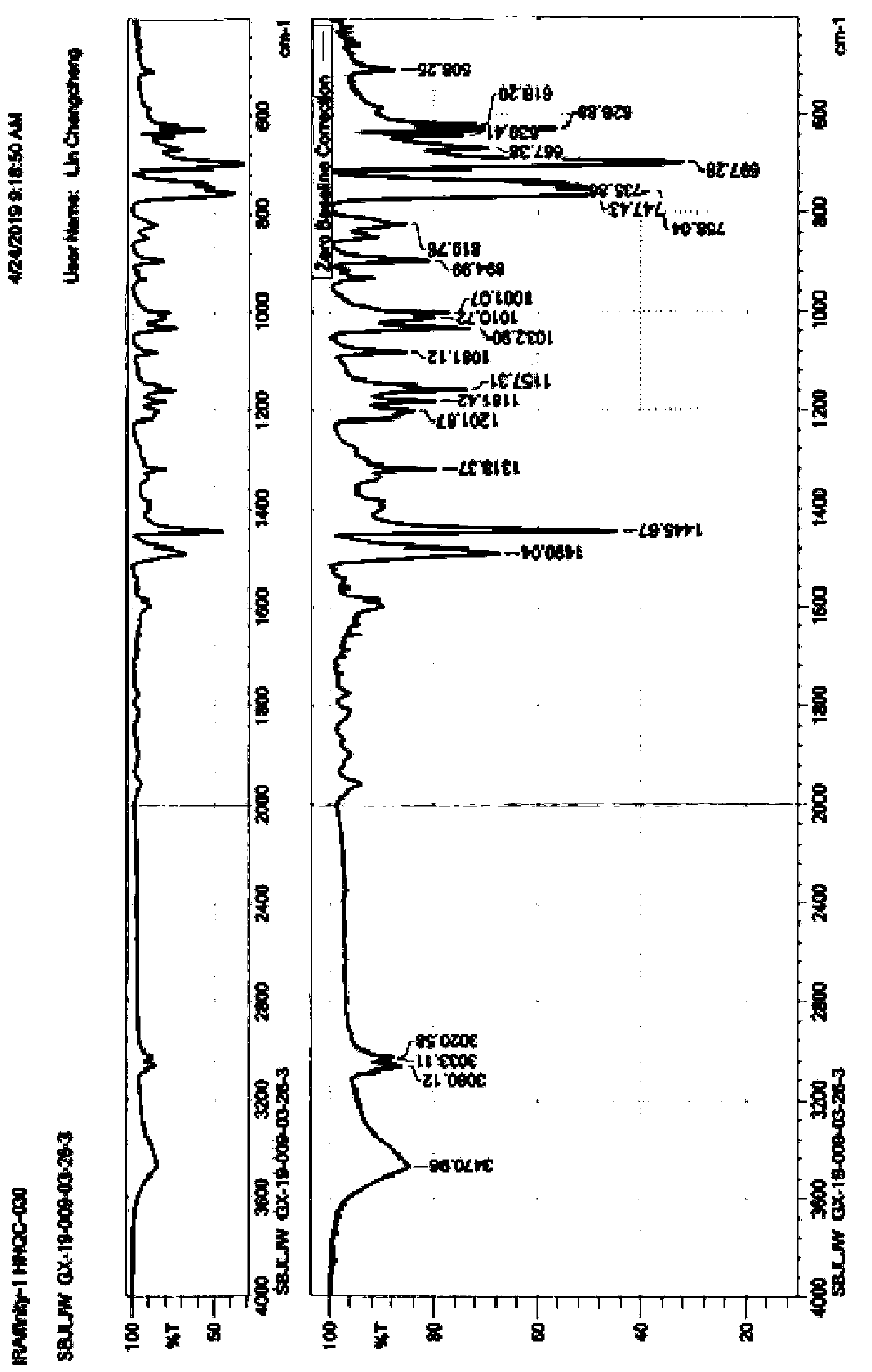

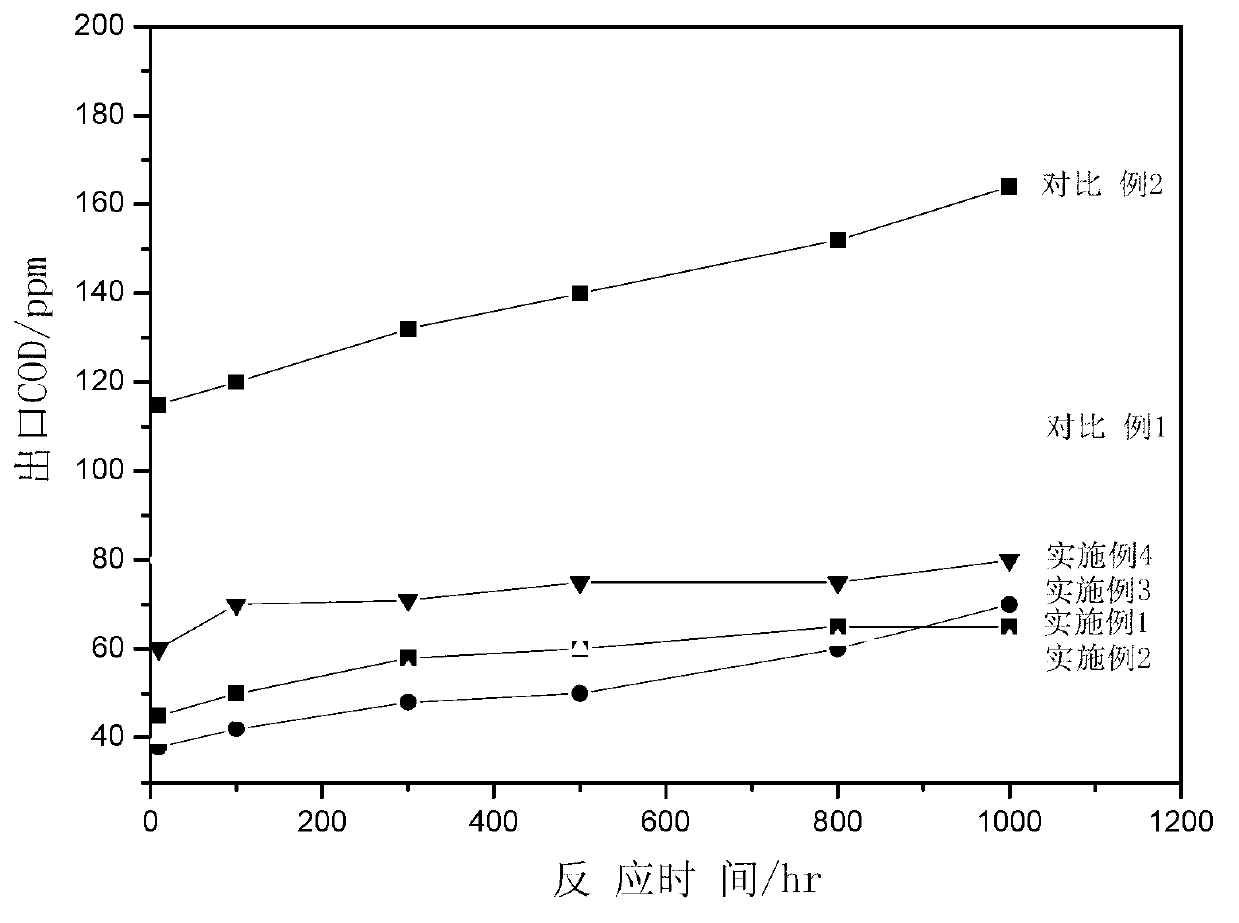

Preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water

ActiveCN101982237ASimple preparation stepsSuitable for industrial scale-upMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationParticulatesFerric hydroxide

The invention relates to a preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water. Amorphous aluminium oxide powder and ferric hydroxide powder are mixed by dry basis weight ratio of 100: 1-30, and rolling pelleting, maintaining, drying and roasting are carried out, thus obtaining the finished product catalyst. The method includes the following steps: (a) amorphous aluminium oxide and ferric hydroxide powder are mixed to be uniform; (b) the mixture is placed into a rotary pelleting machine, binder is sprayed, and rolling pelleting is carried out, the binder is sprayed in solution or colloid form in an atomizing way, and the amount of binder sprayed into the pelleting machine is 2-50% of total mass of amorphous aluminium oxide; and diameter of pelleting is controlled to be 1-8mm; (c) particle matter is maintained for 3-24 hours under the condition that temperature of water vapour is 100-110 DEG C; (d) catalyst is dried, drying temperature is 50-180 DEG C, drying time is 2-10 hours, and then roasting is carried out; and roasting temperature of catalyst is 400-600 DEG C, roasting time is 2-8 hours, and finished product catalyst is obtained.

Owner:CHINA NAT OFFSHORE OIL CORP +2

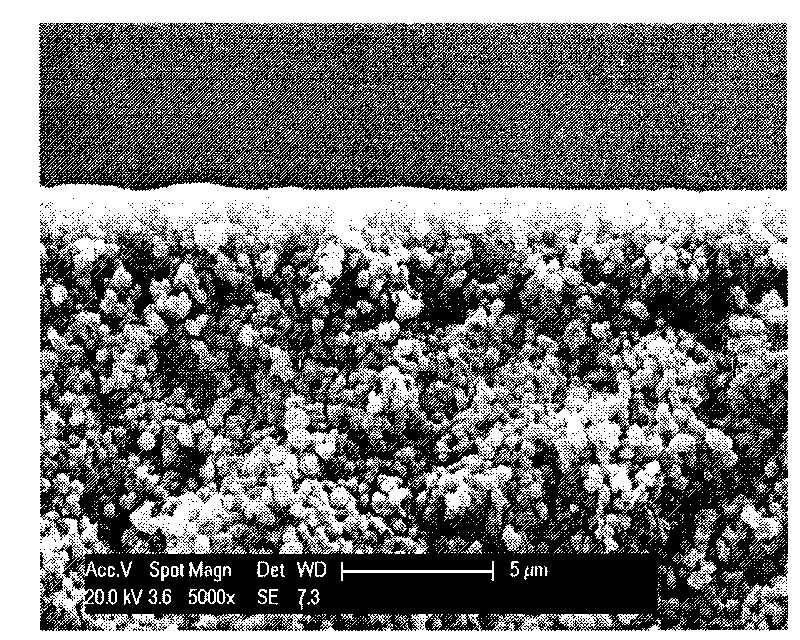

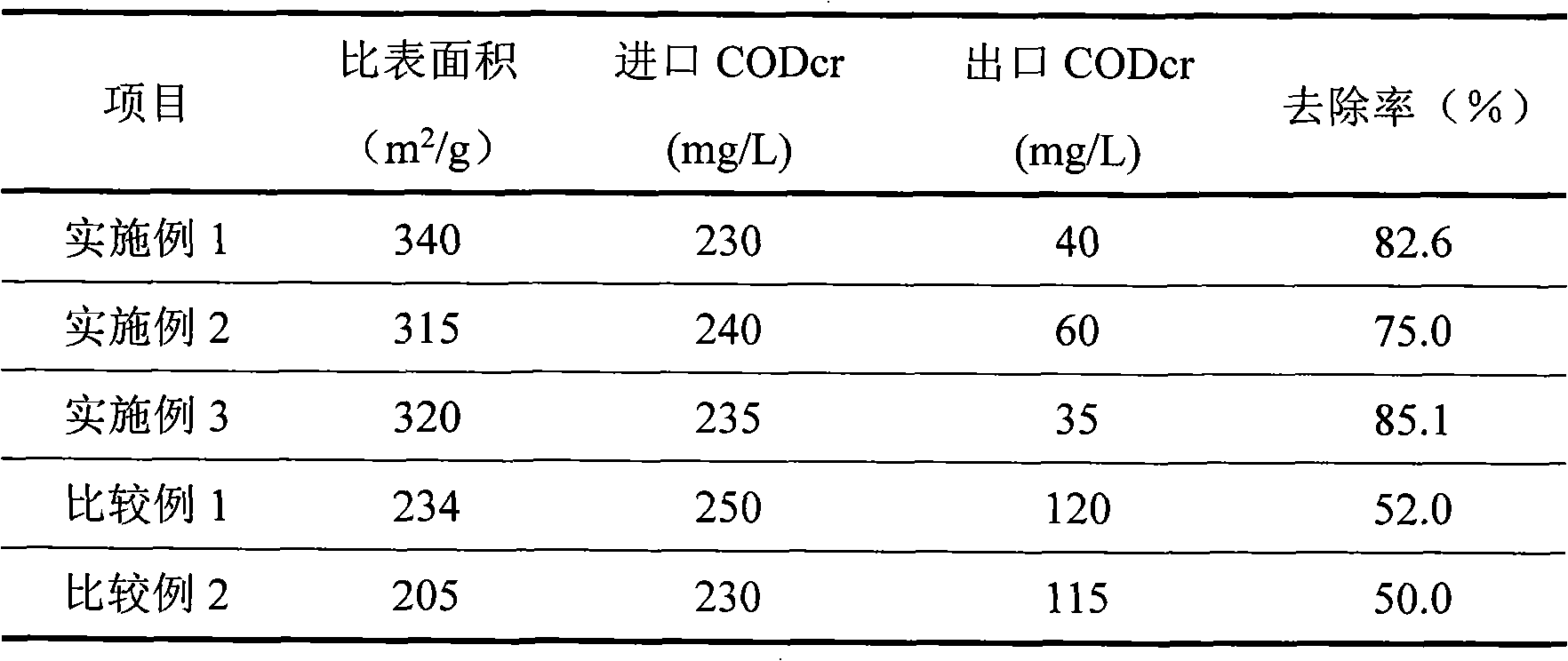

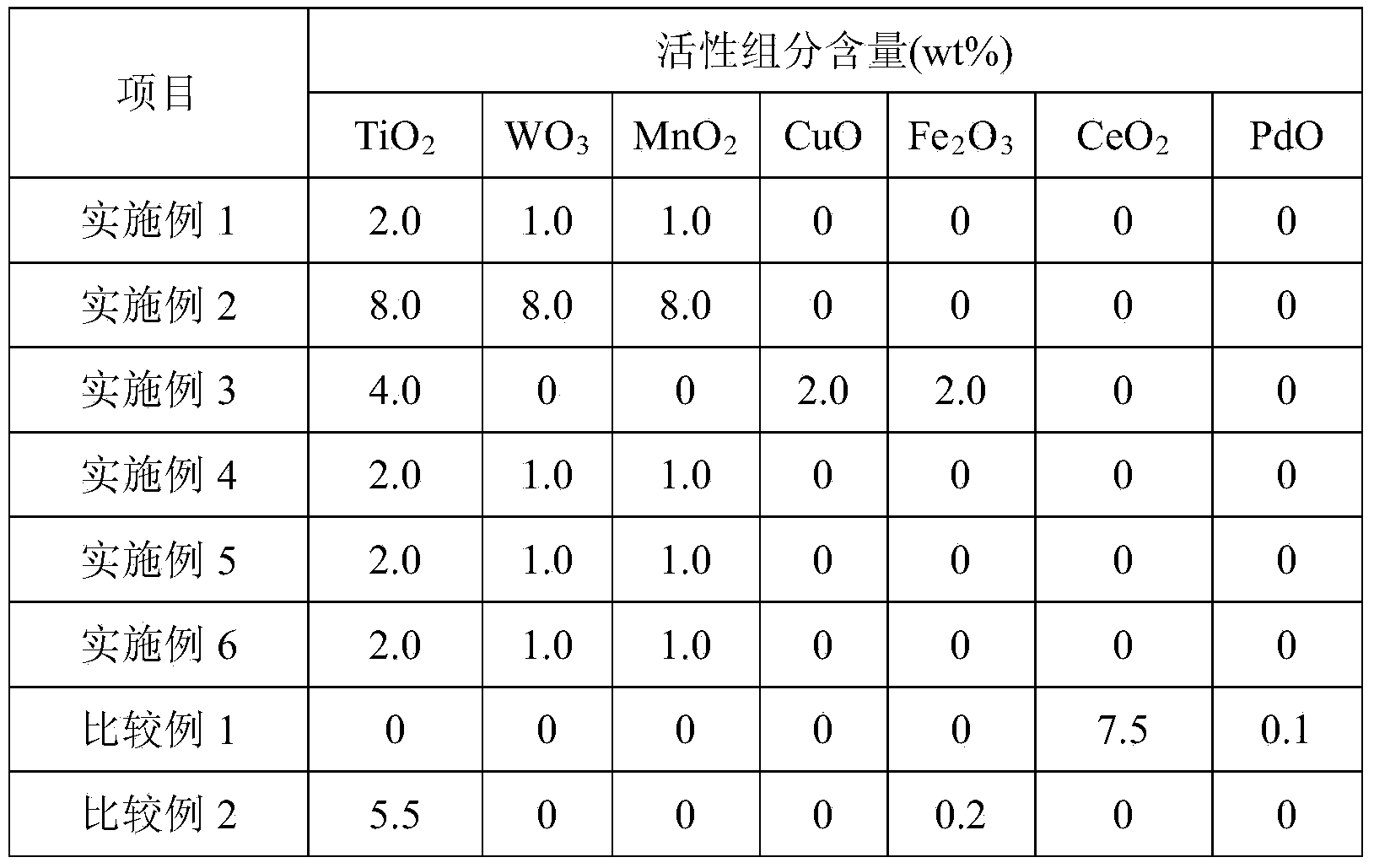

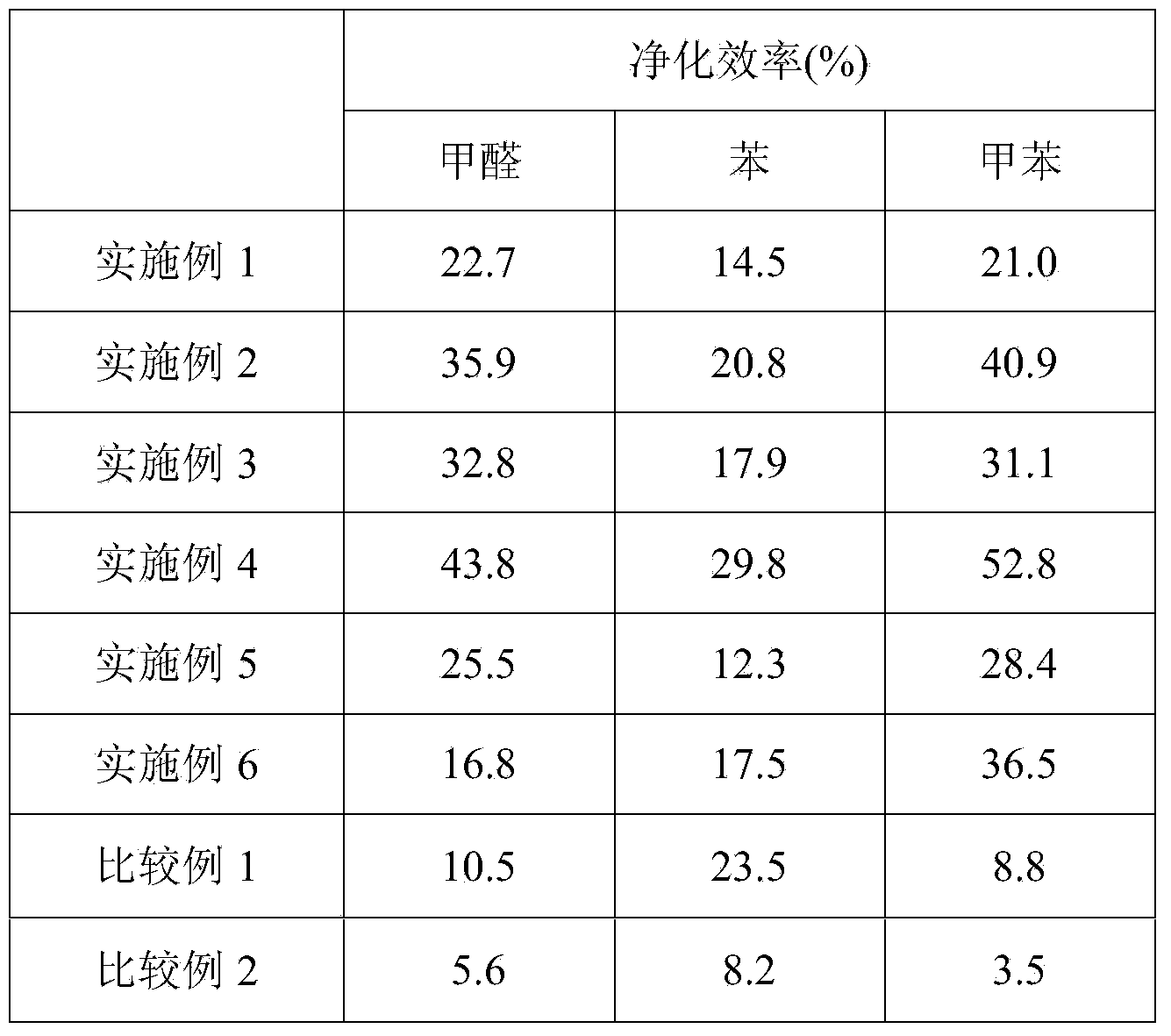

Preparation method for photocatalyst used for treating volatile organic compounds

ActiveCN103521218ASimple preparation stepsLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsIonCoating

The invention provides a preparation method for a photocatalyst used for treating volatile organic compounds. The preparation method is characterized in that titanium dioxide is used as a main active component, a transition metal is added as an auxiliary agent, and a normal temperature spraying process is employed to load titanium dioxide on a metal or ceramic honeycomb carrier. The preparation method comprises the following concrete steps: A) dissolving titanyl sulfate in deionized water, adjusting a pH value to 7 to 10 by using a 5 to 25% ammonia-water solution, subjecting an obtained white precipitate to centrifugation and washing, mixing and beating the precipitate and deionized water and adjusting the pH value to 7 to 10 by using H2O2 and HCl with stirring so as to obtain a titanium sol; B) adding a surfactant into the titanium sol, adding micro metal oxide powder with stirring, adding a binder and carrying out high-speed shearing and uniform stirring so as to prepare a stable coating solution; and C) uniformly spraying the coating solution on the carrier and drying and roasting the carrier so as to obtain a finished catalyst product. The catalyst prepared by using the method has the characteristics of high volatile organic compound removal efficiency, a long life, easy loading and unloading, a low price, etc.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Method for preparing ozone catalytic oxidation catalyst for treating cyanide waste water

ActiveCN102008965AEfficient removalSimple preparation stepsWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsParticulatesWater vapor

The invention relates to a method for preparing an ozone catalytic oxidation catalyst for treating cyanide waste water, which is characterized in that amorphous alumina is used as a carrier, and in the process of pelltizing, copper, ferrum and tin which serve as active ingredients are sprayed in form of solution, and are subjected to curing, drying and roasting to prepare a catalyst. The method comprises the following steps of: (a) dissolving metal salts of the copper, the ferrum and the tin into water to form solution; (b) putting the amorphous alumina into a rotating pelletizer, spraying the solution in the step (a) into the pelletizer to perform rolling pelltizing, and controlling the pelltizing diameter; (c) curing the particulate matters obtained in the step (b) for 3 to 24 hours under the condition of water vapor of between 100 and 110 DEG C; and (d) drying and roasting the obtained catalyst in the step (c) to obtain a catalyst serving as a finished product, wherein the drying temperature is between 50 and 180 DEG C, the drying time is between 2 and 10 hours, the roasting temperature is between 400 and 600 DEG C, and the roasting time is between 2 and 8 hours.

Owner:CHINA NAT OFFSHORE OIL CORP +1

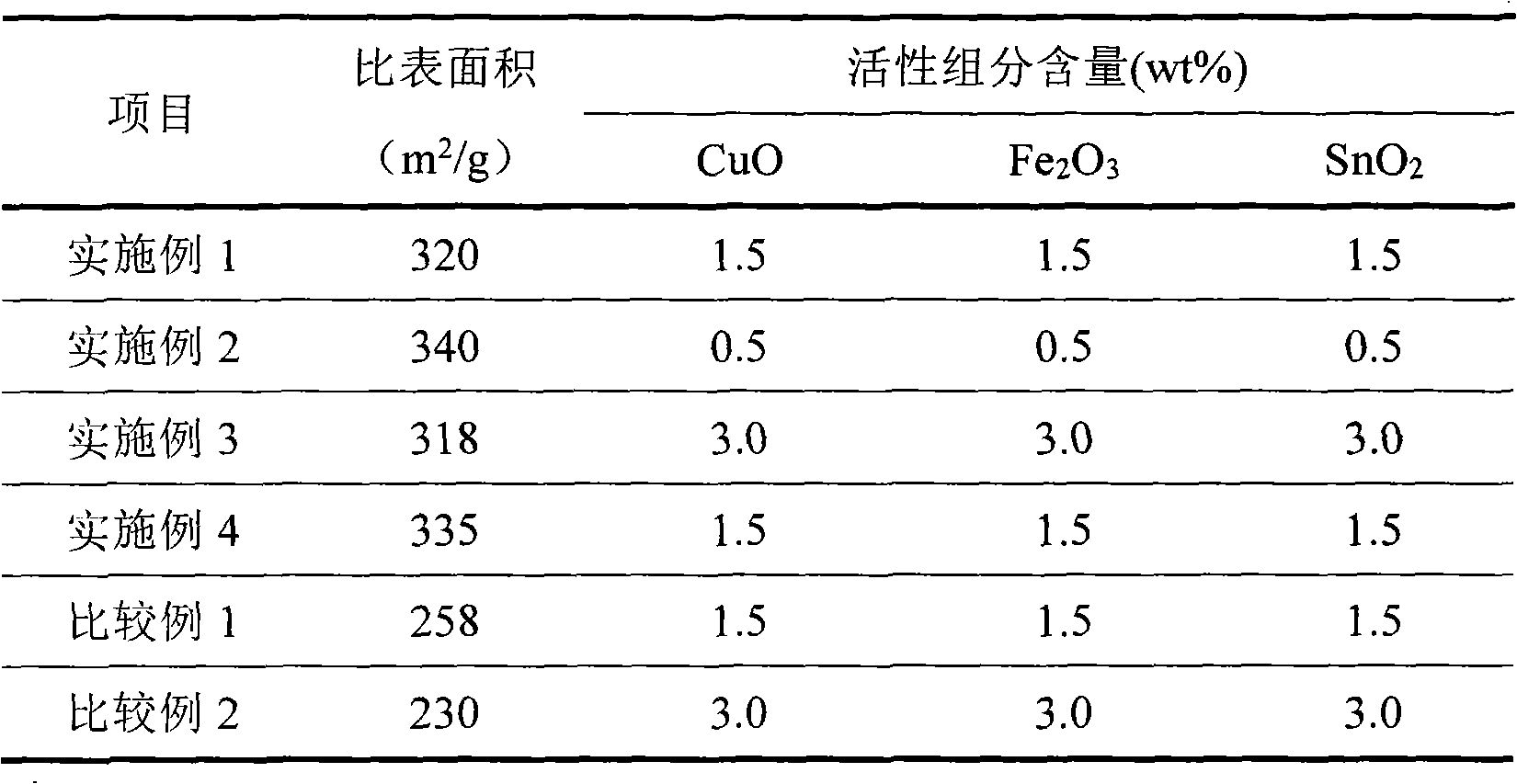

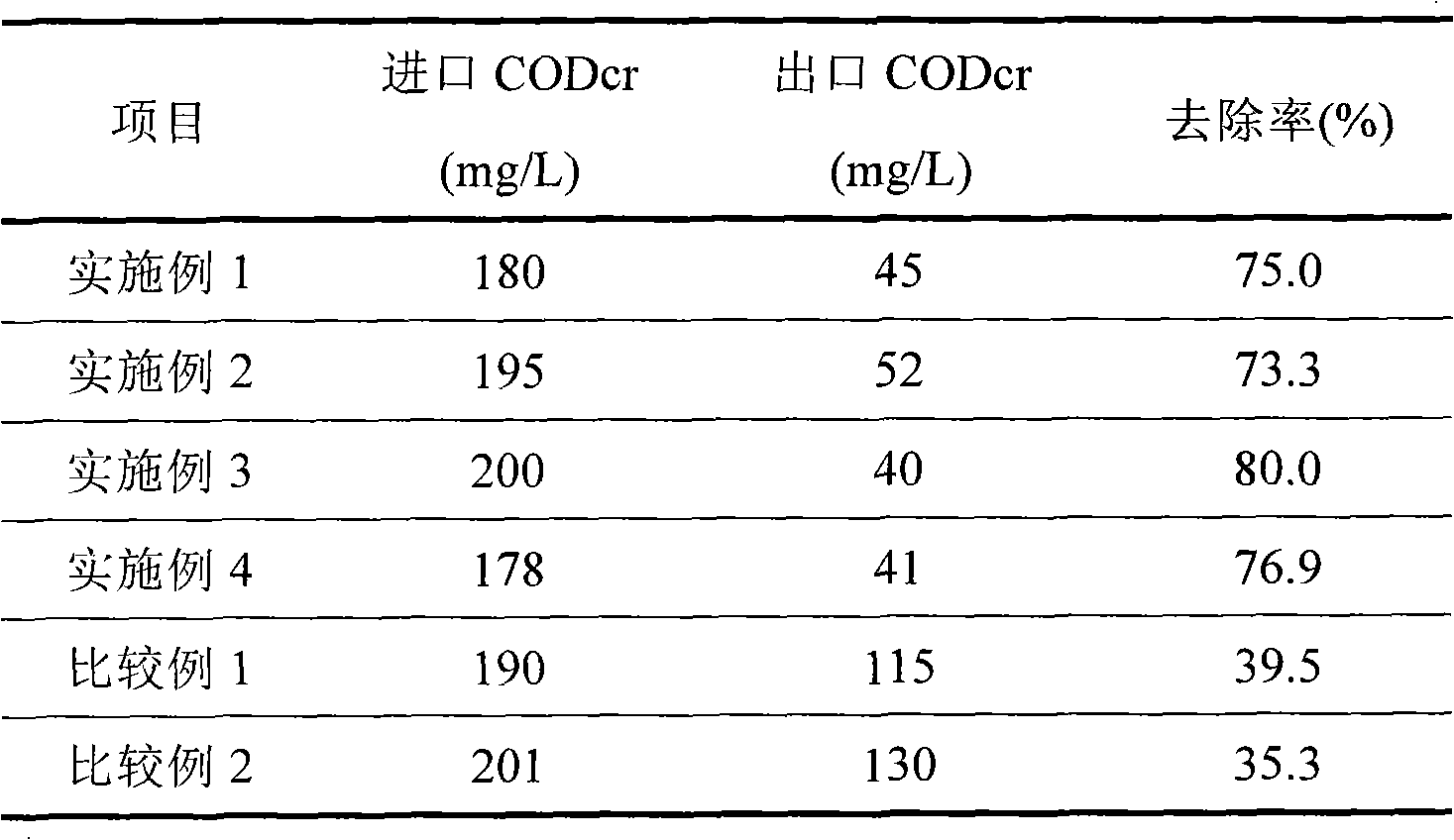

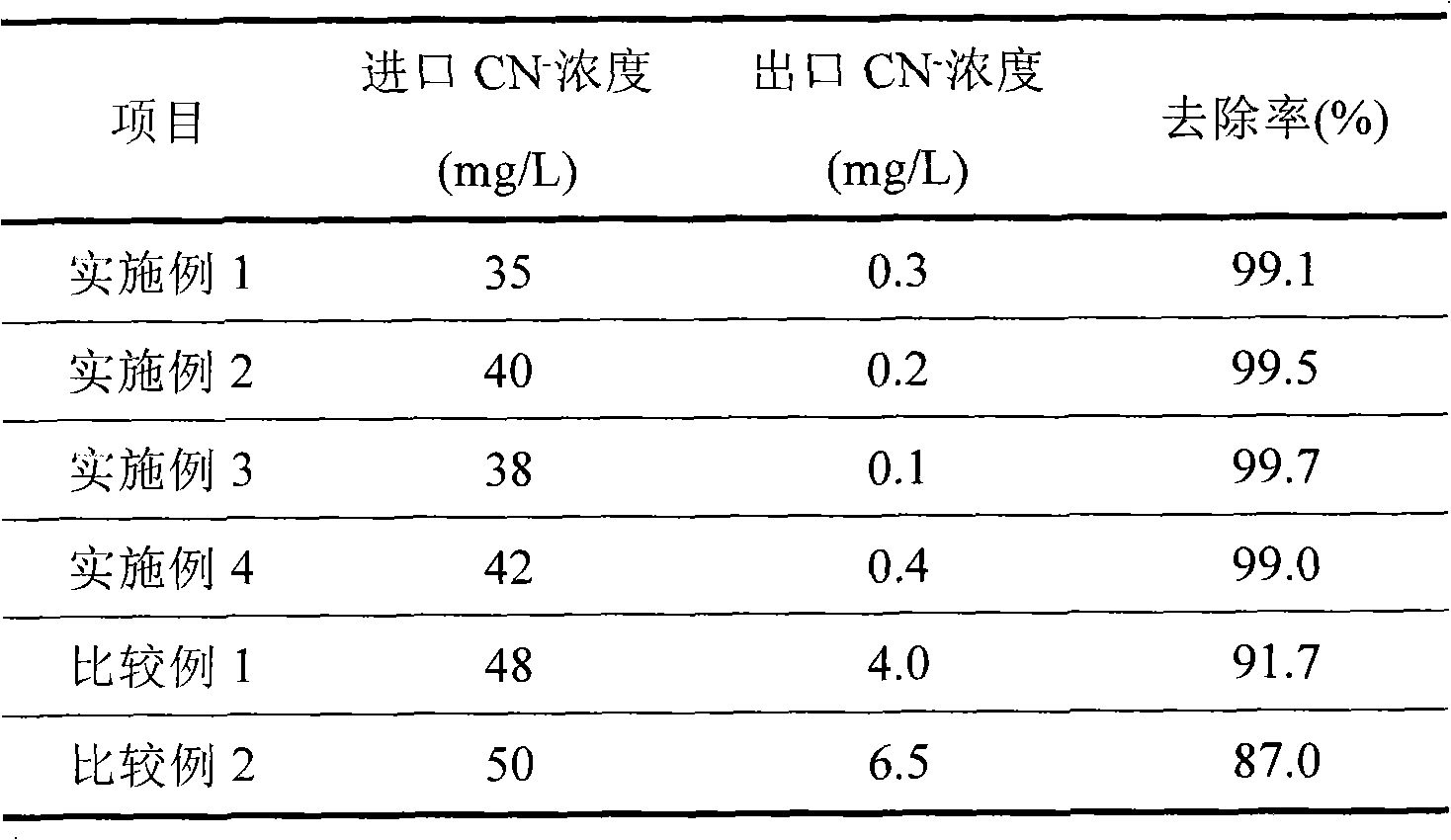

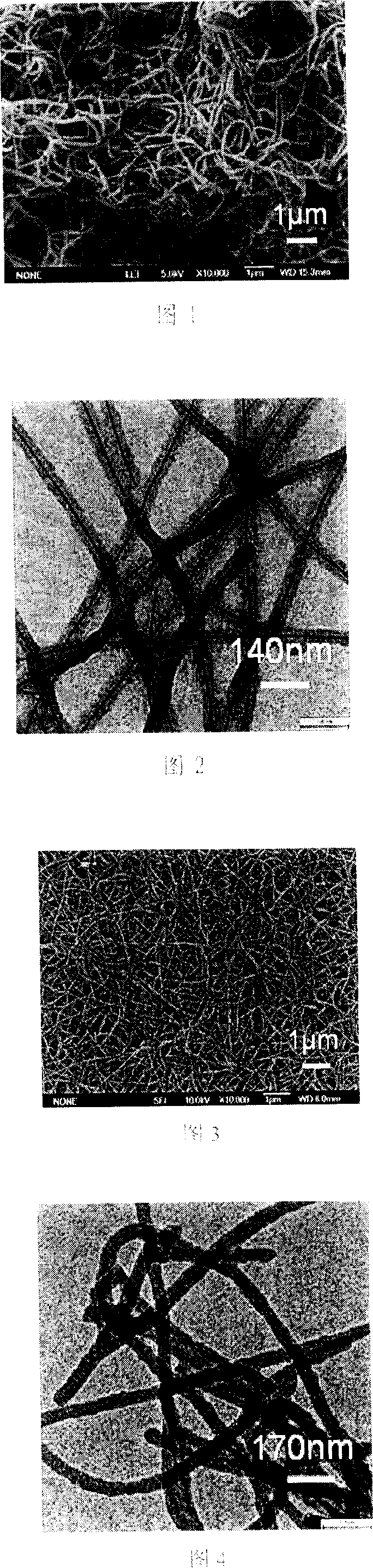

Method for preparing carbon nano fiber

InactiveCN1935638AMild preparation conditionsEasy to operateNanostructure manufactureFiberHydrazine compound

The invention is a method of preparing carbon nano fibers, characterized in adopting hydrazine hydrate and high molecular surface active agnet polyvinylpyrrolidone to hydrothermally synthesize nano lines of semiconductor Te at 160-200DEG C; then adopting the nano lines as template and adopting carbohydrate to react at 160-220DEG C for 4-20 h and synthesizing carbon-coated Te nano cables as intermediate for preparing carbon nano fiber; and oxidizing to remove Te cores from the nano cables and obtaining the carbon nano fibers. And it avoids production of carbon balls in the carbonizing course, and the surfaces of the obtained carbon-coated Te nano cables and carbon nano fibers all have large numbers of functional groups. And it is relatively suitable for industrialized production.

Owner:UNIV OF SCI & TECH OF CHINA

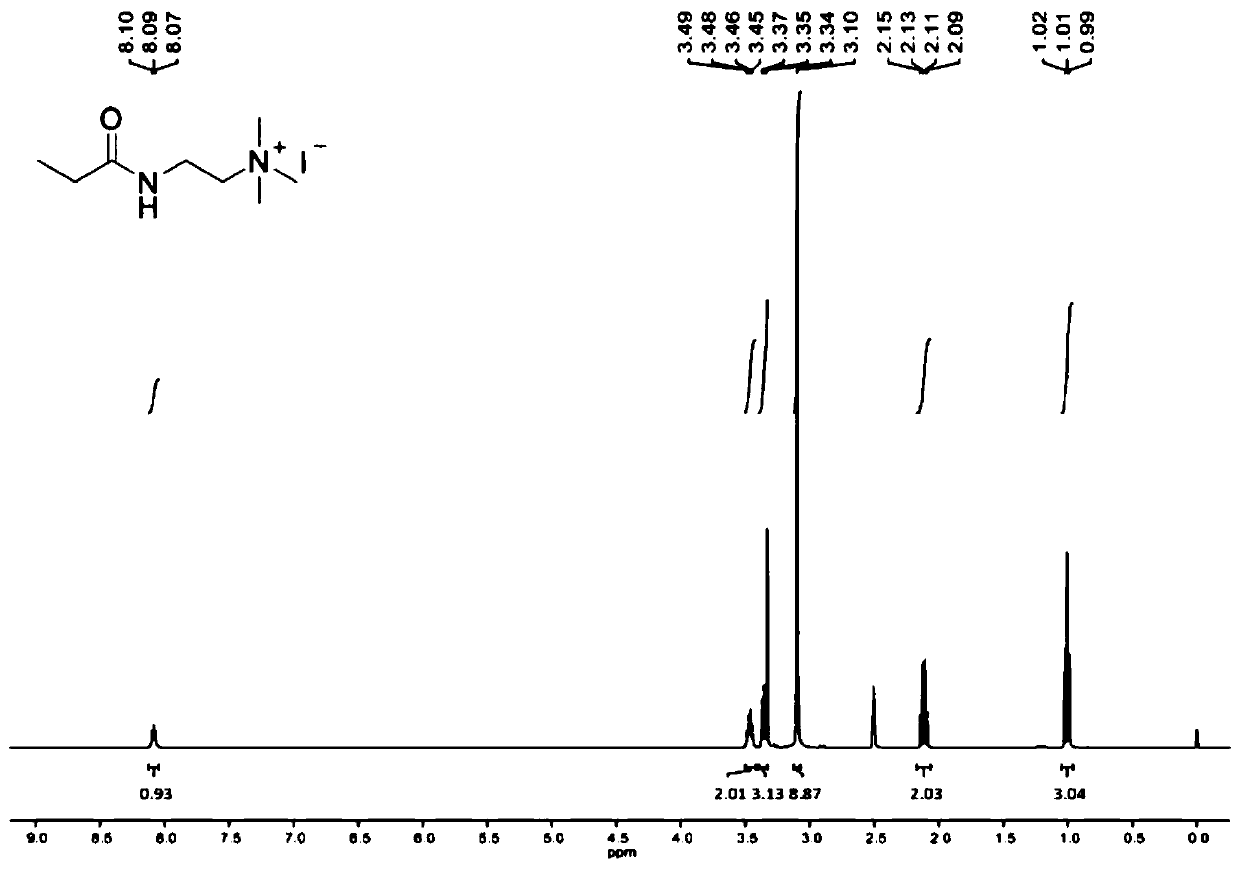

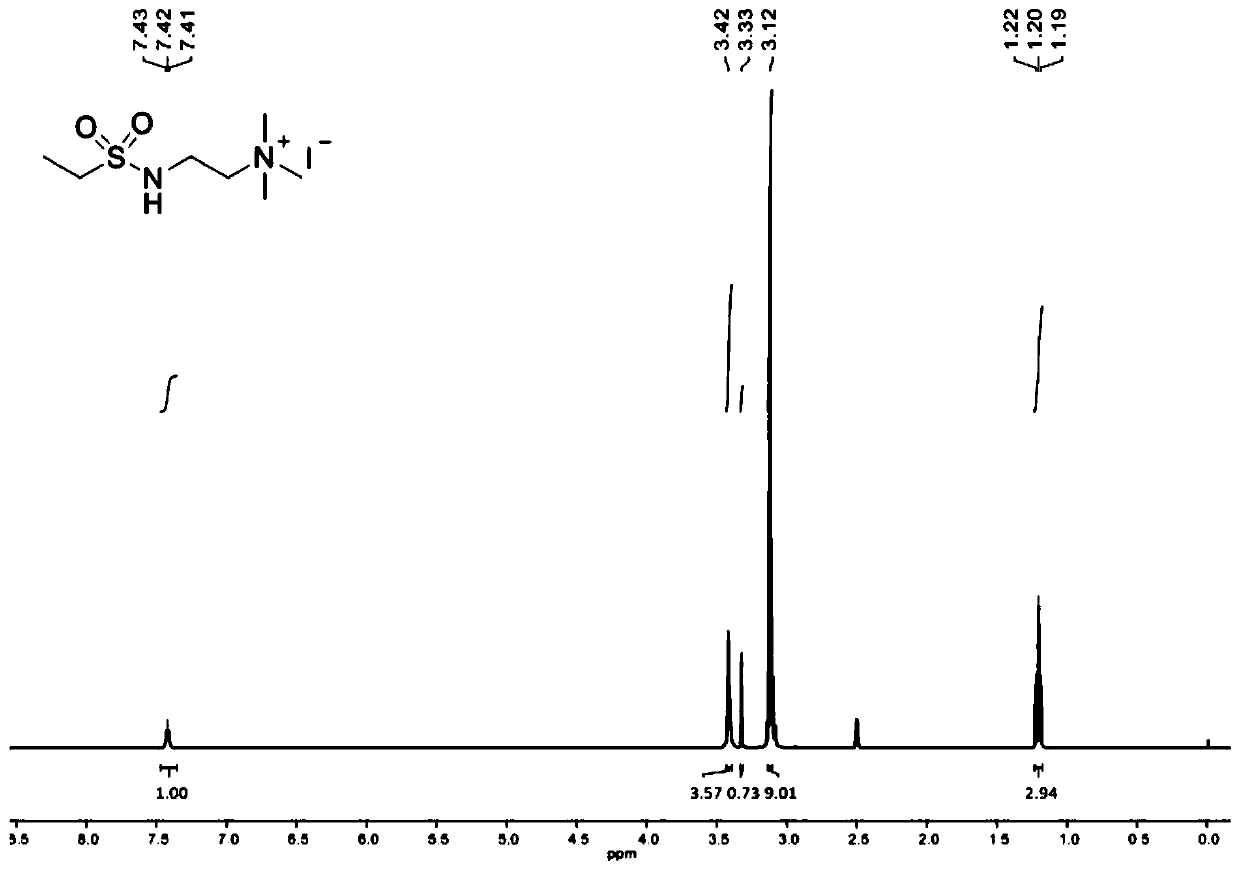

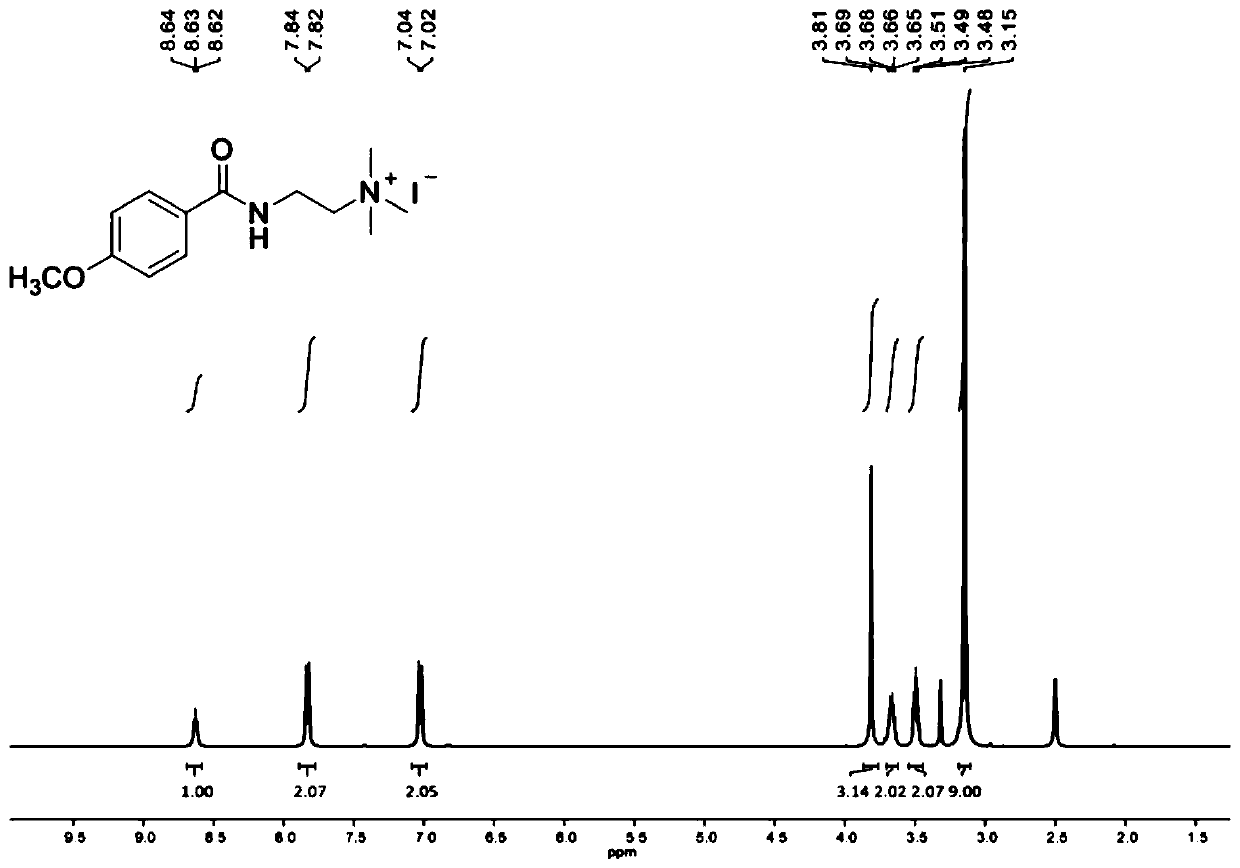

Process for the Preparation of a RAF Kinase Inhibitor and Intermediates for Use in the Process

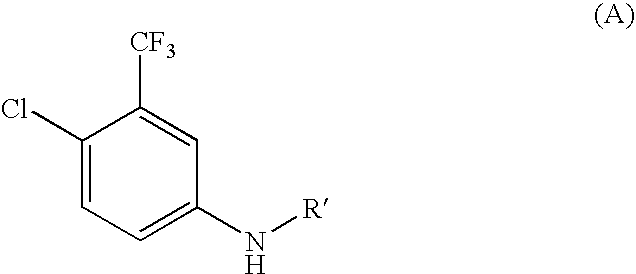

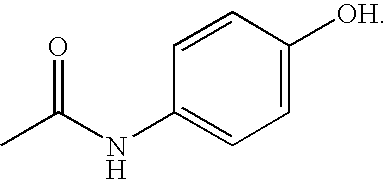

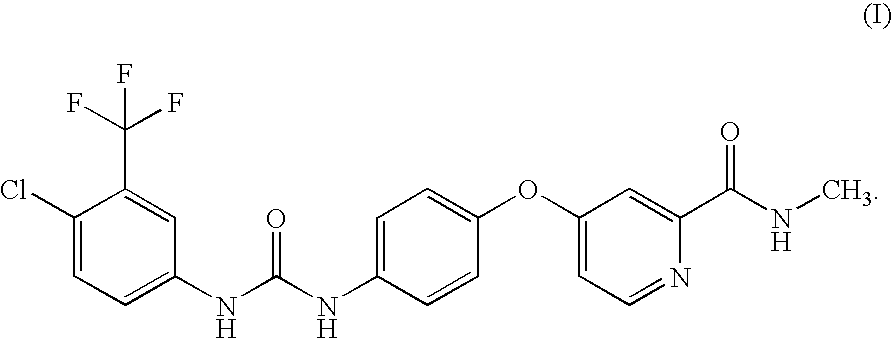

InactiveUS20100311980A1Suitable for industrial scale upHazardous to makeUrea derivatives preparationOrganic compound preparationRaf Kinase InhibitorPhenylcarbamic acid

There is provided a process for preparing sorafenib or a salt thereof comprising the use of a compound of formula (A)wherein R′ is selected from the group consisting of hydrogen, —C(O)OA, —C(O)CX3, —C(O)NH2, —C(O)—NHOH orThere is also provided intermediate compounds of general formula (A), N-methyl-4-(4-ureidophenoxy)picolinamide, 4-(2-(methylcarbamoyl)pyridin-4-yloxy)phenylcarbamate derivative and N-methyl-4-(4-(2,2,2-trihaloacetamido)phenoxy)picolinamide, processes for their preparation and their use in the preparation of sorafenib.

Owner:CIPLA LTD

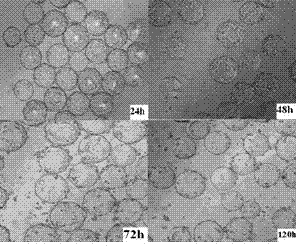

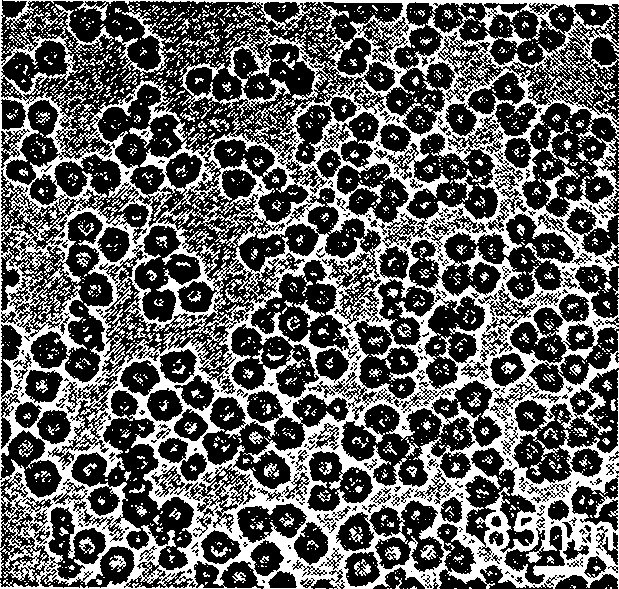

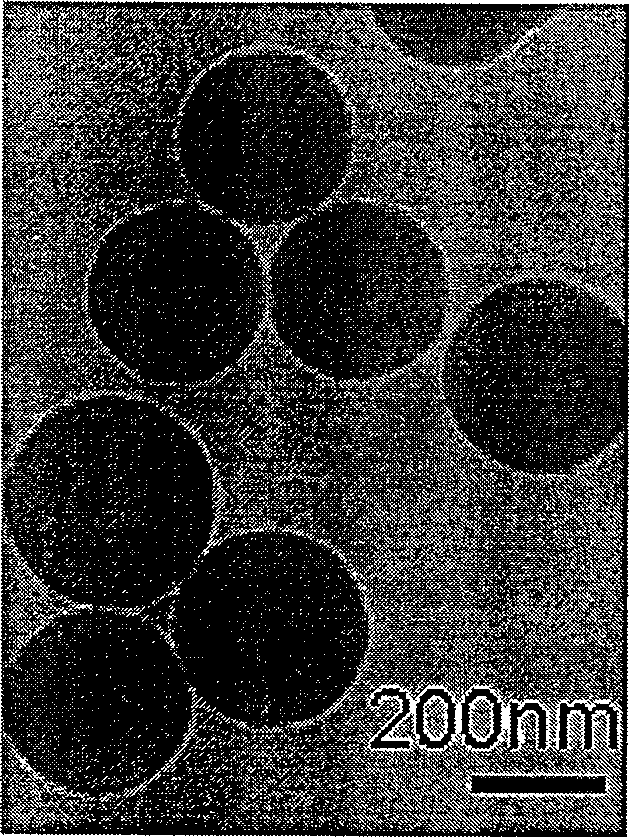

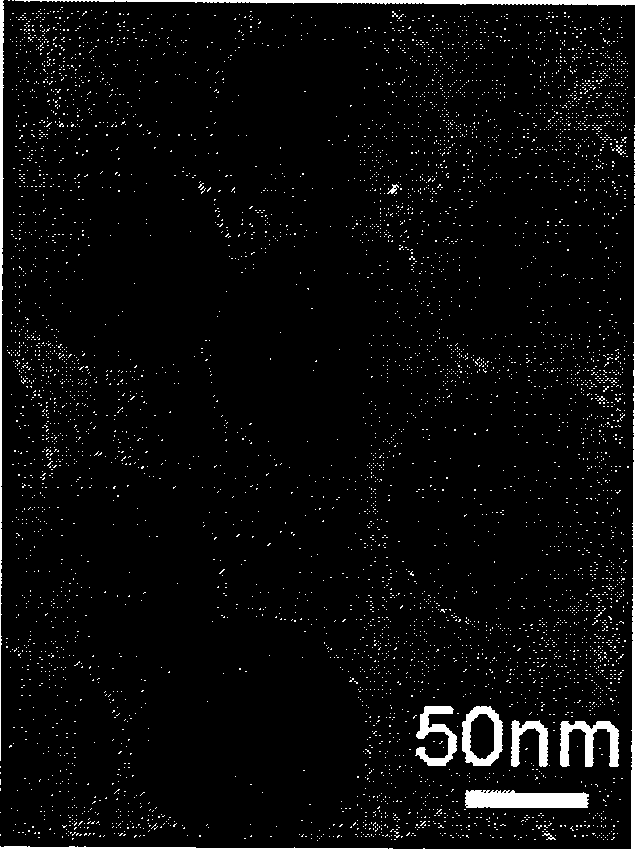

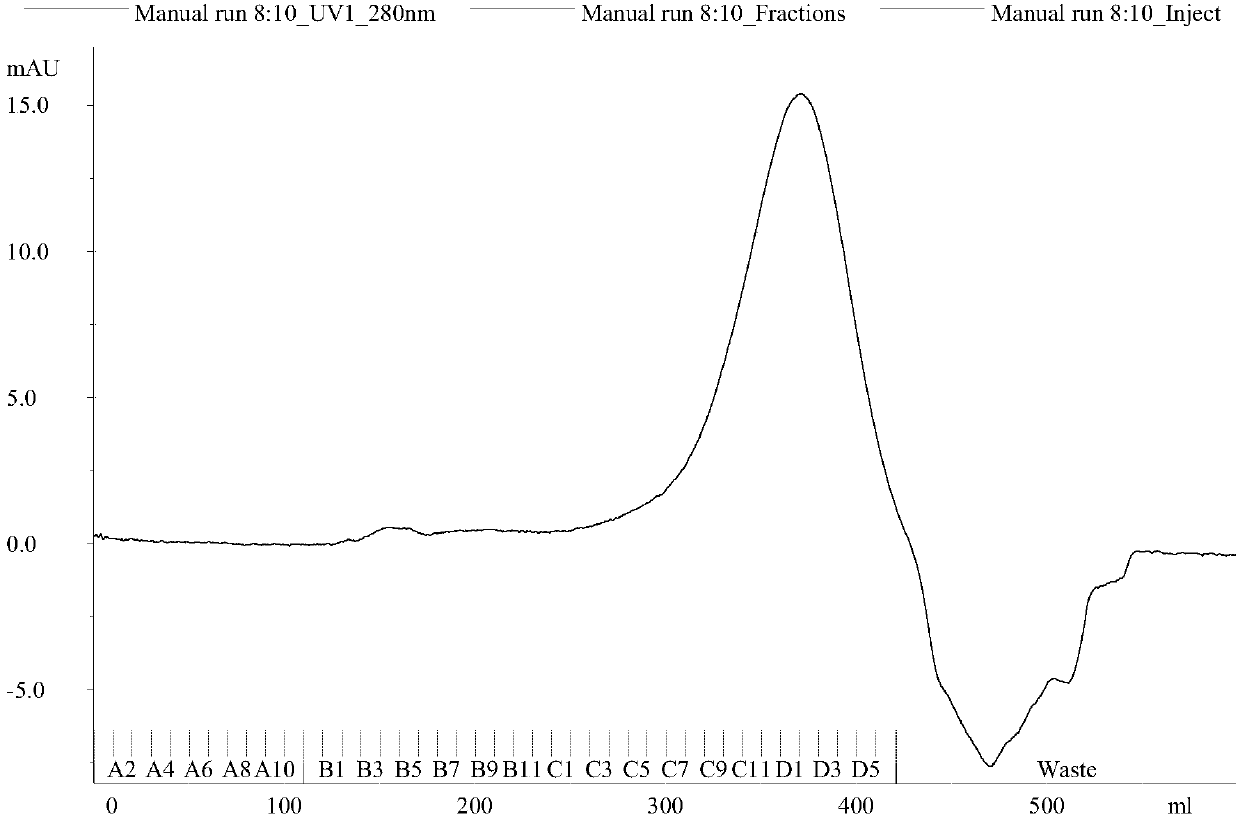

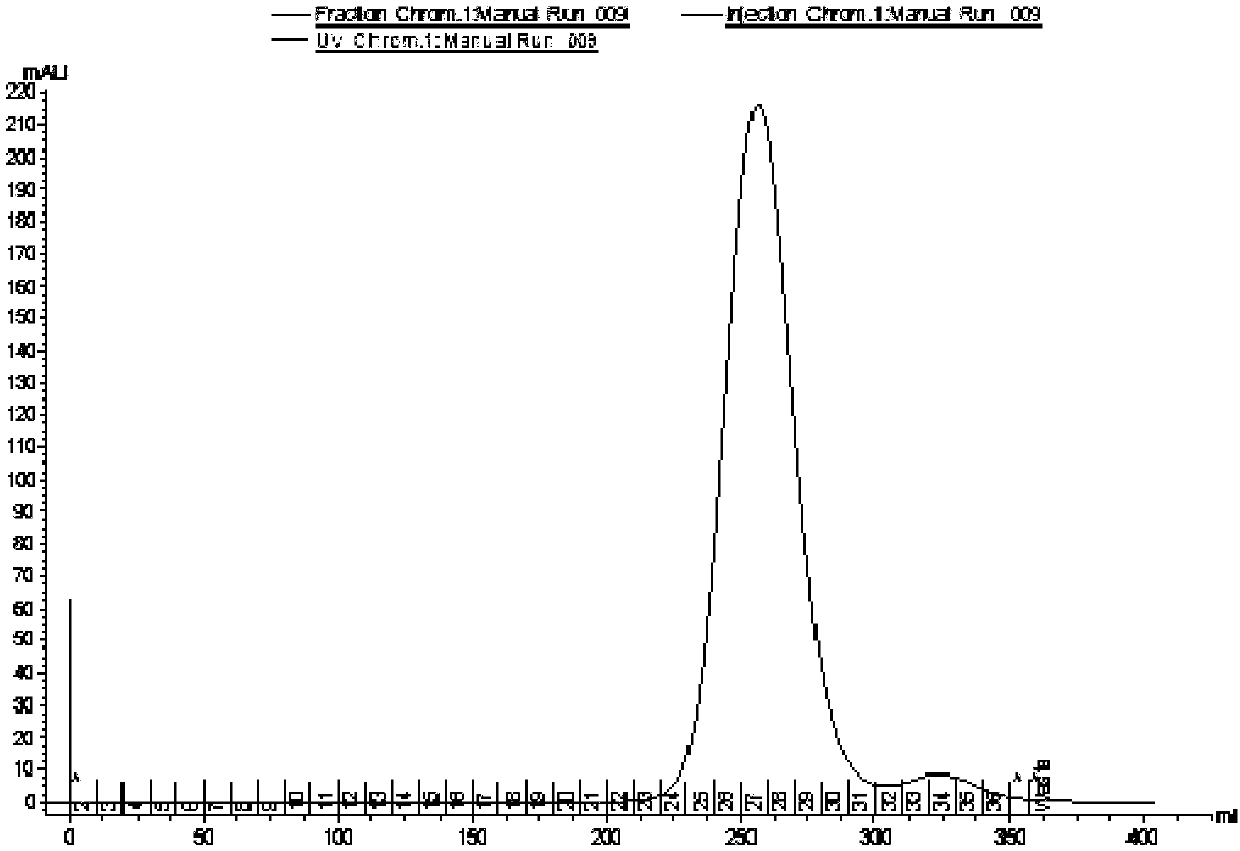

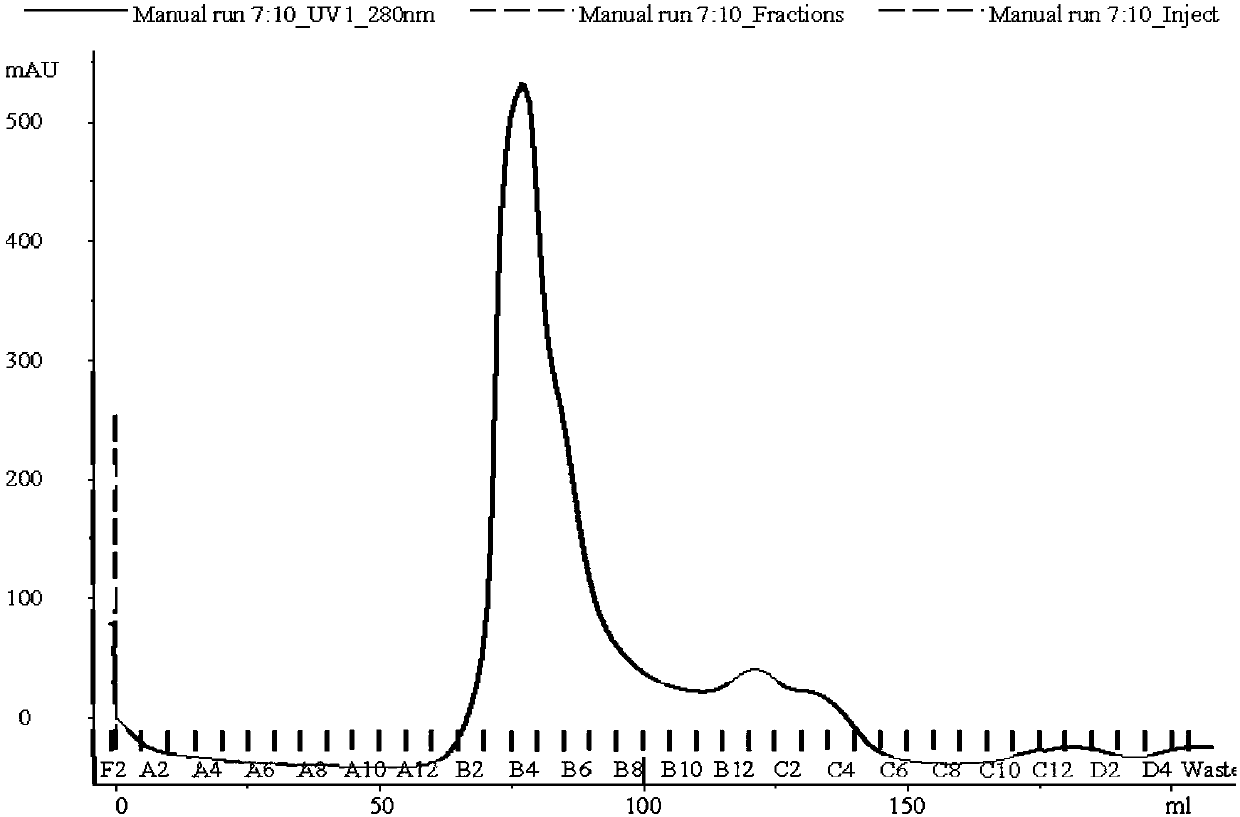

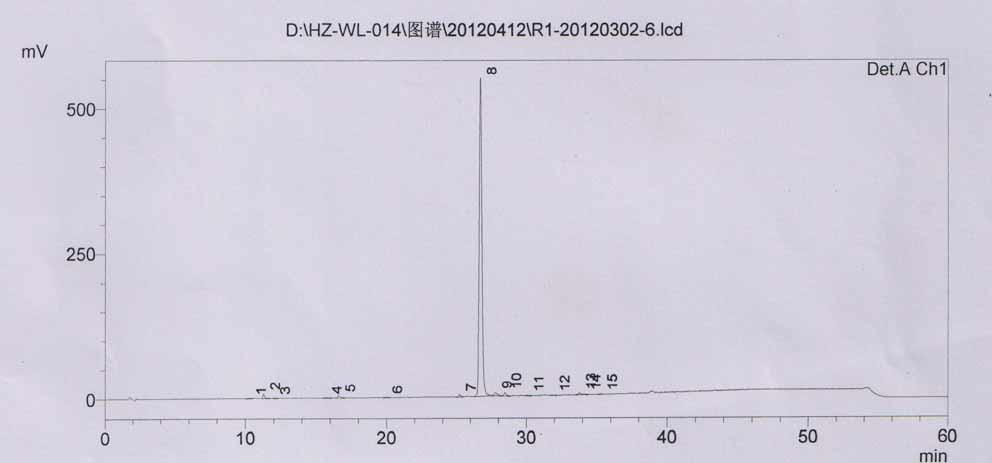

Separation and purification method for recombinant hepatitis B core antigen

ActiveCN108047316AImprove thermal stabilityAggregate compact and stableVirus peptidesPeptide preparation methodsAntigenPurification methods

The invention relates to a separation and purification method for a recombinant hepatitis B core antigen. The method includes the steps of thermal denaturation and clarification; ammonium sulfate precipitation; ultrafiltration and concentration, washing filtering and liquid exchange; depolymerization; first-step molecular sieve chromatography; ultrafiltration and concentration, washing filtering and liquid exchange; repolymerization; second-step chromatography. By means of the method, the high-purity, low-host-residue and high-stability recombinant hepatitis B core antigen with a uniform granular structure can be obtained, that is to say, the method has the advantages that the antigen purity is high, the residue of host protein and host nucleic acid is low, antigen particles are uniform, and industrial enlargement is easy.

Owner:JIANGSU THERAVAC BIO PHARMA

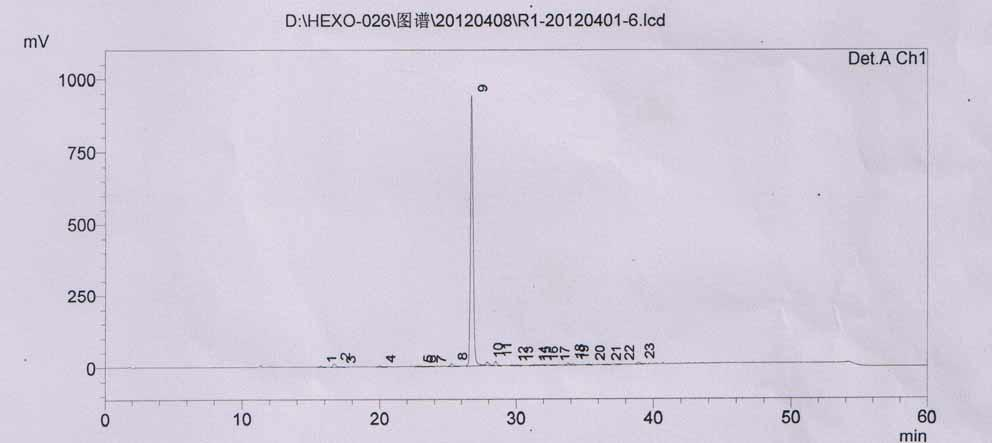

Preparation method and application of 3-(4-chlorobutyl)-5-cyano-1H-indole

The invention relates to a preparation method and application of 3-(4-chlorobutyl)-5-cyano-1H-indole. The preparation method comprises the following steps: after dissolving 3-(4-chlorobutyryl)-5-cyano-1H-indole in a solvent, adding trifluoroacetic acid, adding sodium borohydride in batches, and treating the reaction liquid to obtain the 3-(4-chlorobutyl)-5-cyano-1H-indole. The method overcomes the defects in the existing preparation method of an important intermediate 3-(4-chlorobutyl)-5-cyano-1H-indole of an antidepressant vilazodone hydrochloride, and has obvious creativity and practical application value. The reaction formula is disclosed in the specification.

Owner:HANGZHOU HEZE PHARMA TECH

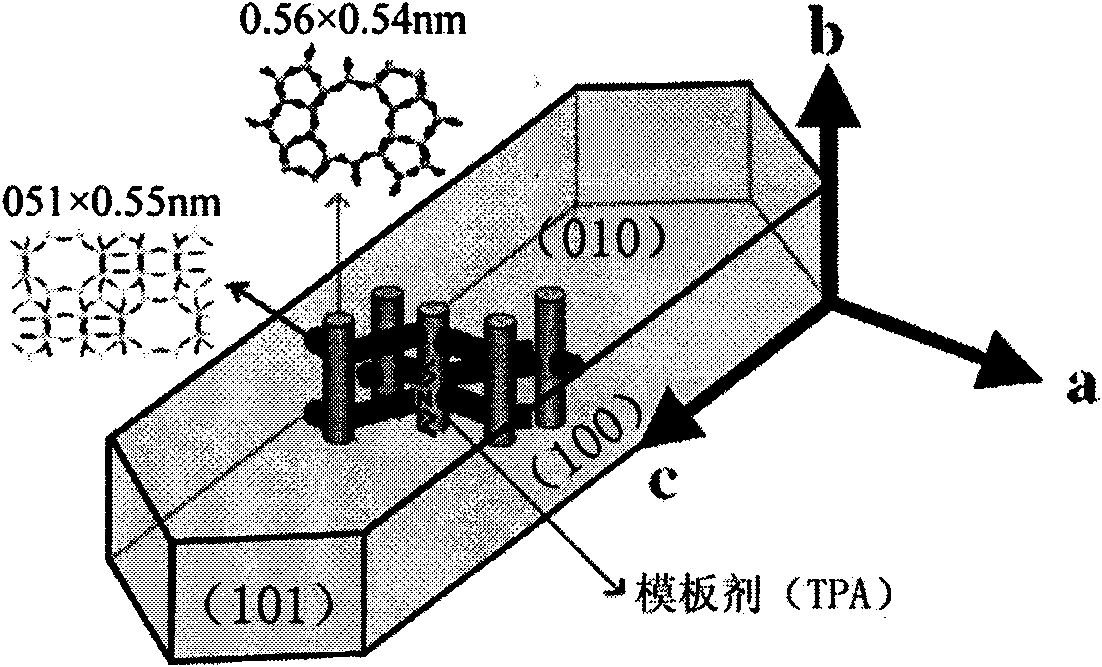

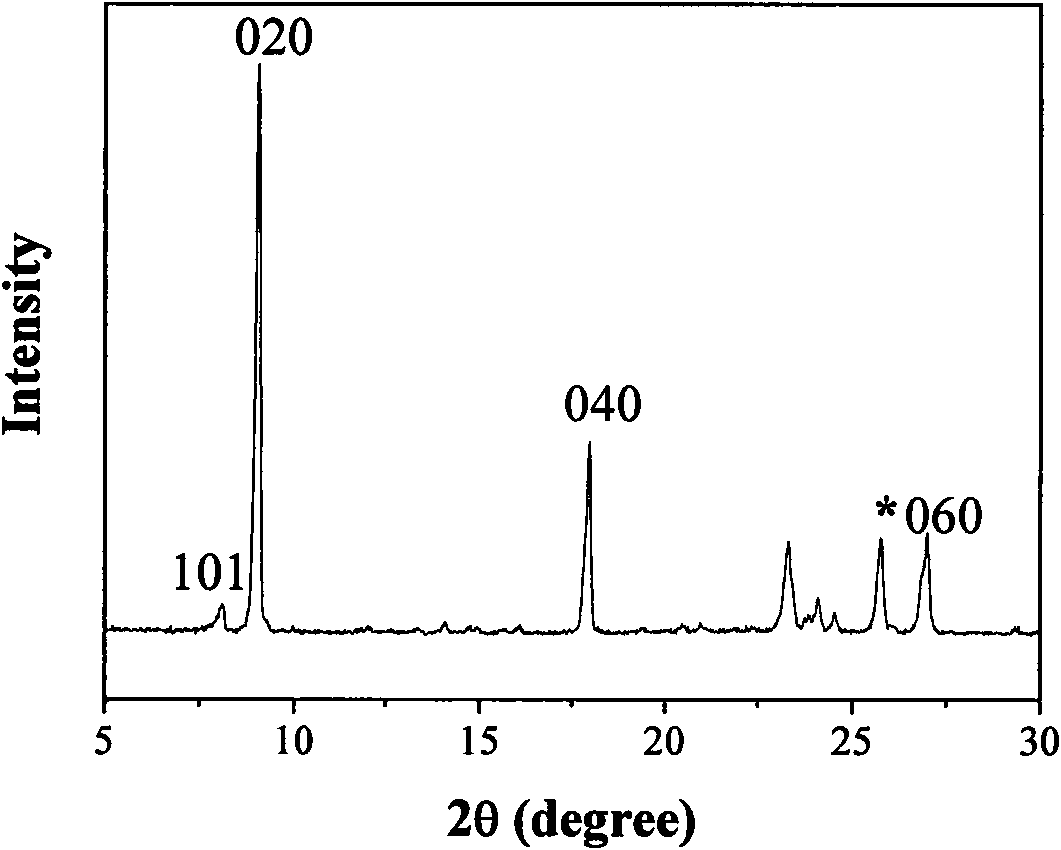

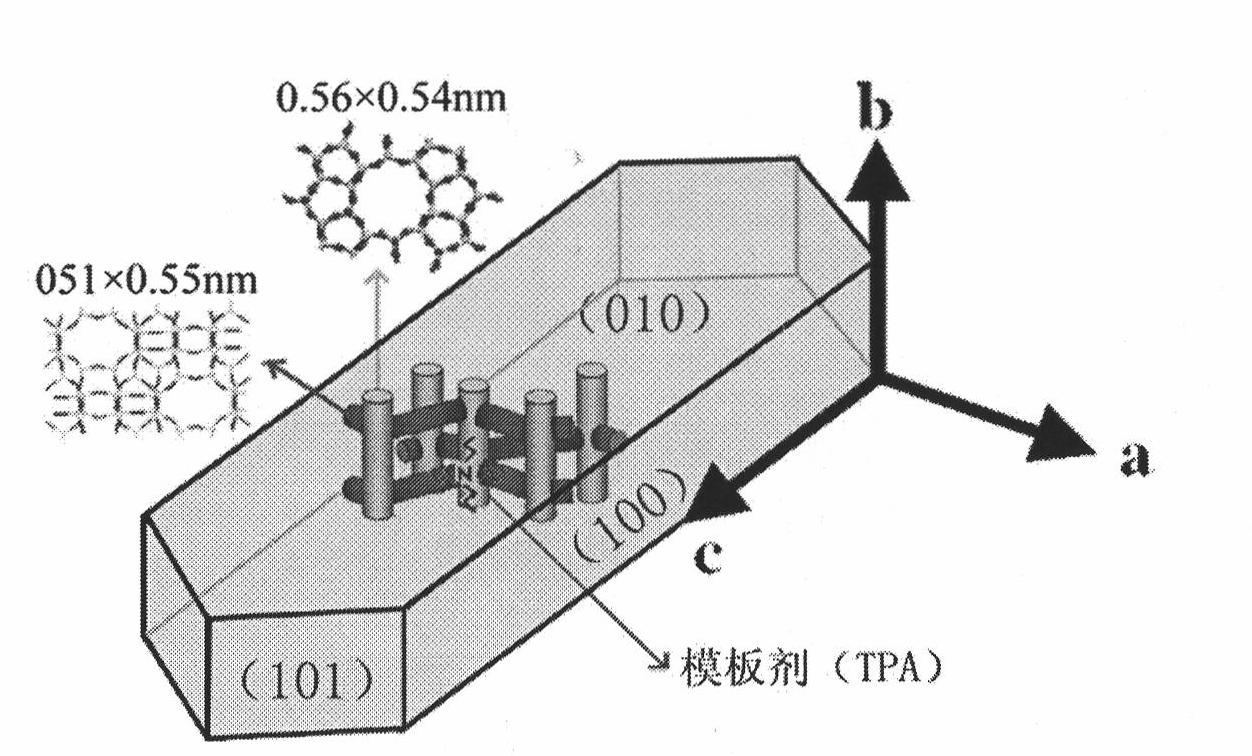

Method for preparing oriented molecular sieve membrane by using diauxic growth method

InactiveCN101774607AQuality improvementContinuous loadPentasil aluminosilicate zeoliteMolecular sieveSeed crystal

The invention relates to a method for preparing an oriented molecular sieve membrane by using a diauxic growth method, which comprises that molecular sieve seed crystals are carried on a carrier by using an electrostatic absorption-ultrasound method to form a seed crystal layer; the pH value of seed crystal liquid is adjusted to form a surface electrostatic layer, and the seed crystals are made to contact with the carrier with the maximum a-c surface through the assistance of ultrasound to form an even and successive b-axis oriented molecular sieve seed crystal layer; the molecular sieve seed crystal layer is prepared into a dense and successive b-axis oriented molecular sieve seed crystal membrane through diauxic growth. The method has the advantages of easy control of the thickness and orientation of molecular sieve membranes, repeatability and suitability for scale production.

Owner:TAIYUAN UNIV OF TECH

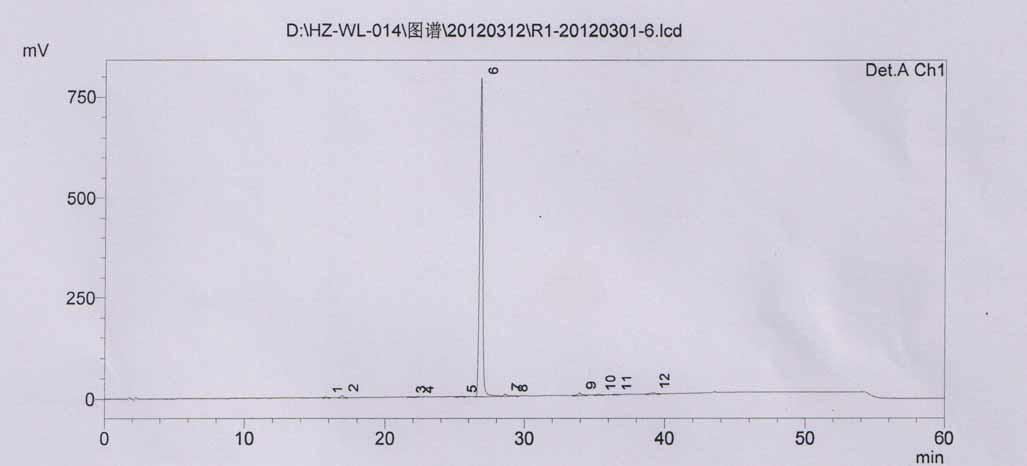

Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine

The invention discloses a preparation method of (R)-9-[2-(phosphoryl phenol methoxyl)propyl]adenine. The preparation method comprises the following steps: adding (R)-9-[2-(phosphoryl methoxy) propyl] adenine represented by the formula (I) into a solvent, controlling the temperature at -10 to 115 DEG C, adding triphenyl phosphite, starting to stir, controlling the temperature at -10 to 115 DEG C, carrying out a reaction, post-treating the reaction liquid obtained after completion of the reaction, and thus obtaining (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine represented by the formula (II). The preparation method is simple to operate, high in product yield, low in production cost, and suitable for industrial production.

Owner:HANGZHOU HEZE PHARMA TECH

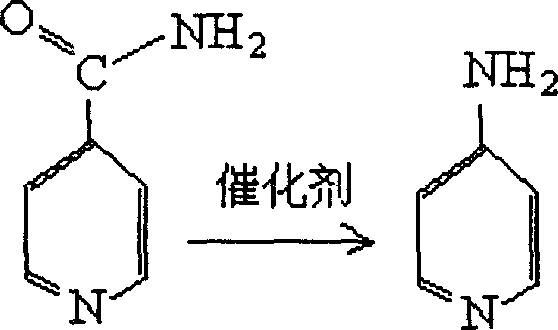

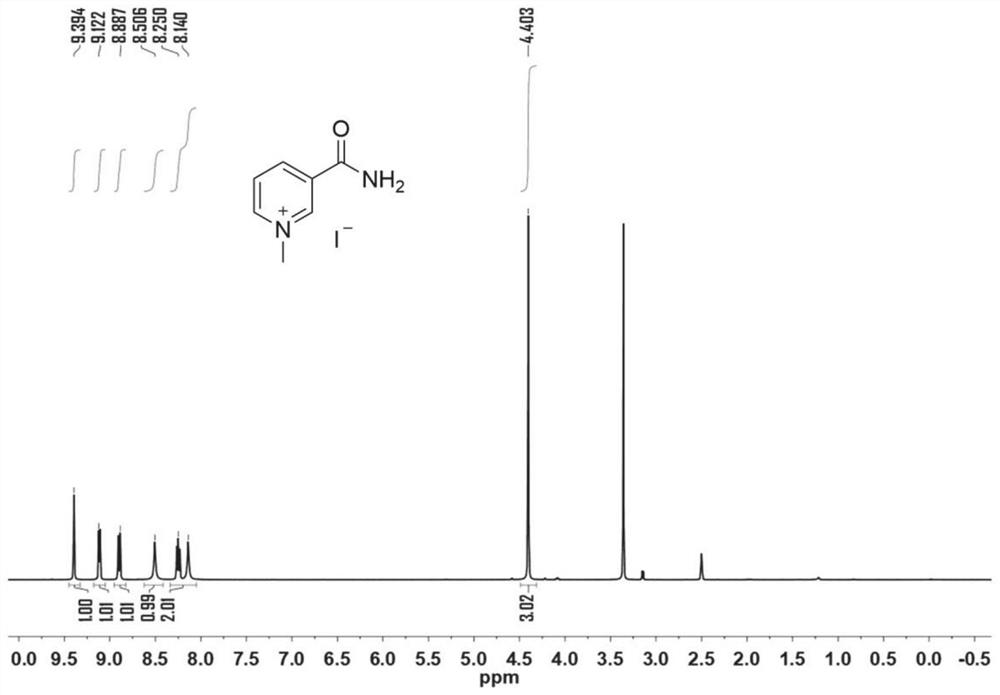

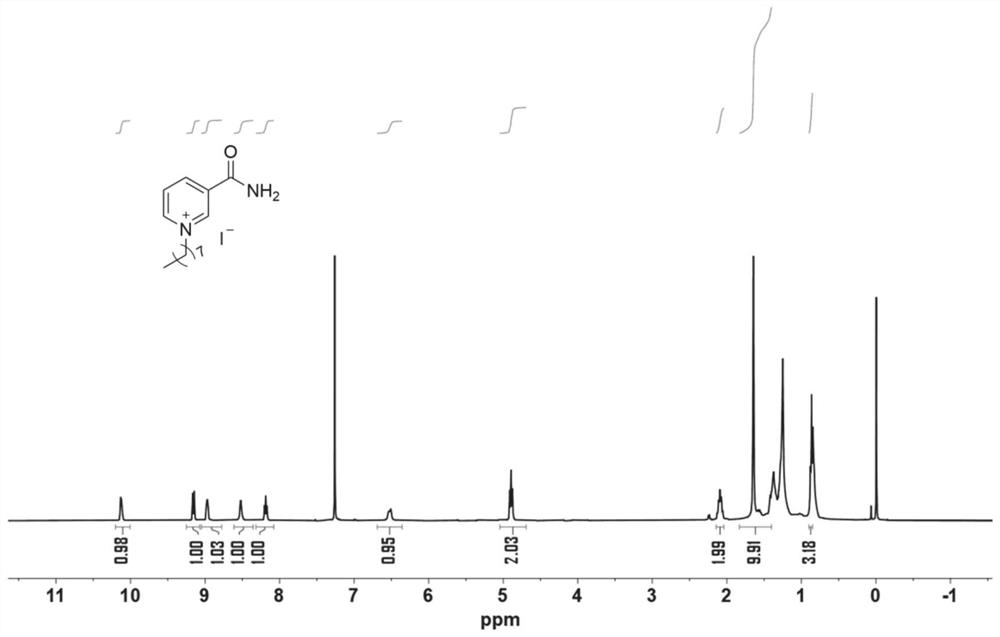

4-aminopyridine preparation method

The invention relates to a Method for preparation of 4-aminopyridine. This invention is based on the Hofmann degradation rezction of iosniacinamide to prepare 4-aminopyridine, making catalyzer by low-cost iodine or alkali metal iodide, sodium hydroxide orporassium hudroxide and bromine according to certain proportion and condition. The productivity of Hofmann degradation rezction of iosniacinamide is improved above 90%, the purity of 4-aminopyridine is higher than 99%. This can not only improve the productivity of 4-aminopyridine which is made by isonicotinic acid, but also reduce the cost of catalyzer greatly. It has important application-value to prepare 4-aminopyridine which is made by isonicotinic acid.

Owner:BEIJING UNIV OF CHEM TECH

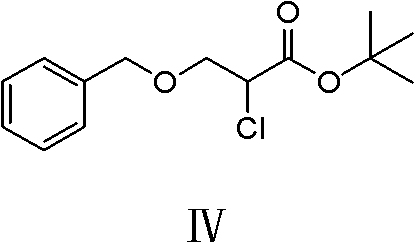

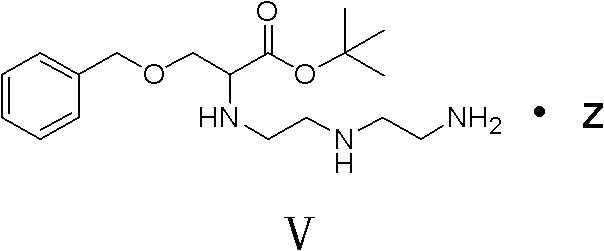

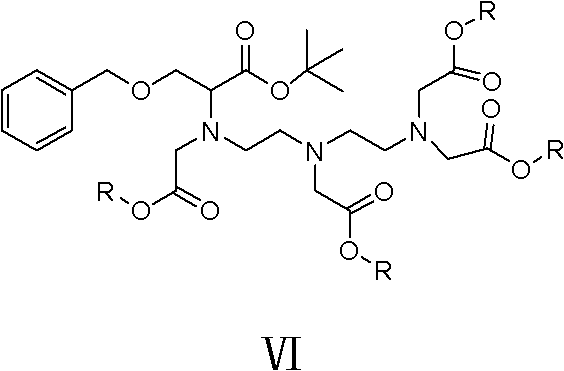

New preparation method of gadobenate dimeglumine

InactiveCN102408348AAvoid high pressureAvoid operabilityOrganic compound preparationAmino-carboxyl compound preparationToxic gasResonance

The invention provides a preparation method of a magnetic resonance contrast agent gadobenate dimeglumine and relates to a synthetic process of a new intermediate. In order to overcome the defects of the prior arts, the process is optimized and improved, the chlorine addition reaction is omitted and the reaction and operation of high-pressure and toxic gas are avoided; and the synthesized intermediate of each step can be purified through recrystallization, the quality control of the product is stable and the operation process is more suitable for industrialized large-scale preparation.

Owner:TIANJIN HAIWEN PUNING TECH DEV

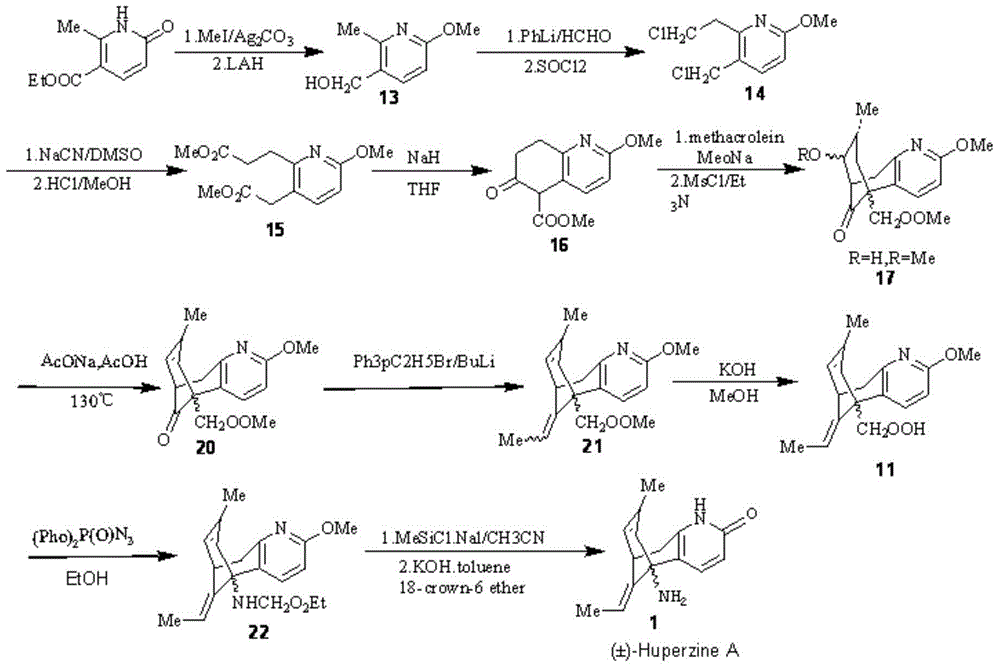

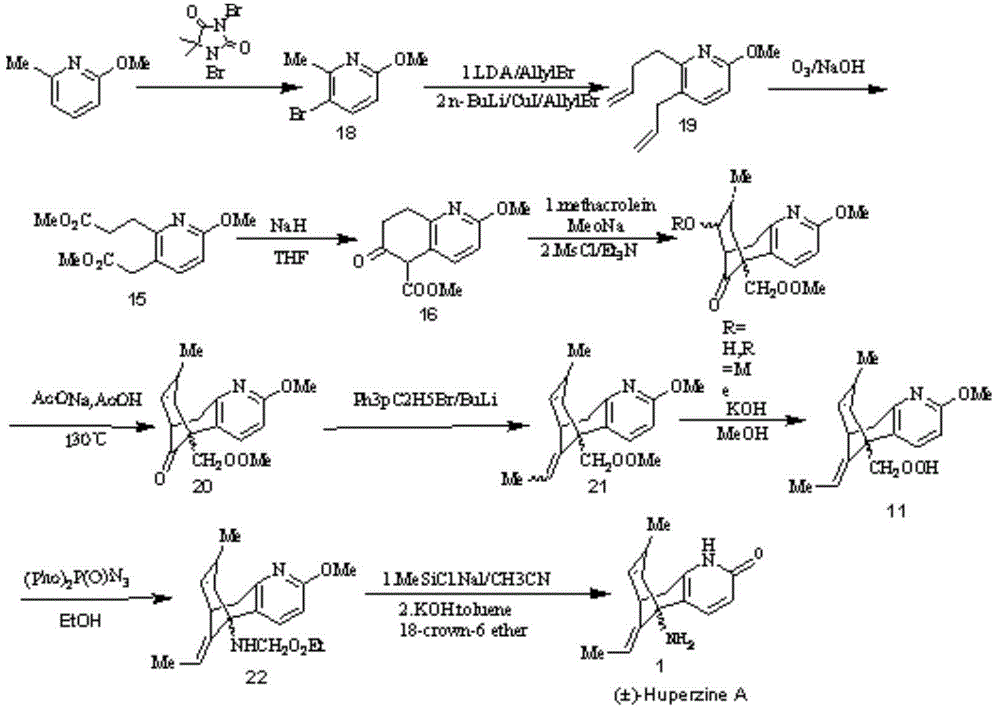

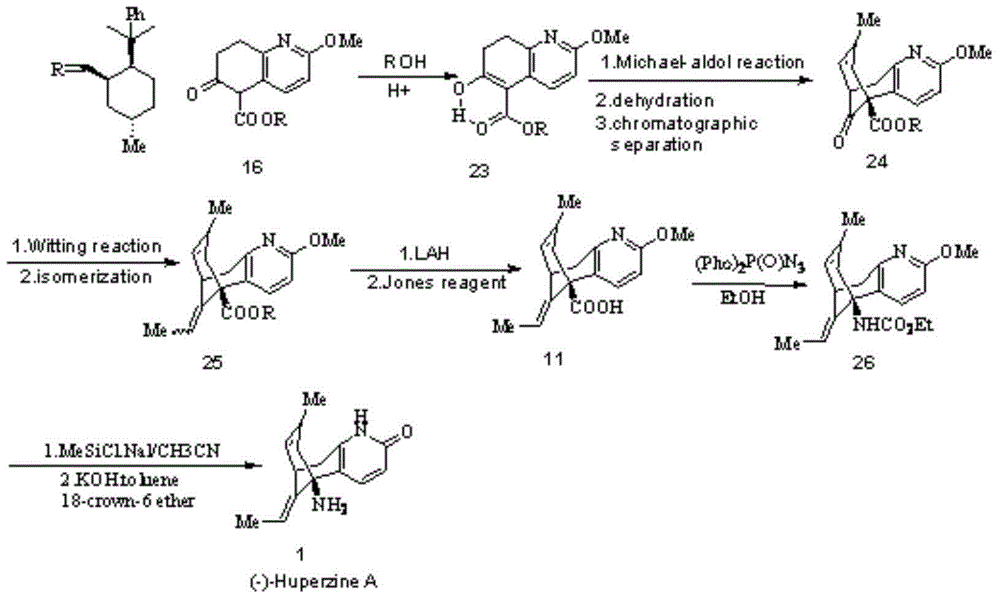

Reversible acetylcholinesterase inhibitor huperzine-A synthesis method

InactiveCN105399672AHigh ee valueLow costOrganic chemistryCholinesterase inhibitionSynthesis methods

The present invention discloses a reversible acetylcholinesterase inhibitor huperzine-A synthesis method, wherein the route is defined in the specification. The method of the present invention has advantages of easily-available raw materials, simple operation, high yield, low cost, high purity of the final product, easy quality control and the like, and is suitable for industrial production.

Owner:SHANGHAI HONGJING BIOTECH CO LTD

Method for preparing orientation molecular sieve membrane

InactiveCN101654260AReduce adverse effectsSynthesis conditions are easy to controlPentasil aluminosilicate zeoliteAlcoholEvaporation

The invention provides a method for preparing an orientation molecular sieve membrane, comprising the following steps: removing alcohol in pro-glue solution in an evaporation way by improving the hydrolysis temperature of silicon source and germanium source and promoting the hydrolysis thereof; directly contact heating up the pro-glue solution and a carrier; crystallizing under self-generated pressure; and preparing b-axial orientation Ge-ZSM-5 molecular sieve membrane. The orientation molecular sieve membrane is even and compact, and has no defect of large holes, wherein molecular sieve membrane crystalloid is oriented along the b axis, thereby being good for the process of mass transferring. The method can obviously improve the capability of the synthetic Ge-ZSM-5 molecular sieve membrane, has high repetitiveness and high raw materials utilization factor, and is suitable for industrial production.

Owner:TAIYUAN UNIV OF TECH

Stable everolimus tablet

ActiveCN104721158AEffective dissolutionSimple preparation processOrganic active ingredientsAntimycoticsEverolimusAdhesive

The invention provides a stable everolimus tablet containing one or several selected from everolimus, 2,6-tert-butyl-4-methylphenol, a filling agent, an adhesive, a disintegrating agent and a lubricating agent, wherein everolimus is micronized before being tabletted, and the micronized median particle diameter D50 does not exceed 100mu m. The everolimus tablet prepared by the invention has the advantages of relatively high dissolution rate, favorable stability, low production cost, stable and controllable process parameters and the like.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

Preparation method of cyclic carbonate

InactiveCN111253360AHigh activityImprove hydrogen supply capacityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention belongs to the technical field of green catalytic synthesis, and particularly relates to a preparation method of cyclic carbonate. Epoxide and carbon dioxide are catalyzed by using a catalyst provided by the invention to obtain the cyclic carbonate. According to the invention, the synthesis method is simple, cost is low, the catalyst has high activity and high selectivity, a reactioncondition is mild, and good reusability is realized.

Owner:NANJING UNIV OF TECH

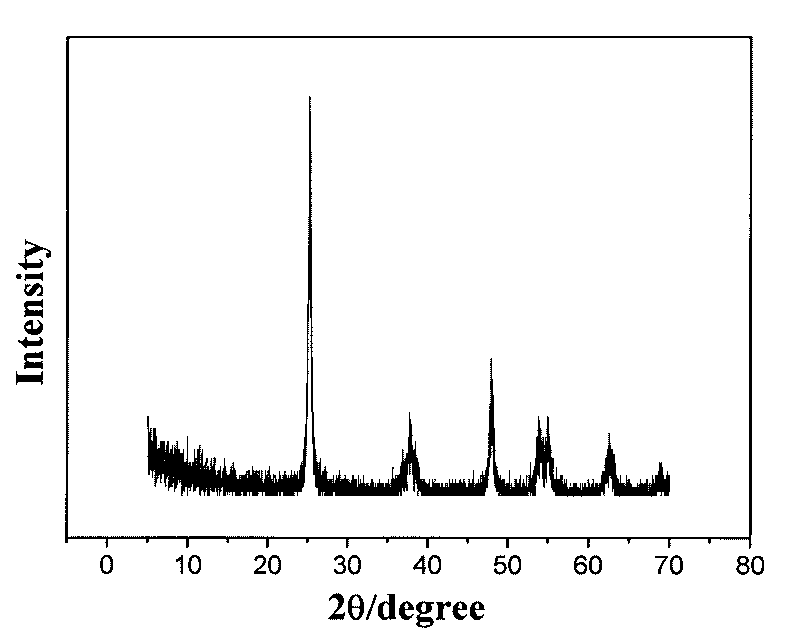

Method for preparing TiO2/Al2O3 composite film

InactiveCN101721918AHigh selectivityImprove permeabilitySemi-permeable membranesCatalyst carriersComposite filmPore distribution

The invention relates to a method for preparing a TiO2 / Al2O3 composite film, which takes chitosan derivative as organic additive, adopts organic titanium salt as titanium source and uses water as solvent to prepare colloidal sol. The method comprises: taking alpha-Al2O3 as carrier, and preparing the TiO2 / Al2O3 composite film by film coating, drying and calcining. The film material prepared by the method is thin in film layer, large in porosity, narrow in pore distribution, high in permeation flux and good in separating performance. Furthermore, the preparation method is simple in technique, has higher repeatability, improves the utilization rate of raw materials, is beneficial to reducing the cost and is suitable for industrial amplification.

Owner:TAIYUAN UNIV OF TECH

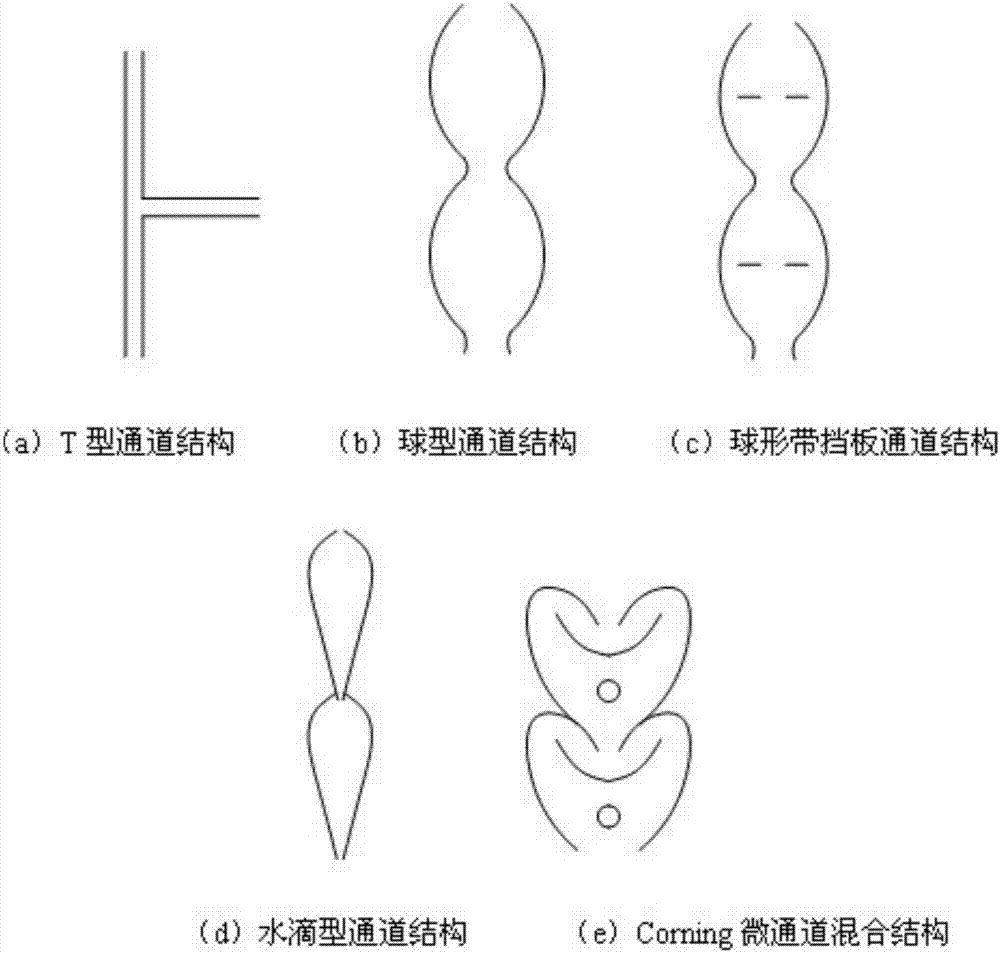

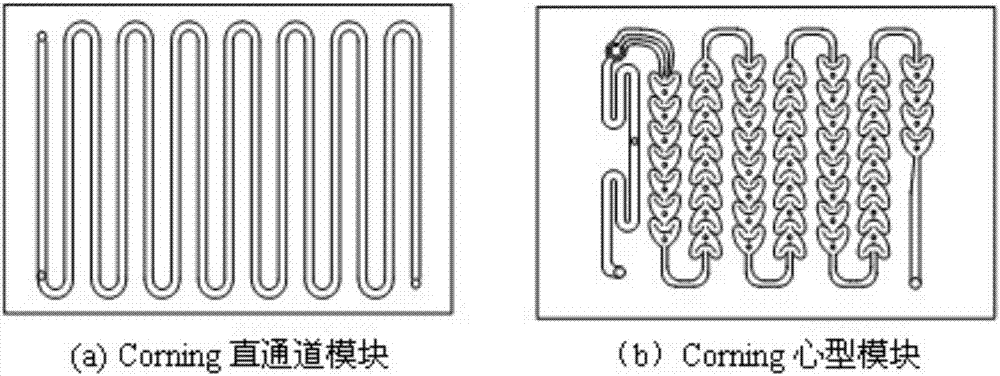

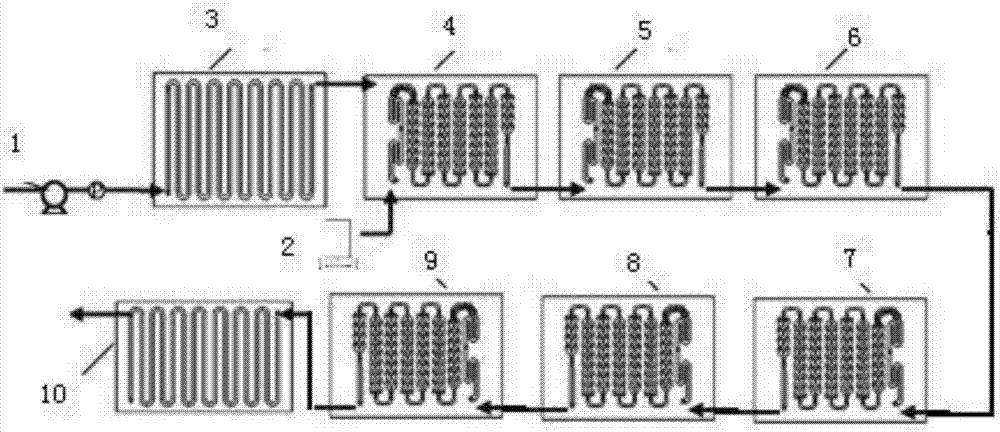

Continuous preparation method of perfluoropolyether

ActiveCN107383355AImprove conversion rateShort reaction timeOrganic chemistryOrganic compound preparationPerfluoropolyetherChemistry

The invention discloses a method for continuously preparing perfluoropolyether by using a microchannel reactor. CF3CF2CF2O(CF2CF(CF3)O)<n-2>CF(CF3)COOH used as a raw material reacts with F2 to obtain the corresponding perfluoropolyether. The method provided by the invention has the advantages of high conversion rate, short reaction time and safe and controllable reaction, and is suitable for industrialized amplification.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

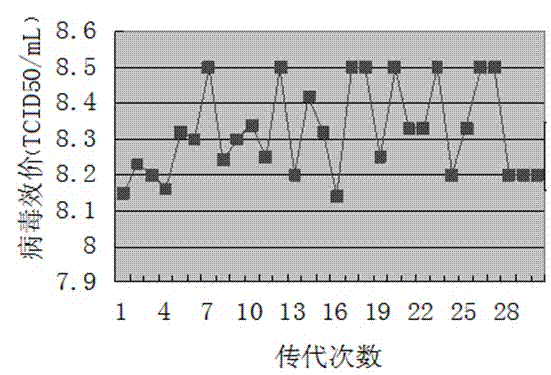

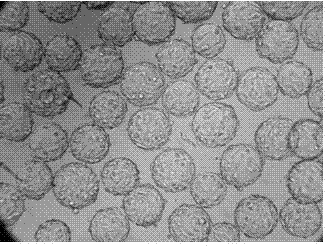

Infectious bursal disease virus Vero cell-adapted strain and application thereof

InactiveCN103923885AStable proliferationImprove securityViral antigen ingredientsMicroorganism based processesOil emulsionEmbryo

The invention provides an infectious bursal disease virus Vero cell-adapted strain and belongs to the field of bioengineering. The related infectious bursal disease virus Vero cell-adapted strain is named Ck / Jiangsu / NJ-23 / 2008 and has a collection No. of CGMCCNO.8852. The infectious bursal disease virus Vero cell-adapted strain which can efficiently multiply on serum-free cultured Vero cell is finally obtained through wild strain separation, chick embryo passage, Vero cell passage adaption; the infectious bursal disease virus Vero cell-adapted strain is subjected to continuous passage culture on the serum-free cultured Vero cell and TCID50 can be kept to be higher than 108.5 / mL. Virus culture solution is inactivated and prepared into oil emulsion; after the prepared oil emulsion is used to immunize chicken, detection proves that the prepared oil emulsion has good immunogenicity. The infectious bursal disease virus (IBDV) strain and the production process thereof are simple, safe and efficient and suitable for industrial culture.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

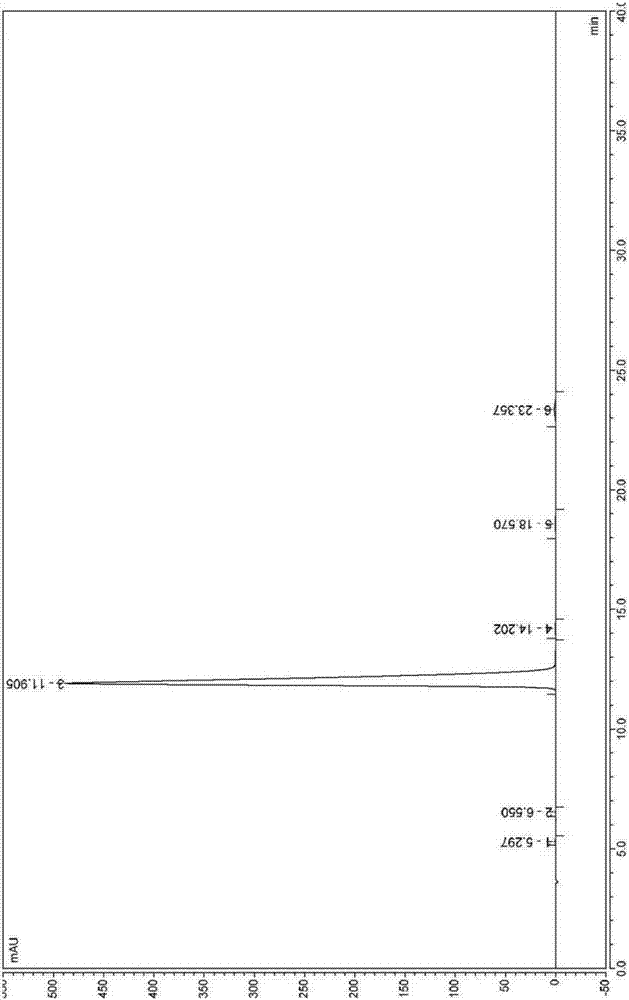

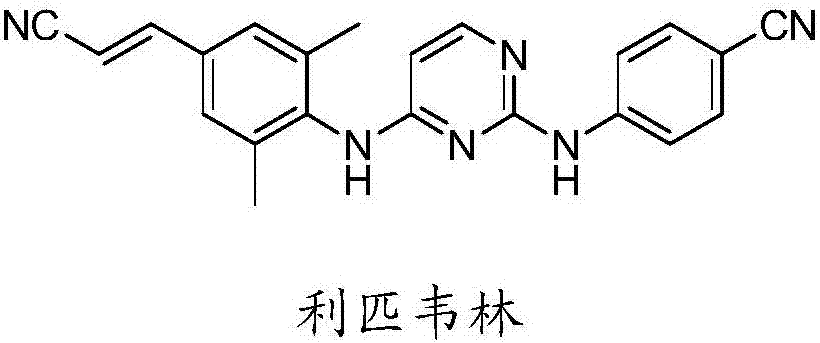

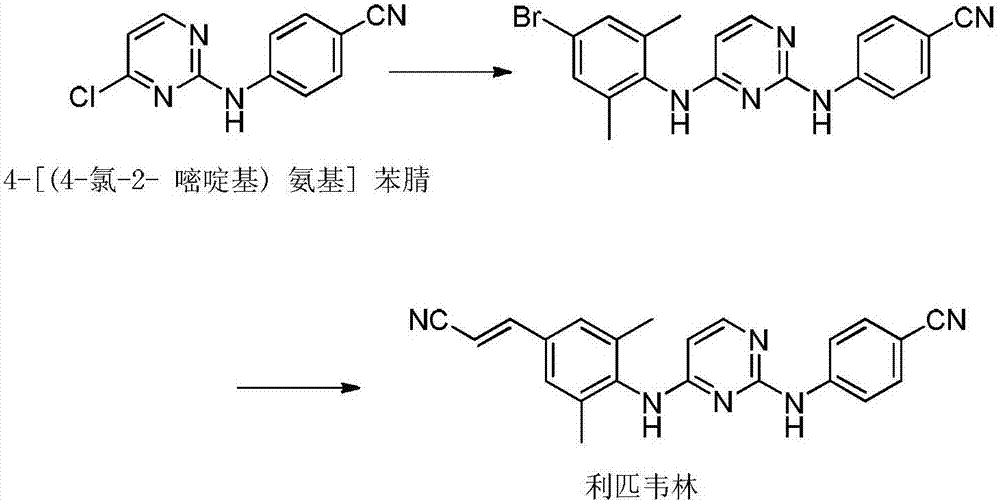

Industrial synthesis method of rilpivirine and intermediate compound

InactiveCN107162987AReduce usageSimple and fast operationOrganic chemistrySynthesis methodsHydrochloride

The invention discloses an industrial synthesis method of rilpivirine. A compound as shown in a formula I and compound hydrochloride as shown in a formula VI react to obtain rilpivirine. The invention further discloses an intermediate compound as shown in the formula I and a synthesis method of the intermediate compound. Compared with the prior art, the synthesis method is simple to operate, mild in condition, high in yield and purity and suitable for industrial production.

Owner:YICHANG HUMANWELL PHARMA

Low-molecular-weight chondroitin sulfate and preparation method thereof

InactiveCN111741963AGood specificityHigh enzyme activityEsterified saccharide compoundsCosmetic preparationsProtein contentOligosaccharide

The invention discloses a low-molecular-weight chondroitin sulfate and a preparation method thereof. Macromolecular chondroitin sulfate is used as a raw material, and the low-molecular-weight chondroitin sulfate having average molecular weight of less than 1000 daltons is produced through a production process comprising chondroitin sulfate lyase degradation, deproteinization, filtration sterilization, drying, and the like. According to the low-molecular-weight chondroitin sulfate, the molecular weight distribution range is narrow, the content of chondroitin sulfate disaccharide is 43-60%, thecontent of chondroitin sulfate tetrasaccharide is 30-45%, the sum of contents of the chondroitin sulfate disaccharide and the chondroitin sulfate tetrasaccharide is greater than 87%, the total contentof oligosaccharides in the low-molecular-weight chondroitin sulfate is 97% or above, and the protein content is not more than 0.5%. Compared with common marketed macromolecular chondroitin sulfate, the product has a more obvious repairing effect on chondrocytes damaged by 1mM hydrogen peroxide at a concentration of 50-100 [mu]g / mL, has a strong repairing ability and a repair rate between 14% and23%, can be used to treat joint injuries, and is an important raw material for medical products, healthcare products, cosmetics, food, etc..

Owner:NANJING HANXIN PHARMA TECH CO LTD

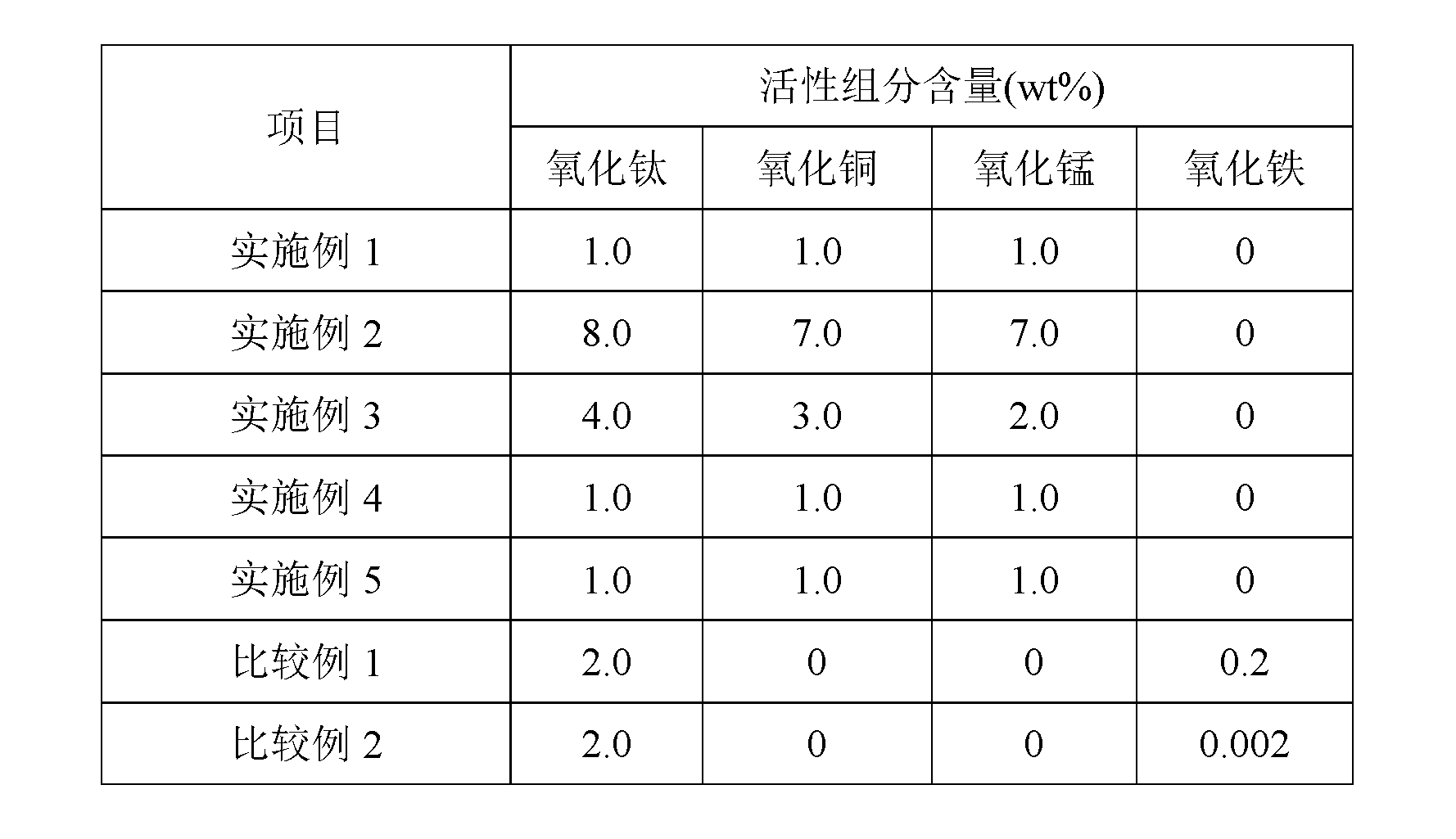

Method for preparing photocatalyst for treating petroleum pollutants in water

ActiveCN103007951ARemove applicableSimple preparation stepsWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsManganeseSlurry

The invention relates to a method for preparing a photocatalyst for treating petroleum pollutants in water. The method is characterized in that titanium dioxide and Cu and Mn oxides are taken as active ingredients and are loaded on a floating type foaming ceramic carrier through adopting a rolling load technology. The method comprises the following specific steps: (a) dissolving titanyl sulfate into deionized water, regulating the pH value to 7-10 by using a 5-25% ammonia solution, cleaning the obtained white precipitate centrifugally, mixing the white precipitate with the deionized water, pulping and regulating the pH value to 7-10 under a mixing condition by using H2O2 and HCl so as to obtain titanium sol; (b) dissolving manganese salt and copper salt into the deionized water, mixing with a permanganate solution, dripping a NaOH solution to regulate the pH value to 8-12 and spray-drying the obtained size to obtain catalyst precursor powder; and (c) adding foaming ceramic balls into a rotary granulator, spreading the catalyst precursor slowing under the rolling condition, spraying titanium sol to be used as an adhesion agent, carrying out roll coating, drying and calcinating to obtain a catalyst finished product.

Owner:CHINA NAT OFFSHORE OIL CORP +1

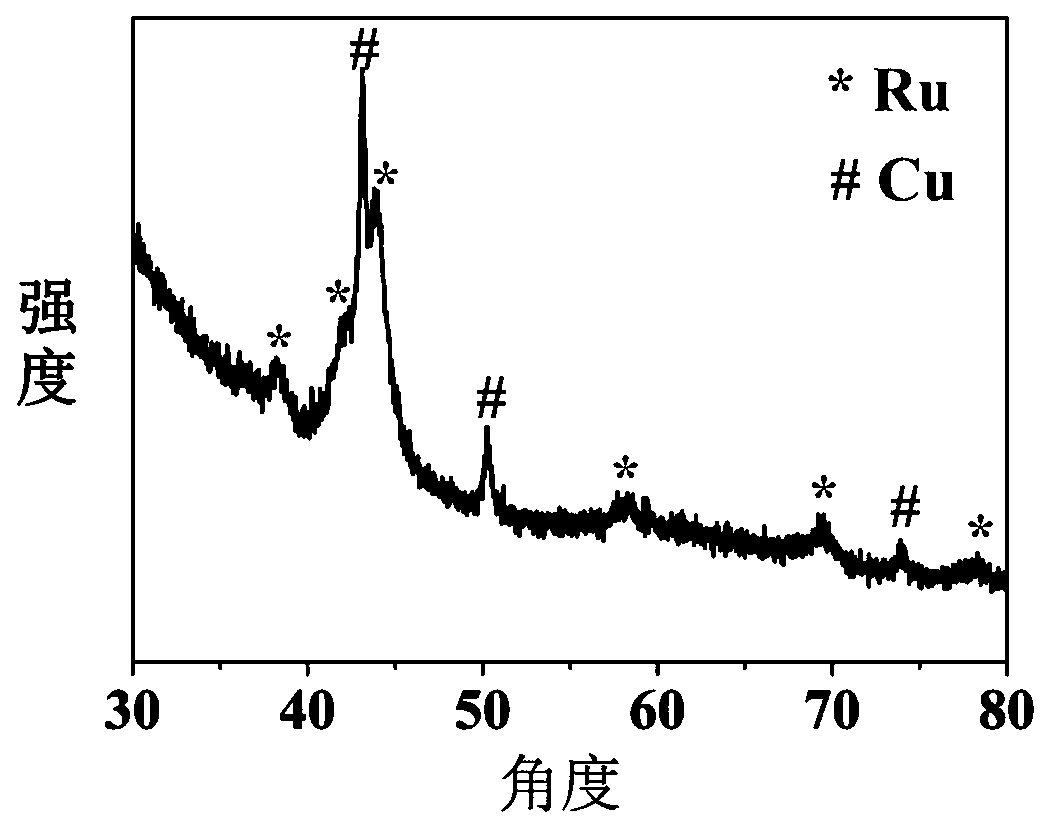

Li-CO2 battery anode catalyst material and preparation method thereof, battery anode material and battery

ActiveCN109301268AAvoid severe clumpingNo reunionFuel and secondary cellsCell electrodesBenzaldehydeArgon atmosphere

The invention belongs to the technical field of electrochemistry, and relates to a Li-CO2 battery anode catalyst material and a preparation method thereof, a battery anode material and a battery. Theanode catalyst material preparation method includes the following steps: dissolving graphene, ruthenium trichloride hydrate, copper acetate and polyvinylpyrrolidone in ethylene glycol to prepare a precursor solution, and performing ultrasound; and uniformly stirring the solution for two minutes under an oil bath at 180 DEG C in an argon atmosphere, adding benzaldehyde, continuously stirring for 1hour, cooling, centrifuging, vacuum drying and calcining, so as to obtain the ruthenium-copper bimetallic anode catalyst material dispersed on the graphene. When the Li-CO2 battery anode catalyst material is applied to the Li-CO2 battery anode, under the current density of 200 mA / g, the voltage range is 2-4.5 V, the cut-off capacity is 1000 mAh / g, the performance of the Li-CO2 battery anode is still very stable after 100 cycles, compared with using copper or ruthenium as the anode catalyst, the electrocatalytic performance of the Li-CO2 battery anode is greatly improved, so that the Li-CO2 battery anode catalyst material has wide application prospect in the Li-CO2 battery field.

Owner:XINYANG NORMAL UNIVERSITY

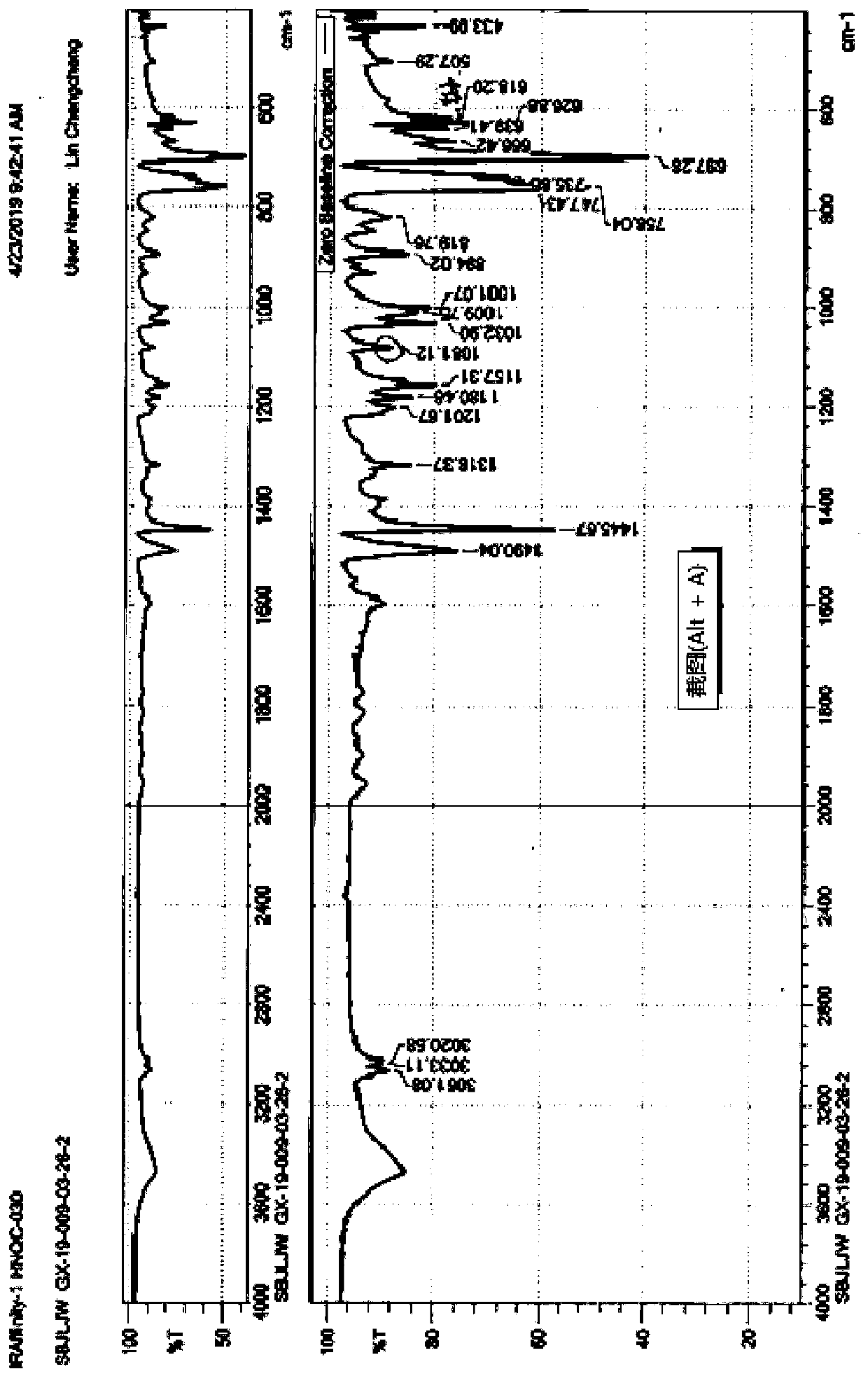

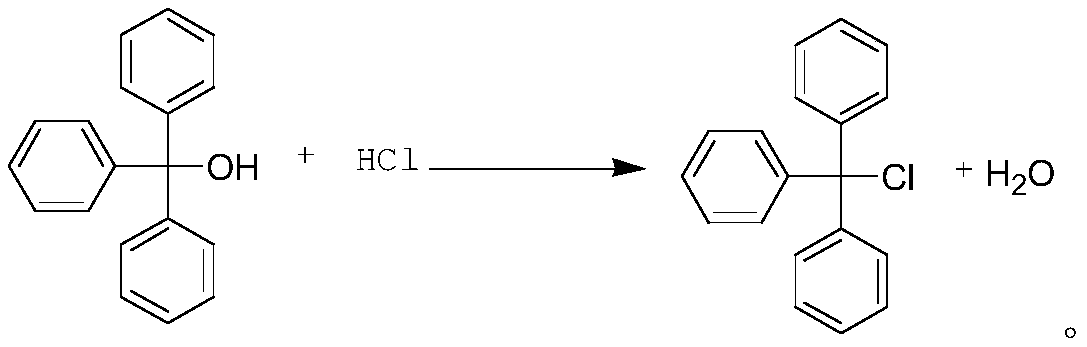

Recycling and reuse technology for preparing triphenylchloromethane

InactiveCN110204413AHigh yieldHigh product contentHalogenated hydrocarbon preparationSolventPollution

The invention provides a recycling and reuse technology for preparing triphenylchloromethane. The technology comprises the following steps that hydrochloric acid or a mixture of the hydrochloric acidand Lewis acid is added into a solvent of triphenylcarbinol, stirring is conducted at a certain temperature, after a reaction is finished, separation is conducted, or after separation, recrystallization is further conducted, and the triphenylchloromethane is obtained after drying, wherein the reaction equation is shown in the description. The reuse technology is a recycling and reuse technology which is wide in raw material source, low in price and simple in production process operation and causes little pollution, and the technology is very suitable for commercialized production.

Owner:LINHAI HUANAN CHEM CO LTD +1

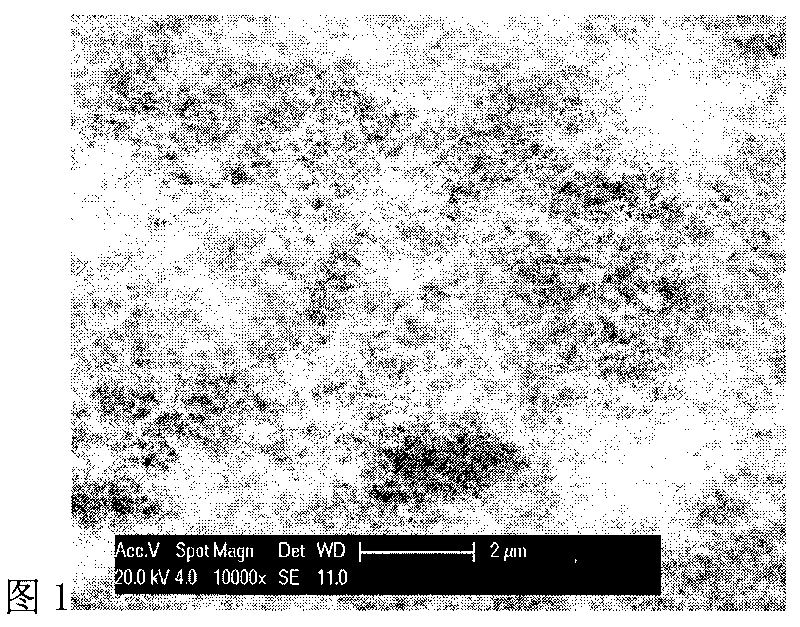

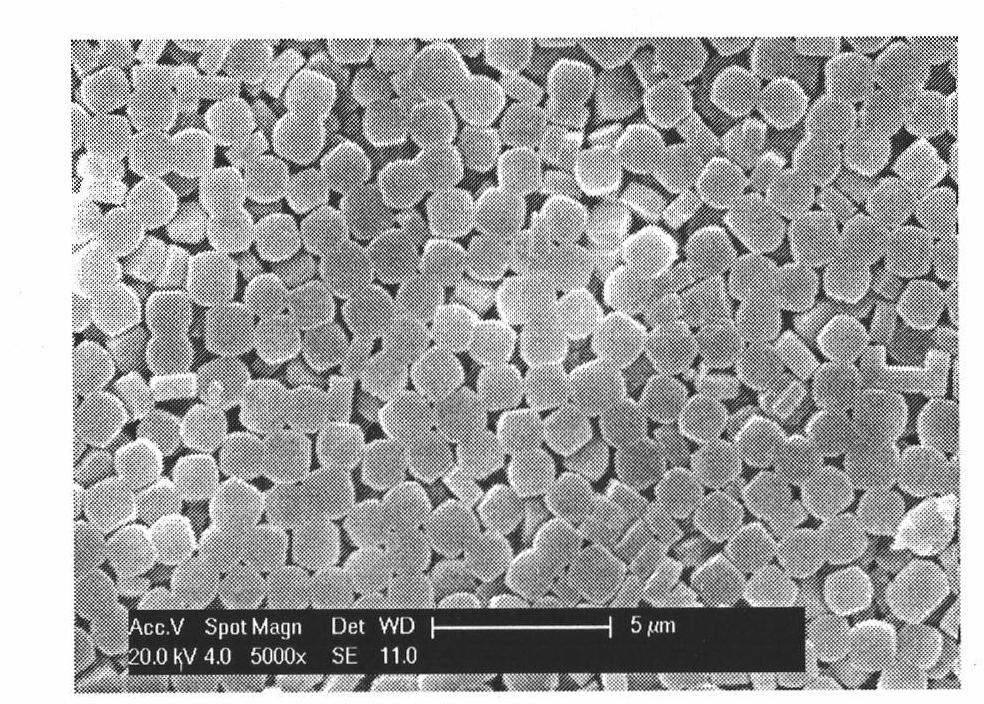

Preparation method of photoelectrocatalytic oxidation catalyst for treating high-salinity wastewater

ActiveCN102806075ASimple preparation stepsNo pollution in the processPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystPhysical chemistry

The invention relates to a preparation method of a photoelectrocatalytic oxidation catalyst for treating high-salinity wastewater. The photoelectrocatalytic oxidation catalyst is prepared by steps of utilizing porous Al2O3 as a carrier, loading active component TiO2 onto the carrier by means of liquid-phase deposition and then drying and calcining to prepare the photoelectrocatalytic oxidation catalyst. The prepared catalyst is in the shape of a porous cylinder, fluid and ultraviolet light can access the inside of the photoelectrocatalytic oxidation catalyst freely, and particles of the active component TiO2 are small in particle size and uniform in distribution.

Owner:CHINA NAT OFFSHORE OIL CORP +1

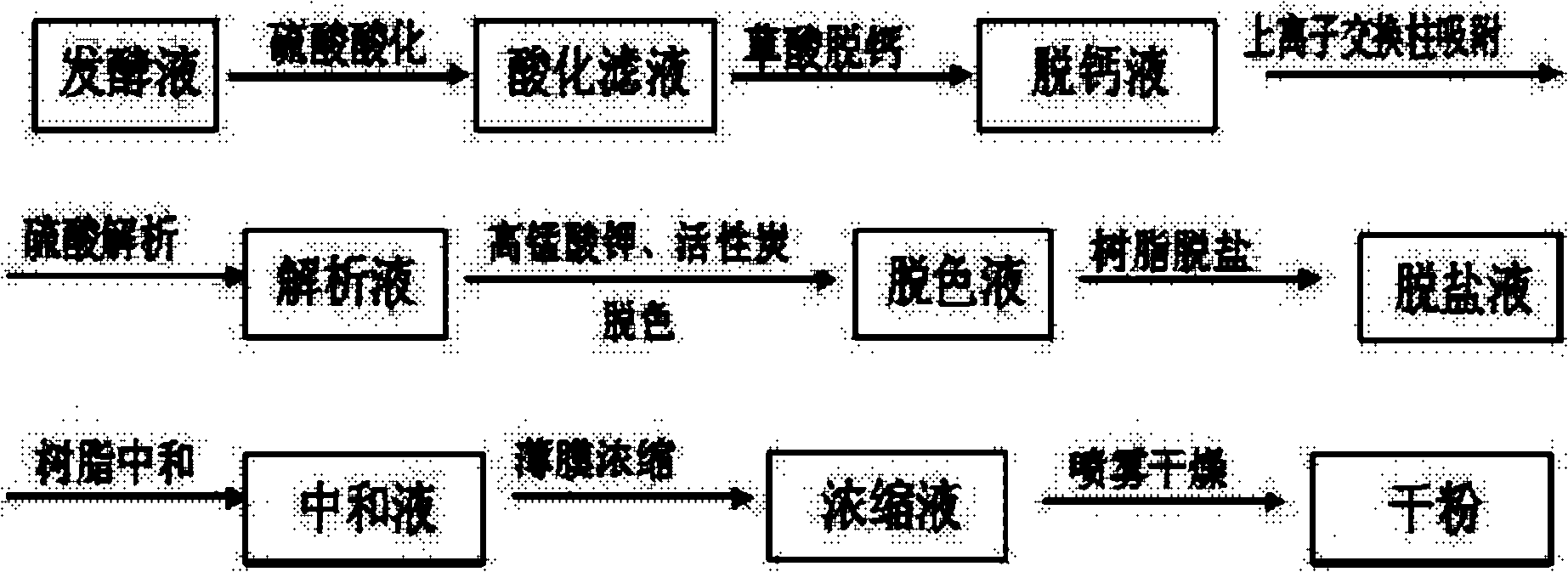

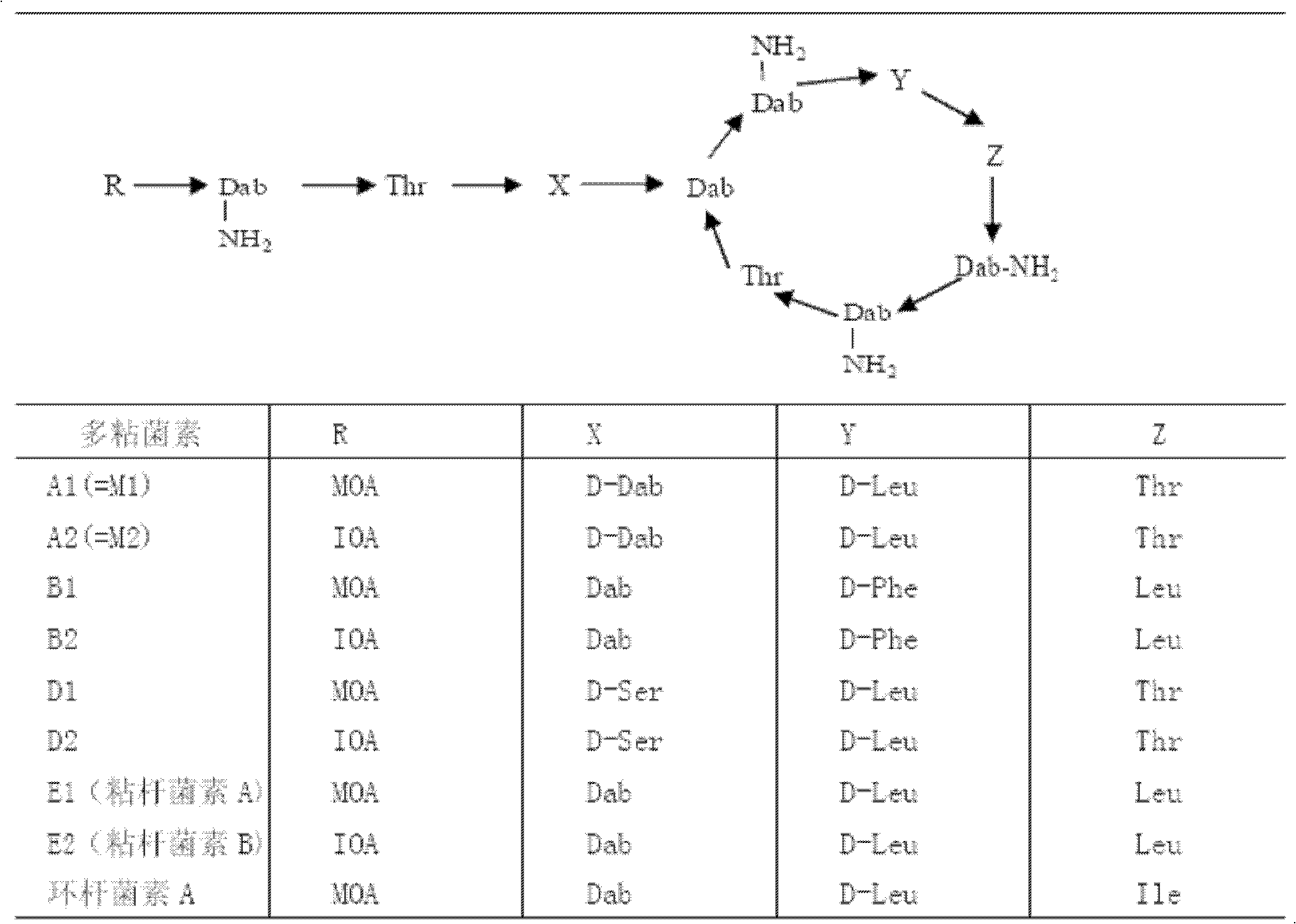

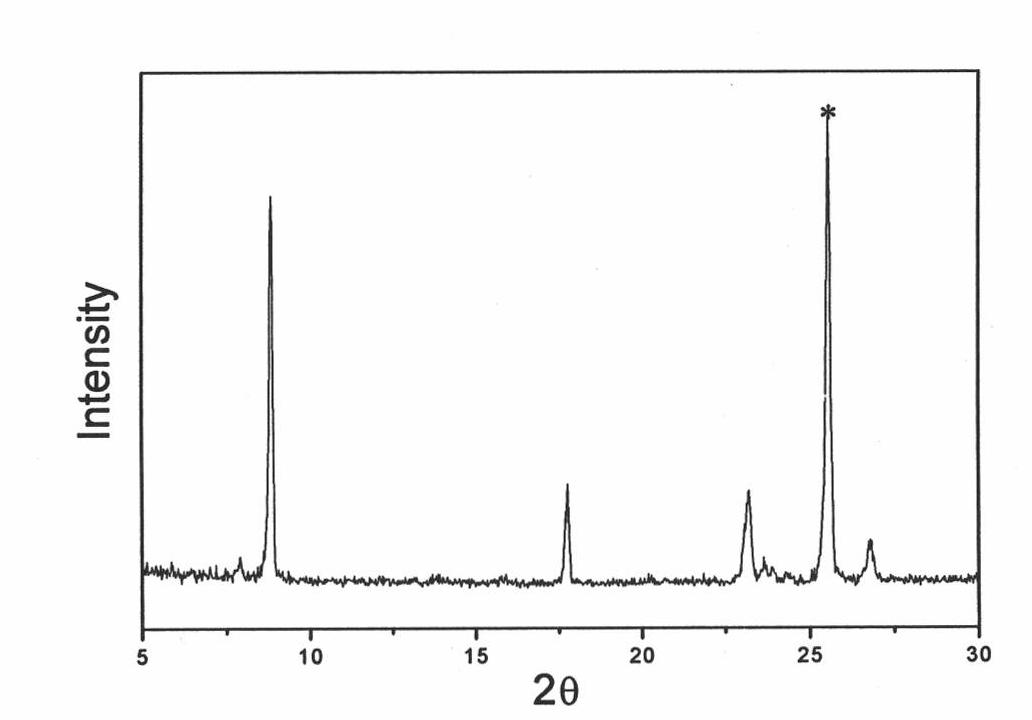

Method for improving total component content of colistin sulphate

ActiveCN101948514AEasy to recycleHigh purityPolymyxinsPeptide preparation methodsKetone solventsPharmaceutical drug

The invention belongs to the field of antibiotic medicaments and in particular discloses a method for improving the total component content of colistin sulphate. By adding an alcohol solvent or a ketone solvent with no more than six carbon atoms into aqueous solution of the colistin sulphate, the total component content of the colistin sulphate is obviously improved to reach the standard of EP6.0. Besides, a high-purity colistin sulphate sample also can be obtained by the method of the invention. The method has the advantages of low cost, convenient recovery of the solvent, simple operation, suitability for industrial amplification and capacity of efficiently improving the purity of the colistin sulphate.

Owner:APELOA PHARM CO LTD +1

Method for synthesizing cyclic carbonate and derivatives thereof

ActiveCN112409317AHigh activityLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic synthesisEpoxide Compound

The invention belongs to the field of organic synthesis, and particularly relates to a method for synthesizing cyclic carbonate and derivatives thereof, which comprises the following step of: reactingan epoxy compound shown in a formula I with carbon dioxide under the catalysis of a catalyst shown in a formula II to obtain a target product. The product prepared by the method has the advantages ofhigh yield, high purity, low catalyst cost and mild synthesis conditions, and the obtained product has no metal residue.

Owner:NANJING UNIV OF TECH

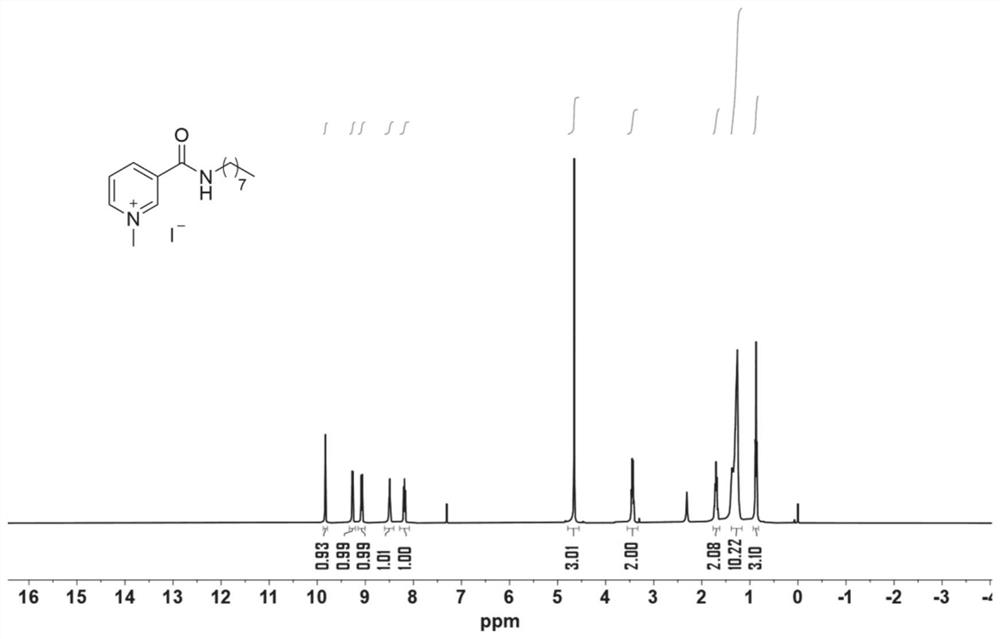

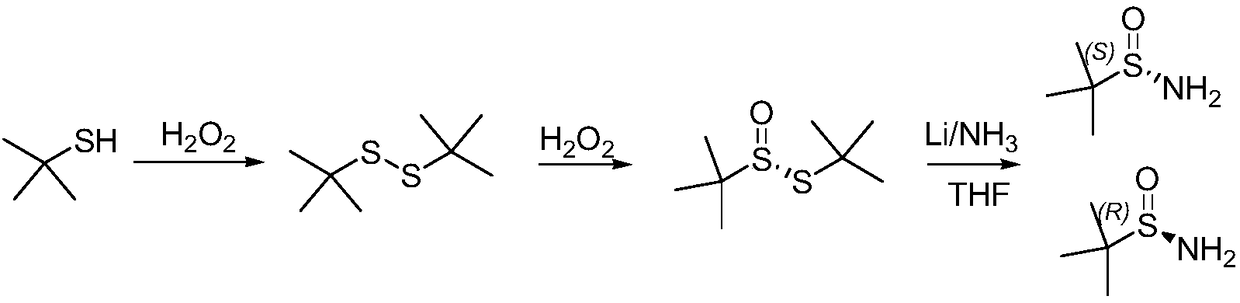

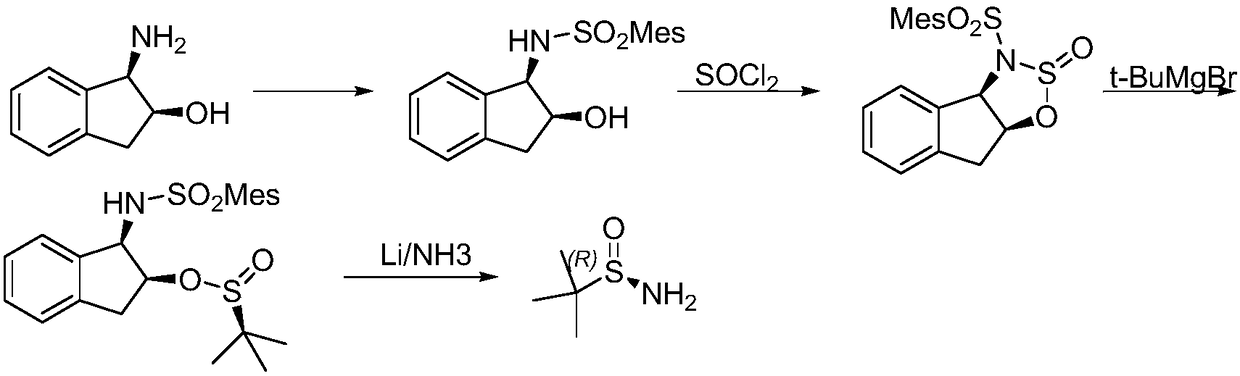

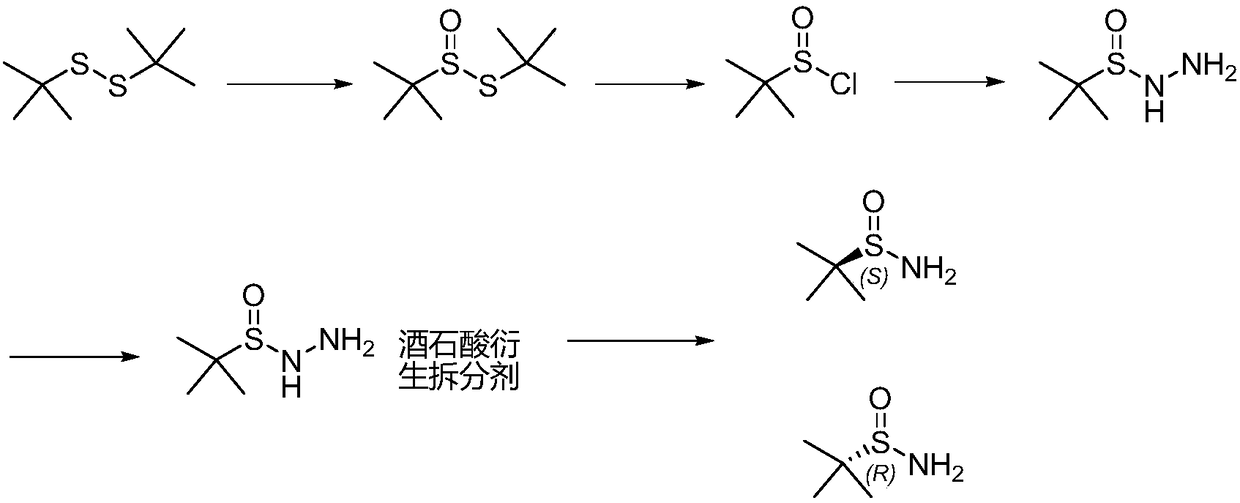

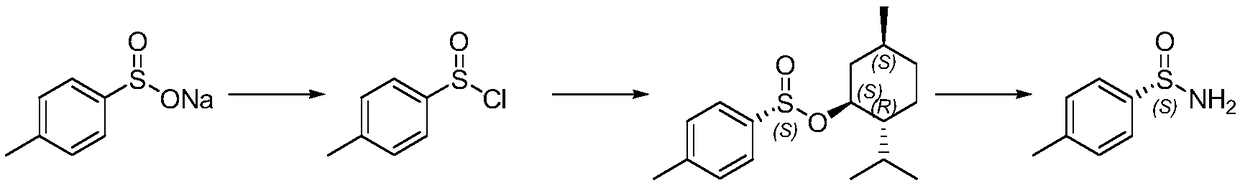

Method for preparing pure enantio-methylpropane-2-sulfinamide

ActiveCN108558715AShort reaction timeThe synthetic route is simpleOptically-active compound separationOrganic racemisationChlorideTert butyl

The invention discloses a method for preparing pure enantio-methylpropane-2-sulfinamide. The method comprises the following steps: carrying out selective oxidation on di-tert-butyl disulfide and hydrogen peroxide, reacting with an acylation reagent so as to obtain tert-butylsulfinyl chloride and tertiary butyl sulfonyl bromide, further reacting with hydrazine hydrate so as to obtain tertiary butylhydrazide, further carrying out resolution and separation with a DBTA resolving agent, and carrying out cracking with zinc acetate, thereby obtaining the pure enantio-methylpropane-2-sulfinamide. Themethod is simple, convenient and stable in process operation, high in yield and good in environment protection, and compared with a conventional process, the method is cheap and easy in raw materialobtaining, low in production cost of pure enantio-methylpropane-2-sulfinamide, and beneficial to industrial on-scale production.

Owner:安庆融创生物科技有限公司

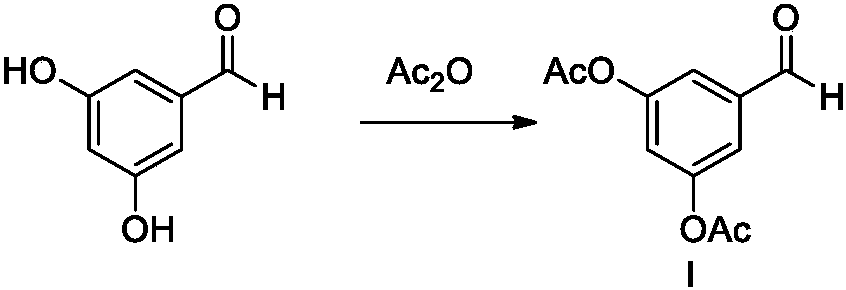

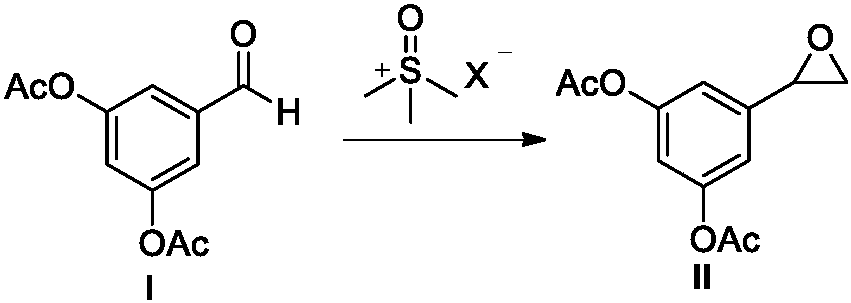

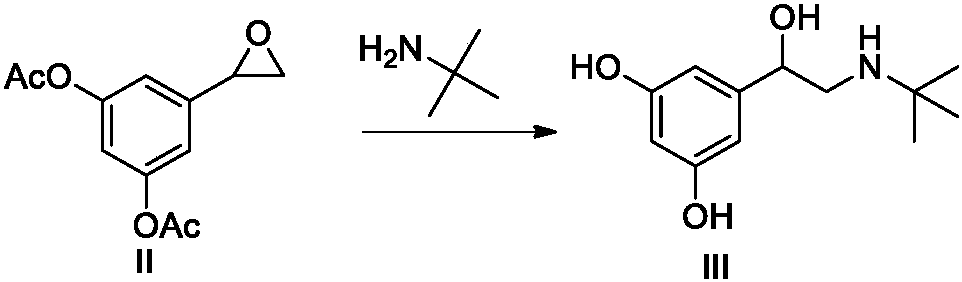

Novel preparation method of terbutaline sulfate

InactiveCN110835306AMild reaction conditionsSuitable for industrial scale-upOrganic compound preparationCarboxylic acid esters preparationBronchial SpasmDisease

The invention belongs to the field of organic synthesis of medicines, and concretely relates to a novel preparation method of a medicine terbutaline sulfate for treating bronchial spasm caused by bronchial asthma, chronic bronchitis, emphysema and other lung diseases. The synthesis route of the preparation method comprises the following steps: reacting 3,5-dihydroxybenzaldehyde with acetic anhydride to generate a compound I; reacting the compound I with trimethyloxosulfonium halide to generate a compound II; reacting the compound II with tert-butylamine to generate terbutaline; and salifying the terbutaline to generate the terbutaline sulfate. The method has the advantages of avoiding of dangerous chemical reagents, low price of adopted reagents, mild reaction conditions, and suitablenessfor industrial amplification.

Owner:HARVEST PHARMA HUNAN CO LTD

Preparation process of hollow silica ball

The preparation process of hollow silica ball includes the following steps: adding alcohol solvent into ammonia water solution of polymer electrolyte in 3-500 g / L concentration, dropping silicon source precursor solution of 1.1-4.4 mol / L concentration in the speed of 0.05-0.2 ml and silicon source precursor / ammonia water volume ratio of 1 / 15 to 2, reaction in a sealed container at 10-40 deg.c for 2-24 hr, and washing and drying the product, with the ammonia water having concentration of 10-25 wt% and the volume ratio between alcohol solvent and ammonia water being 3 to 25. The preparation process of the present invention is simple and suitable for industrial production, and has mild reaction condition, no environmental pollution and high yield, and the obtained hollow silica ball is loose, has inner diameter of 10-250 nm and water thickness of 10-40 nm, and may be used as medicine carrier and catalyst carrier.

Owner:UNIV OF SCI & TECH OF CHINA

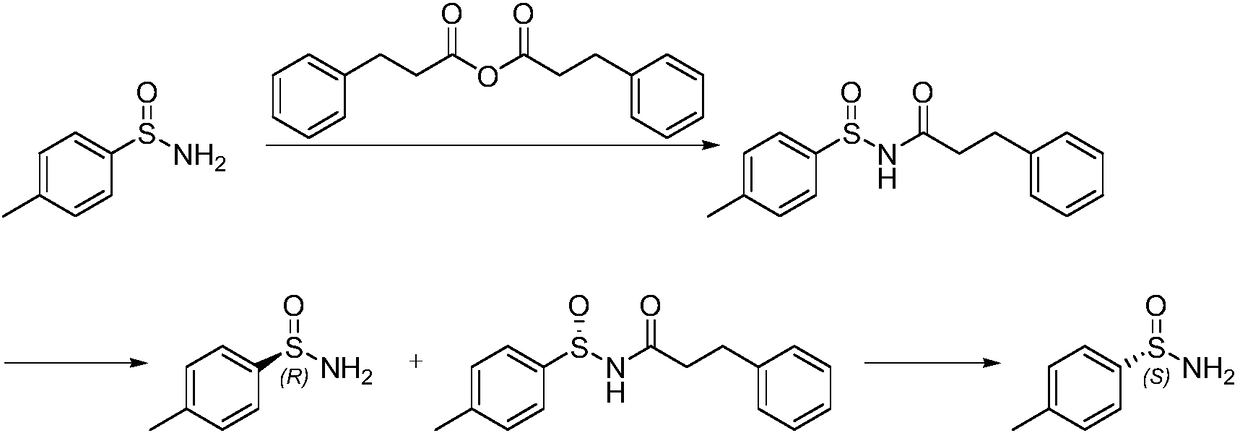

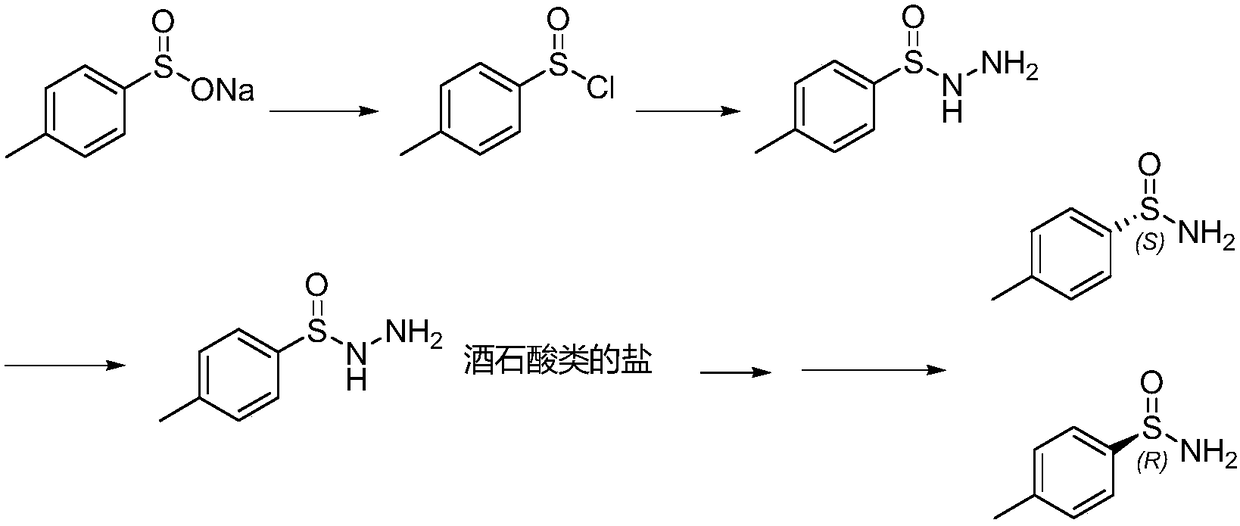

Preparation method of chiral optical pure p-toluene sulfamide

ActiveCN108558714AFacilitate industrial scale-up productionLow costOrganic compound preparationOrganic chemistry methodsSulfonyl chlorideDecomposition

The invention discloses a preparation method of chiral optical pure p-toluene sulfamide. The preparation method comprises the following steps: performing acylating chlorination by using sodium p-tolylsulfinate and an acylating chlorination reagent to obtain p-toluene sulfonyl chloride, then mixing the p-toluene sulfonyl chloride with hydrazine hydrate to obtain p-toluene sulfonyl hydrazine, performing separation and dissociation with a tartaric acid resolving agent, and performing splitting decomposition with zinc acetate to obtain the pure p-toluene sulfamide. The process disclosed by the invention is easy and convenient to operate, stable, high in yield and environmentally friendly. Compared with the conventional process, the preparation method has the advantages that the raw materials are easy to obtain, the production cost of the existing chiral optical pure p-toluene sulfamide is substantially reduced, and the industrial large-scale production is facilitated.

Owner:SHANGHAI TIANYE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine](https://images-eureka.patsnap.com/patent_img/041574dc-f60b-4238-b227-acc93ffcbaaa/HDA0000409045230000011.PNG)

![Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine](https://images-eureka.patsnap.com/patent_img/041574dc-f60b-4238-b227-acc93ffcbaaa/HDA0000409045230000012.PNG)

![Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine Preparation method of (R)-9-[2-(phosphoryl phenol methoxy)propyl]adenine](https://images-eureka.patsnap.com/patent_img/041574dc-f60b-4238-b227-acc93ffcbaaa/HDA0000409045230000021.PNG)